Patents

Literature

36results about How to "Guaranteed batch stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

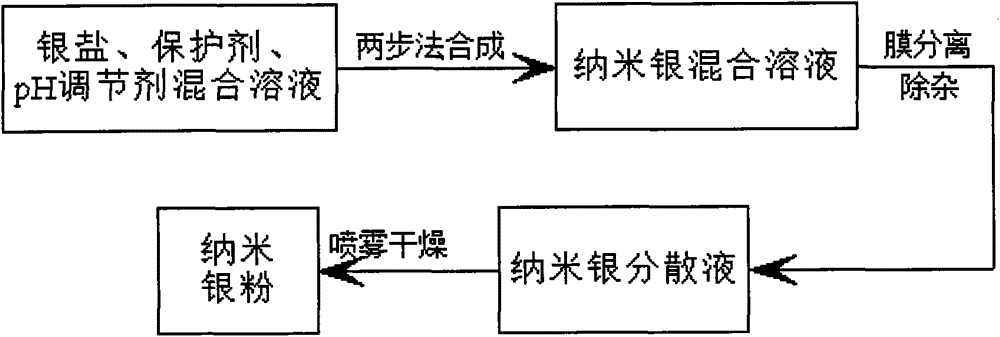

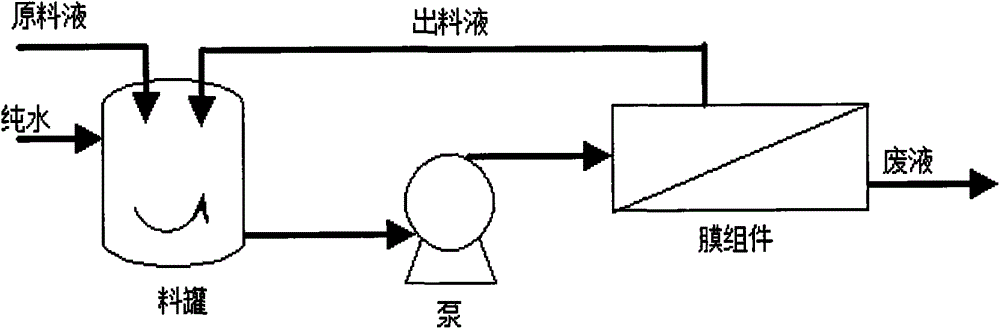

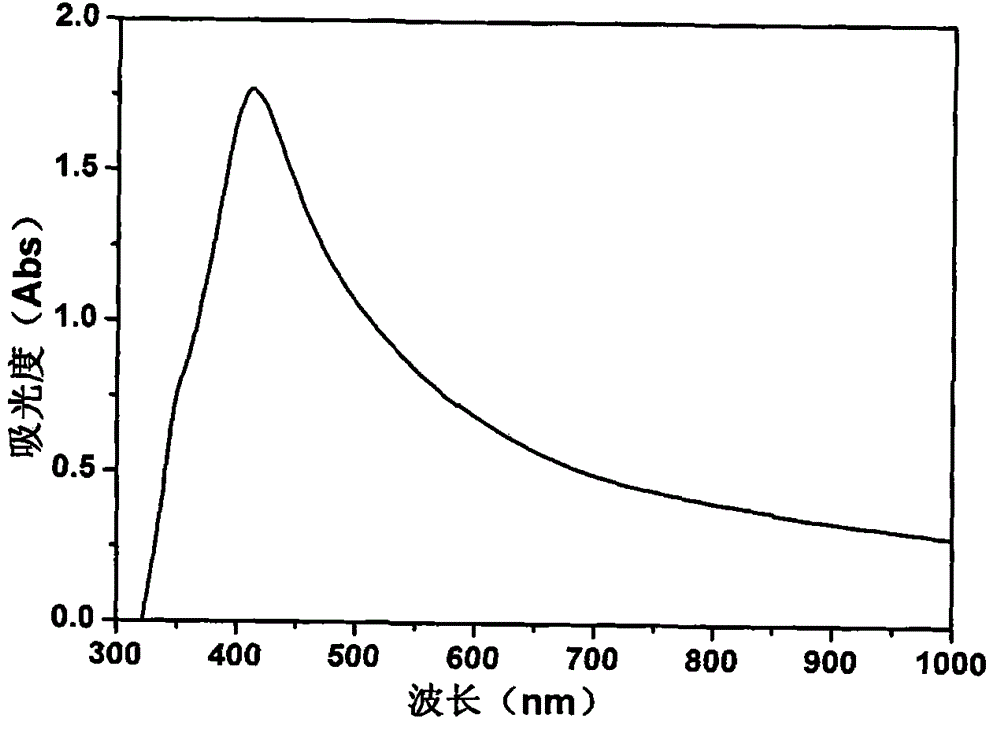

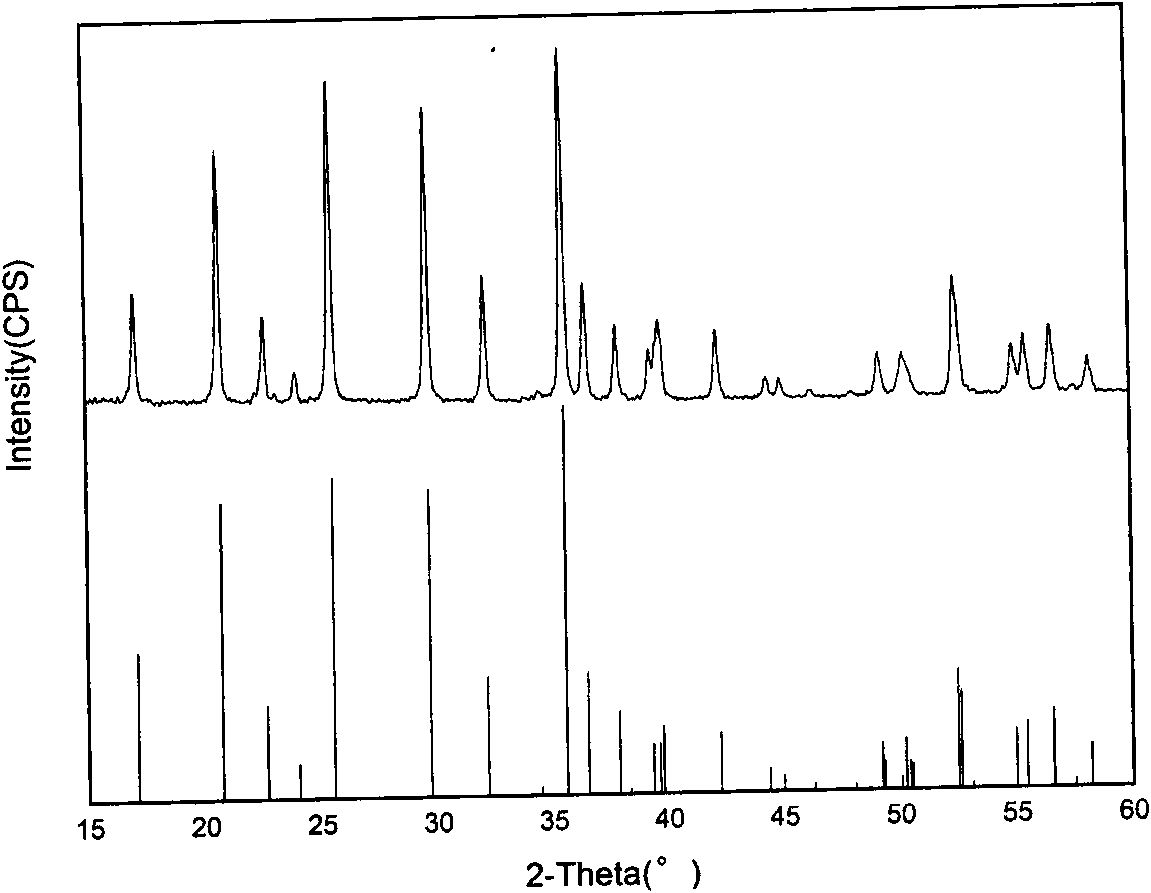

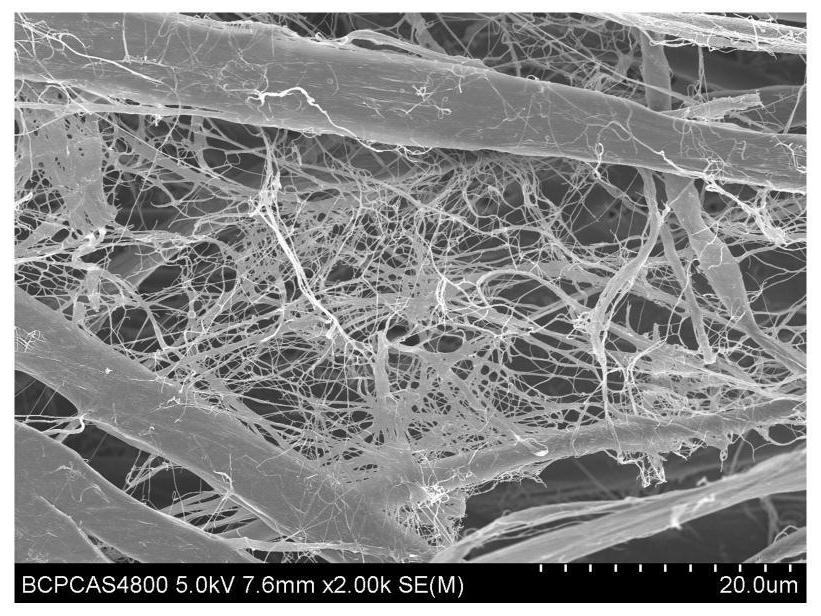

Method for preparing nanosilver powder in batches

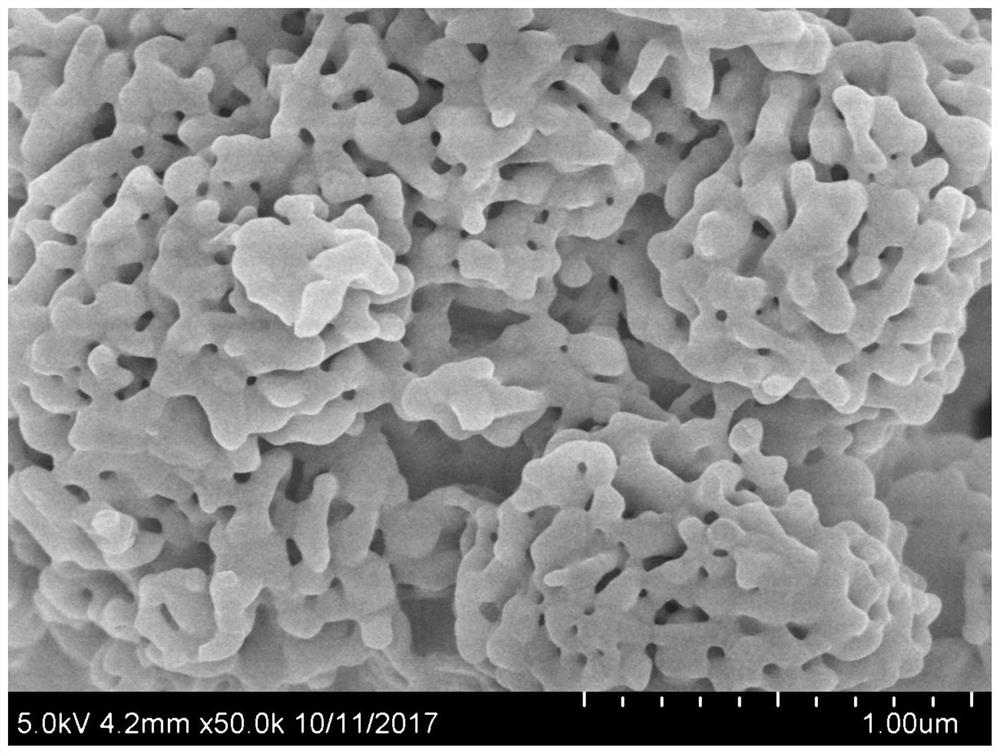

ActiveCN104923801ASimple methodGuaranteed batch stabilityNanotechnologyBatch productionHigh concentration

The invention provides a method for preparing nanosilver powder in batches, belonging to the field of nano-material preparation. Nanosilver particles are synthetized in two steps, at first, a low-concentration reducing agent solution is slowly added into a solution mixed with silver salt, a protective agent, and a pH conditioning agent drop by drop, and then a high-concentration reducing agent solution is rapidly added drop by drop to obtain a nanosilver mixed solution; impurities in the nanosilver mixed solution are removed through a membrane separation device to obtain a nanosilver dispersion liquid; and at the end, absolute ethyl alcohol and a high-molecular dispersant are added into the nanosilver dispersion liquid, and spray drying is carried out by a spray drying device to obtain nanosilver powder in a certain particle size. The particle size of the prepared nanosilver powder is controllable, the batches are stable, the problems of non-uniform particle size during the synthesis of nanosilver, nanosilver separation, and agglomeration and acaking during powder preparation are solved, the preparation process and the operation are simple, and industrial and batches production is realized.

Owner:NANO TOP ELECTRONICS TECH

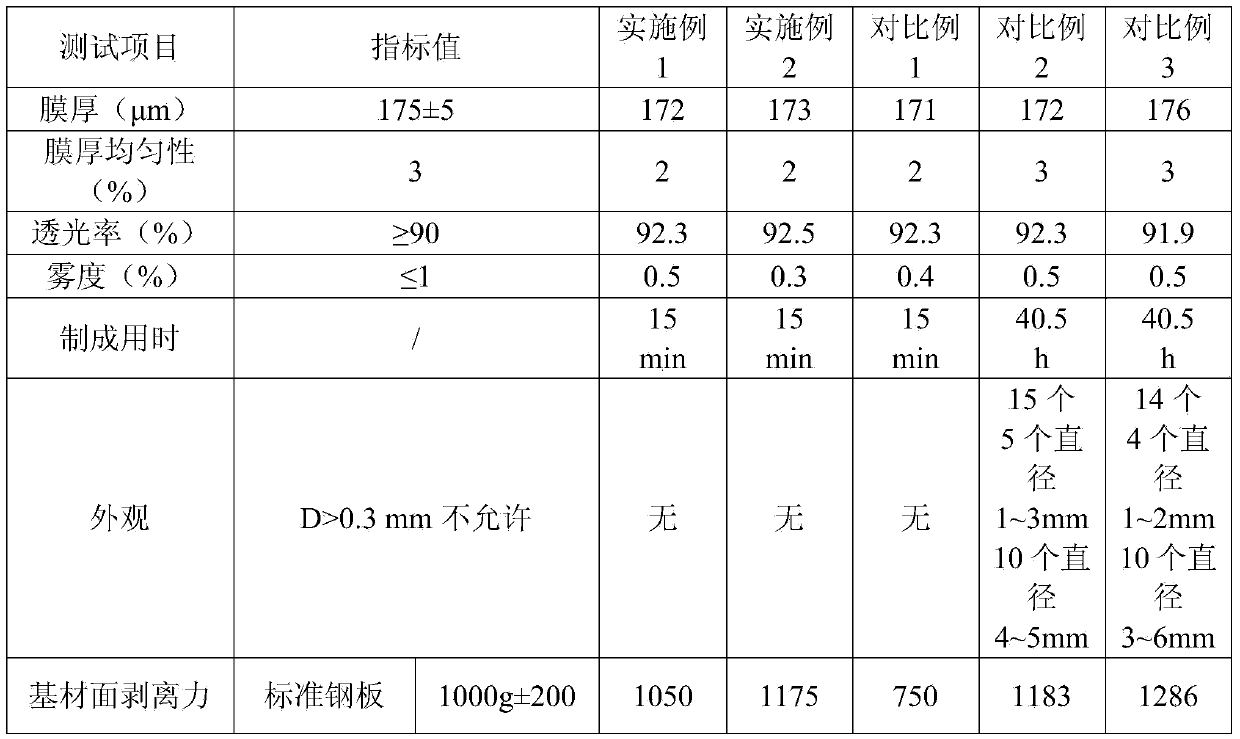

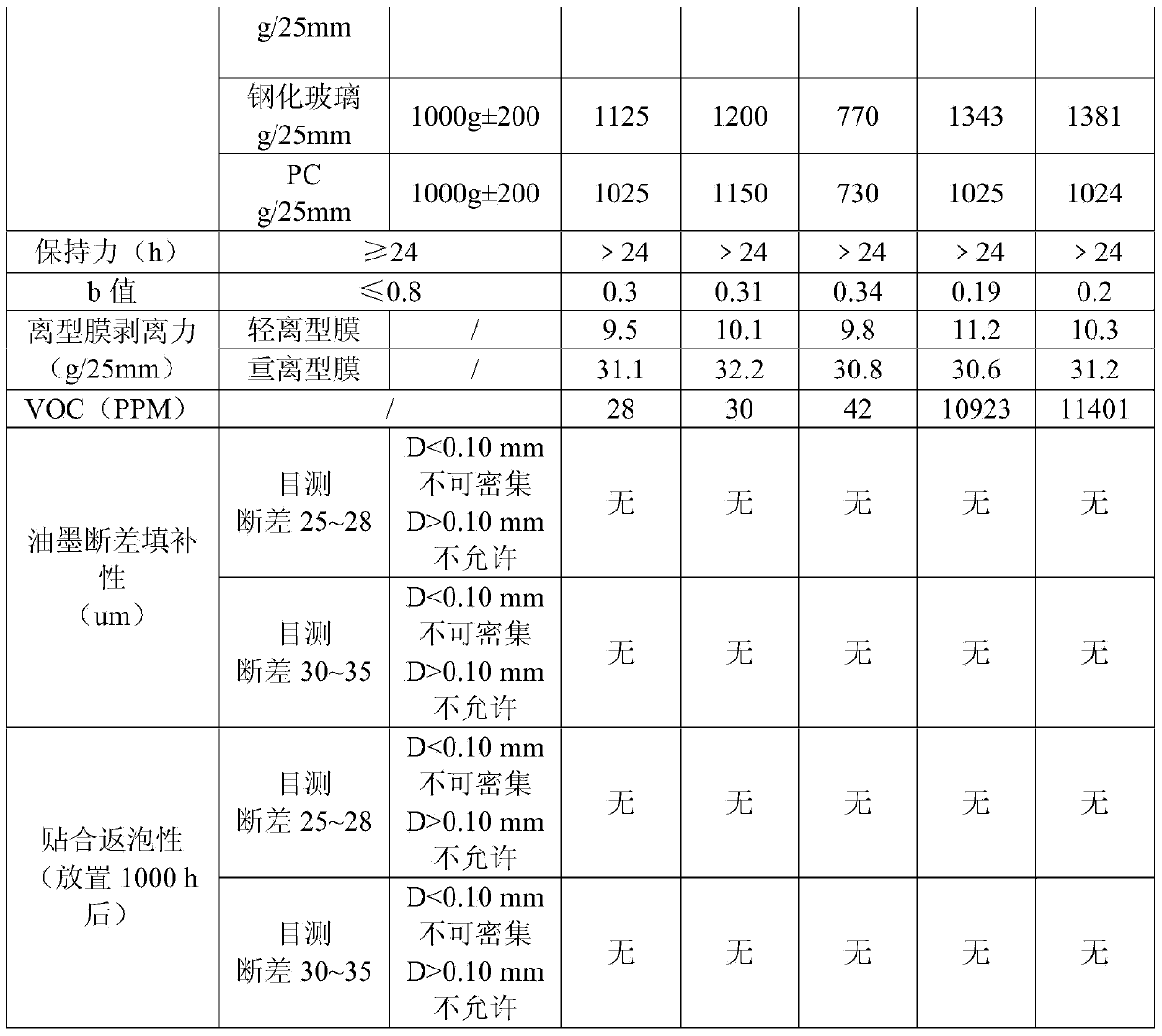

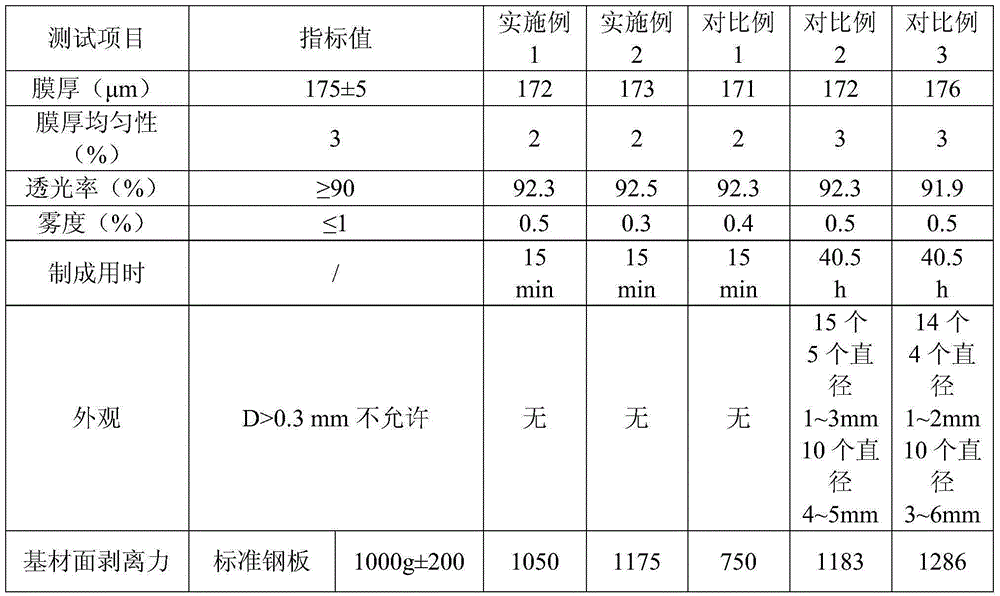

Solvent-free UV (ultraviolet) curing glue for optical transparent adhesive tape and preparation method and application thereof

ActiveCN103725245ALow VOCGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSolvent free

The invention belongs to the technical field of UV (ultraviolet) curing glue, and discloses solvent-free UV curing glue for an optical transparent adhesive tape and a preparation method and application thereof. The glue comprises the following components in parts by mass: 20-60 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 10-25 parts of acrylate monomer, 1-10 parts of thiol, 1-10 parts of tackifying resin, 0.1-1 part of leveling agent, 0.5-2 parts of antifoaming agent and 0.5-2 parts of photoinitiator. In the invention, the colloid crosslinking density and colloid strength are improved by preferentially adopting aliphatic polyurethane acrylate with low functionality degree and adding hyperbranched polyester acrylate; the acrylate monomer adjusts the viscosity and enhances the colloid strength; the caking property is improved by adding the thiol containing an ether structure; the prepared non-solvent UV curing glue for an optical transparent adhesive tape has high toughness, high light transmittance, low haze, high colloid strength, high viscosity, high thickness and low VOC (volatile organic compound) content.

