Patents

Literature

1595 results about "Counter rotating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

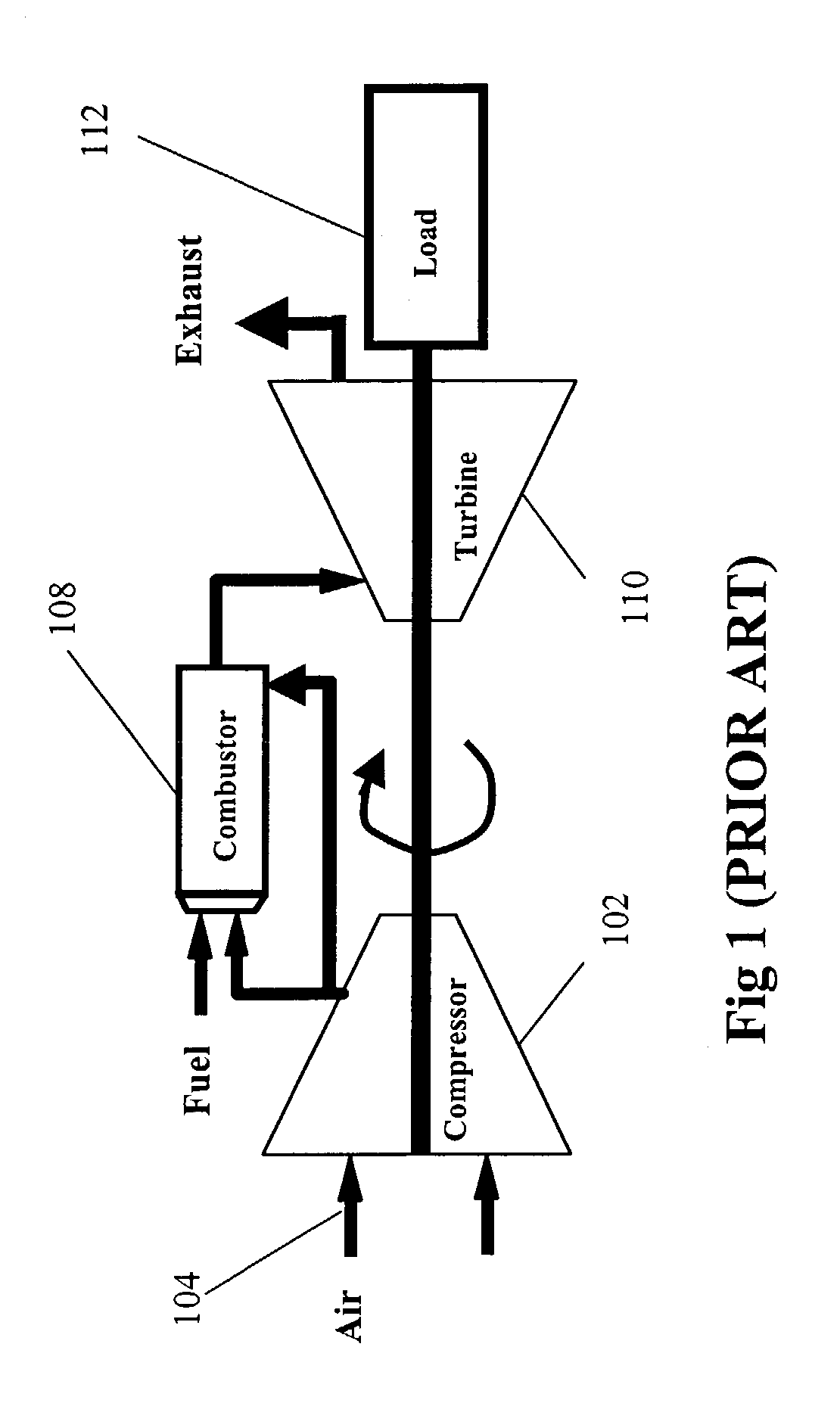

Counter-rotating propellers generally spin clockwise on the left engine and counter-clockwise on the right. The advantage of such designs is that counter-rotating propellers balance the effects of torque and P-factor, meaning that such aircraft do not have a critical engine in the case of engine failure.

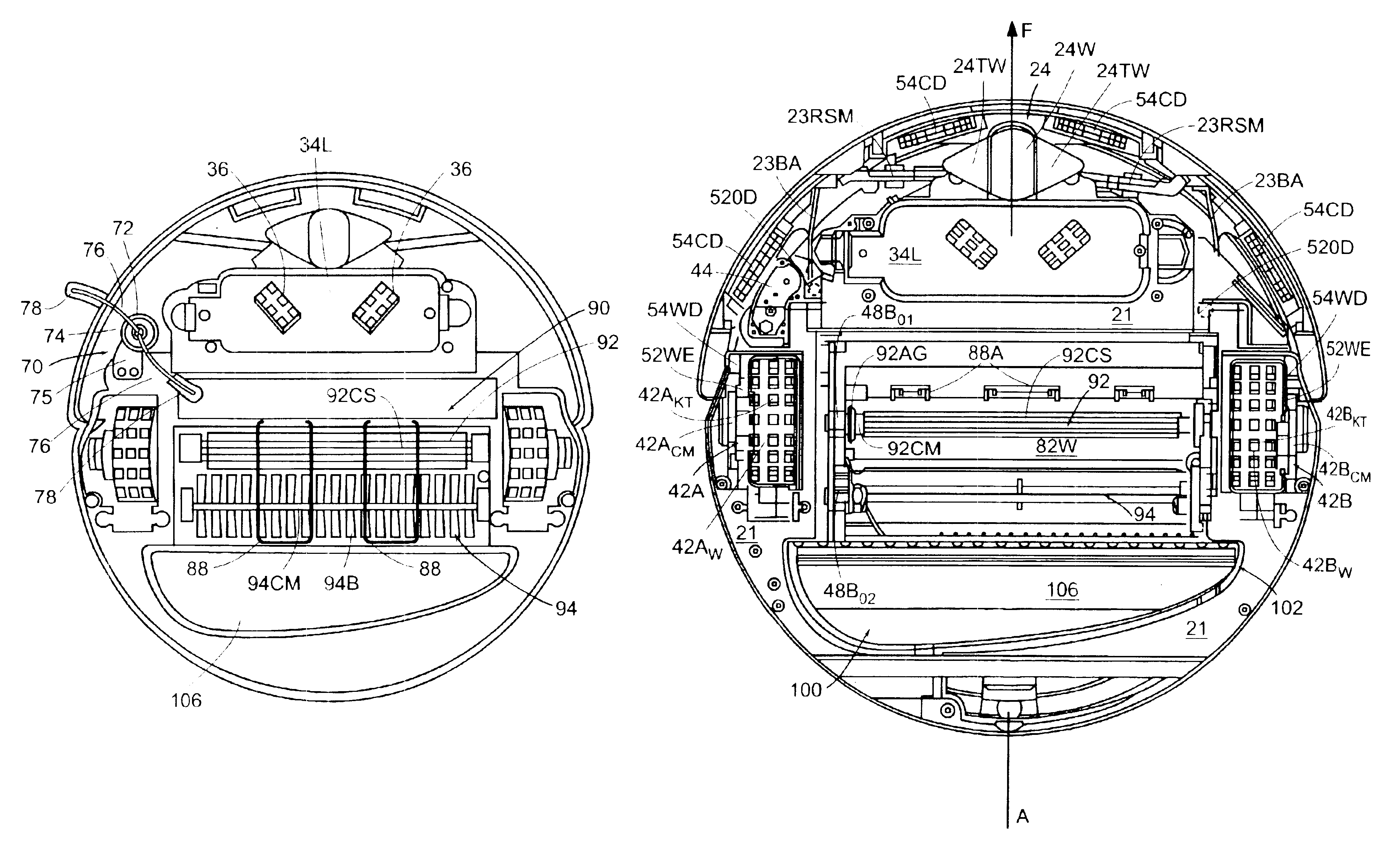

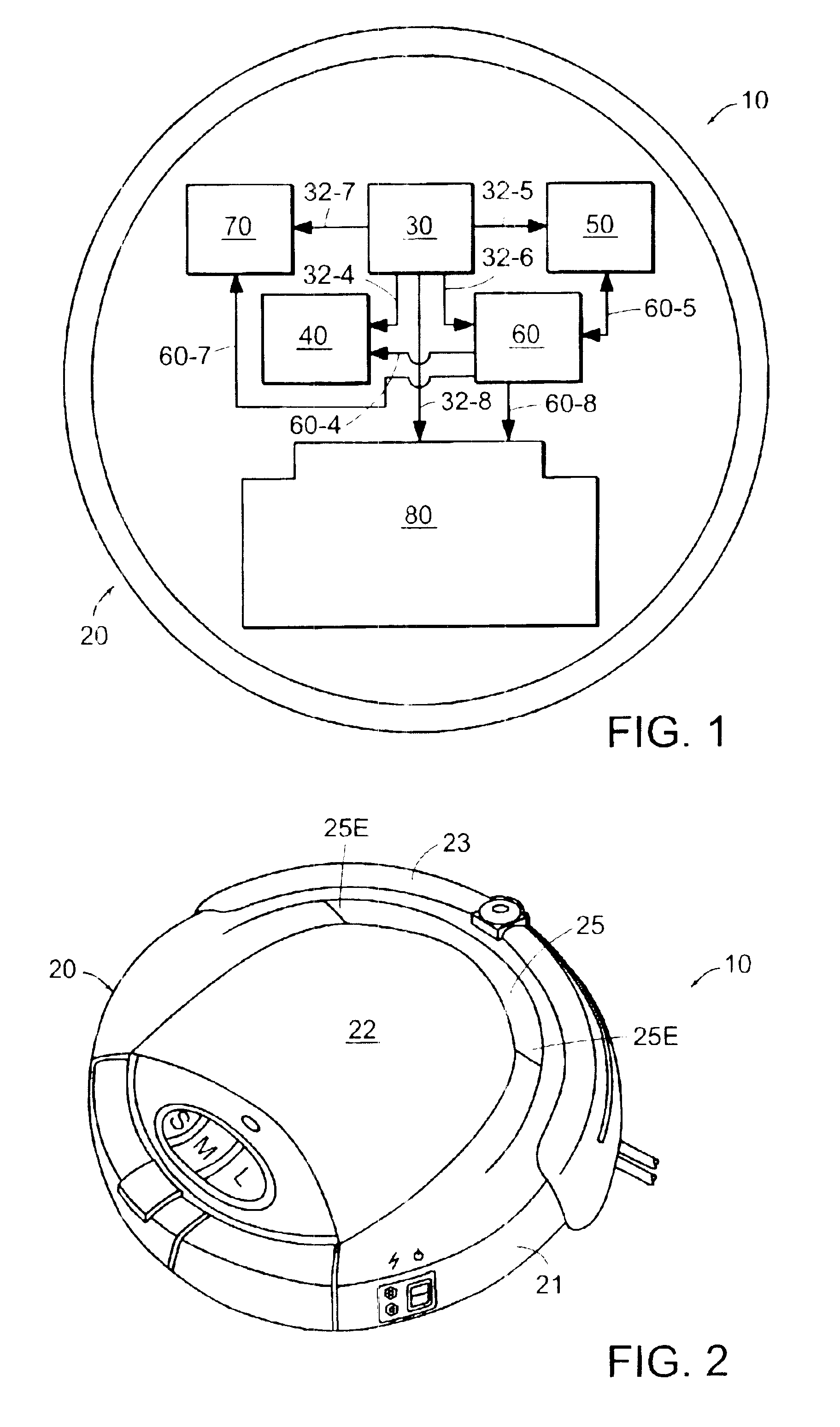

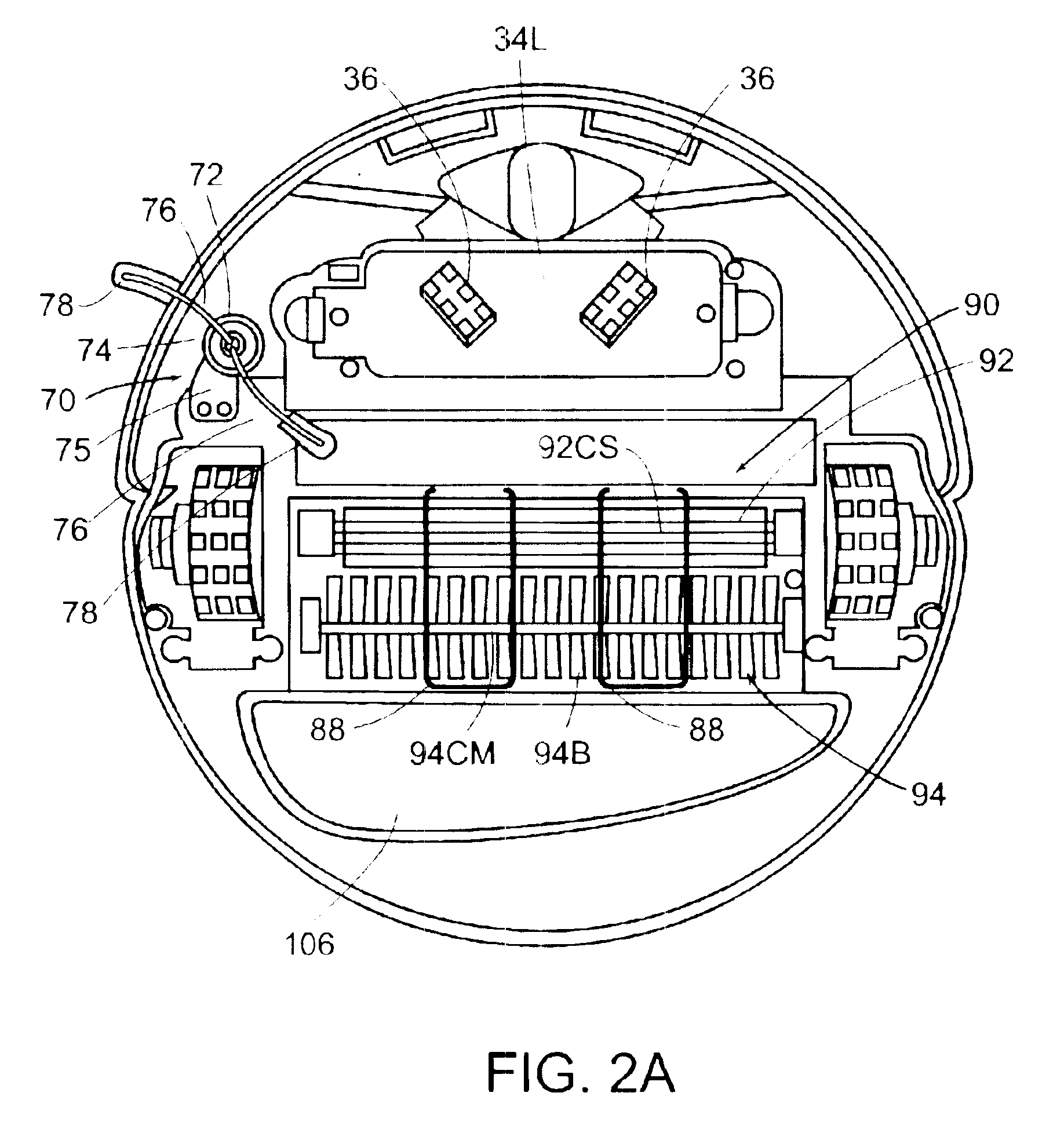

Autonomous floor-cleaning robot

InactiveUS6883201B2Improve rendering capabilitiesImprove efficiencyAutomatic obstacle detectionTravelling automatic controlDual stageEngineering

Owner:IROBOT CORP

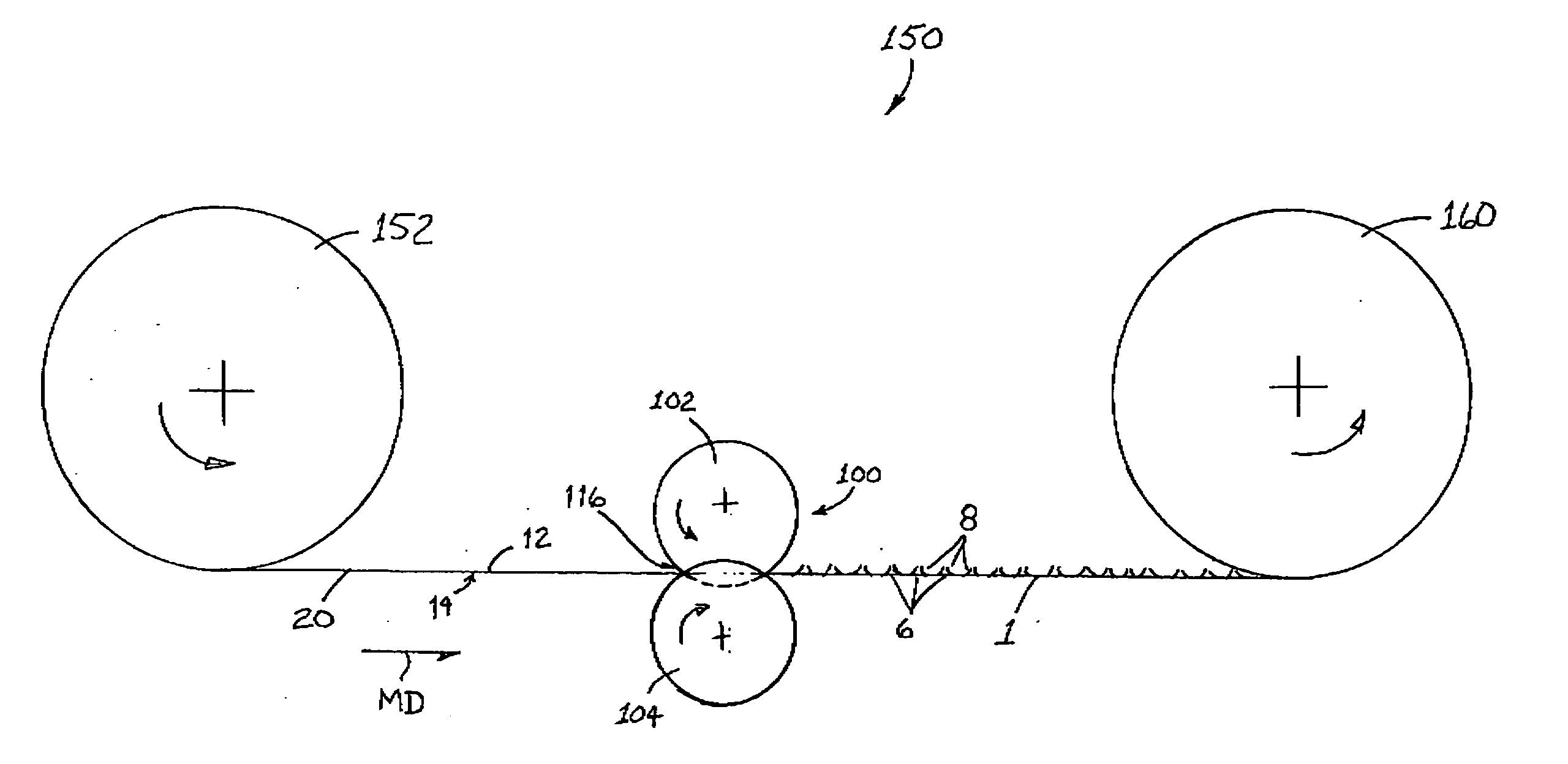

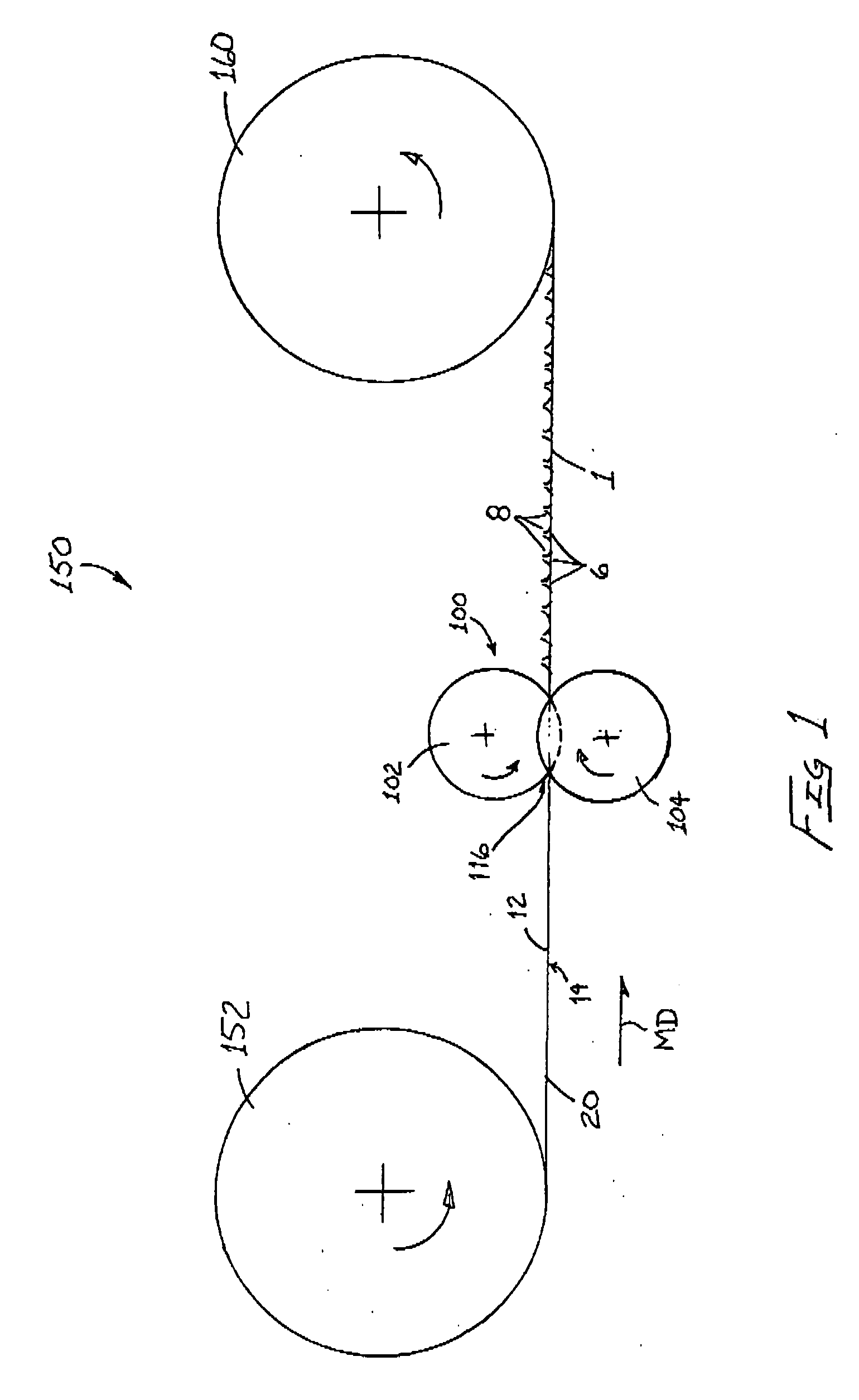

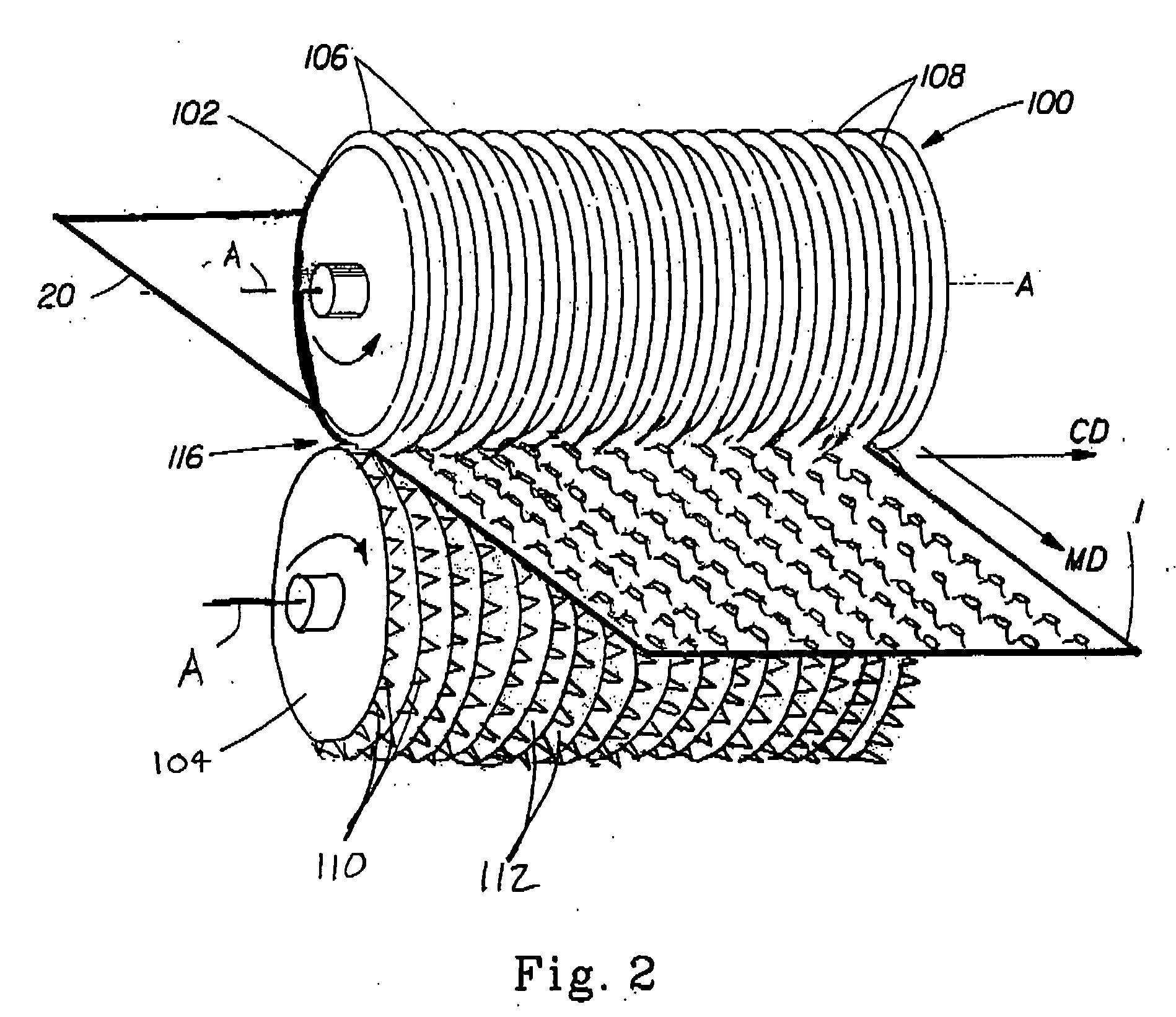

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

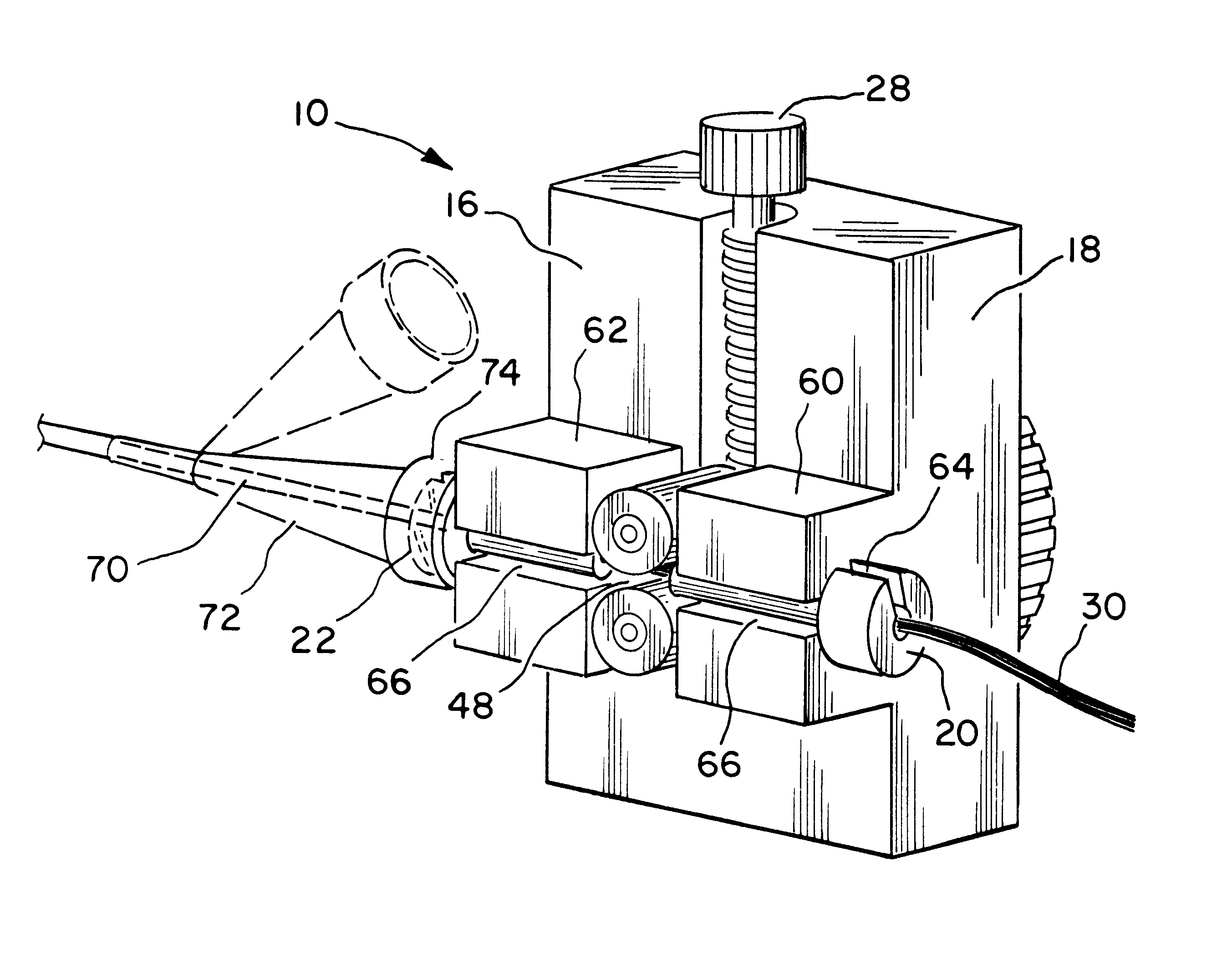

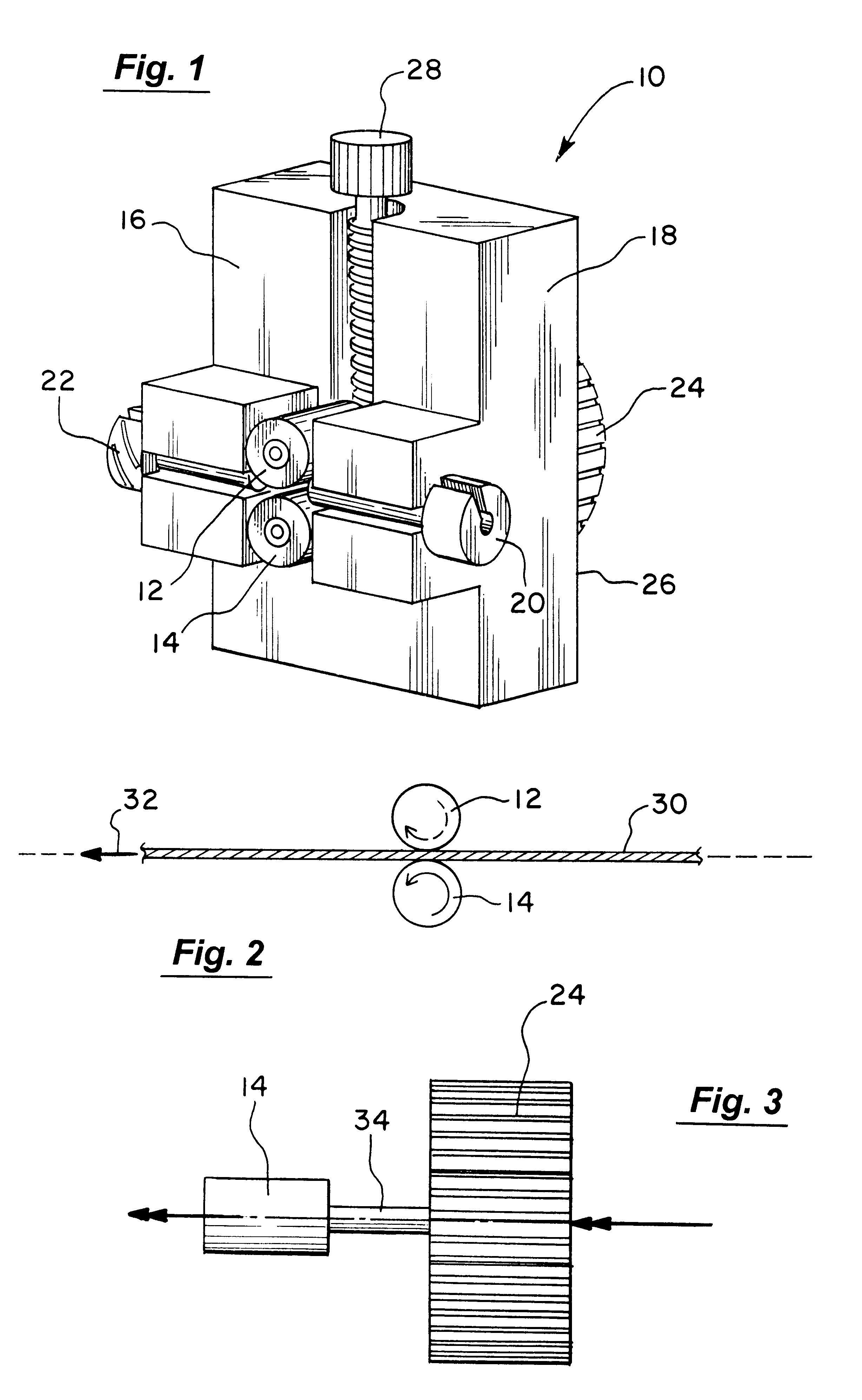

Imaging gore loading tool

A tool for coaxially loading a flexible member into a lumen of a catheter. Typically, the flexible member is a flexible imaging core or similar device. The tool includes a body which has a connector, which connects the body to a hub located on the catheter. A pair of opposed rollers, disposed proximate to the connector, are used to advance the flexible member, through the connector, and into the catheter, which is connected to the connector. The flexible member is advanced by counter rotating the rollers.

Owner:SCI MED LIFE SYST

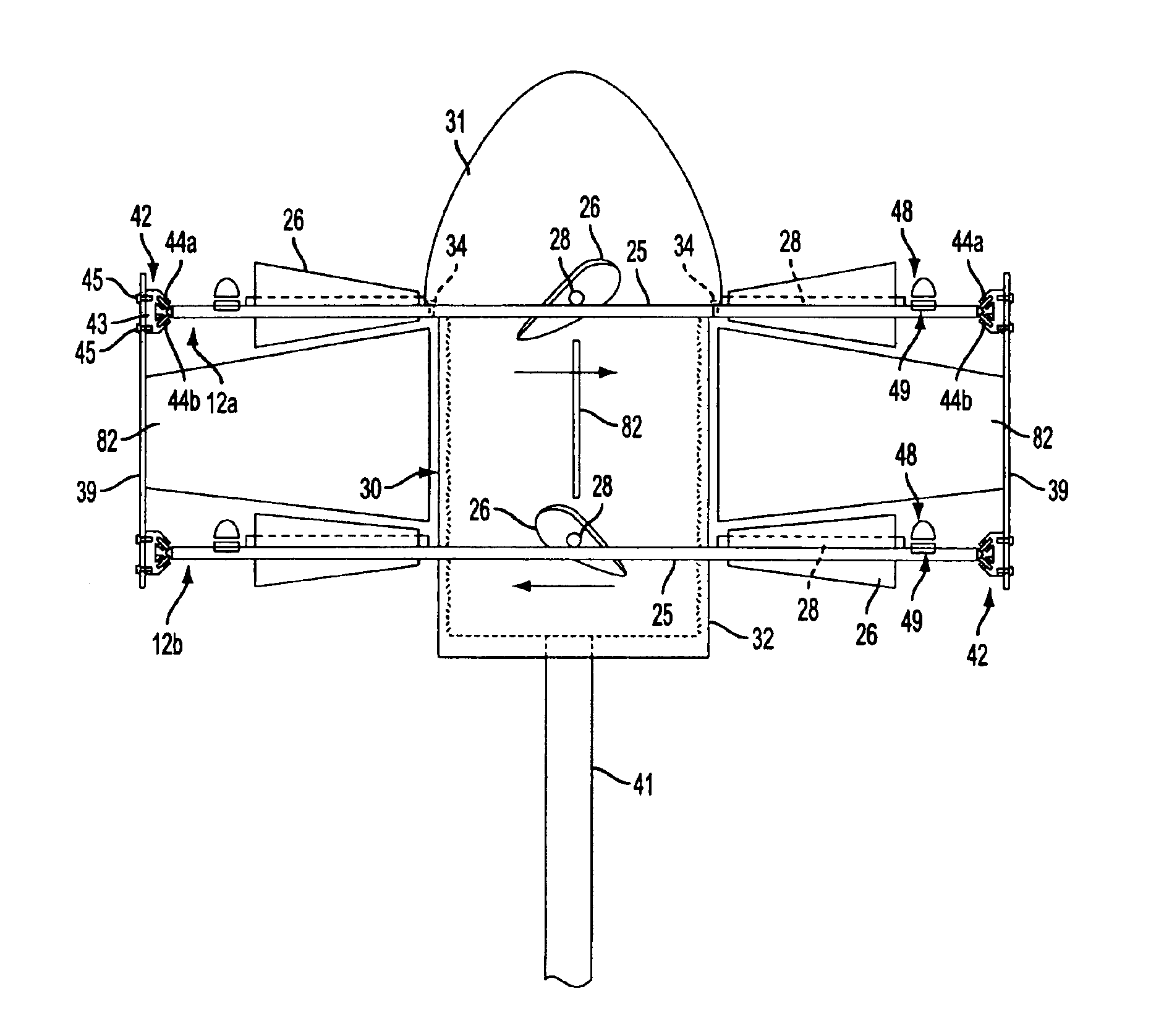

Ducted fan vertical take-off and landing vehicle

InactiveUS20060226281A1Process controlSafe travelVertical landing/take-off aircraftsRotocraftGear wheelFlight vehicle

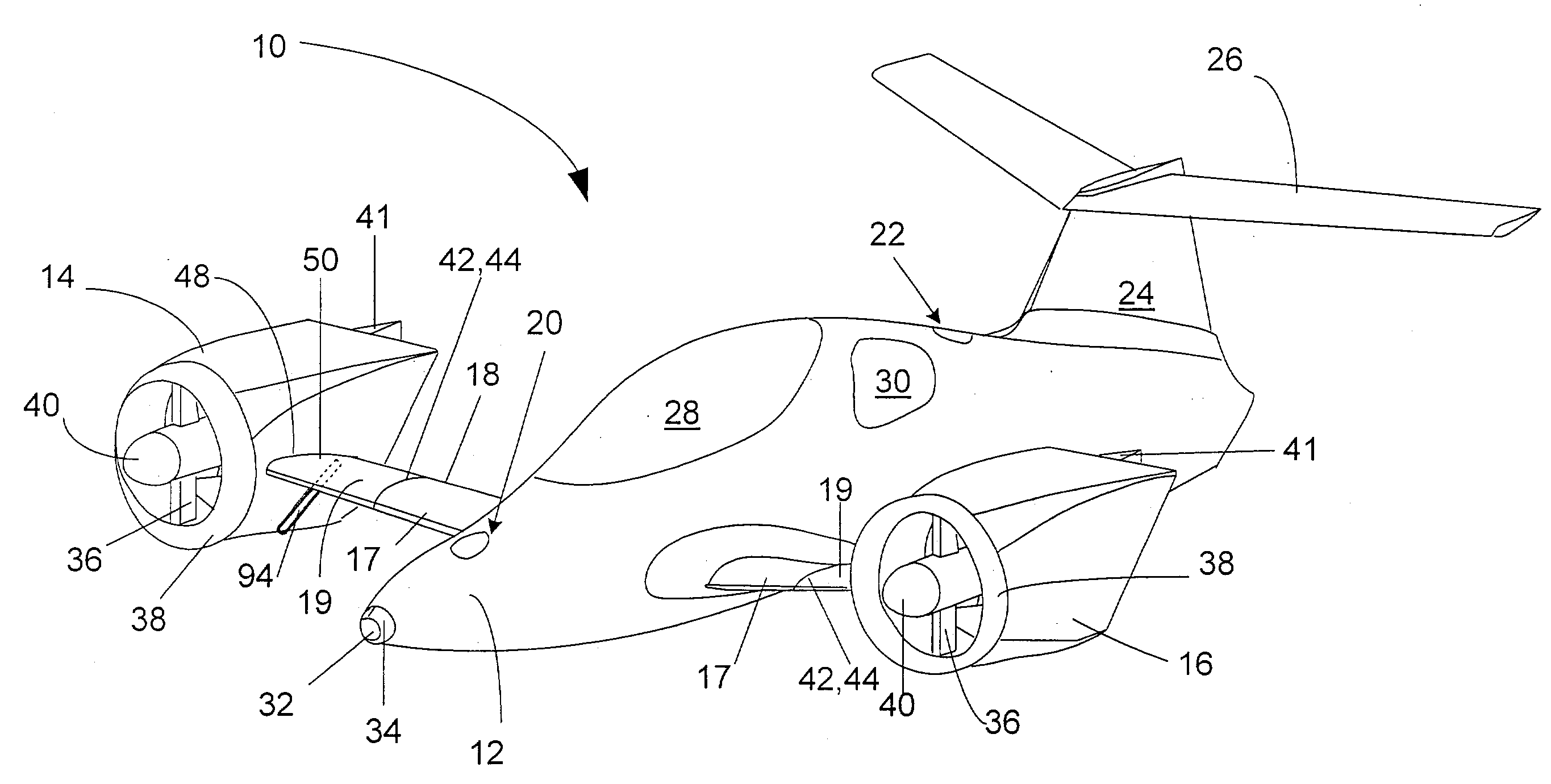

A vertical take-off and landing vehicle comprised of a fuselage having a front, a rear, and two lateral sides and a set of four thrusters set to the front, the left, the right, and the rear of said fuselage. The thrusters are either independently powered thrusters or could utilize a single power source. The thrusters, which are ducted fan units capable of providing a vertically upward force to the aircraft, are provided with such redundancy that the aircraft can hover with up to two thrusters inoperative. The thrusters are comprised of a set of two counter rotating propellers both of which creates lift. The two counter rotating propellers cancel out the torque effect normally created by using only one propeller. The Ducted fan units being movable between a first position in which they provide vertical lift and a second position in which they provide horizontal thrust using a set of servos and gears.

