Patents

Literature

945results about How to "Realize continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

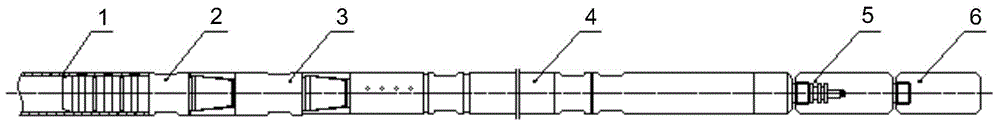

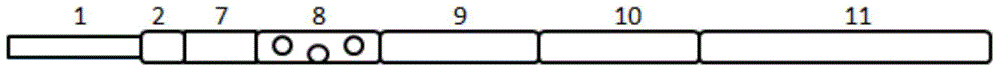

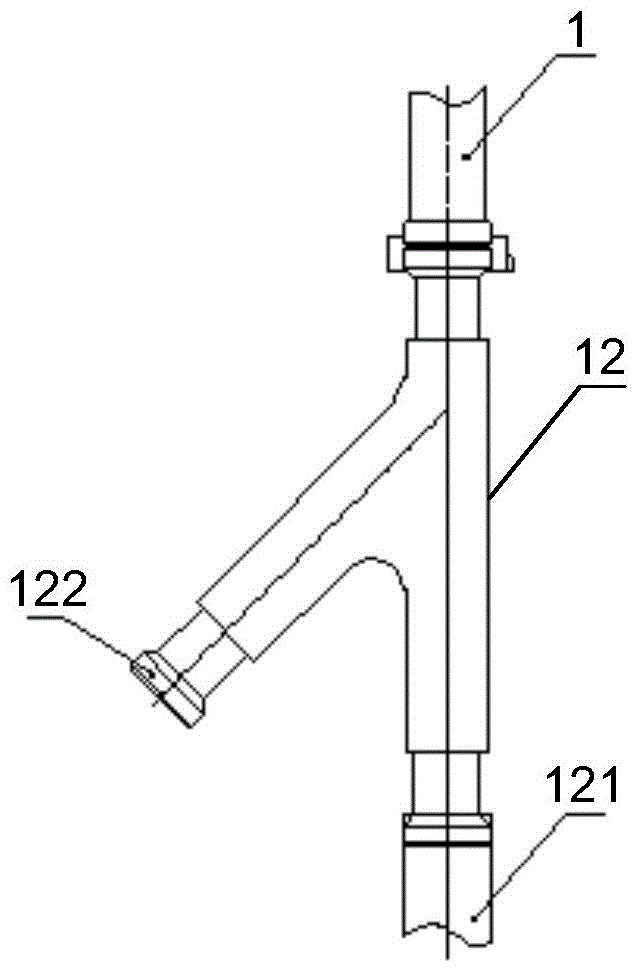

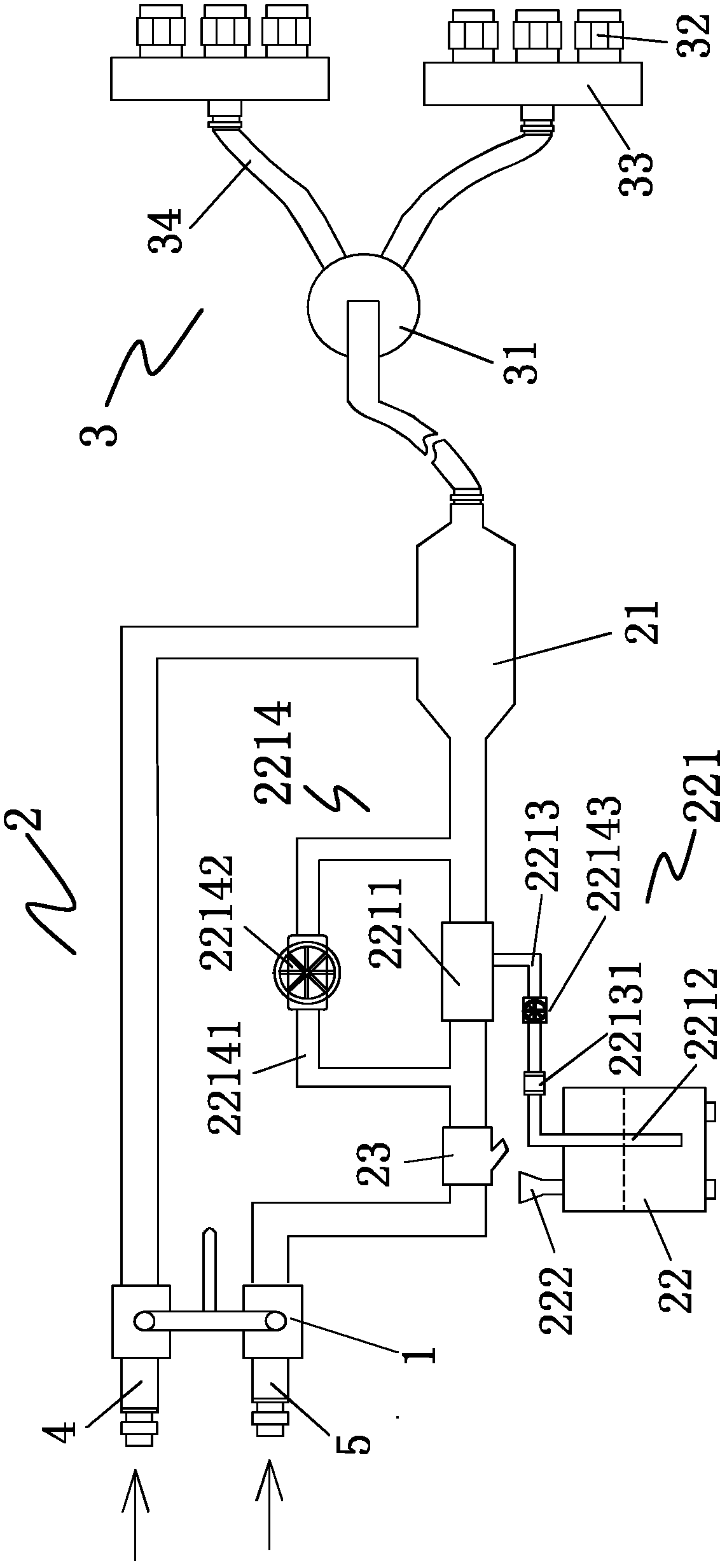

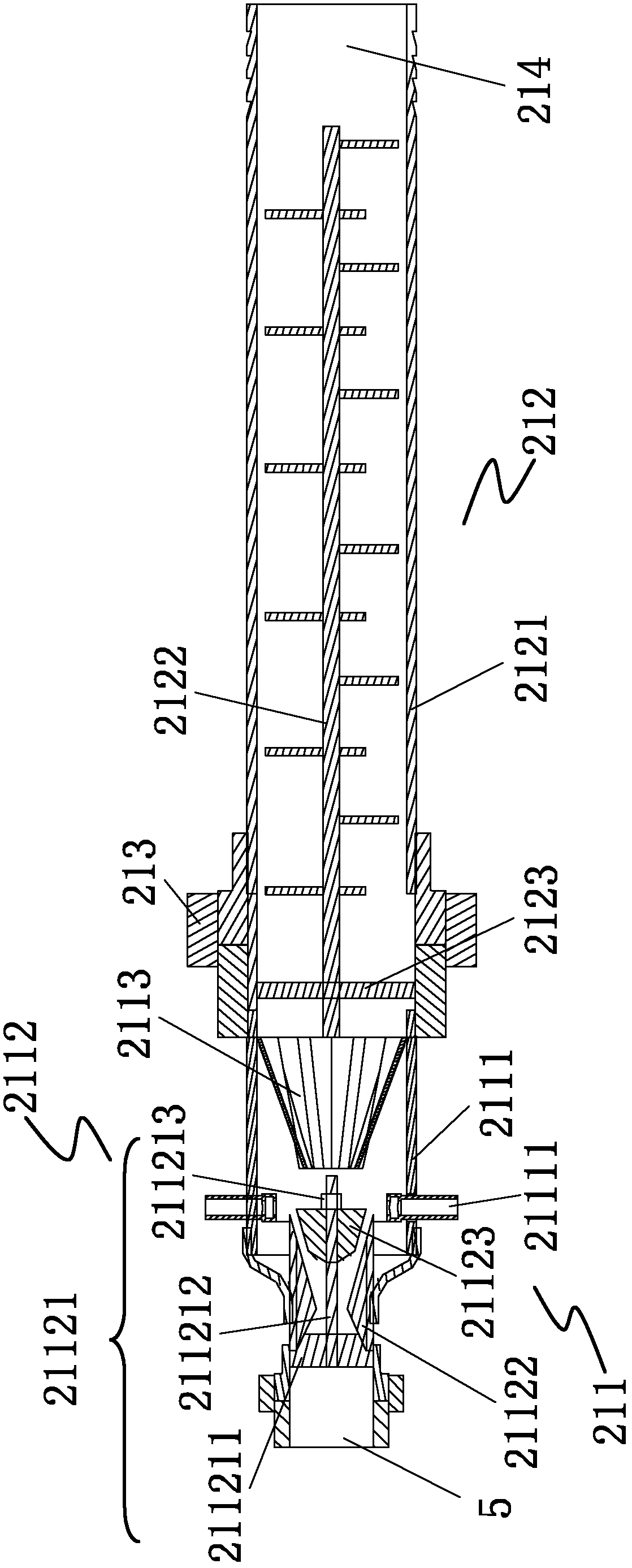

Coiled tubing tool set with cable perforations and technology

InactiveCN104533392AHigh strengthImprove toughnessSurveyFluid removalHorizontal wellsEconomic benefits

The invention discloses a coiled tubing tool set with cable perforations. The coiled tubing tool set comprises coiled tubing, a coiled tubing joint and a logging tool string or a perforation tool set. A cable is arranged in the coiled tubing. According to the coiled tubing tool set with the cable perforations, the structure of combining the coiled tubing and the logging tool string or the perforation tool set is adopted, and on the one hand, due to the characteristic that the coiled tubing is high in strength, toughness and loading capacity to work under pressure, the perforation requirements for highly-deviated wells and horizontal wells can be met, and the application range is wider; on the other hand, the coiled tubing can continuously work, work time is short, and efficiency is high. Meanwhile, due to production under pressure, a press does not need to be introduced, and the overall equipment occupied area is small. Therefore, through the coiled tubing, the cost of a work well is lowered, and economic benefits are improved. The invention further discloses a coiled tubing technology with cable perforations adopting the coiled tubing tool set with the cable perforations.

Owner:JEREH ENERGY SERVICES

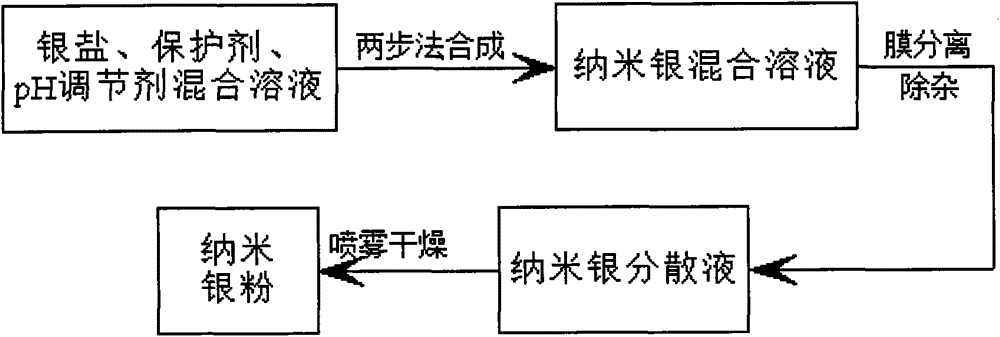

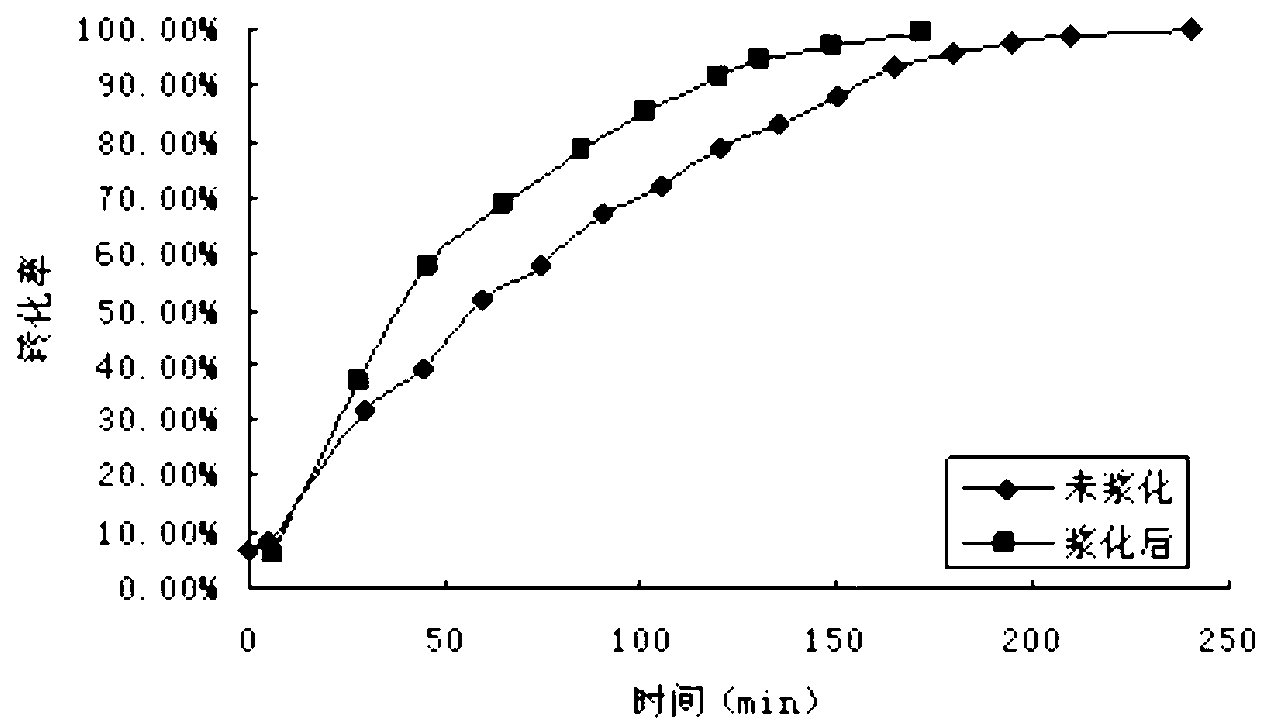

Method for preparing nanosilver powder in batches

ActiveCN104923801ASimple methodGuaranteed batch stabilityNanotechnologyBatch productionHigh concentration

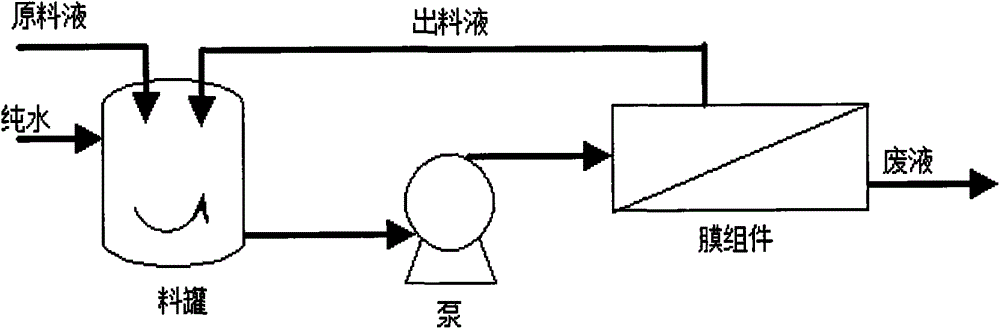

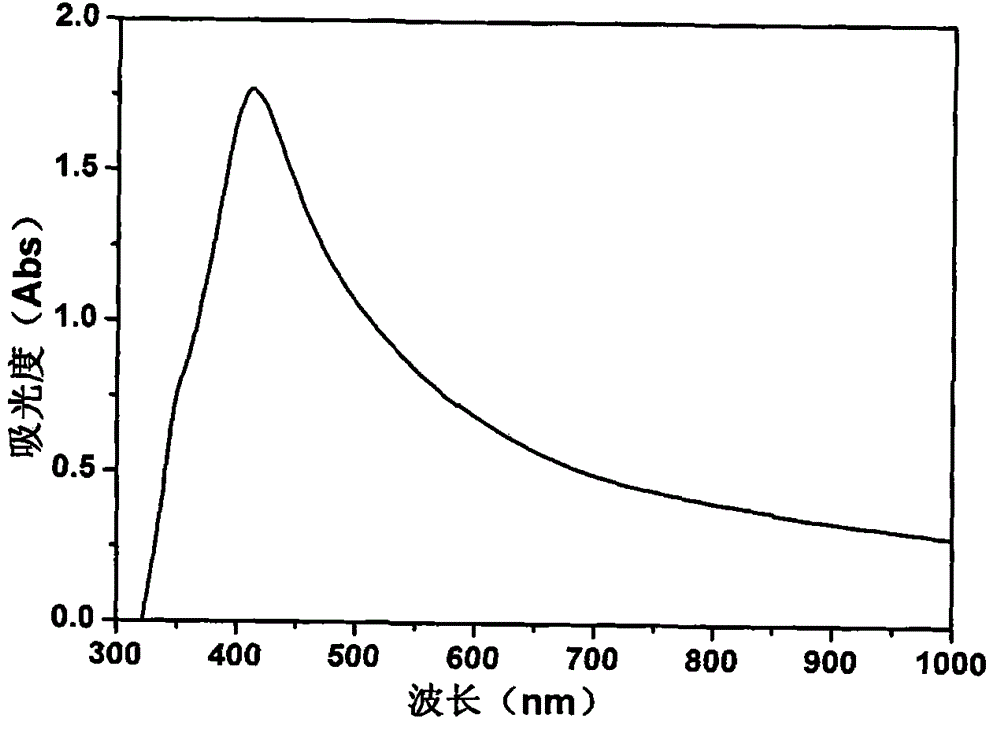

The invention provides a method for preparing nanosilver powder in batches, belonging to the field of nano-material preparation. Nanosilver particles are synthetized in two steps, at first, a low-concentration reducing agent solution is slowly added into a solution mixed with silver salt, a protective agent, and a pH conditioning agent drop by drop, and then a high-concentration reducing agent solution is rapidly added drop by drop to obtain a nanosilver mixed solution; impurities in the nanosilver mixed solution are removed through a membrane separation device to obtain a nanosilver dispersion liquid; and at the end, absolute ethyl alcohol and a high-molecular dispersant are added into the nanosilver dispersion liquid, and spray drying is carried out by a spray drying device to obtain nanosilver powder in a certain particle size. The particle size of the prepared nanosilver powder is controllable, the batches are stable, the problems of non-uniform particle size during the synthesis of nanosilver, nanosilver separation, and agglomeration and acaking during powder preparation are solved, the preparation process and the operation are simple, and industrial and batches production is realized.

Owner:NANO TOP ELECTRONICS TECH

Coal mine down-hole foam dedusting system

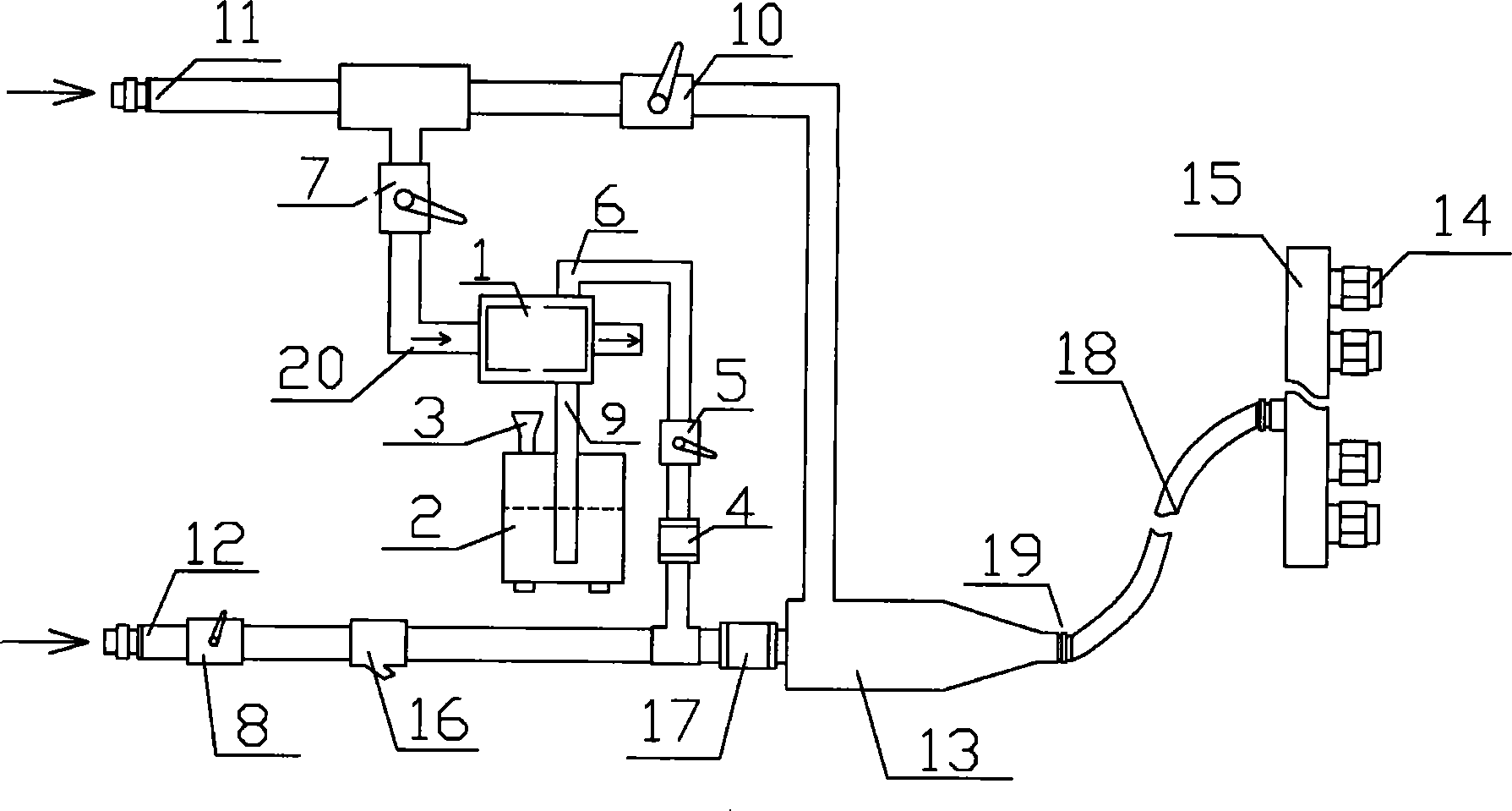

InactiveCN101251025AEvenly dispersedWill not cause accumulationMixing methodsDust removalFoaming agentCoal

The invention relates to a foam dust removal system used for coal mine underground mining, mainly comprising a fixed quantity addition pump, a foaming agent reservoir, a compressed air pipeline, a clean water pipeline, a foam generator, a foam spray head and so on. By utilization of the prior water pipe in a dust removal place, foaming agents are added into the water pipe by the small-flow fixed quantity addition pump; mixed liquid and compressed air which contain the foaming agents pass through the foam generator simultaneously, and a great amount of foams are generated, conveyed to the foam spray head through a hose, ejected from the foam spray head in the form of an umbrella and cover dust producing points. The invention is particularly suitable for the coal mine underground mining work surface, traveling belt transfer points, a tunnel excavated section or other dust producing points with small space and effectively controls the dust producing sources. The foam dust removal system used has the advantages of simple structure, convenient operation, capability of operating continuously, high dust removal efficiency, no electric elements and safety and reliability.