Owner:广州慧谷功能材料有限公司

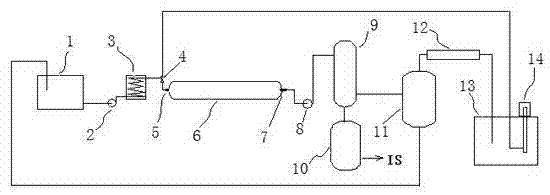

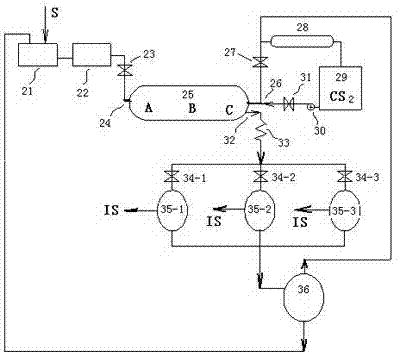

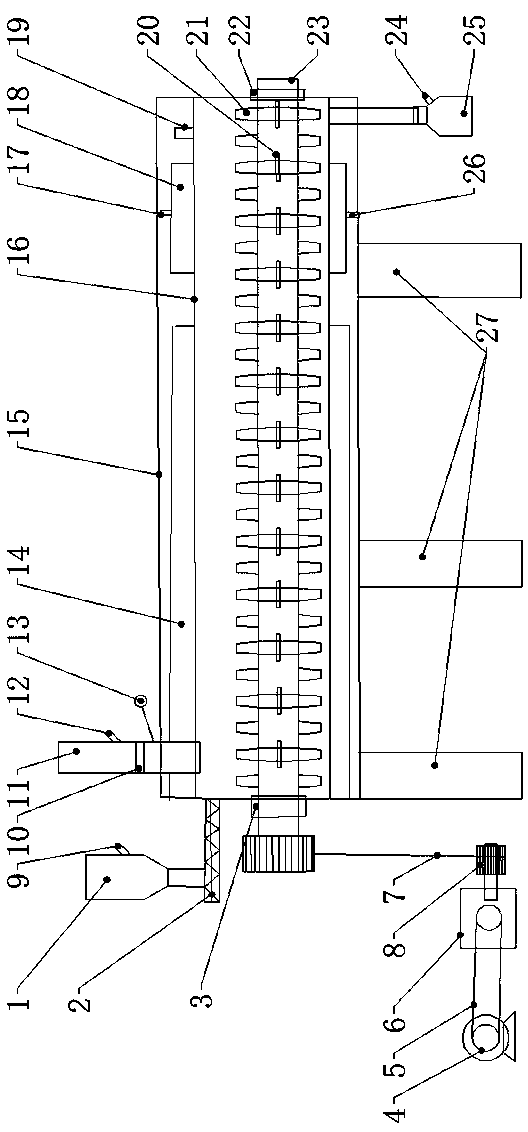

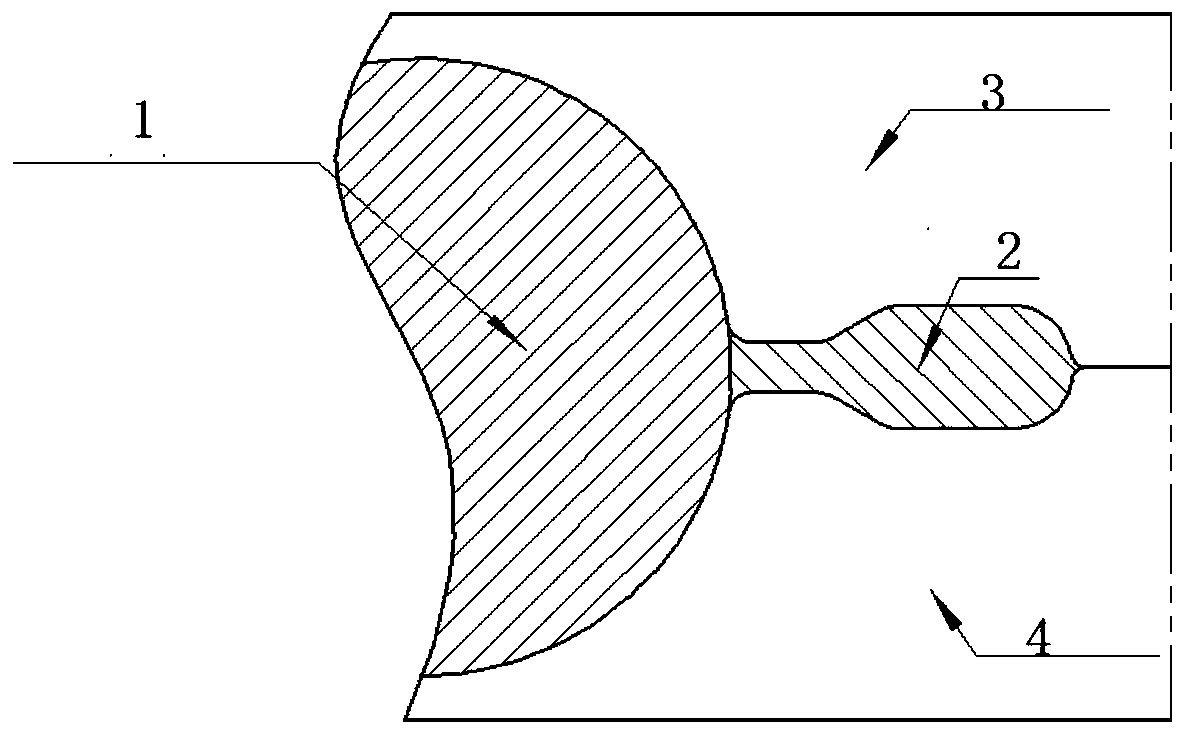

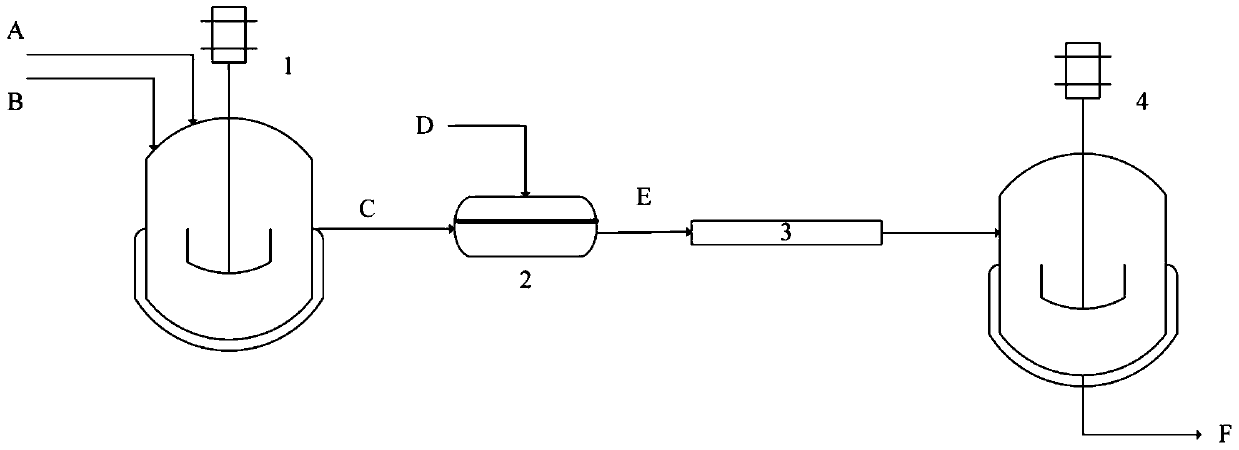

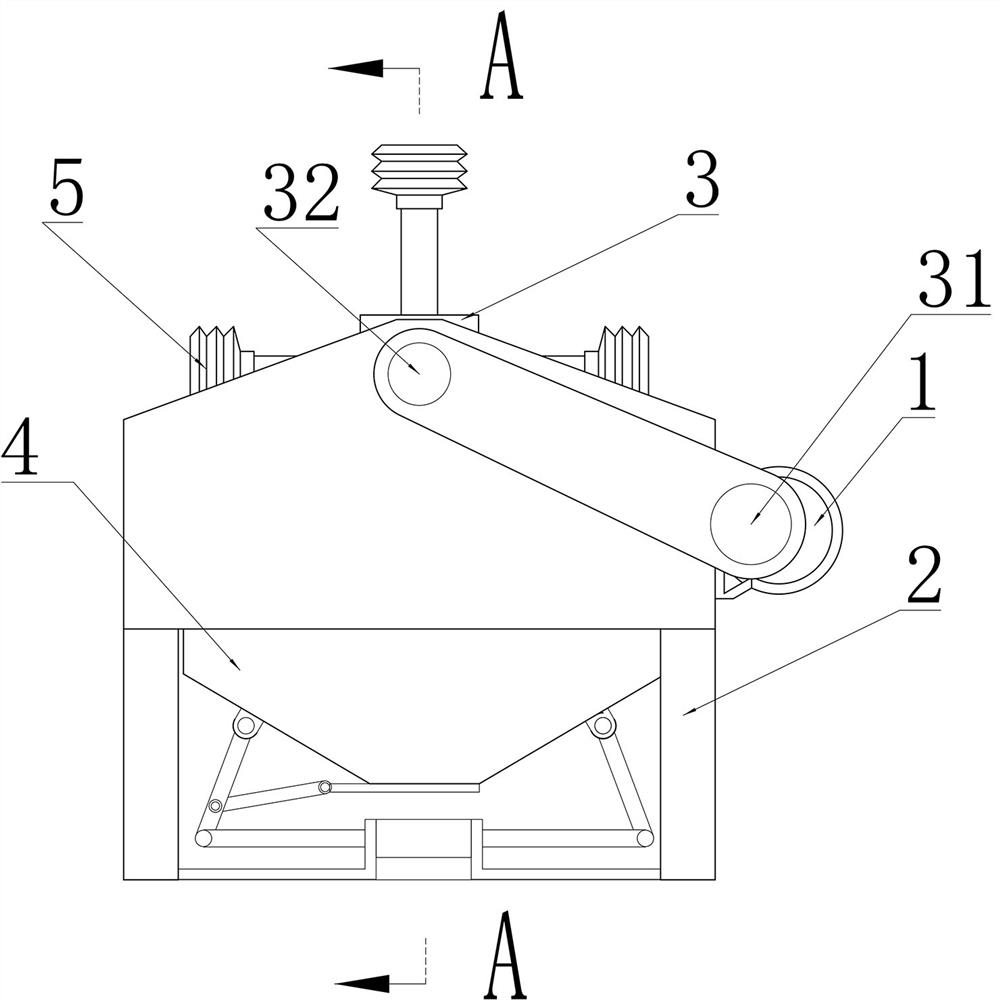

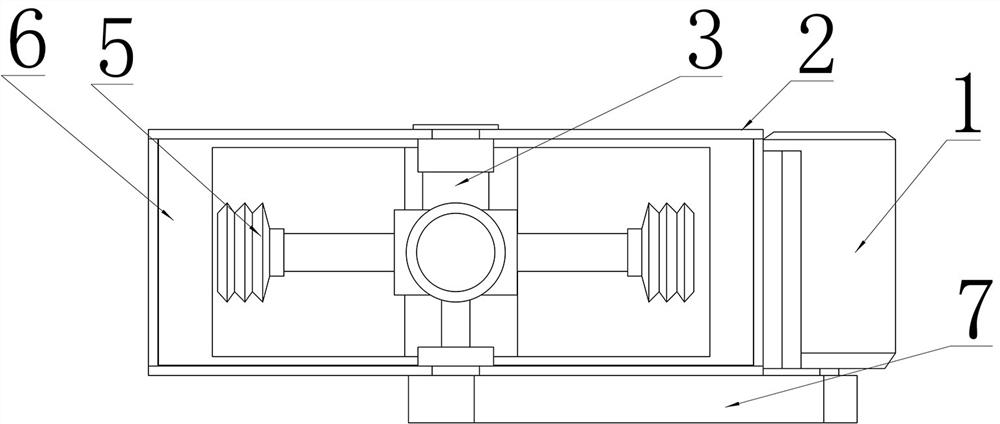

Continuous production method of insoluble sulfur

InactiveCN103193205AGuaranteed batch stabilityAvoid pollutionSulfur preparation/purificationPhysical chemistryEngineering

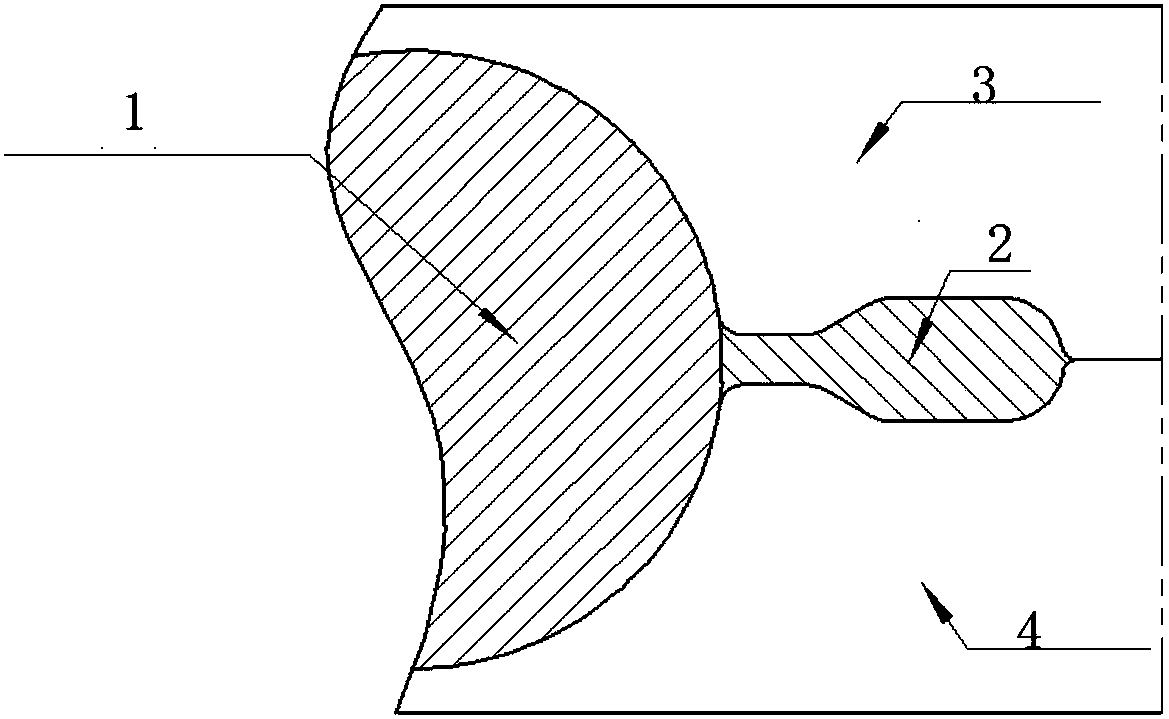

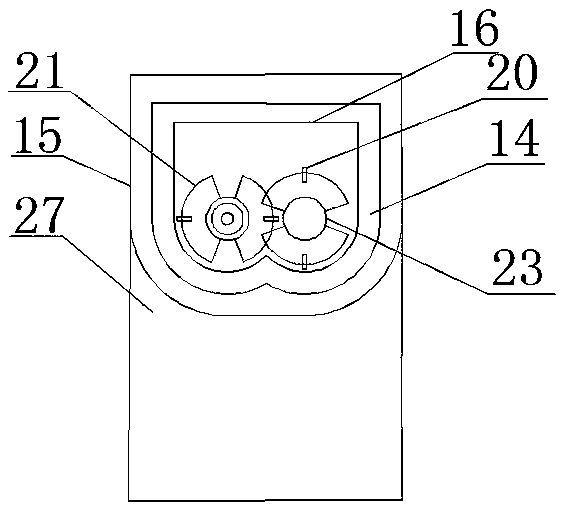

A continuous production method of insoluble sulfur comprises the steps of sulfur melting, extraction, curing, crushing and drying. The continuous production method of insoluble sulfur is carried out under a totally closed condition. The method concretely comprises the following steps: 1, placing sulfur in a sulfur melting pool (1), melting, pumping the molten sulfur to a heating coil tube (3) through a metering pump (2), heating, and mixing high-temperature sulfur with low-temperature carbon disulfide in an ejector (4) to complete quenching; 2, letting the quenched mixed liquid comprising insoluble sulfur and carbon disulfide into a continuous-rotation rotary kiln (6) through a rotary joint (5) to form a mixed liquid containing cured insoluble sulfur particles and carbon disulfide; 3, conveying the mixed liquid obtained in step 2 to a crushing pump (8), and crushing; 4, sending the mixed liquid containing crushed insoluble sulfur and carbon disulfide to a material crushing pot (9), and carrying out solid-liquid separation through a filter screen; and 5, sending insoluble sulfur to a vacuum dryer (10), and drying. The method has the advantages of continuous production of the insoluble sulfur under the totally closed condition, safety, environmental protection, stable product quality, high efficiency, and low energy consumption.

