Patents

Literature

2757 results about "Induction furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tonnes, and are used to melt iron and steel, copper, aluminium, and precious metals.

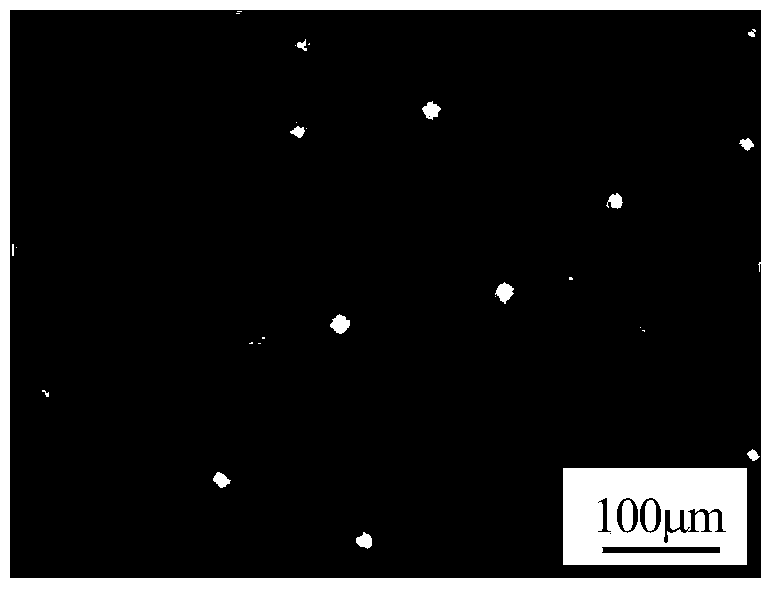

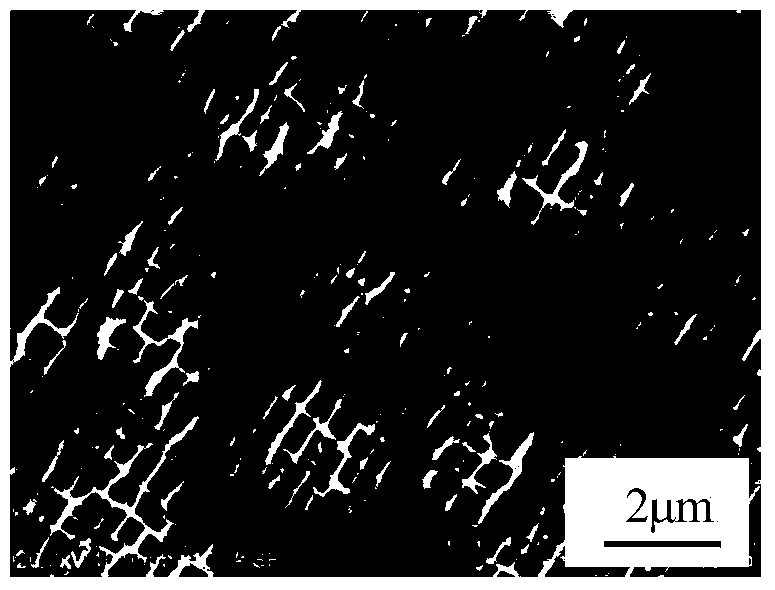

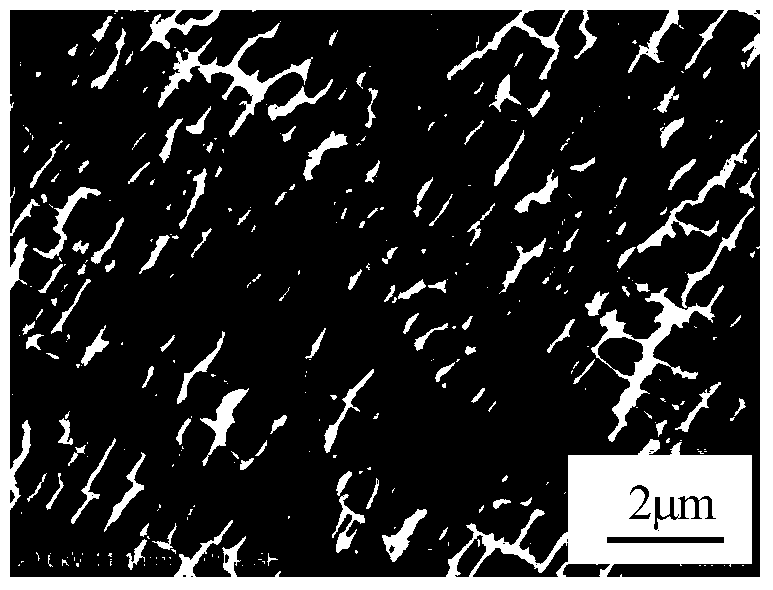

Aluminium-titanium-horon rare earth fining agent, and its preparing method

The invention relates to the thinning reagent having the aluminum, the boron and the lanthanide of the aluminum and the aluminum alloy, it belongs to the domain of the applied technique of the aluminum alloy. The said thinning reagent factors include the aluminum, the boron, the titanium and the lanthanide (mainly includes the lanthanum and the Ce), the said producing process is showed as follows: the pure aluminum ingot, the alloy ingot having the aluminum and the lanthanide, the potassium hexafluorotitanate and the potassium borofluoride are prepared according to the thinning reagent element confecting in advance; the aluminum ingot and the aluminum lanthanide ingot are heated and melted in the intermediate frequency inducing stove, then several material are added; the fusing body acts with the high temperature; the temperature keeps even and the dregs is removed after the action; then the fusing body is irrigated to the ingot or connecting cast and rolled to the line material. According to the said process condition, the high pure aluminum can be removed the pole crystal, the size of the crystal grain of the industry pure aluminum and all series of distortional aluminum alloy can be divided to under the 100um, the casting form crystal grain core can be reduced to under 2um firmly to all sorts of the aluminum used in the foil material; the size of the crystal grain of the alloy of the aluminum and the silicon can be reduced to under 150-200um. At the same time, the intension, the molding ability and the tenacity of the industry pure aluminum and all sorts of the aluminum alloy can be improved highly.

Owner:TSINGHUA UNIV

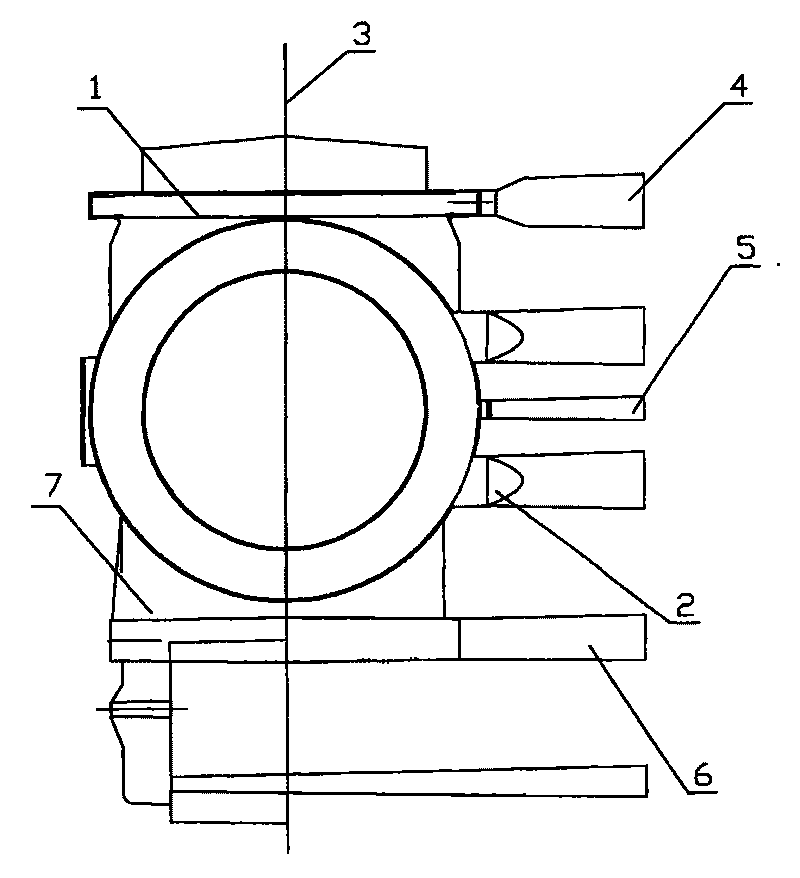

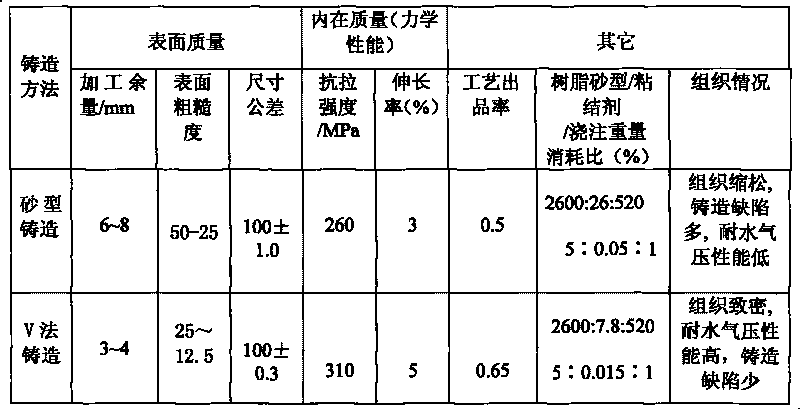

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

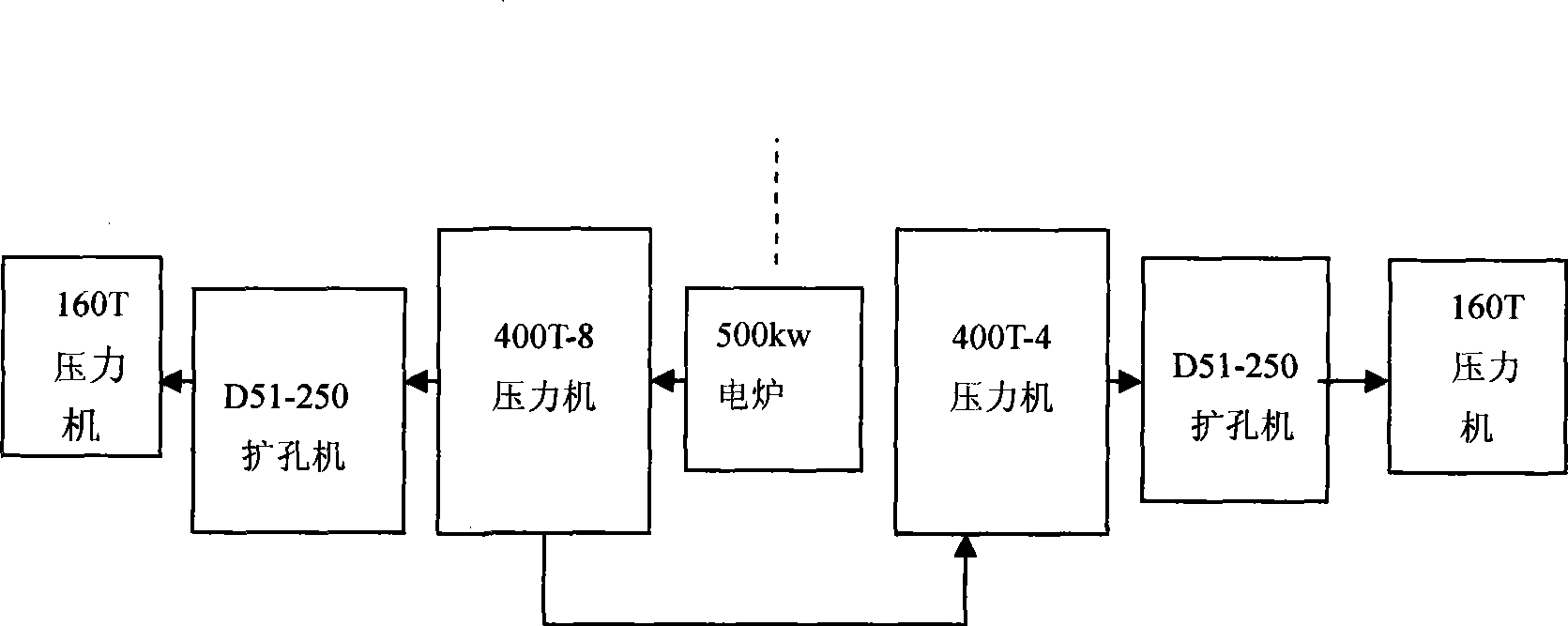

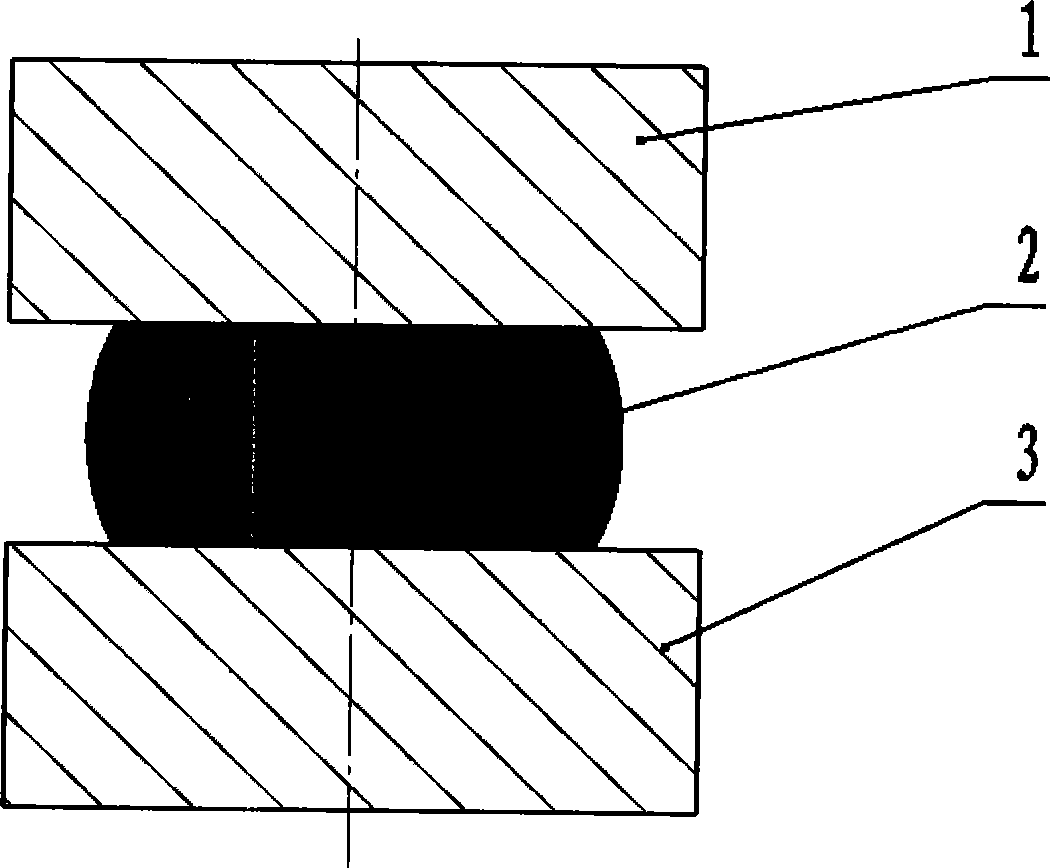

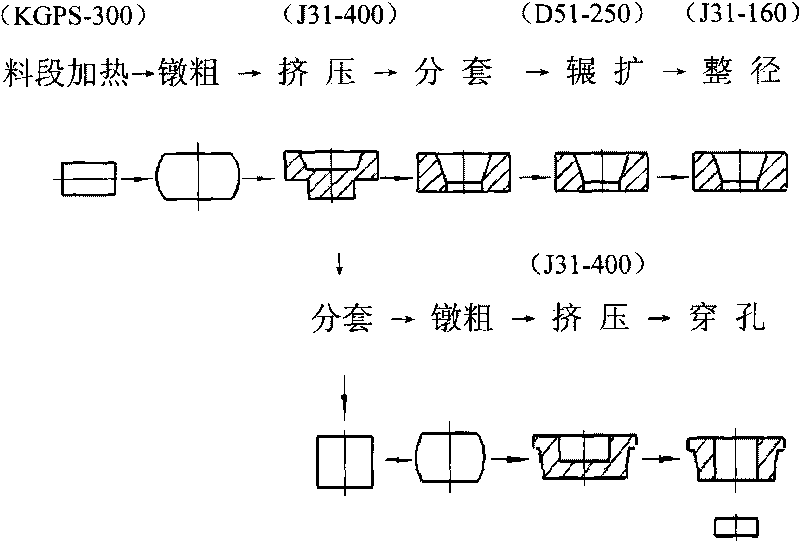

Tapered roller bearing ring double extension-sleeve forging technique

ActiveCN101417379AReduce labor intensityIncrease profitMetal rollingHigh volume manufacturingDouble diffusion

The invention relates to a double diffusion intussusception forge technique of a bearing ring of a tapered roller, belongs to the technical field of forging of the bearing ring of the tapered roller and mainly aims at solving the problems that the existing ring forging technique is not suitable for various bearing rings of the large and medium size tapered rollers. The technique is mainly characterized in that: (1) a GCr15 steel material section is heated to 1050 DEG C on a medium frequency induction furnace, then upset on a press, extruded backward and forward, formed, sheathed respectively and is separated into an outer sleeve and an inner sleeve or a small outer sleeve blank; (2) the outer sleeve blank is ring-rolled on a ring rolling machine, then reeled on the press and cooled into an outer sleeve forged parts of a bearing; and (3) the inner sleeve or the small outer sleeve blank is placed on the press, upset again, extruded and punched and then a ring part is obtained which is ring-rolled on the ring rolling machine, then an inner sleeve hot forged part after being ring-rolled is reeled on the press and then cooled to obtain the inner sleeve forged part of the bearing. The technique is mainly used for manufacturing the inner and outer ring forged parts of the bearing of the large and medium size tapered roller with various types, small batch or large batch.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

Production technology of aluminum alloy sectional bar for automobile bumper

ActiveCN102978488AUniform chemical compositionUniform temperatureStirring devicesFiltrationThermal deformation

The invention discloses a production technology of an aluminum alloy sectional bar for an automobile bumper and belongs to the technical field of metal machining. The aluminum alloy sectional baral bar for the bumper is processed through the steps of mixing, melting, permanent magnetic stirring, temperature measurement, sampling, ingredient and temperature adjustment, turning down, refining(first purification), standing still, online addition of Al-Ti-B wire, online removal of gas and sand (secondary purification), two-stage filtration, same-level hot top casting, cast ingot homogenization, machining of cast ingot, inspection of cast ingot, heating of cast ingot by an induction furnace, extrusion, precise on-line quenching, stretching and straightening, aging, structure and property inspection of sectional bars, and delivery. The aluminum alloy sectional bar processed by the technology is excellent in thermal deformation performance, and high in strength due to on-line quenching during extrusion. The product has excellent welding performance and corrosion resistance, certain resistance to stress corrosion, and especially has strong shock absorption and folding resistance.