Owner:CHINA UNIV OF MINING & TECH

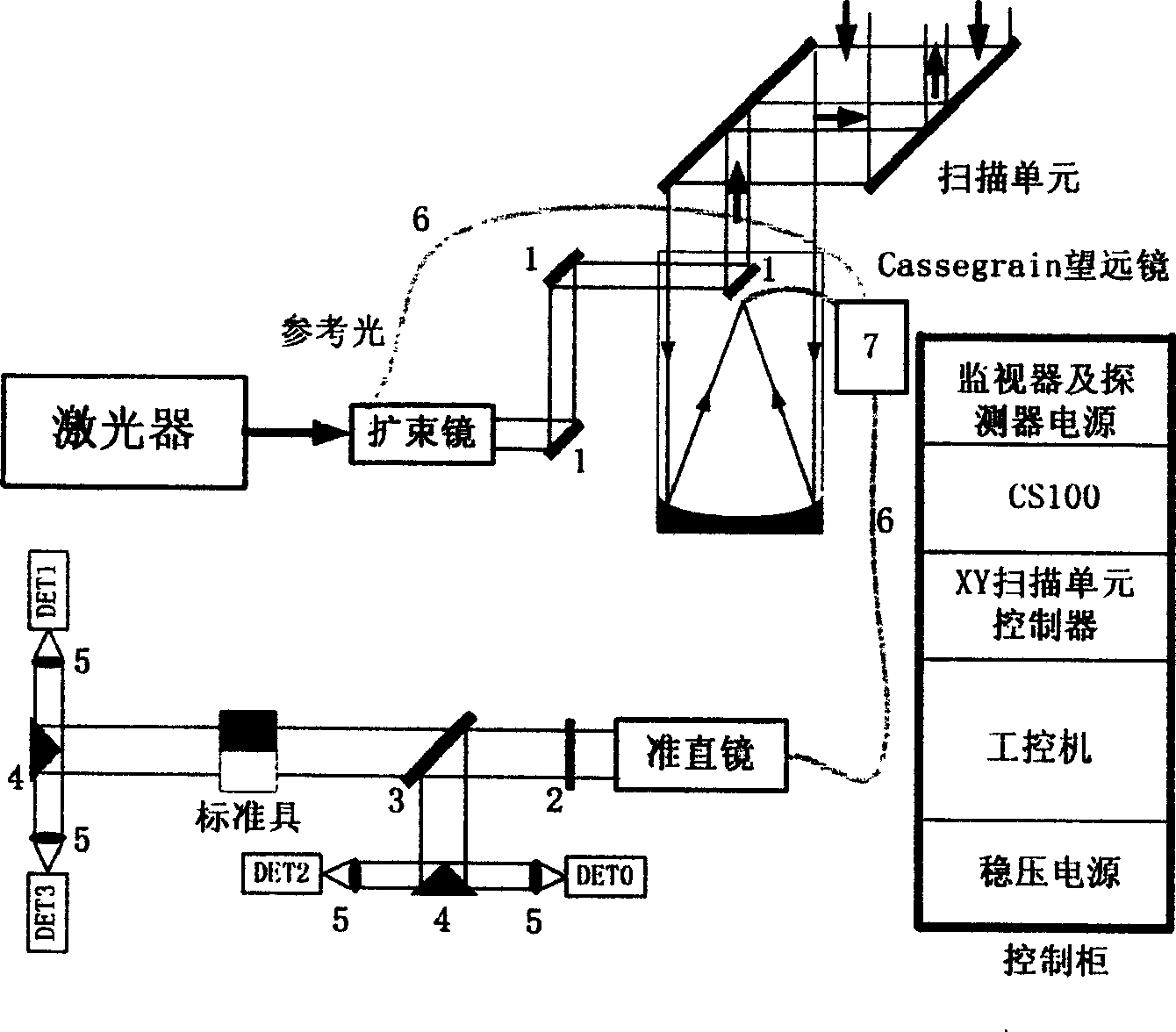

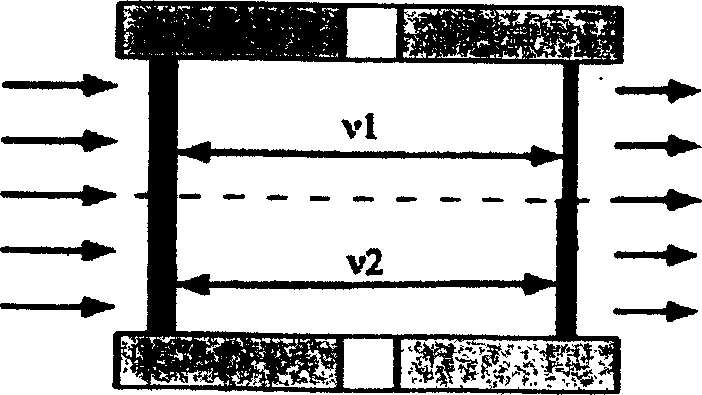

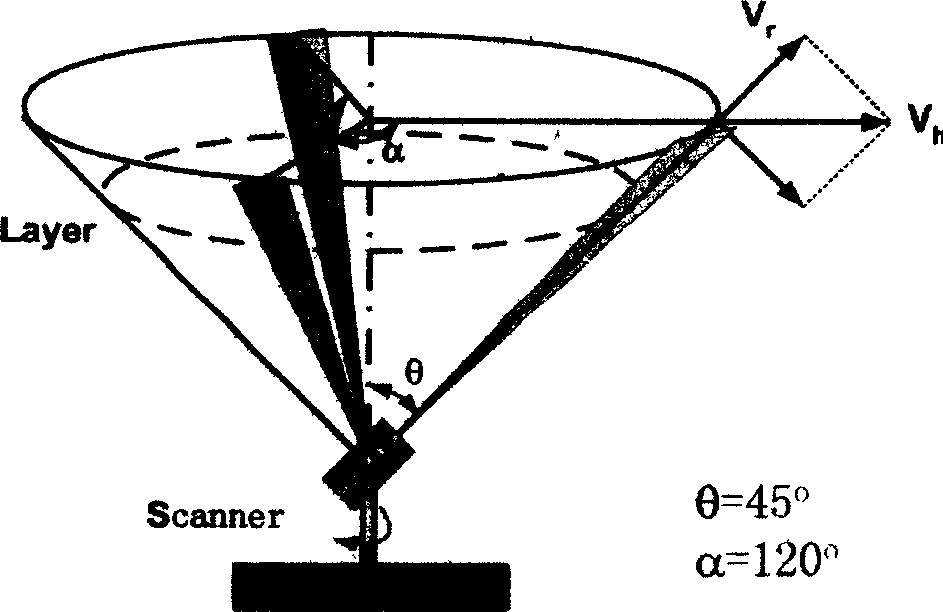

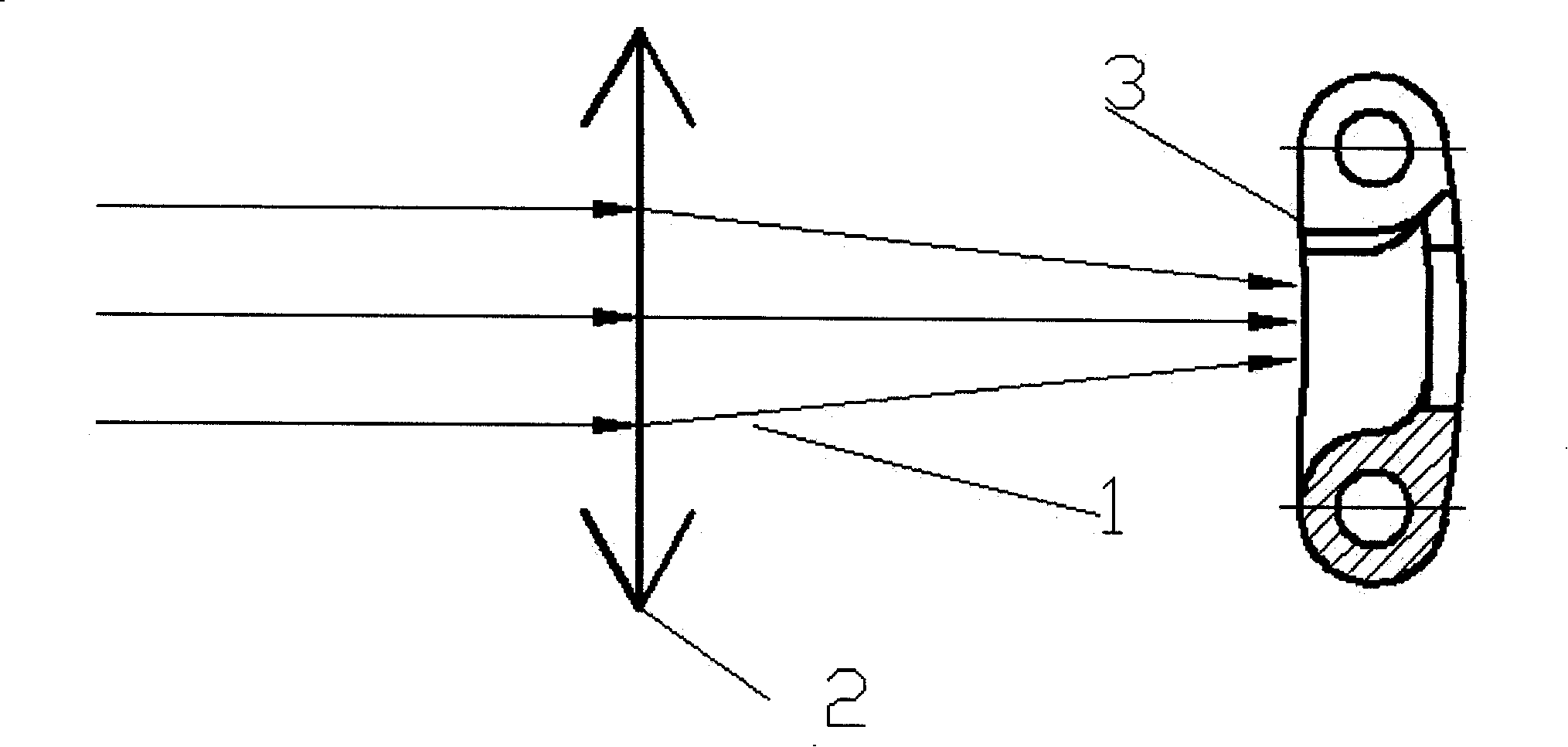

Structure of Doppler wind lidar based on F-P standard utensil and detection method thereof

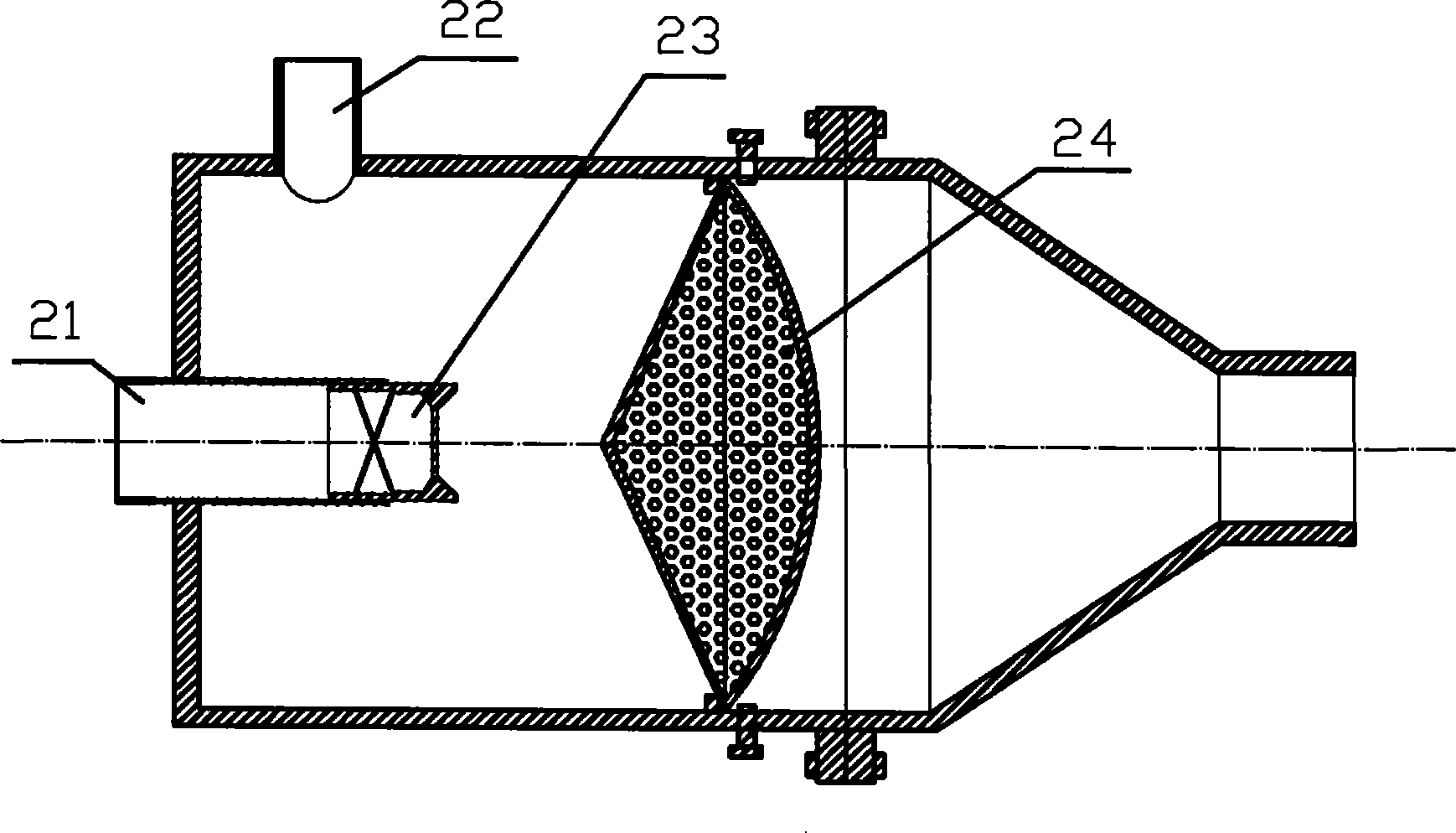

InactiveCN1880969AIncreased detection heightHigh spatial and temporal resolutionElectromagnetic wave reradiationICT adaptationOptical pathPhoton counting detector

The invention discloses a Doppler anemometer laser radar structure and detecting method based on F-P etalon, which is characterized by the following: the optical path contains Nd: YAG laser to output two beams of laser, wherein one beam is launched towards sky through two-dimensional scanning unit of plane reflector; the other beam laser intersects the input end of two-in-one optical fiber coupler through optical fiber; the optical fiber receiving port is loaded at the focus point of telescope cylinder with the optical fiber intersecting the input end of two-in-one optical fiber coupler; the output end of two-in-one optical fiber coupler connects collimating mirror through optical fiber, whose optical path loads color filter, beam splitting piece at 4:1 transparent-reflect rate, F-P etalon; one rectangle reflecting lens is set in the reflecting optical path of transparent optical path and beam splitting piece of etalon separately with one photon count detector setting on two sides of reflecting surface of each rectangle reflecting lens; the output end of photon count detector intersects data gathering and disposing equipment; the invention adopts double-brink technology to detect the layout of tropospheric atmospheric wind field directly.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

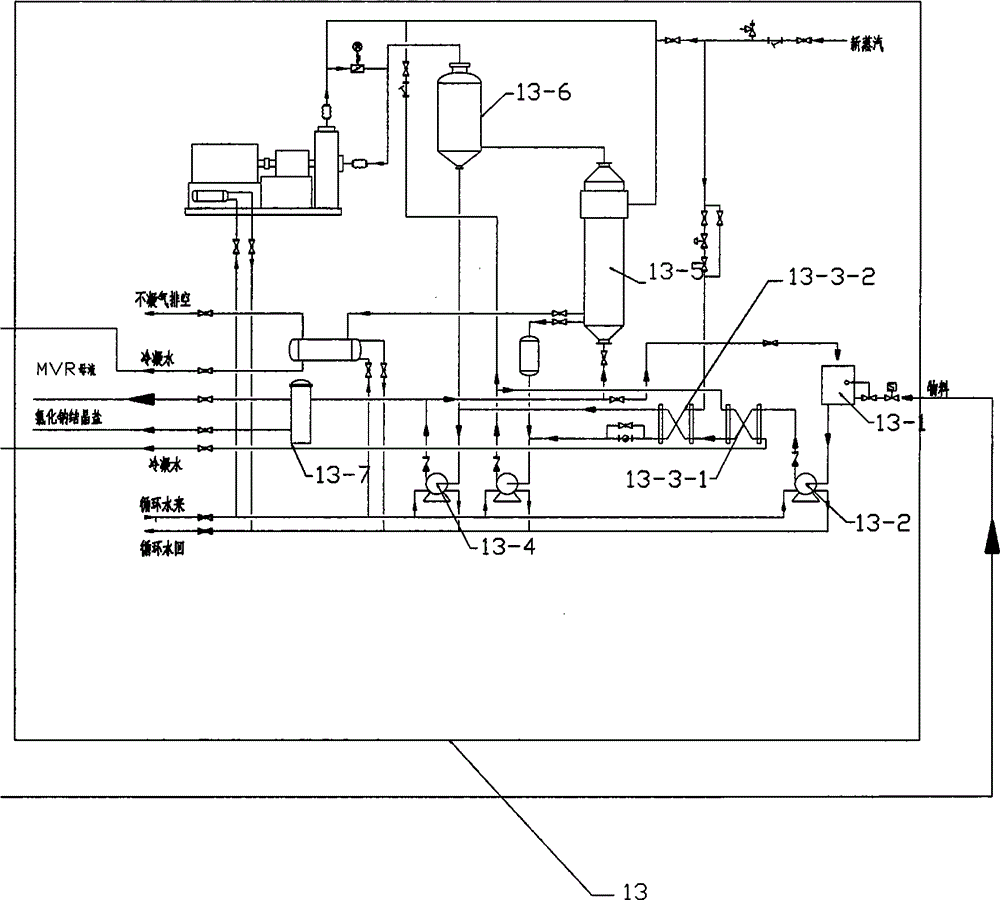

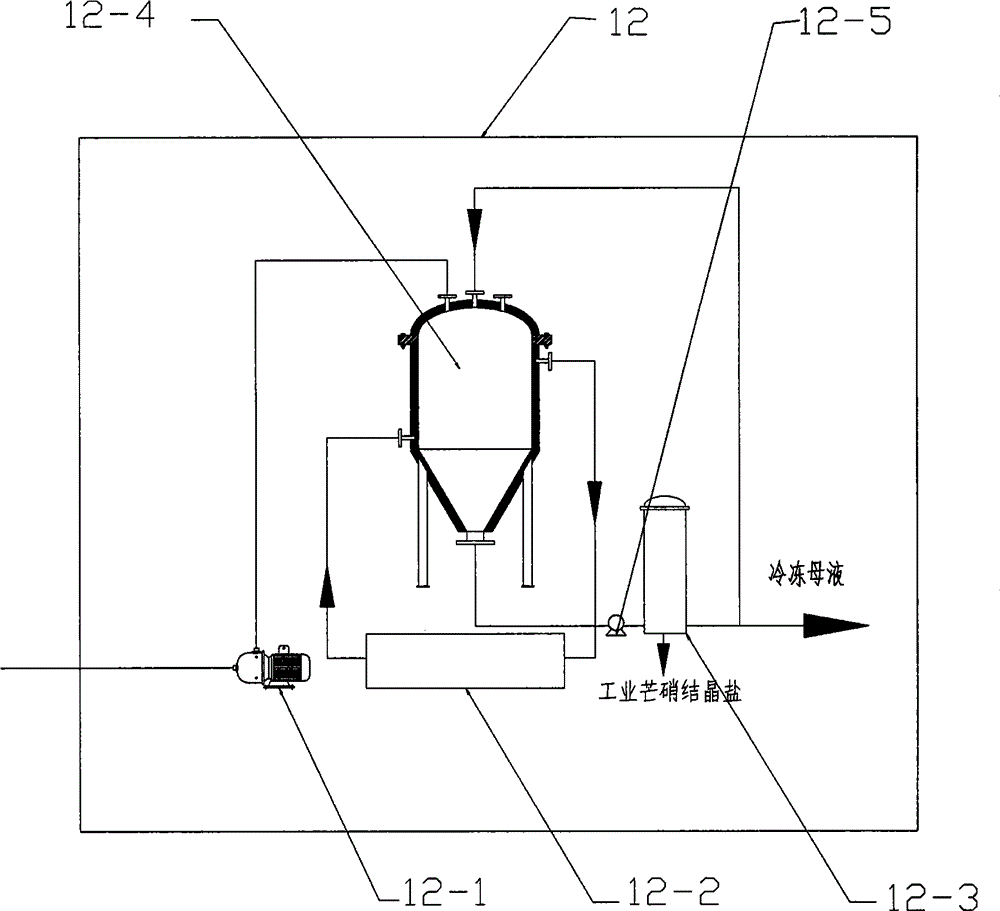

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Foam dust suppression system and foam dust suppression method for mine excavation

InactiveCN102434187AEasy to operateImprove stabilityFlow mixersMixing methodsEngineeringLiquid storage

Provided are a foam dust suppression system and a foam dust suppression method for mine excavation. The foam dust suppression system comprises a control device, a foam generating device and a foam sprinkling device. The foam generating device comprises a foam generator and a foaming agent liquid storage pot. The foam generator is respectively connected with a compressed air pipeline of a mine shaft, a clear water pipeline of the mine shaft and the foam sprinkling device. The control device is installed on the compressed air pipeline and the clear water pipeline and used for controlling opening and closing of the compressed air pipeline and the clear water pipeline. The foaming agent liquid storage pot is arranged on the clear water pipeline between the control device and the foam generator and is communicated with the clear water pipeline through a material sucking device. The foam dust suppression method comprises the steps of starting control, foam forming and foam sprinkling. The foam dust suppression system is small in volume, simple in operation, even in foam output and capable of working continuously, stably and reliably and being flexibly applied to a mine excavation working face or a transferring point and other narrow spaces.

