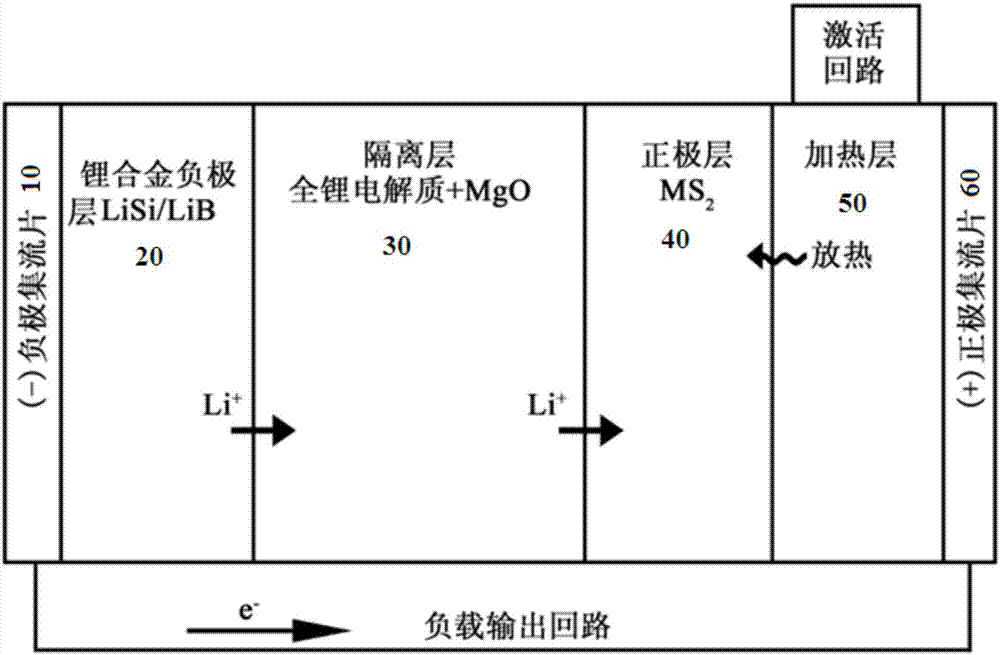

Three-layer structure single battery of thermal battery

A single battery, three-layer structure technology, applied in the direction of delayed action cells, etc., can solve the problems of no practical application and poor discharge effect, and achieve the effect of improving the weight ratio, high versatility and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

