Patents

Literature

43results about How to "Good spinnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic, antibacterial and graphene-reinforced composite polyester fiber and preparation method thereof

InactiveCN103710790AGood spinnabilityGood electrical conductivityFilament/thread formingConjugated synthetic polymer artificial filamentsCvd grapheneChemistry

The invention provides an antistatic, antibacterial and graphene-reinforced composite polyester fiber, which is characterized in that the composite polyester fiber comprises a component A and a component B, wherein the component A is polyester excluding graphene, and the component B is polyester including 0.3-3.0wt% of graphene. The invention also provides a preparation method of the composite polyester fiber. The composite polyester fiber provided by the invention is low in cost, high in strength, and high in antistatic and antibacterial properties.

Owner:厦门翔鹭化纤股份有限公司

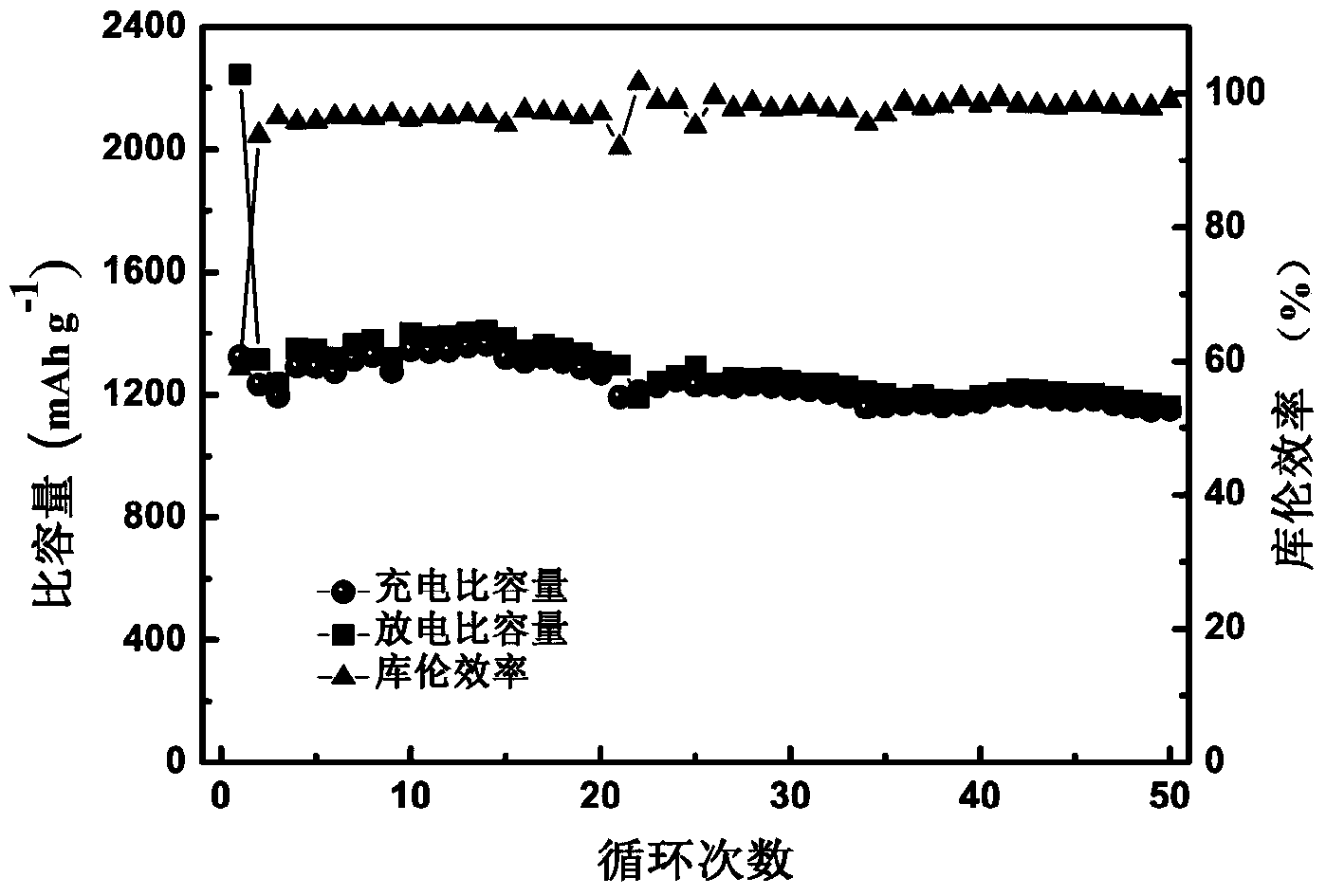

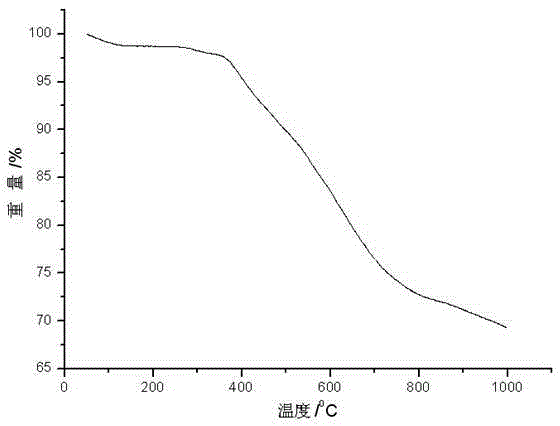

Method for preparing nitrogen-doped porous carbon nanofiber cloth

ActiveCN103855361ALow costGood spinnabilityMicroscopic fiber electrodesSecondary cellsLithium electrodeCarbon nanofiber

The invention relates to a method for preparing nitrogen-doped porous carbon nanofiber cloth. The nitrogen-doped porous carbon nanofiber cloth is prepared by adding a nitrogen-rich compound into an organic solution, electrospinning and subsequent carbonizing-activating, has a self-support structure, omits preparation steps of size mixing, coating and the like, needs no conductive agent or binder, and can be directly used as the negative electrode of a lithium ion battery. The electrochemical performance of the negative electrode material of the lithium ion battery is improved by doping nitrogen and activating and forming pores; compared with a commercial graphite lithium ion battery negative electrode material, the nitrogen doping porous carbon nanofiber cloth used as the negative electrode material of the lithium ion battery has simple steps for preparing the electrode, has higher specific capacity, good power performance and circulatory stability. The method also can be used as the electrode material of super capacitors and other novel batteries.

Owner:TSINGHUA UNIV

Zirconium oxide fabrics prepared from organic polyzirconium fore spinning solution by silk process

InactiveCN1584155AGood effectRaw materials are cheap and easy to getInorganic material artificial filamentsFuranSolvent

The manufacture method of a kind of zirconia fibre cotton relates to the field of resistance of fire fibre material. We compose van-style acetamide acetone zirconium polymer according to chloridze zirconia, acetamide acetone and three-ethylamine. We use methanol as the dilute impregnant, we mix round them to let hloridize zirconia, acetamide acetone and three-ethylamine react at 40-20 deg.C, and we can receive poly-acetamide acetone zirconium van-substance. Four-hydrogen furan filtrate and remove the outgrowth hydrochloric three-ethylamine. The offspring dissolve in the filature liquid made of methanol. After centrifugal swing, we can receive van-substance fibre. After we do special hear treatment, the zirconia fibre cotton we receive has the characteristic of good filature ability, high content of zirconium, equality andclarity and jarles capability. It can be used as industrial stove, roomage fusion stove, atomic energy reactor and the high temperature heat insulation material used in aviation and military. The material of the invention cost low, the method is easy, the impregnant can be recycled, the preparation of fibre cost low.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Method for preparing black polyurethane elastic fiber via in situ polymerization

ActiveCN102899739AGood spinnabilityLong lasting black effectMonocomponent synthetic polymer artificial filamentArtifical filament manufactureSolventPrepolymer

The invention relates to a method for preparing a black polyurethane elastic fiber via in situ polymerization, comprising the following steps: (1) evenly dispersing nanometer carbon black particles in low-polymer polyhydric alcohol by using a grinding or ultrasonic and powerful mechanical stirring method so as to form a stable mixture, (2) adding diisocyanate in the polyhydric alcohol containing the carbon black particles for full reaction and adding a solvent for full dissolution to obtain NCO end capped prepolymer polyurethane formic ether solution; (3) carrying out chain extension and chain termination on the prepolymer solution by using mixed amine solution to generate polyurethane urea solution, and (4) curing the polyurethane urea solution and spinning the polyurethane urea solution into the black polyurethane elastic fiber by means of a dry spinning system. The polyurethane elastic fiber prepared via an in situ polymerization method is lasting in black effect and high in color fastness, so that the subsequent processing is free of dyeing; and at the same time, the polyurethane elastic fiber has relatively good mechanical property.