Owner:康立杰

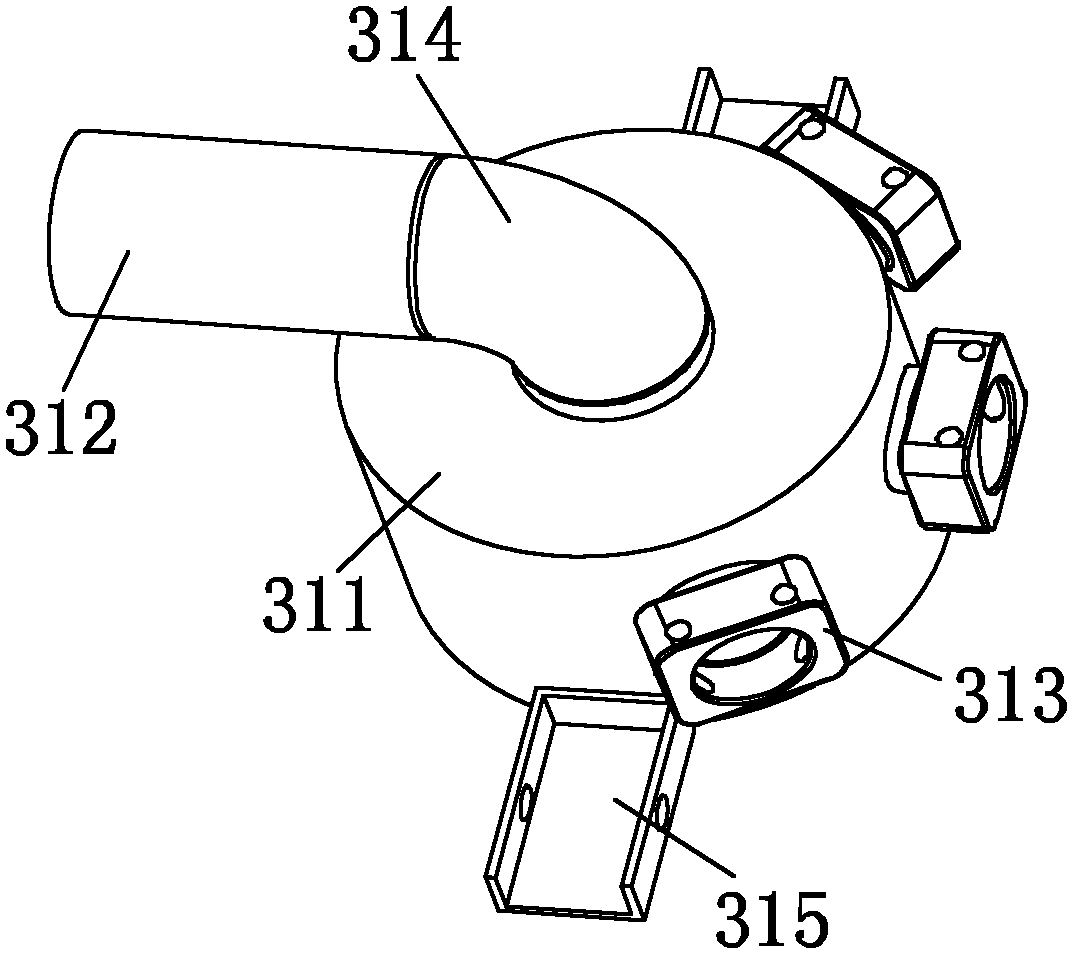

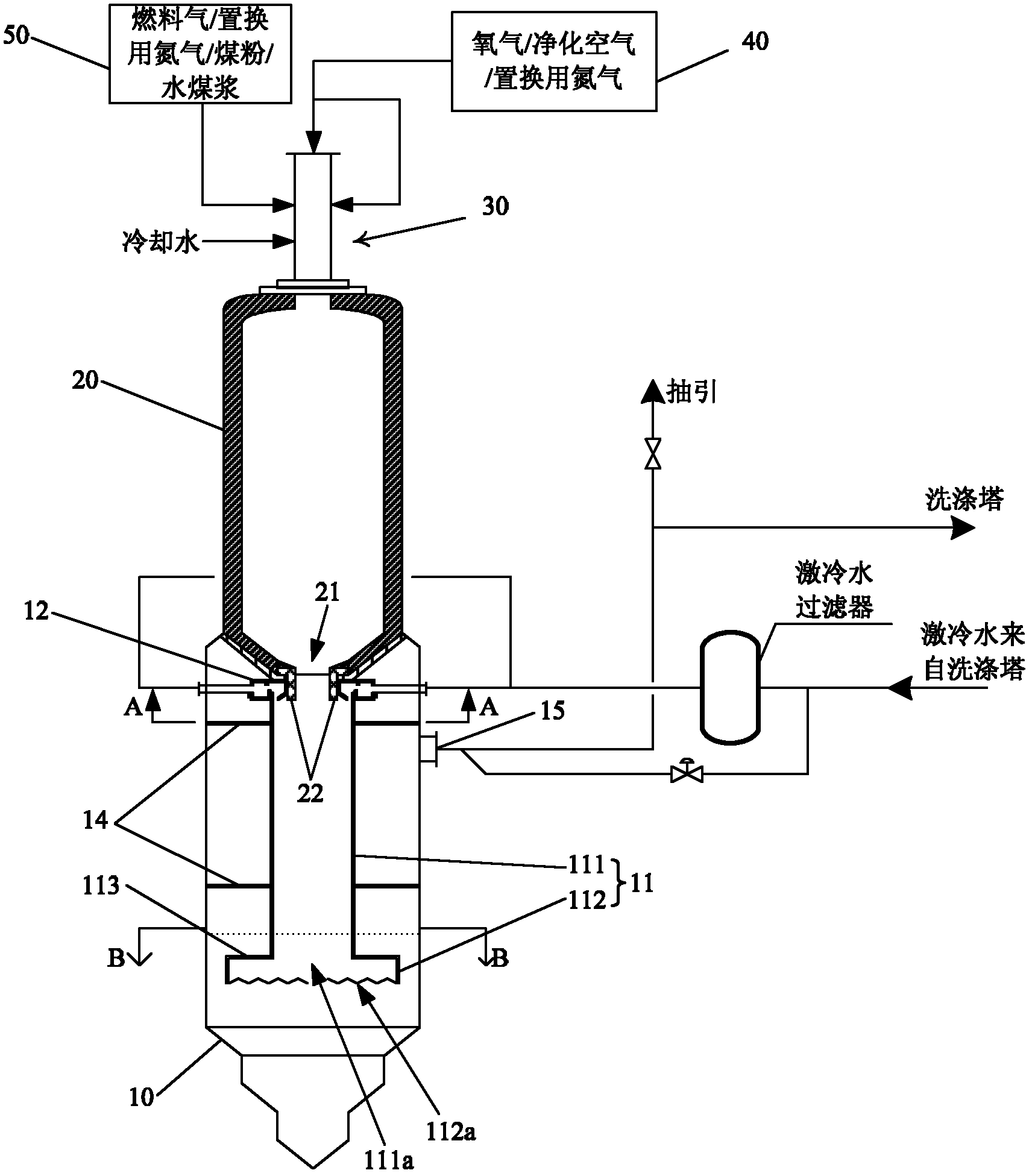

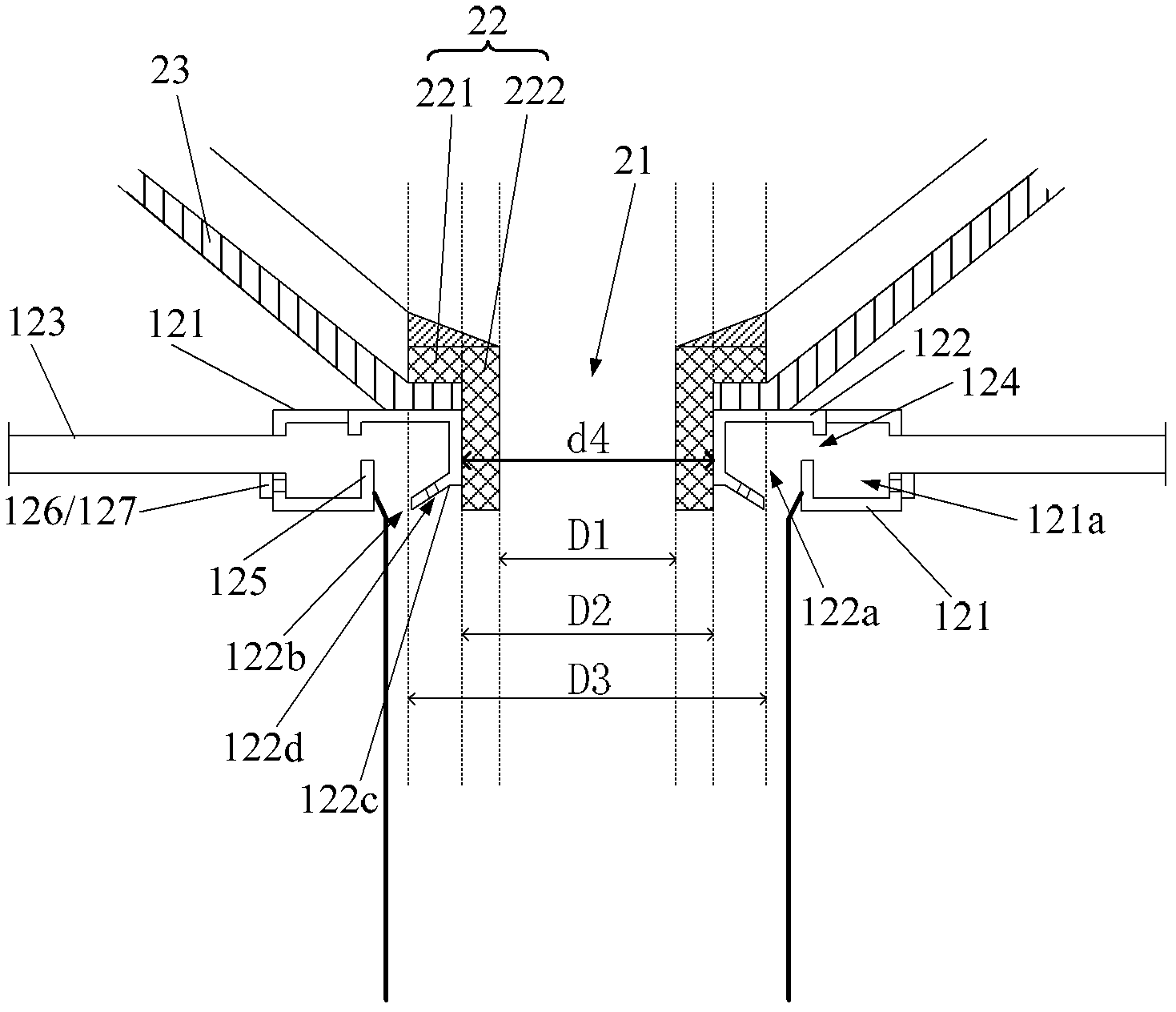

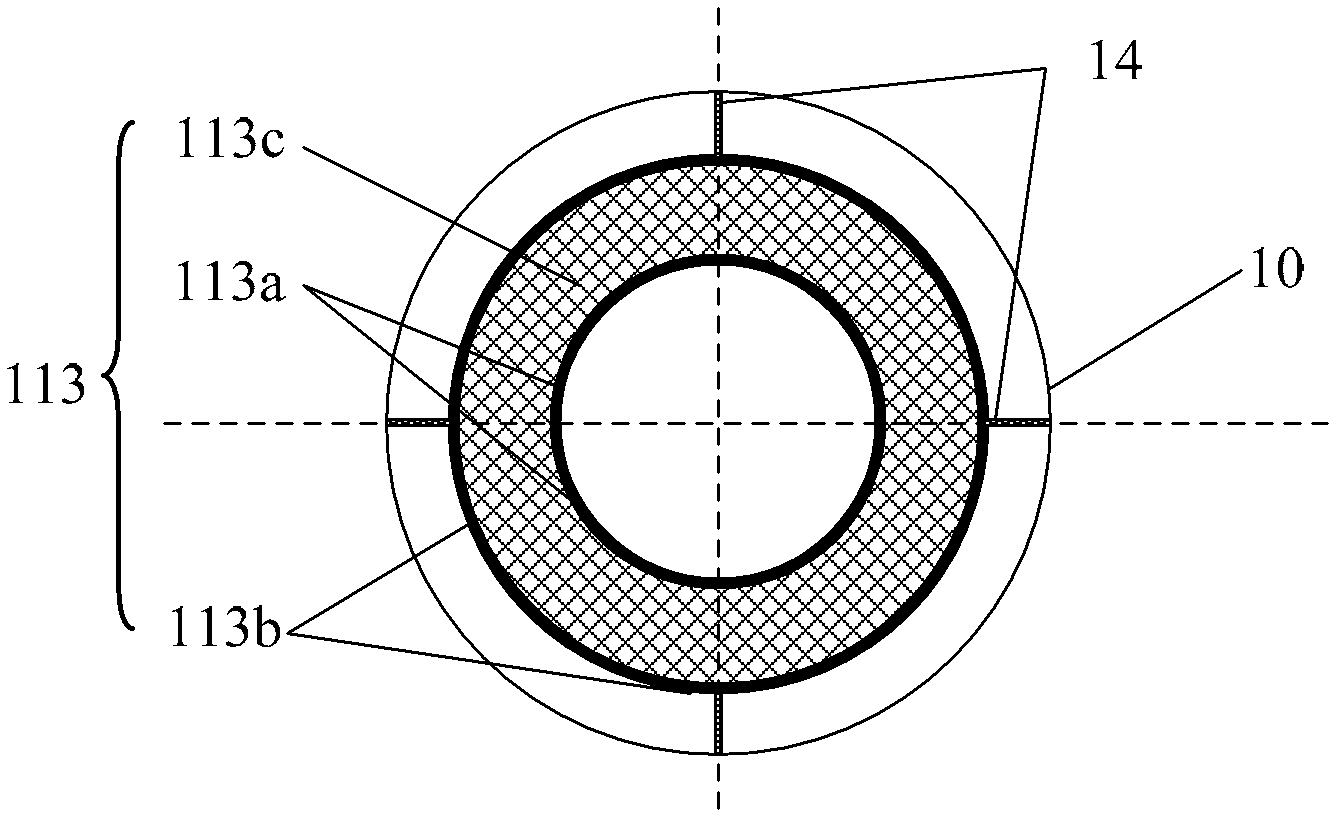

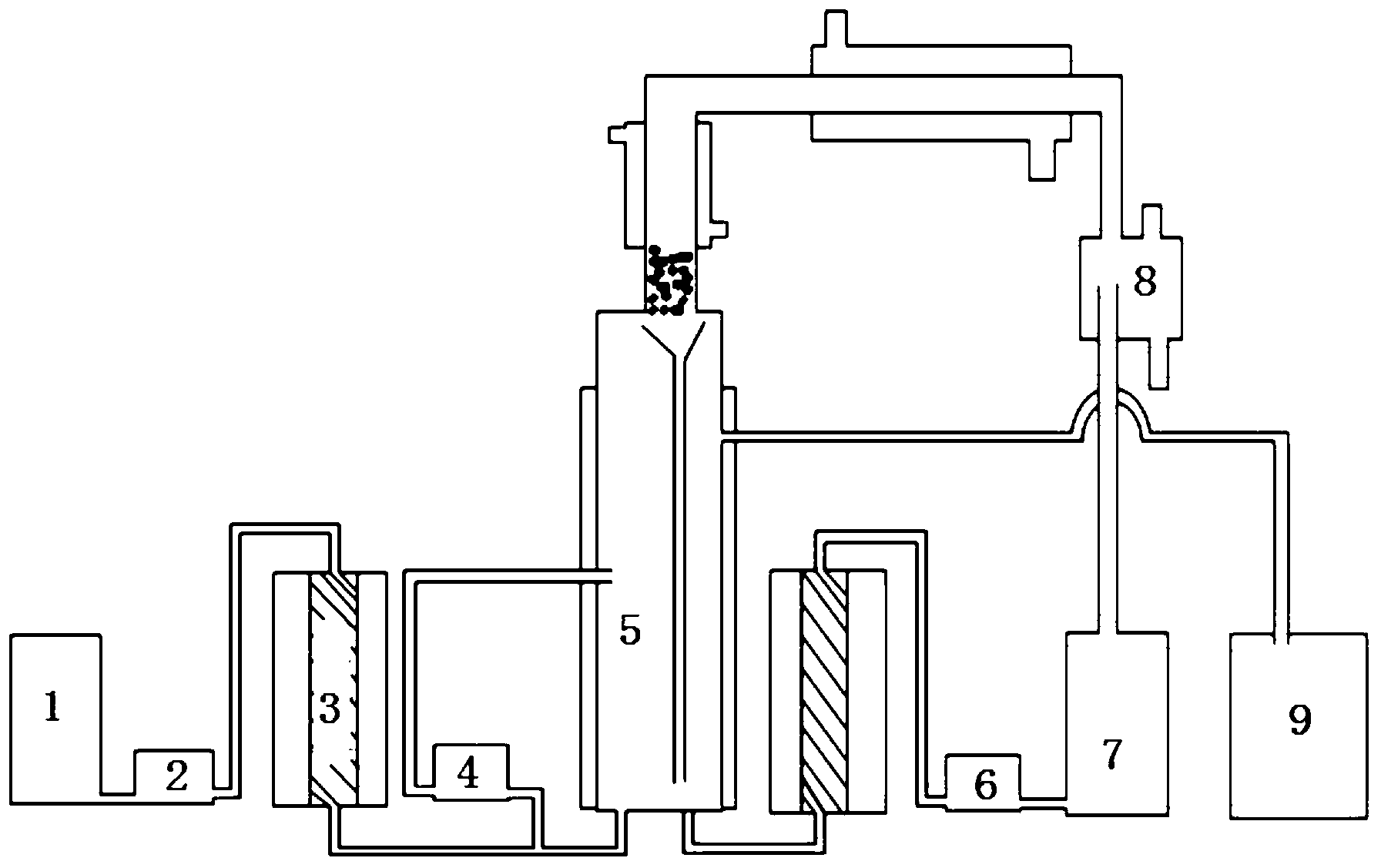

Pulverized coal or water coal slurry gasification furnace system

ActiveCN102643678AExtended operating cycleAvoid enteringGranular/pulverulent flues gasificationSyngasCombustor

The invention discloses a pulverized coal or water coal slurry gasification furnace system which comprises a gasification furnace, a feeding system for feeding the gasification furnace and a follow-up treatment system of a discharge compound gas, wherein the gasification furnace comprises a combustor and a quench chamber positioned below the combustor; the quench chamber is provided with a downcomer and a quench ring; the quench ring is arranged at the top part of the downcomer and provides quench water; the downcomer comprises an air reduction barrel and an air distribution barrel; the lower end of the air reduction barrel extends to the air distribution barrel; an air diffusion mesh is arranged on a ring-shaped cross section between the air distribution barrel and the air reduction barrel; and the lower edge of the air reduction barrel is in a sawtooth shape. According to the pulverized coal or water coal slurry gasification furnace system, water and ash containing in a synthetic gas in the quench chamber are lightened; the service lives of the quench ring and the downcomer are prolonged; the stable production is kept; the operation period of the gasification furnace is prolonged; and the continuous operation of over baking and chemical engineering feeding.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

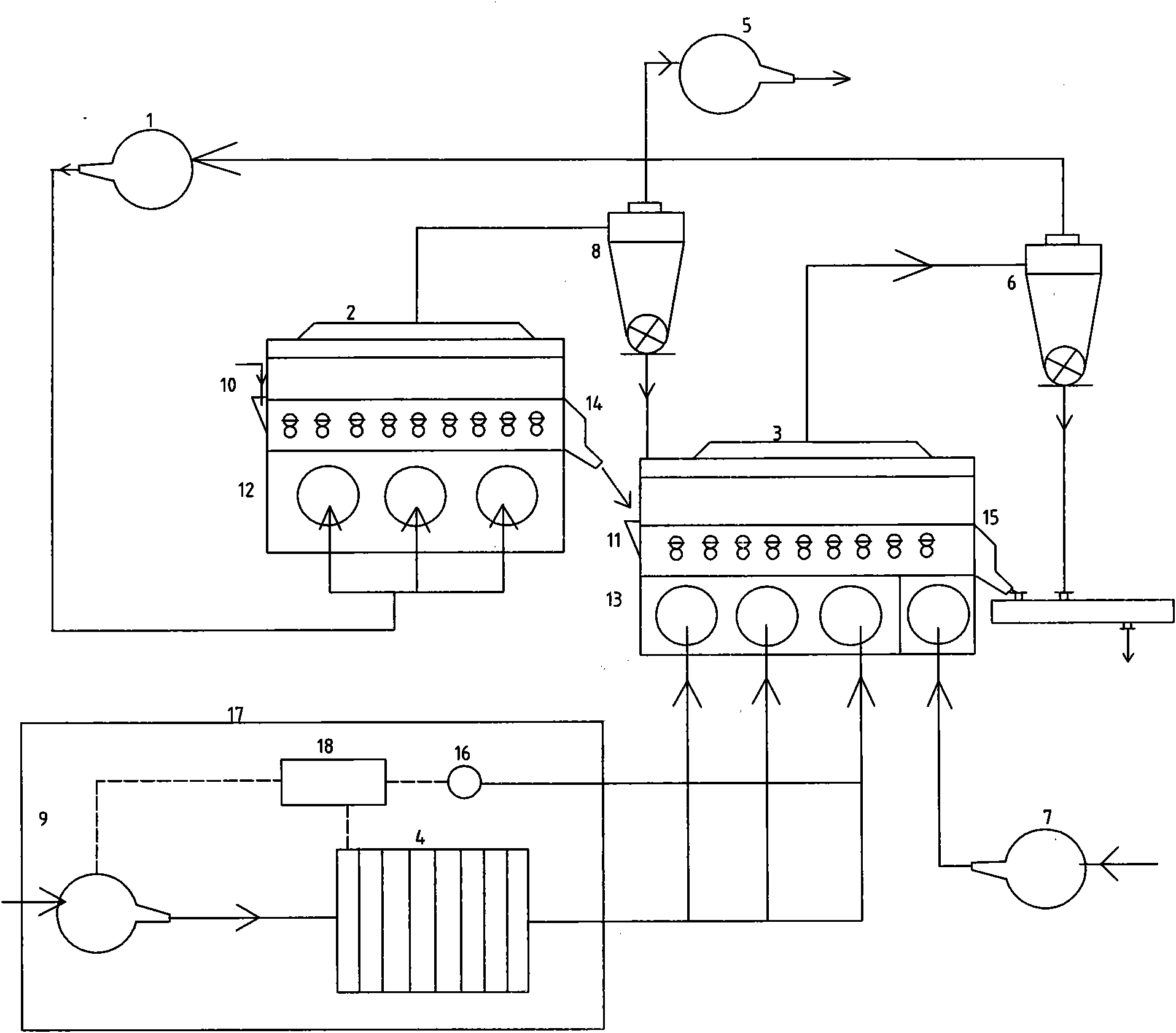

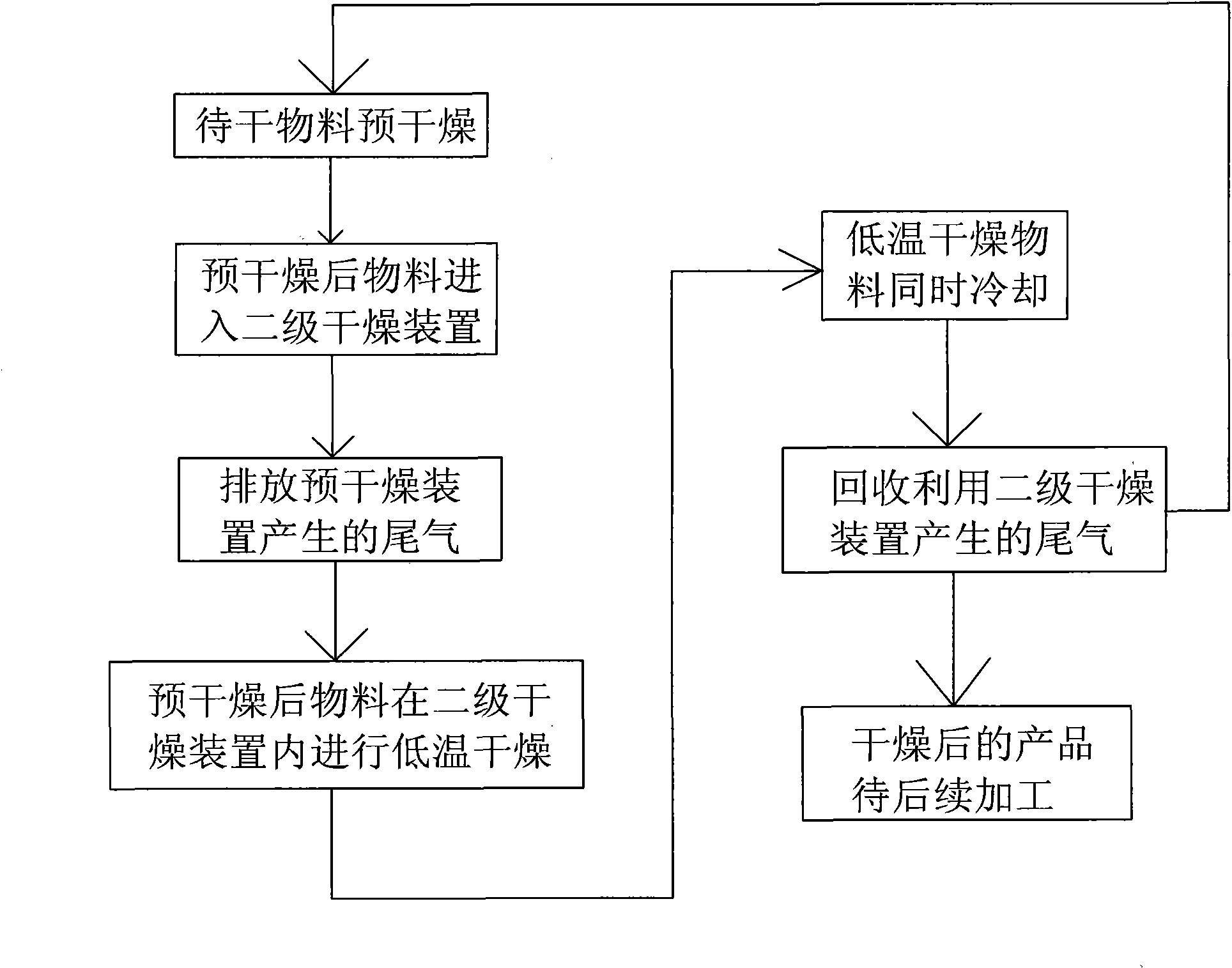

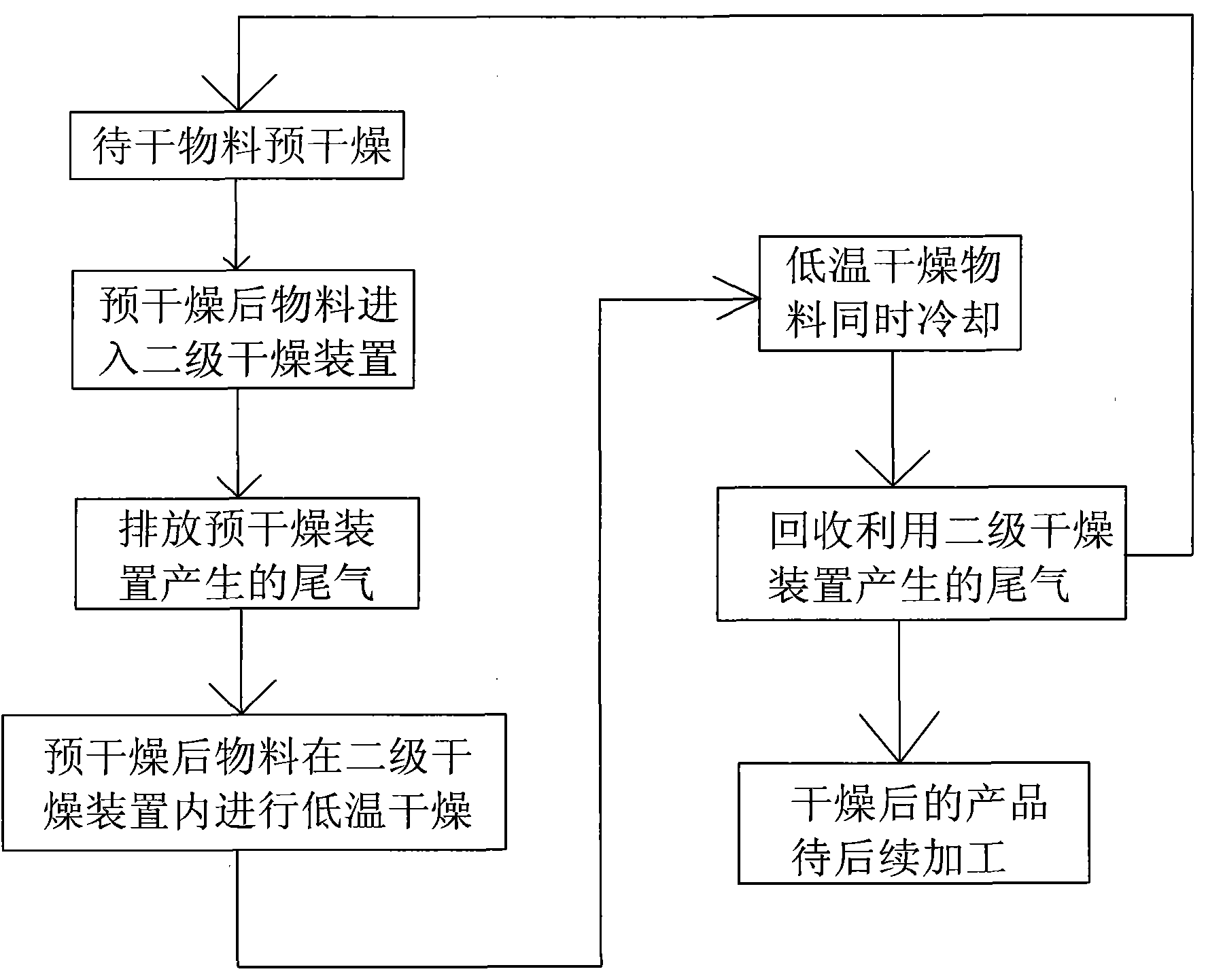

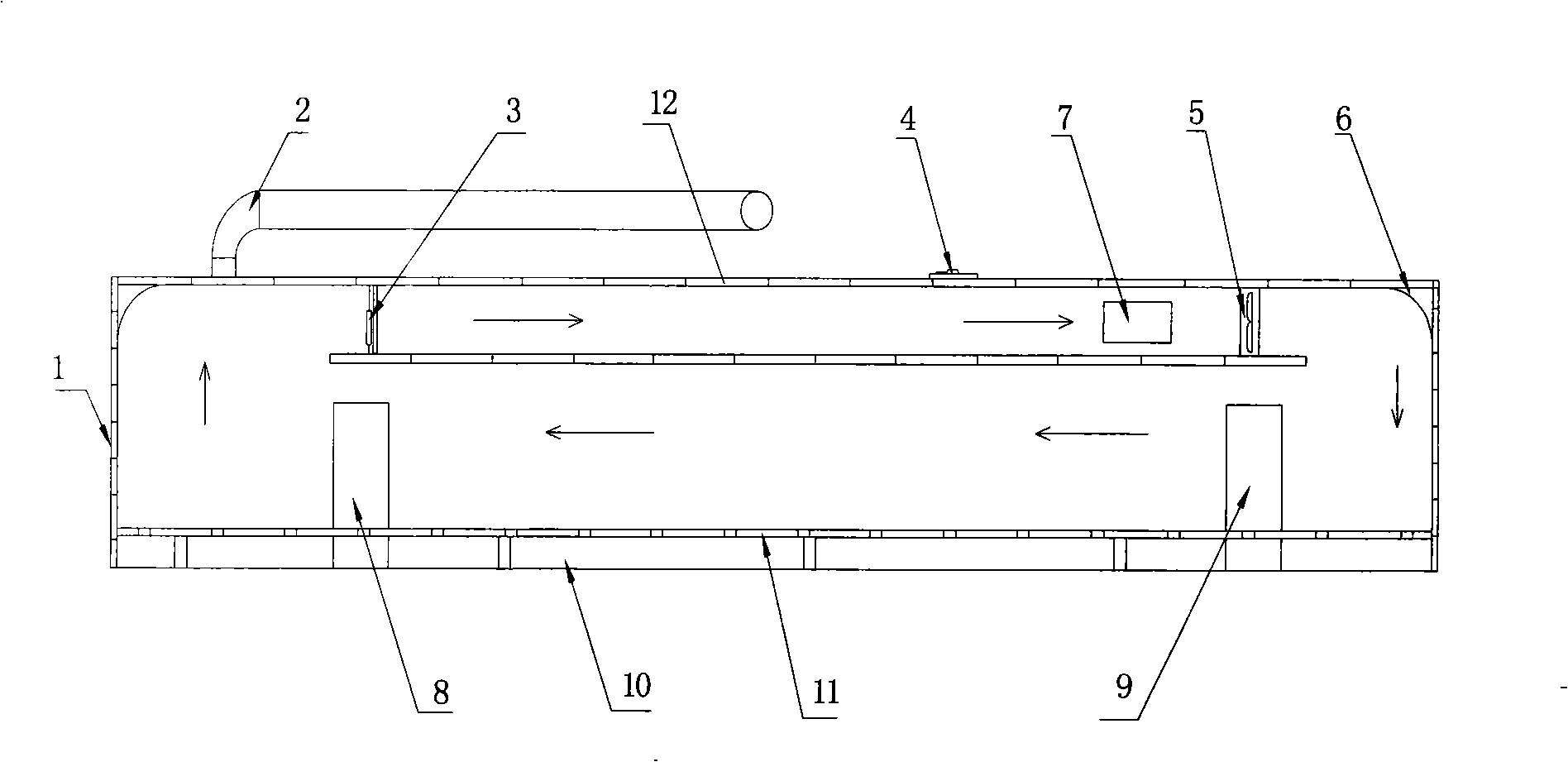

Low-temperature high-efficiency fluidization combined drying process and equipment thereof

