Patents

Literature

268results about How to "Good electrochemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

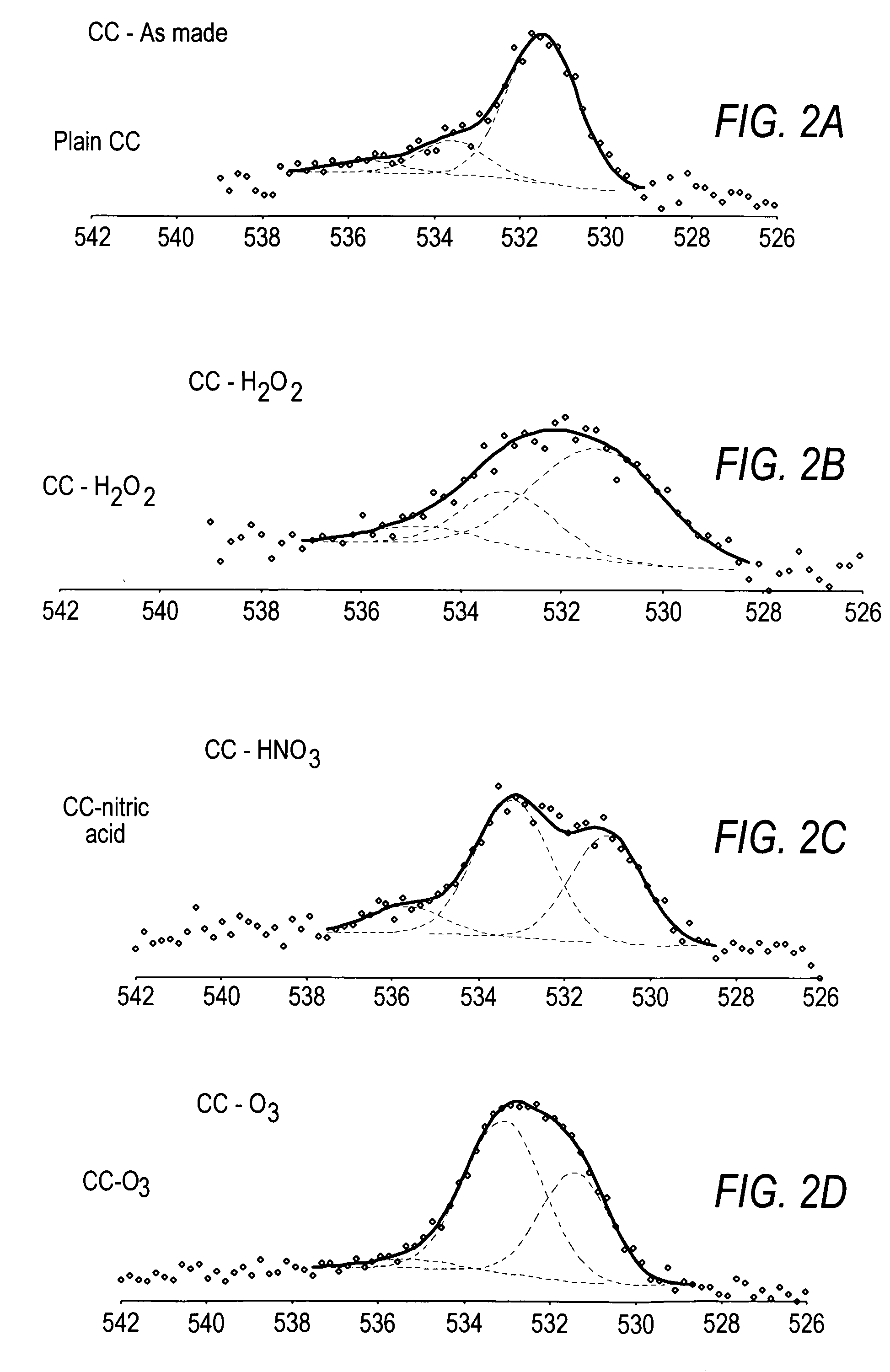

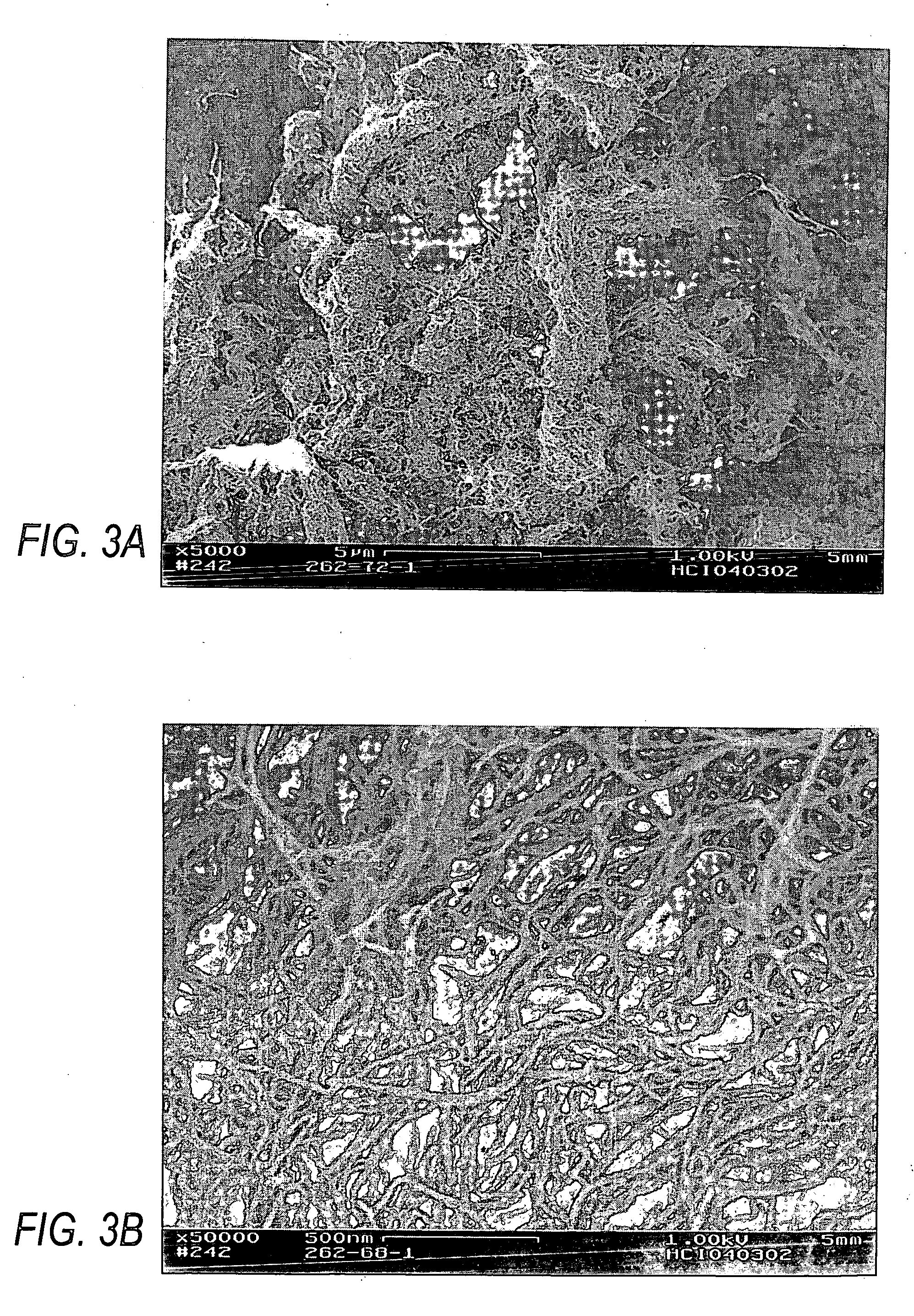

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20060239891A1Good electrochemical propertiesMaterial nanotechnologyHybrid capacitor electrodesMultiwalled carbonElectrochemistry

