Patents

Literature

126results about How to "Good dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

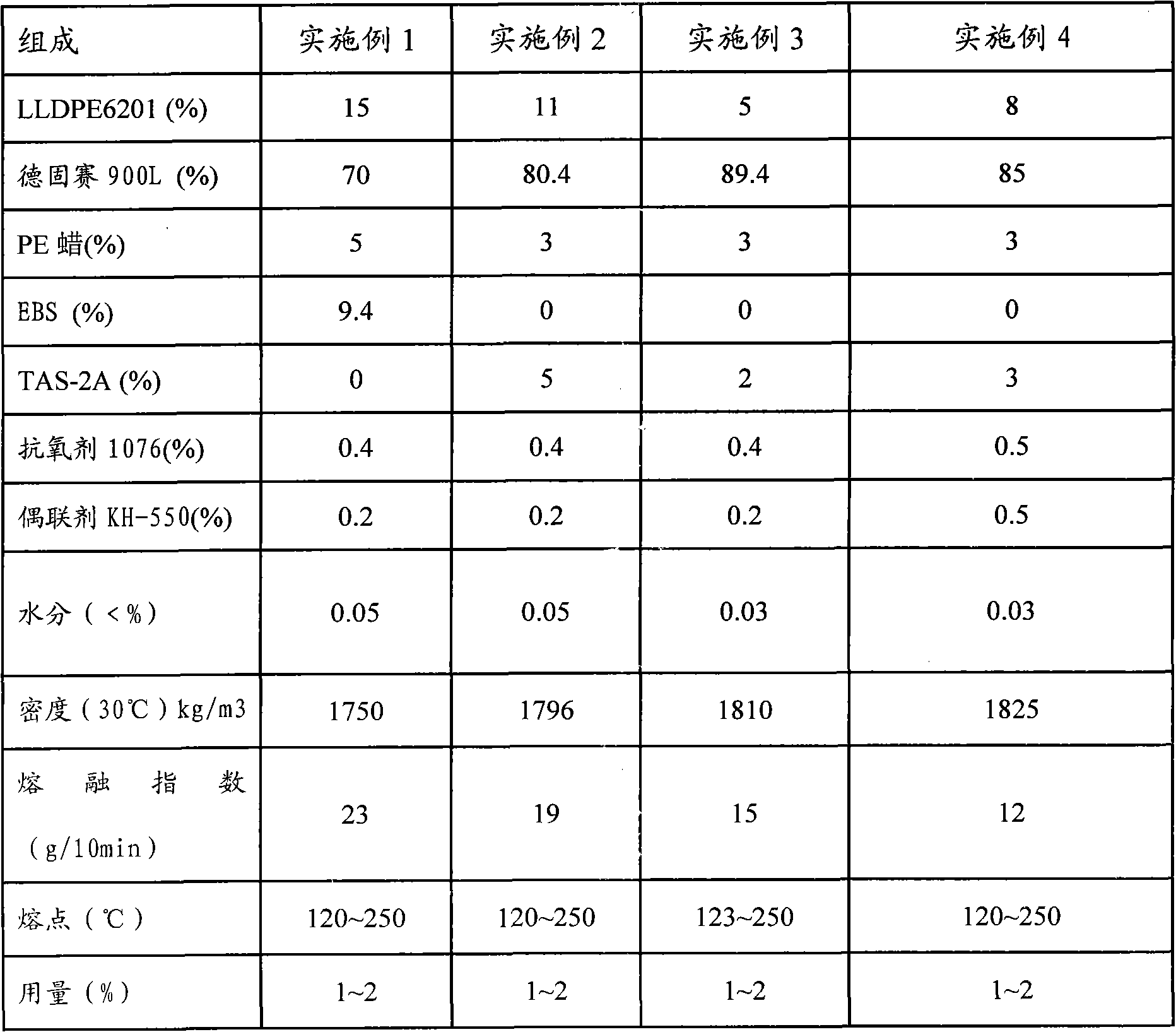

Black master batch and preparation method thereof

The invention discloses a black master batch and a preparation method thereof. The black master batch comprises the following components in percentage by weight: 5-15% of carrier resin, 70-90% of carbon black, 5-15% of dispersion lubricating agent and 0.6-1% of other auxiliaries. The black master batch prepared by the formula disclosed by the invention has the characteristics of high carbon black concentration, good dyeing effect, good dispersion high blackness brightness and no influence to mechanical properties of products compared with the existing black master batch, thus being widely applied to polyolefine resin and ABS (acrylonitrile butadiene styrene) resin.

Owner:SHENZHEN KEJU NEW MATERIAL

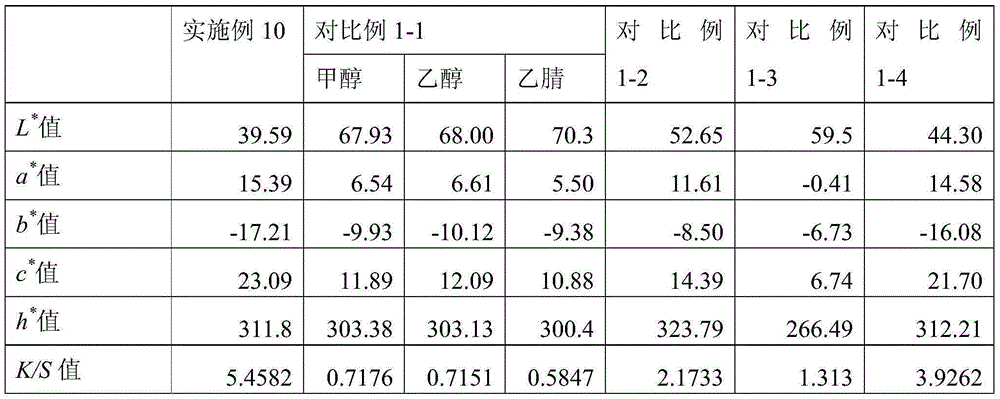

Extraction of natural gromwell dye and application thereof

The invention relates to extraction of natural gromwell dye and application thereof. The extraction comprises the following steps of: crushing gromwell, ultrasonically extracting the crushed gromwell at a certain temperature by using ethanol solution as a solvent to obtain pasty natural gromwell dye, and adding an emulsifying agent into the pasty natural gromwell dye to perform emulsification so as to obtain aqueous solution of the natural gromwell dye. The natural gromwell dye used for dyeing protein, cotton, polyester fibers, yarns or fabrics has good dyeing effect. The natural dye is extracted from the gromwell, and the solvent is reclaimed for reuse, so the environment is not polluted; and the dye extraction process is simple, and the natural gromwell dye has stable quality and broad market prospect.

Owner:CHANGZHOU UNIV +1

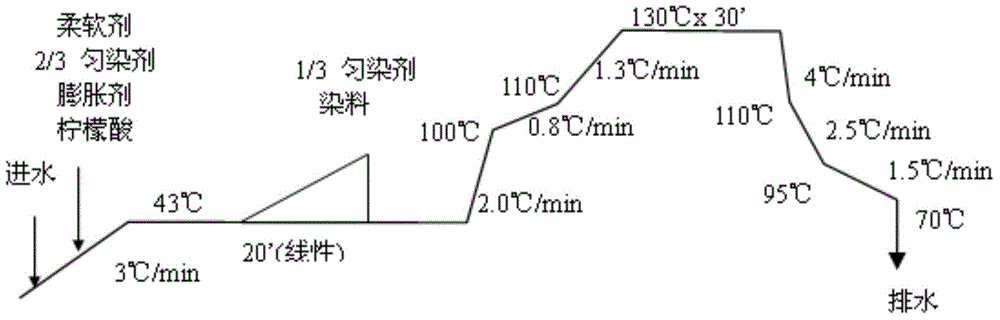

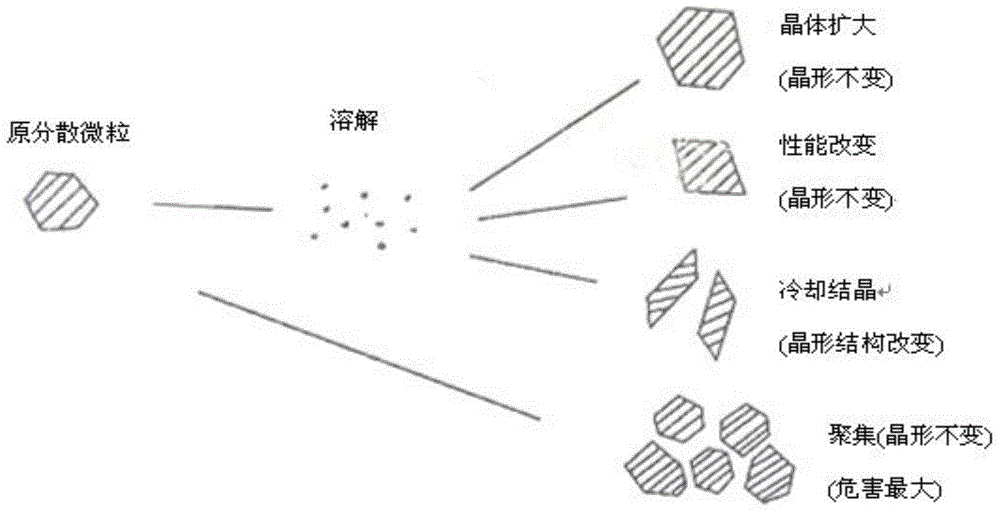

Method for dyeing superfine terylene fabric

ActiveCN104878618AGuaranteed color fastnessImprove dye uptakeDyeing processDisperse dyeColour fastness

The invention discloses a method for dyeing a superfine terylene fabric. The method comprises the following dyeing steps: adding a softening agent, part of a leveling agent, and an expansive agent into the soppy superfine terylene fabric to prepare a working solution; adding a pH regulator to regulate the pH value of the working solution to 3.5-4.0; heating the working solution with the adjusted pH value to 43 DEG C, and adding disperse dye and the residual leveling agent to prepare a dye liquor; carrying out heating and dyeing. The method aims at dyeing of a brightly colored superfine terylene fabric, and has the advantages the softening agent, the leveling agent and the expansive agent are added simultaneously, and the pH value of the dye liquor is regulated to 3.5-4.0, so that poor leveling property, uneven dyeing and other quality problems existing in a low-bath-ratio dyeing process can be solved; moreover, the dye-uptake rate of the disperse dye can be improved, secondary aggregation of the disperse dye in a high-temperature descending process is prevented, all color fastness indices of the superfine terylene fabric exceed 4-level, the dyeing property is improved, and the dyeing effect is ideal; the method further has the advantages of being environment-friendly and low in energy consumption.

Owner:PACIFIC (PANYU) TEXTILES LTD

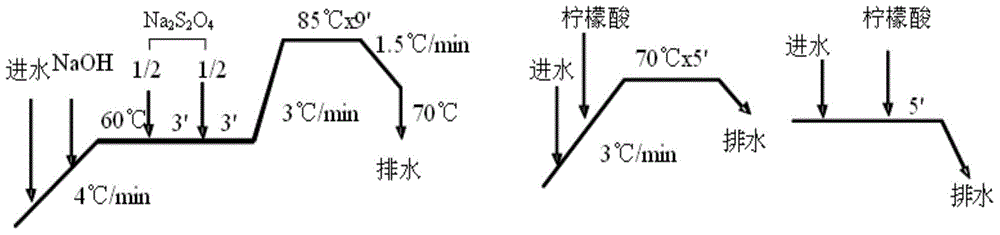

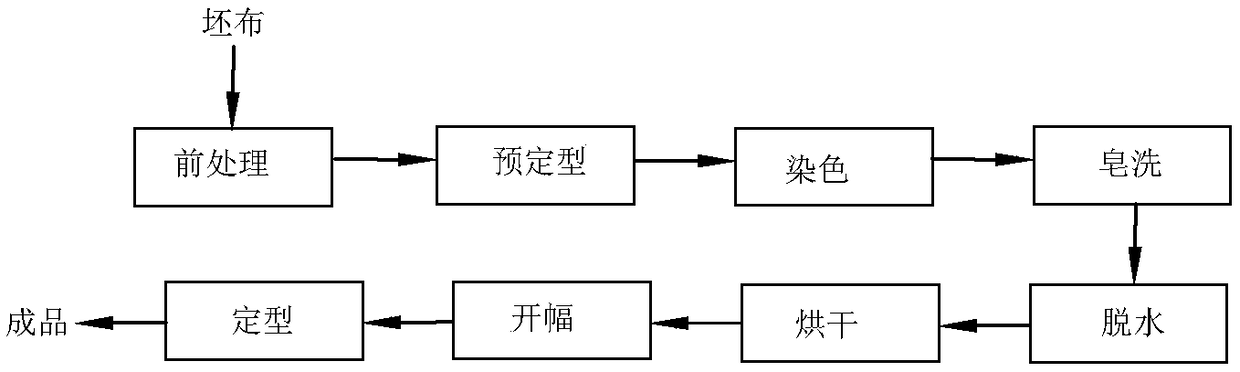

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

Silicon based non-aqueous medium dyeing method suitable for cheese

ActiveCN107794788AGood dyeing effectMedia is easy to recycleDyeing processPulp and paper industryDyeing wastewater

The invention discloses a silicon based non-aqueous medium dyeing method suitable for cheese, and belongs to the technical field of textile dyeing and finishing. The dyeing method comprises the following steps: (1) preparing a dye solution; (2) dyeing cheese: soaking cheese in a silicon based non-aqueous medium, and adding the dye solution to carry out dyeing in a cheese dyeing facility; and (3) after dyeing, carrying out dehydration, soap washing, water washing, and drying to obtain a finished product. The method has the advantages that only a little amount of water and alkali is needed, other dyeing aids are not needed; the water for dyeing and dyeing wastewater are largely reduced, and dye uptake and fixation rate of cheese dyeing are improved effectively. After dyeing, the silicon based non-aqueous medium can be separated from water and is capable of being used repeatedly. The ecological dyeing of cheese is realized. The shortages of conventional water bath cheese dyeing such as much wastewater, difficulty in wastewater treatment, low dye uptake and fixation rate, and the like, are overcome.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Nylon fabric dyeing process

InactiveCN103243585AIncrease productivityGood dyeing effectFibre typesDyeing processColor differenceDyeing

The invention discloses a nylon fabric dyeing process which comprises the following steps: (1) performing cold pad-batch treatment on a fabric; (2) performing desizing treatment; (3) performing cold impregnation; (4) feeding the fabric subjected to cold impregnation into a dyeing machine, and dyeing; (5) fixing the dyed fabric, wherein the initial temperature is 30-40 DEG C, the fixing temperature is 80 DEG C, the fixing time is 20-25 minutes, a fixing agent is A-12 and NS-1, and the concentration of the fixing agent is 2-4g / L; and (6) finally setting, wherein the setting temperature is 145-155 DEG C, and the setting time is 0.5-1 minute. According to the invention, a fabric can be directly put in a dye vat and dyed, the fabric can not be creased or scratched in the dyeing process so as to avoid crease marks, the traditional wrapping method does not need to be used, and the production efficiency is greatly improved; and the fabric has better dyeing effect, and the dye has better permeability in the fabric. Thus, the finished product has less color difference, thereby omitting the reworking and shading step, saving manpower and material resources and improving the quality of the finished product.