InactiveCN101881550AQuality improvementReduce heat consumptionDrying solid materials with heatDrying machine combinationsProcess systemsProcess engineering

The invention discloses a low-temperature high-efficiency fluidization combined drying process and equipment thereof; the drying equipment comprises an afterheat utilization primary pre-heating device, a secondary drying device, cyclone separators, blowers and a temperature control device; the afterheat utilization primary pre-drying device or the secondary drying device comprises a feed opening, a discharge port, a vent and a drying chamber; the discharge port of the afterheat utilization primary pre-drying device is connected with the feed opening of the secondary drying device; the vent of the afterheat utilization primary pre-drying device is sequentially connected with a cyclone separator A, the secondary drying device, a cyclone separator B, a blower A and the drying chamber of the afterheat utilization primary pre-drying device; the vent of the cyclone separator A is connected with the blower B; and the drying chamber of the secondary drying device is respectively connected with a blower C and the temperature control device. The invention quickly and homogeneously dries material to be dried under the premise of meeting the original quality of raw grain, leavening and other products, has the advantages of energy-saving, environment production, low temperature and high efficiency, meets the requirements of continuous and scale production, and has good process system maintenance performance.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

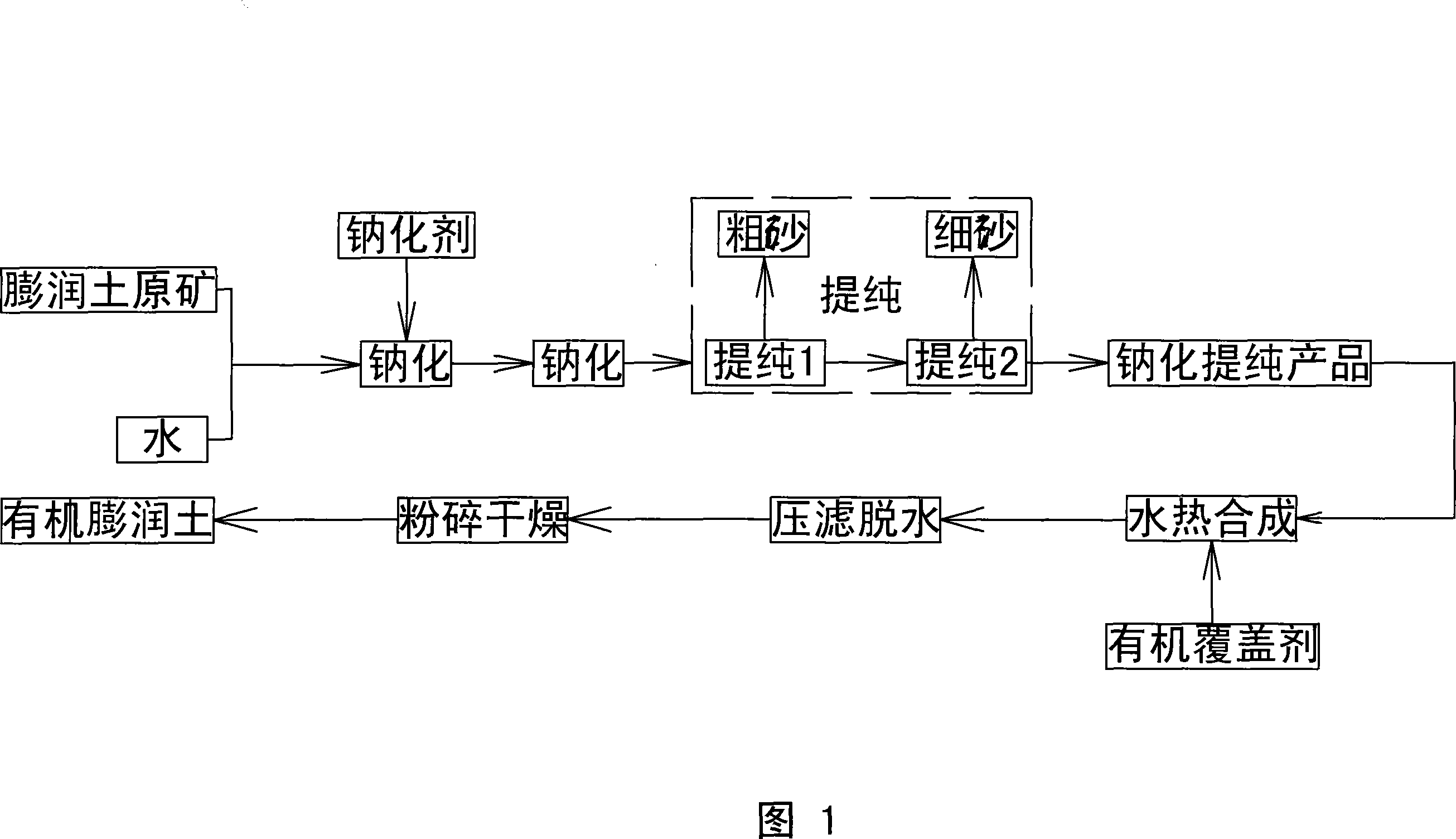

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

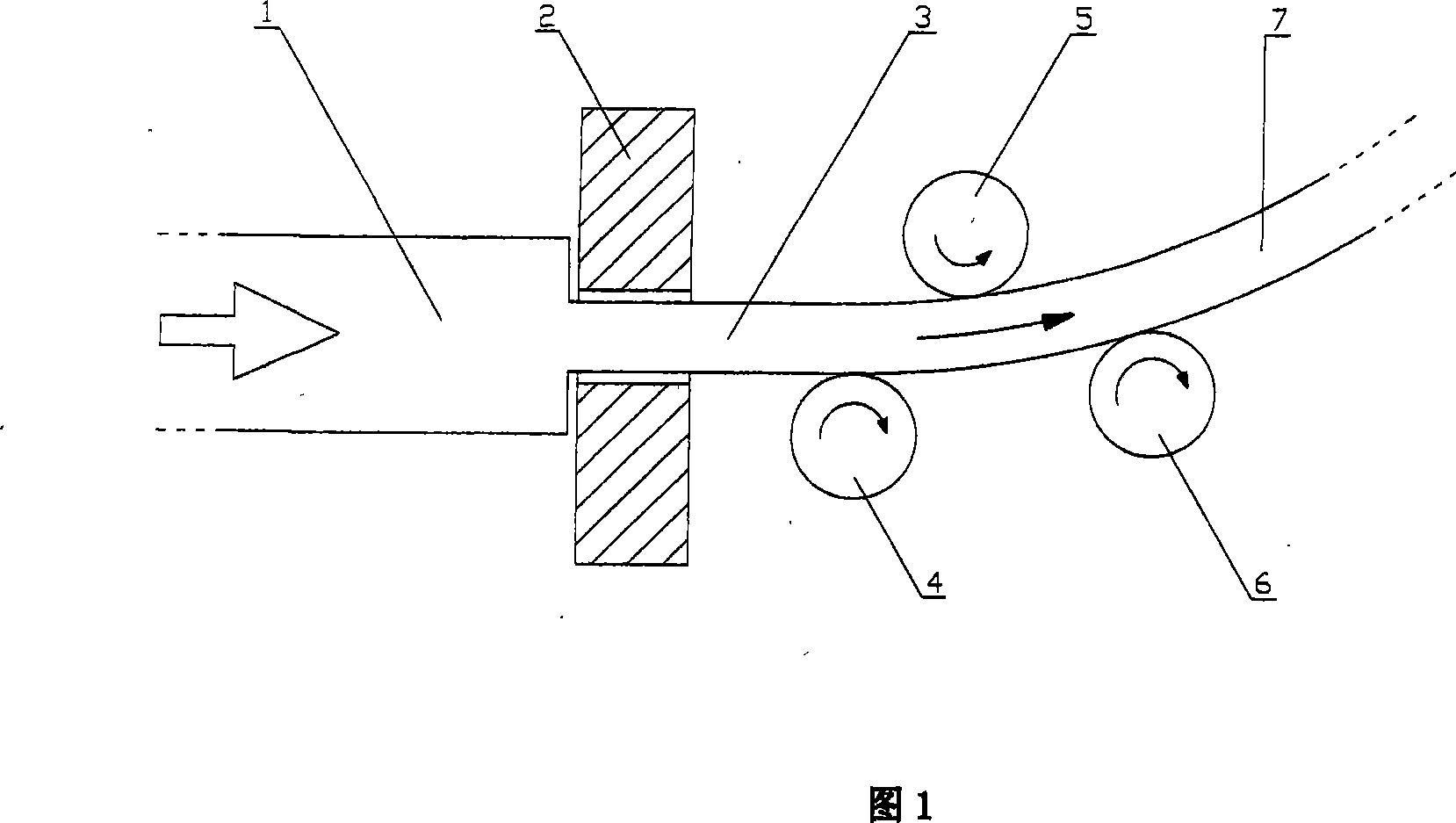

Extruding-bending integral forming method for magnesium alloy profiles

The invention relates to a technical method used for extruding-bending-integral forming of a magnesium alloy sectional material, pertaining to the technical field of plasticity processing. A set of three-wheel roll bending device is arranged near a discharge port of the original horizontal extruding machine, magnesium alloy ingot blanks are molded into the sectional material through hot extrusion, the sectional material is put into the roll bending mechanism directly before being cooled, bending moment is carried out to the sectional materials by the three roll wheels that are arranged on a same surface so as to achieve bending and molding, and the movement and position of the roll wheels are controlled to gain a bending angle and a bending radius that are required. The invention can realize the extrusion, bending and continuous molding of the magnesium alloy sectional material under the condition of only heating original ingot blanks, thereby having high production efficiency and low cost.

Owner:SHANGHAI JIAO TONG UNIV

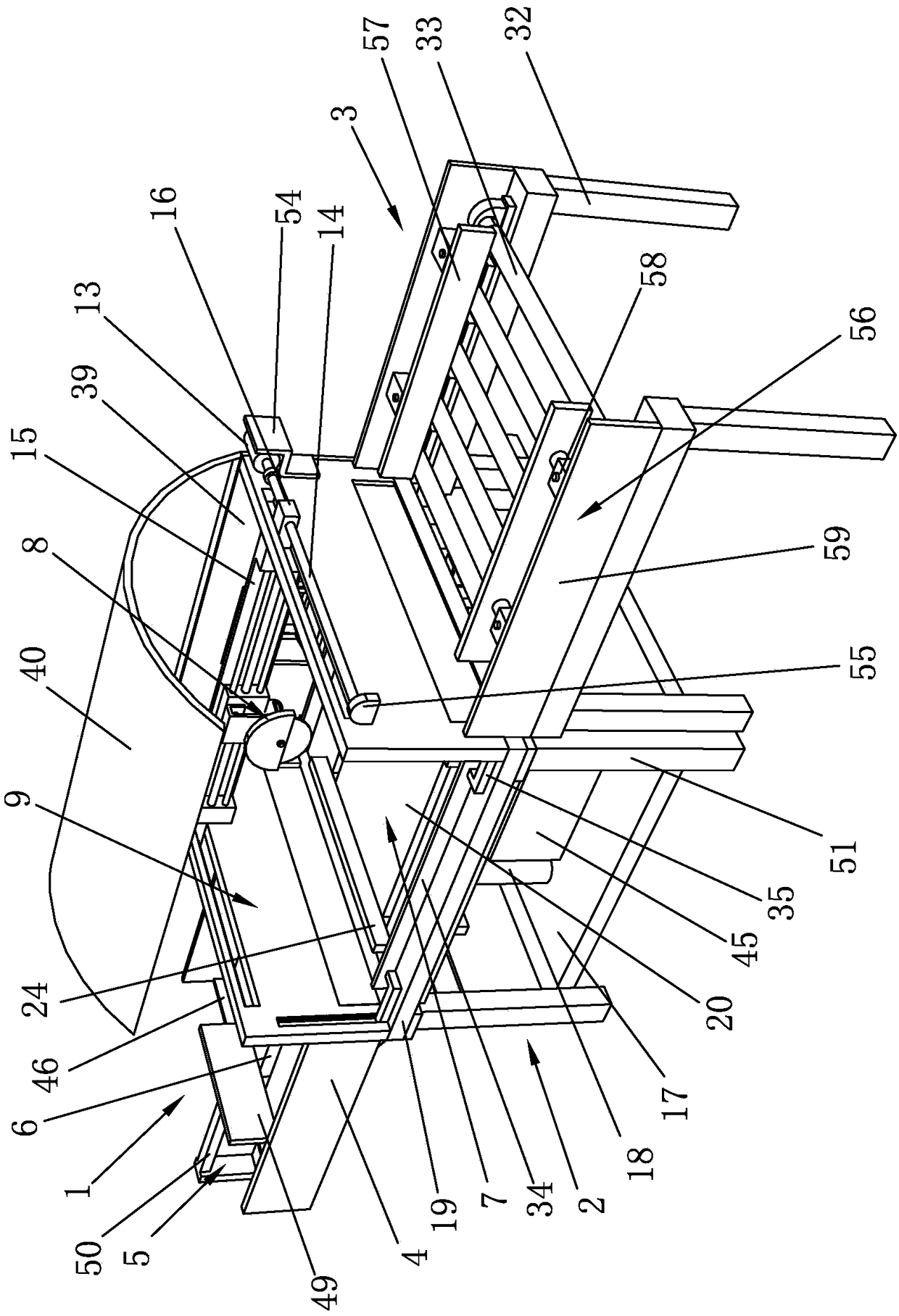

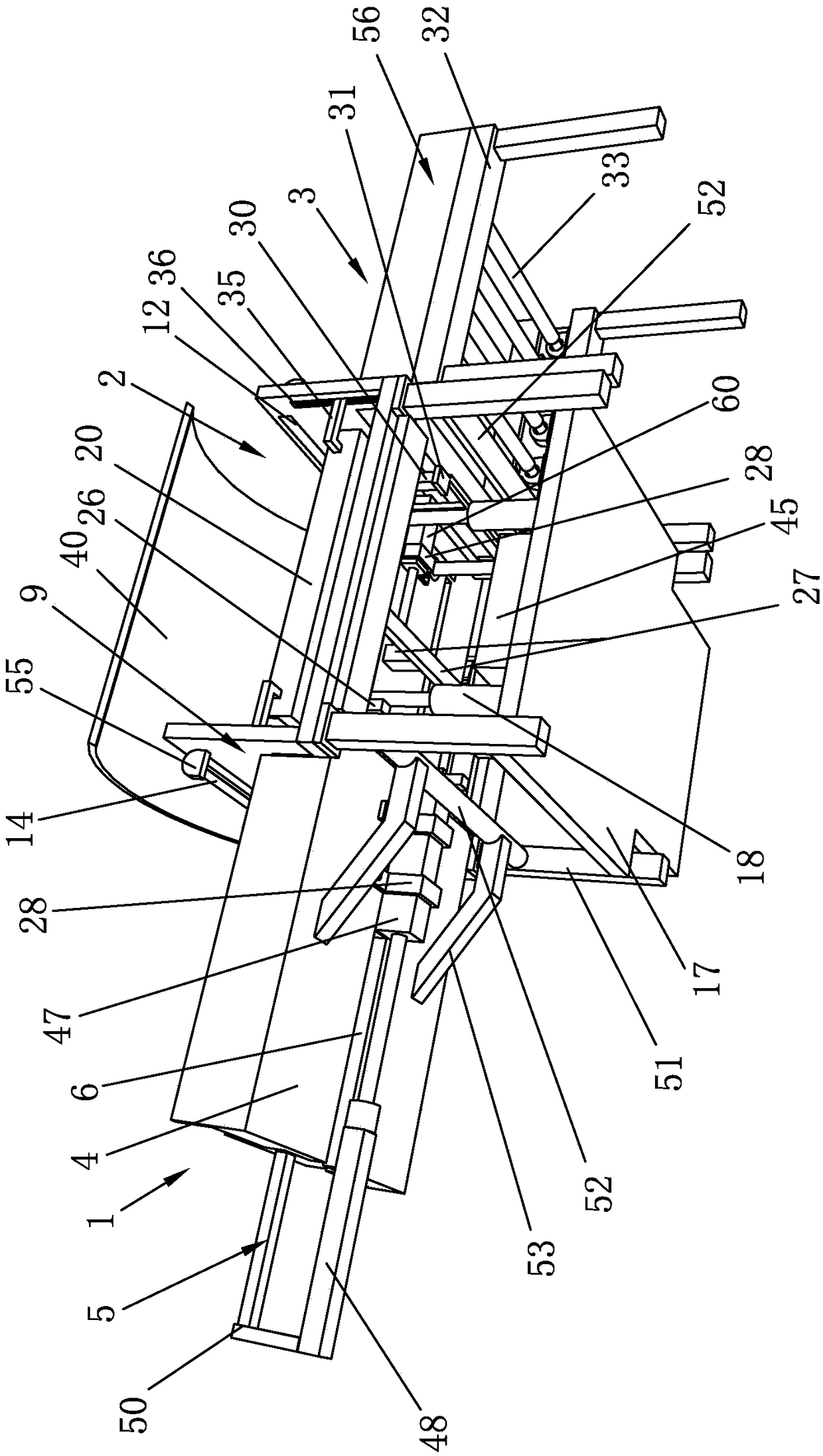

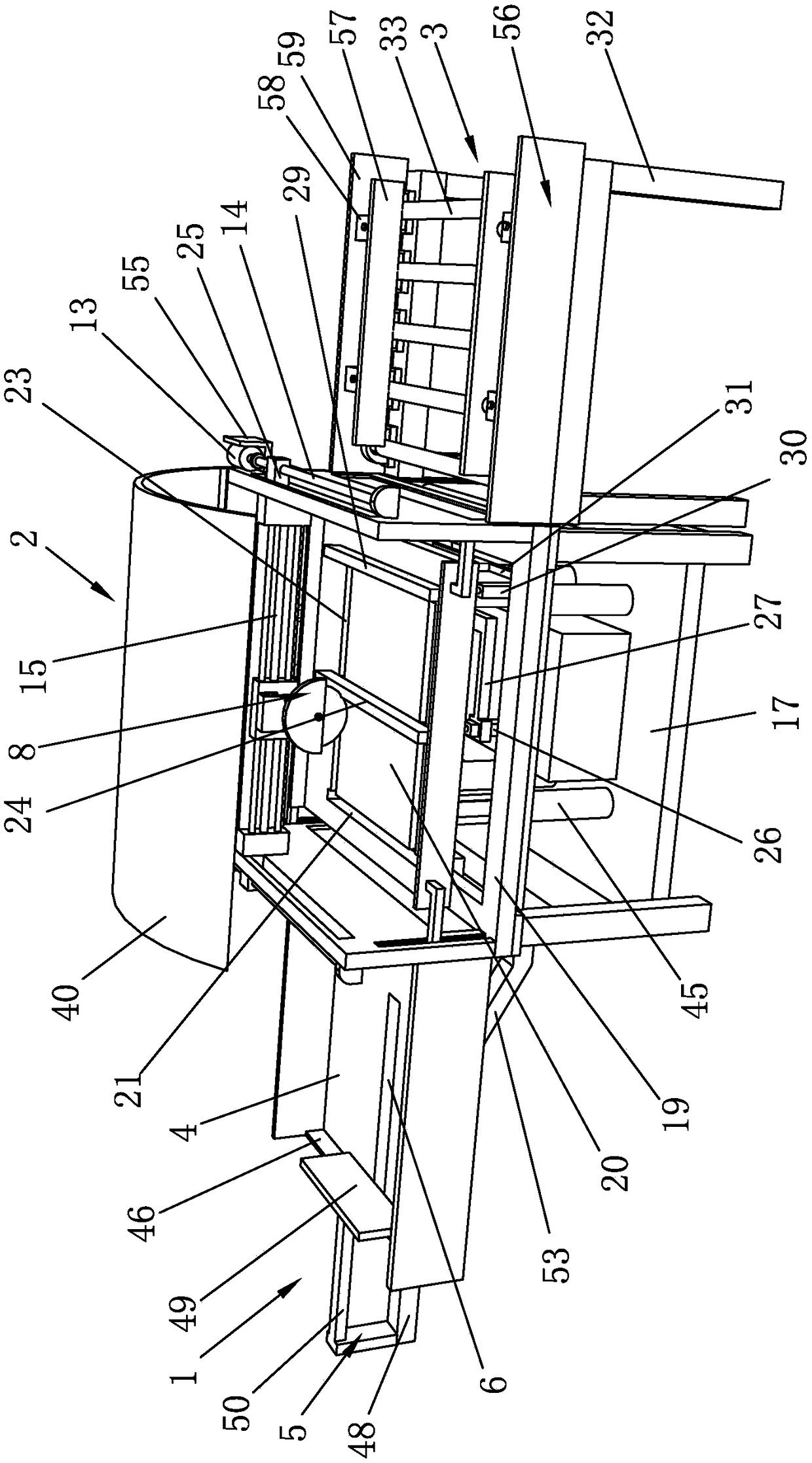

Cutting device for mechanical automatic production of spare and accessory parts

ActiveCN109227663APlay a limiting roleSwipe up and down smoothlyMetal working apparatusEngineeringOperation safety

The invention discloses a cutting device for mechanical automatic production of spare and accessory parts, which includes a feeding mechanism, a cutting mechanism and an unloading mechanism, wherein the feeding mechanism includes a feeding table and a pushing mechanism and the cutting mechanism includes a cutting table and a cutting head group. Gate components are arranged on both sides of the cutting table, a supporting plate is arranged under the cutting table, and lifter columns are evenly arranged between the supporting plate and the cutting table. The cutting table comprises a supportingbracket and a lifting table. A longitudinal chute and a transverse chute are arranged on the top face of lifting table. The longitudinal chute includes a left longitudinal chute and a right longitudinal chute, wherein a left spacing splint is arranged in the longitudinal chute and a right spacing splint is arranged in the right longitudinal chute, and the transverse chute is communicated with theleft longitudinal chute. The overall structure of the cutting device for mechanical automatic production of spare and accessory parts is ingenious and reasonable. The automatic operation is achieved by the design of the feeding mechanism and the unloading mechanism which can feed and unload workpieces automatically, thereby reducing the labor intensity and hidden safety hazard, improving the operation safety performance and the cutting speed.

