Patents

Literature

351 results about "Square Millimeter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A unit of area measurement equal to a square measuring one millimeter on each side. One square millimeter is equal to 10(E-2) square centimeter and 10(E-6) square meter.(NCI)

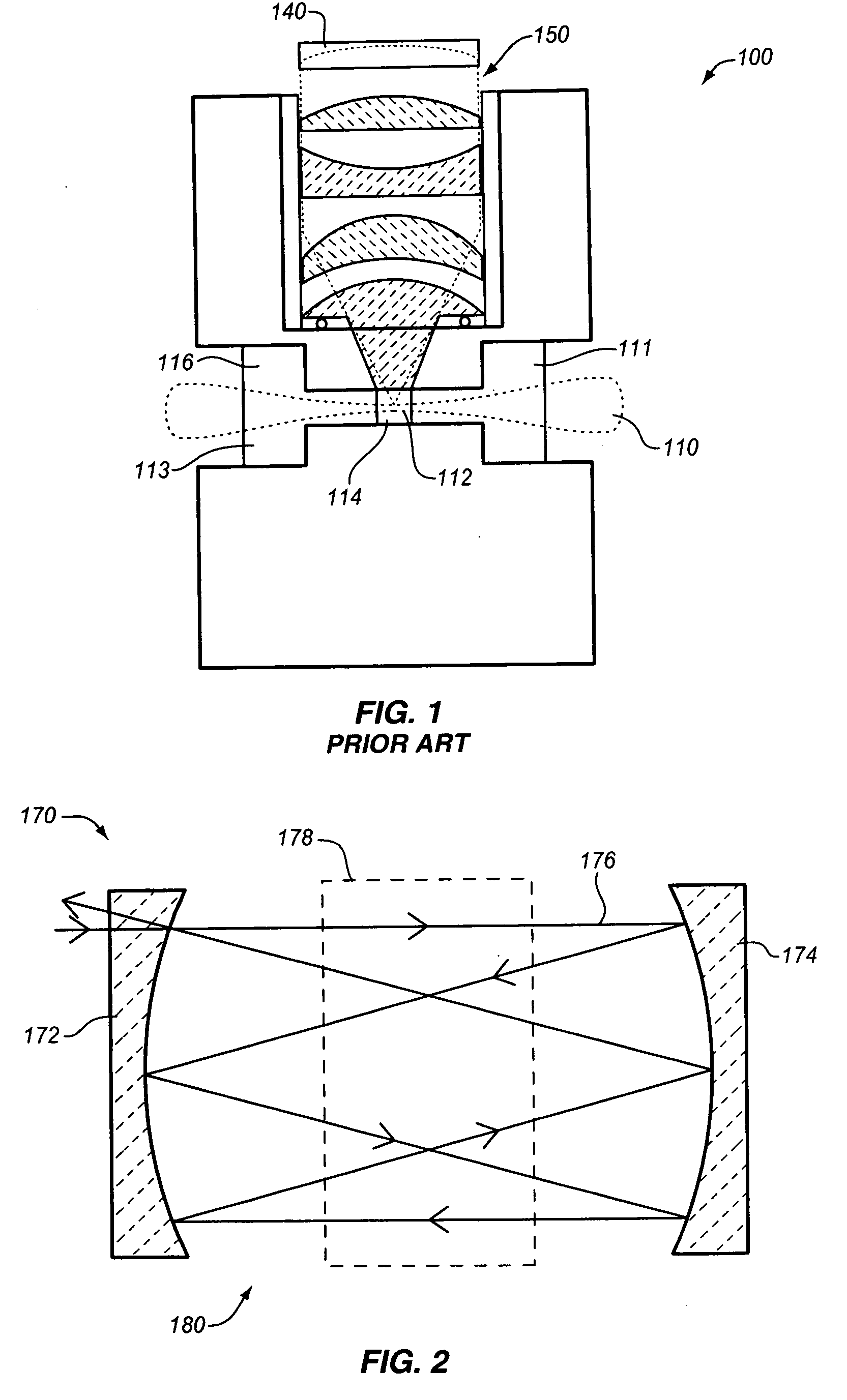

Aerosol particle sensor with axial fan

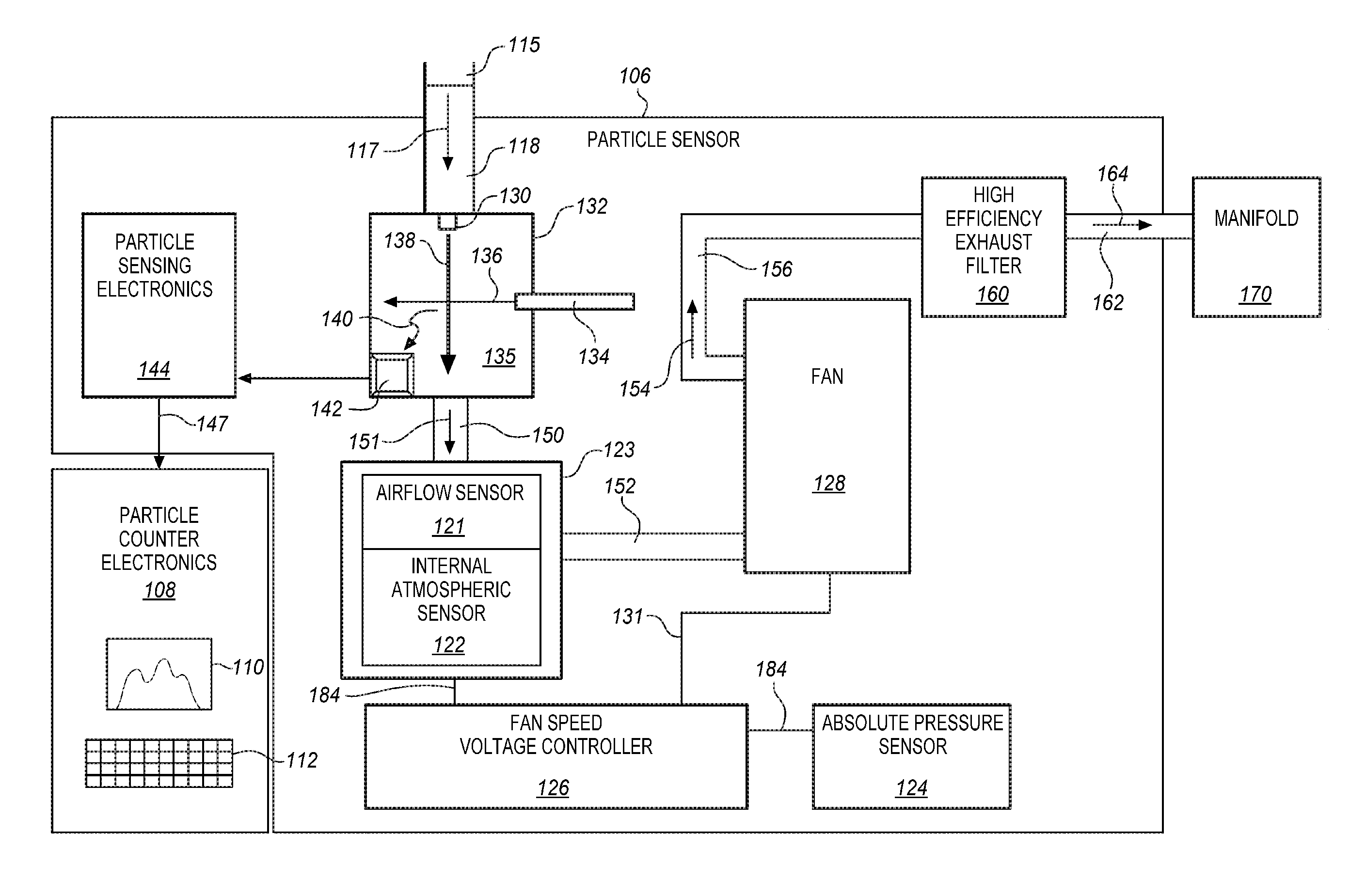

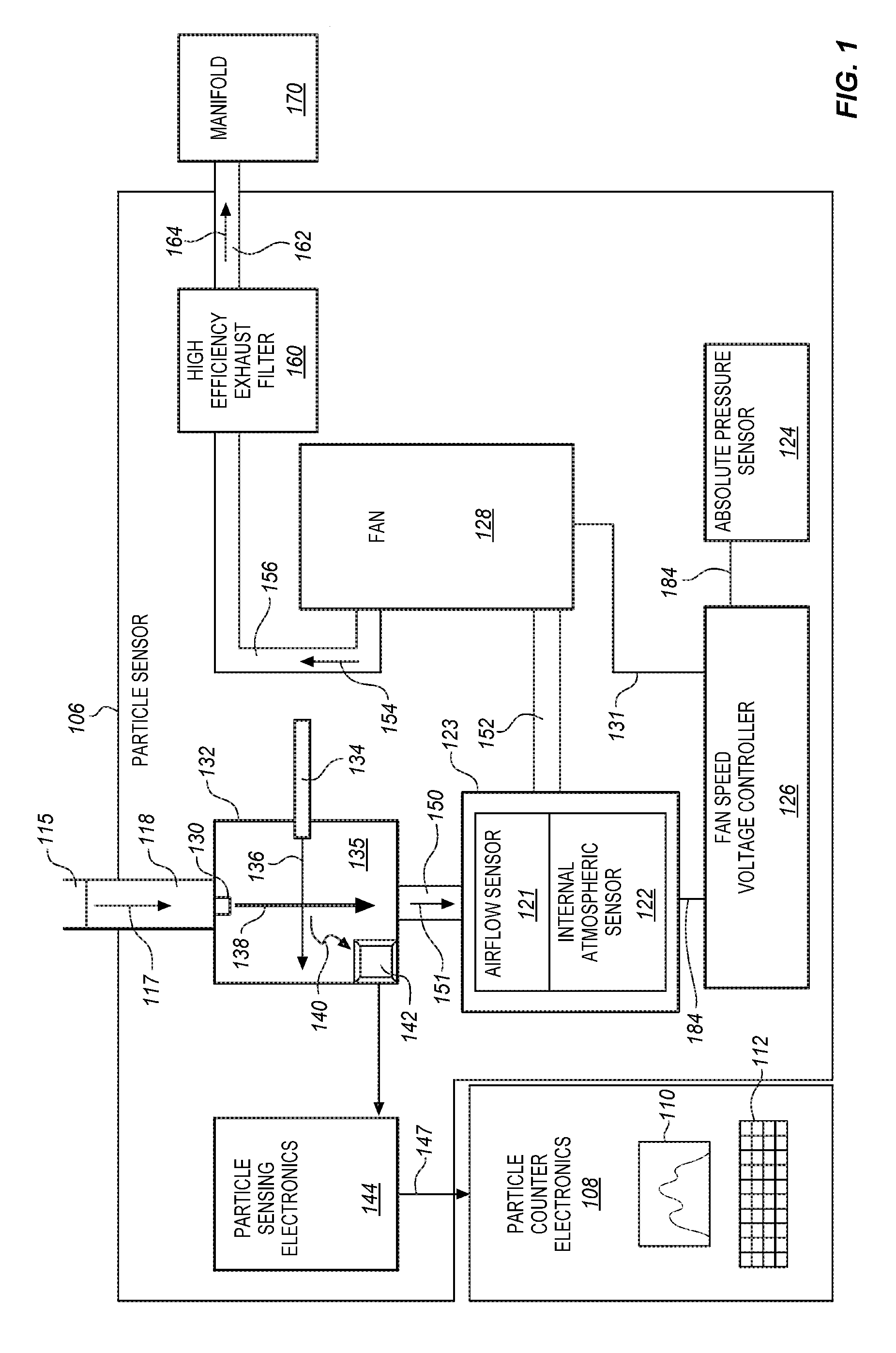

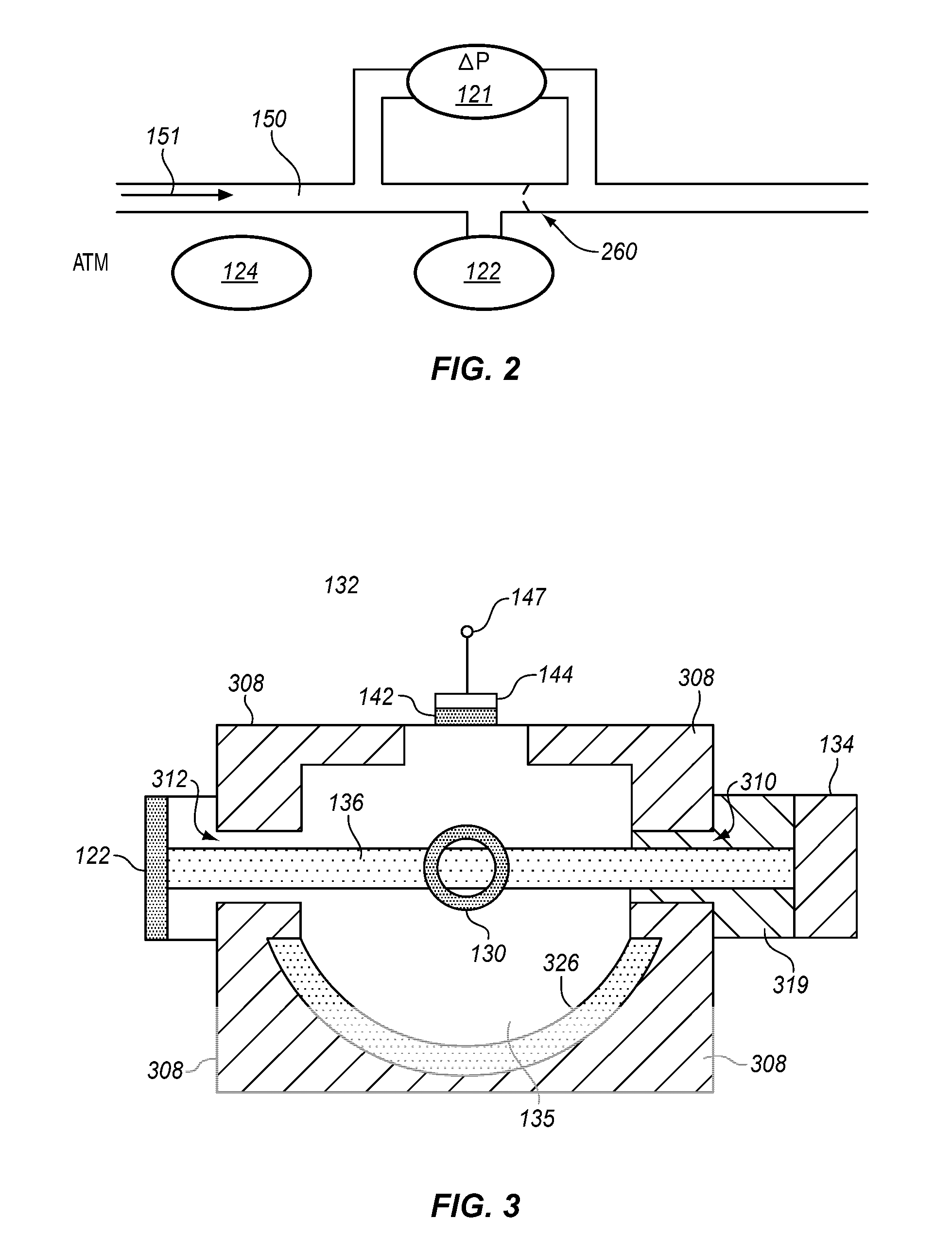

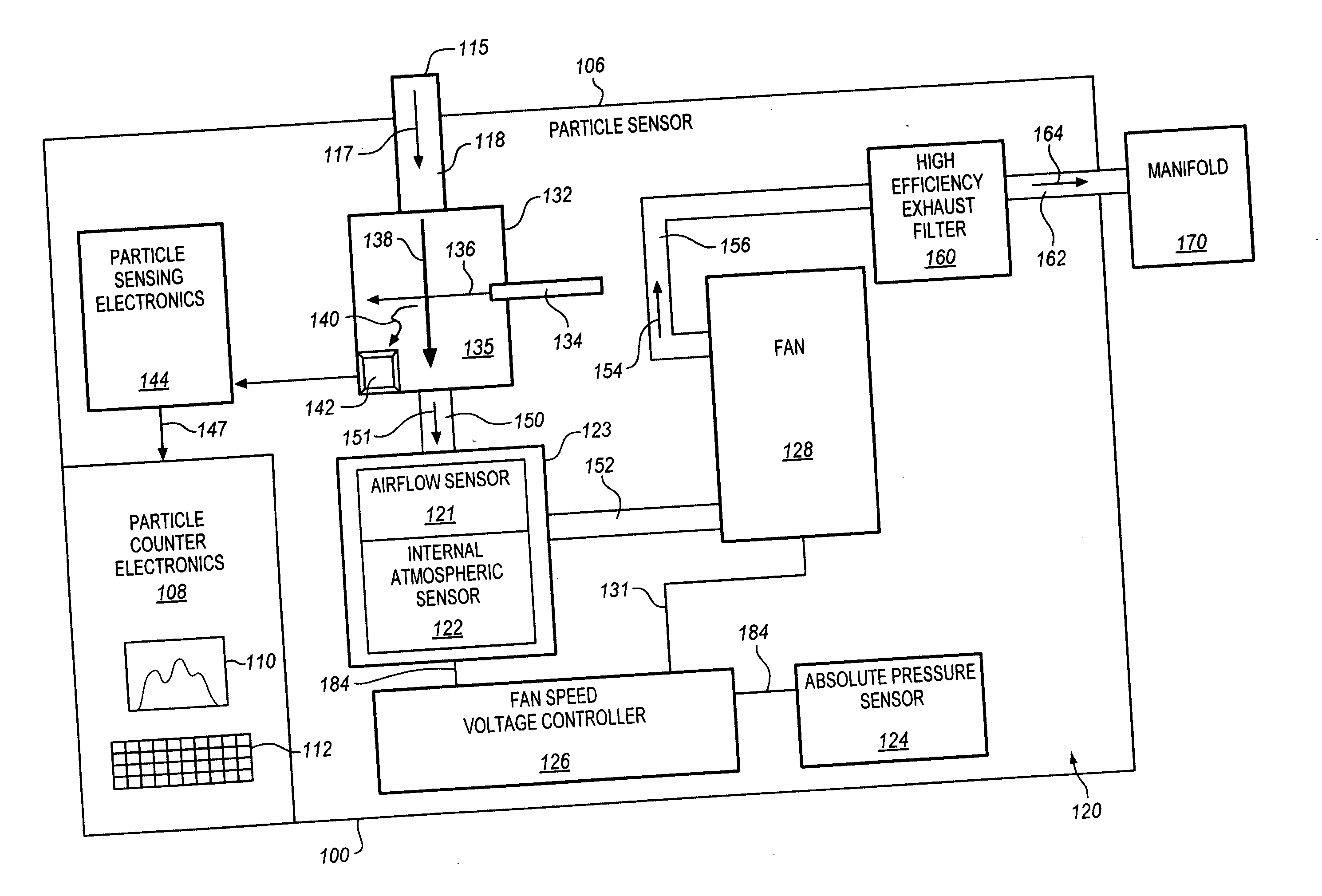

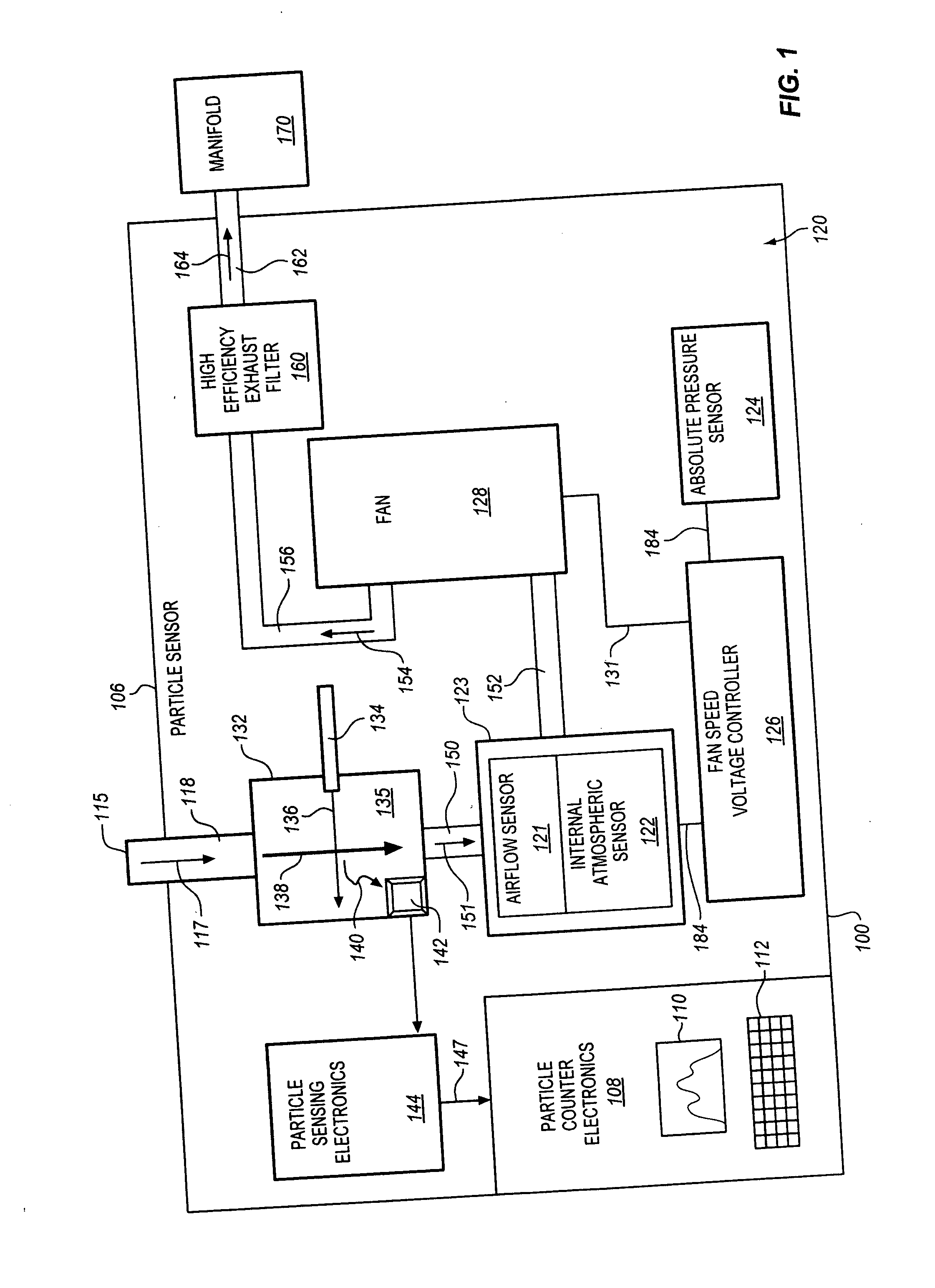

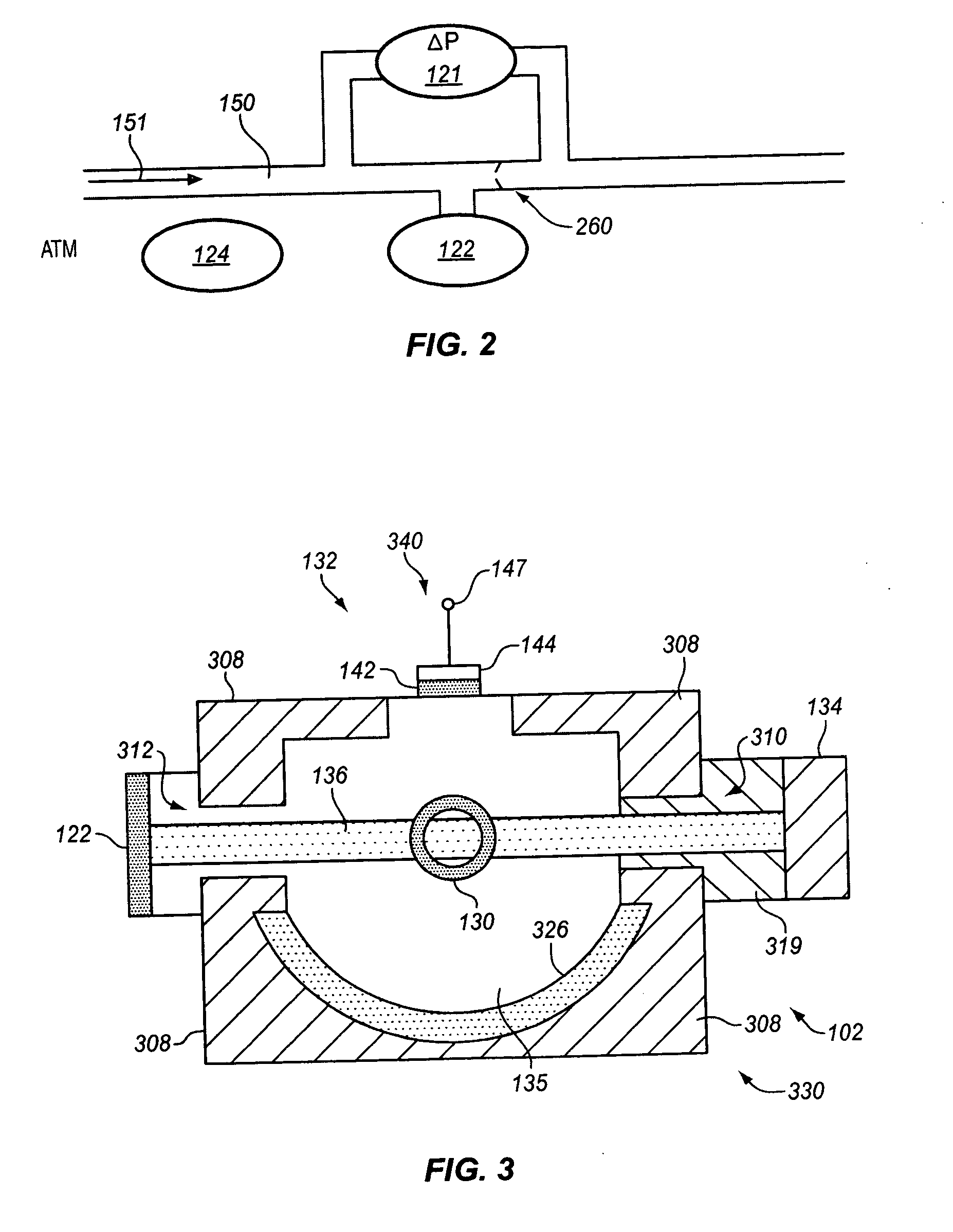

ActiveUS7667839B2Reduces cost and size and power consumptionWhole plant particle counter systems are greatly simplifiedSamplingMaterial analysis by optical meansSquare MillimeterCollection system

A particle sensor for optically detecting an unconstrained particle suspended in a flowing gas includes a sample chamber having a gas inlet and a gas outlet; a gas flow system for flowing said gas from said gas inlet through said sample chamber to said gas outlet, a source of light; an optical system directing said light through said sample chamber, an optical collection system located to collect light scattered by said particles in the gas, and a detection system located to detect the collected light. The total pressure drop through said gas flow system is 3 inches of water or less. The gas flow system includes an axial fan, which may be a high static pressure fan or a counter-rotating fan. In a 1.0 CFM system, the gas inlet nozzle has an area of 25 square millimeters or more.

Owner:PARTICLE MEASURING SYST

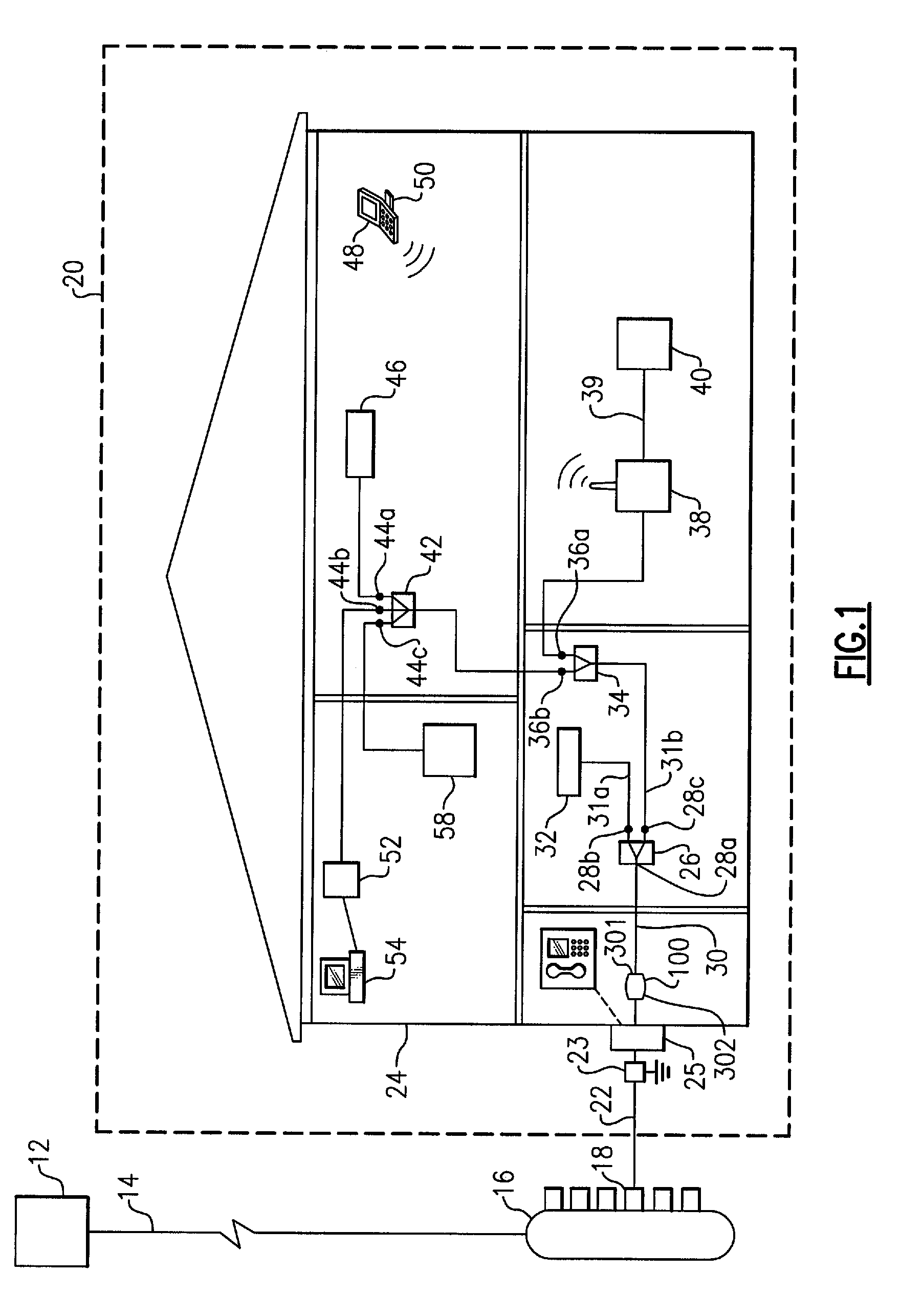

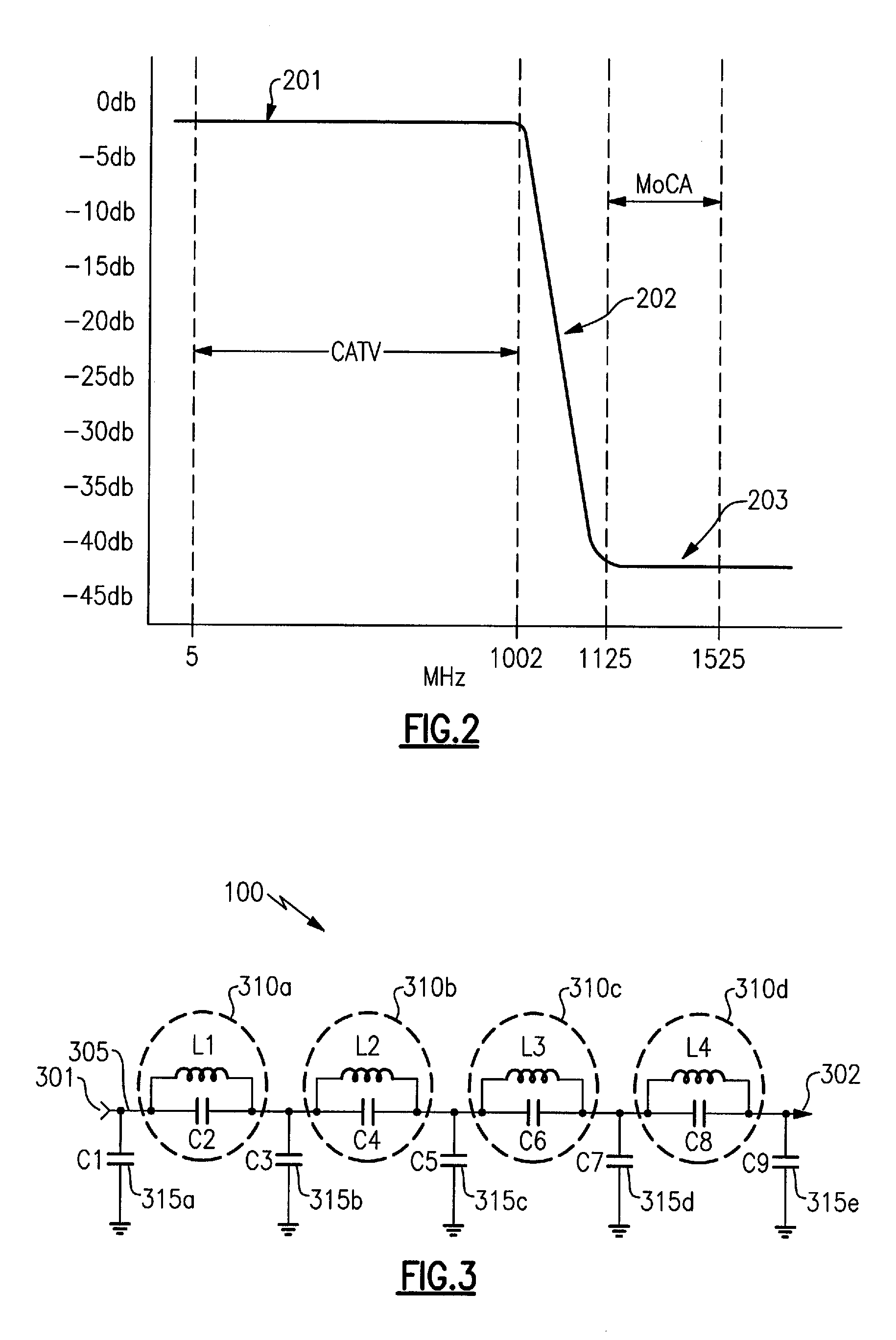

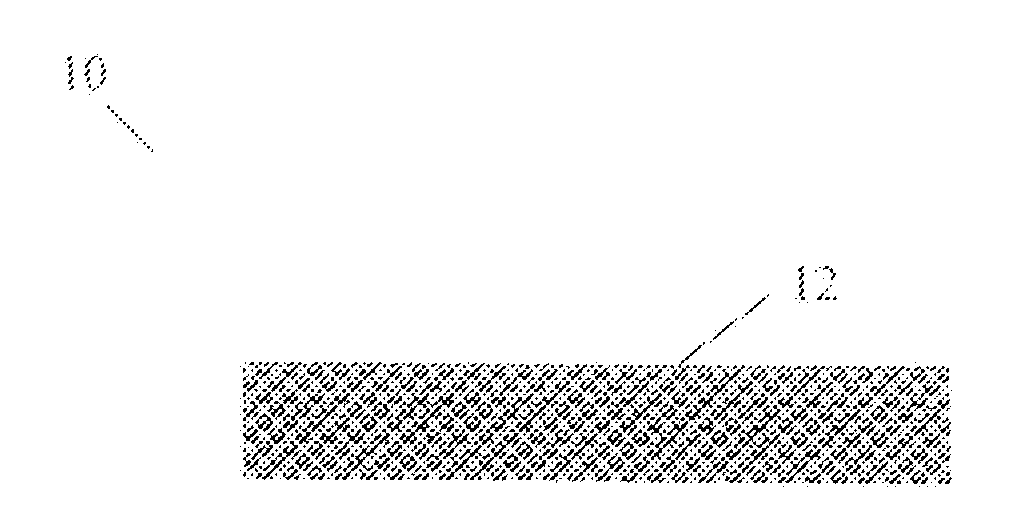

Filter circuit

ActiveUS20110010749A1Multiple-port networksCross-talk/noise/interference reductionSquare MillimeterCoaxial cable

A filter for use in a coaxial cable network includes a printed circuit board having first and second opposed major surfaces, and first and second opposing sides. The opposed major surfaces are substantially parallel to a single plane, and are bisected by a longitudinal axis. The first and second opposing sides are substantially parallel to the longitudinal axis. The filter further includes an input terminal and an output terminal connected to the printed circuit board. The input terminal and the output terminal have an axis extending substantially parallel to the longitudinal axis. A signal path is disposed on the printed circuit board and extends from the input terminal toward the output terminal. The filter further includes a plurality of resonator elements fabricated upon the first opposed major surface. In one embodiment, the inductor elements are arranged in series along the signal path defining a footprint of less than 540 square millimeters. The filter passes a first range of frequencies in a provider bandwidth and attenuates a second range of frequencies in a personal data network bandwidth. In one embodiment, the resonator elements are parallel inductor elements and capacitor elements, the inductor elements being etched spiral inductors.