Owner:WALTON JOH PAUL CHRISTOPHER

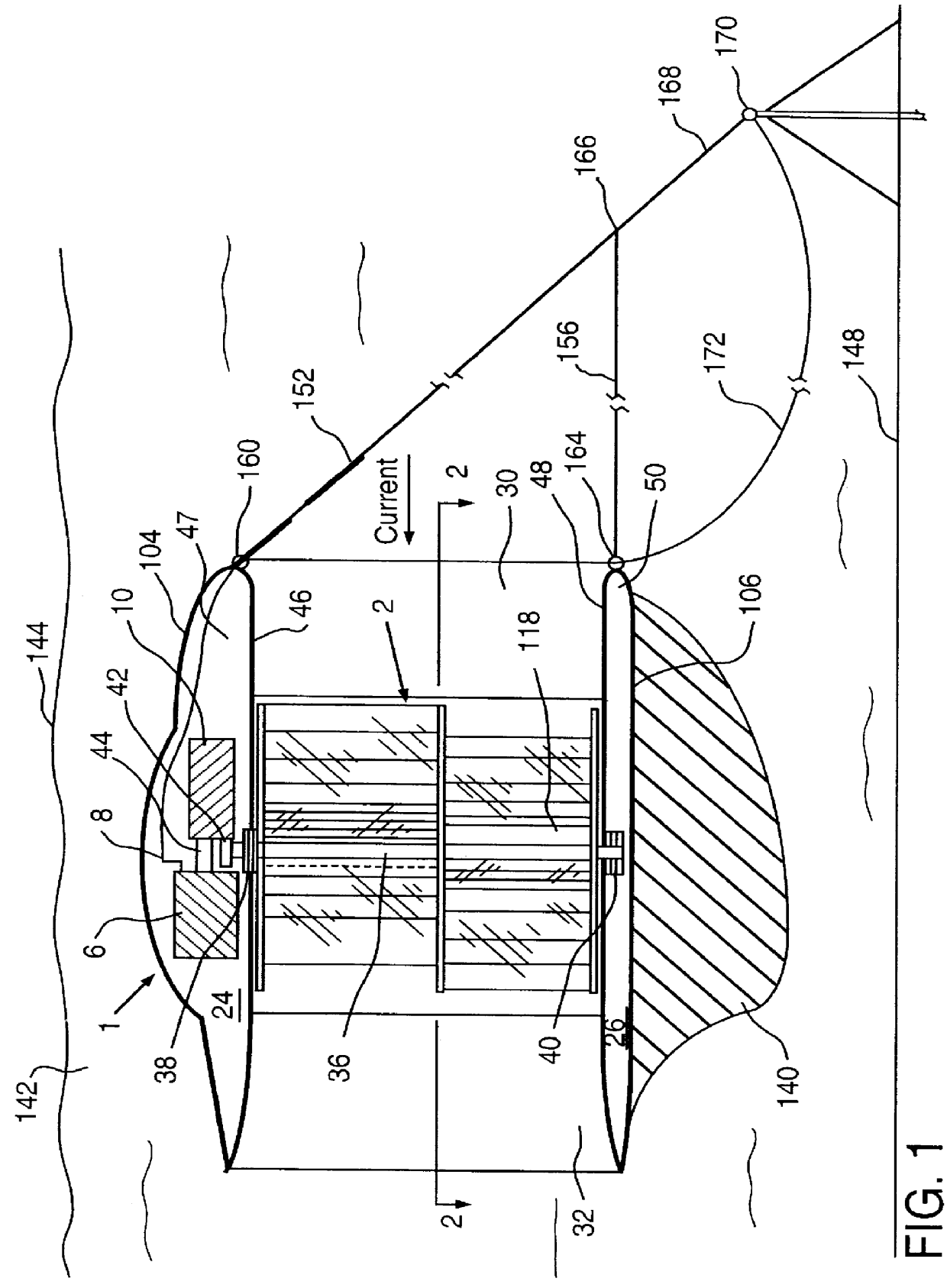

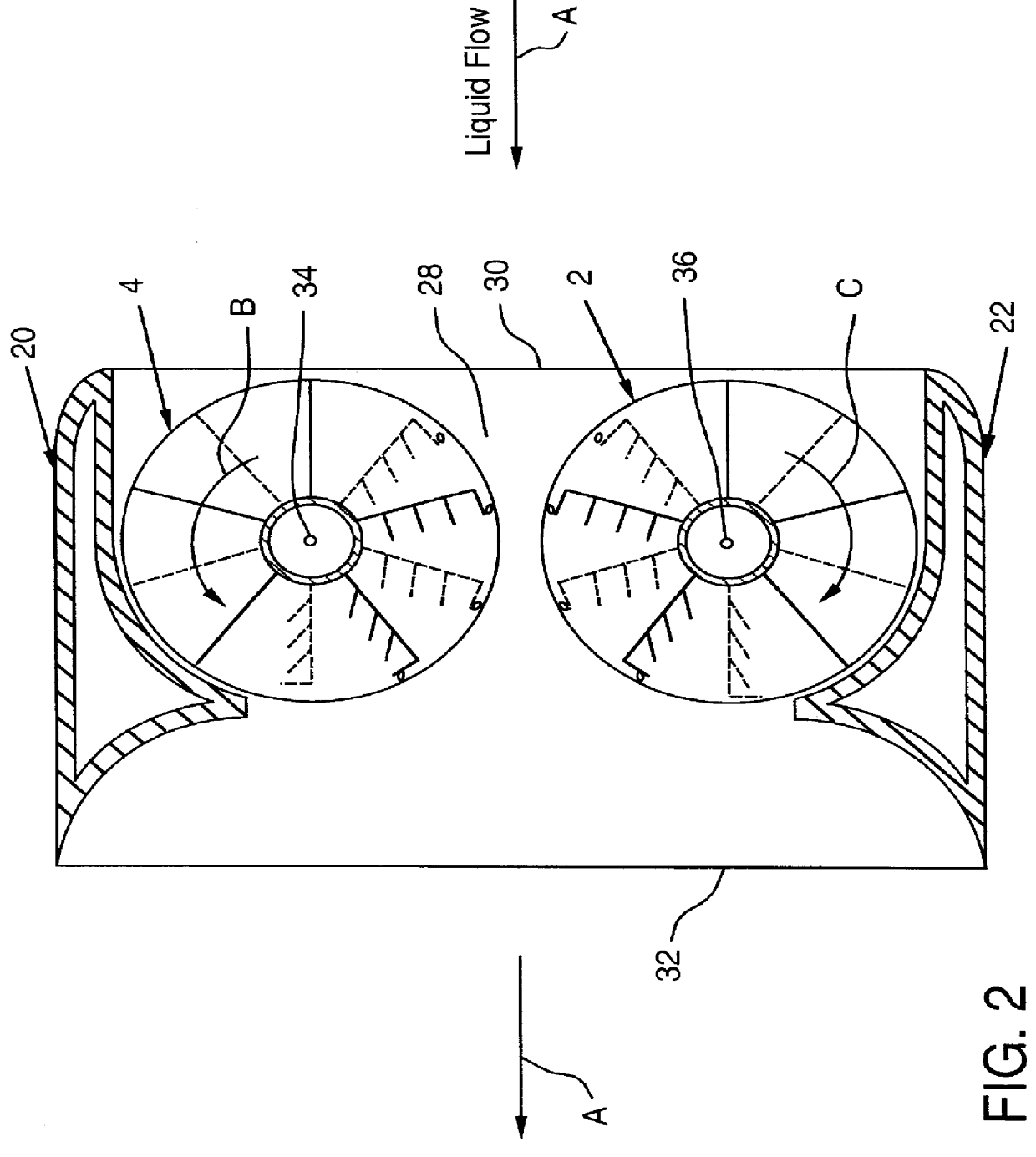

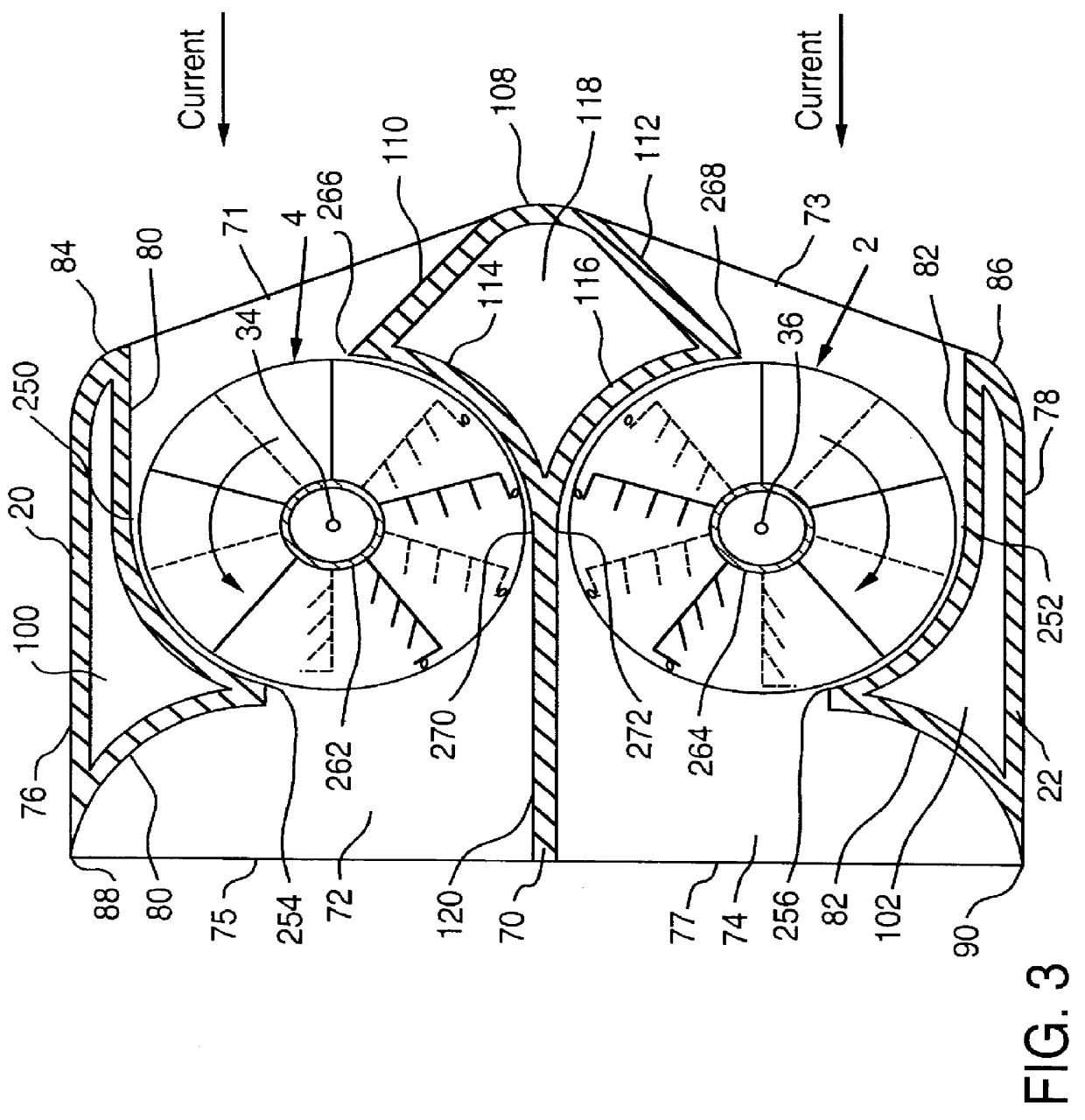

Submersible appartus for generating electricity and associated method

InactiveUS6109863AReduce the impactReduce impactCircumferential flow pumpsWind motor controlElectricityMarine engineering

A fully submersible apparatus for generating electricity from liquid flow as in an ocean or river current. A buoyant structure is fully submersible and has at least one pair of counter-rotating side-by-side motors with a plurality of angularly spaced radial vanes each having a plurality of rotatable subvanes such that current impinging upon the motor will impinge on a closed or solid vane to effect rotation of the motor and its shaft during a first phase of the rotational cycle and will impinge on open vanes for free passage therethrough on the return or second phase of rotation of the motor. Motors may also be provided with vanes in overlying and underlying relationship. An associated method is provided.

Owner:MILLIKEN LARRY D

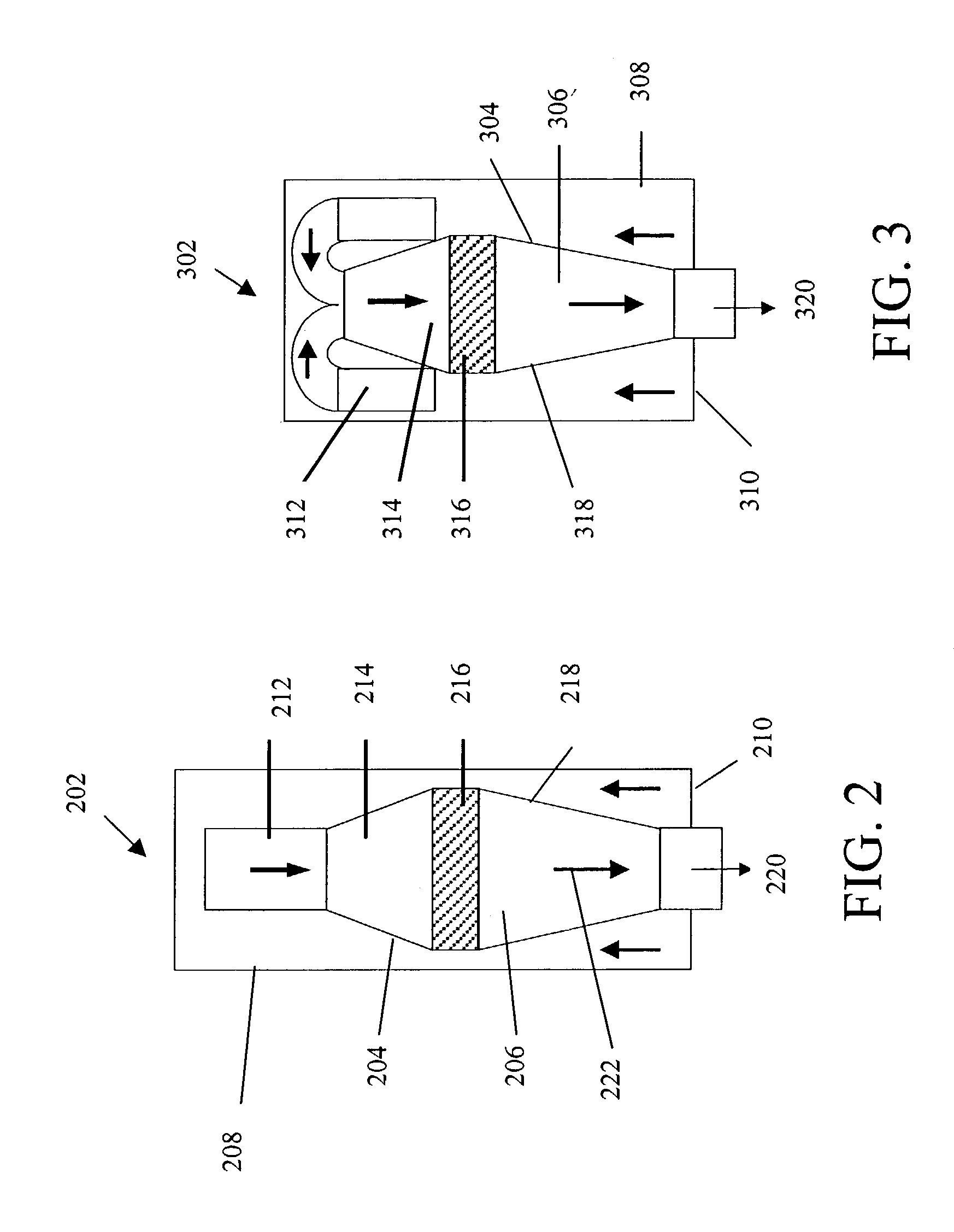

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

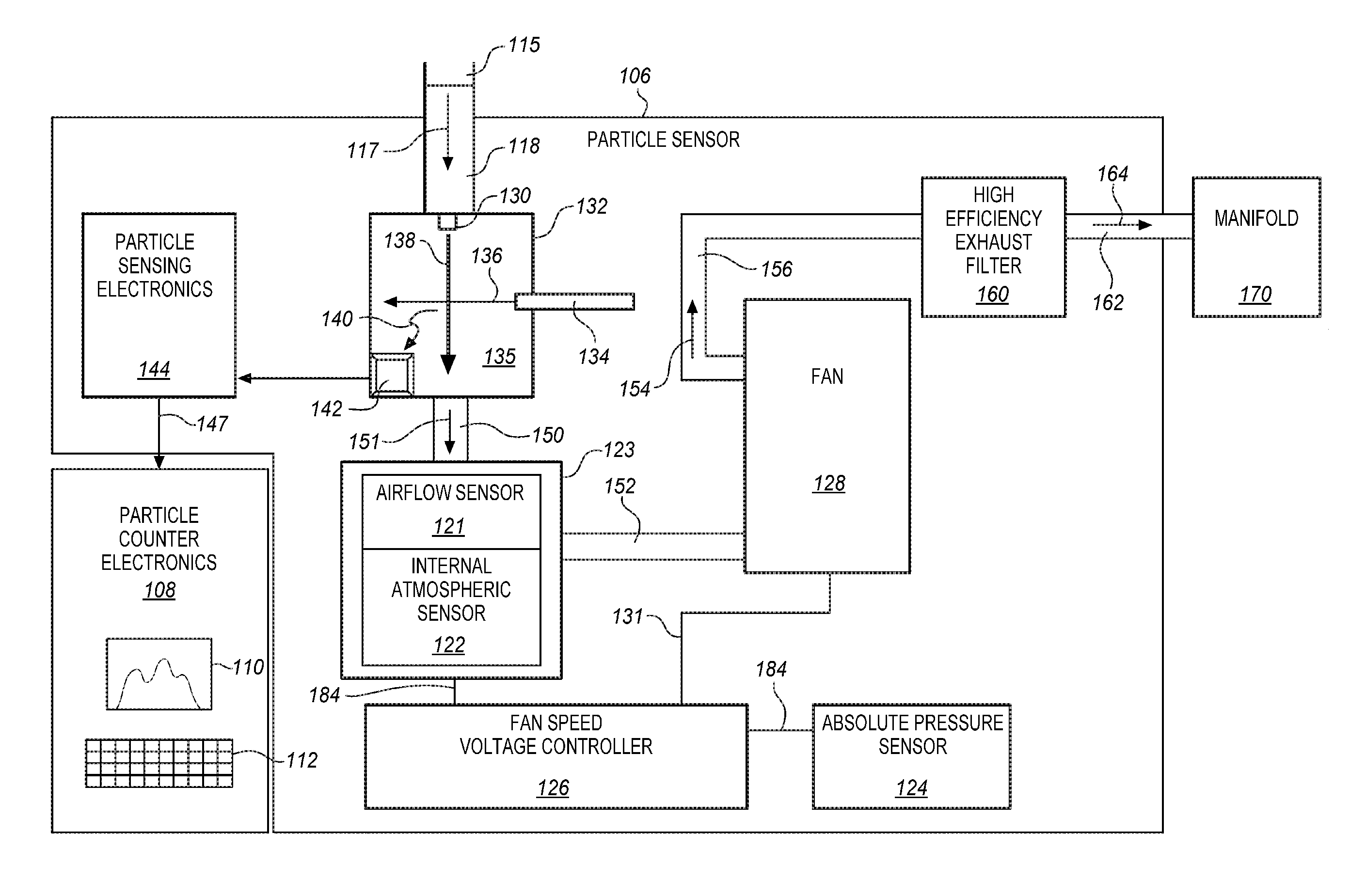

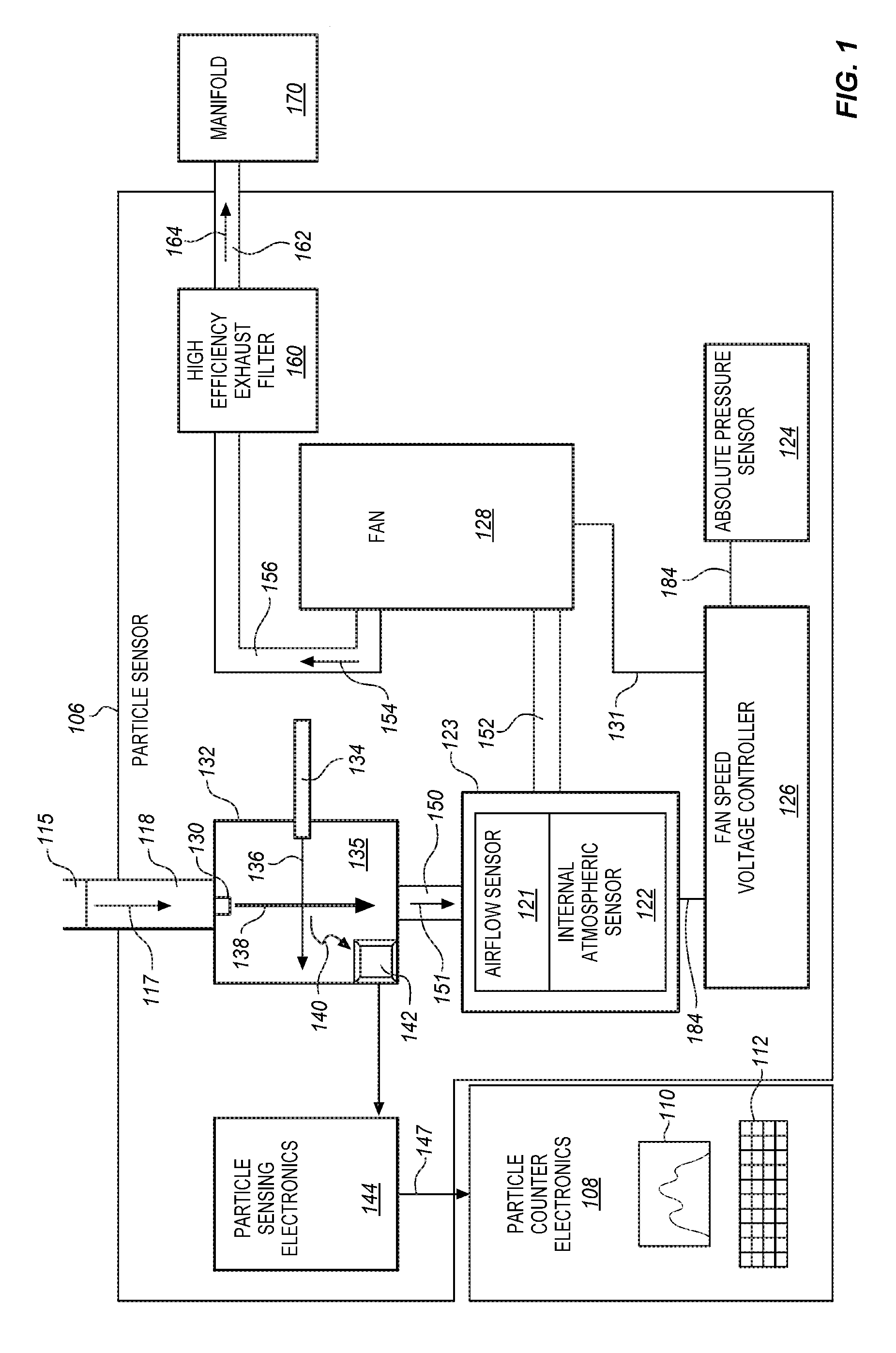

Aerosol particle sensor with axial fan

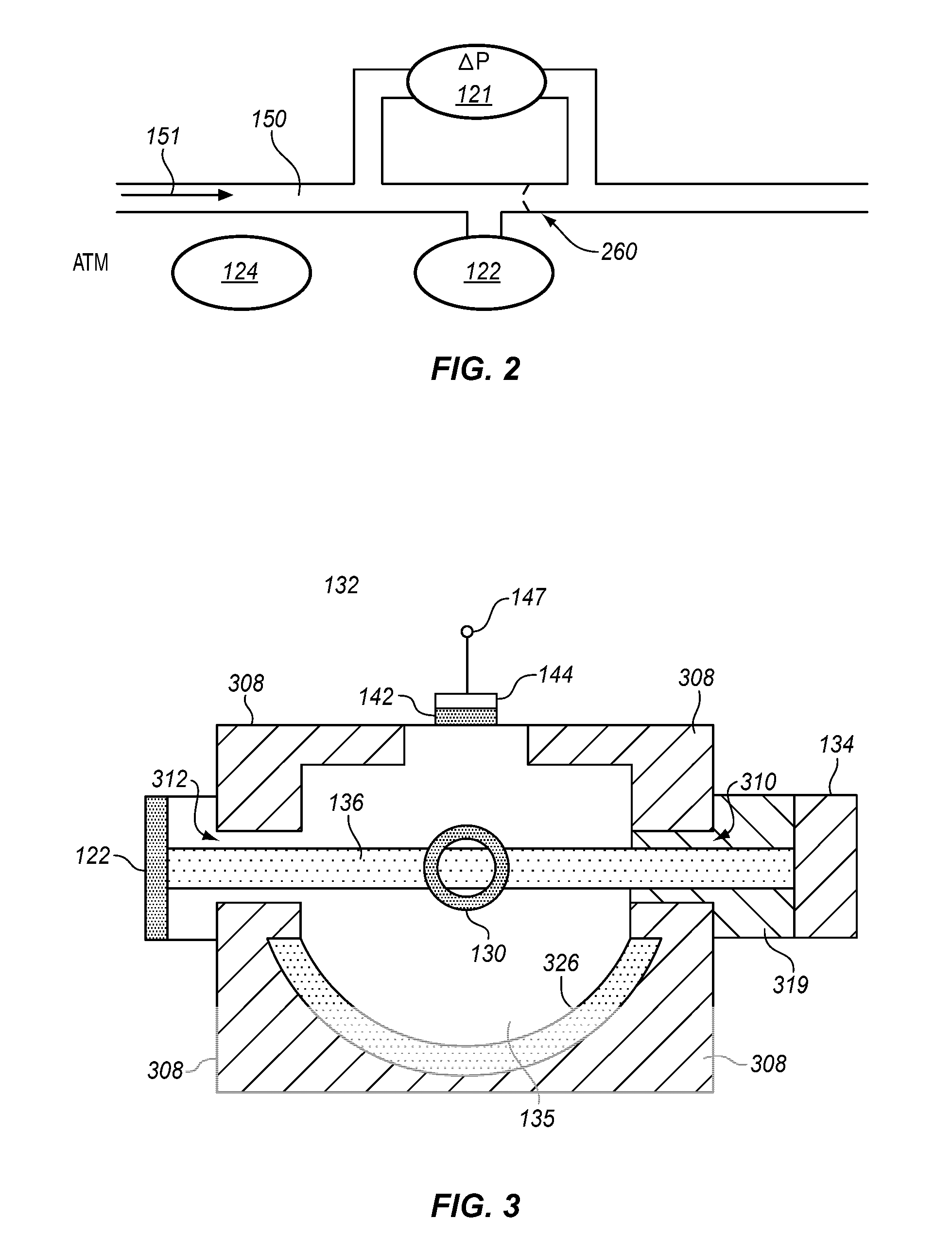

ActiveUS7667839B2Reduces cost and size and power consumptionWhole plant particle counter systems are greatly simplifiedSamplingMaterial analysis by optical meansSquare MillimeterCollection system

A particle sensor for optically detecting an unconstrained particle suspended in a flowing gas includes a sample chamber having a gas inlet and a gas outlet; a gas flow system for flowing said gas from said gas inlet through said sample chamber to said gas outlet, a source of light; an optical system directing said light through said sample chamber, an optical collection system located to collect light scattered by said particles in the gas, and a detection system located to detect the collected light. The total pressure drop through said gas flow system is 3 inches of water or less. The gas flow system includes an axial fan, which may be a high static pressure fan or a counter-rotating fan. In a 1.0 CFM system, the gas inlet nozzle has an area of 25 square millimeters or more.