Owner:ZHEJIANG HUAFENG SPANDEX

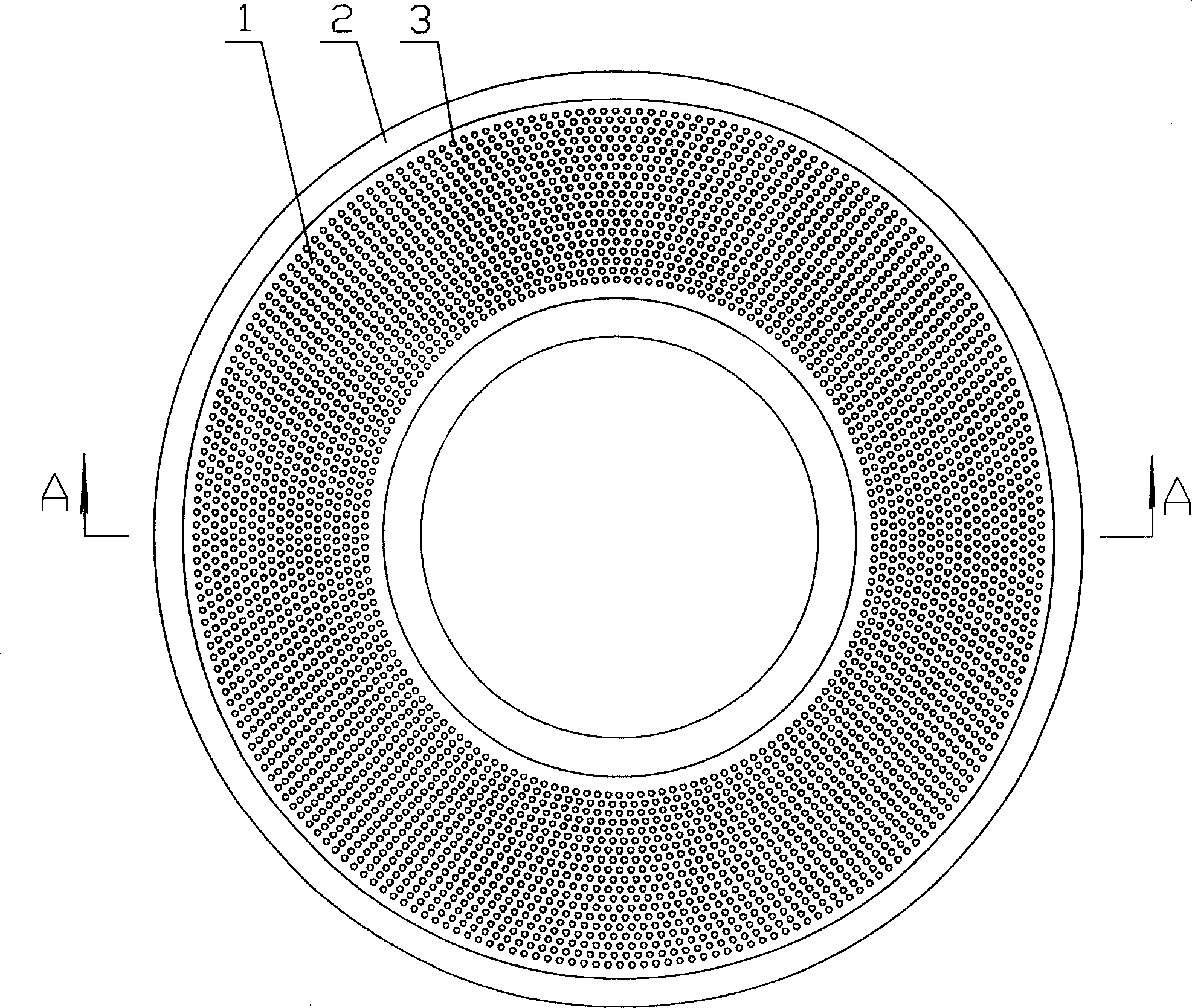

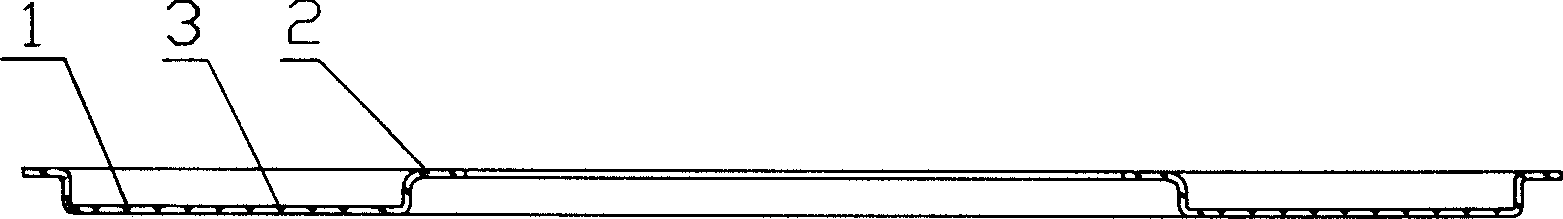

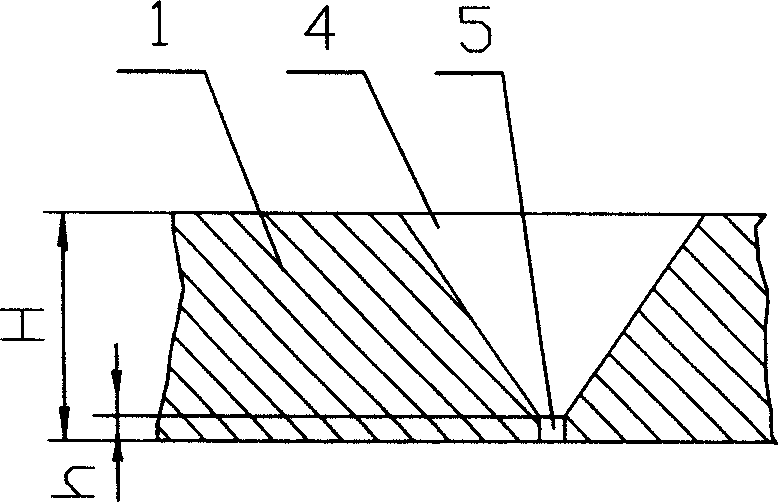

Method for making acrylic fibre by fine denier dry method and spinning nozzle

InactiveCN1752301AGood spinnabilityGood spinning position stabilitySpinnerette packsMonocomponent synthetic polymer artificial filamentAcrylic fibreProcess engineering

The present invention optimizes and properly regulates the technological conditions of original Dupont dry spinning of acrylic fibre, such as properly raising temperature difference of internal and external side temperatures of mass, reasonably controlling nitrogen gas temperature and flow rate, water-washing temperature and draft multiple and speed and using cotton type oil agent to oil, etc. and reasonably designs the spinneret with high-density nozzle hole, its hole number is 3600-4400, its aperture is 0.09-0.13 mm, and the holes are arranged and distributed on 15-21 concentric circles, so that it can implement industrial production of fine-denier dry acrylic fibre.

Owner:浙江金甬腈纶有限公司

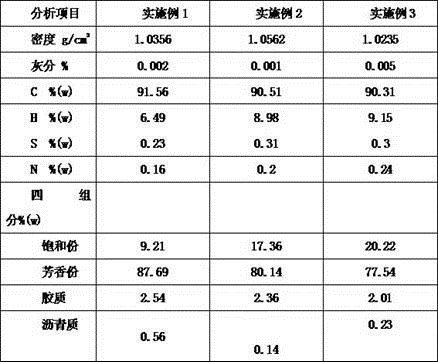

Method for preparing mesophase pitch through catalytic cracking oil slurry hydrogenation reduction and co-carbonization

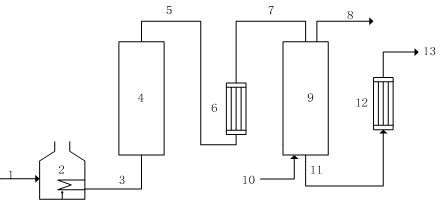

ActiveCN105238431ALow mesophase contentHigh content of mesophaseWorking-up pitch/asphalt/bitumen by chemical meansCarbonizationSlurry

The invention provides a preparation method of petroleum base mesophase pitch with even high mesophase content. The FCC oil slurry of naphthenic crude oil or intermediate base crude oil serves as the raw material, under the action of a catalyst, haloalkane is mixed with the raw material, the temperature is increased to range from 280 DEG C to 350 DEG C, the pressure ranges from 0 MPa to 2 MPa, reaction is conducted for 5-20 h, and modified oil is obtained. Distillate oil, obtained at the temperature higher than 400 DEG C, of the modified oil is taken, the distillate oil is mixed with a co-carbonization agent, the temperature ranges from 360 DEG C to 480 DEG C, the reaction pressure ranges from 4 MPa to 10 MPa, reaction is conducted for 2-10 h, and the high-quality mesophase pitch is obtained. According to the preparation method of the petroleum base mesophase pitch with the even high mesophase content, preparation technology is simple and easy to operate, the anisotropic structure of the prepared mesophase pitch is uniform, the mesophase content is high and larger than 96 percent, the softening point is low, the temperature ranges from 240 DEG C to 260 DGE C, and the spinnability is good.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

