Monochrome ink gun structure

An inkjet head and inkjet technology, applied in printing and other directions, can solve the problems of inkjet head temperature rise, inkjet head damage, price reduction, etc., achieve high-performance printing and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the invention is capable of various changes in different aspects without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

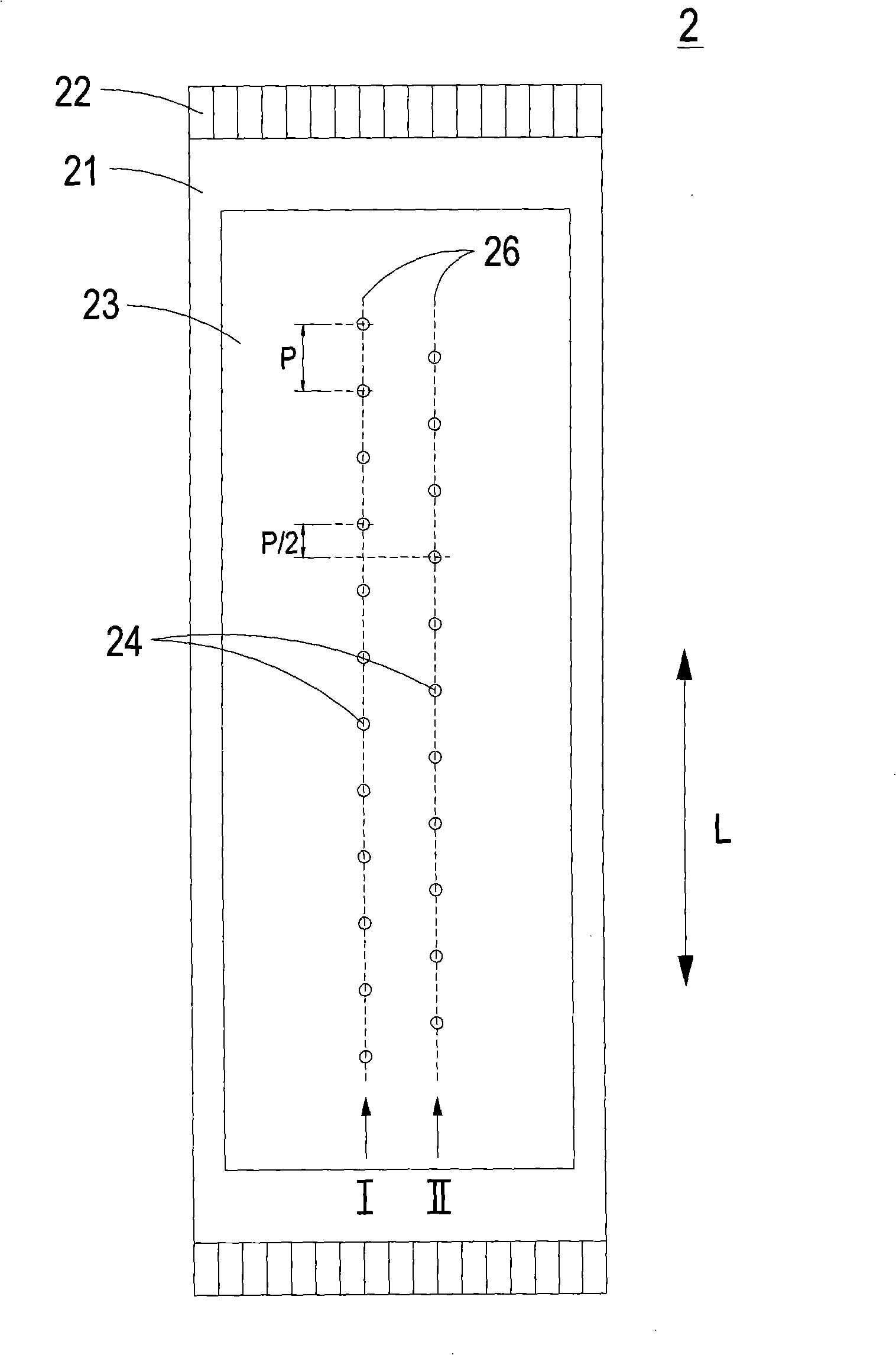

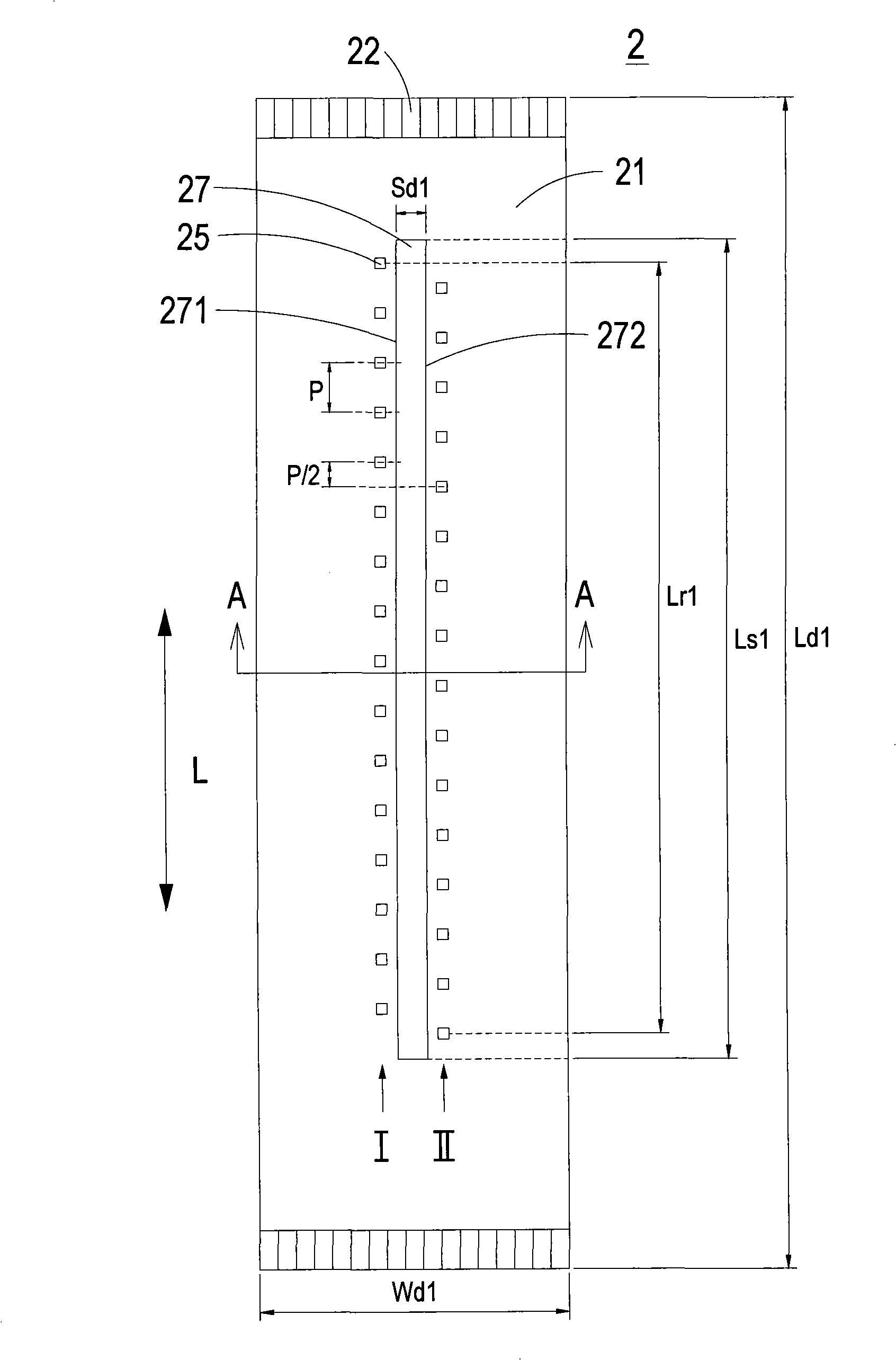

[0030] The structure of the inkjet head of the present invention mainly arranges a large number of nozzle holes on the inkjet head in a staggered manner, so as to reduce the size of the inkjet head and provide higher printing resolution with fewer scanning and printing times, that is, The effective orifice density of the inkjet medium on the feed shaft is increased to provide a high-resolution printing speed, thereby making the inkjet head structure of the present invention applicable to relatively low-cost inkjet printers.