Owner:PPC BROADBAND INC

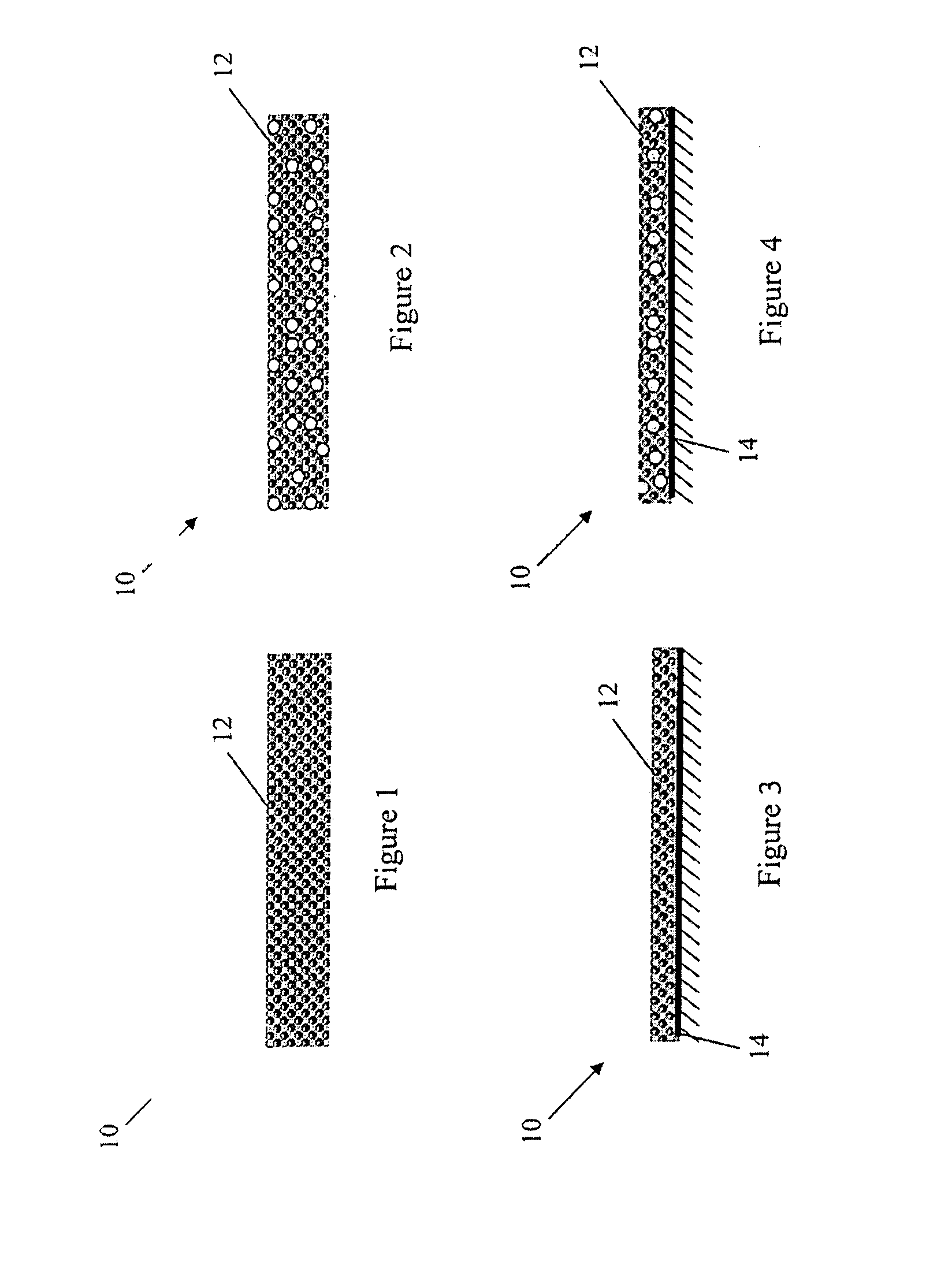

Medical devices and methods of making and using

Owner:INFRAMAT CORPORATION

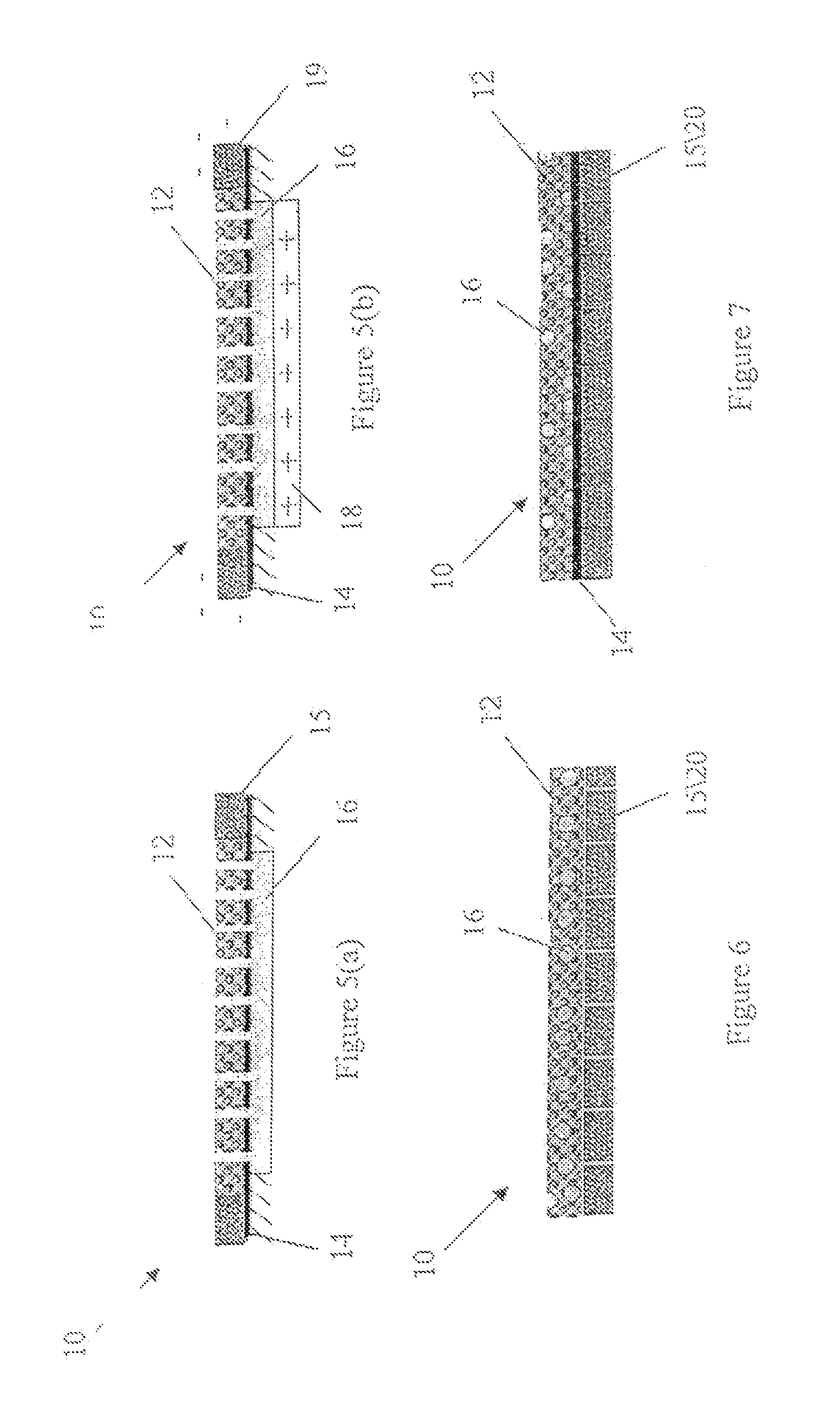

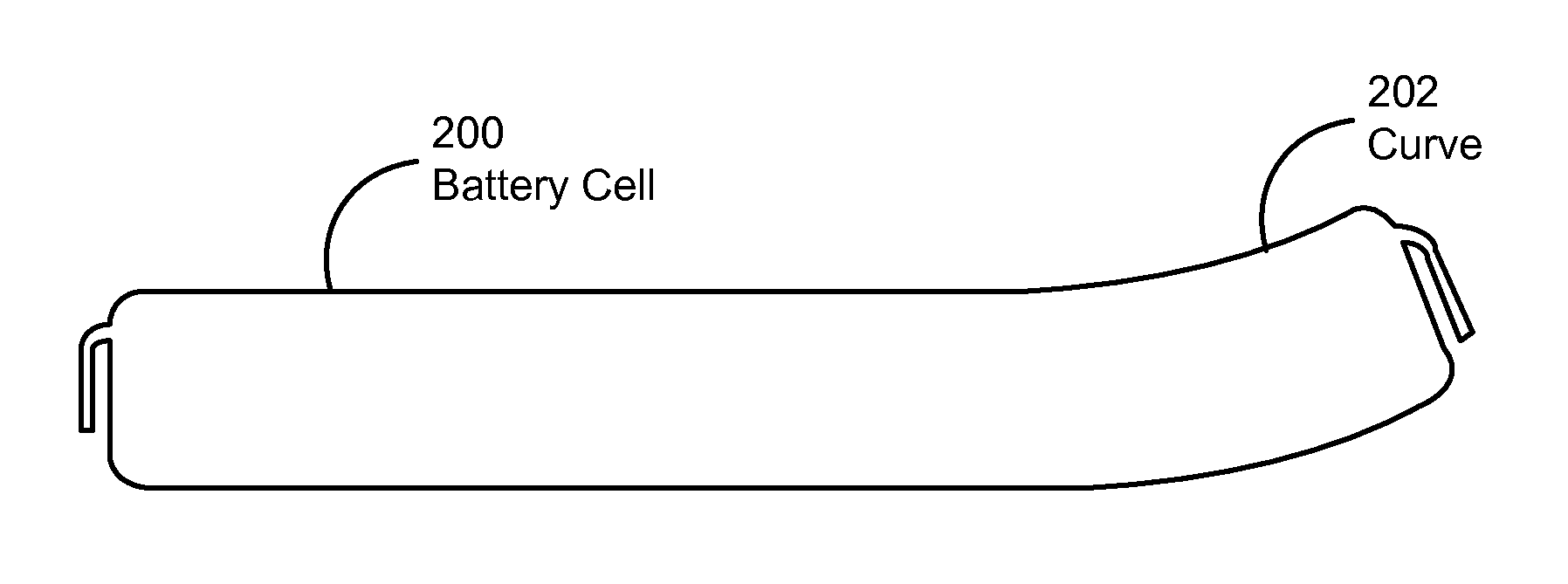

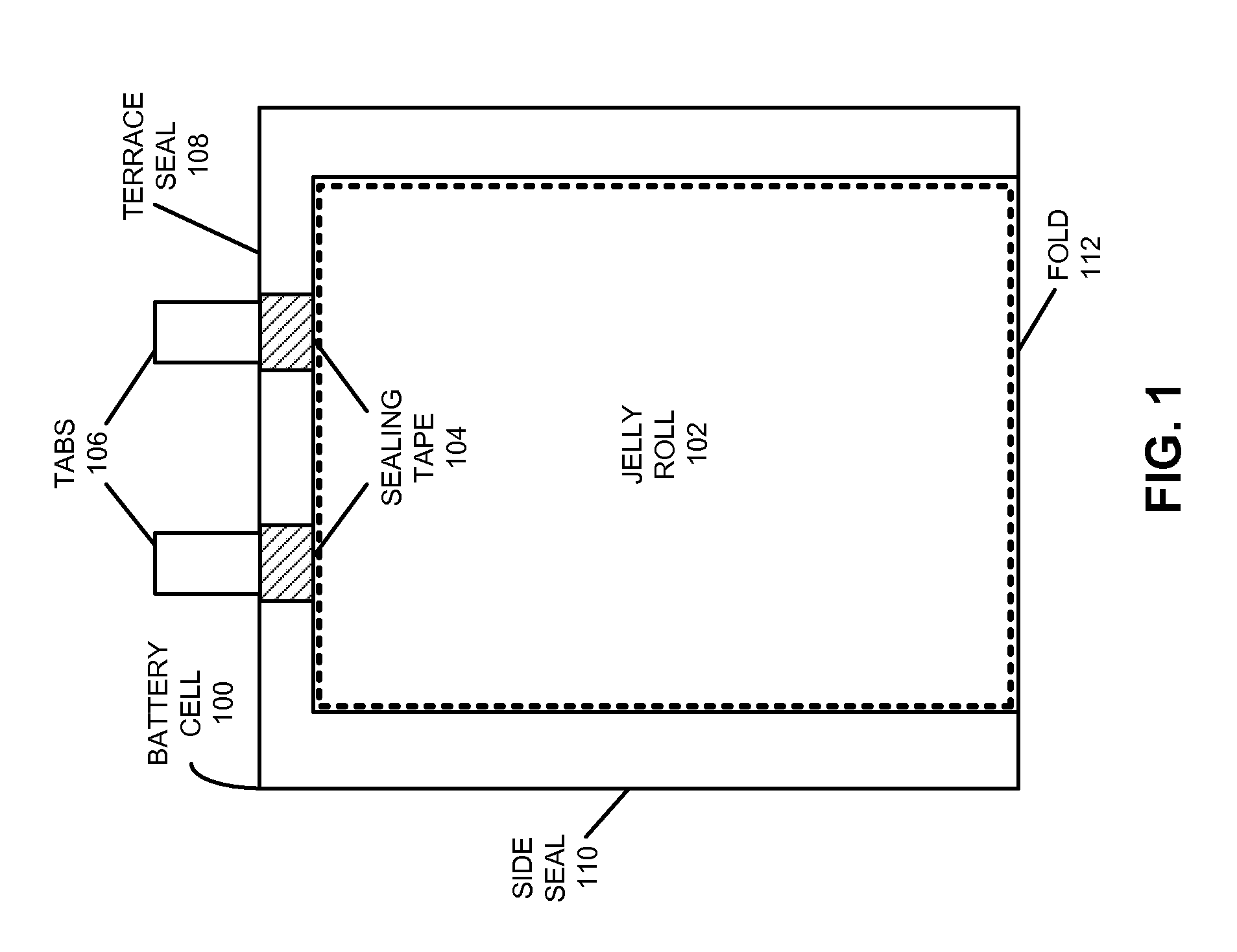

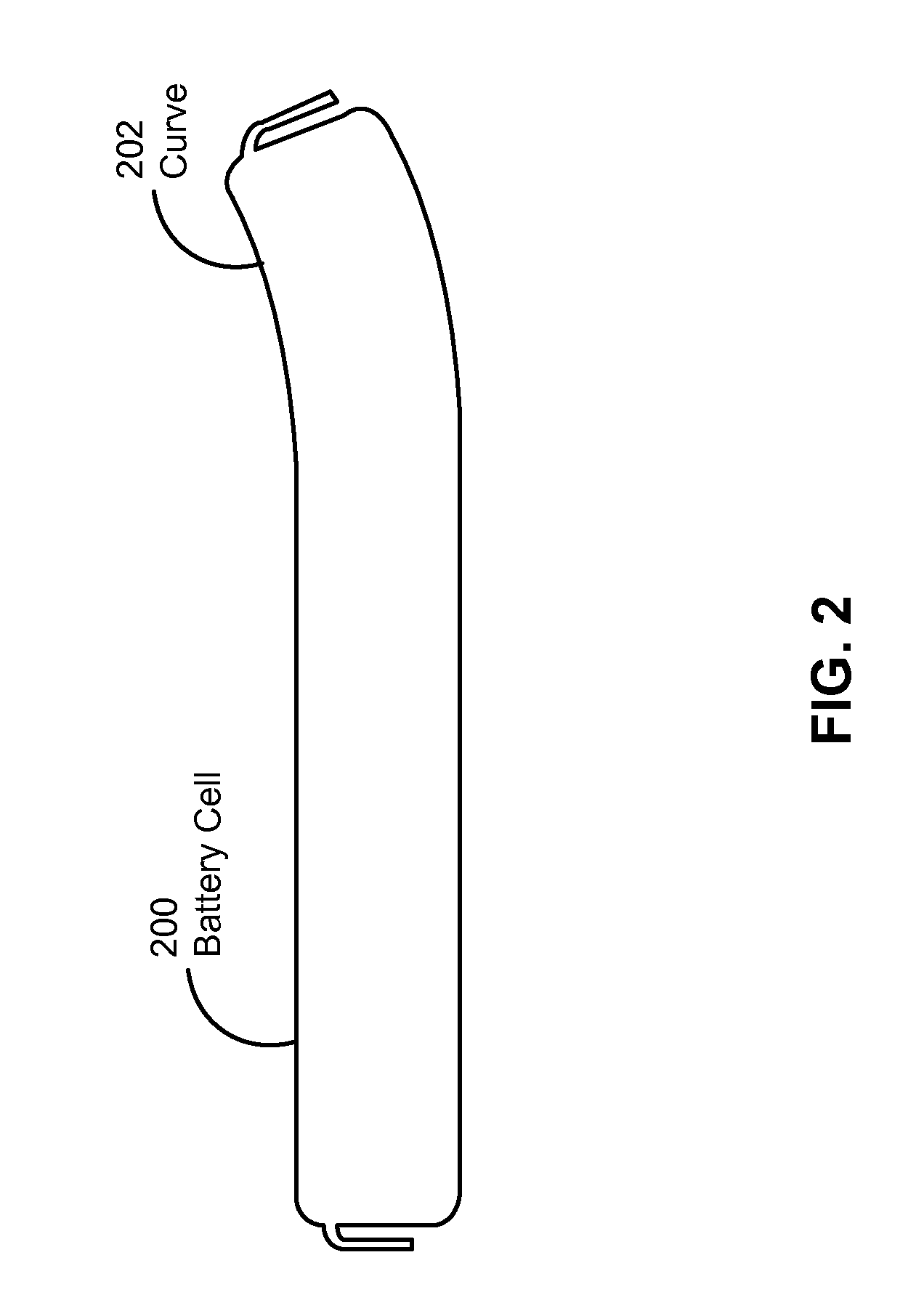

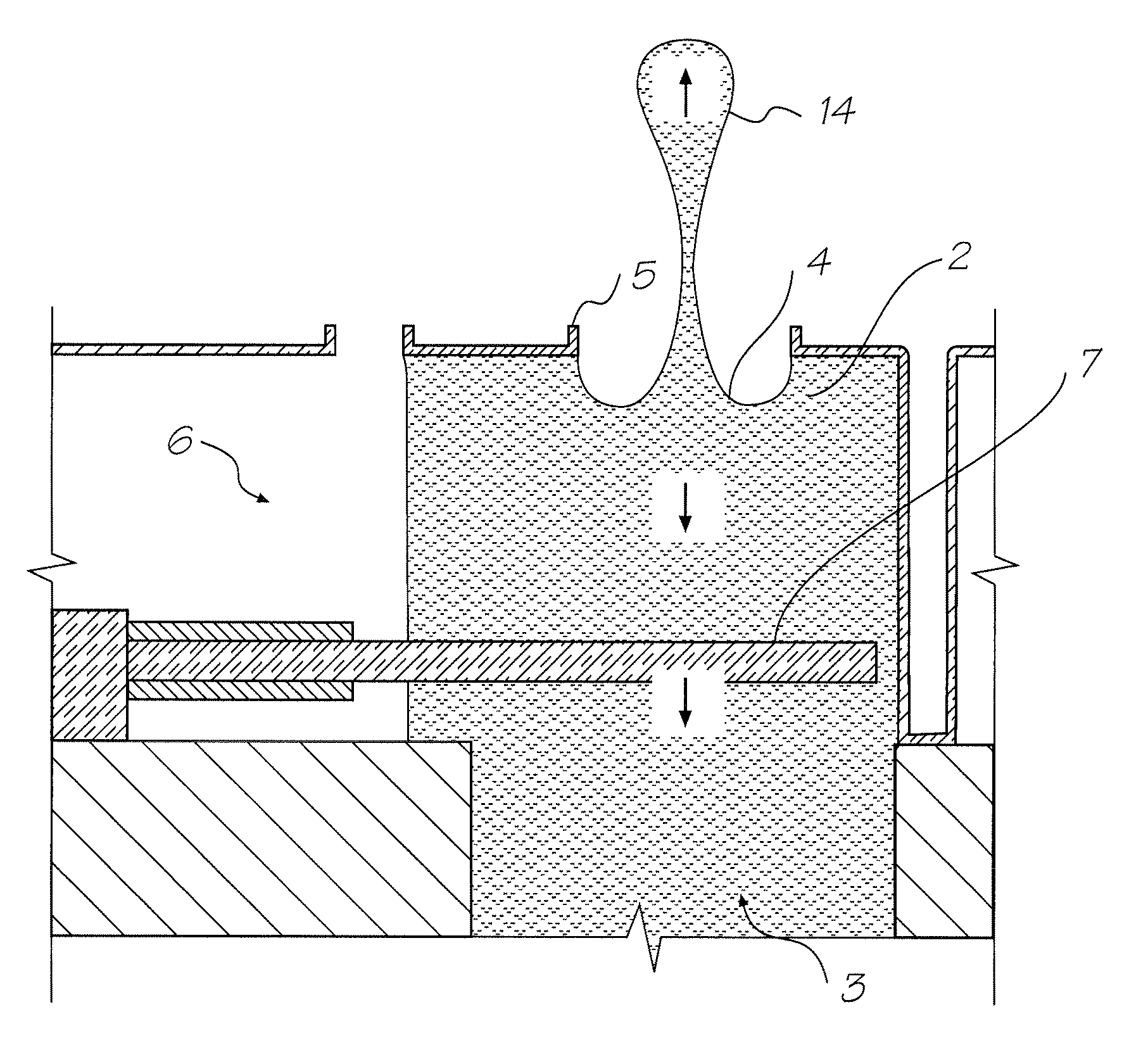

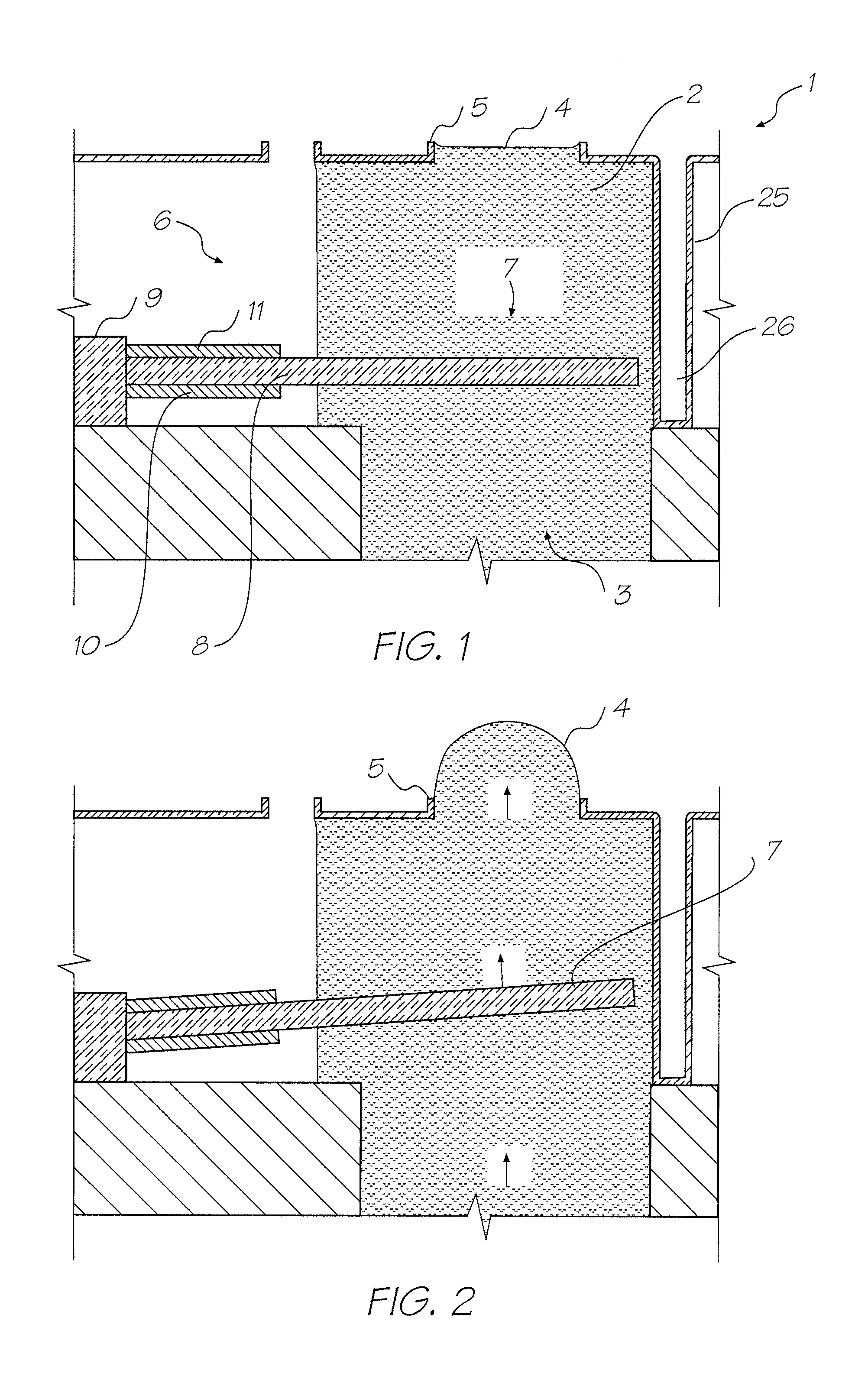

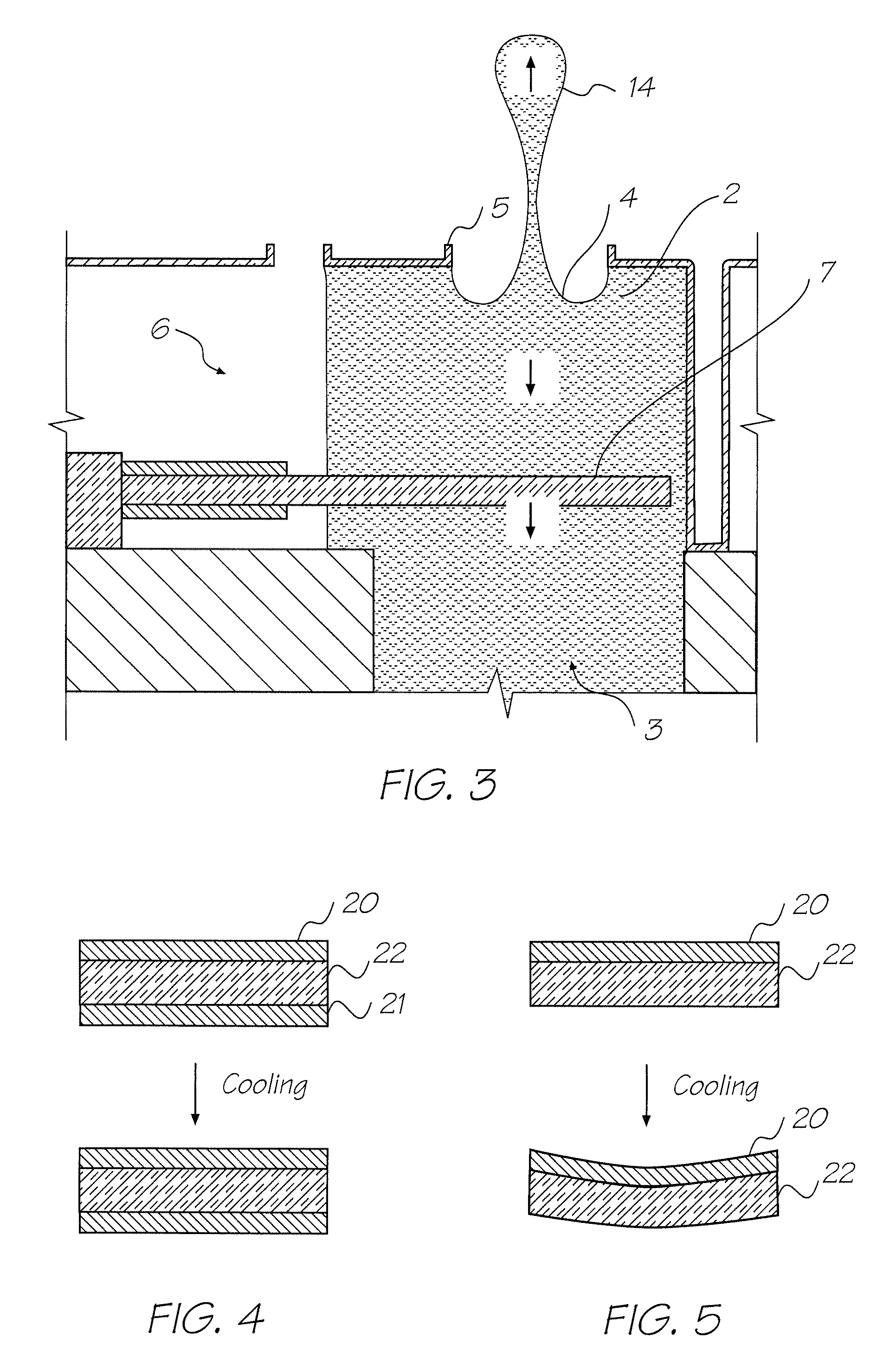

Curved battery cells for portable electronic devices

InactiveUS20130108907A1Facilitate efficient use of spaceBatteries circuit arrangementsFinal product manufactureKilogram-forceSquare Millimeter

The disclosed embodiments relate to the manufacture of a battery cell. The battery cell includes a set of layers including a cathode with an active coating, a separator, and an anode with an active coating. The battery cell also includes a pouch enclosing the layers, wherein the pouch is flexible. The layers may be wound to create a jelly roll prior to sealing the layers in the flexible pouch. A curve may also be formed in the battery cell by applying a pressure of at least 0.13 kilogram-force (kgf) per square millimeter to the layers using a set of curved plates applying a temperature of about 85° C. to the layers.

