Patents

Literature

5145results about How to "Avoid entanglement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

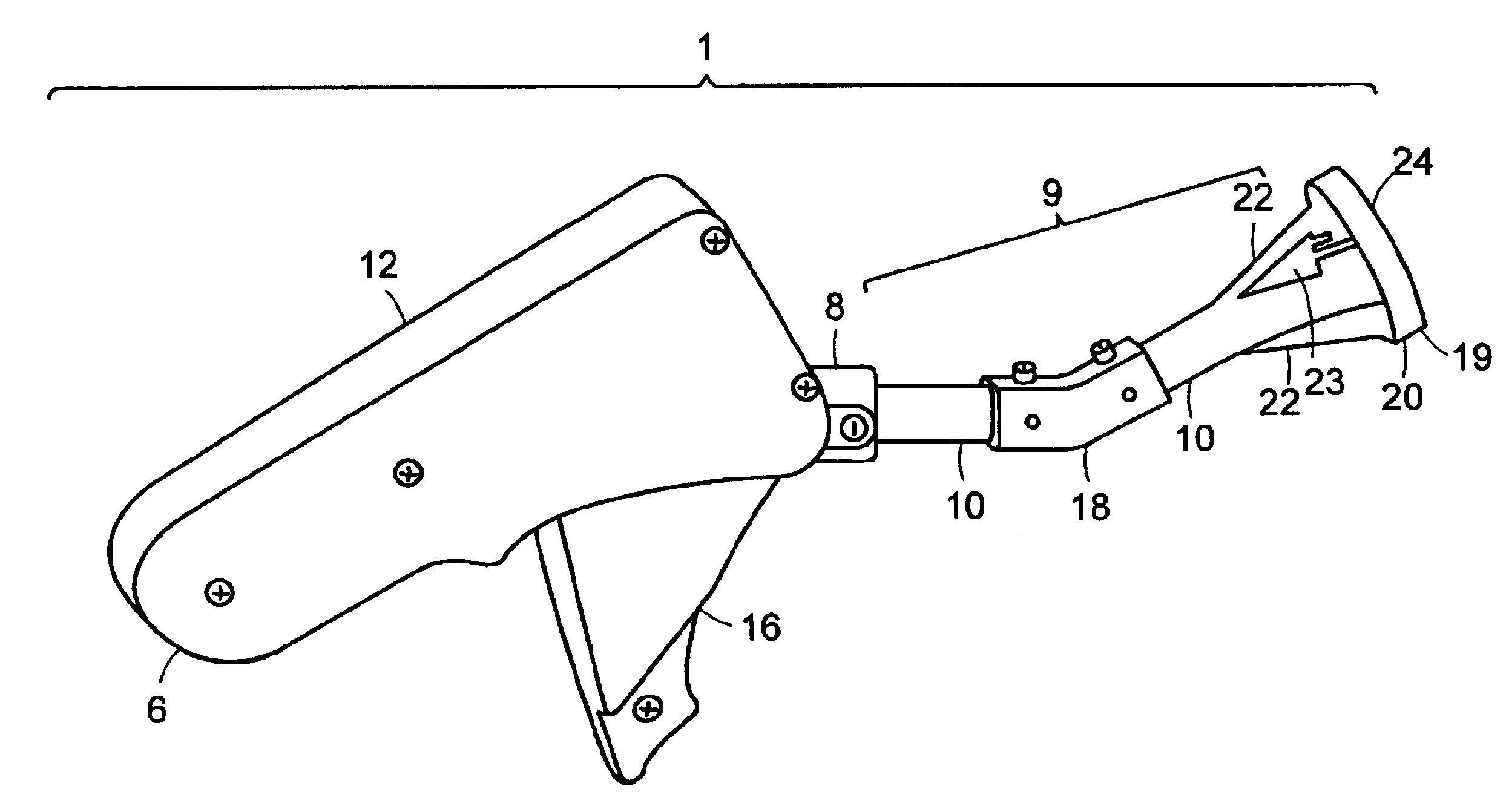

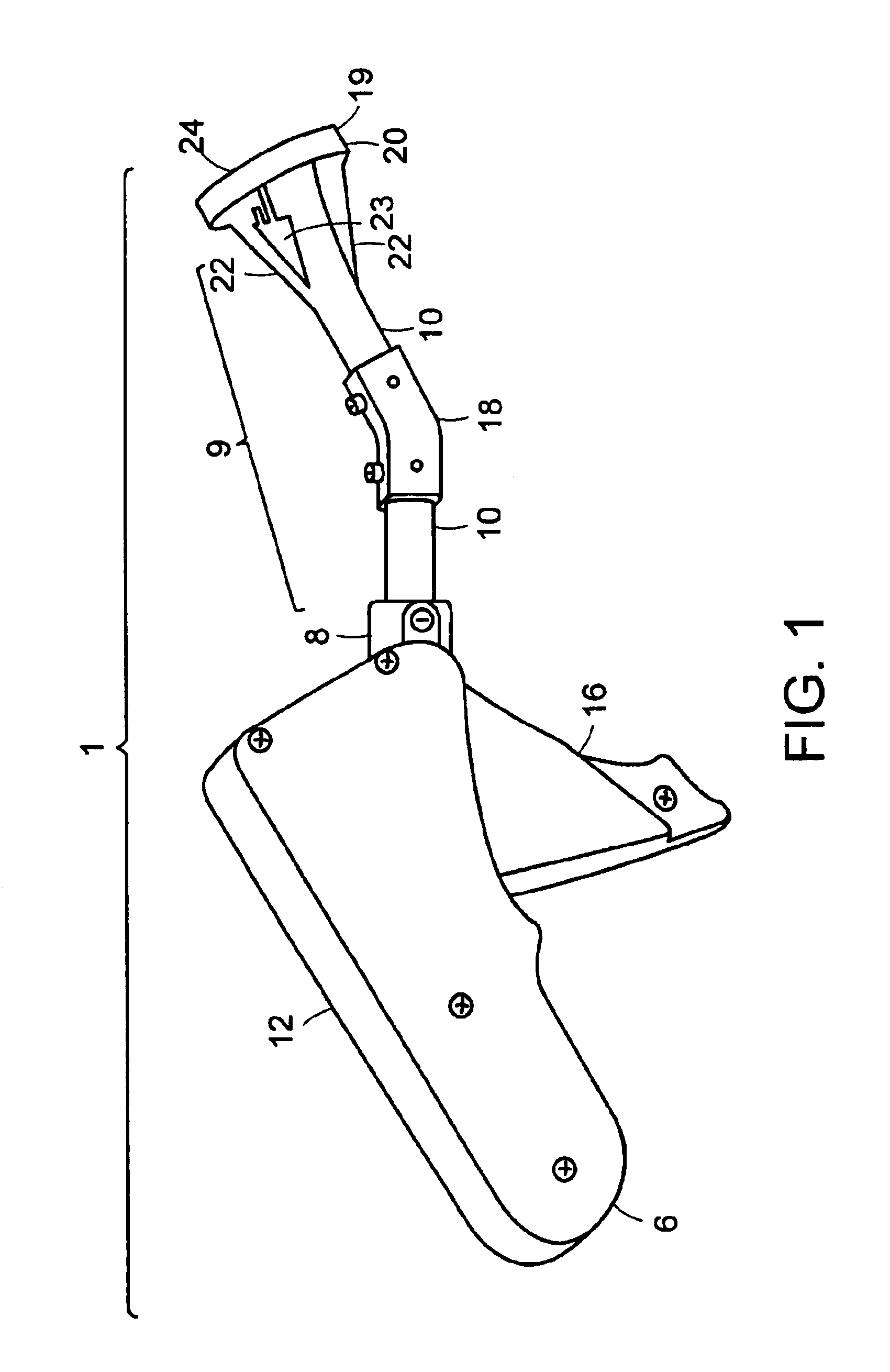

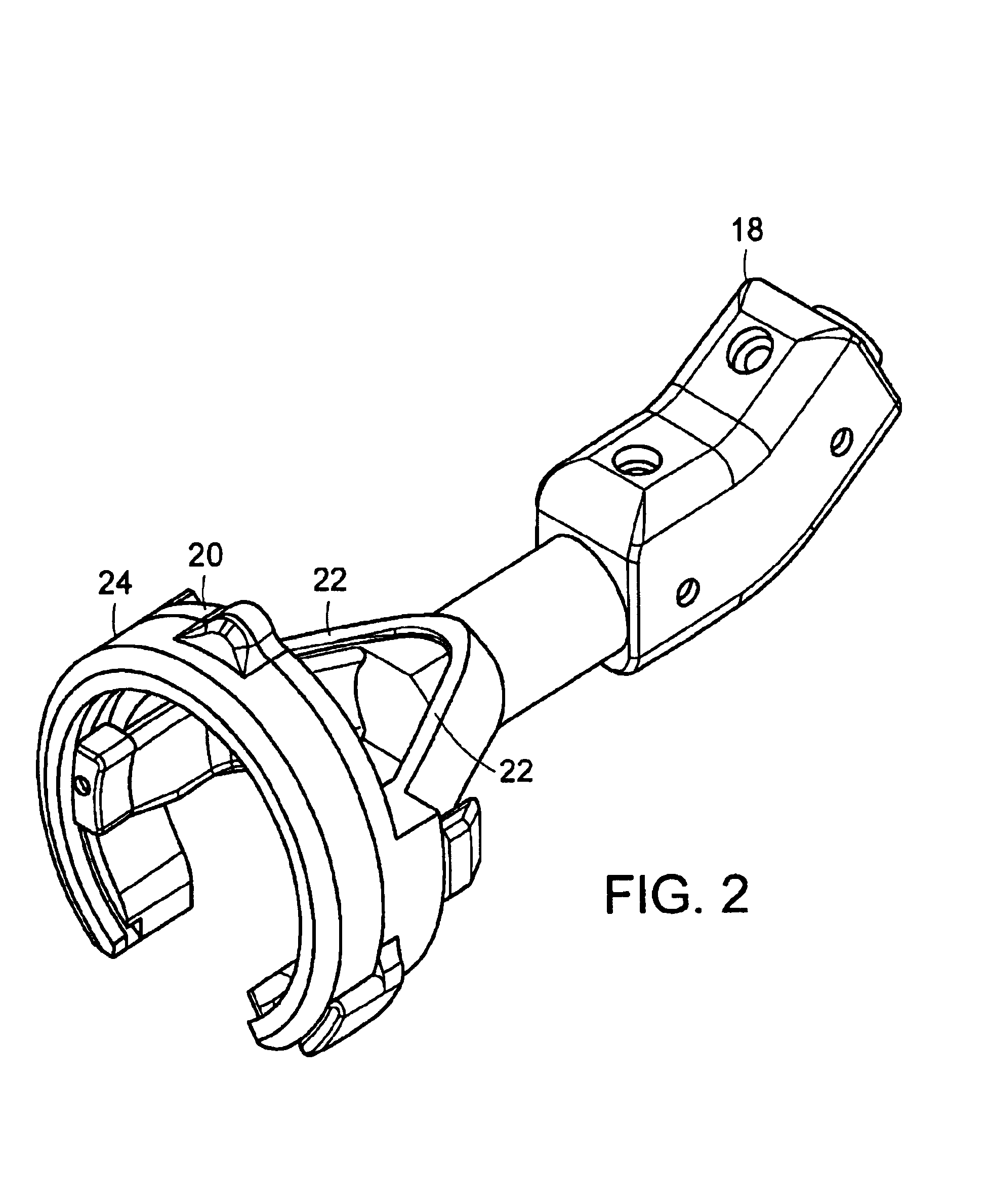

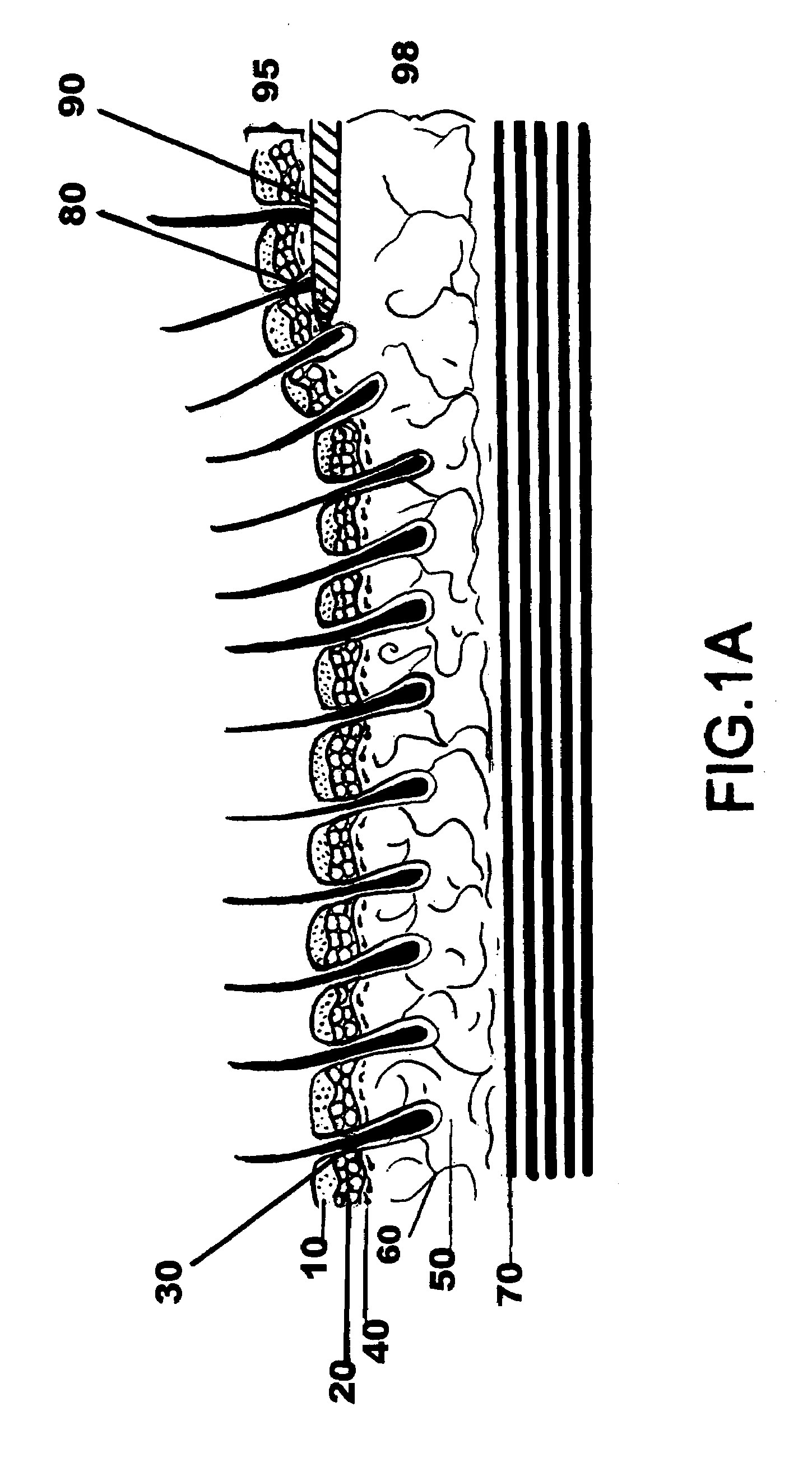

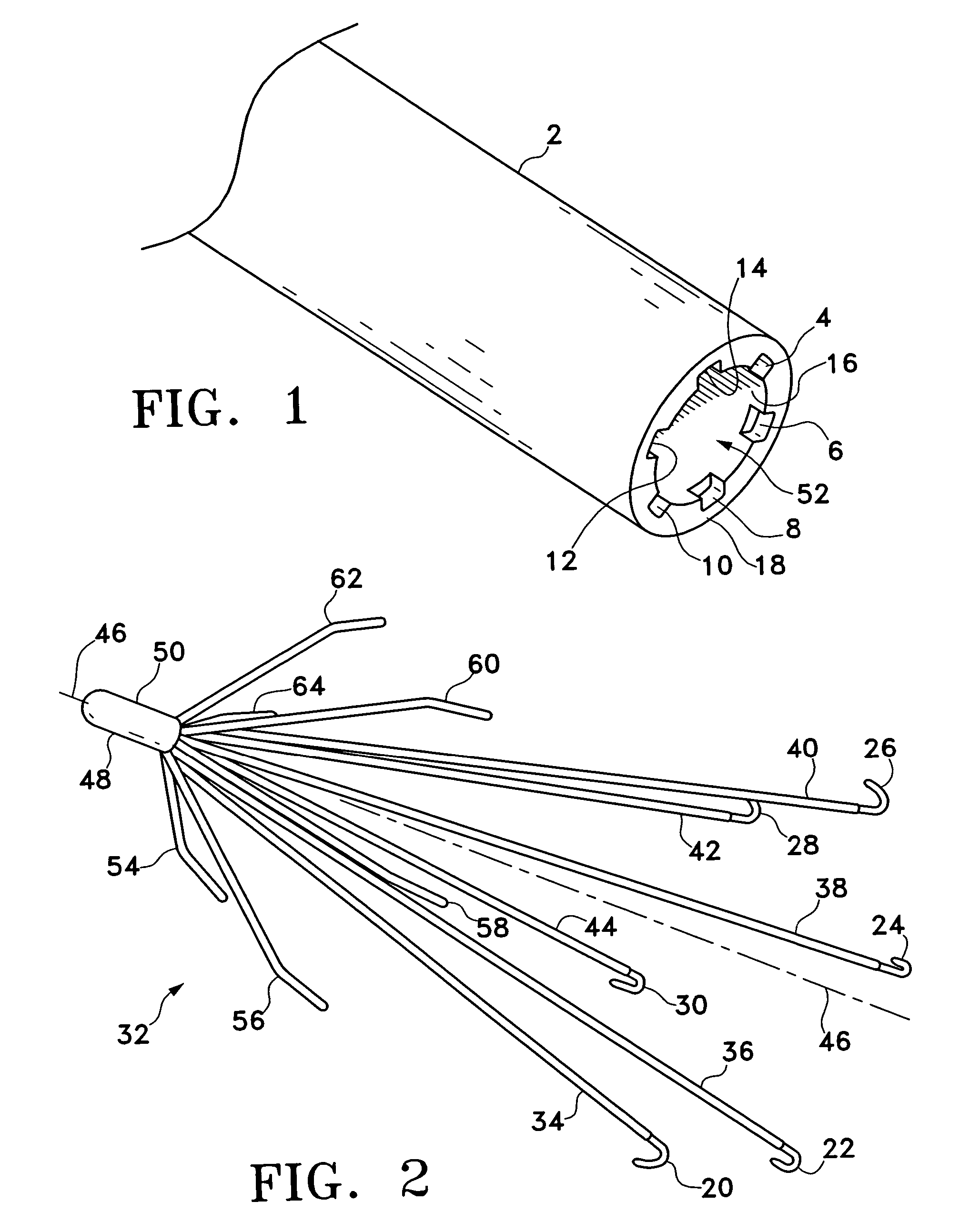

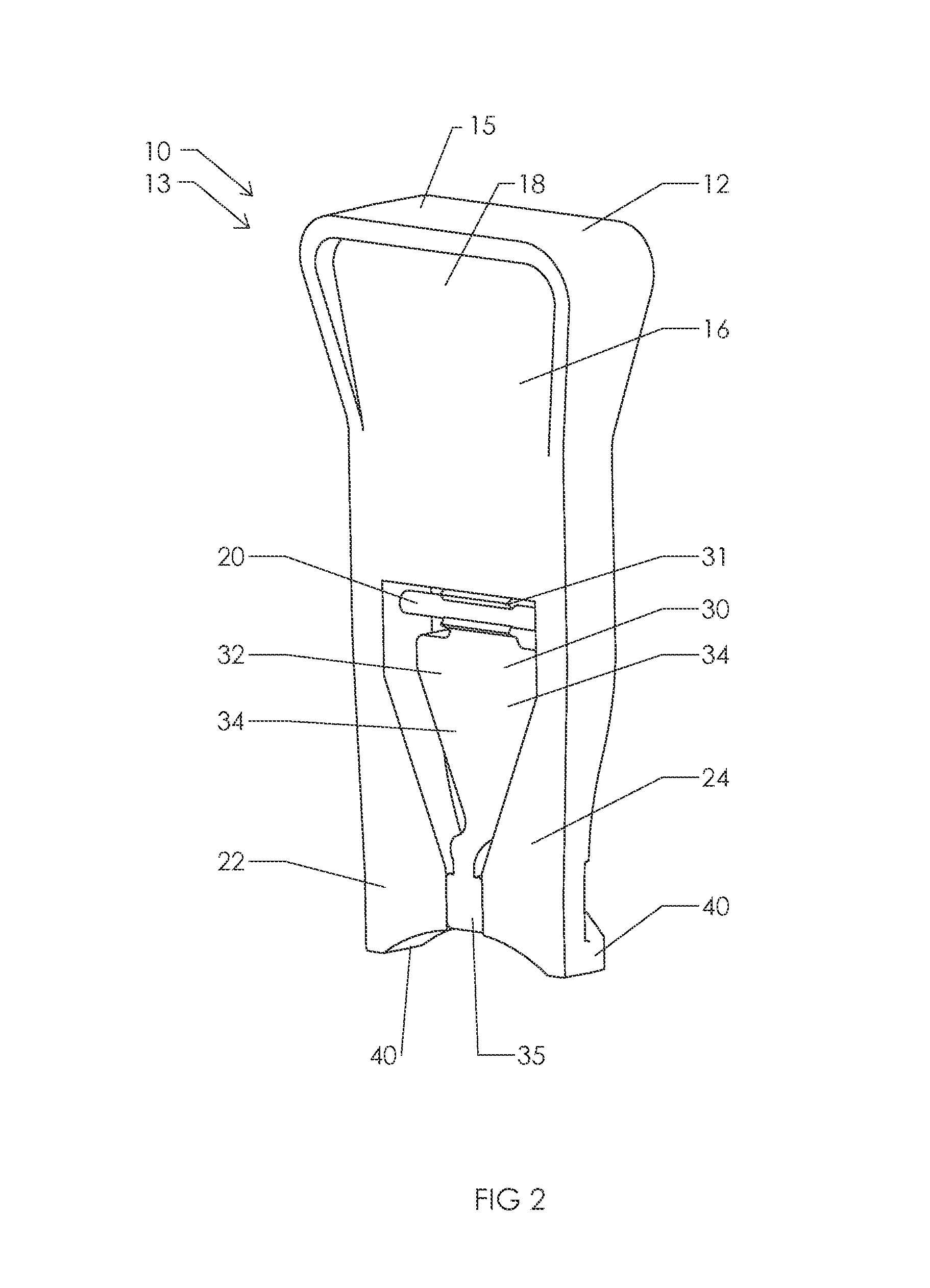

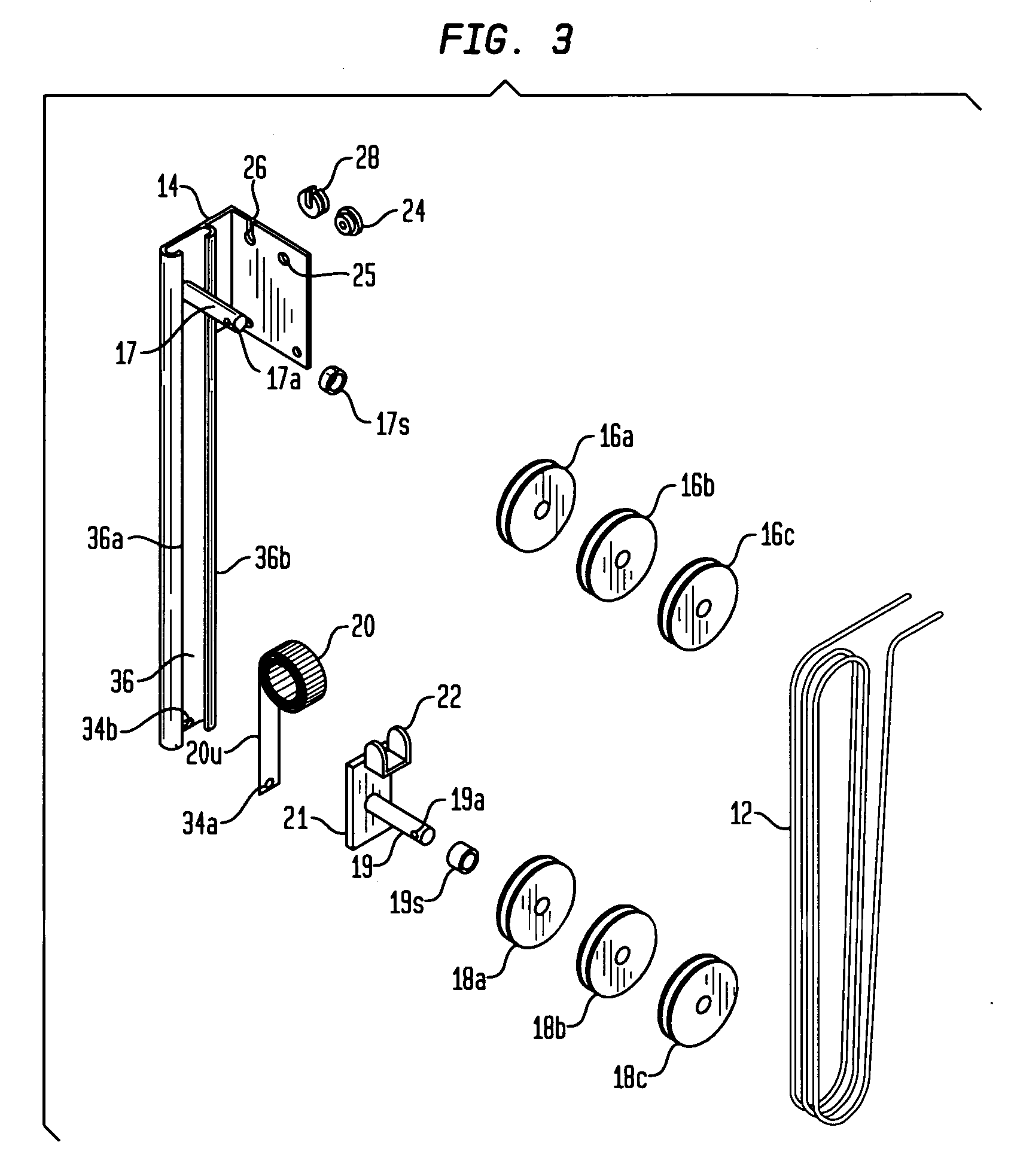

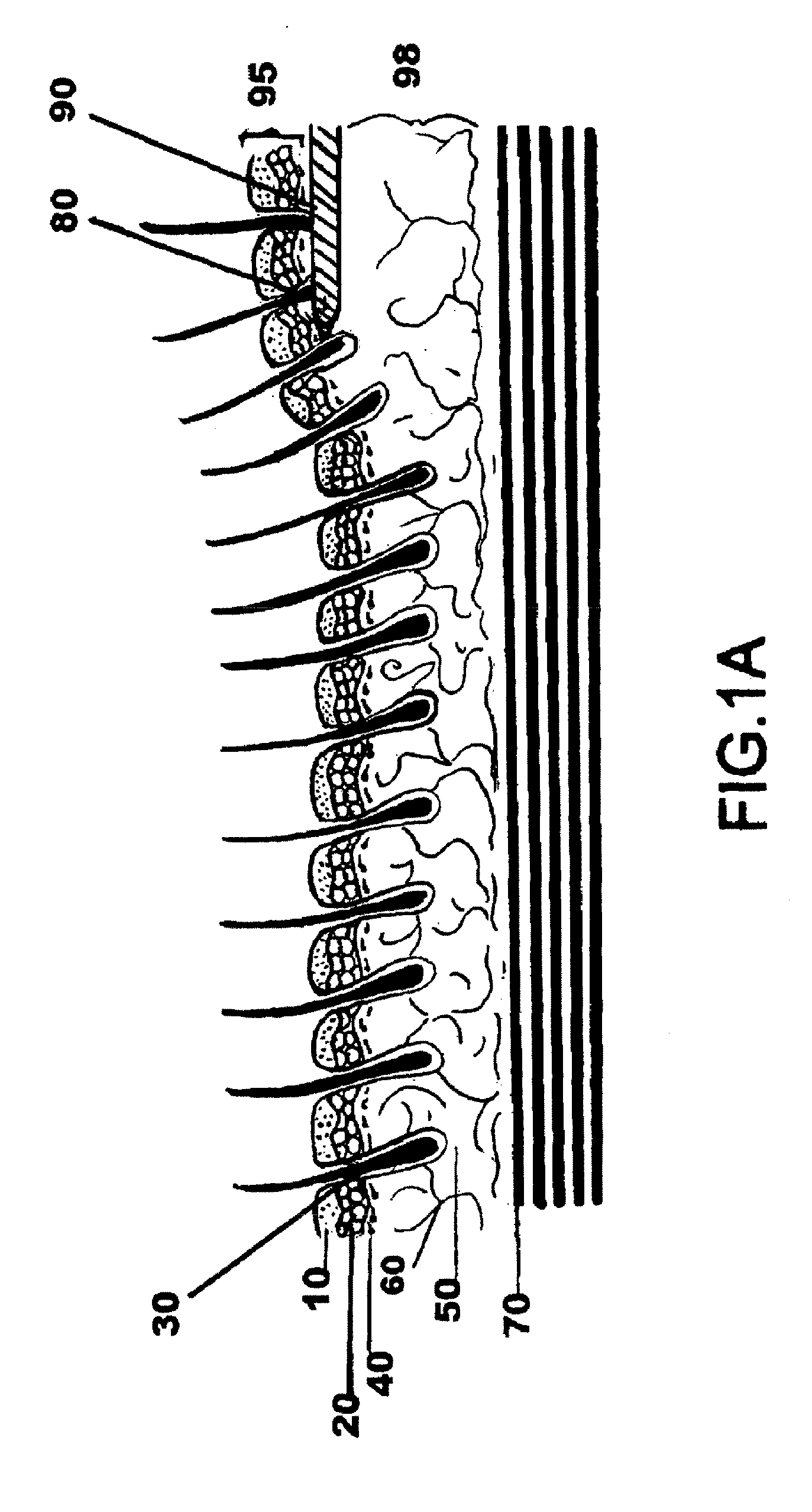

Apparatus and method for surgical suturing with thread management

InactiveUS6923819B2Efficient preparationExcellent ease of useSuture equipmentsDiagnosticsSuturing needleEngineering

An apparatus and a method for surgical suturing with thread management. An apparatus for tissue suturing comprising a cartridge having a suturing needle having a pointed end and a blunt end, the suturing needle capable of rotating about an axis; a pusher assembly comprising a cartridge holder having a needle rotation drive capable of releasably engaging the cartridge and rotating the suturing needle about the axis; and an actuator capable of releasably engaging the needle rotation drive to rotate the needle rotation drive. A method for suturing tissue comprising placing a suturing device having a cartridge containing a suturing needle to span separated tissue segments; activating an actuator to cause rotational movement of the suturing needle through the separated tissue segments; and deactivating the actuator to stop an advancing movement of the suturing needle to cause a suturing material to be pulled through the separated tissue segments forming a stitch.

