Patents

Literature

2287 results about "Lithium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium titanate is a compound with the chemical formula Li₂TiO₃. It is a white powder with a melting point of 1,325 °C (2,417 °F). Lithium titanate is the anode component of the fast recharging lithium-titanate battery. It is also used as an additive in porcelain enamels and ceramic insulating bodies based on titanates. It is frequently utilized as a flux due to its good stability. In recent years, along with other lithium ceramics, metatitanate pebbles have been the subject of research efforts towards tritium breeding materials in nuclear fusion applications.

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

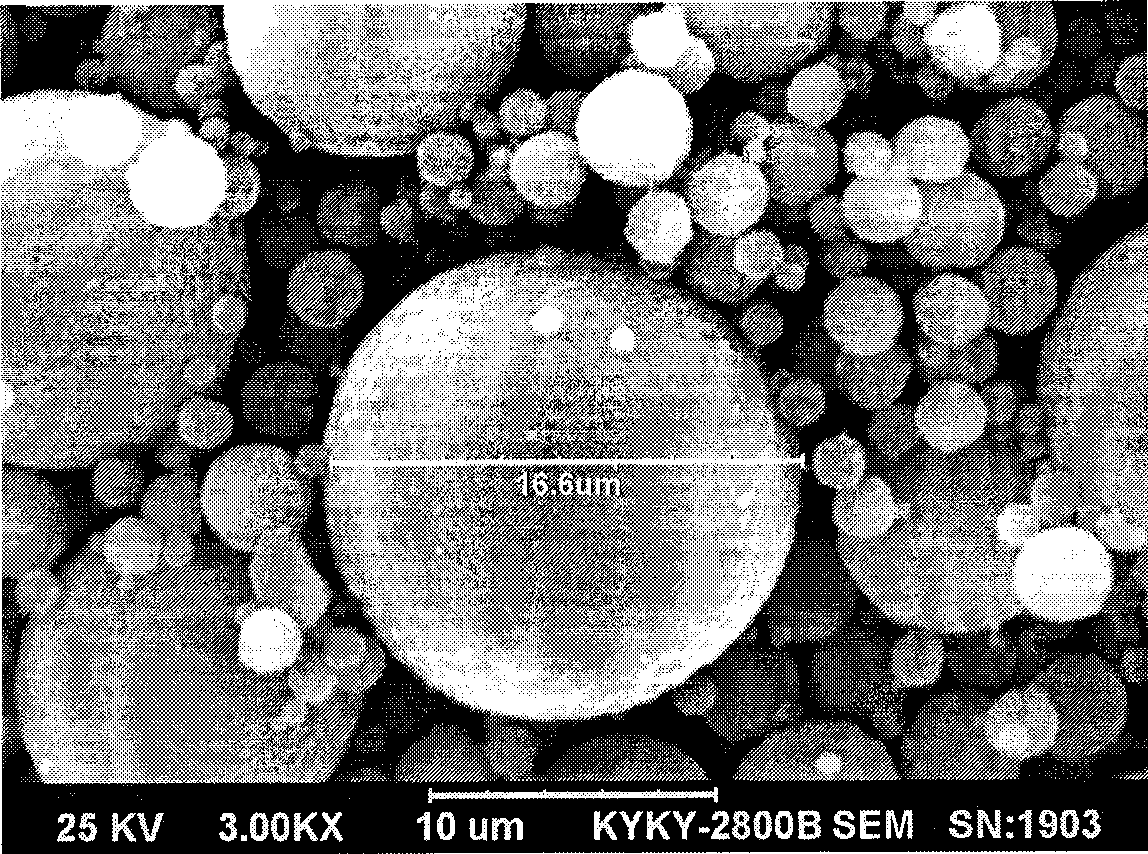

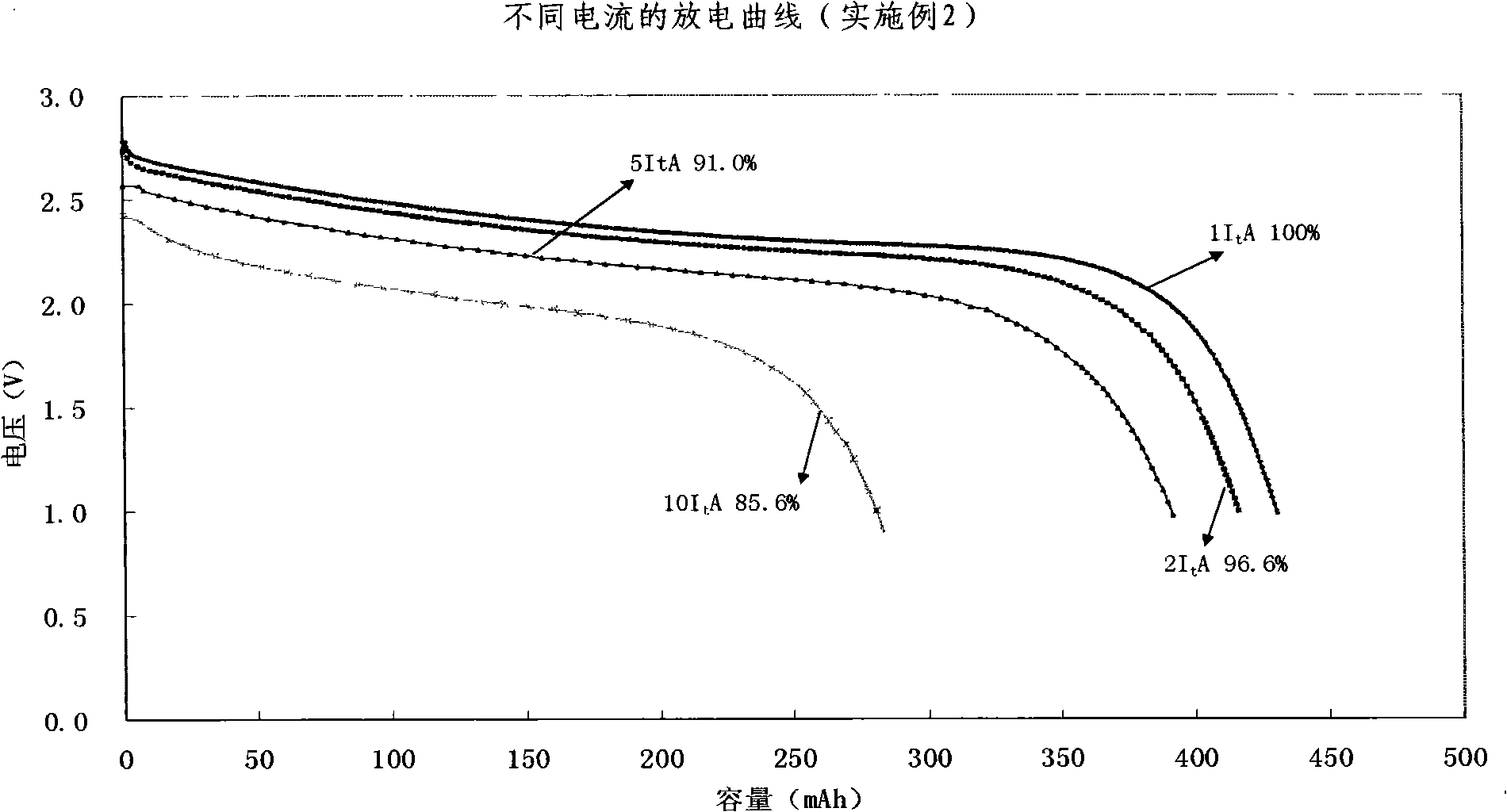

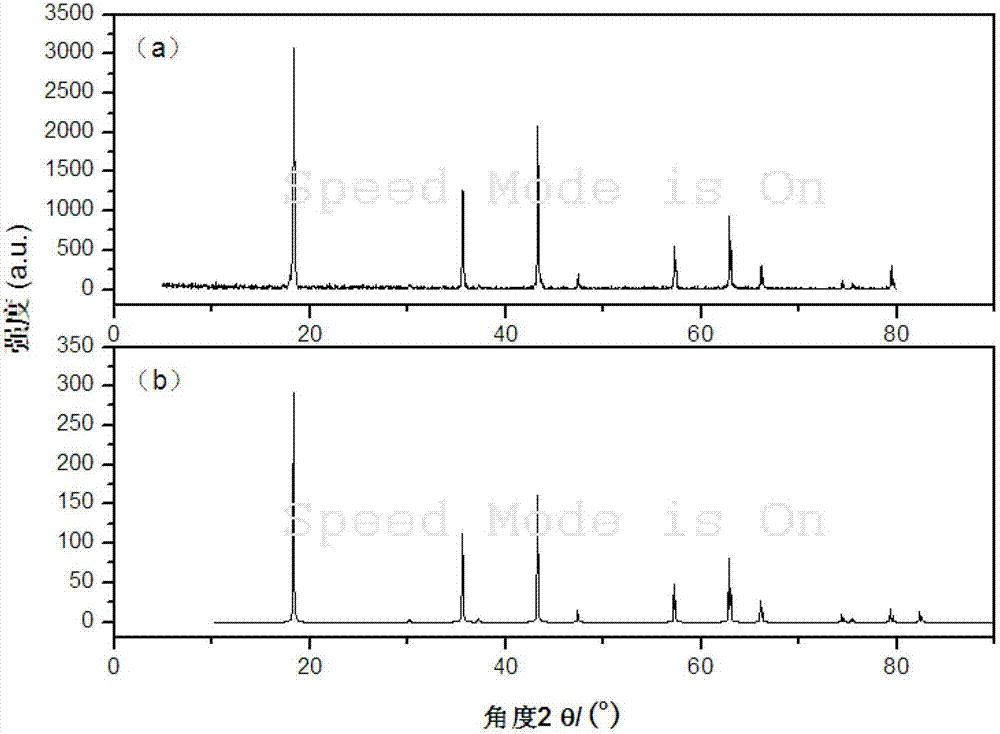

ActiveCN101373829AIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

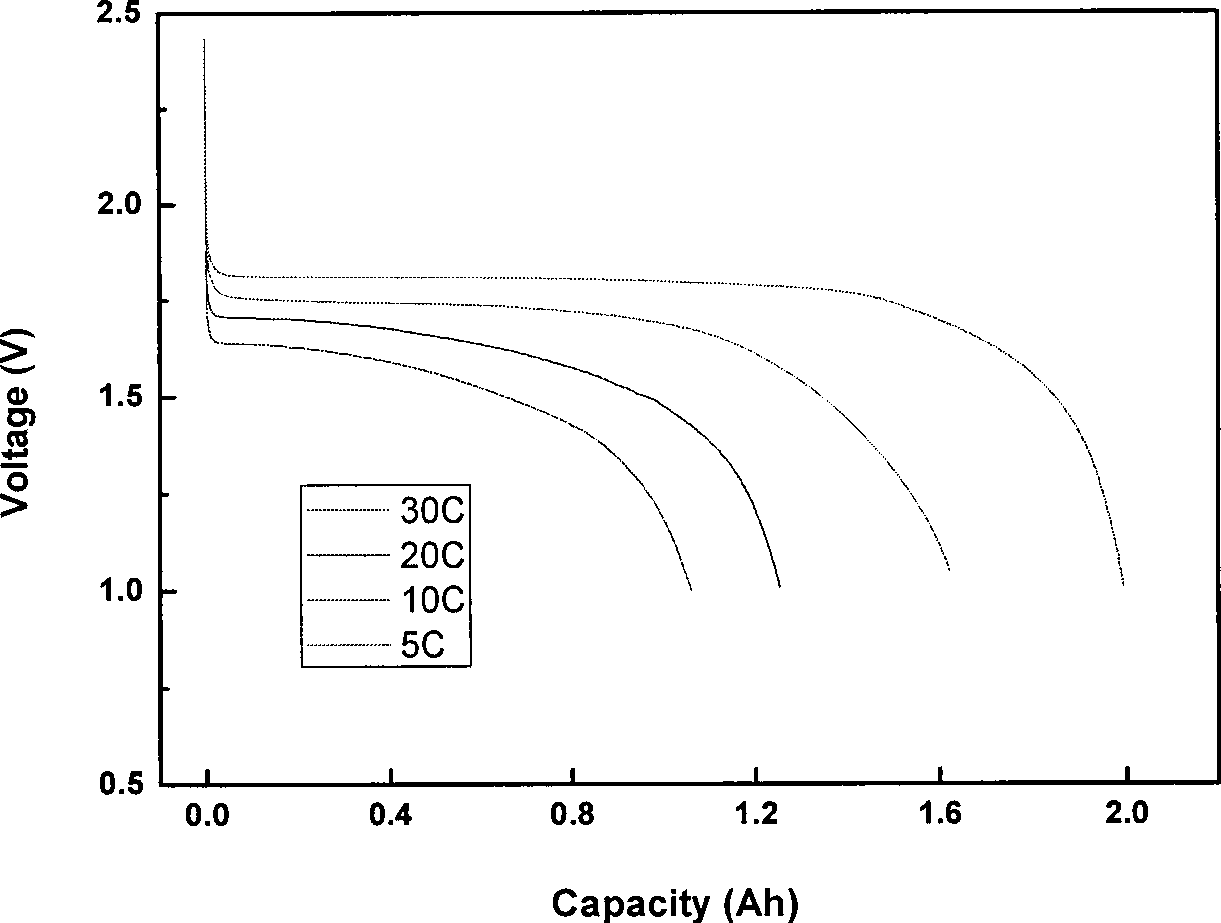

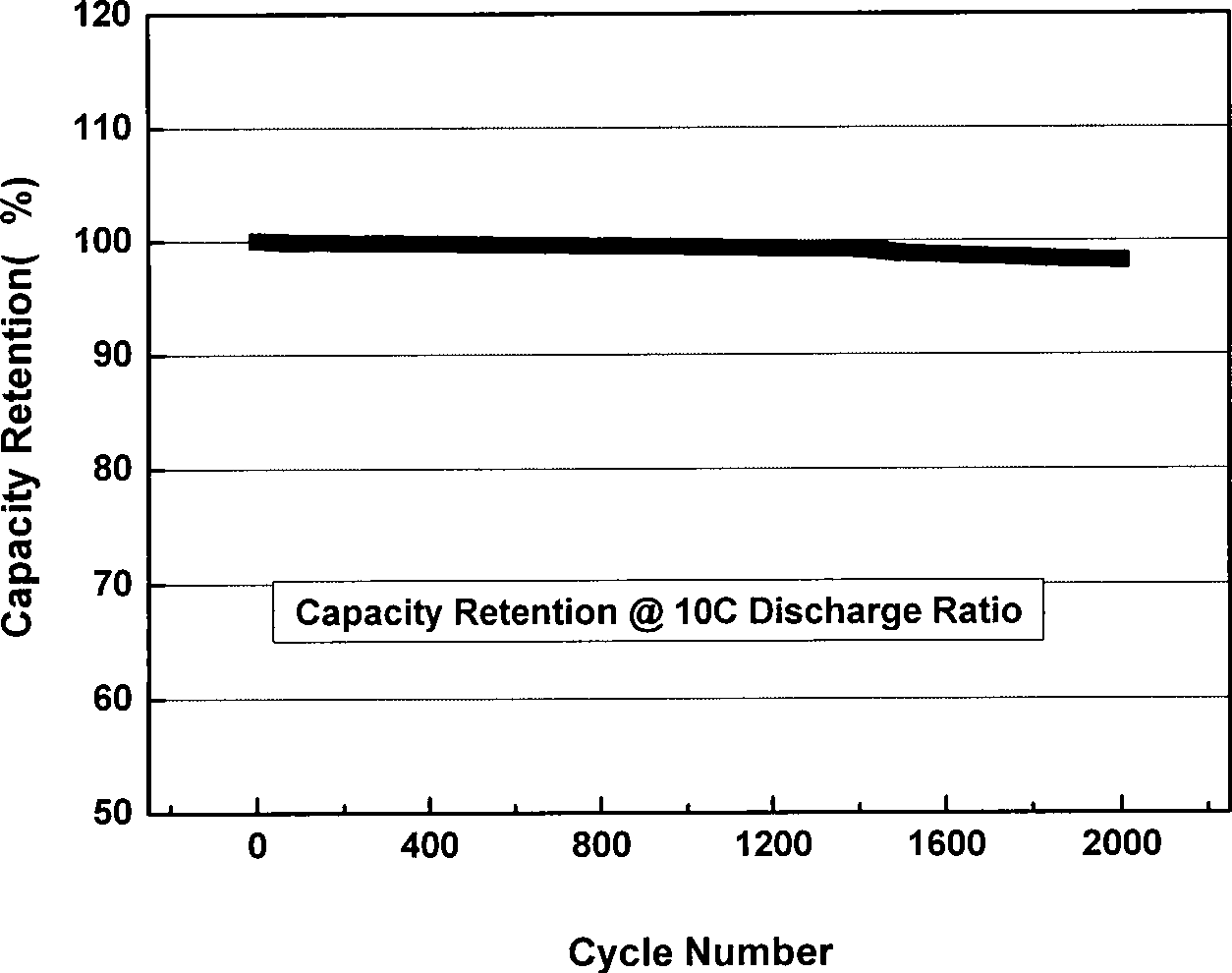

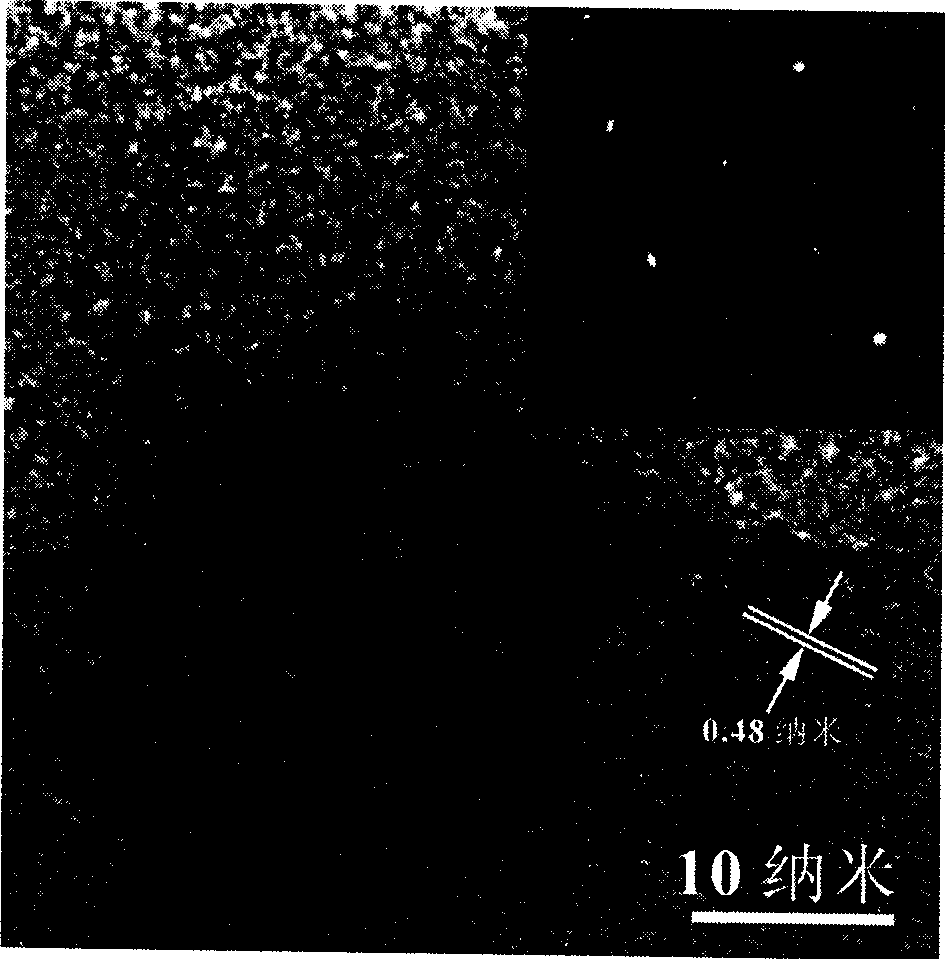

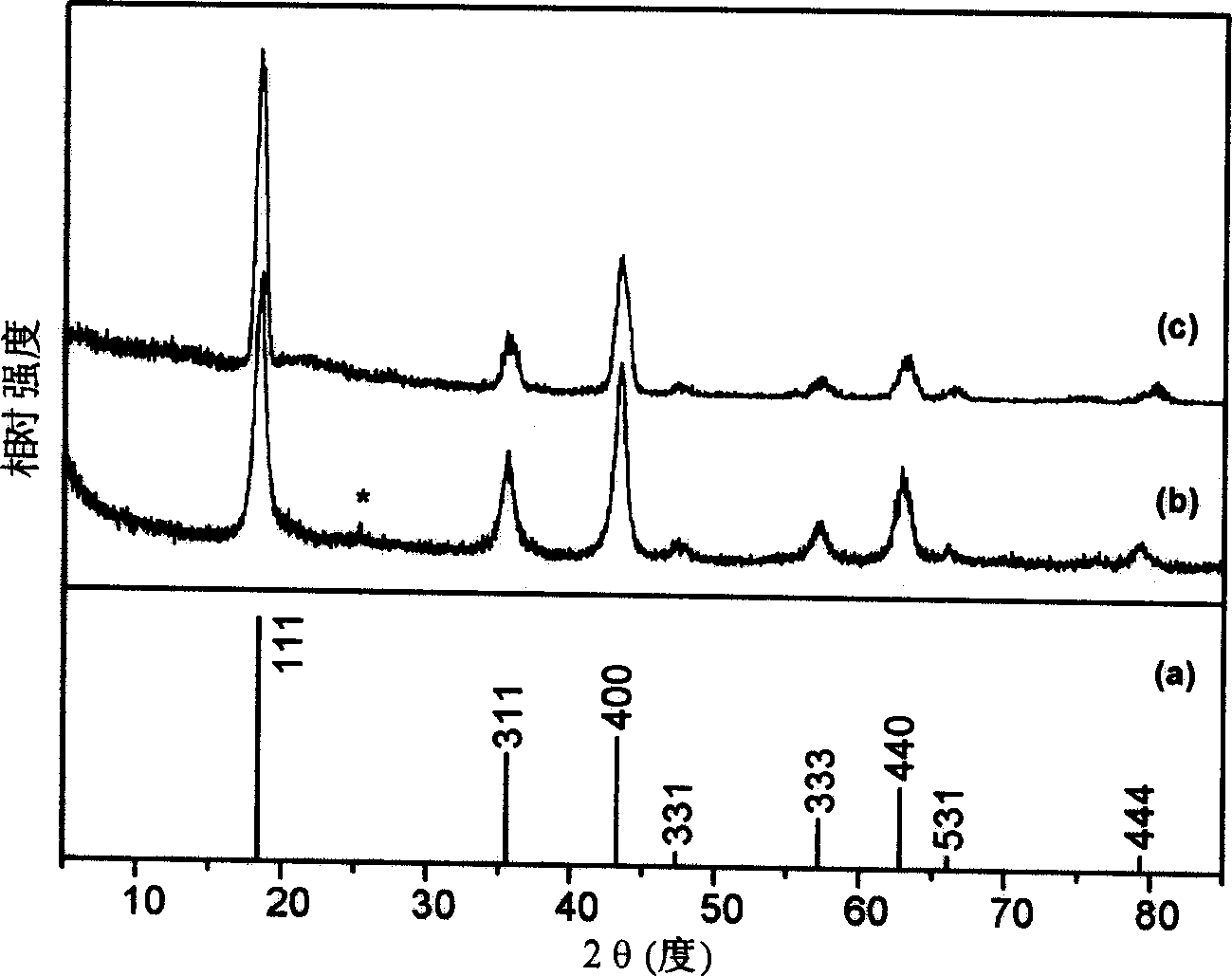

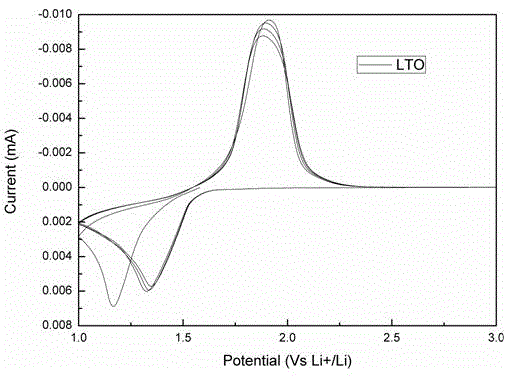

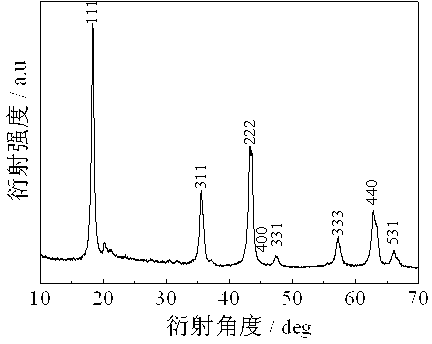

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, and aims to solve the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