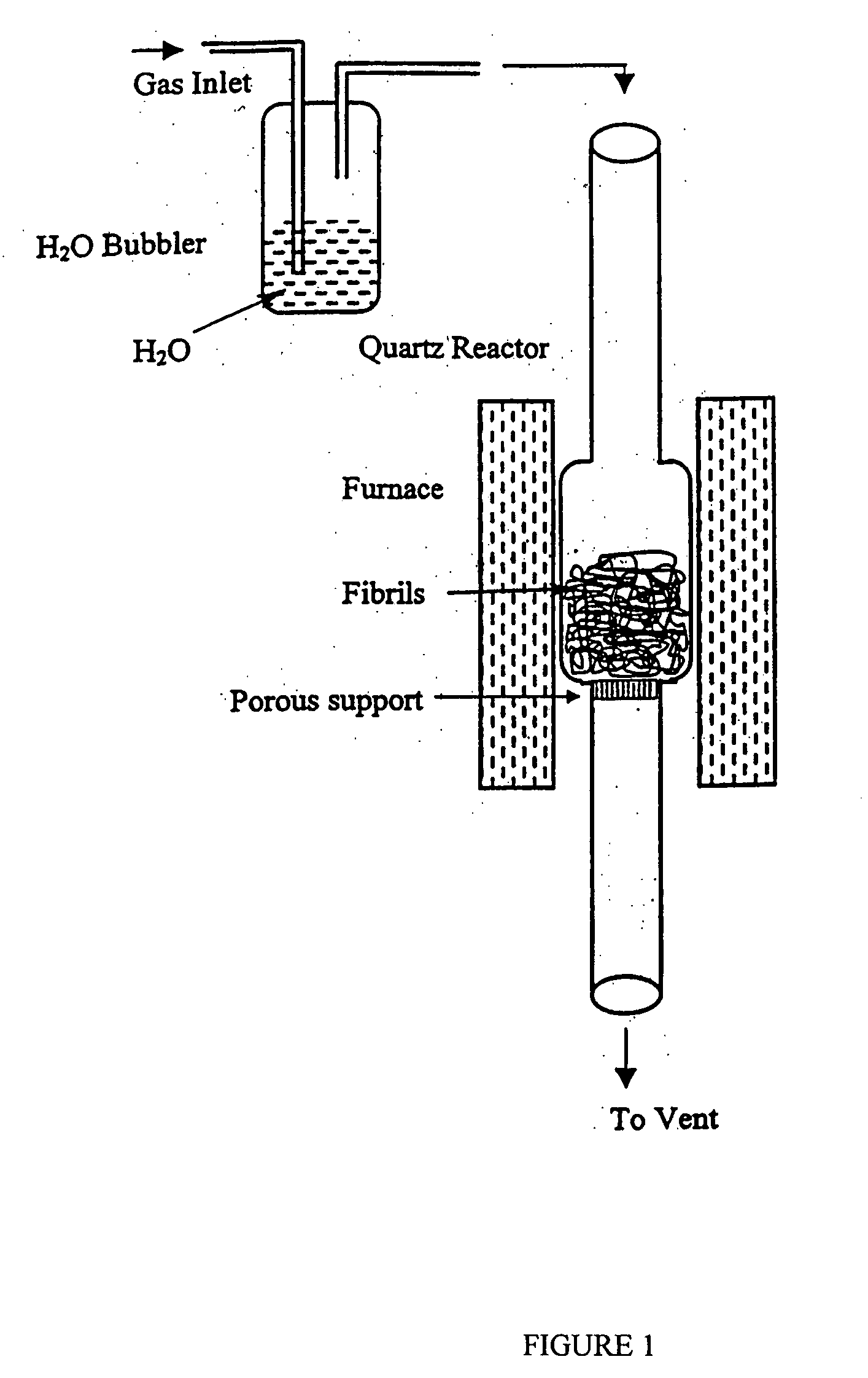

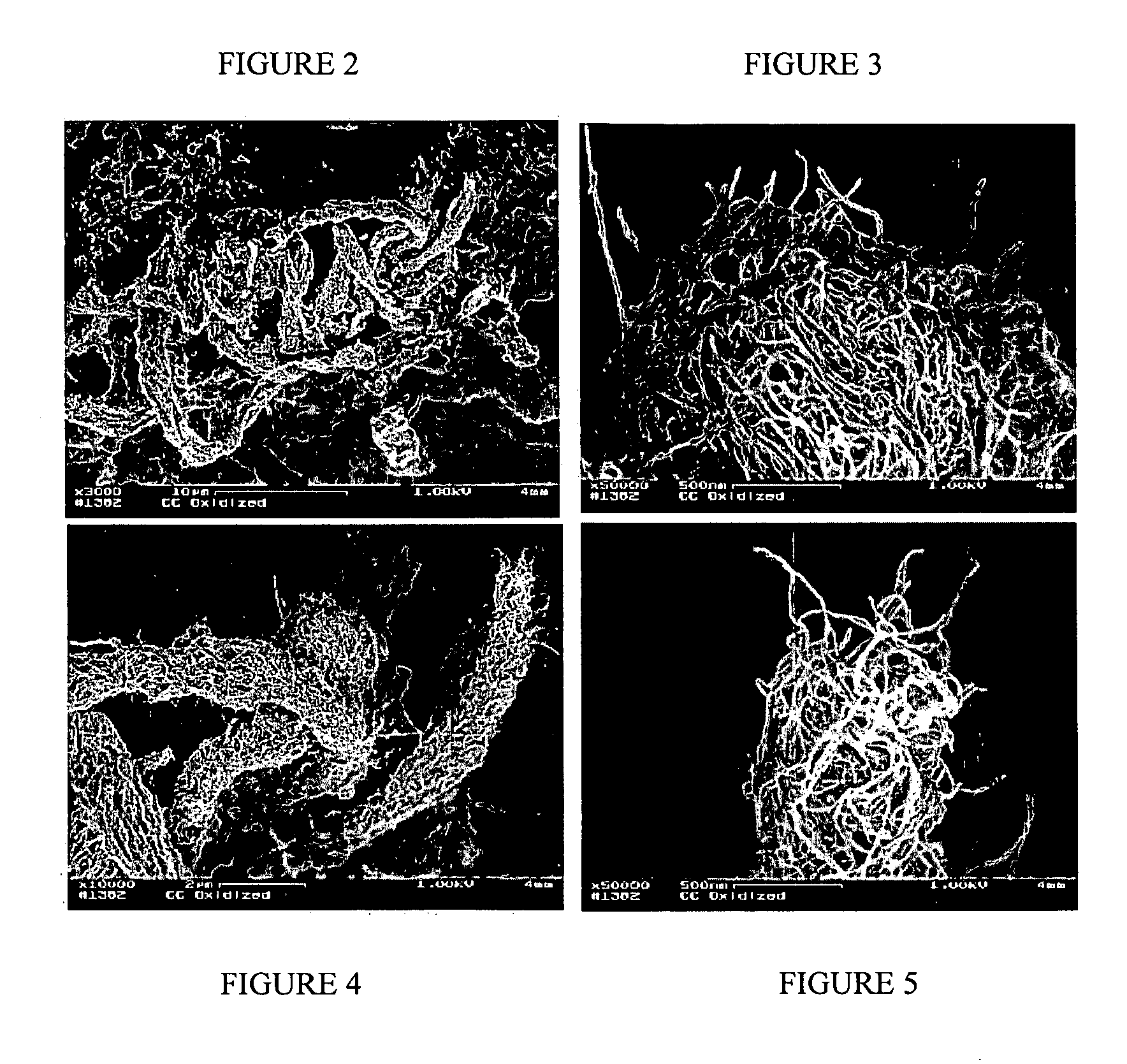

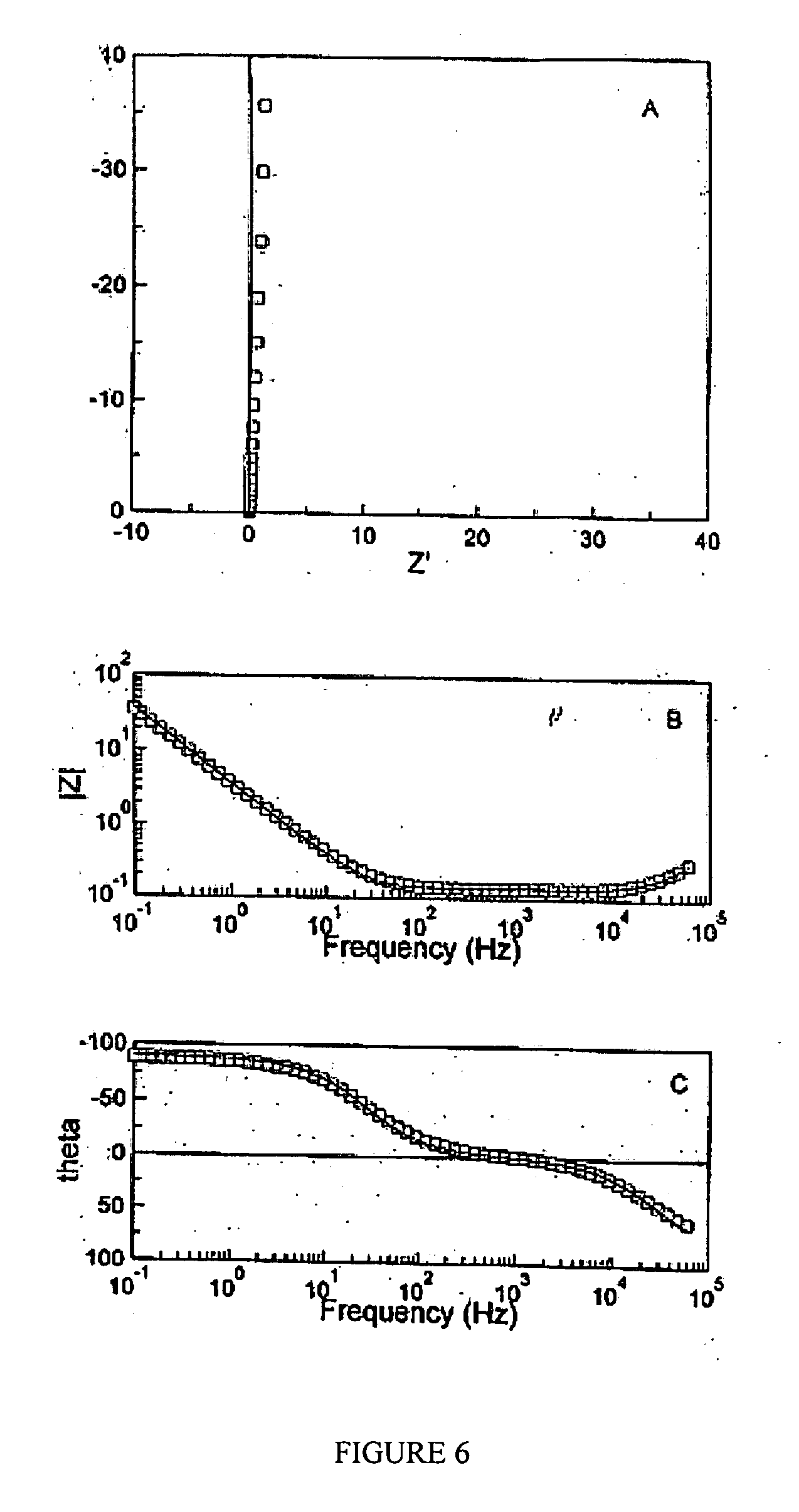

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

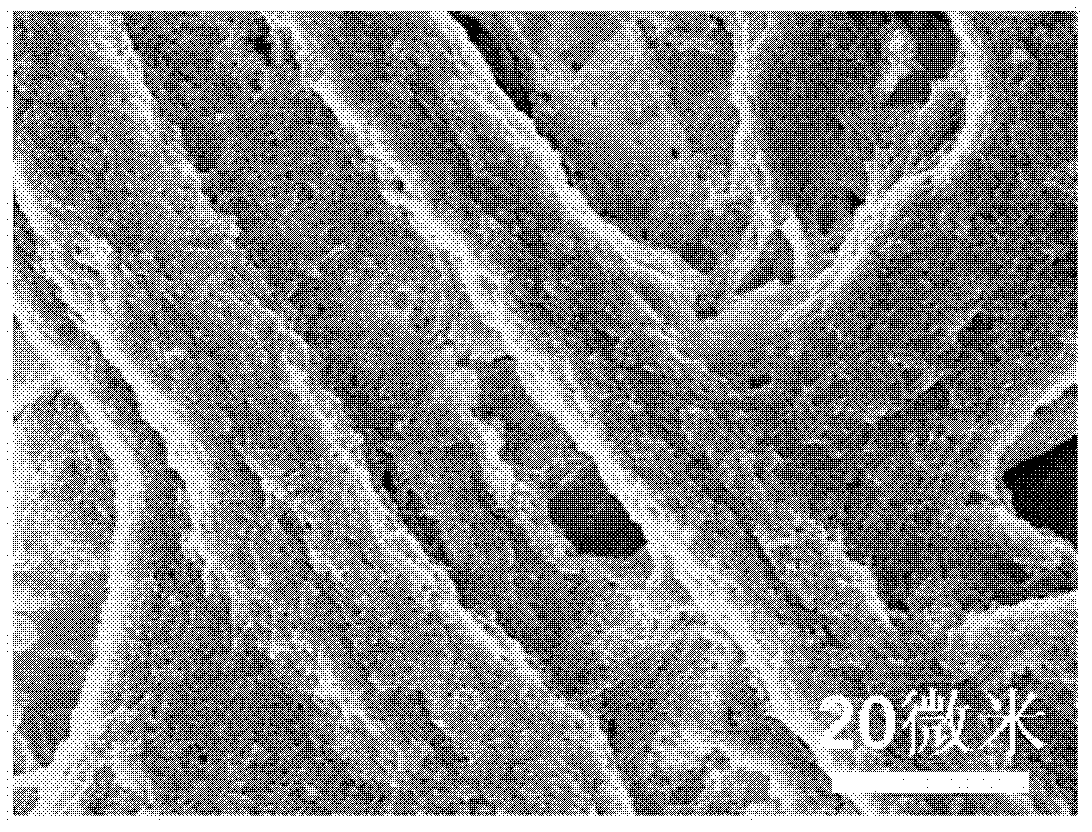

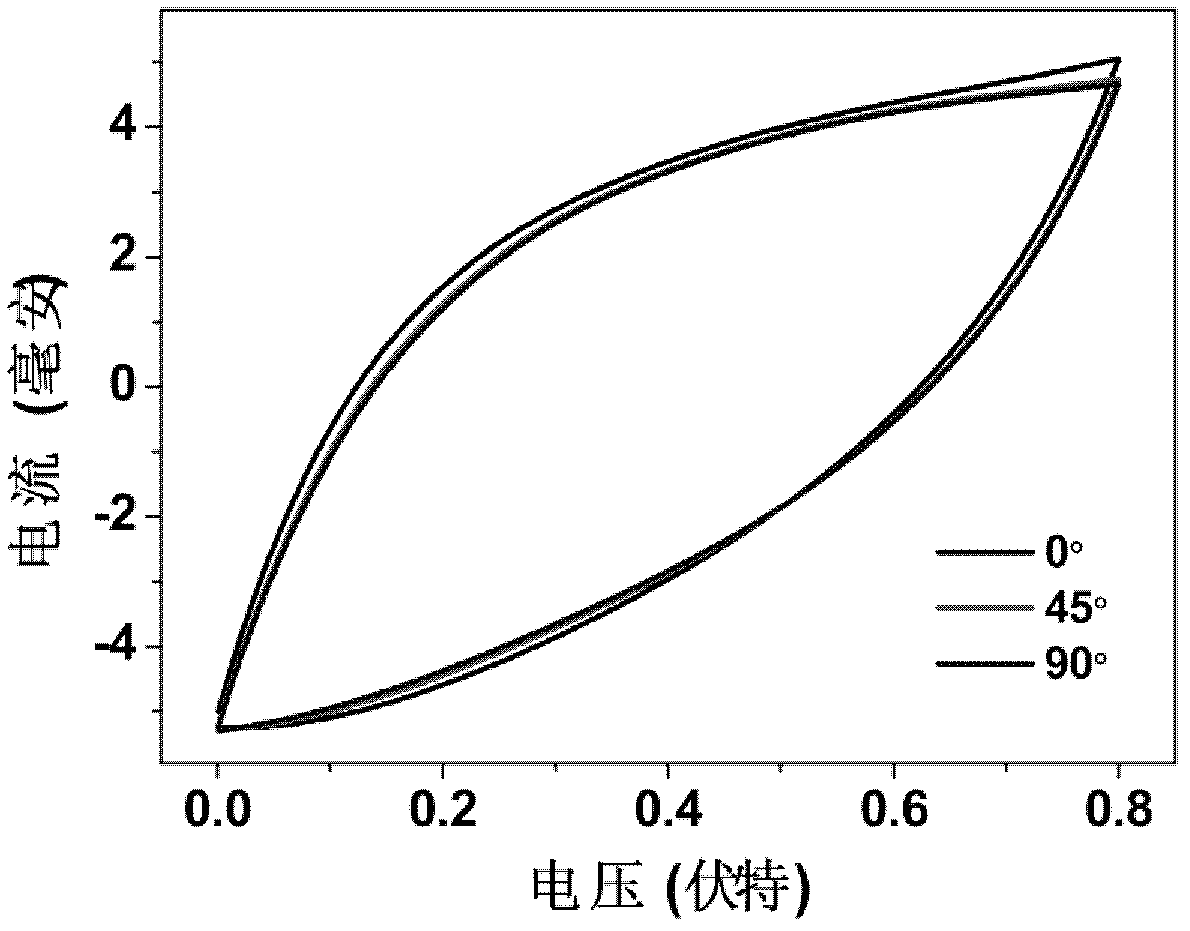

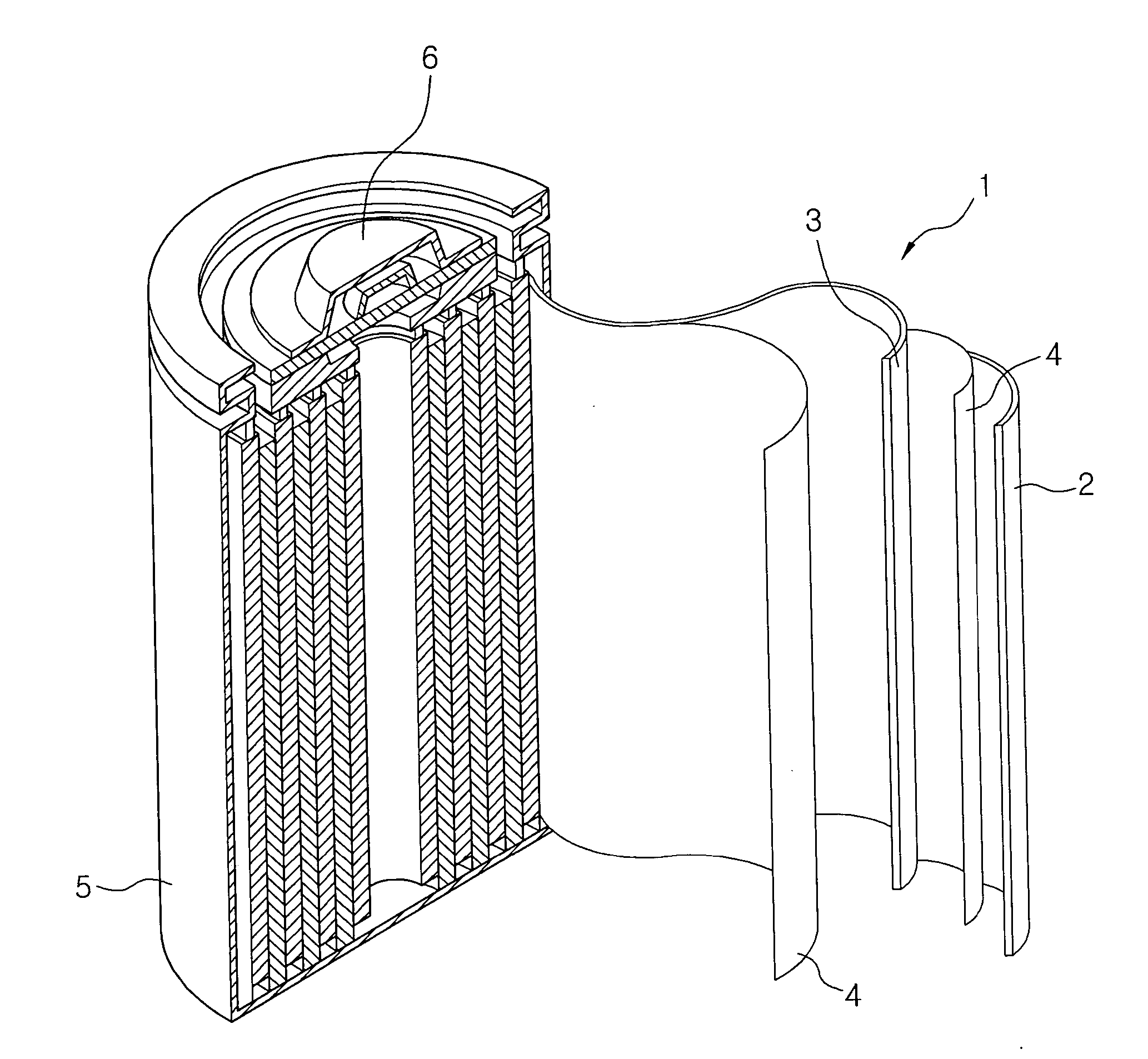

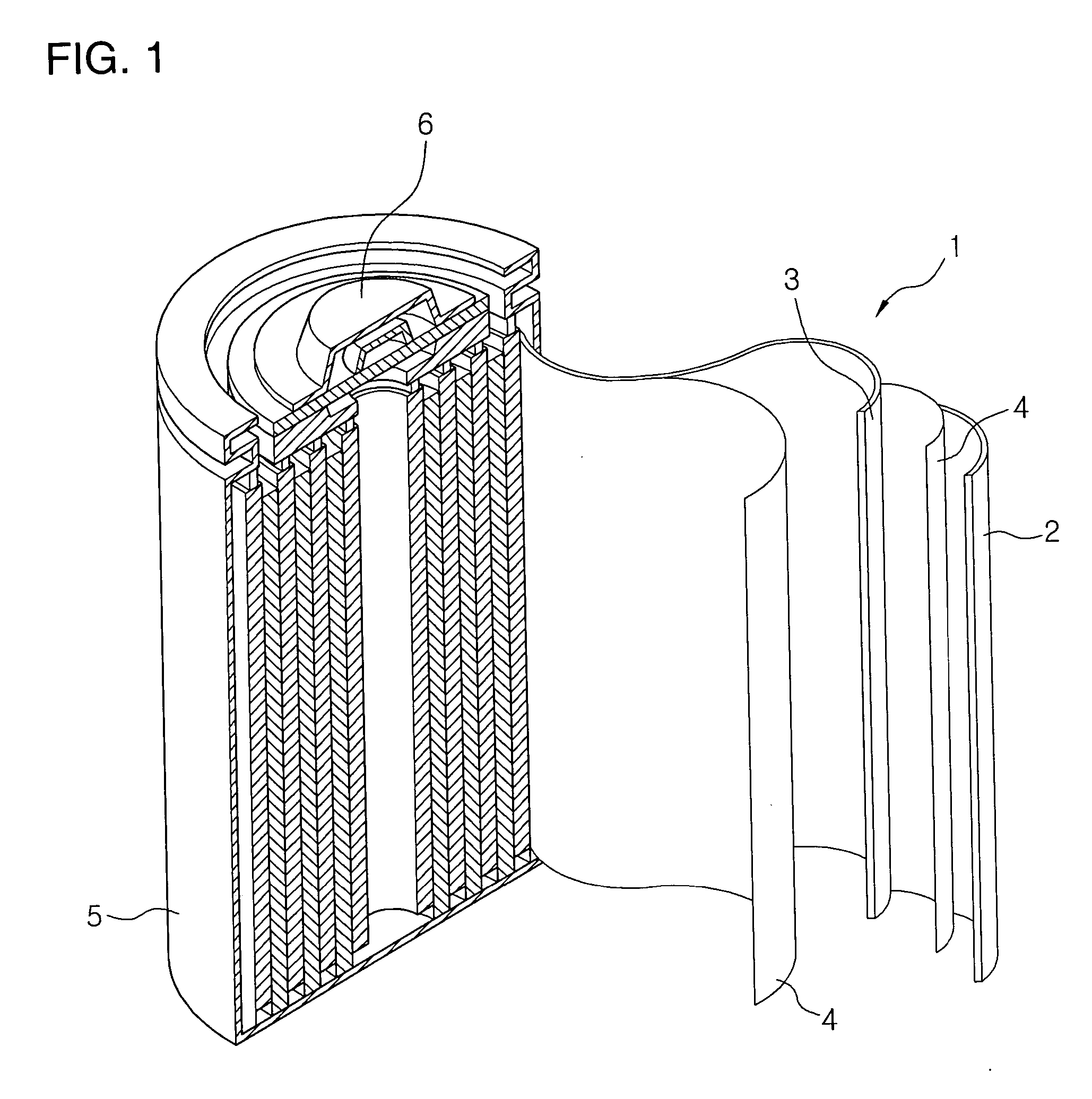

Preparation method of flexible super capacitor based on paper and application thereof

ActiveCN102568865AGood bendabilityGood electrochemical propertiesElectrolytic capacitorsHybrid capacitor electrodesEnergy managementOxide

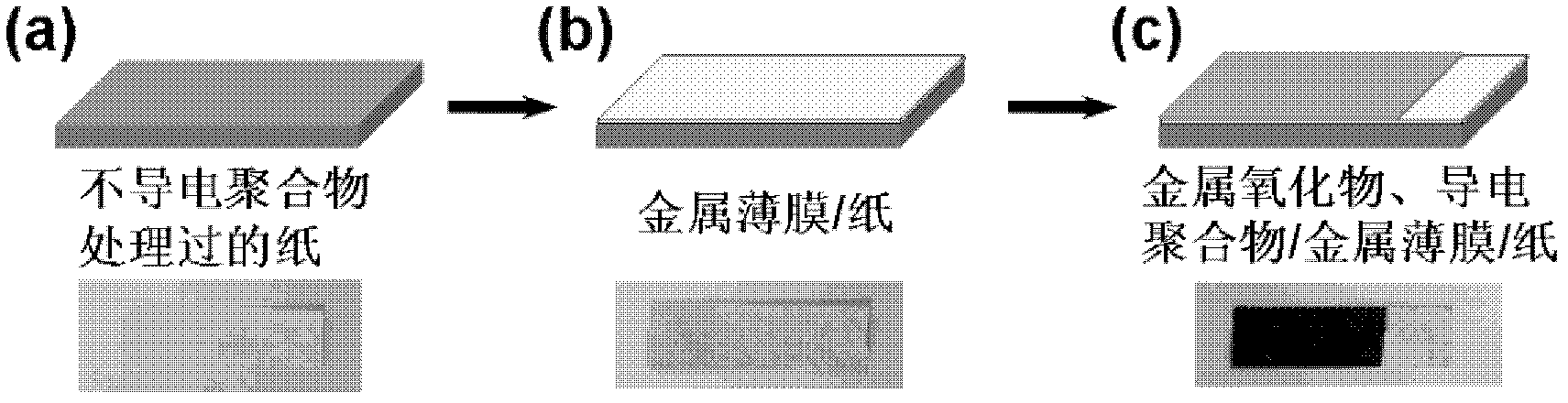

The invention discloses a preparation method of a flexible super capacitor based on paper and application thereof in a self-drive system. The preparation method concretely comprises the following steps: firstly depositing a layer of non-conductive polymer on the surface of the paper; secondly, depositing a metal membrane on the surface of the processed paper to form a flexible conductive paper substrate; thirdly, preparing a metal oxide or a conductive polymer on the conductive substrate to form an electrode material; and finally, assembling two electrode materials by adopting a solid electrolyte to form a super capacitor. The flexible full-solid super capacitor prepared by the method has good bending property and electrochemical properties and has good application prospect in the aspects of energy storage and energy management, especially in the self-drive system.

