Method for producing jute natural antibiotic bath mat

A natural antibacterial, production method technology, applied in carpets, dyeing methods, fabrics, etc., can solve problems such as difficulty in adapting to spinning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

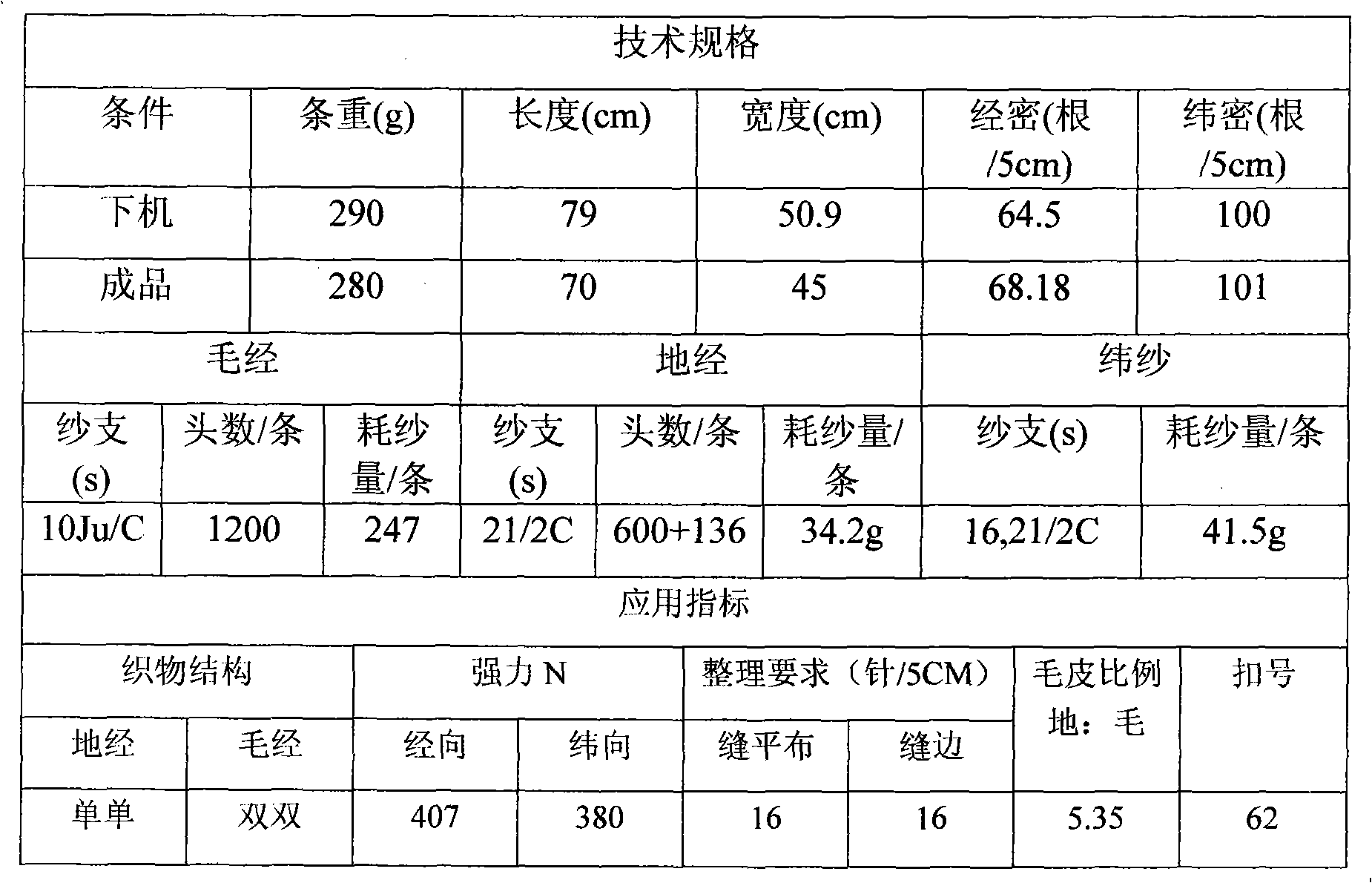

[0016] Embodiment 1: the production method of jute natural antibacterial ground towel, comprise spinning-bleach dyeing-sizing-warping-weaving-aftertreatment-loose type drying-punching-shearing-sewing-finished product inspection-packaging, raw material is jute and Cotton, the ratio of the two when spinning 10s yarn is 45% / 55%, humidify the jute fiber before spinning, the humidification rate reaches 13%, add 4% soft sesame oil and 1% softener, and place it in an airtight place for 36 hours. In order to achieve uniform wetting, in order to prevent insufficient cohesion and low strength, the twist coefficient of the yarn during yarn formation should be greater than that of the equivalent cotton yarn. As shown in the table below, the twist coefficient of 10s yarn is 609. Jute yarn index table:

[0017] yarn count

Ju / C

twist

twist factor

powerful

MAXc

MIN

heavy bias

resurgence

10s

45 / 55

79.6 / 10cm

609

3...

Embodiment 2

[0020] Embodiment 2: the production method of jute natural antibacterial ground towel, comprise spinning-bleach dyeing-sizing-warping-weaving-aftertreatment-loose type drying-punching-shearing-sewing-finished product inspection-packaging, raw material is jute and Cotton, when spinning 16s yarn, the ratio of the two is 35% / 65%, the jute fiber is humidified before spinning, the humidification rate reaches 15%, and 3% soft sesame oil and 0.8% softener are added, and it is sealed for 48 hours. In order to prevent insufficient cohesion and low strength, the twist coefficient of the yarn should be greater than that of the same cotton yarn during yarn formation. As shown in the table, the twist coefficient of 16s yarn is 644.

[0021] Jute yarn index table:

[0022] yarn count

Ju / C

twist

twist factor

powerful

MAXc

MIN

heavy bias

resurgence

16s

35 / 65

106.3 / 10cm

644

254cn

334

136

+2.2%

...

Embodiment 3

[0027] Embodiment 3: the production method of jute natural antibacterial ground towel, comprise spinning-bleach dyeing-sizing-warping-weaving-aftertreatment-loose type drying-punching-shearing-sewing-finished product inspection-packaging, raw material is jute and For cotton, the ratio of the two when spinning 21s yarn is 20% / 80%. Humidify the jute fiber before spinning, the humidification rate reaches 15%, and add 3% soft sesame oil and 0.8% softener, and place it in an airtight place for 48 hours. In order to prevent insufficient cohesion and low strength, the twist coefficient of the yarn during yarn formation It is larger than the same cotton yarn, and the relative humidity of the spinning environment reaches 84%;

[0028] Carry out softening and softening treatment while sizing, the sizing rate is 0.9%, add tallow, lubricating agent, liquid wax, and softening agent to process simultaneously.

[0029] When weaving, use a humidifier to directly humidify the warp beam space,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com