Owner:APPLE INC

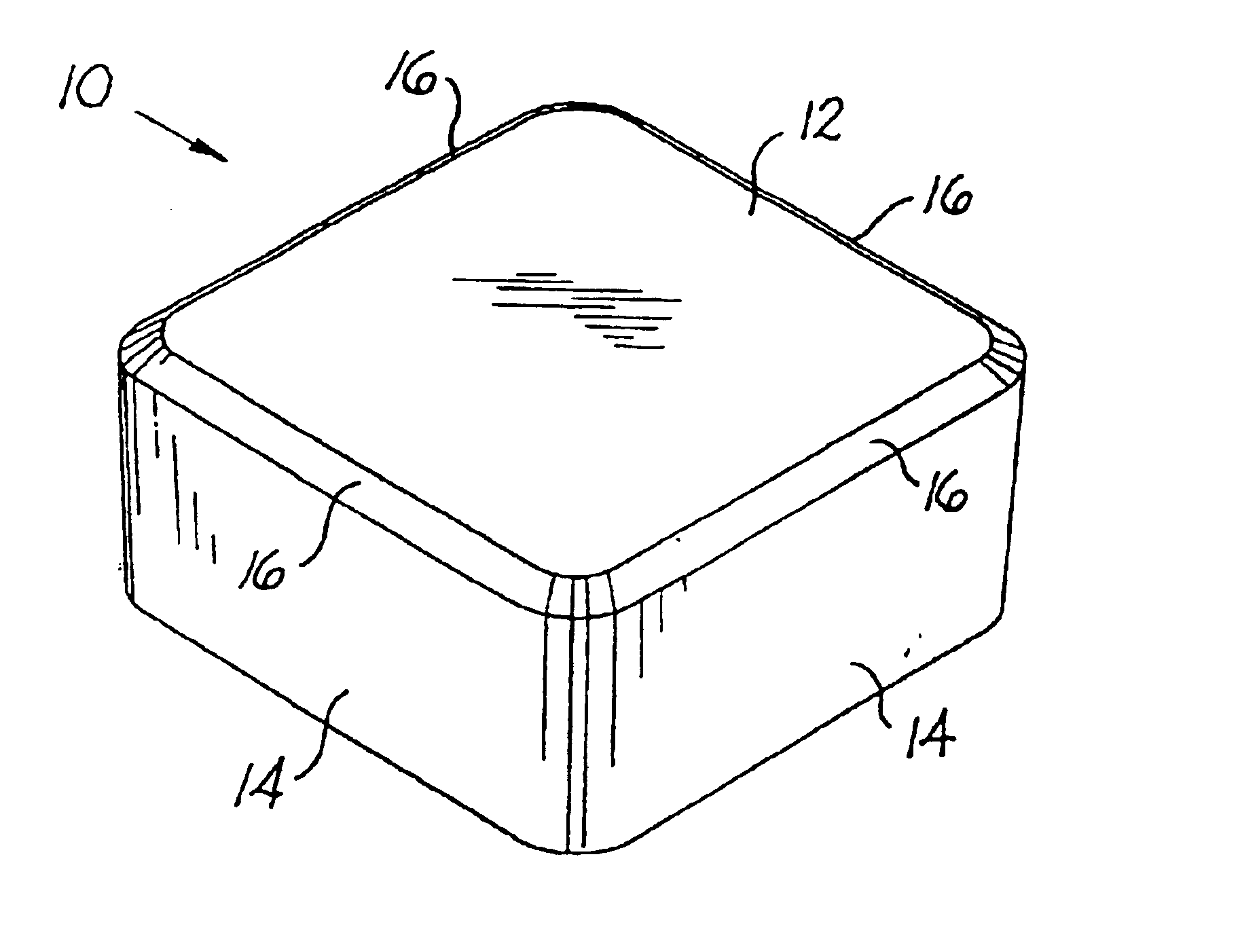

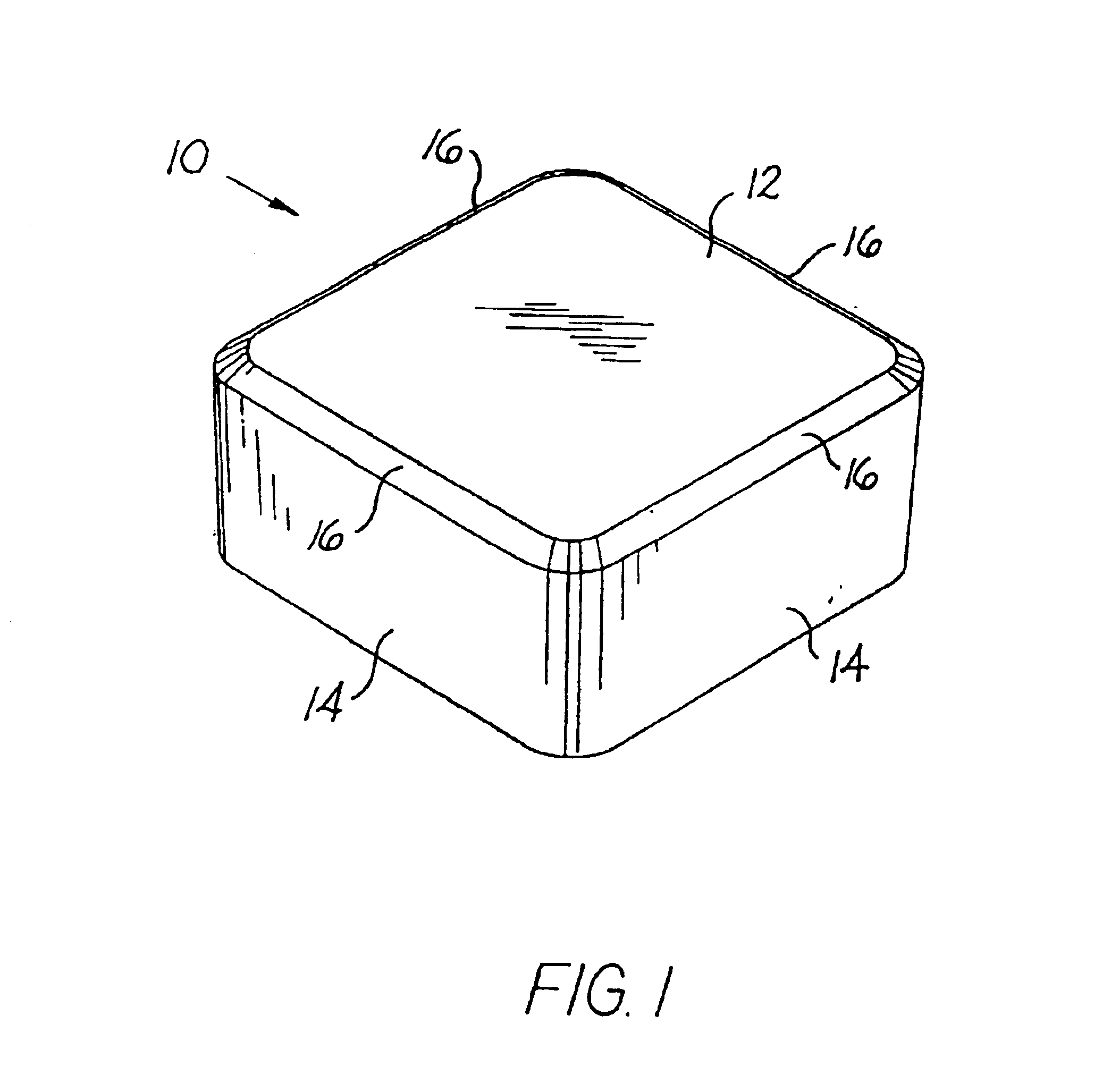

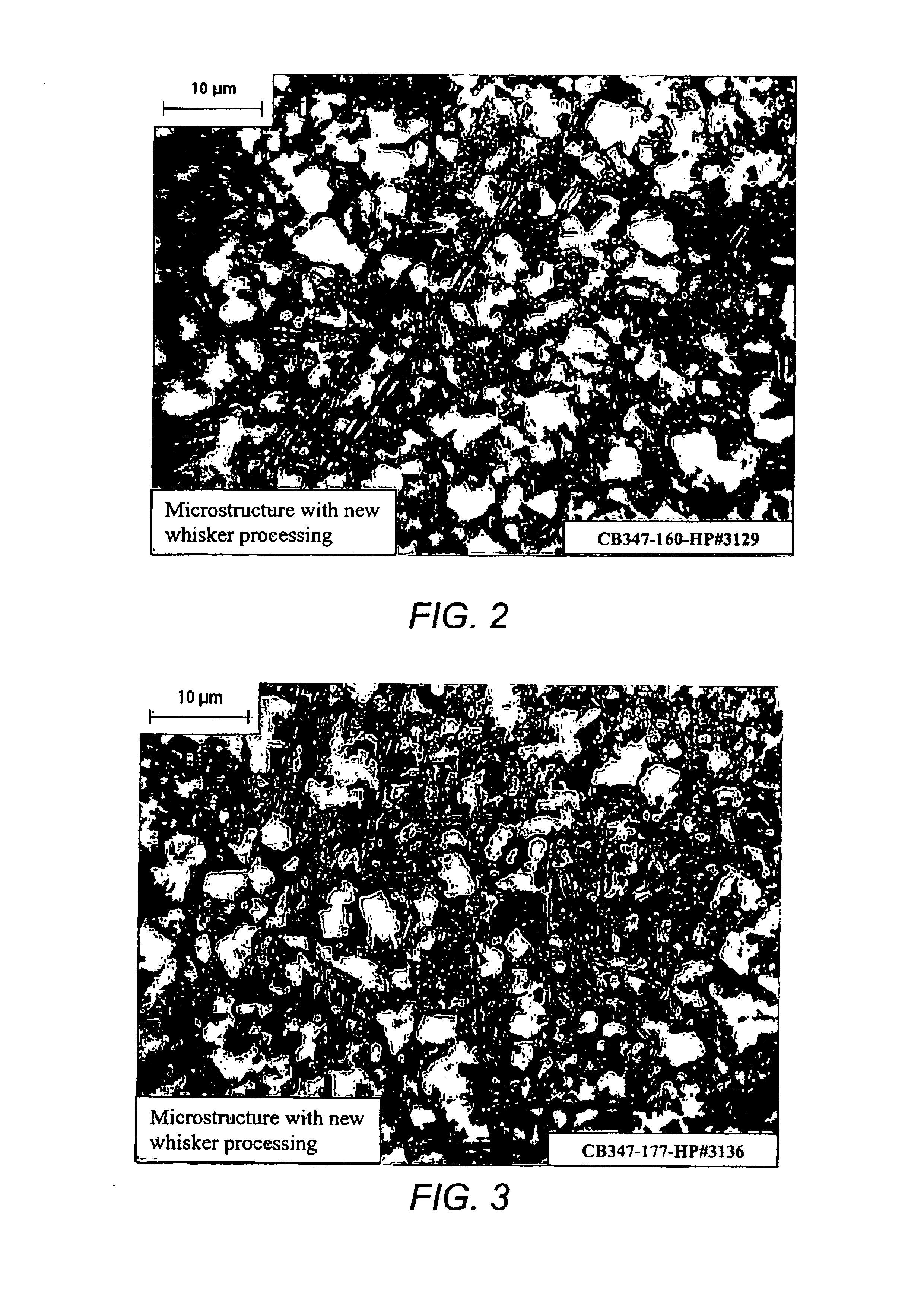

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

Lumen - supporting devices and methods of making and using

Disclosed herein are medical devices, particularly lumen-supporting devices, which include a biocompatible nanostructured ceramic material configured to be disposed adjacent to a luminal surface and having an average grain size dimension of about 1 nanometer to about 1000 nanometers, a strain to failure of at least about 1 percent, and a cross-sectional hardness greater than or equal to about 350 kilograms per square millimeter. Also disclosed are methods of making and using the lumen-supporting devices.

Owner:INFRAMAT CORPORATION

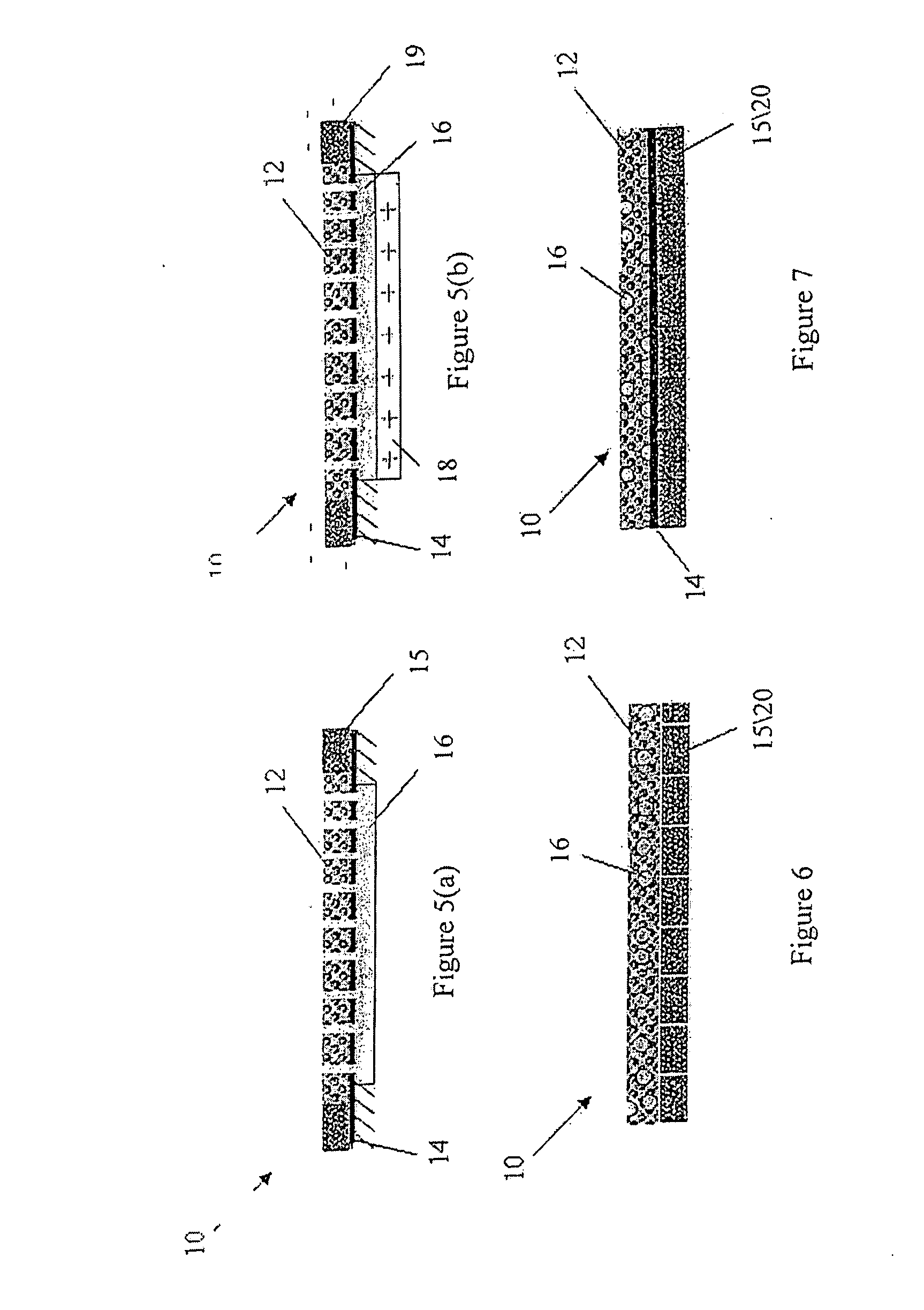

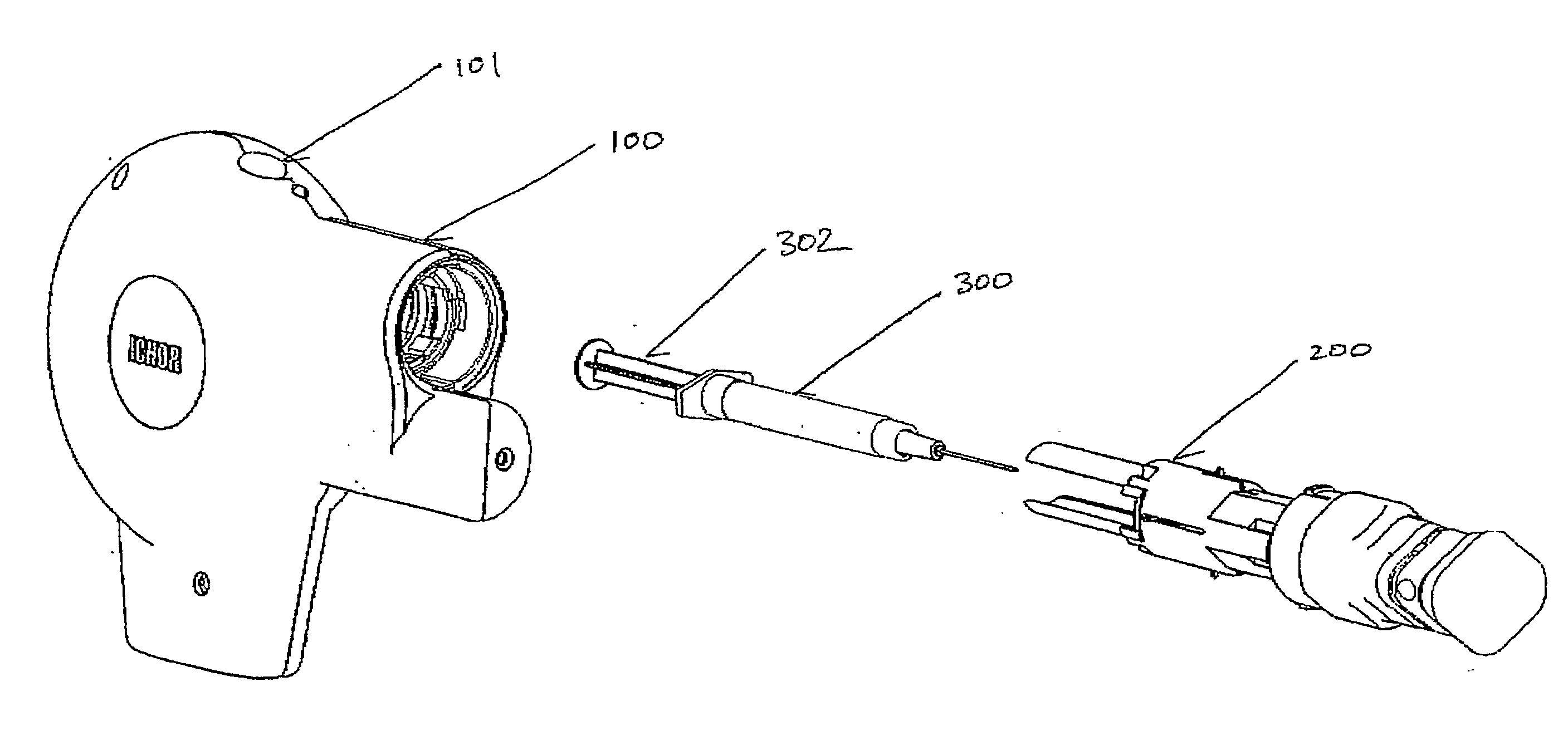

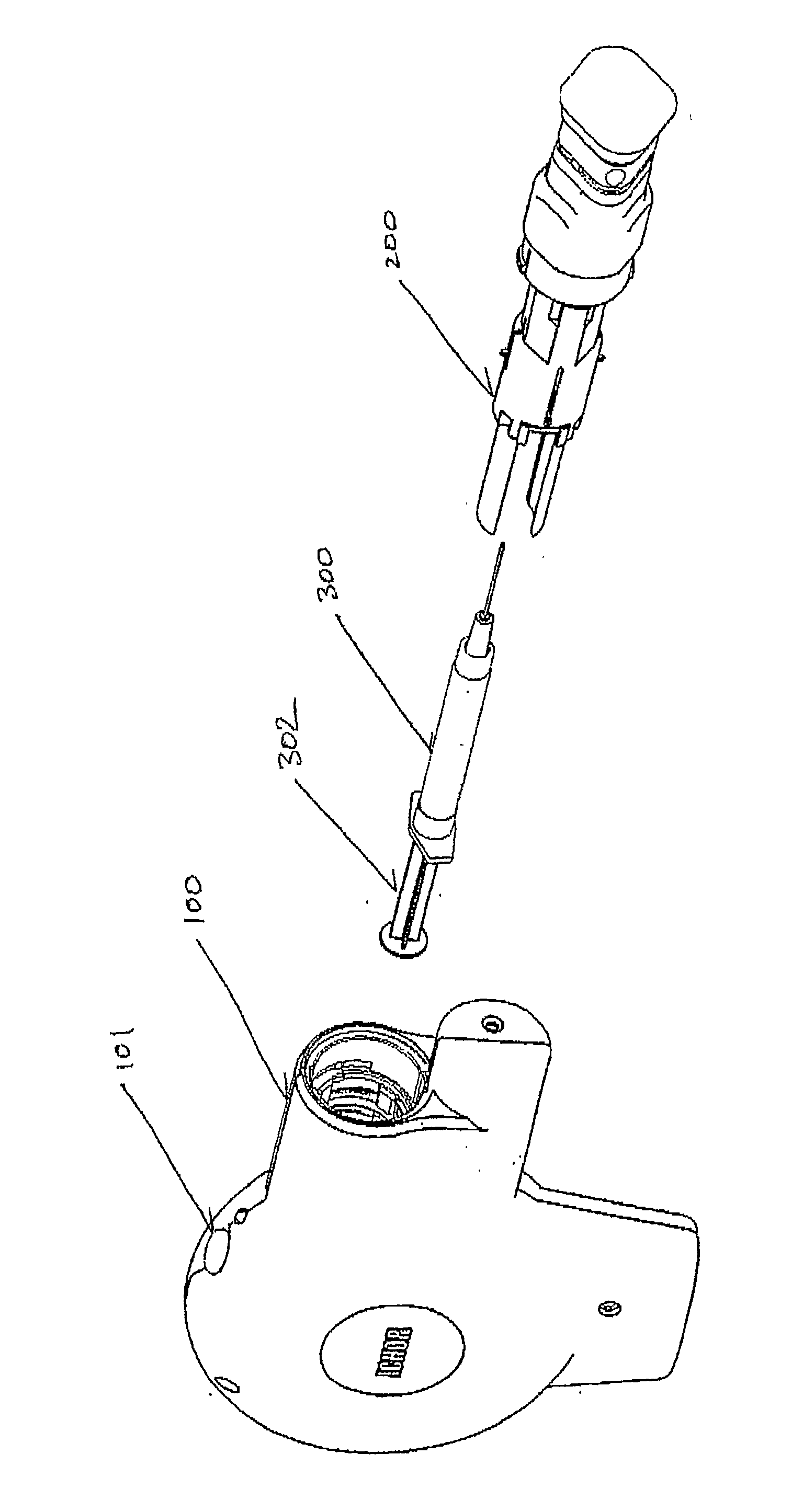

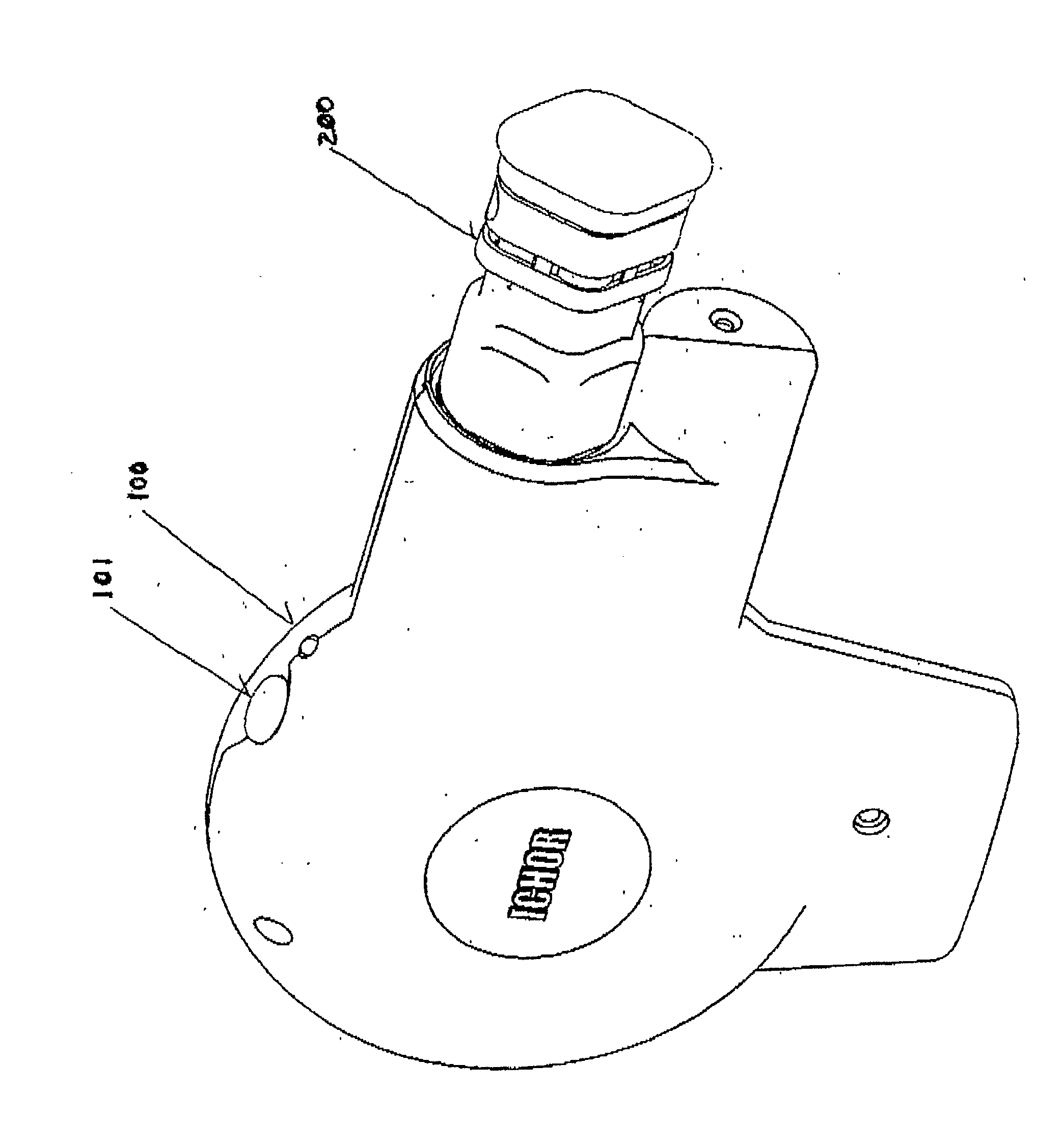

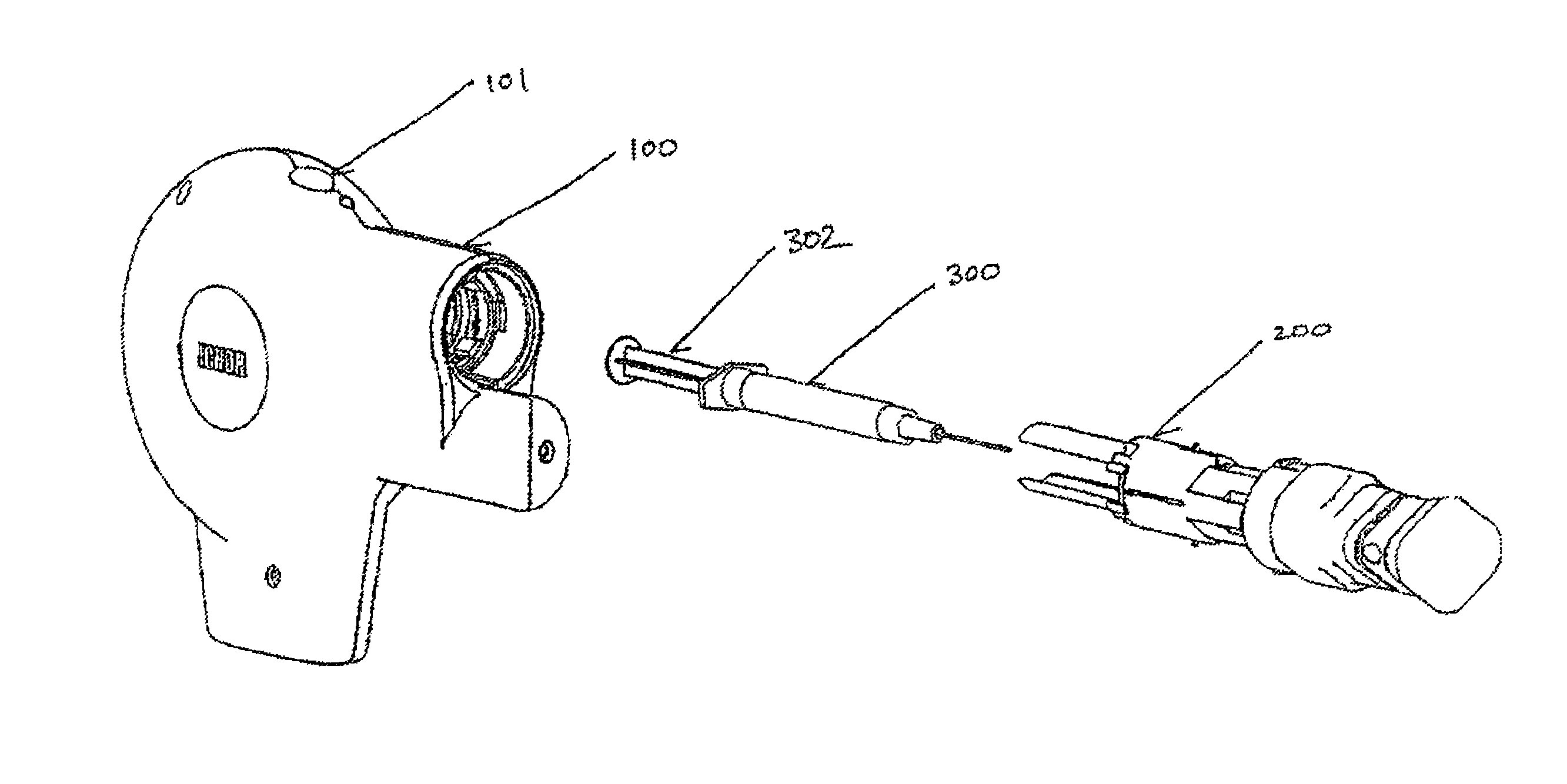

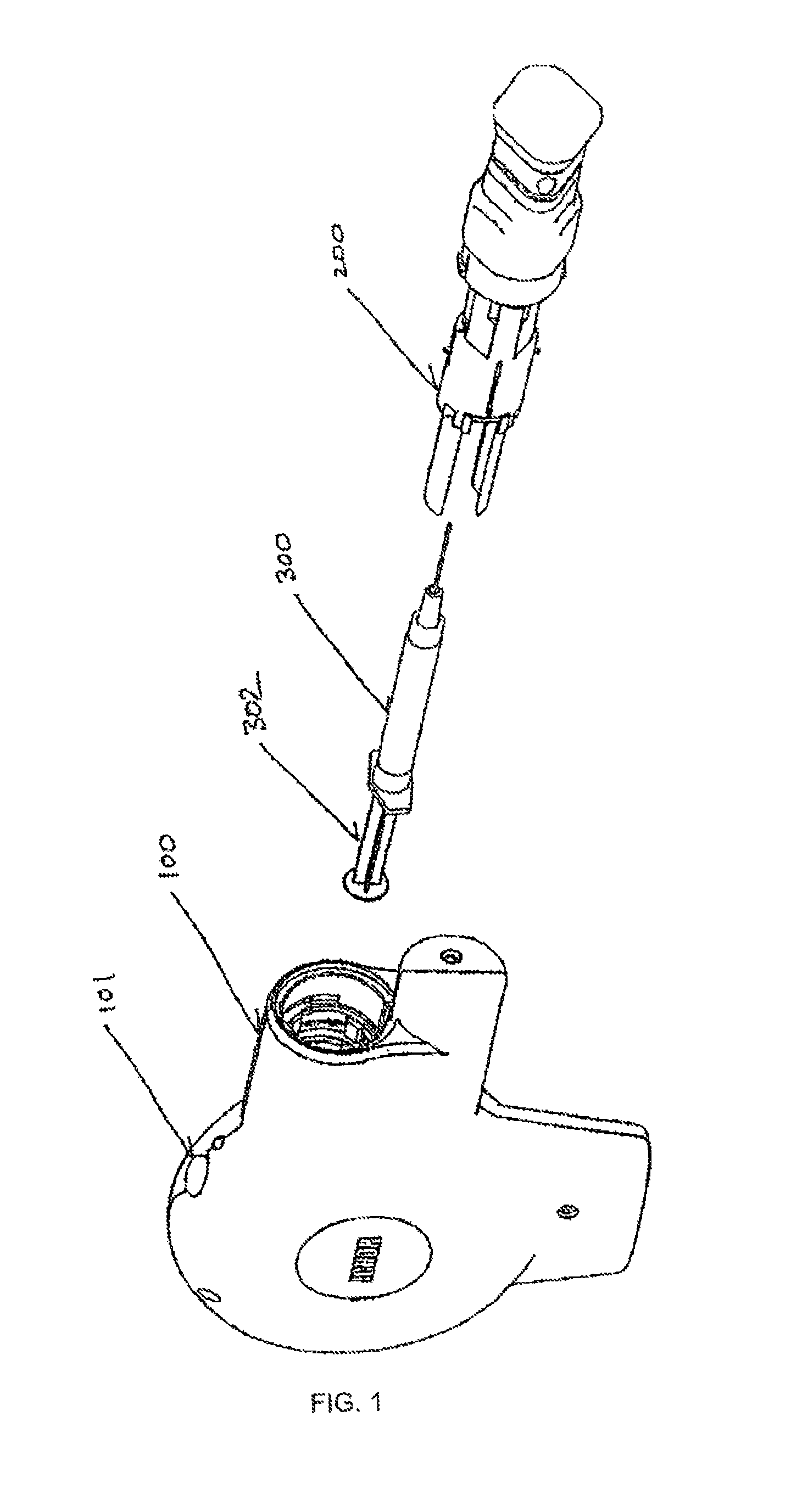

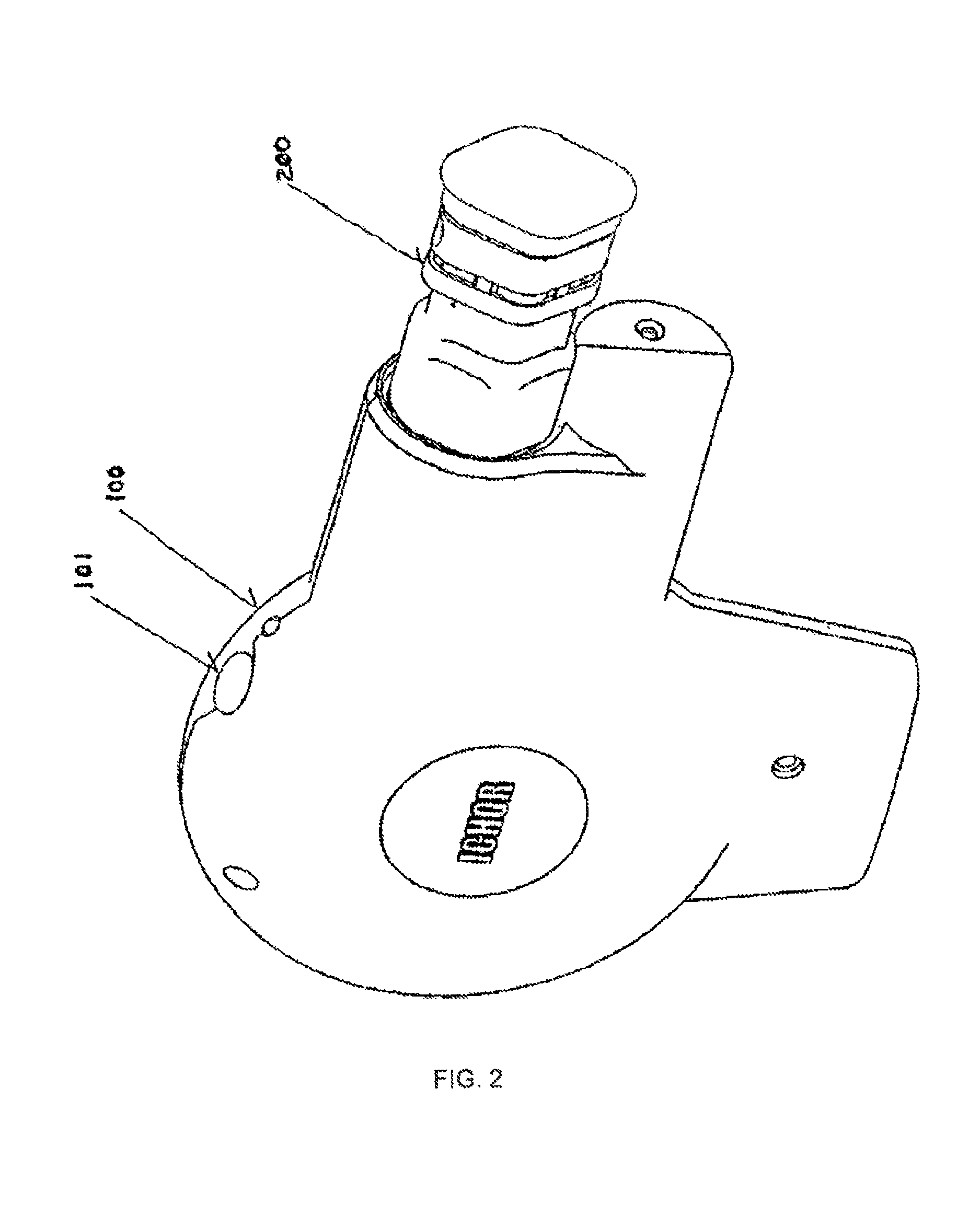

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS20120078161A1Easy to adaptFunction increaseSkin piercing electrodesElectricitySquare Millimeter

Apparatus for the delivery of an electrical field which facilitates the intracellular delivery of a therapeutic agent to a predetermined site within the tissue of a patient. The apparatus will comprise a plurality of penetrating electrodes arranged in a predetermined spatial relationship, each electrode with a cross sectional area contributing to the total cross sectional area of all electrodes, and structural means incorporating an inanimate source of energy operatively connected to the plurality of electrodes for deploying the electrodes, wherein the source of energy is sufficient to impart a force of at least 1000 pounds per square inch (0.7 kilogram per square millimeter) of total cross sectional area of all electrodes at the initiation of the deployment of the electrodes. The apparatus will also comprise means for generating an electrical field which facilitates the intracellular delivery of a therapeutic agent, which means is operatively connected to said electrodes at least in their deployed state.

