Automatic spraying device, spraying production equipment and automatic spraying method for floor side

A technology of automatic spraying and production equipment, which is applied to the device, spraying device, coating and other directions of coating liquid on the surface, can solve the problems of paint waste, loss of use value, wood waste, etc., to solve the difficulty of paint recycling and improve paint The effect of utilization rate and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

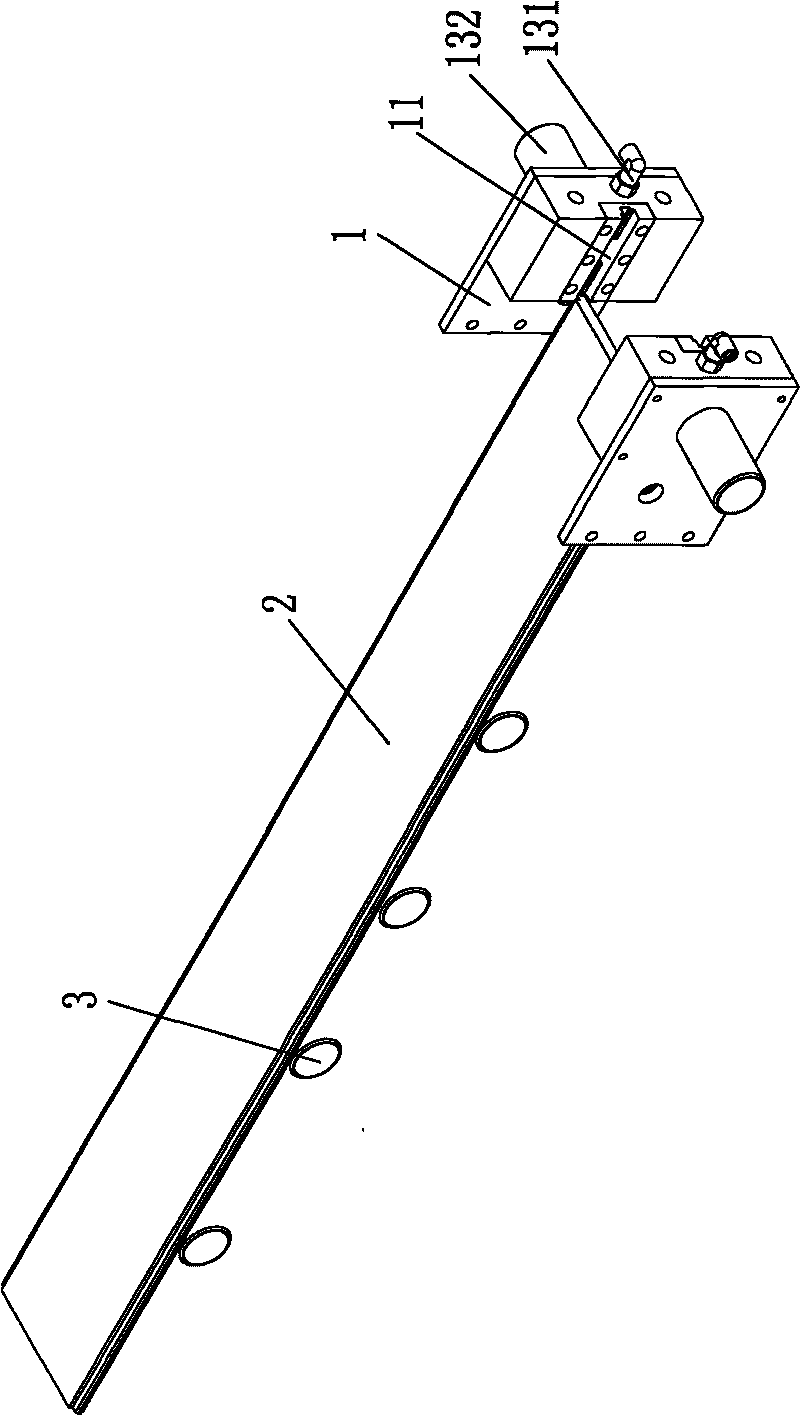

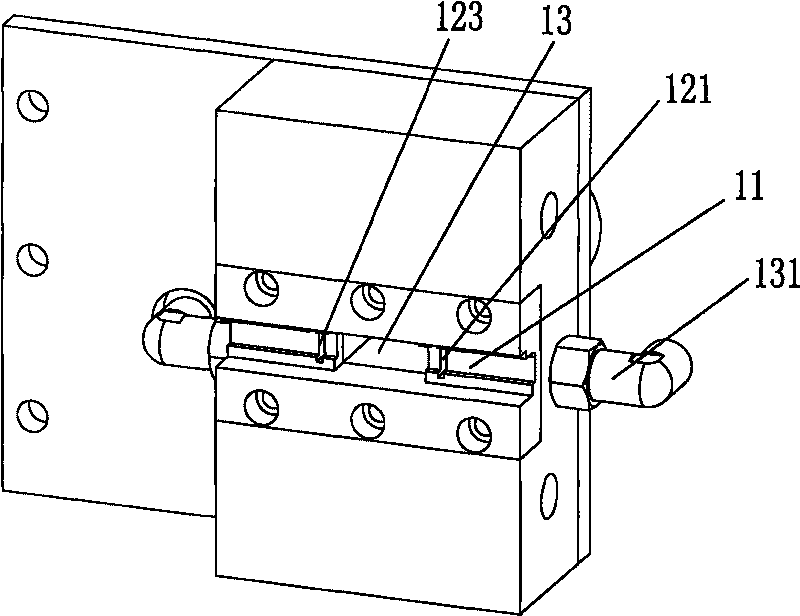

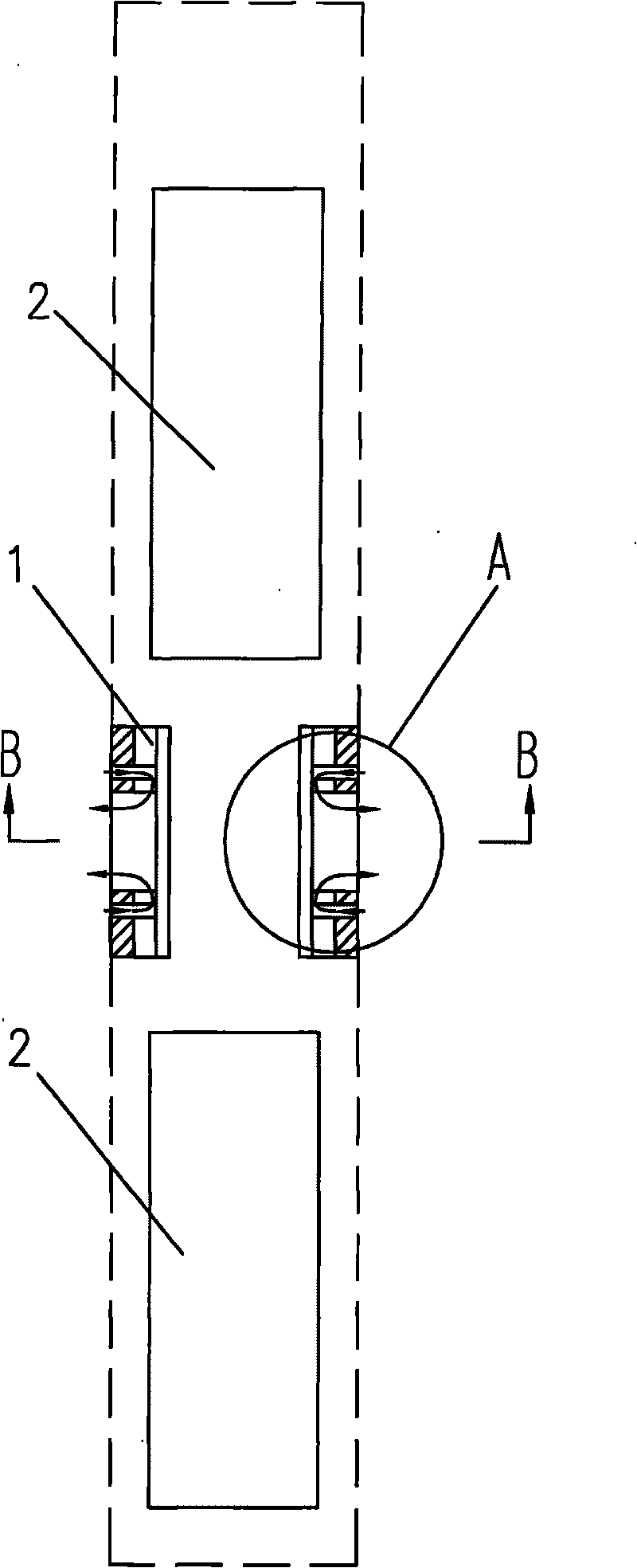

[0027] Such as figure 1 The shown floor side automatic spraying production equipment includes floor feeding device 3, automatic spraying device 1, drying device (not shown in the figure), grinding device (not shown in the figure) and belt adjustment device (not shown in the figure ).

[0028] The floor feeding device adopts double-track roller conveying, with anti-slip chains on the track, and a pneumatic jacking device on the side of the track, which is mainly used for feeding multiple floors at the same time;

[0029] The drying device adopts an infrared drying oven, which is mainly used for the rapid drying of UV paint;

[0030] The grinding device adopts automatic centering, clamping and polishing. It is mainly used for polishing the paint on the side of the floor and removing burrs. The top of the grinding device is equipped with an automatic dust outlet to ensure the cleanliness of the internal environment of the workshop.

[0031] The belt adjustment device is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com