Patents

Literature

93results about How to "Strong color fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural hair dye prepared by using phytochrome curcumin and hair dyeing method of natural hair dye

InactiveCN102423286AImprove dyeing effectEasy to floatCosmetic preparationsHair cosmeticsPolyolHair dyes

The invention relates to a hair dye, in particular to a natural hair dye prepared by using phytochrome curcumin and a hair dyeing method of the natural hair dye. The hair dye comprises an agent A and an agent B, and is characterized in that: the agent A contains 0.1 to 10 weight percent of curcumin, 20 to 50 weight percent of polyol, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant and the balance of water, and the pH value is regulated to be 3 to 7; and the agent B contains 1 to 10 weight percent of metal ion mordant, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant, 0.1 to 0.3 weight percent of natural essence and the balance of water, and the pH value is regulated to be 3 to 7. The hair dyeing method comprises the following steps of: uniformly spreading the agent A on the hair when the hair is dyed, and dyeing the hair for 10 to 40min at the temperature of between normal temperature and 60 DEG C; and uniformly spreading the agent B on the hair, mordanting for 10 to 20min, cleaning the hair and blow-drying. The curcumin has a good dyeing effect and also has the effects of resisting bacteria and protecting skin. Reagents which are toxic to human bodies are not used in the hair dye, and substances which are toxic to the human bodies are also not generated in the hair dyeing process, so the hair dye is high in safety. The adopted curcumin is insoluble in water and cannot fall off easily in the washing process, so the hair dye has a good dyeing effect, and the color of the dyed hair can be kept for a long time.

