Patents

Literature

223results about How to "Achieve smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

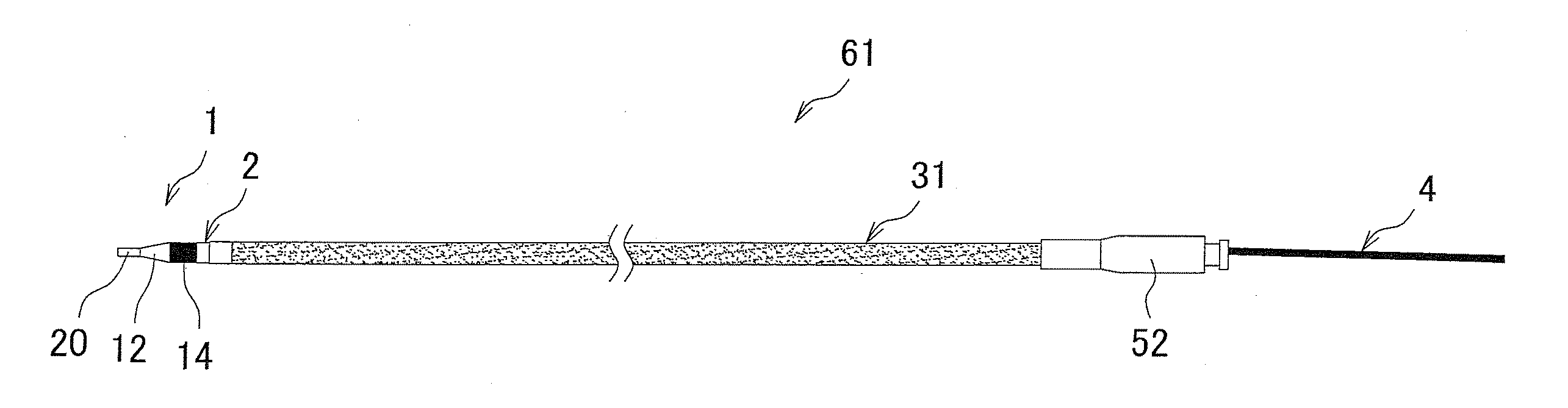

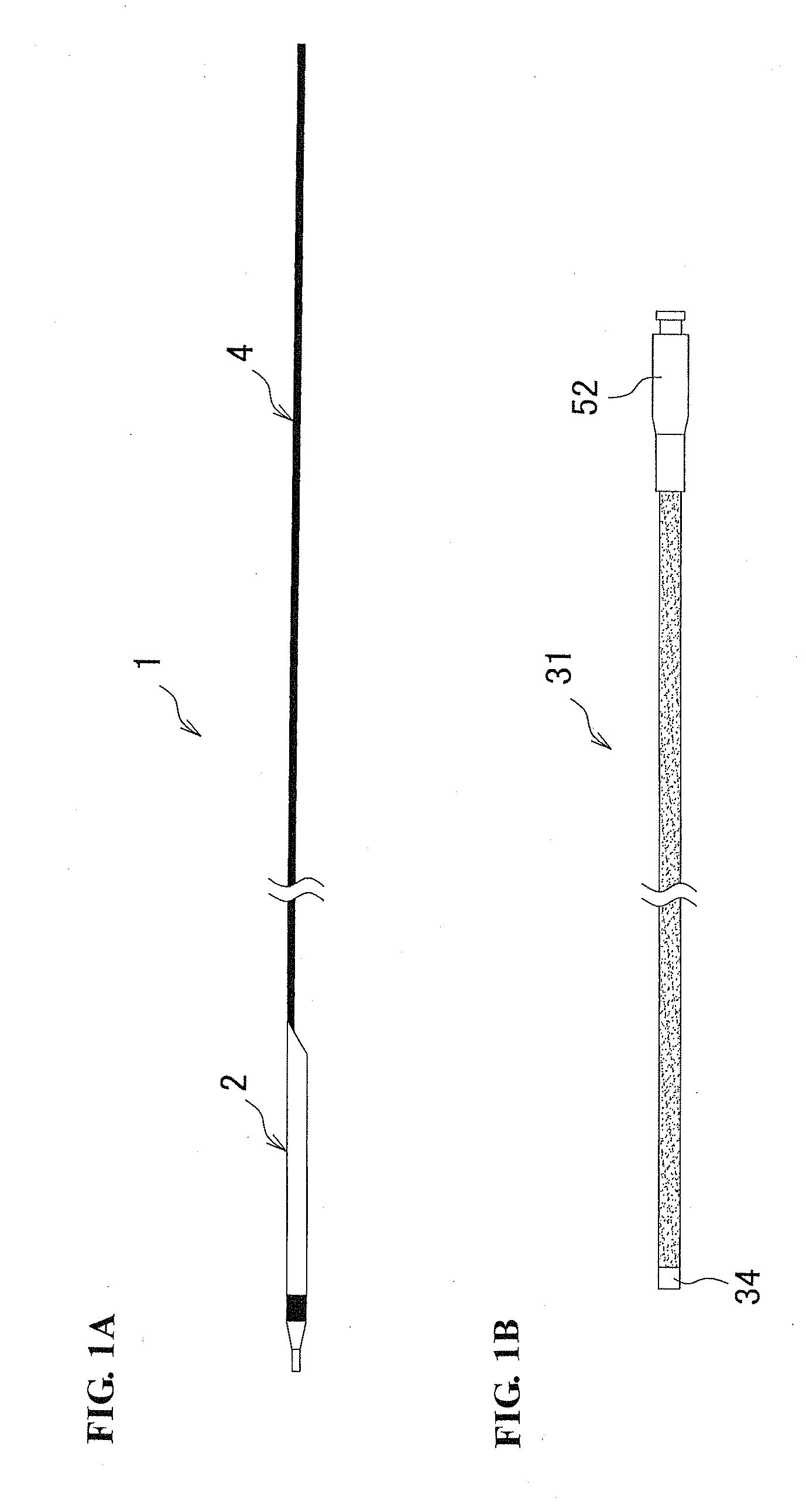

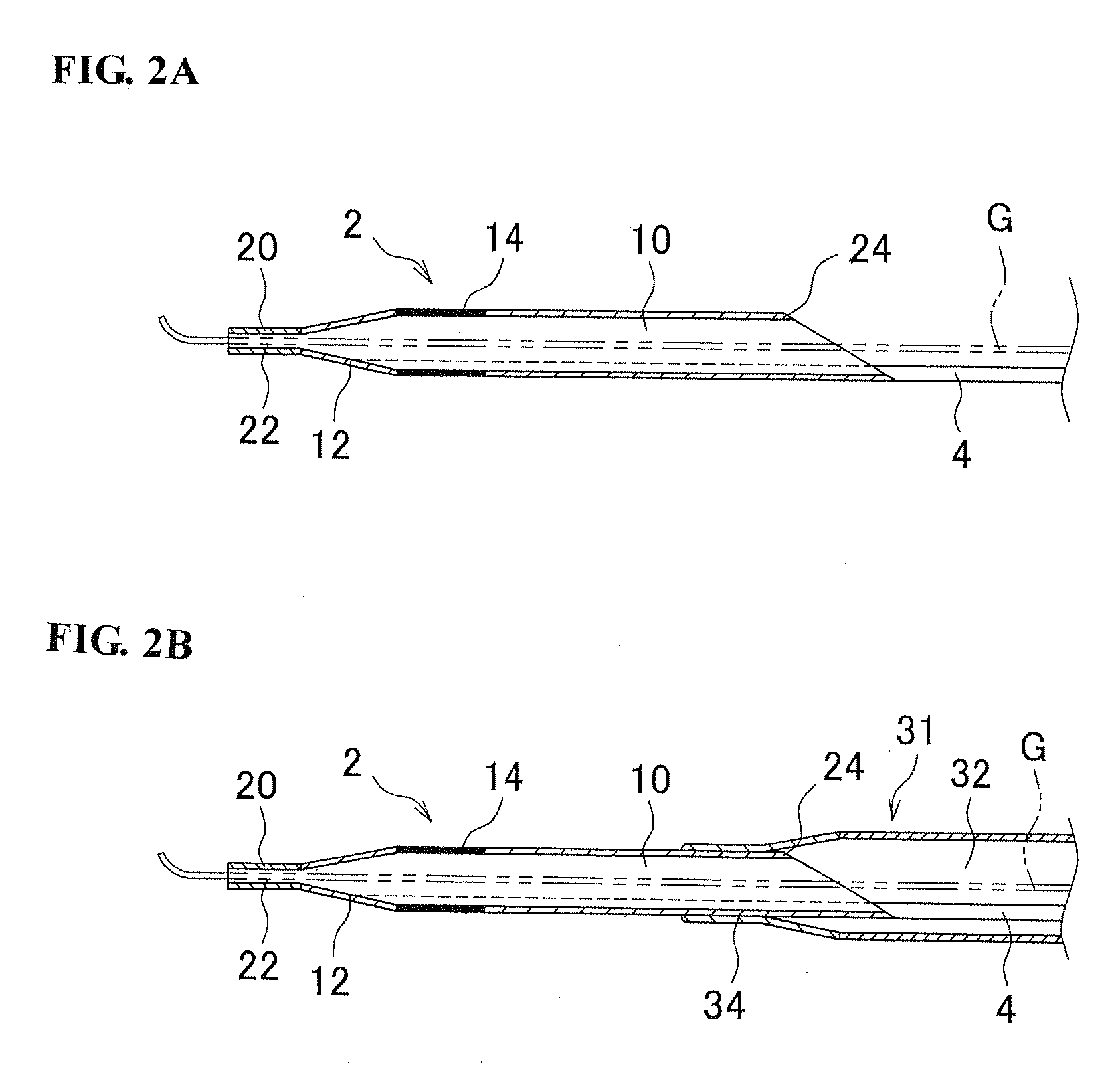

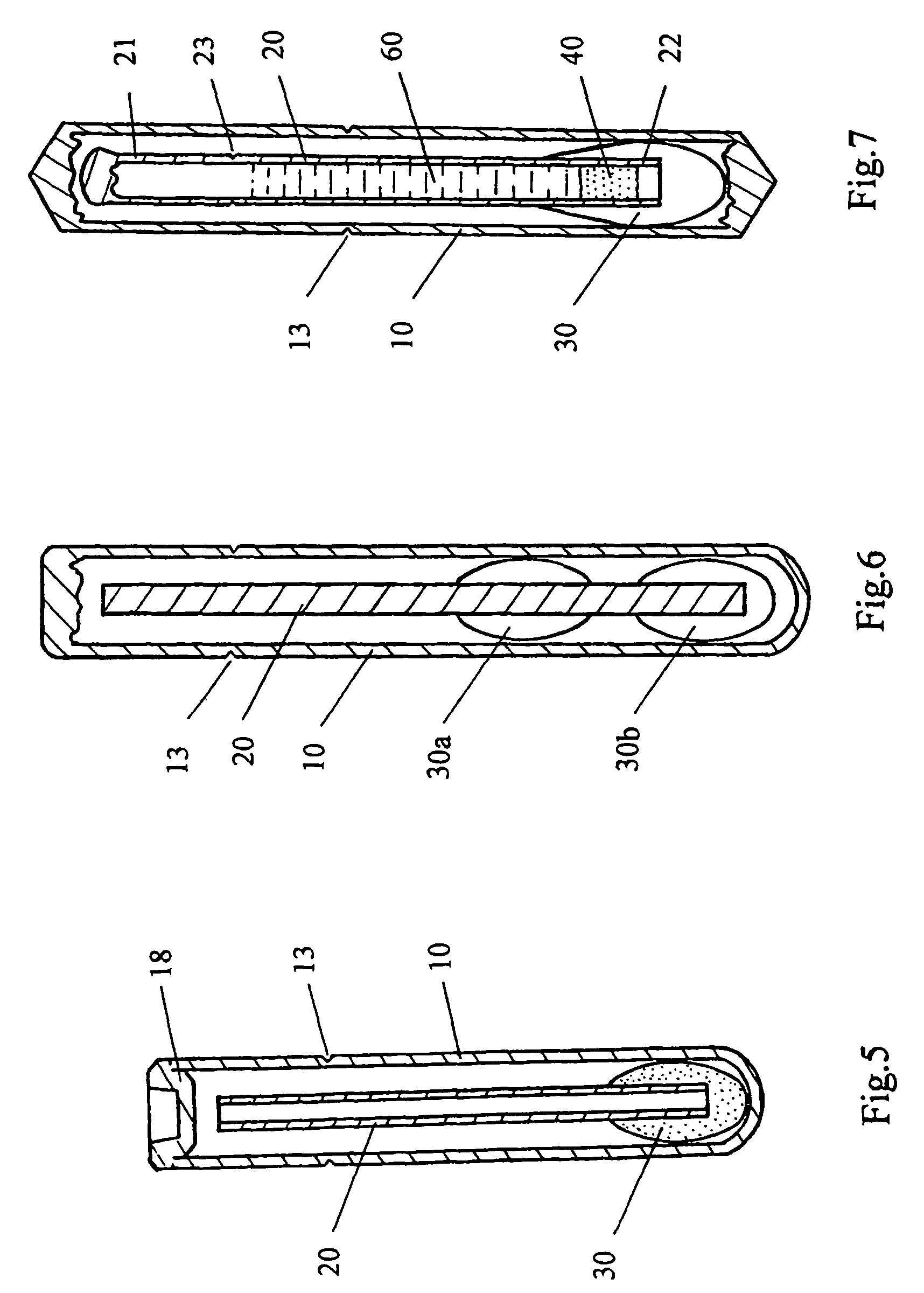

Insertion assisting tool for catheter, catheter assembly, and catheter set

InactiveUS20090264865A1Easy to insertSmoothly inserted intoGuide needlesGuide wiresExtremity PartGuide wires

An insertion assisting tool inserted into a catheter and positioned ahead of the catheter is provided so as to assist an insertion of the catheter. The insertion assisting tool includes: a distal end portion whose end is tapered and which has a guide wire lumen opening at a tip end and a proximal end of the distal end portion; and a shaft extending from a part of a proximal-end surface of the distal end portion to a proximal end of the insertion assisting tool.

Owner:GOODMAN & COMPANY

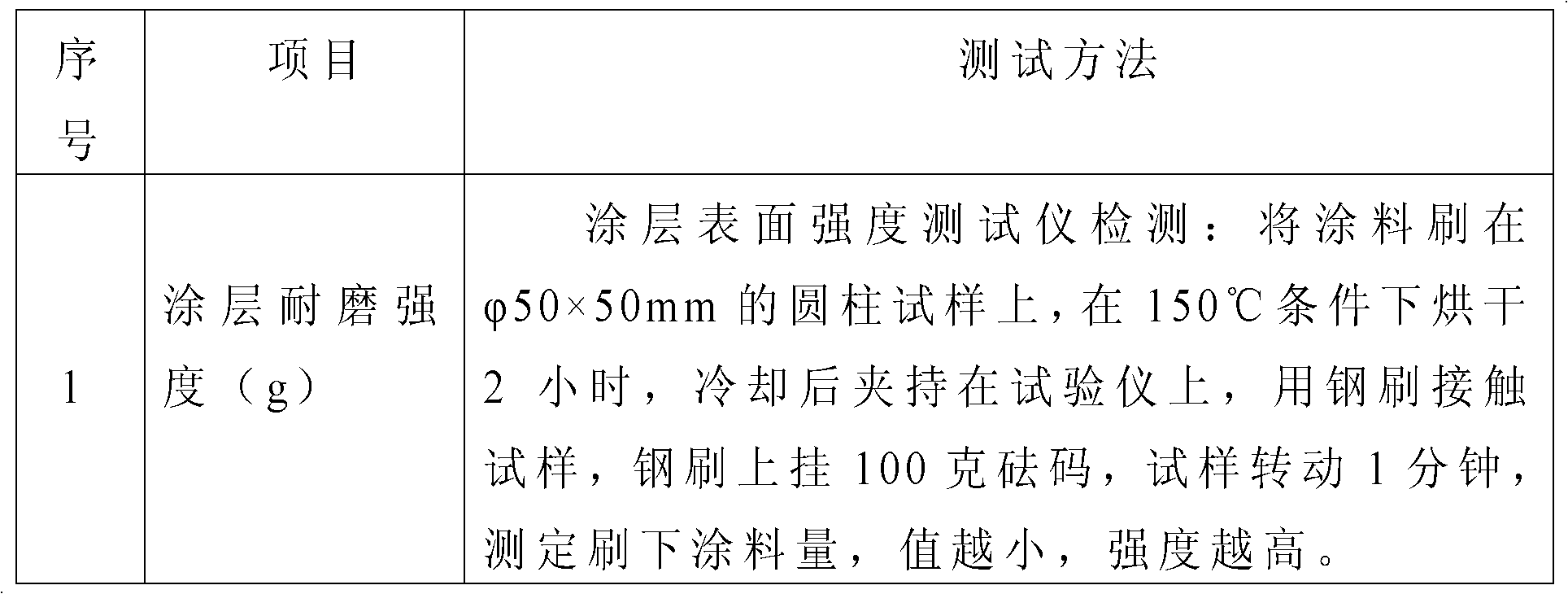

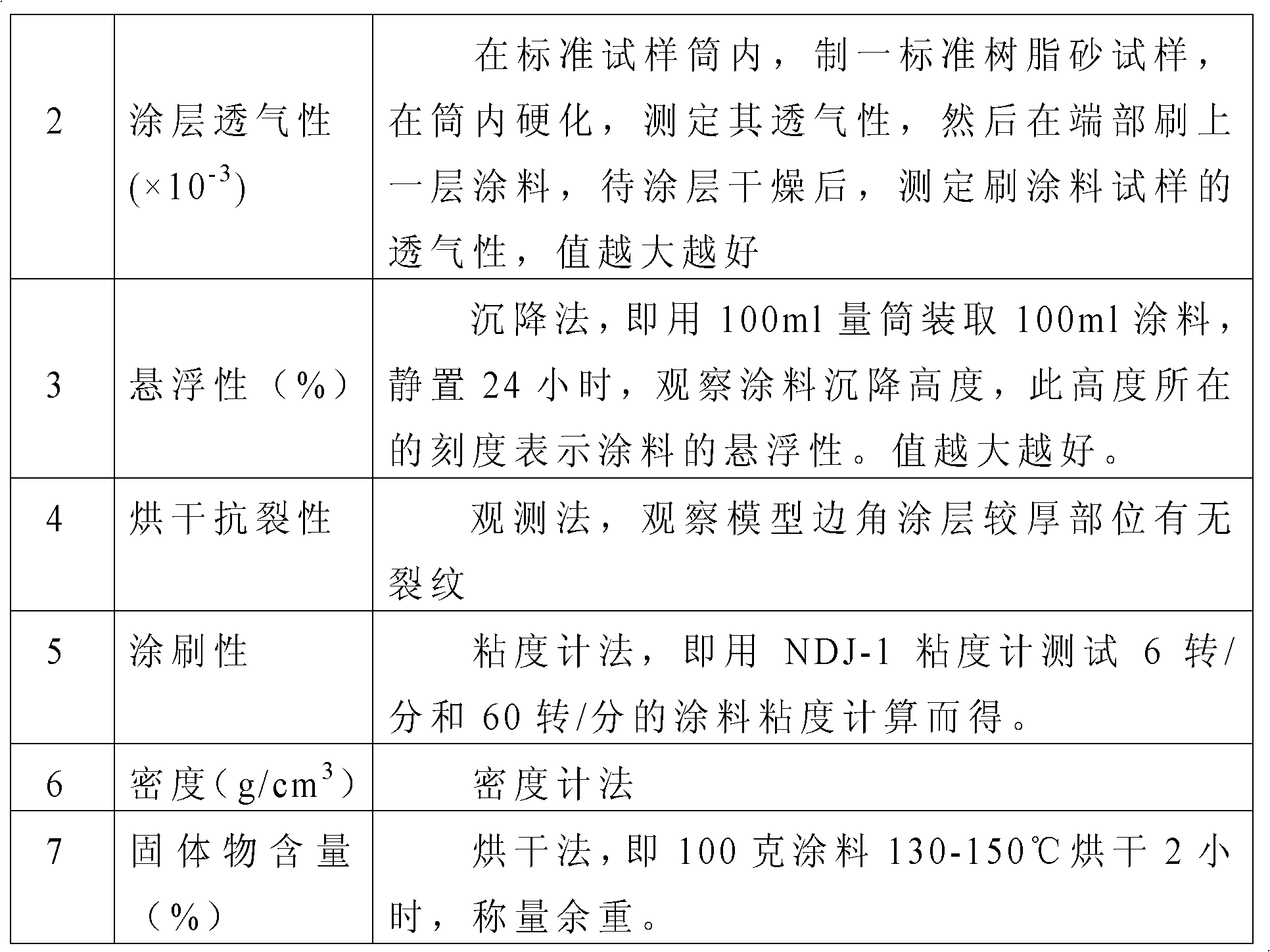

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

Corrosion-resistance iron-based austenite oil well pipe and manufacturing method thereof

InactiveCN104962836AMeet the slow strain test requirementsAchieve smoothSolid solutionElectro-slag remelting

The invention discloses a corrosion-resistance iron-based austenite oil well pipe and a manufacturing method thereof. The main chemical components of the oil well pipe include C larger than 0 and smaller than or equal to 0.03%, Si larger than 0 and smaller than or equal to 1.00%, Mn larger than 0 and smaller than or equal to 2.50%, P smaller than or equal to 0.03%, S smaller than or equal to 0.03%, 20.0%-28.0% of Cr, 20.0%-38.0% of Ni, 3.0%-5.0% of Mo and 0.50%-2.00% of Cu. The manufacturing method includes the first step of smelting; the second step of billet pouring; the third step of electroslag remelting; the fourth step of homogenizing annealing; the fifth step of billet forging; the sixth step of pipe billet preparing; the seventhly step of hot extruding, wherein a seamless steel pipe is formed through pipe billet preheating, power frequency induction furnace heating, pipe billet broaching, secondary induction heating and extruding; the eighth step of solid solution treating; and the ninth step of conducting of a deformation strengthening mode in cold drawing, wherein the percentage reduction of area is controlled within 20-40%, and the oil well pipe is manufactured. According to the corrosion-resistance iron-based austenite oil well pipe and the manufacturing method thereof, the wall thickness of the manufactured oil well pipe ranges from 15 mm to 40 mm, the yield strength is 760 MPa or higher, the tensile strength is 793 MPa or higher, the impact energy is 100 J or higher, the corrosion resistance is good, and the requirement for strictest and slow-strain tests is met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

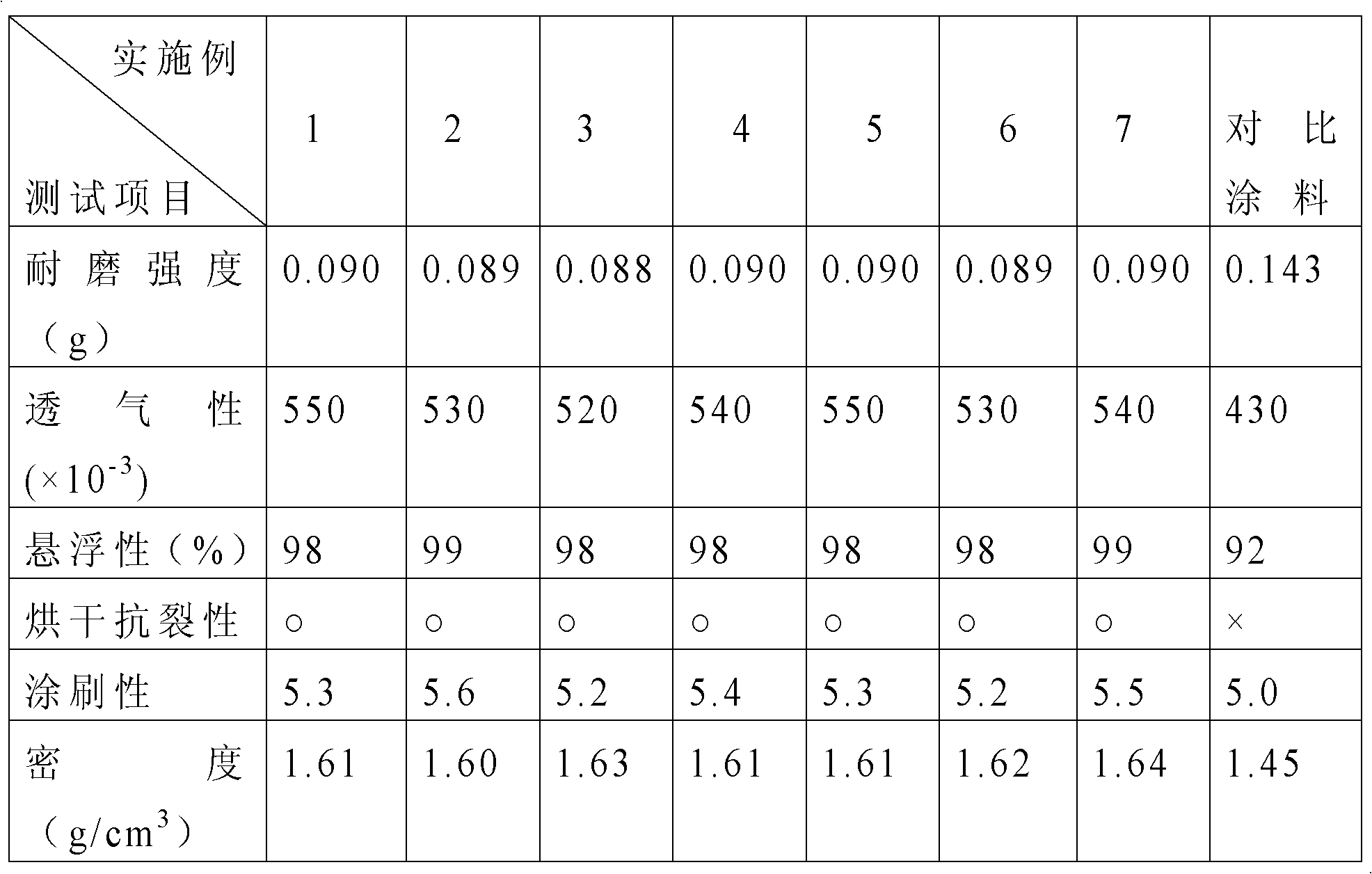

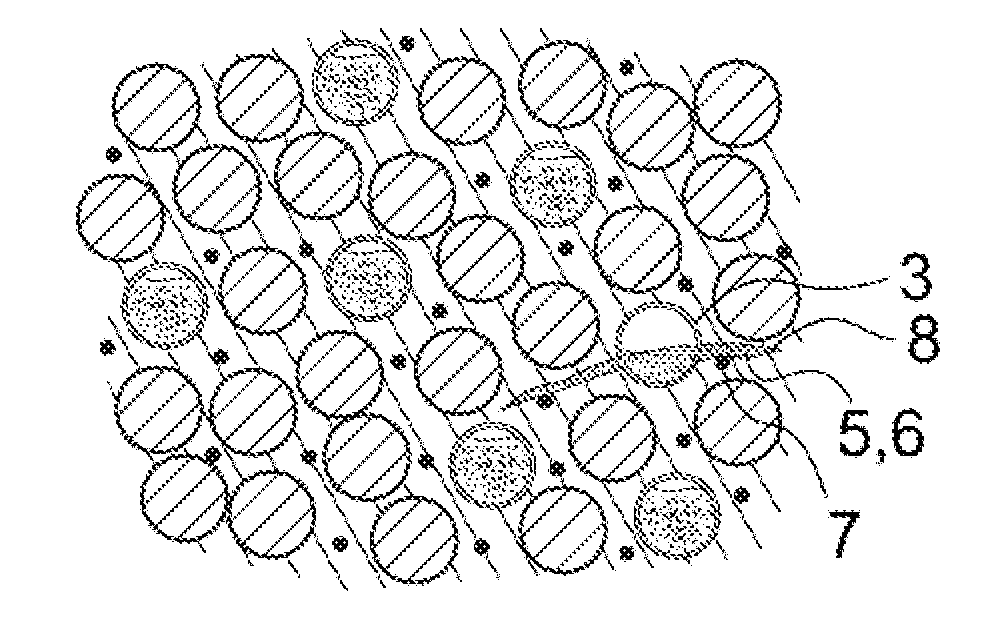

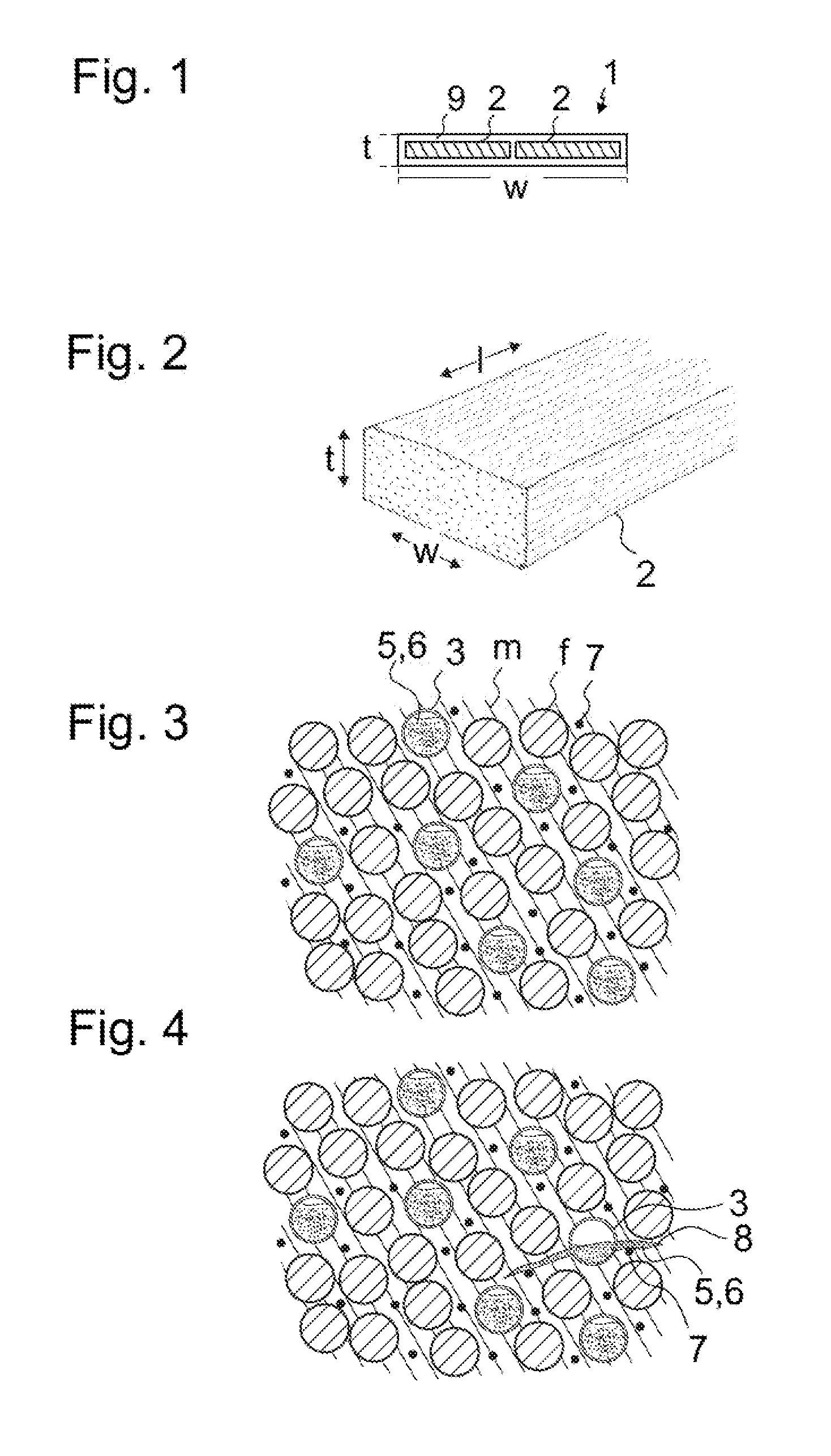

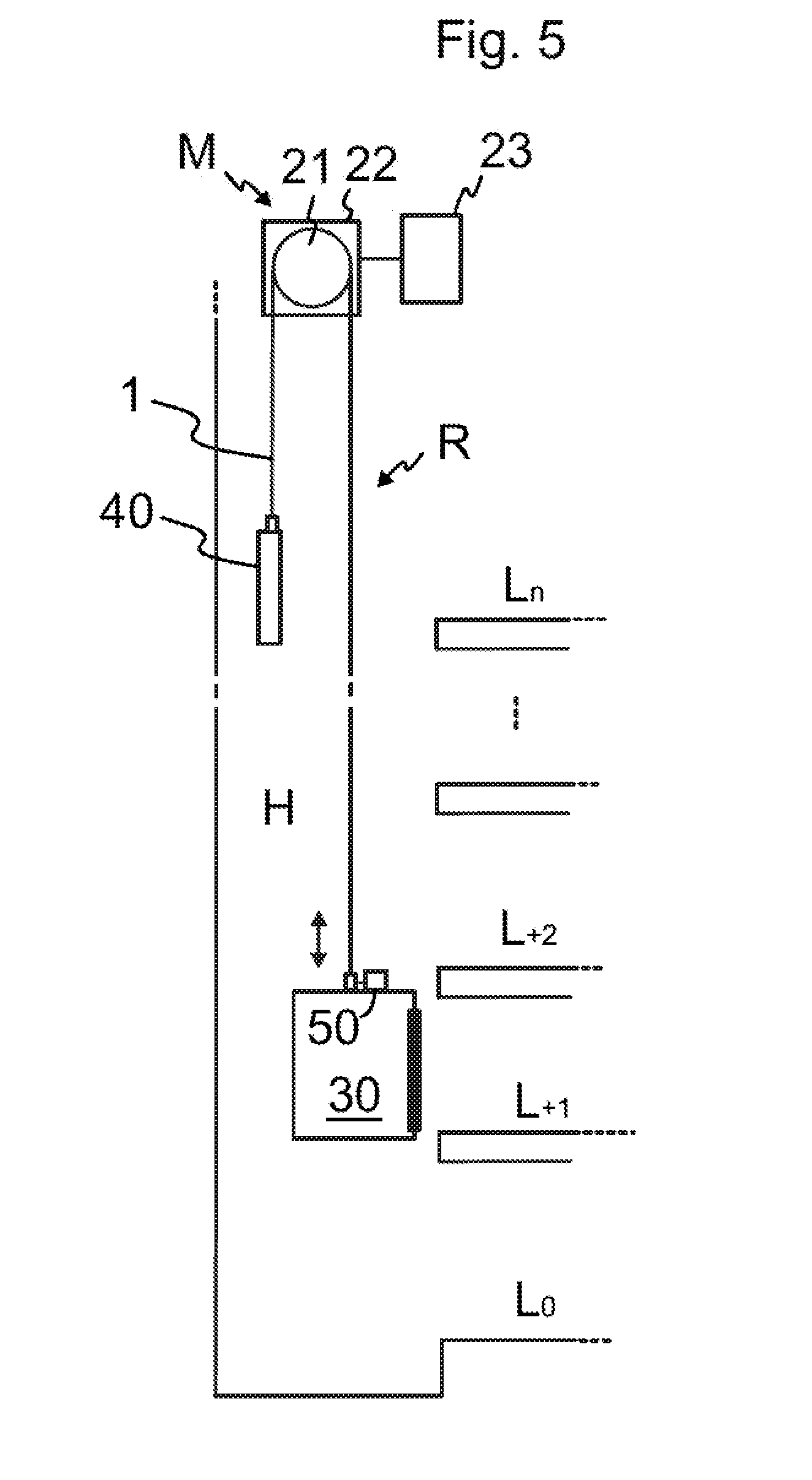

Rope for an elevator, elevator and method

ActiveUS20150191332A1Transportation safetyImprove staminaControlSynthetic resin layered productsFiberBiomedical engineering

A rope for a hoisting device, in particular for an elevator, includes at least one continuous load bearing member extending in longitudinal direction of the rope throughout the length of the rope, the load bearing member being made of composite material including reinforcing fibers embedded in polymer matrix. The composite material includes capsules embedded in the polymer matrix, the capsules storing monomer substance in fluid form. An elevator includes a rope of the aforementioned kind and a method for condition monitoring of a rope of an elevator.