Composite lithium titanate electrode material and preparation method thereof

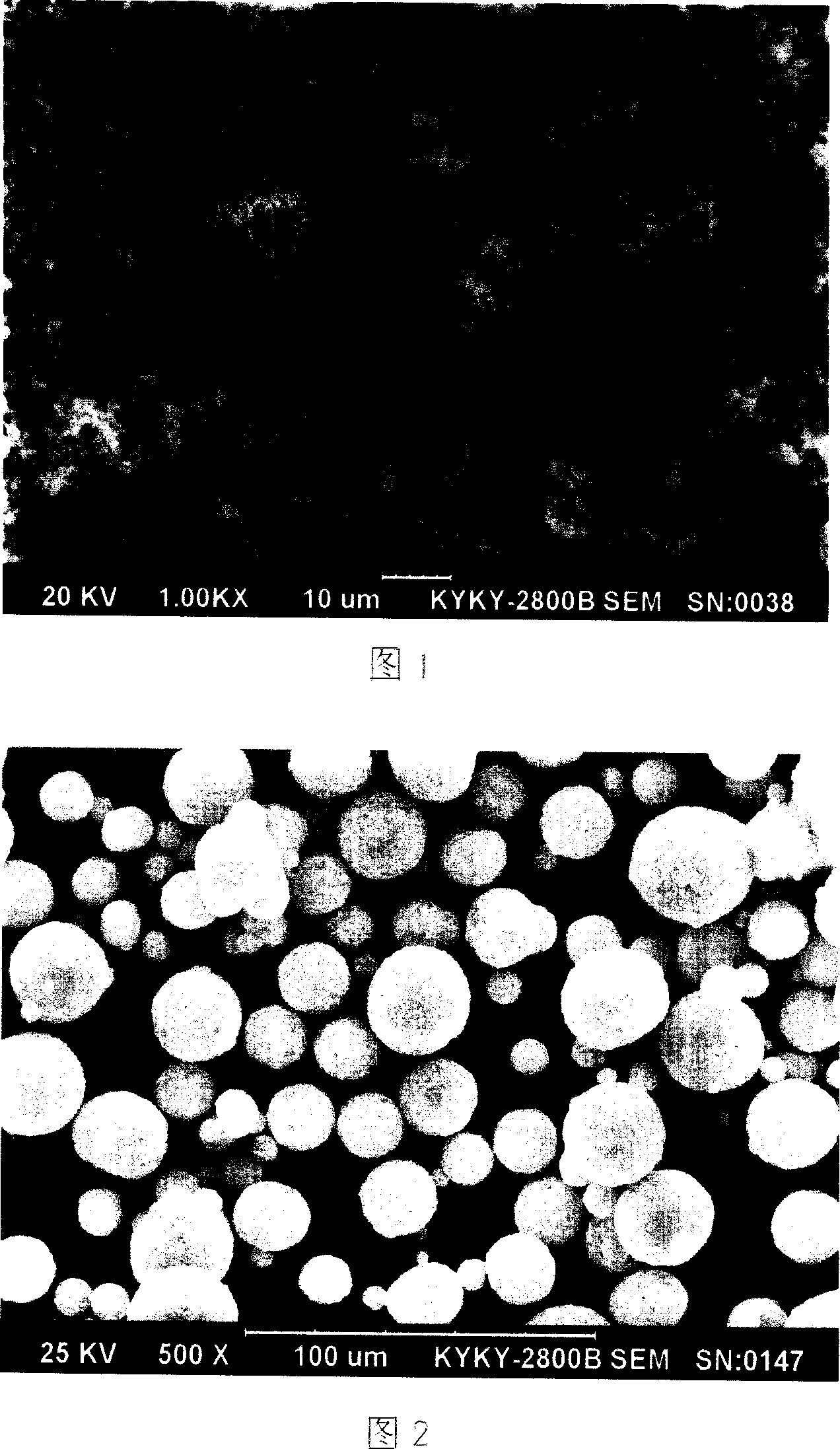

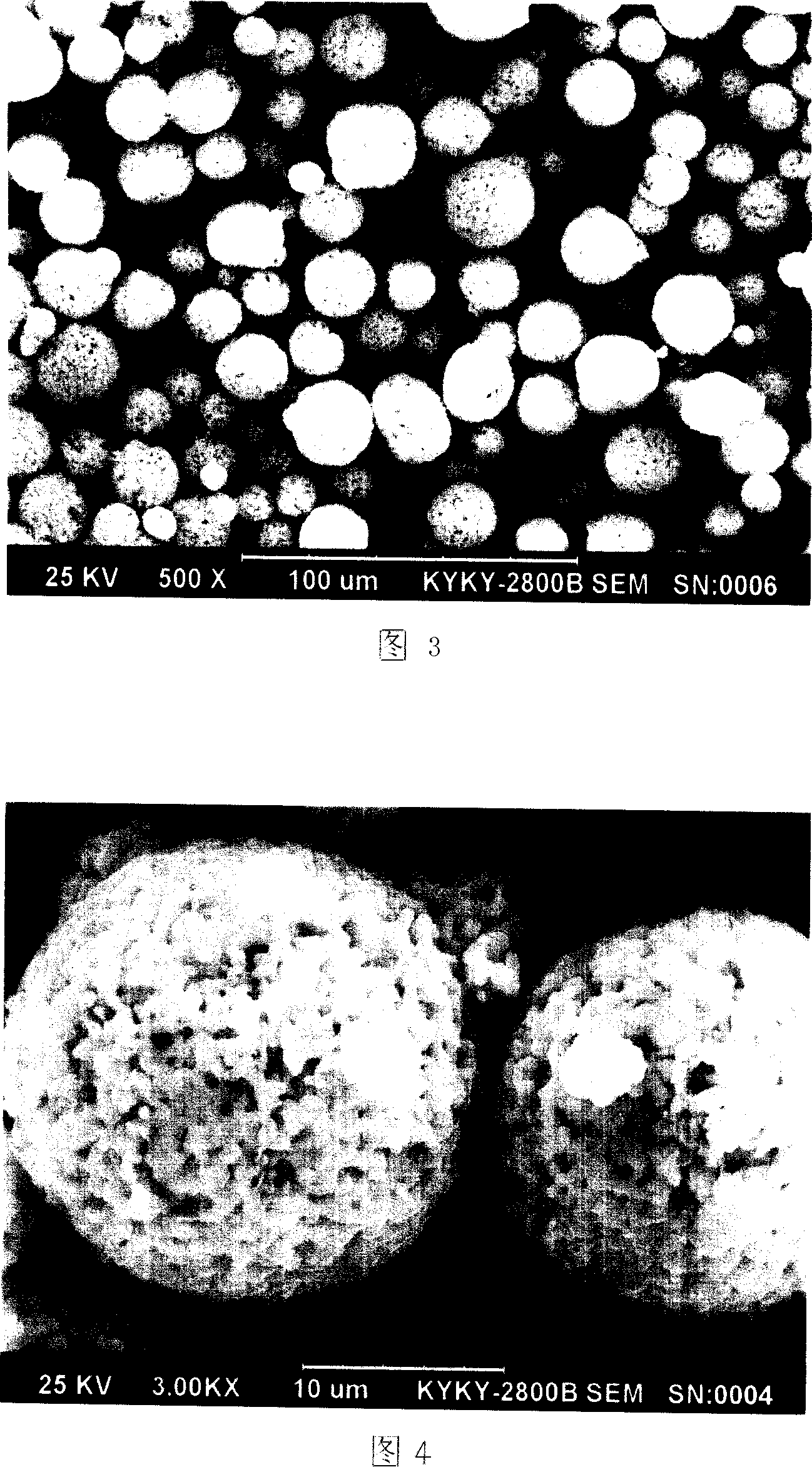

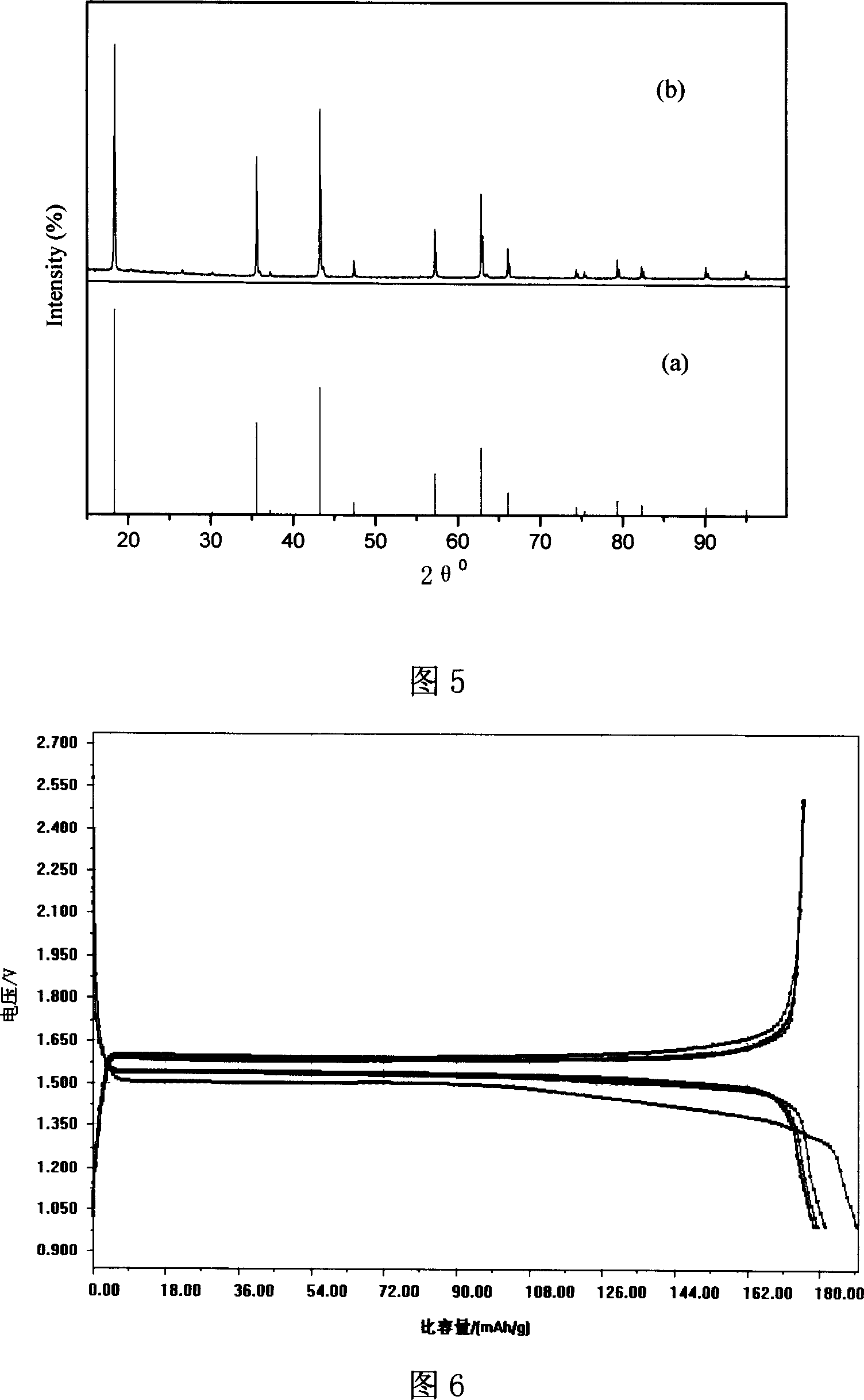

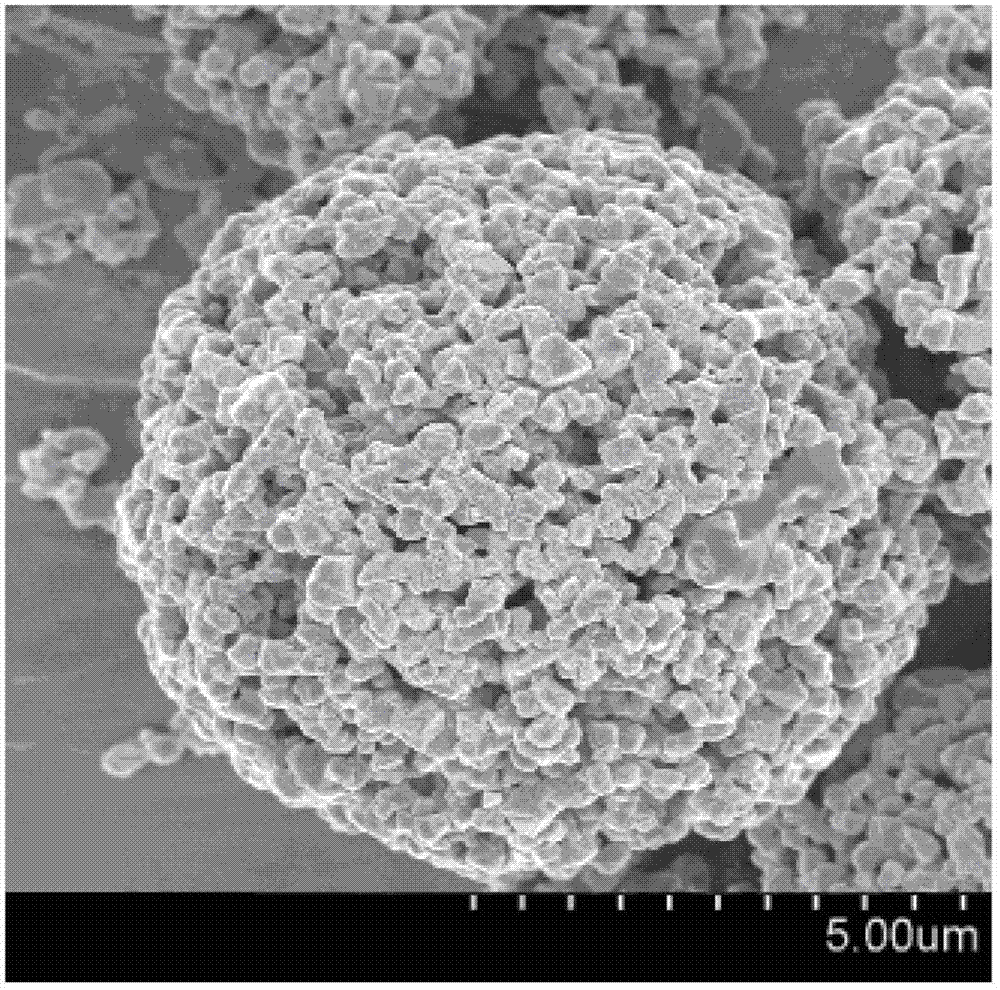

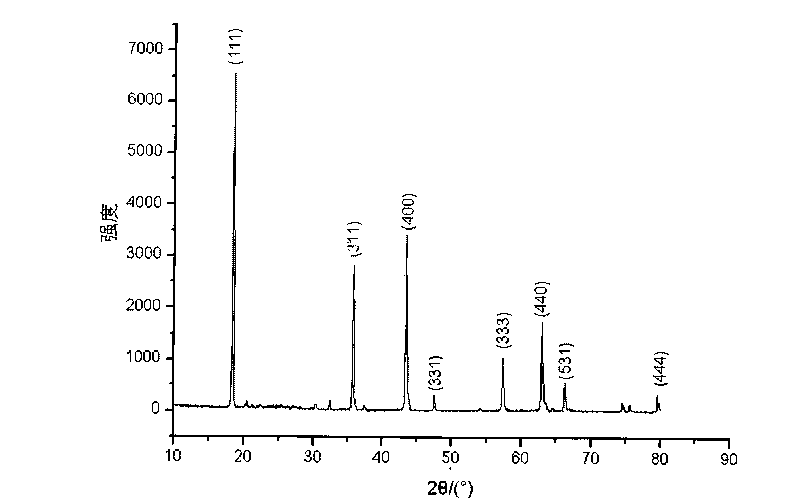

ActiveCN101000960AHigh reversible electrochemical capacityImproved magnification performanceElectrode manufacturing processesChemical/physical/physico-chemical processesHigh rateSpherical shaped

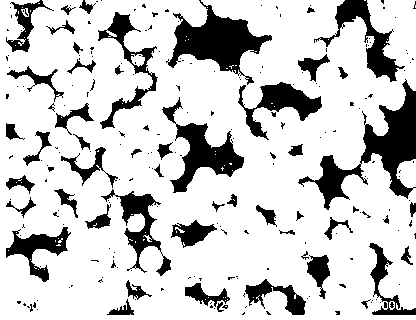

The invention discloses an electrode material of composite lithium titanate and its preparation method, which is secondary particles with spherical or similar spherical shape and porous nanometer channels, which is made from lithium titanate particles, nano-carbon coated materials and doped modifier. The preparation method includes: milling the inorganic lithium salt, titanium dioxide, nano-carbon coated material or doped modifier, scattering them into the organic solvent for further drying, processing heat treatment, and cooling. Comparing with the existing technologies, this electrode material has the high-rate performance, highly reversible electrochemical capacity, and smaller surface area to enhance its first Coulomb efficiency and cycle stability, applying to rechargeable and once-use lithium-ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