Owner:JIANGNAN UNIV

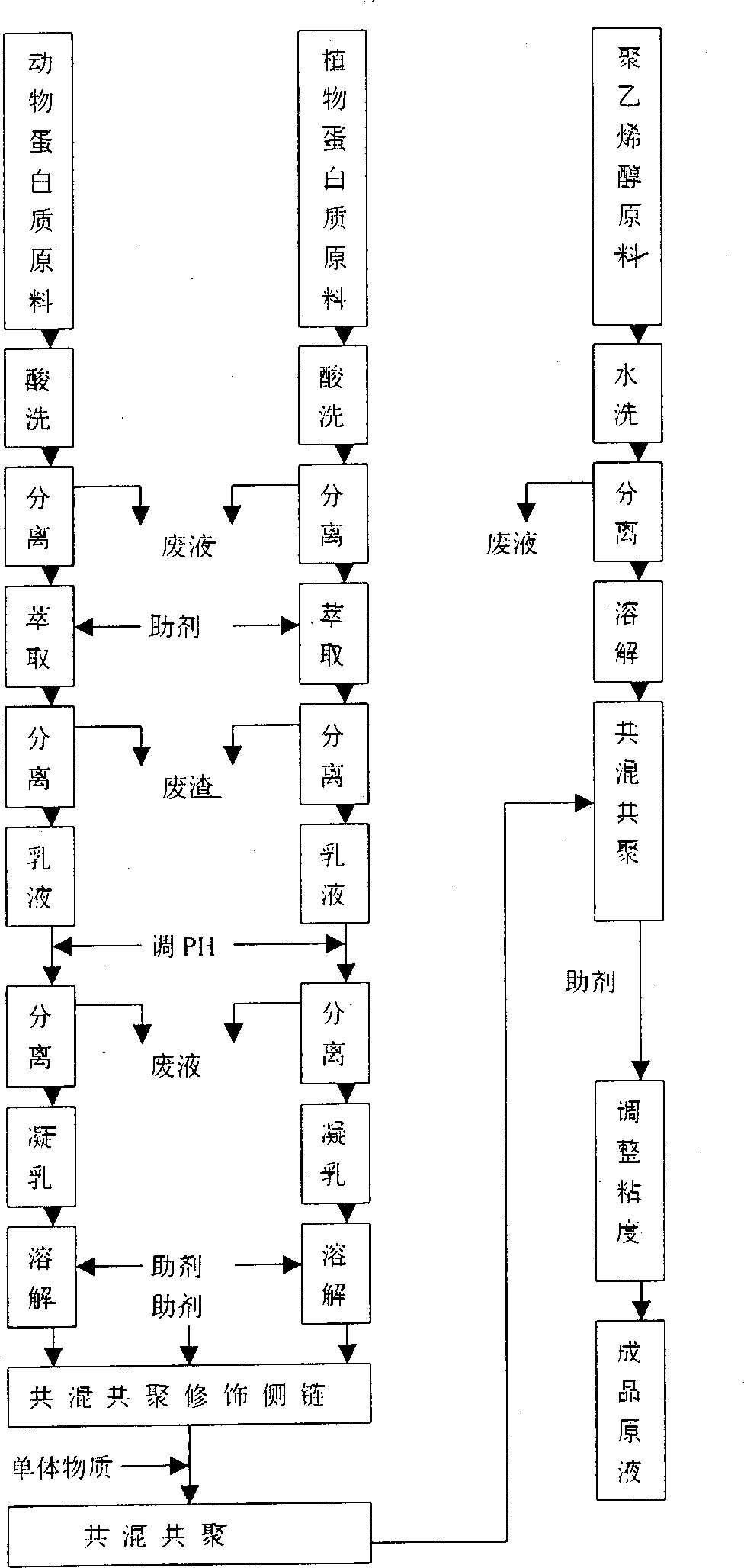

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

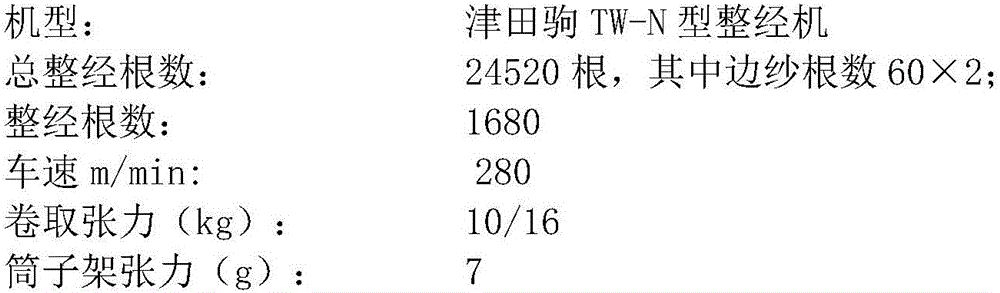

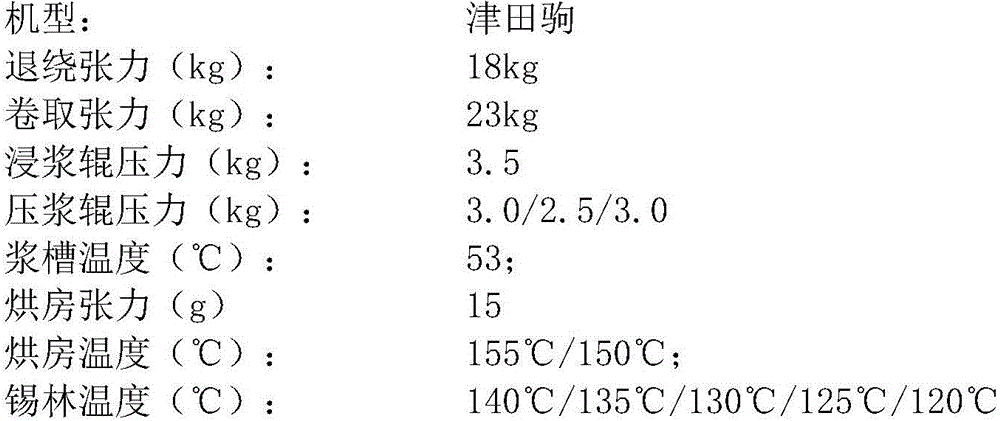

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

Chemical coloring method for copper and alloys of copper

ActiveCN102031509AUniform tooth colorStrong color fastnessMetallic material coating processesZincBronze color

The invention discloses a chemical coloring method for copper and alloys of copper, which comprises the following steps of: firstly, abrading and polishing the surface of an copper alloy to be colored; and then, activating the surface of the copper alloy to be colored and washing; microetching the surface of the copper alloy to form a light yellow zinc-enriched membrane layer on the surface of the copper alloy; reacting making the zinc-enriched membrane layer on the surface of the copper alloy react with chemical coloring liquid to generate a metallic compound membrane layer of selenium, wherein the color of the metallic compound membrane layer is reddish black, also calledi.e. red bronze color. A zipper made by the method disclosed in the invention has simulated bronze teeth which have even color and strong color fastness.

Owner:HUA SHENG ZIPPER

Production of offset thermal transfer paper and transfer method thereof

InactiveCN101590751AStrong color fastnessVariety of colorsTransfer printingThermographyPulp and paper industryMetal sheet

The invention discloses production of offset thermal transfer paper and a transfer method thereof. The method for producing the offset thermal transfer paper comprises the following steps: designing a transfer pattern; separating colors of the pattern by a computer so as to produce each color separating film after color separation; exposing and printing down by each color separating film; producing a color separating printed backplane; and assembling the printed backplane on an offset printer, and separately overprinting the pattern on thermal transfer paper for printing by transfer ink to produce the offset thermal transfer paper. The method for transferring a metal plane sheet comprises the following steps: removing impurities on the metal surface to be transferred, and coating paint on the surface; attaching the surface of the offset thermal transfer paper printed with the transfer ink to the metal surface with a paint film; heating the metal surface to a temperature of between 190 and 200 DEG C by a flat-bed press; pressing the offset thermal transfer paper and the paint film to ensure that the offset thermal transfer paper and the surface of the paint film are attached closely; and peeling off the transfer paper to complete transfer of the pattern after heating and pressing for 33 to 40 seconds. The method for transferring on fabrics is similar to that of on the metal sheet, but paint is not painted.