Owner:KONE CORP

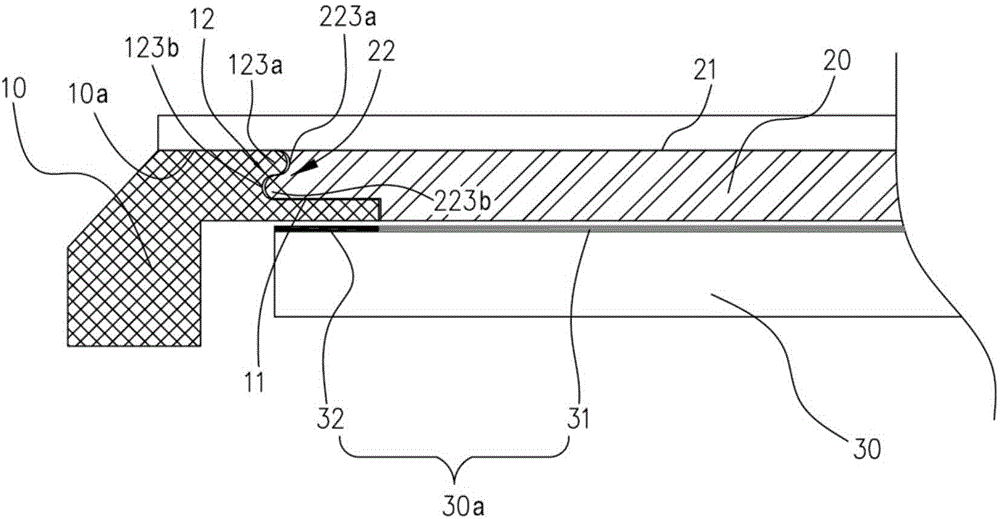

Terminal front cover and terminal

ActiveCN104866018AGood lookingImprove ergonomicsDigital data processing detailsTelephone set constructionsGlass sheetComputer engineering

The invention discloses a terminal front cover and a terminal. The terminal front cover includes a frame, a glass plate and a display screen, wherein the display screen includes a display surface; the display surface includes a display area and a non-display area; the non-display area surrounds the display area; the frame is fixed on the display surface and includes a visual surface and a first inner connecting surface connected to the visual surface; the glass plate comprises an upper surface and a second inner connecting surface connected to the upper surface; the first inner connecting surface is arranged on the inner side of the frame; the second inner connecting surface is arranged on the periphery of the glass plate; the frame is integrally formed on the glass plate; the first inner connecting surface of the frame is fitted with the second inner connecting surface of the glass plate; the visual surface and the upper surface are smoothly connected with each other to form a seamless smooth outer surface; the visual surface correspondingly shields the non-display area.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

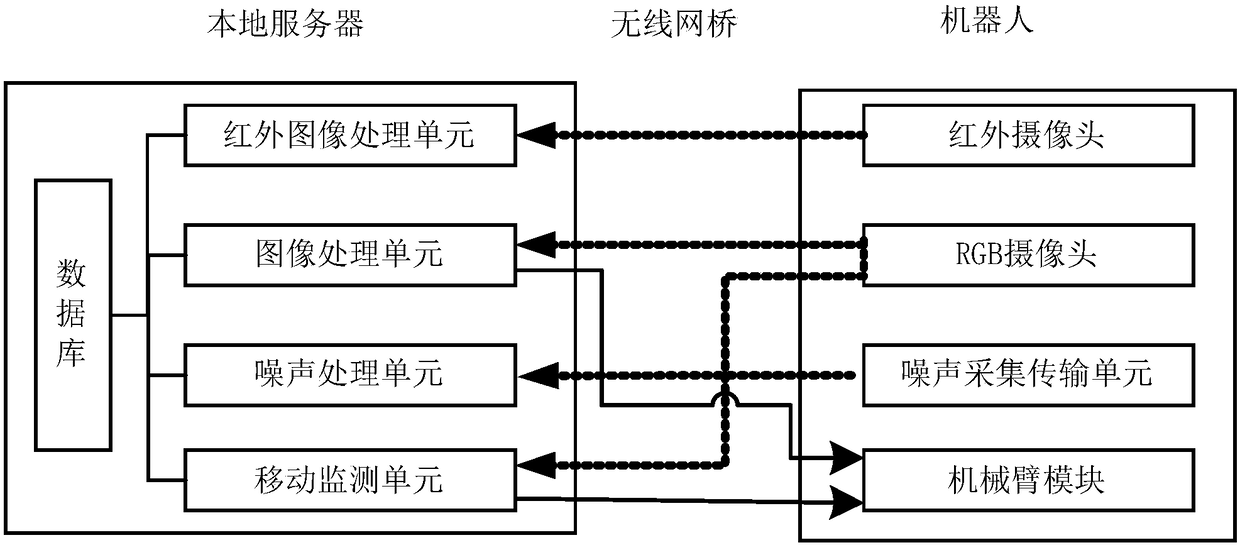

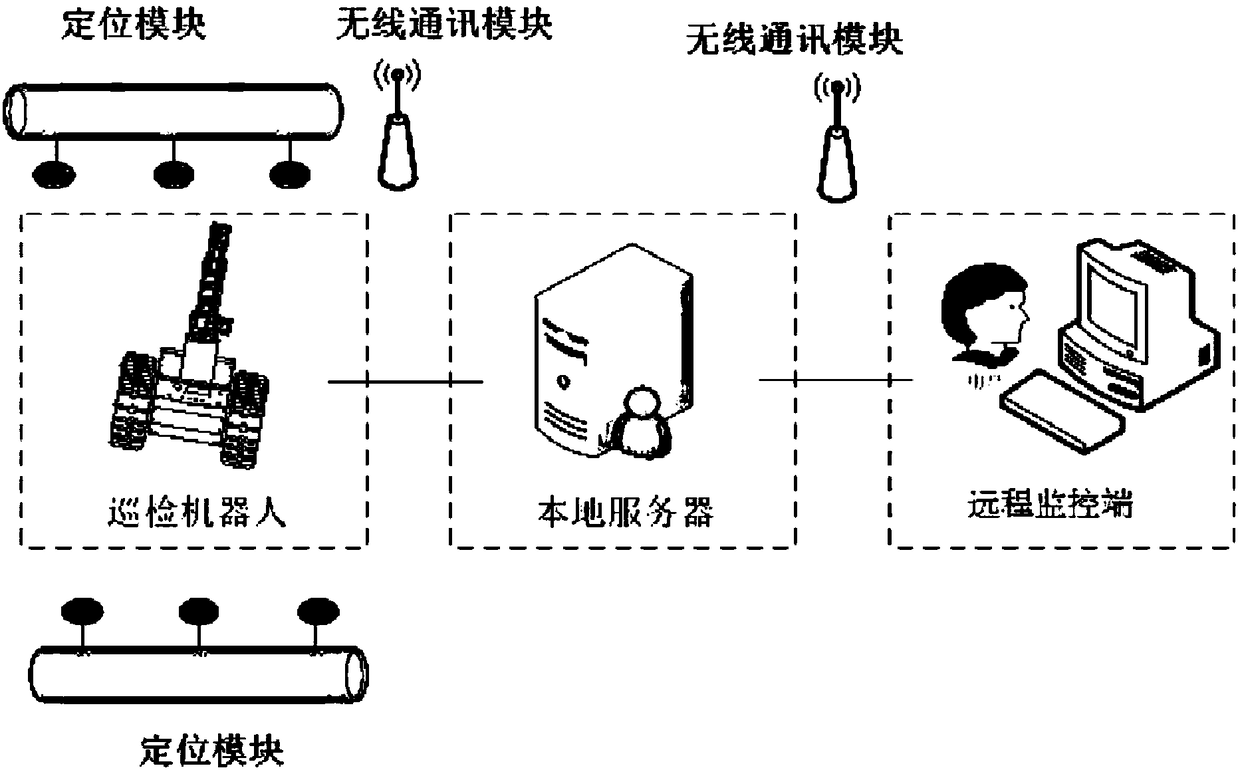

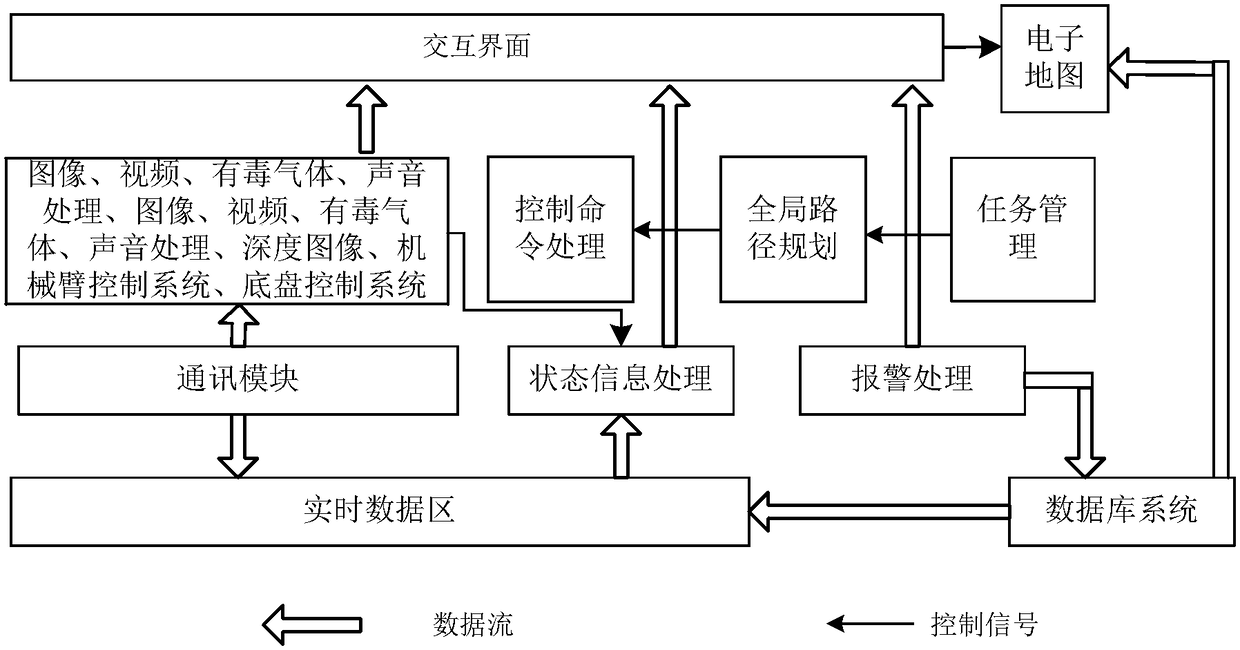

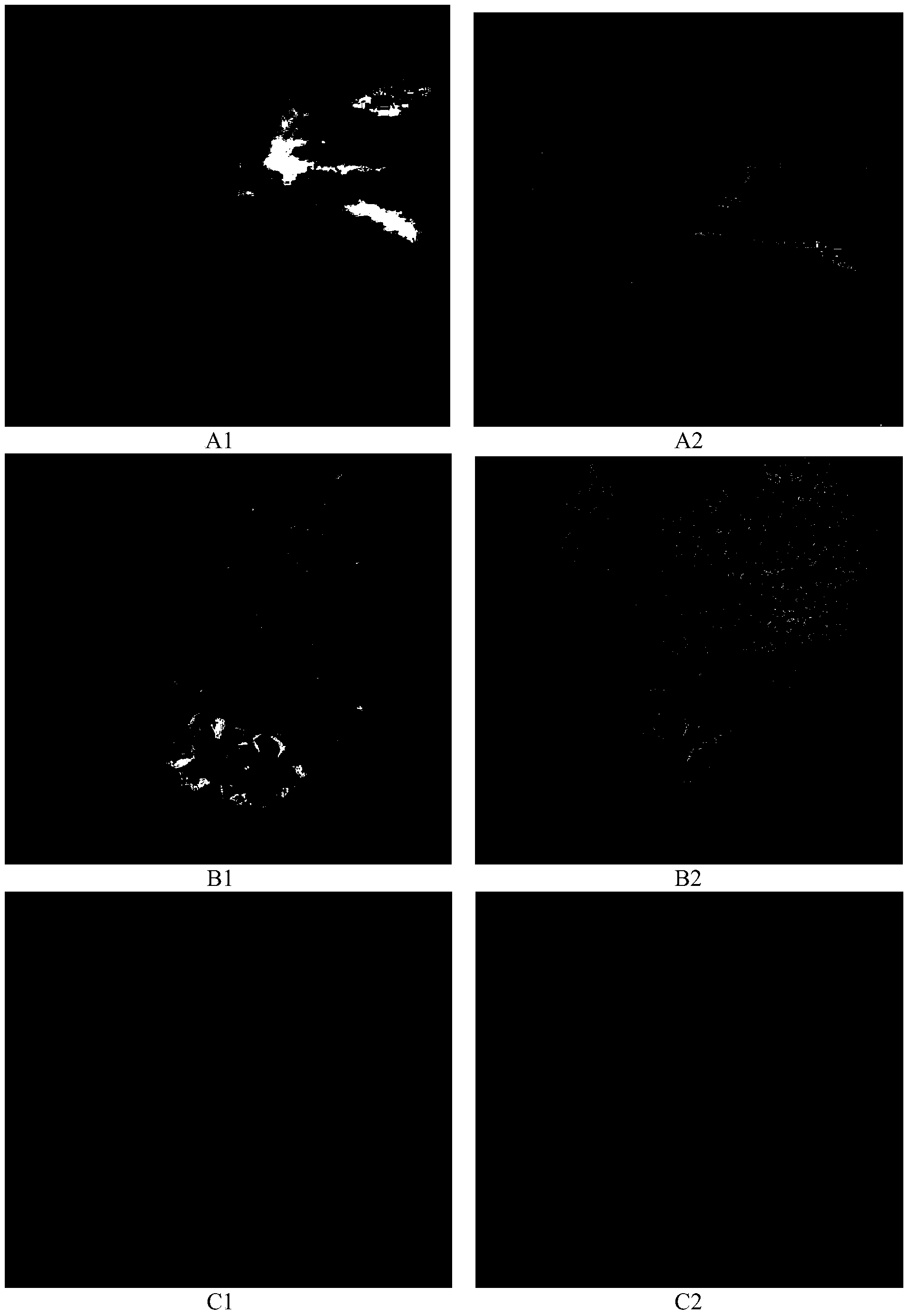

Comprehensive pipe gallery three-dimensional routing inspection robot with autonomous navigation and positioning functions

InactiveCN108247634ARealize autonomous navigation and positioning functionGuaranteed uptimeProgramme-controlled manipulatorSelf adaptiveMarine navigation

The invention provides a comprehensive pipe gallery three-dimensional routing inspection robot with autonomous navigation and positioning functions. A stroke positioning self-adaption coding unit anda decoding control unit are used for monitoring the stroke of the robot and receiving the coding marks, sent by stroke detecting coding equipment, of different routing inspection points, the coding marks are verified, if error codes occur, the coding rule is changed, and meanwhile the decoded routing inspection point position marks are sent to a server and a remote monitoring terminal; the strokedetecting coding equipment codes the positions of the different routing points according to the coding rule sent by the stroke positioning self-adaption coding unit and the decoding control unit; andwhen the corresponding routing inspection positions are detected, positions codes are sent to the stroke positioning self-adaption coding unit and the decoding control unit. According to the comprehensive pipe gallery three-dimensional routing inspection robot, through the provided stroke positioning self-adaption coding unit, the remote monitoring terminal, the server, the decoding control unit and the stroke detecting coding equipment, the robot autonomous navigation and positioning functions are achieved, and the problem that the error codes are received by the rotor and thus the robot cannot normally operate is avoided.

Owner:安徽对称轴智能安全科技有限公司

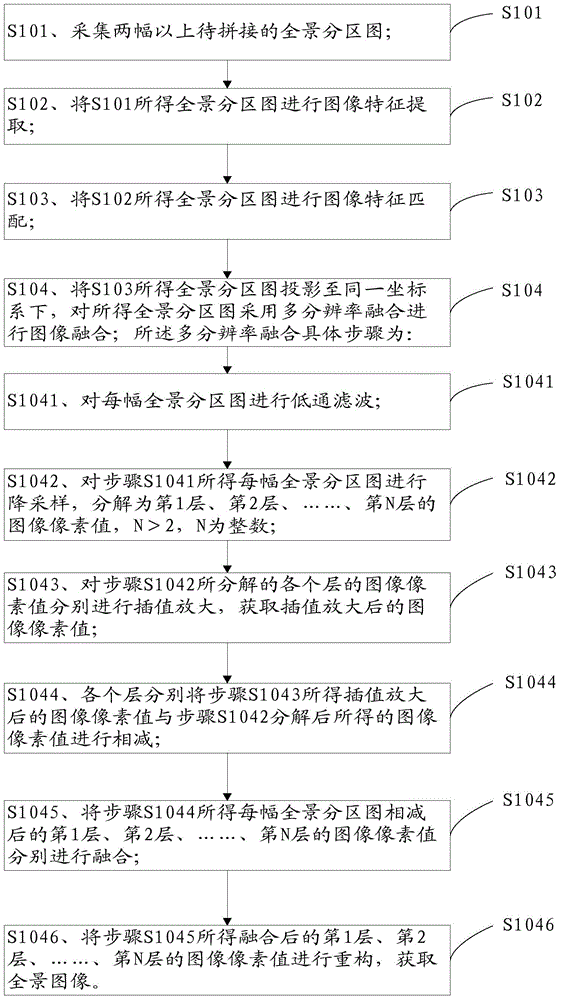

Method and device for smoothing seams of panoramic stitched image

InactiveCN105678721AAvoid it happening againAchieve smoothImage enhancementGeometric image transformationVideo monitoringMulti band

The invention relates to the technical field of image processing, in particular to a method and device for smoothing seams of panoramic stitching images. By decomposing each panoramic partition image into multi-layer frequency bands, the fusion of images is carried out separately in different frequency bands, which can effectively avoid ghost images during image fusion, and achieve smoothness at the seams of panoramic stitching images, and due to the multi-layer frequency bands of images Decomposition and reconstruction are a reciprocal process, and using this method can guarantee the correctness of the resulting stitched image. The generation of panoramas meets the requirements of video surveillance with a large field of view. With the continuous expansion of the monitoring range, it is necessary to monitor the entire bridge, airport, a long section of road or high-rise buildings. The field of view of most cameras cannot reach this A large monitoring range has gradually formed a high-end demand. Smoothing the seams of panorama stitched images can make the panorama look smoother.

Owner:SHENZHEN INFINOVA

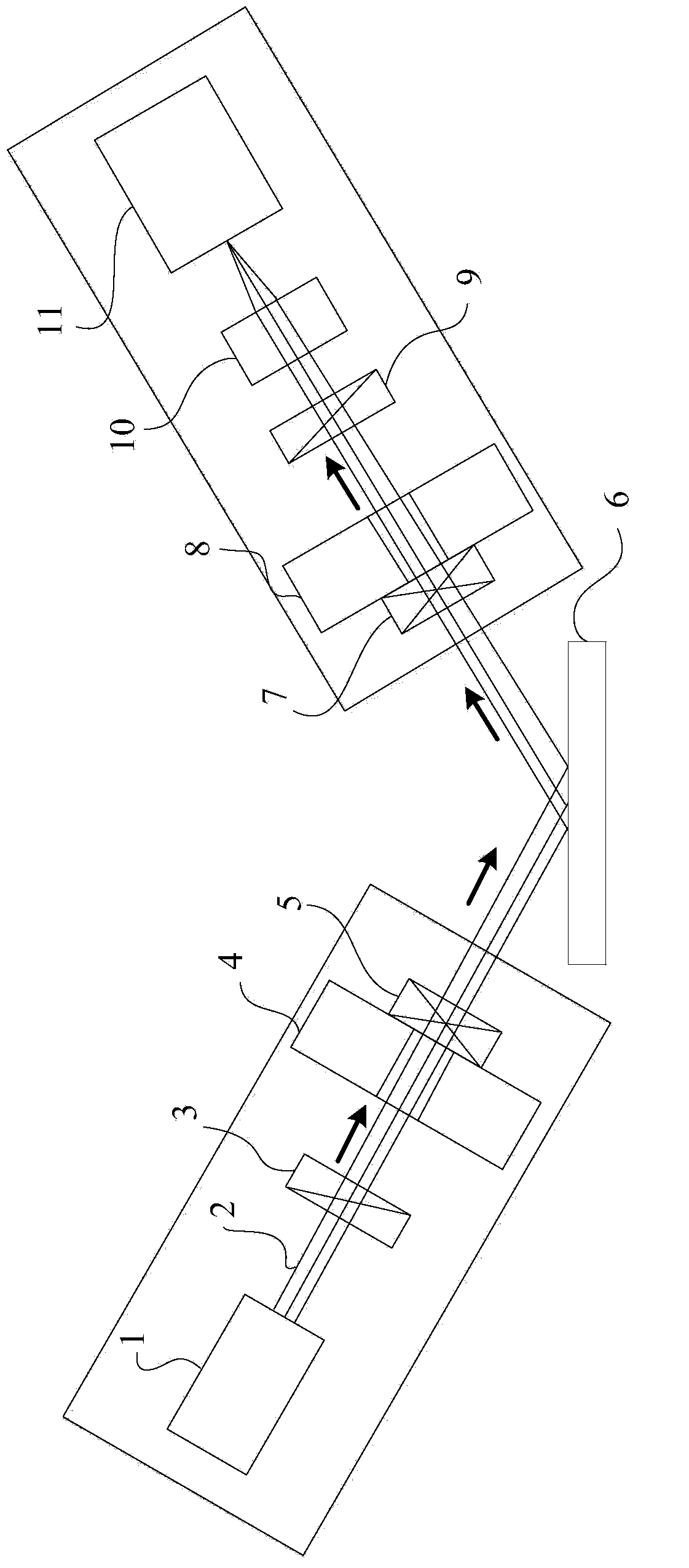

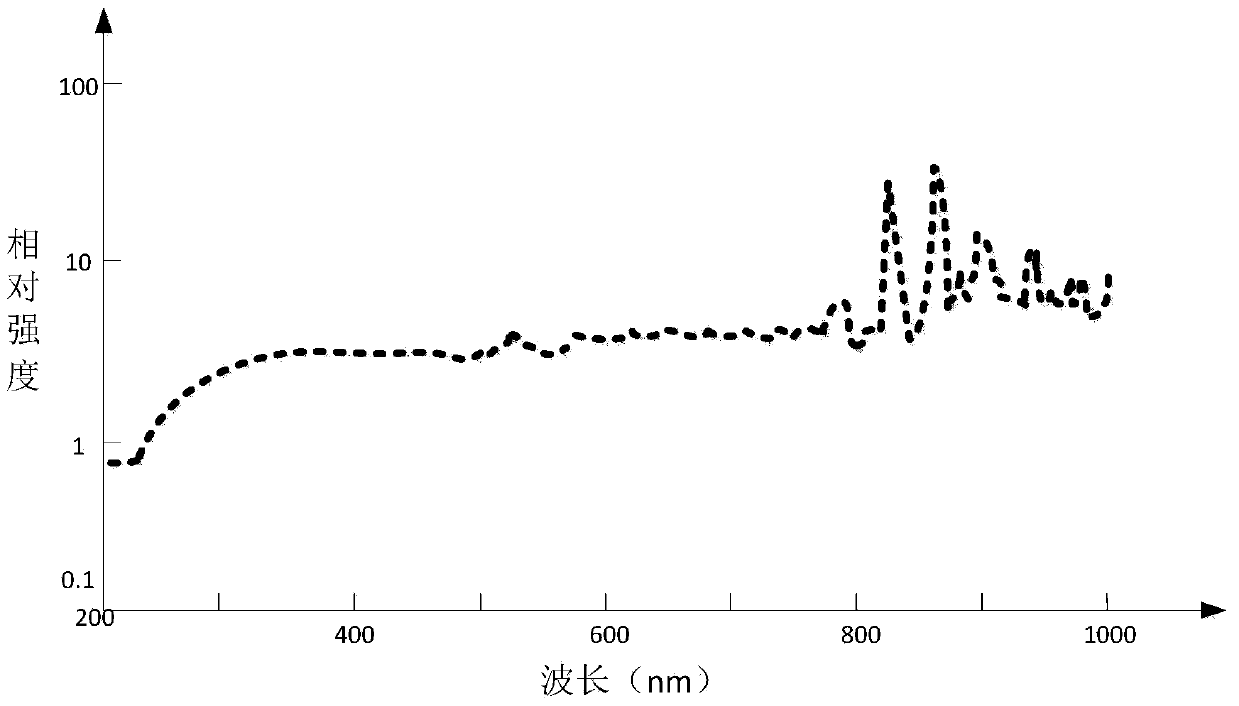

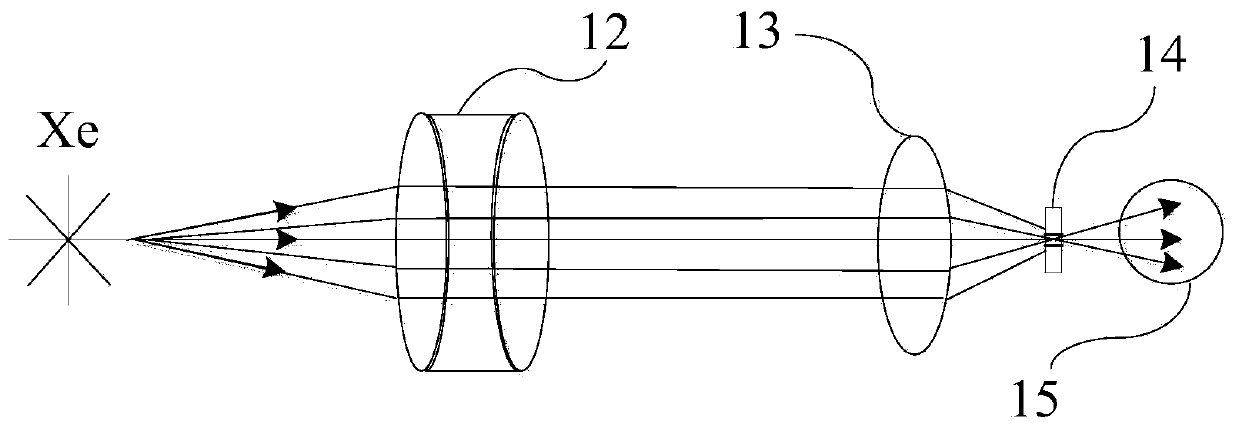

Light intensity smoothing device and method of xenon lamp light sources in spectrum ellipsometer

ActiveCN103471992AReduce intensityLight intensity curve smoothPolarisation-affecting propertiesLight spotUltraviolet

The invention discloses a light intensity smoothing device and method of xenon lamp light sources in a spectrum ellipsometer. The light intensity smoothing device comprises a collimating lens, a convergent lens and a diaphragm, wherein the collimating lens is an achromatic lens, and is used for collimating to-be-processed xenon lamp light rays into parallel light beams; the convergent lens is a single lens, and is used for converging and focusing the parallel light beams, and the sizes of light spots after convergence increase along with the increasing of wavelengths; the diaphragm is arranged behind the convergent lens and at the focal length part at an interval of certain wavelength, and the size of the diaphragm is set to ensure that light spots at an ultraviolet wave band can pass through the diaphragm while light spots at a visible near-infrared wave band are blocked, thereby reducing the light intensity of light beams at the visible near-infrared wave band and further achieving smoothness. The invention also discloses a xenon lamp light ray intensity smoothing method. According to the invention, light rays at any wave band are not lost, and a detector or a spectrograph can normally respond to light rays at a full-spectrum range, so that the spectrum ellipsometer can perform accurate measurement in a full-spectrum range from ultraviolet to near-infrared.

Owner:HUAZHONG UNIV OF SCI & TECH

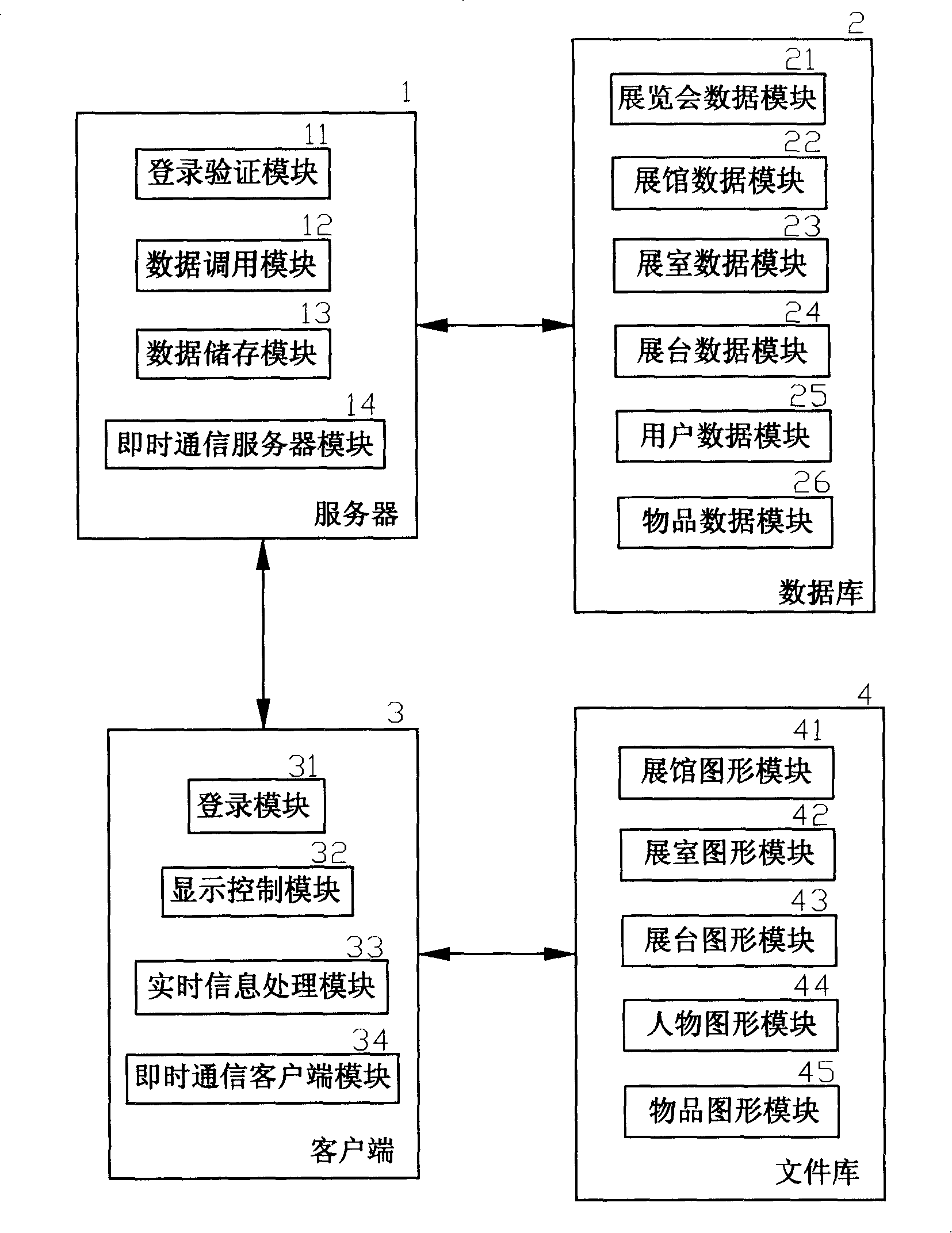

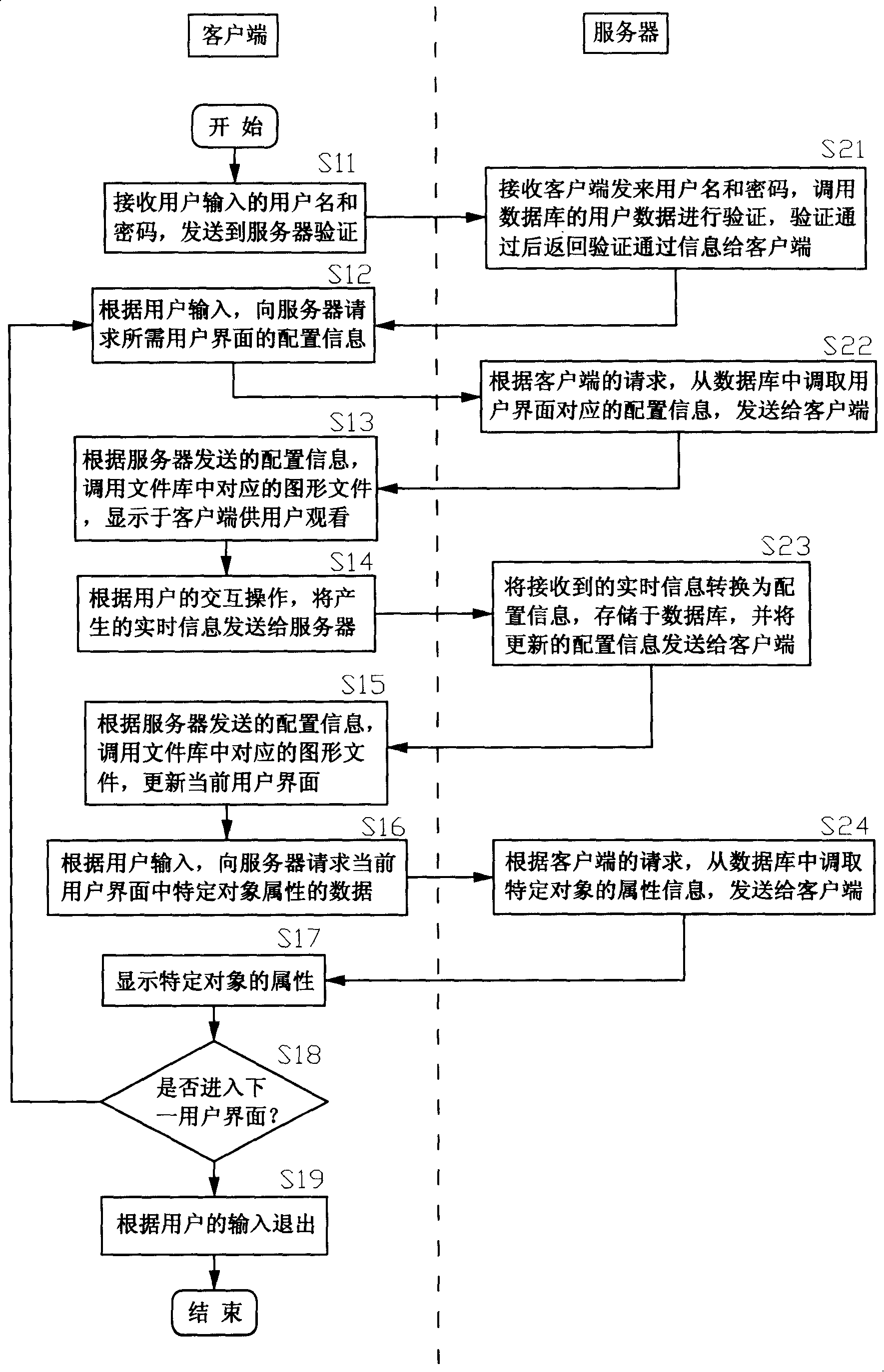

Network virtual exhibition method and system

InactiveCN101206742AEasy to collectEasy to publishSpecial service provision for substationCommerceTime informationGraphics

The invention relates to a network virtual exhibiting method and a system thereof and comprises that: a user interface of a virtual exhibition is provided in a client and is used for interaction with a user; real-time information of the virtual exhibition produced in the interacting process is sent to a server; the real-time information of the virtual exhibition from the client is received by the server and converted to the configuration information of the virtual exhibition which is then stored in a database; according to the configuration information of the virtual exhibition in the database, an image file display command is sent to the client; according to the image file display command sent by the server, the client transfers the image file display of the virtual exhibition in a document library. The invention avoids the disadvantages that the prior exhibition wastes mass manpower, material resource, financial resource and time in order that exhibitors can exchange and communicate in real time and the users can fully see a real-time exhibition in the client.

