Patents

Literature

57 results about "Hand rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hand rubbing is a gesture that conveys in many cultures either that one has a feeling of excited expectation, or that one is simply cold. In Ekman and Friesen's 1969 classification system for gestures, hand-rubbing as an indication of coldness is an emblem intentional gesture that could equally well be verbalized.

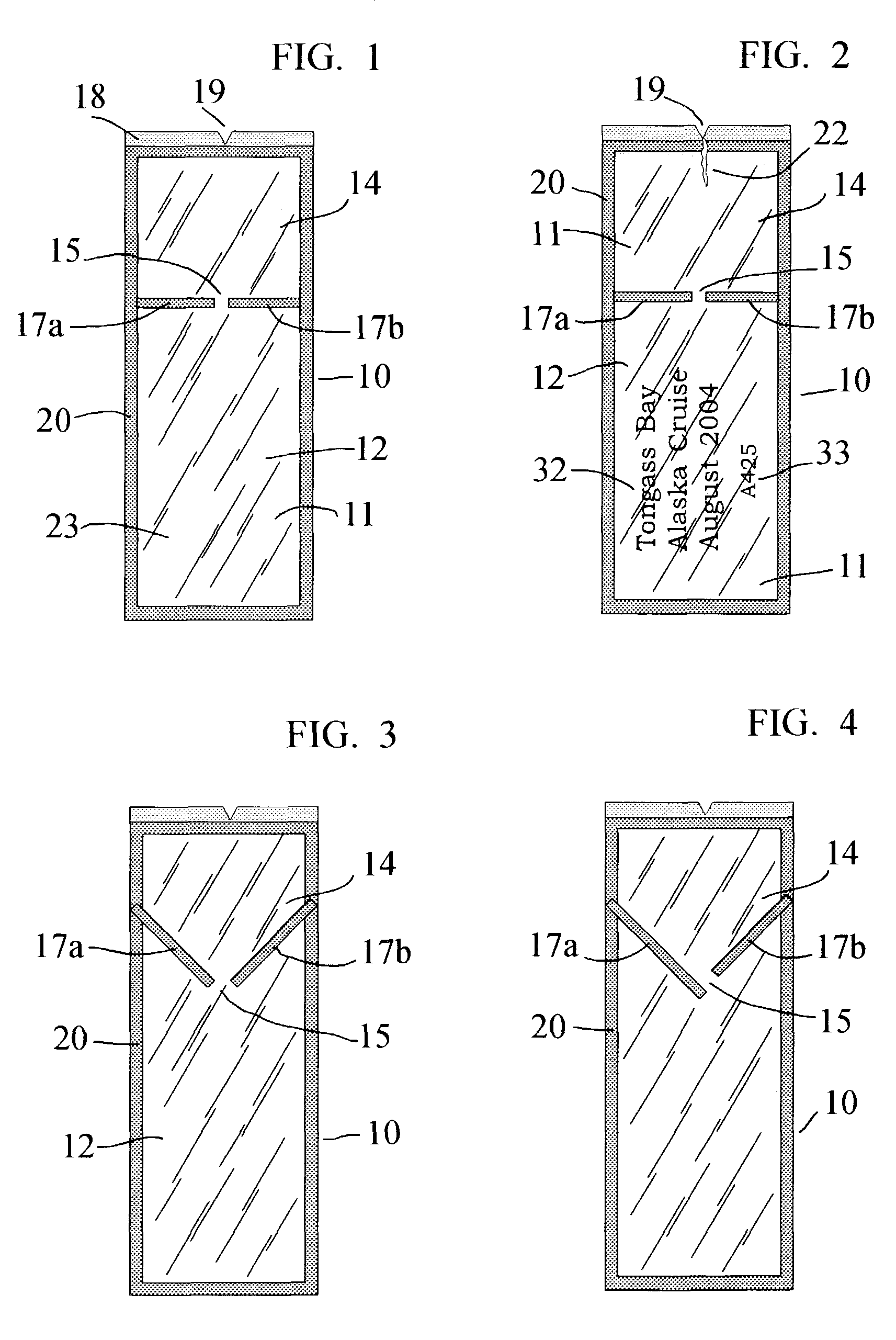

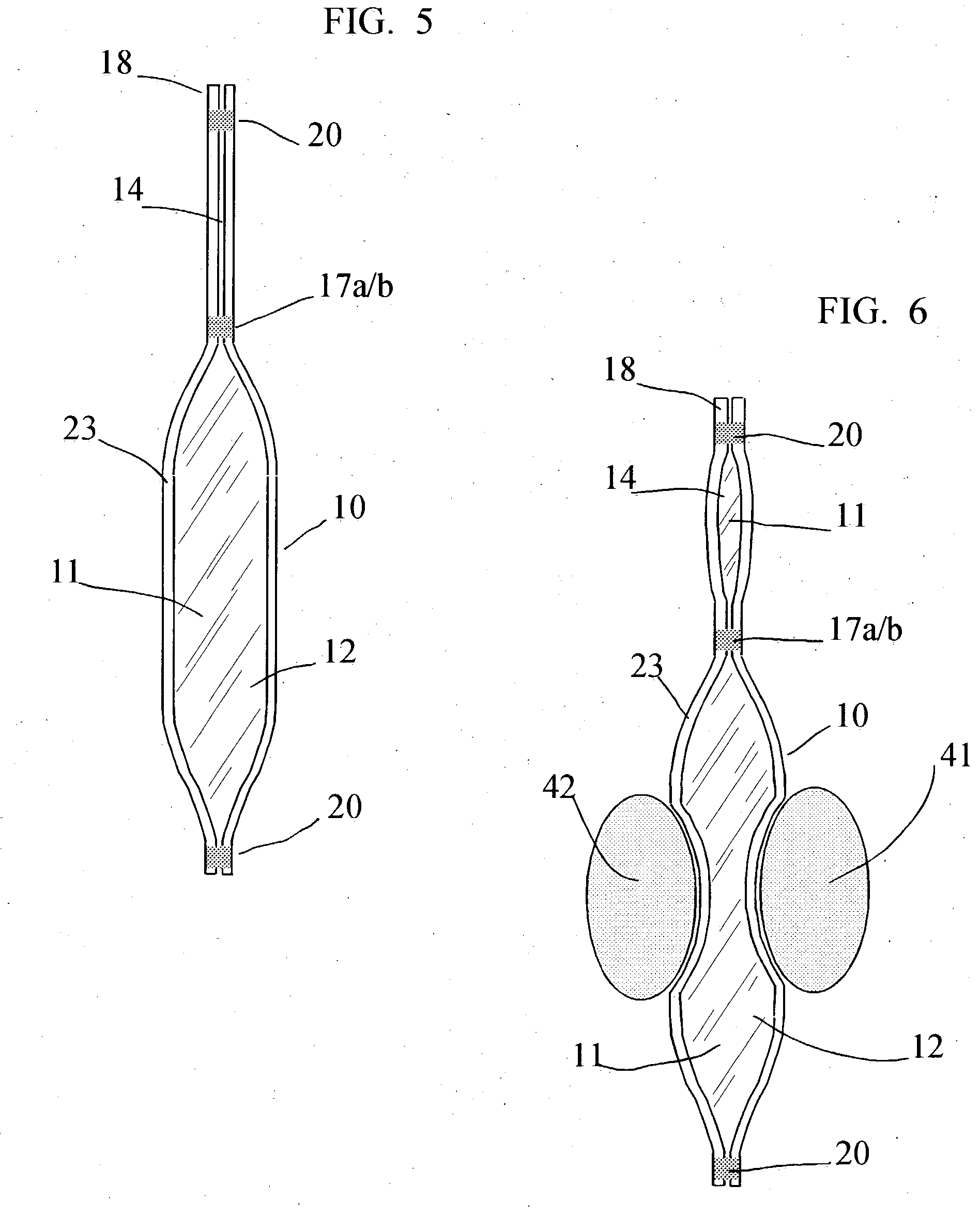

Hand sanitizing packet and methods

InactiveUS7004354B2Increase opportunitiesFast evaporationPortable flexible containersFlexible containersEngineeringFinger operation

Described are methods and apparatus for promoting and attaining effective hand hygiene based on the employment of a class of packaging which provides timely access to and convenient use of hand sanitizing fluids for hand rubbing. A specific and novel type of package representative of this class found to be particularly useful in facilitating this method is a small, flat, disposable, twin chambered, multi-dose, self-sealing polymer packet designed to be pocket carried by the user. Through simple and direct finger manipulation a measured dose of hand sanitizing fluid is drawn on to the hand in a controlled and wasteless manner from a metering chamber opened for dispersal through a tear in the packet wall. The self-sealing packet reserves and preserves the remaining fluid for future uses and permits the packet to be immediately returned to a pocket without any closure manipulation. Rubbing the hands to distribute the fluid achieves an effective degree of hand sanitation by substantially reducing the presence of hand-borne pathogens. Distribution of the packets is encouraged by the use of lottery and gaming techniques that heighten the opportunity of using a hand sanitizing fluid for proper hand hygiene.

