Patents

Literature

164 results about "Phase volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase Volume. the volume in phase space. For a mechanical system with N degrees of freedom, the elementary phase volume is equal to dpdq = dpldq1 . . . dpNdqN, where q1, . . ., qN are the generalized coordinates and p1, . . ., pN are the generalized momenta of the system. The phase volume of a finite phase region G is equal to...

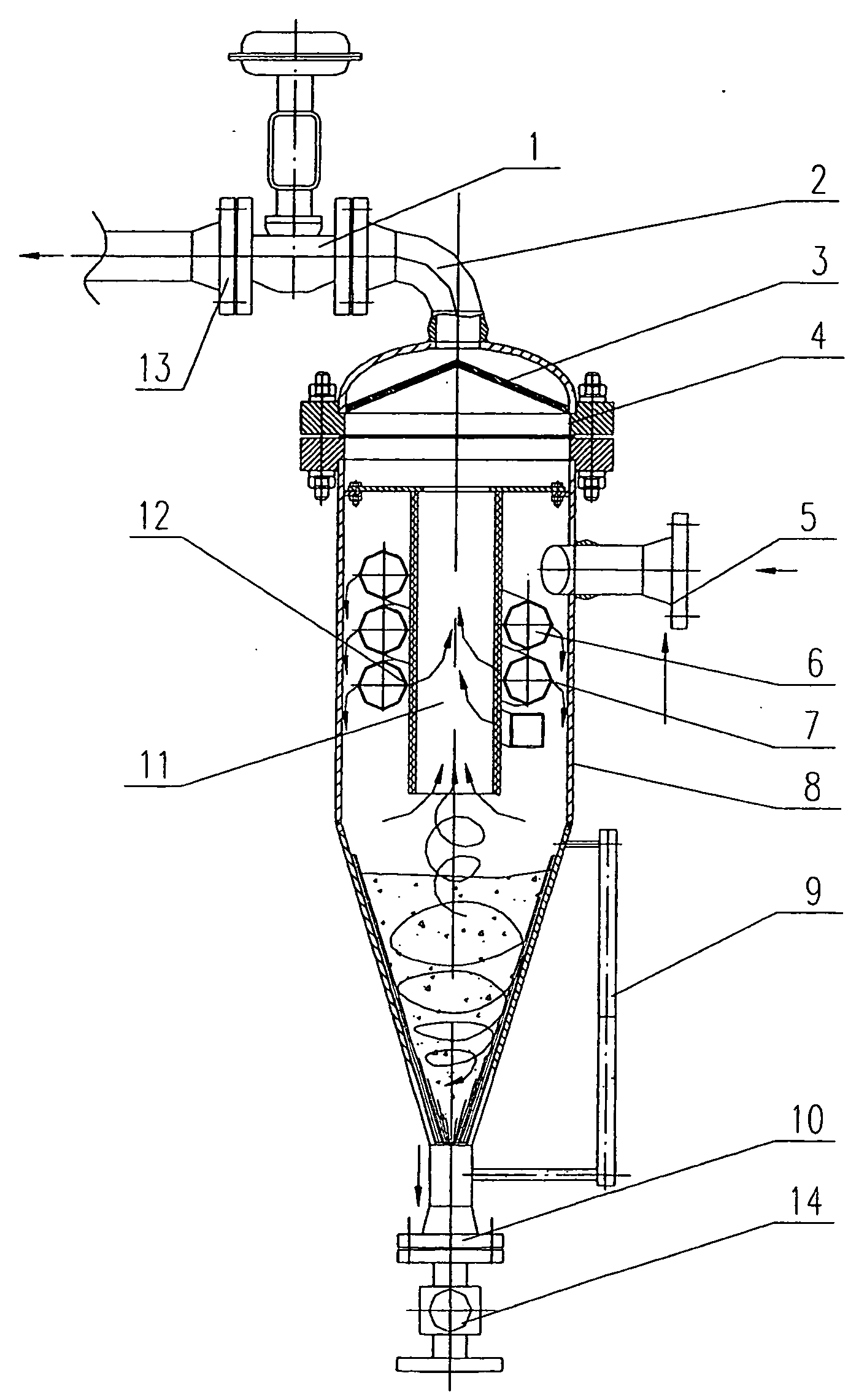

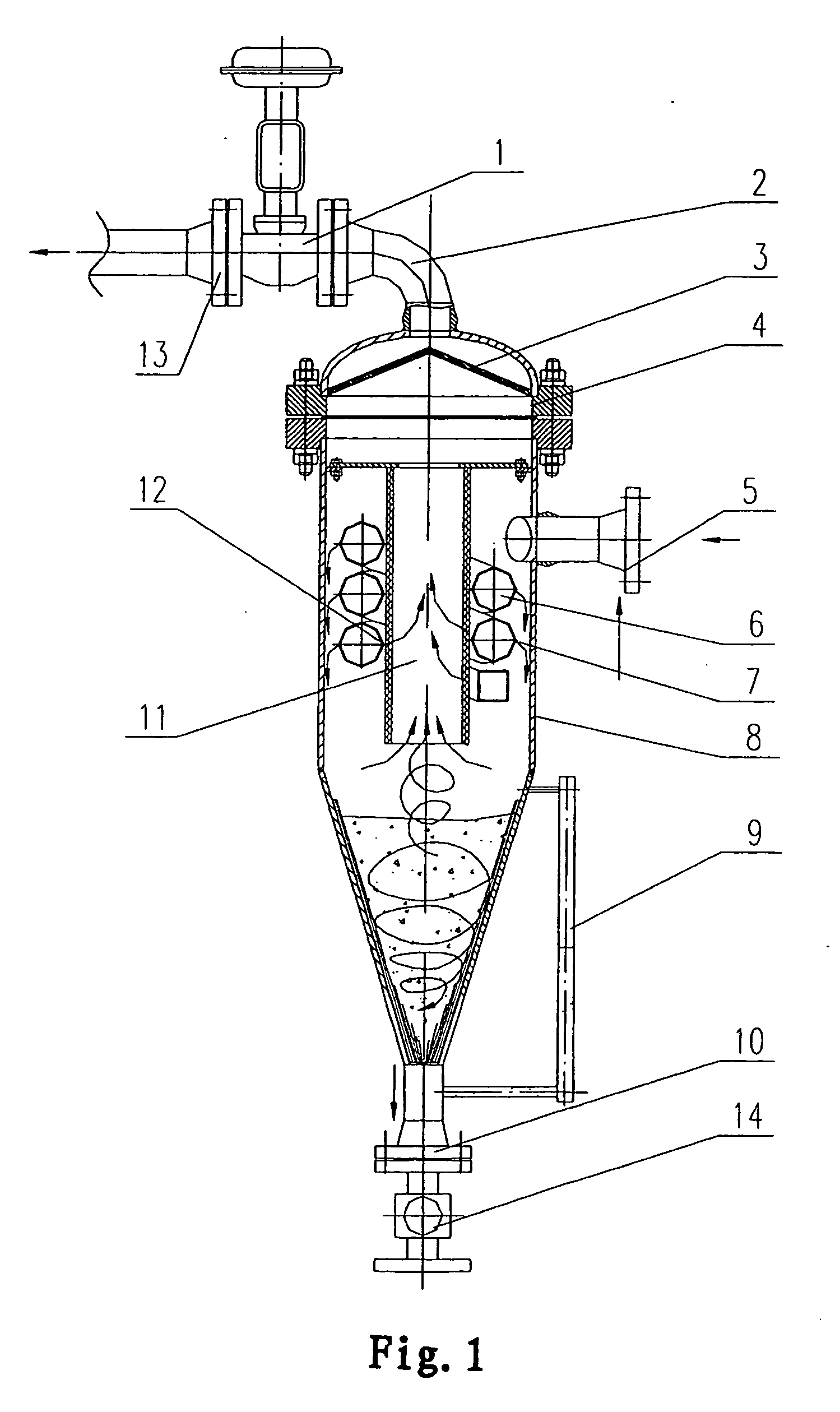

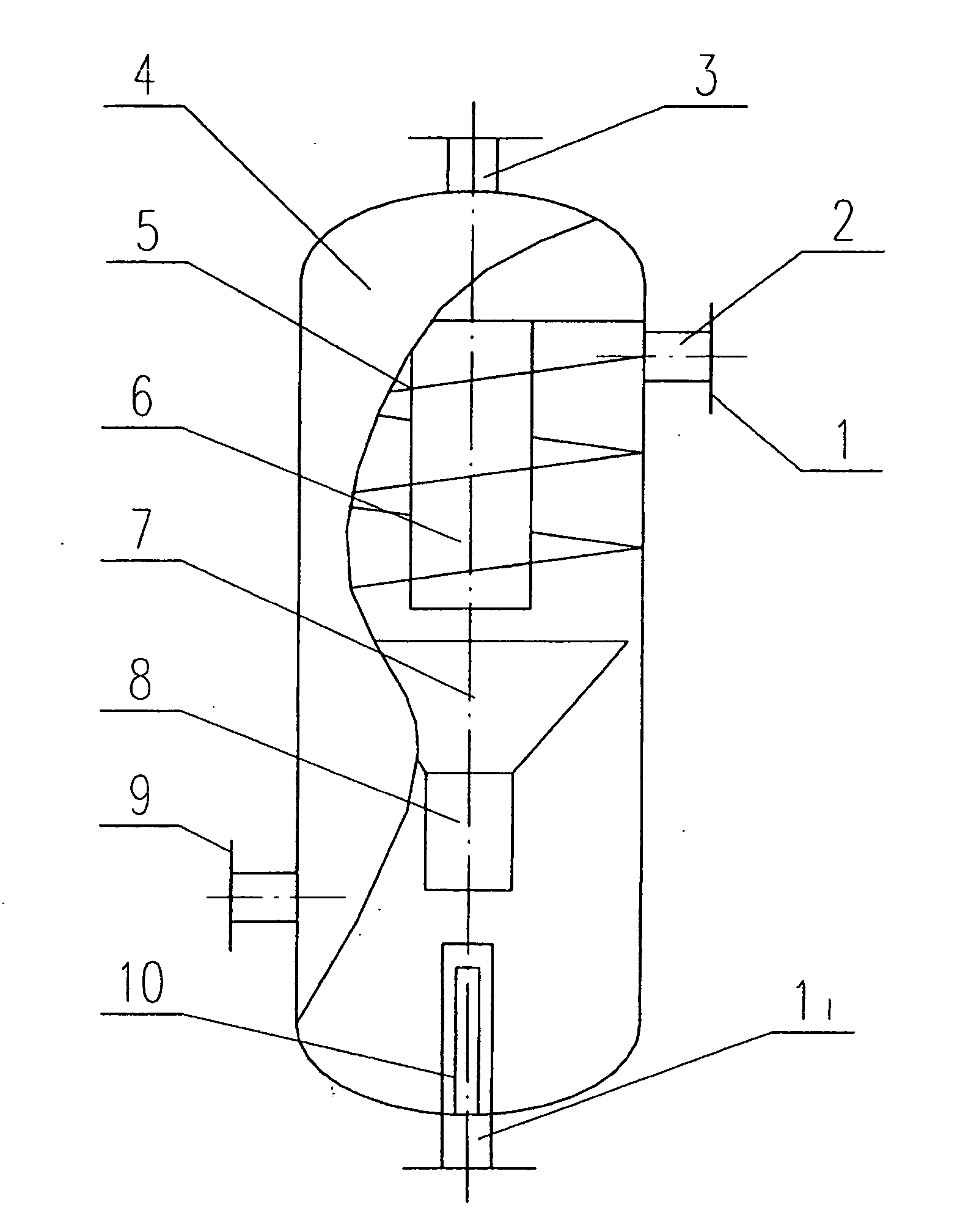

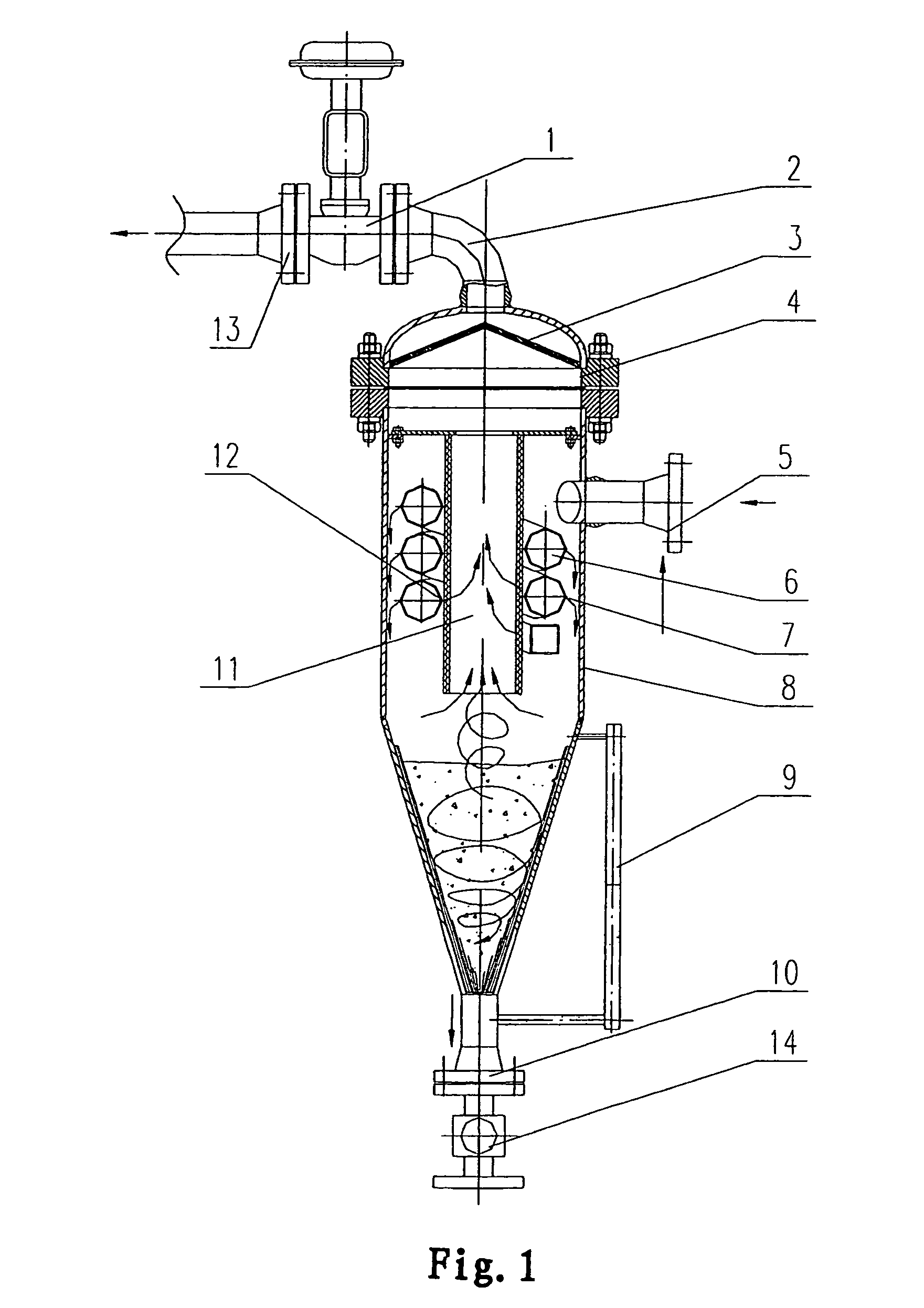

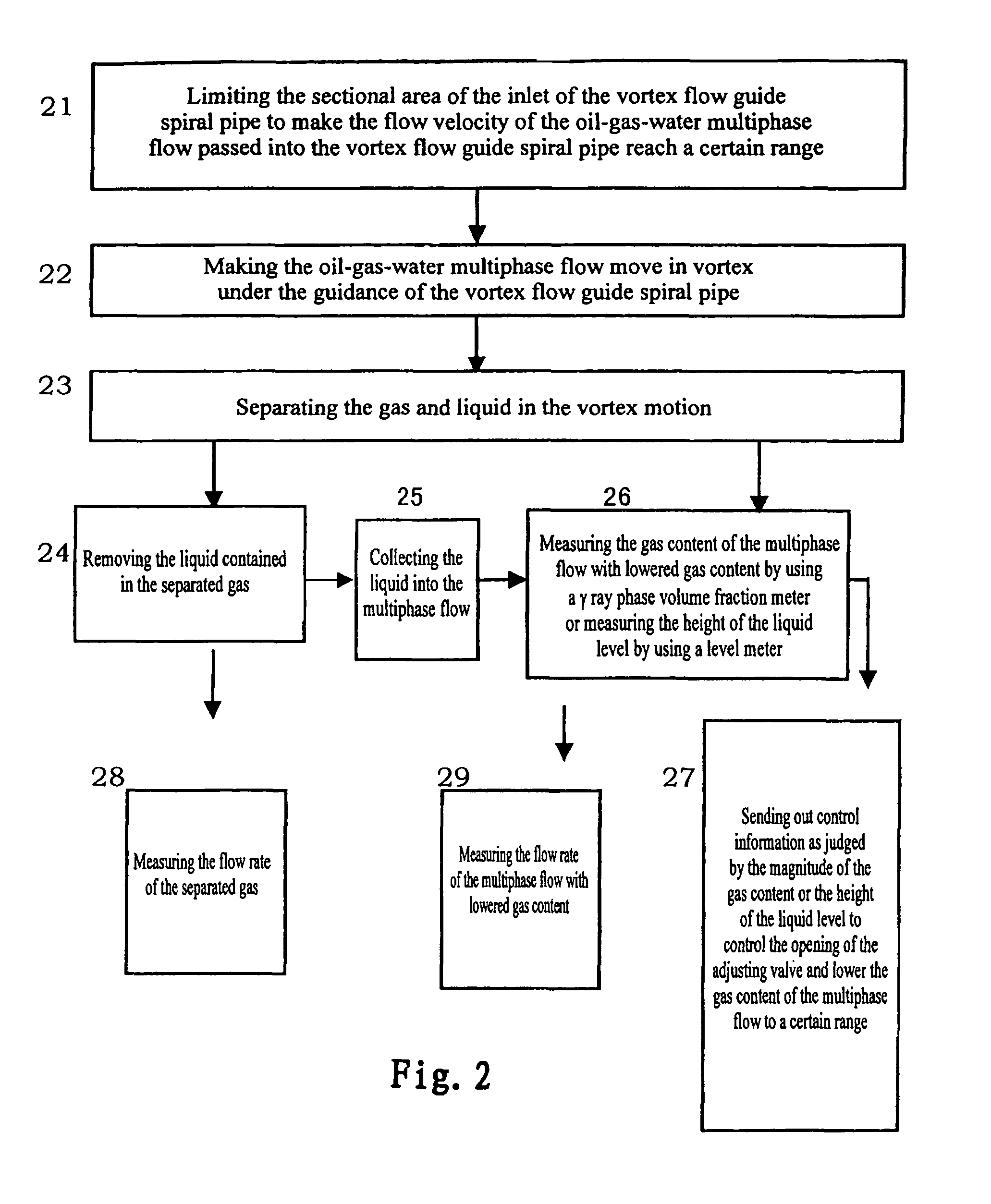

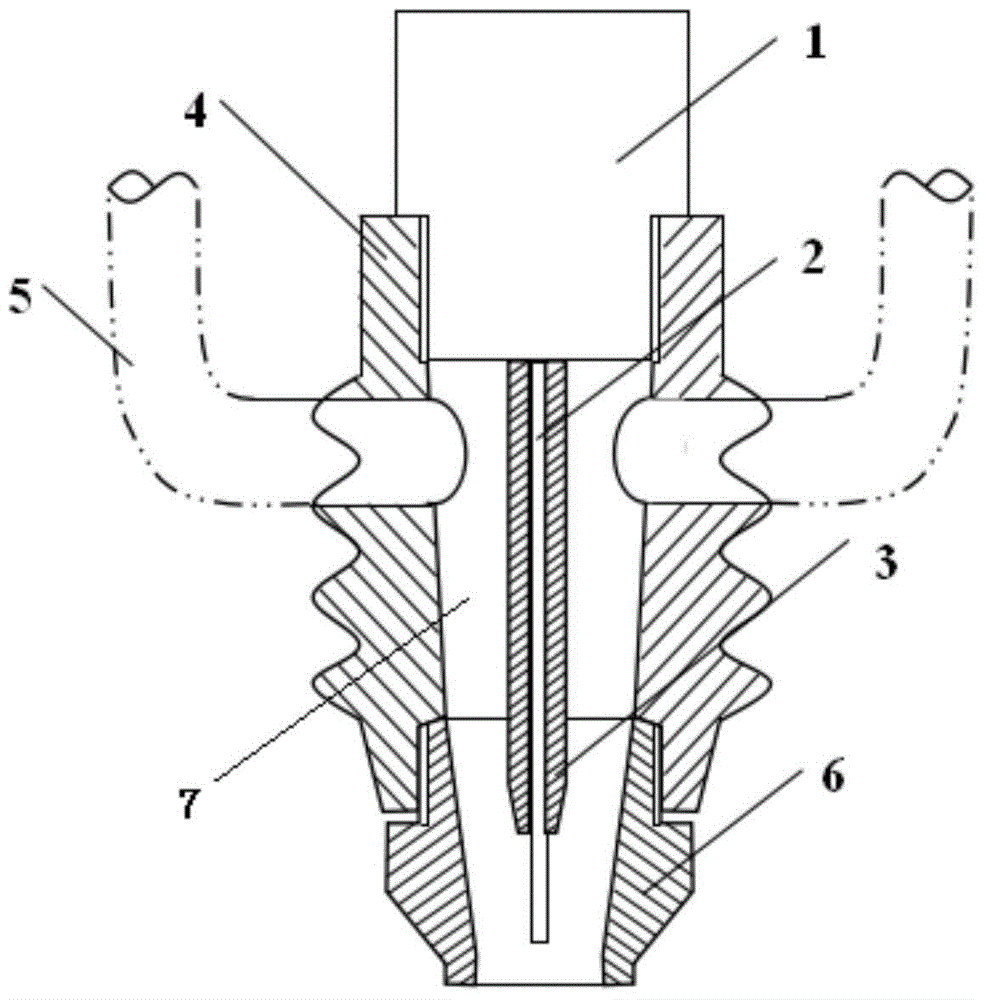

Adjustable gas-liquid centrifugal separator and separating method

ActiveUS20070084340A1Reduce gas contentSmall volumeCombination devicesLiquid degasificationEngineeringPhase volume

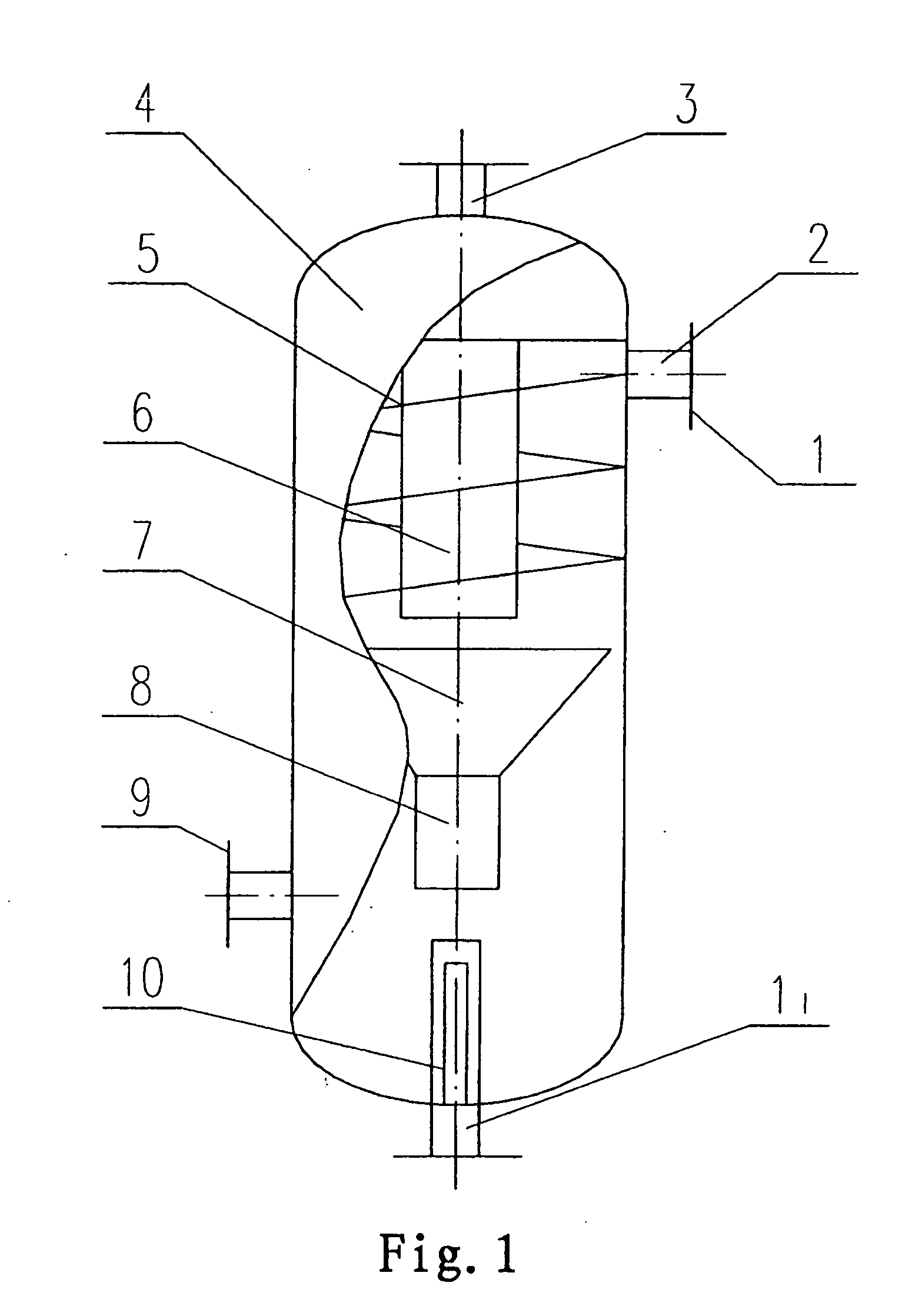

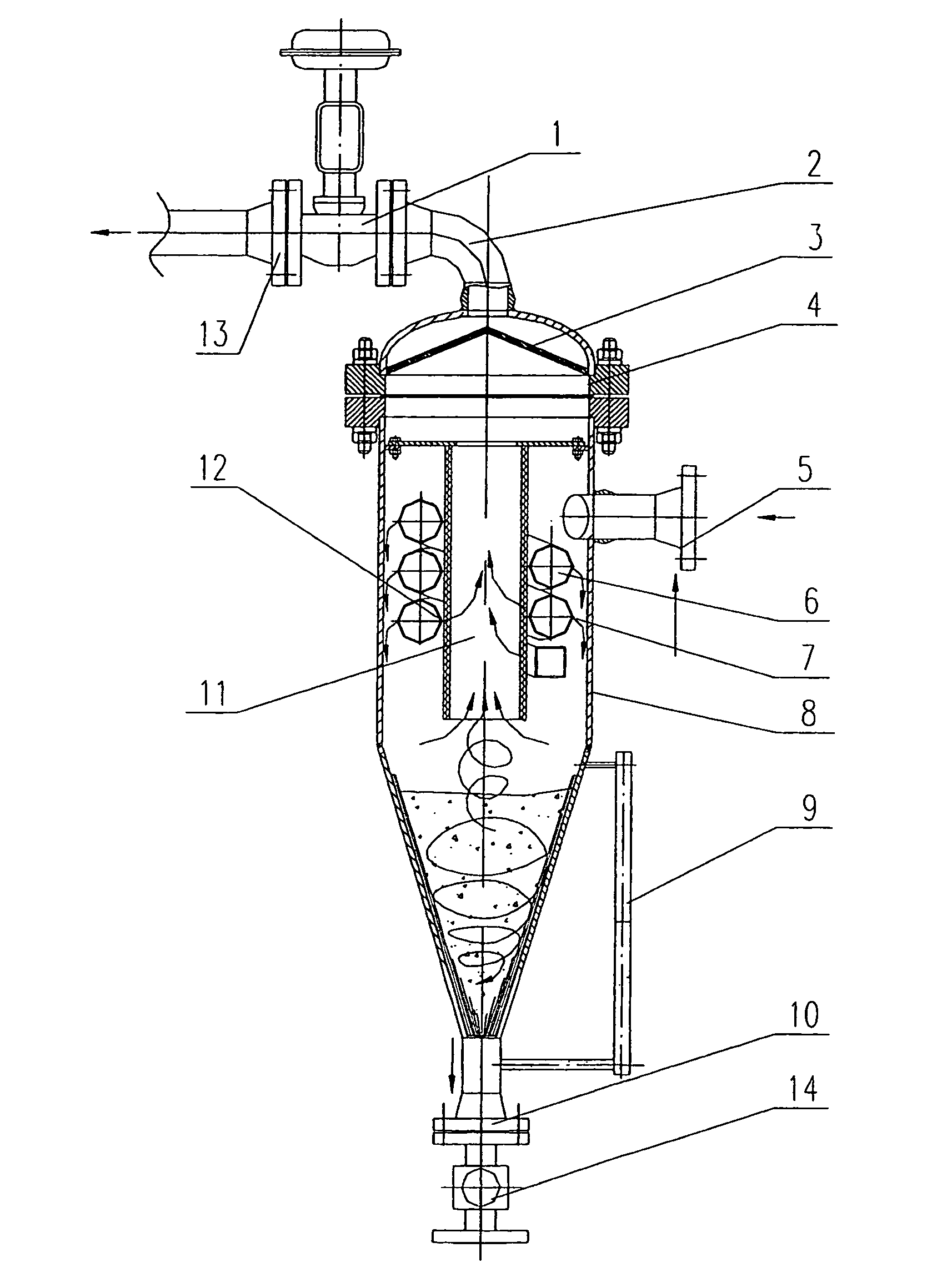

An adjustable type guide vortex gas-liquid separating apparatus is provided, it comprises a case, a vortex flow guide spiral pipe, a mist eliminator, an adjusting valve and a γ ray phase volume fraction meter. Its separating method is to make the oil-gas-water multiphase flow move in vortex, and thus to realize the gas-liquid separation, then to measure the gas content of the separated liquid phase by using the γ ray phase volume fraction meter and to send out control information as judged by the magnitude of the gas content in the liquid phase, so as to control the opening of the adjusting valve of the gas circuit, thus to achieve adjustment of the gas-liquid separation effects, and to control the gas content of the liquid phase to a certain range.