Owner:INTUITIVE SURGICAL OPERATIONS INC

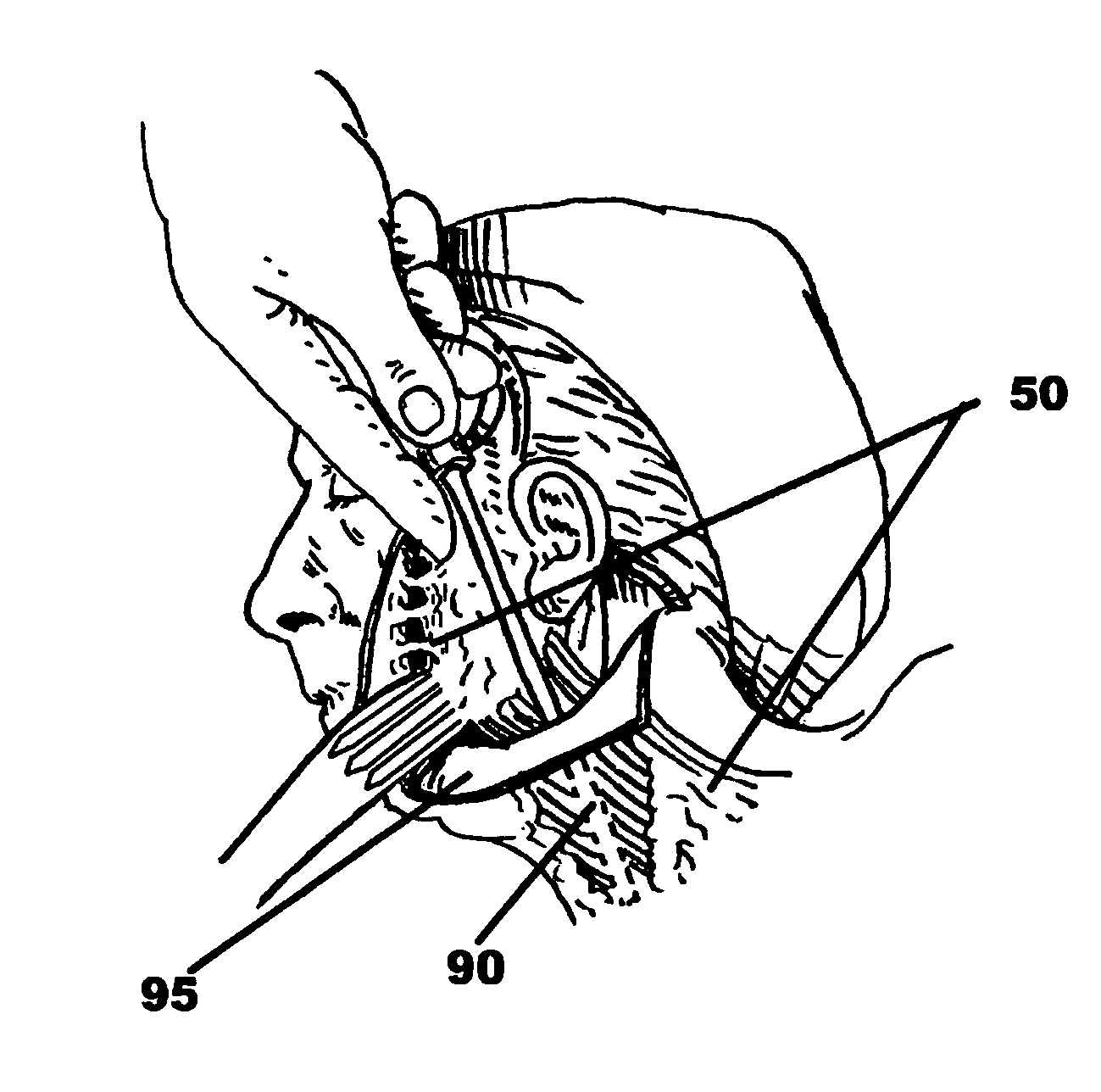

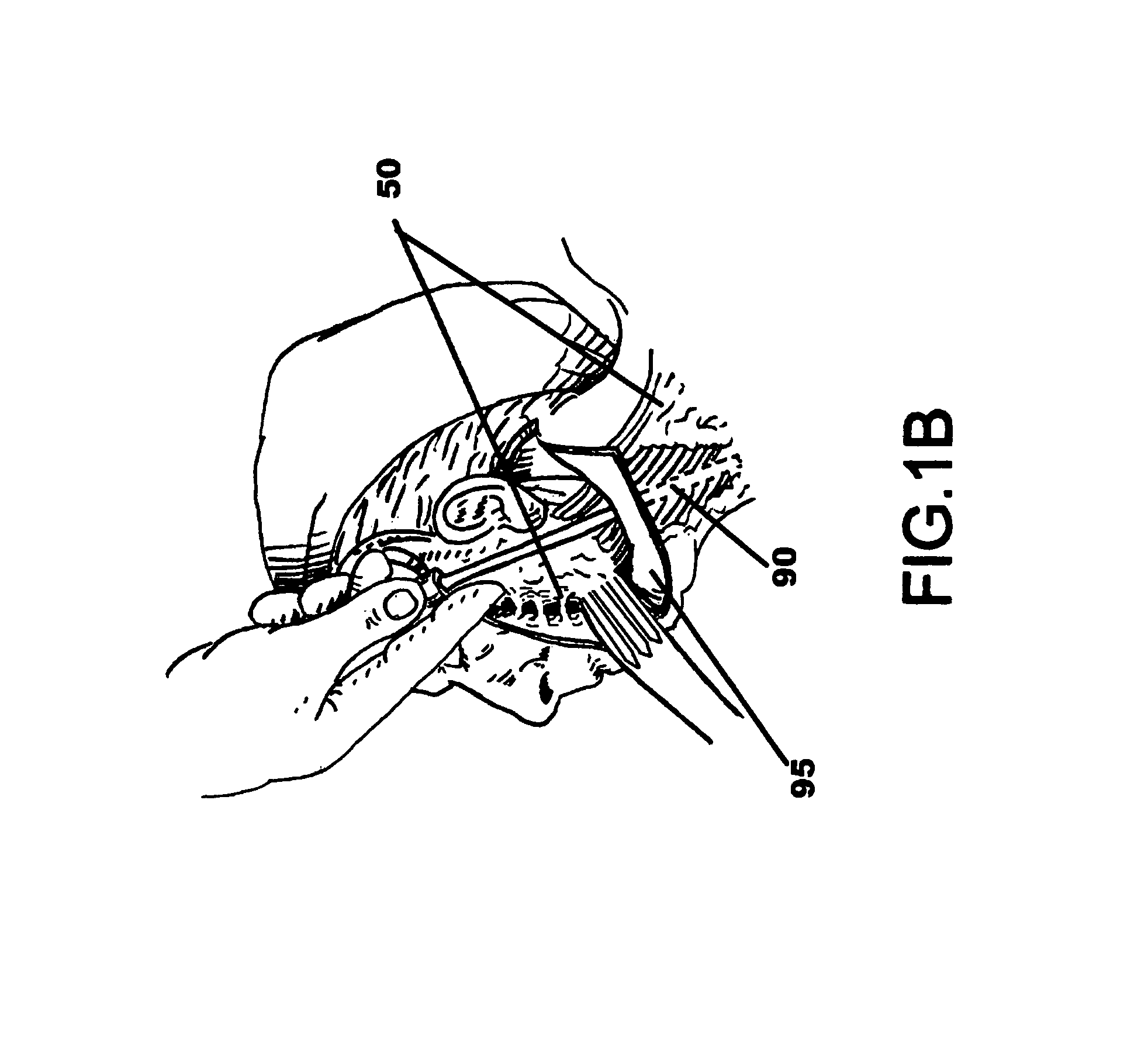

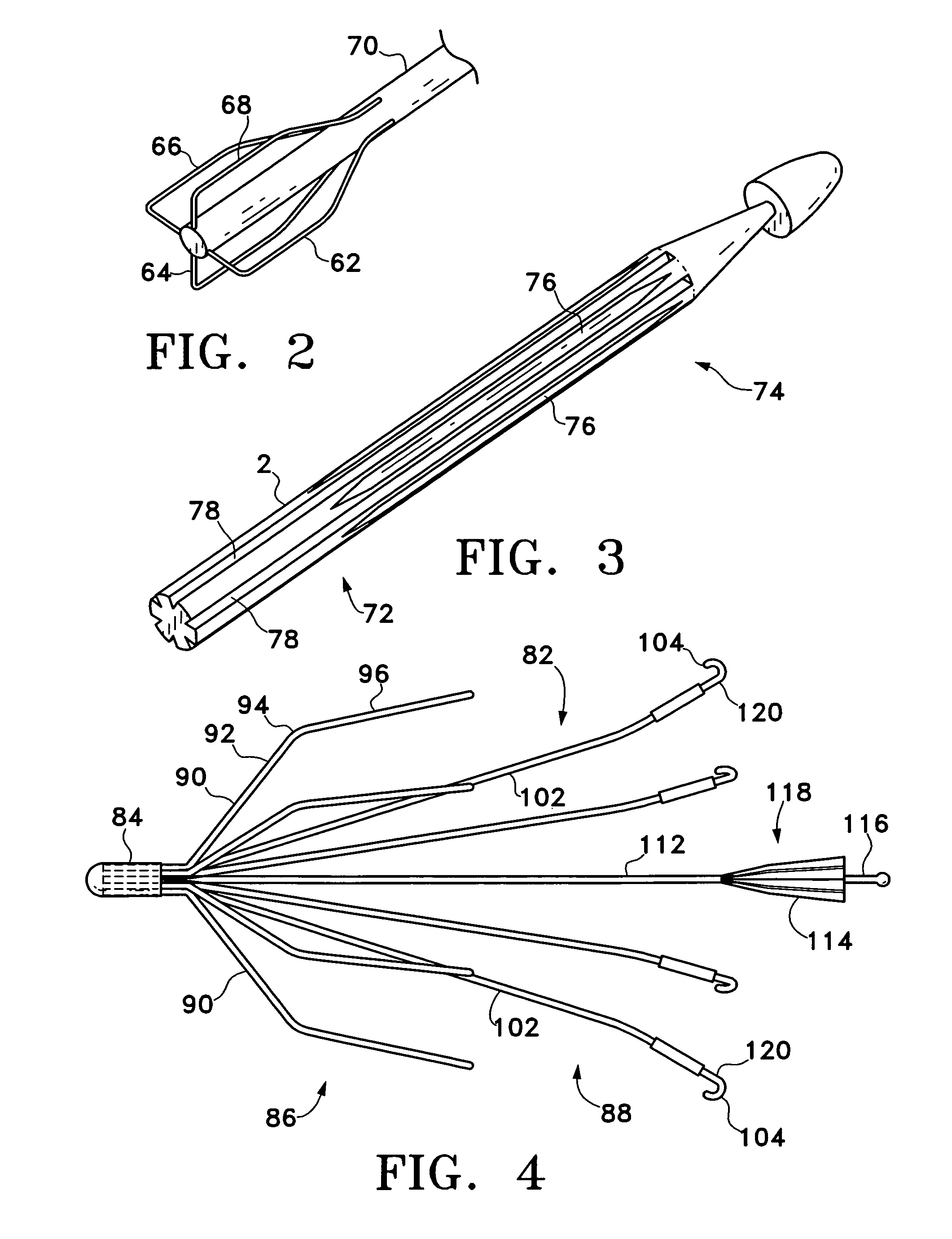

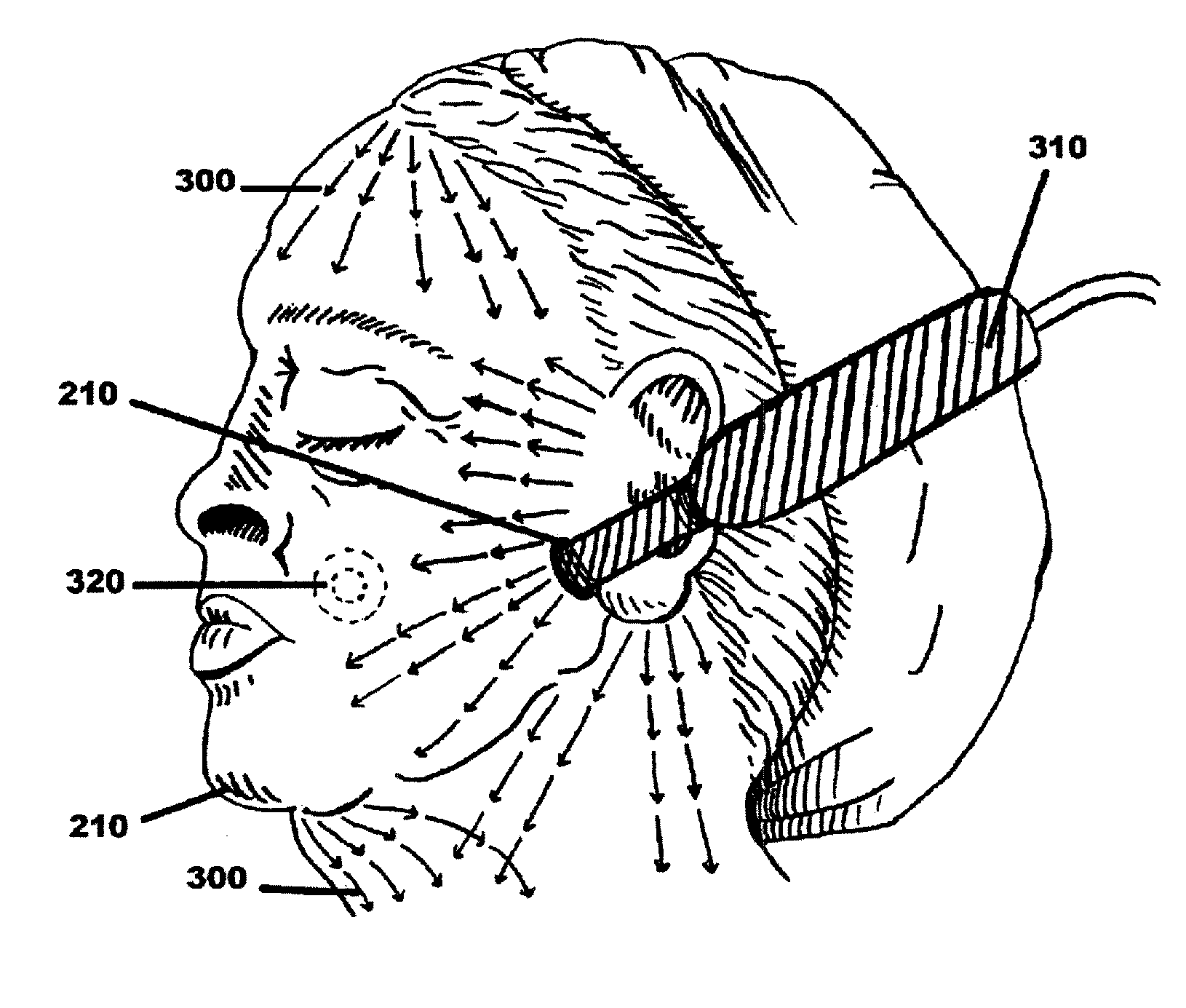

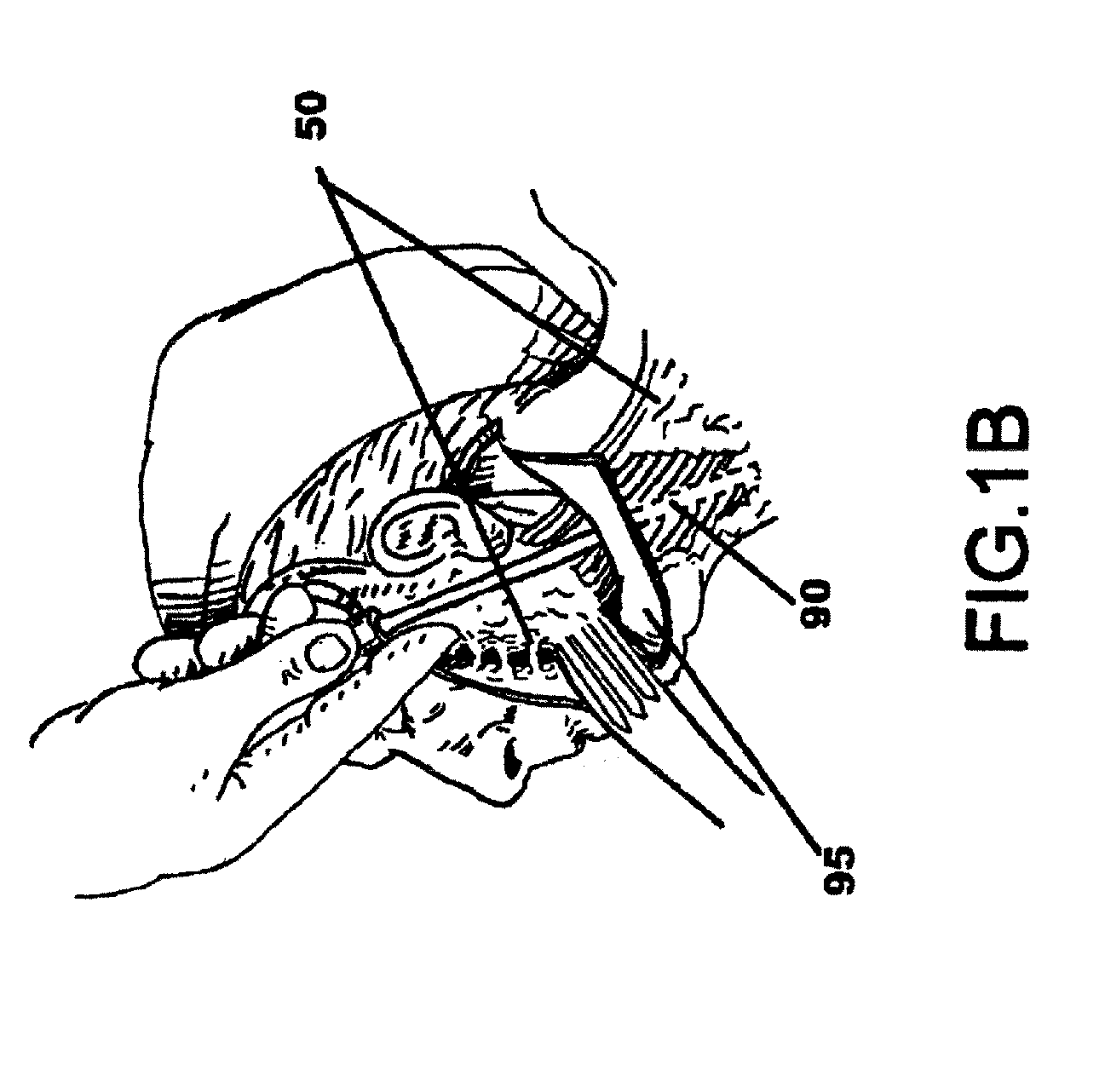

Facial tissue strengthening and tightening device and methods

InactiveUS7494488B2Improve efficacyImprove securityUltrasound therapyElectrotherapyForms of energyFacial tissue

A device is described that can be used quickly and accurately by surgeons to provide uniform facial tissue planes that are tunnel-free and wall-free thus optimizing face lifting, tightening, and implant delivery. The device is comprised of a shaft with a substantially planar tip further comprised of relative protrusions and energized relative recession lysing segments. Forward motion of the device precisely divides and energizes various tissue planes causing contraction, especially via the fibrous tissues. Other forms of energy and matter can be delivered down the shaft to further enhance desirable tissue modification and contraction.

Owner:WEBER PAUL J

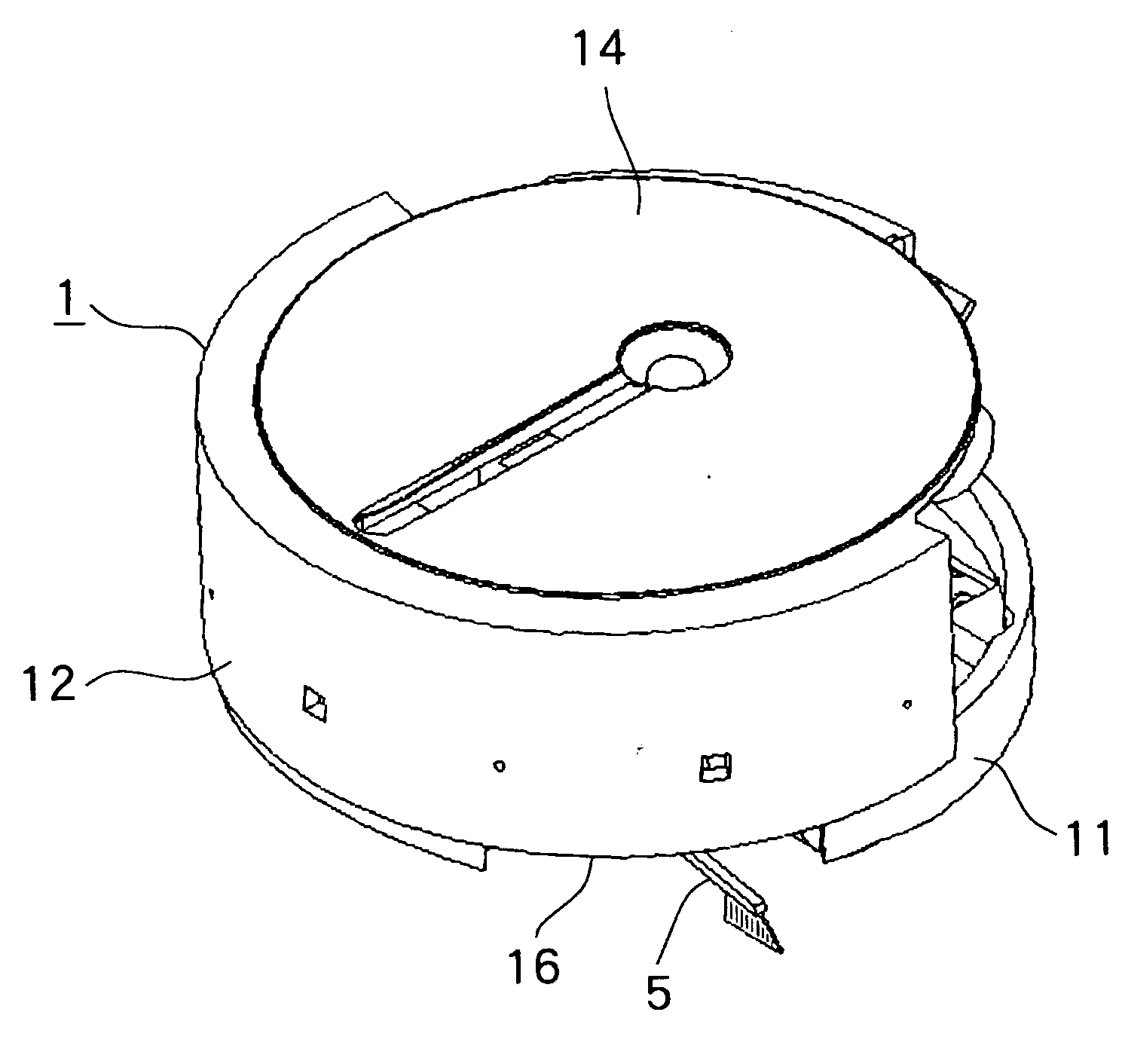

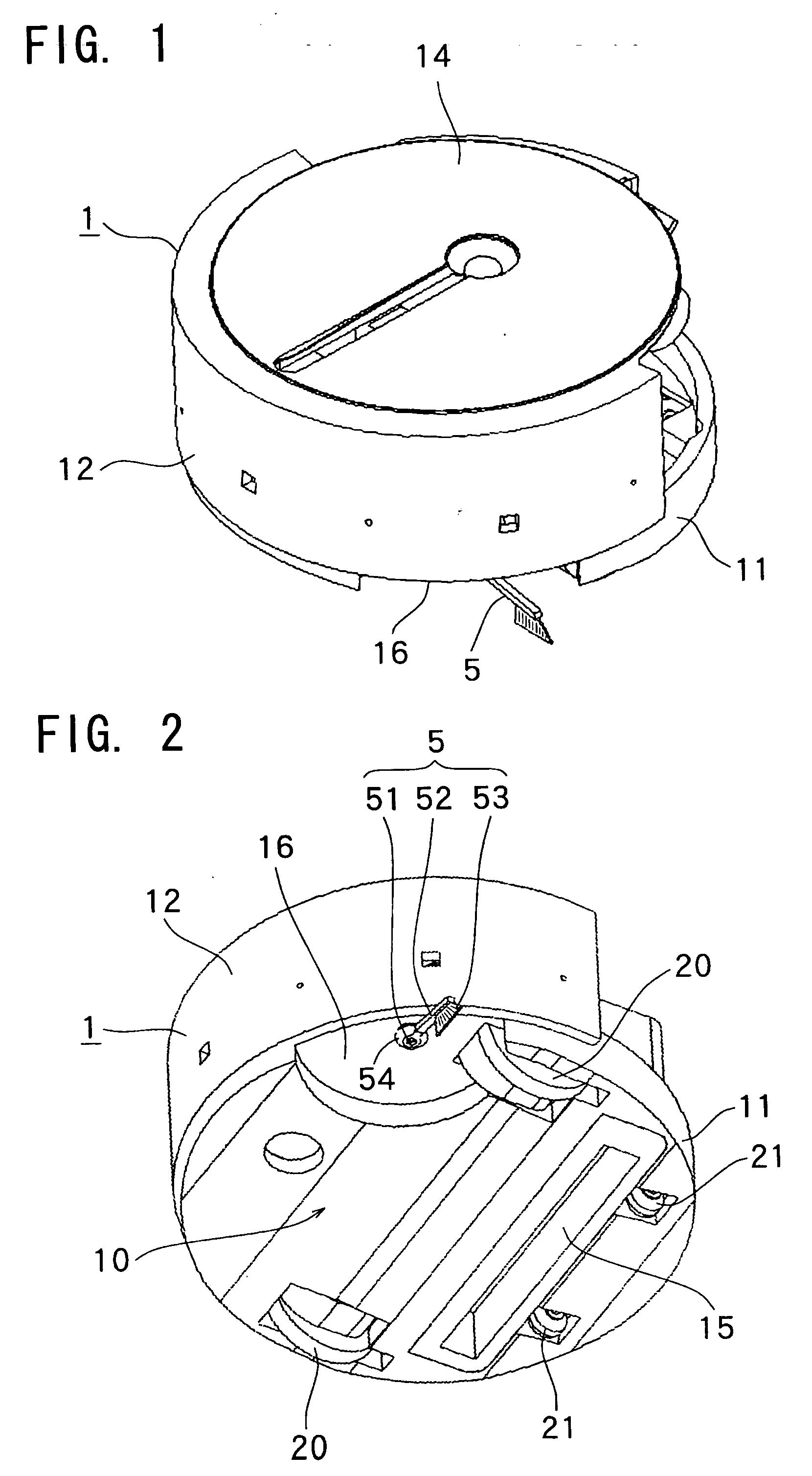

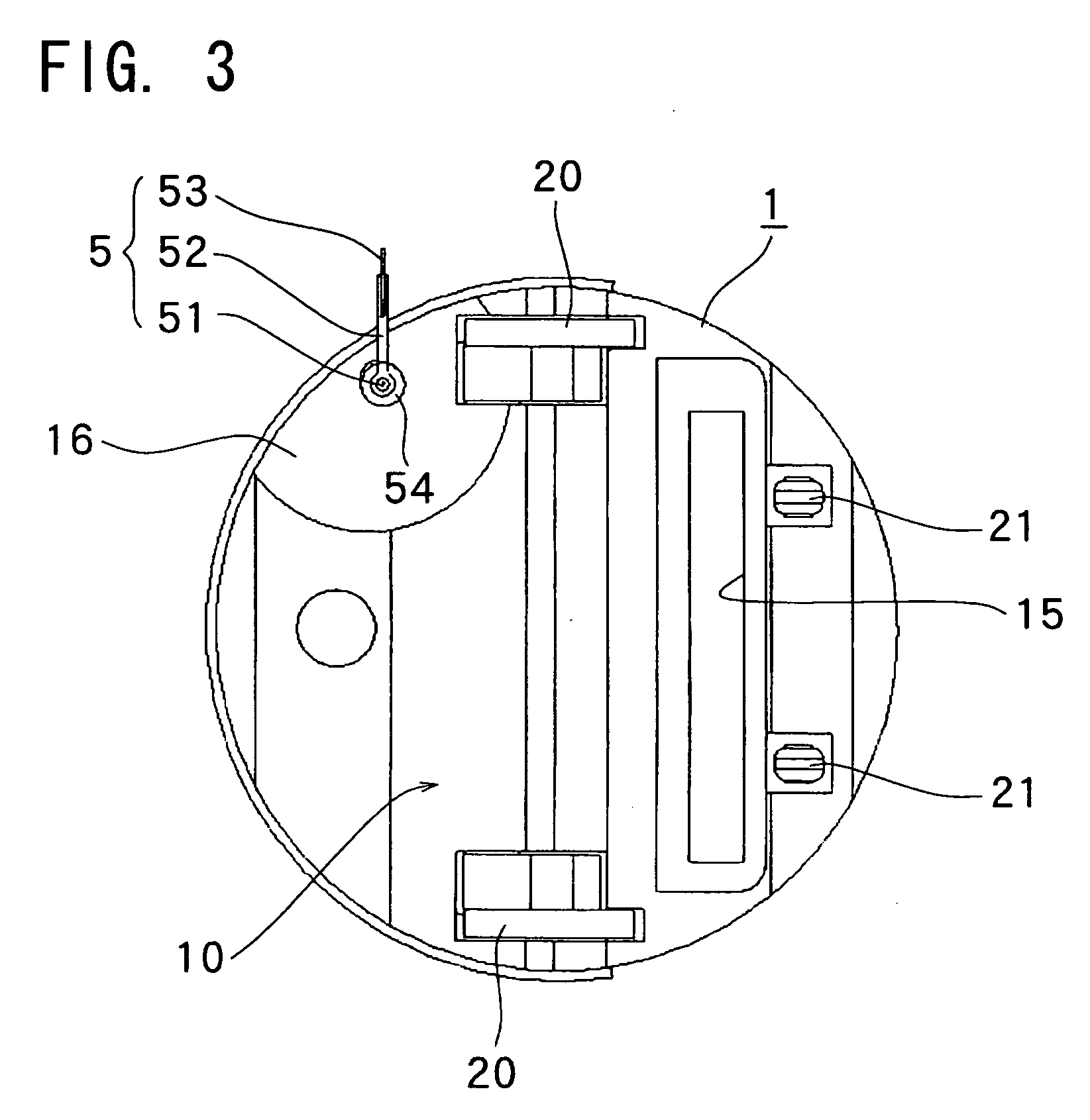

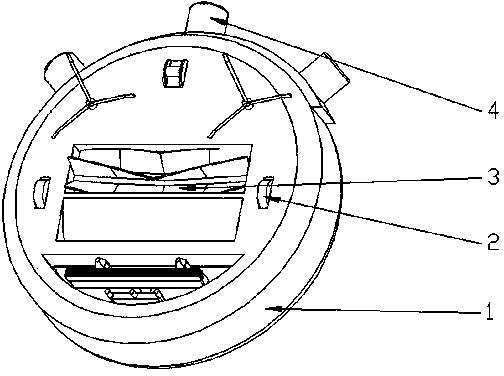

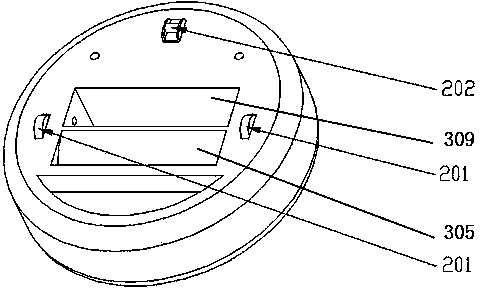

Self-traveling cleaner

InactiveUS20060021168A1Avoid entanglementFacilitated releaseMechanical cleaningPressure cleaningEngineeringMechanical engineering

In a self-traveling cleaner of the present invention, a cleaning mechanism includes a brush mechanism rotatable along a floor surface and a driving mechanism for rotatingly driving the brush mechanism. The brush mechanism includes a rotation axis extending perpendicular to the floor surface, one arm projecting laterally from a lower end of the rotation axis, and a brush planted on the arm. The rotation axis is provided within a reverse side of the main body, and the arm has a rotation angle range in which the arm projects outwardly from an outer periphery of the main body and a rotation angle range in which the arm is contained within the outer periphery of the main body.

Owner:SANYO ELECTRIC CO LTD

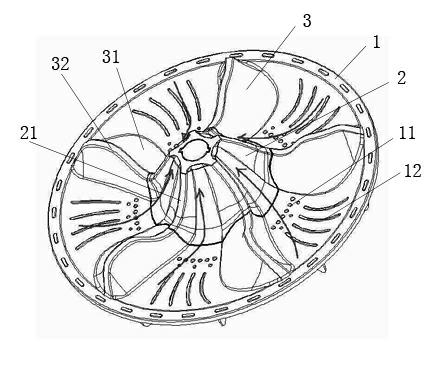

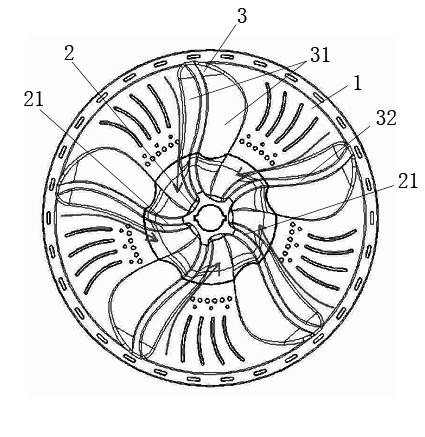

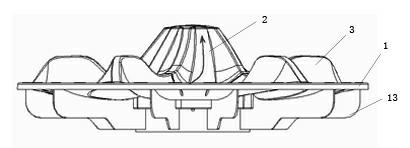

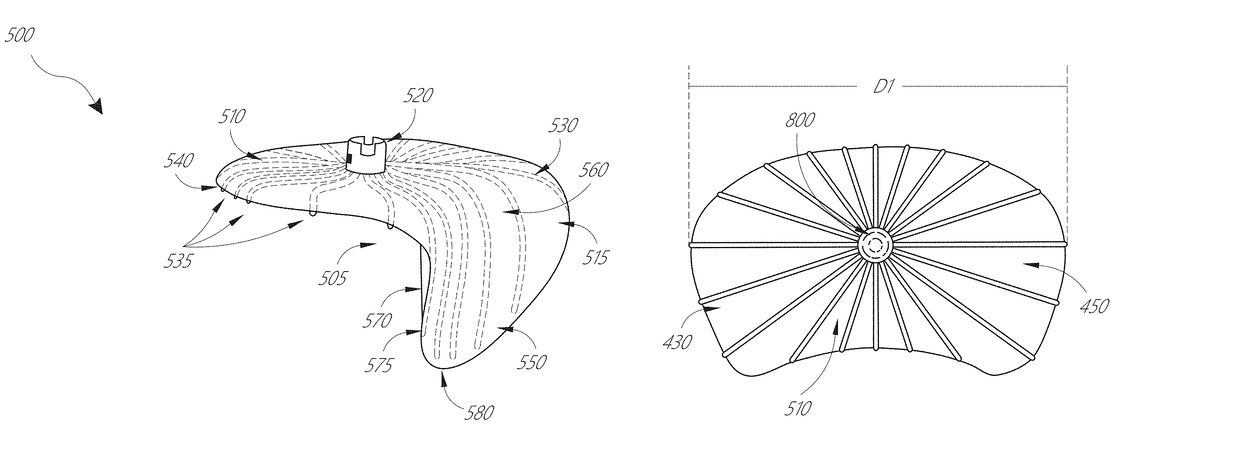

Wave wheel of washing machine

ActiveCN102587072AAvoid damageExcellent washing abilityWashing machine with receptaclesTextiles and paperWater flowPropeller

The invention discloses a wave wheel of a washing machine, comprising a base and a plurality of blades arranged on the base, wherein the blades are provided with veins and water propelling surfaces with slopes at two sides. The wave wheel is characterized in that a cone-shaped platform is arranged at the middle part of the base; raised propelling ribs of which the quantity is same as the quantity of the blades are arranged on the vertical face of the cone-shaped platform and smoothly connected to the corresponding veins; water propelling surfaces of each blade have different slopes; concave surfaces and convex surfaces are arranged on the water propelling surfaces; the veins are S-shaped for corresponding to the curve surface changes of the concave surfaces and convex surfaces of the water propelling surfaces; moreover, side-looking lines of the veins are continuous curves firstly concave and then convex outwards from the center of the base. According to the invention, the blades show a streamline shape like a propeller and the water propelling surfaces are smooth and temperate, but the motive power is strong and the washing ability is outstanding; meanwhile, water flow raised in the middle can be generated to ensure that clothes rotated to the central position of a wash bucket are scattered and effectively prevented from being intertwisted; in addition, the destroy of backward rotation to water flow trend is decreased to ensure that the anti-intertwist ability is further increased.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

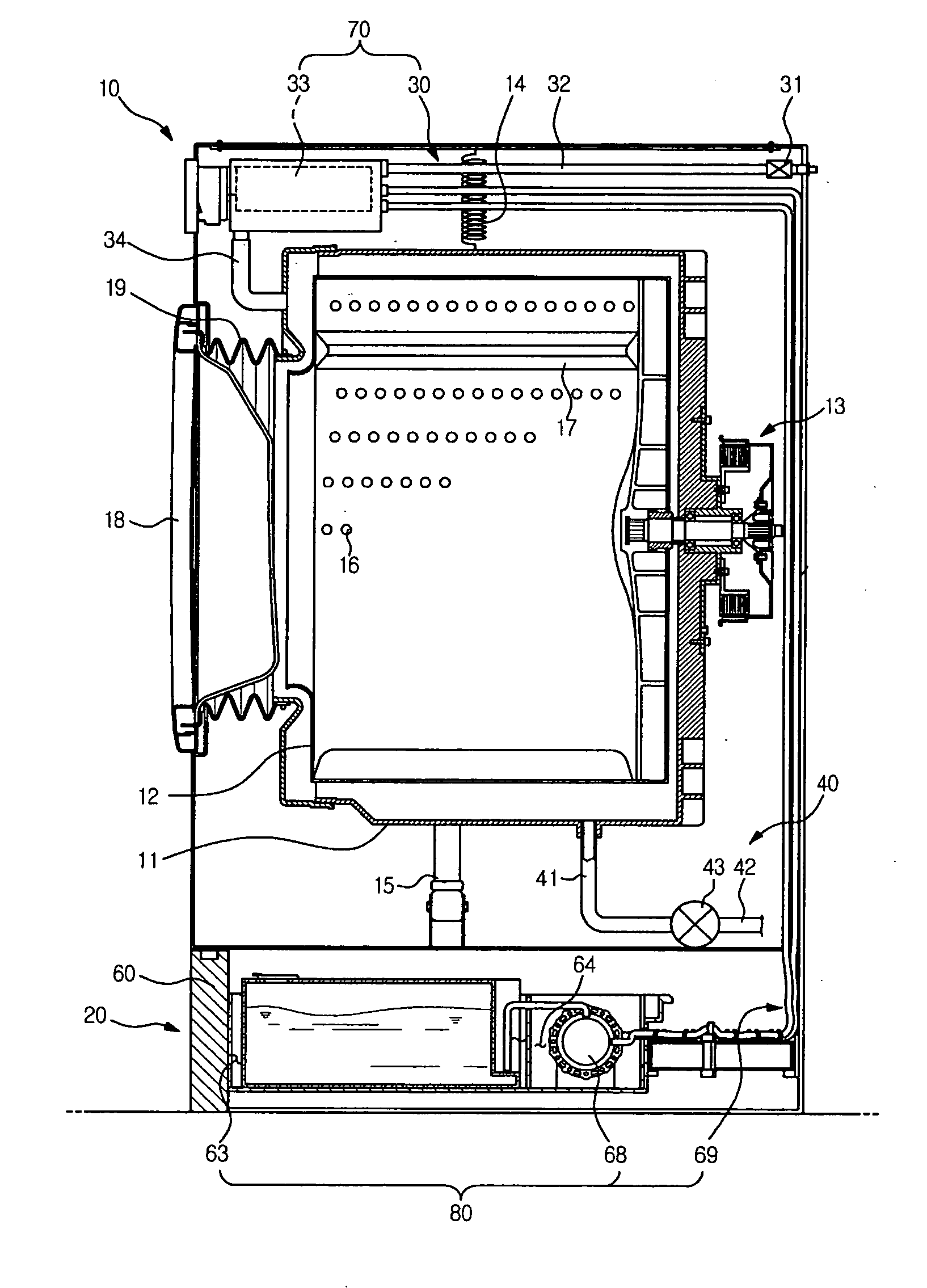

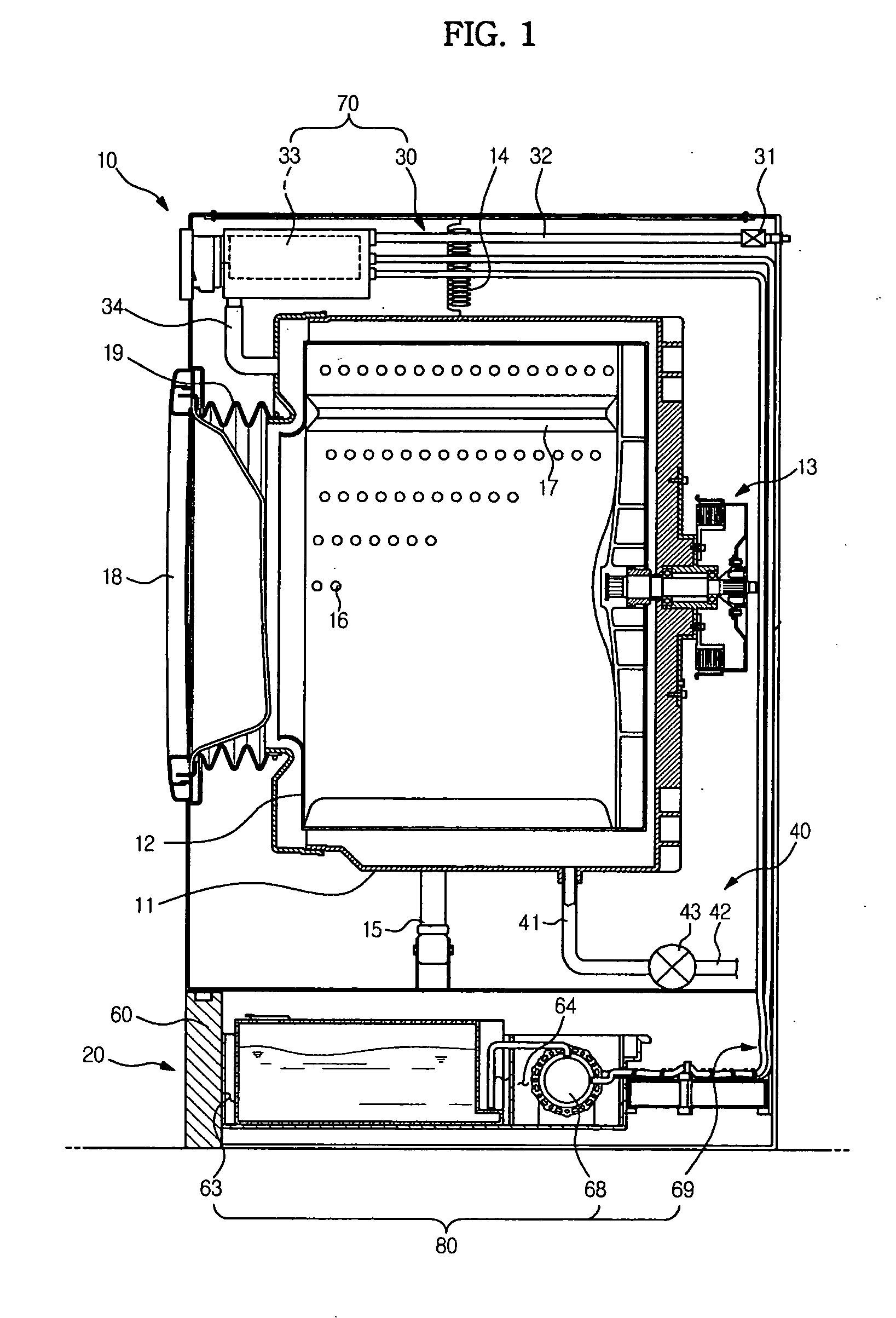

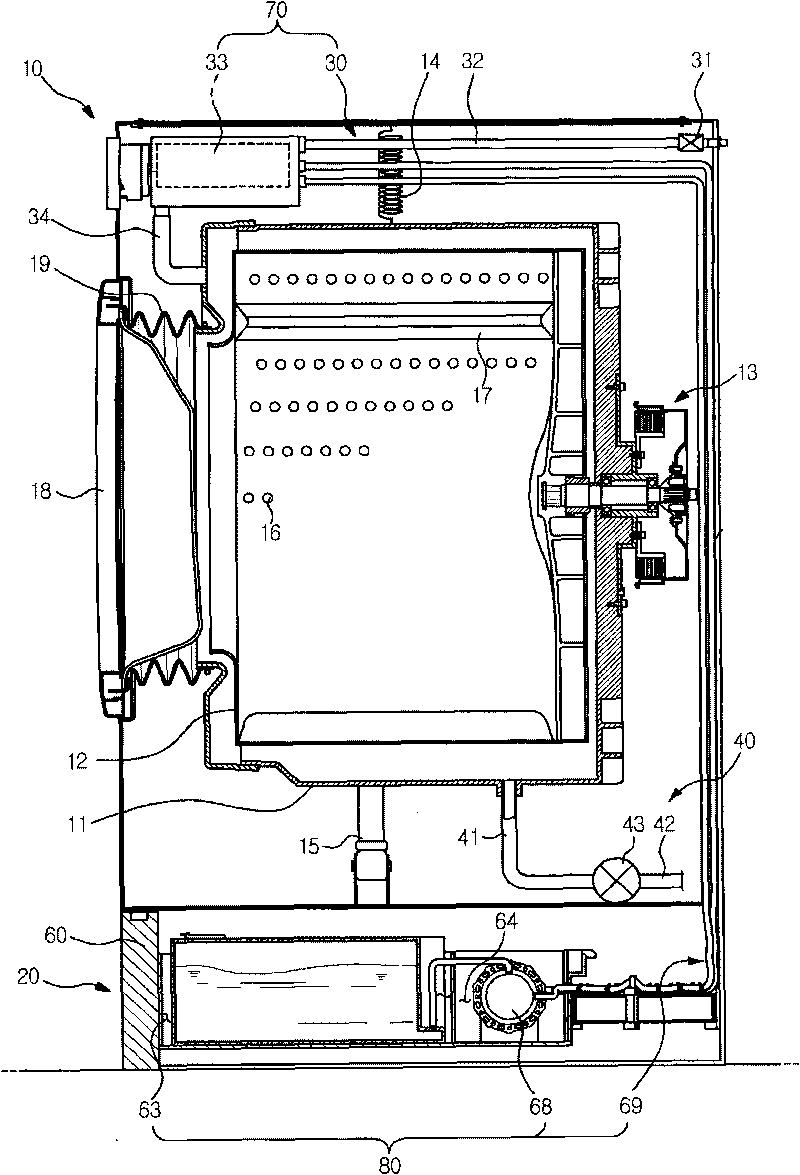

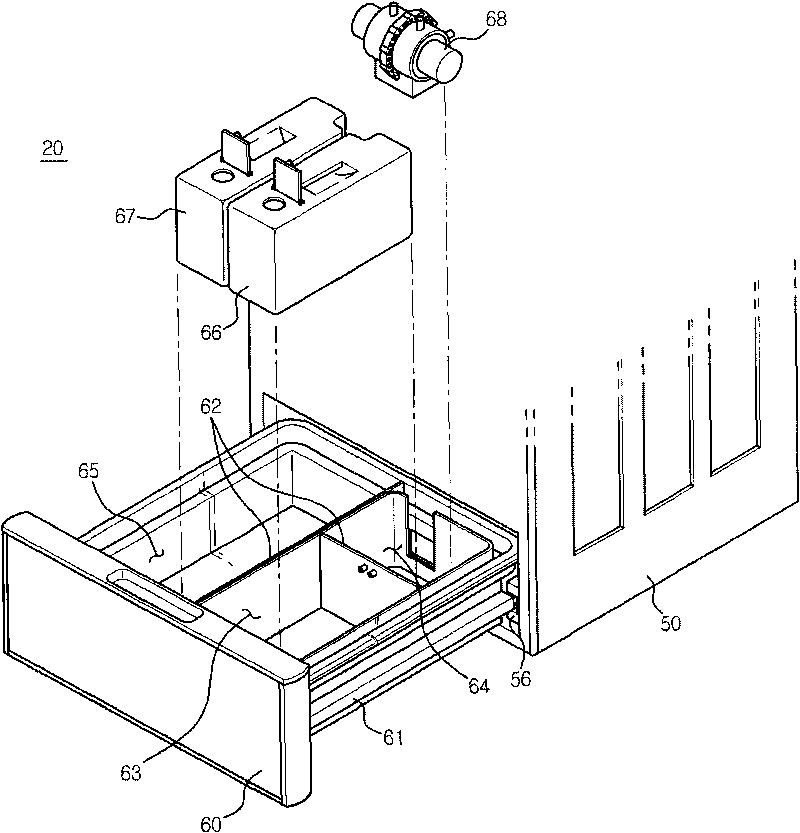

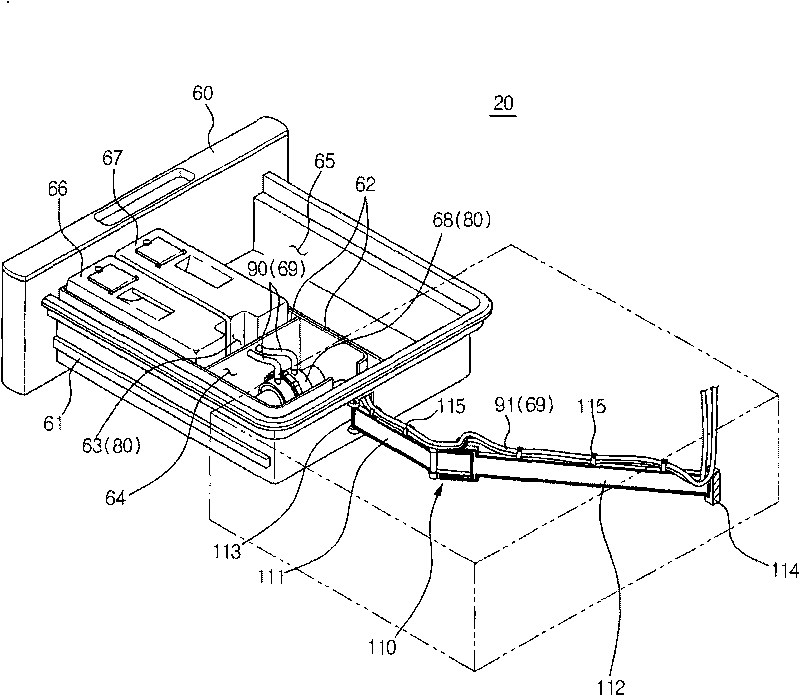

Washing machine with detergent supply path

ActiveUS20100107704A1Avoid entanglementHigh trafficOther washing machinesLiquid transferring devicesEngineeringMechanical engineering

Disclosed herein are a washing machine and a detergent supply path which guides detergent stored in a lower part of a main body of the washing machine to an upper part of the main body. The washing machine includes a main body; a support base removably mounted to the main body; a detergent storage unit mounted at a lower part of the main body to be moved in and out of the main body; a detergent supply path guiding the detergent stored in the detergent storage unit that is in the lower part of the main body, to an upper part of the main body; and a guide unit guiding movement of the detergent supply path according to the movement in and out of the detergent storage unit.