Owner:丛林铝业科技(山东)有限责任公司

Directional solidification heat corrosion resistant nickel base cast superalloy and preparation method thereof

InactiveCN101294250AImprove performanceElimination of lateral grain boundariesLiquid metalInduction furnace

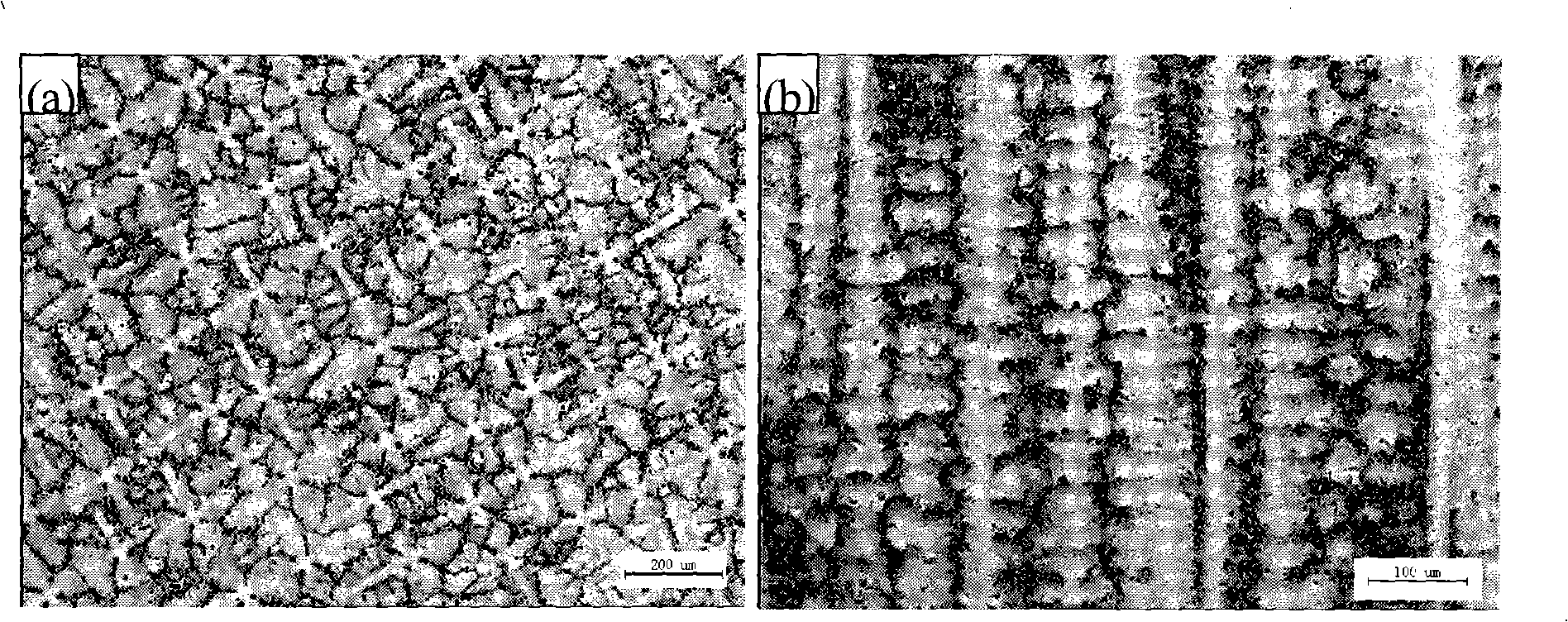

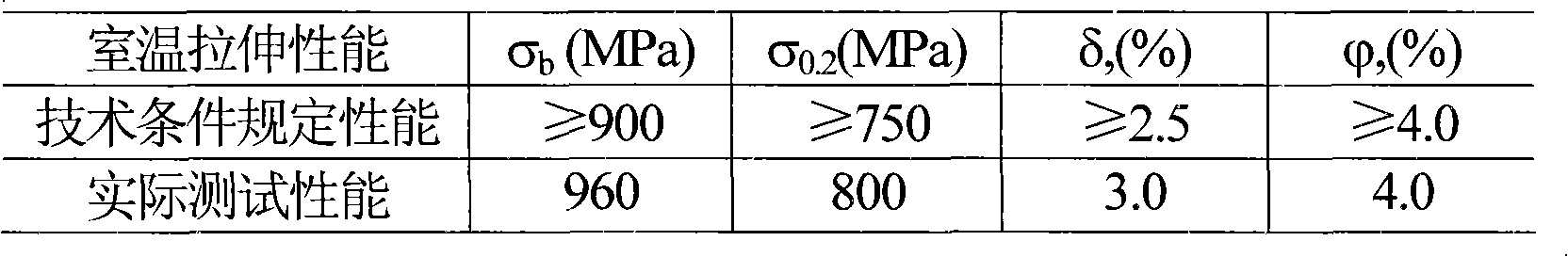

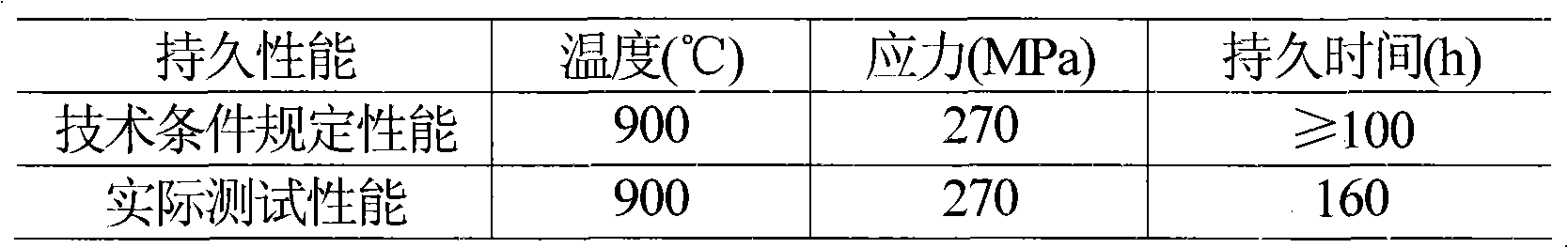

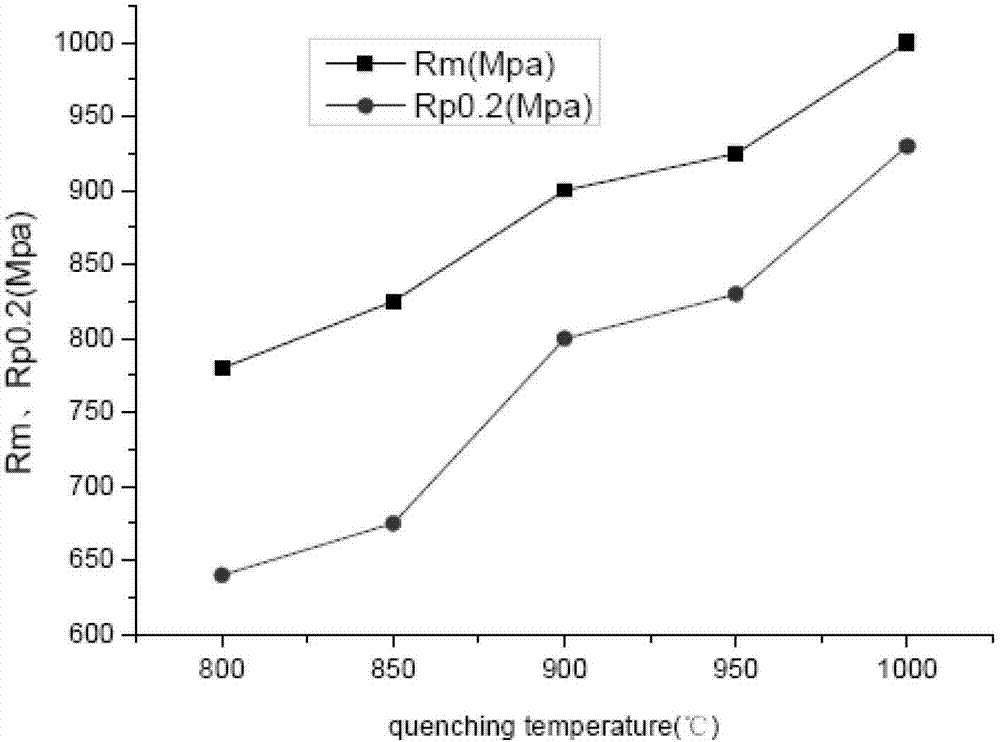

The invention relates to a directional-freezing heat-proof corrosion-resistant nickel base cast superalloy with low cost and excellent performance. The cast superalloy has the chemical composition range by weight percentage as follows: C is 0.04 to 0.09; Cr is 14.5 to 15.3; Co is 9.0 to 9.9; W is 4.7 to 5.9; Mo is 1.6 to 2.3; Al is 2.8 to 3.3; Ti is 4.2 to 5.0; Hf is 0.3 to 0.6; Ta is 0.3 to 1.5; B is 0.06 to 0.10; Y (adding quantity) is 0.015; Mn is less than or equals to 0.2; Si is less than or equals to 0.2; P is less than or equals to 0.008; S is less than or equals to 0.008; Fe is less than or equals to 0.5; the other weight percentage is composed of Ni. A vacuum induction furnace is adopted to smelt master alloy, and the directional-freezing is performed in a liquid-metal-cooled (LMC) furnace to prepare columnar grain alloy; the vacuum degree of a directional furnace is less than or equals to 5*10<-4>mmHg, the casting temperature ranges from 1480 to 1570 DEG C, the drawing velocity is 3 to 15mm / min, the temperature gradient is 95 to 145 DEG C / cm, and the temperature of melting tin ranges from 250 to 350 DEG C. The invention provides the heat-proof corrosion-resistant superalloy, which contains Ta, does not contain alloying elements that are Re (with low cost), Nb, Zr and Ce, and has a stable microstructure. Compared with cheC88 Y-BN, the tensile-strength (using Delta (b) and Delta0.2 to represent) is increased more than 30 percent, the plasticity is improved obviously, the lasting temperature is risen by 30 DEG C under the same stress condition, and the cast superalloy is applied to manufacture turbine blades of a combustion turbine which is used under 930 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

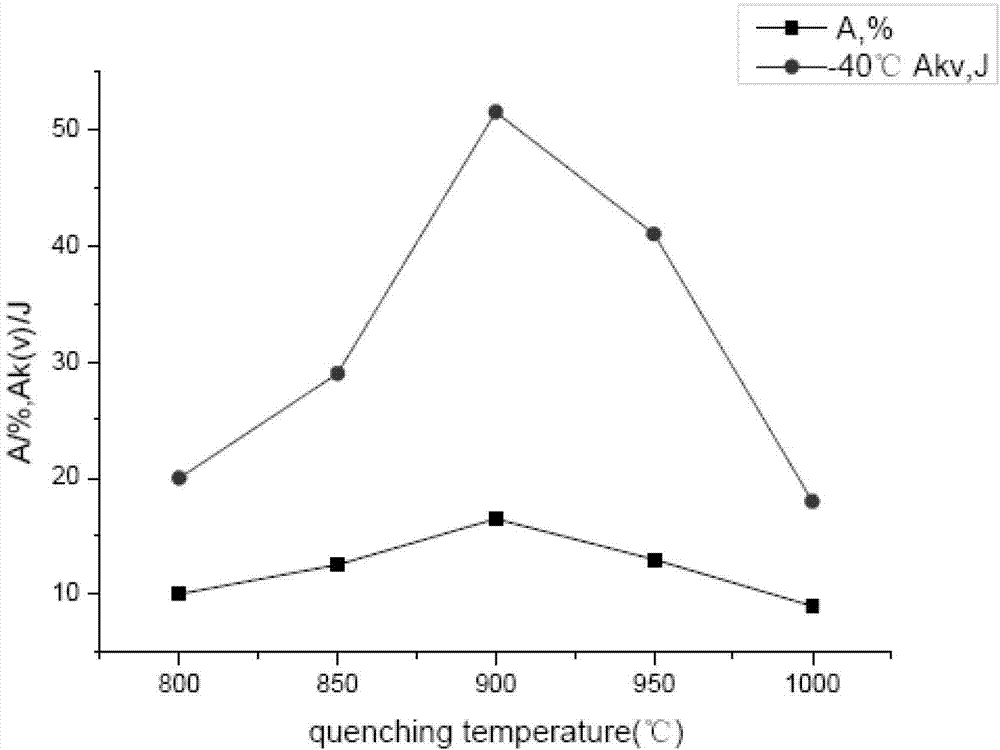

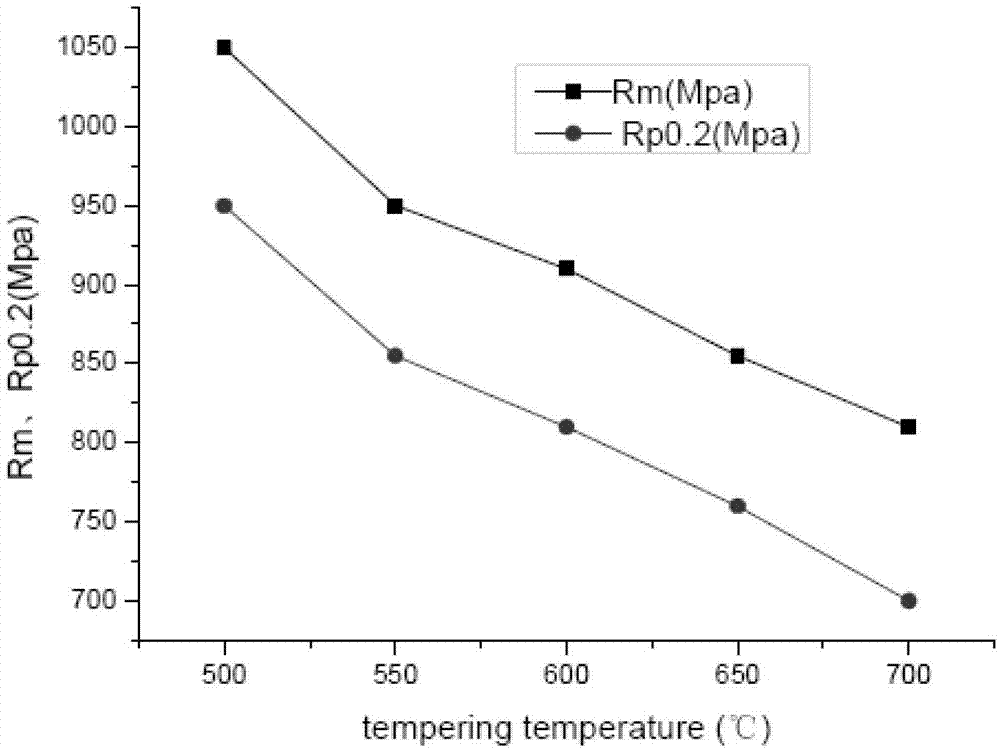

Low-alloy high-strength cast steel, and smelting and heat treatment method thereof

The invention discloses low-alloy high-strength cast steel, and a smelting and heat treatment method thereof. The cast steel comprises the following chemical components in percentage by weight: 0.17-0.22% of carbon, 0.20-0.60% of silicon, 0.80-1.20% of manganese, less than or equal to 0.020% of phosphorus, less than or equal to 0.015% of sulfur, 0.45-1.05% of chromium, 0.4-0.9% of nickel, 0.4-0.95% of molybdenum and less than or equal to 0.30% of copper, and the balance of iron and inevitable impurities. An electric arc furnace oxidation-reduction method or a medium-frequency induction furnace is used for smelting. After a wind power planet carrier casting poured by the low-alloy cast steel disclosed by the invention is heated, the mechanical properties can be stably achieved, the strength of extension is greater than or equal to 830Mpa, the yield strength is greater than or equal to 790MPa, the extension rate is greater than or equal to 12%, and the impact absorption power with a lower temperature of minus 40 DEG C is greater than or equal to 27J.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