Owner:PARTICLE MEASURING SYST

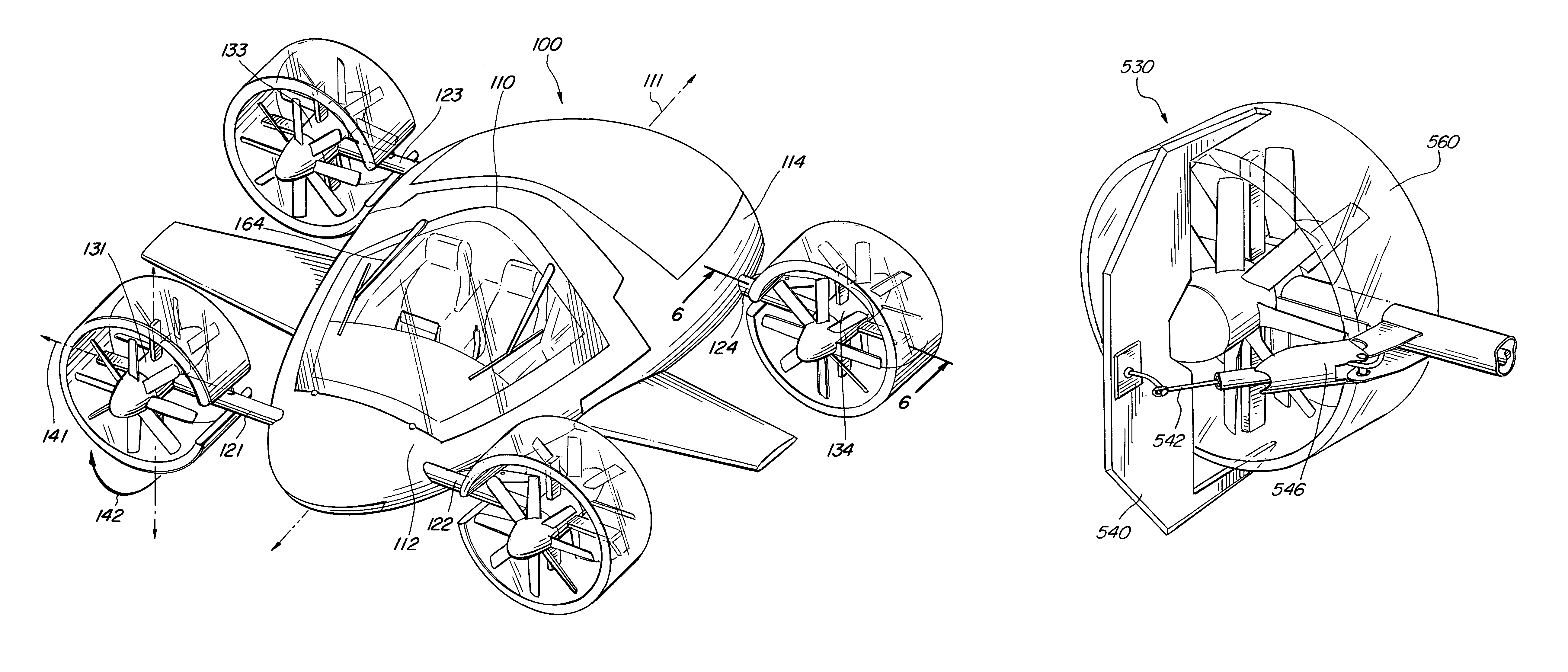

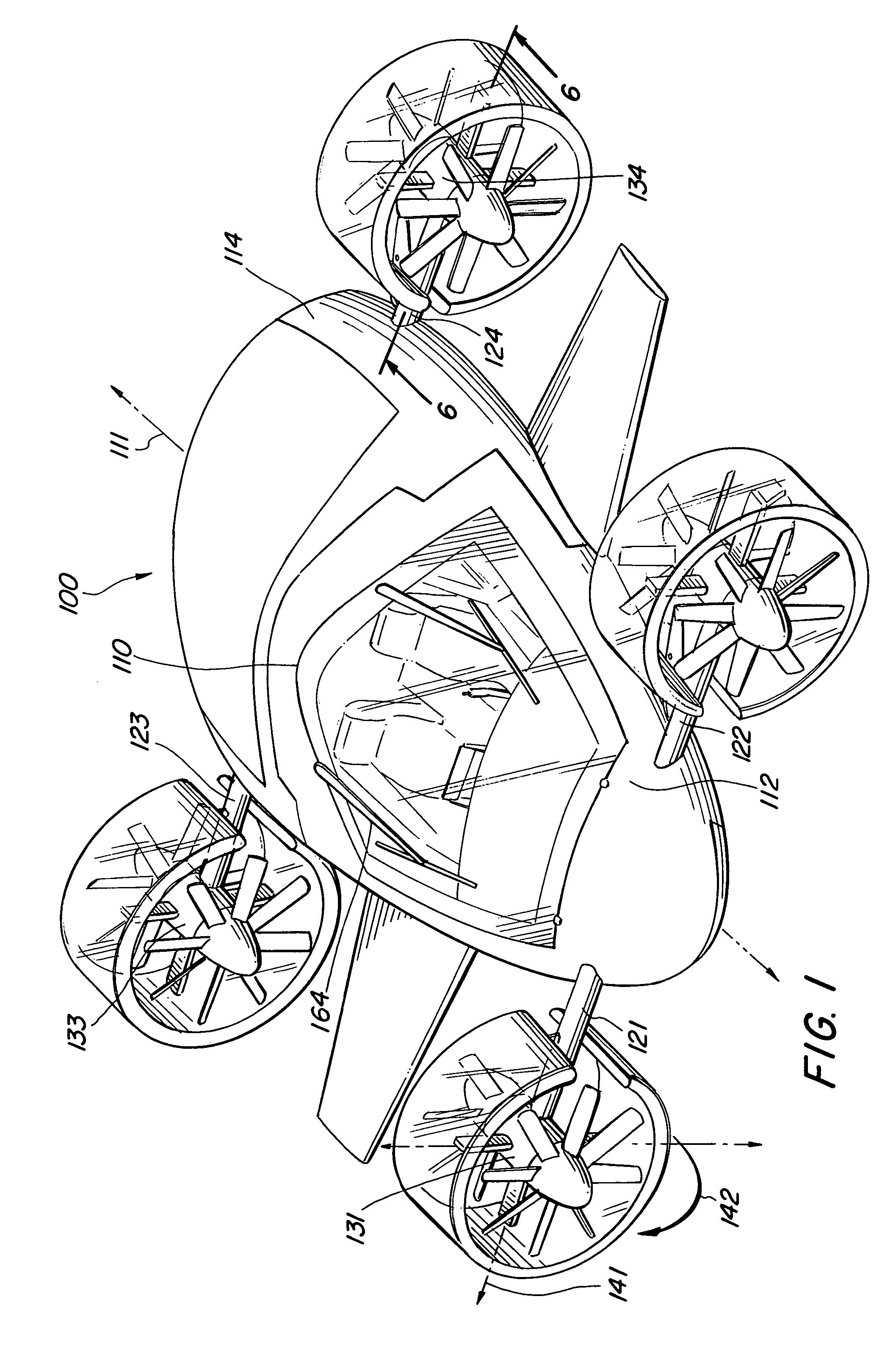

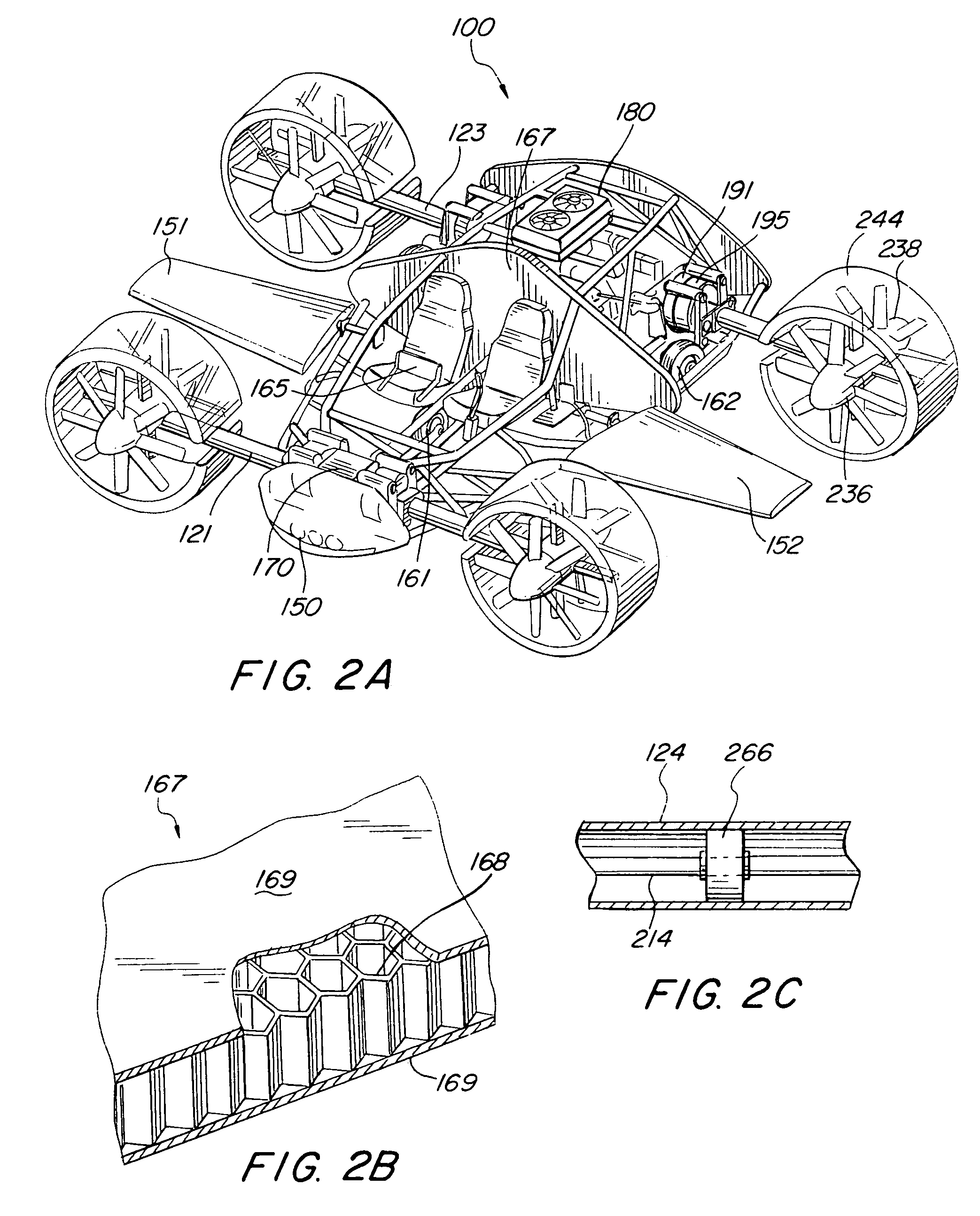

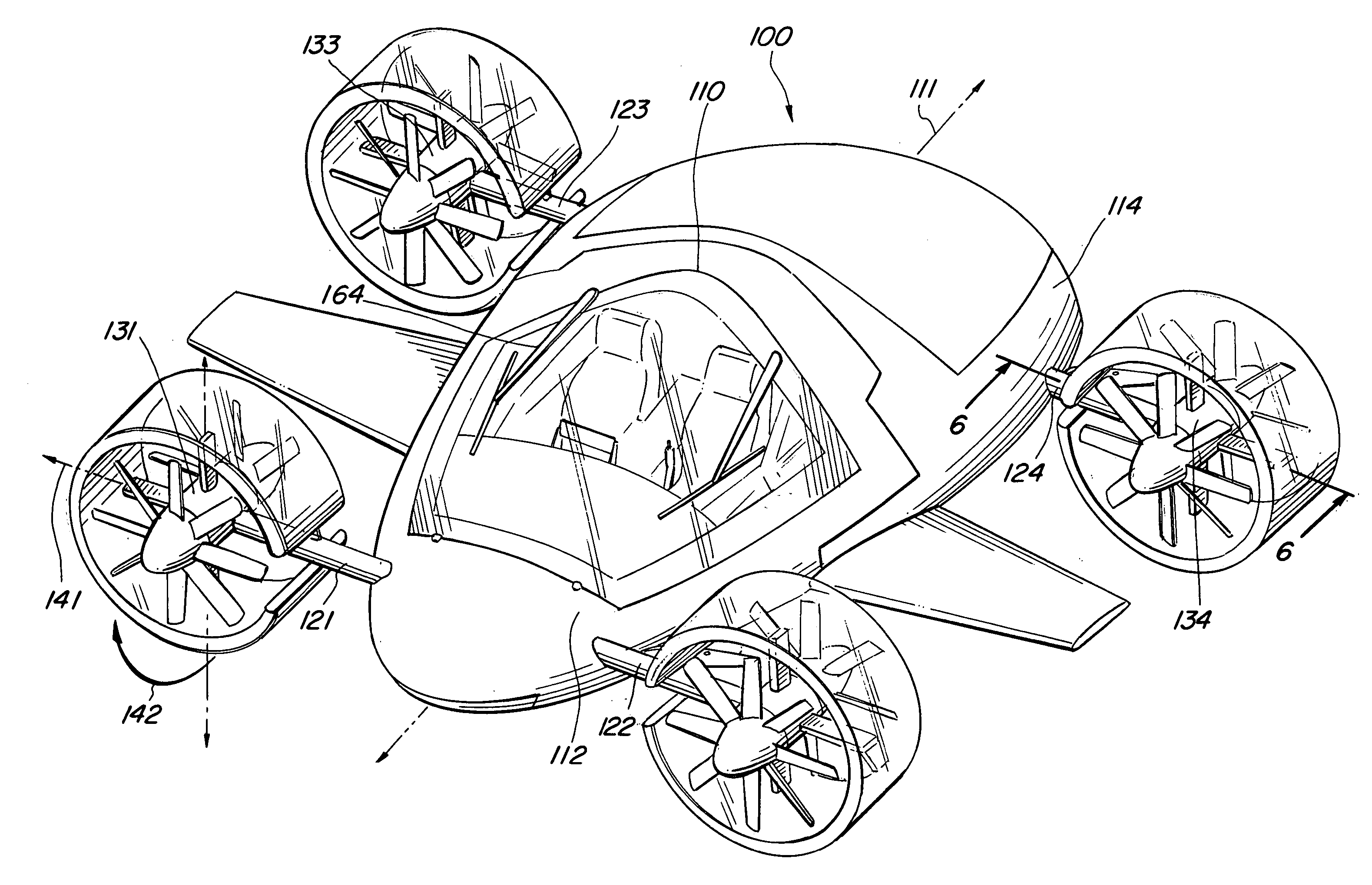

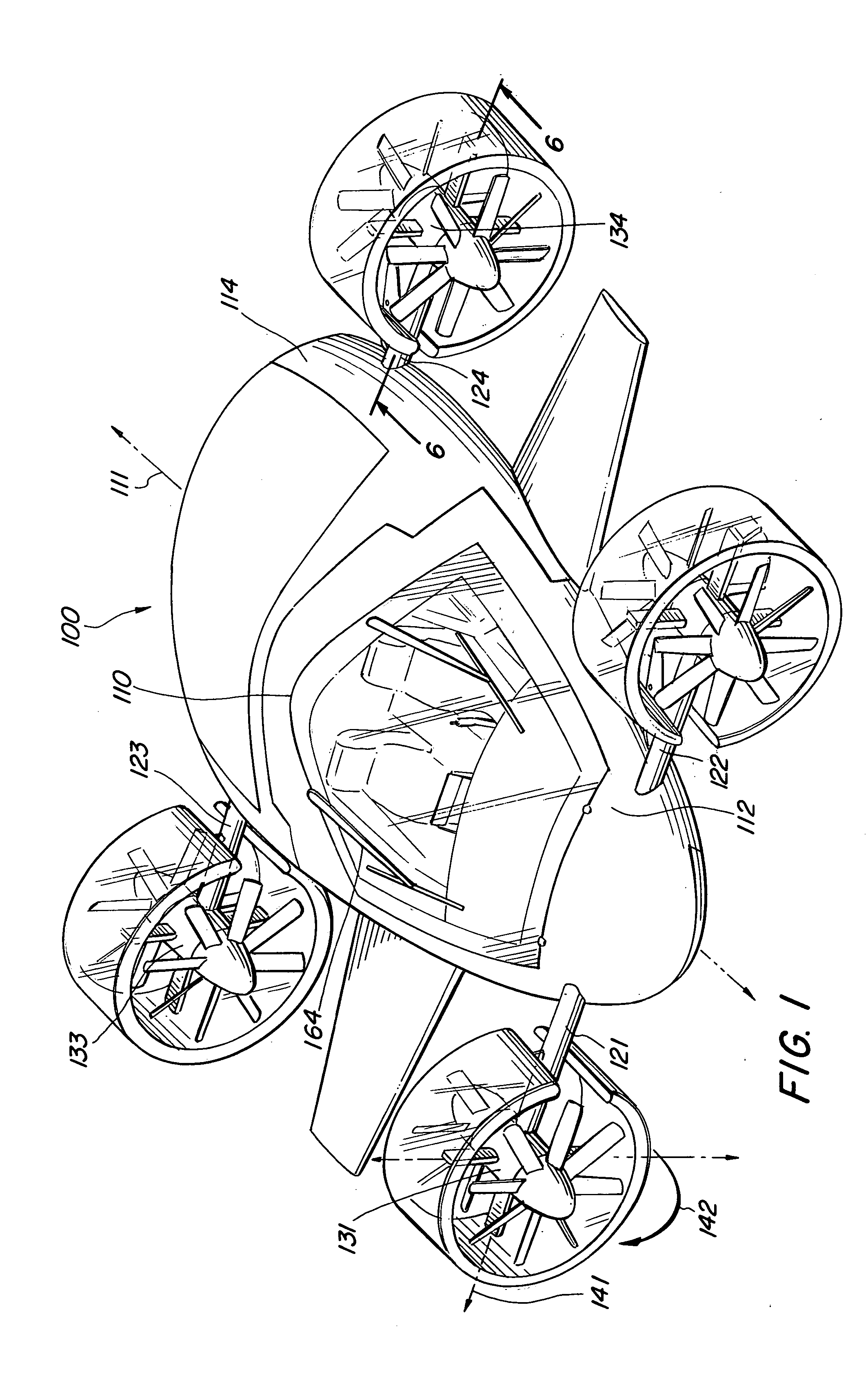

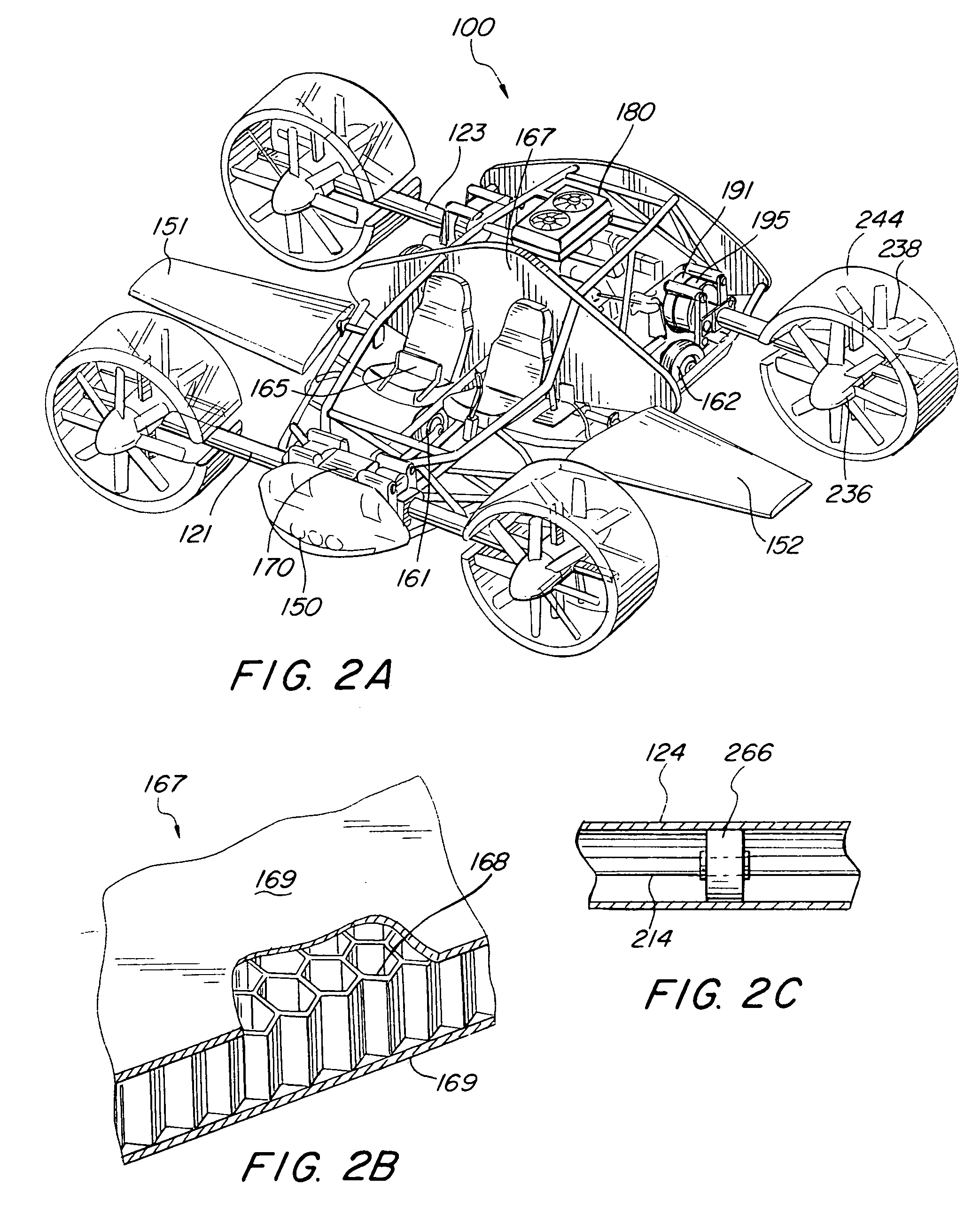

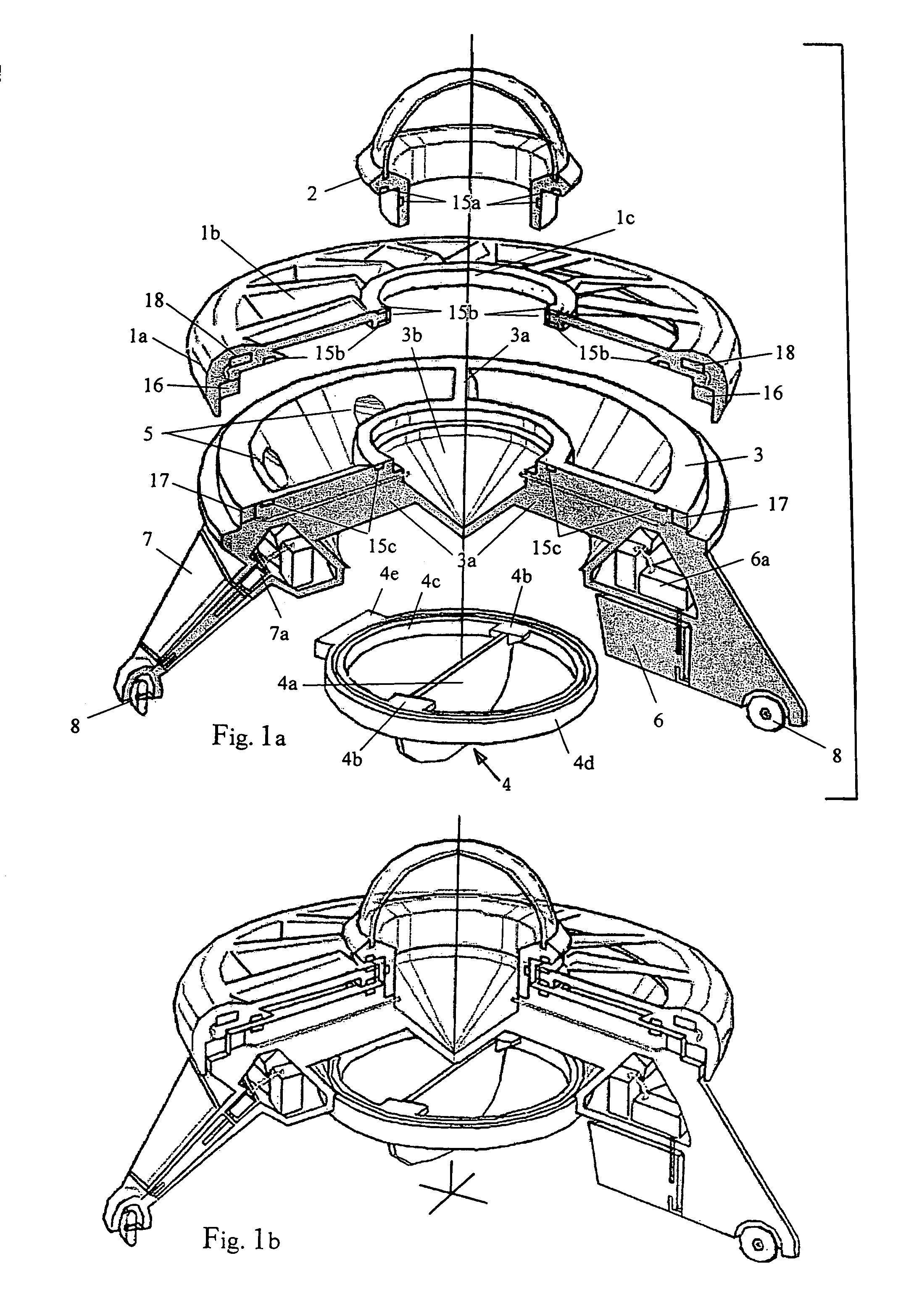

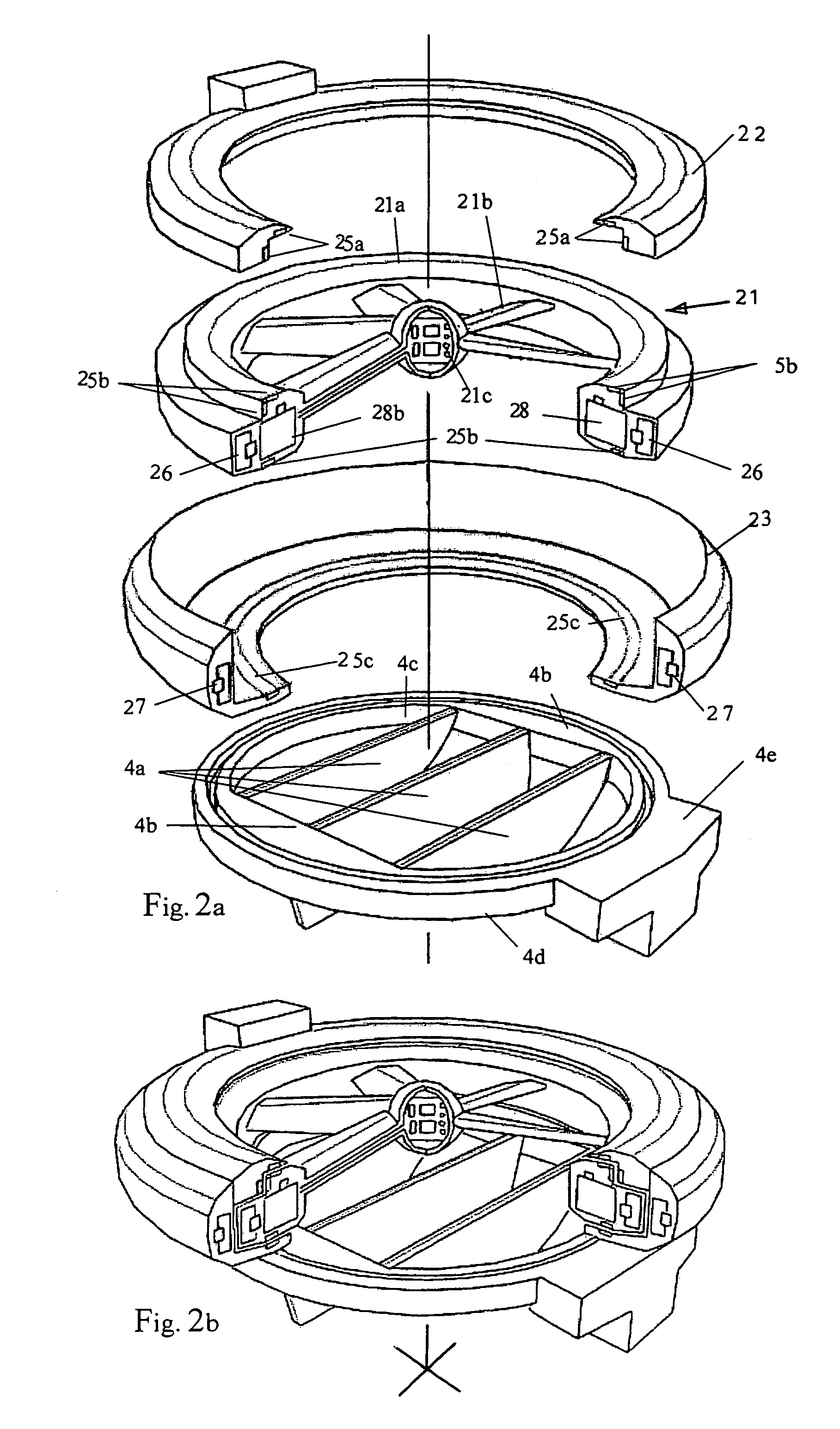

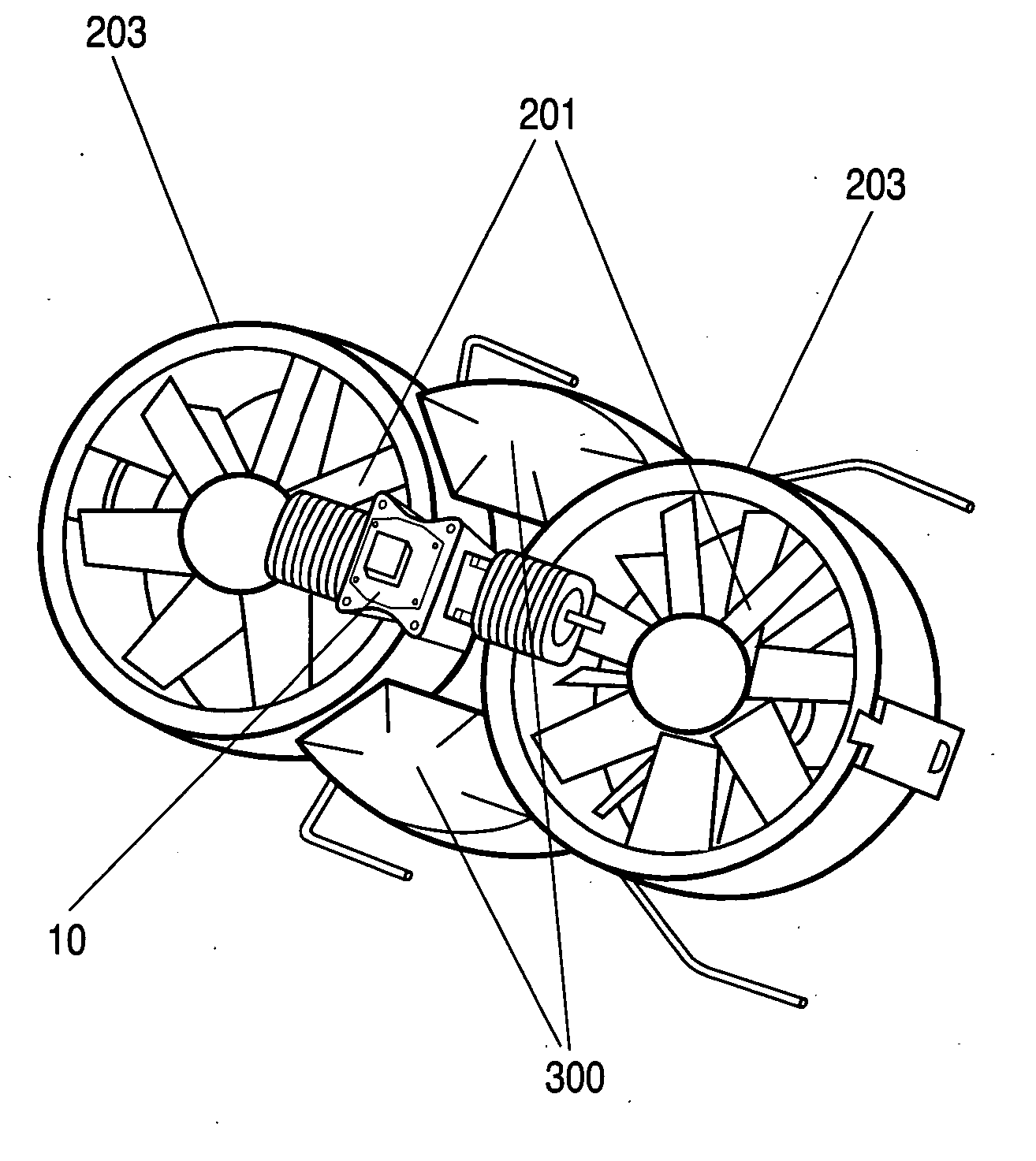

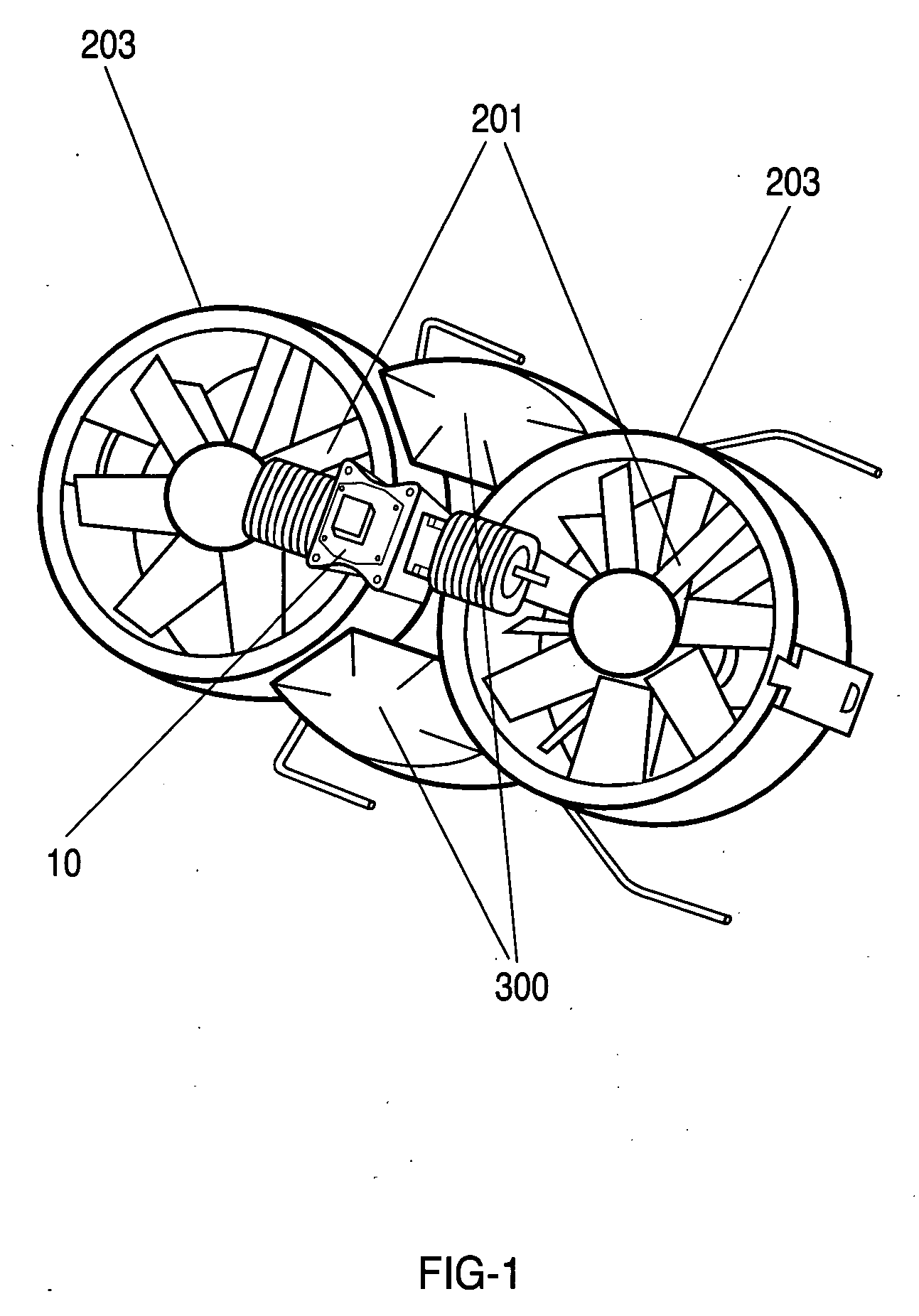

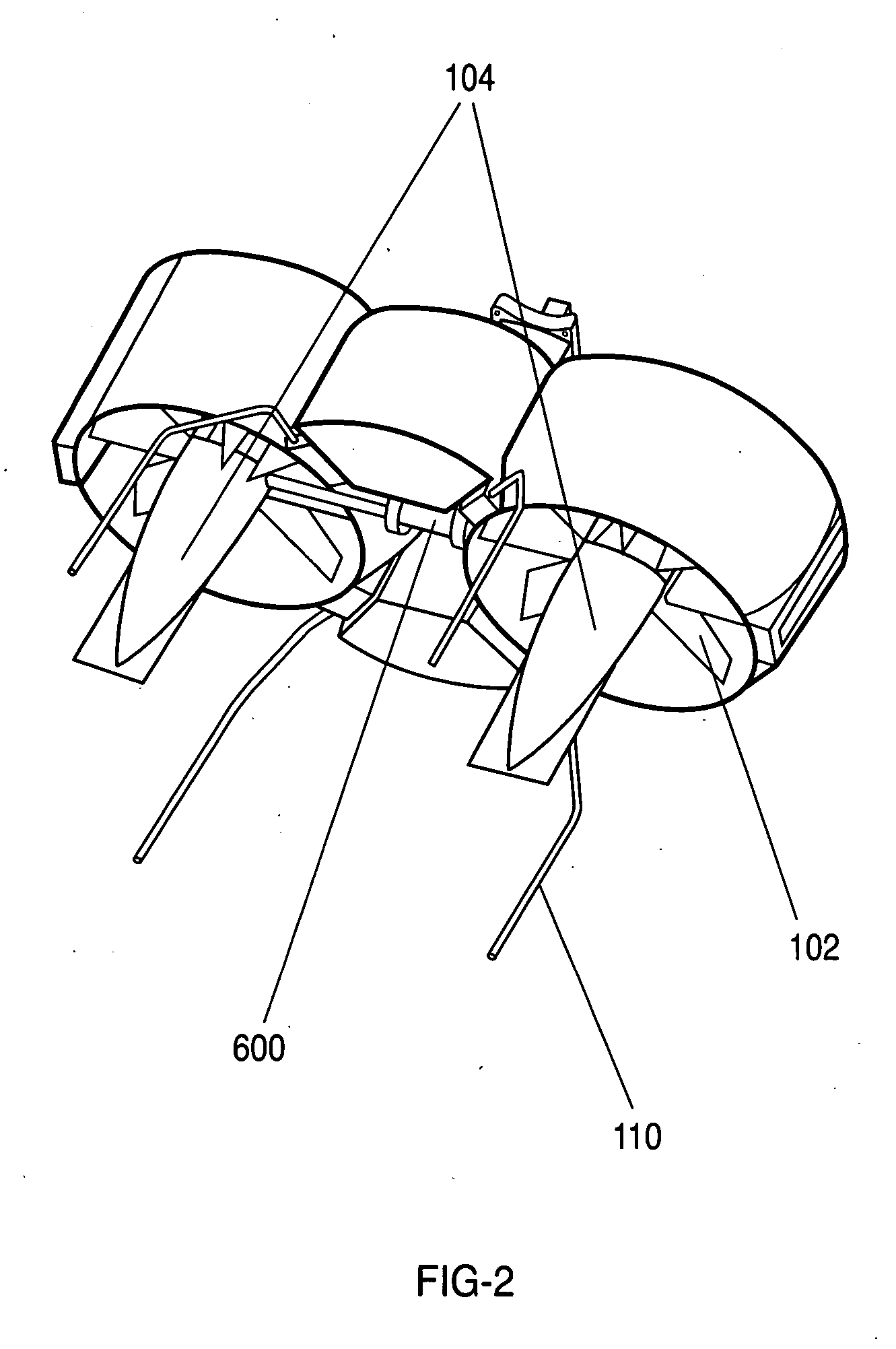

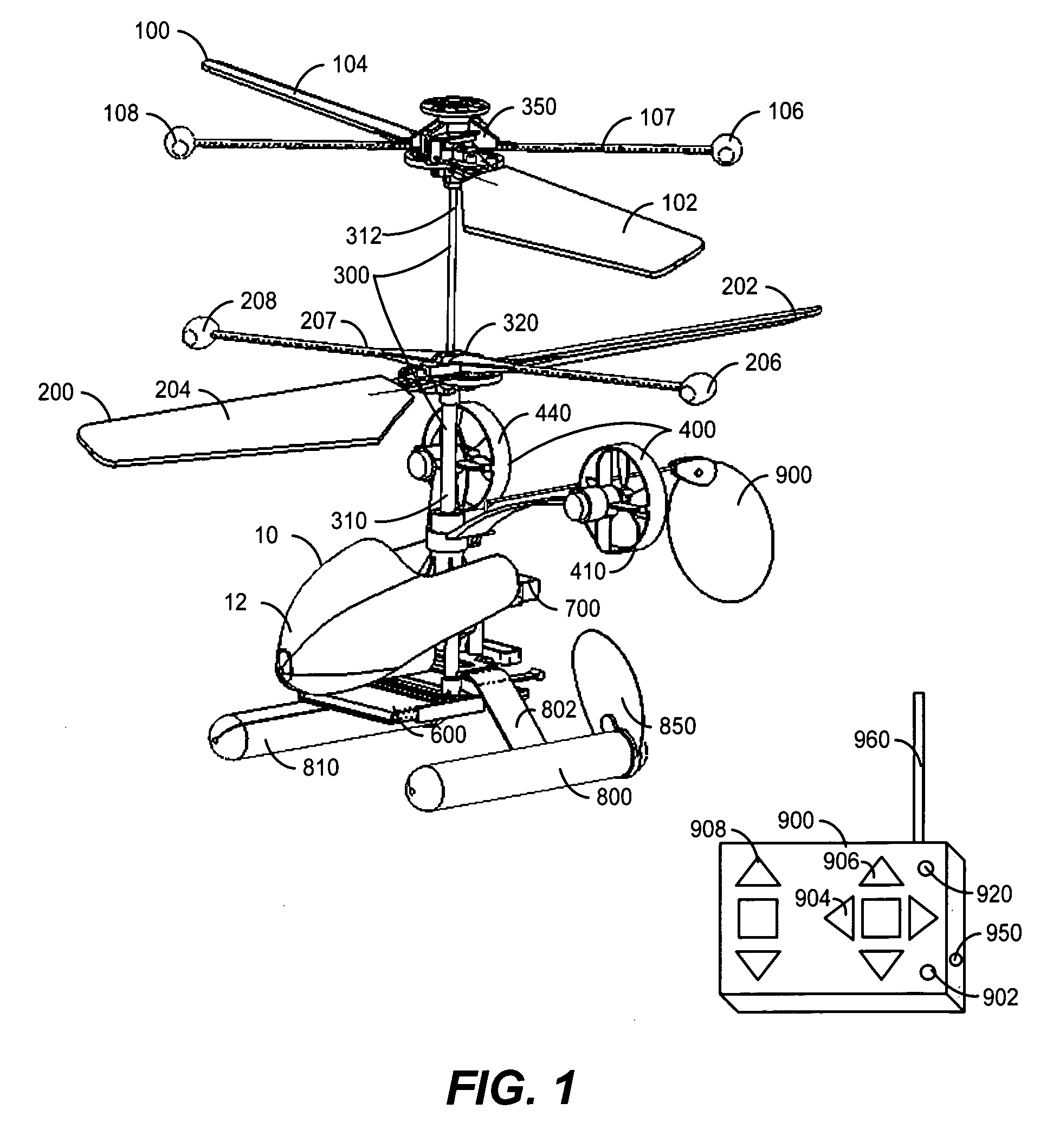

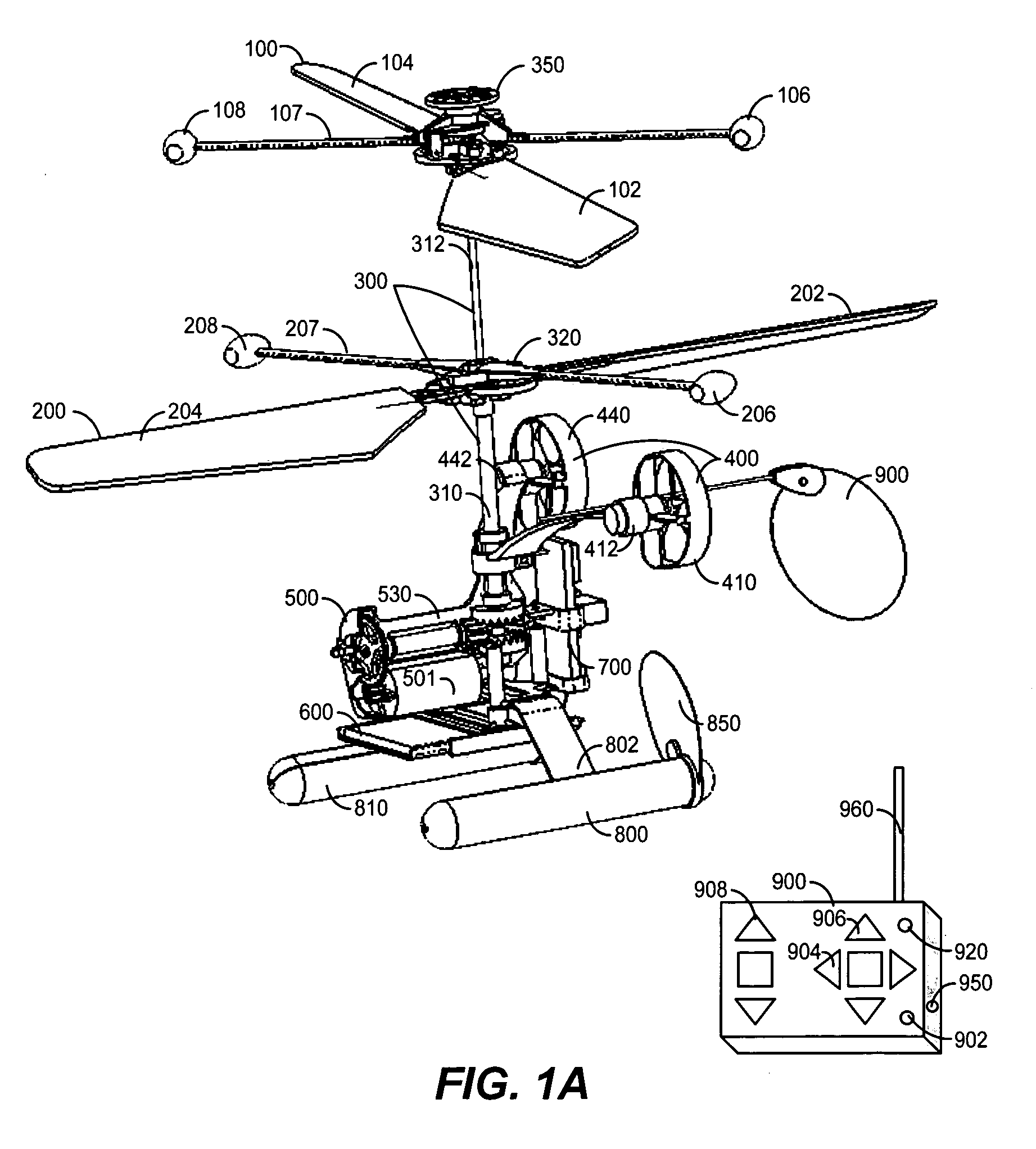

Sky hopper

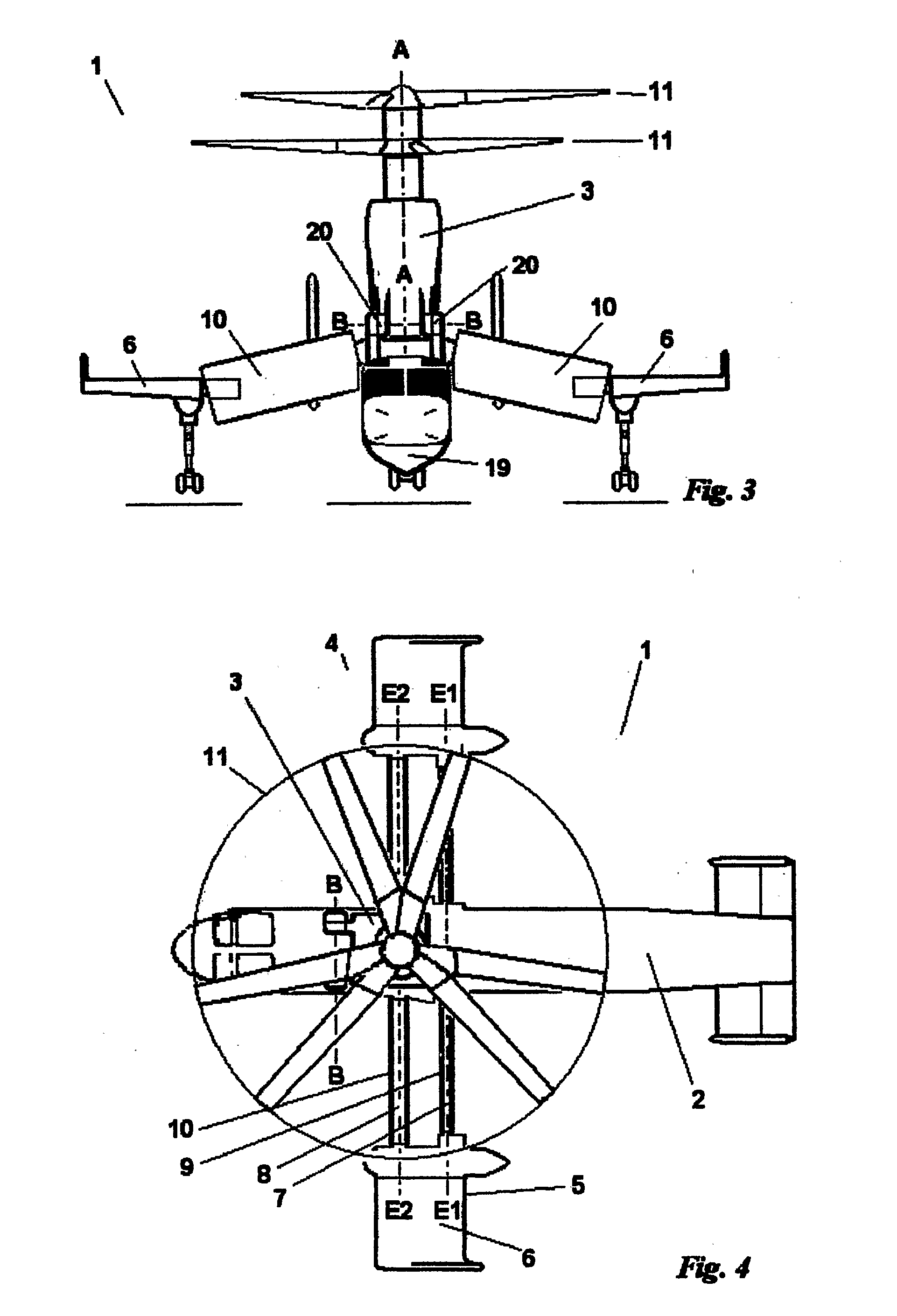

InactiveUS7472863B2Increase shaft powerAircraft navigation controlToy aircraftsSkyExternal combustion engine