Owner:HARPER WILLIAM ANTHONY

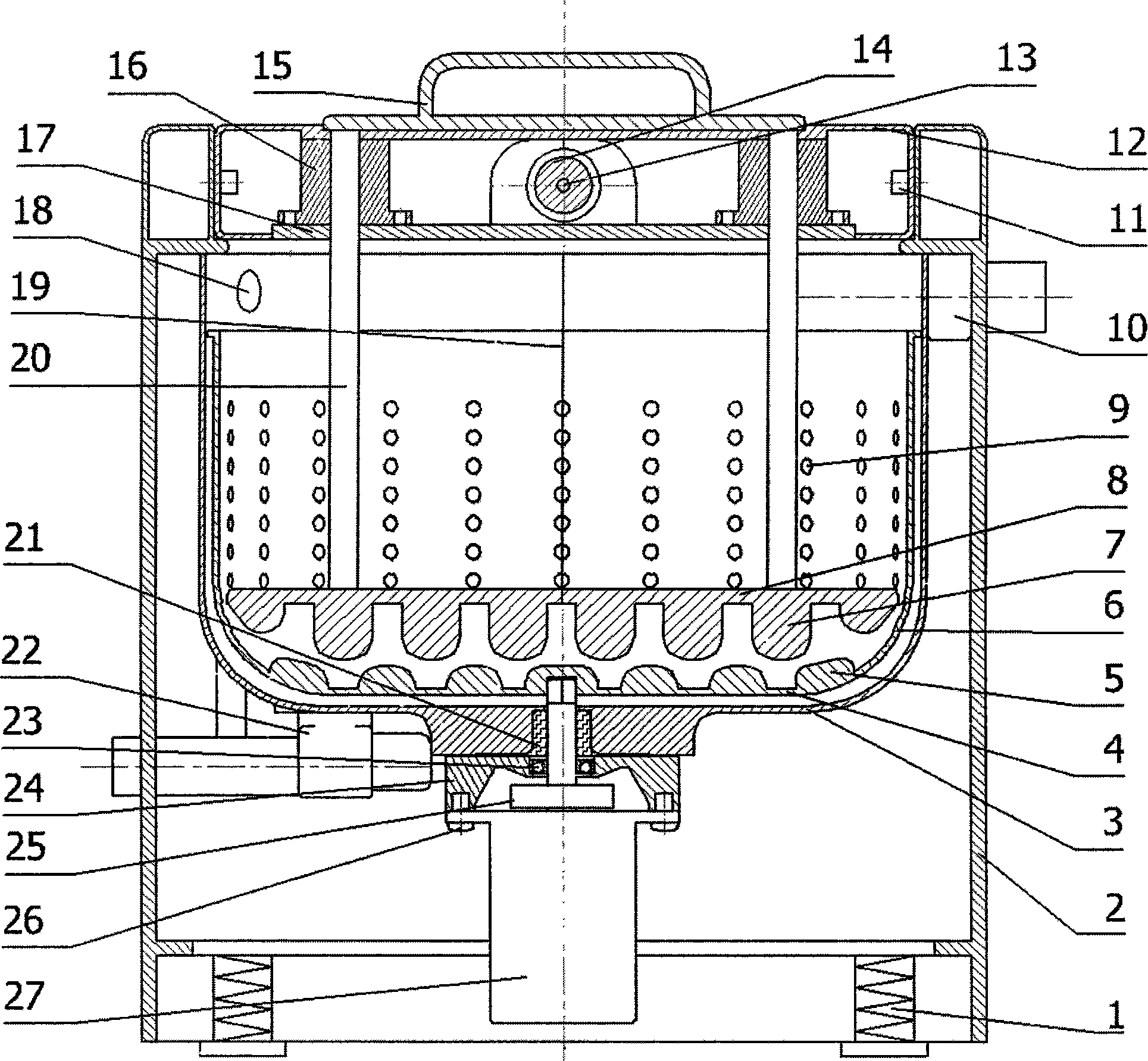

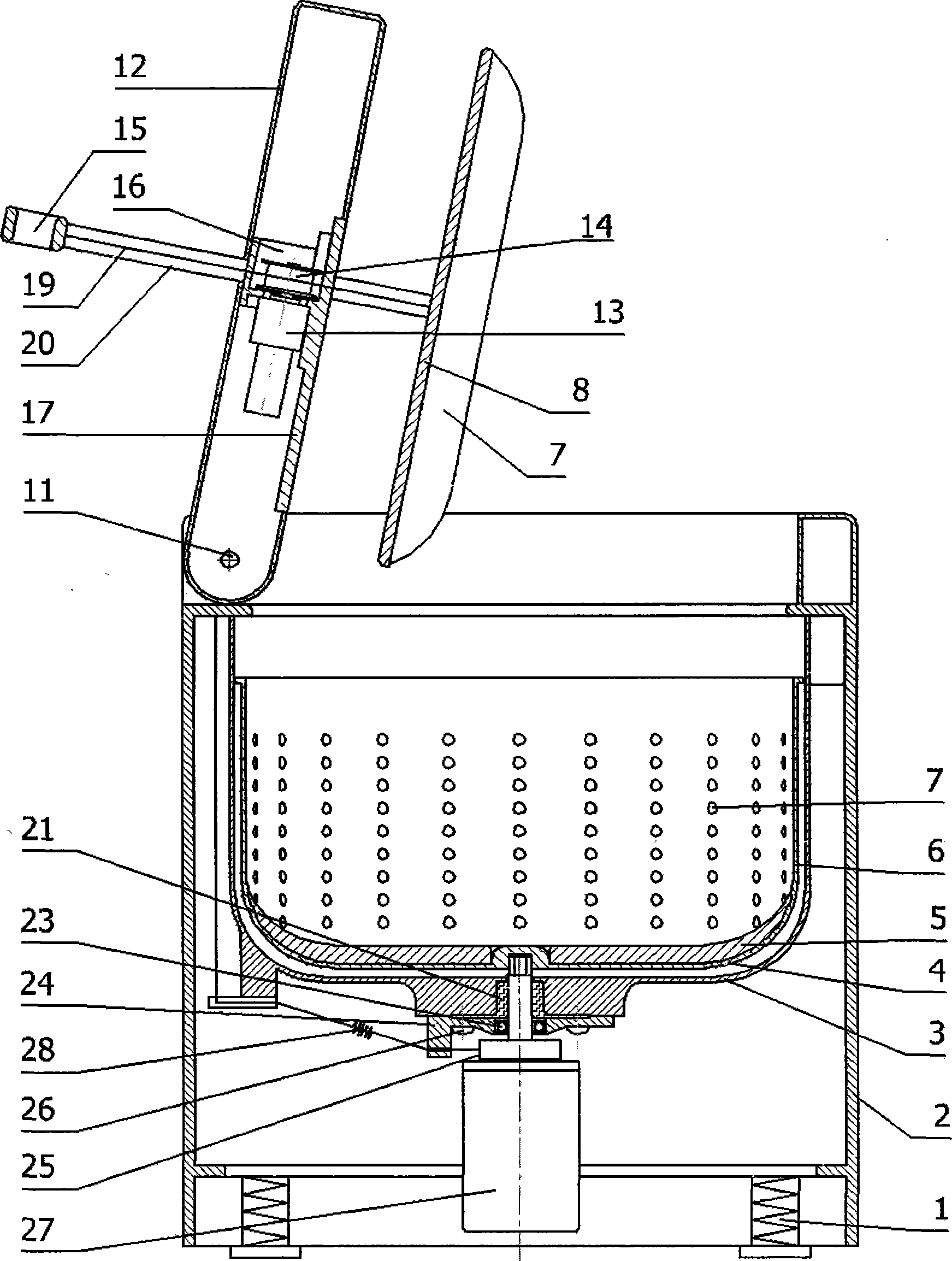

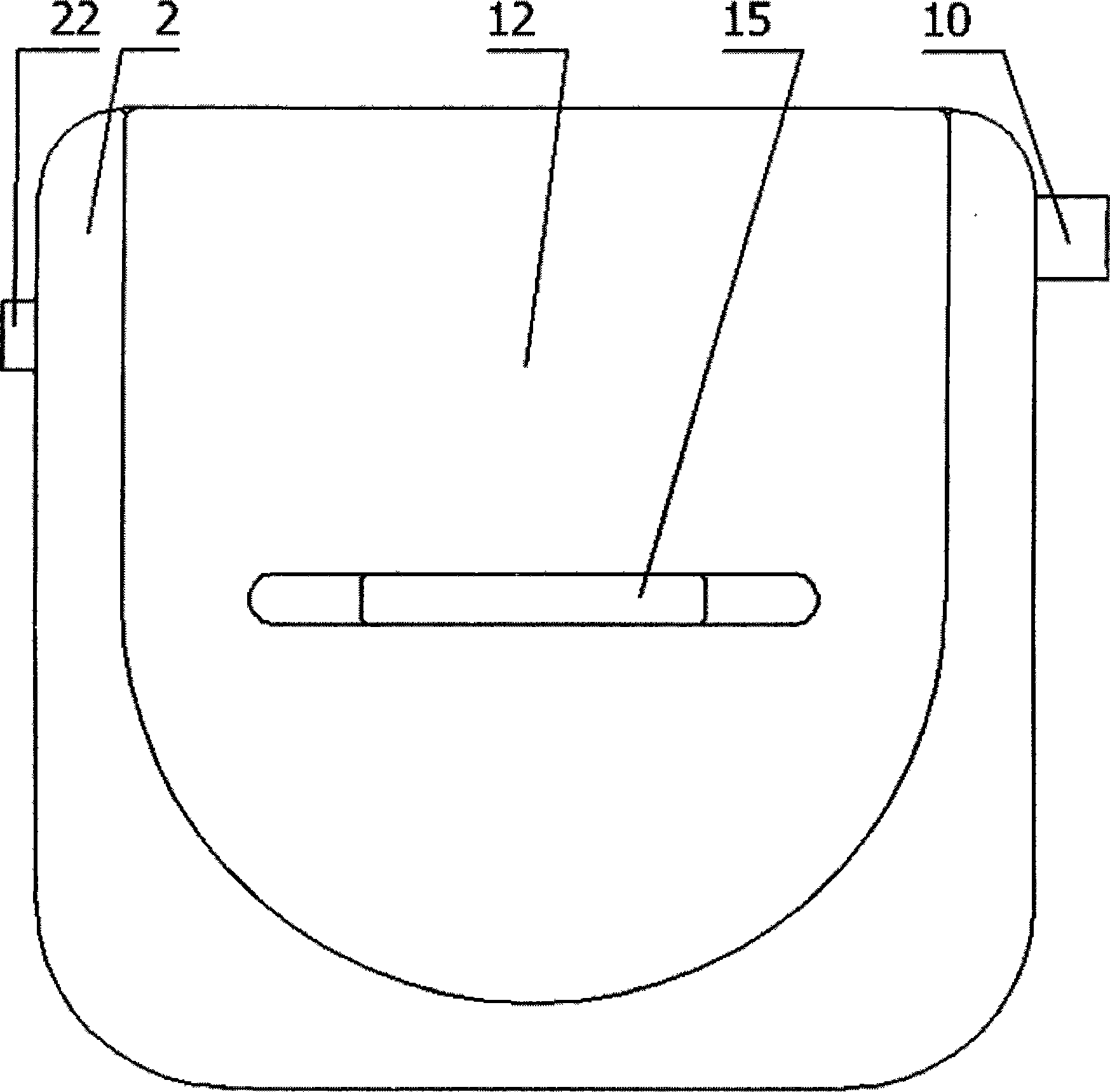

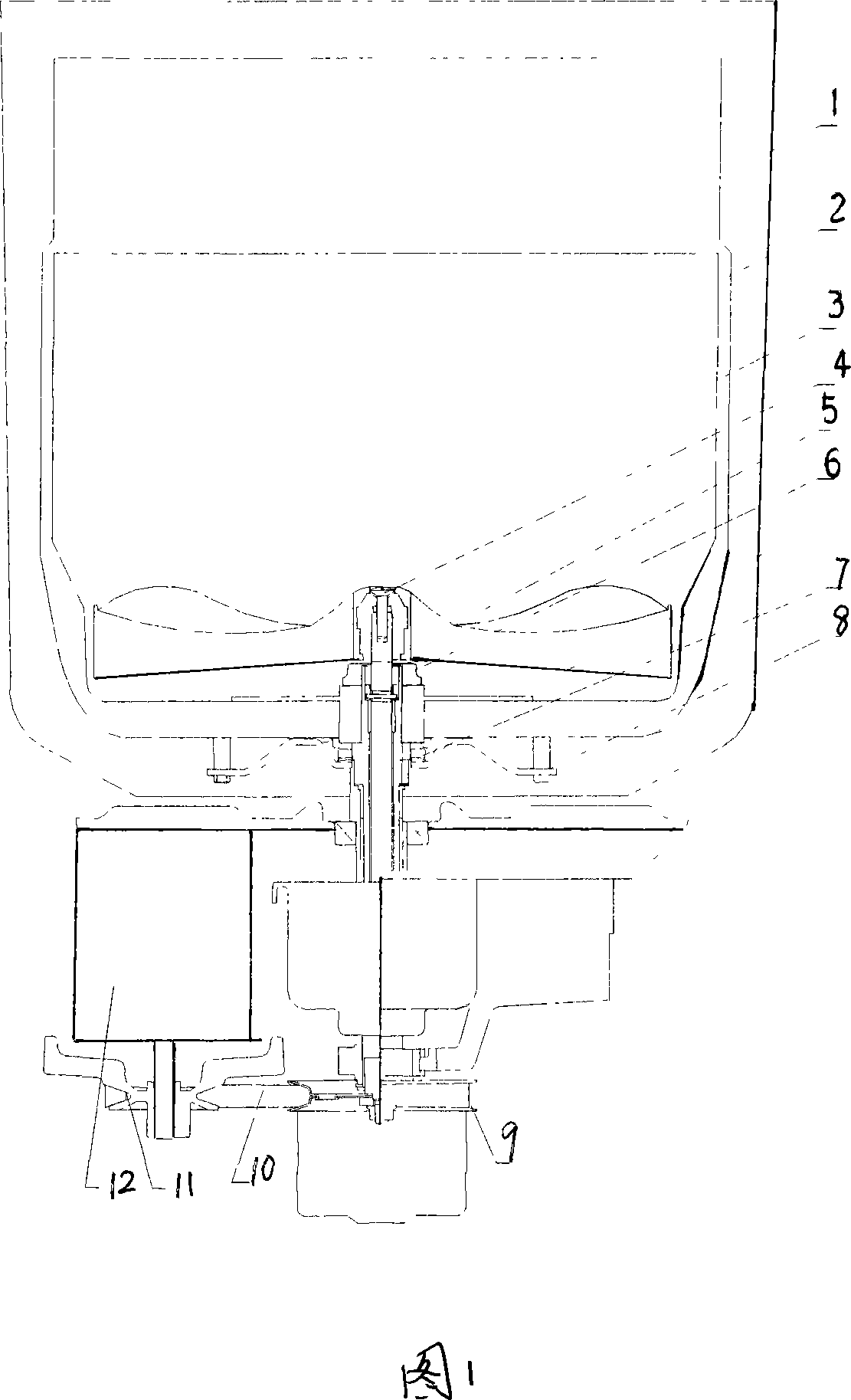

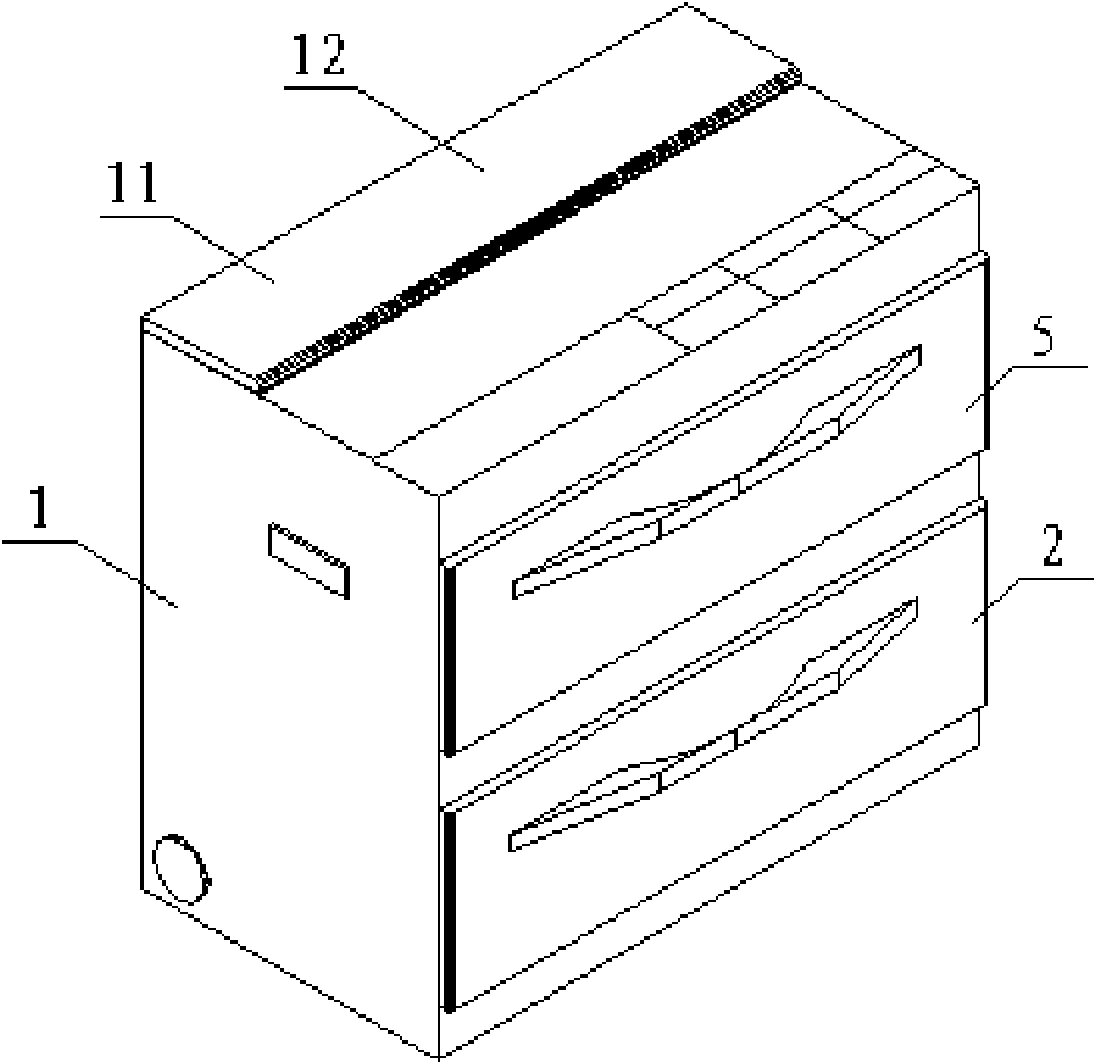

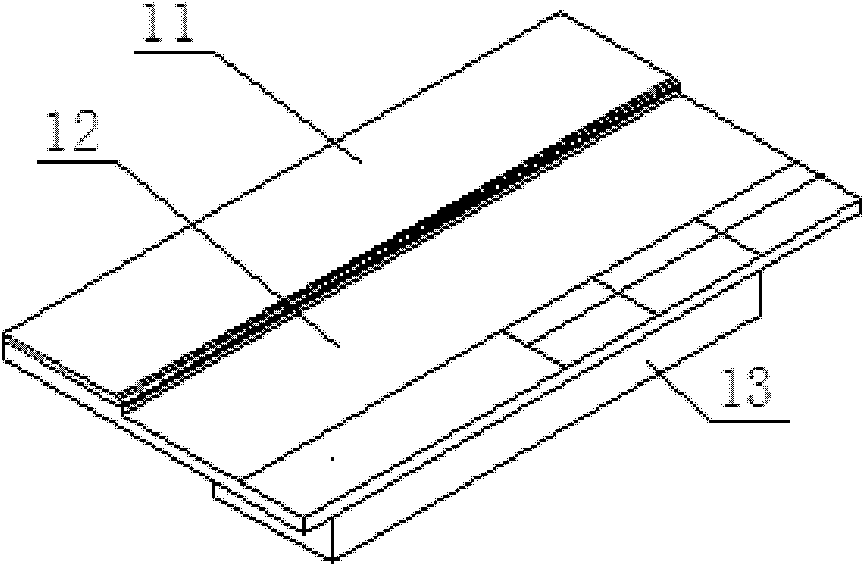

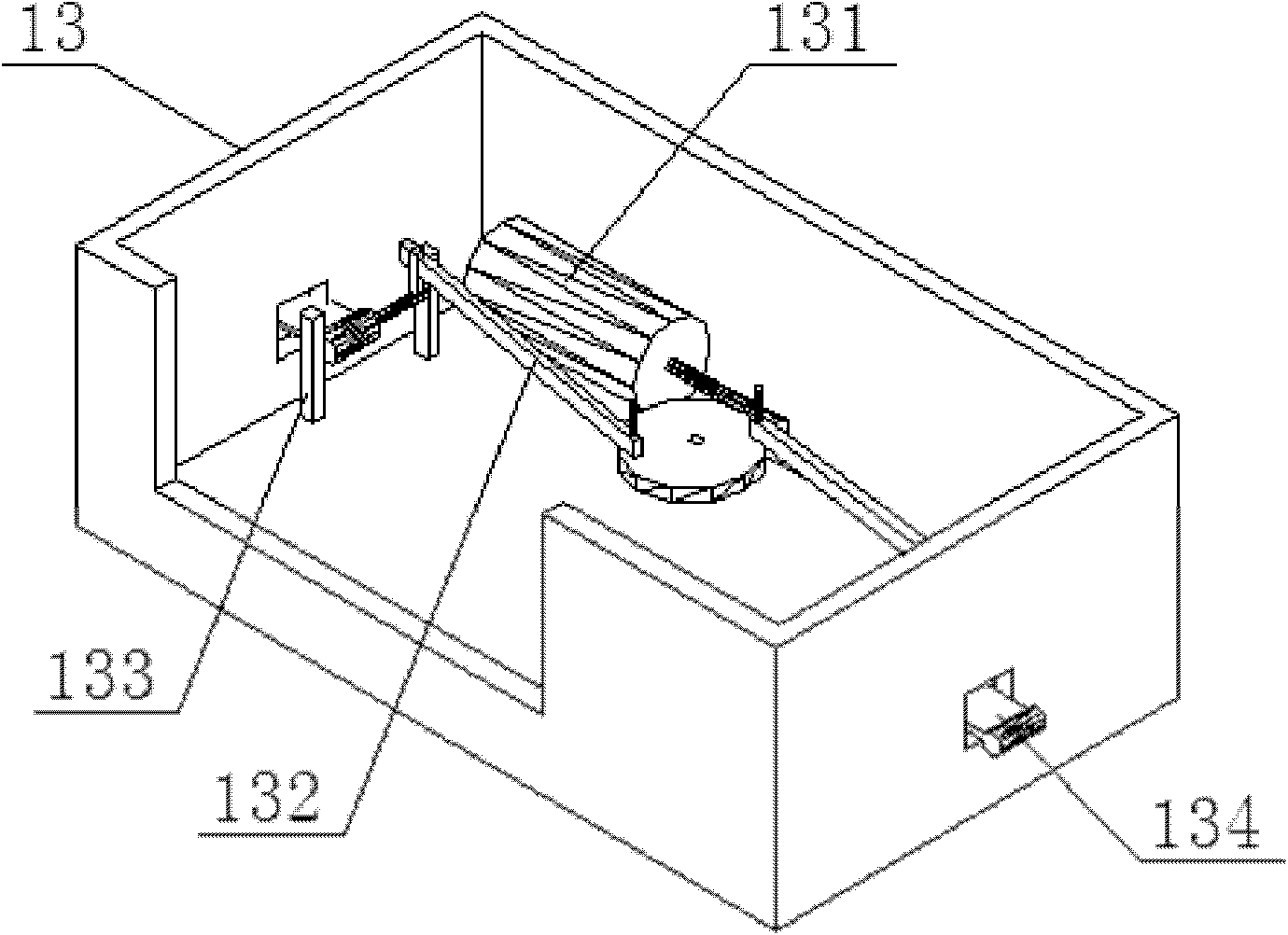

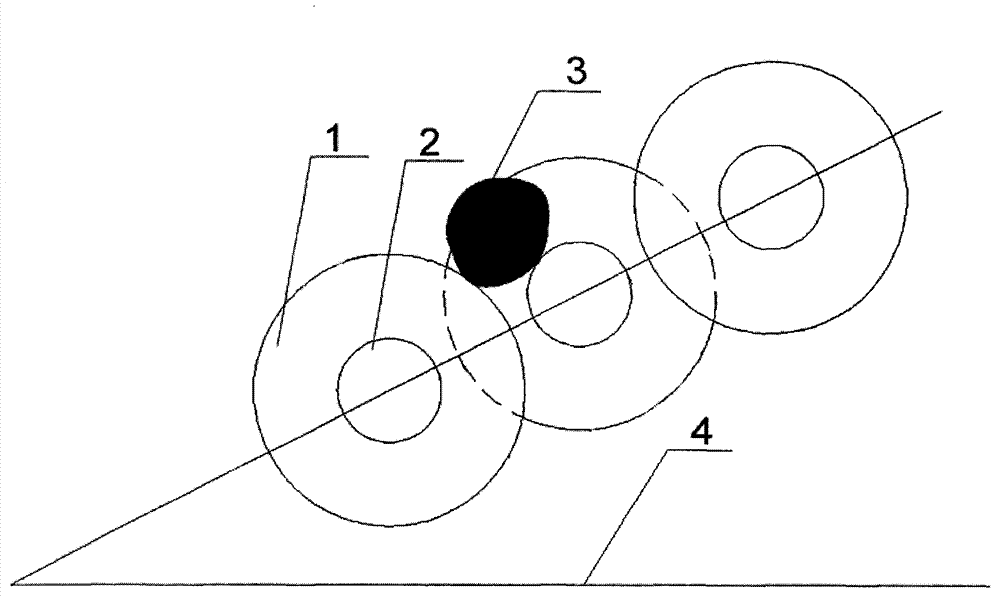

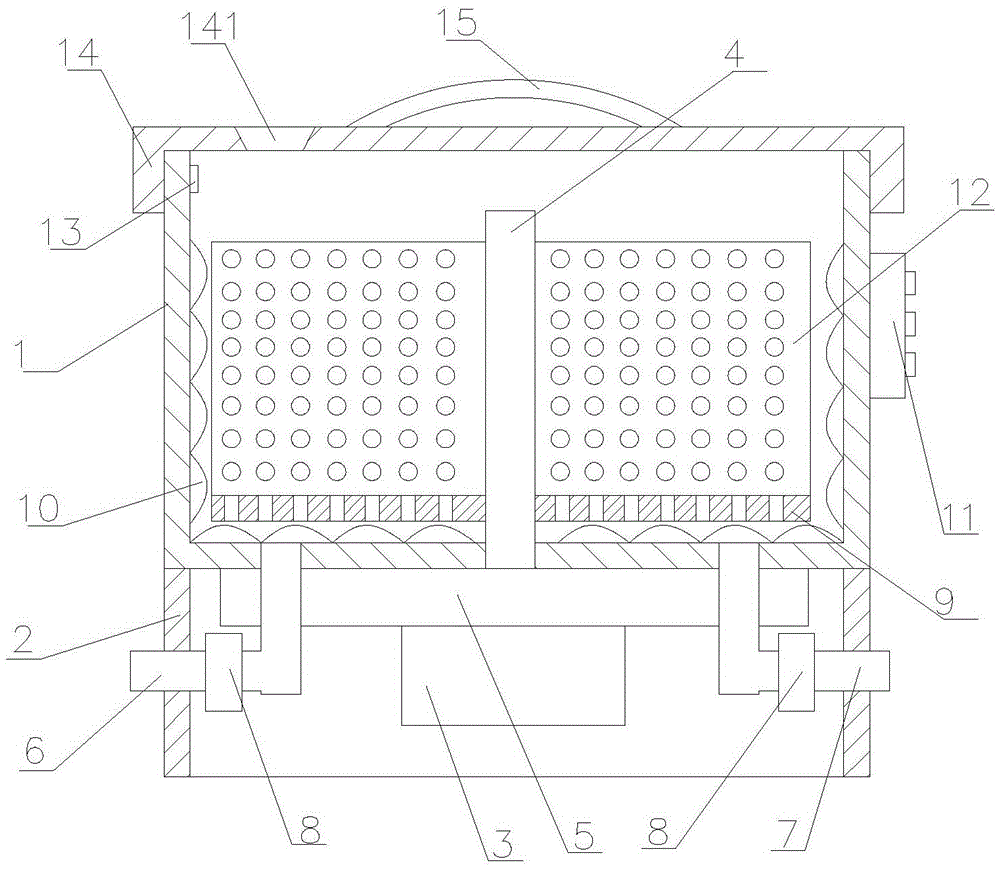

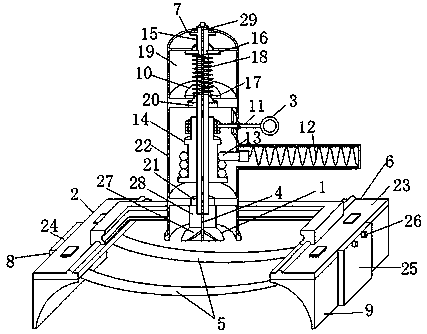

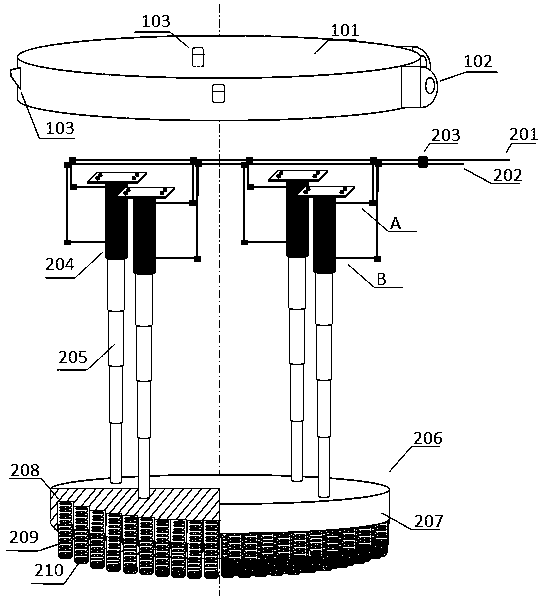

Micro full-automatic hand-rubbing-type washing machine

InactiveCN103696201ASimple structureEfficient washingOther washing machinesWashing machine with receptaclesElectricityLow speed

The invention provides a micro full-automatic hand-rubbing-type washing machine, which is mainly used for separately washing small clothing such as underclothes, socks and baby clothes which are required to be frequently changed and washed in daily life. The micro full-automatic hand-rubbing-type washing machine mainly comprises a combined cover, an inner tub, an outer tub, a washing motor and a lifting motor. A lower rubbing plate is arranged at the bottom of the inner tub. An upper rubbing plate is arranged on the combined cover. During washing, the lower rubbing plate is driven by the washing motor to rotate forwards and reversely at low speed and the upper rubbing plate squeezes downwards to realize a hand-rubbing function. During spinning, the upper rubbing plate is driven by the lifting motor to get far away from the lower rubbing plate and a spinning function is realized through a centrifugal effect produced by unidirectional high-speed rotation. By adopting the technical scheme provided by the invention, the trouble of washing small clothing which is easy to get dirty, is difficult to wash and is required to be frequently changed and washed in daily life is effectively solved and the effects of being worry-free and saving labor, water and electricity during washing of small clothing are simultaneously realized.

Owner:张源湘

Hand sanitizing packet and methods

InactiveUS20050006404A1Increase opportunitiesFast evaporationPortable flexible containersFlexible containersHand sanitizerEngineering

Owner:HARPER WILLIAM ANTHONY

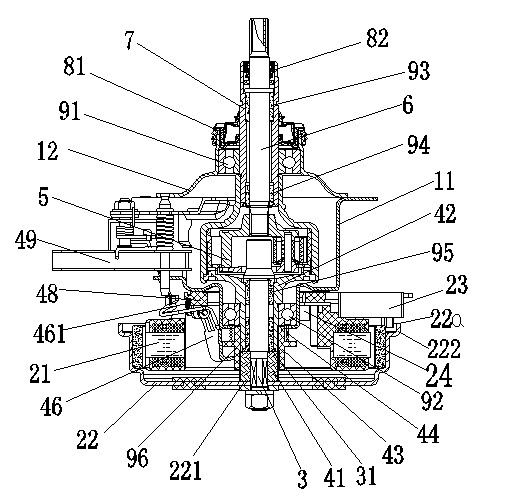

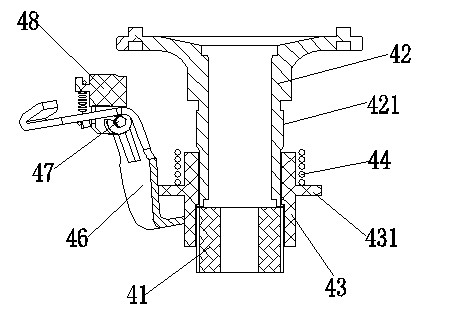

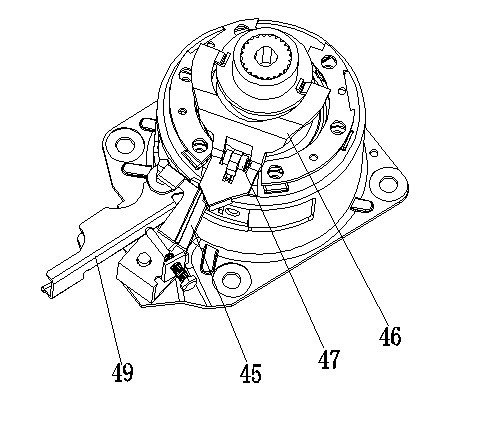

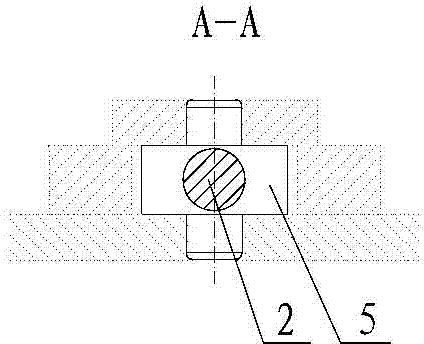

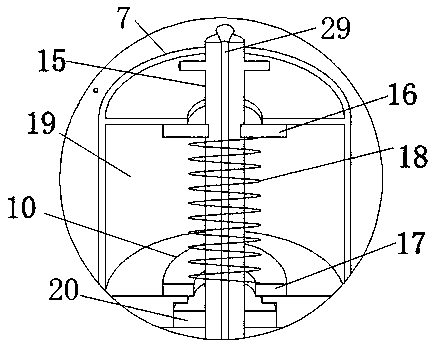

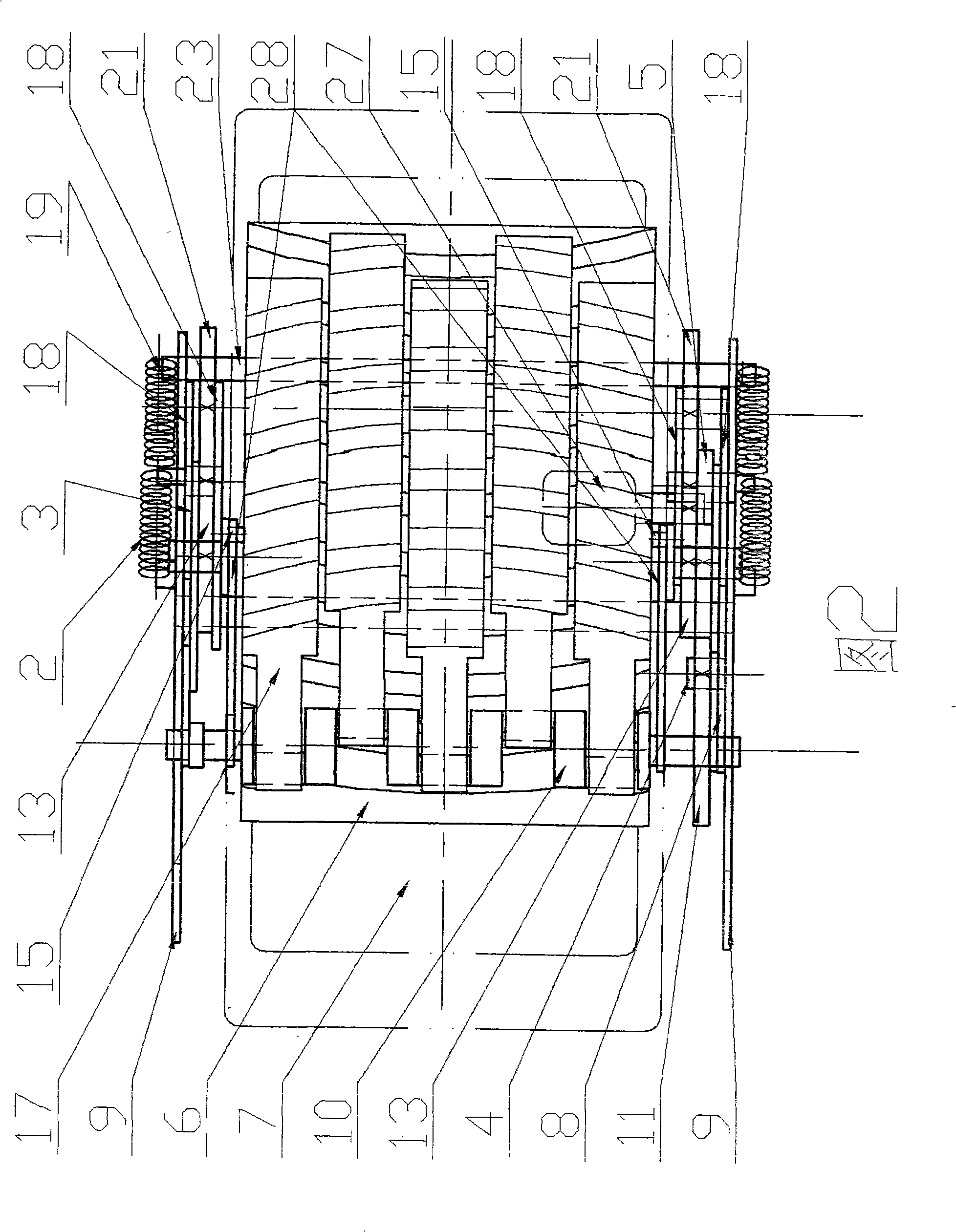

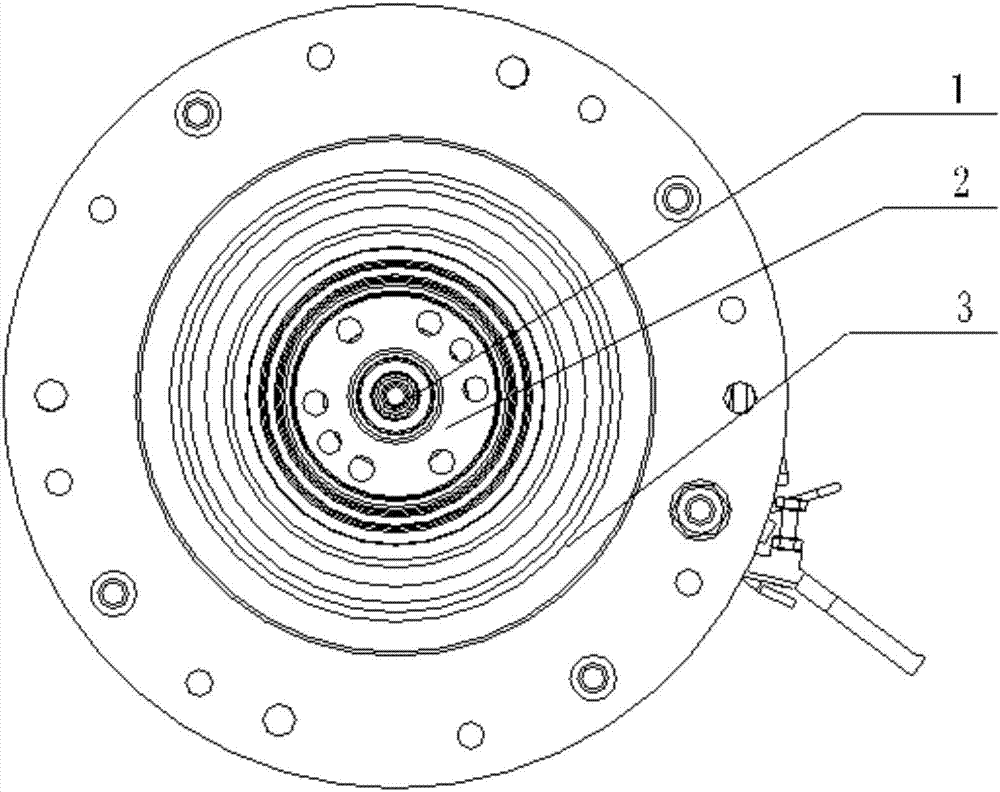

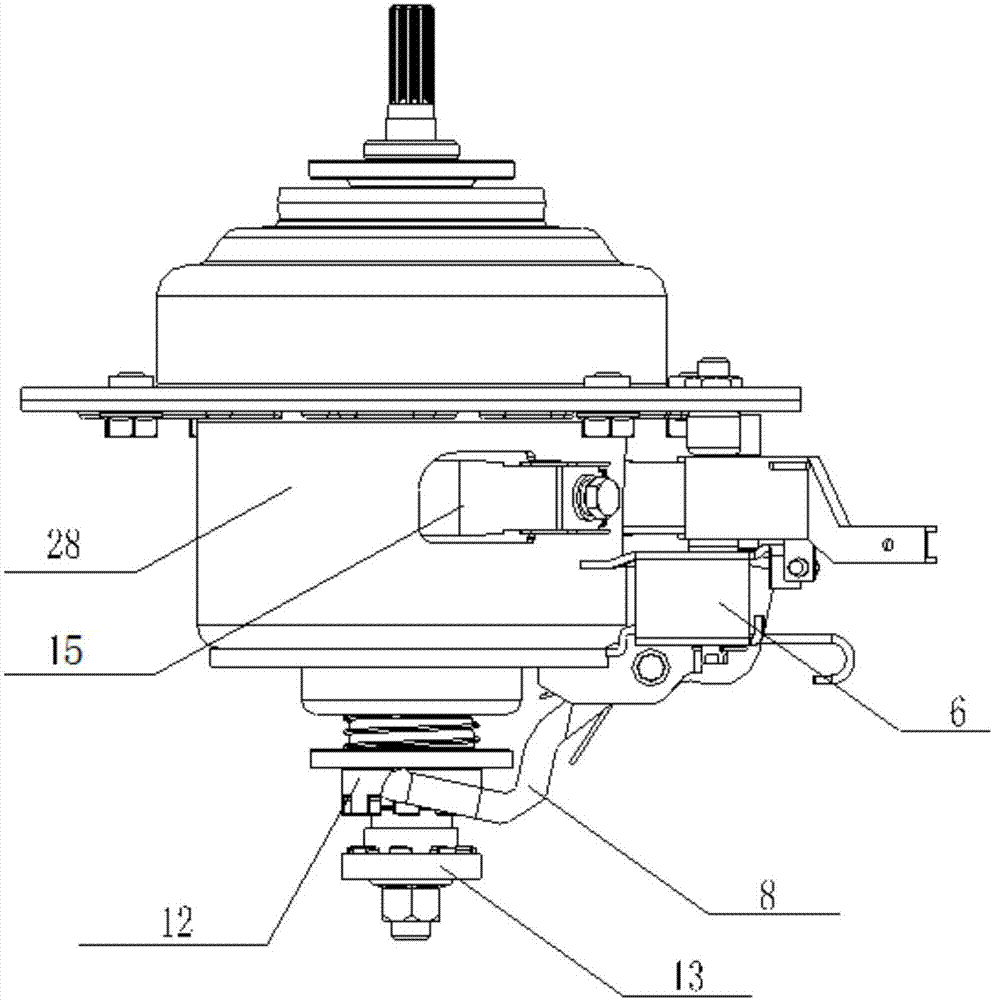

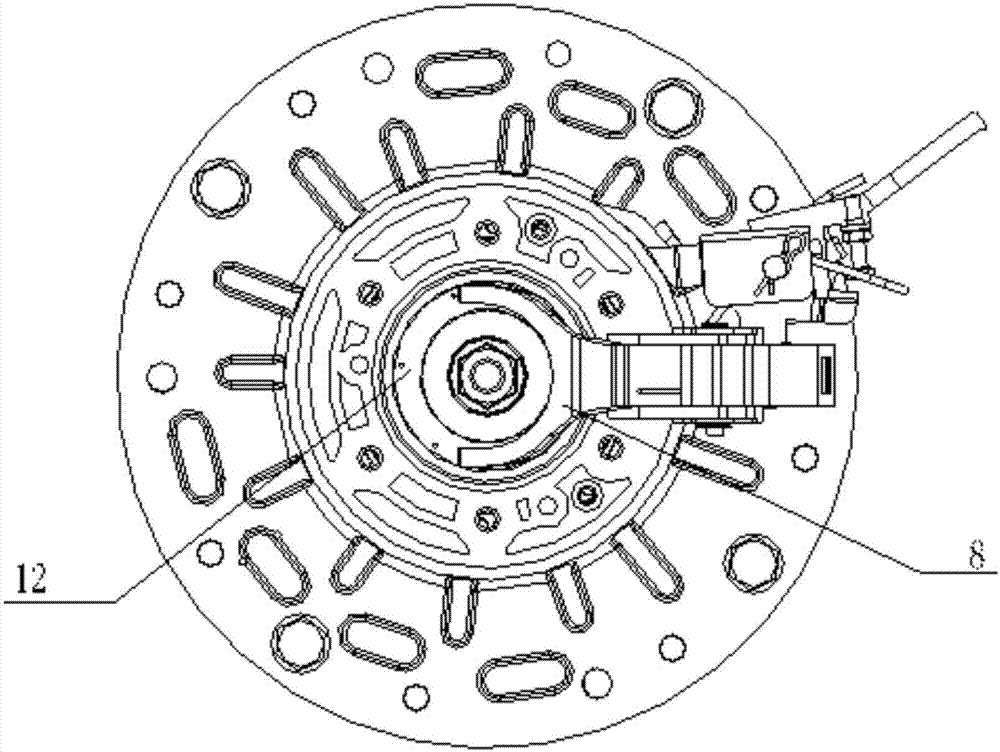

Washing machine bionic hand rub frequency conversion deceleration clutch

ActiveCN102277710AEasy to installImprove insulation performanceOther washing machinesTextiles and paperLow noiseBrushless motors

The invention discloses a variable-frequency speed-reducing clutch of bionic hand rubbing of a washing machine. The clutch provided by the invention comprises a lower shell and an input shaft which are matched; the lower shell is equipped with a stator of a direct-current brushless motor and the end part of the input shaft is connected with an external rotor of the direct-current brushless motor;the stator of the direct-current brushless motor is located at an inner cavity of the external rotor of the direct-current brushless motor and the input shaft is assembled with a sliding clutch mechanism composed of a shaft sleeve, a clutch shaft, a clutch sliding block and a clutch spring; the shaft sleeve covers the input shaft and the clutch shaft is located above the shaft sleeve to rotatablycover the input shaft; the shaft sleeve and the clutch shaft are all provided with peripheral splines; guiding splines on the inner periphery of the clutch sliding block are slidingly matched with the peripheral spline of the clutch shaft; the clutch spring is pressed on an annular lug boss on the periphery of the clutch sliding block and the clutch sliding block is connected with a clutch control mechanism. The clutch provided by the invention realizes the variable-frequency washing of the bionic hand rubbing of the washing machine; and the clutch enriches the washing function and has the advantages of low noise, energy source conversation, good safety performance and the like.