Owner:SAMSUNG ELECTRONICS CO LTD

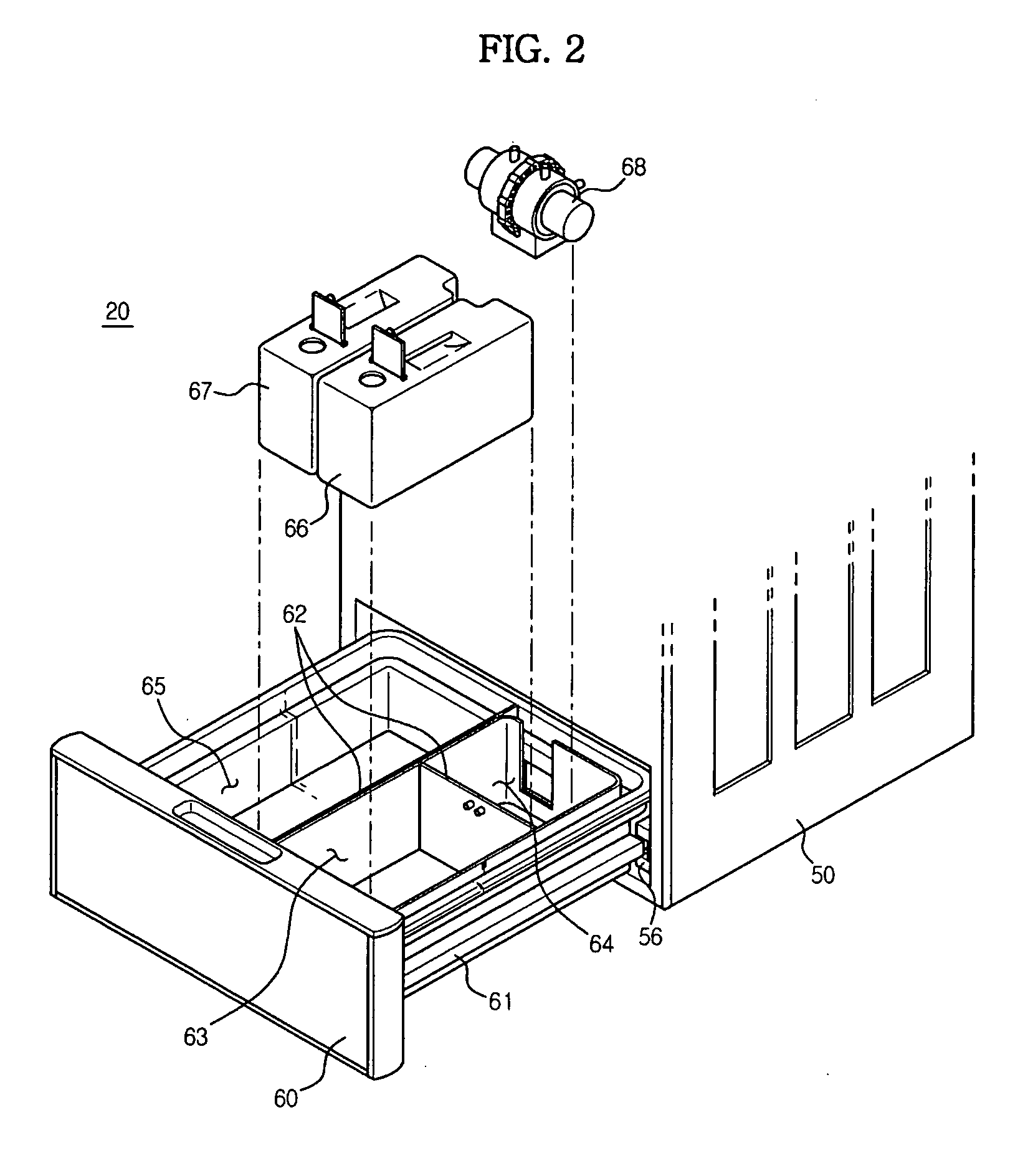

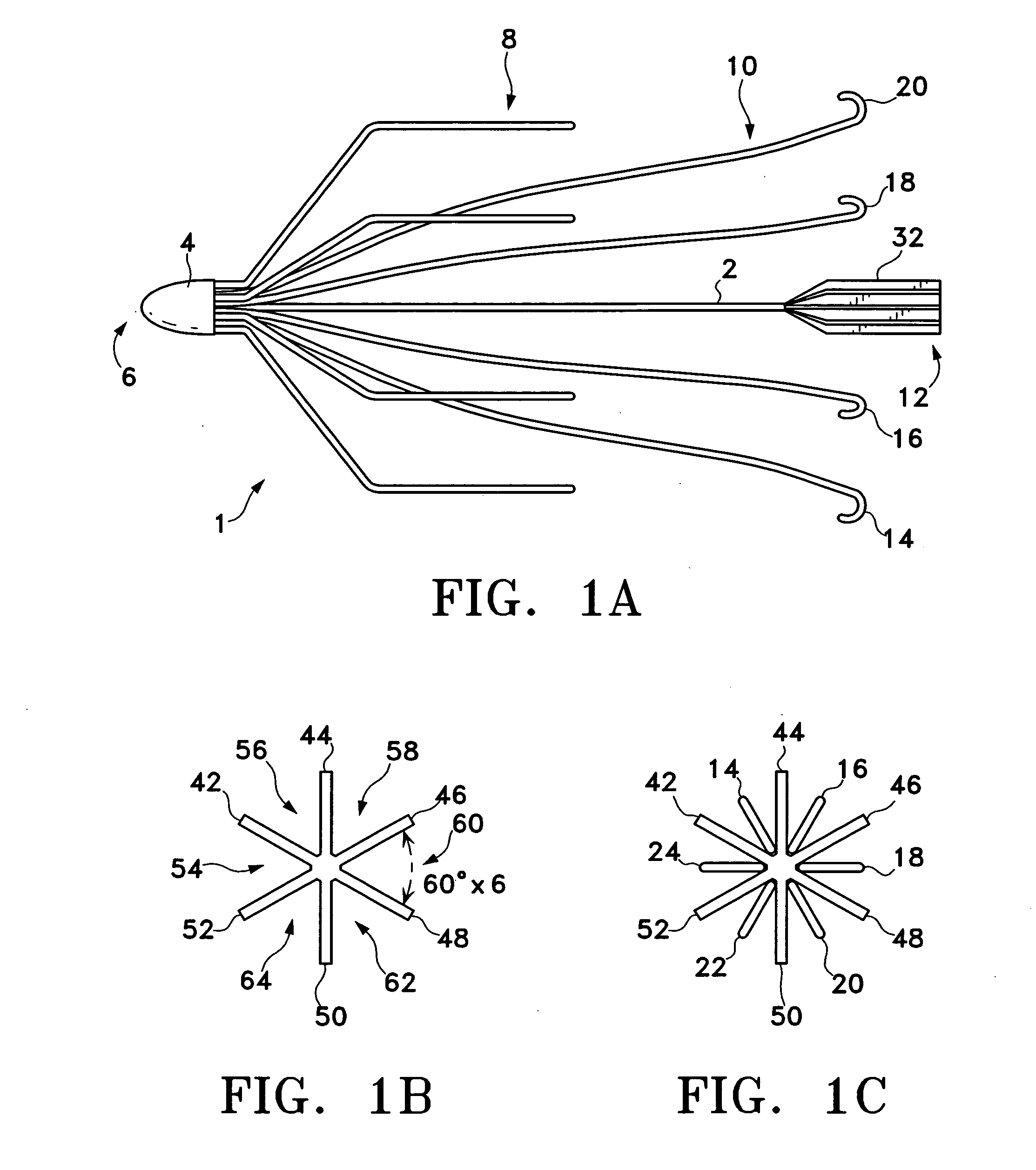

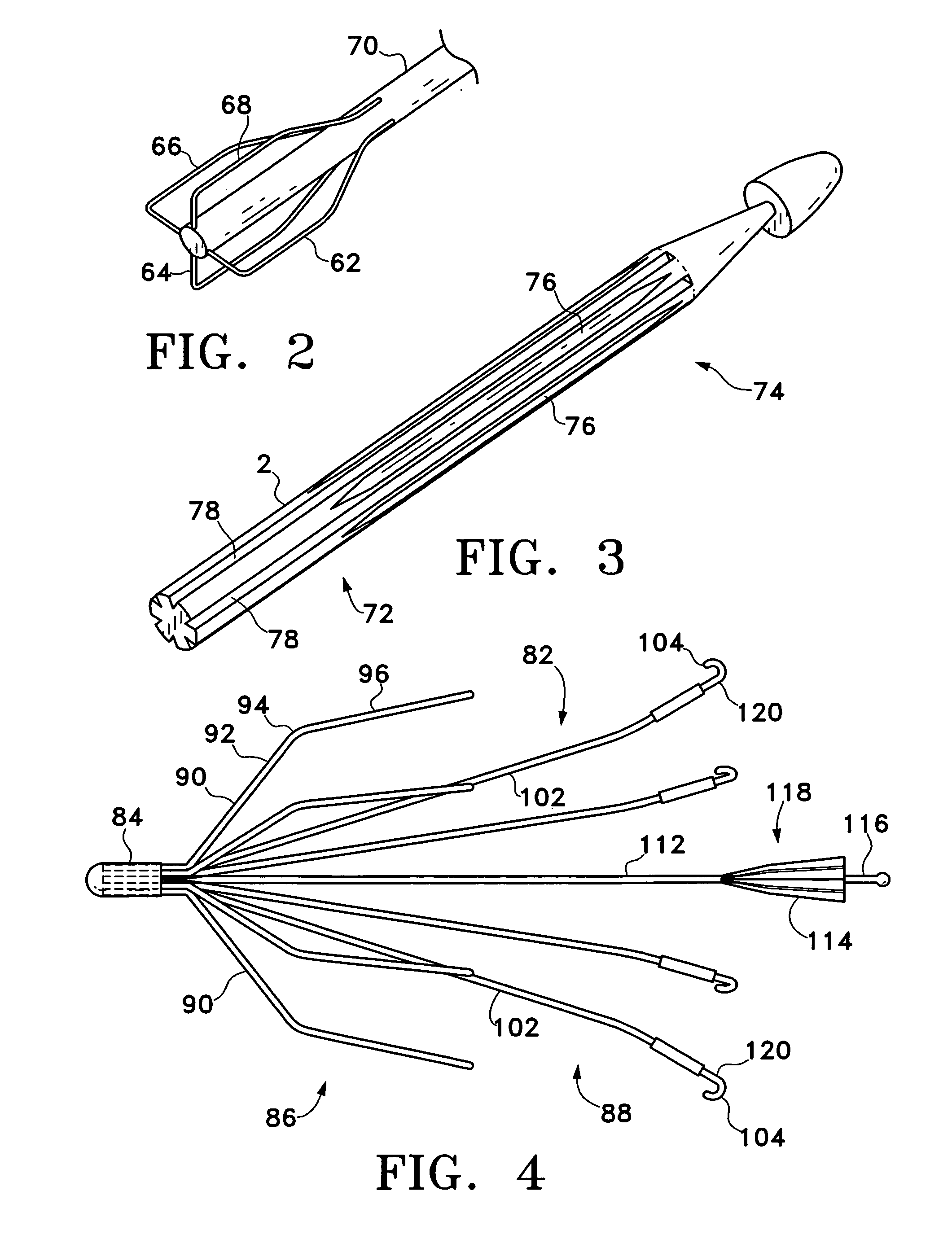

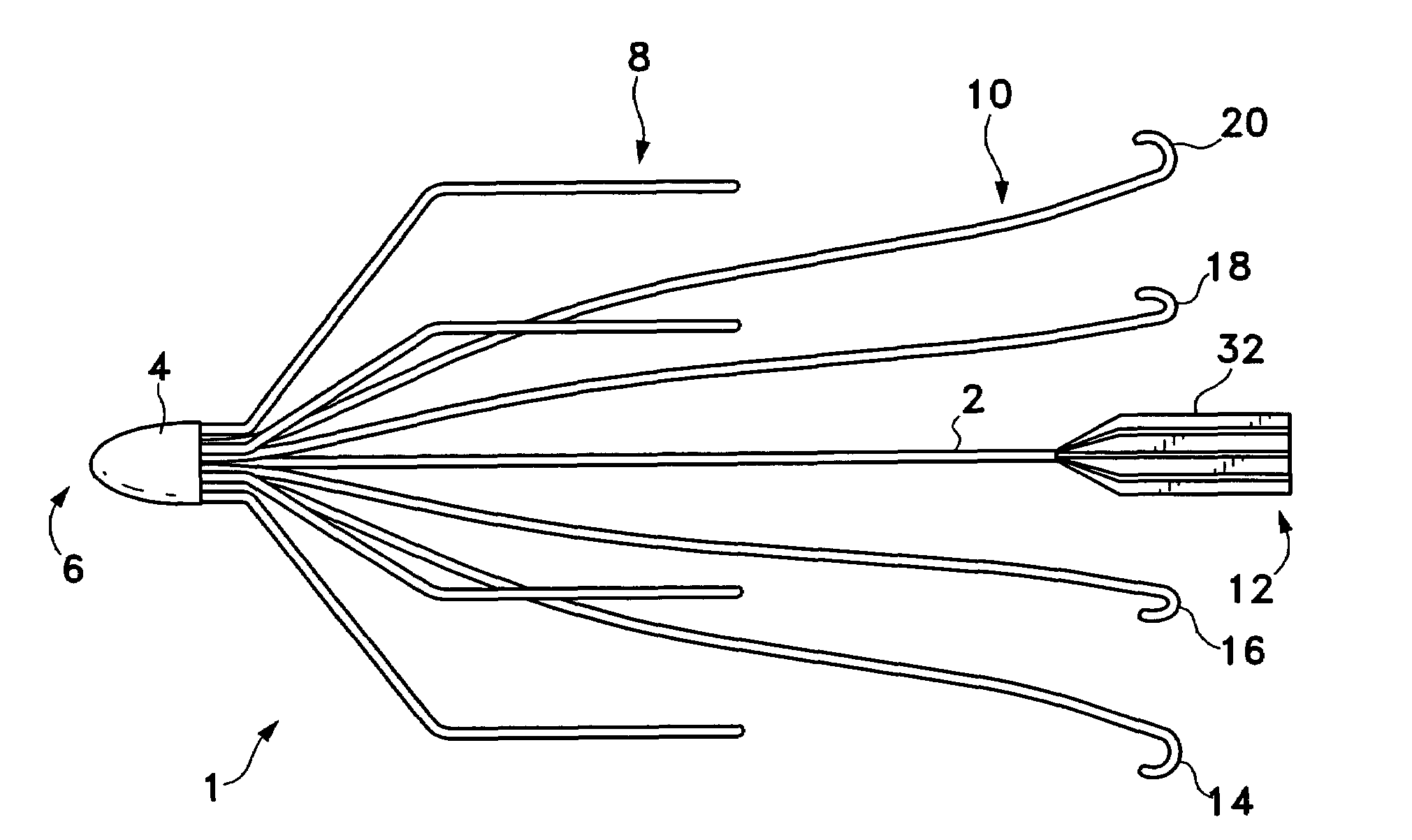

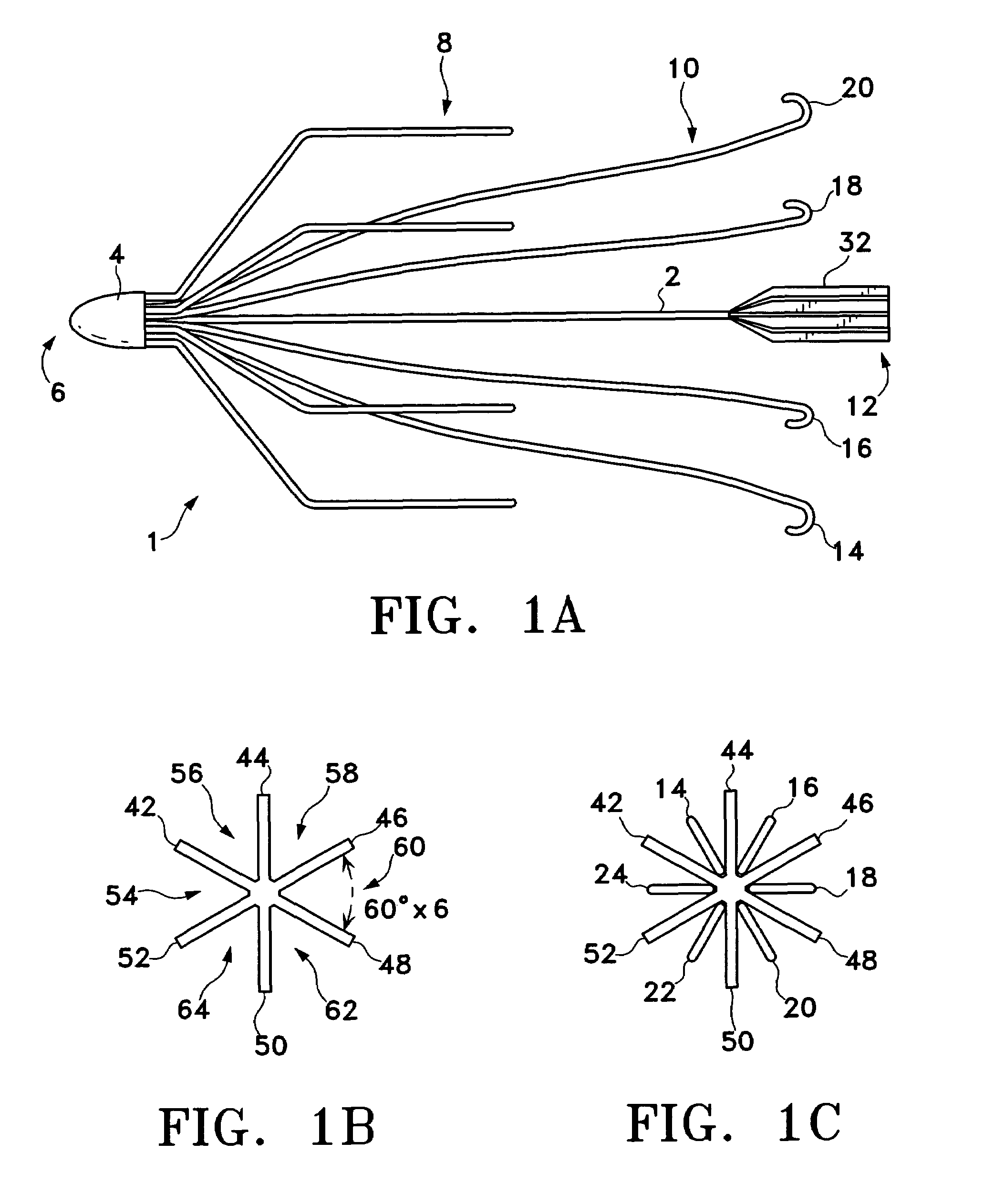

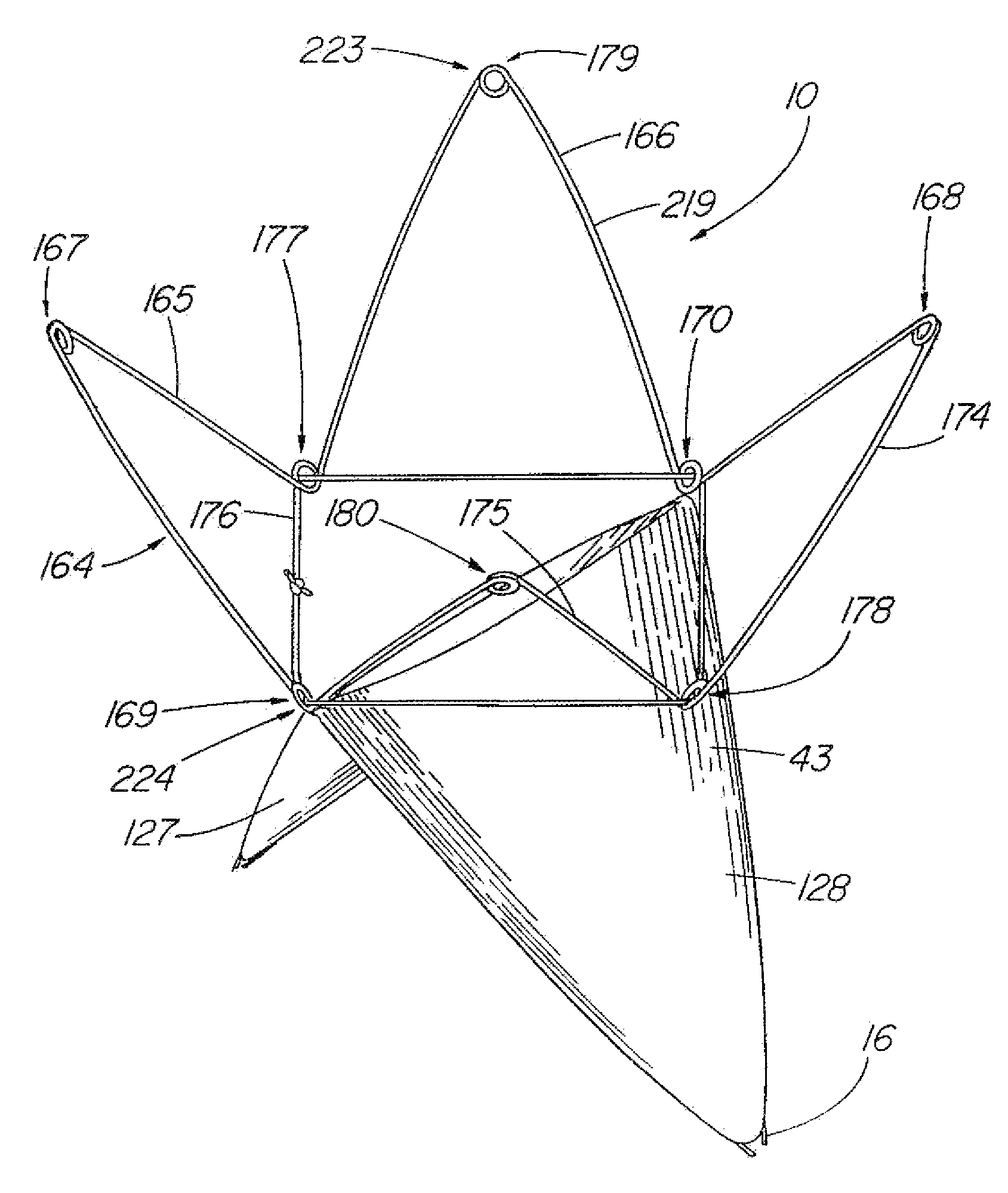

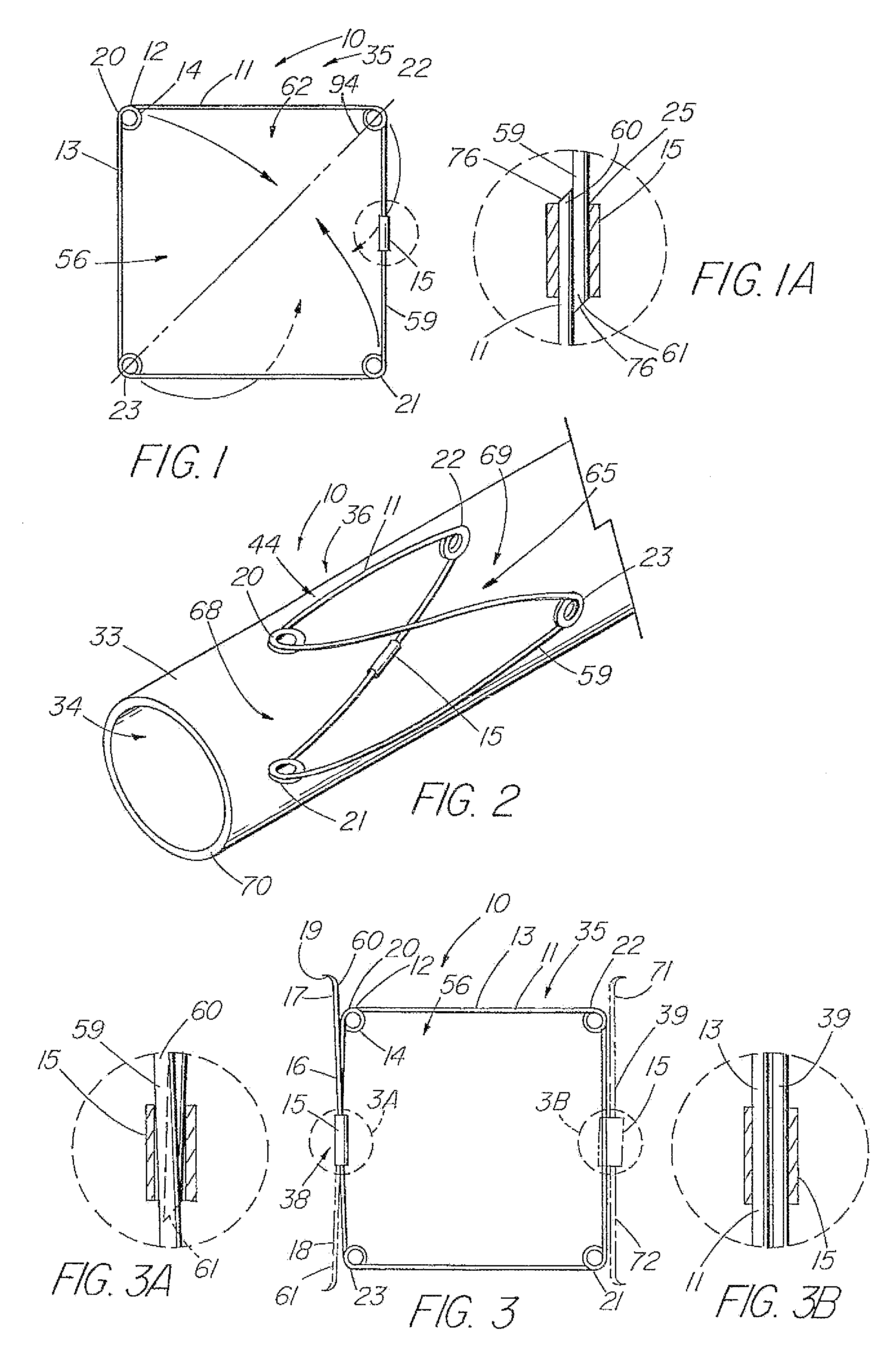

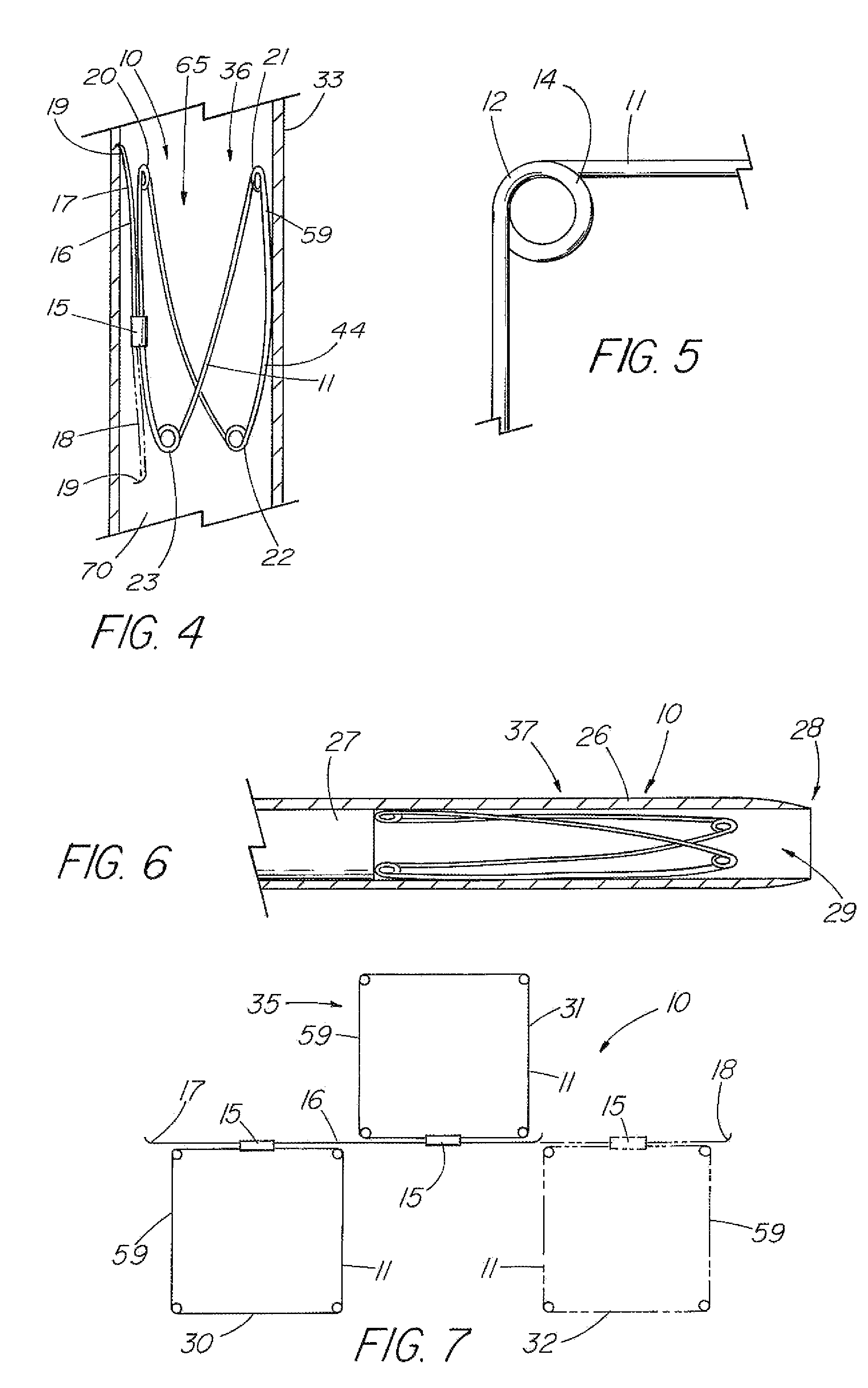

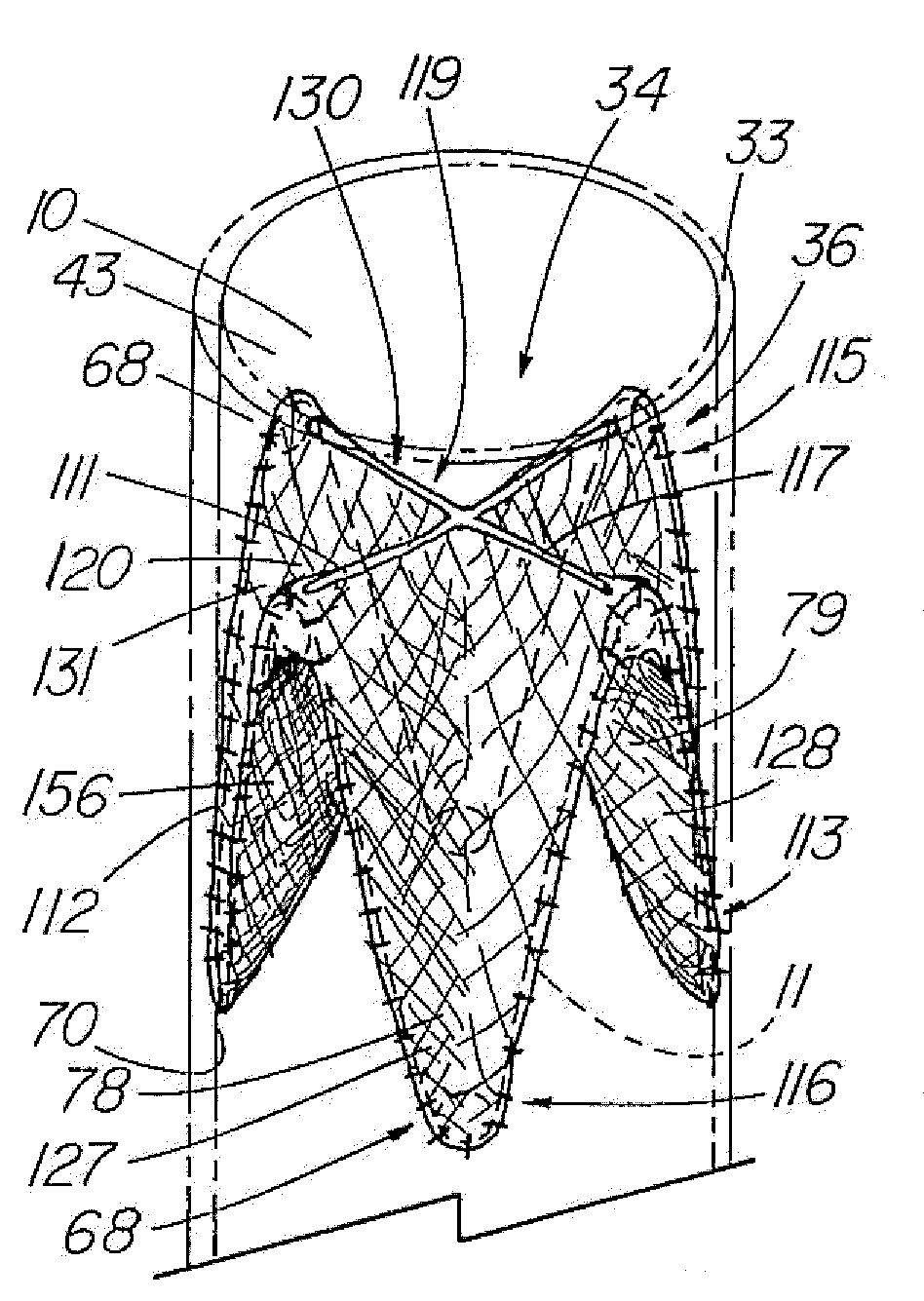

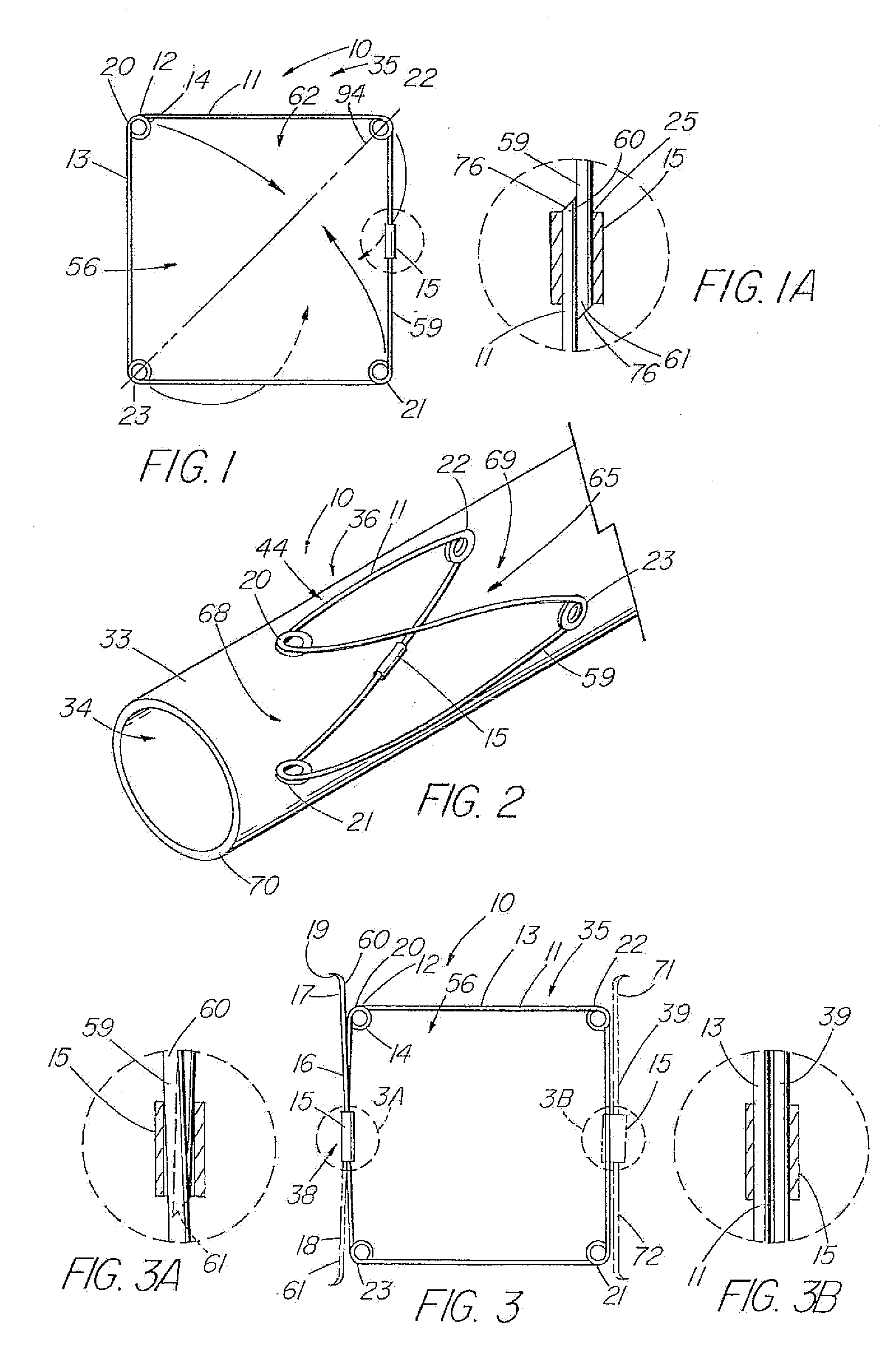

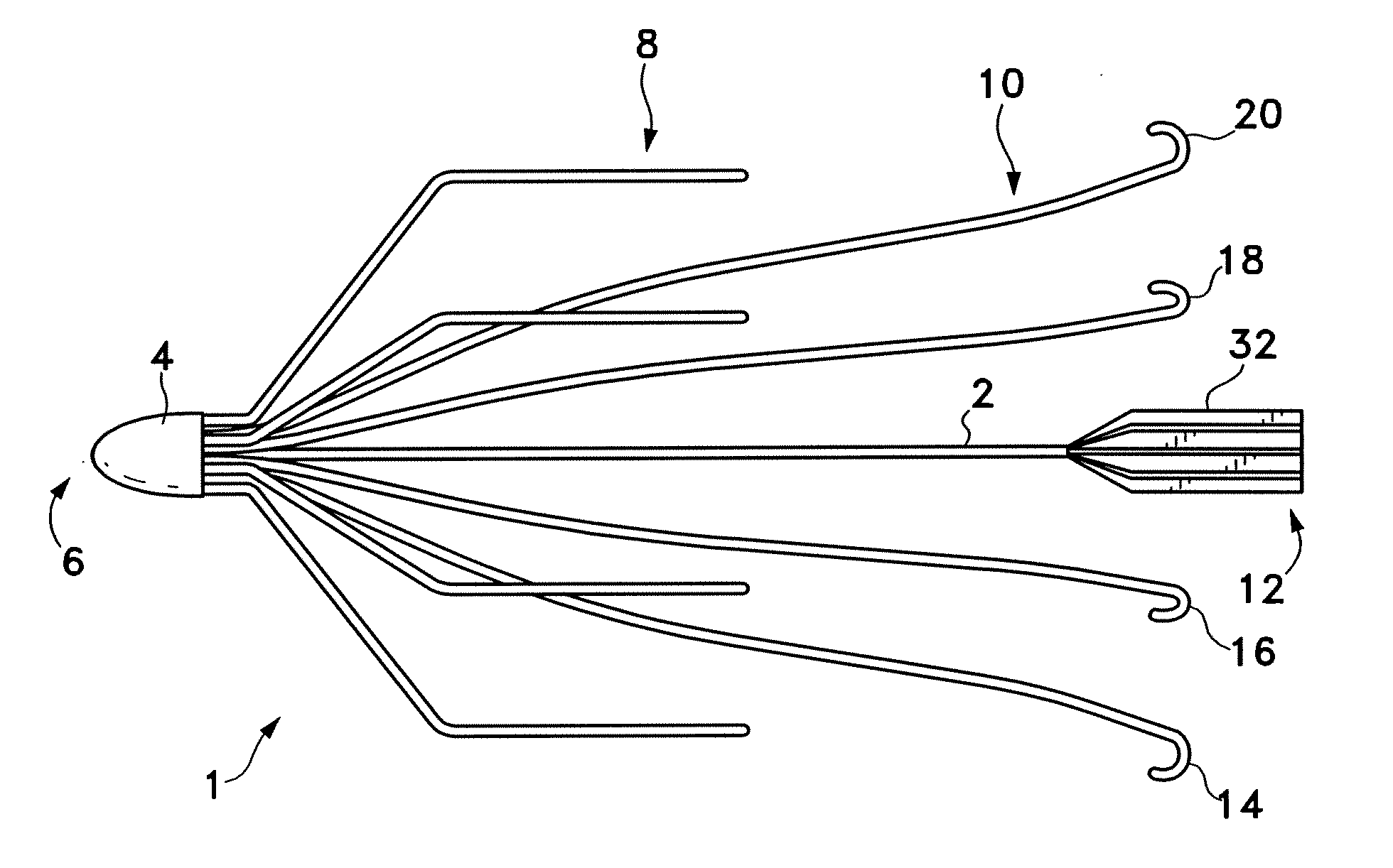

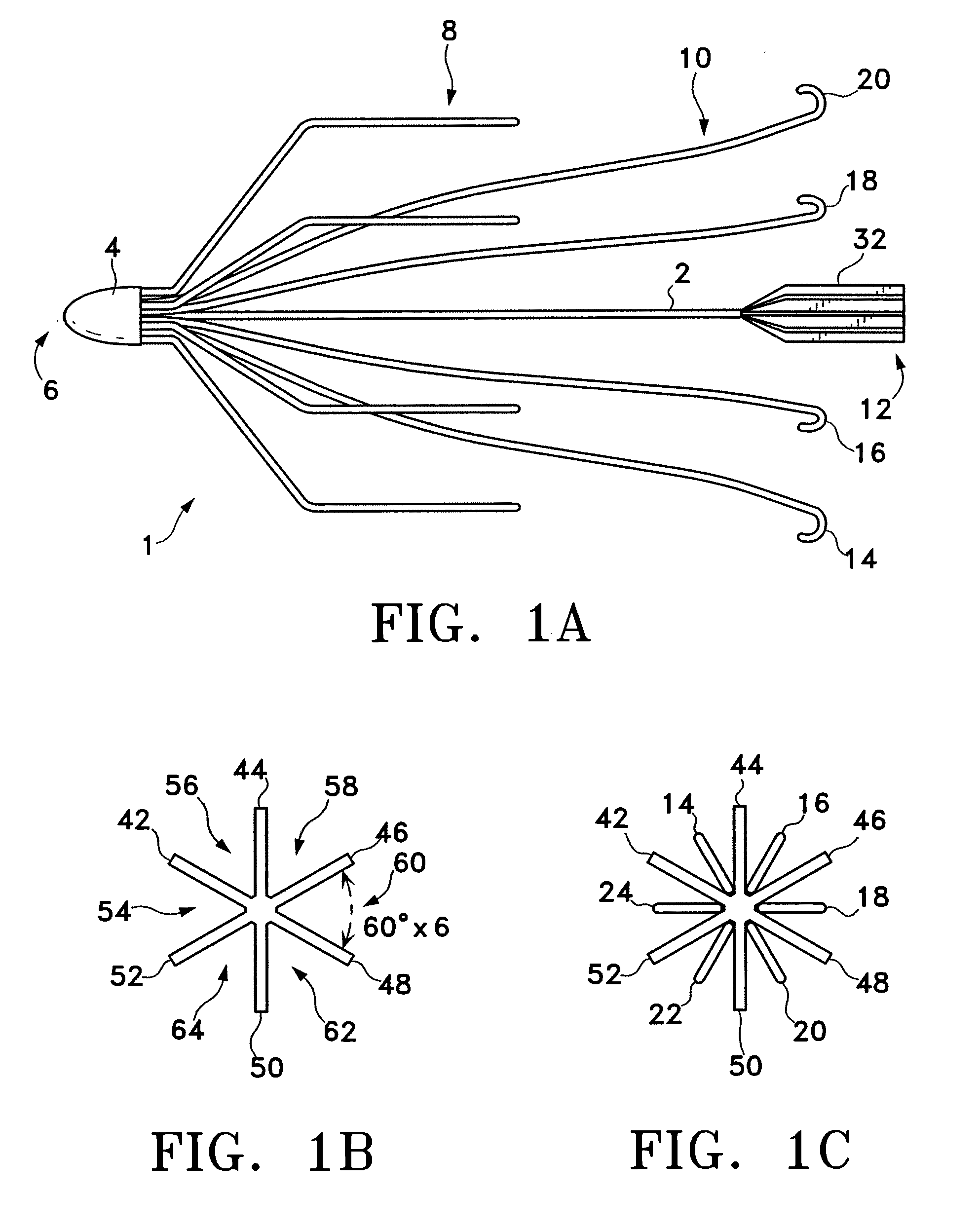

Non-entangling vena cava filter

ActiveUS20060030875A1Improved delivery systemImproved deployabilitySurgeryDilatorsBiomedical engineeringVena cava filters

An implantable vessel filter device having a plurality of radially expandable legs with hooks, and a center-post configured to prevent entanglement of the radially expandable legs when they are compressed against the center-post. In one variation, the filter device comprises a first set of legs, forming a first filter basket in the expanded position, and a second set of legs, forming a second filter basket distal to the first filter in the expanded position. Hooks may be provided on the second set of legs to prevent migration of the filter along the vessel after