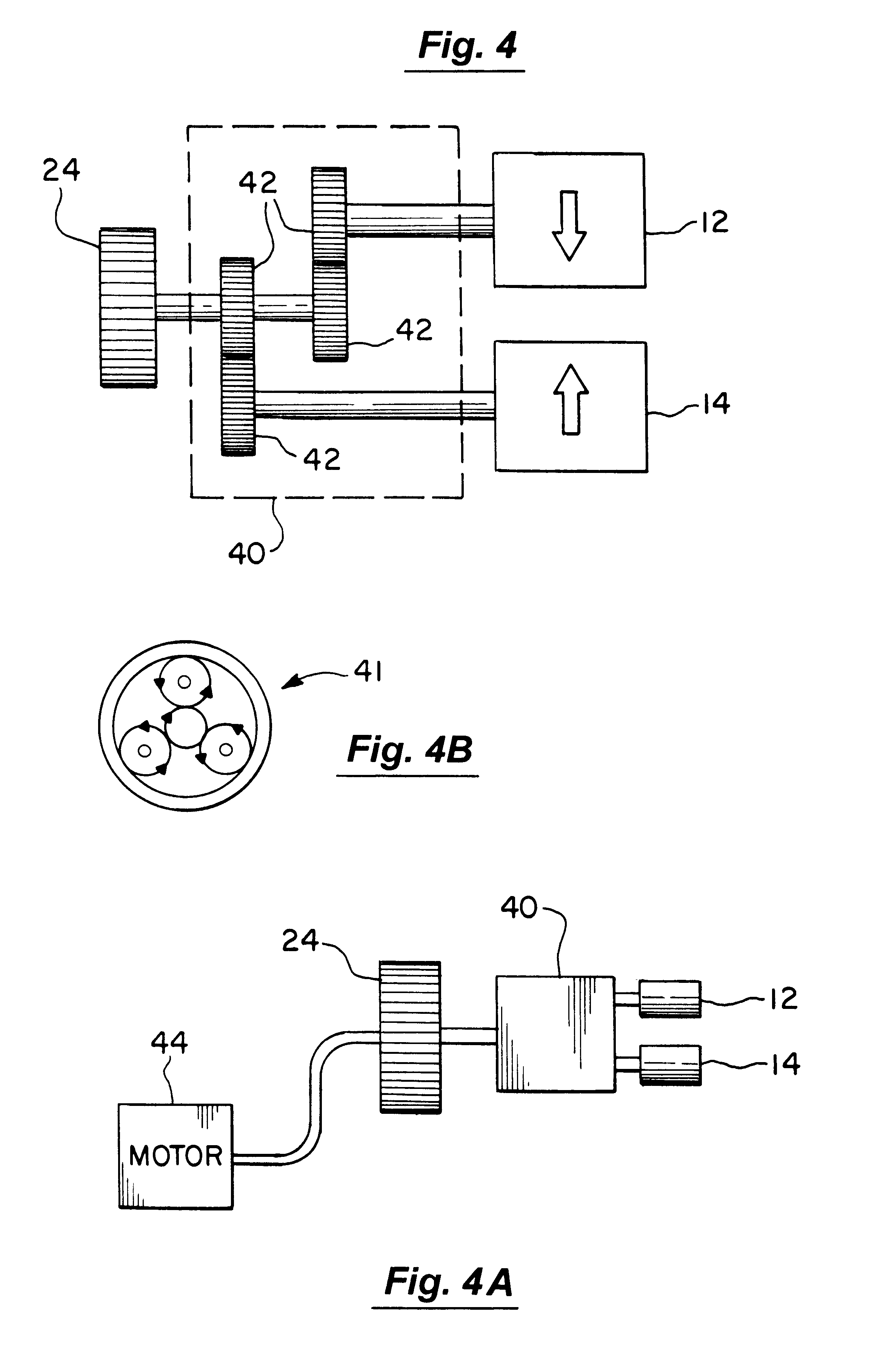

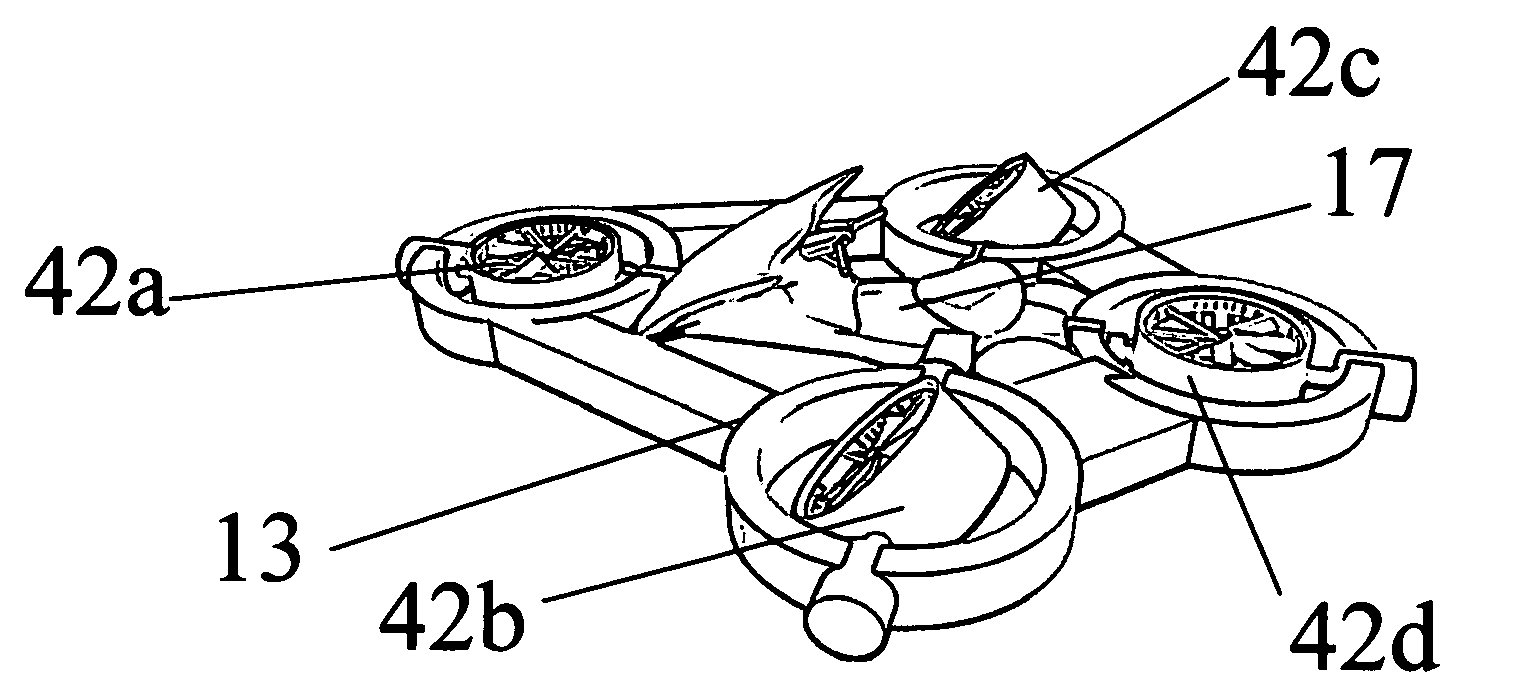

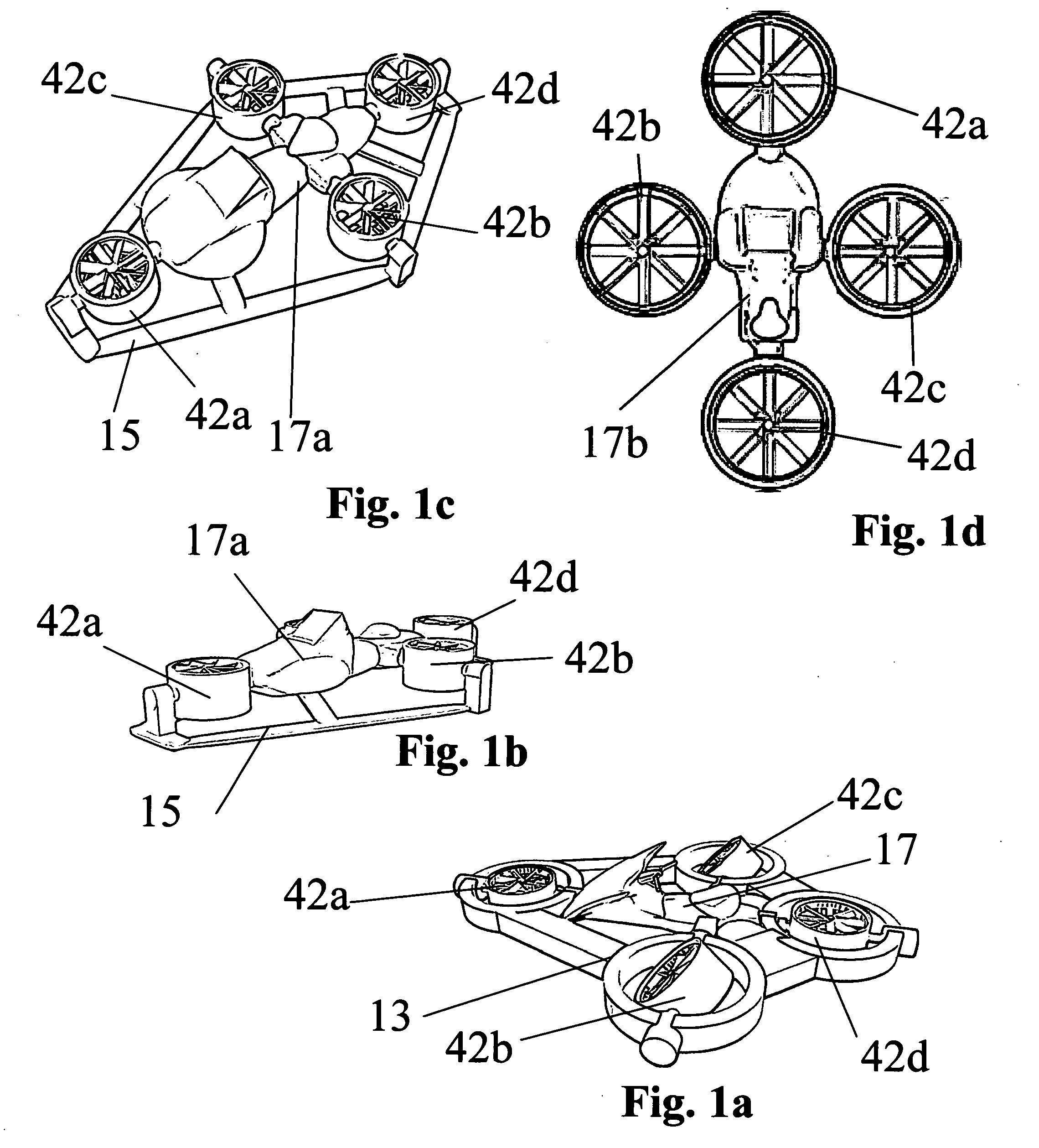

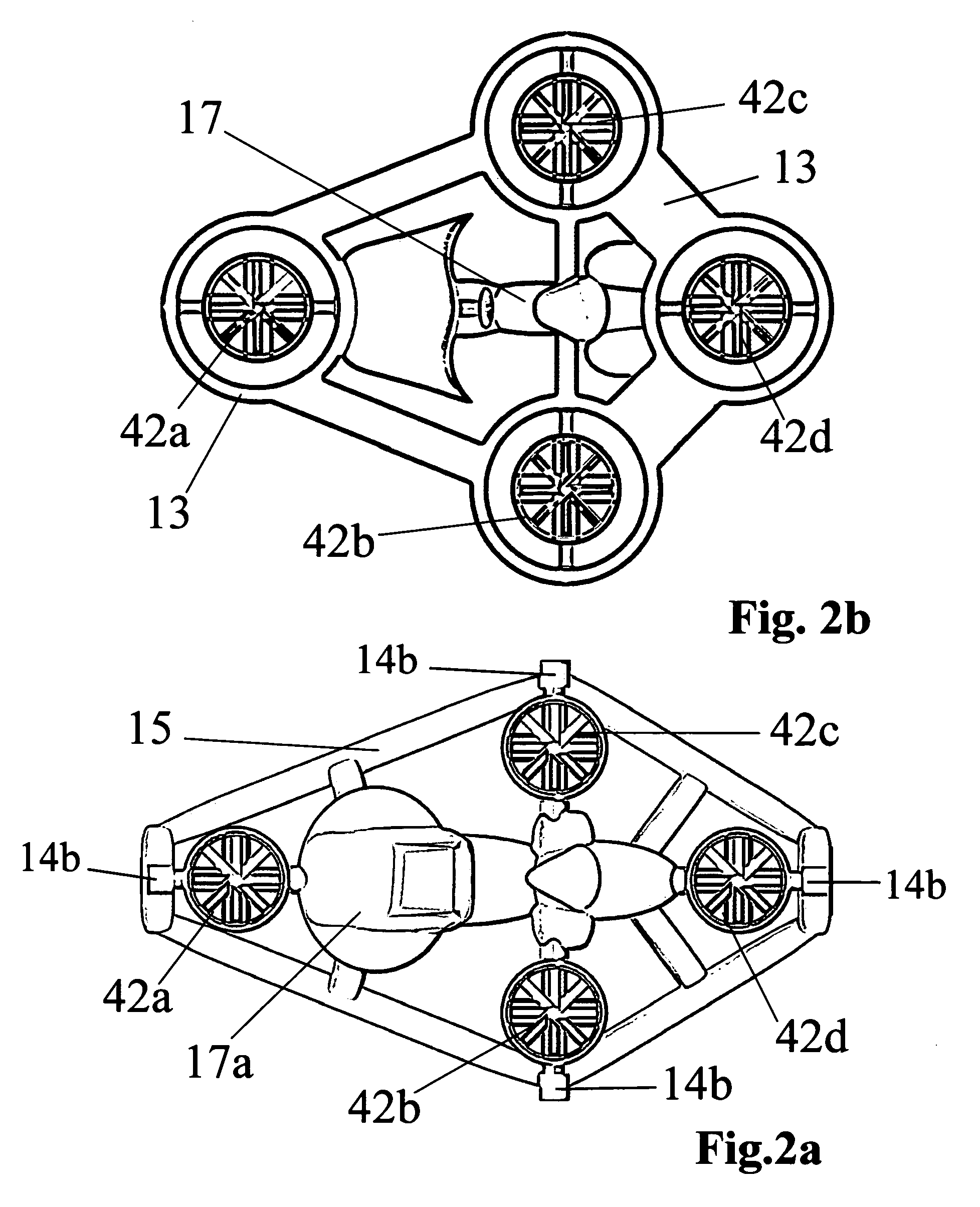

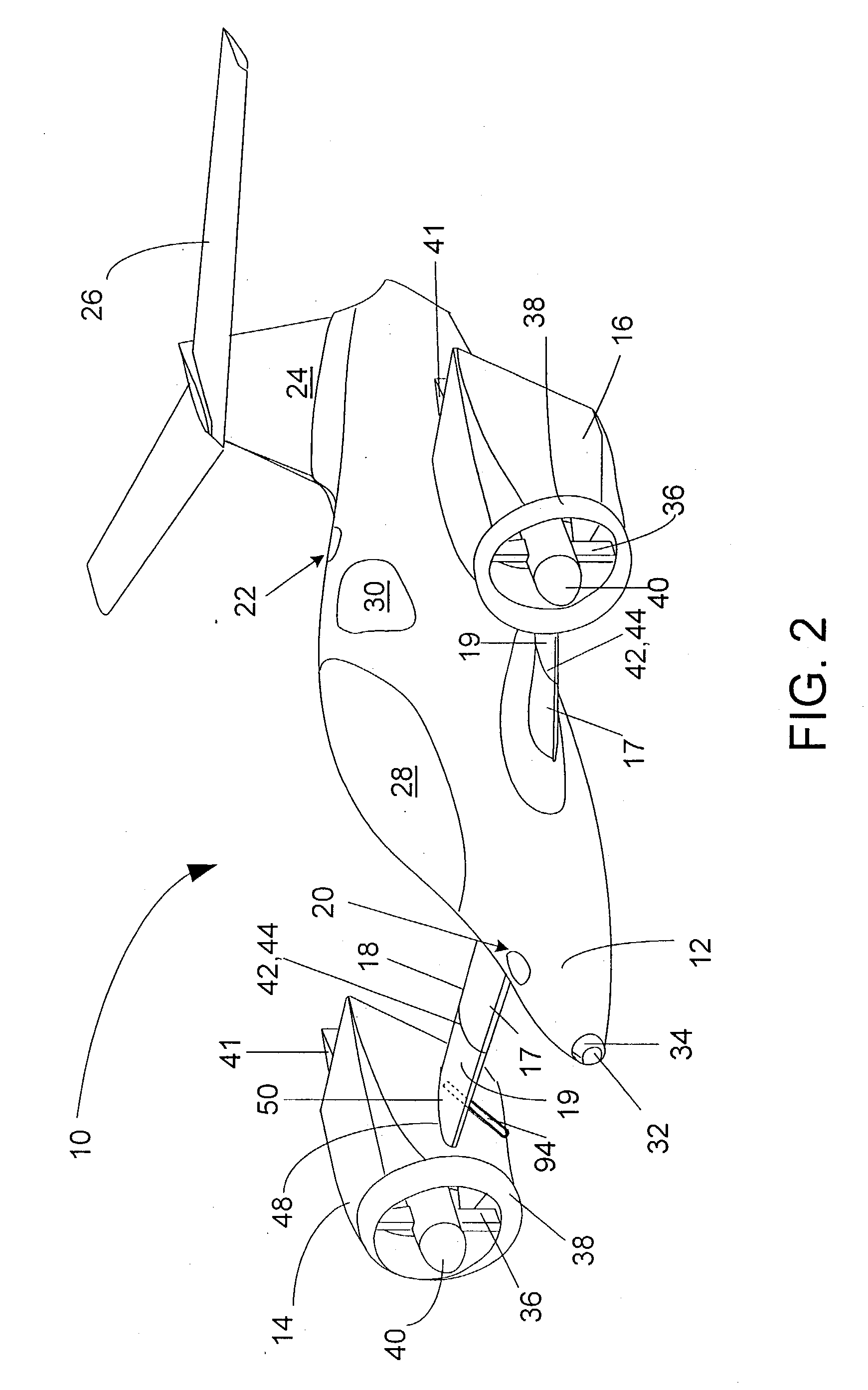

A vertical takeoff and landing (VTOL) aircraft design particularly suitable as a full-sized aircraft or remote controlled (RC) model aircraft is disclosed. The invention employs lightweight, high strength materials to reduce the power requirements of the propulsion plant. A preferred system of the invention comprises one internal combustion engine able to spit shaft power to four fan units. The fan units further employ counter rotating fan blades for stability. Separate horizontal and vertical tilting mechanisms delivered to the fan units are additionally disclosed. A variation in design is further included wherein electric motors provide the necessary shaft power.

Owner:PAK STEVE

Sky hopper

InactiveUS20060016930A1Increase shaft powerAircraft navigation controlToy aircraftsSkyRemote control

A vertical takeoff and landing (VTOL) aircraft design particularly suitable as a full-sized aircraft or remote controlled (RC) model aircraft is disclosed. The invention employs lightweight, high strength materials to reduce the power requirements of the propulsion plant. A preferred system of the invention comprises one internal combustion engine able to spit shaft power to four fan units. The fan units further employ counter rotating fan blades for stability. Separate horizontal and vertical tilting mechanisms delivered to the fan units are additionally disclosed. A variation in design is further included wherein electric motors provide the necessary shaft power.

Owner:PAK STEVE

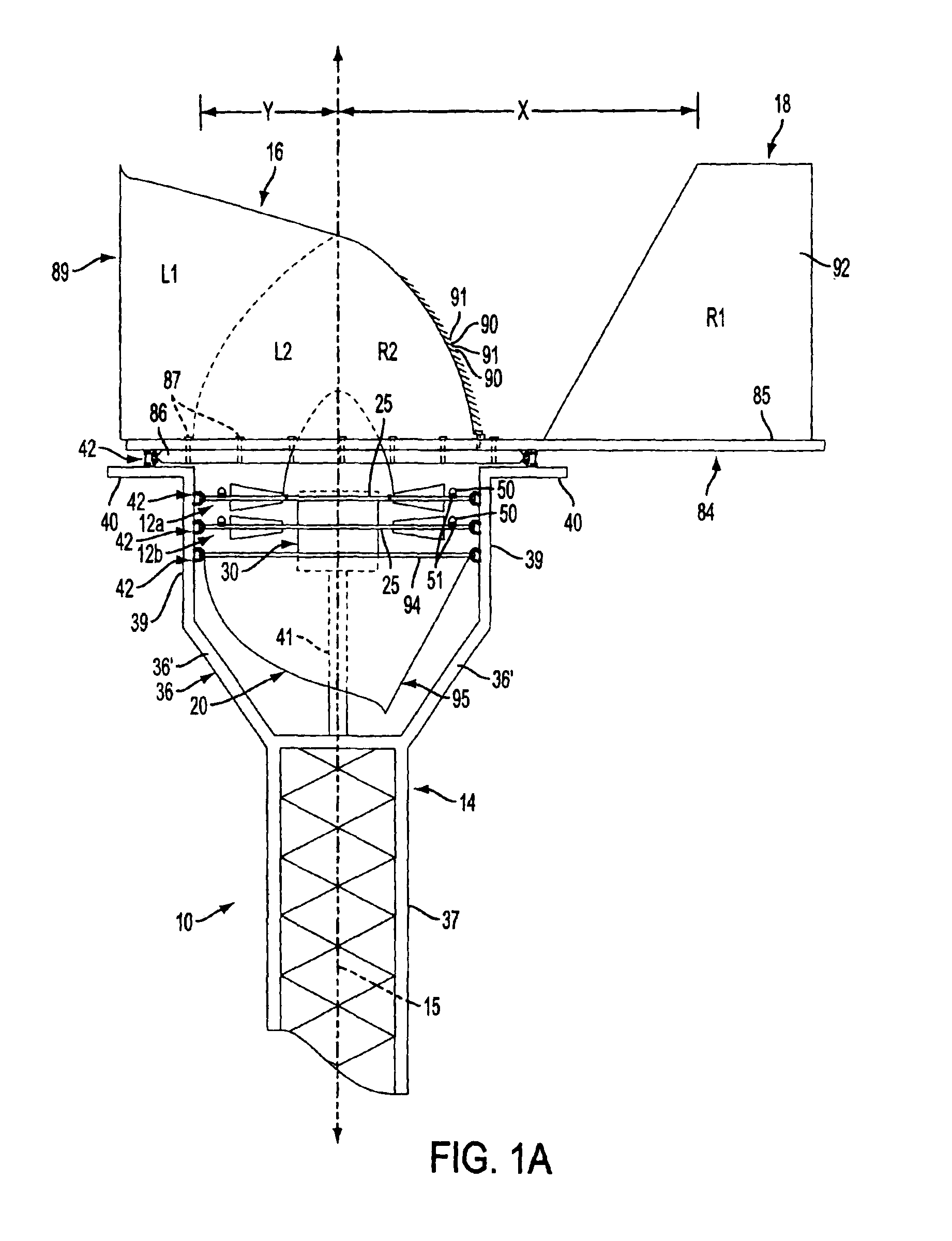

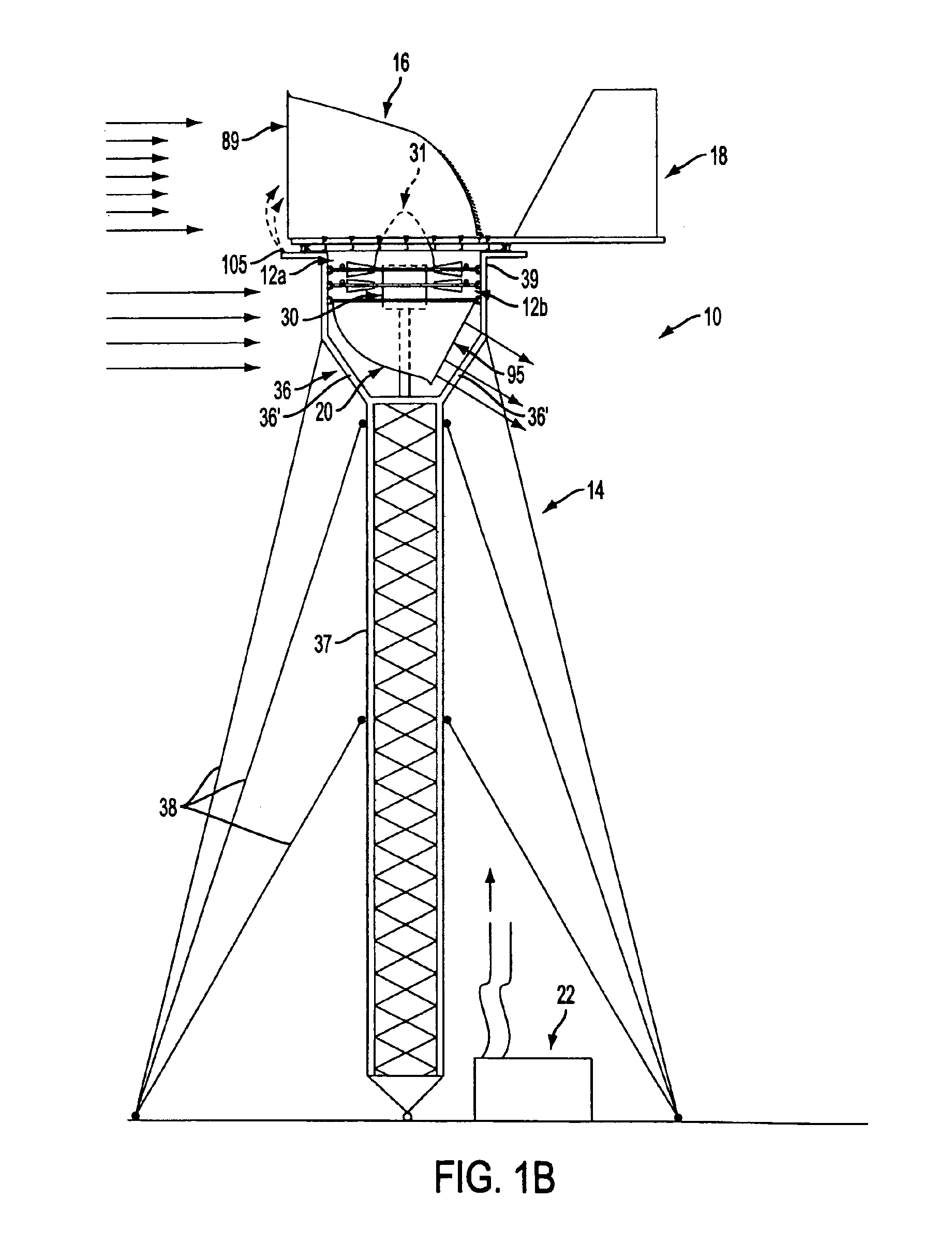

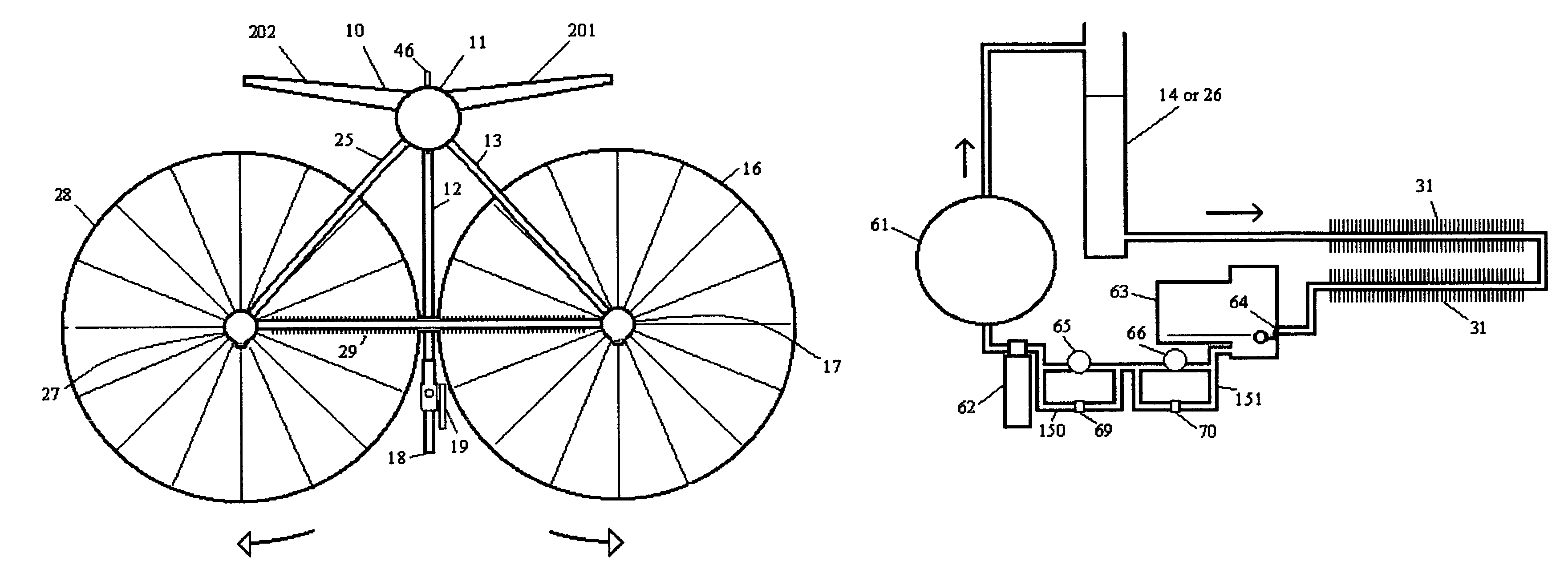

Wind energy conversion system

InactiveUS6952058B2Reduced weight and mass and costAdjustable sizePropellersWind motor supports/mountsWind energy conversionEngineering

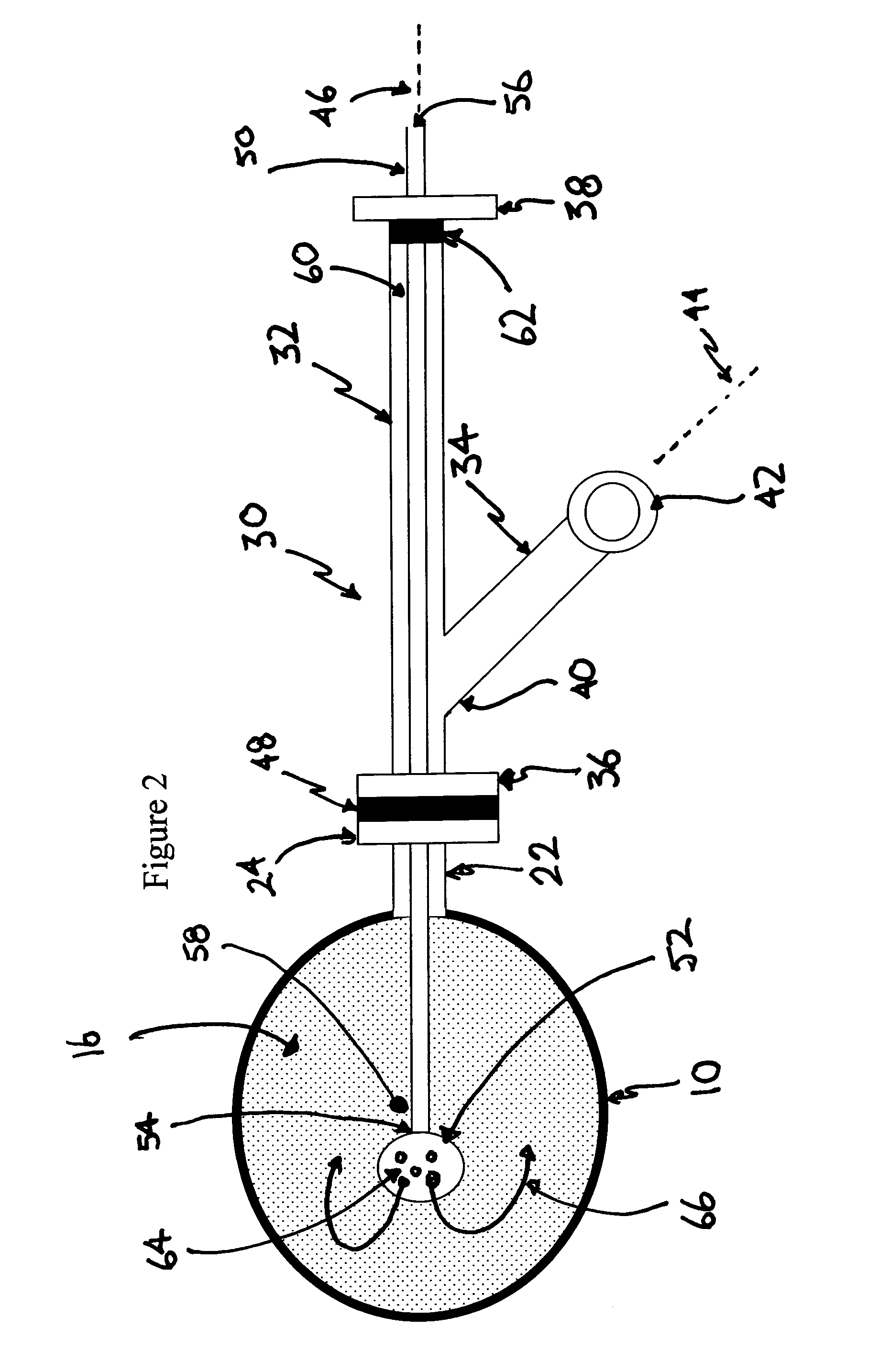

A wind energy conversion system includes upper and lower wind turbines having counter-rotating blade assemblies supported for rotation about a vertical rotation axis, with each blade assembly carrying a rotor for rotation past a stator to produce an electrical output. The wind turbines are supported by a tower at an elevated position above the ground. Each wind turbine produces torque, and the wind energy conversion system provides for balancing the torques to avoid a net torque on the tower. Adjustment mechanisms are provided for adjusting blade pitch and for adjusting the size of an air gap between a stator and a rotor that comes into alignment with the stator as the rotor rotates therepast. The wind energy conversion system provides a hood for supplying intake air to a wind turbine and an exhaust plenum for exhausting air from the wind turbine, with the hood and the exhaust plenum being directionally positionable.

Owner:WECS

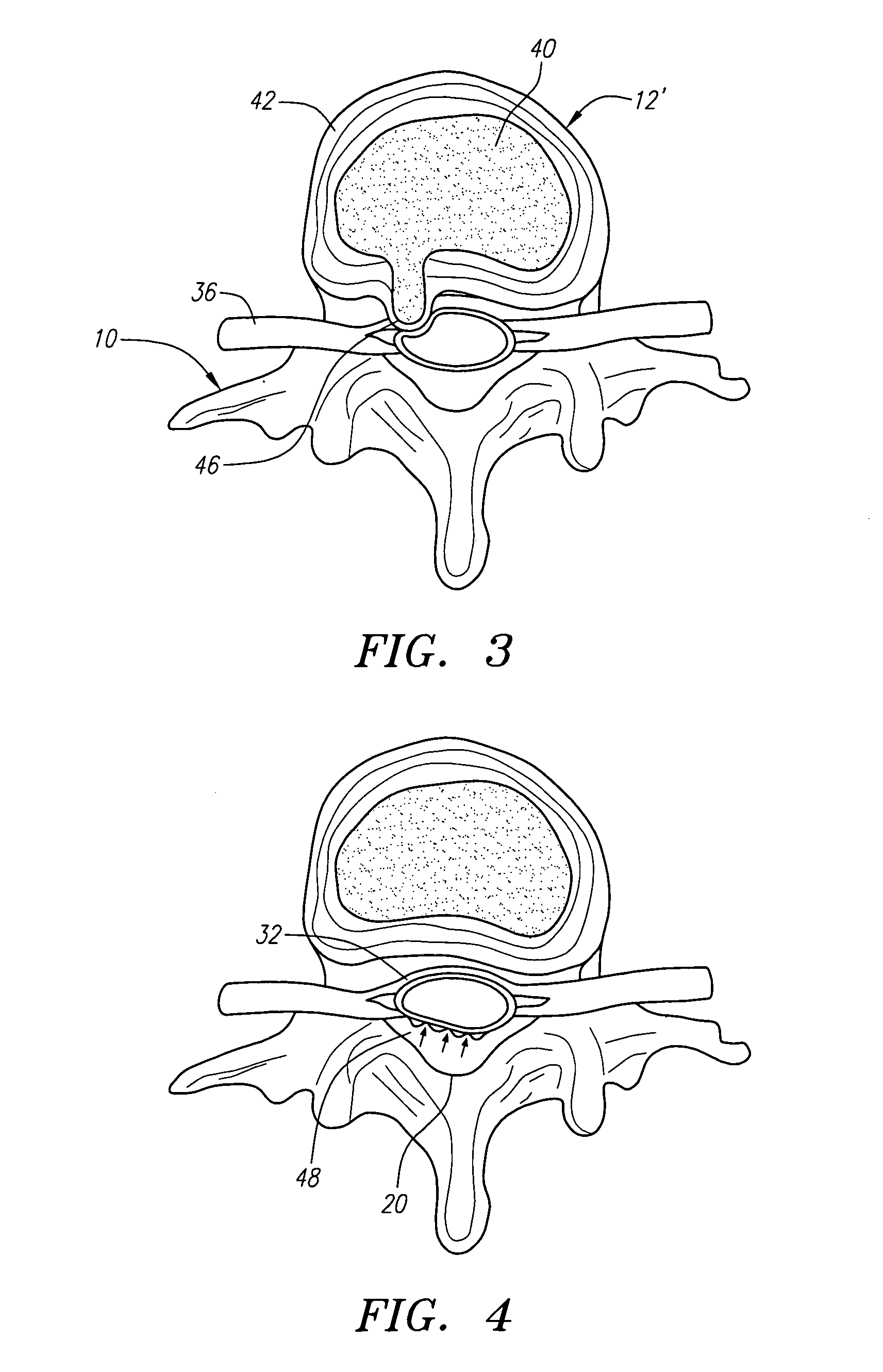

Apparatus and methods for removing vertebral bone and disc tissue

ActiveUS20050203527A1Improves Structural IntegrityPrevents and minimizes buildExcision instrumentsEndoscopic cutting instrumentsDrive shaftVertebral bone

Tissue removal probes comprise an elongated member, a drive shaft rotatably disposed within the member, and a rotatably tissue removal element mounted to the distal end of the drive shaft. One tissue removal element comprises a plurality of tissue-cutting filaments affixed at proximal and distal ends of the tissue removal element. The cutting filaments may have optional hinge points that allow the distal end of the tissue removal element to be inverted, thereby transforming the tissue removal element from a tissue-cutting device to a tissue-grasping device. Another tissue removal element may have a blunted tip to prevent distal tissue trauma and an irrigation port to provide irrigation fluid to the removed tissue and / or tissue removal element. Another tissue removal element has a proximal and distal spiral grooves that are oppositely pitched, so that removed tissue can be collected in the middle of the tissue removal element. Another tissue removal element has independent counter-rotating tissue removal elements to maintain stability during a bone cutting procedure. Still another tissue removal element takes the form of a drill bit with fluted cutting grooves. Yet another tissue removal element has cascading tissue-cutting notches that can be reciprocatably moved to remove tissue within a hole.

Owner:BOSTON SCI SCIMED INC

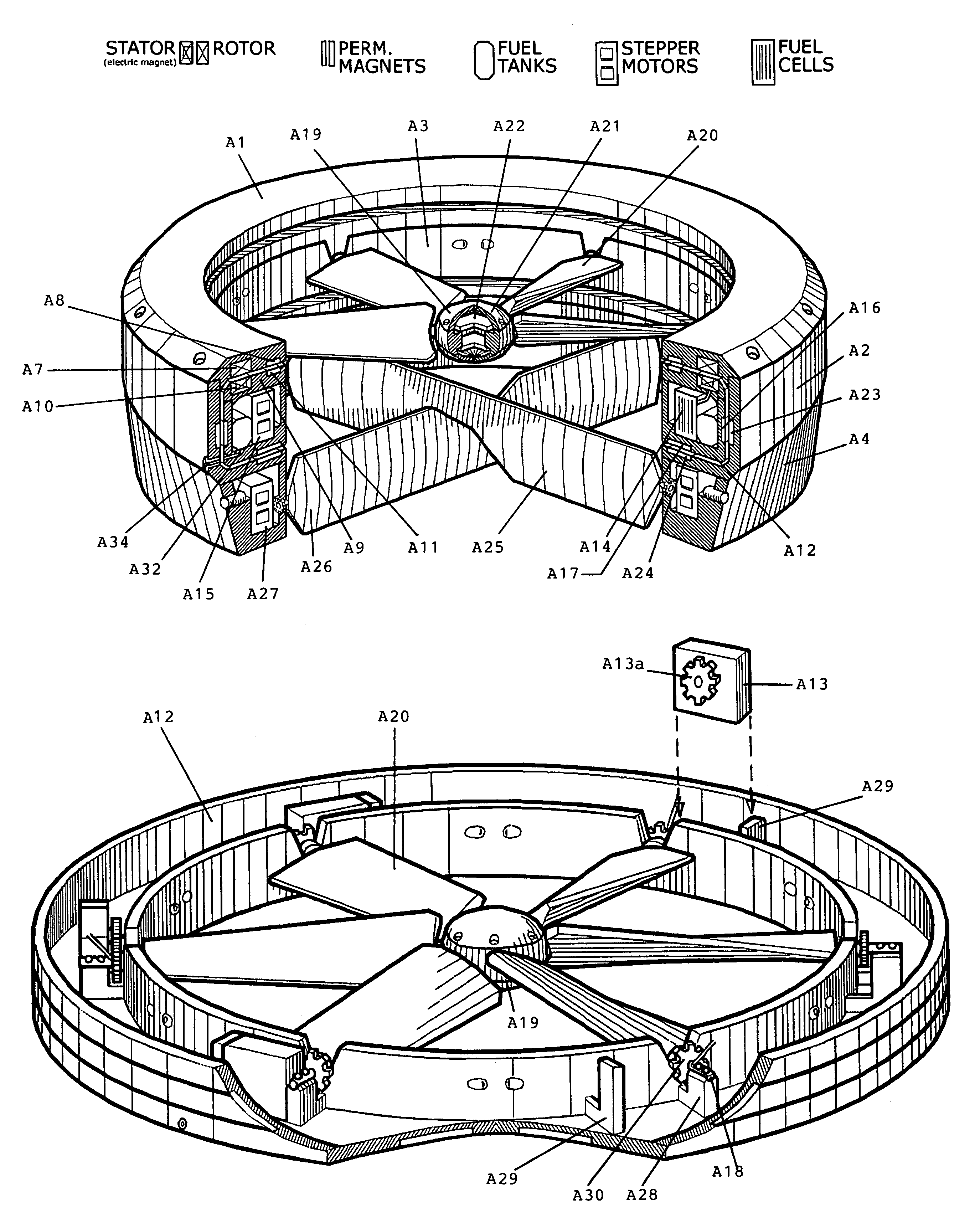

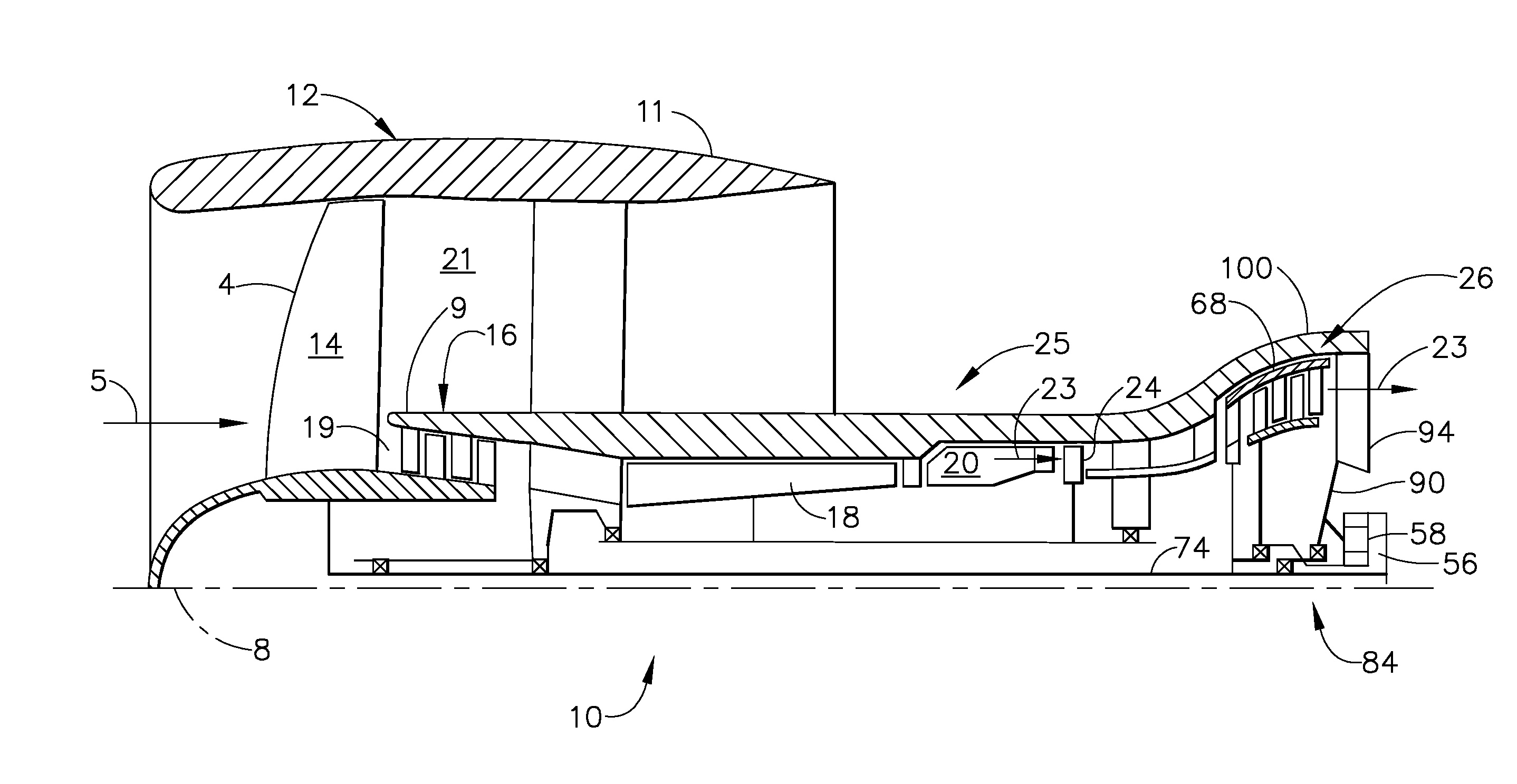

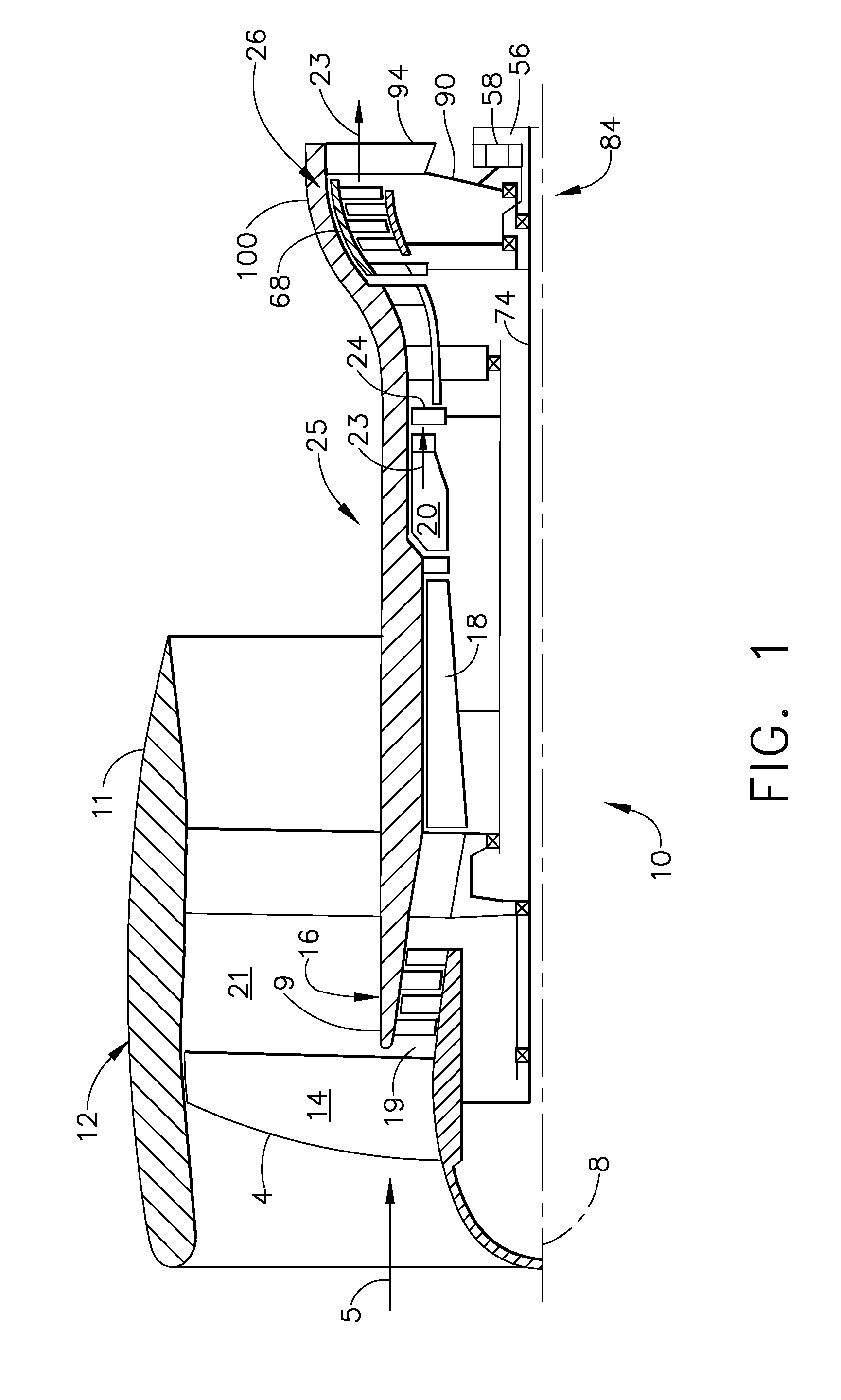

Quiet vertical takeoff and landing aircraft using ducted, magnetic induction air-impeller rotors

InactiveUS7032861B2Improve performanceImprove stabilityAircraft navigation controlUnmanned aerial vehiclesFlight control modesRudder

A hover aircraft employs an air impeller engine having an air channel duct and a rotor with outer ends of its blades fixed to an annular impeller disk that is driven by magnetic induction elements arrayed in the air channel duct. The air-impeller engine is arranged vertically in the aircraft frame to provide vertical thrust for vertical takeoff and landing. Preferably, the air-impeller engine employs dual, coaxial, contra-rotating rotors for increased thrust and gyroscopic stability. An air vane assembly directs a portion of the air thrust output at a desired angle to provide a horizontal thrust component for flight maneuvering or translation movement. The aircraft can employ a single engine in an annular fuselage, two engines on a longitudinal fuselage chassis, three engines in a triangular arrangement for forward flight stability, or other multiple engine arrangements in a symmetric, balanced configuration. Other flight control mechanisms may be employed, including side winglets, an overhead wing, and / or air rudders or flaps. An integrated flight control system can be used to operate the various flight control mechanisms. Electric power is supplied to the magnetic induction drives by high-capacity lightweight batteries or fuel cells. The hover aircraft is especially well suited for applications requiring VTOL deployment, hover operation for quiet surveillance, maneuvering in close air spaces, and long duration flights for continuous surveillance of ground targets and important facilities requiring constant monitoring.