Owner:张新新

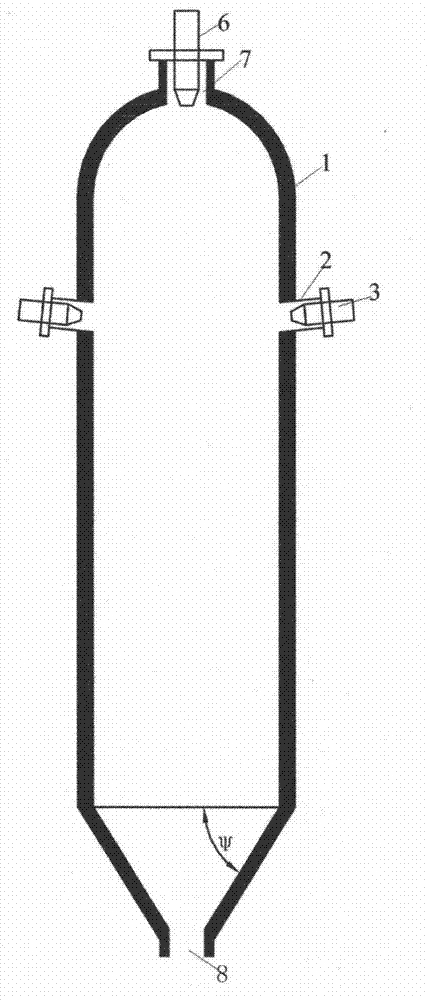

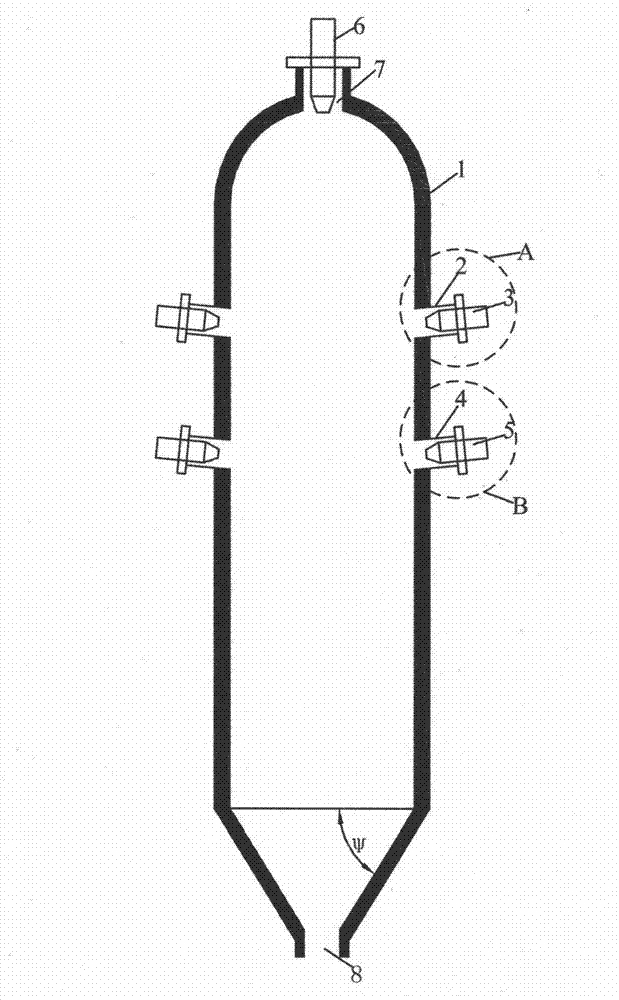

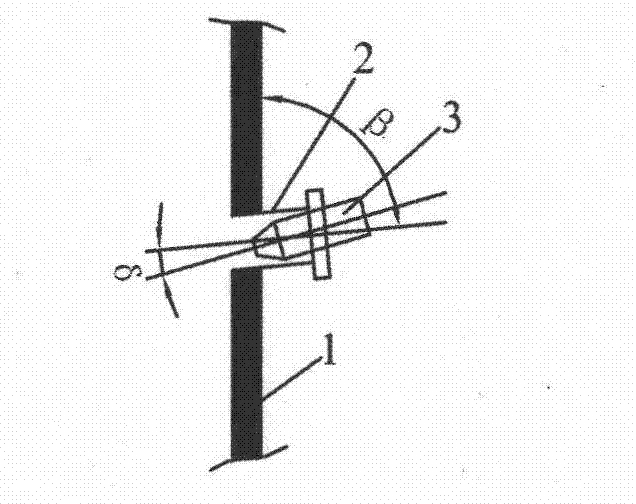

Two-section type multi-nozzle gasifying furnace with hierarchical oxygen supplying function and gasifying method of gasifying furnace

InactiveCN102816605AExtend your lifeImprove temperature distributionGranular/pulverulent flues gasificationProcess engineeringOxygen supply

The invention relates to a two-section type multi-nozzle gasifying furnace with a hierarchical oxygen supplying function. The two-section type multi-nozzle gasifying furnace comprises a gasifying furnace body. A top technical nozzle chamber with a top technical nozzle inside is arranged on the top of the gasifying furnace body, at least two side technical nozzle chambers with side technical nozzles inside are arranged on sides of the gasifying furnace body, a discharge outlet is arranged at the bottom of the gasifying furnace body, and at least two secondary oxygen supply spraying gun chambers are arranged on the straight section, between the side technical nozzle chambers and the discharge outlet, of the gasifying furnace body. The two-section type multi-nozzle gasifying furnace with the hierarchical oxygen supplying function is characterized in that the side technical nozzle chambers and the secondary oxygen supply spraying gun chambers are symmetrically arranged on the periphery of the gasifying furnace body, and secondary oxygen supply spraying guns are mounted in the secondary oxygen supply spraying gun chambers. The invention further provides a gasifying method of the two-section type multi-nozzle gasifying furnace with the hierarchical oxygen supplying function. Temperature in the gasifying furnace is more uniform and reasonable in distribution and local high temperature inside the gasifying furnace is avoided.

Owner:SHANGHAI BOILER WORKS

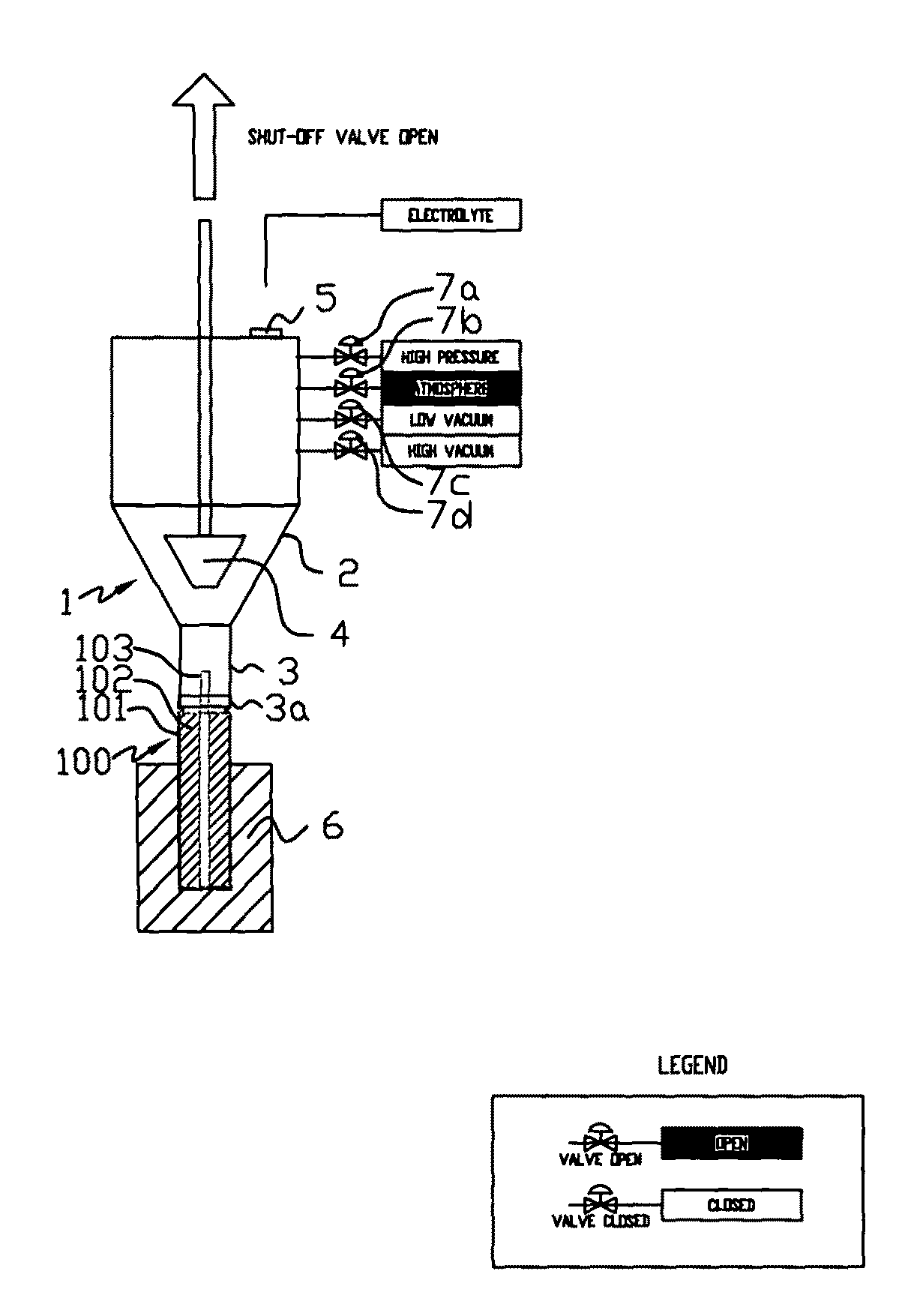

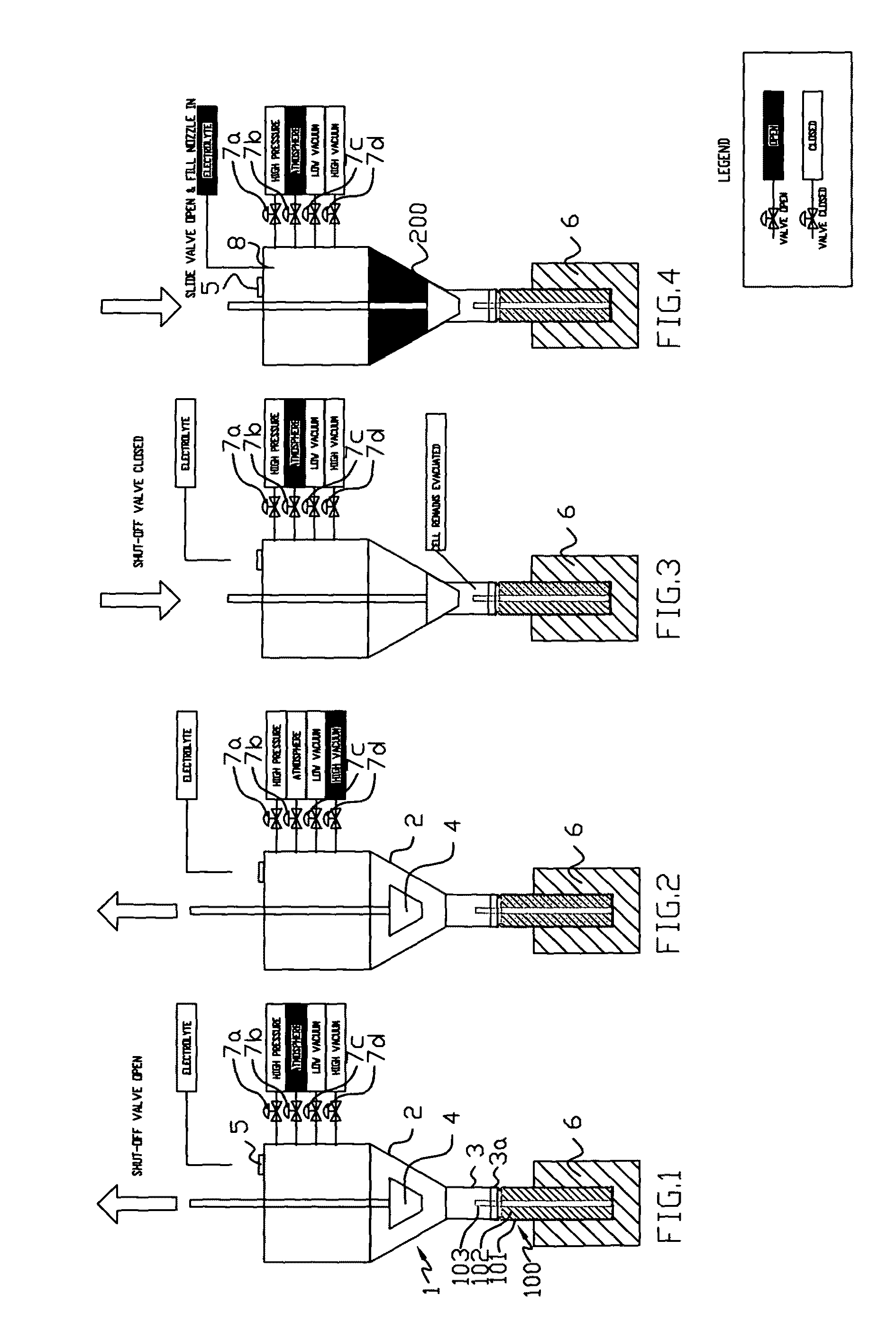

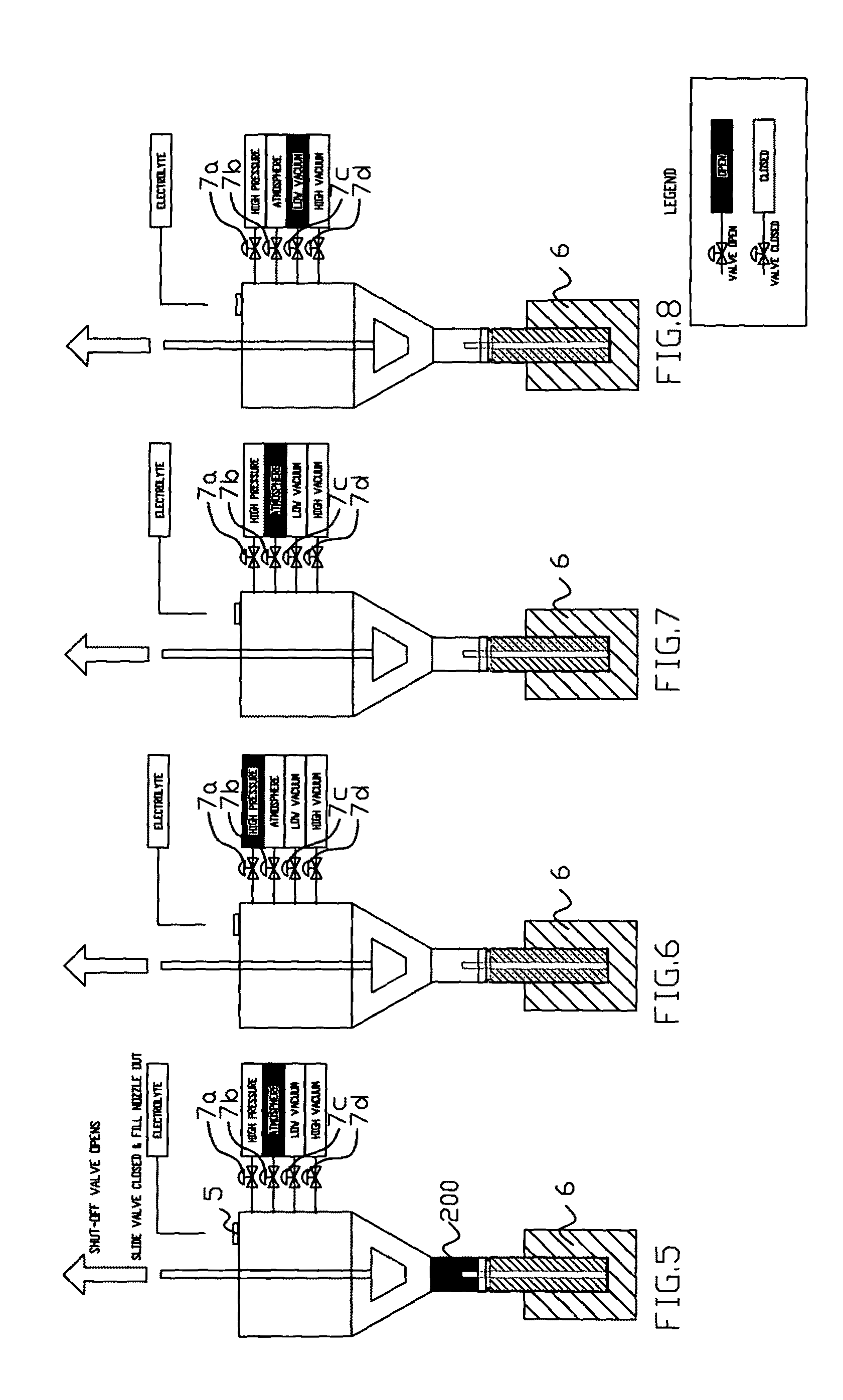

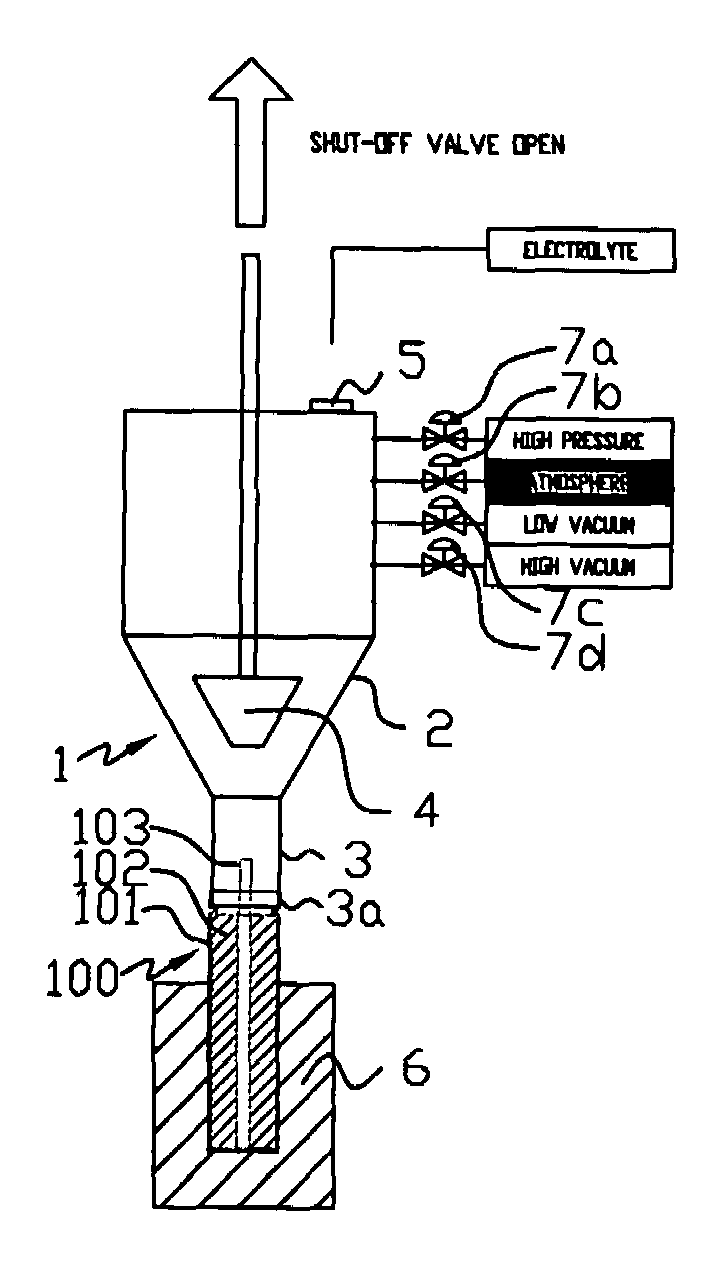

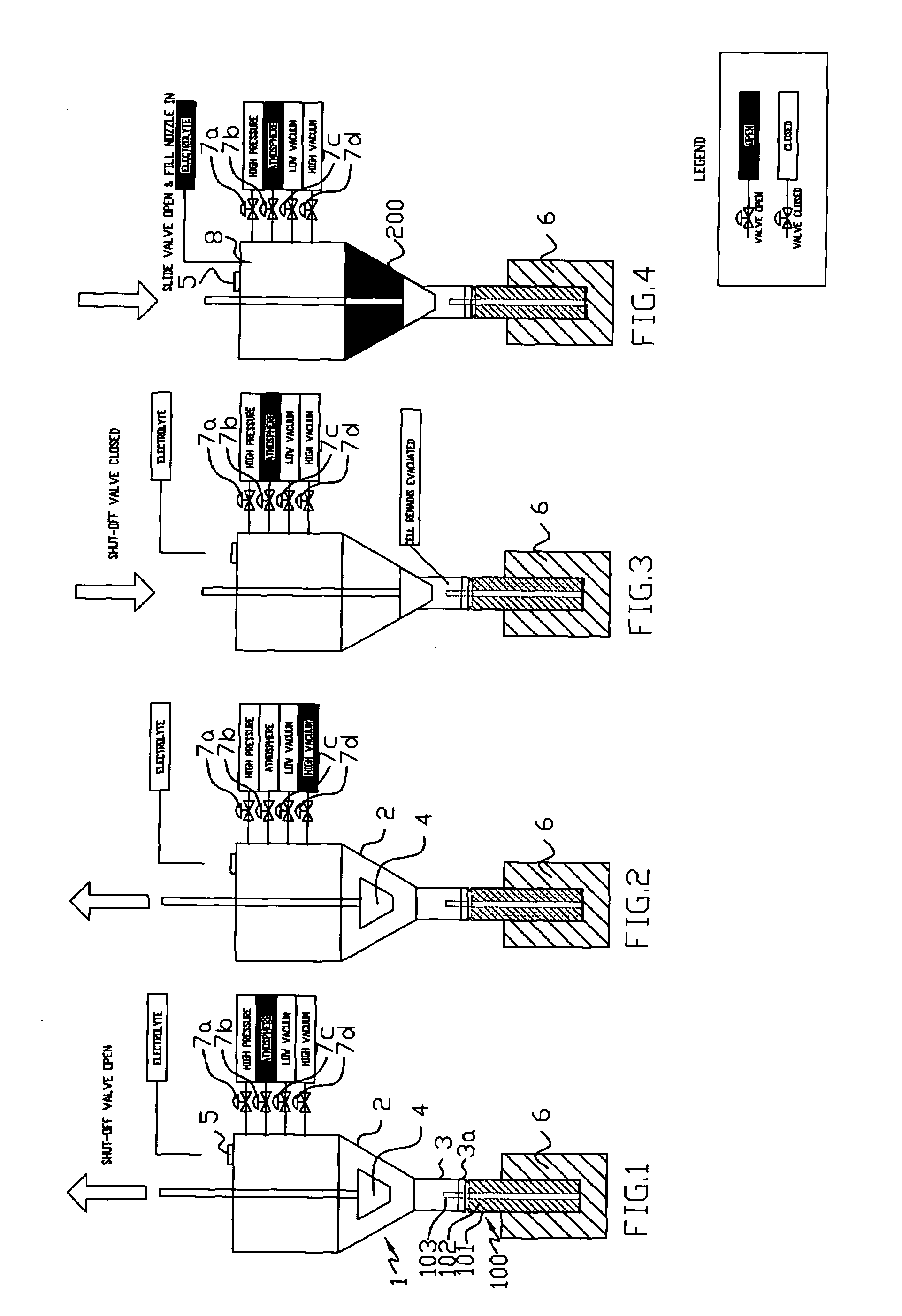

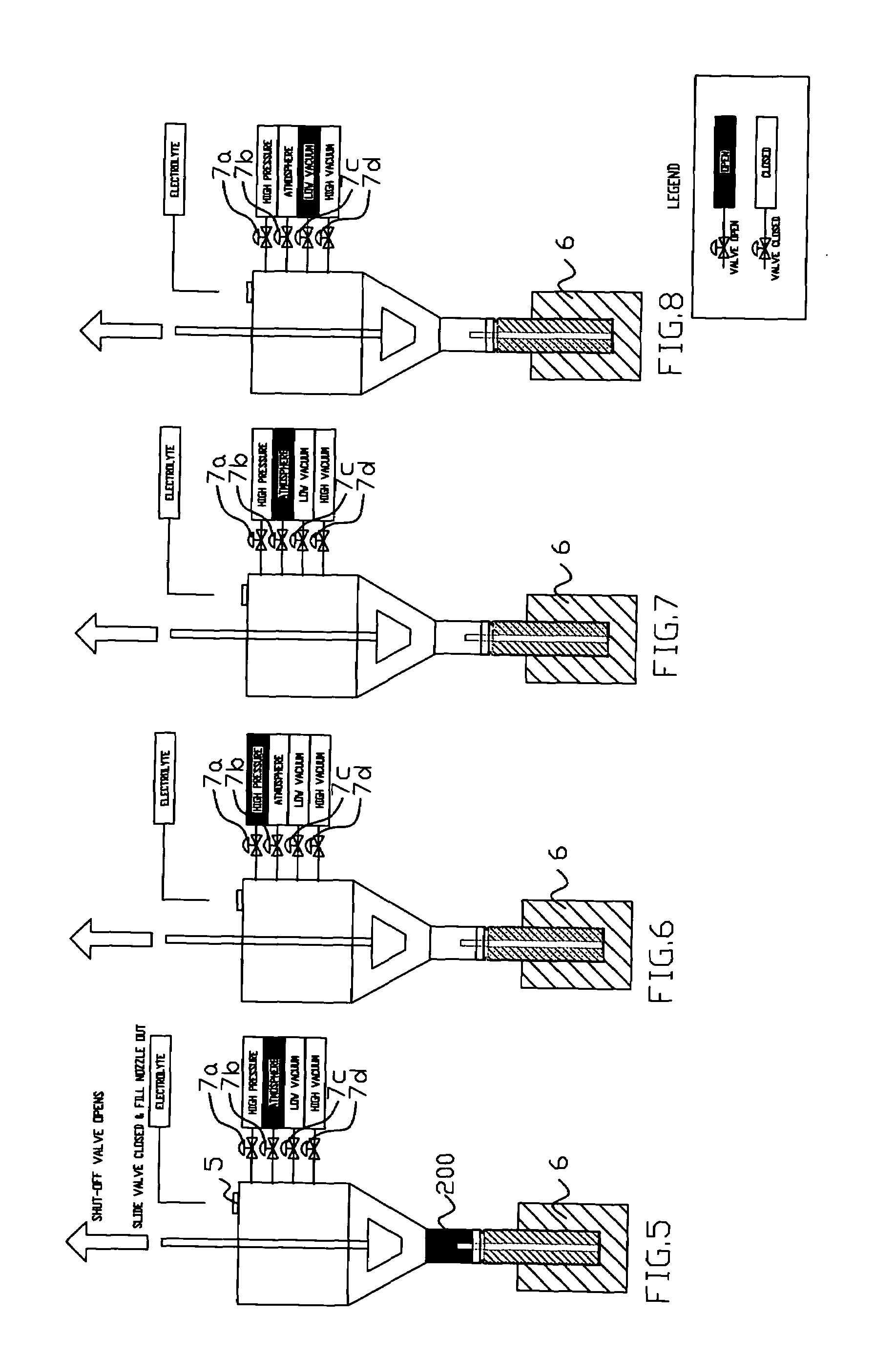

Method for filling electrolyte into battery cell and apparatus for carrying out the method

ActiveUS8047241B2Efficient removalEffective spaceSecondary cellsPackaging by pressurising/gasifyingProduct gasEngineering