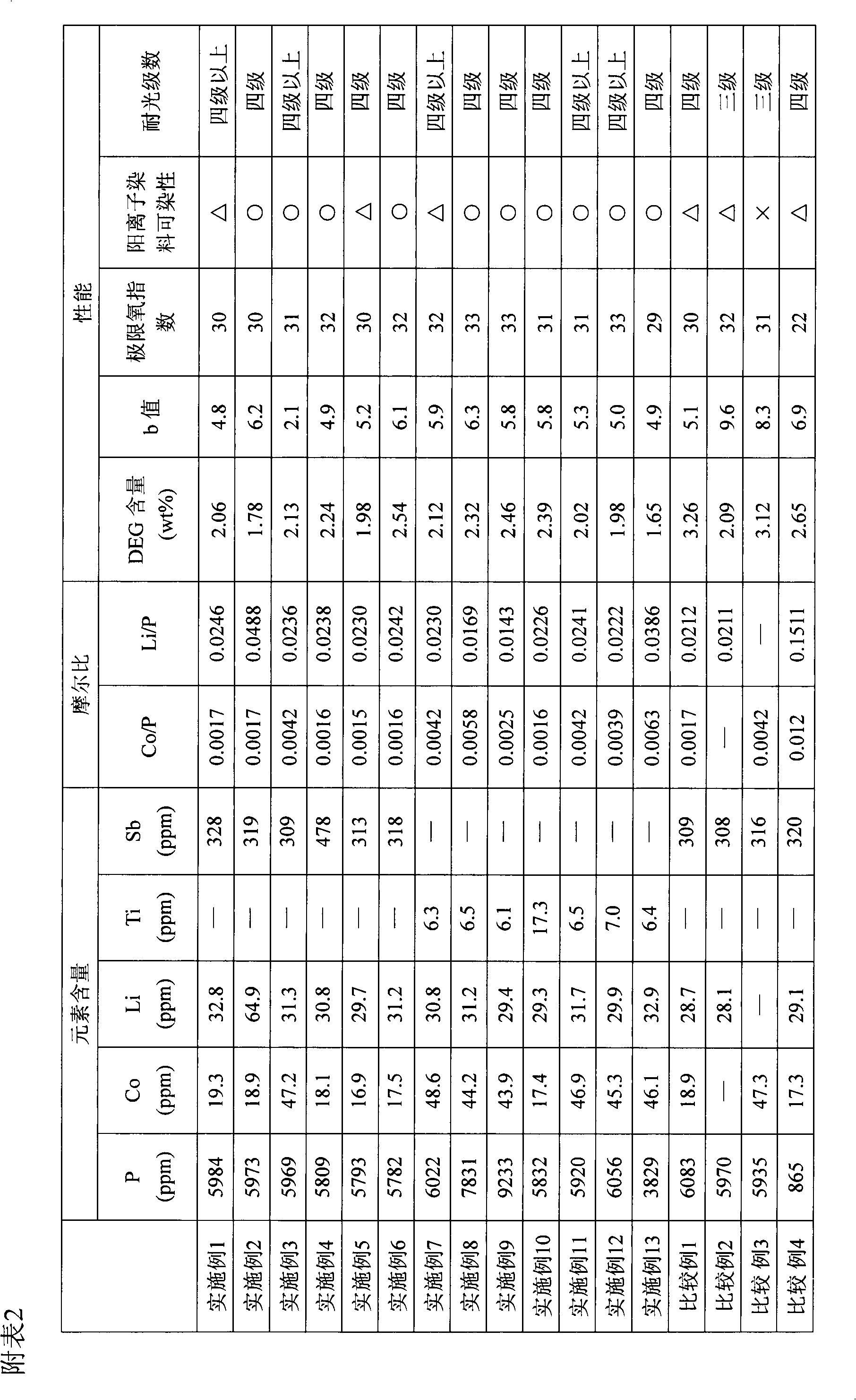

Flame retardant cationic dyeable polyesters and preparation method

InactiveCN101200535AImprove flame retardant performanceExcellent cationic dyeabilityDyeing processMonocomponent polyesters artificial filamentFiberPolymer science

The present invention discloses a flame-retardant cation dyeable polyester copolymer and the preparation method. The method includes esterification and condensation reactions and the reactions take terephthalic acid and ethylene alcohol as a first monomer and a second monomer, and reactive phosphorus flame retardant and m-phthalic acid ester with sulphonate respectively as a third monomer and a fourth monomer; metatitanic acid ester is catalyst, phosphorus compound is stabilizer and alkali metal compound is assistant additive. The fiber of the product provided by the present invention with excellent flame retardant and cation dyeability can ensure good processing ability and dynamic performance and apply the polyester to different spinning processes.

Owner:TORAY IND INC

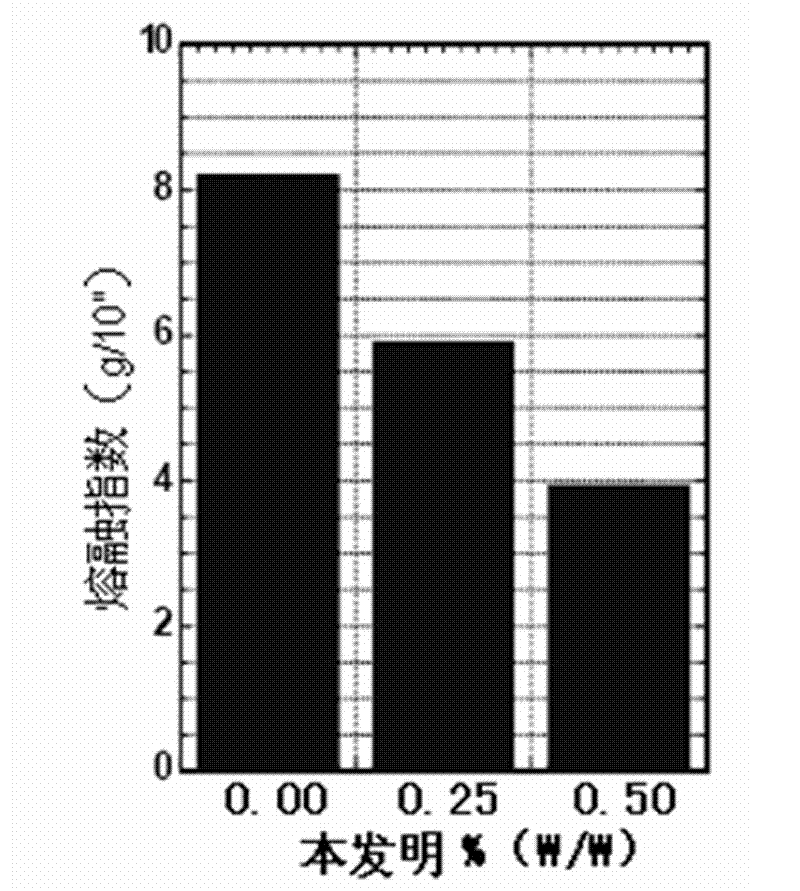

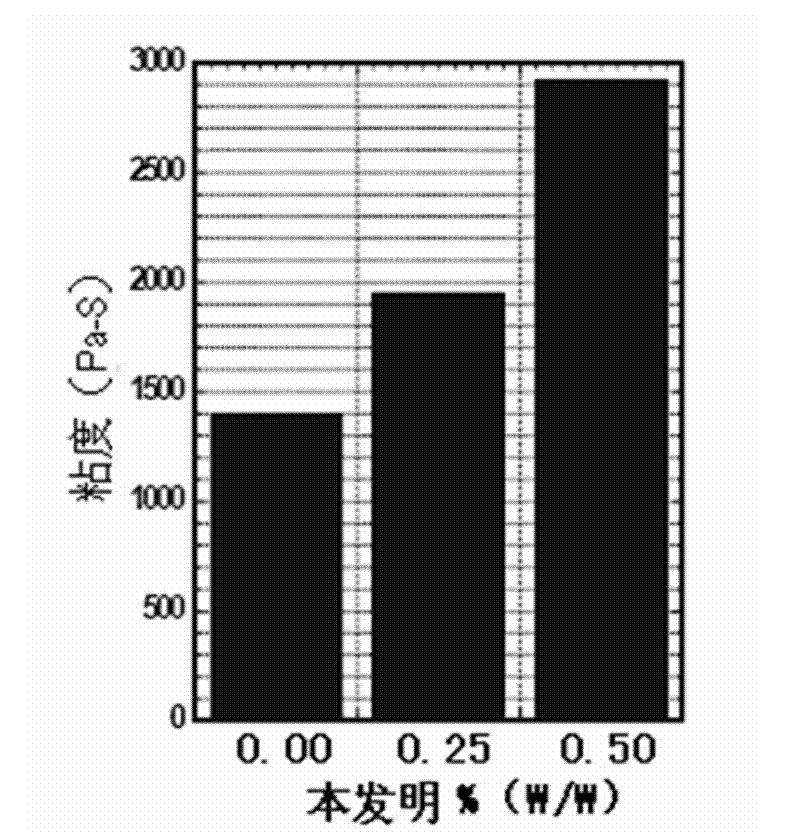

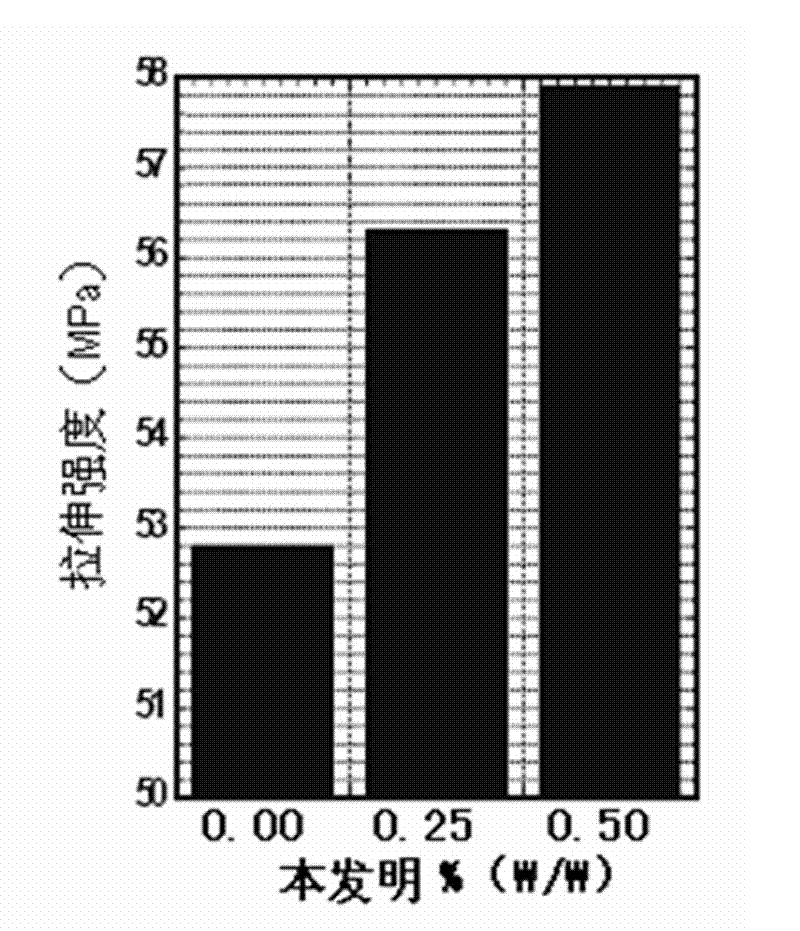

Chain extender for polyamide preparation through chain extending

The invention relates to a chain extender for polyamide preparation through chain extending. The chain extender is prepared by the step of: reacting polymethyl methacrylate with styrene in a stainless steel reaction vessel equipped with a mixer, a condenser and a temperature control device as well as nitrogen atmosphere for 2-3h at a temperature of 108DEG C-112DEG C, thus obtaining a copolymer with a number-average molecular weight of 6000-7500 and a glass transition temperature of 50DEG C-60DEG C, with the styrene of 0.05 wt%-2 wt% in content. The invention also relates to application of the chain extender in a direct polymerization technology of polycaprolactam. Polycaprolactam slices obtained by a direct polymerization technology employing the chain extender have stable amino end group content, and high dyeing uniformity in a post processing process as well as good spinnability, thus being suitable for polyamide high-speed spinning and fine denier yarn production.