Owner:HAIMO TECH INC

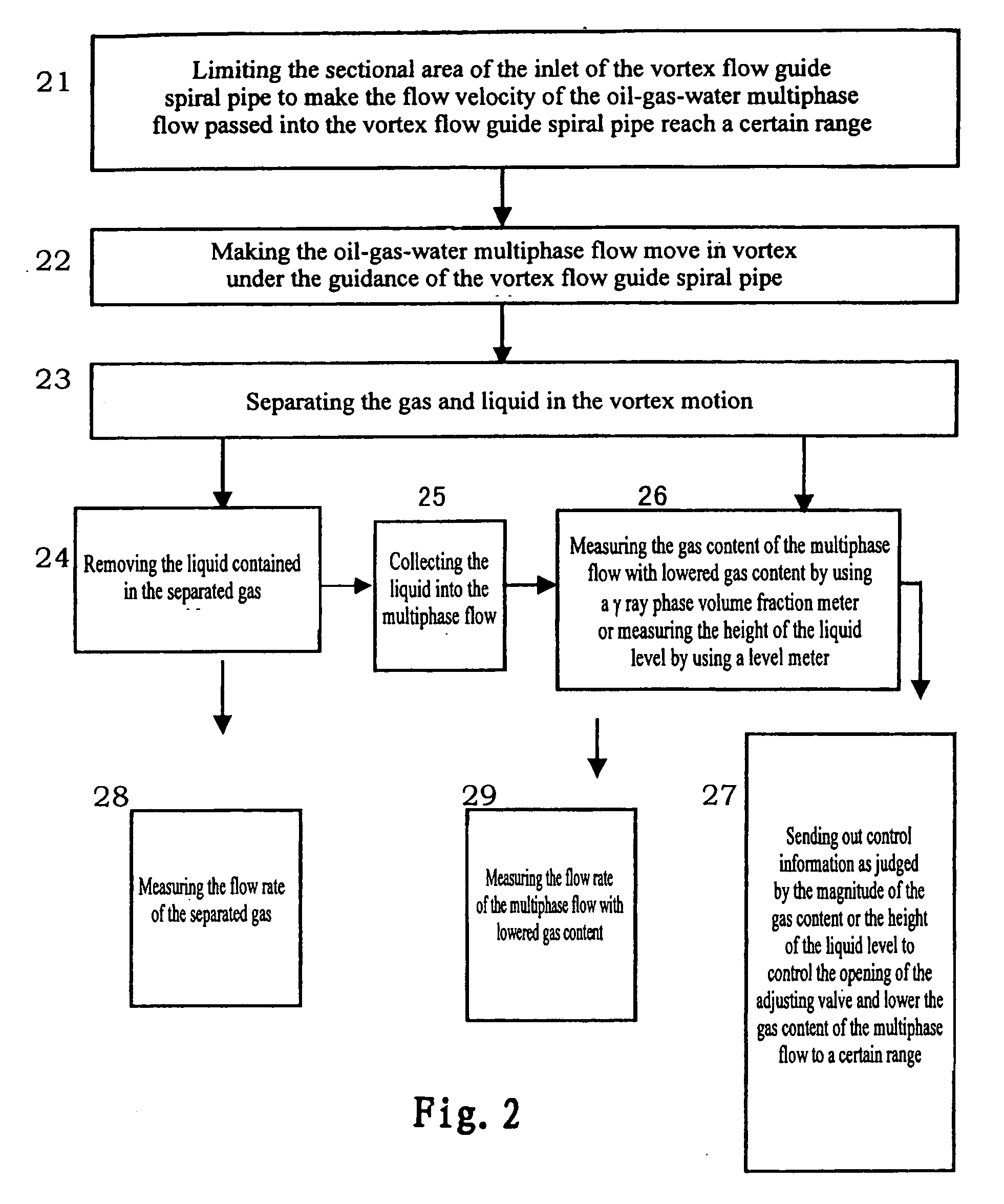

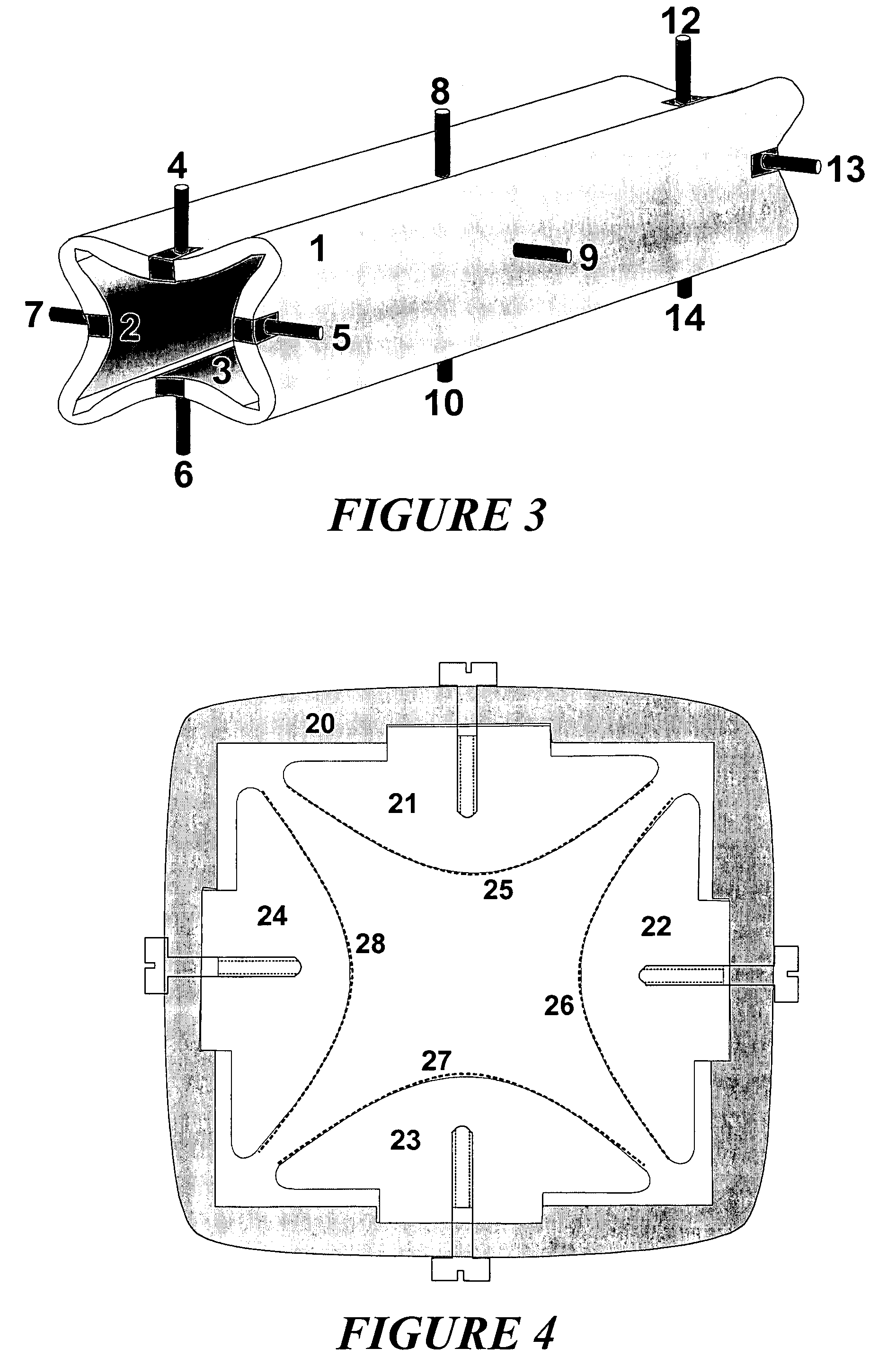

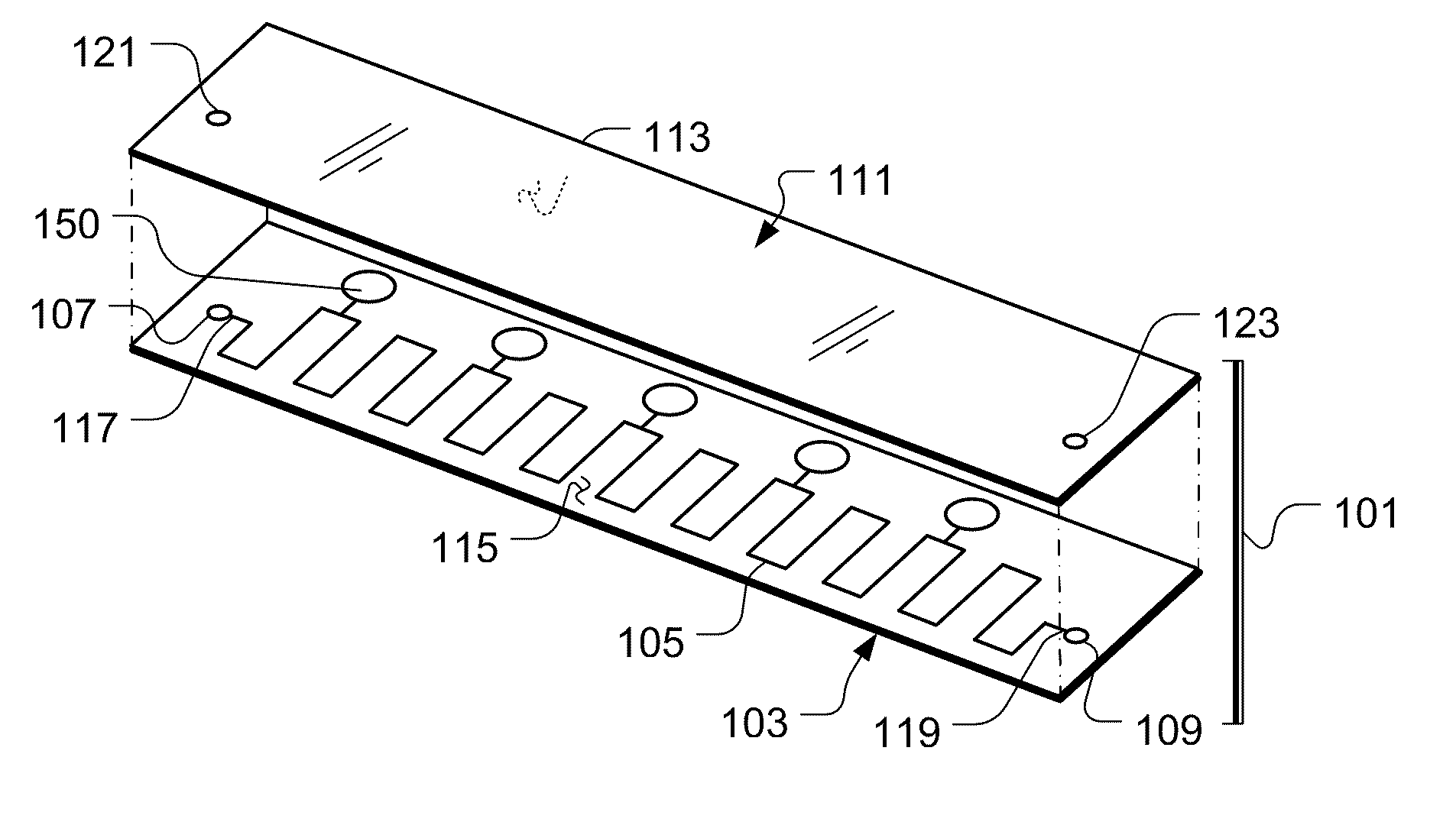

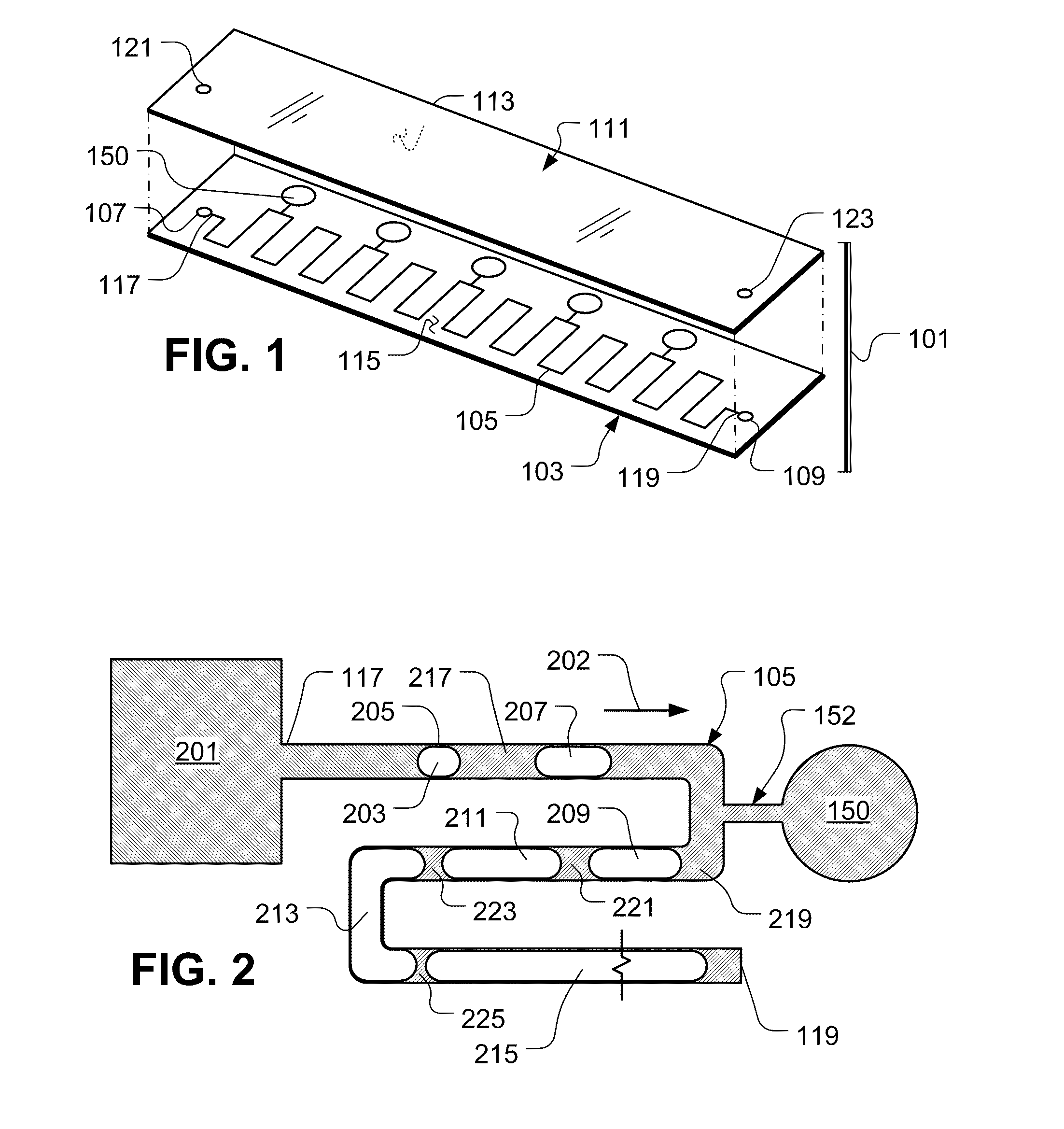

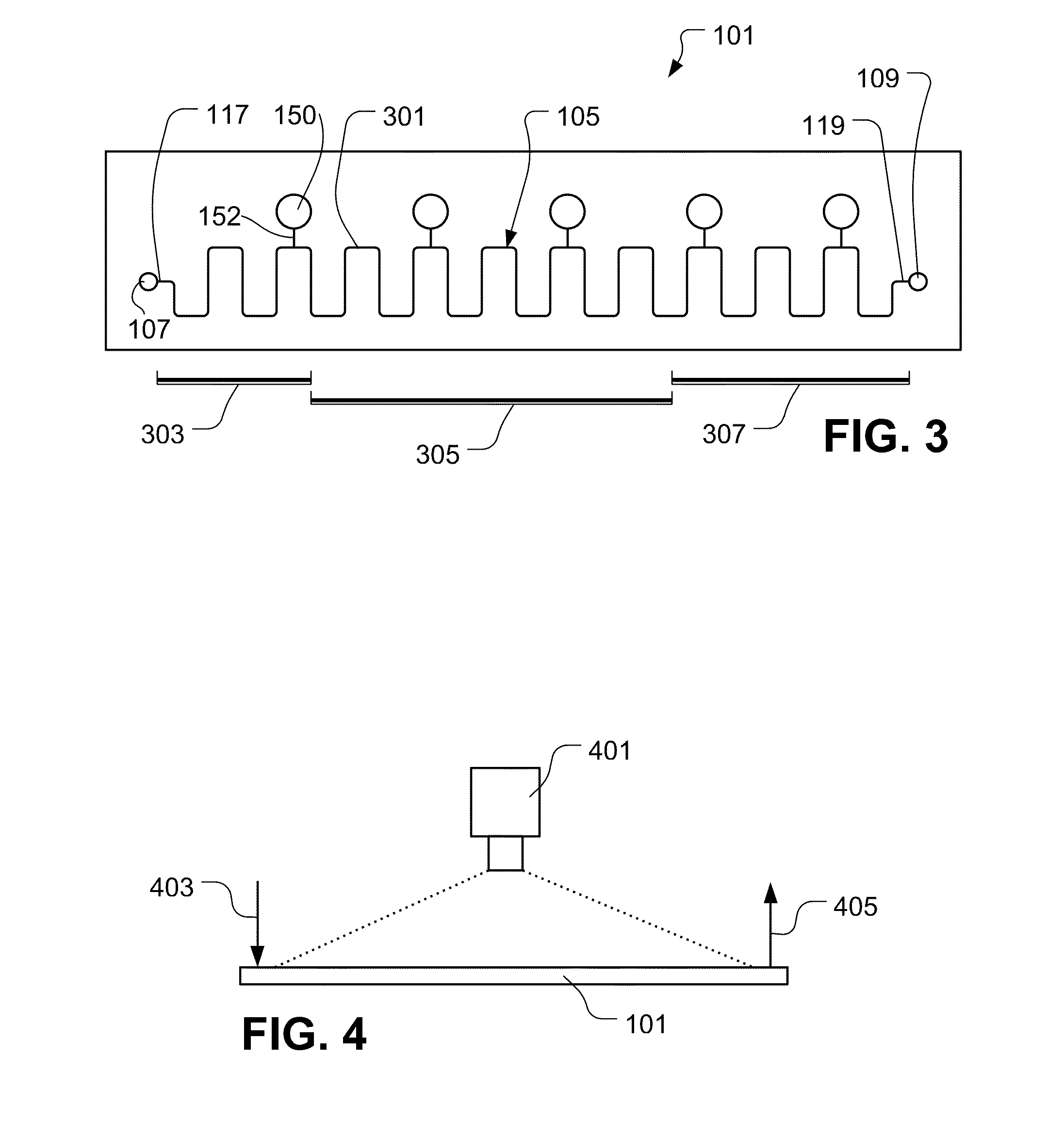

Authentication system and method

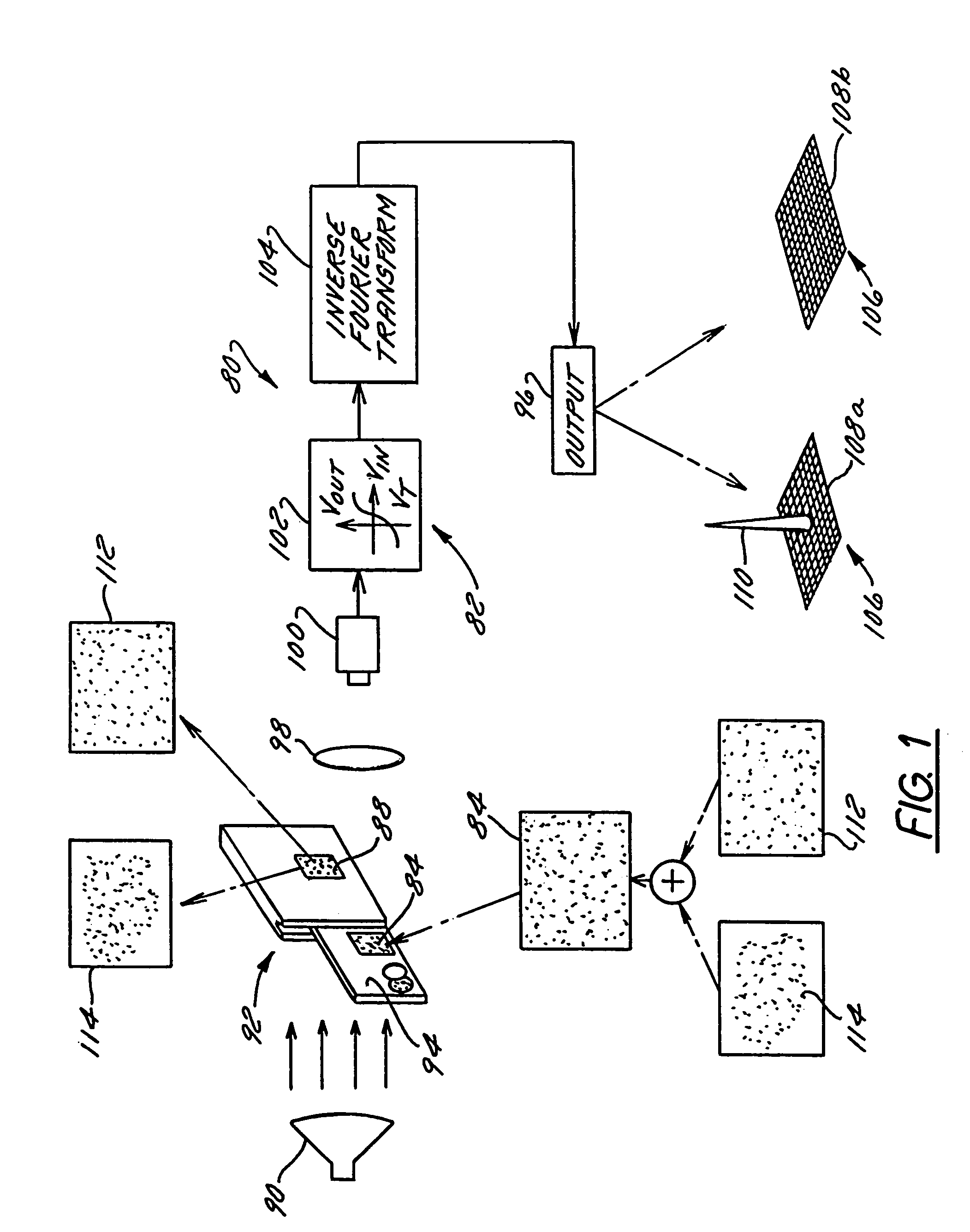

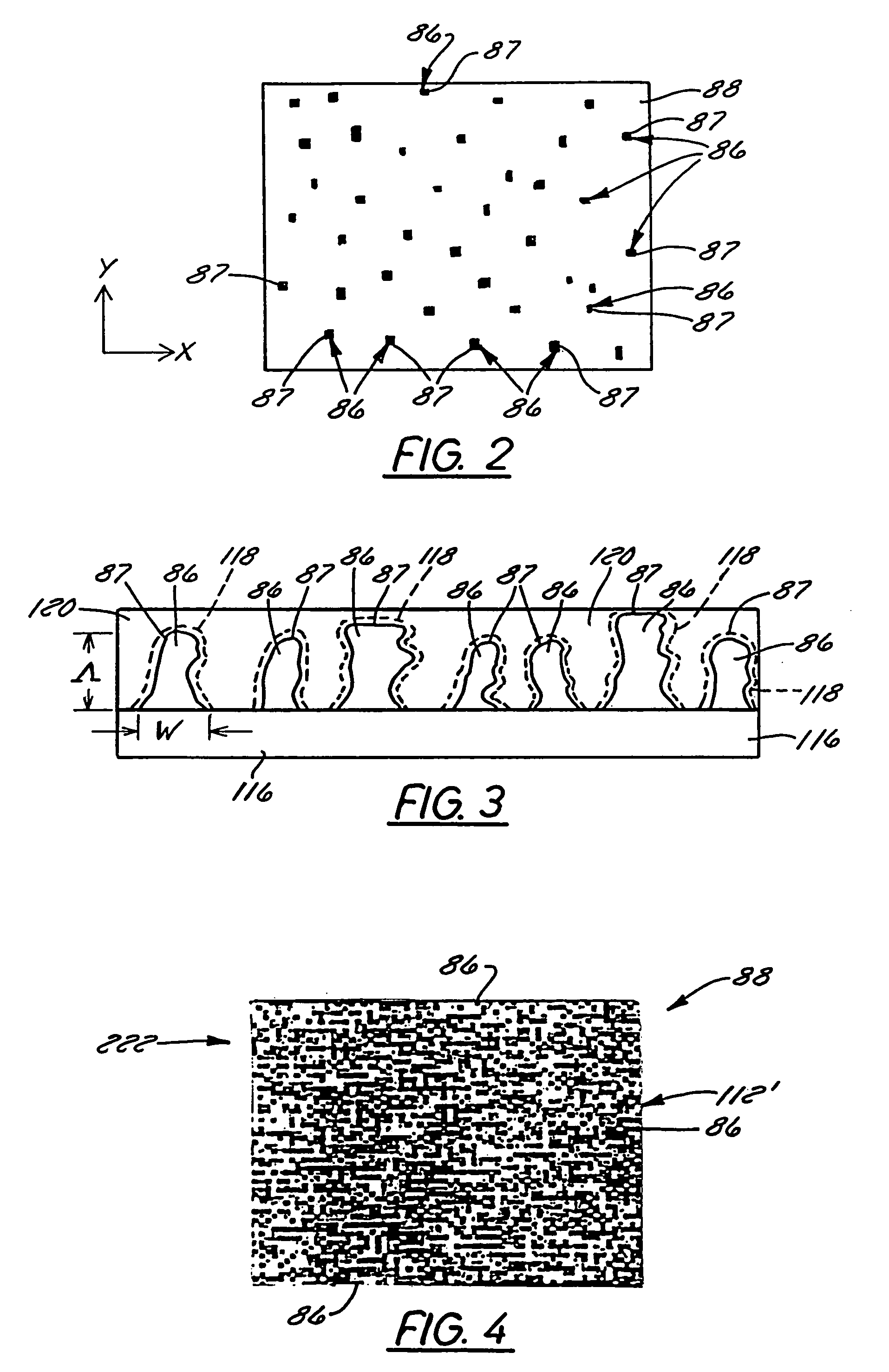

InactiveUS7317814B2Cheaply replicatedRaise security concernsRadiation pyrometryCo-operative working arrangementsSpatial light modulatorFourier transform on finite groups

An authentication system using a correlator that correlates an input with a reference wherein at least one of the input and reference comprises a phase volume mask having structures, preferably points, that are each less than about six microns in size and can have an aspect ratio (AR) greater than 1:1 so as to produce a phase encoded random pattern having millions of combinations in a mask that is as small as one square millimeter. The random pattern can be convolved with a second pattern, such as a biometric pattern, to produce a phase convolved mask. The correlator preferably is a nonlinear joint transform correlator that can use “chirp” encoding to permit the input to be located in a different plane than the reference. The correlator optically Fourier transforms images of the reference and input that are thereafter nonlinearly transformed and inverse Fourier transformed by a processor to determine the presence or absence of a correlation spike indicative of authenticity. A spatial light modulator (SLM) can be used as an input or reference and preferably is a liquid crystal panel having pixels or elements whose phase or grey scale intensity can be selectively controlled by a processor. The SLM can be used to display a biometric pattern, preferably scanned in real time from a person, that is correlated against an input or reference that can comprise a label on a card, a tag, or another object.

Owner:PHYSICAL OPTICS CORP

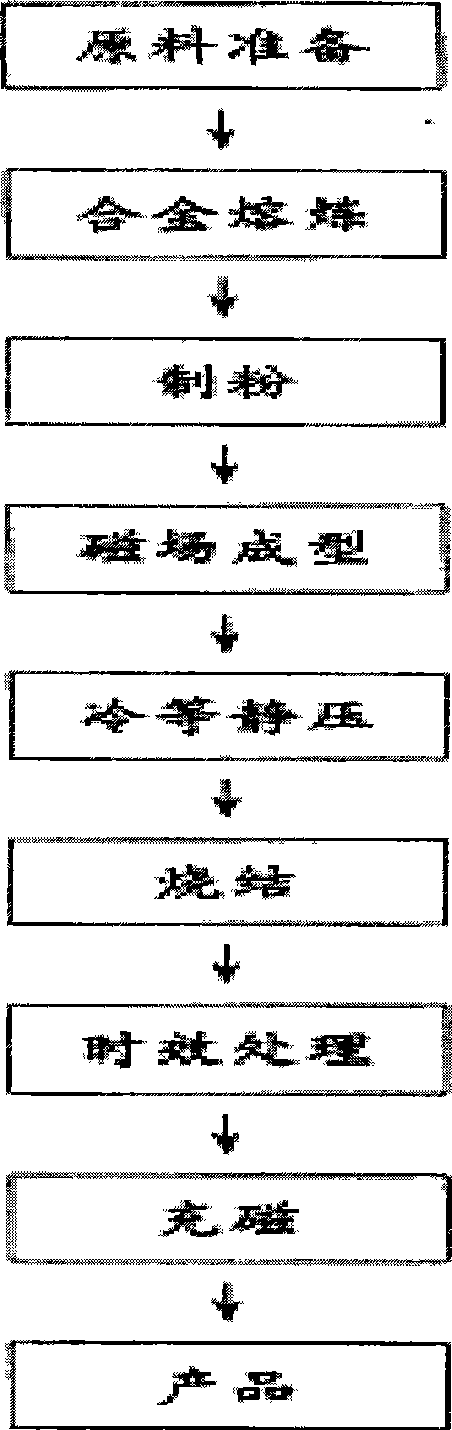

Permanent magnetic RE material and preparation thereof

ActiveCN101364465ASmall temperature coefficientLow coercivityInorganic material magnetismCrystalline oxideSamarium–cobalt magnet

The invention relates to a rare earth permanent magnetic material and a preparation method thereof. The rare earth permanent magnetic material comprises a (Pr, Nd)-Fe-R-Co-Al-Cu-B-M system, and the rare earth as a main phase component has a phase volume ratio of 90%-98%; wherein R is at least two elements selected from Nb, Tb, Dy and Ho; M is at least two nanometer crystalline oxides with particle size of 10-100 nm selected from ZrO2, MgO and ZnO; and the weight of the nanometer crystalline oxides is 0.1%-3% of the total weight. The rare earth permanent magnetic material is a compound nanometer oxidizer enhanced and sintered praseodymium (Pr)-neodymium (Nd)-based permanent magnet with high coercitive force. The inventive product has magnetic features of low temperature coefficient, high coercitive force, low cost and 220 DEG C working temperature, and can overcome the shortcomings of lower coercitive force, high temperature coefficient and high cost of the prior sintered Nd-Fe-B permanent magnet and the sintered samarium-cobalt magnet in application of large motor products. The preparation method provides a powerful guarantee for realizing the positive effects.

