Preparation method of silk fibroin oligopeptide for skin-care products

A technology of oligopeptides and skin care products, applied in the field of biopolymer materials, can solve the problems of silk fibroin such as large molecular weight, low controllability, and complicated process, and achieve high biological activity, easy absorption, and high output rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

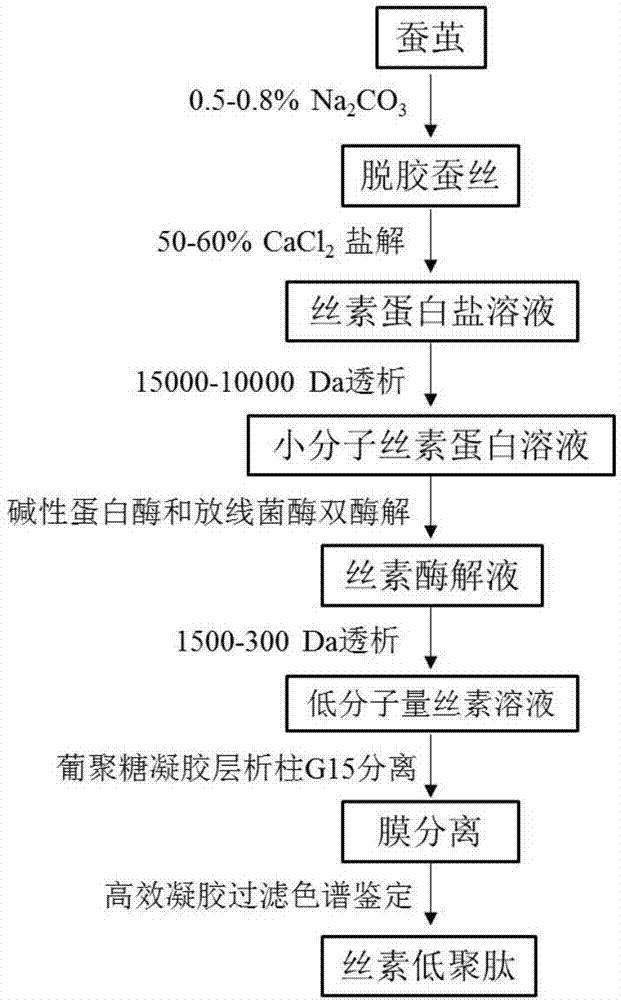

[0023] A method for preparing silk fibroin oligopeptides for skin care products, the preparation steps are as follows:

[0024] (1) Degumming: Cut silkworm cocoons into 1-2cm 2 , with 0.5-0.8% Na 2 CO 3 Degumming by soaking in the solution for 30 minutes, with a solid-to-liquid mass ratio of 1:200, then washing with water, repeating dipping and washing for 2-3 times, drying naturally or drying at 60°C to obtain degummed silk;

[0025] (2) Salt solution: put the degummed silk obtained in step (1) into 50-60% CaCl 2 The solution was heated to boiling and dissolved for 20 minutes, the solid-to-liquid mass ratio was 1:20, and after cooling, it was centrifuged at a speed of 3500 r / min for 20 minutes to obtain a salt solution;

[0026] (3) Dialysis: the salt solution obtained in step (2) was dialyzed for 2-3 days with a dialysis bag with a molecular weight cut-off of 15000-10000Da to obtain a low-molecular-weight silk fibroin solution;

[0027] (4) Double enzymolysis: mix the co...

Embodiment 2

[0032] A method for preparing silk fibroin oligopeptides for skin care products, the preparation steps are as follows:

[0033] (1) Degumming: Cut silkworm cocoons into 1-2cm 2 , with 0.5-0.8% Na 2 CO 3 Degumming by solution immersion for 35 minutes, with a solid-to-liquid mass ratio of 1:200, then washing with water, repeating the immersion and cleaning 2-3 times, and drying naturally or at 65°C to obtain degummed silk;

[0034] (2) Salt solution: put the degummed silk obtained in step (1) into 50-60% CaCl 2 The solution was heated to boiling and dissolved for 25 minutes, the solid-to-liquid mass ratio was 1:20, and after cooling, it was centrifuged at 3800 r / min for 25 minutes to obtain a salt solution;

[0035] (3) Dialysis: the salt solution obtained in step (2) was dialyzed for 2-3 days with a dialysis bag with a molecular weight cut-off of 15000-10000Da to obtain a low-molecular-weight silk fibroin solution;

[0036] (4) Double enzymolysis: mix the composite enzyme w...

Embodiment 3

[0041] A method for preparing silk fibroin oligopeptides for skin care products, the preparation steps are as follows:

[0042] (1) Degumming: cut the cocoon into 1-2cm 2 , with 0.5-0.8% Na 2 CO 3 Degumming by solution immersion for 40 minutes, with a solid-to-liquid mass ratio of 1:200, then washing with water, repeating the immersion and cleaning 2-3 times, and drying naturally or at 70°C to obtain degummed silk;

[0043] (2) Salt solution: put the degummed silk obtained in step (1) into 50-60% CaCl 2 The solution was heated to boiling and dissolved for 30 minutes, the solid-to-liquid mass ratio was 1:20, and after cooling, it was centrifuged at 4000 r / min for 30 minutes to obtain a salt solution;

[0044] (3) Dialysis: the salt solution obtained in step (2) was dialyzed for 2-3 days with a dialysis bag with a molecular weight cut-off of 15000-10000Da to obtain a low-molecular-weight silk fibroin solution;

[0045] (4) Double enzymolysis: mix the compound enzyme with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com