Owner:ZHANGJIAGANG CHAINENG BIOLOGICAL TECH

Pearl fiber blended yarn

InactiveCN102978766AGood moisture absorption and air permeabilityGood spinnabilityYarnRegenerated celluloseYarn

The invention discloses a pearl fiber blended yarn. The pearl fiber blended yarn is made from pearl fiber and regenerated cellulose fiber of one same type or two types in a blending way, wherein the content of the pearl fiber is 25% to 35% and the content of the regenerated cellulose fiber is 65% to 75%; and the specification of the pearl fiber blended yarn is 14.8tex. Through the way, the blended yarn provided by the invention has the effects of aging resistance, anaphylaxis resistance, static resistance, antibiosis, deodorization, beauty maintenance, skin protection and the like; and meanwhile, the pearl fiber blended yarn has excellent moisture absorption and air permeability, comfortableness and heat insulation performance as a clothing fabric, good spinnability, durability and capability of preventing ultraviolet.

Owner:WUJIANG GAOFA TEXTILE

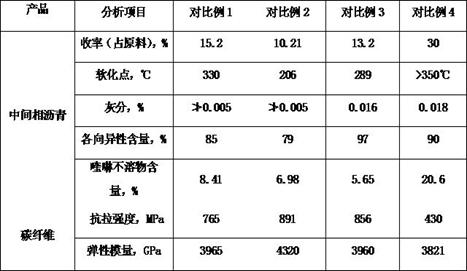

Method for preparing spinnable pitch from coal tar pitch

ActiveCN109181733AHigh yieldHigh overall yield (27-32%), softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationNitrogen

A method for preparing spinnable pitch from coal tar pitch comprises the following steps: crushing medium-low-temperature coal tar pitch to 20 meshes or below, performing extracting by using tetrahydrofuran, performing filtration to obtain a medium-low-temperature coal tar pitch soluble component, and recovering the tetrahydrofuran solvent from the soluble component to obtain refined pitch; and mixing the refined pitch with petrolatum, adding the obtained mixture into a reactor, introducing nitrogen under normal pressure, heating the reactor to 180-220 DEG C at a heating rate of 1-10 DEG C / min, switching to air, introducing the air into the reactor at a rate of 10-60 mL / min.g, heating the reactor to 280-350 DEG C at a heating rate of 1-10 DEG C / min, and allowing the obtained mixture to stay for 1-10 h to obtain the spinnable pitch. The method has the advantages of high yield, low price and moderate thermal polycondensation temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Production and processing process of ultra-coarse denier polyester filament yarn

InactiveCN101302671AGood product performanceGood spinnabilityTextiles and paperHot boxMachining process

The invention relates to a production process technique for super-coarse denier polyester filament. The POY processed by spun yarn is submitted for false twist after inspection and equilibration. The precursor fiber is fed by a first roller and enters the twist stop for stop twisting; after being drawn in a first thermal chamber, the fiber is cooled by a cooling plate, then enters the false twister for false-twist texturing, and then enters a network machine to allow the fiber to form a network; after directly passing a second thermal chamber (the temperature of the thermal chamber is closed) and a third roller, the fiber is winded into a spinning cake after oiling in an oiling roller, finally, the whole process is finished after inspecting and packaging the spinning cake obtained. The spun yarn is processed into 400-denier POY by a single spinneret, and then processed into 800-denier DTY by false-twist and bunching combination. The second thermal chamber is closed during the process to provide the finished DTY with high elastic property.

Owner:许燕红

Graphene composite fiber yarn, preparation method and application thereof

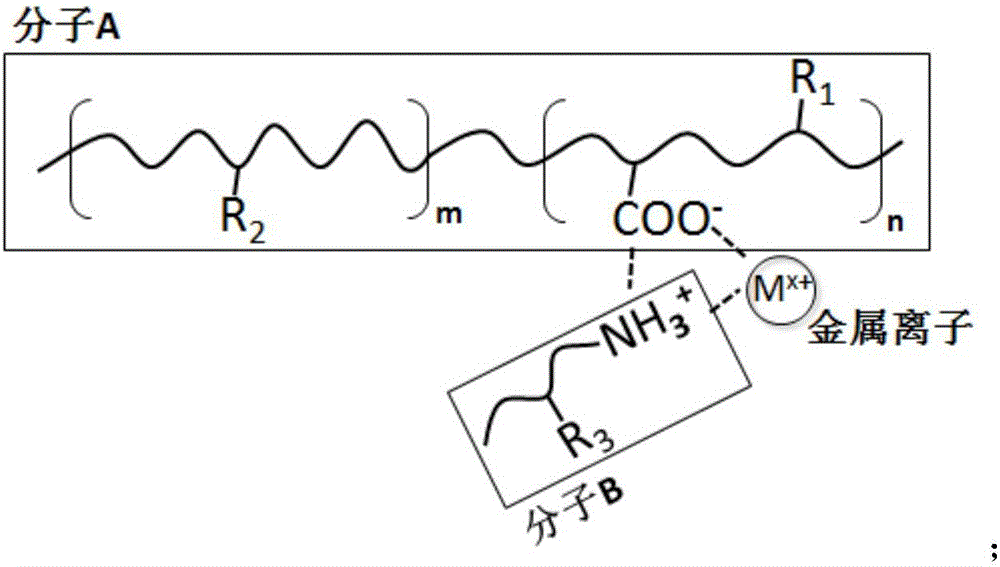

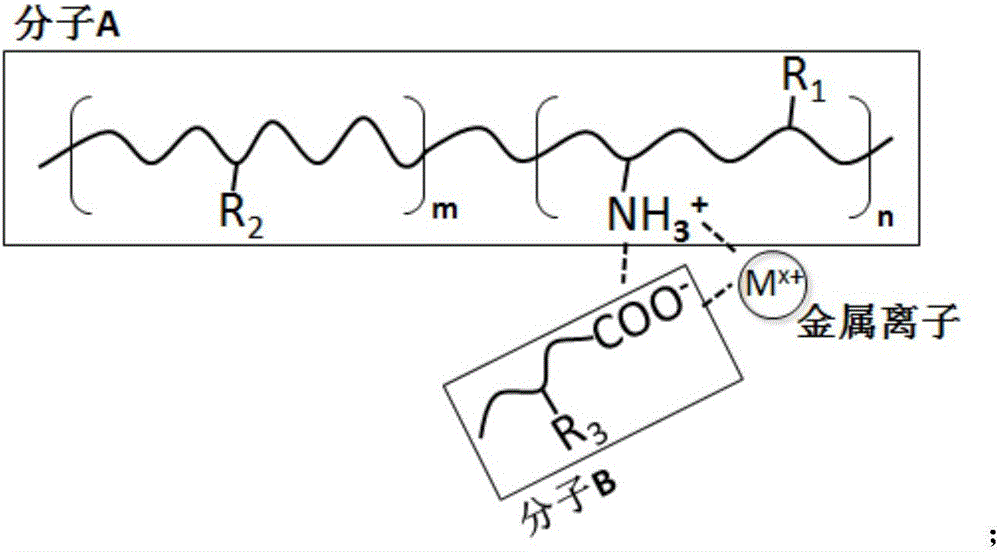

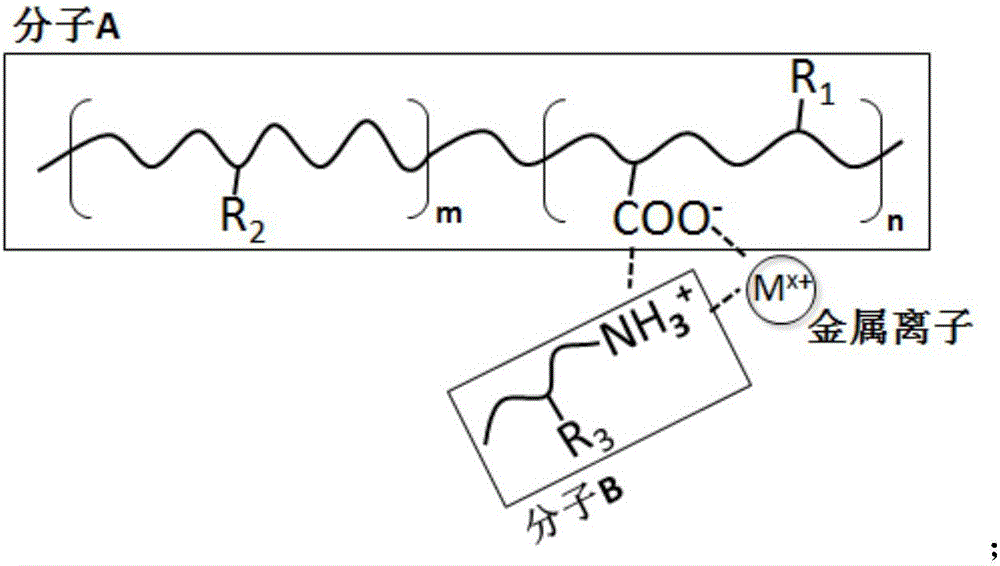

ActiveCN109402815AGood spinnability and continuityGood spinnabilityArtificial filaments from viscoseYarnIonYarn