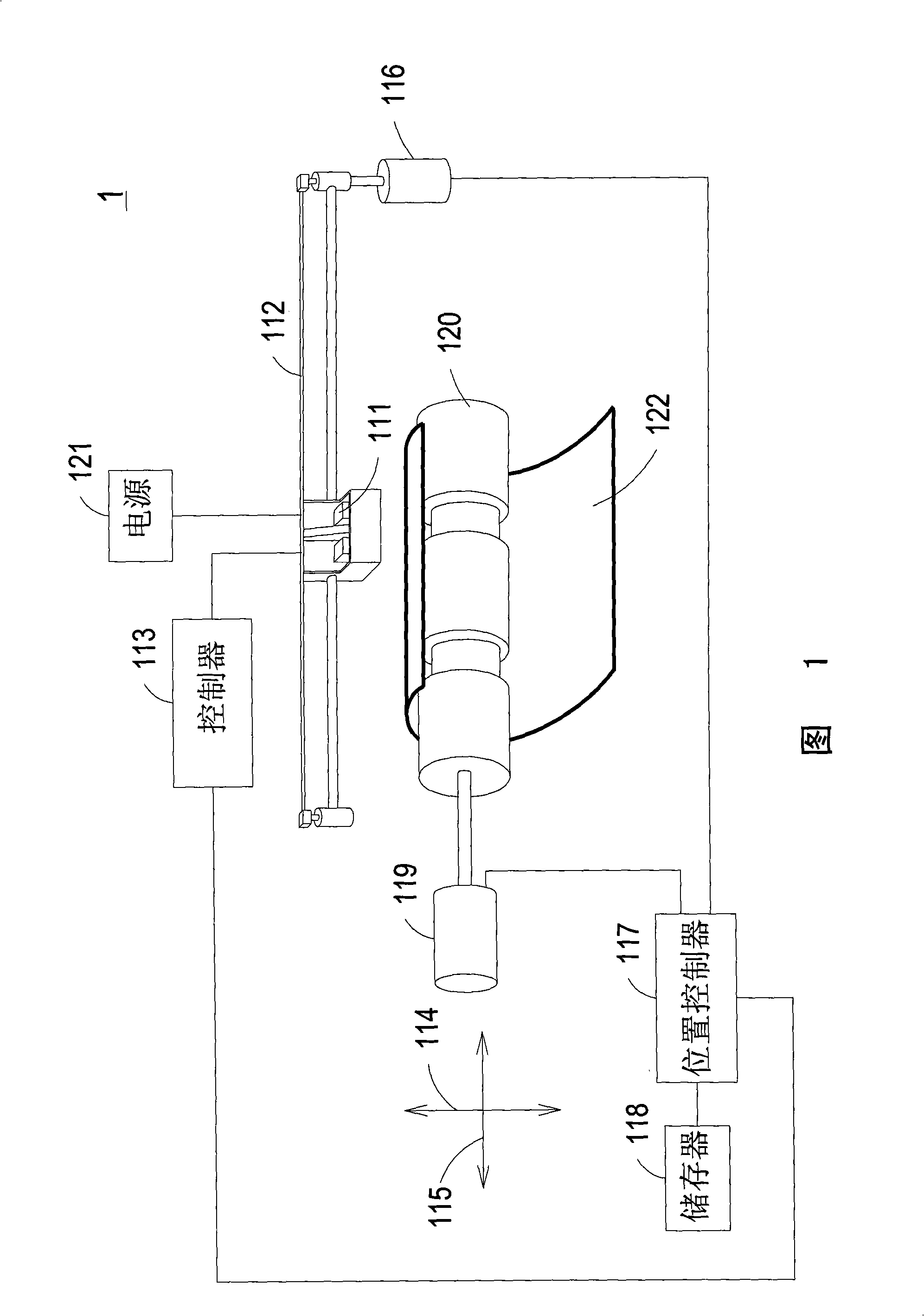

[0031]Please refer to Fig. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com