Owner:柳州蒸达机械配件有限公司

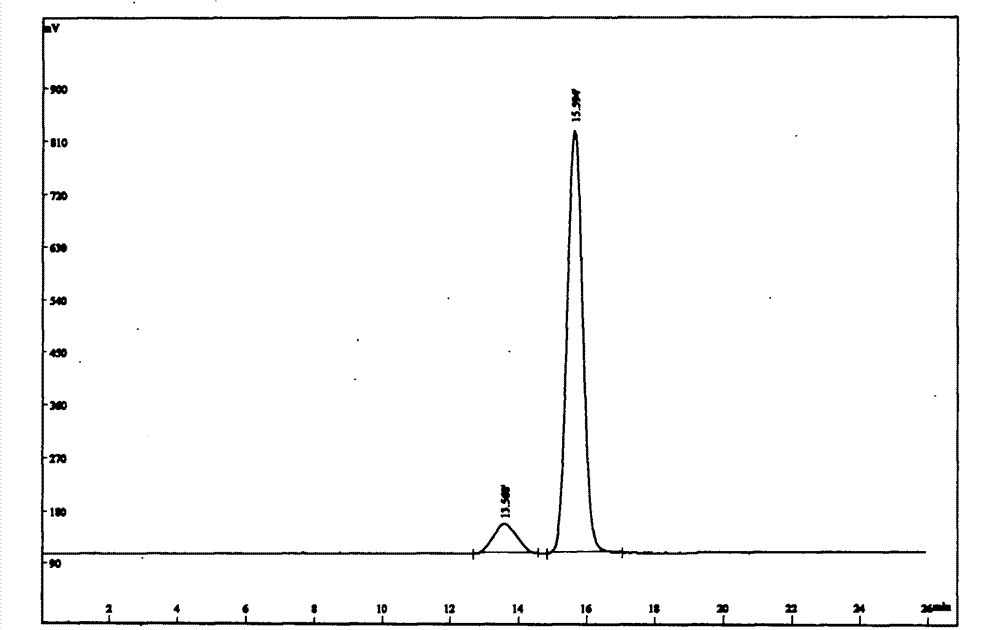

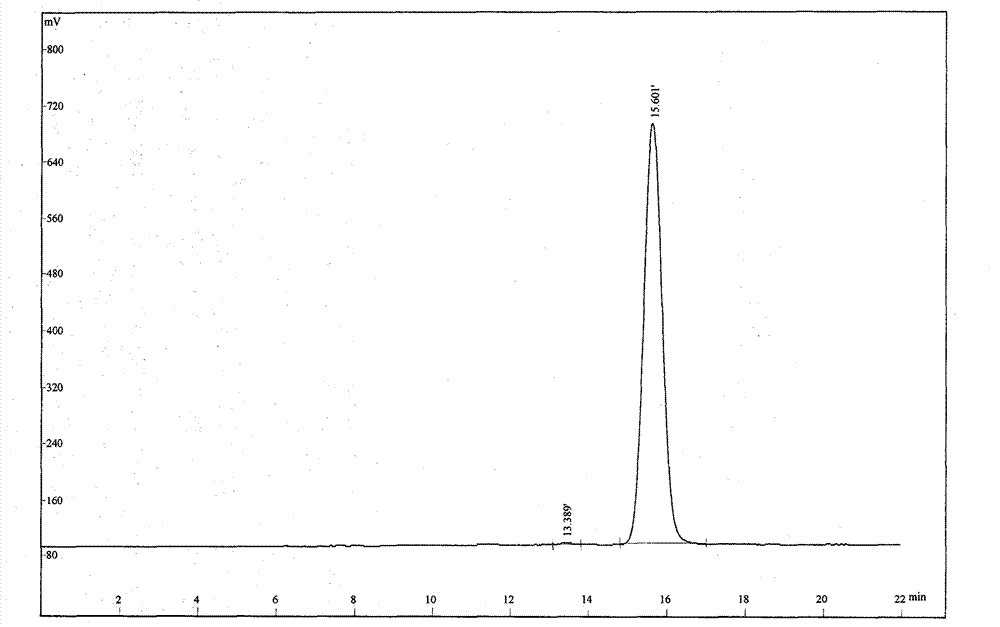

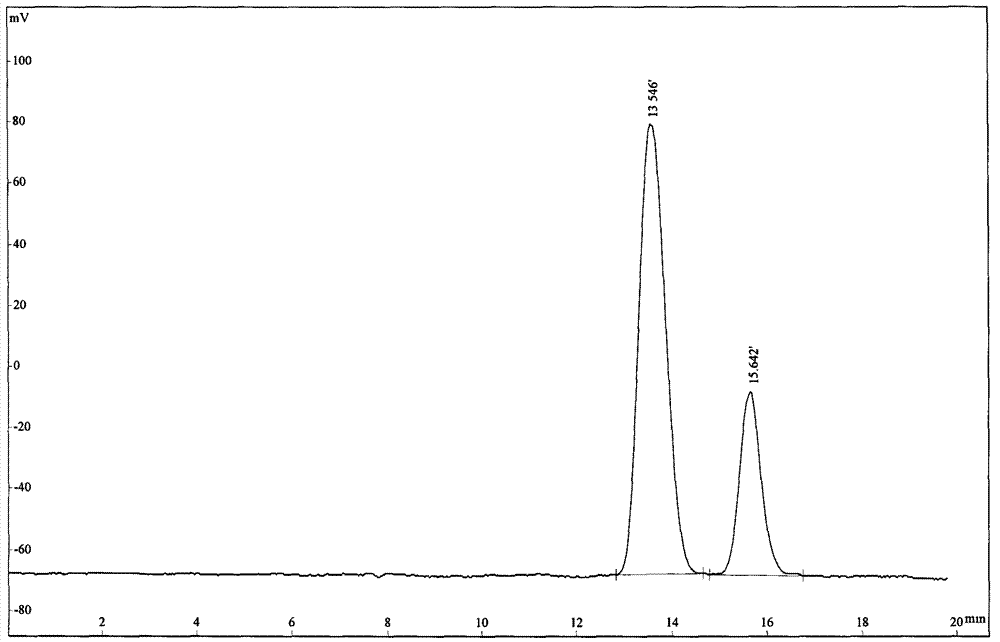

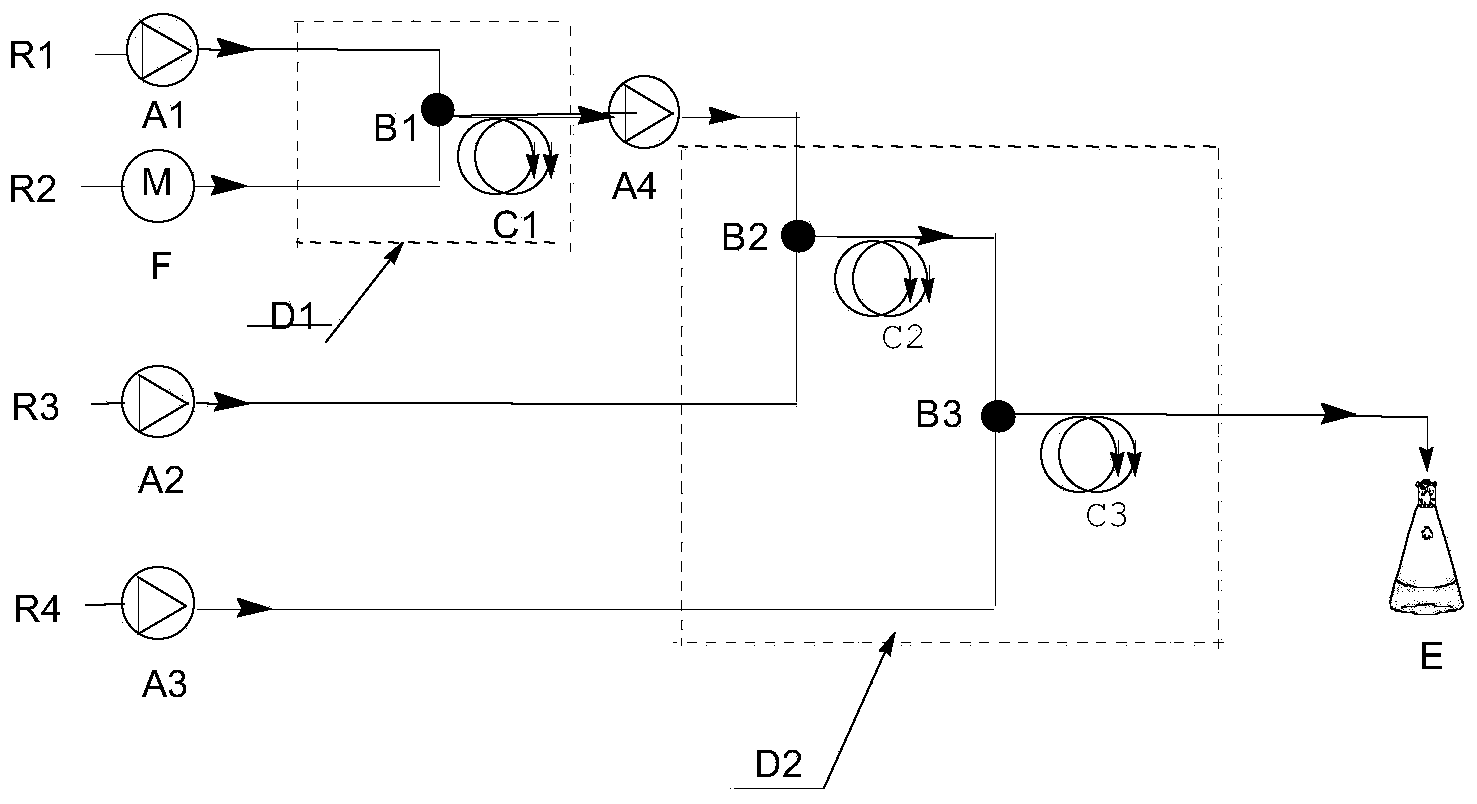

Preparation method of mannose

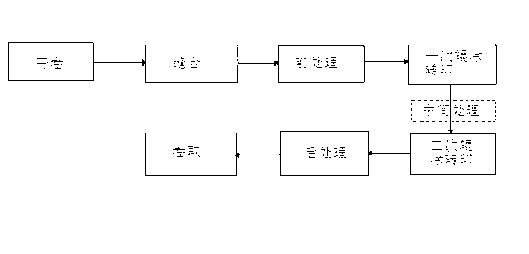

InactiveCN102807593AReduce viscosityOvercome the disadvantage of easy moisture absorptionSugar derivativesSugar derivatives preparationSimulated moving bedD-Glucose

The invention discloses a preparation method of D-mannose, which comprises the following steps that glucose is epimerized under a normal pressure or pressurized condition by using ammonium molybdate as catalyst to obtain mixed solution of glucose and mannose; the mixed solution is discolored, desalted and refined and then enters a simulated moving bed 1 for separation and purification to obtain a component A rich in mannose and a component B rich in glucose; the component A enters a simulated moving bed 2 for separation to obtain a component C rich in mannose and a component D rich in glucose; the component B is filtered through a membrane and then enters the step of epimerization; the component D is filtered through a membrane and then enters the simulated moving bed 1 for cyclic separation; and the component C is centrifugally spray-dried to obtain D-mannose finished products. The preparation method of the D-mannose has the advantages of simple steps and easiness in operation. The purity of the D-mannose finished products prepared by adopting the method reaches more than 99 percent and the total yield reaches 53-60.4 percent.

Owner:白心亮

Method for smelting vanadium-rich pig iron from vanadium-containing steel slag

The invention discloses a method for smelting vanadium-rich pig iron from vanadium-containing steel slag, which comprises the following steps: adding 63-67 parts of vanadium-containing steel slag, 14-18 parts of iron powder, 8-12 parts of silica, 4-6 parts of carbon powder and 3-4 parts of aluminum shot into a smelting furnace, and heating to melt the mixture; and after the reaction is finished, separating furnace slag from molten iron, and cooling the molten iron to obtain the vanadium-rich pig iron, wherein the vanadium-containing steel slag is slag left after smelting vanadium-containing molten iron in a converter. The method can enrich 85% of vanadium in the vanadium-containing steel slag into pig iron to obtain the vanadium-rich pig iron, well utilizes the steel slag, has the advantages of simple production technique, strong operability and low production cost, and is convenient for development in industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

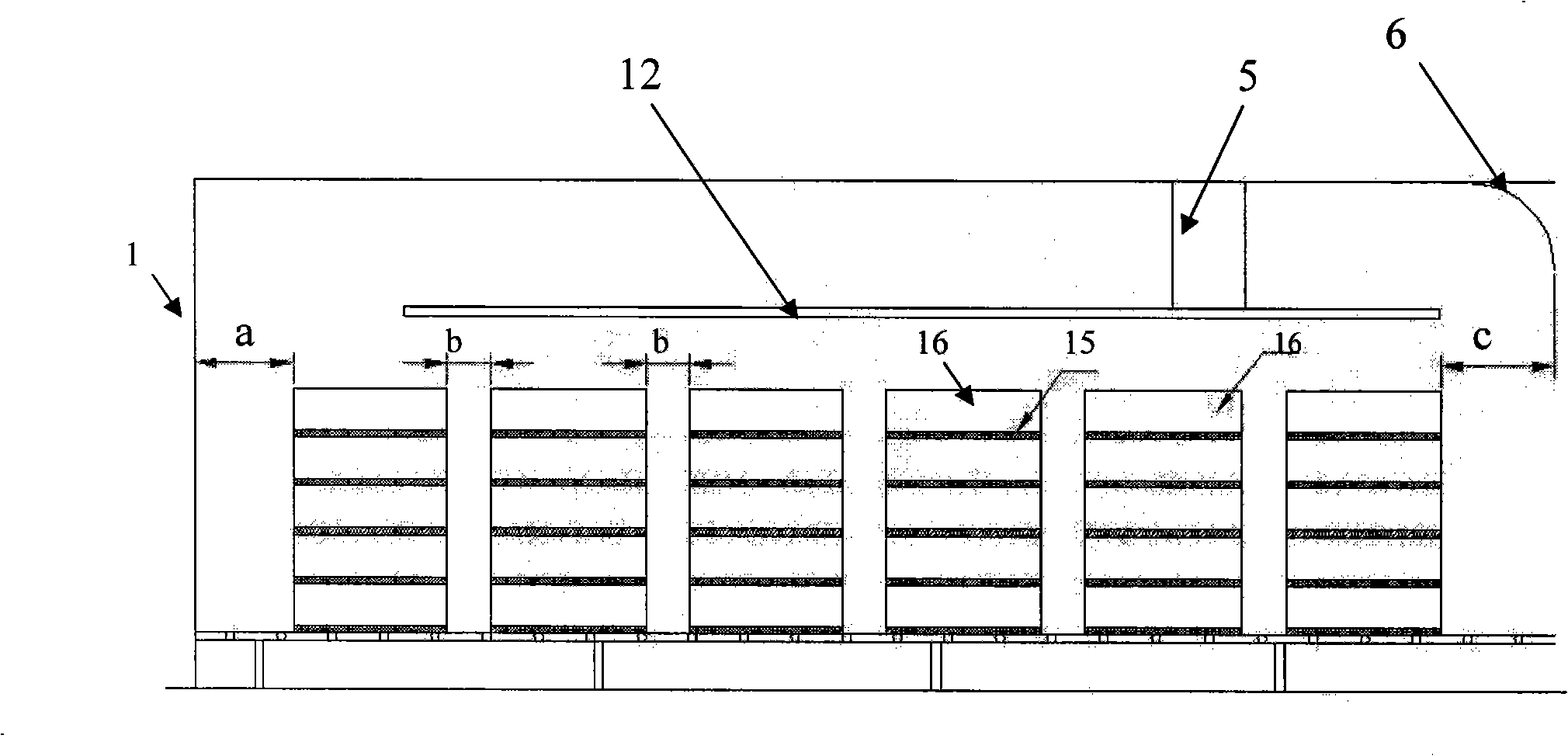

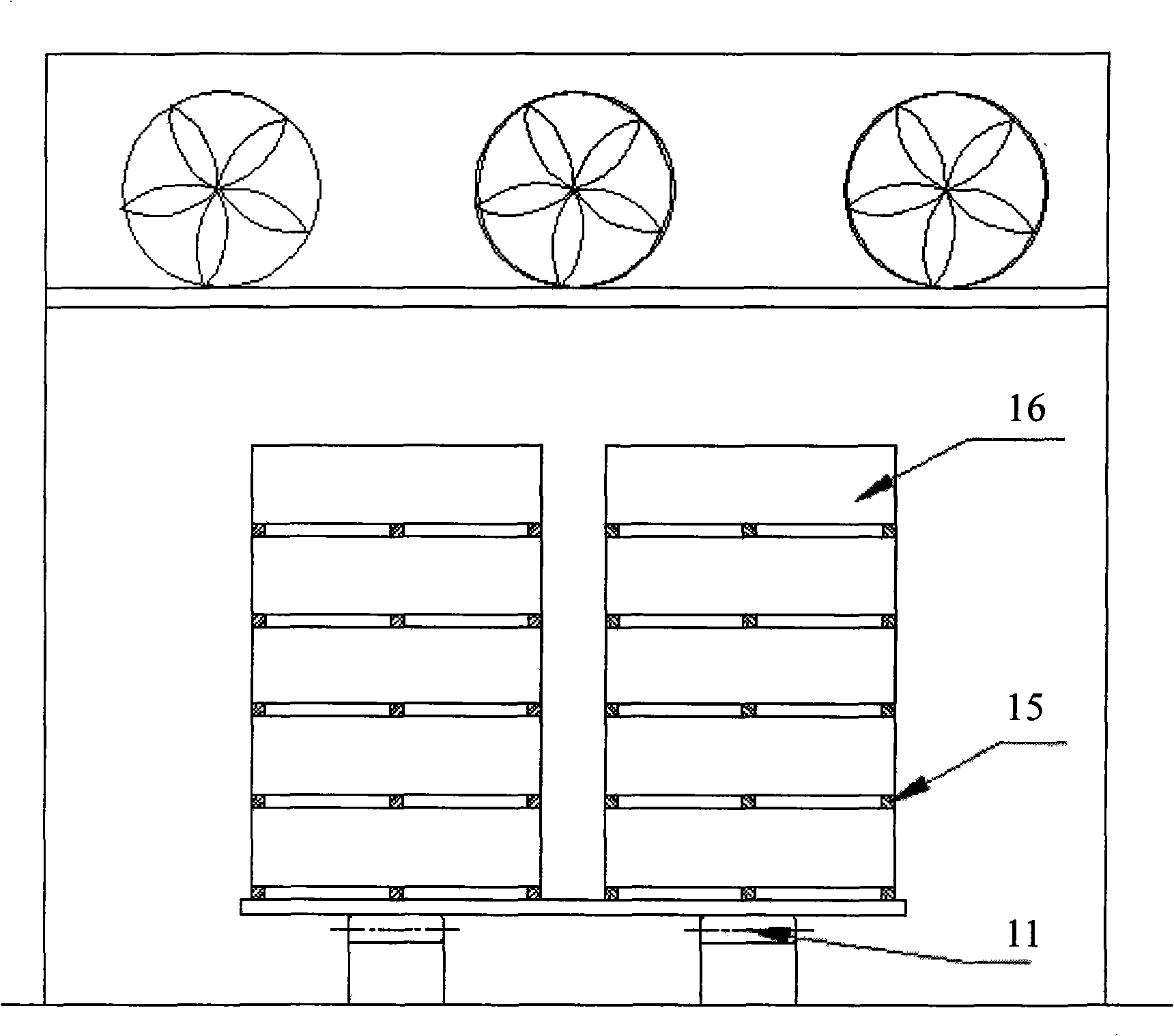

Board balance health-preserving chamber and board health-preserving method

InactiveCN101491907AImprove yieldImprove quality stabilityOther plywood/veneer working apparatusWood dampingWater contentProduct gas

The invention relates to a board balance reconditioning chamber and a method for reconditioning boards. The inside of the board balance reconditioning chamber is provided with a dehumidifier, a humidifier and temperature control equipment, and the middle part of the board balance reconditioning chamber is provided with an air flow guide device. The method for reconditioning boards comprises the following steps: 1) piling boards in the board balance reconditioning chamber; 2) adjusting the temperature and humidity of the board balance reconditioning chamber and determining the board processing time according to the preset water content range of the boards to balance the water content of all parts of the boards and to release the inner stress of the boards in a constant temperature and humidity environment; and 3) determining the water content of the boards and completing the reconditioning treatment when the water content of the boards reaches a preset value. The invention provides the constant temperature and humidity environment with flowing air to balance the water content of all parts of the boards, to release the inner stress of the wood fibers and to reduce the drawbacks of wood floors such as deformation and bending, thereby improving the percentage of cut-turn and the stability of the quality of the wood floors.