Owner:ICHOR MEDICAL SYST

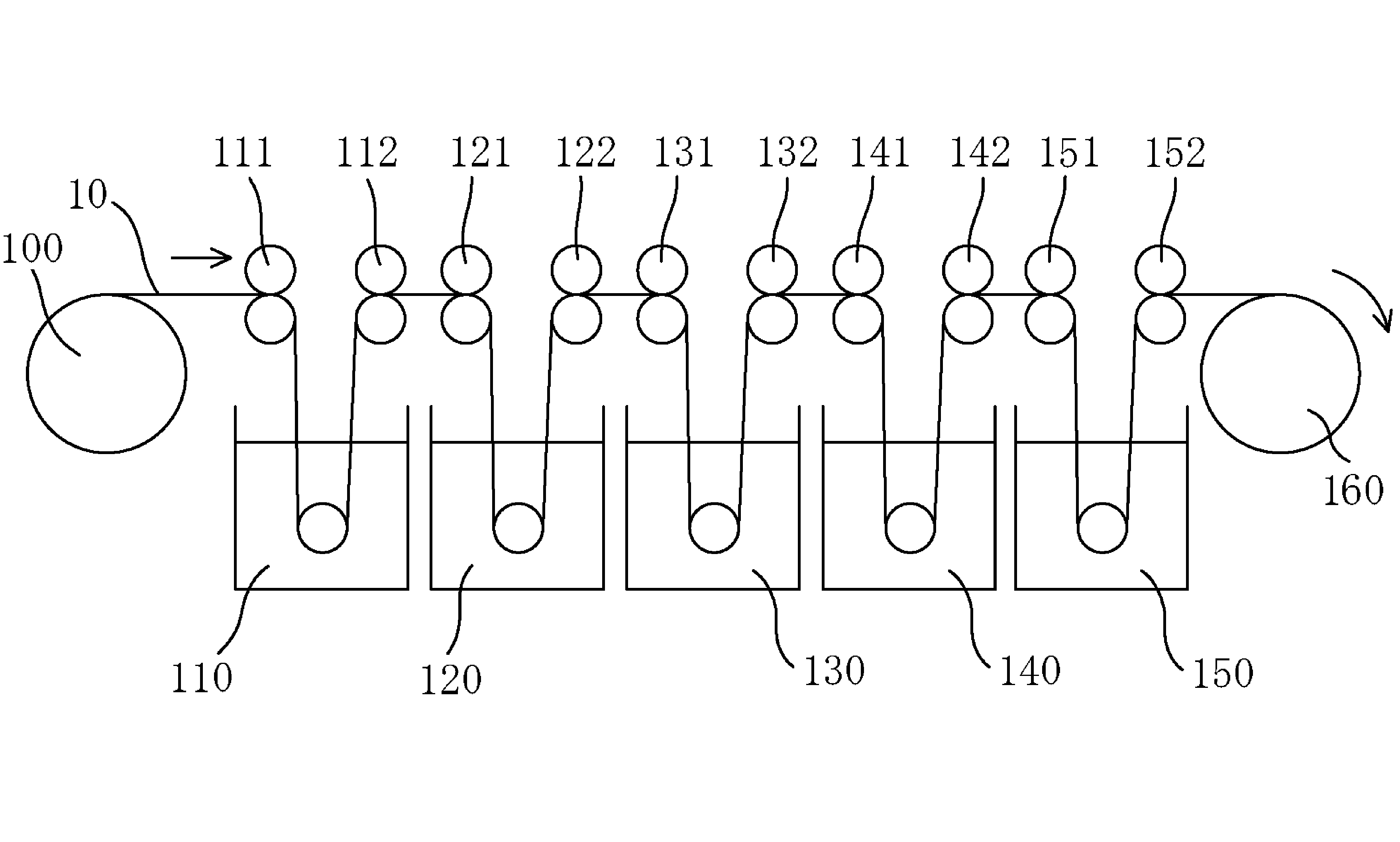

High nozzle density printhead ejecting low drop volumes

InactiveUS7677686B2Avoid flowReduce the overall heightInking apparatusOther printing apparatusWater basedSquare Millimeter

A printhead assembly that has a printhead substrate having a plurality of drop generators formed thereon at an area density of at least six drop generators per square millimeter. The droplets emitted have a drop volume less than 8 pico liters. The fluid forming the droplets has a viscosity in the range of 2 to 5 centipoise. A high area density of drop generators and relatively low droplet volume of water-based ink provides high print resolutions and energy efficient operation.

Owner:MEMJET TECH LTD +1

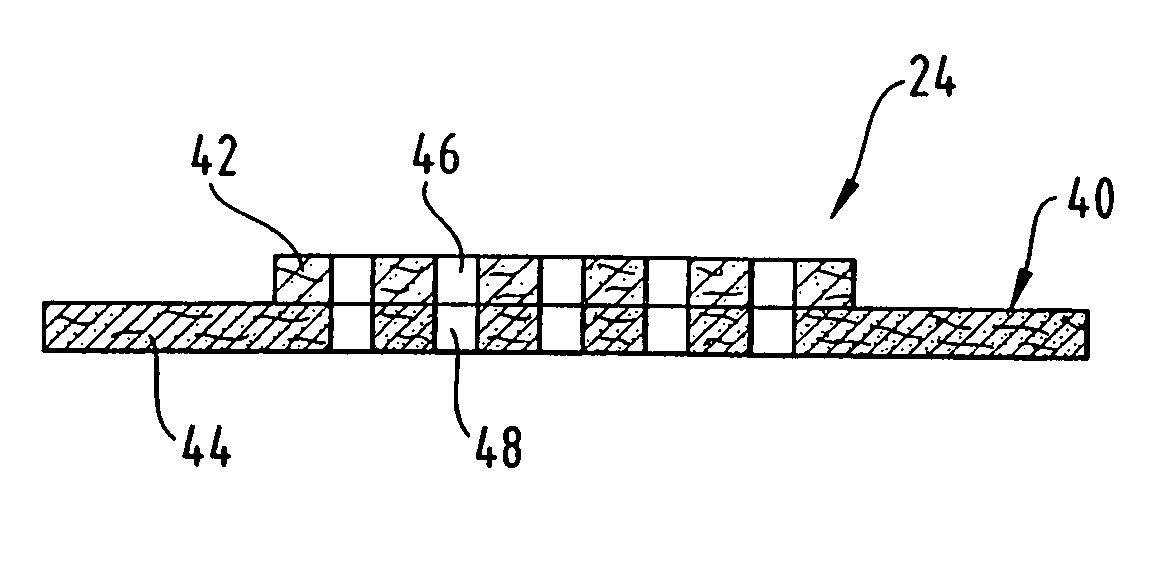

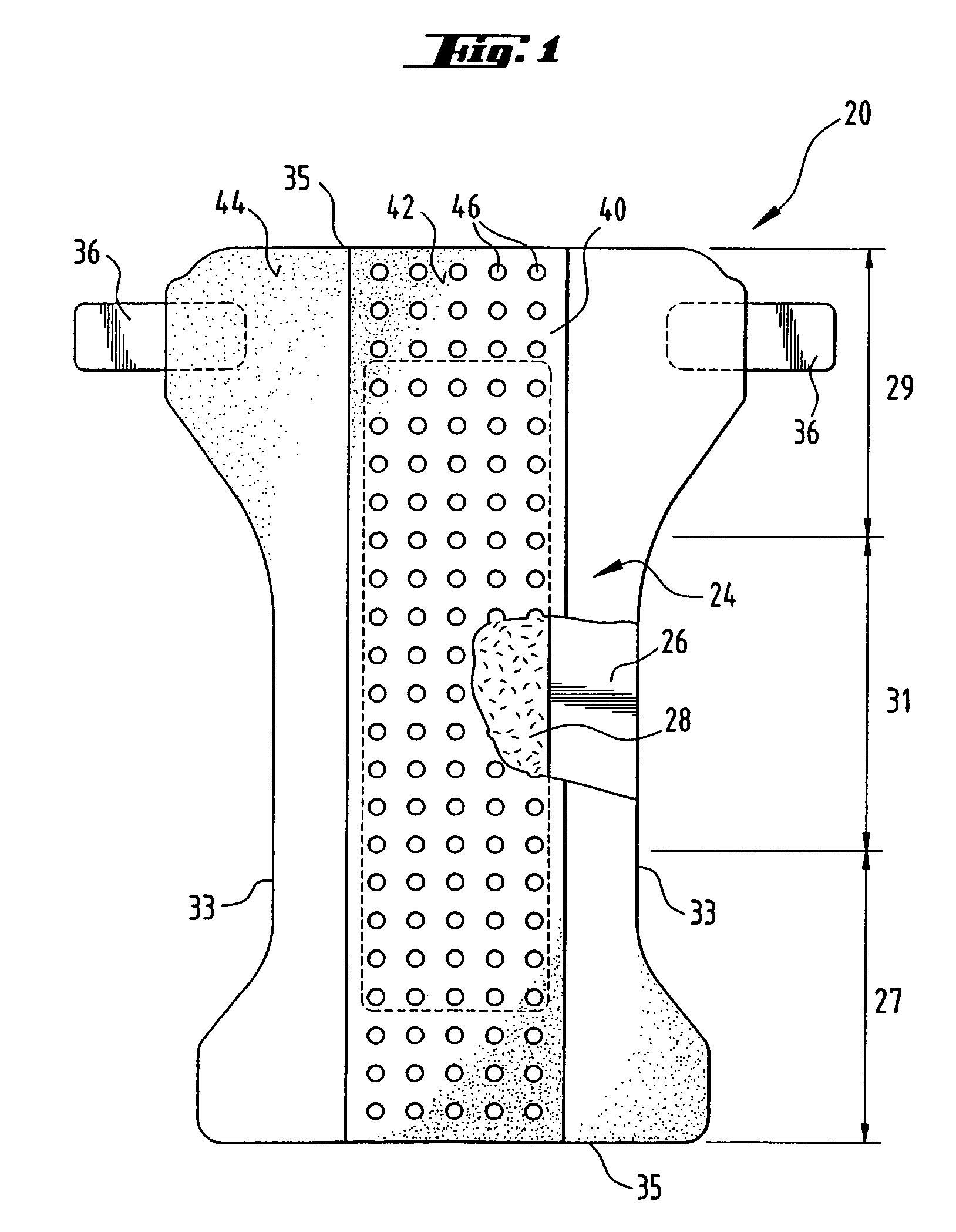

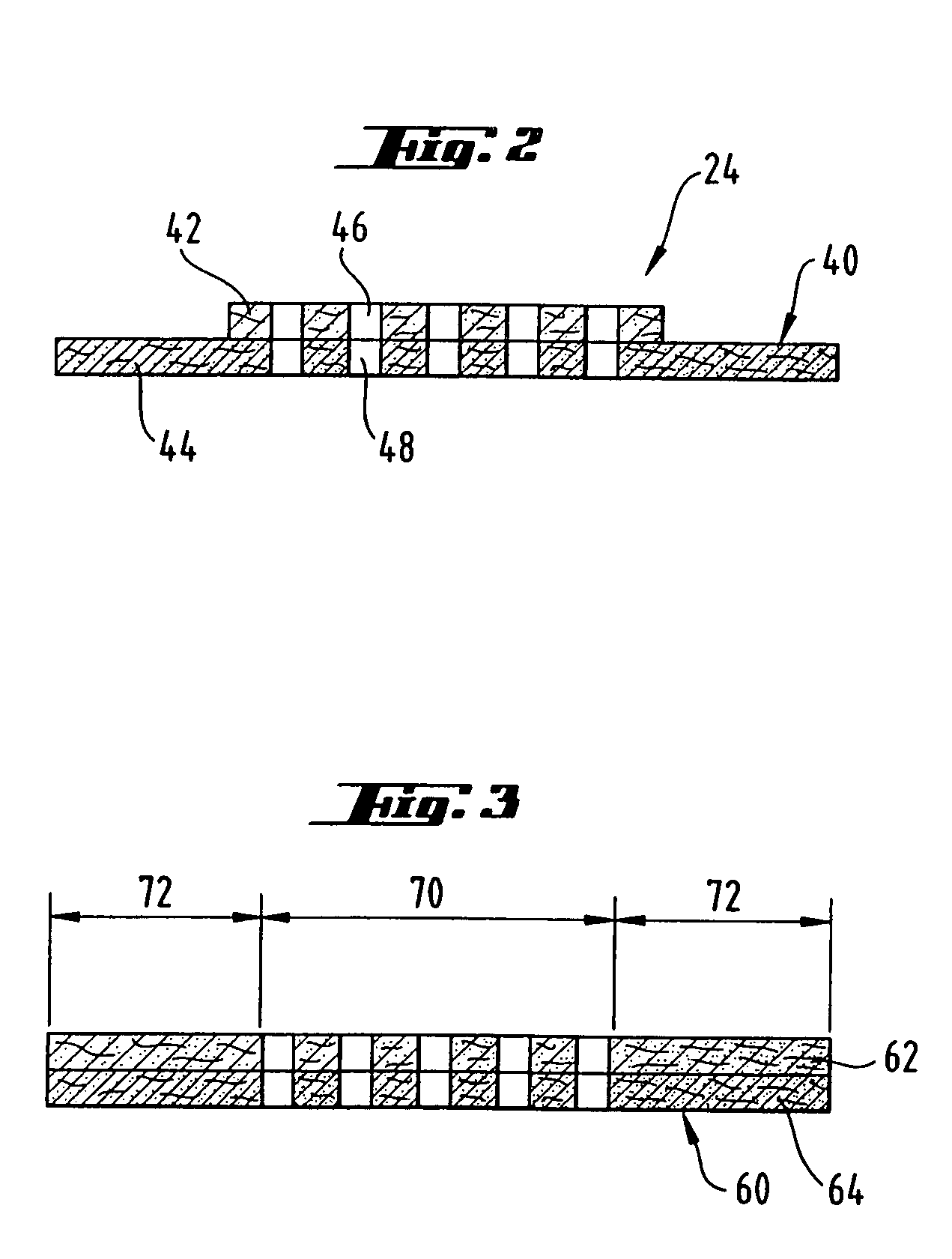

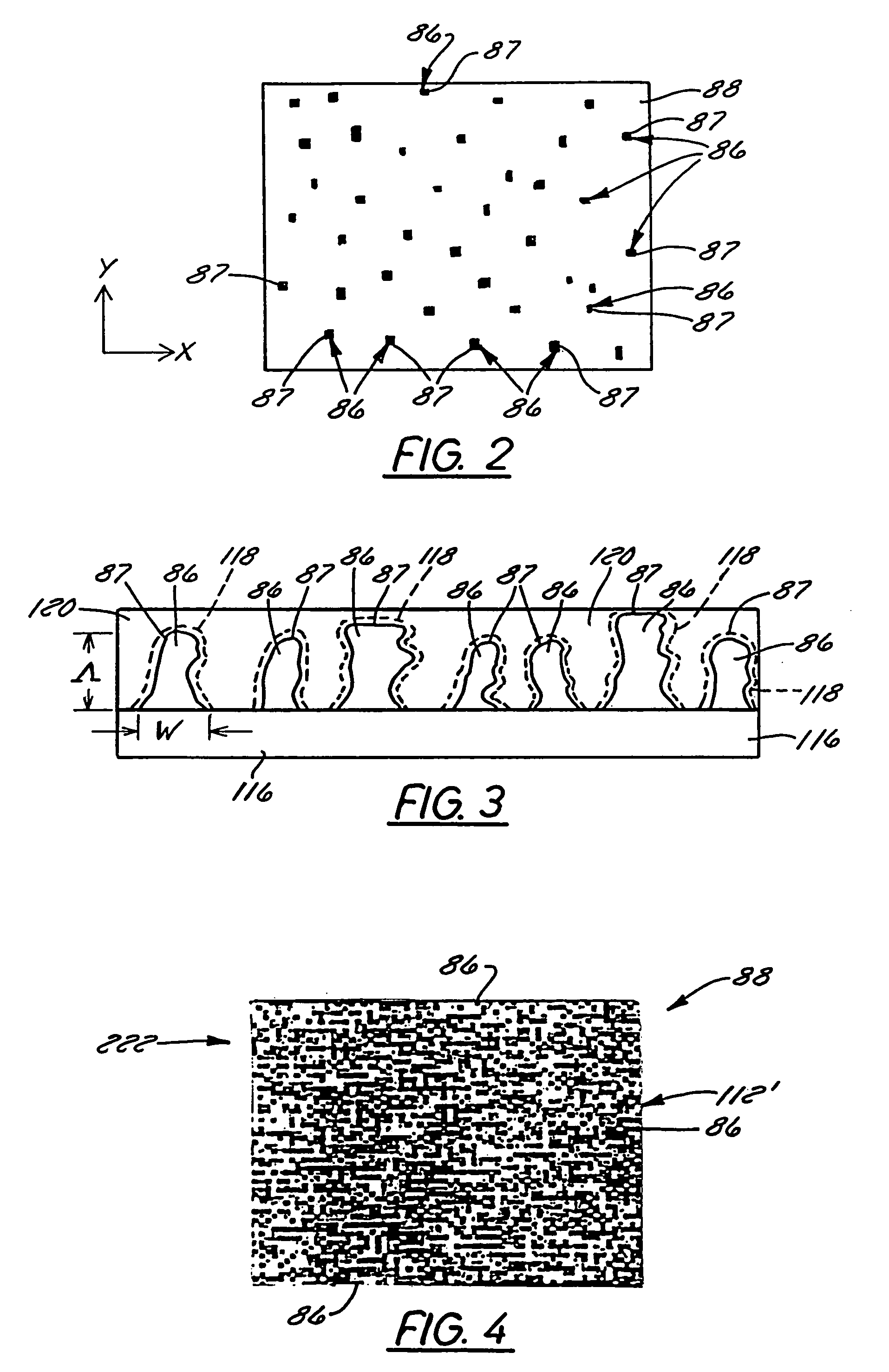

Apertured laminate web

An apertured laminate web which may be used as a topsheet on a disposable absorbent article, such as a diaper. The laminate web is formed of a liquid pervious first material and a liquid pervious second material attached to the first material. The first material has an effective open area of at least about 10% and a plurality of apertures with an effective size of at least than 0.2 square millimeters. The second material has an effective open area of at least about 10% and a plurality of apertures with an effective size of at least 0.2 square millimeters. The apertures of the second material are aligned with the apertures of the first material. The second material preferably has a hydrophilicity which is greater than the hydrophilicity of the first material.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS9364664B2Function increaseShorten the lengthSkin piercing electrodesElectricitySquare Millimeter

Owner:ICHOR MEDICAL SYST

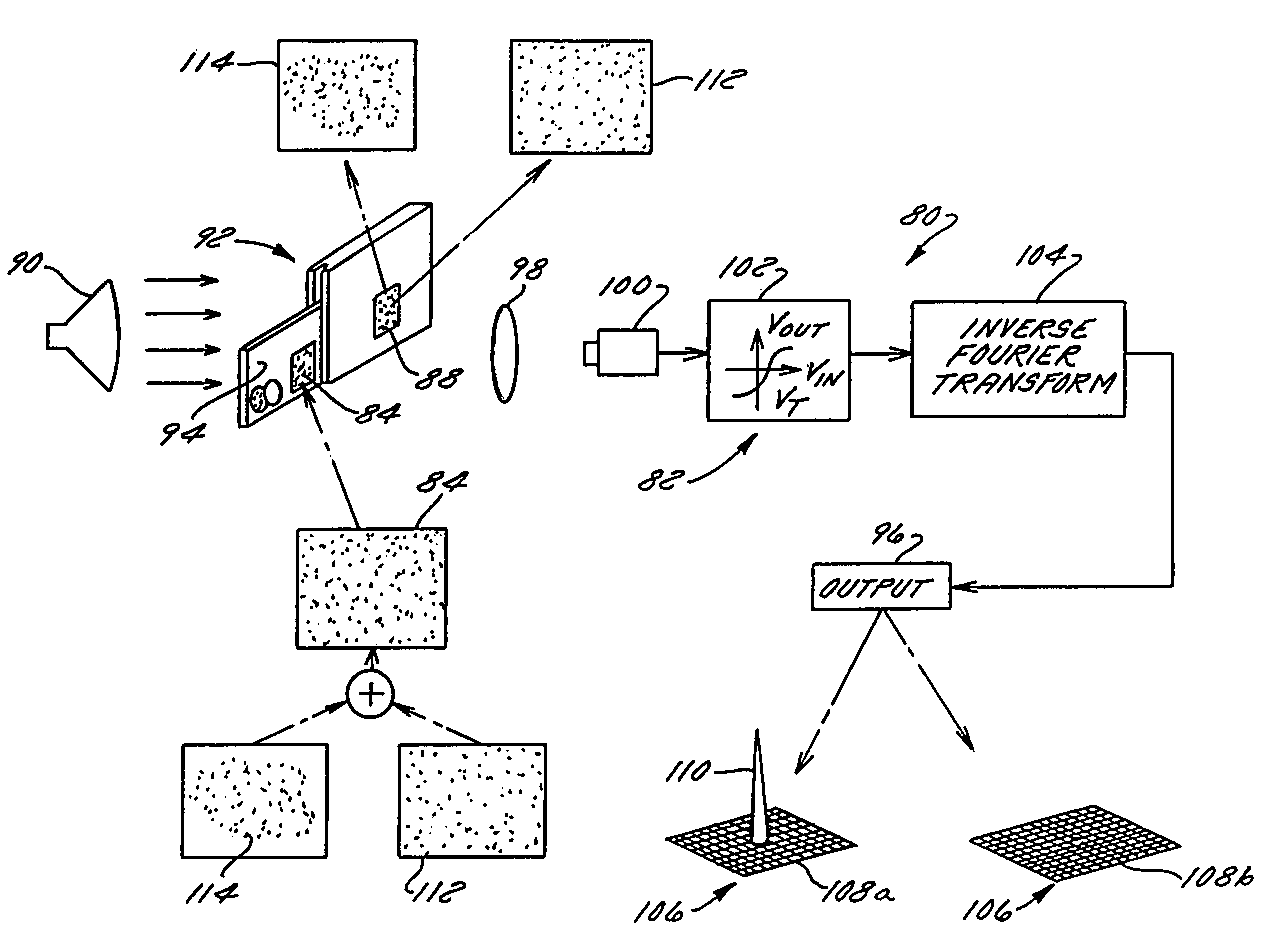

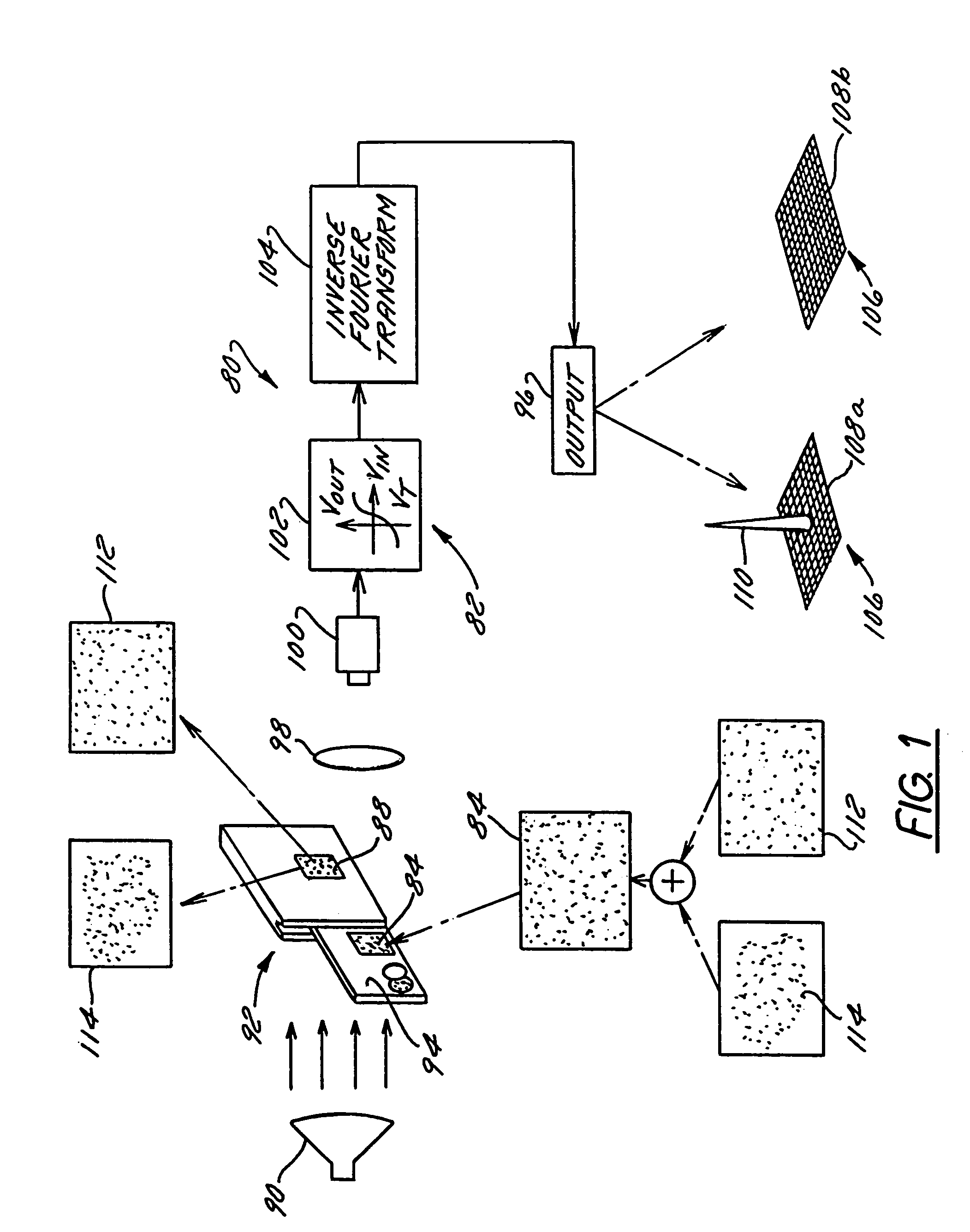

Authentication system and method

InactiveUS7317814B2Cheaply replicatedRaise security concernsRadiation pyrometryCo-operative working arrangementsSpatial light modulatorFourier transform on finite groups

An authentication system using a correlator that correlates an input with a reference wherein at least one of the input and reference comprises a phase volume mask having structures, preferably points, that are each less than about six microns in size and can have an aspect ratio (AR) greater than 1:1 so as to produce a phase encoded random pattern having millions of combinations in a mask that is as small as one square millimeter. The random pattern can be convolved with a second pattern, such as a biometric pattern, to produce a phase convolved mask. The correlator preferably is a nonlinear joint transform correlator that can use “chirp” encoding to permit the input to be located in a different plane than the reference. The correlator optically Fourier transforms images of the reference and input that are thereafter nonlinearly transformed and inverse Fourier transformed by a processor to determine the presence or absence of a correlation spike indicative of authenticity. A spatial light modulator (SLM) can be used as an input or reference and preferably is a liquid crystal panel having pixels or elements whose phase or grey scale intensity can be selectively controlled by a processor. The SLM can be used to display a biometric pattern, preferably scanned in real time from a person, that is correlated against an input or reference that can comprise a label on a card, a tag, or another object.

