Dyeing method of rayon elastic knitted fabric

A dyeing method and technology for knitted fabrics, which are applied in the dyeing field of rayon elastic knitted fabrics, can solve the problems of color fastness, low utilization rate of uniform dyestuffs, unstable dyeing quality, low dyeing rate, etc., and achieve dyeing effect Good, improve smoothness, strong color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

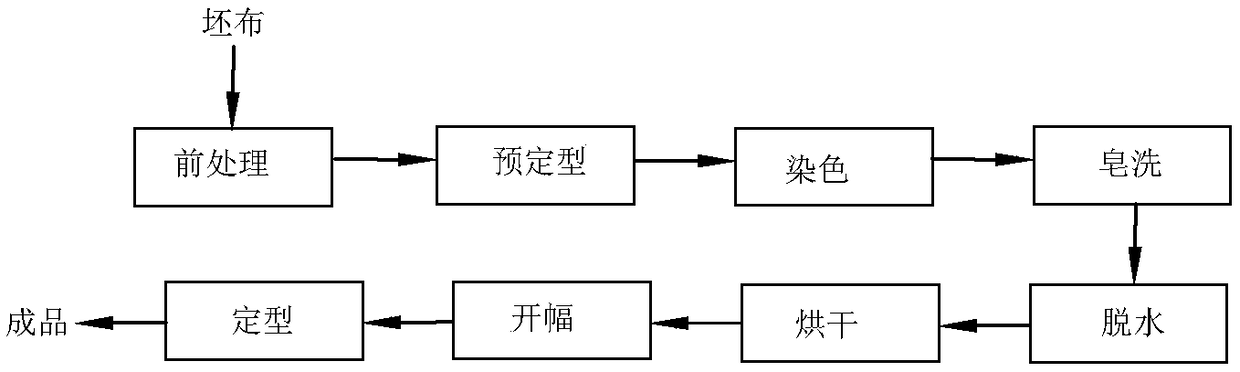

[0023] A method for dyeing rayon elastic knitted fabric, comprising the following steps:

[0024] a) Pre-treatment, arrange the rayon elastic knitting in the desizing machine, add 2g / L of deoiling spirit, 7g / L of soda ash, 4g / L of hydrogen peroxide, the bath ratio is 1:15, and the water bath is heated up at a rate of 1.5°C / min, when the temperature rises to 80°C, keep it warm for 10 minutes, then cool down in a water bath at a rate of 2°C / min, and when the temperature drops to 45°C, discharge the waste water and inject cold water for 10 minutes;

[0025] b) Pre-setting, arrange the pre-treated rayon elastic knitting on the pre-setting machine, the temperature is controlled at 160°C; the speed is 30m / min;

[0026] c) Dyeing, put the pre-shaped rayon elastic knitted fabric into the dyeing machine, add reactive dye 0.5% owf, leveling agent alkyl polyoxyethylene ether 0.1g / L, soda ash 0.4 g / L, chelating dispersant sodium lignosulfonate 0.4g / L, bath ratio 1:20, then heat up in w...

Embodiment 2

[0033] A method for dyeing rayon elastic knitted fabric, comprising the following steps:

[0034] a) Pre-treatment, arrange the rayon elastic knitting in the desizing machine, add 3g / L of deoiling spirit, 9g / L of soda ash, 6g / L of hydrogen peroxide, the bath ratio is 1:15, and the water bath is heated up at a rate of 1.5°C / min, when the temperature rises to 90°C, keep it warm for 20 minutes, then cool down in a water bath at a rate of 2°C / min, and when the temperature drops to 50°C, discharge the waste water and inject cold water for 15 minutes;

[0035] b) Pre-setting, arrange the pre-treated rayon elastic knitting on the pre-setting machine, the temperature is controlled at 170°C; the speed is 35m / min;

[0036] c) Dyeing, put the pre-shaped rayon elastic knitted fabric into the dyeing machine. L, chelating dispersant sodium lignosulfonate 0.7g / L, bath ratio 1:20, then heat up in a water bath at a rate of 1°C / min, when the temperature rises to 70°C, keep warm for 40min, dis...

Embodiment 3

[0043] A method for dyeing rayon elastic knitted fabric, comprising the following steps:

[0044] a) Pre-treatment, arrange the rayon elastic knitting in the desizing machine, add 5g / L of deoiling spirit, 11g / L of soda ash, 8g / L of hydrogen peroxide, the bath ratio is 1:15, and the water bath is heated up at a rate of 1.5°C / min, when the temperature rises to 100°C, keep it warm for 30 minutes, then cool down in a water bath at a rate of 2°C / min, and when the temperature drops to 60°C, discharge the waste water and inject cold water for 20 minutes;

[0045] b) Pre-setting, arrange the pre-treated rayon elastic knitting on the pre-setting machine, the temperature is controlled at 180°C; the speed is 45m / min;

[0046] c) Dyeing, put the pre-shaped rayon elastic knitted fabric into the dyeing machine, add reactive dye 4%owf, leveling agent alkyl polyoxyethylene ether 0.3g / L, and soda ash 1g / L in the water bath at room temperature , chelating dispersant sodium lignosulfonate 1g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com