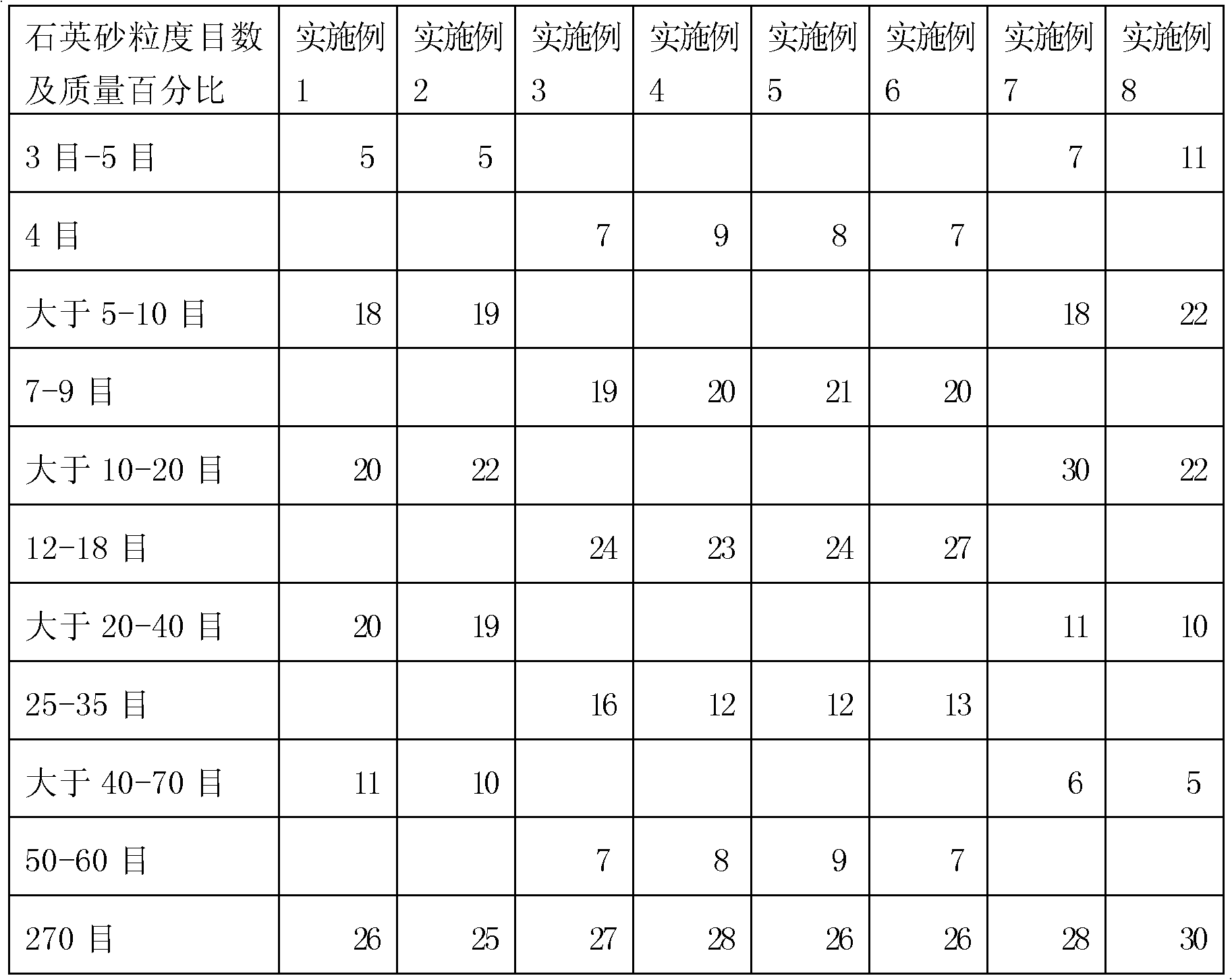

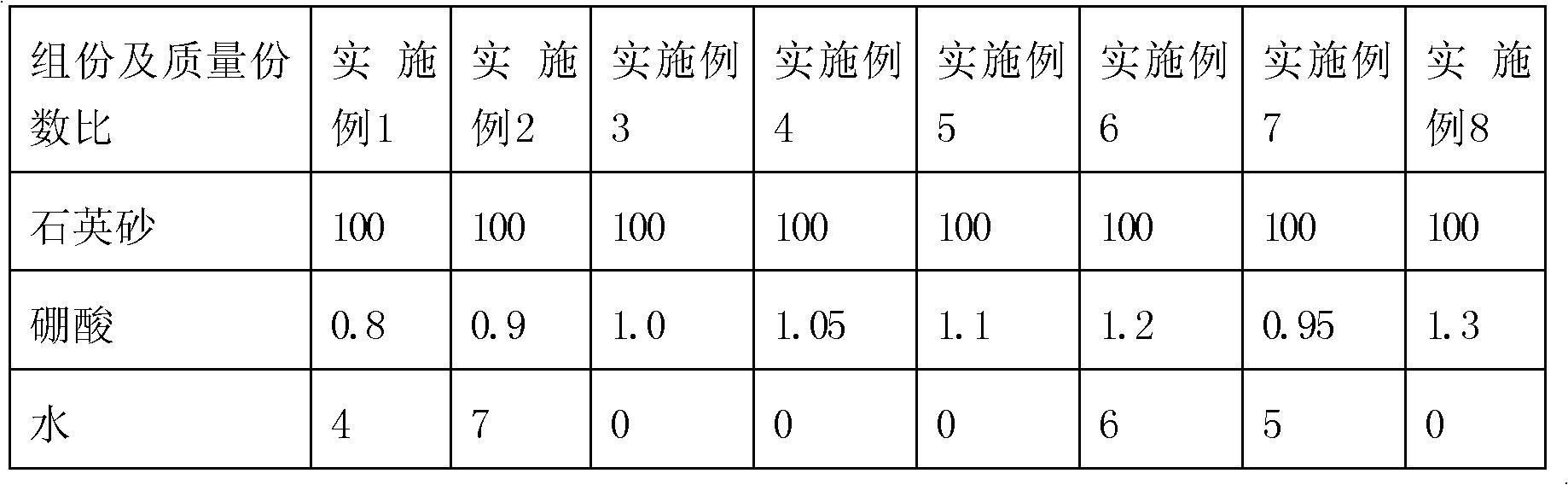

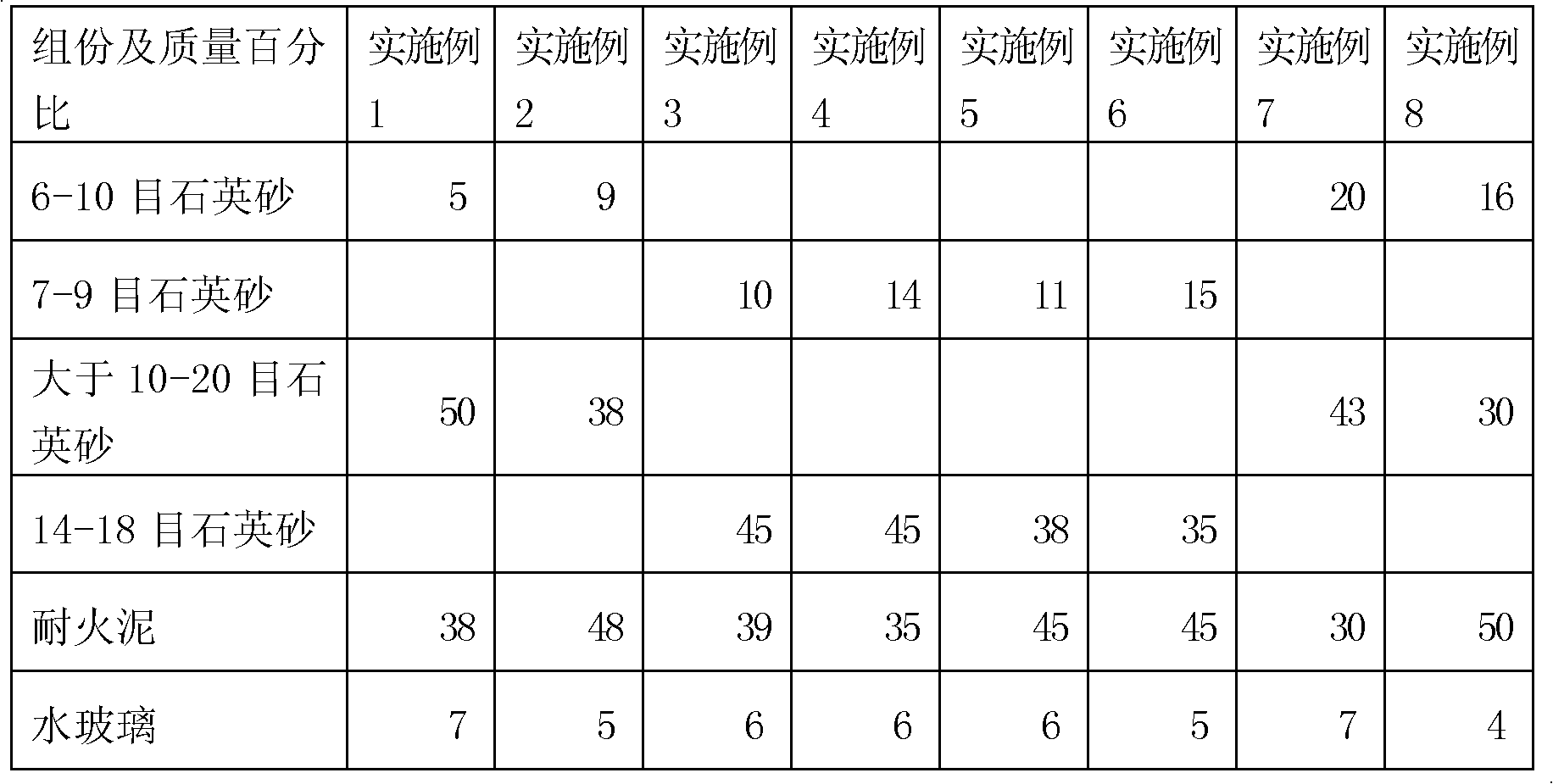

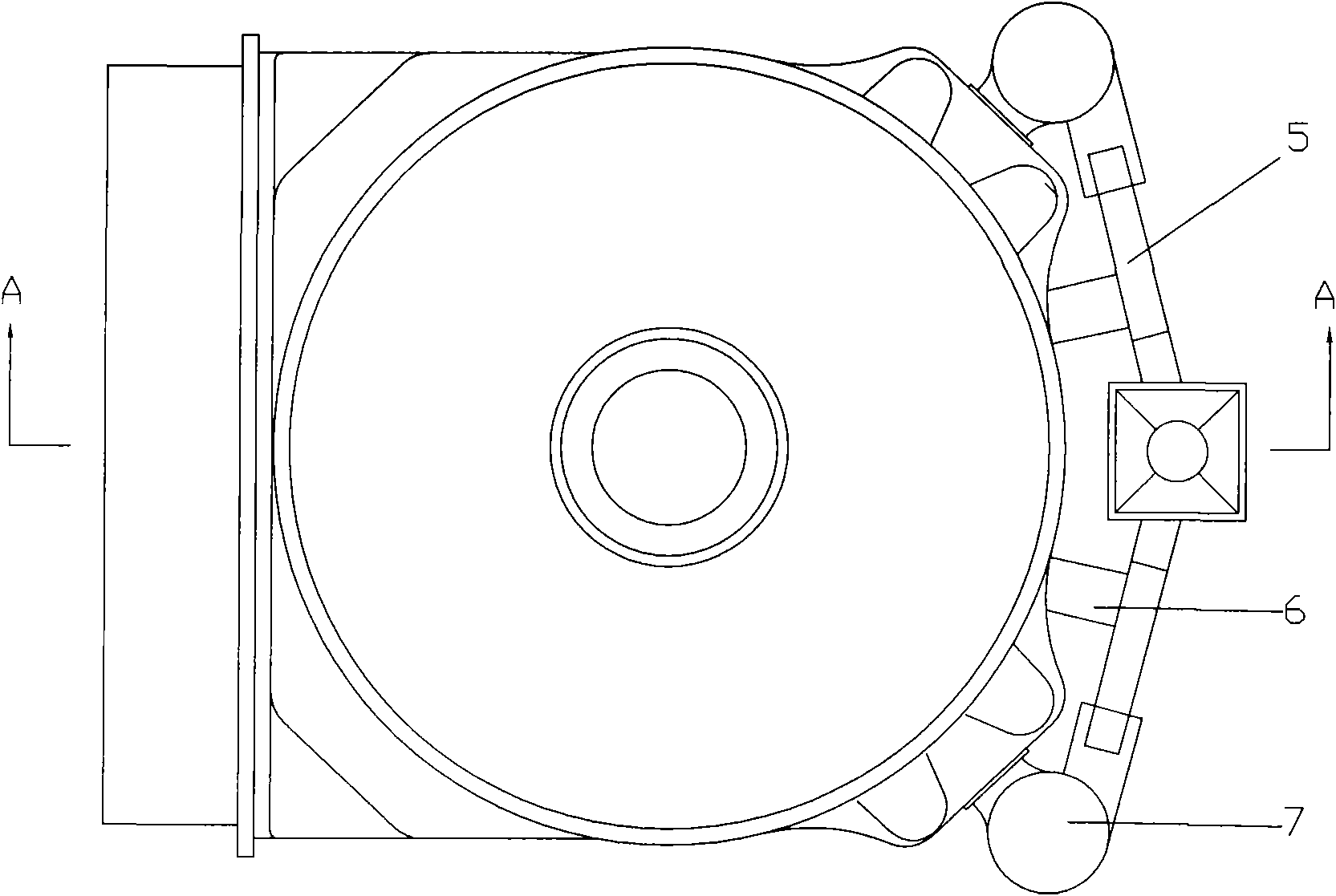

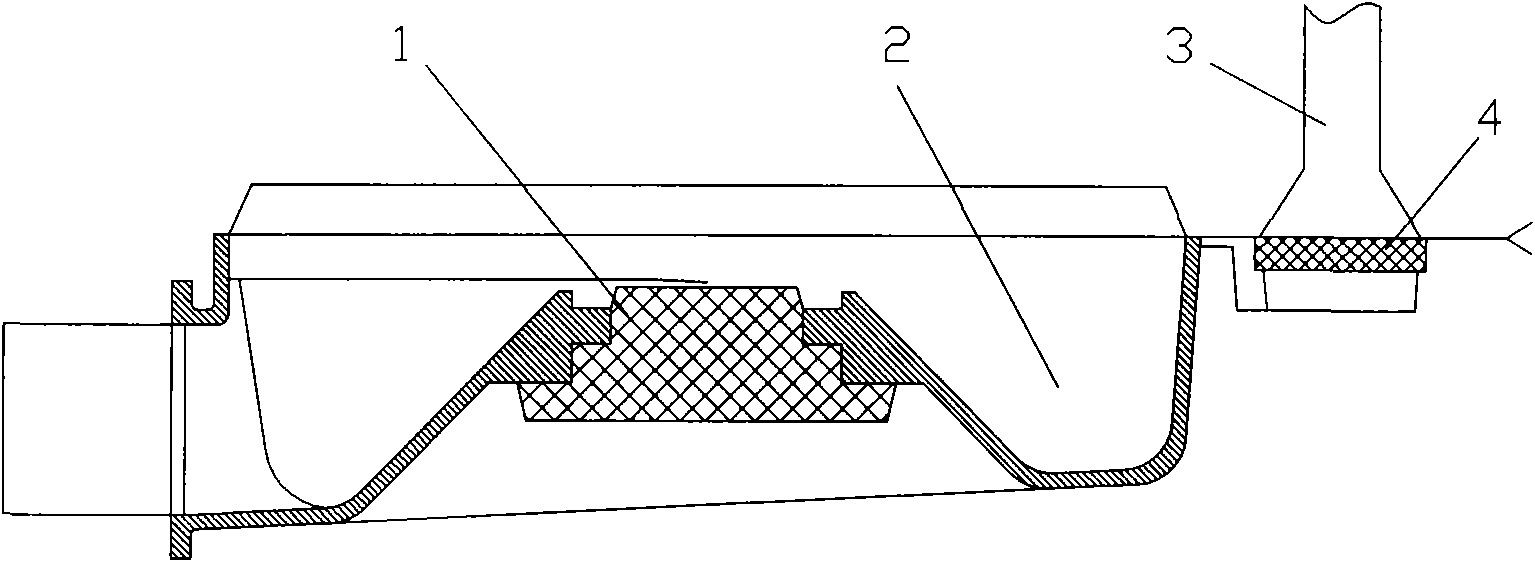

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

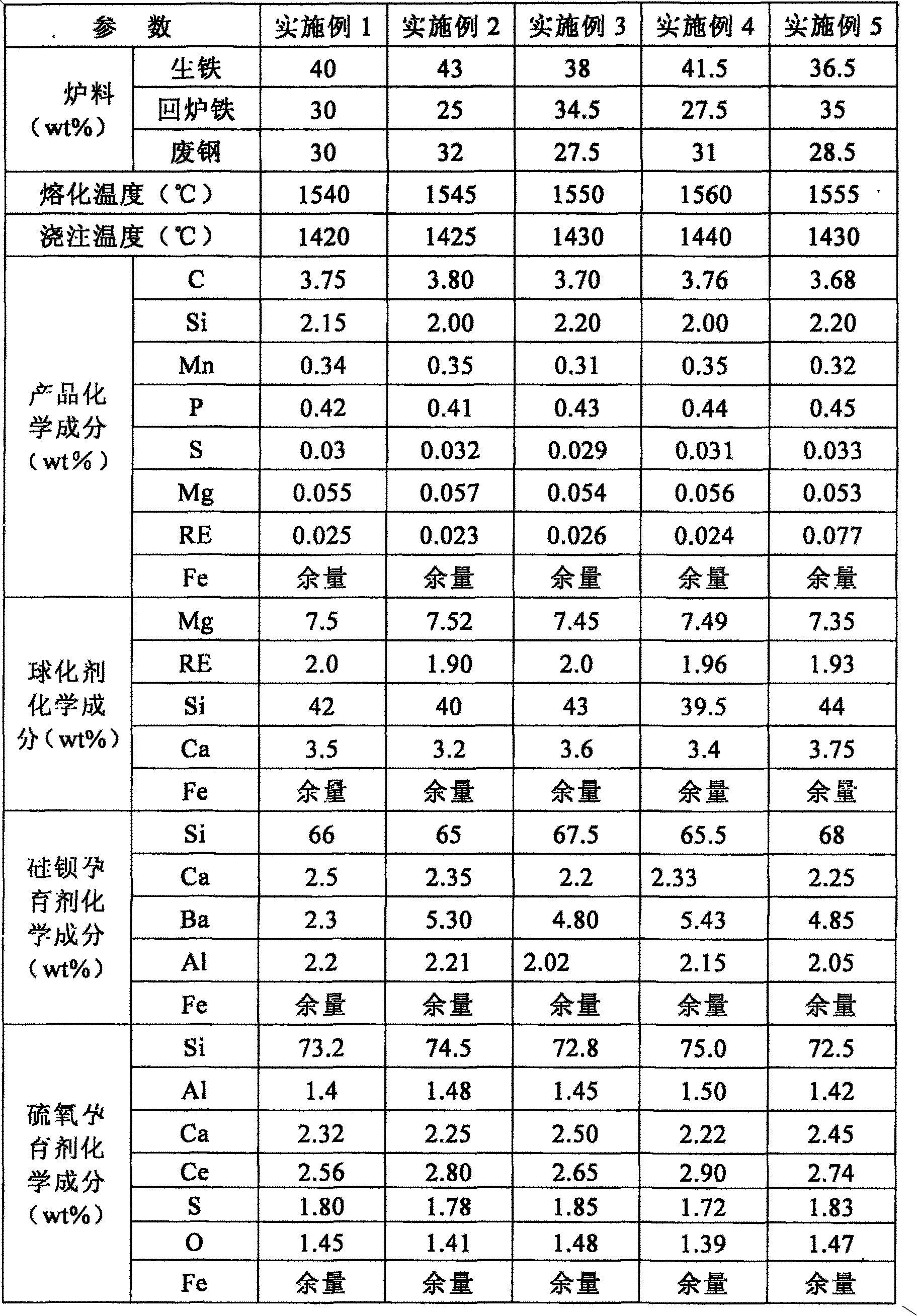

Method for casting as-cast high-tenacity cast iron bearing cover of locomotive

The invention relates to a method for casting an as-cast high-tenacity cast iron bearing cover of a locomotive. The method comprises the following steps: sand mulling, molding, core making, mould assembly, charging smelting, tapping spheroidization inoculation treatment, casting, cooling, unboxing and casting cleaning. The step of charging smelting comprises charging arrangement and smelting, as well as the smelting of a medium-frequency induction furnace, wherein the charging comprises 35-45 percent of pig iron, 25-35 percent of returning iron and 25-35 percent of waste steel according to weight percentage. The tapping spheroidization inoculation treatment comprises spheroidization treatment and secondary silicon-barium inoculation. Stream inoculation of tertiary sulfur-oxygen nucleating agent is conducted during the casting. The bearing cover of the locomotive produced by the method has a tensile strength higher than or equal to 400 MPa, a specific elongation more than or equal to 18 percent, a hardness HBS ranging from 130 to 180 and a low temperature (-20 DEG C) impact value higher than or equal to 12 J / cm; the spheroidization rate the metallurgical structure of casting body is higher than or equal to 85 percent, and the ferrite content is higher than or equal to 95 percent; the thickness difference of casting walls is less than or equal to + / - 1 mm; and the detection result of the casting ultrasonic and magnetic powder inspection reaches the second grade standard of the state.

Owner:上海华新合金有限公司

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

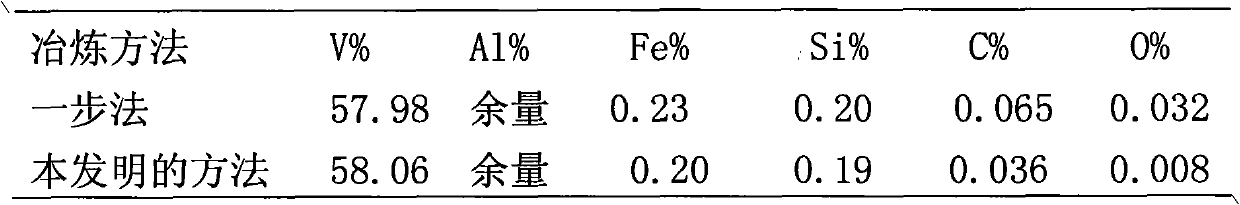

Method for preparing vanadium-aluminum alloy

InactiveCN101906546ASolving the melting puzzleImprove appearance qualityIntermediate frequencyTitanium alloy

The invention discloses a method for preparing a vanadium-aluminum alloy and relates to a method for preparing a vanadium-aluminum intermediate alloy for producing a titanium alloy. The method is characterized by comprising the following steps of: firstly, with aluminum as a reducing agent, reducing vanadium pentoxide to prepare a vanadium-aluminum alloy in one step by adopting a metallothermic reduction method; secondly, crushing and drying the vanadium-aluminum alloy prepared in one step; and adding aluminum in the dried vanadium-aluminum alloy prepared in one step and refining in a second step in a vacuum intermediate-frequency induction furnace to obtain a final product of the vanadium-aluminum alloy. In the method, by taking the aluminum as the reducing agent in the metallothermic reduction method (one-step method) and reserving a small part of aluminum during smelting of the vanadium-aluminum alloy and adding the aluminum in the refining of the vacuum intermediate-frequency induction furnace, the problem that the vanadium-aluminum alloy is molten in the vacuum intermediate-frequency induction furnace can be effectively solved. In addition, compared with the one-step method for preparing the alloy, the appearance quality, the consistency, impurity components, the uniformity and other aspects of the alloy are superior and the aim of refining can be achieved. Meanwhile, when being used for refining the vanadium-aluminum alloy, the process can be used for completely molting the alloy at the lower feeding power and has remarkable the energy-saving effect.