The invention provides a graphene composite fiber yarn and a preparation method and application thereof. The method comprises the steps of dispersing graphene in deionized water to obtain a graphene dispersion; mixing a viscose with the graphene dispersion to obtain a spinning glue; conducting wet spinning on the spinning glue to obtain a graphene composite fiber; conducting spinning on the graphene composite fiber to obtain a graphene composite fiber yarn. The preparation method can prepare the graphene dispersion with high concentration and stable dispersion, the crystal structure of the graphene is complete, the spinnability is good when spinning with the glue, the spinning quality is high, and convenience is provided for the graphene composite fiber yarn to be widely used in the textile field.

Owner:福建祥业生物工程技术有限公司

Method for preparing spinnable asphalt from coal tar

ActiveCN109181732AGood rheological propertiesGood spinnabilityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionChemistryFuel oil

A method for preparing spinnable asphalt from coal tar comprises the following steps: carrying out high-temperature reduced pressure distillation on the coal tar to obtain a coal tar heavy component;extracting the coal tar heavy component with a primary extraction solvent to obtain a primary extract and a primary raffinate; recovering the solvent from the primary extract to obtain heavy oil; drying the primary raffinate, and extracting the dried primary raffinate with a secondary extraction solvent to obtain a secondary extract and a secondary raffinate; recovering the solvent from the secondary extract to obtain asphaltene; drying the secondary raffinate, and extracting the dried raffinate with a tertiary extraction solvent to obtain a tertiary extract and a tertiary raffinate; recovering the solvent from the tertiary extract to obtain asphaltene; and uniformly mixing all above obtained asphaltenes, adding the obtained mixture into a fixed bed reactor, and carrying out thermal polycondensation to prepare the spinnable asphalt. The method has the advantages of simple process, easiness in solvent recovery, low cost and high yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

