Patents

Literature

666results about How to "Good moisture absorption and air permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

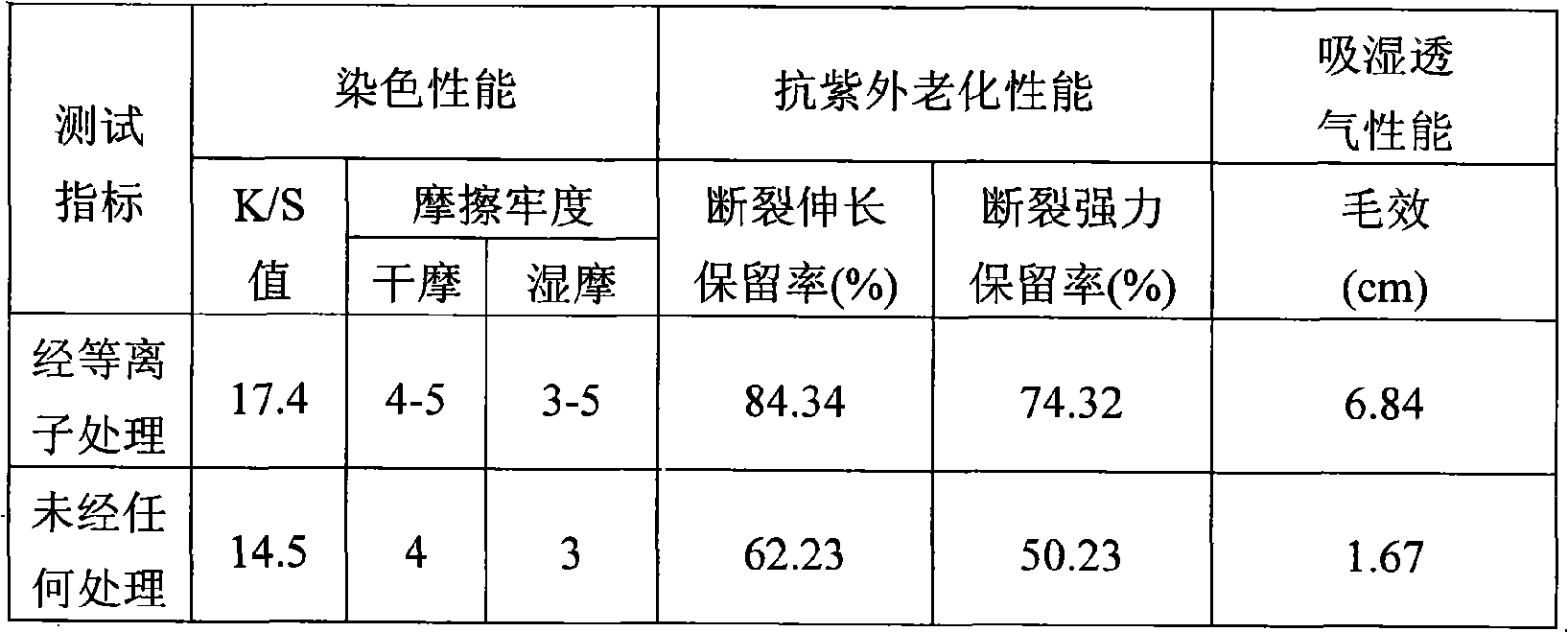

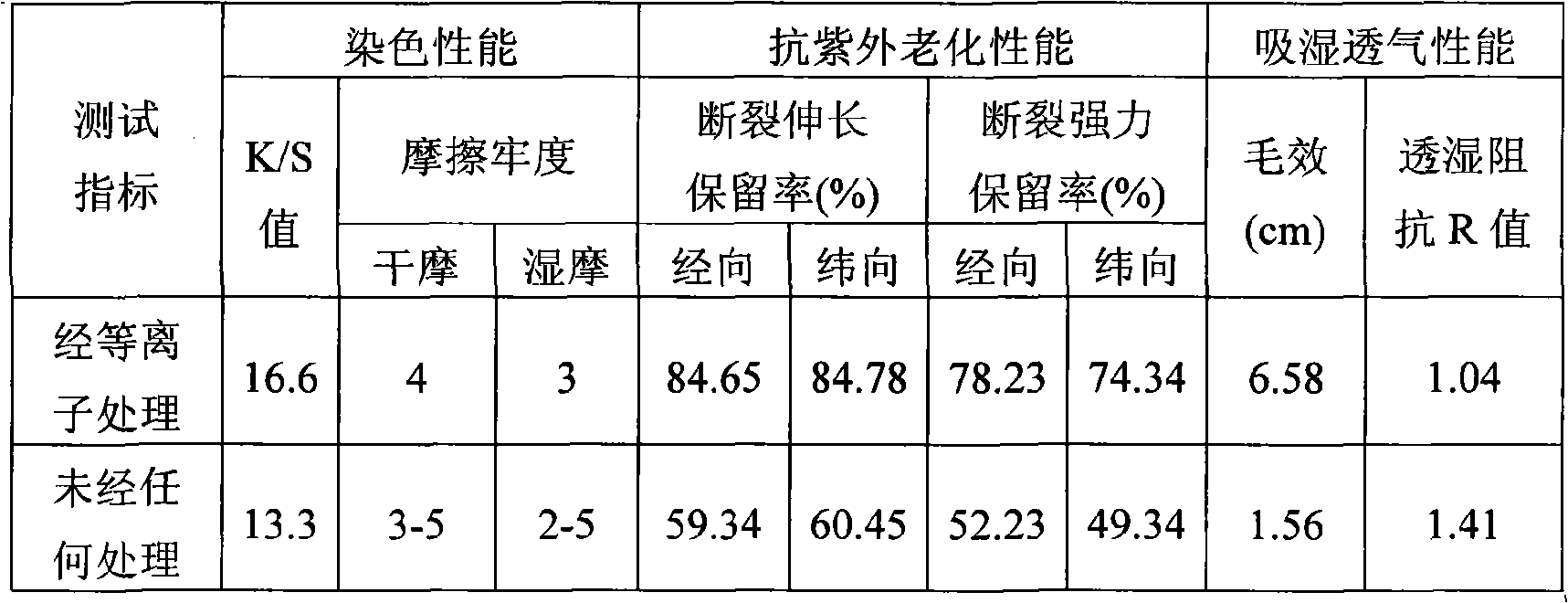

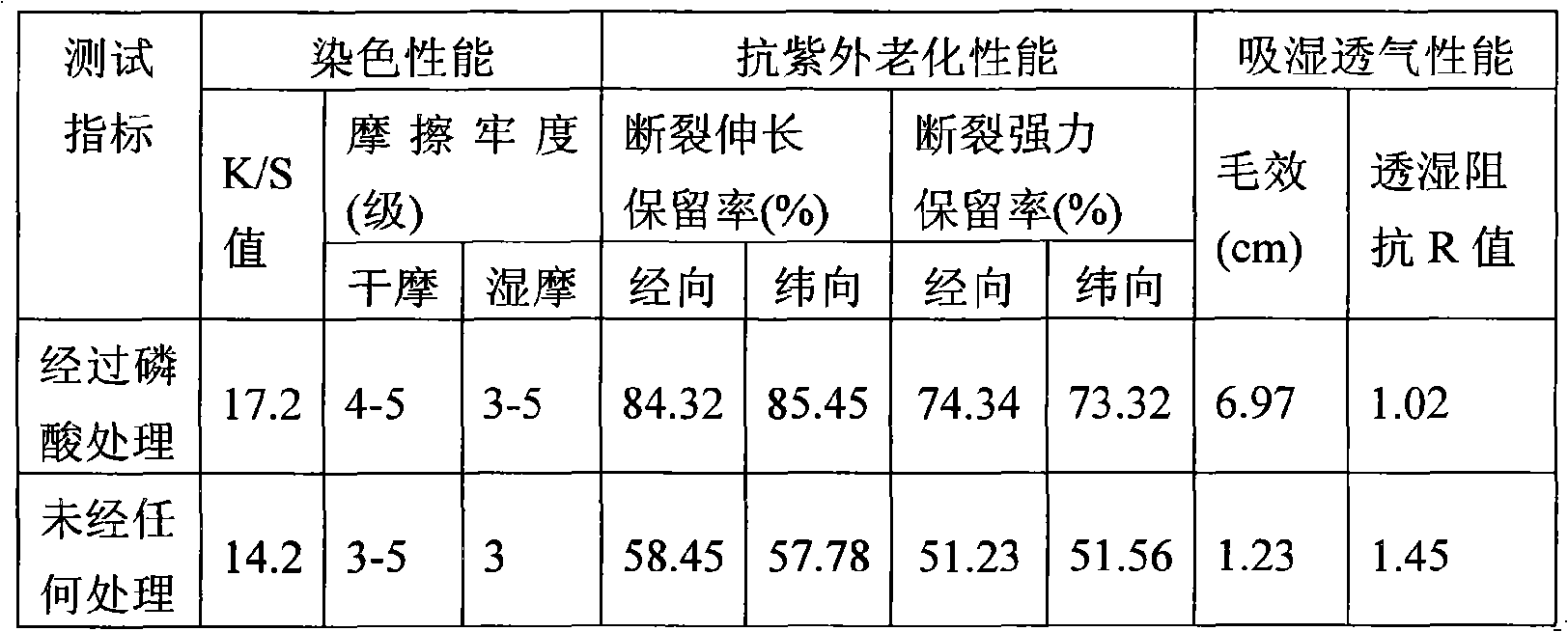

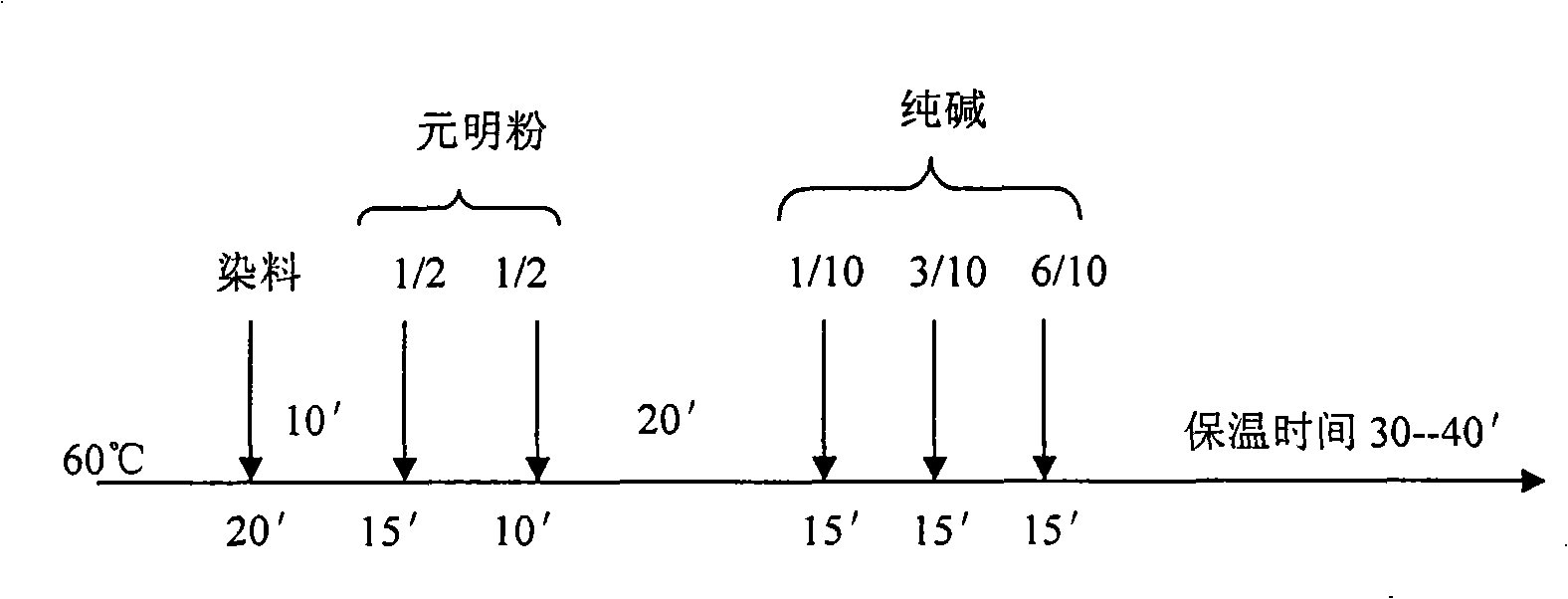

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

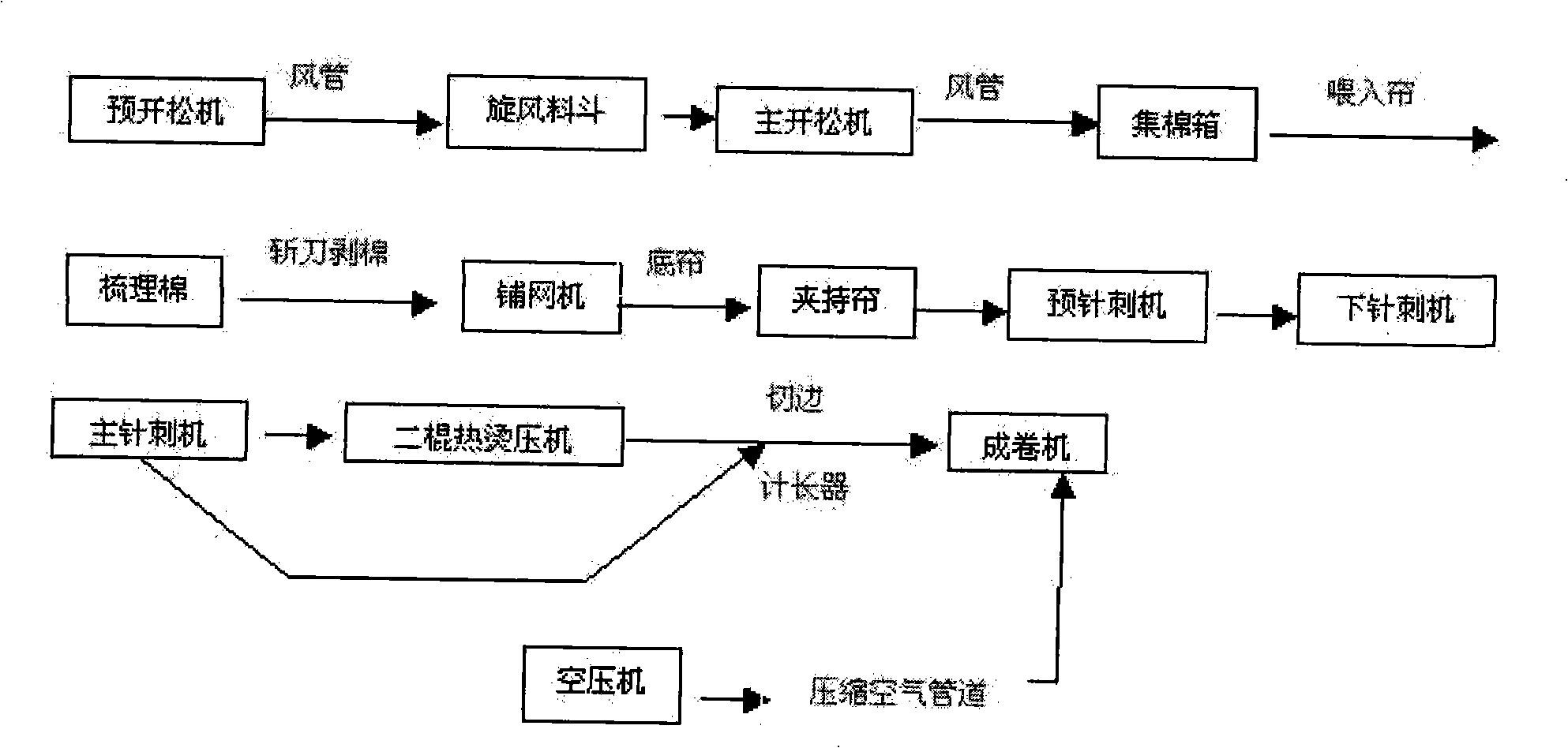

Fire retardant cotton nonwoven fabrics and manufacture method thereof

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

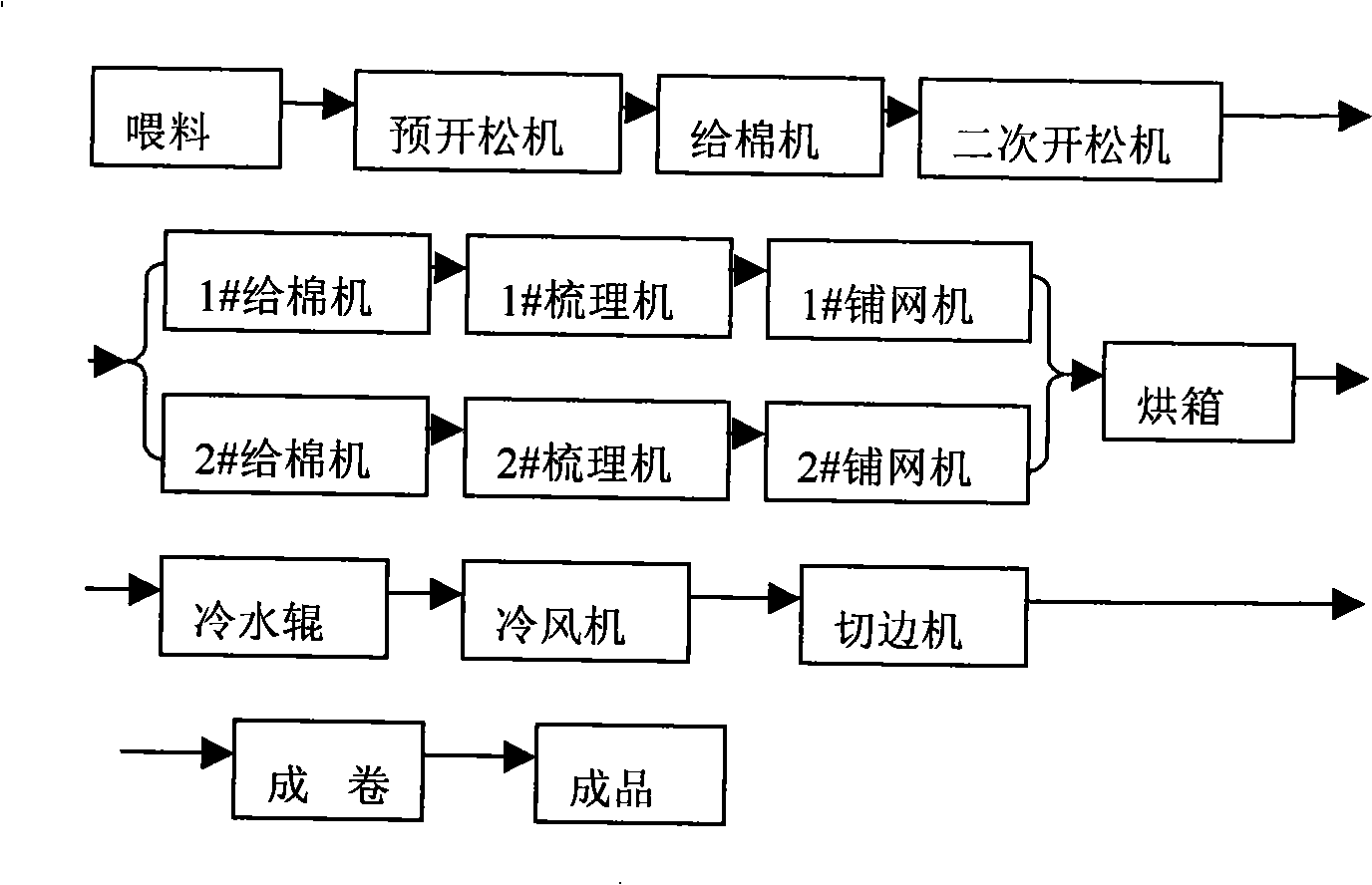

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

Method of processing semi-worsted flax blended yarn

The present invention involves a processing method of semi-worsted flax blended yarn, and it belongs to flax blended yarn technical field. The counts of the semi-worsted flax blended yarn is 30-85 Nm / 2D, the raw materials consists of flax 10-60 and other fiber 40-90; degelatinizing, dyeing and preserving flax, pretreating other fiber, then putting together wool, blowing cotton, carding and drawing, then prespinning and shirting, last the products are prepared after cheese winding, twisting and double twisting processes. The invention combines the 'straight' of flax fiber and the 'softness' of other fibers effectively; the prepared semi-worsted flax blended yarn has many advantages of good textile strands and less granulite, it is suitable for the face fabric of thin summer inner wear and coat.

Owner:山东恒泰纺织有限公司

Ecological bacteriostatic breathable smooth tatting fabric

ActiveCN102383235AExcellent ecological antibacterialGood moisture absorptionBleaching apparatusWoven fabricsAfter treatmentEngineering

The invention relates to an ecological bacteriostatic breathable smooth tatting fabric, which can overcome defects of being not ecological bacteriostatic, moisture-adsorption, breathable or smooth and being coarse and poor in comfortableness in the prior art. The ecological bacteriostatic breathable smooth tatting fabric enables the fabric to meet special ecological bacteriostatic, breathable andsmooth requirements, and special weaving and after treatment of the fiber can simultaneously achieve excellent ecological bacteriostatic, moisture-adsorption, breathable, smooth and comfortable performances.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

Composite textile fabric with functions of cooling, sweat releasing and moisture absorbing

ActiveCN102380987AImprove comfortHigh glossFibre treatmentSynthetic resin layered productsPerspirationAfter treatment