Owner:CHENGDE TIANDA VANADIUM IND

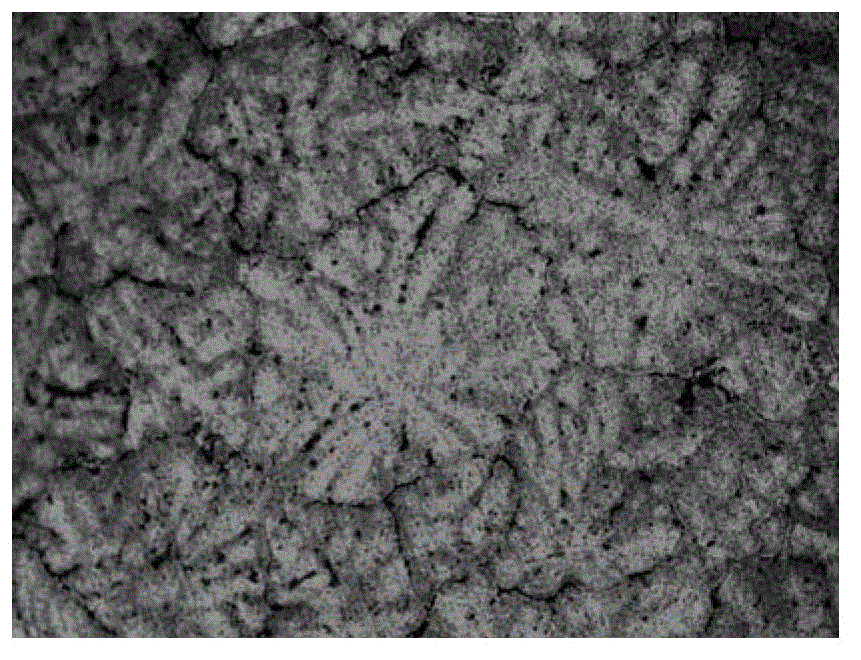

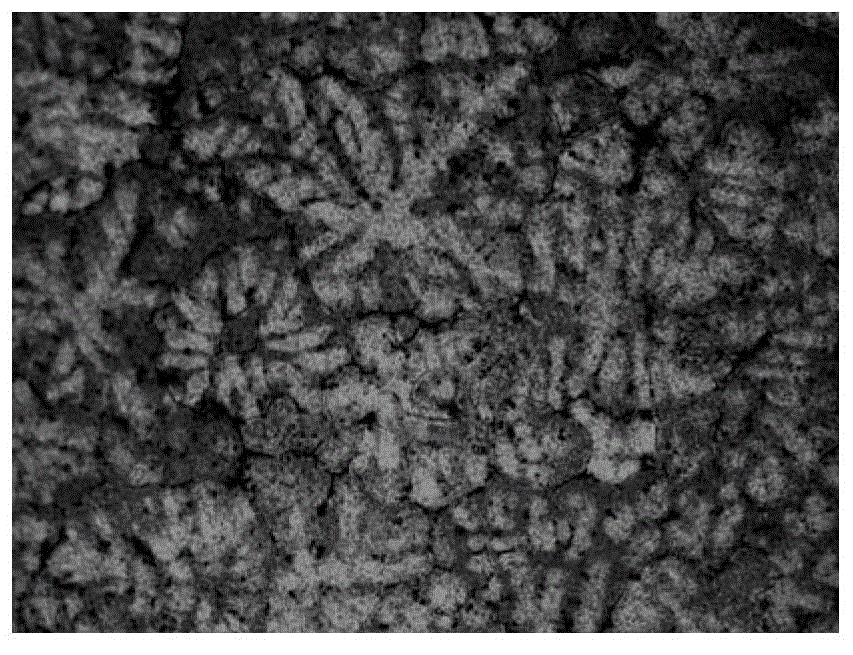

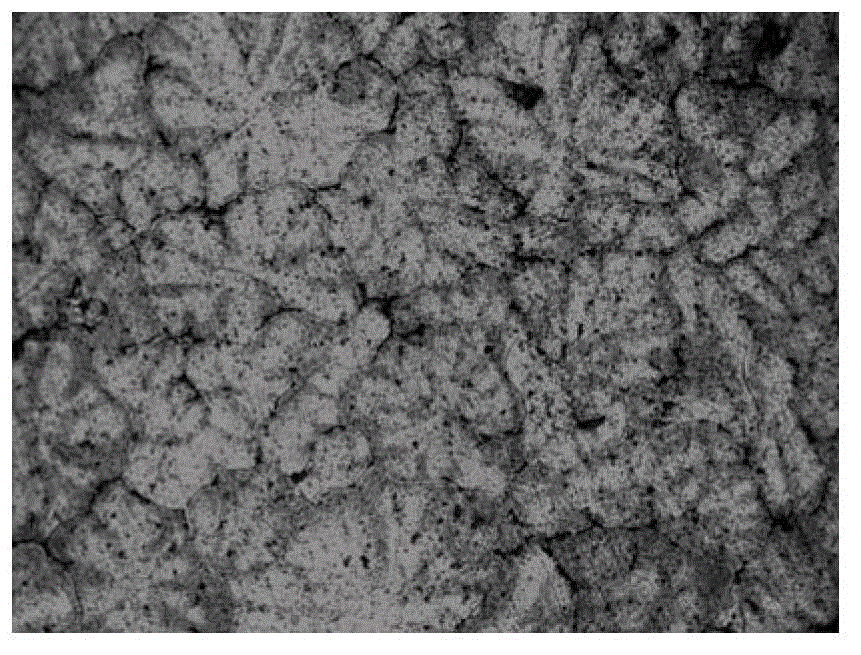

Preparation of aluminium titanium carbide intermediate alloy grain refiner in the ultrasonic field

The invention relates to the composition, structure characteristics and preparation method of a new type of aluminum-titanium-carbon master alloy grain refiner and its application to aluminum and aluminum alloy grain refinement methods and effects. The present invention proposes a composition of an aluminum-titanium-carbon master alloy refiner prepared under the action of an ultrasonic field, which is characterized in that the main component of this type of refiner only needs to include aluminum (Al) , Titanium (Ti), carbon (C) without the need for other additional components. The method for preparing an aluminum-titanium-carbon master alloy under the action of an ultrasonic field proposed by the present invention is characterized in that raw materials such as pure aluminum ingot, potassium fluorotitanate, and graphite carbon are prepared according to the pre-designed master alloy composition; The aluminum ingot is melted by internal heating, and then various raw materials are added; ultrasonic waves are added to the melt that starts to react; after the reaction is completed, the temperature is raised, kept warm, left still, and slag is removed, and then cast into ingots or continuously cast and rolled into wire rods, thereby Get the required master alloy refiner with various components and shapes.

Owner:TSINGHUA UNIV

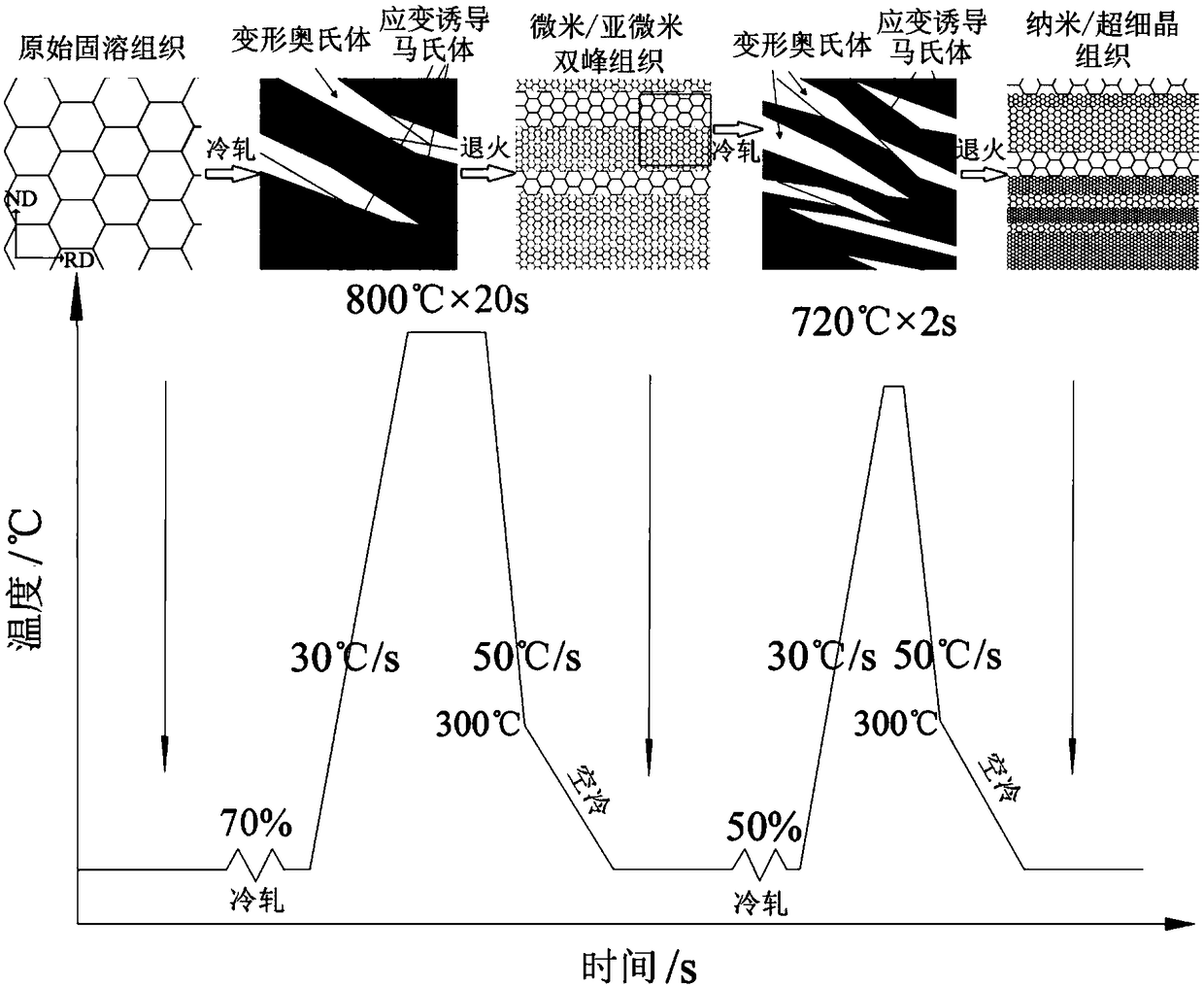

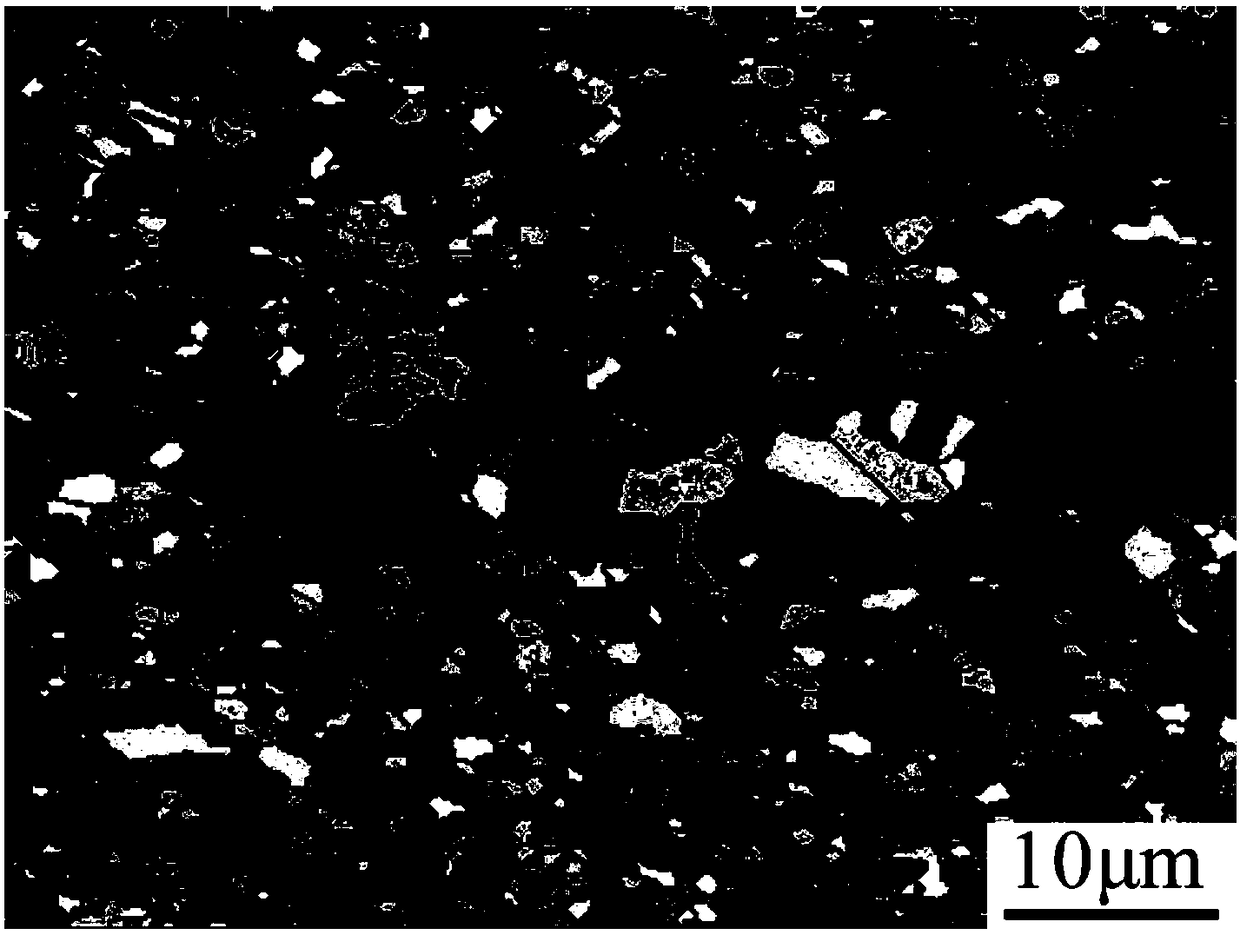

Nanometer/ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and preparation method

The invention discloses nanometer / ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and a preparation method, and belongs to the field of ultrahigh-strength plasticity alloy steel production. Raw materials comprise the following chemical components: 0.08-0.15% of C, 0.35-0.75% of Si, 7.5-10% of Mn, 0.5-0.9% of Cu, 1-1.5% of Ni, 14-16% of Cr, 0.1-0.25% of N, P notmore than 0.06%, S not more than 0.03%, and the balance of iron and inevitable impurities. After smelting by a vacuum induction furnace, a casting blank is forged, and a forging is hot rolled; twicecold rolling annealing is performed after the solid solution treatment; a nanometer / ultrafine crystal composite structure is obtained by using reversion of strain induction martensite and recrystallization of deformation austenite. The ultrahigh-strength plasticity of stainless steel is realized through fine crystal strengthening, back stress reinforcement, deformation induction twins effect and deformation induction martensite effect. The prepared stainless steel is prominent in comprehensive mechanical performance; the yield strength reaches 1150-1320 MPa, and is 3.2-4.5 times in an originalsolid solution state; the tensile strength reaches 1350-1440 MPa; the ductility still achieves a higher level of 39.2-47.3%; the cost is lower; and the preparation method is simple and feasible.

