Permanent magnetic RE material and preparation thereof

A rare earth permanent magnet and rare earth technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of reduced intrinsic coercive force, unreasonable, large grains of magnetic materials, etc., and achieve high coercive force , low cost, low temperature coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

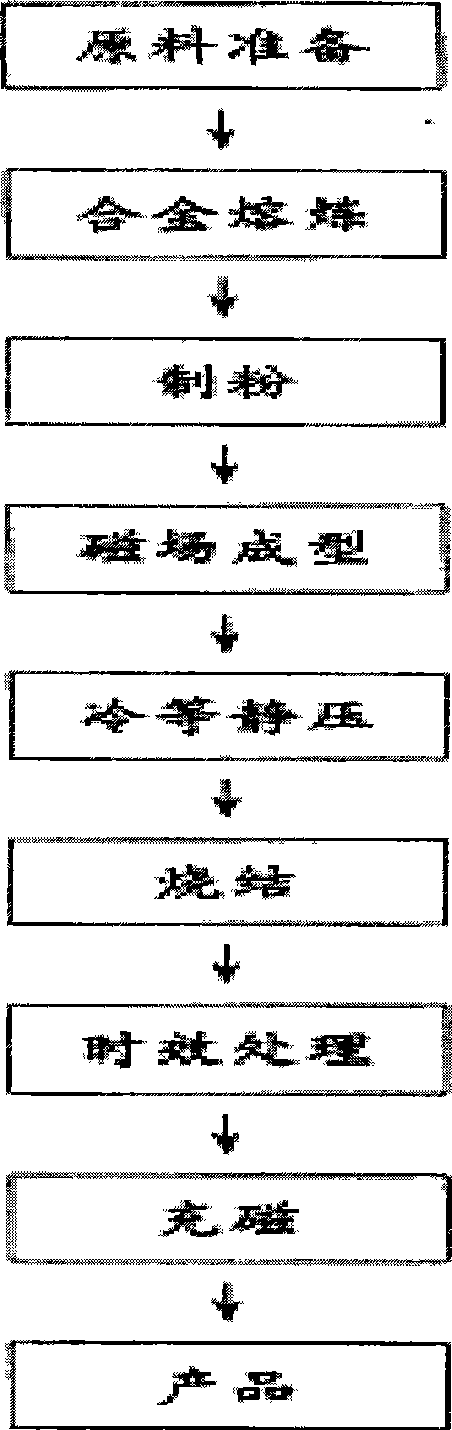

[0019] The present invention also provides a method for preparing the above-mentioned rare earth permanent magnet material, which is characterized in that it comprises the following eight steps:

[0020] a) Raw material preparation (batching): batching the raw materials that have been surface cleaned according to the alloy composition;

[0021] b) Alloy smelting (homogenization treatment): put the above ingredients in an intermediate frequency vacuum induction melting furnace and melt them into ingots; then place the ingots in a vacuum furnace for homogenization treatment, and the heat treatment temperature is 800°C to 1000°C , the sintering time is 8-10 hours;

[0022] c) Milling (grinding): Grinding the homogenized ingot into 3-5um magnetic powder;

[0023] d) Magnetic field molding: put the above-mentioned magnetic powder in a magnetic field of 1.2T-2.0T for orientation, and press molding at a pressure of 10MPa-20MPa;

[0024] e) Cold isostatic pressing: The formed magnet...

Embodiment 1

[0037] Select alloy composition: Pr 5 Nd 22 Fe 64.5 Nd 0.4 Tb 5.2 Dy 0.4 co 1.22 al 0.1 Cu 0.2 B 0.98 ;

[0038] Nano oxidant doping amount: 0.1% ZrO 2 and 0.5% TiO 2 ;

[0039] Raw materials are prepared, smelted in a vacuum intermediate frequency induction furnace under the protection of high-purity argon, and alloy ingots are produced through a cooler. Crushing and fine grinding are carried out under the protection of high-purity nitrogen to obtain praseodymium-neodymium permanent magnet alloy powder with an average particle size of 4.3um. The alloy powder is mixed with a small amount of antioxidant and lubricant for 2 hours, and then pressed evenly after mixing. The pressing pressure is generally 12MPa. After pressing, the size of the permanent magnet body can be controlled to 58.20×30.3×64.3mm, and then subjected to 250MPa isostatic pressing 15 minutes of holding pressure pressing. Sintering was carried out in a sintering furnace at a temperature of 1110° C....

Embodiment 2

[0043] Select alloy composition: Pr 5 Nd 22 Fe 64.5 Nd 0.4 Tb 5.2 Dy 0.4 co 1.22 al 0.1 Cu 0.2 B 0.98

[0044] Nano oxidant doping amount: 0.2% ZrO 2 and 0.3% MgO

[0045] Raw materials are prepared, smelted in a vacuum intermediate frequency induction furnace under the protection of high-purity argon, and alloy ingots are produced through a cooler. Crushing and fine grinding are carried out under the protection of high-purity nitrogen to obtain praseodymium-neodymium permanent magnet alloy powder with an average particle size of 4.3um. The alloy powder is mixed with a small amount of antioxidant and lubricant for 2 hours, and then pressed evenly after mixing. The pressing pressure is generally 12MPa, and the size of the permanent magnet body after pressing is 58.20×30.3×64.3mm; and then isostatically pressed at 250MPa for 15 minutes pressure-holding and pressing; put into the sintering furnace at 1110°C for 2 hours for sintering, the first tempering and aging heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com