Owner:GUANGDONG YINGRAN WOOD IND

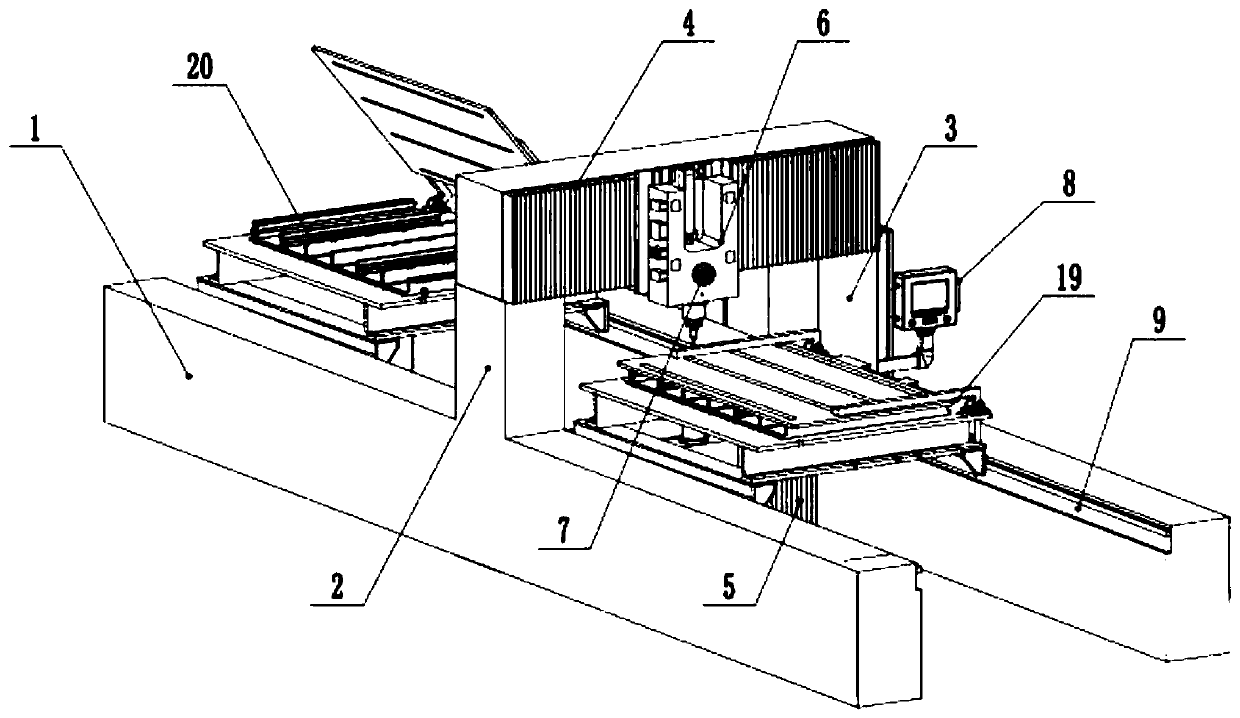

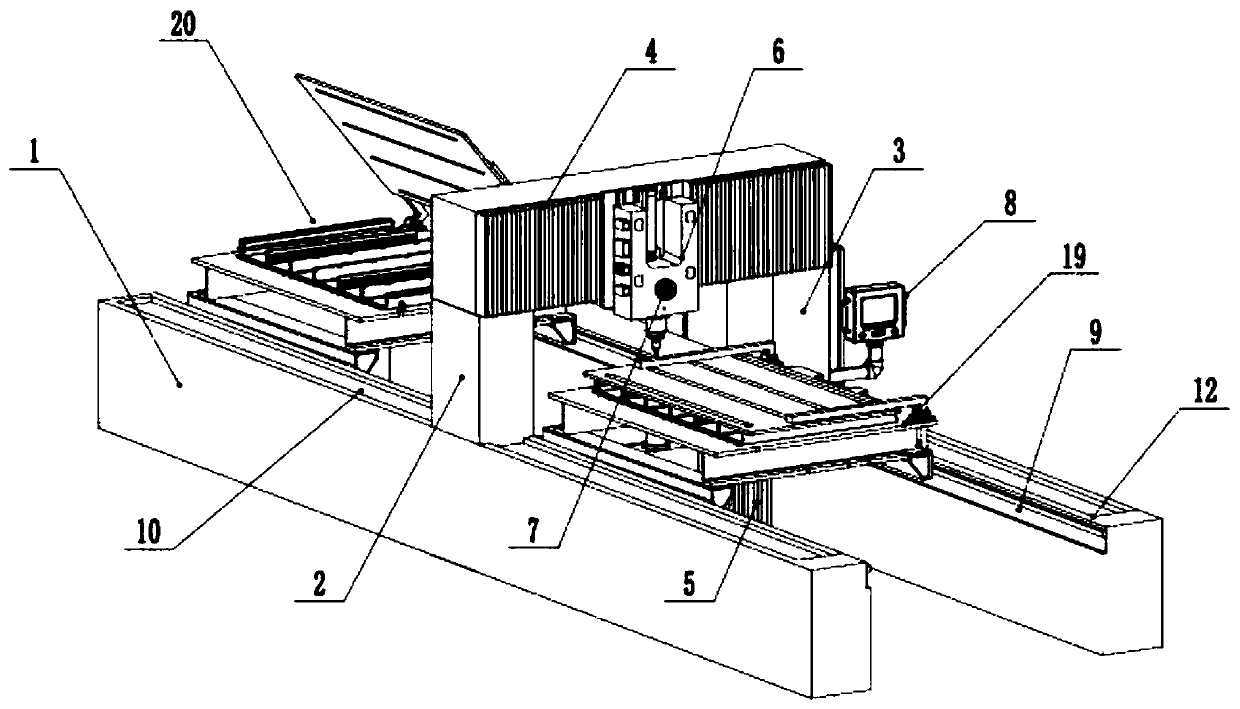

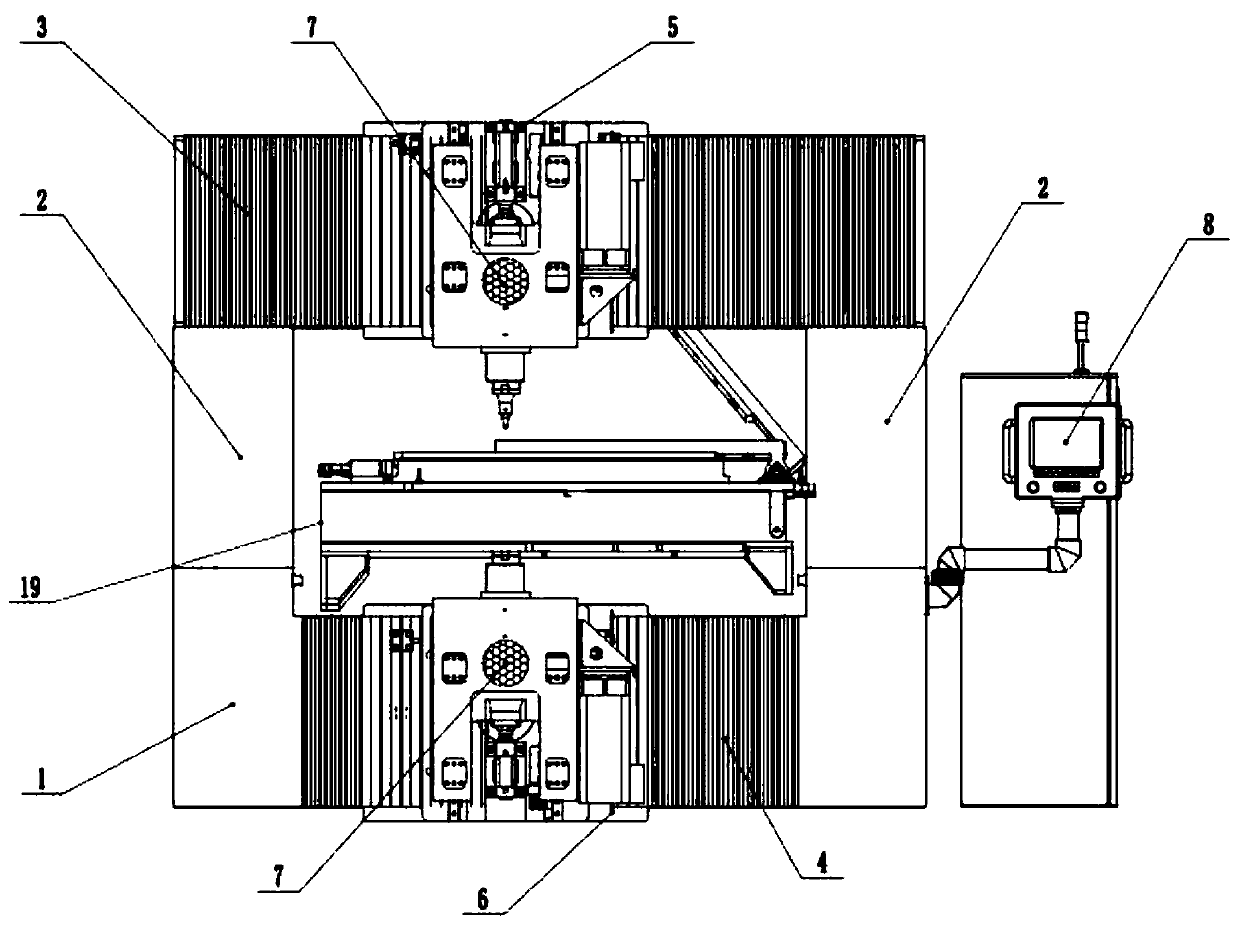

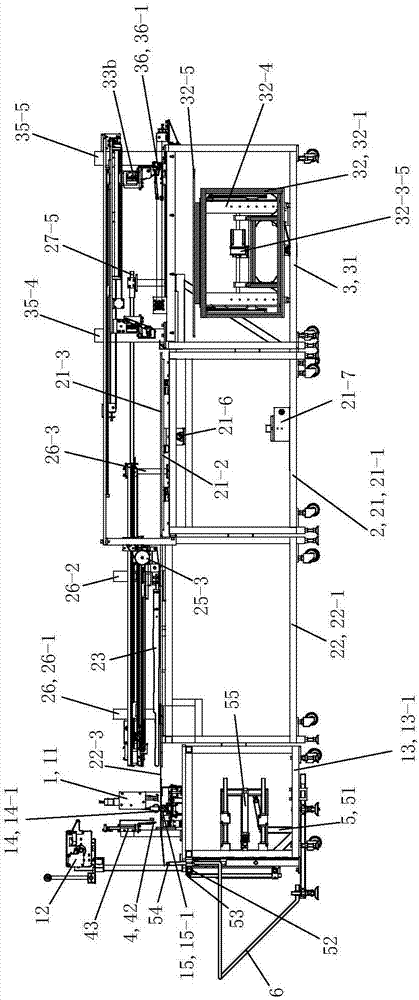

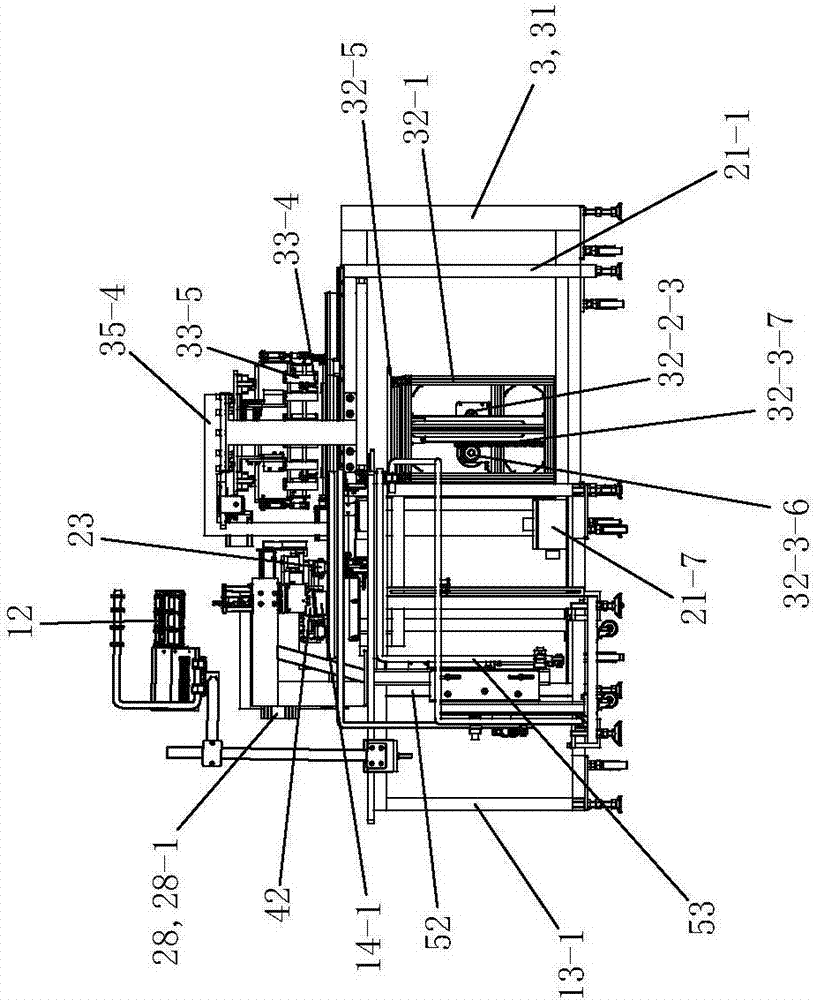

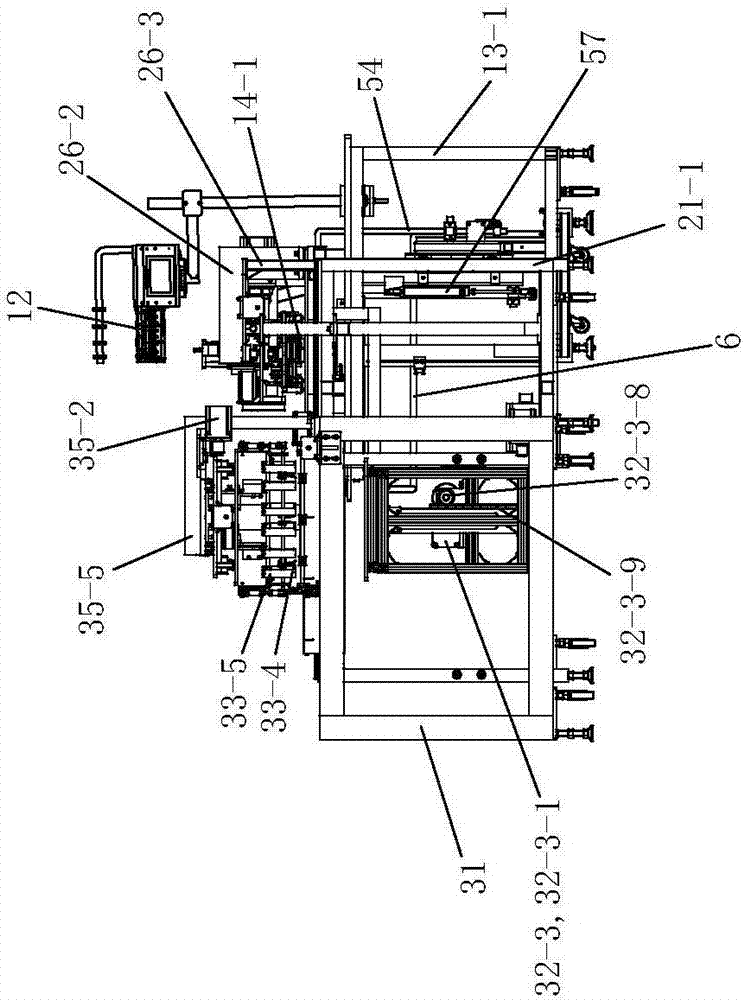

Double-head and double-sided friction stir welding equipment with high efficiency, and welding method thereof

ActiveCN109822208AShorten the timeImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPortal frame

The invention discloses double-head and double-sided friction stir welding equipment with high efficiency, and a welding method thereof. The equipment comprises a base, upright columns, an upper crossbeam, a lower cross beam, at least one working table, visual sensors and a CNC controller; the upper cross beam is provided with an upper head, and the lower cross beam is provided with a lower head;the upright columns, the upper cross beam and the lower cross beam form a portal frame of an integral structure, and the upper head and the lower head can be moved along an X axis, a Y axis and a Z axis, and rotated along the Z axis through a driving device and a transmission mechanism; the working table is connected with the horizontal plane of the base, and the working table is located betweenthe upper head and the lower head; the working table and the portal frame can be moved relatively for achieving welding, and the visual sensors are installed on the upper head and the lower head, andused for navigation and identification of weld joints; and the CNC controller is used for controlling the portal frame, the upper head, the lower head, the working table and the visual sensors to work.

Owner:BEIJING FSW TECH

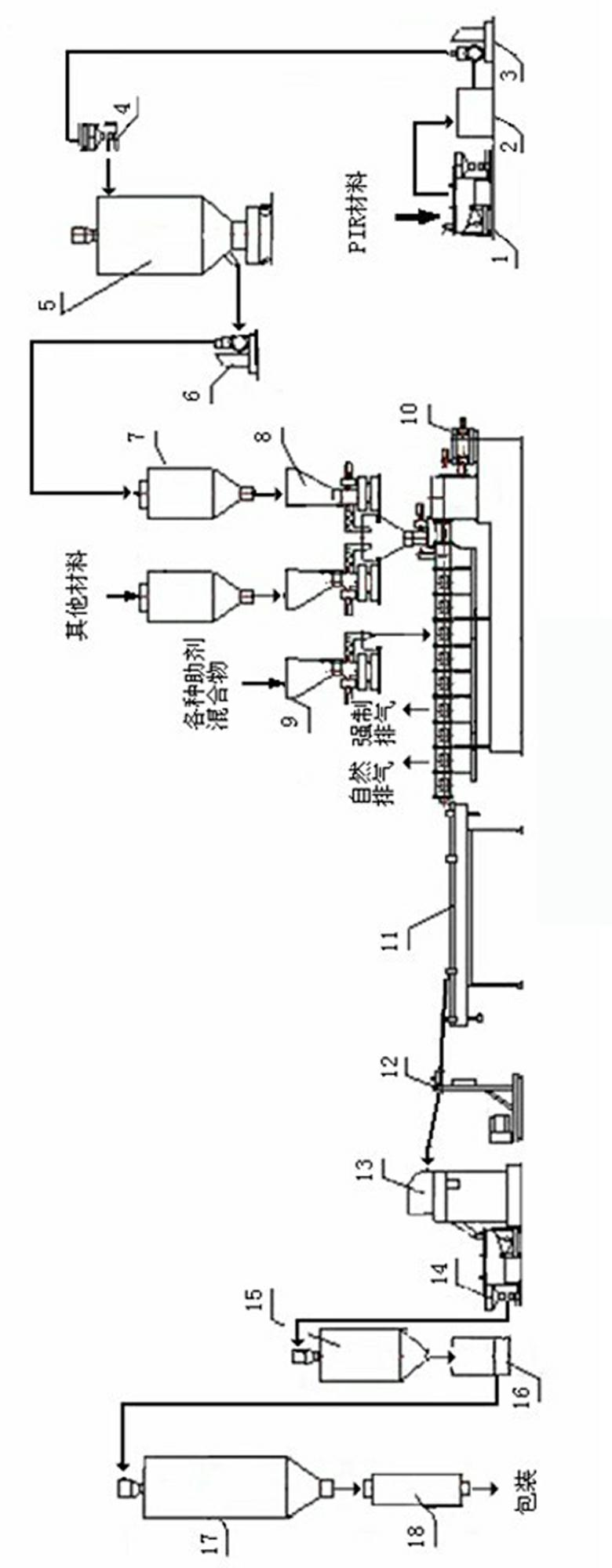

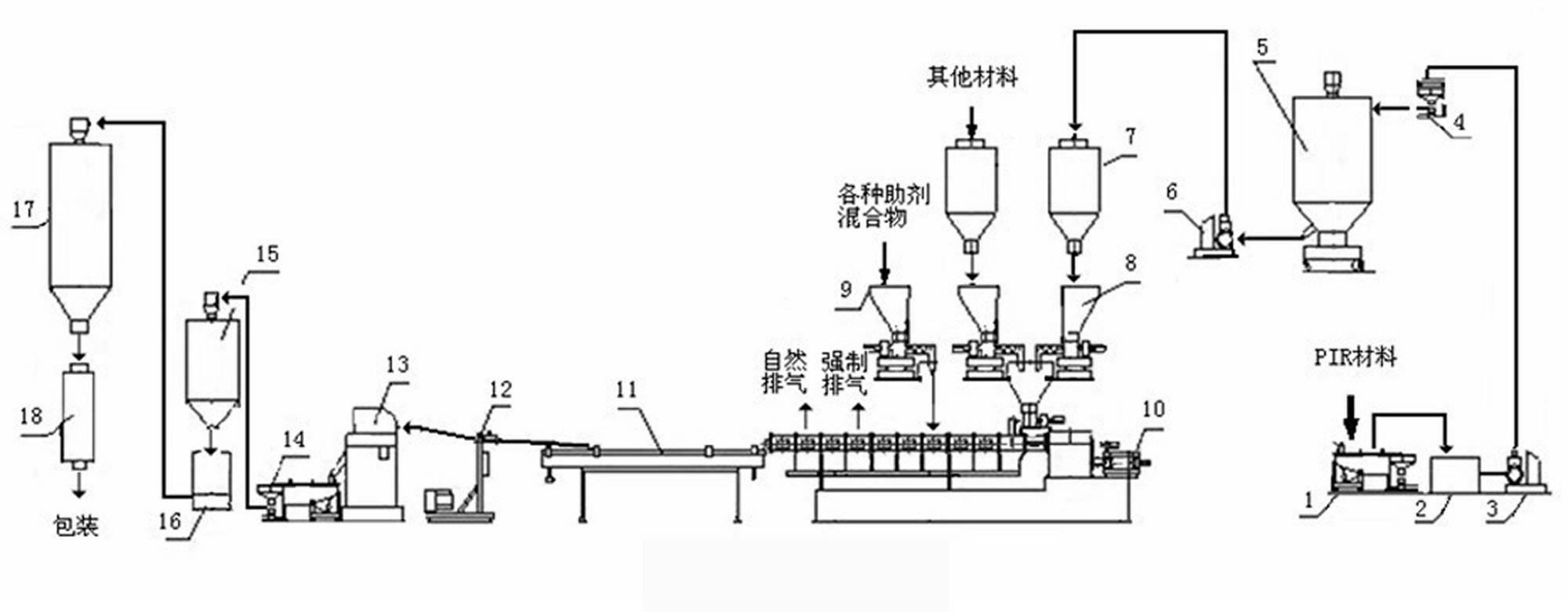

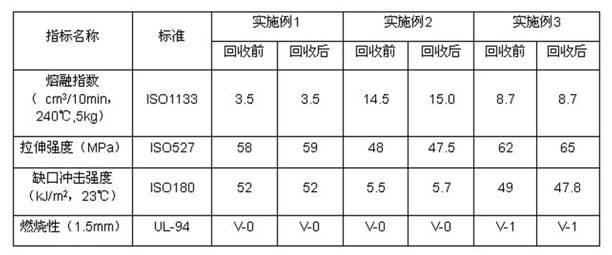

Method for recycling post-industrial recycling waste plastic

ActiveCN102581986AAvoid performance degradationThe process method is compact and completePlastic recyclingMechanical material recoveryPlasticultureProcess engineering

The invention discloses a method for recycling a post-industrial recycling waste plastic, which is mainly used for recycling wastes such as gate materials, leftover materials, imperfect products and outmoded products in the production machining process of manufacturing a plastic product. The method provided by the invention comprises the following steps of: primary separation of a vibration screen, secondary separation of a metal separator, drying of a hot drier, blending, granulation and post-treatment of a full-engaged homonymous dual-screw extruder. With the adoption of the method disclosed by the invention, the problem of bad properties of a recycled material, caused by the traditional recycling manner, can be better avoided, the process method is compact and complete, and the continuous operation can be realized. The blending and plastification process can be completed by using the full-engaged homonymous dual-screw extruder with small cutting force and high exhaust effects, so that the problem that the waste plastic is easy to degrade during a fusion and plastification process is solved. Therefore, the recycled material product has a very high property retention rate.

Owner:大河宝利材料科技(苏州)有限公司

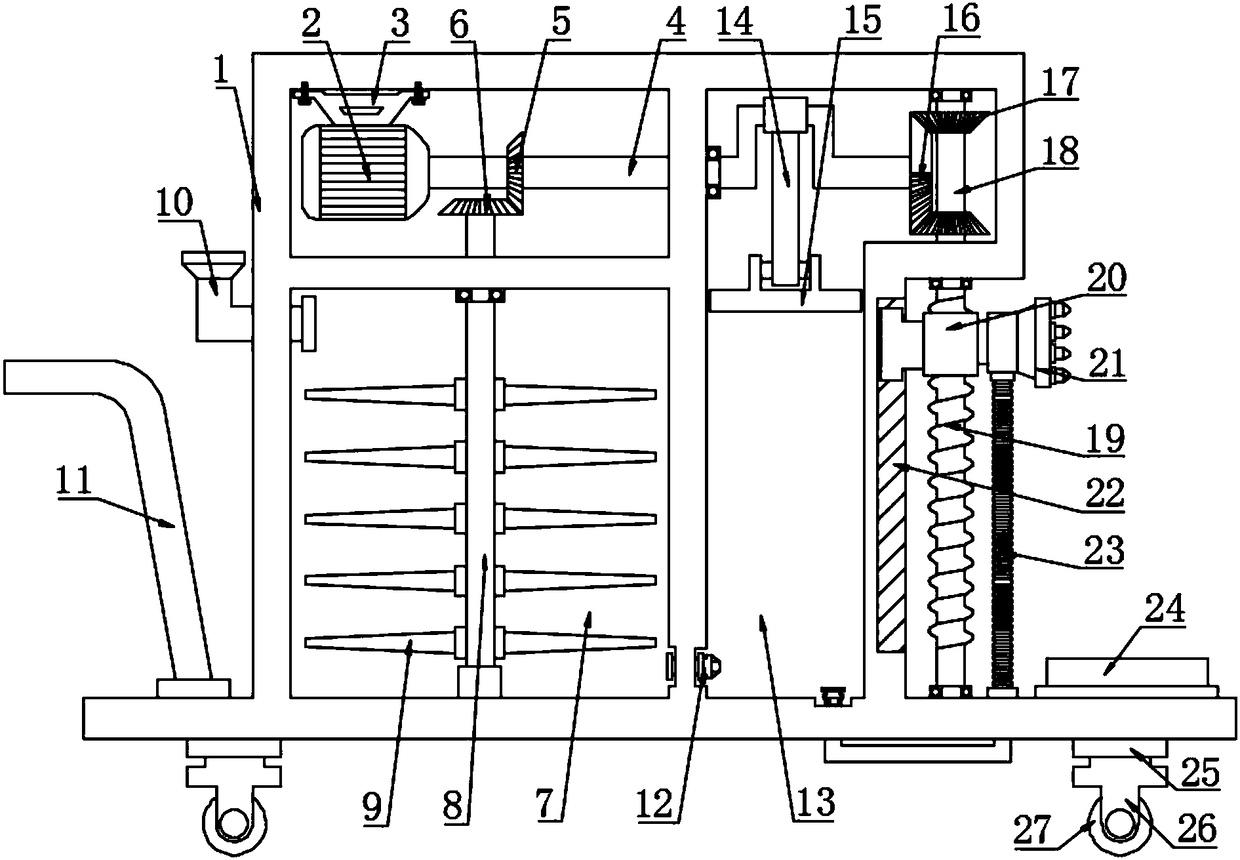

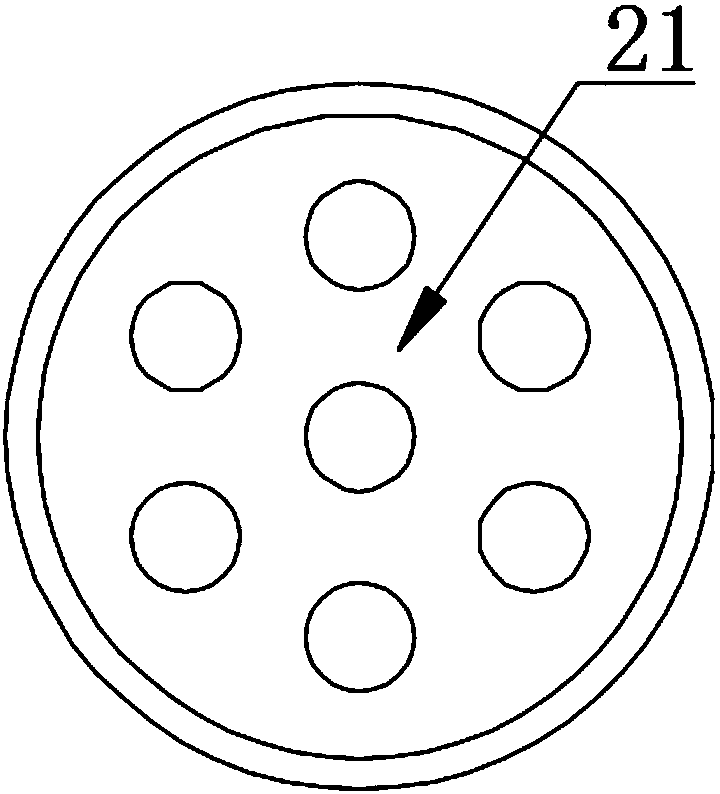

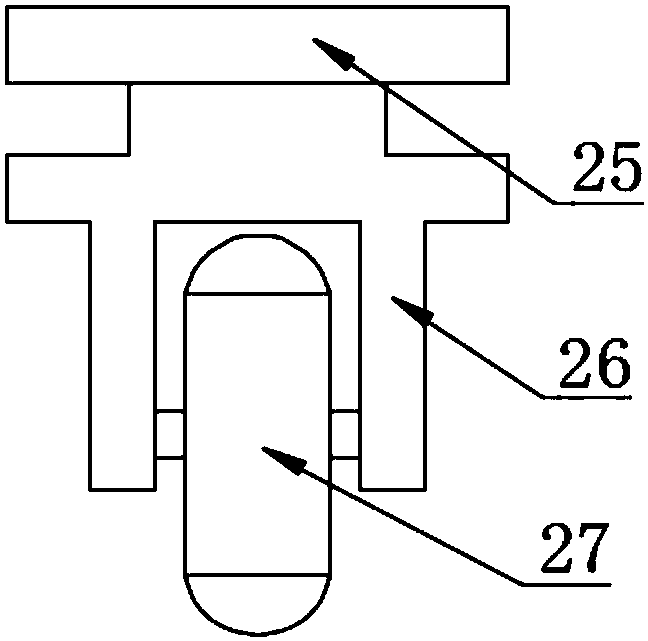

Reciprocating type external facade uniform paint spraying device

The invention discloses a reciprocating type external facade uniform paint spraying device. A drive motor is arranged on the left side of the upper portion of the device body, the right side of the drive motor is rotatably connected with a crankshaft, a mixing chamber is arranged on the left side of the device body, the left side of the crankshaft is fixedly connected with a first conical gear, asecond conical gear is fixedly connected with a driven shaft, the driven shaft is rotatably connected with the mixing chamber, multiple stirring rods are arranged on the surface of the driven shaft, apaint spraying chamber is arranged on the right side of the mixing chamber, the lower end of the mixing chamber is provided with a one-way valve, the one-way valve is communicated with the paint spraying chamber, according to the device, the rotating crankshaft drives the first conical gear to rotate so as to drive the driven shaft to rotate, the driven shaft drives the stirring rods to enable paint in the mixing chamber to be sufficiently mixed and stirred, meanwhile, a connecting rod drives a piston plate to do reciprocating up and down sliding along the inner wall of the paint spraying chamber to extrude paint in the paint spraying chamber, a thread rod which rotates positively and reversely in a reciprocating manner drives a casing block to reciprocate and move up and down along a sliding groove so as to drive a spraying head to spray paint along with the reciprocated up and down moving, paint spraying is more uniform, and continuous work of paint spraying of the external facade can be achieved.