Owner:WUJIANG CHUANGXIN DYEING & PRINTING FACTORY

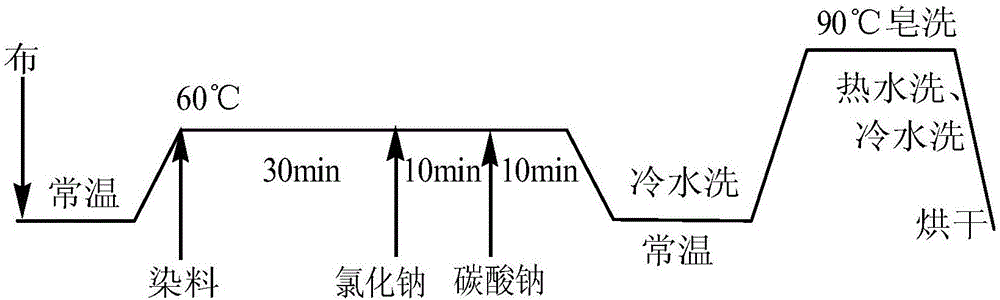

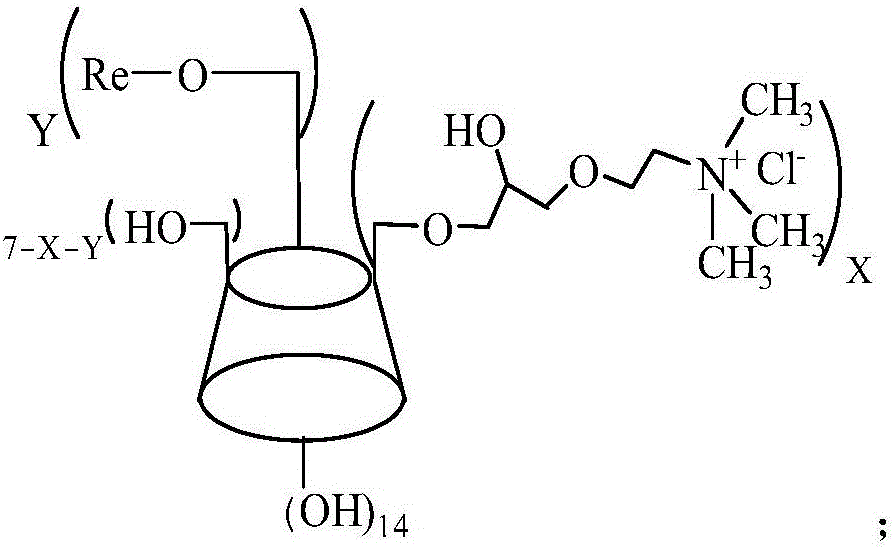

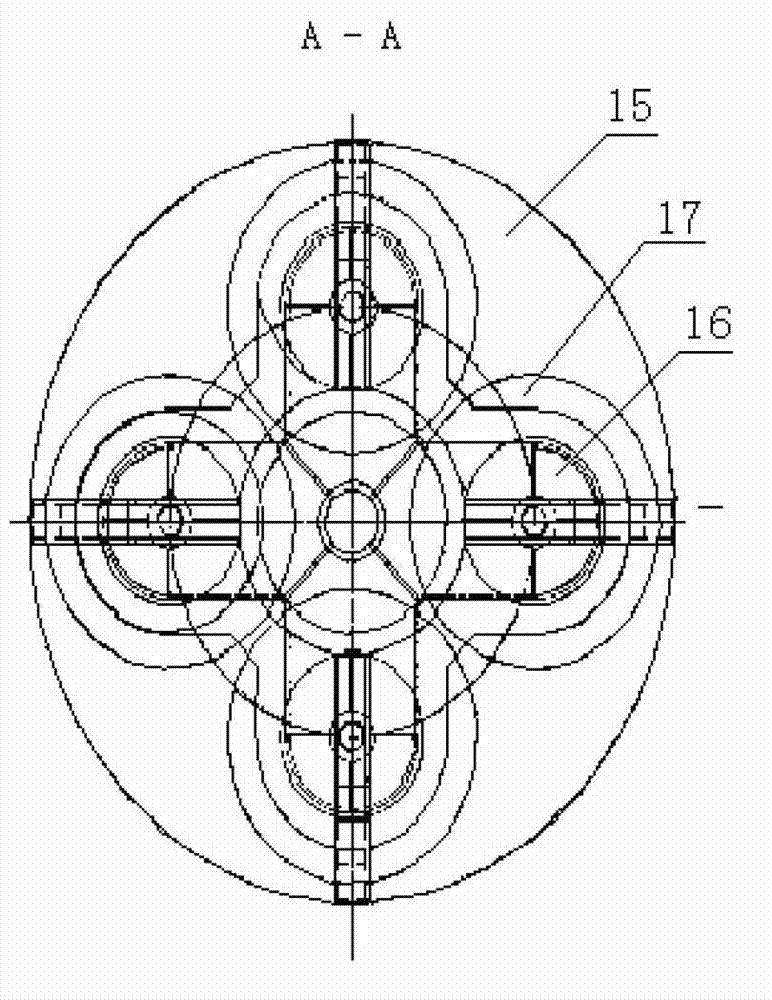

Reactive beta-cyclodextrin quaternary ammonium salt as well as preparation method and application thereof

The invention relates to reactive beta-cyclodextrin quaternary ammonium salt as well as a preparation method and application thereof. The reactive beta-cyclodextrin quaternary ammonium salt is synthesized through two steps, namely, step 1, taking beta-cyclodextrin, choline chloride and epoxy chloropropane as raw materials to be subjected a ring opening substitution reaction to generate beta-cyclodextrin quaternary ammonium salt; step 2, taking the beta-cyclodextrin quaternary ammonium salt and a compound as raw materials to be subjected to a substitution reaction to generate the reactive beta-cyclodextrin quaternary ammonium salt. The reactive beta-cyclodextrin quaternary ammonium salt has no toxic or side effect; when being used for salt-free dyeing of an active dyestuff of cotton fabric, the reactive beta-cyclodextrin quaternary ammonium salt has relatively good dyeing effect; the pollution to the environment by salt in wastewater is reduced and treatment pressure of dyeing and finishing wastewater is alleviated; the dyed fabric has relatively good dyeing effect; the dyeing rate of the active dyestuff is 65 percent to 85 percent and the color fixation rate is 55 percent to 70 percent; the dry rubbing fastness is more than grade 4 and the wet rubbing fastness is more than grade 3.

Owner:那坡同益新丝绸科技实业有限公司

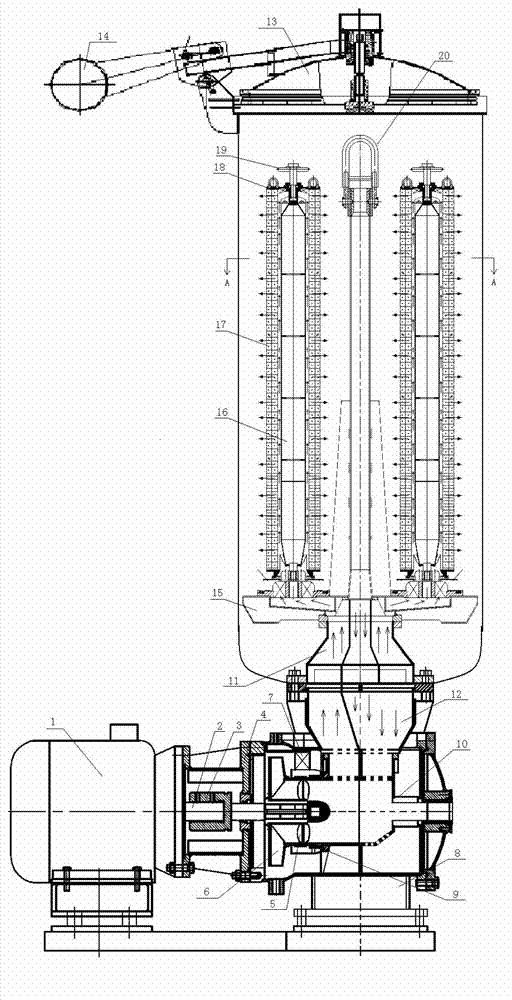

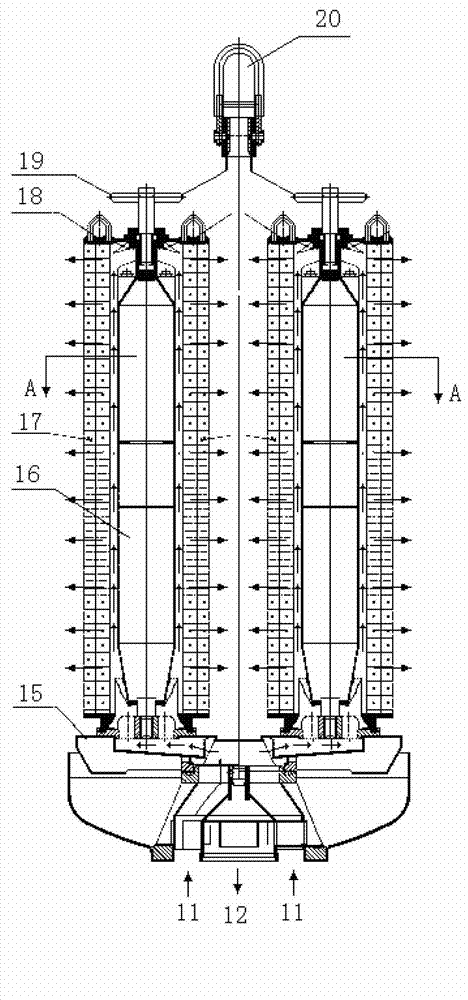

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

One-bath processing method for pure-cotton knitted fabric scouring and bleaching and pigment dyeing

InactiveCN102605653AStable decompositionEfficient decompositionBiochemical fibre treatmentBleaching apparatusWater savingTextile dyeing

The invention relates to a one-bath processing method for pure-cotton knitted fabric scouring and bleaching and pigment dyeing, belonging to the technical field of textile dyeing and finishing. The process adopted in the invention comprises the following steps: (1) carrying out scouring and bleaching treatment on pure-cotton knitted fabric, wherein waste liquid discharge is not needed after the treatment is completed; (2) after the scouring and bleaching treatment is completed, adjusting the treating fluid to a certain condition, and then adding catalase, so that residual hydrogen peroxide is sufficiently decomposed; and (3) preparing a pigment dyeing solution by utilizing the residual fluid and dyeing the pure-cotton knitted fabric, adding a binding agent to the residual fluid after the dyeing is completed for fixation, and finally taking out the knitted fabric and carrying out dehydration, drying and curing treatment. According to the invention, two processes, namely pure-cotton knitted fabric scouring and bleaching and pigment dyeing, are combined and carried out in a same treatment bath, thereby not only ensuring the dyeing effect, but also repeatedly utilizing the scouring and bleaching residual fluid, and being remarkable in water-saving and energy-saving effects.

Owner:QINGDAO UNIV

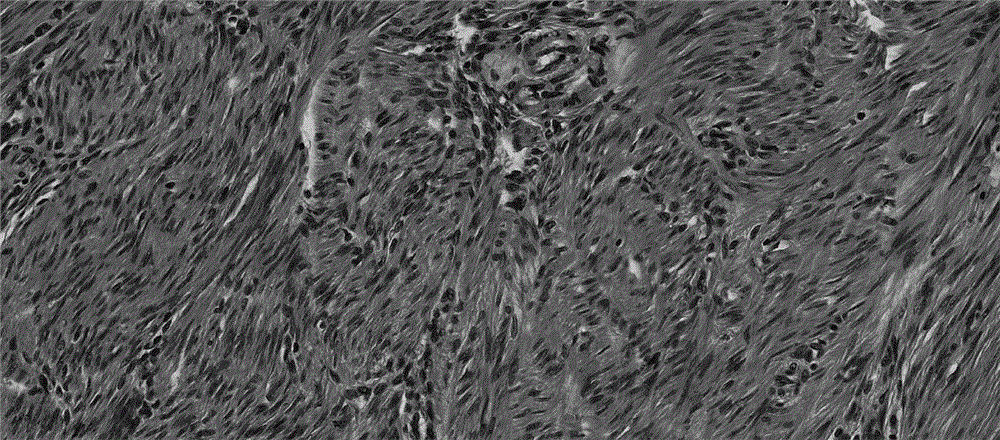

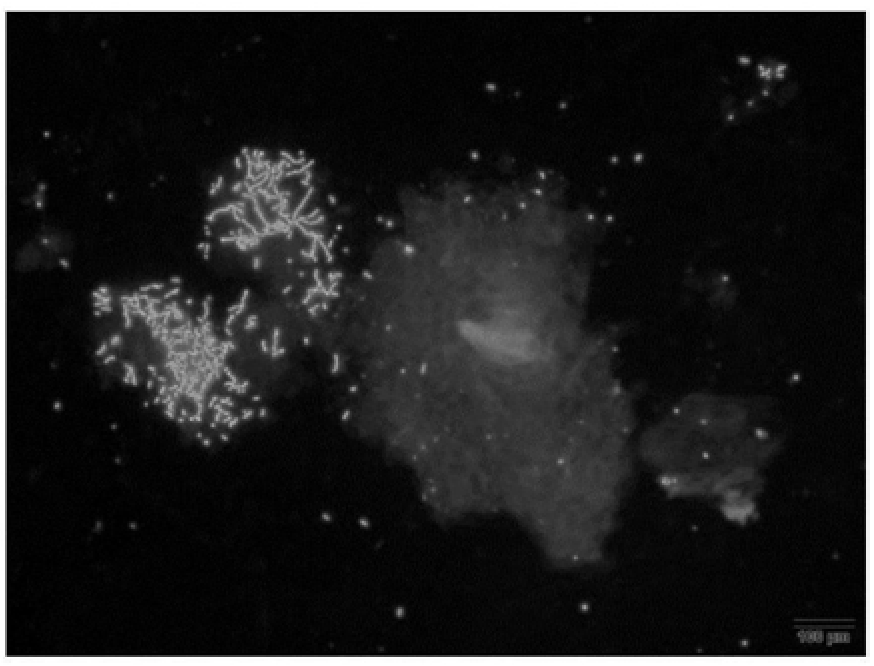

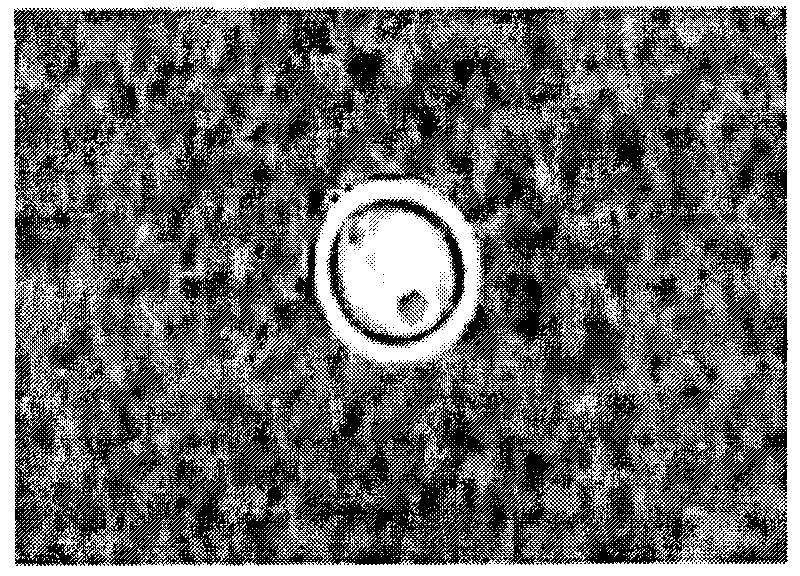

Fungus detection fluorescent dyeing liquid and use thereof

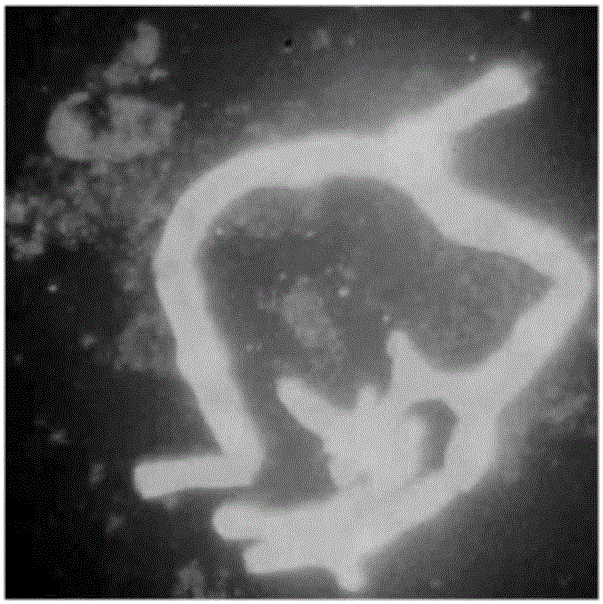

InactiveCN106198470AClear structureEasy to findPreparing sample for investigationFluorescence/phosphorescenceParaffin waxFluorescence

The invention discloses a fungus detection fluorescent dyeing liquid and a use thereof. The fungus detection fluorescent dyeing liquid comprises an independent dyeing liquid A and an independent re-dyeing liquid B. The dyeing liquid A comprises, by weight, 0.02-0.043% of a fluorescent brightener, 1-10% of potassium hydroxide, 10-20% of dimethyl sulfoxide, 0-5% of glycerin and 65-87% of water. The re-dyeing liquid B comprises, by weight, 0.1-0.5% of Evans blue and 99.50-99.90% of water. The invention discloses a use of the fungus detection fluorescent dyeing liquid. The invention provides a novel fast fungus infection detection product. The product can be used for detecting various fungi which may exist in a fresh or frozen clinical sample and paraffin and ethylene glycol methacrylate-coated tissue.

