Pneumatic double-hand rubbing bionic device

A two-handed, pneumatic technology, used in transmissions, fluid transmissions, belts/chains/gears, etc., can solve the problems of high cost, high cost, complex structure, etc., and achieve high work reliability, widespread use, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

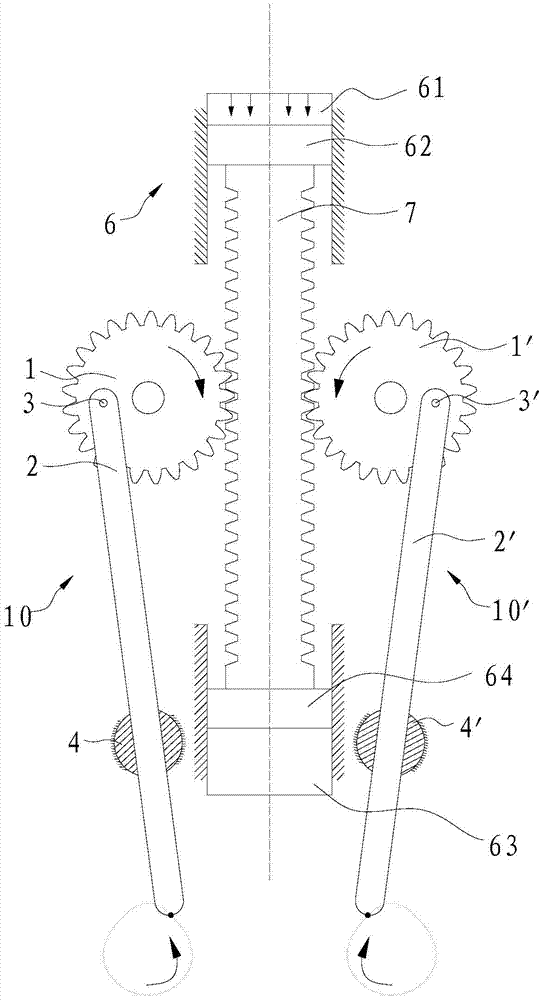

[0028] see figure 1 The shown bionic device for pneumatic hands rubbing includes a frame (not shown in the figure), and two sets of rubbing components 10, 10' arranged on the frame.

[0029] The kneading assembly 10 includes a gear 1 which is rotatably arranged on the frame around the axis, a connecting rod 2 which is rotatably arranged on the gear 1 through a pin shaft 3, and is hinged on the frame and can rotate around its own axis. Cylinder 4. There is an eccentric pin hole on the gear 1, the center line of the pin hole is parallel to the axis line of the gear 1, one end of the pin shaft 3 is connected to the upper part of the connecting rod 2, and the other end is rotatably passed through the above pin hole middle.

[0030] The axis line of the cylinder 4 is parallel to the axis line of the gear 1, and the cylinder 4 is provided with a through hole penetrating in the radial direction. The lower end is exposed outside the through hole. A plane low pair is formed b...

Embodiment 2

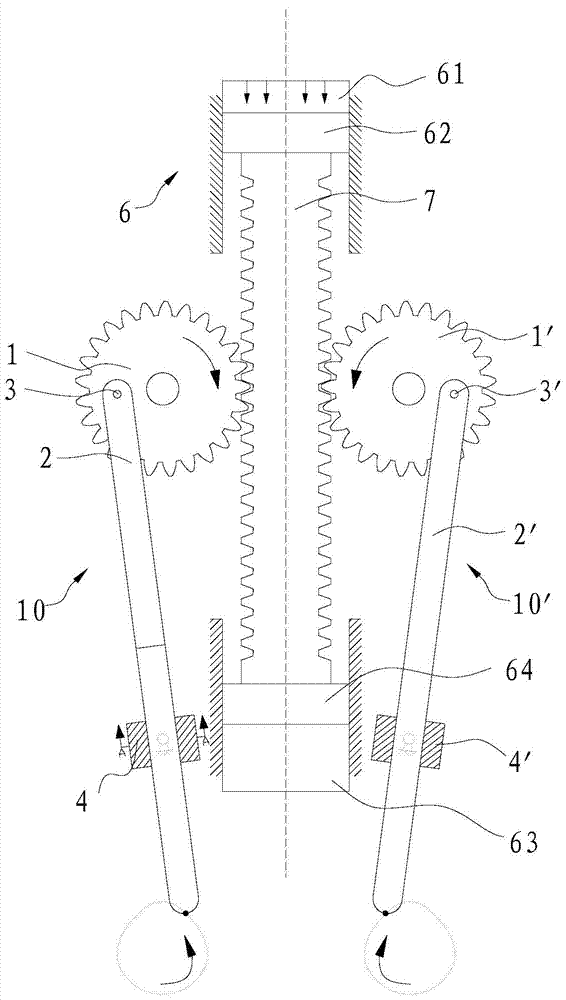

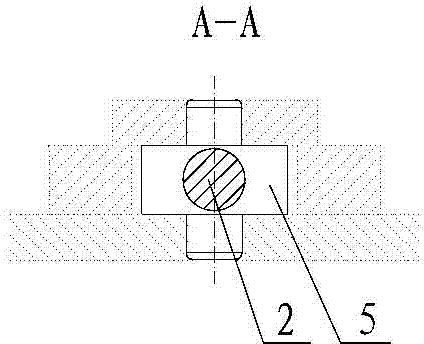

[0035] see figure 2 Shown is a bionic device for rubbing with both hands, the difference between this bionic device and Embodiment 1 is mainly in the setting of the parts that provide the guides of the connecting rods 2, 2'. In this embodiment, the connecting rod 2, 2' is provided as the center of the sliding seat 5, 5' hinged on the frame, and the two axial ends of the sliding seat 5, 5' are at the hinge point on the frame. The connecting line is parallel to the axes of the gears 1 and 1'. The sliding seats 5, 5' are respectively provided with through holes for the connecting rods 2, 2' to penetrate, and the connecting rods 2, 2' are respectively fitted in the through holes on the sliding seats 5, 5' with a clearance fit. 2, 2' and the sliding seat 5, 5' form a plane low pair, when the double-sided rack 7 moves along the length direction and drives the gear 1 and the gear 1' to rotate, the connecting rod 2, 2' is respectively on the pin shaft 3, 3 'Under the action of sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com