Owner:宁波普尔机电制造有限公司

Rotary drum washing machine scouring barrel capable of forming compound solid current and scouring method

InactiveCN101177879AGood for all-round washingPrevent spot washingOther washing machinesWashing machine with receptaclesWater flowProcess engineering

The invention discloses a washing bucket of a whirlpool agitator washing machine that can form composite stereoscopic flows and a washing method: the washing bucket of the whirlpool agitator washing machine comprises a plurality of washing buckets, which are usually divided into a half upper washing bucket and a half lower washing bucket; an whirlpool agitator is arranged in the half lower washing bucket; the half upper washing bucket, the half lower washing bucket and the whirlpool agitator are connected with three power ends of three output shaft clutches respectively; the whirlpool agitator and the half lower washing machine rotate in reverse directions, and the half lower washing machine and the half upper washing machine rotate in reverse directions, all of which have the rubbing out effects and good washing effect. During the washing process, the exchange forward rotation and revere rotation of the upper washing bucket, the lower washing bucket and the whirlpool agitator is driven through the natural rotation and the reverse rotation of a motor, just like a huge hand rubbing out. The invention integrates the advantages of the swirl washing machine and the bucket washing machine, thereby improving washing effect and preventing the clothes from enwinding.

Owner:HEFEI MIDEA WASHING MACHINE

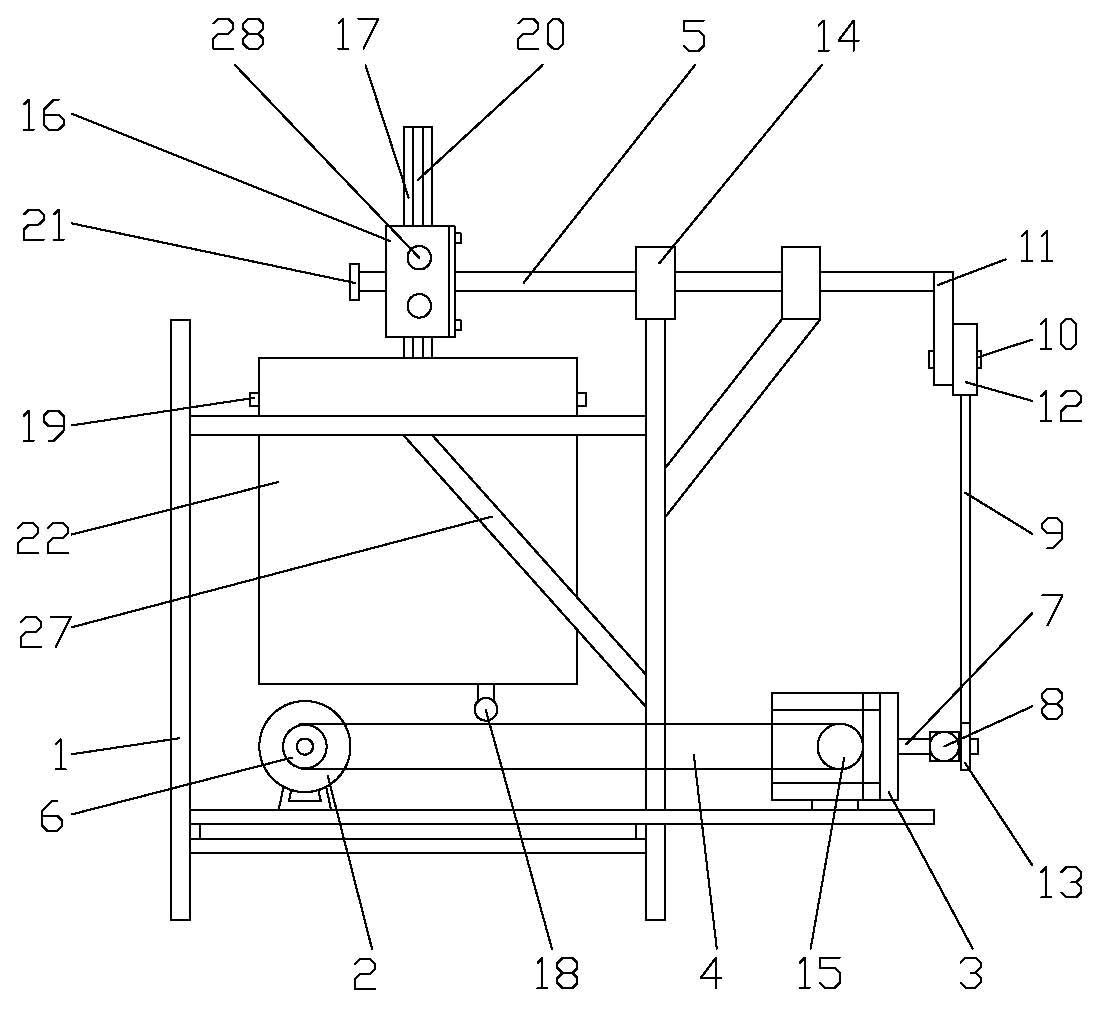

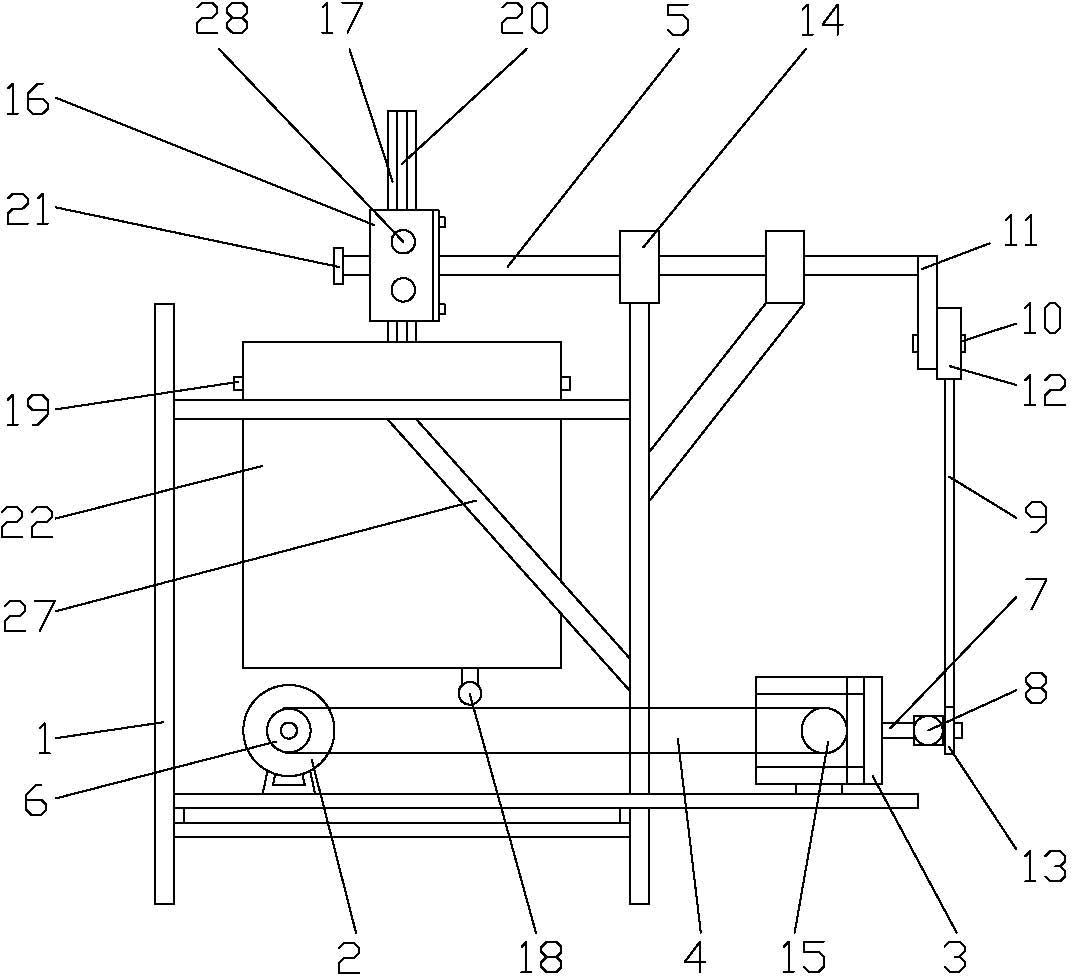

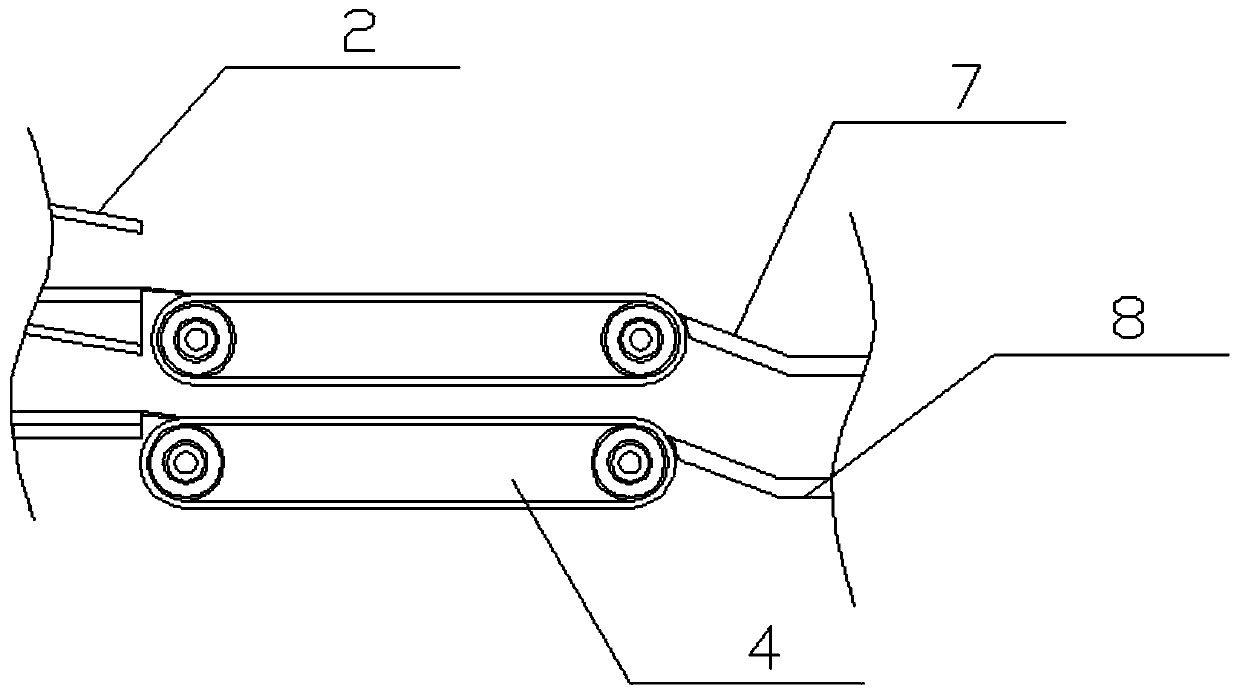

Imitation Hand Washing Machine

InactiveCN102286866ANovel structureLow costOther washing machinesTextiles and paperHorizontal axisEngineering

The invention relates to an imitation hand-rubbing washing machine, which can effectively solve the problem of poor decontamination ability and difficulty in cleaning the neckline and cuffs of clothes at one time. There is a flat shaft on the bracket, the fixed body of the washboard arm and the movable arm of the upper washboard are installed on the inner end of the flat shaft, the upper washboard placed in the washing tank is installed at the lower end of the movable wall of the upper washboard, and the second One eccentric rod, the first eccentric rod is equipped with the first rotating bearing through the rotating shaft, the first rotating bearing is equipped with a fixed connecting rod, the lower bottom of the frame is equipped with a reducer, the motor wheel of the motor and the reducer wheel pass through The transmission belt is connected, the second eccentric rod is installed on the reducer shaft, the second rotating bearing is housed on the second eccentric rod, and the connecting rod is fixedly installed on the second rotating bearing. The invention has novel and unique structure, low cost, easy production, convenient and safe use, strong decontamination ability, high efficiency, environmental protection and energy saving.

Owner:王大文

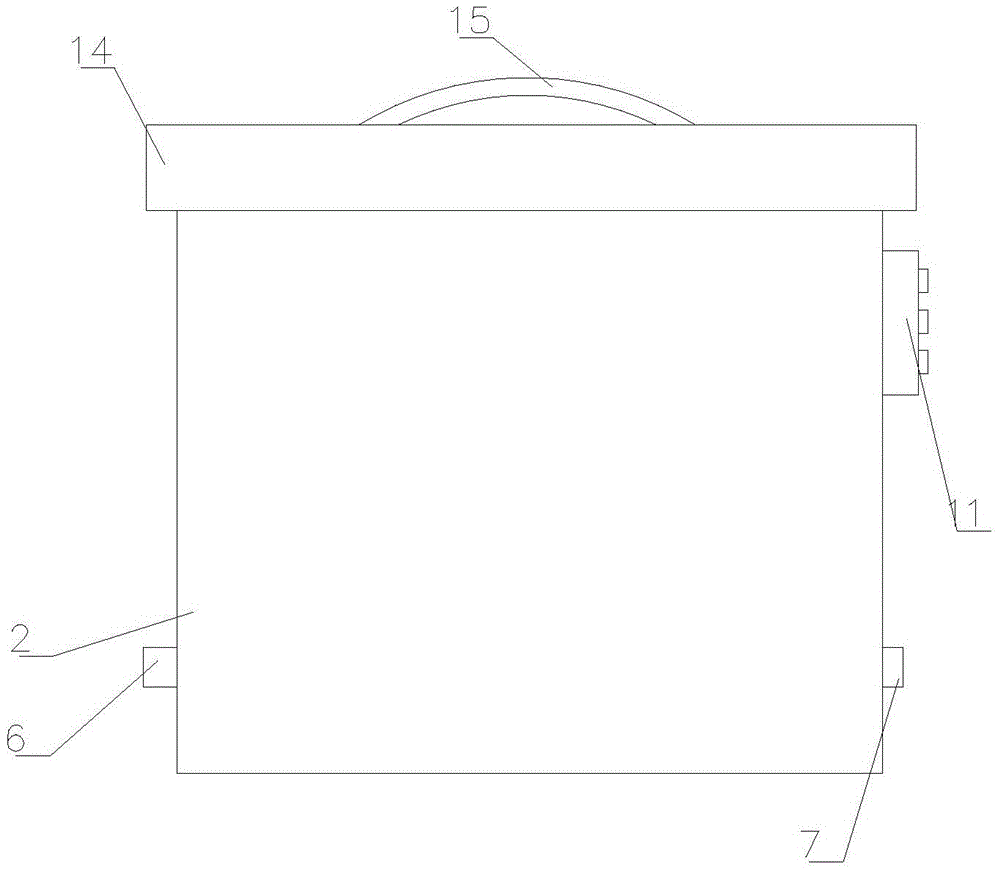

Rubbing washing machine

InactiveCN102182042AAvoid cross infectionImprove cleanlinessOther washing machinesTextiles and paperLow noiseElectricity

The invention belongs to the technical field of washing machines and in particular discloses a rubbing washing machine. The machine comprises a machine body and a drum washing chamber which is arranged in the machine body and is used for washing big clothes, wherein the drum washing chamber is provided with a water inlet and a water outlet; the machine body is provided with at least three independently distributed rubbing washing chambers; each independent rubbing washing chamber is provided with a washing net for pocketing the clothes; each rubbing washing chamber is provided with a manipulator device for simulating the human hands to rub and wash the clothes in the washing net; each independent rubbing washing chamber is provided with a water inlet and a water outlet; and a main driving motor is arranged at the rear part of the machine body. The rubbing washing machine has the following beneficial effects: the clothes can be classified and put in different washing chambers to be washed, thus greatly reducing the opportunity of cross infection of the clothes; by simulating the human hand rubbing mode, the rubbing washing machine has high detergency and can well protect the clothes from being worn; and besides, the rubbing washing machine saves water and electricity and has low noise.