Owner:JIANGSU LIFETIME BIOLOGICAL TECH

Manufacturing technique of flour-linen jacquard interval fabric mesh cloth

ActiveCN106560538AHigh pattern precisionImprove stabilityFabric breaking/softeningWarp knittingFiberYarn

The invention discloses a manufacturing technique of flour-linen jacquard interval fabric mesh cloth. The manufacturing technique comprises the first step of production and manufacturing of chemical fiber yarn, the second step of flower-type process design of the flour-linen jacquard interval fabric mesh cloth, the third step of weaving and manufacturing, and the fourth step of dyeing and finishing and sizing, wherein in the second step, the upper layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB1 to guide bar GB3; the middle layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB4; the lower layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB5 and guide bar GB6. According to the flour-linen jacquard interval fabric mesh cloth prepared through the manufacturing technique, distortion or deformation of the flower-type are not easily caused, the precision of the flower-type is high, the stability is good, after dyeing treatment of half matt gloss polyester yarn and terylene CD yarn on the upper layer of the mesh cloth, the surface of the finished product mesh cloth presents an effect of two-tone flour-linen, dyefastness is good, and a very good overall dyeing effect is achieved.

Owner:SINCETECH FUJIAN TECH CO LTD

Tent fabrics and preparation method thereof

InactiveCN104859231AKeep warmGood dyeing effectSynthetic resin layered productsVegetal fibresHemp fiberPolyester

The invention discloses tent fabrics and a preparation method of the tent fabrics. The tent fabrics comprise base cloth and waterproof coating. The base cloth comprises, by weight 50-65% of polyester fiber, 15-25% of hemp fiber is, 10-20% of bamboo fiber and 5-10% of wool fiber. The tent fabrics adopt special waterproofing treatment and dyeing processing, not only ensure the waterproof washing color fastness, the color fastness to light and the waterproof effect, but also ensure the wearability to the largest extent through the fiber blending weaving, and enable the blending fibers to have good-strength, anti-bacteria, heat-insulation, uvioresistant and anti-static effects.

Owner:湖州丝葳纺织有限公司

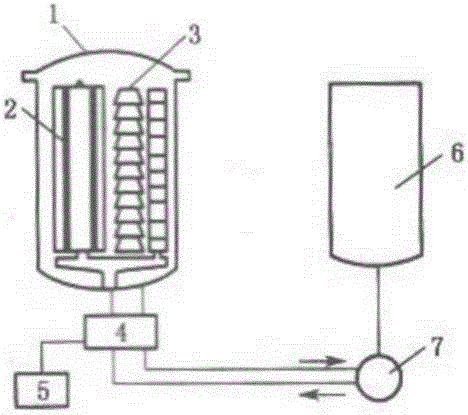

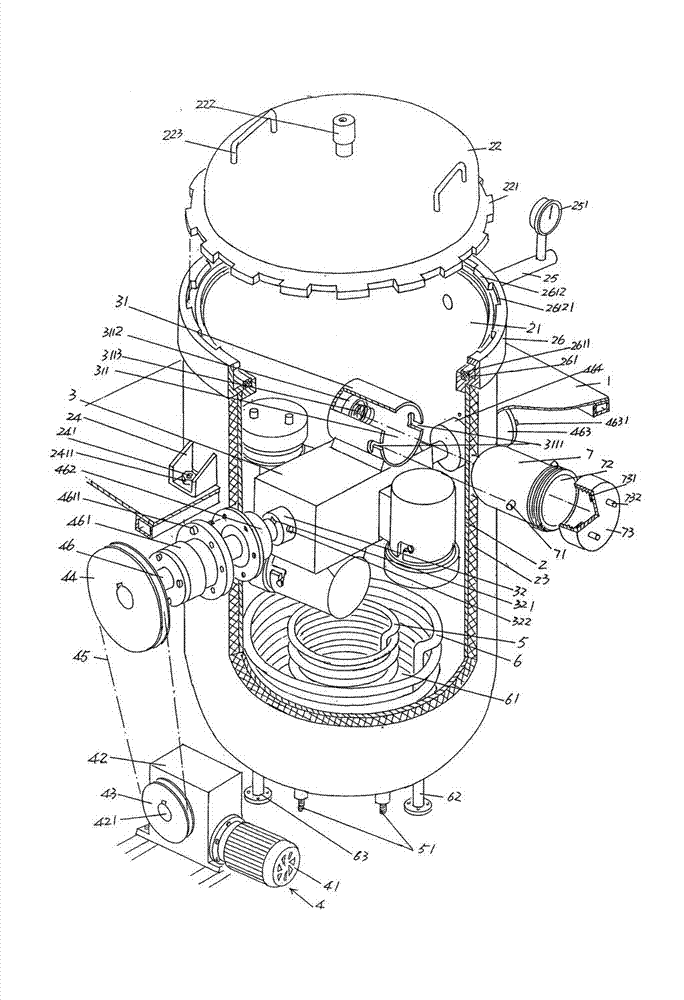

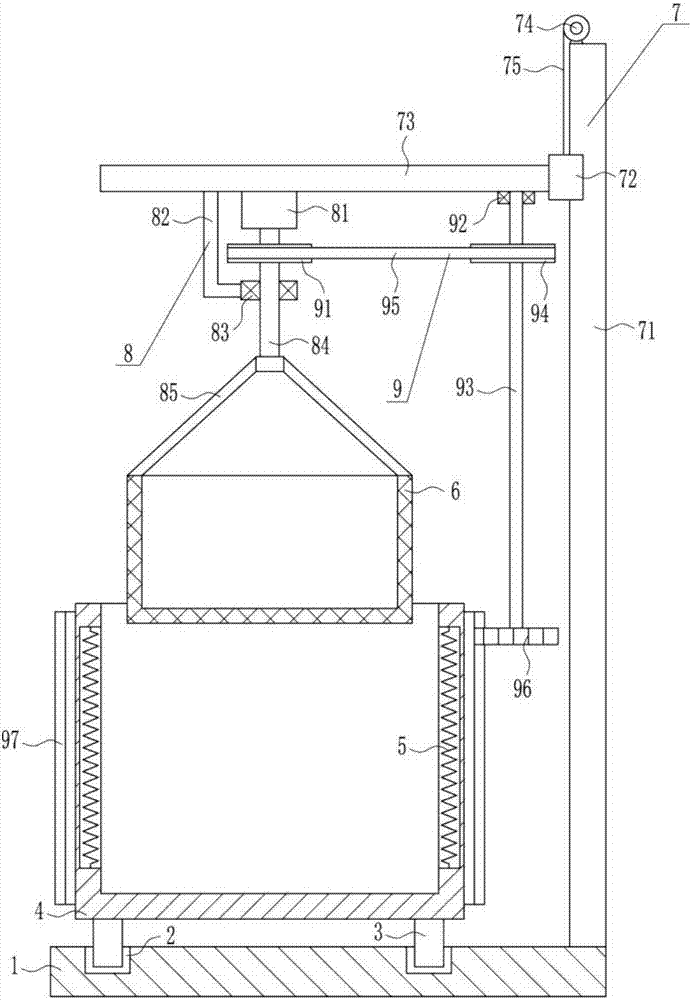

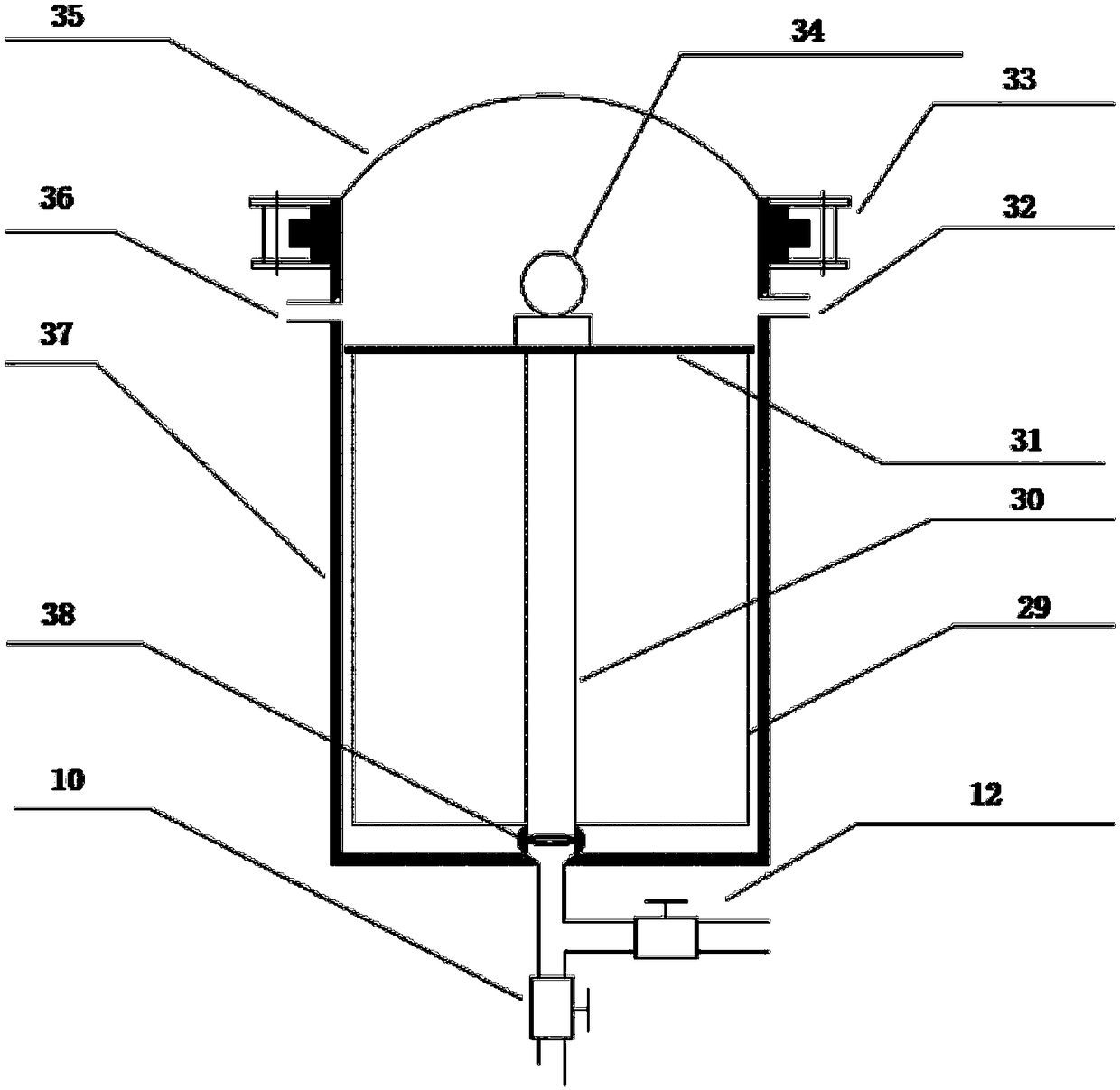

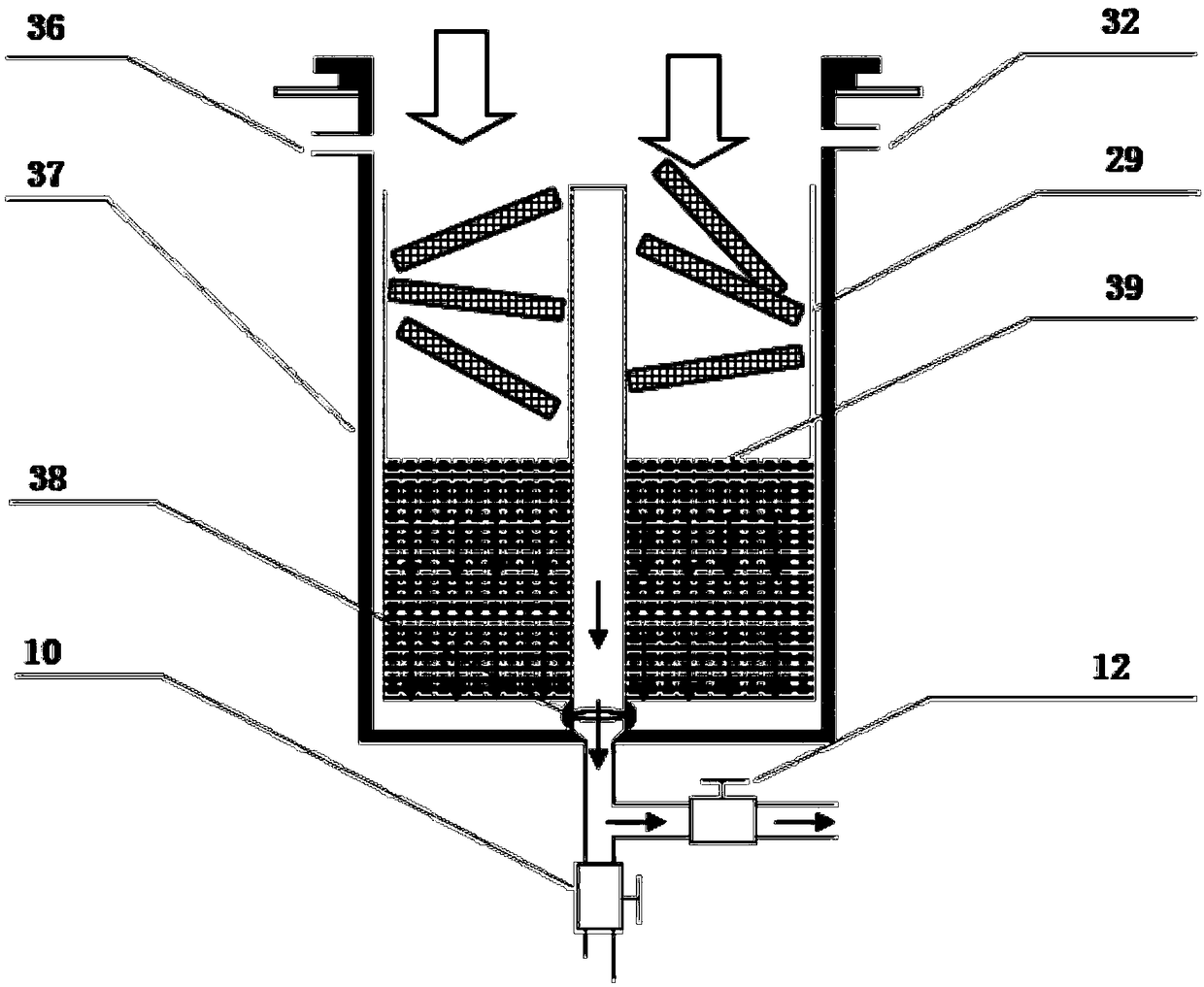

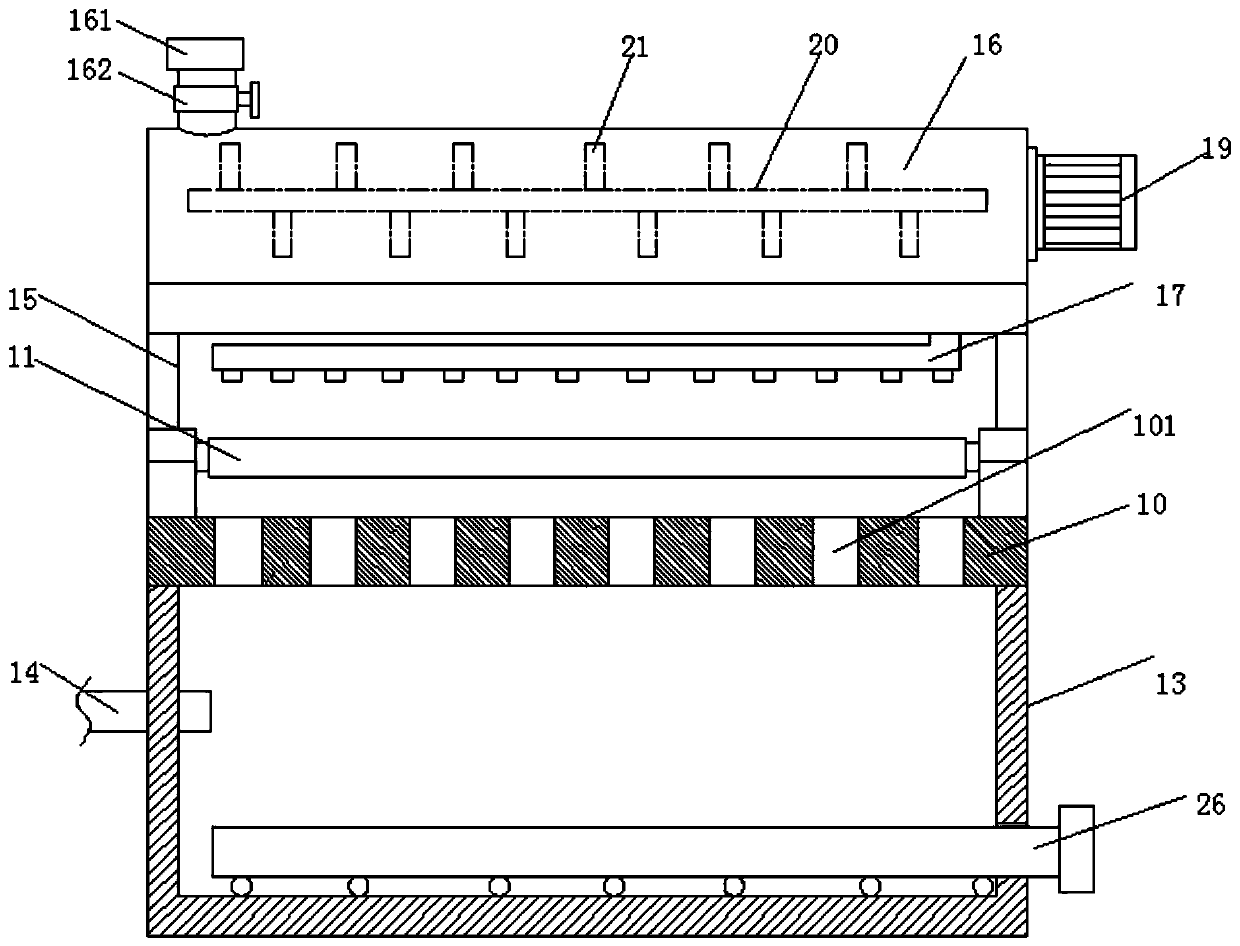

Cheese dyeing machine

InactiveCN104452141AGood dyeing effectImprove processing qualityTextile treatment containersTextile treatment machine arrangementsBobbinPulp and paper industry