the filter is deployed. Grooves may be provided along the shaft of the center-post to receive the hooks and prevent the hooks from interlocking when the legs of the filter are compressed along the center-post.

Owner:CR BARD INC

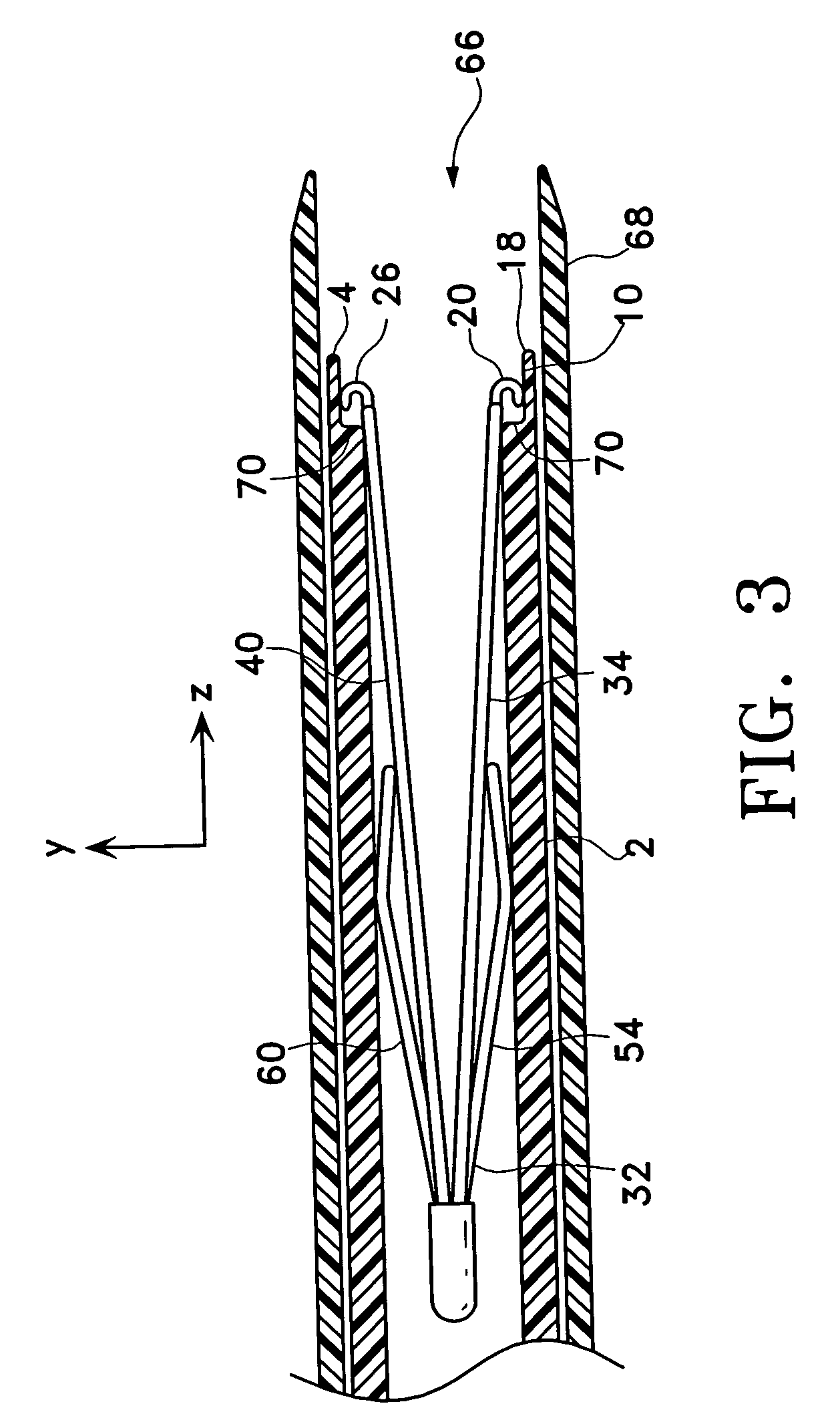

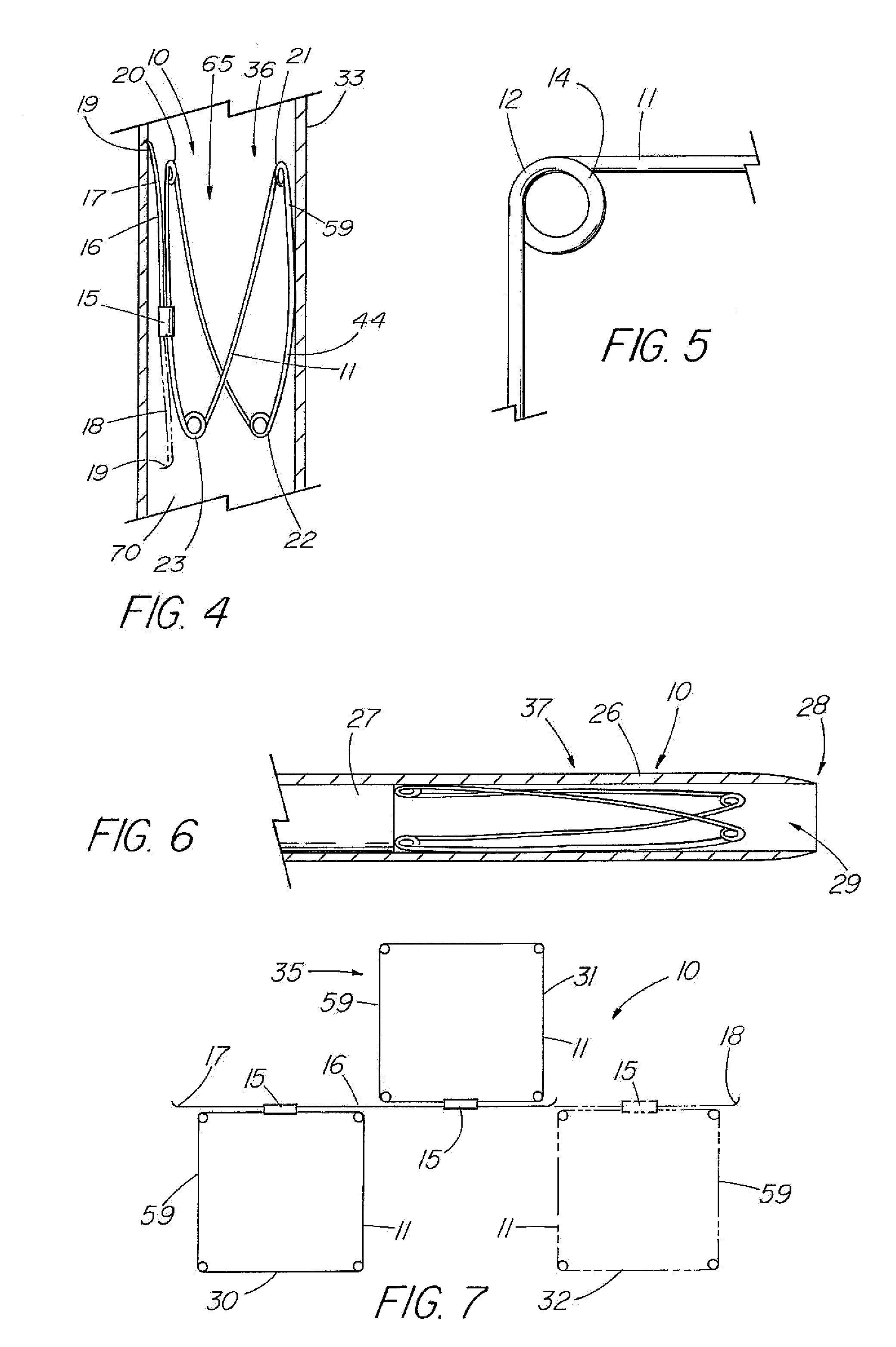

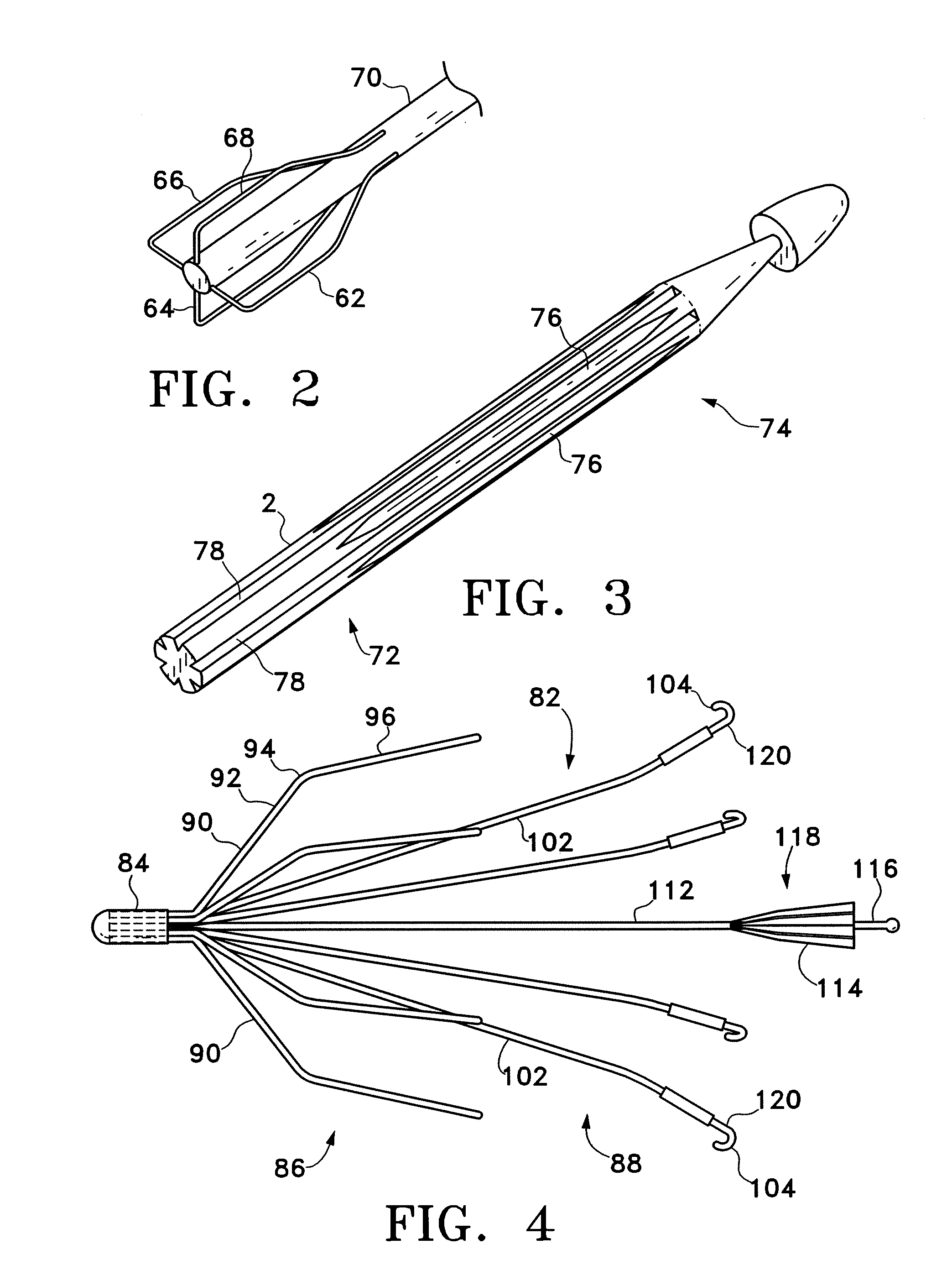

Filter delivery system

A filter delivery device for implanting a vessel filter within a blood vessel of a patient's body. The filter delivery device includes a mechanism for preventing hooks and / or legs on a vessel filter from entangling with each other while the vessel filter is loaded within the delivery device. In one variation, the filter delivery device includes a delivery catheter with grooves at the distal end lumen opening. When a vessel filter with radially expanding legs is compressed and inserted into the distal end of the delivery catheter, the hooks on the distal end of the legs are received and separated by the corresponding grooves on the delivery catheter. In another variation, a pusher rod, with a receptacle for receiving the hooks, is positioned within a delivery catheter to prevent the entanglement of the hooks and / or legs of a filter loaded within the delivery catheter.