Owner:HUAZHONG UNIV OF SCI & TECH

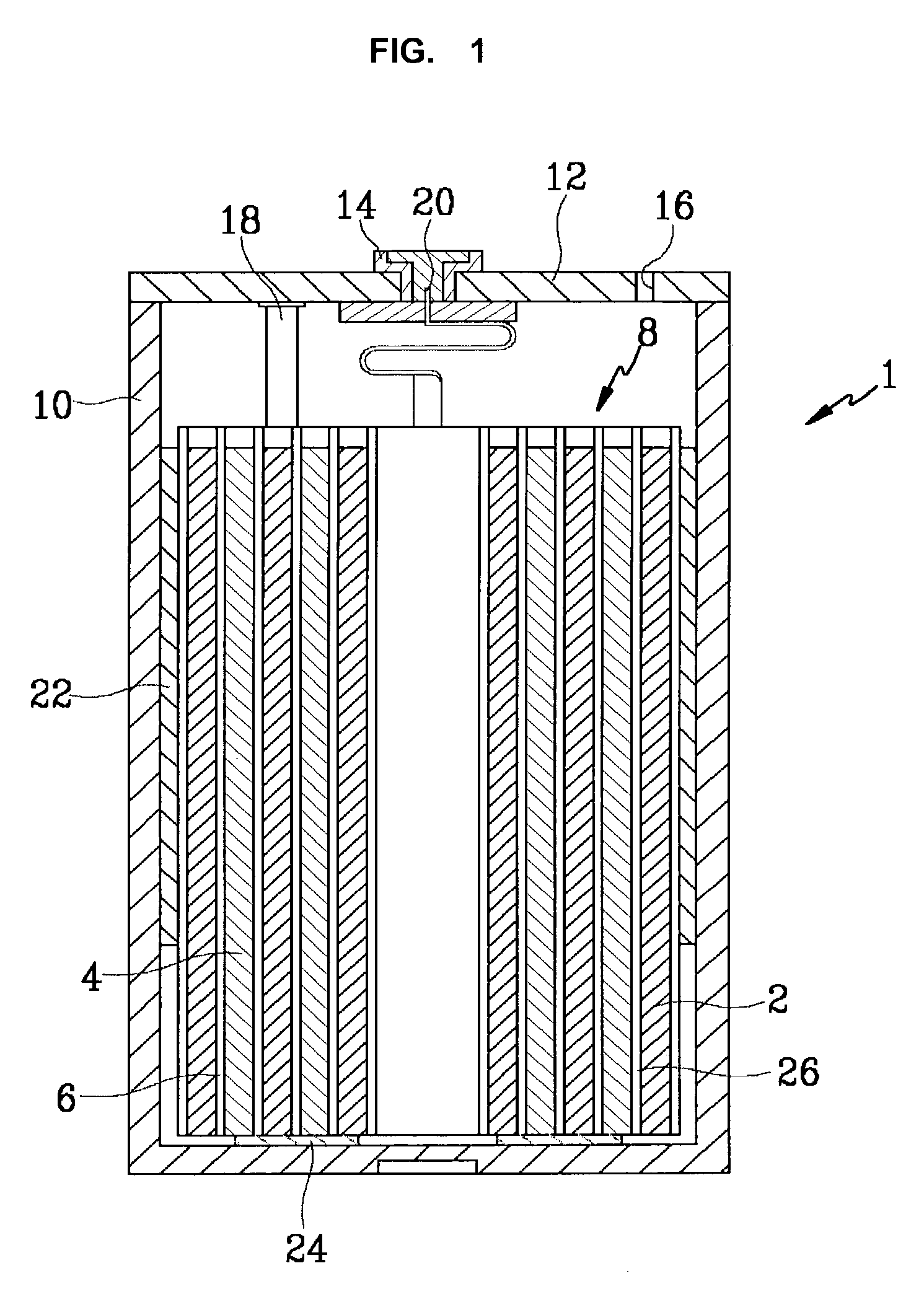

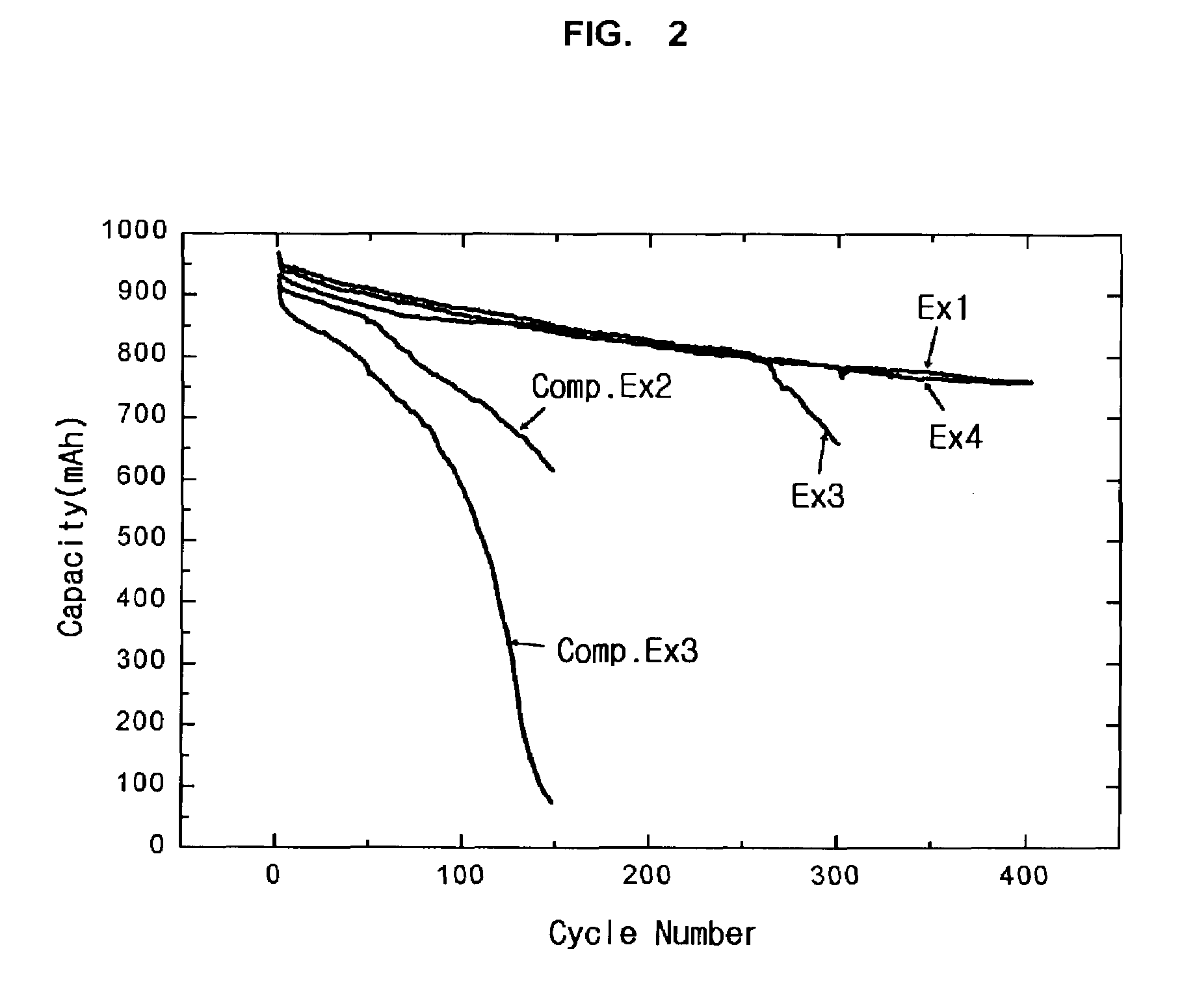

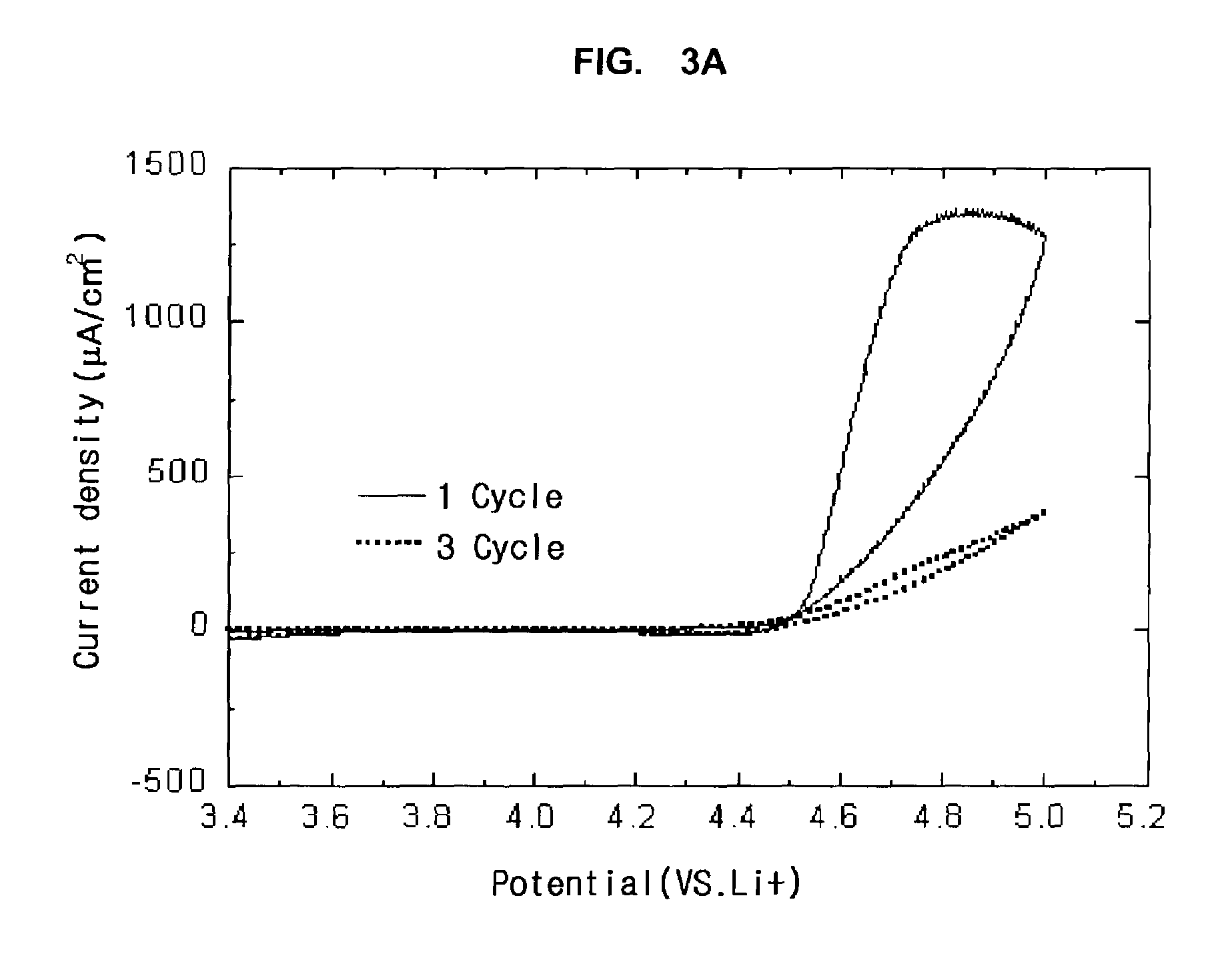

Electrolyte for lithium secondary battery and lithium secondary battery comprising same

ActiveUS20060003232A1Improve battery safetyGood electrochemical propertiesNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsHigh temperature storageLithium

An electrolyte for a lithium secondary battery is provided. The electrolyte improves battery safety, high temperature storage characteristics, and electrochemical properties of lithium batteries. The electrolyte comprises at least one lithium salt and a non-aqueous organic solvent comprising a cyclic carbonate and a lactone-based compound. The lactone based compound comprises substituents selected from the group consisting of alkyl groups, alkenyl groups, alkynyl groups, aryl groups, and combinations thereof. A lithium battery is also provided, which comprises a negative electrode capable of intercalating / deintercalating lithium, a positive electrode capable of intercalating / deintercalating lithium, and an inventive electrolyte.

Owner:SAMSUNG SDI CO LTD

Ozonolysis of carbon nanotubes

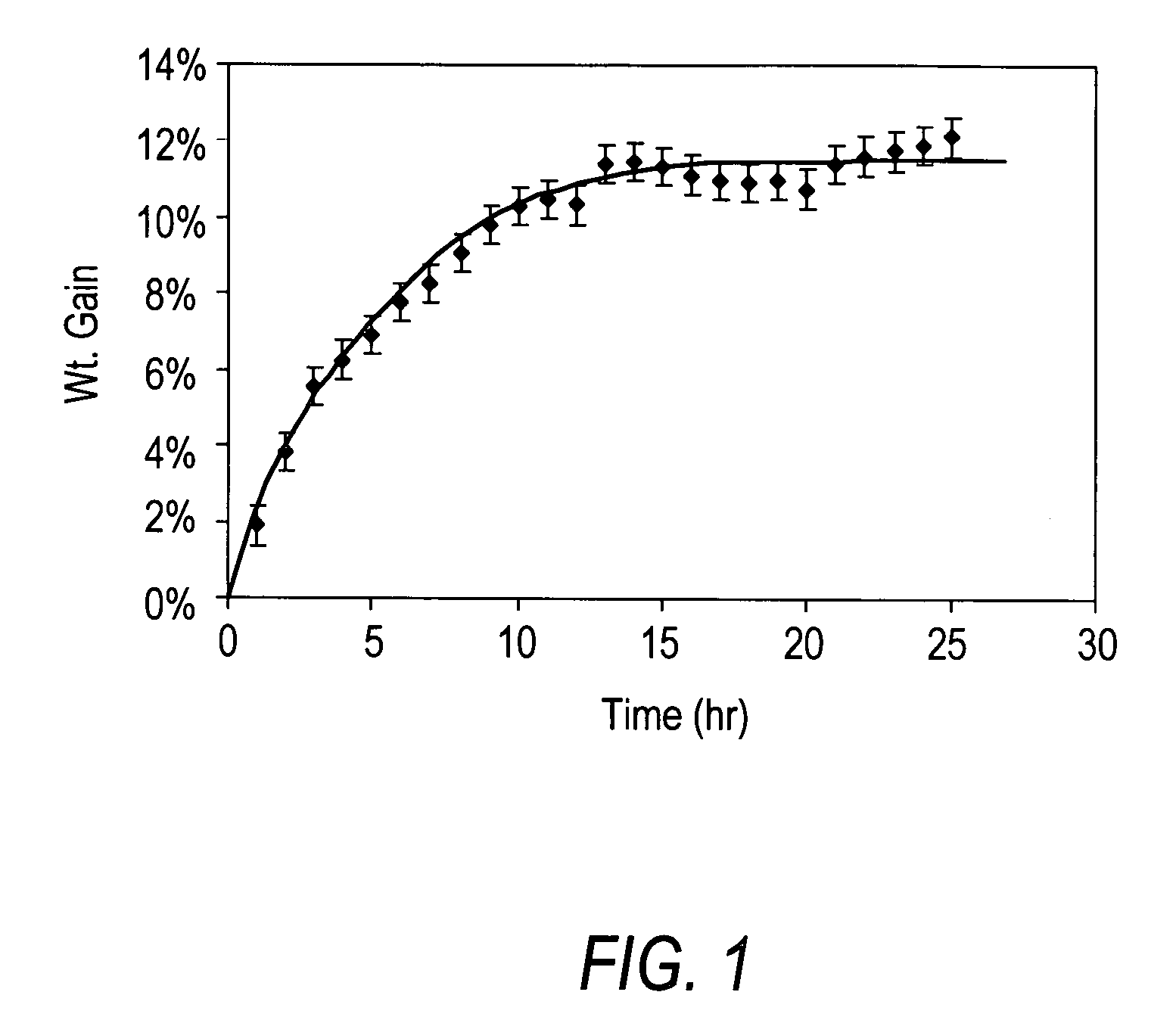

InactiveUS20080031802A1Easy to keepHigh catalyst loadingMaterial nanotechnologyNanostructure manufactureMultiwalled carbonOzonolysis

Methods of treating single walled and multiwalled carbon nanotubes with ozone are provided. The carbon nanotubes are treated by contacting the carbon nanotubes with ozone at a temperature range between 0° C. and 100° C. to yield functionalized nanotubes which are greater in weight than the untreated carbon nanotubes. The carbon nanotubes treated according to methods of the invention can be used to prepare complex structures such as three dimensional networks or rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors. Useful catalyst supports are prepared by contacting carbon nanotube structures such as carbon nanotube aggregates, three dimensional networks or rigid porous structures with ozone in the temperature range between 0° C. and 100° C.

Owner:HYPERION CATALYSIS INT

Active material for battery and method of preparing the same

InactiveUS7135251B2Good electrochemical characteristicGood electrochemical propertiesElectrode manufacturing processesLi-accumulatorsRare-earth elementChemistry

An active material for a battery has a surface-treatment layer including a compound of the formula (1):MXOk (1)wherein M is at least one element selected from an alkali metal, an alkaline earth metal, a group 13 element, a group 14 element, a transition metal, and a rare-earth element, X is an element capable of forming a double bond with oxygen, and k is a numerical value in the range of 2 to 4.

Owner:SAMSUNG SDI CO LTD

Active material for battery and battery having the same

InactiveUS20060281005A1Good electrochemical propertiesImprove thermal stabilityElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesRare-earth elementAlkaline earth metal

Owner:SAMSUNG SDI CO LTD

Graphene quantum dot-graphene composite material as well as preparation method and application thereof

InactiveCN104201357AImprove electrochemical performanceGreat application potentialMaterial nanotechnologyCell electrodesVacuum dryingAlkali metal

The invention relates to a graphene quantum dot-graphene composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, enabling full-halogenated benzene, alkali metal elementary substances and substituted aromatic compounds to be stirred and sealed in a reactor, and performing the reaction on the mixture under the reaction pressure higher than the barometric pressure; secondly, after ending the reaction, relieving the pressure to normal pressure, naturally cooling to room temperature, and performing centrifugal separation to obtain a solid; performing washing and vacuum drying on the solid to obtain a dried sample; thirdly, performing high-temperature treatment on the dried sample under the protection of inert gases to obtain the graphene quantum dot-graphene composite material. An oxygen reduction electrode made of the graphene quantum dot-graphene composite material has excellent electrochemical performance, so that the graphene quantum dot-graphene composite material can be applied to the field of fuel cells.

Owner:WENZHOU UNIVERSITY

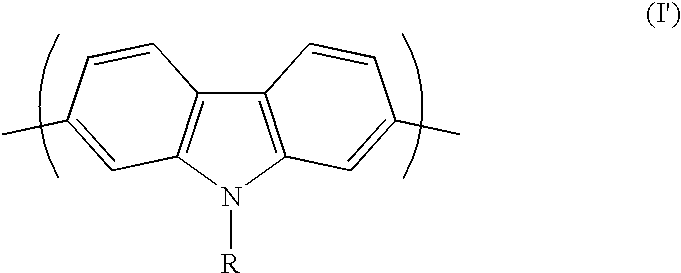

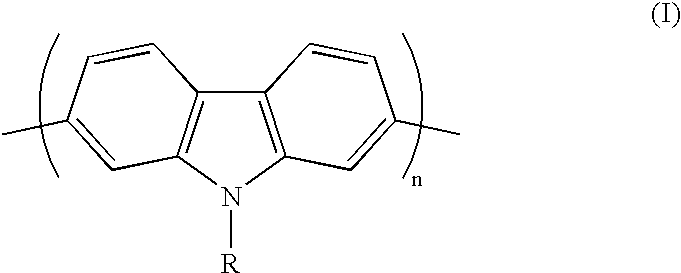

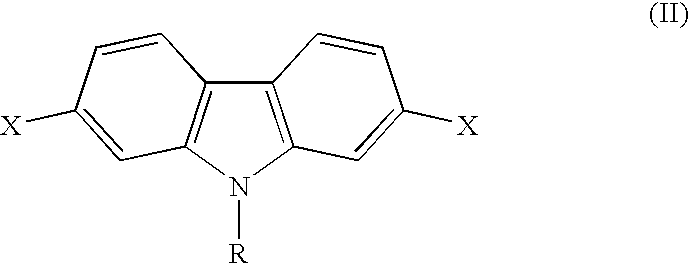

Conjugated polycarbazole derivatives and process for the preparation thereof

InactiveUS20020103332A1Improved opticalGood electrochemical propertiesCarbazole derivativePhotochemistry

The invention relates to conjugated polycarbazole derivates comprising repeating or alternating units of the formula: wherein R represents a linear or branched alkyl group having 1 to 22 carbon atoms. The conjugated polycarbazole derivatives according to the invention have interesting optical and electrochemical properties which render them suitable for use in the manufacture of diverse electrical, optical and electro-optical devices.