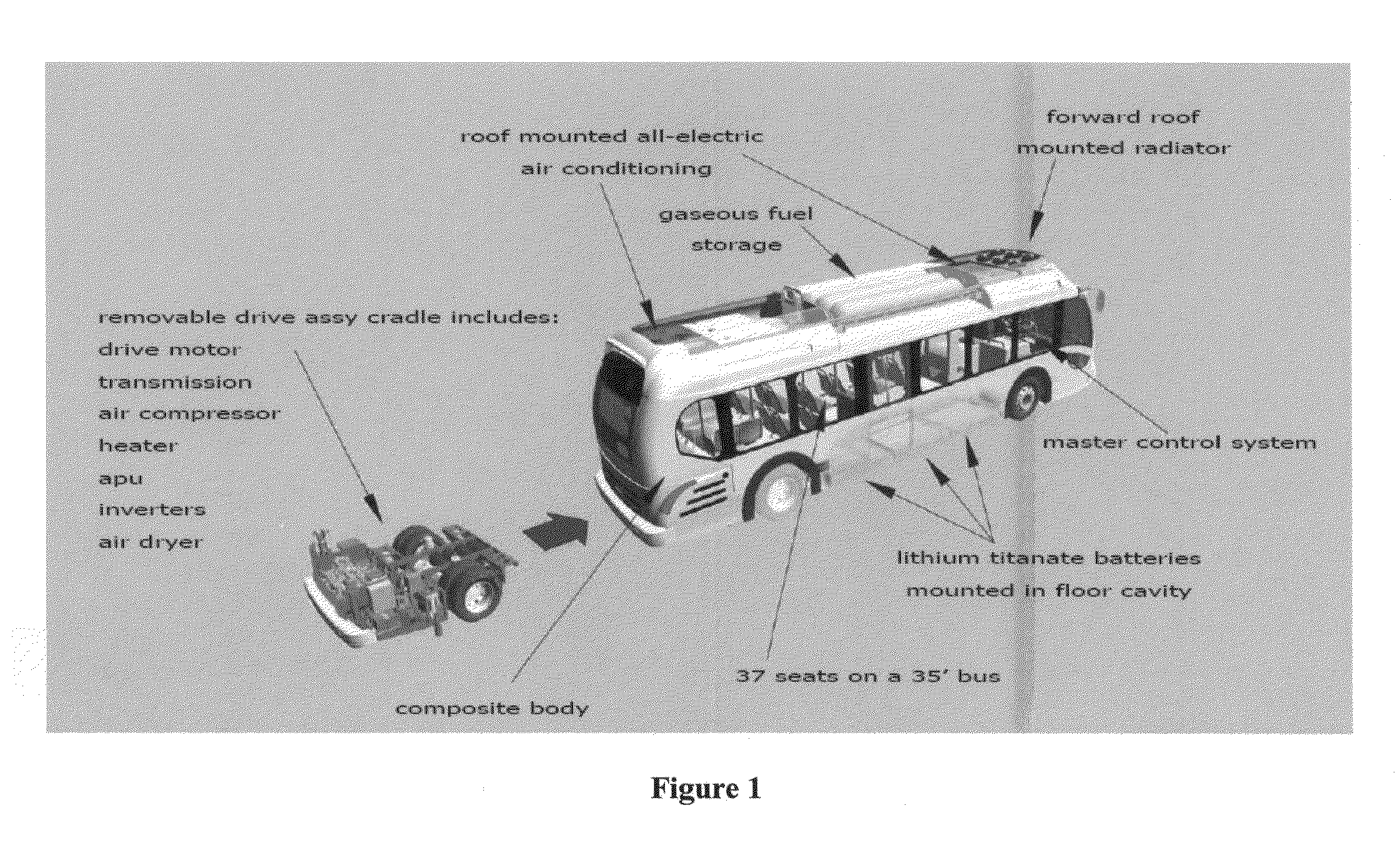

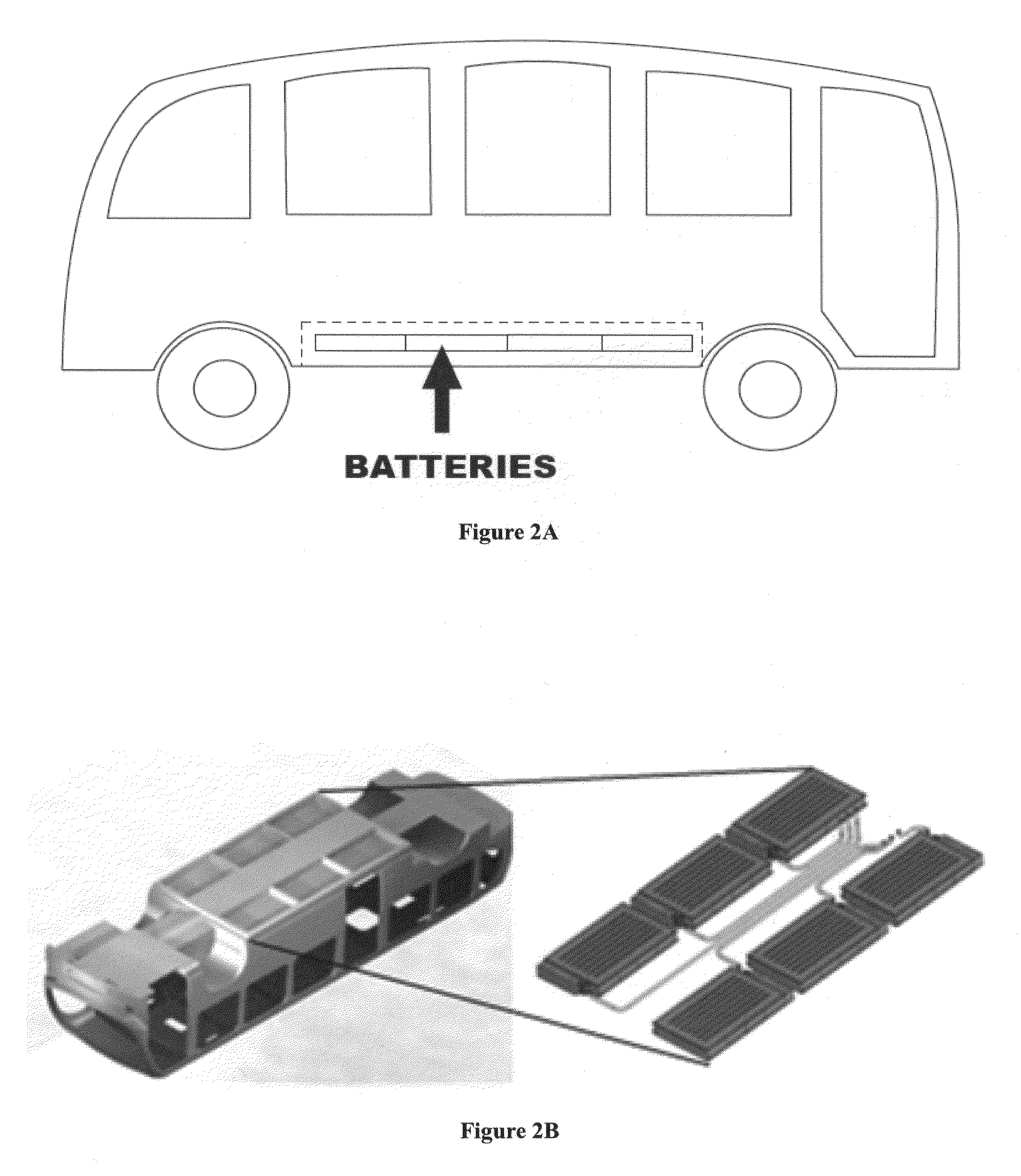

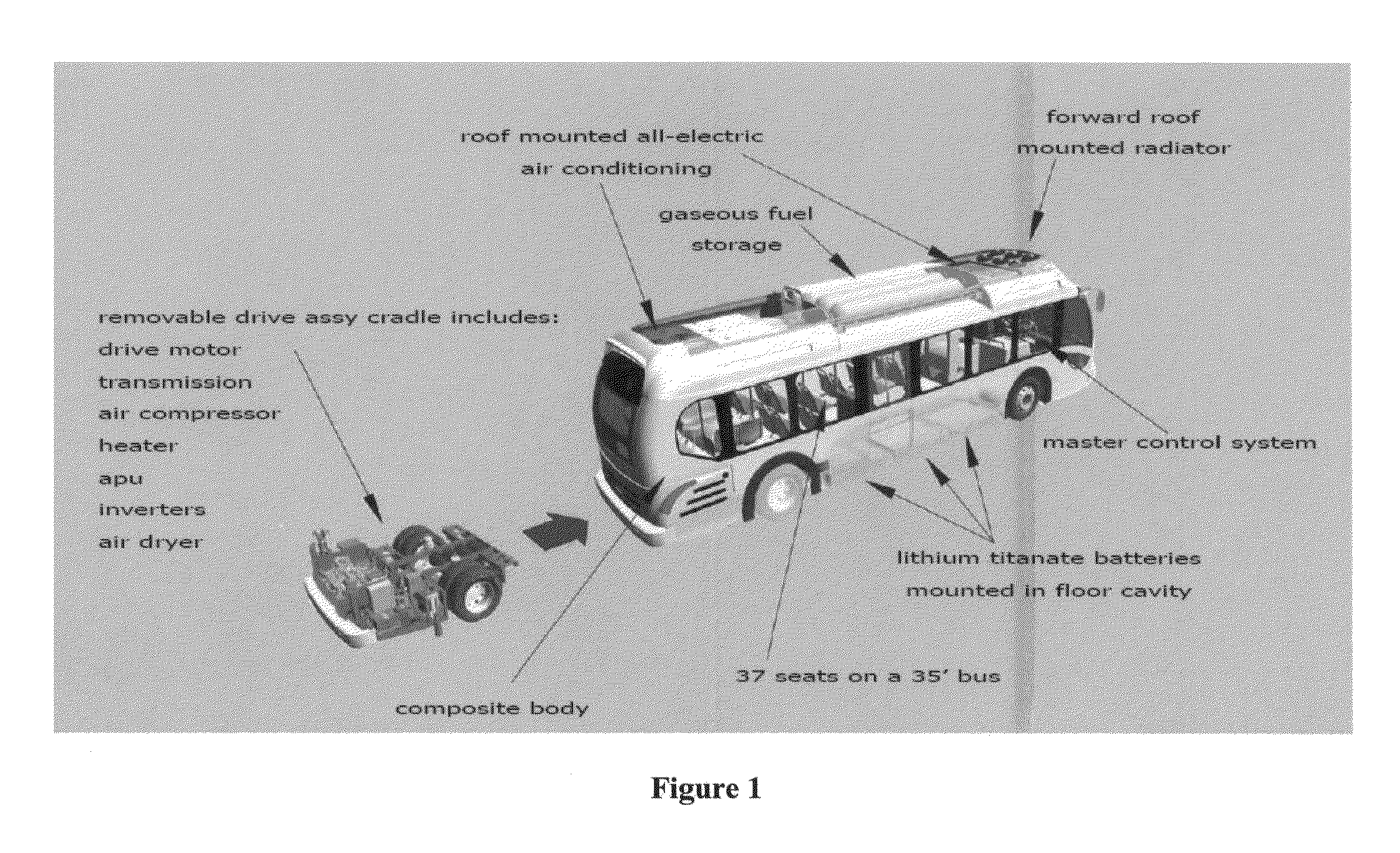

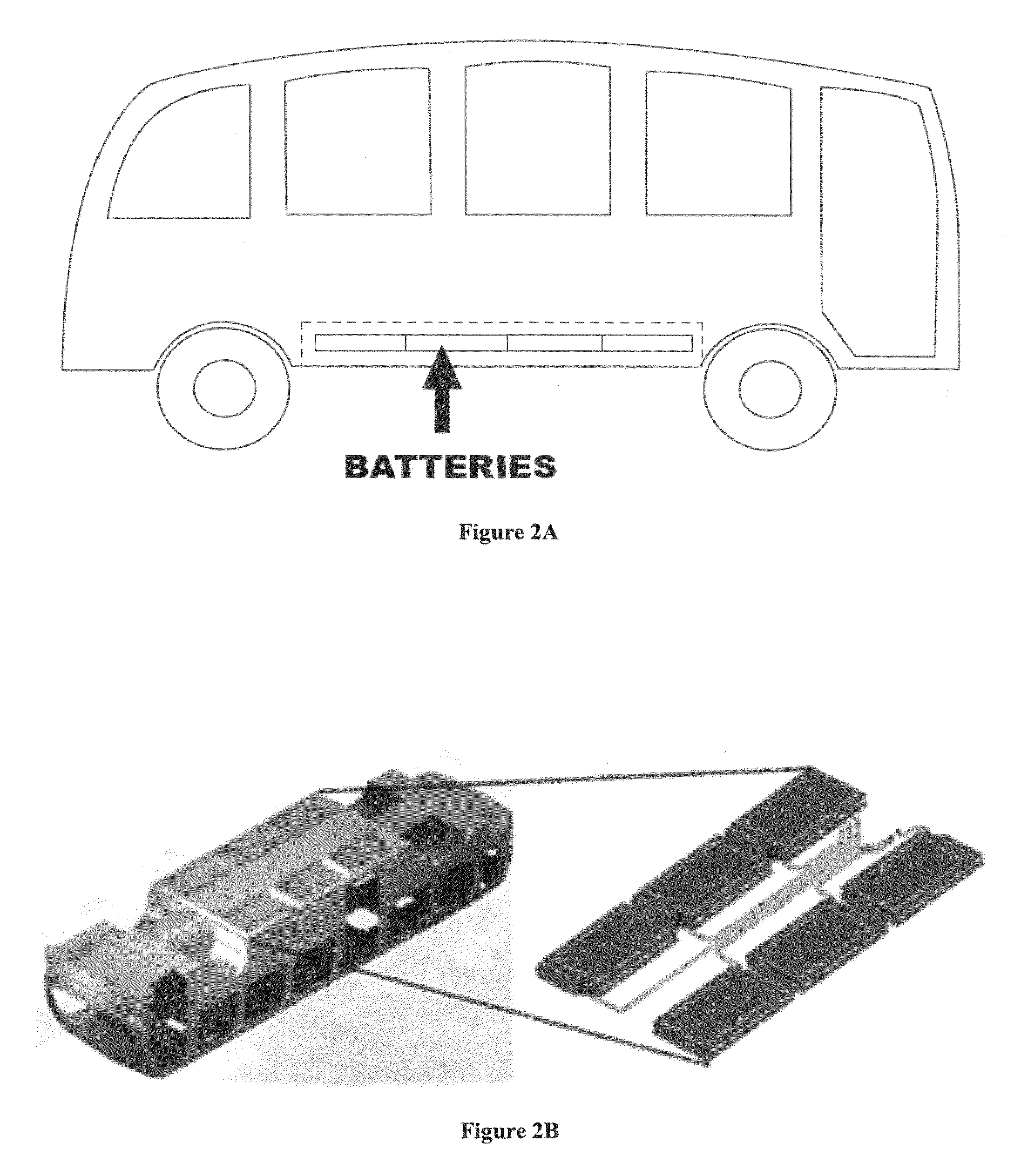

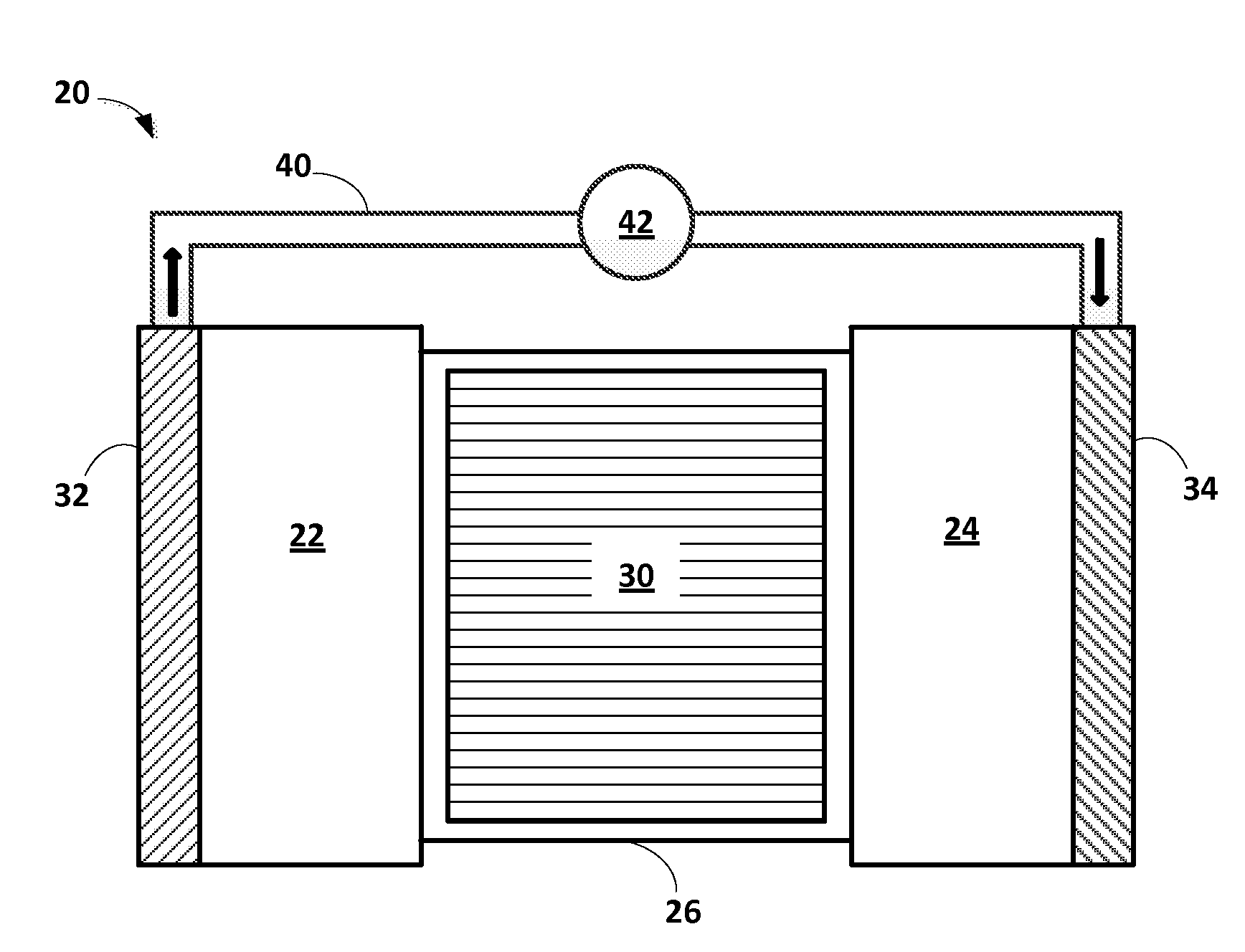

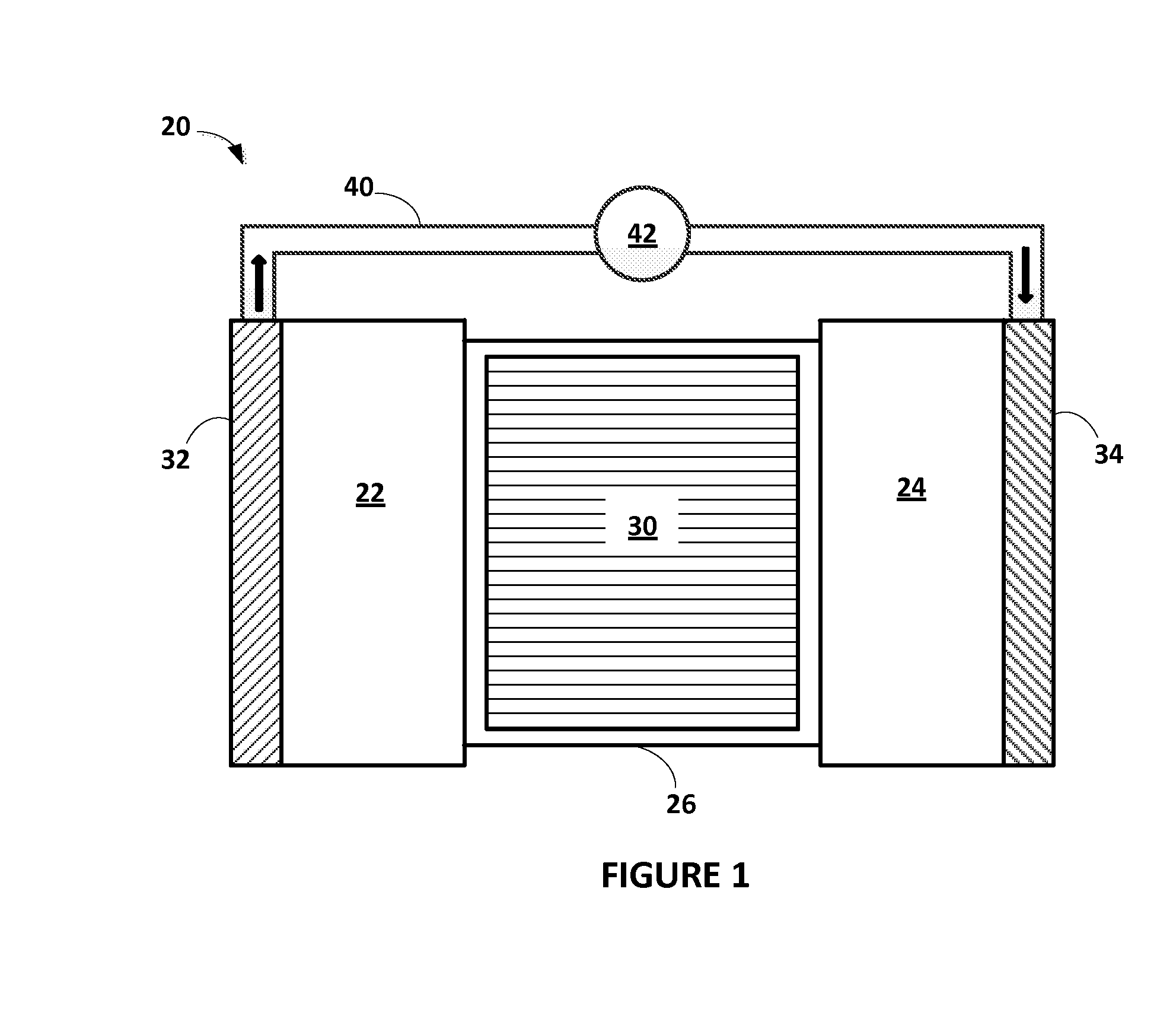

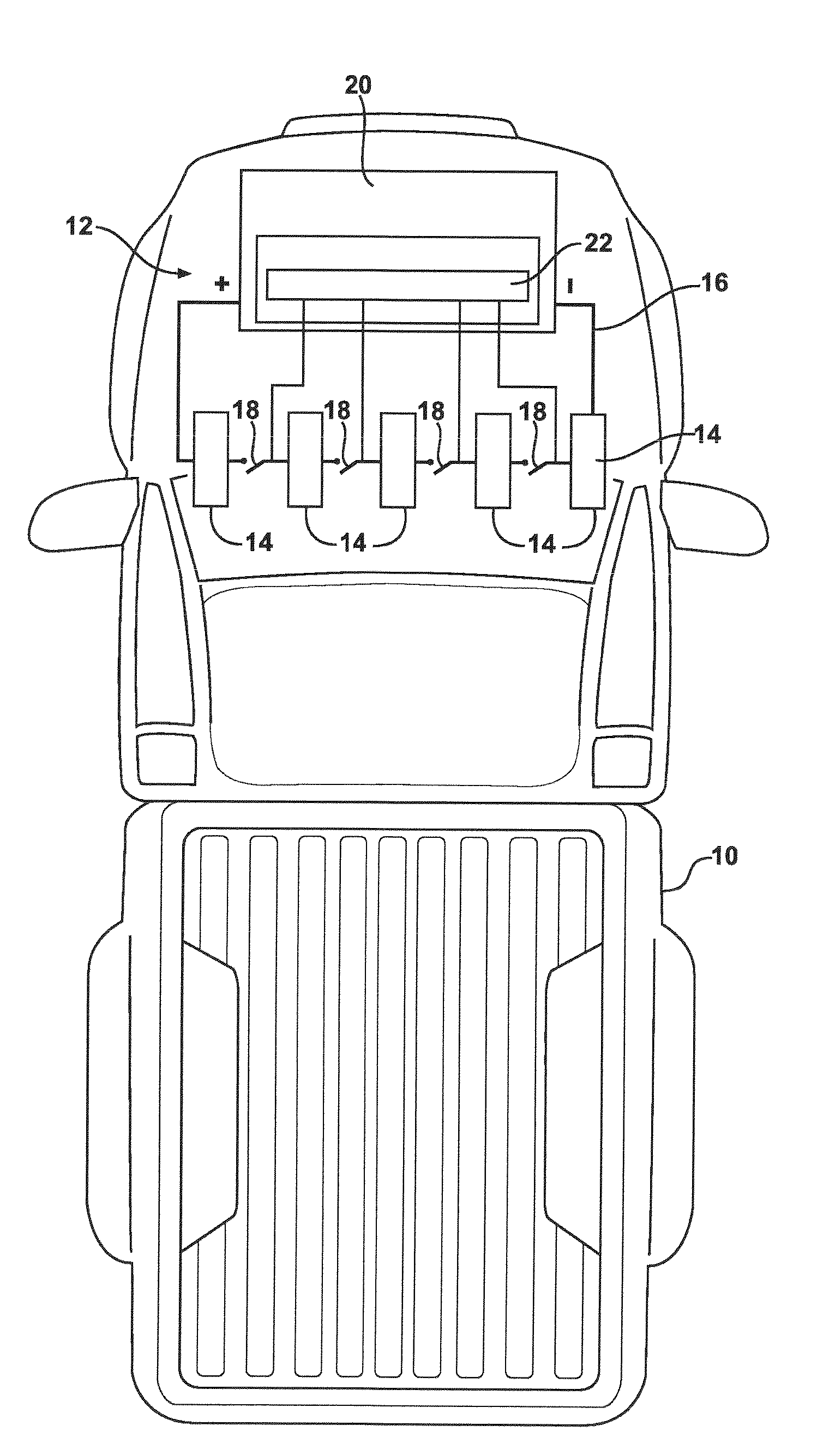

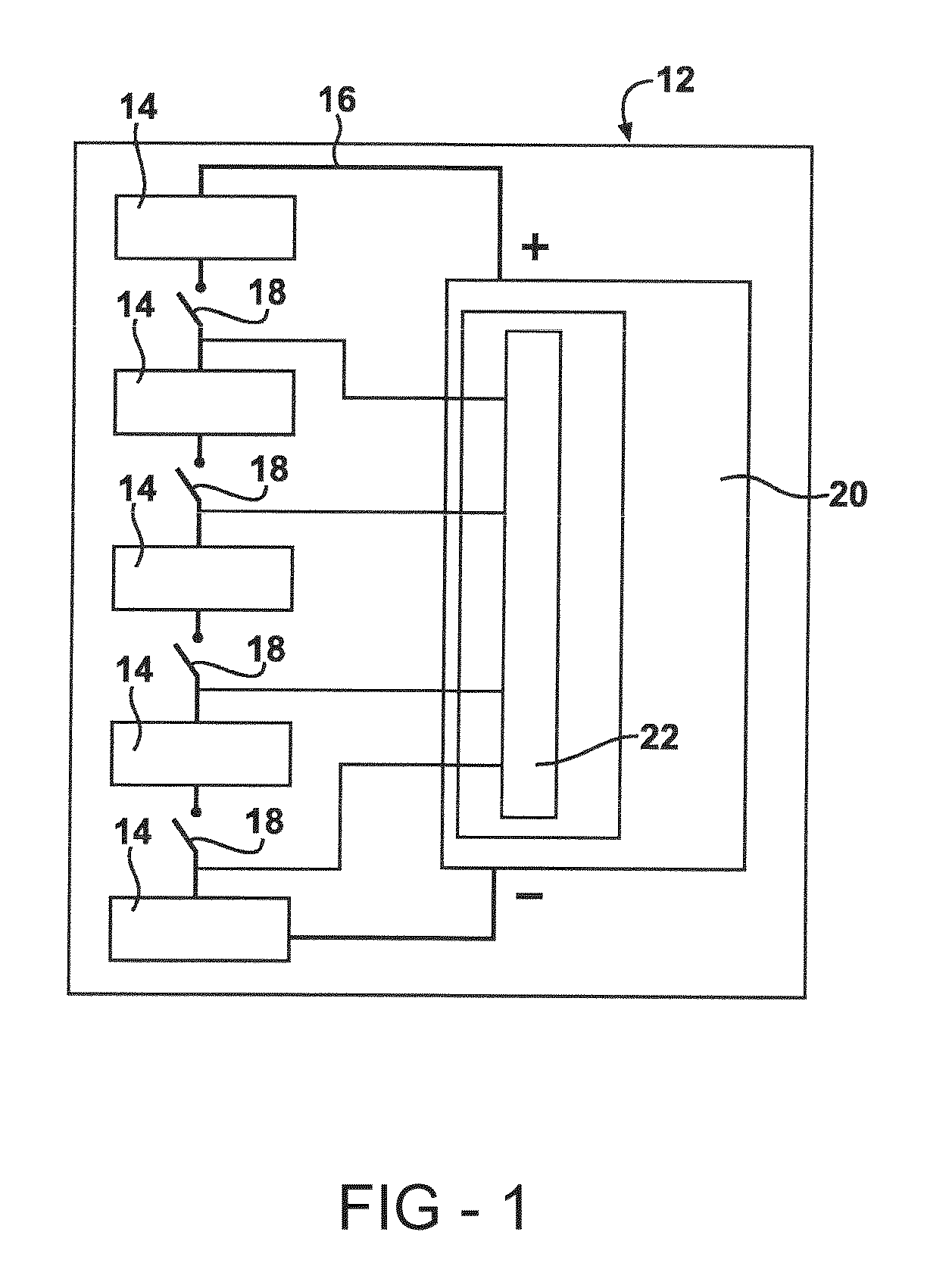

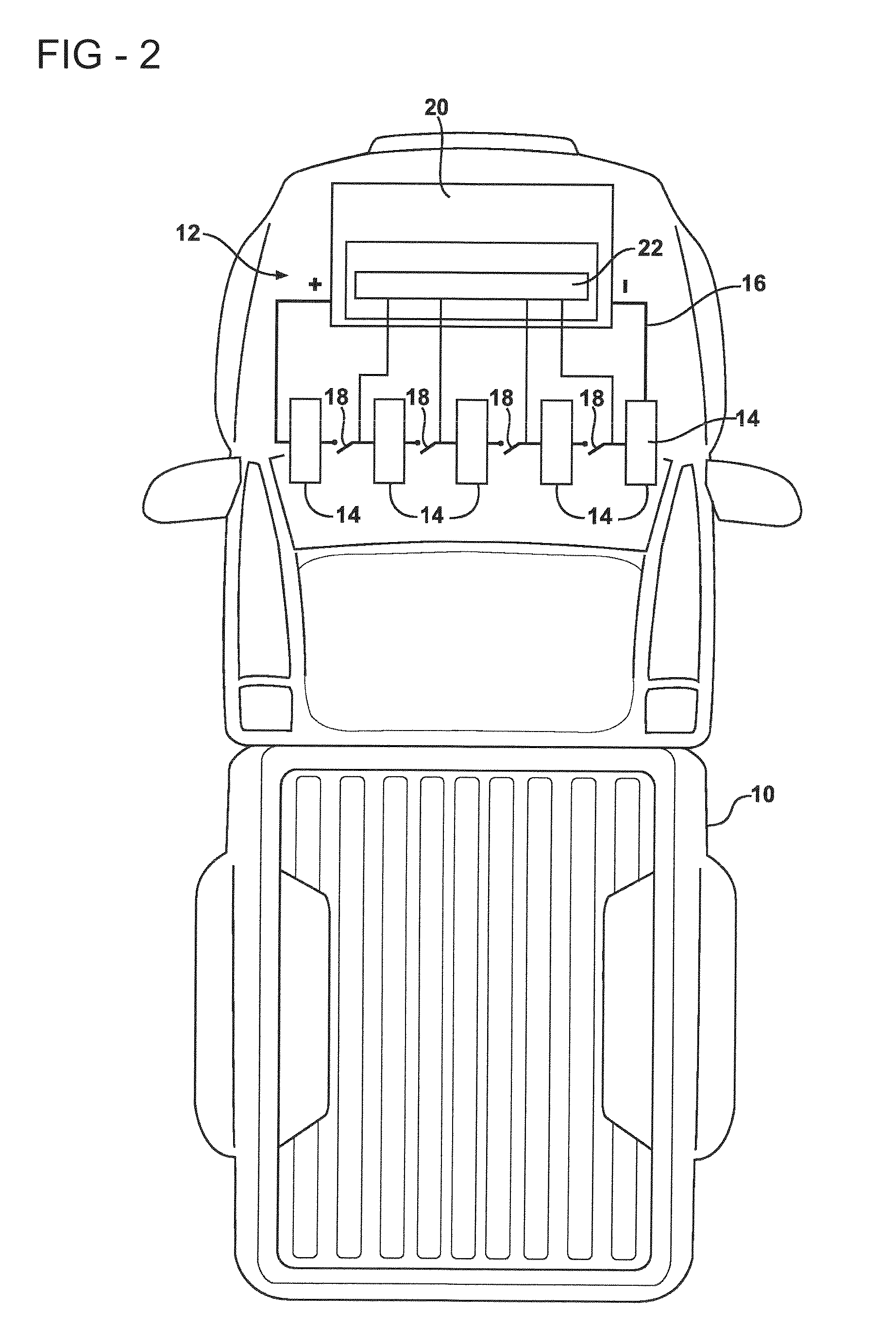

Vehicle battery systems and methods

The invention provides for a high occupancy or heavy-duty vehicle with a battery propulsion power source, which may include lithium titanate batteries. The vehicle may be all-battery or may be a hybrid, and may have a composite body. The vehicle battery system may be housed within the floor of the vehicle and may have different groupings and arrangements.

Owner:PROTERRA OPERATING CO INC

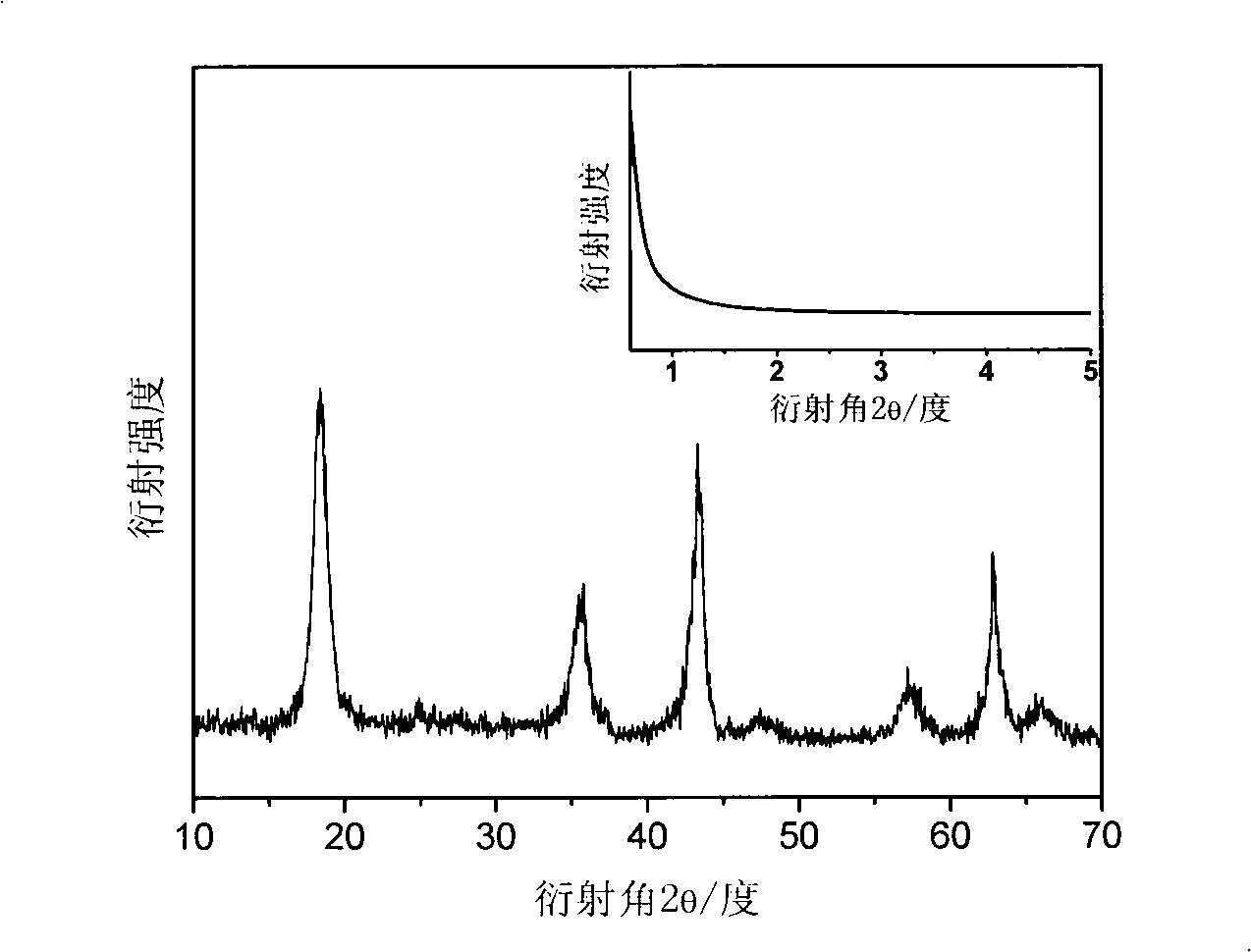

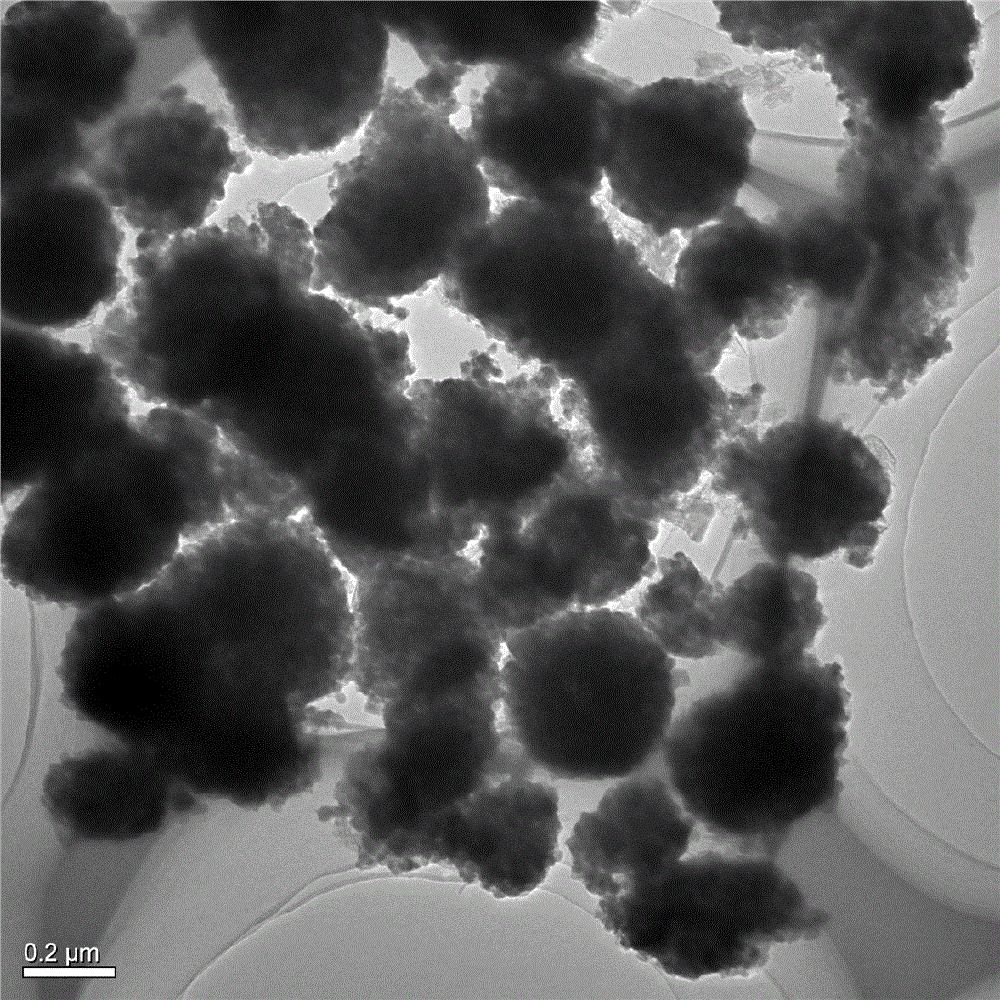

Nanostructure lithium titanate electrode for high cycle rate rechargeable electrochemical cell

