Patents

Literature

3519 results about "Hinge point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

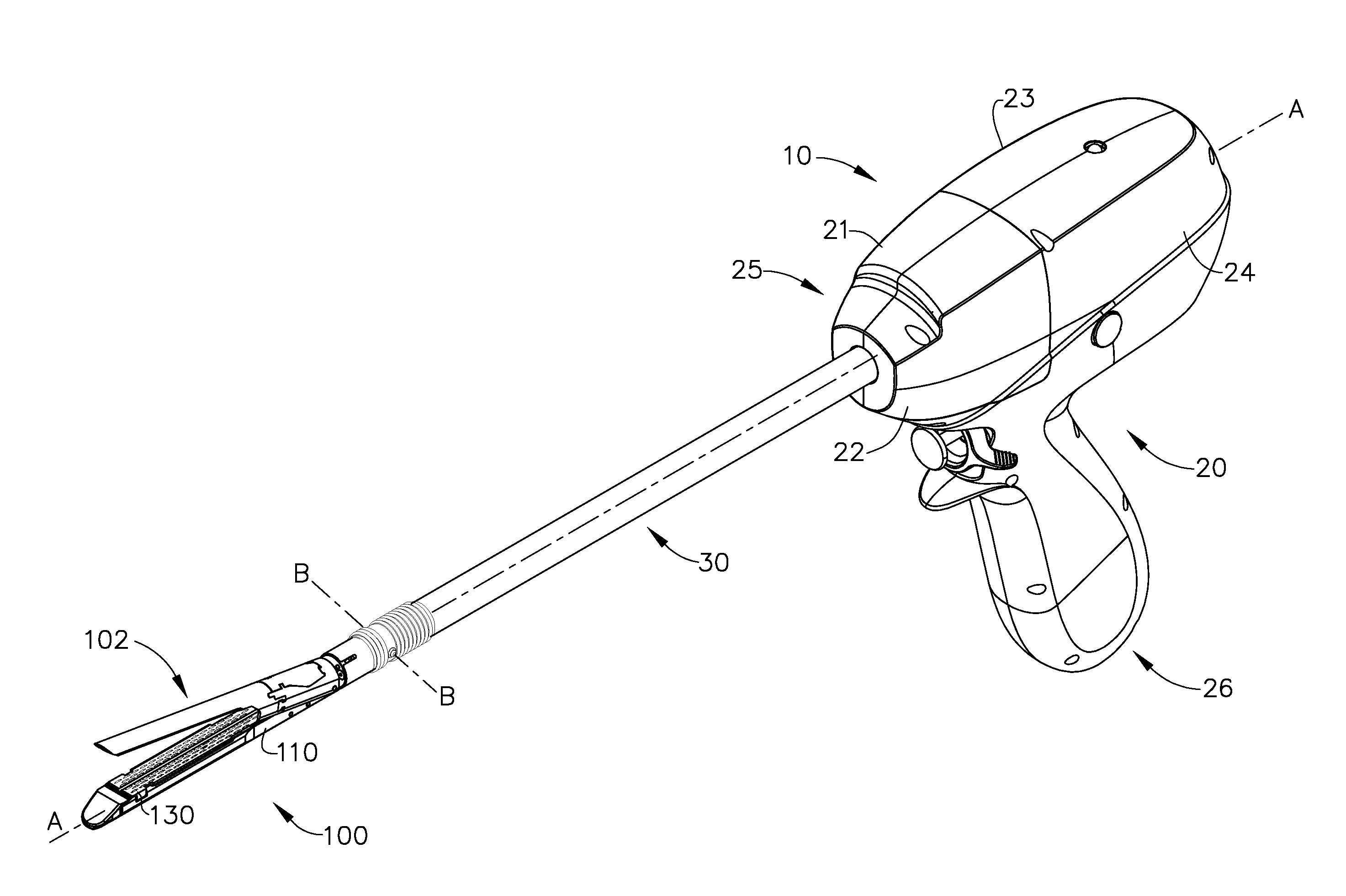

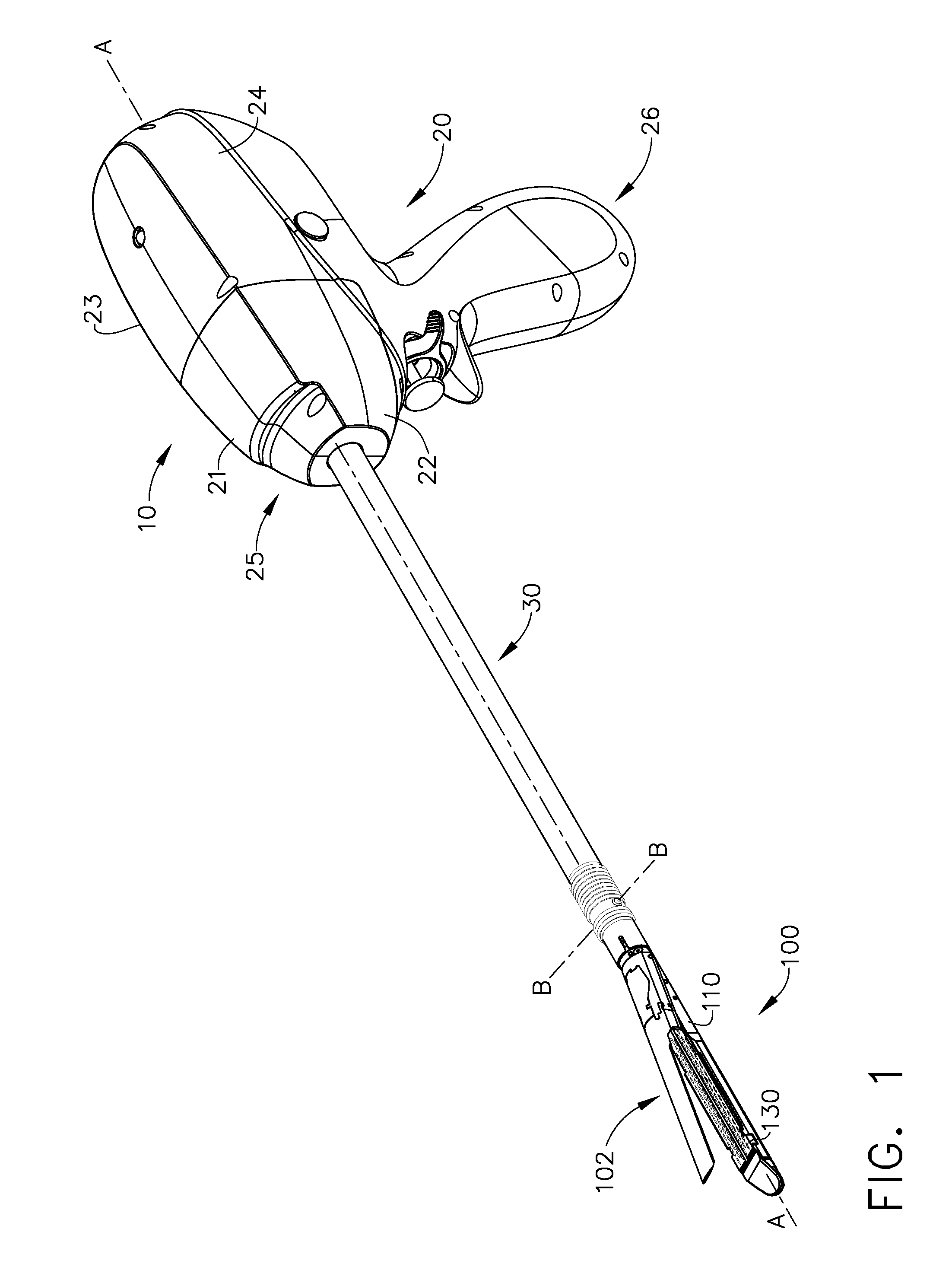

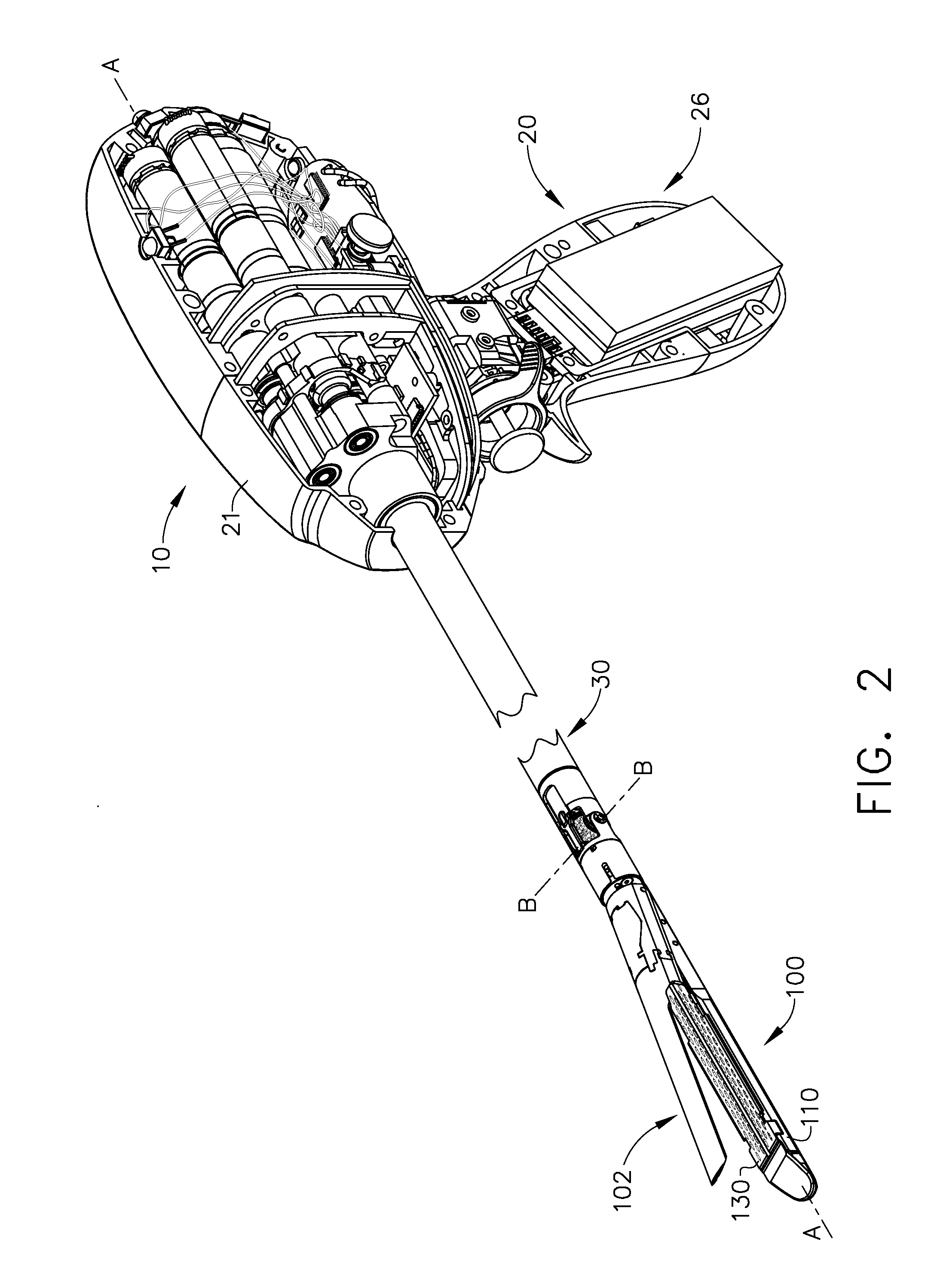

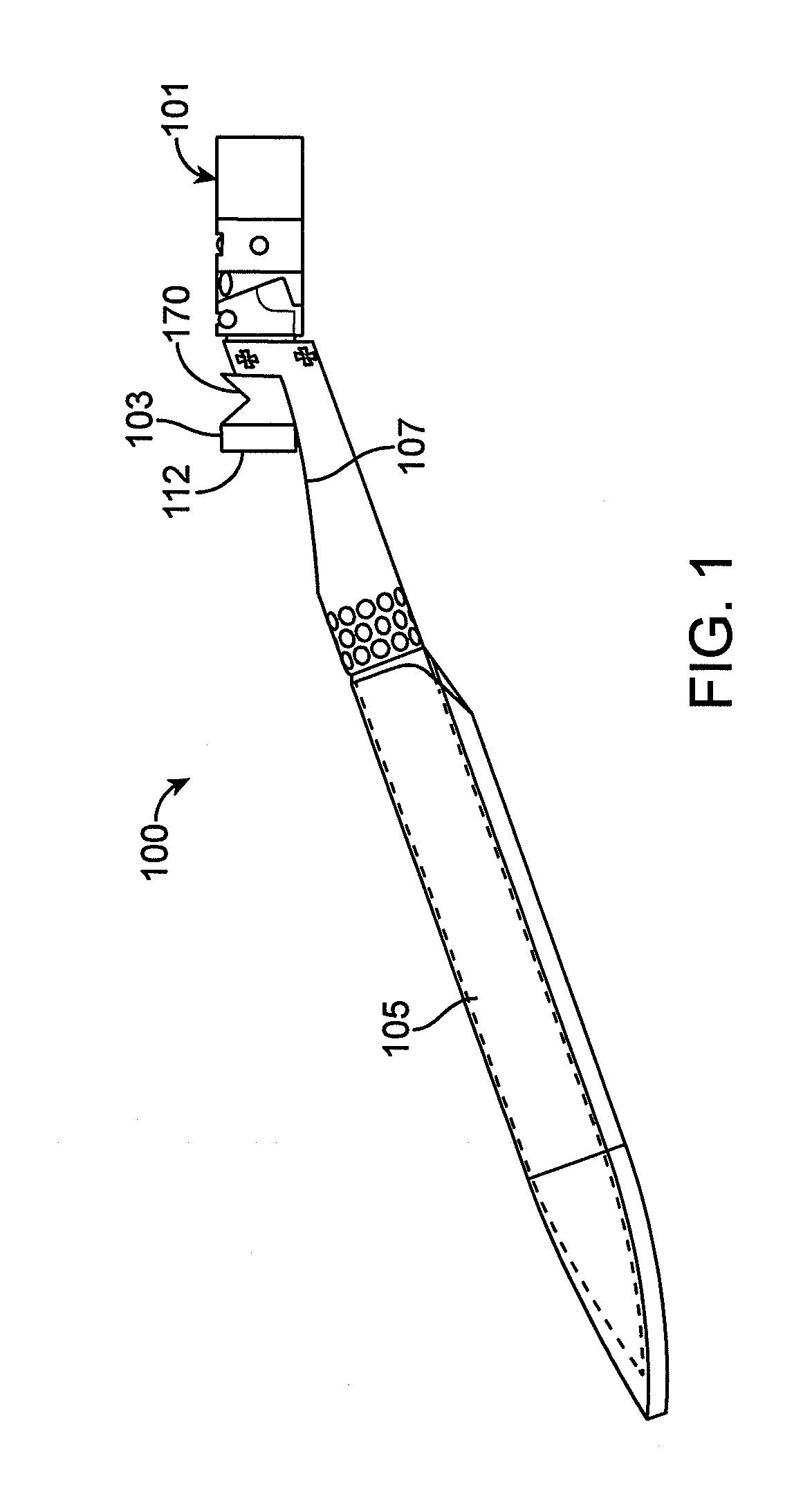

Sensor straightened end effector during removal through trocar

In various forms, a sensor-straightened end effector is disclosed. The sensor-straightened end effector may comprise an end effector coupled to a shaft at an articulation point. The end effector may be articulable at an angle with respect to the shaft. A sensor may be disposed on the sensor-straightened end effector, such as on the shaft or on the end effector. The sensor is configured to detect a gross proximal movement. When detecting a gross proximal movement, the sensor may generate a signal to control a motor to begin a straightening process to straighten the end effector with respect to the shaft.