Owner:PHYSICAL OPTICS CORP

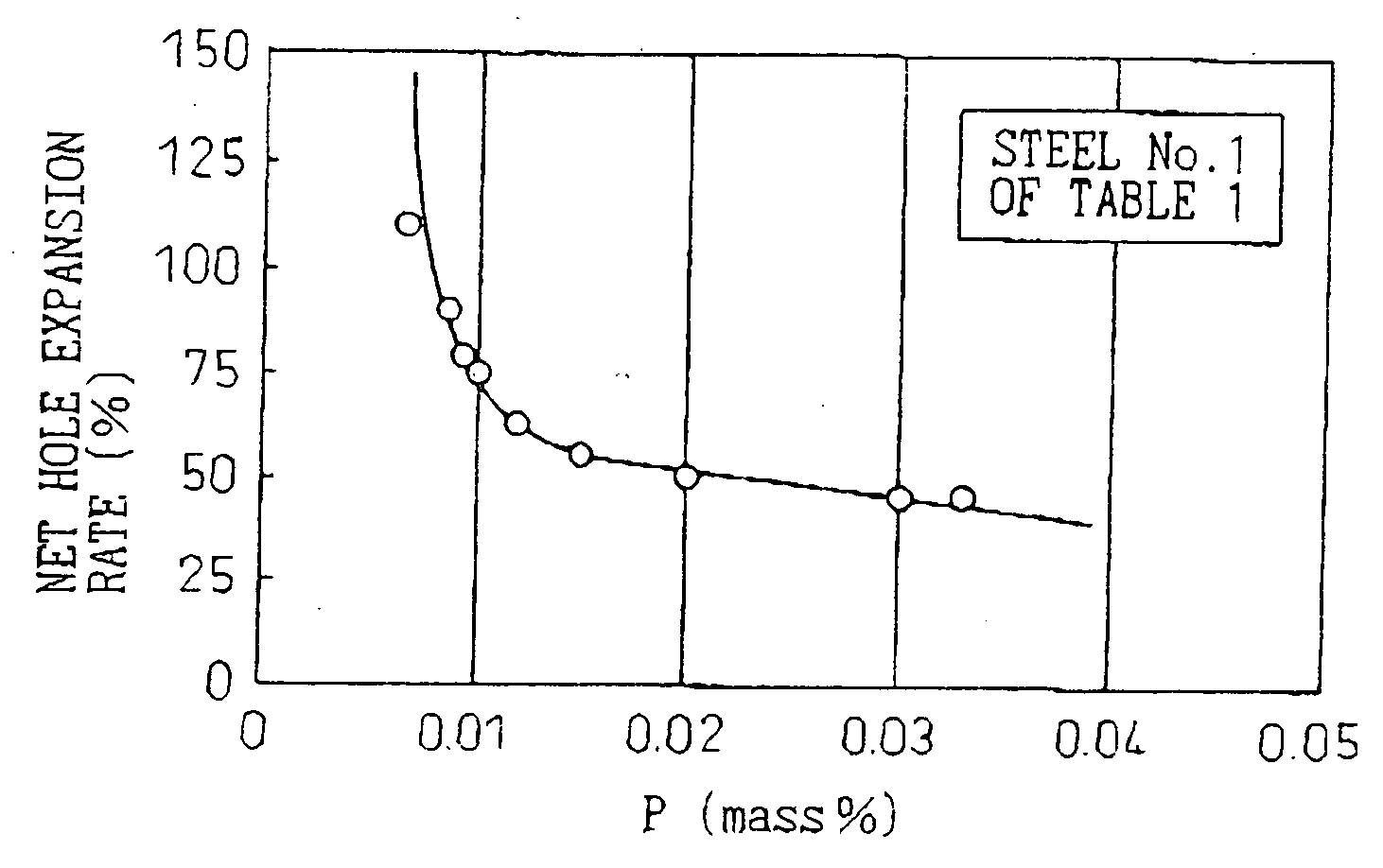

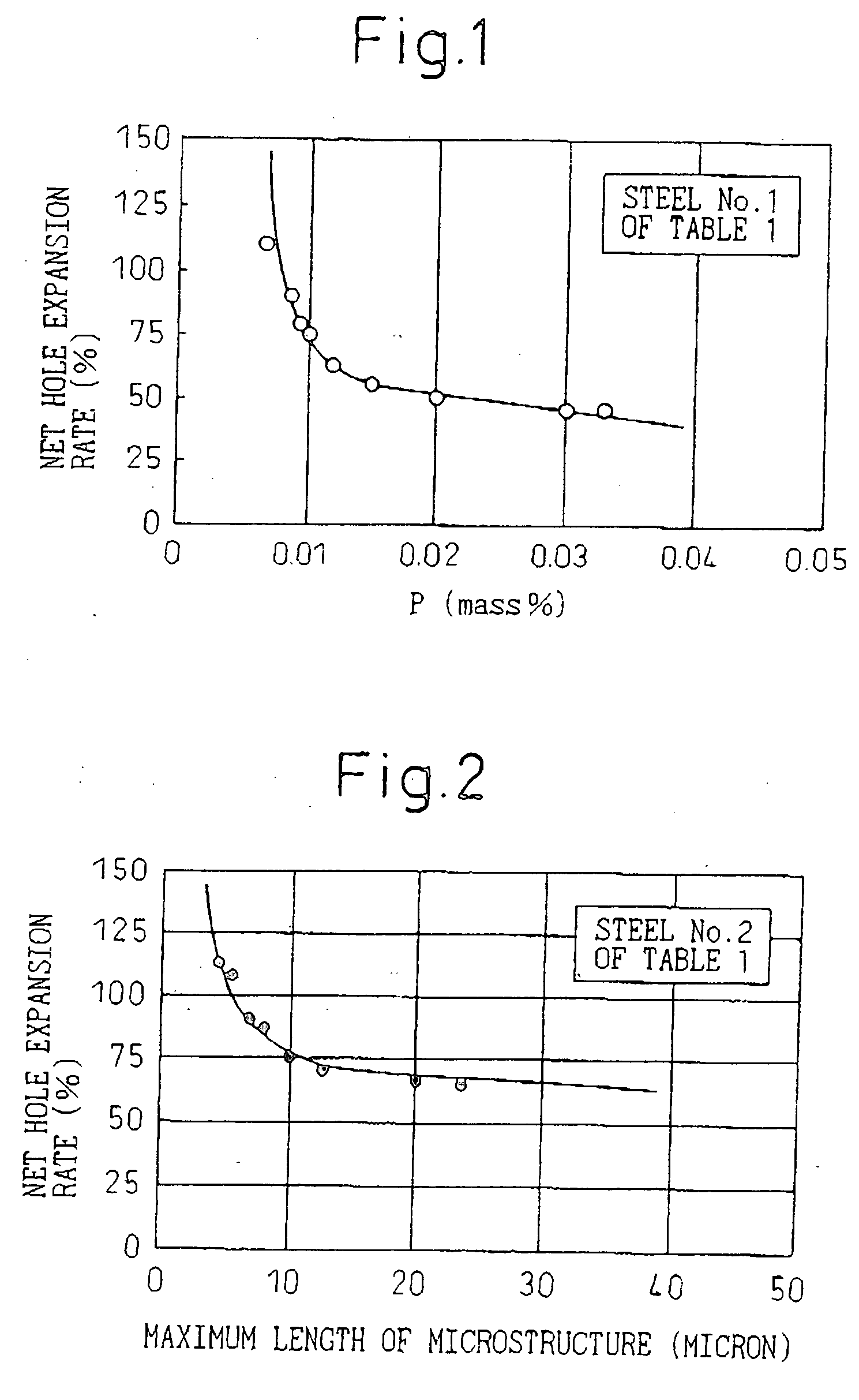

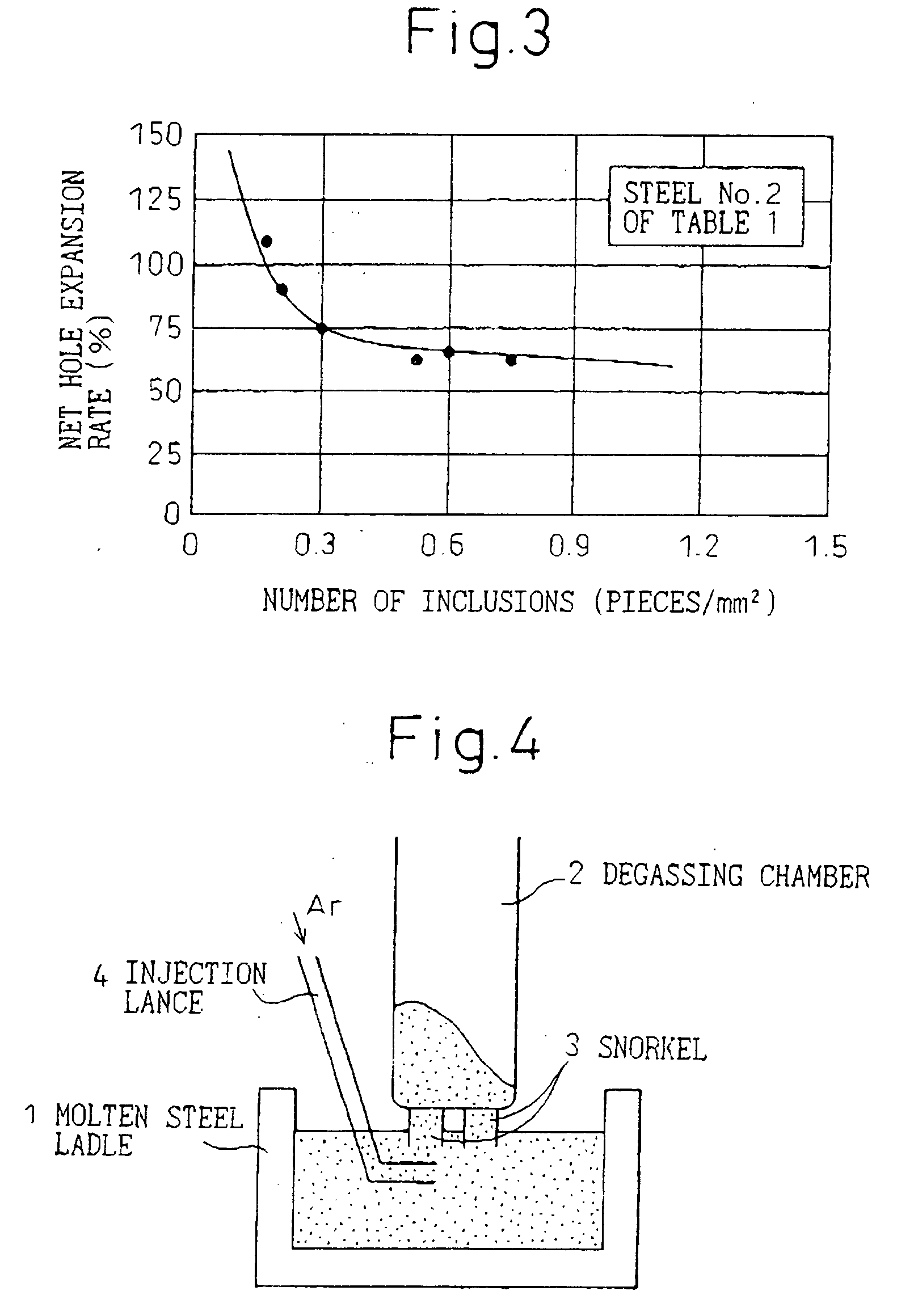

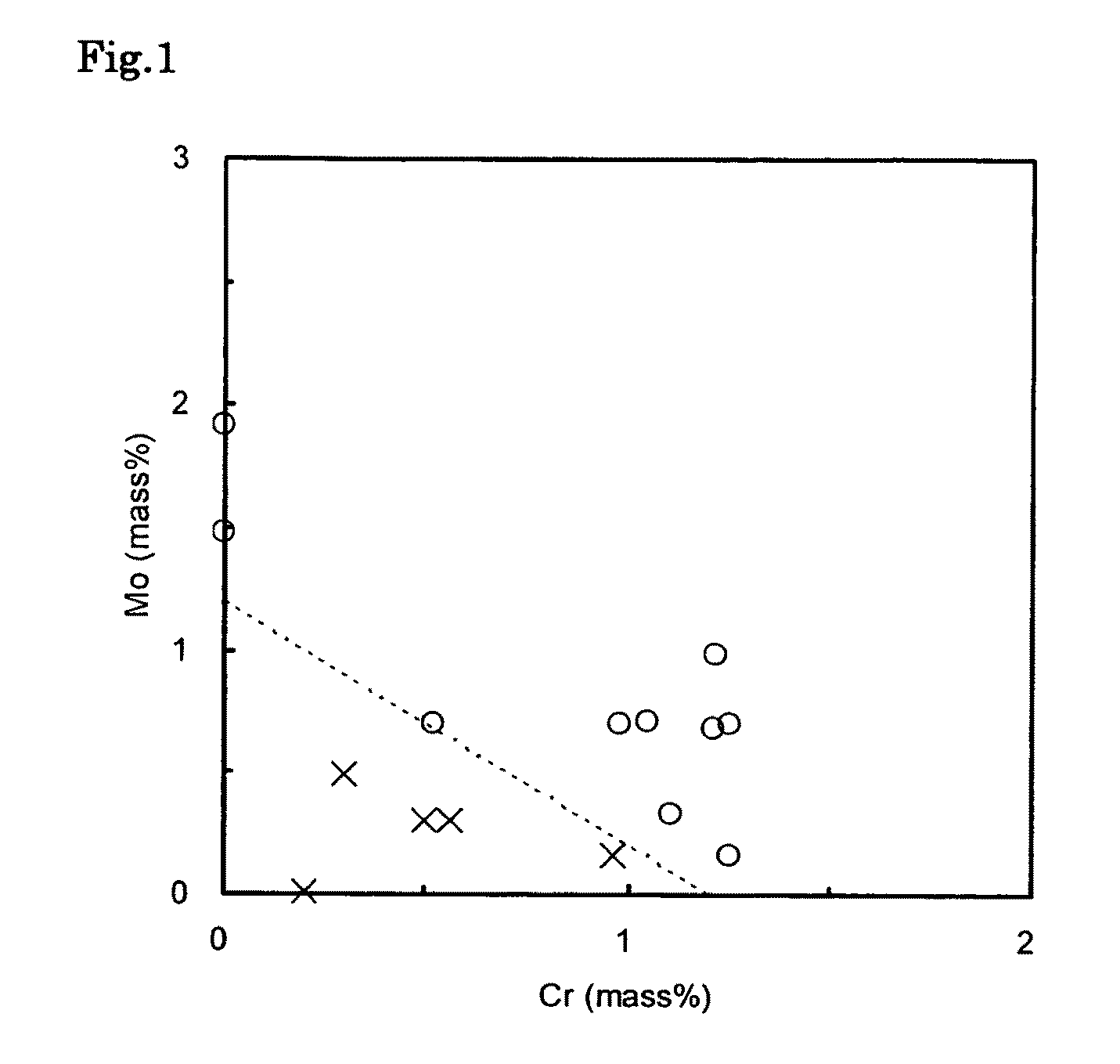

Multi-phase steel sheet excellent in hole expandability and method of producing the same

The present invention provides a steel sheet excellent in both a balance between strength and elongation and a balance between strength and hole expandability, in other words, a multi-phase steel sheet having an excellent balance between strength and hole expandability. The present invention is a multi-phase steel sheet excellent in hole expandability characterized in that: the steel sheet contains, as chemical components in mass, C: 0.03 to 0.15%, P: not more than 0.010%, S: not more than 0.003%, and either one or both of Si and Al in a total amount of 0.5 to 4%, and one or more of Mn, Ni, Cr, Mo and Cu in a total amount of 0.5 to 4%, with the balance consisting of Fe and unavoidable impurities; the microstructure at a section of the steel sheet is composed of either one or both of retained austenite and martensite which account(s) for 3 to 30% in total in area percentage and the balance consisting of either one or both of ferrite and bainite; the maximum length of the crystal grains in the microstructure is not more than 10 microns; and the number of inclusions 20 microns or larger in size at a section of the steel sheet is not more than 0.3 piece per square millimeter.

Owner:NIPPON STEEL CORP

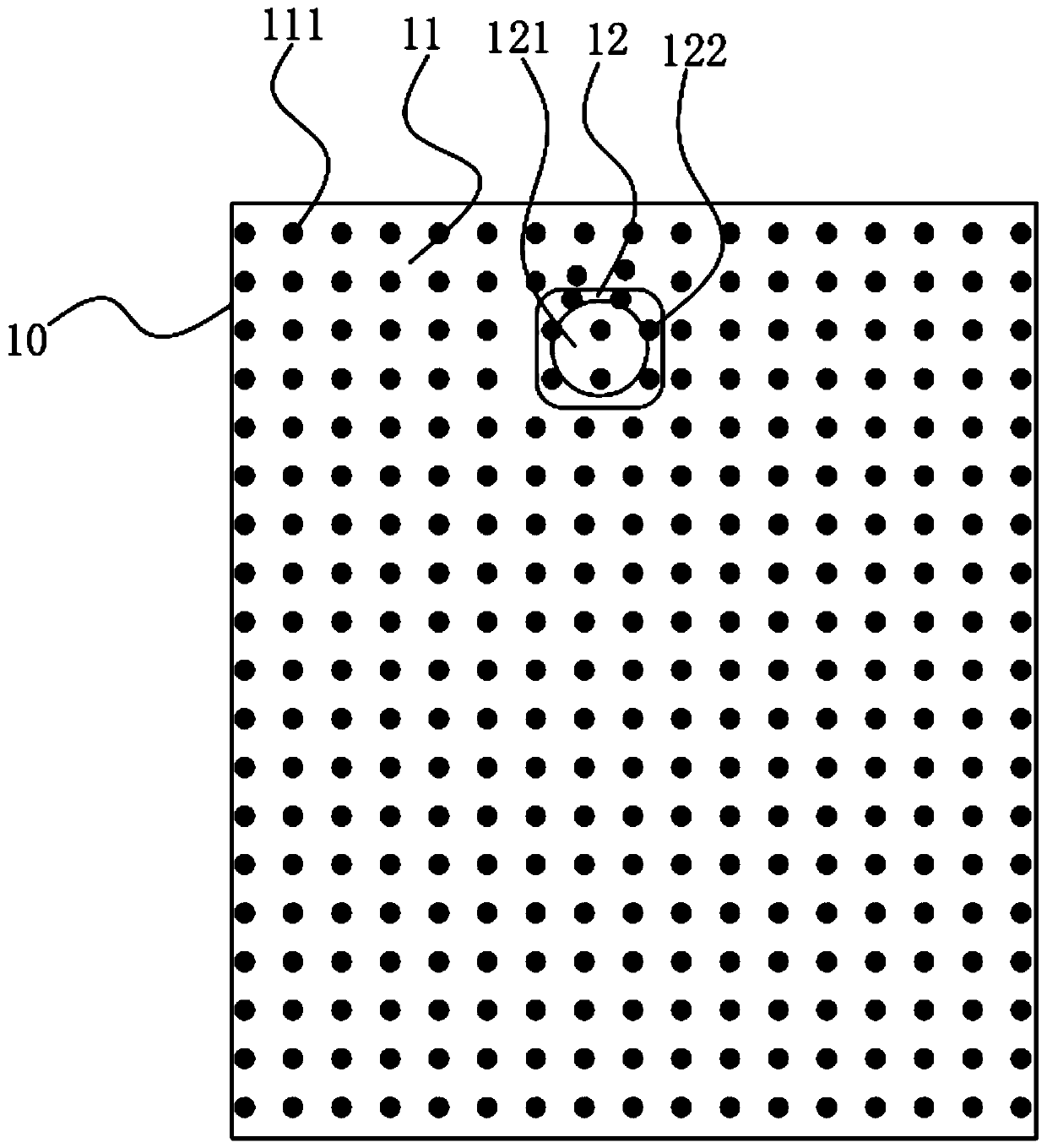

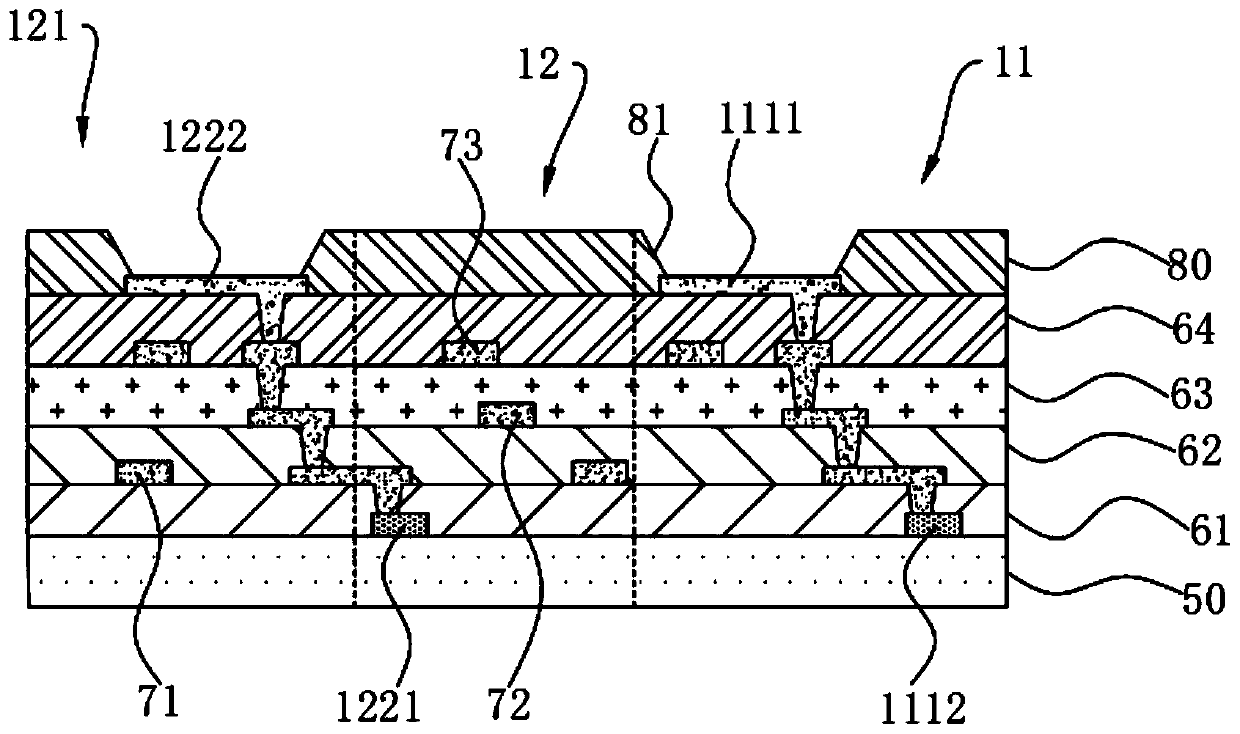

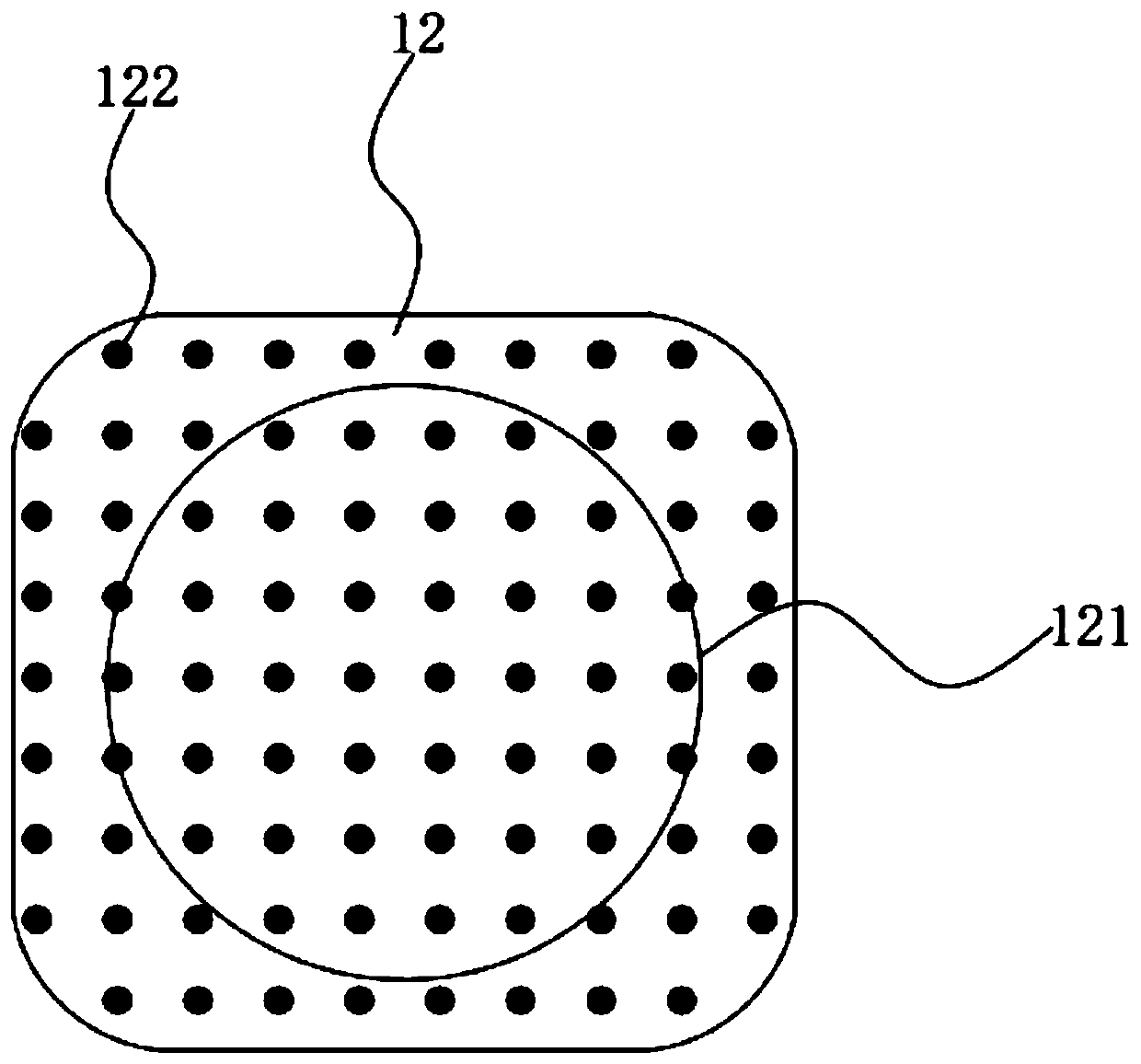

Display device

PendingCN110492018AHigh light transmittanceImprove experienceStatic indicating devicesSolid-state devicesSquare MillimeterDisplay device

A display device includes a display panel including a main display area and a function additional area, at least a portion of the function additional area being surrounded by the main display area; wherein a plurality of first pixels are arranged in the function additional area, at least one light-transmitting area is arranged in the function additional area, and the area of each light-transmitting area is larger than or equal to 0.32 square millimeter. By reasonably setting the shape and area of the light-transmitting area and limiting the area of the first anode located in the light-transmitting area, it is guaranteed that the function additional area can be used for displaying images, and therefore the display panel can show the full-screen display effect and can also be used for installing a camera and other photosensitive elements, and the user experience is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

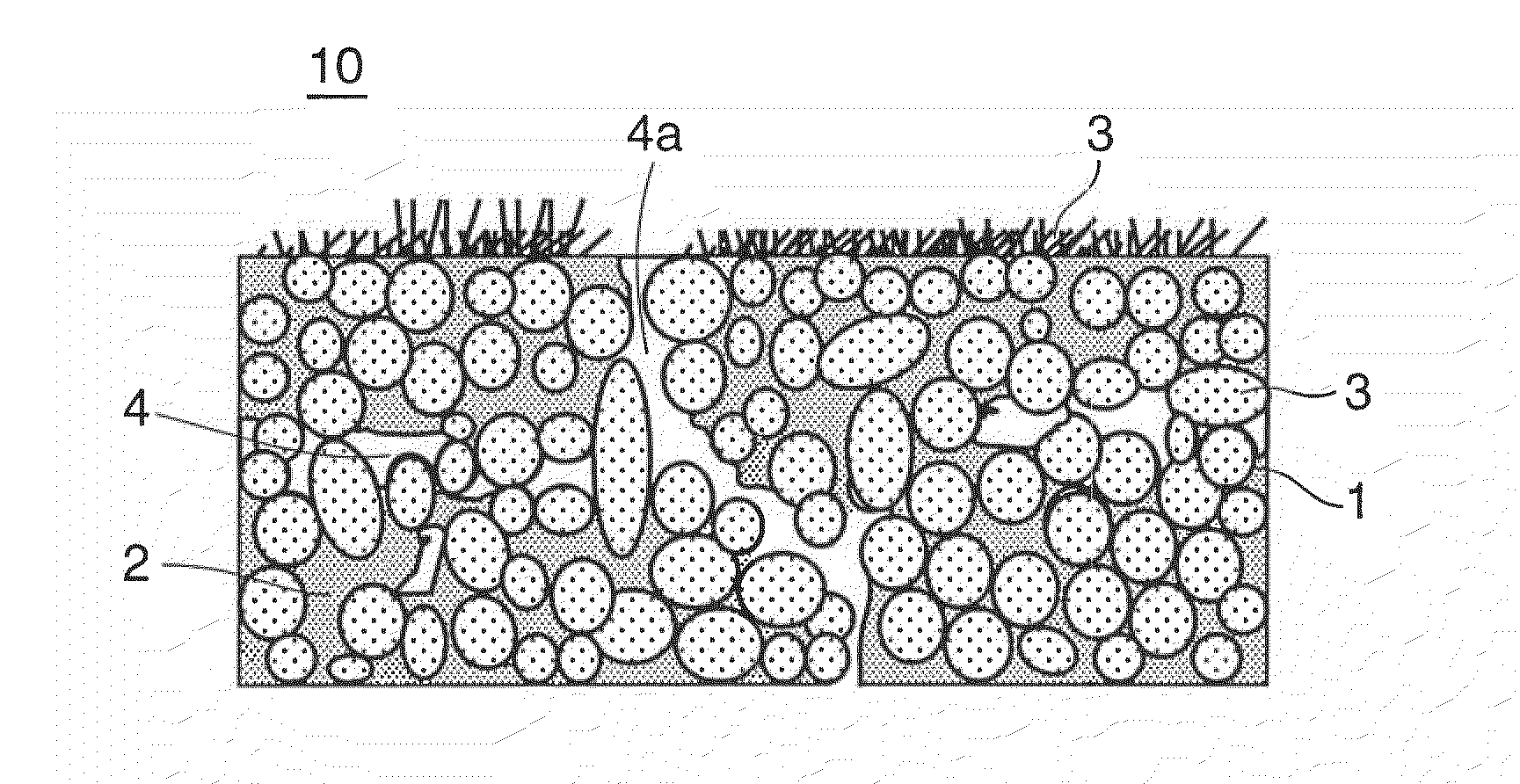

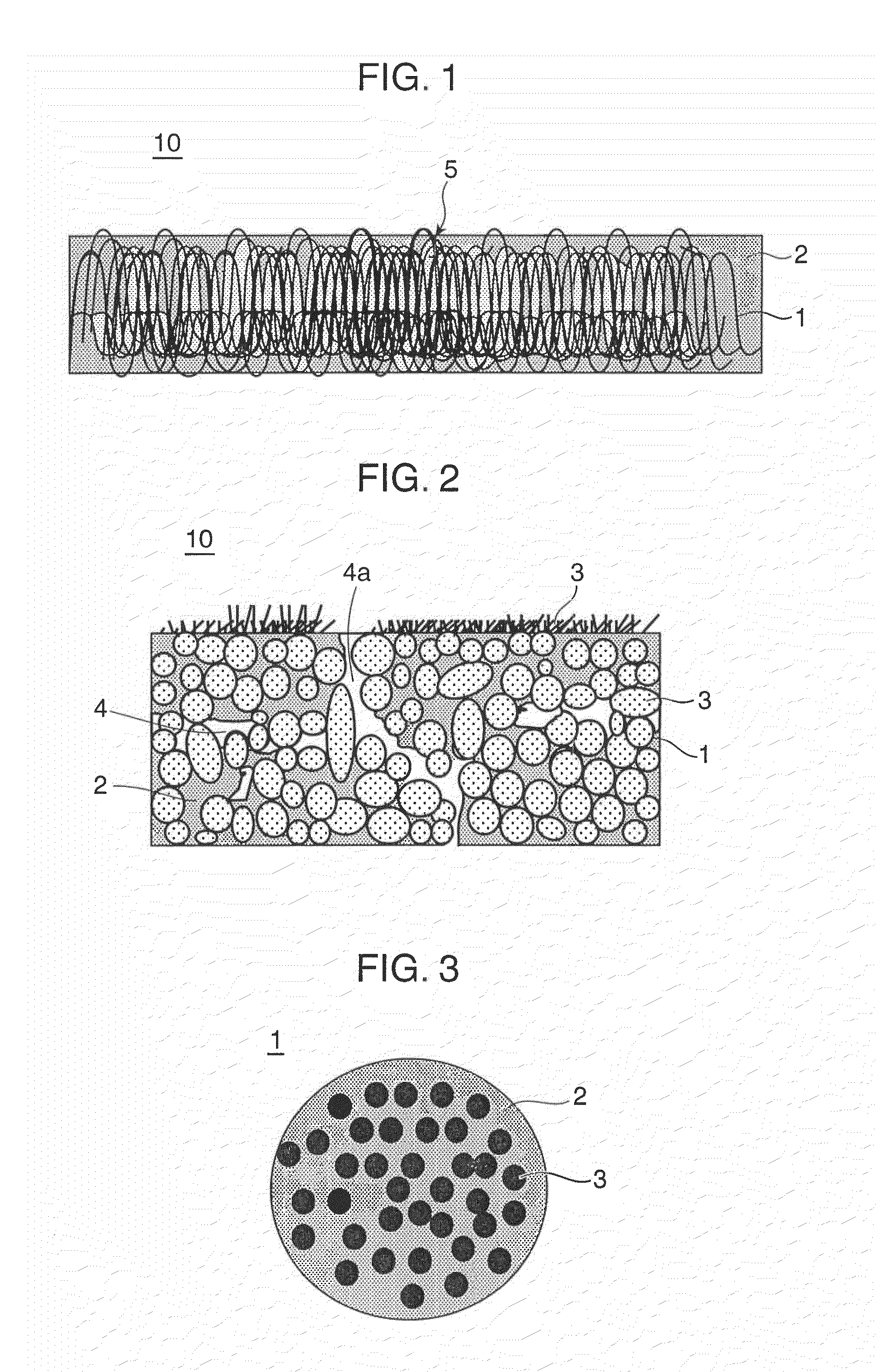

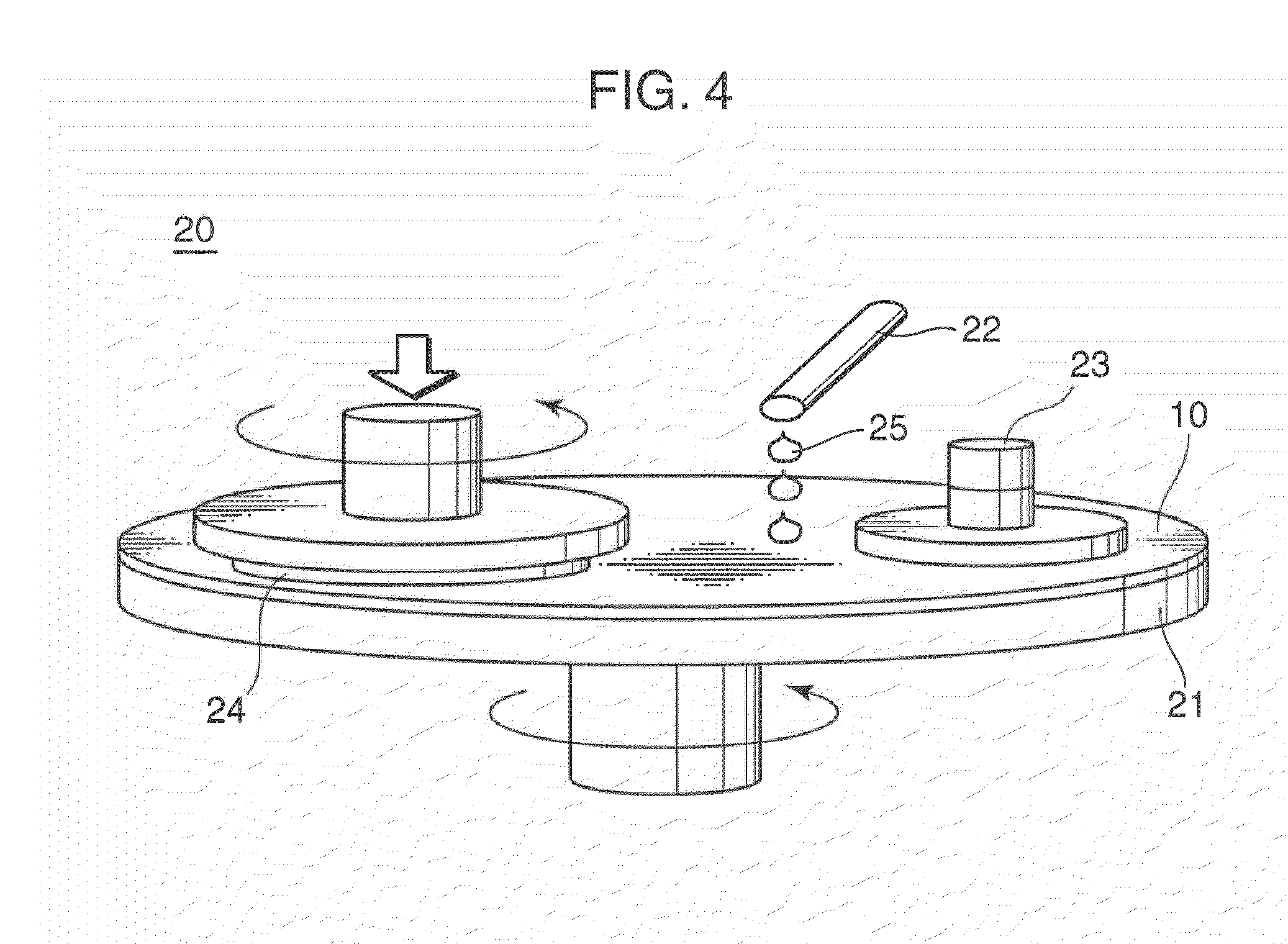

Polishing pad, and method for manufacturing polishing pad

ActiveUS20100087128A1Scratch resistantImprove flattening effectRevolution surface grinding machinesSemiconductor/solid-state device manufacturingElastomerFiber bundle

It is an object of the present invention to provide a polishing pad that is resistant to scratching and also has excellent flattening performance. One aspect of the present invention is a polishing pad, comprising a fiber-entangled body formed from fiber bundles made up of ultrafine fibers in which the average cross sectional area is between 0.01 and 30 μm2, and a macromolecular elastomer, wherein part of the macromolecular elastomer is present inside the fiber bundles, whereby the ultrafine fibers are bundled, the number of fiber bundles per unit of surface area present in a cross section in the thickness direction is at least 600 bundles per square millimeter, and the volumetric ratio of a portion excluding voids is between 55 and 95%.