The invention relates to a composite textile fabric with functions of cooling, sweat releasing and moisture absorbing, which overcomes the disadvantages of air impermeability, heavy moisture permeability, poor moisture absorption performance and air impermeability performance, no perspiration after heating and poor comfortableness in the prior art. The composite textile fabric with functions of cooling, sweat releasing and moisture absorbing is capable of satisfying the requirements of cooling, sweat releasing and moisture absorbing, and the after treatment of the special double layer structural fabric is capable of realizing the performances of excellent luster, good moisture absorption and permeability, excellent cooling, sweat releasing and comfortableness of the textile fabric.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Flame retardant blended yarn and production method thereof

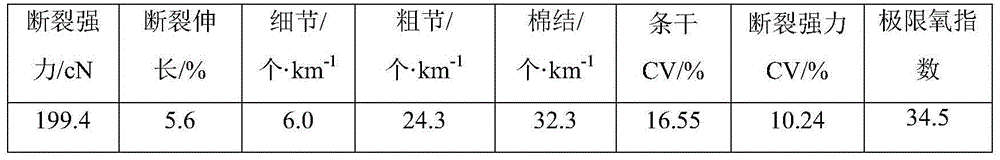

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

Ordering method for pure cotton fabric weftwise elasticity

The invention provides a method for conditioning latitudinal elastic force of pure cotton fabric, in particular to a method for processing a pure cotton elastic weft fabric without adding elastic fibers such as spandex, which sequentially comprises the following steps of: weaving grey fabrics, singeing and desizing, mercerizing with caustic soda, stentering and setting and pre-shrinking. The method is characterized in that a pure cotton yarn or a wrapped yarn including pure cotton and water-soluble polyvinyl alcohol fiber are adopted in the weft in the grey fabric weaving procedure; the mercerizing procedure adopts 20 to 30% caustic soda solution; a fabric expanding device is adopted for keeping 80 to 100% the breadth of the fabric after the singeing and desizing procedure; and the fabric expanding device is adopted in the stentering and setting procedure to keep the 100 to 102% the breadth of the fabric after the mercerizing procedure, thereby ensuring the elasticity of the fabric. The process fabric has soft handle, good moisture absorption and permeability, and good elasticity within 15 to 25%. Clothes made from the fabrics are comfortable and natural, and can maintain good flat state and elasticity after washing and drying.

Owner:LUTAI TEXTILE

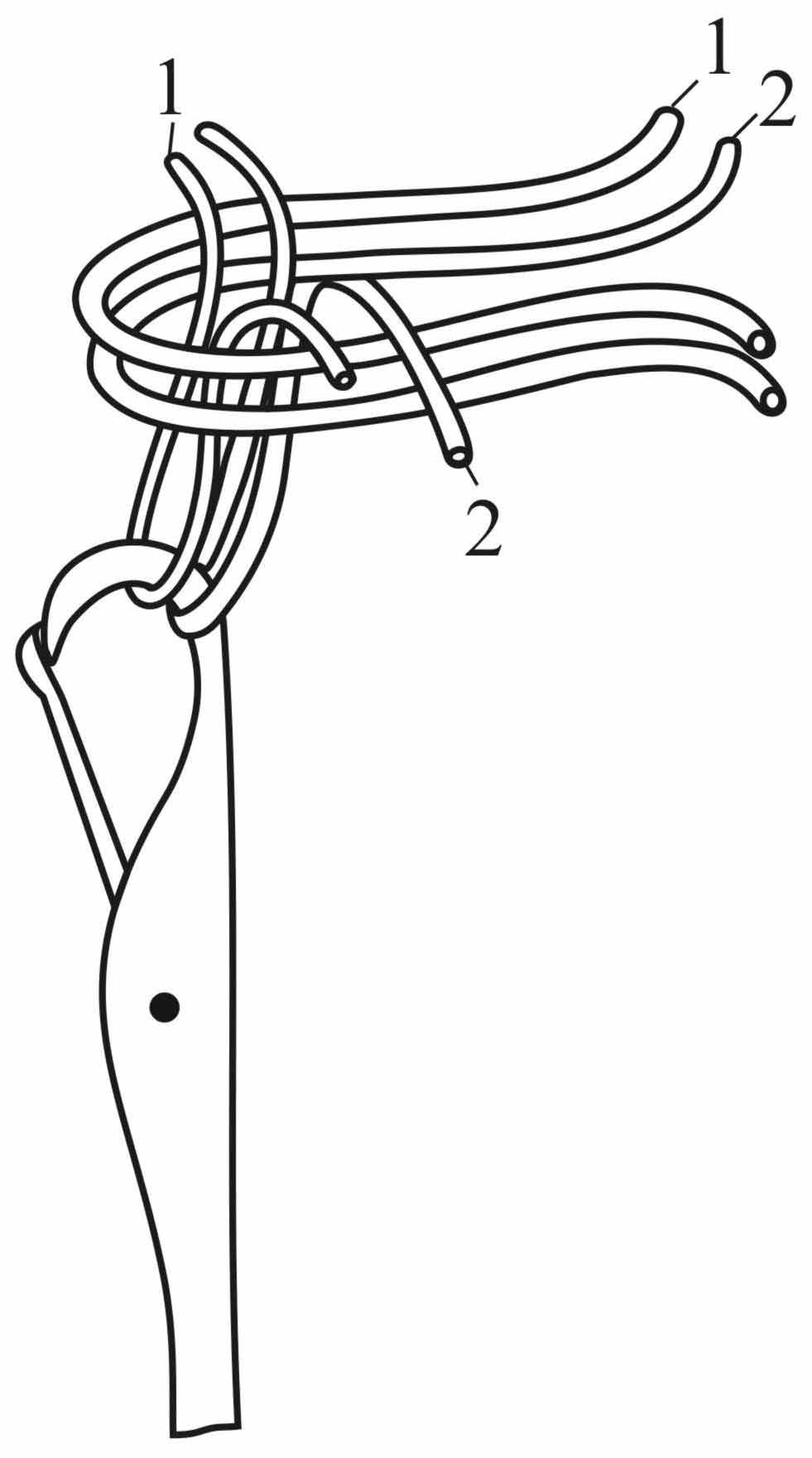

One-way wet-guide quick-drying real silk facing material

InactiveCN101270524ADistinct silk styleSpeed up moisture transferFilament/thread formingWoven fabricsMoisture absorptionEngineering