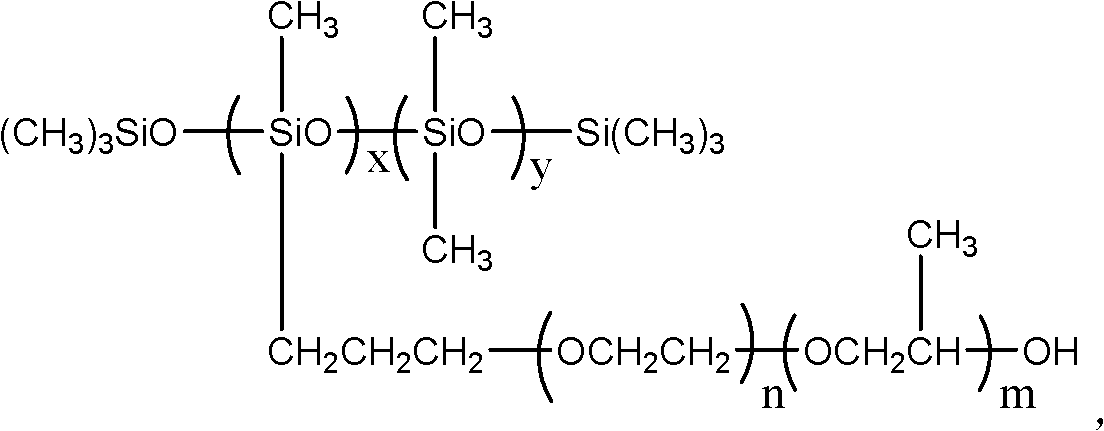

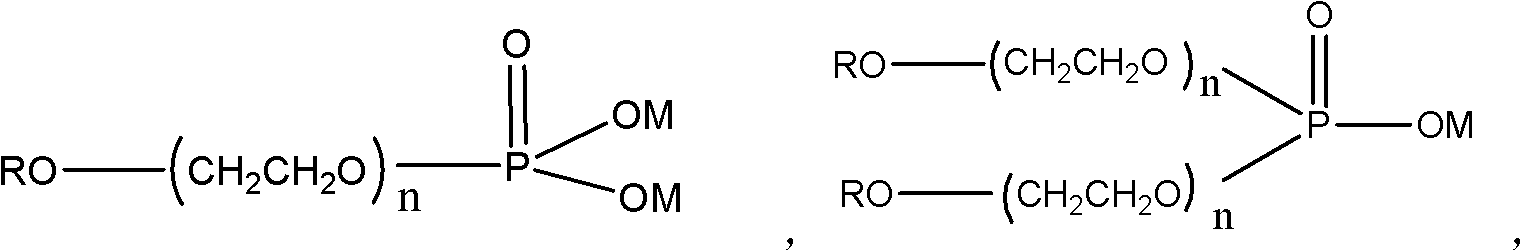

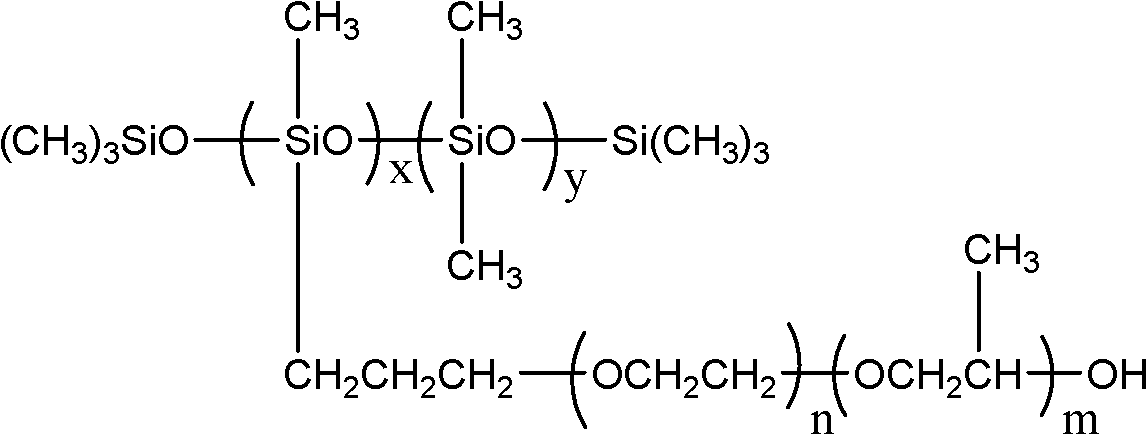

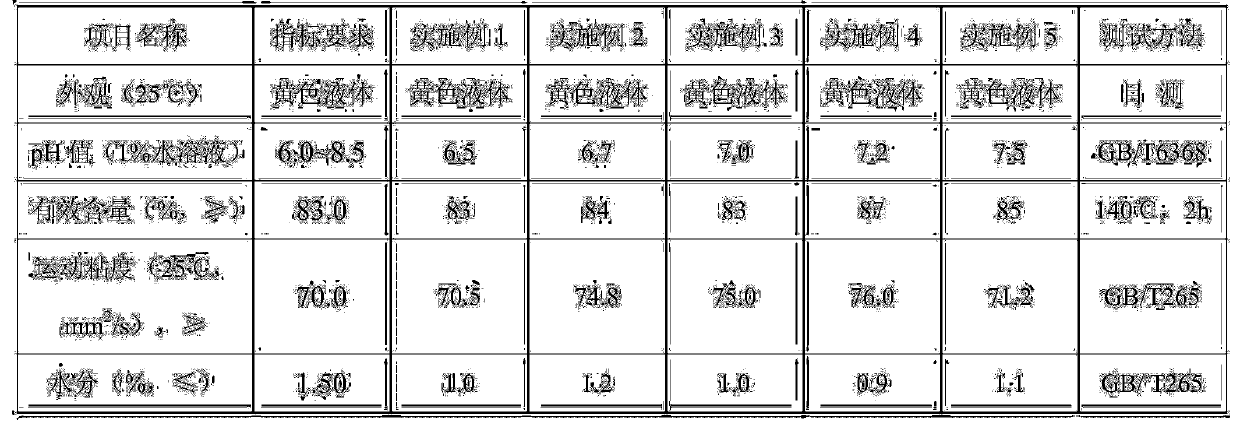

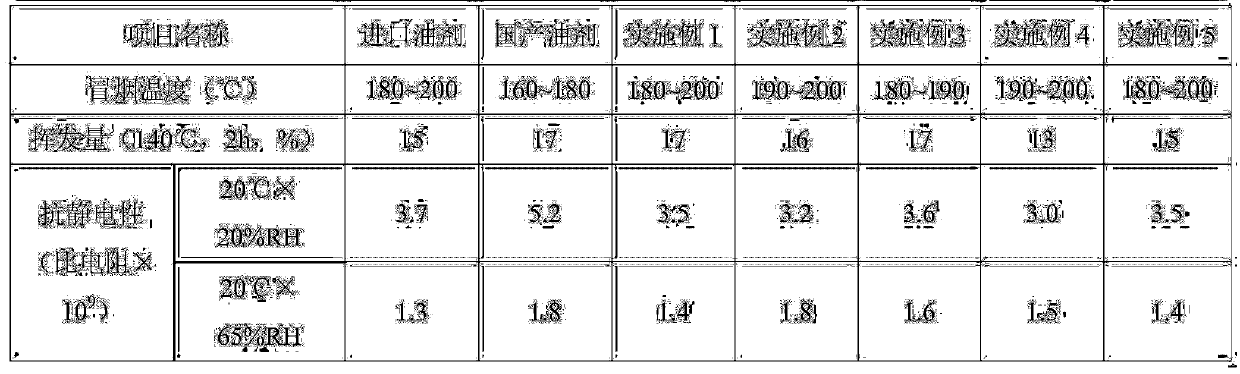

Polyester staple fiber hydrophilic spinning oil

Staple fibers produced by the existing oil are all water-repellent and cannot be applicable for the fields with hydrophilic requirement on the fibers. The invention provides polyester staple fiber hydrophilic spinning oil, which comprises the following components in percentage by weight: 70 to 80 percent of component A, i.e. polyether modified silicone oil; 10 to 20 percent of component B, i.e. isomeric alcohol polyoxyethylene ether phosphate; and 5 to 10 percent of component C, i.e. aliphatic amine polyether. An emulsion is prepared from the three components by adding water. The effective concentration of the emulsion is between 0.3 and 2.5 percent. A pH value of the emulsion is regulated to between 8.0 and 10.0. Not only the polyester staple fiber hydrophilic spinning oil of the invention is suitable for each process of the staple fiber spinning, but also the produced fibers have excellent hydrophilicity. The polyester staple fiber hydrophilic spinning oil can be directly used in the field of non-woven fabric weaving with hydrophilic requirement.

Owner:HANGZHOU TRANSFAR CHEM LTD +3

Method for preparing continuous zirconium boride ceramic precursor fiber

The invention relates to a method for preparing a continuous zirconium boride ceramic precursor fiber. The method comprises the following steps: 1, adjusting the pH value of a prepared zirconium boride precursor solution to 4-5, mixing with an alcoholic solution of polyethylene, adding a surfactant, concentrating, and deaerating to obtain a zirconium boride ceramic fiber precursor spinning solution; and 2, carrying out continuous spinning by allowing the zirconium boride ceramic fiber precursor spinning solution to go through a metering pump, a spinning casing and a spinneret under 1-50MPa, and carrying out dry molding and reeling of spinning channels. The preparation method is simple, and the prepared spinning solution is uniform and has a good spinnability; and the continuous and uniform kilograme-level zirconium boride ceramic precursor fiber can be prepared through adopting a dry spinning device in the invention.

Owner:DONGHUA UNIV

High-temperature oil agent for polyester industrial yarns, and preparation method thereof

The invention provides a high-temperature oil agent for polyester industrial yarns, and a preparation method thereof, and in particular relates to the technical field of textiles of polyester industrial yarns. The high-temperature oil agent in the invention is composed of the following components in mass percentage: 45-65% of a smoothing agent, 8-18% of an emulsifying agent, 2-8% of a collecting agent, 5-10% of an anti-static agent, 2-5% of a dispersing agent, 1-3% of a humectant, 8-18% of a diluent solvent, 0.1-1.5% of an antioxygen, 0.1-0.5% of a pH adjusting stabilizer, and 0.5-1% of water,wherein the smoothing agent is a synthetic ester smoothing agent. Various components are compounded and modulated into the high-temperature oil agent according to the ratio. The high-temperature oilagent in the invention has good lubricating property, and can effectively inhibit electrostatic generation; and simultaneously, the igh-temperature oil agent in the invention is good in high-temperature resistance, low in tarring degree on a hot roller, little in blue smoke generation, uniform to oil, low in oiling rate, and good in tow spinnability.

Owner:金浦新材料股份有限公司

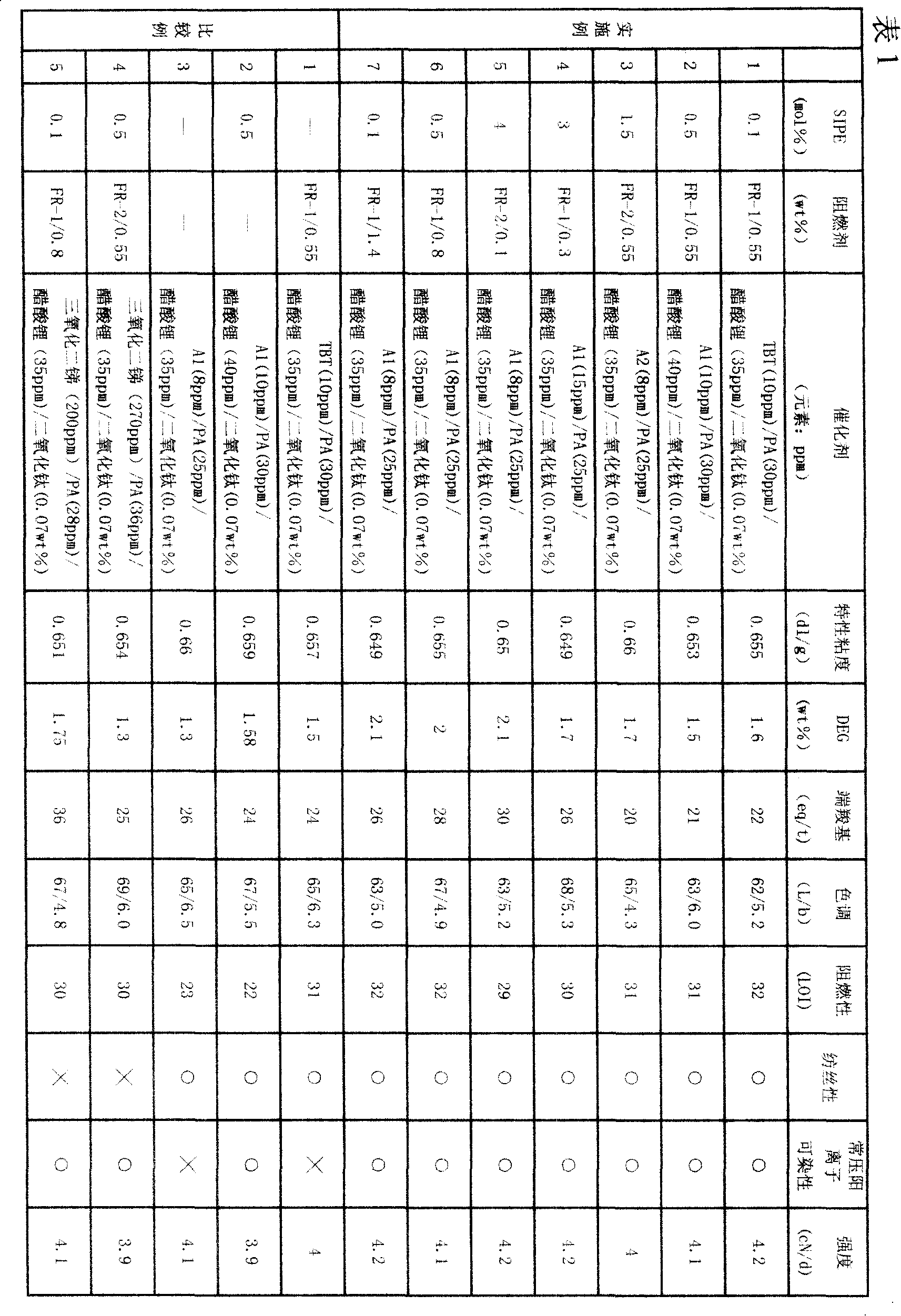

Production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool

ActiveCN102433601AReduce self-aggregationReduce broken endsMonocomponent copolyesters artificial filamentStretch-spinning methodsFiberFatty acid

The invention relates to a production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool. The normal-pressure cation dyeable copolyester endless tow is obtained by spinning normal-pressure cation dyeable copolyesters. A preparation method of the normal-pressure cation dyeable copolyesters comprises the following steps of: (1) carrying out an esterification reaction on ethylene glycol, terephthalic acid and m-phthalic acid; (2) adding ethylene glycol, mixing, adding an SIPE (5-Sodium Sulfonate Isophthalate Ethyl-ester) solution and carrying out an ester exchange reaction; and (3) adding a mixture obtained in the ester exchange reaction into binary fatty acid, mixing uniformly, and carrying out a condensation polymerization reaction to obtain the normal-pressure cation dyeable copolyesters, wherein the molar ratio of the terephthalic acid to the m-phthalic acid is 50:1-90:1; the ratio of the mole number of the ethylene glycol added in the step (2) to the total mole number of the terephthalic acid and the m-phthalic acid is 0.1:1-0.5:1; and the ratio of the total mole number of the terephthalic acid, the m-phthalic acid and the binary fatty acid to the total mole number of sulfonic acid groups in the SIPE solution is 9:1-28:1.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Preparing method for ablation-resistant high-ortho phenolic fibers

InactiveCN105332081AIncreased fracture energyImproves ablation resistanceMonocomponent synthetic polymer artificial filamentMelt spinning methodsRoom temperatureNitrogen

The invention discloses a preparing method for ablation-resistant high-ortho phenolic fibers. A phenolic compound and formaldehyde are mixed according to a certain proportion, then a certain amount of citric acid as a catalyst is added, and a boiling reaction is carried out for 0.5-4 h; diluted concentrated sulfuric acid is added, and the reaction continues for 30-50 min; decompression and dehydration are carried out for 0.5-2.9 h, boric acid accounting for 1-8% by mass is added for a modification reaction after the temperature reaches 90-97 DEG C, and boiling is carried out for 2 h at the constant temperature; decompression and dehydration are carried out, and dehydration is stopped when the temperature of resin reaches 110 DEG C; the resin is subjected to melt spinning at 120-160 DEG C; nascent fibers are put into a prepared curing solution, the temperature is increased to 95 DEG C gradually from the room temperature, and the nascent fibers are naturally cooled to the room temperature after constant temperature is achieved; the temperature is gradually increased for thermosetting under the nitrogen condition. The fiber strength of the high-ortho phenolic fibers ranges from 3 cN / dtex to 36 cN / dtex, the modulus ranges from 40 cN / dtex to 400 cN / dtex, and the cross-linking degree ranges from 32% to 38%.