Owner:周济民

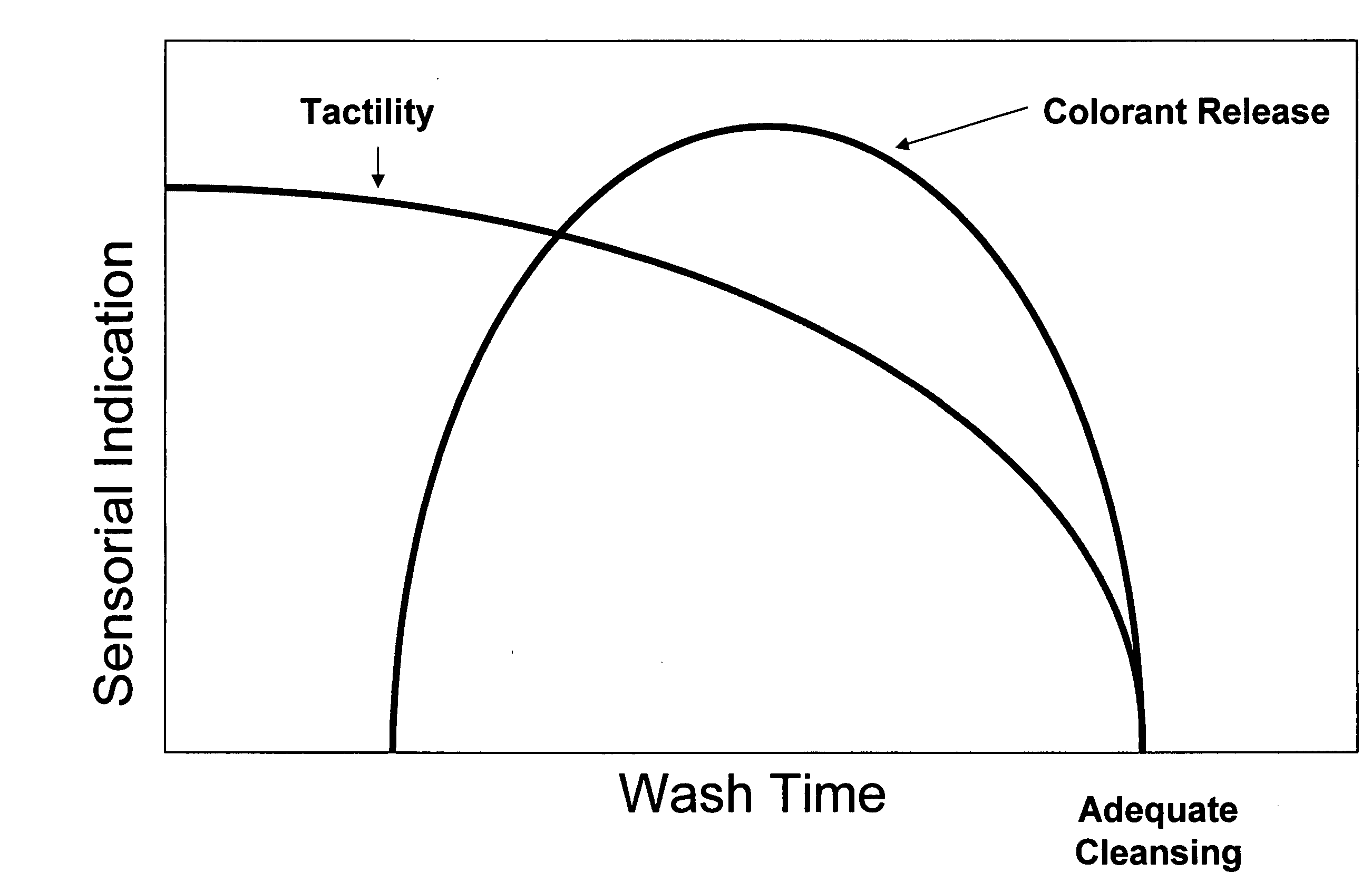

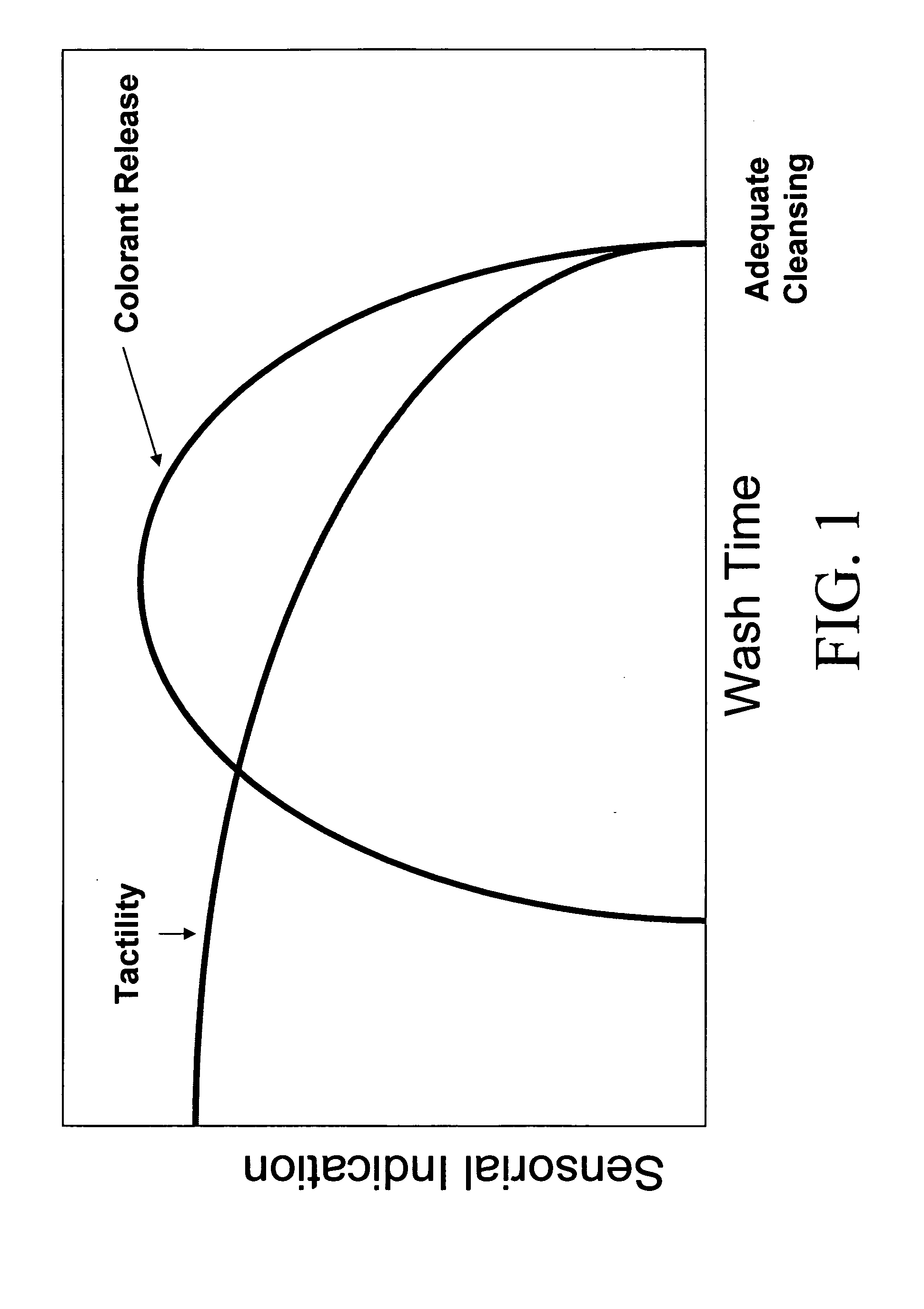

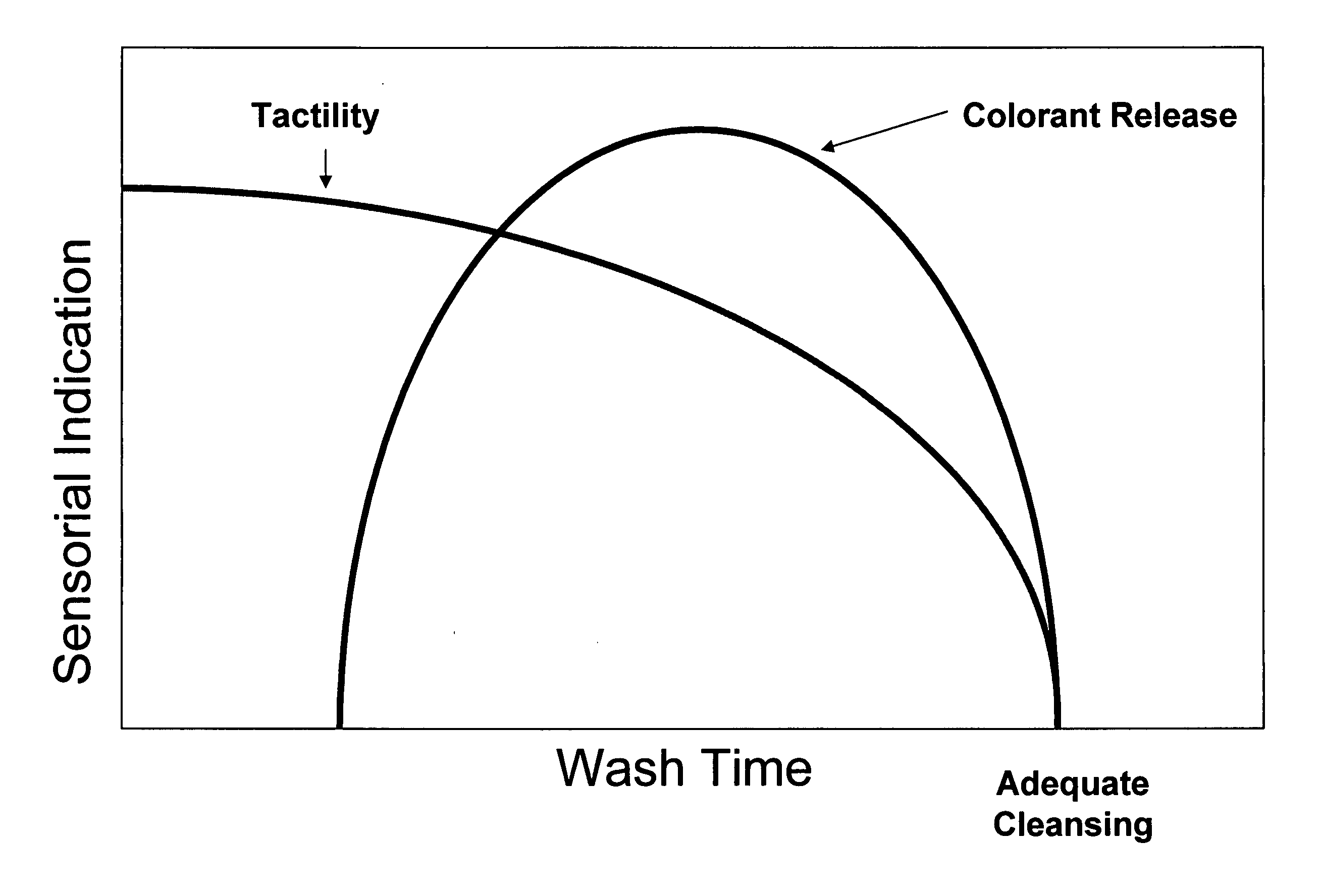

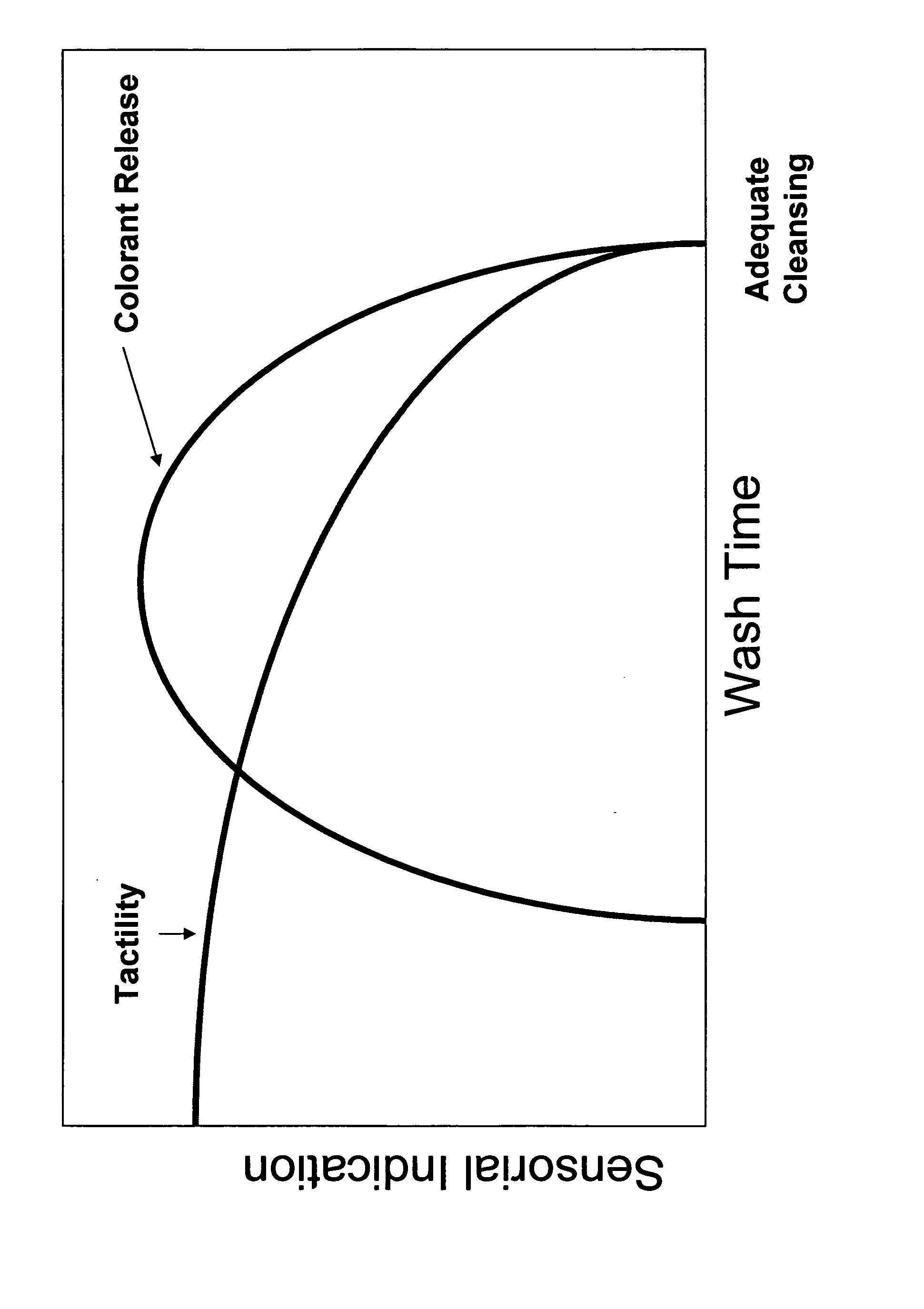

Liquid skin cleanser with multiple signals of adequate wash duration with adequate mechanical force

A personal cleansing composition includes a carrier, and a first plurality of beads entrained in the carrier. The beads impart, to a user applying the cleansing composition with hand rubbing force, perceivable tactility for a limited predetermined duration that corresponds to a minimum adequate cleansing time period. In accordance with another embodiment of the present invention, the personal cleansing composition further includes a second plurality of beads entrained in the carrier. The second plurality of beads imparts to the user a perceivable change in color for the cleansing composition for a second limited predetermined duration that is substantially equal to the duration that the tactility imparted by the first plurality of beads is perceivable to the user.

Owner:HENKEL KGAA

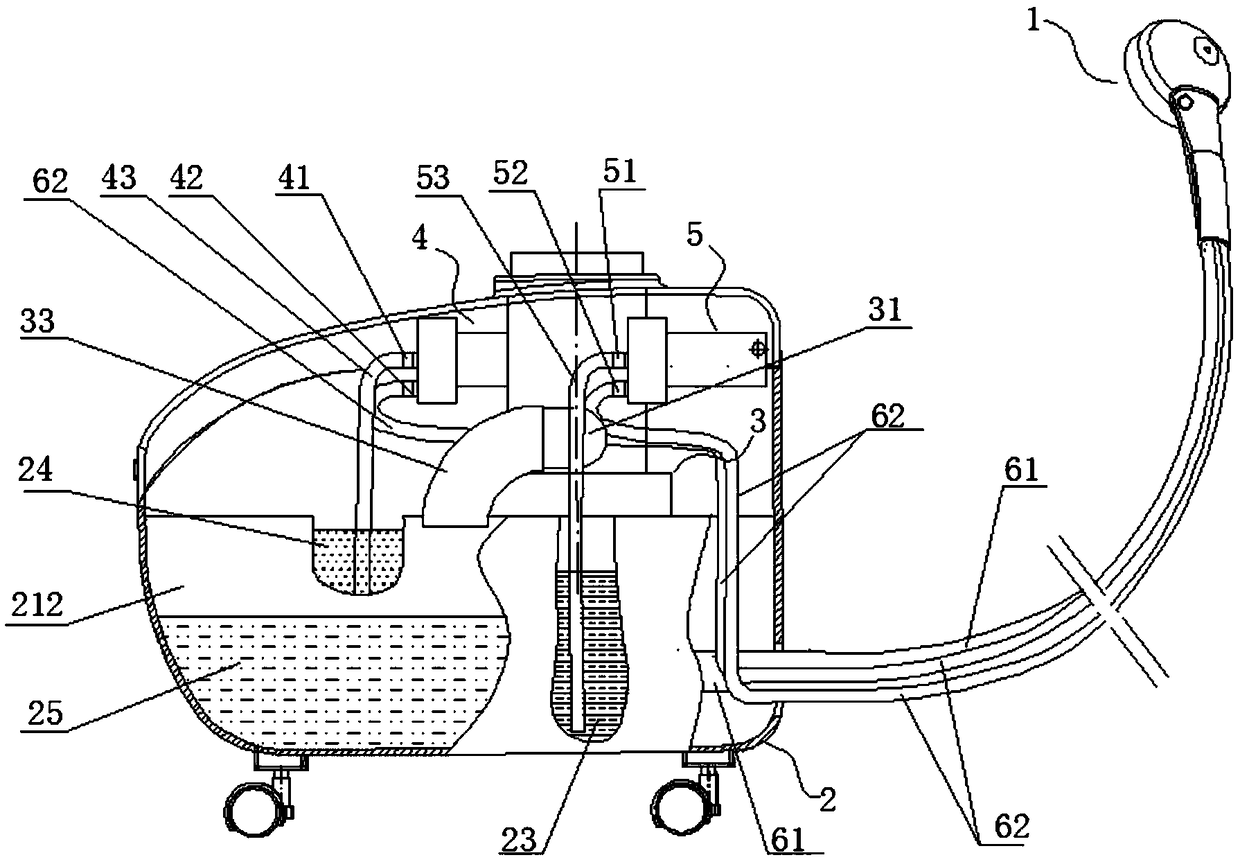

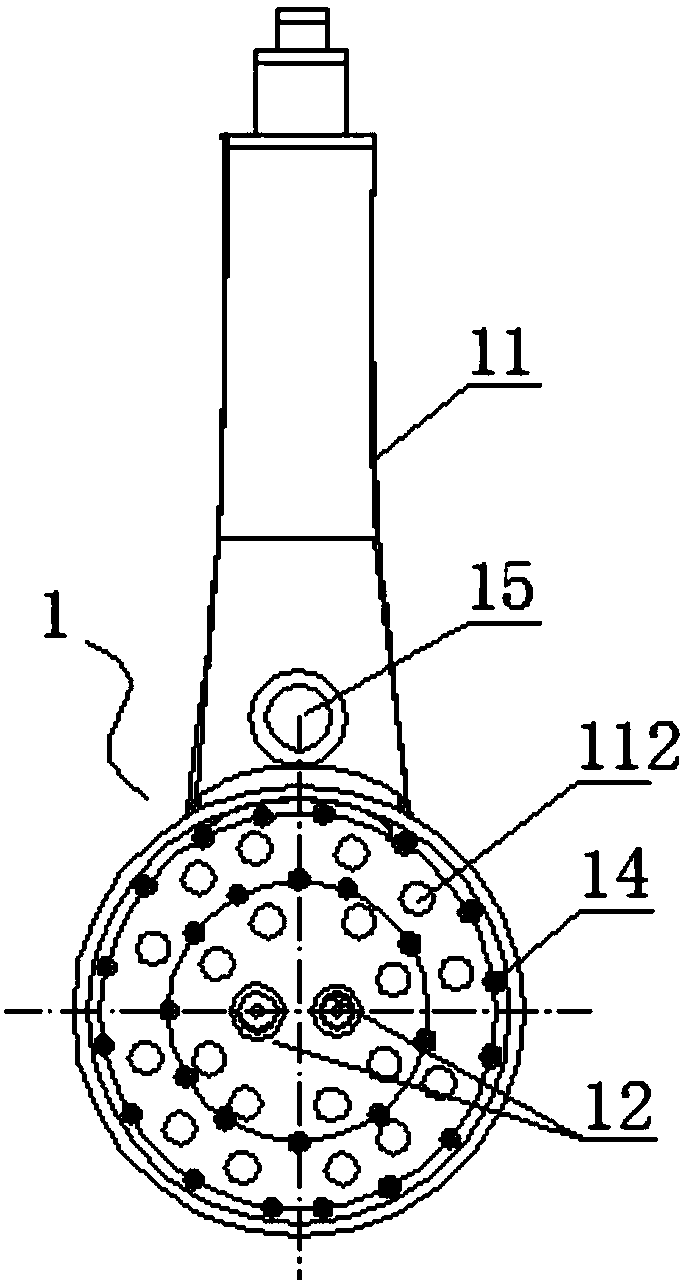

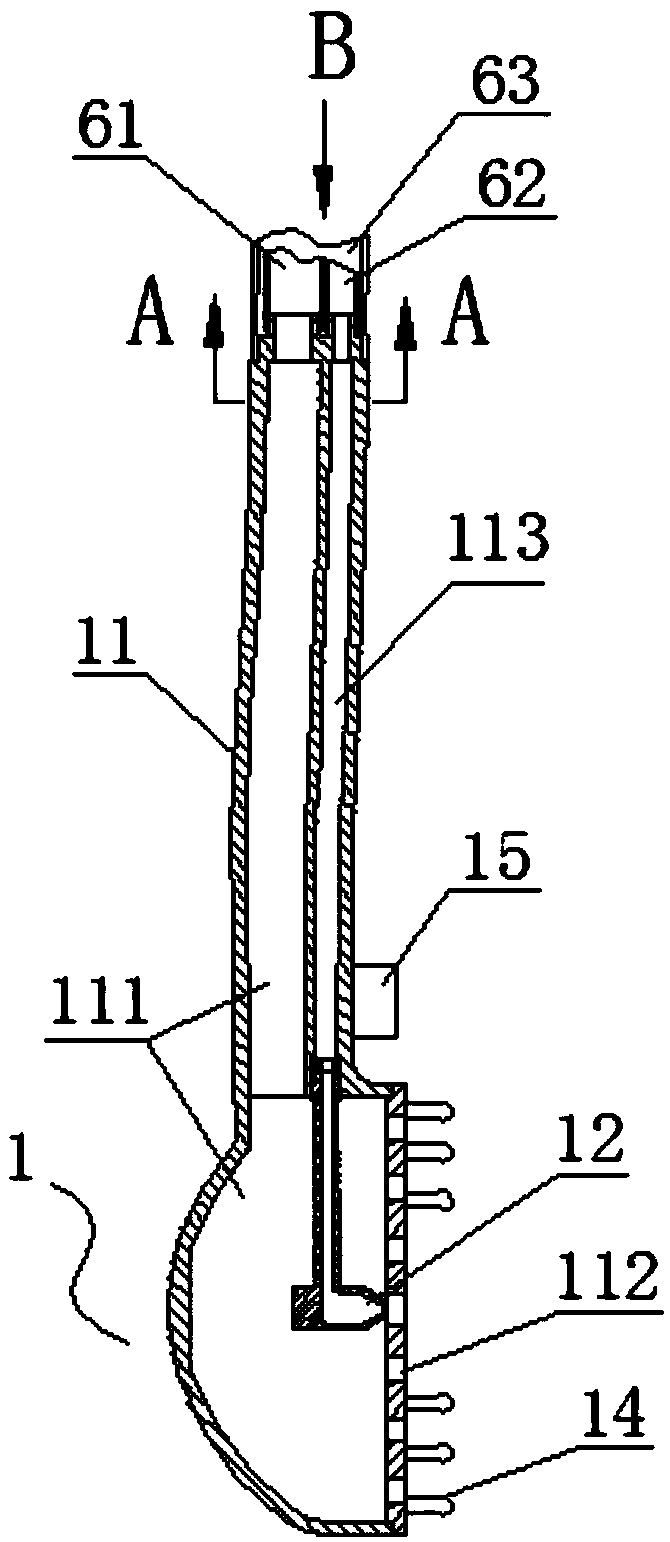

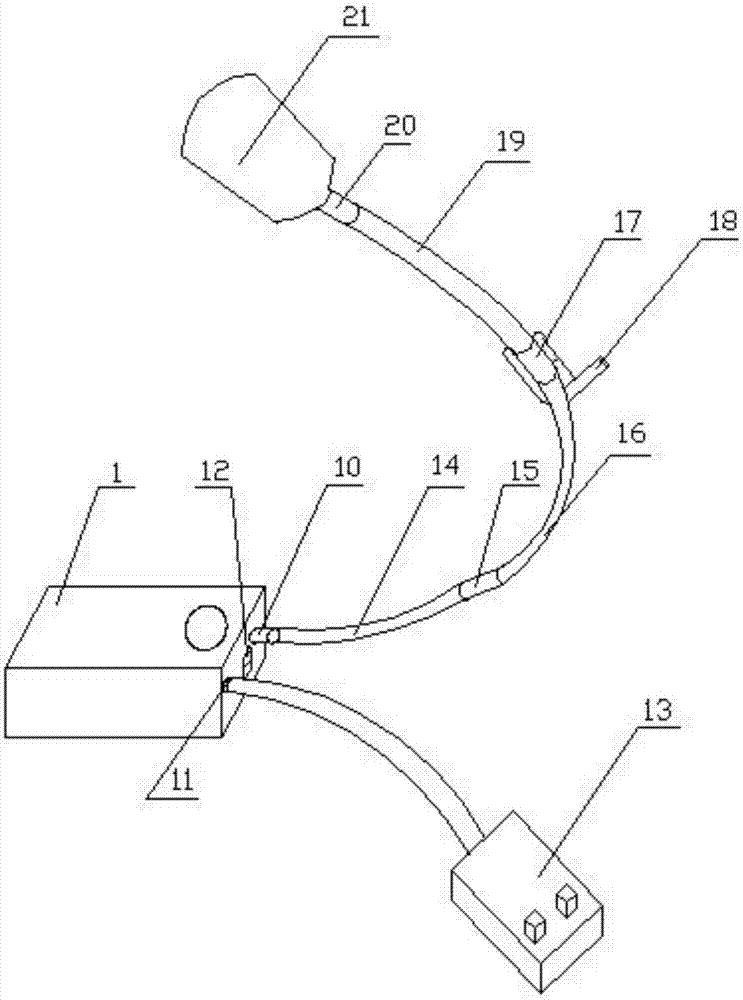

Movable spray washing device

InactiveCN109172211ANo splatterNo downward flowAmbulance serviceGrooming devicesLiquid wasteHand held

The invention relates to a movable spray washing device, comprising a hand-held washing head, a first connecting pipe, a second connecting pipe, a waste liquid discharge pump, a clear water extractionpump, a washing liquid extraction pump, a movable base and a waste liquid recovery tank, a clear water reserve tank and a washing liquid reserve tank arranged on the movable base; the suction ends ofthe clean water extraction pump and the washing liquid extraction pump respectively communicate with the corresponding liquid level of the clean water reserve tank and the washing liquid reserve tank, the discharge ends communicate with the hand-held washing head through the second connecting pipe, the suction end of the waste liquid discharge pump communicates with the liquid suction chamber inthe hand-held washing head through the first connecting pipe, and the discharge end communicates with the waste liquid recovery tank. The movable spray device can replace the hand rubbing action during cleaning by simultaneously spraying the cleaning liquid and the clean water through the double nozzles, has a good cleaning effect and is not wetted by the surrounding environment, and is particularly suitable for cleaning patients and pets who are in bed.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

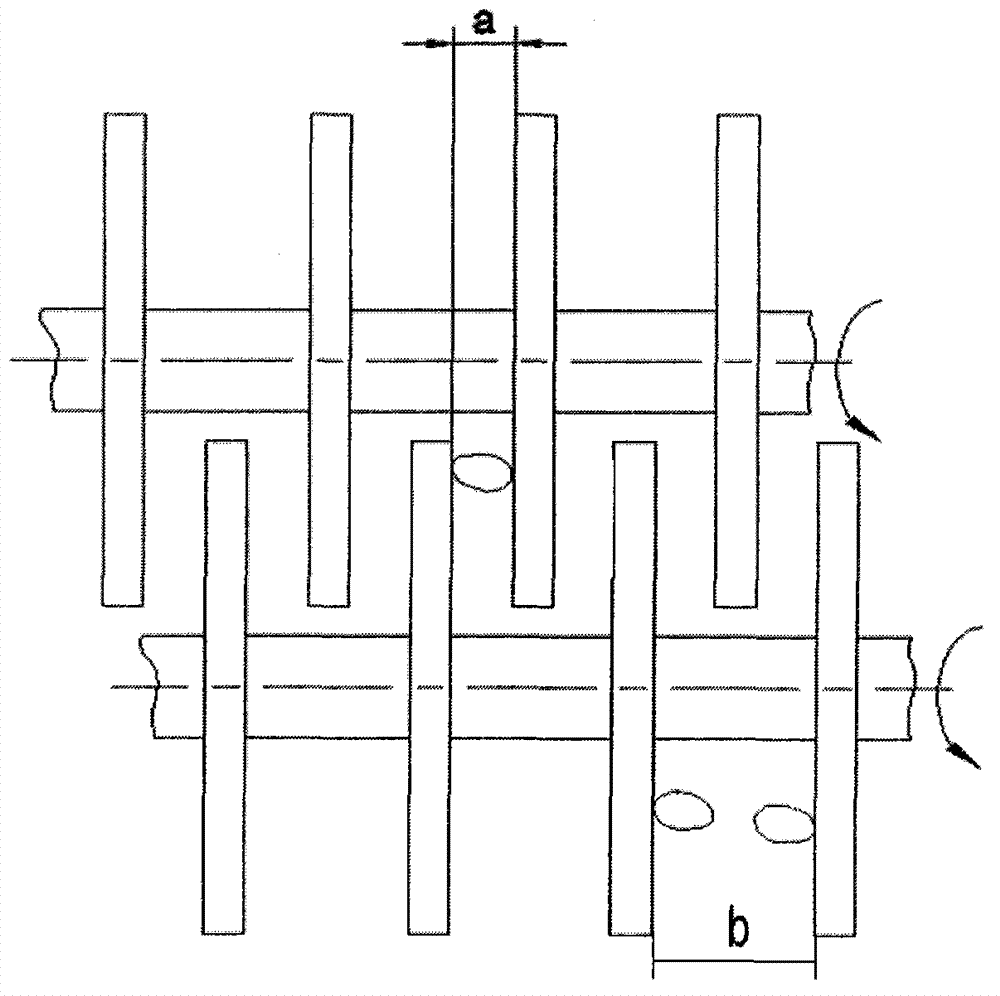

Screen capable of preventing materials from blocking during material processing and self-cleaning method thereof

InactiveCN104259094ARealize self-cleaningRealize the cleaning of stickingSievingScreeningRelative motionEngineering

The invention discloses a screen capable of preventing materials from blocking during material processing and a self-cleaning method thereof. The screen comprises rotary shafts, screen sheets which are arranged on the rotary shafts and a motor which drives the rotary shaft to rotate; the screen sheets on the adjacent two rotary shafts are alternately arranged in an interpenetrating mode; gaps between the screen sheets form into channels which are for materials to pass. The self-cleaning method comprises that the materials fall on the channels of the screen, on one hand, cleaning through a hand rubbing mode which is generated by relative movement of the adjacent screen sheets which form into the channels is generated, on the other hand, large materials automatically rotate and turn over in the channels along rotation of the rotary shafts, and accordingly sticky materials on the screen sheets are brought away and a cleaning effect is achieved. According to the screen capable of preventing the materials from blocking during the material processing, self-cleaning is achieved due to the fact that particles in the materials can automatically rotate in the screen, and large particles can stay for a short time and rotate when stay, the above process is similar to a process of hand washing, fine sand is added between palms, the palms are ceaselessly twisted, the sand is added between the palms without stop, and accordingly mud on hands is taken away through the screen.

Owner:石家庄功倍重型机械有限公司

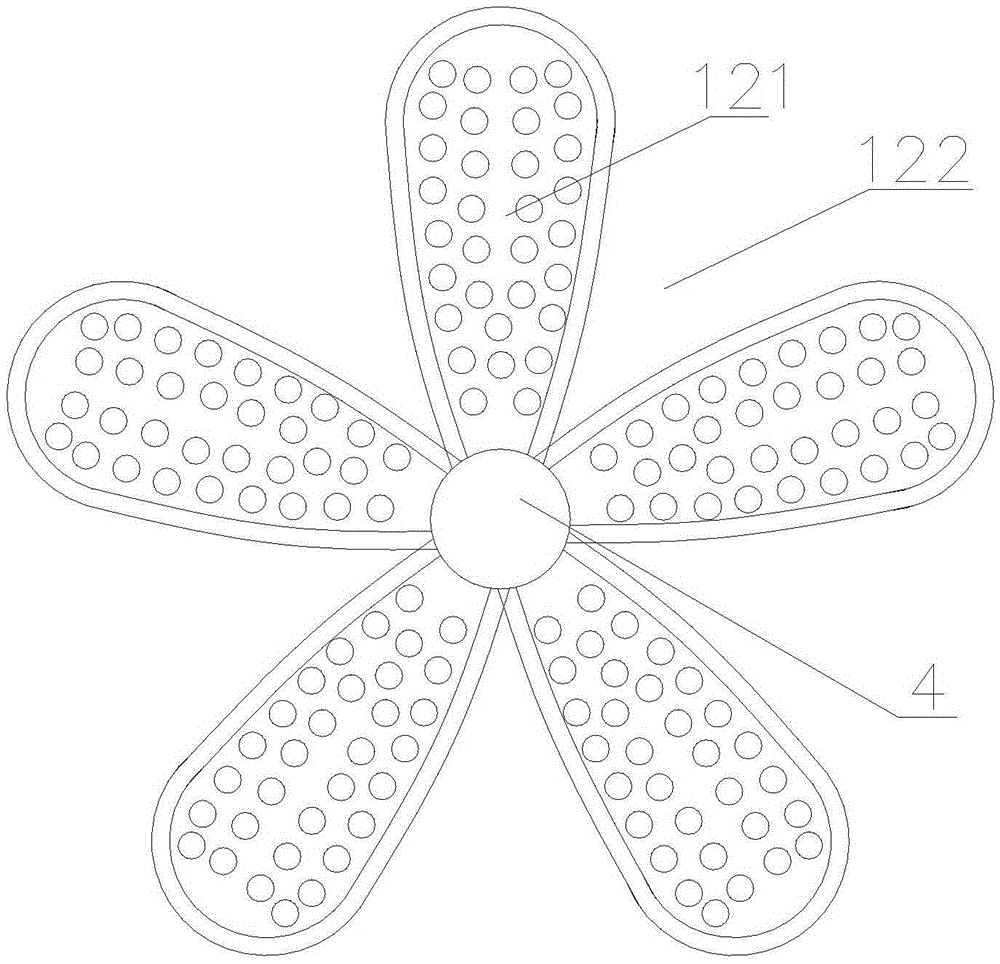

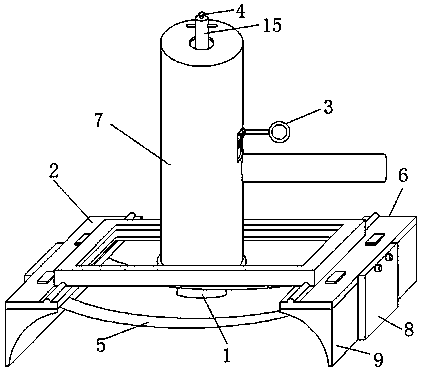

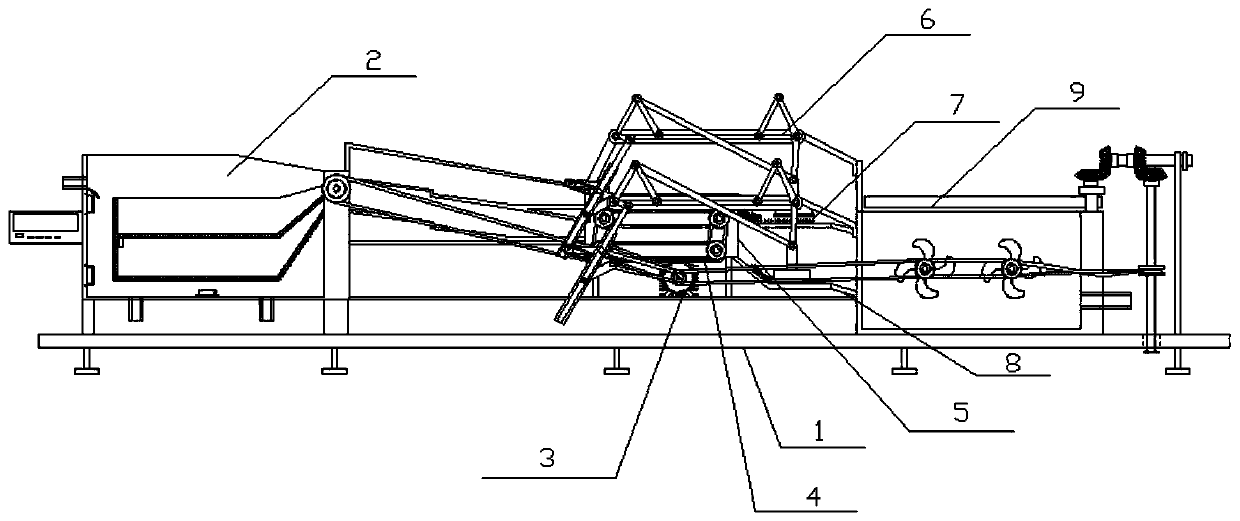

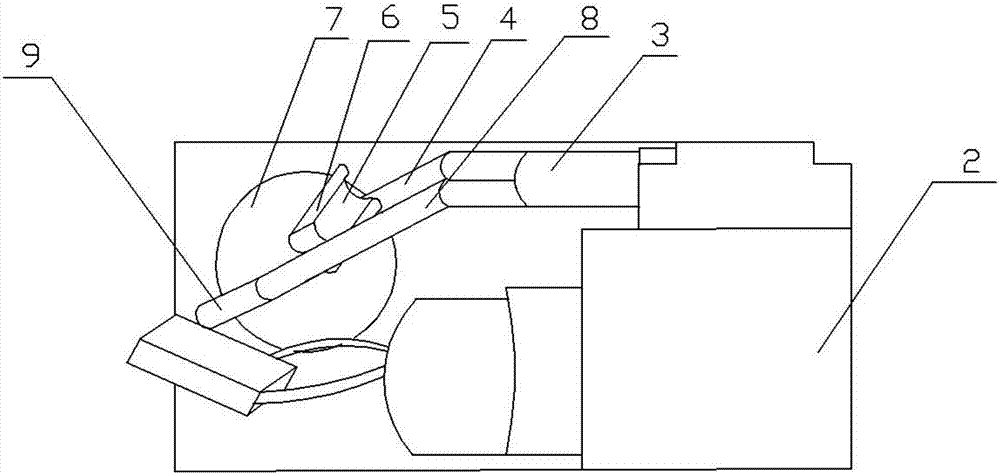

Profiling rubbing type mini-sized washing machine

ActiveCN105463755AReduce volumeConserve waterOther washing machinesTextiles and paperSOCKSPulp and paper industry

The invention discloses a profiling rubbing type mini-sized washing machine. The profiling rubbing type mini-sized washing machine comprises a main water tank, a base barrel, a stirring motor, a stirring shaft, a heating device, a water drainage pipe, a water inlet pipe, a temperature sensor, a water tank cover and a handle. The two ends of each rubbing plate are fixed to the stirring shaft. A supporting plate is arranged below the rubbing plates. The supporting plate and each rubbing plate are each provided with water passing holes. Electromagnetic valves are arranged on the water drainage pipe and the water inlet pipe respectively. A control box is arranged on the side portion of the main water tank and internally provided with a processor, a storage, a display screen and control keys. The processor is connected with the storage, the display screen and the control keys through wires respectively. The handle is in a semicircular shape. Small clothes such as socks can be washed, the size is small, and socks can be thoroughly washed by simulating the human hand rubbing mode; meanwhile spin-drying is achieved, and the profiling rubbing type mini-sized washing machine is low in water consumption, high in efficiency and easy and convenient to operate.