The invention relates to a unidirectional wicking fast-drying true silk fabric which is characterized in that the front surface of the fabric is two first or three first twill-weave; the back surface corresponding to the front surface is one second or one third twill-weave; the material of the front surface adopts silk with the specification of 15 to111dtex; the material of the back surface adopts ultrathin denier wicking fast-drying terylene DTY long thread with the single thread density of 0.2 to 0.8dtex; the section of the long thread is crisscross; the invention adopts a embedded weaving method for weaving and manufacture. The surface of the fabric obviously assumes the styles of true silk which has fleshy and soft hand feelings as well as excellent moisture absorption and ventilation properties. As the wicking fast-drying terylener is adopted as the back surface of the fabric, the excellent fast-drying property thereof can quicken the wicking speed of the true silk fiber on the front surface after absorbing moisture and simultaneously can not go so far to reveal the defects of hard hand feeling, easy pilling and generating static of the terylener.

Owner:SUZHOU HUACHOU TECH

Preparation method of fibroin/graphene conductive fiber

ActiveCN104674362ANot easy to reuniteEasy to manufactureMonocomponent protein artificial filamentElectroconductive/antistatic filament manufactureFiberElectrospinning

The invention discloses a preparation method of fibroin / graphene conductive fiber. The preparation method comprises the following steps: mixing a graphene oxide solution and a fibroin solution, pouring a mixture into a polytetrafluoroethylene mould, drying to obtain a graphene oxide / fibroin compound membrane, putting the graphene oxide / fibroin compound membrane into a solvent, stirring till the graphene oxide / fibroin compound membrane is completely dissolved, performing ultrasonic treatment to obtain a spinning solution, putting the spinning solution into a container of electrostatic spinning equipment, performing high-voltage electric spinning to obtain composite fiber, and performing steam treatment to obtain the fibroin / graphene conductive fiber. The concentrations of fibroin and graphene in the fibroin / graphene conductive fiber prepared by the preparation method are high, so that the fibroin / graphene conductive fiber has good conductivity besides excellent wearability.

Owner:苏州欧尔迪威地暖科技有限公司

Production method for enabling pure mulberry silk fabric to have natural elasticity style in weft direction

ActiveCN101634097AWeft stress balance and stabilityGuaranteed uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberMoisture absorption

The invention discloses a production method for enabling a pure mulberry silk fabric to have a natural elasticity style in a weft direction. The technological processes sequentially comprise blank silk weaving, preprocessing, cooked smelting, bleaching, water washing, pickling, dewatering or squeezing, coiling, baking stentering and check mounting, wherein the cooked smelting comprises primary smelting and secondary smelting. The baking stentering comprises the following steps: firstly, carrying out baking shaping on a wool carpet finishing machine and then at least carrying out stentering processing for more than two times on a stentering machine. The technological processes of the blank cloth weaving comprise the selection of wefts, the selection of the twisting degree and the twisting direction of the wefts and the twisting direction arrangement of weft combination. Because the pure mulberry silk fabric does not depend on elastic fibre, such as urethane elastic fibre and the like, and adopts blank silk woven by super-strong twisting real silk wefts to carry out the methods of degumming, stentering, shaping and processing so as to enable a pure real silk fabric to obtain better weft direction elasticity and excellent elastic restoring force, the fabric is not easy to crack and has relatively flexible hand feel and good moisture absorption and air permeability, and a dress article made by the fabric shapes the body and has convenient movement, good form retention, small dimensional change rate and small seam slippage.

Owner:DALI SILK ZHEJIANG

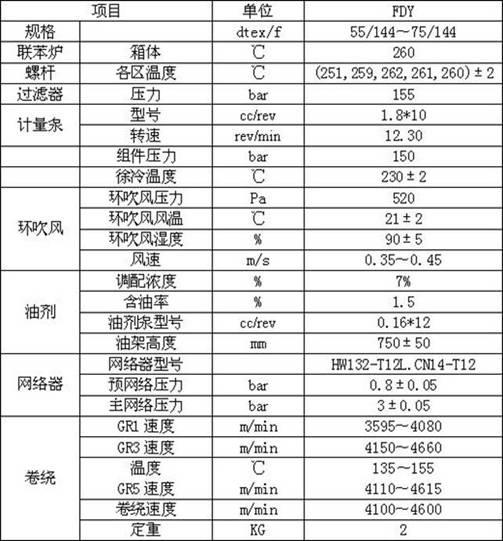

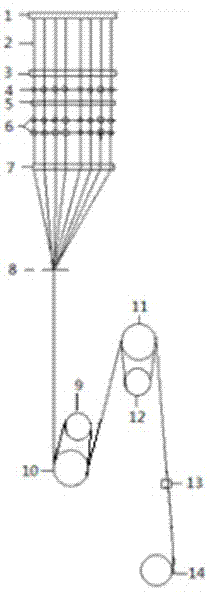

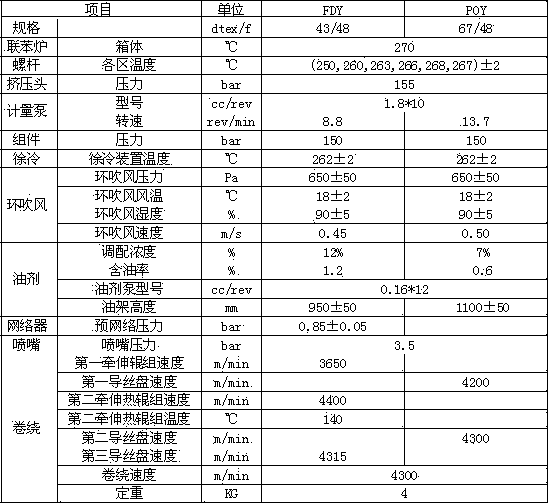

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

Method for preparing peanut protein composite fiber by using ionic liquid

InactiveCN102586942ADissolve fastReduce solubilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentHigh concentrationStrong acids

The invention discloses a method for preparing a peanut protein composite fiber by using ionic liquid. The method comprises the following steps of: dissolving peanut protein and polyvinyl alcohol in imidazole ionic liquid respectively to obtain a peanut protein ionic liquid solution and a polyvinyl alcohol ionic liquid solution; mixing the peanut protein ionic liquid solution and the polyvinyl alcohol ionic liquid solution in a mixed ratio of 1:3-1:5; adding an aid to obtain a spinning solution, and entering a coagulating bath; preparing a peanut protein / polyvinyl alcohol composite fiber by awet spinning method in the coagulating bath; and stretching, washing, performing acetal treatment, applying oil, drying, curling, sizing, and thus obtaining the mixed fiber. By the method, the ionic liquid instead of strong acid and strong alkali is used as a solvent in the process of synthesizing a peanut protein fiber, so that the peanut protein and the polyvinyl alcohol can be quickly dissolved at high concentration and a low temperature, and the preparation process is non-toxic and pollution-free at the same time.

Owner:SHANDONG PEANUT RES INST +1

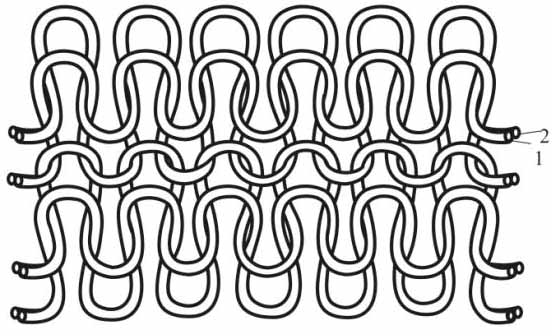

Electromagnetic radiation resistant knitted fabric and weaving method thereof

The invention discloses a knitted electromagnetic radiation resistant fabric and a weaving method thereof. The fabric is a plain stitch-based or 1+1 rib-based all-plated tissue knitted fabric, all coils in the fabric are formed by superposing at least two coils, one kind of yarn is exposed at one side of the fabric, and the other kind of yarn is exposed at the other side of the fabric; and one kind of yarn is common yarn or polyurethane core-spun yarn, and the other kind of yarn is conductive fiber yarn. The fabric produced by adopting the weaving method organically combining the common yarn or the polyurethane core-spun yarn and the conductive fiber yarn has electromagnetic radiation resistance, and the electromagnetic radiation resisting capacity of the fabric can reach over 99 percent. The fabric has the advantages of soft and smooth handfeel, good moisture permeability, bright color, washing resistance, subtleness and good wrinkle resistance.

Owner:JIANGSU TANGWEAR IND

Nice and cool purified cotton yarn dyed fabric manufacturing process

InactiveCN103526391ARaw materials are natural and greenReduce contact surfaceWoven fabricsPulp and paper industryMoisture absorption

The invention relates to a nice and cool purified cotton yarn dyed fabric manufacturing process. The structure of a nice and cool purified cotton yarn dyed fabric comprises 1 / 1 plain weave, 1 / 1 plain back plus through holes, 1 / 1 plain back plus 3 / 1 twill weave or 2 / 2 basket weave, and the specification of the nice and cool purified cotton yarn dyed fabric comprises that yarn counts range from 35s to 70s, warp density ranges from 110 to 190 per inch, and weft density ranges from 58 to 110 per inch. The nice and cool purified cotton yarn dyed fabric manufacturing process is characterized by sequentially comprising the following processing steps of spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, noniron finishing, tentering, preshrinking and finished product obtaining, or spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, tentering, preshrinking and finished product obtaining. A finished product fabric processed through the nice and cool purified cotton yarn dyed fabric manufacturing process has a soft hand feel, no special auxiliary which feels cool is added in the production process, the contact area between yarn and the skin is reduced, gaps between the yarn are enlarged, the superficial area for moisture and heat dissipation is enlarged, moisture absorption and air permeability are more than doubled, and therefore a wearer can feel quite cool in summer.