Owner:CR BARD INC

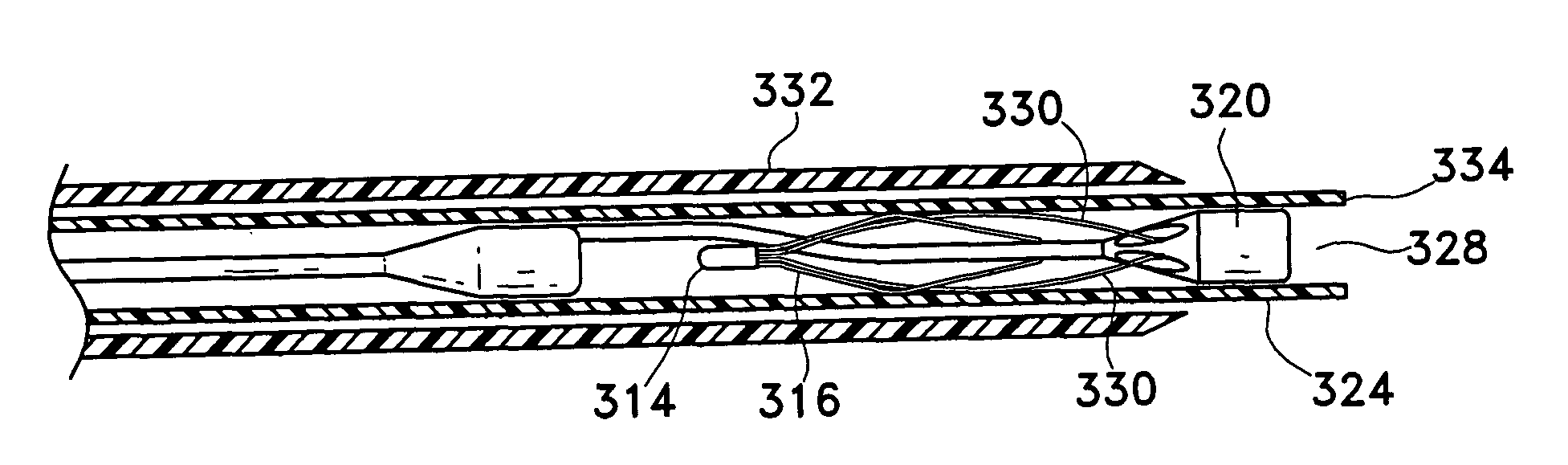

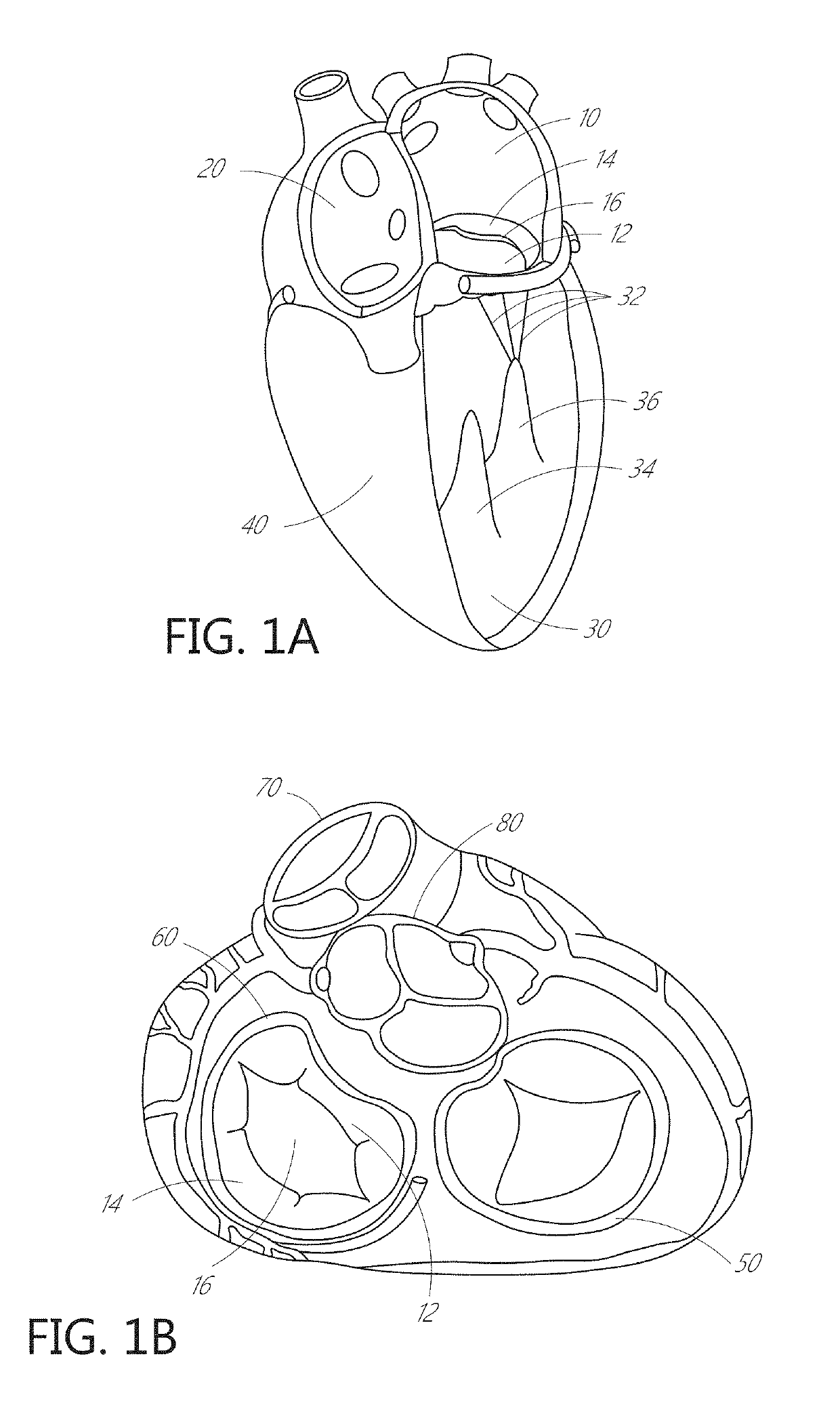

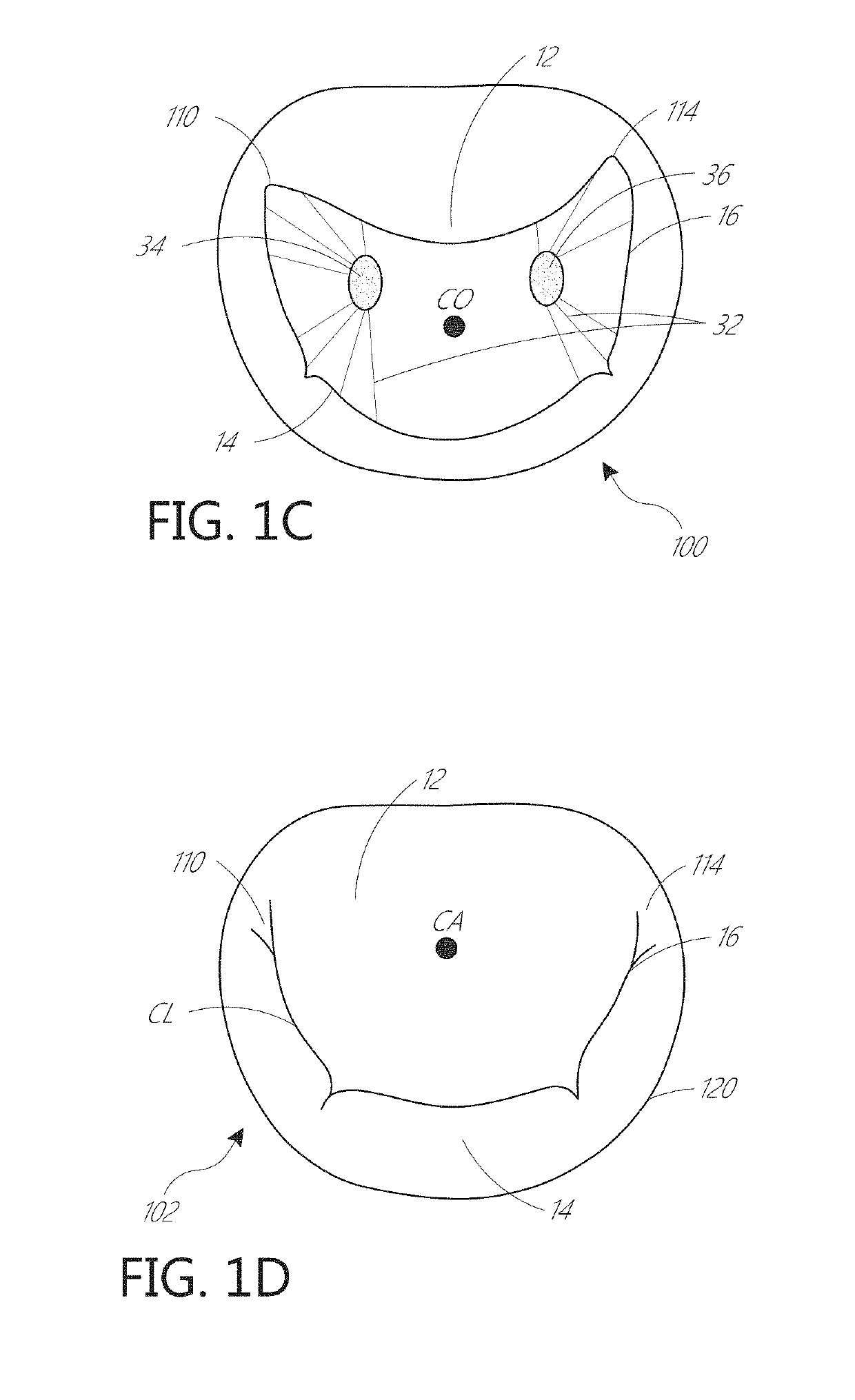

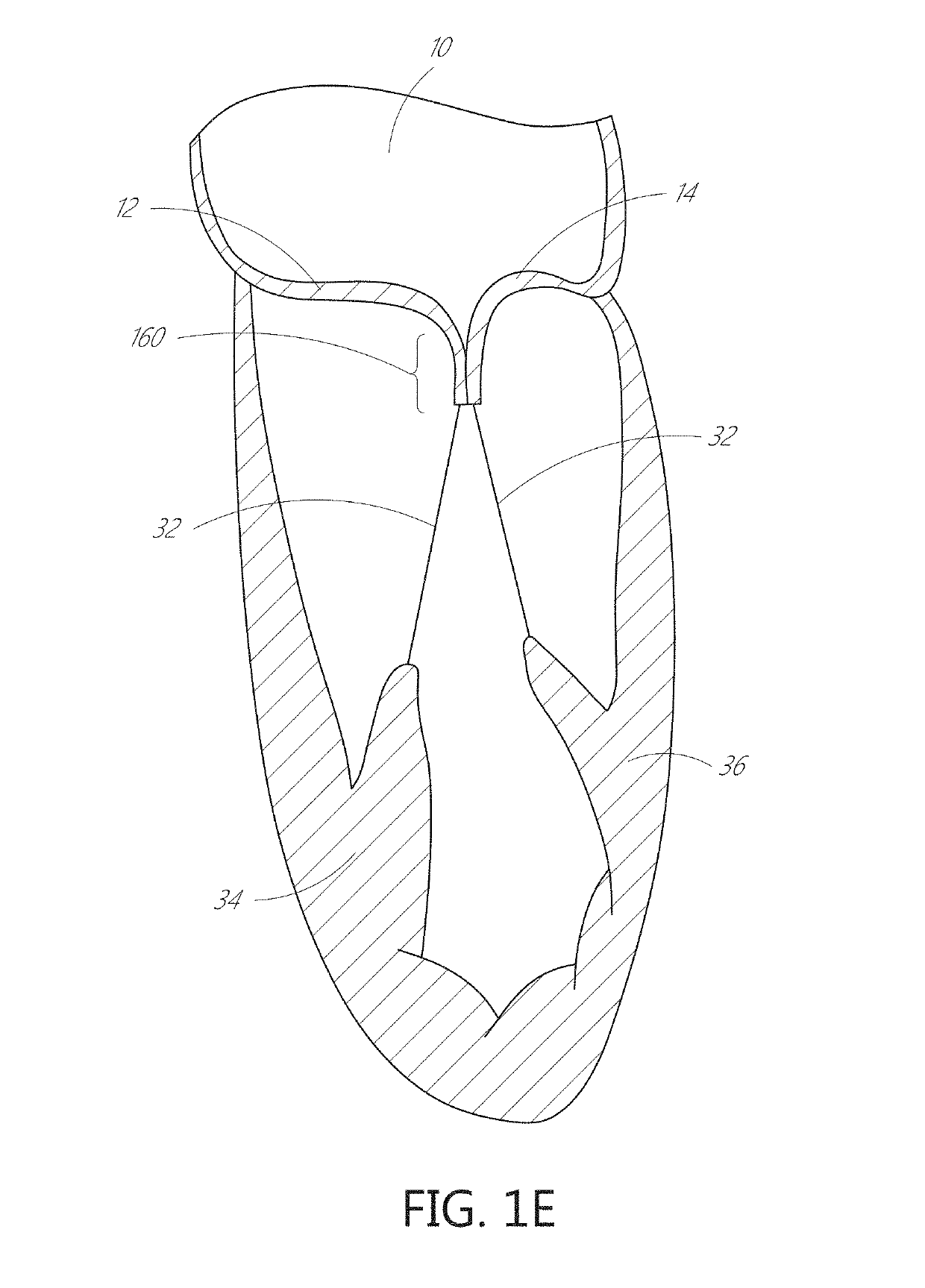

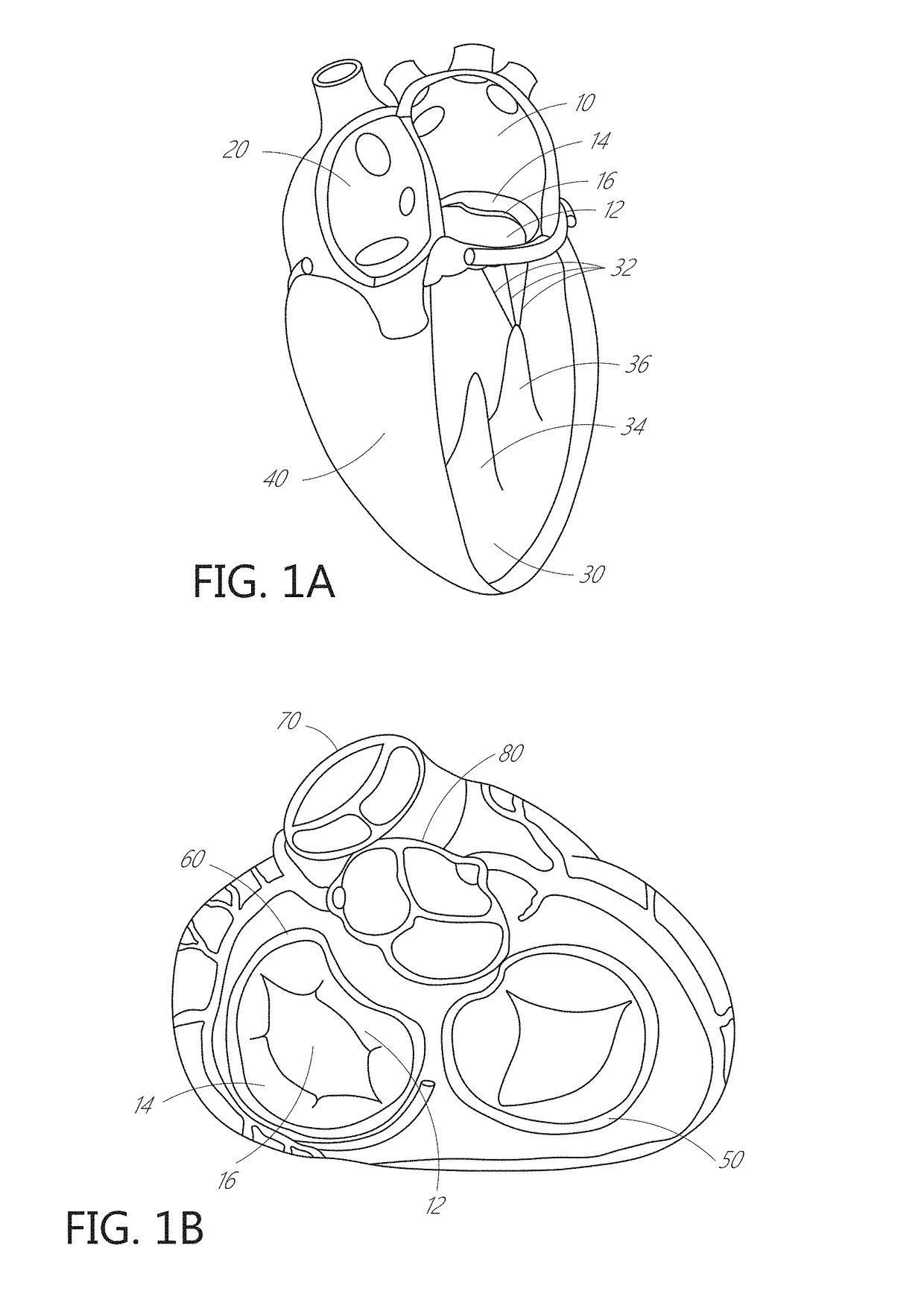

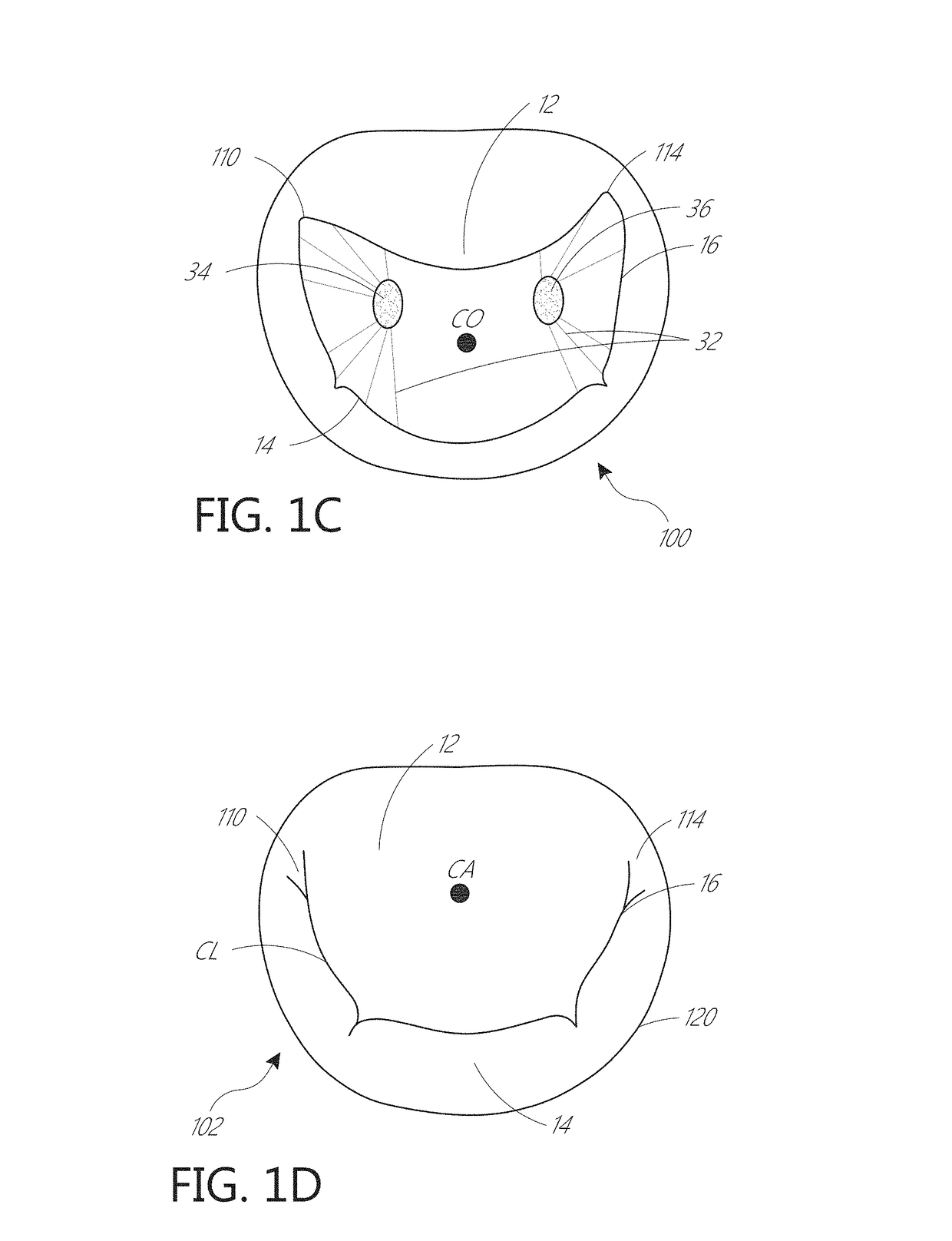

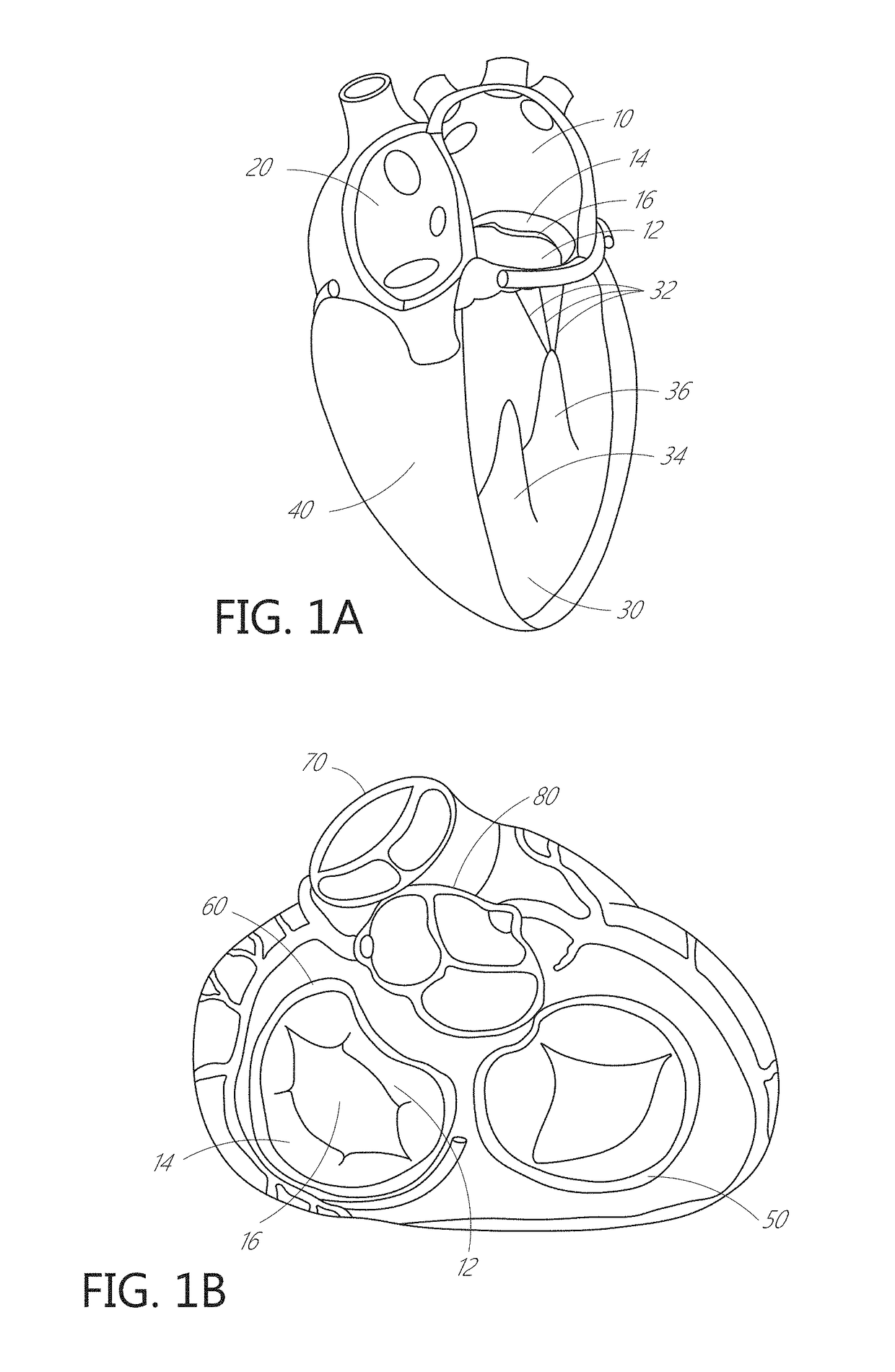

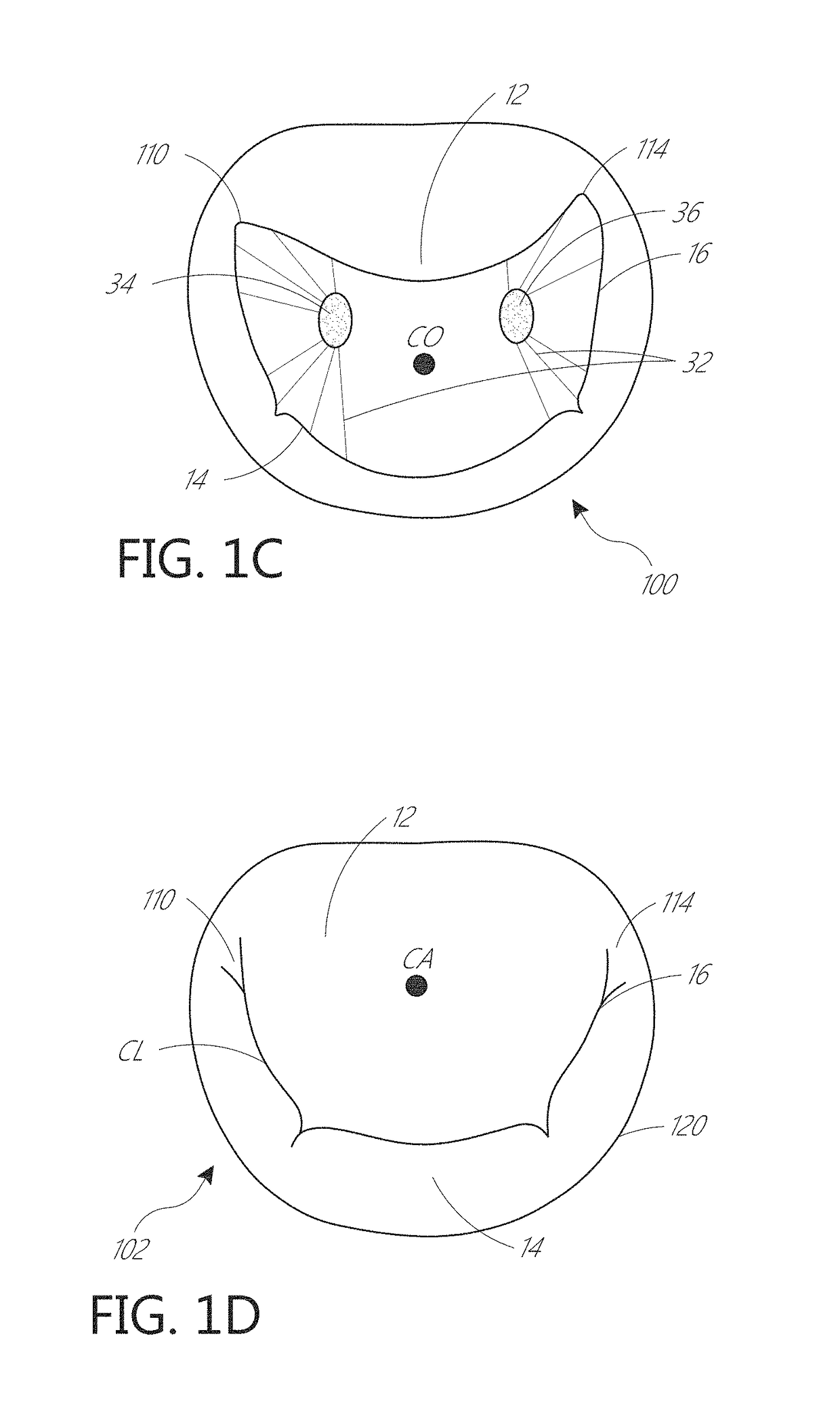

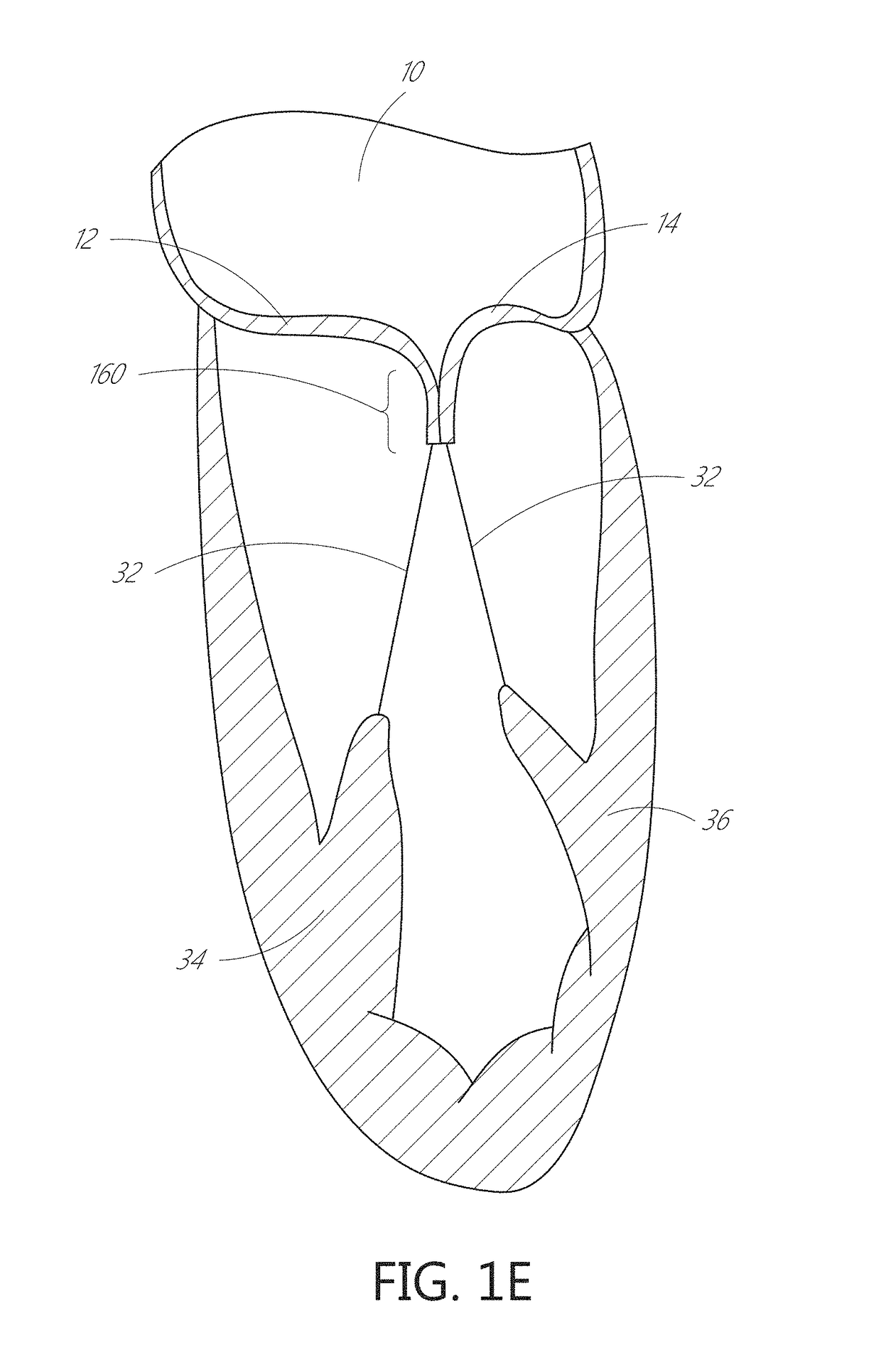

Device, system, and method for transcatheter treatment of valvular regurgitation

ActiveUS20190175344A1Ability to adjustPrecise cuttingDiagnosticsAnnuloplasty ringsValvular regurgitationGuide tube

The invention relates to a device for use in the transcatheter treatment of mitral valve regurgitation, specifically a coaptation assistance element for implantation across the valve; a system including the coaptation assistance element and anchors for implantation; a system including the coaptation assistance element and delivery catheter; and a method for transcatheter implantation of a coaptation element across a heart valve.

Owner:POLARES MEDICAL INC

Non-entangling vena cava filter

An implantable vessel filter device having a plurality of radially expandable legs with hooks, and a center-post configured to prevent entanglement of the radially expandable legs when they are compressed against the center-post. In one variation, the filter device includes a first set of legs, forming a first filter basket in the expanded position, and a second set of legs, forming a second filter basket distal to the first filter in the expanded position. Hooks may be provided on the second set of legs to prevent migration of the filter along the vessel after the filter is deployed. Grooves may be provided along the shaft of the center-post to receive the hooks and prevent the hooks from interlocking when the legs of the filter are compressed along the center-post.

Owner:CR BARD INC

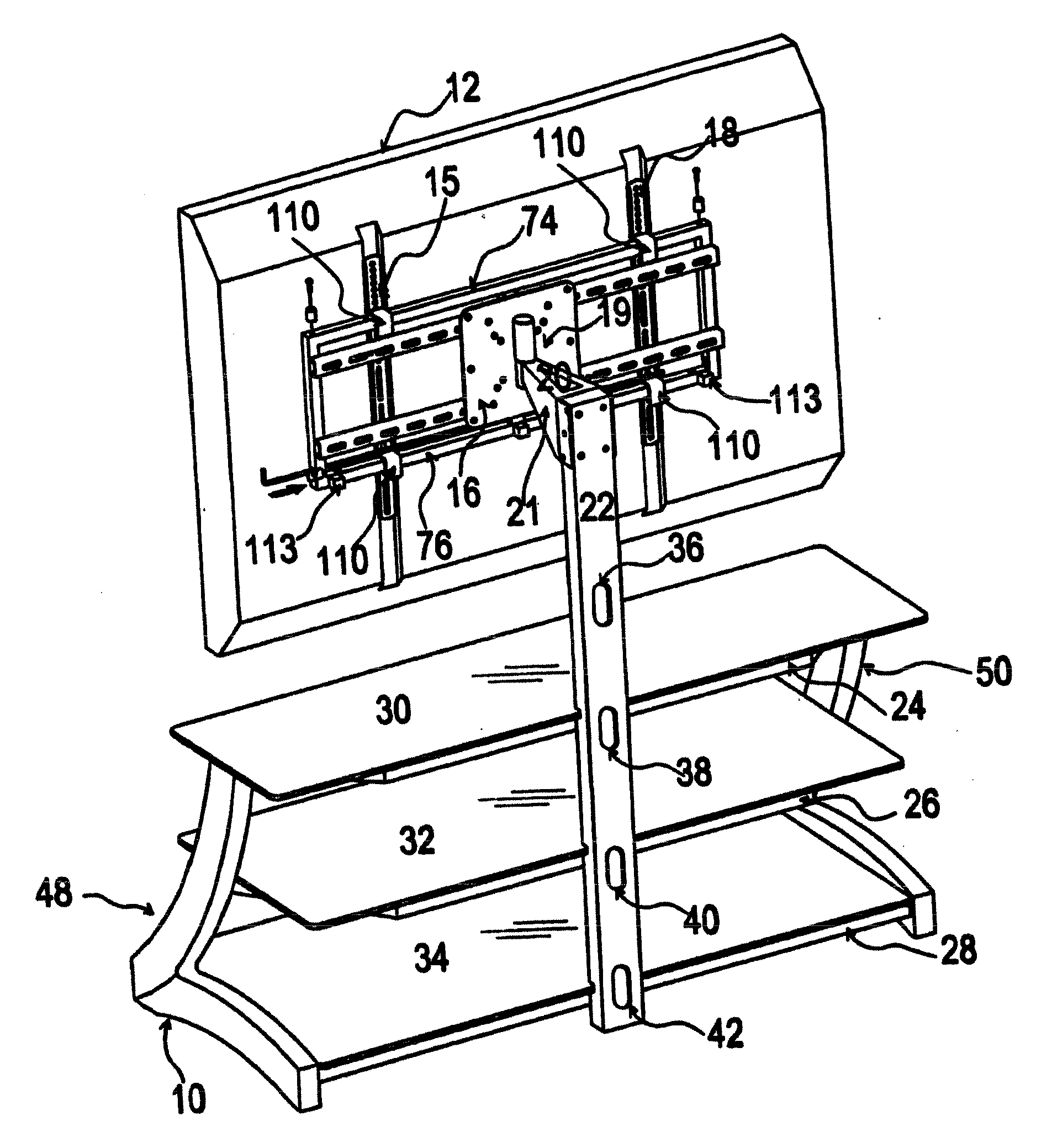

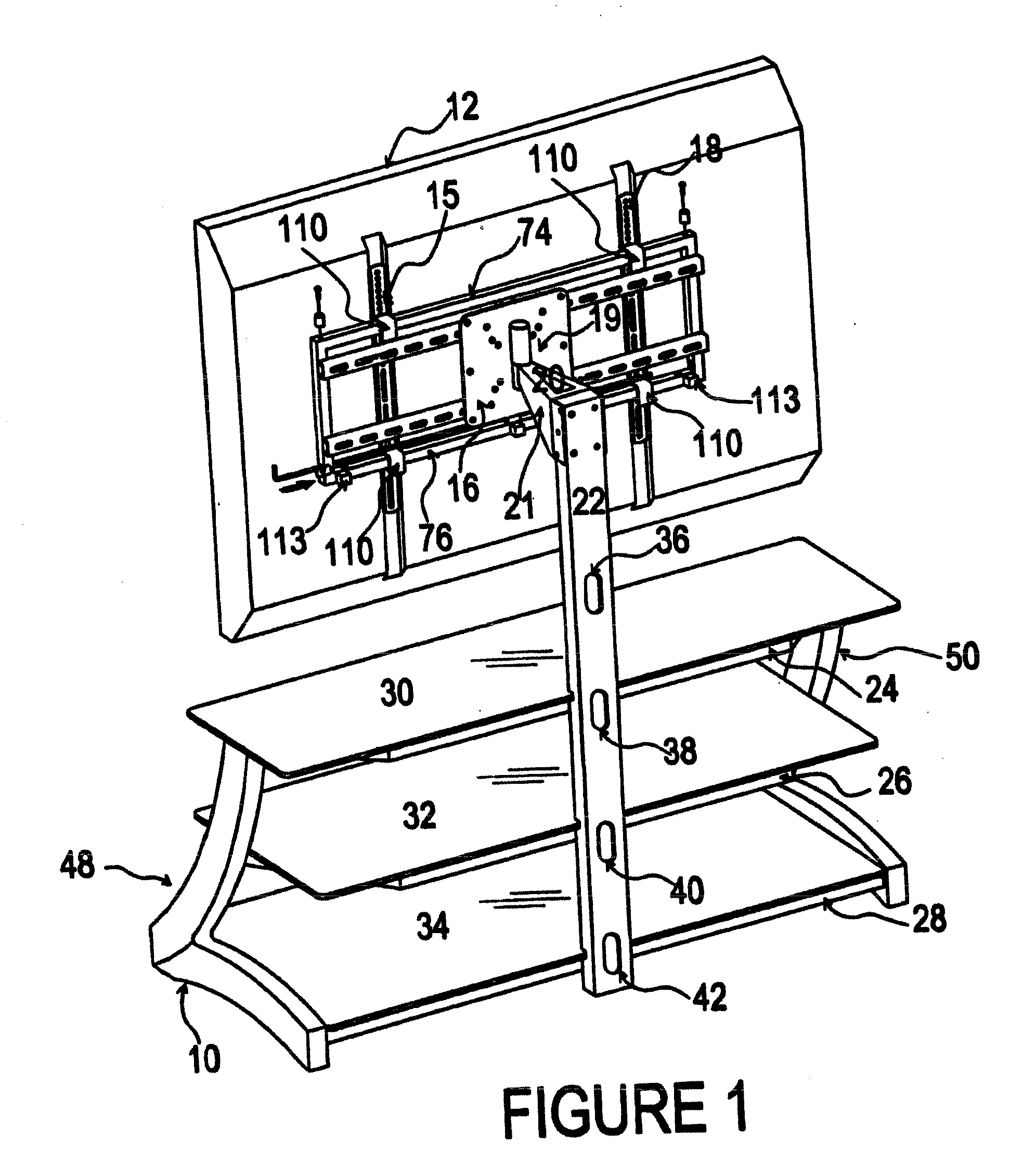

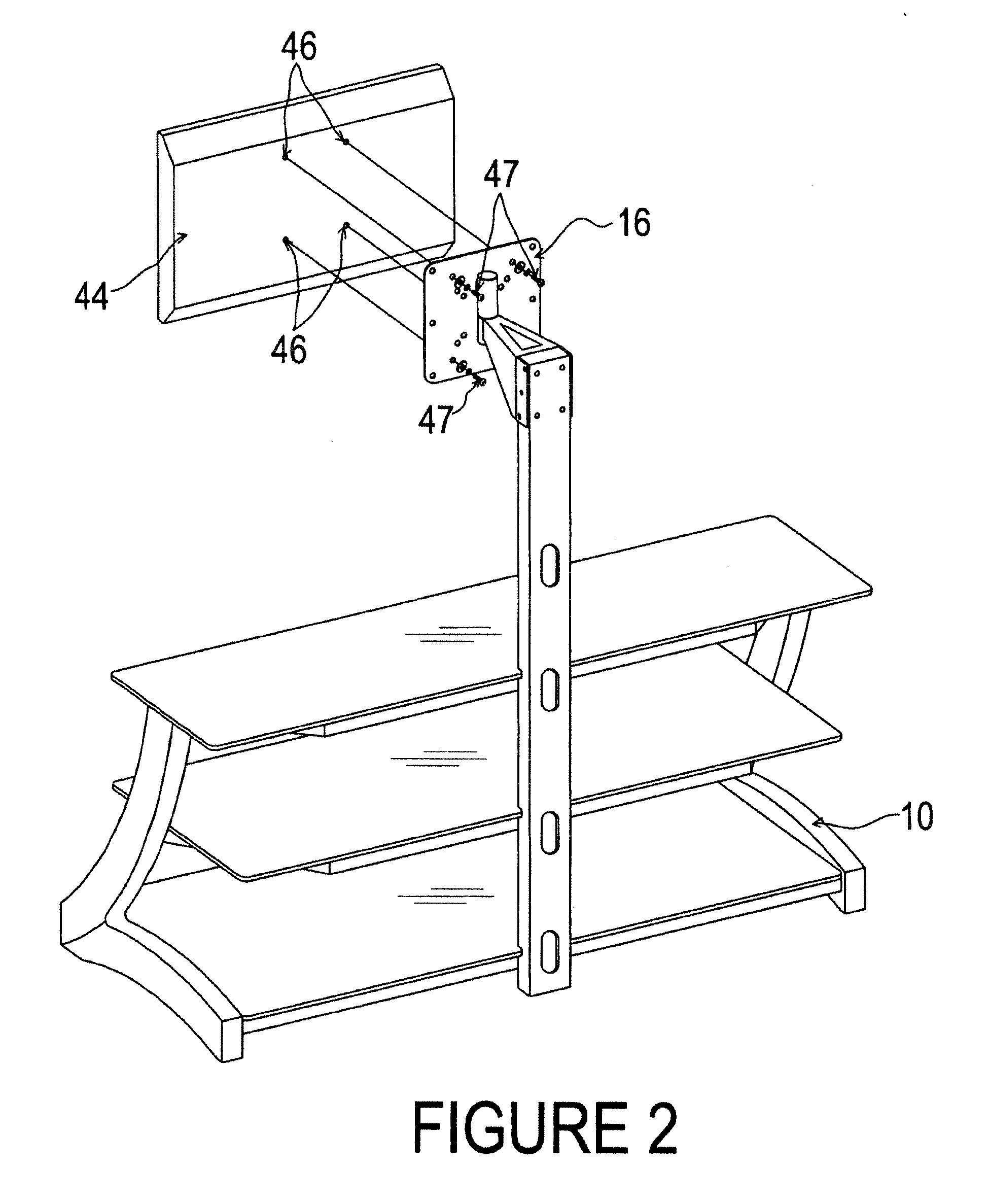

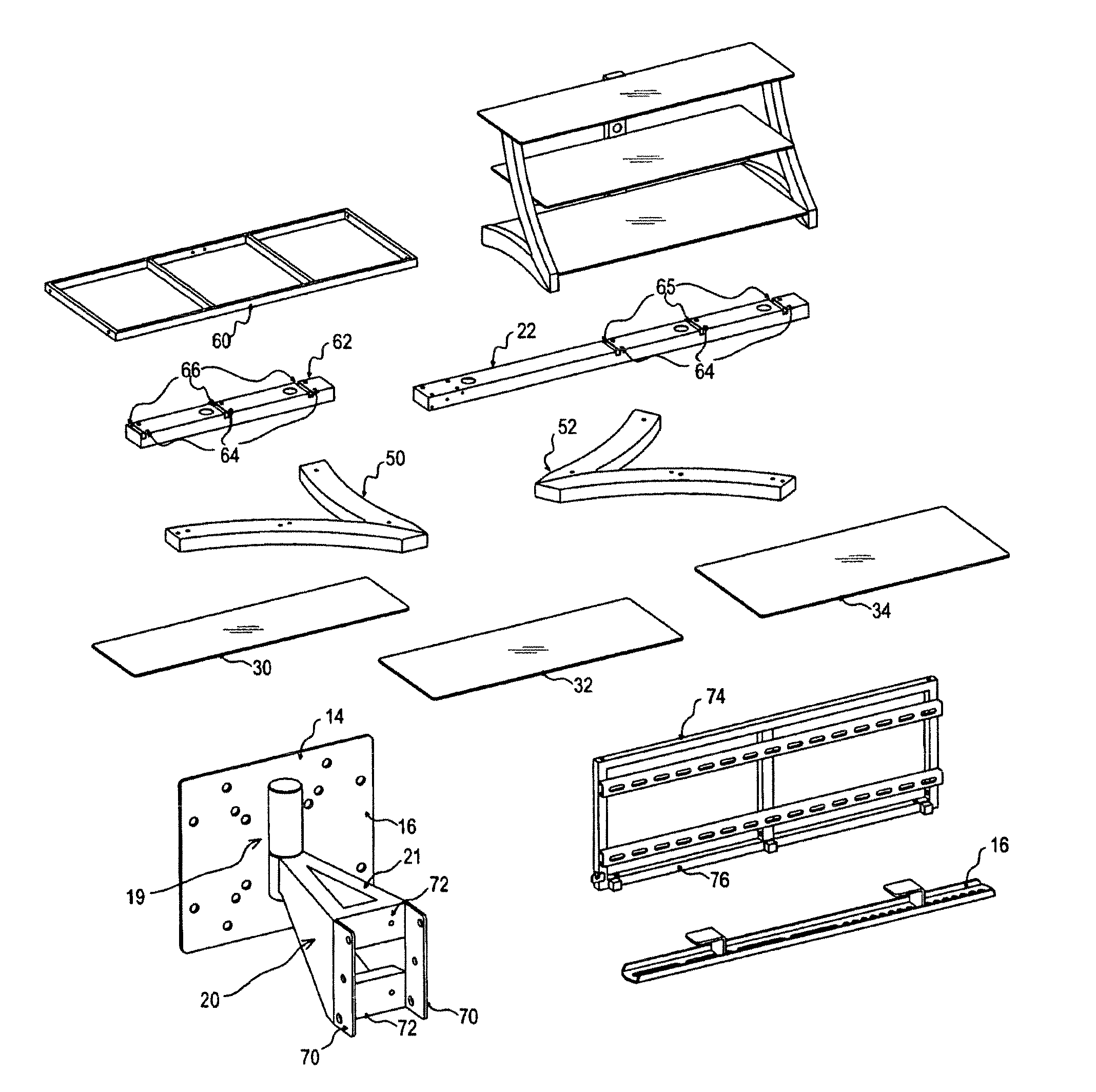

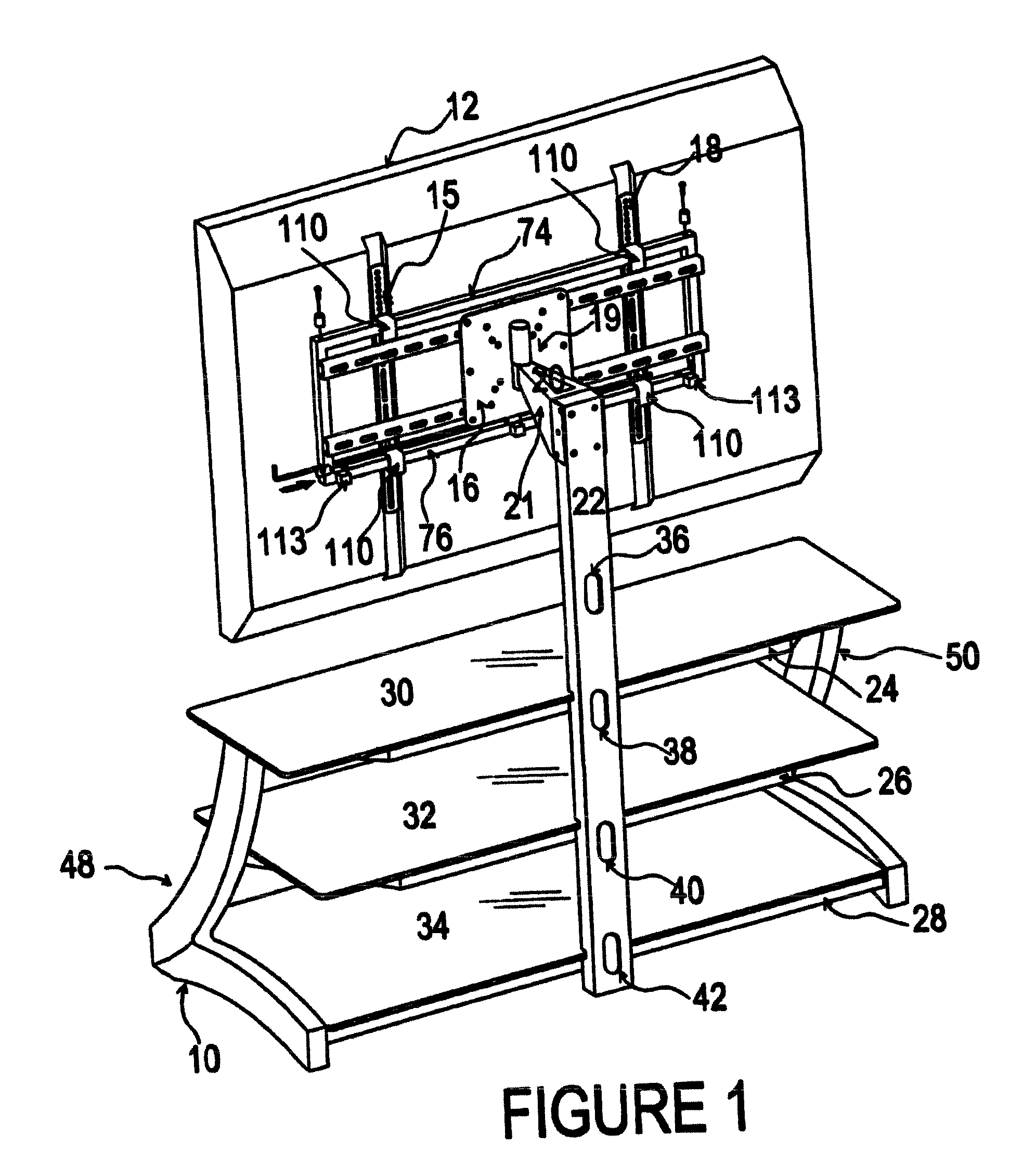

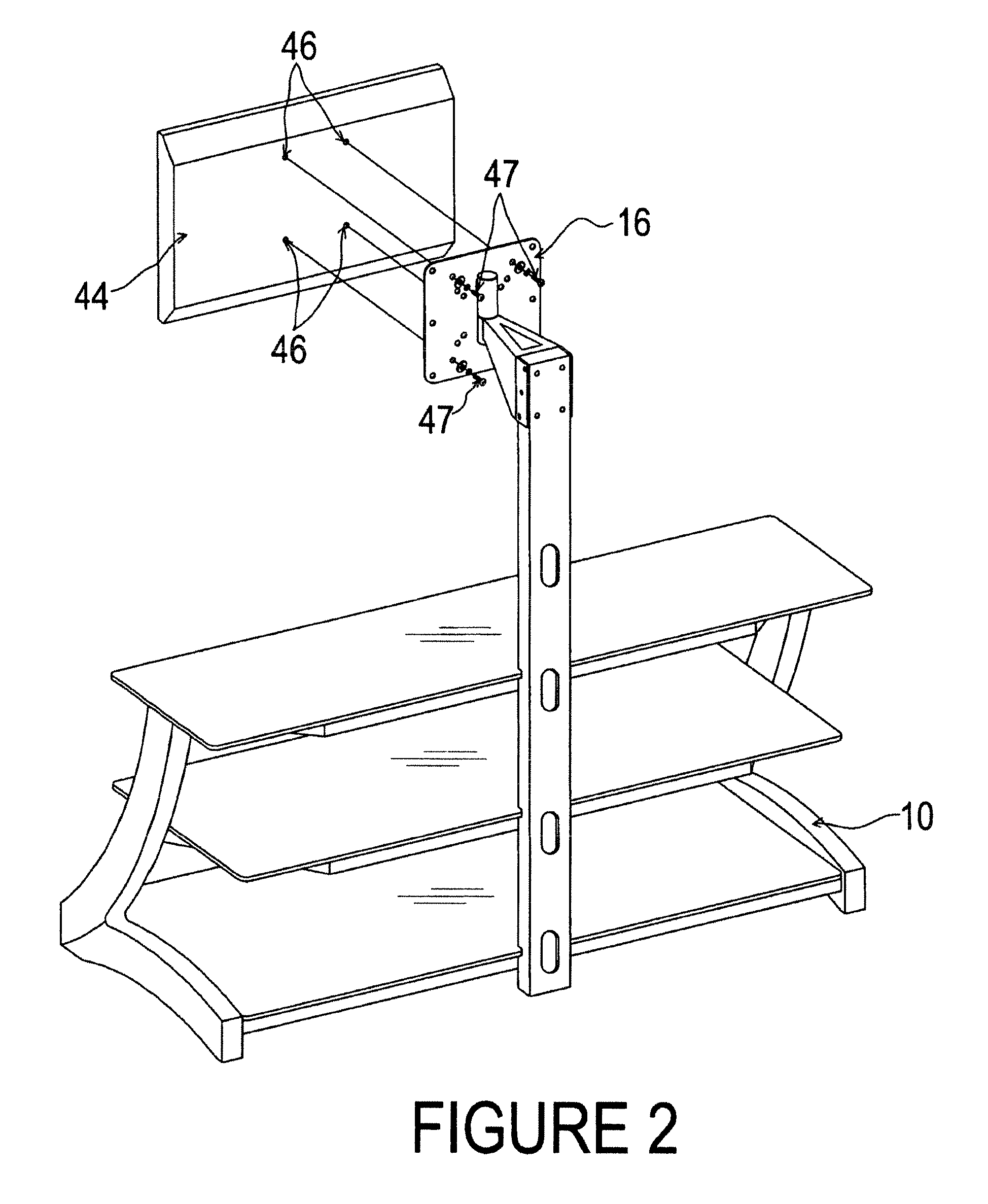

Television Support and Mounting Kit

ActiveUS20090039212A1Improve carrying capacityAvoid entanglementBed-tablesFurniture partsEngineeringCRTS

A universal TV support and mounting kit that accommodates the principal varieties of TVs that have to be mounted or supported, namely CRT type and two panel types (plasma and LCD), in a single kit. The kit that allows the consumer to employ any of the three modes of support, namely stand mount, console mount and wall mount. The console mount incorporates a vertical spine and a gooseneck mount. A frame is provided that can be attached to the gooseneck mount or to a wall. Pivoting and tilting is accommodated by the gooseneck mount.