Owner:SANDERS JR JOHN K +3

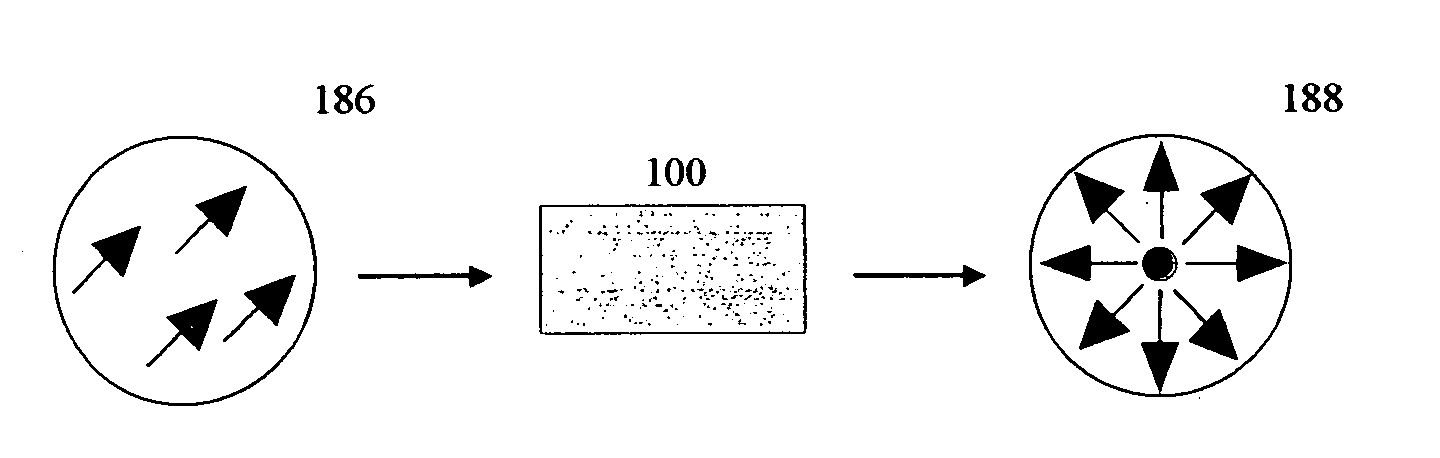

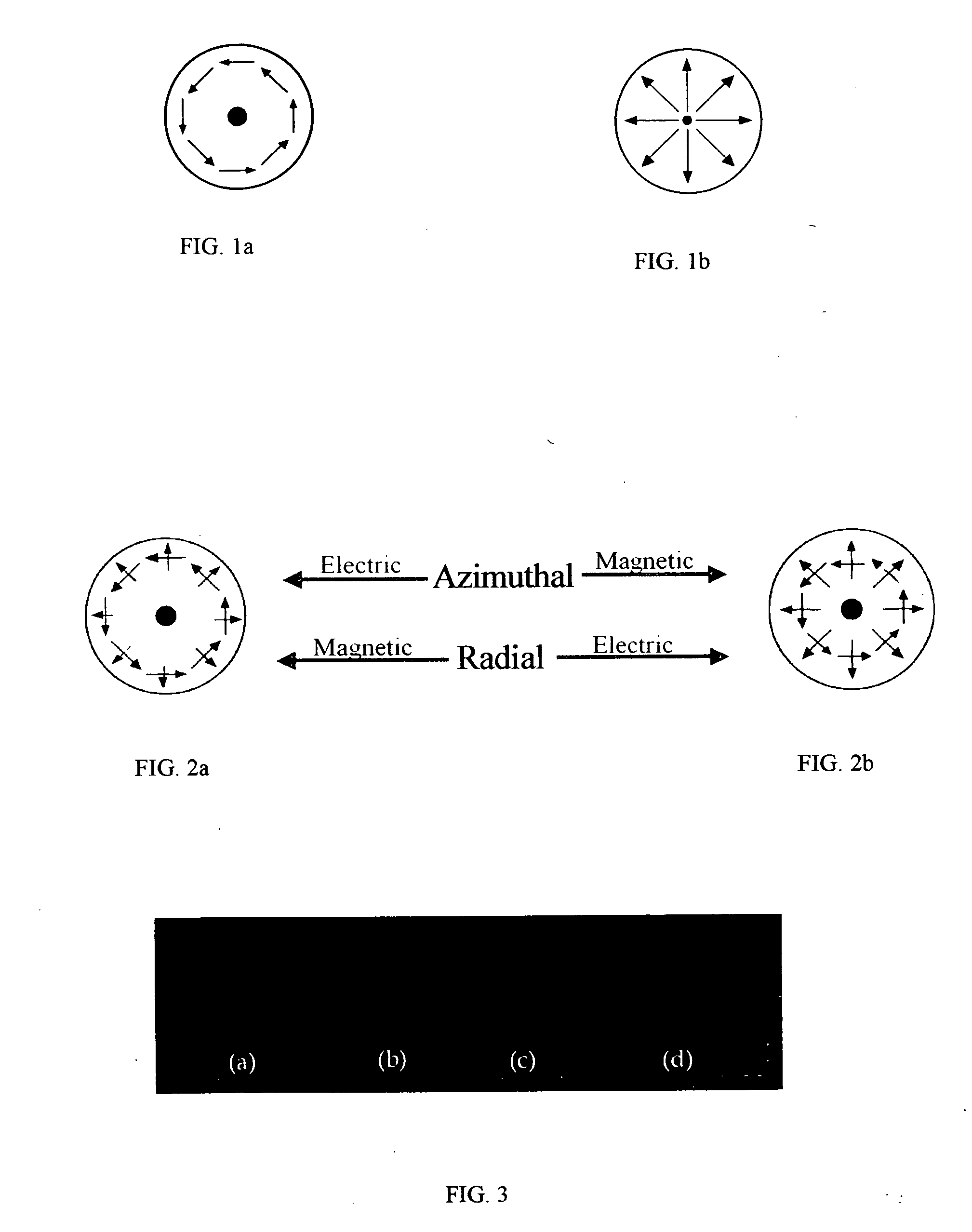

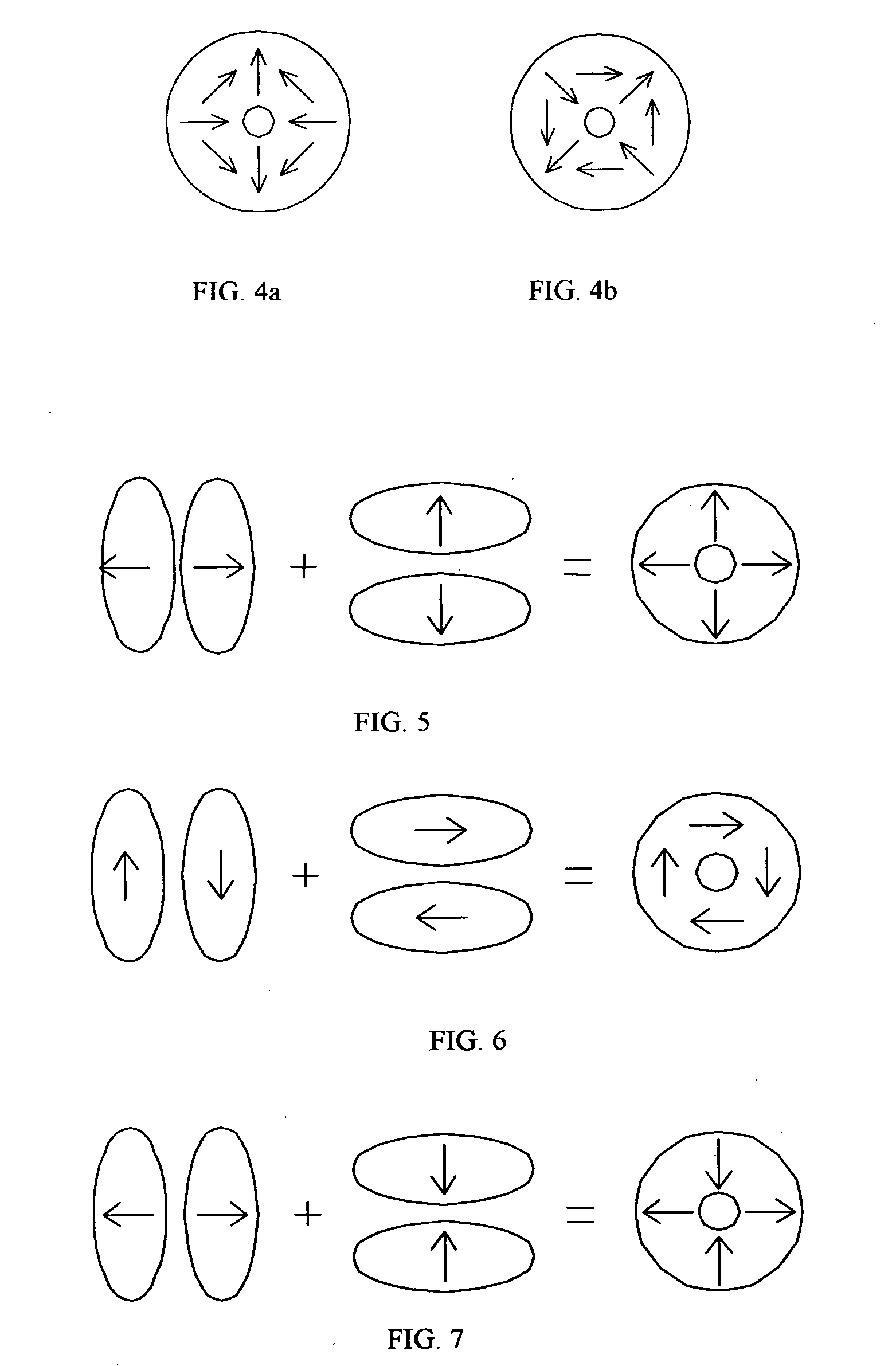

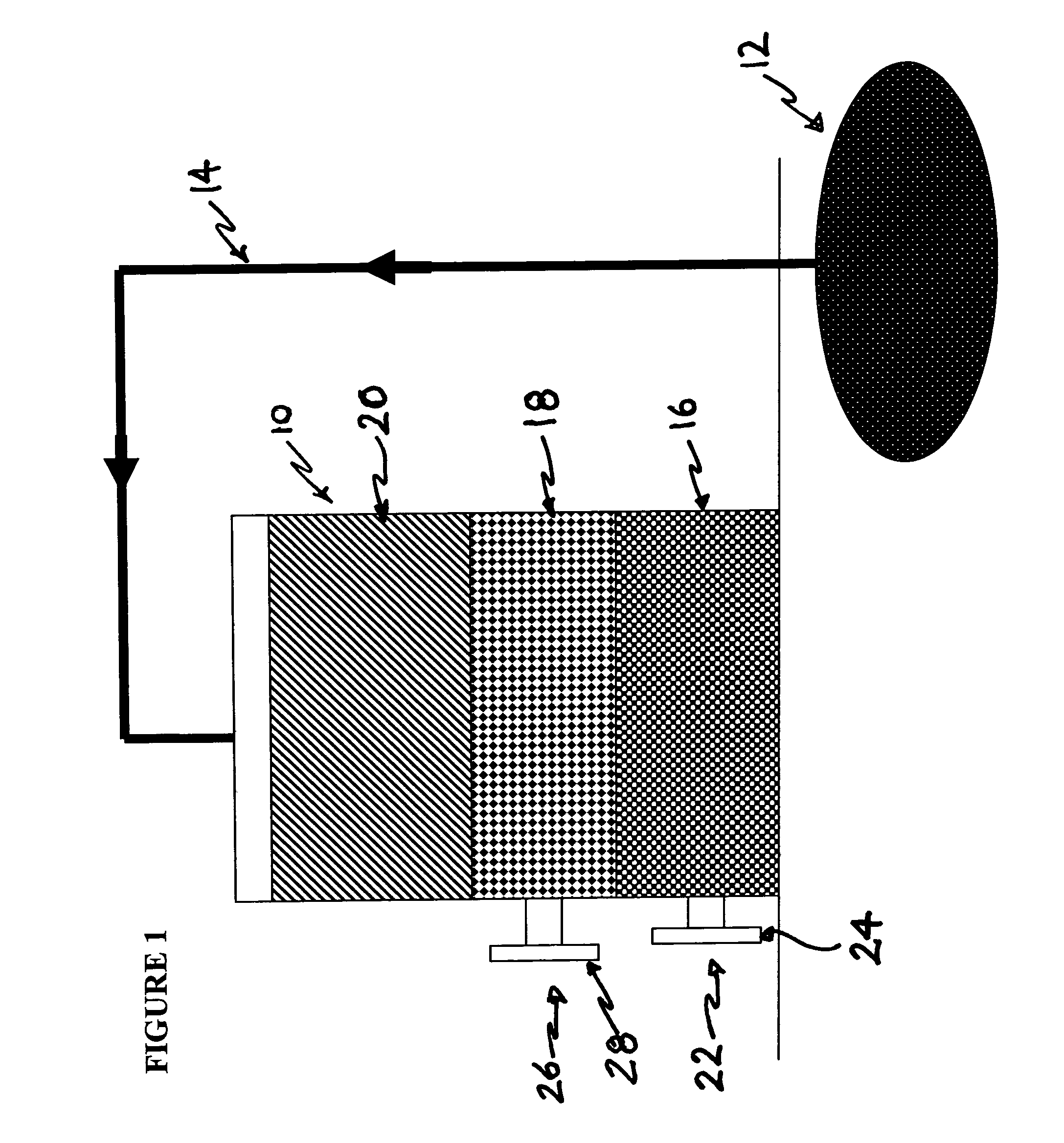

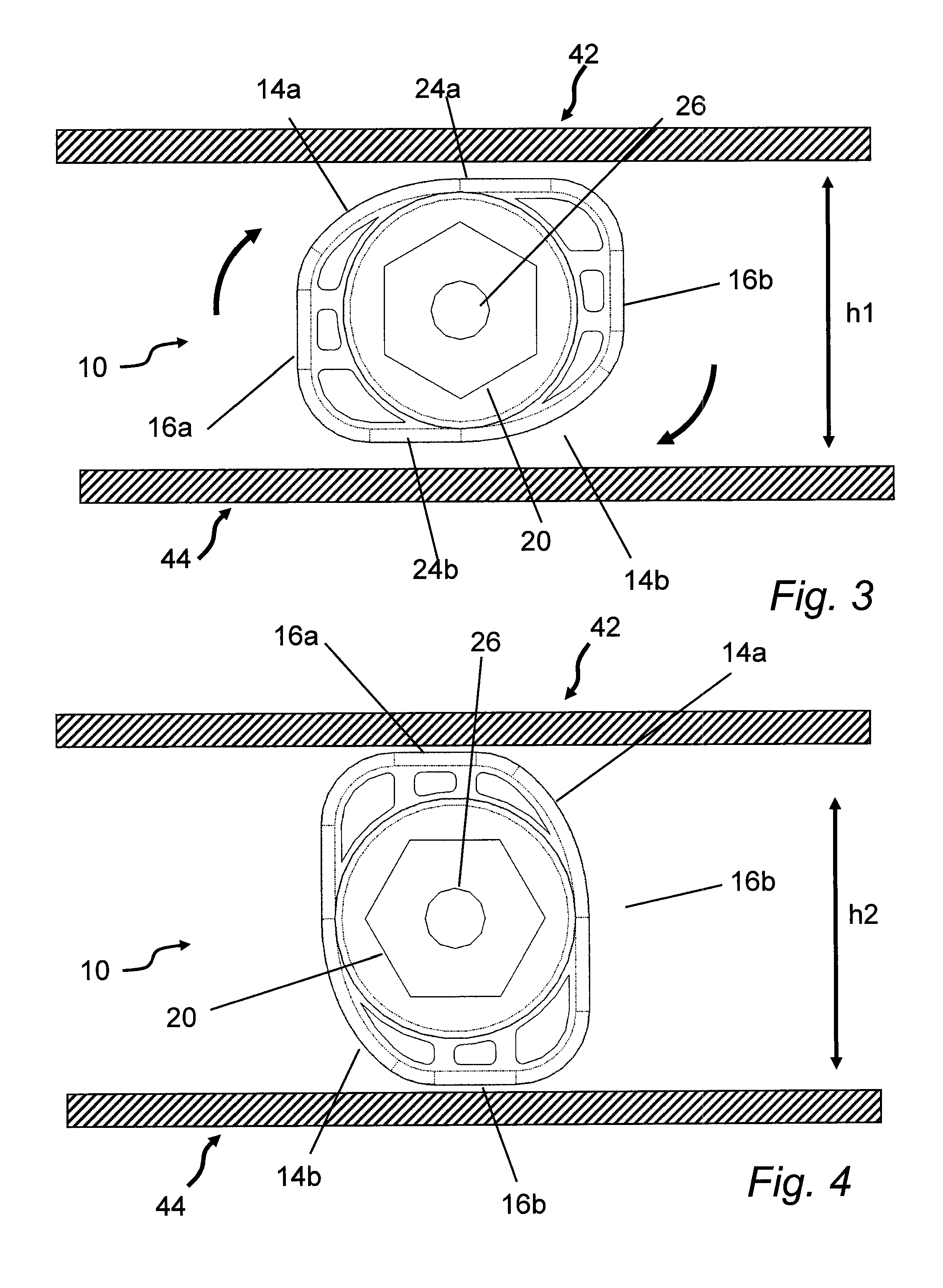

Space-variant waveplate for polarization conversion, methods and applications

InactiveUS20070115551A1Improve optical qualityPhotomechanical apparatusPolarising elementsPupilOptical polarization

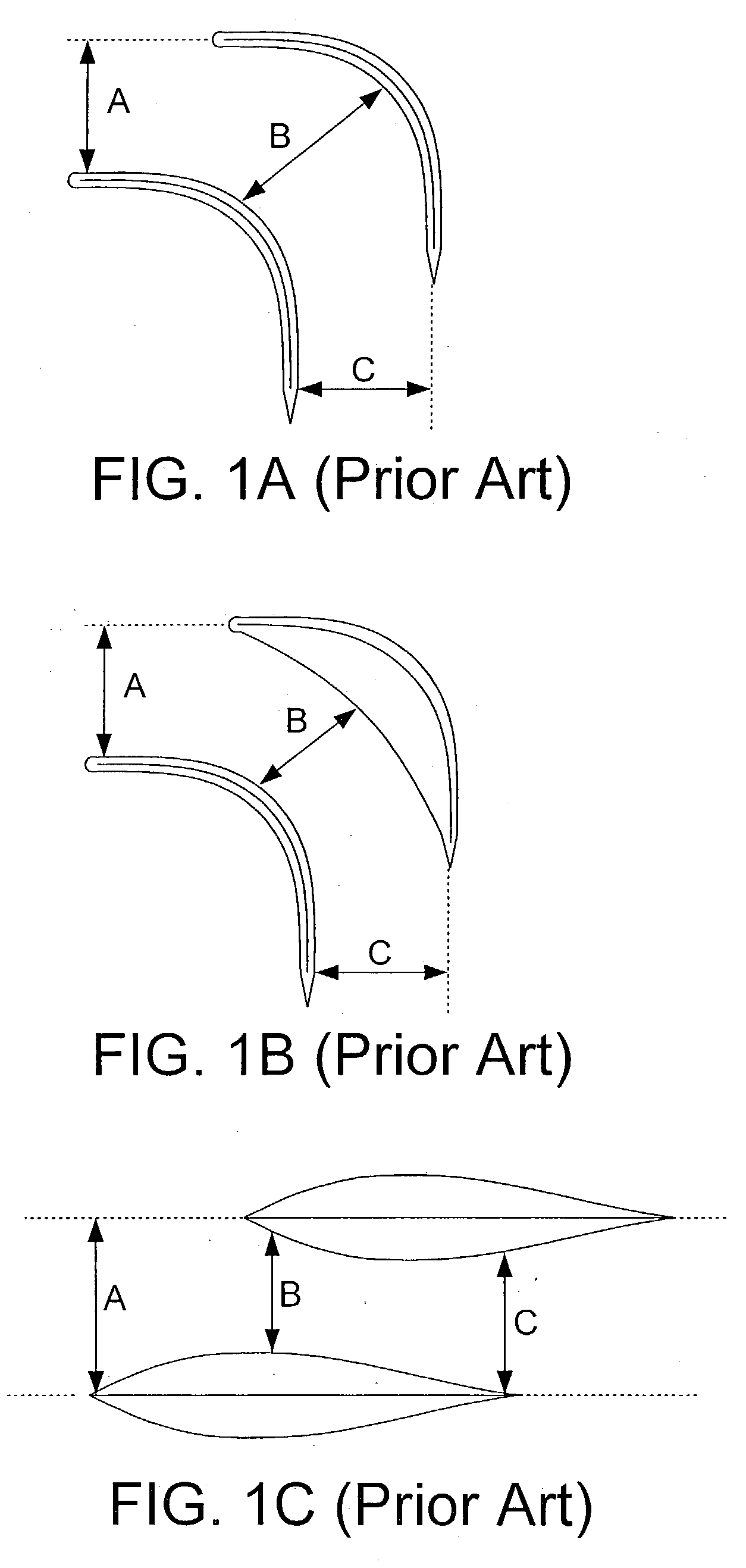

Embodiments of the invention are directed to apparatus and methods for converting spatially homogeneously polarized light into spatially inhomogeneously polarized light having a fast axis orientation that varies in a smooth and continuous manner over a pupil aperture. A space-variant waveplate referred to herein as a polarization converter includes an optically transmissive window characterized by a symmetric stress birefringence that provides at least λ / 4 retardance and, more particularly, λ / 2 retardance over an annular region centered about the optical axis of the window. Structural embodiments of the polarization converter include a mechanical compression housing and a thermal compression housing. Radially and azimuthally polarized vortex beams including cylindrical vector beams and counter-rotating beams can be generated from uniformly plane polarized input beams propagating through the polarization converter. Low-order polarization vortex beams can be optically combined to produce higher-order scalar vortex beams. Embodiments of the invention are also directed to various optical illumination and imaging systems utilizing the apparatus and methods described herein.

Owner:SPILMAN ALEXIS +1

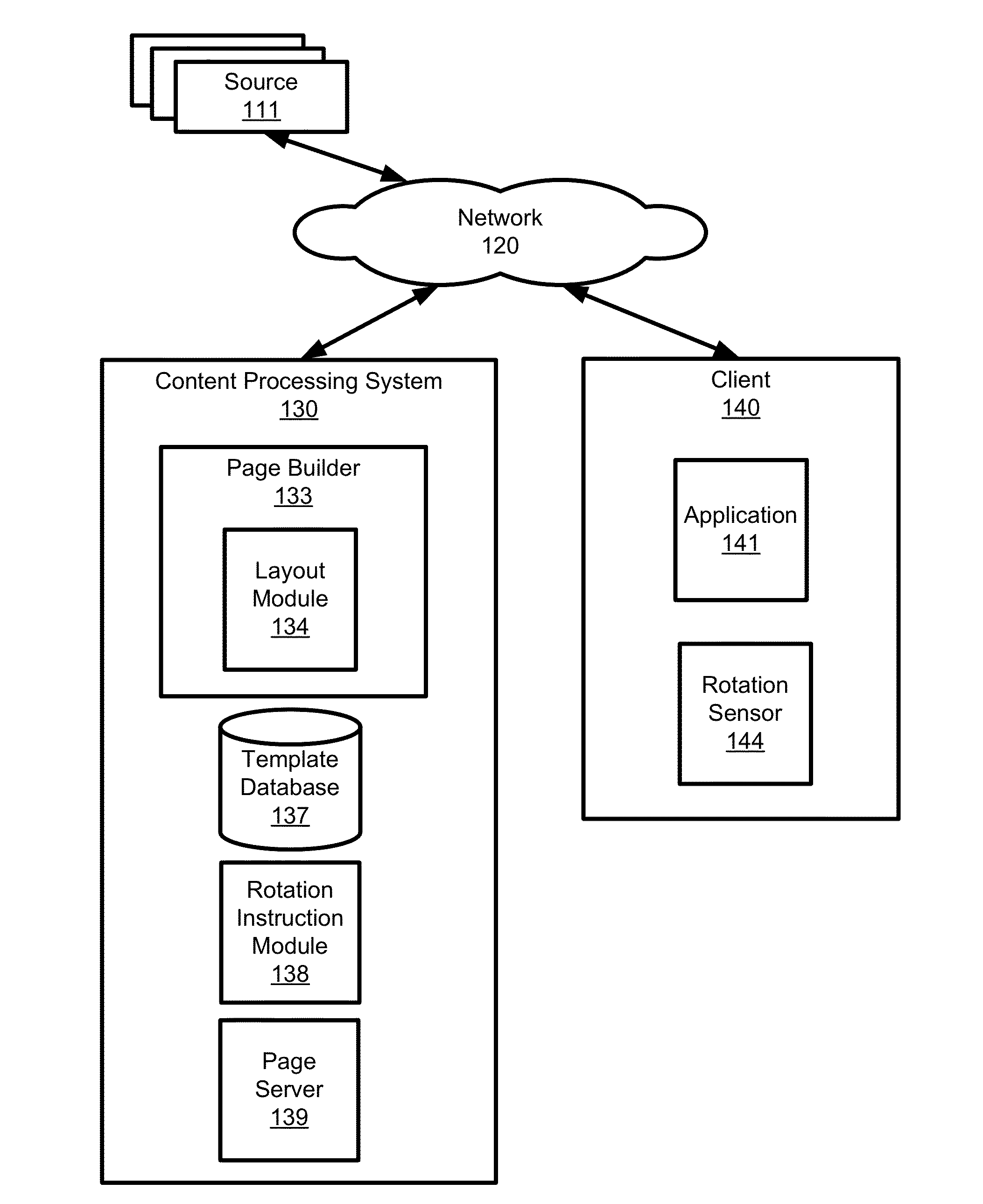

Adjusting Orientation of Content Regions in a Page Layout

ActiveUS20130021377A1Cathode-ray tube indicatorsDetails for portable computersComputer graphics (images)Display device

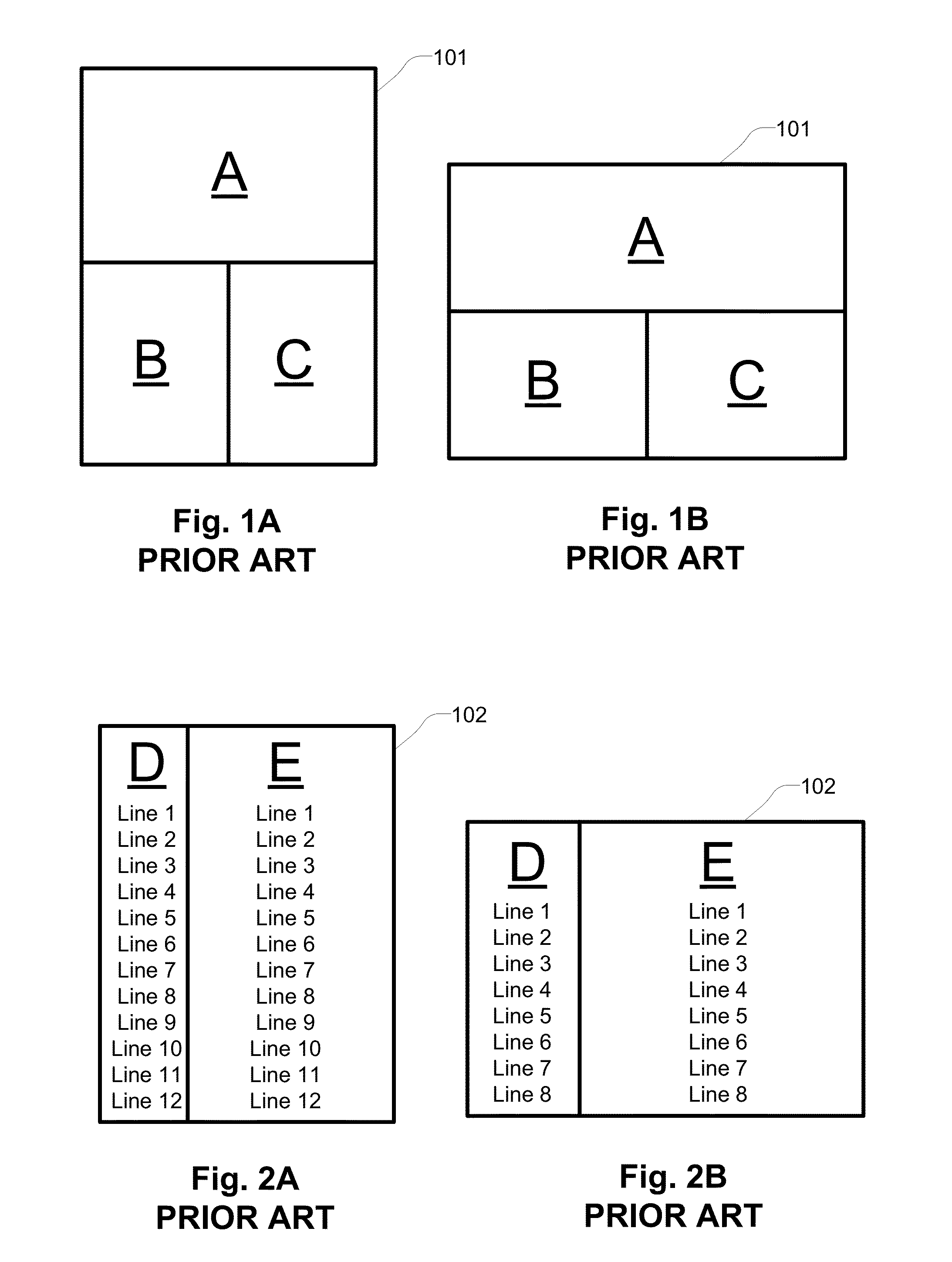

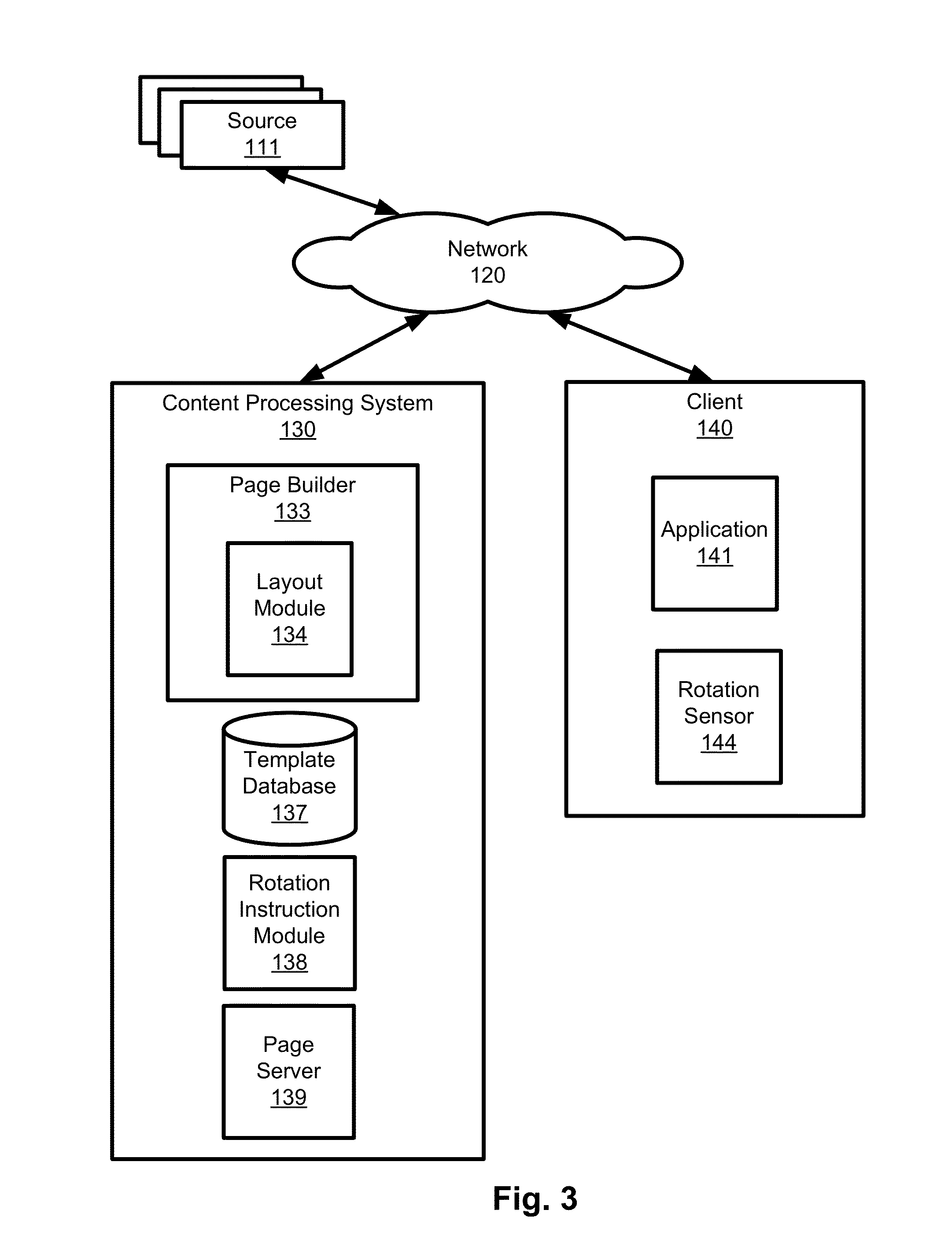

When the device is rotated from a portrait orientation to landscape orientation, or vice versa, the display device rotates the content items within distinct respective content regions of a page template (“slots”) that each appear to stay in their same position with respect to a frame of reference of the display device. While the content regions stay in their same positions, the content within each content region counter-rotates in place to offset the rotation of the display device. Thus, the content within the content regions maintains an orientation with respect to a constant (non-rotating) frame of reference, regardless of the orientation or rotation of the display device. In one embodiment, a slot's position, height, and width in a template in a second orientation are determined from the slot's position, height, and width in the template in a first orientation.

Owner:FLIPBOARD

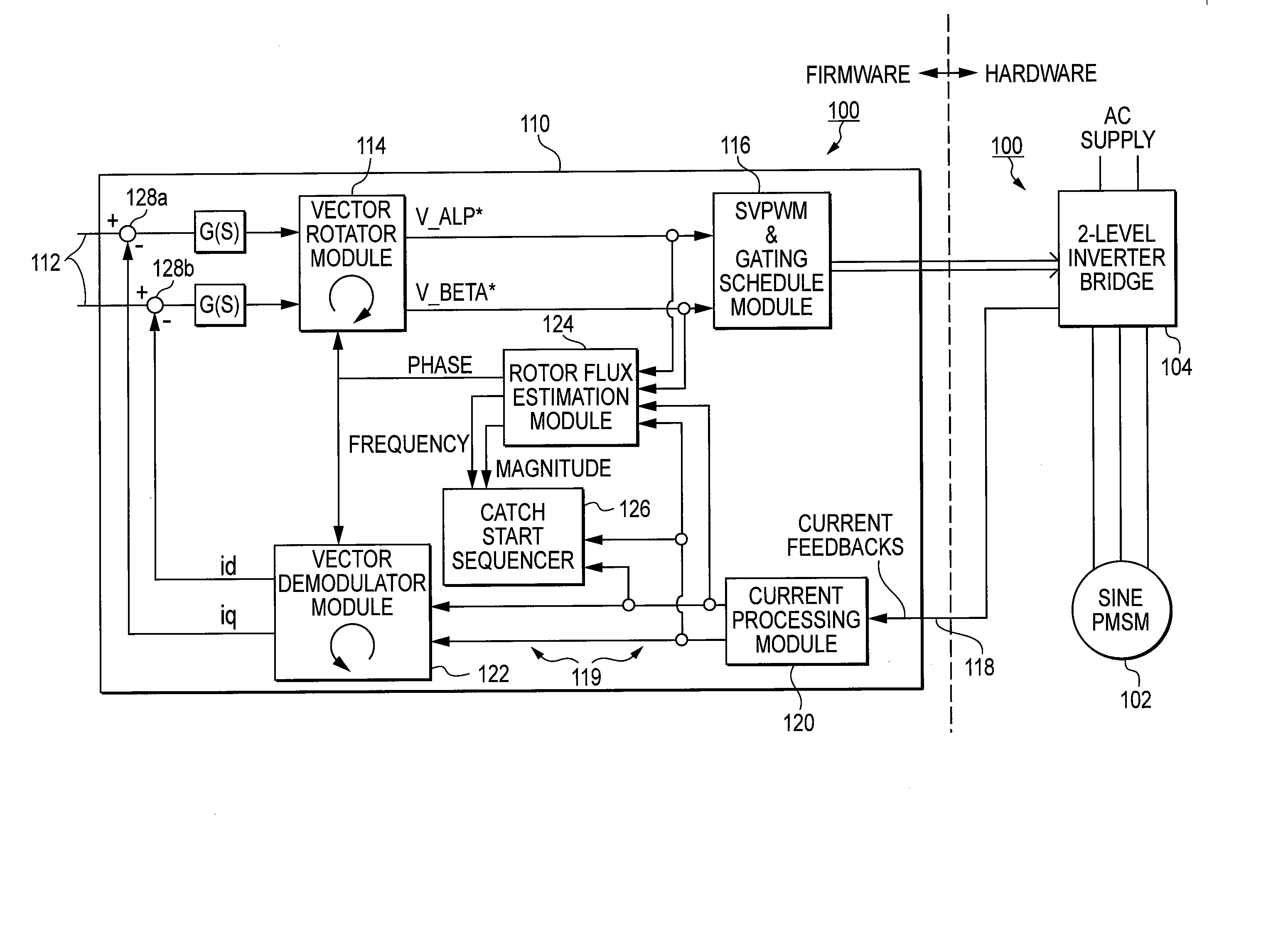

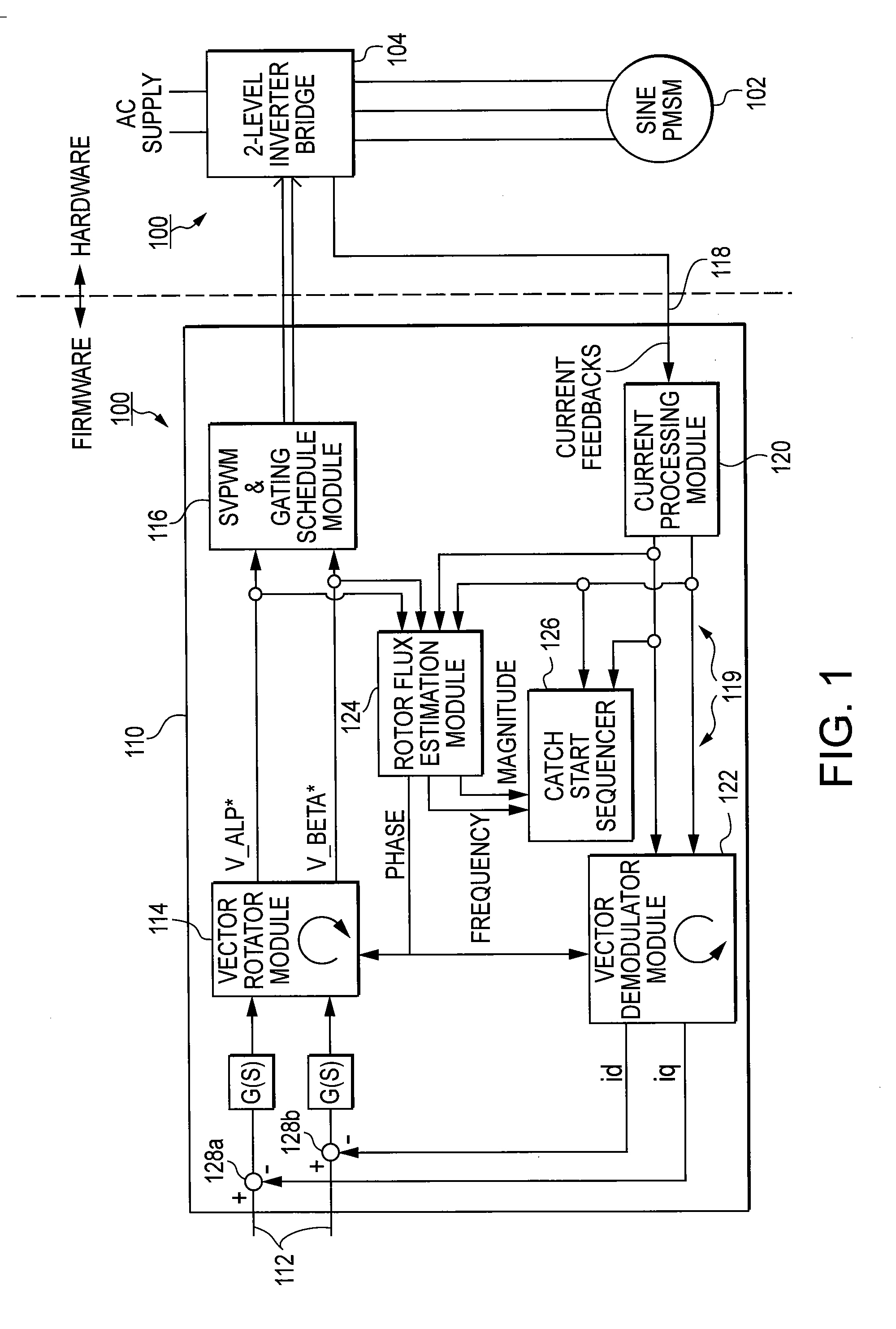

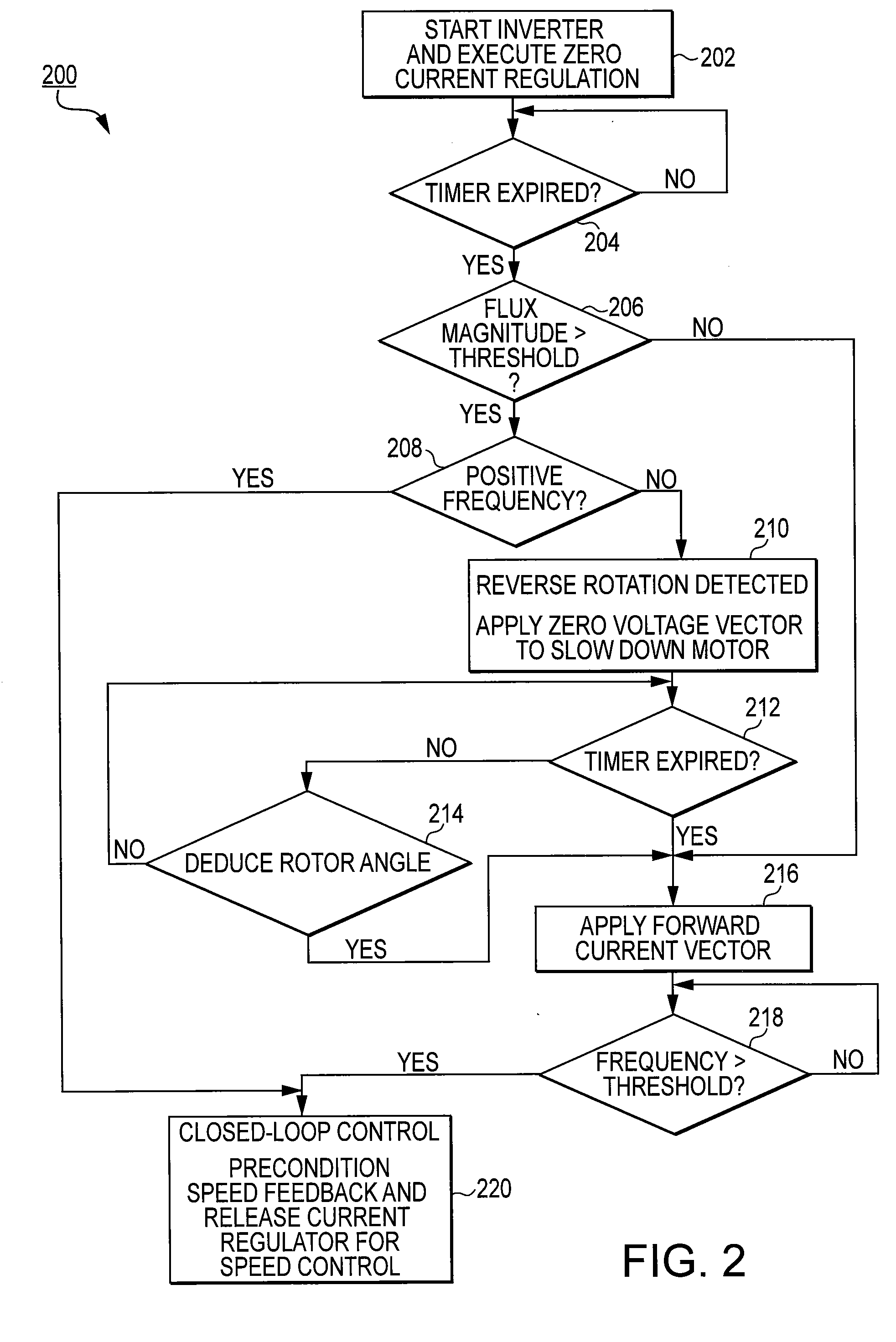

Method and system for starting a sensorless motor

ActiveUS20070001635A1Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveEngineering

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

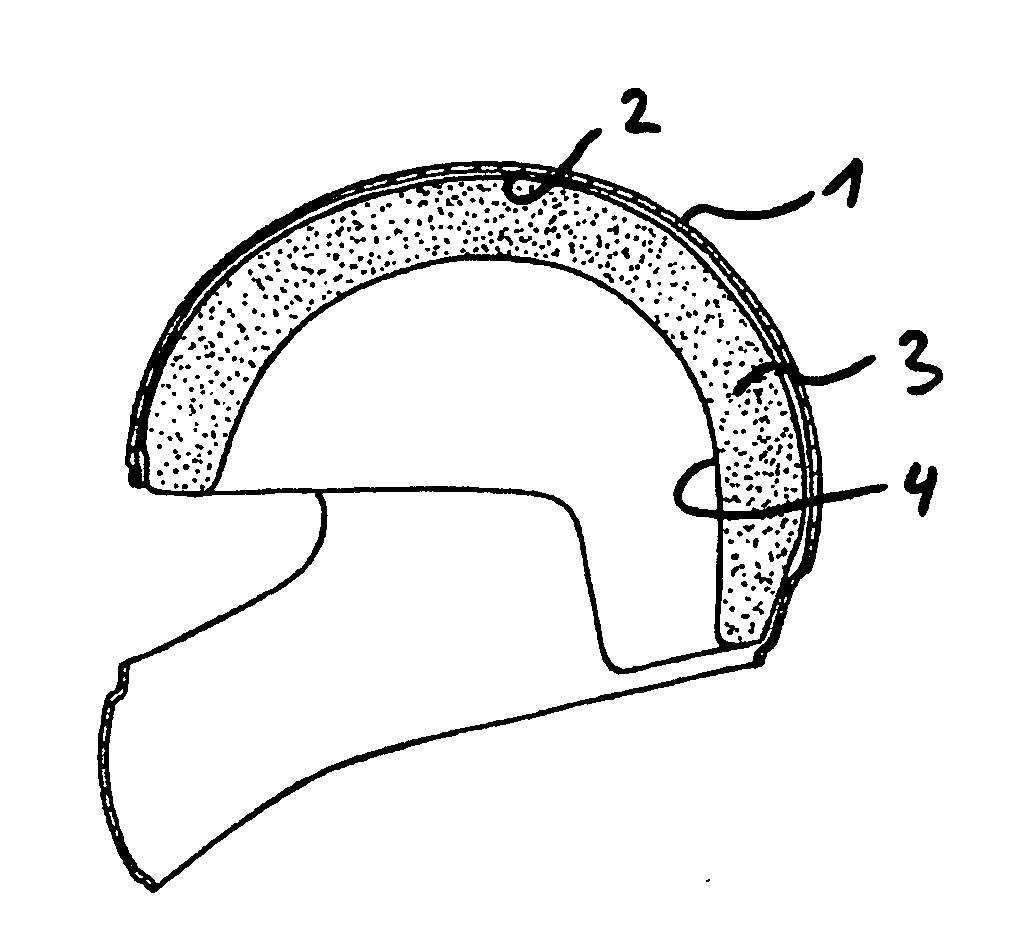

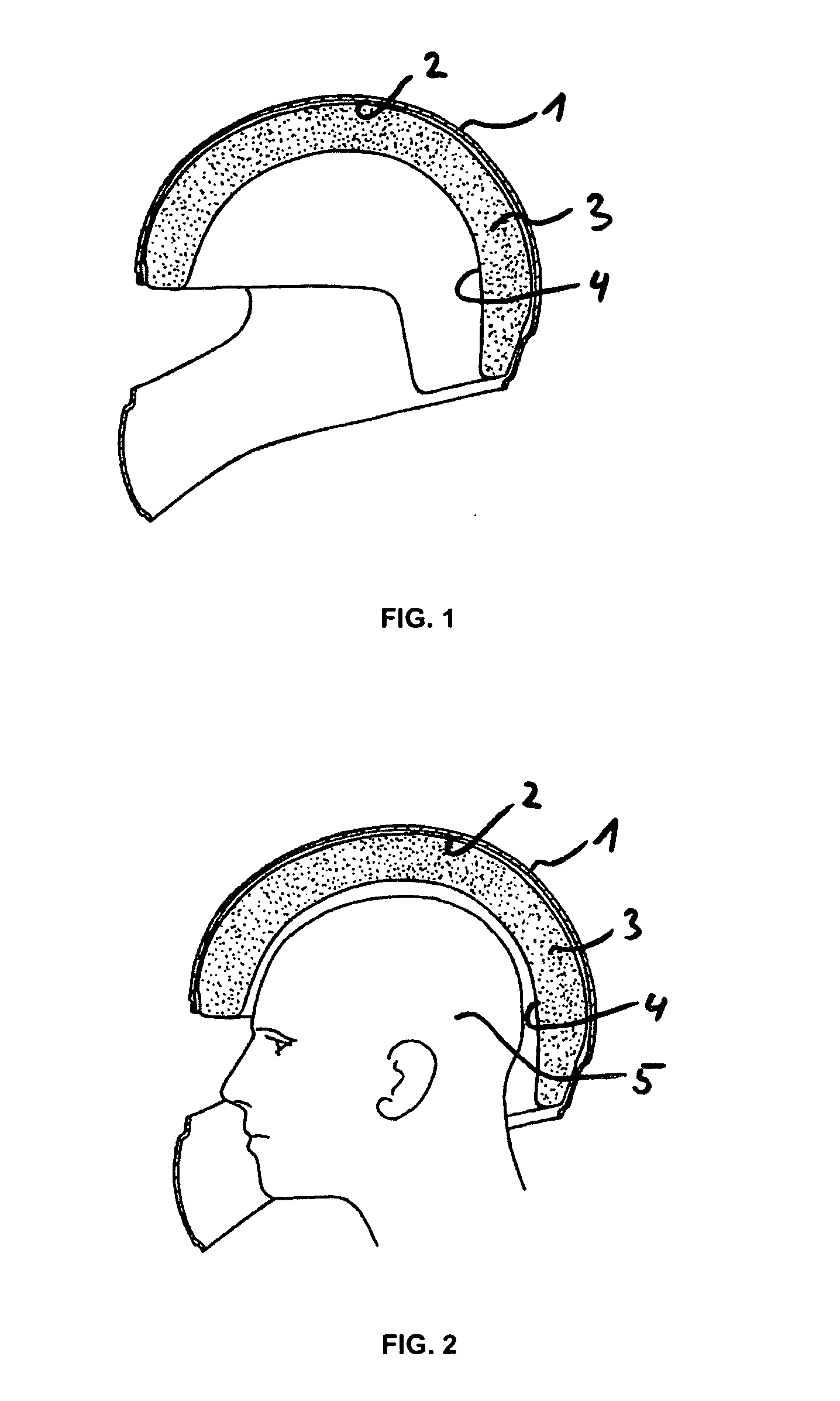

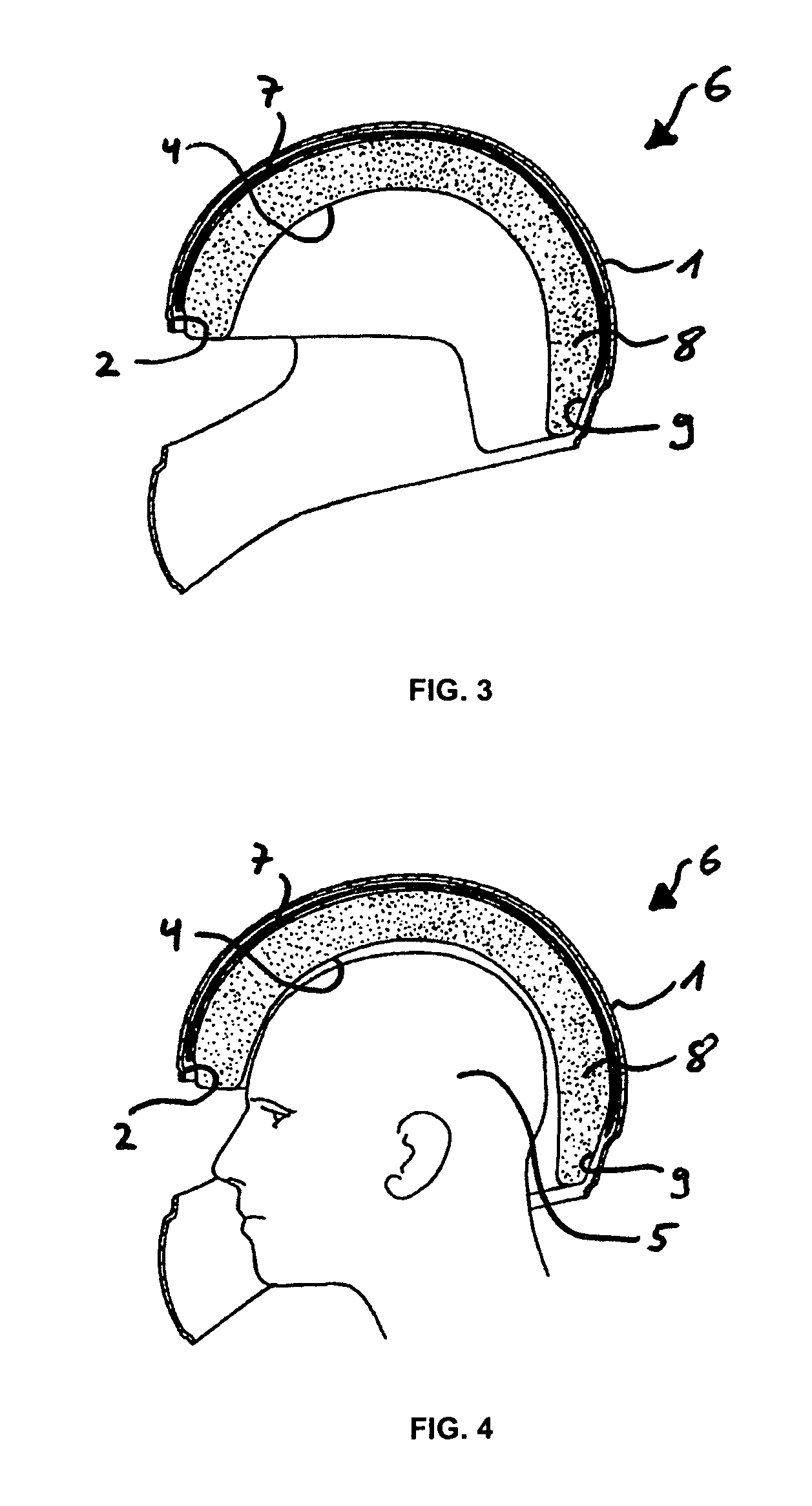

Protective helmet; Method for mitigating or preventing a head injury

InactiveUS20120060251A1Mitigating and preventing injurySimple designHatsPersonal protection gearEngineeringAngular acceleration

Disclosed is a protective helmet and a method for mitigating or preventing a head injury, in which a shock-absorbing, or shock-absorbing and comfort-providing, inner wearing unit, which can comprise liners, comfort pads, protective pads, nubbed cages and / or strapped wearing units (for example spider-shaped wearing elements, wearing straps, head bands or the like), is divided into a shell-side insert and a head-side insert, which can be counter-rotated (preferably starting from application of a predetermined force) in at least one direction, wherein a sliding surface is provided that assumes the function of a rotational surface, so that the angular acceleration introduced by a blow is drastically reduced or prevented because the head-side insert and the shell-side insert, and thus the head of the wearer and the outer helmet shell, can be counter-rotated quickly and without impediment, preferably in all directions.

Owner:SCHIMPF OLIVER

Double ducted hovering air-vehicle

InactiveUS20060192047A1Improve lifting performanceHeavy loadPower plant arrangements/mountingUnmanned aerial vehiclesAviationGear wheel

A dual ducted fan arrangement in which the duct components, engine, and avionics / payload pods are capable of being quickly disassembled to fit within common backpacking systems.. Each duct is identical in fan, stator, and control vane design. Assembly connections between ducted fans and electronic modules are also identical. An engine or APU drives the dual ducted fans through a splined shaft to a differential or through electric motors. Energy is transferred to the ducted fans by a single gear mounted to the stator hub. Relative speeds of the individual ducted fans are controlled through separate frictional or generator load control braking mechanisms on each of the splined shafts between the differential and ducted fans. In the electric motor case relative speed is through electronic speed control. The fans are counter rotating for torque balancing. The electronic module locations are vertically variable for longitudinal center of gravity for variations in payloads.

Owner:HONEYWELL INT INC

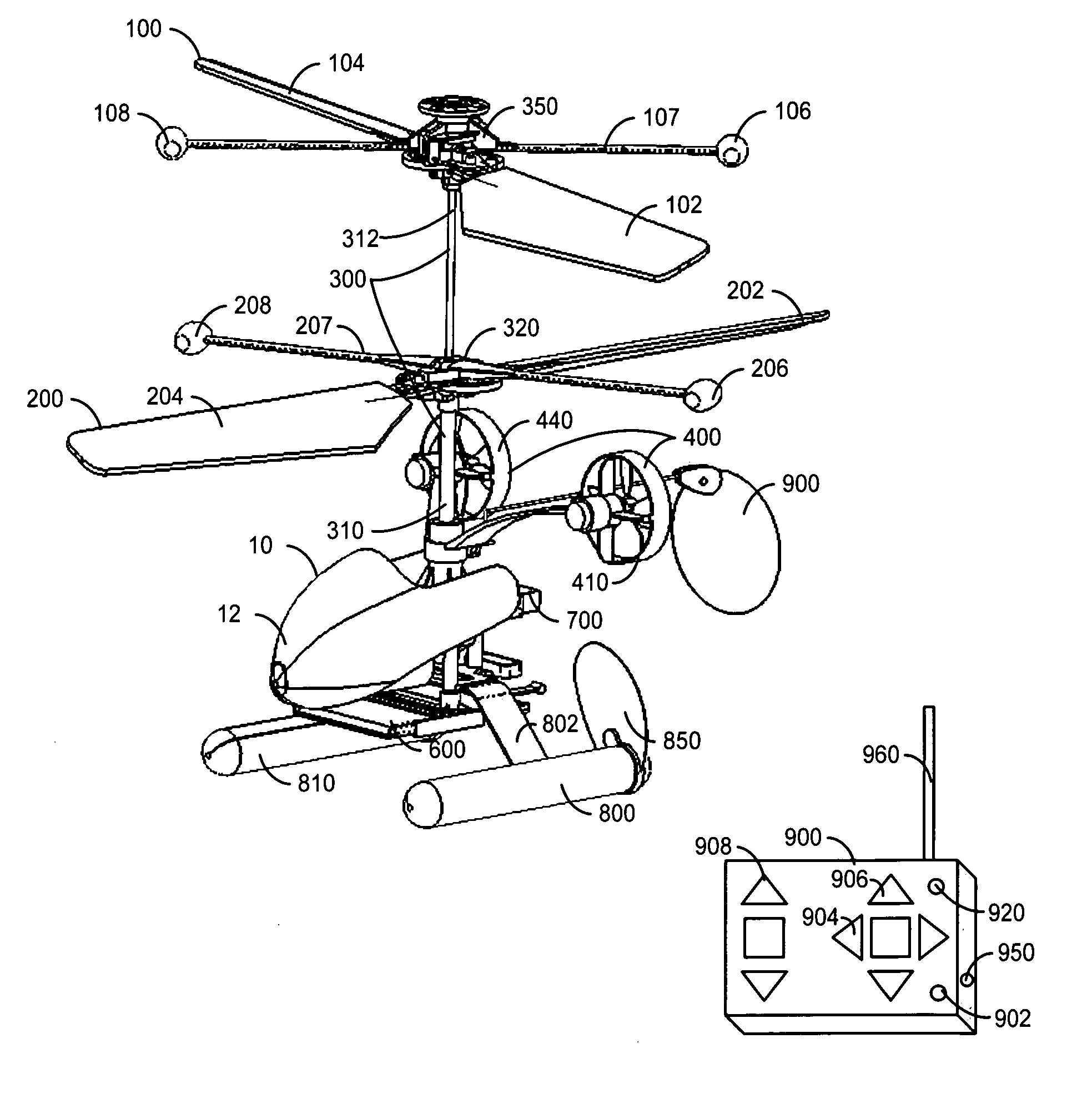

Rotary-wing vehicle system and methods patent

InactiveUS20060231677A1Improved yaw stabilityImprove flight stabilityToy aircraftsRotocraftAviationFlight vehicle

A rotary-wing apparatus that is aeronautically stable, easy to fly with a multidimensional control, small size, and safe to fly and low cost to produce. The rotary-wing apparatus includes a coaxial counter rotating rotor drive providing lifting power with an inherent aeronautical stability; Auxiliary propellers that face the direction of flight and are located on opposite sides of said coaxial Rotary-wing apparatus and enable flying forwards, backwards and perform yawing; A rotary-wing coaxial helicopter toy that is remotely controlled and safe to fly in doors and out doors, while performing exciting maneuvers even by untrained kids

Owner:ZIMET NACHMAN +1

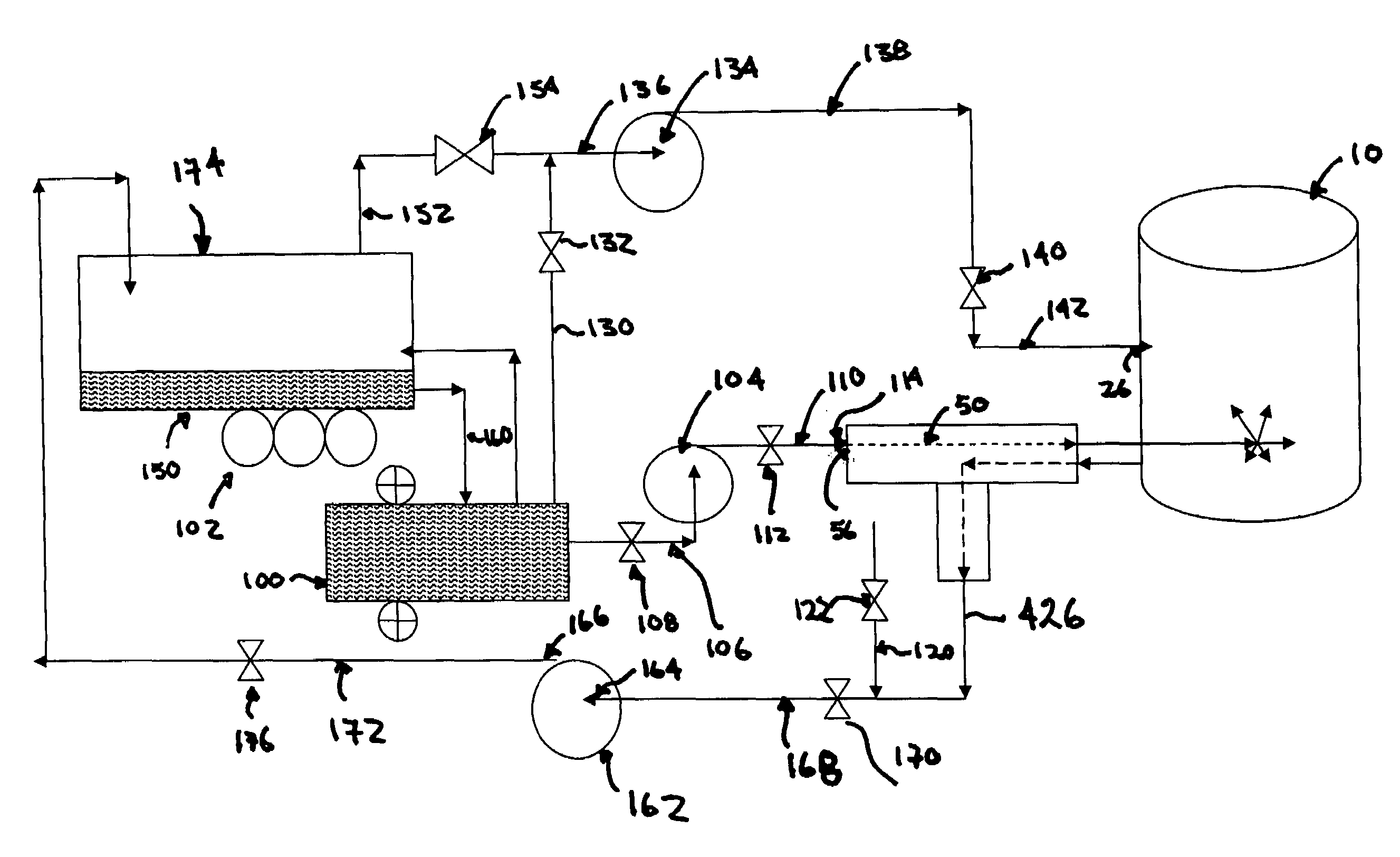

Trailer mounted mobile apparatus for dewatering and recovering formation sand

InactiveUS7240681B2Prevent leakageElectrostatic cleaningMultistage water/sewage treatmentDrive wheelHigh pressure water

An apparatus for removing formation sand from an oil storage tank. The apparatus is mounted to a truck towable trailer so that it may be transported to remote sites. Mounted to the truck towable trailer is a container adapted to accept and dewater a sand-water slurry pumped from the oil storage tank. The slurry is formed by injecting high pressure water from a water reservoir mounted to the truck towable trailer into the approximate centre of mass of the formation sand by way of a pipe having a nozzle generating a spherical spray pattern within the slurry. The pipe is forced into the slurry by way of a two counter-rotating drive wheels in frictional contact with the pipe. Included in the apparatus is a bifurcated conduit adapted for attachment to the storage tank drain port adapted for the injection of high pressure through one branch of the conduit and withdrawal of slurry from the other branch and into the container by way of a slurry pump. The dewatering of the slurry takes place by a plurality of screen filters mounted to the bottom, side and front inside walls of the container. Oil and water extracted from the slurry is recycled back into the storage tank for later removal and treatment. All pumps and conduits are mounted to the truck towable trailer so that the apparatus is self-contained.

Owner:SAIK LARRY

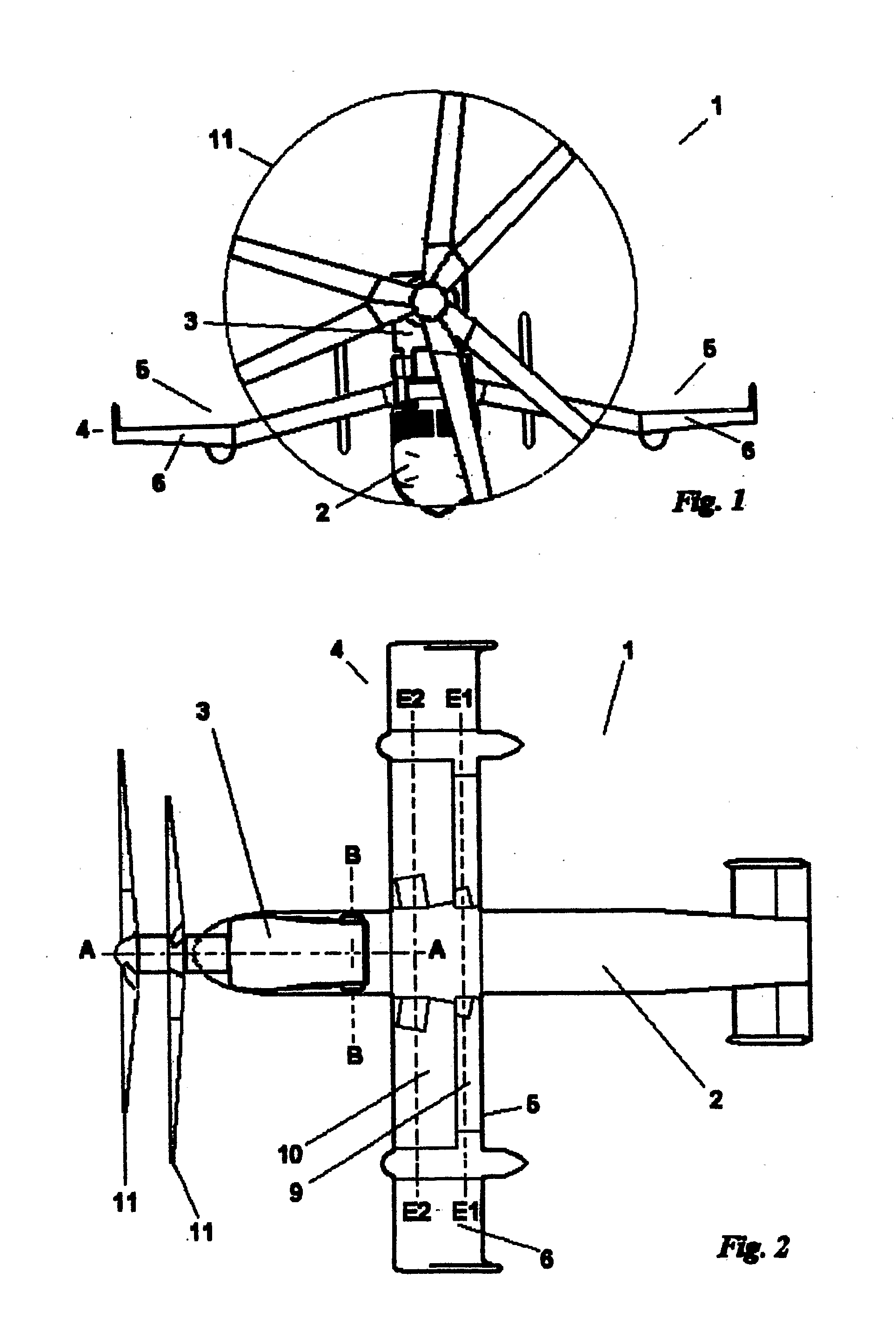

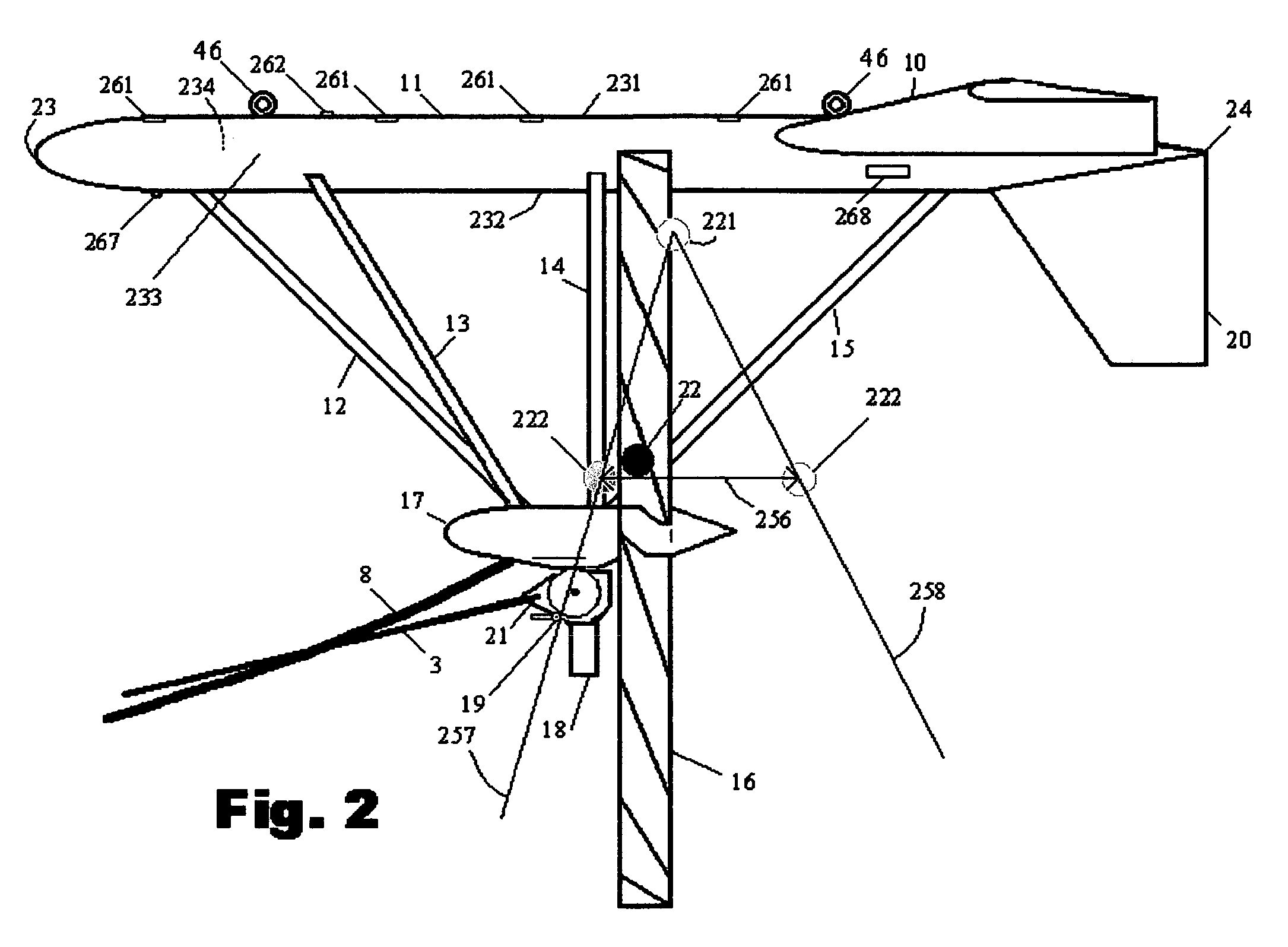

Vertical take-off and landing vehicles

A VTOL vehicle including a fuselage with two foldable wings, two tiltable nacelles attached to the wings, a vertical stabilizer, a horizontal stabilizer, and two auxiliary thrusters. Each nacelle contains a system of vanes located at the rear opening thereof, and actuators are provided for extending and retracting the vanes in conjunction with nacelle tilting mechanisms to deflect the airflow over a predetermined range of angles from the horizontal. Each nacelle also contains two rotary engines, each of which directly drives a fan. The fans face each other and operate in counter-rotating directions at the same rotational speed. An alternative embodiment includes two additional nacelles attached to the fuselage instead of having the auxiliary thrusters. A redundant computerized flight control system maintains stability of the vehicle as it transitions from one flight mode to another.

Owner:MOLLER INT

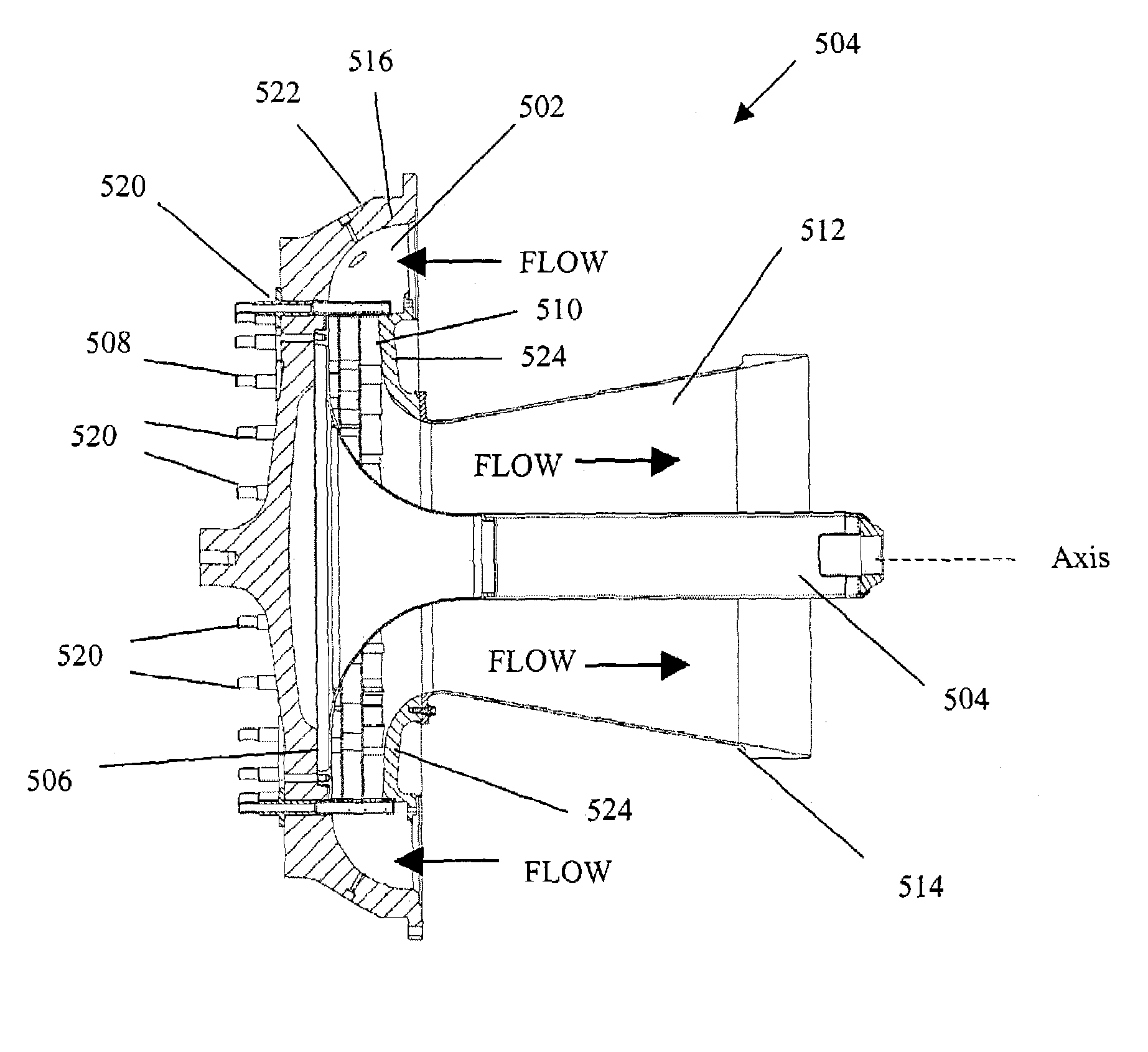

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

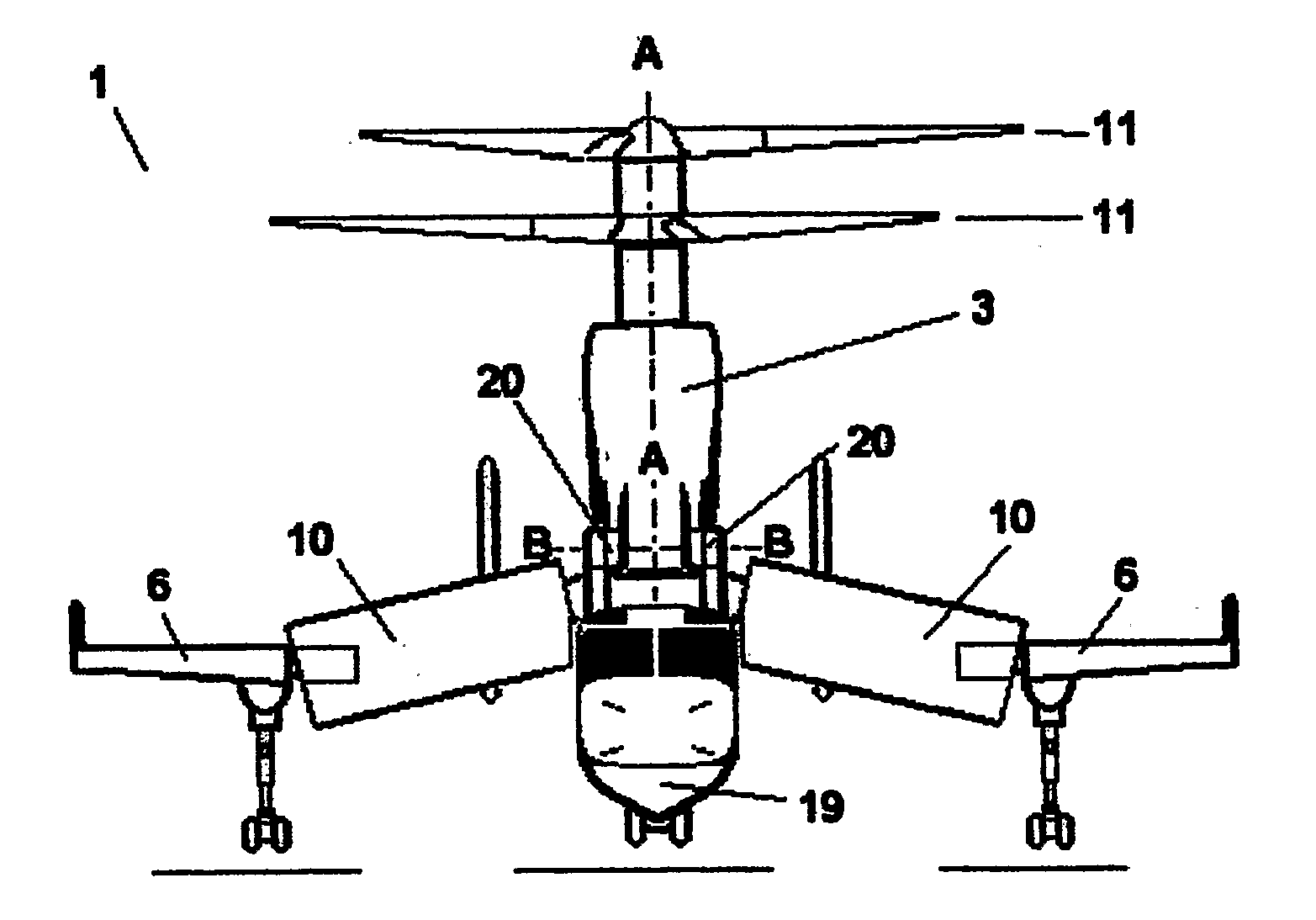

Tilt-rotor aircraft

ActiveUS20070158494A1Reduce download forceSimple supportPower plant arrangements/mountingAircraft power plant componentsFlight vehicleFuselage

A tilt-rotor aircraft (1) comprising a pair of contra-rotating co-axial tiltable rotors (11) on the longitudinal centre line of the aircraft. The rotors (11) may be tiltable sequentially and independently. They may be moveable between a lift position and a flight position in front of or behind the fuselage (19).