Owner:CILAG GMBH INTERNATIONAL

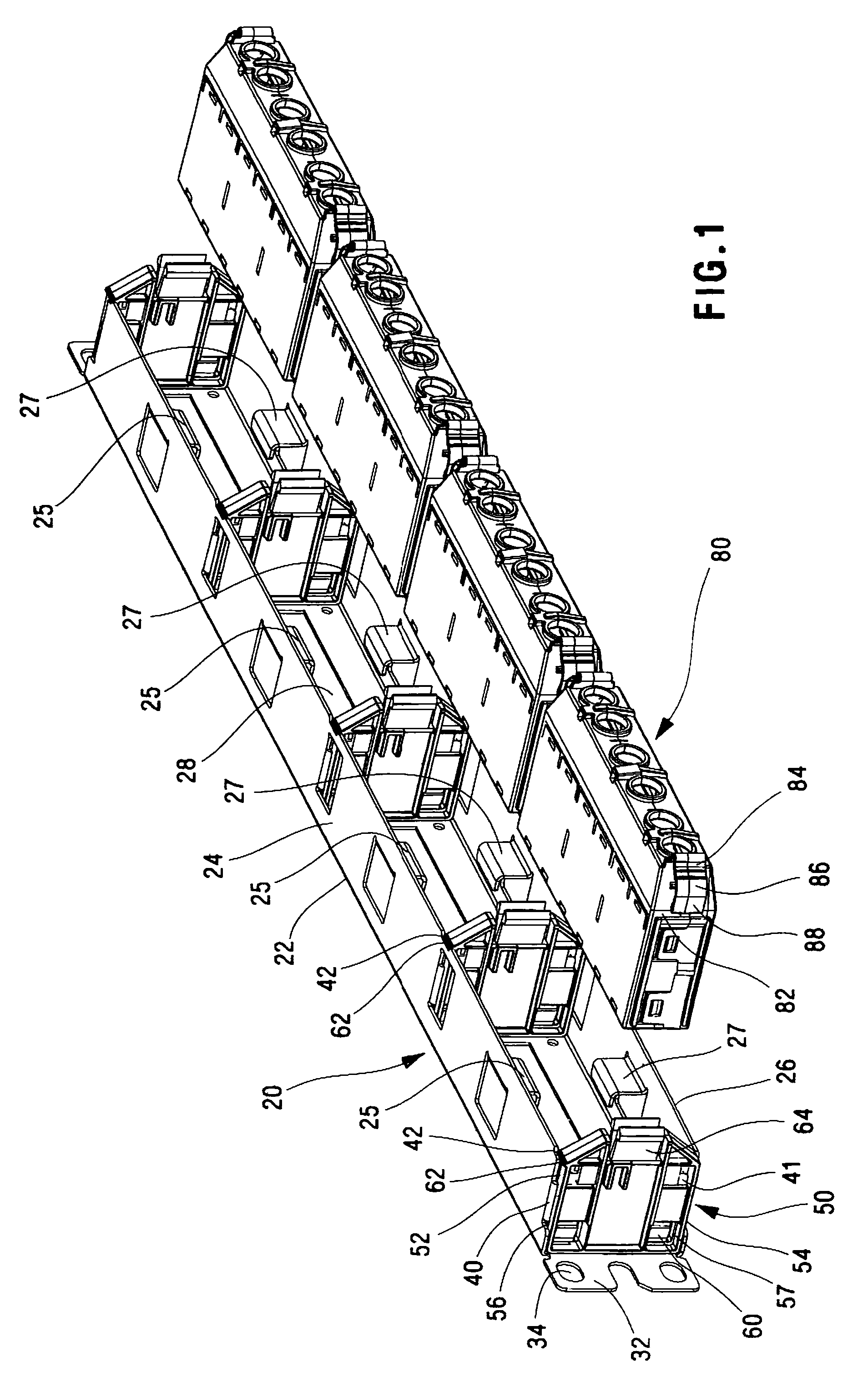

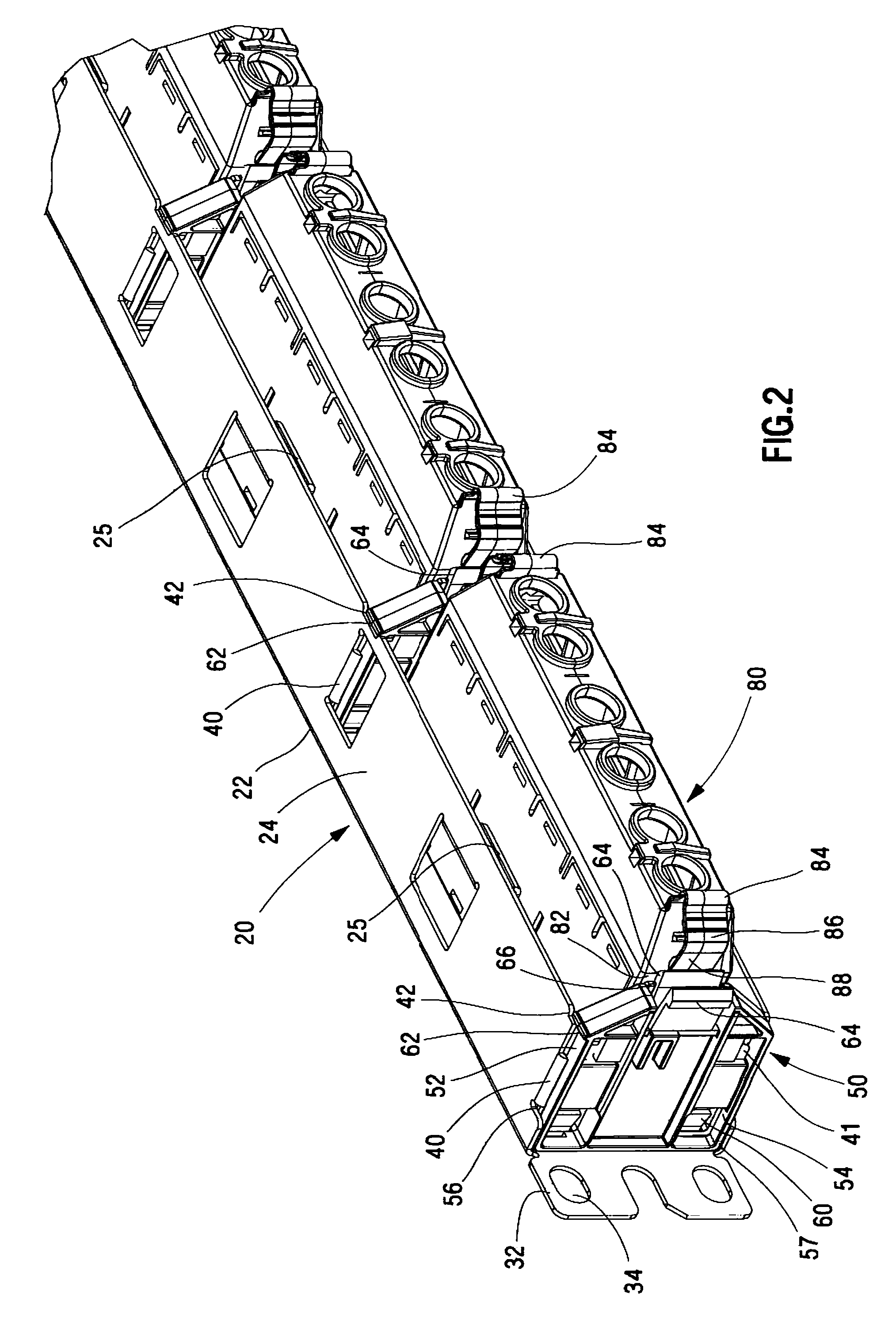

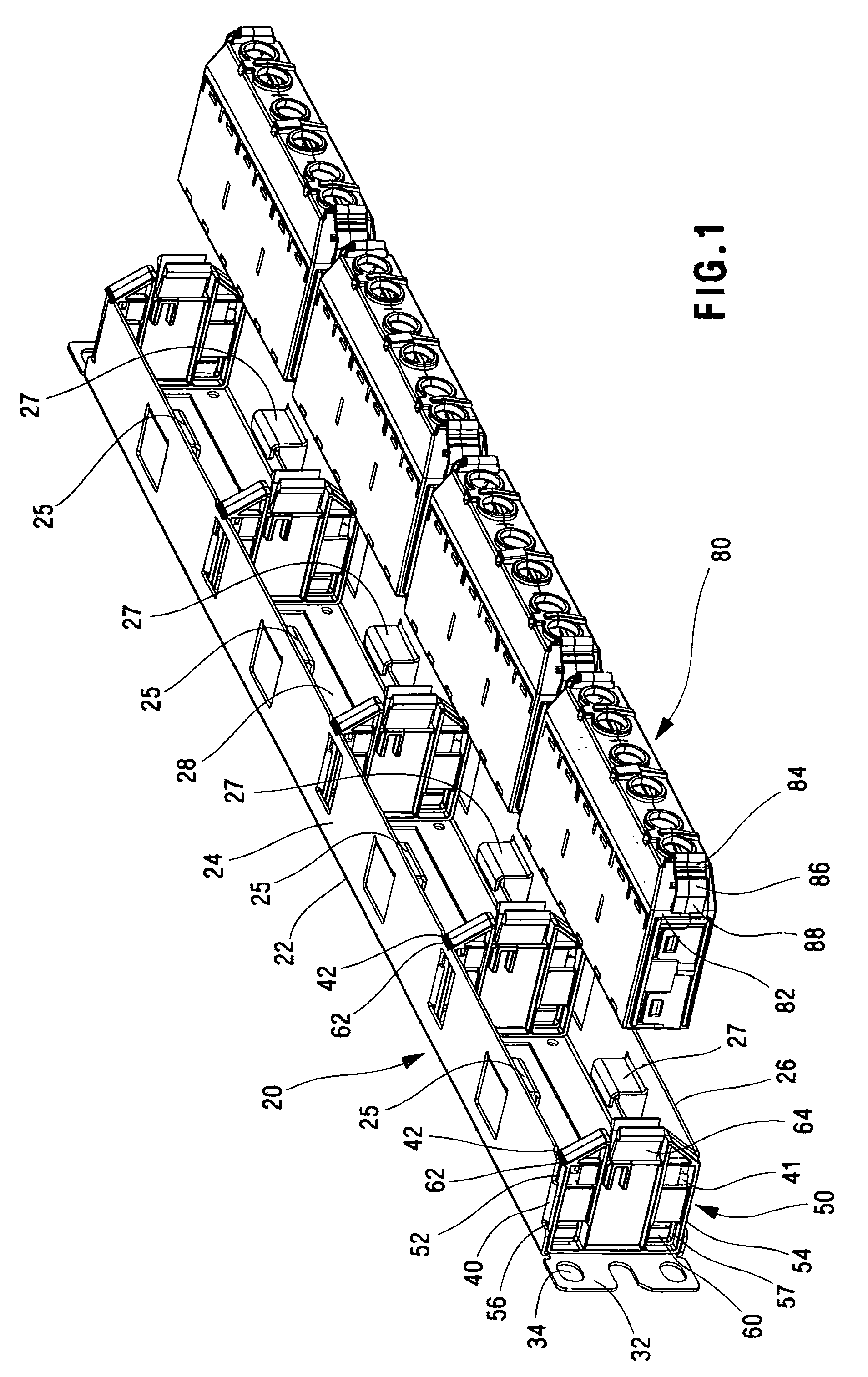

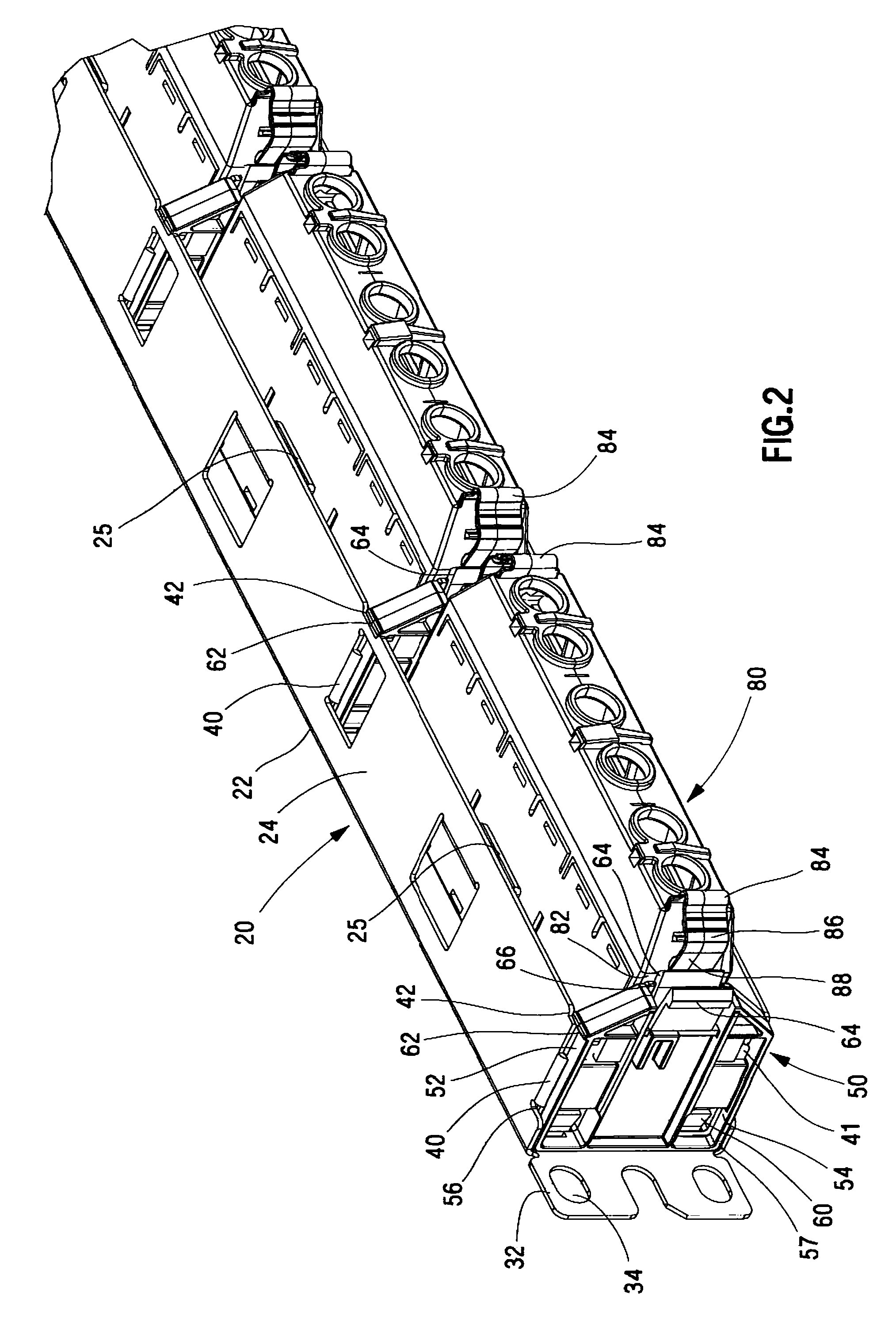

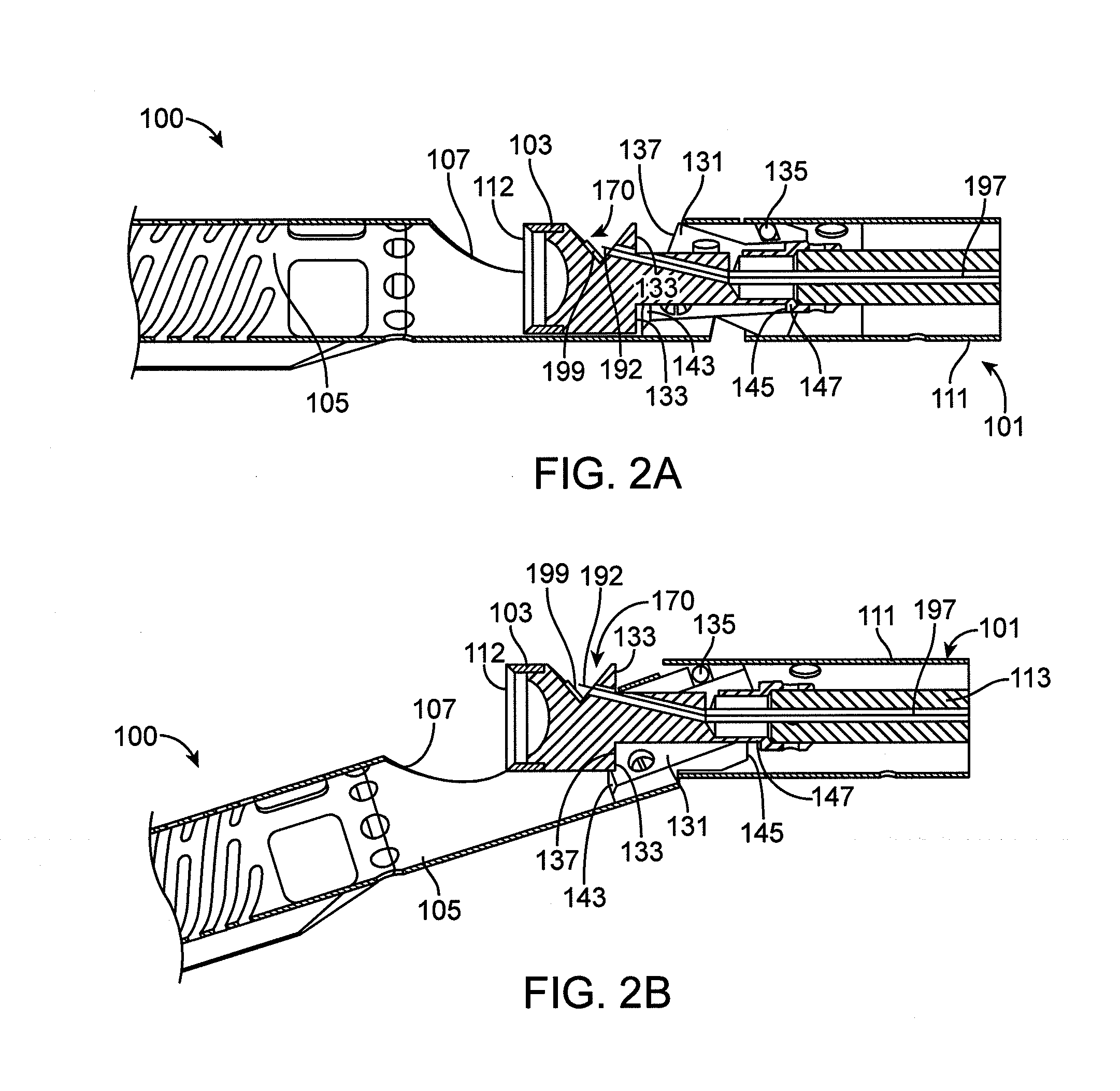

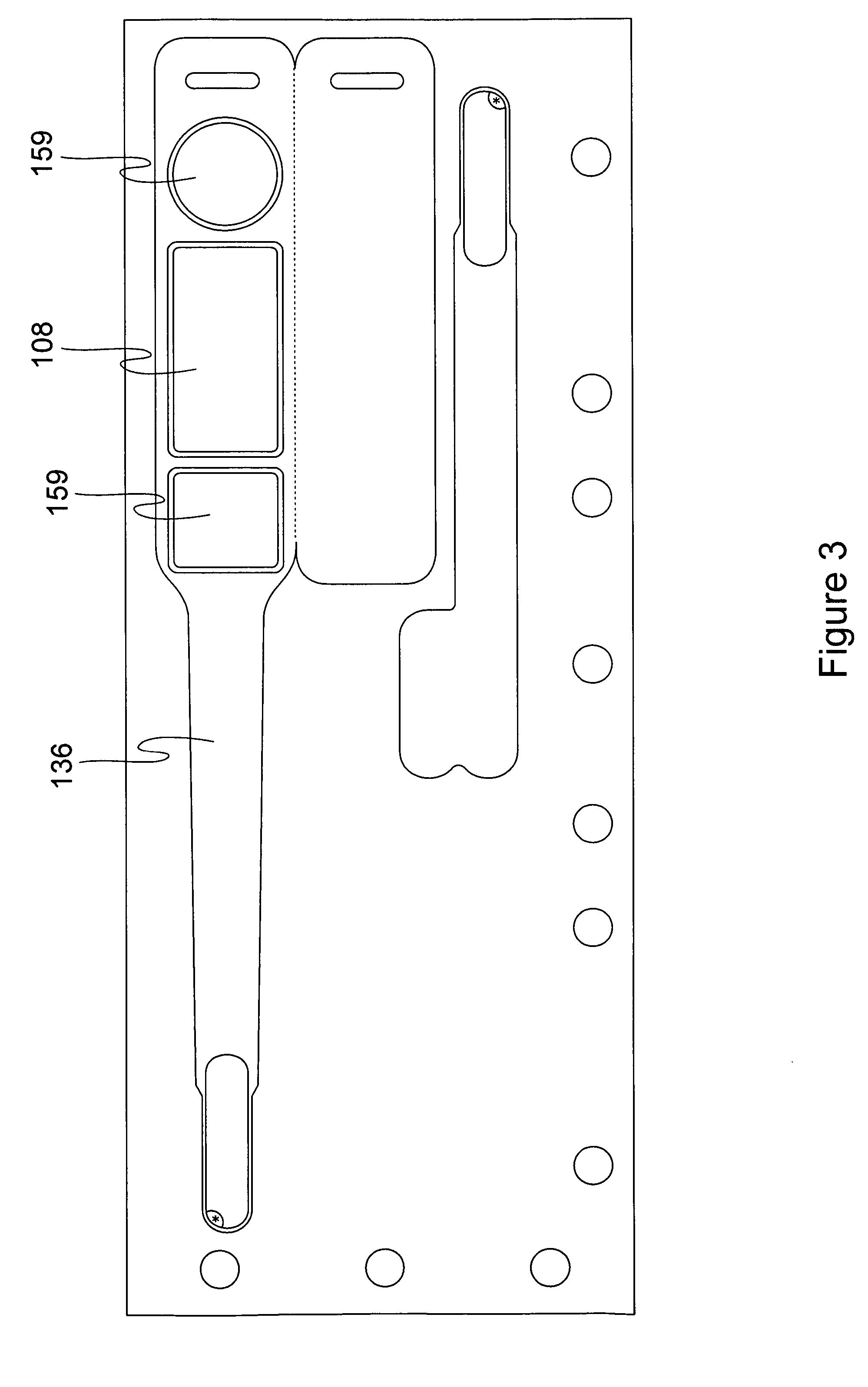

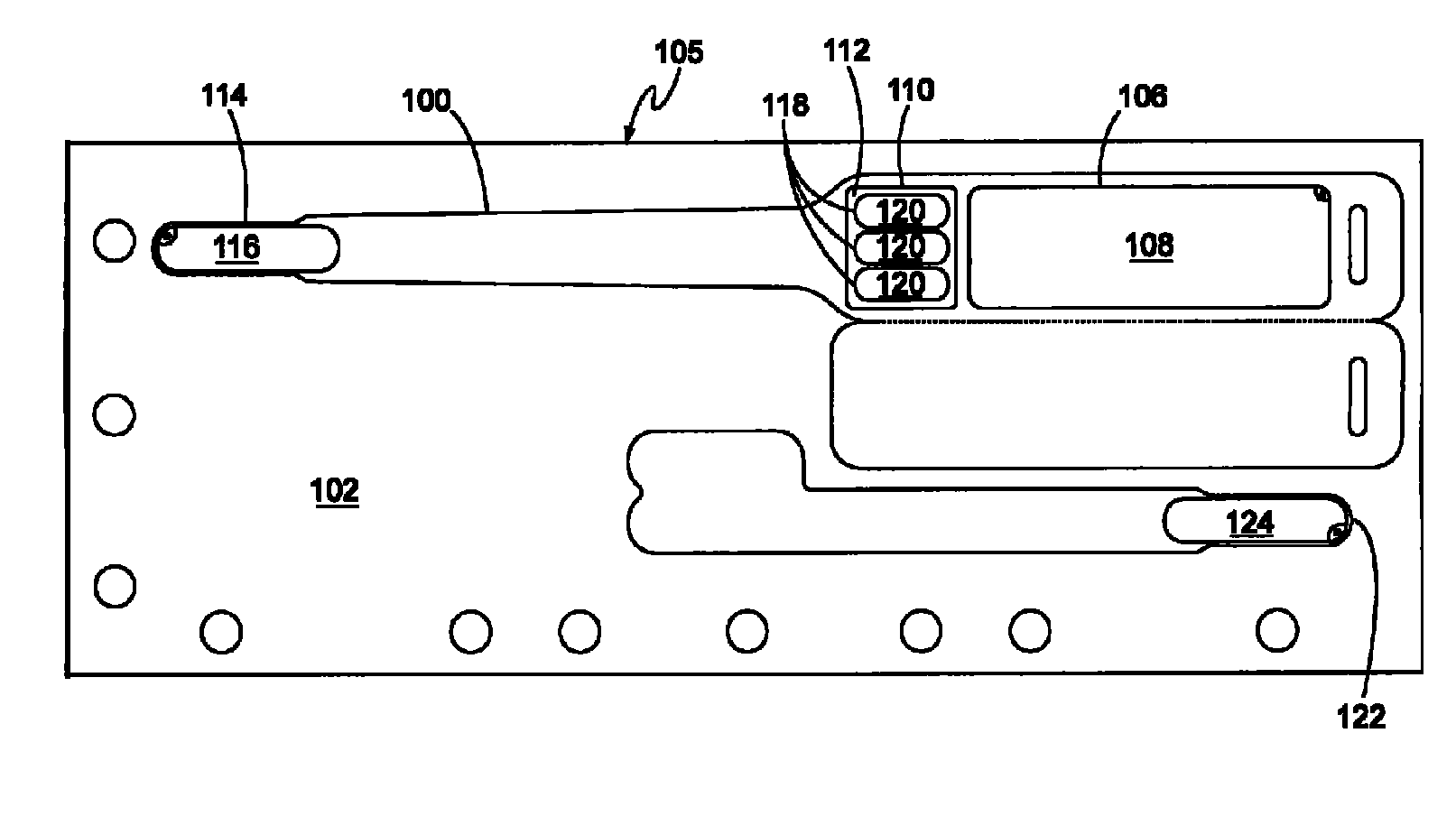

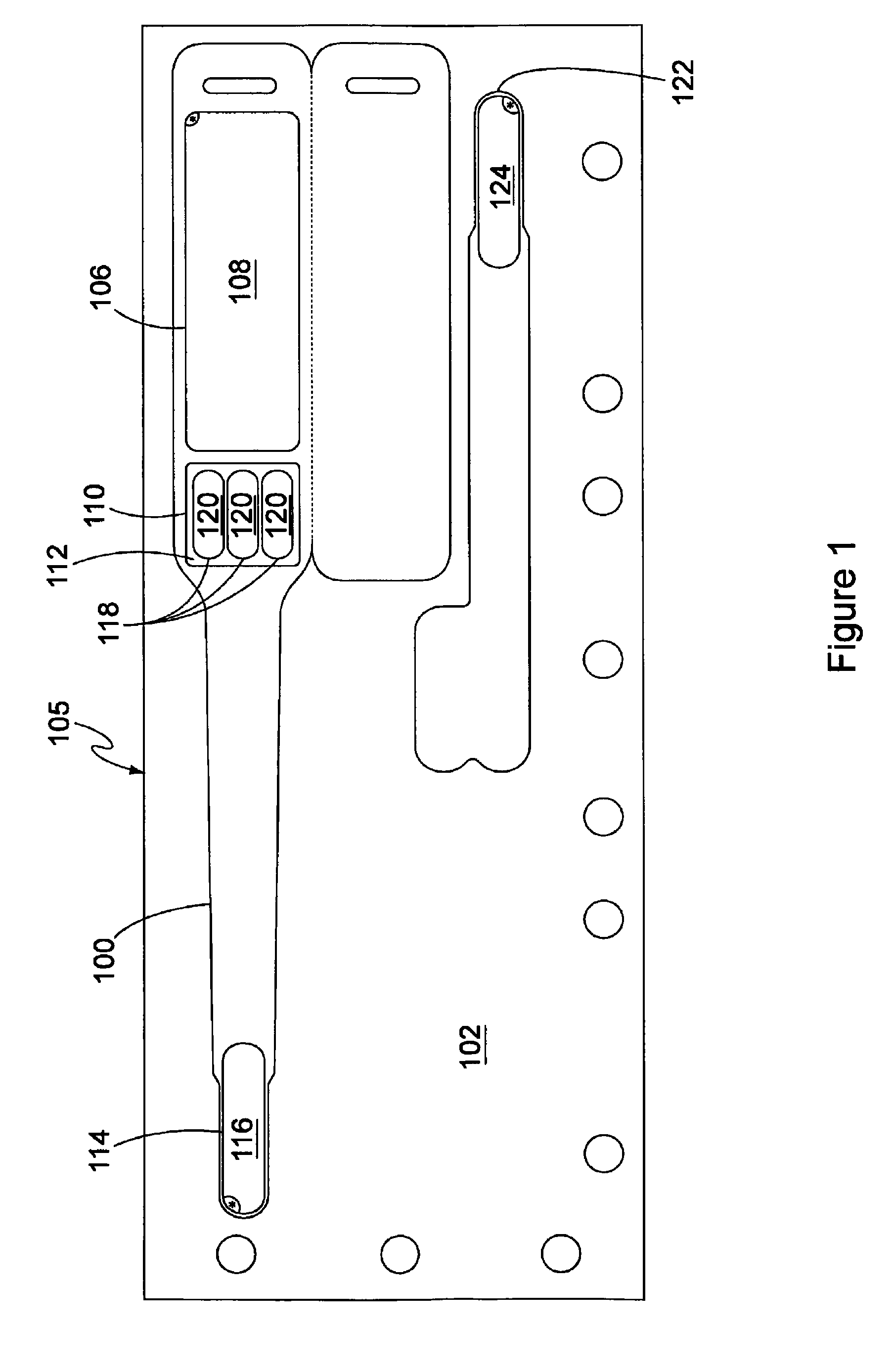

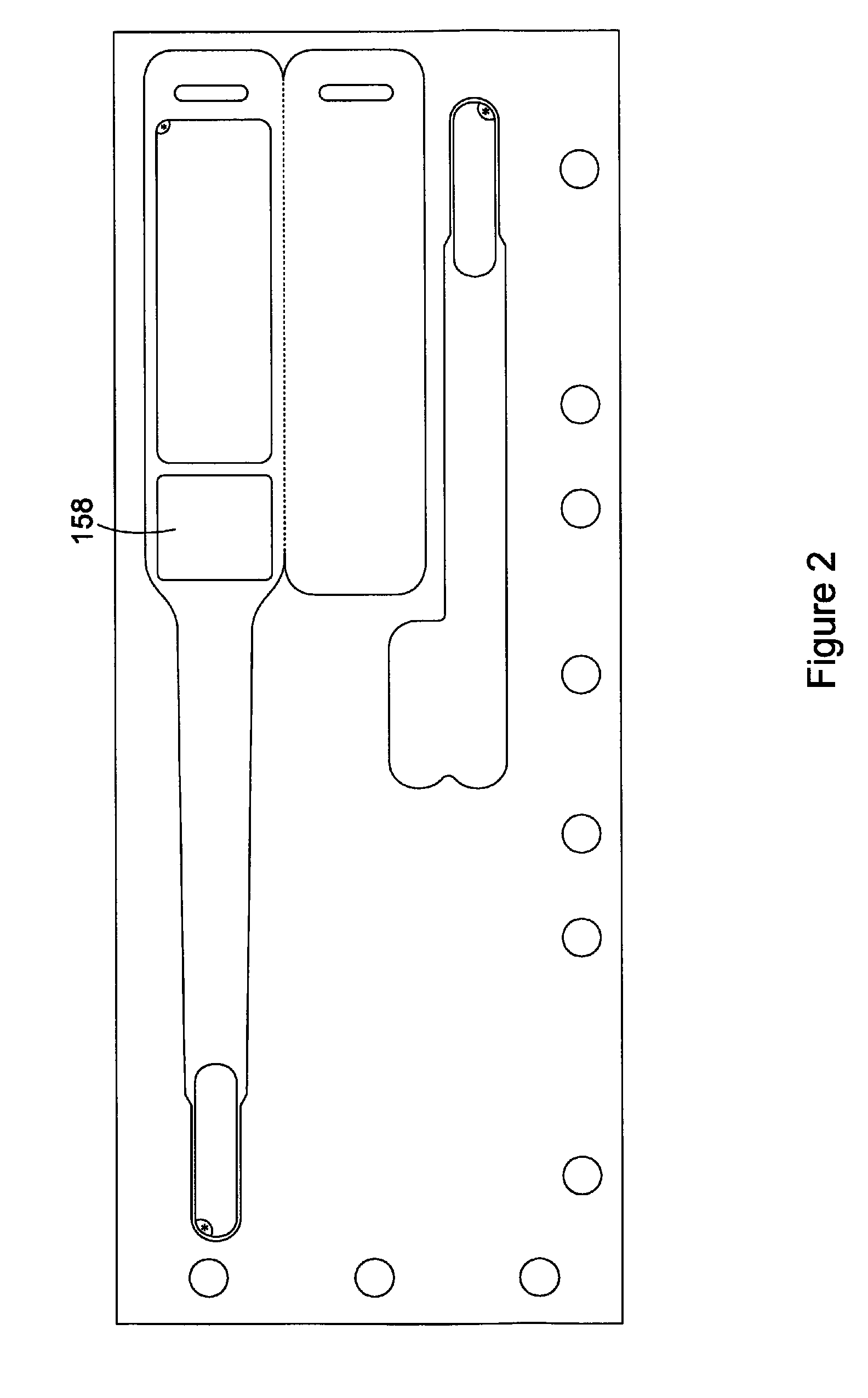

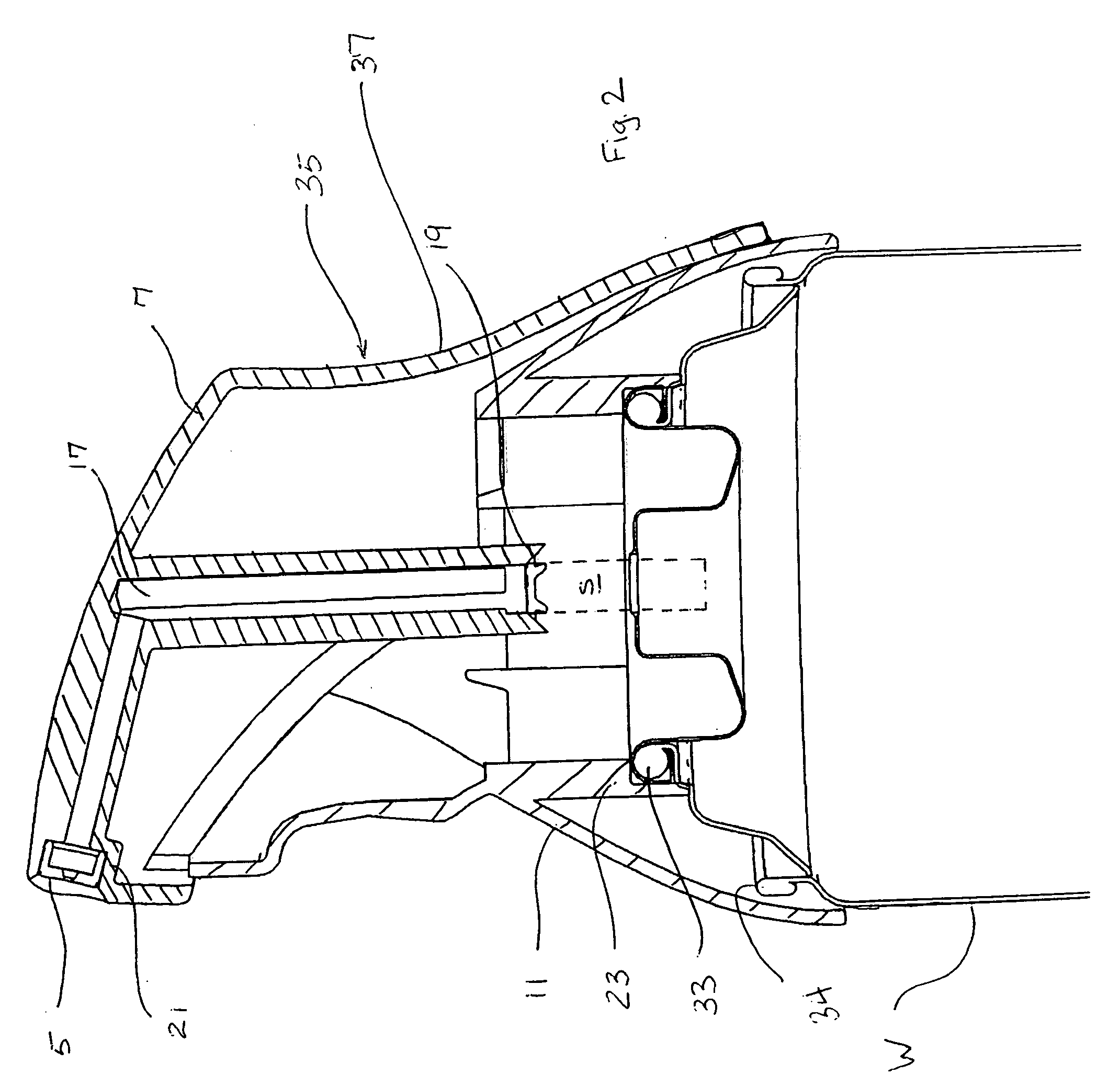

Release latch for pre-terminated cassette

ActiveUS7689089B2Increase deflectionEasy to removeOptical light guidesSelection arrangementsPatch panelMagnetic tape

A release latch for a pre-terminated cassette is described. The pre-terminated cassette includes a release latch to allow removal of the pre-terminated cassette from a patch panel, where the patch panel includes a retaining feature for retaining the pre-terminated cassette. The release latch includes a cantilever beam located on the sidewall of the pre-terminated cassette. The cantilever beam has a hinge point that allows the beam to deflect with respect to the sidewall. The release latch further includes a depressing tab provided at the distal end of the cantilever beam and a latch tab protruding from the surface of the cantilever beam between the hinge point and the depressing tab. The latch tab is capable of engagement with the retaining feature of the patch panel when the cassette is installed in the patch panel.

Owner:PANDUIT

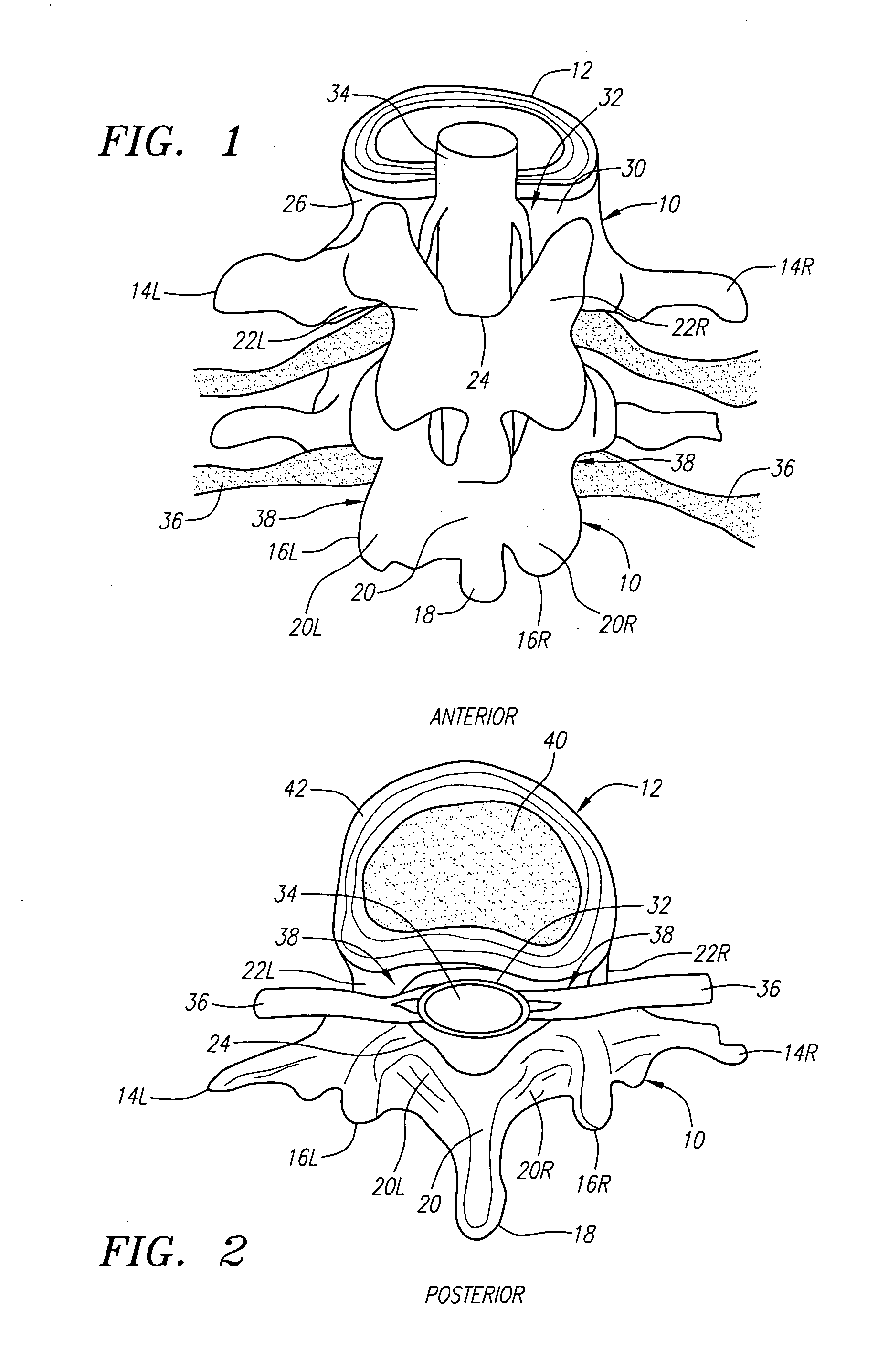

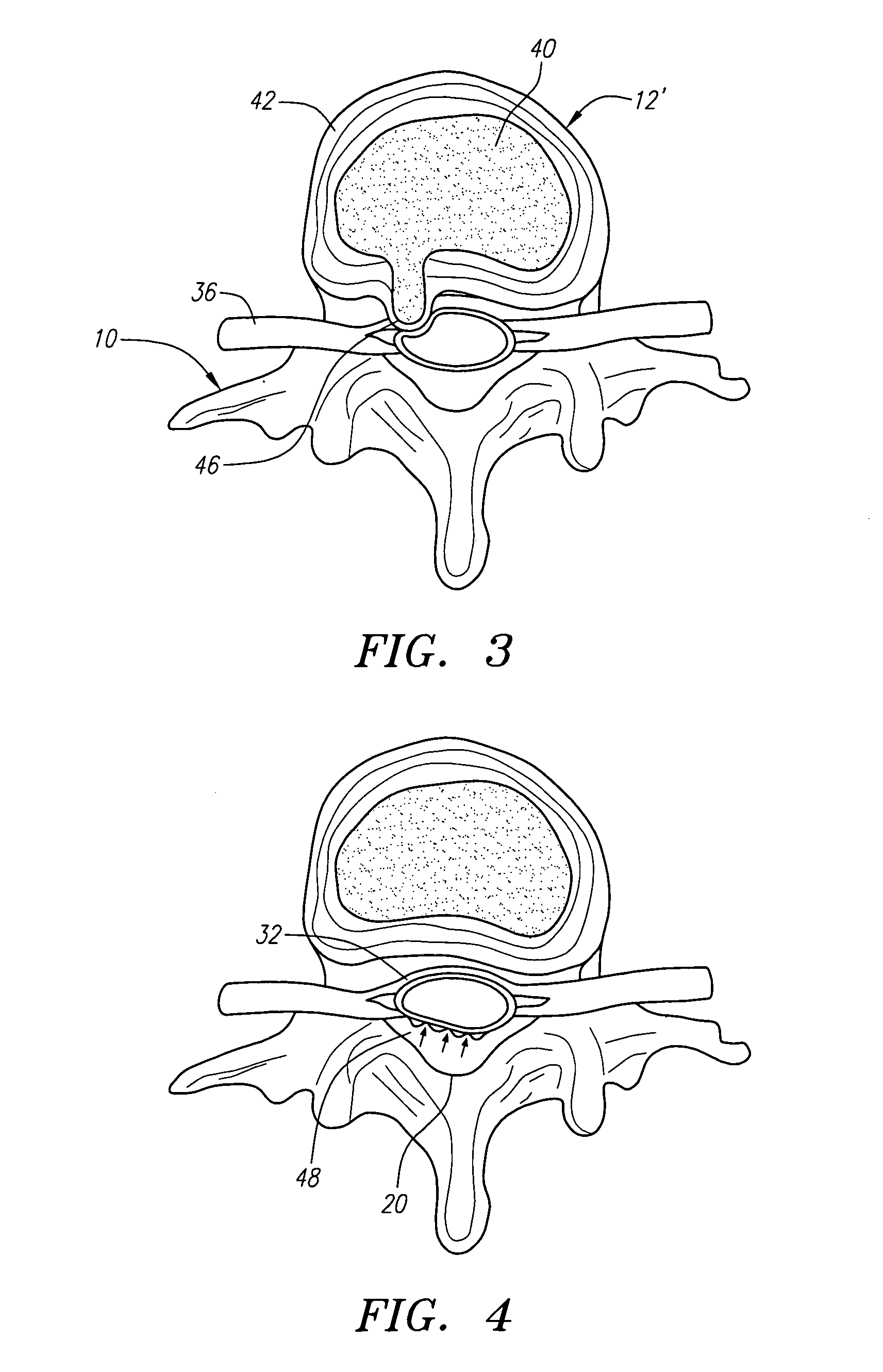

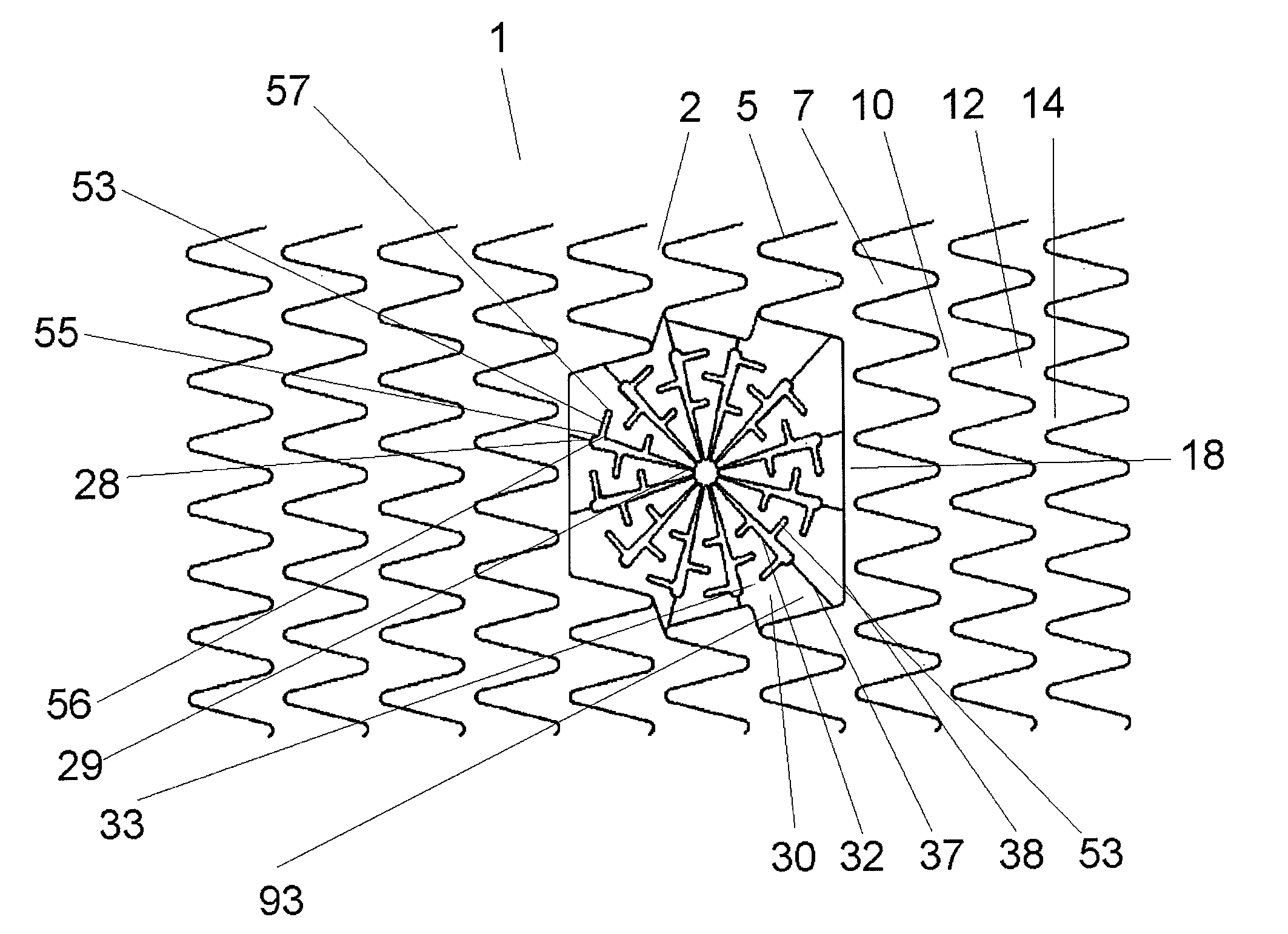

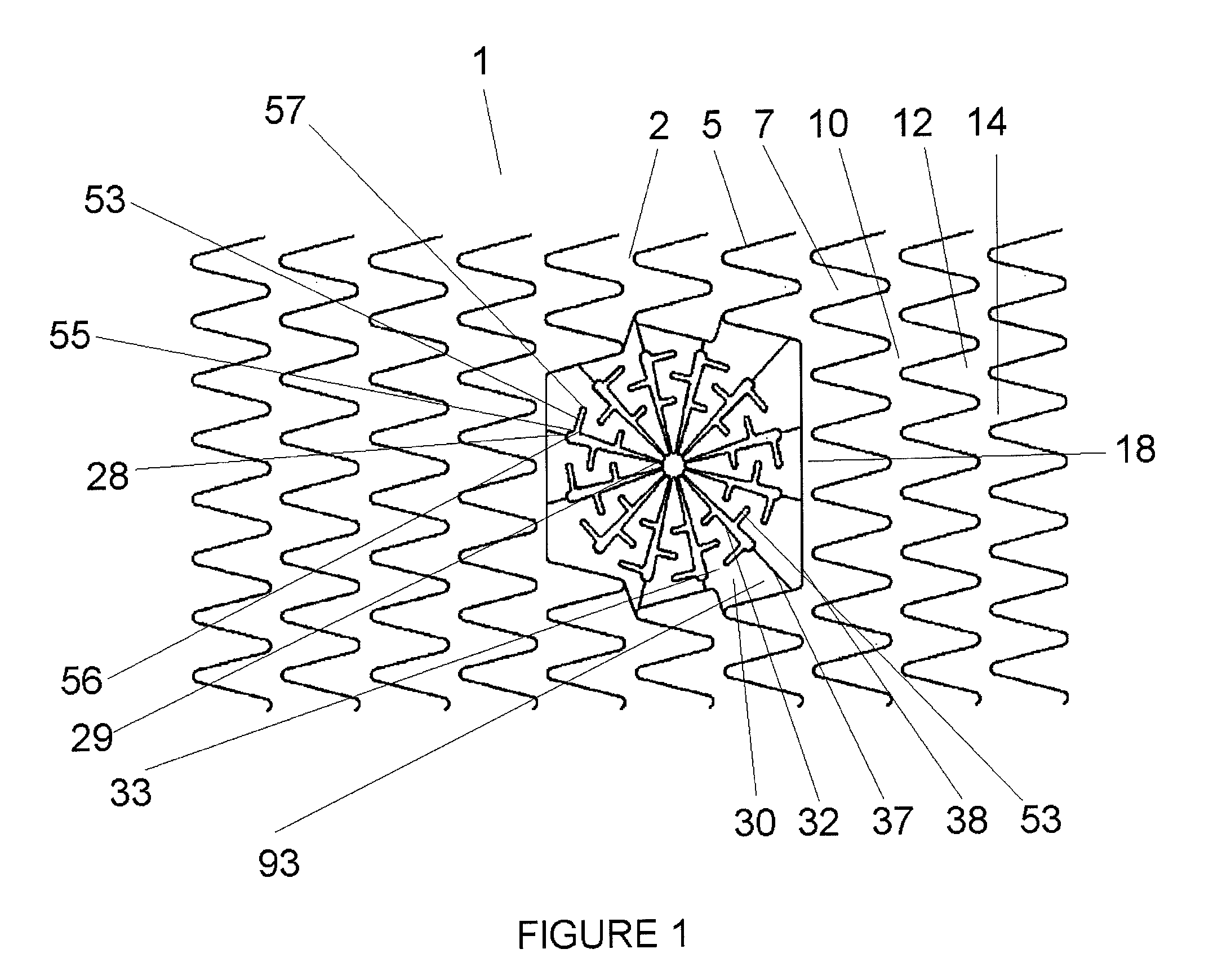

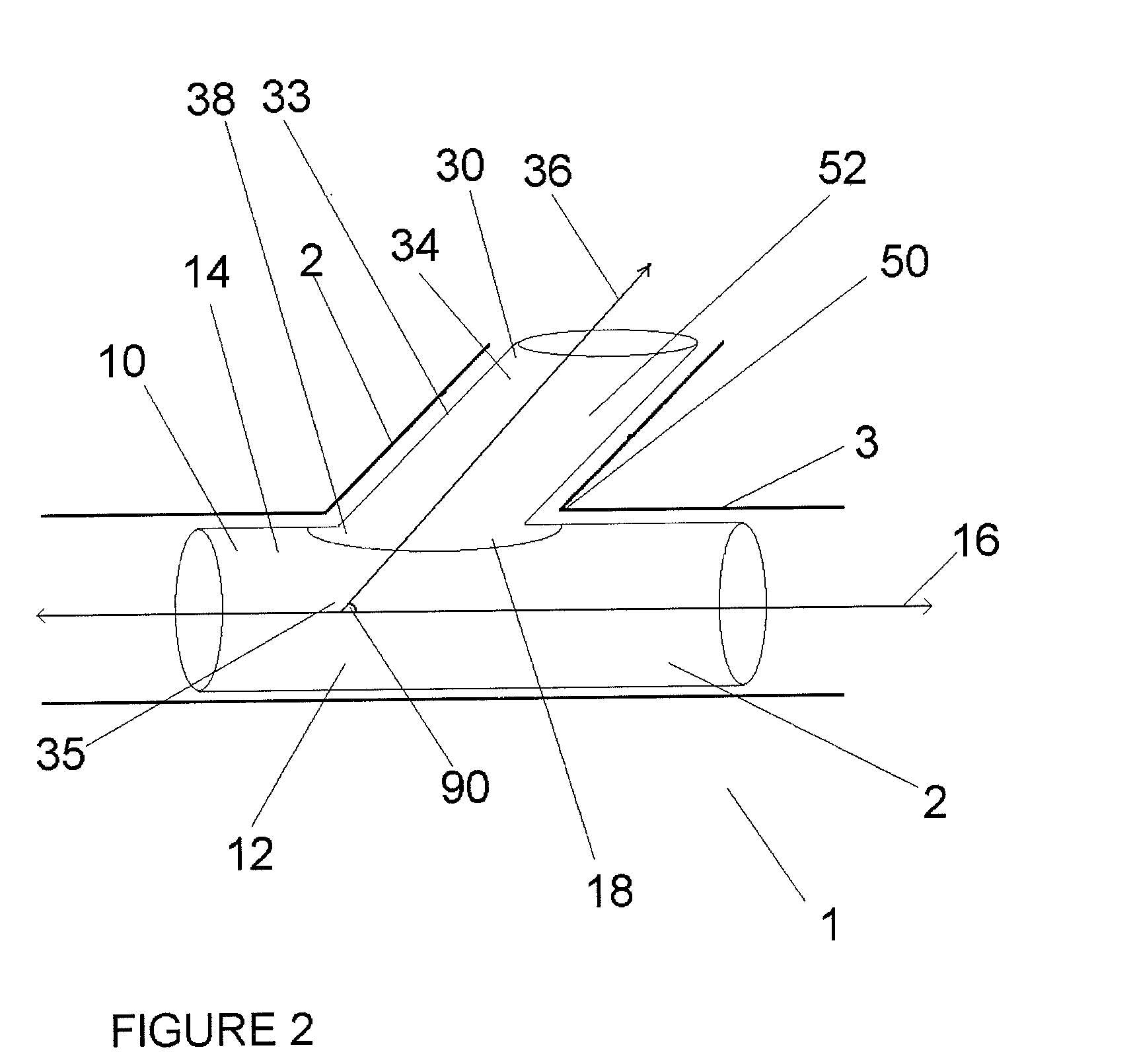

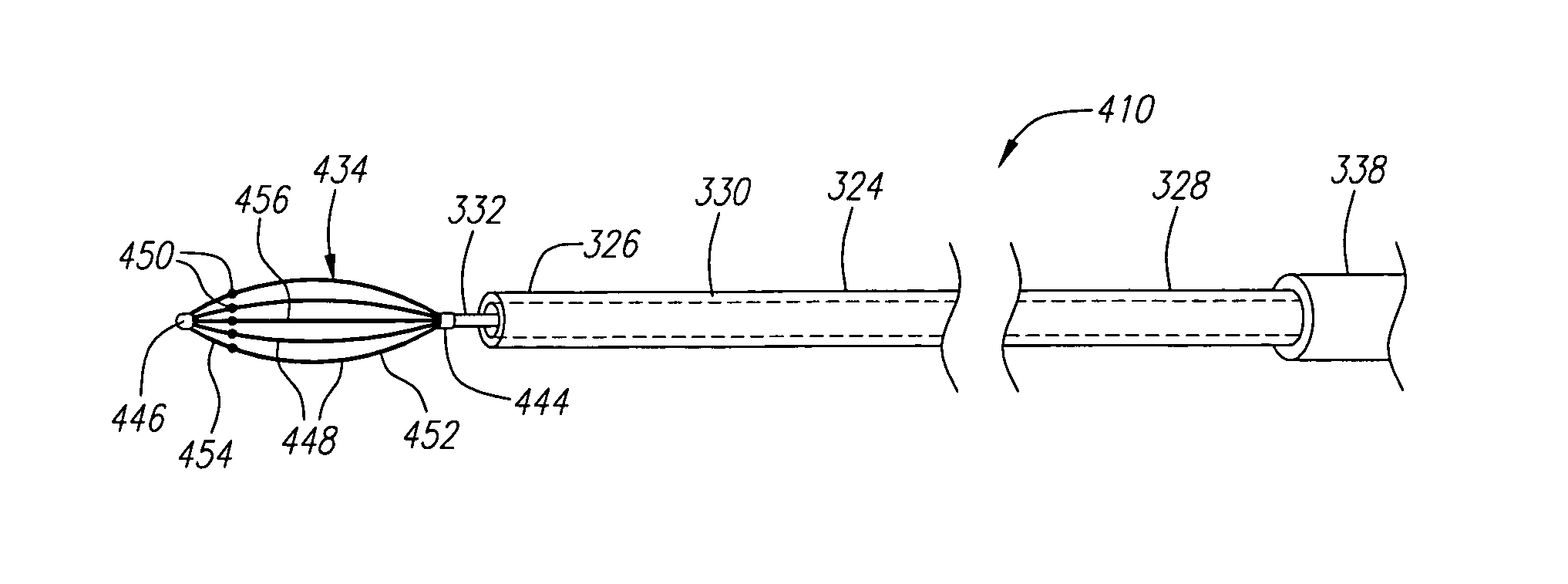

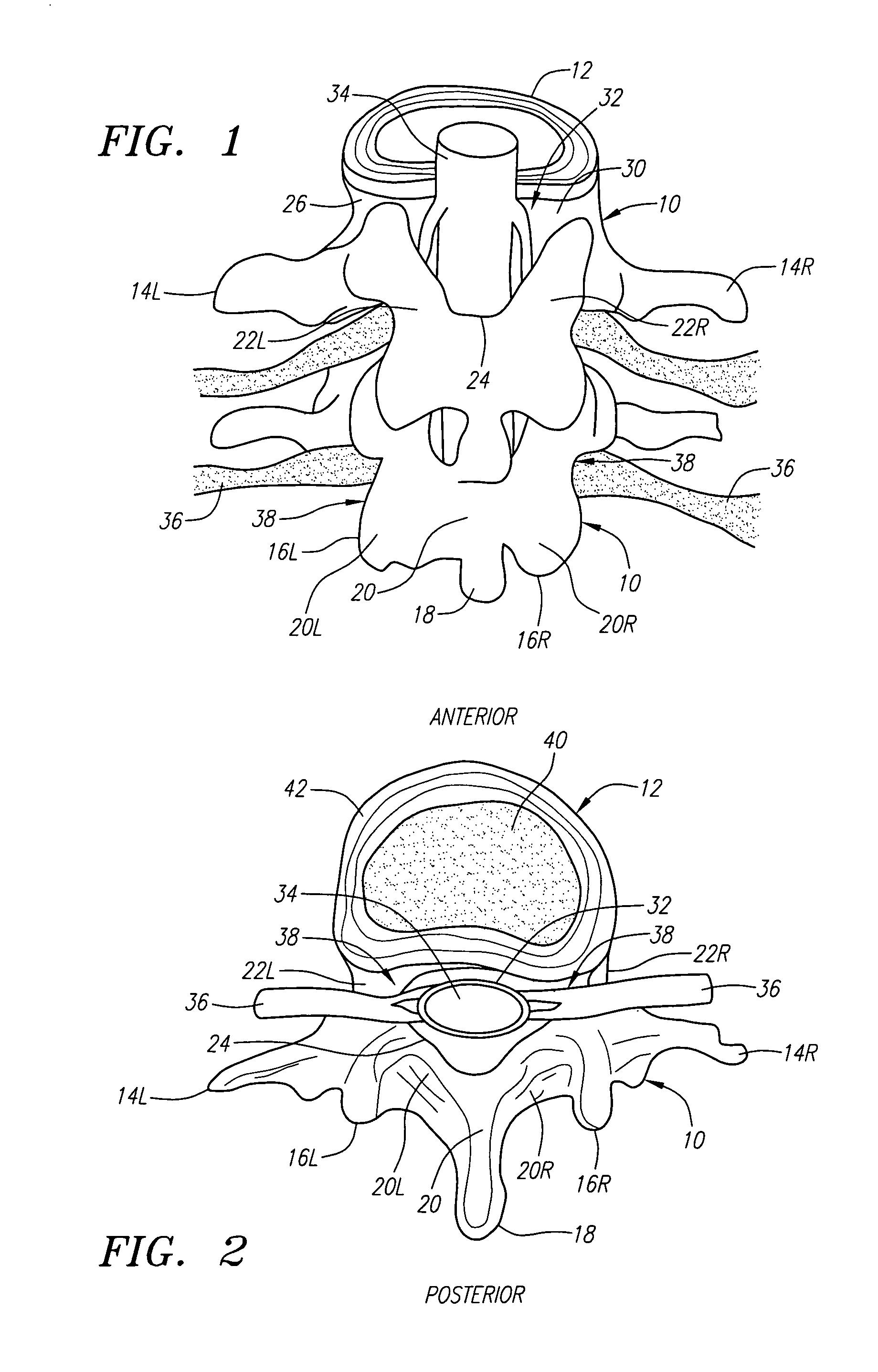

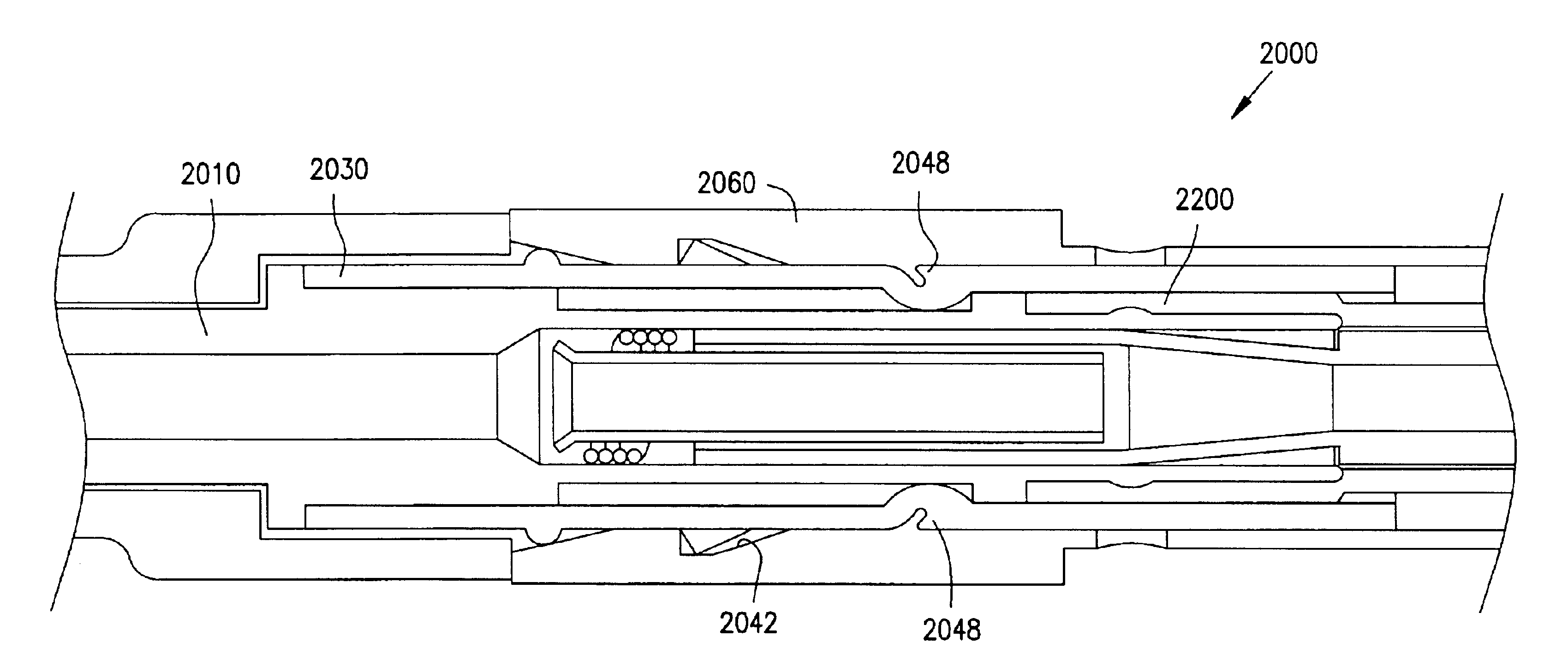

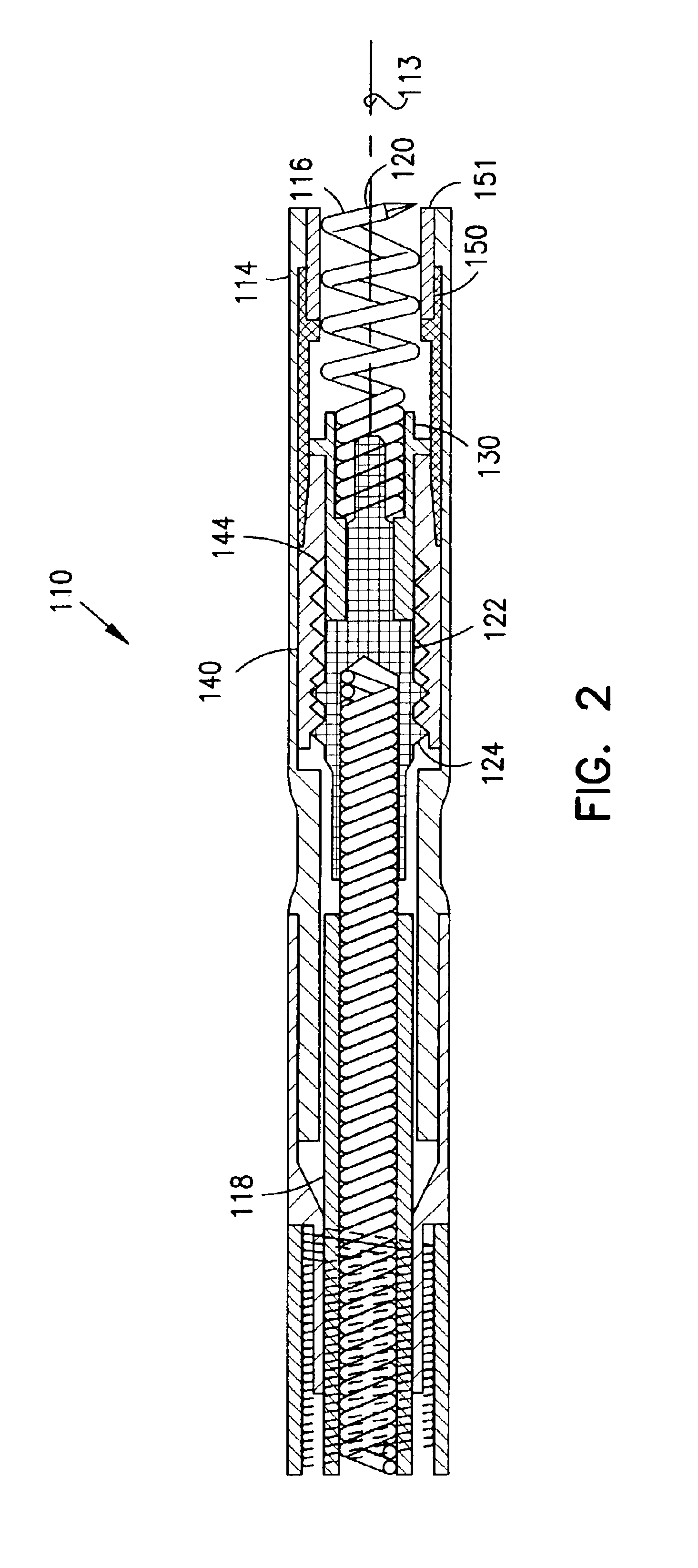

Apparatus and methods for removing vertebral bone and disc tissue

ActiveUS20050203527A1Improves Structural IntegrityPrevents and minimizes buildExcision instrumentsEndoscopic cutting instrumentsDrive shaftVertebral bone

Tissue removal probes comprise an elongated member, a drive shaft rotatably disposed within the member, and a rotatably tissue removal element mounted to the distal end of the drive shaft. One tissue removal element comprises a plurality of tissue-cutting filaments affixed at proximal and distal ends of the tissue removal element. The cutting filaments may have optional hinge points that allow the distal end of the tissue removal element to be inverted, thereby transforming the tissue removal element from a tissue-cutting device to a tissue-grasping device. Another tissue removal element may have a blunted tip to prevent distal tissue trauma and an irrigation port to provide irrigation fluid to the removed tissue and / or tissue removal element. Another tissue removal element has a proximal and distal spiral grooves that are oppositely pitched, so that removed tissue can be collected in the middle of the tissue removal element. Another tissue removal element has independent counter-rotating tissue removal elements to maintain stability during a bone cutting procedure. Still another tissue removal element takes the form of a drill bit with fluted cutting grooves. Yet another tissue removal element has cascading tissue-cutting notches that can be reciprocatably moved to remove tissue within a hole.