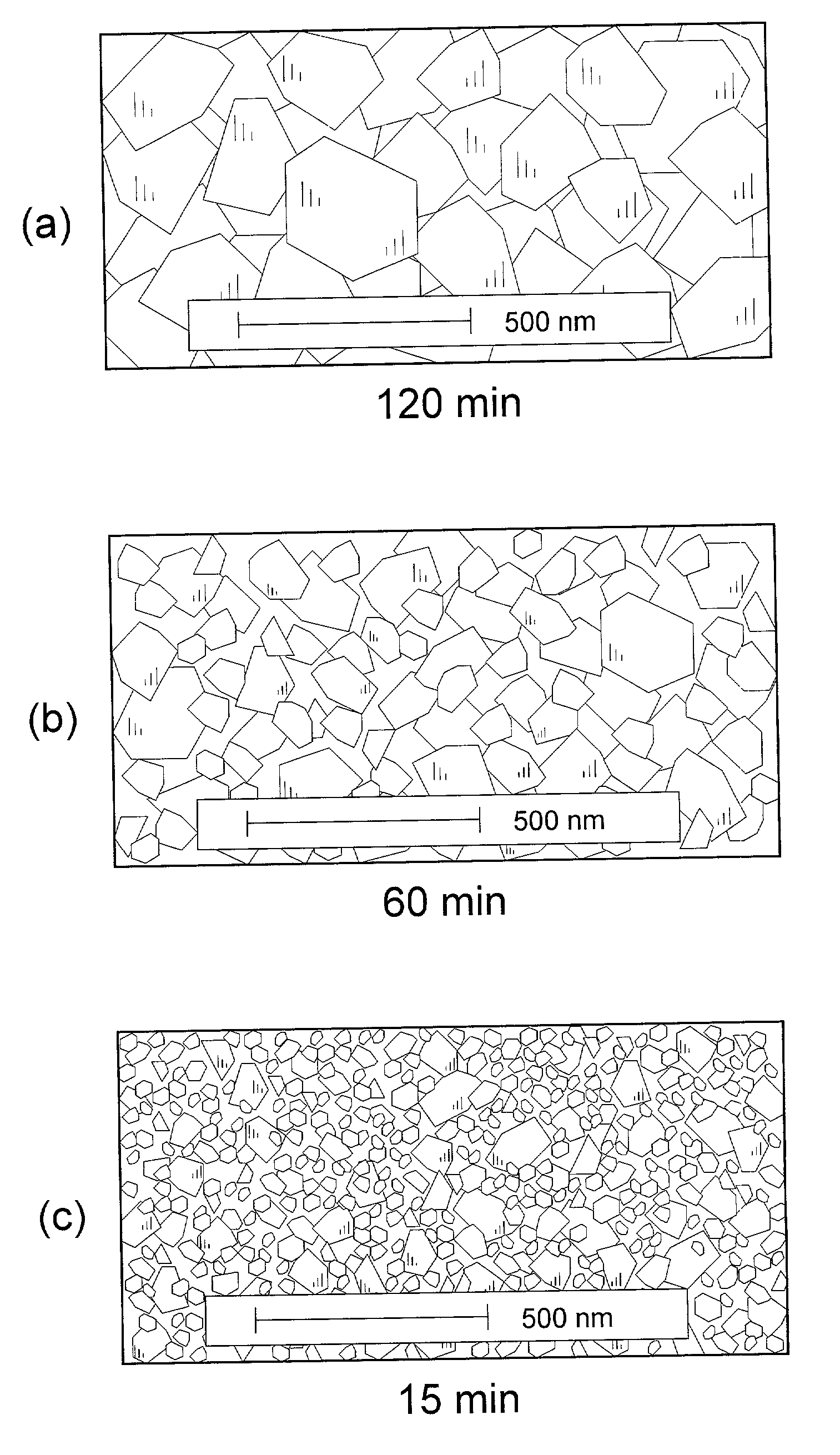

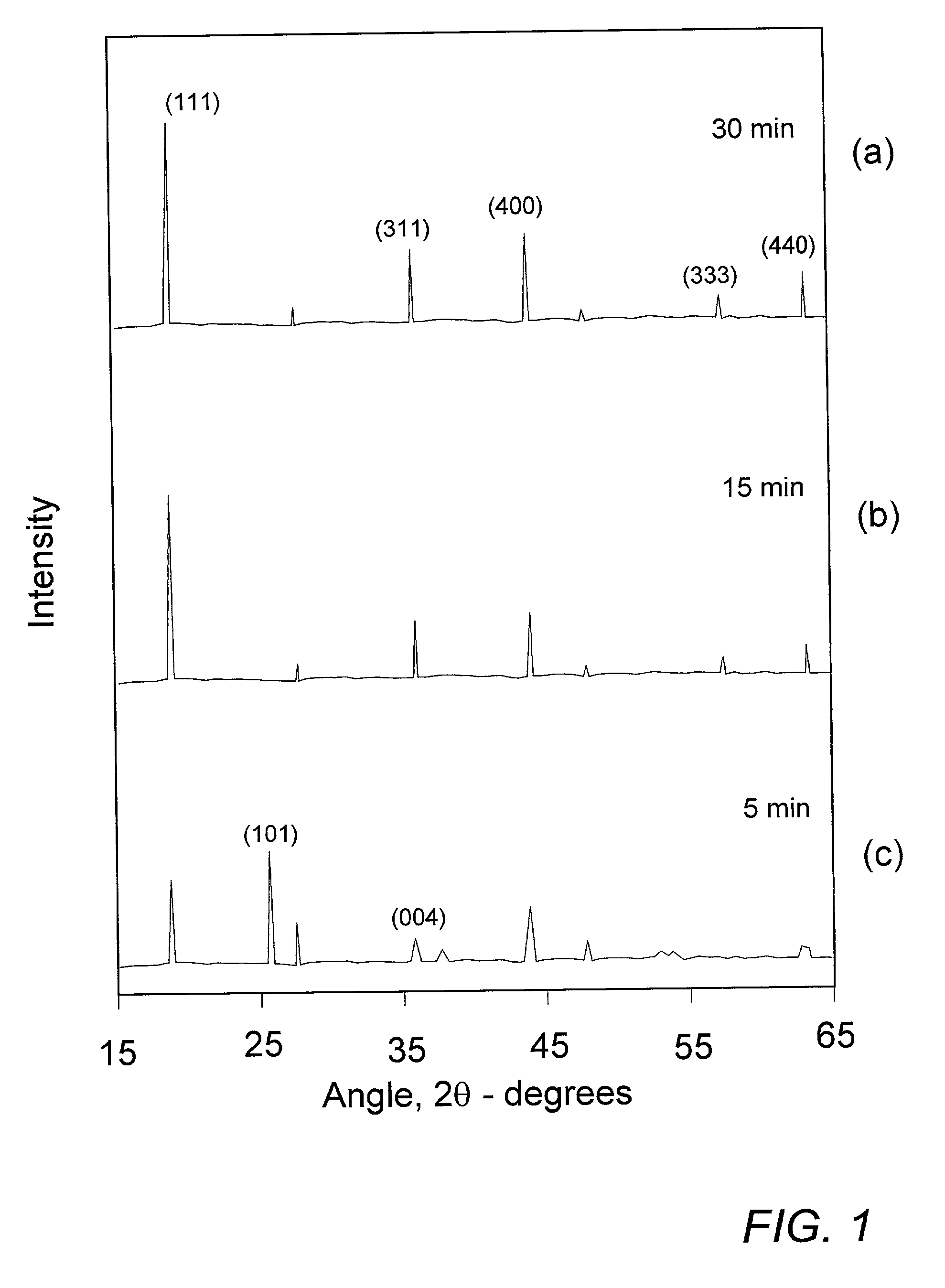

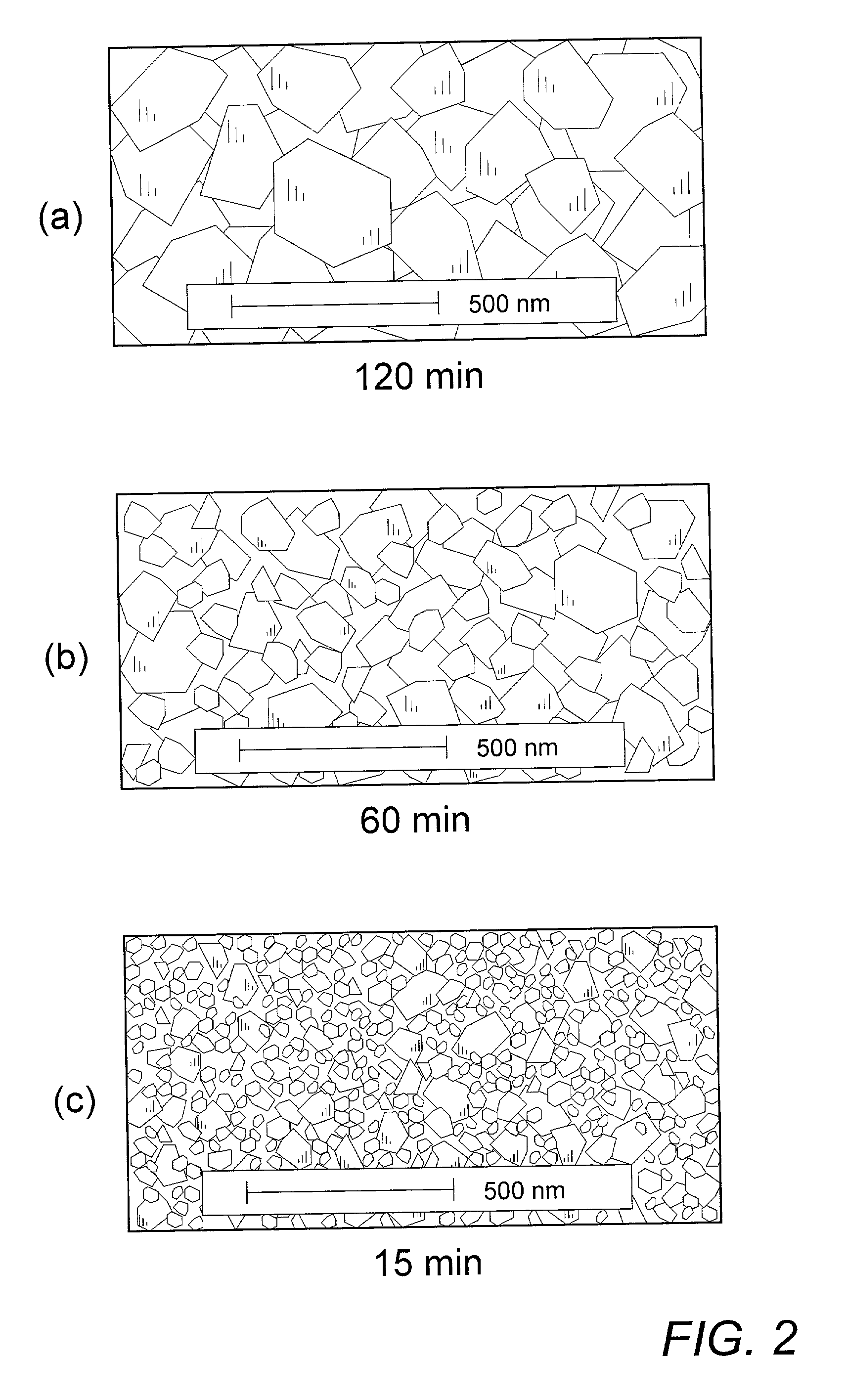

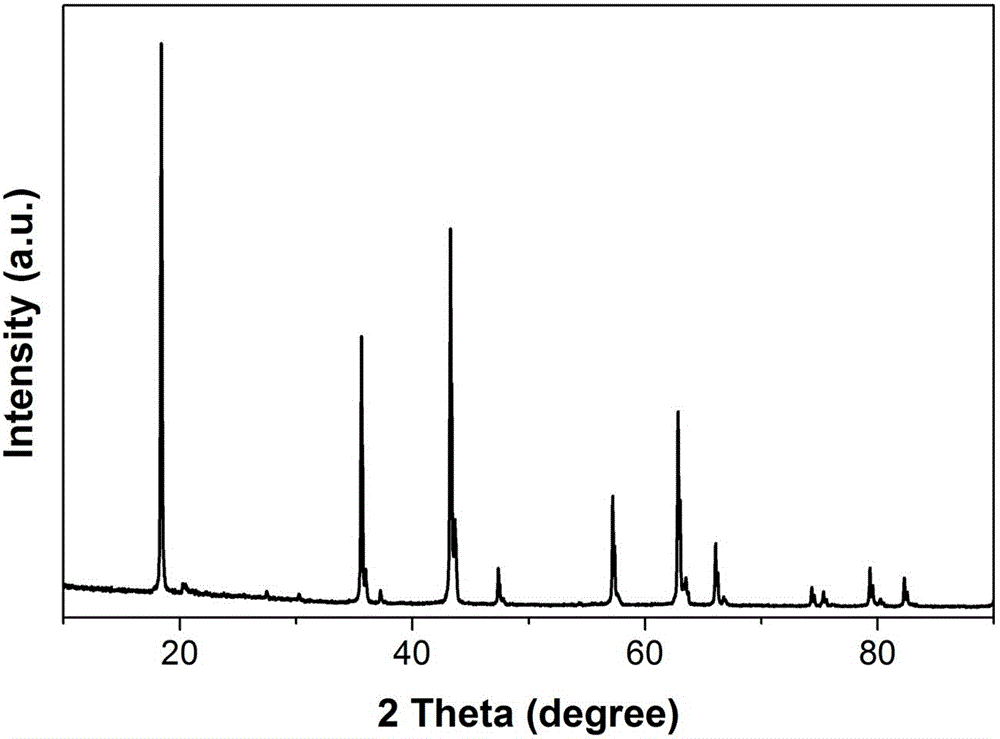

Rechargeable electrochemical cells, such as lithium batteries and asymmetric hybrid battery / supercapacitor systems, exhibiting exceptional specific capacity levels and stability over extended high-rate recharge cycling comprise nanostructure zero strain Li4Ti5O12 intercalation electrode material synthesized in a short duration process of annealing mixed TiO2 and Li-source precursor compounds at about 800° C. for a time of about 15–30 min which is not substantially longer than that required to effect maximum available reaction between the precursors, thereby substantially eliminating the growth of synthesized Li4Ti5O12 particles beyond nanostructure size. The process reduces by order of magnitude the time and energy required for synthesis of the active electrode material and fabrication of utilizing cell devices, and provides such nanostructure material which enables repeated, high-rate recharge cycling without loss of cell capacity or efficiency.

Owner:RUTGERS THE STATE UNIV

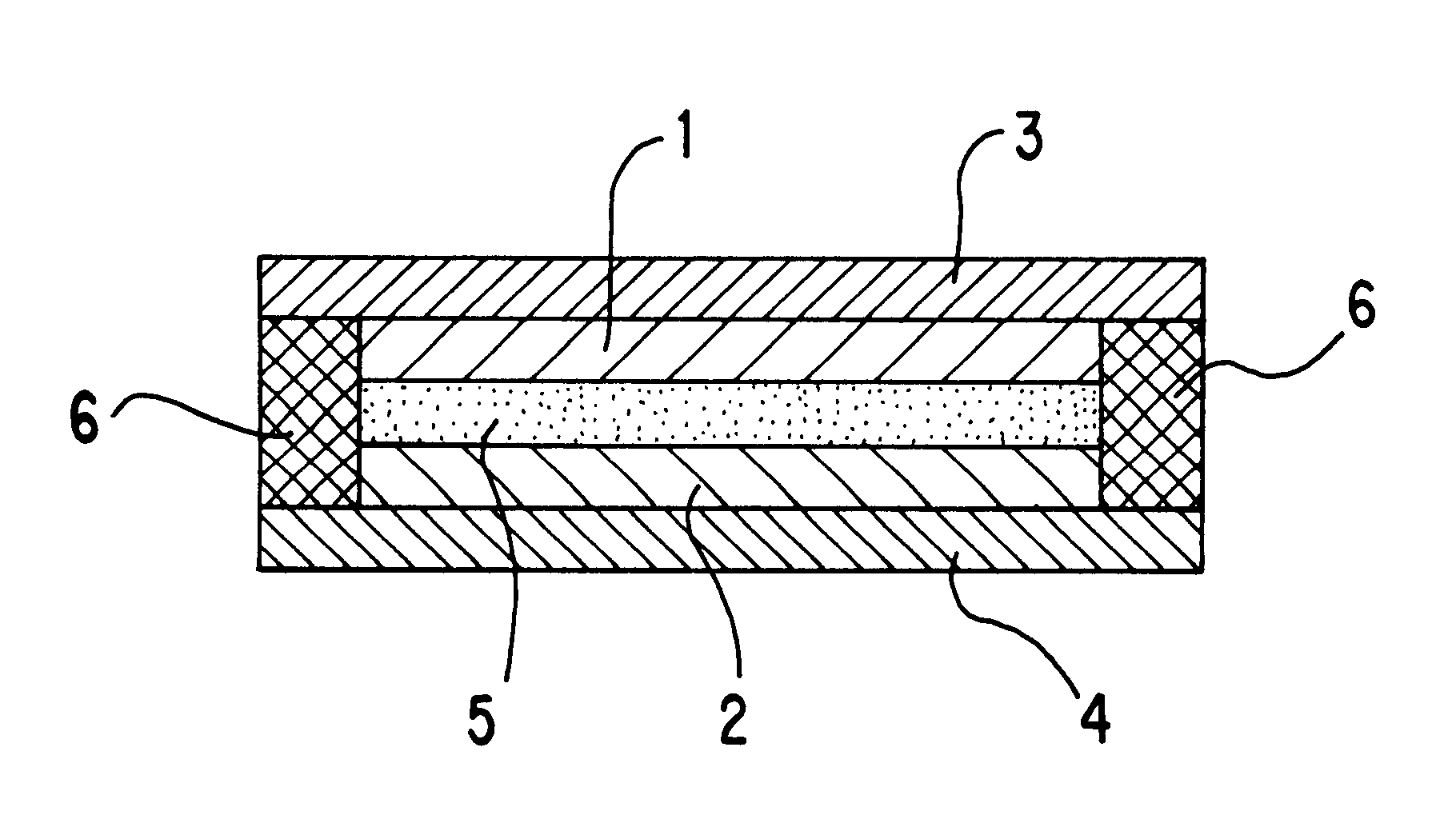

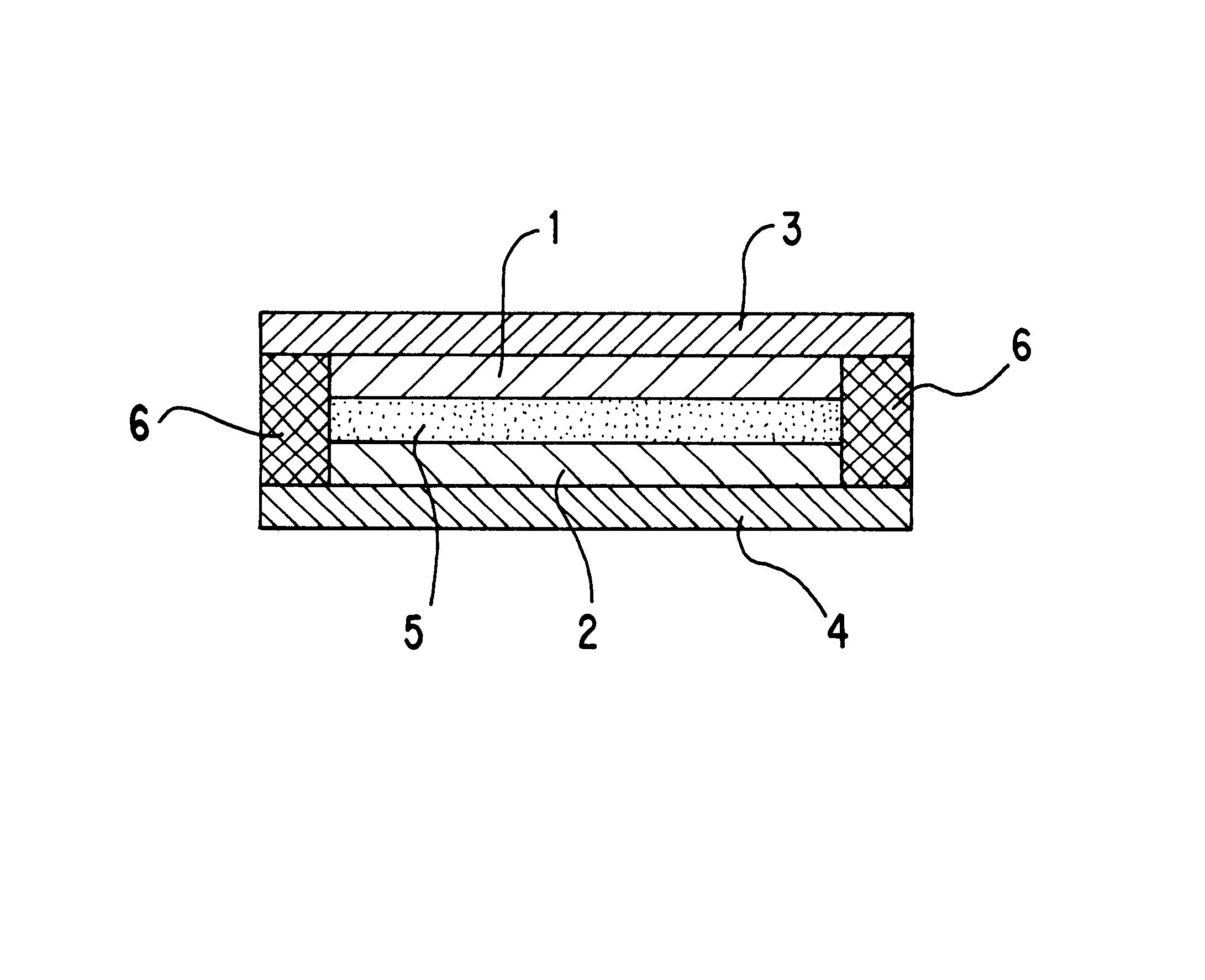

Non-aqueous electrolyte battery and charging method therefor

InactiveUS6316145B1Improve efficiencyLow efficiencyNegative electrodesSolid electrolyte cellsDischarge efficiencyTitanium oxide

In a non-aqueous electrolyte battery using titanium oxide or lithium titanate as a negative electrode material for negative electrode, polymeric electrolyte is interposed between the negative electrode and a positive electrode. If titanium oxide or lithium titanate is used as the negative electrode material for negative electrode and the polymeric electrolyte is interposed between the negative electrode and the positive electrode, the polymeric electrolyte is less liable to be decomposed by catalytic reduction induced by titanium oxide or lithium titanate. This prevents decline in the charge / discharge efficiency which occurs when a non-aqueous electrolyte solution is used. Thus, the non-aqueous electrolyte battery excellent in charge / discharge efficiency is provided.

Owner:SANYO ELECTRIC CO LTD

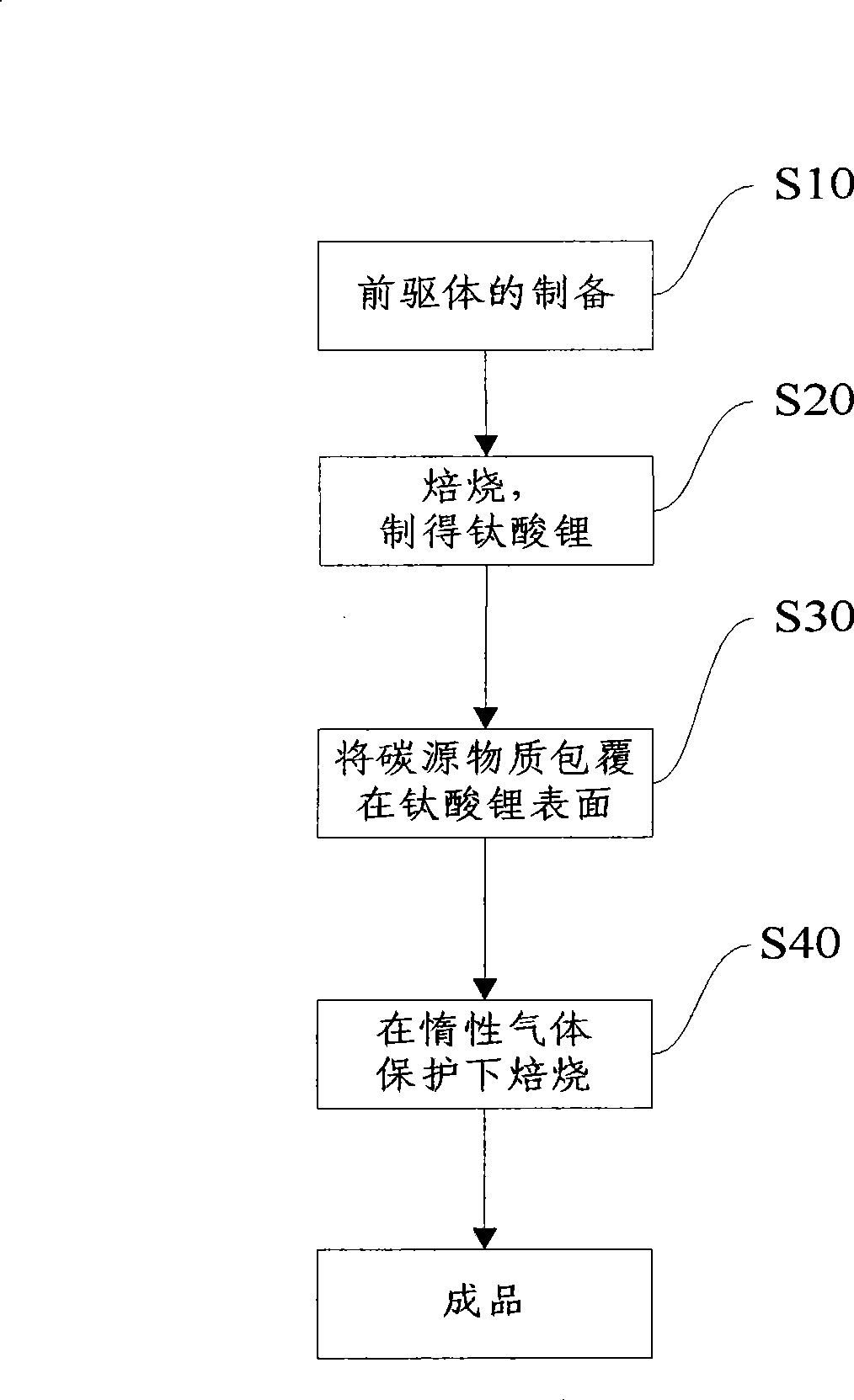

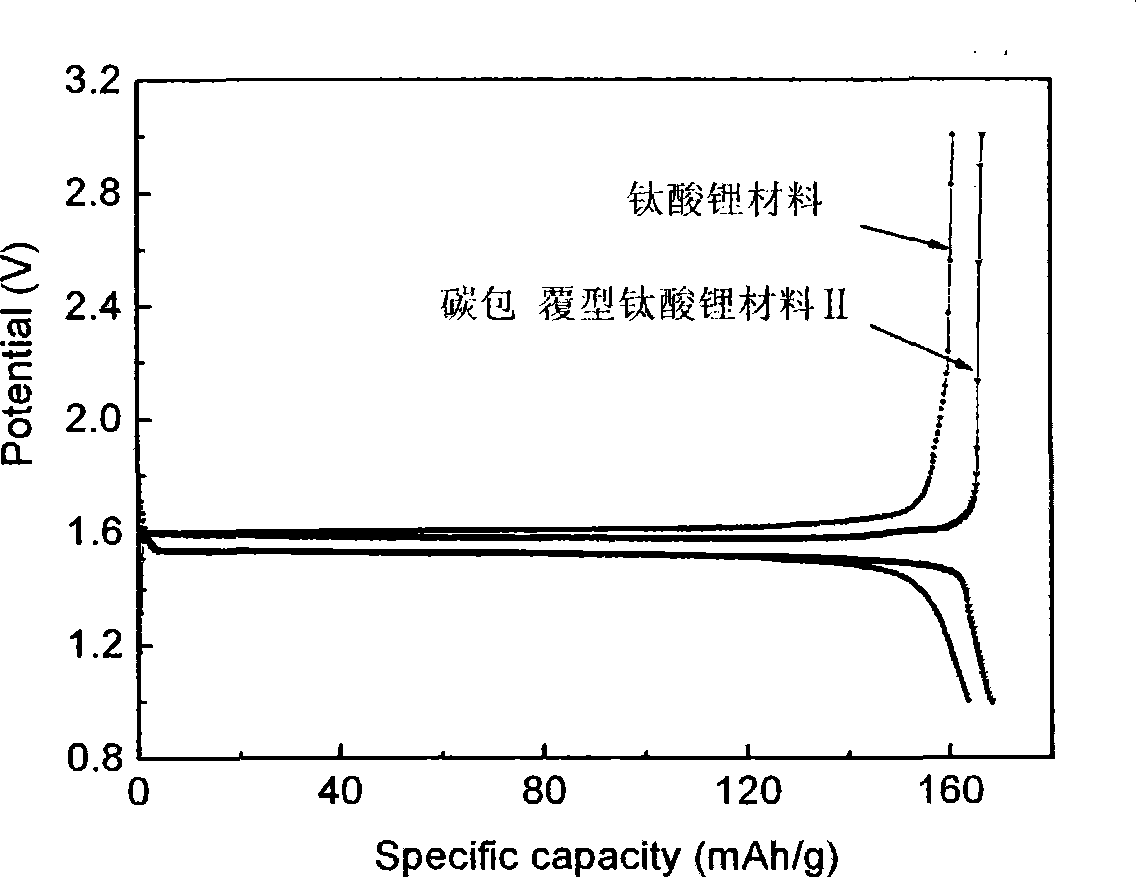

Method for preparing carbon-coating type lithium titanate for lithium ion battery

InactiveCN101378119AImprove electronic conductivityImprove rate charge and discharge performanceElectrode manufacturing processesCarbon coatedElectron

The invention discloses a preparation method of carbon-coated lithium titanate used for a lithium ion battery; the method comprises the following steps: (1) lithium salt and titanium dioxide are weighted according to proportion, a dispersing agent is added, a ball milling method is used for mixing fully and then the obtained mixture is dried in vacuum, thus obtaining a precursor; (2) the obtained precursor is roasted for 8 to 20 hours at the temperature of 750 to 1000 DEG C so as to prepare lithium titanate; (3) carbon source materials are coated on the surface of the prepared lithium titanate by a dipping and steaming method; and (4) the lithium titanate coated with the carbon source materials is placed in a tubular furnace, and is roasted for 0.5 to 5 hours at the temperature of 750 to 1000 DEG C under the protection of inert gas so as to obtain the carbon-coated lithium titanate. The preparation method of the invention forms chemically coated carbon on the surface of the lithium titanate by the pyrolytic reaction of the carbon-coated materials, and the surface contact of the coated carbon and the lithium titanate material is more firm and tight, thus improving the electron conductivity of the materials greatly and enhancing the charge and discharge performance of magnification of the materials.