Owner:UNIV LAVAL

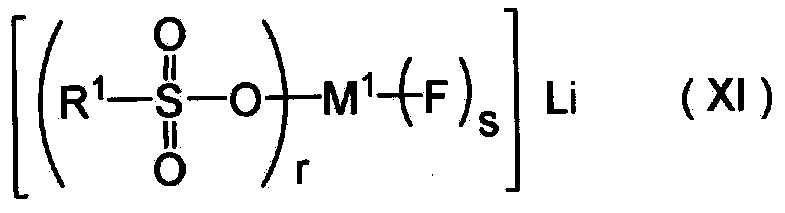

Electrolyte for lithium battery and lithium battery comprising same

ActiveUS7205073B2Improve securityGood electrochemical propertiesElectrolytic capacitorsOrganic electrolyte cellsArylHalogen

An electrolyte for a lithium battery includes a non-aqueous organic solvent, a lithium salt, and an additive comprising a) a compound represented by the following Formula (1), and b) a compound selected from the group consisting of a sulfone-based compound, a poly(ester)(metha)acrylate, a polymer of poly(ester)(metha)acrylate, and a mixture thereof:wherein R1 is a C1 to C10 alkyl, a C1 to C10 alkoxy, or a C6 to C10 aryl, and preferably a methyl, ethyl, or methoxy, X is a halogen, and m and n are integers ranging from 1 to 5, where m+n is less than or equal to 6.

Owner:SAMSUNG SDI CO LTD

Recycling method of positive electrode piece of lithium ion battery

InactiveCN105576314AEfficient removalImprove structural propertiesSolid waste disposalTransportation and packagingManganeseSodium-ion battery

The invention discloses a recycling method of a positive electrode piece of a lithium ion battery, aiming at solving the problem of recycling of a nickel cobalt lithium manganite (nickel cobalt lithium aluminate) positive electrode piece and a lithium cobaltate positive electrode piece generated in a production process of the lithium ion battery. According to the technical scheme disclosed by the invention, the recycling method comprises the following steps: 1, crushing the electrode pieces by classes; 2, immersing with an organic solvent; 3, carrying out stirring treatment; 4, filtering with a sieve net; 5, carrying out centrifugal separation; 6, immersing with an alkaline solution; 7, carrying out the centrifugal separation again; 8, drying and removing iron; 9, carrying out ICP (Inductively Coupled Plasma) analysis; and 10, calcining the materials. The recycling method disclosed by the invention can be used for effectively recycling waste materials of the positive electrode pieces of the waste lithium ion batteries, so that the cost is saved; and by immersing with the alkaline solution and carrying out a plurality of times of separation and washing, impurities, such as metal aluminum, in powder grains can be effectively removed. With the adoption of the recycling method, a positive electrode material and an aluminum foil can be completely separated, and the positive electrode material keeps a relatively good structure and electrochemical properties; and the synthesis of a precursor is not needed and the adding amount of a lithium salt is relatively less.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

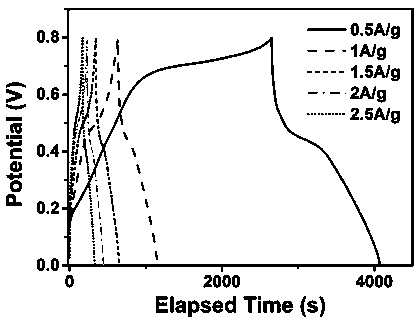

Method for manufacturing electrode material of supercapacitor by cotton-stalk-based active carbon material

InactiveCN102730683ALarge specific surface areaGood capacitance characteristicsCarbon compoundsElectrolytic capacitorsCapacitanceSupercapacitor

The invention relates to a method for manufacturing an electrode material of a supercapacitor by a cotton-stalk-based active carbon material. The method comprises the following steps of: firstly removing skin and crushing a cotton stalk raw material, mixing and dipping with an activating agent, and carrying out processes of activation treatment, washing, drying and the like to obtain an active carbon electrode material required by the supercapacitor. The electrode material of the supercapacitor prepared by the method provided by the invention has higher specific surface area and excellent capacitance characters. An assembled simulation button type supercapacitor has higher specific capacitance, smaller equivalent series resistance, higher charge and discharge efficiencies and the like. The method disclosed by the invention is of important significance to increase an economical additional value of cotton stalk, realize sustainable development on the cotton stalk, improve the performance of supercapacitor and reduce the production cost.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

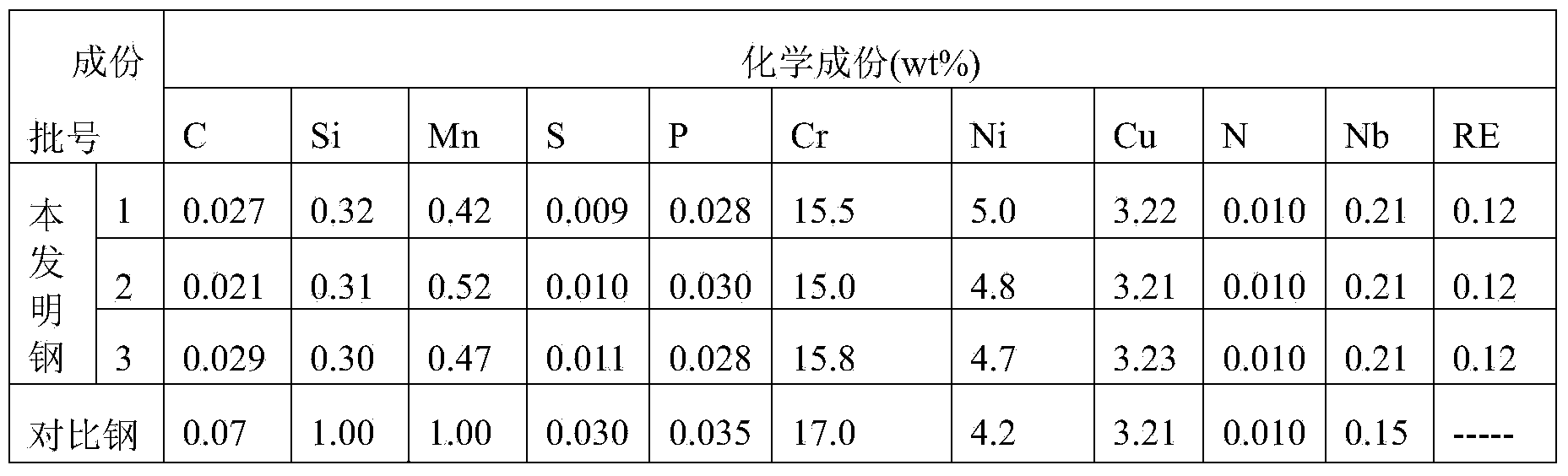

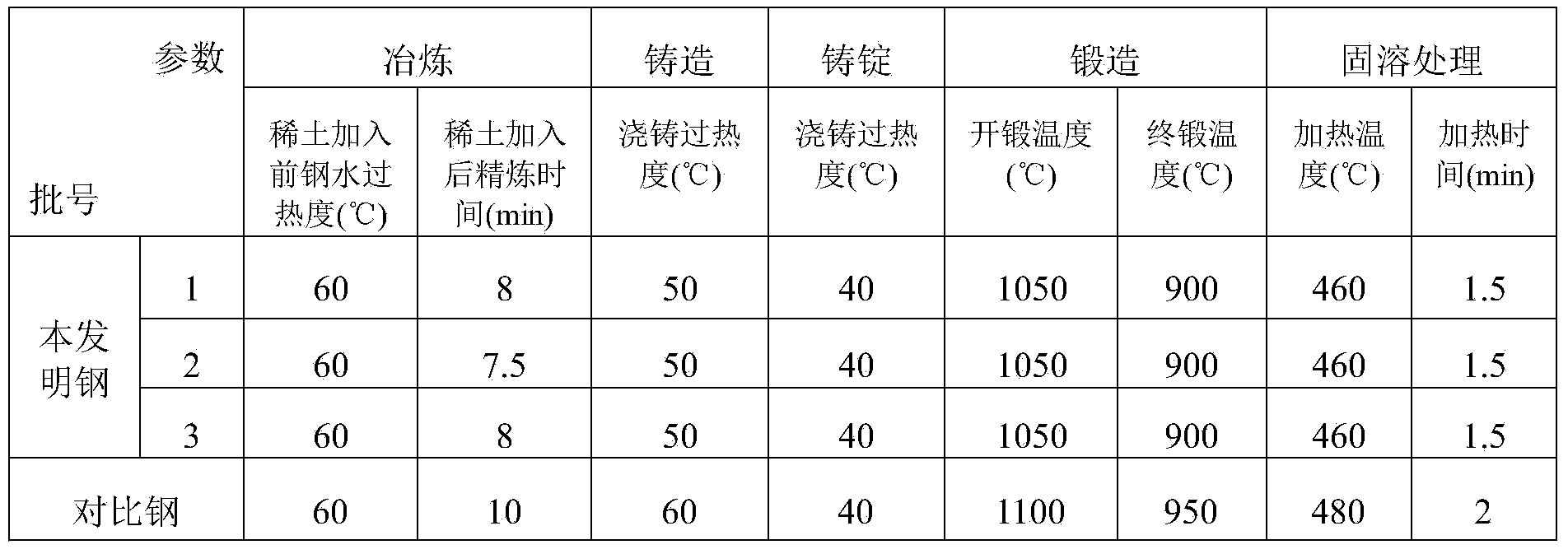

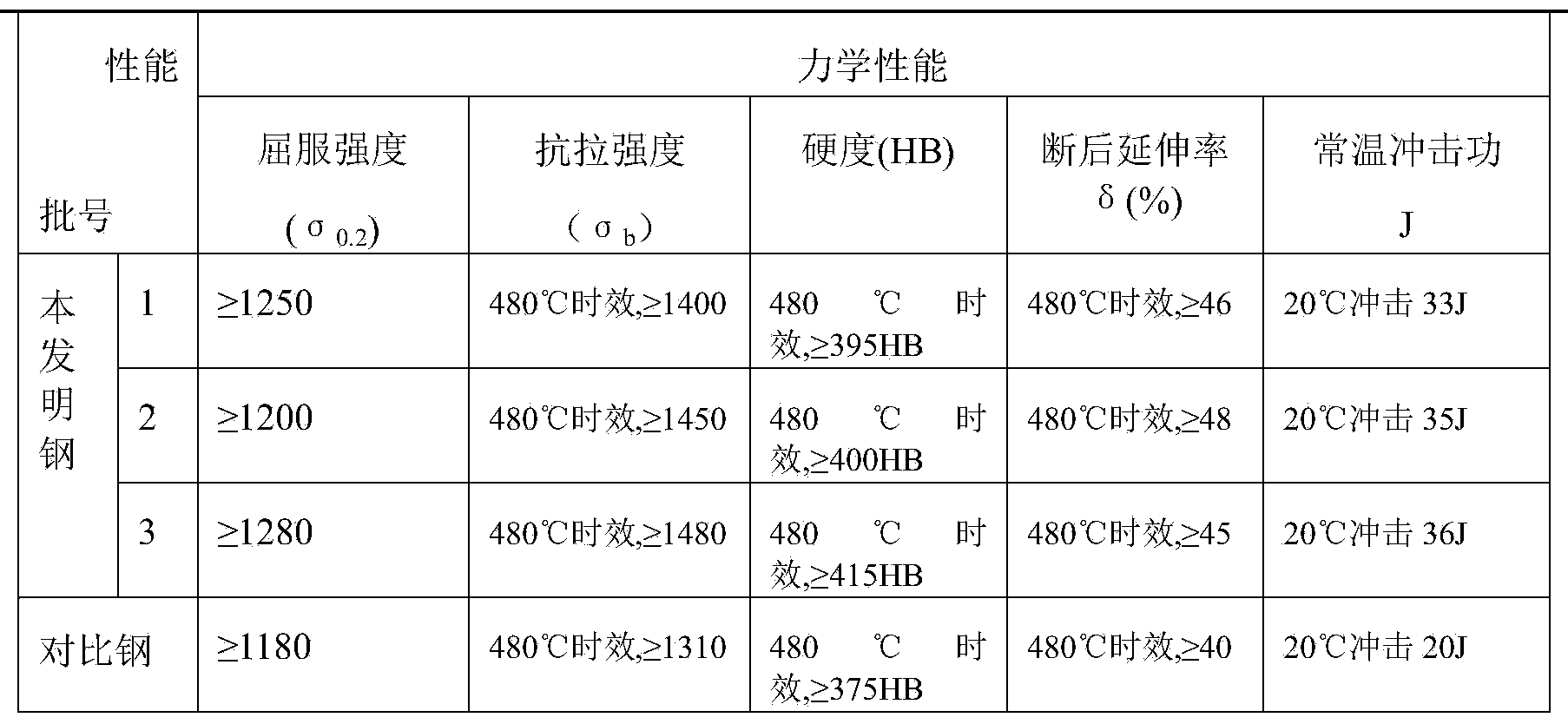

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

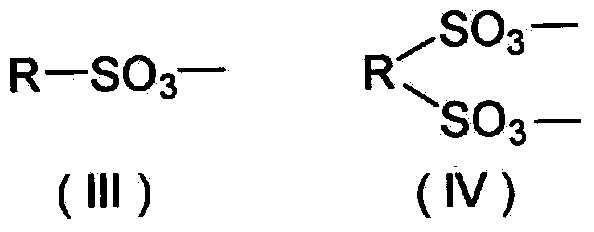

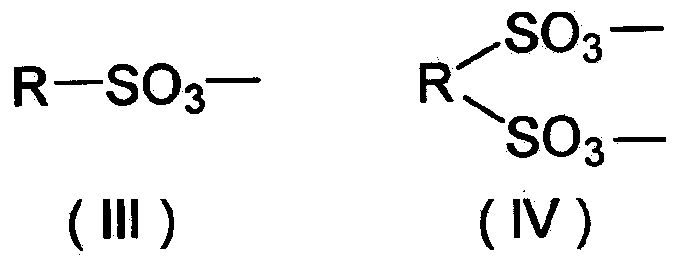

Electrolyte for lithium secondary battery and lithium secondary battery comprising same

PURPOSE: Provided are a non-aqueous electrolyte capable of improving the electrochemical property, and a lithium secondary cell excellent in electrochemical property. CONSTITUTION: The electrolyte comprises a lithium salt; a non-aqueous, organic solvent; and at least one of organic compound selected from compounds of formula 1 to 4(wherein the formula 3 is R9-SO3-Si-(CmH2m+1)3 and formula 4 is CnX2n+1-SO3-Si(CmH2m+1)3). In the formulae, each of R1 to R9 independently represents primary, secondary, or tertiary alkyl group, alkenyl group or aryl group, X is hydrogen or halogen atom, and each of n and m is 0-3. The lithium salt is selected from the group consisting of lithium hexafluorophosphate(LiPF6), lithium tetrafluoroborate(LiBF4), lithium perchlorate(LiClO4), lithium trifluoromethanesulfonate(LiCF3SO3), lithium hexafluoroarsenate(LiAsF6), and mixture thereof.