Owner:江西恒兴源化工有限公司

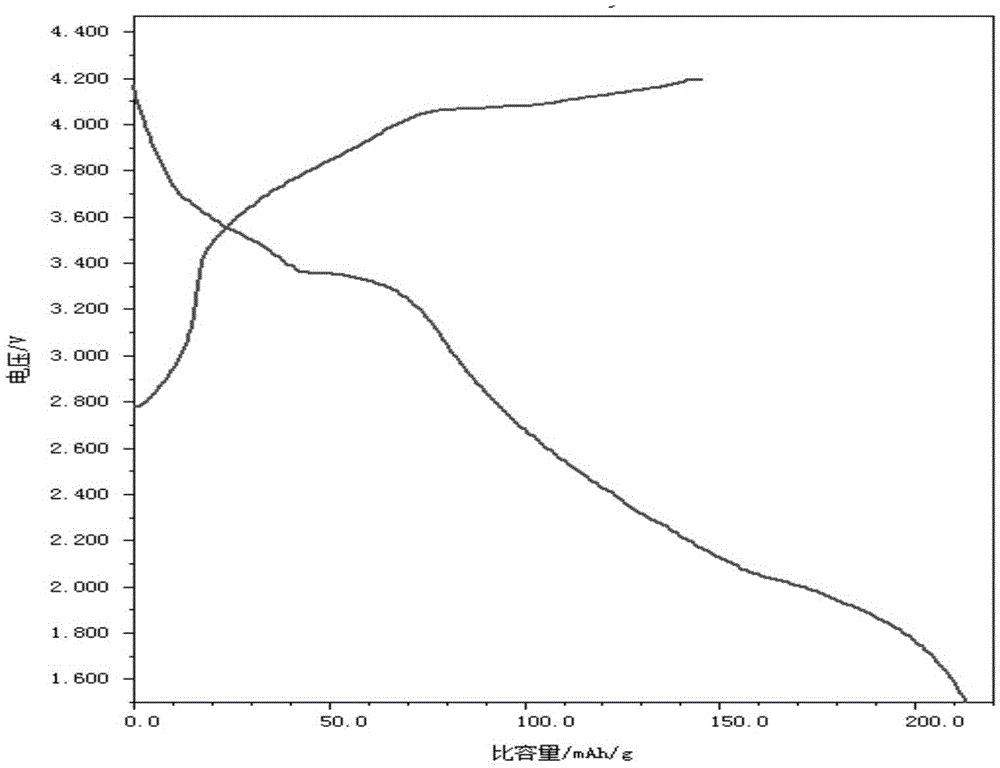

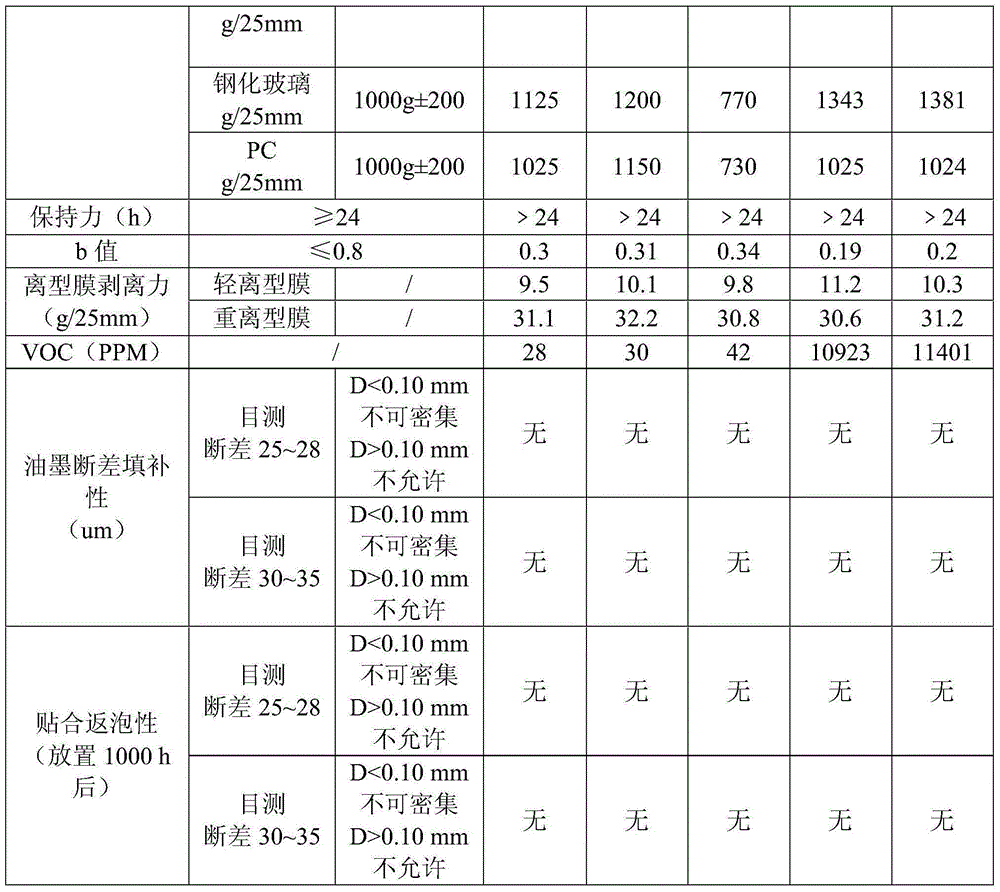

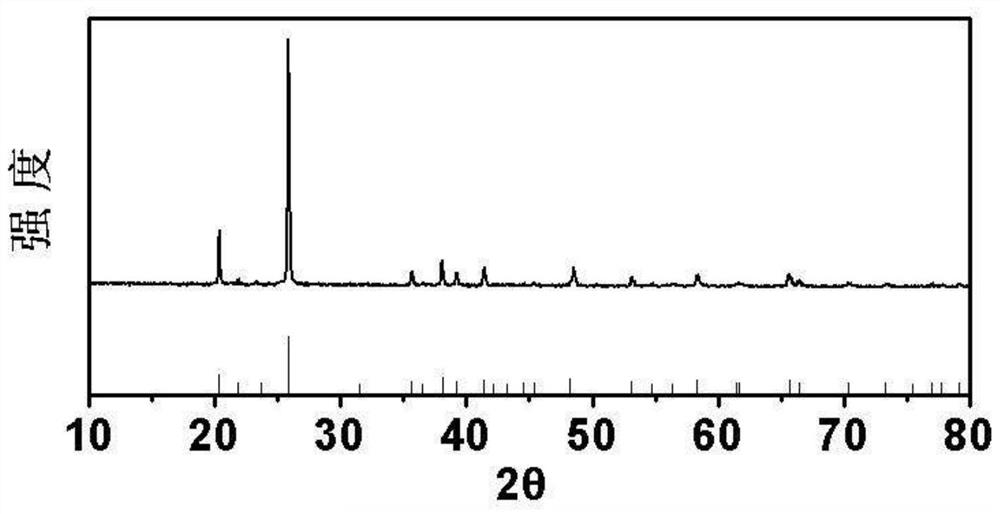

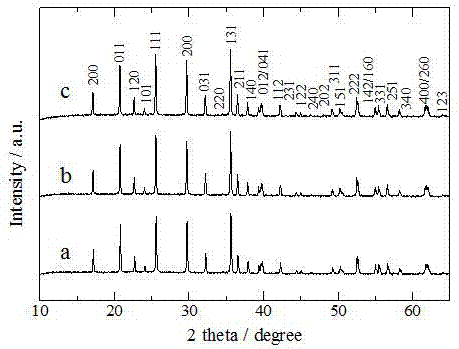

Method for preparing multielement positive pole material for sodium-ion batteries

InactiveCN105576229AEvenly crushedWell mixedCell electrodesSecondary cellsTunnel kilnSodium-ion battery

The invention relates to a method for preparing a multielement positive pole material for sodium-ion batteries and belongs to the technical field of lithium-ion batteries. The method for preparing the multielement positive pole material for the sodium-ion batteries comprises the following steps: (1) weighing a nickel source compound, a ferrum source compound, a manganese source compound and a lithium source compound according to the atomic ratio of x, y and z in a chemical formula, i.e., Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2) of a predetermined synthesized product, and carrying out preliminary mixing on the raw materials, wherein each of x, y and z is not smaller than 0.01 and is smaller than 1; (2) feeding the preliminary-mixed raw materials to an airtight gas tank by using high-speed gas flow, and subjecting the raw materials to mutual collision and mutual friction inside the airtight gas tank, so as to obtain a crushed, mixed and activated precursor; (3) placing the precursor, which is crushed and activated by the high-speed gas flow, into a high-temperature tunnel kiln, heating the precursor to the temperature of 875 DEG C to 950 DEG C in an air or oxygen atmosphere, carrying out heat preservation for 15 hours to 20 hours, and carrying out cooling, thereby preparing a powder product of the multielement positive pole material Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2). The method has the advantages that the process is simple, the cost is low, the production efficiency is high, the uniformity of the product is good, the electrochemical properties are excellent, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

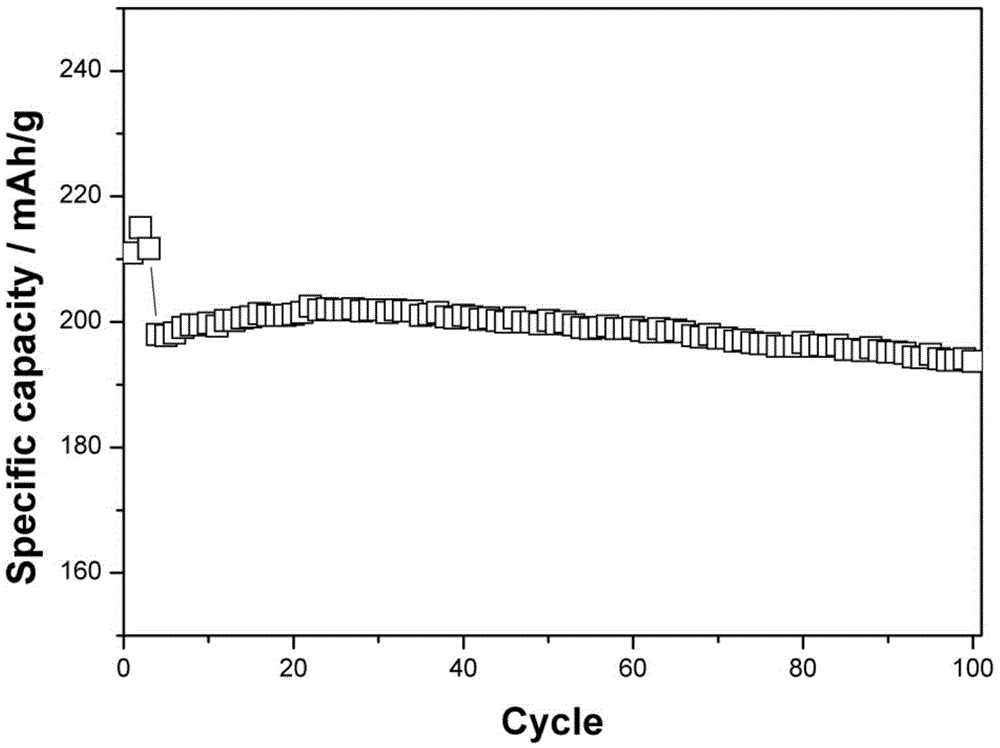

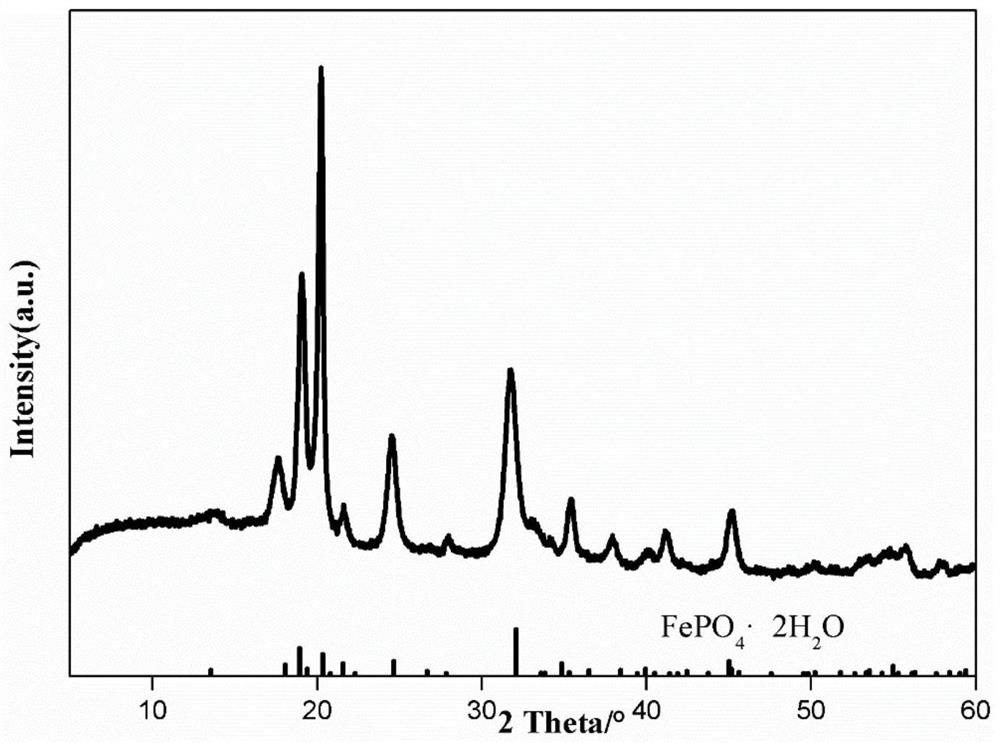

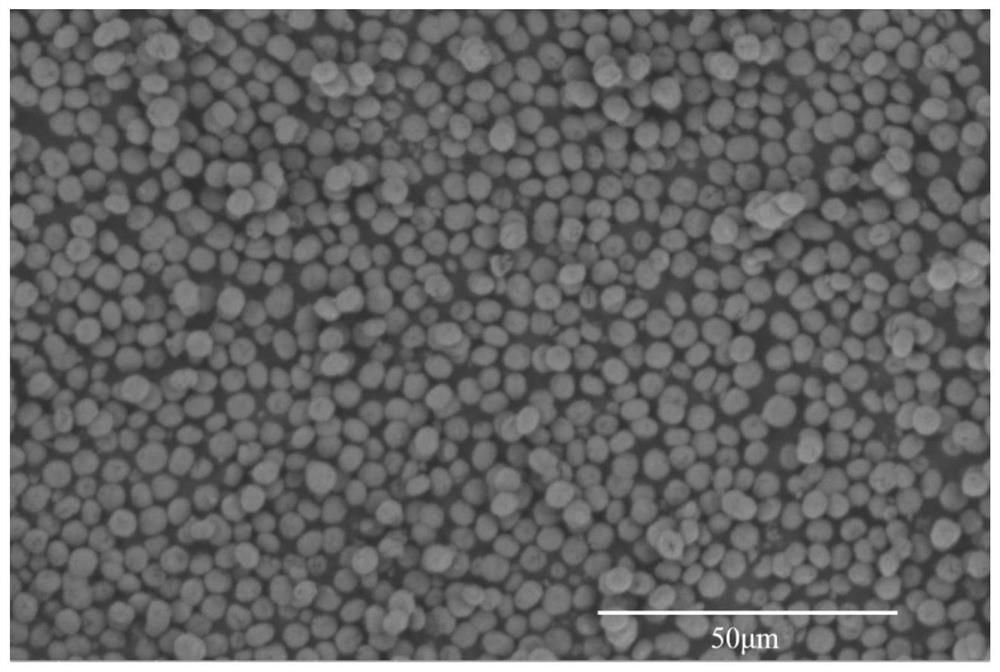

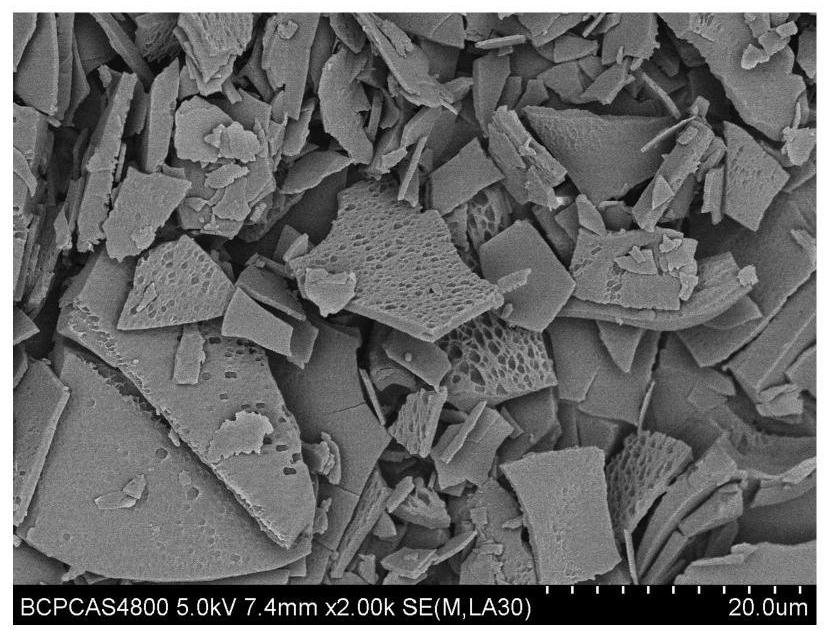

Battery-grade iron phosphate, preparation method and application thereof

PendingCN112624077ALow impurity contentStable qualityCell electrodesPhosphorus compoundsElectrical batteryIron phosphate

The invention belongs to the field of battery materials, and discloses battery-grade iron phosphate, a preparation method and application thereof. The preparation method comprises the following steps: roasting iron phosphate waste, adding into acid liquor, dissolving, and filtering to obtain a solution A containing an iron element and a phosphorus element; stirring the solution A and alkali liquor, adjusting the pH value to be acidic, and reacting to obtain iron phosphate slurry; heating the iron phosphate slurry, adding phosphoric acid, stirring for aging reaction, washing and filtering to obtain an iron phosphate dihydrate filter cake, and drying to obtain iron phosphate dihydrate powder; and roasting, dehydrating and cooling the iron phosphate dihydrate powder to obtain the battery-grade iron phosphate. According to the invention, recovered ferrophosphorus waste is used as a raw material, NaOH is used for precipitating amorphous iron phosphate, phosphoric acid is used as an aging agent under the high-temperature stirring condition, and battery-grade iron phosphate with the impurity content smaller than or equal to 1.0% is prepared through a one-step method.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

A kind of solvent-free UV curing glue for optical scotch tape and its preparation and application

ActiveCN103725245BLow VOCGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPliabilitySolvent free

The invention belongs to the technical field of UV (ultraviolet) curing glue, and discloses solvent-free UV curing glue for an optical transparent adhesive tape and a preparation method and application thereof. The glue comprises the following components in parts by mass: 20-60 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 10-25 parts of acrylate monomer, 1-10 parts of thiol, 1-10 parts of tackifying resin, 0.1-1 part of leveling agent, 0.5-2 parts of antifoaming agent and 0.5-2 parts of photoinitiator. In the invention, the colloid crosslinking density and colloid strength are improved by preferentially adopting aliphatic polyurethane acrylate with low functionality degree and adding hyperbranched polyester acrylate; the acrylate monomer adjusts the viscosity and enhances the colloid strength; the caking property is improved by adding the thiol containing an ether structure; the prepared non-solvent UV curing glue for an optical transparent adhesive tape has high toughness, high light transmittance, low haze, high colloid strength, high viscosity, high thickness and low VOC (volatile organic compound) content.