Owner:HIBAR SYST +1

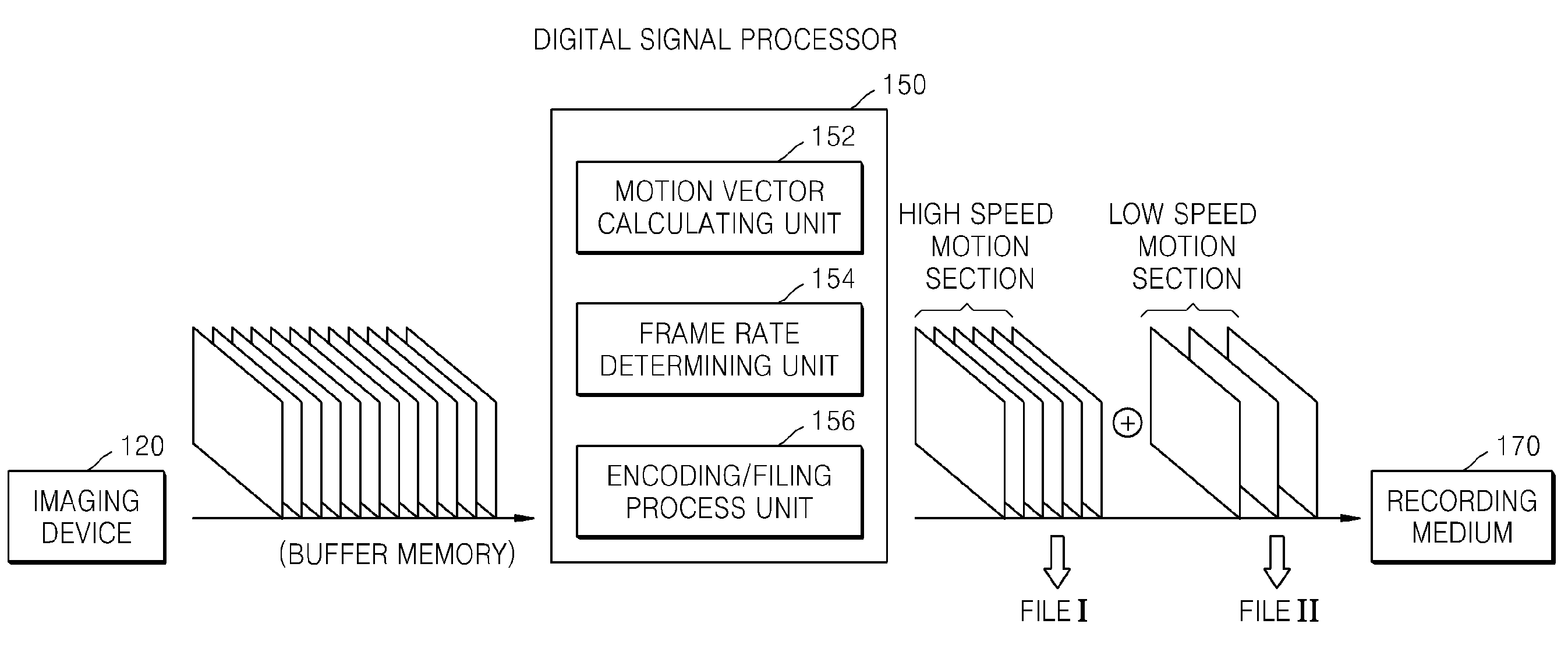

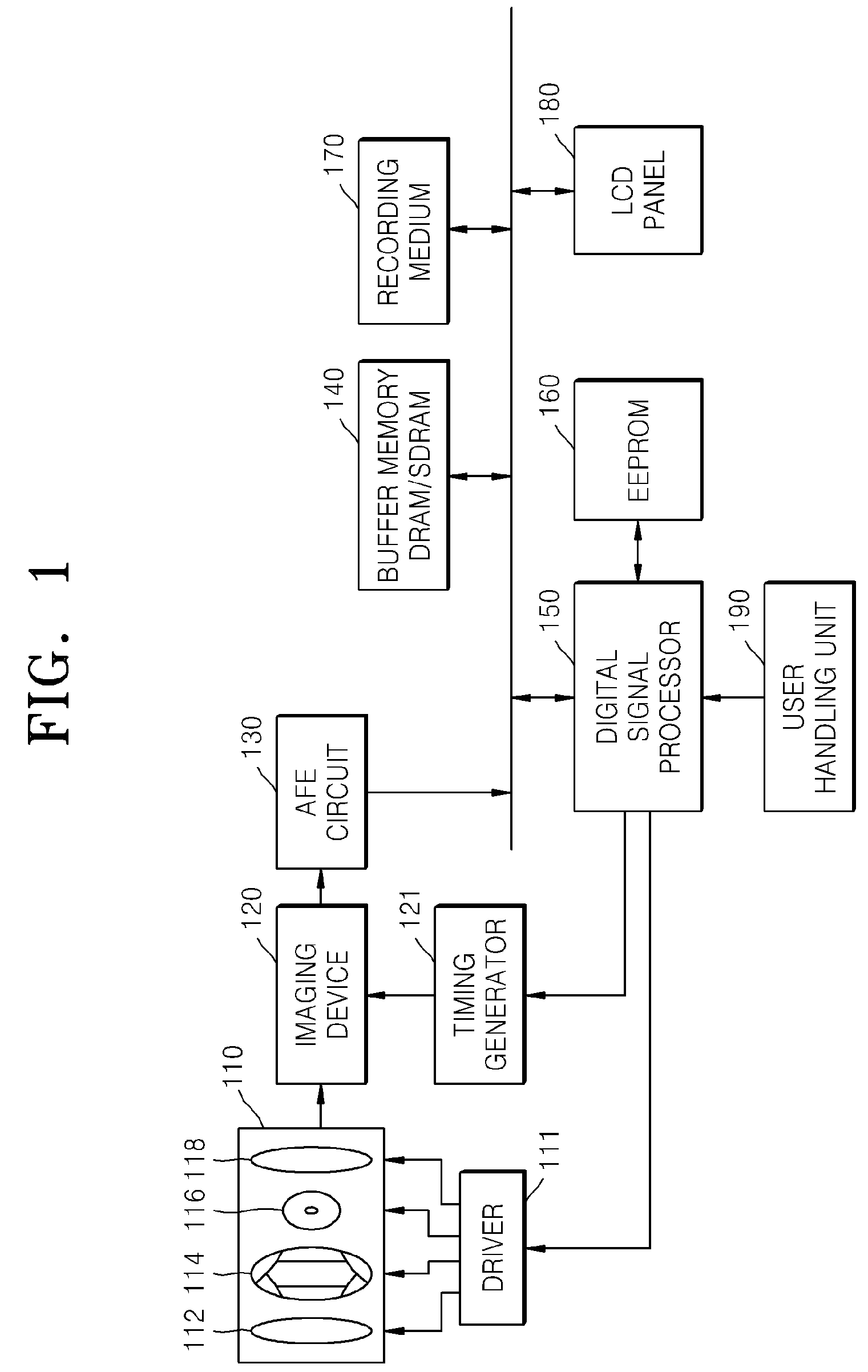

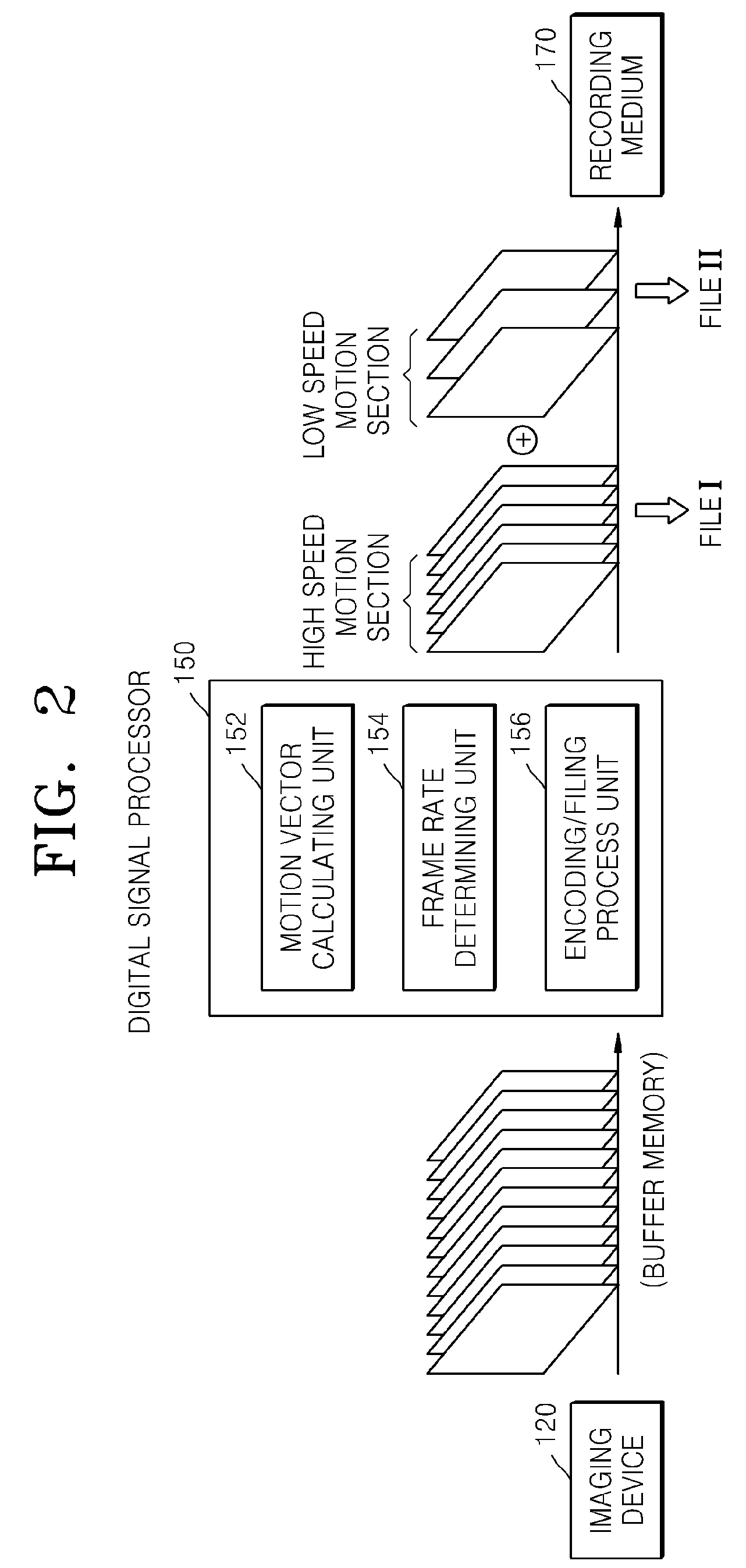

Digital camera having a variable frame rate and method of controlling the digital camera

ActiveUS8319859B2Reduce data sizeSave memory resourcesTelevision system detailsColor television detailsLow speedVariable frame rate

A digital camera capable of variably setting a frame rate may include an imaging device which outputs a plurality of temporally continuous image frames when photographing a moving image. The digital camera may also include a digital signal processor that determines a frame rate with which the image frames are filed, wherein the digital signal processor variably determines the frame rate according to a motion speed of a subject in the frames. The digital camera may further include a recording medium in which the filed image frames are stored. Accordingly, as the frame rate is varied according to the motion of a subject, the motion of the subject can be smoothly realized in a high motion speed section from a reproduction perspective, and substantially repeated image frames can be removed in a low speed motion section. Thus, the size of moving image files can be reduced, saving memory resources.

Owner:SAMSUNG ELECTRONICS CO LTD

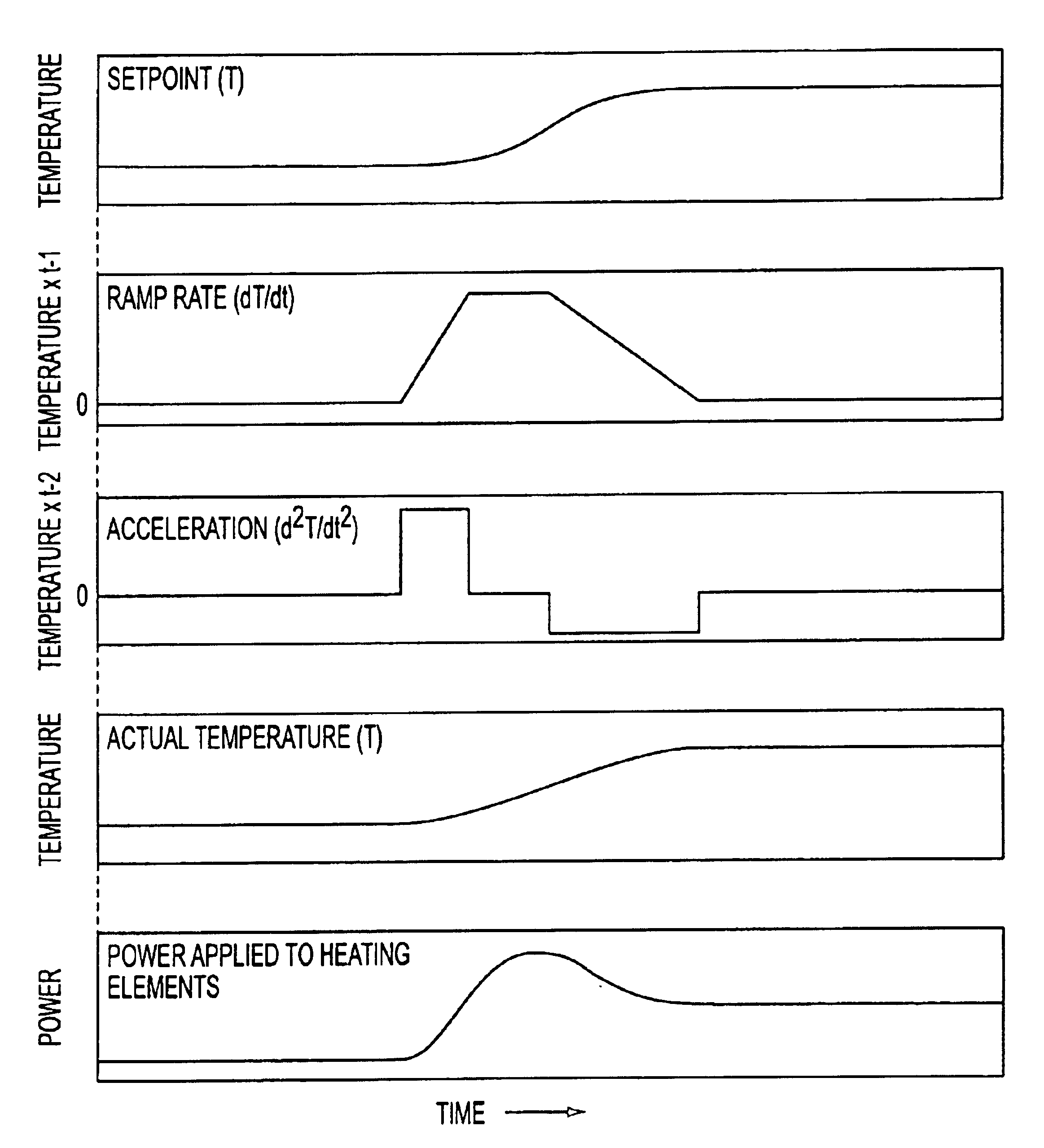

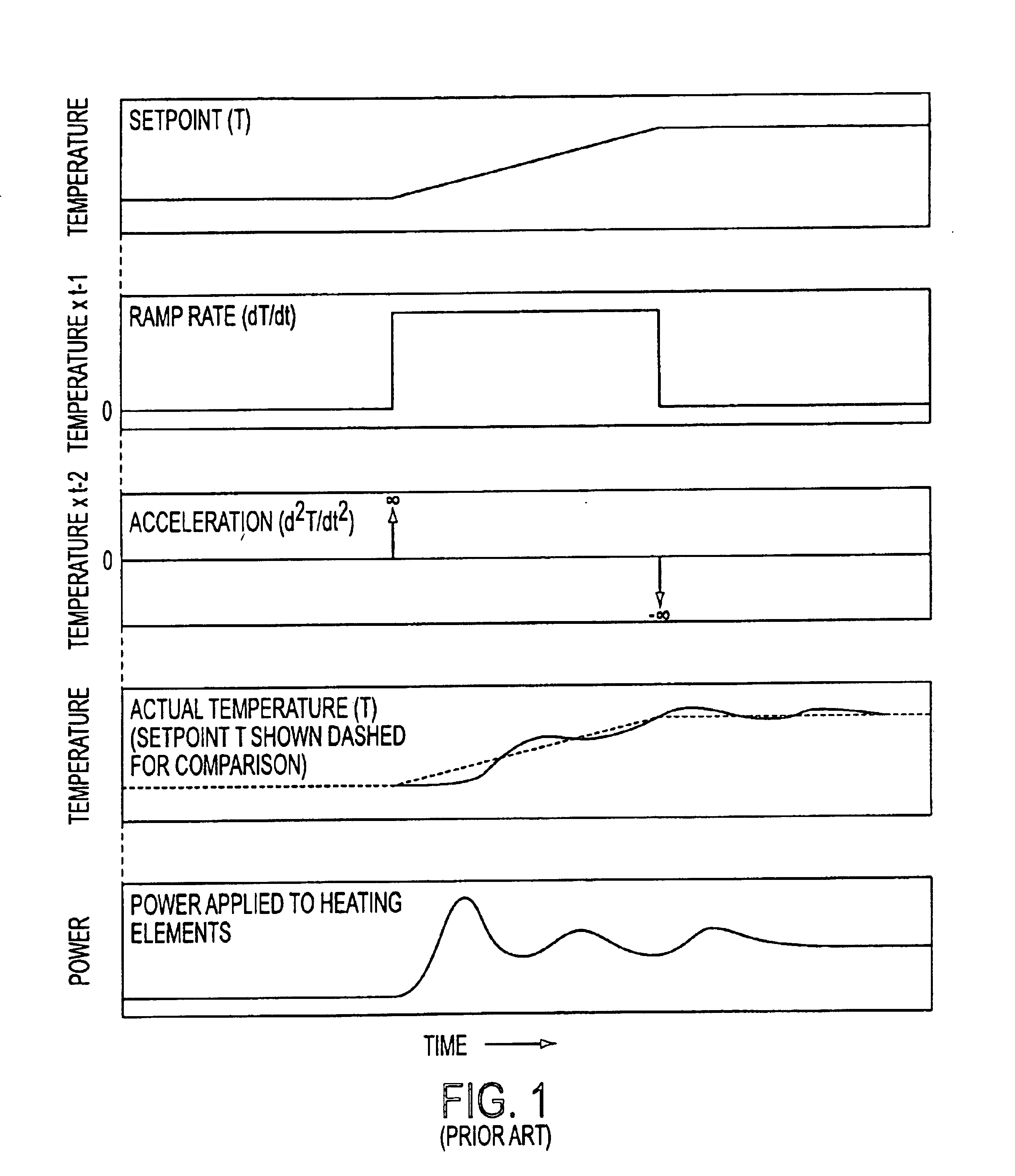

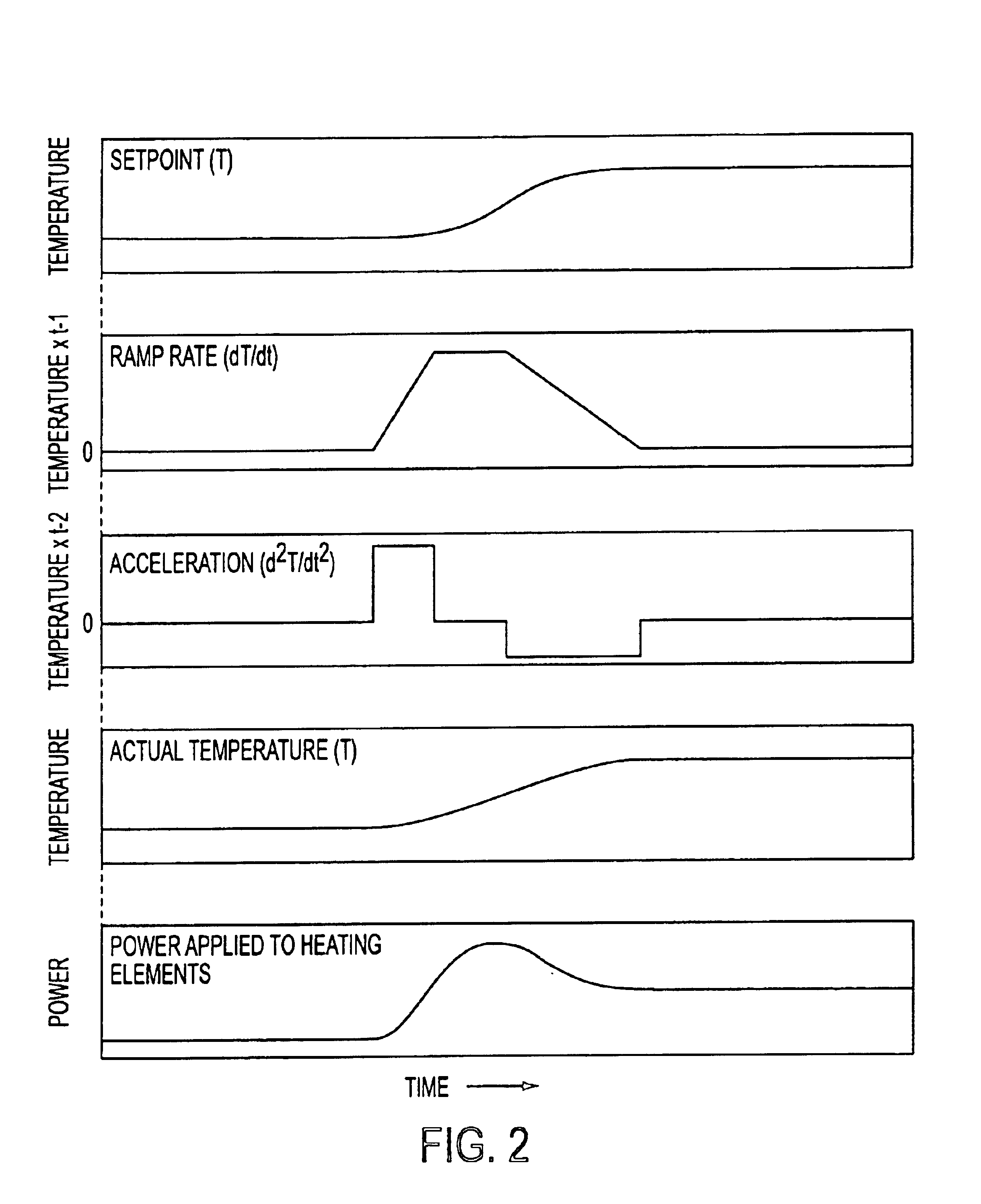

Inertial temperature control system and method

InactiveUS6901317B2Achieve smoothSampled-variable control systemsComputer controlTemperature controlControl system

An inertial temperature control system and method are provided for changing the temperature of a body between two temperatures such that the ending temperature is reached smoothly without substantial temperature overshoot or oscillation. A temperature control algorithm is fed a set point temperature that accelerates and decelerates at a physically attainable rate.

Owner:AVIZA TECHNOLOGY INC

Method for filling electrolyte into battery cell and apparatus for carrying out the method

ActiveUS20090242073A1Efficient removalEffective spaceSecondary cellsPackaging by pressurising/gasifyingProduct gasEngineering

A method for filling a battery cell with electrolyte, comprising:a) connecting the battery cell and a lower portion of a fill head chamber connected through respective first, second, third and fourth valves to a source of high pressure, the free atmosphere, a source of high vacuum and optionally a source of low vacuum, wherein only one of said valves can be open at any time, while said second valve is open;b) opening said third valve for a predetermined first period to discharge air from the interior of said battery cell through said chamber;c) separating the major upper portion of said chamber from the lower portion thereof by a sliding shut-off plunger and opening said second valve;d) dispensing a prescribed amount of electrolyte into said upper portion of said chamber above said plunger, while keeping said second valve open;e) raising said plunger to let a major portion of said dispensed liquid be sucked into said battery cell under the effect of the vacuum established therein in step b) and allowing any gas bubble in said battery cell to get removed through the electrolyte;f) opening said first valve for a second predetermined period to push said electrolyte into said battery cell;g) opening said second valve for a third predetermined period;h) repeating steps f) and g) at least once for the more complete removal of gases from the battery cell and filling the prescribed volume of electrolyte; and,i) disconnecting said battery cell from said fill head.

Owner:HIBAR SYST +1

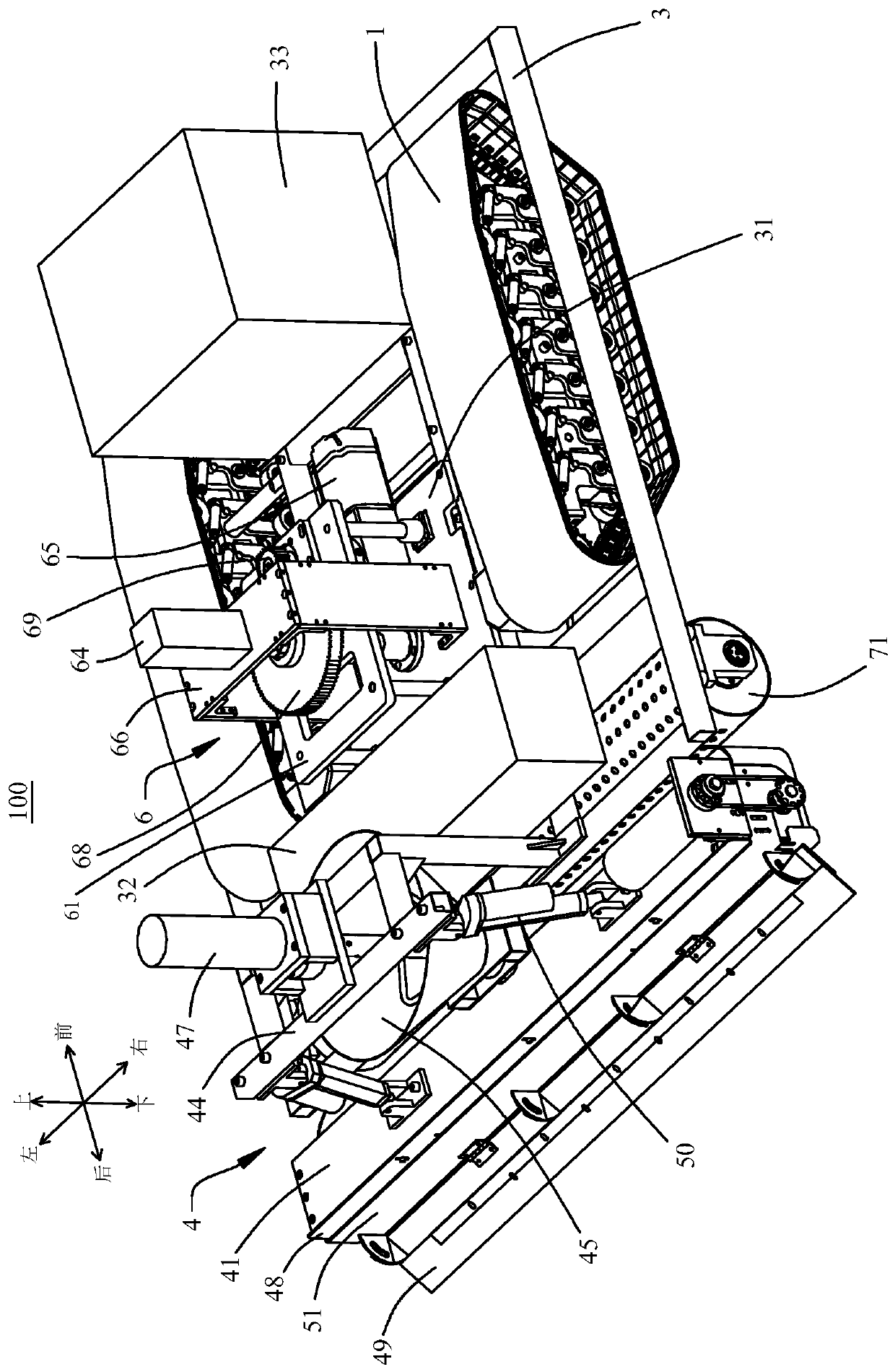

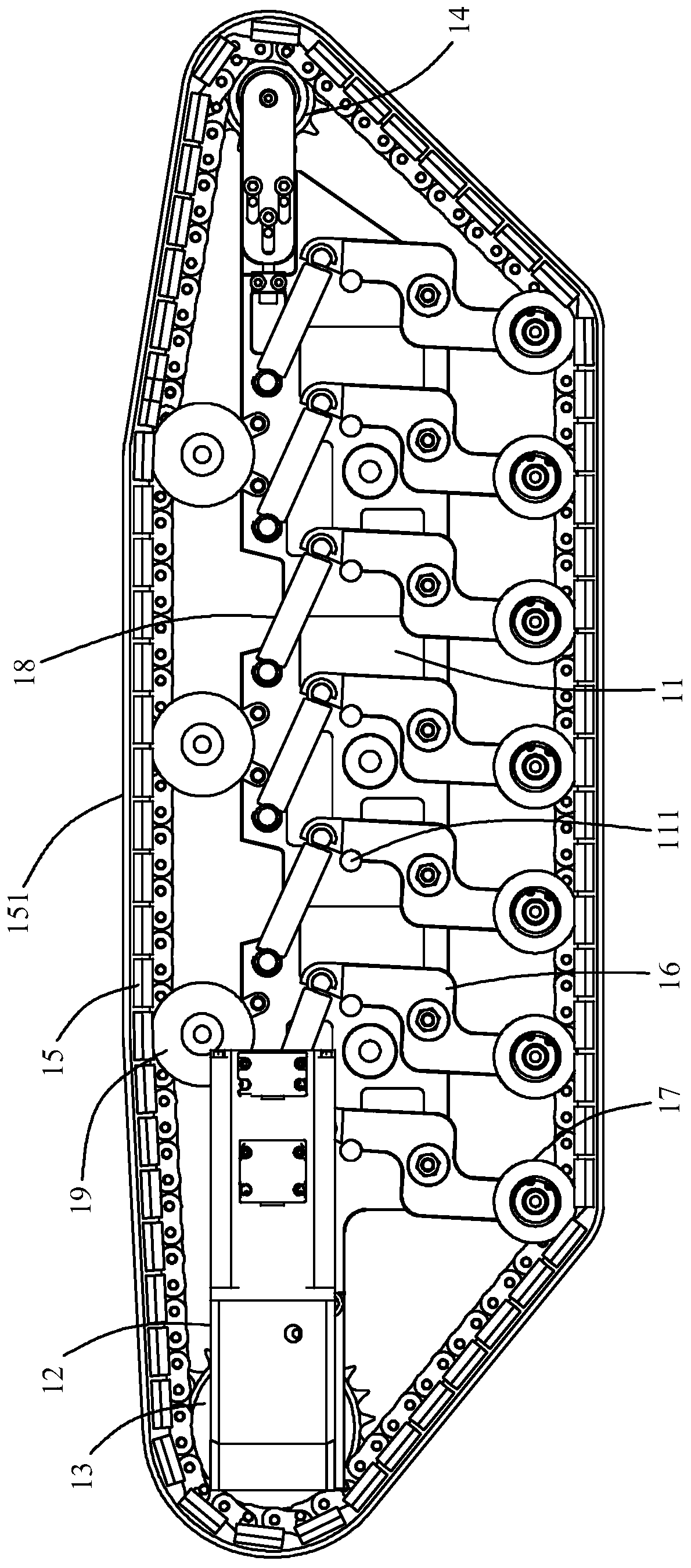

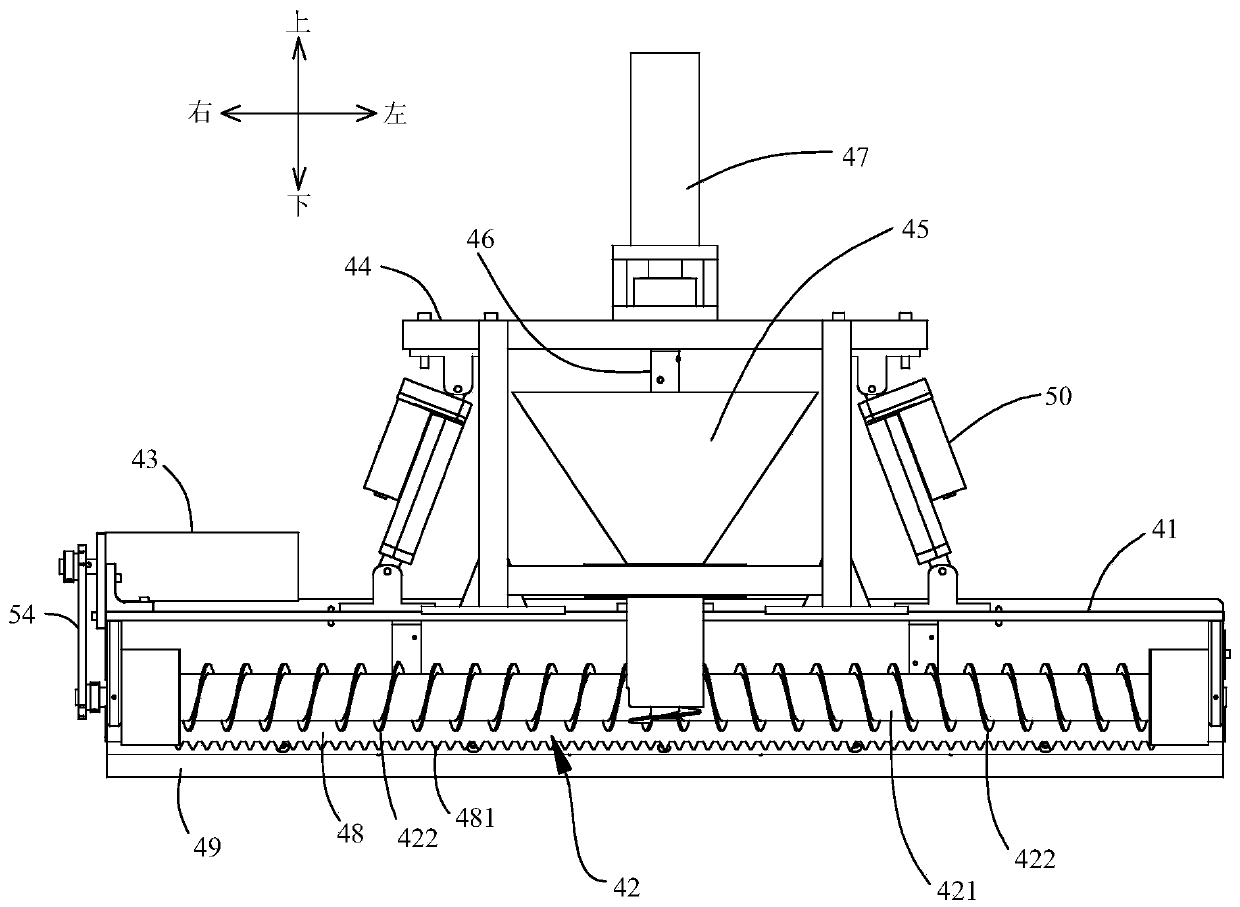

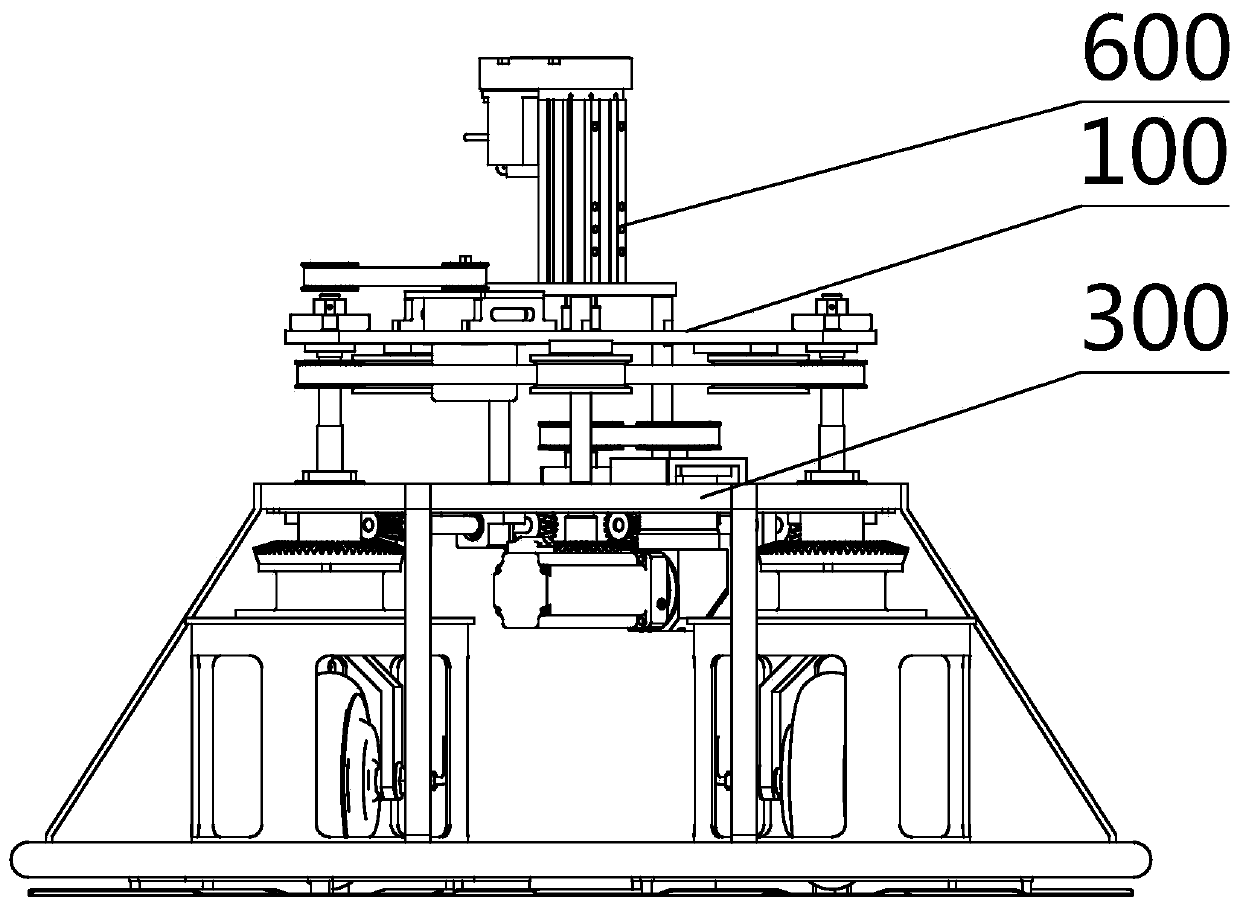

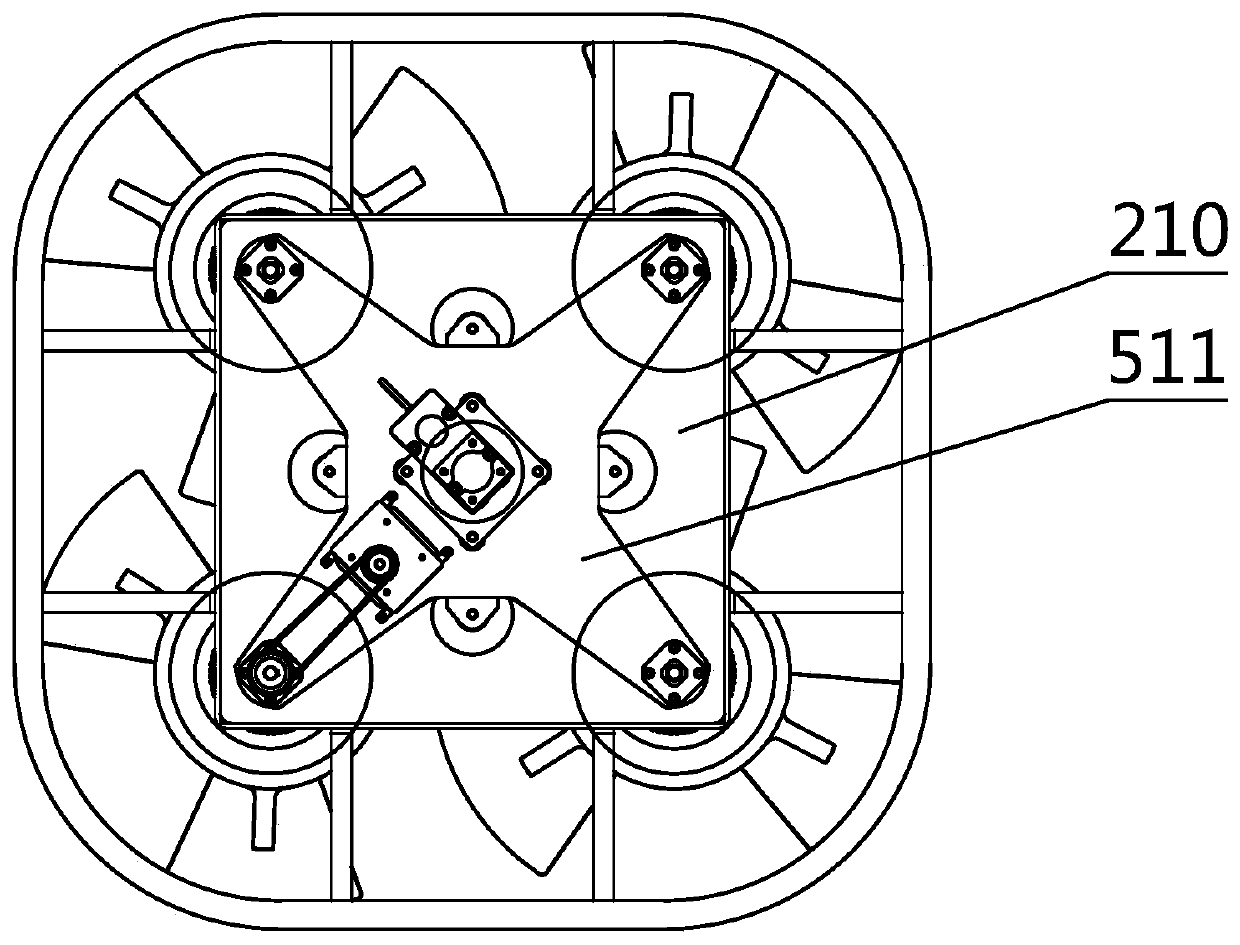

Troweling robot

ActiveCN110629643AImprove troweling work efficiencyImprove work efficiencyRoads maintainenceElectric machineryDrive motor