Owner:TIANJIN B&M SCI & TECH

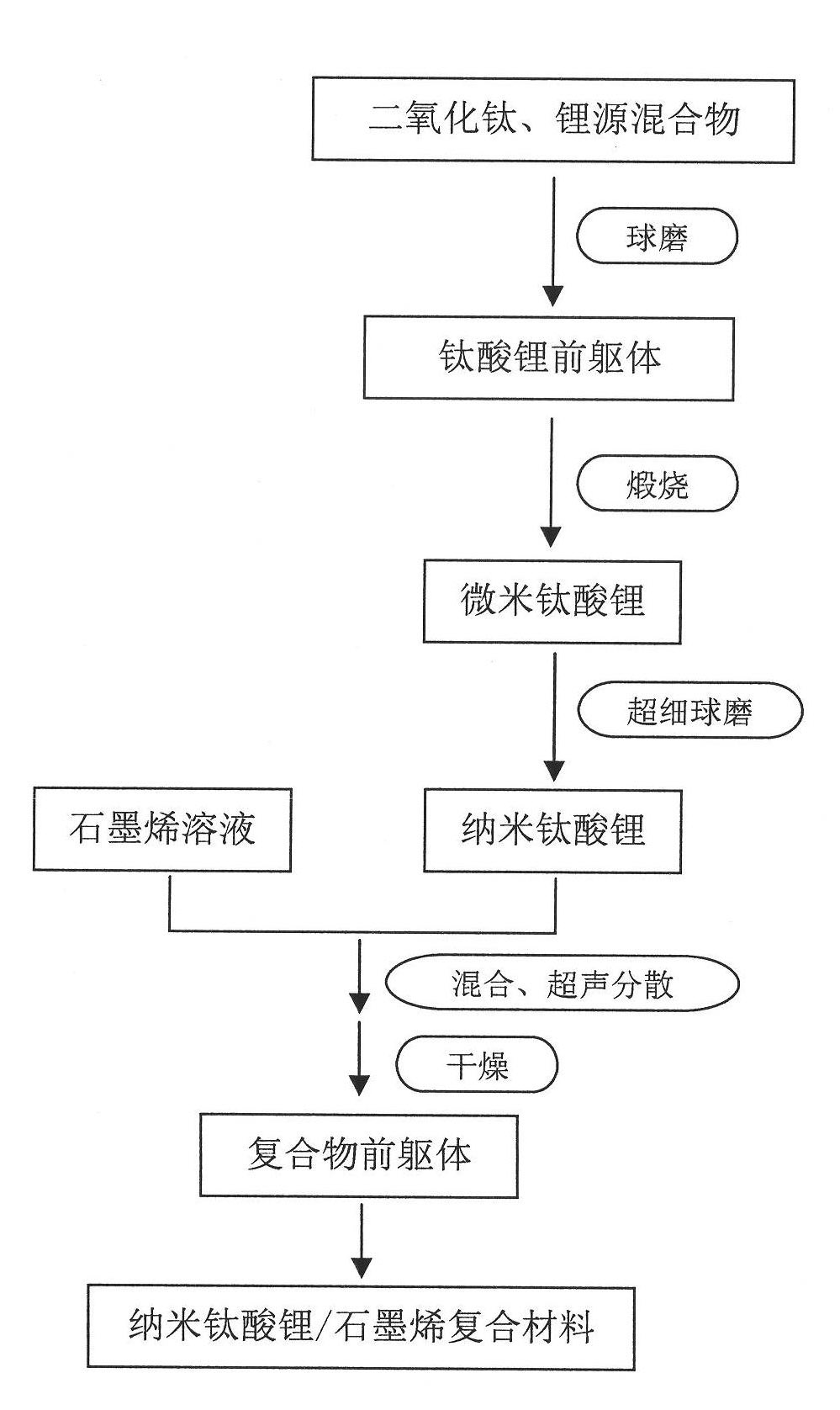

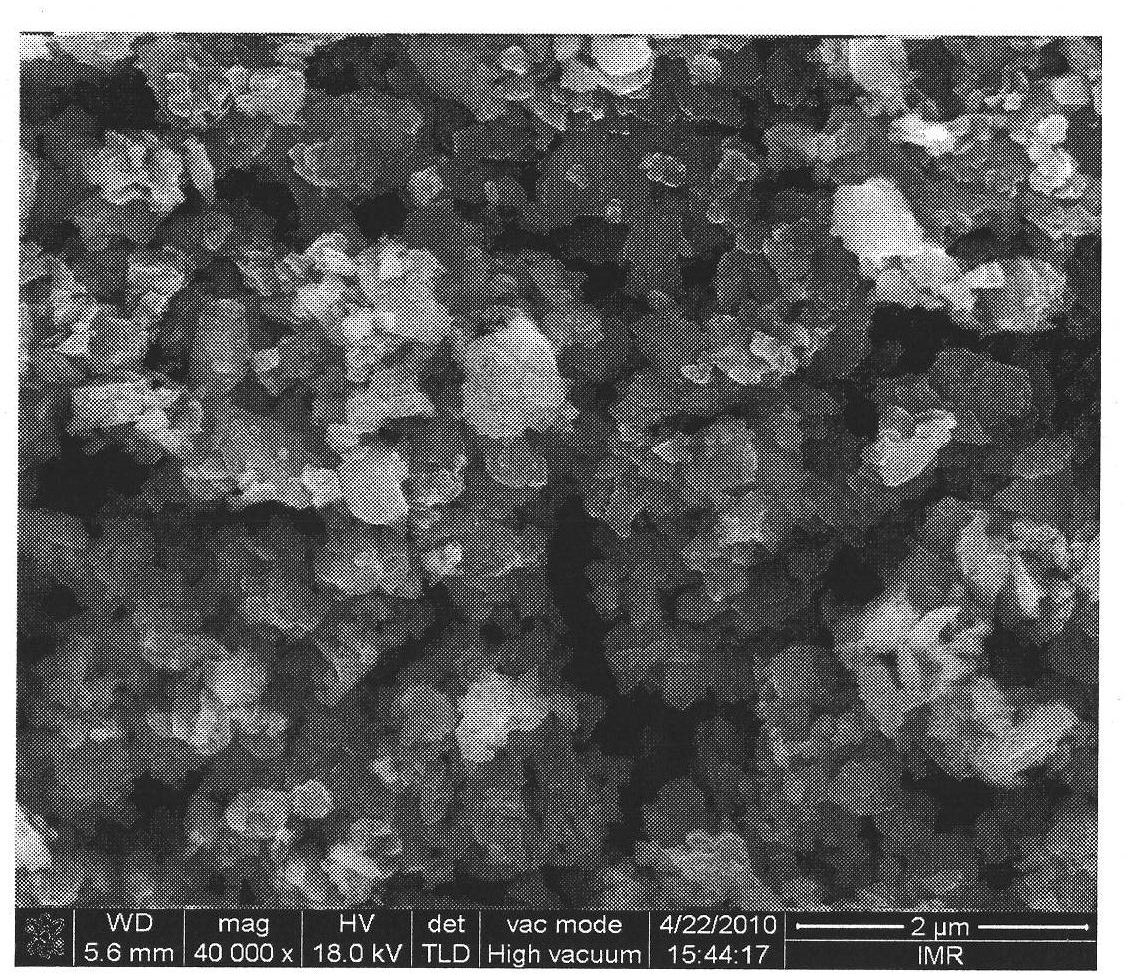

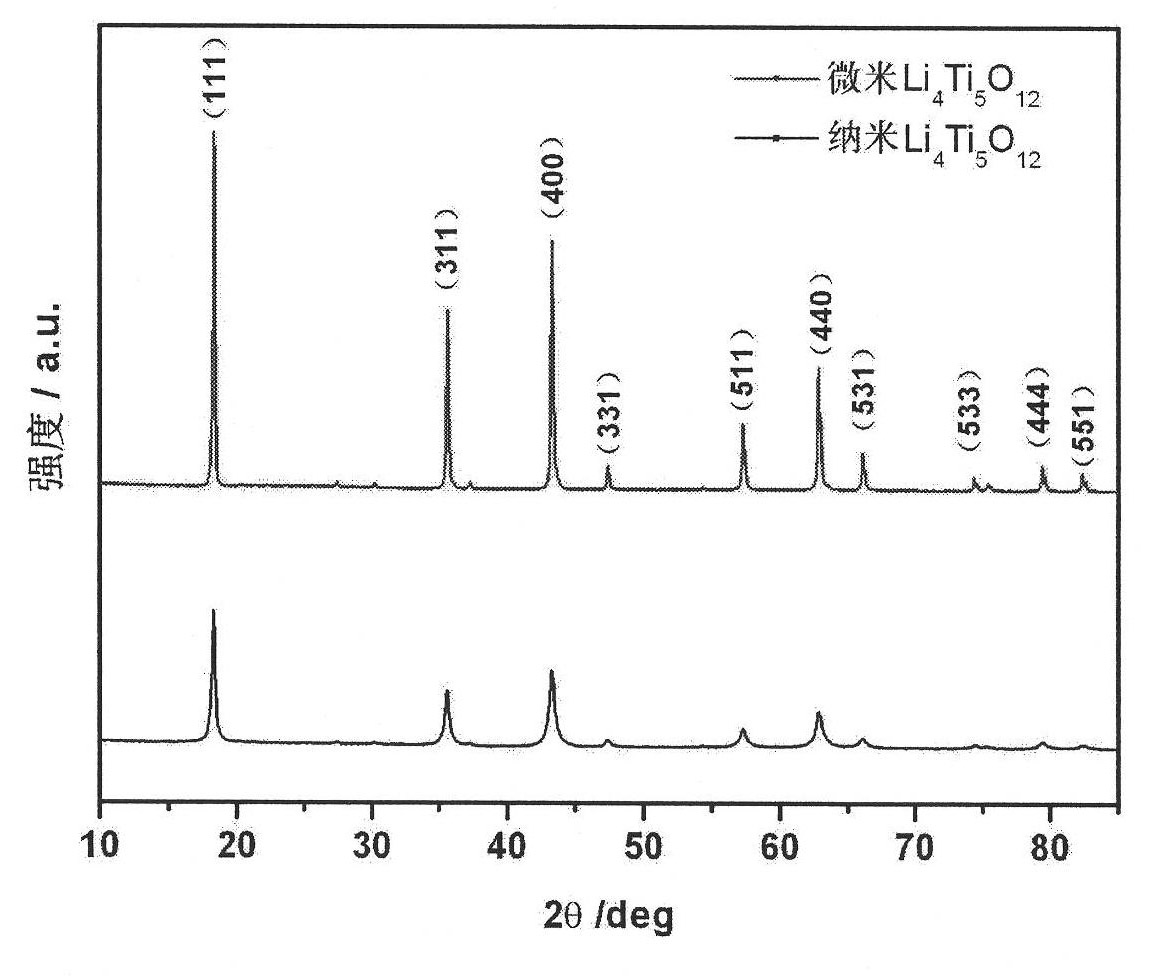

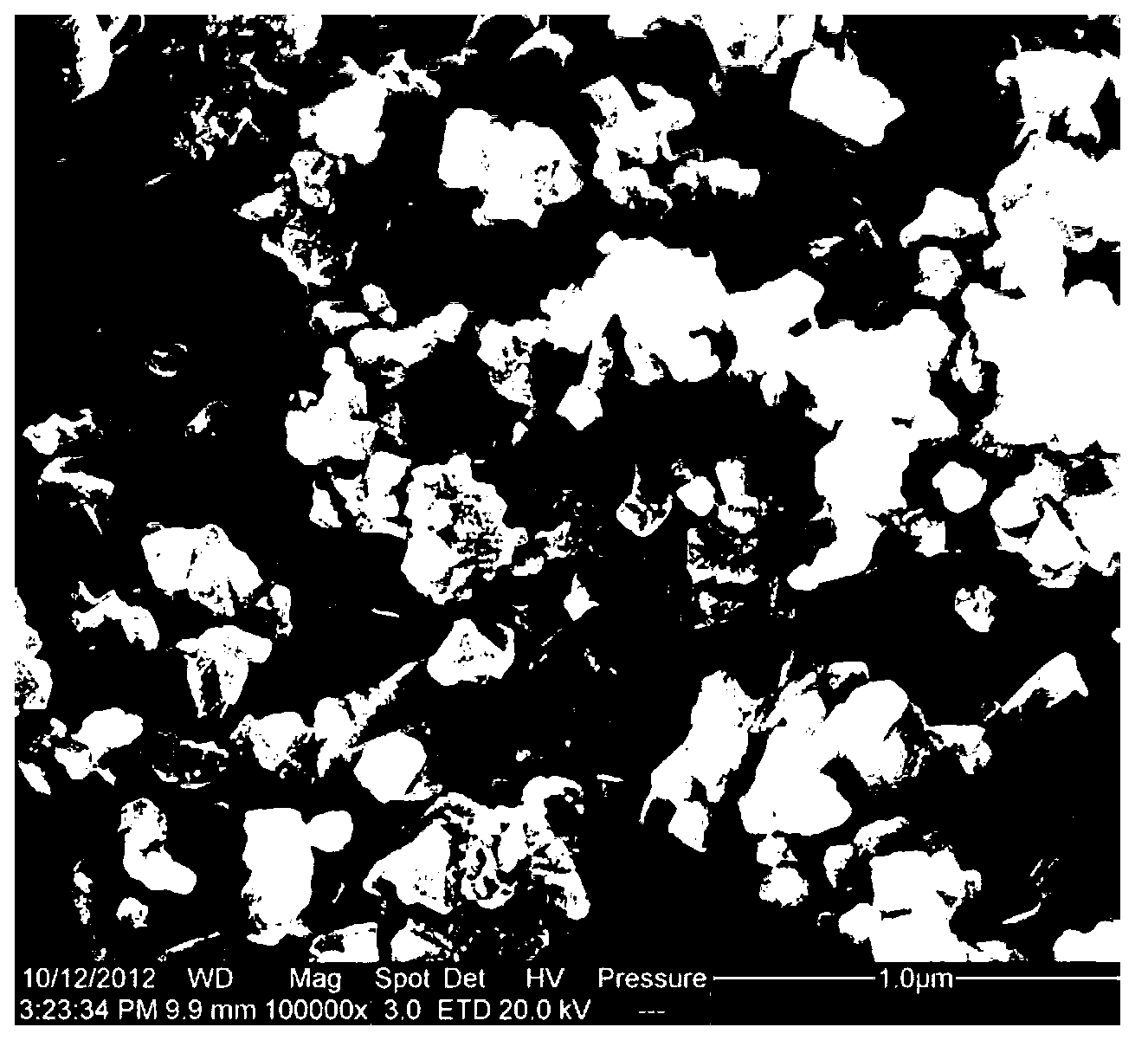

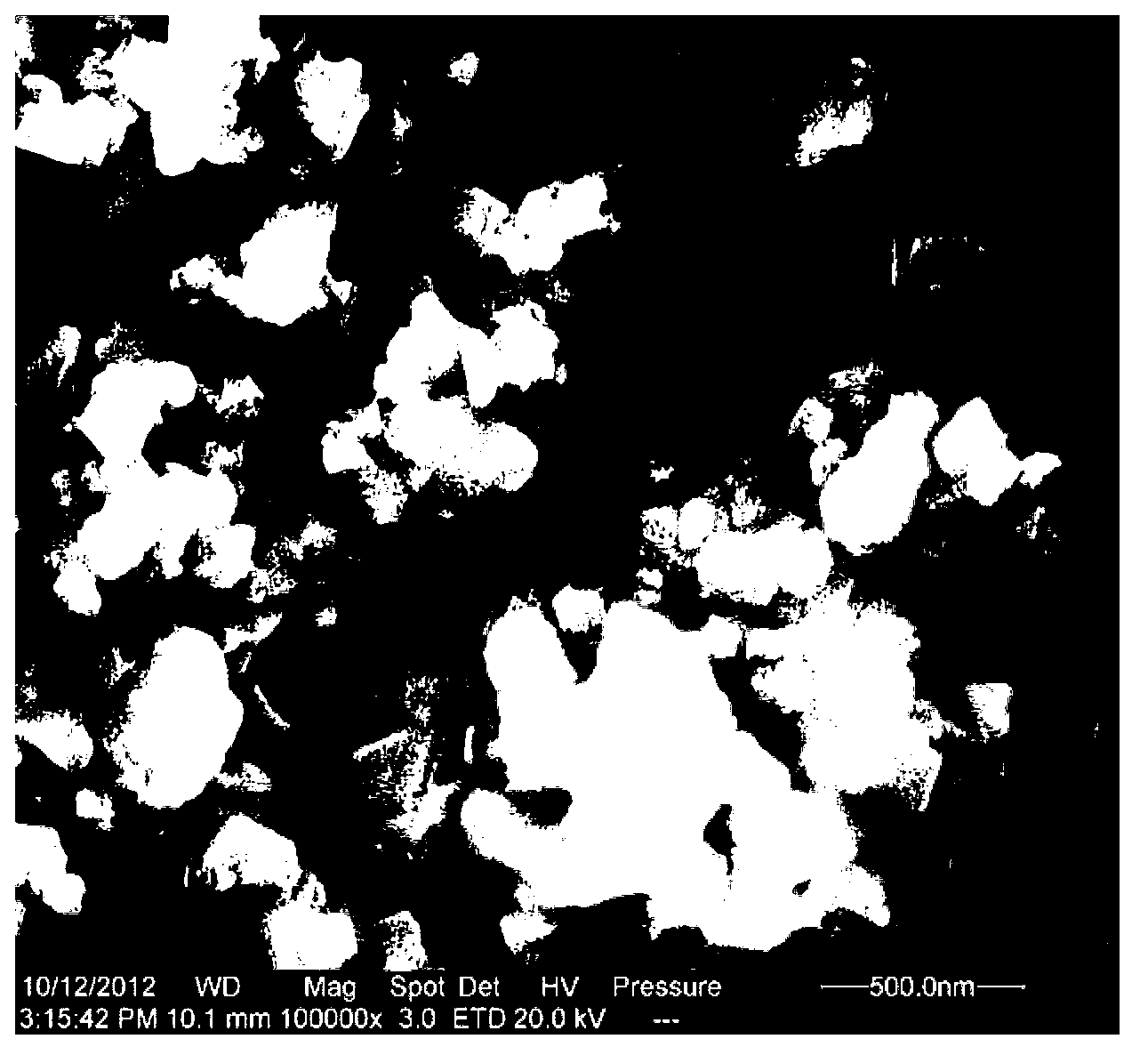

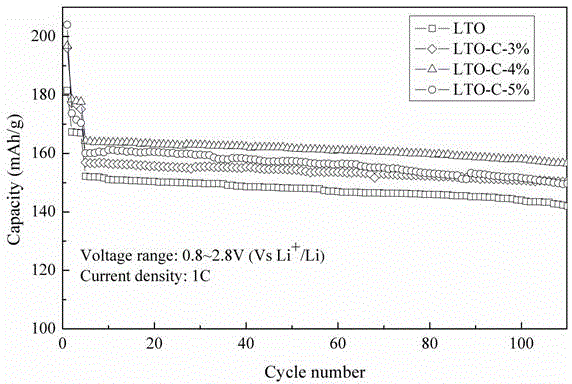

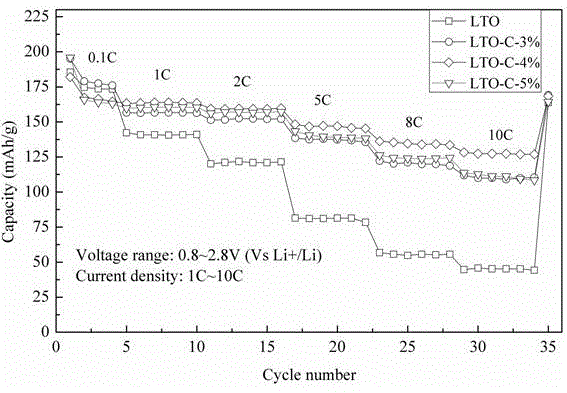

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Vehicle battery systems and methods

The invention provides for a high occupancy or heavy-duty vehicle with a battery propulsion power source, which may include lithium titanate batteries. The vehicle may be all-battery or may be a hybrid, and may have a composite body. The vehicle battery system may be housed within the floor of the vehicle and may have different groupings and arrangements.

Owner:PROTERRA OPERATING CO INC

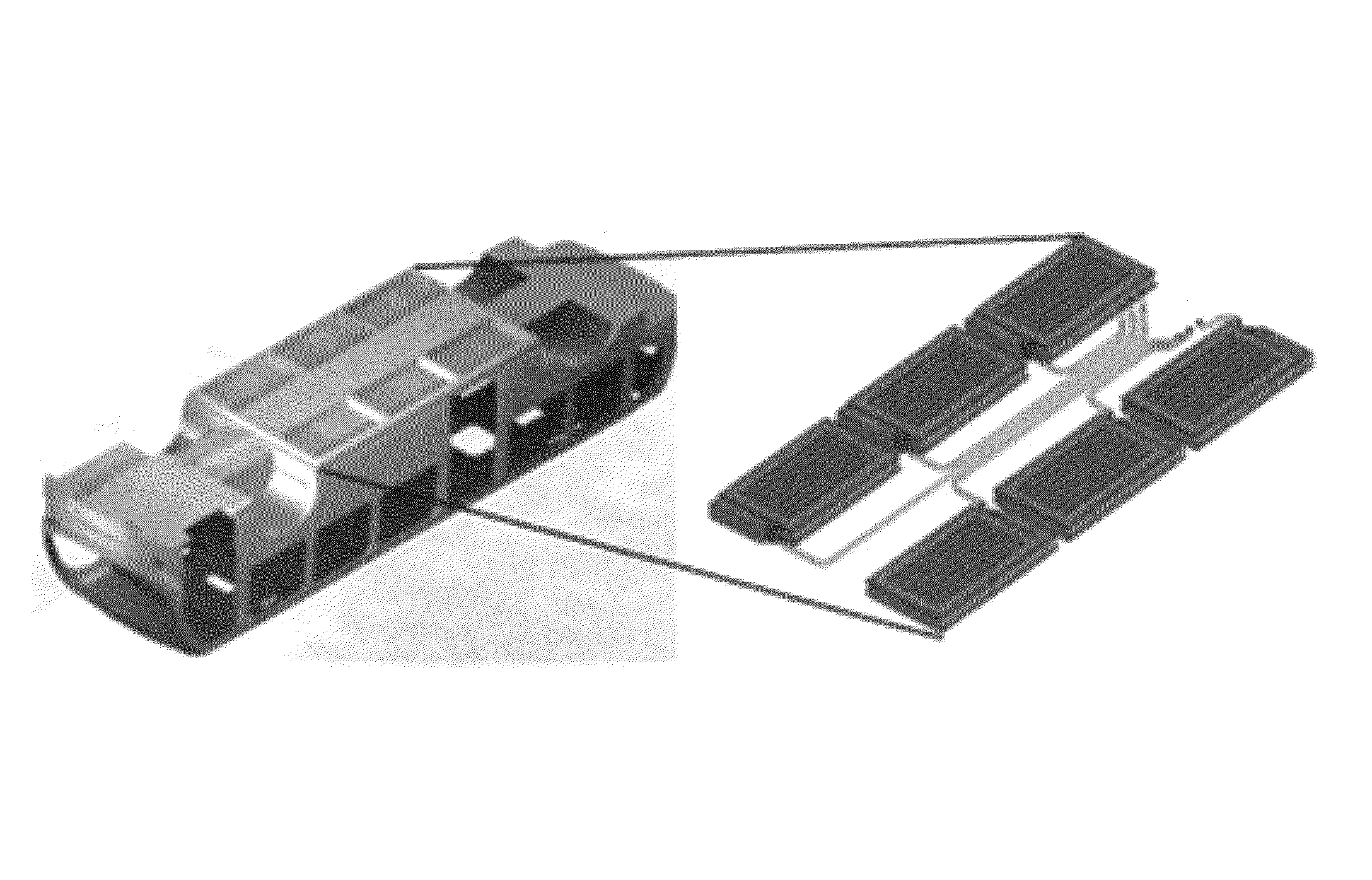

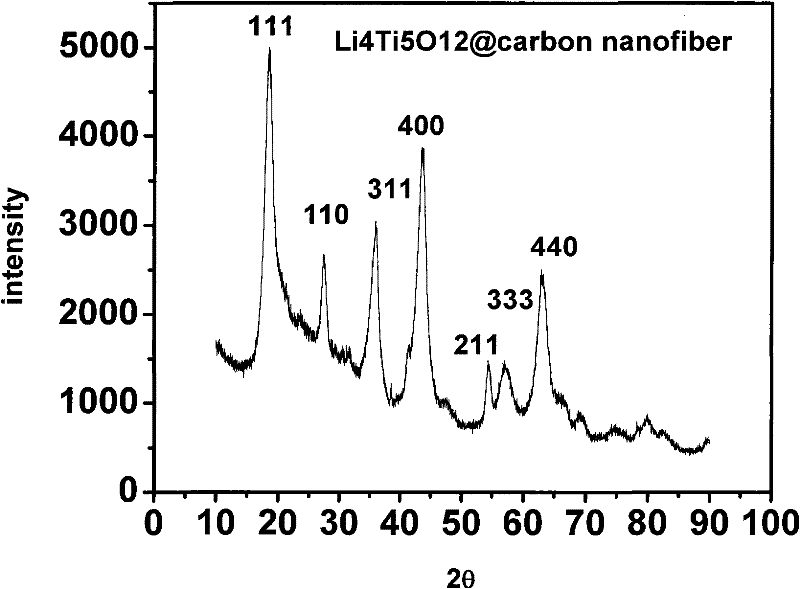

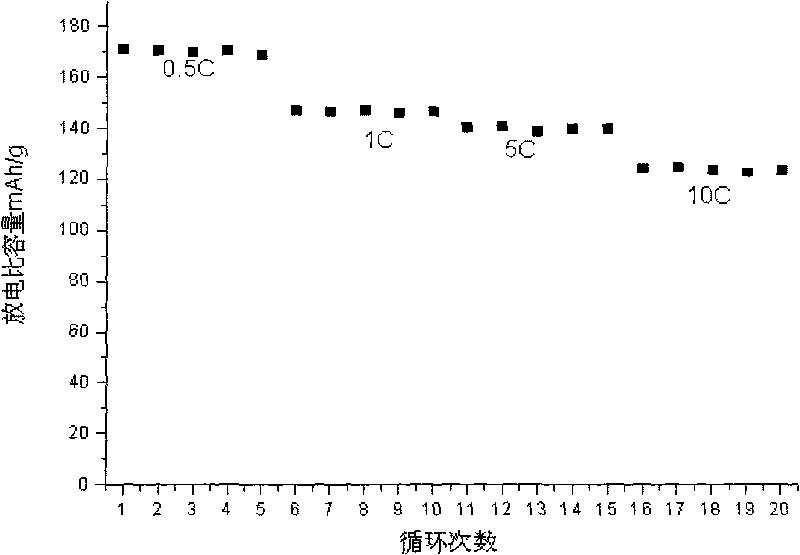

Lithium titanate-carbon composite nano-material, preparation method thereof and application thereof

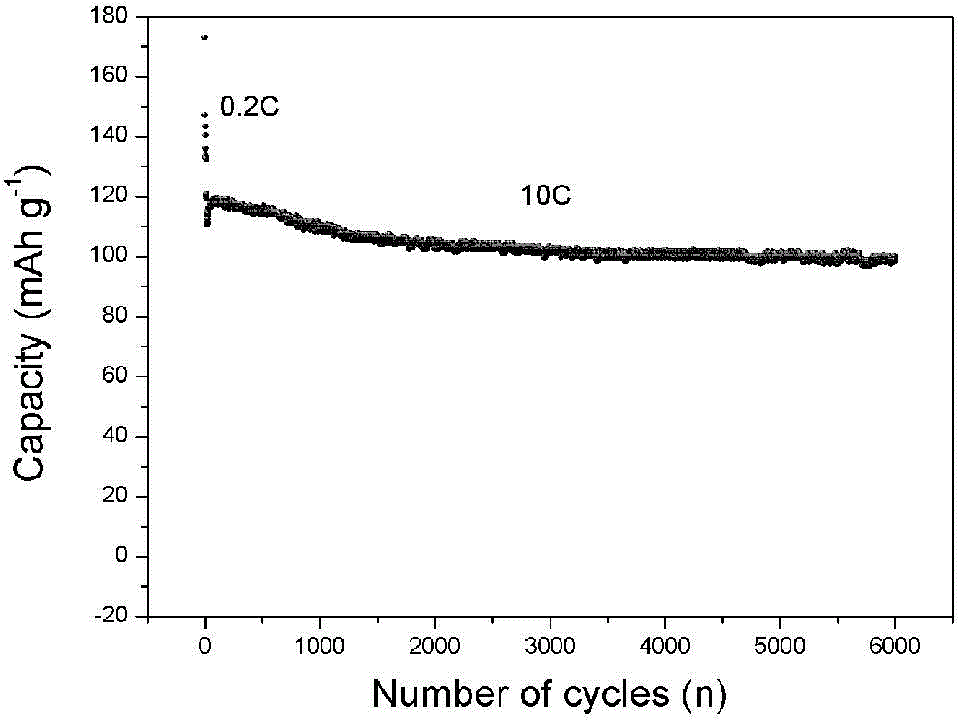

InactiveCN101752560AHigh crystallinityImprove conductivityElectrolytic capacitorsCell electrodesCarbon compositesElectrical battery

The invention discloses a lithium titanate-carbon composite nano-material, a preparation method thereof and application thereof. The method comprises the following steps: 1) statically spinning lithium titanate sol, or lithium titanate sol doped with a conductive substance or lithium titanate sol doped with metal ions to obtain a thin film, wherein the conductive substance is conductive metal or conductive carbon; and 2) heat treating the thin film in inert atmosphere to obtain the lithium titanate-carbon composite nano-material. The lithium titanate-carbon composite nano-material provided by the invention has a standard one-dimensional morphological structure, high crystallinity, high conductivity and high safety performance, and has high lithium ion diffusion speed and high electronic conductivity when applied as the cathode material of the lithium ion battery. Moreover, the lithium titanate-carbon composite nano-material has high charge / discharge capacity, excellent high-current charge / discharge performance and stable cycling performance. The 10c charge / discharge capacity is 125mAh / g, the 40C charge / discharge capacity reaches 95mAh / g, and the retention rate of the high-current 40C charge / discharge capacity within 3000 times reaches 85 percent.

Owner:PEKING UNIV

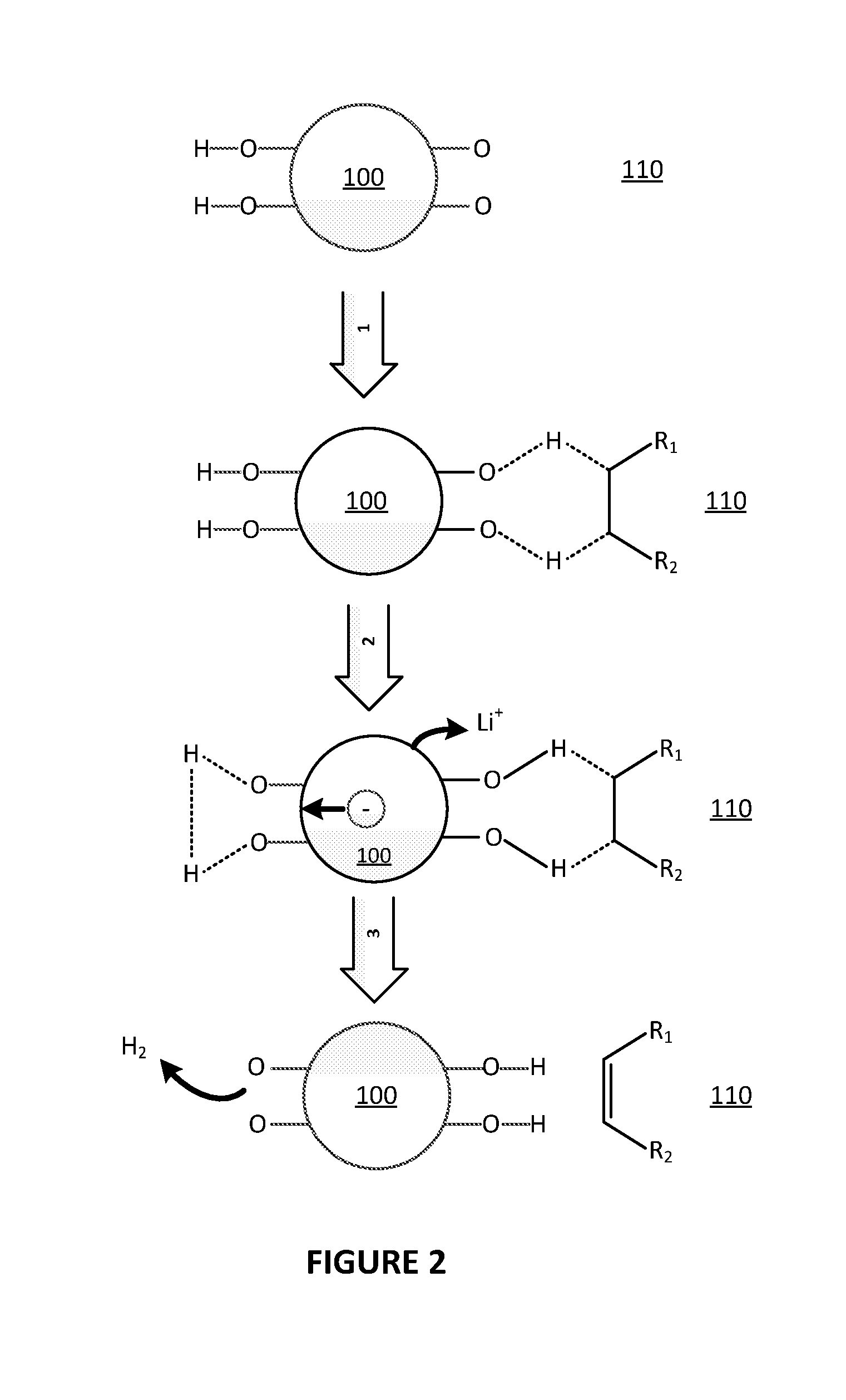

Coatings for lithium titanate to suppress gas generation in lithium-ion batteries and methods for making and use thereof

ActiveUS20140113197A1Reduced and suppressed gas generationLess hydrogenMaterial nanotechnologyElectrode manufacturing processesElectrical batteryElectrochemical cell

An electroactive material for use in an electrochemical cell, like a lithium-ion battery, is provided. The electroactive material comprises lithium titanate oxide (LTO) and has a surface coating with a thickness of less than or equal to about 30 nm that suppresses formation of gases within the electrochemical cell. Methods for making such materials and using such materials to suppress gas formation in electrochemical cells are likewise provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

