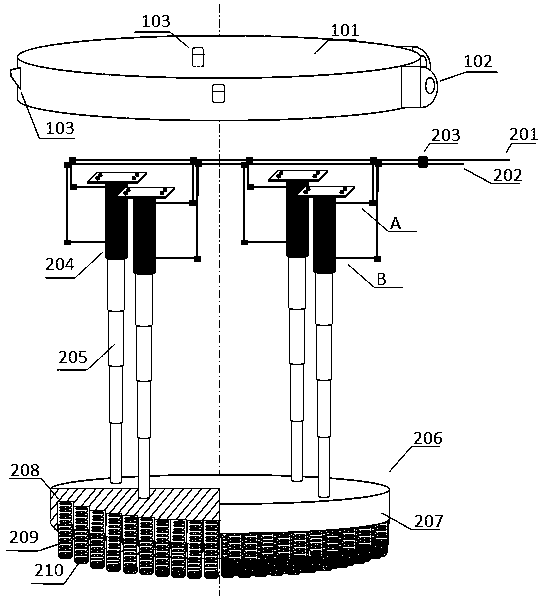

A spring extrusion type washing machine

A washing machine and extrusion technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of itching in the boots and the inability to really wash clothes, etc., and achieve the effect of high cleaning degree and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] Specific implementation methods: 1. Since the upper cover of the washing machine has to bear the upward force, it is necessary to set a door lock on the other three sides except the side where the hinge of the upper cover of the washing machine is connected with the rotating shaft of the washing machine body around the upper cover of the washing machine. The lock tongue is locked when the upper cover is closed. 2. The opening and closing of the cover can be controlled by computer program. When opening the cover, the electromagnet pulls in and unlocks, and the electric motor opens the cover synchronously. If you need to move the relevant handle manually. The control switches of the three-sided deadbolt can be concentrated on one handle, and the handle can be lifted upwards to open the upper cover while unlocking. 3. When the cylinder is working, the function of opening the cover is locked. 4. When the extruding part is retracted to the upper cover of the washing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com