The application relates to a troweling robot and belongs to the technical field of troweling machinery. The troweling robot includes a travelling mechanism and the troweling mechanism, and the travelling mechanism includes two crawler devices, wherein each crawler device includes a crawler beam, a crawler driving motor, a drive sprocket, a tensioner sprocket and a crawler belt; the drive sprocketand the tensioner sprocket are arranged on the crawler beam; the crawler is coated on the drive sprocket and the tensioner sprocket; and the crawler driving motor is used for driving the drive sprocket to rotate; the troweling mechanism is connected with the travelling mechanism to move under the driving of the travelling mechanism, and the troweling mechanism includes a mounting base, a double spiral reverse screw rod and a milling motor, wherein two ends of the double spiral reverse screw rod are mounted on the mounting base in a rotatable manner, the milling motor is mounted on the mountingbase and used for driving the double spiral reverse screw rod to rotate forwards or backwards. The troweling robot provided in the embodiment of the application can realize automatic travelling and troweling and has high working efficiency.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

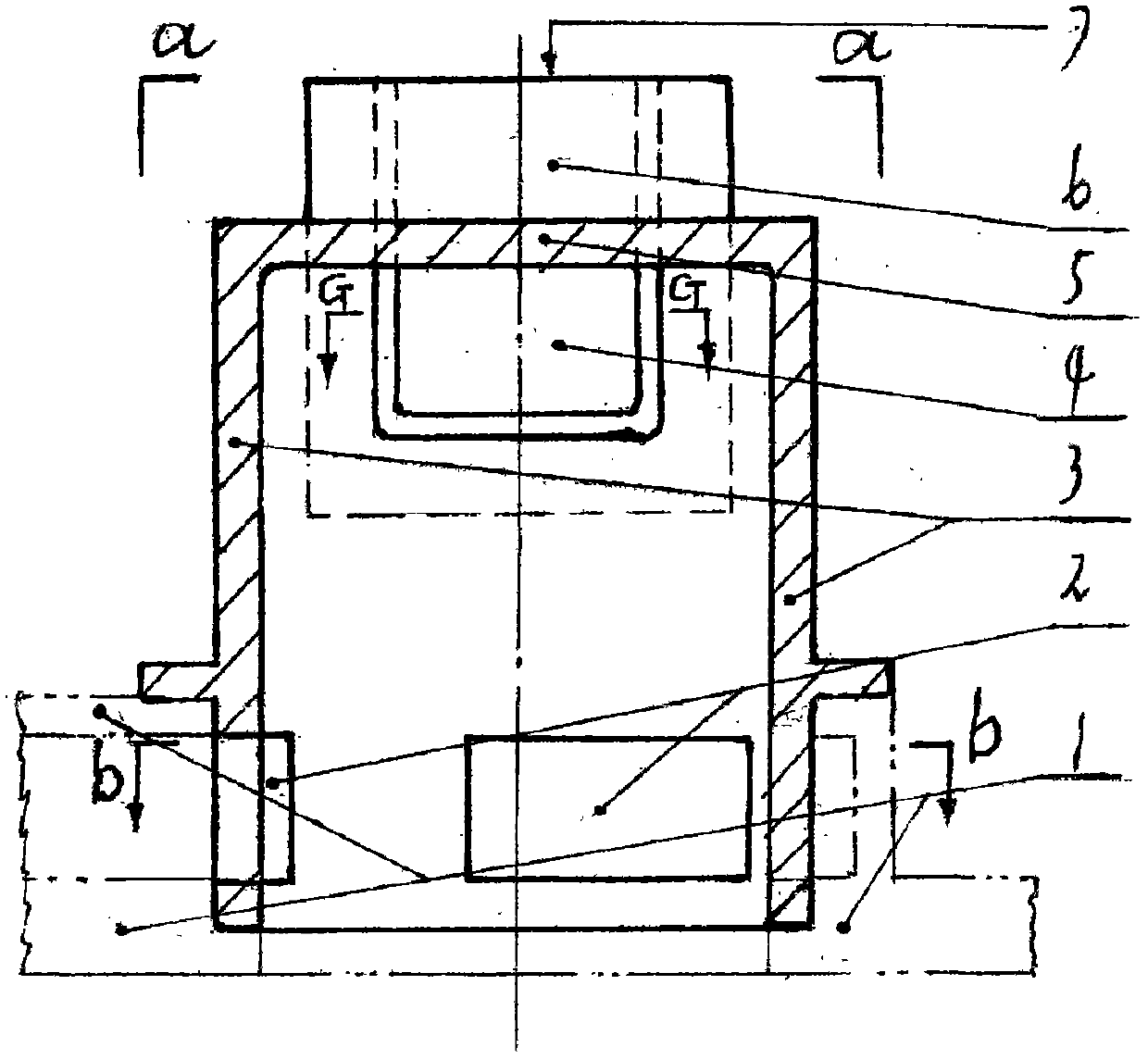

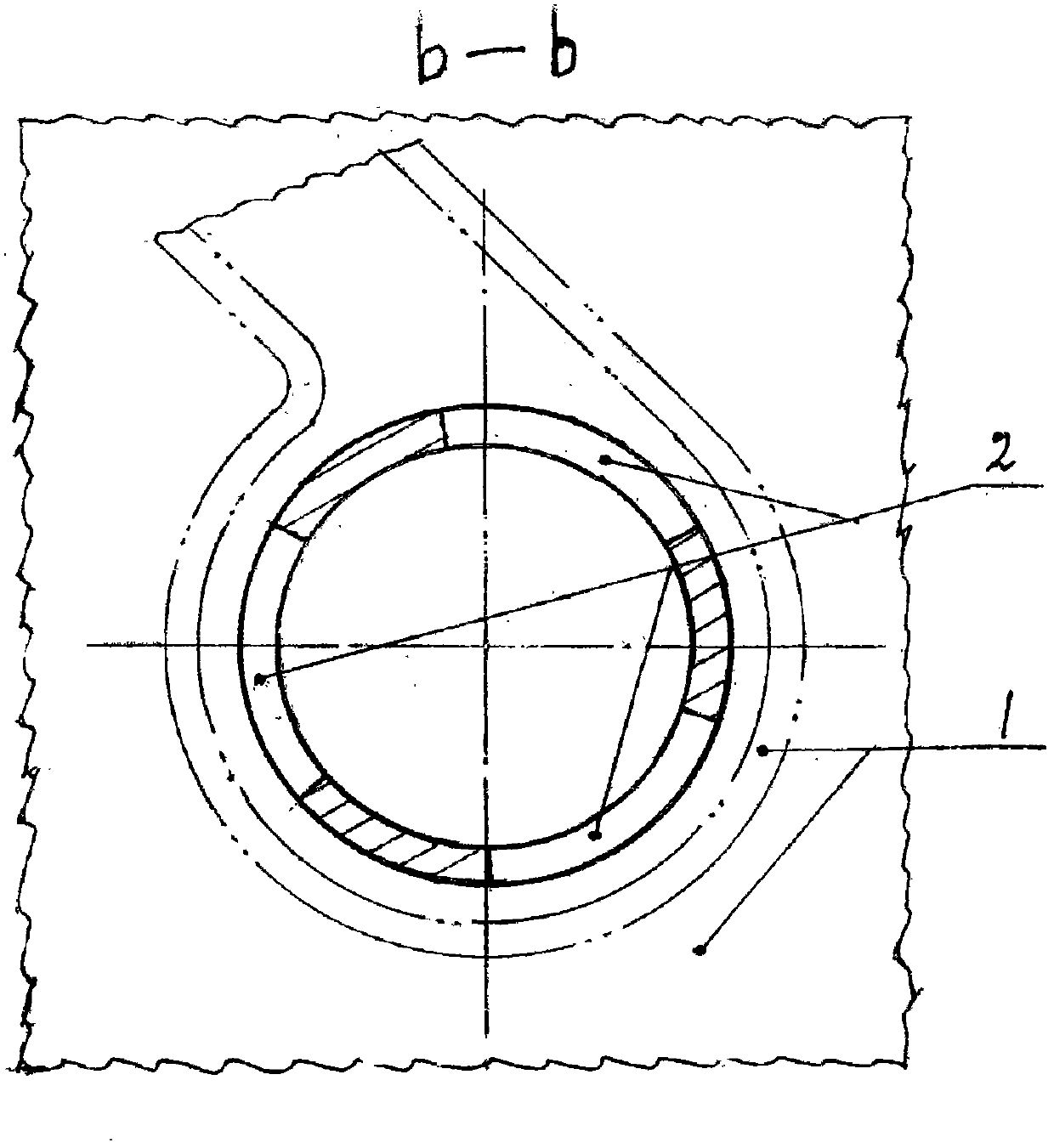

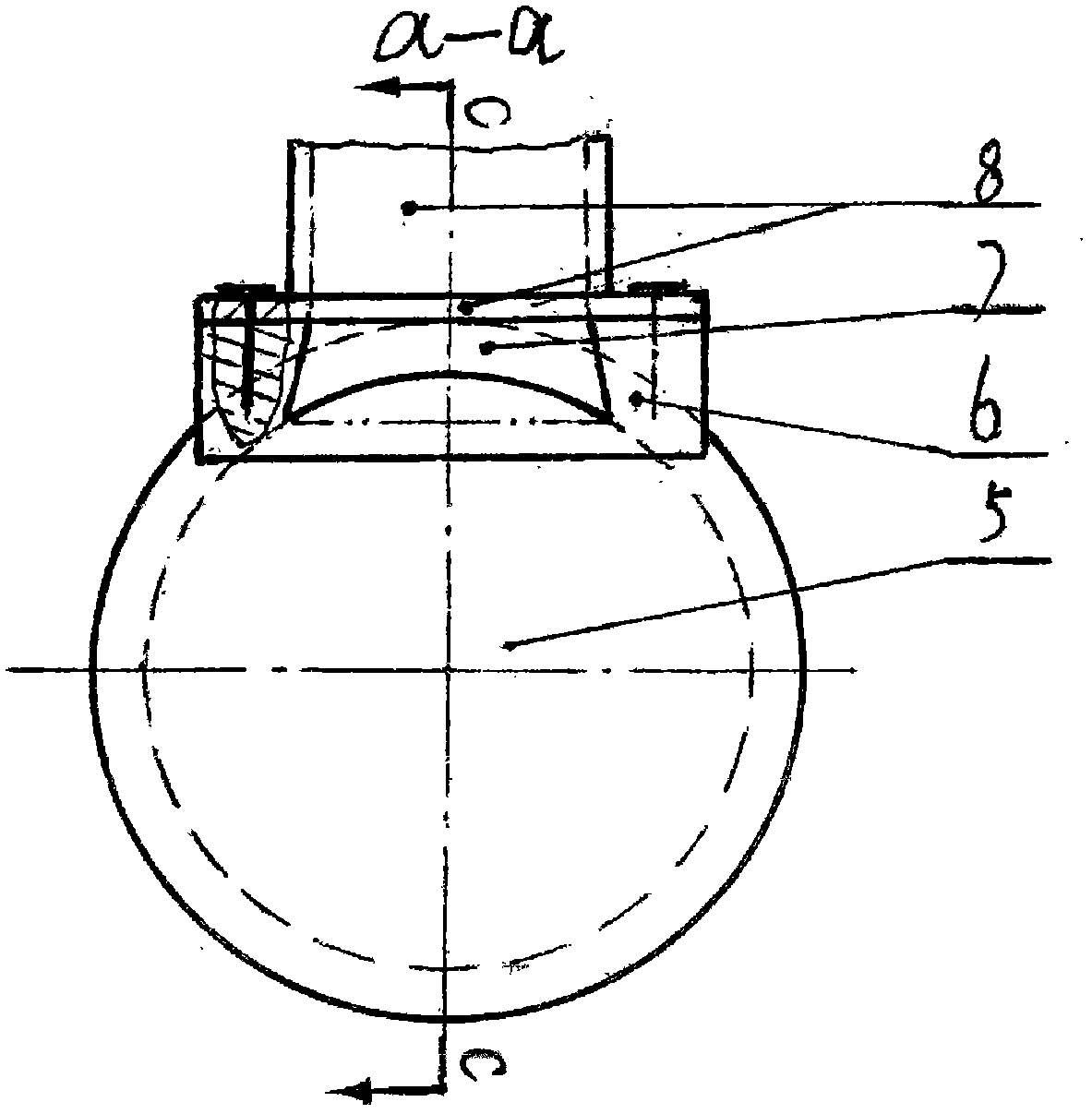

Starting cylinder of piston reciprocating internal combustion engine and air exhausting device of starting cylinder of piston reciprocating internal combustion engine

ActiveCN103993972AGood DC scavenging effectClose tightlyExhaust apparatusCylinder headsExternal combustion engineControl system

The invention discloses a starting cylinder of a piston reciprocating internal combustion engine and an air exhausting device of the starting cylinder of the piston reciprocating internal combustion engine. The starting cylinder and the air exhausting device are mainly characterized in that the mode that an air exhausting opening is formed in a starting cylinder cover plate, namely an engine cover plate, of an existing four-stroke or two-stroke direct current scavenging engine and connected with an air exhausting channel is changed into the mode that the air exhausting opening is formed in the side of a starting cylinder body and connected with the air exhausting channel, and meanwhile a mushroom-shaped vent valve is changed into a gate vent valve; in this way, the problem that a working mechanism must be arranged on the engine cover plate or multiple working parts are difficult to arrange is solved, damage, caused by air exhausting heat loads, to the engine cover plate and the arrangement on the engine cover plate is avoided, and indispensable conditions are particularly created for multiple overhead working systems and an overhead comprehensive regulating and control system which are invented in the ZL200710193939.4 invention with the publication patent number CN101205861B and a novel piston reciprocating internal combustion engine invented in the ZL200710193938.X invention with the publication patent number CN151289956B, wherein according to a pressurizing mechanism combination of the novel piston reciprocating internal combustion engine, energy is greatly saved, stains are greatly removed, and the specific weight of the engine is greatly reduced.

Owner:肖光宇

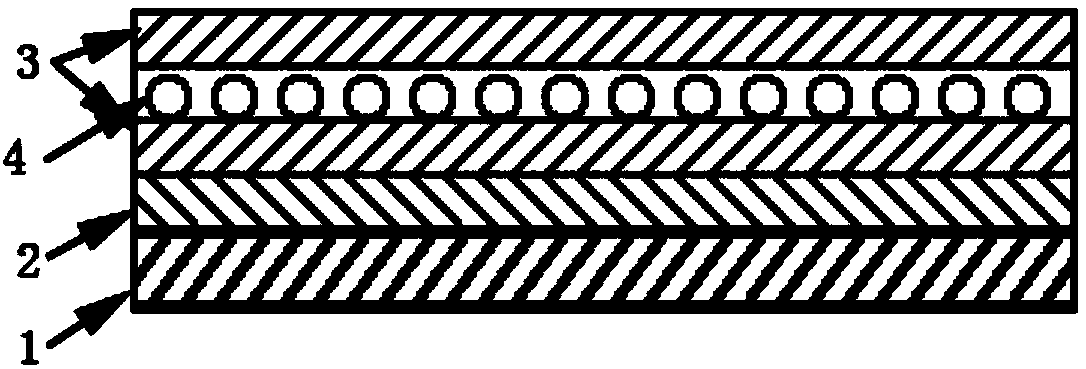

Inkjet printing method of ultra-thin thin fabric and inkjet printing combination layer thereof

The invention discloses an inkjet printing method of ultra-thin thin fabric. The method includes the steps that printing assistant is dissolved in solvent, pasting material is added and stirred, and a sizing agent is prepared; the sizing agent is pressed on the ultra-thin thin fabric in a soaked mode, or the ultra-thin thin fabric is coated with the sizing agent, and the ultra-thin thin fabric with the sizing agent is dried and coiled for use; a carrier is coated with adhesive to serve as a cushion layer carrier, and the carrier coated with the adhesive is dried for use; the ultra-thin thin fabric processed in the coating or soaking pressing mode is attached to the adhesive side of the cushion layer carrier, pressurizing is performed, the ultra-thin thin fabric and the cushion layer carrier are combined together to form an inkjet printing combination layer, and the inkjet printing combination layer is coiled for use; the inkjet printing combination layer is installed on the inkjet printing machine, inkjet printing is performed on one side, where the sizing agent is distributed, of the ultra-thin thin fabric, and meanwhile drying and coiling are performed; the ultra-thin thin fabric is processed in an after-finish fixation mode and then is washed by water, forming or stentering is performed, and the ultra-thin thin fabric with inkjet printed patterns is formed.

Owner:张家港市普坤羊绒制品有限公司

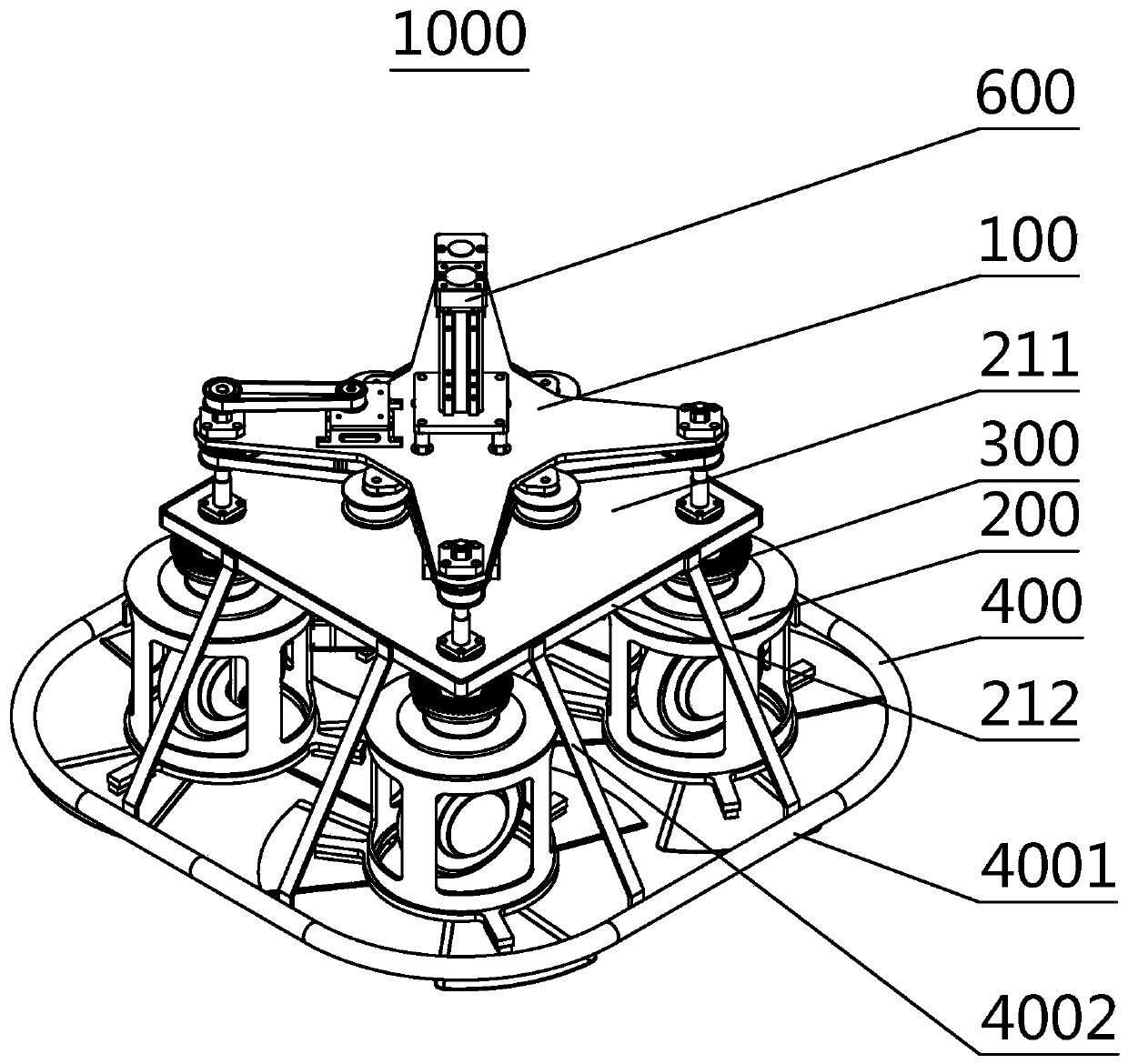

Leveling robot

ActiveCN110565925ANo interferenceAchieve smoothBuilding constructionsEngineeringMechanical engineering

The invention provides a leveling robot, and relates to the field of building robots. The leveling robot comprises a travelling mechanism and a leveling execution mechanism; the travelling mechanism comprises a first base, a plurality of guide shafts and a plurality of travelling wheels, wherein the upper end of each guide shaft is connected to the first base, and the lower ends of the guide shafts are provided with the travelling wheels; and the leveling execution mechanism comprises a second base, a leveling disc driving device and a plurality of leveling disc units, wherein the leveling disc driving device and the plurality of leveling disc units are mounted on the second base, the leveling disc driving device is used for driving the leveling disc units to rotate relative to the secondbase, the second base is slidably arranged on the guiding shafts in a sleeving mode, the plurality of leveling disc units are in one-to-one correspondence with the plurality of guide shafts, and eachleveling disc unit coaxially sleeves the corresponding guide shaft. Under installation cooperation among the travelling mechanism, the leveling execution mechanism and a leveling downward pressing force control mechanism, the leveling robot is compact in structure and good in integrity, can be flexibly turned, is full in covering area during leveling, and can also control the downward pressing force.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Automatic spraying device, spraying production equipment and automatic spraying method for floor side

InactiveCN101733224AUniform amount of sprayingIncrease profitSpraying apparatusPretreated surfacesEngineeringContinuous operation

The invention relates to a processing technology of floors. An automatic spraying device for a floor side comprises a containing slot, wherein the containing slot can be used for containing the floor side, the containing slot is provided with a spray head and a paint recovering opening, the spray head is connected with a paint transmission pipeline, and the paint recovering opening is connected with a paint recovering pipeline. Automatic spraying production equipment for the floor side comprises a floor feeding device, an automatic spraying device, a drying device and a polishing device, wherein the automatic spraying device comprises the containing slot which can be used for containing the floor side, the containing slot is provided with the spray head and the paint recovering opening, the spray head is connected with the paint transmission pipeline, and the paint recovering opening is connected with the paint recovering pipeline. The automatic spraying device for the floor side is used for spraying, the automation degree is high, and both sides of the floor have uniform spray amount and uniform color, thereby solving the problem of a manually operated original method, lowering the labor intensity of workers and realizing continuous operation; and the paint recovering opening is arranged, thereby improving the utilization ratio of paint and greatly lowering the production cost.

Owner:GUANGDONG YINGRAN WOOD IND

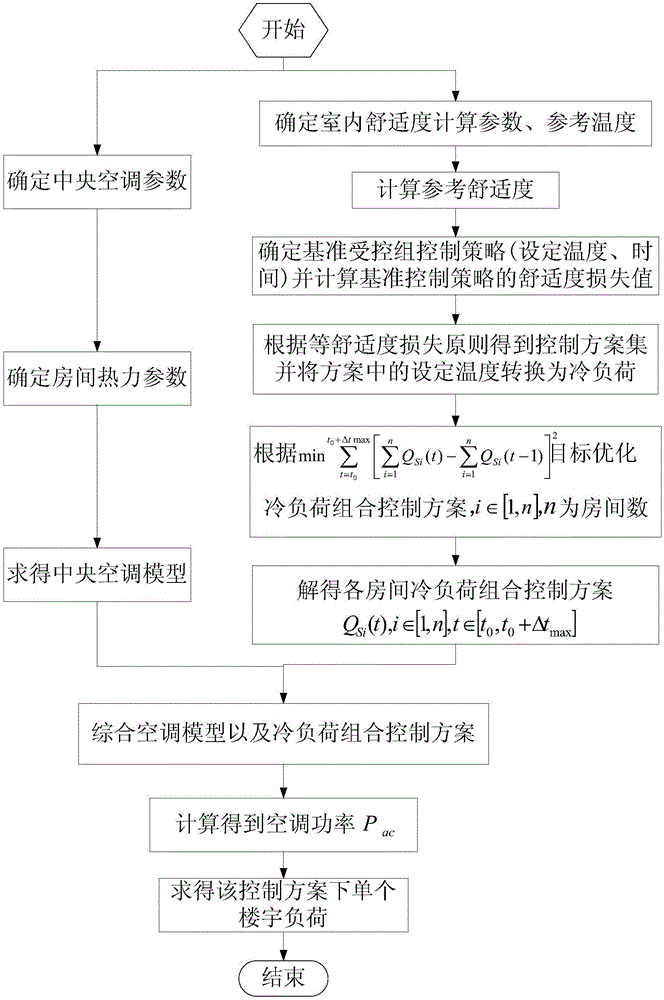

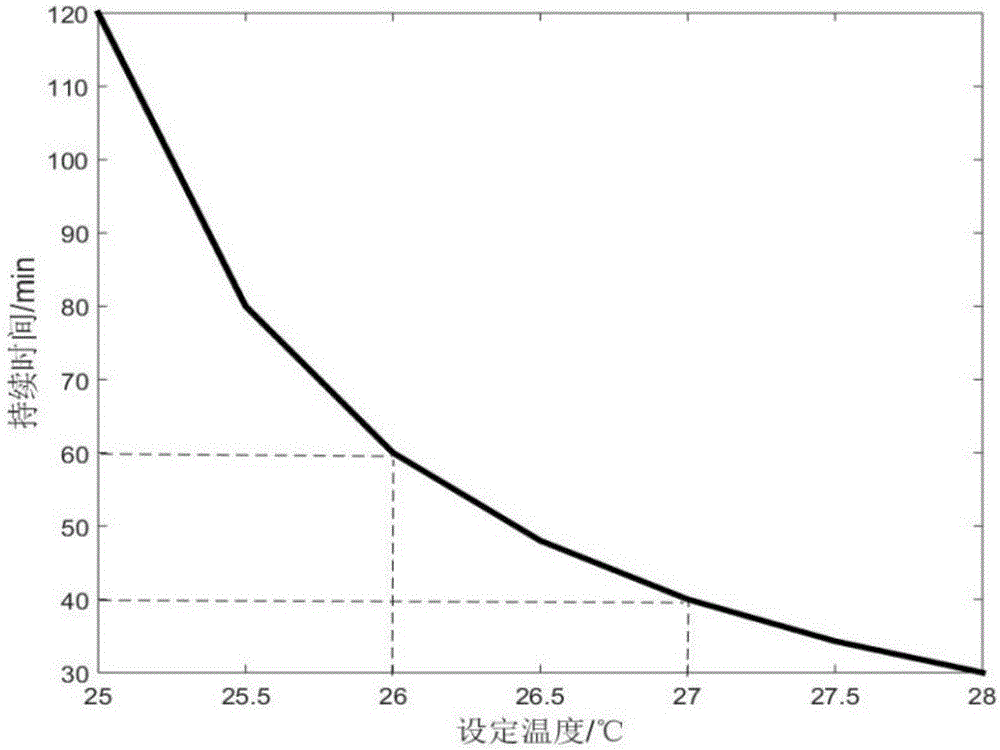

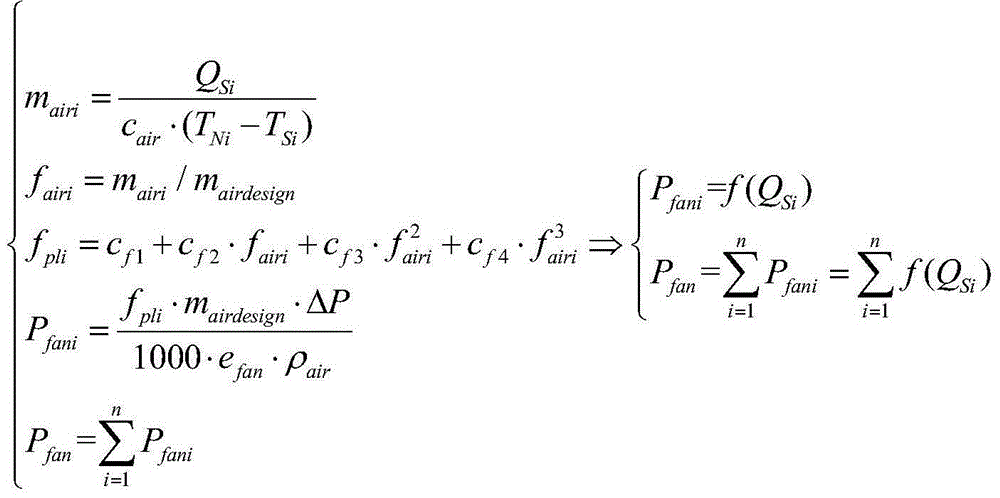

Central air conditioner load-reduction temperature-adjusting method based on equal comfort level loss principle

ActiveCN105020859AAchieving load reductionWon't wear outMechanical apparatusSpace heating and ventilation safety systemsEngineeringDemand response

The invention discloses a central air conditioner load-reduction temperature-adjusting method based on an equal comfort level loss principle. The central air conditioner load-reduction temperature-adjusting method includes the steps that on the basis of a central air conditioner model, terminal set temperature values of all rooms and indoor cold load conditions of all rooms in a commercial building are considered; according to the principle that human body comfort level loss values of all rooms are equal, the load reduction lasting time of all rooms is obtained, then temperature adjustment control over all rooms is carried out, and load reduction of a central system is achieved. According to the central air conditioner load-reduction temperature-adjusting method, the user comfort level is sufficiently considered, the commercial building participates in demand responses to achieve load reduction, and the reasonability and the scientificity of a load reduction scheme are improved.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

