Method for solving flatulence of lithium titanate cathode of lithium battery by using double-boundary wrapping

A lithium-ion battery, lithium titanate technology, applied in battery electrodes, electrical components, circuits, etc., to achieve the effect of improving cycle life and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

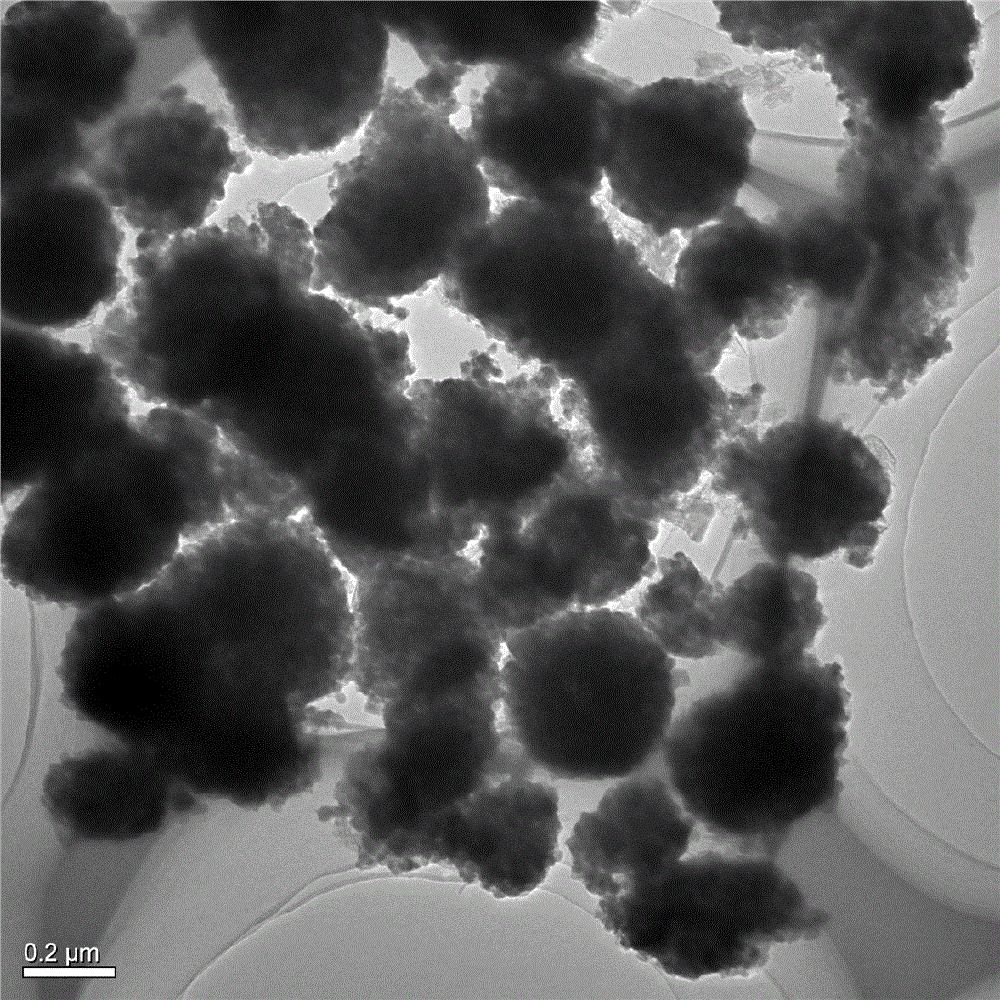

[0018] Weigh Li according to weight percentage 18:1 4 Ti 5 o 12 and nano-TiN powder, using a ball mill for 2 h to fully mix the two, put the mixed powder in an Ar gas atmosphere in a resistance furnace at 600 °C for 4 h, and cool to obtain TiN-coated Li 4 Ti 5 o 12 Negative electrode material, then, take 0.2 g of electrode material powder and disperse it in 20 mL of 10% polytetrafluoroethylene (PTFE) emulsion, ultrasonically disperse for 30 minutes, so that PTFE molecules are evenly coated on the surface of the electrode material, and finally centrifugally dry to obtain TiN - PTFE double coated Li 4 Ti 5 o 12 Negative material. The transmission electron microscope picture of gained powder product is shown in figure 1 . Li double coated with TiN-PTFE 4 Ti 5 o 12 Anode material, LiFePO 4 As the positive electrode material, celguard 2500 diaphragm, electrolyte EC:DMC=1:1, 1 mol L -1 LiF 6 An 800 mAh soft-pack lithium-ion battery assembled for the electrolyte, the...