Owner:广州慧谷功能材料有限公司

Feed for large-size part metal powder injection molding and preparing method thereof

InactiveCN108941574AAdvantages of feedingHigh tap densityTransportation and packagingMetal-working apparatusInjection pressureMass ratio

The invention discloses feed for large-size part metal powder injection molding. The feed is composed of a bonding agent and gas atomization metal powder; the mass ratio of the bonding agent to the metal powder ranges from 96:4 to 92:8. Powder used in feed is gas atomization spherical powder, the high vibration density is achieved, the metal powder size proportion is high, after feed injection forming green blank sintering, the shrinkage rate is small, and the sintering size of a large-size part can be precisely controlled. Feed fluidity is good, low injection pressure and injection speed canbe used for forming the large-size part, the internal stress of the injection green blank is reduced, the phenomenon that the injection green blank is not full and flow lines exist is avoided, and thestable shrinkage rate after injection green blank degreasing and sintering can be kept; raw materials of components are cheap and easy to obtain, the adding amount is flexibly adjusted according to equipment, part molds and product quality, the mixing process is simple and easy to operate, and batch stability and high production efficiency of the feed can be ensured.

Owner:POCO HLDG CO LTD +2

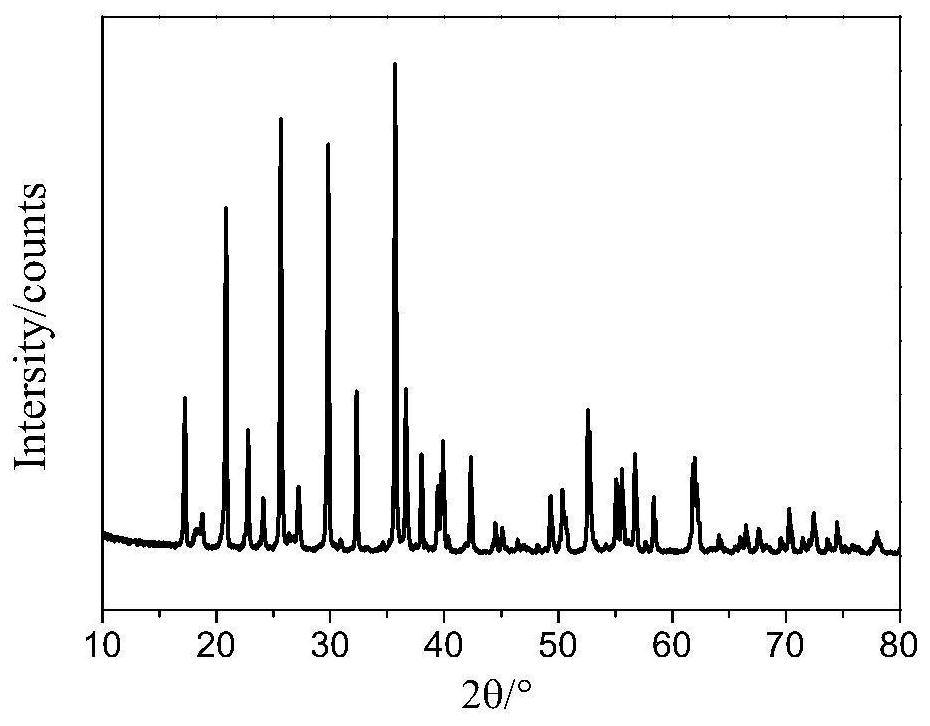

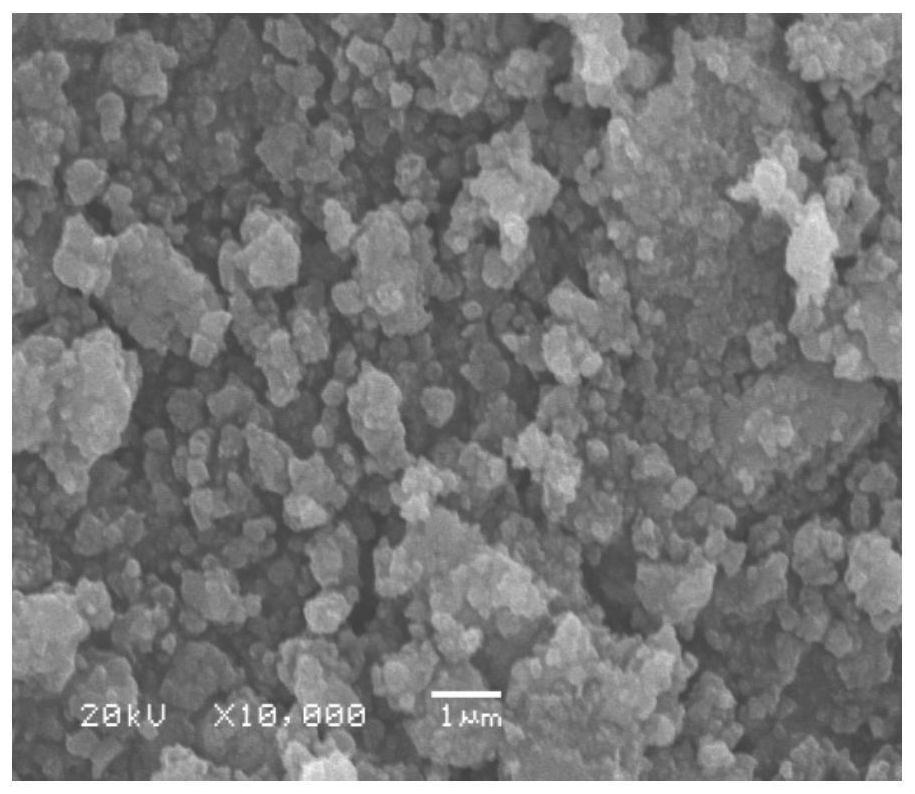

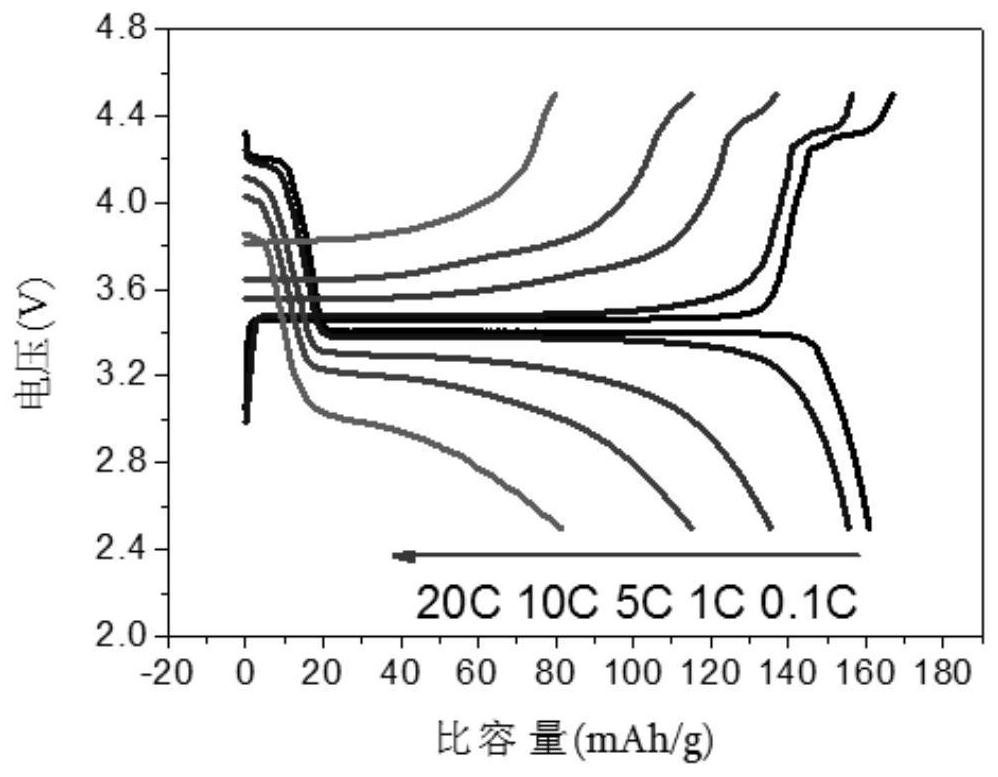

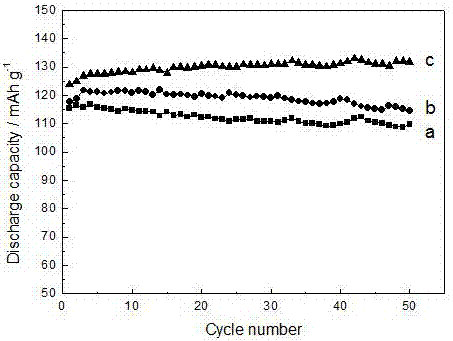

LiFePO4/CG compounded anode material prepared by liquid phase synthesis-microwave solid phase sintering method

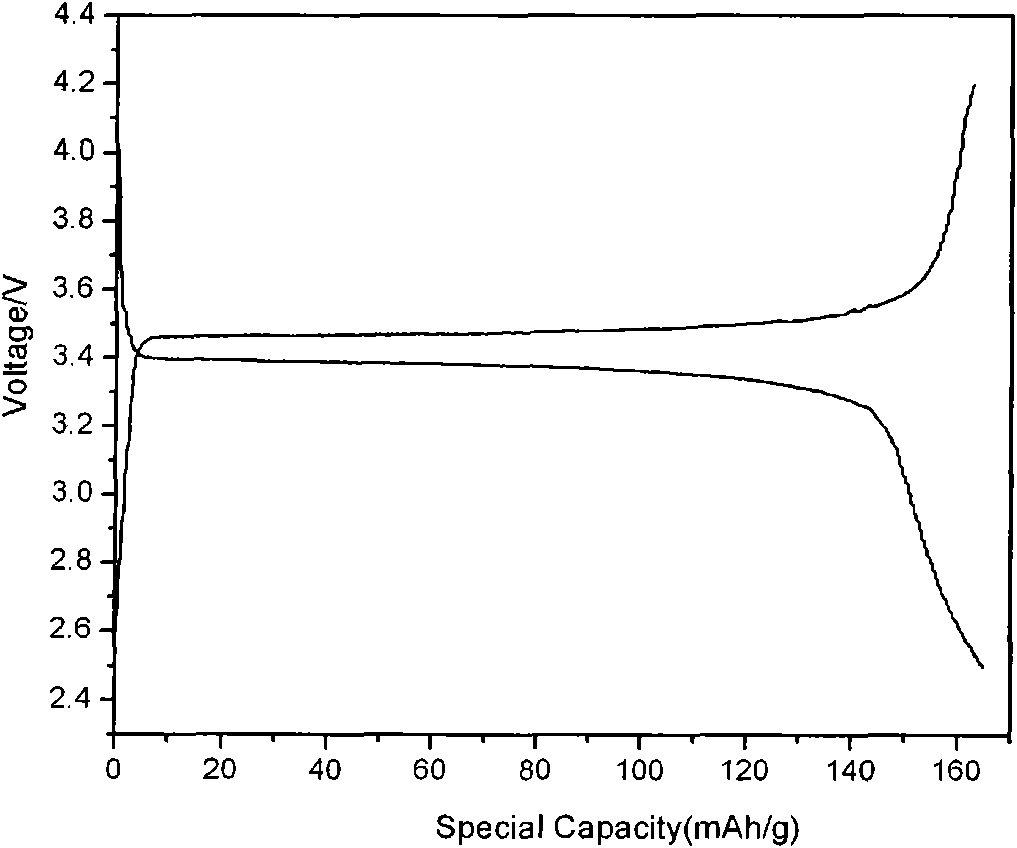

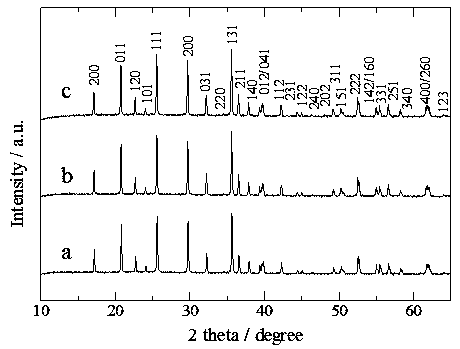

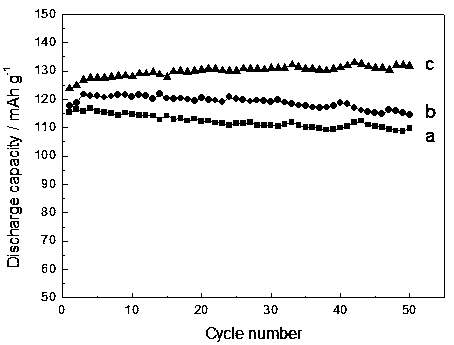

InactiveCN101572304AGuaranteed batch stabilityImprove cycle stabilityElectrode manufacturing processesElectrode carriers/collectorsMaterials preparationLithium-ion battery

The invention relates to LiFePO4 / CG (carbon gel) compounded anode material and a preparation method thereof, and belongs to the technical field of lithium ion battery material preparation. The preparation method comprises the following steps: adopting a liquid phase synthesis-microwave solid phase sintering method; weighing a certain amount of lithium source, iron source and phosphorous source according to the Li:Fe:P molar ratio of (0.9 to 1.2):(1.0 to 1.1):(1.0 to 1.1), and dissolving the lithium source, iron source and phosphorous source in deionized water to prepare a mixed suspension; adding a certain amount of CG (carbon gel) and surfactant to form a suspension through stirring; drying the suspension to obtain a powdery precursor; and obtaining the LiFePO4 / CG (carbon gel) compounded anode material after the grinding and microwave sintering of the powdery precursor . The technical method has the advantages of simple process, low energy consumption, greenness and no pollution, easily controlled process, and the like. The prepared lithium ion battery compounded anode material has high purity, small primary grain size, and stable electrochemical properties under the condition of high magnification charge and discharge.