Owner:LUTAI TEXTILE

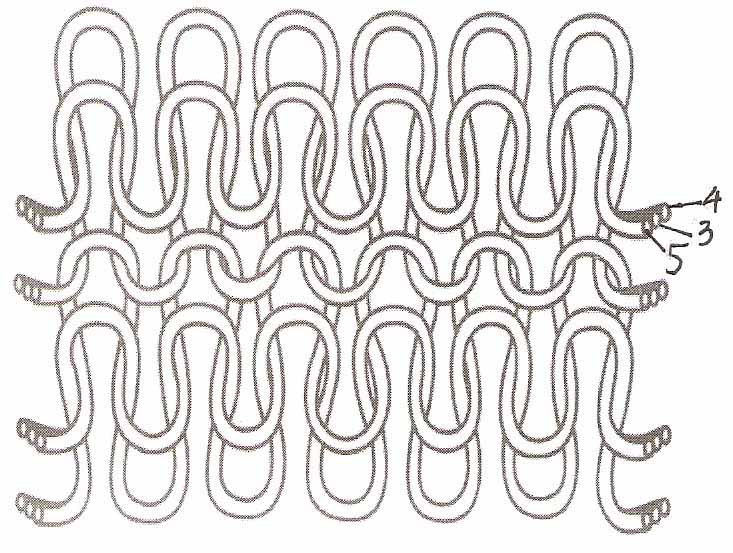

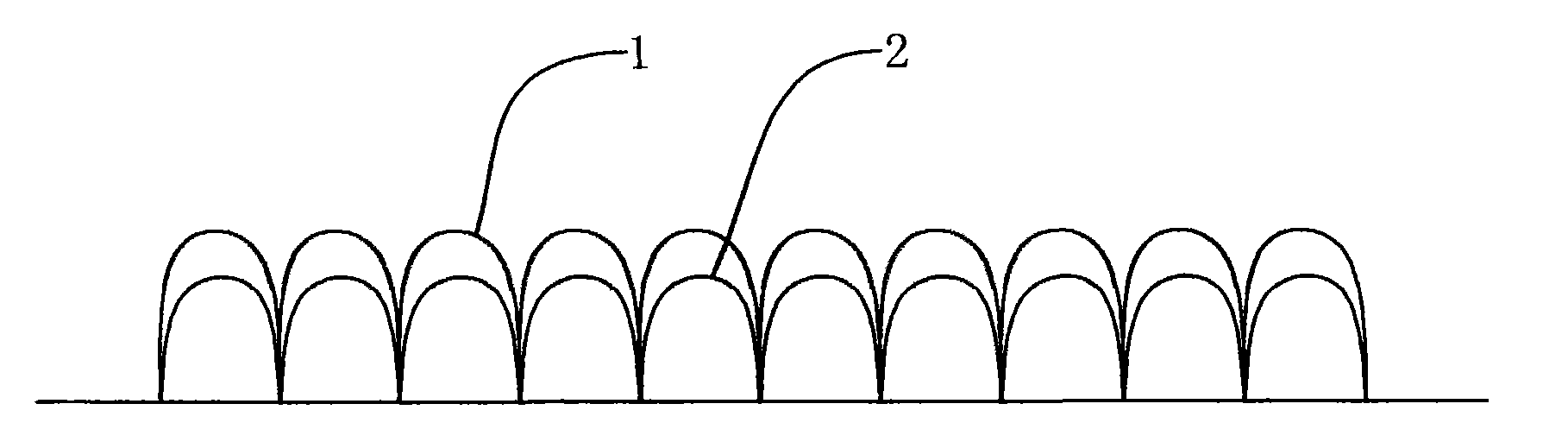

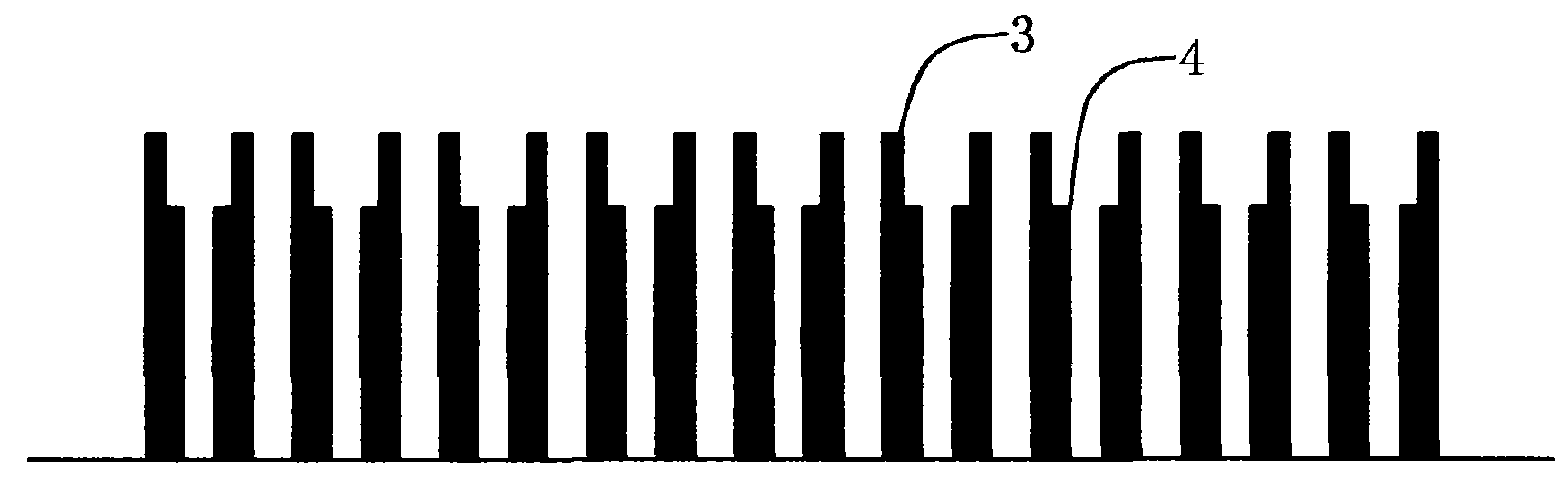

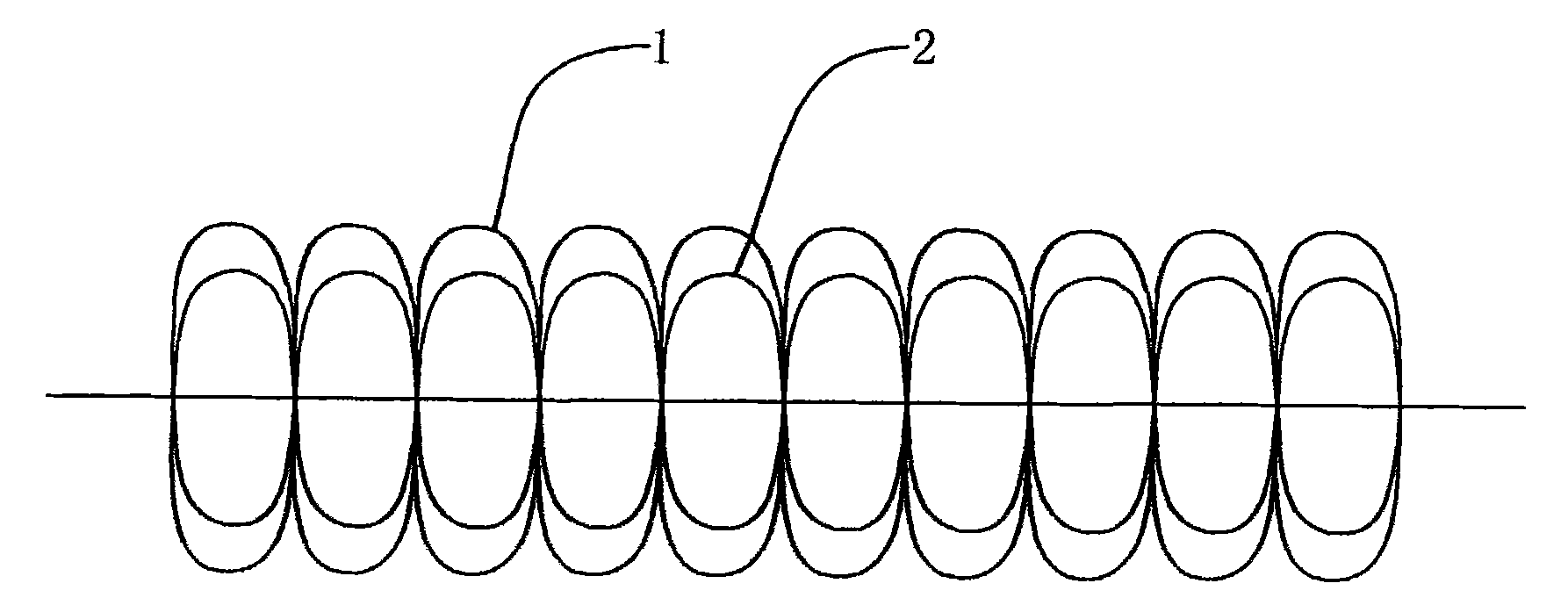

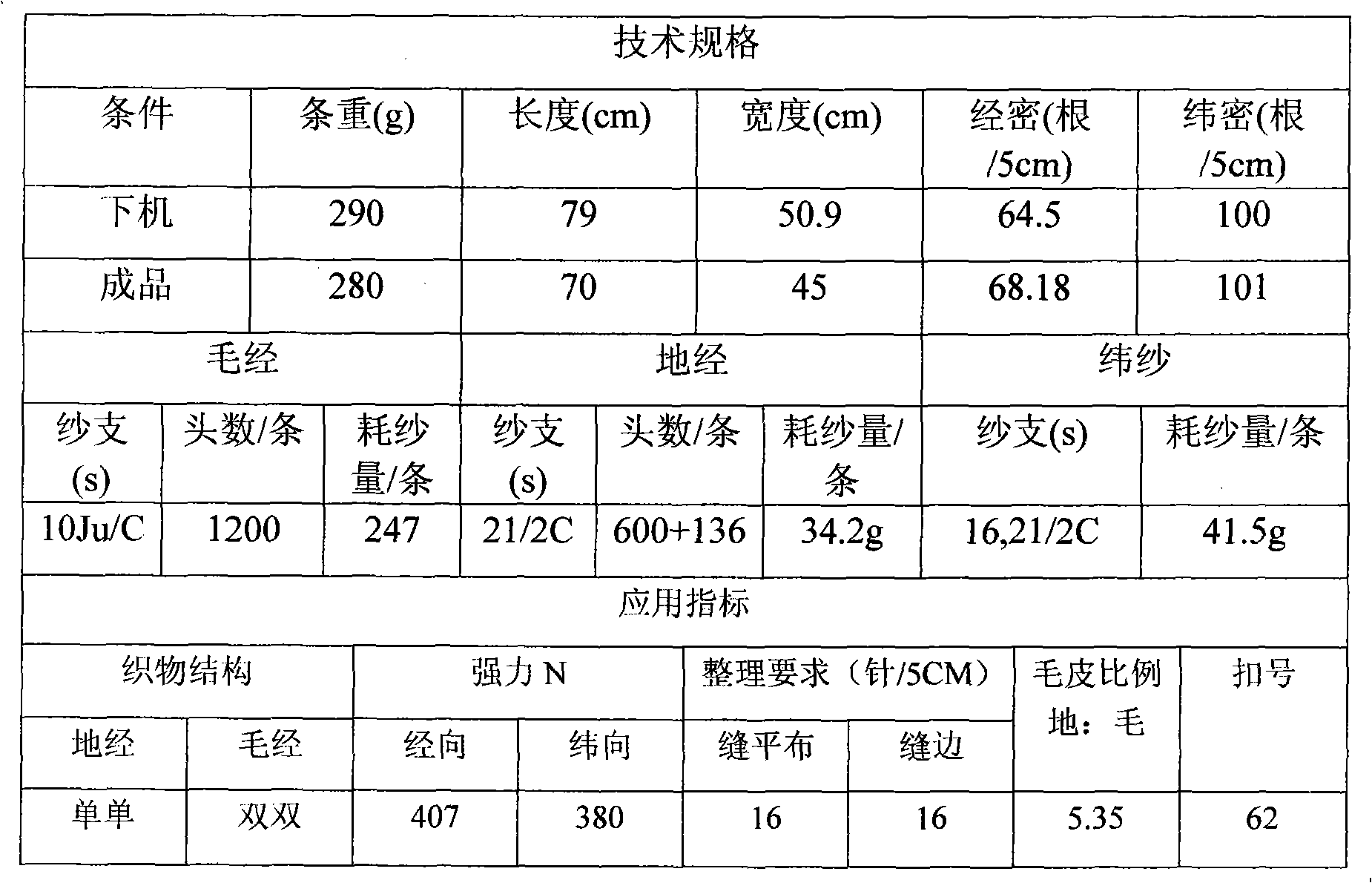

Novel pile loop fabric and method for producing same

ActiveCN102071517AGood comfortGood moisture absorption and air permeabilityWeft knittingWarp knittingNatural fiberMoisture

The invention discloses a method for producing a pile loop fabric. The fabric is a single-sided or double-sided pile loop fabric. Pile loops comprise outer pile loops and inner pile loops; and the pile loop fabric is a novel piled loop fabric which is produced by using natural fibers and ultrathin fibers as piled loop raw materials and chemical fiber filaments or natural fibers as base structure raw material, and by warping, greige cloth weaving, greige cloth post treatment. By combining the respective characteristics and functional advantages of the natural fibers and the ultrathin fibers, the piled loop fabric meets the requirements of people for high comfort degree, high moisture absorbability and high breathability of natural fiber products and enjoys great advantages over pure natural piled loop (velvet) fabrics in terms of bulkiness, softness, water absorbability, convenience for moisturizing, quickness for dying, durability, mildew proof performance and other performance.

Owner:段宏伟

Method for producing advanced triple-wire double-calcination pure cotton fabrics

InactiveCN101718022AIncrease reflective areaShinyMercerising of yarns/threads/filamentsSingeingLiquid ammoniaDyeing

The invention provides a method for producing advanced triple-wire double-calcination pure cotton fabrics, comprising the working procedures of yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, tenter setting and preshrinking. The method is characterized in that before being dyed, grey yarns are mercerized and singed, and a liquid ammonia working procedure is added between alkali mercerization and tenter setting, thereby forming the whole processing steps sequentially including yarn mercerization, yarn singeing, yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, liquid ammonia, tentering and preshrinking. Compared with the traditional mercerized pure cotton fabrics, the triple-mercerization pure cotton fabrics obtained by the method have the advantages of higher lustre and high tinctorial yieldof yarns, fresher color of fabrics, good moisture absorption and ventilation, soft handle and high resilience, and the triple-wire double-calcination pure cotton fabrics are softer after being washed and maintain other excellent performances thereof.