Owner:UNIV OF SCI & TECH BEIJING

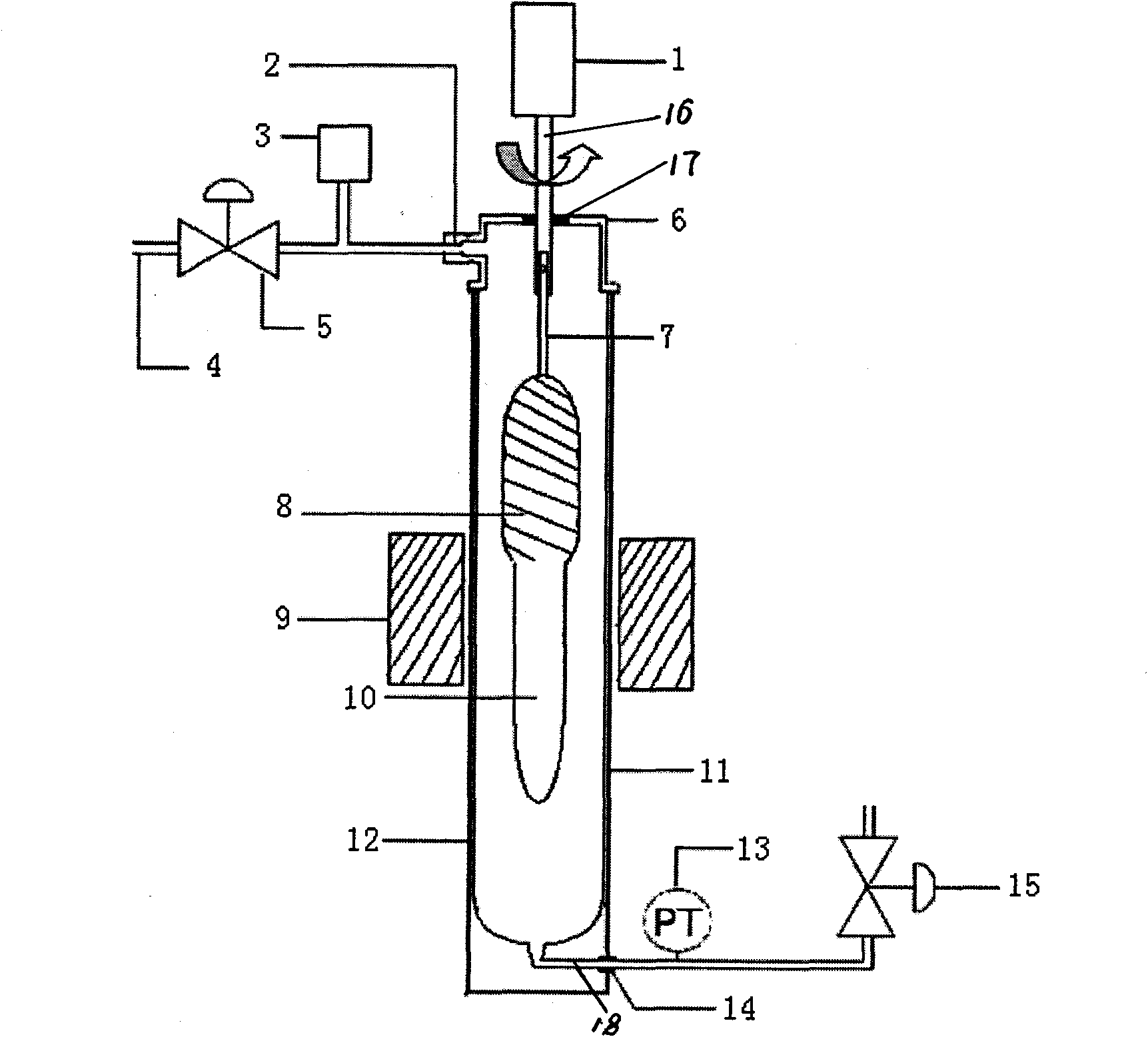

Equipment for loose body optical fiber prefabricated rod integral sintering desaeration and method thereof

The invention provides equipment for loose body optical fiber prefabricated rod integral sintering desaeration and a method thereof, which relate to a manufacture method of a single mold optical fiber prefabricated rod, in particular to equipment and method thereof for simultaneously carrying out vitrification and desaeration of the loose body optical fiber prefabricated rod. The equipment comprises a rod conveying device, a vacuum pump, a waste gas discharge stop valve, a quartz furnace core pipe cover plate, a graphite resistance furnace or an induction furnace, a carbon furnace core pipe, a quartz furnace core pipe, a pressure meter and a furnace inside gas inlet stop valve, wherein the quartz furnace core pipe is arranged in the carbon furnace core pipe, the middle part of the quartz furnace core pipe is provided with a sintering furnace, the upper part of the quartz furnace core pipe and the upper part of the carbon furnace core pipe are provided with the quartz furnace core pipe cover plate, the upper part of the quartz furnace core pipe cover plate is provided with the rod conveying device, one side of the quartz furnace core pipe cover plate is provided with a quartz furnace core pipe gas exhaust opening, a waste gas exhaust pipeline is placed into the quartz furnace core pipe gas exhaust opening, the waste gas exhaust pipeline is connected with the vacuum pump, a gas inlet pipe is arranged at the bottom of the quartz furnace core pipe, and the furnace inside gas inlet stop valve is arranged at the gas inlet end of the gas inlet pipe.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

Tellurium copper alloy material for electric power industry and method for producing the same

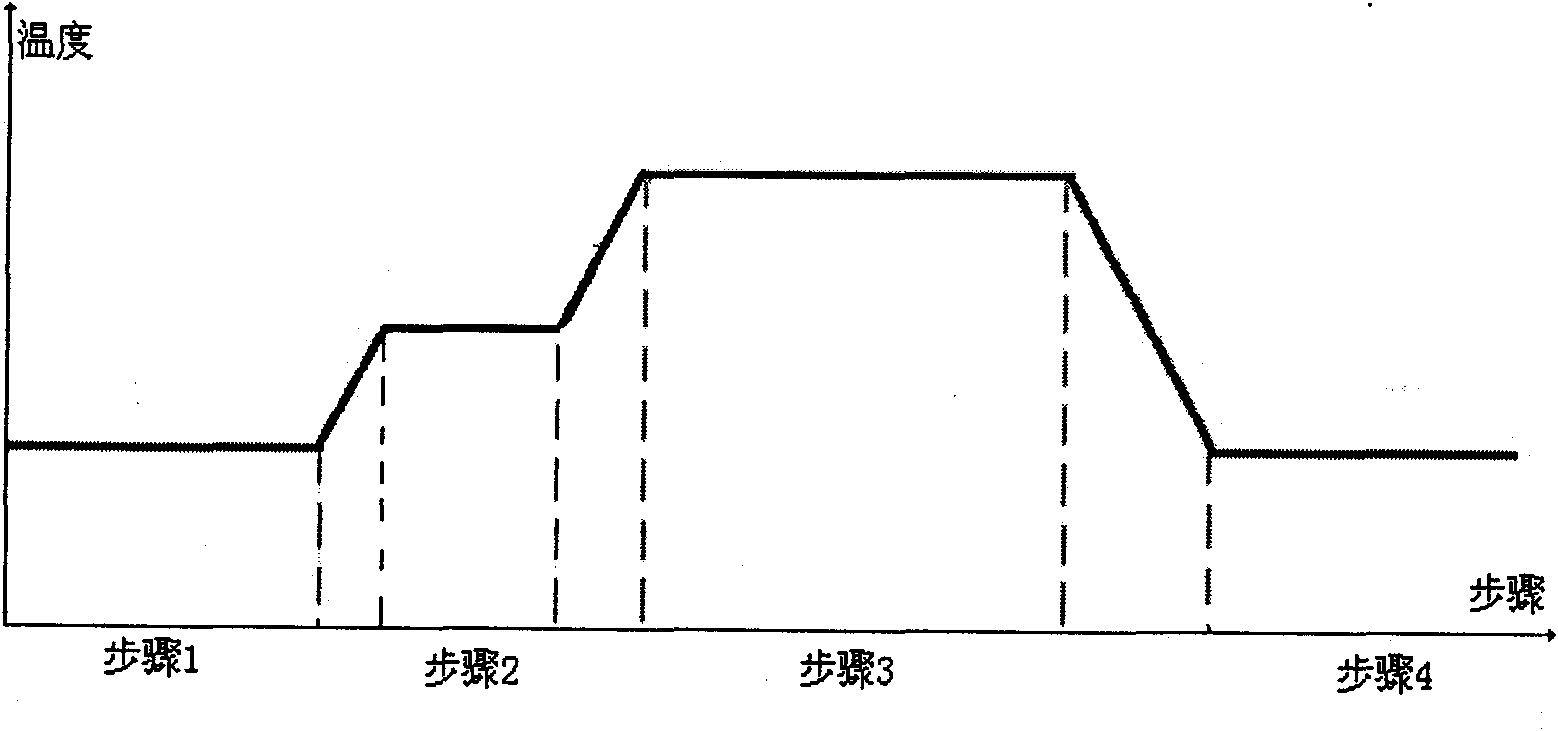

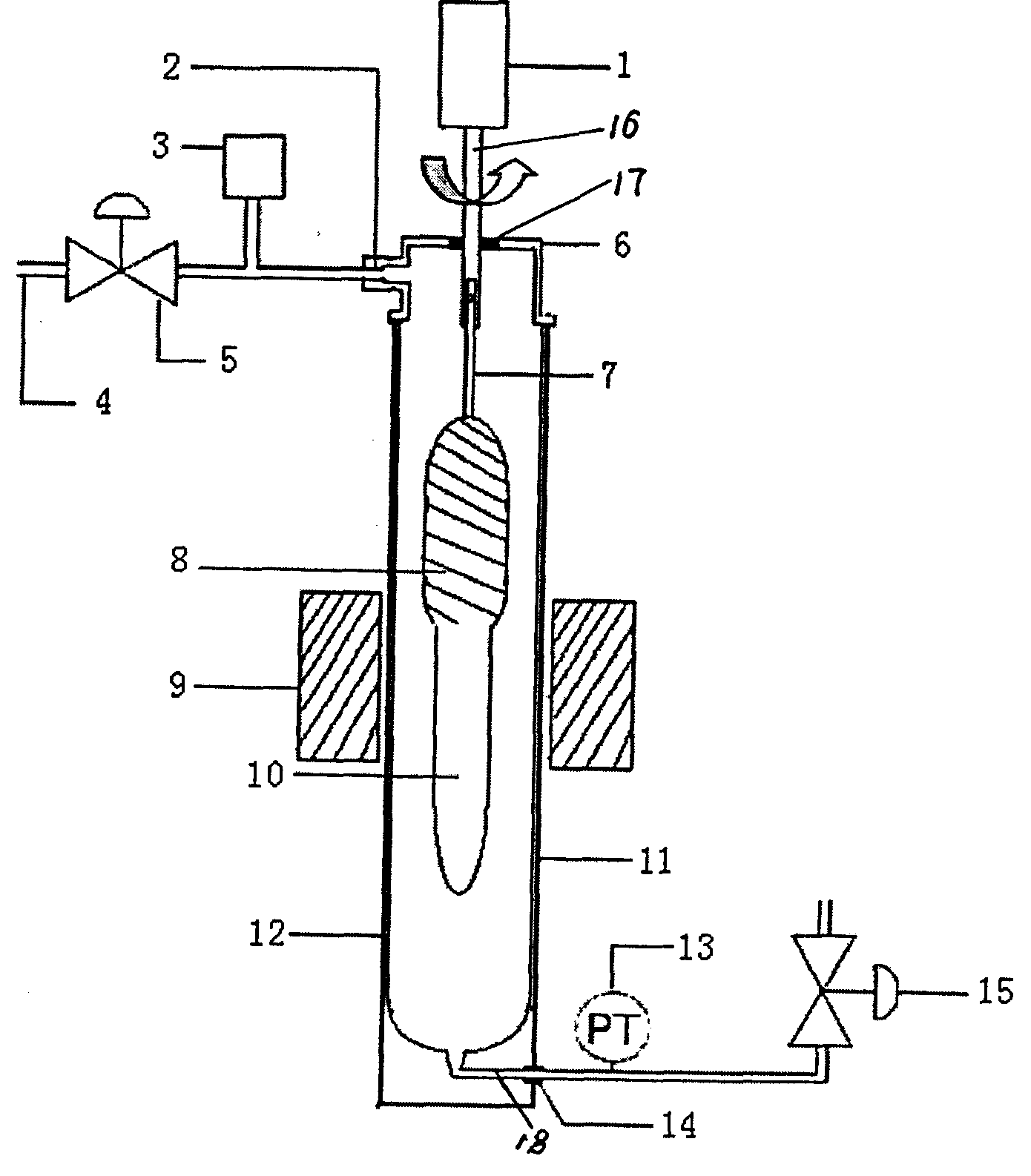

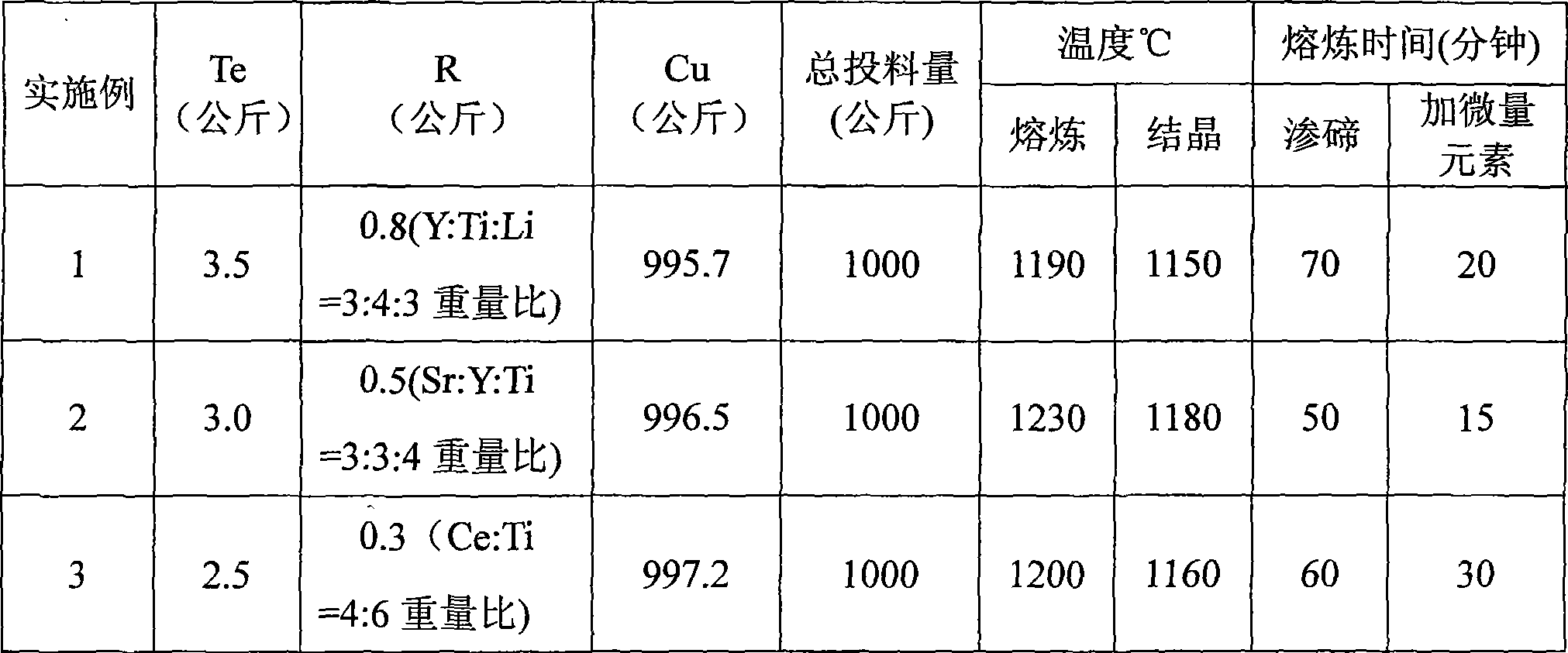

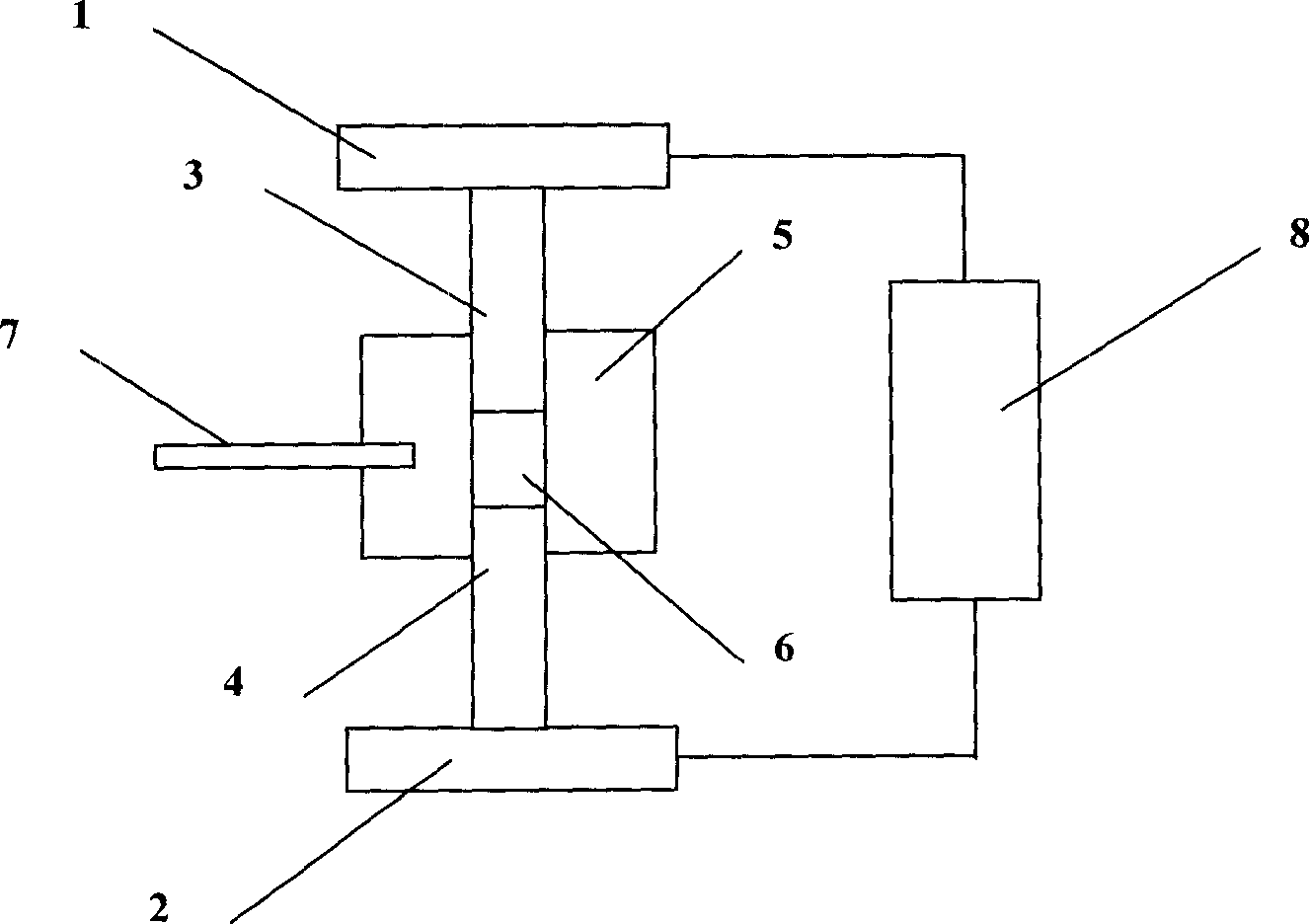

The invention discloses a tellurium copper alloy material for the electric power industry and a method for preparing the same. The method is characterized by comprising the following steps: gradually adding 99.55 to 99.89 weight percent of industrial pure copper after a molten channel of a power-frequency induction furnace is melted; raising the temperature of a copper liquid to between 1,190 and 1,230 DEG C after solid state copper is melted down, and covering the copper liquid with charcoal to keep the temperature; enwrapping 0.1 to 0.4 weight percent of pure tellurium, and pressing the pure tellurium to the bottom of a power-frequency furnace close to a molten channel opening at a furnace temperature of between 1,190 and 1,230 DEG C; adding 0.01 to 0.05 weight percent of microelement into a tellurium copper alloy liquid after 50 to 80 minutes; finishing the smelting of the tellurium copper alloy liquid after 15 to 30 minutes; reducing the furnace temperature to between 1,150 and 1,180 DEG C; pouring the alloy liquid into a graphite crystallizer for crystallization; towing a cast ingot by using the prior method and sawing the cast ingot into short cast ingots with specific lengths; sampling the short cast ingots to test the content; and packaging the short cast ingots into finished products.

Owner:SICHUAN XINJU MINERAL RESOURCE DEV CO LTD

Method for preparing rare-earth iron series biphase nanocrystalline composite permanent-magnet material

InactiveCN1737955AHigh densityImprove magnetismInorganic material magnetismRare earthInduction furnace

The invention belongs to the field of magnetic material. At present much of the permanent magnet material is thin belt or powder, and since the custom sintering process for preparing block material will make the crystal grow, the magnetic property drops significantly. The steps of said invention comprises: the alloy whose component is RxFeyBz, in which R stands for rare-earth Nd or Pr element and the content of x is 4-10, y is 78-88, z is 6-18, is smelted for mother alloy in induction furnace in vacuum; Then preparing the quenched alloy in amorphous, nanometer crystalline state or amorphous-nanometer mixed state by smelting quick-quench method; the linear speed of smelting quick-quench is arranged between 10-50 m / s; under the protection of inertance gas, abrading the alloy into powder whose coarseness is lower than 80 items; encasing the powder into module to precompression and shaping, while range of pressure is 10-1000MPa; carrying the process of discharging plasma sintering, while the sintering temperature is 550Deg C.-700Deg C., the pressure is 30-1000MPa, the elevated temperature speed is 50-500Deg C. / min, the time of heat preservation is 0-10 min, the elevated temperature speed is 50-200Deg C. / min, Said invention can realize high magnetic property material with high degree of compactness, whose crystal grain is smaller than 100 nanometers, and it can be used in high temperature.