Owner:纪美

Method for preparing high-purity chicory and helianthus tuberosus fructo-oligosaccharide in coproduction of polyfructosan

The invention relates to the technical field of extraction and preparation of saccharides, and in particular relates to a method for preparing high-purity chicory and helianthus tuberosus fructo-oligosaccharide in coproduction of polyfructosan. The method comprises the steps of cleaning, slicing, drying and grinding chicory root or helianthus tuberosus tuber, and implementing continuous countercurrent ultrasonic extraction by an alkaline extraction solution to obtain an inulin solution; classifying the inulin solution through an ultra-filtration member to separate macromolecular filtrate and micromolecular filtrate; implementing enzymolysis on the micro-molecular filtrate, condensing after enzymolysis, implementing chromatographic separation, decoloring, transforming, condensing and drying to obtain fructo-oligosaccharide; and decoloring, transforming, condensing and drying the macromolecular filtrate to obtain the polyfructosan. The method realizes coproduction with the polyfructosan and obviously improves raw material utilization rate; the method saves time and improves extraction rate, and can realize continuous production and greatly improve production efficiency.

Owner:BAOLINGBAO BIOLOGY

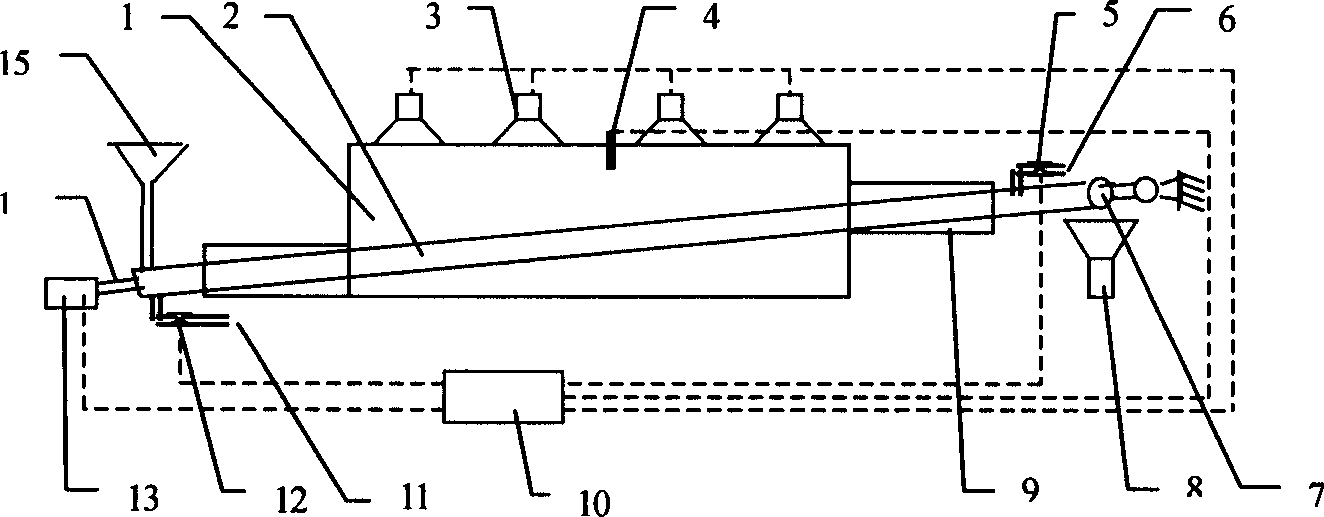

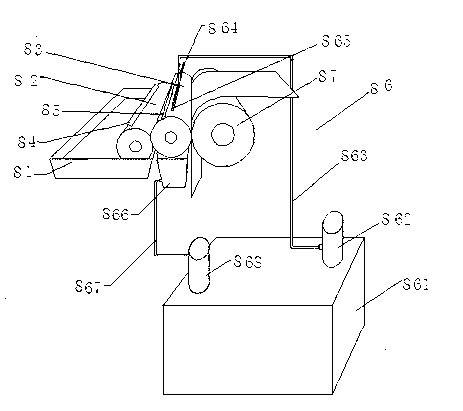

Microwave exractor

InactiveCN1583209AImprove processing efficiencyShorten the timeSolid solvent extractionMicrowaveEngineering

Owner:SOUTH CHINA UNIV OF TECH

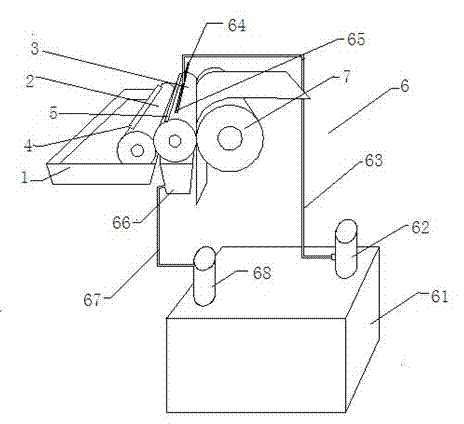

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

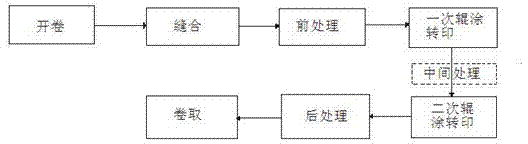

Production method of multicolor pattern color steel plate

InactiveCN103029502AConsistent speedConsistent workmanshipDecorative surface effectsRotary pressesProduction lineProgrammable logic controller

The invention provides a production method of a multicolor pattern color steel plate. For the once transfer printing, on one hand, a PLC (programmable logic controller) control module in a servo control system is used for computing the theoretical roller surface linear velocity of each roller in a roll coater set by acquiring the technical velocity and the rotation velocity of each roller in the roll coater set, and enables the theoretical roll surface linear velocity to be accordant with the technical rotation velocity; and on the other hand, a servo control module with a coder acquires the practical roller surface linear velocity of each roller in the roll coater set, and inputs the practical roller surface linear velocity into the PLC control module, so that a PLC control system can be used for comparing the practical roller surface linear velocity with the theoretical roller surface linear velocity, and adjusting the current frequency till the practical roller surface linear velocity is accordant with the theoretical roller surface linear velocity. According to the control method, the practical roller surface linear velocity is adjusted to be accordant with the theoretical roller surface linear velocity, and the theoretical roller surface linear velocity is adjusted to be accordant with the technical velocity, so that the practical roller surface linear velocity is adjusted to be accordant with the technical velocity, and furthermore, the adjustment by stopping a production line does not need in the process of production, so that the production efficiency can be improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

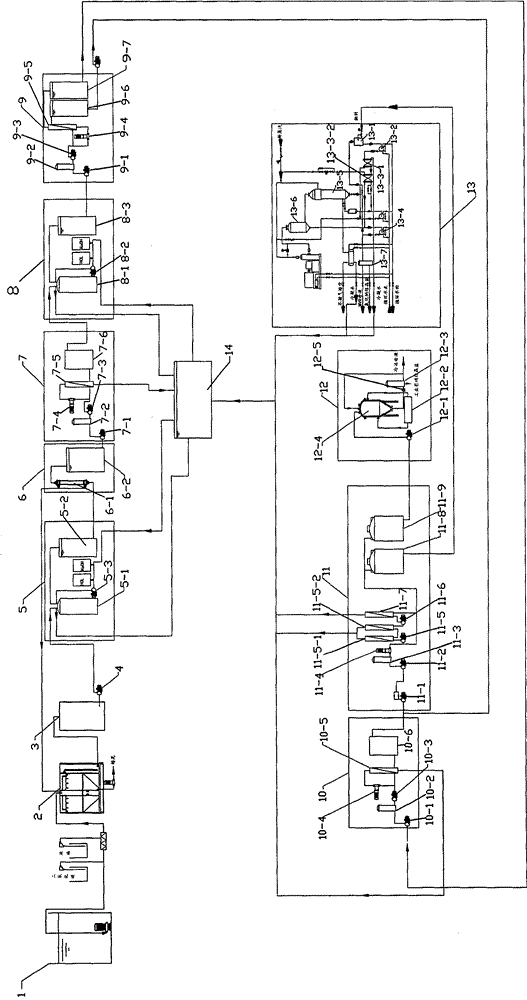

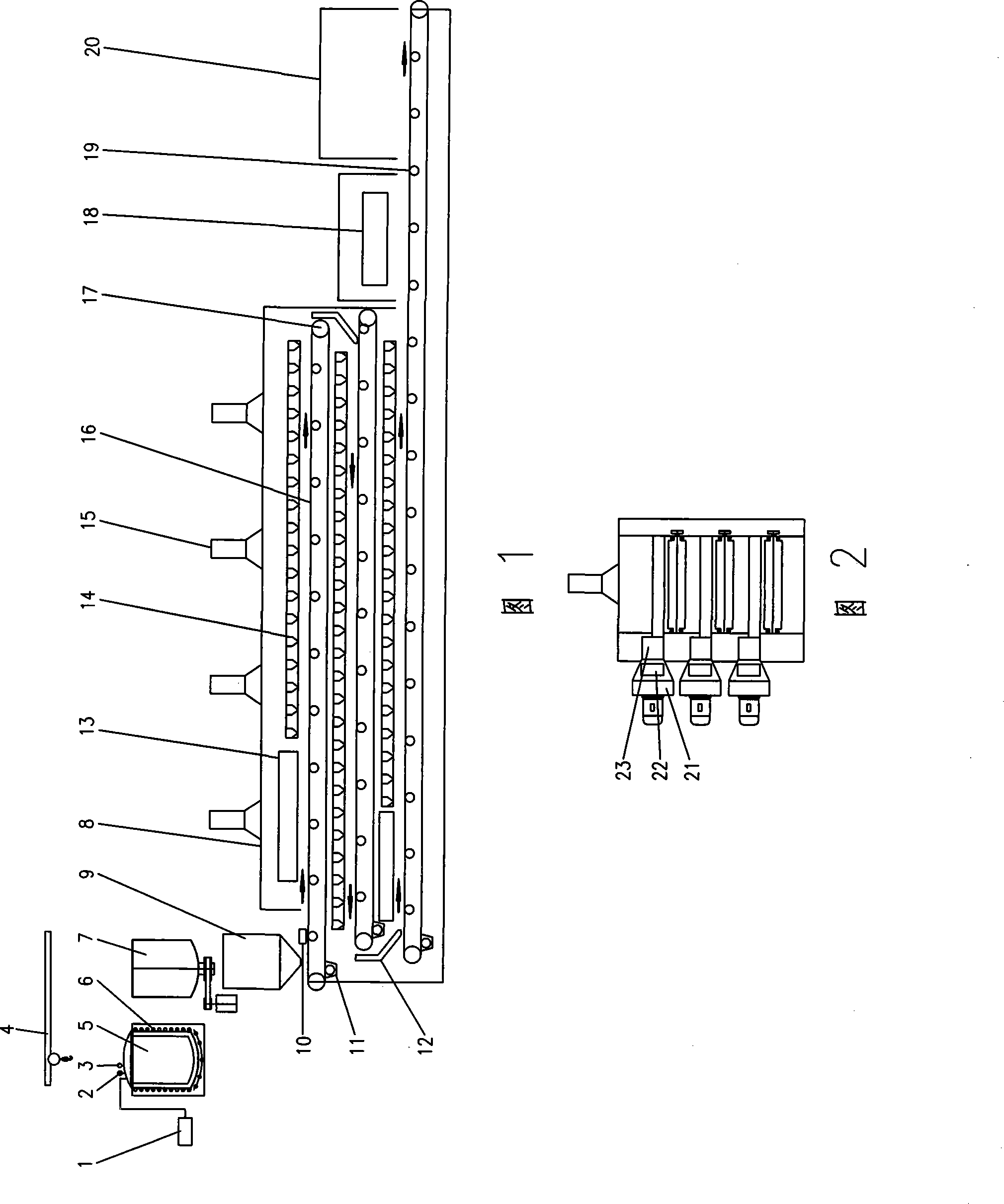

High-efficiency energy-saving automatic roasted seeds and nuts producing system

InactiveCN101238864AReduce energy consumptionShort energy consumptionFood preparationFood treatmentMaterial consumptionProcess engineering

The invention involves a high efficiency energy saving automatic system for producing roasted seeds and nuts, which includes cooking device, after being cooked by cooking device the product is lifted into dehydrator by lifting device, after dehydration the product is transferred into dryer through conveyor belt, entrance region of first layer conveyor belt in the dryer and last layer conveyor belt are equipped with infrared heater respectively, the top part of the dryer is equipped with humidity-discharging port, at least one layer of conveyor belt is installed in the dryer, the conveyor belt is driven by conveying roller and carrier roller belt, the upper part of the conveyor belt is installed with hot air injector, after being dried the product is cooled in cooler, after being cooled the product is separated in separator, at last the finished product is packed. The invention has merits of low energy consumption, low material consumption, high work efficiency, low producing cost and small occupation area.

Owner:邓元恺

Production line of multi-color patterned roller-coated steel plate

InactiveCN102990360AConsistent speedConsistent workmanshipOther manufacturing equipments/toolsRotary pressesProduction lineProgrammable logic controller

The invention provides a production line of a multi-color patterned steel plate. On one hand, a PLC (programmable logic controller) control module in a servo control system is used for collecting the process speed and the rotating speed of every roller of a roller coating unit, calculating the theoretical linear speed of the surface of every roller in the roller coating unit and making the theoretical linear speed of the roller surfaces identical to the process speed; on the other hand, the actual linear speed of the surface of every roller in the rolling coating unit is collected by a servo control module with an encoder, the signal of the actual linear speed of the surface of every roller is input into the PLC control system, the actual linear speed of the surface of every roller is compared with the theoretical linear speed of the surface of every roller through the PLC control system, and the current frequency is adjusted until the actual linear speed of the surface of every roller is identical to the theoretical linear speed of the surface of every roller. By adopting the control method, the actual linear speed of the surface of every roller can be ensured to be identical to the process speed, stoppage is not needed in the production process for adjustment, and the production efficiency is improved. Moreover, a steel strip is subject to pre-transfer treatment in the production method in order to improve the adhesion between a coating and the surface of the steel strip and the moldability of the steel strip after printing.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

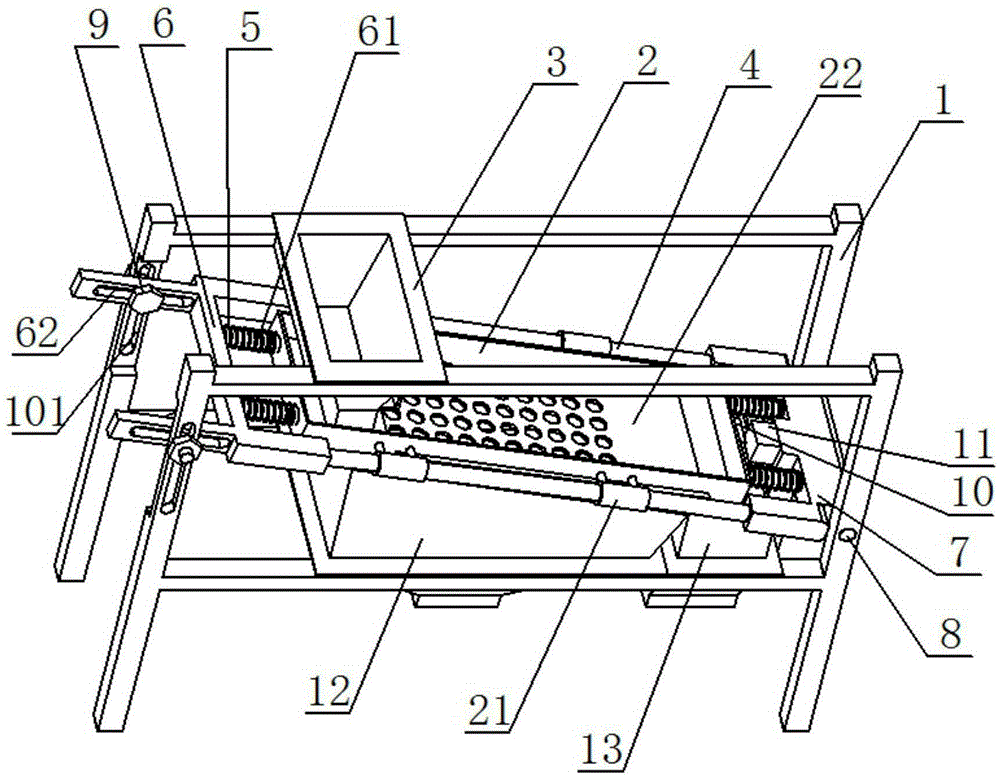

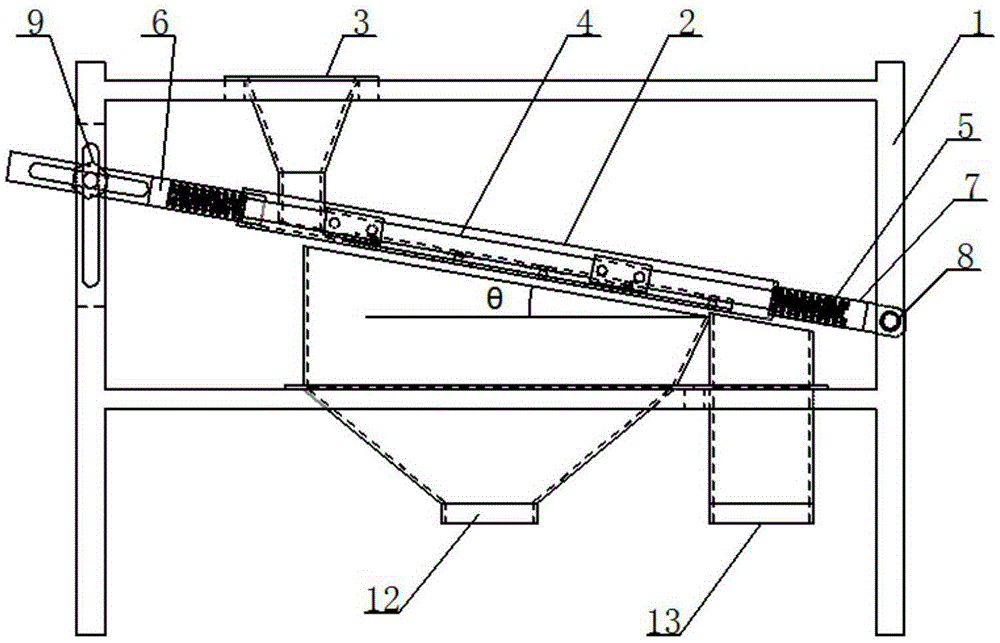

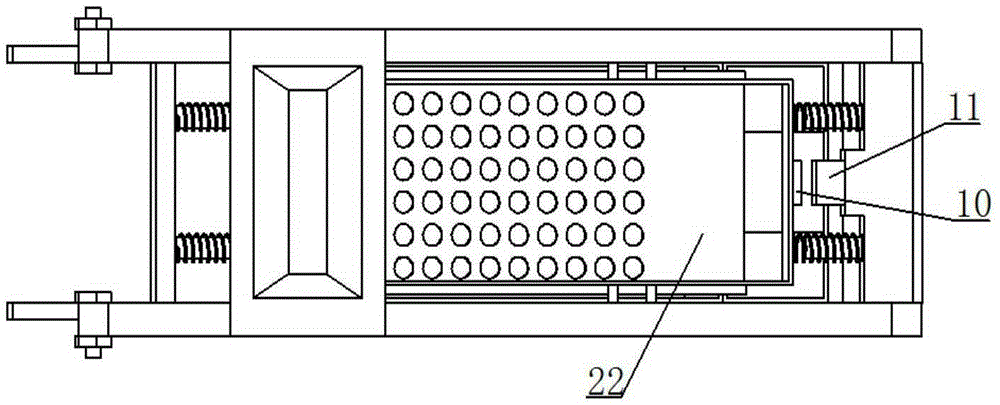

Screening device capable of vibrating parallel to screen plate and efficient screening method

ActiveCN105396775ASolve the high false screening rateSolve the difficulty of screeningSievingScreeningScreening methodEngineering

The invention discloses a screening device capable of vibrating parallel to a screen plate and an efficient screening method, and relates to the field of screening machines. The screening device is mainly composed of a main support, a screen box, a first movable frame, a second movable frame, a guide rod, an electromagnet, an exciting coil, a spring, a positioning bolt, a long pin, a feeding hopper, a screened object receiving hopper and an oversize product receiving hopper. According to the efficient screening method, the screen box is driven by the exciting coil and the electromagnet to vibrate along the screen plate face under the guide effect of the guide rod; the inclination angle theta, the screen hole diameter and screen hole distribution of the screen box are adjusted, and through control over the amplitude and the frequency of the electromagnet and the exciting coil, rapid slippage of particles on the screen plate can be achieved, and efficient screening is achieved. Accurate vibration in the direction parallel to the screen face can be achieved, the method is particularly suitable for selecting and grading of long-strip-shaped particles such as medlar, rice grains, melon seeds and long and short straw, and the problems that the error-sifting rate is high, and screening is difficult are solved.

Owner:JIANGSU UNIV

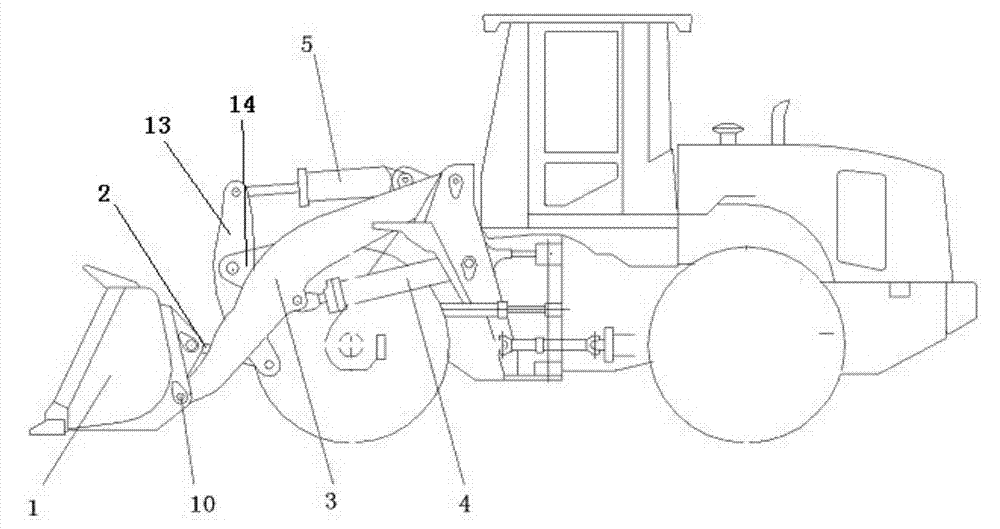

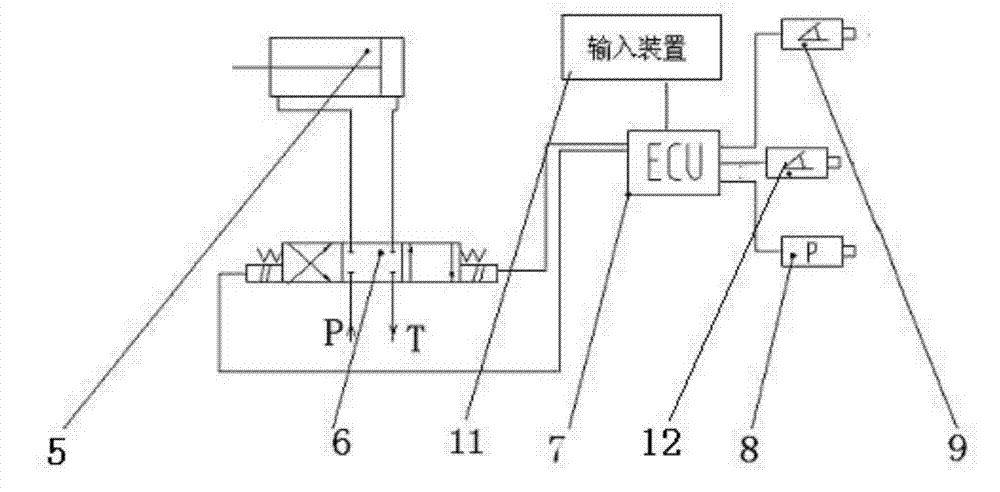

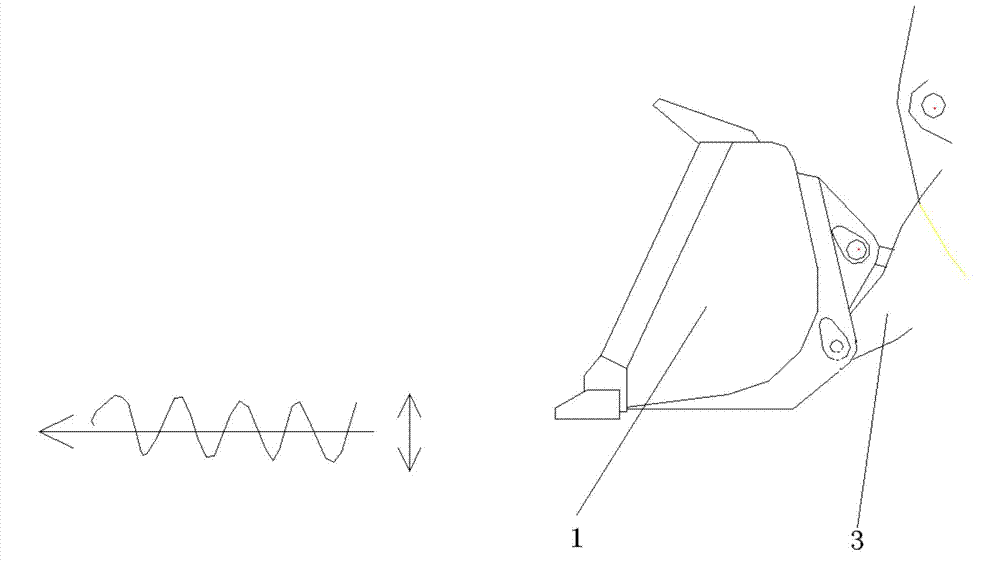

Loader and bucket loading operation control method thereof

ActiveCN103615024AReduce frictional resistanceRealize continuous operationMechanical machines/dredgersEngineeringMechanical engineering

The invention relates to a loader and a bucket loading operation control method thereof, in order to solve the problem that existing loaders are low in efficiency when used for bucket loading of materials. According to the bucket loading operation control method of the loader, when a bucket is inserted into materials for excavation operation, flow direction of hydraulic oil in a driving oil circuit of a rotating bucket oil cylinder of the loader is controlled to enable the bucket to rotate and swing up and down around a bucket hinge pin shaft according to preset swing frequency and amplitude. The loader is characterized in that an electromagnetic valve for changing the flow direction of the hydraulic oil is arranged on the driving oil circuit of the rotating bucket oil cylinder. When the bucket is inserted into the bucket loading materials, the bucket is enabled to rotate and swing according to the preset frequency and amplitude, so that certain gap is enabled to be formed between the bottom surface of the bucket and the excavated materials in the excavation process so as to reduce frictional resistance between the materials and the bucket during excavation; meanwhile, continuity of the excavated materials can be interrupted by swing, frictional resistance between the materials in the bucket and the inner wall of the bucket is reduced, continuous operation of the excavation process is realized, and loading operation efficiency is improved while energy consumption is lowered.