Owner:BOSTON SCI SCIMED INC

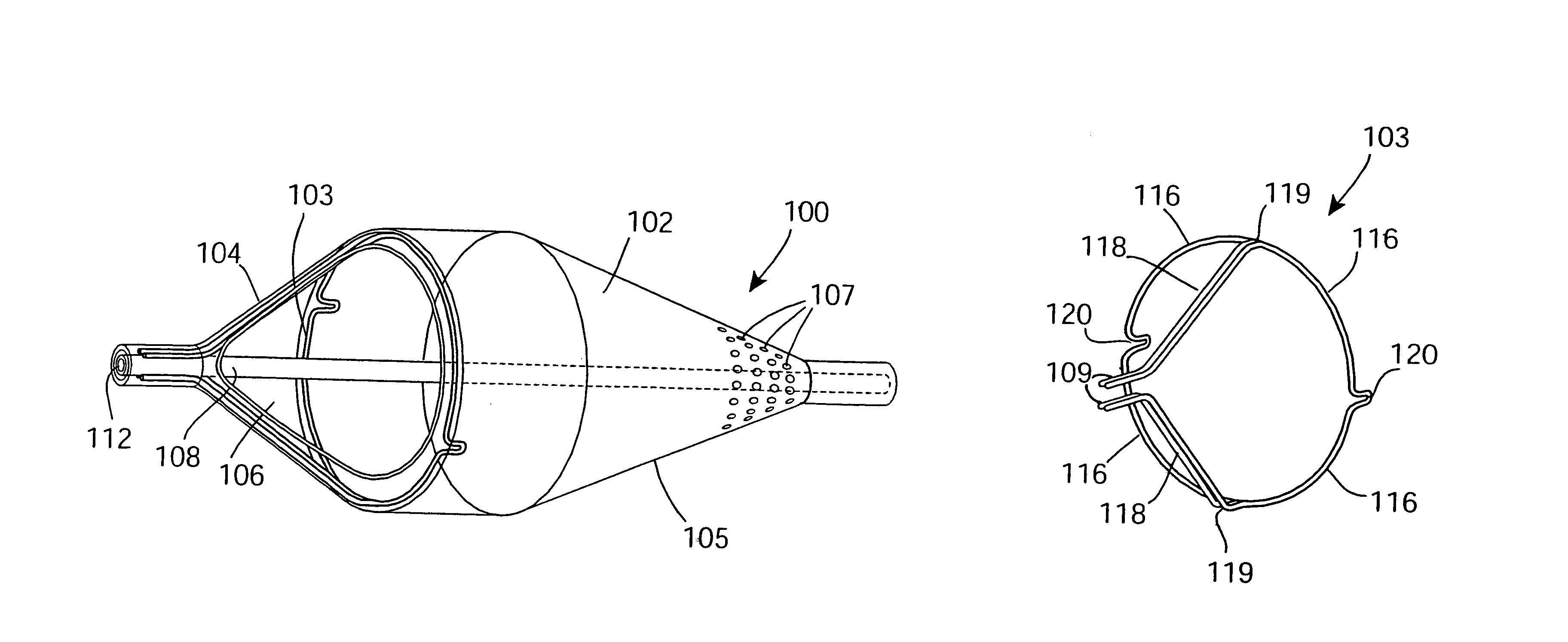

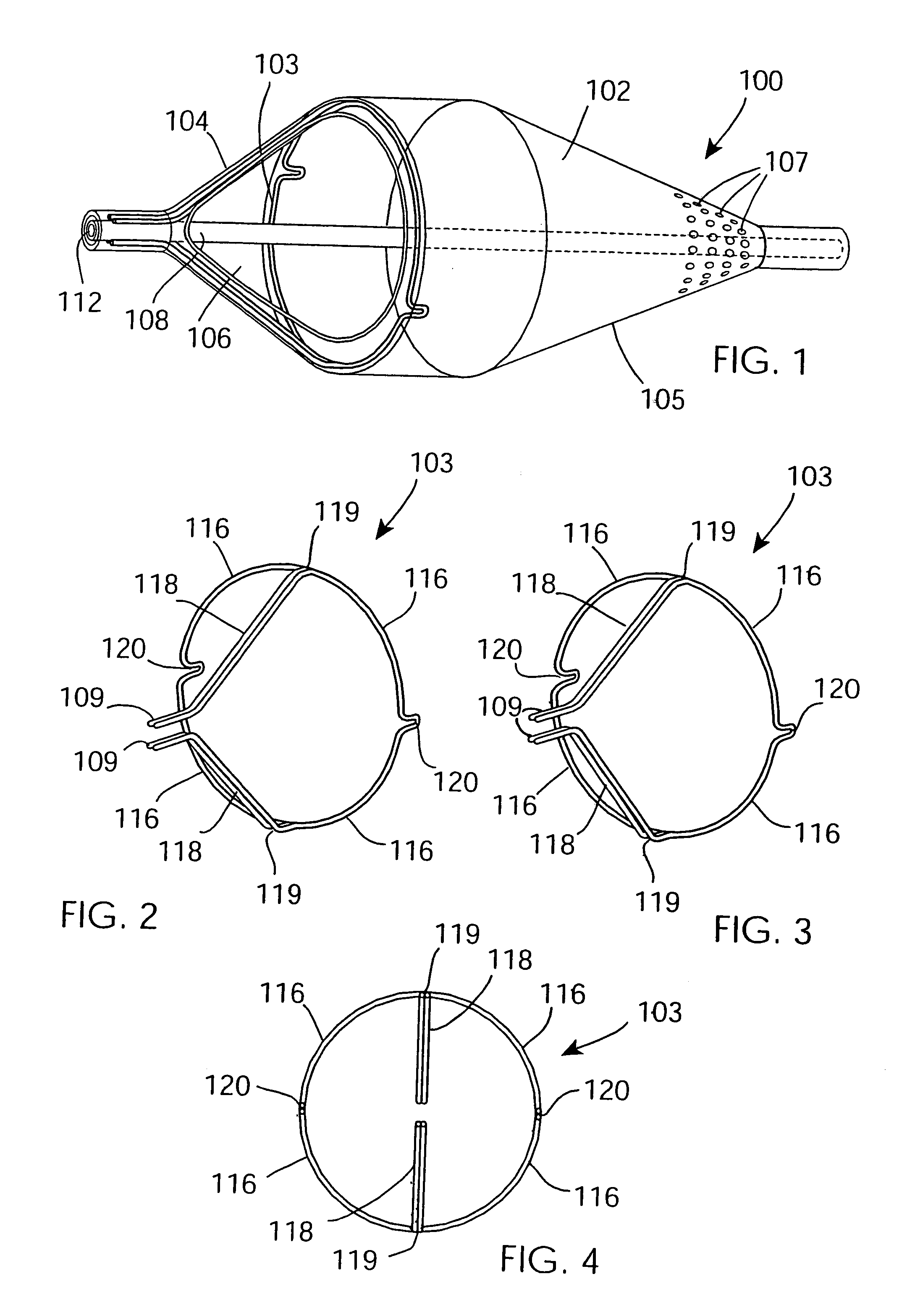

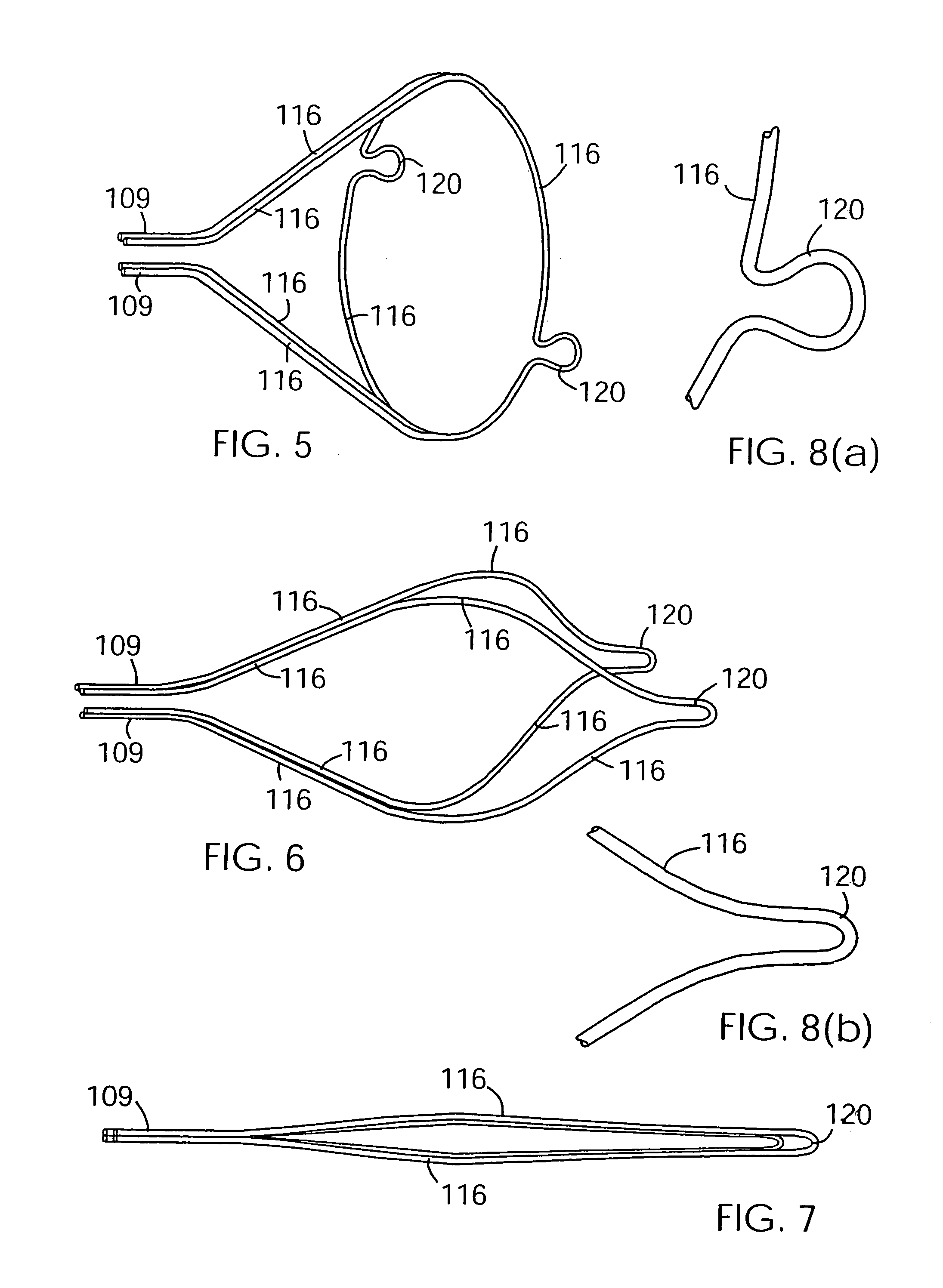

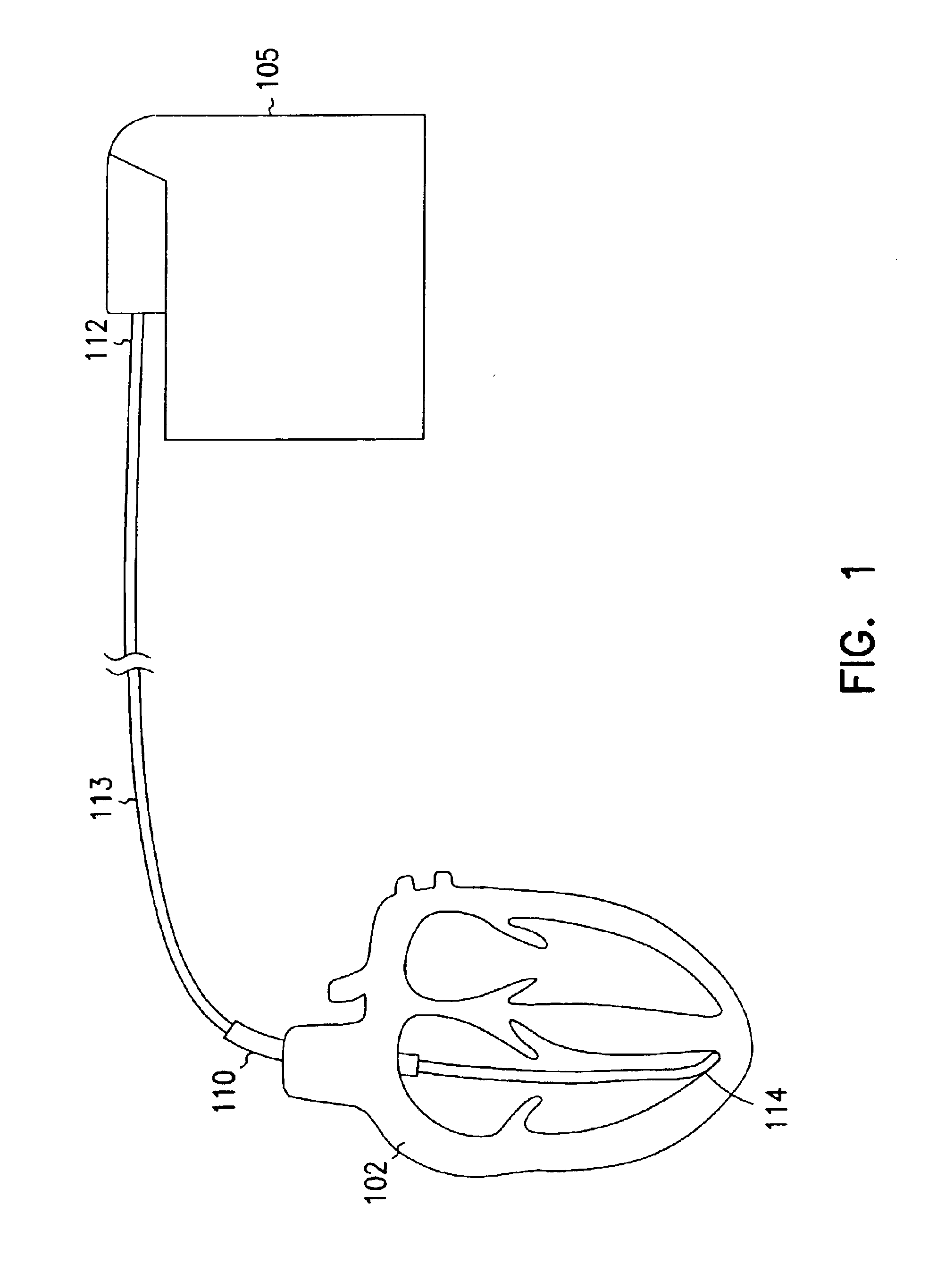

Support frame for an embolic protection device

InactiveUS7037320B2Good flexibilitySlow its advancementSurgeryDilatorsEmbolic Protection DevicesMechanical engineering

A support 103 for an embolic protection device comprises round wires 116 which may form one or more support hoops for a filter body. The circumferential hoop formed by the wires 116 ensures that in the expanded position, the filter body 102 will be supported by the support frame 103 in circumferential apposition with the interior wall of the vasculature. The wires 116 may have a strain distributing linkage element in the form of a loop 120 in. The loop 120 acts as a diameter or circumference adjuster allowing an embolic protection device to adapt to different vessel contours and sizes whilst maintaining apposition with the vessel wall. The strain relieving geometry of the loops enhances the compliance of the bend points without creating a weakened hinge point, thus ensuring that there is no discontinuity in the circumferential seal against the vessel wall.

Owner:SALVIAC

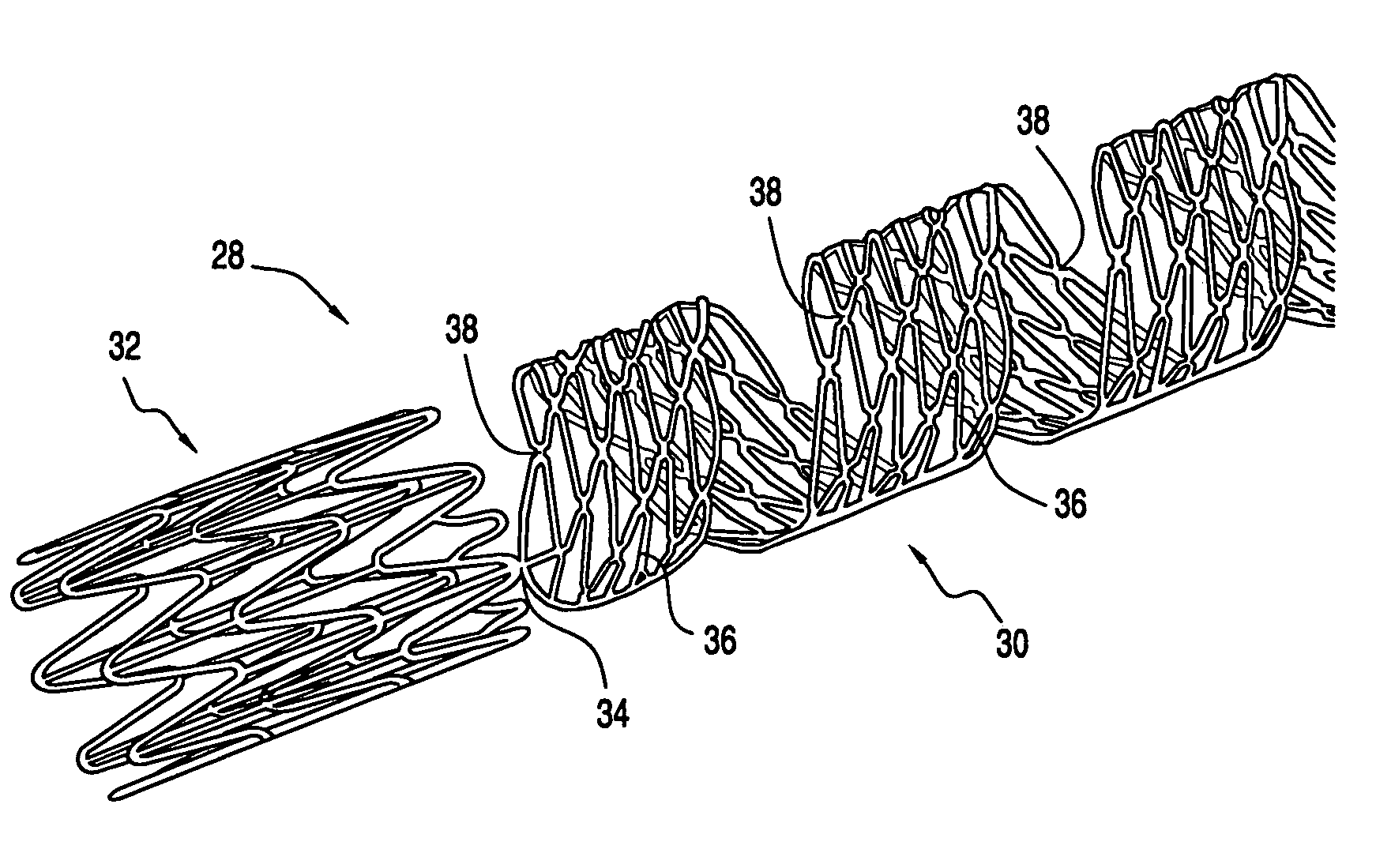

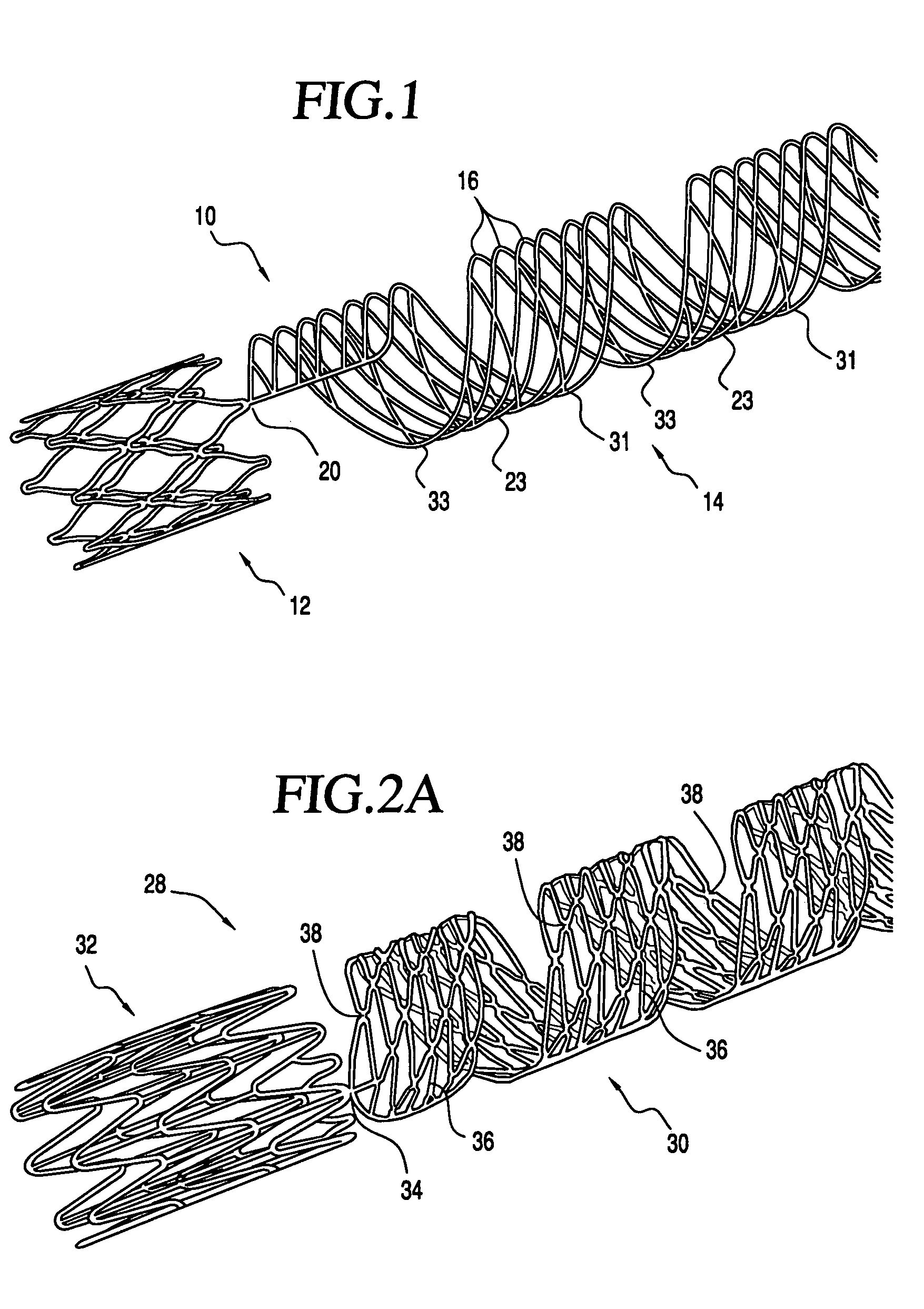

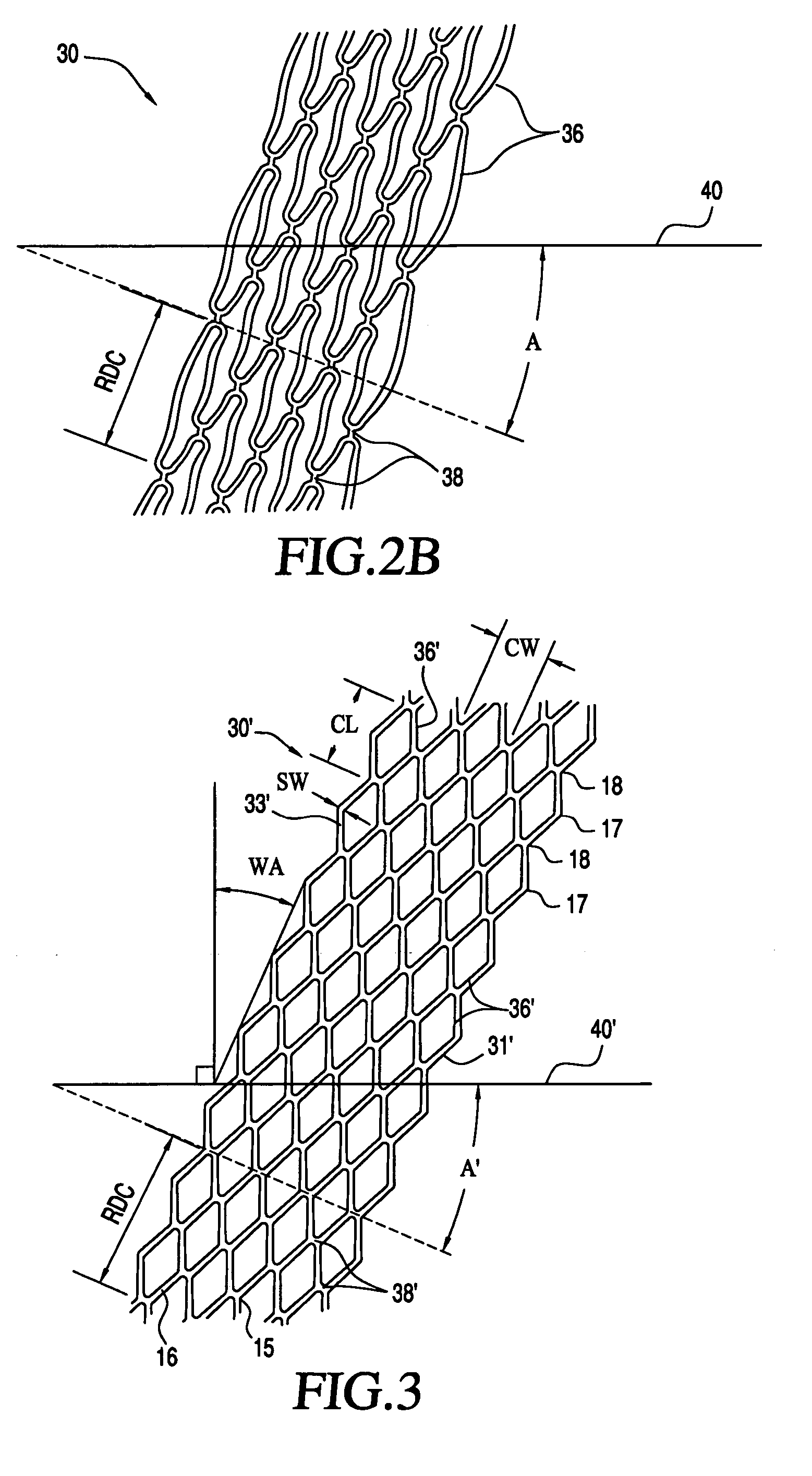

Vascular prosthesis having improved flexibility and nested cell delivery configuration

InactiveUS20060030934A1Increase flexibilityReduced delivery profileStentsBlood vesselsVascular prosthesisBiomedical engineering

An implantable vascular prosthesis having improved flexibility is provided comprising a helical body portion having a reduced delivery configuration and an expanded deployed configuration, the helical body portion comprising a plurality of cells interconnected by hinge points that enhances flexibility of the vascular prosthesis and provides at least partial nesting of adjacent turns of the helical body portion in the reduced delivery configuration.

Owner:NOVOSTENT CORP

Release Latch for Pre-Terminated Cassette

ActiveUS20080089656A1Increase deflectionEasy to removeOptical light guidesSelection arrangementsPatch panelEngineering

A release latch for a pre-terminated cassette is described. The pre-terminated cassette includes a release latch to allow removal of the pre-terminated cassette from a patch panel, where the patch panel includes a retaining feature for retaining the pre-terminated cassette. The release latch includes a cantilever beam located on the sidewall of the pre-terminated cassette. The cantilever beam has a hinge point that allows the beam to deflect with respect to the sidewall. The release latch further includes a depressing tab provided at the distal end of the cantilever beam and a latch tab protruding from the surface of the cantilever beam between the hinge point and the depressing tab. The latch tab is capable of engagement with the retaining feature of the patch panel when the cassette is installed in the patch panel.

Owner:PANDUIT

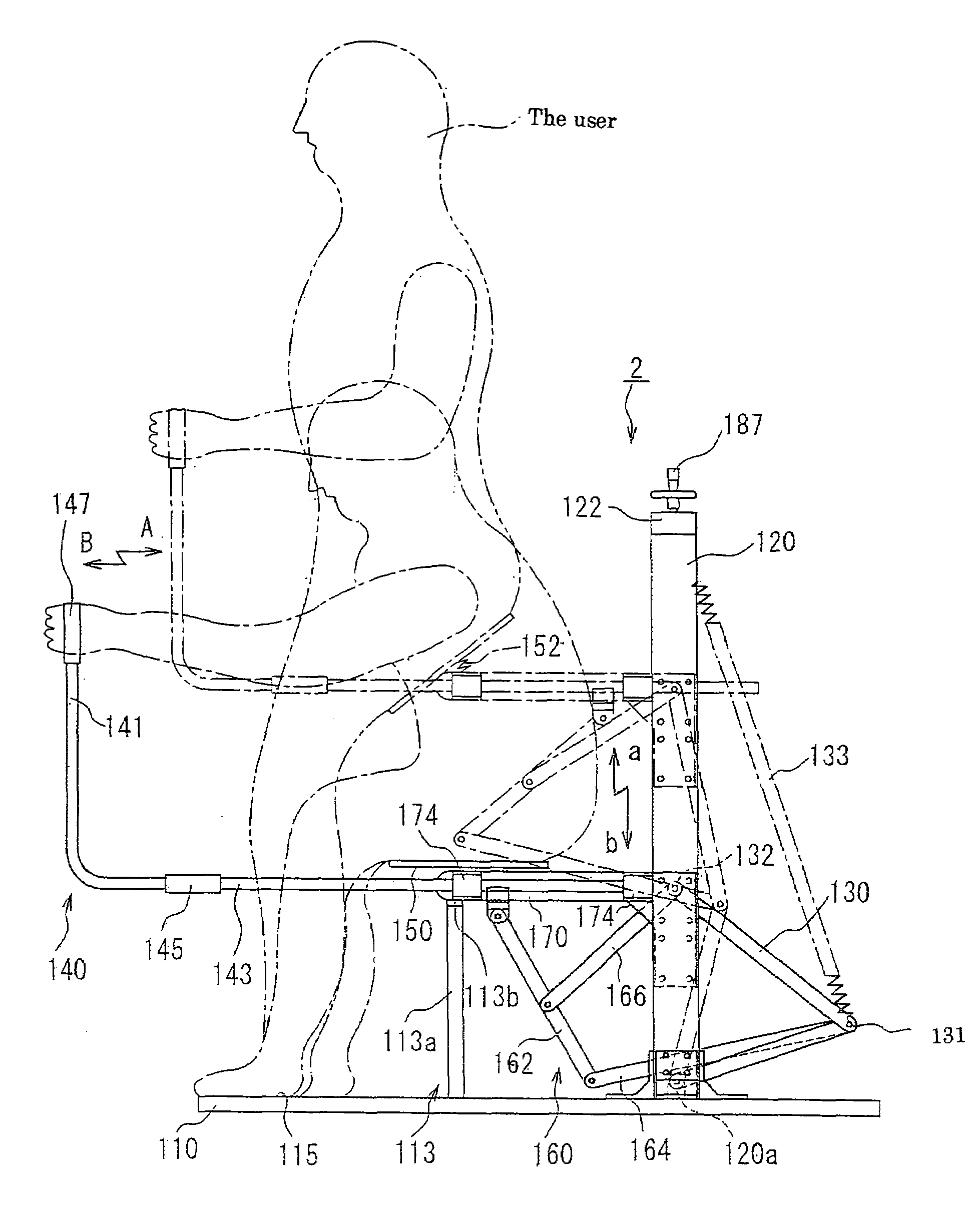

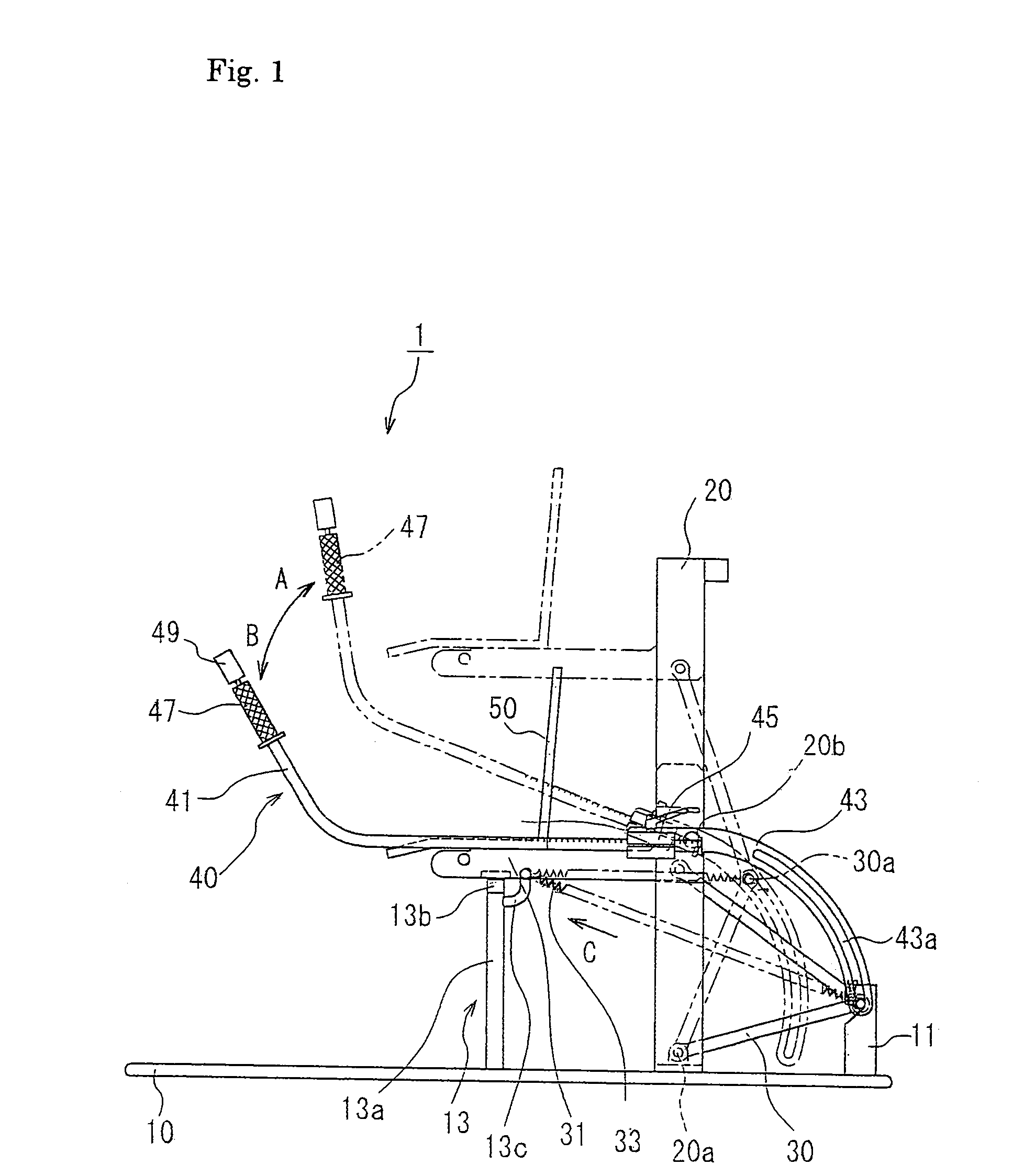

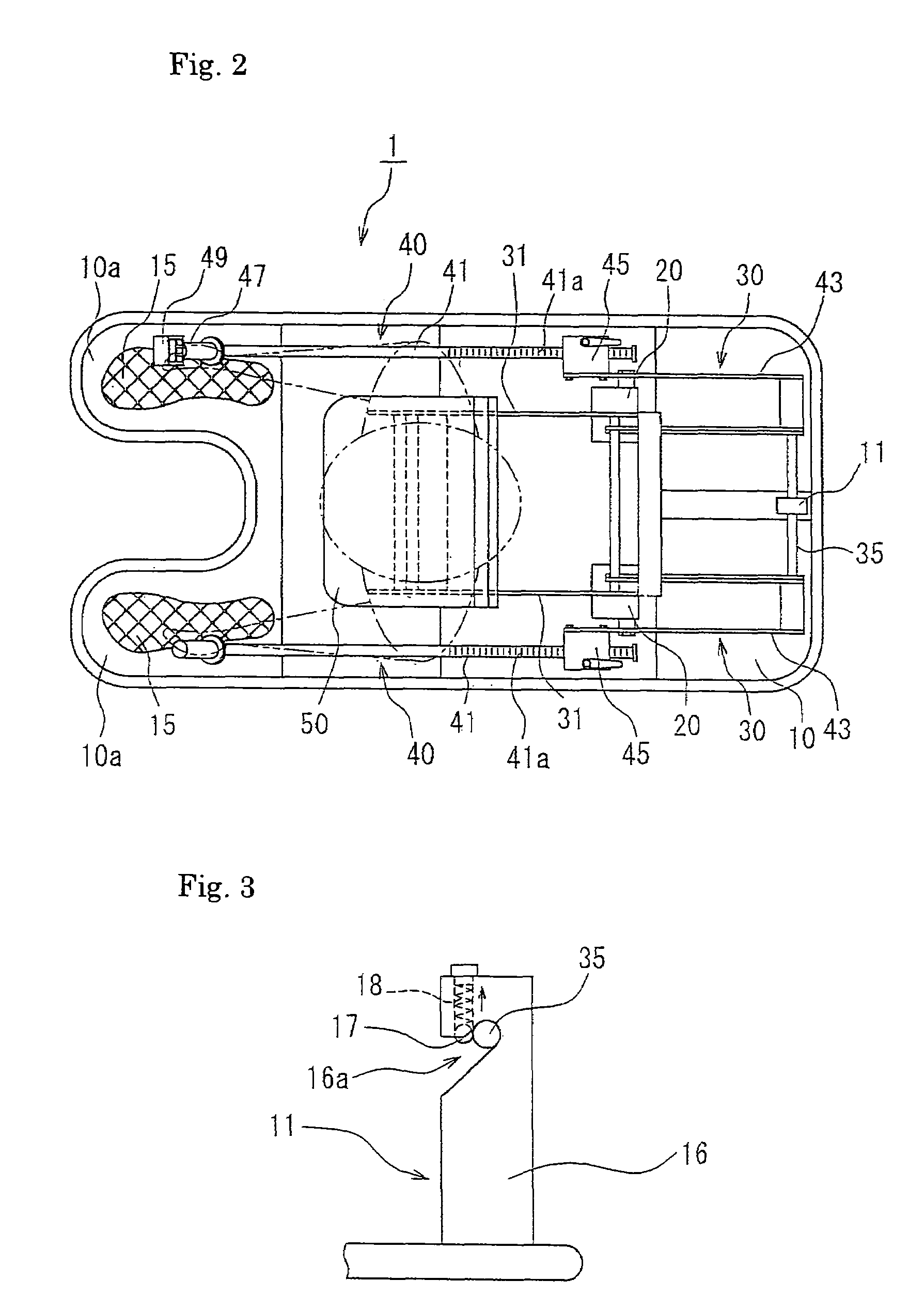

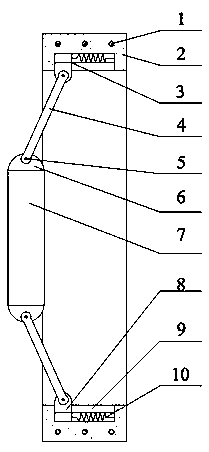

Exercise assisting machine

InactiveUS7247128B2Done safelyReduce the burden onVehicle seatsResilient force resistorsEngineeringHinge point

An exercise assisting instrument assists the user's knee-bending exercise, and lightens a burden and maintains safety of the user. It has a base 10, supporting columns 20, lifting mechanisms 30 consisting of lifting arms, lever arms 40, and a chair 50. A three-member linkage system is formed by the supporting columns 20 and the lifting mechanisms 30, so that the chair 50 may move upward and downward. Further, it is equipped with an upward movement assisting device 33, which provides a force in the raising direction to the hinge point 30a of the lifting arms, so that stand-up movement of the user is assisted and lightening the user's burden is possible. Moreover, a locking device 11 and a stopper 13 are equipped, so the user's safety may be improved.