Owner:BEIJING UNIV OF TECH

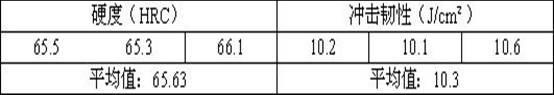

Hypoeutectic high-chromium white cast iron and preparation method thereof

The invention discloses a hypoeutectic high-chromium white cast iron, which comprises the following components calculated according to mass fraction: 1.9-2.4 of C, 16-22 of Cr, less than or equal to 0.8 of Si, less than or equal to 0.7 of Mn, 0.5-1.0 of Ni, 1.0-1.7 of Mo, less than 0.04 of S, less than 0.06 of P, 0.05-0.4 of RE, 0.5-1.0 of Cu, 0.05-0.15 of Zn, 0.1-0.3 of V and the balance of Fe. The preparation method comprises the following steps of: defining the mixture ratio according to the requirement of mass fraction and mixing; mixing scrap steel and pig iron in an intermediate-frequency induction furnace and heating the mixture to be melt; after molten iron is smelt, sequentially adding high carbon ferro-chrome, manganese iron, nickel and molybdenum and smelting again; feeding a zinc ingot with small granularity and rare earth or vanadium at the bottom of a casting ladle, covering a steel sheet or scrap iron and compacting; pouring the molten iron into the casting ladle and carrying out metamorphism and deslagging treatment; casting the molten iron and forming to obtain a hypoeutectic high-chromium white cast iron piece; then placing the hypoeutectic high-chromium white cast iron piece into a heat treatment furnace for thermally treating; and quenching and tempering to obtain a hypoeutectic high-chromium white cast iron material with the hardness of 60-66HRC (Hardness Rockwell) and the impact ductility of 10-14J / cm<2>. The hypoeutectic high-chromium white cast iron has the advantages of low cost, high wear resistance and reliable use safety. In addition, the preparation method of the hypoeutectic high-chromium white cast iron is simpler, and is easy in operation and strong in practicability.

Owner:云南化铸科技有限责任公司

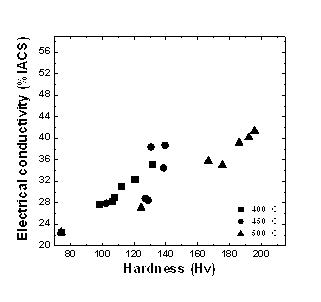

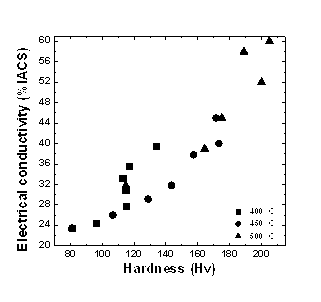

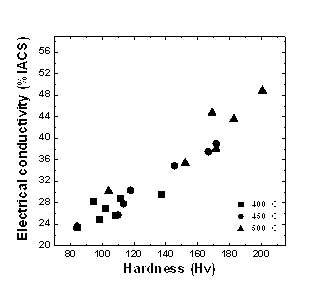

Cu-Ni-Si-based alloy and preparation method thereof

The invention belongs to the technical field of copper alloy material, and discloses Cu-Ni-Si-based alloy with high strength and high conductivity, and a preparation method thereof. The Cu-Ni-Si-based alloy is characterized in that the Cu-Ni-Si-V alloy comprises the following components in weight percent: 95.5-97.5% of Cu, 2.0-3.0% of Ni, 0.5-1.2% of Si, and 0-0.3% of V; and the method comprises specific steps as follows: smelting pure copper, pure silicon, pure nickel and pure vanadium in an induction furnace according to the proportion, casting in a metal die to obtain a blank, and performing ageing and solution treatment for the blank after hot rolling and cold rolling deformation treatment. As shown by experimental results, the added alloy V has the remarkable grain refinement function on the CU-Ni-Si alloy; and appropriately-added V (0.086 weight percent) can significantly improve the conductivity of the alloy, at the same time, the combination properties of the alloy are improved to the conductivity of 60% IACS and the hardness number of 205 Hv from the conductivity of 41.4% IACS and the hardness number of 195.7 Hv only with slight reduction in hardness; and the alloy with 0.086 weight percent V can separate out second phase with a volume fraction twice of that of the alloy before adding V.

Owner:TAIYUAN UNIV OF TECH

Corrosion-resistance iron-based austenite oil well pipe and manufacturing method thereof

InactiveCN104962836AMeet the slow strain test requirementsAchieve smoothSolid solutionElectro-slag remelting

The invention discloses a corrosion-resistance iron-based austenite oil well pipe and a manufacturing method thereof. The main chemical components of the oil well pipe include C larger than 0 and smaller than or equal to 0.03%, Si larger than 0 and smaller than or equal to 1.00%, Mn larger than 0 and smaller than or equal to 2.50%, P smaller than or equal to 0.03%, S smaller than or equal to 0.03%, 20.0%-28.0% of Cr, 20.0%-38.0% of Ni, 3.0%-5.0% of Mo and 0.50%-2.00% of Cu. The manufacturing method includes the first step of smelting; the second step of billet pouring; the third step of electroslag remelting; the fourth step of homogenizing annealing; the fifth step of billet forging; the sixth step of pipe billet preparing; the seventhly step of hot extruding, wherein a seamless steel pipe is formed through pipe billet preheating, power frequency induction furnace heating, pipe billet broaching, secondary induction heating and extruding; the eighth step of solid solution treating; and the ninth step of conducting of a deformation strengthening mode in cold drawing, wherein the percentage reduction of area is controlled within 20-40%, and the oil well pipe is manufactured. According to the corrosion-resistance iron-based austenite oil well pipe and the manufacturing method thereof, the wall thickness of the manufactured oil well pipe ranges from 15 mm to 40 mm, the yield strength is 760 MPa or higher, the tensile strength is 793 MPa or higher, the impact energy is 100 J or higher, the corrosion resistance is good, and the requirement for strictest and slow-strain tests is met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

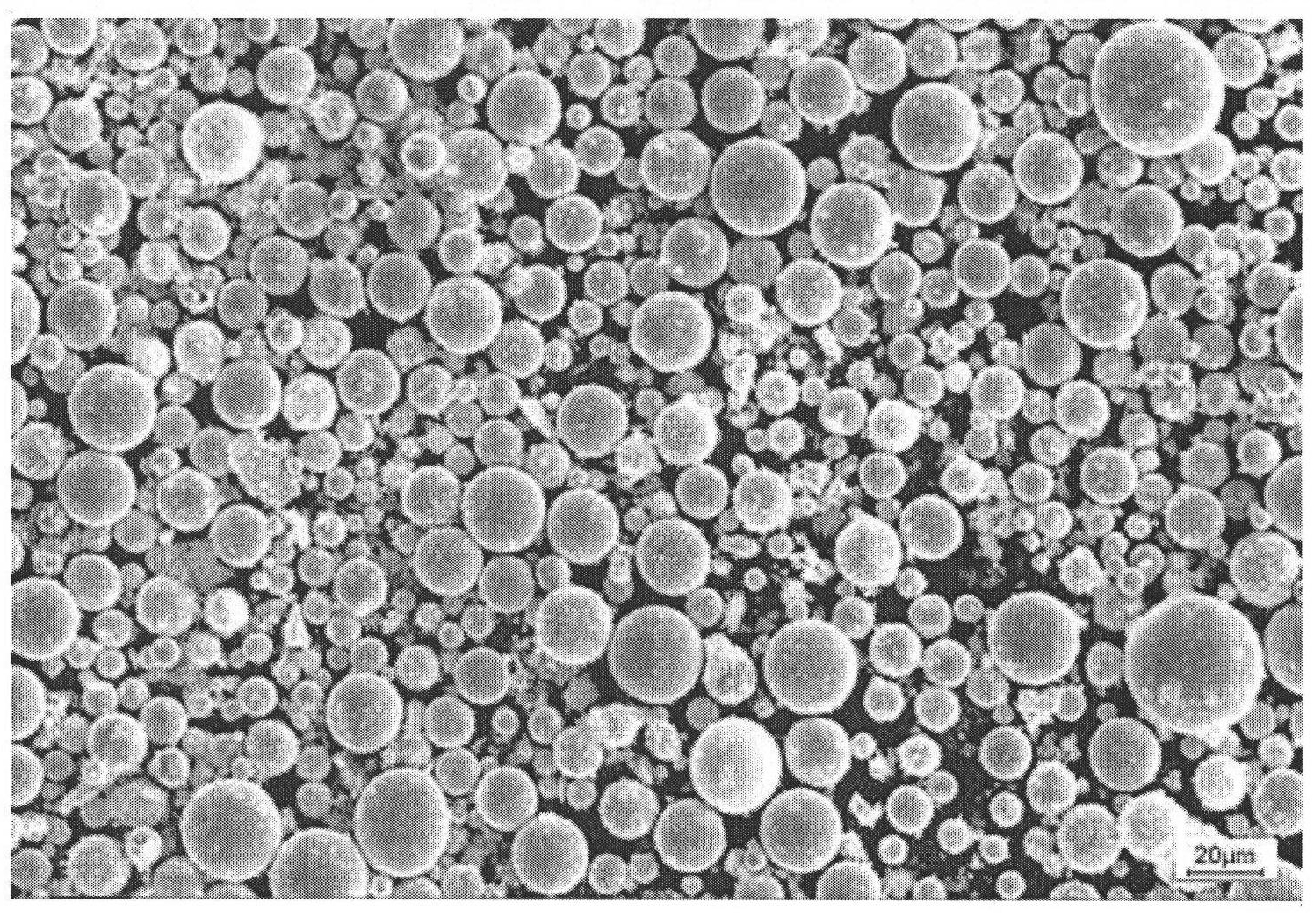

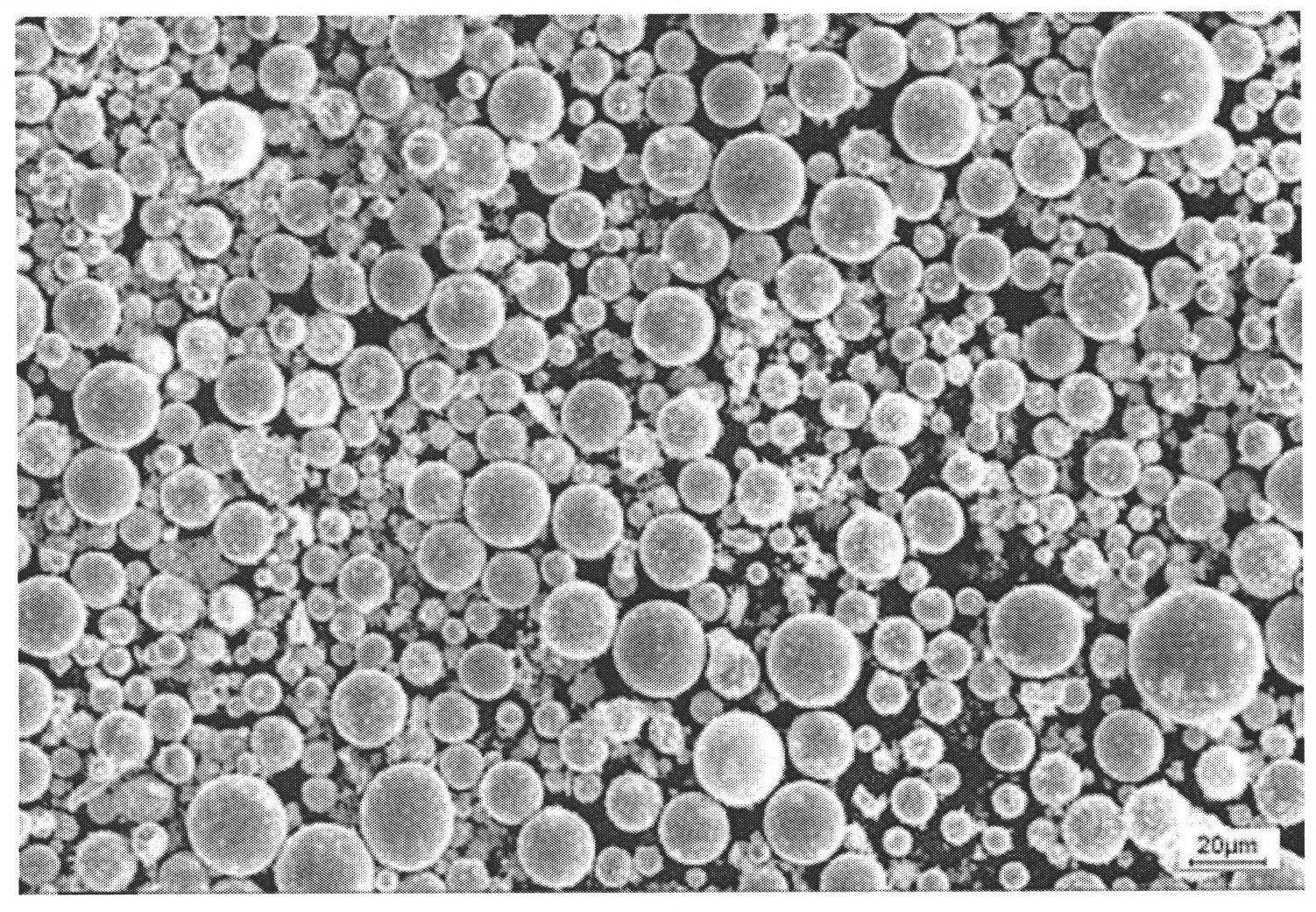

Method for largely preparing superfine spherical titanium aluminium-based alloyed powder

The invention provides a method for largely preparing superfine spherical titanium aluminium-based alloyed powder, which belongs to the technical field of powder preparation. The method comprises the following steps: smelting high-purity aluminium and titanium sponge as main raw materials and Al-Nb intermediate alloy, Ti-B alloy, tungsten powder and high-purity yttrium scraps as auxiliary raw materials into an alloy cast ingot in a vacuum consumable electrode arc skull furnace or a vacuum induction furnace; then carrying out coarse crushing and vortex airflow milling to prepare irregular superfine alloy powder; and finally carrying out plasma spheroidization of radio frequency (RF) and the like to prepare the superfine spherical titanium aluminium-based alloyed powder. The prepared alloy powder has the advantages of high purity, fine particle size, narrow particle size distribution, good uniformity, high sphericity, good flowability and the like and can meet the demands of the technical industrial production of injection forming, gel injection molding forming, thermal spraying and the like.

Owner:UNIV OF SCI & TECH BEIJING

Cu-Cr-Zr alloy preparation technology for contact wire

The invention discloses a process for preparing Cu-Cr-Zr alloys applicable to contact lines. The process comprises the following steps that alloys comprising 0.30 to 0.50 percent of Cu, 0.10 to 0.15 percent of Cr, 0.01 to 0.02 percent of Zr and Si are melt in a vacuum induction furnace, wherein alloy elements, namely Cr, Zr and Si, are added by master alloys; fine casting-state crystal grains and oversaturated matrix tissues having secondary dendritic crystal spaces are obtained by controlling solidification velocity and cooling velocity; rolling in fit, drawing deformation and annealing thermal treatment to the fine casting-state crystal grains and oversaturated matrix tissues are carried out so as to control deformation degrees and parameters for the thermal treatment; and the strain-hardening effect and the precipitation strengthening effect are organically combined. Therefore, the alloys have the advantages of excellent tensile strength, electrical conductivity and high-temperature resistant softening capacity and lower cost under the conditions of simplified process and the simpler apparatus and components, and are applicable to industrial production.

Owner:邢台鑫晖铜业特种线材有限公司 +3

Production technology of aluminum alloy sections used for brake pad

The invention discloses a production technology of aluminum alloy sections used for a brake pad, and belongs to the technical field of metal mechanical machining. The machining of vehicle bumper aluminum alloy sections is finished through the following processes of: preparing materials, smelting, stirring with a permanent magnet, sampling, adjusting ingredients and temperature, turning down, refining (primary purification), standing, adding Al-Ti-B silk in an on-line manner, performing on-line degassing and deslagging (secondary purification), performing two-stage filtering, performing hot top casting at the same level, homogenizing an ingot, mechanically machining the ingot, heating the ingot with an induction furnace, extruding, performing on-line quenching, stretching and straightening, aging, detecting the structure and performance of the sections and carrying out delivery. The aluminum alloy sections machined by the invention is good in abrasion resistance and corrosion resistance, stale in dimension, resistant to high temperature, high in strength, good in fatigue resistance performance and long in service life.

Owner:龙口市丛林铝材有限公司

Method for preparing SmCo7 permanent-magnetic alloy with particle size smaller than 20nm

The invention discloses a preparing method of SmCo7 permanent magnet alloy whose grain size is smaller than 20nm, the RE, Co, Fe, Cu, T whose fineness is bigger than 99. 9% is mixed together just as proportion of RE(CobalFexCuyTw)z and placed in the induction furnace, the alloy ingoting which is after the fusion is cased into the quartz tube equipped with nozzle at the bottom to be melt, ejected to the surface of copper roller which is tail-wagging via the nozzle at the bottom of the quartz tube to form amorphous state alloy belt, the film belt obtained is airproofed in the quartz tube, then it is placed to the microwave welding furnace for crystal process, the temperature and time range of crystal process in the microwave welding furnace is 400-900deg.C and 10min-180min, then it is placed into water for cooling. The craftwork of the invention is simple, the cost is low, the grain size of nanometer crystal magnet which includes SmCo7 main phase is about 20nm, and it is lower than grain size obtained by general heat treatment method, the exchange coupled function between grains is increased greatly.