Owner:BURRAGE ROBERT GRAHAM

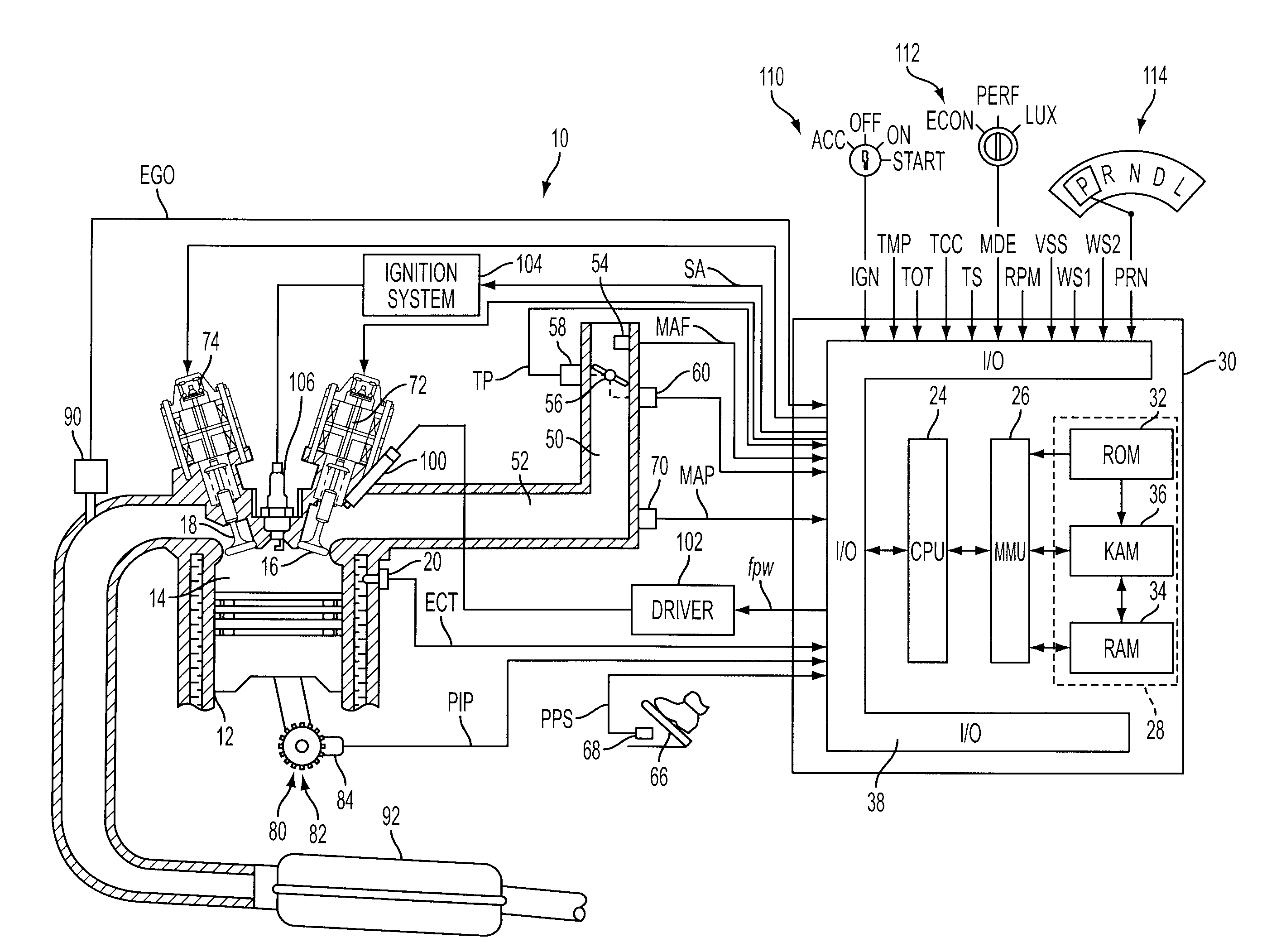

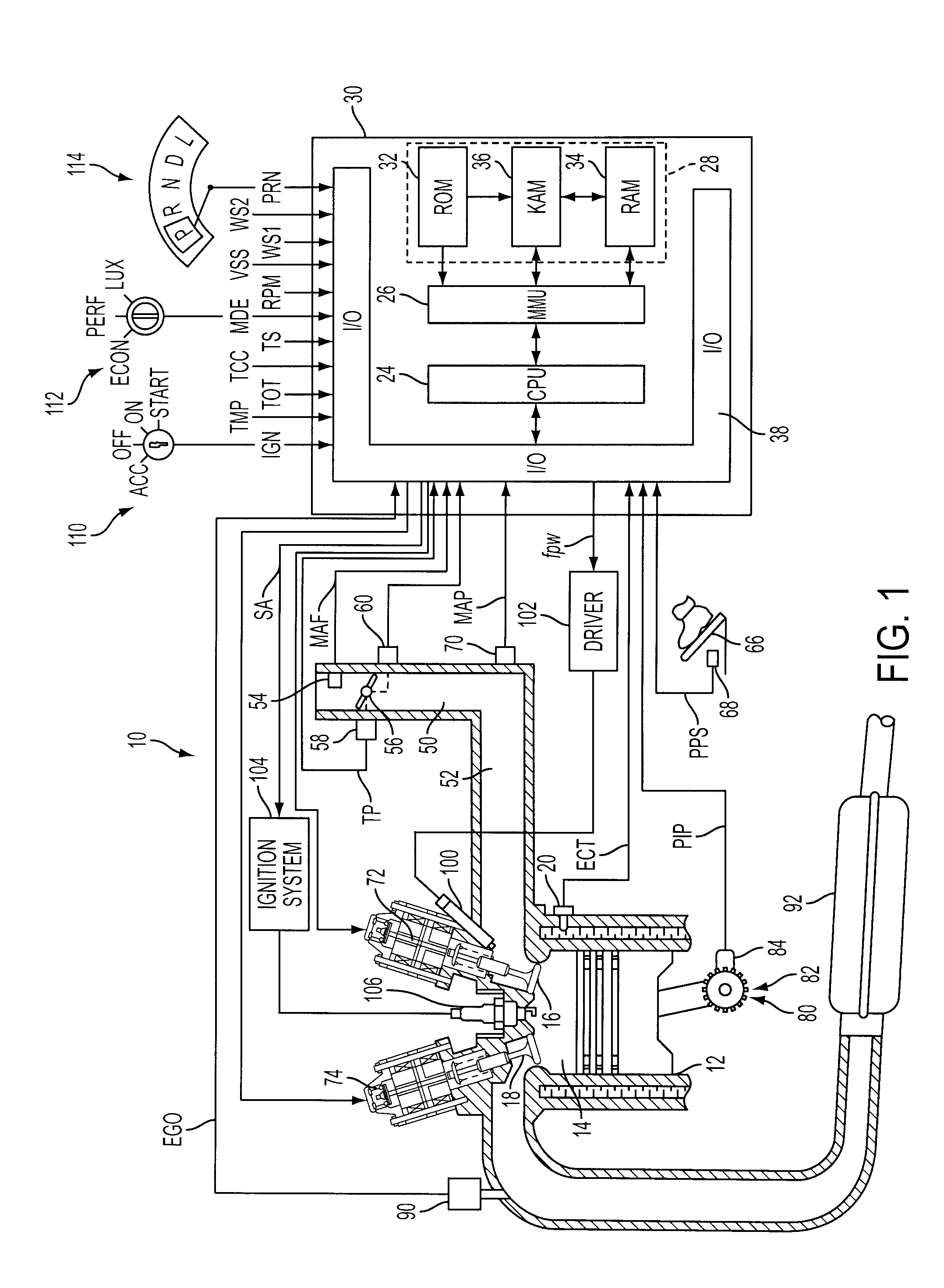

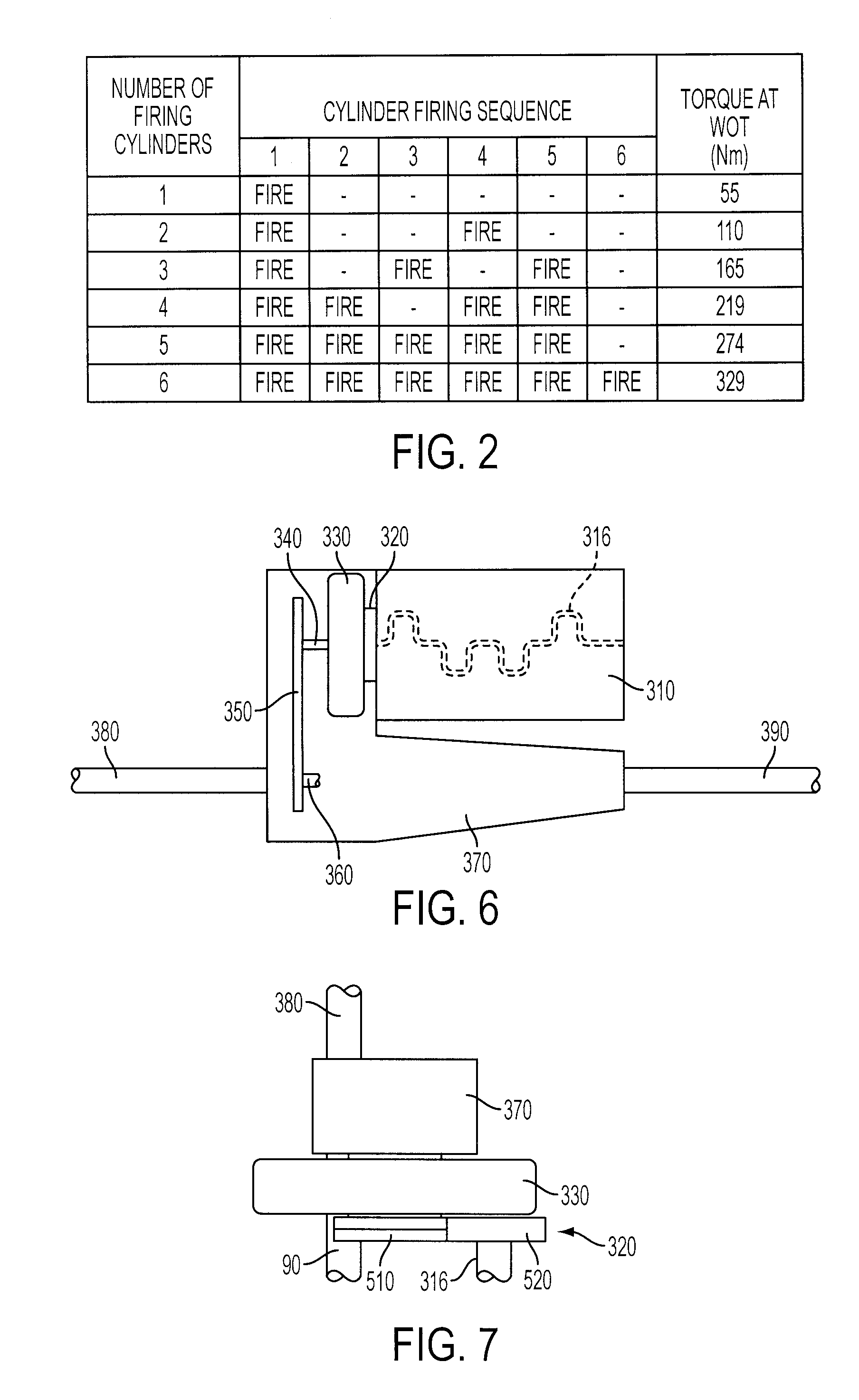

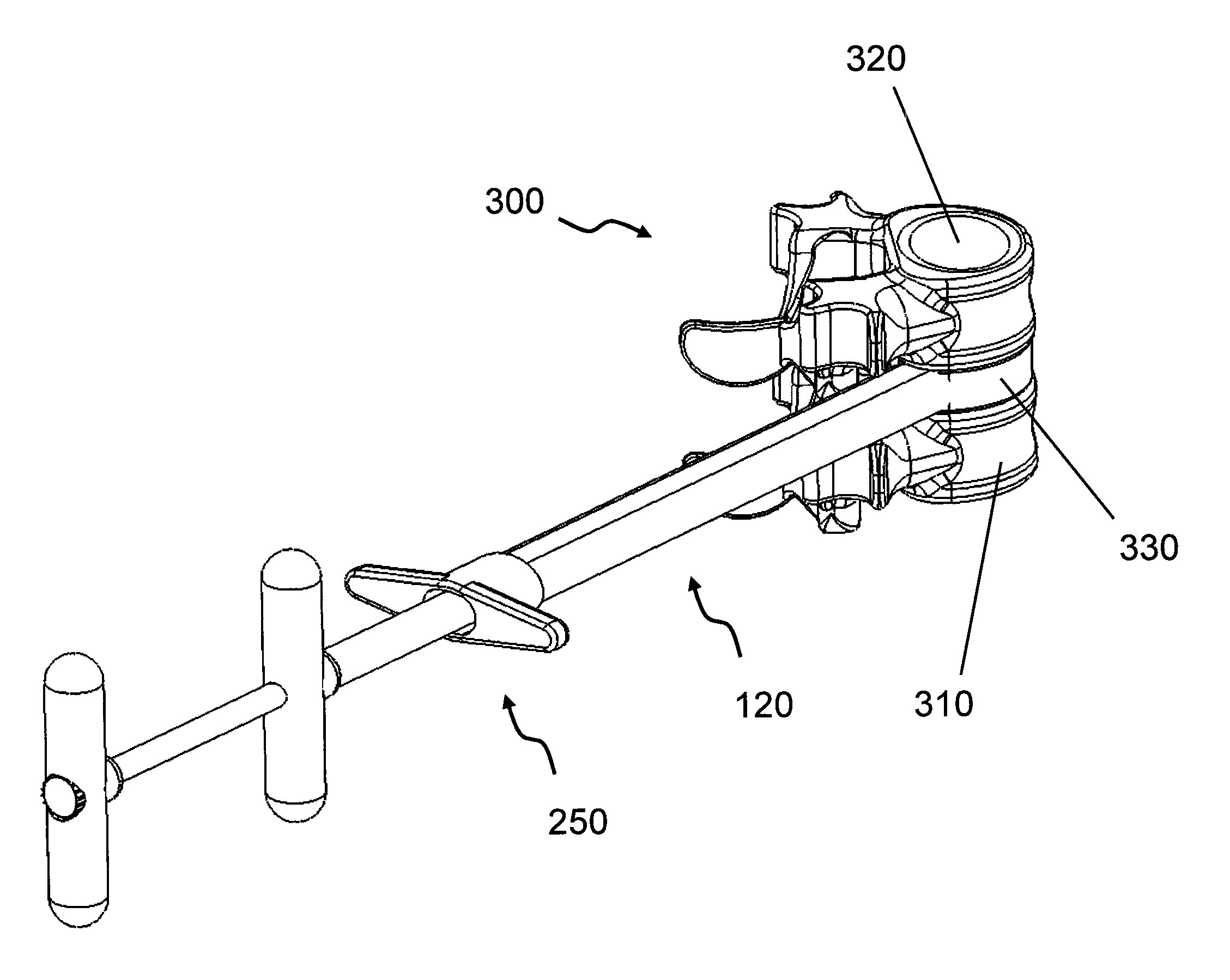

Variable Displacement Engine Operation With NVH Management

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

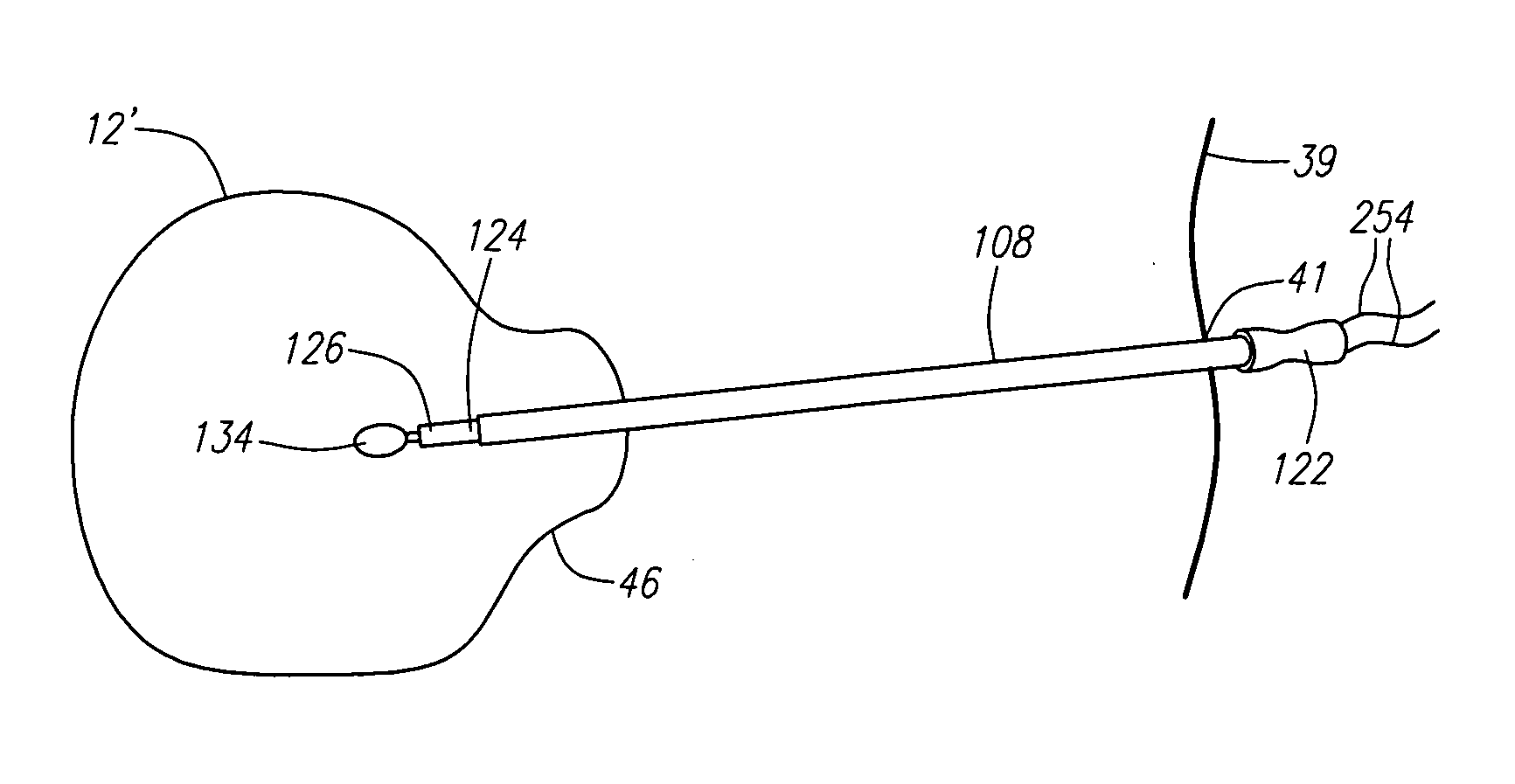

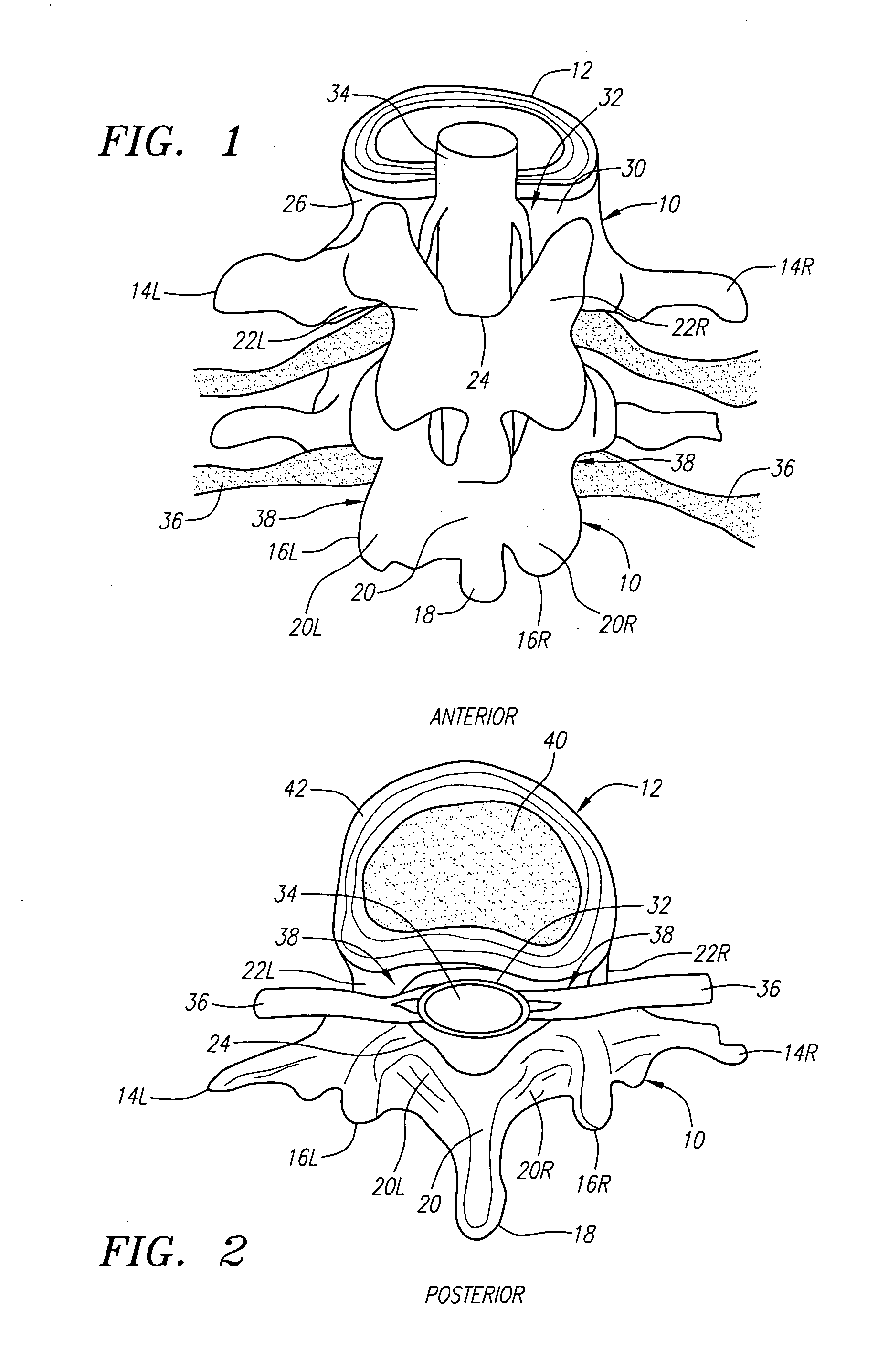

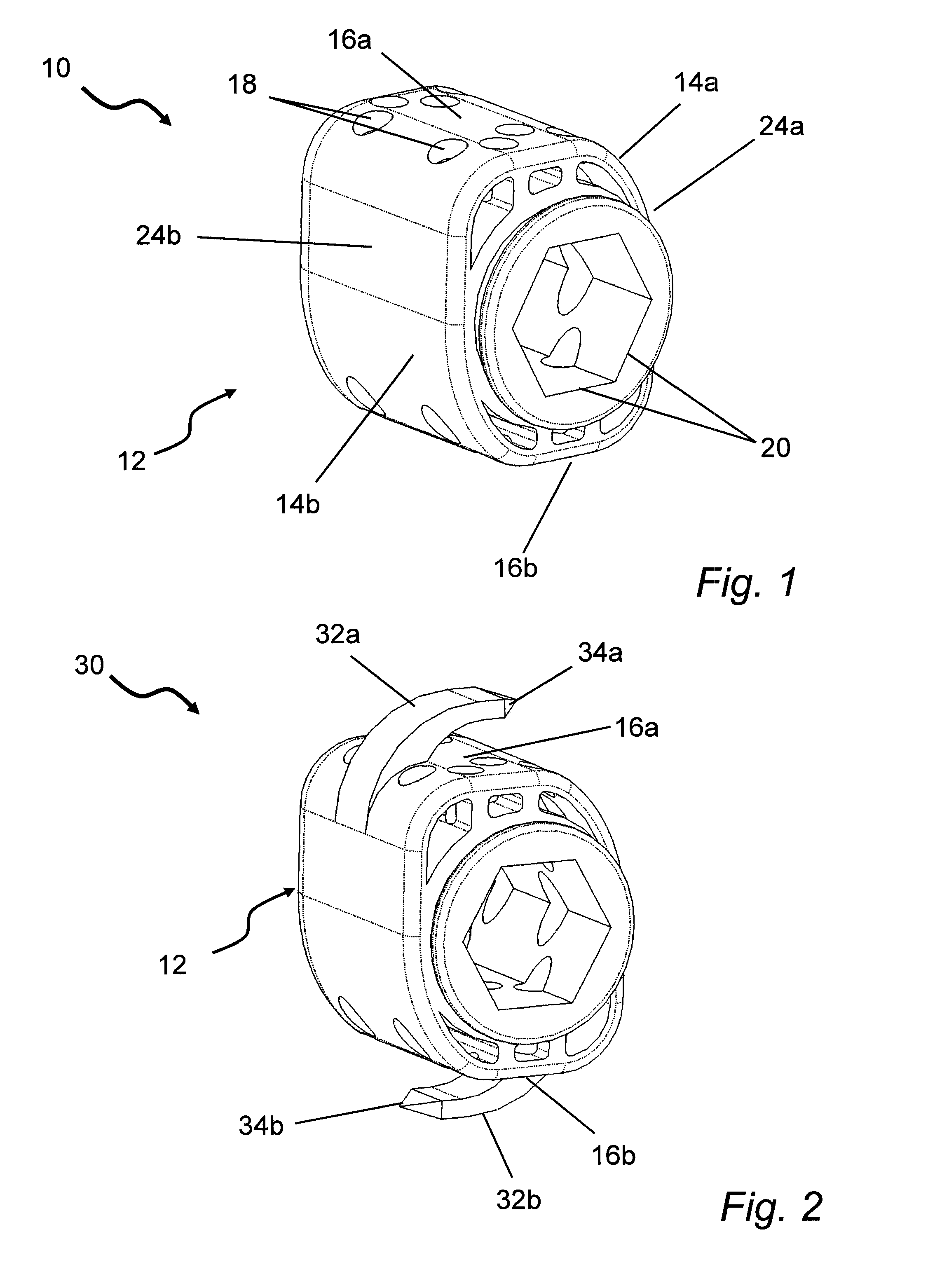

Percutaneous interbody spine fusion devices, nuclear support device, spine fracture support device, delivery tools, percutaneous off-angle bone stapling/nailing fixation device and methods of use

InactiveUS20110196494A1High repetitionAids in indirect decompression of spinal canalBone implantSpinal implantsSpinal columnSpine fracture

Percutaneous interbody spine fusion devices are provided. These devices may have a number of different designs and exemplary features. One device consists of a single rotating hollow cam cage with perforations (with or without fixation anchors) and a delivery tool. Another device consists of a counter-rotating cam cage (with or without fixation anchors) and a delivery tool. A third device consists of an expanding cam with anchors and delivery tool; this device may consist of a single expanding cam or a series of expanding cams. A delivery tool is included. A fourth device consists of a spring cage; this device may be a stand-alone device, can be combined with expanding cam device, and may be incorporated into a cage. A delivery tool is included. This spring cage may or may not have fixation anchors. A fifth device consists of a random coil support device that can be used as a nuclear or spine fracture support device; a delivery tool is included. A sixth device consists of a directional ribbon strip coil device and delivery tool. Also provided is a percutaneous off-angle bone stapling / nailing fixation device.

Owner:OSTEO INNOVATIONS

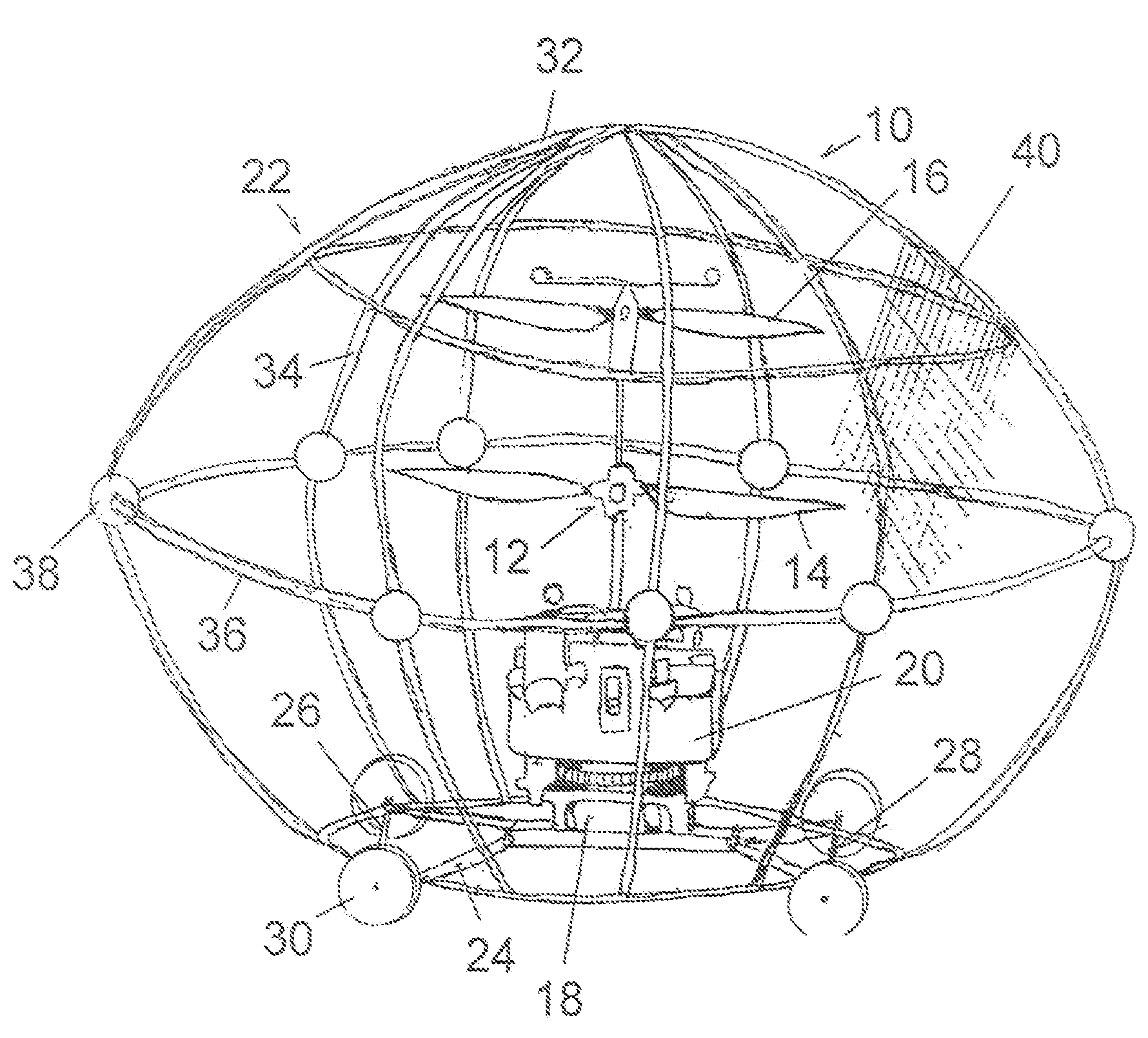

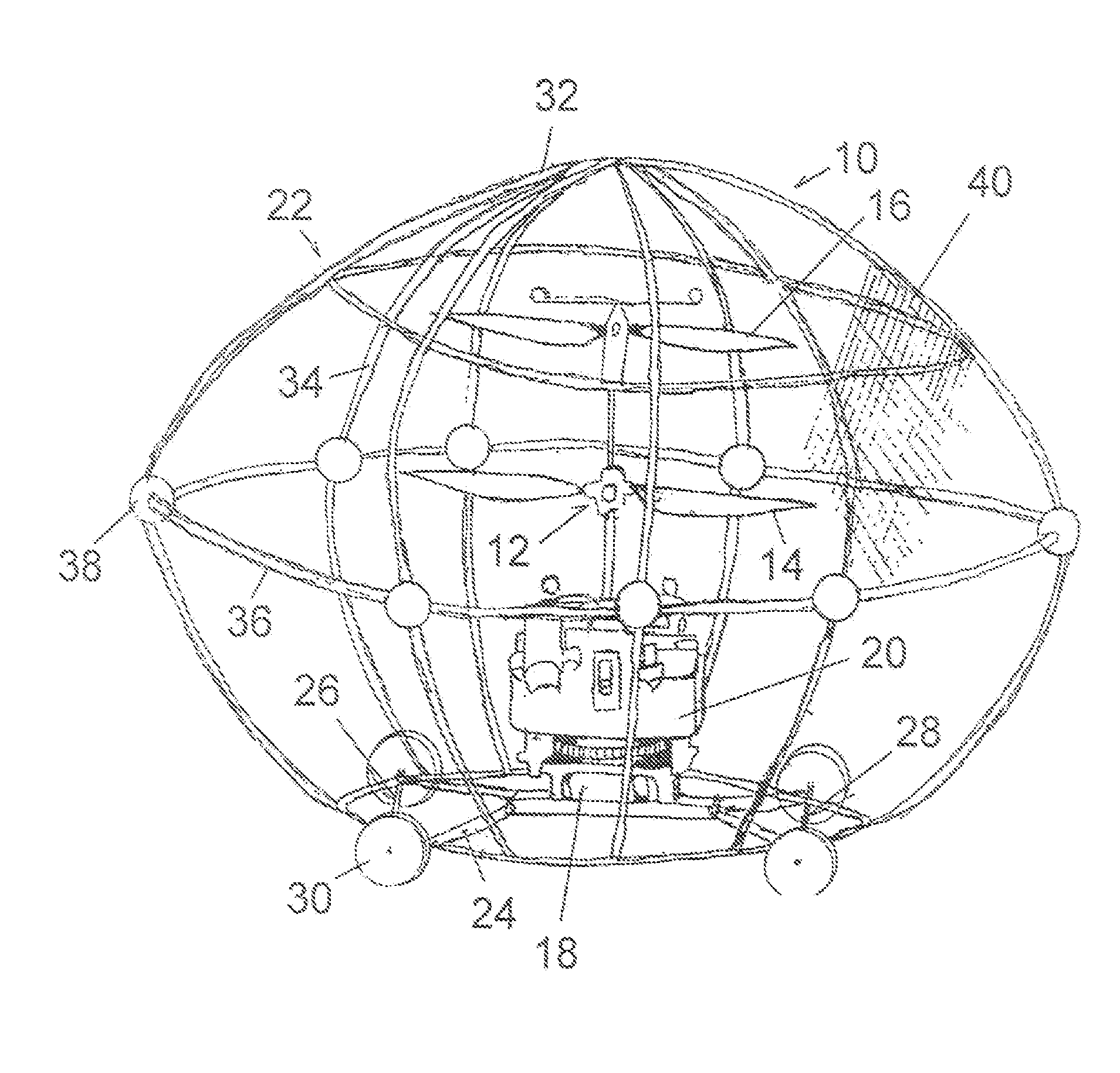

Vertical lift craft

InactiveUS7273195B1Easy to operateUnmanned aerial vehiclesToy aircraftsCounter rotatingAerospace engineering

A vertical lift craft includes a vertical lift craft, a powered rotor system including two counter-rotating lift rotors rotatably mounted to the body and a cage fixed to the body and extending about the powered rotor system, the cage including flexible rods extending in an open mesh pattern and mutually attached at a plurality of intersections between the flexible rods and netting extending between the flexible rods to cover the cage. The mesh pattern includes latitudinally and longitudinally extending flexible rods and the cage further includes elastomeric bumpers at the plurality of intersections between flexible rods. A base has axles fixed relative to the body and wheels on the axles.