Owner:LUTAI TEXTILE

Production method of permanent ultraviolet protecting, moisture absorbing and sweat removing fabric

ActiveCN104799458AReduce surface tensionImprove permeabilitySingeingHeating/cooling textile fabricsChemistryPolyester

The invention discloses a production method of a permanent ultraviolet protecting, moisture absorbing and sweat removing fabric. The method comprises the steps of blending and weaving; singeing; desizing-scouring-bleaching; mercerizing; sizing; dyeing; softening and tentering; pre-shrinking and arranging. The fabric manufactured by the production process is outstanding in permanent ultraviolet resisting function; the UPF is not less than 150; micro pores of CTATEX super-comfortable polyester fibers can be opened fully by the desizing-scouring-bleaching and mercerizing, holes in the fibers are smooth, the moisture absorbing and breathing performances of the fabric can be improved under the absorbing effect of hole cores, and the water drops can be absorbed within 3 seconds according to the test; the fuzzing and pilling resistance of the fabric is more than 4 grades; the advantages of wearing resistance, non-ironing, wrinkle preventing and quick drying of the polyester fibers are remained to the maximum; the fabric is particularly suitable for wearing when working and living outdoor in a hot season.

Owner:SWOTO PROTECTION & TECH CO LTD +1

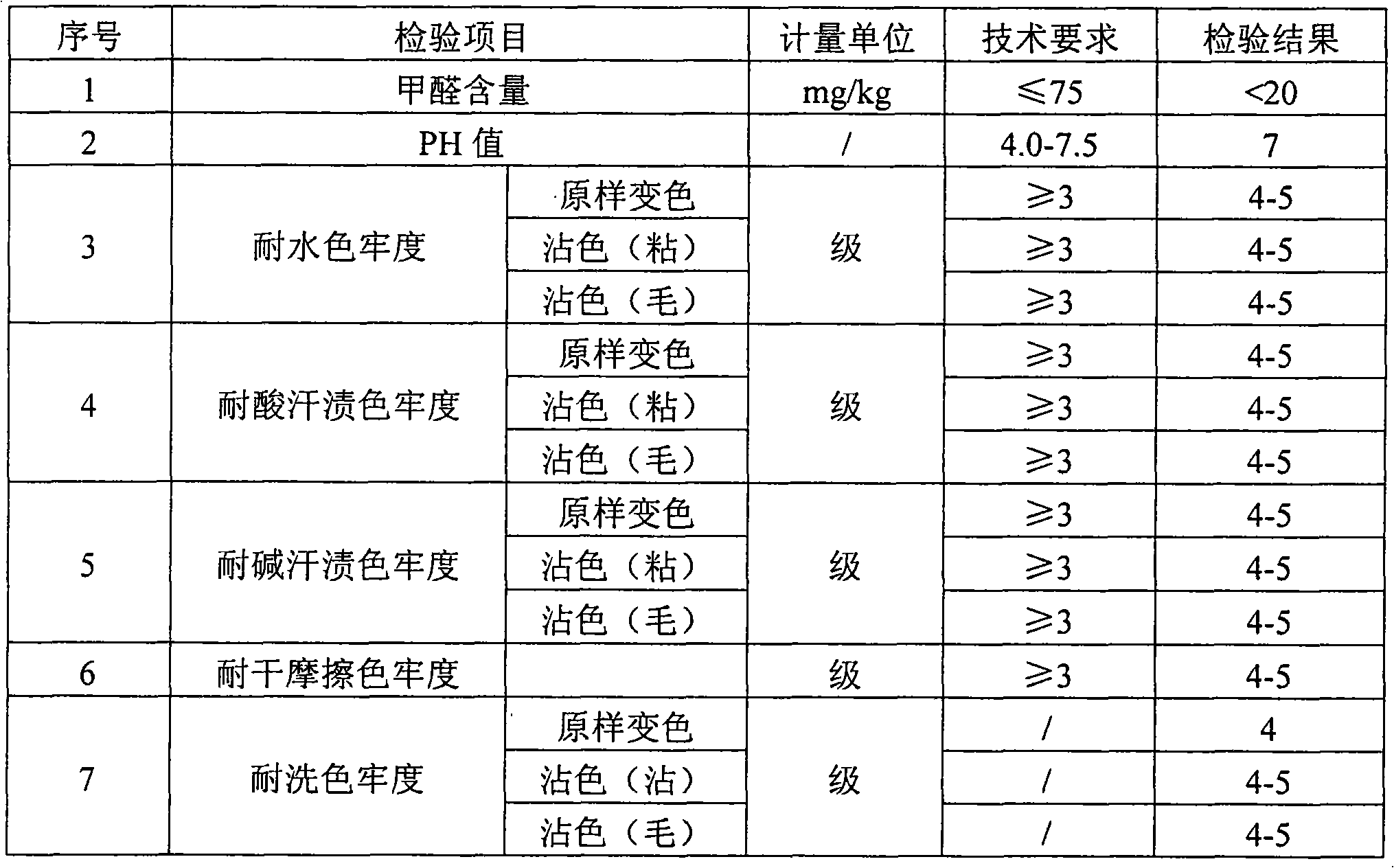

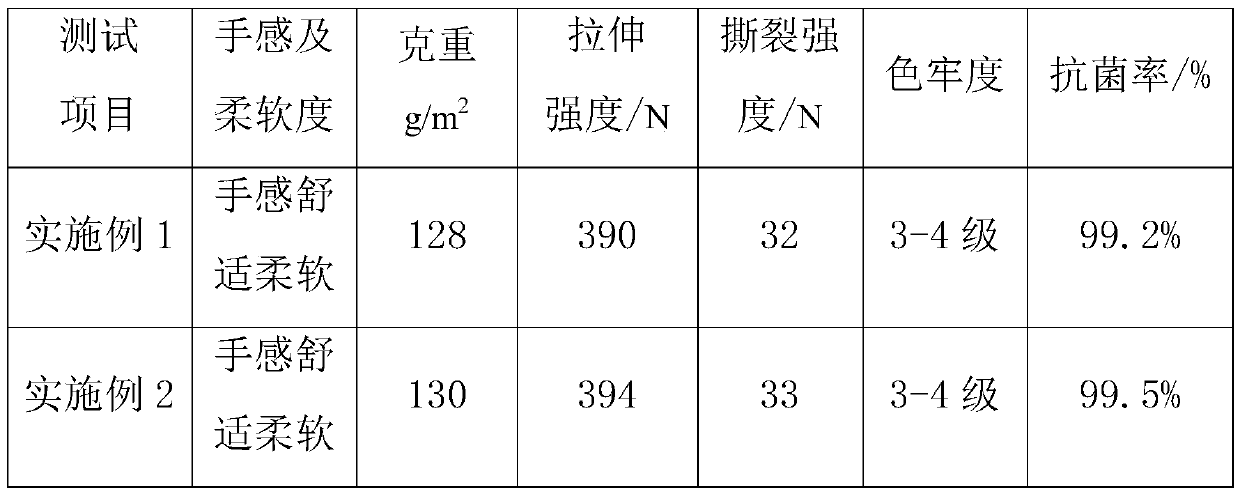

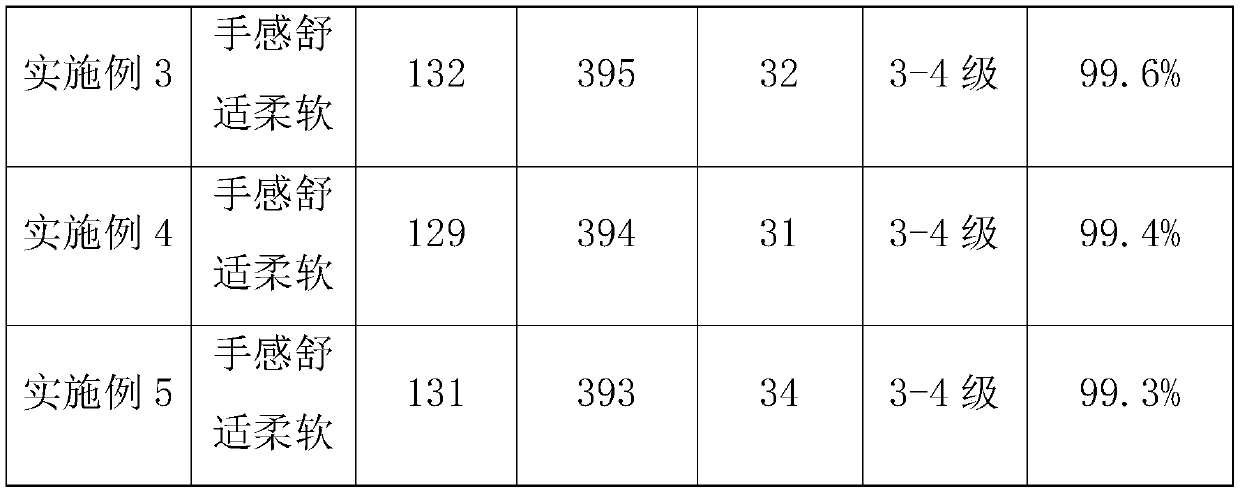

Nursing type mixed fabric and production method thereof

InactiveCN101525803AHas broad-spectrum antibacterial functionStrong persistenceWeft knittingWarp knittingGramNational standard

The invention discloses a nursing type mixed fabric and a production method thereof. The nursing type mixed fabric is characterized by being formed by mixing milk silk fibres, Modal fibres, Newdal fibres and urethane elastic fibres which are taken as raw materials and being counted by raw material percentage by weight, a finished fabric is made of the following raw materials by weight: 10-55 percent of milk silk fibres, 20-50 percent of Modal fibres, 20-60 percent of Newdal fibres and 2-8 percent of urethane elastic fibres, and the gram weight of the finished fabric is 250-300g / M<2>. The nursing type mixed fabric has the aroma of milk silk, good heat preservation and ventilation property, natural skin nursing function and soft, smooth and silky feel. The invention also provides two coloration methods aiming at the nursing type mixed fabric. With the two coloration methods, each dyefastness index reaches or surpasses national standards.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

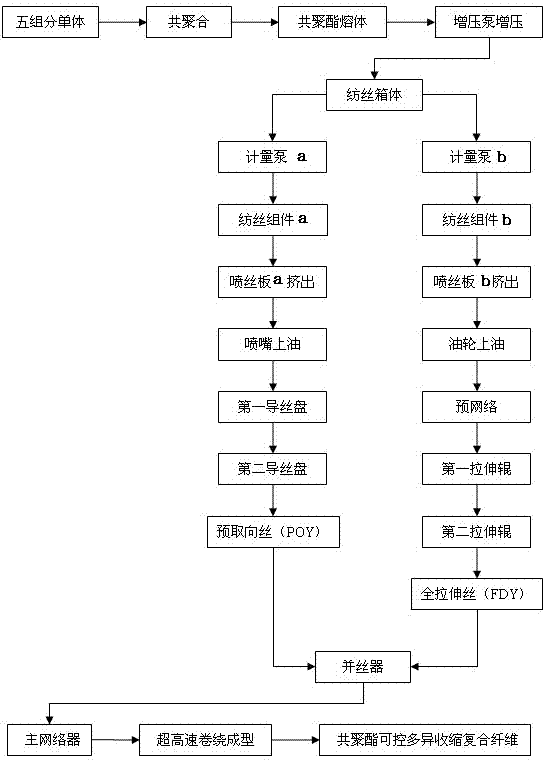

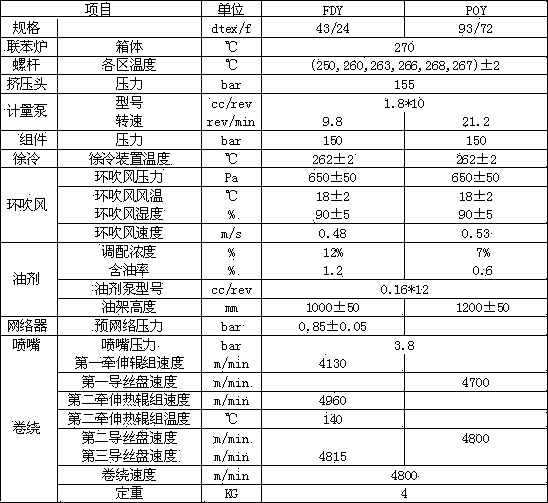

Controllable multiple-differential-shrinkage composition fiber made from copolyester melt through ultra-fast direct spinning, and preparation method of composition fiber

InactiveCN103484967AIncrease spinning speedIncrease added valueArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a controllable multiple-differential-shrinkage composition fiber made from a copolyester melt through ultra-fast direct spinning, and a preparation method of the composition fiber. The copolyester melt, which is made from five components including terephthalic acid, ethylene glycol, poly ethylene glycol, diethylene glycol and pentaerythritol, is pressurized by a booster pump and transported through a melt pipeline into a spinning box body, and is then divided by two measuring pumps into two branches, which enter a spinning component and a spinneret respectively and finally be extruded. After cooling and curing, two yarns are formed, wherein one yarn is subject to oiling by an oil wheel, pre-entwining, stretching and thermoforming to obtain an FDY yarn, and the other yarn is subject to oiling by an oil nozzle, and is guided to two spinning discs to obtain a POY yarn; the two yarns are simultaneously input into a doubling device and a main entwining device for combination, and are formed through the ultra-fast rolling, so as to obtain the composition fiber. The composition fiber has the characteristics of relatively good micro three-dimensional morphological structure, moisture absorption property, moisture preservation property, air permeability and antistatic property, easiness in dyeing, uniform dyeing, high coloration uniformity and the like; the composition fiber is high in processing speed, high in yield, low in consumption, low in manufacturing cost, high in value added, high in product functions, good in quality, and obvious in advantage of performance price ratio.