Owner:云霄县食品快检中心

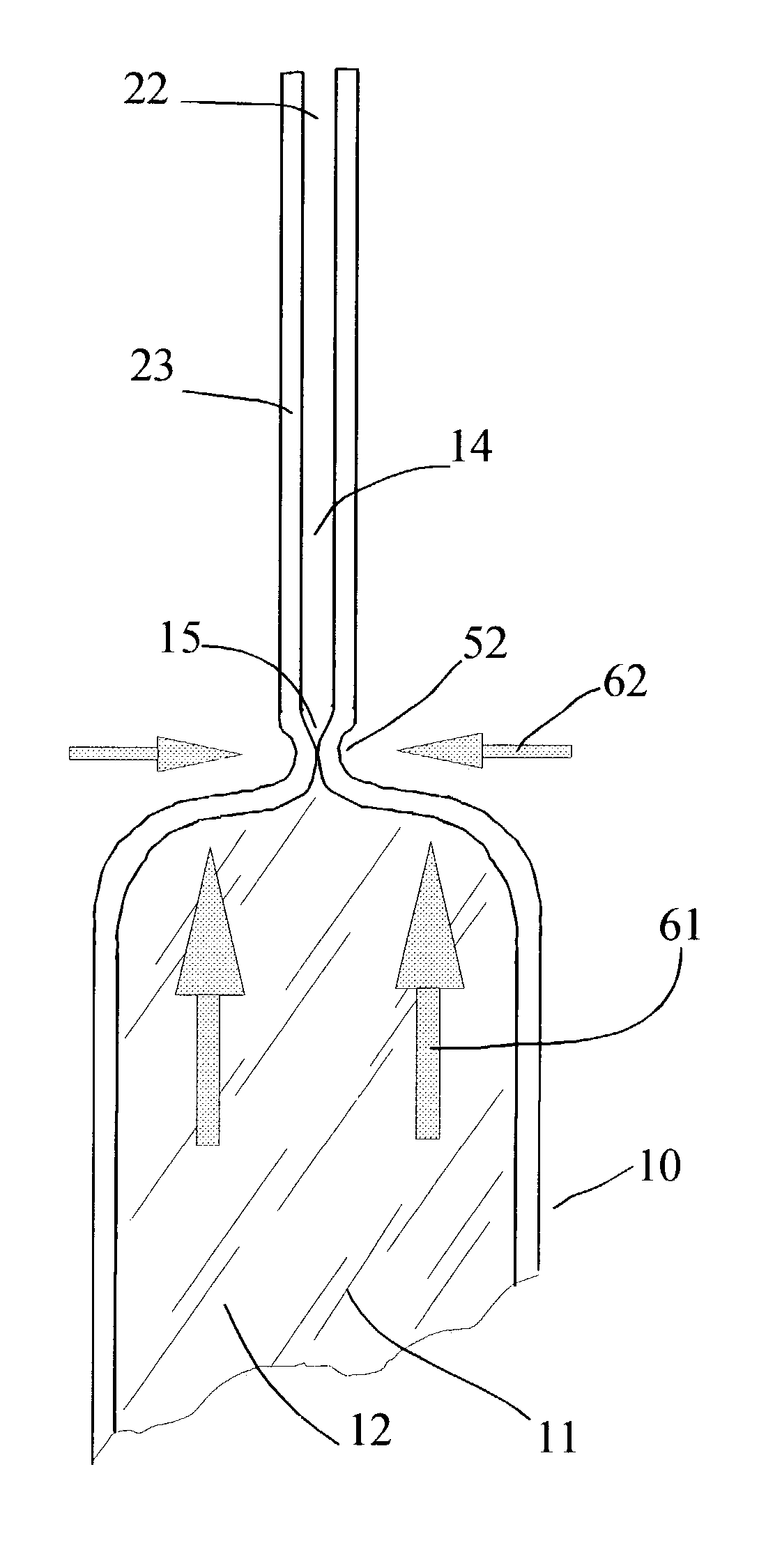

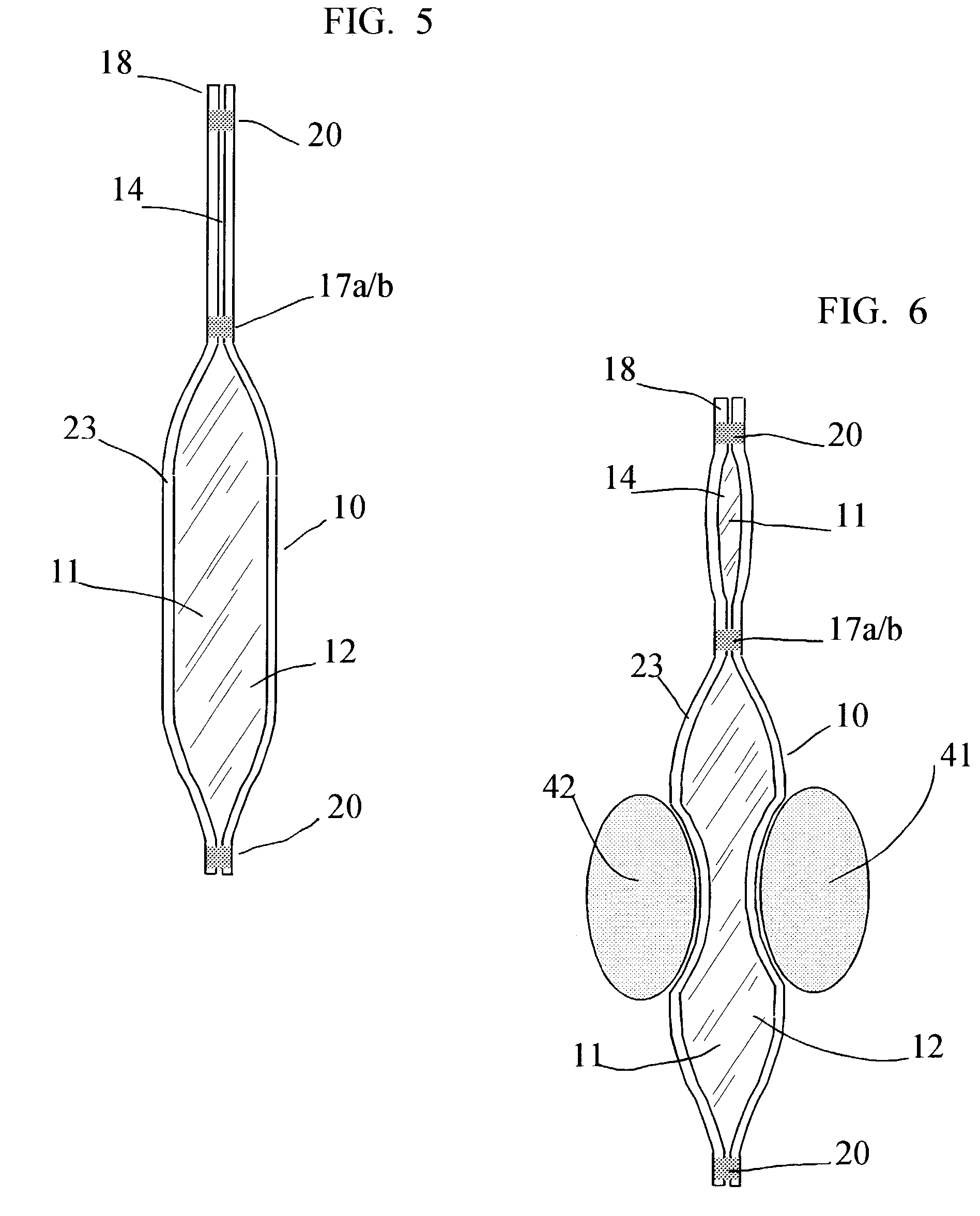

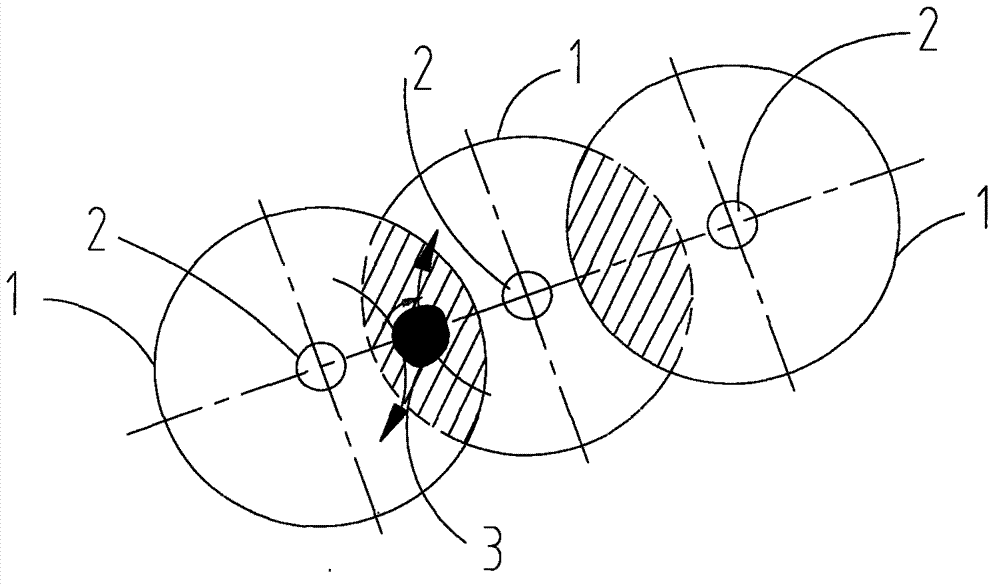

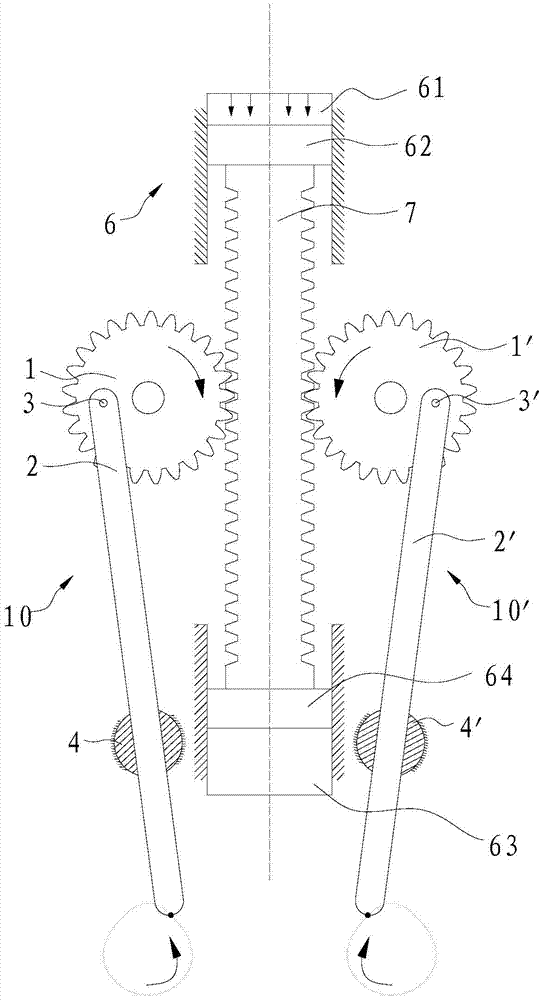

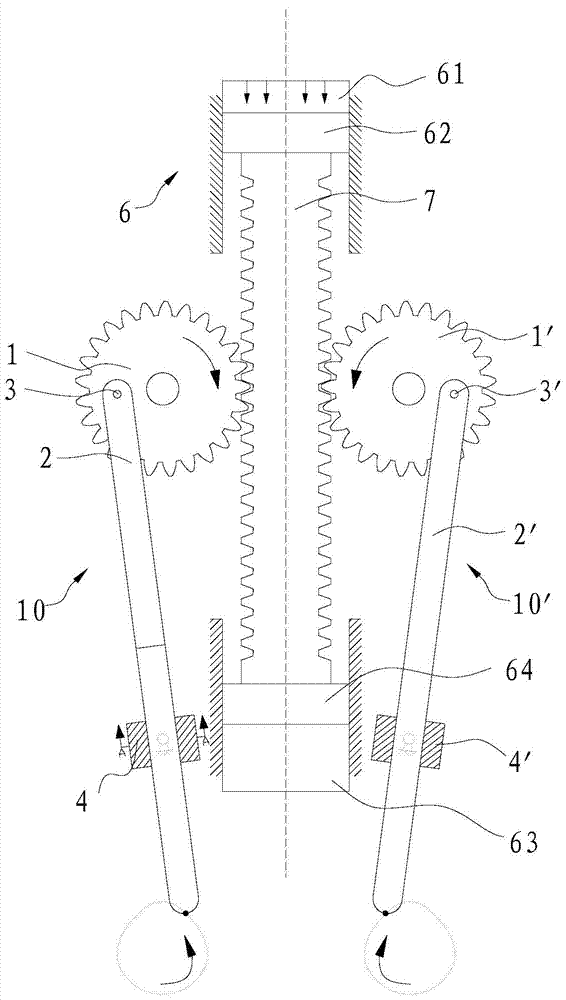

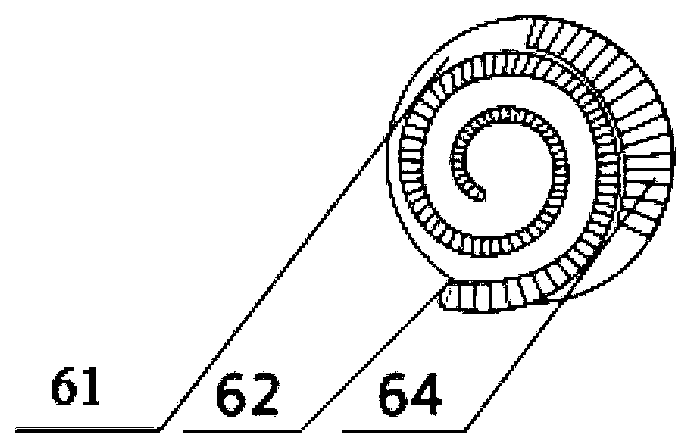

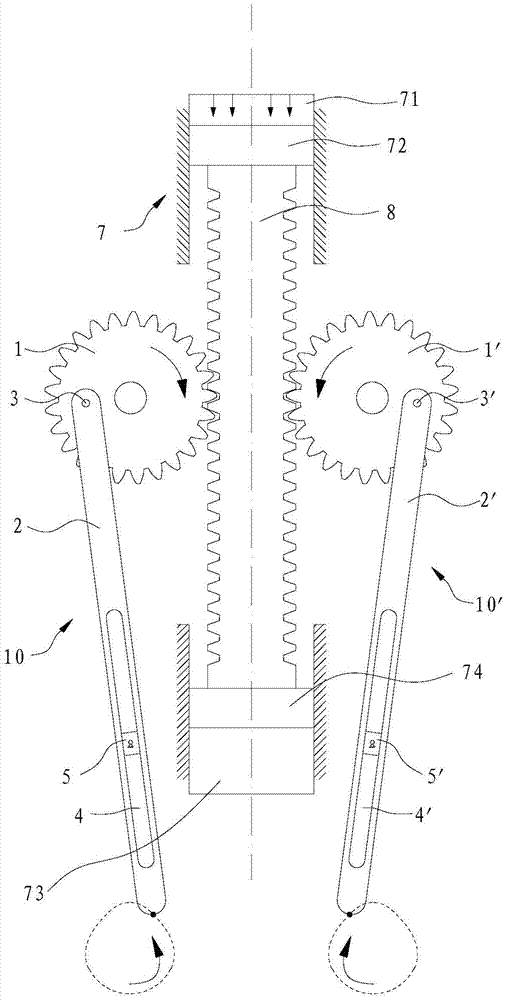

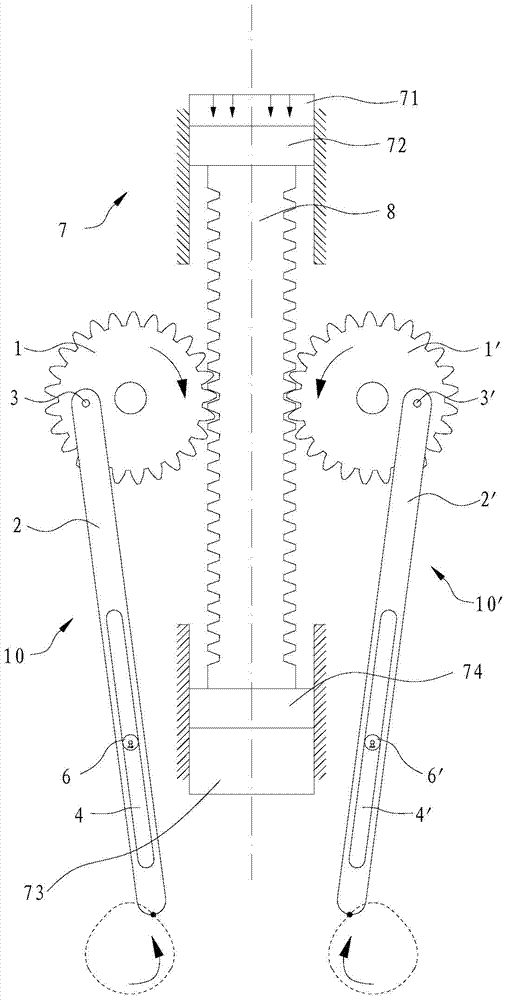

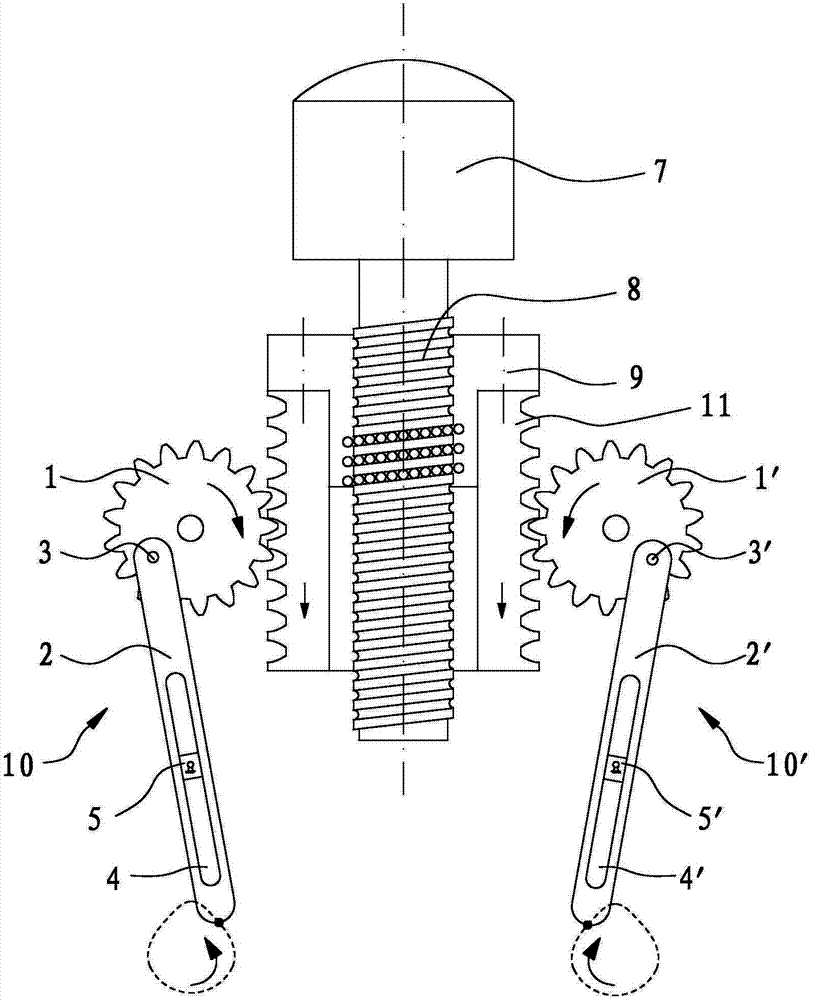

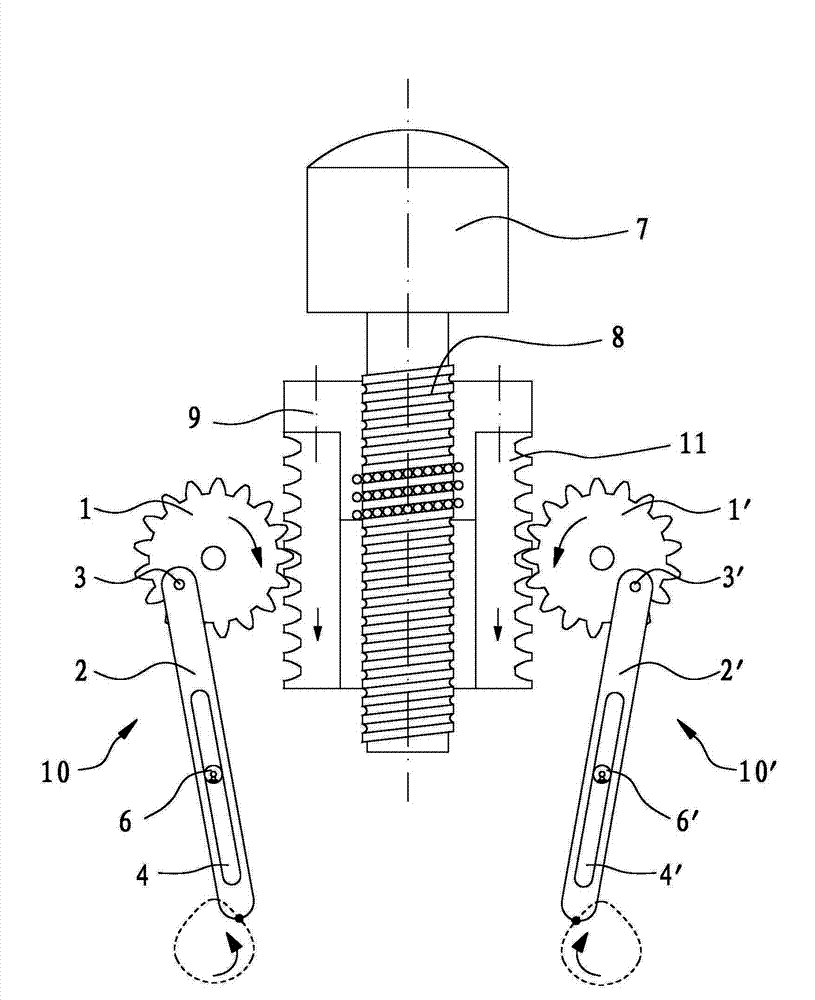

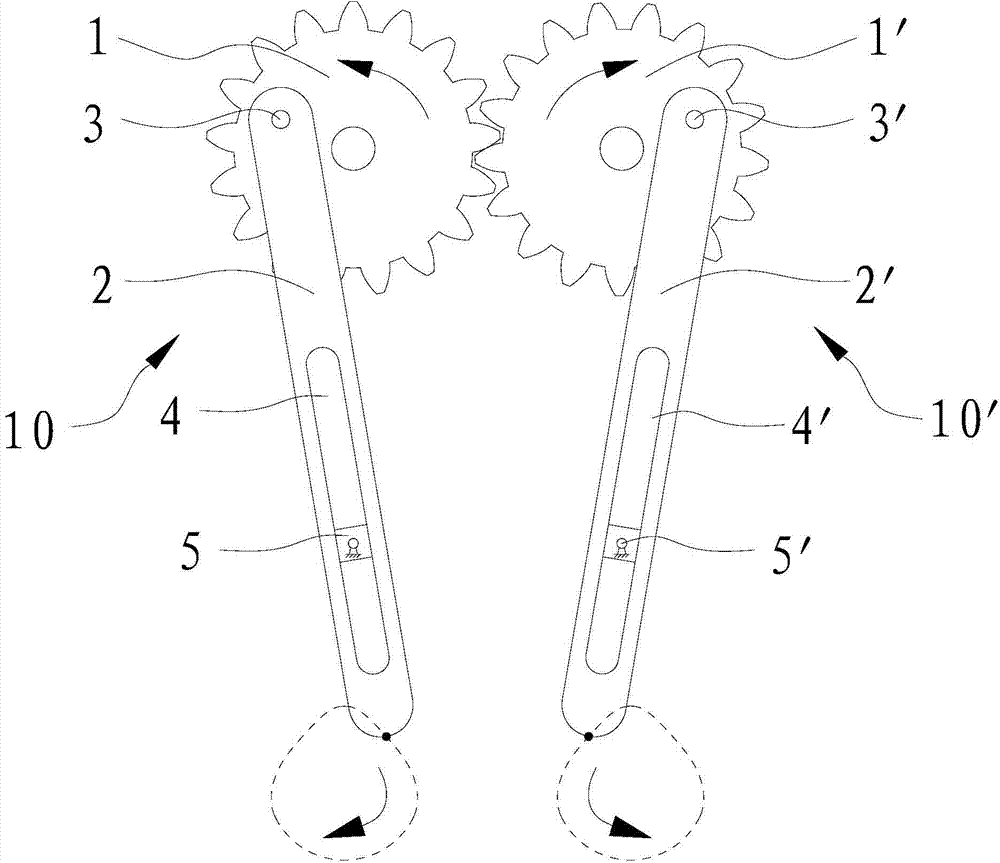

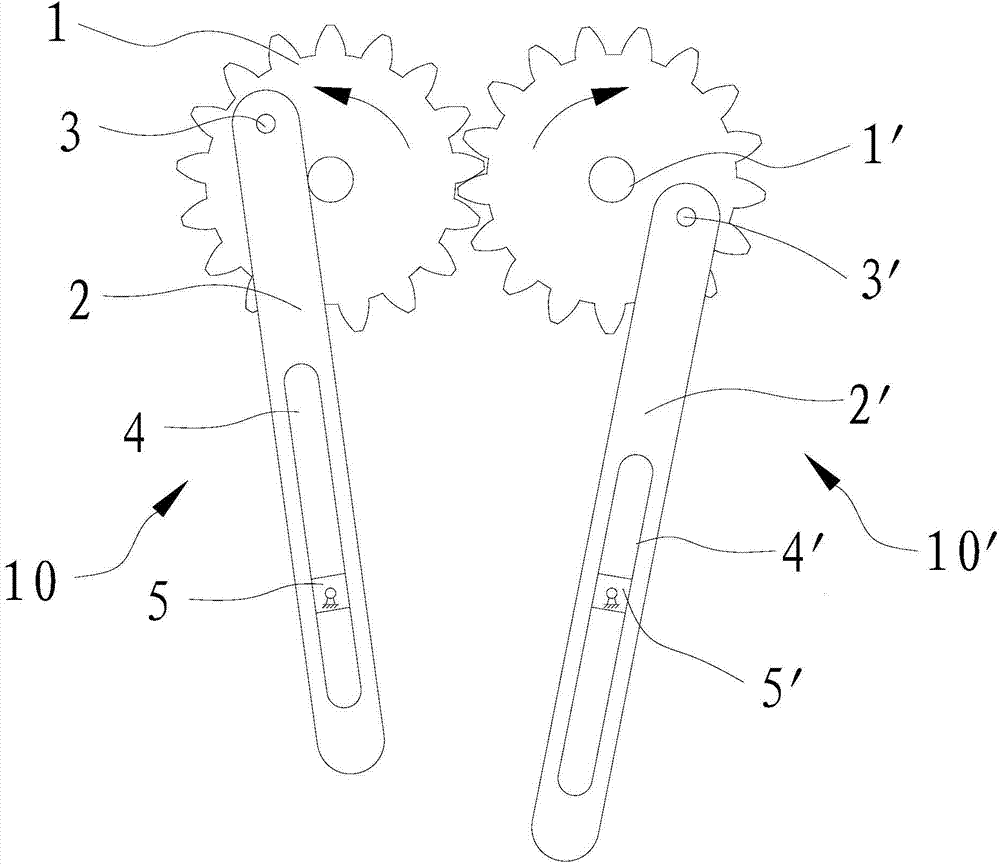

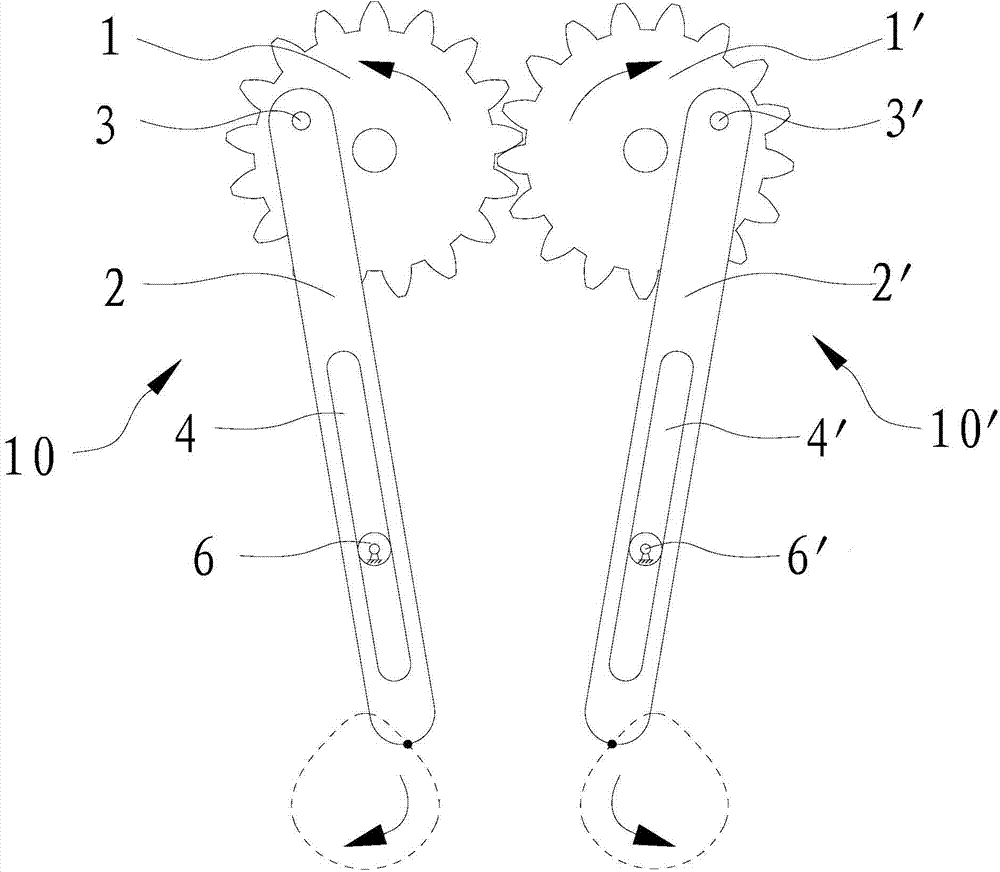

Pneumatic double-hand rubbing bionic device

The invention discloses a pneumatic double-hand rubbing bionic device. According to the pneumatic double-hand rubbing bionic device, only the simple parts including air cylinders, double-face racks, gears, connecting rods and cylinders or sliding bases are used, and the complex plane motion of simulating double-hand rubbing can be realized, wherein the centers of the cylinders or the centers of the sliding bases are hinged to a machine frame. Rubbing tools with different functions are fixed to the lower ends of the connecting rods so that various pneumatic double-hand rubbing bionic devices with different functions can be formed. The pneumatic double-hand rubbing bionic device is extremely simple in structure, especially low in manufacturing cost, high in working reliability, and capable of meeting the requirements for the rubbing bionic devices of different industries. A striking contrast is formed between the pneumatic double-hand rubbing bionic device and other bionic devices which are huge and complex in structure and extremely high in manufacturing cost, and the pneumatic double-hand rubbing bionic device can be widely popularized and used.

Owner:SUZHOU UNIV

Liquid skin cleanser with multiple signals of adequate wash duration with adequate mechanical force

A personal cleansing composition includes a carrier, and a first plurality of beads entrained in the carrier. The beads impart, to a user applying the cleansing composition with hand rubbing force, perceivable tactility for a limited predetermined duration that corresponds to a minimum adequate cleansing time period. In accordance with another embodiment of the present invention, the personal cleansing composition further includes a second plurality of beads entrained in the carrier. The second plurality of beads imparts to the user a perceivable change in color for the cleansing composition for a second limited predetermined duration that is substantially equal to the duration that the tactility imparted by the first plurality of beads is perceivable to the user.

Owner:HENKEL KGAA

Medicinal oil rubbing tool

The invention relates to the technical field of medicinal oil rubbing, in particular to a medicinal oil rubbing tool which comprises a rubbing body, a body fixing seat and a driver, wherein the driveris mounted on the body fixing seat. The rubbing body is connected with the body fixing seat through the driver, and an oil passage is arranged in the rubbing body. By the aid of the body fixing seat,people can rapidly stably fix the medicinal oil rubbing tool onto a body and conveniently apply force to rub medicinal oil, the driver allows people to easily drive the rubbing body to rub the medicinal oil flowing onto the body from the oil passage into skins, so that the human body efficiently absorbs the medicinal oil, and hand weakness caused by customary hand rubbing is avoided.

Owner:潘兆坤

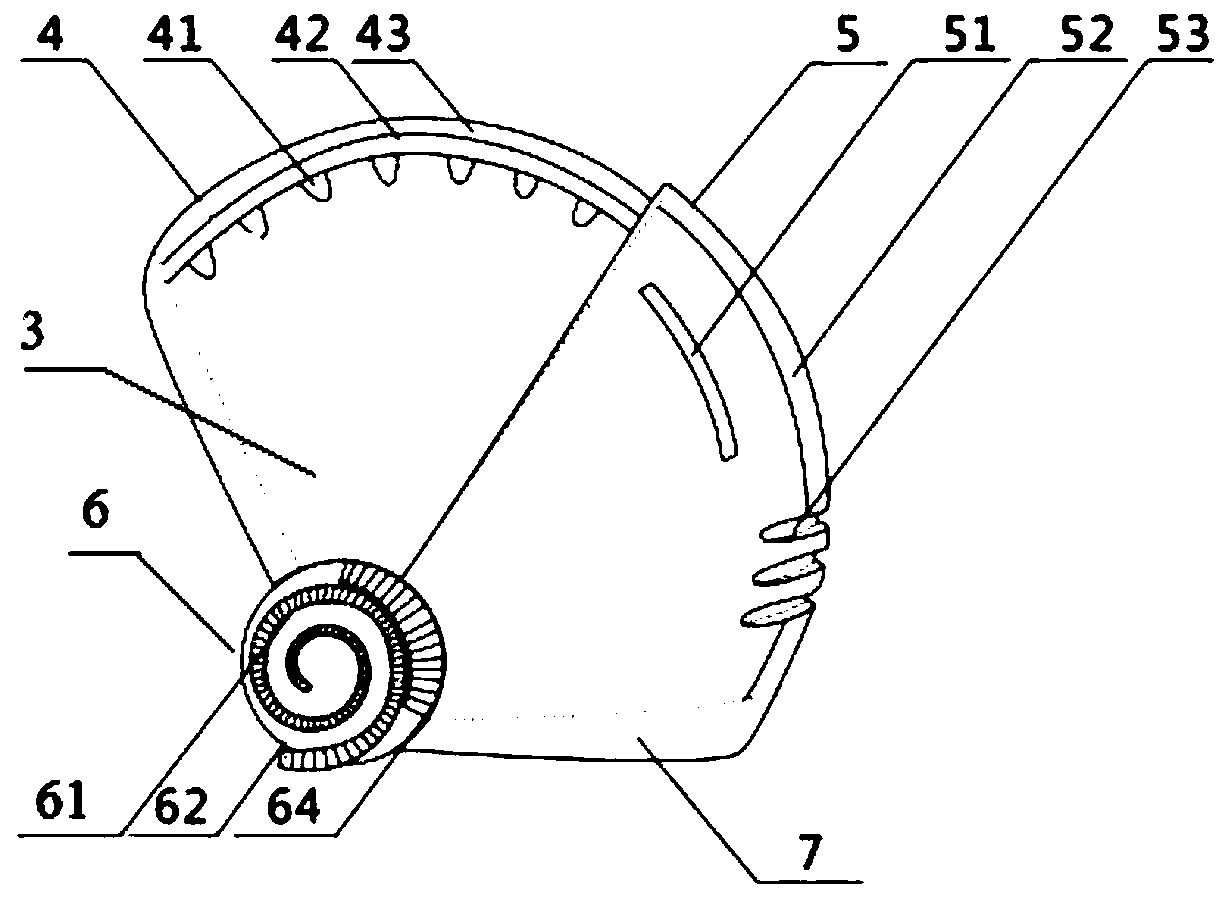

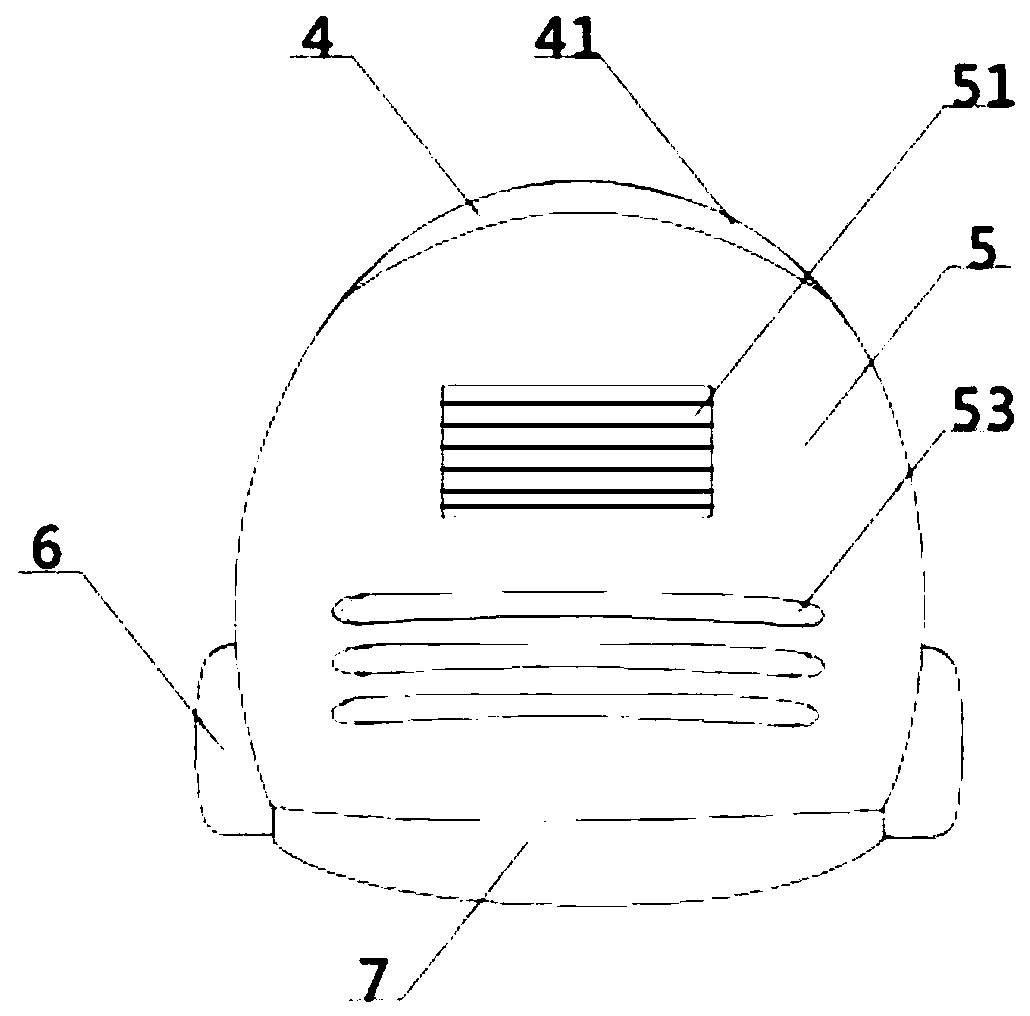

Hair washing cap and self-service hair washing equipment comprising same

PendingCN110881773AMeet different needsEfficient and convenient shampooHair dryingPackaging toiletriesMassageSurgery