Owner:浙江西子富沃德电机有限公司

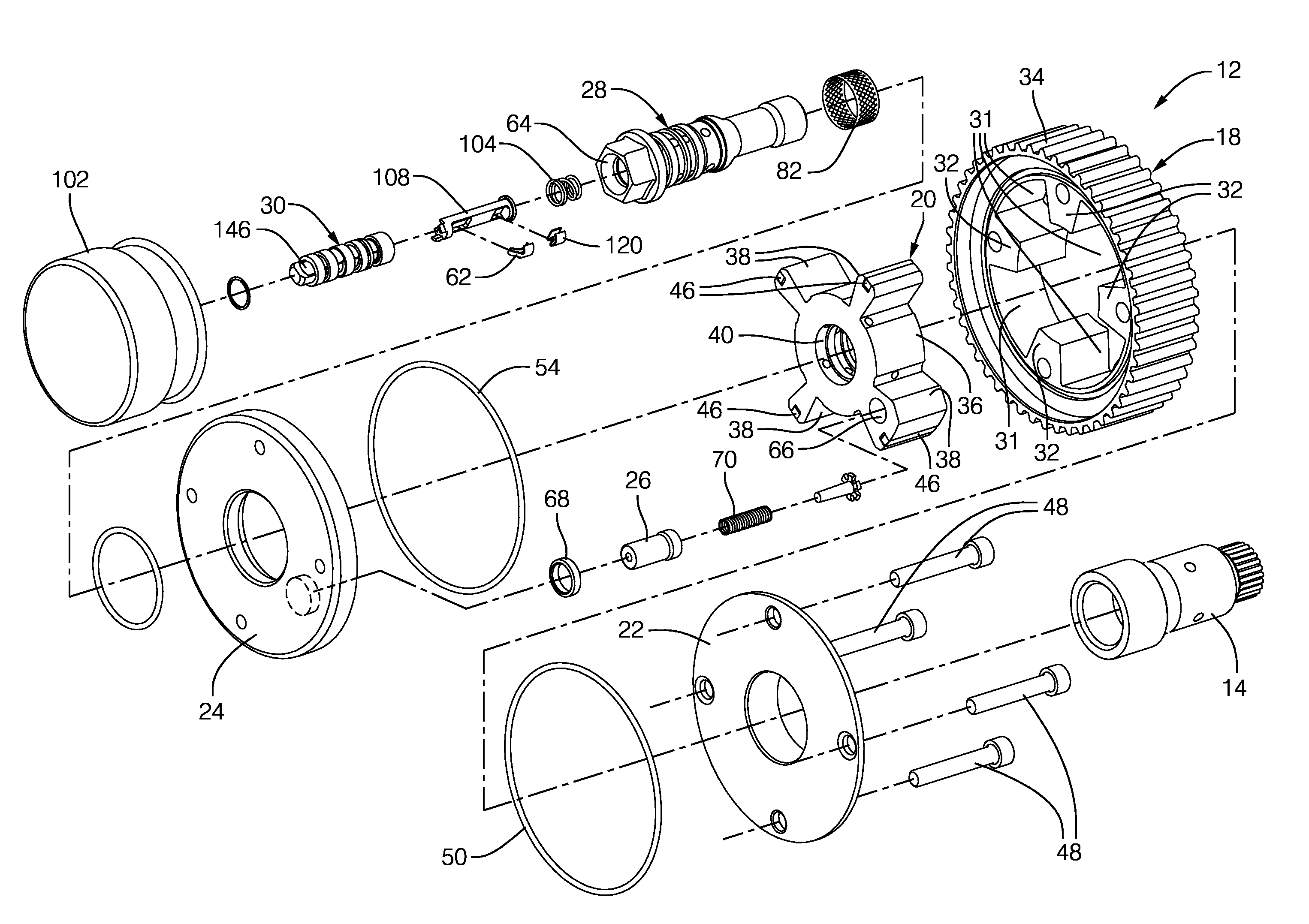

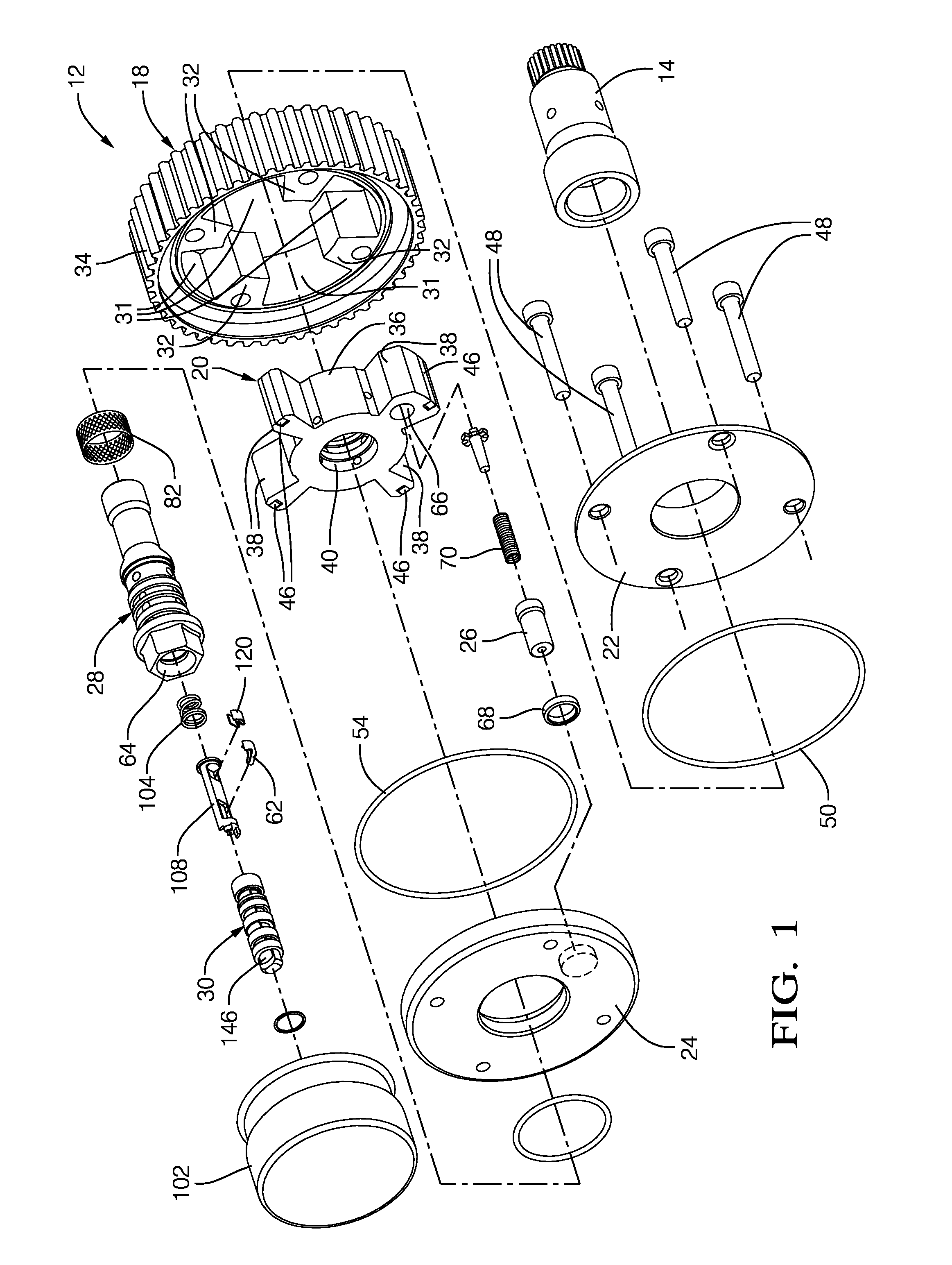

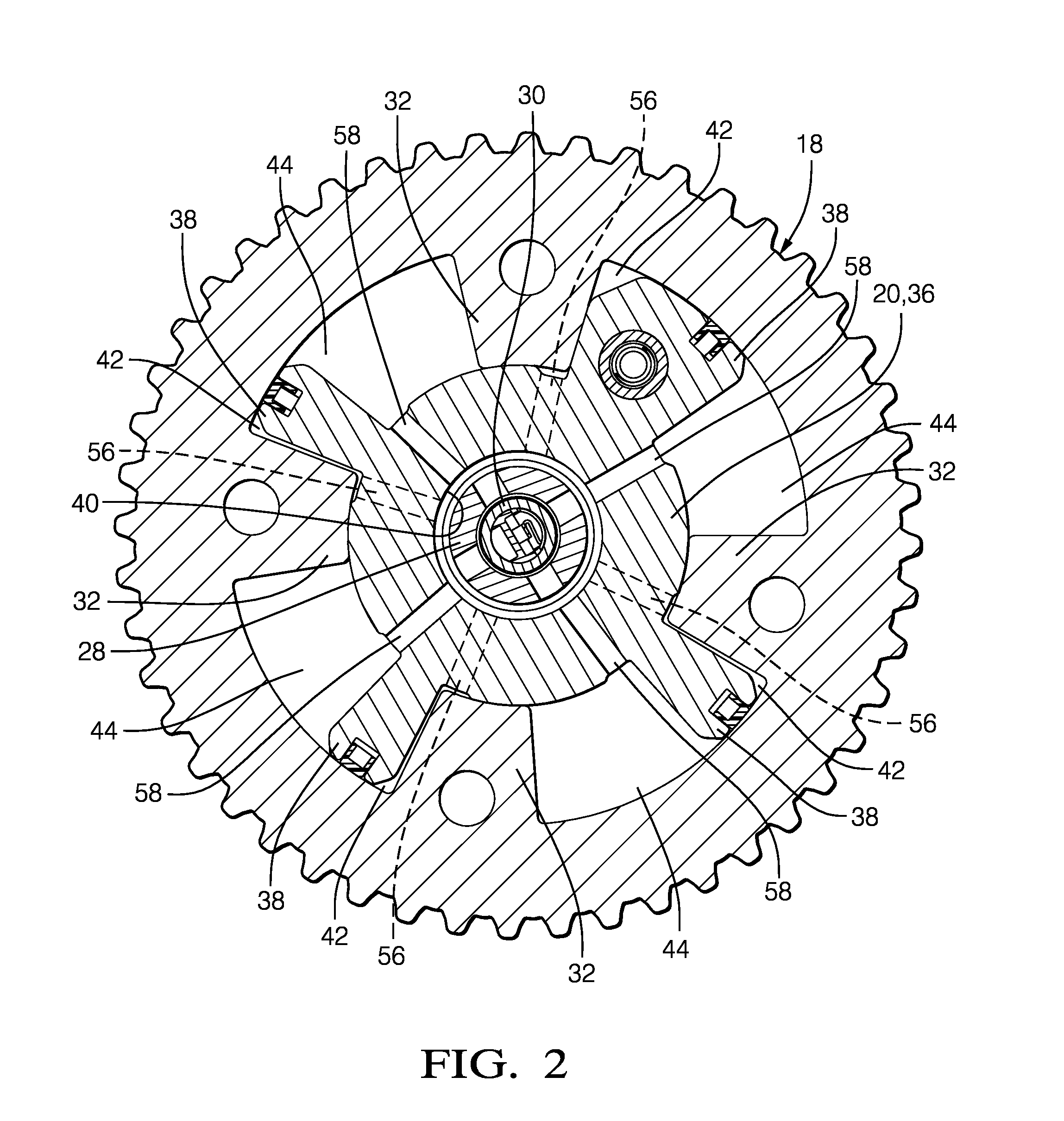

Camshaft phaser

A camshaft phaser includes an input member; an output member defining an advance chamber and a retard chamber with the input member; a valve spool moveable between an advance position and a retard position and having a valve spool bore with a phasing volume and a venting volume defined therein such that the phasing volume is fluidly segregated from the venting volume; and a phasing check valve within the valve spool. The advance position allows oil to flow through the phasing check valve and through the phasing volume from the advance chamber to the retard chamber while preventing oil from flowing from the retard chamber to the advance chamber and the retard position allows oil to flow through the check valve and through the phasing volume from the retard chamber to the advance chamber while preventing oil from flowing from the advance chamber to the retard chamber.

Owner:DELPHI TECH IP LTD

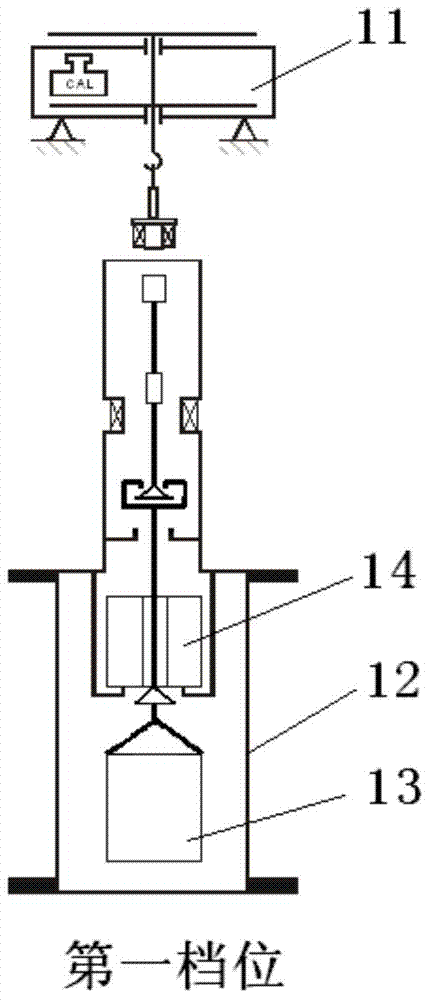

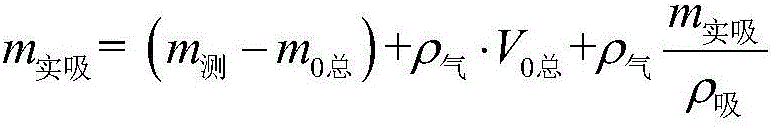

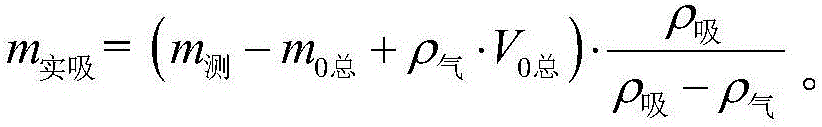

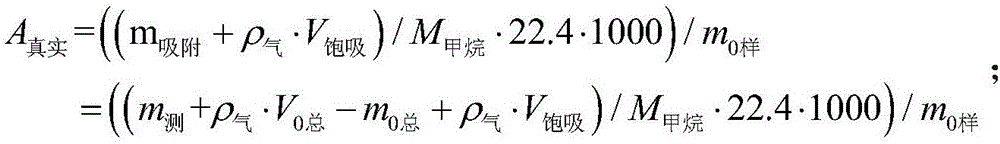

Method for accurately measuring absorbed phase density of methane on shale

InactiveCN104713803AThe result is accurateImprove applicabilitySpecific gravity measurementSubstance amountPhase volume

The invention relates to a method for accurately measuring absorbed phase density of methane on shale. The method comprises the following steps: 1) smashing a piece of shale sample to be 60-80 meshes, and dividing the powder into two; 2) performing a volumetric method isothermal adsorption experiment on the first shale sample, and obtaining a calculation model of the amount n, adsorbing CH4, of the adsorbed state methane substance; 3) performing a weight method isothermal adsorption experiment on the second shale sample, and obtaining a calculation model of the mass m, adsorbing CH4, of the adsorbed state methane; 4) performing adsorbed phase volume correction on the calculation model of the amount n, adsorbing CH4, of the adsorbed state methane substance, obtained in the step 2) and the calculation model of the mass m, adsorbing CH4, of the adsorbed state methane, obtained in the step 3), so as to obtain the corrected substance amount calculation model and the corrected mass calculation model of the adsorbed state methane; 5) according to a definition formula of the amount of substance, combining with the two calculation models in the step 4), and determining the mass m, adsorbing CH4, and the volume V adsorption of the adsorbed state methane; 6) according to the definition of the density, determining an exact adsorption value of the adsorbed phase density rho of methane on the shale.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

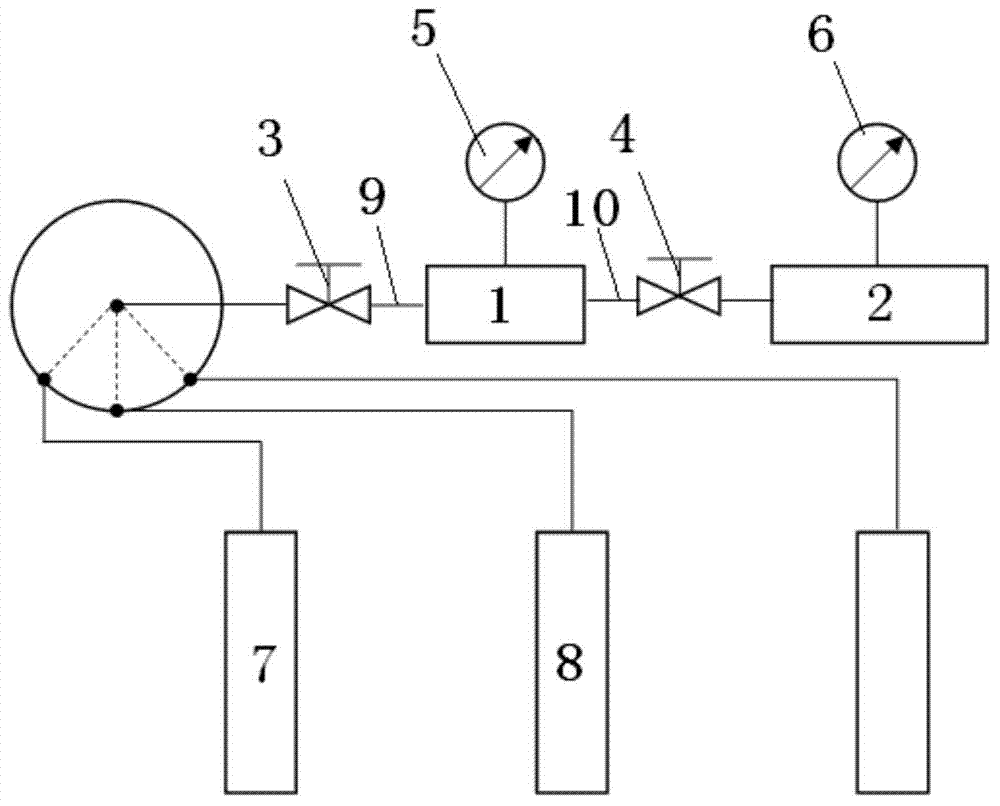

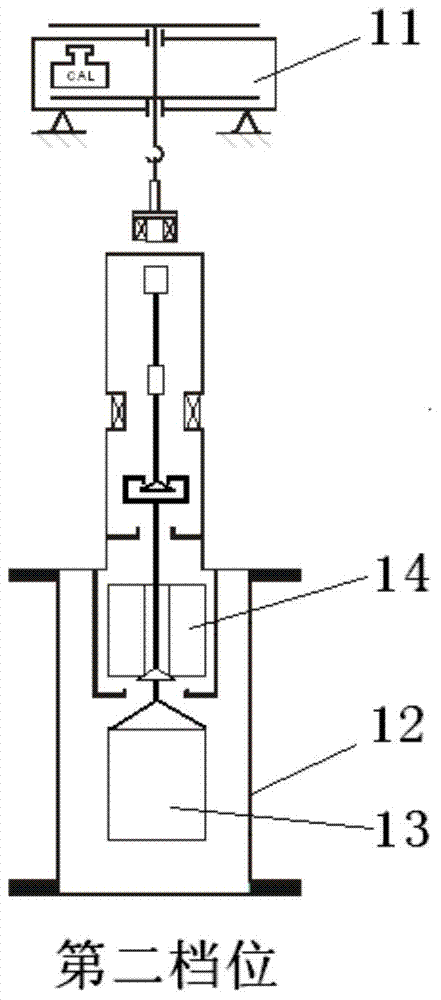

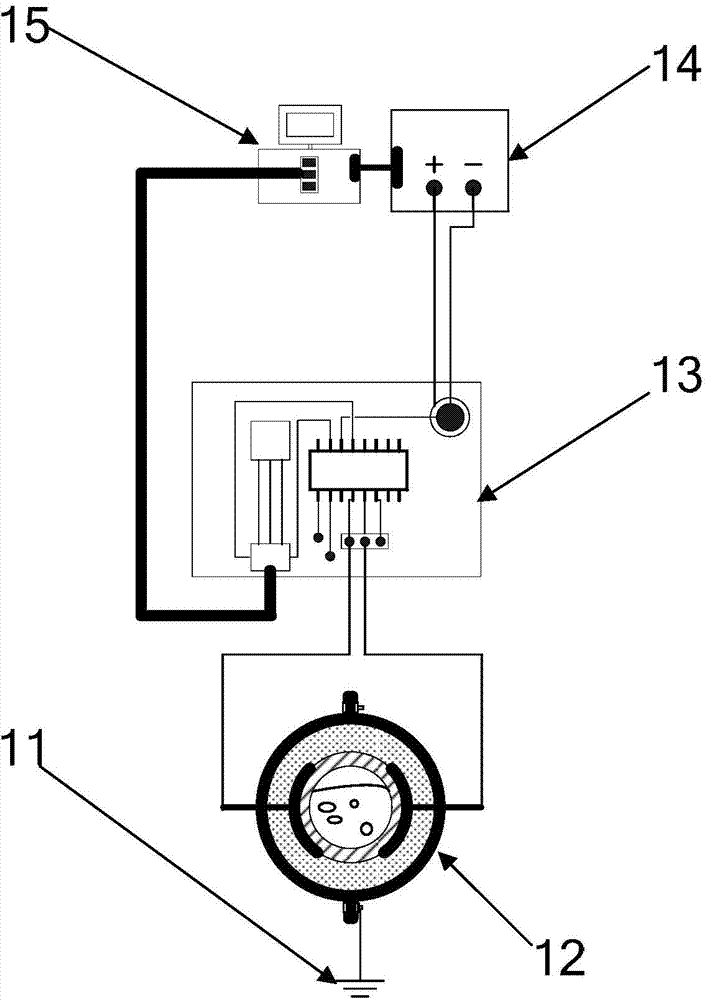

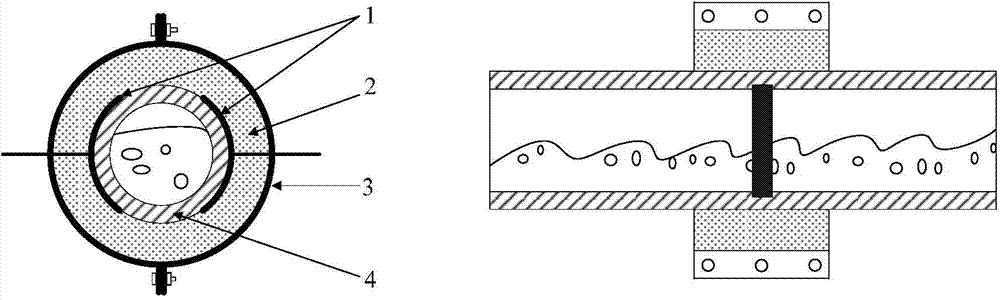

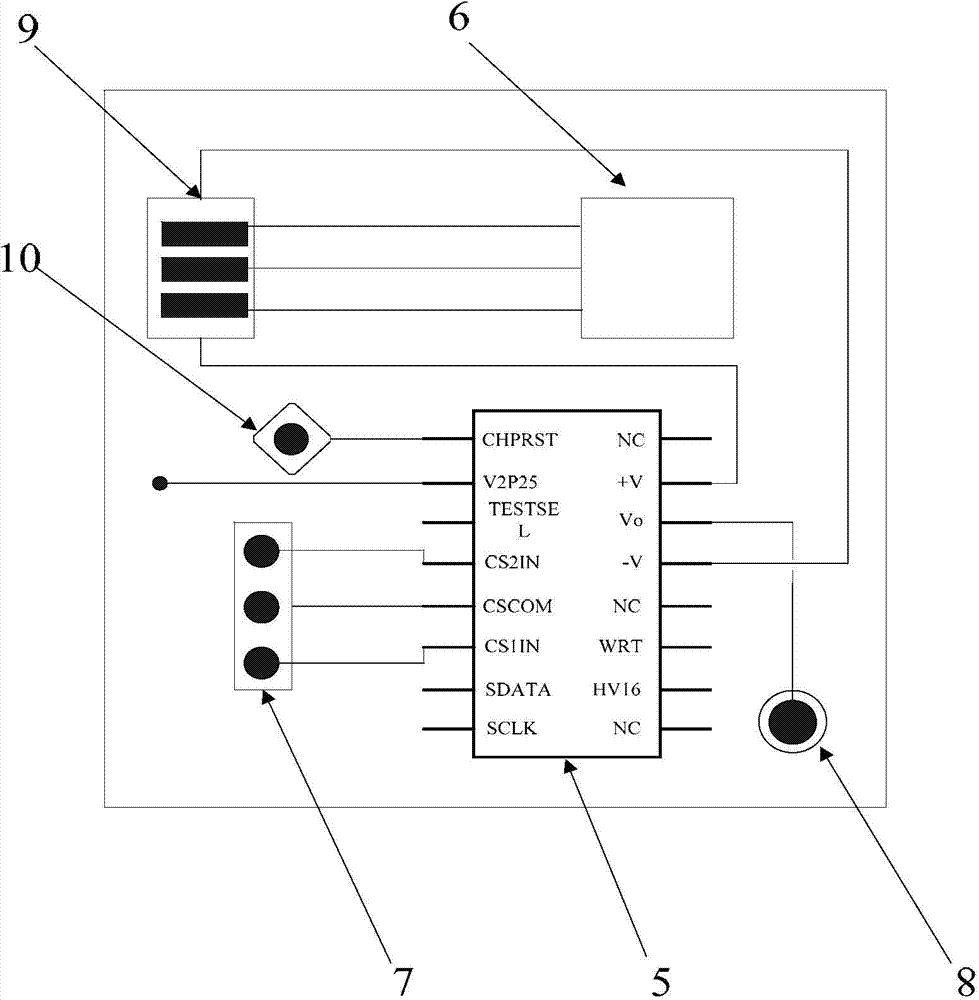

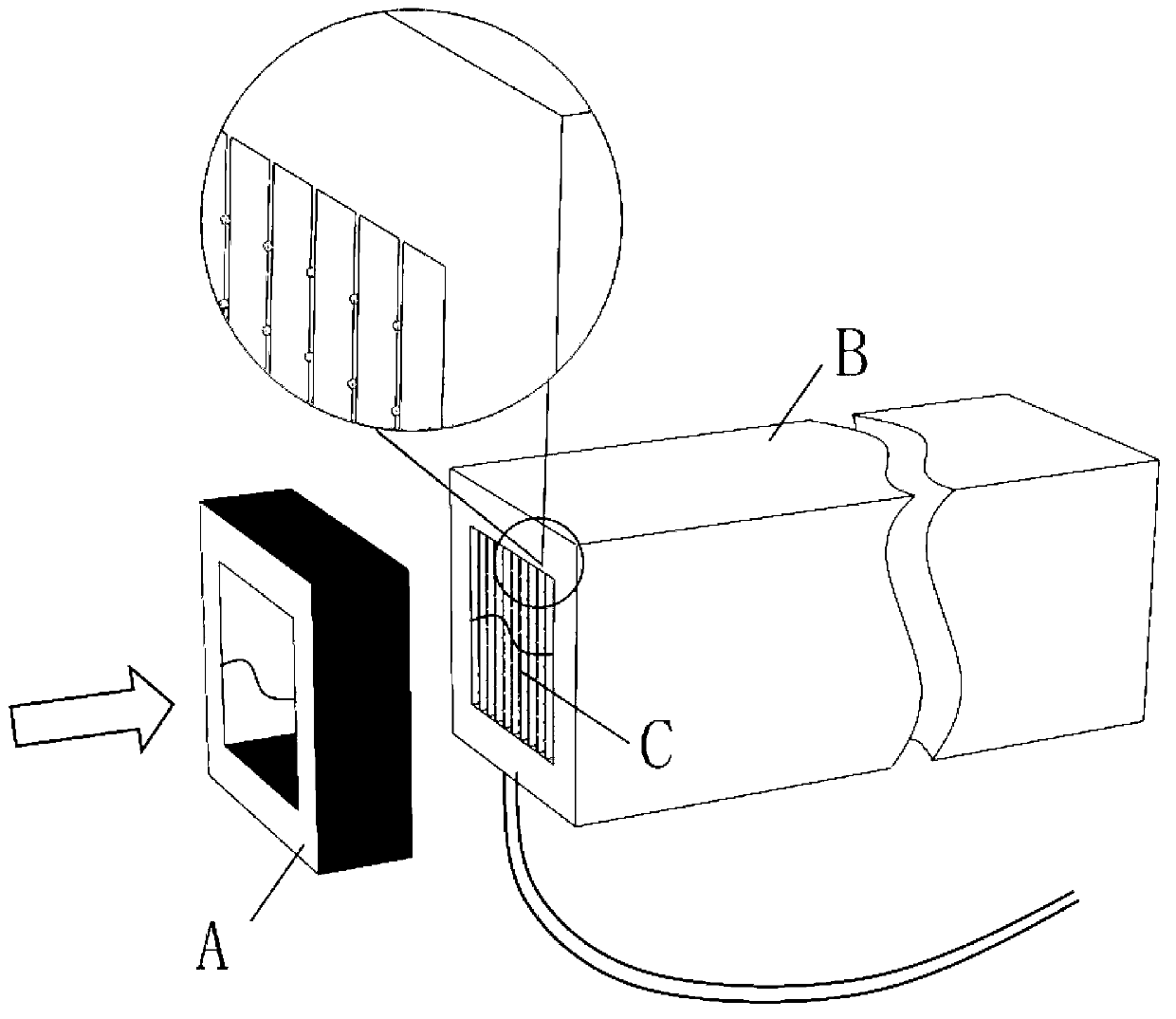

Real-time capacitance measurement system for phase volume fraction of gas-liquid two-phase flow and measurement method thereof

