Wave wheel of washing machine

A washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of clothes entanglement, achieve the effects of reducing damage, improving anti-winding ability, and avoiding entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is the optimal solution of the present invention.

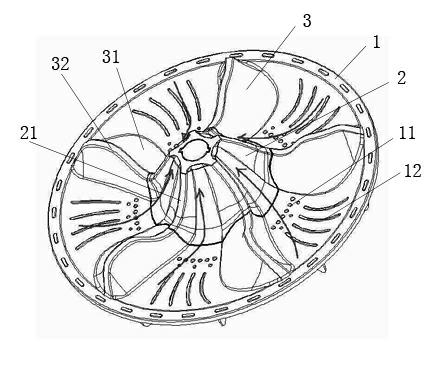

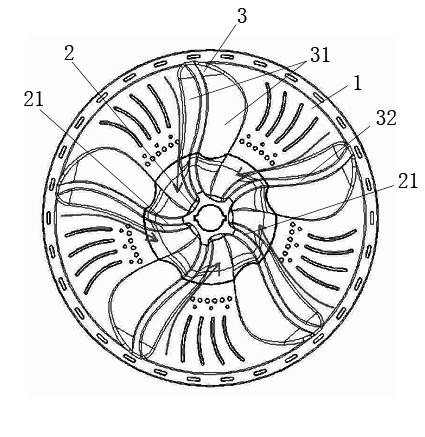

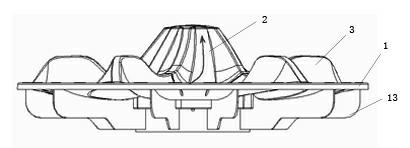

[0019] Such as figure 1 , the base 1 is disc-shaped, the center is fixed on the rotating shaft, and it rotates to work. The bottom surface of the entire base 1 is concaved toward the center on all sides. At the central position, a conical platform 2 concentric with the base 1 is provided. The diameter of the conical platform 2 is about 1 / 3 of the diameter of the base 1. The horizontal Higher than the outermost edge of the base.

[0020] In addition to the middle portion of the conical platform 2, five blades 3 are arranged on the bottom surface of the base 1 along the outward divergence line in the middle, and the five blades 3 are arranged in equal angles, that is, at intervals of 72 degrees. Water permeable holes 11 and auxiliary water flow ribs 12 are provided on the bottom surface of the base between the blades.

[0021] Such as figure 1 and figure 2 As shown, the shape of the blade 3 is the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com