Owner:SAMSUNG SDI CO LTD +1

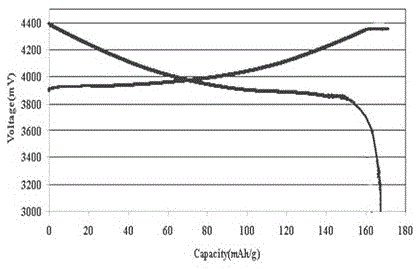

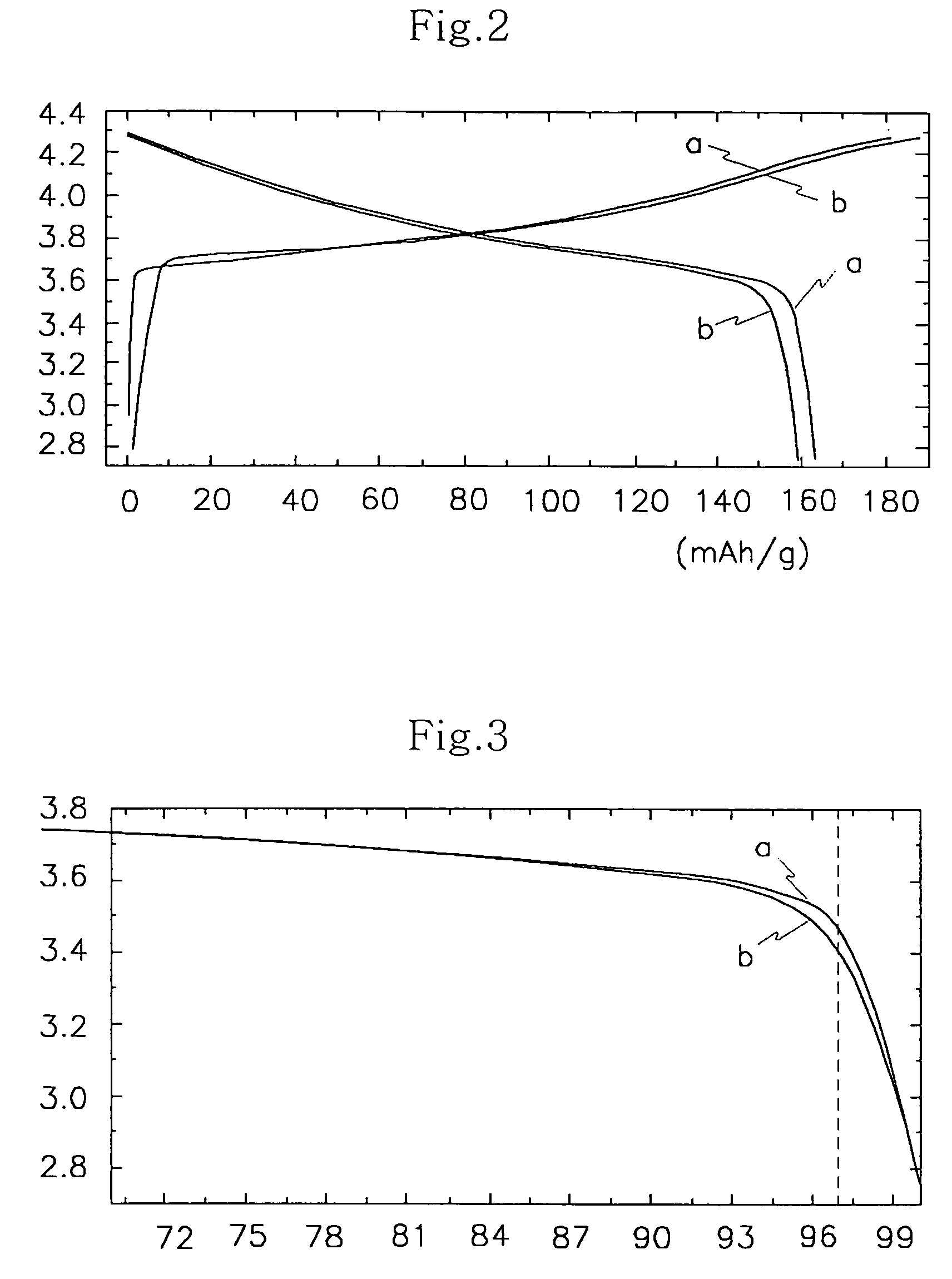

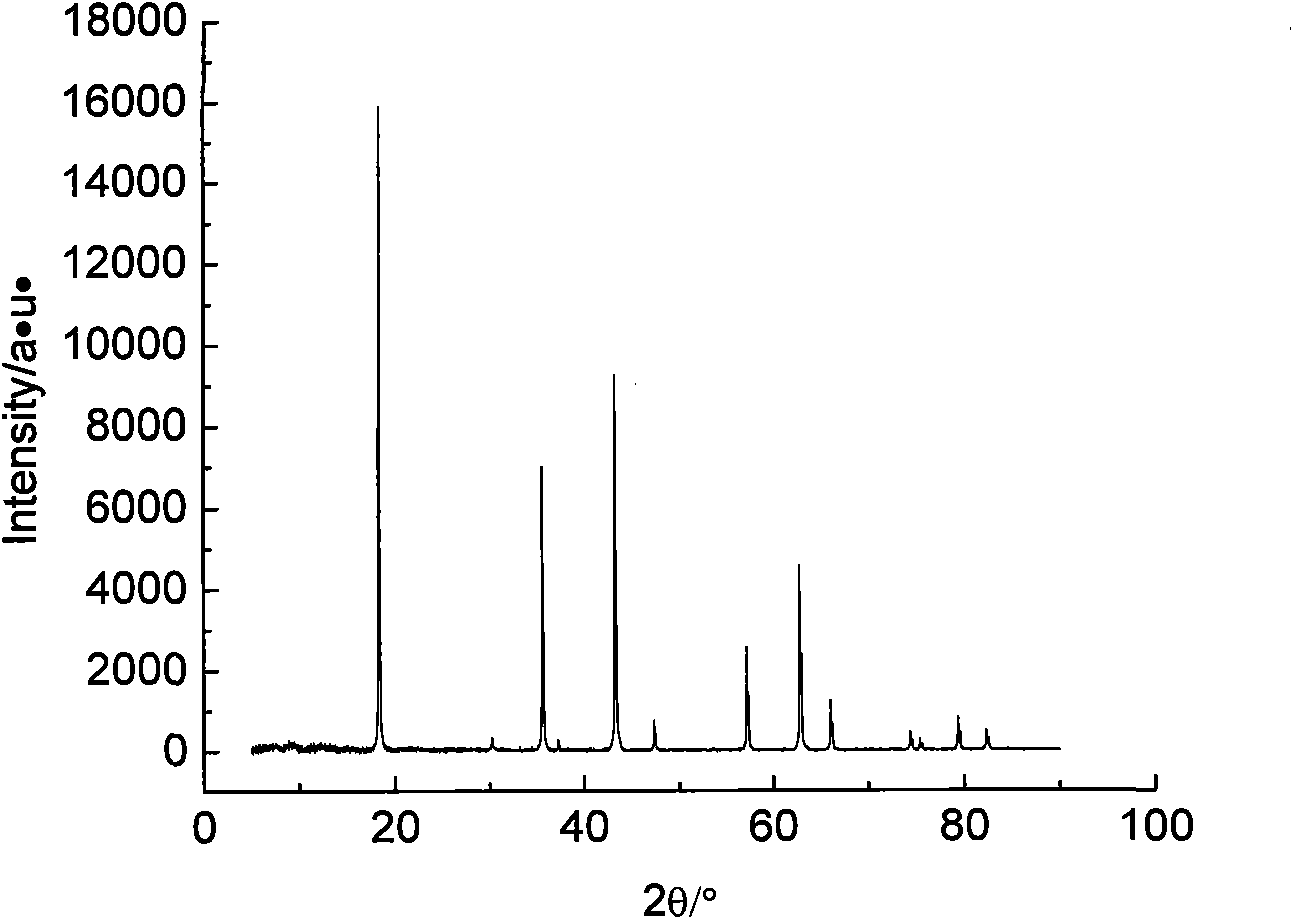

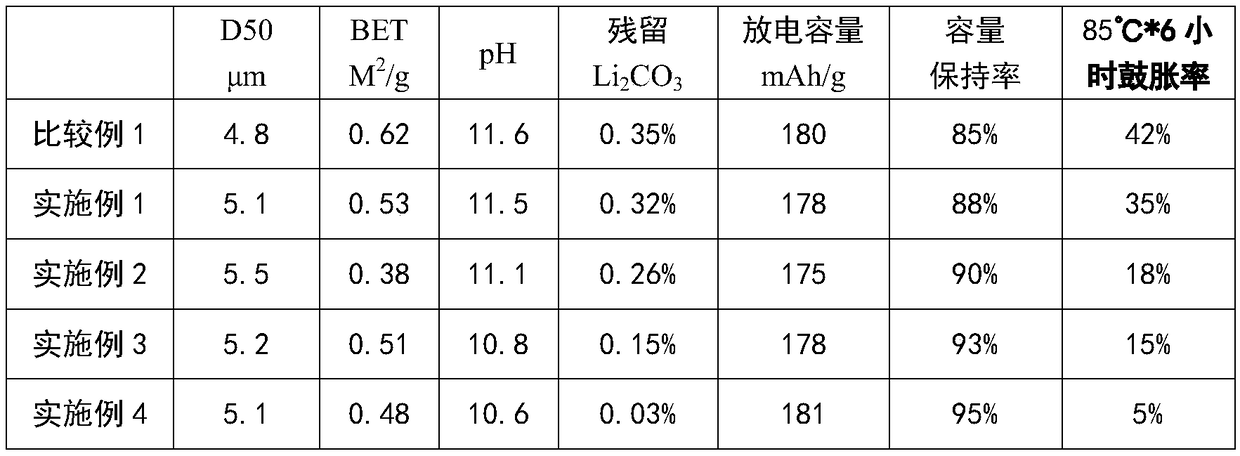

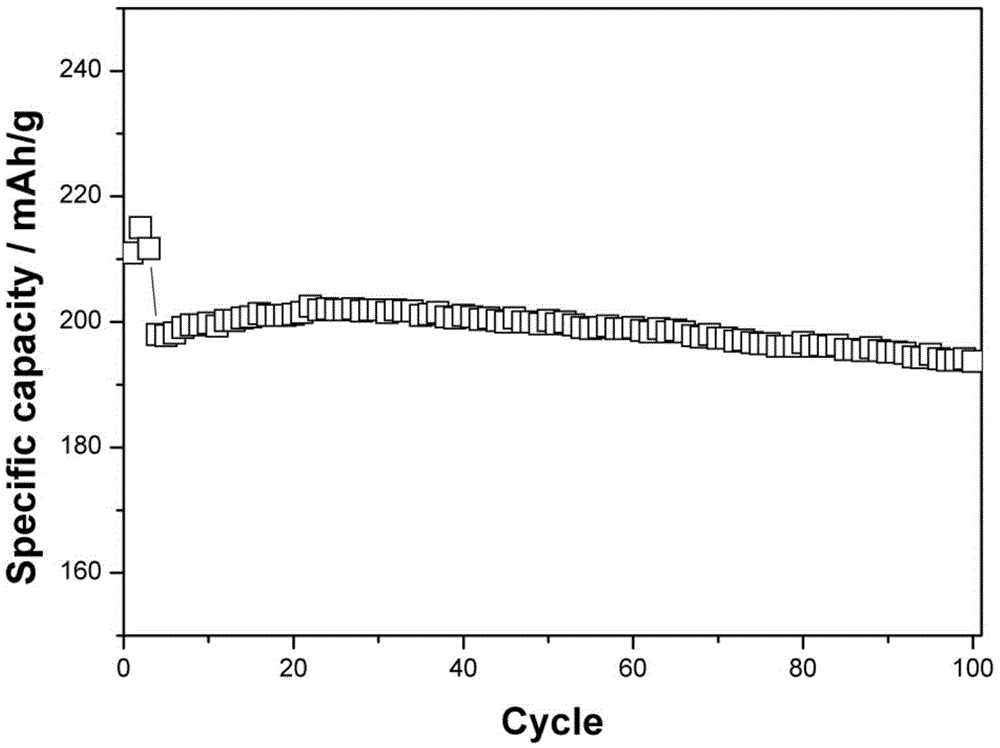

Lithium ion battery positive material and preparation method thereof

The purpose of the invention is to provide a lithium ion battery positive material of high specific capacity, good multiplying power performance, good cycle performance, compatible high and low temperature performance and low technology cost, and a preparation method of the lithium ion battery positive material of high specific capacity. The molecule structural formula of the lithium ion battery positive material is LiaMnbFecMdO2, and the method comprises the preparing steps: (1) preparing slurry; (2) preparing gel; (3) drying the gel, and sintering. Compared with the prior art, the inventionhas significant advantages of high specific capacity, good multiplying power performance, good cycle performance, compatible high and low temperature performance(from -20 DEG C to +50 DEG C), simple process and low process cost.

Owner:HENAN NORMAL UNIV

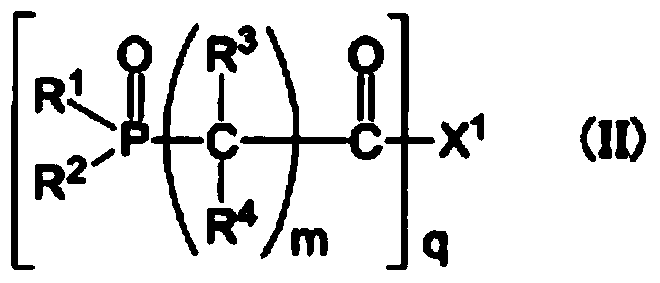

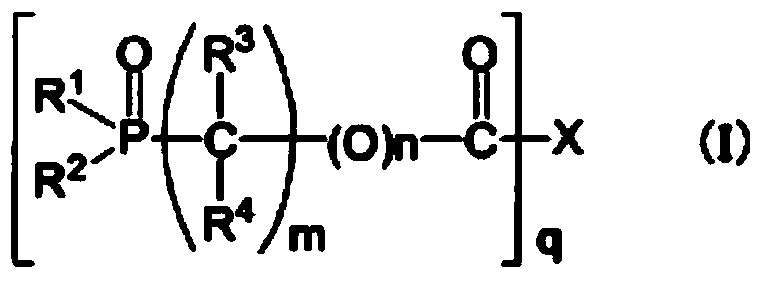

Nonaqueous electrolyte solution and electrochemical element using same

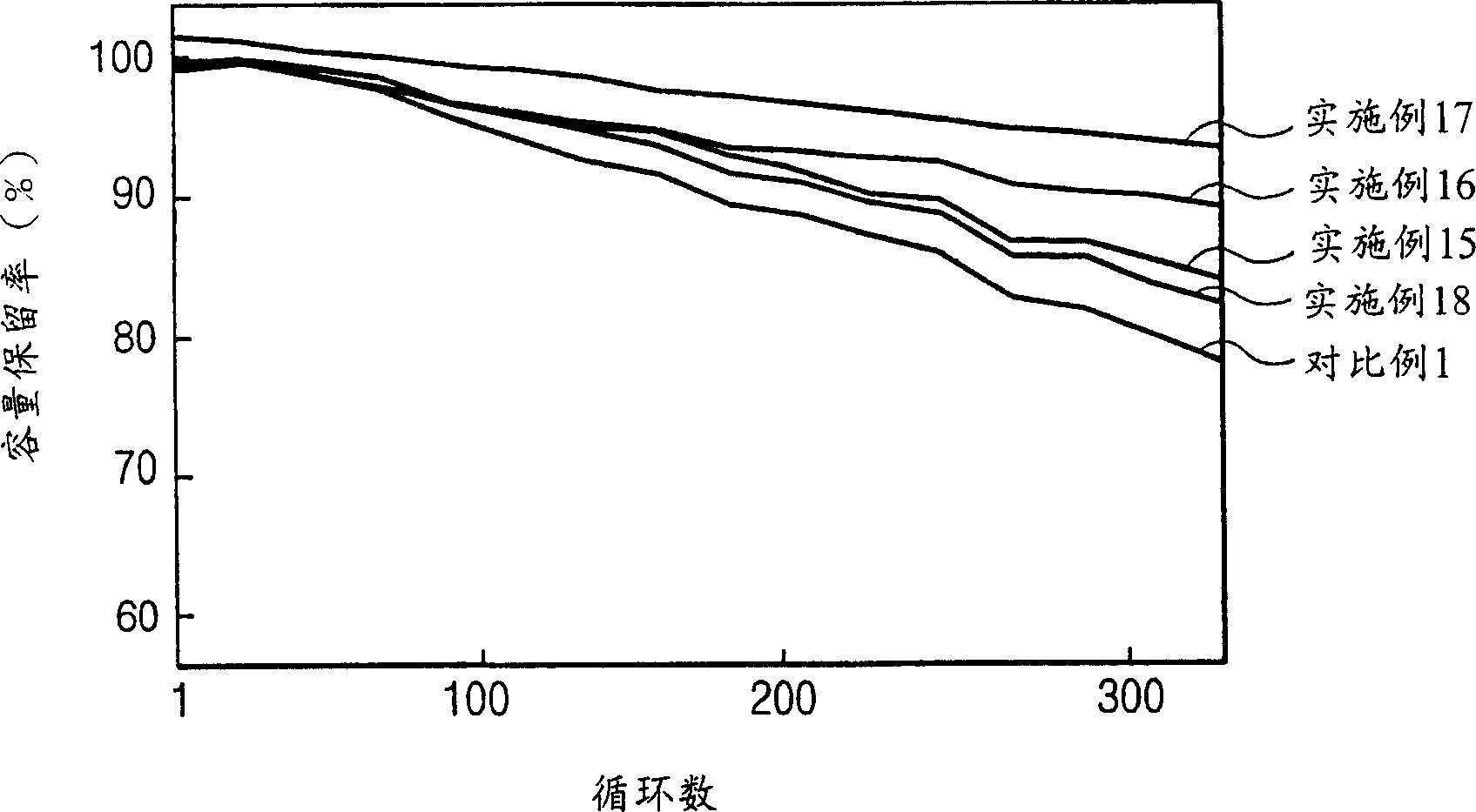

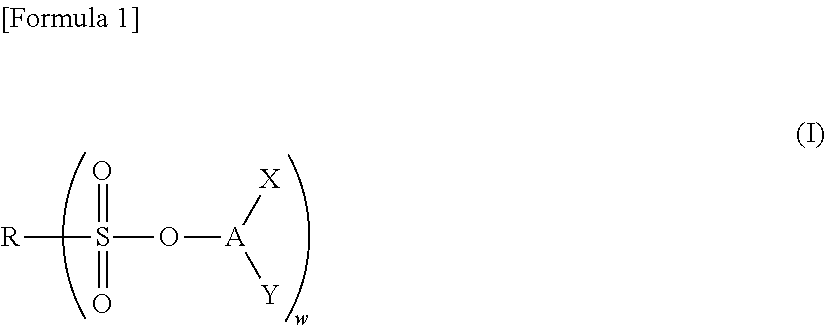

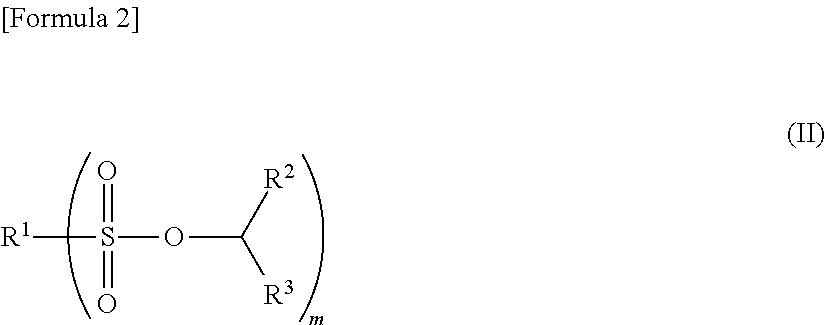

ActiveUS20130071733A1Good electrochemical propertiesImprove featuresHybrid capacitor electrolytesOrganic electrolyte cellsArylHydrogen atom

The present invention provides a nonaqueous electrolytic solution which can improve the electrochemical characteristics in a broad temperature range, an electrochemical element produced by using the same and a sulfonic ester compound having a branched structure which is used for the same.The present invention relates to a nonaqueous electrolytic solution prepared by dissolving an electrolyte salt in a nonaqueous solvent, which comprises a sulfonic ester compound represented by the following Formula (I) in an amount of 0.001 to 5% by mass of the nonaqueous electrolytic solution:(wherein R represents an alkyl group or an aryl group; A represents a >CH group or a >SiZ group (Z represents an alkyl group or an aryl group); X represents an alkyl group, a cycloalkyl group or an aryl group; Y represents a cycloalkyl group, a -L1CHRaOSO2Rb group or a —Si(Rc)(Rd)OSO2Rb group; W represents 1 or 2; Ra represents an alkyl group; Rb, Rc and Rd represent an alkyl group or an aryl group; L1 represents an alkylene group in which at least one hydrogen atom may be substituted with —OSO2Re (Re has the same meaning as that of R), a divalent linkage group containing at least one ether bond or a single bond).