ActiveCN103884747AUnaffected by inhomogeneous phase distributionSignificant difference in output voltage valuesMaterial capacitanceMicrocomputerAir interface

The invention discloses a real-time capacitance measurement system for a phase volume fraction of gas-liquid two-phase flow and a measurement method thereof. The real-time capacitance measurement system comprises a double-concave-surface capacitance electrode device consisting of a double-concave-surface capacitance electrode group mounted on the outer wall of an insulating pipeline, an insulating filling material and a copper protection shell, a signal source and capacitance-voltage conversion integrated circuit, an acquisition board card and a computer, wherein the signal source and capacitance-voltage conversion integrated circuit comprises an MS3110 chip, an INPUT CAP, a USB (universal serial bus) interface, a single-chip microcomputer, a Vout air interface and a restarting key. The measurement method comprises the steps of setting a chip parameter; performing static gas-liquid two-phase flow calibration through the double-concave-surface capacitance electrode device, assembling a double-concave-surface capacitance electrode on the outer wall of a pipeline to be measured, and performing phase volume fraction measurement on the gas-liquid two-phase flow moving in the pipeline. According to the real-time capacitance measurement system, the radial length of the pipeline is large, and the real-time capacitance measurement system is sensitive to the micro change of the phase volume fraction on the inner section of the pipeline; a difference of output voltage values is enabled to be outstanding by changing a built-in parameter of the chip.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

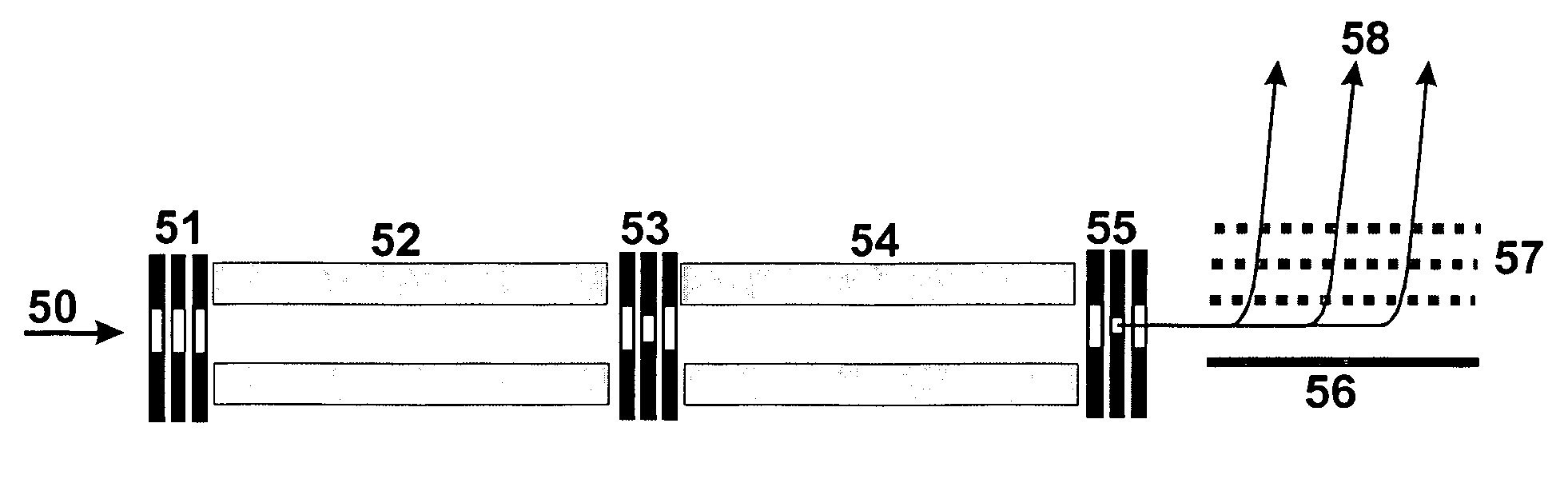

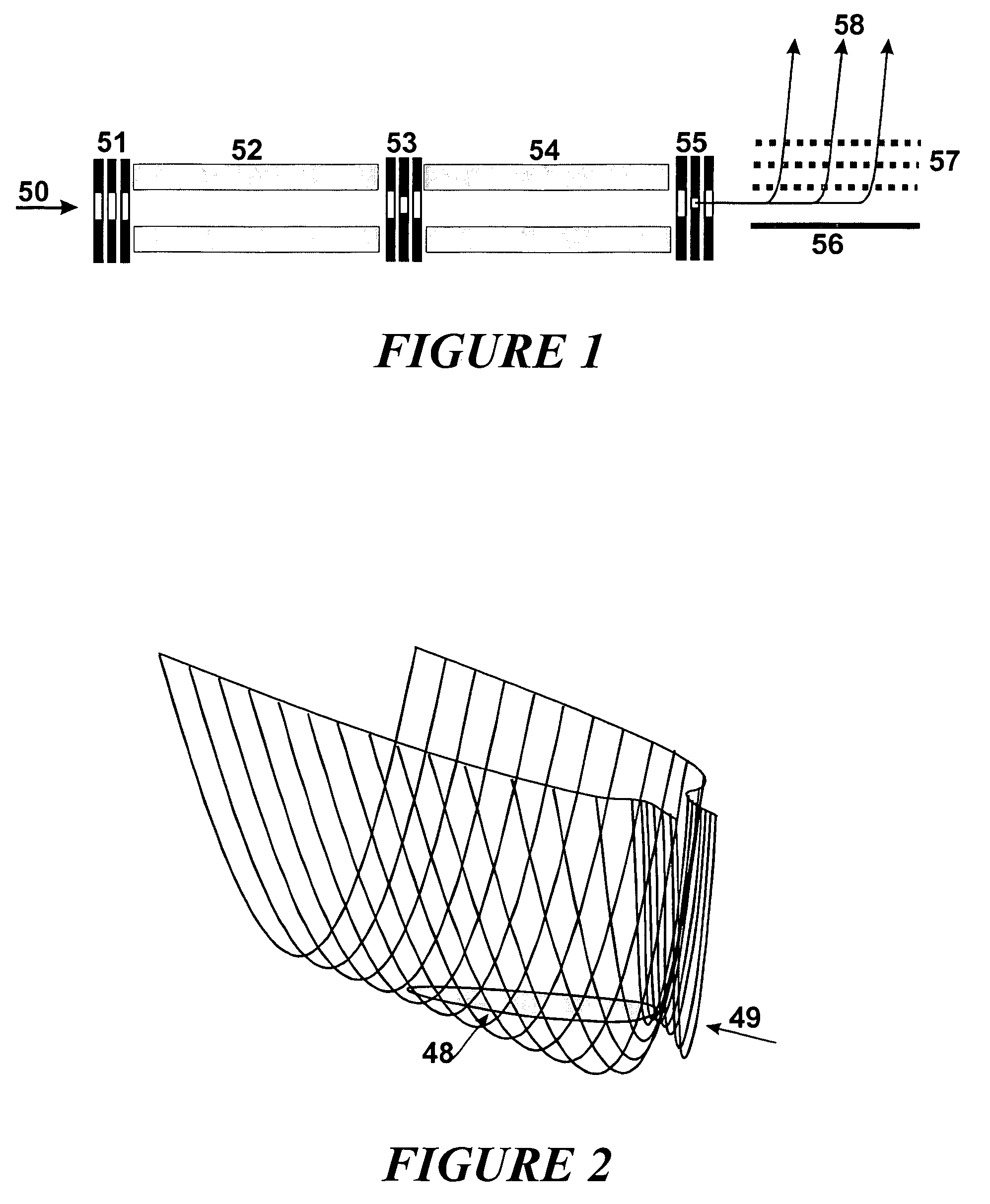

Ion-optical phase volume compression

ActiveUS7276688B2Easy to produceCompression volumeStability-of-path spectrometersTime-of-flight spectrometersIon beamPhase volume

The invention relates to a method for damping the kinetic energy of ions in ion cells filled with collision gas and with an exit aperture to drain the ions out of the cell. The invention uses a conditioning cell with an adjustable DC potential which decreases towards the exit aperture to compress the phase volume of the ions by damping their kinetic energies, collecting the ions after thermalization in the spatial potential minimum thus created and letting them drain away relatively slowly through a central potential minimum in the exit aperture system. This facilitates the production of very fine, highly parallel ion beams which consist of almost monoenergetic ions. In particular, the method can also be coupled with a fragmentation of the ions.

Owner:BRUKER DALTONIK GMBH & CO KG

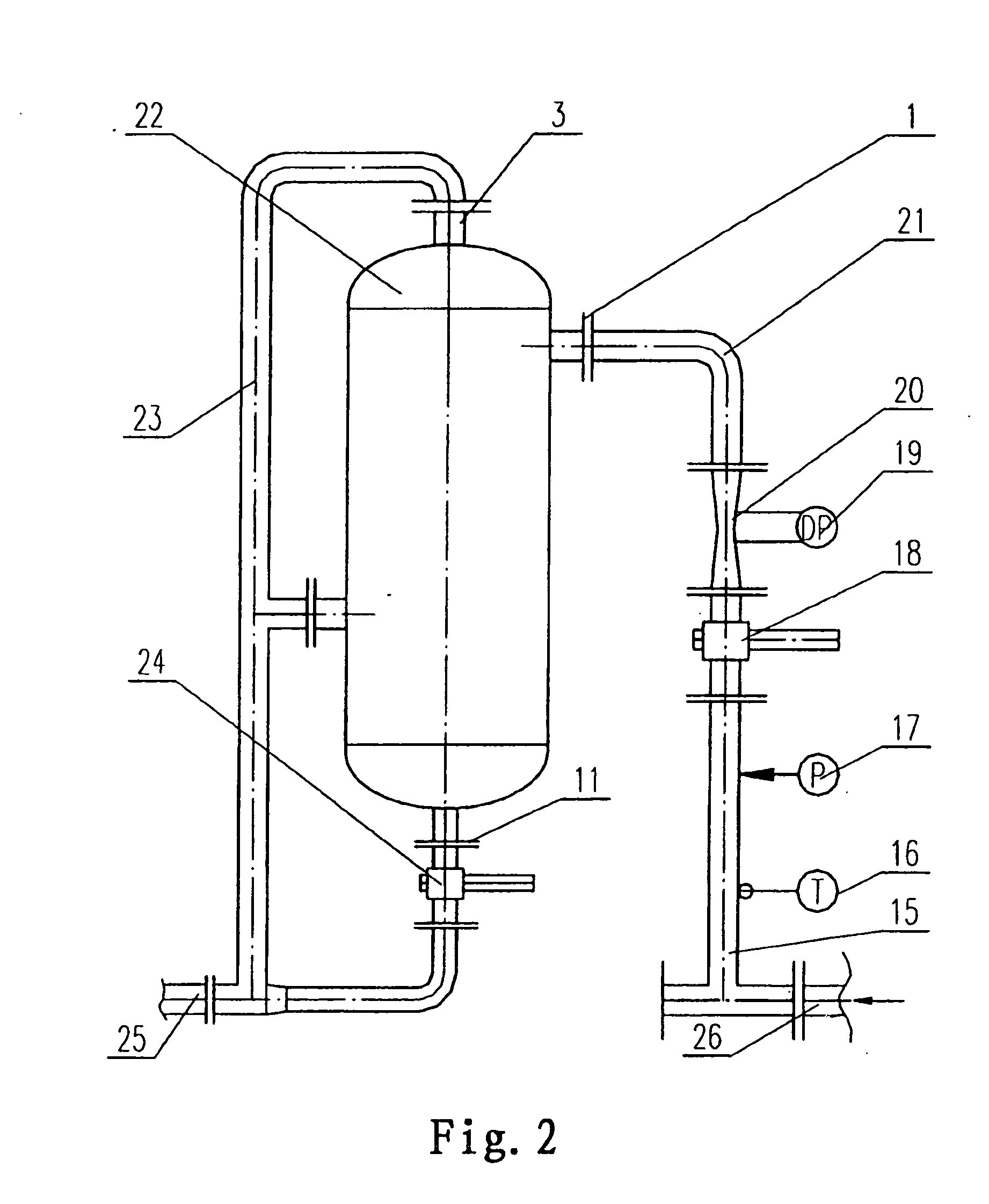

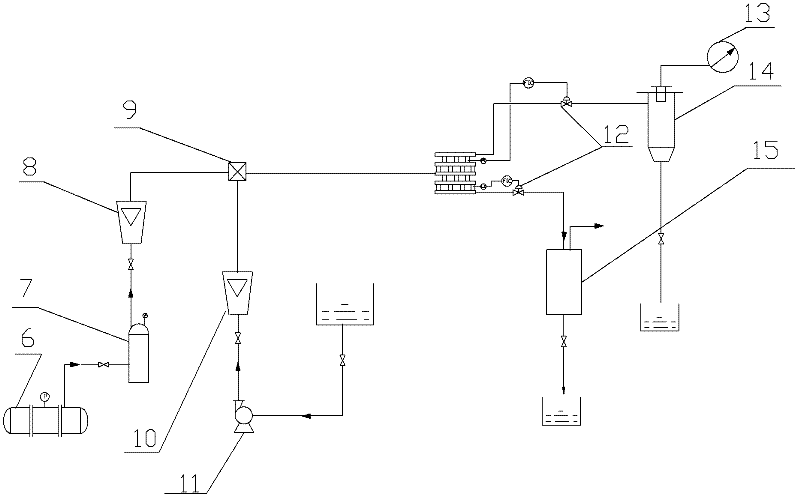

Oil-gas-water multi-phase flow adjusting apparatus and oil-gas-water multi-phase flow rate measuring apparatus and measuring method

ActiveUS20070089609A1Small volumeLight weightCombination devicesLiquid degasificationMeasurement deviceDifferential pressure

The invention relates to an oil-gas-water multi-phase flow adjusting apparatus, which mainly comprises an inlet accelerating pipe section, a vortex flow guide spiral pipe, a gas circuit exit connection pipe section, a liquid receiving cone, a mixed liquid relief exit connection pipe section and a sampler exit connection pipe section, and which has the function for changing at intervals the flow pattern, the flow state and the components of the oil-gas-water multi-phase flow. The invention also relates to an oil-gas-water multi-phase flow rate measuring apparatus and its measuring method. The measuring apparatus comprises a blind three-way mixing means, a pressure differential type flow measuring device, a single-γ phase volume fraction meter, a dual-γ phase volume fraction meter, an oil-gas-water multi-phase flow adjusting apparatus and a computing system. The measuring method is as follows: the single-γ phase volume fraction meter and the dual-γ phase volume fraction meter measure the gas content GVF and the water content WC respectively; the pressure differential type flow measuring device measures the differential pressure ΔP of the total flow rate; the computing unit computes the oil flow rate Qo, the gas flow rate Qg and the water flow rate Qw.

Owner:HAIMO TECH INC

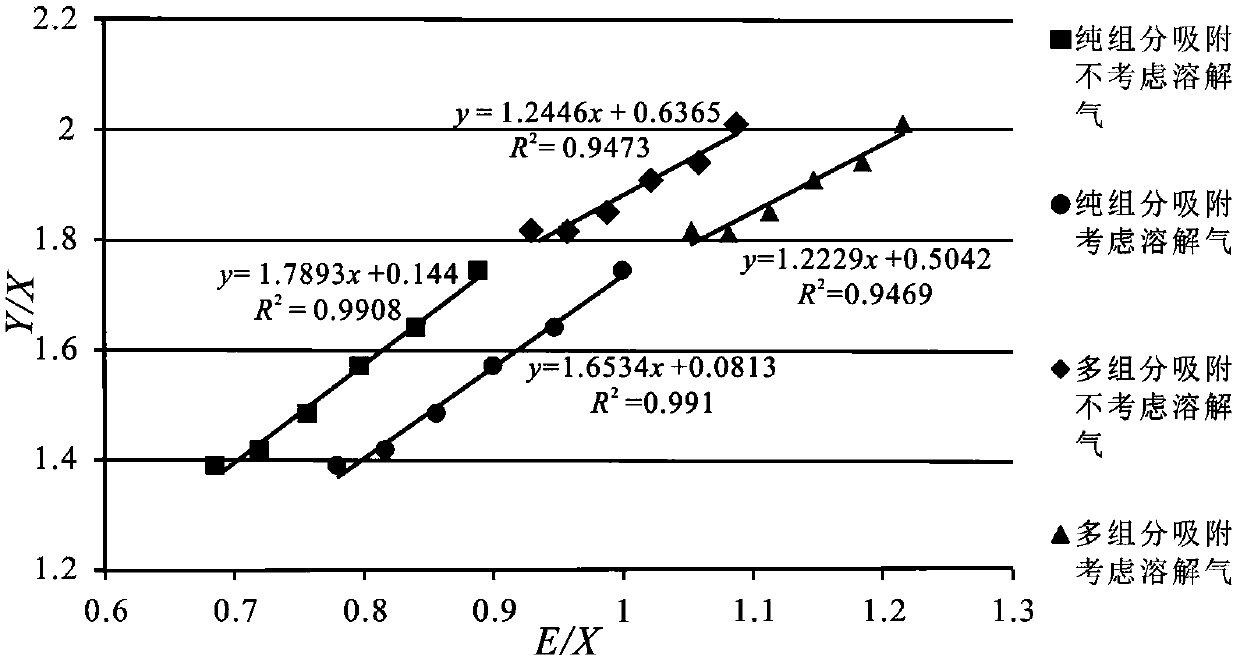

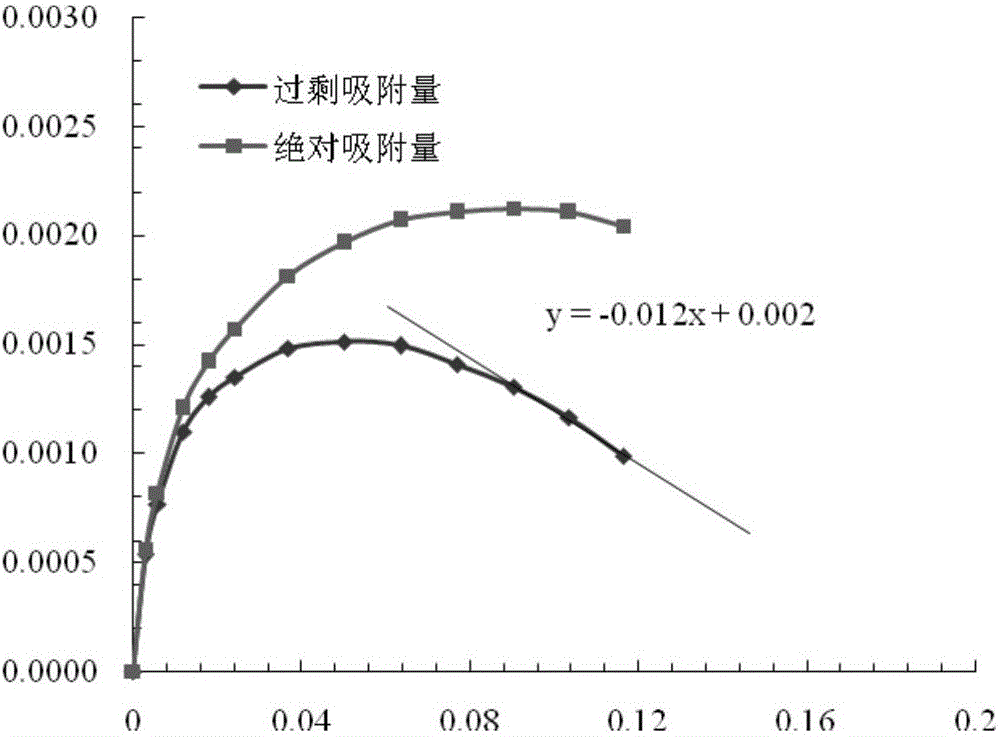

Method for accurately calculating real adsorption quantity of methane on shale

ActiveCN106198297AAccurate measurement of excess adsorptionImprove applicabilityPreparing sample for investigationWeighing by absorbing componentThermostatHigh pressure

The invention provides a method for accurately calculating the real adsorption quantity of methane on shale. The method comprises the following steps: crushing muddy shale samples; drying in a thermostat; obtaining the change data of quality of the muddy shale samples along the gas pressure, and calculating the initial volume and quality of samples and a sample cylinder; calculating the excessive adsorption quantity of the samples under different pressures; making a plot of the quality and gas density of measured samples at high-pressure section in a rectangular Cartesian coordinate system, and fitting to obtain an analytic expression, requiring fitting R<2>=1; calculating the saturated adsorption quality and saturated adsorption phase volume of the samples, wherein the ratio of the two is density value of an adsorption phase; and correcting the excessive adsorption quantity of saturated adsorption points on an absolute line through the adsorption phase volume, and correcting the excessive adsorption quantity on front other points through adsorption phase density, thus obtaining the true adsorption quantity of methane on shale.