The invention discloses a hair washing cap and self-service hair washing equipment comprising the same. The hair washing cap comprises two earplugs, a water supply device used for conveying water andshampoo during hair washing; a massage device simulating hand rubbing of the scalp; a drainage device used for draining water after washing; and a drying device used for drying the hair. The self-service hair washing equipment comprises a cabinet body, wherein the cabinet body is provided with a first accommodating part for accommodating the hair washing cap and a control panel for controlling thehair washing cap. The massage strength, the addition and discharge of water and the blow-drying of hair are controlled through the control panel. Different requirements of different users during hairwashing are met, so that the purposes of saving time and labor cost are achieved.

Owner:HUBEI UNIV OF TECH

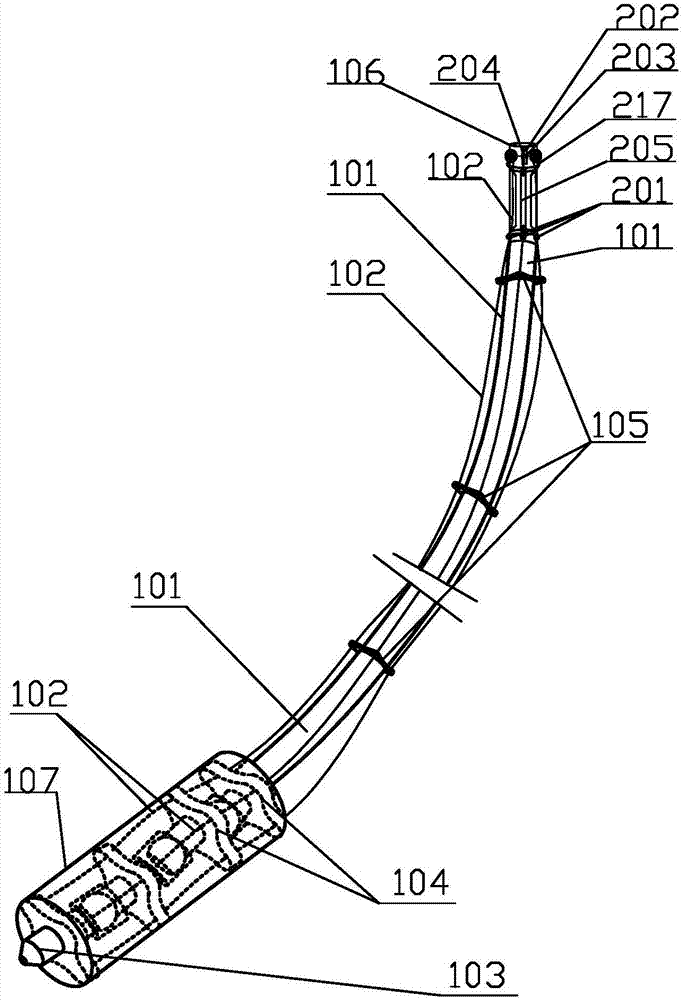

Device for radiotherapy

The invention discloses a device for radiotherapy. The device comprises a handheld end. The handheld end comprises an outer wall, a hollow cavity arranged in the outer wall and a coiling device. The coiling device comprises a hand rubbing wheel and a coiling wheel. Each group of the hand rubbing wheel and the coiling wheel coaxially form a connection group which is matched with a hollowed hole in the outer wall of the handheld end. A hollow guide pipe ball head is arranged on one end, away from the handheld end, of a guide pipe, and is connected with a joint device. A protection sleeve is arranged on the outer side of the joint device which is connected with a radiation bin. The radiation bin cooperates with a radiation source. According to the invention, it is achieved that radiation in different angles and different distances can be performed on focuses of a patient; radiation regions are allowed to be quite precise; and damages to normal tissues in the patient body are reduced.

Owner:SHANDONG TRAFFIC HOSIPITAL

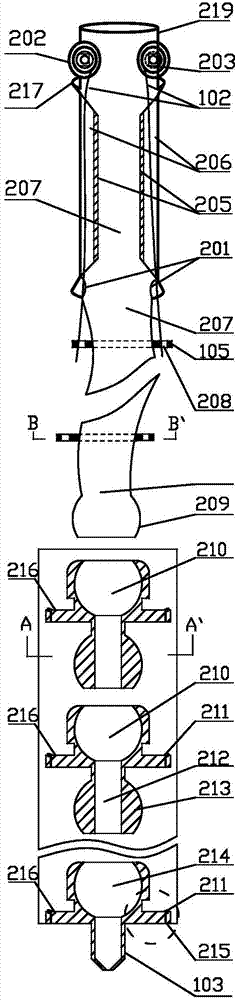

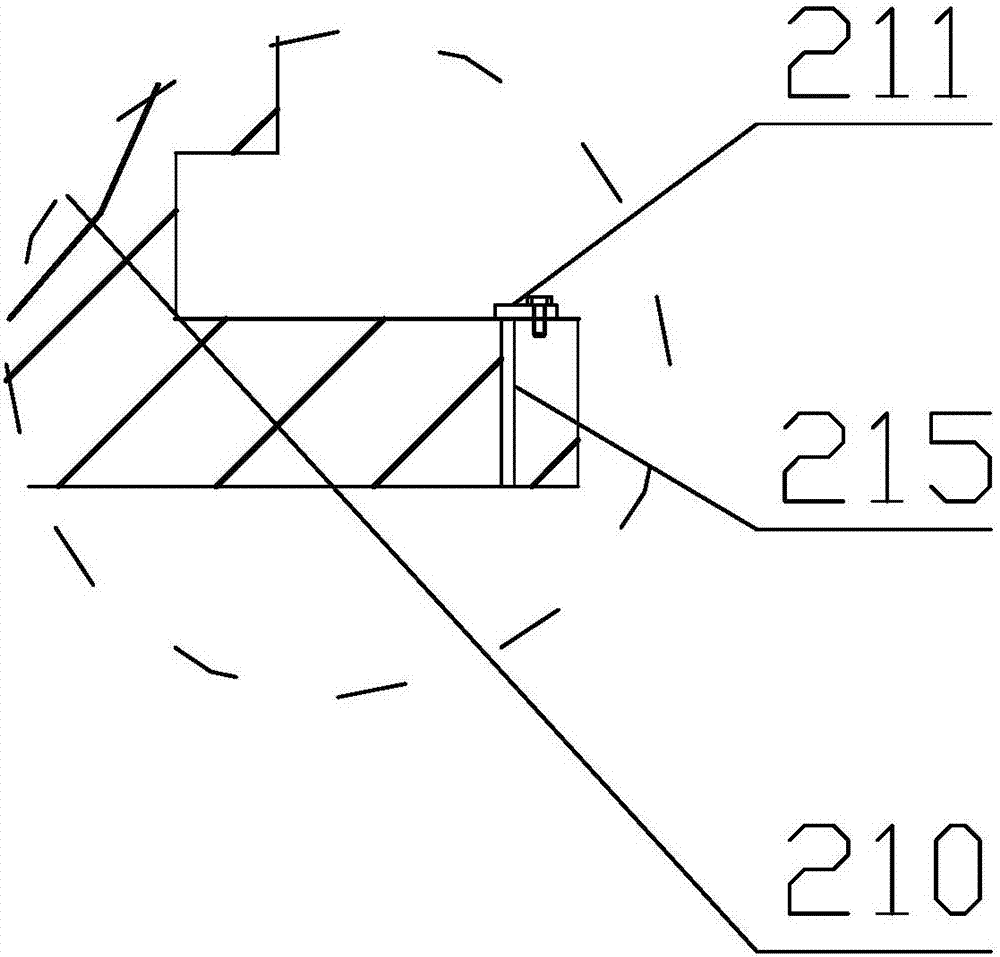

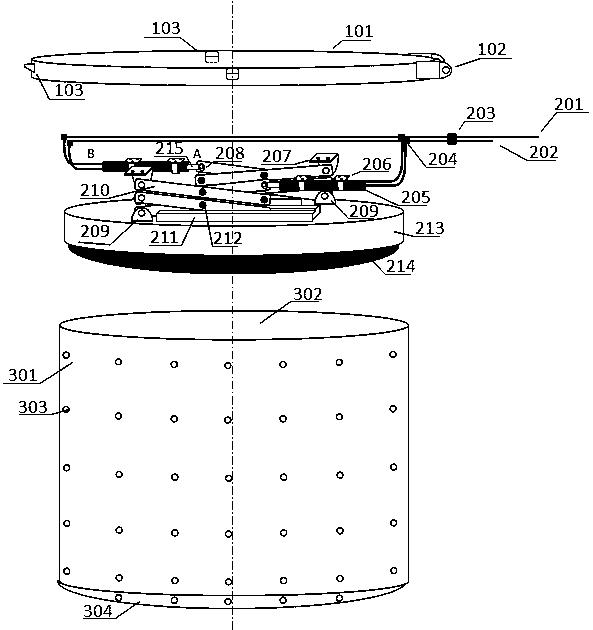

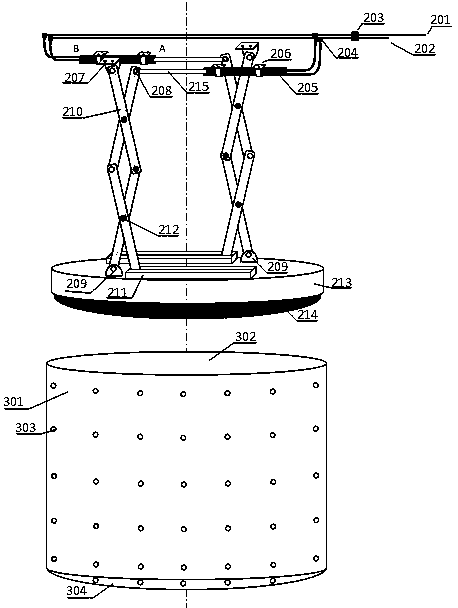

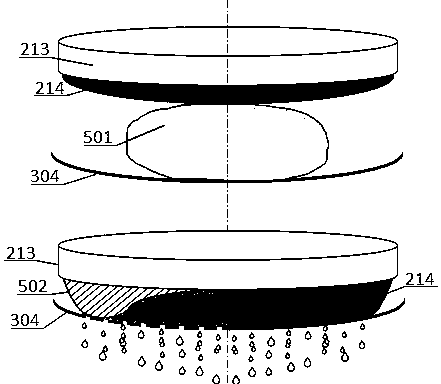

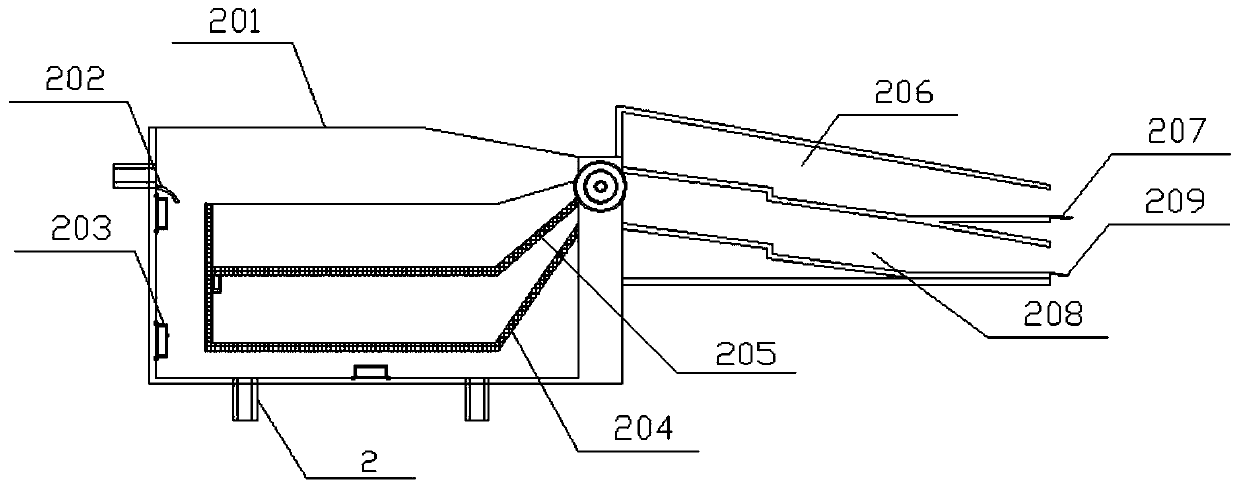

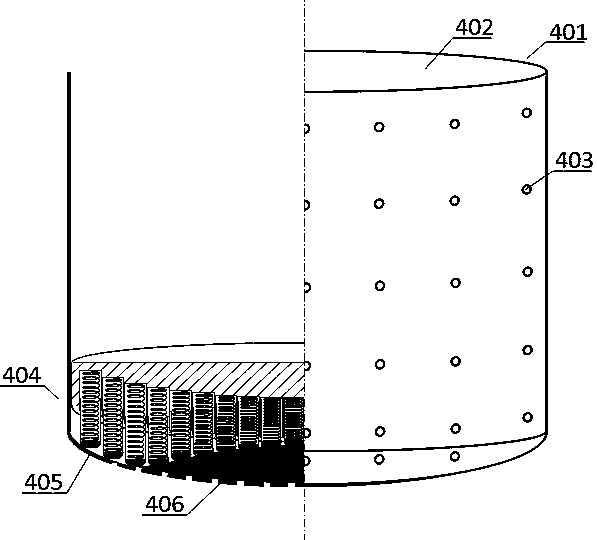

Pneumatic extrusion type washing machine

The invention in particular relates to a pneumatic extrusion type washing machine which directly applies pressure onto fiber tissues of clothes, imitates hand rubbing effect and does not damage the clothes. A working principle of the pneumatic extrusion type washing machine comprises that air pressure produced by an electric air pump is acted on inner wall of an air cylinder (205) fixed below an upper cover of washing machine under the control of an air suction and air exhaust change-over electromagnetic valve (203), and a piston rod (215) is pushed to extend or retract; the piston rod drivesa telescopic frame movable arm (208) connected with the piston rod, and actions that the telescopic frame stretches downward and is fixed or retracted to upper cover of washing machine are completed;when telescopic frame stretches and a plastic extrusion head (214) approaches a barrel head, the plastic extrusion head (214) compresses clothes (501), moisture inside fiber tissues of the clothes isextruded out, and stains, dissolved by moisture, on clothes and the moisture are discharged together from the interior of the fiber tissues; after an extrusion state is maintained for a period of time, the air suction and air exhaust change-over electromagnetic valve (203) of the air cylinder changes over, air suction and air exhaust directions are changed, the piston rod of the air cylinder is retracted, the telescopic frame is driven to be retracted, and the extrusion head is driven to go up; when the plastic extrusion head leaves the surface of the clothes, the telescopic frame stops retracting, and the moisture in the washing machine enters the interior of the fiber tissues of the clothes again; then the telescopic frame continuously stretches downward, the plastic extrusion head continuously applies pressure to the clothes, and the moisture in the clothes is extruded; and the process is continuously repeated, so that the aim of cleaning the clothes is achieved.