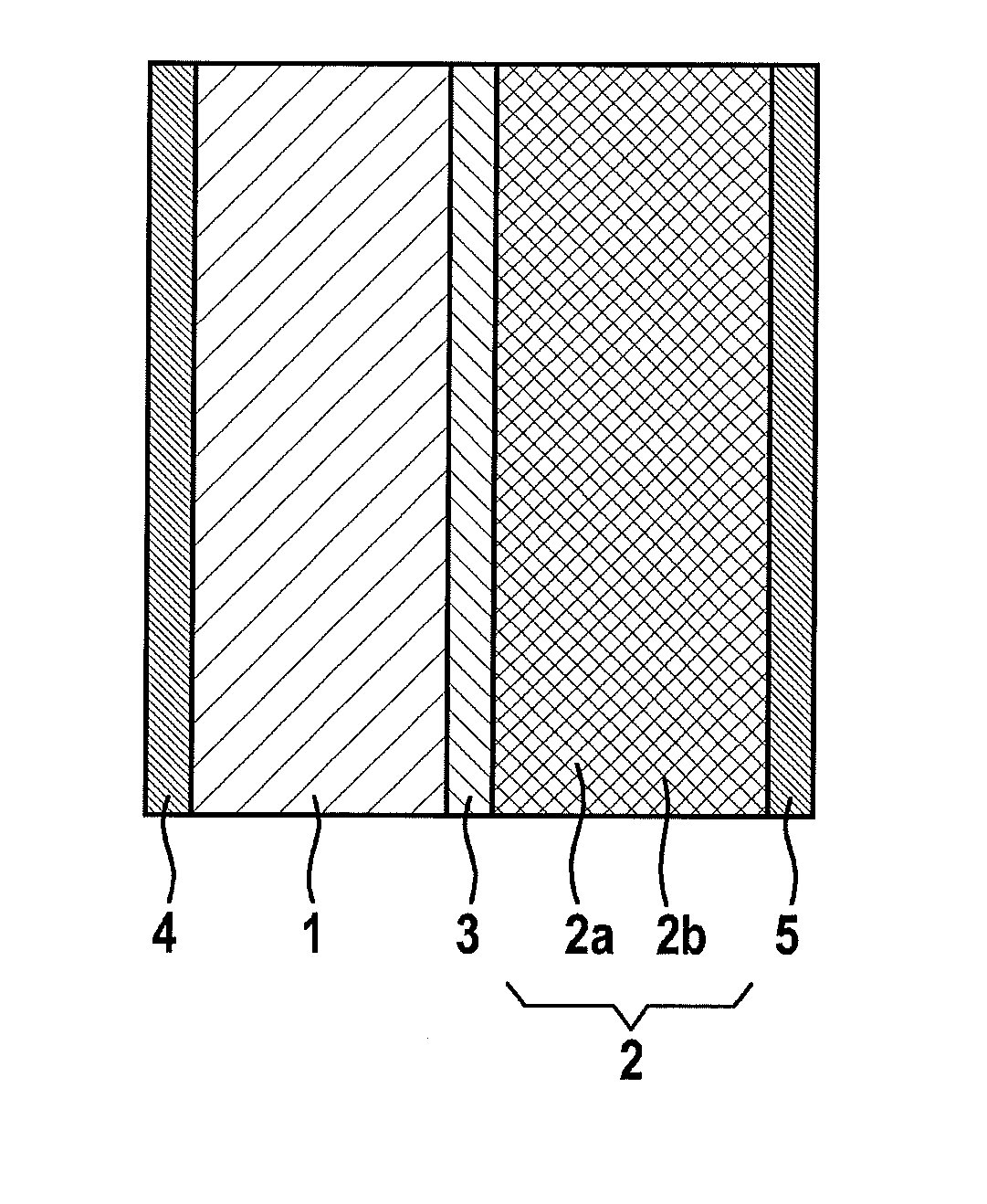

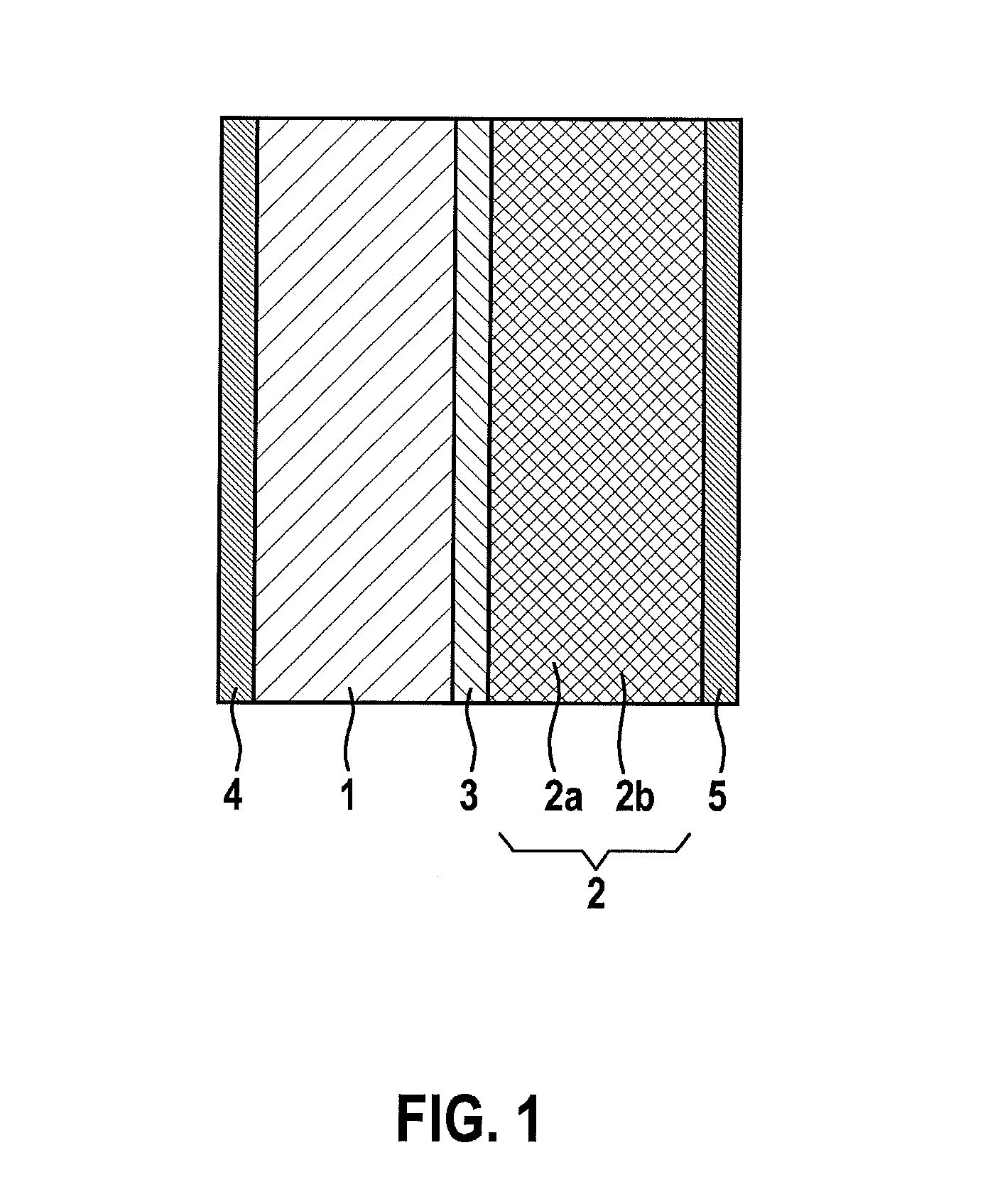

All-solid-state cell

ActiveUS20150044576A1Transportation is highImprove cycle stabilityAlkali titanatesTantalum compoundsAll solid stateSolid state electrolyte

An all-solid-state cell, which includes a lithium-containing anode, a cathode and a lithium ions-conducting solid-state electrolyte separator situated between the anode and the cathode. To improve the safety and cycle stability of the cell, the cathode includes a composite material including at least one lithium titanate and at least one lithium ions-conducting solid-state electrolyte. Furthermore, the invention relates to a corresponding all-solid-state battery and a mobile or stationary system equipped with it.

Owner:ROBERT BOSCH GMBH

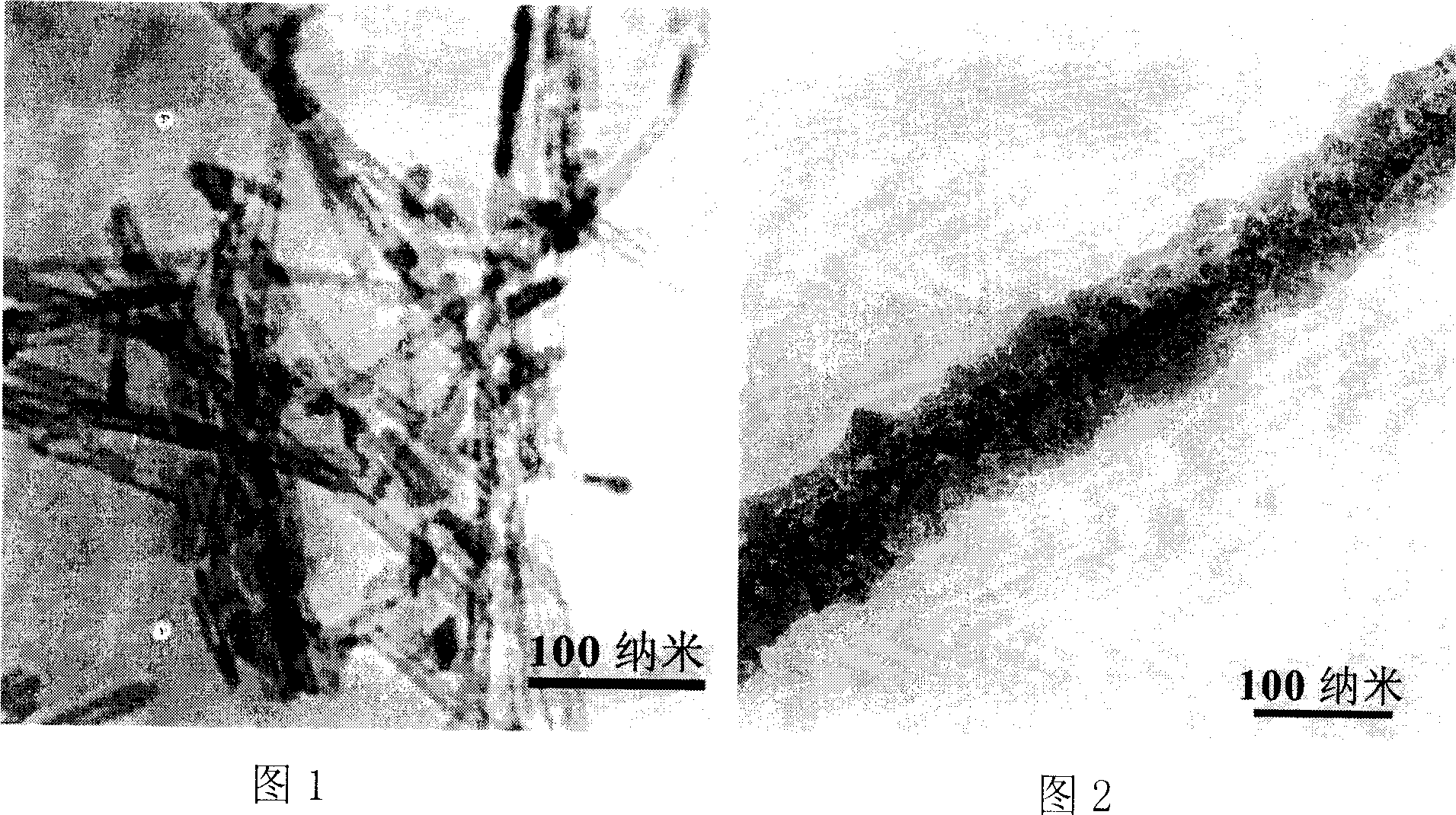

Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

InactiveCN1725530AReduce energy consumptionUniform shapeNanostructure manufactureElectrode manufacturing processesNanowireIon exchange

This invention discloses a preparation method for spinel lithium titanate nm pipes / nm lines used in Li batteries and capacitors, which applies cheap industrial TiO2 as the raw material and supersonic chemical method to prepare said nm pipes / lines then takes them as the raw materials to be mixed with a certain quantity of soluble Li salt solution to be baked in air and by low-temperature hydrothermal ion exchange method to manufacture spinel lithium titanate nm pipes / lines with uniform shape, uniform diameter and even larger major diameter ratio and big ratio surface area.

Owner:TSINGHUA UNIV

Lithium-titanate composite negative pole material and preparation method thereof

ActiveCN103151505AImprove electrochemical performanceImprove lithium ion diffusion coefficientCell electrodesCarbon nanotubeLoop stability

The invention relates to a lithium-titanate composite negative pole material and a preparation method thereof. The lithium-titanate composite negative pole material provided by the invention comprises lithium titanate, doping elements and a graphene / carbon nanotube composite material. The preparation method comprises the following steps: preparing a titanium source, a lithium source, soluble compounds of doping elements and the graphene / carbon nanotube composite material into a precursor by sol-gel in-situ synthesis, and calcining the precursor at 400-1100 DEG C to obtain the lithium-titanate composite negative pole material. The graphene / carbon nanotube composite material is utilized to effectively improve the electronic conductivity and rate capability of the lithium-titanate negative pole material; and the doping elements are introduced to effectively enhance the electrochemical properties and loop stability of the lithium-titanate negative pole material. The lithium-titanate negative pole material provided by the invention has wide application prospects in the field of lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Quickly chargeable lithium ion battery and its making method

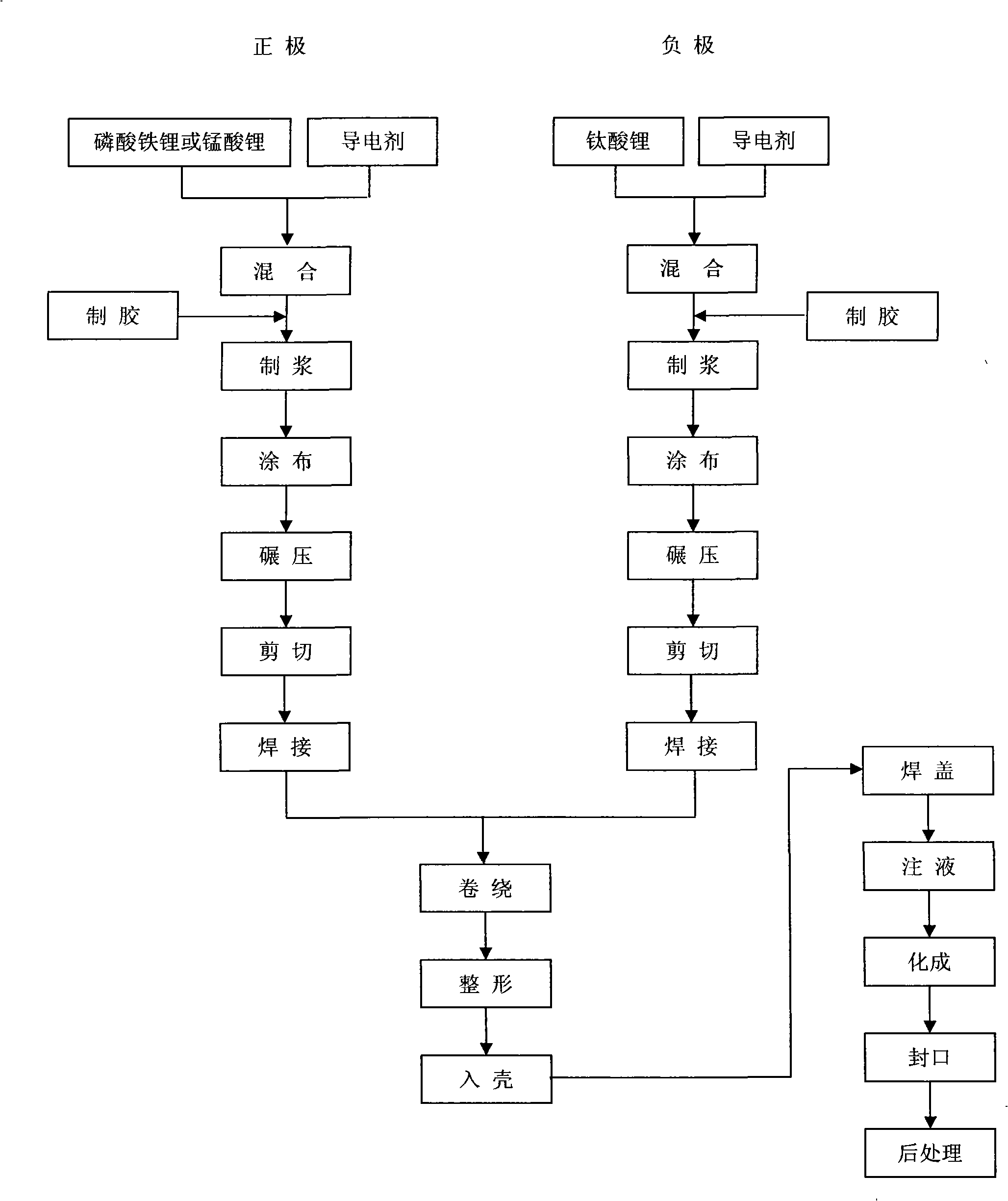

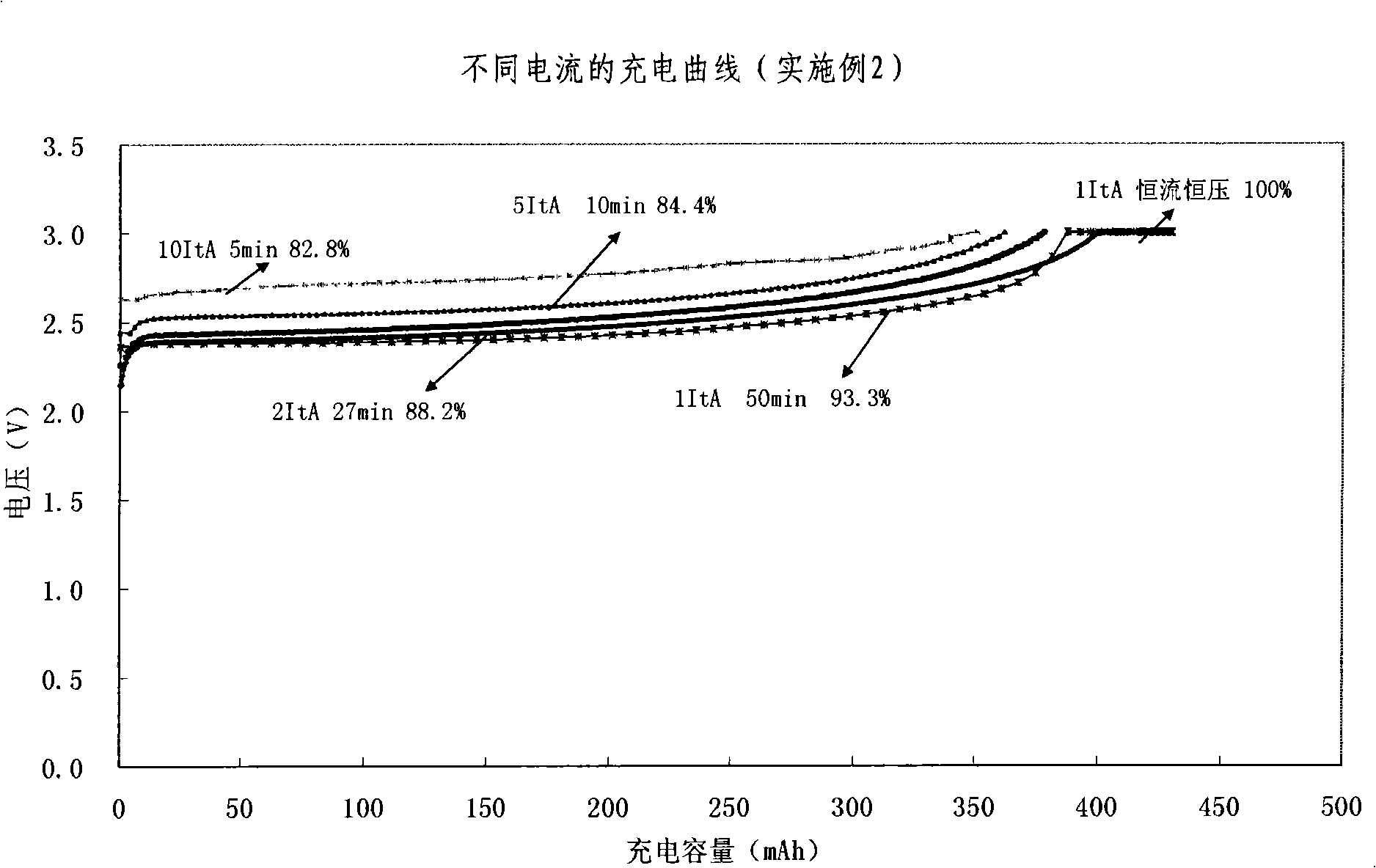

InactiveCN101262078AExcellent fast charge and discharge performanceCell electrodesFinal product manufactureMethyl carbonateManganate

The invention discloses a lithium-ion battery with fast charge property, which comprises an anode, a cathode, a diaphragm sandwiched between the anode and the cathode and an organic electrolyte, wherein, sub micrometer lithium titanate is used as the active substance of the cathode; one or several materials of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) are used as active materials of the anode, or a mixture of lithium cobalt (LiCoO2) and one of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) is adopted as the active materials of the anode; lithium hexafluorophosphate (LiPF6) is adopted as the electrolyte, and a multicomponent mixture of ethylene carbonate (EC), dimethylcarbonate(DMC), Ethyl Methyl Carbonate (EMC) is used as a solution. The invention also discloses a preparation method of the lithium-ion battery with fast charged property. The lithium-ion battery of the invention has excellent fast charging and discharging performance.

Owner:TIANJIN B&M SCI & TECH

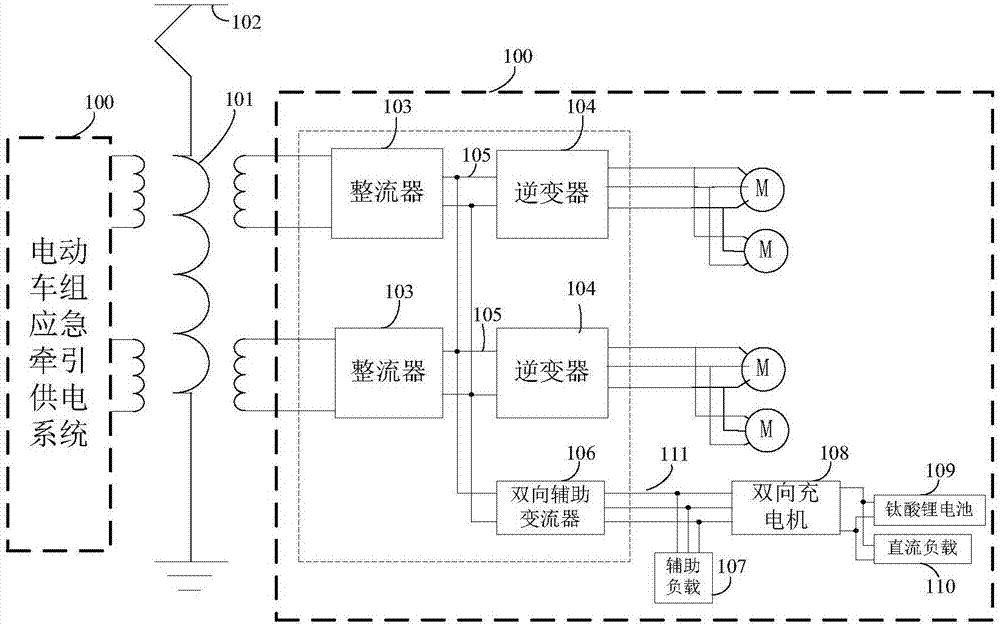

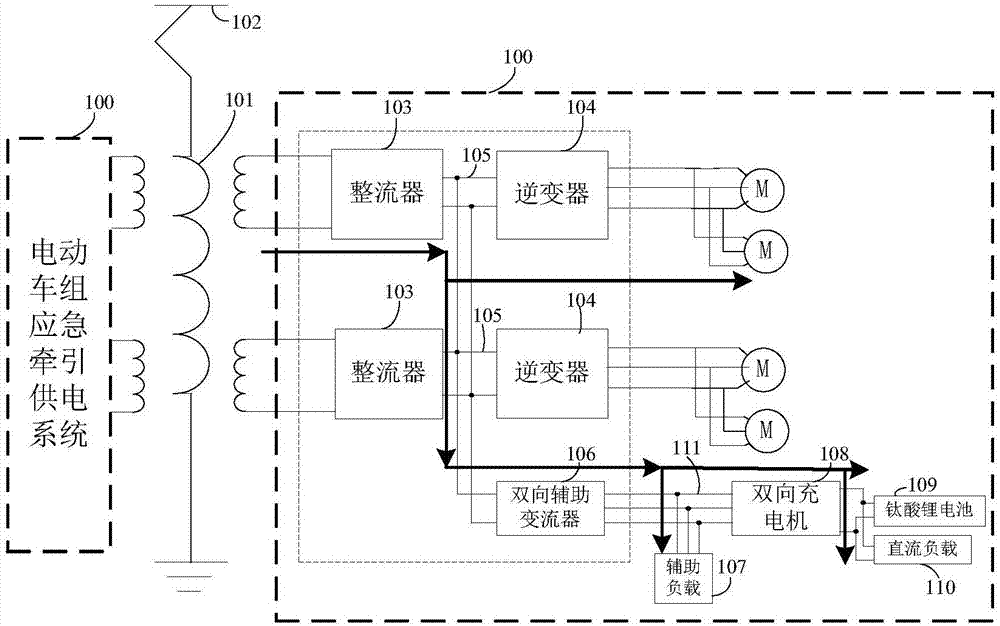

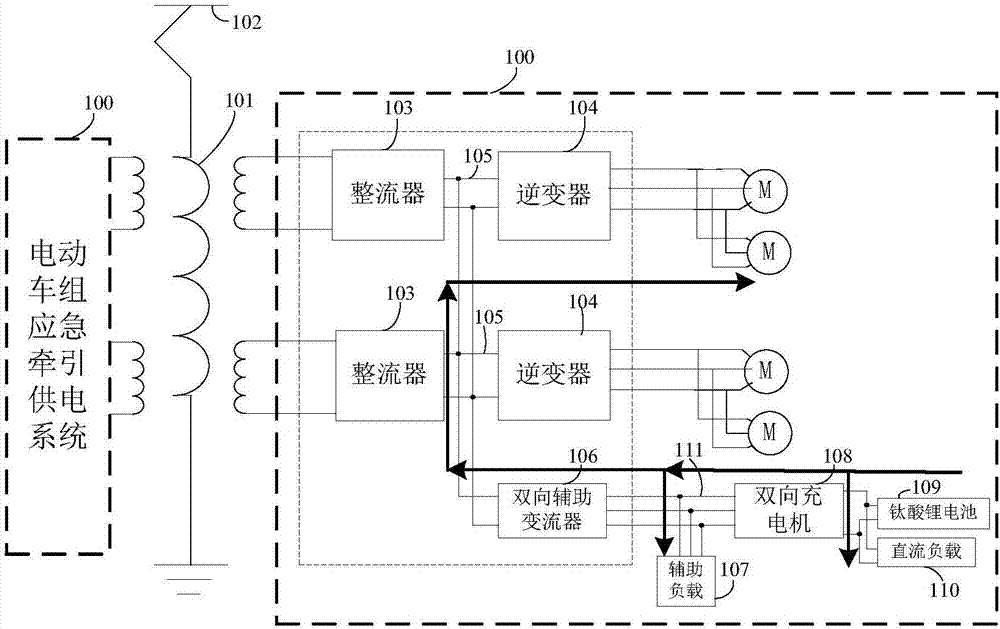

Emergency traction power supply system of electric motor unit

PendingCN107128183AMaintain normalMaintain performancePropulsion using ac induction motorsElectric energy managementContact networkBusbar

The invention discloses an emergency traction power supply system of an electric motor unit, which comprises a traction transformer used for reducing high voltage of a contact network, two rectifiers used for rectifying alternating current of secondary side windings of the traction transformer into voltage of middle direct current links, two inverters used for taking electricity from the middle direct current links and performing inversion into three-phase alternating current, a two-way auxiliary current transformer used for taking electricity from the middle direct current links and performing inversion into three-phase alternating current or taking electricity from a two-way charger and then performing boosting and rectification into the voltage of the middle direct current links, an auxiliary load used for obtaining the three-phase alternating current from the two-way auxiliary current transformer or the two-way charger by an auxiliary load power supply busbar, and the two-way charger used for obtaining the three-phase alternating current from a three-phase alternating current output side of the two-way auxiliary current transformer and performing voltage reduction and rectification on the three-phase alternating current into direct current to supply power to a lithium titanate battery and a direct current load which are connected with the two-way charger, or used for taking electricity from the lithium titanate battery and performing boosting and inversion into the three-phase alternating current to supply power to the auxiliary current transformer.