Owner:MU IONIC SOLUTIONS CORP

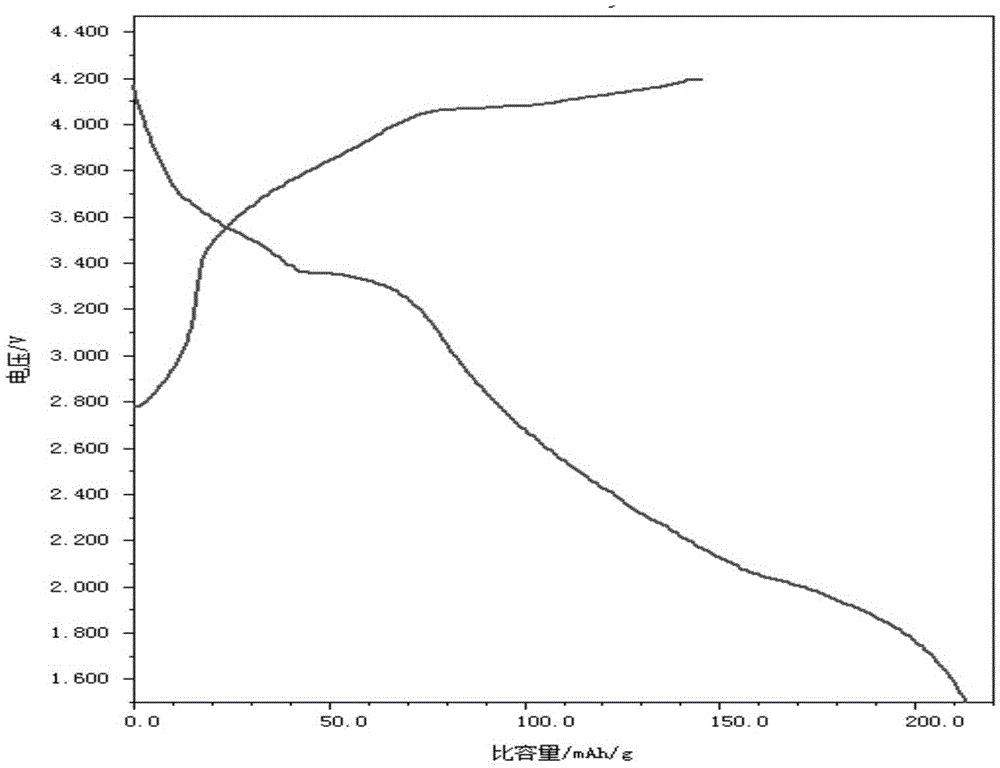

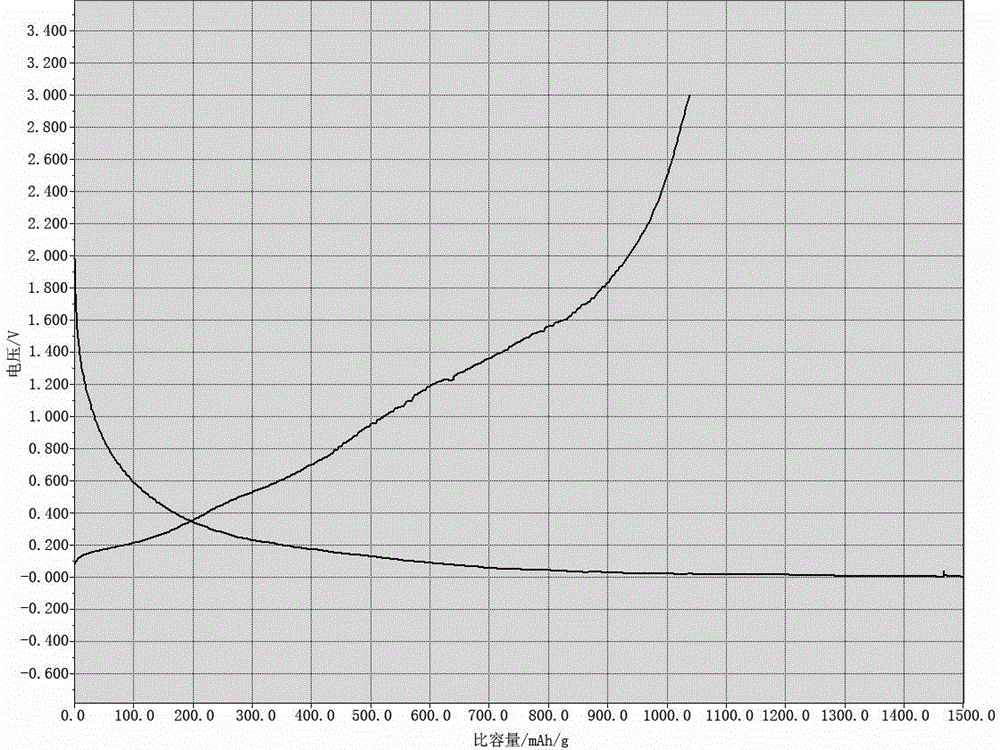

Phosphate-based anode composite material of Li-ion battery and preparation method and functions thereof

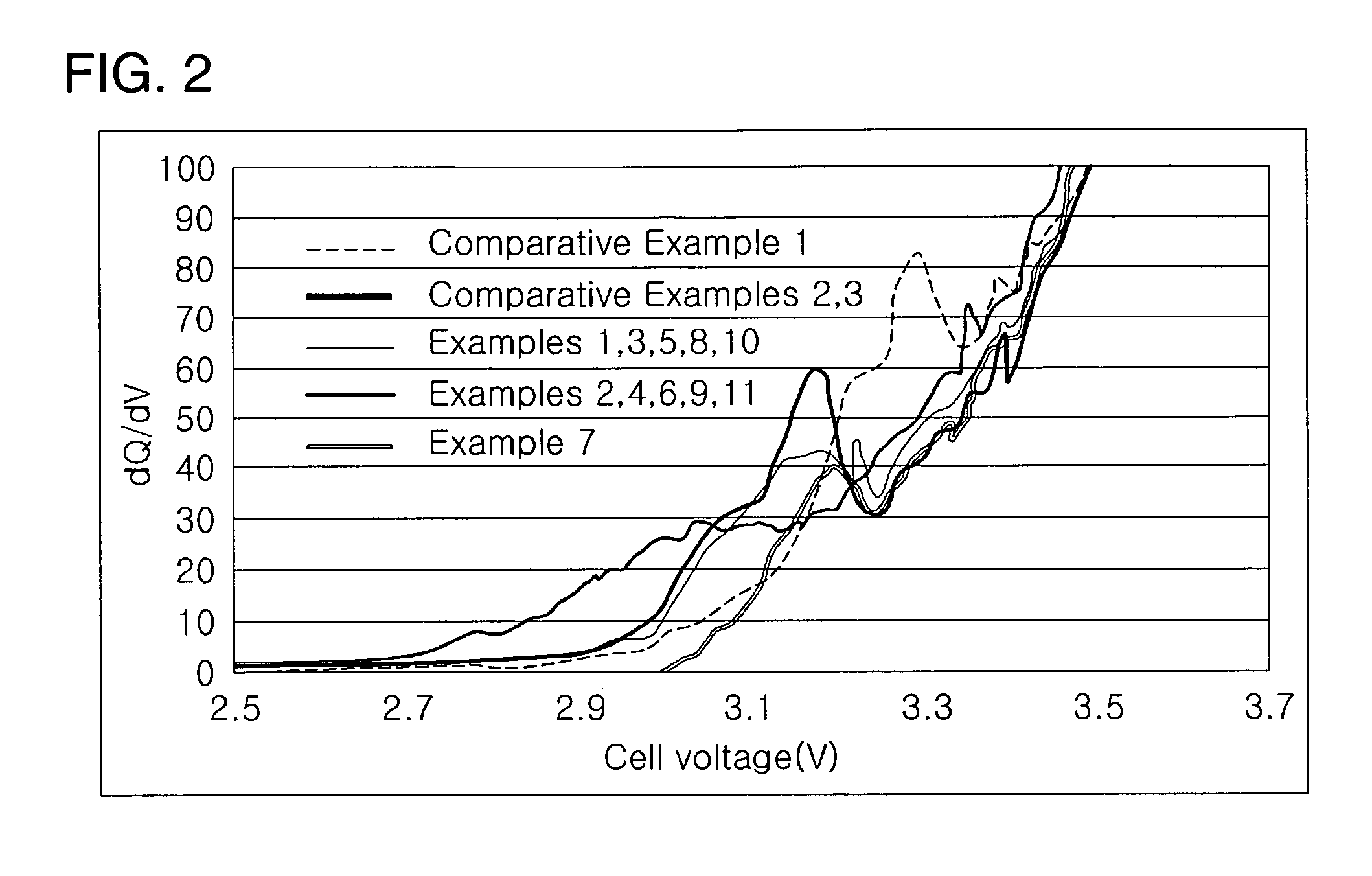

ActiveCN103165883AHigh reversible capacityImprove cycle stabilityCell electrodesSecondary cellsCarbon layerPhosphate

The invention relates to a phosphate-based anode composite material of a Li-ion battery and a preparation method of the composite material and functions of the composite material, and particularly discloses the phosphate-based anode composite material of the Li-ion battery. The composite material has a lattice structure of LiMn1-xFexPO4 and a lattice structure of Li3V2(PO4)3. The chemical formula of the composite material is yLiMn1-xFexPO4-(1-y)Li3V2(PO4)3 / C, wherein x is 0.00-0.40, y is 0.50-0.95, and C is a carbon layer. The preparation method and the functions of the composite material are also disclosed. The composite material has the advantages of having a high potential plateau with voltage of 4.1V, being high in reversible capacity and good in cycling stability, having an electric quality warning function, and being low in cost, environment-friendly and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of preparing positive active material for rechargeable lithium battery

InactiveUS6974601B2Good electrochemical propertiesImprove thermal stabilityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsMetalLithium battery

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4:LixNi1-yMnyF2 (1)LixNi1-yMnyS2 (2)LixNi1-y-zMnyMzO2-aFa (3)LixNi1-y-zMnyMzO2-aSa (4)where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, Pu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95≦x≦1.1, 0<y≦0.99, 0≦z≦0.5, and 0≦a≦0.5; and a metal oxide or composite metal oxide layer formed on the compound.

Owner:SAMSUNG SDI CO LTD

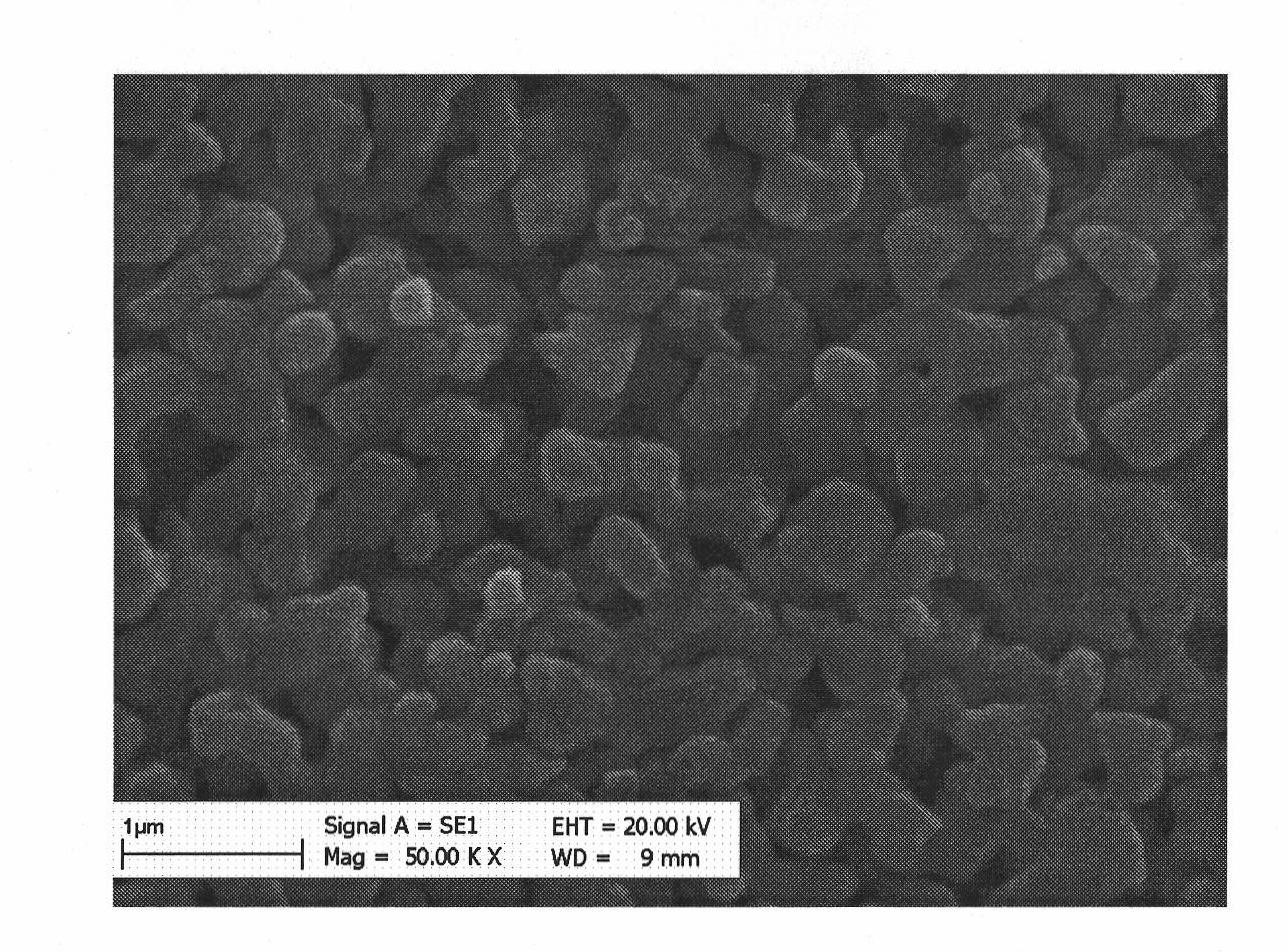

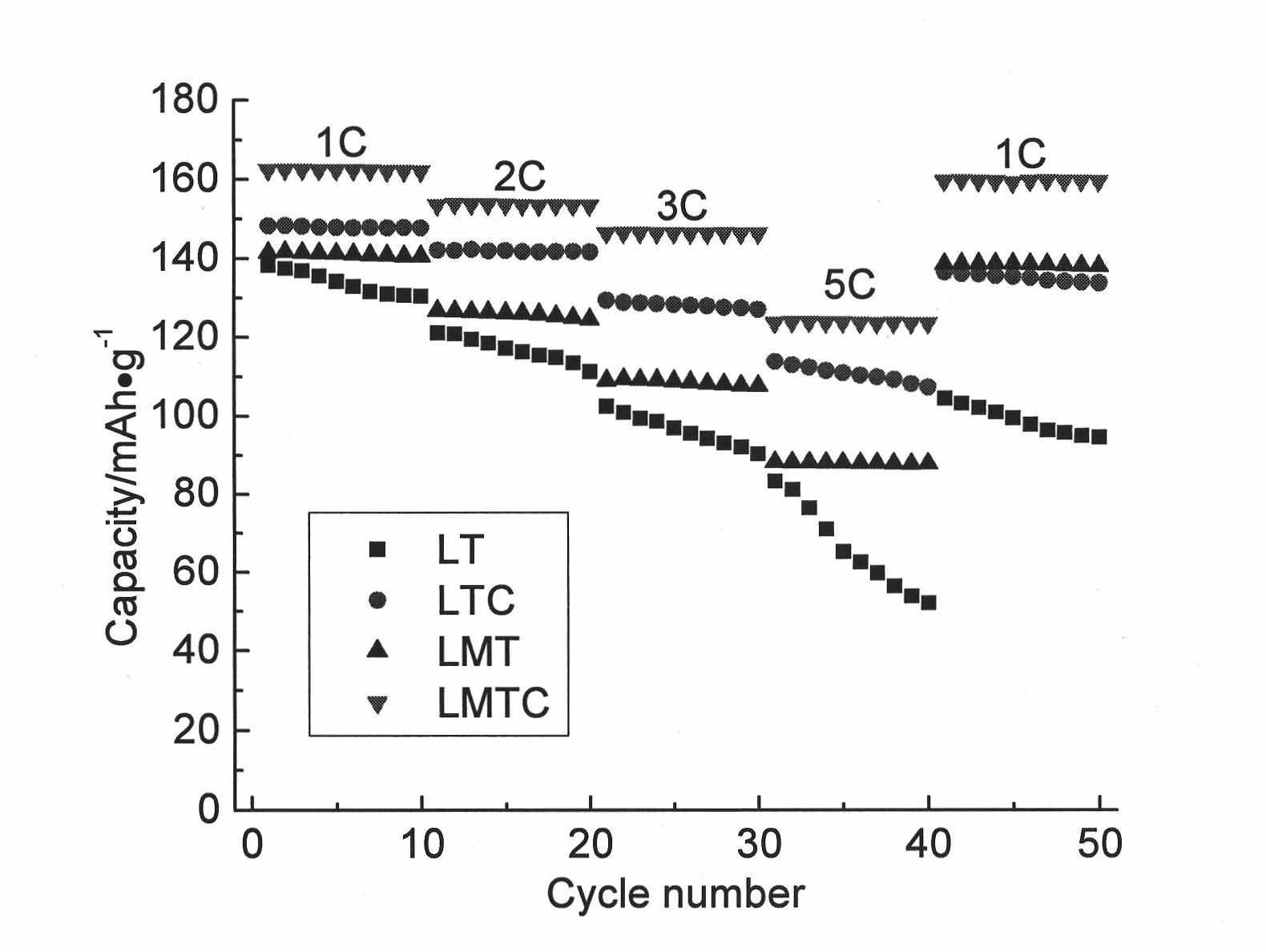

Method for preparing carbon-coated manganese-doped lithium titanate negative electrode material of lithium ion battery

InactiveCN101800307AEasy to controlImprove electrochemical performanceCell electrodesBall millCarbon coated