Owner:上海微纳科技有限公司

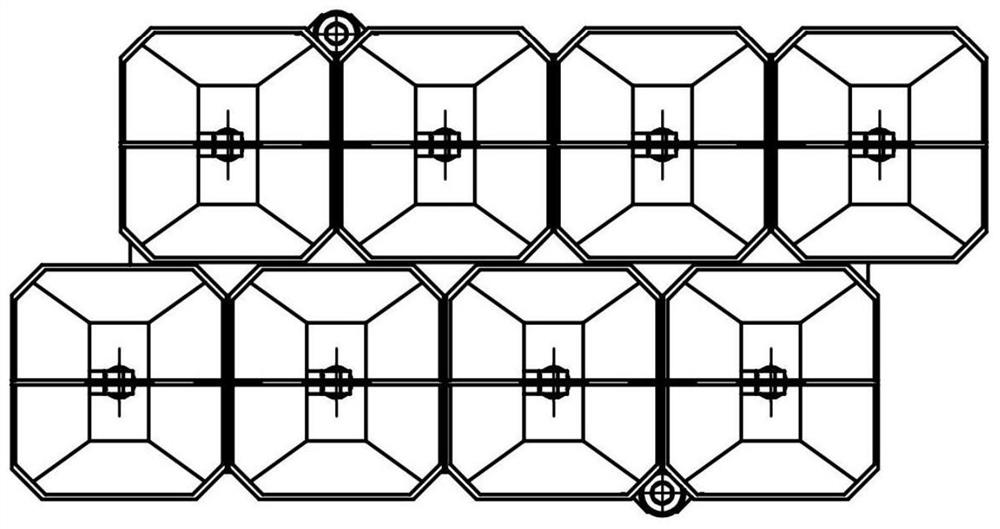

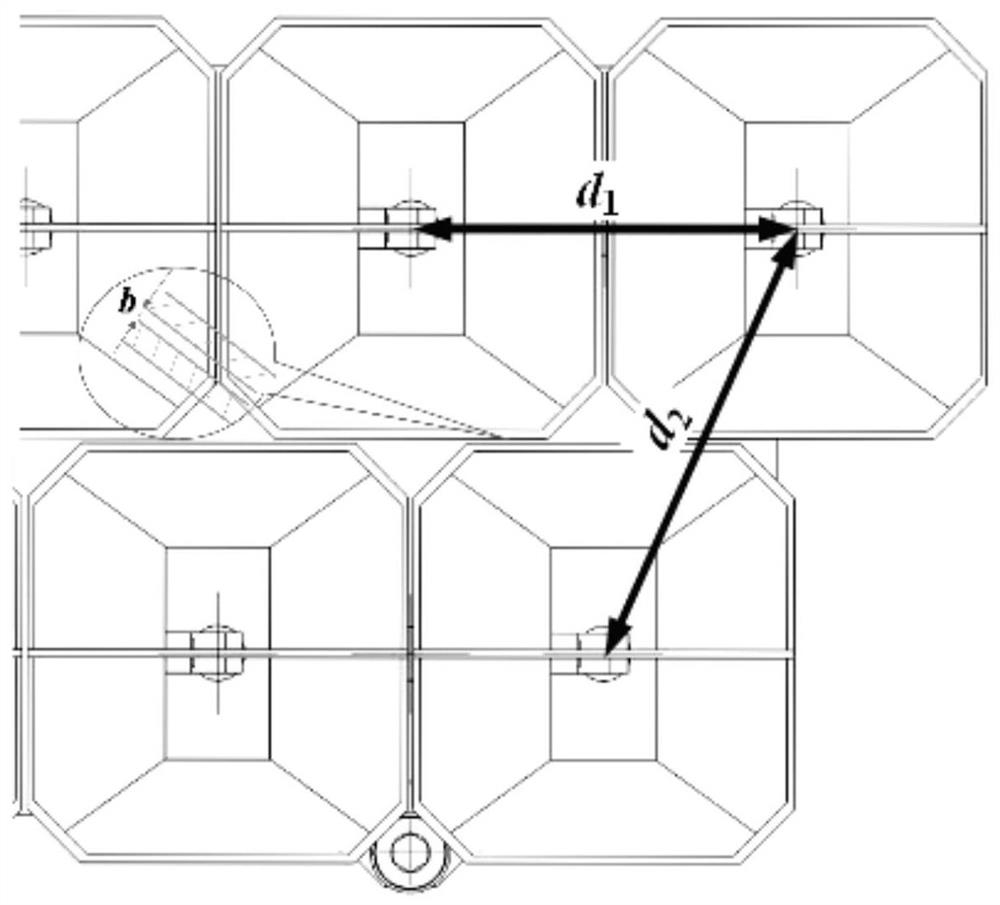

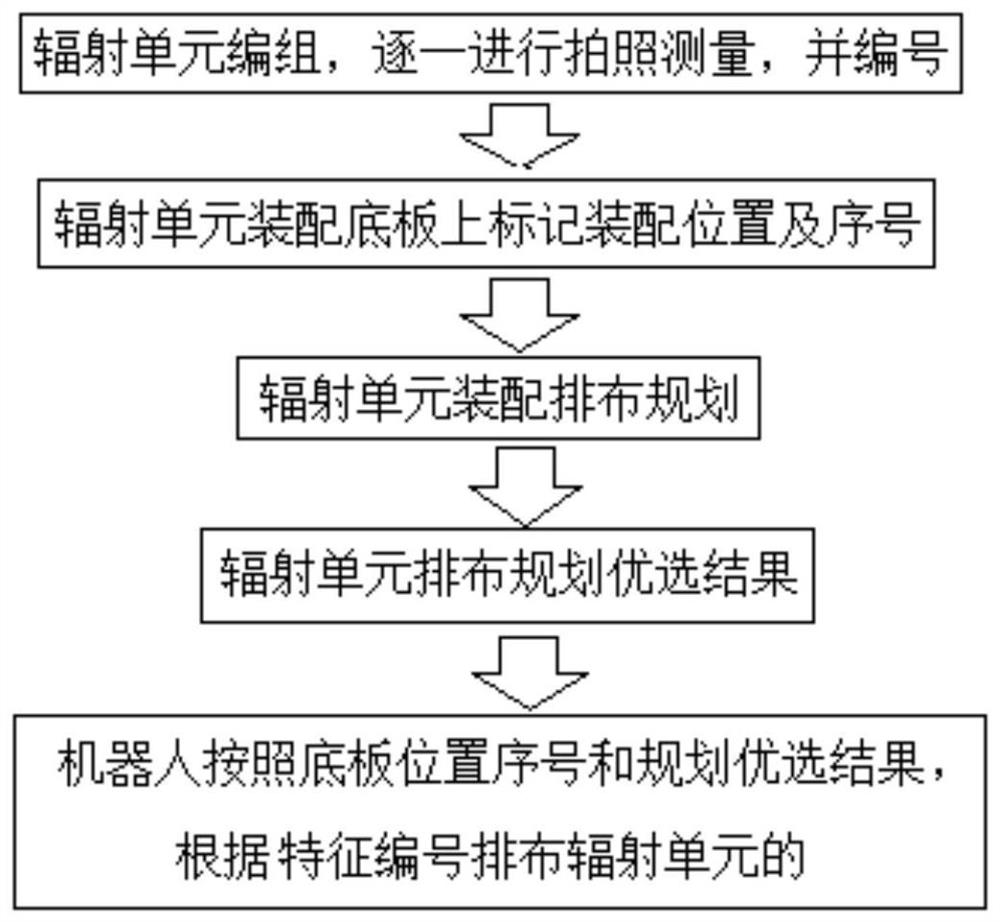

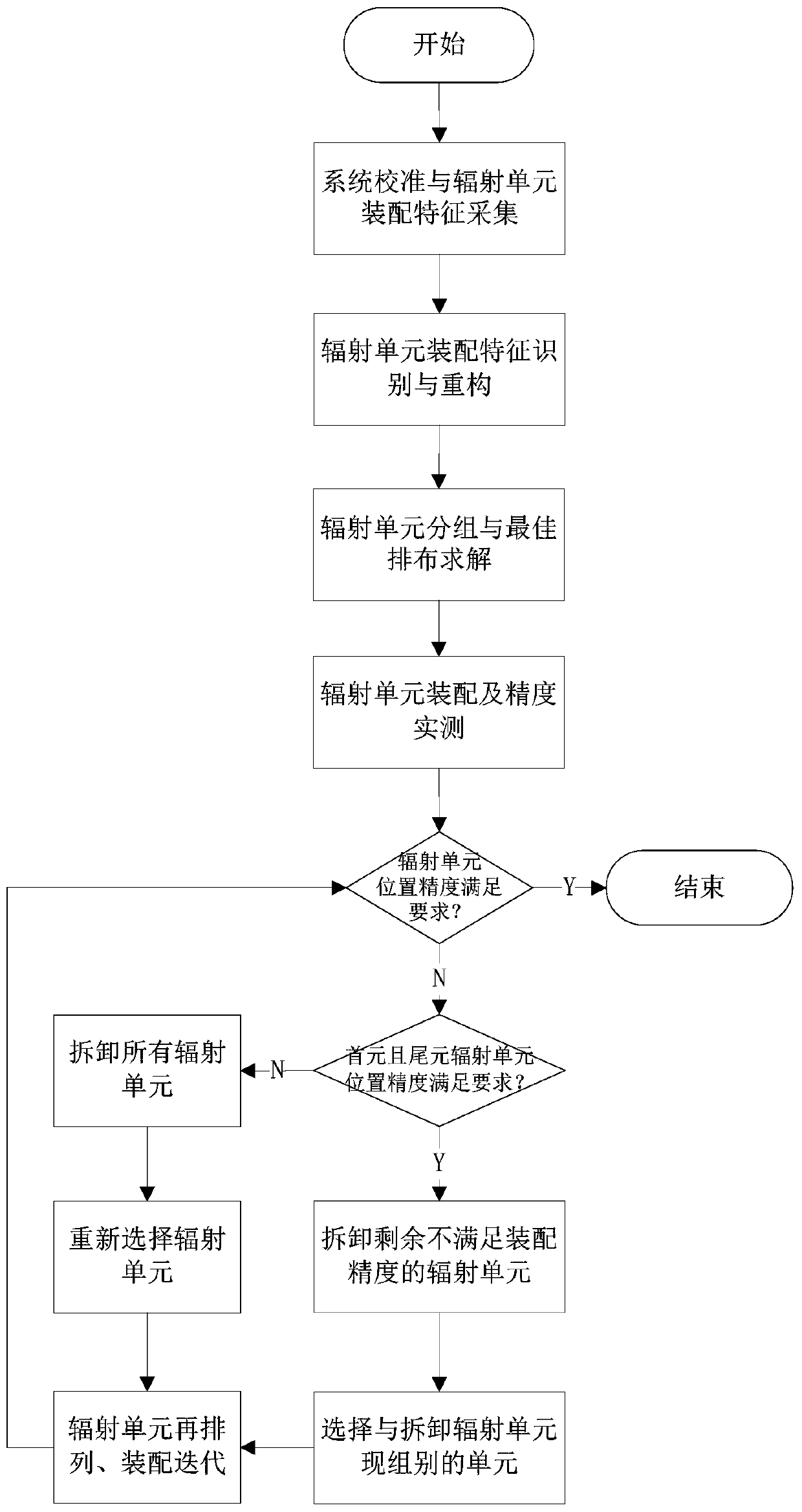

Intelligent arrangement and assembly method of feature numbers based on radiation units

PendingCN112018508AReduce the probability of interferenceHigh precisionRadiating elements structural formsIndividually energised antenna arraysSoftware engineeringMechanical engineering

An intelligent arrangement and assembly method of the feature numbers based on radiation units comprises the following steps: A) grouping the radiation units to be assembled, photographing and measuring the radiation units one by one, numbering the radiation units one by one, and calculating a required mouth edge center distance and a mouth edge margin; B) sequencing, numbering and marking serialnumbers of to-be-assembled arrangement positions on a radiation unit array assembly bottom plate; C) enabling an upper computer to carry out radiation unit assembling arrangement planning; D) enablingthe upper computer to determine a radiation unit arrangement planning optimization result; and E) enabling a robot to automatically and intelligently arrange the radiation units according to the position serial number of the bottom plate, the arrangement planning optimization result and the feature numbers and assemble the radiation units into an array according to the output data of the upper computer. The one-time assembly success rate and the efficiency of the whole assembly process are improved, the assembly preparation period is greatly shortened, and the assembly precision and consistency of the radiation unit are greatly improved; and completely efficient and automatic operation can be achieved for large-scale radiation unit array arrangement and assembly which are difficult to achieve by manpower.

Owner:SHANGHAI CAMA OPTOELECTRONICS EQUIP

Badminton racket handle and preparation method thereof

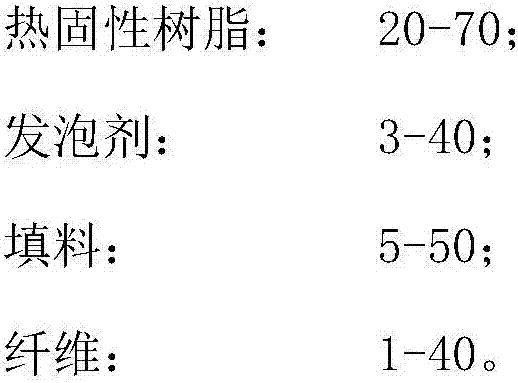

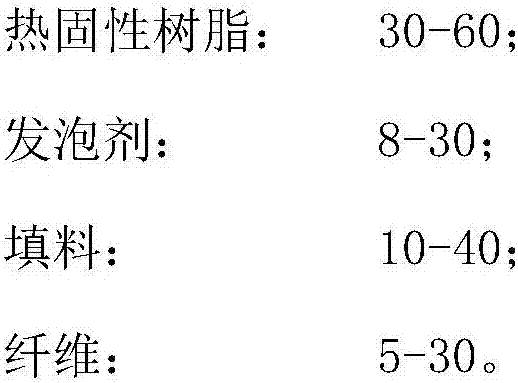

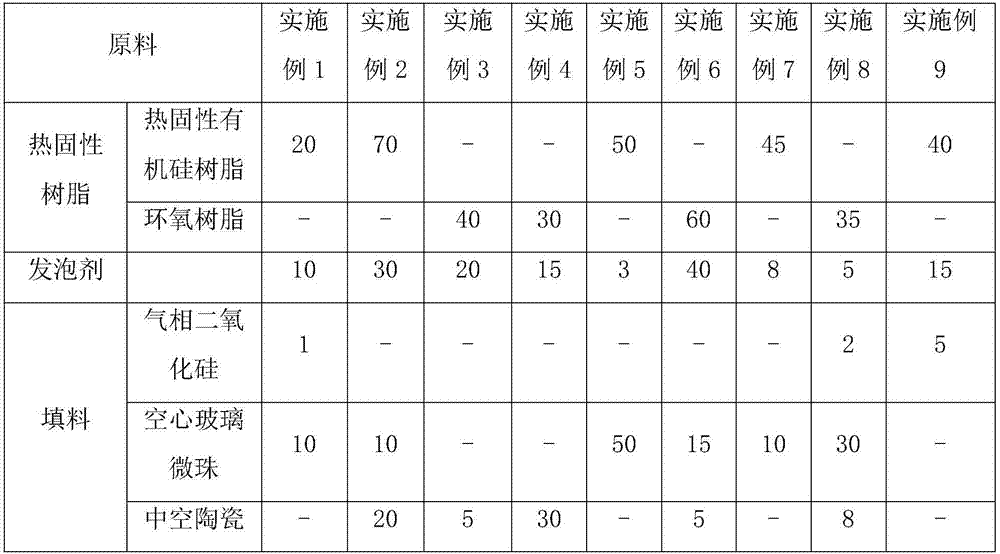

The invention relates to a badminton racket handle and a preparation method thereof. The badminton racket handle is prepared from badminton racket handle high-energy glue through one-step curing formation. The badminton racket handle high-energy glue is prepared from 20 to 70 weight parts of thermosetting resin, 3 to 40 weight parts of foaming agents, 5 to 50 weight parts of fillers and 1 to 40 weight parts of fiber. The badminton racket handle prepared by the technical scheme has the advantages that the weight is light; the strength is high; the structure is more stable; the uniformity is good; the quality is stable.

Owner:XIAMEN HOWER MATERIAL

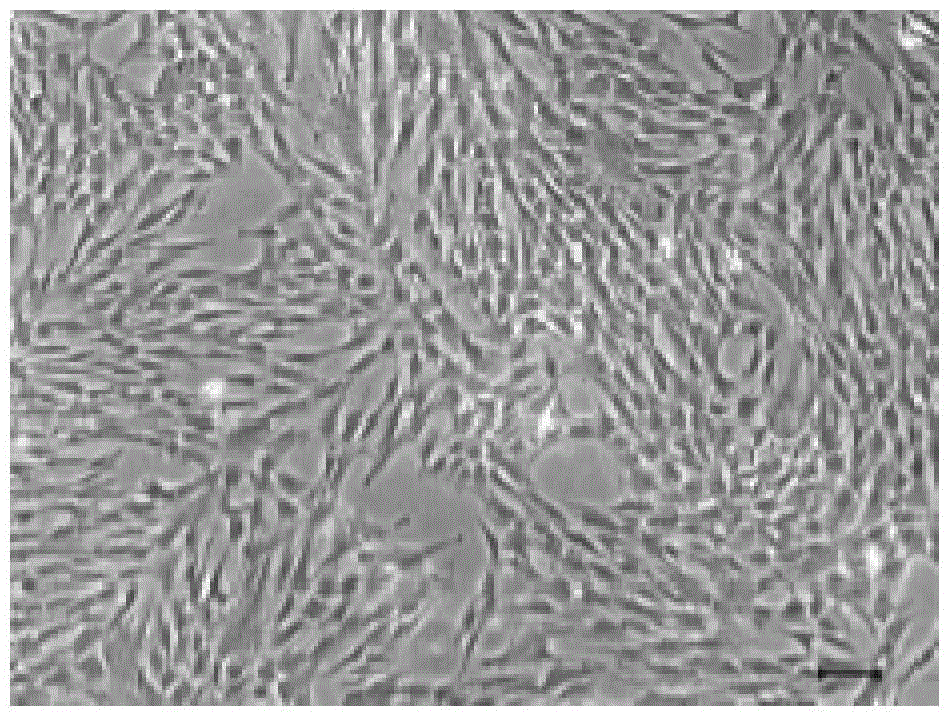

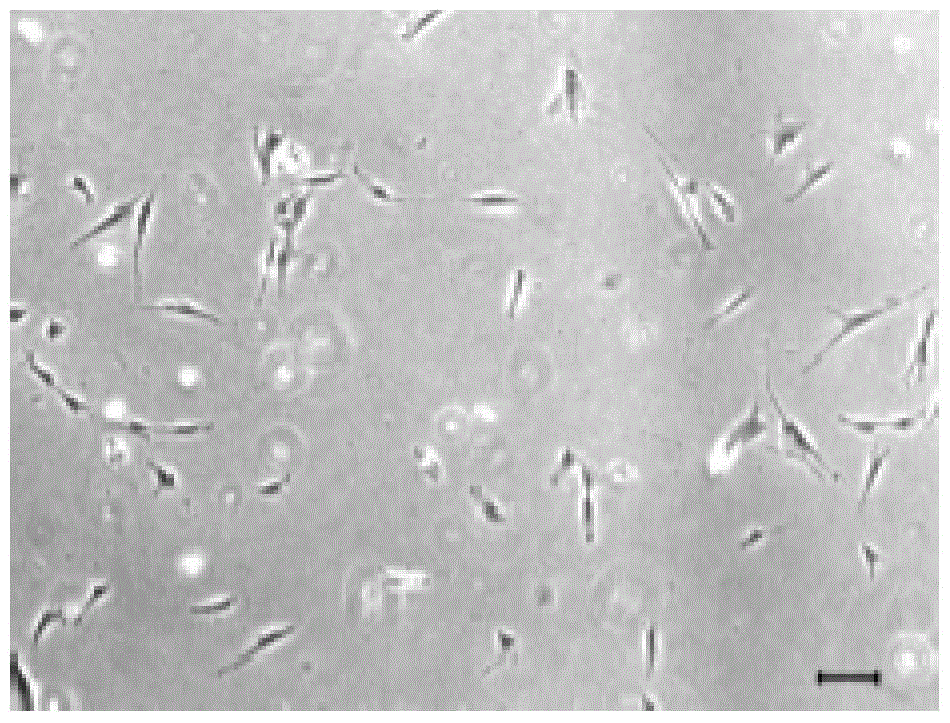

A serum-free medium for culturing mesenchymal stem cells

ActiveCN103555665BClear ingredientsAvoid heterogeneous contaminationSkeletal/connective tissue cellsSodium bicarbonateSerum free media

The invention relates to a serum-free medium for culturing mesenchymal stem cells. Based on the volume of the serum-free medium, it includes the following components: α-MEM 10.2g / L, sodium bicarbonate 2.4g / L, L-glutamine 1-5mM, poloxamer 18850-300mg / L , Recombinant Human Albumin 2‑8g / L, Recombinant Human Transferrin 10‑20mg / L, Recombinant Human Insulin 2‑10mg / L, Hepes1‑5mM, β‑Mercaptoethanol 50nM, Lipid 0.1‑1mg / L, Trace Element 1‑5mg / L, glutathione 0.1‑5mg / L, p-aminobenzoic acid 0.5‑5mg / L, hydrocortisone 1‑50ng / mL, vitamin PP20‑50mg / L, vitamin C5‑50mg / L , compound of formula I 2-10μM, compound of formula II 5-20μM, progesterone 10-20ng / mL, putrescine 1-10mg / L, heparin 1-10IU / mL, EGF1-10ng / mL, b-FGF1- 10ng / mL, HGF1‑10ng / mL, VEGF1‑10ng / mL. The MSCs serum-free medium BPS‑SFM is a chemically defined, animal-derived substance-free, serum-free medium; .

Owner:BEIJING DONGFANG HUAHUI BIOMEDICAL TECH

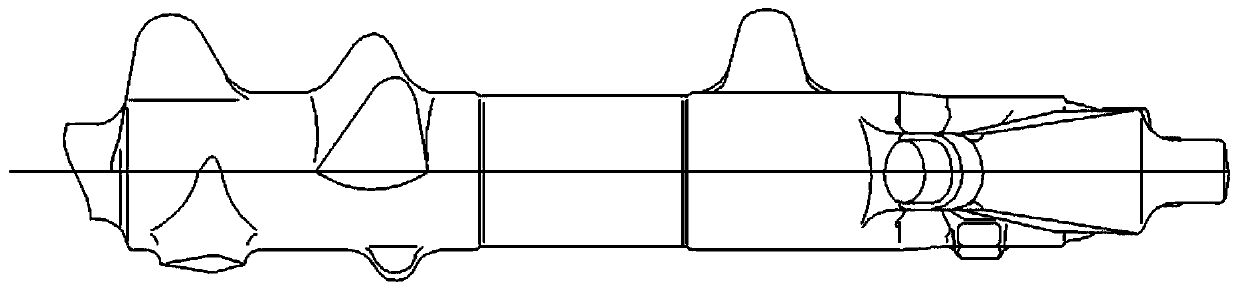

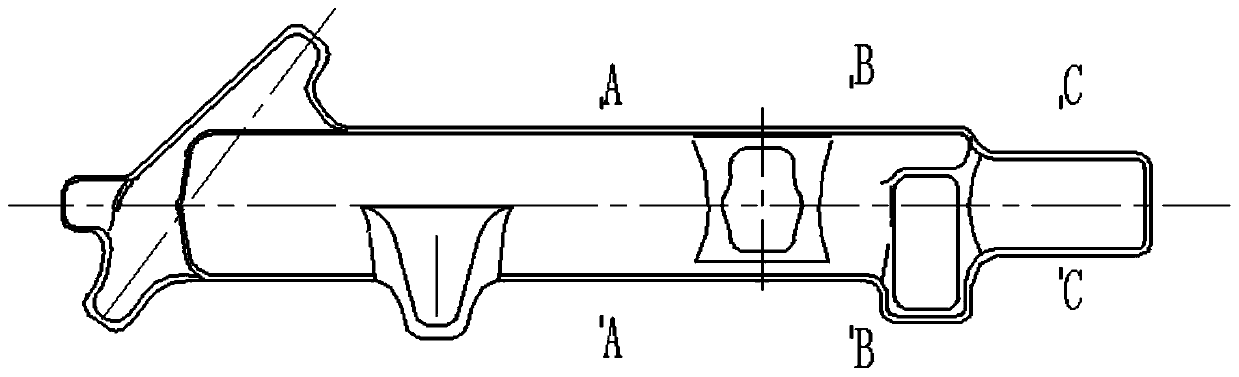

Forging method of large and complex die forging of A-100 steel and design method of pre-forging part thereof

ActiveCN108188338AGuaranteed uniformityGuaranteed tissue homogeneityDomestic articlesSize differenceDesign methods

The invention relates to the field of A-100 steel forging, and discloses a forging method of a large and complex die forging of A-100 steel and a design method of a pre-forging part thereof. The pre-forging part of the large and complex die forging of the A-100 steel adopts the design mode of a rhombic section of a rod portion, the deformation of a forging in the finish forging process can be increased to the maximum, and the deformation of the central portion of the rod portion of the forging can be >=25%; the grain size difference requirement of different positions of the forging is reducedto ensure that a grain grade differential grade of a finish forging is <=3; and meanwhile, the pre-forging part is quickly positioned, the blank in the forging process is prevented from tilting, and the filling of the forging is ensured.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Adhesion sheet and preparation method thereof, and copper clad laminate using adhesion sheet

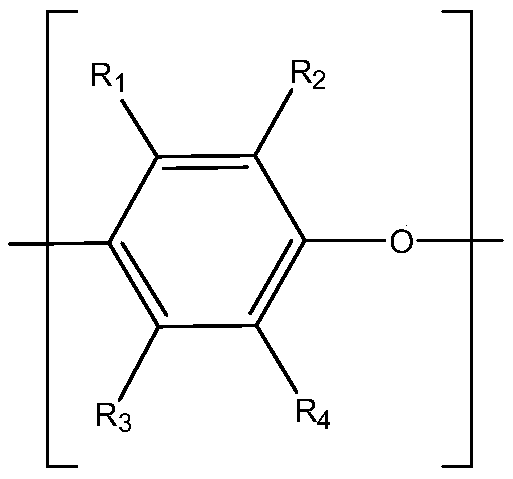

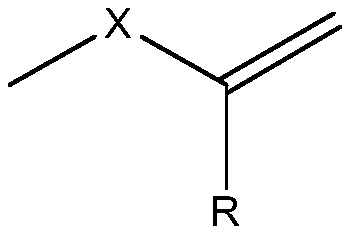

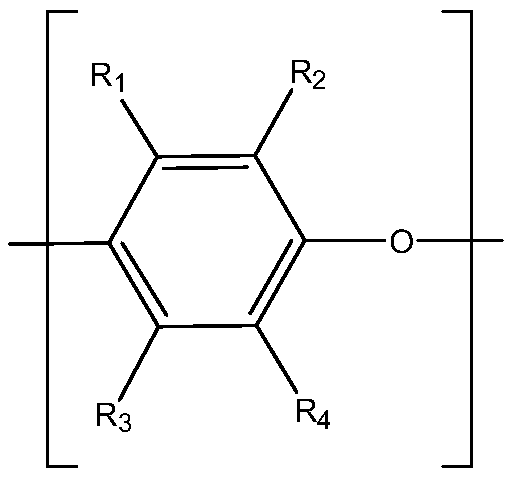

PendingCN110408332AHigh viscosityImprove liquidityNon-macromolecular adhesive additivesSynthetic resin layered productsDielectric lossHeat resistance

The present invention provides an adhesion sheet, which comprises, by mass, 25-65 parts of a matrix resin, 20-60 parts of a fiber reinforcement body, 10-40 parts of a filler, and 0-15 parts of a flameretardant, wherein the matrix resin comprises, by mass, 20-70 parts of modified polyphenylene ether, 30-70 parts of a polydiolefin type polymer, and 0-5 parts of an initiator. The present invention further provides a preparation method of the adhesion sheet, and a copper clad laminate using the adhesion sheet. According to the present invention, the heat resistance of the adhesion sheet and the copper clad laminate can reach more than 200 DEG C, such that the problems of defects, delamination and the like generated in the processing of the multilayer copper clad laminate due to insufficient heat resistance of the adhesion sheet can be solved; the fluidity of the adhesion sheet is maintained at 5-15%, such that the sufficient flowing and filling of the resin in the preparation process of the multi-layer copper clad laminate can be ensured, and the quality and the batch stability of the product can be ensured; and the cured adhesion sheet has low dielectric loss so as to meet the needsof the future high frequency field.