Owner:KURARAY CO LTD

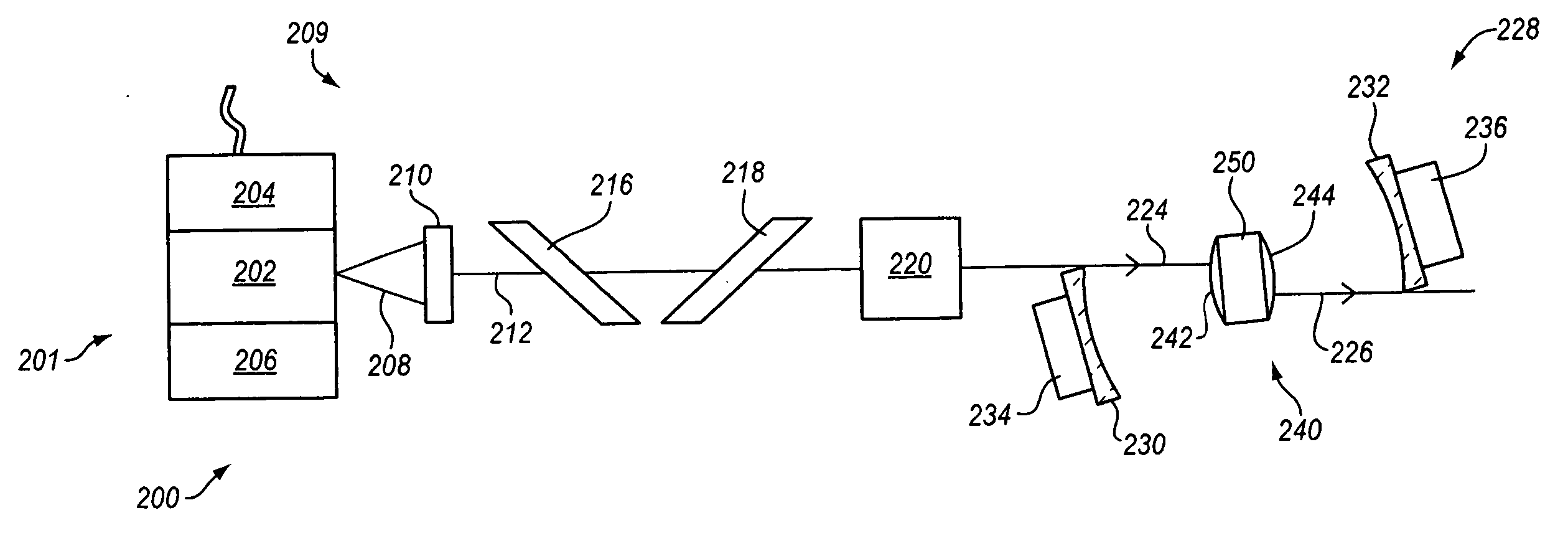

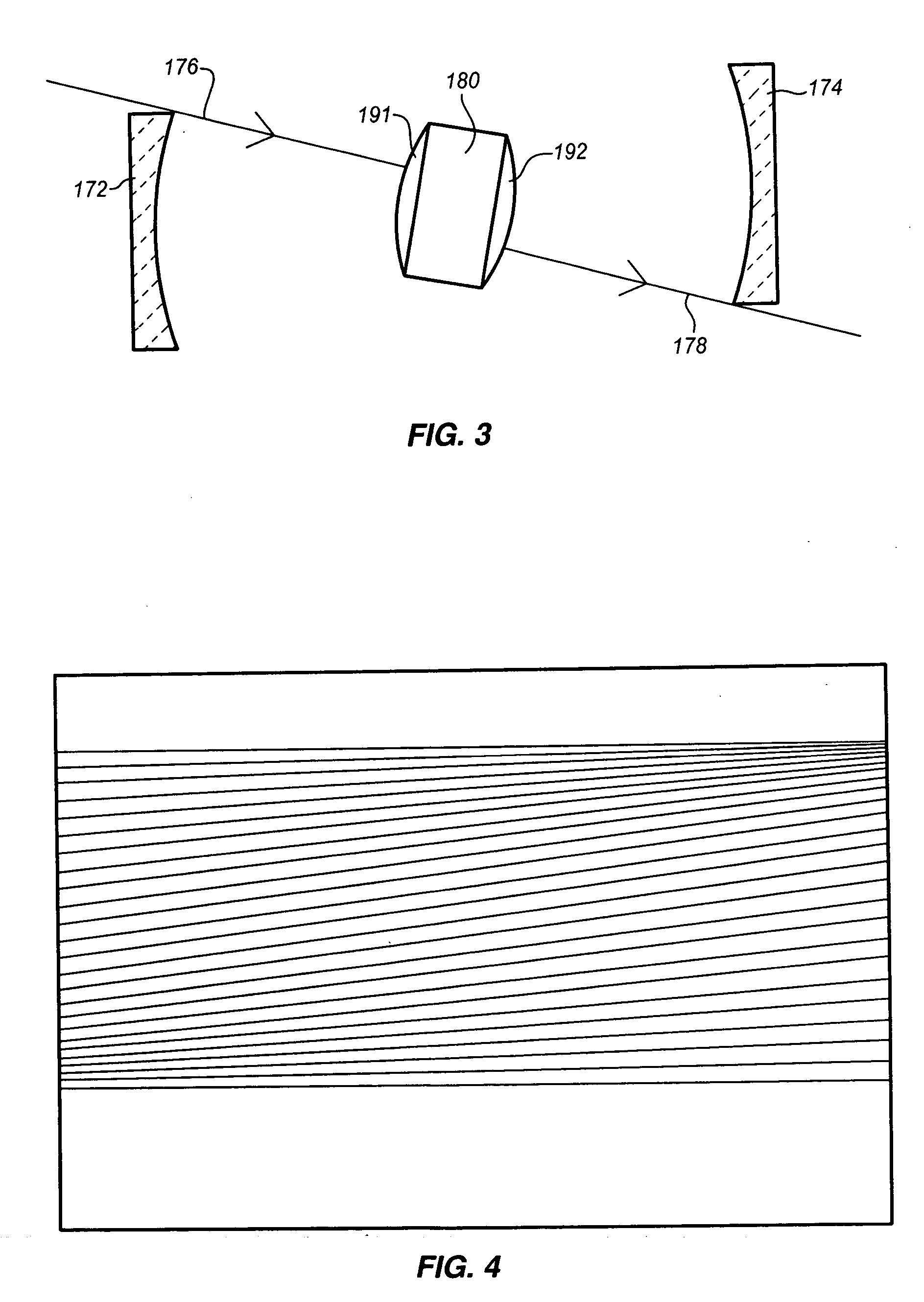

Particle counter with improved image sensor array

ActiveUS20060274309A1Improve signal-to-noise ratioFast countScattering properties measurementsParticle size analysisDetector arrayMultiple pass

A particle counter for optically detecting an unconstrained particle of less than one micron in size suspended in a flowing liquid includes a sample chamber having a fluid inlet and a fluid outlet; a laser module producing a laser beam; a beam shaping optical system providing a multiple laser beam pattern in the sample chamber, and a CMOS optical detector located to detect light scattered by the particles in the sample chamber, the detector producing an electric signal characteristic of a parameter of the particle. The particle counter has a particle sensing area within the sample chamber in which the intensity of light is at least 10 Watts / mm2, the sensing area having an area of 0.5 square mm or more. The detector has thirty or more detector array elements. In the preferred embodiment, the laser optical system reflects and refocuses the laser beam to effect multiple passes of the same laser beam through the sensing area.

Owner:PARTICLE MEASURING SYST

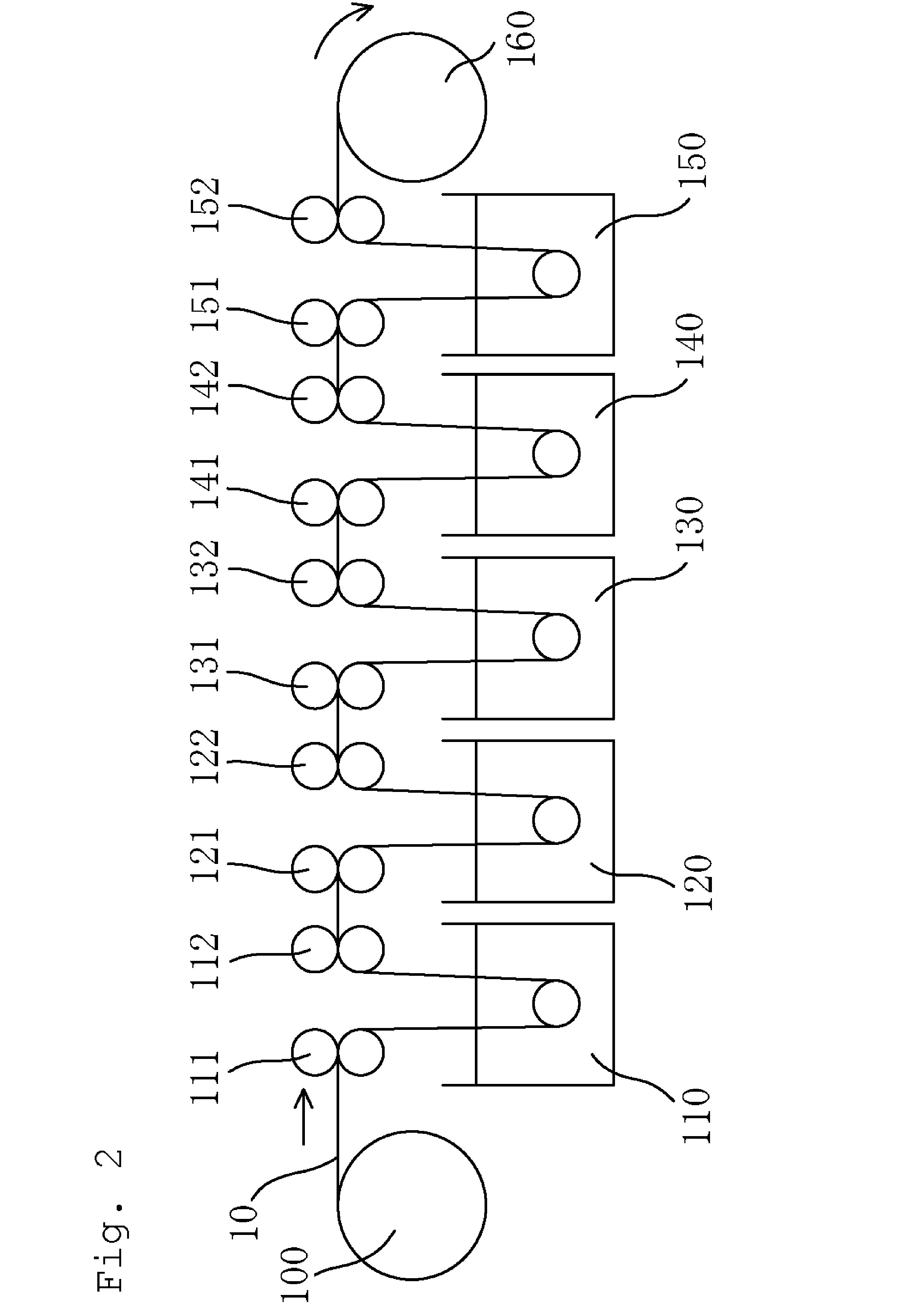

Method for regenerating spinnable fibers from blended worn-out garments

InactiveCN103924326ASolve pollutionSolve environmental problemsTextile disintegration and recoveryFibre disintegrationFiberSquare Millimeter

The invention relates a method for regenerating spinnable fibers from blended worn-out garments. The method includes: sterilizing the worn-out garments, removing buttons, cutting the garment into cut cloth 50-100 square millimeters, using a feeding roller and an opening licker-in to continuously perform opening twice so as to allow the large tangled fibers of the cut cloth to be opened into small or bunchy fibers, using the feeding roller and a carding licker-in to continuously perform disintegration and carding for four times so as to allow the fibers of the cut cloth to be further disintegrated and carded, and obtaining the reusable spinnable fibers. The method has the advantages that the problem that manual operation is high in cost is solved, production efficiency is increased by dozens of times, high automation level is achieved, intelligent production is preliminarily achieved, the problem of impurity pollution is solved, environmental protection is achieved, the whole process is clean and environmentally friendly, and the obtained spinnable fibers are longer and fewer in nep as compared with the fibers processed by traditional processing processes.

Owner:北京中民慈善项目发展中心 +1

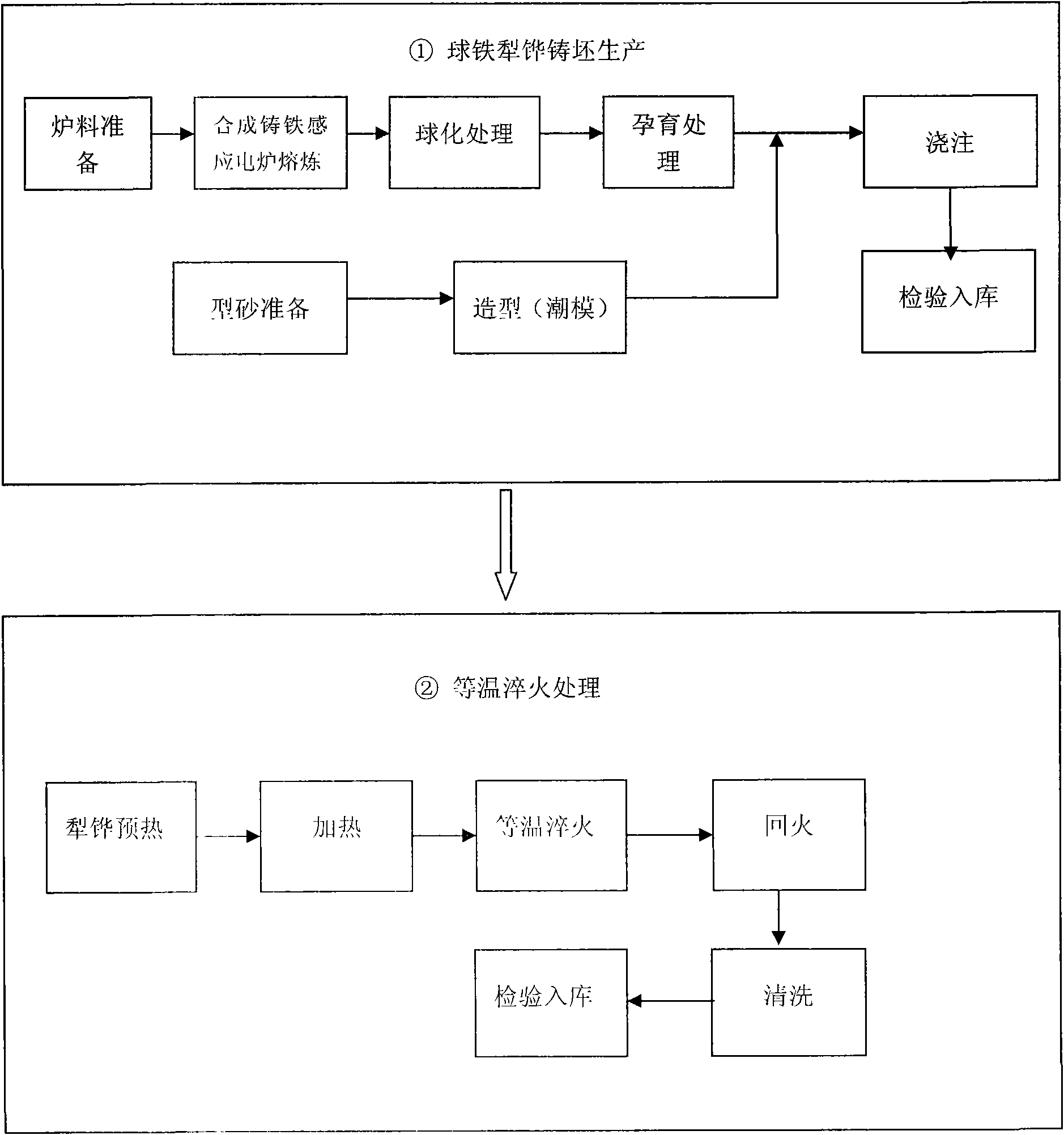

Carbide-containing austempered ductile iron plowshare and production method thereof

The invention discloses a carbide-containing austempered ductile iron plowshare, which uses austempered ductile iron as a raw material, wherein the ductile iron comprises the following chemical components in percentage by weight: 3.40 to 3.80 percent of C, 2.20 to 2.80 percent of Si, 0.20 to 0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.02 percent of S, 0.03 to 0.04 percent of Mg, 0.01 to 0.02 percent of Re, 0.25 to 0.5 percent of Cr, and the balance of Fe; the graphite metallurgical structure in the ductile iron is characterized by a spheroidization rate of above grade-2, a graphite size of above grade-6 and a graphite quantity of more than 100 per square millimeters. The matrix of the ductile iron is martensite and lower bainite and residual austenite and carbide, wherein the carbide is less than 2 weight percent. The carbide-containing austempered ductile iron plowshare has the advantages of improving the conventional process for finely casting plowshares by using low alloy steel in the past, having a service life which is more than three times as long as that of the low alloy steel plowshares and a price as low as two thirds of that of the low alloy steel plowshares and greatly reducing agricultural production cost.

Owner:宣化冶金工业有限责任公司

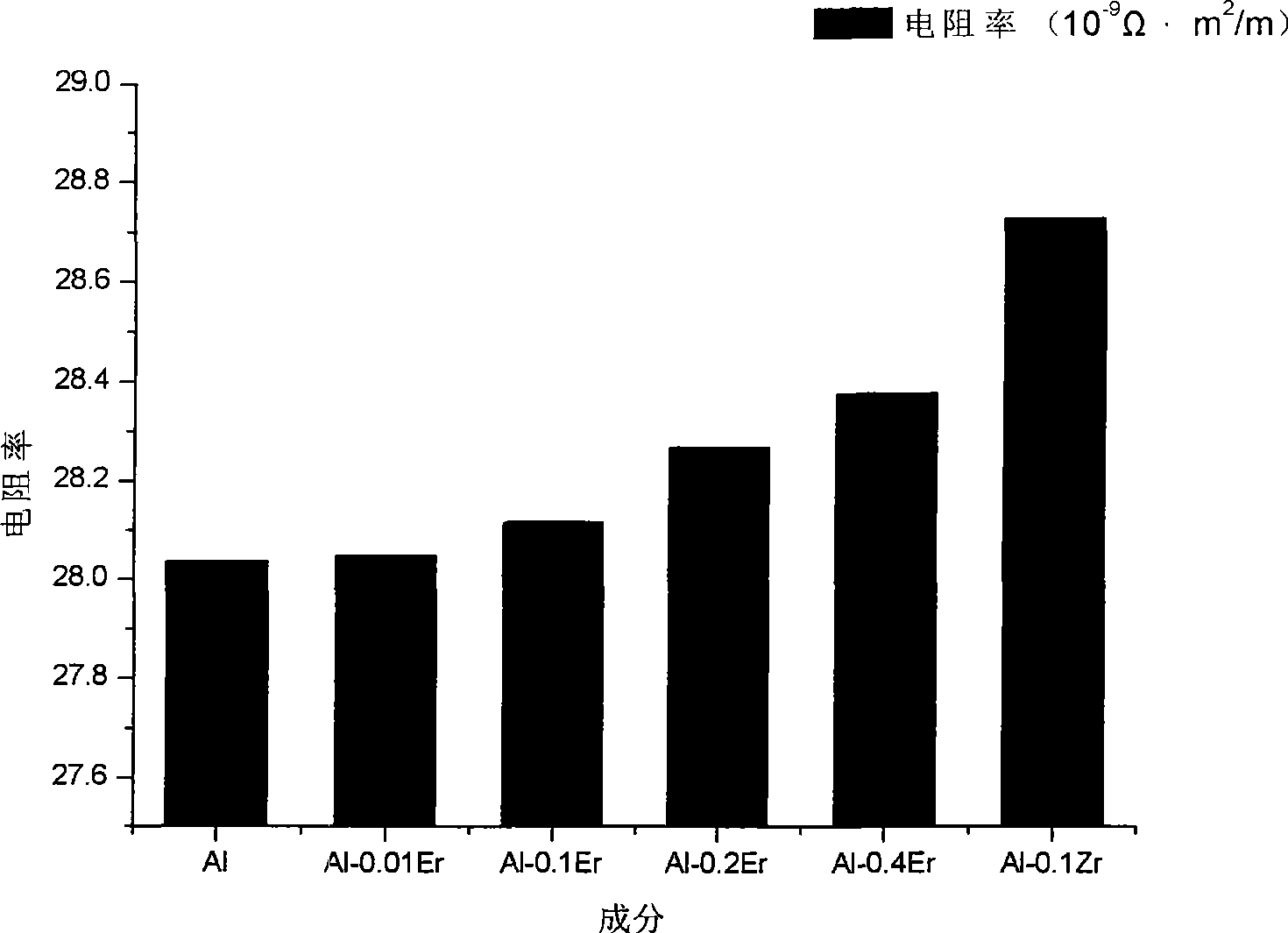

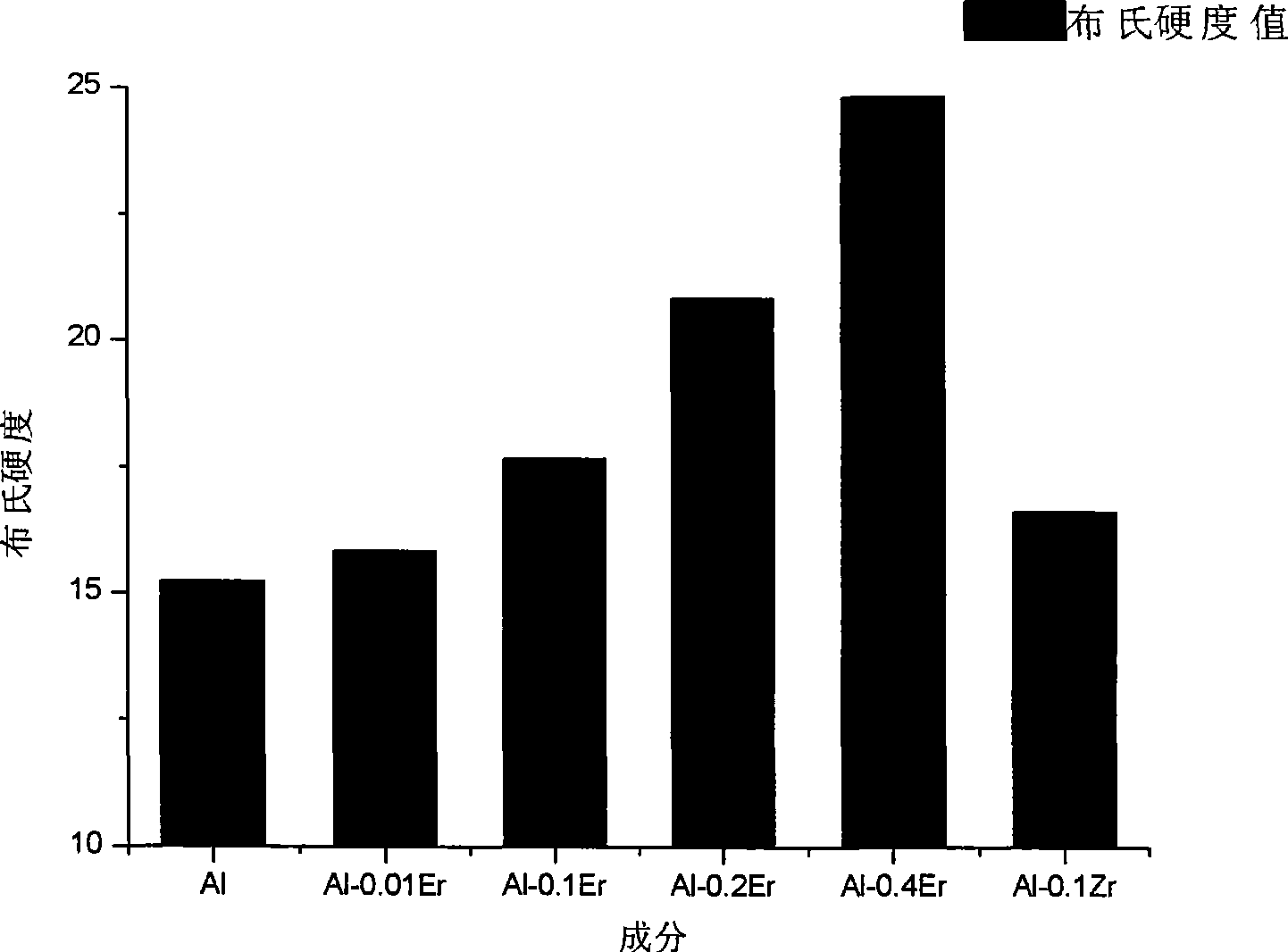

Al-Er alloy conductor material and preparation method thereof

The invention relates to an Al-Er alloy conducting wire material and a preparation method thereof, and belongs to the technical field of metal alloy. The function of Er in an aluminum alloy conducting wire is not reported up to the present. The invention discloses a material for the aluminum alloy conducting wire, which comprises the following chemical compositions: 0.01 to 0.4 weight percent of erbium, the balance being Al and unavoidable impurity. The conducting wire with required specification is prepared by smelting, founding and cold-hot processing. The hardness of the conducting wire is 15.83 to 24.82 HBS; the specific resistance of the conducting wire is 0.02806 to 0.02837 ohm square millimeter in per meter; and the electric conductivity of the conducting wire is 60.8 to 61.4 percent IACS. The alloy is a material with favorable cost performance and huge potential for application on high-strong heat-resisting aluminum alloy conducting wires.

Owner:BEIJING UNIV OF TECH

Aerosol particle sensor with axial fan

ActiveUS20070229825A1Low costSmall sizeSamplingScattering properties measurementsSquare MillimeterCollection system

A particle sensor for optically detecting an unconstrained particle suspended in a flowing gas includes a sample chamber having a gas inlet and a gas outlet; a gas flow system for flowing said gas from said gas inlet through said sample chamber to said gas outlet, a source of light; an optical system directing said light through said sample chamber, an optical collection system located to collect light scattered by said particles in the gas, and a detection system located to detect the collected light. The total pressure drop through said gas flow system is 3 inches of water or less. The gas flow system includes an axial fan, which may be a high static pressure fan or a counter-rotating fan. In a 1.0 CFM system, the gas inlet nozzle has an area of 25 square millimeters or more.

Owner:PARTICLE MEASURING SYST

Refrigerating machine oil combination and preparation method thereof

ActiveCN101177643AImprove solubilityGood fluidity at low temperatureLiquid hydrocarbon mixtures productionBase-materialsAlkaneSolubility

The invention relates to a refrigerant machine oil composition, comprising a mixed Alpha olefin polymer oil which is adopted as base oil and additive, wherein, a viscosity of the mixed Alpha olefin polymer oil at 40 DEG C ranges from 3 square millimeter per second to less than 6 square millimeter per second; the mixed Alpha olefin polymer oil is C15-C22 mixed isoolefine, C15-C22 mixed isoparaffin or the mixture of C15-C22 mixed isoolefine and C15-C22 mixed isoparaffin. The refrigerant machine oil composition provided by the invention has the advantages that: (1) good solubility with R600A refrigerating fluid, and floc point being lowered to minus 70 DEG C; (2) excellent fluidity in low temperature, with a pour point lowering to minus 70 DEG C, and a kinematic coefficient of the viscosity being less than 500 square millimeter per second at minus 40 DEG C; (3) comparatively apparent energy saving effect which is respectively higher than the refrigerant machine oil with a viscosity of 22 and 10 square millimeter per second by 14 percent and 4 percent at 40 DEG C.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

Thin polarizing film, optical laminate with thin polarizing film, and production method for thin polarizing film

ActiveUS20130128357A1Raise the ratioGood mannersOptical articlesPolarising elementsIon chromatographySquare Millimeter

The present invention provides a thin polarizing film which has only a small environmental load and has excellent optical characteristics.The thin polarizing film is produced by forming a polyvinyl alcohol-based resin layer on a thermoplastic resin substrate. The thin polarizing film has a thickness of 10 μm or less, a single axis transmittance of 42.0% or more, a polarization degree of 99.95% or more, and an iodine content of 17.6 grams per 400×700 square millimeters or less, which is measured by an ion chromatography method.

Owner:NITTO DENKO CORP

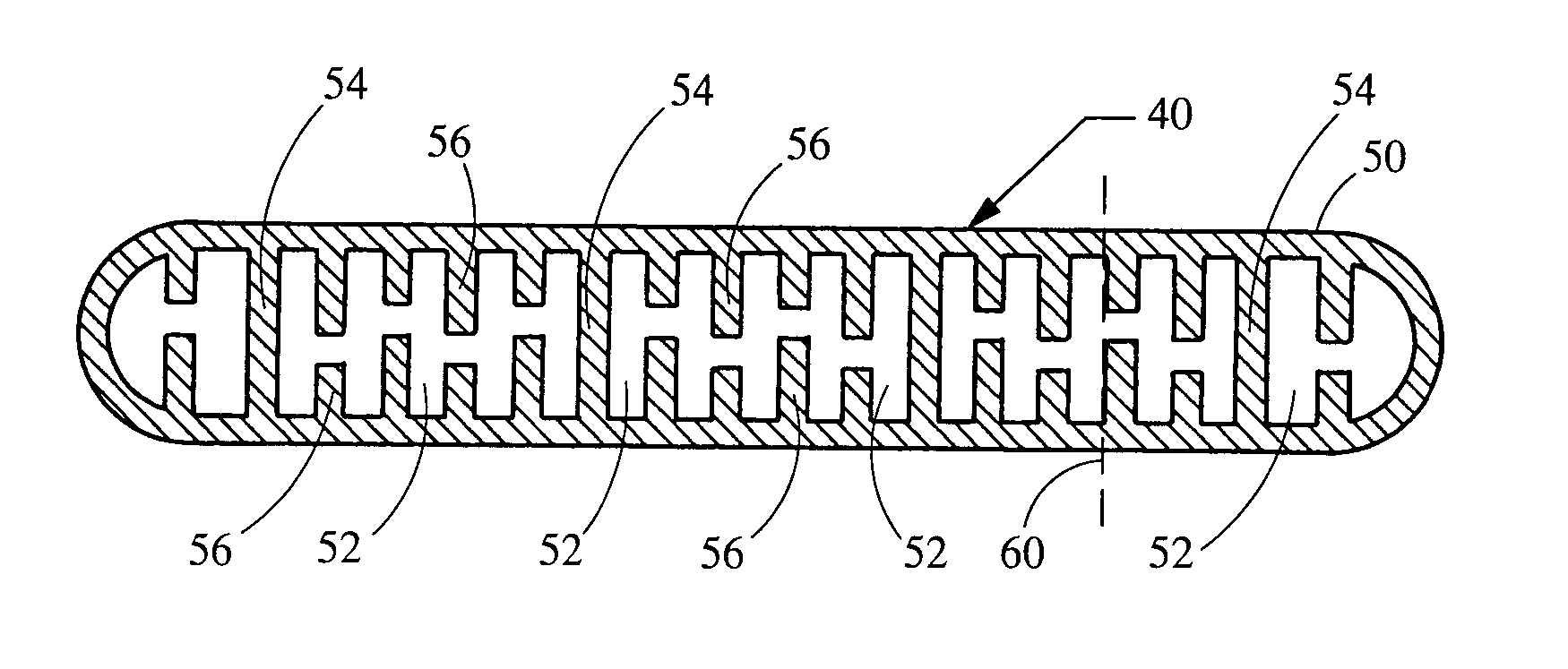

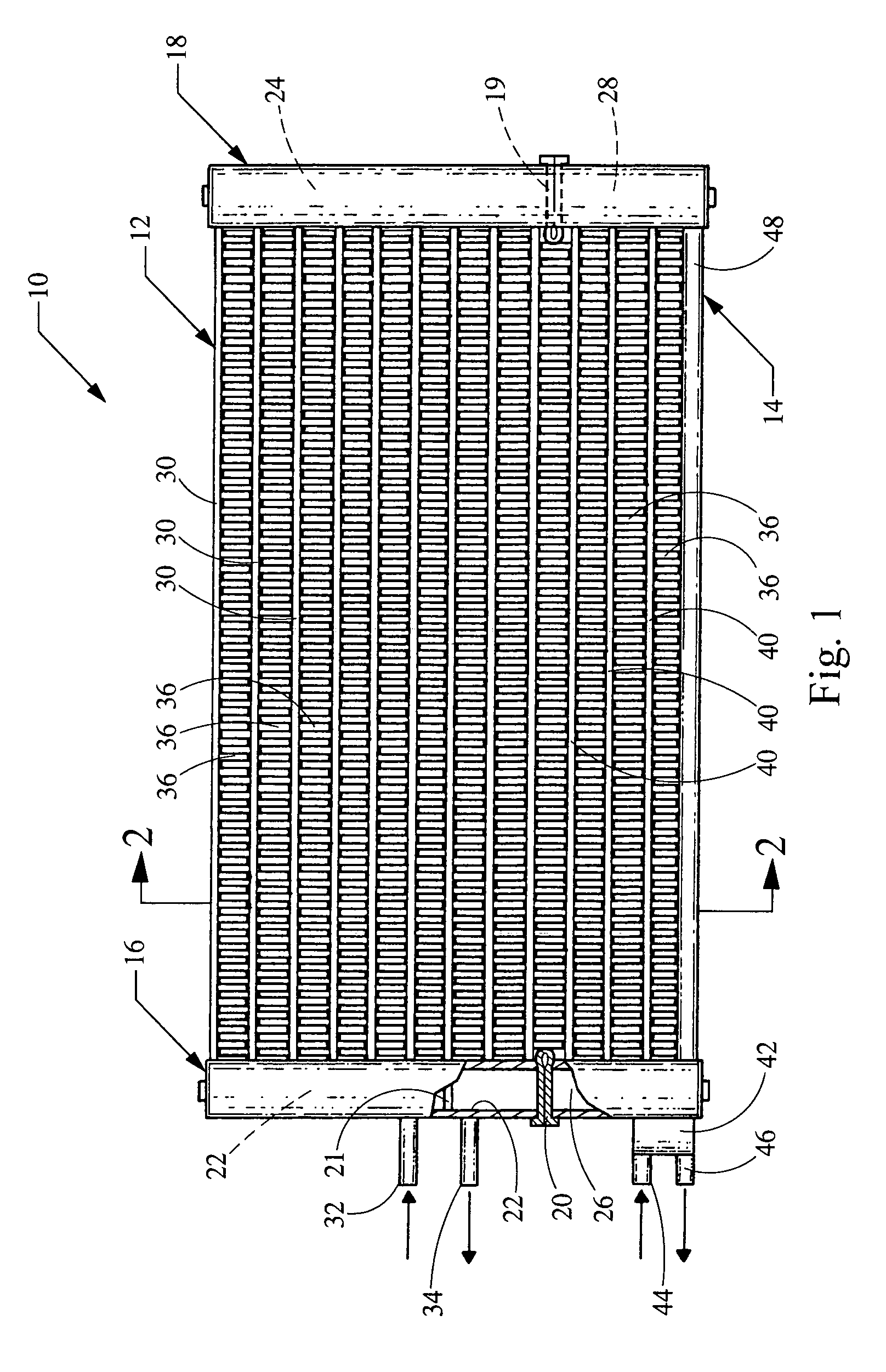

Automotive heat exchanger

ActiveUS7073570B2Improve cooling efficiencyShorten the lengthHeat exhanger finsStationary conduit assembliesSquare MillimeterPlate heat exchanger

A heat exchanger includes a first section and a second section for cooling distinct fluids, wherein the second section is adapted for cooling oil. The heat exchanger includes first and second manifolds divided by baffles into first and second chambers. A plurality of tubes connect the manifolds in fluid communication with the first chambers to form the first section of the heat exchanger. A plurality of oil cooling tubes connect the manifolds in fluid communication with the second chambers to form the second section. The oil cooling tubes have a cross-section characterized by a performance ratio between about 3.9 and 8.5 wherein the performance ratio is the ratio of the wetted perimeter in millimeters divided by the cross-sectional area of tube metal in square millimeters. The oil cooling tubes may be formed of extruded metal with internal fins or an extruded tube having a stamped metal insert.