Owner:CHINA RAILWAYS CORPORATION +3

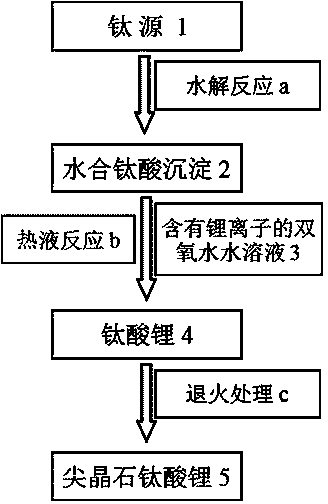

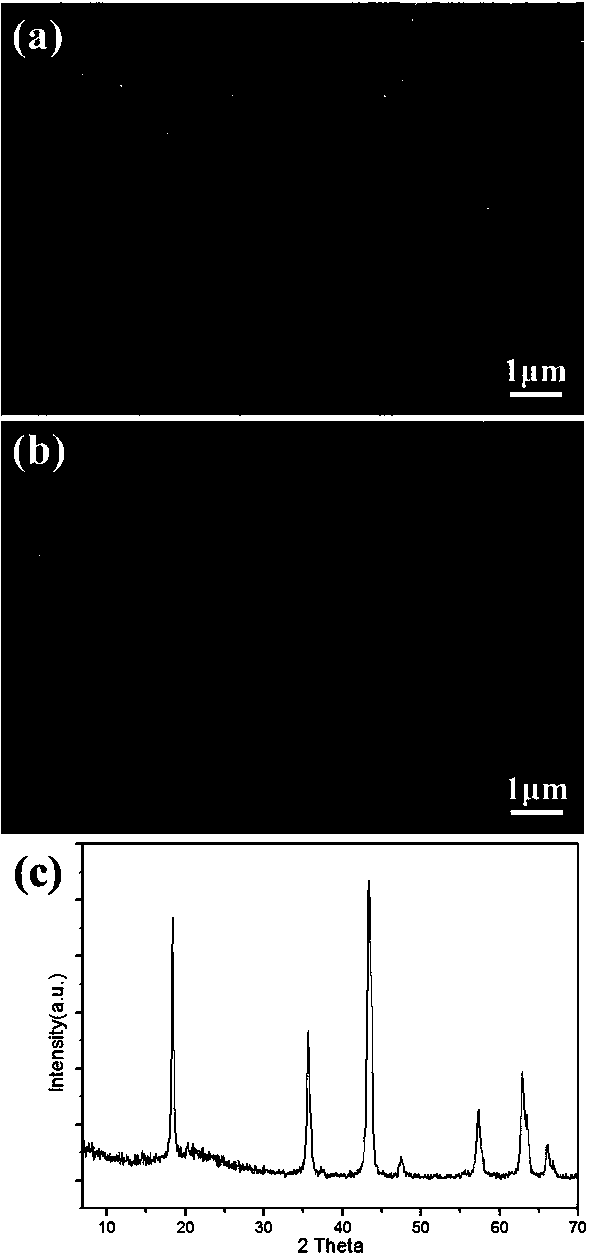

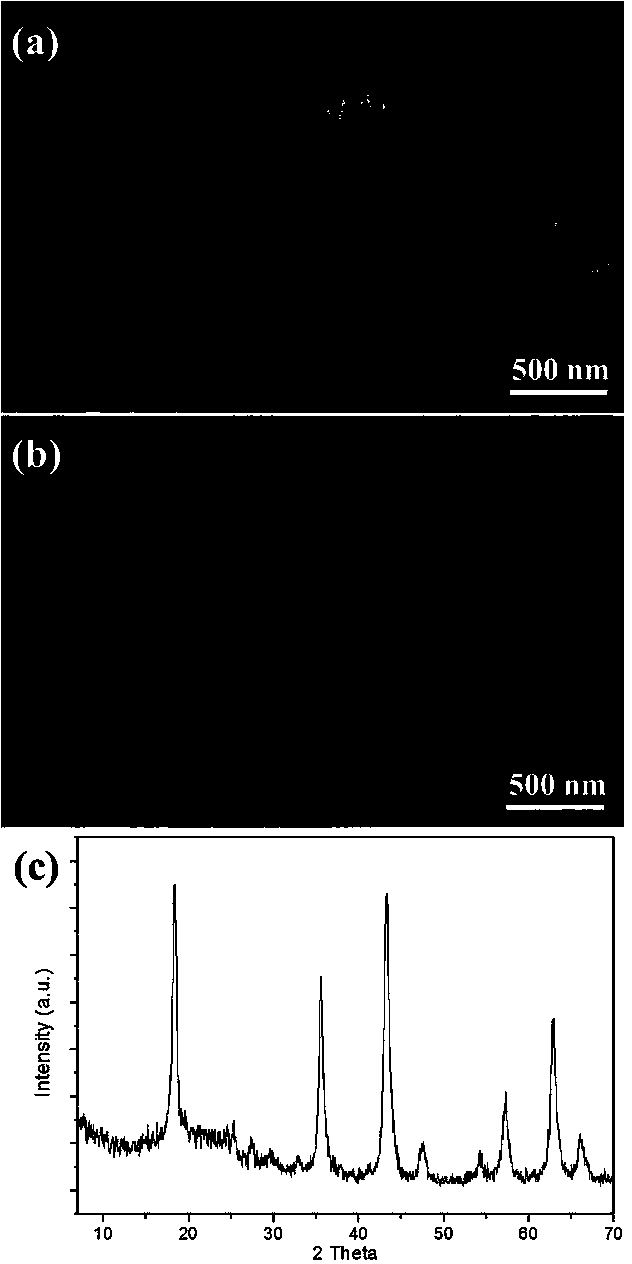

Method for preparing spinel lithium titanate

InactiveCN104201364AOvercome conductivityLow priceMaterial nanotechnologyAlkali titanatesLithiumNanowire

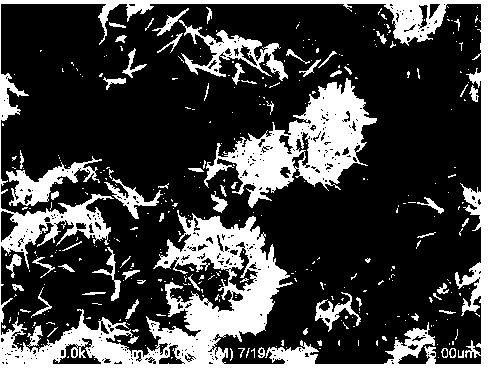

The invention discloses a method for preparing spinel lithium titanate. The method is characterized by comprising the steps of S1, performing hydrolysis reaction on a titanium source to obtain hydrated titanium acid sediments; S2, dispersing the hydrated titanium acid sediments into lithium ion-containing hydrogen peroxide aqueous solution to obtain a mixture; S3, performing hydrothermal reaction on the mixture to obtain nanowire type lithium titanate and / or lithium titanate with a nano differential level structure; S4, annealing the nanowire type lithium titanate and / or the lithium titanate with the nano differential level structure to obtain nanowire type spinel lithium titanate and / or the spinel lithium titanate with the nano differential level structure. According to the method, both spinel lithium titanate nanowires and the spinel lithium titanate with the nano differential level structure can be prepared.

Owner:李建明

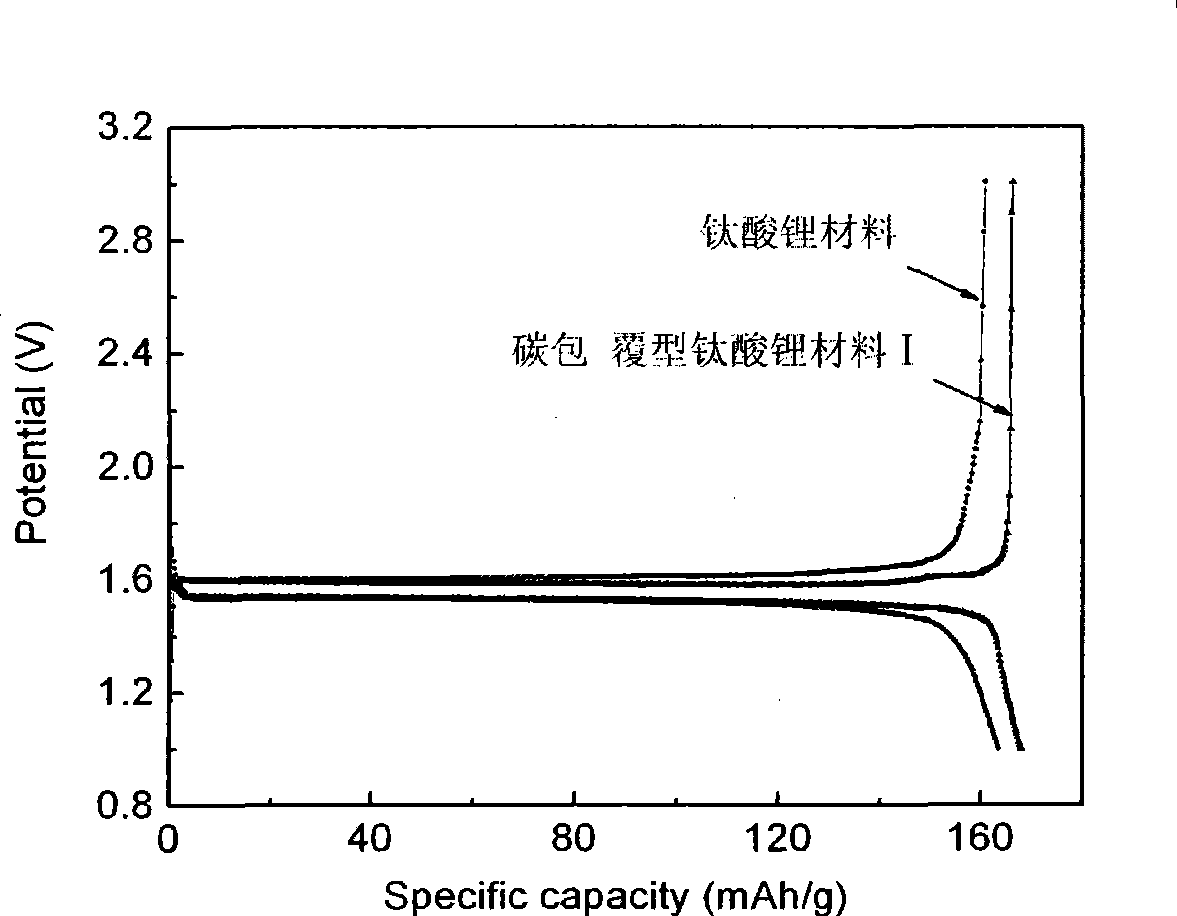

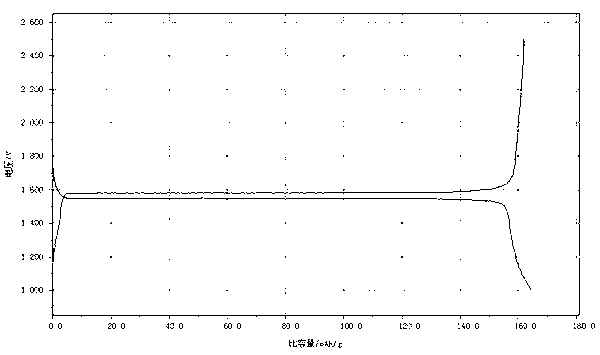

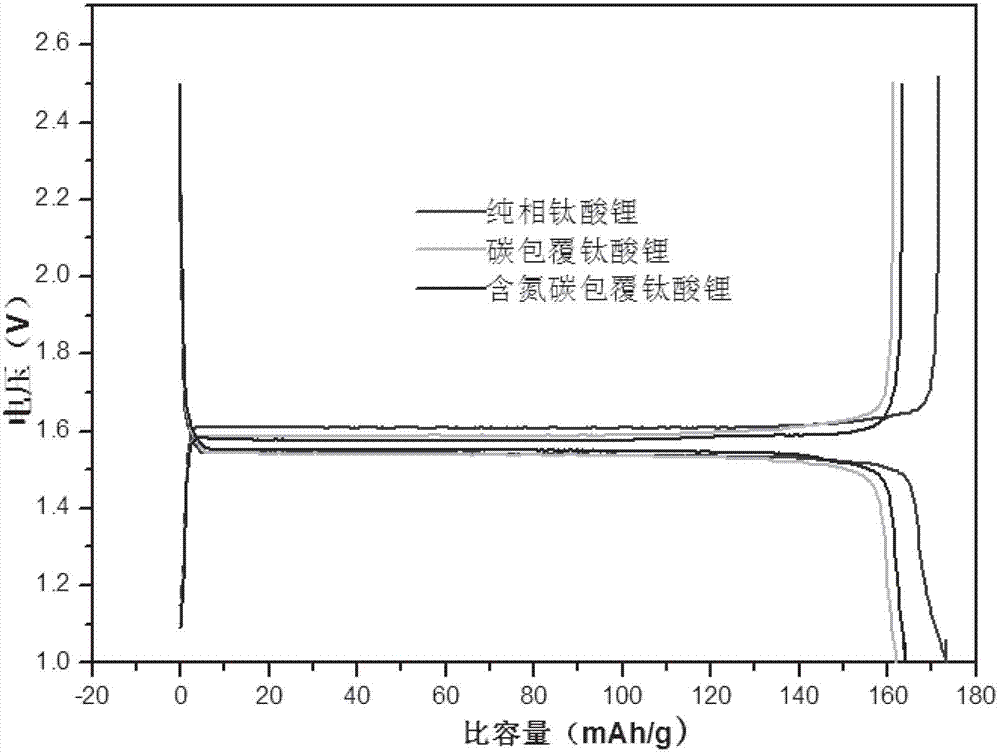

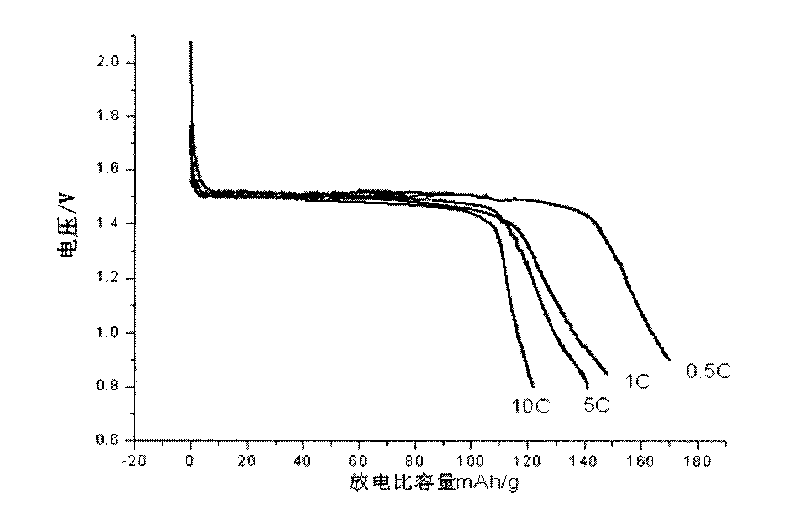

Preparation method for high-conductivity lithium titanate cathode material of lithium battery

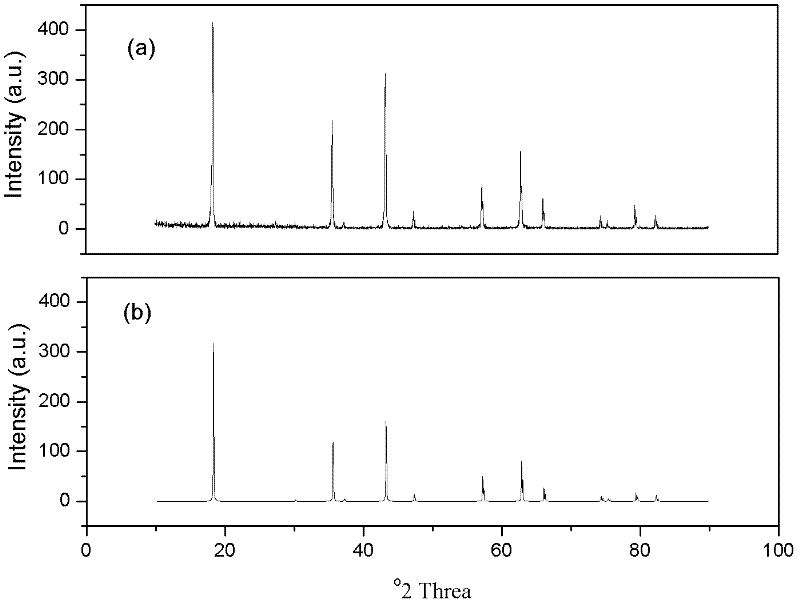

ActiveCN103022462AImprove conductivityPromote commercial applicationCell electrodesBattery cellElectronic conductivity

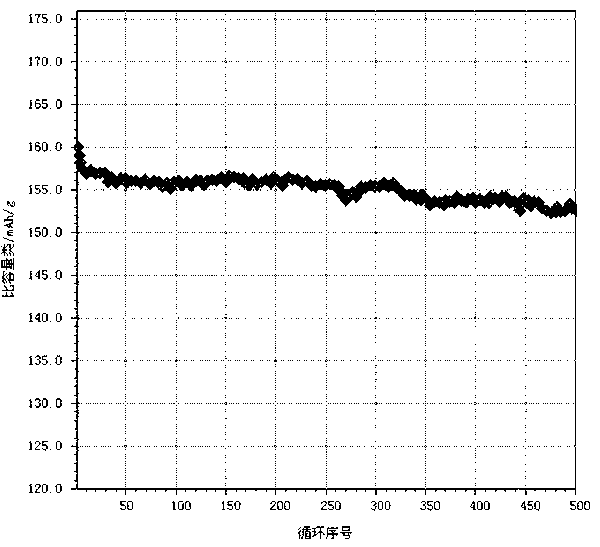

The invention relates to a preparation method for a high-conductivity lithium titanate cathode material of a lithium battery, and belongs to the technical field of cathode materials of lithium ion batteries. Firstly, better lithium titanate crystals can be obtained by preparing pure spinel lithium titanate, and the conductivity of the lithium titanate material can be improved by carrying out carbon covering at a later stage; and secondly, a solid-phase sintering method with low cost is adopted for the contribution to commercial application, the initial charge specific capacity of the produced lithium titanate material at the rate of 1 C (1 C is 175 mA / g) can reach 160 mAh / g, and the capacity can keep more than 95% after 500 times of circulation.

Owner:DONGFANG ELECTRIC CORP LTD

Lithium ion battery capable of quick charging

InactiveCN104347880AIncrease gram capacityImproved magnification performanceCell electrodesSecondary cellsLithium iron phosphateAdhesive

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery capable of quick charging. The battery includes a positive plate, a negative plate, isolating films arranged between the positive and negative plates at intervals, and electrolyte. The positive plate includes a positive current collector and a positive electrode active material layer arranged on the surface of the positive current collector. The positive electrode active material layer includes a positive electrode active material, a positive electrode conductive agent and a positive adhesive. The positive electrode active material includes components A and B. the component A is selected from at least one of nickel-cobalt lithium aluminate, nickel-cobalt lithium manganate, lithium manganate and lithium cobaltate. The component B is selected from at least one of lithium iron phosphate and lithium titanate. The mass percent of the component B in the positive electrode active material is 5-9 percent. In comparison with the prior art, the lithium ion battery has the advantages that the time of low voltage constant current charging can be prolonged due to use of the mixed positive electrode active material, and thus the charging speed is increased.

Owner:DONGGUAN AMPEREX TECH

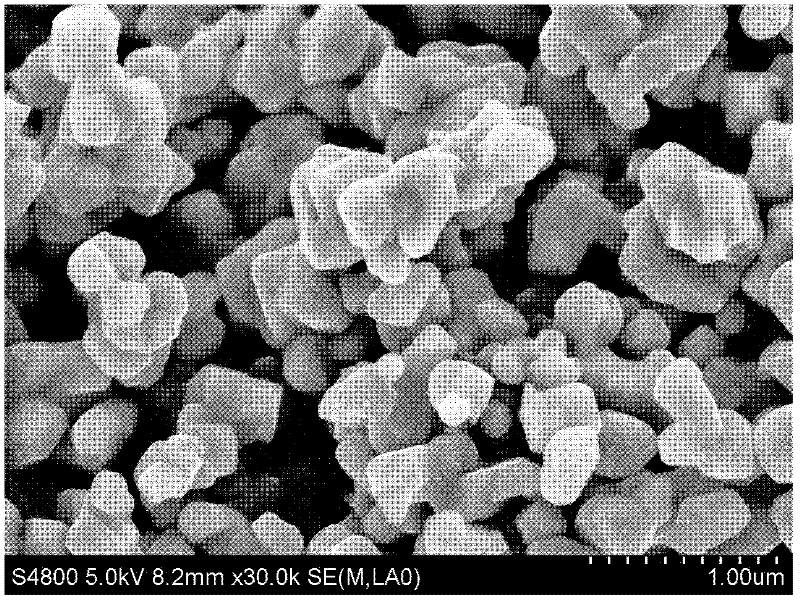

Preparation method of aluminum-oxide-coated nano lithium titanate composite material

ActiveCN102376947AExcellent rate performanceImprove cycle performanceCell electrodesFree coolingRoom temperature

The invention discloses a preparation method of aluminum-oxide-coated nano lithium titanate composite material, which comprises the steps of: adding aluminum salt solution into prepared Li4Ti5O12 suspending liquid under the stirring condition, wherein the adding quantity of the aluminum salt solution is in accordance with the molar ratio as follows: Ti: Al=5: x, and x=0.01-0.55; simultaneously, adding a right amount of ammonia water, and adjusting the pH value to be 8-10; stirring for reaction for 30-50 minutes, and standing still for about 6 hours; after filtering, washing and drying, obtaining precursor of the aluminum-oxide-coated nano lithium titanate composite material; and finally, sintering the obtained precursor of the aluminum-oxide-coated nano lithium titanate composite materialat 400-600 DEG C for 4-10 hours, naturally cooling to be room temperature, and obtaining the aluminum-oxide-coated nano lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

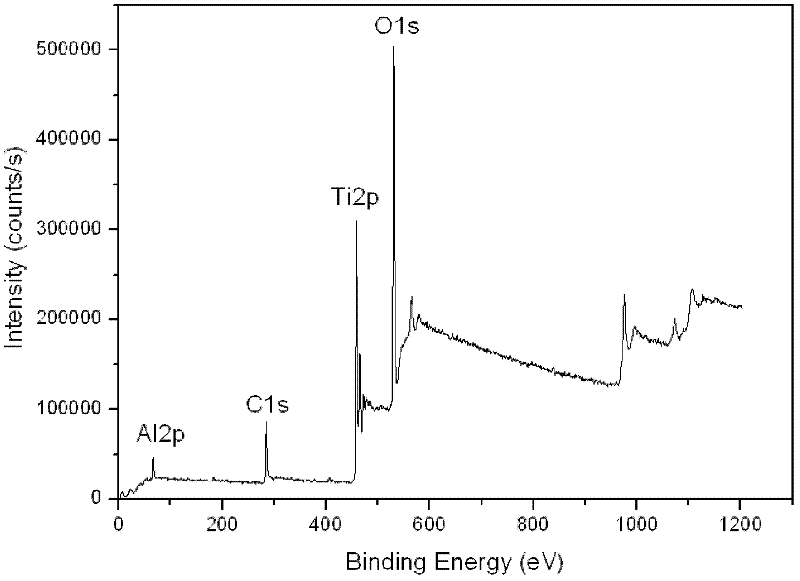

Synthetic method of nitrogen-enriched carbon coated lithium titanate composite material prepared by introduction of ionic liquid as carbon source

InactiveCN102820458AImprove electronic conductivityImprove surface stabilityCell electrodesSecondary cells servicing/maintenanceVacuum dryingCarbon coated

The invention discloses a synthetic method of a nitrogen-enriched carbon coated lithium titanate composite material prepared by the introduction of an ionic liquid as a carbon source. The synthetic method comprises the following steps of: 1) weighing lithium salt, titanium dioxide and the carbon source in proportion, adding alcohol, carrying out ball milling dispersion, and carrying out vacuum drying to prepare a precursor; 2) sintering the prepared precursor at the temperature of 750-950 DEG C under the protection of an inert atmosphere so as to preliminarily obtain lithium titanate with a carbon material coated on the surface; and 3) adding the ionic liquid and deionized water in proportion into the preliminarily obtained carbon-coated lithium titanate, carrying out ball milling, stirring and sintering. The lithium titanate composite material has a spherical morphology of nano-primary particle composed micrometer secondary particles, and the surface of the lithium titanate composite material is uniformly coated with a layer of nitrogen-enriched carbon material. Its electronic conductivity is not only effectively raised, but surface stability of the material is also enhanced. The obtained material has excellent rate capability and cycle performance. In addition, gas expansion problem of lithium titanate cells is effectively improved. The nitrogen-enriched carbon coated lithium titanate composite material has a wide application prospect in the field of lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing lithium titanate cathode material of lithium ion battery

InactiveCN101409341AExcellent high rate charge and discharge performanceElectrode manufacturing processesHigh rateLithium hydroxide

The invention discloses a preparation method of a lithium titanate cathode material for a lithium ion battery. Titanium dioxide colloid is taken as an initial raw material; the titanium dioxide colloid and lithium hydroxide are added to a mixture of water and ethanol while stirring, then the obtained solution is transferred to a hydrothermal reaction kettle for hydrothermal ion exchange reaction at 150-200 DEG C for 10-18h, the reacted solution is naturally cooled to room temperature, then filtered to obtain white precipitate; the obtained precipitate is placed in a muffle furnace with the temperature of 350-600 DEG C for 1-3h heat treatment to obtain the lithium titanate cathode material used in the lithium ion battery. The lithium titanate cathode material which is used in the lithium ion battery and synthesized by the method has stable discharge specific capacity of 125mAh / g at the rate of 20C (3.5A / g), and has good high-rate charge and discharge performance.

Owner:SHANGHAI JIAO TONG UNIV +1

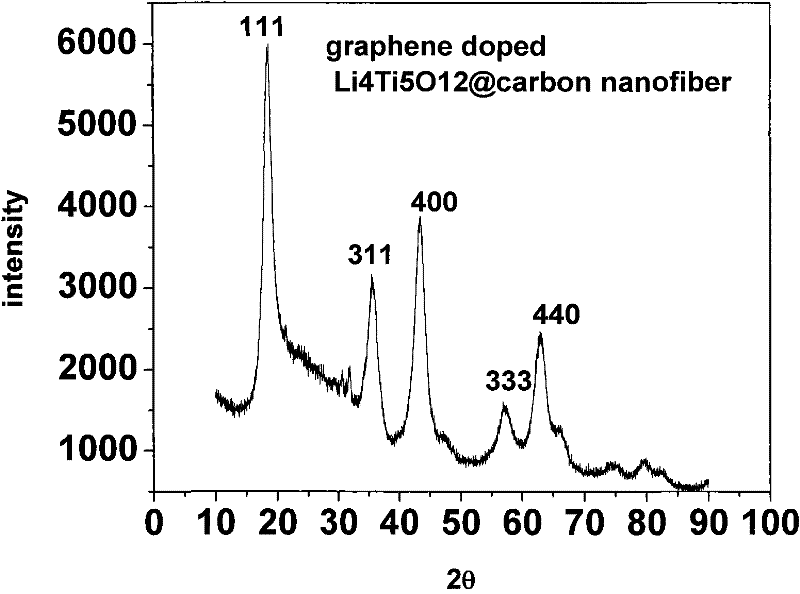

Preparation method for three-dimensional porous graphene doping and coating lithium titanate composite anode material

InactiveCN102646810AImprove conductivityHigh specific capacityElectrode manufacturing processesPorous grapheneCarbon layer

The invention discloses a preparation method for a three-dimensional porous graphene doping and coating lithium titanate composite anode material. The problem that a high ratio property of lithium titanate is poor can be solved by a doping vario-property of a carbon nano material to the lithium titanate, and the spinel structure of the lithium titanate can not be affected. A nano carbon layer made of the carbon nano material is doped in a carbon nano material doping lithium titanate composite material to have an effect of an electrical transmission cushion layer, so that a cyclic property of the carbon nano material doping lithium titanate composite material is improved, besides, an introduction of the carbon nano material can effectively restrain a gathering of lithium titanate particles in a heat treatment process, and simultaneously diffusion coefficients of lithium-ions in the carbon nano material doping lithium titanate composite material are increased. According to the preparation method for the three-dimensional porous graphene doping and coating lithium titanate composite anode material, the prepared three-dimensional porous grapheme has a high specific surface area, and thereby the high ratio property of the lithium titanate is further improved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

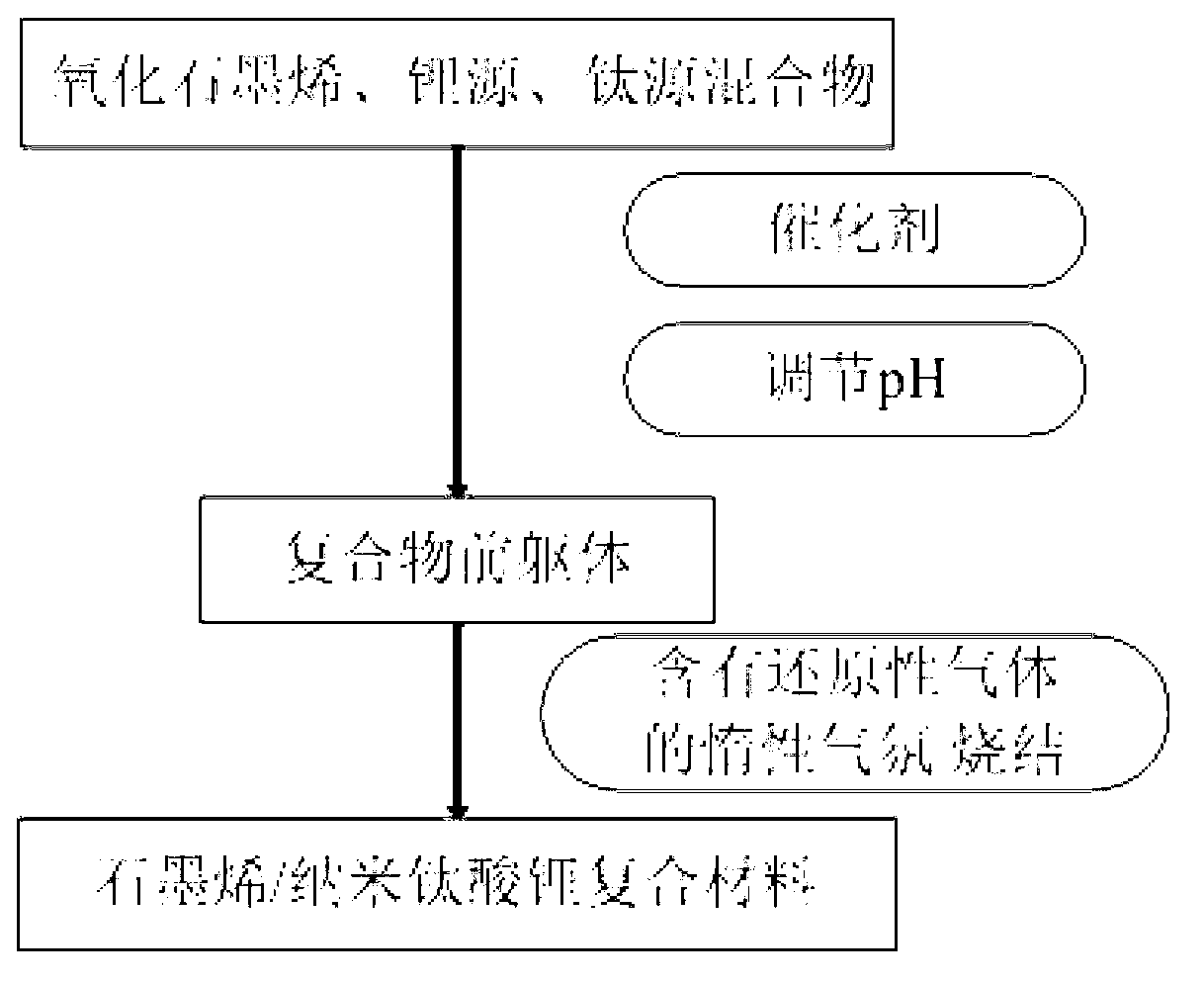

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459AImprove electrochemical performanceGood magnificationCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

