Coating system and coating method

A coating and coating technology, which is applied to the device and coating of the surface coating liquid, etc., can solve the problem that the amount of spraying and the speed of the rotation of the roller are difficult to accurately control, the sprayed film layer is uneven, and the film is easily scratched, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the embodiments to be described below will refer to the corresponding drawings, which constitute a part of the embodiments, and describe the embodiments that can be used to realize the present invention. It is to be understood that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

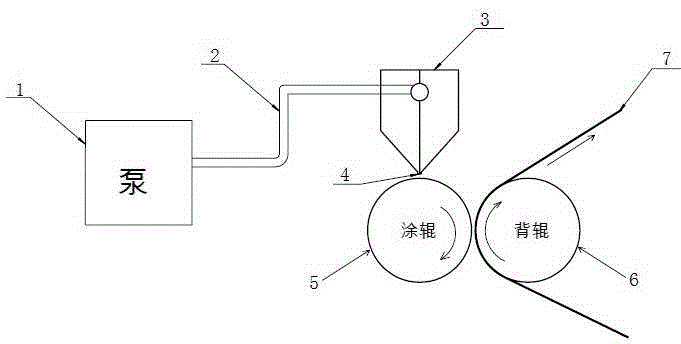

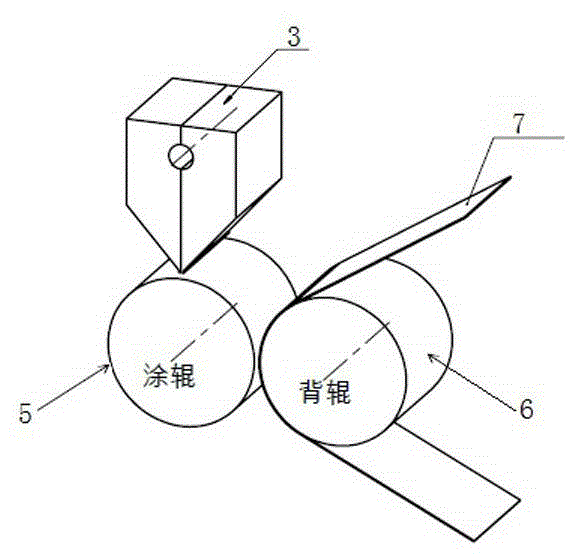

[0026] Such as figure 1 with 2 Shown, provide a kind of coating system embodiment, the coating system of a kind of coater, comprise paint meter 3 and be arranged on the nozzle 4 of paint meter bottom, connect paint meter 3 and pump for paint meter 3 The pump 1 sending paint, the coating roller 5 at the corresponding position at the bottom of the nozzle 4, the back roller 6 arranged in parallel with the coating roller 5, the strip material 7 that is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com