Owner:SUZHOU UNIV

Device for producing polyamide 6POY/FDY composite fiber according to high-speed spinning and confounding one-step method

InactiveCN104032397AGood melt uniformityShort production processNew-spun product collectionSpinning head liquid feederPolyamideYarn

The invention discloses a device for producing polyamide 6POY / FDY composite fiber according to a high-speed spinning and confounding one-step method. A cooling device of the device is a gradually-cooling device which is arranged below a spinneret plate. A cross air blow cooling device is arranged below a heater of the gradually-cooling device, the effect of lowering the cooling speed of melt thin flow can be achieved by enabling melt extruded out of the spinneret plate to pass through the cooling device, and yarn bundle cooling is uniform and consistent. An oil spraying device is arranged below the cross air blow cooling device. A stretching heat setting device and a yarn guiding and winding device are arranged in parallel. The stretching heat setting device is used for preparing polyamide 6POY fully-drawn yarn. The yarn guiding and winding device is used for preparing polyamide 6FDY fully-drawn yarn. A winding device is used for compositing 6POY with FDY at the speed ranging from 4000m / min to 5000m / min. The device has the advantages of being short in production process, simple in procedure, low in device production cost, low in energy consumption, high in efficacy, diversified in product structure and good in quality.

Owner:SUZHOU UNIV

Making method of single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric

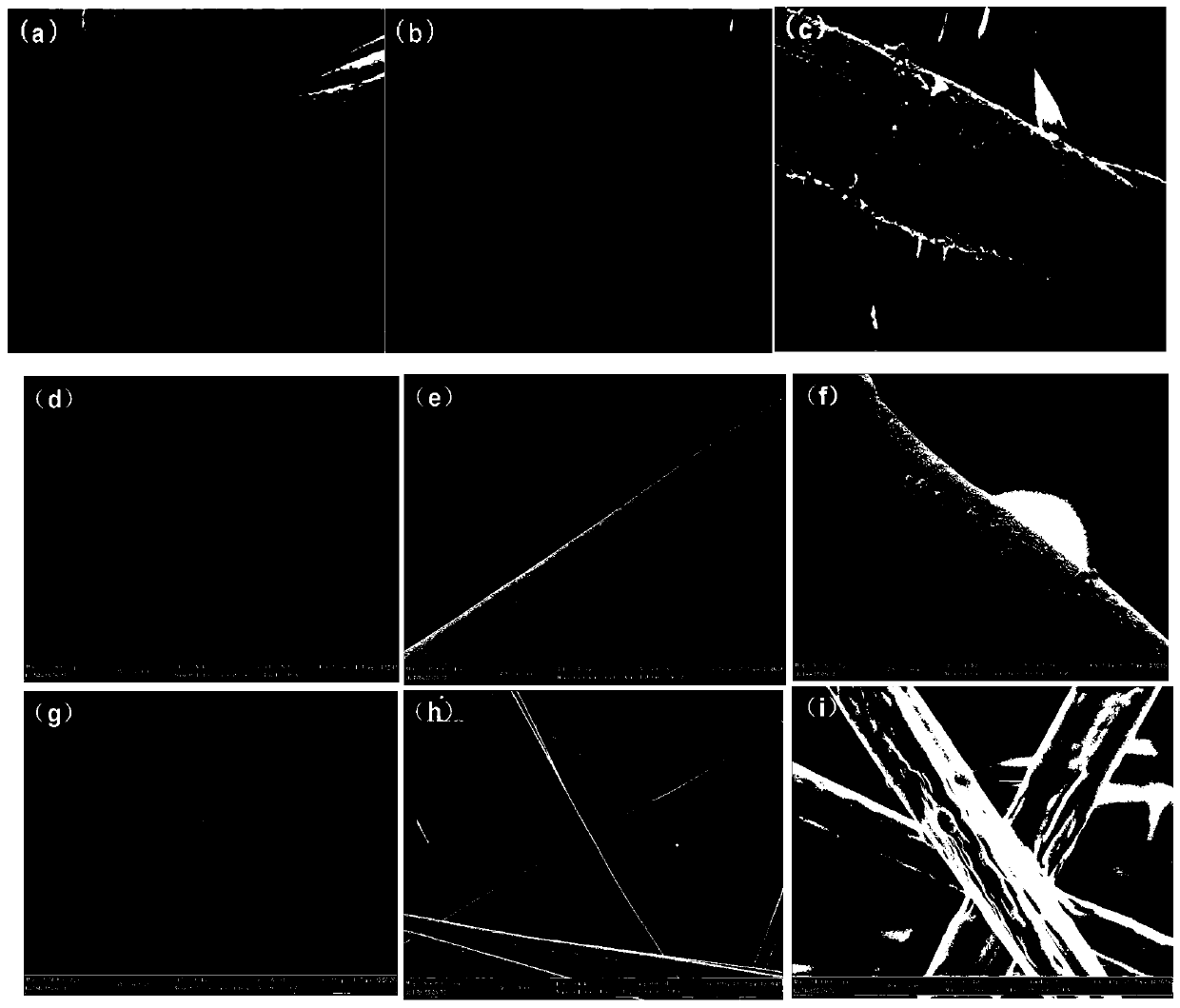

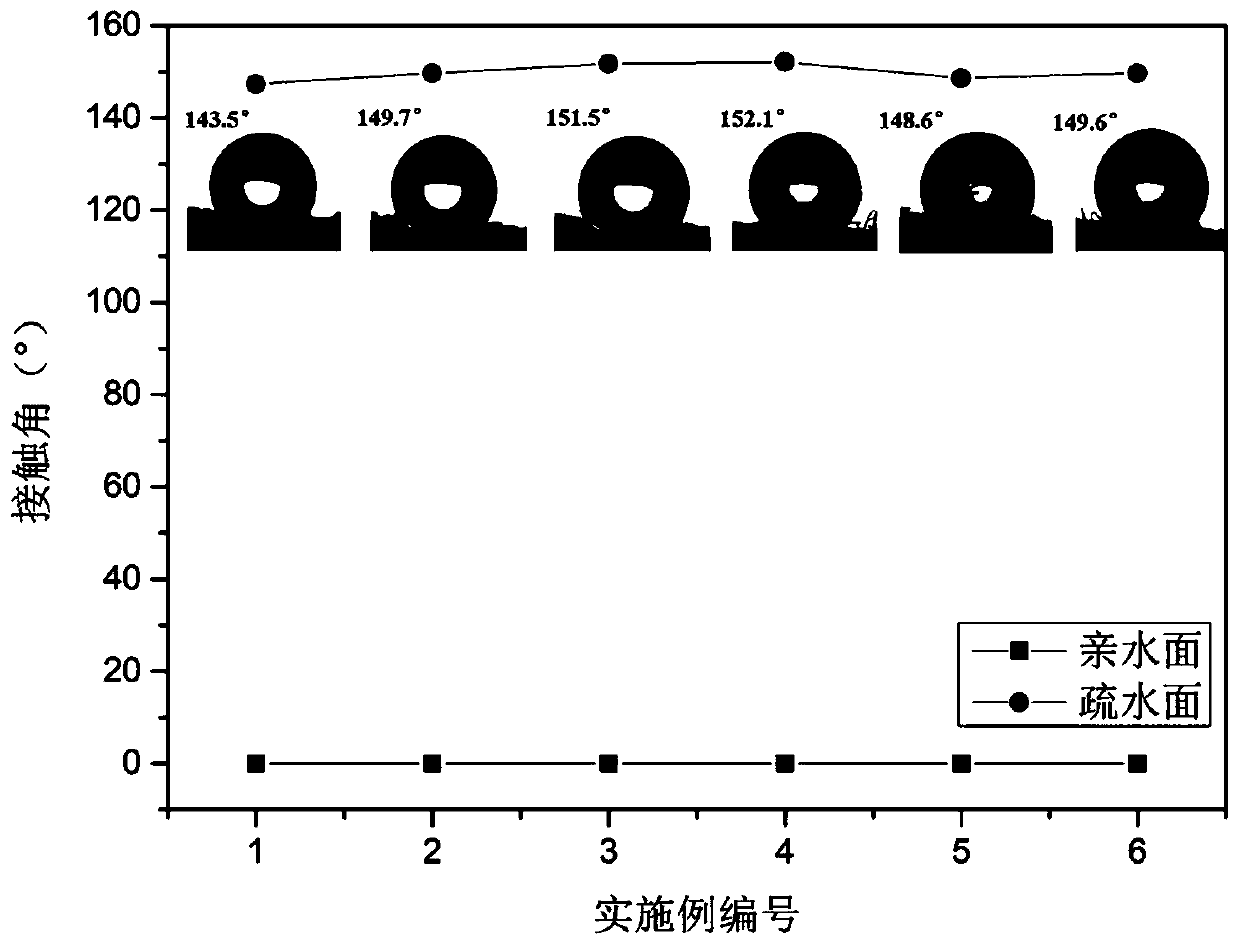

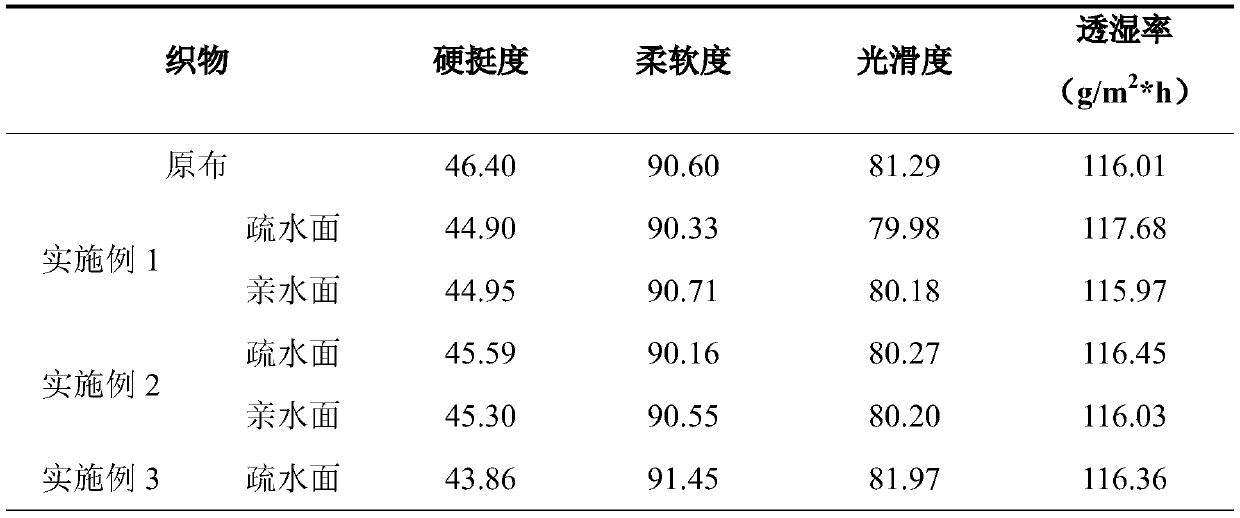

InactiveCN109706735AGood softnessGood performanceUltrasonic/sonic fibre treatmentVegetal fibresGlow dischargeWoven fabric

The invention relates to a making method of a fabric, in particular to a making method of a single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric and belongs to the field of textile function arrangement. The method comprises the following steps that 1, the fabric is cleaned and then dried for use; 2, the single face of the fabric is protected, under the condition of constantoxygen pressure intensity, plasma glow discharge treatment is conducted on the single face of the fabric, after oxygen is switched off, under the condition of constant steam pressure intensity of a grafting monomer, plasma glow discharge treatment is conducted again, and the single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric is obtained. According to plasma glow dischargetreatment, a cold plasma treatment instrument is used for generating plasma glow, the plasma treatment power is within 30-120 W, and the time is within 1-10 min. According to the method, the technology is simple and easy to control, the method is suitable for single-face treatment of various cotton fabrics and acetate fiber non-woven fabrics, the functionality demand is met, and the method also has good wearing performance.