The invention discloses a cheese dyeing machine which comprises a dyeing groove and a liquid storage groove. The cheese dyeing machine is characterized in that the cheese dyeing machine further comprises a bobbin creel, a cheese, a circulating pump, an automatic circulating reversing device and a liquid feeding pump, the dyeing groove is internally provided with the bobbin creel, the cheese can be arranged on the bobbin creel, the liquid storage groove is connected with the liquid feeding pump through a pipe, the liquid feeding pump is connected with a forward flowing opening of the circulating pump through a liquid inlet pipe. The circulating pump is connected with a dyeing groove liquid inlet through a pipe. A dyeing groove liquid outlet is connected with a reversing flowing opening of the circulating pump through a pipe. The circulating pump is connected with the liquid feeding pump through a liquid outlet pipe. The automatic circulating reversing device is connected with the circulating pump and used for controlling shifting of the flowing direction of the circulating pump. The cheese dyeing machine solves the problems that dyeing liquid of a dyeing machine can only flow in one direction, the dyeing effect is poor, residues in the dyeing liquid cannot be discharged out of the dyeing groove, and later processing is affected and is simple in structure, convenient to use and capable of flowing in a bidirectional mode and removing the residues in the dyeing liquid.

Owner:高雅

Preparation of anthocyanin dye and application of anthocyanin dye in cellulosic fiber fabric dyeing

InactiveCN105348851AImprove extraction efficiencyQuality improvementNatural dyesDyeing processWarm waterDistillation

The invention discloses a preparation method of a natural anthocyanin dye. The preparation method comprises the following steps: pounding the plant raw material containing anthocyanin pigment to form plant raw material slurry; adding acidified ethanol water into the plant raw material slurry, and carrying out ultrasonic extraction; adding petroleum ether with the same volume into the obtained anthocyanin extracting solution; carrying out reduced pressure distillation on the ethanol water layer obtained through liquid separation, so as to obtain a natural anthocyanin dye concentration solution. The invention further provides a method for dyeing fabric through the natural anthocyanin dye prepared through the method. The method comprises the following steps: carrying out modification treatment on the cellulosic fiber fabric; weighing the natural anthocyanin dye concentration solution with the weight 2-20% of that of the fabric; weighing a metal mordant with the weight 2-10% of that of the fabric; adding water to form dye liquor with the bath ratio of (1: 50)-(1: 100); after wetting the modified fabric with warm water, dyeing for 60-90 minutes at the temperature of 40-80 DEG C; after dyeing, taking out the fabric, washing, and drying at the temperature of 45-55 DEG C.

Owner:ZHEJIANG SCI-TECH UNIV

Cationic dyed mixed-fibre processed filament and its production

InactiveCN1896348AGood dyeing effectImprove dyeing effectConjugated synthetic polymer artificial filamentsChemistryPolyethylene terephthalate glycol

The present invention discloses a cationic dyeable commingled twitty processing yarns and its production process. The commingled components are composed of cationic dyeable filament, and ordinary polyester filament which has alternated twits. The production process includes spinning with cationic dyeable polyethylene terephthalate (PET) chip and common PET chip through different micropores of the same spinneret to produce commingled yarn, and false-twisting with incomplete drafting of the commingled yarn to obtain the product. This invention fully utilizes the strong points of different processing method of fancy yarns and produces commingled grey yarn via one-step spinning for false twisting. The product in this invention has a good dyeing result. Three colors can be acquired by incubating common disperse dyes with cationic dyes when dyeing the produced yarns.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