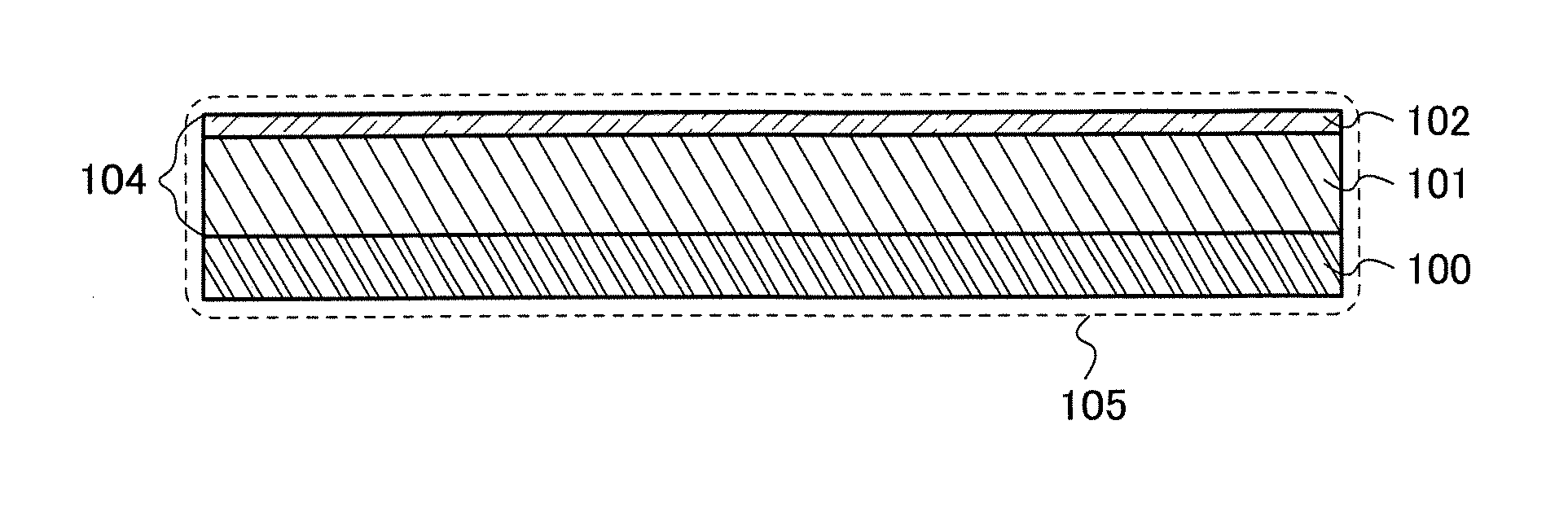

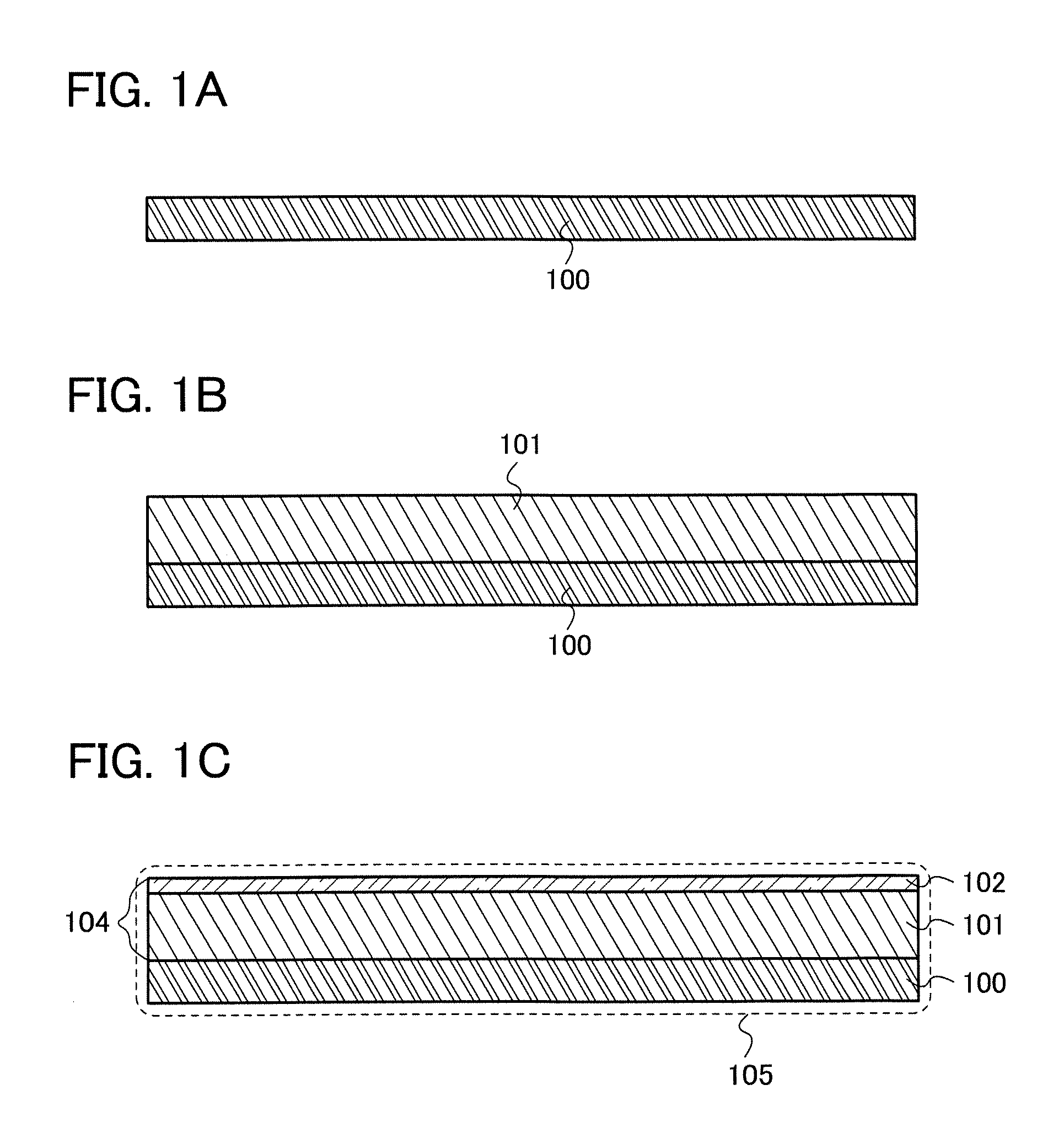

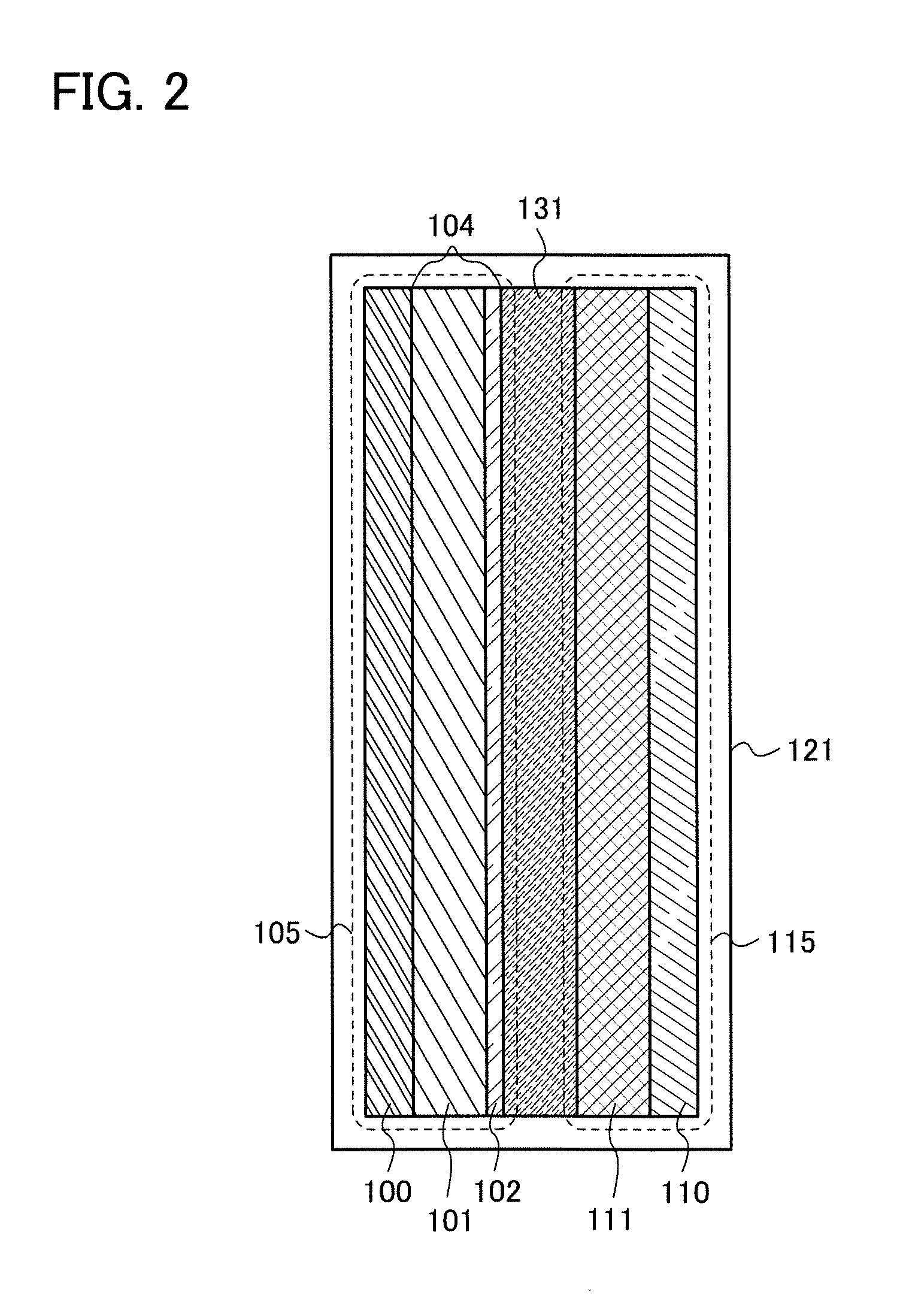

Electricity storage device

ActiveUS20110177396A1Improve adhesionSmall contact resistanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceElectricity

An object is to improve characteristics of a power storage device. The present invention relates to an electricity storage device comprising a current collector and a negative electrode-active material layer formed over the current collector. The negative electrode-active material layer includes a negative electrode comprising a first negative electrode layer in contact with the current collector; a second negative electrode layer in contact with the first negative electrode layer, having a smaller capacitance than the first negative electrode layer and containing one material selected from a nitride of lithium and a transition metal represented by LiaMbNz (M is a transition metal, 0.1≦a≦2.8, 0.2≦b≦1 and 0.6≦z≦1.4), a silicon material, and lithium titanate; a positive electrode that is paired with the negative electrode; and a solid electrolyte interposed between the positive electrode and the negative electrode.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

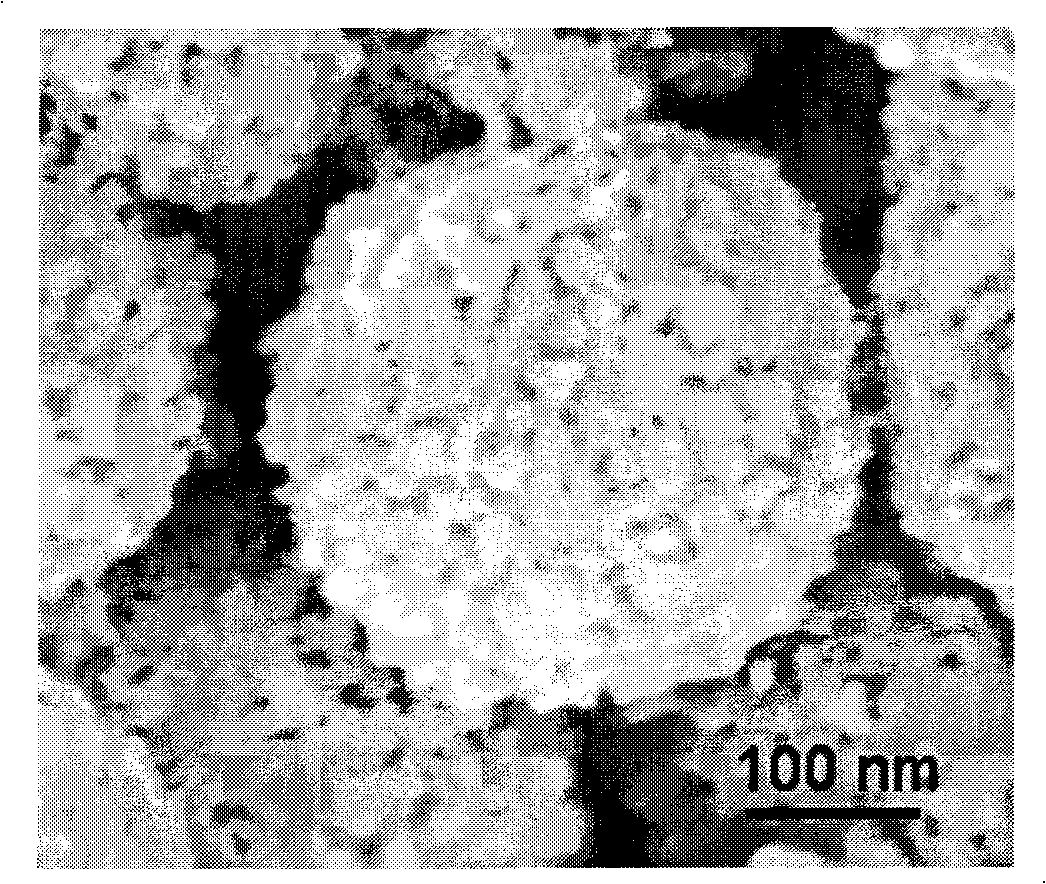

Preparation method of lithium titanate negative electrode material with micro-nanostructure

InactiveCN103107321AGood dispersionNarrow size distributionCell electrodesHigh rateLithium hydroxide

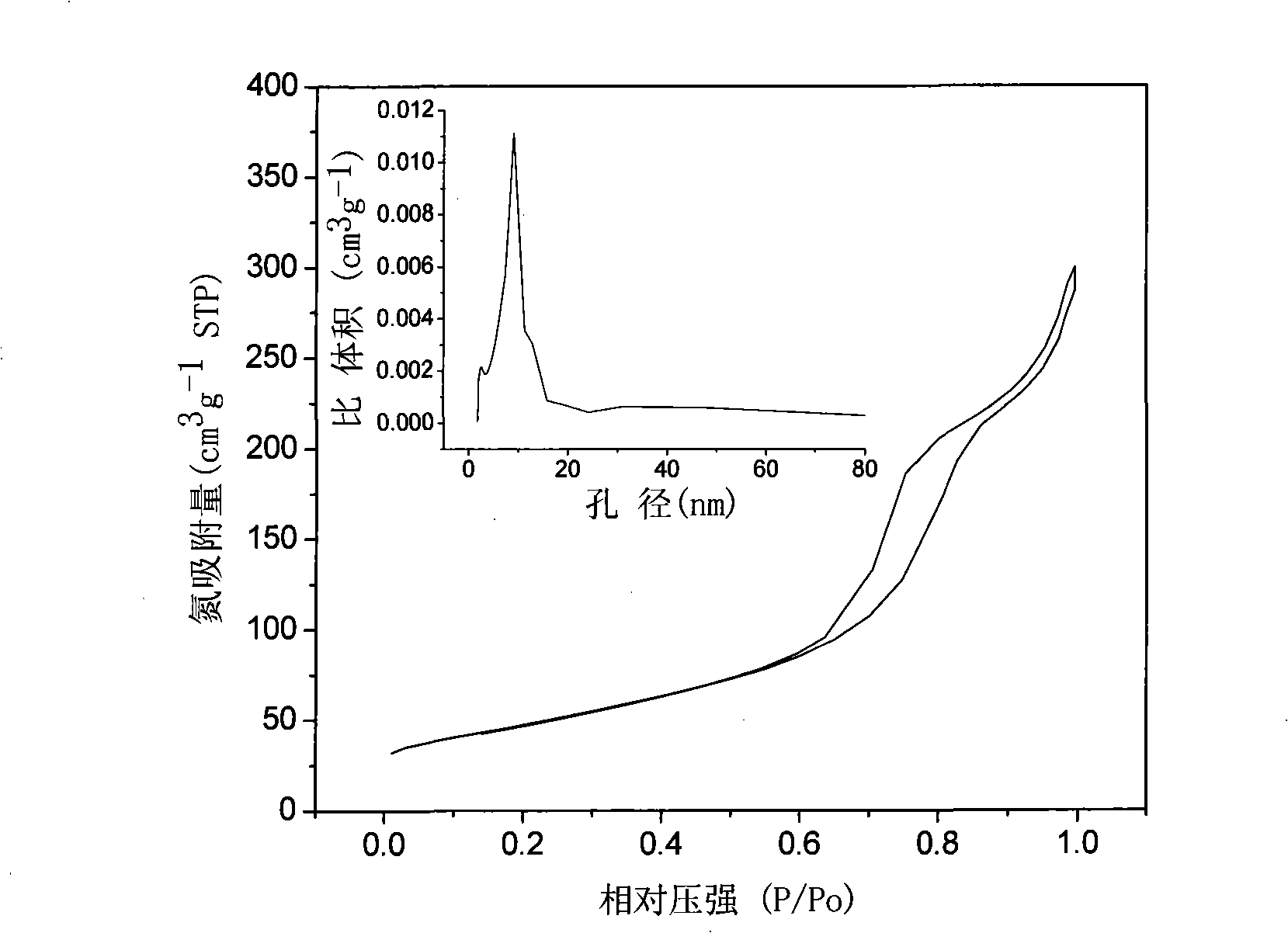

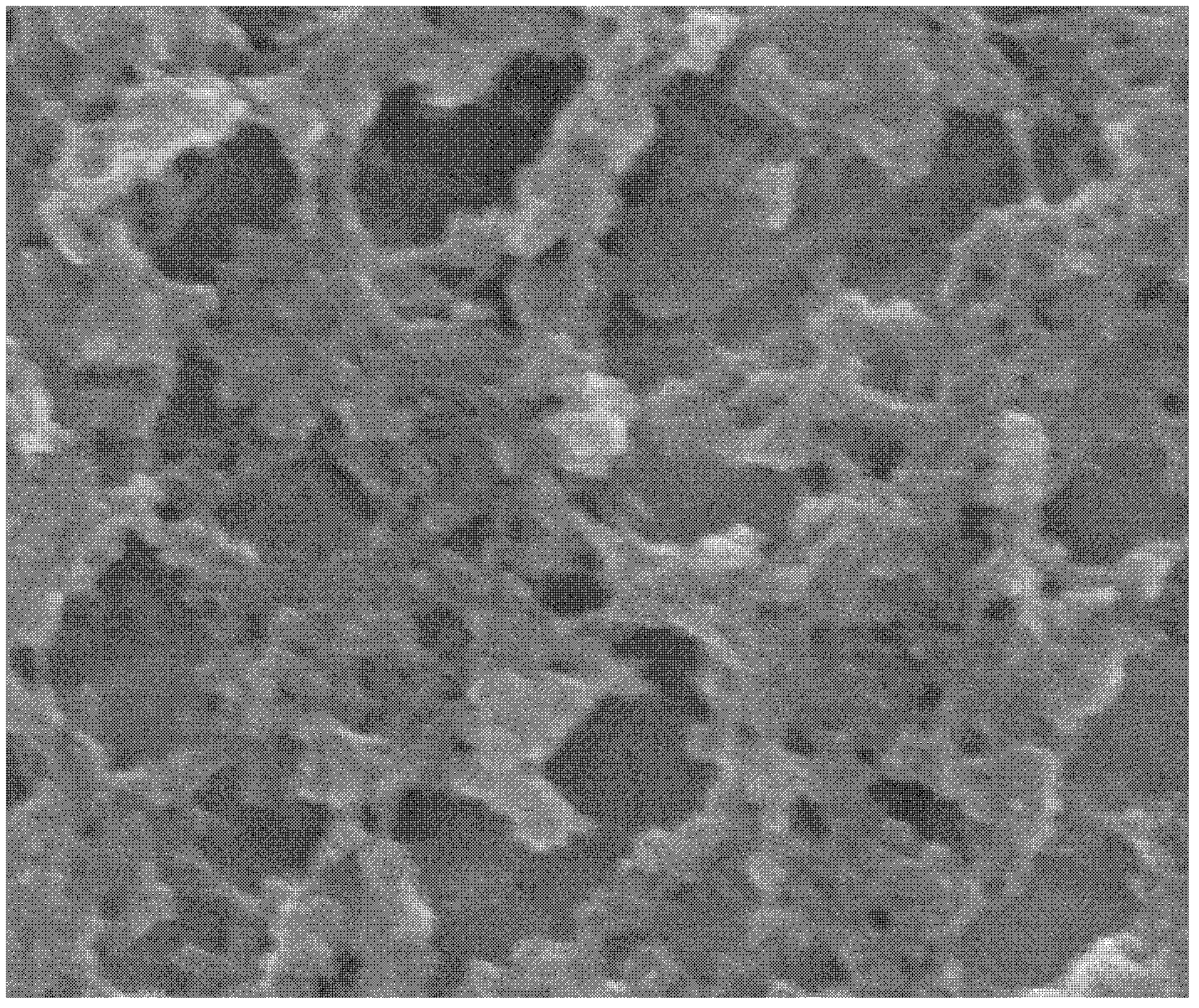

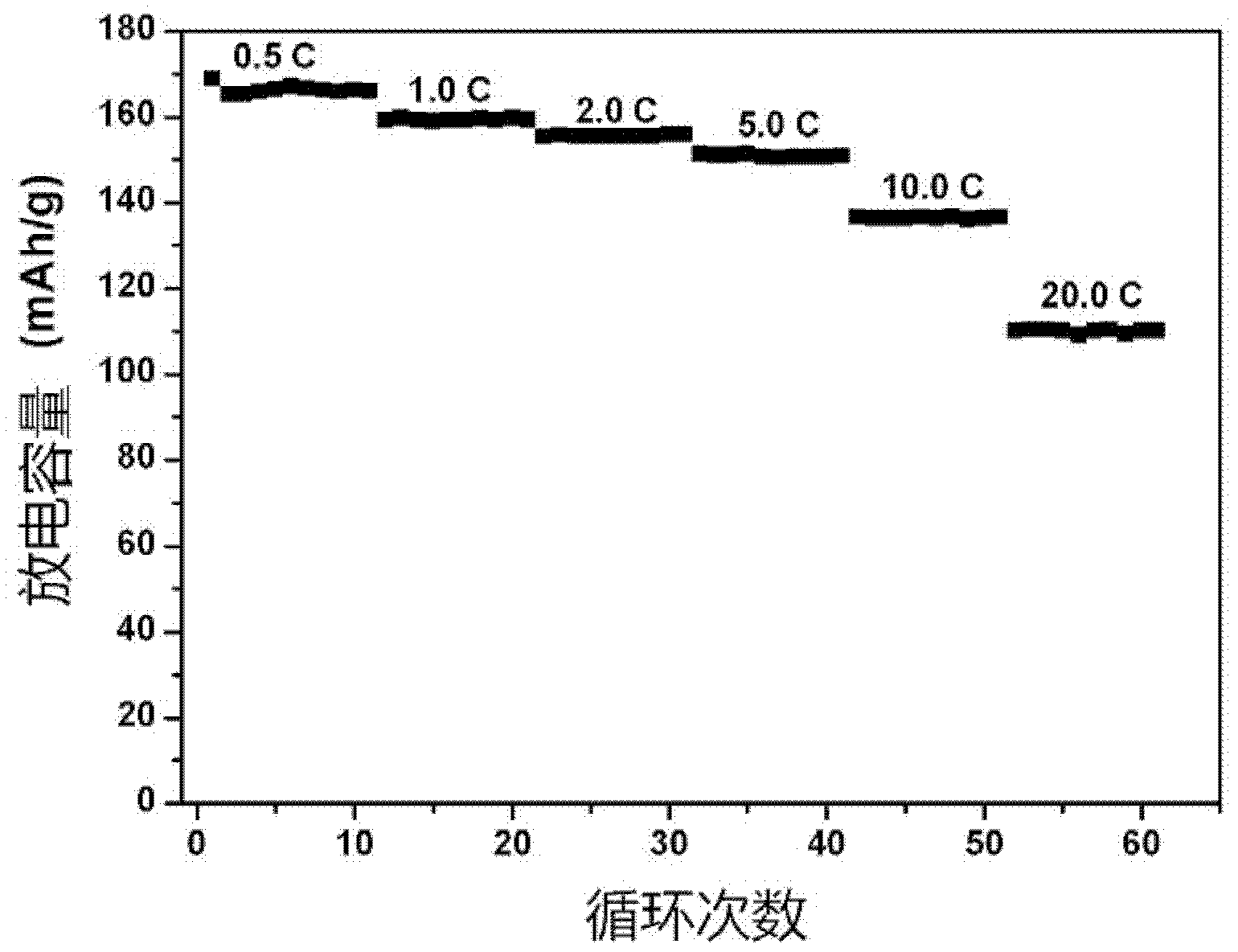

The invention provides a preparation method of a lithium titanate negative electrode material with a micro-nanostructure. The method is characterized by comprising the steps of: a. preparing a titanium dioxide precursor; b. under a stirring state, adding the titanium dioxide precursor into water, or a mixed solution of water and ethanol, further adding lithium hydroxide under a stirring state, then transferring the solution into a hydrothermal reaction kettle to undergo a hydrothermal reaction, leaving the solution to natural cooling to room temperature, then carrying out filtering, washing, drying and calcination, thus obtaining the lithium titanate negative electrode material end product. The method adopts spherical titanium dioxide as an initial raw material, and takes water or ethanol as a reaction solvent to prepare plush-like hollow microspheres with an average diameter of 1.5-3 micrometers through a hydrothermal reaction and a calcination treatment. The microspheres are composed of nanosheets. The material also shows certain mesoporous characteristic, the inner micropores of the material have an average diameter of 5-15nm. The lithium titanate negative electrode material with a micro-nanostructure involved in the invention has the characteristic of excellent high-rate discharge, and is suitable for use by power batteries.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Lithium titanate cell with reduced gassing

InactiveUS20110067230A1Sufficient durationAvoid decompositionAlkali titanatesFinal product manufactureElectrolyteOperating voltage

A method of manufacturing a lithium cell is disclosed. The method can include providing a lithium cell having an operating voltage range, where the lithium cell includes a negative electrode, a positive electrode, and an electrolyte in contact with, and between, the negative electrode and the positive electrode. The negative electrode can include lithium titanate and the electrolyte can include an additive. The method can also include reducing the additive to form a coating on a surface of the negative electrode in contact with the electrolyte. The reducing step can include overcharging the lithium cell to a voltage greater than an upper limit of the operating voltage range and dropping a voltage of the negative electrode to 0.2-1V vs. lithium.

Owner:ENERDEL

Method for solving flatulence of lithium titanate cathode of lithium battery by using double-boundary wrapping

ActiveCN103187562AImprove cycle stabilityImprove cycle lifeCell electrodesNickel–lithium batteryFlatulence

The invention relates to a method for solving flatulence of a lithium titanate cathode of a lithium battery by using double-boundary wrapping, and belongs to the technical field of energy materials. The method is characterized in that firstly, boundary stabilizing layer wrapping is carried out on a nitride of a lithium titanate cathode material, so as to establish an electrochemistry stable boundary between an electrode material and electrolyte, and subsequently hydrophobic surface layer wrapping is carried out by adopting a nitrogen-containing compound so as to establish a hydrophobic electrode boundary and prevent the crystal water in the electrode material from entering electrolyte; and at the same time the trace moisture of an electrolyte system is prevented from diffusing to the electrode boundary to cause catalysis reaction, and the electrolyte is prevented from decomposing to generate gas in the charging and discharging process, so that the problem that a lithium ion battery is swelled is solved, and the circulation service life of the battery is prolonged.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

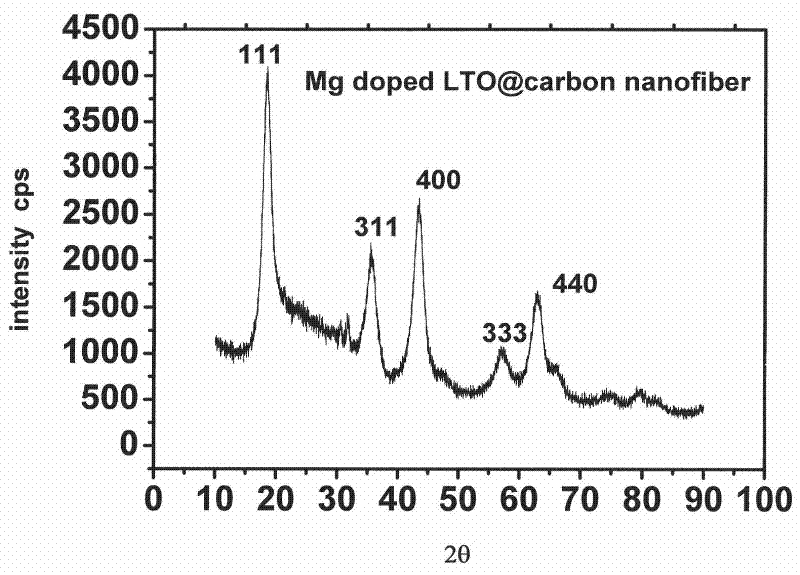

Lithium titanate for lithium ion battery negative electrode material and preparation method thereof

InactiveCN101764207AImprove discharge rateImprove cycle performanceElectrode manufacturing processesAir atmosphereAlcohol

The invention discloses lithium titanate for a lithium ion battery negative electrode material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: mixing titanium dioxide with a lithium source in a molar ratio of 5:4.2; based on the total mass of the titanium dioxide and the lithium source, adding 5 to 15 percent of carbonaceous organic material and 2 to 5 percent of metal compound; adding alcohol or acetone into the mixture to stir into paste and ball-milling uniformly; drying the mixture and raising the temperature in air atmosphere to 600 to 750 DEG C at a rate of 3 to 5 DEG C per minute and preserving the heat for 6 to 12 hours; then raising the temperature to 800 to 900 DEG C and preserving the heat for 16 to 24 hours; and cooling the mixture to obtain doped lithium titanate Li4-xMxTi5O12, wherein M is metal Fe, Mg, Mn, Ag, Al, V, Sn or Cu; and x is less than or equal to 0.3 and more than or equal to 0.05. The lithium titanate can be used as the negative electrode material of the lithium ion battery, has the advantages of good rapid charge / discharge capacity, high safety performance, no pollution and excellent large-power charge / discharge performance, is suitable for industrialized production, and can be applied in the fields of electric automobiles, energy storage equipment and electric tools.

Owner:HEFEI UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com