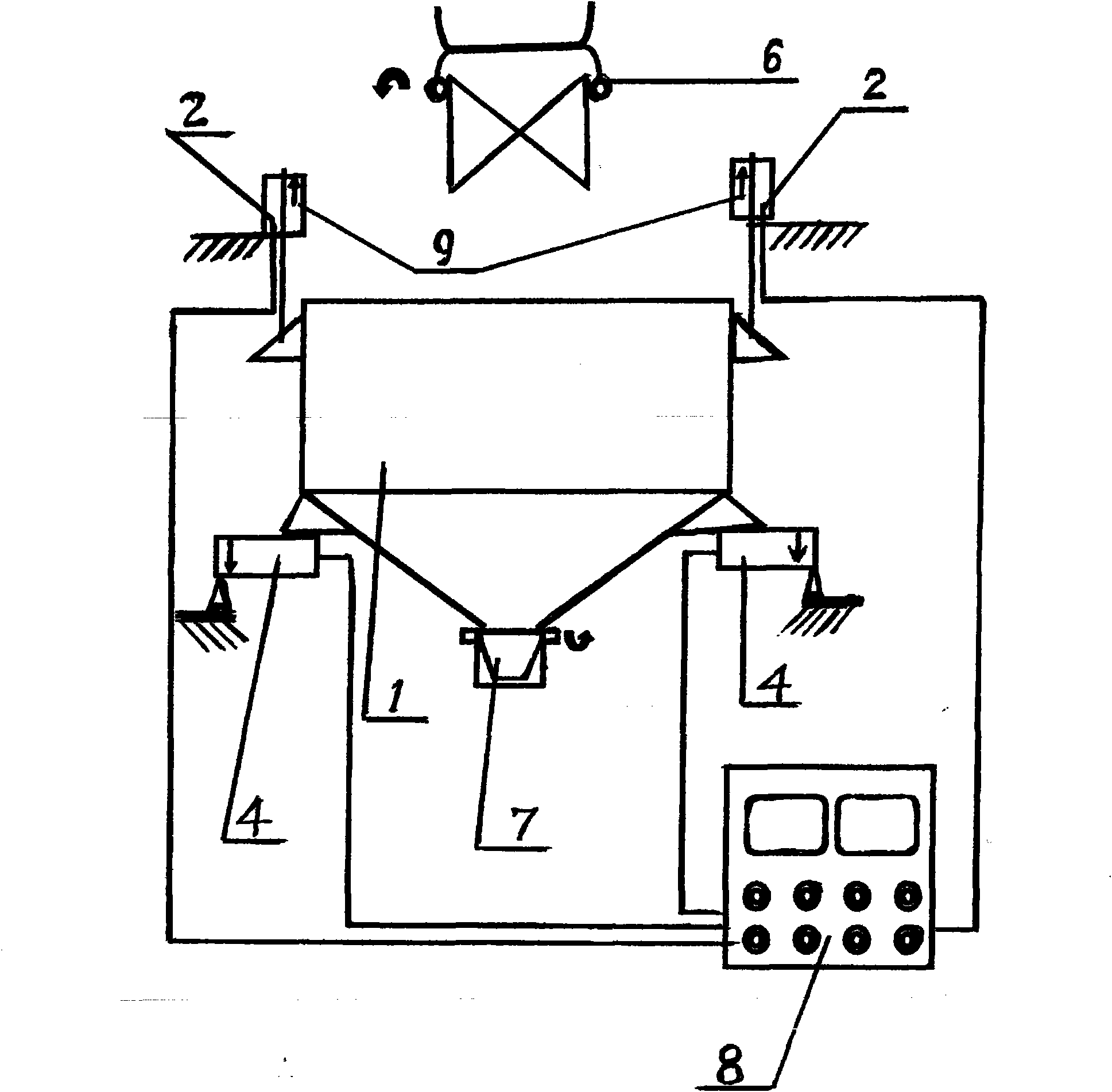

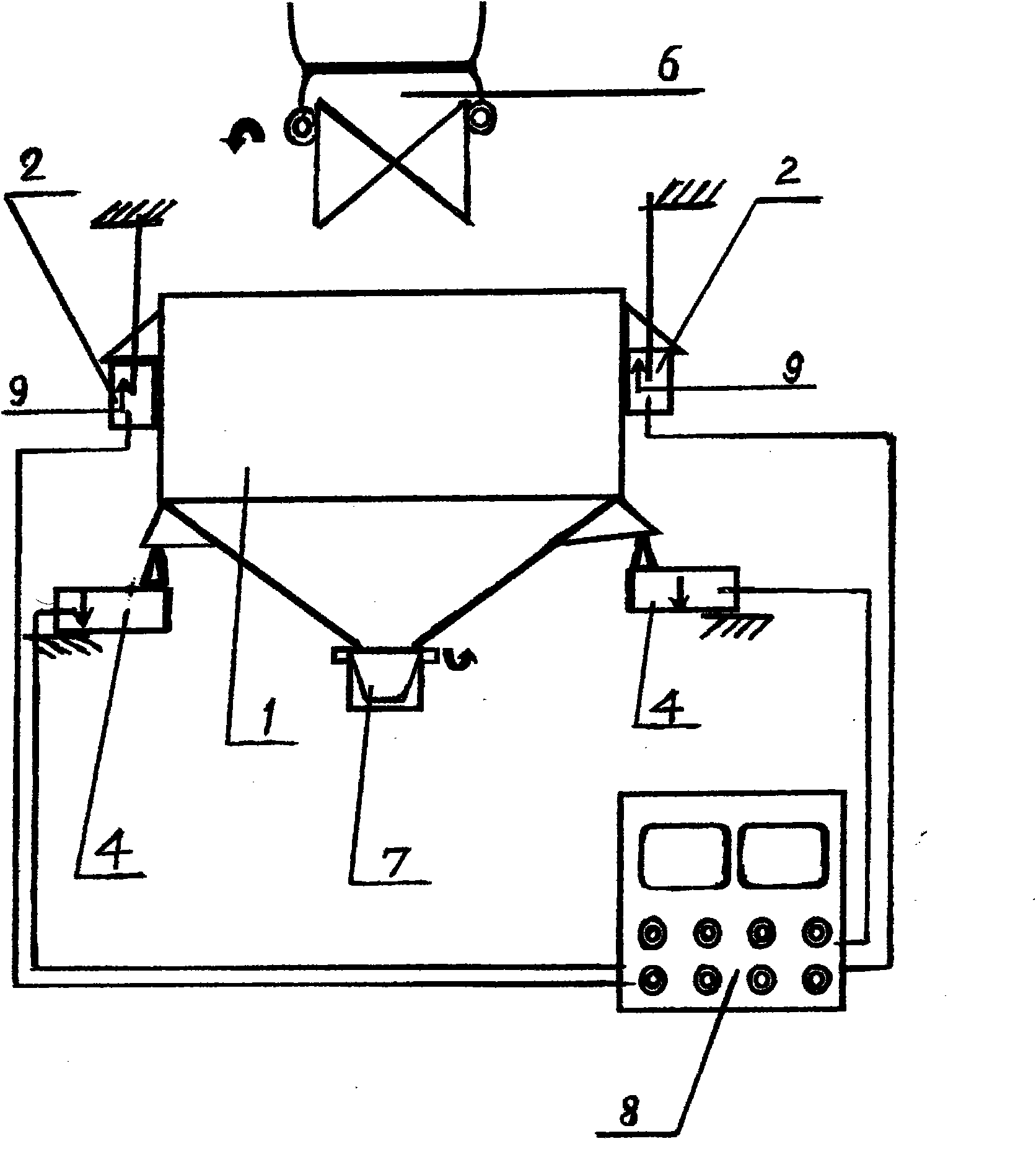

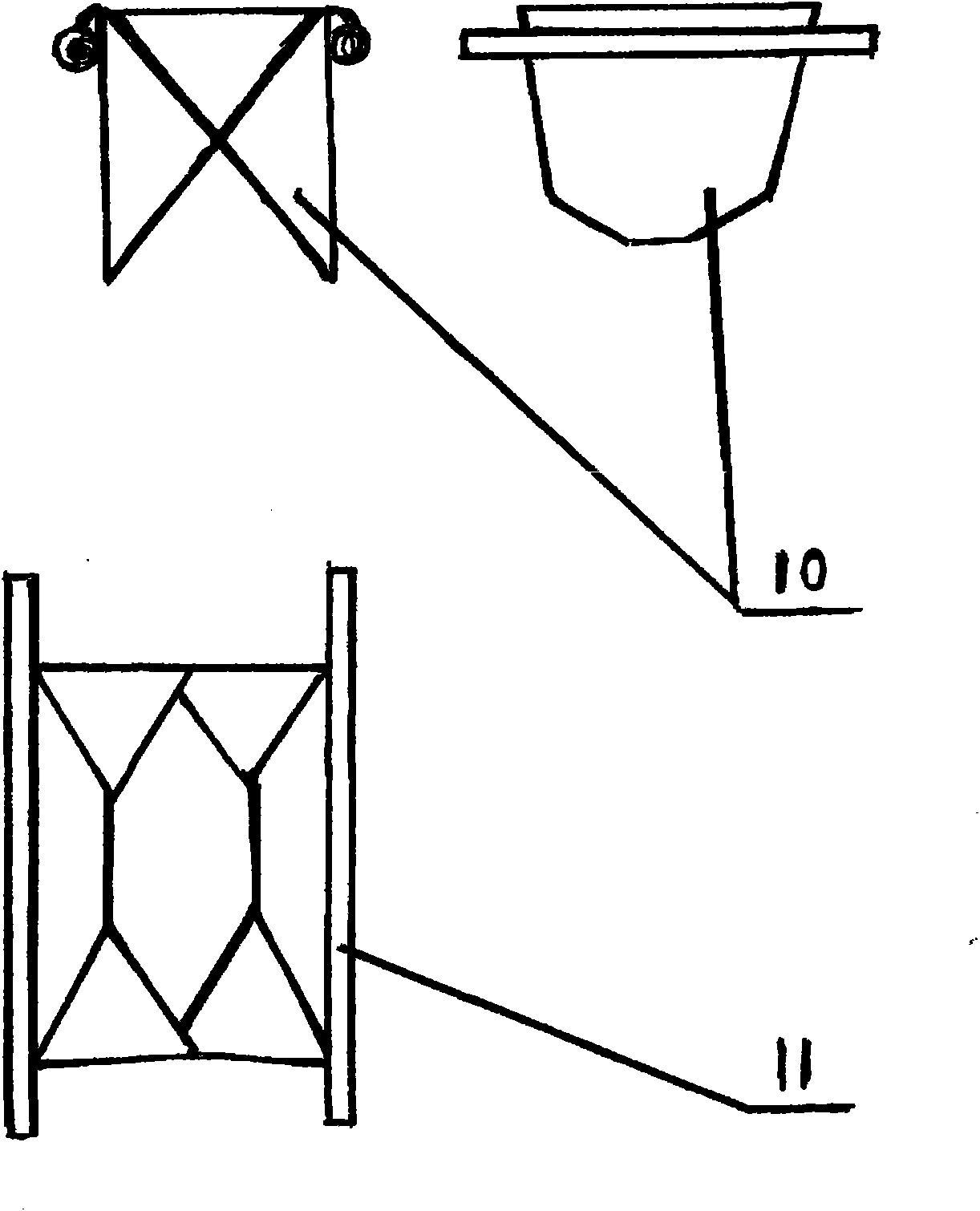

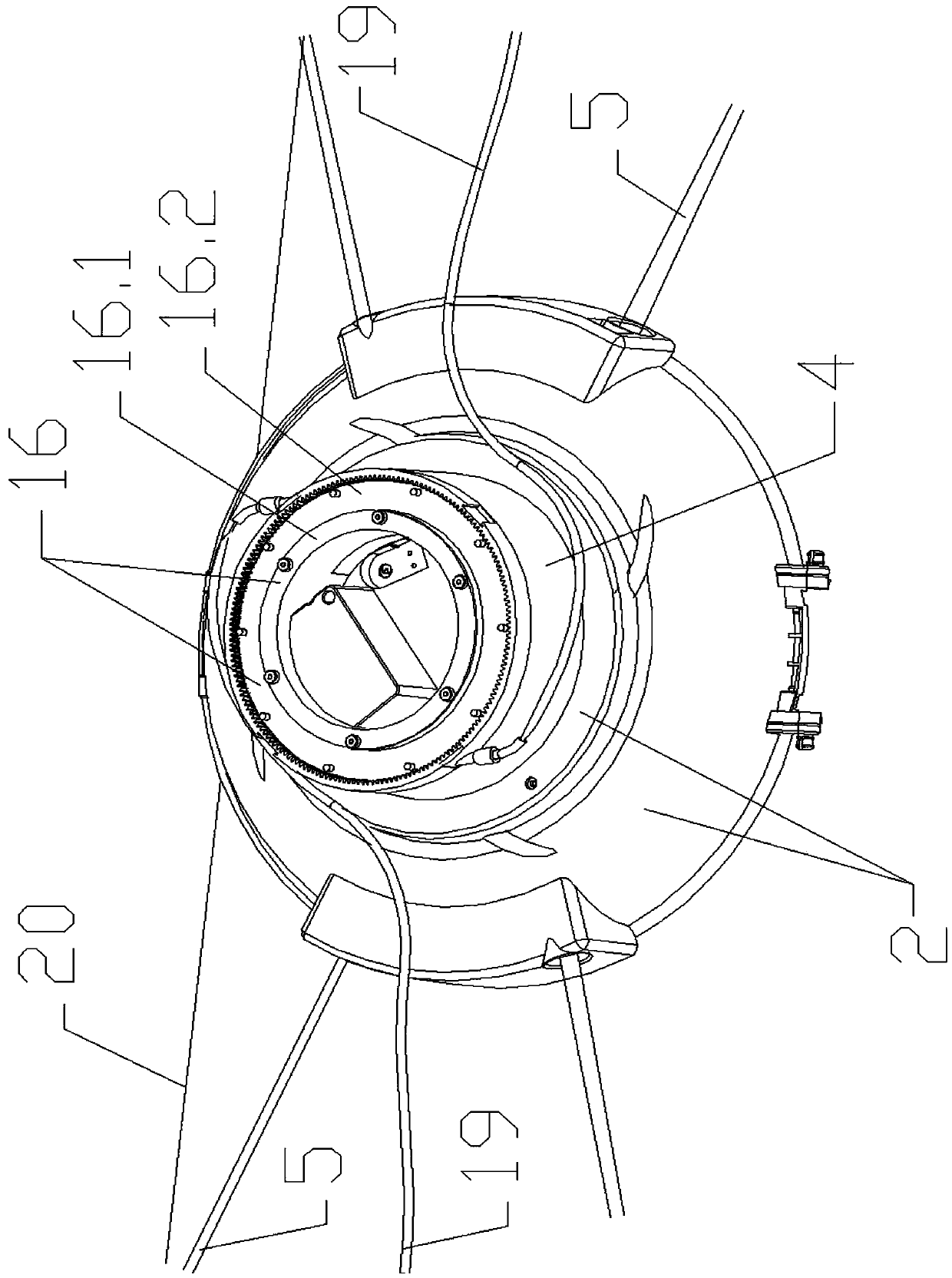

Scale

InactiveCN101782422AStable structureGuaranteed costPackagingWeighing apparatus with automatic feed/dischargeEngineeringControl measure

Owner:胡东兵

Full-automatic automobile cover

The invention provides a full-automatic automobile cover. The full-automatic automobile cover comprises a cloth cover body unfolding mechanism, a cloth cover body, a cloth cover body closing mechanism and cloth cover body auxiliary unfolding mechanisms, wherein the cloth cover body unfolding mechanism is installed on a roof of an automobile, the cloth cover body is fixedly arranged on the cloth cover body unfolding mechanism in a sleeved mode through a top sleeve opening, the cloth cover body closing mechanism is arranged on the cloth cover body unfolding mechanism, the cloth cover body auxiliary unfolding mechanisms are arranged on the cloth cover body unfolding mechanism and the cloth cover body closing mechanism, the cloth cover body is driven by the cloth cover body unfolding mechanism to be unfolded or folded, the cloth cover body closing mechanism is driven by the cloth cover body unfolding mechanism to close an opening formed in the lower end of the cloth cover body when an automobile body is covered with the cloth cover body, the cloth cover body auxiliary unfolding mechanisms smoothen the cloth cover body in the whole process so that the cloth cover body can be smoothly unfolded or folded, and the cloth cover body auxiliary unfolding mechanisms remove dirt on the cloth cover body when the cloth cover body is folded. According to the full-automatic automobile cover, the cloth cover body can be unfolded or folded, and when the cloth cover body is unfolded or folded, the cloth cover body can be smoothened so that the cloth cover body can be smoothly unfolded or folded; in addition, dirt on the cloth cover body can be removed in time during folding; besides, air is effectively prevented from entering the cloth cover body from the opening formed in the lower end of the cloth cover body.

Owner:胡建明

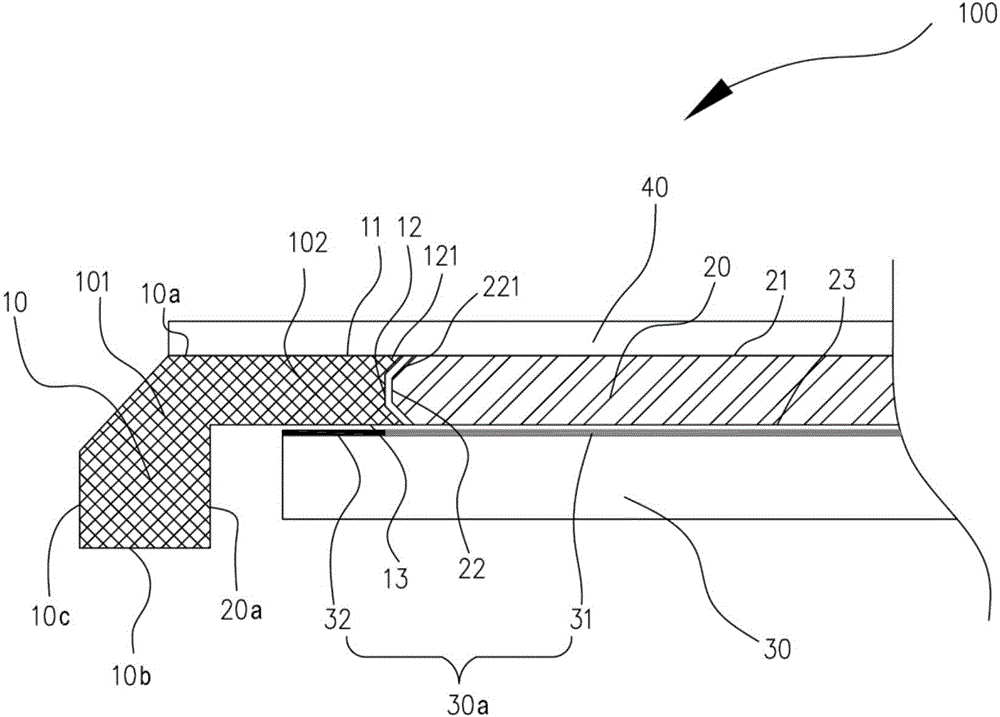

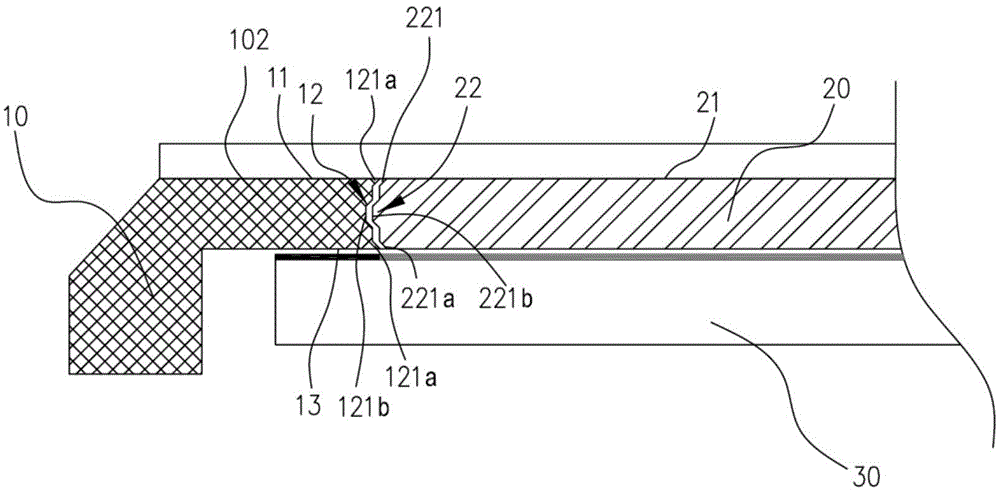

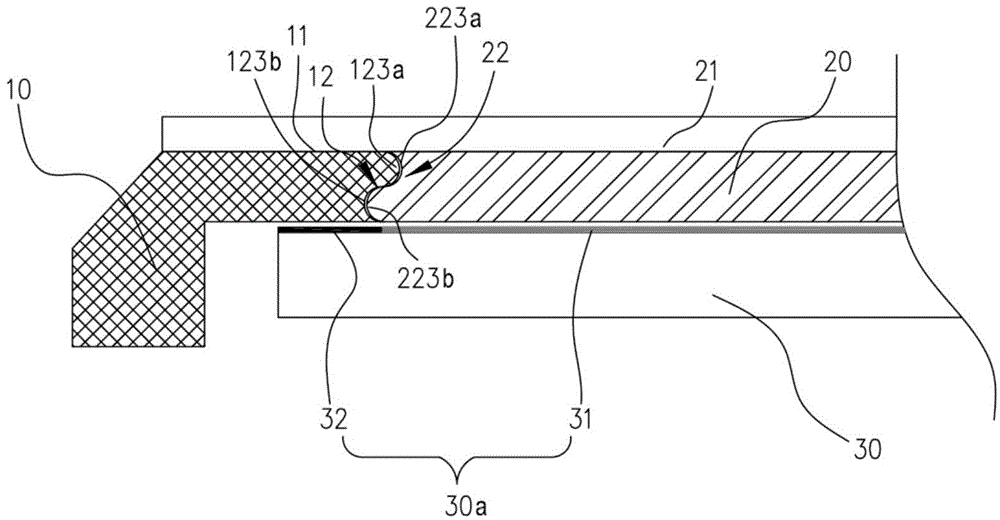

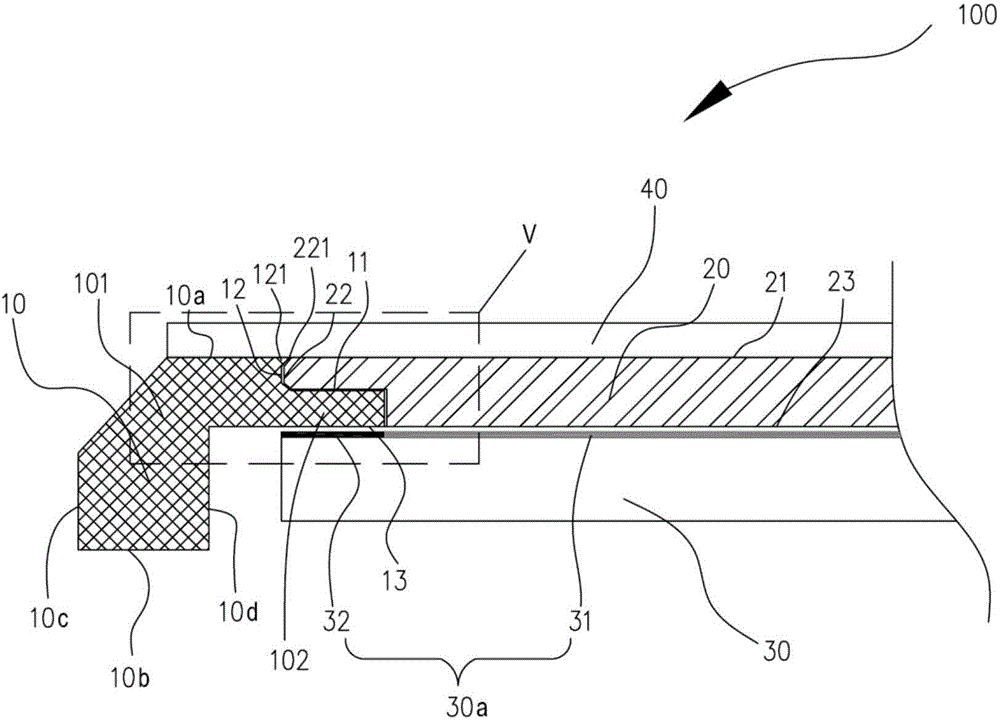

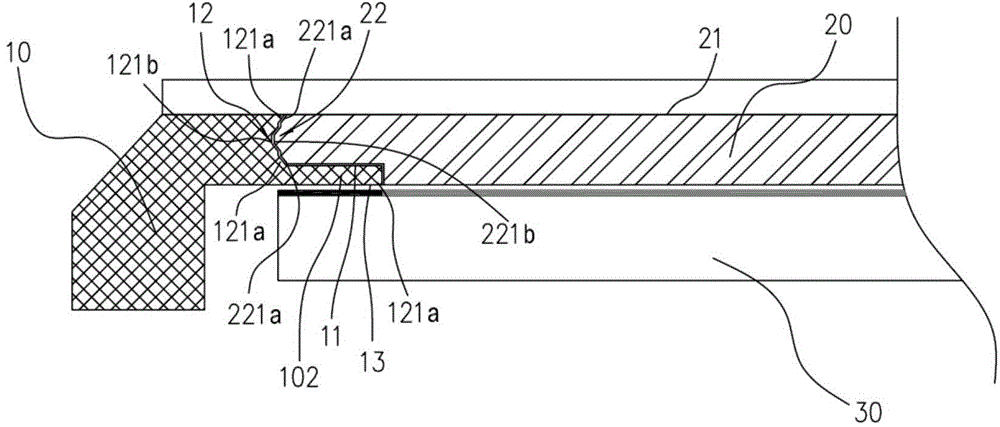

Terminal front cover and terminal

The invention discloses a terminal front cover which includes a frame, a glass plate and a display screen, wherein the display screen includes a display surface; the display surface includes a display area and a non-display area; the non-display area surrounds the display area; the frame is fixed on the display surface and includes a top surface and a first inner connecting surface connected to the top surface; the glass plate comprises an upper surface and a second inner connecting surface connected to the upper surface; the frame is integrally formed on the glass plate; the first inner connecting surface of the frame is fitted with the second inner connecting surface of the glass plate; a visual surface and the upper surface are smoothly connected with each other to form a seamless smooth outer surface; a frame flange is arranged on the first inner connecting surface and close to the display screen, and correspondingly shields the non-display area. According to the terminal front cover provided by the invention, the smooth surface of the terminal front cover is realized, and the frame of the terminal front cover does not have a black ink edge and meets the ergonomic requirement.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

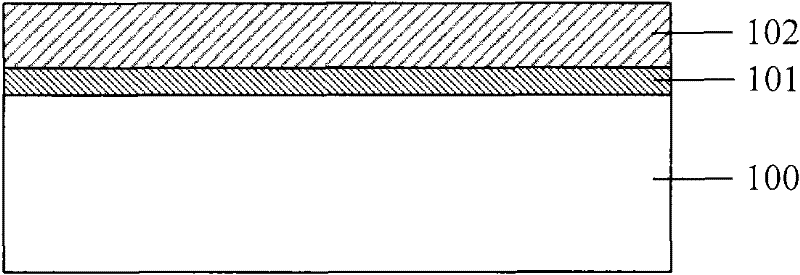

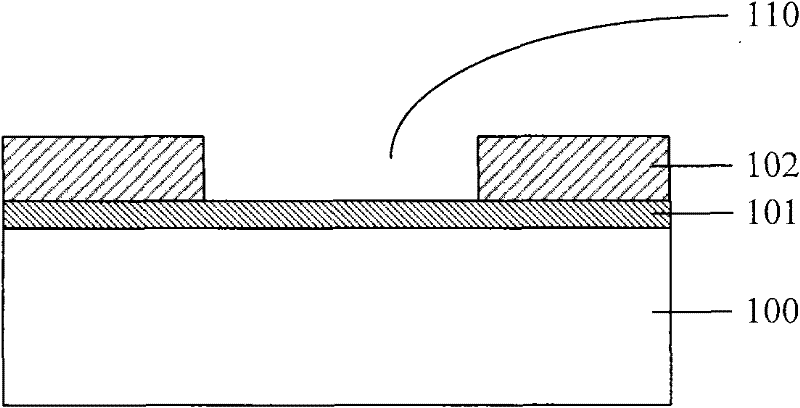

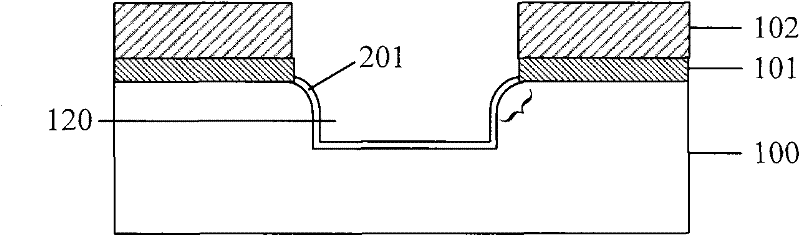

Manufacturing method of shallow trench isolation

ActiveCN102222636AImprove uniformityAchieve smoothSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a manufacturing method of shallow trench isolation, which comprises the steps of: providing a semiconductor substrate with a masking structure covered on a surface, wherein an opening for exposing the semiconductor substrate is formed on the masking structure; etching a trench corresponding to the opening on the semiconductor substrate by taking the masking structure as a mask; forming lining oxidizing layers on sidewalls and the bottom of the trench; annealing under an argon atmosphere; and filling an insulating medium in the trench to form the shallow trench isolation. The manufacturing method provided by the invention can ensure that corners on the top of the trench are smoothened; and in addition, compared with the prior art, the manufacturing method has the advantages of simplifying process steps and lowering process cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