The invention relates to a method for preparing a carbon-coated manganese-doped lithium titanate negative electrode material of a lithium ion battery. In the method, the amount of doped manganese and experimental conditions are controlled; lithium salt, manganese dioxide or manganese tetroxide, titanium dioxide and sugar or glucose are used as raw materials; and the raw materials are put in a ball mill for ball milling, and are dried and sintered to obtain a carbon-coated manganese-doped lithium titanate composite material. In the method, carbon coating is performed on the doping inside lithium titanate cells and the outside of grains by using manganese ions and the lithium titanate is modified simultaneously, so the electrical conductivity of the lithium titanate is greatly improved, the cyclical stability and the reversible capacity of large currents are obviously improved, and the performance requirements of the negative electrode material of a power lithium ion battery are met. The method has a simple preparation process and is easy to realize industrialization; and the carbon-coated manganese-doped lithium titanate composite material obtained by the method has excellent electrochemical performance, realizes the optimal combination of the maximum reversible circulation capacity and the optimal high electrical conductivity, and can be applied to high-power lithium ion batteries.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

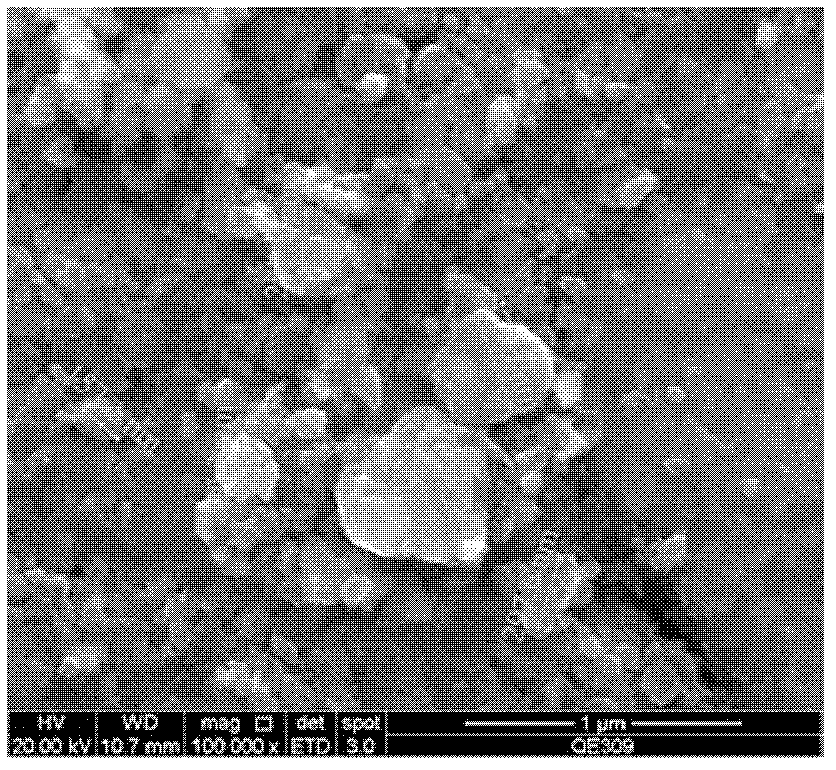

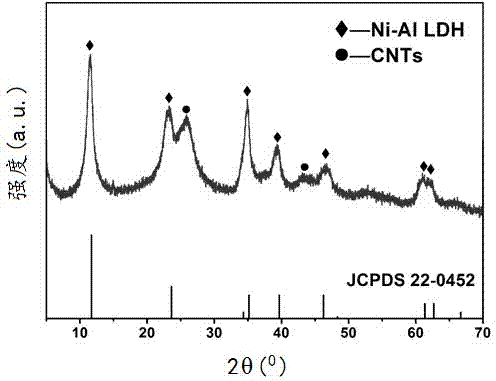

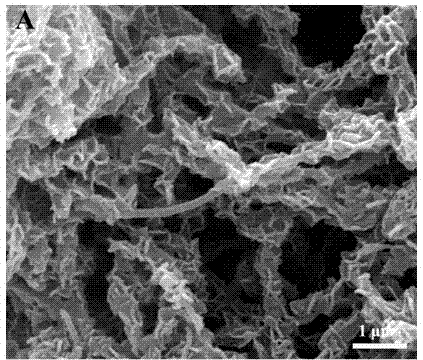

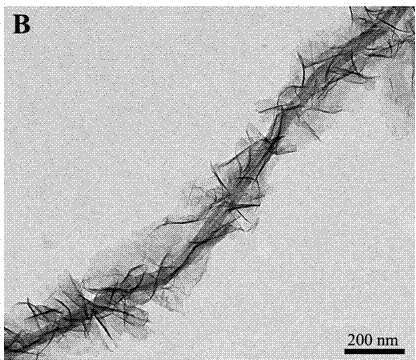

CNTs@SiO2@Ni/Al-LDH shell structure three-dimensional nanometer material and preparation method thereof

ActiveCN104843805ASolve reunionSolve conductivity problemsMaterial nanotechnologySilicaMaterials preparationSupercapacitor

The present invention discloses a CNTs@SiO2@Ni / Al-LDH shell structure three-dimensional nanometer material preparation, which comprises: (1) dispersing carbon nano-tubes in a solution by using hexadecyl trimethyl ammonium bromide (CTAB); (2) coating a SiO2 shell layer on the surface of the uniformly-dispersed carbon nano-tubes to form a CNTs@SiO2 core-shell structure; (3) preparing a AlOOH sol precursor; (4) coating the AlOOH sol precursor on the surface of the CNTs@SiO2 core-shell structure to form a CNTs@SiO2@AlOOH core-shell structure; and (5) preparing a CNTs@SiO2@Ni / Al-LDH core-shell structure through an in-situ growth method. The material and the method of the present invention are mainly used in the fields of super-capacitors, catalysts, sensors and the like.

Owner:英能基(成都)科技有限公司

A high-voltage monocrystalline ternary material and a preparation method thereof

InactiveCN109065880AGood electrochemical propertiesGood microscopic appearanceCell electrodesChemistryElectrochemistry

The invention discloses a high-voltage single crystal ternary material and a preparation method thereof. The chemical formula of the high-voltage single crystal nickel-cobalt-manganese ternary material in the invention is LiNi0. 5Co0. 2Mn0. 3MxO2, wherein x=0. 01-0.1, coprecipitating Ni-Co-Mn hydroxide coprecipitate body is formed by coprecipitation method, and then proper amount of lithium carbonate or lithium hydroxide is added to form lithium carbonate or lithium hydroxide-Nickel cobalt manganese hydroxide co-sediment mixed paste, mixed with paste, evenly mixed, dried, ground, sieved with 160 mesh sieve, the obtained mixture is loaded into an alumina crucible, put into an oxidation furnace for burning, and the firing temperature is controlled at 900-1050 DEG C, heat preservation 10-15 hour, that sintered body is subject to crushing, airflow classification, surface coating treatment of the alumina sol and low-temperature atmosphere heat treatment to obtain a high-voltage monocrystalline nickel-cobalt-manganese ternary material powder. The invention has the characteristics of good electrochemical characteristics under the high-voltage condition, excellent micro-morphology, simplemanufacturing method and easy industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Polyaniline-based MOF nanocomposite flexible supercapacitor and preparation method thereof

ActiveCN107731545AExtended conduction pathImprove electrochemical cycle stabilityMaterial nanotechnologyHybrid capacitor electrodesFiberSlurry

The invention discloses a polyaniline-based MOF nanocomposite flexible supercapacitor and a preparation method thereof. MIL-101 is one of MOF materials with excellent acid-resistance stability. The method provided by the invention comprises the steps that a PANI / MIL-101 composite material is prepared; the PANI / MIL-101 composite material, acetylene black and polyvinylidene fluoride (PVDF) are uniformly dispersed in N-methyl-2-pyrrolidone (NMP) in a certain proportion to form a slurry, and the slurry is coated on carbon fiber cloth to form electrodes; a gel electrolyte is used to symmetrically stack two electrodes, and the middle space is separated by a diaphragm; and the electrodes are packaged to prepare the flexible supercapacitor. The specific capacity of the electrode material is up to1197 F / g. The prepared supercapacitor has only 10% attenuation of the specific capacity after 1000 times of bending. The cyclic stability test 10000 cycles can maintain more than 90% of the specific capacity. Four supercapacitors are connected in series to light up a 1.8V red LED. The flexible supercapacitor prepared by the invention has good flexibility and electrochemical performance, and has agood application prospect in the aspects of flexible electronic devices and energy storage.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing multielement positive pole material for sodium-ion batteries

InactiveCN105576229AEvenly crushedWell mixedCell electrodesSecondary cellsTunnel kilnSodium-ion battery

The invention relates to a method for preparing a multielement positive pole material for sodium-ion batteries and belongs to the technical field of lithium-ion batteries. The method for preparing the multielement positive pole material for the sodium-ion batteries comprises the following steps: (1) weighing a nickel source compound, a ferrum source compound, a manganese source compound and a lithium source compound according to the atomic ratio of x, y and z in a chemical formula, i.e., Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2) of a predetermined synthesized product, and carrying out preliminary mixing on the raw materials, wherein each of x, y and z is not smaller than 0.01 and is smaller than 1; (2) feeding the preliminary-mixed raw materials to an airtight gas tank by using high-speed gas flow, and subjecting the raw materials to mutual collision and mutual friction inside the airtight gas tank, so as to obtain a crushed, mixed and activated precursor; (3) placing the precursor, which is crushed and activated by the high-speed gas flow, into a high-temperature tunnel kiln, heating the precursor to the temperature of 875 DEG C to 950 DEG C in an air or oxygen atmosphere, carrying out heat preservation for 15 hours to 20 hours, and carrying out cooling, thereby preparing a powder product of the multielement positive pole material Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2). The method has the advantages that the process is simple, the cost is low, the production efficiency is high, the uniformity of the product is good, the electrochemical properties are excellent, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Gel polymer electrolyte, method for preparing same, and electrochemical device comprising same

ActiveUS20180034101A1Improve adhesionGood electrochemical propertiesHybrid capacitor separatorsSolid electrolytesPolymer electrolytesOrganic solvent

Disclosed herein are a gel polymer electrolyte, a method of manufacturing the same, and an electrochemical device including the same. According to the present invention, a gel polymer electrolyte including: a multi-component crosslinked polymer matrix; a dissociable salt; and an organic solvent, wherein a content of the multi-component crosslinked polymer matrix is 1 to 50 wt % and the multi-component crosslinked polymer matrix has a net structure formed by crosslinking at least three different kinds of crosslinkable monomers, each of the crosslinkable monomers including at least two functional groups selected from the group consisting of a carboxylic group, an acrylate group, and a cyano group, a method of manufacturing the same using a thermal crosslinking or photo-crosslinking process, and an electrochemical device including the same, may be provided.

Owner:JENAX

Method for producing all-hydrogel stretchable supercapacitor and capacitor

ActiveCN108586664AGood electrochemical propertiesGood stabilityHybrid capacitor electrolytesHybrid capacitor electrodesCarbon nanotubePolyacrylamide

The invention belongs to the field of supercapacitor production and specifically discloses a method for producing an all-hydrogel stretchable supercapacitor and the capacitor. The stretchable supercapacitor is assembled in a traditional sandwich structure by taking sodium alginate / polyacrylamide / carbon nanotube / poly(3,4-ethylendioxythiophene)-polystyrolsulfon acid composite hydrogel with high stretchability as an electrode material and sodium alginate / polyacrylamide / sodium sulfate / redox couple composite hydrogel with high stretchability as electrolyte. Each of the electrode material and electrolyte provided in the method is based on a stretchable hydrogel material, and strong adhesion exists between the electrode material and the electrolyte, so that the constraint that an existing assembling technology needs the help of a stretchable base can be avoided. The all-hydrogel stretchable supercapacitor is suitable for a traditional application field of the supercapacitor and high-end application fields such as wearable electronic equipment, stretchable electronic equipment, electronic skins and portable integrated devices.

Owner:HUAZHONG UNIV OF SCI & TECH

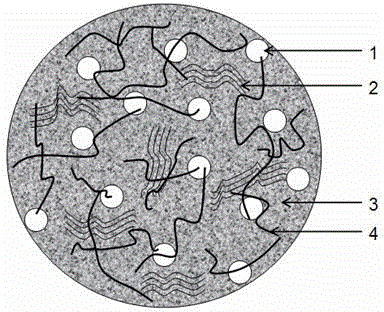

Multi-component composite anode material and preparation method thereof

InactiveCN103560249AGood electrochemical propertiesPlay a conductive roleCell electrodesSecondary cellsPolyethylene glycolCarbon nanotube

The invention relates to a multi-component composite anode material and a preparation method thereof. The multi-component composite anode material is characterized by comprising the following components in mass fraction: 15 to 30% of nano silicon powder, 5 to 9% of carbon nano tube, 19 to 40% of expanded graphite, and 37 to 55% of amorphous carbon. The multi-component composite anode material is prepared by carbonizing polyving akohol or polyethylene glycol at high temperature. The nano silicon powder serving as a core active material is used for storing energy; the carbon nano tube is used for conducting electricity; the expanded graphite is dual-functional, including effects of serving as a massive and rigid buffer space and a conductive additive during charging and discharging through silica powder; the amorphous carbon is prepared by carbonizing polyving akohol or polyethylene glycol at high temperature and can be used as a flexible buffer space. The composite material is outstanding in electrochemical properties.

Owner:CHINA FIRST AUTOMOBILE

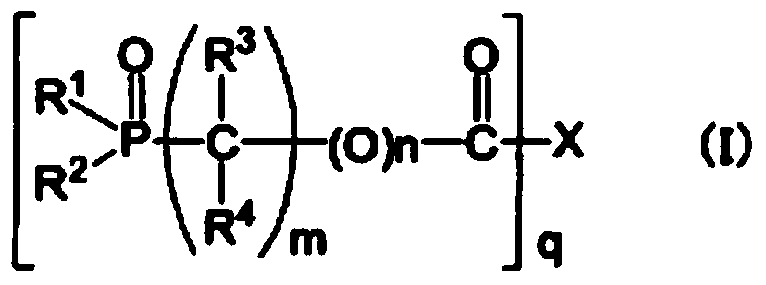

Non-aqueous electrolyte solution and electricity-storage device using same

ActiveCN103460495AImprove high temperature cycle characteristicsGood electrochemical propertiesHybrid capacitor electrolytesCell electrodesArylElectricity

The present invention comprises: a non-aqueous electrolyte solution that produces improved electrochemical properties in high-temperature environments and is characterized by containing at least one organic phosphorus compound represented by general formula (I); an electricity-storage device using said non-aqueous electrolyte solution; and a specific organic phosphorus compound. In the formula, R1 and R2 each independently represent an alkyl group, a cycloalkyl group, an alkenyl group, an alkynyl group, an alkoxy group, a cycloalkoxy group, an alkenyloxy group, an alkynyloxy group, an alkyl-halide group, an alkoxy-halide group, an aryl group, or an aryloxy group; R3 and R4 each independently represent a hydrogen atom, a halogen atom, or an alkyl group; m represents an integer from 1 to 4; n represents 0 or 1; q represents 1 or 2; if q is 1 and n is 0, X represents an alkoxy group, an alkynyloxy group, an alkyloxy-alkoxy group, an aryloxy group, or the like; if q is 1 and n is 1, X represents an alkyl group, an alkynyl group, an alkoxy group, an alkynyloxy group, an alkyloxy-alkoxy group, or the like; and if q is 2, X represents -O-L3-O-, -OC(=O)-C(=O)O-, or a single bond.

Owner:MU IONIC SOLUTIONS CORP

Non-aqueous electrolyte and power storage device using same

InactiveCN104285332AGood electrochemical propertiesHybrid capacitor electrolytesCell electrodesSolventNon aqueous electrolytes

The present invention relates to [1] a non-aqueous electrolyte in which electrolyte salt is dissolved in a non-aqueous solvent, the non-aqueous electrolyte containing between 0.001 and 5 mass% of a specific acyclic lithium salt and being capable of improving electrochemical properties over a wide temperature range, and [2] a power storage device provided with a positive electrode, a negative electrode, and the non-aqueous electrolyte in which electrolyte salt is dissolved in the non-aqueous solvent, the power storage device containing between 0.001 and 5 mass% of a specific acyclic lithium salt in the non-aqueous electrolyte.