Owner:周福根

Dye of walnut green husk prepared by walnut green husk, its preparation method and method for dyeing fabric

ActiveCN102516804AThe method steps are simpleEasy to operateClimate change adaptationEnergy inputHuskWarm water

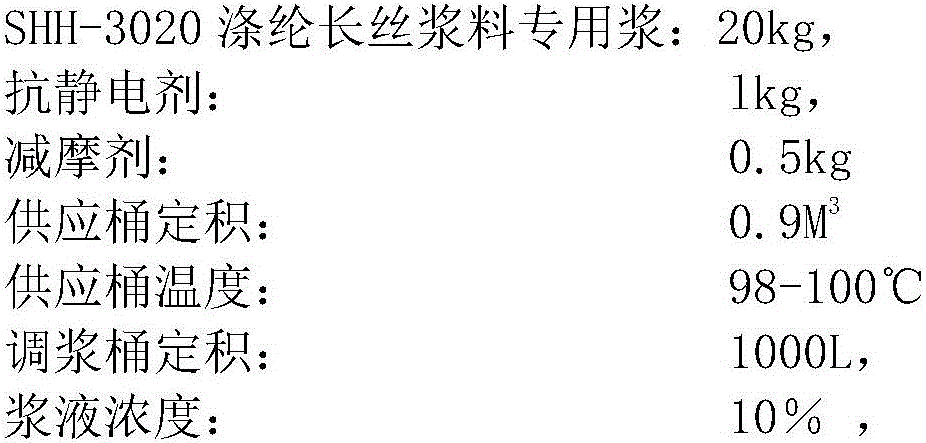

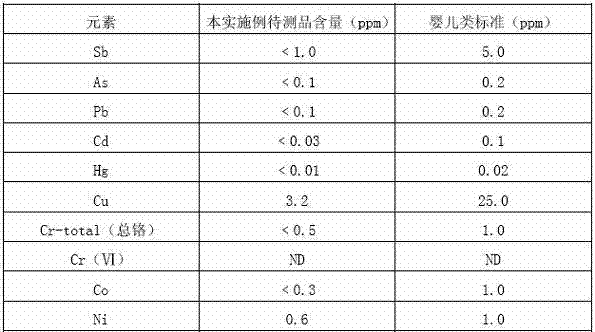

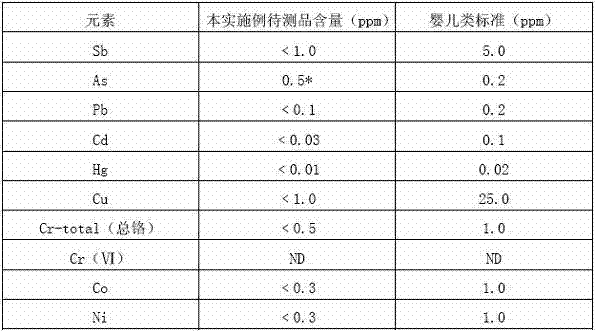

The present invention discloses a dye of walnut green husk prepared by walnut green husk, its preparation method and a method for dyeing fabric. The preparation method comprises the following steps dechlorinating the tap water and softening for next application; heating a part of dechlorination softened water to 60-65 DEG C; drying, crushing and cleaning the collected walnut peel; then putting the peels in warm water to soak for 8-12 hours according to mass ratio of 10.008-0.012 8-12 of the walnut peel to sodium hydroxide solid to water; moving the soaked solid-liquid mixture into a filter, collecting the filtrate; then placing the filtrate into a vacuum evaporator to concentrate, concentrating 10 parts of the filtrate to 2-5 parts; and then adding ferrous sulfate and sodium chloride into the concentrated solution to prepare the dye for dyeing. The steps of the present invention are easy to operate, and each indicator of the fabric dye accordance with the method is superior to the standard indicators of synthetic dyes for baby fabric.