Owner:GUANGXI LIUGONG MASCH CO LTD

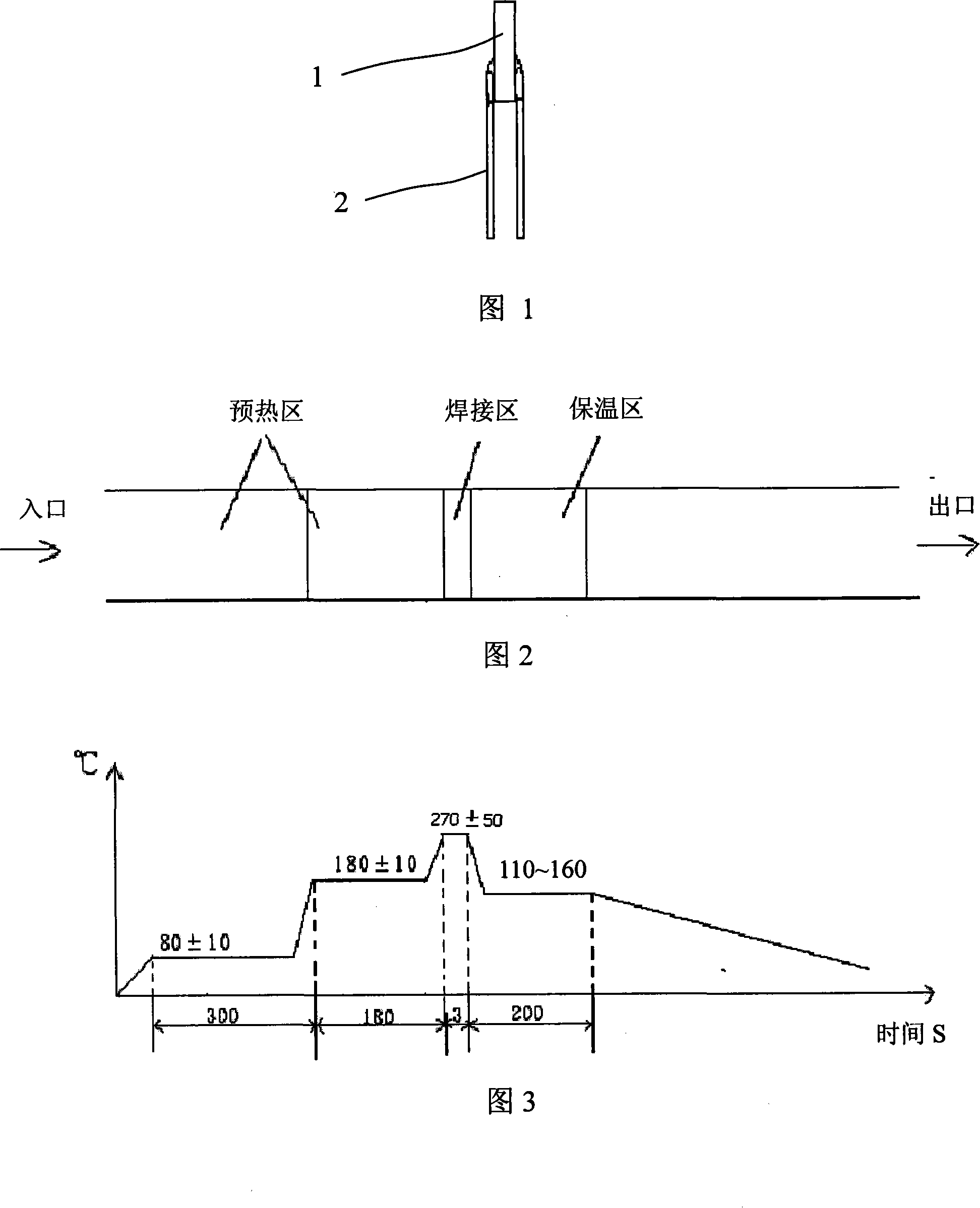

Method of welding thermistance chip and down lead

InactiveCN101229602ANo damageIncrease productionSoldering apparatusNon-adjustable resistorsElectrical resistance and conductanceRoom temperature

The invention relates to a method for welding a chip and a lead wire of a thermal resistor, comprising the following steps: a lead wire is formed; a chip is inserted with a wire and a staged hot-air welding machine is started heating a low-temperature preheating zone, a high-temperature preheating zone, a welding zone and a heat-keeping zone in a furnace to a preset temperature; the wire rows with a good insertion are sent into the low-temperature preheating zone and the high-temperature preheating zone in sequence for preheating; the preheated chip and the wire row are sent to the welding zone; soldering tin in the lead wire is melted due to the hot air from a hot-air welding gun, which ensures the lead wire and the chip are fixedly welded together; the well welded product is then sent to the heat-keeping zone for carrying out an insulation treatment; after the insulation treatment, the product is moved out from the furnace and is naturally cooled to room temperature. The product is then self-checked, washed and dried in the air for entering the next process. In the invention, welding happens after fully preheating and the welded product is slowly cooled after insulation treatment; therefore, the chip does not experience heat shocks and generates micro-cracks; the product has good durability and liability, and decrease of the withstand voltage of the product is small. The invention has good process controllability and can realize progressive production work, thus having high output.

Owner:深圳市伟林高科技股份有限公司

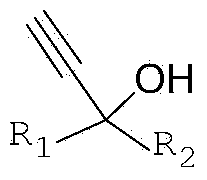

Method for preparing propargyl alcohol by using micro-structural reactor

InactiveCN103896737AGood choiceMild reaction conditionsOrganic compound preparationHydroxy compound preparationGrignard reagentProduct selection

The invention provides a method for preparing propargyl alcohol by using a micro-structural reactor, which comprises the steps of by taking a simple Grignard reagent as a raw material, carrying out gas-liquid Grignard exchange reaction on the simple Grignard reagent and acetylene gas to generate a high-quality acetylene-based magnesium bromide Grignard reagent, carrying out nucleophilic addition reaction on the obtained acetylene-based magnesium bromide Grignard reagent and an electrophilic reagent in a continuous flow condition, and carrying out hydrolysis, separation and refining on the product to obtain a substitution propargyl alcohol product. The method provided by the invention has the advantages that the operation is simple, the raw material and the reagent are simple, cheap and easily available, the process is continuous, rapid and controllable, the condition is mild, the product has good selectivity and industrial production can be realized.

Owner:NANJING UNIV OF TECH

Continuous preparation process for environment-friendly plasticizer and device used in process

InactiveCN103242164ASmall granularityIncrease return flowOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholAlcohol

The invention relates to a continuous preparation process for an environment-friendly plasticizer and a device used in the process. The process comprises the following steps of: enabling solid terephthalic acid and isooctyl alcohol which serve as raw materials to react in the existence of an esterification catalyst and an antioxidant for continuously preparing dioctyl terephthalate (DOTP); pulpifying the solid terephthalic acid in the isooctyl alcohol until the particle size of the solid terephthalic acid reaches 5 to 20 mu m; adding the isooctyl alcohol so as to adjust the mole ratio of alcohol to acid in pulp liquid as 2:1 to 4:1; adding into a slurry tank, preheating, and entering a reaction kettle from the bottom; reacting with the preheated isooctyl alcohol which enters from the bottom of the reaction kettle in the reaction kettle in the existence of the esterification catalyst and / or the antioxidant; reacting until an acid value decreases to be below 2, and continuously feeding the raw materials namely the solid terephthalic acid and the isooctyl alcohol; and adding the DOTP which is generated in reaction from the upper part of the reaction kettle to a product tank, condensing the isooctyl alcohol which does not completely reacts and the generated steam through a condenser on the top of the reaction kettle, separating through an oil water separator, and entering an octyl alcohol tank for recirculation.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

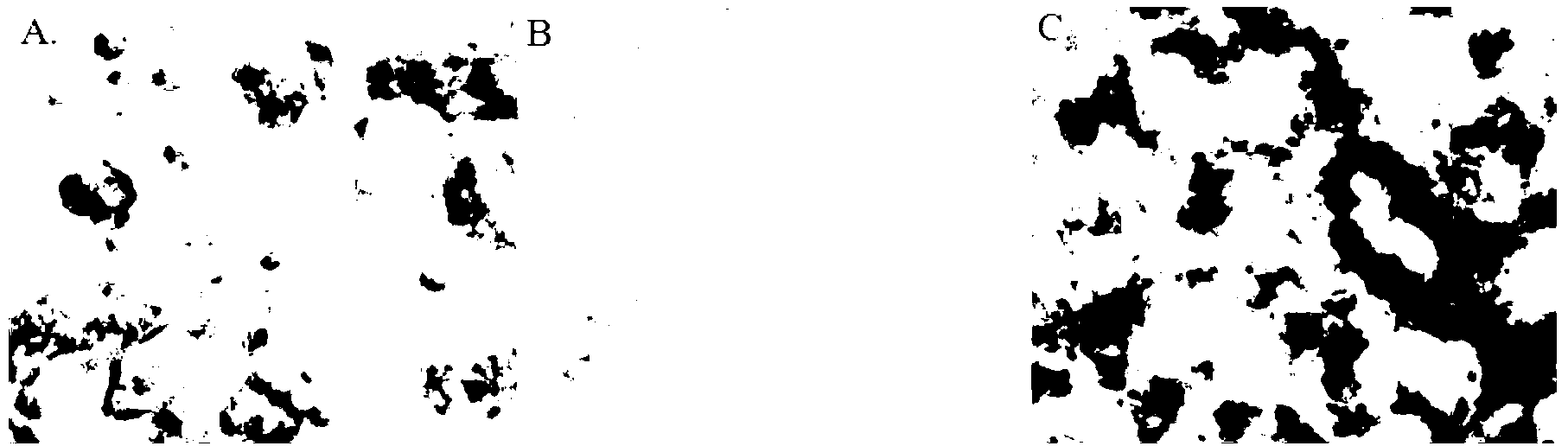

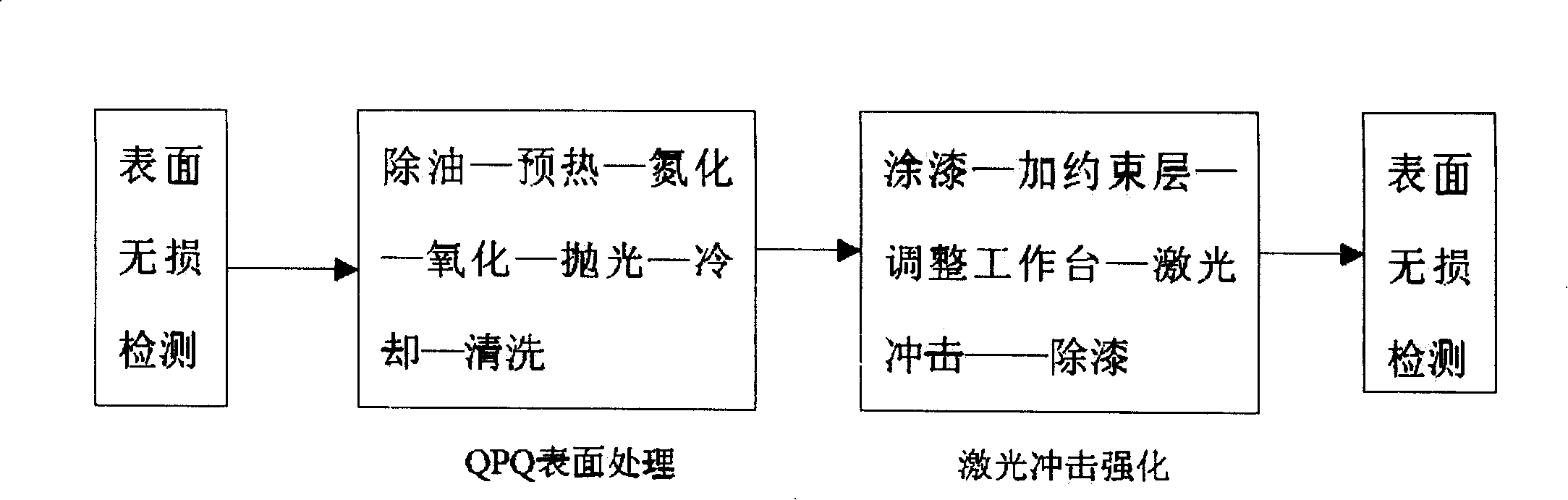

Composite treating method for prolonging life of grating machine key components

ActiveCN101225456APrecise positioningSave resourcesSolid state diffusion coatingHeat treatment process controlStress concentrationMolten salt

The invention relates to a complex processing method for prolonging the service lift of chain grate key parts, belonging to mechanical manufacturing and material processing and application technical field, which comprises: firstly, surface nondestructive testing is carried out on the key parts of the chain grate of process; molten salt complex processing are carried out in parts of the surface according to the surface drawbacks tested by surface nondestructive testing; before the laser shocks, the workpiece surface is coated with black coating layer and use water as protective layer, and the laser shock processes the area which is easy to fatigue and fracture and has concentrated stress. The molten iron pretreatment spray-feeding device before iron-making blast furnace has the advantages of simple shortcut, high efficiency, low maintenance cost, short processing time (30 minutes to 5 hours), and the continuous operation can be realized, thus, high efficiency of production is ensured.

Owner:江苏宏大特种钢机械厂有限公司

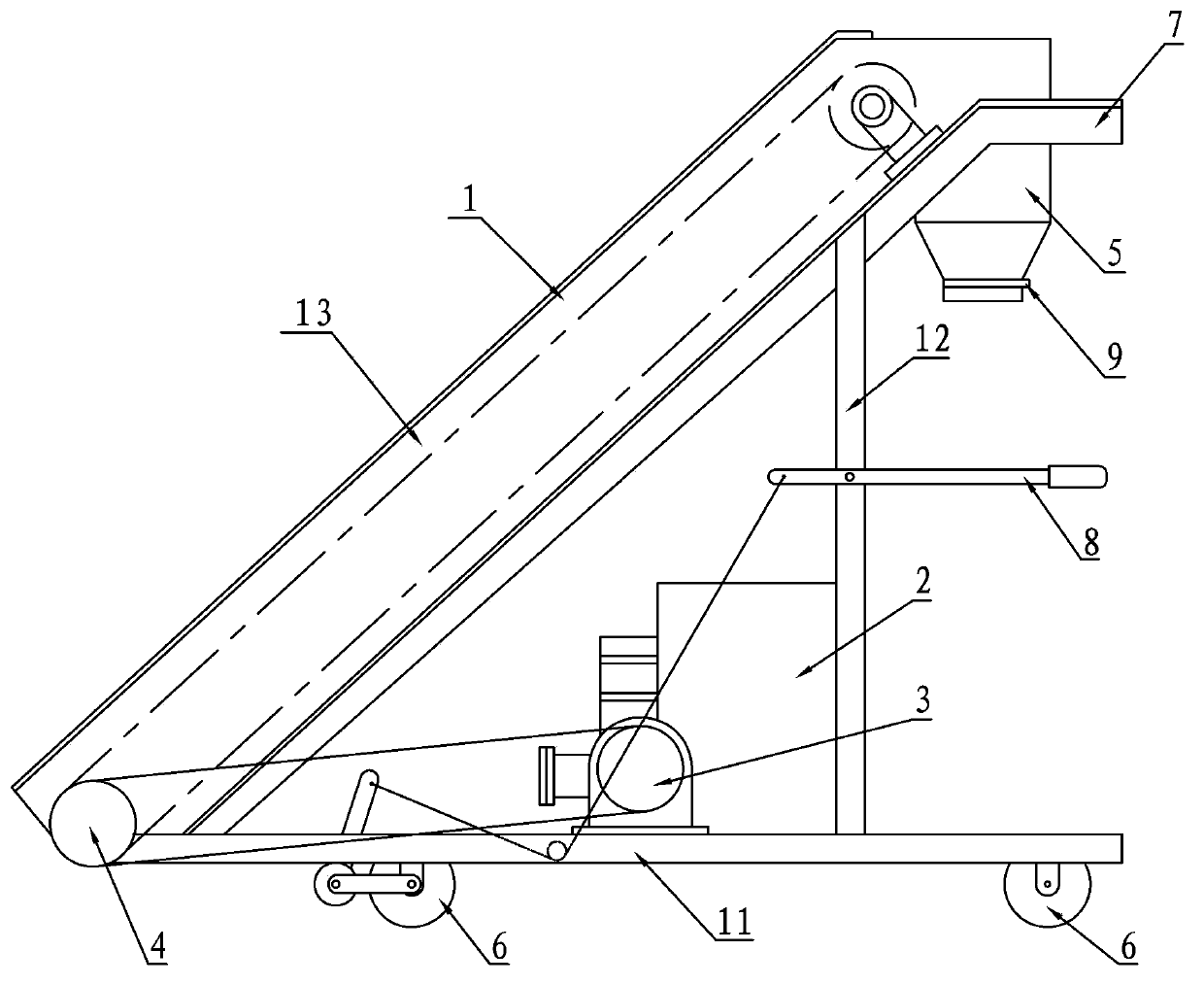

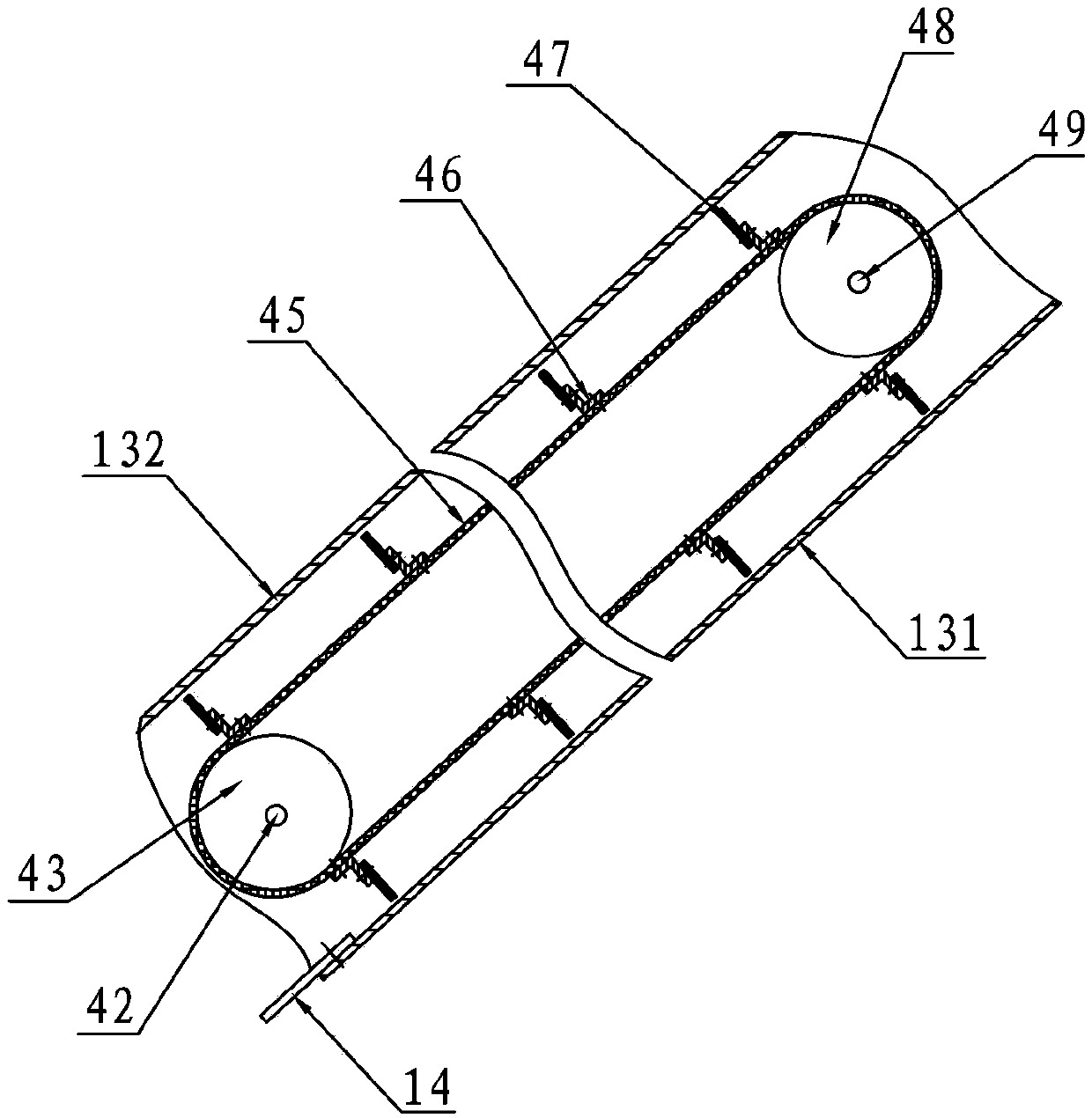

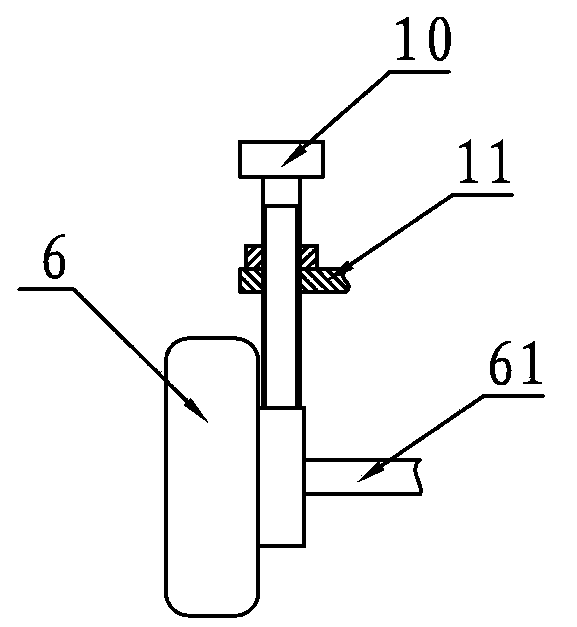

Hand-push type rapid grain collector for sunning ground

The invention discloses a hand-push type rapid grain collector for a sunning ground. The grain collector comprises a rack, a power machine, a gearbox, a cyclic grain collection device, a discharging box, movable rollers and a hand pushrod, wherein the rack is a right triangle-shaped frame body formed by fixedly connecting a bottom frame, a vertical frame and an inclined case; the power machine and the gearbox are arranged on the bottom frame; a power input wheel of the cyclic grain collection device is arranged at one end of a driving shaft; the driving shaft and a driven shaft are arranged at the lower end and the upper end of the inclined case through two bearing blocks respectively; a driving pulley and a driven pulley are arranged on the driving shaft and the driven shaft respectively; a belt is sleeved between the driving pulley and the driven pulley; grain raking rods with grain raking pieces are fixedly arranged on the belt; the discharging box is arranged at the upper end of the inclined case; the movable rollers are arranged below the bottom frame; and the hand pushrod is arranged on the discharging box. The grain collector is lower in cost and low in user investment, and has remarkable economic benefits and broad development prospect, the problem of difficulty in grain collection in busy seasons is completely solved, and a gap in the mechanization of a grain collection link of planting is filled.

Owner:柳锁兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com