Owner:关柏华

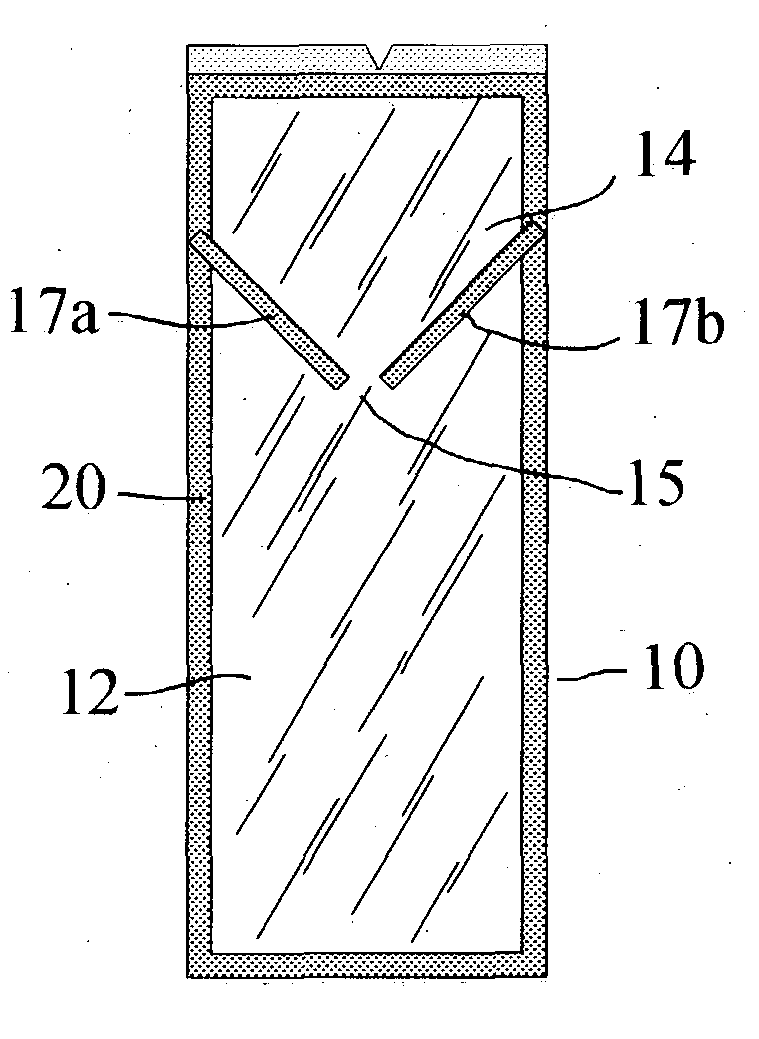

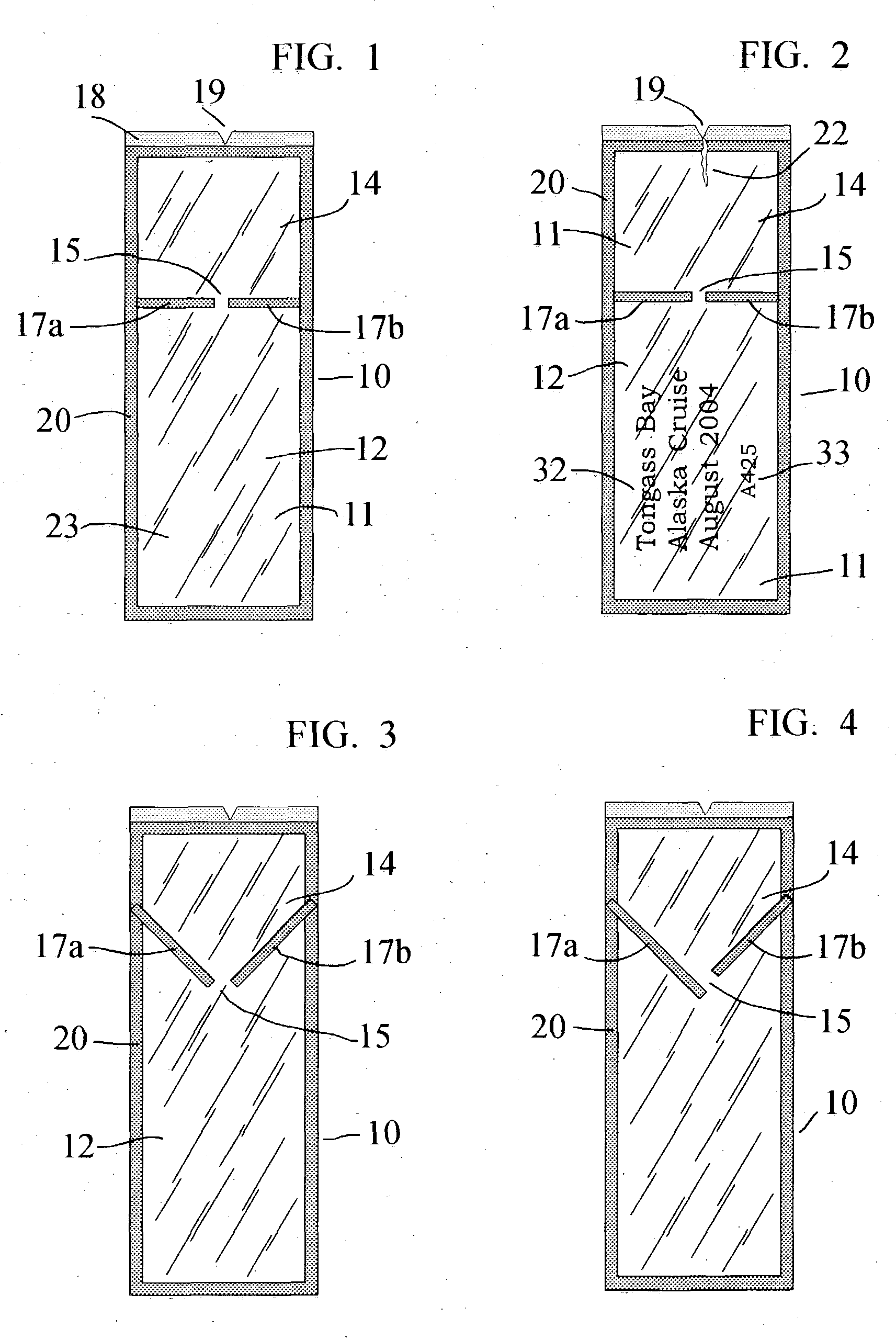

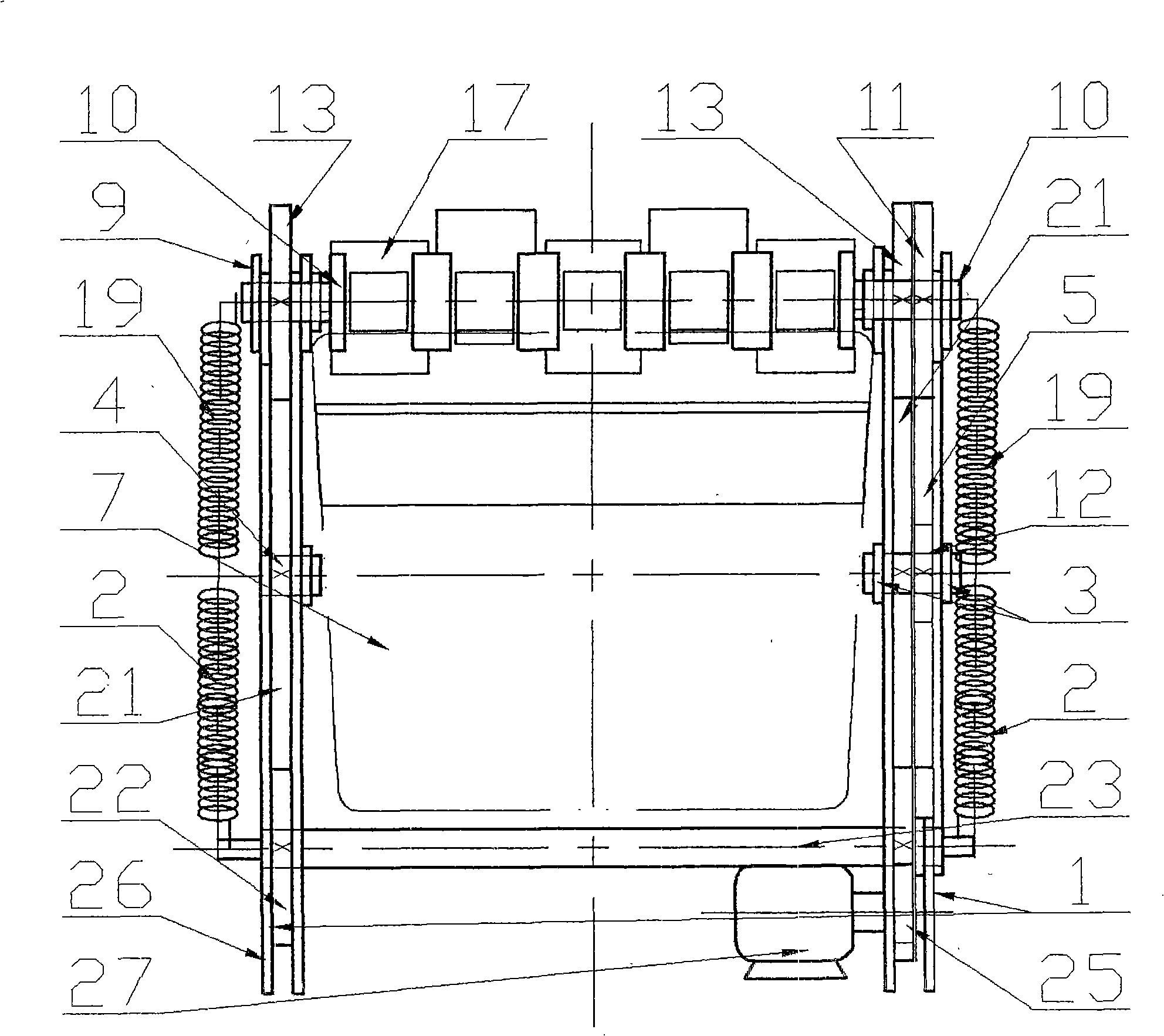

Hand rubbing type washing machine

InactiveCN101333744AAvoid damageReduce usageOther washing machinesTextiles and paperMotor driveEngineering

Disclosed is a hand-washing type washing machine, which is mainly composed of a transmission system and a self-adjusting system. The transmission system is characterized in that a motor drives two transmission gears on the same machine by means of a motor gear to respectively transmit eccentric pull rods at the two ends and synchronously pull crankshafts and drive two groups of upper washboards to transversely move reciprocally and wash clothes from both sides of the washing machine by means of the respective gear transmission system; and after a speed change pinion decelerates, another gear rotational system drives the crankshafts to rotate so as to make the two groups of upper washboards be coordinated with position-restricted pins to move up and down slowly so that the two groups of upper washboards move alternatively and will wash clothes. The self-adjusting system is characterized in that two groups of tension springs are respectively pulled on upper washing frames and tension spring frames; under the effects of the two groups of tension springs, the upper washboards can be clung to lower washboards; and the two groups of tension springs apply certain pressure so that the washing machine can automatically adjust the clearance between the upper washboards and the lower washboards when the washing machine washes clothes of different thicknesses, thereby washing various clothes conveniently.

Owner:石殿来

Energy-saving and detergent-free infant washing machine

InactiveCN107164913AAvoid harmEasy to cleanOther washing machinesWashing machine with receptaclesWater flowPulp and paper industry

The invention discloses an energy-saving washing machine for infants and young children without detergent, which comprises a machine body and a barrel, the barrel is installed in the body, the barrel is a cavity structure, and the barrel is provided with an external A water inlet; a base plate is provided at the bottom of the cylinder, and an ultrasonic generator is provided under the base plate. The beneficial effect is that the washing machine can clean the clothes of infants and young children, use ultrasonic vibration to shake off the stains, use simulated hand rubbing water flow to rub the clothes, and use ultraviolet rays to sterilize, which can effectively improve the cleaning effect and avoid the use of washing machines. The agent does not cause harm to infants and young children, and at the same time has the effects of energy saving and easy use.

Owner:李一鸣

Mung bean hull breaking, separation and extraction device for dairy product processing

The invention discloses a mung bean hull breaking, separation and extraction device for dairy product processing. The device structurally comprises an underframe, a motor, a transmission mechanism, a baffle, a first deflector, a second deflector, a grading mechanism, a crushing mechanism and a separation mechanism, wherein the left side of the top end of the underframe is welded with the grading mechanism. The device has the following beneficial effects: in order to solve the problems that cost consumption is high since manual peeling is generally adopted after soaking in mung bean processing and peeling by manual hand rubbing enables a great quantity of soaked bean kernels to remain in mung bean hulls, and in order to solve the problems that an object obtained by drying the seed coat of the mung bean hull in the sun can be used as a medicine and is capable of removing heat toxin and removing eye nebula but efficiency for directly soaking the seed coat is low during processing and an internal wrapping contact area is small, the device designs the grading mechanism, the crushing mechanism and the separation mechanism. When the device is used, the mung bean is firstly subjected to dust removal in the grading mechanism and is then subjected to grading screening, the obtained mung bean is crushed by the crushing mechanism, and then, the hull and the kernel are separated to realize the effects of grading crushing and hull-kernel separation and soaking.

Owner:CHONGQING TIANYOU DAIRY CO LTD

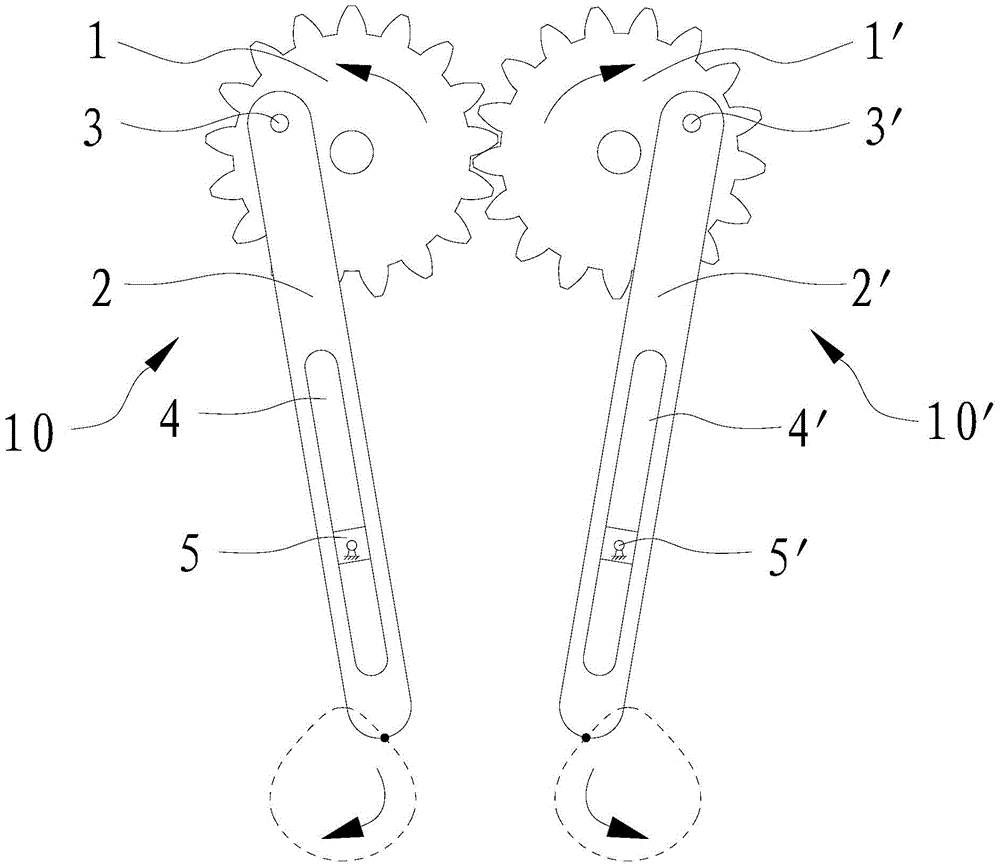

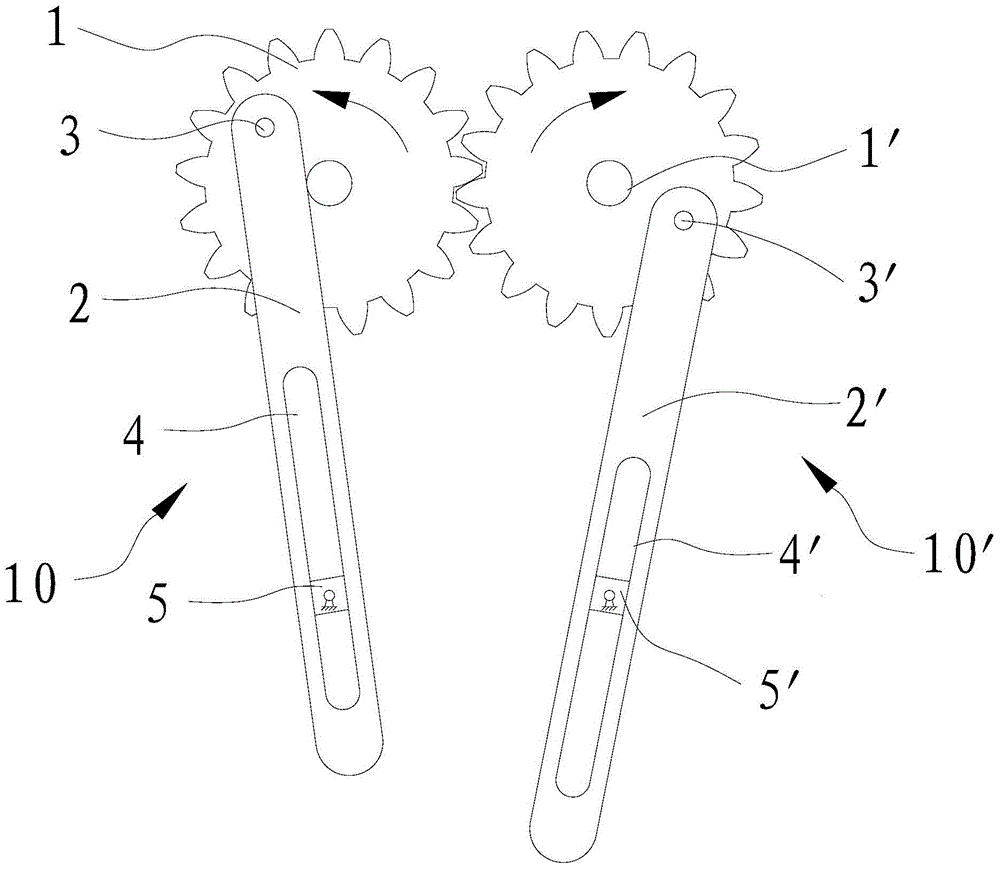

Pneumatic double-hand rubbing bionic device

The invention discloses a pneumatic double-hand rubbing bionic device. According to the pneumatic double-hand rubbing bionic device, only the simple parts including air cylinders, double-face racks, gears, connecting rods and sliding blocks or guiding parts are used, and the complex plane motion of simulating double-hand rubbing can be realized, wherein the centers of the sliding blocks are hinged to a machine frame or the centers of the guiding parts are fixed to the machine frame and the outer surfaces of the guiding parts are cylindrical. Rubbing tools with different functions are fixed to the lower ends of the connecting rods so that various pneumatic double-hand rubbing bionic devices with different functions can be formed. The pneumatic double-hand rubbing bionic device is extremely simple in structure, especially low in manufacturing cost, high in working reliability, and capable of meeting the requirements for the rubbing bionic devices of different industries. A striking contrast is formed between the pneumatic double-hand rubbing bionic device and other bionic devices which are huge and complex in structure and extremely high in manufacturing cost, and the pneumatic double-hand rubbing bionic device can be widely popularized and used.

Owner:SUZHOU UNIV

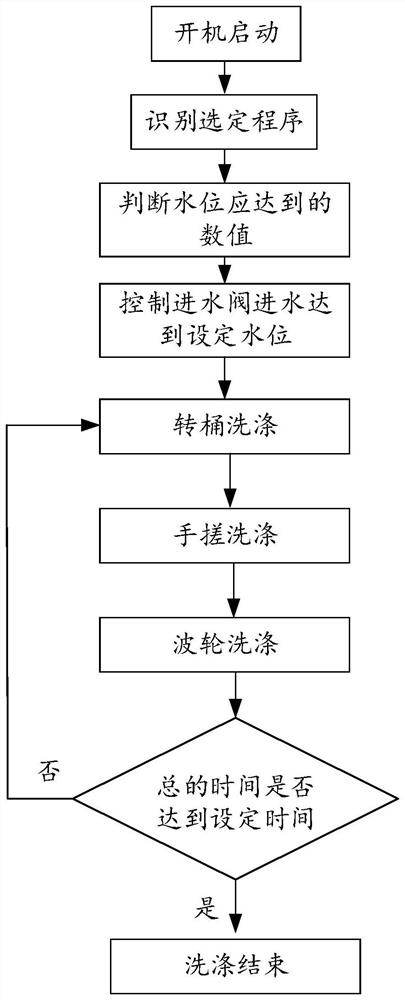

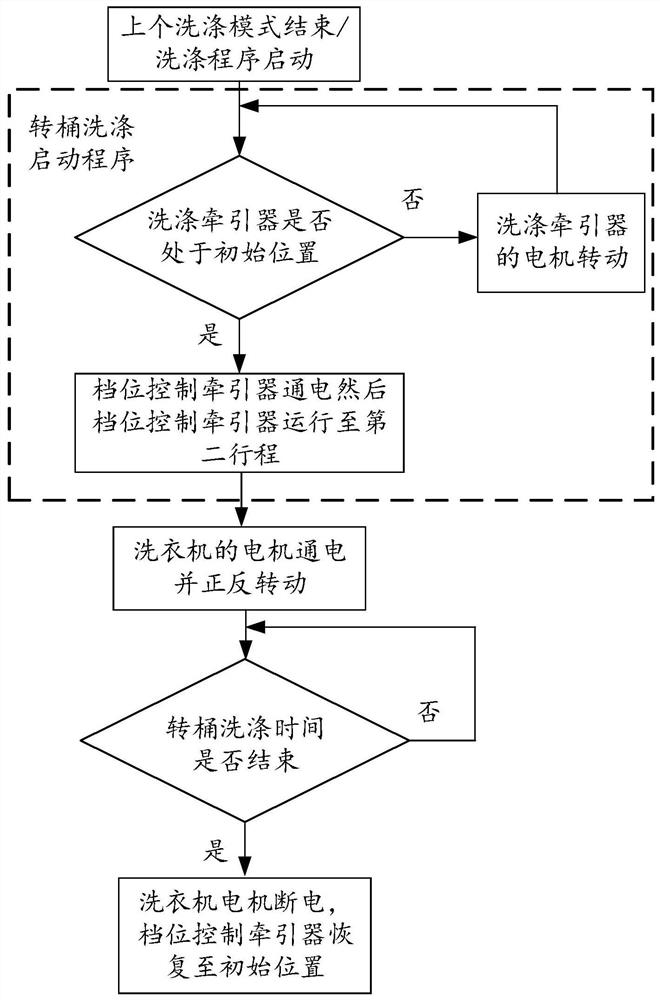

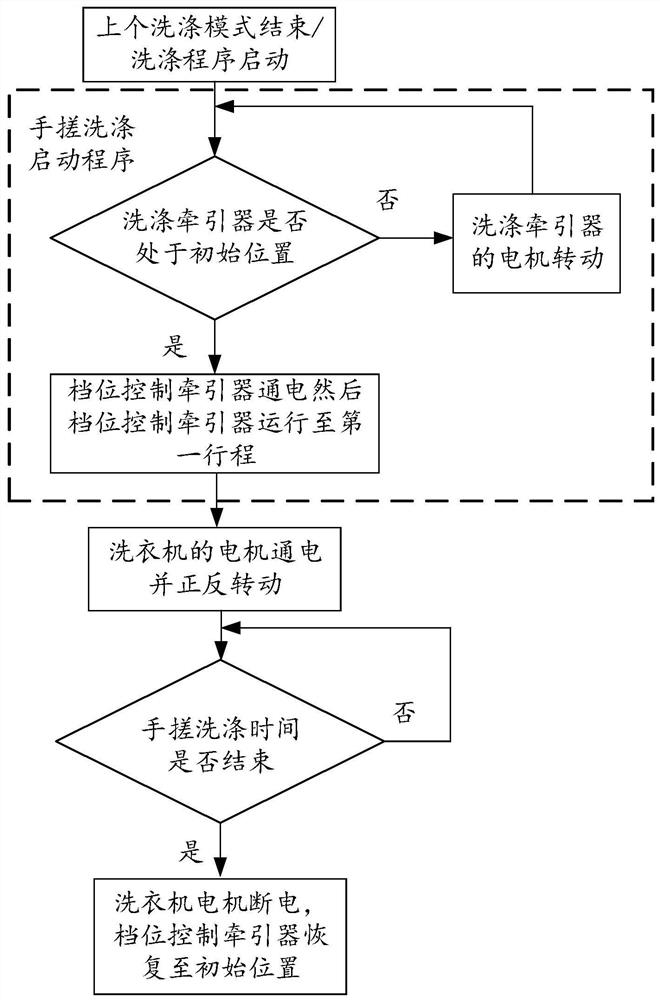

Soft washing method of washing machine

ActiveCN113337997AGuaranteed uptimeControl devices for washing apparatusTextiles and paperLaundry washing machineElectric machinery

The invention provides a soft washing method of a washing machine. The method comprises a washing program S4; in the process of executing the washing program, at least two washing modes of a rotary drum washing mode, a hand rubbing washing mode and an impeller washing mode alternately run until the washing program is finished; when the washing machine is in the rotary drum washing mode, a brake structure does not act on a speed reducing mechanism, a connecting piece is meshed with upper teeth, and a motor drives an impeller and an inner drum to rotate synchronously; when the washing machine is in the hand rubbing washing mode, the brake structure does not act on the speed reducing mechanism, the connecting piece is located between a tooth holder and the upper teeth and is not meshed with the upper teeth and the tooth holder, and the motor drives the impeller and the inner drum to rotate in the opposite direction; when the washing machine is in the impeller washing mode, the connecting piece is meshed with the tooth holder, and the motor drives the impeller to rotate independently; and the method can realize soft washing, can be better suitable for high-grade clothes such as wool clothes which are easy to stretch and wear, reduces the wear of the clothes, and improves the user experience.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

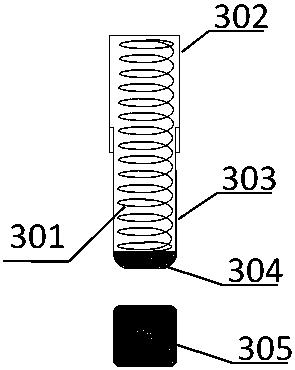

A spring extrusion type washing machine

InactiveCN108265457ASimple structureImprove cleanlinessOther washing machinesTextiles and paperFiberAir pump

The invention relates to a spring extrusion type washing machine which directly applies pressure to fiber textures of clothes and achieves a hand-rubbing-similar effect without causing damage to clothes. The working principle of the washing machine is that: air pressure generated by an electric air pump passes through an air intake pipe; an intake and exhaust switching electromagnetic valve controls holes A of cylinders to perform air intake and holes B to perform air exhaust, so that piston rods stretch out and drive extrusion parts to press clothes; multiple independent spring extrusion heads apply pressure to all parts of clothes and extrude water in fiber textures of the clothes; stains on the clothes, which are dissolved by water, are discharged from the inside of fiber textures together with water; when the holes B of the cylinders perform air intake and the holes A performs air exhaust, the piston rods retract and drive the extrusion parts to rise; when the extrusion parts leavethe surfaces of the clothes, the piston rods of the cylinders stop retracting, and then water in the washing machine enters the fiber textures of the clothes again; then the spring extrusion heads again apply pressure to the clothes to extrude water in the clothes out. The process is repeated again and again to clean clothes.