Owner:常州云卿生物科技有限公司

Resin composition for water-based high-performance color gloss coating and preparation method of resin composition

The invention discloses a resin composition for a water-based high-performance color gloss coating and a preparation method of the resin composition. The resin composition is prepared from 30%-60% of water-based castor oil-modified alkyd resin and 40%-70% of water-based acrylic resin, wherein the water-based castor oil-modified alkyd resin is mainly prepared from castor oil, trimethylolpropane, phthalic anhydride, trimellitic anhydride, butoxyethanol, n-butyl alcohol and xylene; and the water-based acrylic resin is prepared from a solvent, methyl methacrylate, butyl acrylate, styrene, hydroxyethyl methylacrylate, crylic acid, benzoyl peroxide, tert-butyl peroxybenzoate, ammonium hydroxide and water. The pigment disclosed by the invention is easily dispersed to below 10 microns, and is stable in storage; the prepared coating performance is excellent; and the glossiness of a film is not reduced during adding water and diluting.

Owner:肇庆千江高新材料科技股份公司

Pure natural plant dyeing process of full-manual natural grass cloth

ActiveCN103451964ASoft textureImprove wrinkle resistanceBleaching apparatusDyeing processPulp and paper industryCrocus

The invention provides a pure natural plant dyeing process of a full-manual natural grass cloth. The process comprises the following steps of 1, preparing dyeing liquid through raw materials; sealing and storing; 2, soaking a grey grass cloth in water containing soda; transferring into a sealing container to naturally ferment for one week; 3, pulling out the cloth and cleaning through clean water and sulfuric acid; transferring into equipment to boil off; bleaching after boiling off; cleaning to remove impurities on the grey cloth; 4, adjusting the dyeing liquid; pouring into a dyeing machine to dye for the first time; and 5, adding a dye-fixing agent to the dyeing machine for solid wash, dyeing for the second time, drying after dyeing; arranging, sizing, and warehousing. According to the pure natural plant dyeing process of the full-manual natural grass cloth, gardenia jasminoides, coptis chinensis, saffron crocus, isatis root, persimmon and other plants are used for dyeing; the made clothes or household goods are soft, draped, straight, comfortable, antibacterial, health-care, warm in winter and cool in summer, high in wrinkle resistance and outstanding in air permeability, and have the effects of dissipating heat and clearing damp. The full-manual natural grass cloth is lightweight and anti-mildew, and is an outstanding pure natural green and health care fabric.

Owner:RONGCHANG YIHE TEXTILE CO LTD

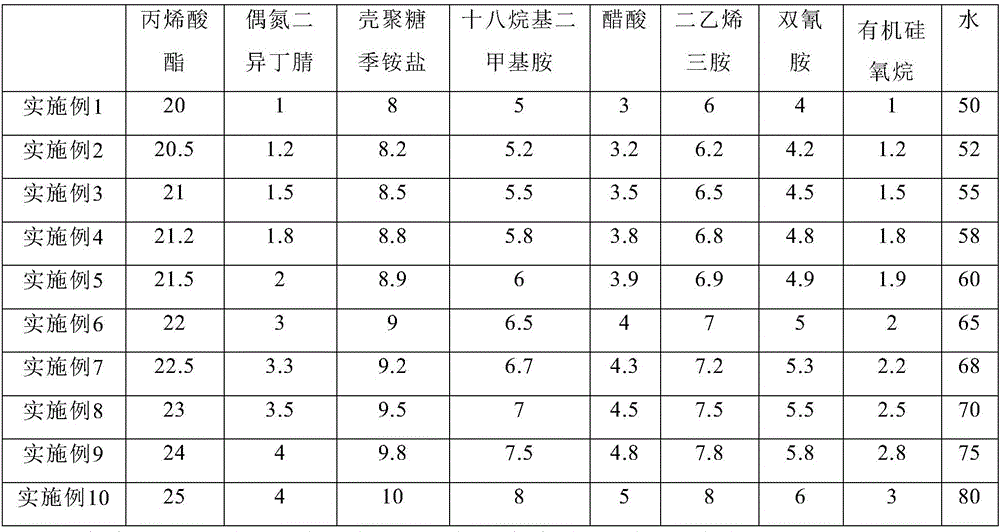

Fabric color fixing agent for clothing and preparation method thereof

The invention provides a fabric color fixing agent. The fixing agent is prepared from, by weight, 20-25 parts of acrylic ester, 1-4 parts of azodiisobutyronitrile, 8-10 parts of chitosan quaternary ammonium salt, 5-8 parts of octadecyl dimethyl amine, 3-5 parts of acetic acid, 6-8 parts of diethylenetriamine, 4-6 parts of dicyandiamide, 1-3 parts of organic siloxane and 50-80 parts of water. The invention further provides a preparation method of the fixing agent. The preparation method comprises the following steps that a formula amount of acrylic ester is mixed with the azodiisobutyronitrile, heating is performed to reach 45-60 DEG C, reaction is performed during stirring for 2-4 hours, the residual components are added according to the formula amounts after cooling is performed to reach room temperature, reaction is performed during stirring for 1-1.5 hours to obtain the fixing agent. The fixing agent is non-toxic, formaldehyde-free, green and environmentally friendly, has no harm to human and strong color fastness, is antibacterial, anti-wrinkle and antistatic, a preparation process is simple, reaction conditions are mild, and the raw materials are easy to obtain.