Owner:SOUTHWEST PETROLEUM UNIV

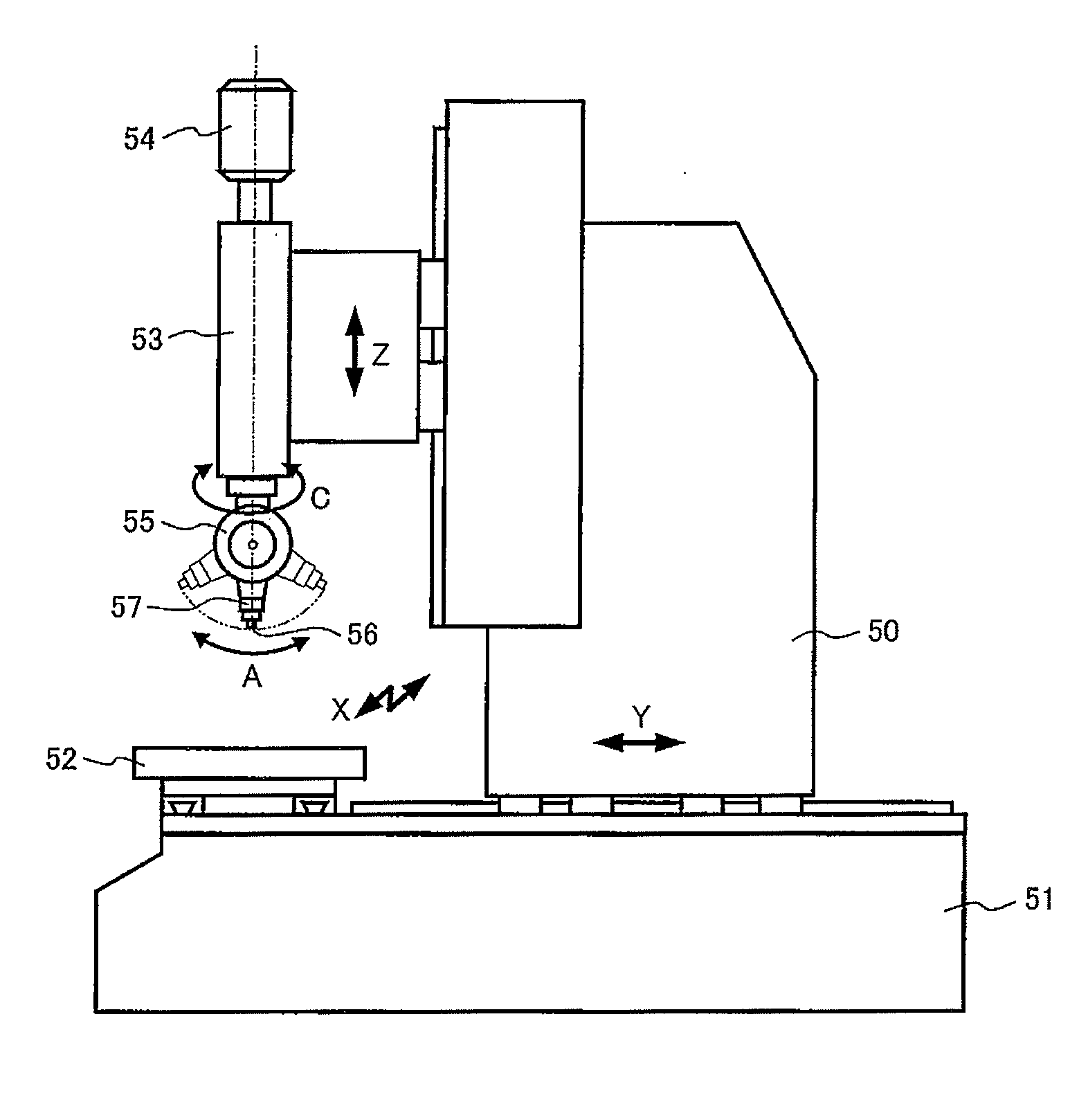

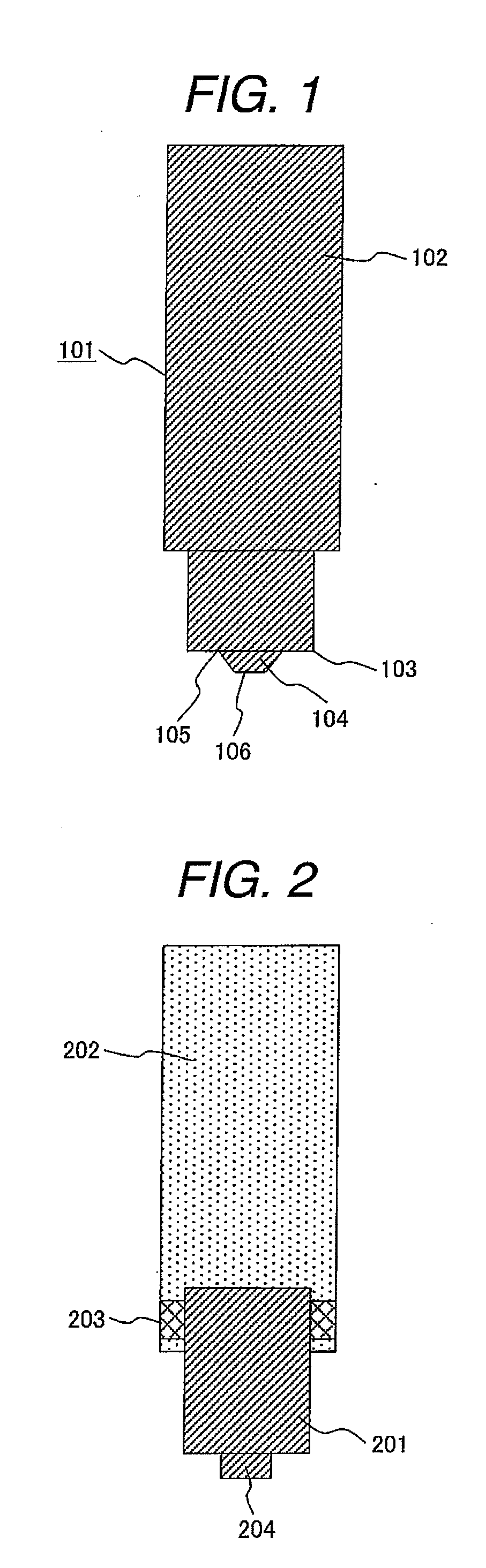

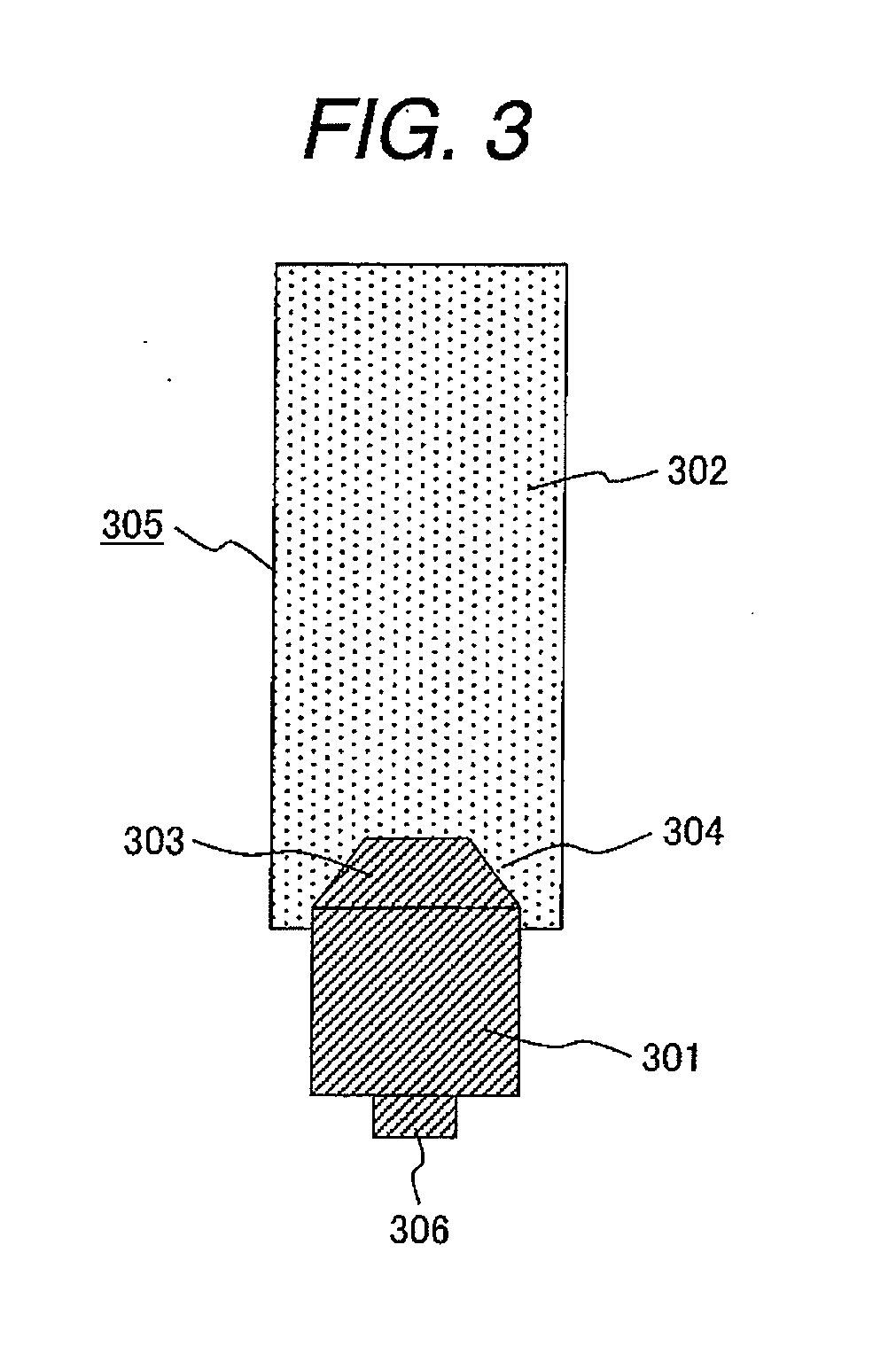

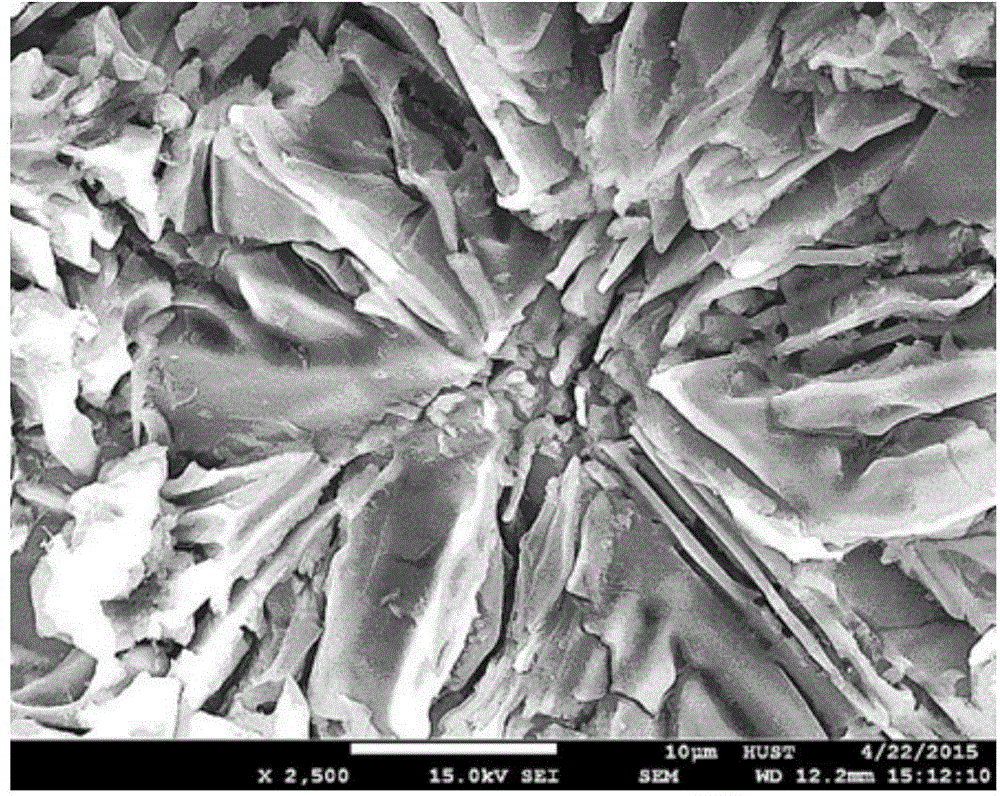

Friction Stir Welding Tool and Friction Stir Welding Apparatus

InactiveUS20080128472A1Maintain good propertiesHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingMetallic materials

An object of the present invention is to provide a friction stir welding tool which enables friction stir welding of a wide range of materials, from low-melting temperature metallic materials including aluminum to high-melting temperature metallic materials including steel.An entire friction stir welding tool or a tool tip including a pin is made of Mo alloy having a dual phase microstructure of Mo and intermetallic compound Mo5SiB2. It is desirable that the Mo alloy be composed of 6.0 to 10.0 mol % of Si, 10.0 to 20.0 mol % of B, and 20 to 60% of Mo-phase volume content. This Mo alloy tool has excellent high-temperature strength and wear-resistance properties and hardly deform and wear when used for the welding of steel.

Owner:TOHOKU UNIV +1

Phase behavoir analysis using a microfluidic platform

ActiveUS20090326827A1Electric/magnetic detection for well-loggingGas dispersion analysisGas phasePhase state

Methods and related systems are described for analyzing phase properties in a microfluidic device. A fluid is introduced under pressure into microchannel, and phase states of the fluid are optically detected at a number of locations along the microchannel. Gas and liquid phases of the fluid are distinguished based on a plurality of digital images of the fluid in the microchannel. Bi-level images can be generated based on the digital images, and the fraction of liquid or gas in the fluid can be estimated versus pressure based on the bi-level images. Properties such as bubble point values and / or a phase volume distribution ratio versus pressure for the fluid are can be estimated based on the detected phase states of the fluid.

Owner:SCHLUMBERGER TECH CORP

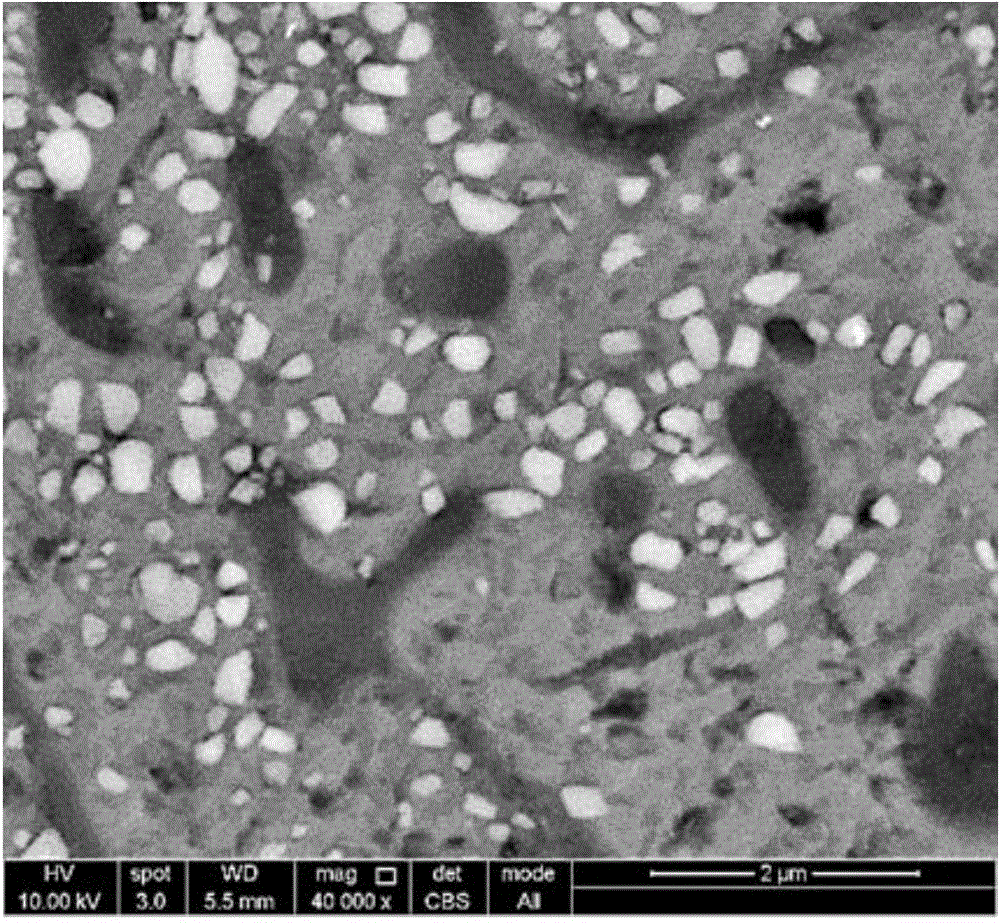

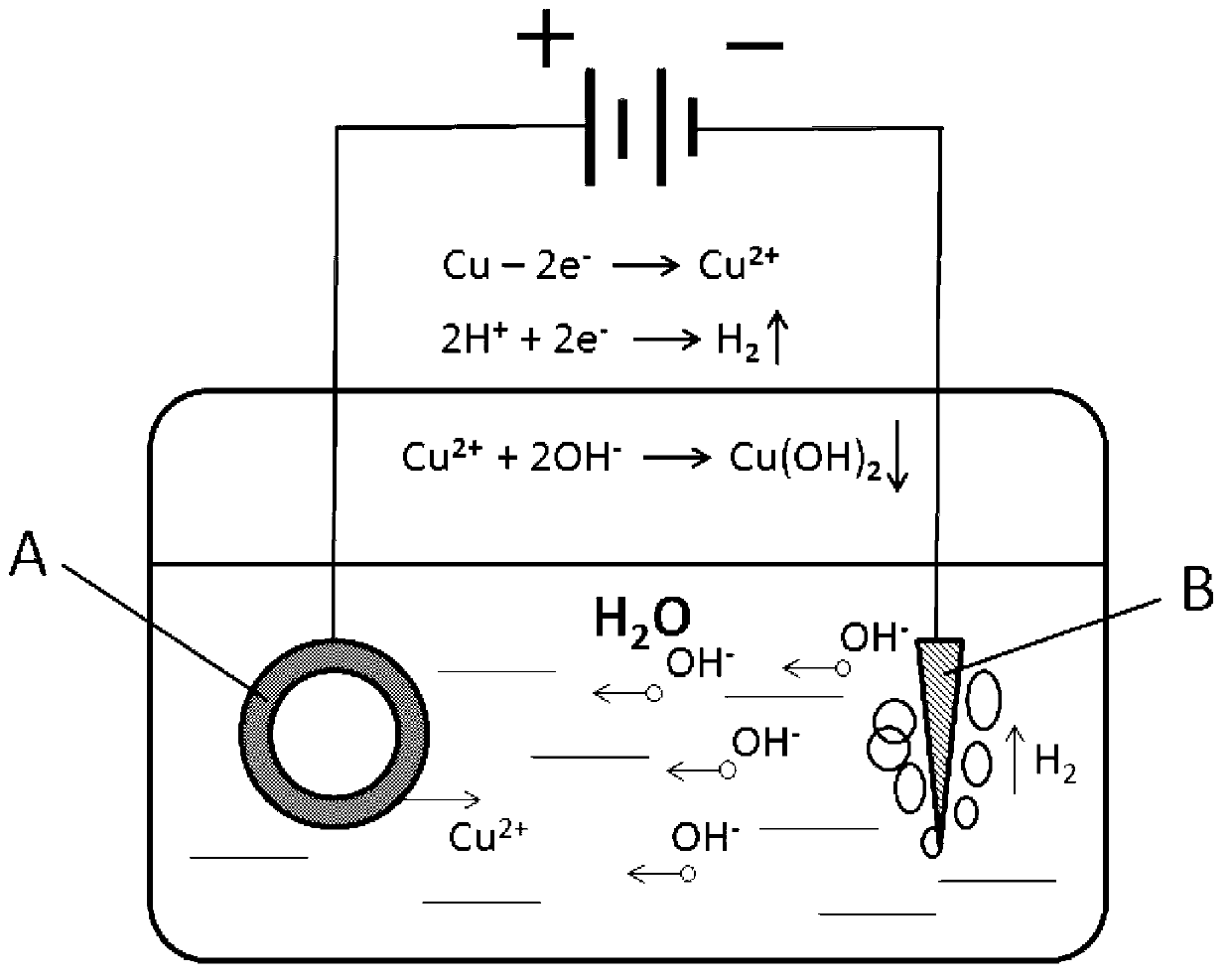

In-situ particle mixed reinforced aluminum-based composite material and preparation method thereof

ActiveCN104911416AGuaranteed lightweight requirementsIncrease volume fractionPhase volumeMaterials science

The invention discloses an in-situ particle mixed reinforced aluminum-based composite material and a preparation method thereof. TiB2 and Mg2Si are taken as particle reinforcements, and are generated by reacting KBF4 and K2TiF6 mixed salts and adding alloy elements, respectively; the volume fractions of the two reinforcements (TiB2 and Mg2Si) in the whole composite material are 1-10% and 2-20%, respectively. The aluminum alloy matrix is an Al-Mg alloy. The preparation method comprises the following steps: pretreatment, namely drying and mixing the alloy accessories and mixed salts; melting the alloy and keeping the temperature at 700-900 DEG C; adding the mixed salts and stirring mechanically; preserving the heat of the melt and synthesizing TiB2; after finishing heat preservation, reducing the temperature to about 700-780 DEG C and removing the reaction salt residue; adding Si in the form of an Al-Si intermediate alloy and adding pure Mg, wherein the atomic ratio of Si to pure Mg is 1: 2; preserving heat at the temperature of 700-780 DEG C and stirring to synthesize Mg2Si; refining and degassing the melt and pouring. The composite material has the advantages of low density, excellent mechanical properties, large reinforcement phase volume fraction range and the like. The aluminum-based composite material with better mechanical properties can be provided while the lightweight requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

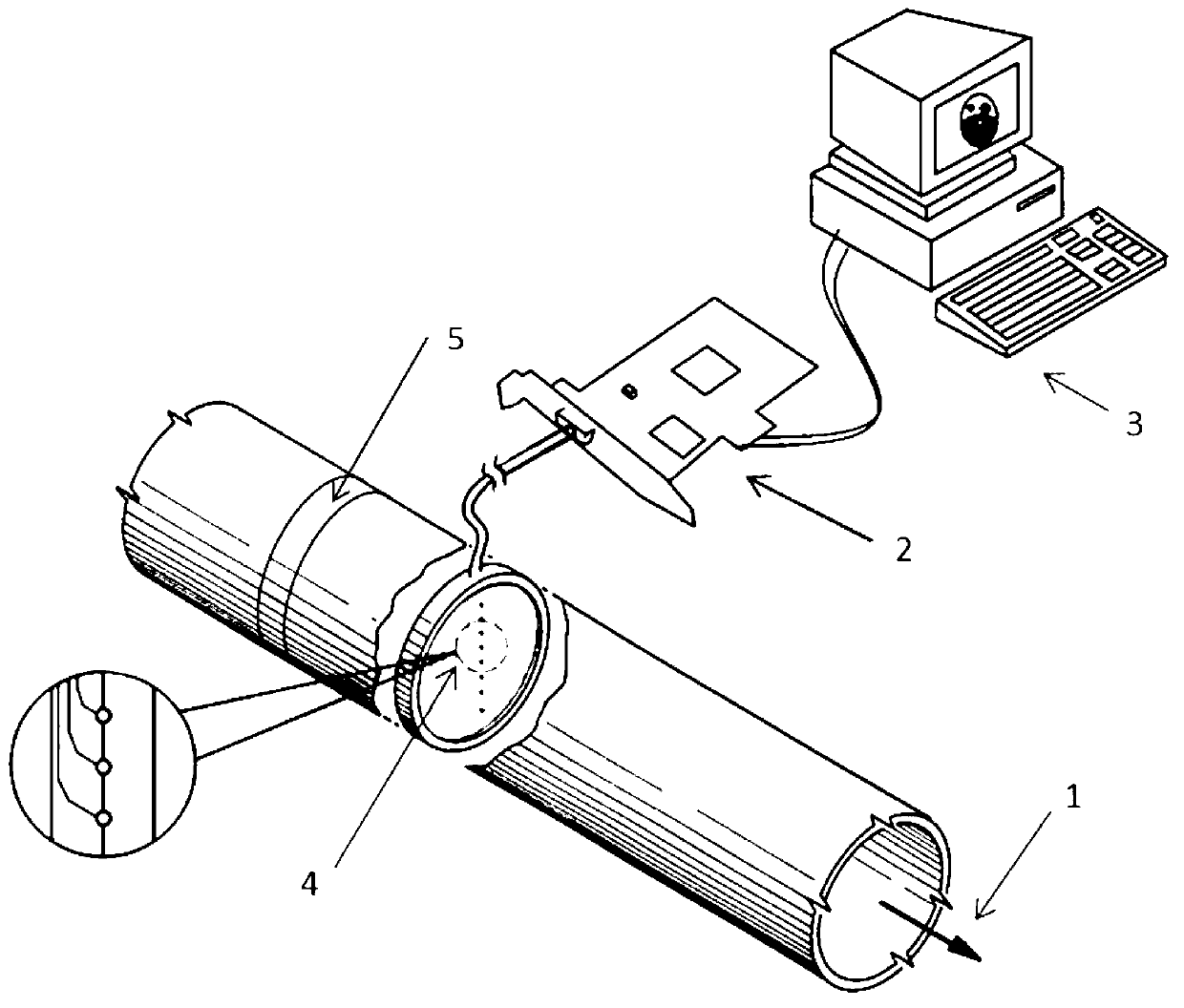

Two-phase flow tomography system based on array-type monopole conducting probe

InactiveCN102998343AFacilitate human intuitive recognitionSimple partsMaterial resistanceTomographyElectric conductance

The invention discloses a two-phase flow tomography system based on an array-type monopole conducting probe. The system comprises a flow pipeline, the array-type monopole conducting probe, multi-channel collection equipment and an annular anode, wherein the array-type monopole conducting probe is fixedly mounted on the inner wall of the flow pipeline and comprises a plurality of detecting points and detecting point lead-out wires; each detecting point lead-out wire passes through the pipe wall of the flow pipeline, and is electrically connected with a lead wire terminal on the outer wall of the flow pipeline; the multi-channel collection equipment is connected with the lead wire terminal and is used for collecting a potential value of each detecting point; and the annular anode is mounted on the inner wall or at the interior of the flow pipeline, and is used for applying motivation to fluid. The two-phase flow tomography system provided by the invention adopts a simple and reliable principle, can effectively lower the uncertainty of fluid detection, can be used for monitoring and recording the phase volume fraction of a cross section further in real time, and can reach certain available precision.

Owner:UNIV OF SCI & TECH OF CHINA

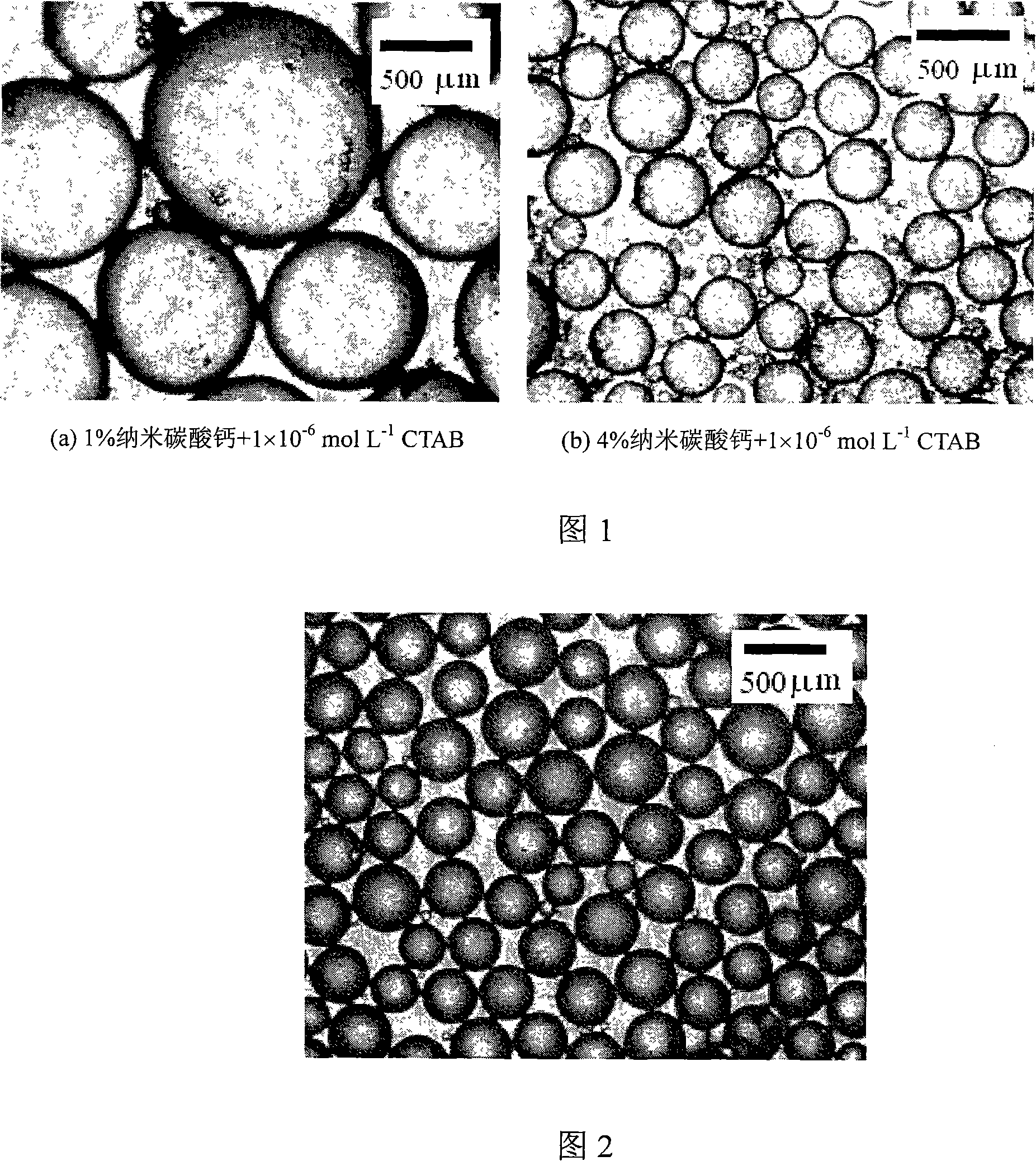

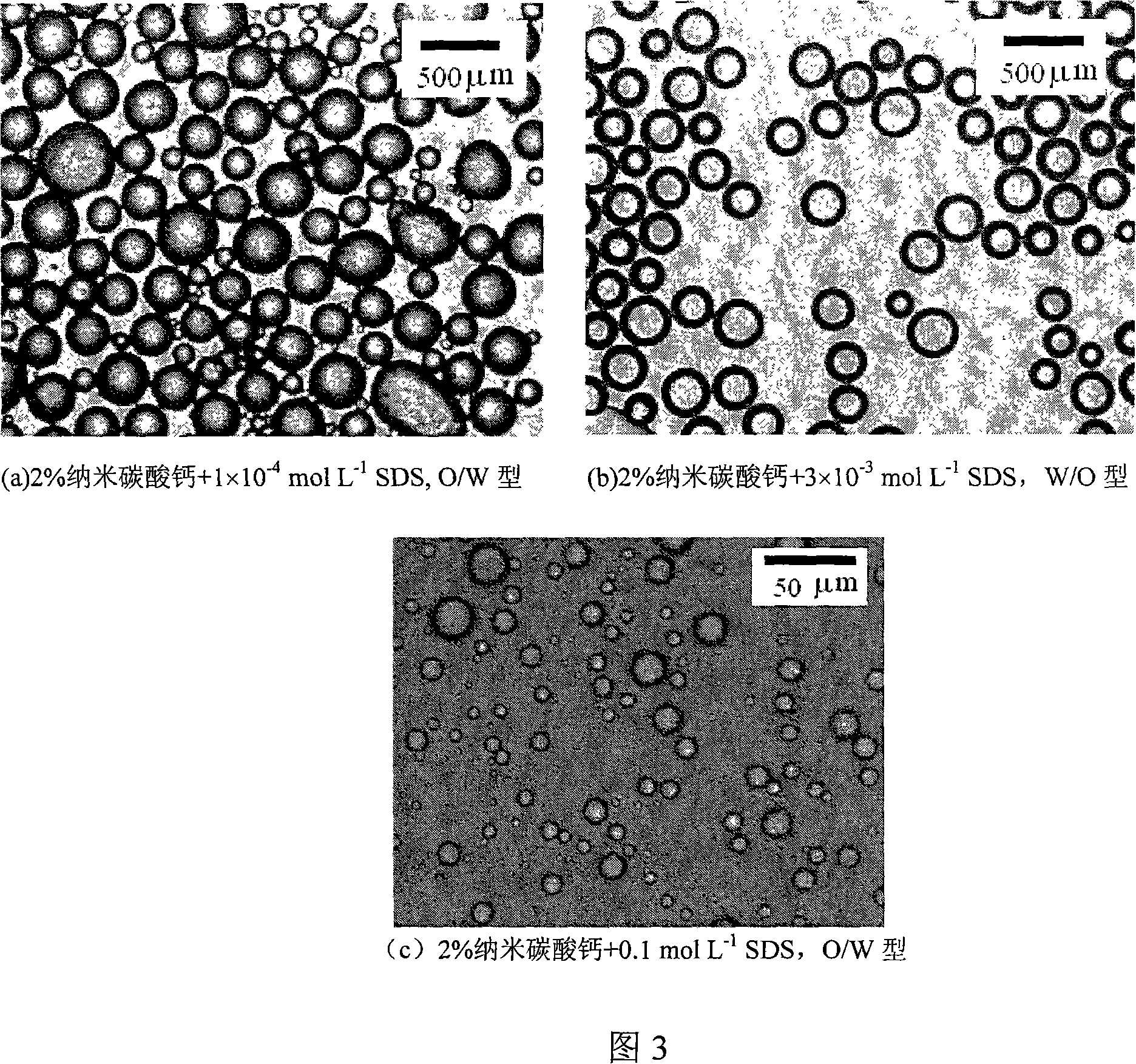

Emulsion of hyperstable latex capable of varying phase of circulation

ActiveCN101108324ASurfactant hasTransportation and packagingMixing methodsOil productionPhase volume

An super stable emulsion emulsifier which can make the circle direction change is provided, which belongs to surface activating agent and colloid field. The invention is composed of Nami calcium carbonate grains without modification and ion-typed surface activating agent The Nami calcium carbonate grains and the ion-typed surface activating agent take effect to each other in aqueous medium, which changes the surface humidity of the Nami grains at site and makes the Nami grains have surface activity, thus be able of collecting or adsorbing on oil or water interface, and make the emulsion stable; with changing the usage proportion of the Nami calcium carbonate grains (adding concentration is counted by emulsion aqueous phase weight as 0.5 per cent to 6 per cent) and the ion-typed surface activating agent (the using concentration is counted by emulsion aqueous phase volume as 1 multiply 10 to 6 to 0.5 mol L-1) to realize circle direction change, namely from oil in water (O / W) to water in oil (W / O), then change into oil in water (O / W). The emulsifier can be used in pesticide, paint, dope, oil production, fuel watering and multiple technology field.