Owner:ZHONGYUAN ENGINEERING COLLEGE

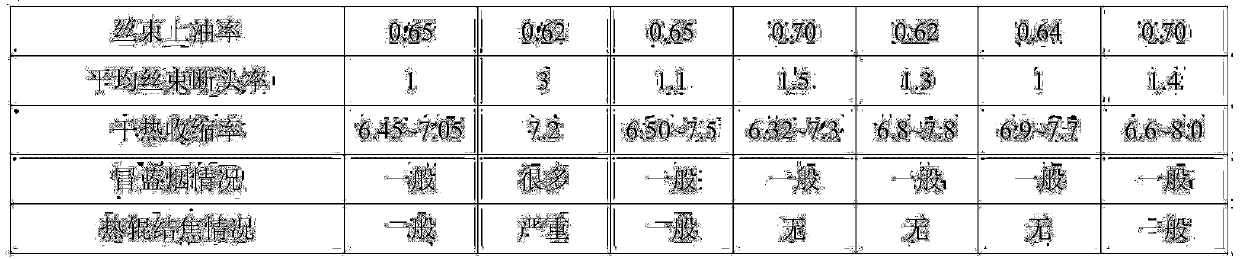

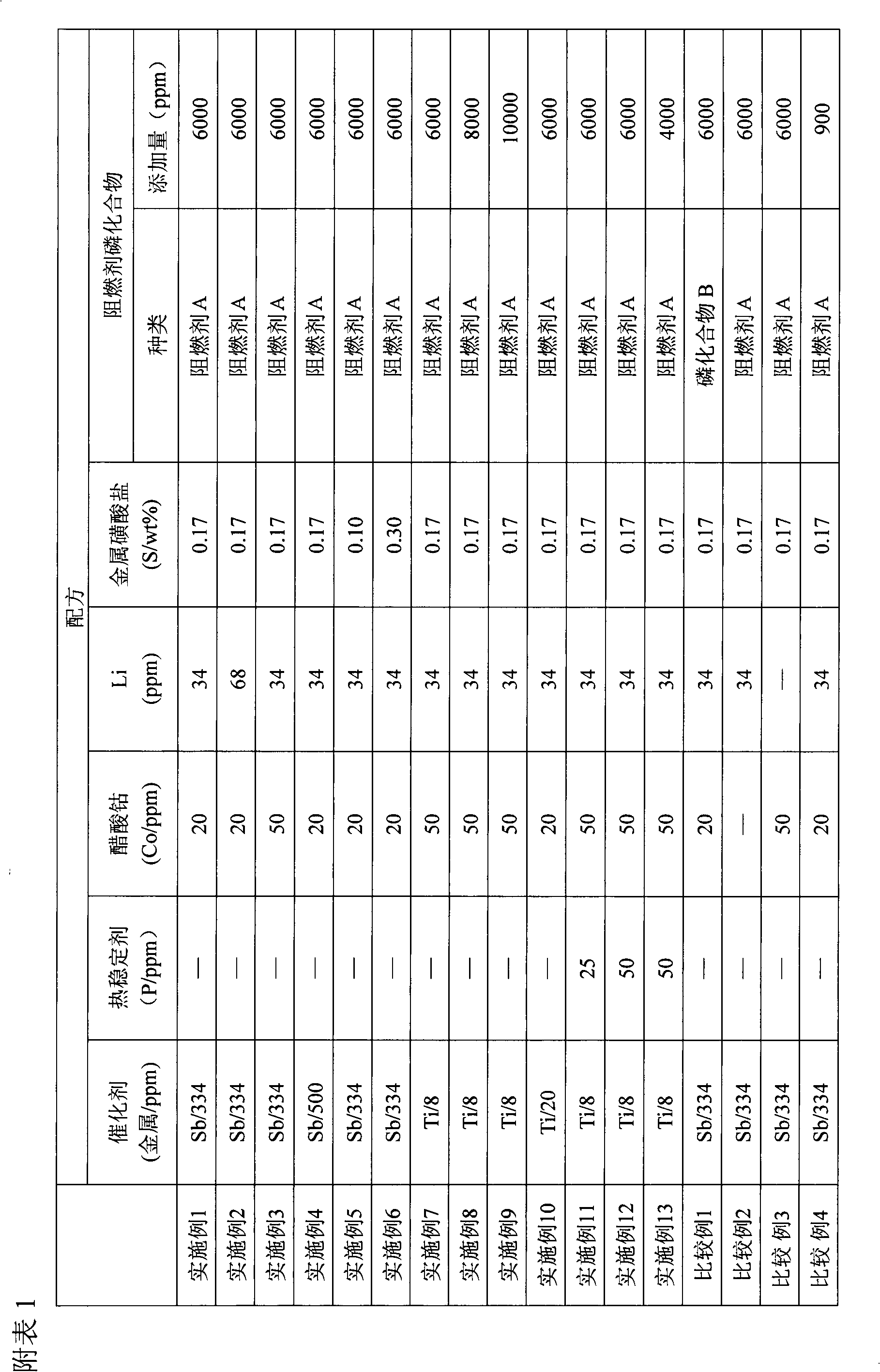

Cation dyeable flame-retardant polyester and preparation method thereof

ActiveCN103122059AExcellent toneGood light fastnessMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPolymer science

The invention discloses normal-pressure cation dyeable flame-retardant polyester and a preparation method thereof. The preparation method includes: subjecting monomer aromatic dicarboxylic acid or derivatives thereof, alkylidence diol and isophthalic acid containing metal sulfonate or derivatives thereof to polycondensation under conditions of phosphorous based flame retardant, catalyst and auxiliaries, wherein the phosphorous flame retardant is reactive phosphorous flame retardant, phosphorous content in polyester is 2000-20000ppm in the total polyester. The tone value b of the polyester is smaller than 6, the DEG (diethylene glycol) content is lower than 2.5wt%, light fastness of fabric obtained by spinning and high-order processing the polyester can be up to the fouth or above level. The normal-pressure cation dyeable flame-retardant polyester has lasting and excellent flame retardancy is high in thermal stability, good in spinnability, excellent in tone and good in light fastness.

Owner:TORAY IND INC

Preparation method of luminous polyethylene terephthalate

ActiveCN103374120AGood spinnabilityLong-lasting glowMonocomponent polyesters artificial filamentArtifical filament manufacturePolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to a preparation method of luminous polyethylene terephthalate. Ethylene glycol, a terephthalic acid and a high-molecular compound modified nano illuminant-ethylene glycol sol are polymerized so as to obtain the luminous polyethylene terephthalate; the weight of a nano illuminant accounts for 0.1-10% of the weight of the polyethylene terephthalate; the weight of the nano illuminant accounts for 1-10% of the weight of the nano illuminant-ethylene glycol sol; the weight of a high-molecular compound accounts for 0.1-5% of the weight of the nano illuminant-ethylene glycol sol; and the intrinsic viscosity of the polyethylene terephthalate is 0.55-0.75 dL / g, and obtained fiber fabrics can emit light continuously for more than 12 hours in the dark under visible light irradiation; and the fabric can emit light continuously for more than 12 hours in the dark within the same time of visible light irradiation after being washed 20 times in a standard manner.

Owner:PETROCHINA CO LTD

High-moisture-absorption heating yarn and application thereof

The invention relates to a high-moisture-absorption heating yarn and application thereof. The yarn is formed in the manner that graft-modified high-moisture-absorption fibers are pre-treated, and thenthe graft-modified high-moisture-absorption fibers are blended with viscose or cotton fibers or modal fibers or acrylic fibers. The high-moisture-absorption heating yarn is prepared through the preparation process which includes the steps of blowing-carding, combing, drawing, roving, spinning, spooling and the like. Two high-moisture-absorption heating yarns are twisted to form a plied yarn. Compared with the prior art, the high-moisture-absorption heating yarn has the advantages of rapid moisture absorption heating and the like, and the comfort of manufactured fabric is further improved.