Owner:太仓红桥服饰有限公司

Aromatic, hydrophilic and antistatic composite functional polyester fibers as well as preparation method and application

InactiveCN105803574AImprove hydrophilic abilityWith antistatic functionElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterPolymer science

The invention discloses a preparation method of aromatic, hydrophilic and antistatic composite functional polyester fibers. High-temperature-resisting powdery essence is selected and uniformly mixed with low-smelting-point polyester powder, an antistatic agent, a dispersant, a coupling agent and an anti-oxidant, and then the mixture is extruded and granulated to prepare aromatic polyester master batches. Double-screw-rod composite spinning equipment is adopted, a mixture of the aromatic polyester master batches and low-smelting-point polyester slices is used as a core and a constant-pressure cation dyeable polyester chip is used as a skin to prepare the aromatic, hydrophilic and antistatic composite functional polyester fibers. The composite functional polyester fibers prepared by the invention can release aromatic flavor for a long period and have washing endurance; the hydrophilic property is strong and the moisture regain reaches more than 0.8 percent; the aromatic, hydrophilic and antistatic composite functional polyester fibers have an antistatic function and the specific resistance is M*10<7>omega.CM (M is more than or equal to 1.0 and less than 10); the aromatic, hydrophilic and antistatic composite functional polyester fibers are easily colored and strong in color fastness.