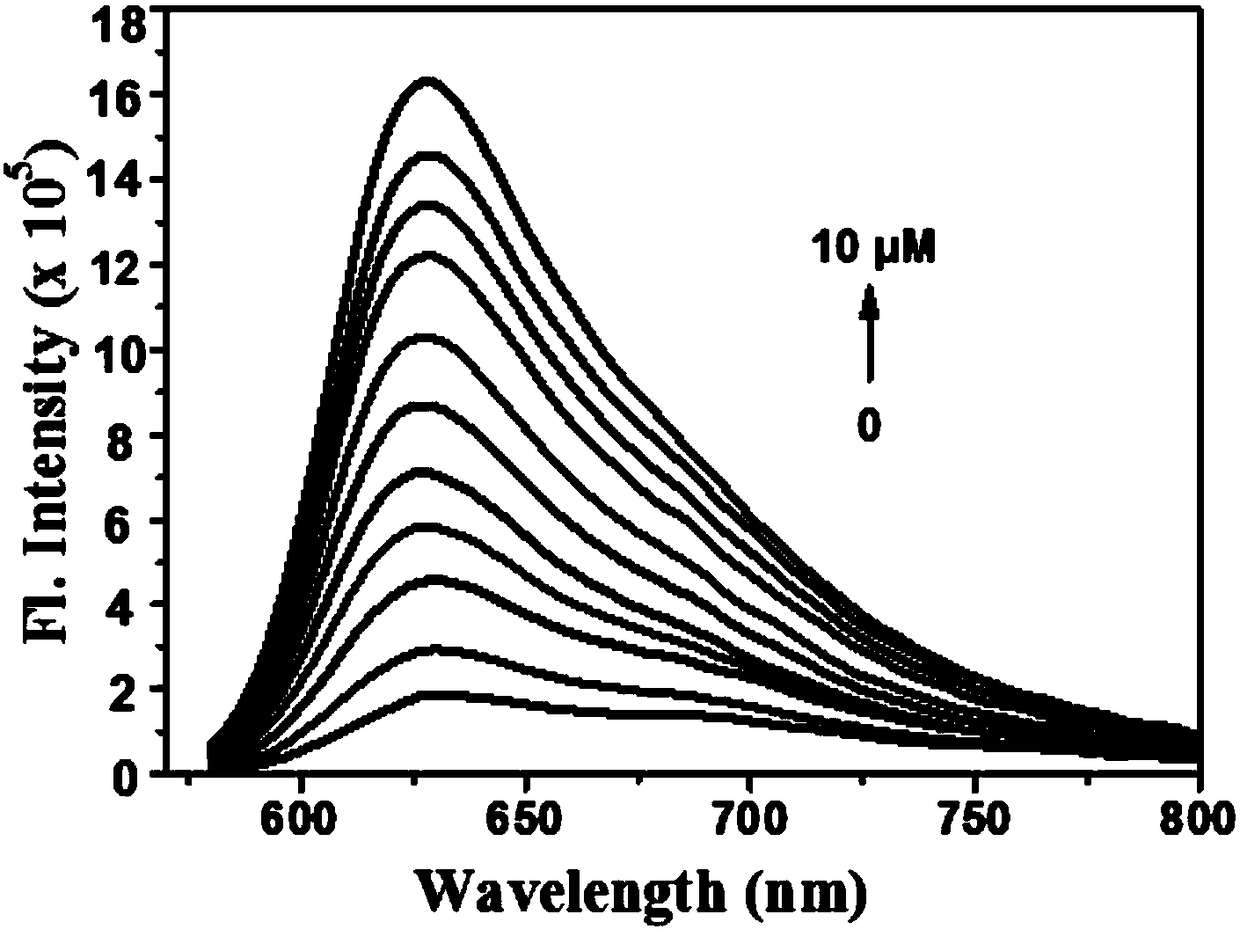

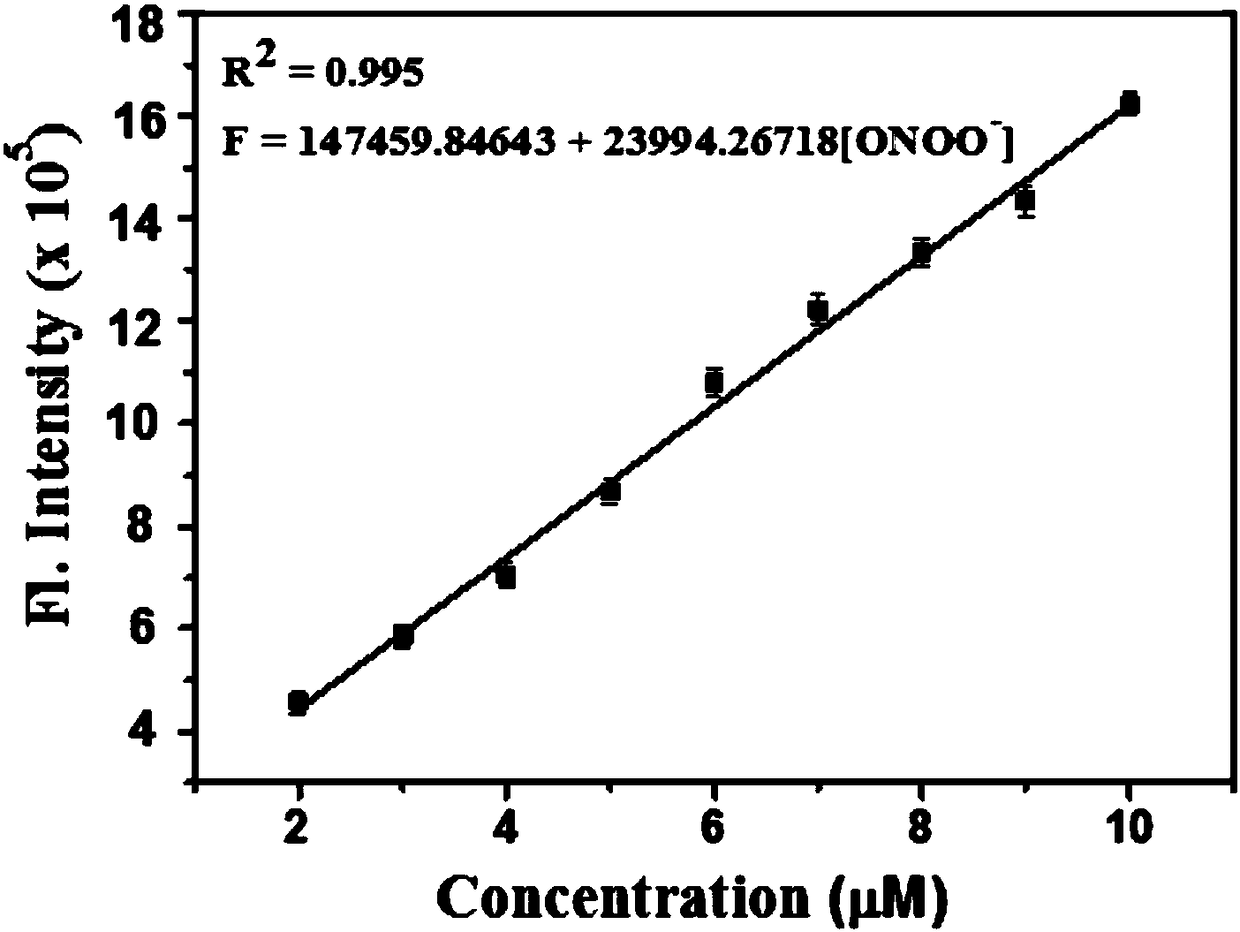

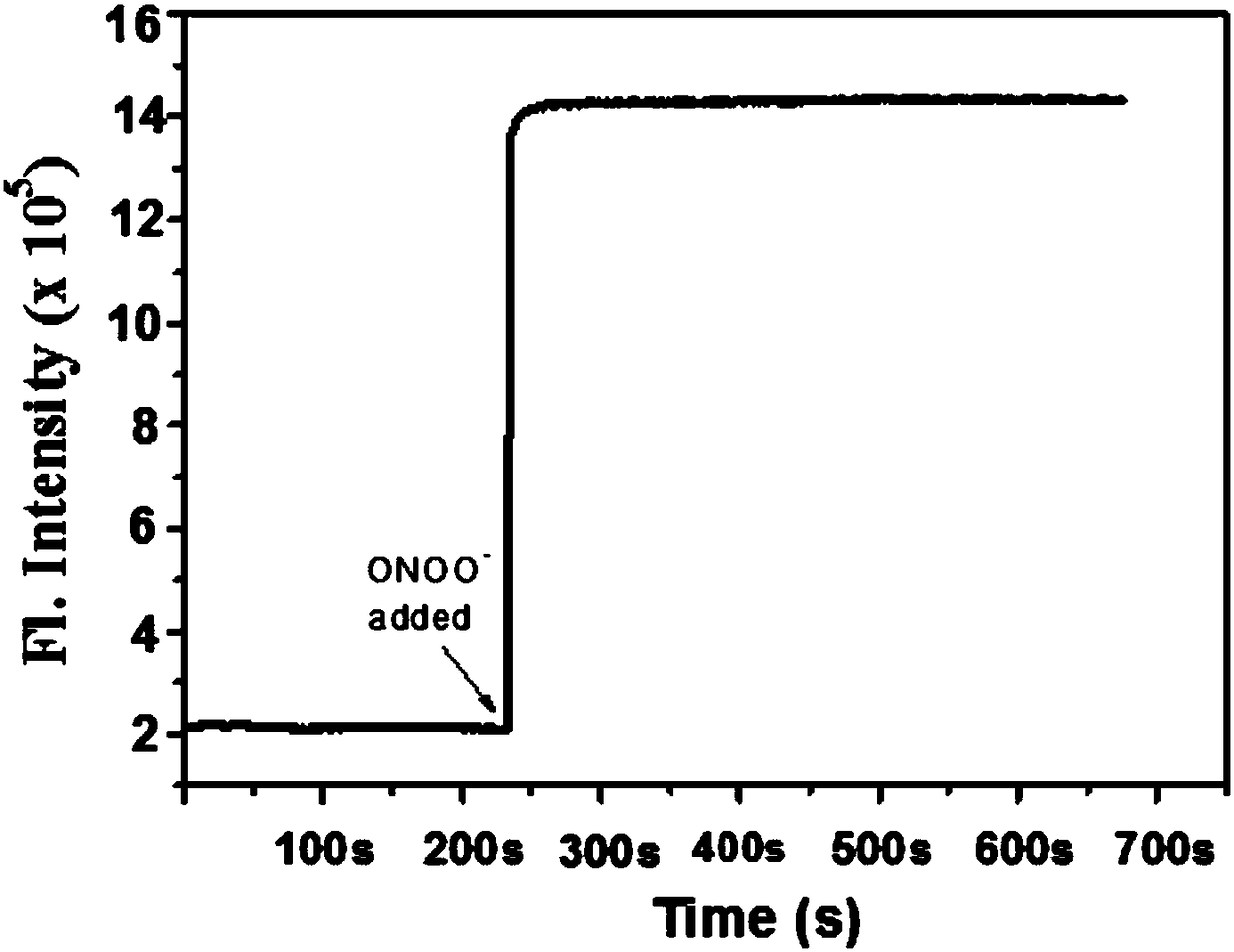

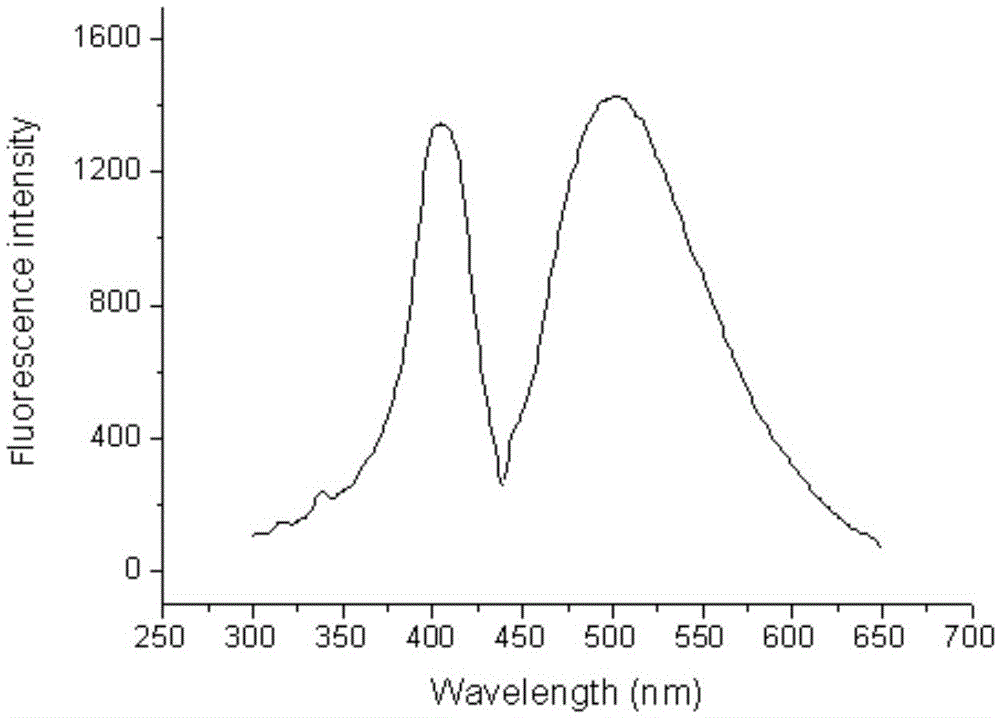

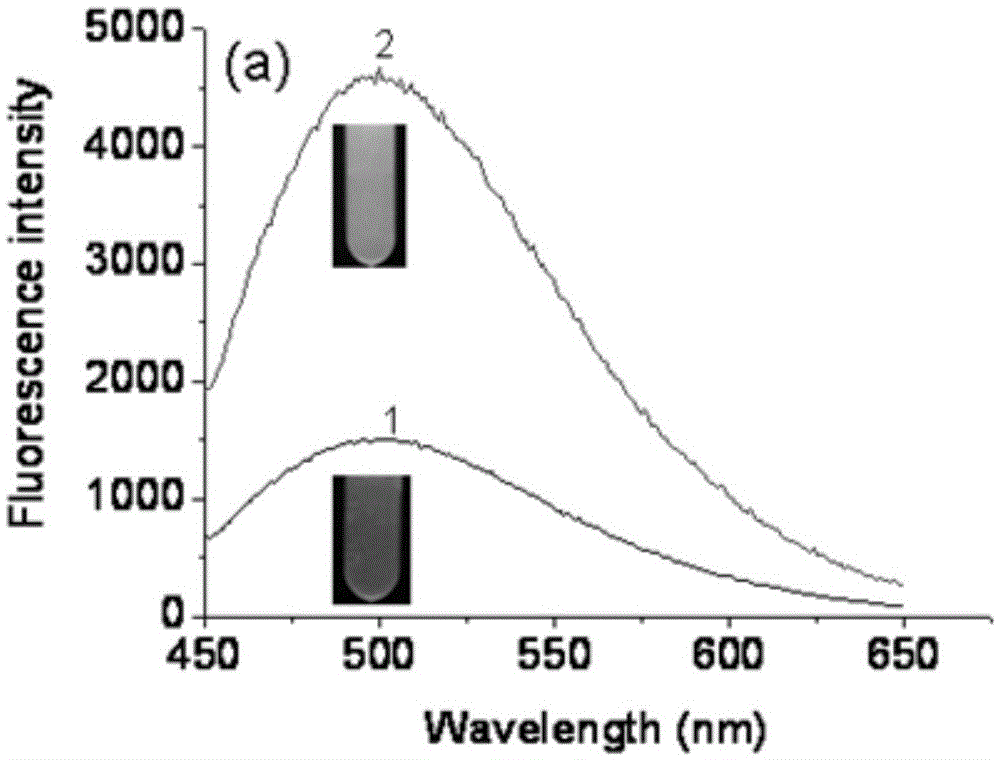

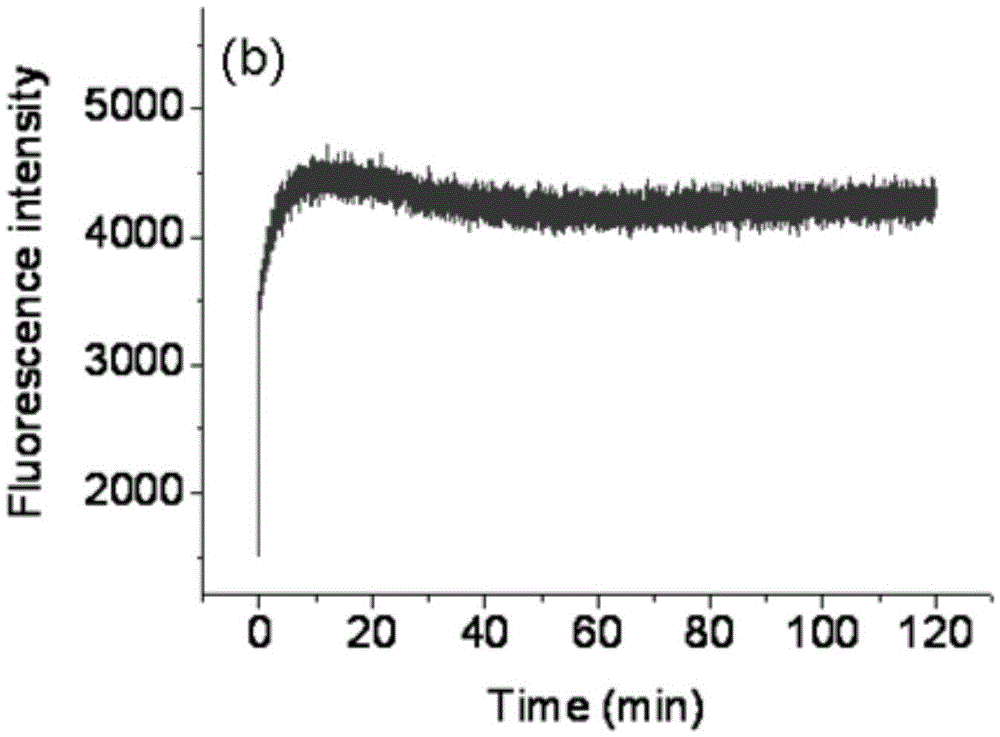

Two-photon fluorescence probe for detecting peroxynitrite as well as preparation method and application of two-photon fluorescence probe

ActiveCN108164494AIncrease penetration depthReduce self-absorptionOrganic chemistryFluorescence/phosphorescencePeroxynitriteStructural formula

The invention discloses a two-photon fluorescence probe for detecting peroxynitrite as well as a preparation method and application of the two-photon fluorescence probe. The two-photon fluorescence probe has the structural formula as shown in the description. The two-photon fluorescence probe is named as TPNIR-FP. The two-photon fluorescence probe adopts a Nile red derivative as a fluorescent group and an alpha-keto-amide functional group as an ONOO-reaction group, can rapidly respond to ONOO- (within 10 seconds), and in addition is high in sensitivity and good in selectivity. The two-photon fluorescence probe can be applied to imaging research on ONOO- in antharcycline antibiotic induced cardiac muscle cell and cardiac muscle tissue damage.

Owner:SHANDONG NORMAL UNIV

Dyeing processing technology of polylactic acid fiber shuttle looms cloth

The invention relates to a dyeing and processing technique for polylactic acid fiber woven fabric, belonging to the technical field of dyeing of textiles. Pure PLA fiber woven fabric or PLA fiber / cotton mixed woven fabric completing preprocessing and dyeing liquor are put into an overflow dyeing machine, temperature rises to 70 DEG C plus or minus 5 DEG C and then rises to 85-95 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 5-10 minutes; if the fiber woven fabric is dyed in medium and light colors, then the temperature keeps rising to 95-105 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 30-45min; if the fiber woven fabric is dyed in dark colors, the temperature rises to 110-120 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 45-60min and then lowered to 60-70 DEG C for soaping; at the temperature of 40 DEG C plus or minus 5 DEG C, reactive dyes and sodium sulphate are continued to be added to PLA fiber / cotton mixed woven fabric, then the temperature is maintained, afterwards, calcined soda is added when the temperature rises to 60 DEG C at a rate of 1-2 DEG C / min, the temperature is lowered for washing after being maintained for 30 plus or minus 5min. The technique features reasonable design, simple and convenient operation and can effectively reduce dosage of addition agent and environmental pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

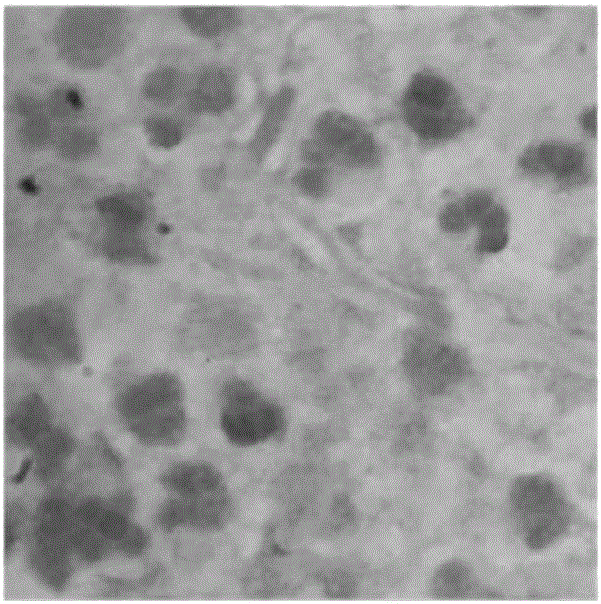

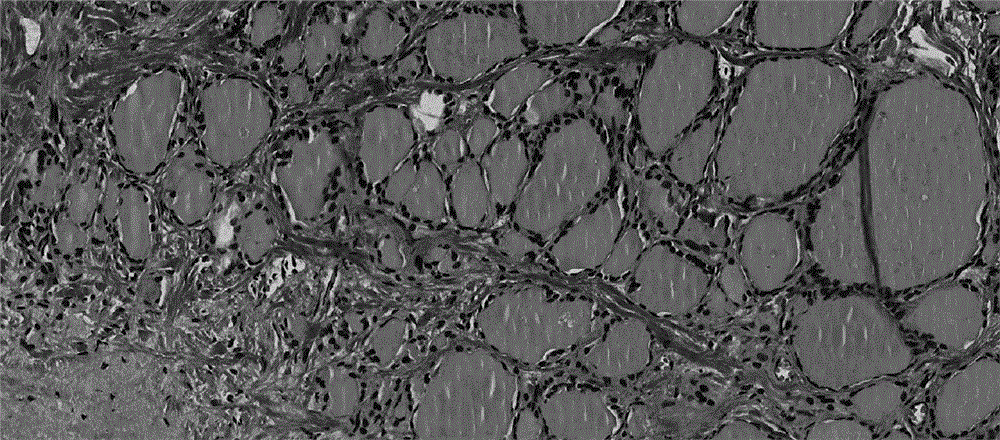

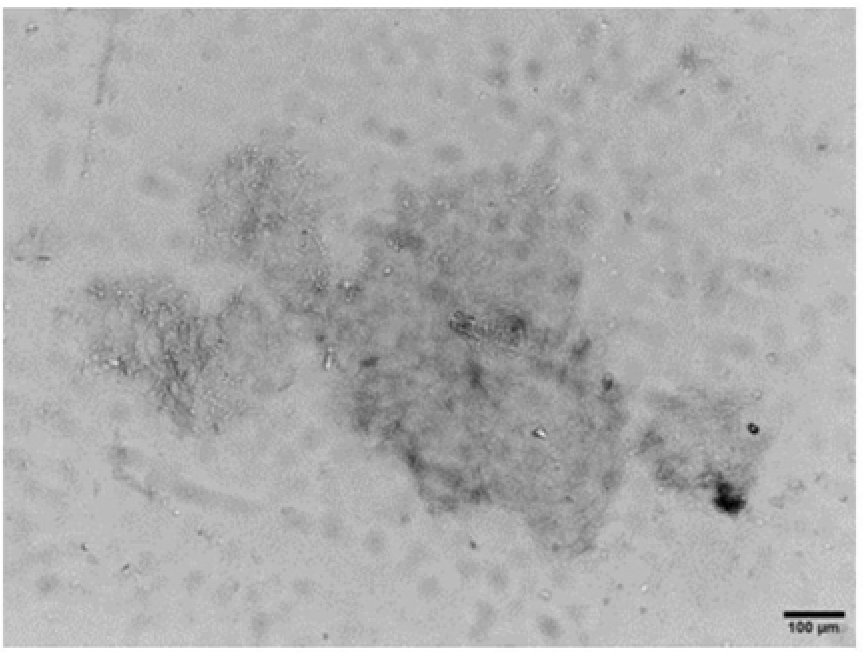

Hematoxylin-eosin one-step dyeing method

ActiveCN106644656AEasy to observe and analyzeGood dyeing effectPreparing sample for investigationEosinDyeing

The invention belongs to a routine dyeing reagent for a routine pathological section making and a use method of the routine dyeing reagent, and discloses a hematoxylin-eosin one-step dyeing method. The hematoxylin-eosin one-step dyeing method disclosed by the invention is characterized by comprising the following steps: preparing a hematoxylin-eosin one-step dyeing solution and a specific pH value buffer solution so that hematoxylin dyeing and eosin dyeing are completed in one step without the steps of differentiating and turning blue, and rinsing the sections with the specific pH value buffer solution before and after dyeing. According to the hematoxylin-eosin one-step dyeing method disclosed by the invention, one-step dyeing of cytoplasm and nucleus can be achieved, the operation steps are simplified and the operation time is shortened; the hematoxylin-eosin one-step dyeing method is good in dyeing effects and stable in results, is suitable for dyeing of routine formalin fixation and paraffin-embedded tissue sections, and can also be used for dyeing of frozen tissue sections or cultured cells, and favorable conditions are provided for rapid and accurate clinical pathological diagnosis.