Owner:AAC TECH NANJING

A kind of lithium iron phosphate/lithium vanadium fluorophosphate/carbon composite cathode material and preparation method thereof

ActiveCN109286005BIncrease intrinsic conductivityImprove uniformityCell electrodesSecondary cellsCarbon compositesLithium iron phosphate

The invention provides a lithium iron phosphate / lithium vanadium phosphate / carbon composite positive electrode material and a preparation method thereof, the molecular formula of which is (1-x)LiFePO 4 ·xLiVPO 4 F / C, where x=5-40wt%, and the mass fraction of C in the composite cathode material is 0.5-2.0wt%. The present invention first synthesizes lithium iron phosphate, and then synthesizes VPO 4 Intermediate, finally lithium iron phosphate, VPO 4 The intermediate is mixed with other raw materials for the synthesis of lithium vanadium phosphate, and then pressed and sintered to ensure that there is no heterophase formation of lithium vanadium phosphate in the composite material, and a composite structure with a dual-phase lithium intercalation active material is formed in the composite material to stabilize phosphoric acid The surface properties of iron-lithium materials can improve the surface / interface diffusion capacity of lithium ions and the transport rate of electrons, and improve their rate performance and cycle performance without sacrificing energy density.

Owner:宜宾天原锂电新材有限公司

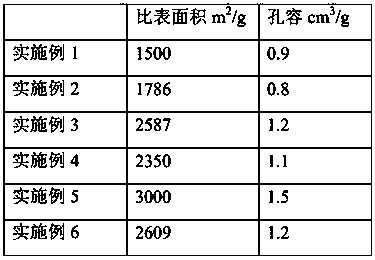

Device for preparing super-capacitor activated carbon by alkali activation method and preparation method thereof

The invention discloses a device for preparing super-capacitor activated carbon by an alkali activation method and a preparation method of the super-capacitor activated carbon. A preparation method ofsuper-capacitor activated carbon belongs to the technical field of super-capacitor carbon preparation, and comprises the following steps: uniformly mixing a carbonized material and an activator, adding into a feeding unit, reacting in a furnace body, conveying through a driving unit to obtain an activated material, washing and drying the activated material to obtain the super-capacitor activatedcarbon. The invention has the following advantages: 1, the wedge-shaped paddle stirring shaft in the furnace body can make the carbonized material and the activator mixed more uniformly, thereby ensuring the batch stability of the product; 2, the relative movement of the material particles in the furnace body and the wedge-shaped surface generates a washing effect, materials attached to the wedge-shaped surface can be washed off, and the wedge-shaped blades have a self-cleaning function, so that the materials are prevented from being adhered to the stirring shaft of the wedge-shaped blades, the materials are prevented from being adhered to the furnace wall, normal discharge in the activation process is ensured, and continuous production of activation is realized.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

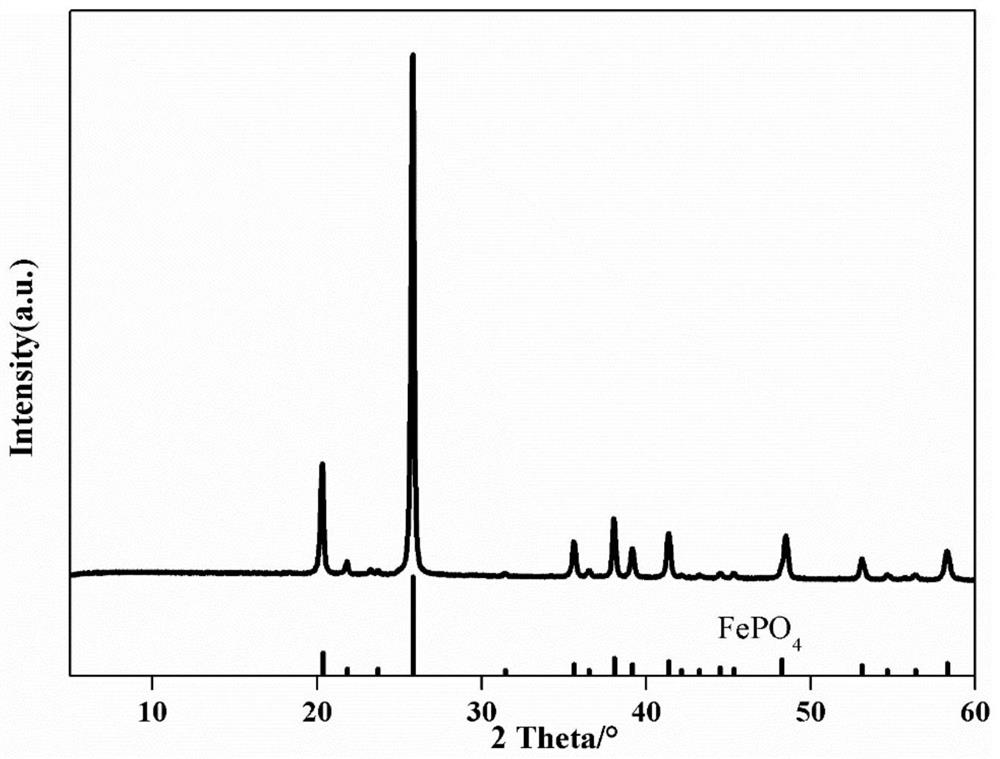

A method for preparing olivine-type lithium iron phosphate cathode material

ActiveCN108011102BConvenient quality controlDoes not change the synthesis processPhosphatesCell electrodesElectrical batteryLithium-ion battery

The invention relates to a method for preparing an olivine type lithium iron phosphate positive electrode material, and belongs to the technical field of lithium ion battery electrode materials. The method comprises the steps: at room temperature, adding water to lithium carbonate, anhydrous iron phosphate and a carbon source and carrying out ball milling mixing, wherein the solid content is 30-70%, the molar ratio of Li to Fe to P is x to 1 to 1, 1<=x<=1.05, anhydrous iron phosphate is a mixed phase of monoclinal structure iron phosphate and tripartite structure iron phosphate with the molarratio of y:(1-y) or a mixed phase of hexagonal structure iron phosphate and tripartite structure iron phosphate with the molar ratio of y:(1-y), and 0<=y<=0.8; and after the ball-milled material is dried, sintering in a nitrogen atmosphere to obtain the olivine type lithium iron phosphate positive electrode material. The invention provides the method comprising that anhydrous iron phosphate havingspecific crystal structure is used as a raw material for preparing lithium iron phosphate, so as to further optimize the synthesis and performance of LiFePO4.