Owner:HIGHTEX CO LTD ZHEJIANG

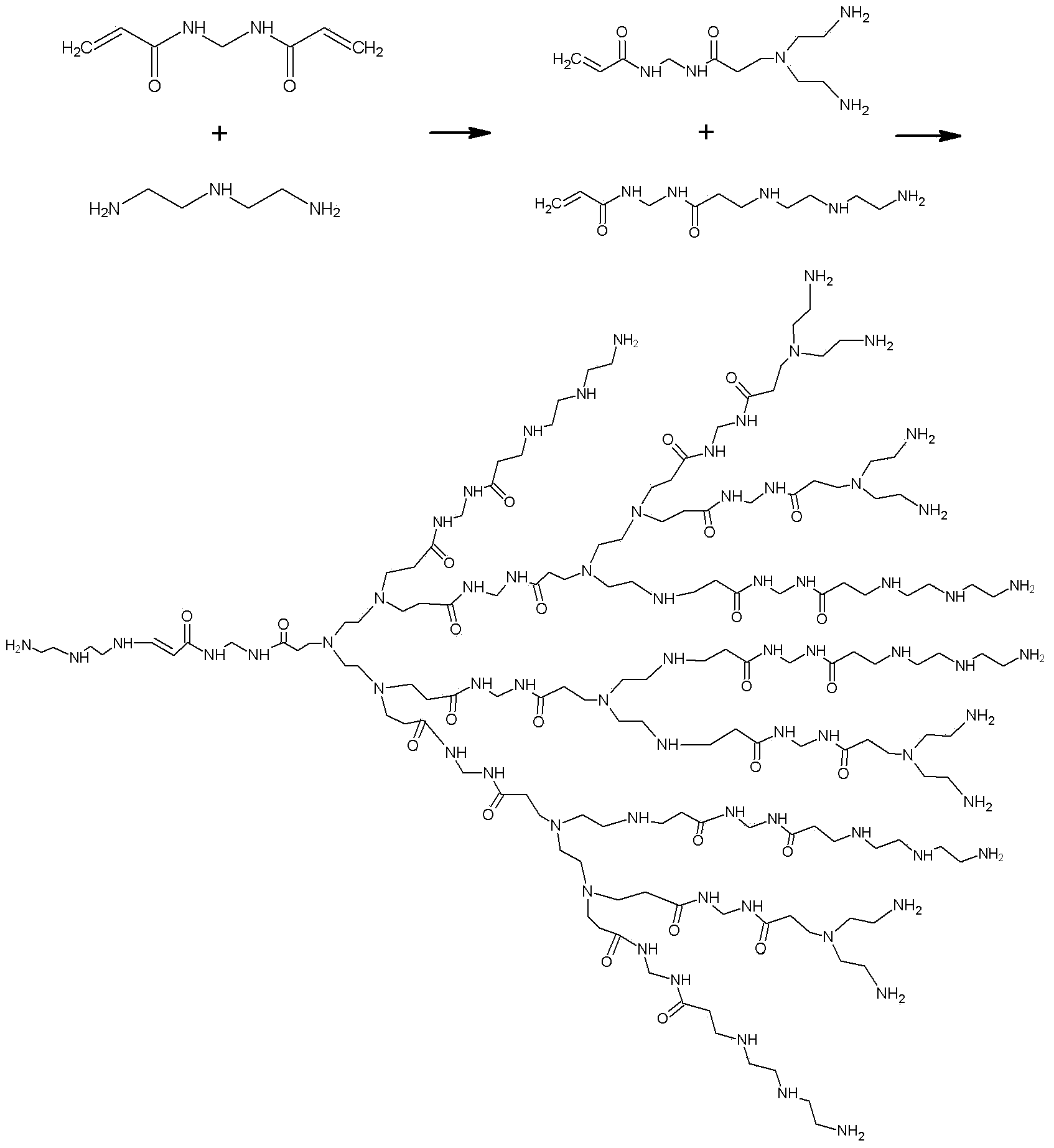

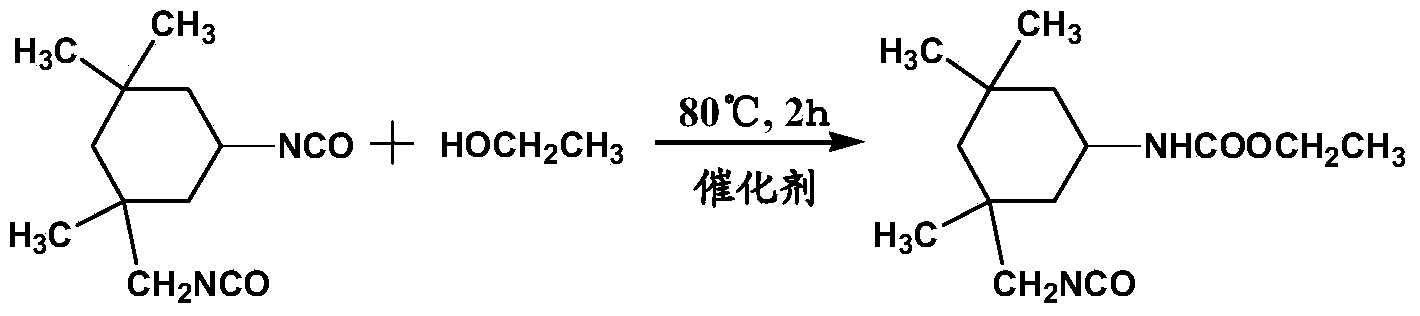

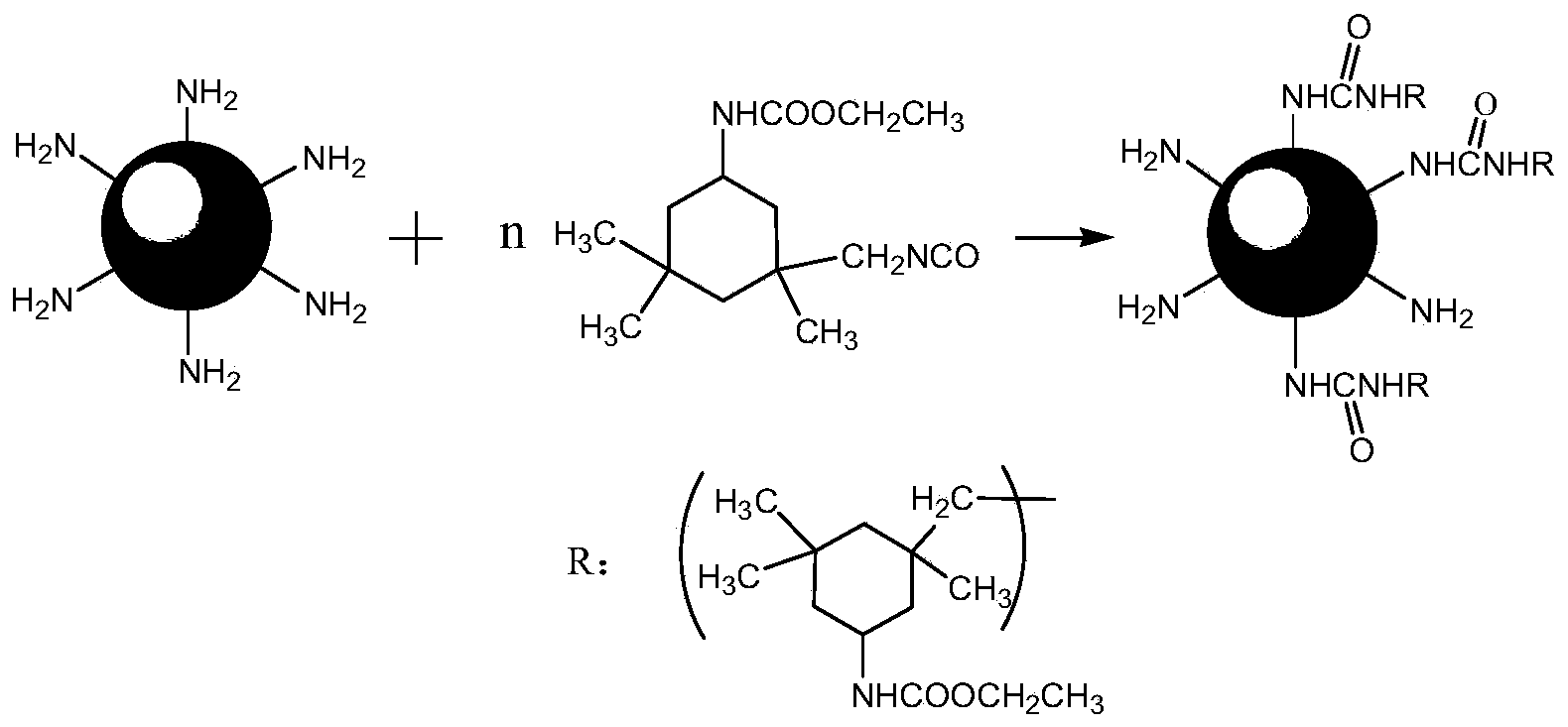

Preparation method for dyeable polyurethane film

The invention discloses a preparation method for a dyeable polyurethane film. The preparation method comprises the following steps: firstly, adding N, N-methylene bisacrylamide and diethylenetriamine into N, N-dimethylformamide to prepare an amino-terminated hyperbranched polymer; terminating the obtained product by using ethanol terminated isophorone diisocyanate; then, adding the terminated product into an N, N-dimethylformamide solution of polyurethane to prepare a casting film solution; pouring the casting film solution on a substrate; dipping in a coagulating bath to form a film by a wet process; and drying to obtain the dyeable polyurethane film. According to the film prepared by the method, as an active group -NH2 is introduced into a component of the film, bonding points of the dye are increased. Moreover, in an acidic solution, the film has positive charges, so that an anionic dye is gradually bonded with amino (P-NH3+) with positive charges in the film by virtue of ionic bonds to play a dyeing effect, thereby improving the dyeing rate and the color fastness. Meanwhile, the method is simple, convenient and feasible to operate, low in requirements on equipment and easy for industrial popularization.

Owner:汕头市亮彩新材料科技有限公司

Method for dyeing plant straw with gradient color

The invention relates to a method for dyeing plant straw with the gradient color. The method is completed through the following steps that the head end and the tail end of the plant straw or rattan are removed; the plant straw or rattan is cleaned, and impurities and impurities covering the outer surface of the plant straw or rattan are removed; the plant straw or the rattan is soaked in a POE flexibilizer, and the plant straw or the rattan is taken out and cleaned and is dried or aired until the water content reaches 10%-18%; vulcanization treatment is conducted on the plant straw or the rattan; and glue and a stiffening agent are applied to the head of the plant straw or the rattan. According to the method for dyeing the plant straw with the gradient color, coloring treatment is conducted on a raw material used for weaving so that the single color of the single material has the gradient color effect, a woven product is bright in color, and the awkward situation that at present, the color is single and old-fashioned is changed; a groove is punched in the outer surface of the plant straw or the rattan, dye is accumulated in the groove and is different from a normal surface, and therefore the color in the groove after dyeing is obviously different from the color of the normal surface, and the artistic effect of embellishment is achieved.