Owner:杨海玉

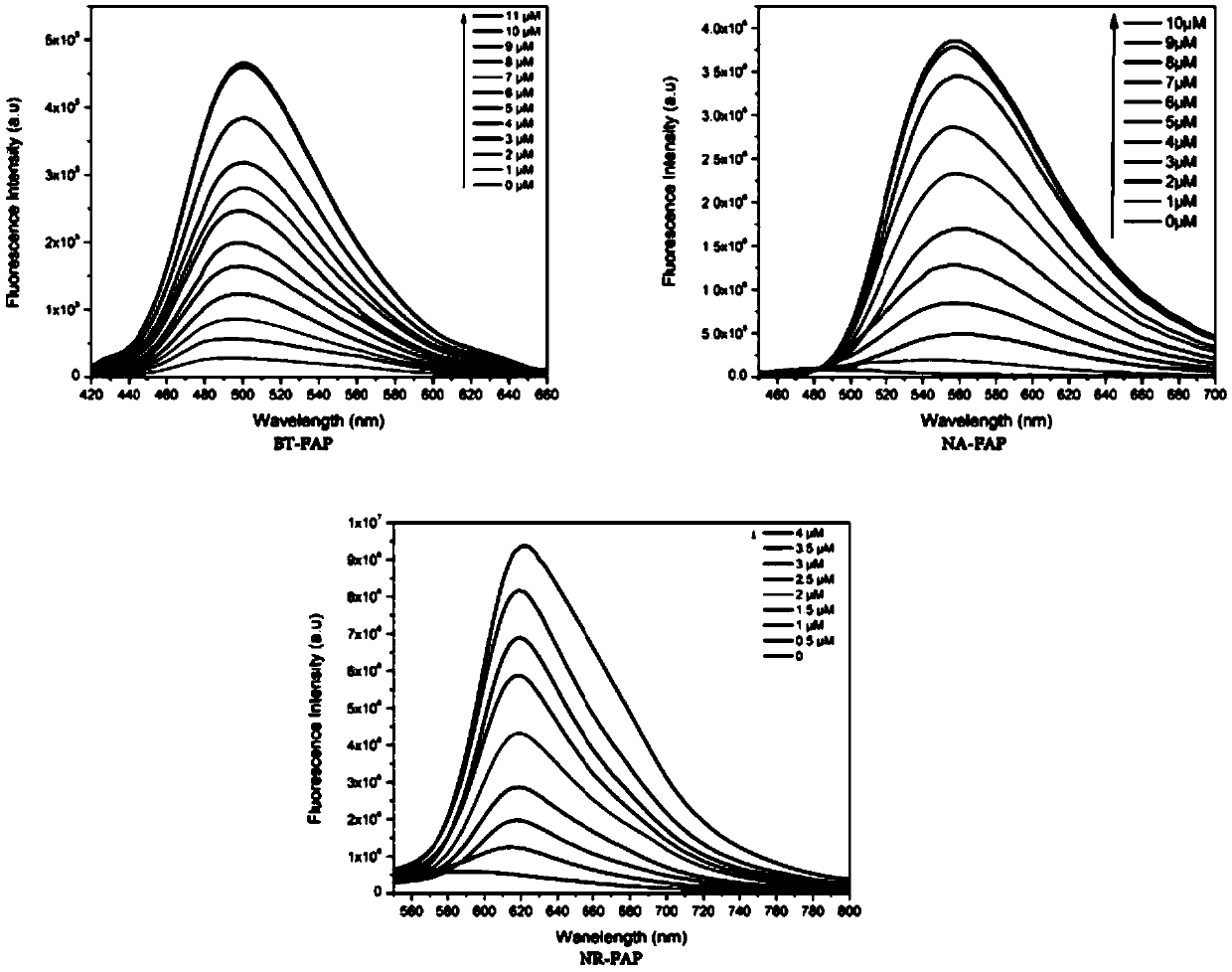

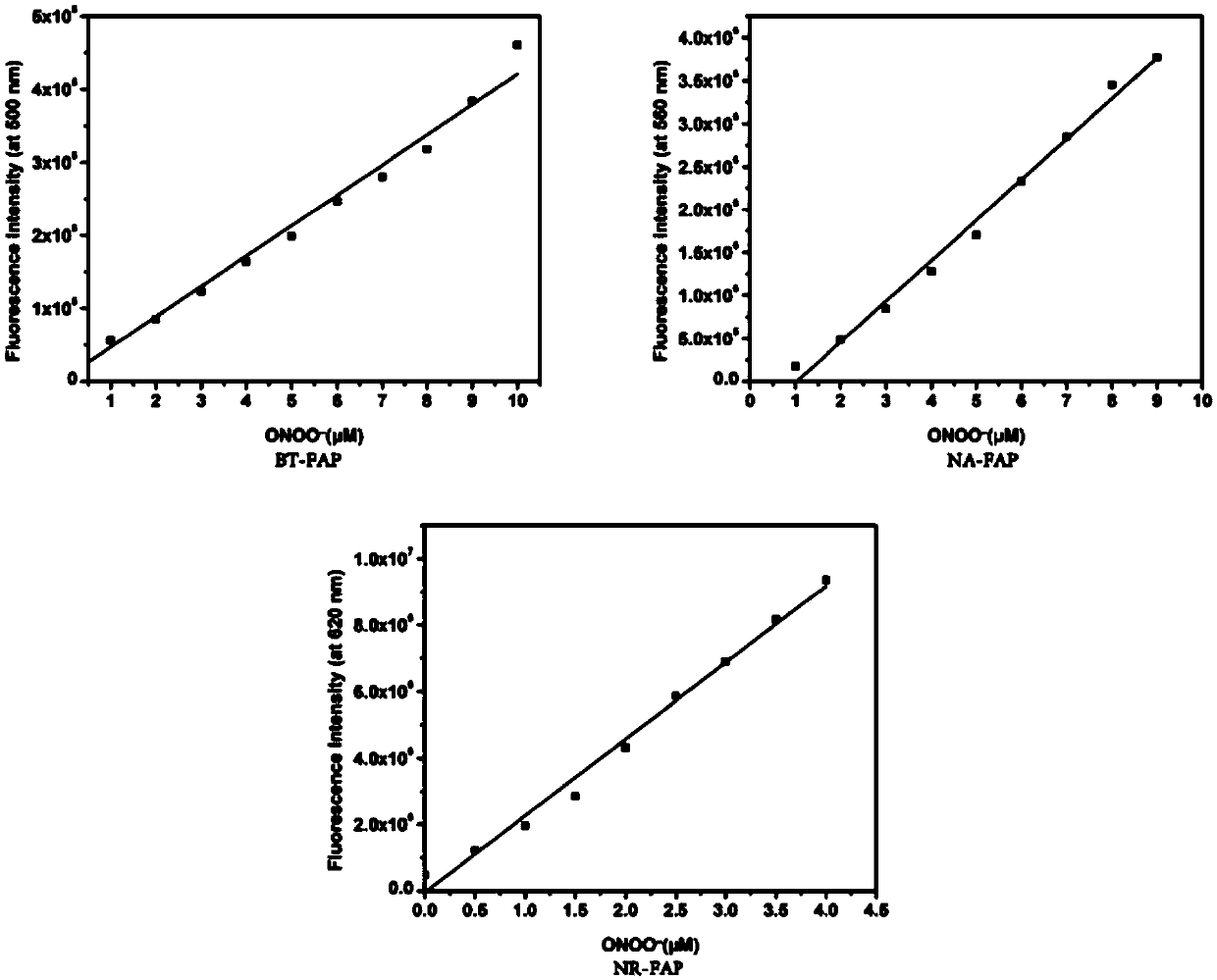

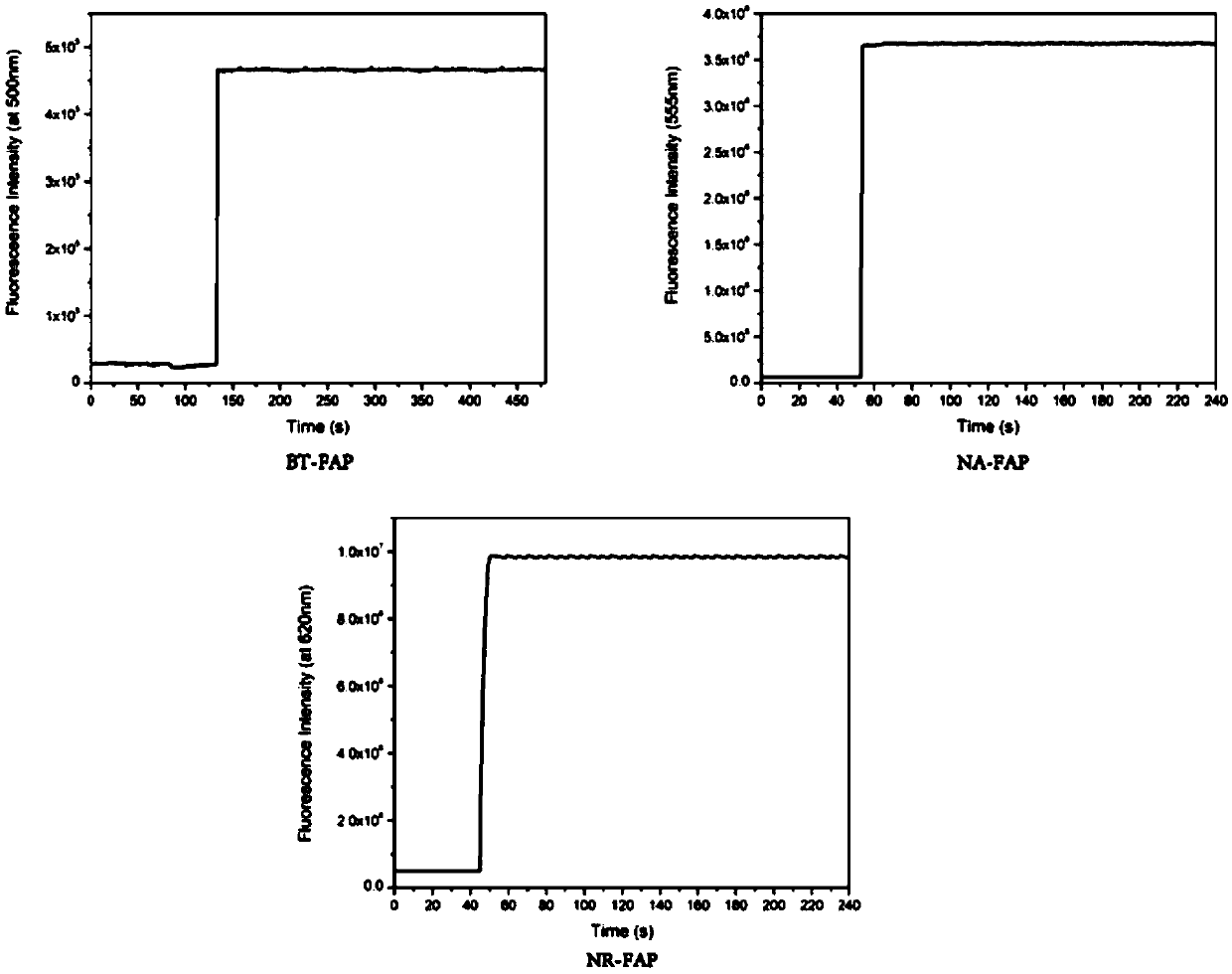

Fluorescent probe for detecting peroxynitrite and preparation method and application thereof

ActiveCN109608414AImprove accuracyReduce self-absorptionOrganic chemistryFluorescence/phosphorescenceNitriteImaging study

The invention belongs to the technical field of synthesis and detection, and particularly relates to a fluorescent probe for detecting peroxynitrite and a preparation method and application thereof. The invention provides a universal identification group for detecting peroxy nitrite, and three new fluorescent probes which are respectively named as BT-FAP, NA-FAP and NR-FAP are formed by connectingthe universal identification group with common fluorophores, wherein aminonaphthalene (BT), naphthalimide (NA) and benzophenoxazine (NR) are the fluorophores, and formamide (FAP) is the identification group to achieve the instant reaction with ONOO (all 4s), the fluorescent probe has high sensitivity and good selectivity, and is very suitable for ONOO fluorescence imaging studies in cells.

Owner:SHANDONG NORMAL UNIV

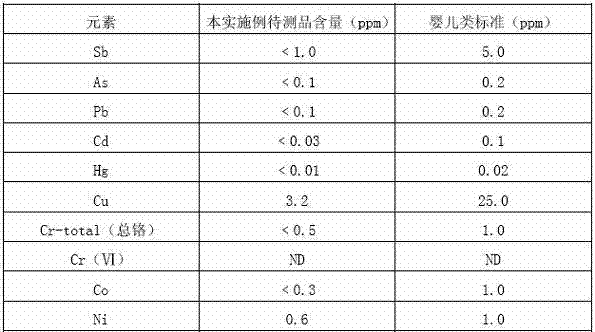

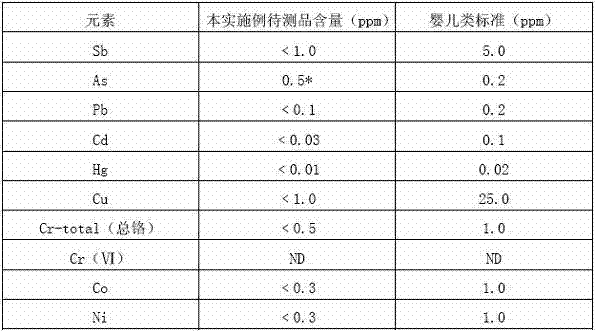

Dye of walnut green husk prepared by walnut green husk, its preparation method and method for dyeing fabric

ActiveCN102516804AThe method steps are simpleEasy to operateClimate change adaptationEnergy inputHuskWarm water

The present invention discloses a dye of walnut green husk prepared by walnut green husk, its preparation method and a method for dyeing fabric. The preparation method comprises the following steps dechlorinating the tap water and softening for next application; heating a part of dechlorination softened water to 60-65 DEG C; drying, crushing and cleaning the collected walnut peel; then putting the peels in warm water to soak for 8-12 hours according to mass ratio of 10.008-0.012 8-12 of the walnut peel to sodium hydroxide solid to water; moving the soaked solid-liquid mixture into a filter, collecting the filtrate; then placing the filtrate into a vacuum evaporator to concentrate, concentrating 10 parts of the filtrate to 2-5 parts; and then adding ferrous sulfate and sodium chloride into the concentrated solution to prepare the dye for dyeing. The steps of the present invention are easy to operate, and each indicator of the fabric dye accordance with the method is superior to the standard indicators of synthetic dyes for baby fabric.

Owner:常州云卿生物科技有限公司

Fluorescent probe for rapidly responding to hydrogen peroxide as well as preparation method and application thereof

InactiveCN105482810AGood dyeing effectShort dyeing timeGroup 3/13 element organic compoundsFluorescence/phosphorescenceAggregation-induced emissionSolvent

The invention discloses a fluorescent probe for rapidly responding to hydrogen peroxide as well as a preparation method and application thereof. The structural formula of the fluorescent probe is shown in the specification. A raw material TPE-Br and bis(pinacolato)diboron are dissolved in a solvent, a reaction is carried out under a heating condition with a catalyst, the probe is obtained, and the probe is named TPE-BO. The probe molecule has an aggregation-induced emission property, and response time between the fluorescent probe and hydrogen peroxide is effectively reduced by 10 minutes. The dyeing effect for living cells is good, the dyeing time is short, and the dyeing efficiency is high. The synthesis steps are relatively simple, the yield is high and purification is easy.

Owner:SHANDONG NORMAL UNIV

Preparation method and dyeing method of sapelli wood natural dye

The invention relates to a natural dye, in particular to a preparation method and dyeing method of a sapelli wood natural dye. The invention mainly solves the technical problems of the prior art that the raw materials of synthetic dyes are renewable high-carbon products such as petroleum and coal which have higher toxicity, and the sapelli wood scraps and saw dust left by the preparation of furniture are mainly processed by incineration and the like so as to cause serious environmental pollution. The preparation method of the sapelli wood natural dye comprises the following steps: pretreating raw material, extracting with ethanol, concentrating and separating, and solidifying at a low temperature. The dyeing method using the sapelli wood natural dye can be adopted to dye wool fabrics, silk fabrics and pure cotton fabrics; the dyed fabrics can not cause environmental pollution; and the fabrics dyed by the natural dye has the advantages of nontoxicity, harmlessness and health.

Owner:杭州集美印染有限公司 +2

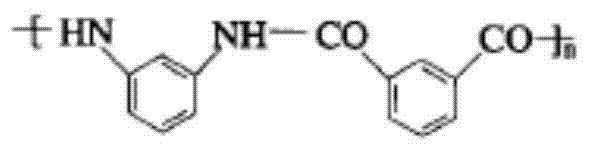

Method for dyeing aramid fiber without carrier

ActiveCN103046401AReduce dyeing costsImprove protectionSucessive textile treatmentsTextile treatment machine arrangementsBuffering agentAramid

The invention relates to a method for dyeing aramid fiber without a carrier, belonging to the technical field of spinning, printing and dyeing. The method comprises the following steps of: preparing a dyeing bath: injecting water into a dyeing container, controlling the bath ratio, adding 0.01-15% (by o.w.f) of dye and 5-20g / L of a levelling agent into the dyeing container, and adding a buffering agent to adjust the pH value to 4-6; and dyeing: soaking the aramid fiber into water, removing the water in the aramid fiber, putting the aramid fiber in the dyeing bath, putting the dyeing container into a dyeing machine to dye, controlling the dyeing temperature, time and pressure of the dyeing machine, taking the dyeing container out of the dyeing machine, taking the aramid fiber out of the dyeing container, and washing with water, cleaning by reducing, washing with water and drying in sequence to obtain the dyed aramid fiber. Because the dyeing bath is prepared reasonably, the aramid fiber is soaked before being introduced into the dyeing bath, is dried after being soaked and is dyed under the set dyeing temperature, time and pressure, the defect of using the carrier in the prior art is avoided. The method can not cause pollution to the environment and achieves an ideal aramid fiber dyeing effect, and the aramid fiber dyeing cost is reduced due to the adoption of the method.