Owner:ZHEJIANG SCI-TECH UNIV

Method for producing jute natural antibiotic bath mat

InactiveCN101260588AGood antibacterialGood antibacterial effectBleaching apparatusDyeing processMoisture absorptionEngineering

The invention relates to a manufacturing method for a jute natural antibacterial floor towel, blending jute and cotton, adequately utilizing the characteristics of the jute such as excellent moisture absorption and moisture wicking, high strength and tensile stretch and good antibacterial and bacteriostatic capability. Jute fibre is humidified before spinning, and the humidified percentage reaches 12-15 percent; the mixture ratio of jute and cotton is 20-50 percent / 50-80 percent during spinning, the relative humidity of spinning environment reaches 83-86 percent, and the relative humidity of textile environment reaches above 85 percent; in order to make up strength and fix short fiber, the sizing ratio is adjusted below 1 percent, and softening treatment and flexible treatment are performed. The manufacturing method for the jute natural antibacterial floor towel changes the jute performance that jute can not be woven, and has the advantages of anti-bacteria, anti-corrosion, anti-wrinkle, moisture absorption, ventilation, flatness and flexibility, good slip resistant and so on.

Owner:石磊

Preparation method of temperature regulating fiber

ActiveCN104831388APhase change performance is maintained for a long timeNot easy to loseArtificial filaments from viscoseHeat-exchange elementsFiltrationKetone

The invention discloses a preparation method of a temperature regulating fiber. The method comprises the following steps: 1, carrying out two-stage dipping, squeezing, crushing, ageing, yellowing reaction, filtration, deaeration and maturation on cellulose pulp to obtain a spinning solution; 2, packaging phase change paraffin in the honeycomb micropores of a packaging material honeycomb silica to prepare phase change particles, adding an osmotic agent, an emulsifier and a ketose cross-linking agent, and uniformly mixing to prepare a phase change emulsion; 3, fully mixing the phase change emulsion with the spinning solution to prepare a phase change spinning solution, wherein the addition amount of the phase change particles is 5-25wt% of alpha-cellulose in the spinning solution; and 4, carrying out spinning formation on the phase change spinning solution, and post-processing to obtain the temperature regulating fiber. The phase change fiber prepared in the invention has the advantages of stable phase change temperature, good phase change performance, long service life and high physical and mechanical performances.

Owner:湖州珠力纳米材料科技开发有限公司

Medical operation towel and preparing method thereof

InactiveCN103417304AGood skin toleranceHigh strengthDiagnosticsSynthetic resin layered productsMoisture absorptionEngineering

The invention discloses a medical operation towel and a preparing method thereof. The medical operation towel comprises two layers of spunlace non-woven fabrics which are laminated together. The spunlace non-woven fabrics are composite spunlace non-woven fabrics. Each spunlace non-woven fabric comprises a base material layer, wherein a plant fiber layer is arranged on the surface of the base material layer. The preparing method comprises the following steps of choosing synthetic fibers as the base material layer to manufacture the non-woven fabrics, adding plant fibers on the non-woven fabrics in a spunlace method to manufacture the composite spunlace non-woven fabrics, and choosing and laminating the two composite spunlace non-woven fabrics in a spunlace method or a high-frequency composite method to obtain the medical operation towel. The medical operation towel has the advantages of being good in skin tolerance, high in strength, good in moisture absorption and breathability and soft in touch. The medical operation towel has the advantages of non-woven fabrics and the advantages of cotton fiber products. Furthermore, the preparing method of the medical operation towel greatly reduces production cost.

Owner:JUNTECH HEALTHCARE MATERIALS

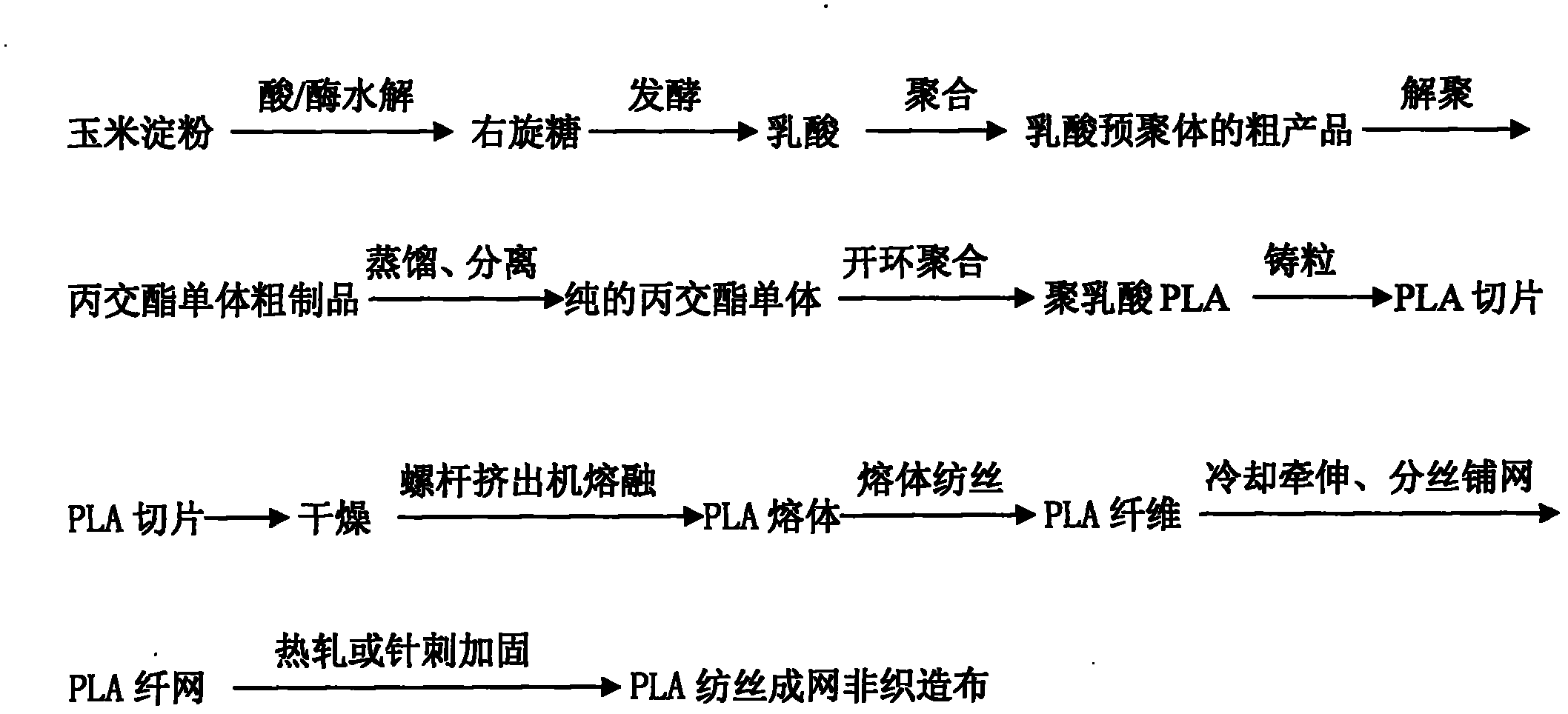

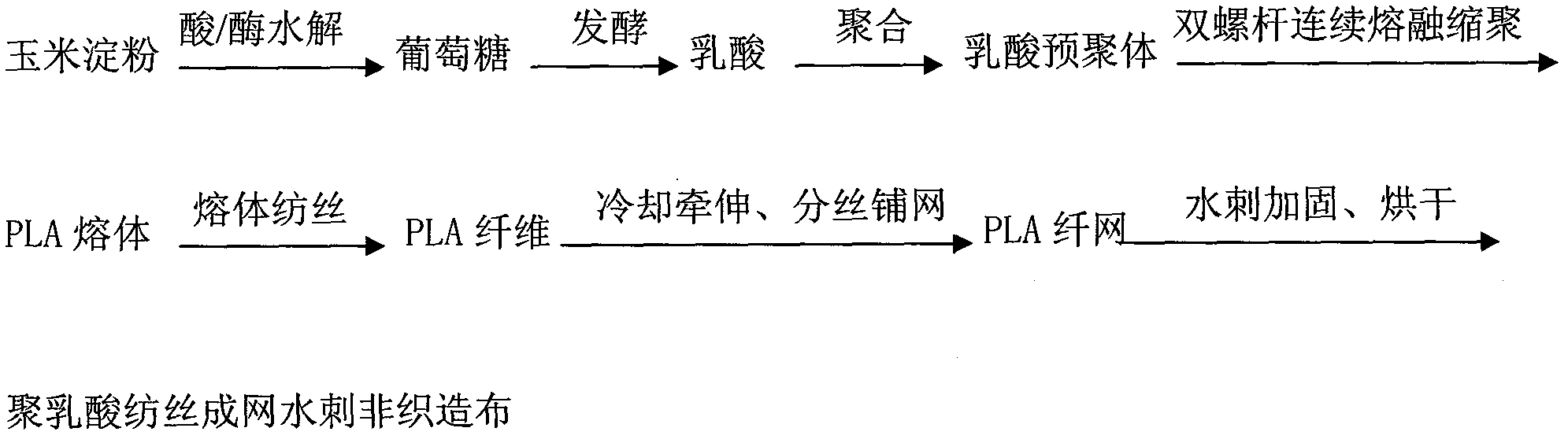

One-step polylactic acid spun-laid spunlace non-woven fabric and manufacturing method of non-woven fabric

InactiveCN102587042AHigh molecular weightReduce crystallinityFilament forming substance formingNon-woven fabricsVitrificationPolymer science

The invention relates to a one-step polylactic acid spun-laid spunlace non-woven fabric and a manufacturing method of the non-woven fabric. The non-woven fabric is prepared from polylactic acid filaments, and the fiber number is in a range of 1-4dtex; the component of the non-woven fabric is crystalline polylactic acid, which has a molecular weight of above 150,000, a melting point of 160-180 DEG C and a glass transition temperature of about 60 DEG C, and is prepared by polymerizing maize starch. The manufacturing method of the non-woven fabric comprises the following steps of: 1, preparing a polylactic acid spun melt, namely, fermenting the maize starch to prepare the polylactic acid, preparing a polylactic acid prepolymer by controlling polymerization conditions with polylactic acid, and preparing the polylactic acid spun melt with a molecular weight of above 150,000 through continuous melt polycondensation by utilizing a double screw; and 2, preparing a polylactic acid spun-bonded spunlace non-woven fabric, namely, spinning the spun melt by a spinning assembly, cooling and drafting by air current, separating and laying, fixing nets by utilizing the spunlace technology, and drying to obtain the polylactic acid spun-laid spunlace non-woven fabric. The polylactic acid spun-laid spunlace non-woven fabric is high in intensity and has the characteristics of good softness, skin affinity, moisture permeability and biodegradability.