Owner:WHALEN LLC

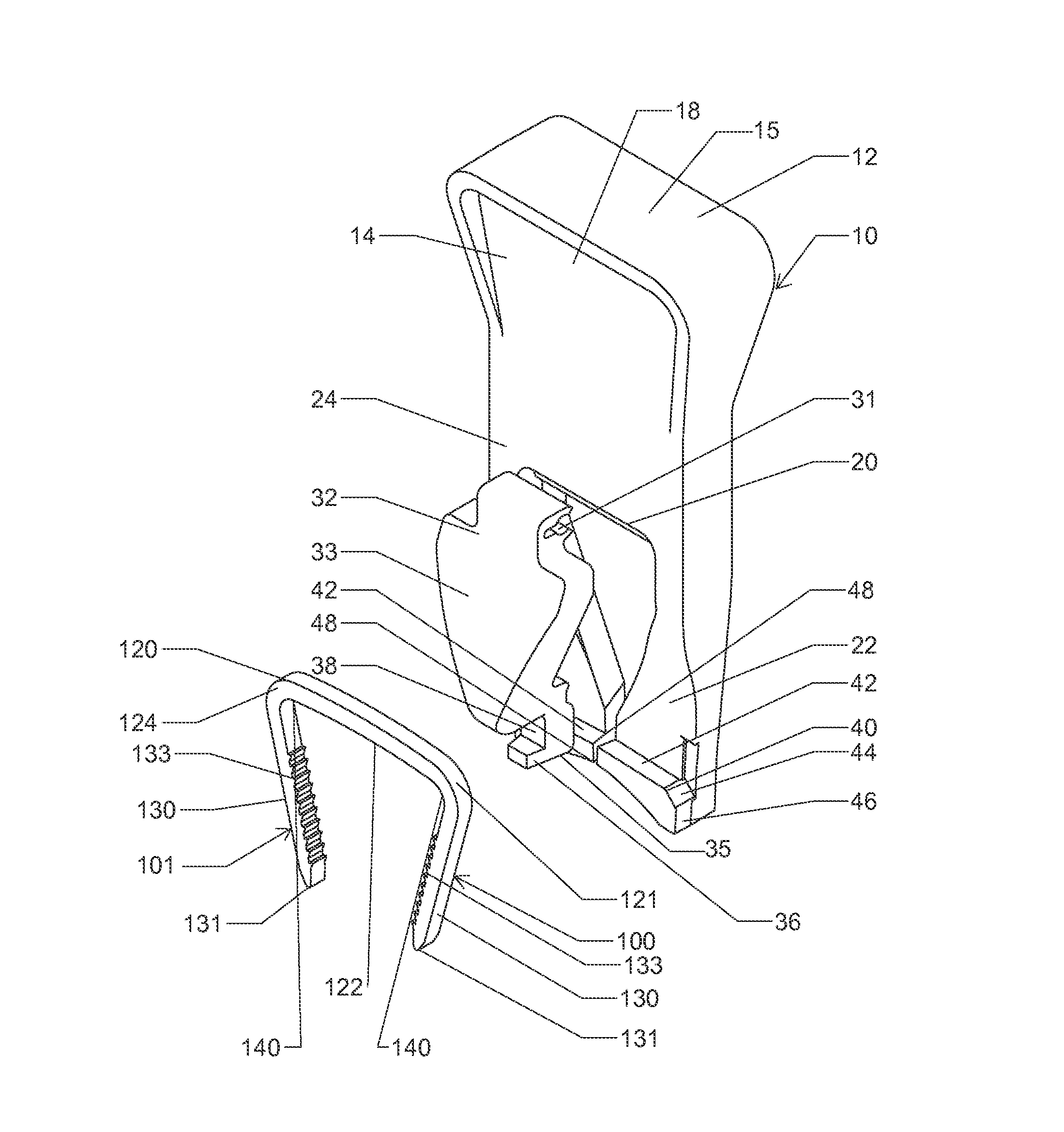

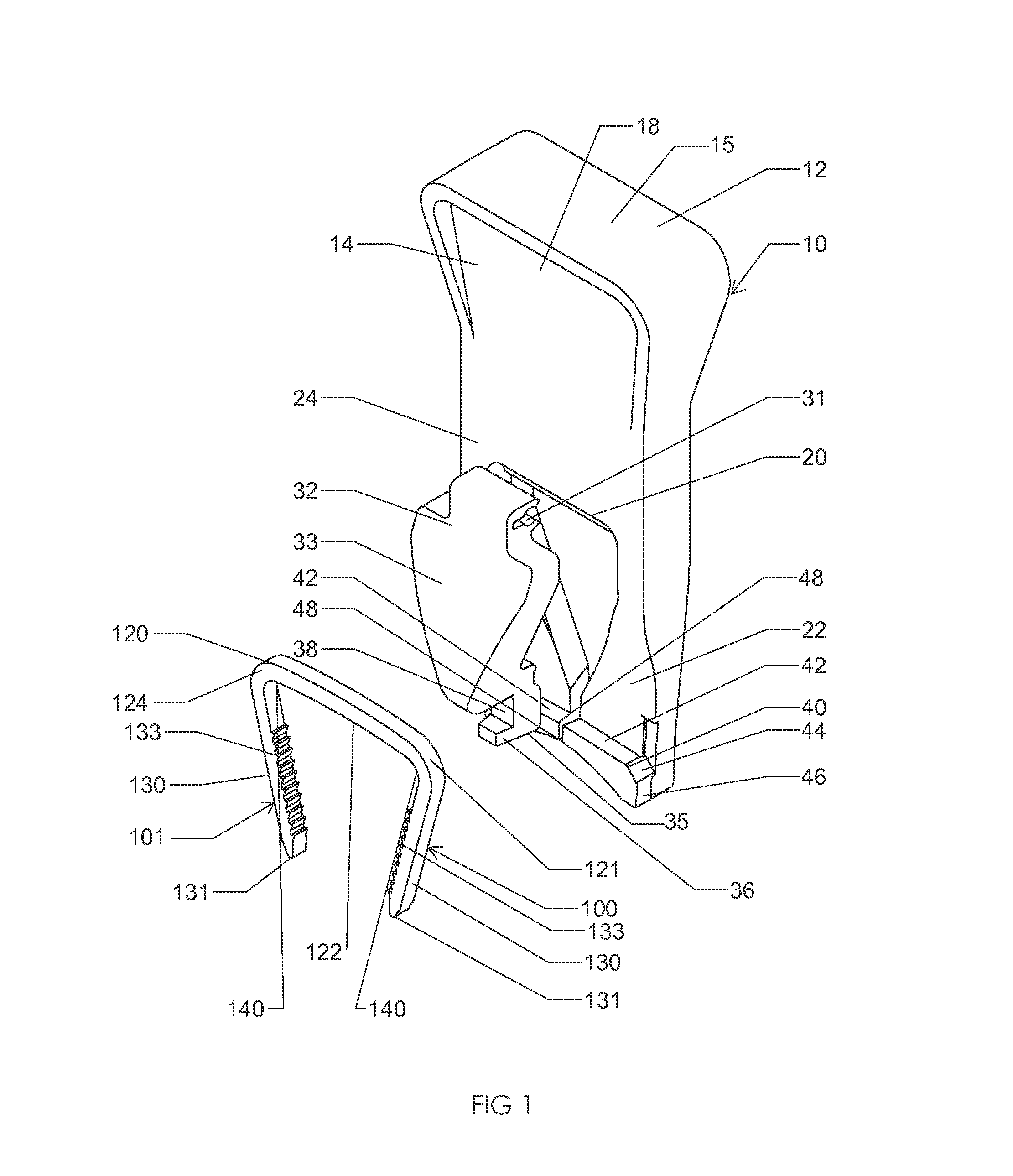

Method and apparatus for loading and implanting a shape memory implant

ActiveUS20140358187A1Avoid entanglementMore stabilityJoint implantsMetal working apparatusInsertion deviceBiomedical engineering

An implant insertion system includes a shape memory implant movable between a first shape a second shape and an implant insertion device movable between an implant disengagement position and an implant engagement position. The implant insertion device receives the shape memory implant in its first shape while in its implant disengagement position. Movement of the implant insertion device from its implant disengagement position to its implant engagement position manipulates the shape memory implant from its first shape to its second shape. The implant insertion device maintains the shape memory implant in its second shape until delivery of the shape memory implant into tissue or bone.

Owner:BIOMEDICAL ENTERPRISES

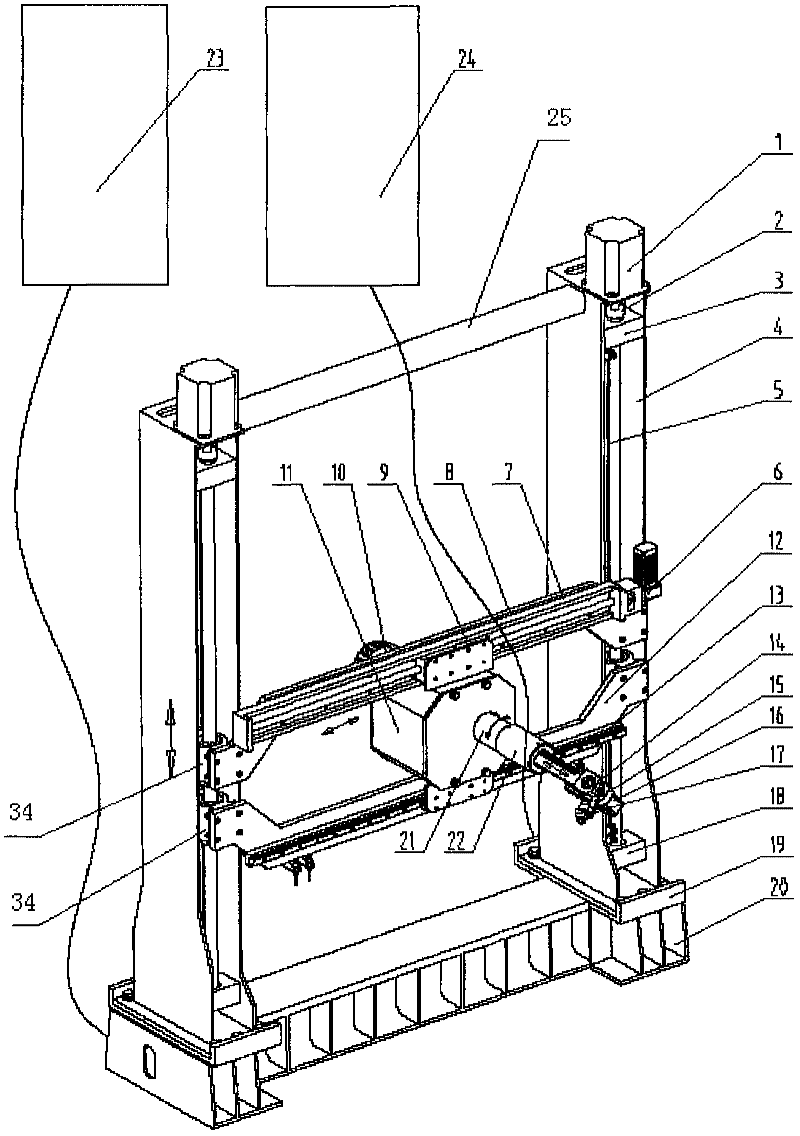

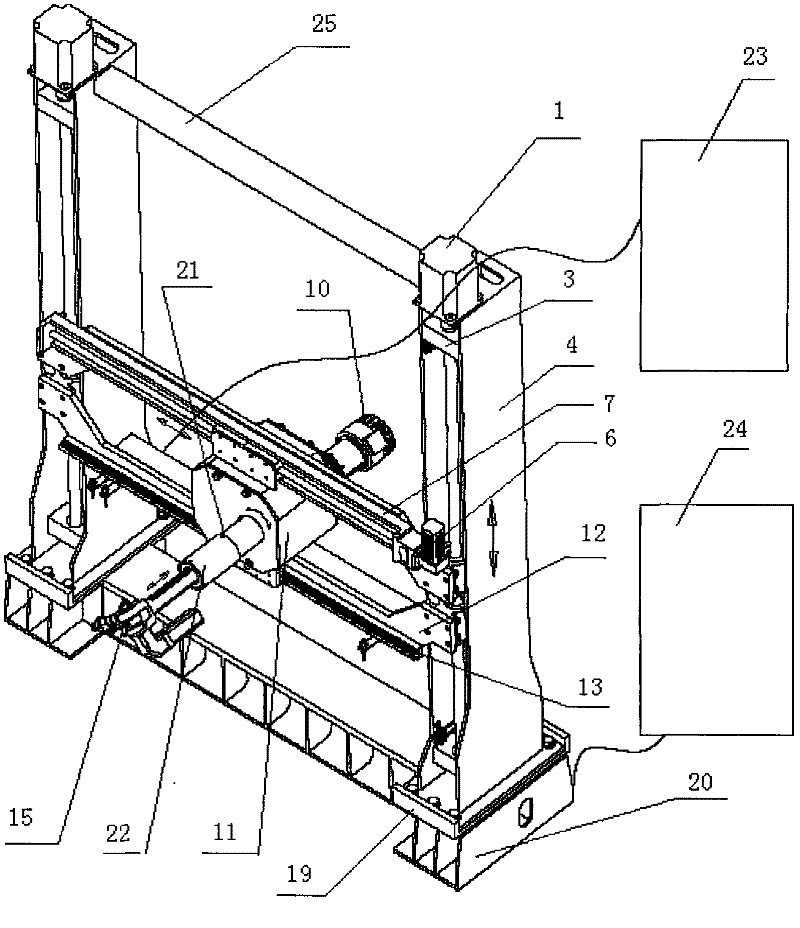

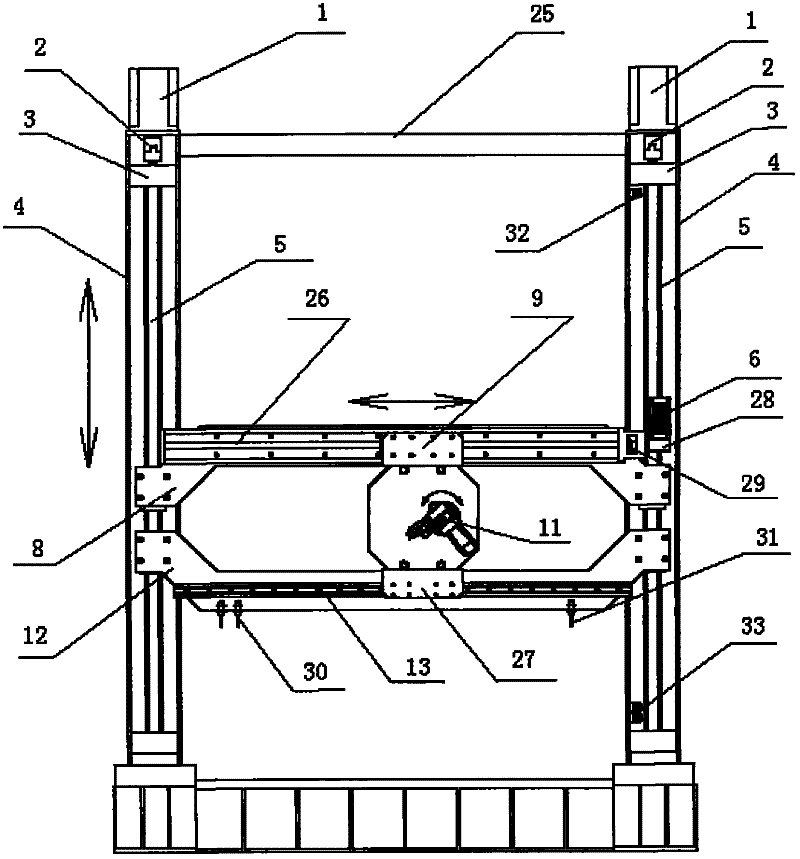

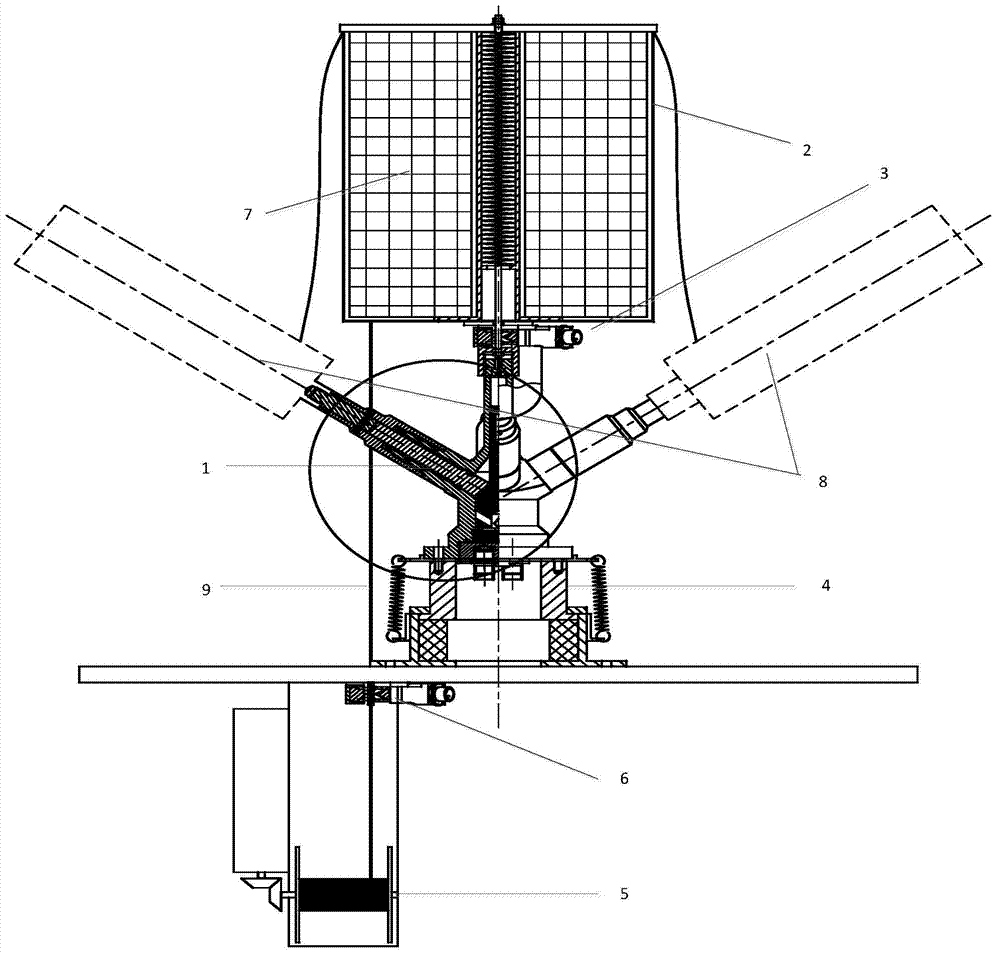

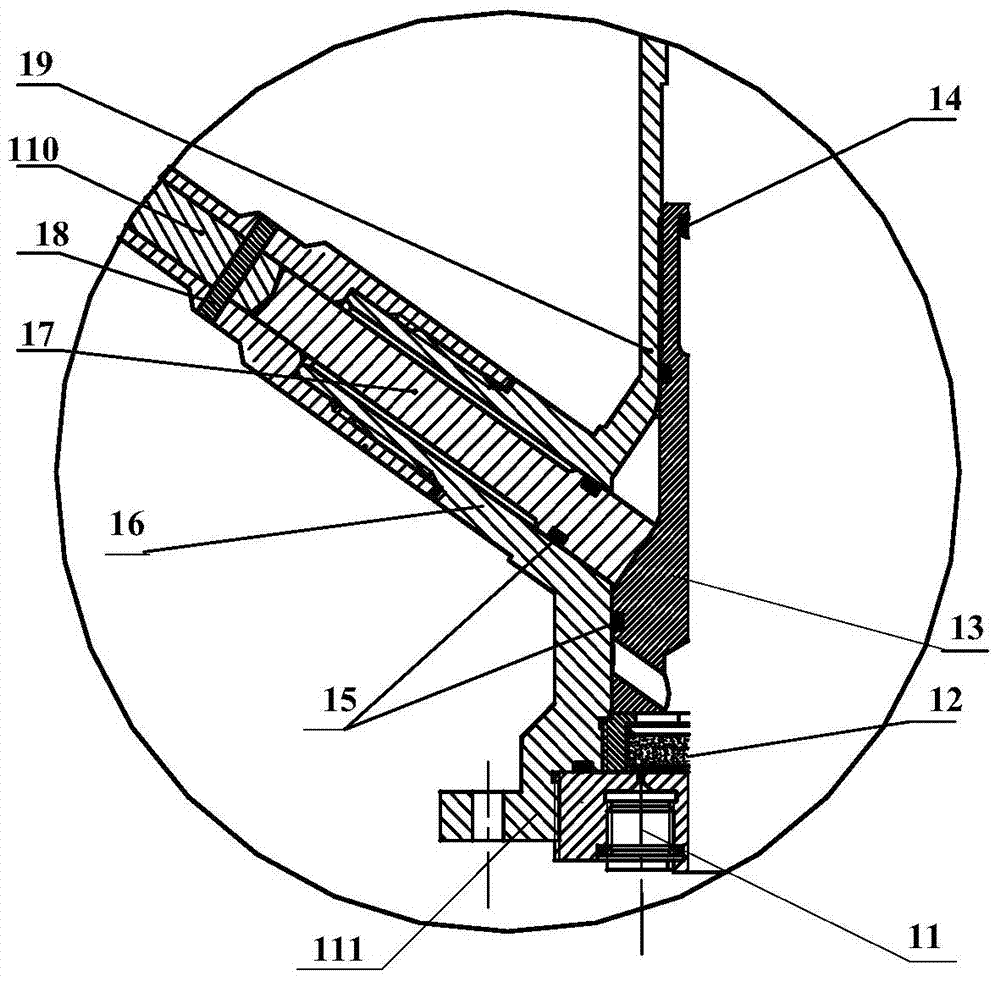

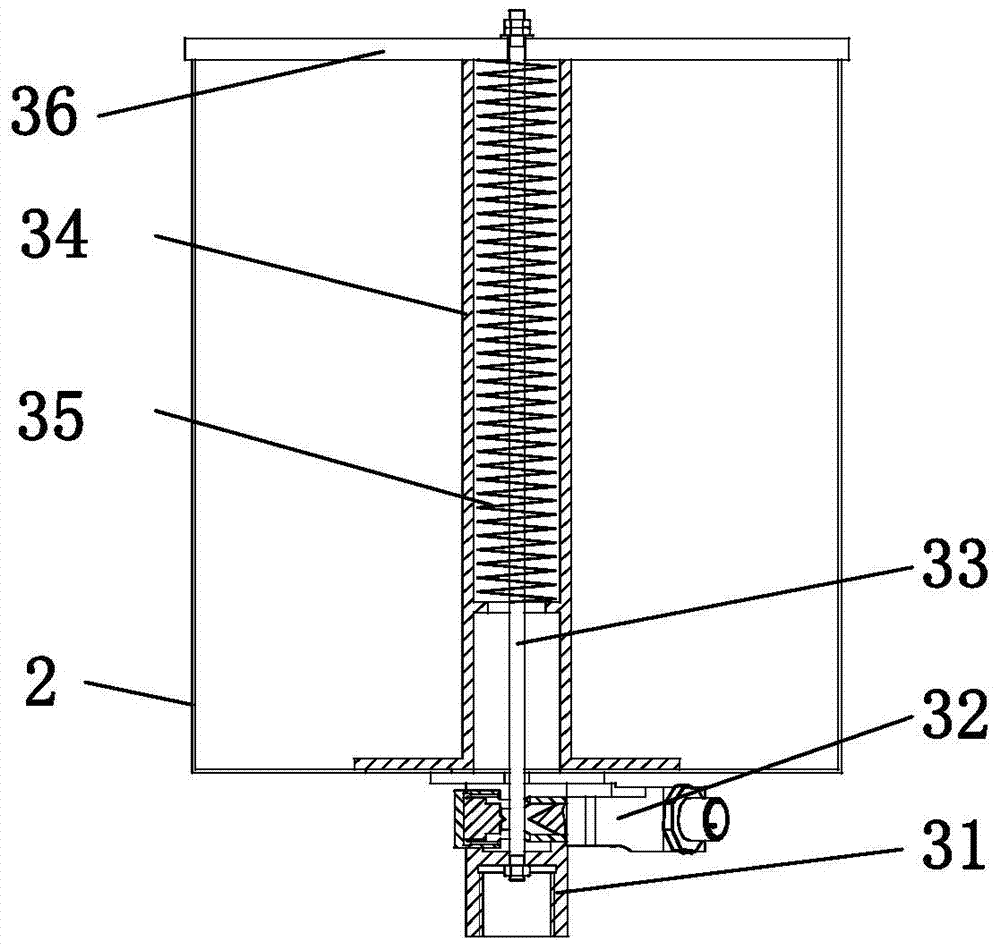

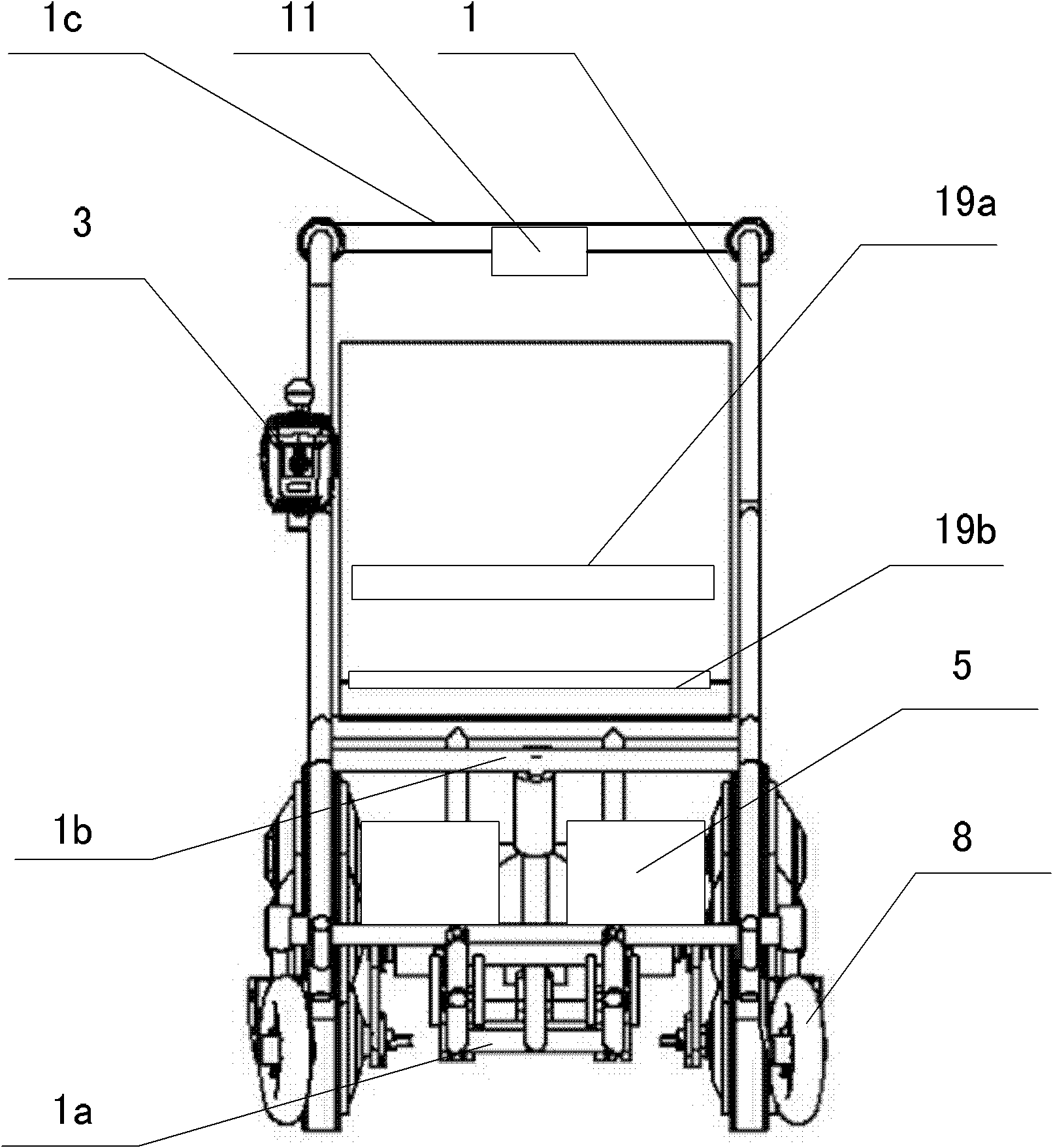

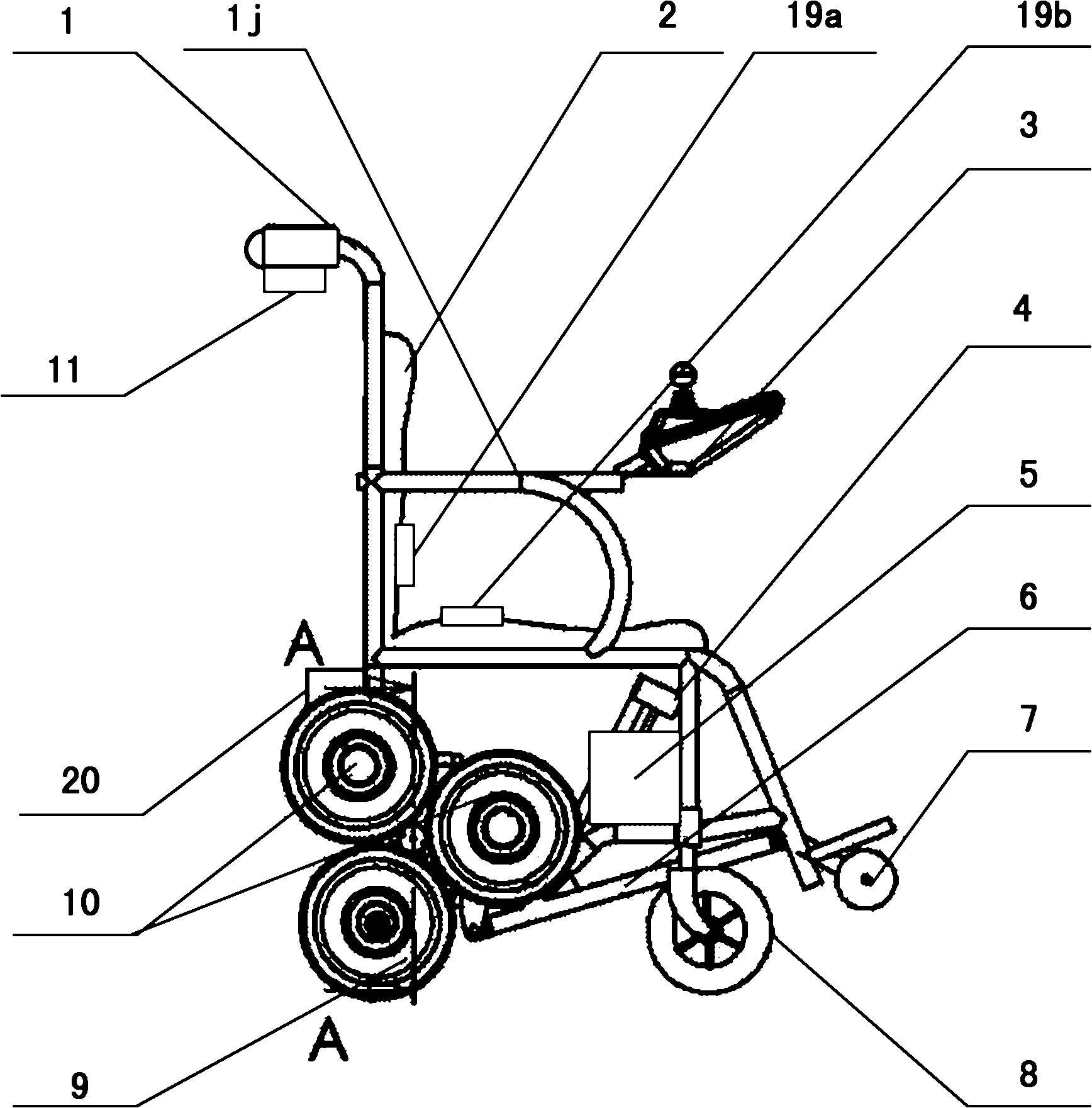

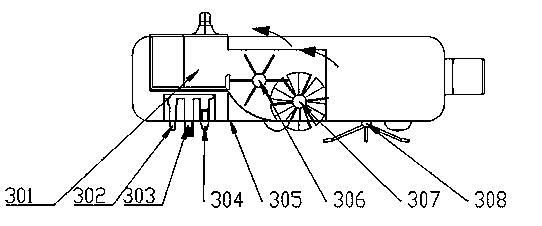

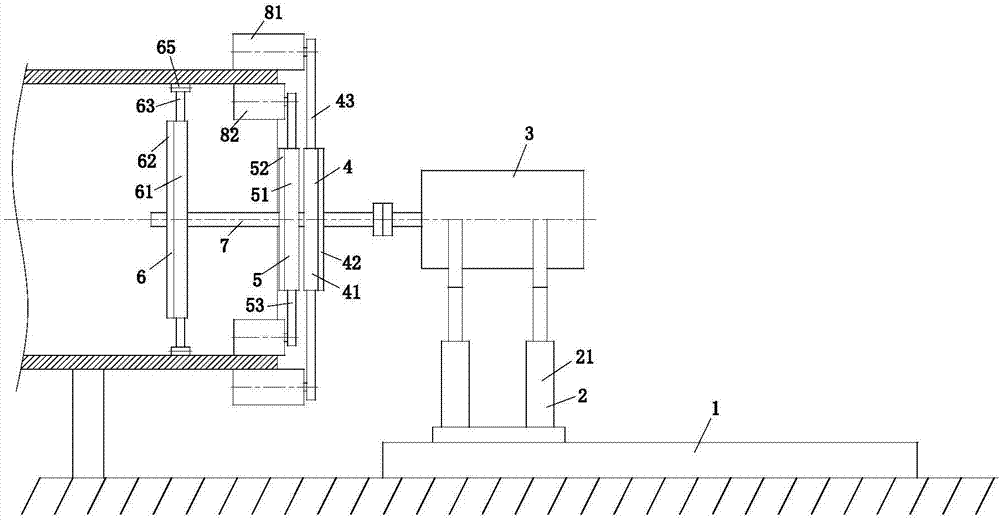

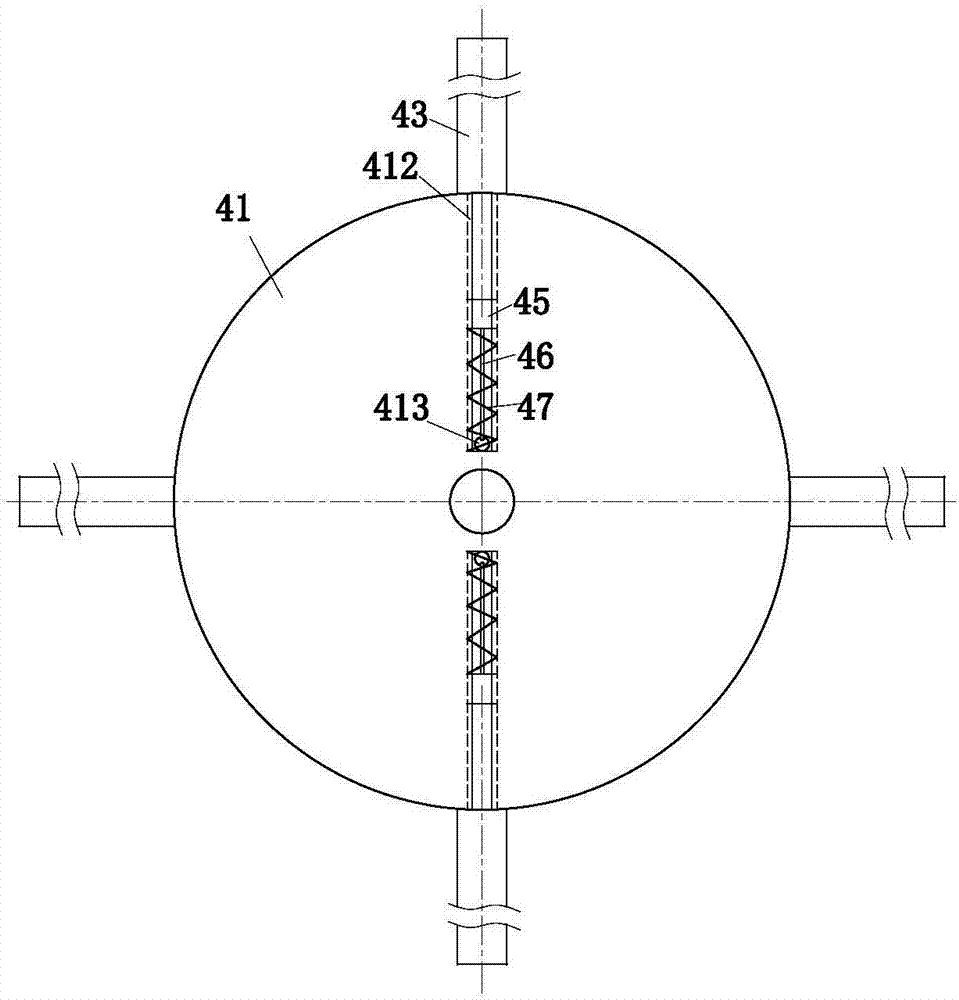

Spraying robot driving device

The invention relates to a robot driving device, comprising a planar intraframe driving device and a mechanical arm driving device, wherein the planar intraframe driving device comprises an up-down lifting driving device and a left-right horizontal driving device. The left-right horizontal driving device drives a spraying robot to horizontally move right and left with a linear module sliding block by virtue of a servo motor, the up-down lifting driving device drives the left-right horizontal driving device to do lifting motion up and down with a ball screw by virtue of the servo motor; the mechanical arm driving device comprises an intermediate rotating driving mechanism, a telescopic driving mechanism and a swinging driving mechanism at the front end, the intermediate rotating driving mechanism drives a mechanical arm to rotate by virtue of the servo motor; the telescopic driving mechanism drives the mechanical arm to do telescopic motion by virtue of the servo motor; and the swinging driving mechanism at the front end drives a spray gun to swing and rotate around by virtue of the servo motor and a reducer.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

Implantable vascular device

InactiveUS7604661B2Improve distributionAvoid entanglementStentsVenous valvesVenous ValvesRetrograde Flow

An valve prosthesis, such as an artificial venous valve, having a support frame and leaf structure comprising one or more leaflets in which the outer edge of each leaflet engages the inner circumference of the bodily passageway along a serpentine path urged against the passageway by an expandable frame, while the inner edges move in response to fluid to restrict retrograde flow. Optionally, one or more elements can extend from the support frame / leaf structure to provide centering support and / or protection from the leaflet adhering to the vessel wall. In one embodiment, the centering support structure comprises a second or third expandable frames attached to and extending from the proximal and / or distal ends of main valve structure and support frame. In another embodiment, one or more support elements extend outward from the valve support frame to engage the vessel wall to provide greater longitudinal stability.