Owner:CHANGSHU BAOFENG SPECIAL FIBER +1

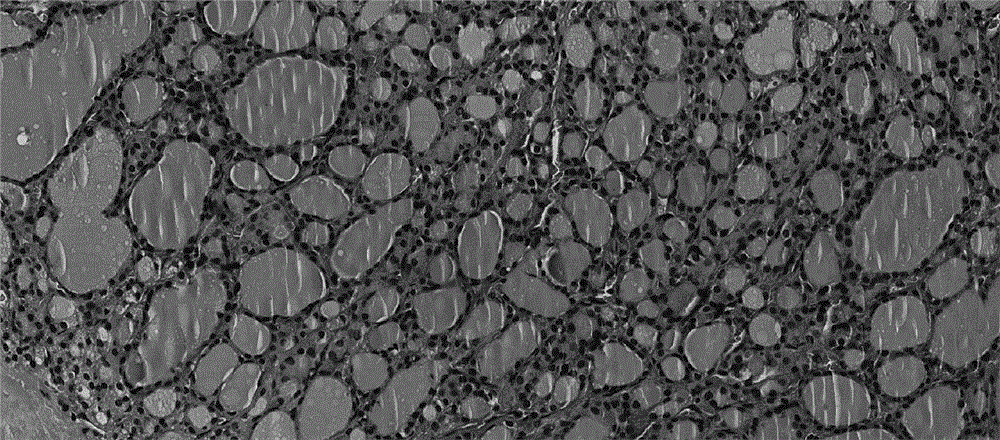

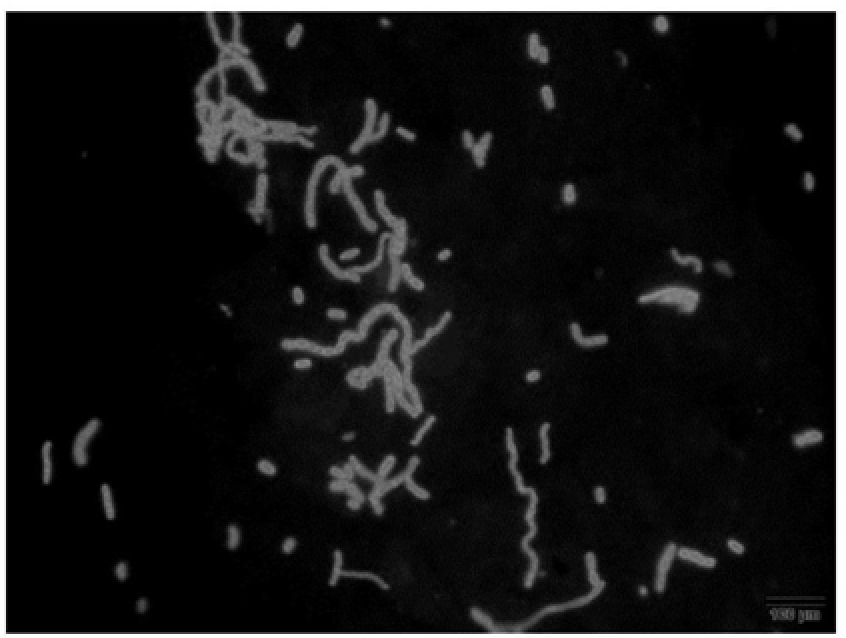

Anti-attenuation fungal fluorescent dyeing liquid and preparation method thereof

InactiveCN109100201APenetrate fastQuick stainPreparing sample for investigationLuminescent compositionsUltrasound attenuationCellulose

The invention discloses an anti-attenuation fungal fluorescent dyeing liquid and a preparation method thereof. Wherein the components of the anti-attenuation fungal fluorescent dyeing liquid include:a fluorescent agent, a solubilizing agent, a penetrating agent, a background dye, an anti-fluorescent attenuation agent, a stabilizer, and deionized water. According to the anti-attenuation fungal fluorescent dyeing liquid and the preparation method thereof, each component is stabilized in a solution system, and filtered by a cellulose membrane, all kinds of minute impurities are effectively removed, thereby having an effect of long-term storage without crystallization and having the advantages that the fungal fluorescence mark and the background dyeing are synchronously carried out in a few seconds; the anti-attenuation fungal fluorescent dyeing liquid does not need to be operated in a dark room, the performance is relatively stable, and has the characteristics of convenient operation, short dyeing time, long attenuation time, high efficiency, comprehensive use range, high observation clarity, good specificity and accurate detection result, and has a good clinical application prospect.

Owner:THE THIRD AFFILIATED HOSPITAL INST OF FIELD SURGERY OF PLA ARMY MEDICAL UNIV

Staining fluid and method for rapidly detecting novel cryptococcus

InactiveCN101724682AEasy to storeEasy to detectMicrobiological testing/measurementMicroorganism based processesAcetic acidStaining

The invention relates to staining fluid and a method for rapidly detecting novel Cryptococcus. The staining fluid comprises 0.5-3.0g of AZO-blue, 1.0-10.0g of glacial acetic acid and 90-110g of distilled water. The method for rapidly detecting novel cryptococcus comprises the steps of preparation of the staining fluid, mixing, detection, counting and the like. The invention has the advantages of simple, convenient, rapid, sensitive and accurate detection, high specificity, easy preservation of the staining fluid, short staining time and excellent staining effect.

Owner:东阳市人民医院

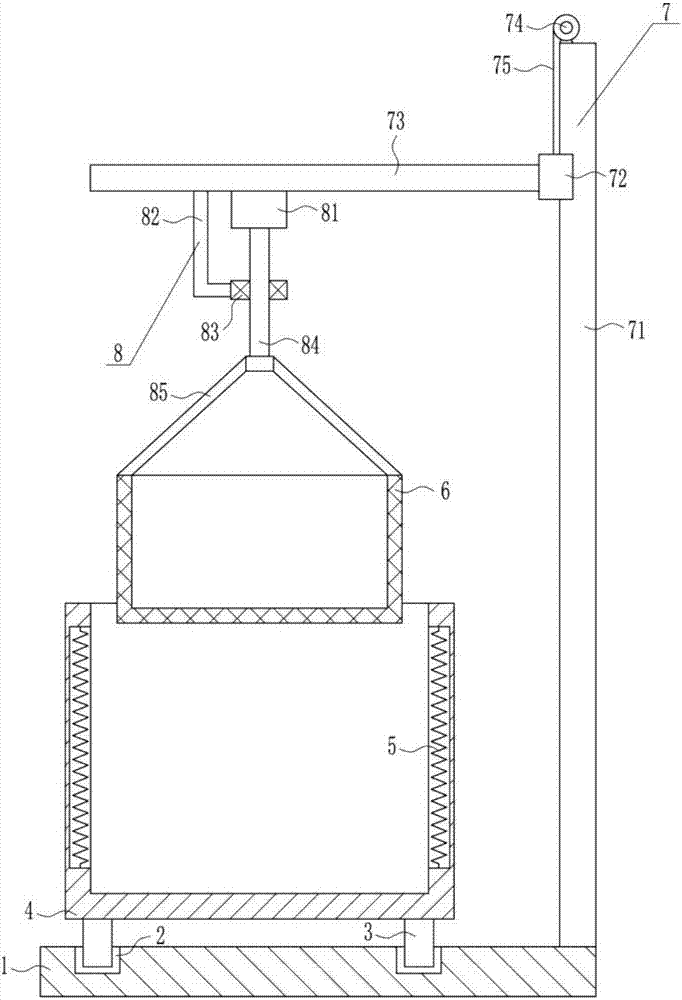

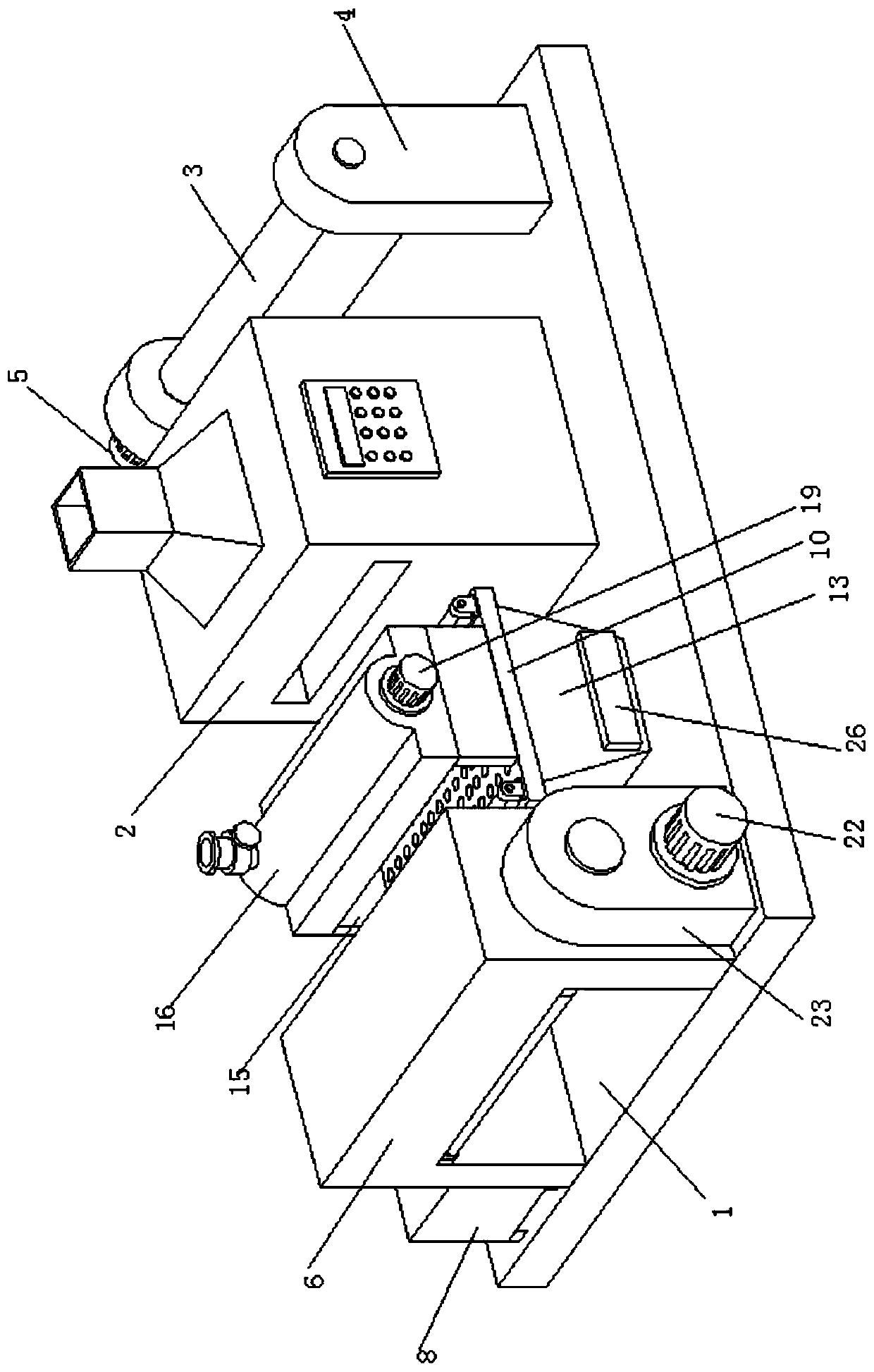

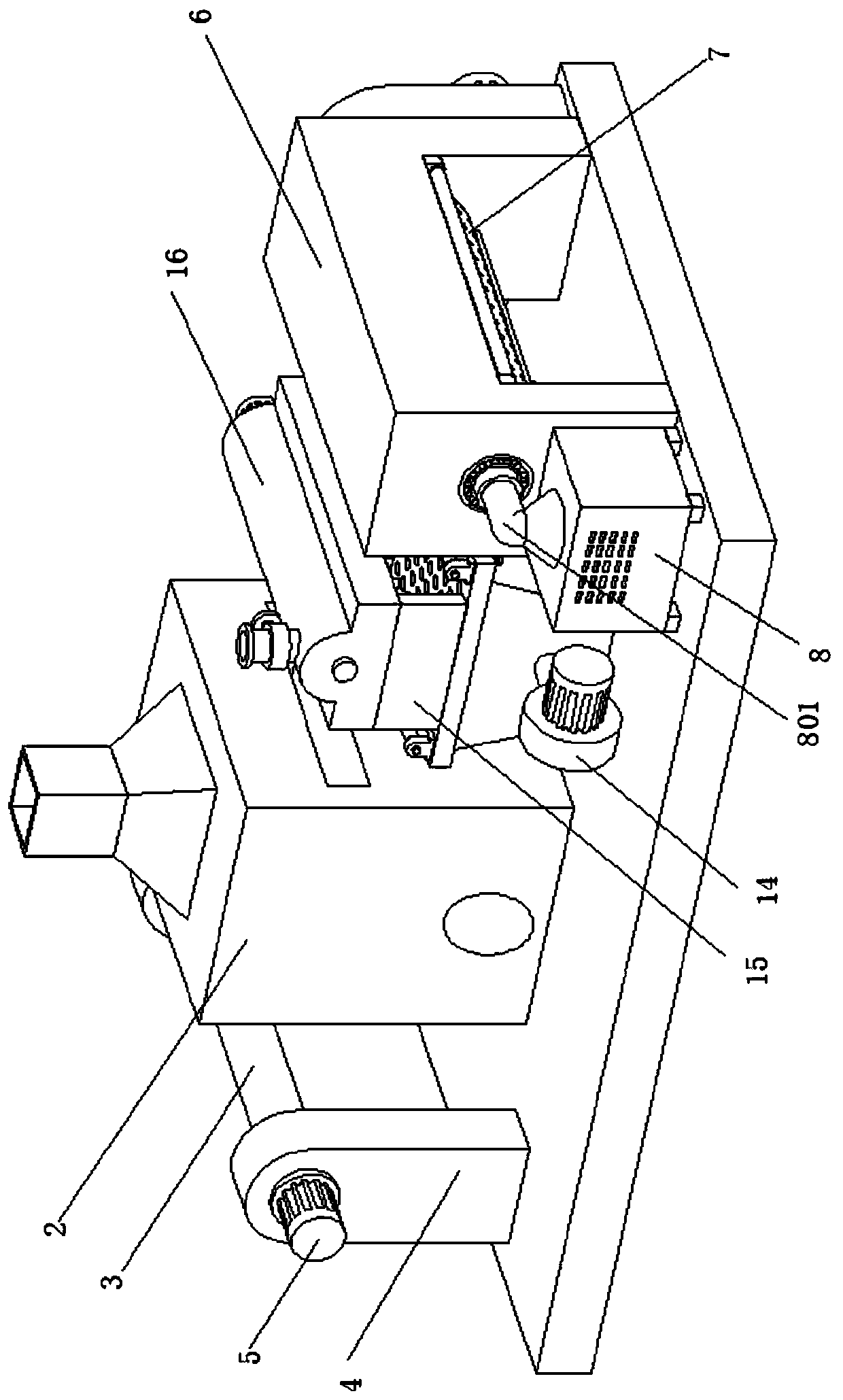

Textile cloth dyeing equipment

InactiveCN107956067AGood dyeing effectImprove dyeing effectTextile treatment machine arrangementsTextile treatment carriersElectricityEngineering

The invention relates to dyeing equipment, in particular to textile cloth dyeing equipment and aims to achieve great dyeing effects and high dyeing efficiency of the textile cloth dyeing equipment. The textile cloth dyeing equipment provided for solving the technical problems comprises a bottom plate, first sliders, a tank, electric heating wires and the like. The top of the bottom plate is provided with an annular slide groove, the first sliders are arranged in the annular slide groove, the tank is mounted at tops of the first sliders, and the electric heating wires are mounted on inner leftand right sides of the tank in an embedded manner. A first rotating device is arranged on a height adjusting device which is arranged on the top right of the bottom plate, and a mesh frame is mountedon the first rotating device and positioned right above the tank. Height adjustment of the mesh frame is realized by the height adjusting device, the first rotating device drives a frame body to rotate for realizing cloth dyeing, and accordingly great dyeing effects and high dyeing efficiency are realized.