Owner:OGA

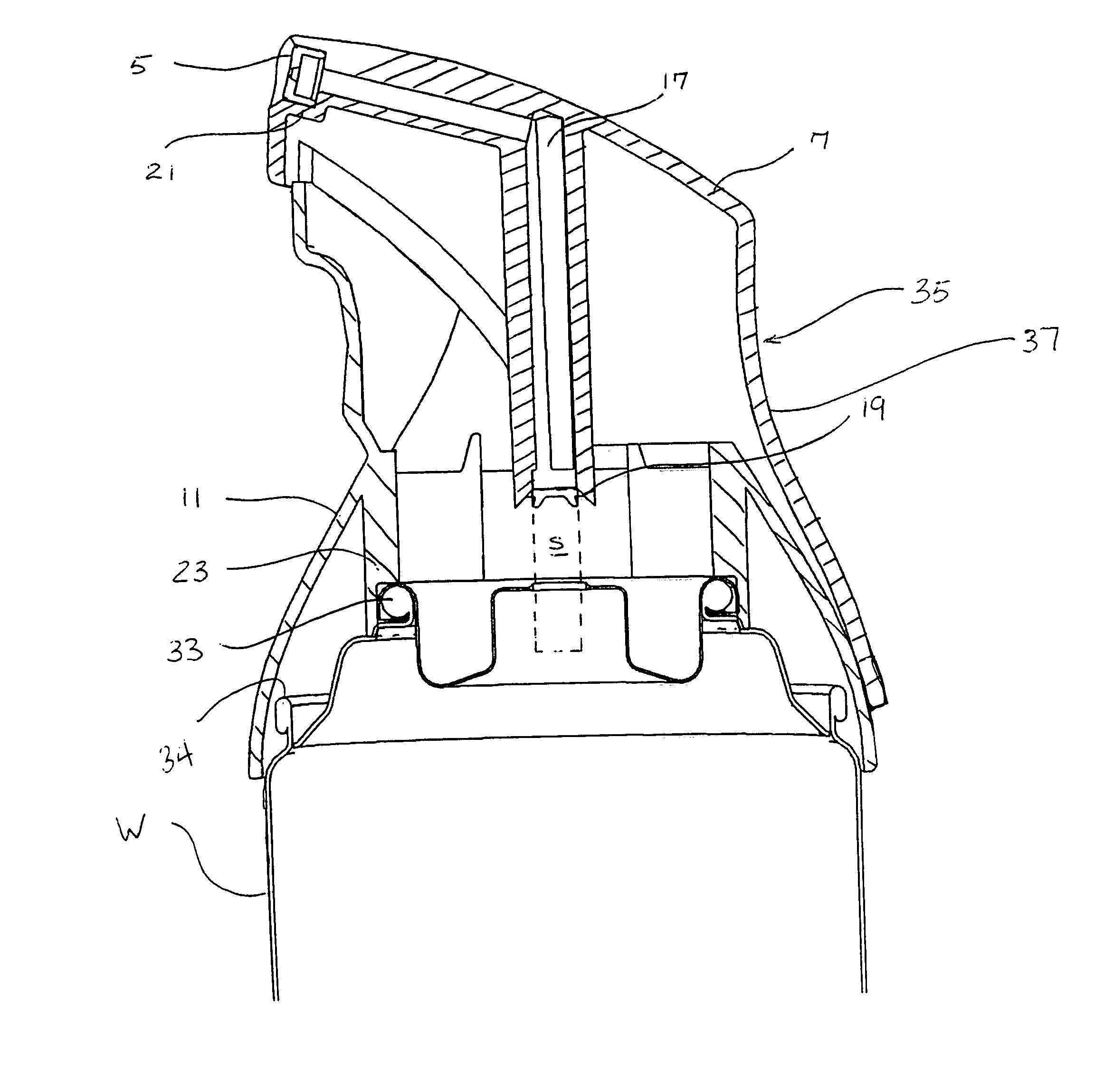

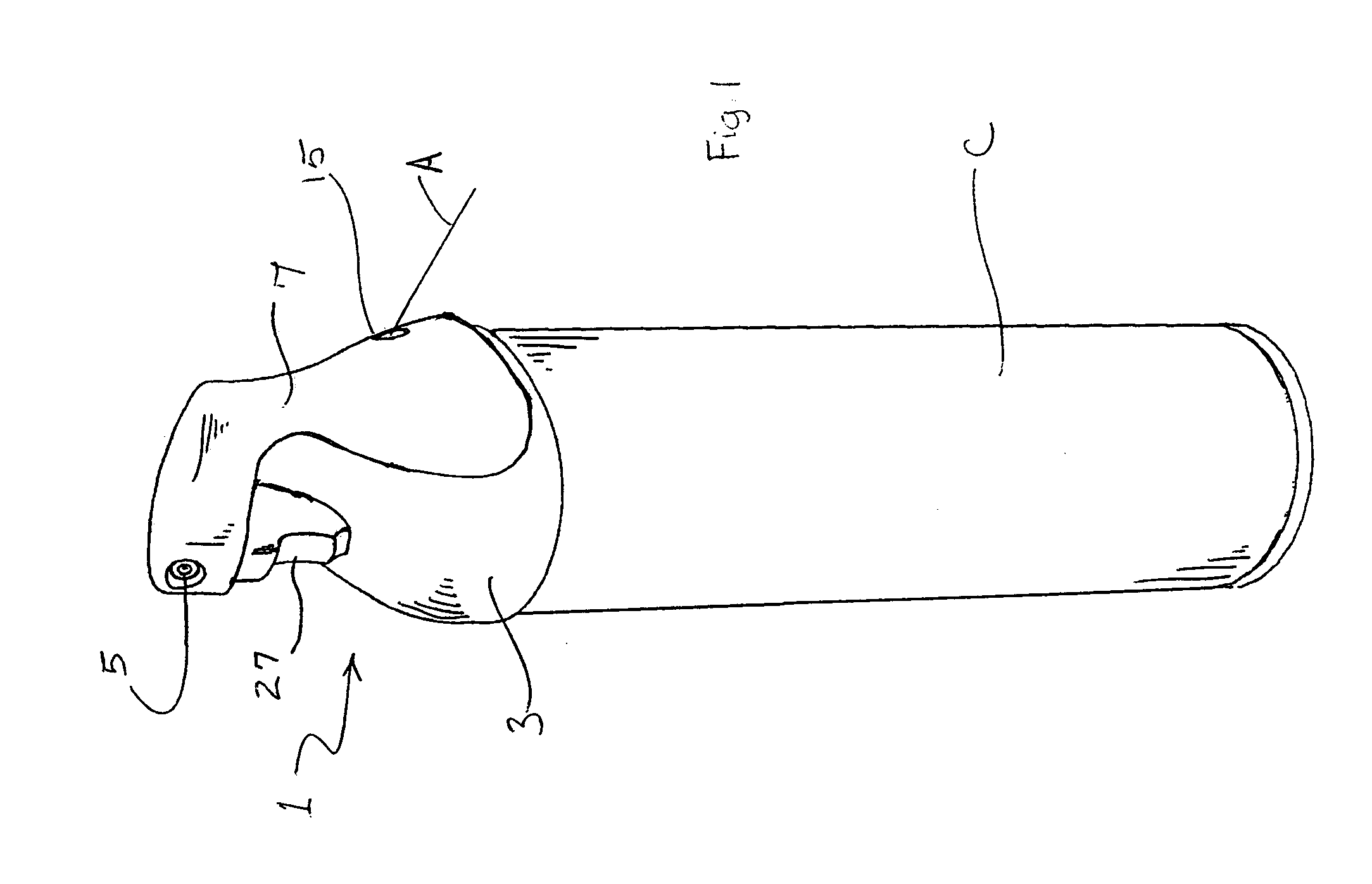

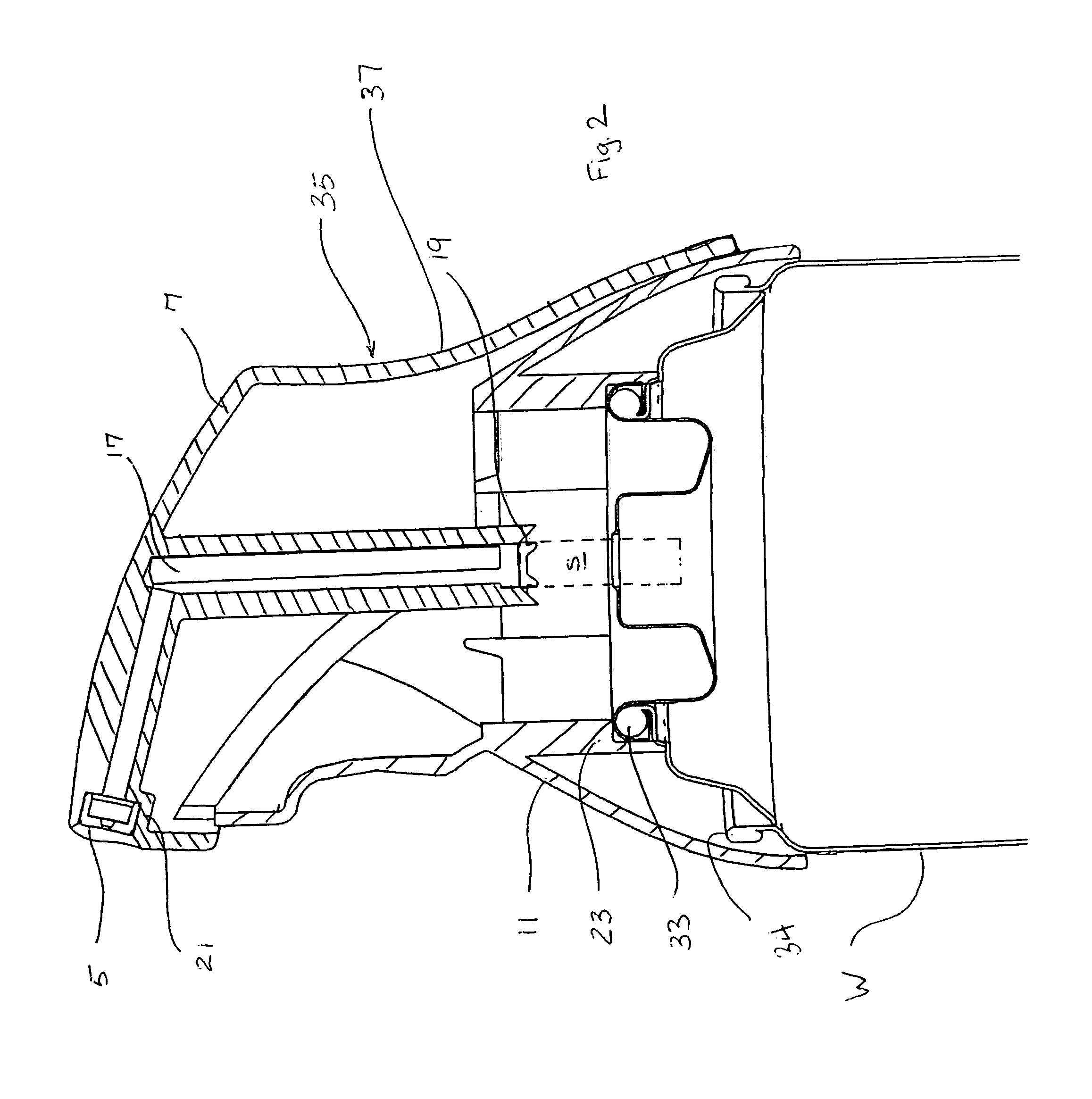

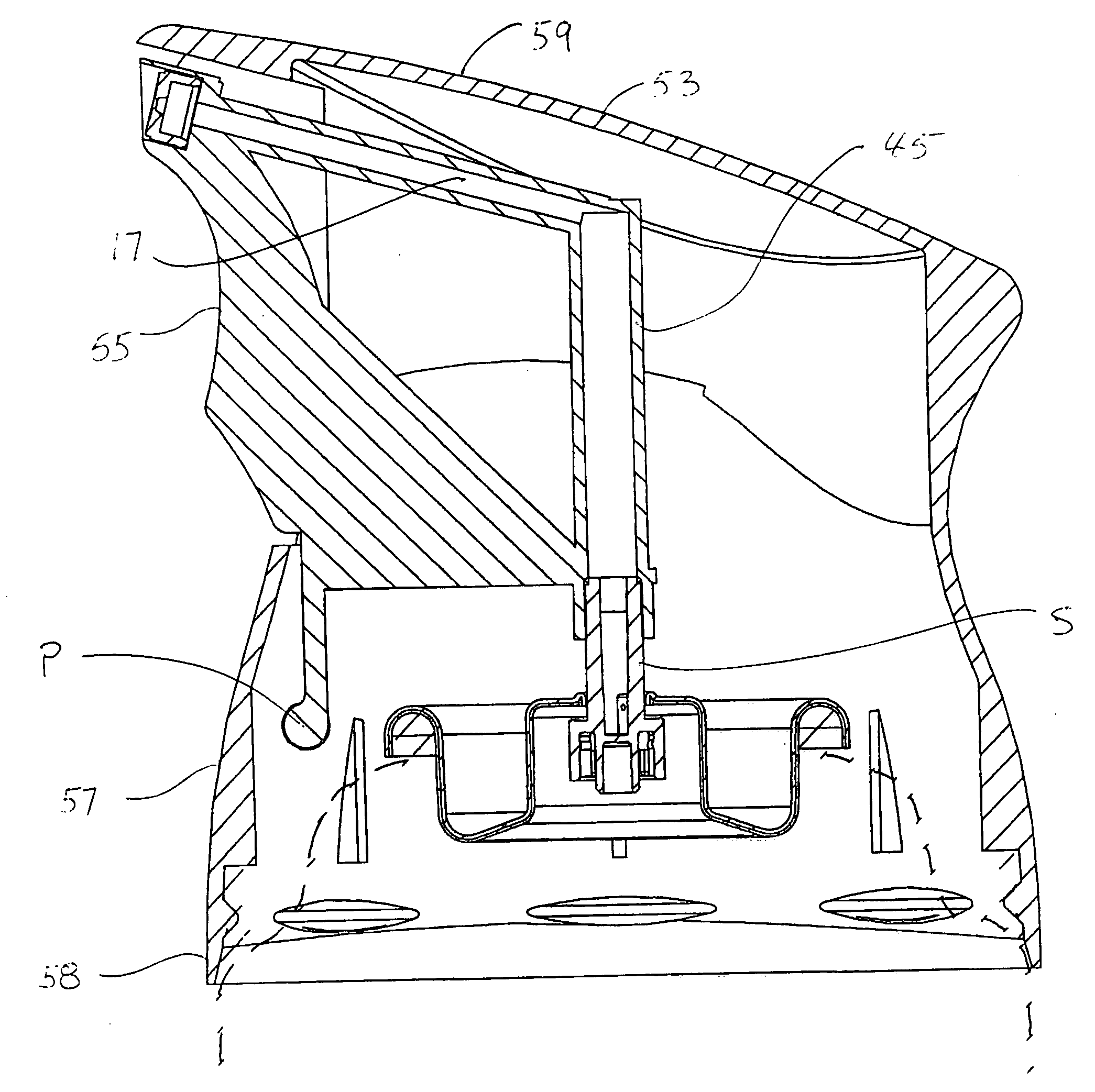

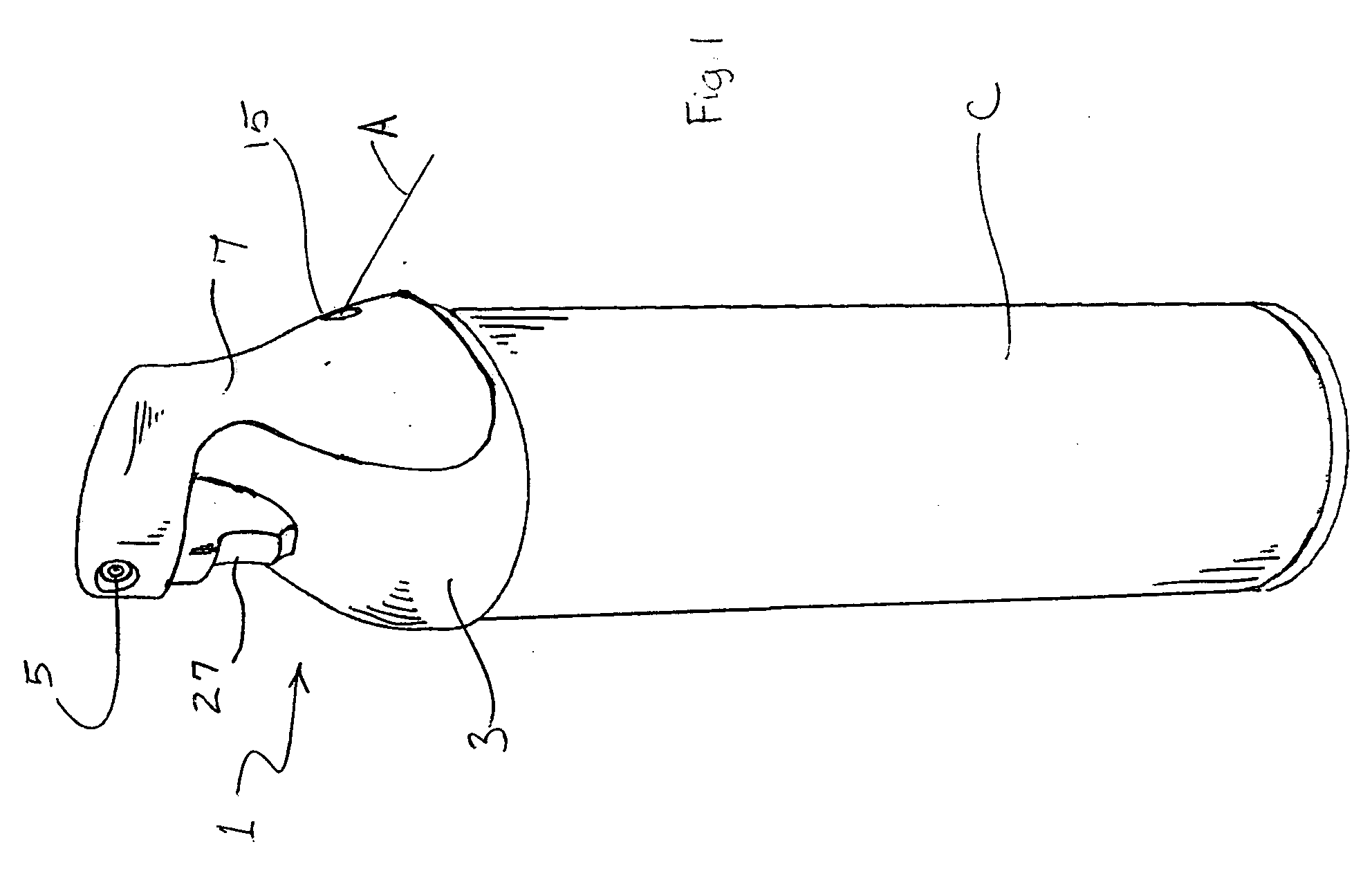

Spray actuating mechanism for a dispensing canister

ActiveUS7204393B2Economical and easy to manufacture and assembleFunction increaseLiquid dispensingEngineeringActuator

A spray actuator for a pressurized aerosol canister that simplifies the mechanical moving parts of a spray actuator to a body and a trigger and a third nozzle piece being inserted at the very end of the product dispensing passage either in the body or the trigger. The moveable trigger rotates about a pivot or hinge point on the body and is biased by engagement with the valve stem or an additional spring return into a neutral unactuated position where the product is not dispensed. When dispensing of the product is desired, the user grasps the actuator and pulls the trigger against the body and overcomes the bias of the valve stem and the valve is actuated as discussed above to dispense the pressurized aerosol product.

Owner:SUMMIT PACKAGING SYST INC

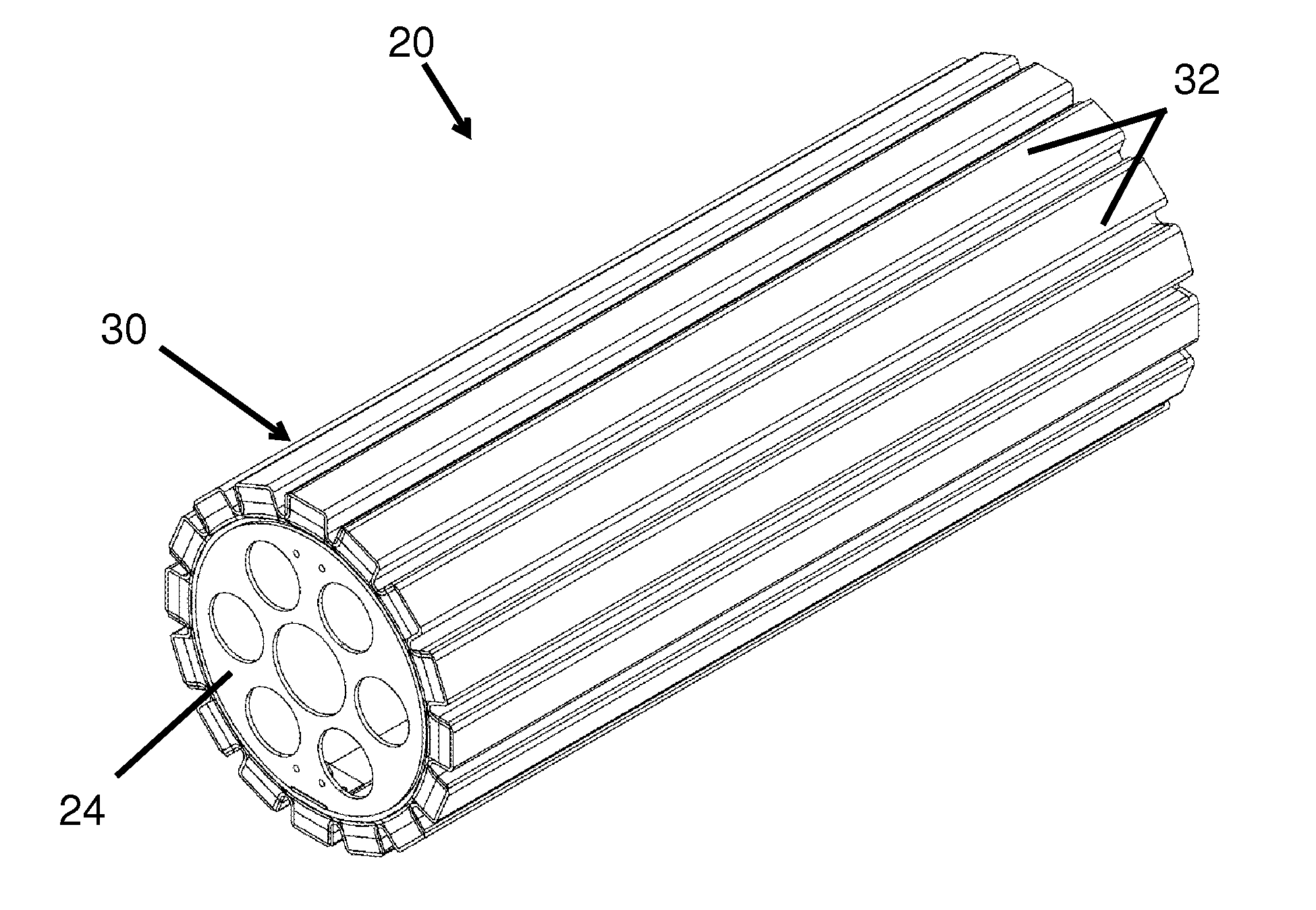

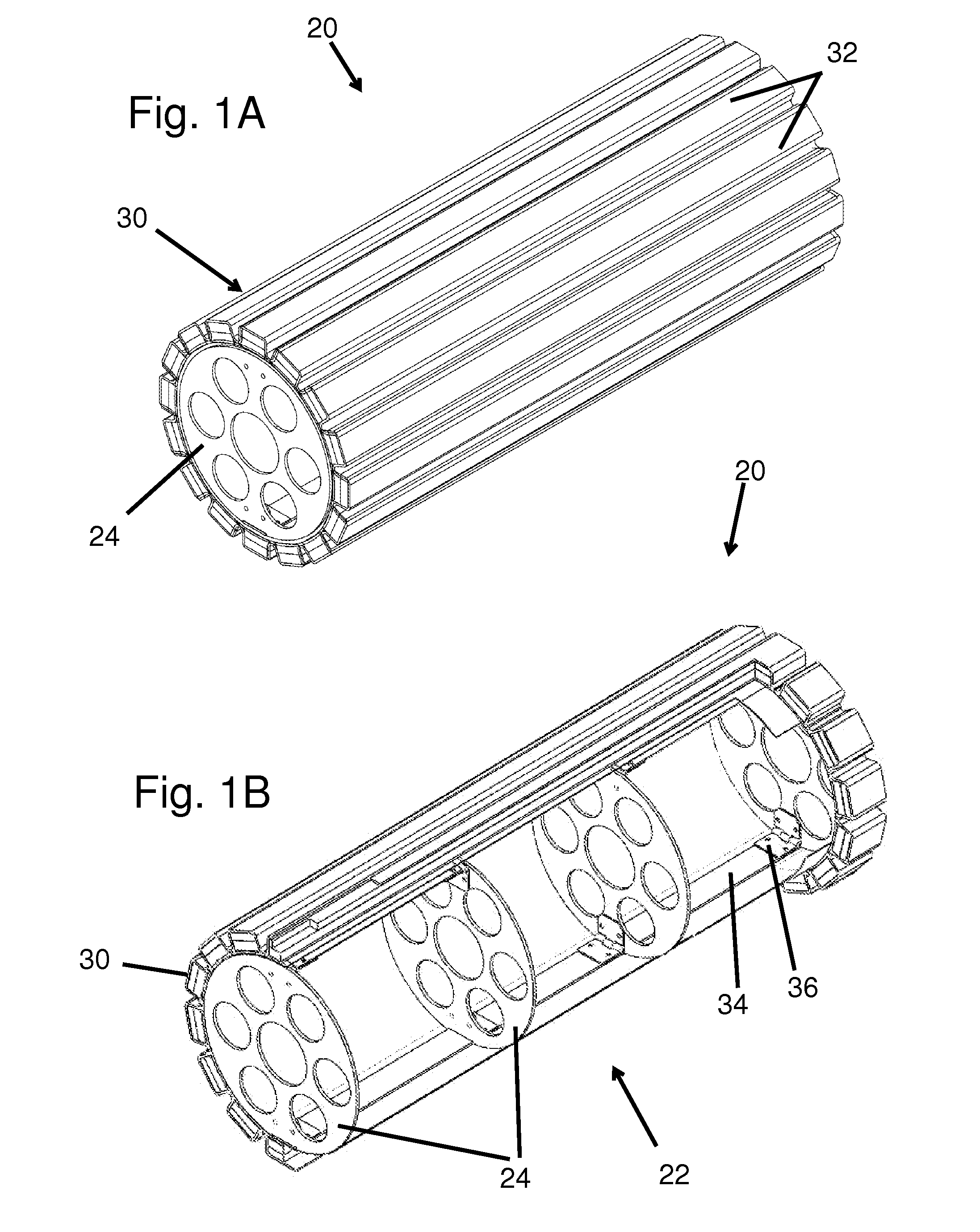

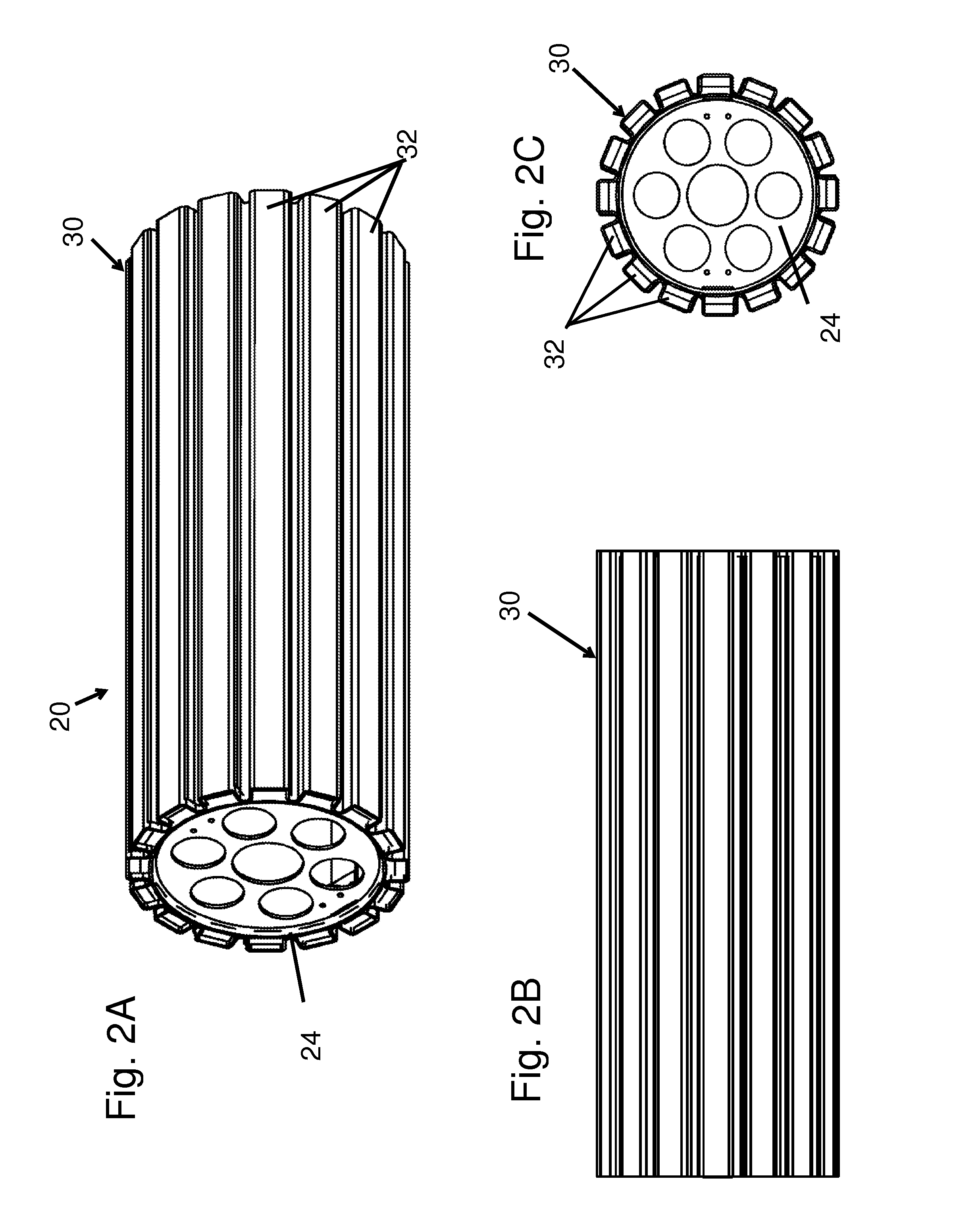

Portable massage roller

A sturdy portable massage roller that collapses flat. The roller includes an outer contact skin formed of a plurality of longitudinal stiffeners connected by longitudinally-extending hinge points, the contact skin defining an inner cavity. A collapsible support structure within the contact skin inner cavity is sized to contact and radially support the longitudinal stiffeners in the expanded shape of the contact skin, and is adapted to collapse so that the massage roller converts between a generally cylindrical expanded shape and a collapsed, flattened shape. The support structure may include a series of rigid discs that either pivot or are folded in half to convert the massage roller between its expanded and flat configurations.

Owner:LAWRIE NATHAN EARL

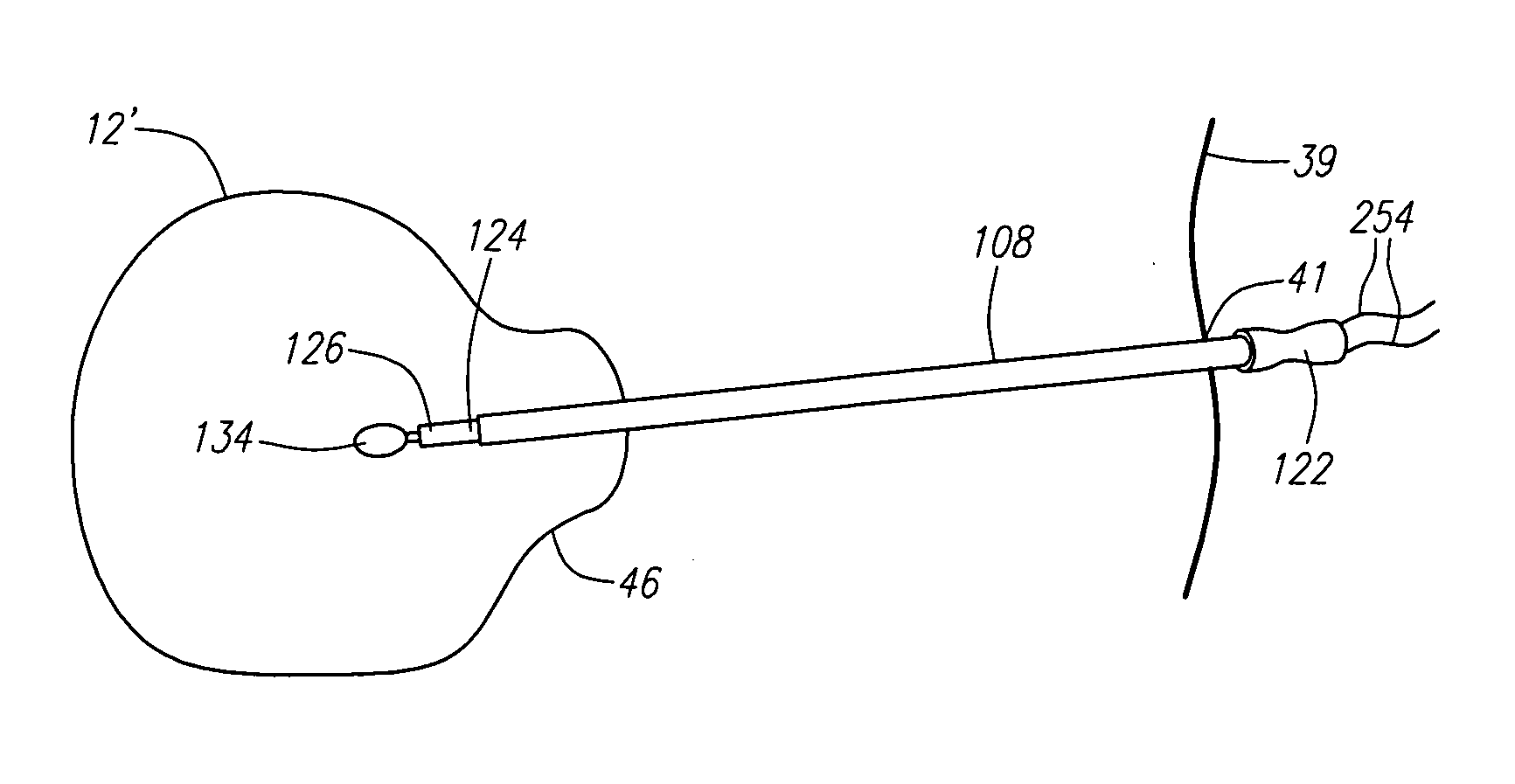

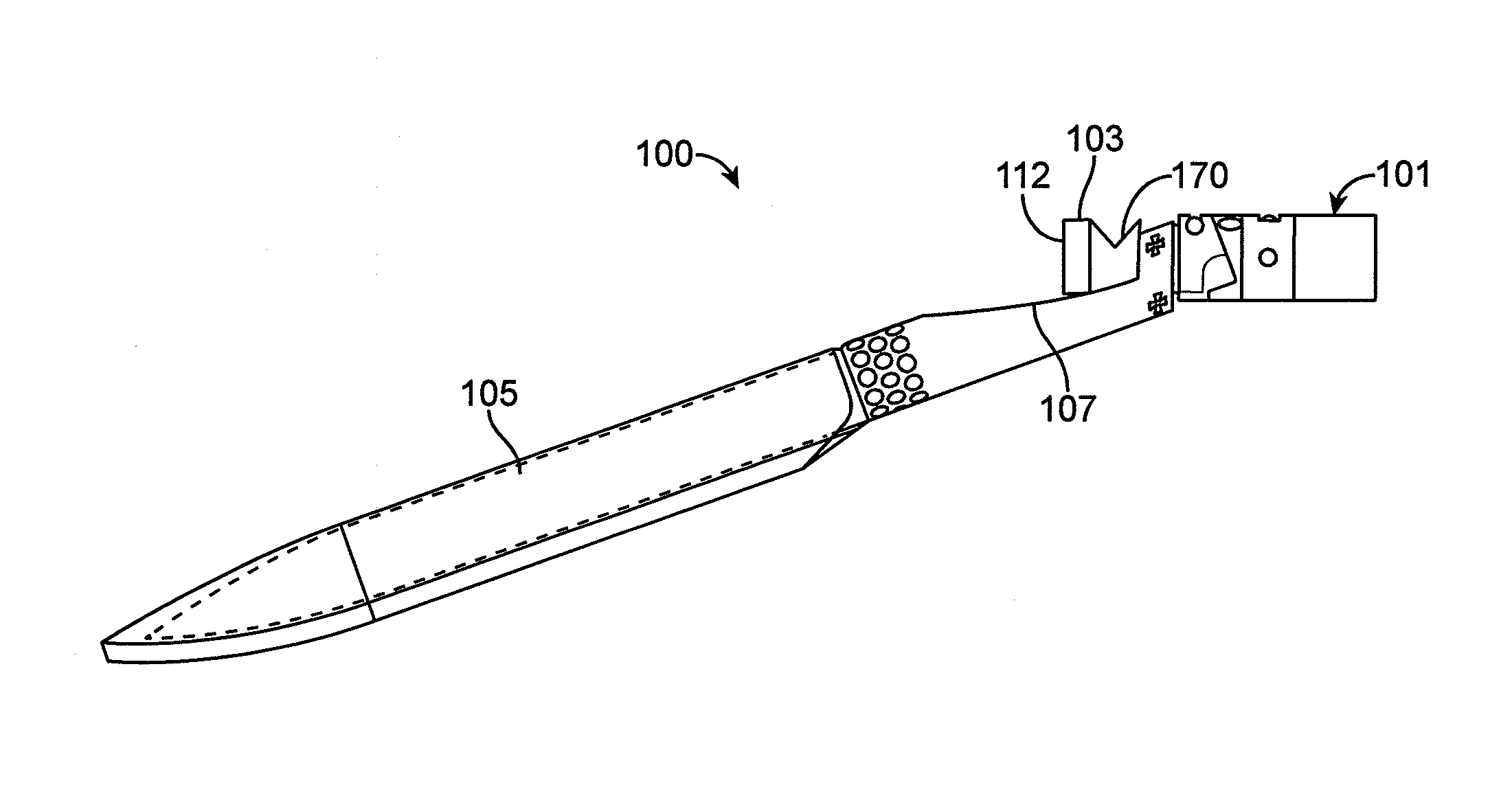

Atherectomy catheters with imaging

An atherectomy catheter includes an elongate flexible catheter body, an elongate deflectable distal tip coupled to the catheter body at a hinge point, a rotatable cutter near the distal end of the catheter body, and a drive shaft extending within the catheter body and configured to rotate the cutter. The atherectomy catheter further includes an optical fiber extending through the drive shaft substantially on-axis with the catheter body and attached to the cutter. The optical fiber is configured to rotate with the drive shaft. The atherectomy catheter further includes a wedge configured to deflect the distal tip away from the catheter body at the hinge point upon axial movement of the drive shaft.