Embodiment 2

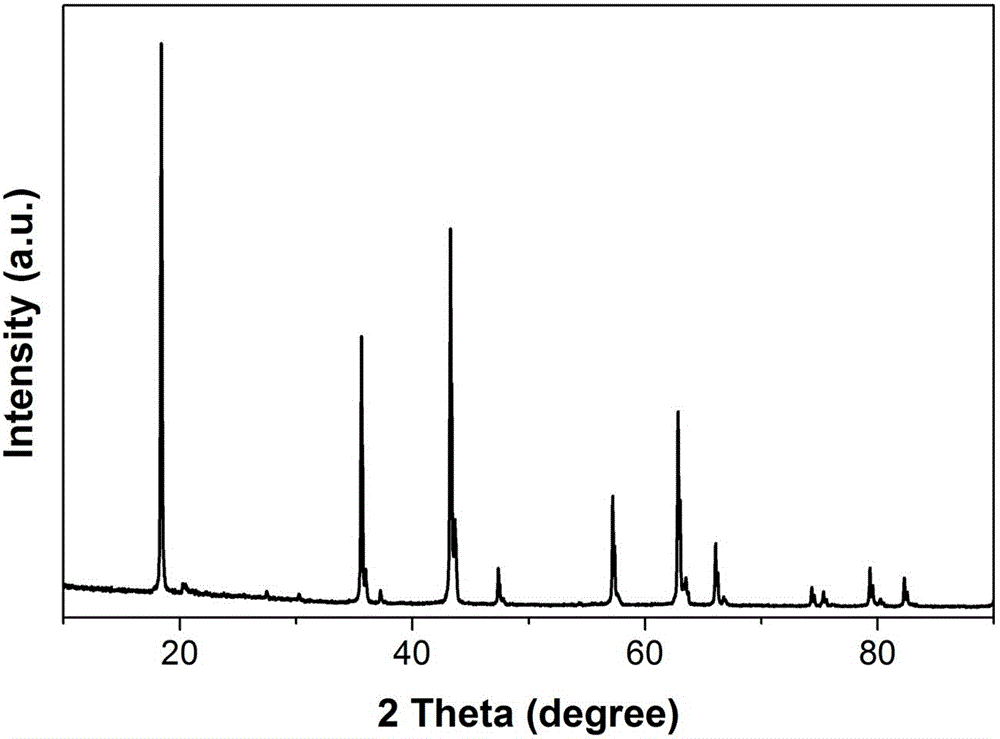

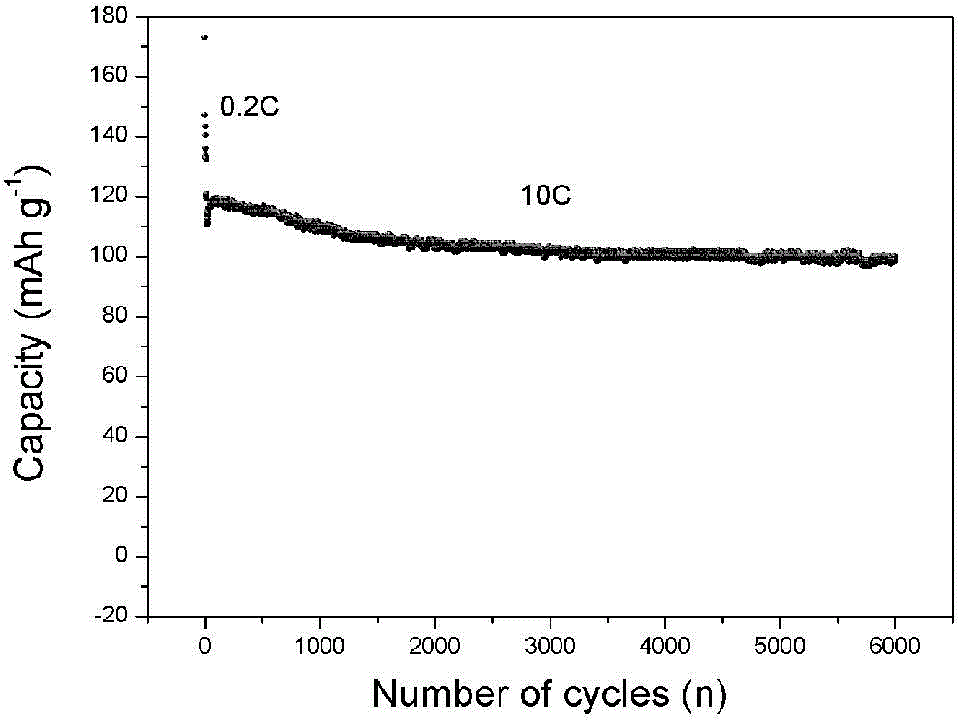

[0020] Take 0.2 g Li 4 Ti 5 o 12 The anode material was dispersed in 10% cyanamide (CH 2 N 2 ) ethanol solution, dried in an oven at 60°C for 3 h to obtain surface-coated CH 2 N 2 Li 4 Ti 5 o 12 powder, and then heat-treated the powder at 700 °C for 3 h under nitrogen atmosphere to make CH 2 N 2 in Li 4 Ti 5 o 12 In situ decomposition of the surface into C 3 N 4 , cooled to obtain C 3 N 4 Surface-coated Li 4 Ti 5 o 12 electrode material. C 3 N 4 Surface-coated Li 4 Ti 5 o 12 The electrode material was dispersed in 5% LiF aqueous solution, sonicated for 15 min and centrifuged, and dried at 50 °C for 4 h to obtain C 3 N 4 -LiF double-coated Li 4 Ti 5 o 12 Negative material. The XRD pattern and 0.1 C charge and discharge pattern of the obtained product are shown in image 3 and Figure 4 , the results show that after C 3 N 4 -LiF double-coated Li 4 Ti 5 o 12 The negative electrode material maintains the spinel cubic structure well, and the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com