Owner:UBE IND LTD

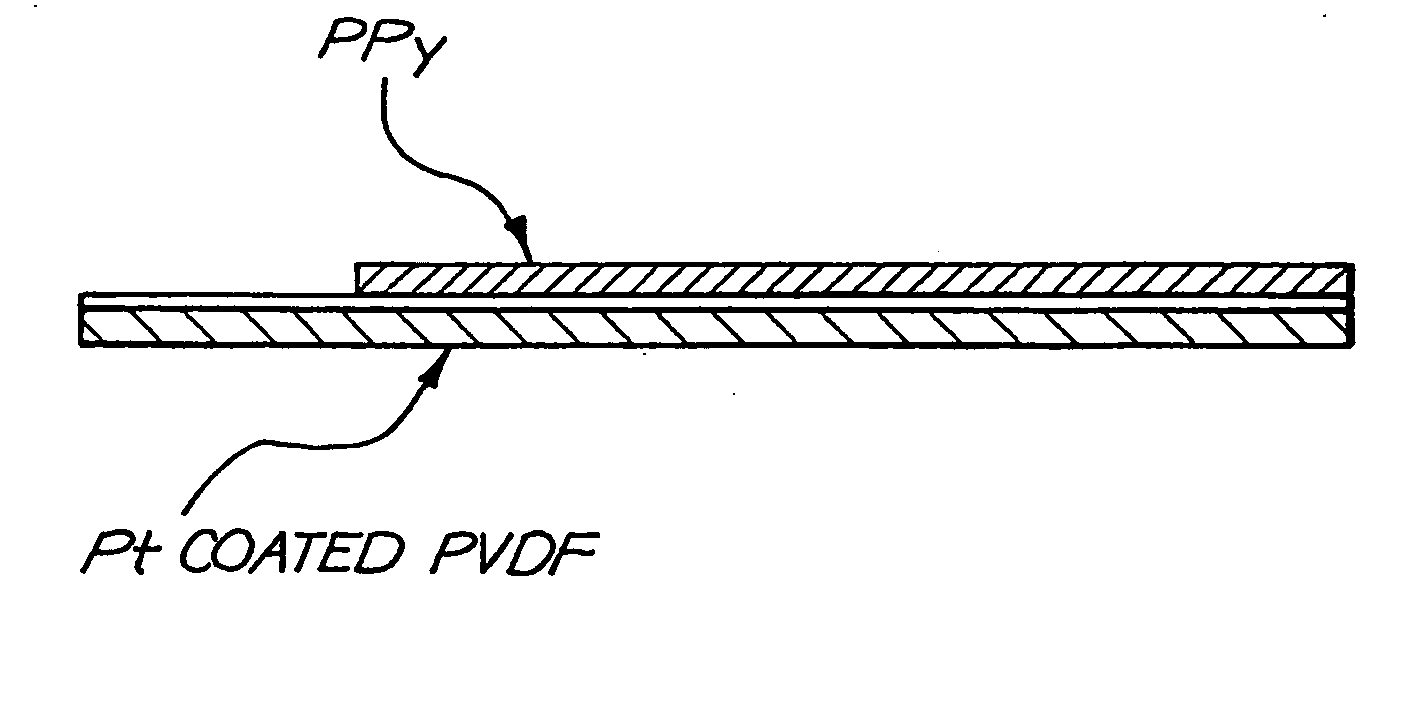

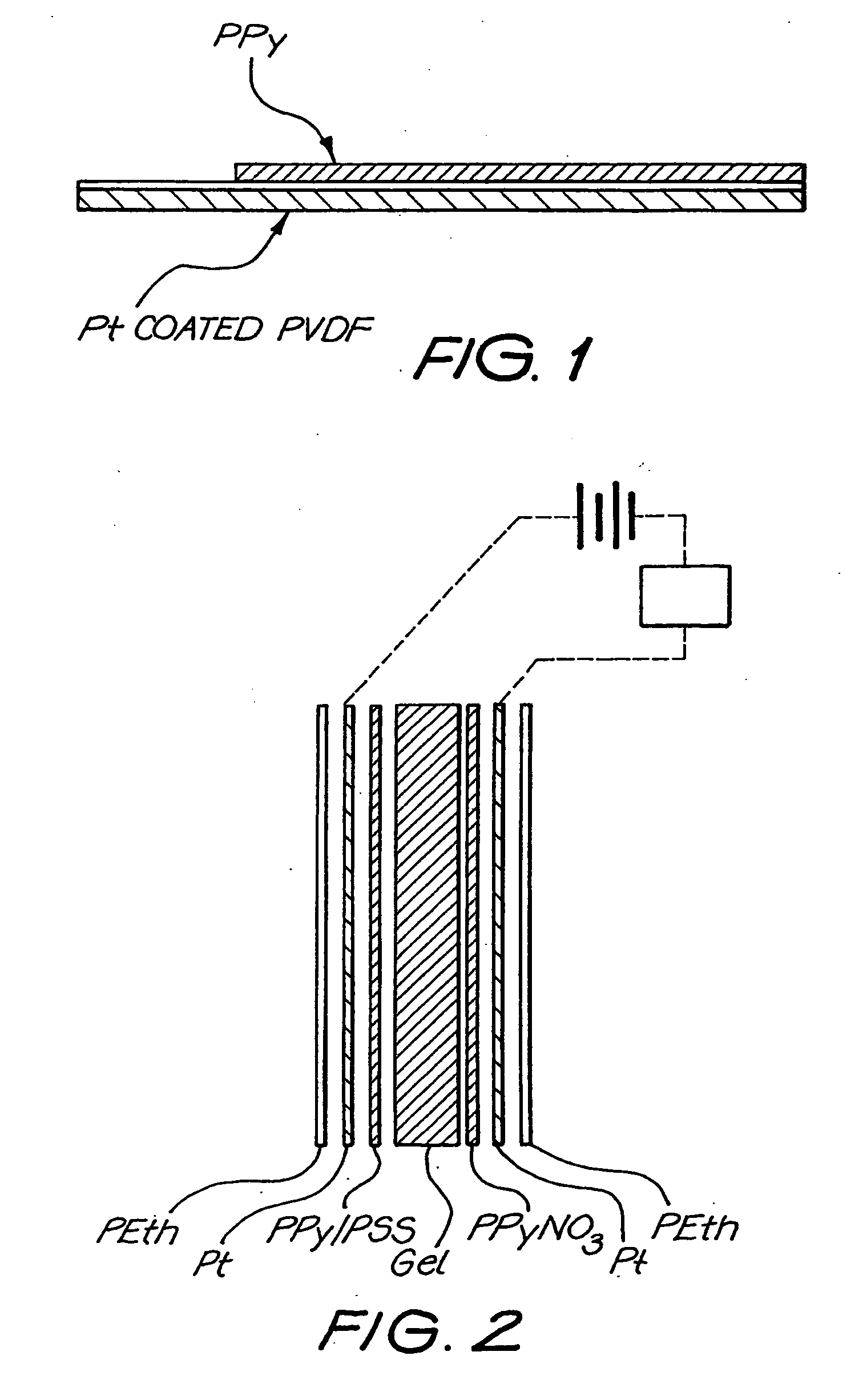

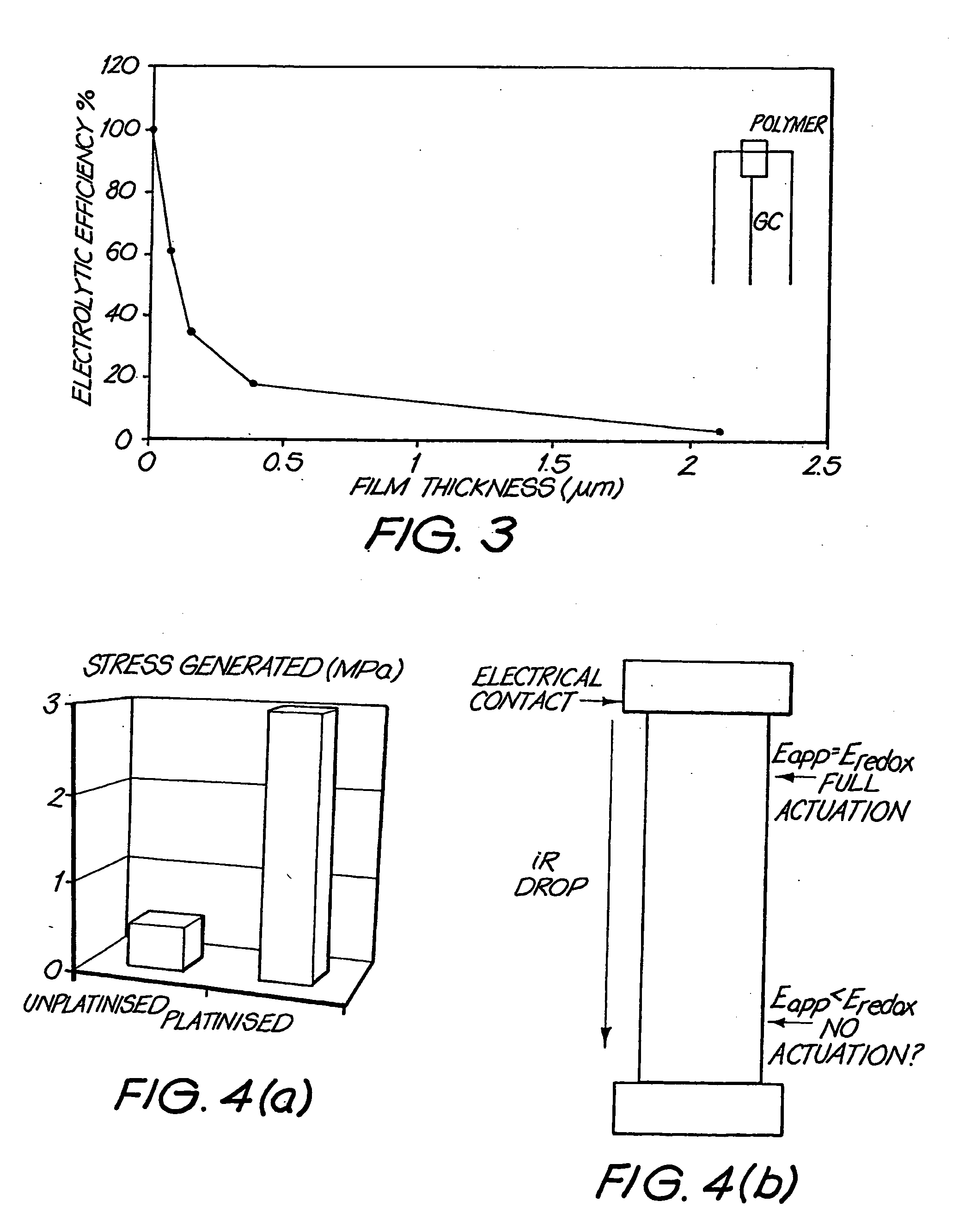

Electromechanical actuator and methods of providing same

InactiveUS20050006989A1Improve featuresGood electrochemical propertiesPiezoelectric/electrostriction/magnetostriction machinesLighting and heating apparatusElectrical conductorConductive polymer

An electromechanical actuator comprising an inherently conducting polymer and a conductor for conducing voltage along the polymer from a first end region thereof. The conductor is adapted for axially extending and contracting with axial expansion and contraction of the polymer. In one form, the conductor is in the form of a helix embedded in the polymer and extends along substantially the entire length of the polymer. Also disclosed is a method for manufacture of the electromechanical actuator.

Owner:UNIV OF WOLLONGONG

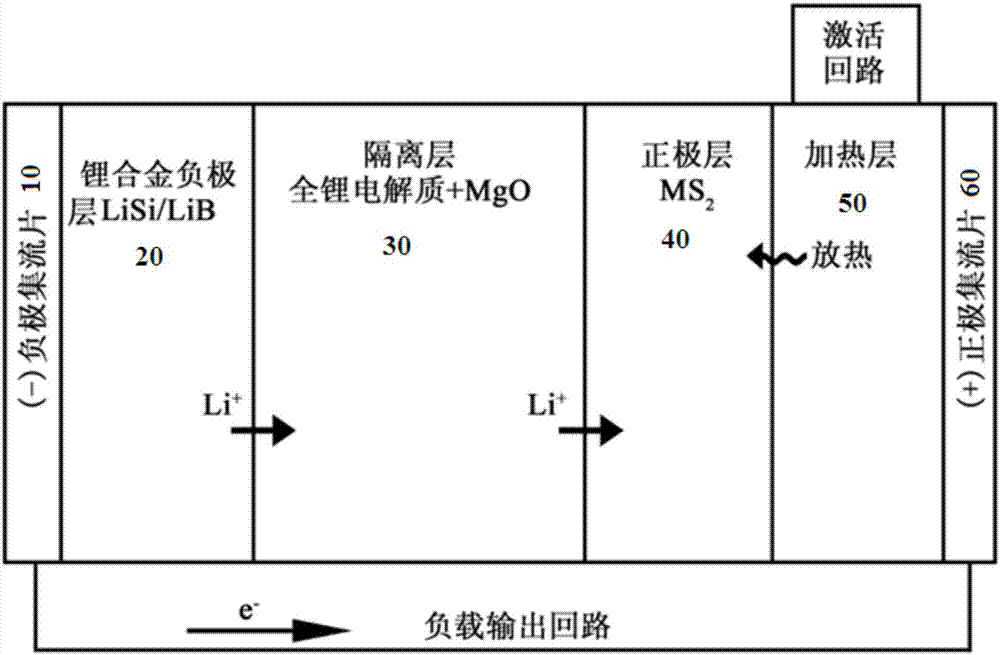

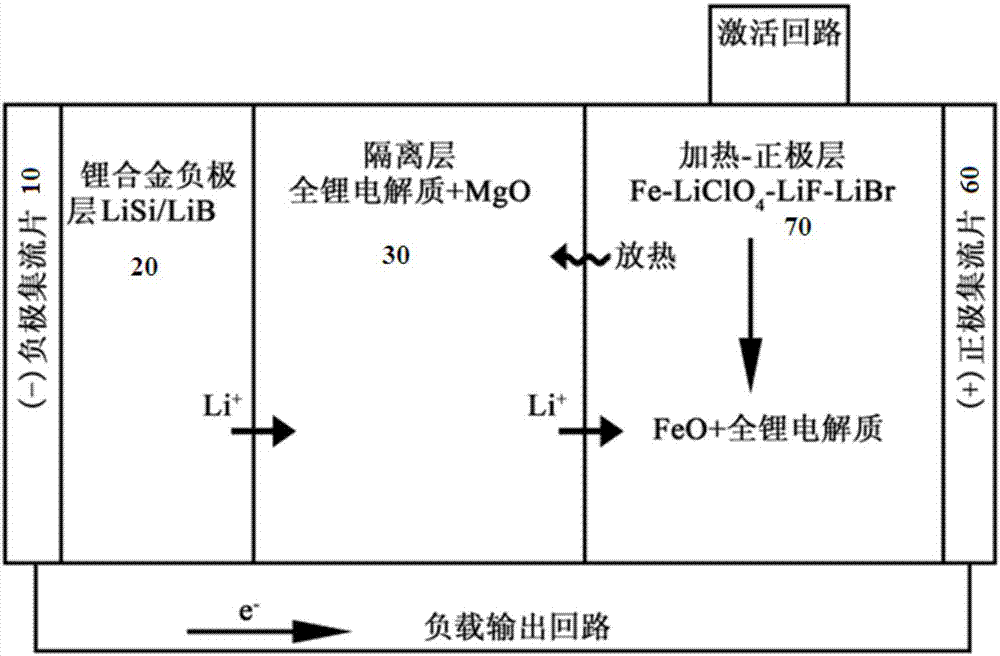

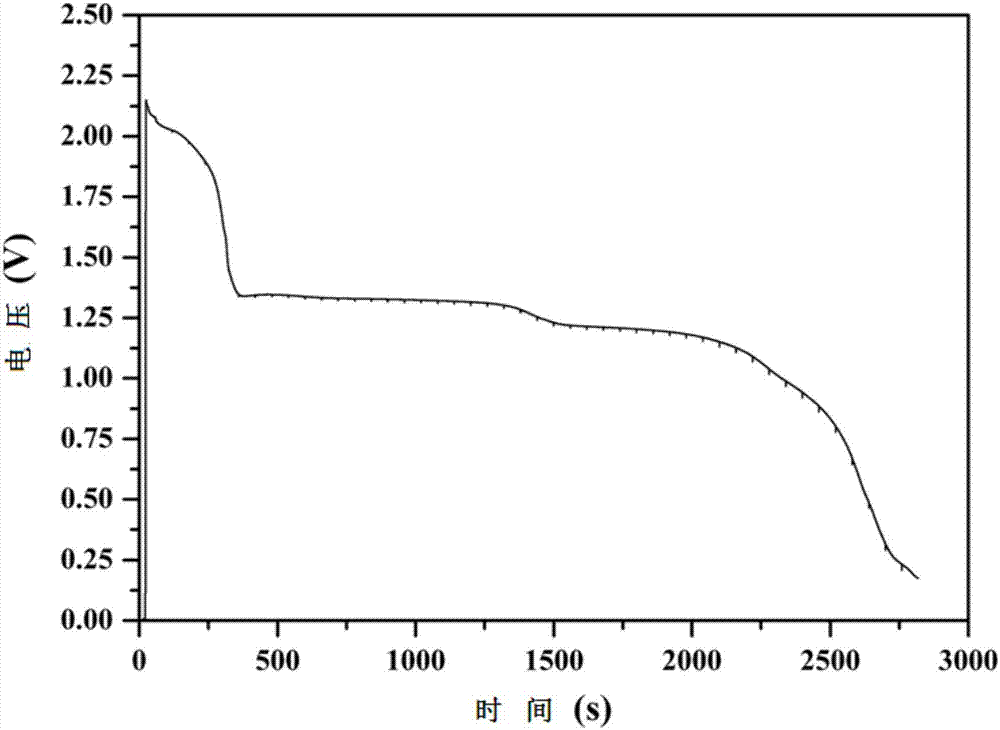

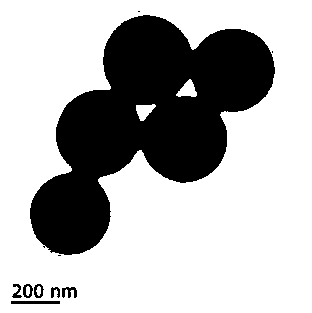

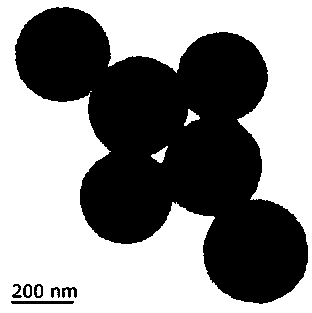

Three-layer structure single battery of thermal battery

InactiveCN107978766AImproved weight-to-weight propertiesImprove versatilityDeferred-action cellsElectrochemical responseExothermic reaction

The invention discloses a three-layer structure single battery of a thermal battery. The single battery comprises a negative current collector plate, a lithium alloy negative electrode layer, an isolation layer, a heating-positive electrode layer and a positive current collector plate which are sequentially laminated, wherein the heating-positive electrode layer is prepared from active Fe powder,LiClO4, anhydrous LiF and anhydrous LiBr. A positive electrode layer in a traditional four-layer structure single thermal battery is abandoned; a novel heating material of LiClO4-active Fe powder is utilized and then the anhydrous LiF and the anhydrous LiBr are added to the novel heating material to form the heating-positive electrode layer; the design of heating powder of the thermal battery is changed; a product after exothermic reaction is ended is directly subjected to electrochemical reaction as a positive electrode material for the thermal battery, so that the specific capacity of the single battery of the thermal battery is significantly improved, the cost is greatly reduced since a traditional sulfide positive electrode material is no longer used, and the economical efficiency is good. Furthermore, the preparation technology of the single battery disclosed by the invention is consistent with that of a traditional thermal battery, the universality of the production process is high, the economical efficiency is good and the single battery has a good engineering application prospect.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Preparation method of carbon-coated tungsten sulfide hollow nanosphere with shell layer with sandwich structure

InactiveCN107611388AUniform particle sizeStable structureCell electrodesSecondary cellsThioureaSulfide

The invention relates to a preparation method of a carbon-coated tungsten sulfide hollow nanosphere with a shell layer with a sandwich structure, and belongs to the technical field of production of anano material. The preparation method comprises the steps of: mixing alcohol, deionized water, ammonium hydroxide, ethyl orthosilicate, resorcinol and formaldehyde to perform a reaction, obtaining a solid phase to dry, and after calcining in argon, etching by aqueous solution of sodium hydroxide to obtain a hollow mesoporous carbon nanosphere; and after dissolving tungsten chloride and thiourea solid in the deionized water, adding the hollow mesoporous carbon nanosphere, after carrying out ultrasonic dispersion, performing a hydrothermal reaction, and after obtaining a solid phase to dry, calcining in the argon so as to obtain the carbon-coated tungsten sulfide hollow nanosphere of which the shell layer has the sandwich structure. The preparation method disclosed by the invention has the characteristics of cheap process raw material, simple and environmental-friendly process, high yield and excellent performance; the prepared carbon-coated tungsten sulfide hollow nanosphere of which the shell layer has the sandwich structure can be applied as a lithium ion battery electrode material, a photocatalysis material or an electro-catalysis material.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com