Owner:AVINGER

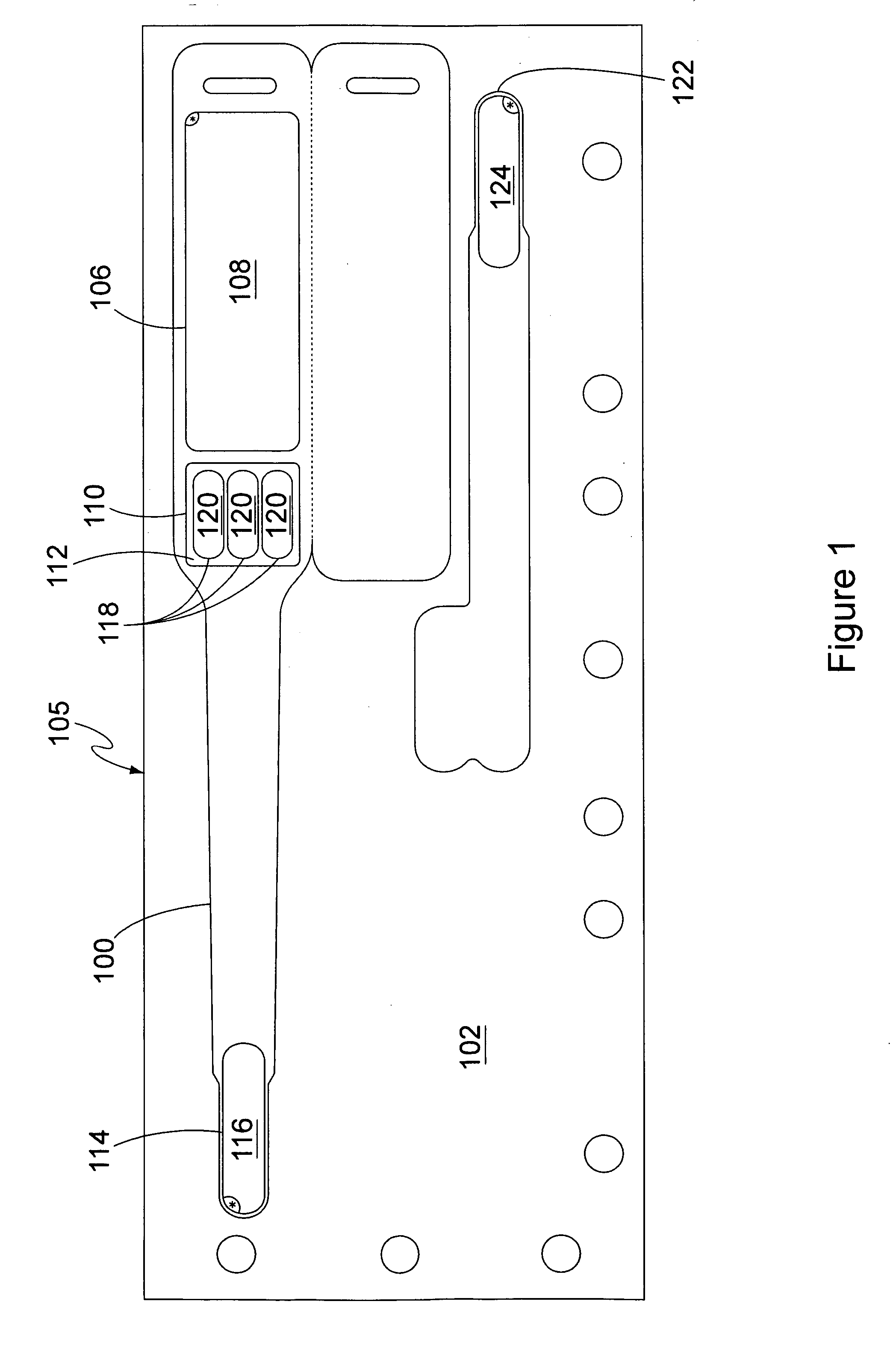

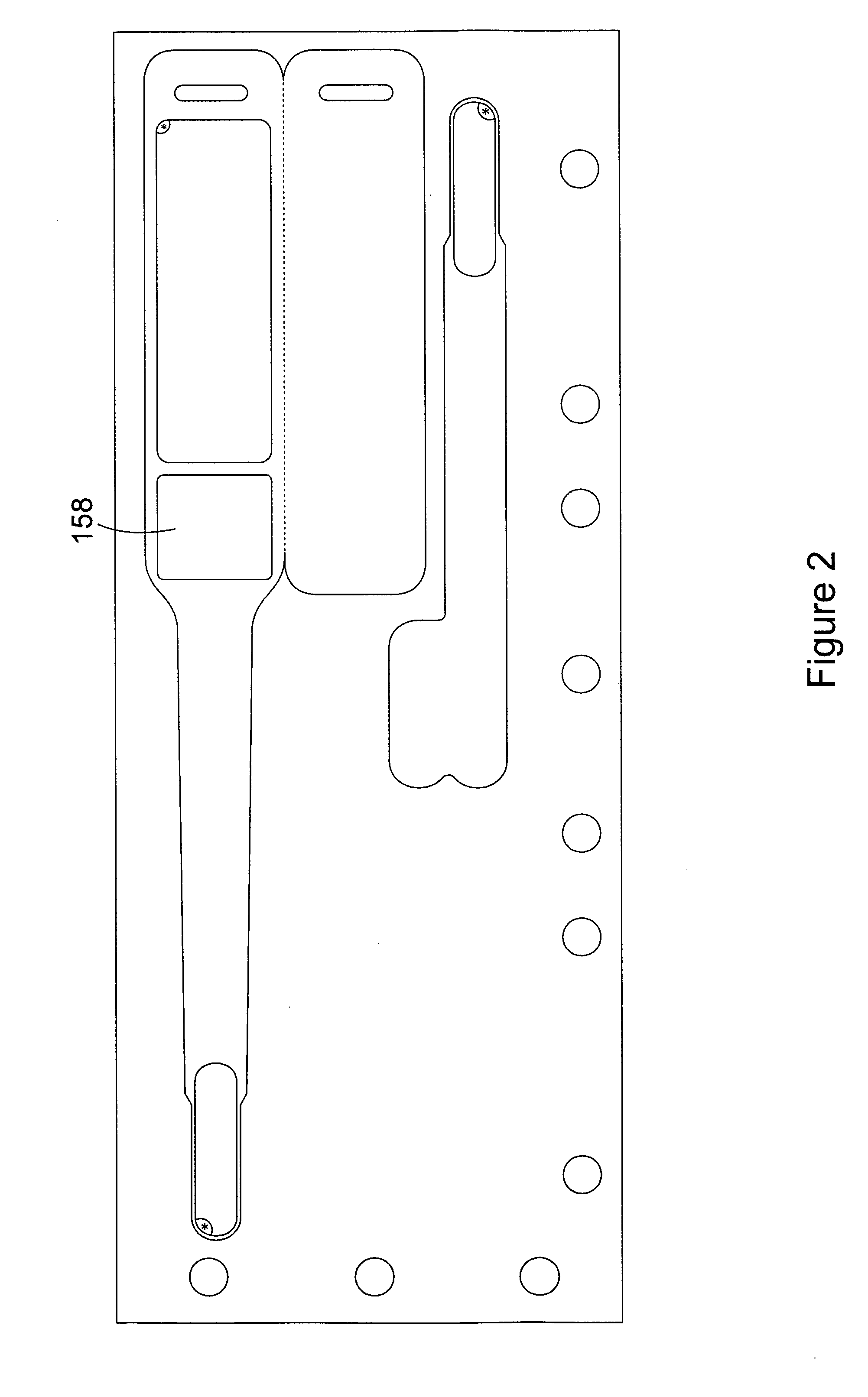

Business form comprising a wristband with multiple imaging areas

InactiveUS20070243361A1Long processImprove readabilityStampsLayered productsComputer scienceBusiness forms

A self laminating wristband separable from a multi-ply page form has a plurality of separated imaging areas, with one larger imaging area for receiving printed data corresponding to the wearer such as his name, i.d. number, etc., with one or more second imaging areas adapted to receive either printed information or markers which may be adhered thereto. The separated imaging areas are aligned along the length of the wristband so that the gap between them acts as a natural hinge point which allows the imaging areas to lie flatter against the wearer's wrist.

Owner:ZEBRA TECH CORP

Nesting twisting hinge points in a bifurcated petal geometry

A bifurcated stent that uses turning segments to reduce the strain at regions which bend at extreme angles. The turning segments can be placed on side branch petals or on connectors connecting the petals to the stent body. Combining the turning segments with connectors of different length and tethers provides for a stent with high flexibility that can accommodate various shaped body vessels. This design allows the bifurcation branch to extend easily, to a useful distance, and to be deployed along oblique angles. Best of all, this design avoids the problems of angularly strained side branch.

Owner:BOSTON SCI SCIMED INC

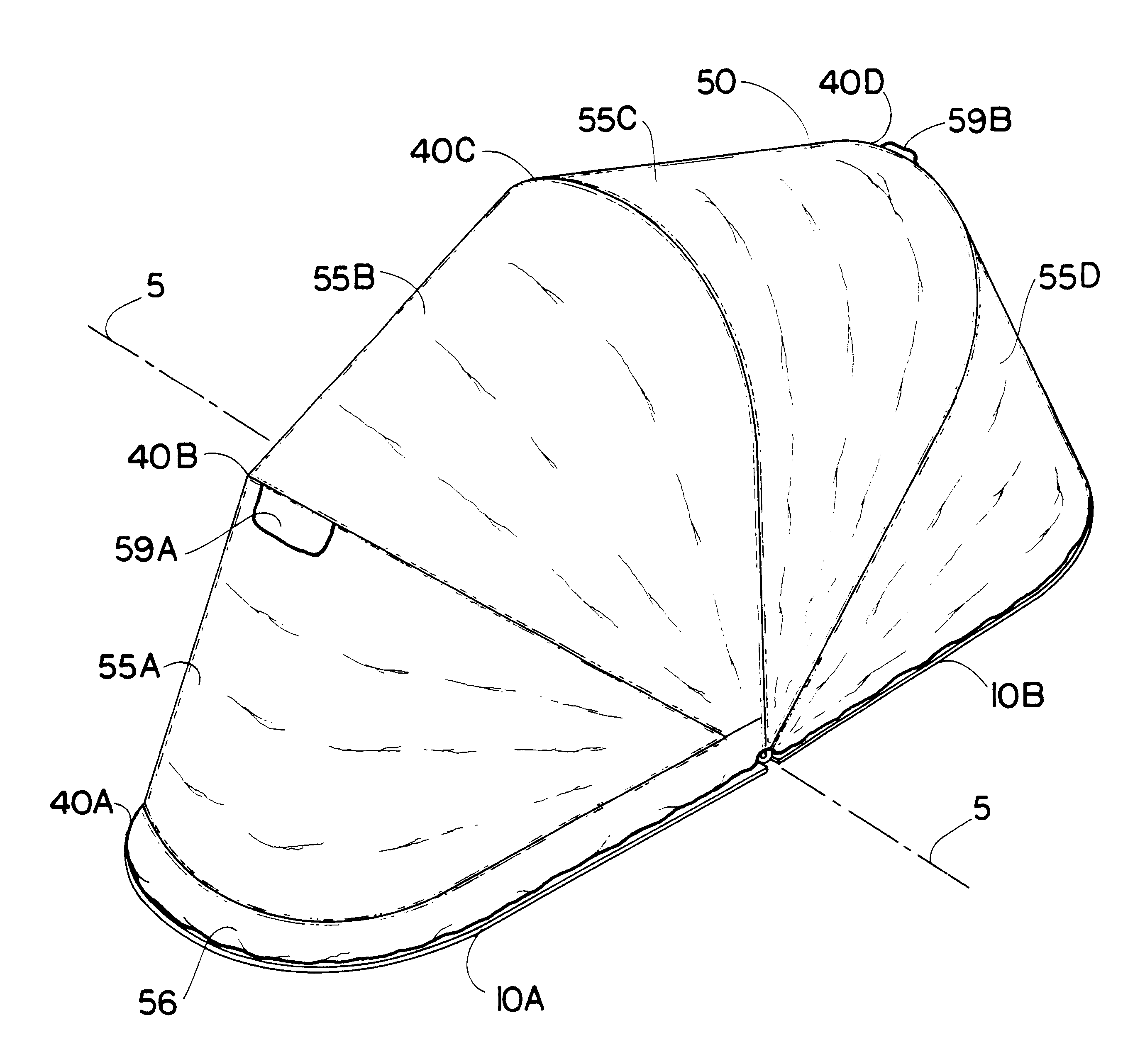

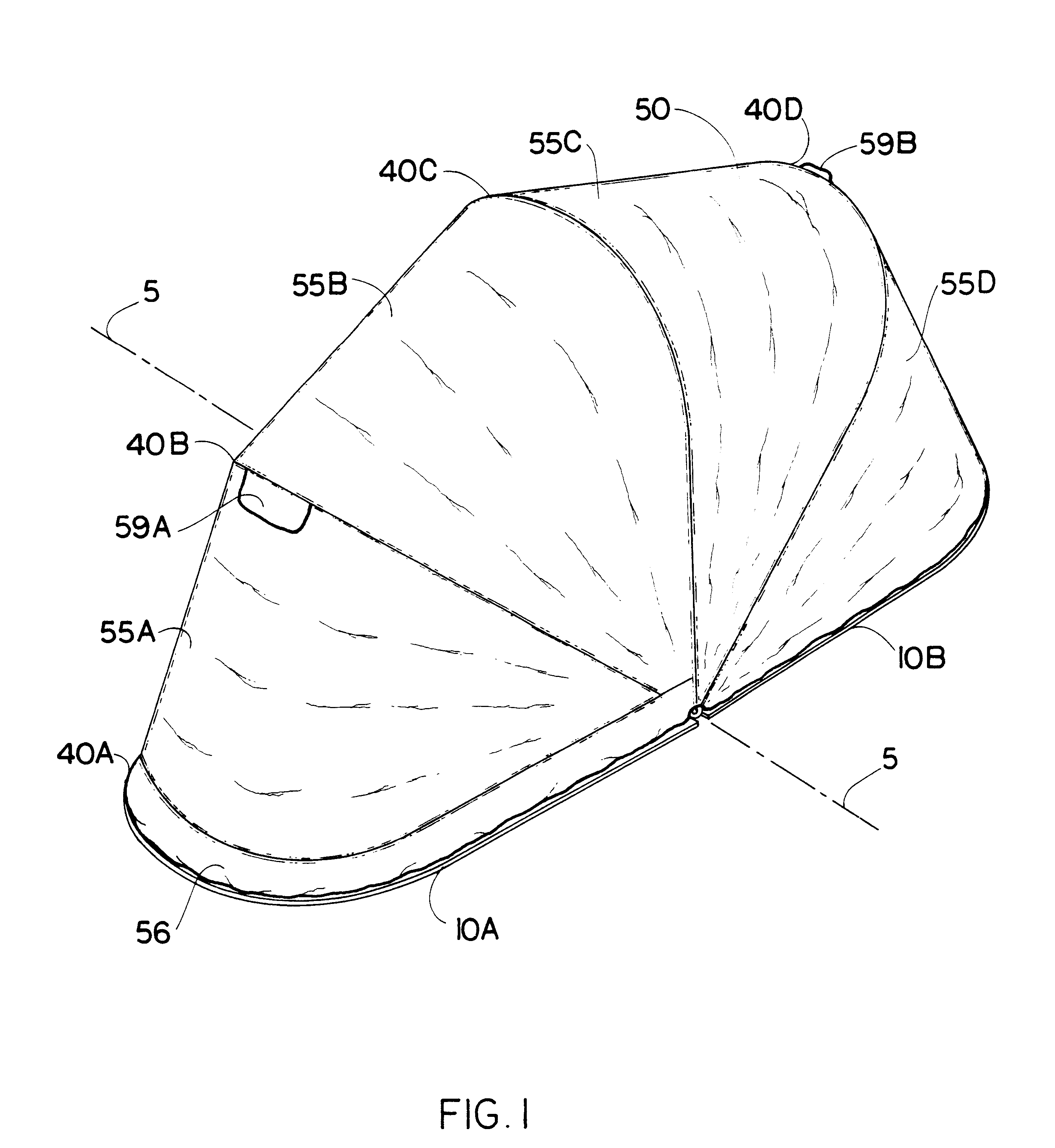

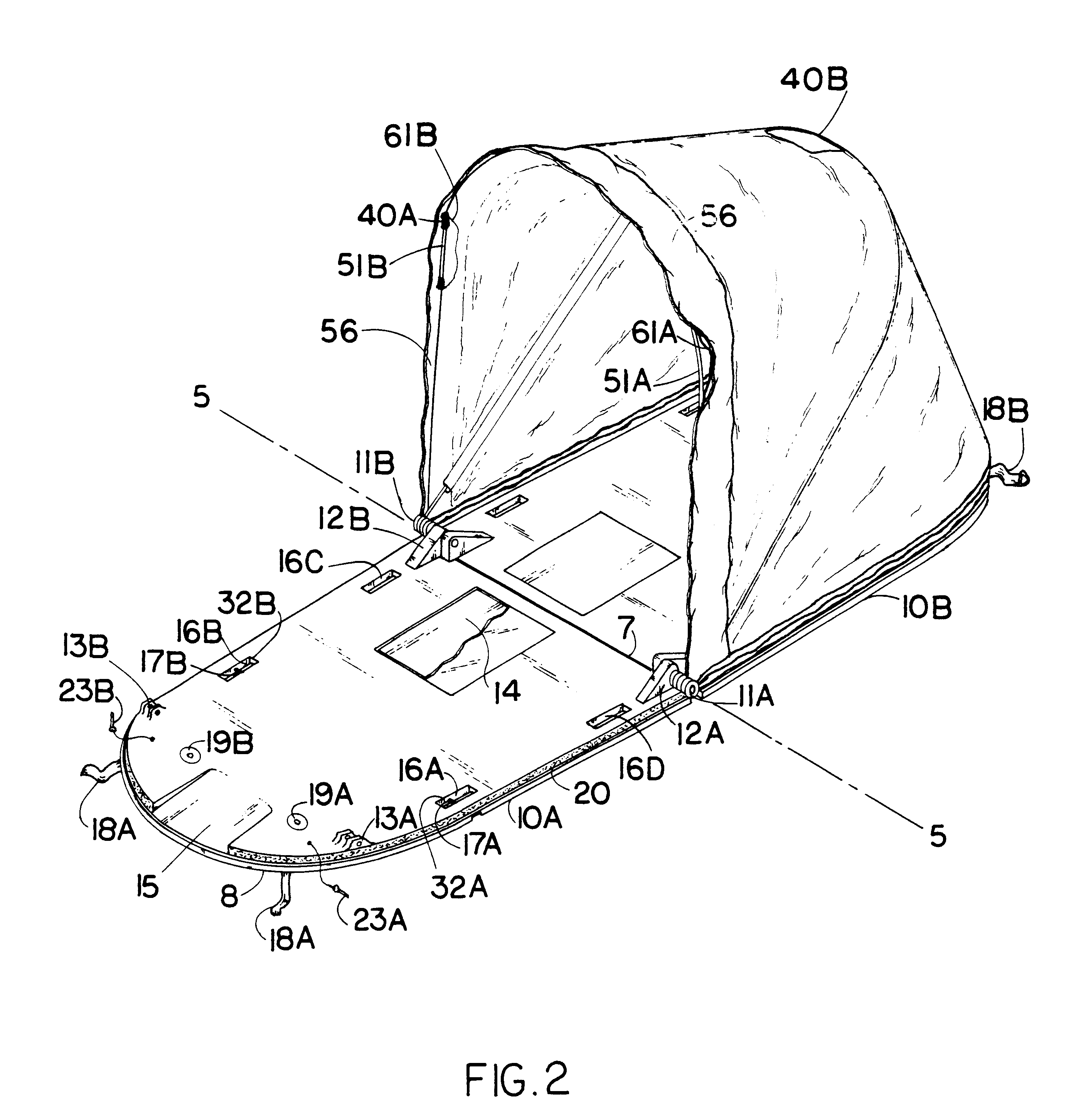

Collapsible small vehicle enclosure

InactiveUS6349732B1Easy to transportEasy to operateBuilding roofsTents/canopiesEngineeringMechanical engineering

A collapsible enclosure that generally comprises a symmetrical pair of base members and a pliable protective cover supported by a plurality of internal frame members pivotally connected on the axis of the hinge points for the base members. By manually rotating the first frame member about its axis, the protective cover and additional frame members unfurl over the base members and surround a vehicle or object in a shell-shaped enclosure. To store or transport the enclosure, the protective cover and frame members collapse in an accordion-like fashion and sandwich between the folded base members.

Owner:COOPER MARK T

Apparatus and methods for removing vertebral bone and disc tissue

ActiveUS8784421B2Improves Structural IntegrityPrevents and minimizes buildExcision instrumentsEndoscopic cutting instrumentsIntervertebral discDrive shaft

Tissue removal probes comprise an elongated member, a drive shaft rotatably disposed within the member, and a rotatable tissue removal element mounted to the distal end of the drive shaft. One tissue removal element comprises a plurality of tissue-cutting filaments affixed at proximal and distal ends of the tissue removal element. The cutting filaments may have optional hinge points that allow the distal end of the tissue removal element to be inverted, thereby transforming the tissue removal element from a tissue-cutting device to a tissue-grasping device. Another tissue removal element may have a blunted tip to prevent distal tissue trauma and an irrigation port to provide irrigation fluid to the removed tissue and / or tissue removal element. Another tissue removal element has a proximal and distal spiral grooves that are oppositely pitched, so that removed tissue can be collected in the middle of the tissue removal element.

Owner:BOSTON SCI SCIMED INC

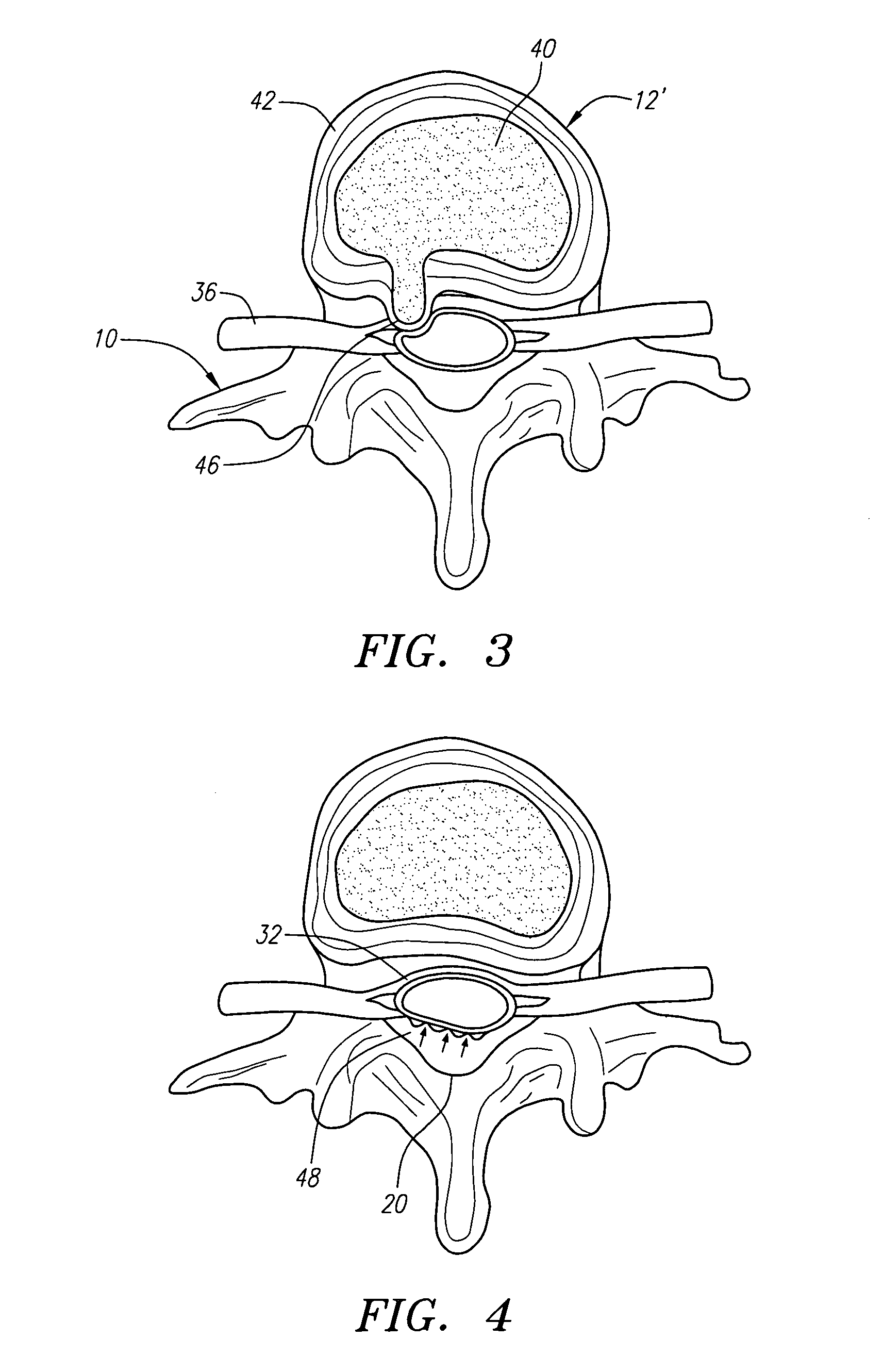

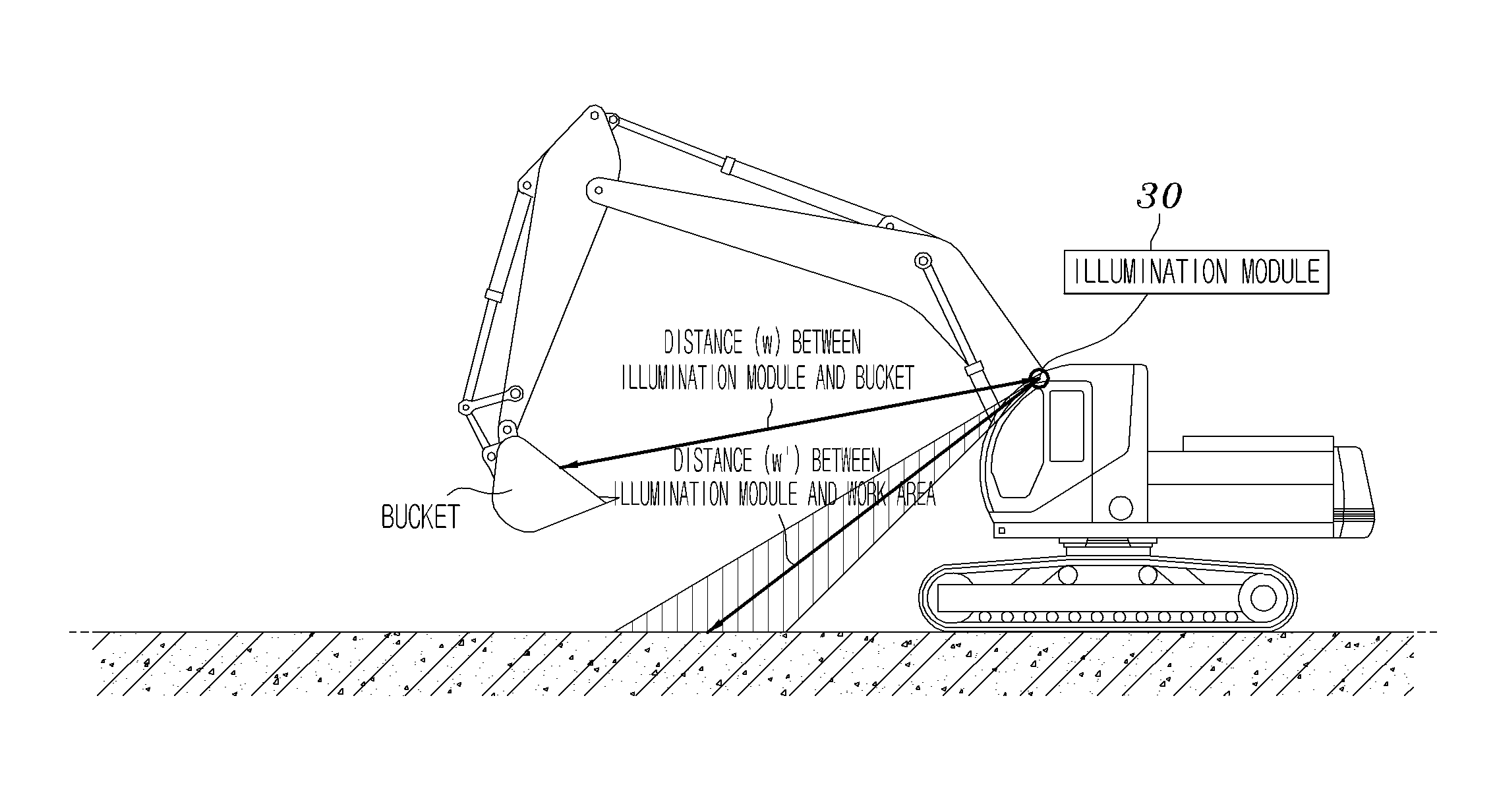

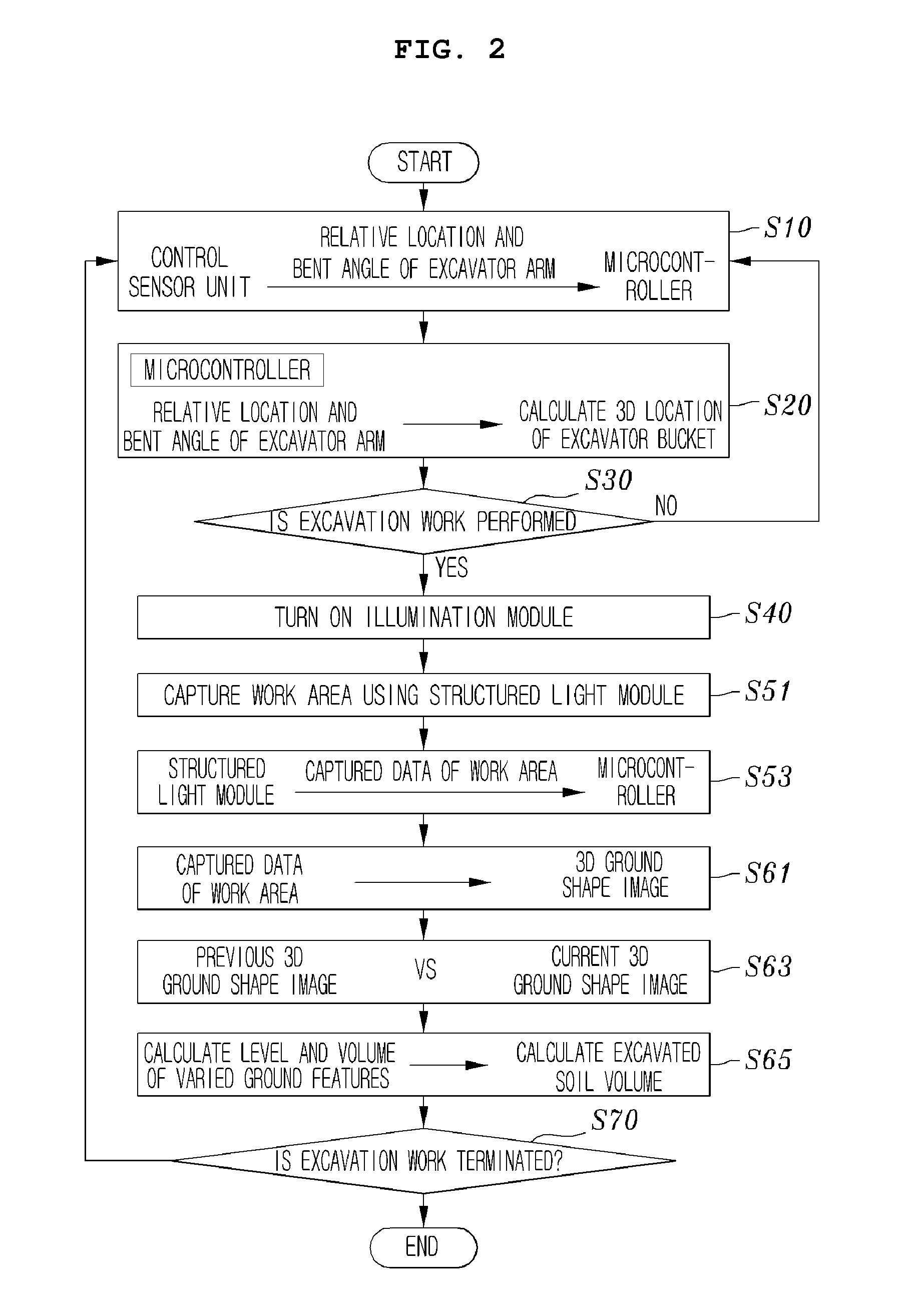

Device for computing the excavated soil volume using structured light vision system and method thereof

InactiveUS20100245542A1Accurate calculationTelevision system detailsMechanical machines/dredgersMicrocontrollerComputer module

A device for computing an excavated soil volume using structured light is disclosed. A control sensor unit is provided at the hinge points of an excavator arm, and is configured to detect and output the location and the bent angle of the excavator arm. A microcontroller is configured to output a control signal so as to capture the images of a work area of a bucket, provided at one end of the excavator arm, using the output of the control sensor unit, convert the captured images into 3-Dimensional (3D) images, and compute an excavated soil volume. An illumination module is configured to include at least one light source that is controlled by the control signal and radiates light onto the work area. A structured light module is configured to capture the work area in response to the control signal.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