Owner:COOK MEDICAL TECH LLC

Rope net type space debris capturing and cleaning system

The invention discloses a rope net type space debris capturing and cleaning system which comprises a transmission subsystem and a fly net subsystem. The transmission subsystem comprises a transmitter, a net cabin, a net cabin cover ejecting device, a buffer device, a tying rope tension control device and a tying rope cutter, and the fly net subsystem comprises a rope net and four mass blocks; a net cabin cover can be ejected out of an outlet of the net cabin, and the rope net can be driven by the net cabin cover to be drawn out of the net cabin; the transmitter works at the moment when the fly net and a tying rope are straightened, the sides of the rope net are driven by four mass blocks according to preset transmitting opening angles, so that the rope net can fly out and is opened simultaneously until the rope net is fully opened, an object is netted after the rope net reaches the objective position, a port of the rope net is tightened under the control of the mass bocks, and the object can be completely captured; after the tying rope draws the captured object aircraft away from an orbit, the tying rope cutter cuts off the tying rope, and the object aircraft can be separated from a satellite platform. The rope net type space debris capturing and cleaning system has the advantages that a secondary transmission mode is adopted, so that twining and knotting can be prevented in rope net spreading procedures; the mass blocks are pushed to be synchronously transmitted, so that a millisecond-level synchronous transmission effect can be realized, and the shape of the rope net can be controlled advantageously.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

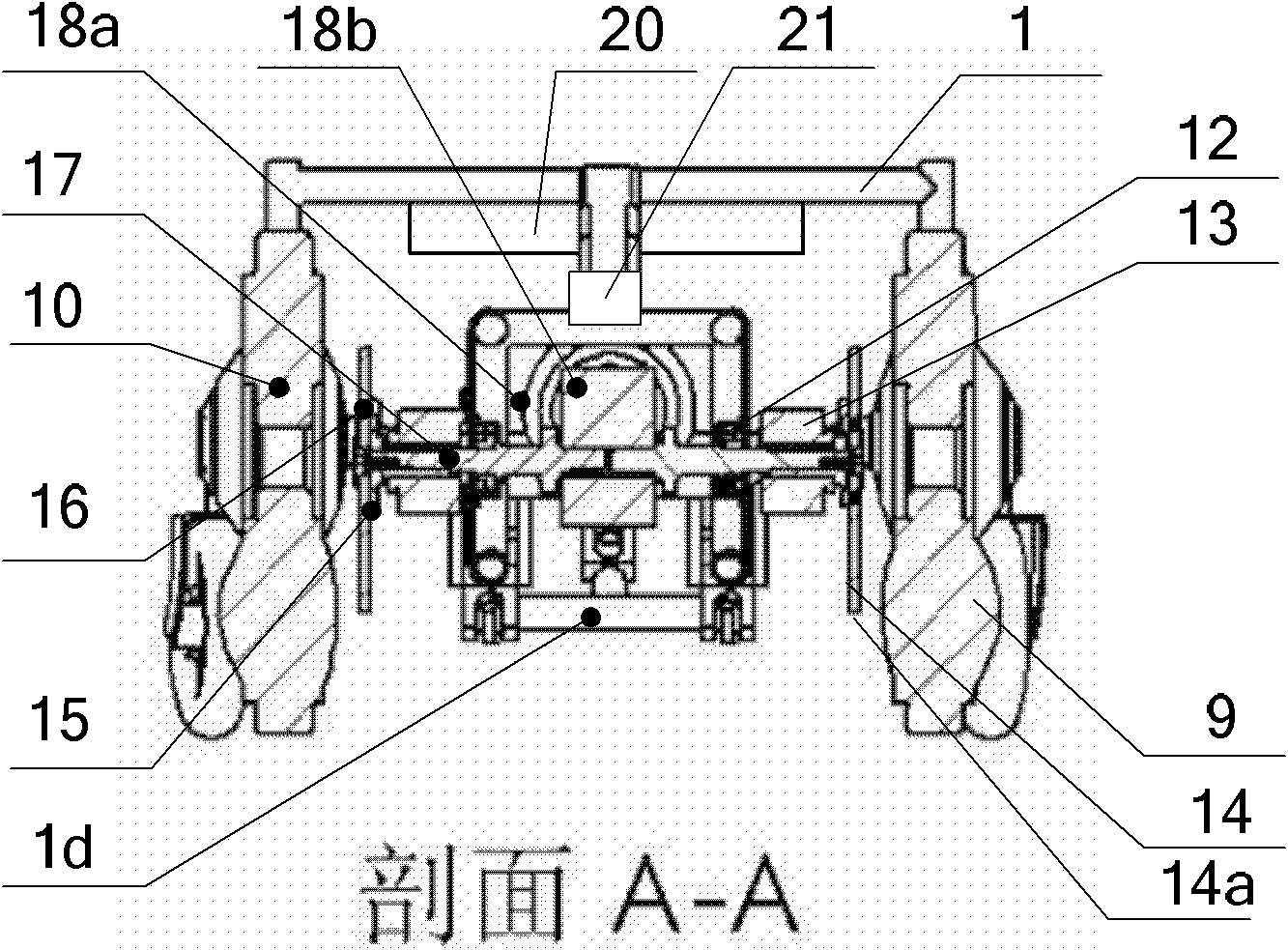

Planet wheel type stair-climbing electric wheelchair

InactiveCN102125488APrevent accidental tippingExcellent control schemeWheelchairs/patient conveyanceStair climbingSpherical roller bearing

The invention provides a planet wheel type stair-climbing electric wheelchair. The wheelchair comprises a wheelchair frame, a chair backrest, an electric wheelchair controller, a battery, a caster, a front wheel assembly, a stair-climbing controller, a centering roller bearing, a centering bearing block, a conducting slip ring, a connecting disc, a wheel axle fixing component, two driving shafts, a direct-current turnover motor, an RV speed reducer, a pressure sensor, a control box, a tilt sensor, an anti-forerake bracket and two planet wheel groups, wherein the anti-forerake bracket is driven by an electric push rod; and the two planet wheel groups are driven by the direct-current turnover motor through the RV speed reducer and symmetrically distributed so as to realize the stair-climbing function of the electric wheelchair. In each of the planet wheel groups, special allocation of a hub motor and two free wheels is adopted; and the planet wheel groups can work in a manual mode, an electric wheelchair mode and a stair-climbing mode. In addition, in the wheelchair, the pressure sensor and the tilt sensor are used for feeding back the wheelchair running state when the electric wheelchair goes upstairs and downstairs.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Device, system, and method for transcatheter treatment of valvular regurgitation

The invention relates to a device for use in the transcatheter treatment of mitral valve regurgitation, specifically a coaptation assistance element for implantation across the valve; a system including the coaptation assistance element and anchors for implantation; a system including the coaptation assistance element and delivery catheter; and a method for transcatheter implantation of a coaptation element across a heart valve.

Owner:POLARES MEDICAL INC

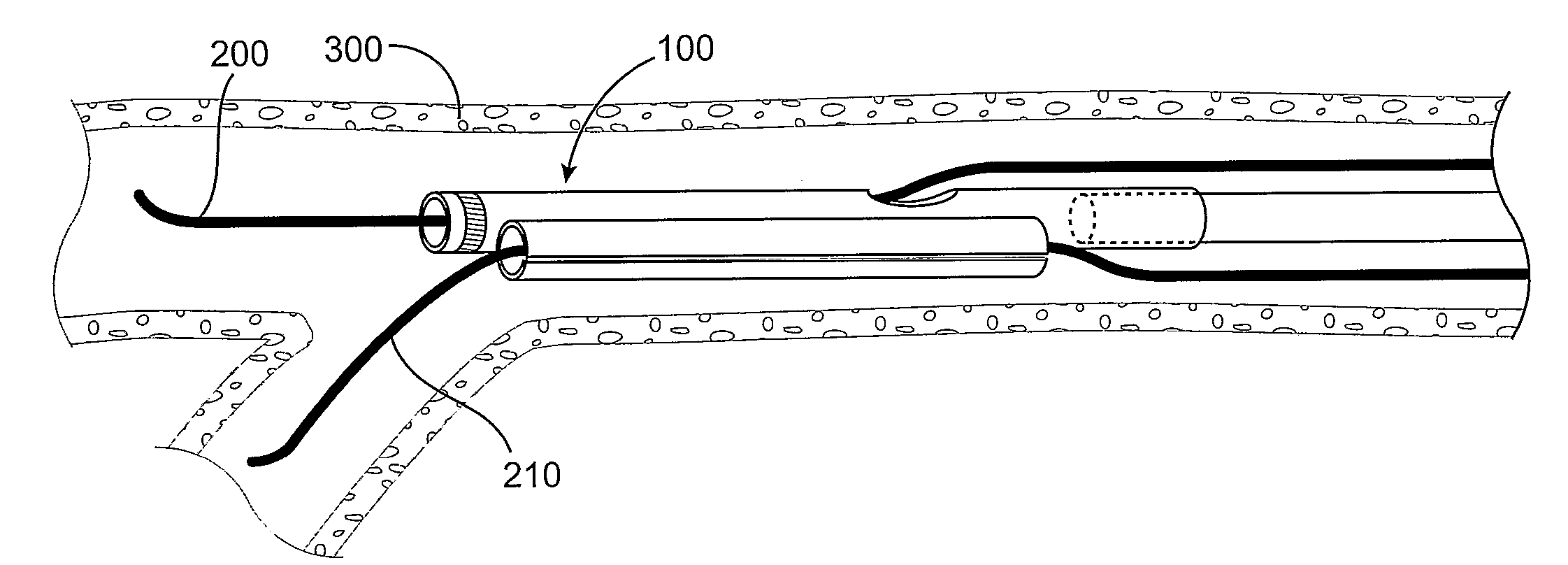

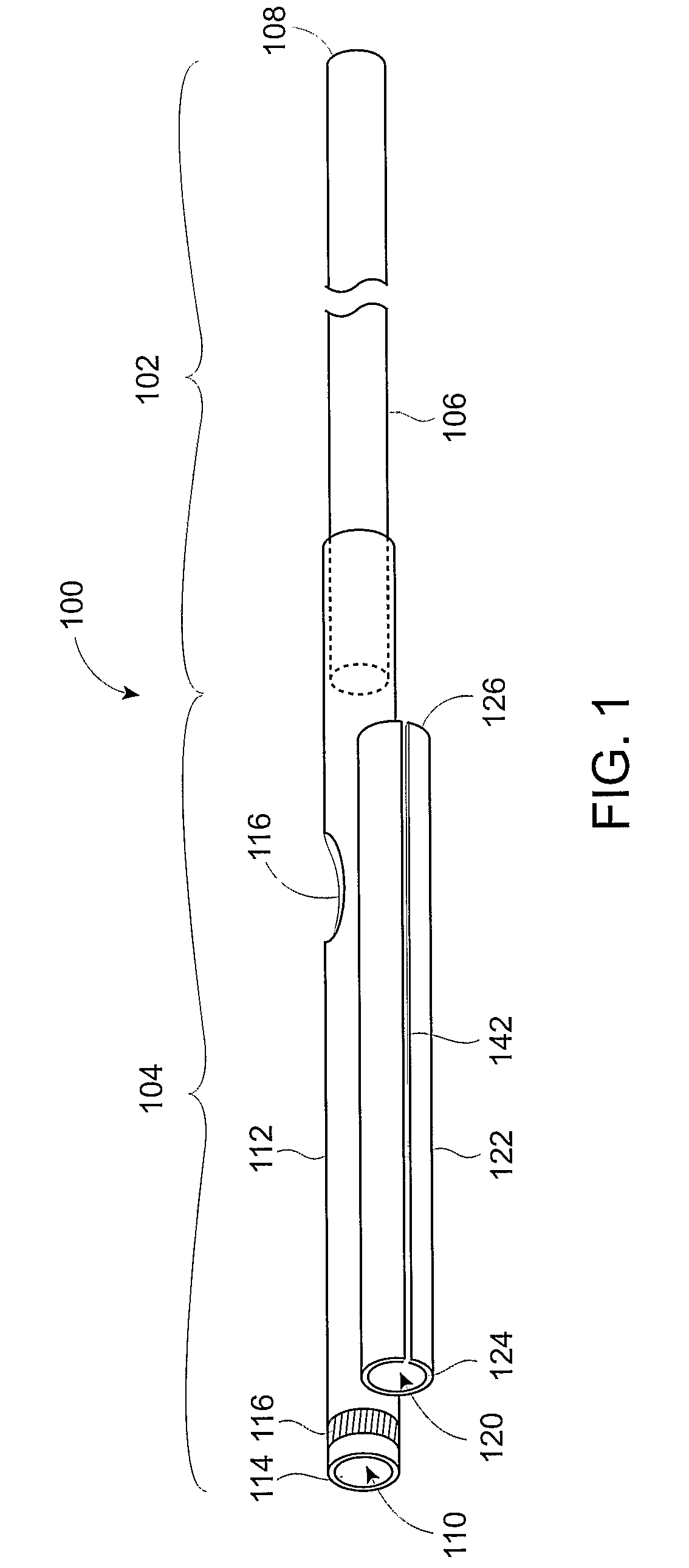

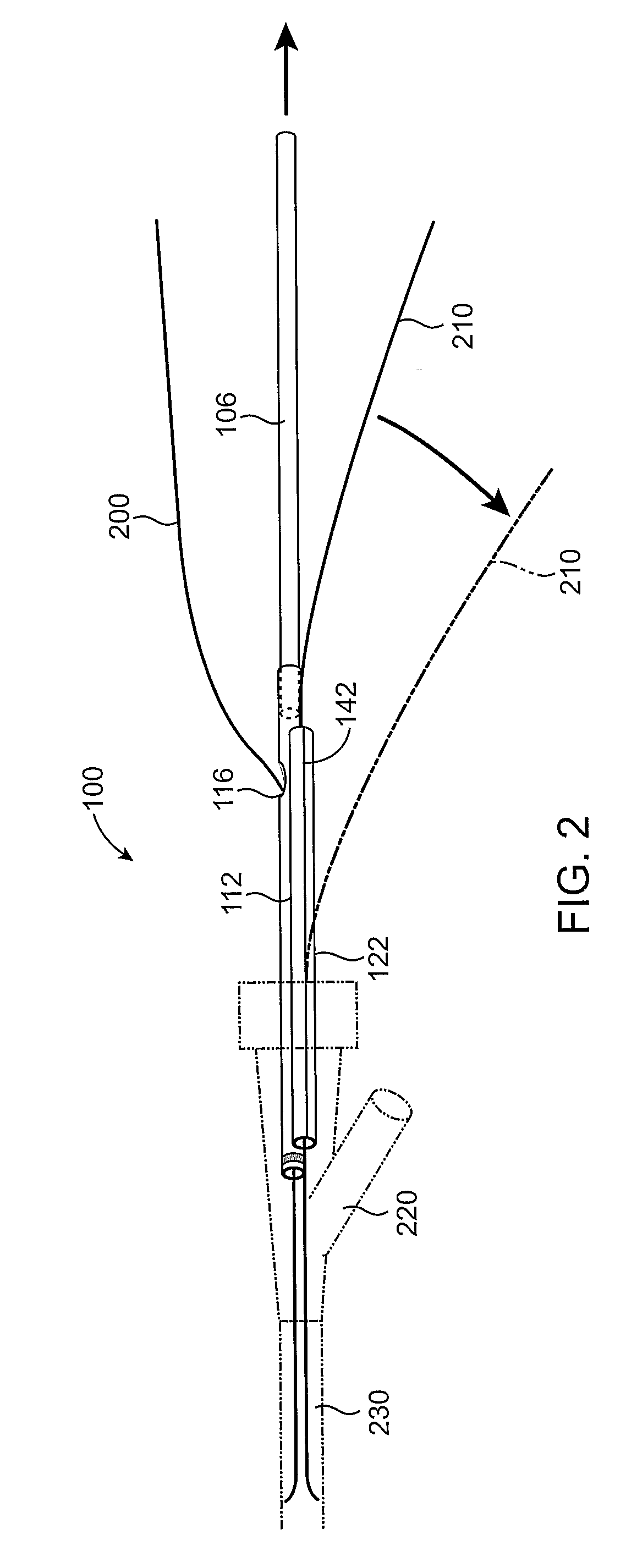

Guidewire Separator Device and Method of Use

InactiveUS20070250001A1Quickly and easily separateAccurate placementStentsBalloon catheterDistal portionPercutaneous angioplasty

A guidewire separator device and methods are described for resolving guidewire entanglement and for introducing guidewires into branch vessels when performing angioplasty or stenting of a bifurcated artery. The device has an elongate tubular distal portion joined to an elongate proximal portion. A first lumen extends through the tubular distal portion of the device, with a first distal guidewire port located near a distal end of the distal portion and a first proximal guidewire port located near a proximal end of the distal portion. A second lumen extends through the tubular distal portion of the device, with a second distal guidewire port located near a distal end of the distal portion and a second proximal guidewire port located near a proximal end of the second lumen. One or both of the lumens may continue through the proximal portion of the device. Optionally, the device includes one or more longitudinal slits to externalize the guidewires from the lumens during withdrawal of device.

Owner:MINVASYS SA

Washing machine with detergent supply path

InactiveCN101725015AFirmly connectedEasy to separateOther washing machinesTextiles and paperEngineeringMechanical engineering

Owner:SAMSUNG ELECTRONICS CO LTD

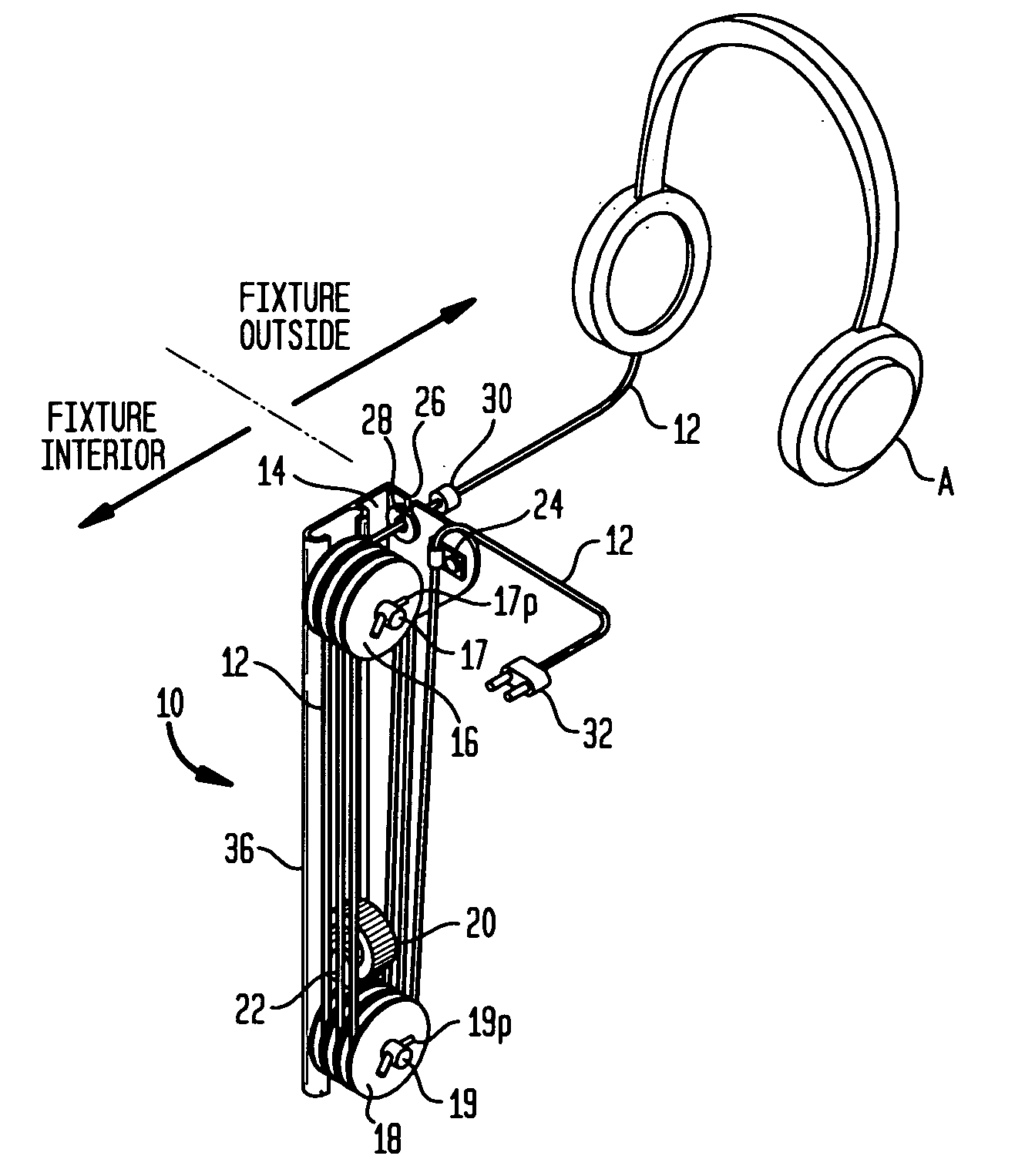

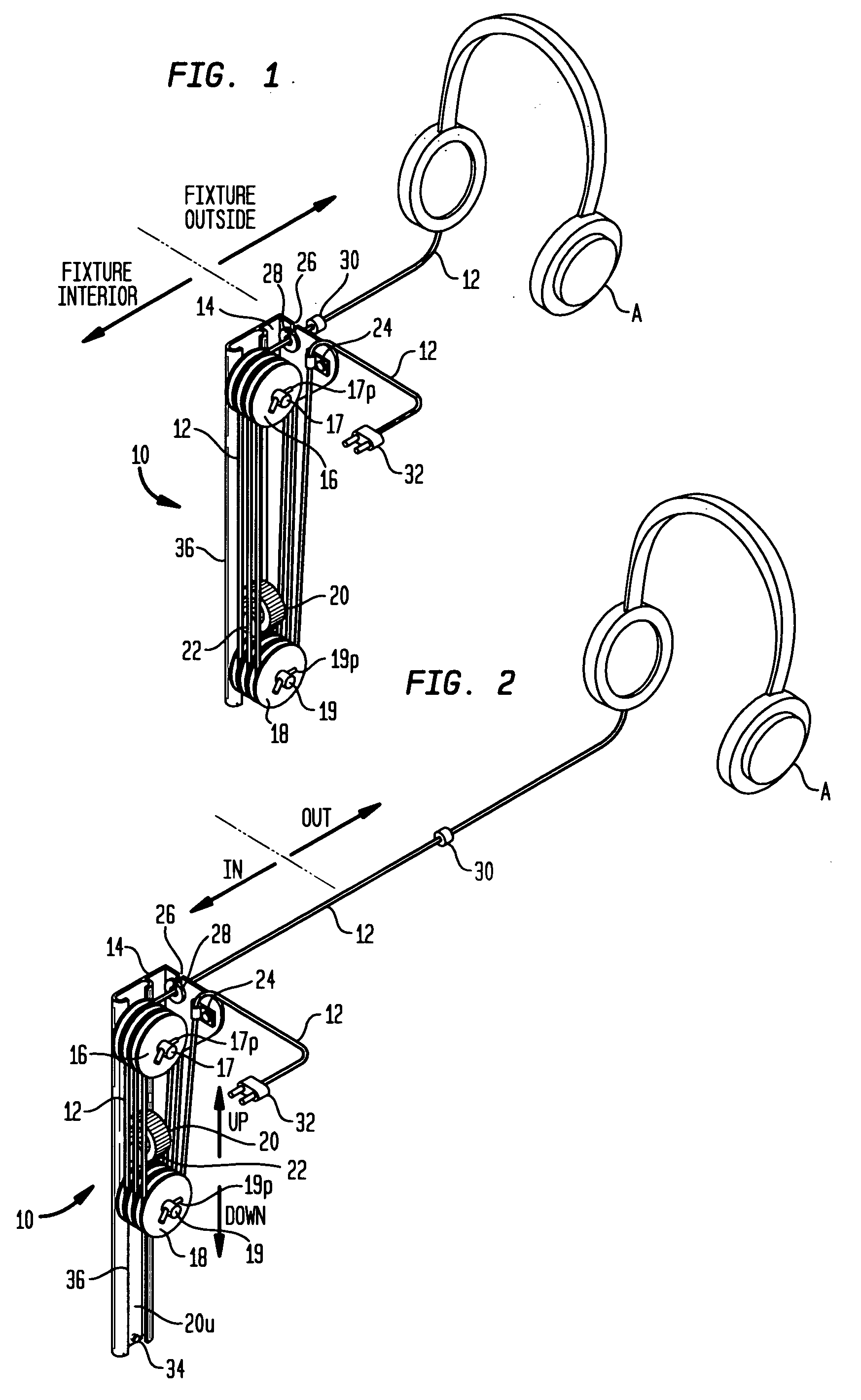

Apparatus for secure display of small electronic devices having an essential signal or power cord

InactiveUS20080156922A1Avoid entanglementEasily and conveniently usableArrangements using spring-loaded loopArrangements using gravity-loaded loopEngineeringFixed position

There is provided an apparatus for secure display of a portable electronic device wherein the device has an attached electrically conductive cable that is integral to the device and essential to the operation thereof, the device cable having a first end connected to the device and a second end, and an intermediate section, the apparatus comprising: device support means normally supporting the device and means for extending and retracting the device cable. The means for extending and retracting the cable includes pulley means having a first set of pulleys having a fixed position and a second set of linearly movable spring loaded pulleys. As the device is moved from the device support the second set of pulleys is urged towards the first set of pulleys thereby extending the device cable against the resistance of the spring loading, thereby creating retractive force for retraction of the cable. When the device is released the cable is retracted to the device support until halted by a cable stop. Headsets and earbud sets are examples of devices that are suitable for display on the apparatus.

Owner:VIRA MFG

Automatic floor cleaning device for domestic use

InactiveCN103799924AAvoid entanglementTangle outMachine detailsFloor sweeping machinesDrive wheelChinese characters

Provided is an automatic floor cleaning device for domestic use. The automatic floor cleaning device is provided with a shell body, a detection control system is arranged in the shell body, an advancing mechanism and a cleaning mechanism are arranged at the bottom of the shell body, the detection control system controls the advancing mechanism and the cleaning mechanism to clean the floor, the advancing mechanism is composed of a driving wheel and two universal wheels, and the driving wheel and the two universal wheels are arranged in the shape of a Chinese character 'pin', and are driven to walk by a power mechanism. The cleaning effect is good, and waste gas is utilized to achieve the flushing, water spraying and drying function through an air pump without increasing a power source.

Owner:LUOYANG INST OF SCI & TECH

Device, system, and method for transcatheter treatment of valvular regurgitation

ActiveUS20190076249A1Improve abilitiesEasy retrievalSuture equipmentsDiagnosticsValvular regurgitationVALVE PORT

The invention relates to a device for use in the transcatheter treatment of mitral valve regurgitation, specifically a coaptation assistance element for implantation across the valve; a system including the coaptation assistance element and anchors for implantation; a system including the coaptation assistance element and delivery catheter; and a method for transcatheter implantation of a coaptation element across a heart valve.

Owner:POLARES MEDICAL INC

Television support and mounting kit

ActiveUS8079311B2Improve carrying capacityAvoid entanglementBed-tablesFurniture partsEngineeringWall mount

A universal TV support and mounting kit that accommodates the principal varieties of TVs that have to be mounted or supported, namely CRT type and two panel types (plasma and LCD), in a single kit. The kit that allows the consumer to employ any of the three modes of support, namely stand mount, console mount and wall mount. The console mount incorporates a vertical spine and a gooseneck mount. A frame is provided that can be attached to the gooseneck mount or to a wall. Pivoting and tilting is accommodated by the gooseneck mount.

Owner:WHALEN LLC

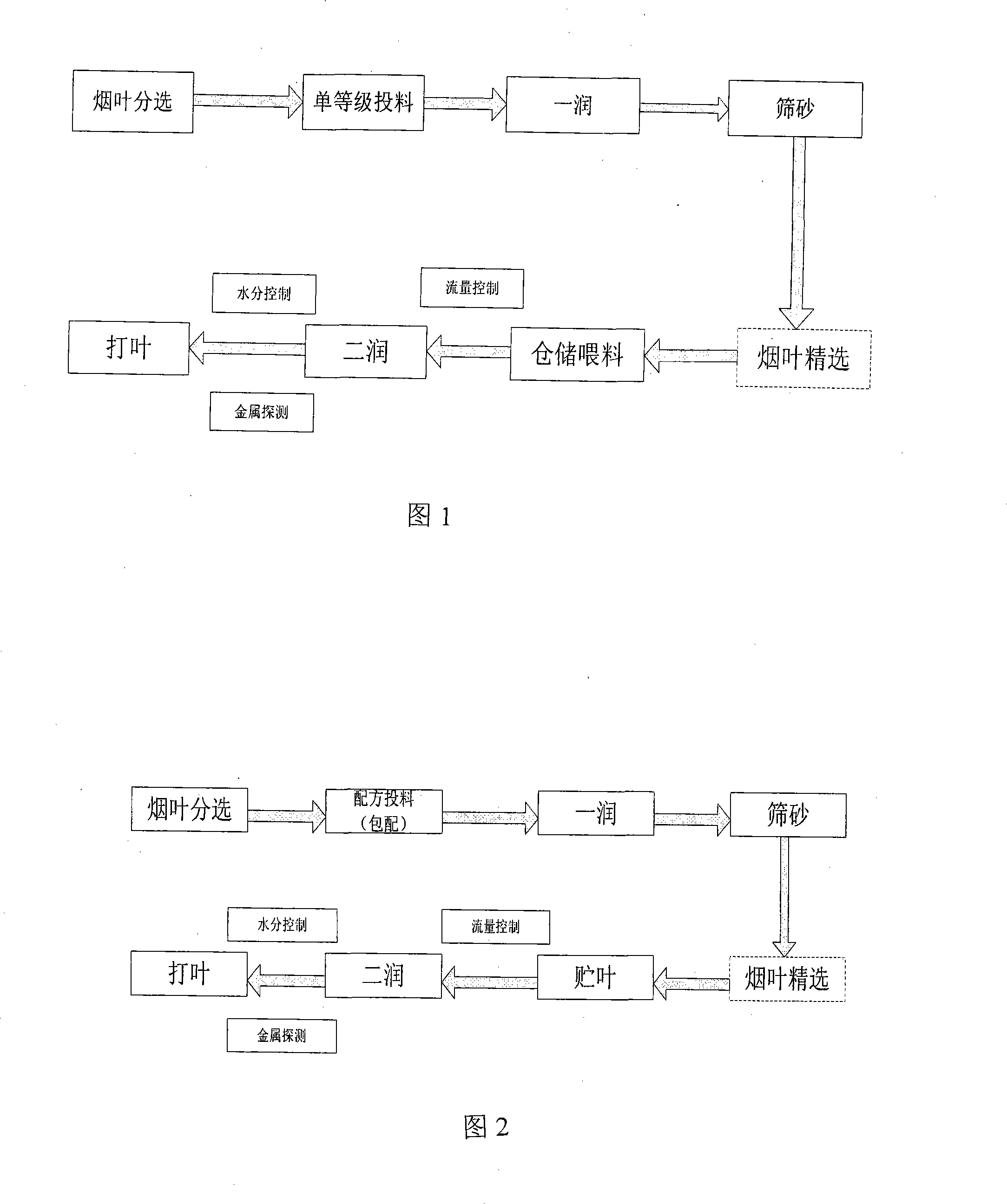

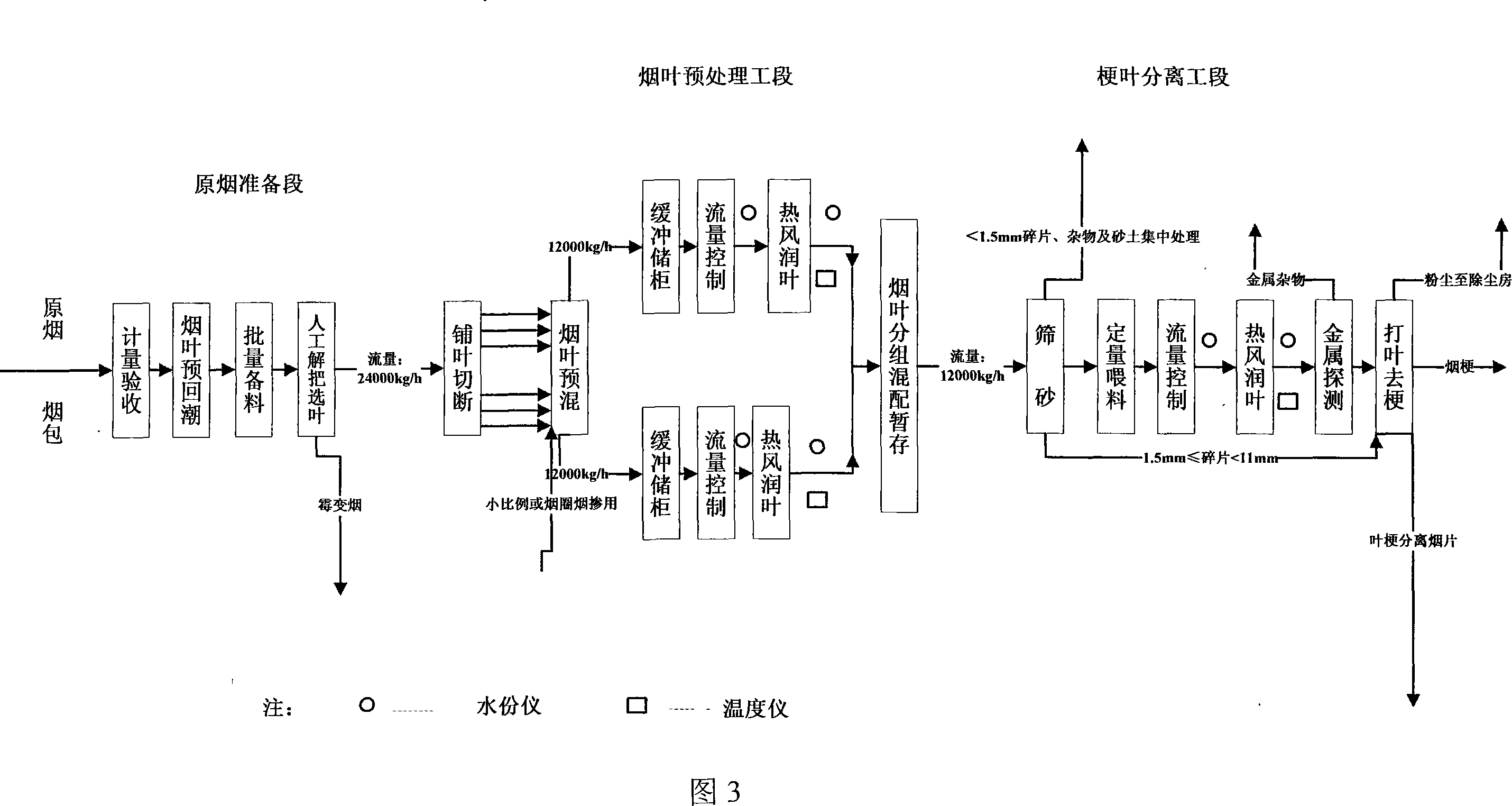

Process technique for threshing and redrying tobacco

InactiveCN101181093ASolve the problem of water lossSolve environmental dustTobacco preparationFluePre treatment

The invention relates to a processing technology of defoliating and redrying tobacco leaves. The pretreatment stage adopts a method that evenly distributing, merging and threshing according to the same type, grade and quality in a certain ratio and a mode of grouping process. A few electronic scales are added in the pretreatment stage, and the mode of assembly line work in section is adopted; the continuous production mode has the steps of laying, separating, parting and dividing and precise distribution; a humidifying and moisture-preserving device is added in the pretreatment stage; parting and dividing technique is adopted; premix counters of tobacco which are top to top are added; and grouping process is adopted; the invention has the advantages of 1. having flexible processing method, being convenient for application and being capable of quick joint with cigarette brand production technology; 2. realizing a mode of merging and defoliating electronic scale and precise distribution technology; 3. realizing the continuous production mode of laying, separating, parting and dividing and precise distribution; 4. effectively solving the problems of water-dissipation and environment dust suppression of initial flue-cured tobacco; 5. ensuring the uniformity of internal quality of the same batch of tobacco; 6. enhancing the use value of tobacco material; 7. increasing the quality in control precision and level of tobacco products.