Owner:SHENZHEN GENE BIOLOGICAL TECH

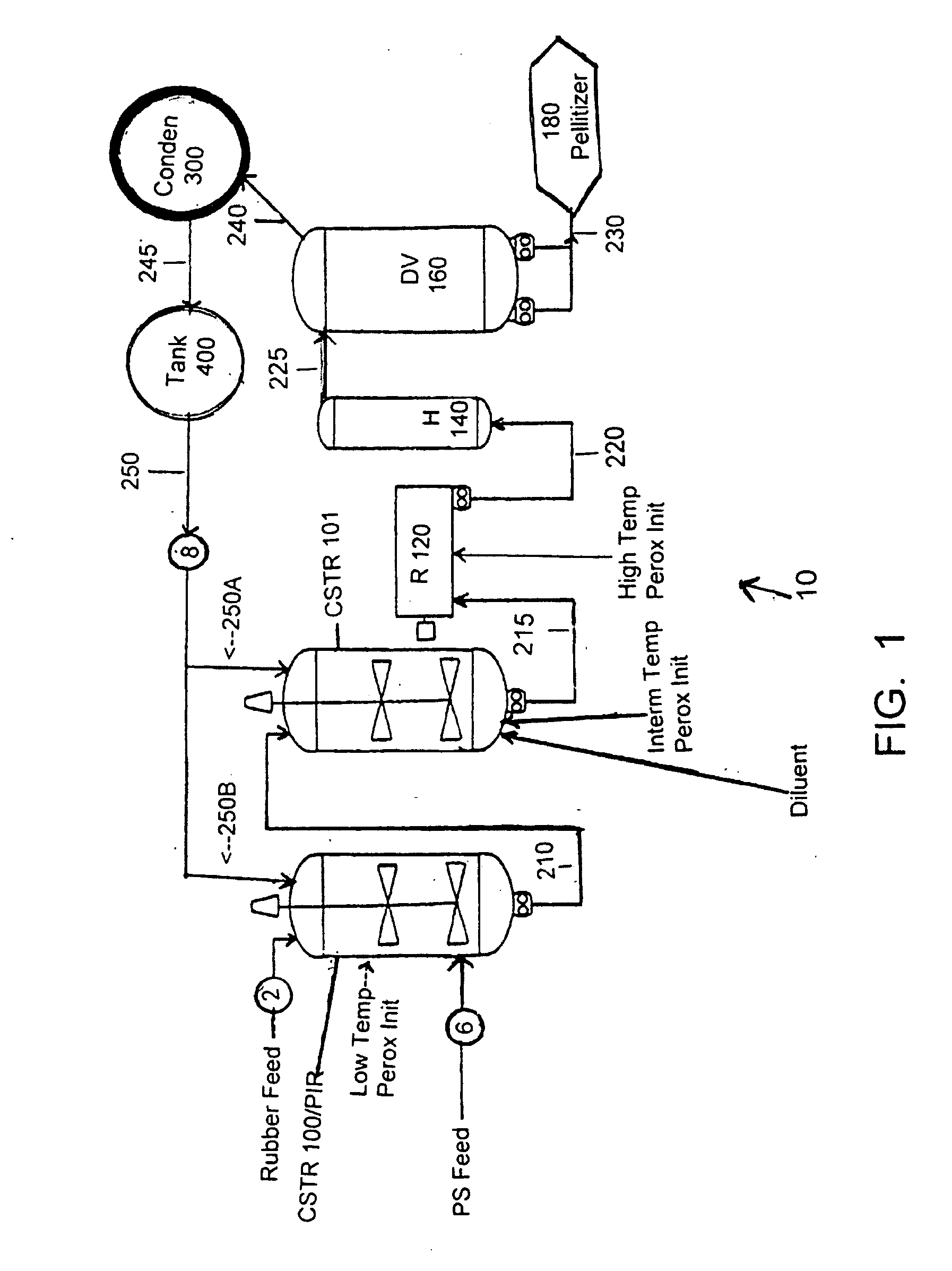

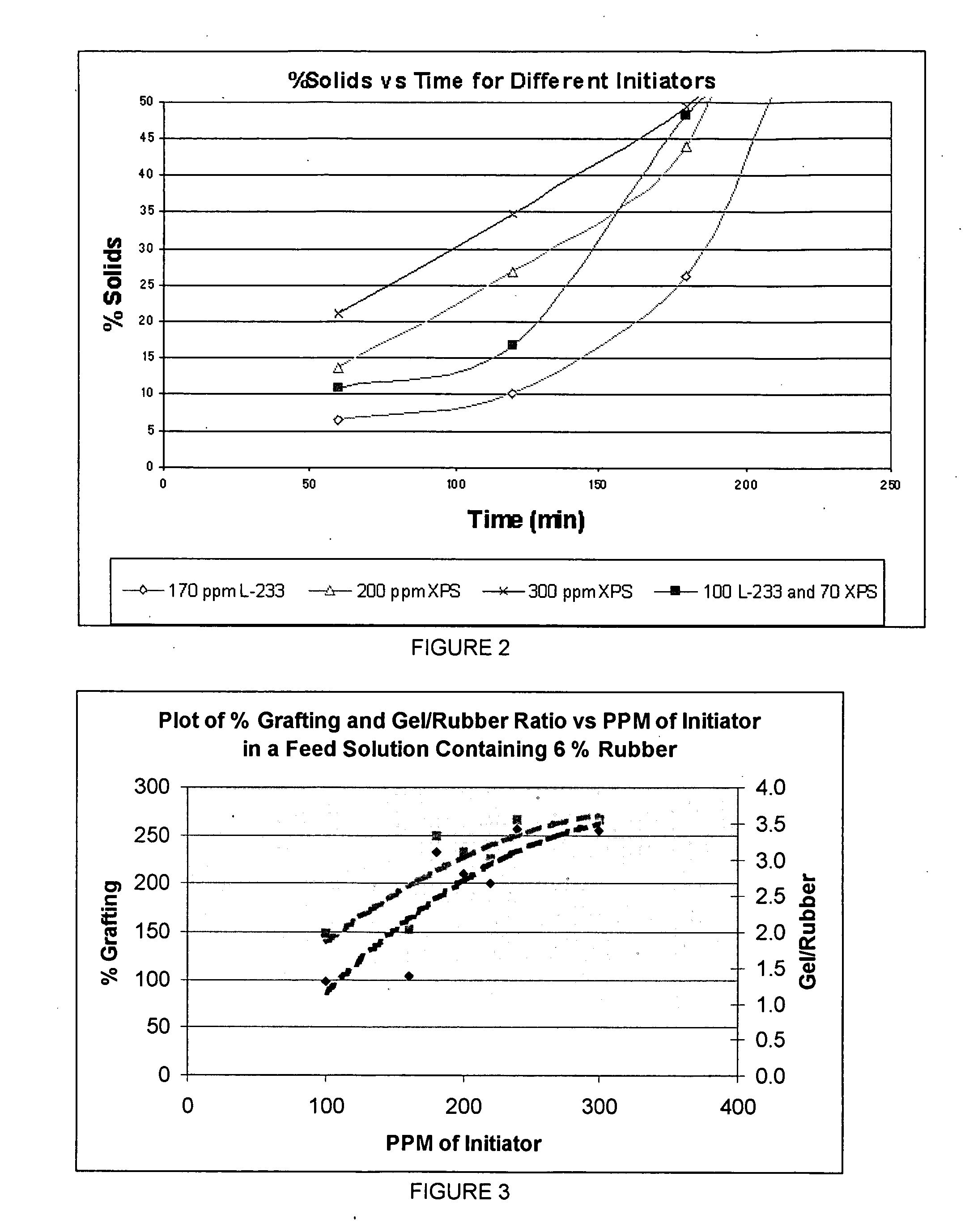

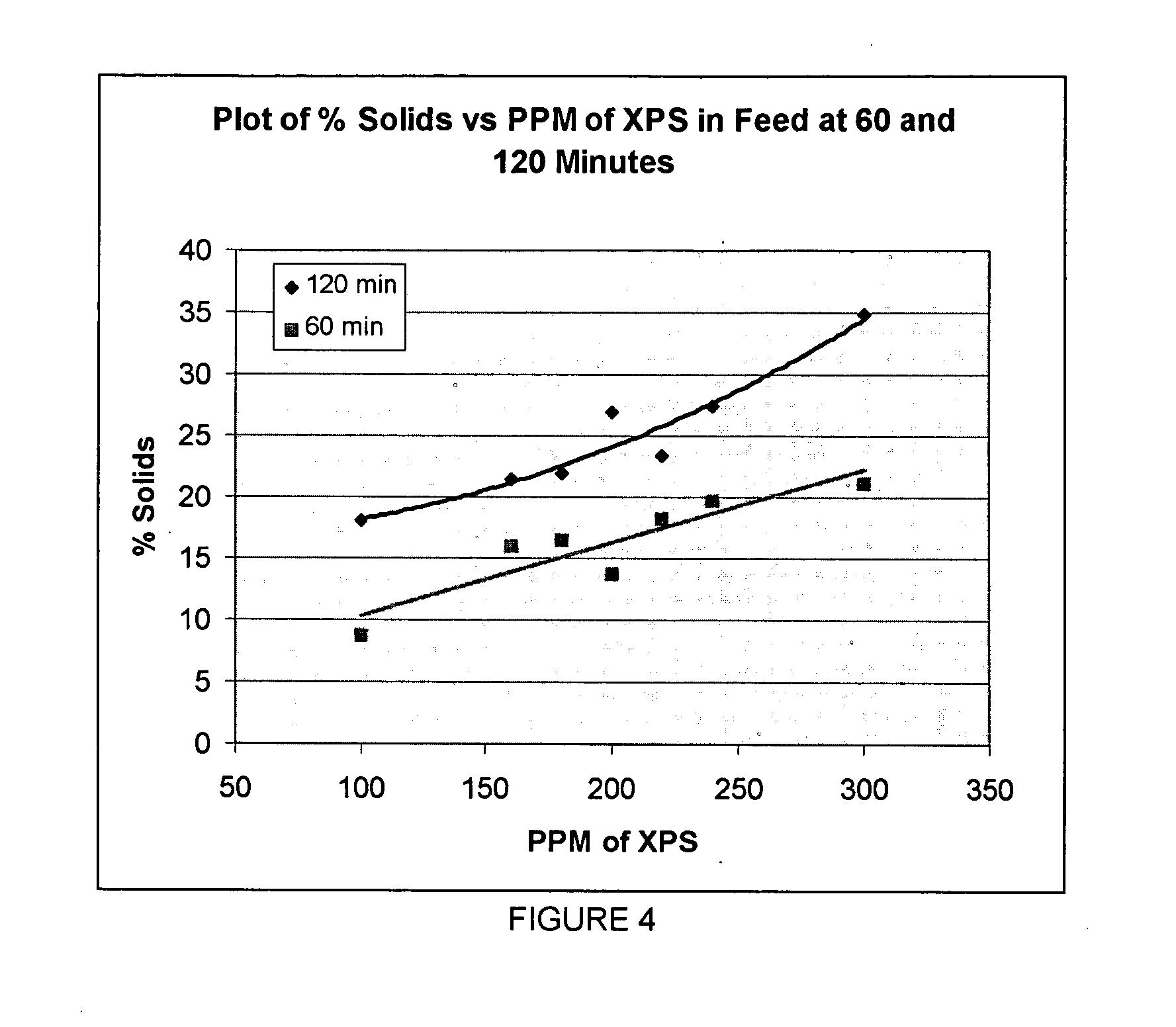

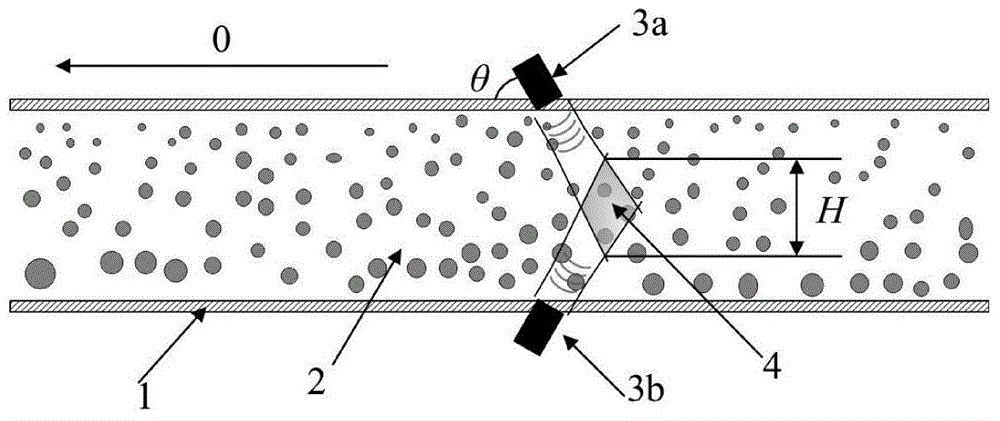

Low temperature initiators for improving the rubber phase volume of HIPS formulations

Peroxide initiators are disclosed that can be used at lower temperatures during HIPS production. Enhanced formation of graft polymers between polystyrene and polybutadiene (rubber) can be accomplished by using these lower temperature peroxide initiators that have a 1 hour half-life period at one or more temperatures from 95° C. to less than 111° C. during the pre-inversion stage. “Higher” temperature initiators are used during and / or after inversion. The use of such “low” temperature initiators improves polymerization rates and grafting values, while reducing the swell index and the amount of rubber used, thereby producing improved HIPS more rapidly and at a lower cost. Also disclosed are HIPS compositions and products produced by such “low” temperature initiators as well as a method of producing improved HIPS.

Owner:FINA TECH

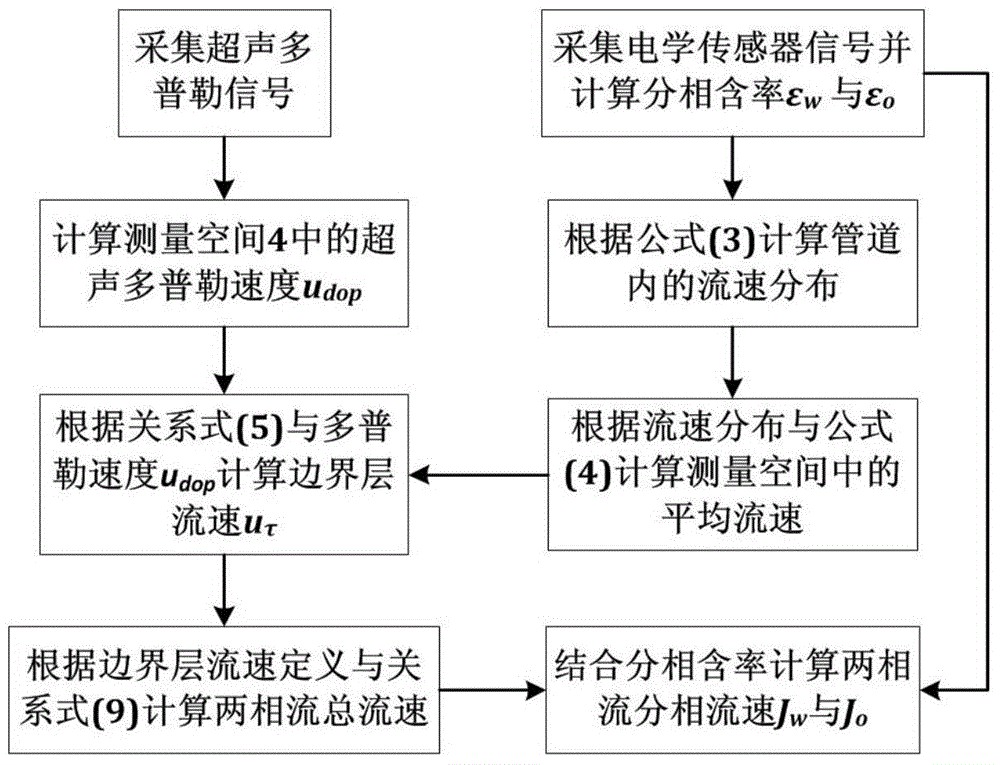

Two-phase flow phase-splitting flow velocity acoustic-electric bimodal measuring method

ActiveCN104965104ADisturbance generationEasy to measureAverage speed measurementFluid speed measurementPhase splittingUltrasonic doppler

The invention provides a two-phase flow phase-splitting flow velocity acoustic-electric bimodal measuring method. A used bimodal sensor comprises an electric sensor and an ultrasonic Doppler probe. The measuring method comprises: acquiring a signal and acquiring water phase volume fraction, oil phase volume fraction, and two-phase flow mixed density by using the electric sensor; determining the measuring space of the ultrasonic Doppler probe and computing the equivalent height of the measuring space; computing a difference between ultrasonic signal frequency acquired by a ultrasonic receiving probe and exciting ultrasonic signal frequency emitted from a ultrasonic emitting probe and computing average flow velocity in the measuring space; establishing a fluid flow velocity distribution relation of a position in a pipeline and a certain distance to the wall of the pipeline; establishing a relation between Doppler measurement flow velocity and boundary layer flow velocity in the measuring space; solving the boundary layer flow velocity; and computing total flow velocity and acquiring the water phase flow velocity and oil phase flow velocity. The two-phase flow phase-splitting flow velocity acoustic-electric bimodal measuring method may accurately acquire two-phase flow phase volume fraction by a noninvasive mode.

Owner:TIANJIN UNIV

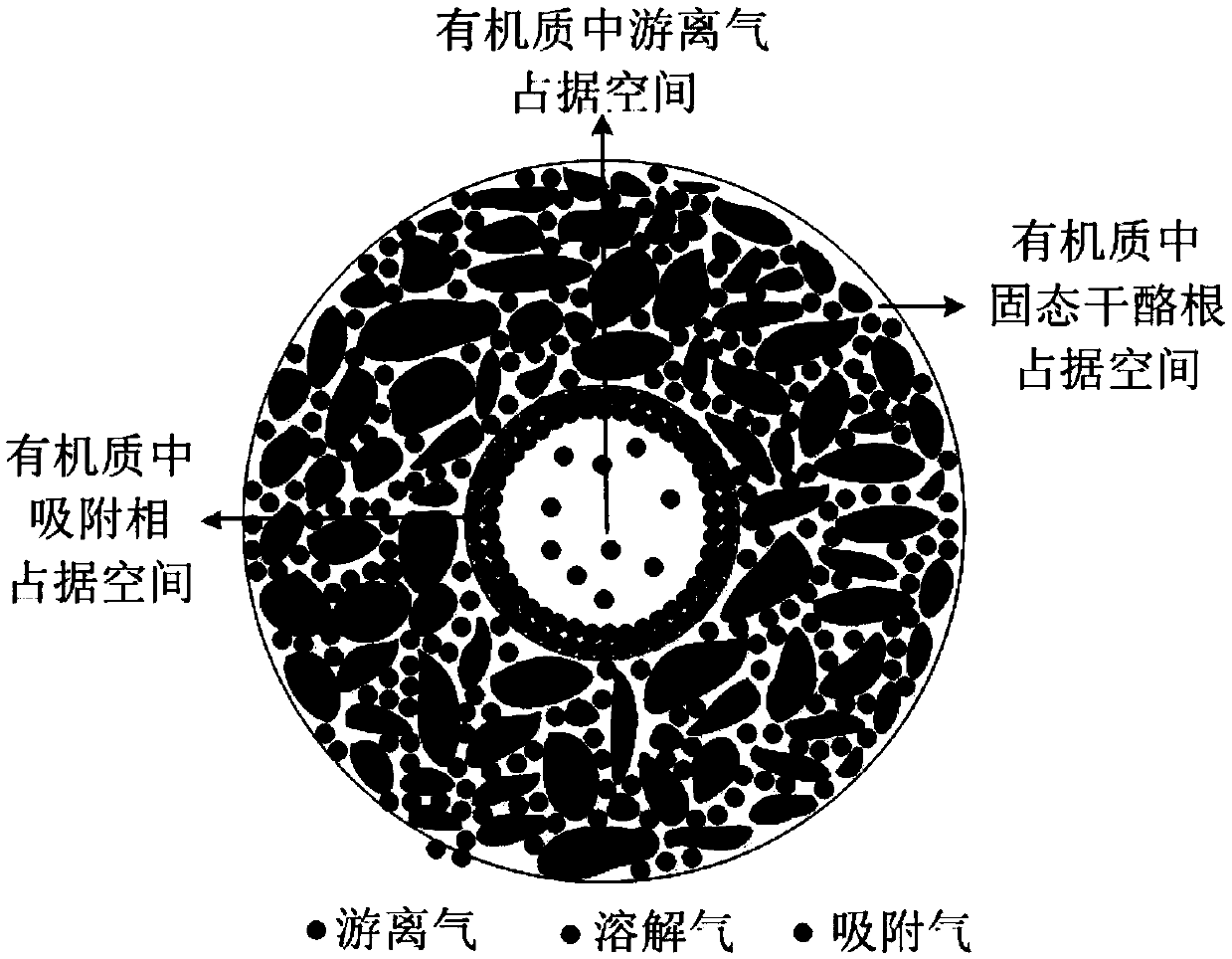

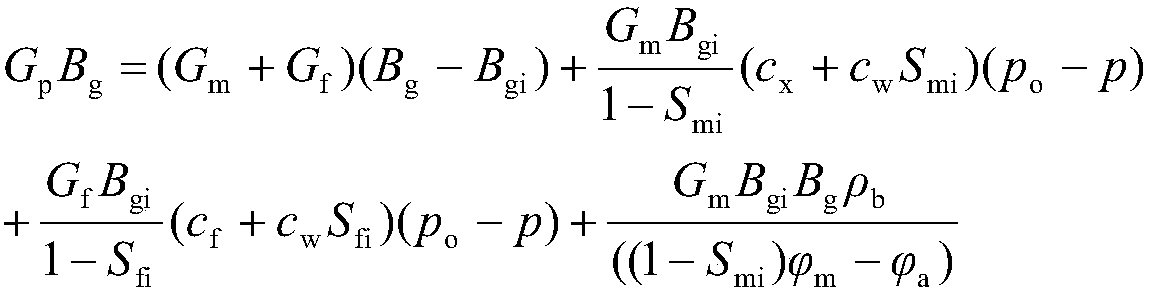

Shale gas reservoir total reserve calculation method considering multiple factors

ActiveCN108710765ACorrected compression factorDesign optimisation/simulationSpecial data processing applicationsPorosityVolume variation

The invention discloses a shale gas reservoir total reserve calculation method considering multiple factors, comprising the following steps: testing and collecting basic parameters and production dataof the shale gas reservoir; considering fractured free gas, porosity of adsorbed phase, volume change of adsorbed phase, critical desorption pressure of adsorbed gas and shrinkage effect of adsorbedgas desorption on matrix, and considering multi-component adsorption and dissolved gas simultaneously, establishing the material balance equation of shale gas reservoir, and finally obtaining the total reserves equation of shale gas reservoir; the basic parameters and production data of shale gas reservoir are processed according to the established material balance equation, and the relevant curves are drawn; finally, calculating the total reserves of shale gas reservoir Gt. A material balance equation of a new shale gas reservoir is established by comprehensively considering that shrinkage effect of multi-component adsorption and dissolving gas, fracture free gas, adsorption phase porosity, adsorption phase volume change, adsorption gas critical desorption pressure and adsorption gas desorption on a substrate, and the equation has important guiding significance for reasonably calculating the dynamic reserve of the shale gas reservoir.

Owner:SOUTHWEST PETROLEUM UNIV

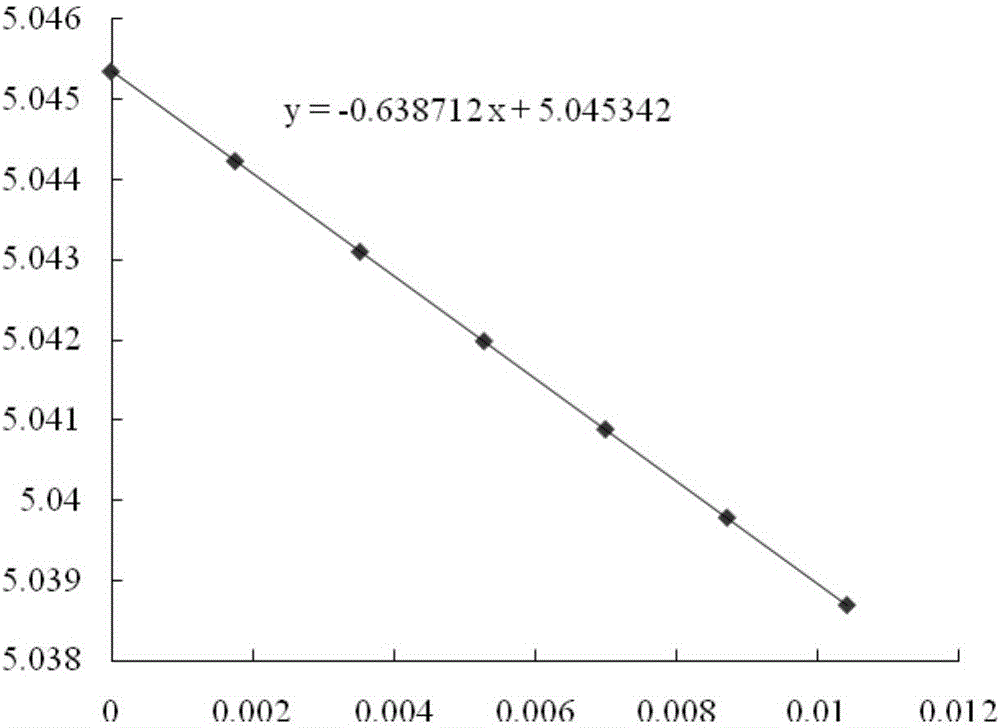

Method for measuring adsorption phase density of adsorbate gas on adsorbate

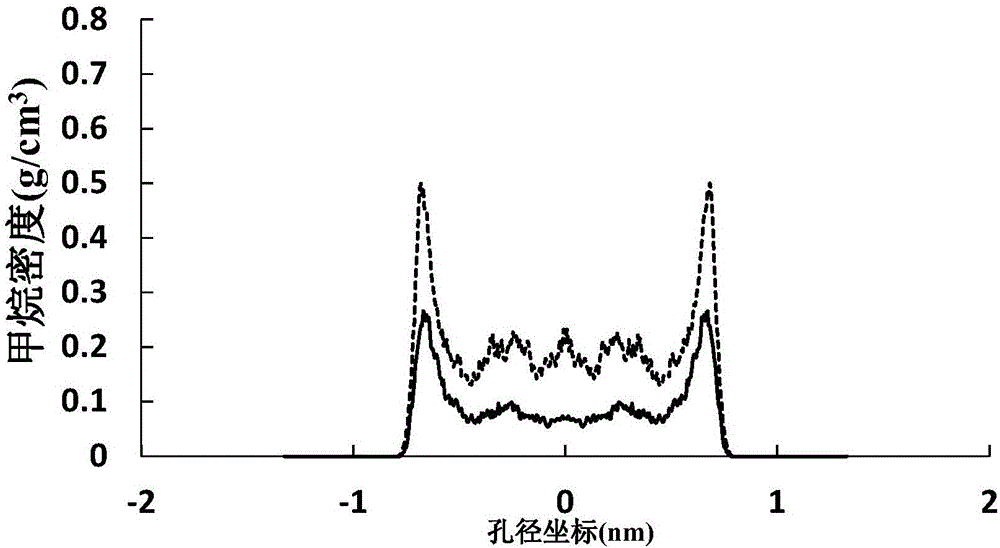

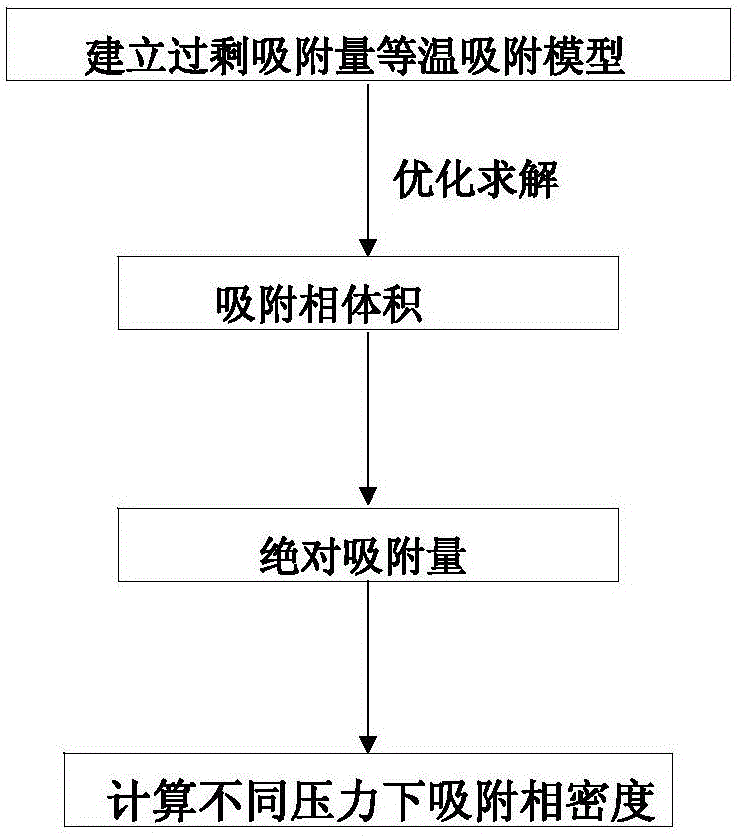

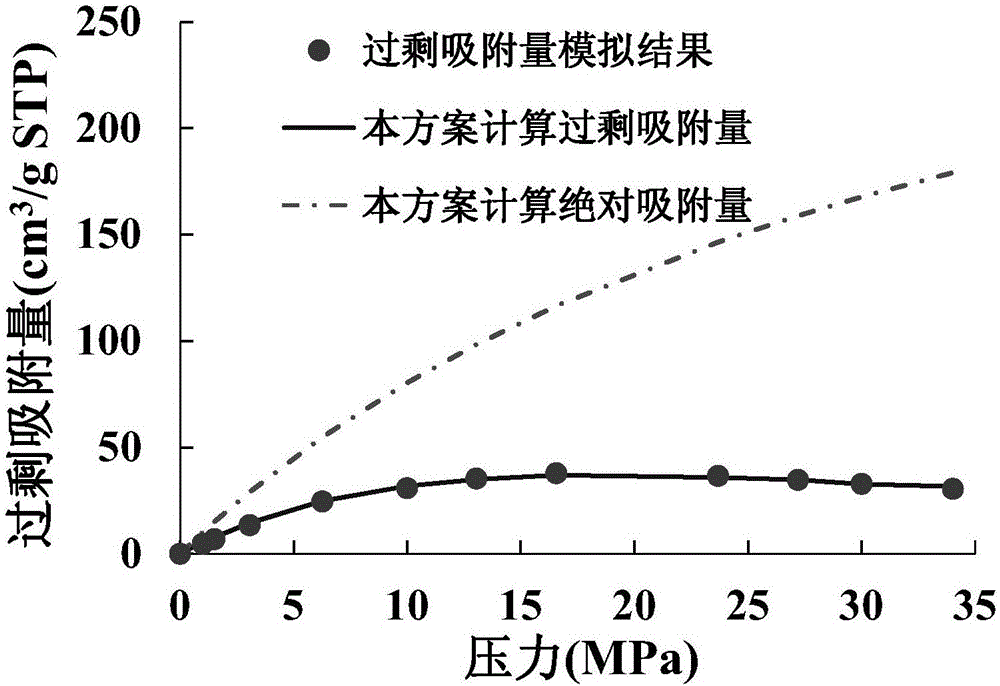

ActiveCN106290061AReasonable assumptionsReasonableSpecific gravity measurementPhysical chemistryPhase volume

The invention discloses a method for measuring the adsorption phase density of adsorbate gas on adsorbate. The method includes the steps: 1) measuring the excess adsorption quantity and the body phase density of the adsorbate gas under at least three different types of pressure; 2) acquiring adsorbed phase volume according to a corrected isothermal adsorption model and the excess adsorption quantity and the body phase density measured in the step 1); 3) acquiring the absolute adsorption quantity of the adsorbate gas on the adsorbate according to the corrected isothermal adsorption model and an isothermal adsorption model; 4) acquiring the adsorbed phase density of the adsorbate gas on the adsorbate according to a formula (1), and denoting the adsorbed phase density as rho adsorption phase with the unit g / cm<3>. The method is directly implemented based on original isothermal adsorption test data, simple, practicable and easy to popularize. According to research of adsorption behaviors by molecular simulation, assumed conditions of the method are more reasonable, and reasonableness is obviously superior to that of a traditional optimization scheme.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Adjustable gas-liquid centrifugal separator and separating method

ActiveUS8025713B2Reduce gas contentSmall volumeCombination devicesLiquid degasificationEngineeringPhase volume

An adjustable type guide vortex gas-liquid separating apparatus is provided, it comprises a case, a vortex flow guide spiral pipe, a mist eliminator, an adjusting valve and a γ ray phase volume fraction meter. Its separating method is to make the oil-gas-water multiphase flow move in vortex, and thus to realize the gas-liquid separation, then to measure the gas content of the separated liquid phase by using the γ ray phase volume fraction meter and to send out control information as judged by the magnitude of the gas content in the liquid phase, so as to control the opening of the adjusting valve of the gas circuit, thus to achieve adjustment of the gas-liquid separation effects, and to control the gas content of the liquid phase to a certain range.