Owner:TIANJIN POLYTECHNIC UNIV

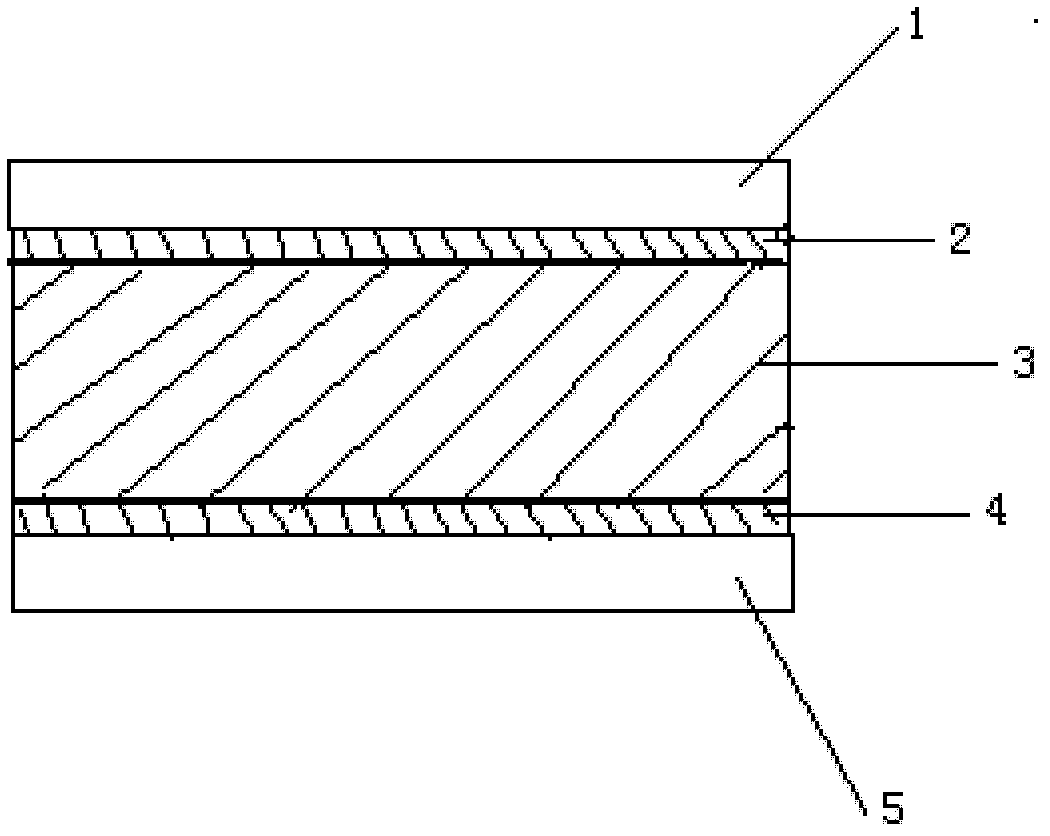

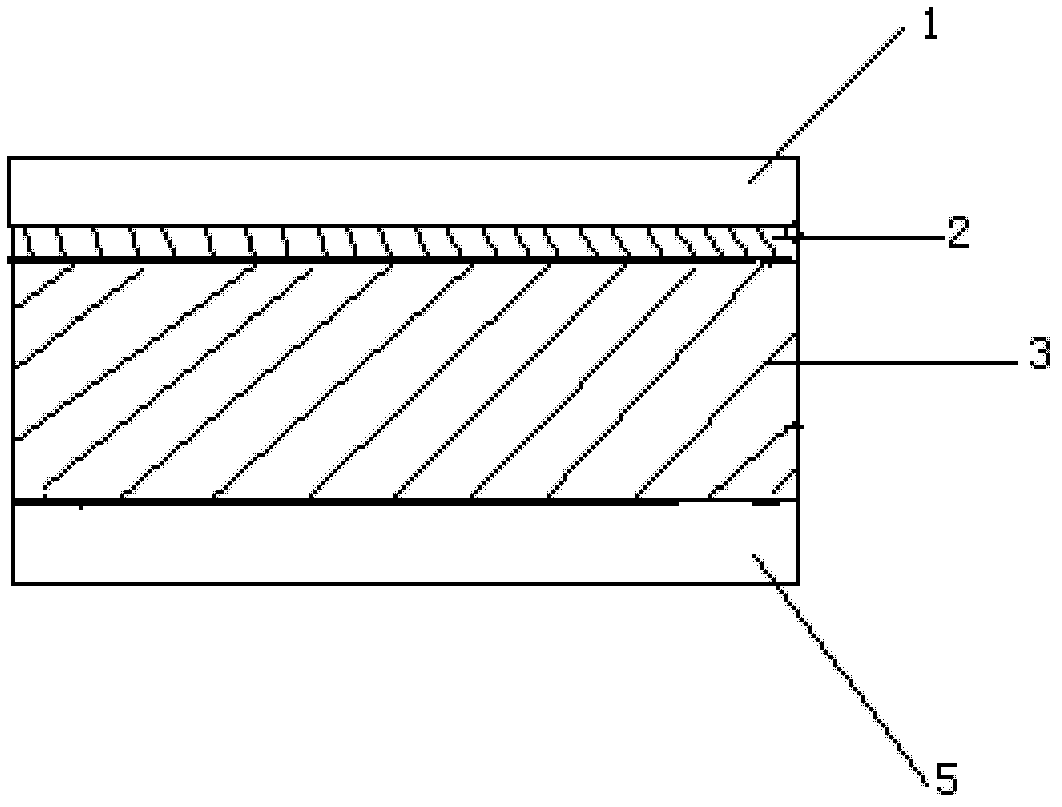

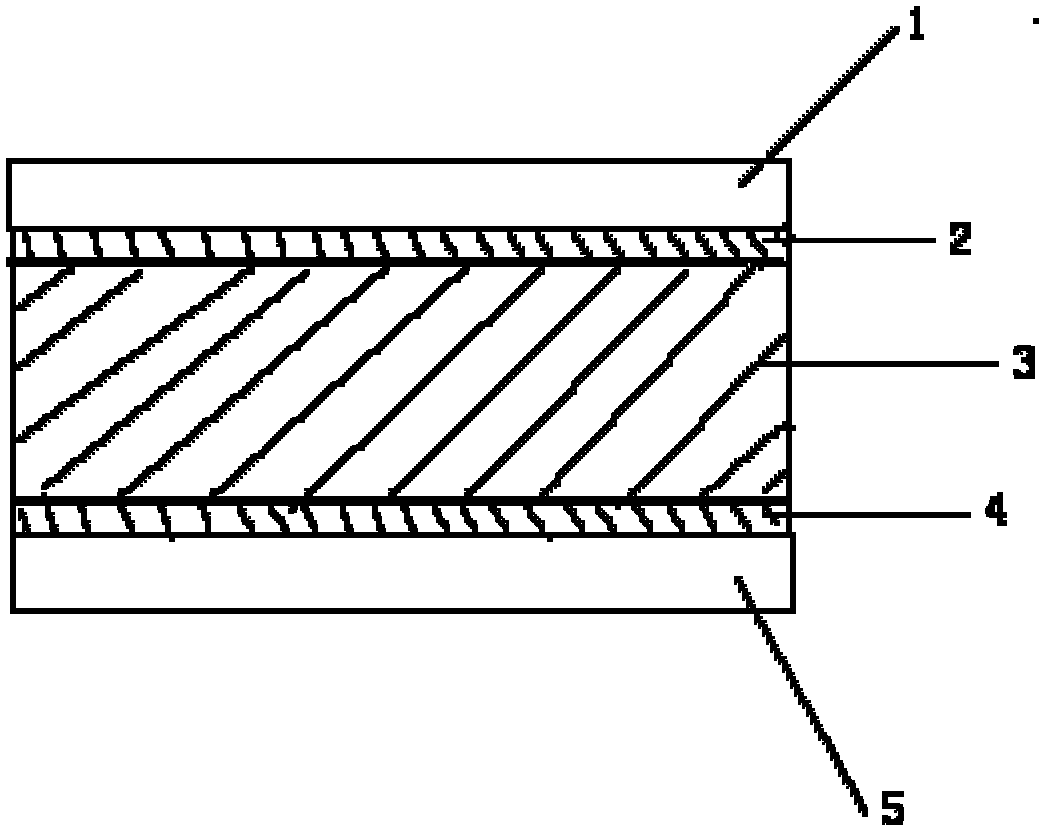

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

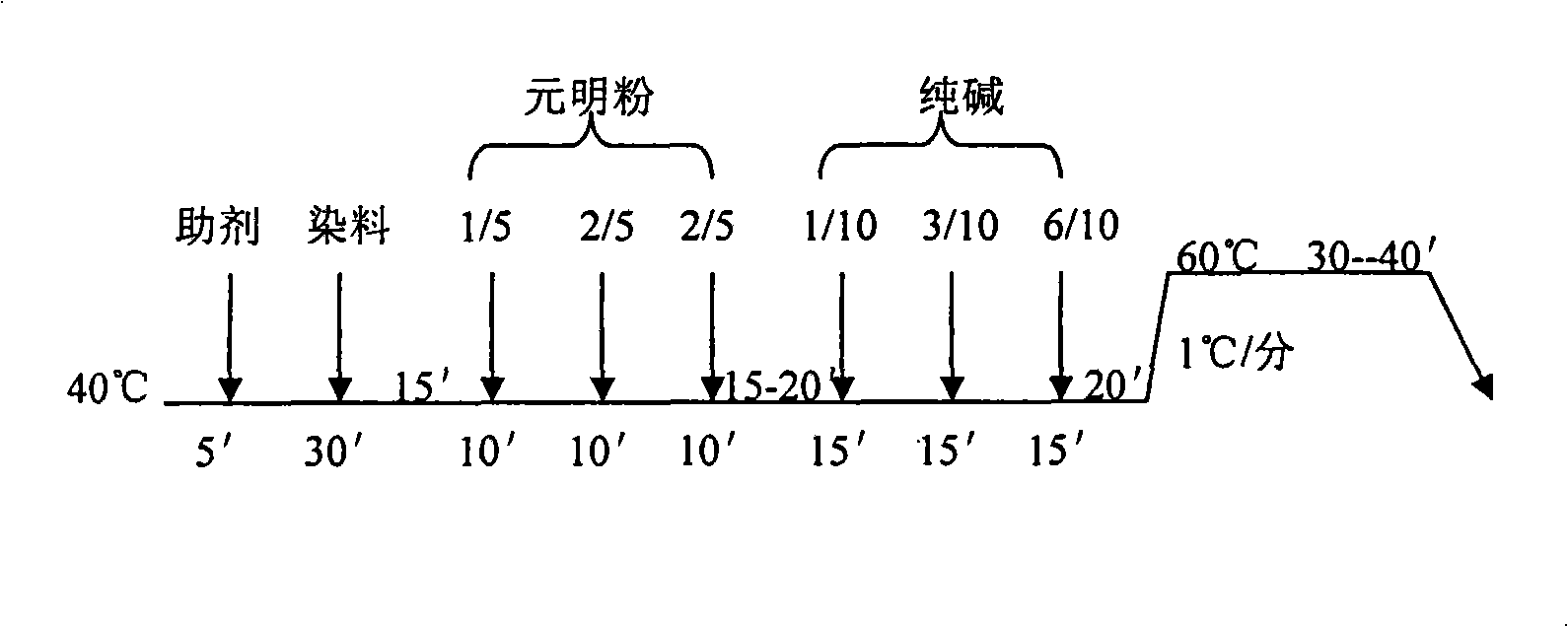

Bamboo fiber four-side elasticity fabric and production method thereof

InactiveCN101736490AGood moisture absorption and air permeabilityNot easy to cause curlingSingeingWoven fabricsProduct inspectionPolyester

The invention provides a bamboo fiber four-side elasticity fabric and a production method thereof. The production method comprises the processes of warp spooling, dyeing, warping, drawing, weaving, gray fabric inspection, finishing, finished product inspection and forming. The production method is characterized in that the dyeing temperature is between 40 and 50 DEG C; and the finishing process also comprises processes of singeing, mercerizing, sizing and weft finishing pre-shrinkage. The bamboo fiber four-side elasticity fabric produced by the method is characterized in that both warps and wefts consist of 48 percent of bamboo fibers, 47 percent of cotton fibers and 5 percent of elastic polyester fibers in turn respectively, wherein the warps are 40 / 2+40D, the wefts are 40 / 2+40D, the density is 102*88, and the fabric is woven by adopting twills; therefore, the fabric integrating terylene is comfortable and has high strength, the moisture permeability of the bamboo fibers and the cotton fibers is good, and the production process is not easy to cause fabric hemming, cockling and fuzzing.

Owner:吴建芳

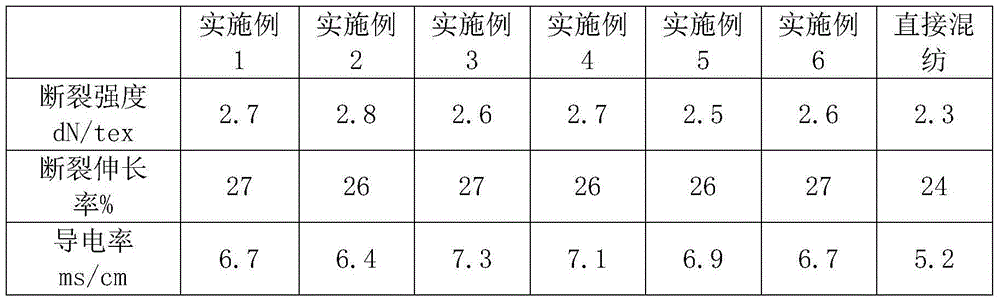

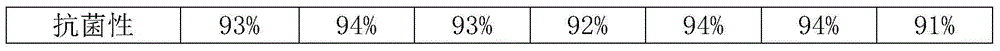

Graphene antibacterial fabric and preparation method thereof

InactiveCN110106603AHighly dispersed bindingImprove antibacterial propertiesElectroconductive/antistatic filament manufactureCarbon fibresYarnPre treatment

The invention discloses a graphene antibacterial fabric. The fabric comprises, by weight, 80-140 parts of graphene composite fibers, 10-15 parts of bamboo charcoal fibers, 6-12 parts of PTT, 30-50 parts of cotton and 8-12 parts of an antibacterial agent, wherein the graphene composite fibers comprise 0.6-1.5 parts of graphene and 79.4-138.5 parts of a fiber matrix. A preparation method of the graphene composite fibers includes the following steps of S1, pretreatment; S2, dry mixing, S3, blending and granulating; S4, melt spinning; S5, drawing and shaping, and then the graphene composite fibersare obtained. A preparation method of the graphene antibacterial fabric comprises the following steps of S1, yarn blending, S2, mercerizing; S3, warping and weaving; S4, fabric weaving; S5, antibacterial finishing; S6, post-treatment including dyeing and finishing, washing, shaping and pre-shrinking. The graphene antibacterial fabric has the advantages of being comfortable, soft, breathable, cool, durable in antibacterial performance and high in efficiency.

Owner:南通尚坊布业有限公司

A natural botanical toilet powder

ActiveCN1965790AFine powderGood moisture absorption and air permeabilityCosmetic preparationsToilet preparationsChemical synthesisAdditive ingredient

The invention relates to a talcum powder comprising extracts of natural plant, wherein the raw materials include plant starch, vegetable fat and other natural plant compositions in replacement of minerals such as talcum powder, porcelain clay, calcium carbonate and magnesium carbonate, as a result, stimulation to human body will be avoided.

Owner:KARLIE COSMETICS MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com