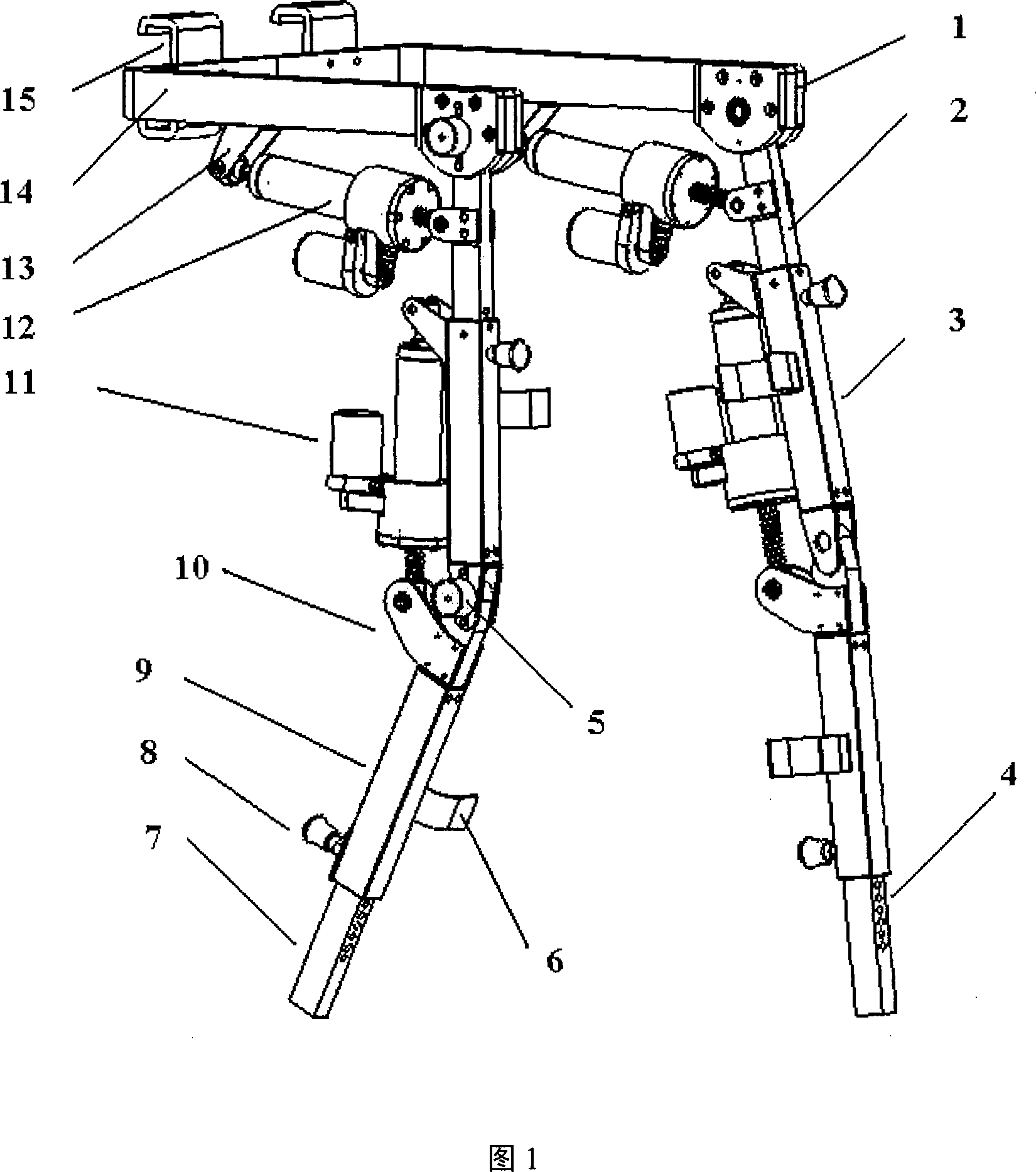

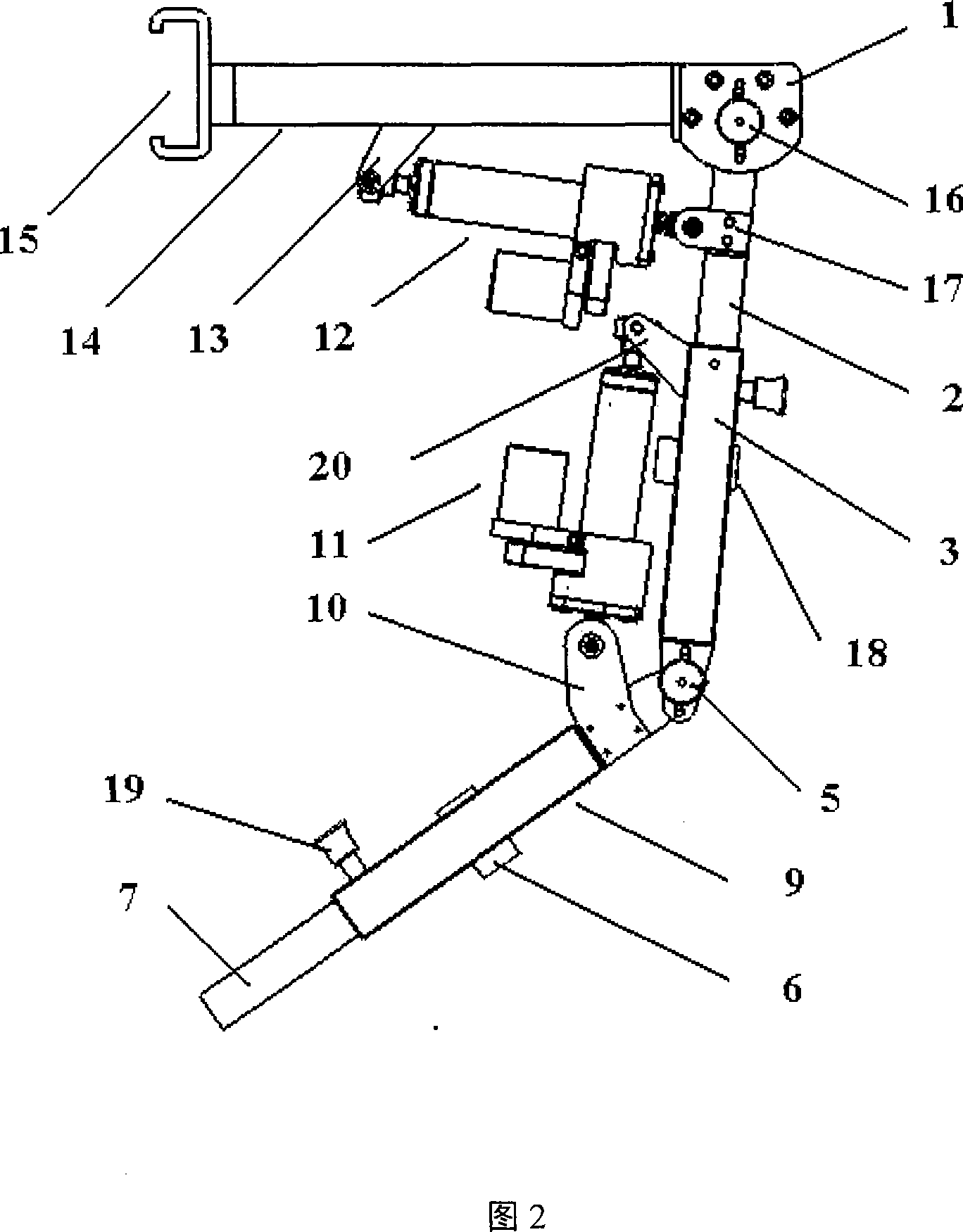

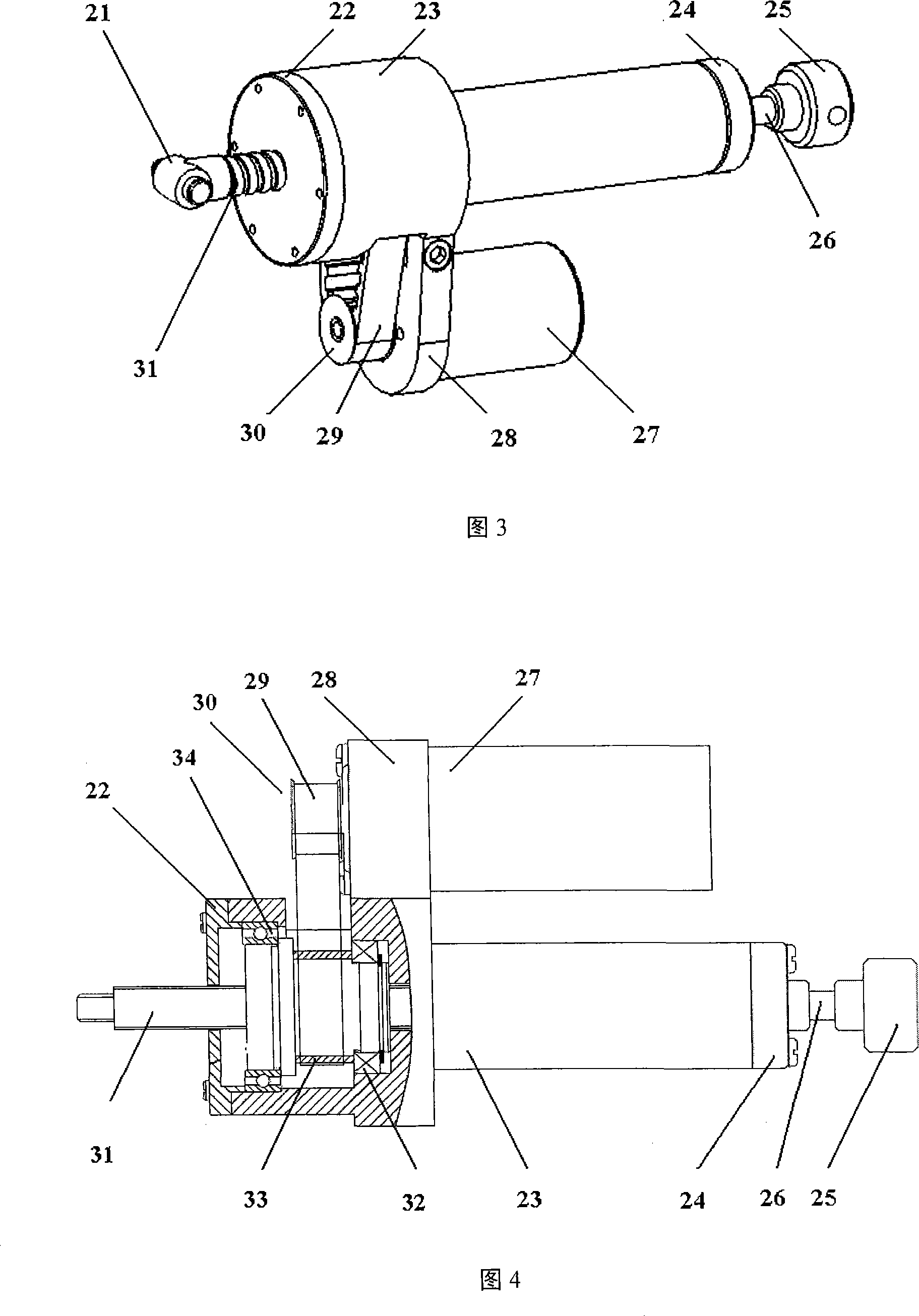

Automatic gait correcting device in lower limb rehabilitation

InactiveCN101204347ADetect and evaluate training effectsAchieve joint movementChiropractic devicesThighEngineering

The invention relates to an automatic gait appliance for the rehabilitation of lower extremity, which comprises an upper leg component and a lower leg component. Two ends of an U-shaped shelf is hinged on the upper leg component and the upper leg component is hinged on the lower leg component; the U-shaped shelf and two upper leg components are hinged on two ends of electrical linear driver, and an encoder is arranged on the hinge point; the upper leg component and the lower leg component are hinged on two ends of the other electrical linear driver, and the encoder is arranged on the hinged point. In the practice period, the patient wears the lower extremity exoskeleton gait appliance to guide the movement of the leg of the patient. The invention has the advantages that the angle joint and the size of the moment are real-timely measured by the sensor; the practice efficiency of the patient is measured and evaluated easily; the best rehabilitation plan is drew up for improving the efficiency of the rehabilitation.

Owner:SHANGHAI UNIV

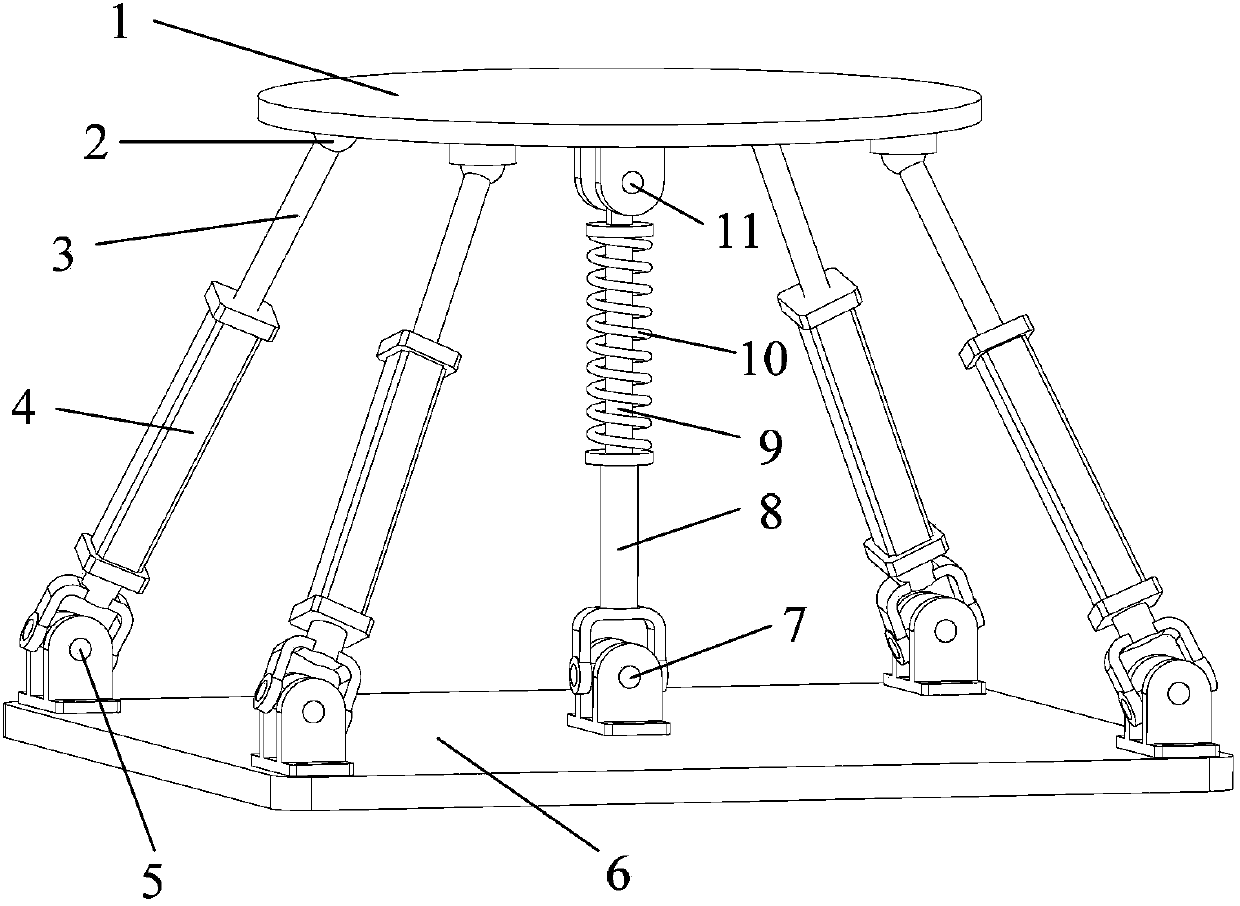

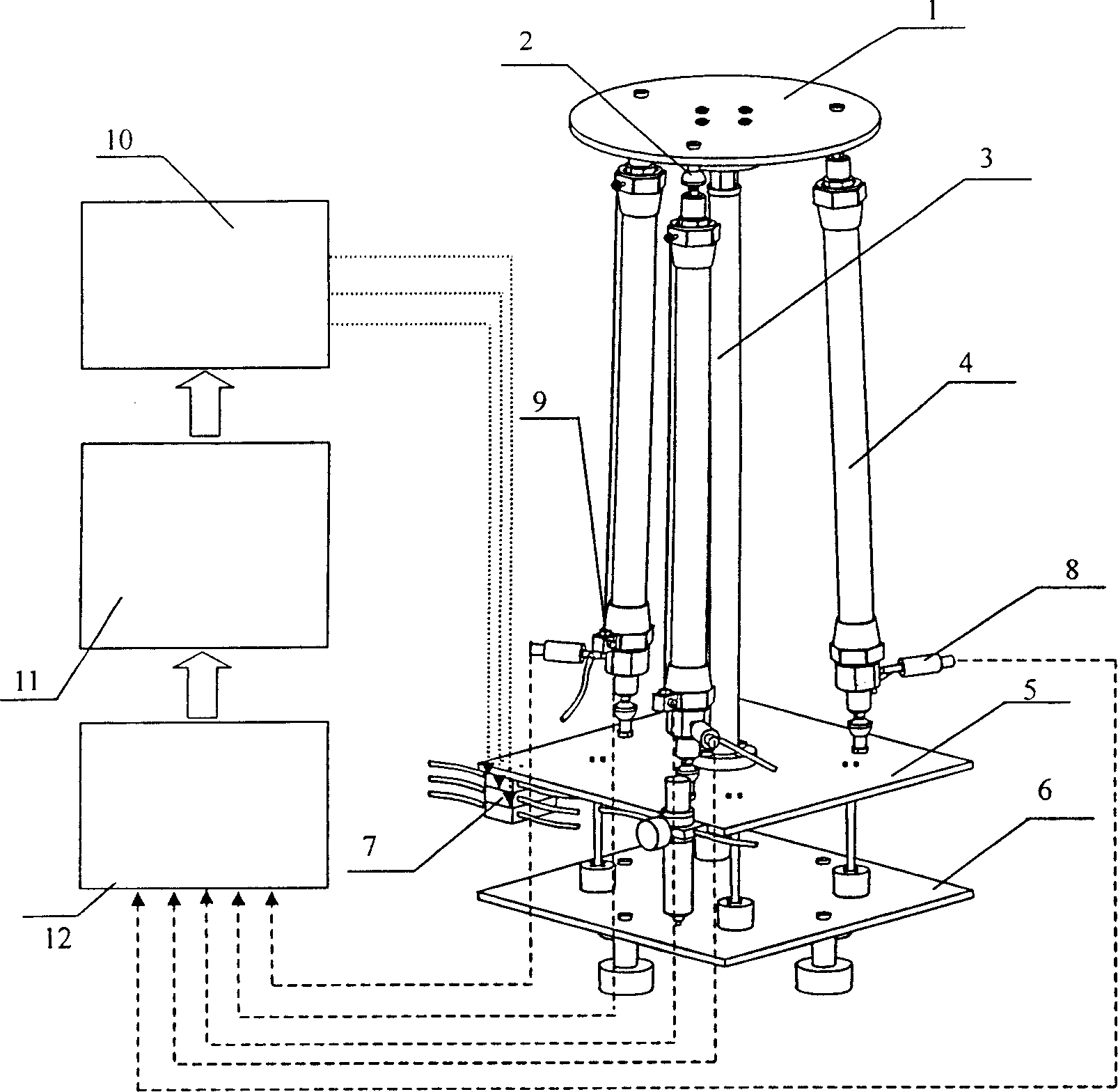

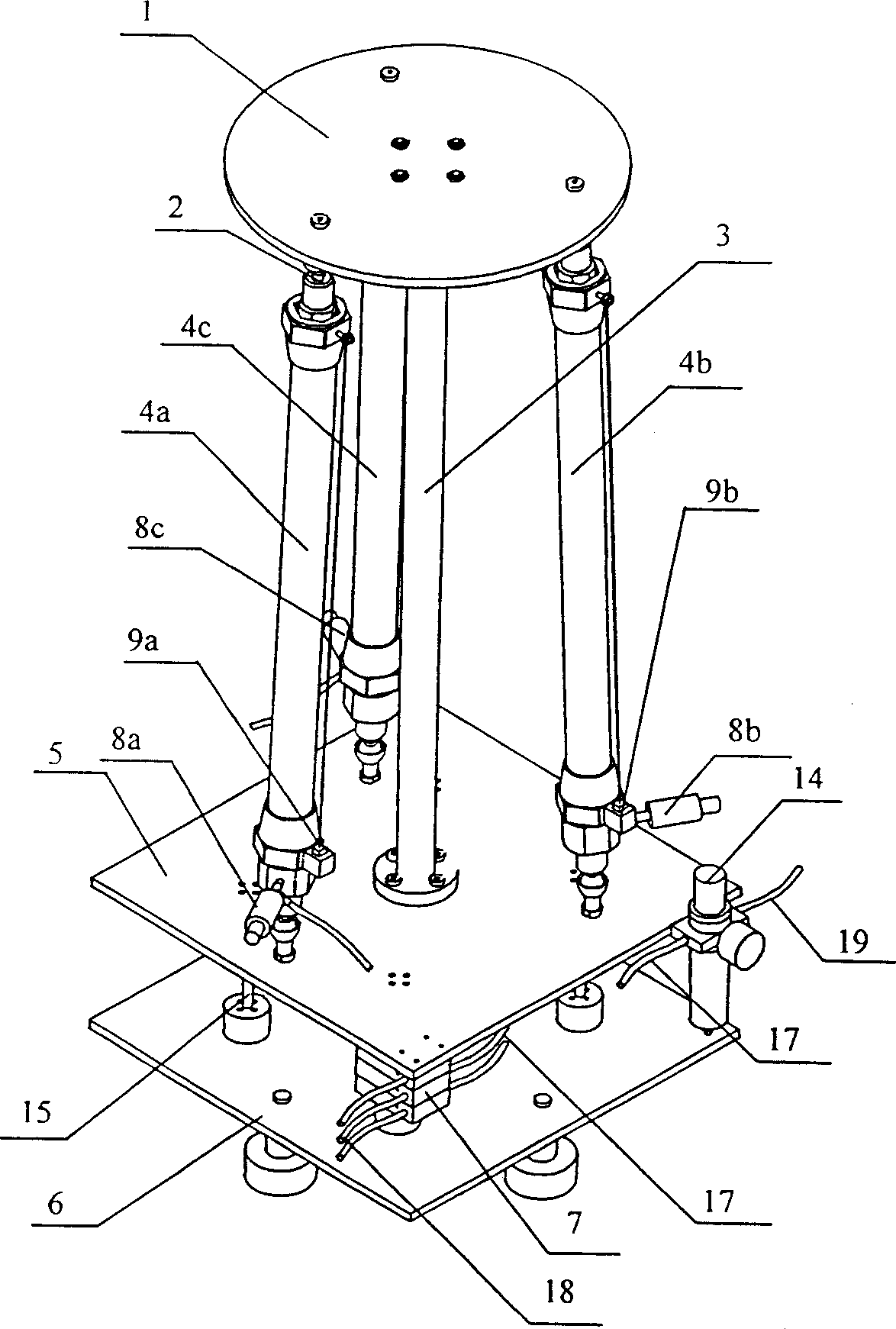

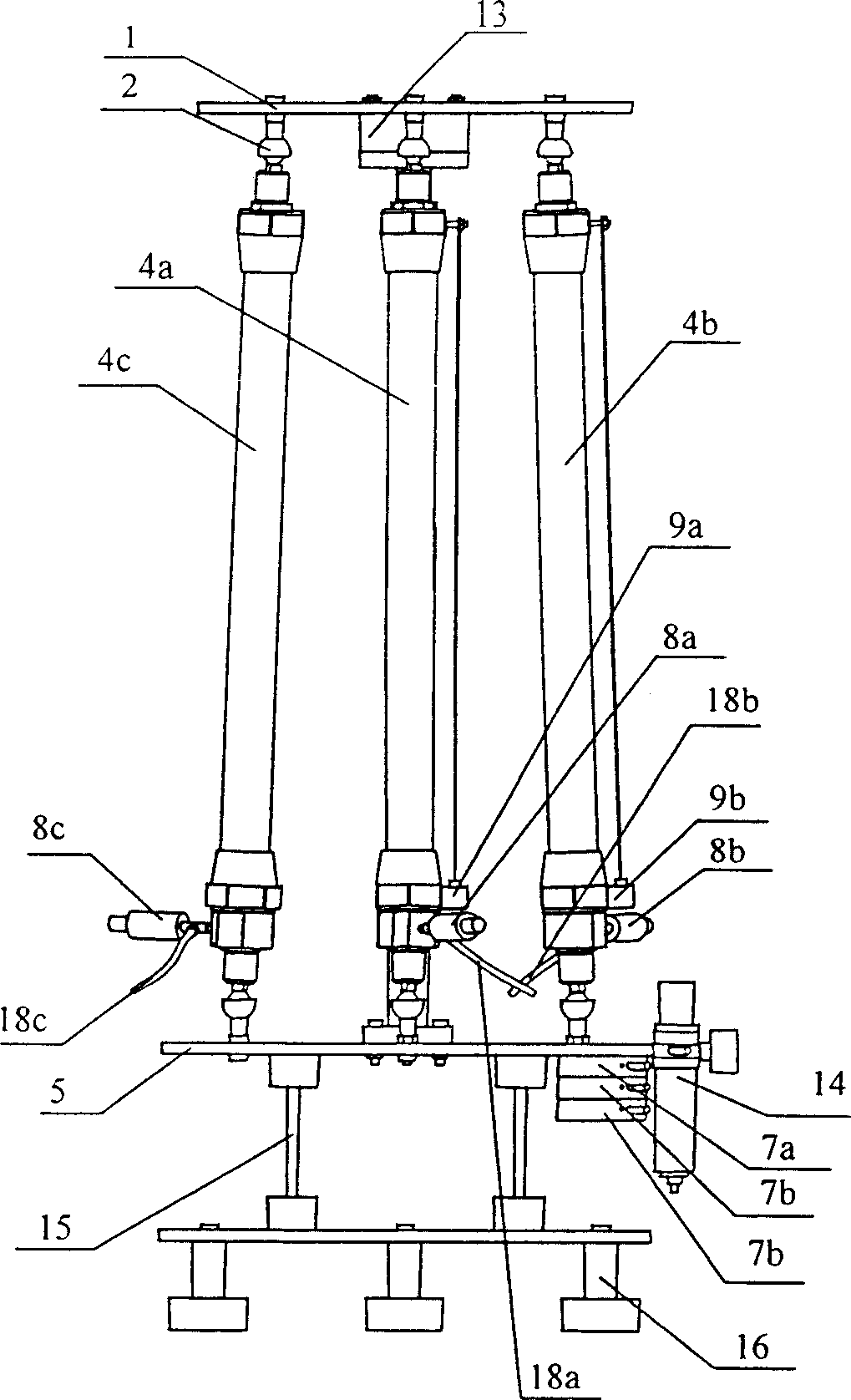

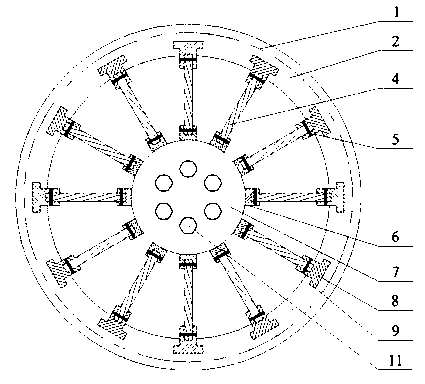

Coupled four-freedom-degree parallel connection vibration isolation platform

InactiveCN103423558ASimple structureLess positional requirementsNon-rotating vibration suppressionStands/trestlesUniversal jointDegrees of freedom

A coupled four-freedom-degree parallel connection vibration isolation platform mainly comprises an upper platform, a lower platform, four main part branches and a middle constraint branch, wherein the four main part branches are identical in structure and used for connecting the upper platform and the lower platform. The tails of actuators of the main part branches are connected with the lower platform through universal joints, telescopic rods of the actuators are connected with the upper platform through ball joints, one end of a lower connecting rod in the middle constraint branch is connected with the lower platform through a universal joint, the other end of the lower connecting rod is connected with an upper connecting rod in a bell socket mode to form a sliding pair, namely the upper connecting rod can expand and retract in the lower connecting rod, the upper connecting rod of the sliding pair is sleeved with a spring, the other end of the upper connecting rod is connected with the upper platform through a rotating pair, and the axis of the rotating pair is parallel to one axis of the universal joint in the middle constraint branch. Lower hinge points of the four main part branches are symmetrically arranged in a square shape, upper hinge points are arranged in a trapezoid shape, and the trapezoid is symmetrical about the axis of a rotating pair of the middle constraint branch. The coupled four-freedom-degree parallel connection vibration isolation platform is simple in structure, large in bearing capacity and good in dynamic response characteristic.

Owner:YANSHAN UNIV

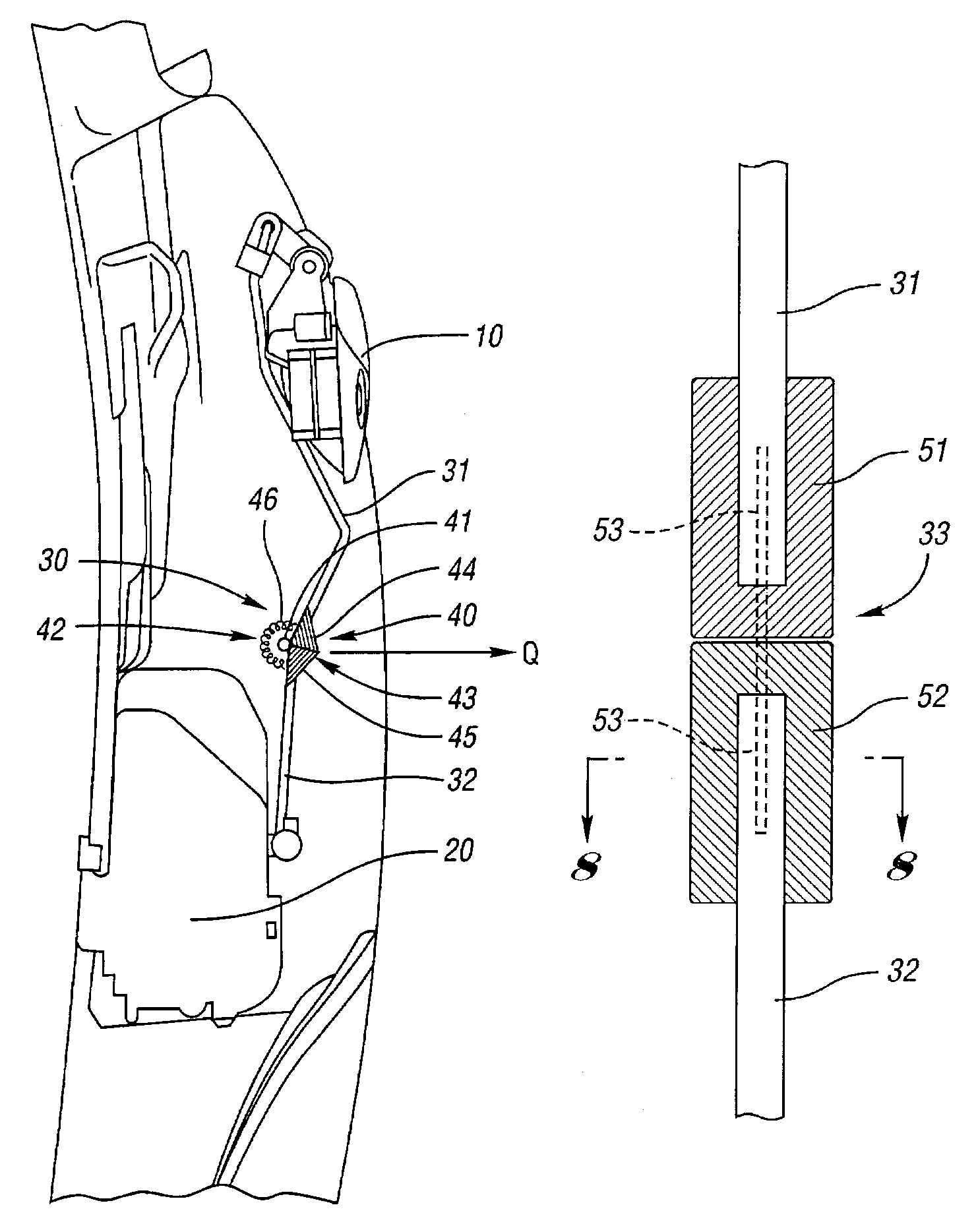

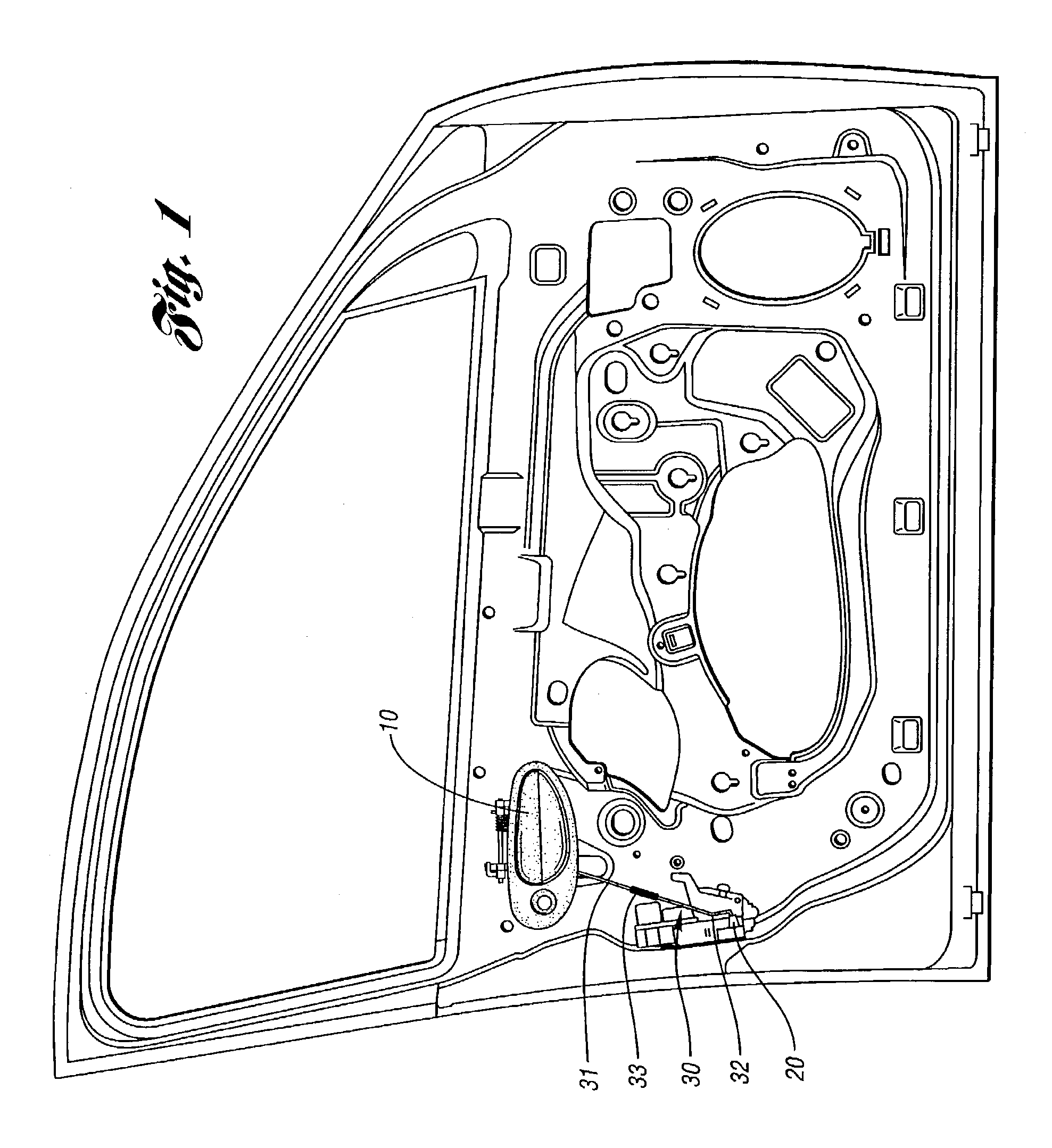

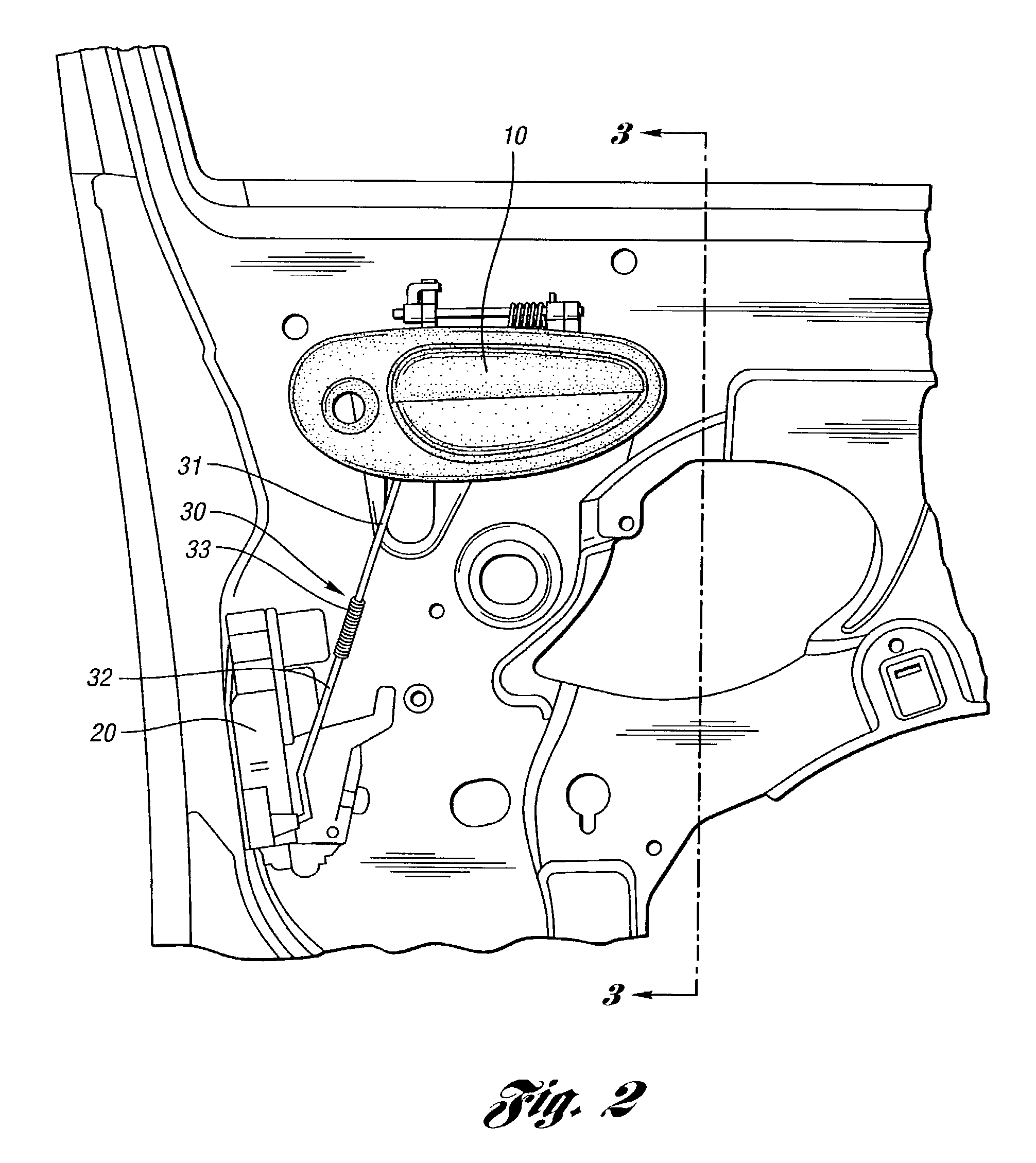

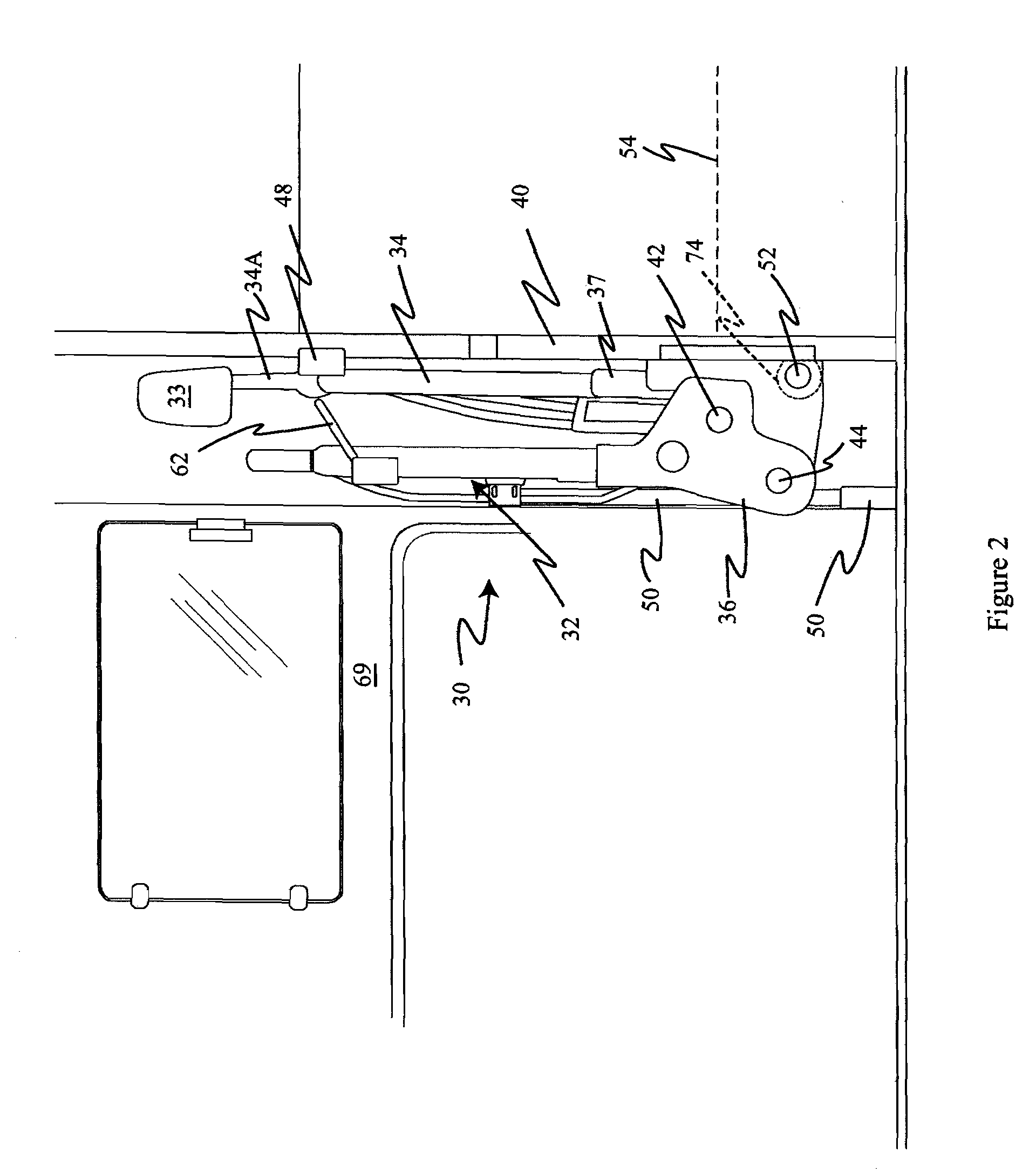

Vehicle door latching mechanism having an improved link rod

InactiveUS6880867B2Simple mechanismEasy to manufactureControlling membersWing fastenersSynthetic materialsEngineering

A link rod flexibly connecting an exterior door handle of a motor vehicle and a door latching mechanism to prevent actuation of the door latching mechanism as the result of a lateral collision, the link rod comprising: a first section connected to the vehicle door handle; a second section operatively connected to the door latching mechanism; and a lateral connector operatively connecting the first section to the second section. The lateral connector may be a laterally flexible spring, laterally flexible synthetic material, or a hinge point.

Owner:FCA US

Air-actuated muscle motion analog control platform device and posture control method

InactiveCN1909017AGreat effortReduce volumeCosmonautic condition simulationsAmusementsControl systemComputer module

The disclosed aerodynamic muscle motion simulation control platform comprises: three very same pieces of aerodynamic muscles connected to a central post and a fixed platform, a motion platform hinged to the muscles with uniform-distributed hinge points, and the central post to rigid connect with the fixed platform and hinge the motion platform through a central ball hinge with the hinge point on platform center to endow the motion platform two rotation DOF. Besides, the control system comprises an input conversion module, a controller, and an output drive amplification module. This invention is fit to different motion simulation.