Owner:HAIMO TECH INC

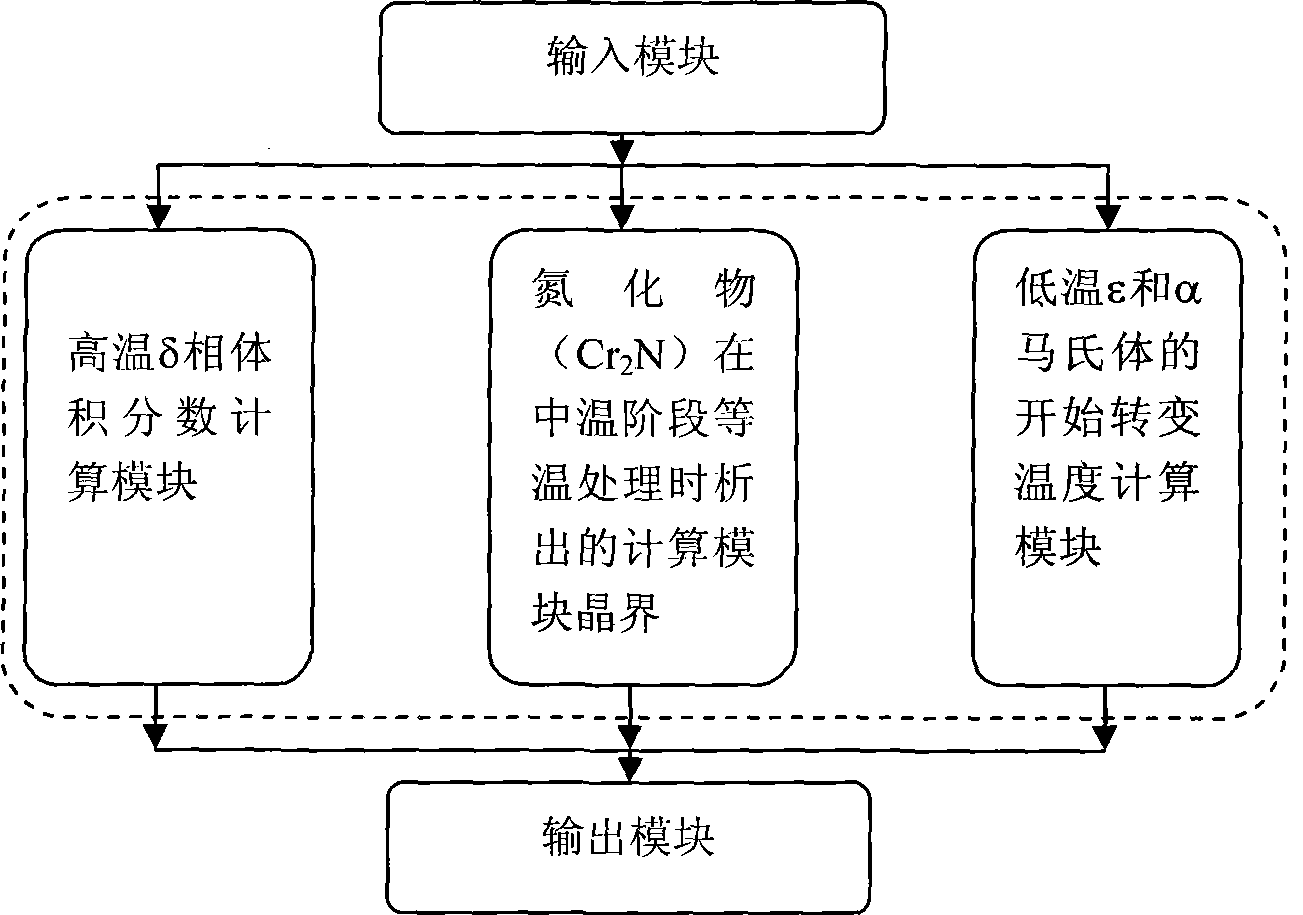

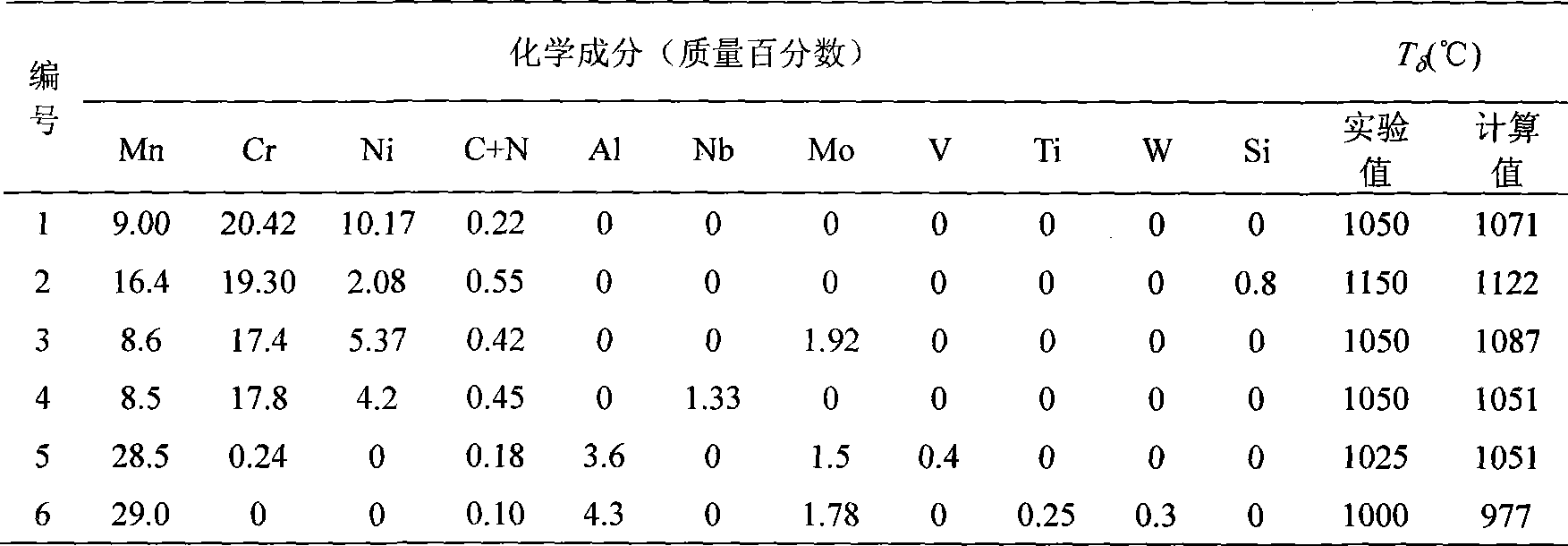

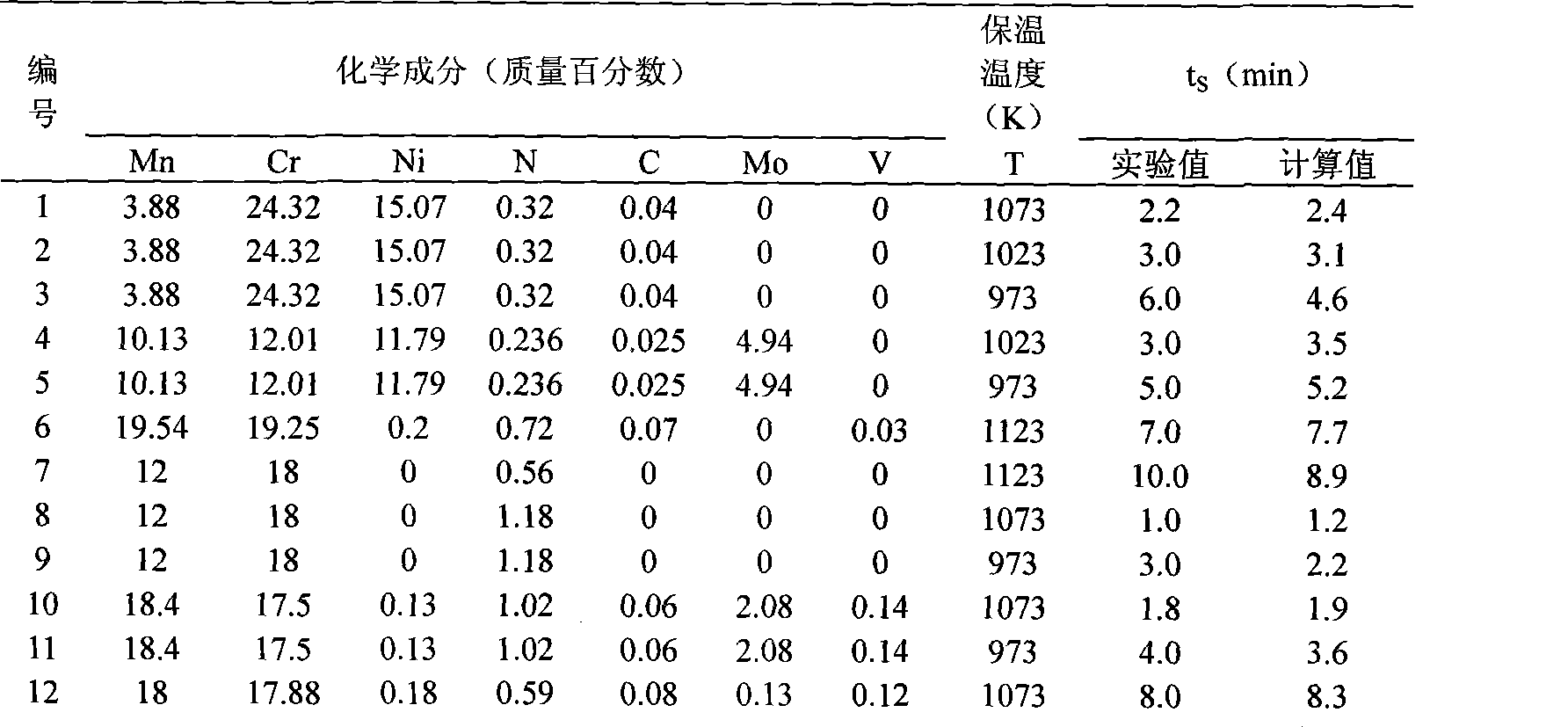

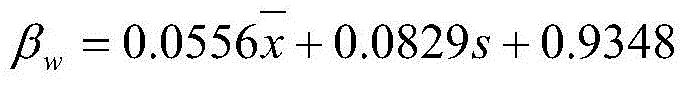

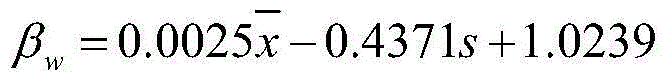

Nitrogen austenite steel microstructure predicting method

InactiveCN101424610AEasy to operateFriendly interfaceSurface/boundary effectTesting metalsMaterial DesignPredictive methods

The invention relates to a prediction method for the microstructure of martensite steel, which comprises an input module, a computing module and an output module, wherein the computing module comprises a high-temperature delta-phase volume fraction computing module, a start transformation temperature computing module of a low-temperature epsilon and alpha martensite, and a grain boundary start precipitation time computing module when a nitride of Cr2N is in isothermal treatment in a medium temperature phase; the input module has the function of providing parameters input by a user, such as alloy contents, temperature, and the like, the computing module utilizes the input parameters and combines computing formulas to compute, and the output module enables the user to obtain computing results. The method can simplify a material development process, decrease the development cost, increase the development speed, provide reference for the material design of nitrogen austenite stainless steel and technological control, such as heat treatment, forging, and the like, and predict the low-temperature structure stability of the nitrogen austenite stainless steel. The invention also has the advantages of convenient data processing, wider alloy content sphere of application, wider sphere of application, and the like, and is favorable to the application of computing technologies in the field of the material design.

Owner:JIANGSU UNIV +1

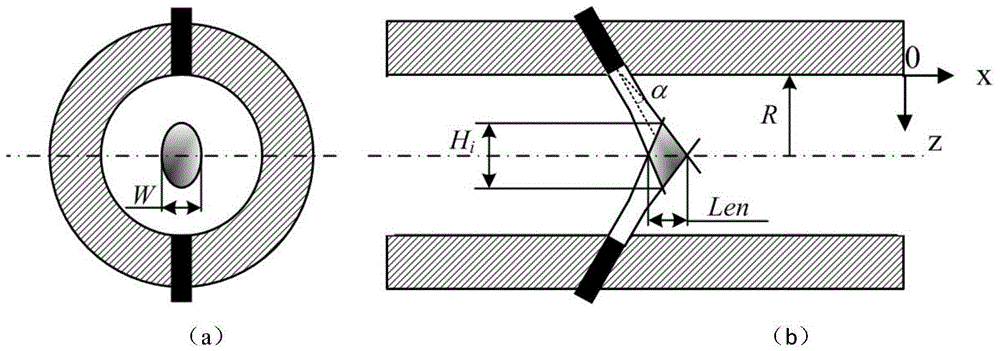

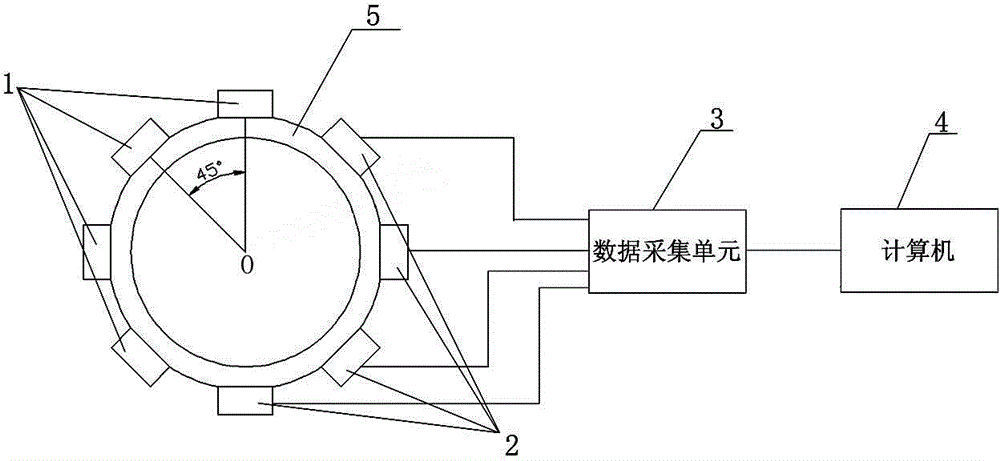

Apparatus and method for measuring sectional phase volume fraction of gas-liquid two-phase flow in pipeline

ActiveCN103558179AReduce the impactGood monochromaticityMaterial analysis by optical meansEnvironment effectPhase volume

The invention provides an apparatus and a method for measuring the sectional phase volume fraction of gas-liquid two-phase flow in a pipeline. The apparatus comprises a near infrared emitting device, a near infrared receiving device, a data acquisition unit and a computer. Near-infrared light emitted by the near infrared emitting device is invisible light which is barely influenced by an external environment, has good monochromaticity and stability, can realize remote accurate tracking of a hot target and has the advantages of strong detection capability and a great action distance, so the near-infrared light can be used for measuring the sectional phase volume fraction of gas-liquid two-phase flow in the case of a severe environment (e.g., in a black lightproof fluid medium produced from an oil well). The near infrared emitting device and the near infrared receiving device are installed on the outer wall of a pipeline and pose no influence on the flow characteristics of the gas-liquid two-phase flow in the pipeline, so real-time on-line measurement can be realized without separation of the gas-liquid two-phase flow. The apparatus needs short response time, can carry out high frequency measurement and accurately determine the sectional phase volume fraction of gas-liquid two-phase flow in a pipeline and is simple and convenient to operate.

Owner:HEBEI UNIVERSITY

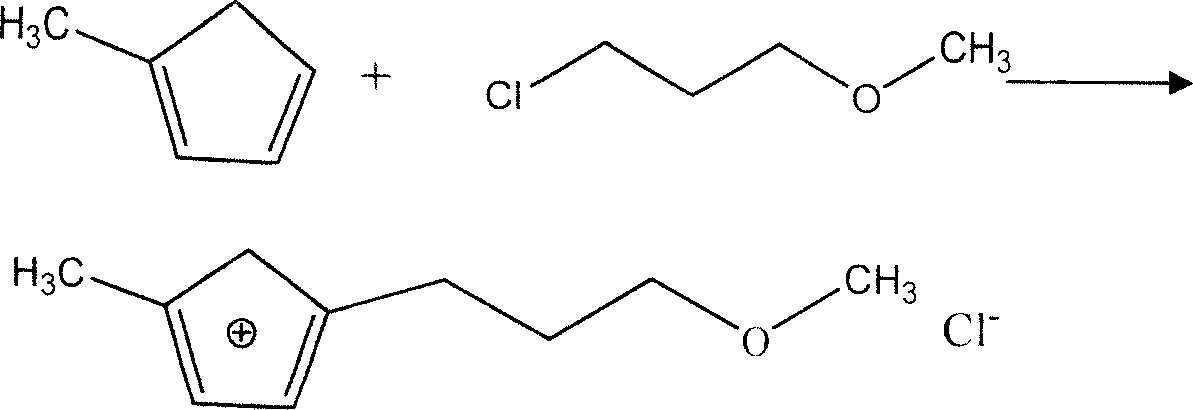

Process for recovering dimethyl formyl amine from waste water using ion liquid extracting process

InactiveCN100999480AImprove hydrophobicityReduce churnCarboxylic acid amide separation/purificationWater/sewage treatment by extractionWater useWastewater

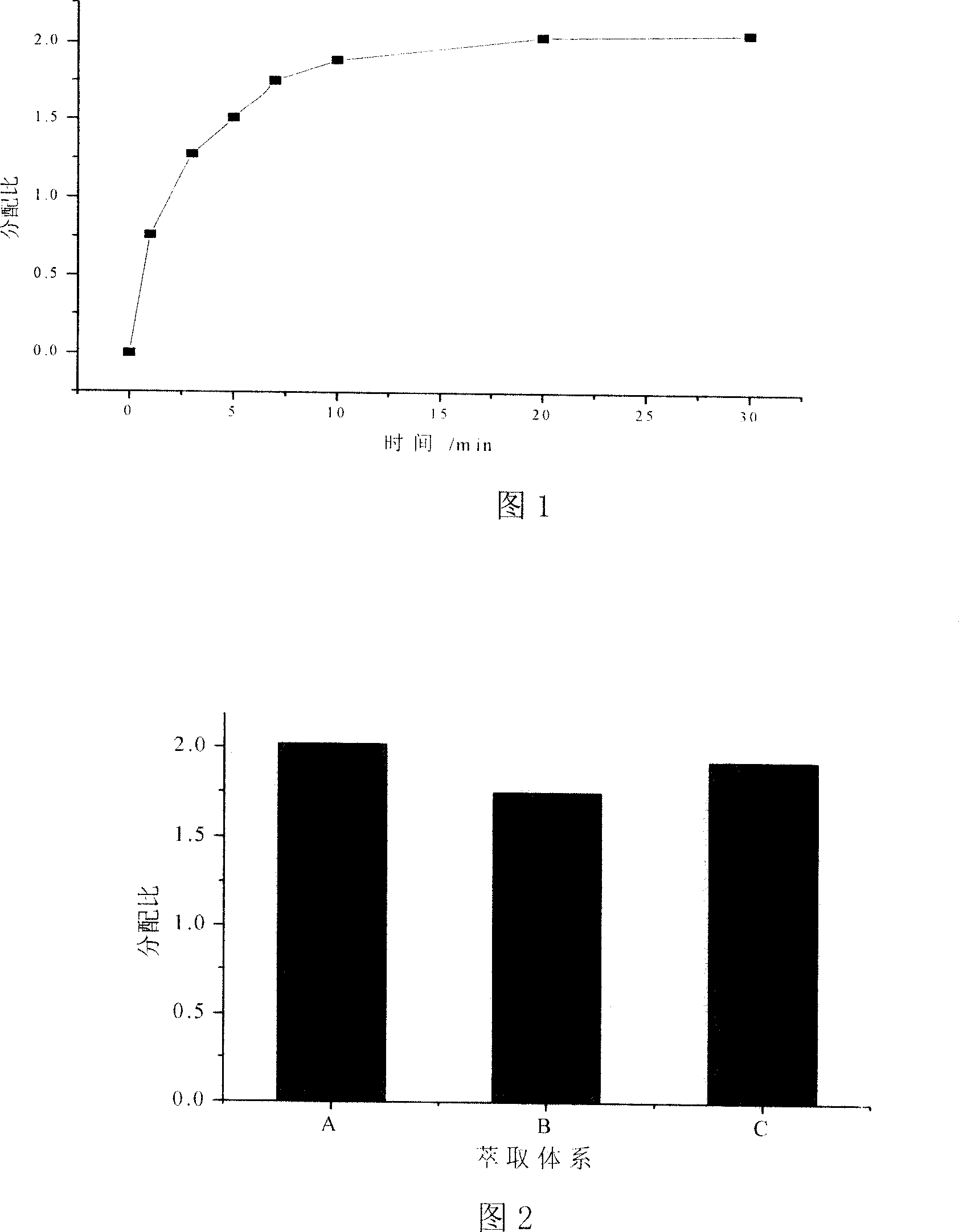

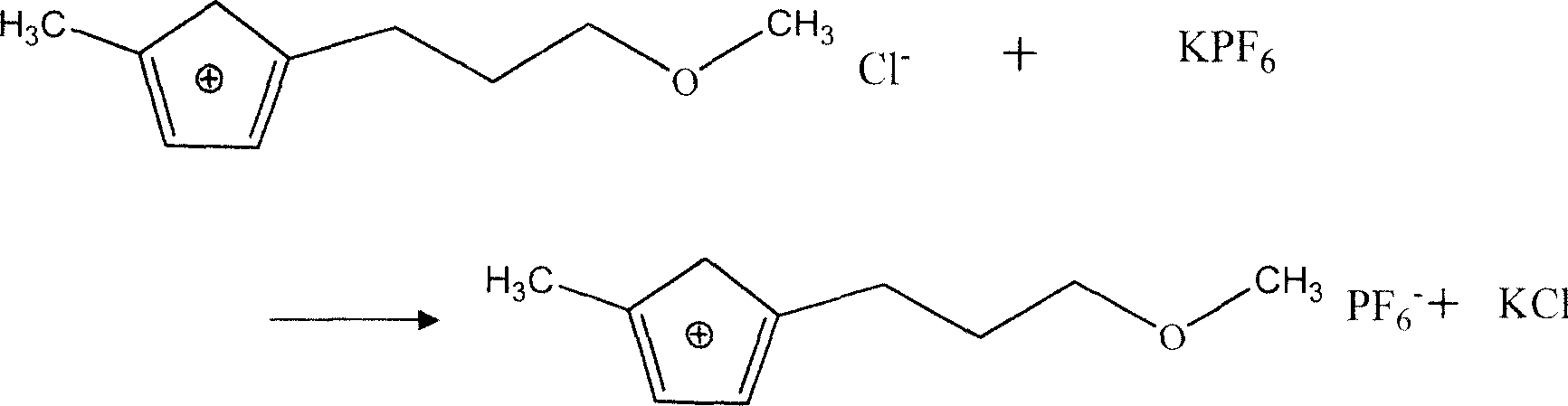

This invention relates to a method of using hydrophobicity ionic liquid as extractant to recycle dimethylformamide (DMF) in waste water. This ionic liquid can mix intensively with low density DMF(1-10wt%) at arbitrarily volume ratio'make DMF enriching in ionic liquid phase from water; And the extraction phase ion liquid through reduction vaporization to steam out the DMF. The ion liquid is recycling. The extraction method of distribution ratio is greater than 2, when the two-phase volume ratio of 1:1, an extraction rate of more than 60%, also can use multi-cascade extraction to enhance the extraction rate. Ionic liquids difficult volatile, stable, the extraction process will basically wear and tear. In addition, the method is simple, non-emulsifying through extraction, stillness stratified fast, extraction process rapidly and significantly superior to the traditional method of solvent recover.

Owner:TSINGHUA UNIV

Method for overlaying nitrogen-reinforced iron-base wear-resistant coating

InactiveCN103949751AGood formabilityEfficient transitionElectrode accessoriesWelding/cutting media/materialsWear resistantLow nitrogen

The invention discloses a method for overlaying a nitrogen-reinforced iron-base wear-resistant coating, relates to an overlaying method, and aims to solve the problems of low nitrogen content in metal of an overlaying layer obtained by using an existing nitrogen alloyed overlaying method, low wear-resistant hard phase volume fraction, non-uniform distribution and slightly low hardness of the overlaying layer. The method comprises the following steps: (1) removing rust and oil from the surface of a base material, and putting the base material into a working table of an overlaying machine; (2) conveying a welding wire into a spray head of the overlaying machine, turning on a welding power supply by using nitrogen as protection gas, striking a high-temperature nitrogen arc between the welding wire and the base material, and meanwhile, feeding alloy powder for overlaying into a high-temperature nitrogen arc area through the spray head of the overlaying machine for overlaying. According to the method, nitrogen elements can be efficiently transited into the metal of the overlaying layer; the content of the nitrogen elements in the obtained overlaying layer can reach 0.3-0.4 percent. The method is applicable to the field of overlaying.

Owner:JIAMUSI UNIVERSITY

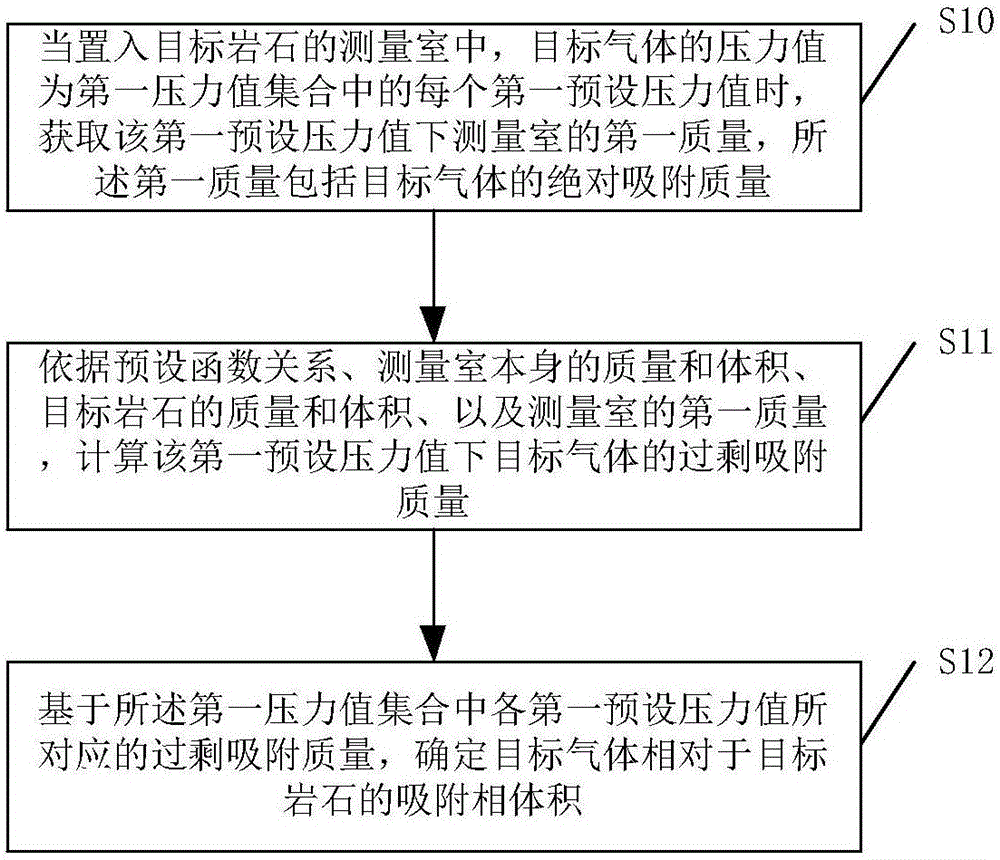

Method and device for measuring rock gas adsorption-phase volume

ActiveCN106153495AAvoid optimizing the fitting processImprove applicabilityMaterial analysisValue setPhase volume

The embodiment of the invention discloses a method and a device for measuring rock gas adsorption-phase volume. The method comprises the following steps: when a target gas is injected in a measurement chamber of target rock and the pressure value of the target gas is each first preset pressure value in a first pressure value set, obtaining first mass of the measurement chamber under the first preset pressure value; calculating excess adsorption mass of the target gas under the first preset pressure value according to a preset function relationship, the mass and volume of the measurement chamber, the mass and volume of the target rock and the first mass of the measurement chamber, wherein the preset function relationship is a function relationship among the excess adsorption mass, absolute adsorption mass and adsorption-phase volume; determining the adsorption-phase volume of the target gas relative to the target rock based on the excess adsorption mass corresponding to each first preset pressure value in the first pressure value set. According to the method and the device, disclosed by the embodiment of the invention, higher applicability and higher accuracy are obtained.