Owner:GOLLIHER CLAYTON R

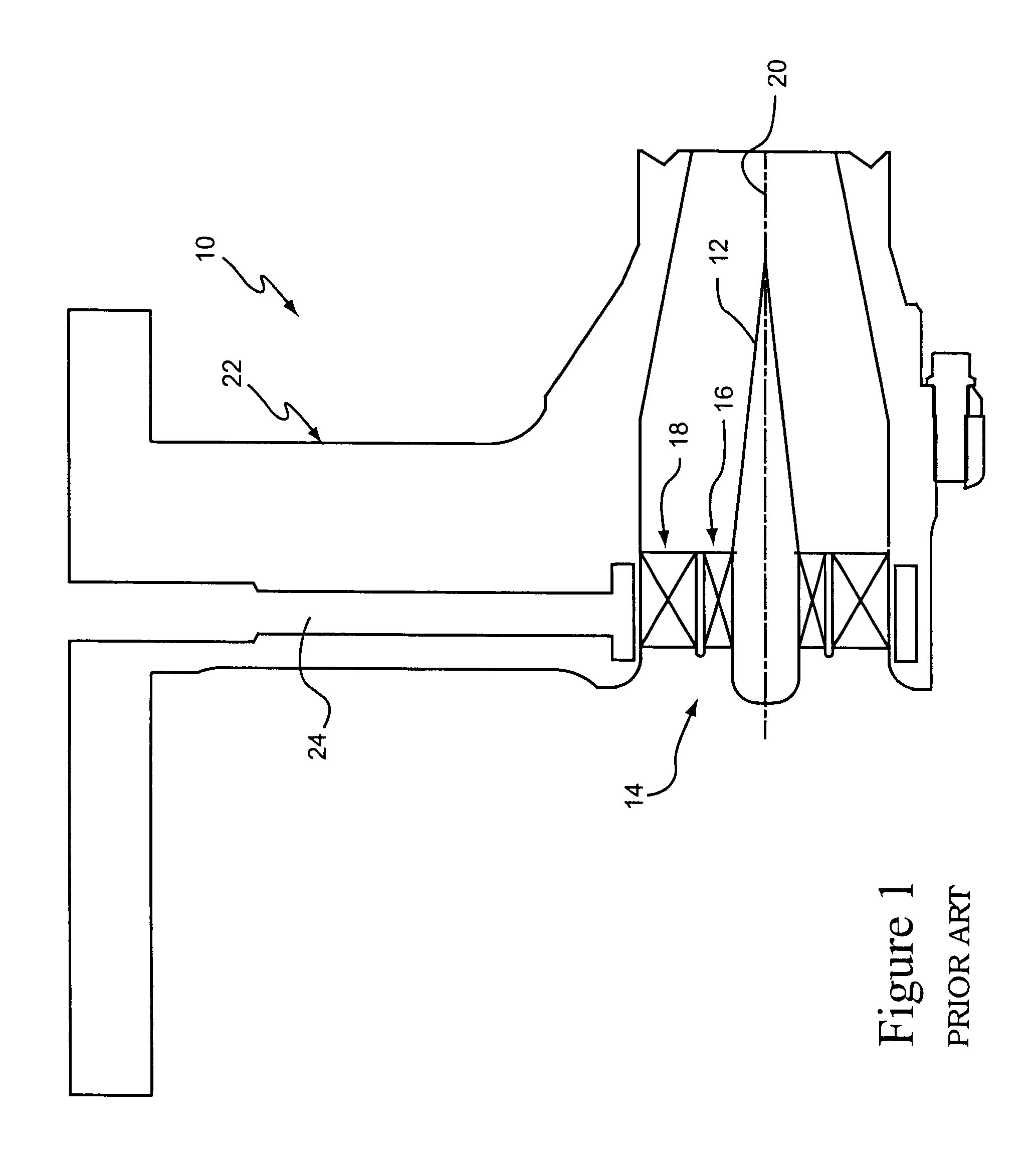

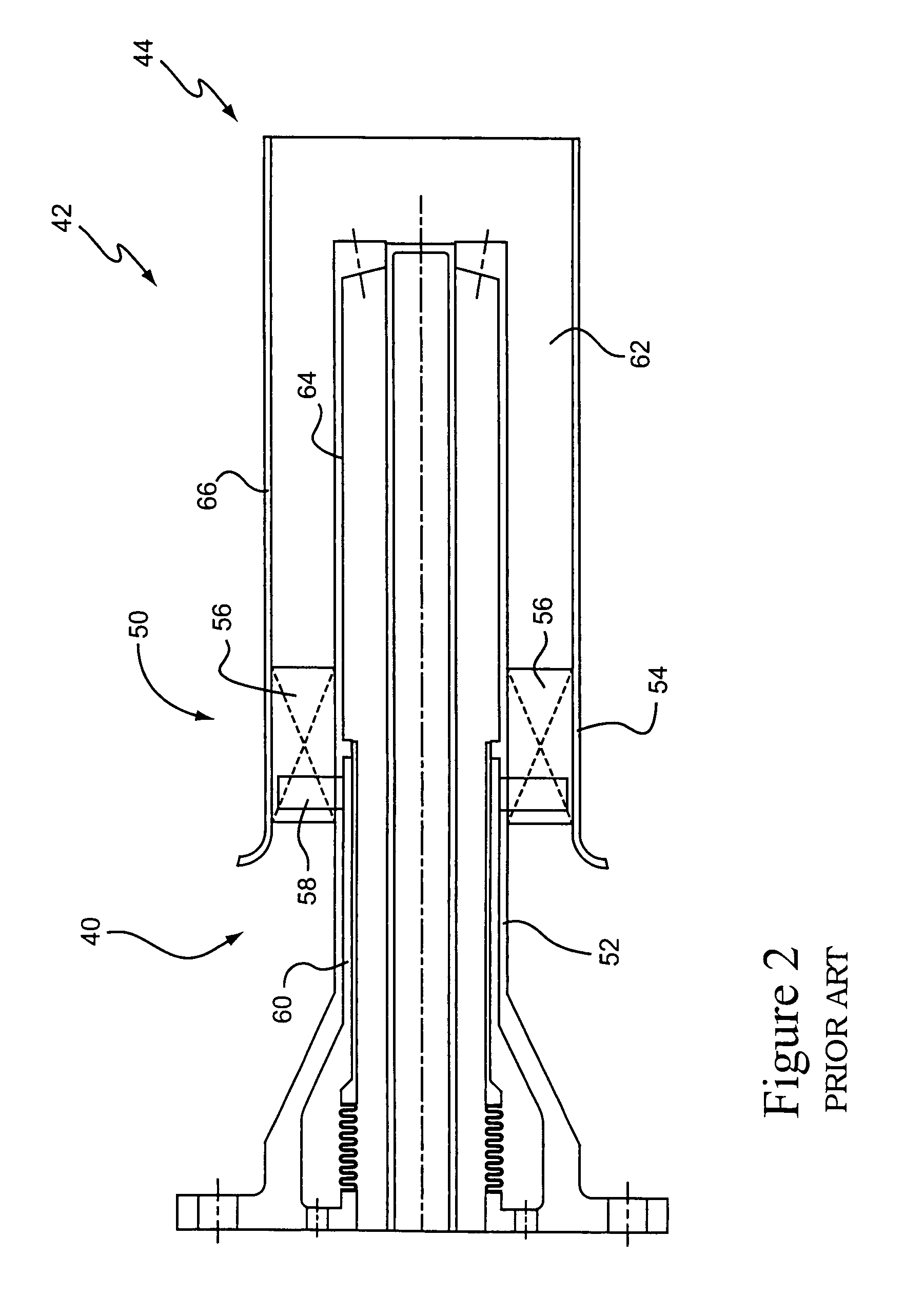

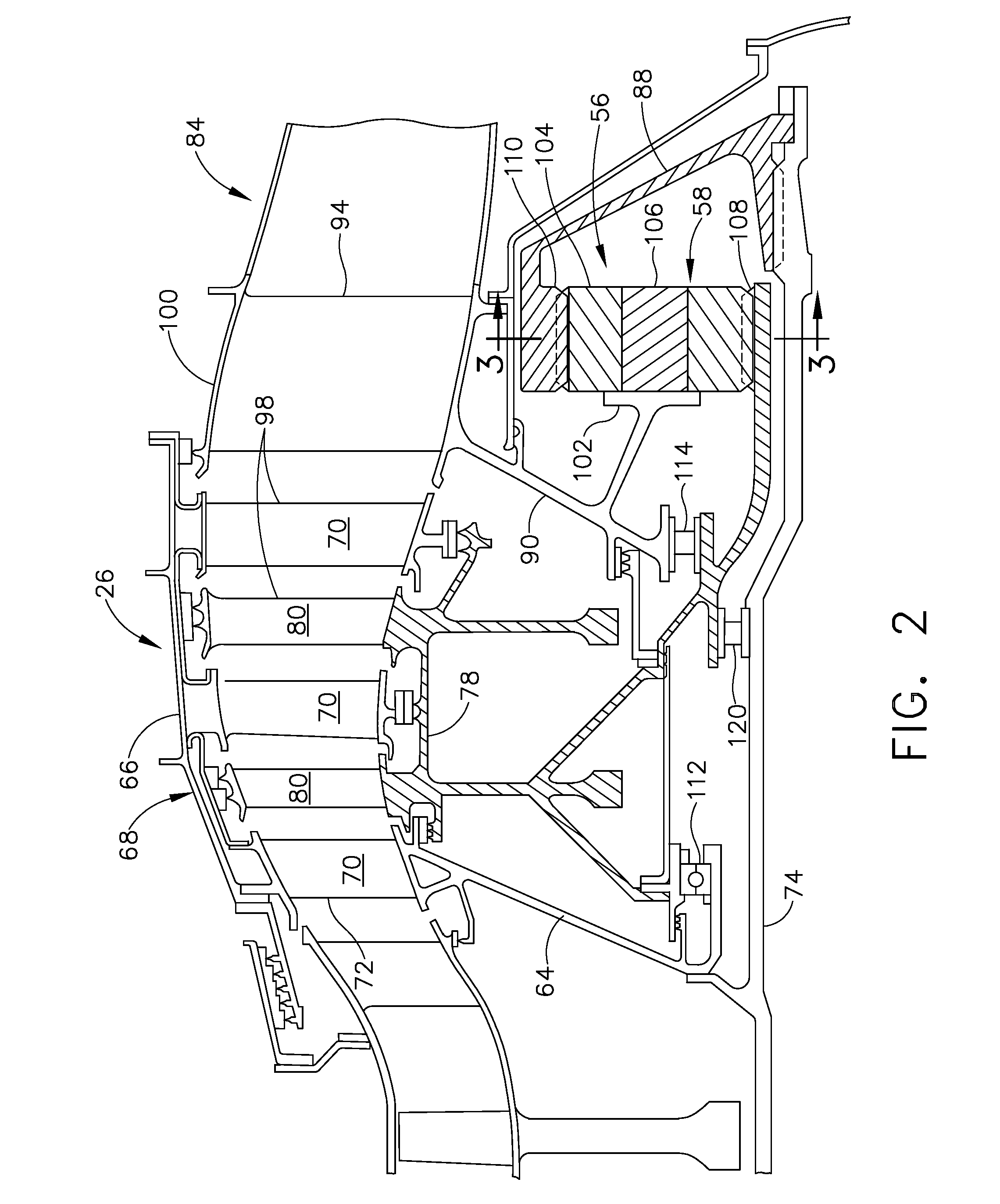

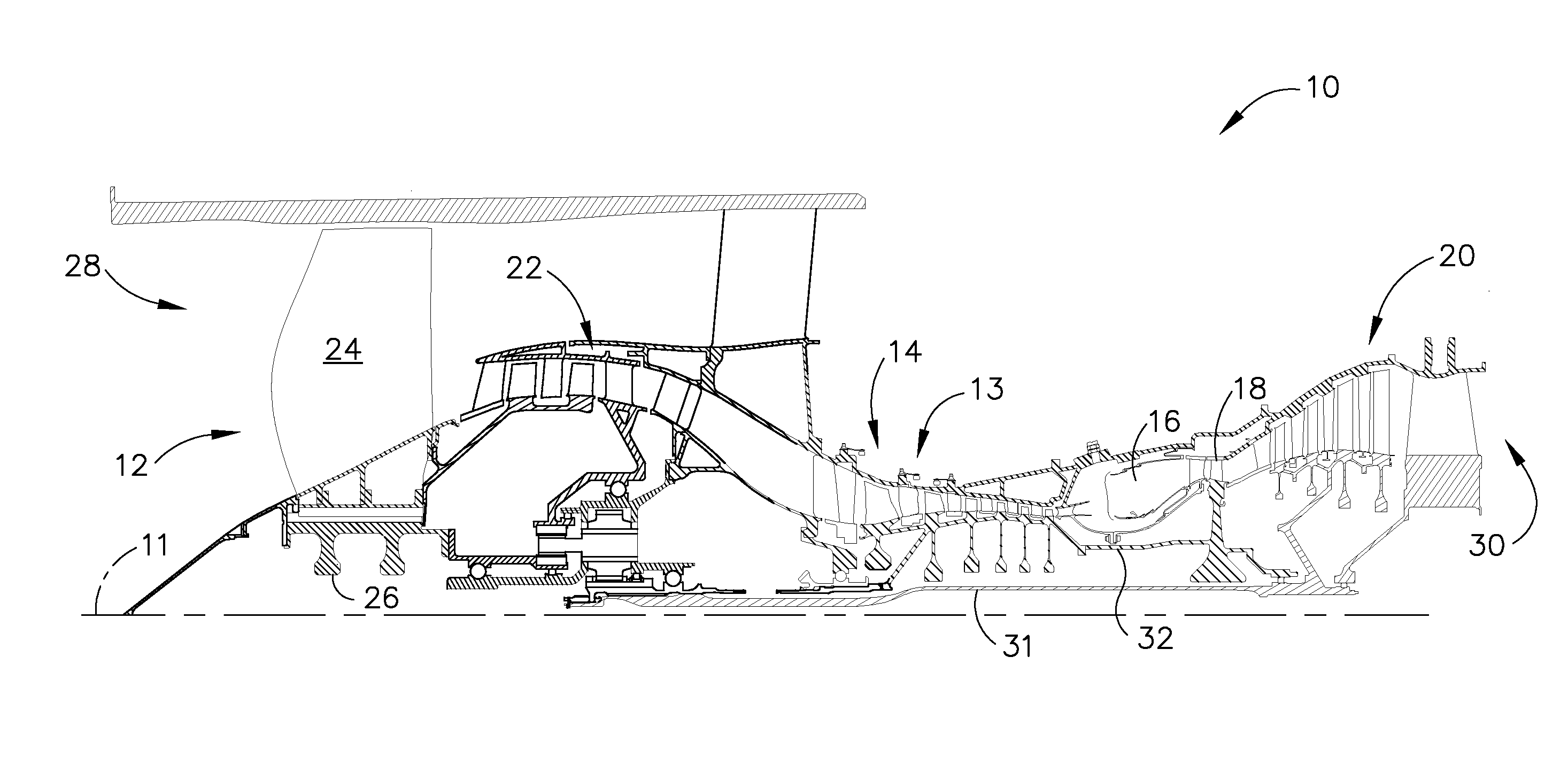

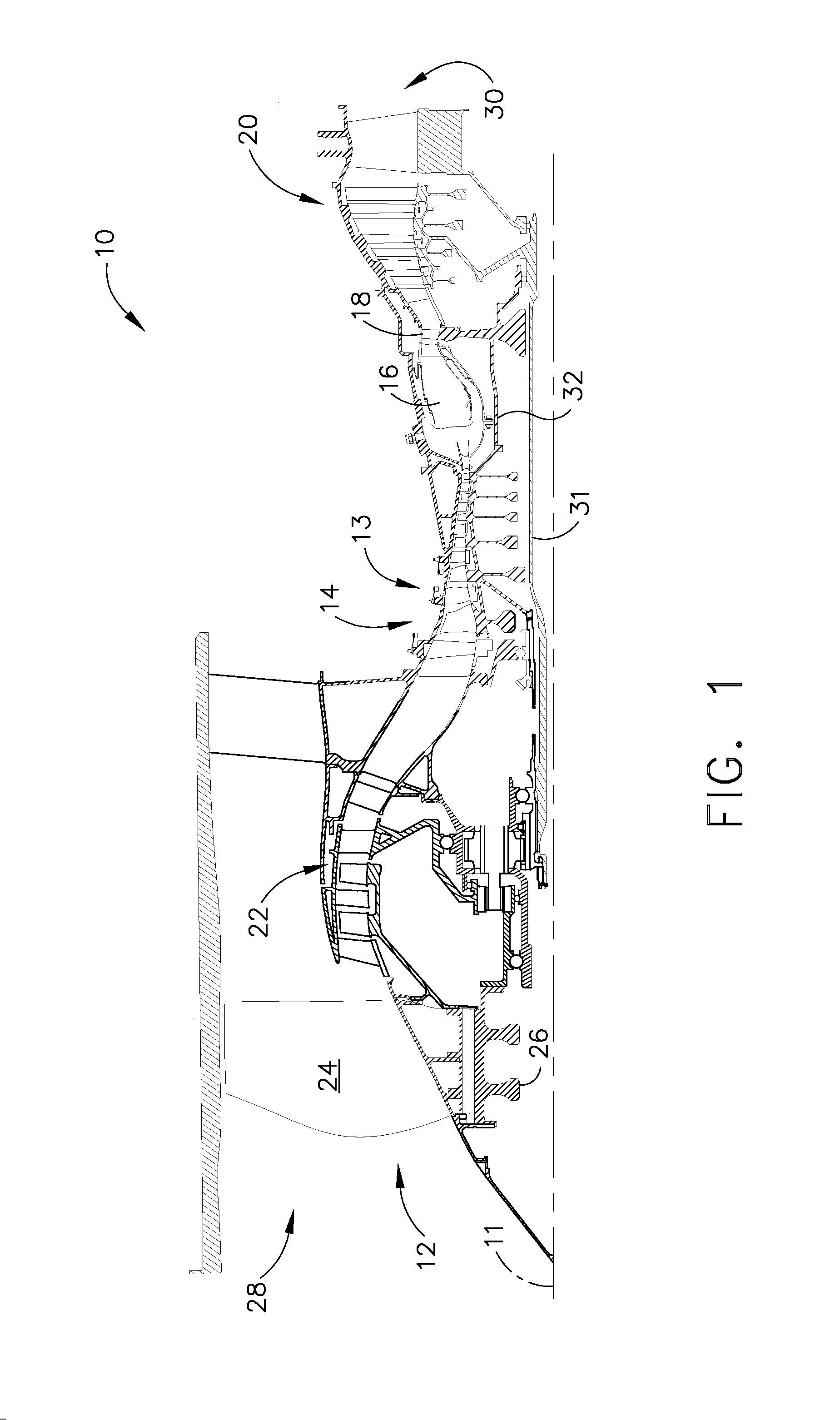

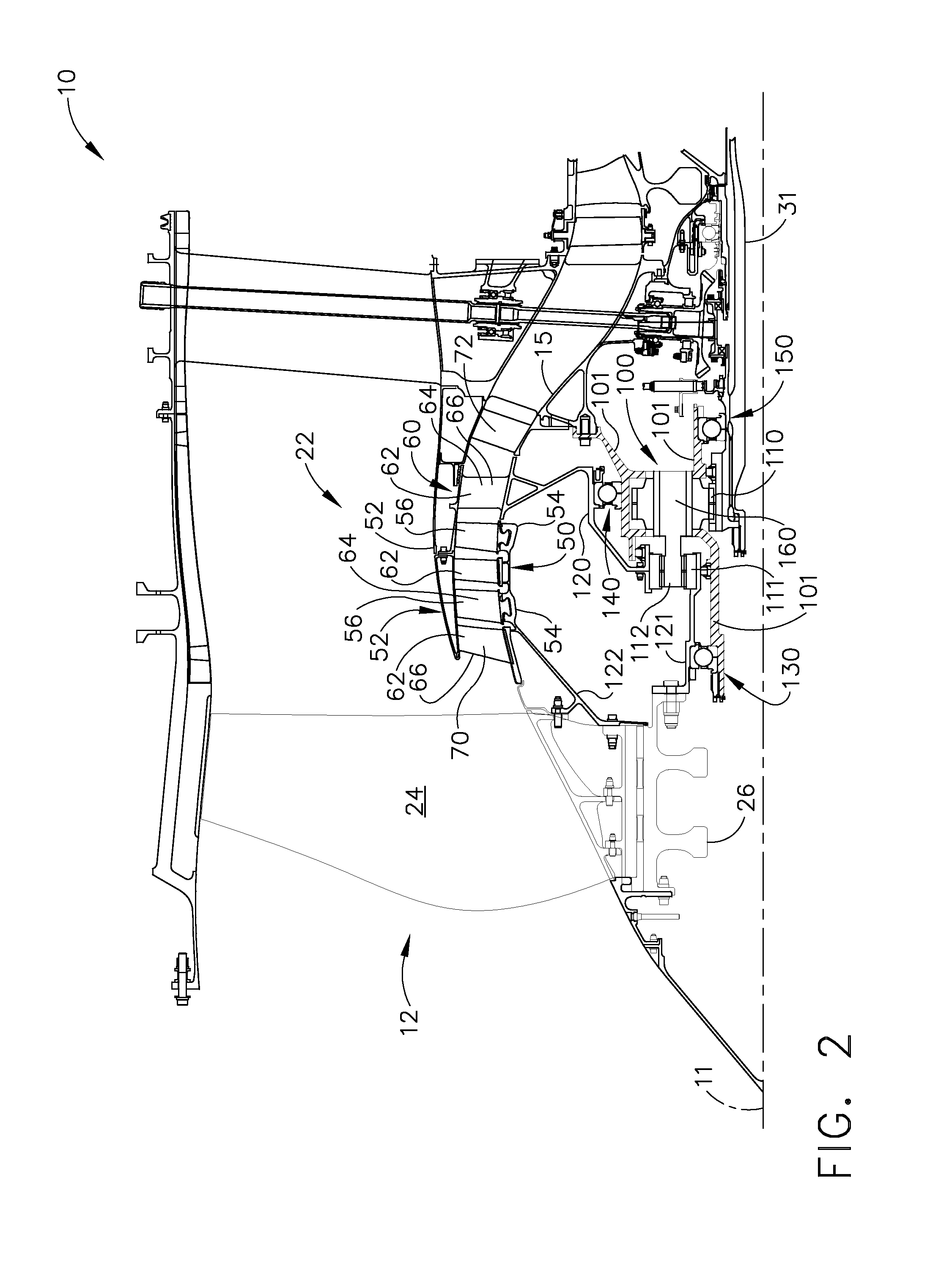

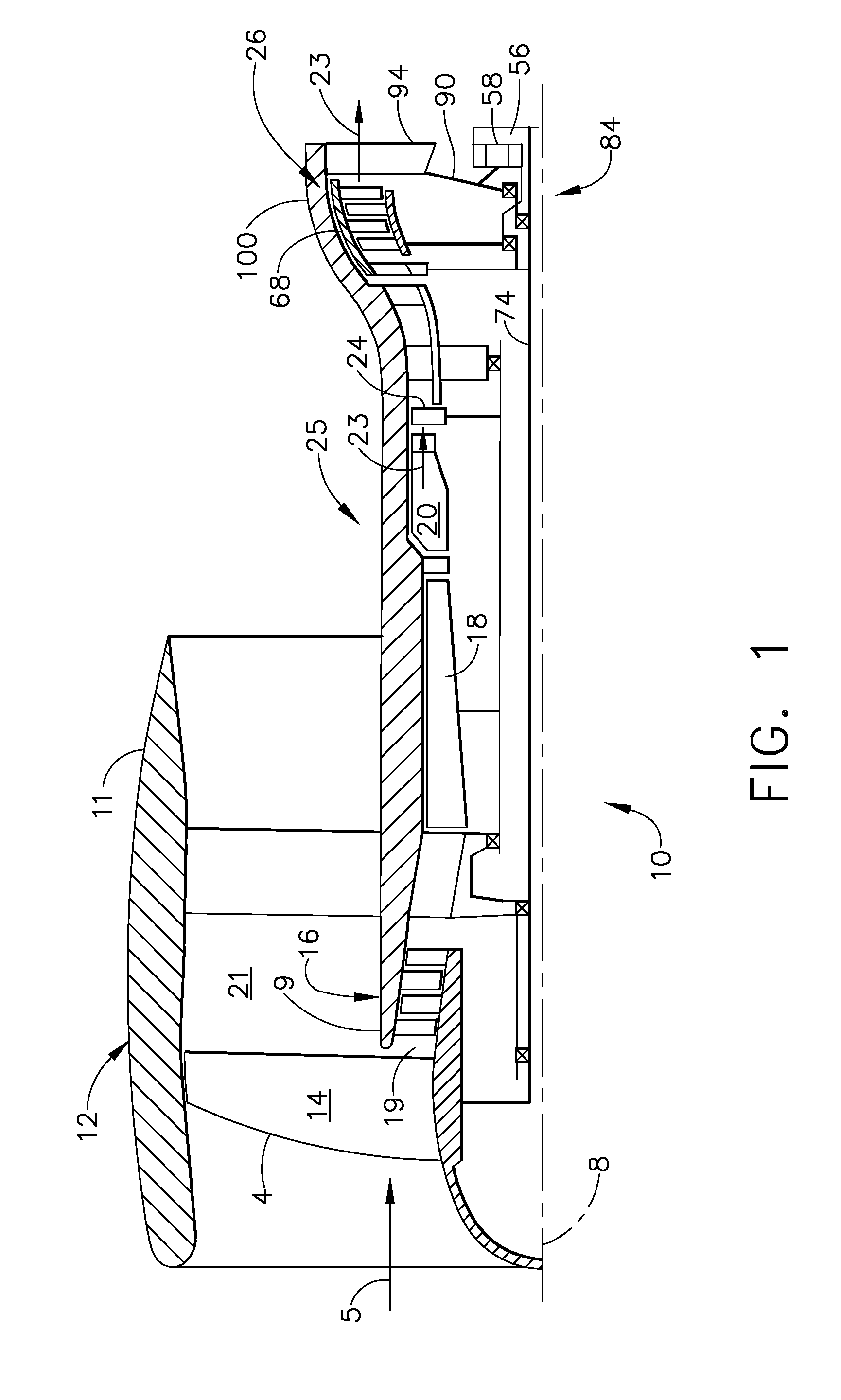

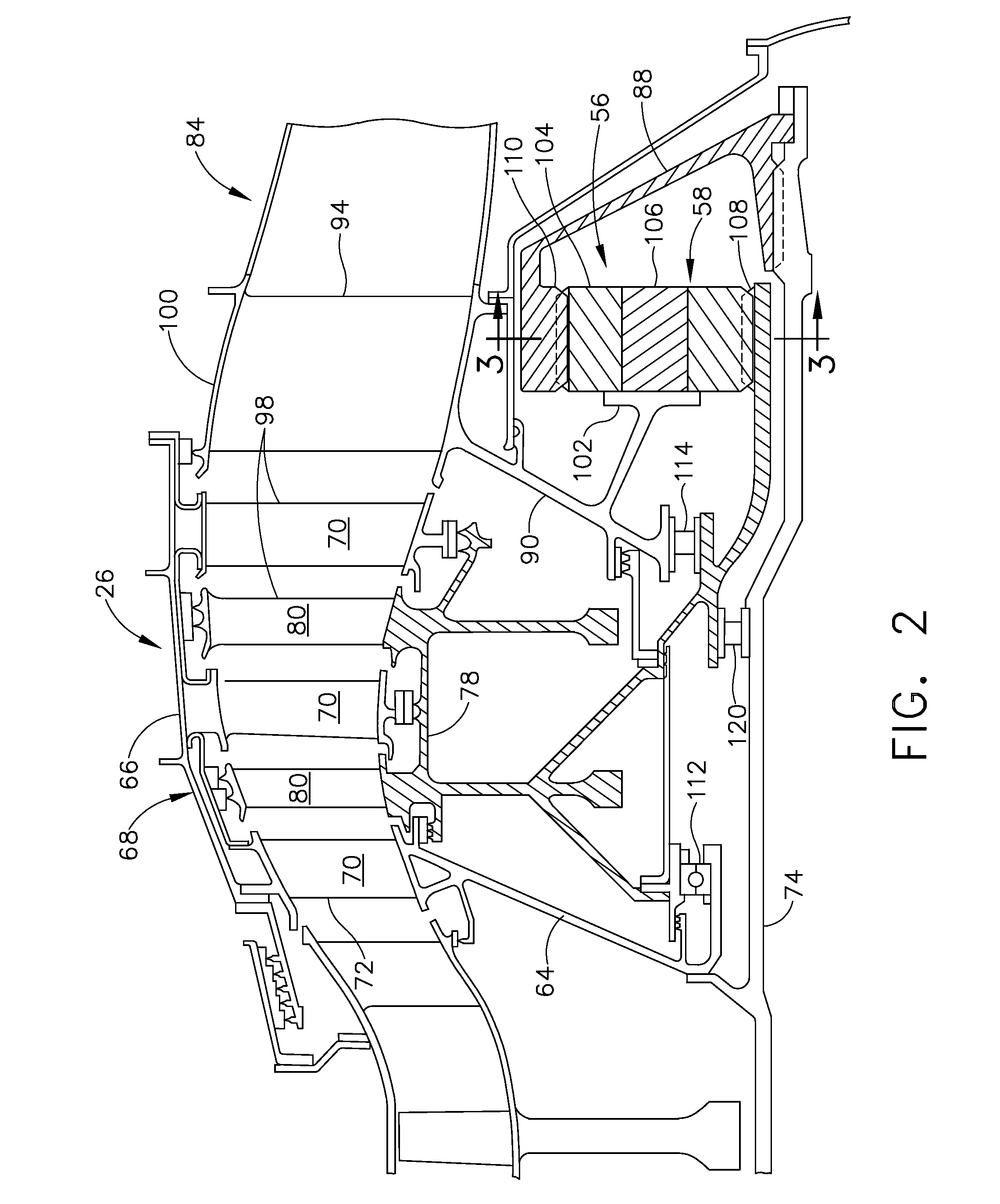

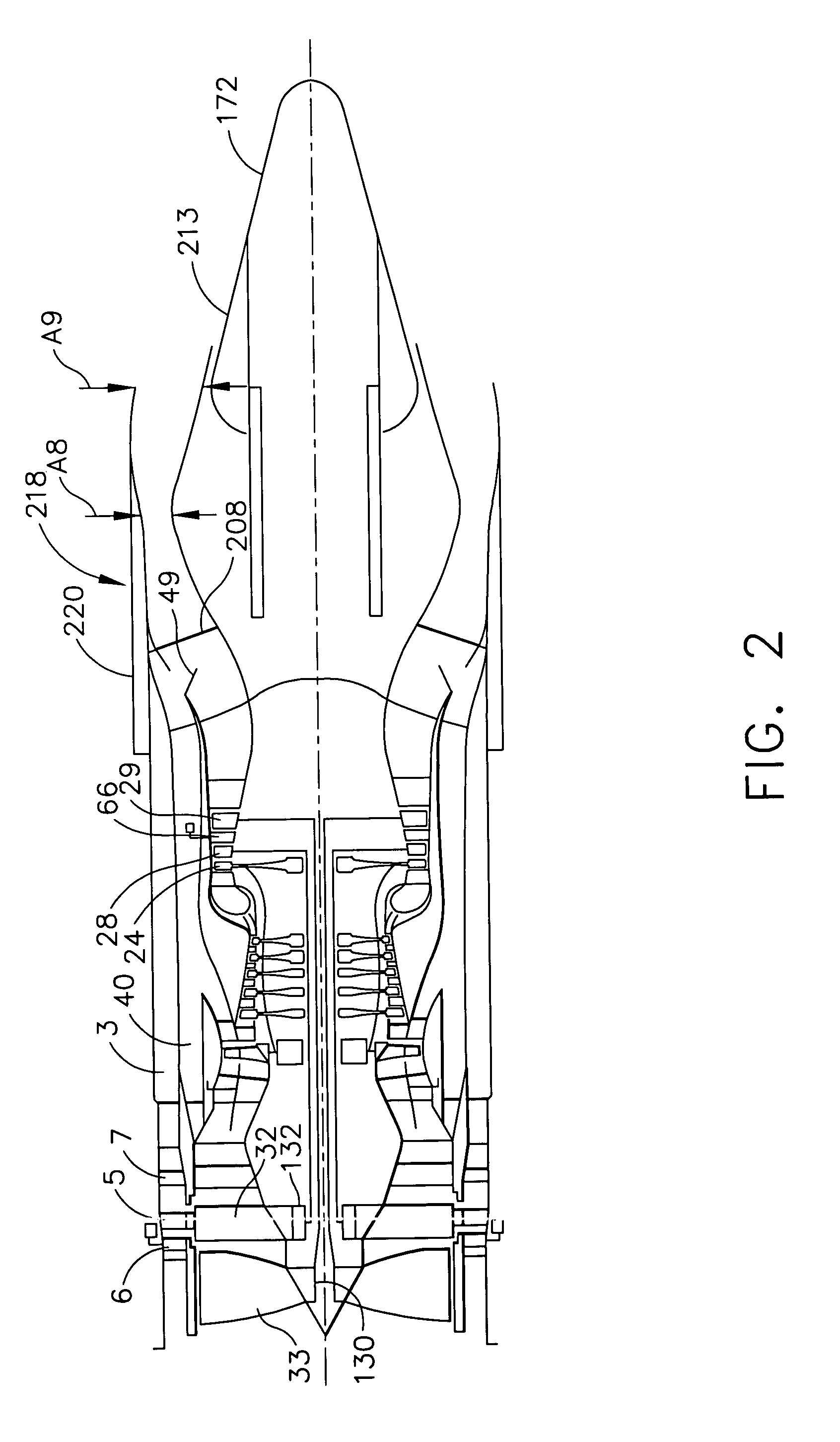

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

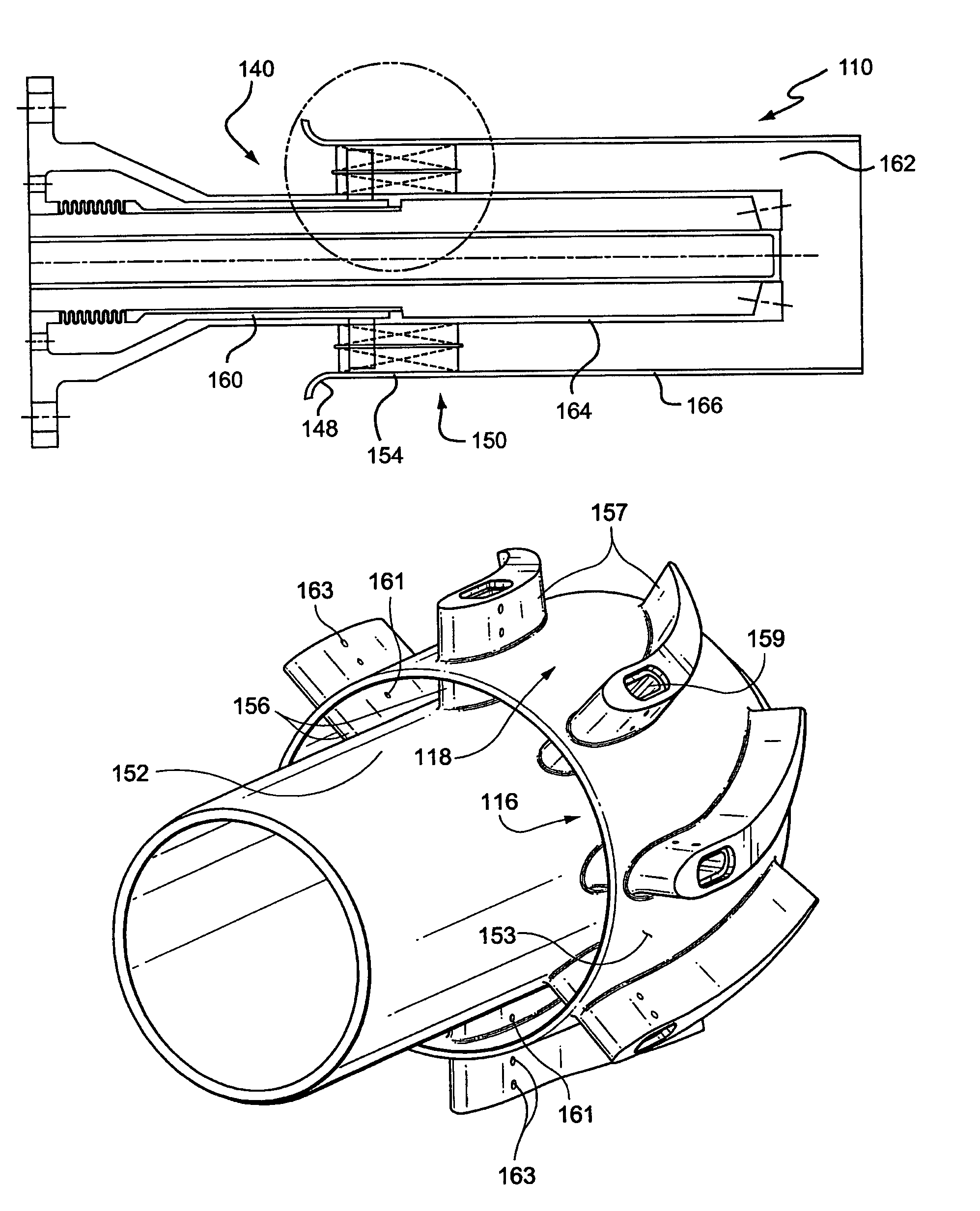

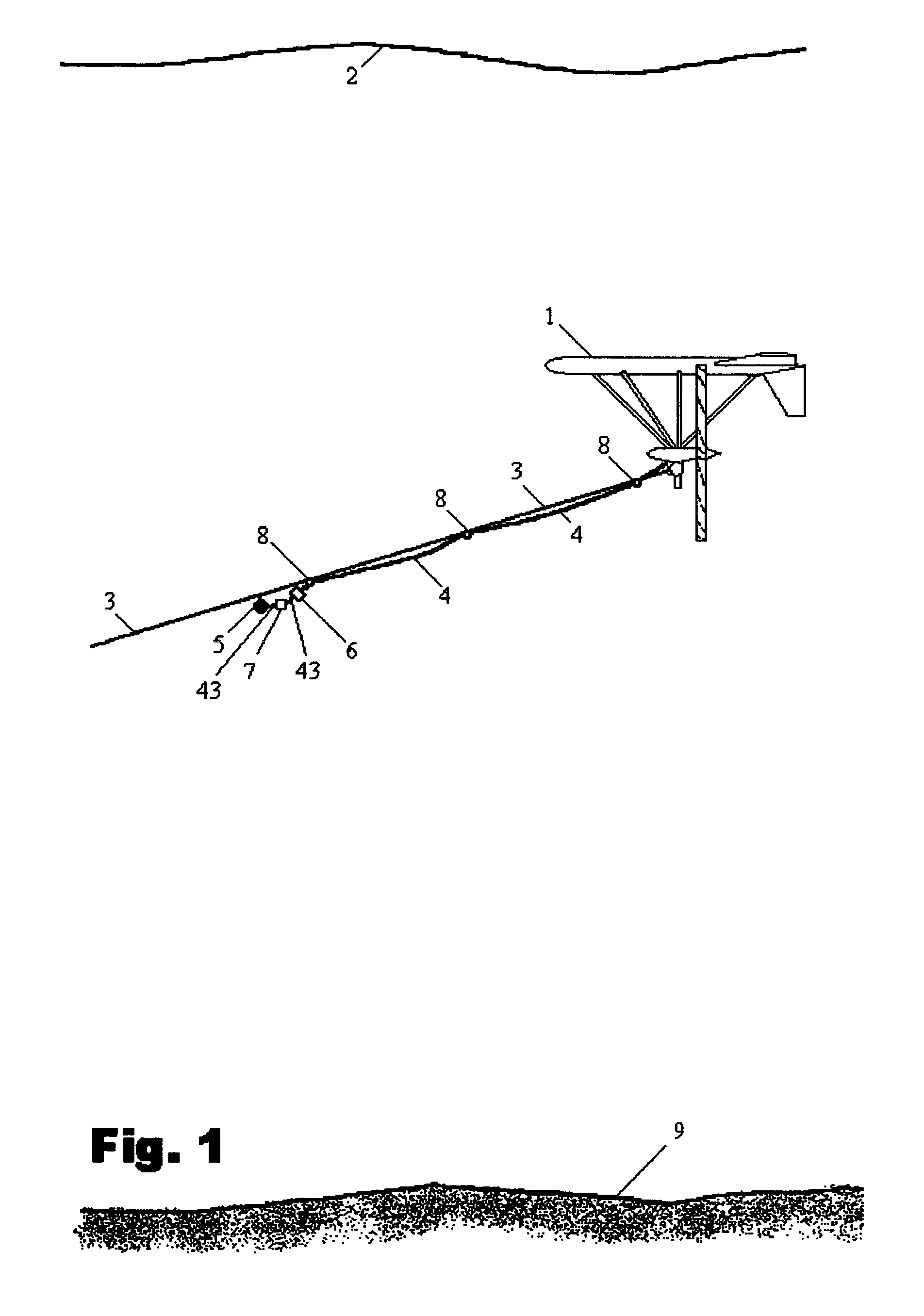

Submersible electrical power generating plant

InactiveUS7291936B1Prevent siphonImproved directional stabilityEnergy industryWind motor combinationsNacelleHorizontal axis

A self-supporting, submersible generating plant for producing electricity from ocean currents, consisting of two counter-rotating, rear-facing turbines with a plurality of rotor blades extending radially outward from two separate horizontal axis that convey the kinetic energy from the two side-by-side, counter-rotating turbine rotors through separate gearboxes to separate generators that are housed in two watertight nacelles that are located sufficiently far apart to provide clearance for the turbine rotors. The two generators and their gearboxes serve as ballast and are located far below a streamlined buoyancy tank that extends fore and aft above and between them. A combination of a leverage system and a pressure-controlled system adjusts the hydrodynamic lifting forces to maintain constant depths. There are systems to purge the ballast water to facilitate the recovery of both individual submersible power plants and a group of many submersible power plants.

Owner:ROBSON JOHN H

Turbofan engine assembly and method of assembling same

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a low-pressure turbine coupled to said core gas turbine engine, a counter-rotating booster compressor comprising a first rotor section configured to rotate in a first direction and a second rotor section configured to rotate in an opposite second direction, and a gearbox comprising an input and an output, said gearbox output coupled to at least one of said first and second rotor sections, said gearbox input coupled to said low-pressure turbine. A method of assembling the turbofan engine assembly described herein is also provided.

Owner:GENERAL ELECTRIC CO

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

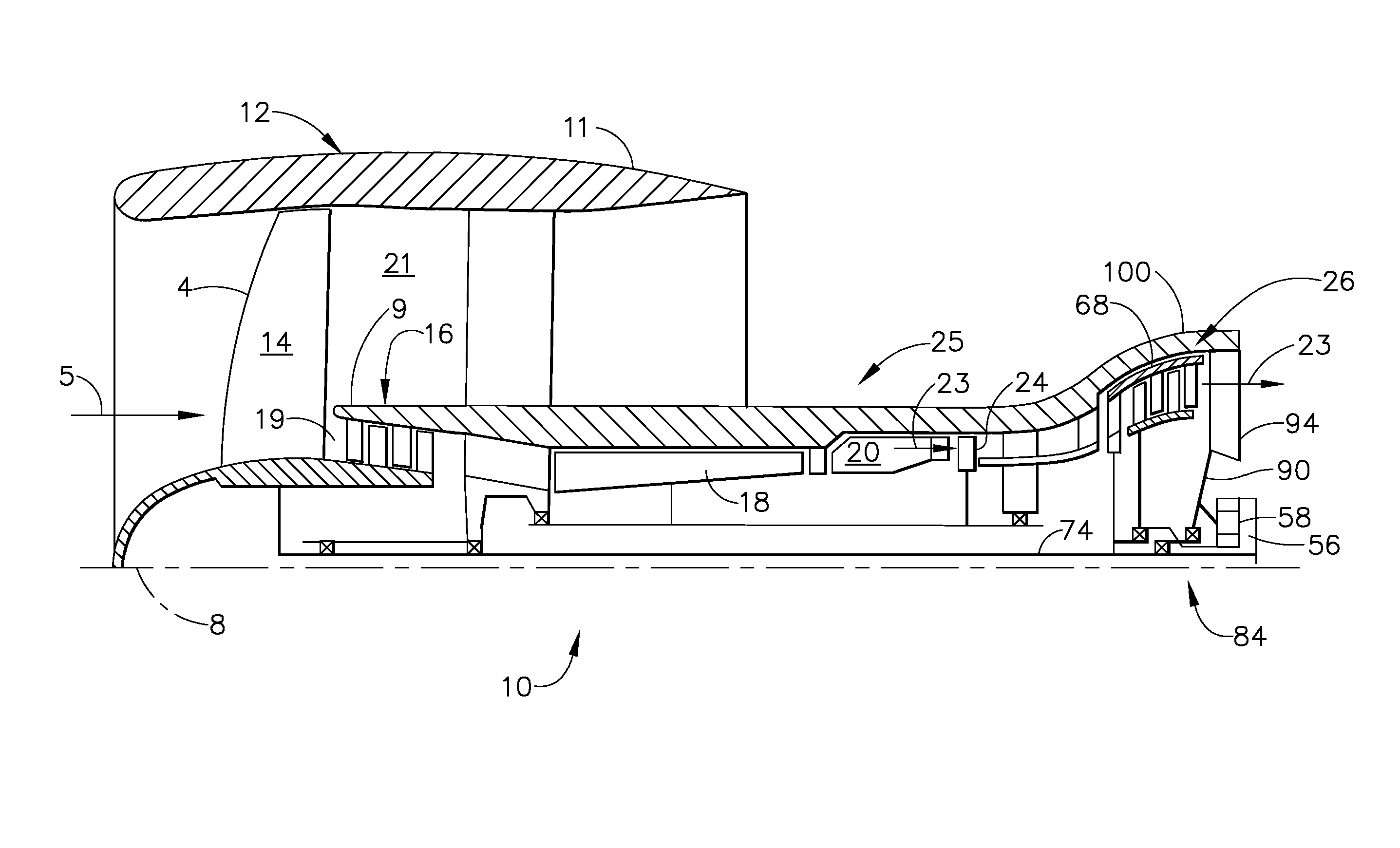

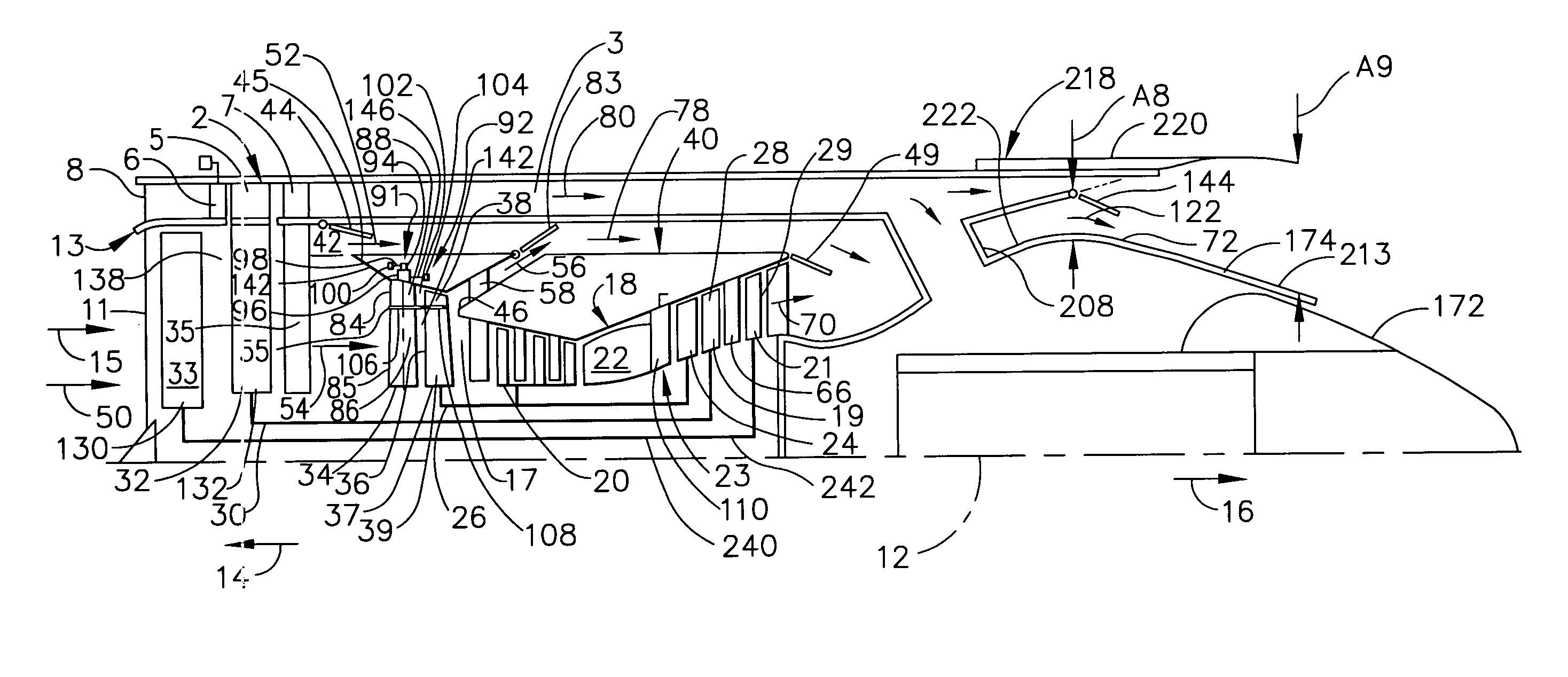

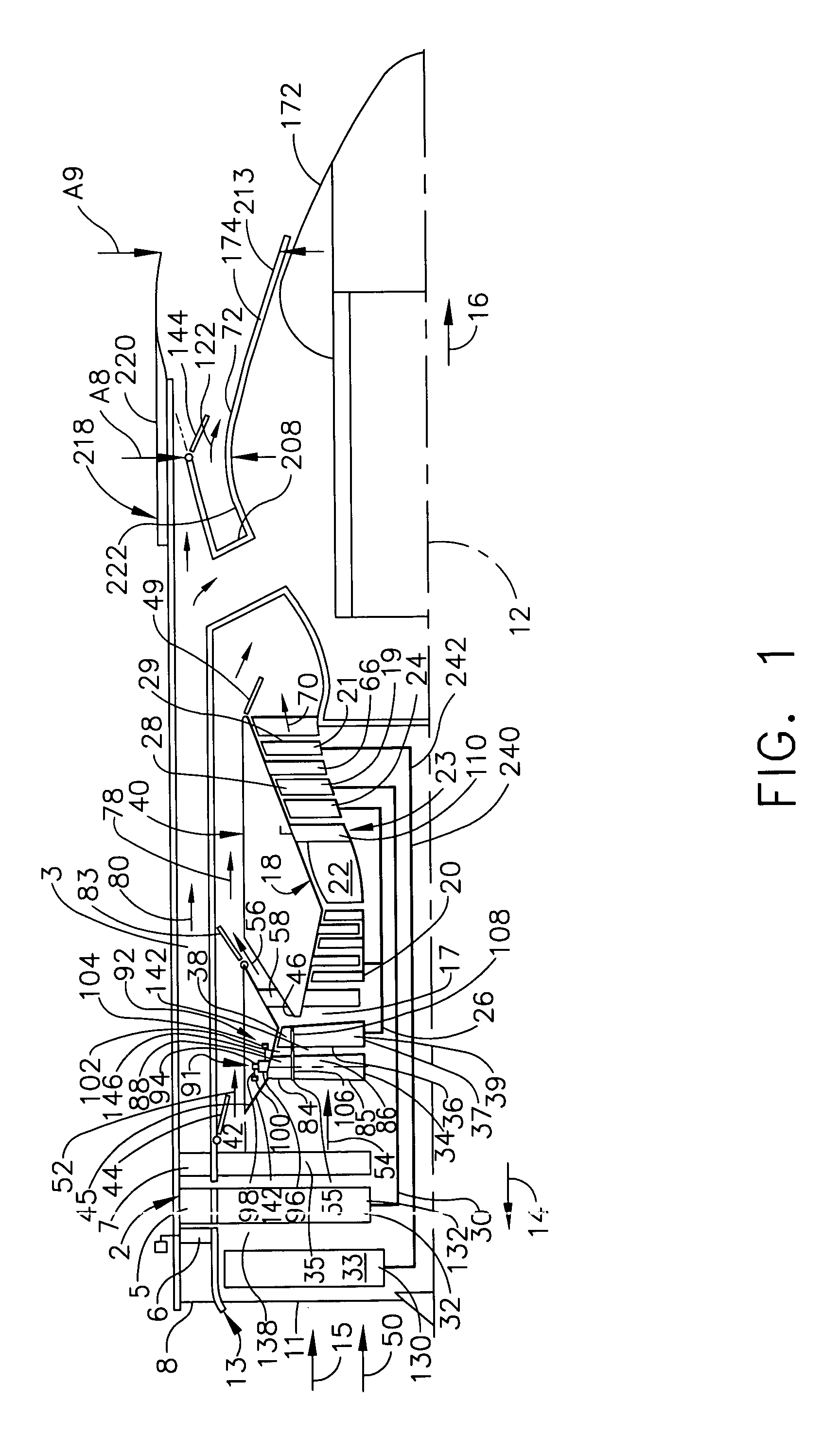

FLADE gas turbine engine with counter-rotatable fans

An exemplary embodiment of a FLADE counter-rotating fan aircraft gas turbine engine includes at least one row of FLADE fan blades disposed radially outwardly of and drivingly connected to one of axially spaced-apart first and second counter-rotatable fans. A core engine located downstream and axially aft of the first and second counter-rotatable fans is circumscribed by a fan bypass duct downstream and axially aft of the first and second counter-rotatable fans. The row of FLADE fan blades radially extend across a FLADE duct circumscribed about the first and second counter-rotatable fans and the fan bypass duct. A second low pressure turbine is drivingly connected to the first counter-rotatable fan and a first low pressure turbine is drivingly connected to the second counter-rotatable fan.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com