Owner:HANON SYST

Method of producing an aperture plate for a nebulizer

Owner:STAMFORD DEVICES LTD

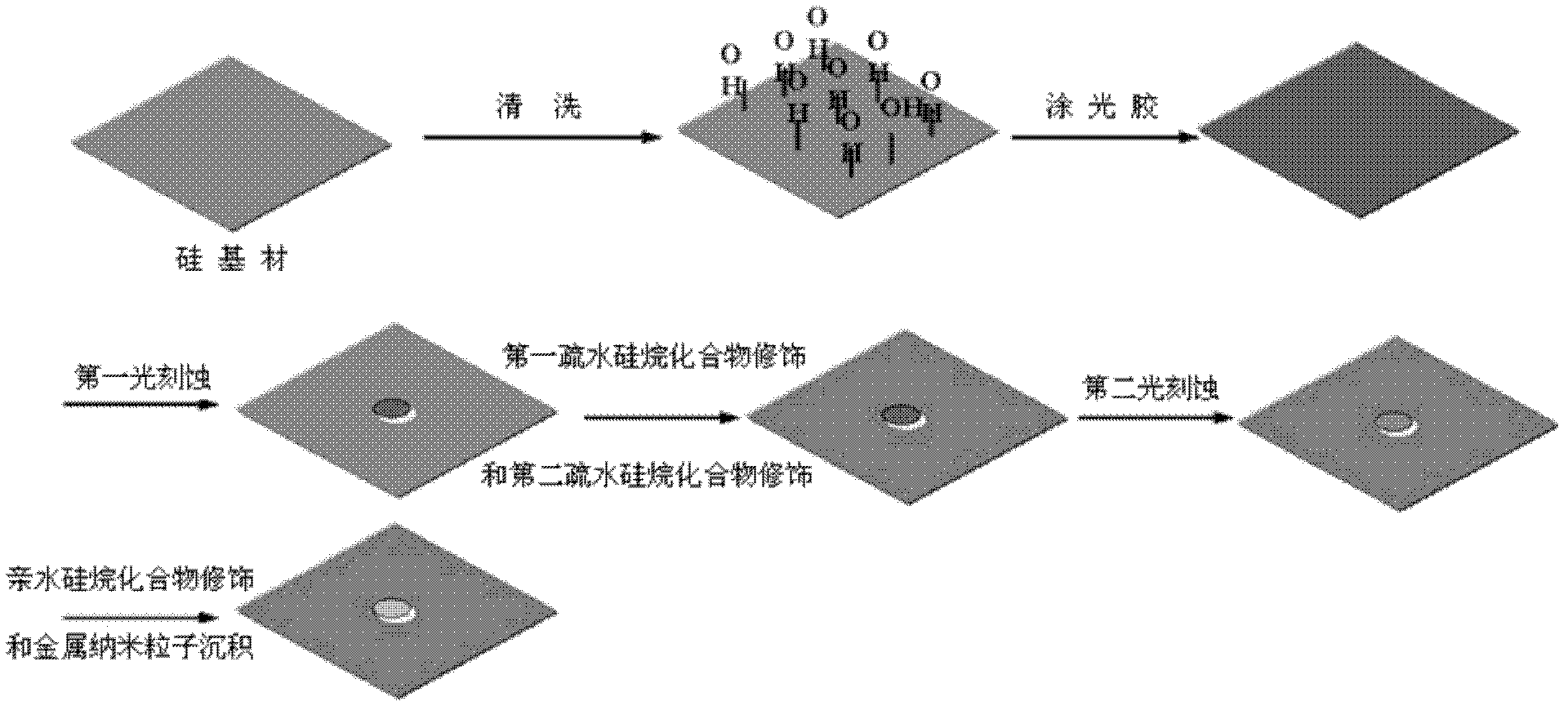

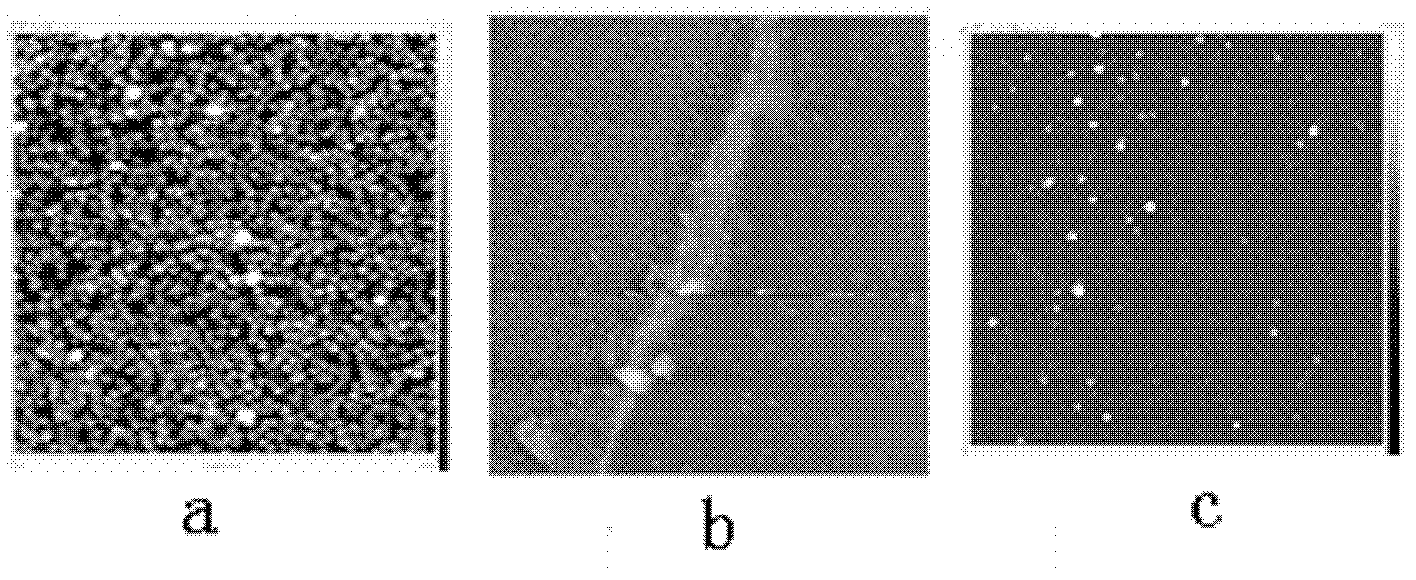

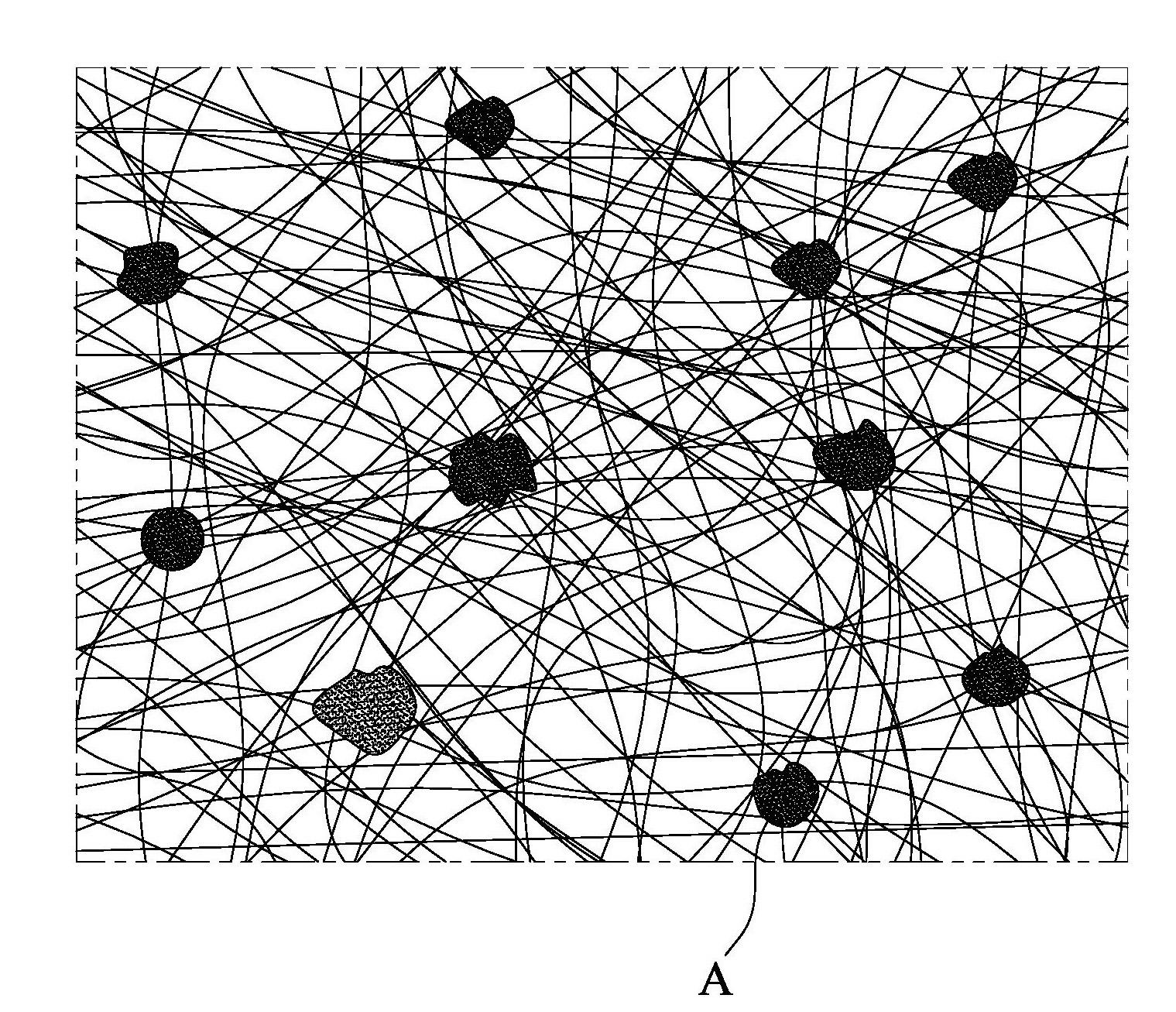

Surface enhanced Raman scattering (SERS) substrate and preparation method thereof

InactiveCN102608103AIncrease signal strengthHigh sensitivityRaman scatteringSilane compoundsSquare Millimeter

The invention provides a surface enhanced Raman scattering (SERS) substrate and a preparation method thereof. The SERS substrate comprises a silicon substrate and a chemical modification layer arranged on the silicon substrate. The chemical modification layer includes a hydrophilic silane compound layer with area smaller than 7.5 square millimeter; a hydrophobic silane compound layer surrounding the hydrophilic silane compound layer; and a mono-layer metal nanoparticle layer arranged on the hydrophilic silane compound layer. Under action of the hydrophilic silane compound layer and the hydrophobic silane compound layer, aqueous solution of to-be-detected substance is concentrated on the middle small-area hydrophilic silane compound layer, to improve concentration degree of aqueous solution of the to-be-detected substance. The metal nanoparticle layer realizes more uniform distribution of aqueous solution of the to-be-detected substance. Therefore, the SERS substrate can improve signal intensity and detection sensitivity.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Abnormal-shape filament non-woven fabric and manufacture technology thereof

InactiveCN102560904AAvoid secondary pollutionReduce transportation linksFilament/thread formingNon-woven fabricsManufacturing cost reductionPolymer science

The invention provides an abnormal-shape filament non-woven fabric, wherein non-woven fabric coiled material consists of abnormal-shape fiber filaments, the length of each abnormal-shape fiber filament is more than or equal to 1000mm, the specific surface area of the abnormal-shape filament is more than 1.3 compared with that of the fiber with the same material, the equal denier and the circular cross section, the abnormal-shape fiber filaments consist of low-melting point thermoplastic high polymers and high-melting point thermoplastic high polymers, the low-melting point thermoplastic high polymers of which the melting point is less than 150 DEG C are arranged on the surface layers of the abnormal-shape fiber filaments, the abnormal-shape fiber filaments are glued with one another by the low-melting point thermoplastic high polymers arranged on the surface layers of the abnormal-shape fibers to form into the non-woven fabric coiled material, each gluing point among each abnormal-shape fiber is the surface layers of the low-melting point thermoplastic high polymers of two abnormal-shape fiber filaments contacted with each other, and the mean value of the area of each gluing point is less than 0.01 square millimeters. The non-woven fabric is fluffy and flexible, thereby being elastic; the transportation link is reduced, and the manufacture cost is reduced; and the non-woven fabric is quick in liquid absorption and good in flow guide effect.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