Owner:KUNMING UNIV OF SCI & TECH

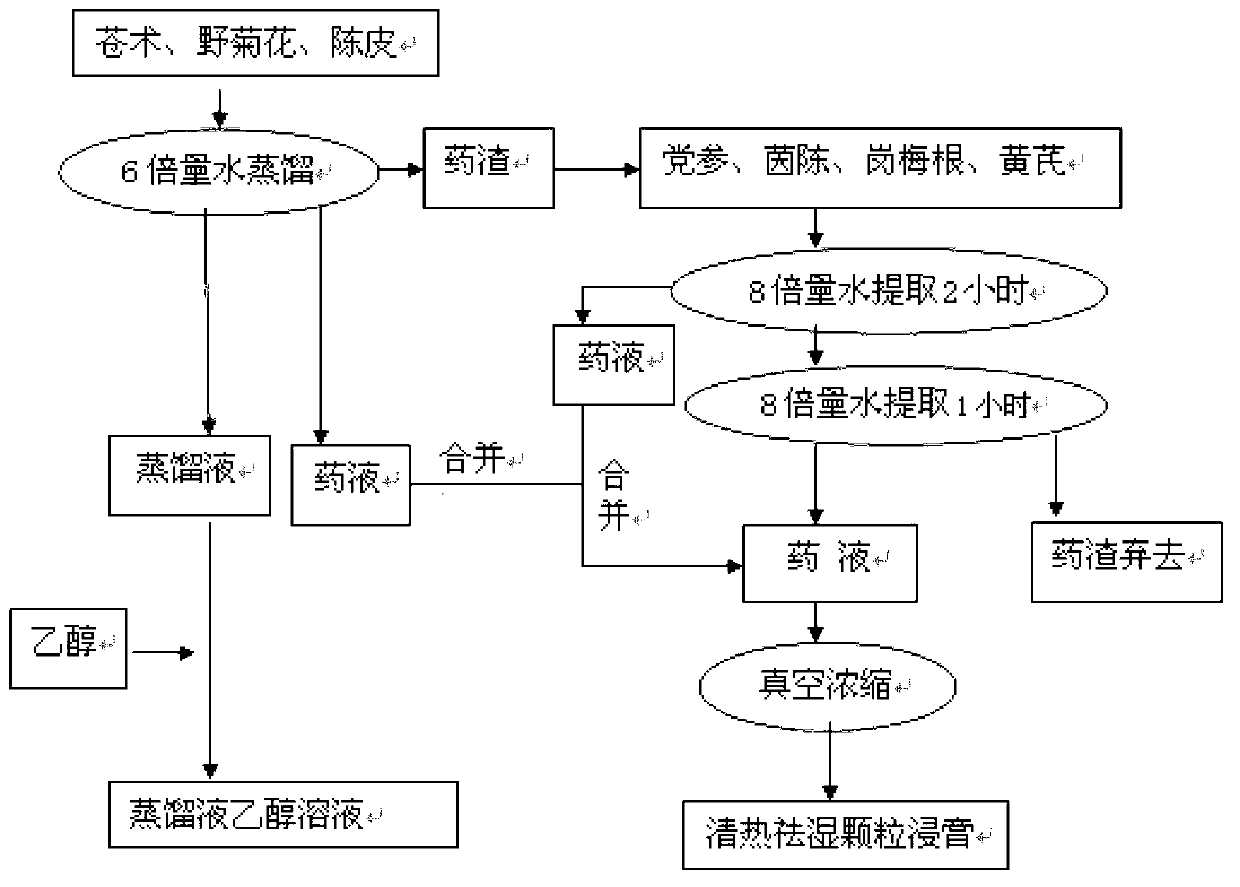

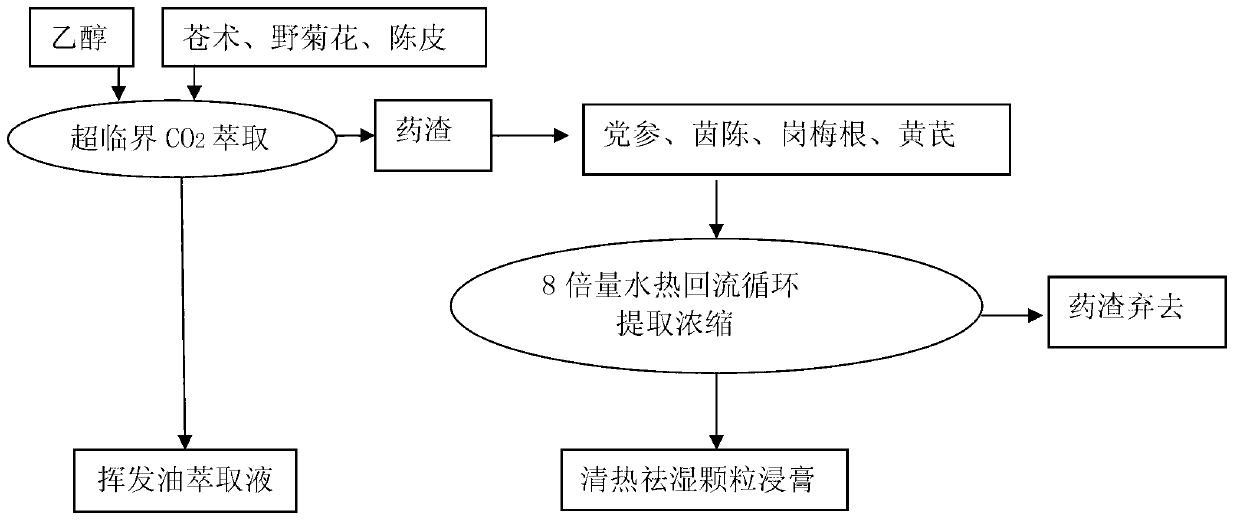

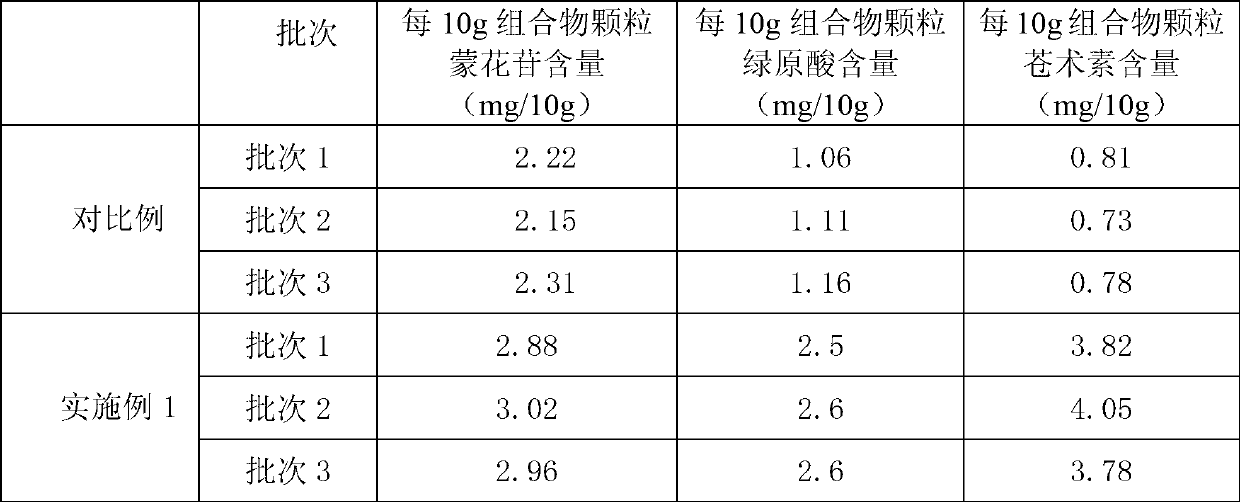

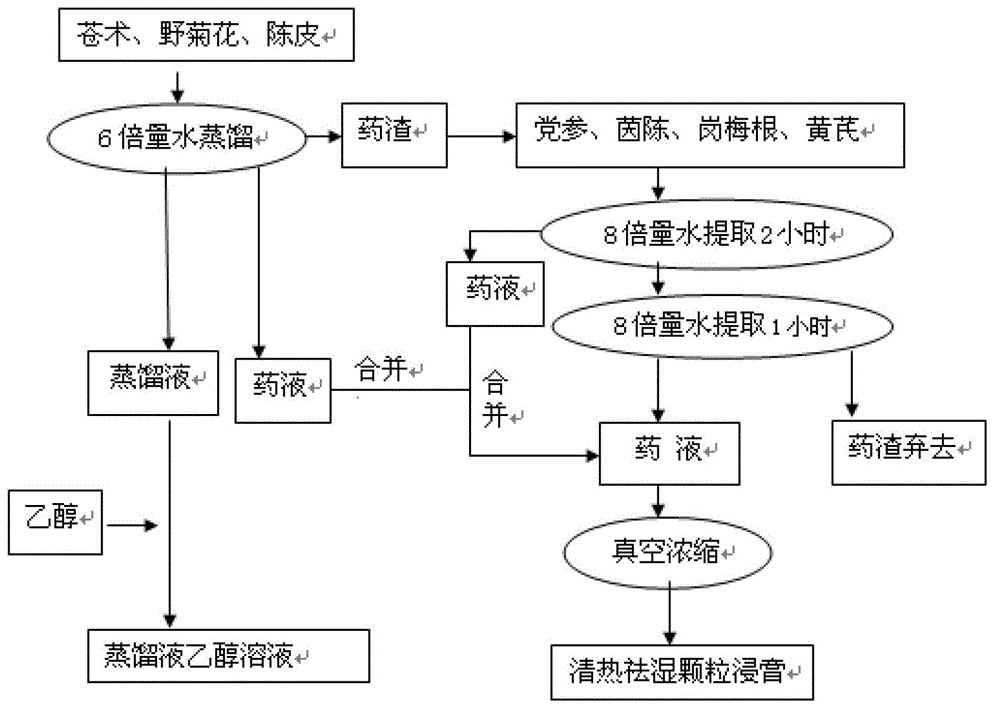

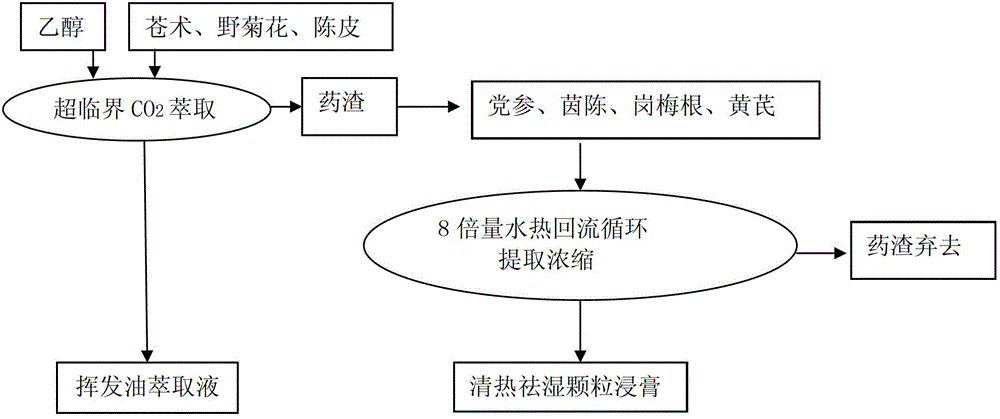

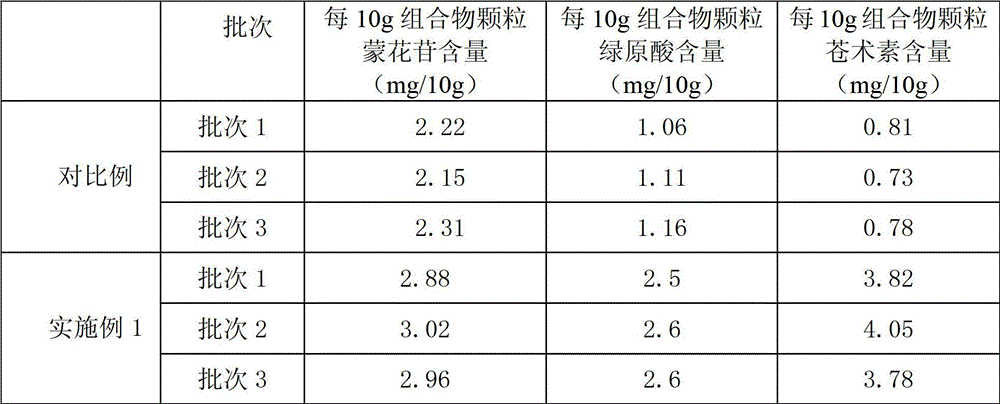

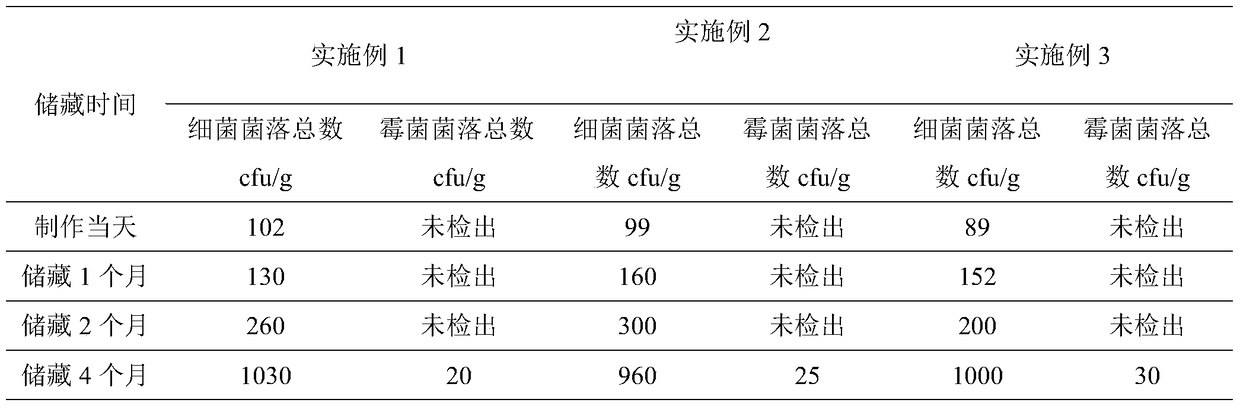

Traditional Chinese medicine composition particles for clearing heat and expelling damp, and preparation method thereof

ActiveCN102973697BHigh extraction rateHigh dissolution rateDigestive systemPlant ingredientsProcess engineeringWater soluble

The invention provides a preparation method of traditional Chinese medicine composition particles for clearing heat and expelling damp, and traditional Chinese medicine composition particles for clearing heat and expelling damp prepared by the method. The preparation method comprises the following steps of: extracting volatile oil by a supercritical extraction method, extracting concentrated water-soluble active ingredients in a recycling way by means of thermal reflow, and further preparing the composition particles by utilizing the prepared condensed extract. The preparation method provided by the invention has the characteristics of being high in extraction efficiency, short in technological process, mild in preparation conditions, and less in energy consumption. The prepared traditional Chinese medicine composition particles for clearing heat and expelling damp is high in active ingredient content.

Owner:TEYI PHARMACEUTICAL GROUP CO LTD

Preparation method of carboxyl magnetic beads for magnetic particle chemiluminescence immunoassay reagent

ActiveCN106215821BReduce lossesUniform particle sizePermanent magnetsMicroballoon preparationCross-linkMicrosphere

The invention discloses a method for preparing carboxyl magnetic beads for a magnetic particle chemiluminescence immune assay reagent. The method comprises the following steps: S1, preparing Fe3O4 nanometer magnetic microspheres; S2, preparing silica magnetic microspheres; S3, aminating the magnetic microspheres; S4, preparing carboxyl magnetic beads; S5, performing magnetic field response screening on the prepared carboxyl magnetic beads. The carboxyl magnetic beads prepared by the method provided by the invention have uniform magnetic field responsiveness, and the magnetic microspheres are cheap and readily available in raw material, simple in equipment, easy to control, high in process repeatability, stable in product quality, safe and reliable in operation, uniform in magnetic field responsiveness and easy for large-scale production. According to the invention, the activating rate and the coupling rate of the magnetic beads can be well controlled in the preparation of immunomagnetic beads, the risk of cross-linking the magnetic beads is reduced, and the stability of batches of magnetic bead coupling is guaranteed.

Owner:JIANGSU ZECEN BIOTECH CO LTD

Traditional Chinese medicine composition particles for clearing heat and expelling damp, and preparation method thereof

ActiveCN102973697AHigh extraction rateHigh dissolution rateDigestive systemPlant ingredientsWater solubleBULK ACTIVE INGREDIENT

The invention provides a preparation method of traditional Chinese medicine composition particles for clearing heat and expelling damp, and traditional Chinese medicine composition particles for clearing heat and expelling damp prepared by the method. The preparation method comprises the following steps of: extracting volatile oil by a supercritical extraction method, extracting concentrated water-soluble active ingredients in a recycling way by means of thermal reflow, and further preparing the composition particles by utilizing the prepared condensed extract. The preparation method provided by the invention has the characteristics of being high in extraction efficiency, short in technological process, mild in preparation conditions, and less in energy consumption. The prepared traditional Chinese medicine composition particles for clearing heat and expelling damp is high in active ingredient content.

Owner:TEYI PHARMACEUTICAL GROUP CO LTD

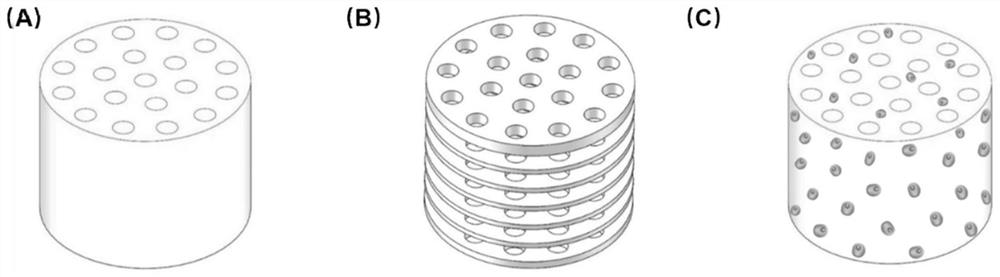

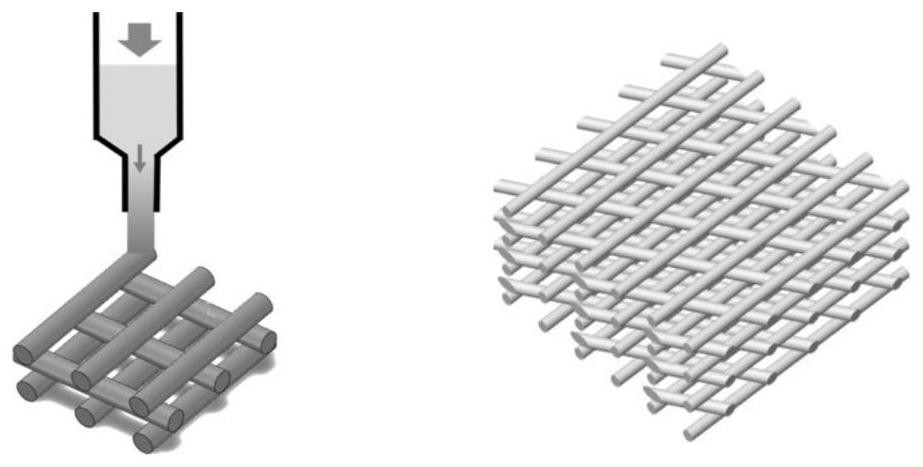

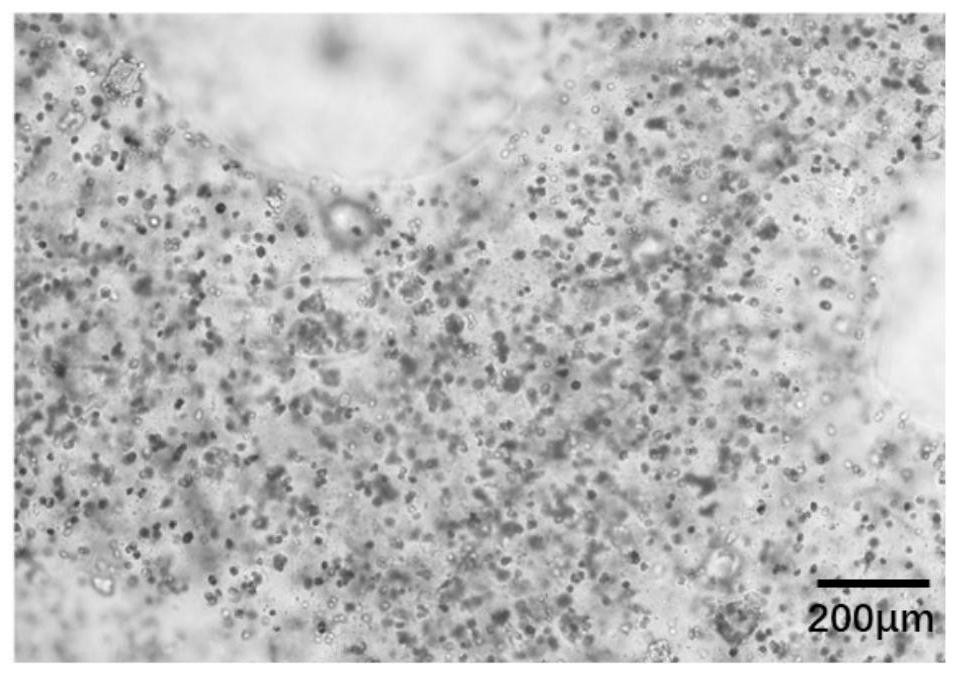

Liver tissue-like structural body as well as preparation method and application thereof

PendingCN114381420AMaintain normal physiological functionHighly biomimetic detoxificationHepatocytesCulture processCell phenotypeDisease

The invention provides a liver-like tissue structure as well as a preparation method and application thereof. The cell phenotypes in the liver tissue-like structural body are highly consistent, and are uniformly dispersed in the whole structure in the form of small-size cell clusters. The liver tissue has a highly bionic physiological function, not only positively expresses symbolic genes and proteins of mature liver tissues, but also has higher physiological functions of albumin secretion, nitrogen metabolism, urea synthesis, detoxification, drug metabolism and the like. According to the preparation method of the liver tissue-like structural body, cells from various sources can be adopted, and customized design and batch production can be realized according to requirements. The liver tissue-like structural body disclosed by the invention is a liver model with wide application, and is used in the fields of liver tissue development research, liver tissue regeneration research, liver disease occurrence and development research, preclinical drug detection, new drug test and development, drug toxicology research and the like.

Owner:TSINGHUA UNIV

A kind of plant stem cell active ingredient and preparation method thereof

ActiveCN109528620BHigh activityImprove anti-aging effectCosmetic preparationsHair cosmeticsBiotechnologyPlant stem

The invention relates to a preparation method of active ingredients of plant stem cells. Plant stem cells in a vigorous growth state are frozen within 20 to 30 minutes under the condition of -20 to -10°C, maintained in the frozen state for 1 to 5 hours, and then frozen at 26 Thawing is carried out under the condition of ~30° C., and the obtained liquid is the active ingredient of the plant stem cells. The extract prepared by the method of the present invention can improve the metabolic mechanism of the skin, can adjust the skin without penetrating into the skin, has high safety, and exhibits significant effects in anti-aging and anti-hair loss, and has Wide application prospects. Moreover, the cultivation method of the present invention has high controllability and can ensure the batch stability of the product.

Owner:东莞东芳漾生物科技有限公司

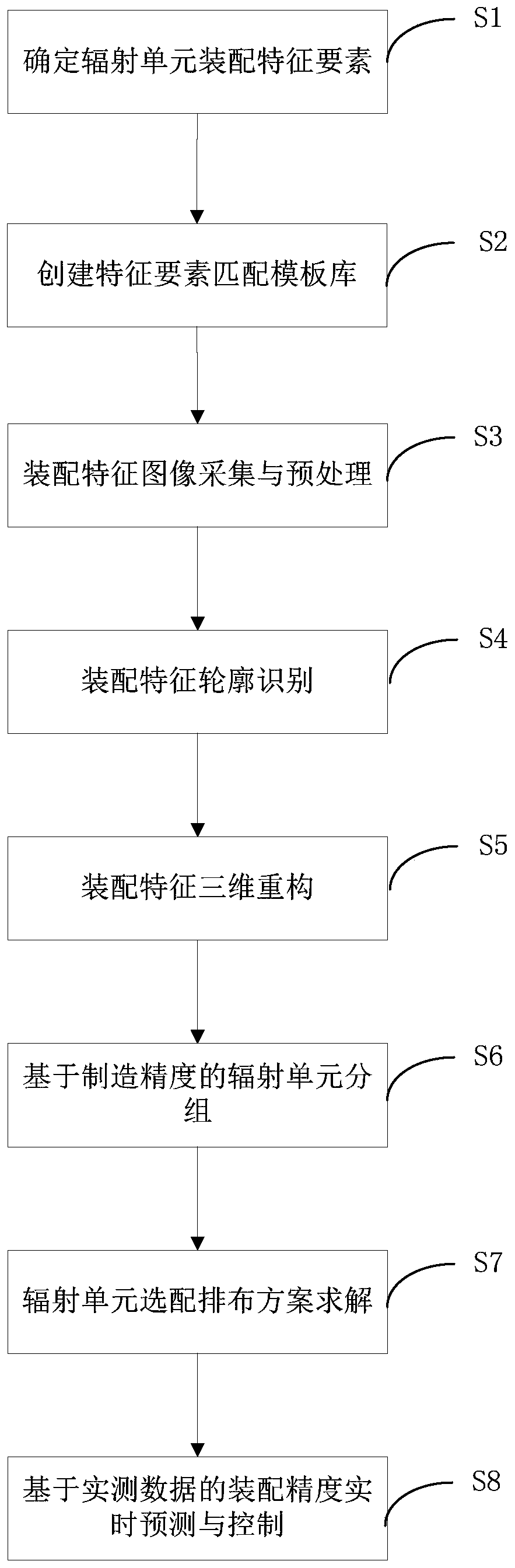

A rapid assembly method for a radiation unit with a special-shaped cavity

ActiveCN108039579BHigh precisionImprove consistencyAntenna arraysRadiating elements structural formsMechanical engineeringReal time prediction

The invention discloses a rapid assembling method of special-shaped cavity radiating units. The method is characterized by comprising the following steps that: S1, the assembling feature elements of radiating units are determined; S2, a feature element matching template library is created; S3, the images of assembling features are acquired and pre-processed; S4, the contours of the assembling features are recognized; S5, 3D reconstruction is performed for the assembling features; S6, the radiating units are grouped based on manufacturing precision; S7, the minimum variance of the selecting andmatching scheme of the radiating units is solved; and S8, assembling accuracy is predicted and controlled in real time based on actually measured data. With the rapid assembling method of the special-shaped cavity radiating units provided by the invention adopted, the accuracy and consistency of the assembling of the radiating units can be greatly improved; the batch stability of product qualitycan be ensured; the assembling features rapid measurement and assembling scheme automatic planning of the radiating units can be realized; assembling preparation cycles can be greatly reduced; an assembling process can be optimized automatically; the squeezing of the radiating units during an assembling process can be avoided; and repeated trail assembling and disassembling processes can be reduced.

Owner:BEIJING INST OF RADIO MEASUREMENT

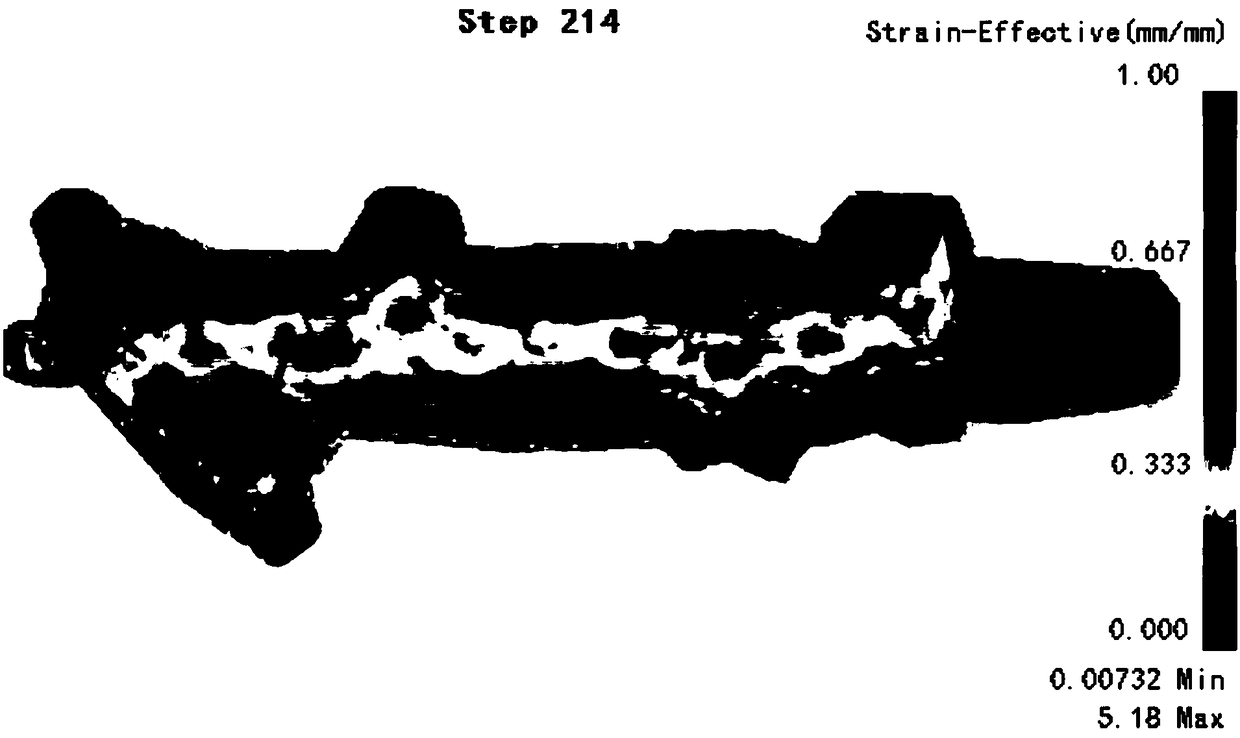

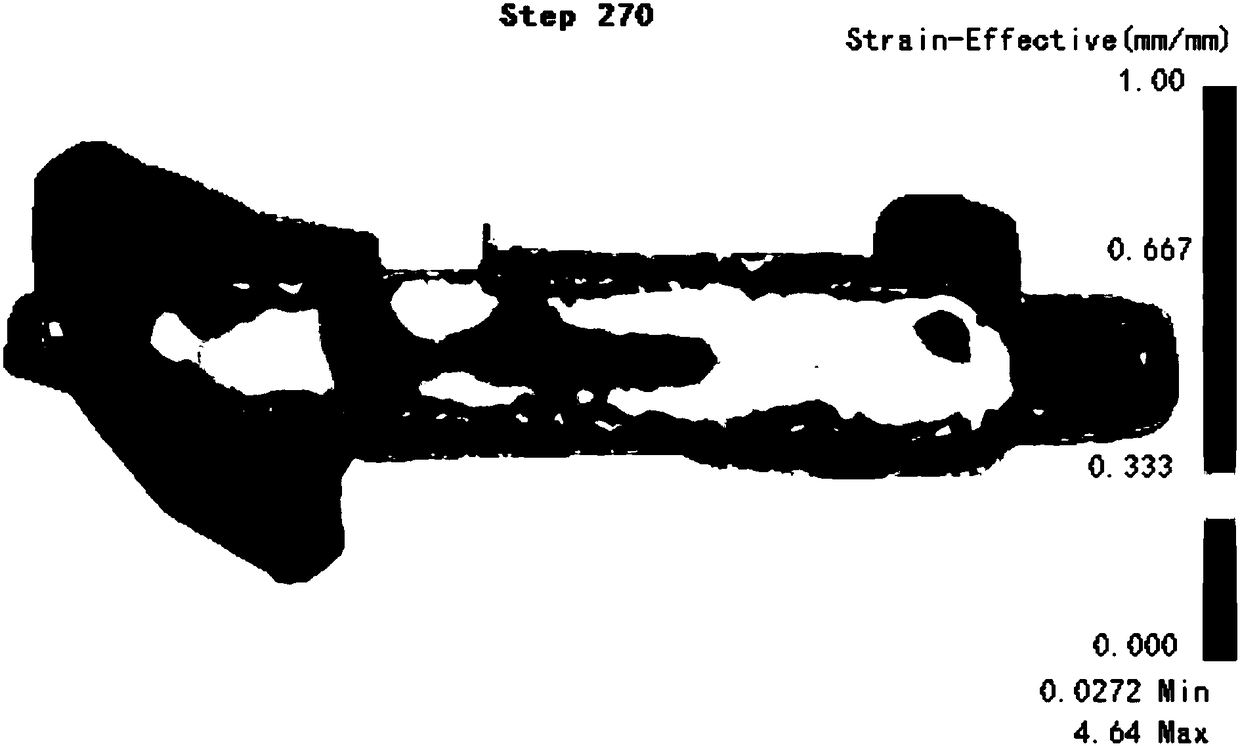

Forging method of a-100 steel die forging for aircraft landing gear and design method of pre-forging