Owner:ZHEJIANG UNIV

Business form comprising a wristband with multiple imaging areas

InactiveUS7763344B2Improve readabilityAccurate readingStampsLayered productsComputer scienceBusiness forms

Owner:ZEBRA TECH CORP

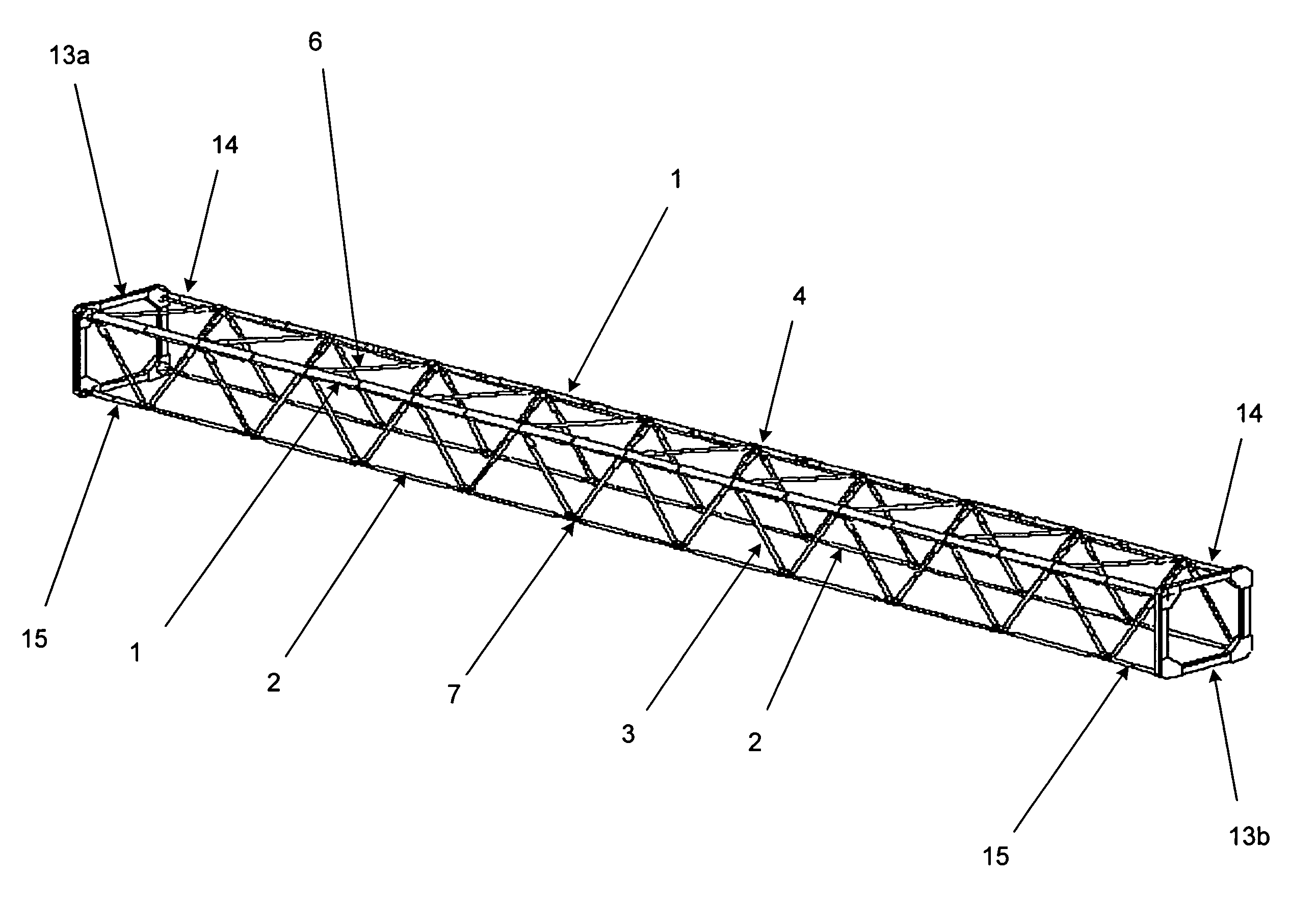

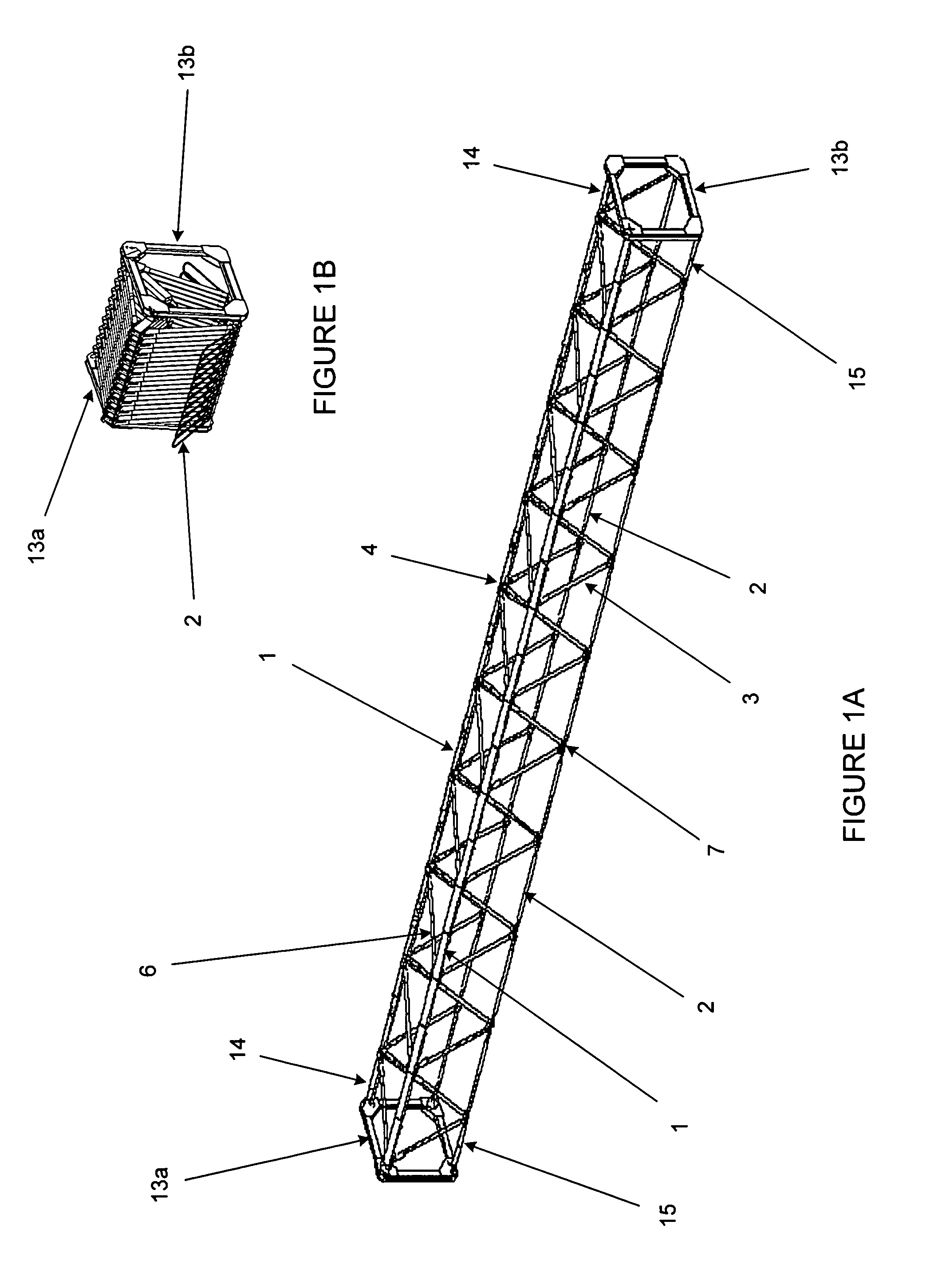

Deployable truss beam with orthogonally-hinged folding diagonals

InactiveUS7028442B2Improve stabilityHigh strengthCosmonautic vehiclesCosmonautic partsDiagonalSecondary chords

A deployable single truss with folding or removable chordal members and diagonals and orthogonal hinge joints for continuous and synchronous retraction and extension, in straight and curved configurations. One or more endframes may be used to close off or mount one of more ends of the deployable trusses. A primary orthogonal hinge joint is used to connect the chordal members and diagonals of the deployable trusses along each primary chord. A secondary orthogonal hinge joint to connect the chordal members and diagonals of the deployable trusses along each secondary chord.

Owner:CPI TECH

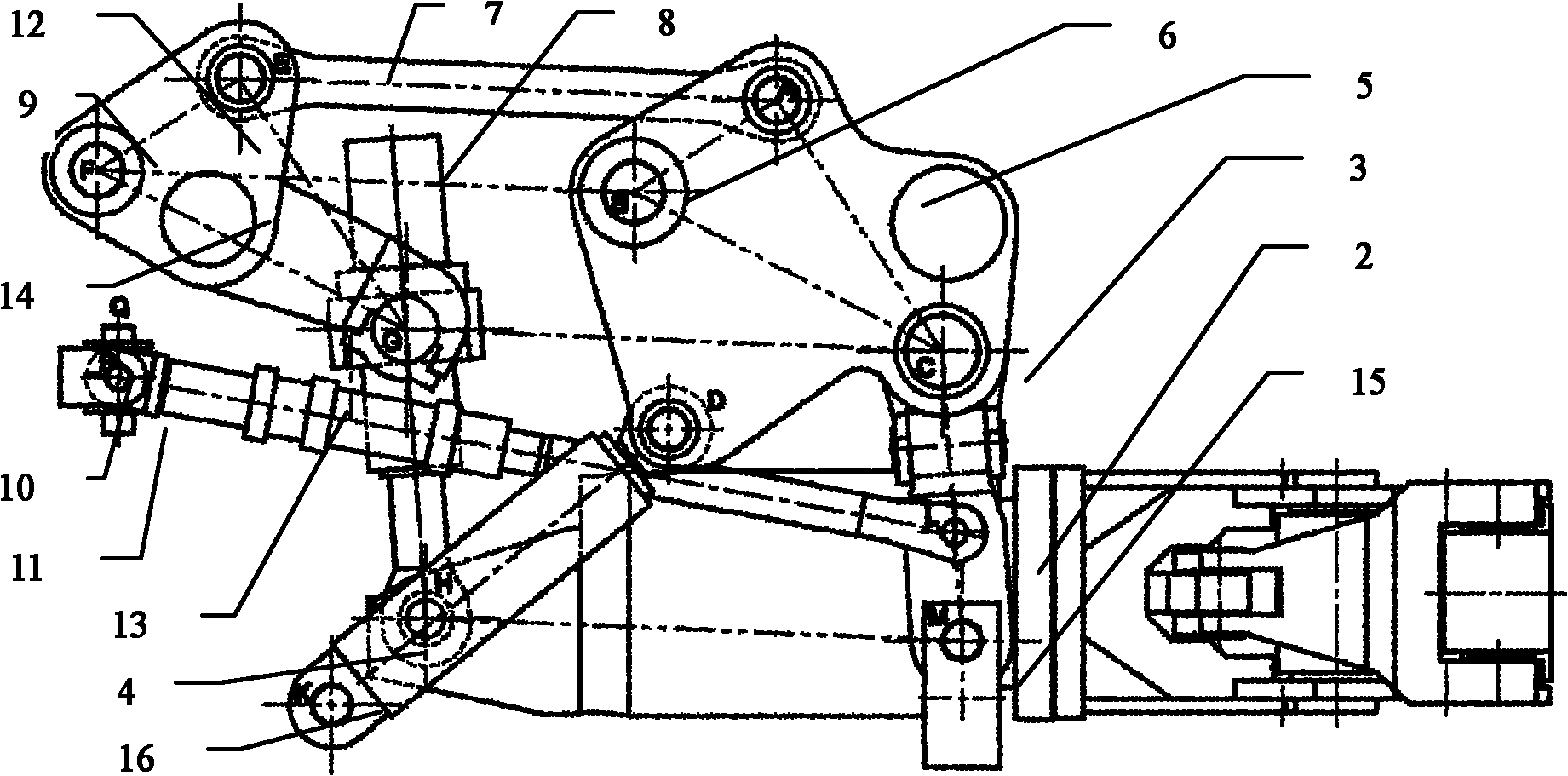

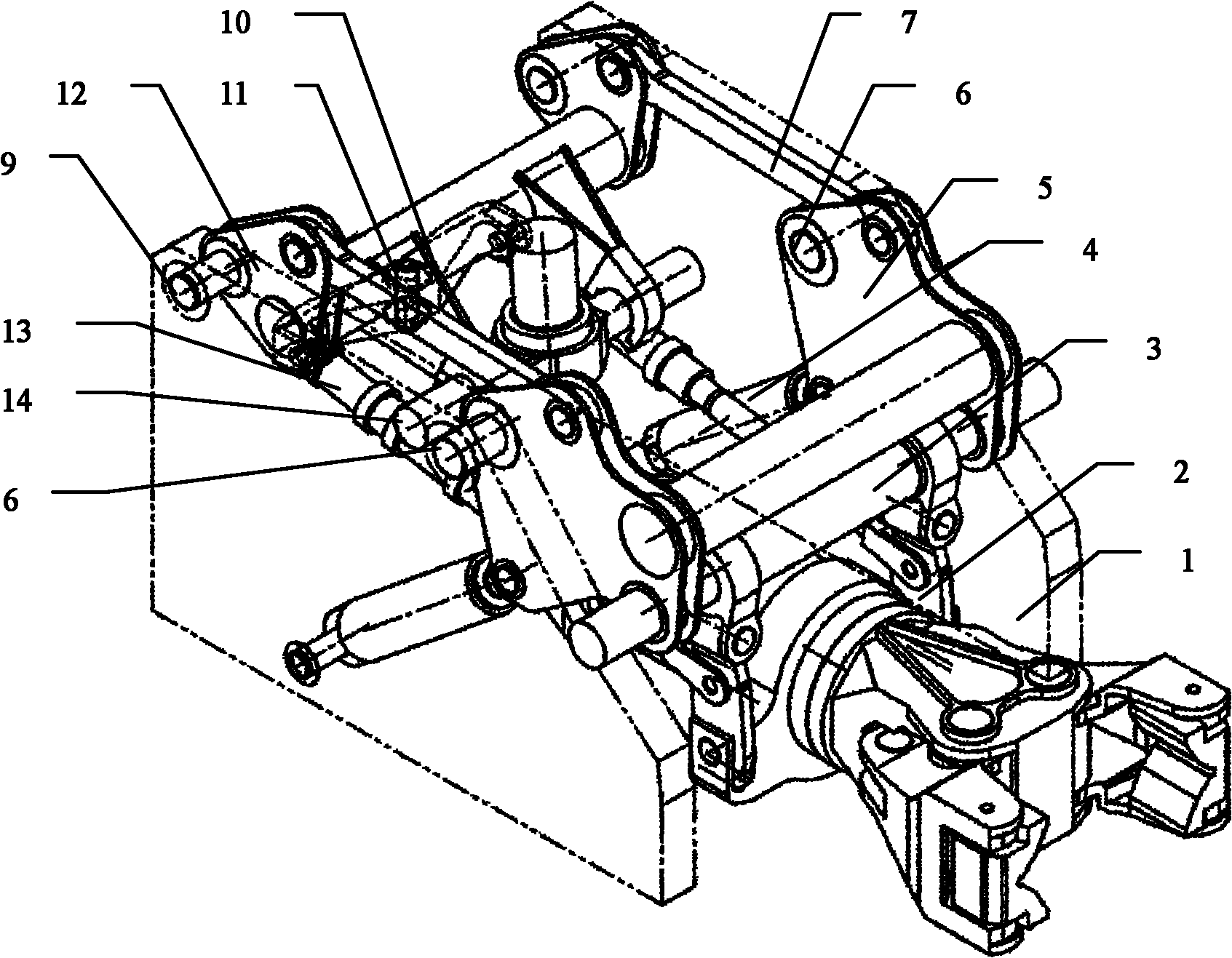

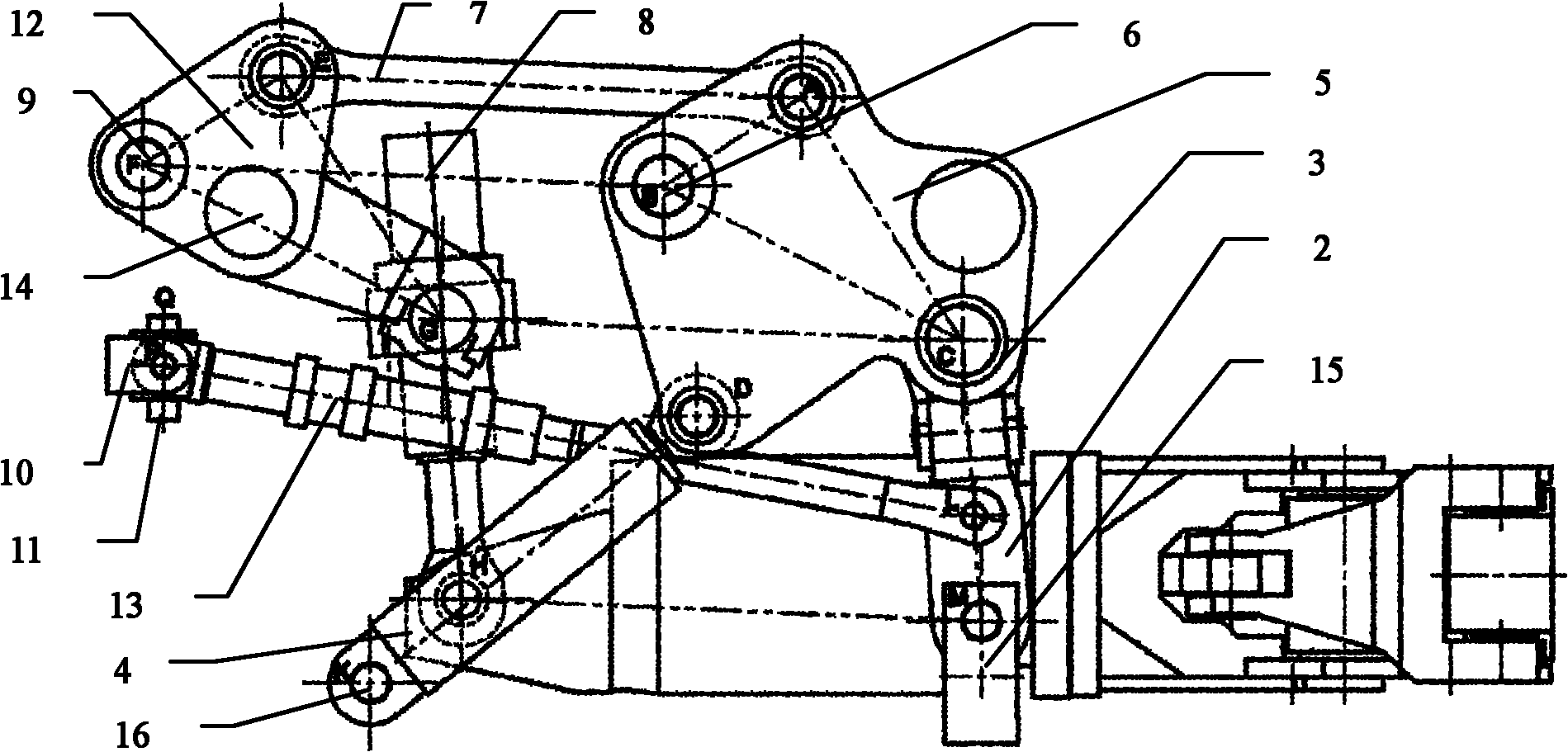

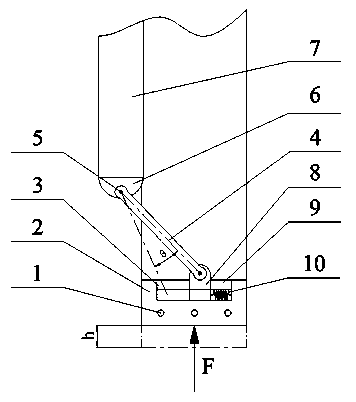

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340AHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

The invention discloses a claw beam lifting mechanism for a forging manipulator, applied to forging industry. The claw beam lifting mechanism mainly comprises a front lifting part, a rear lifting part, a synchronous connector rod, a lifting cylinder, a pitching cylinder and a buffering part, a front fixing shaft in the front lifting part, a rear fixing shaft in the rear lifting part and the lower end of the lifting cylinder are respectively connected with a large machine frame through hinges, the synchronous connecting rod is arranged overhead and always moves in a range above a connecting line of a front fixing hinge point and a rear fixing hinge point of a claw beam lifting and pitching mechanism and the large machine frame, front ends of two buffering cylinders are respectively connected with tow front lifting connecting rods through hinges, the rear ends of the two buffering cylinders are respectively articulated with two ends of a compensating beam, and the middle part of the compensating beam is connected with the middle part of the large machine frame by a hinge through a beam fixing shaft. The claw beam lifting mechanism has novel and scientific design concept, reasonable stress application, high movement precision, simple structure, low manufacturing cost and is convenient to install, adjust and maintain. The invention not only reduces the manufacturing cost of the lifting mechanism under the condition of ensuring the movement precision, but also thoroughly solves the problems that the front fixing shaft and a shaft sleeve matched with the front fixing shaft are worn easily and a side plate of a machine needs to be thickened specifically.

Owner:SHENYANG HEAVY MACHINERY GROUP

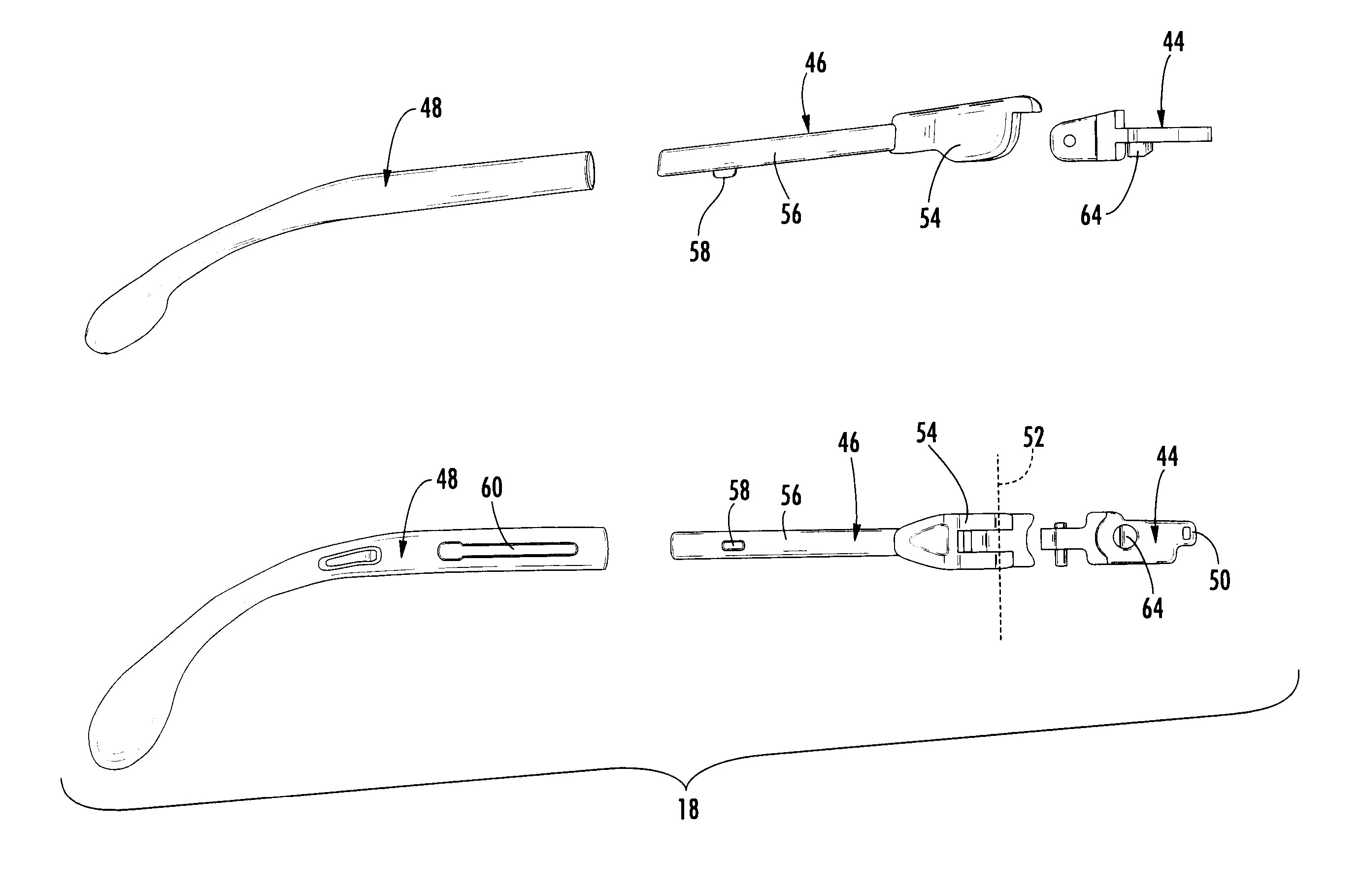

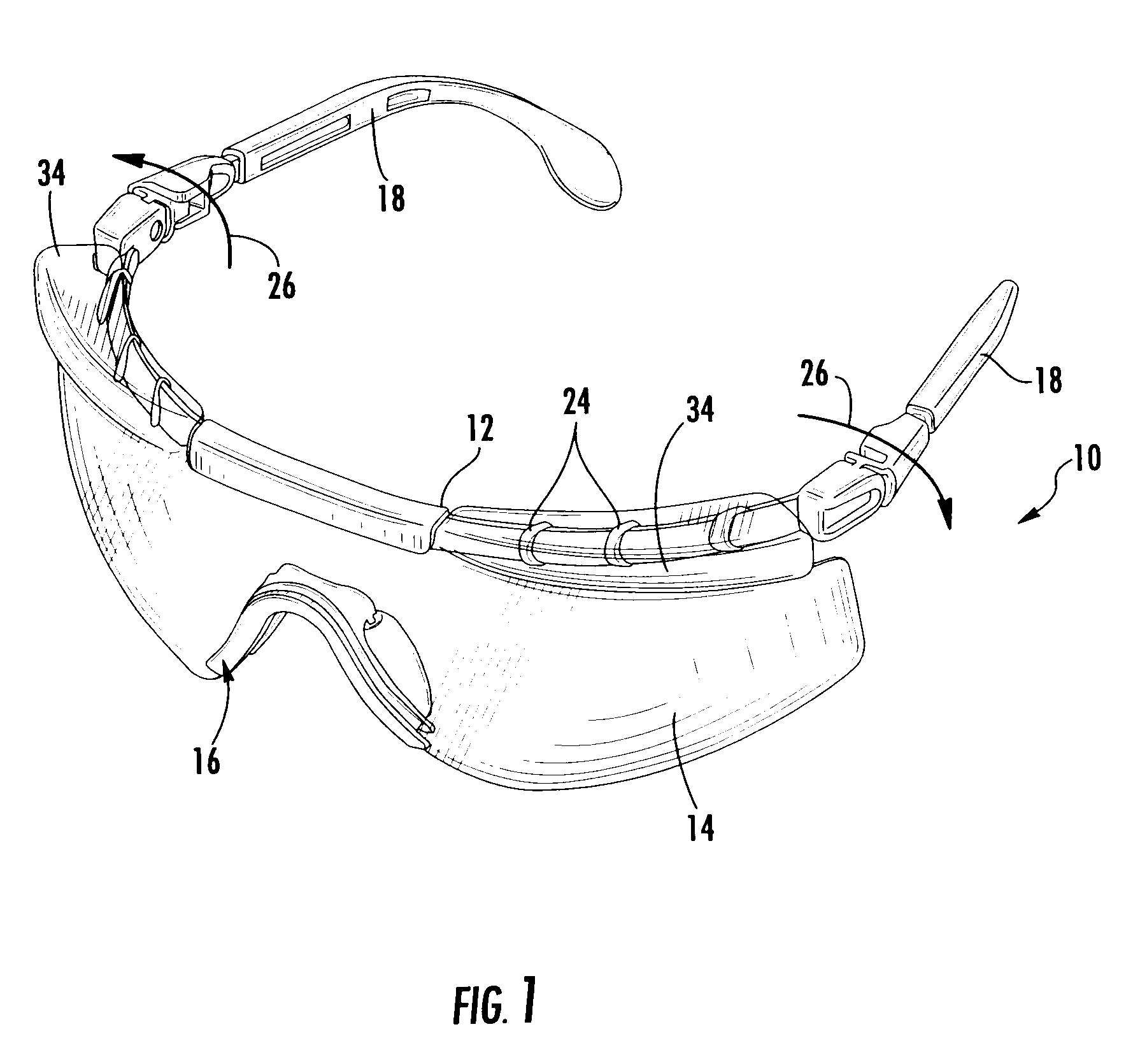

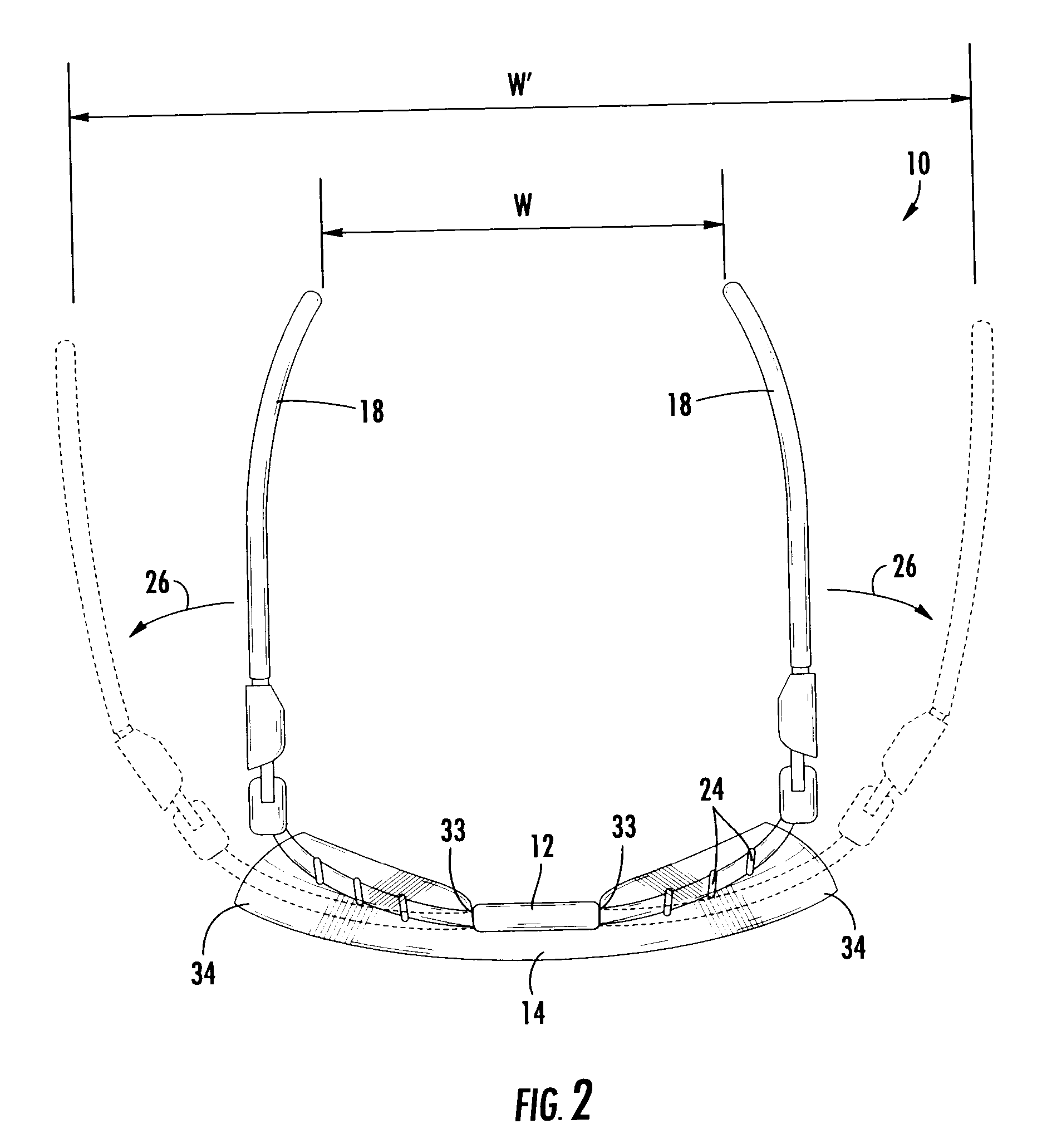

Adjustable length upper frame member for eyeglasses

InactiveUS20050270477A1Easy to adjustReduce complexitySpectales/gogglesNon-optical adjunctsEngineeringMechanical engineering

A frame assembly for eyeglasses is provided wherein the overall width of the eyeglass frame is adjustable by utilizing a telescoping brow bar. The upper frame member or brow bar is formed to include either a pair of telescoping or indexed joints allowing the length of the brow bar to be adjusted thereby placing the hinge points and temple bars further apart from one another. The adjustable length of the brow bar provides excellent adjustability of the overall width of the eyeglass frame in simple mechanical construction. Further, in a unique method of forming the adjustable brow bar assembly a central portion may be formed in a first molding step and an adjustable hinge section is then molded directly over the central portion in a second molding step. The present invention utilizes in-mold-assembly techniques to reduce the assembly steps required to form such an adjustable brow bar assembly while further resulting in an eyeglass frame that has increased adjustability and utility.

Owner:SPERIAN EYE & FACE PROTECTION

Lead with terminal connector assembly

InactiveUS6983185B2Expensive and difficult and costly to cleanConsistent and increased strengthTransvascular endocardial electrodesDiagnostic recording/measuringElectrical conductorEngineering

A lead includes a lead body extending from a distal end to a proximal end, and at least one conductor disposed within the lead body and extending from the distal end to the proximal end of the lead body. The lead further includes an outer terminal ring, a terminal pin, and an insulative sleeve disposed between the outer terminal ring and the terminal pin, where the insulative sleeve is coupled with the outer terminal ring with a snap-fit connection. A pin latch is disposed on an outer periphery surface of the insulative sleeve, where the pin latch is rotatable about a hinge point.

Owner:CARDIAC PACEMAKERS INC

Side-turning resistant elastic wheel

ActiveCN103287201AReduce hysteresisSimple structureHigh resiliency wheelsRubber ringTransverse force

The invention discloses a side-turning resistant elastic wheel and belongs to a wheel structure. The wheel comprises a wheel hub (7), a wheel rubber ring and spoke rods (4), wherein grooves (6) are distributed on the outer side of the wheel hub (7), T-shaped sliding grooves (9) are distributed on the inner side of the wheel rubber ring, a T-shaped sliding block (8) is installed at one end, close to the wheel hub (7), inside each T-shaped sliding groove (9), a reset spring (10) is installed between one end, away from the wheel hub (7), of each T-shaped sliding grove (9) and each T-shaped sliding block (8), one end of each spoke rod (4) is transversely hinged to each groove (6), the other end of each spoke rod (4) is transversely hinged to each T-shaped sliding block (8), and a connecting rod can rotate in a plane perpendicular to a wheel plane about a hinge point and can not rotate in a tangent direction of the wheel. The side-turning resistant elastic wheel is simple in structure, low in cost, few in phenomenon of slow moving of the wheel when driving and braking are conducted and capable of delaying a side-turning tendency when a vehicle makes a turn and transverse force or transverse acceleration is imposed on the wheel, and has a certain side-turning resistant effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

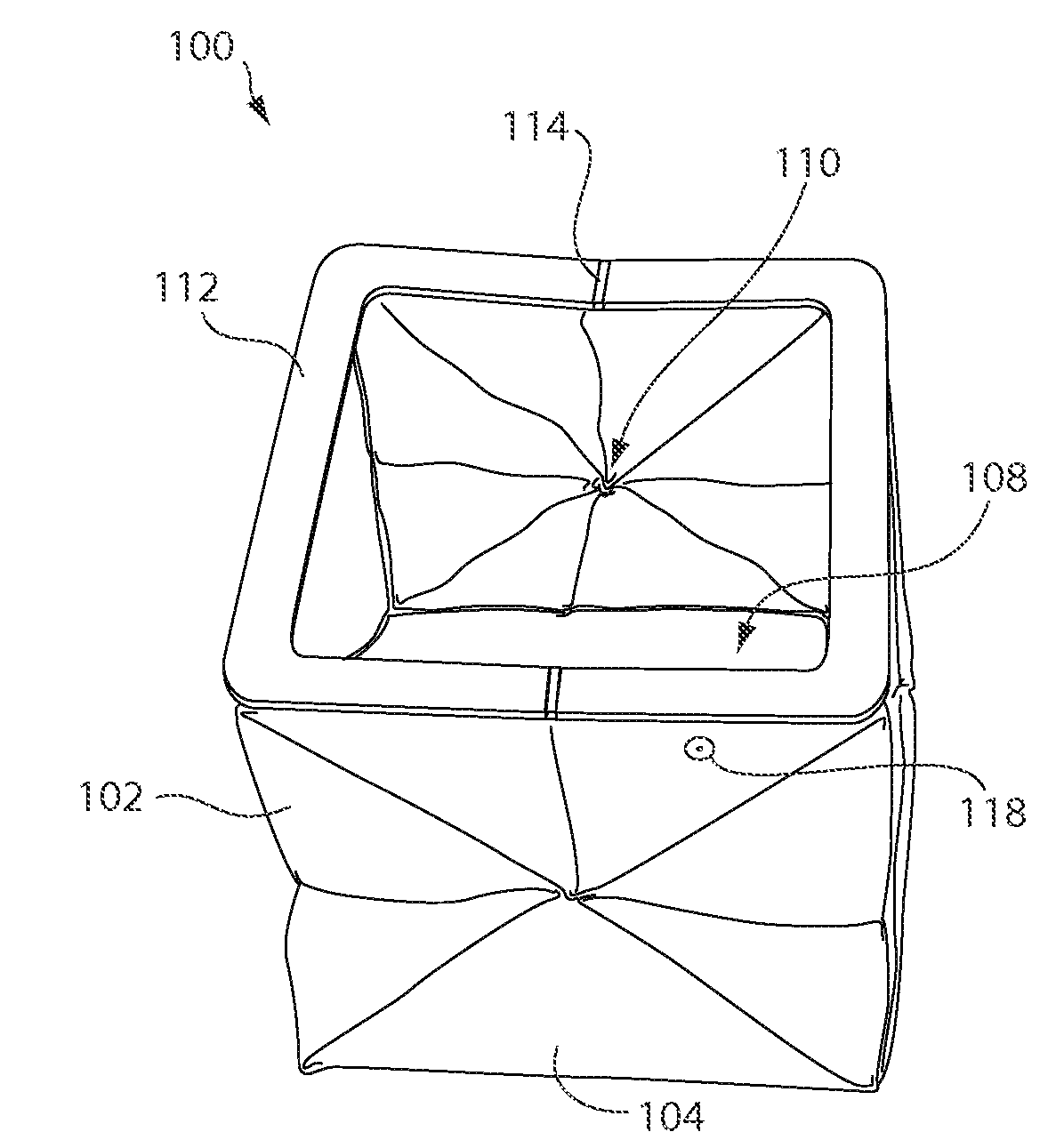

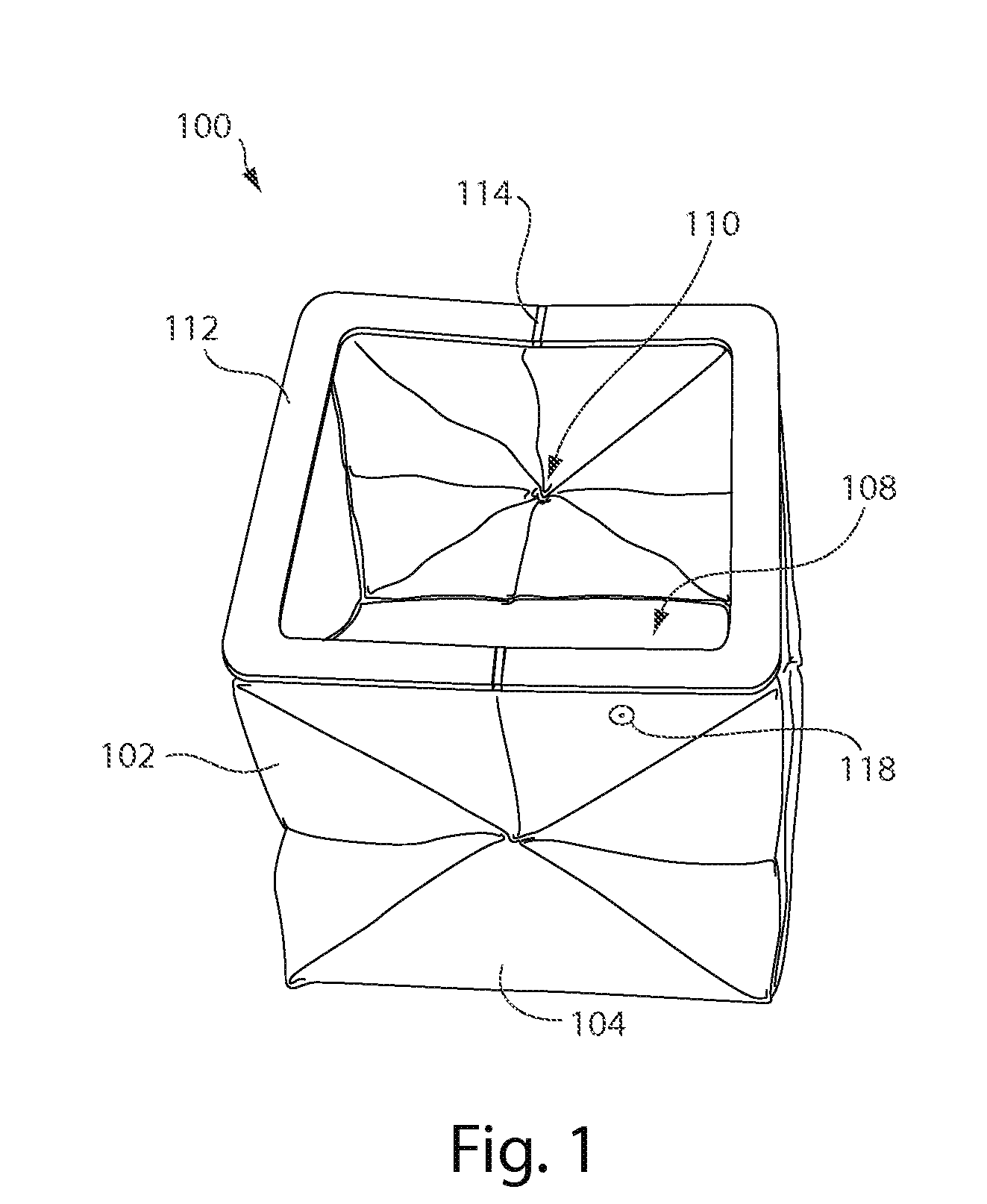

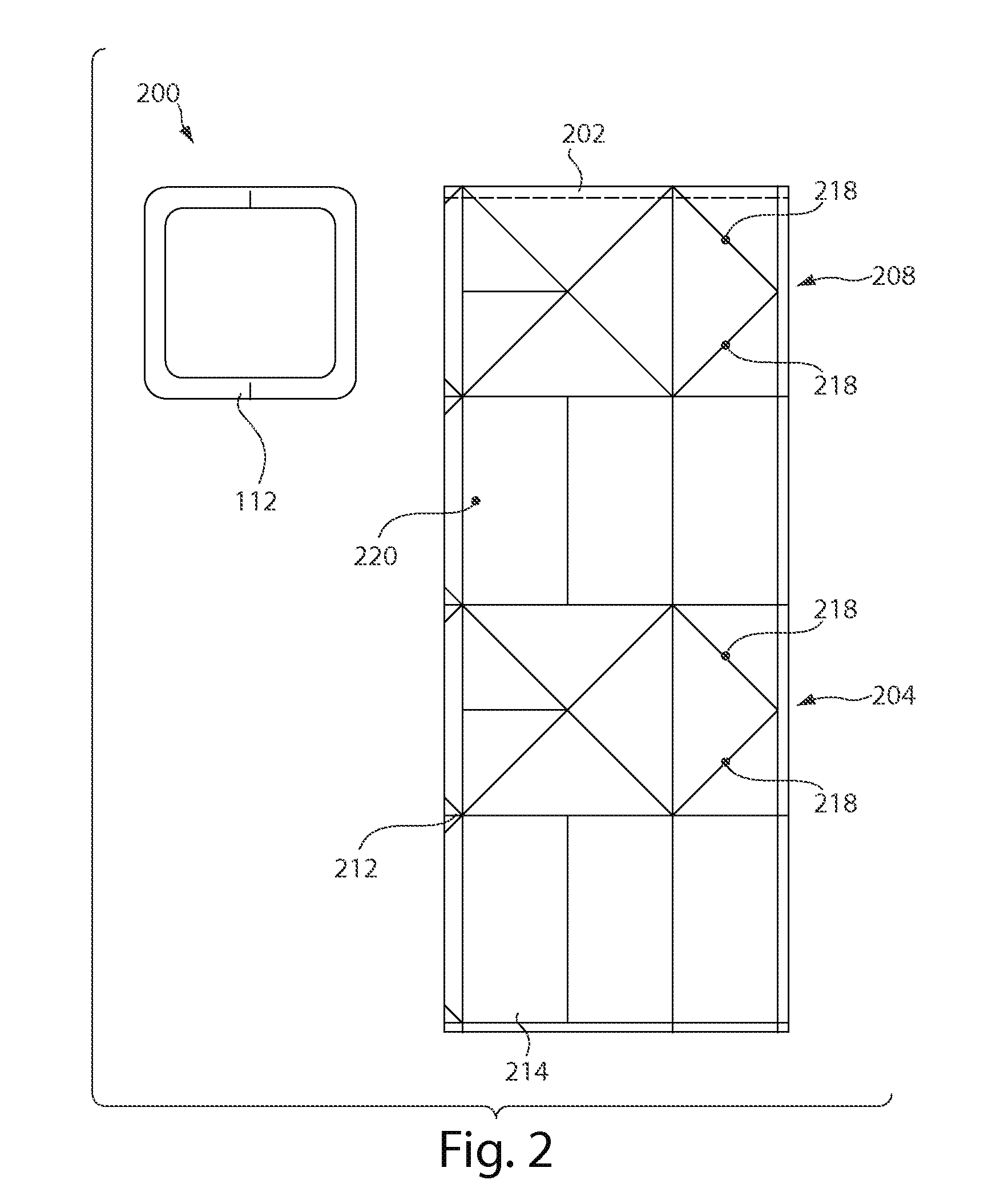

Systems and methods for waste disposal using a disposal bag with a rectangular frame

In embodiments of the present invention improved capabilities are described for waste disposal. A disposal bag may include a bag configured to receive waste, a frame associated with the bag at an opening. The frame may include one or more pair of hinge points configured to open and close the bag when a force is applied on the frame, and a pair of tabs associated with one of the one or more pair of hinge points, wherein the pair of tabs enable stacking of the disposal bag with a plurality of substantially similar disposal bags. In some embodiments of the frame, the frame is conically shaped and may include a sealing facility disposed on at least one part of the frame.