Owner:乐甜桃

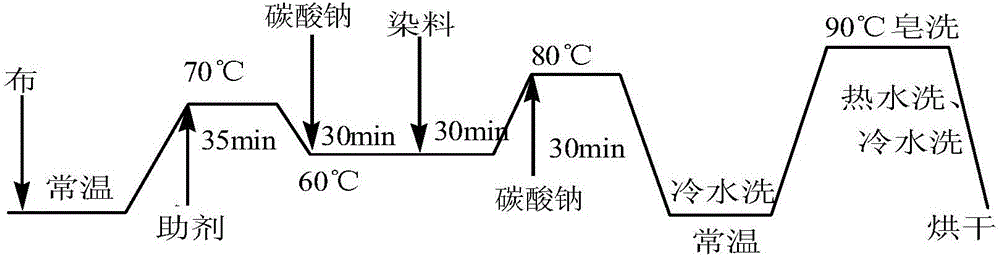

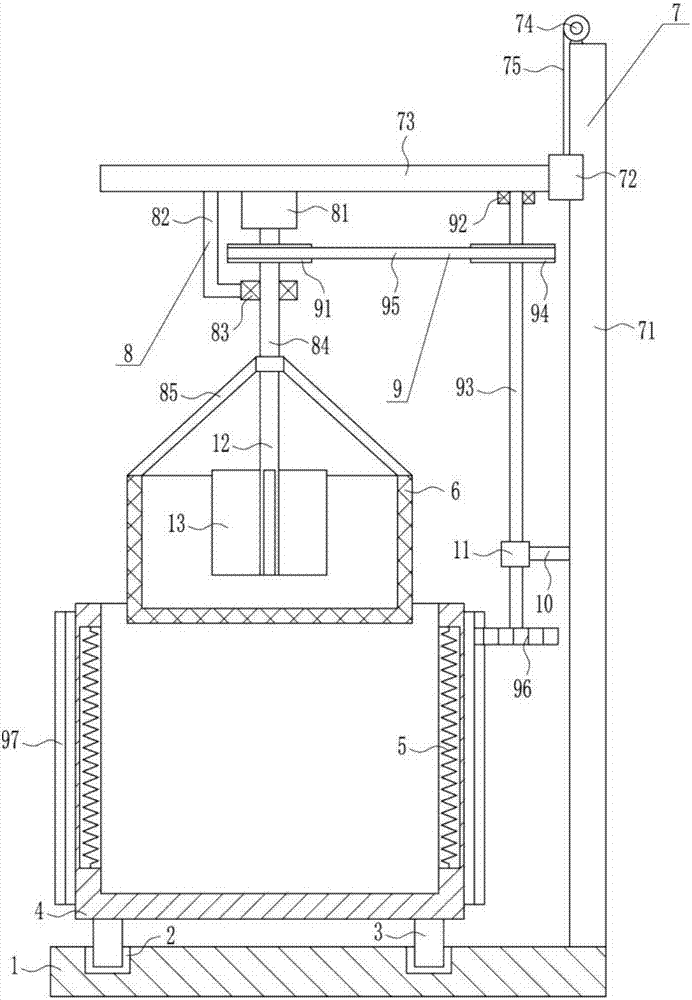

Dyeing method of rayon elastic knitted fabric

InactiveCN109281199AImprove the finishGood dyeing effectDry-cleaning apparatus for textilesDyeing processSodium carbonateReactive dye

The invention discloses a dyeing method of a rayon elastic knitted fabric, and the method comprises the following steps: pre-treating, preshaping, dyeing, soaping, dehydrating, drying, scutching and shaping to obtain the dyed rayon elastic knitted fabric, according to the method, an oil agent and pulp on the fabric in the pretreating process and dir, dust, pigment and the like adsorbed in the weaving and storage and transportation processes are removed; in the dyeing process, phase heating is adopted, and a reactive dye, a leveling agent, sodium carbonate and a chelating dispersant are added,so that the utilization rate of the dye in the production process is improved, the dyeing is uniform, the color fastness is high, meanwhile, the waste water is little, and the energy consumption is low.

Owner:SHAOXING COUNTY KWONG FUNG PRINTING & DYEING

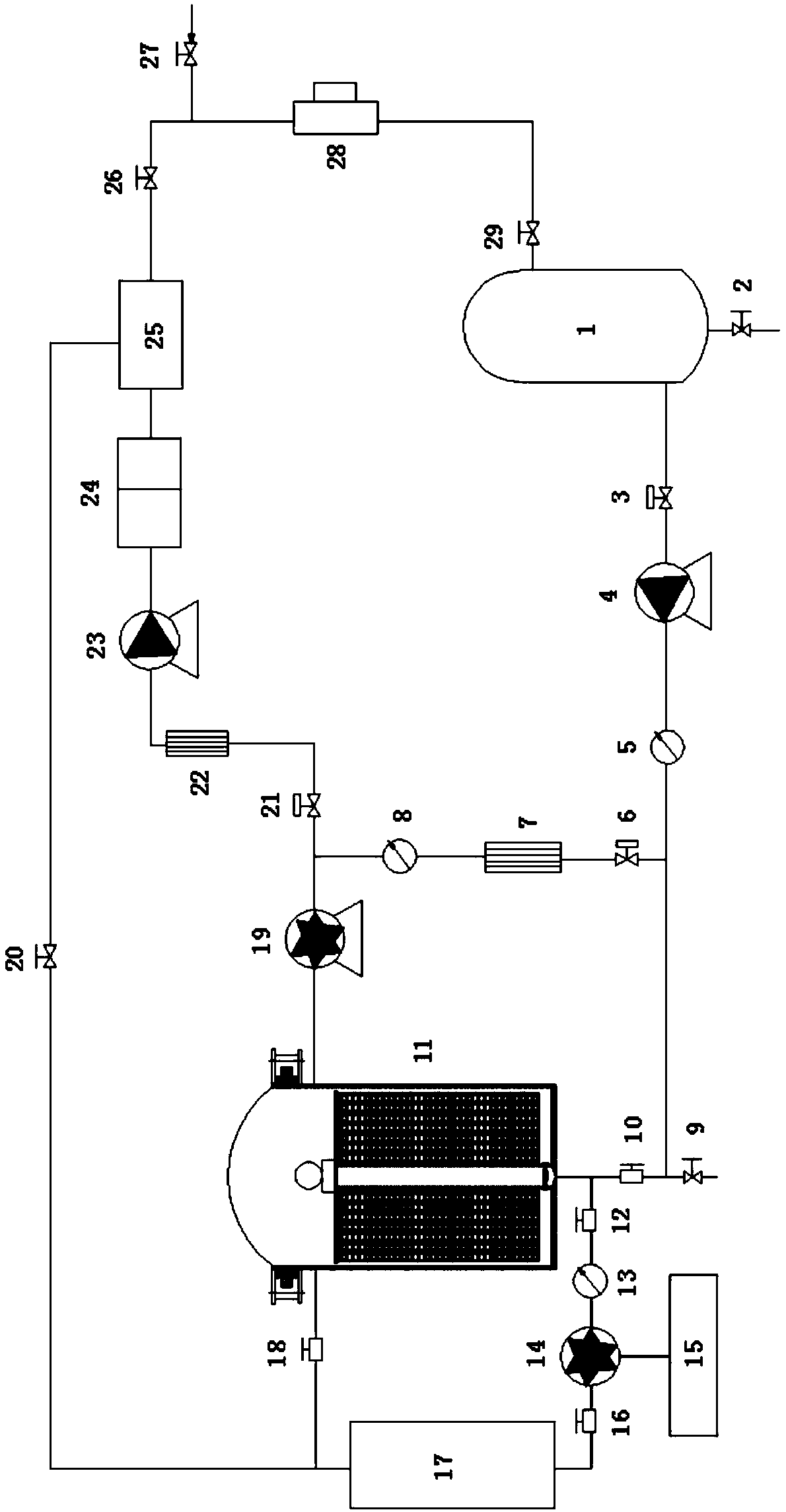

Anhydrous fiber-dyeing dyeing machine for mixing fluid medium

ActiveCN109137342AImprove recycling efficiencyEffectively achieve swellingTextile treatment containersTextile treatment machine arrangementsNatural fiberDye molecule

The invention discloses an anhydrous fiber-dyeing dyeing machine for a mixing fluid medium. The anhydrous fiber-dyeing dyeing machine comprises a dyeing cylinder, a carbon dioxide pressurizing systemand polar medium pressurizing system, a cotton stepping system, a circulating dyeing system, a carbon dioxide recovery system, a polar medium separation and recycling system and an automatic unloadingsystem. Since the two sets of carbon dioxide medium and polar medium pressurizing and separation and recovery systems are arranged in the system, dyeing processing of the mixing fluid medium in an anhydrous fiber-dyeing vat and a dyeing circulation system of the vat as well as effective modification of the hydrophobic carbon dioxide fluid medium is realized effectively, so that the dyeing performance and dyeing effect of the special dye molecules on the hydrophilic natural fibers are remarkably improved. With the cotton stepping system and the unloading system, the treading efficiency of thedyeing vat is improved obviously and the yield of processed products and the automatic operation are enhanced.

Owner:中科首望无水染色智能装备(苏州)有限公司

Environment-friendly efficient chemical fiber fabric printing and dyeing equipment and process

ActiveCN111334955AGood dyeing effectReduce steam consumptionTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringDyeing

The invention relates to the technical fields of textile fabric printing and dyeing, in particular to environment-friendly efficient chemical fiber fabric printing and dyeing equipment and process. The environment-friendly efficient chemical fiber fabric printing and dyeing equipment comprises a bottom plate, a drying box and a wind-up roller, wherein two rotating supports are arranged at the right end of the upper surface of the bottom plate; the wind-up roller is rotatably arranged on the two rotating supports; a winding motor is arranged on one rotating support; and an output shaft of the winding motor penetrates through the rotating support to be connected with the end face of the winding roller. When an atomizer sprays, dyes and colors the upper surface of chemical fiber fabric, a negative pressure exhaust fan draws the interior of a case to a negative pressure state, so that a pressure difference is formed between the upper space and the lower space of the chemical fiber fabric,dye liquor sprayed on the chemical fiber fabric accelerates to permeate from the upper surface of the chemical fiber fabric to the lower surface of the chemical fiber fabric under the action of negative pressure, the quality problem caused by large chromatic aberration difference between a spray dyeing surface and a back surface due to poor penetration effect of the chemical fiber fabric in existing fabric printing and dyeing equipment can be effectively solved, and the dyeing effect is excellent.

Owner:绍兴水乡纺织科技有限公司

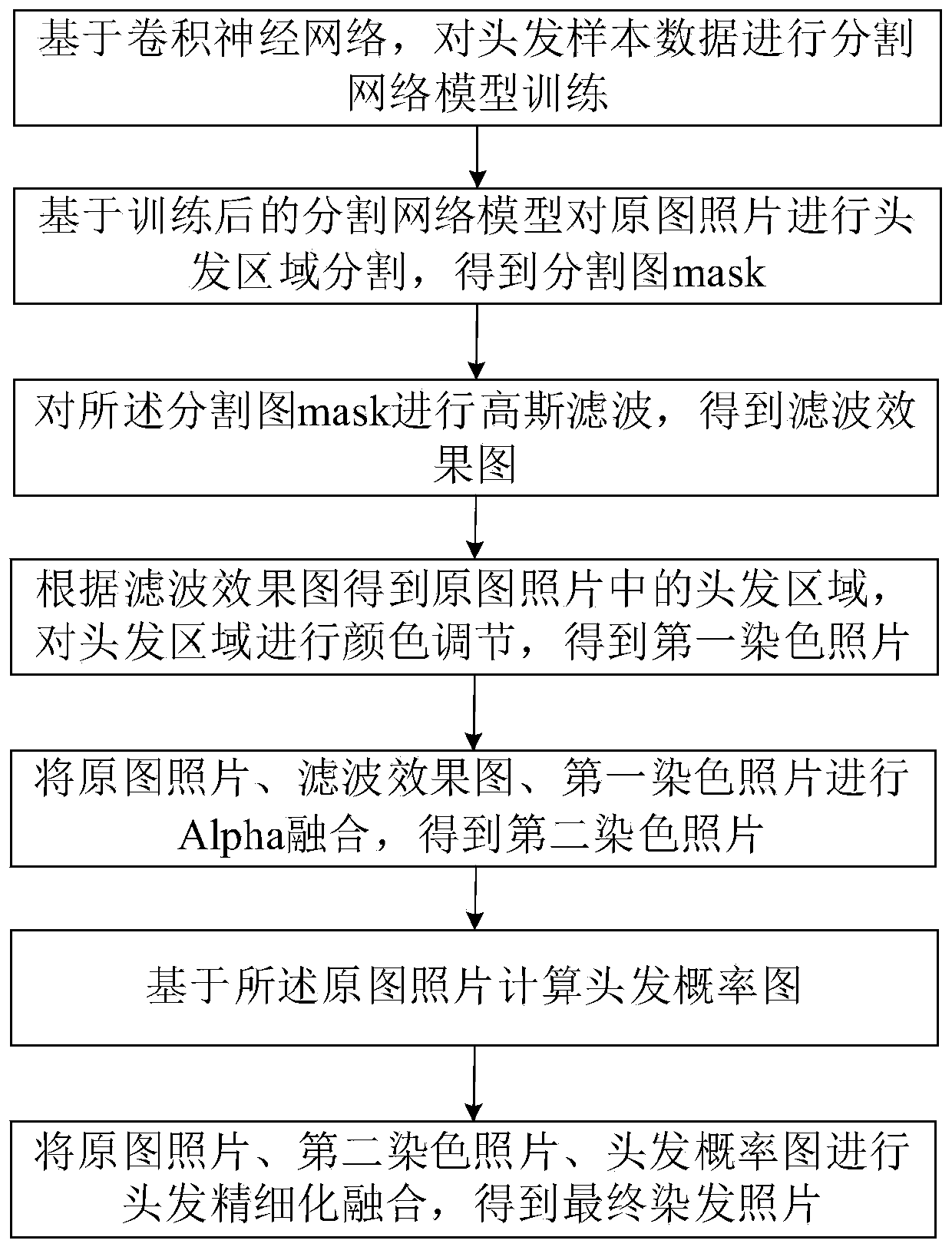

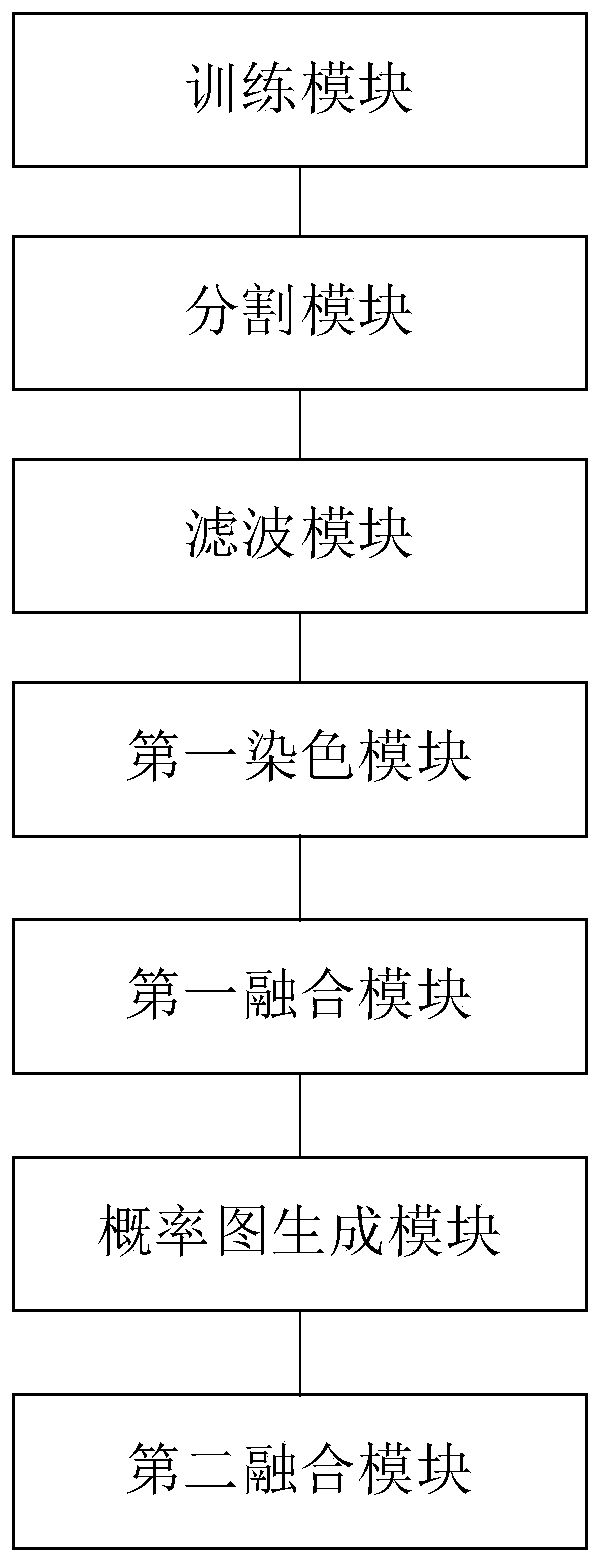

Refined photo hair dyeing method and system

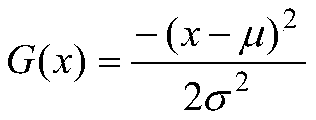

ActiveCN110969631AReduce the impactOvercoming the problem of over-reliance on segmentation modelsImage enhancementImage analysisRadiologyNetwork model

The invention discloses a refined photo hair dyeing method and system, and the method comprises the steps: S1, carrying out the segmentation network model training of hair sample data based on a convolutional neural network; s2, performing hair region segmentation on the original picture based on the trained segmentation network model to obtain a segmentation picture mask; s3, performing Gaussianfiltering on the segmentation image mask to obtain a filtering effect image; s4, obtaining a hair area in the original picture according to the filtering effect picture, and performing color adjustment on the hair area to obtain a first dyed picture; s5, performing Alpha fusion on the original picture, the filtering effect picture and the first dyed picture to obtain a second dyed picture; s6, calculating a hair probability graph based on the original picture; and S7, performing refined hair fusion on the original picture, the second dyed picture and the hair probability graph to obtain a final dyed hair picture. According to the method, the hair probability graph is calculated, the influence of areas such as skin and clothes on hair dyeing is effectively weakened, transition is natural, and the sense of discomfort is small.

Owner:HANGZHOU QUWEI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com