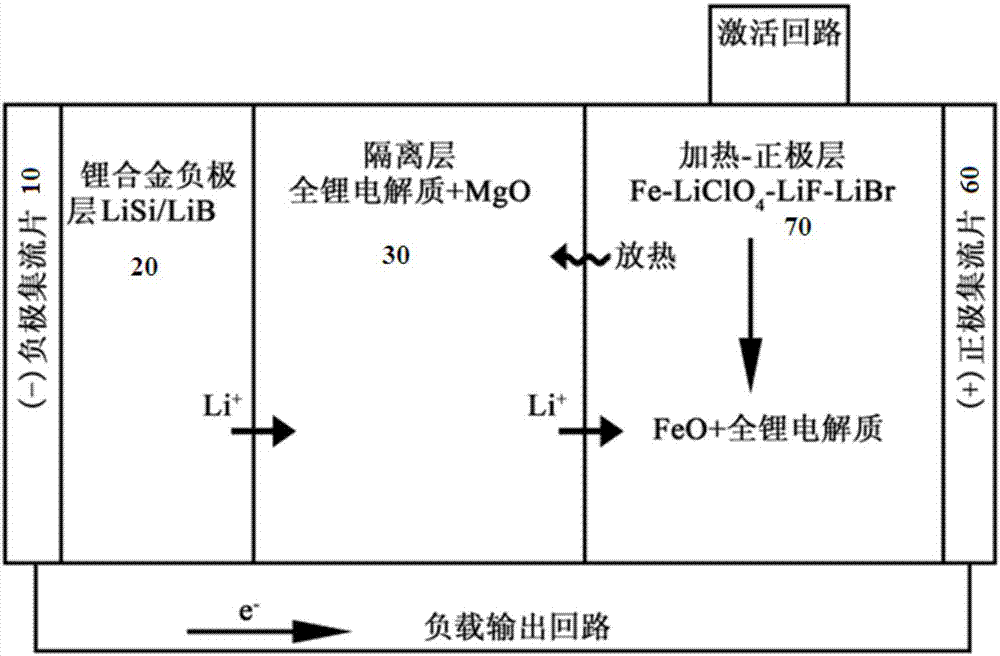

Method used

Image

Examples

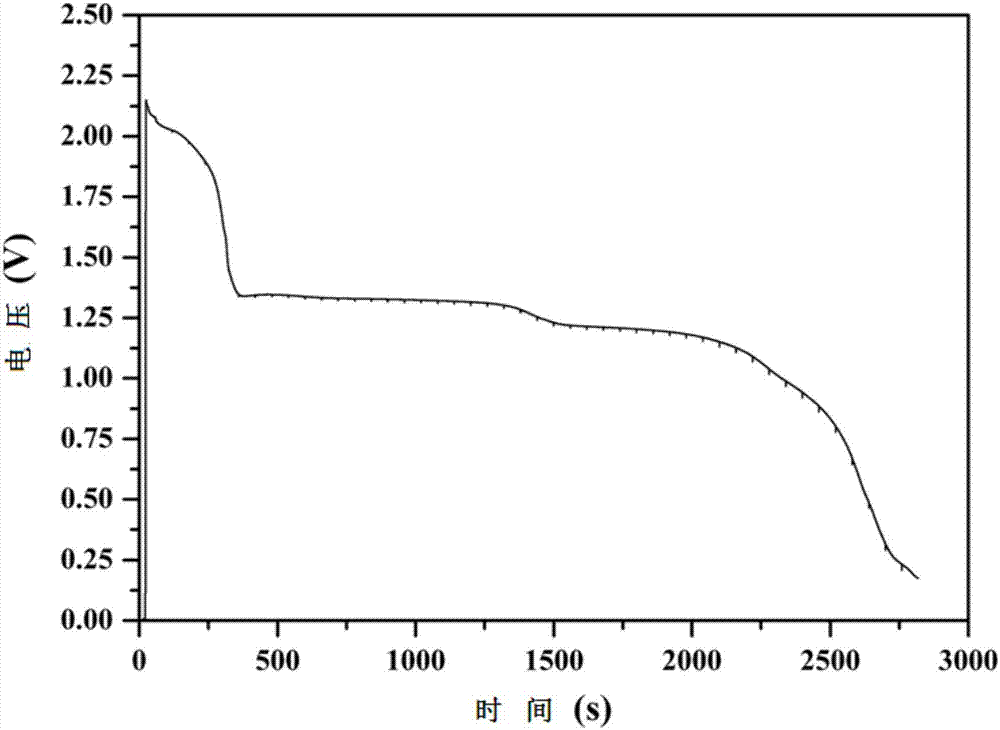

Embodiment 1

[0032] Take the required raw materials according to the content of each component in the heating-positive electrode layer, and the total weight of the raw materials is 3g, wherein the mass percentage of active Fe powder is: 62.4%, LiClO 4 The mass percentage of LiF is 15.6%, the mass percentage of anhydrous LiF is 2.7%, and the mass percentage of anhydrous LiBr is 19.3%. After drying, sieve with a 100-mesh sieve frame, and sieve 30-40 times until the four components are evenly mixed to obtain the required heating powder. Take by weighing 1.0g of LiB alloy, 2.5g of total lithium spacer powder (the mass percentage of MgO is 60%, and the balance is LiF-LiCl-LiBr eutectic salt, and in this eutectic salt, the mass percentage of LiF is 9% , the mass percentage of LiCl is 22%, and the mass percentage of LiBr is 69%). Conduct electrical performance test after assembling the single battery, the test temperature is 550°C, and the steady-state current density is 50mA / cm 2 , pulse curre...

Embodiment 2

[0034] Take the required raw materials according to the content of each component in the heating-positive electrode layer, and the total weight of the raw materials is 3g, wherein the mass percentage of active Fe powder is: 75.2%, LiClO 4The mass percentage of LiF is 10.3%, the mass percentage of anhydrous LiF is 1.8%, and the mass percentage of anhydrous LiBr is 12.7%. After drying, sieve with a 100-mesh sieve frame, and sieve 30-40 times until the four components are evenly mixed to obtain the required heating powder. Take by weighing LiSi alloy 1.0g, all lithium spacer powder 2.5g (the mass percentage composition of MgO is 40%, and surplus is LiF-LiCl-LiBr eutectic salt, and the mass percentage of LiF is 9% in this eutectic salt, The mass percent of LiCl is 22%, and the mass percent of LiBr is 69%). After the single battery is assembled, the electrical performance test is carried out. The weight specific capacity of the single battery is 300A·s / g.

Embodiment 3

[0036] Take the required raw materials according to the content of each component in the heating-positive electrode layer, and the total weight of the raw materials is 3g, wherein the mass percentage of active Fe powder is: 68.5%, LiClO 4 The mass percentage of LiF is 13.0%, the mass percentage of anhydrous LiF is 2.3%, and the mass percentage of anhydrous LiBr is 16.2%. After drying, sieve with a 100-mesh sieve frame, and sieve 30-40 times until the four components are evenly mixed to obtain the required heating powder. Take by weighing LiB alloy 1.0g, all lithium spacer powder 2.5g (the mass percent composition of MgO is 50%, and surplus is LiF-LiCl-LiBr eutectic salt, and in this eutectic salt, the mass percent of LiF is 9% , the mass percentage of LiCl is 22%, and the mass percentage of LiBr is 69%). After the single battery is assembled, the electrical performance test is carried out, and the weight specific capacity of the single battery is 340A·s / g.

[0037] In summar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com