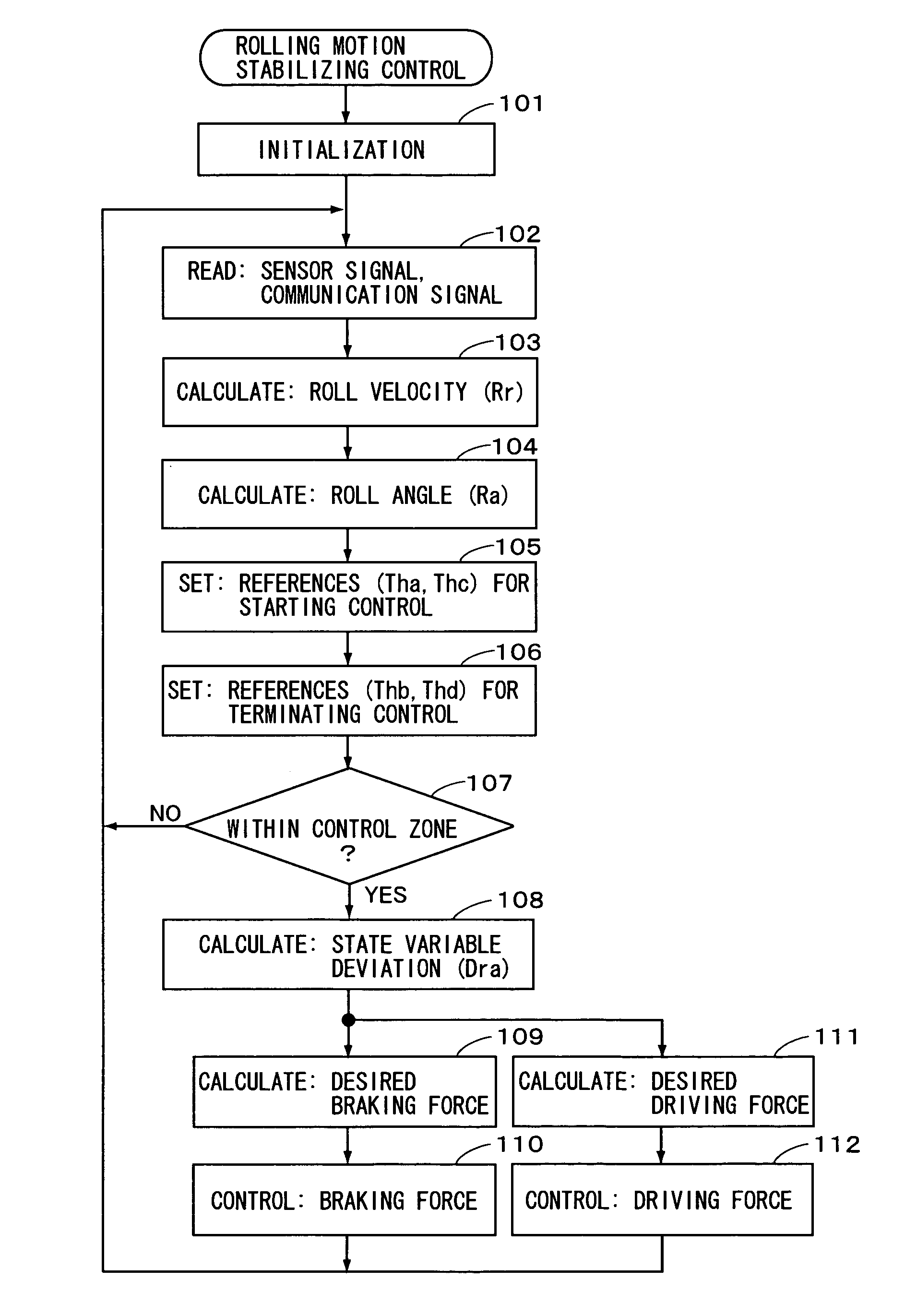

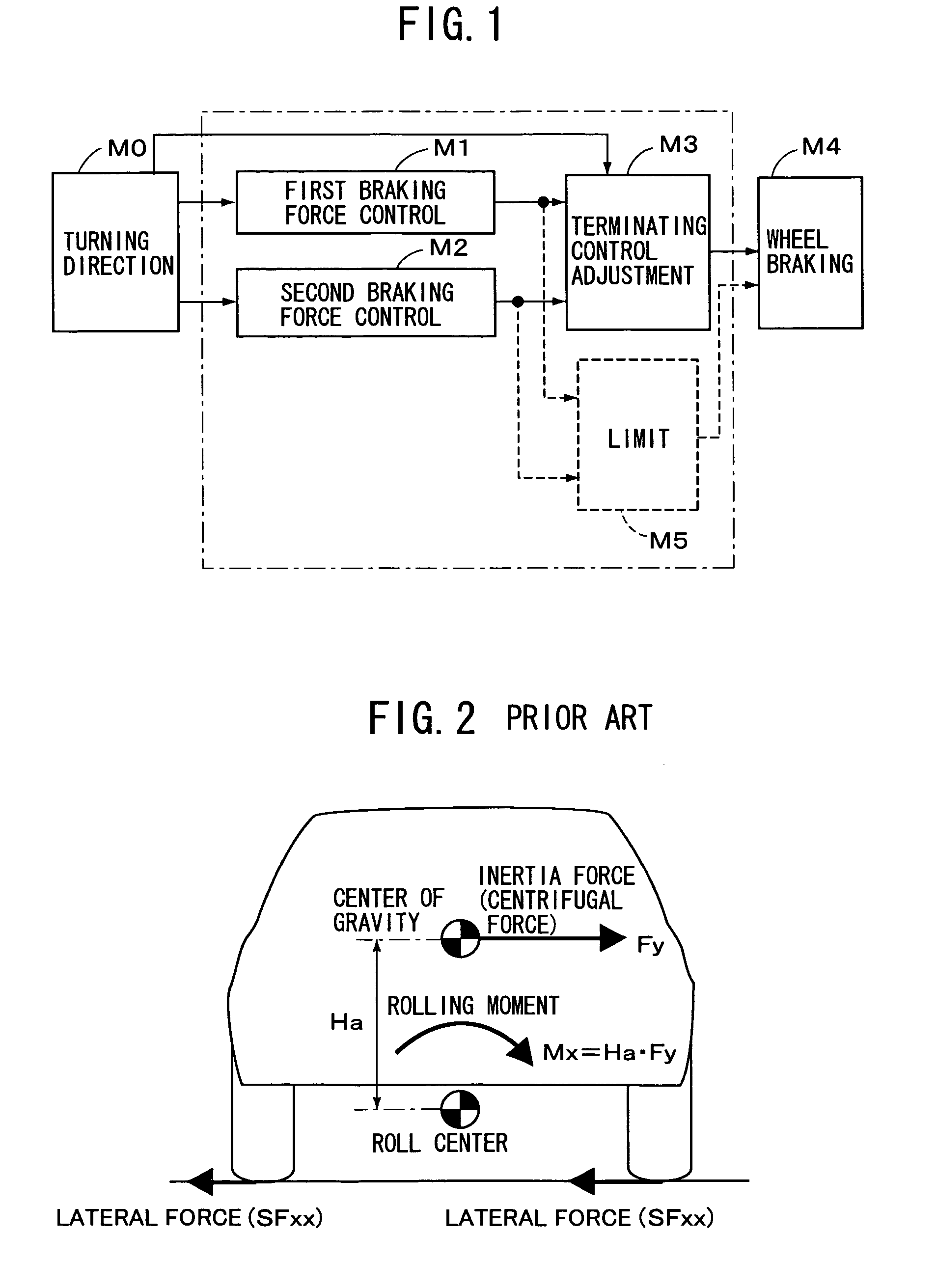

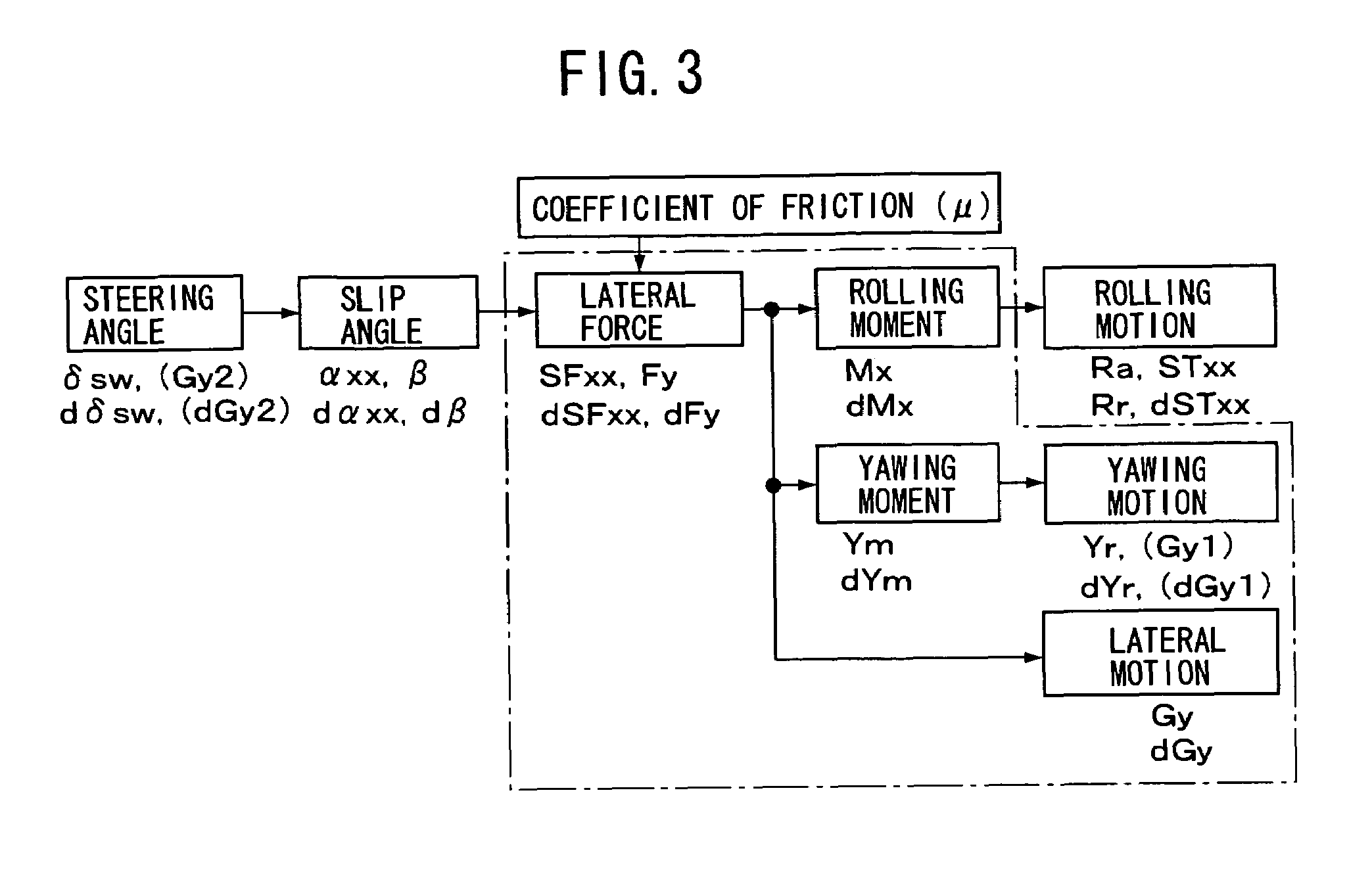

Rolling motion stability control apparatus for a vehicle

ActiveUS7240971B2Stable controlAchieve smoothDigital data processing detailsAnimal undercarriagesBrake forceAutomotive engineering

A rolling motion stability control apparatus restrains a roll increasing tendency of a vehicle, with each wheel of the vehicle being braked by a wheel brake device. A first braking force control device is provided for applying a first braking force to the wheel, when the vehicle is turned to one direction. A second braking force control device is provided for applying a second braking force to the wheel, when the vehicle is turned to the other direction. A terminating control adjustment device is provided for adjusting the braking force control devices to continue the first braking force being applied, until the second braking force is initiated to be applied, when the vehicle is turned to the one direction, and then to the other direction.

Owner:ADVICS CO LTD

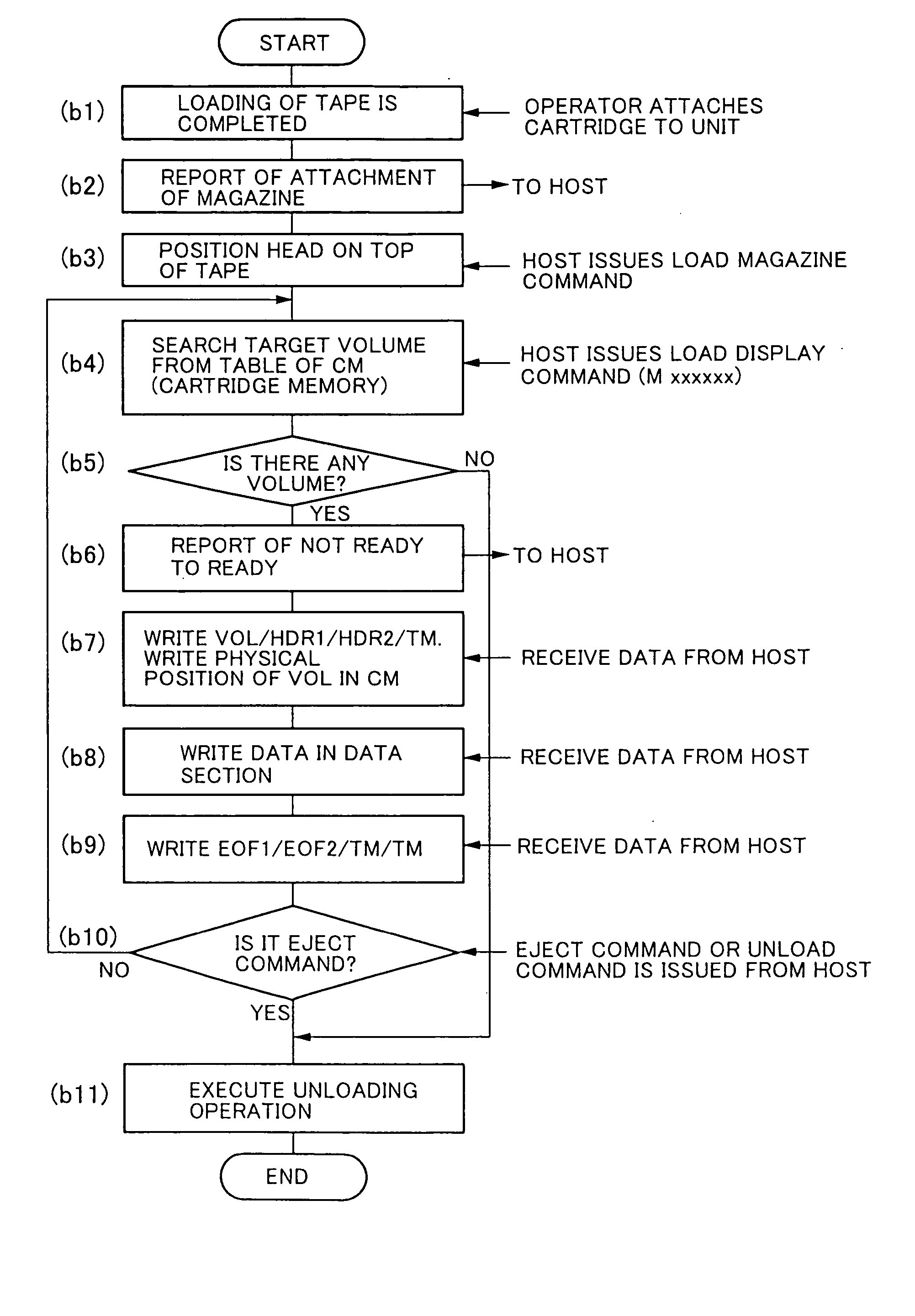

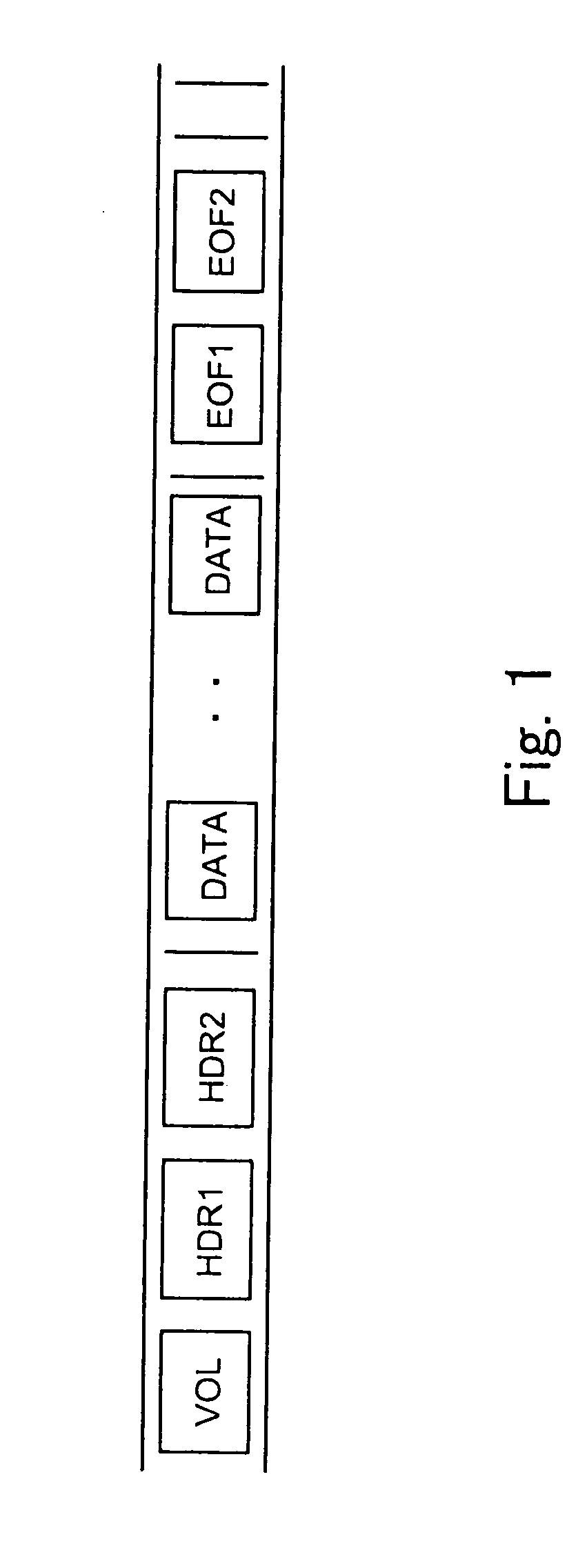

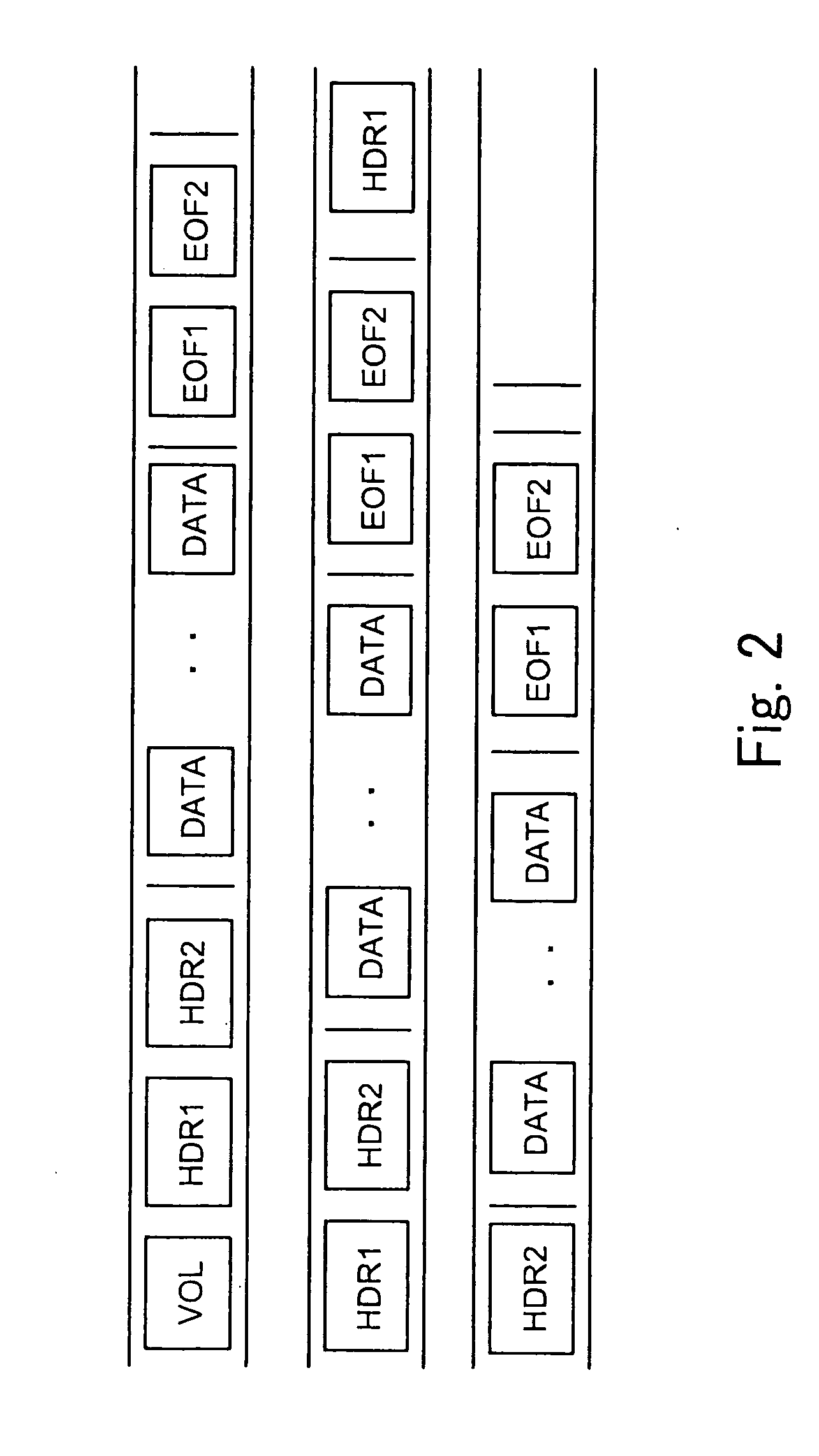

Magnetic tape unit

InactiveUS20050086428A1Achieve smoothRecording carrier detailsInput/output to record carriersMagnetic tapeEngineering

The present invention relates to a magnetic tape unit to which a cartridge having a magnetic tape therein is detachably attached and which accesses a magnetic tape in accordance with an access request from a host. Software of the host which accesses a conventional magnetic tape unit to which a cartridge accommodating a plurality of cartridges is attached is used as it is while using the cartridge accommodating a large-capacity magnetic tape. Management information of a plurality of volumes is written in the cartridge, and a LOAD command from the host is replaced by a command for accessing an actual cartridge.

Owner:FUJITSU LTD

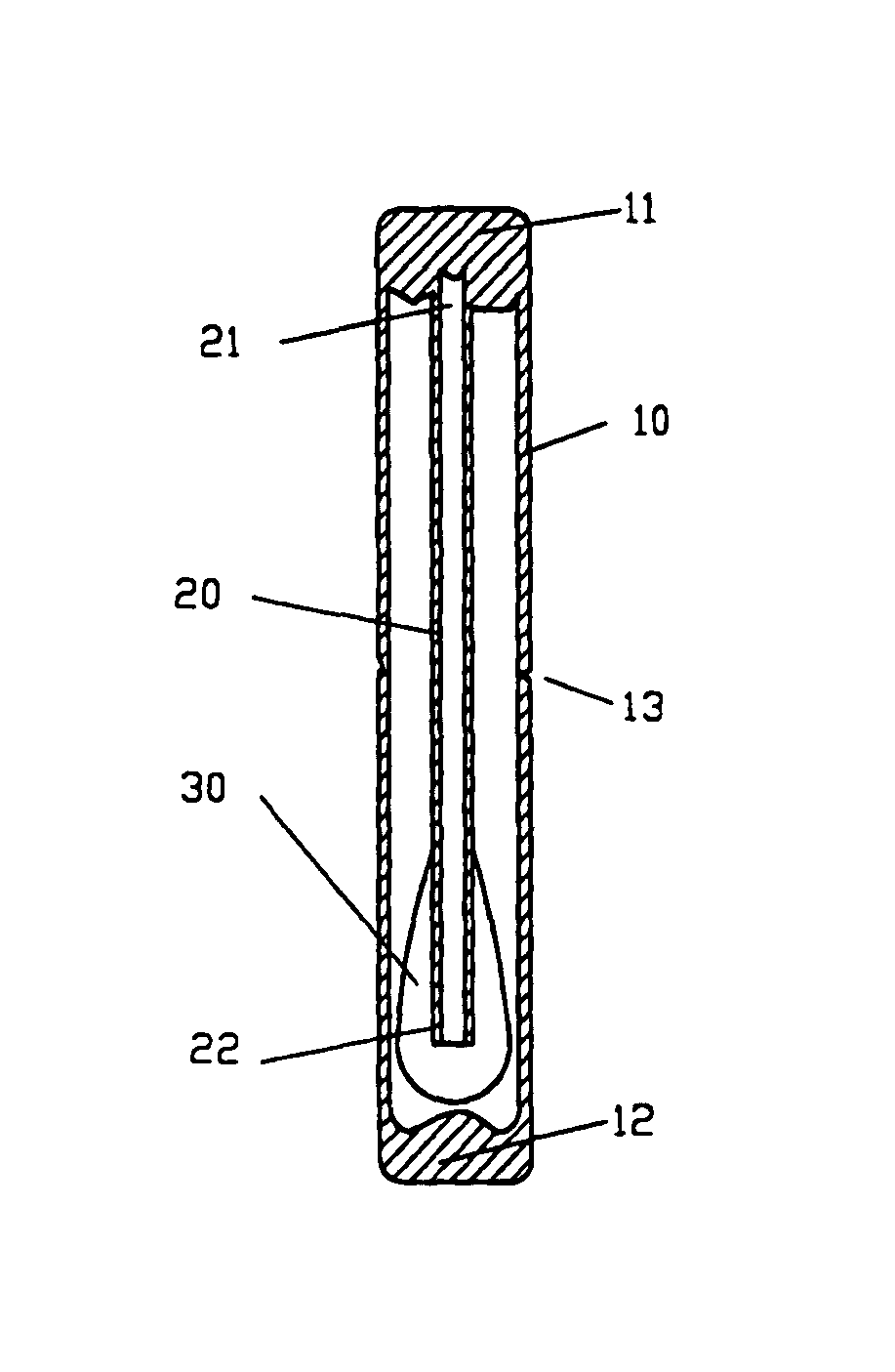

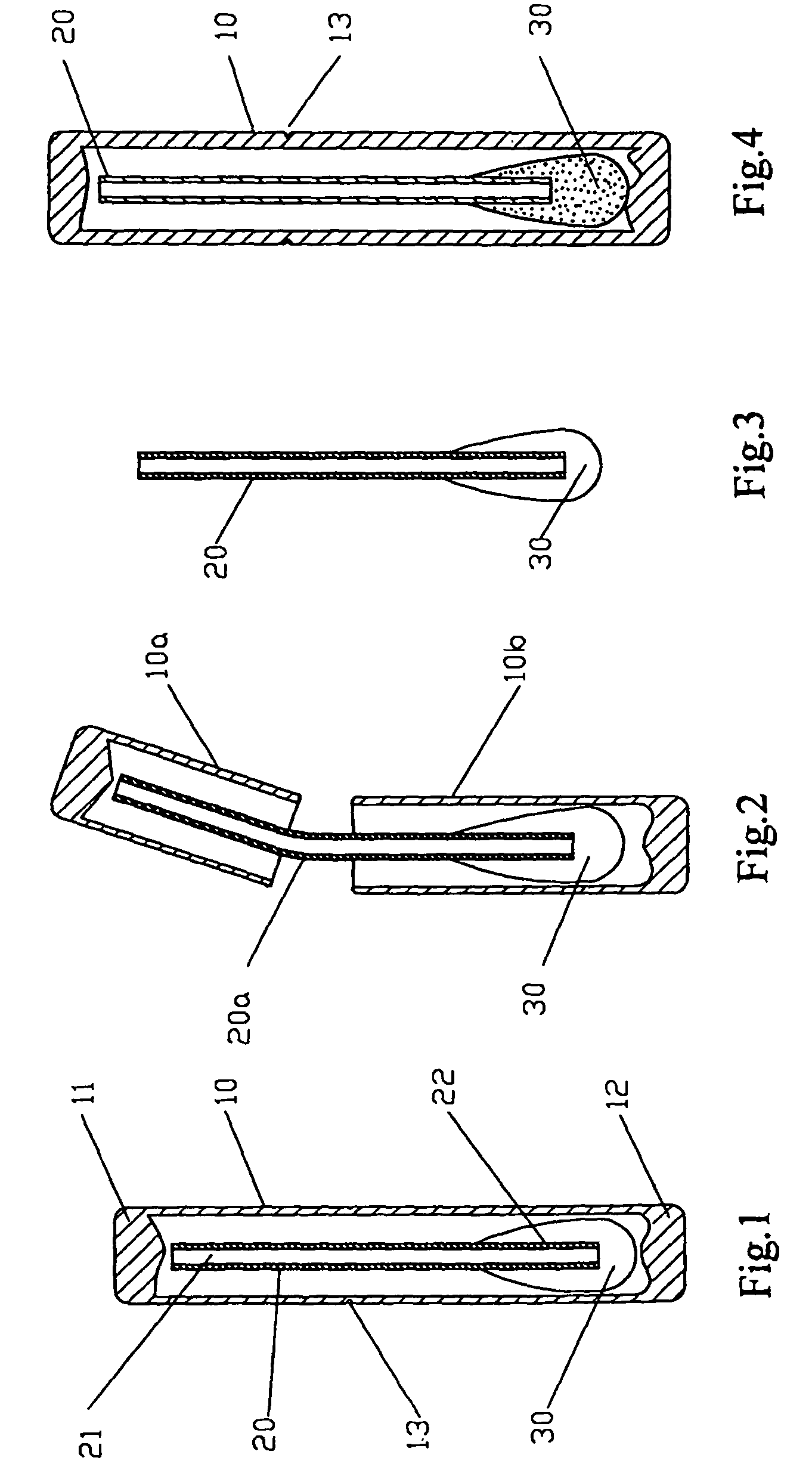

Wiper and the preparing method thereof

ActiveUS8740831B2Easy to operateEasy to useDispensing apparatusMedical applicatorsHigh volume manufacturingEngineering

A wiper comprises a rod (20), a wiping body (30) provided at one end of the rod and an outer packing; the rod (20) is of elasticity, the outer packing is a tube-like container (10) having both ends closed permanently and an easy break-off mark (13) provided on the tube wall; the wiper is firm, airtight and capable of being opened easily, and can be used conveniently and rapidly; the rod and the tube-like container are made from thermoplastic materials by technologies such as extruding, injection-molding and the like, both ends of the tube-like container are closed through fusion, mechanical seal and other manners, and the wiper has a simple production technology and is suitable for mass production and wide application.

Owner:LONGOOD MEDICINE (JIANGSU) CO LTD

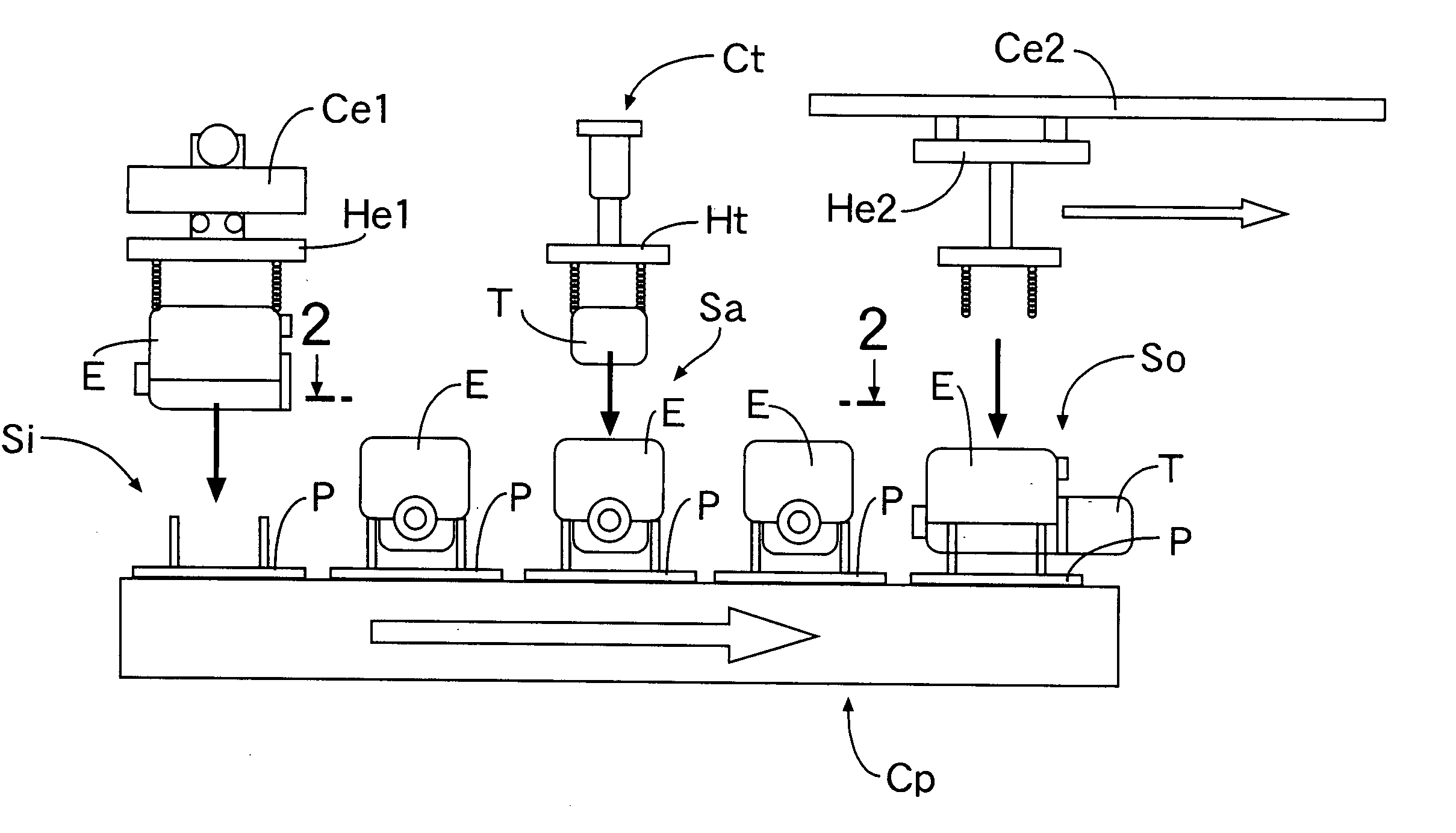

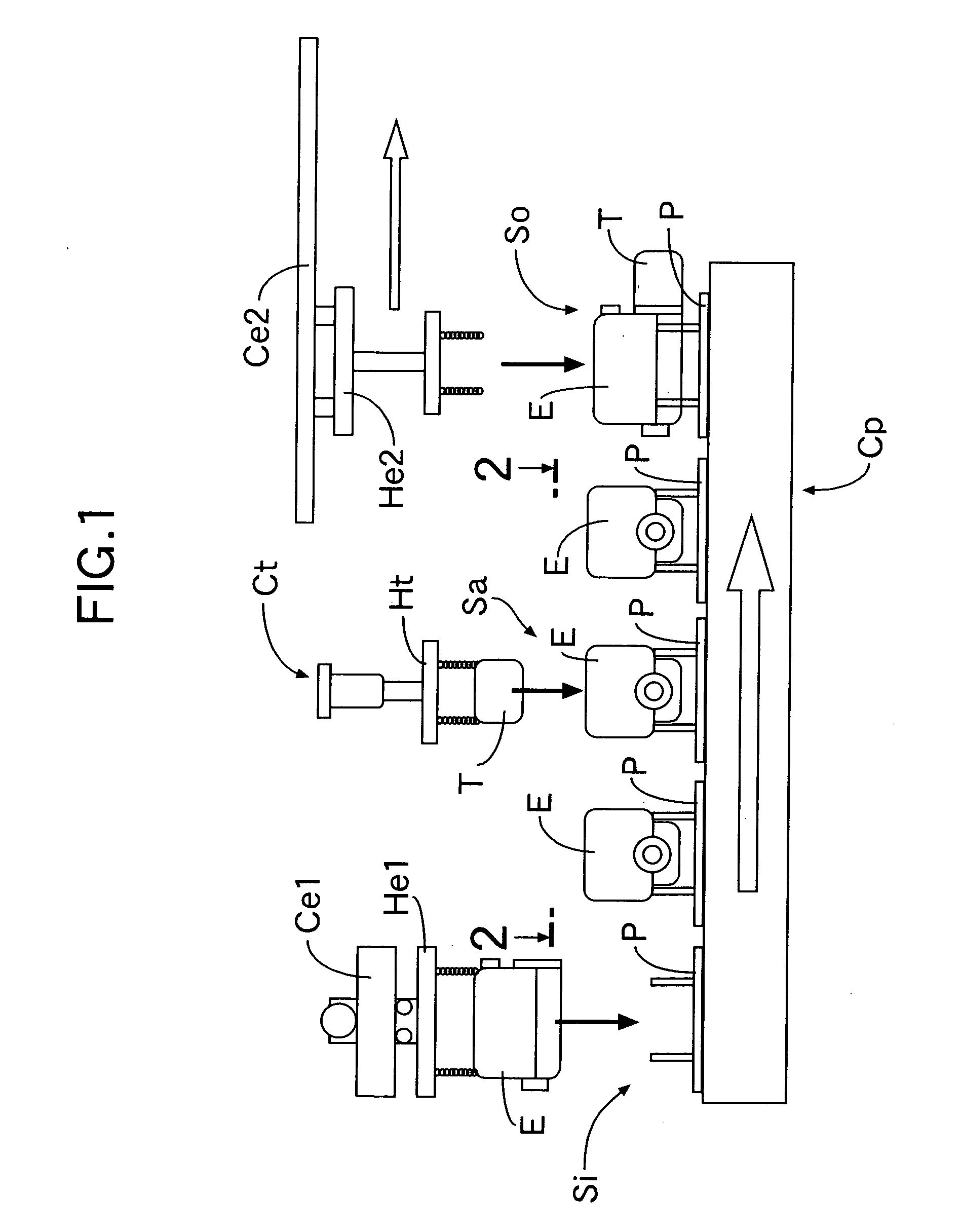

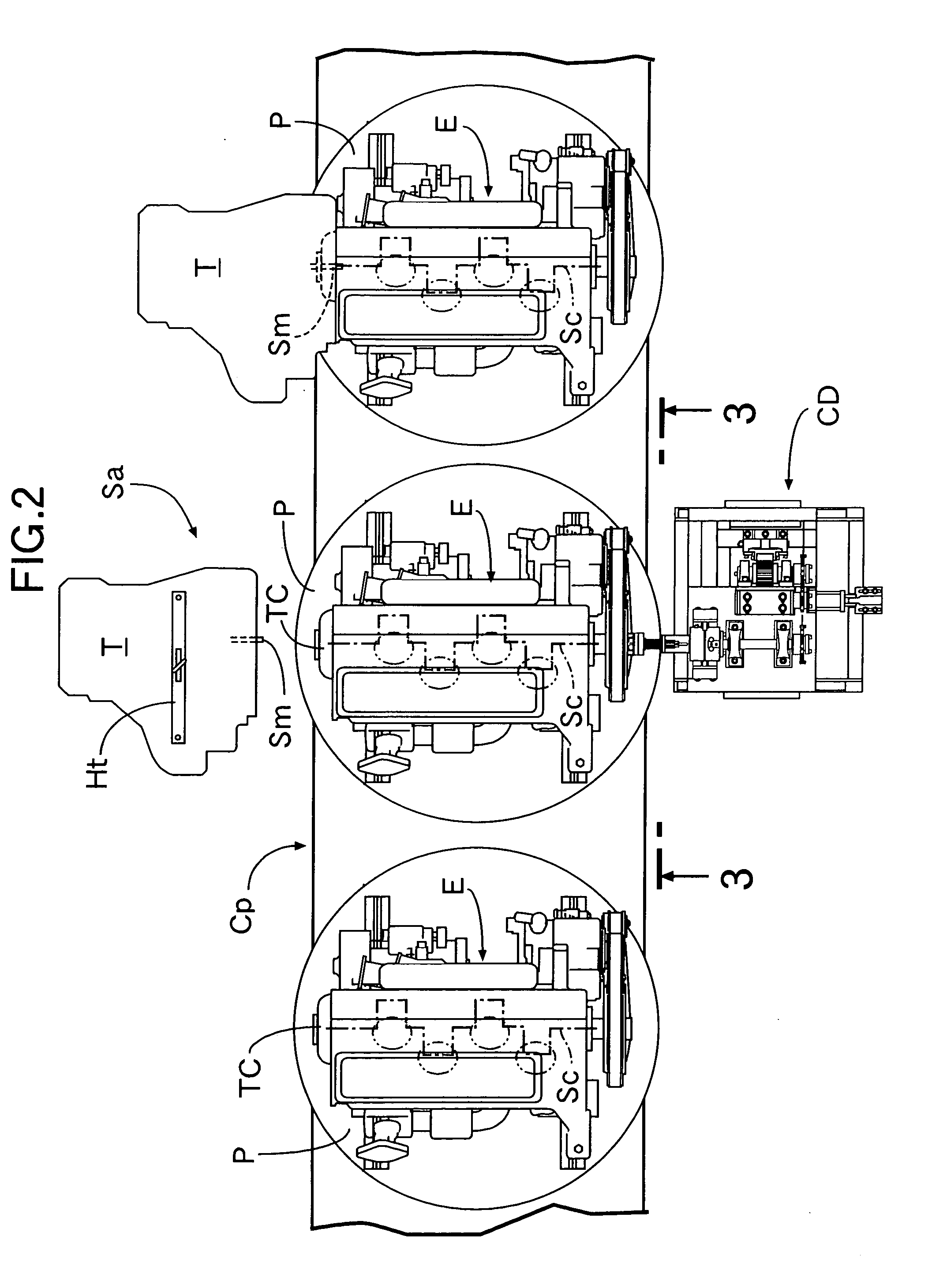

Work assembling auxiliary appratus and work assembling method

InactiveUS20050223545A1Reliable engagementPrevent rotationCasingsAssembly machinesCouplingEngineering

A work-assembling auxiliary device for carrying out the matching of phases in the spline-coupling of a main shaft Sm of a transmission T to a crankshaft Sc of an engine E includes an output shaft 40 radially movably connected through an Oldham coupling 41 to an input shaft 30 connected to and rotated by a drive source. A chamfer 61a is provided at a tip end of a socket 61 mounted on the output shaft 40, and in inserting the socket 61 into a socket hole h in a crank pulley Pc, the output shaft 40 is smoothly aligned with the crankshaft Sc by the action of the chamfer 61a. Further, when the output shaft 40 is reciprocally rotated, the phases of the socket 61 and the socket hole h are smoothly matched with each other, whereby the engagement of the socket 61 and the socket hole h is achieved. Thus, even if a somewhat deviation exists between an axis of the crankshaft Sc of the engine E and an axis of the output shaft 40 of the work-assembling auxiliary device, the socket 61 of the output shaft 40 can be reliably engaged into the socket hole h in the crankshaft Sc.