Owner:PETROCHINA CO LTD

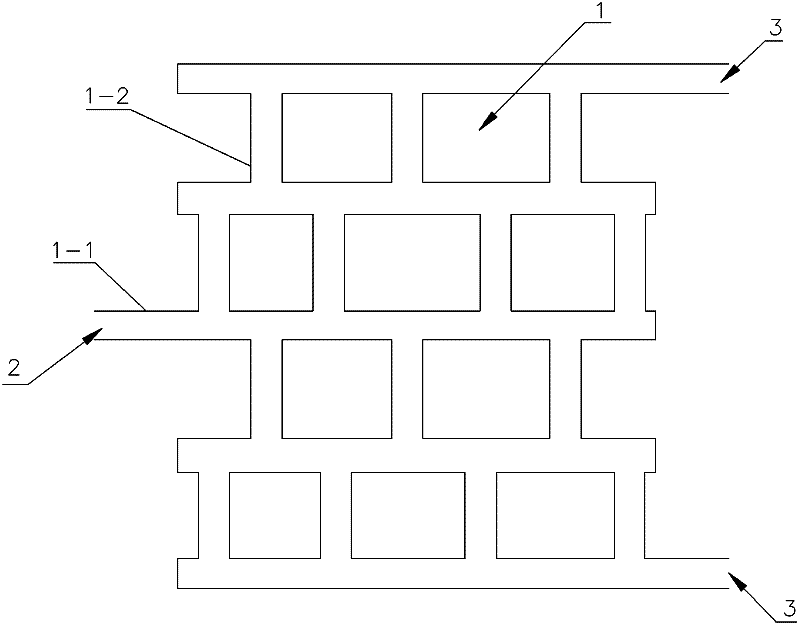

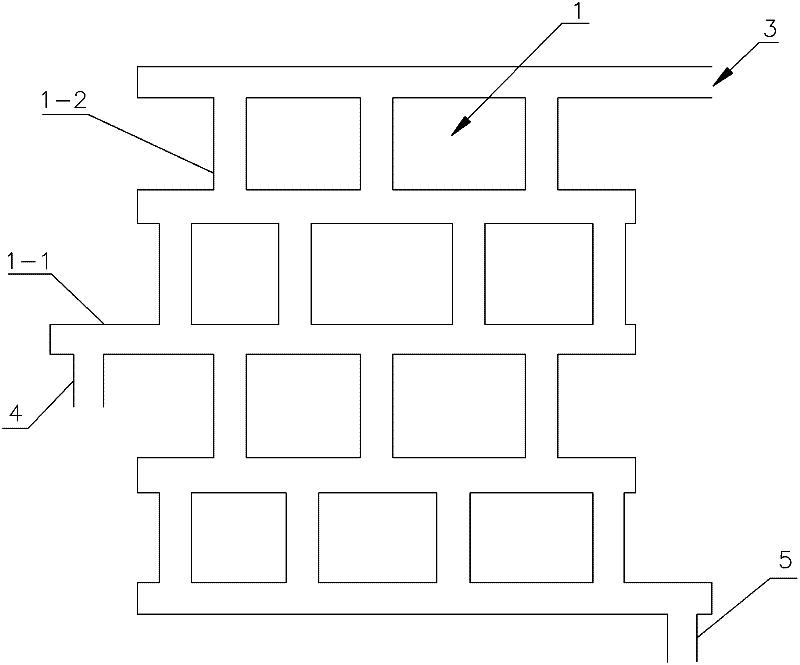

Multi-layer composite T-shaped pipe separator and separation method for separating two-phase flow or multiphase flow

InactiveCN102580354ASimple structureReduce volumeLiquid degasificationNon-miscible liquid separationAutomatic controlEngineering

The invention discloses a multi-layer composite T-shaped pipe separator for separating two-phase flow or multiphase flow. The multi-layer composite T-shaped pipe separator comprises an inflow hole, two outflow holes and at least two composite T-shaped pipe layers, wherein a mixture flows into the separator through the inflow hole; the separated fluid can flow out of the separator through the outflow holes; each composite T-shaped pipe layer comprises two main pipes and at least two intermediate connecting pipes which are vertically communicated between the two main pipes; and one main pipe is shared between every two adjacent composite T-shaped pipe layers. The invention also provides a separation method adopting the multi-layer composite T-shaped pipe separator. In the separation method, automatic control valves arranged at the two outflow holes are used for controlling the fluid allocation proportion of the two outflow holes by respectively taking liquid level, pressure or two-phase volume fraction as a feedback control signal, so that the two-phase flow can be completely separated from each other or almost completely separated from each other. The multi-layer composite T-shaped pipe separator is simple in structure, small in volume and low in cost, and leads two phases to be separated completely according to an ideal separation model; and meanwhile, the multi-layer composite T-shaped pipe separator has a pipe-type structure, thus being more convenient to replace and maintain.

Owner:CHANGZHOU UNIV

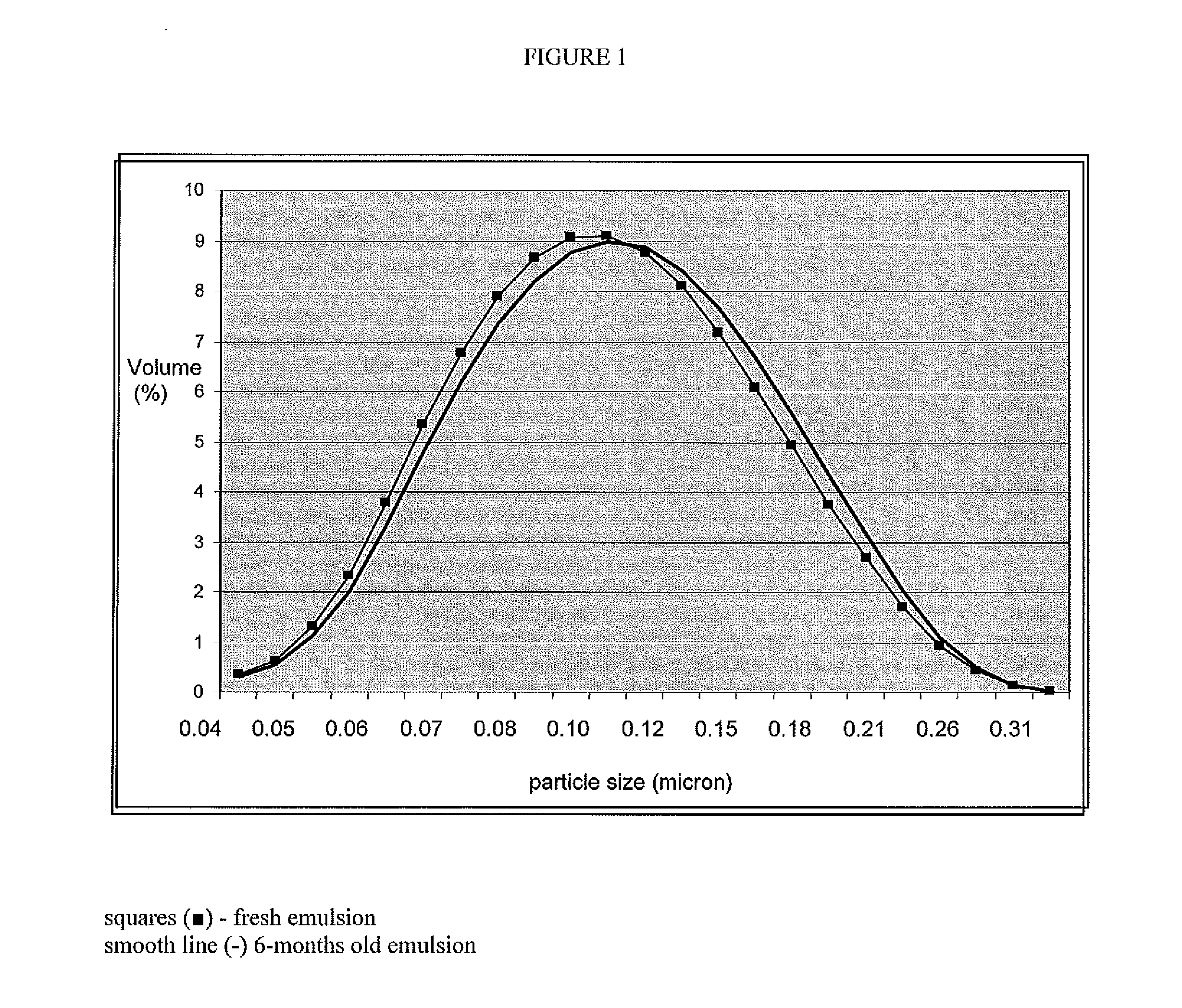

Emulsions useful in beverages

ActiveUS20110236558A1Improve stabilityIncrease fuel capacityTransportation and packagingMixingEmulsionPhase volume

It has now been found that emulsions having a discrete phase volume fraction of 60% to 67% with excellent stability may be prepared using at least one low molecular weight surfactant. Such emulsions have high oil loading and a small mean particle size of less than 0.2 microns. Further, such emulsions may be used in beverages without weighting agents.

Owner:CORN PROD DEV INC

Control method of local loading and shaping equiaxial alpha content of titanium alloy

InactiveCN101603163AAvoid abnormal growthReduce uneven deformationHeat treatment process controlLoad stepTitanium alloy

The invention discloses a control method of local loading and shaping equiaxial alpha content of titanium alloy. After a blank is changed to forge and is pre-shaped, a shaped forging piece is obtained by isothermal local loading and shaping, finishing and heat treating. Local loading is finished by two passes, and each pass is finished by two loading steps. A mould is divided into two to three modules, and the relative position of different modules can be adjusted. In each loading step in the same pass, different modules are used for carrying out deforming on the blank; after all loading steps in the pass are finished, the next step is started, the loading method in the last step is repeated to finish the forging piece deformation; the equiaxial alpha phase volume fraction effectively controlling the local loading and shaping of the forging piece is obtained, and is controlled within 10-20%; the equiaxial alpha phase volume fraction of different positions on the forging piece differs within 5%; equiaxial alpha crystal and beta crystal are both even and small, have no phenomena of coarsing, unevenness and extraordinary growth, and have favourable mechanical property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

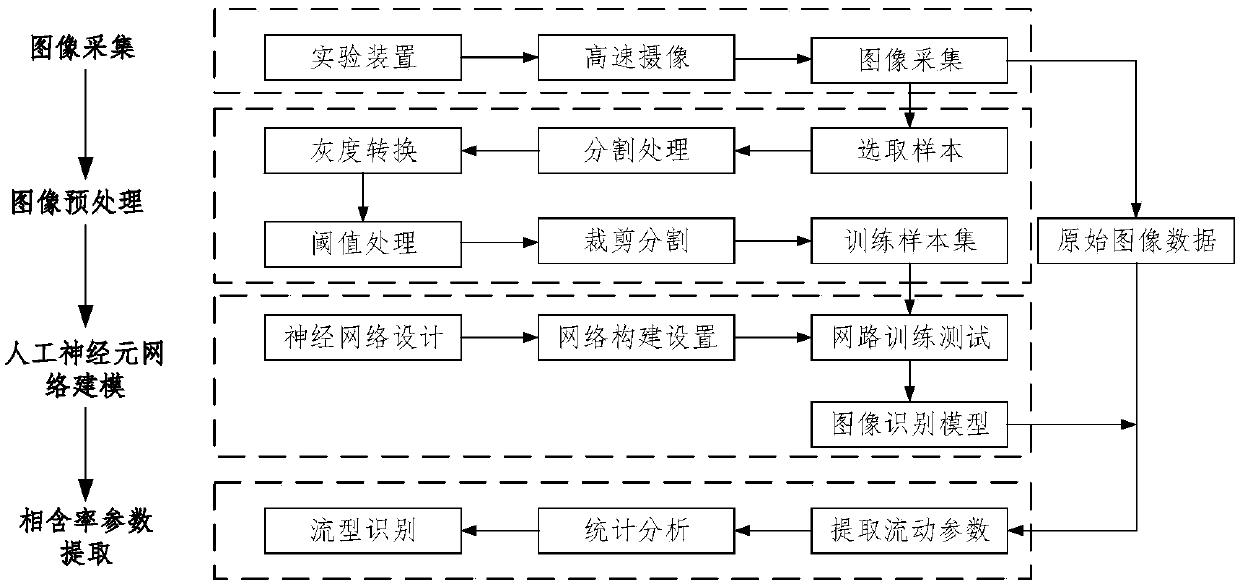

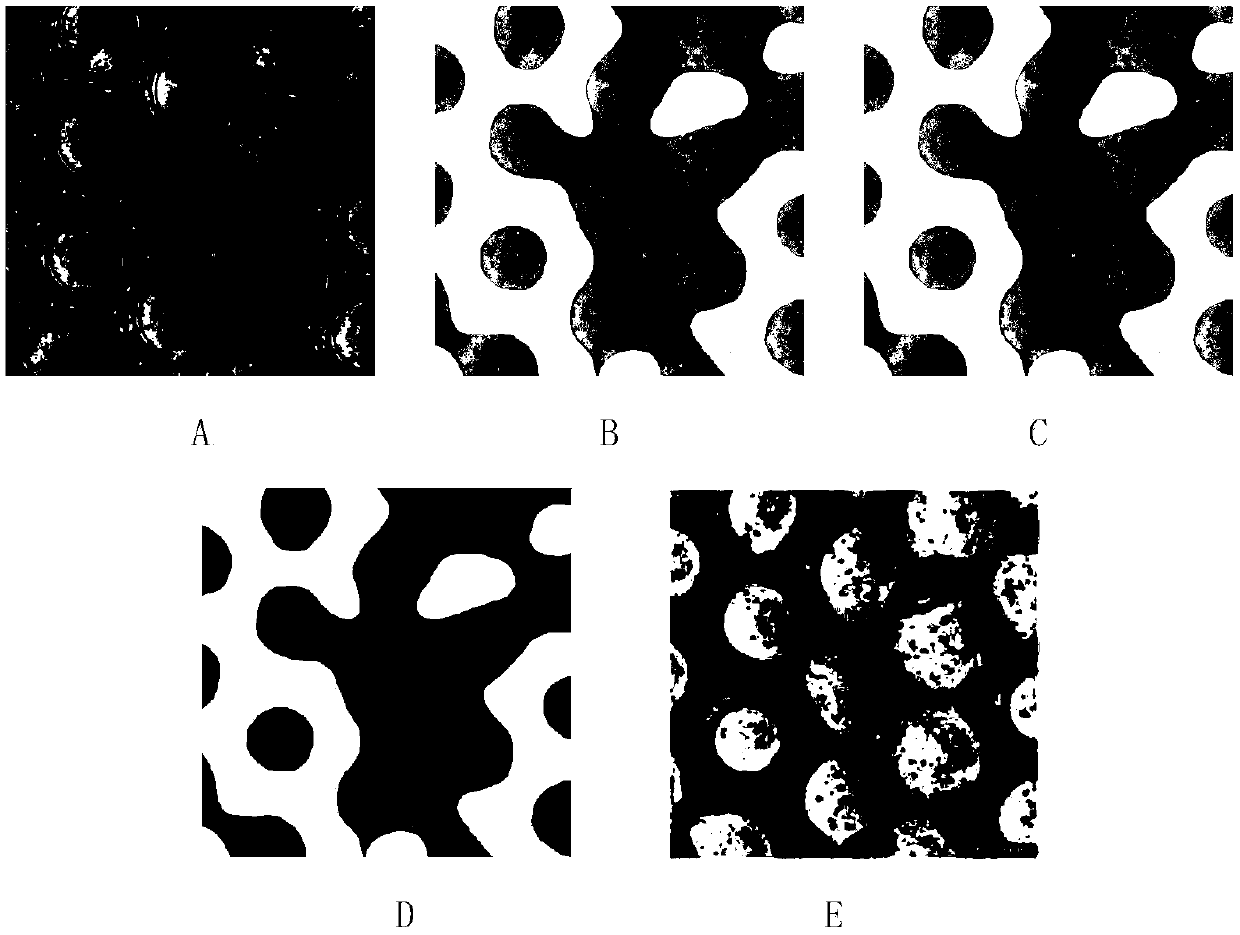

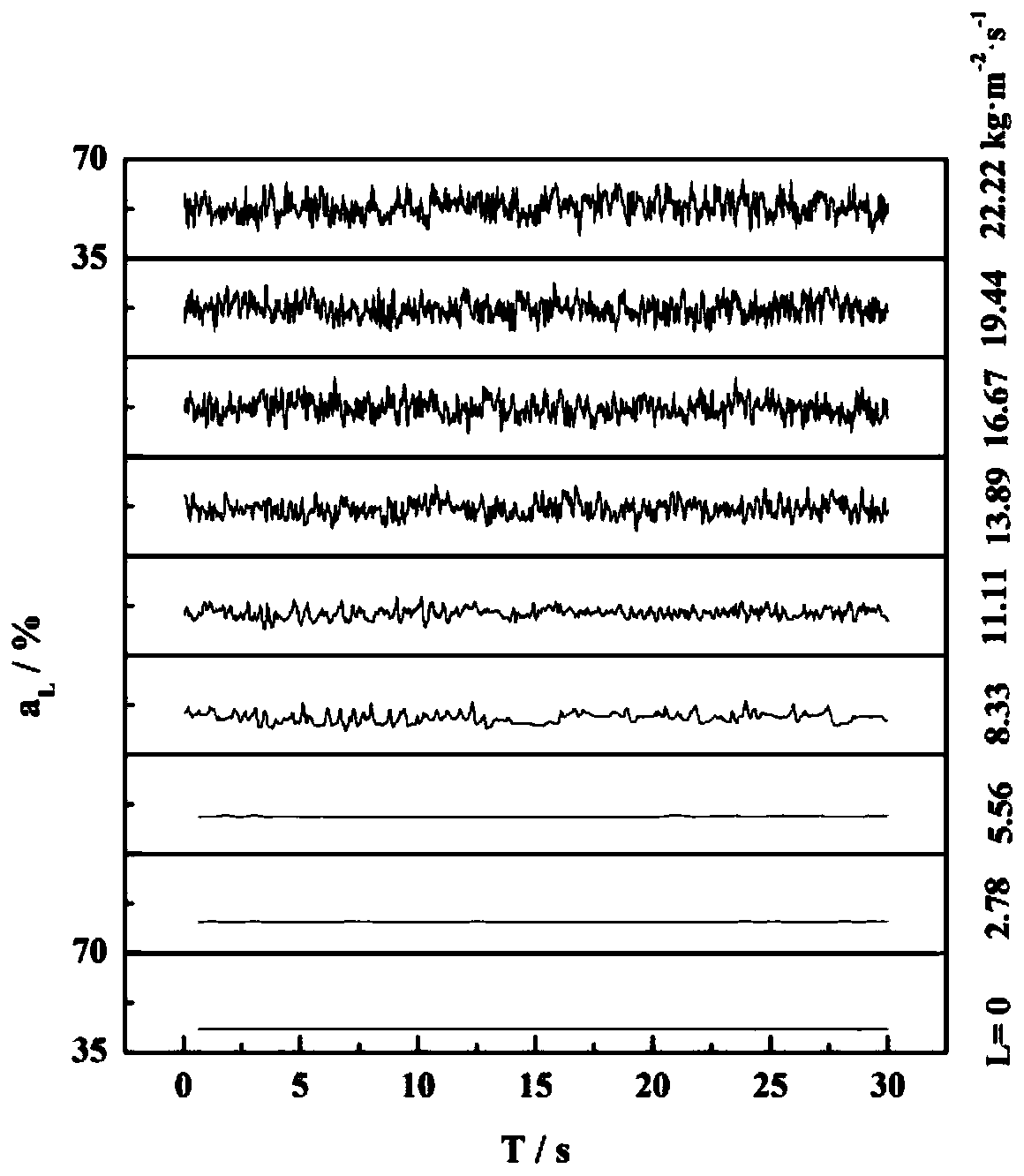

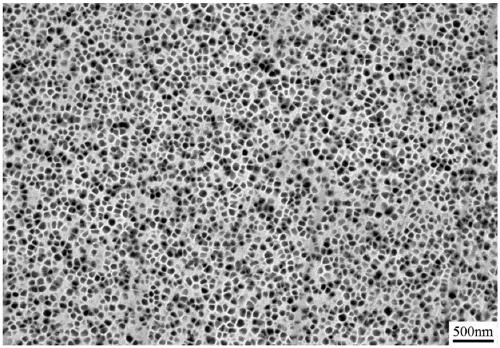

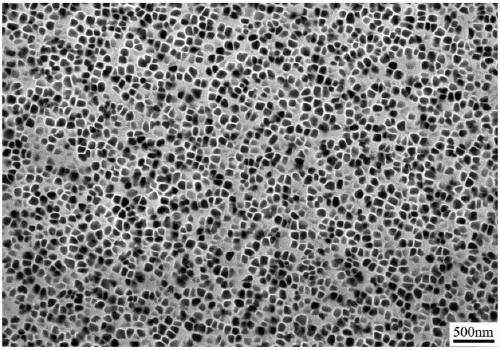

An image measurement method for flow parameters in a gas-liquid-solid three-phase system

ActiveCN109685117AAccurate identificationWith quantitative analysisCharacter and pattern recognitionNeural architecturesStatistical analysisGas phase

The invention discloses an image measurement method for flow parameters in a gas-liquid-solid three-phase system, comprising the steps of image acquisition, image preprocessing, artificial neural network modeling, phase volume fraction parameter extraction and the like, and the flow parameters such as gas phase area, liquid phase area, liquid phase fraction, gas phase fraction and the like can beobtained through the method. Furthermore, the image measurement method processes images at different moments under the same experiment condition to obtain data of the flow parameters changing along with time; Typical flow patterns such as trickle flow, pulse flow and bubbling flow can be identified through statistical analysis. The method can overcome the defects of the existing image recognitiontechnology, breaks through the limitation of extracting quantitative gas-liquid flow parameters by images, and further improves the recognition accuracy of the gas-liquid flow pattern.

Owner:ZHEJIANG UNIV

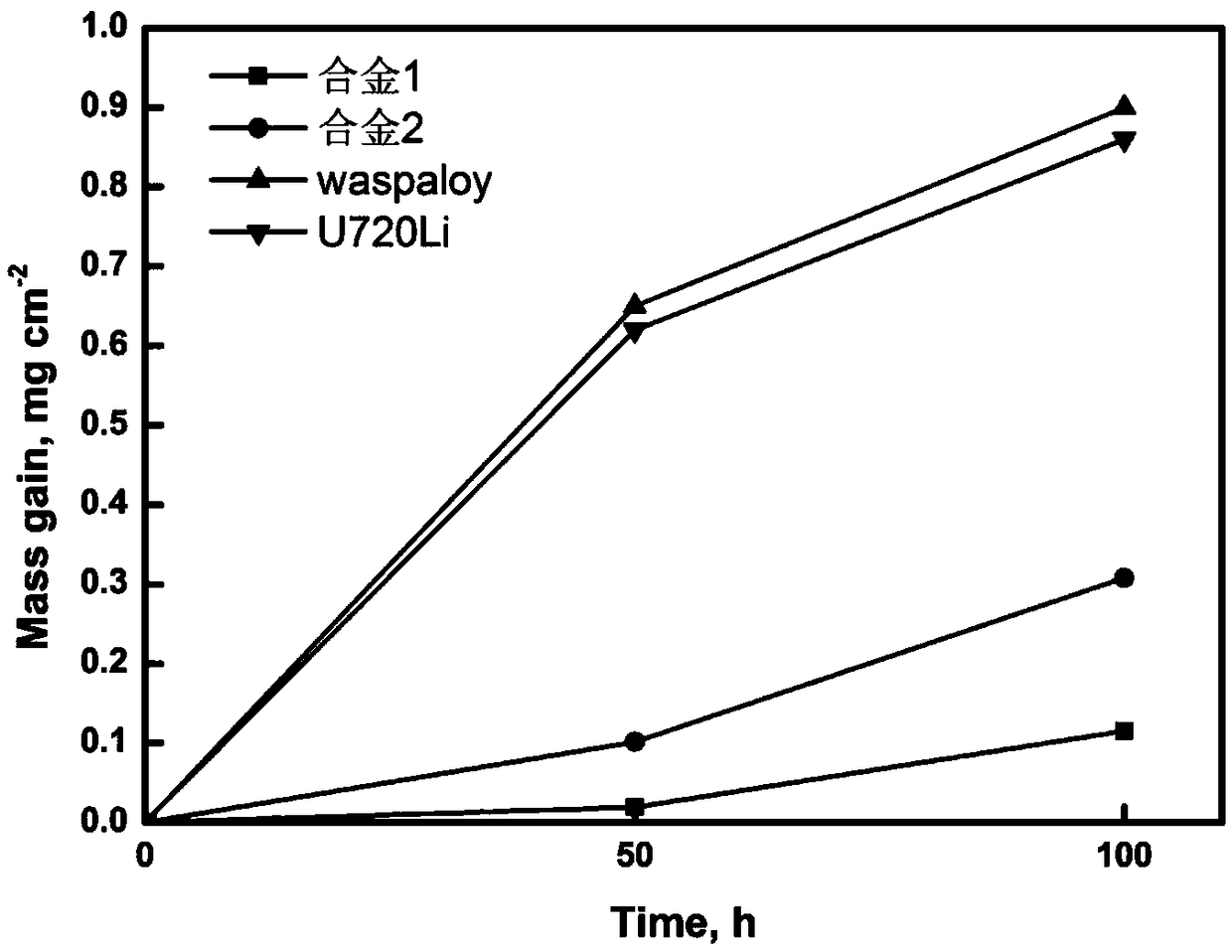

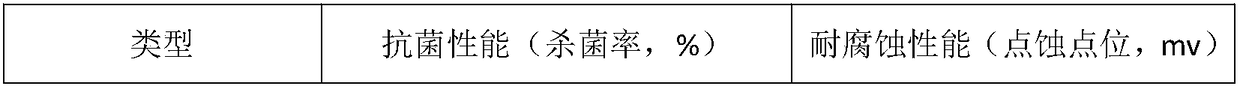

Cobalt-based high-temperature alloy and preparation method thereof

ActiveCN109321786AImprove high temperature mechanical propertiesImprove antioxidant capacitySuperalloyPhase volume

The invention belongs to the field of high-temperature alloys, and particularly relates to a gamma' phase reinforced cobalt-based high-temperature alloy with high-stability structure and good oxidation resistance. The gamma' phase reinforced cobalt-based high-temperature alloy comprise the following chemical components of, by weight, 2.5-4% of Al, 3-10% of W, 0.5-5% of Ti, 1.5-6% of Ta, 18-35% ofNi, 10-14% of Cr, 0-4.5% of Nb, 0-0.5% of Hf, 0-0.1% of C, 0-0.1% of B, 0-0.1% of Zr, 0-0.5% of Si, and the balance Co, and the contents of Al plus Cr is more than or equal to 13.5%, the Al plus the Ti plus the Ta plus the Nb are more than or equal to 9.5%, and the W plus the Ta is less than or equal to 12.5%; and a vacuum arc furnace is adopted for smelting, then solid solution is carried out atthe temperature of 1200-1250 DEG C, and aging heat treatment is carried out at the temperature of 700-900 DEG C. The gamma / gamma' two-phase structure stably exists at the temperature of 700-900 DEG C,and the gamma' strengthening phase volume fraction is larger than 40%; and meanwhile, the alloy has good oxidation resistance, large hot working window and low alloy density, and is an alternative material of a high-temperature disc piece of an aero-engine and an industrial gas turbine.

Owner:UNIV OF SCI & TECH BEIJING

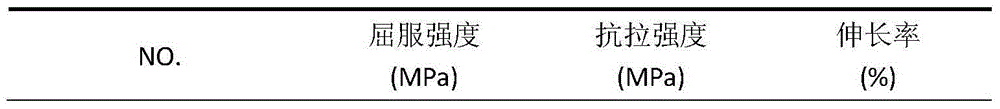

Low-elastic-modulus beta type titanium alloy for dental filling and production method thereof

ActiveCN108486408AImprove mechanical propertiesImprove corrosion resistanceImpression capsAdditive manufacturing apparatusYoung's modulusPhase volume

The invention provides a low-elastic-modulus beta type titanium alloy for dental filling. The low-elastic-modulus beta type titanium alloy is characterized by being prepared from alloy components according to the weight percent: 23 to 24 percent of Mo, 12 to 13 percent of Nb, 2.5 to 2.8 percent of Zr, 2.1 to 2.2 percent of Al, 1.1 to 1.7 percent of Cr, 0.5 to 0.6 percent of Ag, 0.2 to 0.3 percentof Fe, 0.4 to 0.7 percent of Ta, 0.15 to 0.2 percent of Cu, 0.3 to 0.45 percent of Hf, 0.2 to 0.4 percent of Sn, 0.05 to 0.08 percent of Er, less than or equal to 0.05 percent of O, less than or equalto 0.01 percent of H, less than or equal to 0.02 percent of C, less than or equal to 0.01 percent of N and the balance of Ti and unavoidable impurities; the beta type titanium alloy formed by heat treatment has the average crystallization grain diameter of 20 to 40mu m, the yield strength of 900 to 1000MPa, the tensile strength of 1020 to 1150MPa, the elongation percentage of 15 to 17 percent, the Young's modulus of 40 to 60GPa, the primary alpha-phase volume percent of 22 to 25 percent, the size of 2 to 3 microns and the secondary alpha-phase volume percent of 22 to 25 percent.

Owner:山东创瑞健康医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com