Owner:CENT SOUTH UNIV

Preparation method of overlength Cu-Cr-Zr alloyed contact line

ActiveCN101531149AAvoid early precipitationAvoid direct precipitation strengthening effectsTrolley linesContact lineInduction furnace

The invention discloses a preparation method of overlength Cu-Cr-Zr alloyed contact line. The smelting content in an induction furnace is Cu-(0.30-0.60) %Cr-(0.10-0.15) %Zr-(0.01-0.02) %Si alloy. By processes of continuous casting, extrusion, heat treatment, cold drawing and rolling, a contact line with a nominal area of 110-150mm<2> is prepared, under the conditions that processes are simplified and equipment and alloying components are fairly simple, the contact line with a length of simple root of the finished product being up to 1000-1500m has fine tensile strength, electrical conductivity and high temperature softening resistance.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +2

High-strength hot-corrosion-resistant Ni-based single crystal superalloy and preparation method

InactiveCN103966671AImprove high temperature mechanical propertiesExcellent hot corrosion resistancePolycrystalline material growthFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the field of single crystal superalloys, particularly to a high-strength hot-corrosion-resistant Ni-based single crystal superalloy and a preparation method, and is mainly applied to high-temperature components applied to various marine environments and turbine high-temperature components of ground industrial gas turbines. The superalloy comprises chemical components in percentage by weight as follows: 11-15% of Cr, 5-9% of Co, 0.5-2.0% of Mo, 3.0-5.0% of W, 4.5-7.0% of Ta, 3.5-5.6% of Al, 2.3-3.7% of Ti and the balance of Ni. A vacuum induction furnace is used for smelting, a mother alloy is cast firstly, and then the high-strength hot-corrosion-resistant single crystal superalloy is prepared according to a single crystal growth technology and a heat treatment system. The Cr and refractory metallic elements with higher content are selected, but the content of the Ti element is reduced. Meanwhile, the crystal boundary is eliminated through a single crystal technology, so that the hot corrosion resistance, the high-temperature mechanical property and the structure stability of the alloy are further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

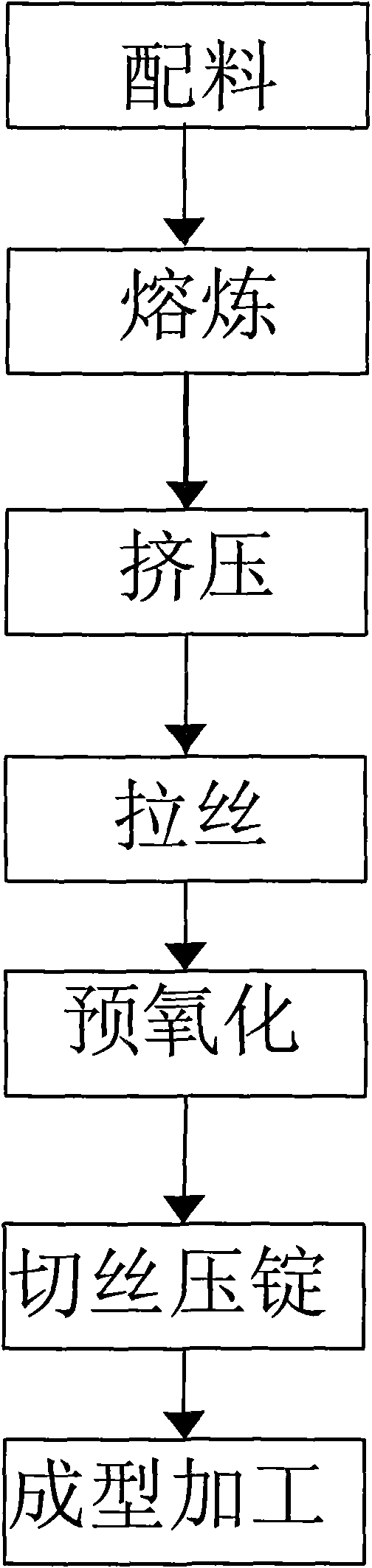

High-performance silver cadmium oxide material and manufacturing method thereof

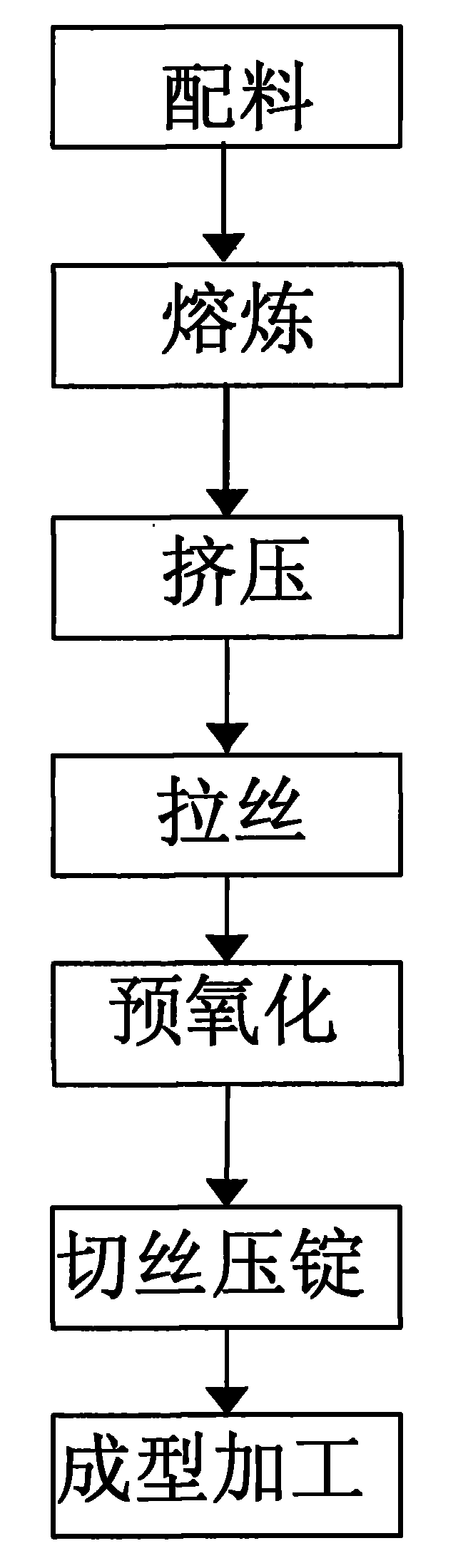

The invention relates to a high-performance silver cadmium oxide material and a manufacturing method thereof, which are characterized in that the silver cadmium oxide material comprises the following components: 85 to 97 percent of silver, 2 to 15 percent of cadmium, 0.01 to 0.5 percent of nickel, 0.01 to 1 percent of tin and 0.01 to 0.5 percent of rear earth mixture. The manufacturing method of the high-performance silver cadmium oxide material is characterized in that: a given quantity of silver, cadmium, nickel, tin and rare earth mixture are measured to be arranged inside a middle-frequency induction furnace to be smelted and cast, the cast ingot is extruded by an extruding machine to be thick wires, the thick wires are stretched by a wire-drawing die to be thin wires, the thin wires are pre-oxidized by an internal oxidization furnace, then the thin wires are cut and preformed and finally is processed and formed. The anti-oxidization performance, electric-arc burning loss resistance and the abrasion resistance of the silver cadmium oxide material are improved, and the service life is prolonged, so the high-performance silver cadmium oxide material can be applied to different working environments, has low production cost, simple manufacturing method and low requirements on the device and the production.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