Owner:SHANGHAI ZHENGJIA MILKFIBER SCI & TECH

Method for degumming jute by using complex enzyme

ActiveCN101135063AGood spinnabilityImprove spinnabilityBiochemical fibre treatmentVegetable materialChemistryPectinase

The process of degumming jute with composite enzyme comprising pectase and laccase includes the following steps: dipping jute in composite enzyme aqua compounded with pectase and laccase in 12-40 times weight of jute; regulating the pH value of composite enzyme aqua to 5.0-5.5, heating to 55-60 deg.c and maintaining for 51-120 min; regulating the pH value of composite enzyme aqua to 7.5-8.0, heating to 60-70 deg.c and maintaining for 20-120 min; and deactivating enzyme of treated jute. The process is simple and has high lignin eliminating effect.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Processing method of fibers for grid type purse net fishing net

ActiveCN106192049AImprove compositionGood spinnabilityClimate change adaptationArtificial filament heat treatmentCarbon blackWollastonite

The invention provides a processing method of fibers for a grid type purse net fishing net. The processing method is characterized by comprising the following steps: pre-mixing UHMWPE (Ultrahigh Molecular Weight Polyethylene) powder, silicone powder, nano silicon dioxide, HDPE (High-density Polyethylene) powder, a nano titanium dioxide silver-loaded antibacterial agent, an antioxidant B225, hydroxystearic acid, nano-grade diatomite, nano-grade white carbon black, nano-grade wollastonite and an ethylene-vinyl acetate copolymer, which are weighed according to a formula, and pouring the mixture into a high-speed kneading pot and carrying out high-speed kneading to obtain a UHMWPE modified material; fusing and extruding the UHMWPE modified material through a double-screw-rod extruder; fusing and extruding an extruded product from a spinneret hole through a metering pump which is additionally arranged on a double-screw-rod outlet; cooling, pre-stretching and hotly setting extruded freshly formed filaments and winding a fiber bundle through a fiber winding machine which utilizes a torque motor; dividing the fiber bundle into fibers through a fiber dividing machine, so as to obtain the fibers for the grid type purse net fishing net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

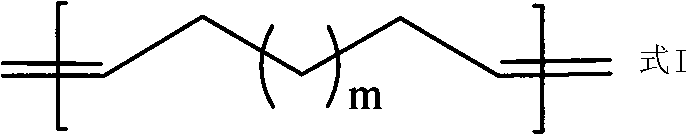

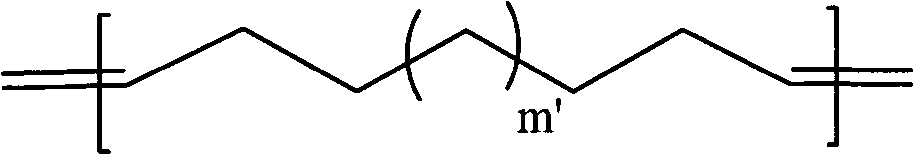

Olefin polymer and blend fiber and preparation methods and applications thereof

InactiveCN102020738AGood spinnabilityHigh strengthSuture equipmentsConjugated synthetic polymer artificial filamentsOlefin polymerizationChemistry

The invention provides an olefin polymer which is an olefin homopolymer composed of constitutional units displayed by a formula I or is an olefin random copolymer composed of constitutional units displayed by the formula I and a formula II, wherein m is equal to 0-8; m' is equal to 0-6; and m is not equal to m'+2. The number of the constitutional units of the formula I and the formula II are respectively 1,000-20,000 and 1,000-10,000. The invention also provides a blend fiber which contains ultrahigh molecular-weight polyethylene and olefin polymers. The invention also provides preparation methods and applications of the olefin polymer and the blend fiber. The blend fiber overcomes the defects of poor spinnability of the traditional ultrahigh molecular-weight polyethylene and low strength of frozen collagen silk and increases the tensile strength and the impact resistance of the fiber, and therefore the blend fiber with good high-strength high-modulus impact resistance performance and good uniformity is obtained.

Owner:ZANNAN SCITECH

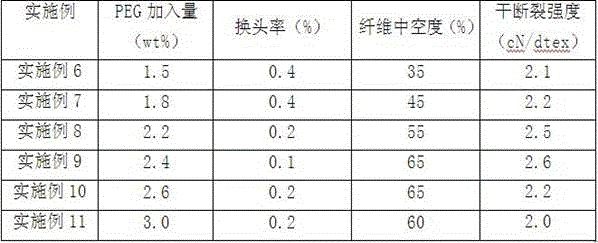

Method for producing dyed hollow filaments by recycled polyester

InactiveCN107447271AUniform average molecular weight distributionHigh strengthHollow filament manufactureFilament/thread formingMasterbatchPolyester

The invention discloses a method for producing dyed hollow filaments by recycled polyester in the field of polyester fiber production methods. The method includes: preparing a recycled material, and making the recycled material into recycled masterbatch; subjecting the recycled masterbatch to solid-phase tackifying under a vacuum state; mixing the tackified material and masterbatch, sending into a screw extruder to realize mixing and extruding, and spinning through a hollow spinneret plate to obtain hollow filaments; cooling and blowing the filaments under the protection of nitrogen; oiling, and subjecting multiple strands of filaments to interlacing treatment through an interlacing jet; winding and storing. The method can be used for recycling of various waste beverage bottles and textile offcut materials, and environmental friendliness and low energy consumption are realized.

Owner:JIANGSU FEILIN FIBER TECH

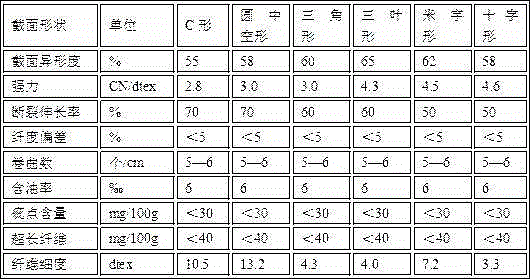

Special-shaped cross section viscose filament yarn and preparation method thereof

ActiveCN105714389ANatural bacteriostasisGood moisture absorption and air permeabilityHollow filament manufactureArtificial filaments from viscosePolymer scienceViscose

The invention provides a special-shaped cross section viscose filament yarn, wherein the cross section of the special-shaped cross section viscose filament yarn is in a C shape, and the special-shaped cross section viscose filament yarn has degree of hollowness of 20-65%, dry breaking strength of more than or equal to 2.00cN / dtex, wet breaking strength of more than or equal to 0.90cN / dtex, dry stretch rate of more than or equal to 19.0% and twist variation coefficient of more than or equal to 11.00%. The invention also provides a preparation method of the special-shaped cross section viscose filament yarn; the preparation method is characterized by comprising a spinning viscose preparation step; a viscose denaturant is added in the spinning viscose preparation step, and the amount of the added viscose denaturant is 0.2-5wt% of that of alpha cellulose in viscose. The special-shaped cross section viscose filament yarn can be produced without purchasing a special-shaped spinning jet, so that the utilization rate of the spinning jet is increased, and the production cost in a spinning exchange process is lowered. The special-shaped cross section viscose filament yarn is widely used for making underwear, clothing, home textiles, imitated silk fabric products and the like.

Owner:潍坊欣龙生物材料有限公司

Spinning stock solution of catalytic material and preparation method thereof

ActiveCN105951213AThe preparation process is simple and easy to operateGood spinnabilityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsIonElectrospinning

The present invention relates to a spinning stock solution of a catalytic material and a preparation method thereof. The spinning stock solution comprises a water-soluble metal ion-loaded hybrid material aqueous solution and a water-soluble chitosan. The water-soluble chitosan is dissolved in the water-soluble metal ion-loaded hybrid material aqueous solution, and then the obtained product is stirred at the room temperature to obtain the spinning stock solution of the catalytic material. The prepared spinning stock solution of the catalytic material is good in spinnability, and easy in spinning process. The catalytic material prepared through the electrostatic spinning process is controllable in catalytic effect and has a good catalytic effect for the synthetic reaction of a variety of polymers.

Owner:DONGHUA UNIV

Preparation method of mesophase pitch

ActiveCN113088313AGood spinnabilityLow ash contentWorking-up pitch/asphalt/bitumen by chemical meansFiberPolymer science

The invention discloses a preparation method of mesophase pitch, the method comprises N times of thermal polymerization reactions, N is an integer greater than 1, preferably an integer greater than 2, and further preferably 2; rapid cooling treatment is carried out after each thermal polymerization reaction; the cooling rate is 20-150 DEG C / min, preferably 50-100 DEG C / min, and the temperature is rapidly reduced to 60%-90% of the temperature of the thermal polymerization reaction, preferably 60%-90%. The method can be used for continuously producing the high-purity mesophase pitch and can be used for producing high-end carbon fibers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Irregular polypropylene fiber short fiber for high-efficiency filtering, and spinning method thereof

InactiveCN106555237ALarge specific surface areaGood spinnabilityHollow filament manufactureMelt spinning methodsOrganosiliconFineness

The invention discloses an irregular polypropylene fiber short fiber for high-efficiency filtering. The cross section of the polypropylene fiber short fiber is shaped as any form from the following: C-shaped, circular hollow-shaped, trilobal-shaped, cross-shaped, Chinese character mi-shaped and triangular-shaped, the fineness of the polypropylene fiber short fiber is set from 3.3dtex to 13.2 dtex, the length is from 38mm to 102mm, the irregularity is from 50% to 70%, the strength is greater than 3.0CN / dtex, and the polypropylene fiber short fiber comprises an organosilicon activator with a weight percentage content of 0.6+ / -0.02%. The irregular polypropylene fiber short fiber provided by the invention is a filtering material which is suitable for industrial production and satisfies ever increasing requirements and is dedicated to the field of filtering for improving the pollutant holding quantity.

Owner:YANGZHOU YONGHUI TEXTILE TECH

Bi-component microfibers with hydrophilic polymers on the surface with enhanced dispersion in alkaline environment for fiber cement roofing application

PendingUS20220089490A1Cut shorterGood spinnabilityWoven fabricsConjugated synthetic polymer artificial filamentsPolyamideReinforced concrete

The present invention provides bi-component core-shell polymeric microfibers for reinforcing concrete comprising as a first component (shell) ethylene-vinyl alcohol (EVOH) polymer and at least one plasticizer, preferably, polyethylene glycol, and as a second component (core) a polymer chosen from a polyamide, a polyester, such as polyethylene terephthalate, and a polymer blend of a polyolefin and an anhydride grafted polyolefin and having an aspect ratio of length to diameter (L / D) or equivalent diameter of from 300 to 1000. The bi-component polymeric microfibers comprise from 5 to 45 wt. % of the first component, are easily processed, and provide fiber cements having improved mechanical properties at relatively low microfiber loadings.

Owner:DOW GLOBAL TECH LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com