Owner:UMAGINATION LABS

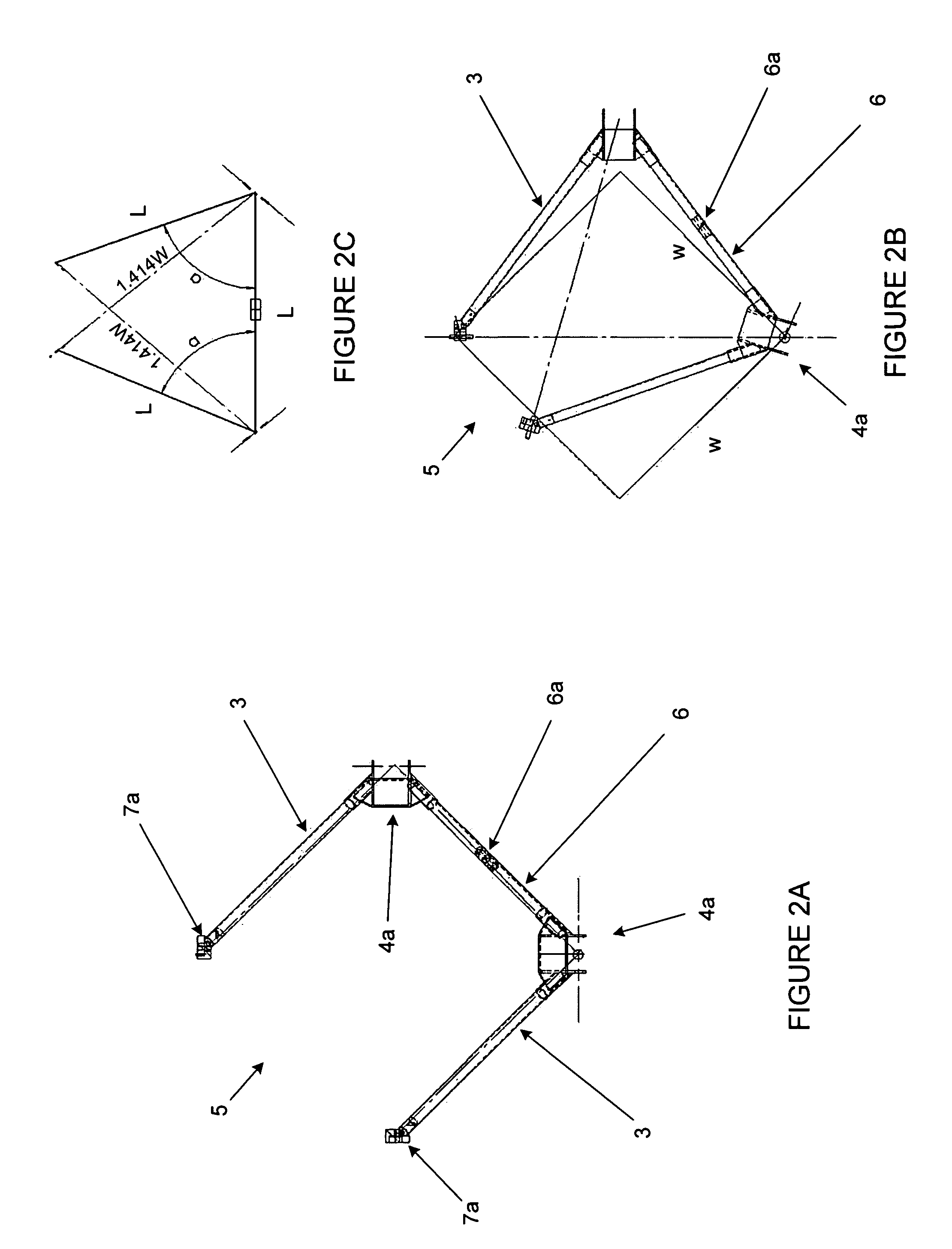

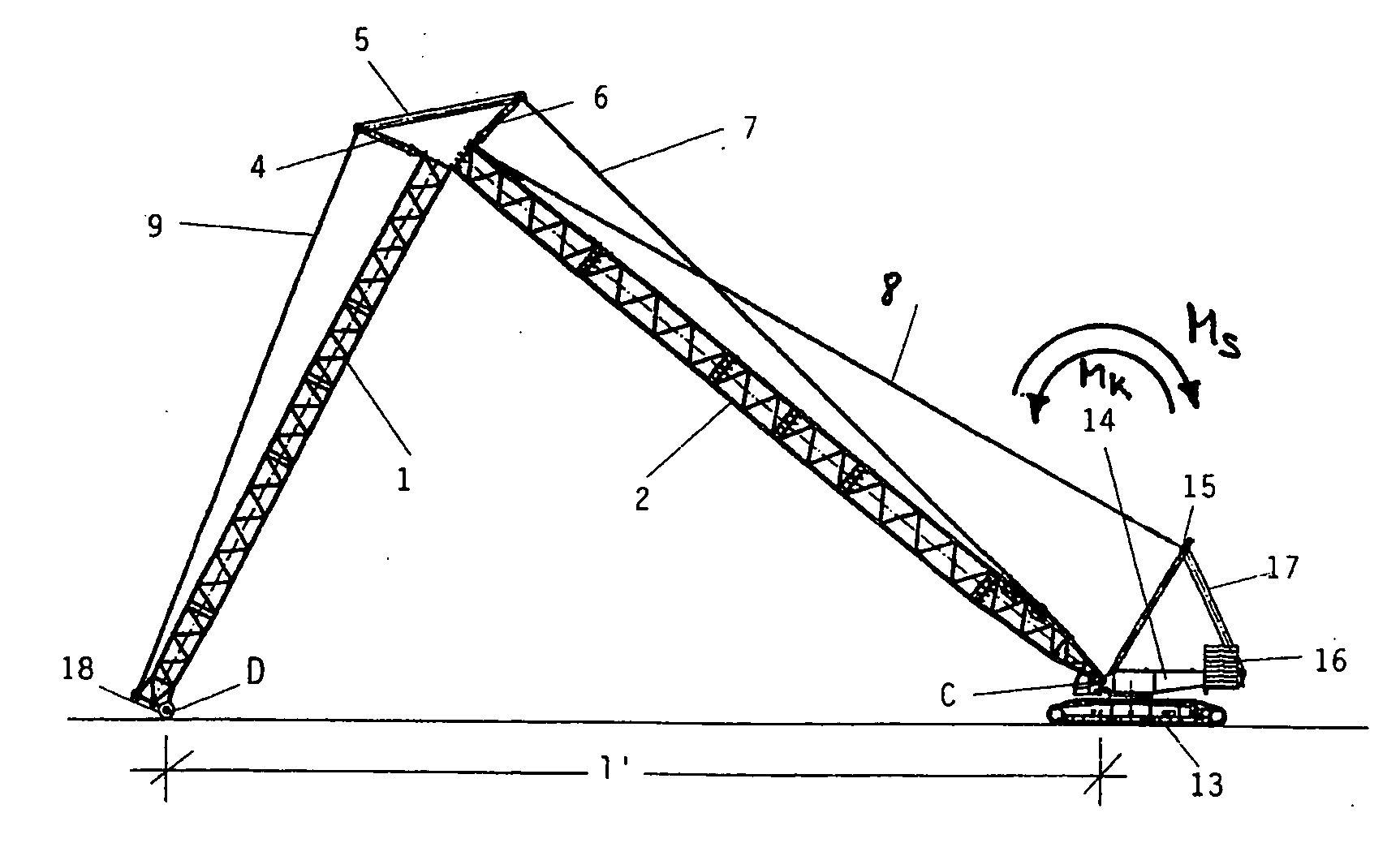

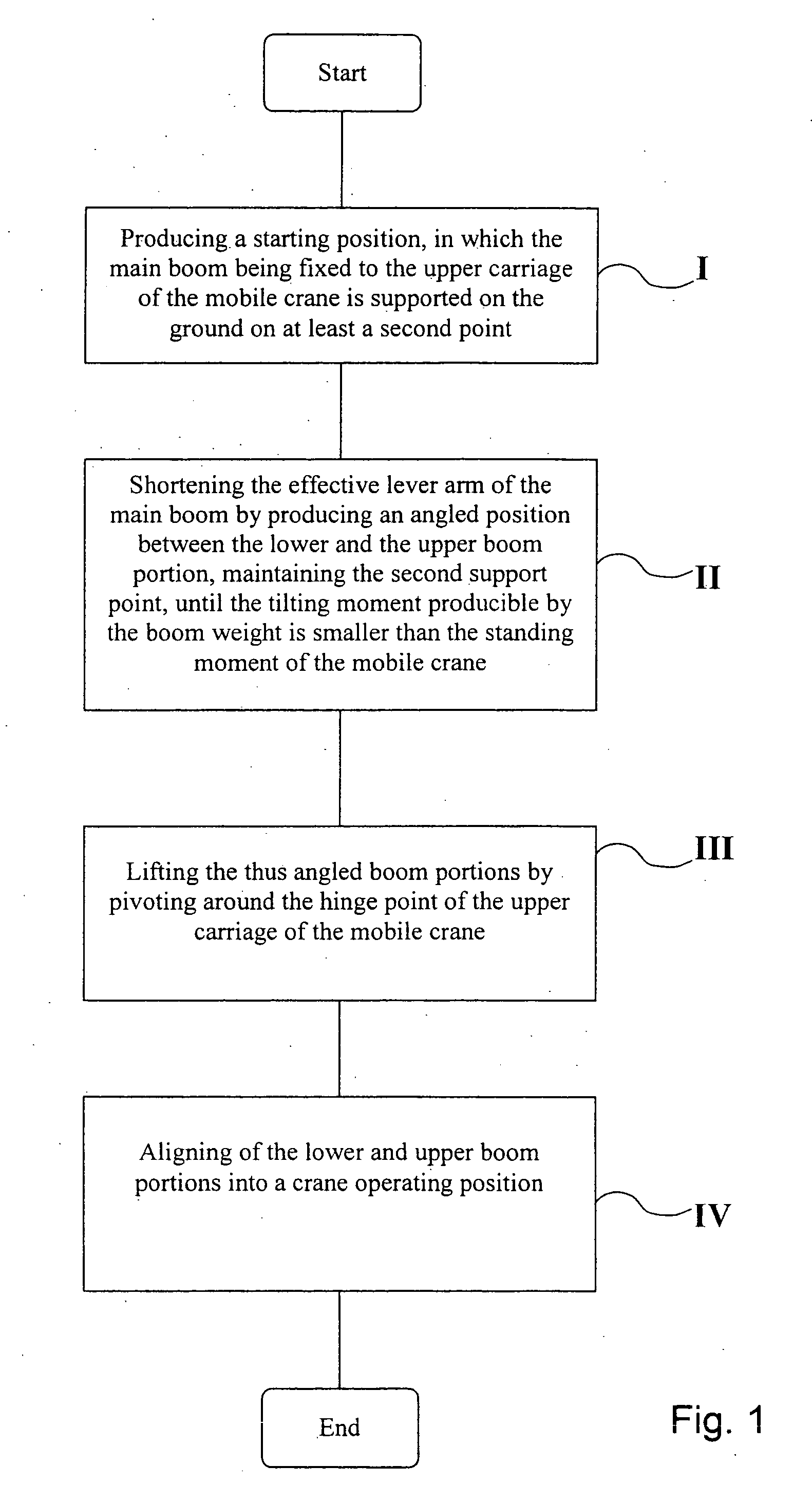

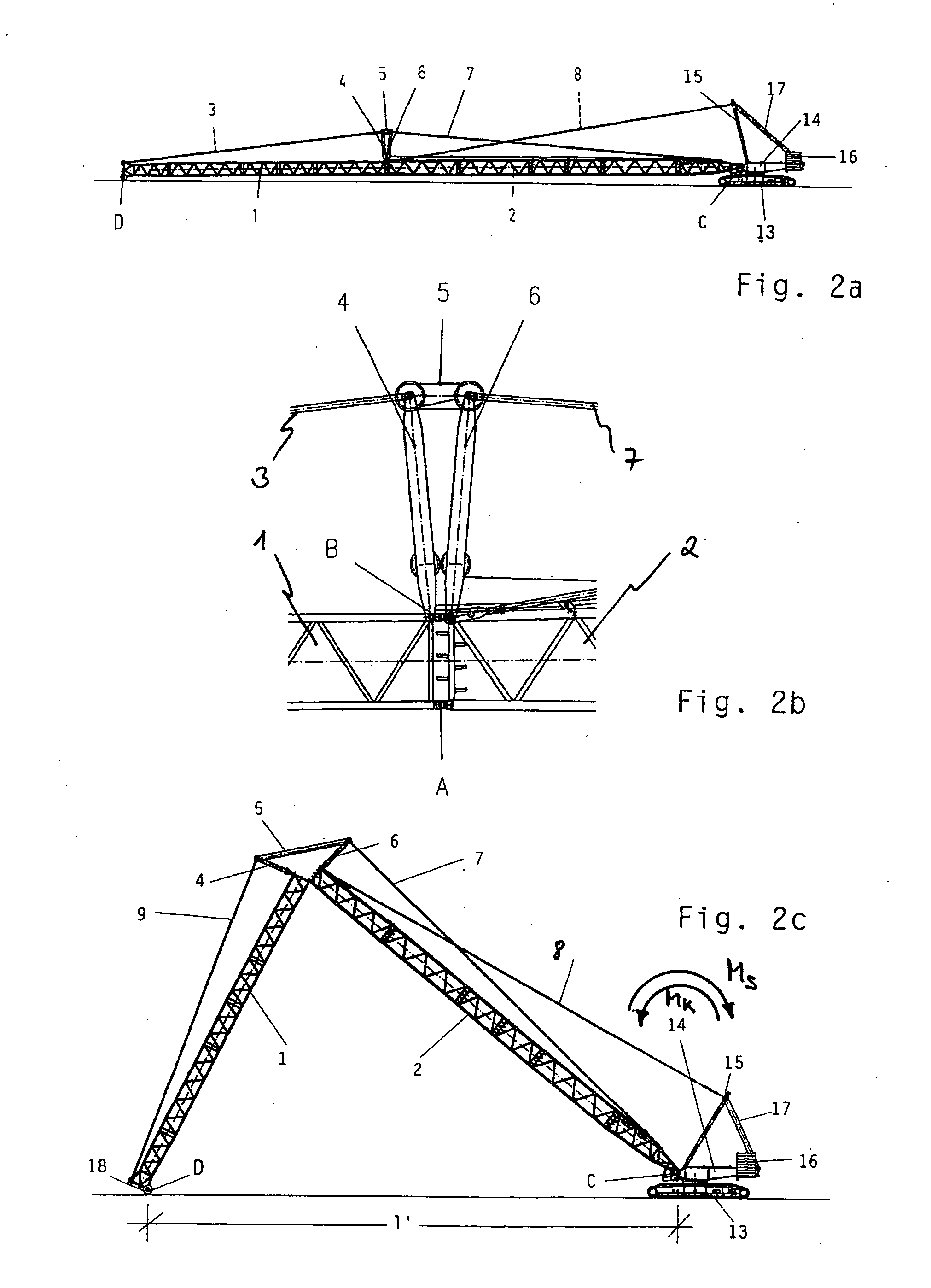

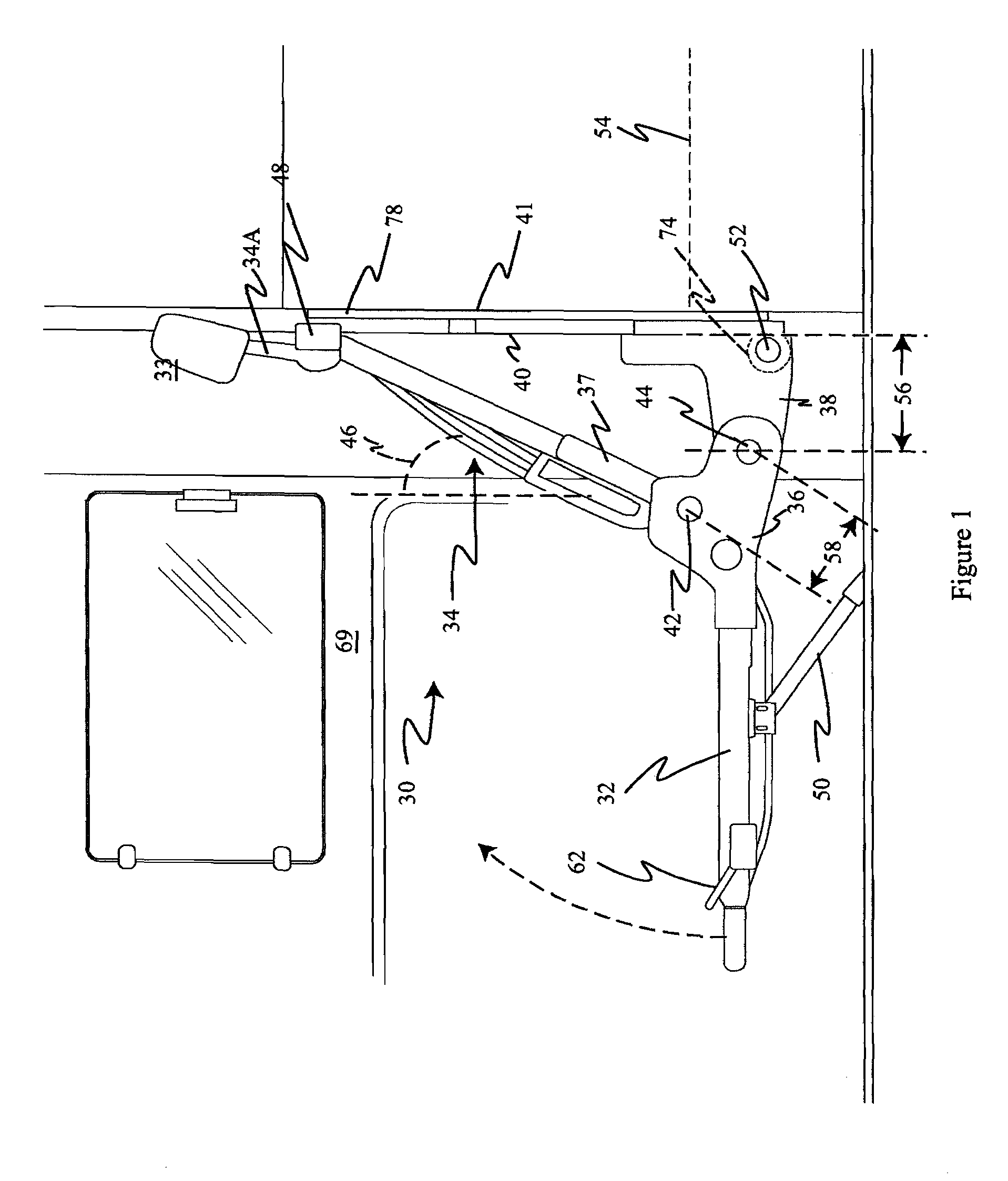

Method for erecting an at least two-piece main boom for a lattice-boom crane and lattice-boom crane built accordingly

ActiveUS20060065616A1Shortening the effective lever armEffective lever arm of the main boom in turn is shortenedLoad-engaging elementsCranesEngineeringMechanical engineering

The present invention substantially relates to a method for erecting and disassembling an at least two-piece main boom for a lattice-boom crane. The erecting and disassembling procedure results in that the geometric kinematic properties of the main boom (1, 2) are used in such a manner that during the erecting and disassembling, the effective lever arm (1′) of the main boom (1, 2) is reduced. This results from the main boom (1, 2) being bent at the hinge point (A), at which at least two boom portions (1, 2) are connected to each other, and thus an angle position is produced between the two boom portions (1, 2). Further, the invention relates to a main boom (1, 2), which can be erected by the method as well as a lattice-boom crane having such an main boom (1, 2).

Owner:TADANO DEMAG GMBH

Spray actuating mechanism for a dispensing canister

A spray actuator for a pressurized aerosol canister that simplifies the mechanical moving parts of a spray actuator to a body and a trigger and a third nozzle piece being inserted at the very end of the product dispensing passage either in the body or the trigger. The moveable trigger rotates about a pivot or hinge point on the body and is biased by engagement with the valve stem or an additional spring return into a neutral unactuated position where the product is not dispensed. When dispensing of the product is desired, the user grasps the actuator and pulls the trigger against the body and overcomes the bias of the valve stem and the valve is actuated as discussed above to dispense the pressurized aerosol product.

Owner:SUMMIT PACKAGING SYST

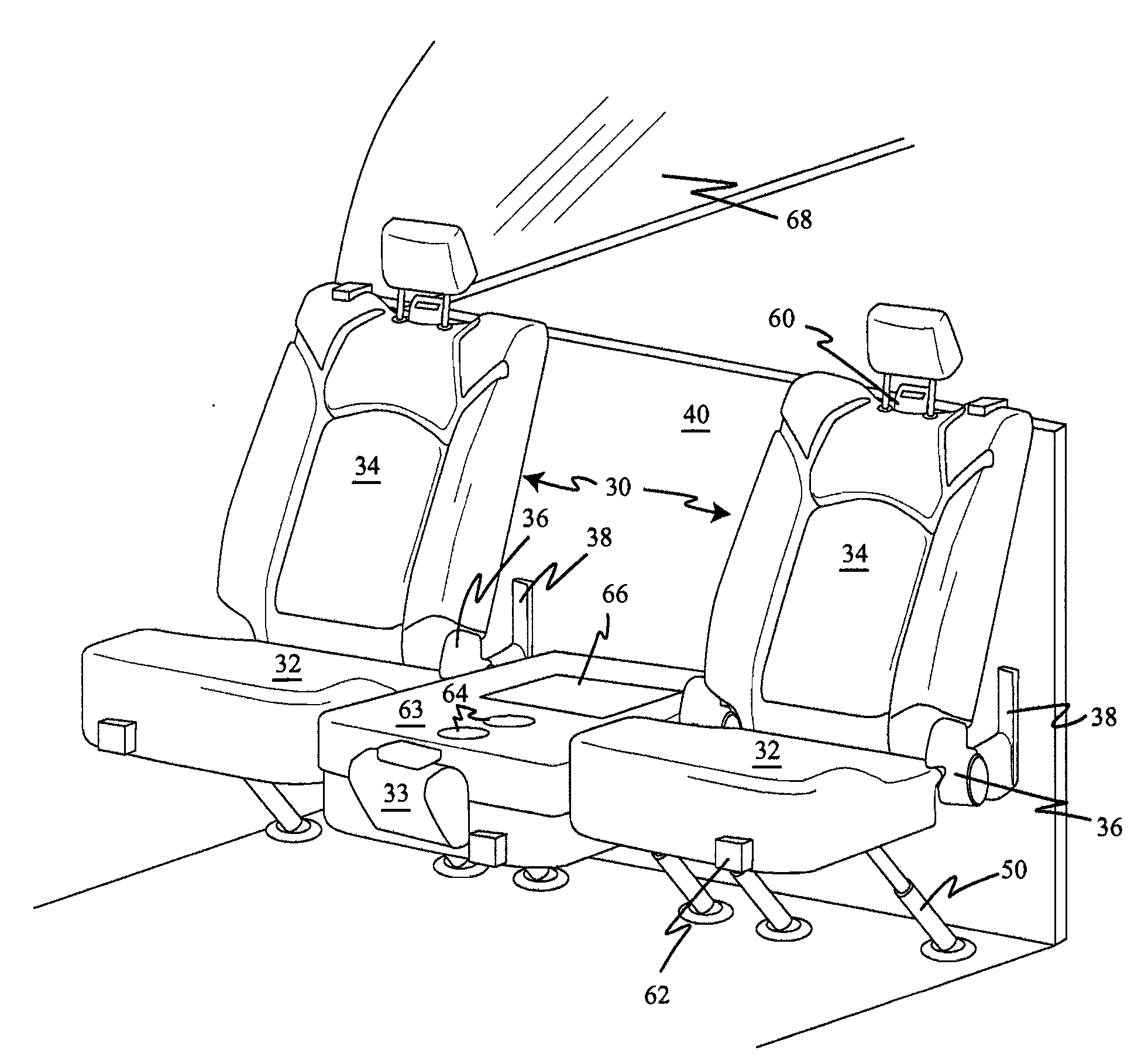

Fold Flat Seating

A folding seat for a vehicle includes a seat base fixed to an intermediate bracket, a seat back having a lower end and a support bracket fixed to the vehicle. An intermediate bracket has a first hinge point where the seat back lower end is hingedly attached to the intermediate bracket. The intermediate bracket has a second hinge point where the intermediate bracket is hingedly attached to the support bracket, and which is spatially removed from the first hinge point. Upon folding of the seat base into a vertical position, the intermediate bracket rotates on the second hinge point, which remains stationary and the first hinge point rotates upwardly and rearwardly around the second hinge point, so that the first hinge point and the lower seat back move rearwardly as the seat back and the seat base are folded into vertical orientation close to the rear vehicle wall.

Owner:SCHUKRA OF NORTH AMERICA

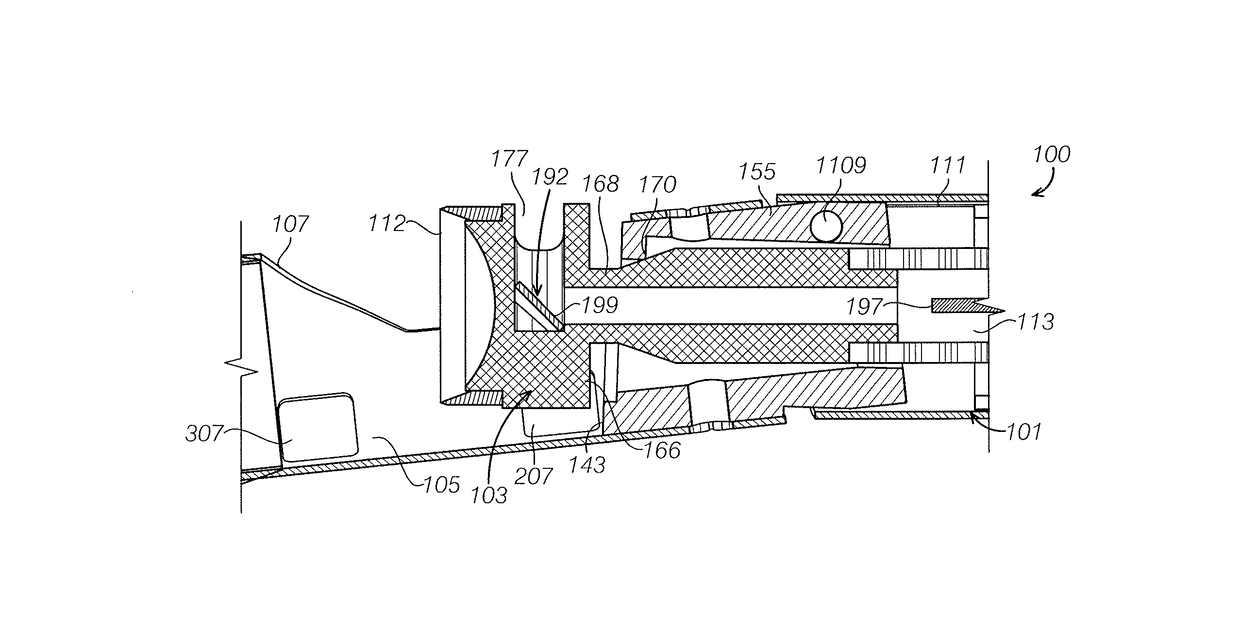

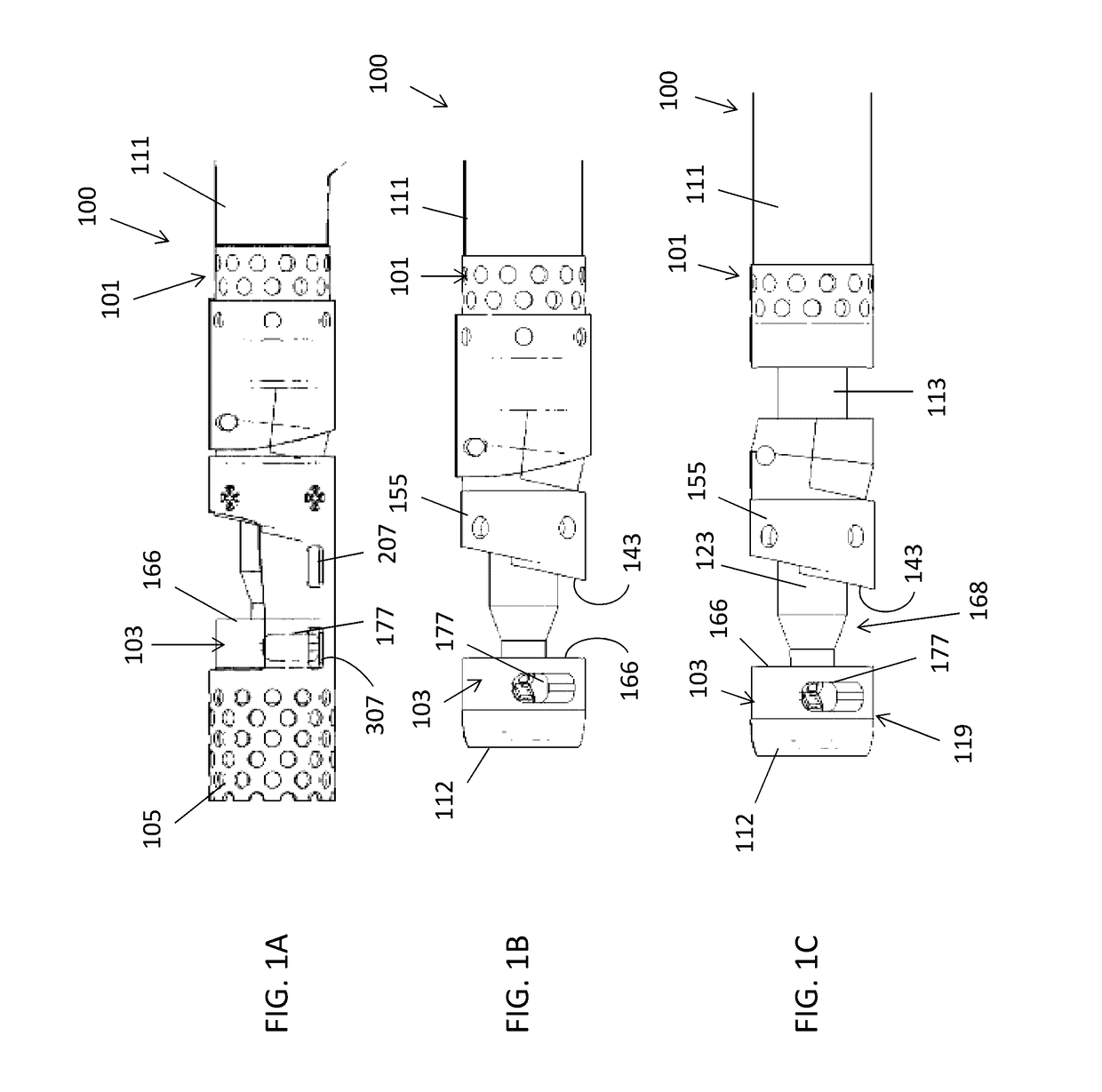

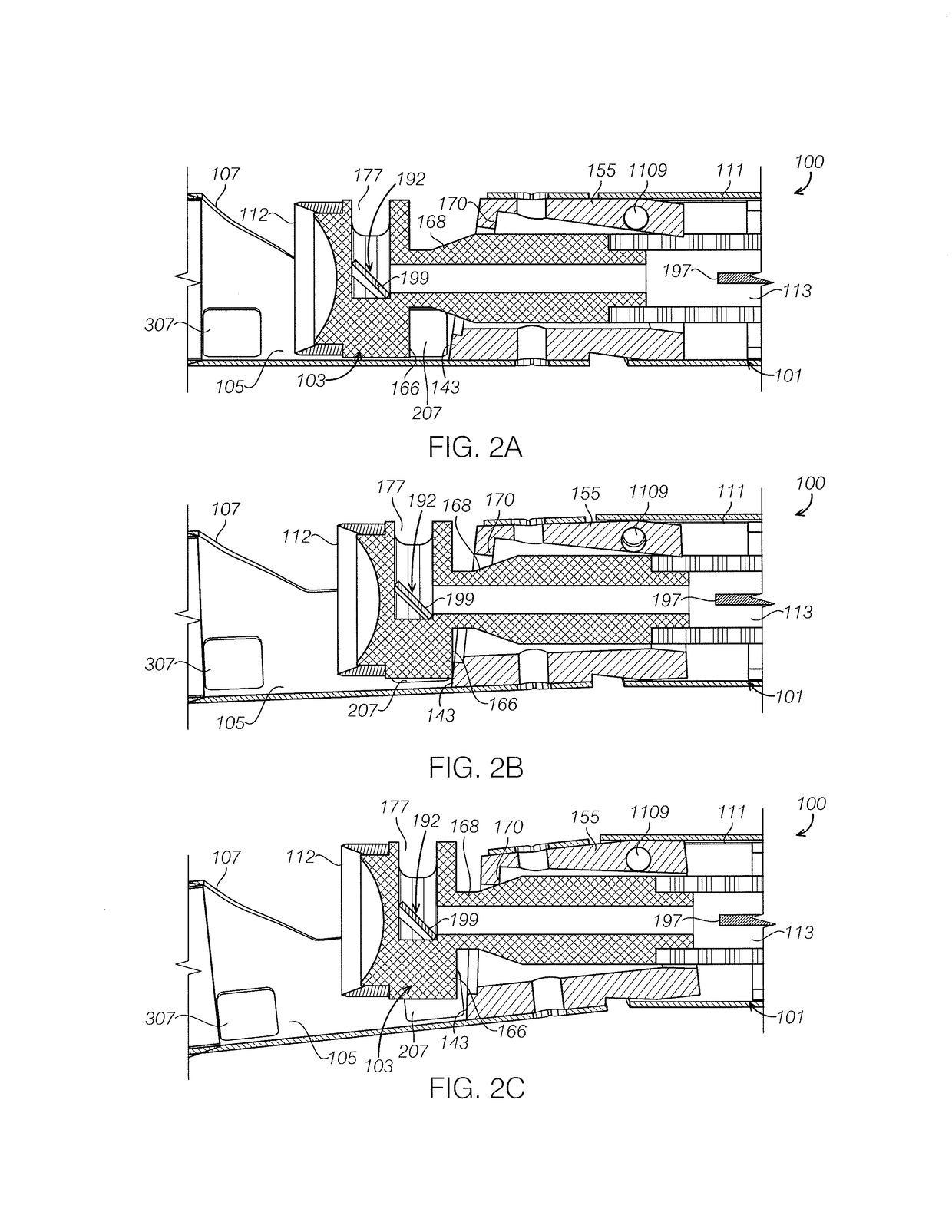

Atherectomy catheters devices having multi-channel bushings

Atherectomy catheters and methods of using them are described herein. In particular, described herein are optical coherence tomography (OCT) catheters that may include a distal tip that can be deflected away from the long axis of the device using a multi-channel bushing. The bushing may include at a hinge point that is offset (e.g., located on a side of the elongate body near the distal end of the elongate body) and a rotatable cutter near an imaging assembly that can be driven against the wall with a high mechanical advantage.

Owner:AVINGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com