Method for preparing multielement positive pole material for sodium-ion batteries

A technology for sodium ion batteries and cathode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of limited mixing uniformity of raw materials, long heat treatment time, high heat treatment temperature, etc., to ensure batch stability, Simple process and the effect of reducing synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

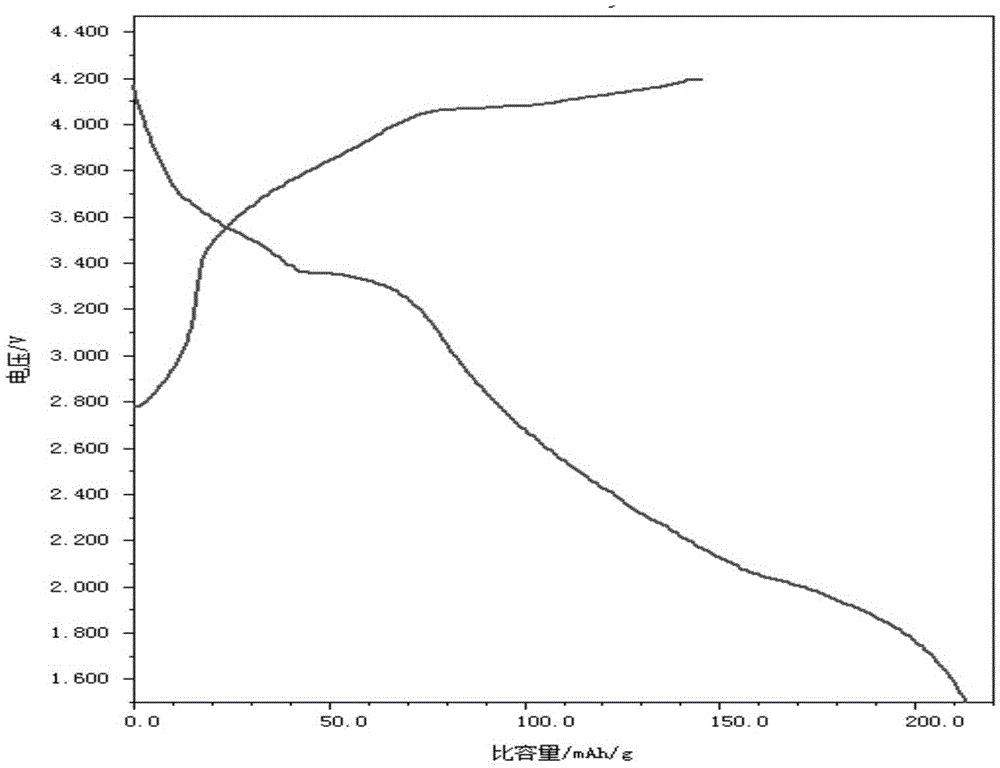

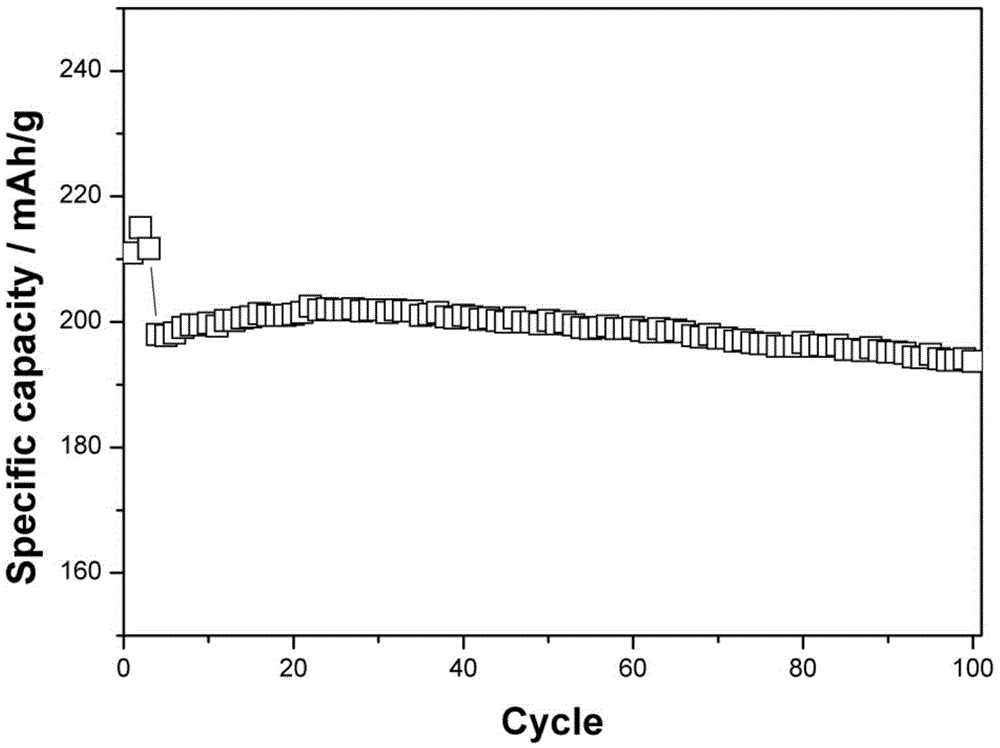

[0029] See attached figure 1 and figure 2 .

[0030] A preparation method for a sodium-ion battery multi-element positive electrode material, comprising the following process steps:

[0031] The multicomponent cathode material prepared in this example is Na 0.67 Ni 0.33 Fe 0.33 mn 0.34 o 2 . First, weigh nickel carbonate, ferrous oxalate, manganese carbonate and sodium sources according to the atomic ratio of the metals. Wherein the sodium source is a mixture of sodium hydroxide and sodium nitrate (sodium hydroxide: sodium nitrate=1:2). Put the weighed raw materials into a double-helix conical mixer, and mix them initially for 0.1h. The primary mixed raw materials are sprayed into the closed air tank through the Venturi nozzle, and the materials are collected by the cyclone dust collector. Put the mixed and activated raw material into a muffle furnace, raise it to 875°C at a speed of 15°C / min in an air atmosphere, keep it warm for 20 hours, and then cool it to room ...

Embodiment 2

[0033] A preparation method for a sodium-ion battery multi-element positive electrode material, comprising the following process steps:

[0034] The multicomponent cathode material prepared in this example is Na 0.67 Ni 0.5 Fe 0.2 mn 0.3 o 2 . First, weigh nickel acetate, iron nitrate, manganese acetate and sodium hydroxide according to the metal atomic ratio, put the weighed raw materials into a double-helix conical mixer, and mix them for 0.2 hours. The primary mixed raw materials are sprayed into the closed air tank through the Laval nozzle, and the materials are collected by the cyclone dust collector. Put the mixed and activated raw materials into a muffle furnace, raise it to 900°C at a rate of 20°C / min in an air atmosphere, keep it warm for 18 hours, and then cool it to room temperature at the same speed to obtain a high-performance multi-component cathode material Na 0.67 Ni 0.5 Fe 0.2 mn 0.3 o 2 . The discharge capacity of the button battery is 174.3mAh / g, ...

Embodiment 3

[0036] A preparation method for a sodium-ion battery multi-element positive electrode material, comprising the following process steps:

[0037] The multicomponent cathode material prepared in this example is Na 0.67 Ni 0.65 Fe 0.15 mn 0.2 o 2. First, weigh oxalic acid, ferrous oxalate, manganese oxalate and sodium carbonate according to the metal atomic ratio, put the weighed raw materials into a double-helix conical mixer, and mix them for 0.3 hours. The primary mixed raw materials are sprayed into the airtight tank through the high-pressure nozzle, and the materials are collected by the non-woven fabric collection bag. Put the mixed and activated raw materials into a muffle furnace, calcinate at 450°C for 2 hours in an air atmosphere, activate and mix with a high-speed air flow again after cooling, and then raise it to 950°C at a speed of 20°C / min in an oxygen atmosphere, and keep it for 15 hours. Then cool to room temperature at the same speed, and after jet milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com