Owner:关柏华

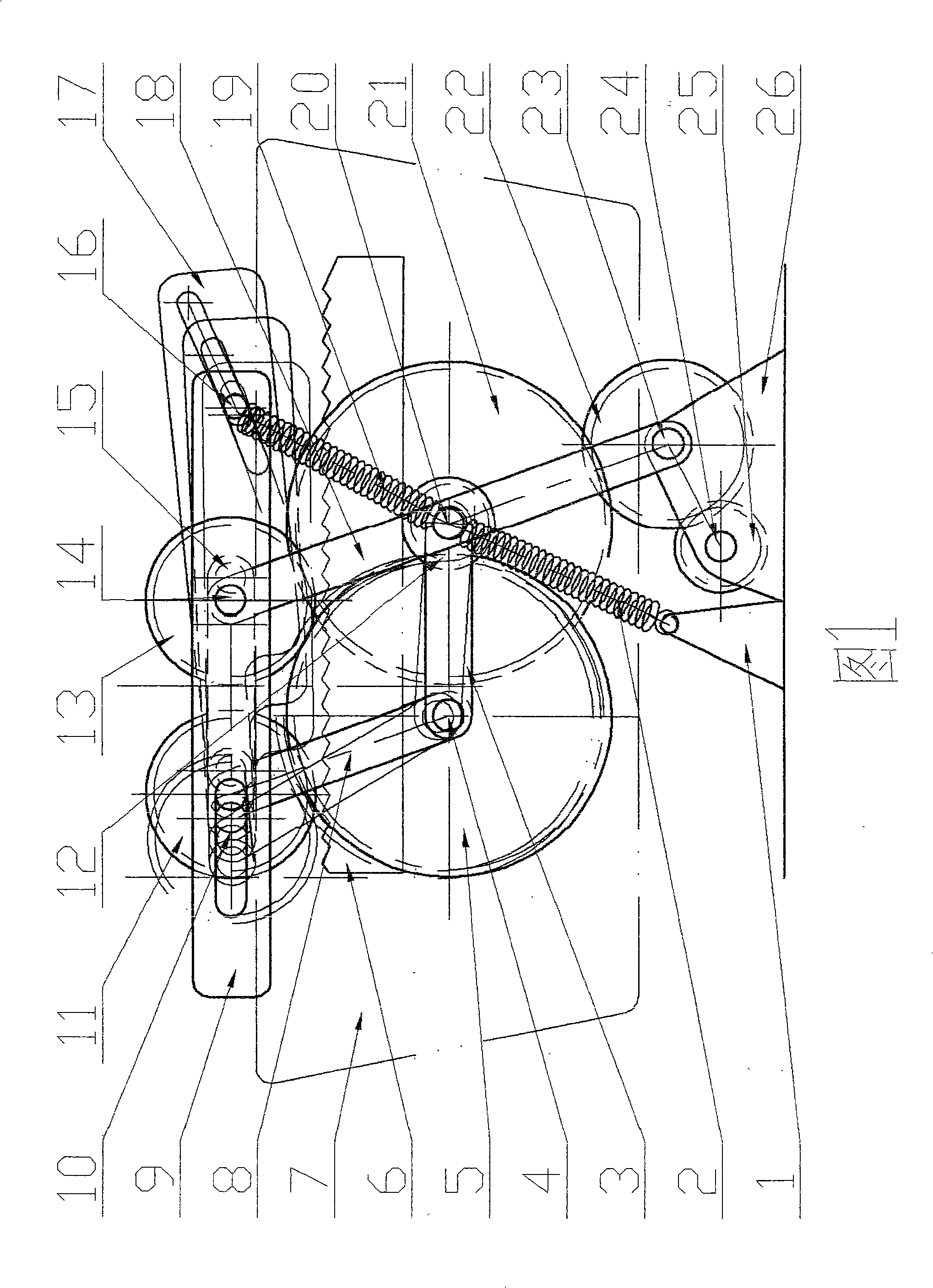

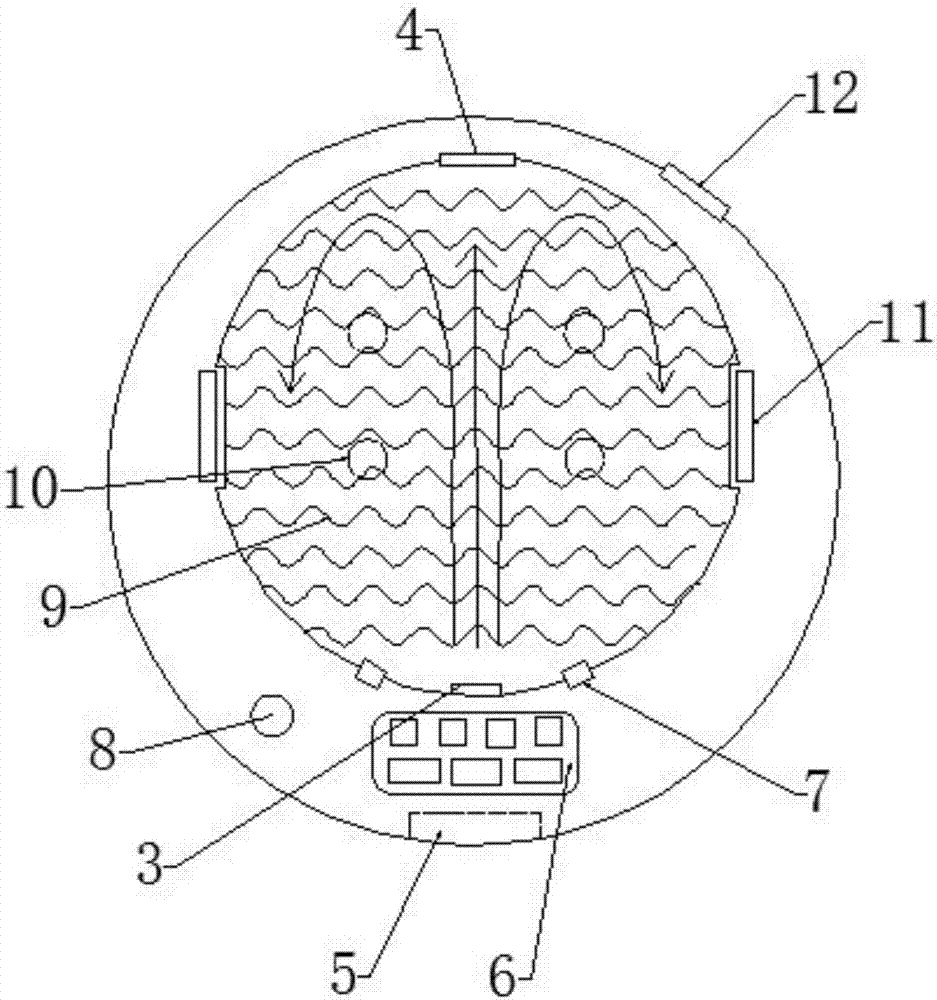

Electric bionic double-hand rubbing device

InactiveCN103498900ASimple structureLow costGearingMechanical energy handlingStructural engineeringMechanical engineering

The invention discloses an electric bionic double-hand rubbing device. By means of a simple screw rod, a nut, a double-face rack, a gear, a connecting rod, a sliding block with the center hinged to a machine frame and a guide element with the center fixed to the outer surface of a cylinder on the machine frame, complex plane motions imitating double-hand rubbing are achieved. The lower end of the connecting rod is fixedly provided with rubbing tools with different functions, so that various electric bionic double-hand rubbing devices with different functions are formed. The electric bionic double-hand rubbing device is simple in structure, low in manufacturing cost and high in work reliability, and can meet requirements for the bionic double-hand rubbing devices in different industries. The electric bionic double-hand rubbing device stands in sharp contrast to an existing bionic device which is large and complex in structure and high in manufacturing cost, and can be widely popularized and used.

Owner:SUZHOU ROARING PRECISION MASCH CO LTD

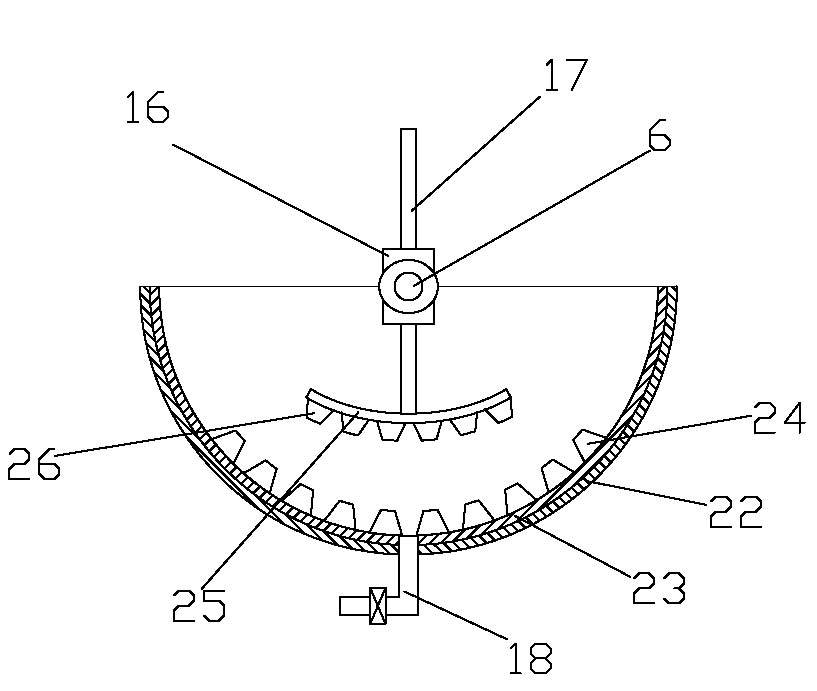

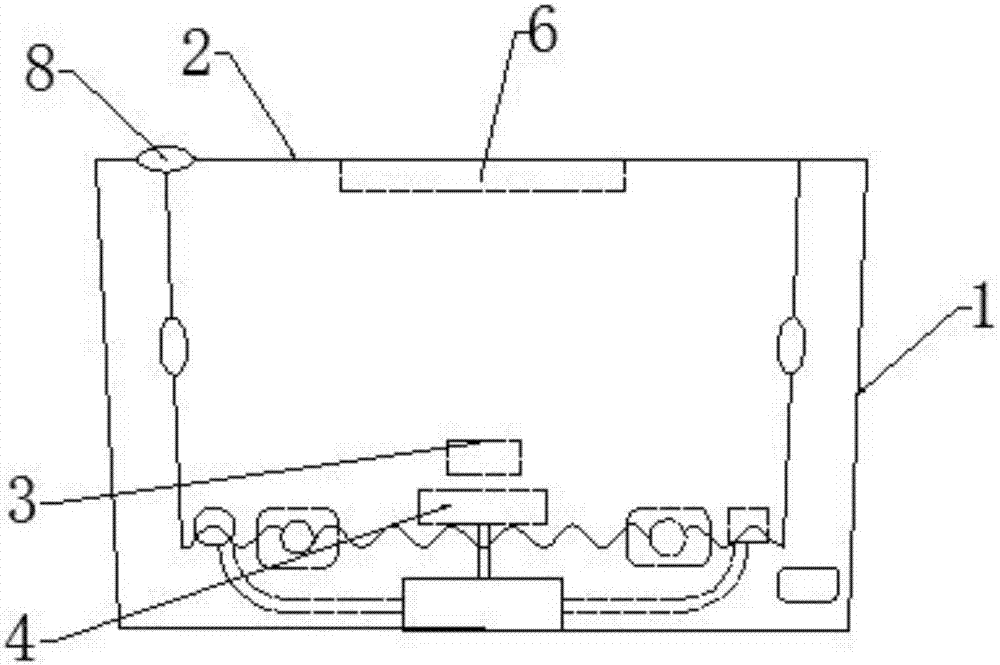

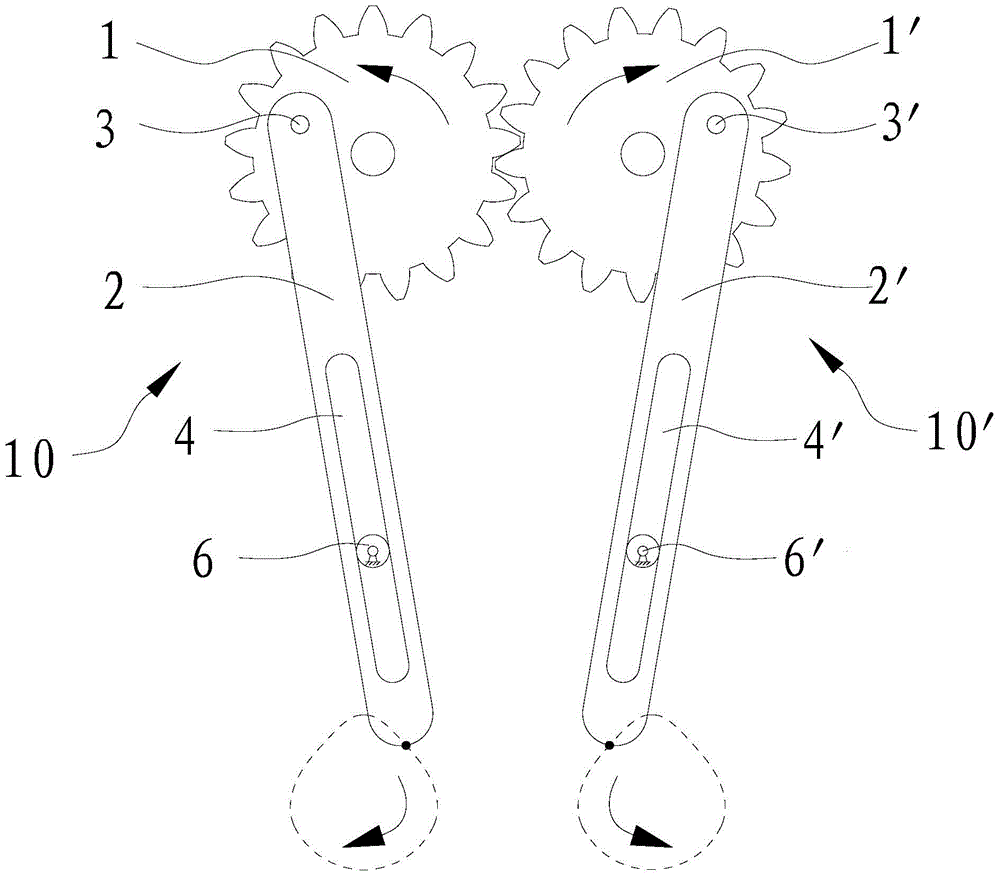

Two-hand rubbing simulation mechanism

InactiveCN103498903ALow costMeet the needs of kneading bionic mechanismGearingInterference fitGear wheel

The invention discloses a two-hand rubbing simulation mechanism which comprises a rack and two sets of rubbing components arranged on the rack. Each rubbing component comprises a gear, a connecting rod, a sliding block with the center hinged to the rack or a guide piece with a cylindrical outer surface, the centers of the guide pieces are fixed to the rack, sliding grooves extending in the length directions of the connecting rods are formed in the connecting rods, the sliding blocks or the guide pieces are arranged in the sliding grooves in an interference fit mode to guide the connecting rods, the two gears on the rubbing components are meshed, and when an external drive mechanism drives the gear on one rubbing component to rotate, the lower ends of the connecting rods of the rubbing components can generate the simulation movement similar to two-hand rubbing. The simulation mechanism achieves the complex plane movement simulating the two-hand rubbing through few parts, is extremely simple in structure, low in manufacturing cost and high in work reliability, can meet the needs of all kinds of corresponding products for the two-hand rubbing simulation mechanism with the extremely low manufacturing cost, and has good practicability.

Owner:SUZHOU ROARING PRECISION MASCH CO LTD

Chemical-free and environment-friendly washing method

InactiveCN109537228AShort processAvoid consumptionPattern makingLiquid/gas/vapor removalOzone degradationWater resources

The invention relates to the technical field of garment washing, in particular to a chemical-free and environment-friendly washing method. A laser printing treatment process is mainly used for replacing traditional hand wiping and coating printing processes, and defects of long process, large consumption and severe pollution of the traditional hand rubbing and coating printing processes are overcome; a pneumatic rubbing whitening treatment process is used to replace chemical material to realize traditional whitening processes such as enzyme washing, stone washing, rinsing and sand washing, a lot of water resources are saved, no sewage is produced, and wastewater emission is reduced; cloth is subjected to decoloration washing with an ozone degradation decoloration process, no chemical materials are used, and environmental pollution is reduced.

Owner:台山市红岭洗染有限公司

Electric constant-pressure cup moving device

PendingCN107982034AReduce weightComfortable gripPneumatic massageCupping glassesLow noiseBody joints

Provided is an electric constant-pressure cup moving device. An internal-threaded metal pneumatic joint of a body of the cup moving device extends to one end of the external of the shell of the body of the cup moving device and is connected with a connecting pipe assembly mechanism through one end of a tracheal hose C, the other end of the tracheal hose C is connected with one end of a negative pressure filter of the connecting pipe assembly mechanism, and the connecting pipe assembly mechanism is connected with one end of an external-threaded metal pneumatic joint C of an ox horn cup mechanism through the other end of a tracheal hose E. The device has the advantages of light weight, a comfortable hold feeling, no hand rubbing, no frangibility, beauty, durability, low noise, small volume,enough pressure, convenient carrying, time saving, labor saving and constant pressure, and the pressure can be freely adjusted according to the patients' bearing capacity; compared with an ordinary cup moving device, the electric constant-pressure cup moving device is convenient to use, and can conduct moving cup treatment on body joints, and when the device is used for persons with thin and smallbodies, the phenomenon of being likely to lose cups does not happen.

Owner:包文峰

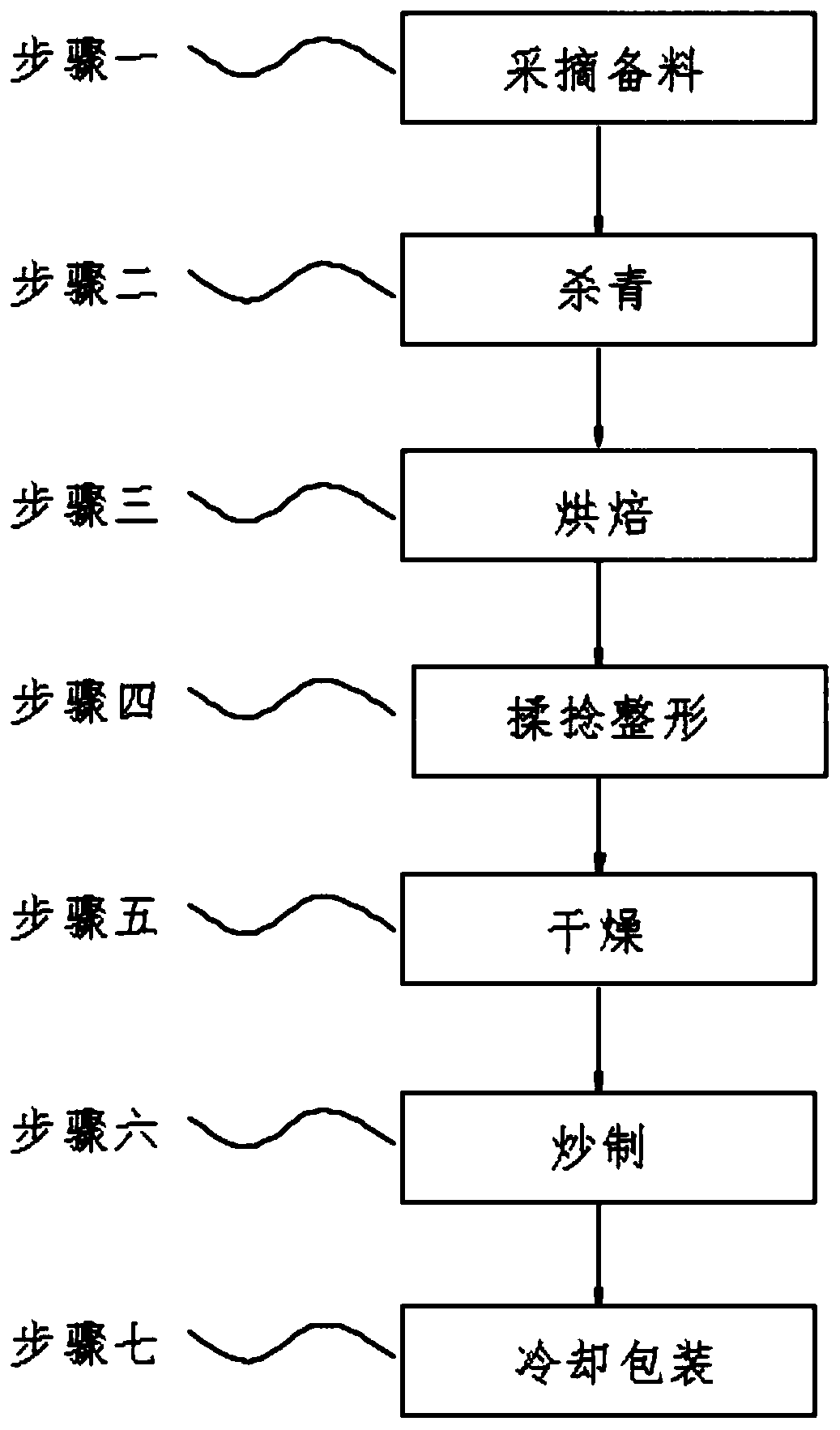

Manual green tea processing technology

InactiveCN110150403AImprove qualityKeep the color greenPre-extraction tea treatmentGreen teaMaterials science

The invention discloses a manual green tea processing technology which comprises the following steps: 1, material picking and preparation; 2, fixation; 3, baking; 4, rolling and shaping; 5, drying; 6,stir-frying; 7, cooling and packaging. According to the invention, a left-hand rubbing method or right-hand rubbing method is adopted to feel the drying and hardening degree of tea leaves through thefinger tips and the palms, the strength is controlled to the degree that pressure exists but not the tea leaves are not crushed, the tea leaves are quickly rubbed, shaped and tightened in place, it can be ensured that tea strips are compact and thin, the tea leaves are exquisitely curled and rolled and are firm in structure, the soaked tea leaves can also be kept green and moist, the standard offamous high-grade tea is achieved, and the quality of tea is greatly improved.

Owner:湖南资兴东江狗脑贡茶业有限公司

Frequency-conversion hand-rubbing motor reducing clutch device and washing machine

ActiveCN107385785AIncrease swipe speedReduce sliding frictionOther washing machinesTextiles and paperFrequency conversionElectric machinery

The invention relates to a frequency-conversion hand-rubbing motor reducing clutch device which comprises a clutch shaft sleeve and a poking fork contacted with the clutch shaft sleeve, wherein relative motion exists between the poking fork and the clutch shaft sleeve; and lubricating grease is applied on a contact face between the poking fork and the clutch shaft sleeve, so slide friction force between the poking fork and the clutch shaft sleeve is reduced. The invention also relates to a washing machine, wherein the frequency-conversion hand-rubbing motor reducing clutch device is disposed on the washing machine. According to the invention, the lubricating grease is applied on the contact face between a positioning convex part and the poking fork, so slide friction force between the poking fork and the positioning convex part is reduced; slide speed of the poking fork is increased; vertical slide speed of the clutch shaft sleeve is increased; separation and approaching speeds of a dewatering shaft and a rotor are increased; the difference between rotation time of a washing bucket and set time is reduced; abnormal friction sounds are reduced; reliability of the reducing clutch device is enhanced; and users' experience effects are improved.

Owner:TIANJIN HAIER WASHING ELECTRICAL APPLIANCE CO LTD +1

Hand rubbing bionic mechanism

The invention discloses a bionic mechanism for hands rubbing, which comprises a frame and two sets of rubbing components arranged on the frame, and each group of rubbing components includes a gear, a connecting rod, a slider whose center is hinged on the frame or a center fixed on the frame. The guide piece on the cylindrical outer surface on the frame, the connecting rod is provided with a chute extending along its length, and the slider or the guide piece are arranged in the chute with clearance fit to provide the guide of the connecting rod. The two gears on the components are engaged. When the external drive mechanism drives the gears on one set of kneading components to rotate, the lower ends of the upper connecting rods of the two sets of kneading components will produce a bionic movement similar to hands kneading. The bionic mechanism realizes the complex planar movement imitating the rubbing of human hands with fewer parts. Its structure is extremely simple, the cost is particularly low, and the work reliability is high. It can meet the requirements of various corresponding products for rubbing hands at a very low cost. Institutional needs, with good practicality.

Owner:SUZHOU ROARING PRECISION MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com