ActiveCN108188338BGuaranteed batch stabilityStable batch supply and reliable guaranteeDomestic articlesAircraft landingDesign methods

The invention relates to the field of A-100 steel forging, and discloses a forging method of a large and complex die forging of A-100 steel and a design method of a pre-forging part thereof. The pre-forging part of the large and complex die forging of the A-100 steel adopts the design mode of a rhombic section of a rod portion, the deformation of a forging in the finish forging process can be increased to the maximum, and the deformation of the central portion of the rod portion of the forging can be >=25%; the grain size difference requirement of different positions of the forging is reducedto ensure that a grain grade differential grade of a finish forging is <=3; and meanwhile, the pre-forging part is quickly positioned, the blank in the forging process is prevented from tilting, and the filling of the forging is ensured.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

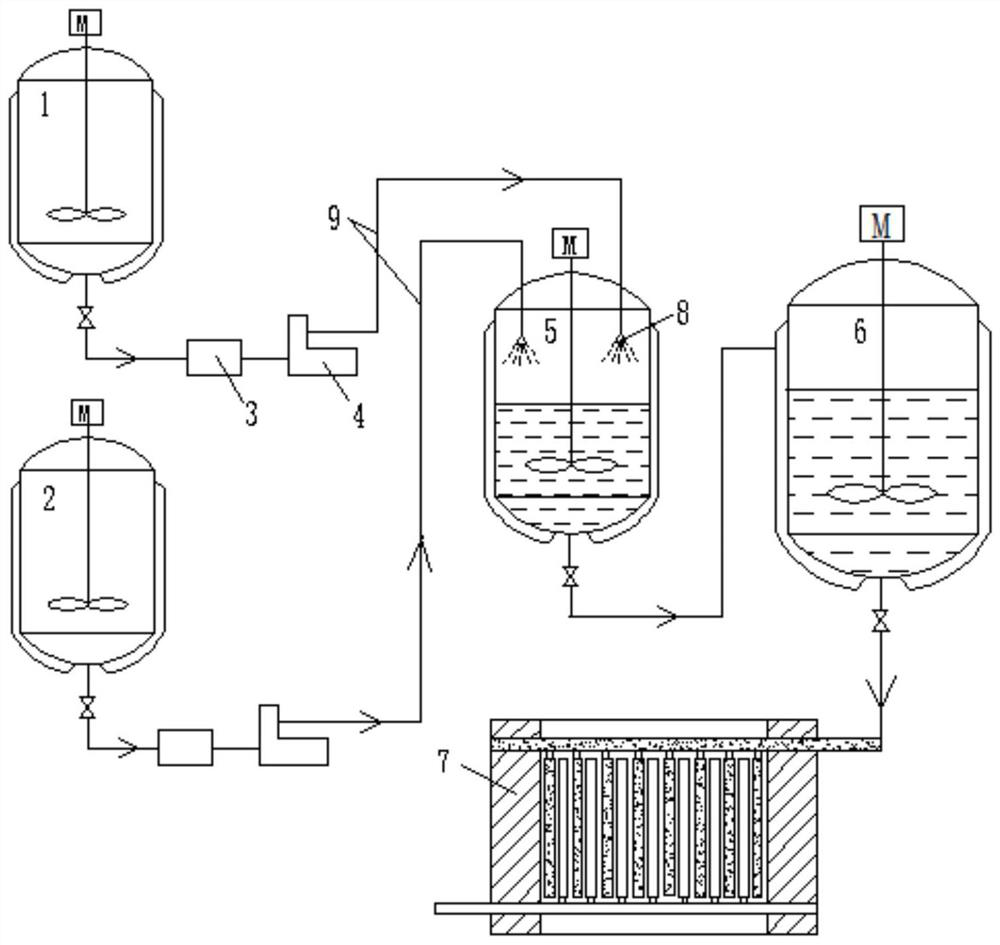

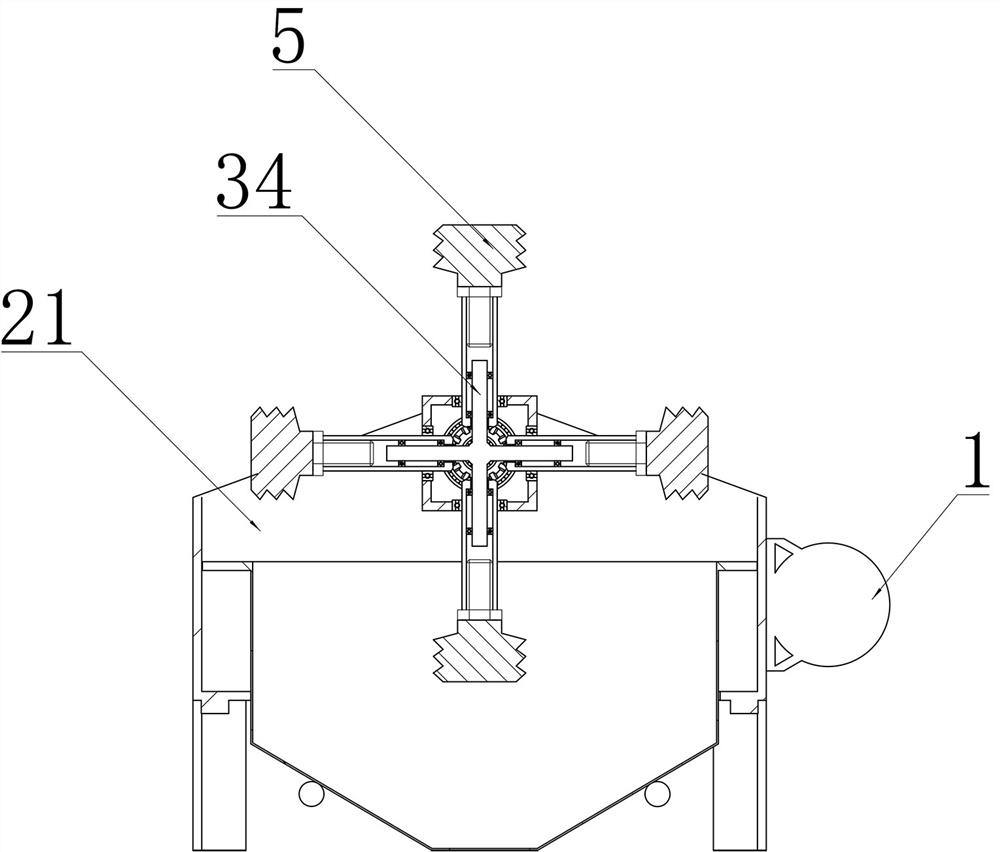

A preparation method and production device of battery-grade iron phosphate

ActiveCN108117055BGuaranteed batch stabilityImprove securityPhosphorus compoundsIron saltsElectrical battery

A method for preparing battery-grade iron phosphate, comprising the following steps: preparing an iron salt solution, preparing a phosphorus source solution, and performing an oxidation precipitation reaction; the reacted feed liquid is filtered through a plate and frame; the filter cake is washed and sintered to finally obtain an iron phosphate product . The production device includes an iron salt storage tank, a phosphate storage tank, a reaction kettle, a retention kettle and a plate frame, and the iron salt storage tank and the phosphate storage tank are respectively connected to the top of the reaction kettle through a feeding pipeline. Connected to the board and frame in turn. The above preparation process adopts a continuous feeding and discharging production device, so that the oxidation precipitation reaction is in a state of dynamic equilibrium, the reaction time is short, the quality of the produced iron phosphate is stable, and the particle size is controllable, realizing the continuous industrial production of iron phosphate.

Owner:山东彩客新材料有限公司 +1

A kind of polyvinyl butyral synthesis process based on microdispersion technology

Owner:TSINGHUA UNIV

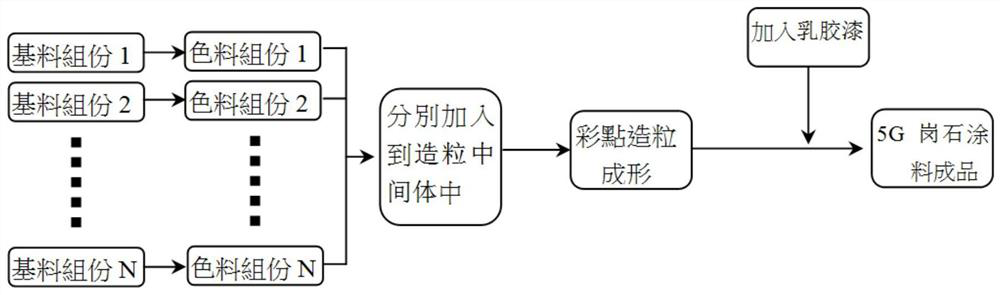

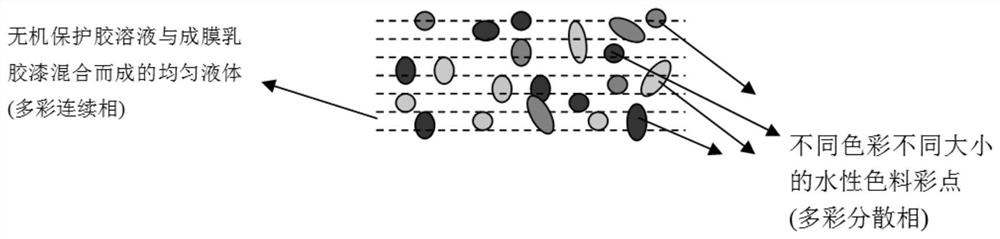

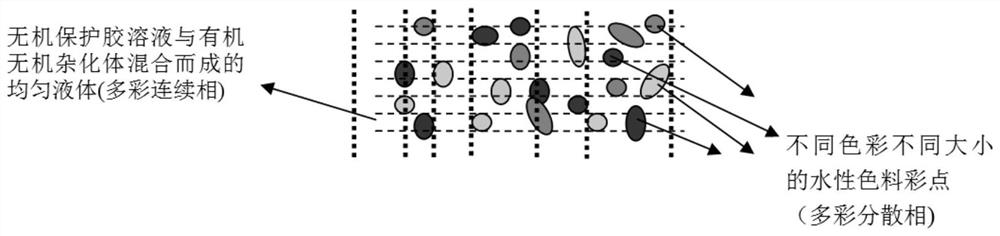

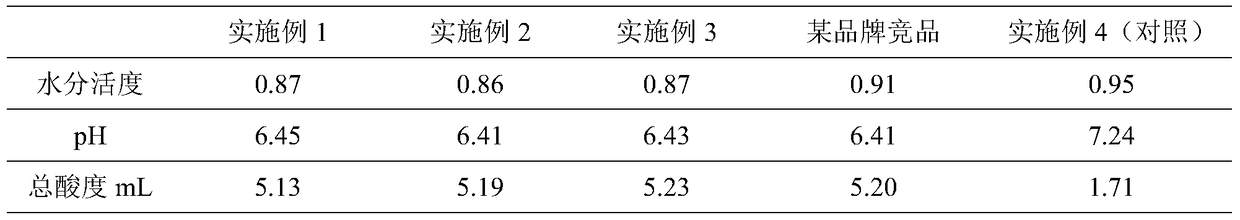

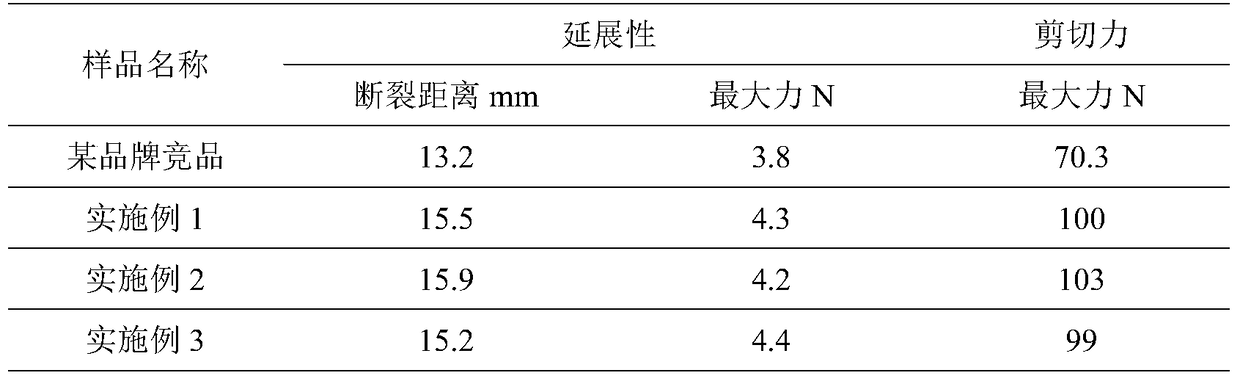

Water-based 5G agglomerated stone imitation coating and preparation method thereof

ActiveCN113881302AIncreased durability, crack resistance, and stain resistanceReduce water permeabilityAntifouling/underwater paintsPaints with biocidesPolymer scienceWeather resistance

The invention relates to a water-based 5G agglomerated stone imitation coating and a preparation method thereof. The coating is composed of a pigment part, a granulation intermediate with lubrication, isolation and protection functions, and latex paint with film forming and weather resistance. The preparation method comprises the following steps: (1) preparing base paint; (2) preparing a granulation intermediate; (3) preparing latex paint; and (4) preparing the water-based 5G agglomerated stone imitation coating: mixing the base paint with color paste for color mixing to form a pigment part, then coating the pigment part with the granulation intermediate, performing granulation through a screen under pressure, then adding the latex paint, conducting mechanical stirring and uniform blending, and conducting standing for reaction to obtain the water-based 5G agglomerated stone imitation coating. Compared with the prior art, the stone imitation coating is specially used for replacing a conventional stone imitation coating in appearance, is different from water-based colorful building paint in structural composition, is not higher than the conventional stone imitation coating in engineering price, and is superior to both stone-like paint and water-based colorful building paint in cost performance.

Owner:上海磐彩环保科技股份有限公司

A method of preparing microwave instant burritos using sourdough

ActiveCN105010463BGood dynamic fluid propertiesImprove the diffusion and dispersibilityBaking processesBakery productsBiotechnologyNutrition

The invention discloses a method for preparing a microwave instant taco through sour dough and belongs to the technical field of food production. According to the method, firstly, liquid sour dough paste fermented through lactobacillus plantarum is prepared; secondly, the sour dough is taken to prepare taco dough, and the taco is prepared through the steps of fermenting, cooking and the like. According to the taco prepared through the method, the product technology can be effectively simplified, the product cost can be reduced, the amount of chemical addition agents can be decreased, the taco can be stored at least for four months at the normal temperature, the shelf expiration date of the product is effectively prolonged, the aging speed of the product is reduced, and the taco has the advantages of being nutrient, health, easy to process and the like.

Owner:JIANGNAN UNIV

Feeding formula in a metal injection molding process and preparation process thereof

Owner:SHANGHAI 3S MIM TECH

Method for preparing olivine type lithium iron phosphate positive electrode material

ActiveCN108011102AConvenient quality controlDoes not change the synthesis processPhosphatesCell electrodesPhosphoric acidOlivine

The invention relates to a method for preparing an olivine type lithium iron phosphate positive electrode material, and belongs to the technical field of lithium ion battery electrode materials. The method comprises the steps: at room temperature, adding water to lithium carbonate, anhydrous iron phosphate and a carbon source and carrying out ball milling mixing, wherein the solid content is 30-70%, the molar ratio of Li to Fe to P is x to 1 to 1, 1<=x<=1.05, anhydrous iron phosphate is a mixed phase of monoclinal structure iron phosphate and tripartite structure iron phosphate with the molarratio of y:(1-y) or a mixed phase of hexagonal structure iron phosphate and tripartite structure iron phosphate with the molar ratio of y:(1-y), and 0<=y<=0.8; and after the ball-milled material is dried, sintering in a nitrogen atmosphere to obtain the olivine type lithium iron phosphate positive electrode material. The invention provides the method comprising that anhydrous iron phosphate havingspecific crystal structure is used as a raw material for preparing lithium iron phosphate, so as to further optimize the synthesis and performance of LiFePO4.

Owner:KUNMING UNIV OF SCI & TECH

Small insulator dip-coating device

PendingCN111790564ADip coating evenlyImprove adhesionLiquid surface applicatorsCoatingsMotor driveElectric machine

The invention provides a dip-coating device which is convenient to operate and stable and uniform in dip-coating layer, in particular to a small insulator dip-coating device which can be used in a transformer substation. The device comprises a protection frame, a motor fixedly connected to the protection frame, a transmission mechanism arranged at the upper end of the protection frame, a materialstorage tank arranged at the lower end of the protection frame, a lifting mechanism for driving the material storage pool to ascend and descend, and an insulator fixedly connected to the transmissionmechanism; the motor drives the transmission mechanism to move; the protection frame comprises a vertically-through shell and supporting feet arranged at the lower end of the shell; the material storage tank is arranged in a cavity of the shell; and the transmission mechanism drives the insulator to rotate and revolve. The small insulator dip-coating device is simple in mechanical structure and few in power source, the production cost is greatly reduced, in addition, automation is achieved in the dip-coating process, manual operation is not needed, and the small insulator dip-coating device has the advantages of being convenient to operate and high in production efficiency.

Owner:HEBEI POWER TRANSMISSION & TRANSFORMATION +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com