Owner:HONGTA TOBACCO GRP

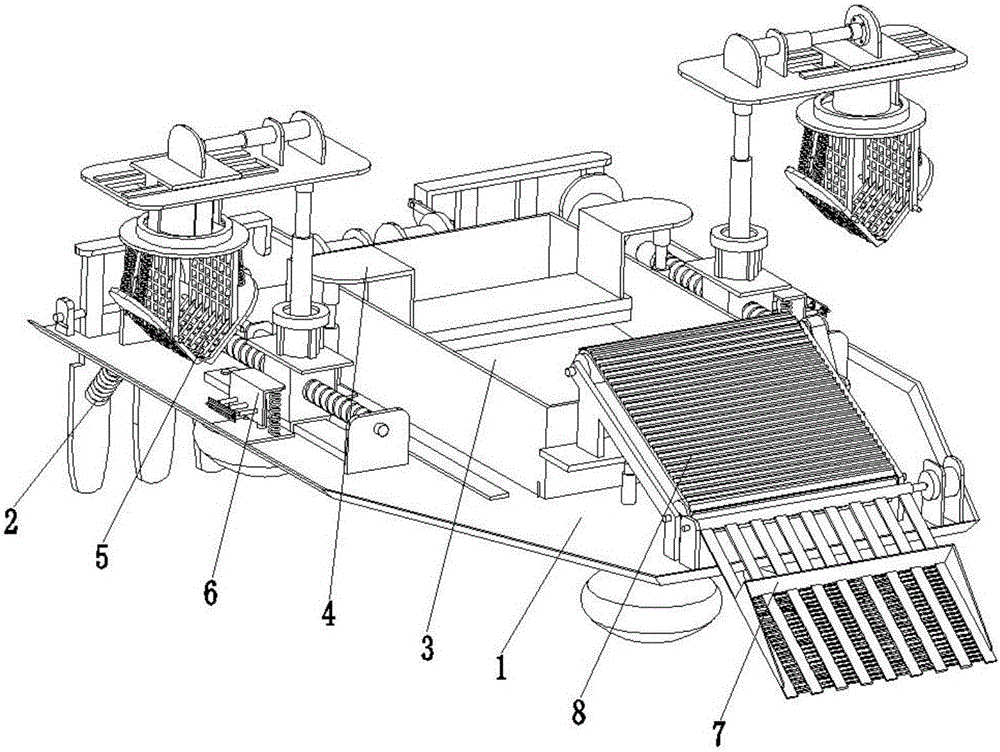

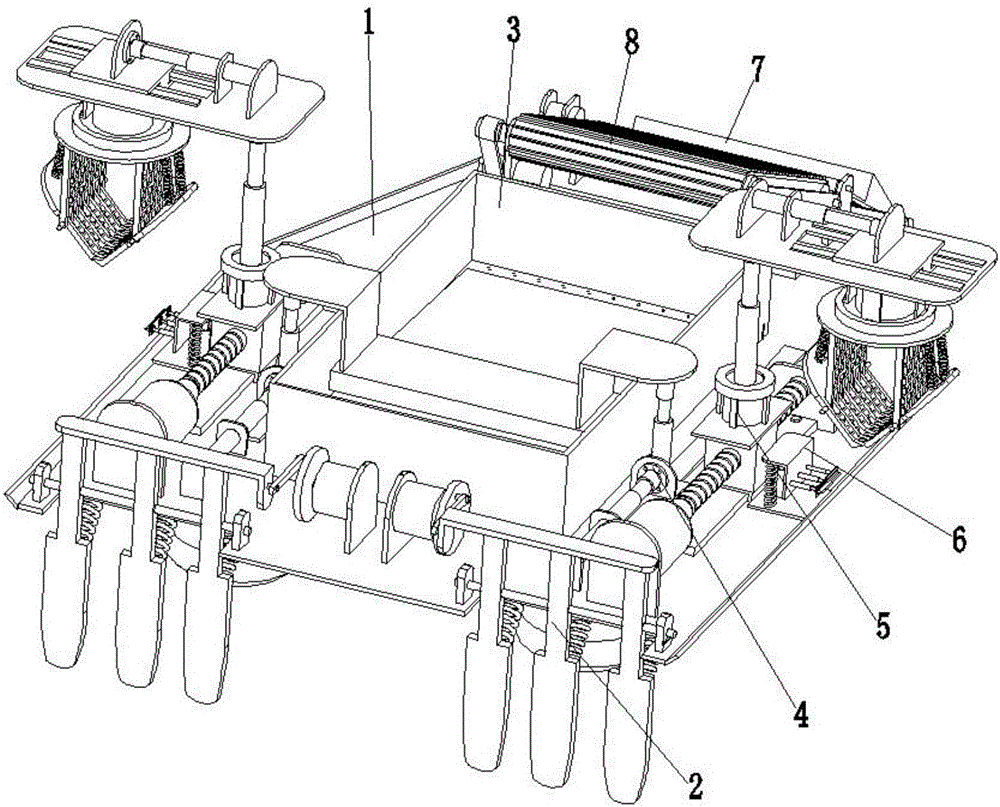

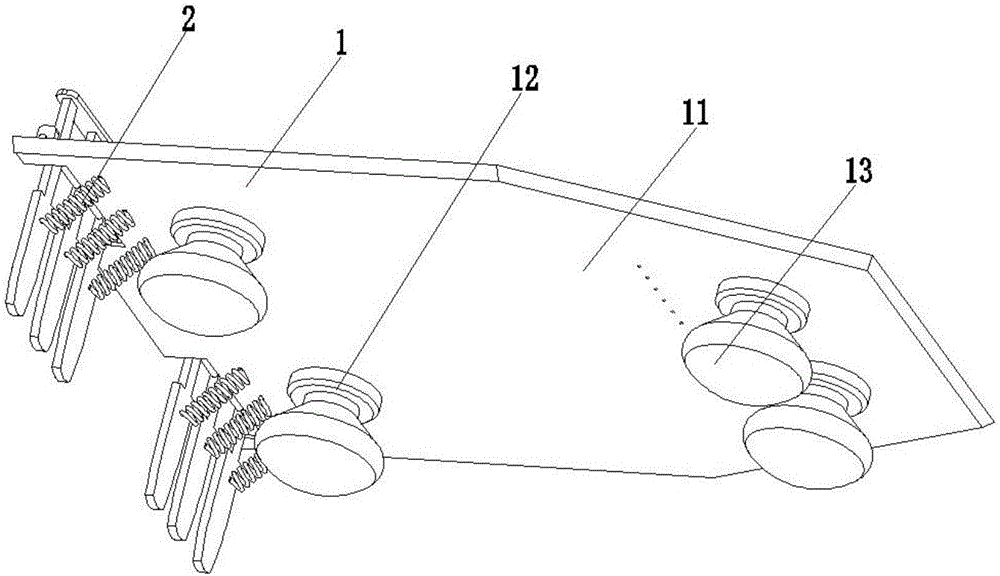

Environment-friendly type river and lake controlling and cleaning equipment

ActiveCN106759196APlay a dredging roleKeep water cleanWater cleaningWaterborne vesselsCompression deviceWater quality

The invention relates to environment-friendly type river and lake controlling and cleaning equipment. The environment-friendly type river and lake controlling and cleaning equipment comprises a boat body, power devices, a storage slot, a compression device, movable gripping devices, cut-off devices, a salvaging device and a conveying device, wherein the power devices are symmetrically mounted at the left side and the right side behind the boat body separately along the longitudinal central axis of the boat body; the compression device is positioned above the storage slot; the movable gripping devices are separately positioned at the left side and the right side of the compression device; the cut-off devices are positioned at the outer sides of the movable gripping devices; the salvaging device is positioned in front of the boat body; and the conveying device is positioned between the salvaging device and the storage slot. The environment-friendly type river and lake controlling and cleaning equipment integrates the functions of floating force adjusting, water-surface travelling, waste compacting, aquatic plant gripping, garbage salvaging, garbage conveying and the like, realizes the functions of eliminating aquatic plants in rivers and lakes as well as floating waste on the water surface, achieves the effect of dredging the rivers and the lakes, keeps water in the rivers and the lakes clean, is high in integral mechanical degree, is complete in function and is high in operating efficiency.

Owner:广东祥实建设有限公司

Implantable vascular device

InactiveUS20100057191A1Improve stabilityAvoid leaningStentsVenous valvesVenous ValvesRetrograde Flow

An valve prosthesis, such as an artificial venous valve, having a support frame and leaf structure comprising one or more leaflets in which the outer edge of each leaflet engages the inner circumference of the bodily passageway along a serpentine path urged against the passageway by an expandable frame, while the inner edges move in response to fluid to restrict retrograde flow. Optionally, one or more elements can extend from the support frame / leaf structure to provide centering support and / or protection from the leaflet adhering to the vessel wall. In one embodiment, the centering support structure comprises a second or third expandable frames attached to and extending from the proximal and / or distal ends of main valve structure and support frame. In another embodiment, one or more support elements extend outward from the valve support frame to engage the vessel wall to provide greater longitudinal stability.

Owner:COOK MEDICAL TECH LLC +1

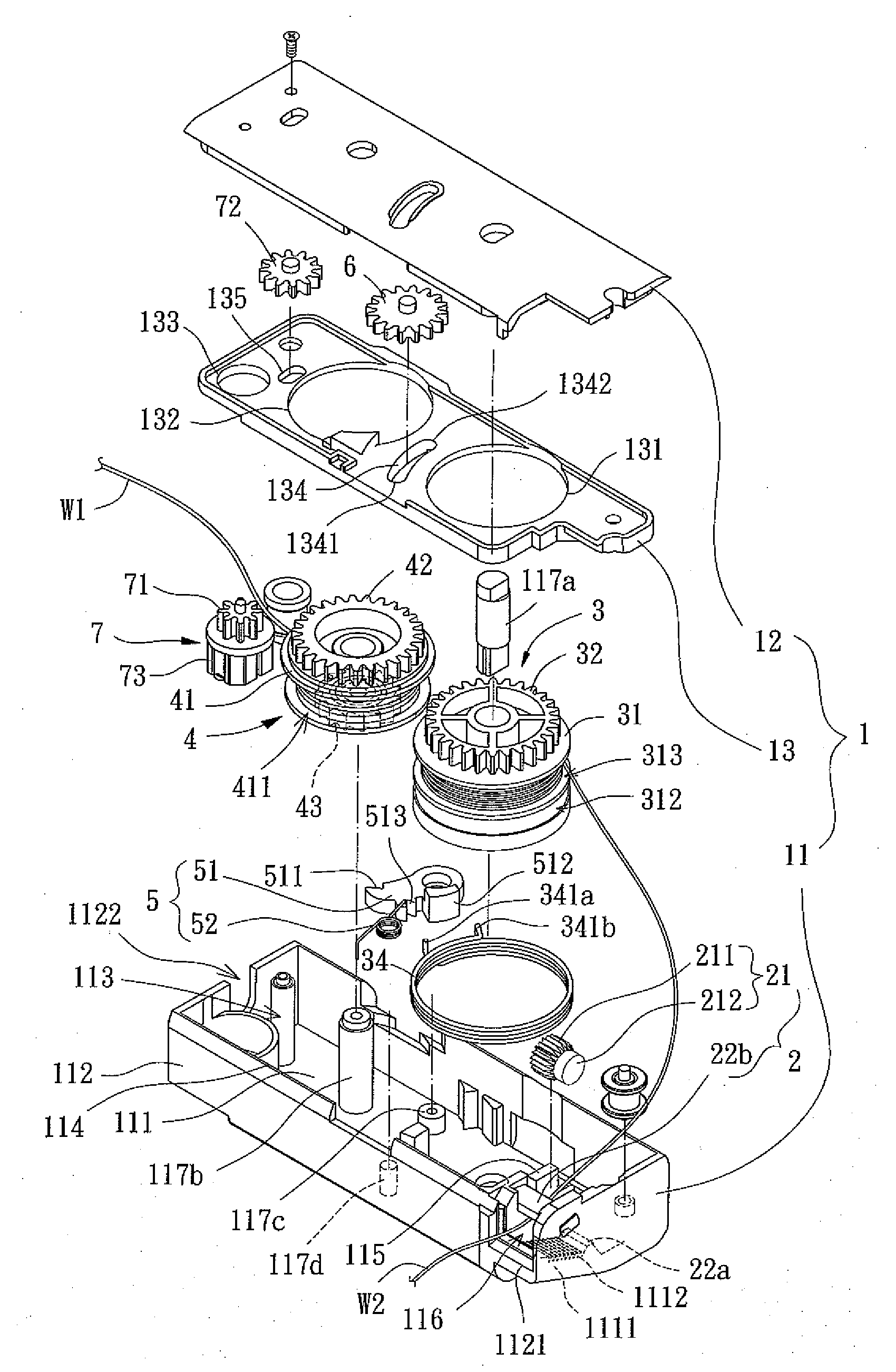

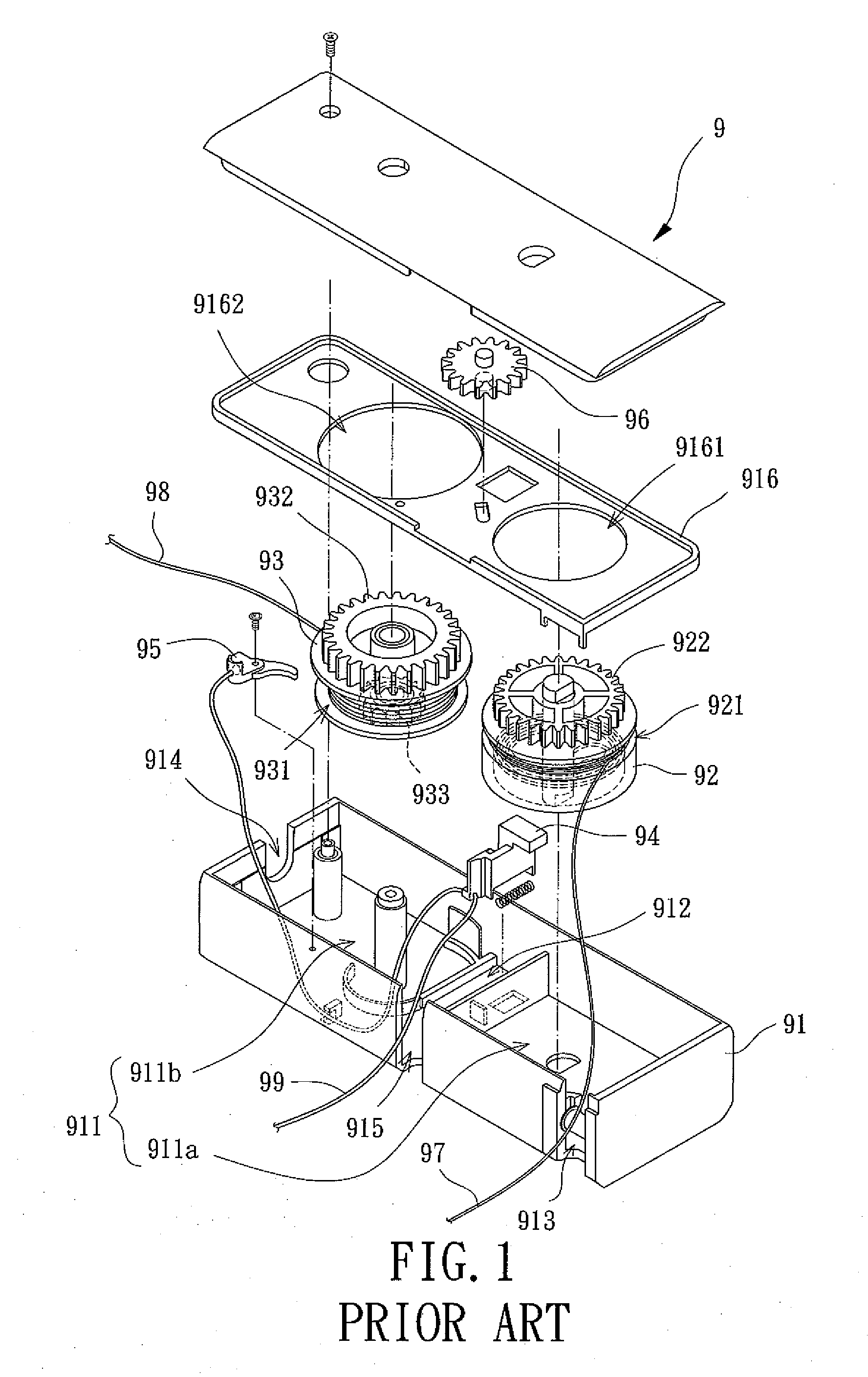

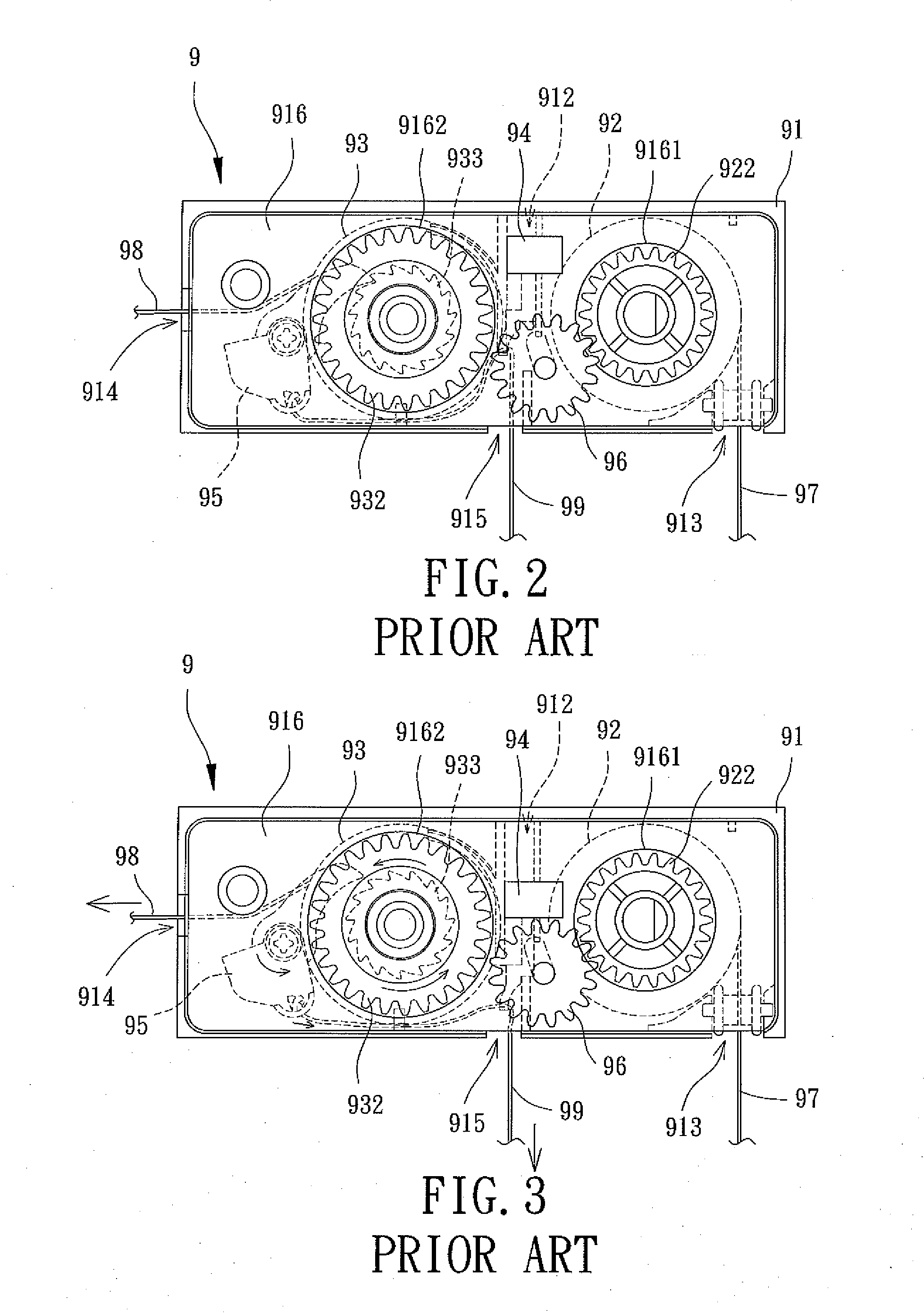

Control Device for folding/unfolding Window Shade

InactiveUS20110290429A1Avoid entanglementImprove convenienceExtensible doors/windowsCurtain accessoriesDrive wheelEngineering

A control device for folding / unfolding a window shade includes a casing rotatably receiving first and second driving wheels around which a pull cord and a tying cord are wound. The first driving wheel includes a first gear and a pressing member. The second driving wheel includes a second gear and an auxiliary gear. A clutch unit is located between the first and second driving wheels and includes a first end releasably engaged with the auxiliary gear on the second driving wheel and a second end abutting the pressing member. A transmission gear is slideably received in the casing. The pull cord is pullable to a desired extent to control the transmission gear to mesh with the first gear or both of the first and second gears, achieving folding or unfolding of the window shade.

Owner:CHENG LI MING

Non-entangling vena cava filter

ActiveUS20100174310A1Avoid entanglementReduce deliverySurgeryDilatorsBiomedical engineeringVena cava filters

Owner:CR BARD INC

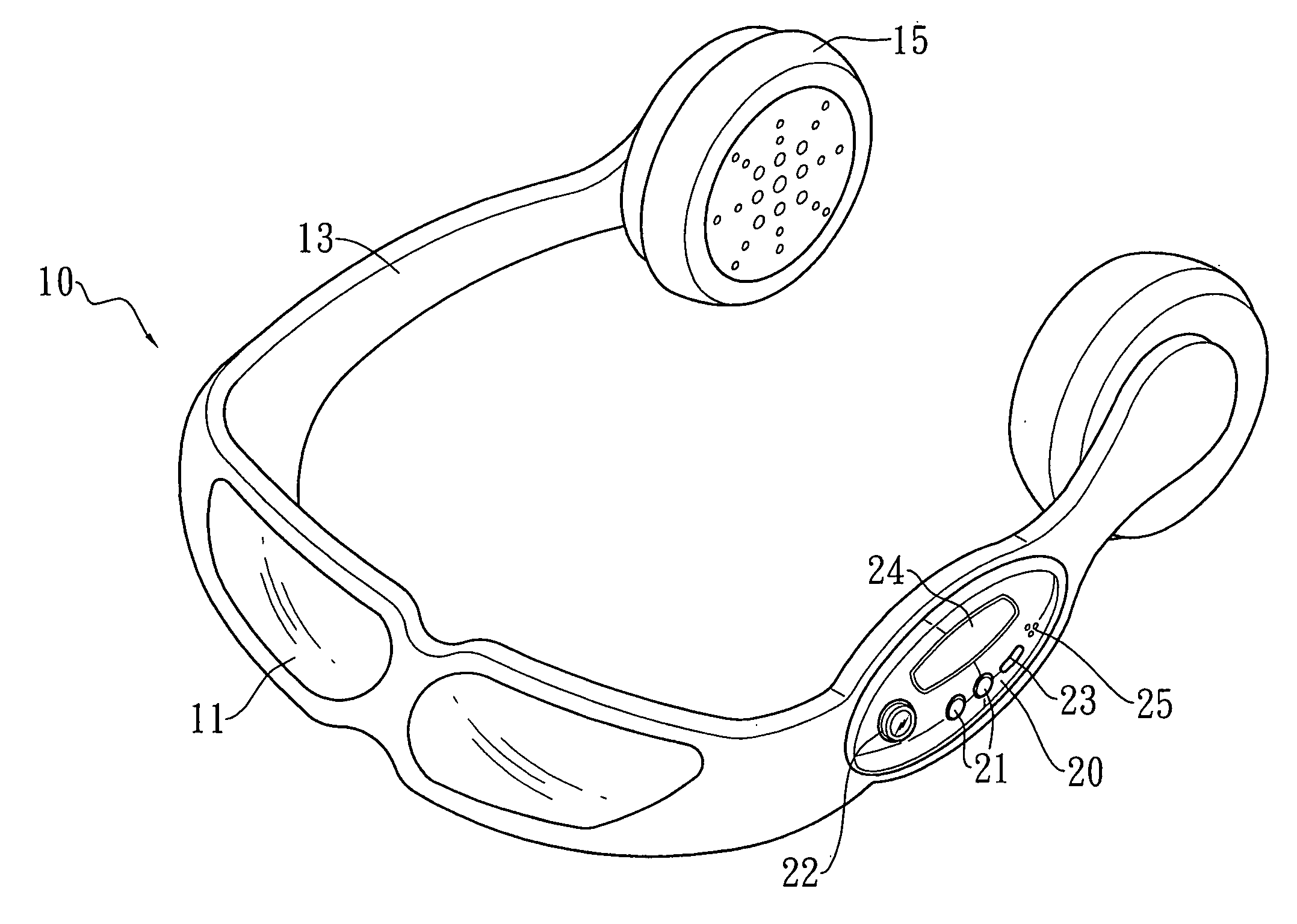

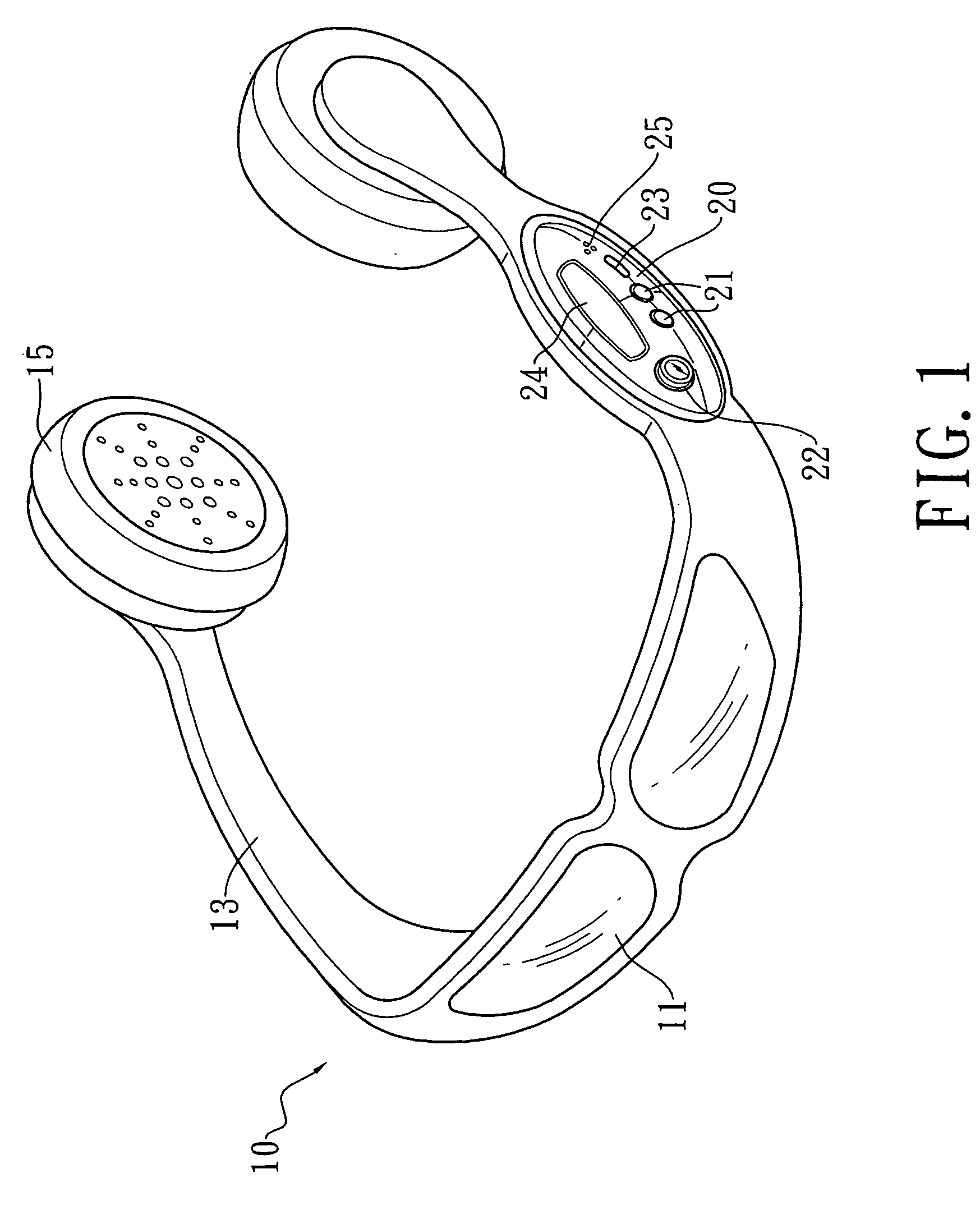

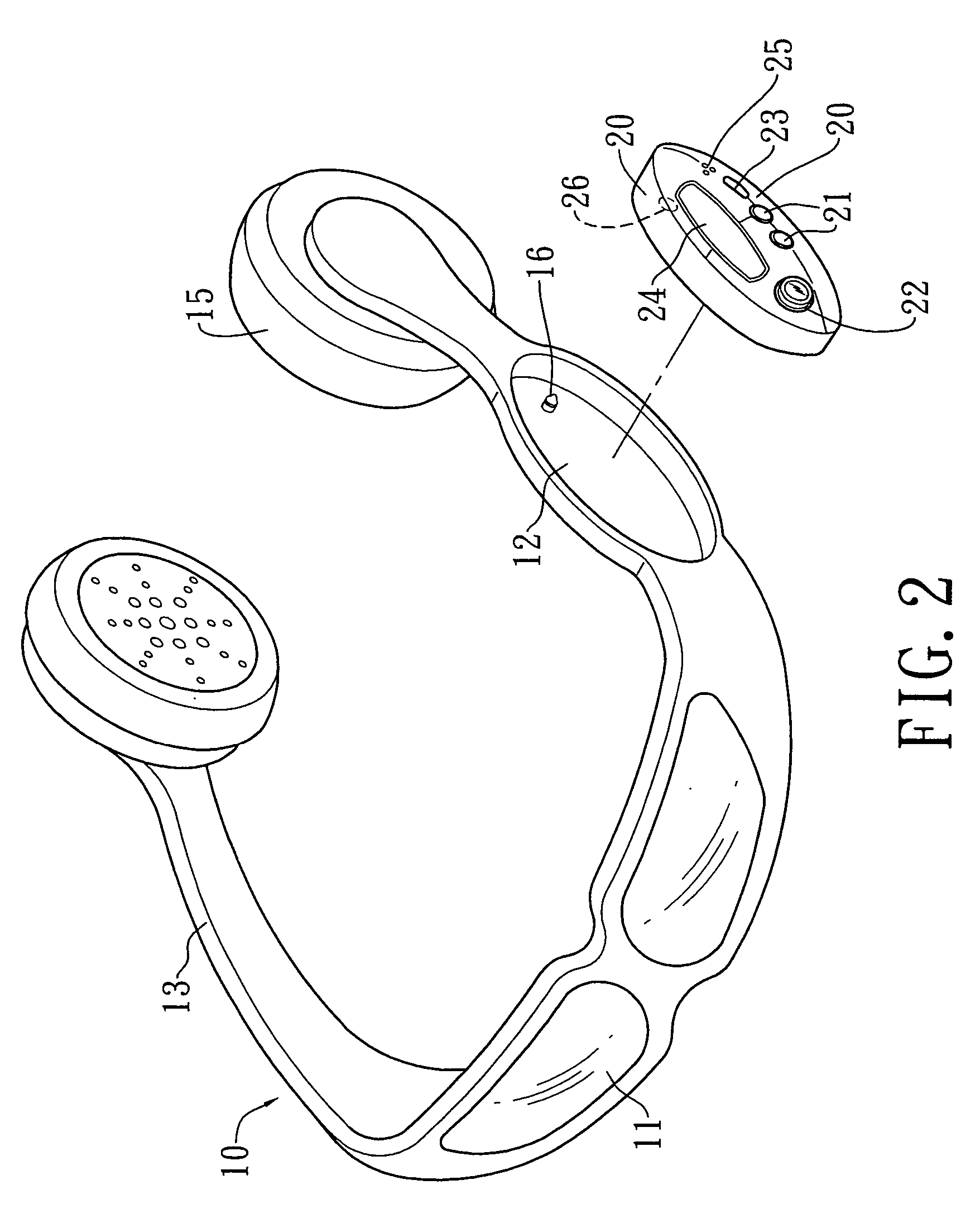

Structure of a pair of glasses

Owner:YEH MING HSIANG

Facial tissue strengthening and tightening device and methods

InactiveUS20110144729A1Quick and accurate face-liftingMinimally invasiveUltrasound therapySurgical instruments for heatingForms of energyFacial tissue

A device is described that can be used quickly and accurately by surgeons to provide uniform facial tissue planes that are tunnel-free and wall-free thus optimizing face lifting, tightening, and implant delivery. The device is comprised of a shaft with a substantially planar tip further comprised of relative protrusions and energized relative recession lysing segments. Forward motion of the device precisely divides and energizes various tissue planes causing contraction, especially via the fibrous tissues. Other forms of energy and matter can be delivered down the shaft to further enhance desirable tissue modification and contraction.

Owner:WEBER PAUL JOSEPH

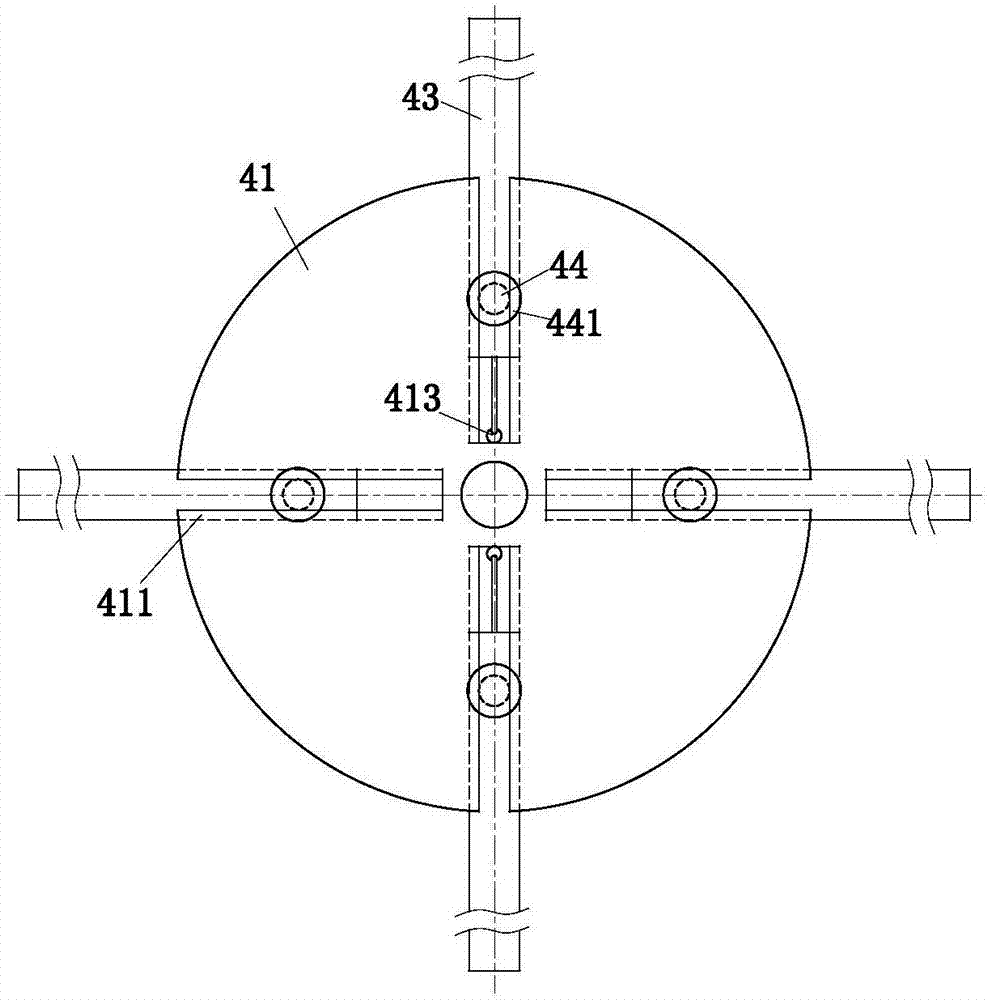

Stainless steel cylinder polishing wire-drawing treatment equipment

ActiveCN107363695ARealize automatic shrinkage adjustmentImprove production efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringDrive motor

The invention belongs to the field of mechanical processing equipment, and in particular discloses stainless steel cylinder polishing wire-drawing treatment equipment which comprises a bottom plate, an adjusting module, a driving motor, an outer cylinder grinding disc, an inner cylinder grinding disc, a centering support and a connecting rotating shaft, wherein the bottom plate is placed on the ground; an adjusting module is arranged on the upper surface of the bottom plate; the driving motor is mounted on the adjusting module; the inclination angle of an axis of the driving motor can be adjusted through the adjusting module; and the outer cylinder grinding disc, the inner cylinder grinding disc and the centering support are detachably mounted on the connecting rotating shaft coaxially. By adopting the equipment, automatic shrinkage adjustment on a polishing wire-drawing radius is achieved under the centrifugal action of the outer cylinder grinding disc and the inner cylinder grinding disc, then operation of polishing and wire-drawing is completed at one time, and the generation efficiency is improved.

Owner:南京拓创精密金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com