Olefin polymer and blend fiber and preparation methods and applications thereof

An olefin polymer and blended fiber technology, applied in the field of olefin polymers, can solve the problems of weak strength of wet frozen collagen filament, poor spinnability and poor uniformity of ultra-high molecular weight polyethylene, and achieve the effect of good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

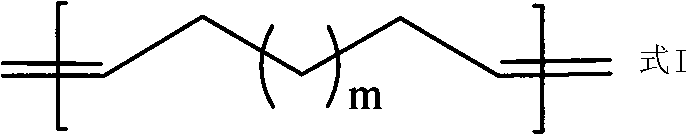

[0072] The preparation of embodiment 1 olefin polymer

[0073]

[0074] The liquid reactants cycloheptene (10 g) and n-heptane solvent (150 mL) were added into a 250 mL three-necked flask filled with argon, and after argon replacement and oxygen removal, Jane's catalyst (compound 2) (2 mg) was added. After 5 minutes, the reaction liquid became viscous, and the reaction temperature was controlled at 30° C., and the reaction time was 12 hours. After the polymerization reaction, the reaction solution was slowly introduced into rapidly stirred acetone for precipitation, and a large amount of white flocculent solids were produced. After the product was filtered and washed for 1-2 times, it was dried in a vacuum oven to obtain 8.9g of white solid macromolecular olefin polymer (15a). After dissolving with toluene, its viscosity was measured to be 0.57, and the weight-average molecular weight was 550,000 (n was about 5730 ), yield 89%.

[0075] After testing, the olefin polymer (...

Embodiment 2

[0077] The preparation of embodiment 2 olefin polymers

[0078]

[0079] The liquid raw material cycloheptene (10g) was added in a 250mL three-necked flask filled with argon, and after passing through argon to replace and exhaust oxygen, 1,2-dichloroethane ( DCE) solution (0.1 mL). After 5 minutes, the reaction solution became viscous and exothermic. The reaction temperature was controlled at 30° C., and the reaction time was 12 hours. After the polymerization reaction is finished, add 150mL of toluene to dissolve, and slowly introduce the dissolved toluene reaction solution into rapidly stirring acetone for precipitation, producing a large amount of white flocculent solid. After the product was filtered and washed for 1-2 times, it was dried in a vacuum oven to obtain 9.2g of white solid macromolecular olefin polymer (15b), and its viscosity measured after dissolving with toluene was 1.53, and the weight average molecular weight was 1.48 million (n was about 15400 ), yie...

Embodiment 3

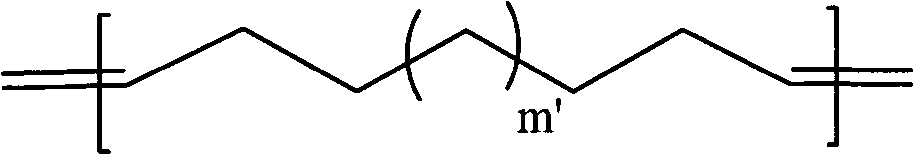

[0082] The preparation of embodiment 3 olefin polymers

[0083]

[0084]The liquid raw material cyclooctene (1.0kg) and toluene solvent (15L) were added into a 30L three-necked flask filled with argon, and a small amount of Jane's catalyst (compound 2) (2mg) was added after passing through argon to replace and exhaust oxygen. After 5 minutes, the reaction solution became viscous, and the reaction temperature should be controlled at 30°C. After the polymerization reaction, the reaction solution was slowly introduced into rapidly stirred acetone for precipitation, and a large amount of white flocculent solids were produced. After the product was filtered and washed for 1-2 times, it was dried in a vacuum oven to obtain 918g of white solid high molecular weight olefin polymer (17a). After dissolving with toluene, its viscosity was measured to be 0.26, and the weight average molecular weight was 230,000 (n was about 2090). , yield 91.8%.

[0085] After detection, the olefin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com