Owner:HONDA MOTOR CO LTD

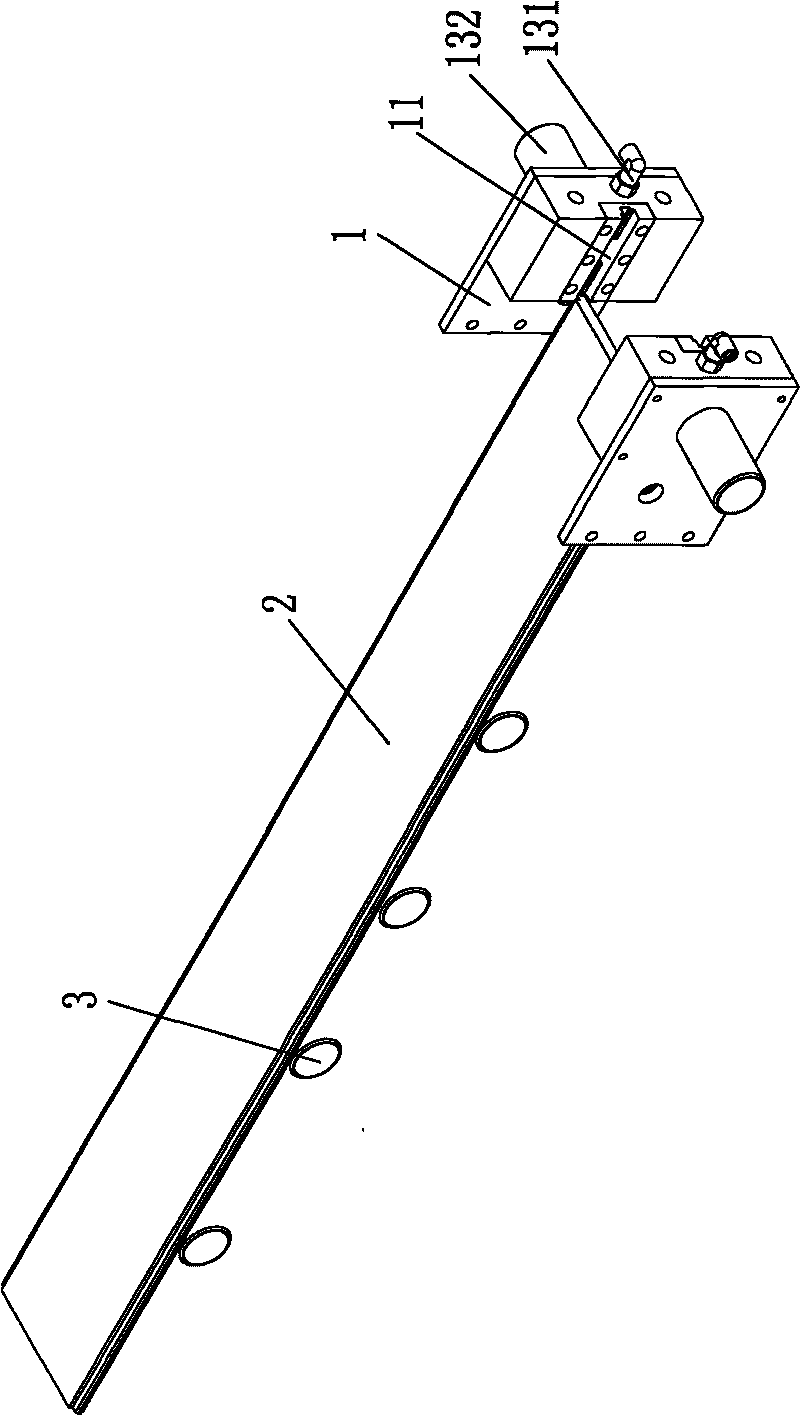

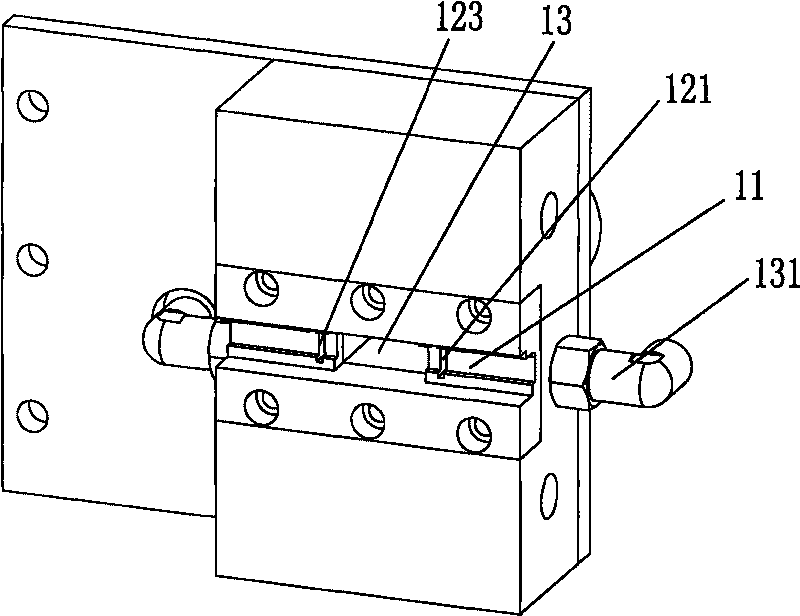

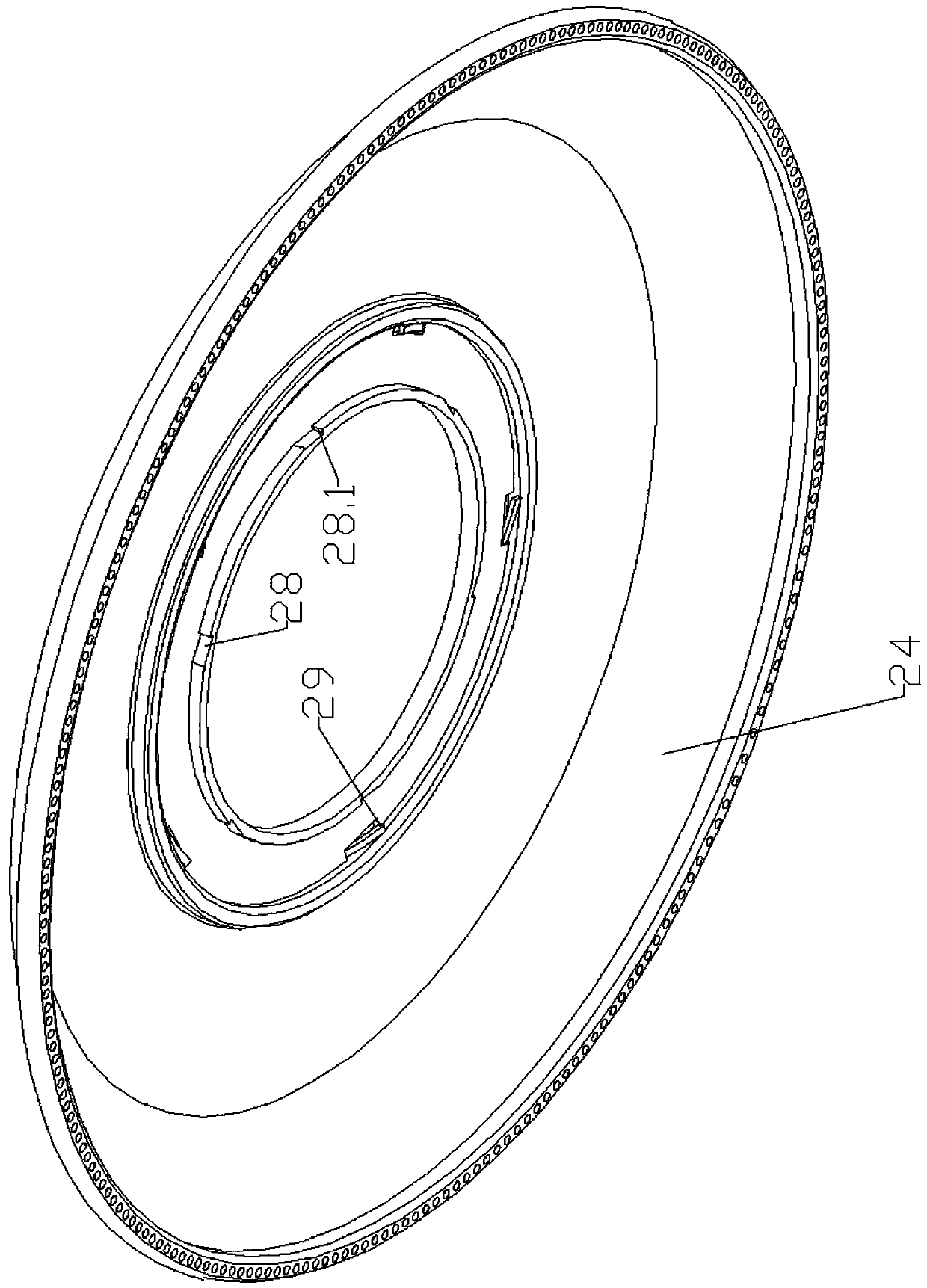

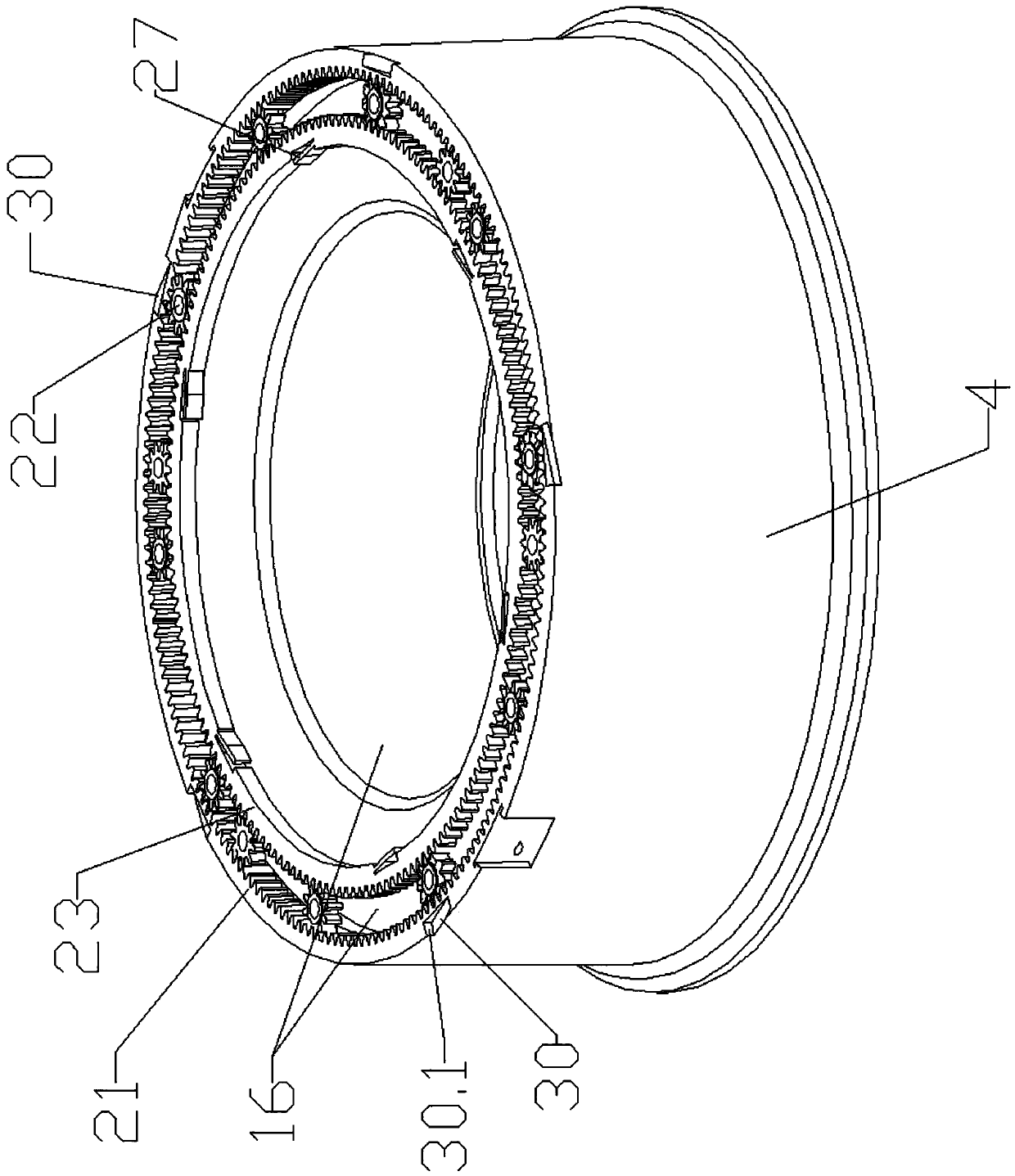

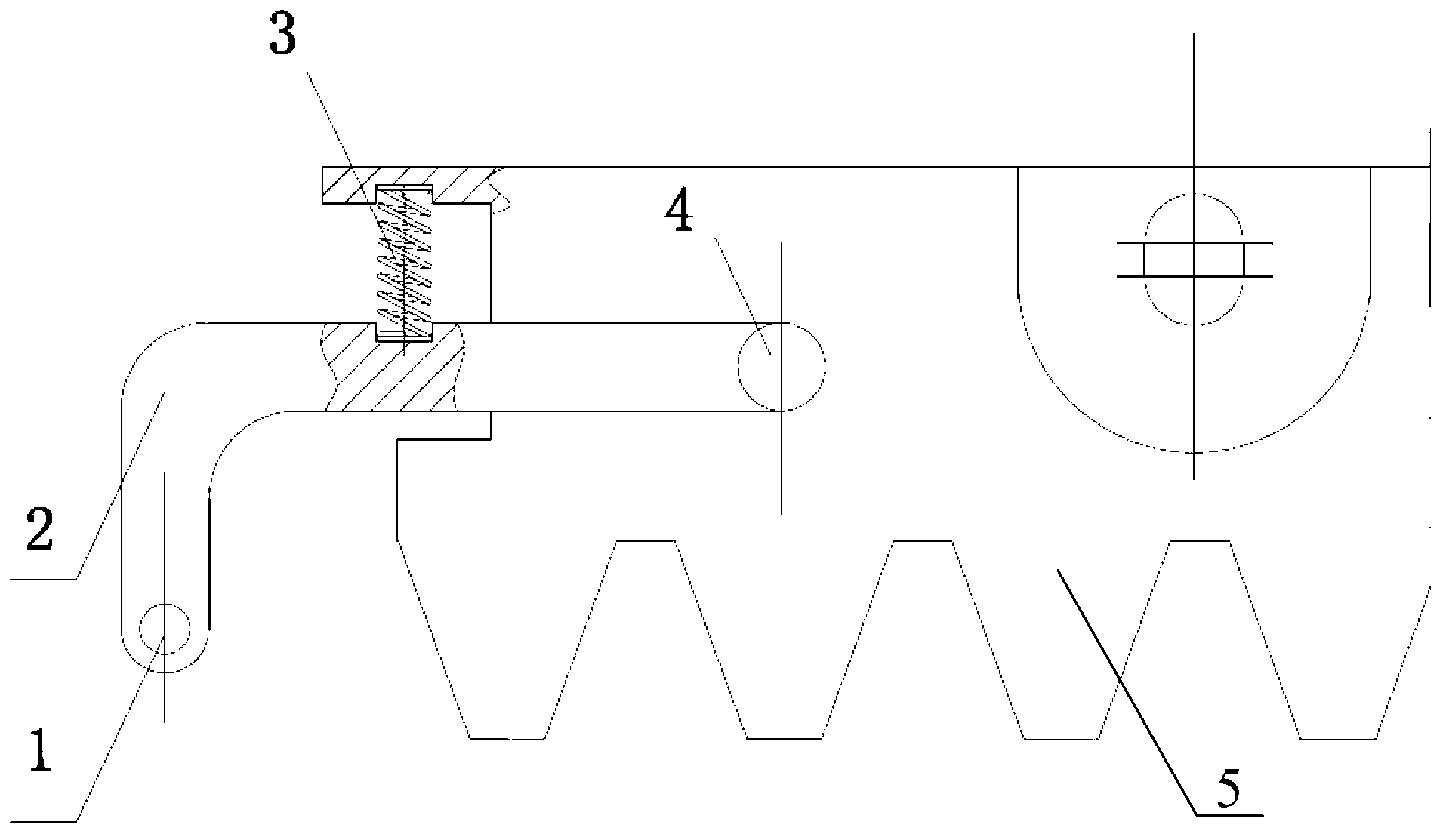

Tooth collision prevention mechanism of relay driving fuel transfer device

ActiveCN103016692AMechanism structure is simple and reliableEasy to process and installGearing detailsFriction gearingsCollision preventionMechanical engineering

The invention relates to the field of transportation of a nuclear fuel assembly, in particular to a tooth collision prevention mechanism of a relay driving fuel transfer device. The tooth collision prevention mechanism of the relay driving fuel transfer device structurally comprises a collision head, wherein the collision head is arranged on a rack; one end of the collision head is actively connected with the rack and further can rotate along a connection point; a spring for absorbing the collision force of connection between a relay driving gear and the rack and further enabling the collision head to return is arranged between the upper part of the collision head and the rack; and the lower end of the front part of the collision head contacts with the driving gear. The tooth collision prevention mechanism causes rigid collision during the process of contact between the gear and the rack to be changed into flexible collision, so that a transmission mechanism is protected; and in addition, the structure is simple, the reliability is high and the processing, the manufacturing and the installation are easy.

Owner:CHINA NUCLEAR POWER ENG CO LTD

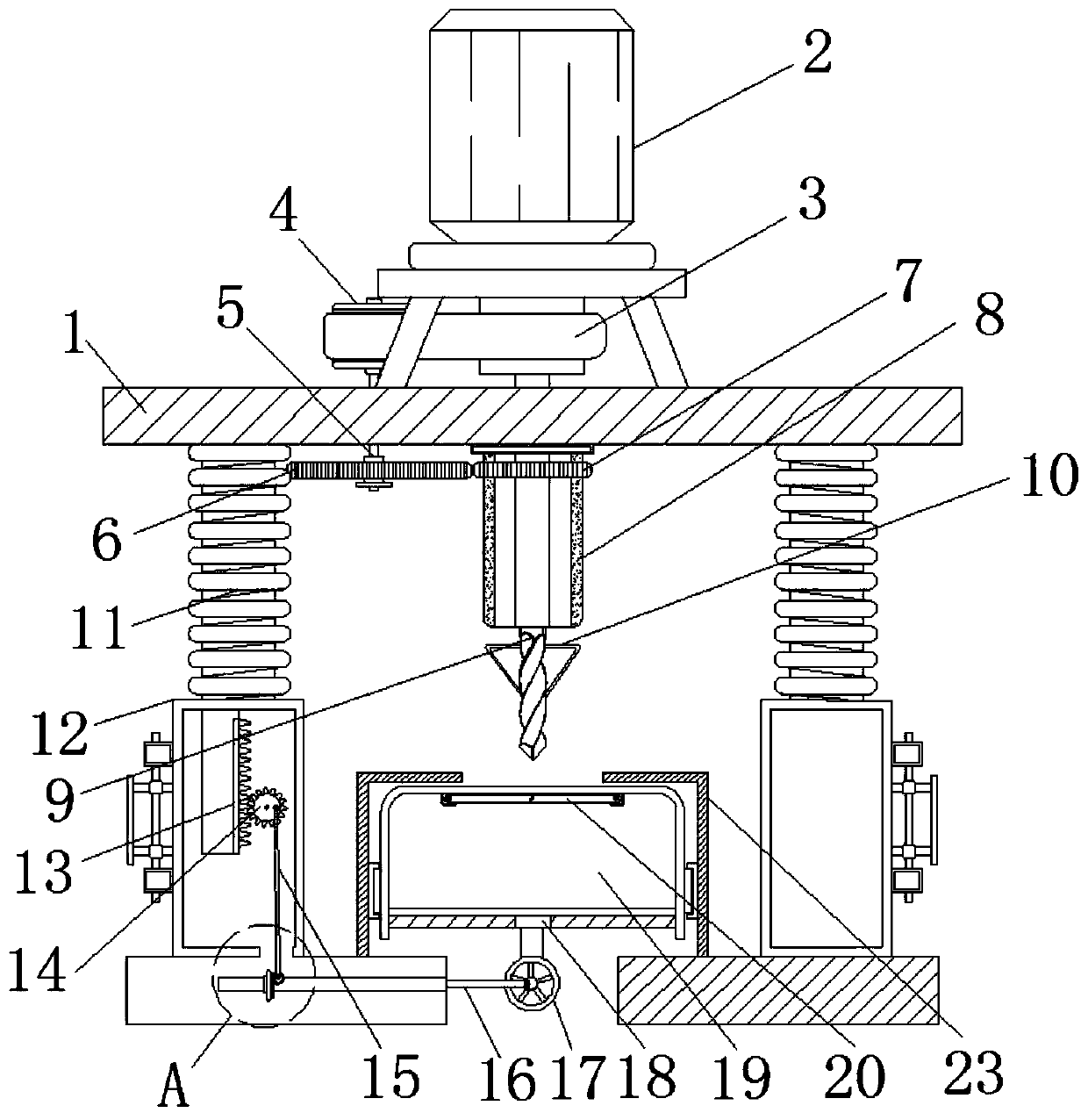

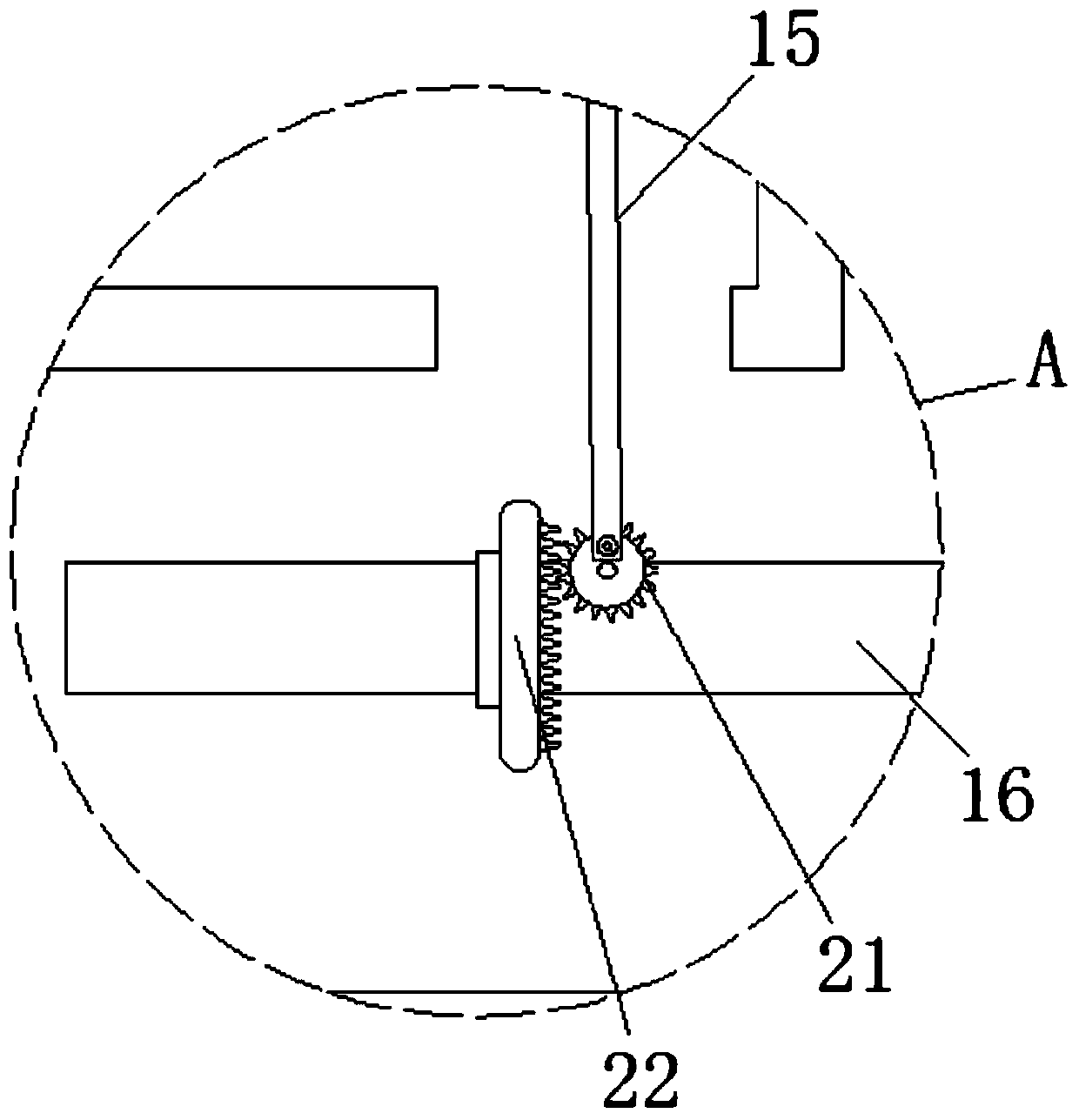

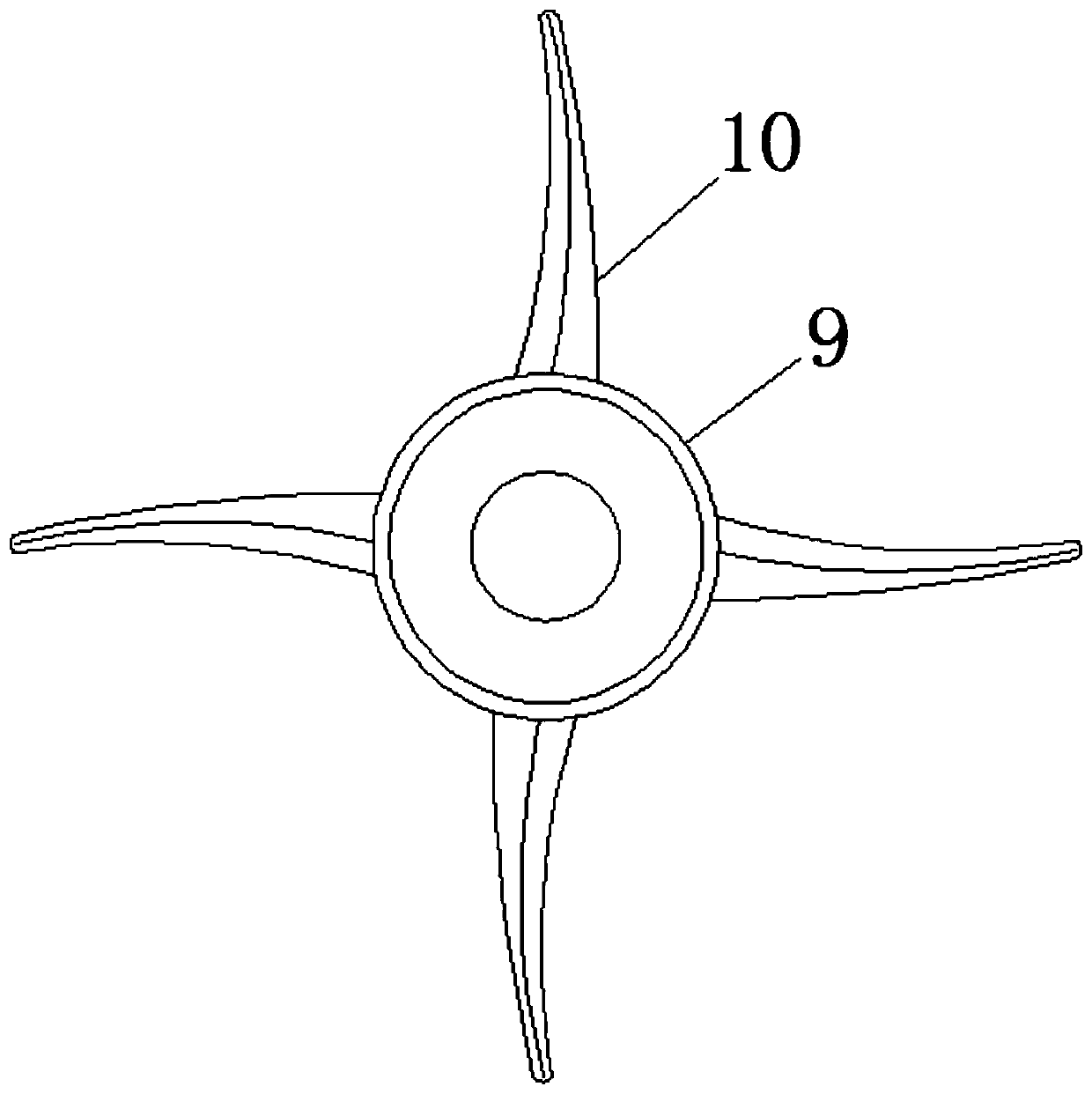

Drilling device for foam insulation board

PendingCN110978127AAchieve smoothPrevent fallingEdge grinding machinesMetal working apparatusGear wheelElectric machinery

The invention discloses a drilling device for a foam insulation board. The drilling device comprises a support and a motor. The motor is fixedly connected with the top end of the support. A belt sleeves the bottom end of the motor. The end, away from the motor, of the belt is fixedly connected with a belt wheel. A connecting rod penetrates through the belt wheel and is sleeved with a first gear. The right end of the first gear is meshed with a second gear. A grinding cylinder is inserted in the second gear. A drill bit is fixedly connected with the bottom end of the grinding cylinder. A drilling piece is fixedly installed on the surface of the drill bit. Springs are fixedly installed at the bottom end of the support. By improving the drill bit during drilling, the hole surface of a drilledhole is smooth, burrs are removed, the process of secondarily deburring and polishing the insulation board during machining of the insulation board is avoided, the machining steps are reduced, work efficiency is improved, and the drilling device is easier to use and easy to operate.

Owner:天津市亿腾顺泰建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com