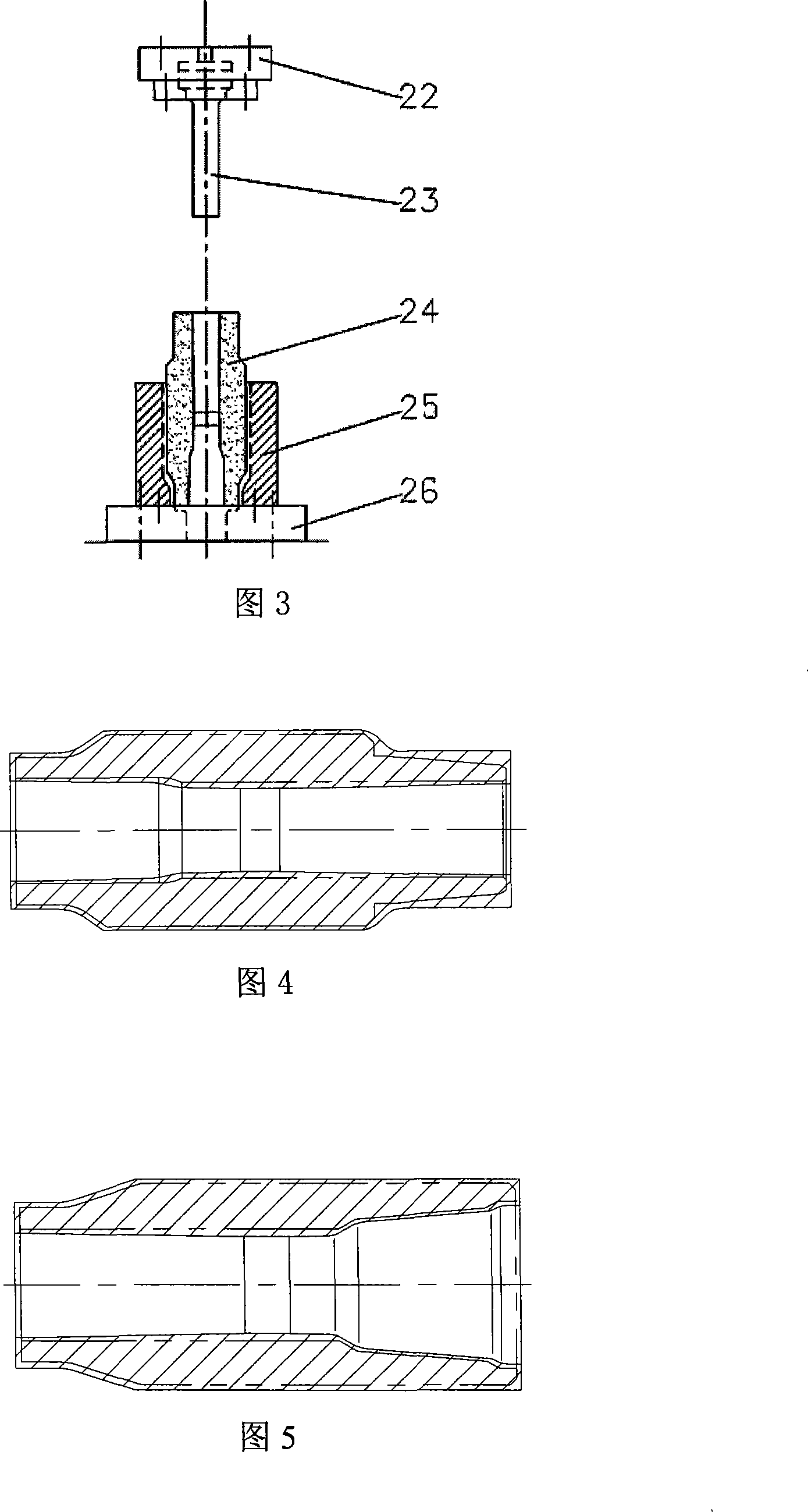

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

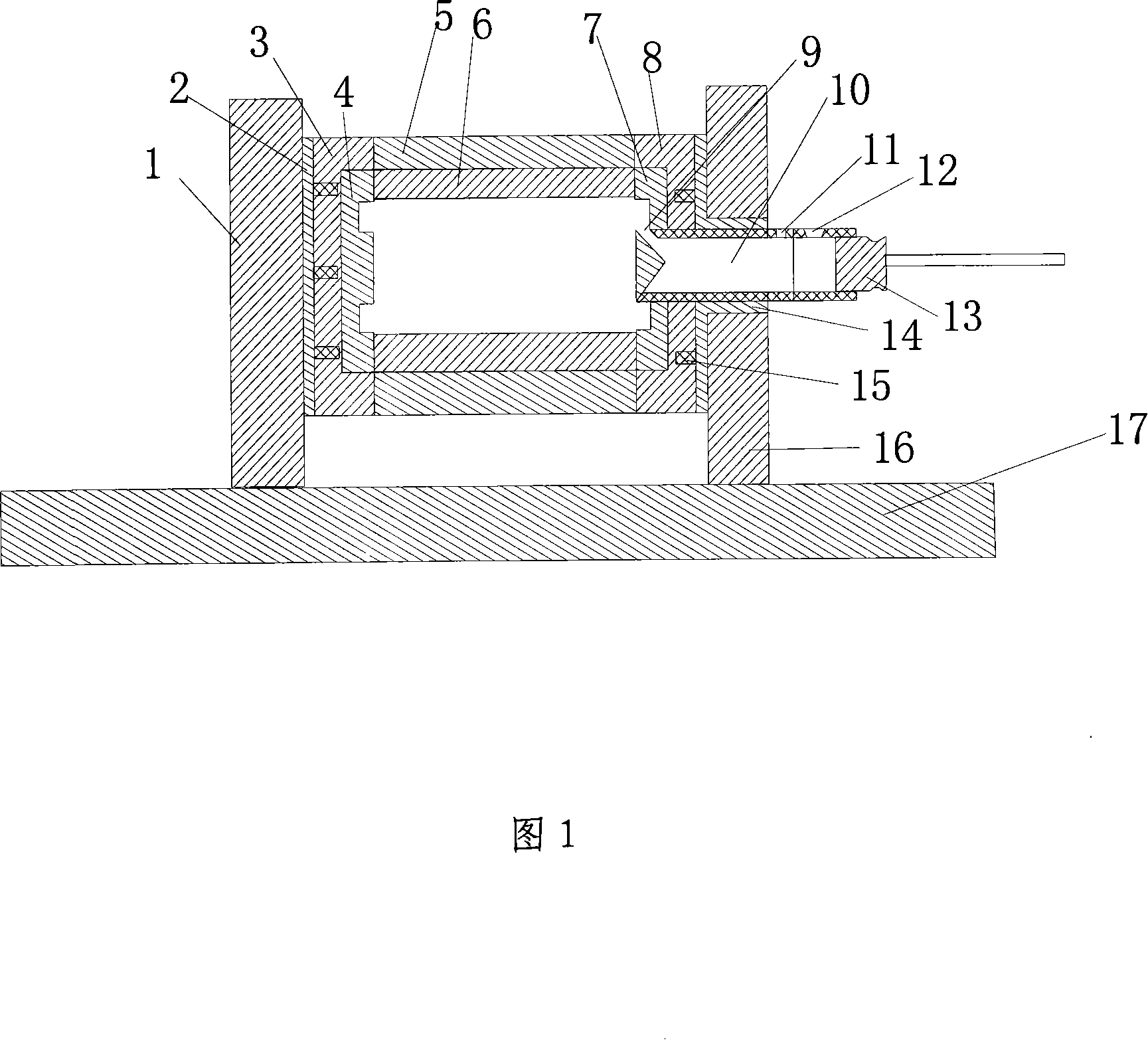

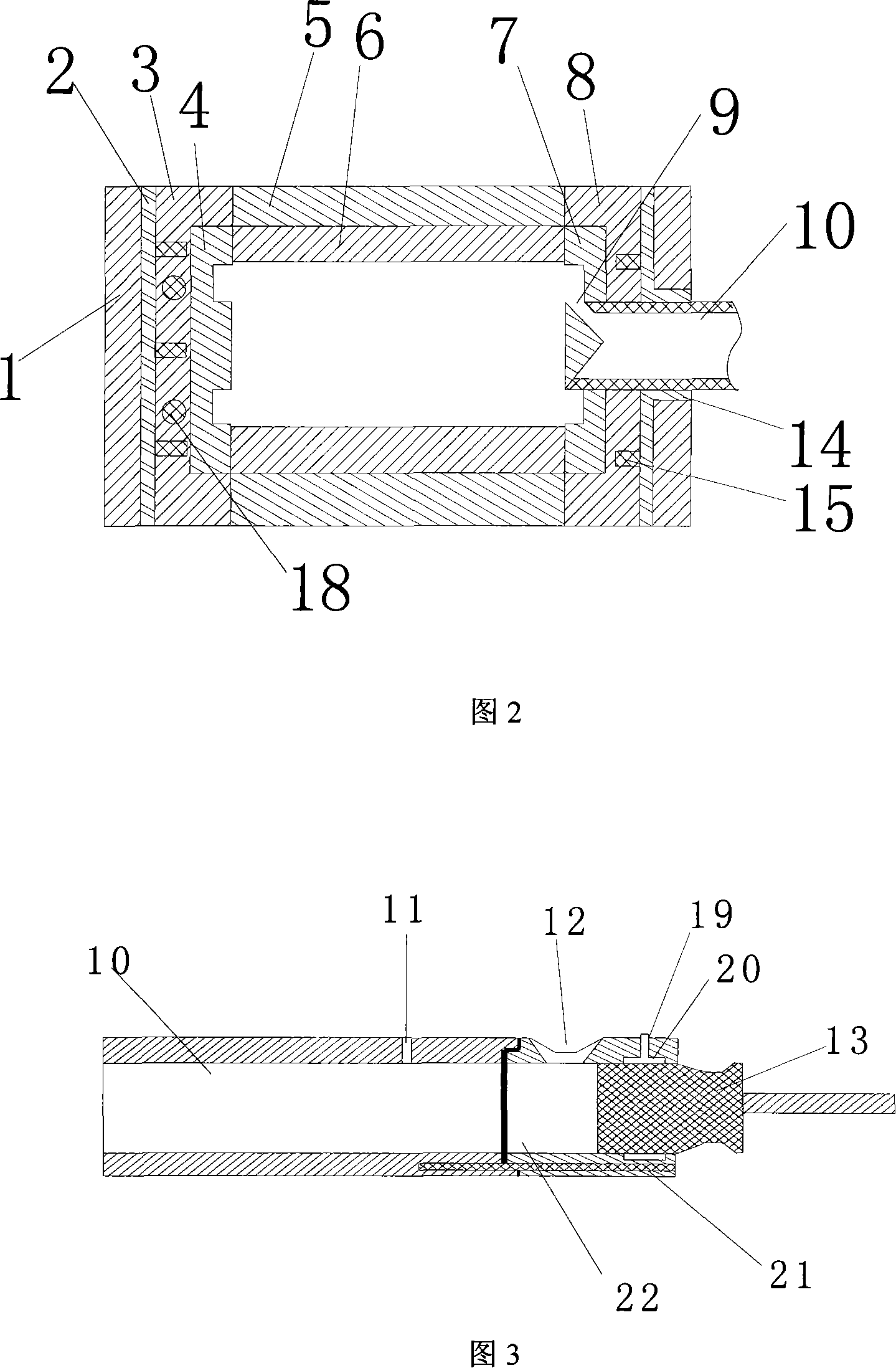

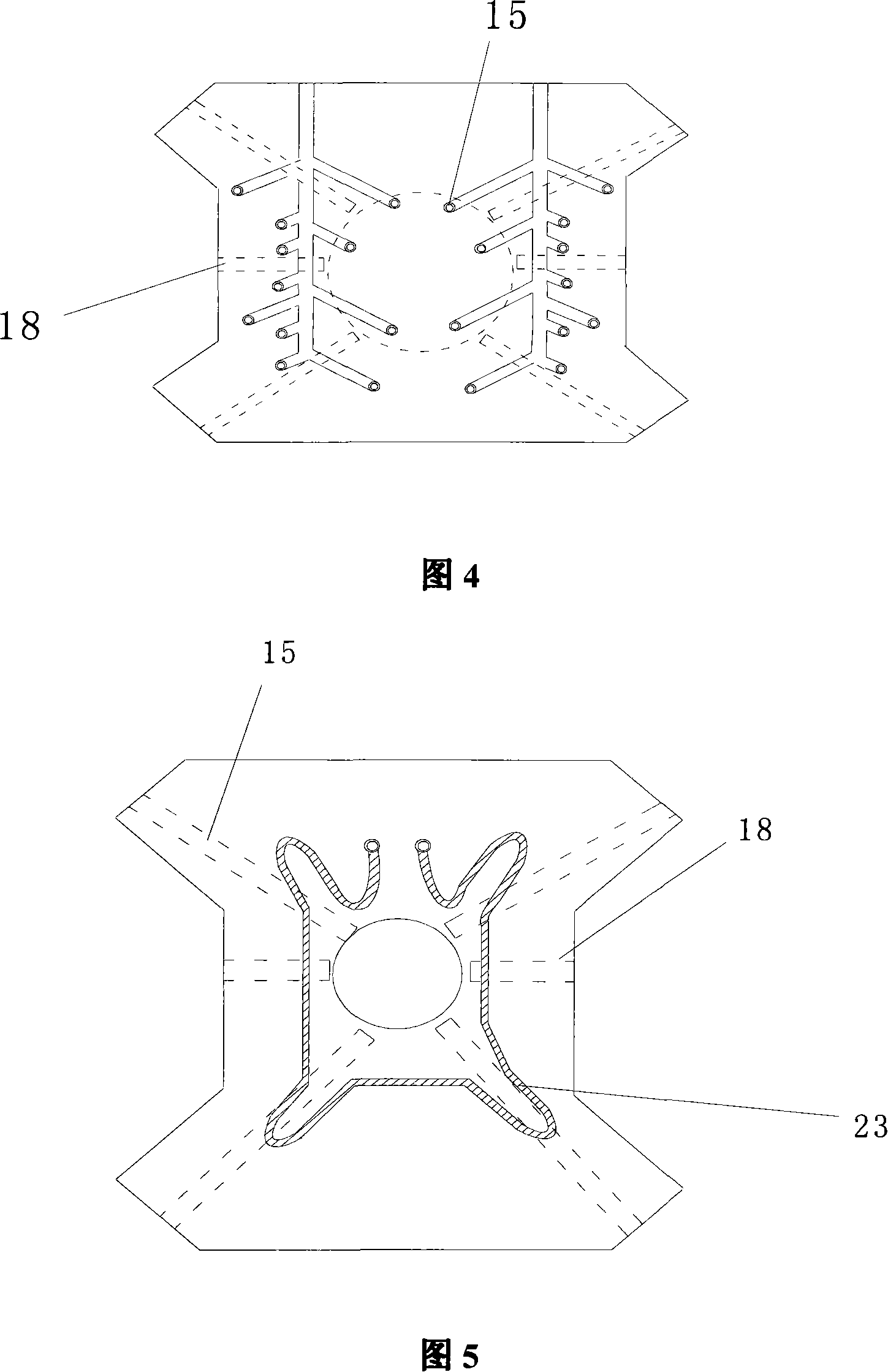

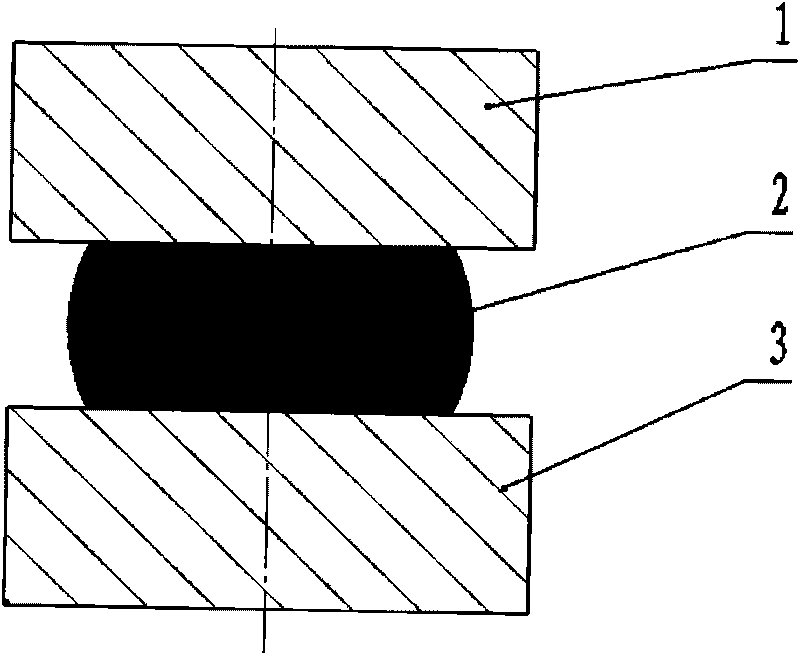

Die-casting method of induction motor copper cage rotor and die casting device thereof

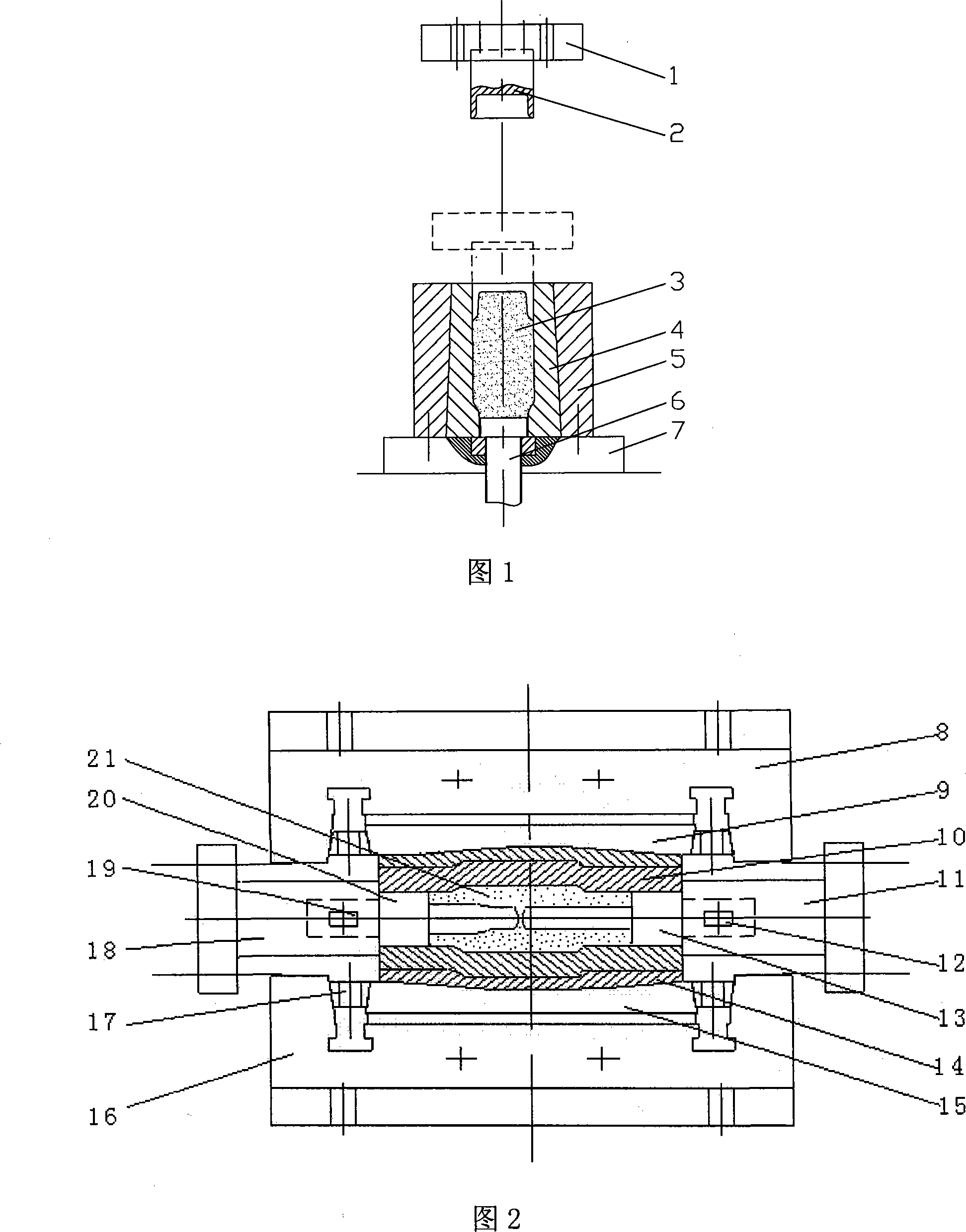

ActiveCN101108416AReduce manufacturing costReasonable workmanshipGearingCylindersMiddle frequencyNon-ferrous extractive metallurgy

The invention relates to a casting method and casting machine of the induction motor cooper squirrel-cage rotor, which is suitable for the casting of pure copper and high copper content alloy. The invention belongs to nonferrous metal smelting and rolling process technology filed. The casting method comprises module pre-process, copper smelting, liquid casting and forming and quench water cooling. The casting method adopts a casting device which is composed of a casting machine and a smelting furnace, wherein, the smelting furnace comprises an integrated pot and middle frequency induction furnace, the heating efficiency of the middle frequency induction furnace is 0 to 100KW; the casting module comprises a group connection which is connected by a plurality of embedded lump. The invention has reasonable technics and equipment, the product has no defects of breakage on casting piece and surface, poor filling and mold sticking, the shaking present value complies with the R degree provision in IEC34-14(1994), which has the advantages of improving by one degree comparing with the N degree stipulated in Y series motor technology condition.

Owner:云南铜业压铸科技有限公司

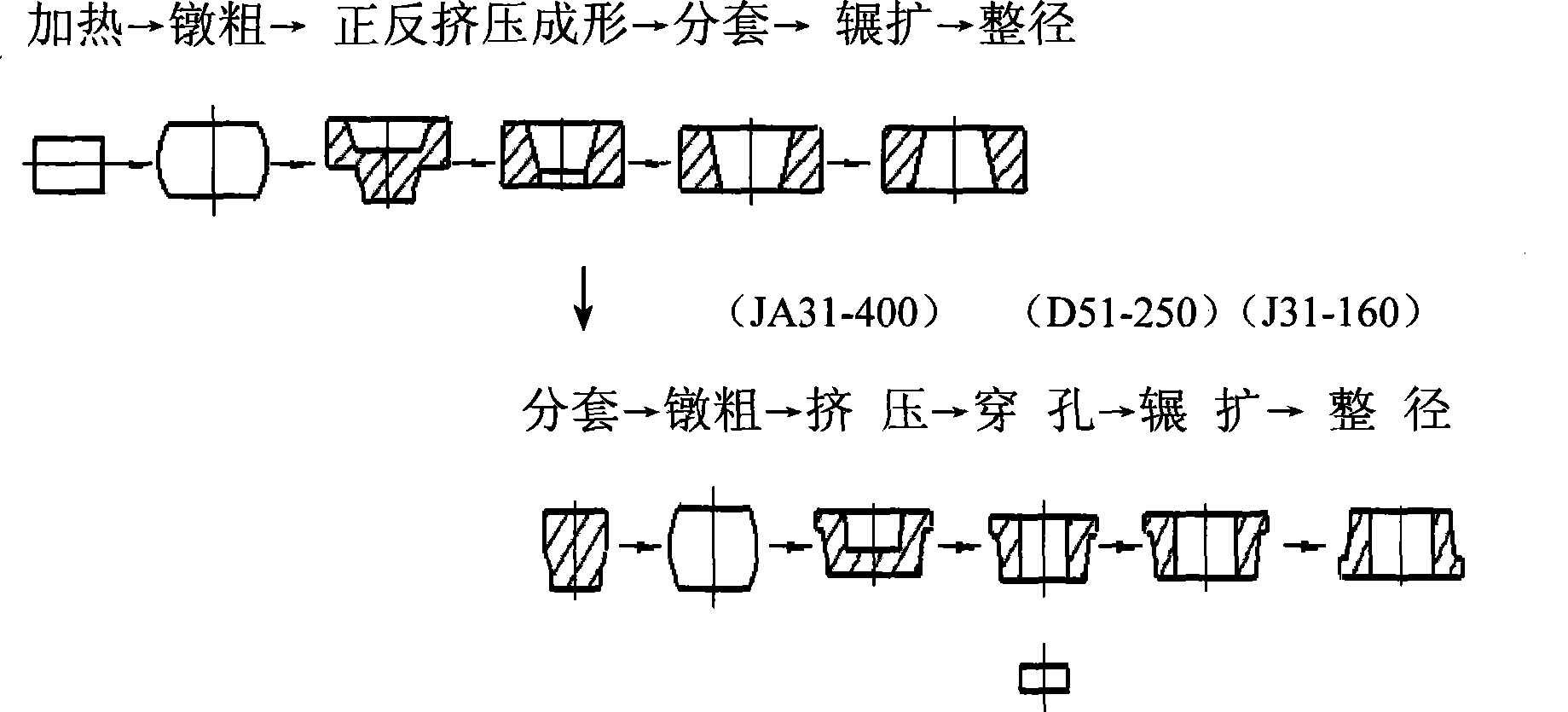

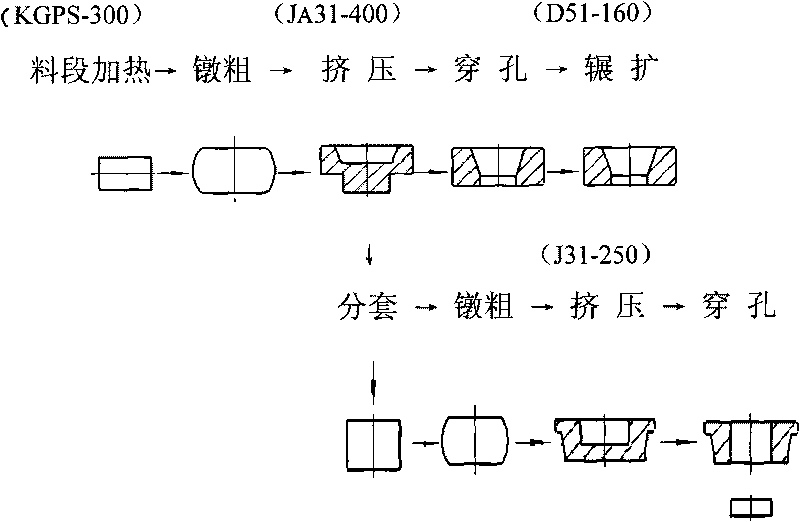

Composite forging inner/outer same set process of small-medium size British system conical bearing sleeved column

InactiveCN101758368AIncrease profitIncrease productivityExtrusion diesMetal rollingMedium frequencyInduction furnace

The invention relates to a composite forging inner / outer same set process of small-medium size British system conical bearing sleeved columns, belonging to the technical field of the forging of British system conical bearing rings, and mainly solving the problems that a traditional British system conical ring forging process cannot realize the simultaneous production of an inner ring and an outer ring and the charging cost in the heterogenic set forging production is increased. The composite forging inner / outer same set process is characterized by comprising the following steps of: (1) heating a GCr15 steel charge segment with the weight of 0.320-1.200kg and the diameter of phi35-phi50 on a medium frequency induction furnace to 1050 DEG C, and then placing the heated charge segment on a pressure machine for upsetting, combined extrusion for forming, and sleeve separating to separate the heated charge segment into an outer bearing sleeve blank and an inner bearing sleeve blank; (2) carrying out ring rolling on the outer sleeve blank on a broking machine, and directly cooling or cooling into an outer bearing sleeve forged piece after finishing diameter on the pressure machine; and (3) placing the inner sleeve blank on the pressure machine for upsetting, extruding, and perforating, cooling and then forming a same set British system conical bearing inner sleeve forge piece. The invention is mainly applied to the manufacture of the forged piece of the same type of medium and small size British system conical bearing inner / outer rings.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

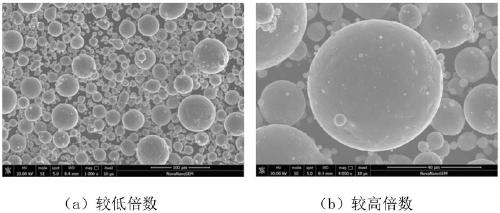

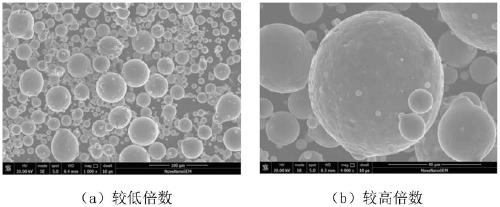

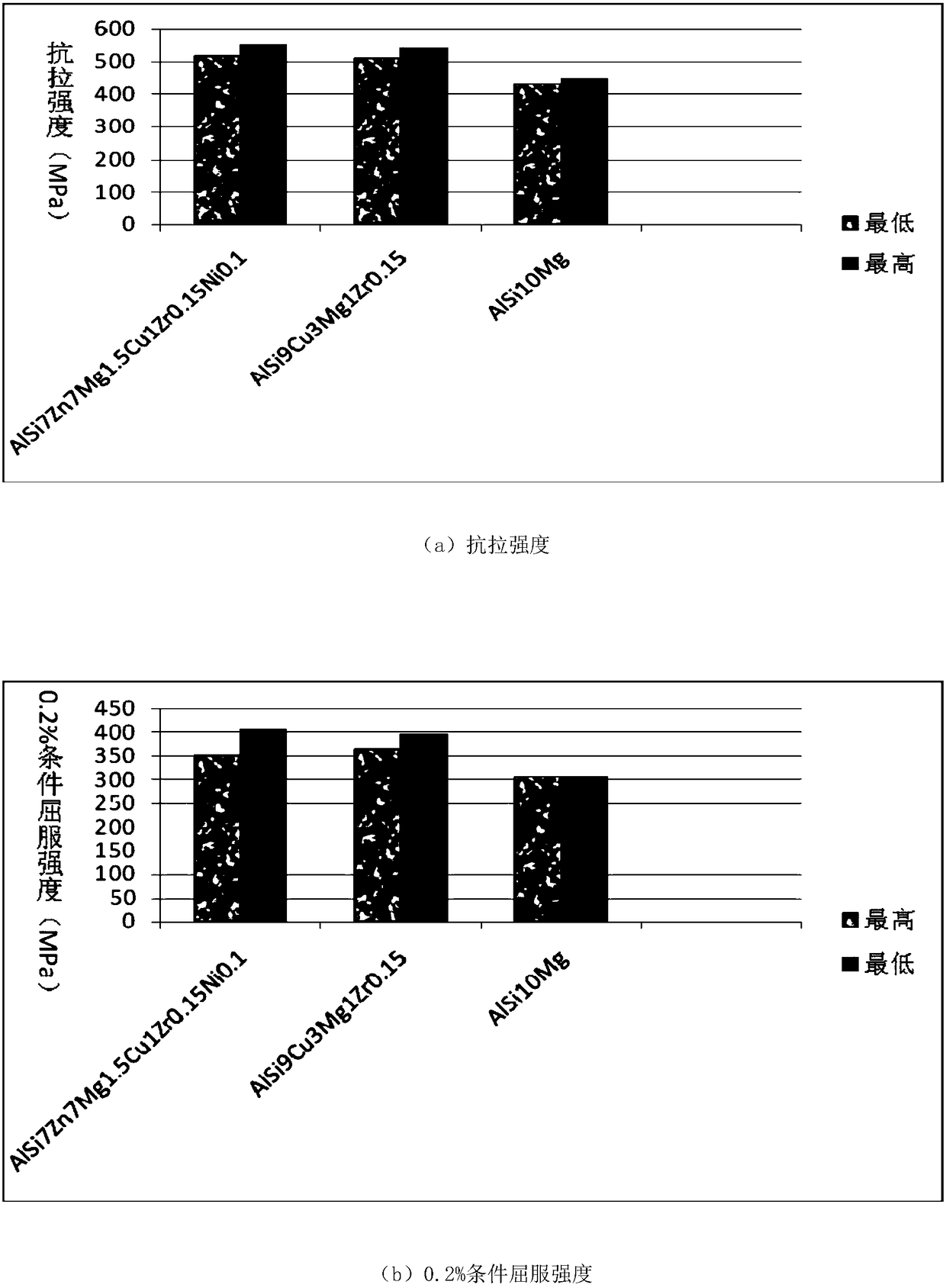

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Smelting production method of low activation martensitic steel for fusion reactor

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com