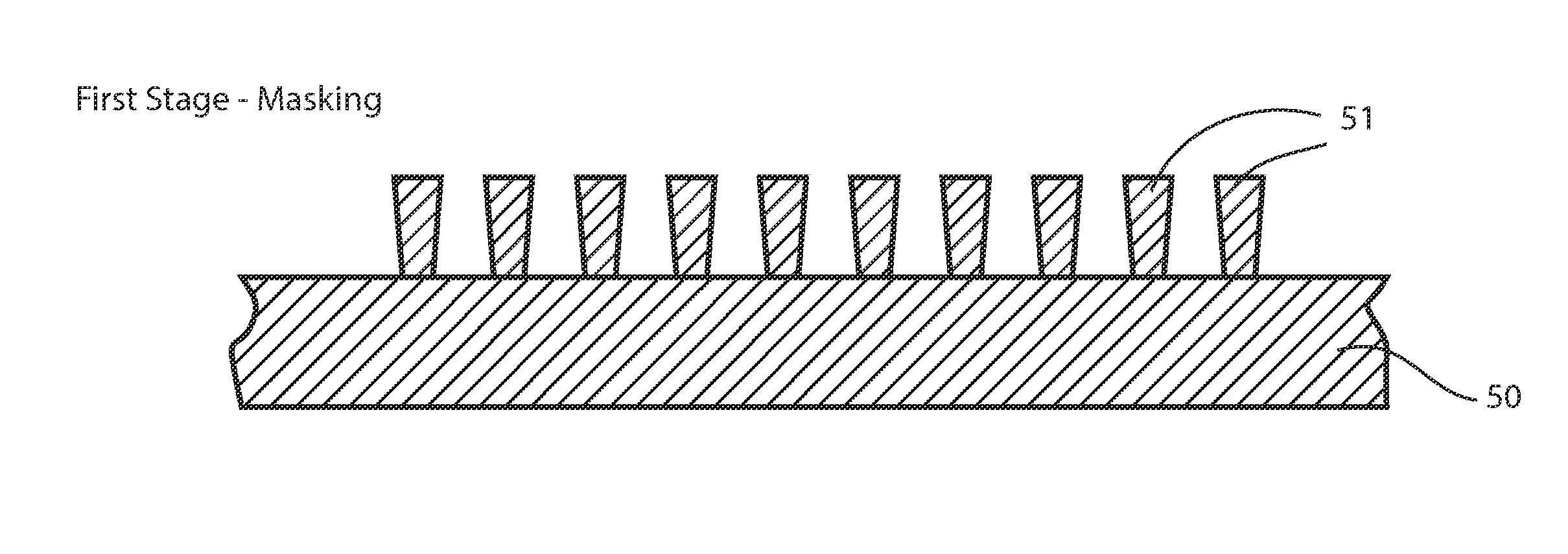

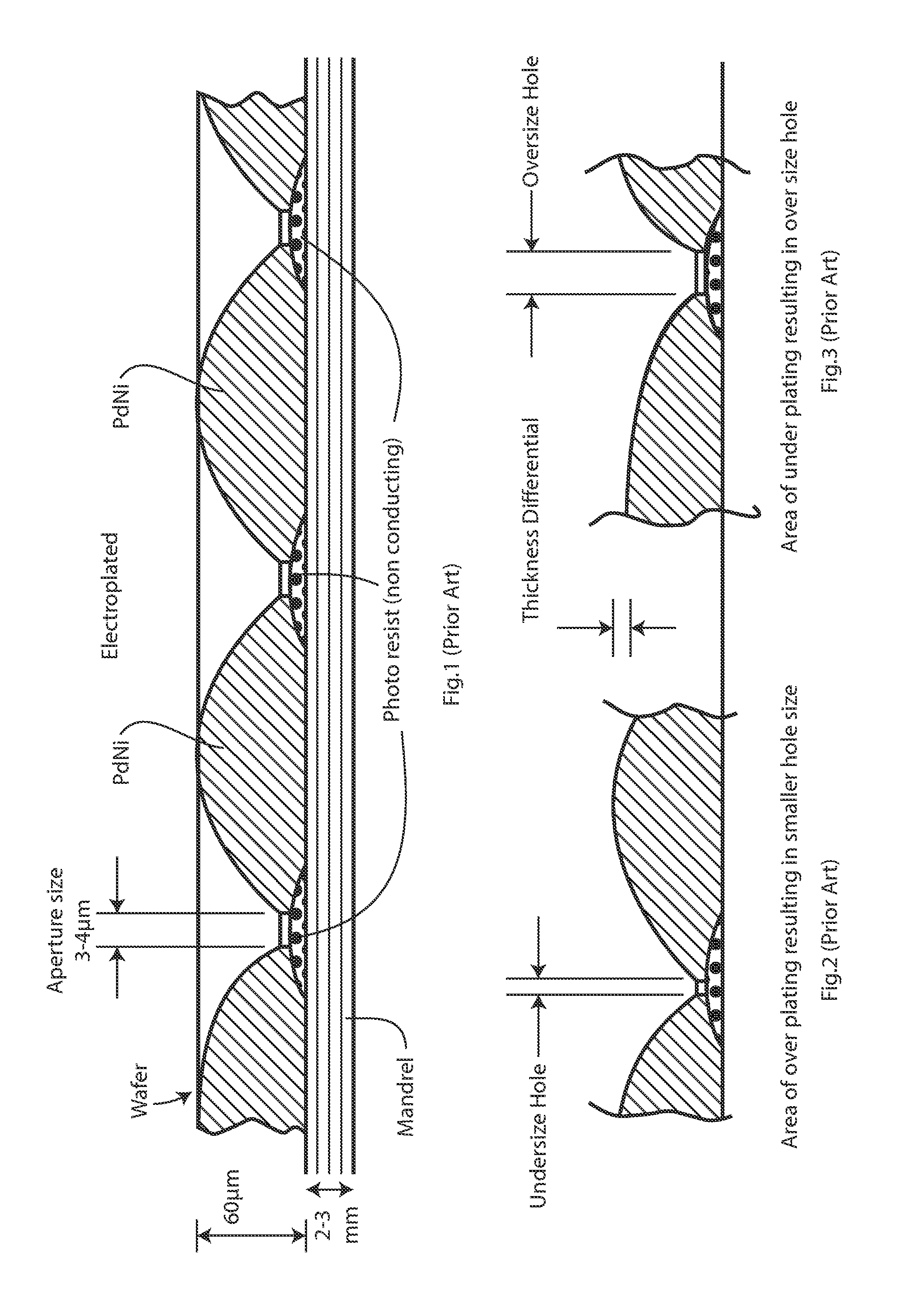

Method for producing an aperture plate

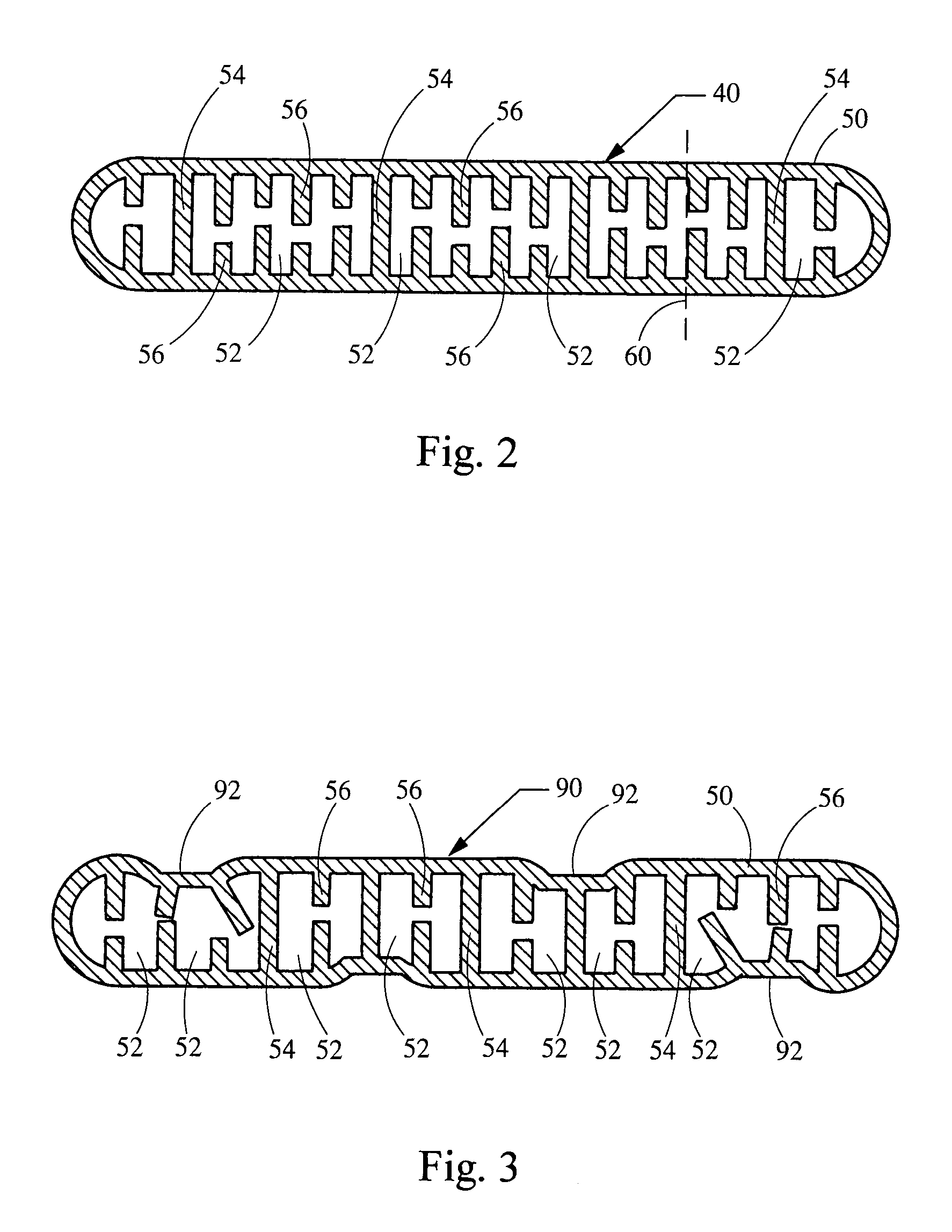

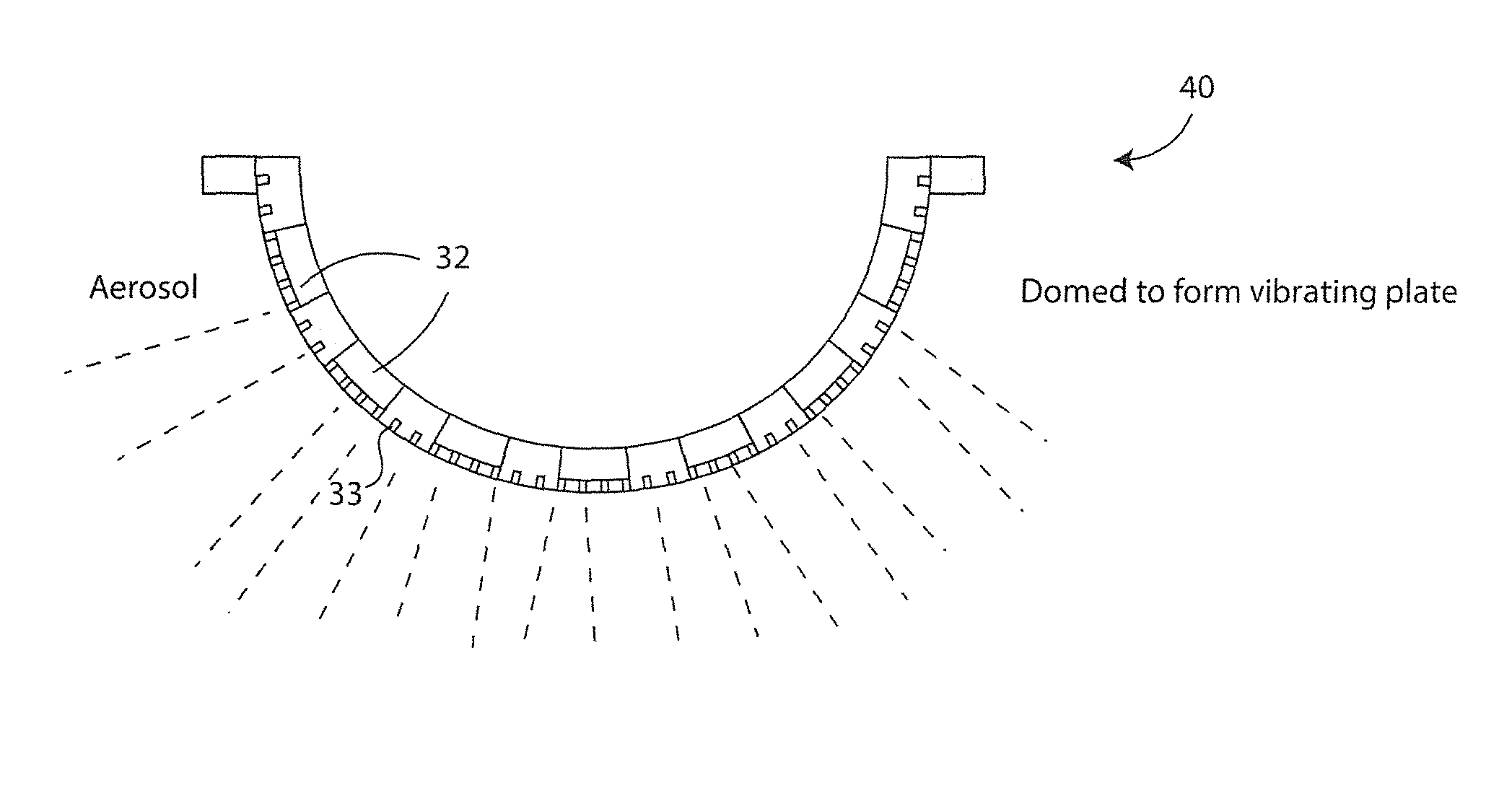

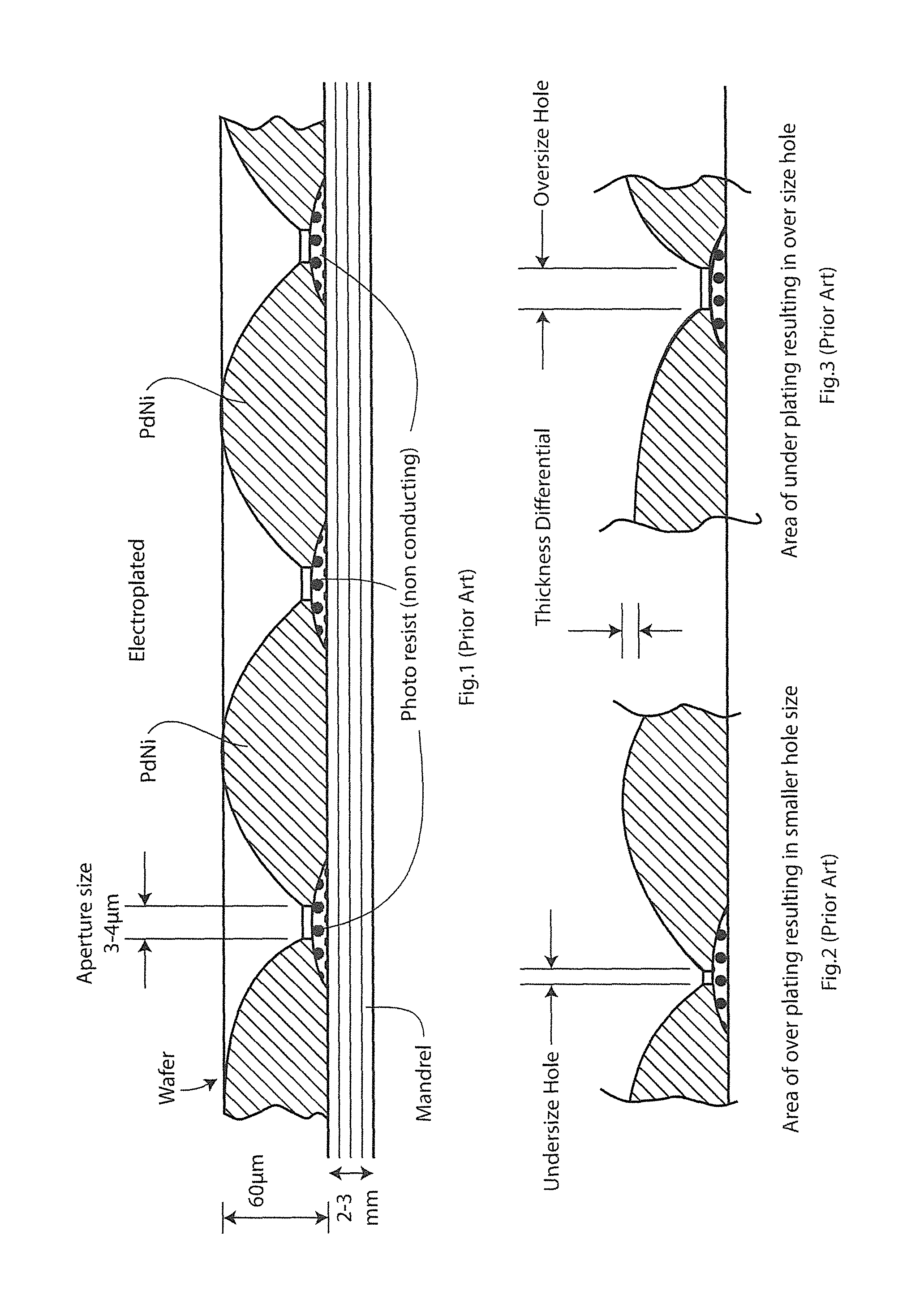

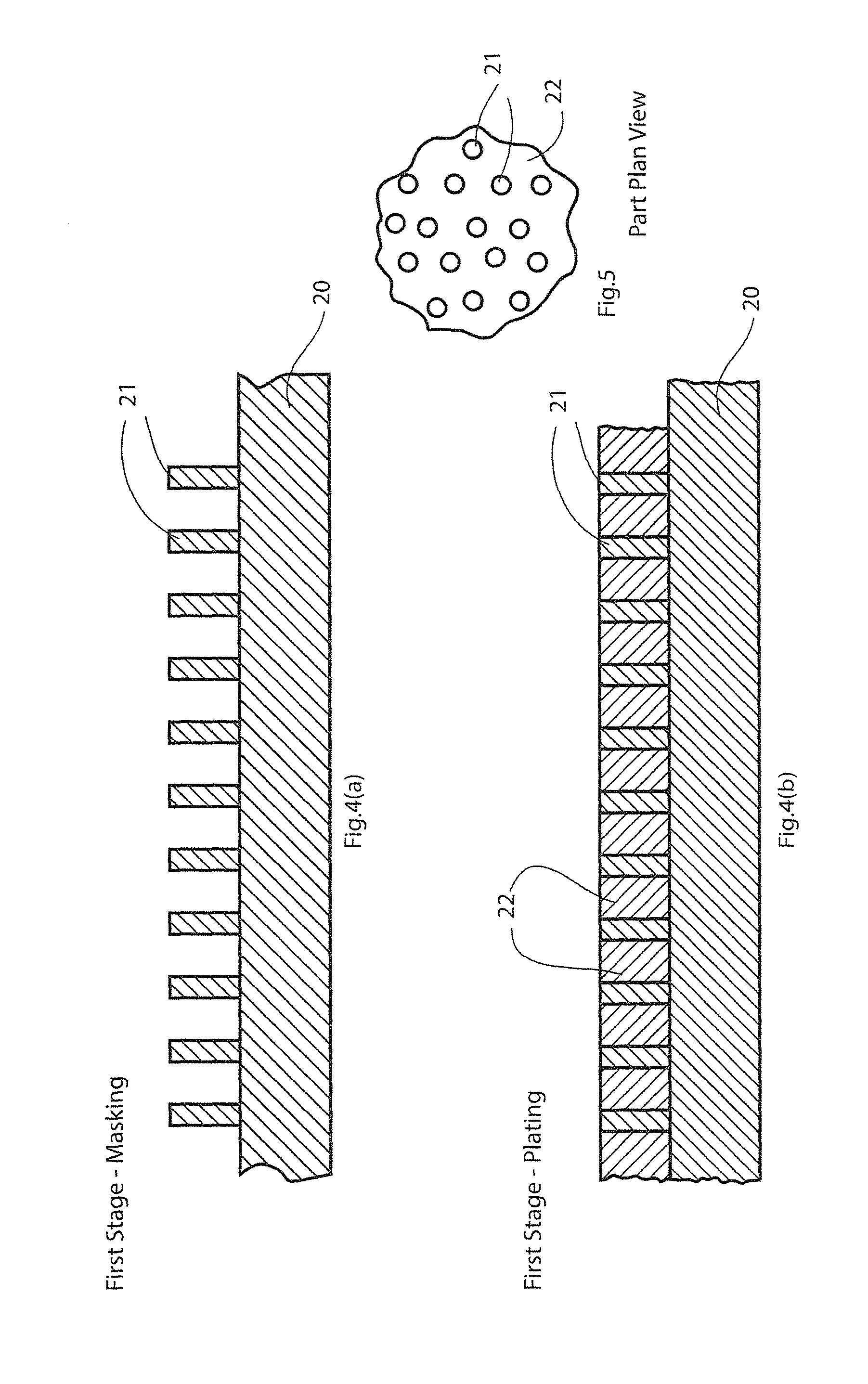

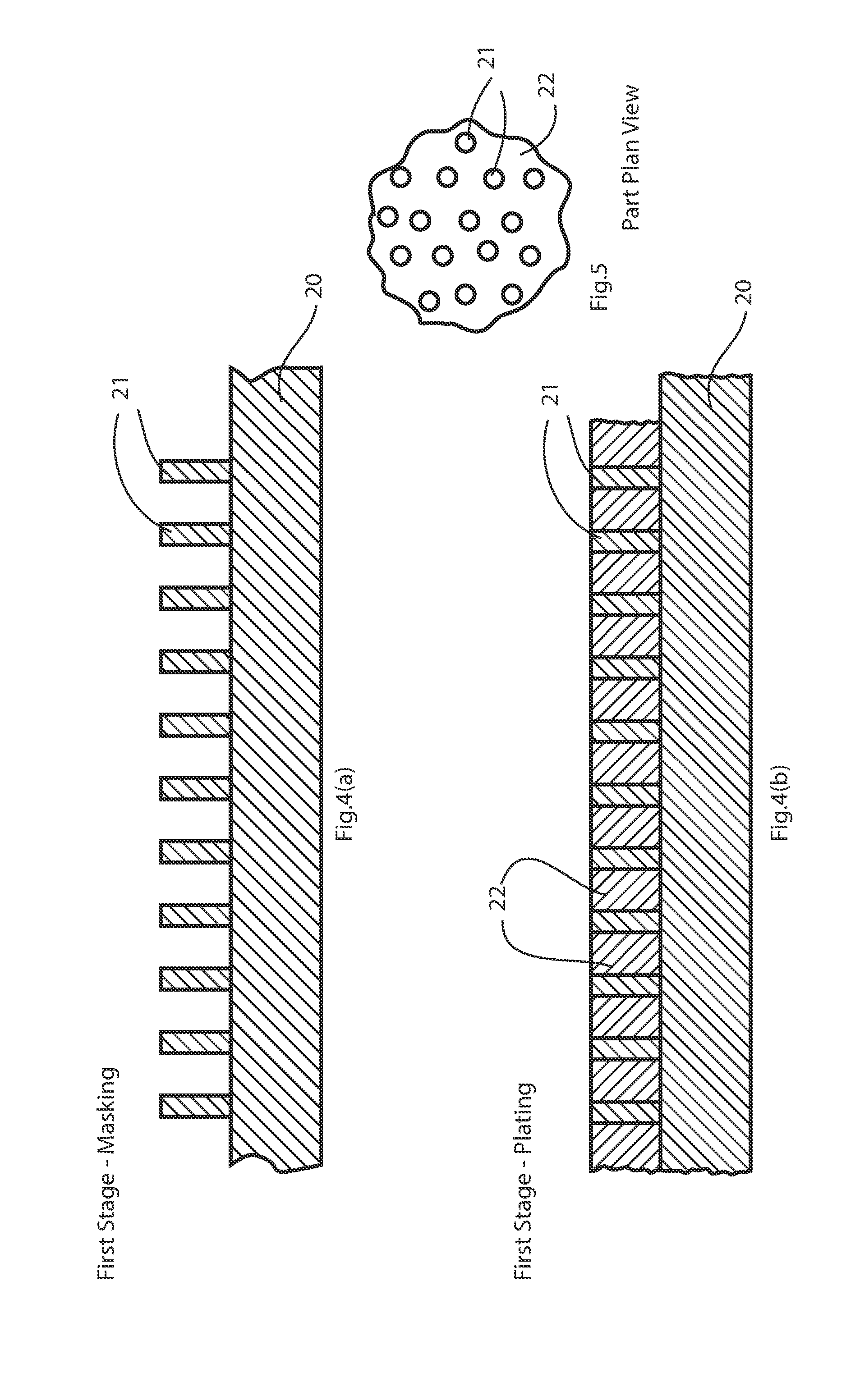

A photo-resist (21) is applied in a pattern of vertical columns having the dimensions of holes or pores of the aperture plate to be produced. This mask pattern provides the apertures which define the aerosol particle size, having up to 2500 holes per square mm. There is electro-deposition of metal (22) into the spaces around the columns (21). There is further application of a second photo-resist mask (25) of much larger (wider and taller) columns, encompassing the area of a number of first columns (2)1. The hole diameter in the second plating layer is chosen according to a desired flow rate.

Owner:STAMFORD DEVICES LTD

Grinding Or Polishing Tool For An Oscillating Drive

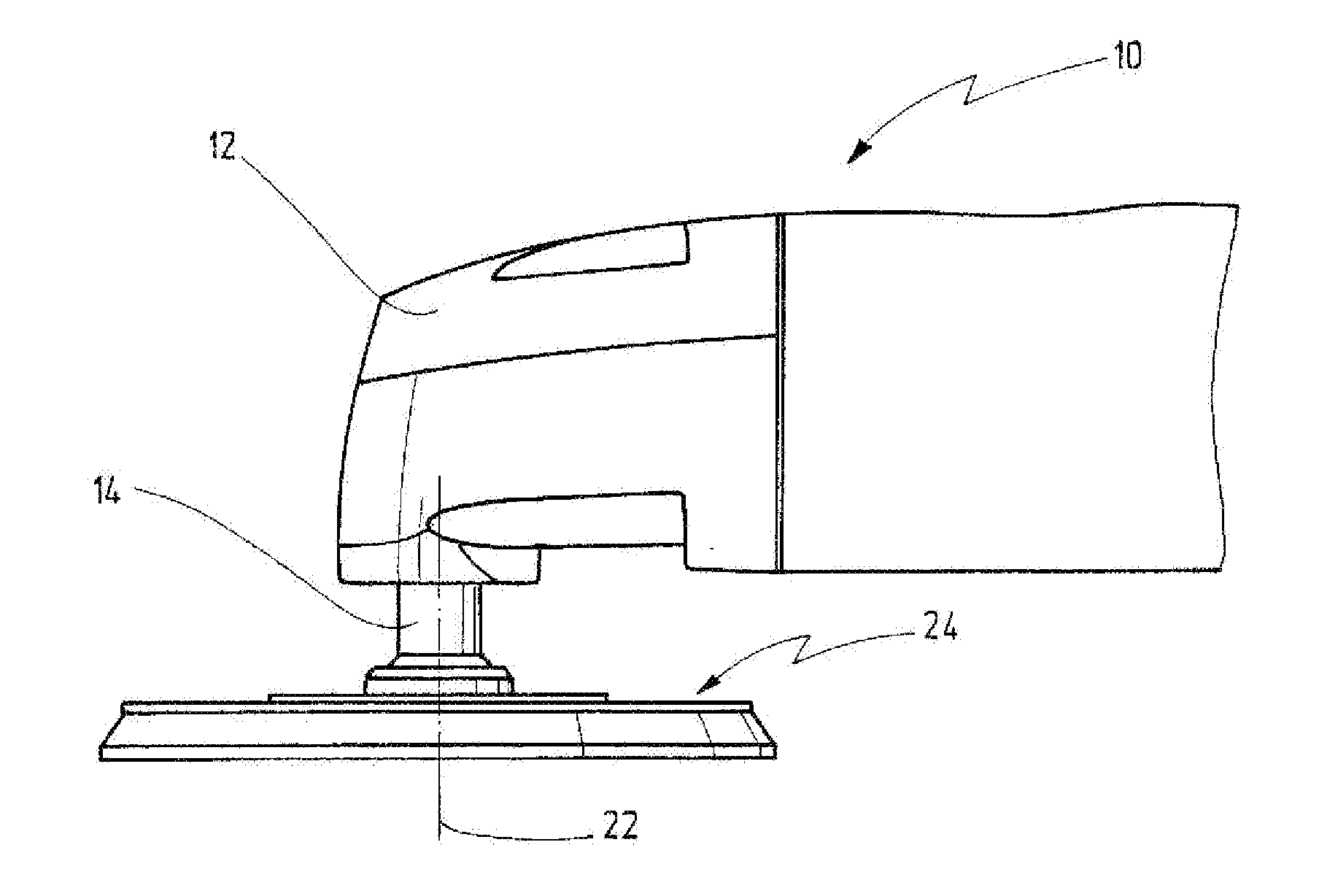

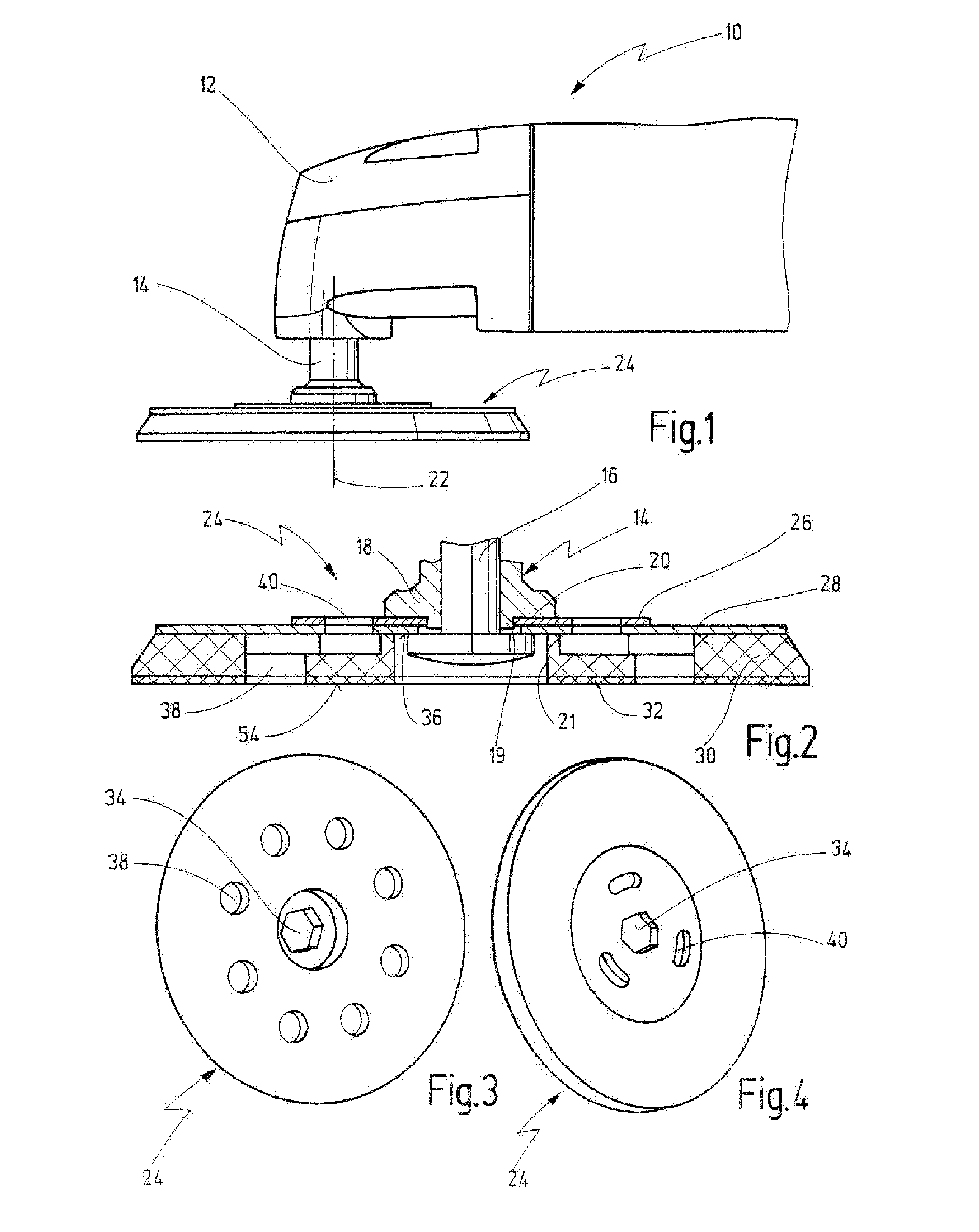

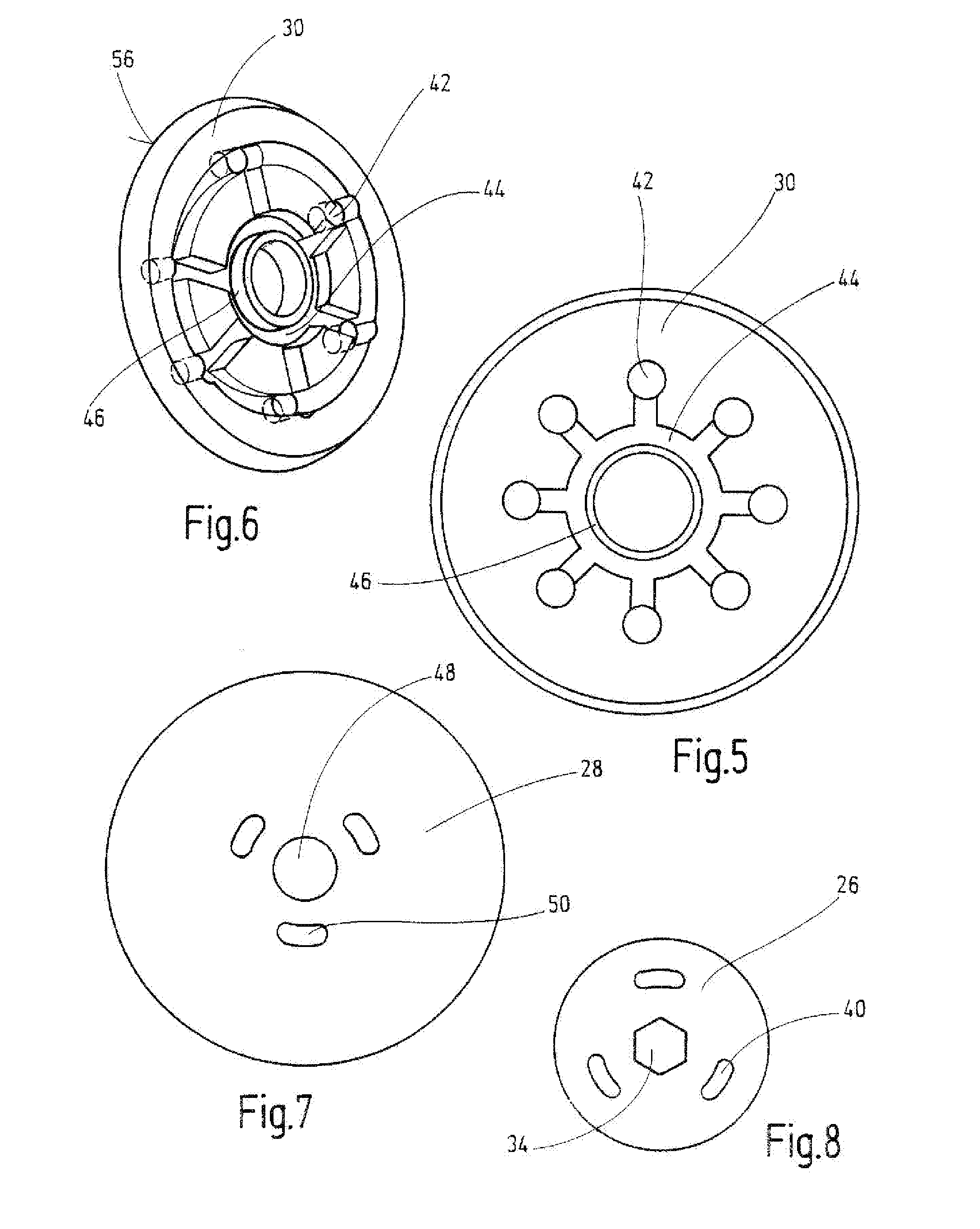

ActiveUS20100210194A1Promote resultsImproved micrographRevolution surface grinding machinesPortable grinding machinesSquare MillimeterEngineering

The invention discloses a tool for grinding and polishing, comprising a drive motor, which has a given machine power (rated input power) and by which a work spindle can be driven about its longitudinal axis in rotatingly oscillating fashion, and further comprising a tool-mounting fixture on the work spindle intended to receive a tool that has a working surface for grinding and polishing operations. The quotient of the working surface (in square millimeters) and the rated power input (in Watts) is at least 35 mm2 / W, while the quotient of the working surface and the deadweight (in grams, without the tool) is at least 5.5 mm2 / g.

Owner:C & E FEIN GMBH & CO KG

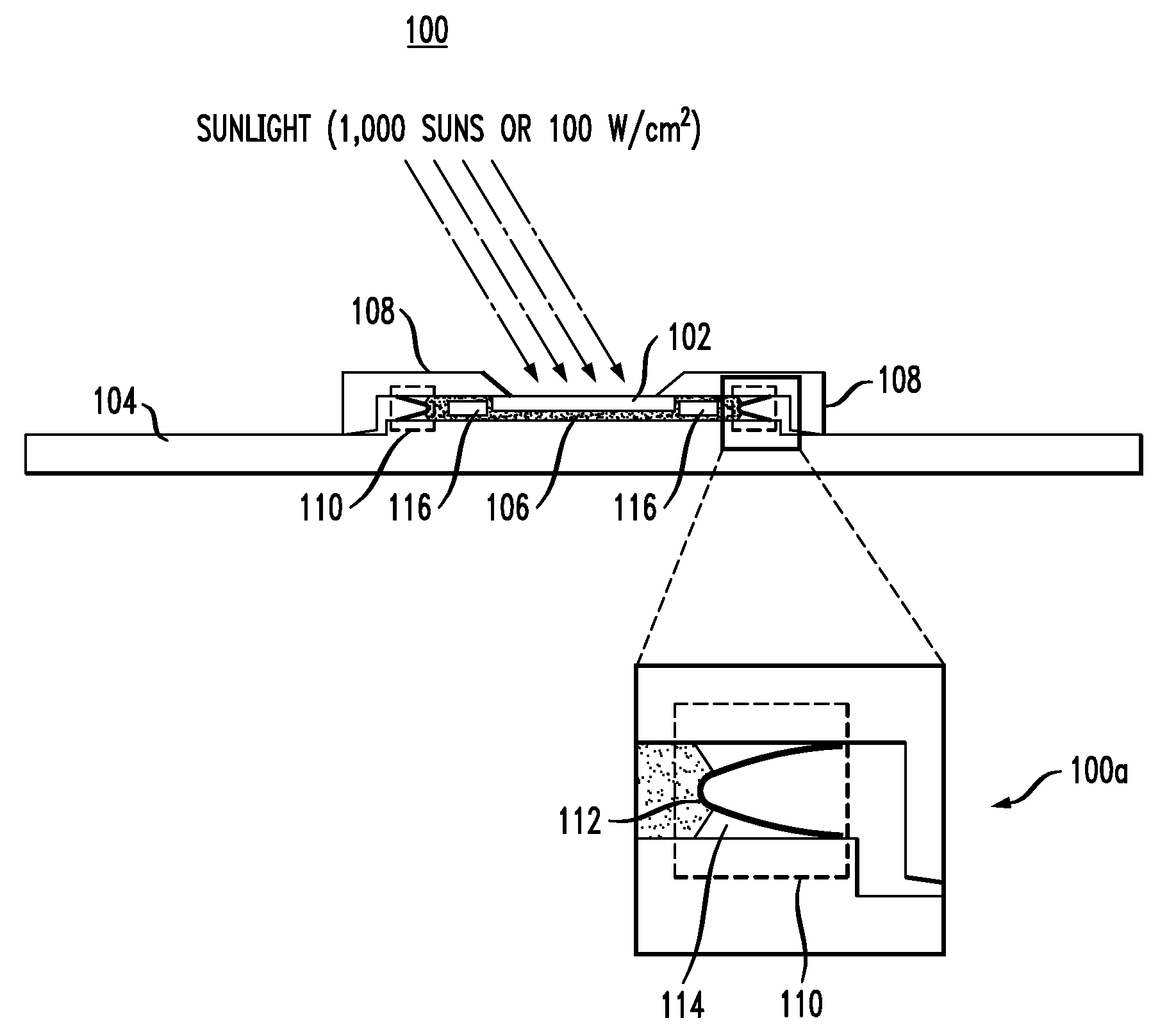

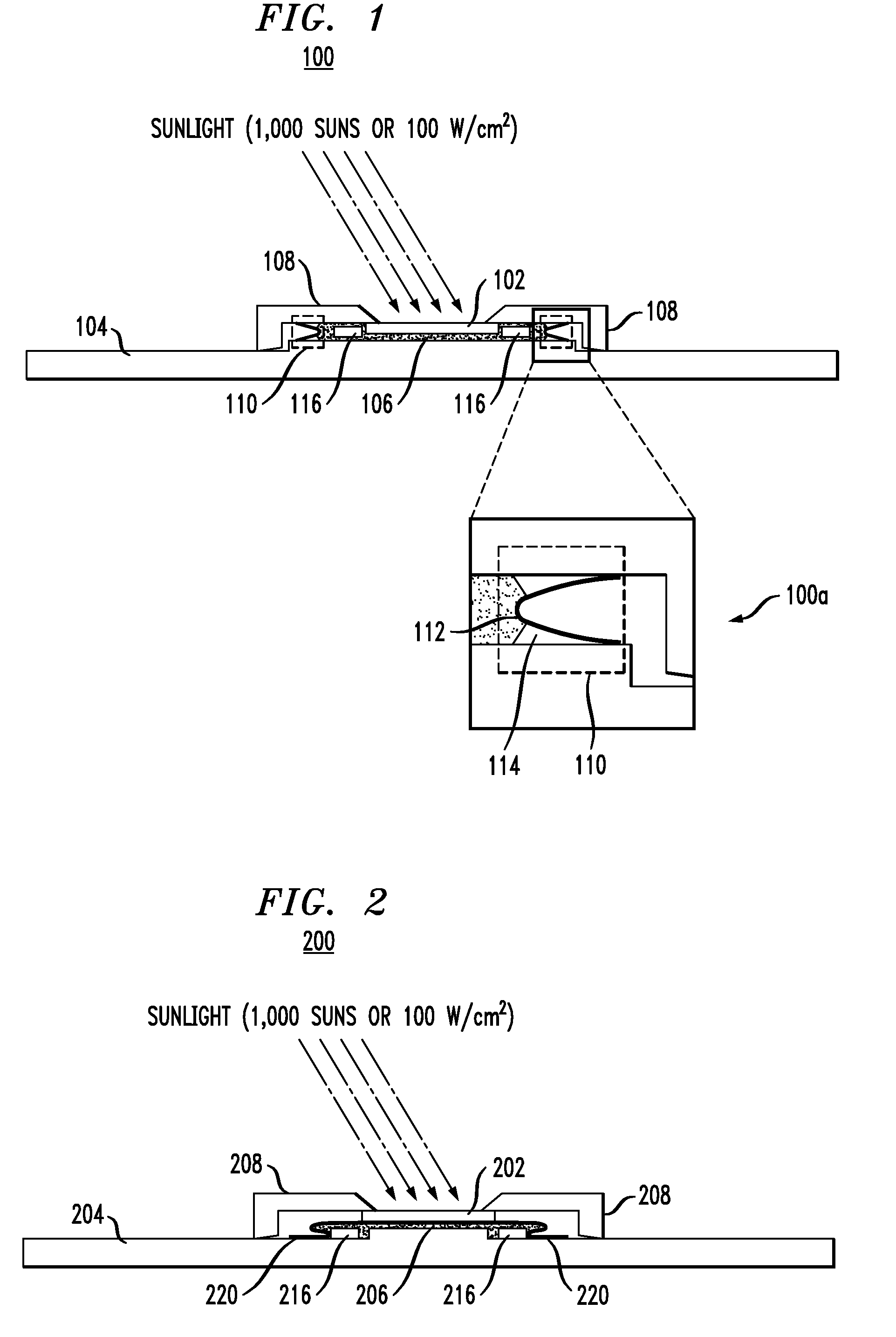

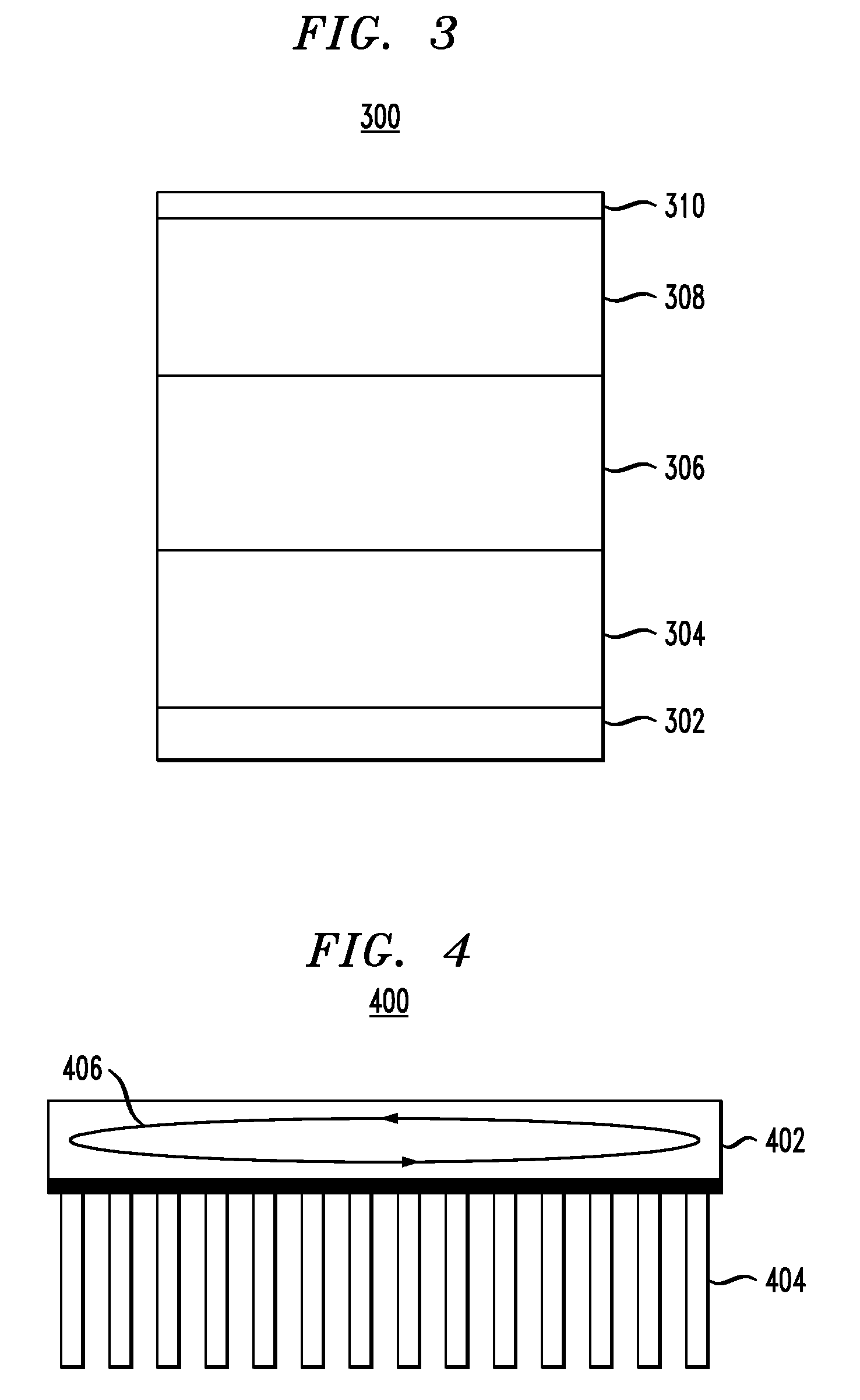

Techniques for Cooling Solar Concentrator Devices

InactiveUS20090084435A1Photovoltaic energy generationSemiconductor devicesManufacturing technologyEngineering

Solar concentrator devices and techniques for the fabrication thereof are provided. In one aspect, a solar concentrator device is provided. The solar concentrator device comprises at least one solar converter cell; a heat sink; and a liquid metal between the solar converter cell and the heat sink, configured to thermally couple the solar converter cell and the heat sink during operation of the device. The solar converter cell can comprise a triple-junction semiconductor solar converter cell fabricated on a germanium (Ge) substrate. The heat sink can comprise a vapor chamber heat sink. The liquid metal can comprise a gallium (Ga) alloy and have a thermal resistance of less than or equal to about five square millimeter degree Celsius per Watt (mm2° C. / W).

Owner:IBM CORP

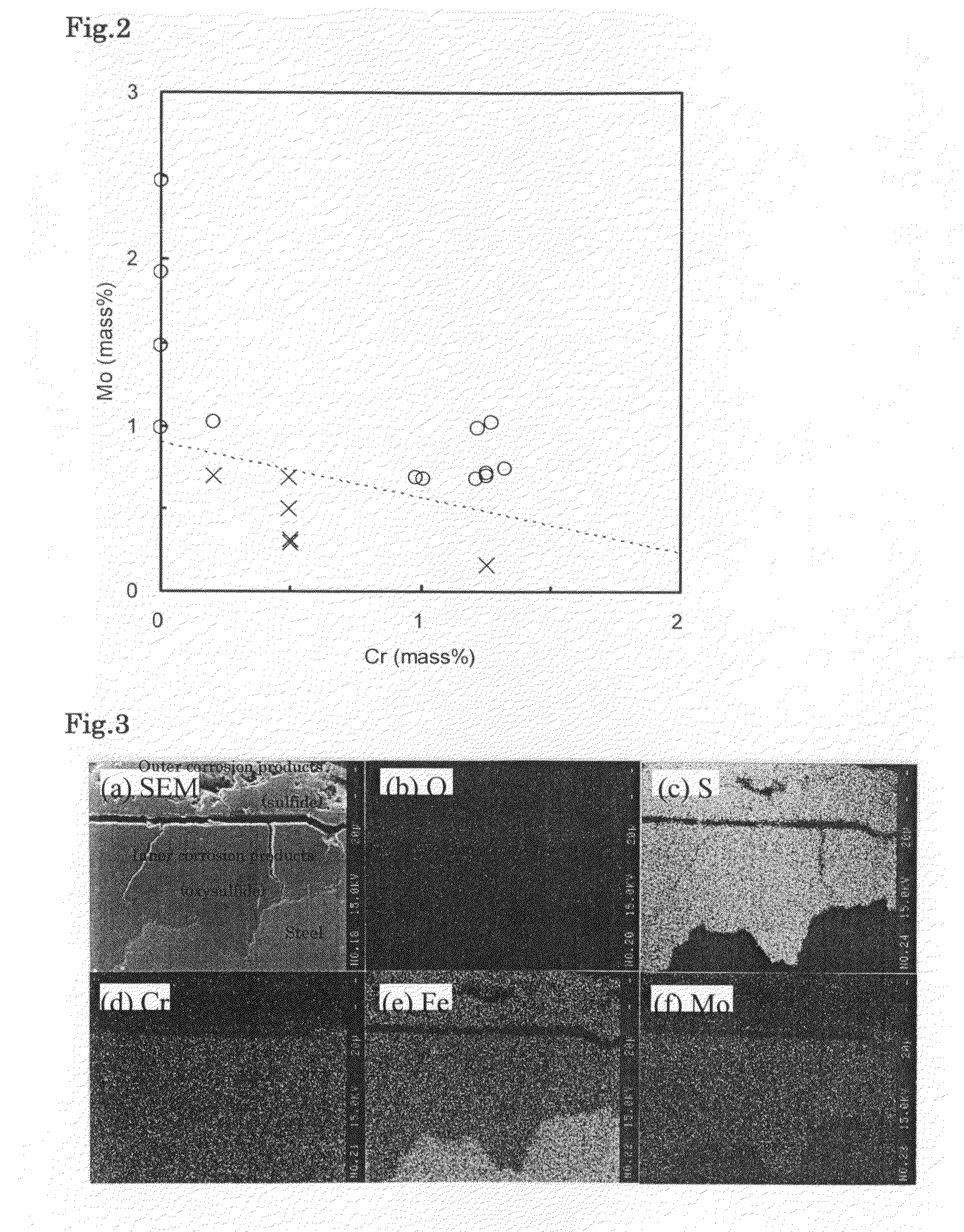

Low alloy steel for oil country tubular goods and seamless steel pipe

InactiveUS20090098403A1Improve the immunityLayered productsBlade accessoriesSquare MillimeterNon-metallic inclusions

A low alloy steel is provided for oil country tubular goods with a yield strength between 654 MPa and 757 MPa, and possessing excellent resistance to HIC and SSC in high-pressure hydrogen sulfides environment, and comprising, by mass %: 0.10 to 0.60% C; 0.05 to 0.5% Si; 0.05 to 3.0% Mn; 0.025% or less P; 0.010% or less S; 0.005 to 0.10% Al; 0.01% or less O (oxygen); 3.0% or less Cr; and 3.0% or less Mo, wherein the amount of Cr and Mo content is 1.2% or more, with the balance being Fe and impurities, and the number of nonmetallic inclusions whose major axis is 10 μm or more is 10 per square millimeter in the inspected cross section. The present invention provides a low alloy steel for oil country tubular goods possessing excellent resistance to sulfide stress cracking, and a seamless steel pipe.

Owner:SUMITOMO METAL IND LTD

Monochrome ink gun structure

ActiveCN101274515AHigh resolutionHigh speed printingPrintingSquare MillimeterVolumetric Mass Density

The invention relates to an inkjet head structure which is used for inkjet printing with self-colored ink, comprising a chip and a plurality of heaters which are arranged on the chip with the density which is higher than the density of 14 heaters per square millimeter (mm2), furthermore, the heaters are arrayed to form at least two axis assemblies along the parallel axes with intervals.

Owner:MICROJET TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com