Owner:金惠萍

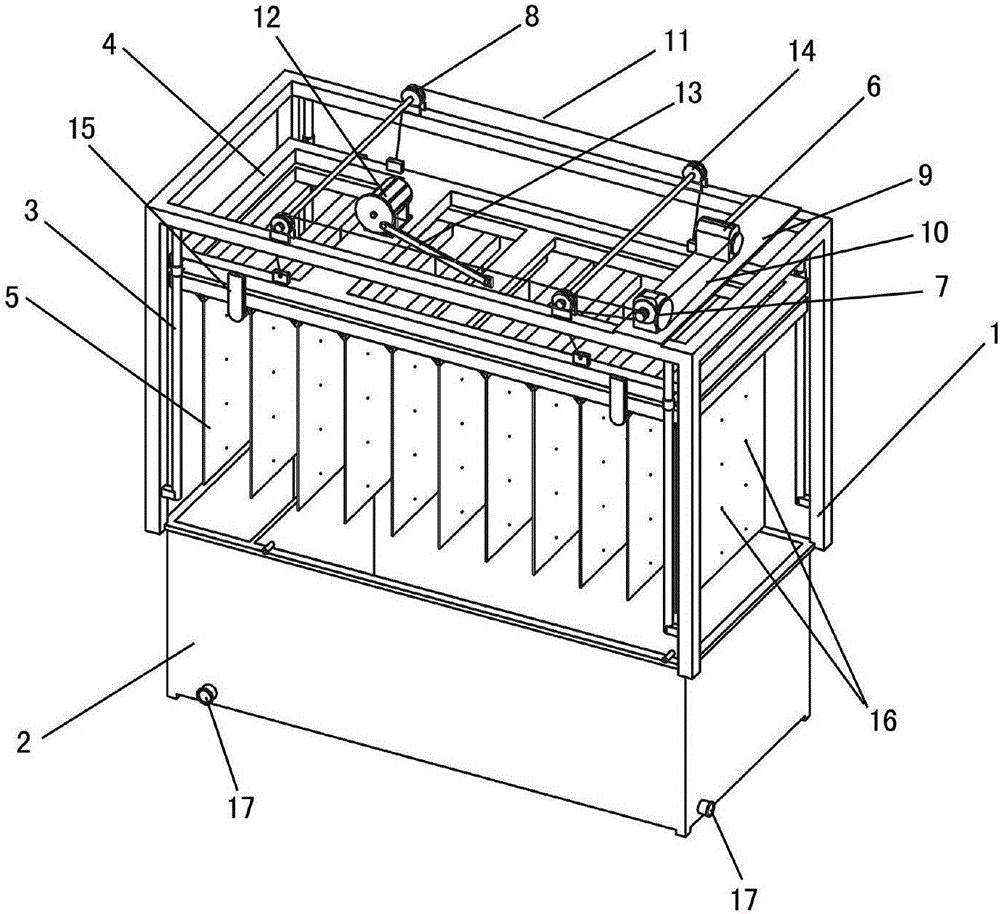

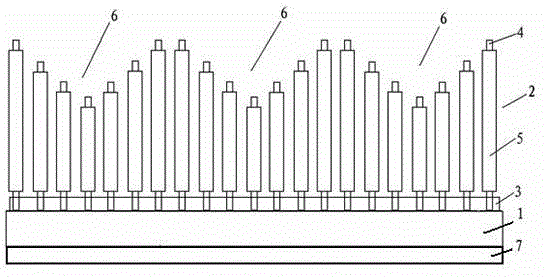

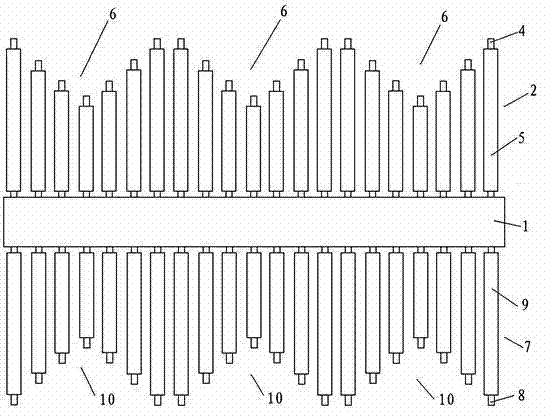

Tibet lamb skin space dyeing process and space dyeing device thereof

ActiveCN106320016ABroaden the field of applicationIncrease added valueLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringReagent

The invention discloses a Tibet lamb skin space dyeing process and a space dyeing device thereof. The process includes the steps of retanning, degreasing, dip dyeing, space dyeing and washing and drying. The process is characterized in that according to space dyeing, Tibet lamb skin obtained after dip dyeing and drying is hung on the space dyeing device, a space dyeing reagent and water are added into a dye liquor tank for heating to 65-70 DEG C, and then corresponding dyes are added for dyeing stage by stage. The space dyeing device thereof comprises a rack, the dye liquor tank is arranged at the bottom of the rack, a lifting rod is arranged on the rack, a movable platform is arranged at the upper end of the lifting rod, and multiple pieces of space dyeing toggling are installed below the movable platform; a lifting control mechanism is arranged above the rack and comprises a motor I, a transmission and a fixed pulley set, the motor I is connected with one end of the transmission through a belt, and the other end of the transmission is connected with the fixed pulley set through a chain. An auxiliary material and the space dyeing device are combined for dyeing, the process is simple, finished products with the art sense are obtained according to requirements, the color fastness of the products is high, layering is distinct, the application fields of the Tibet lamb skin are greatly widened, and the added value of the Tibet lamb skin is greatly increased.

Owner:NINGXIA WUZHONG JINGYI FUR PROD

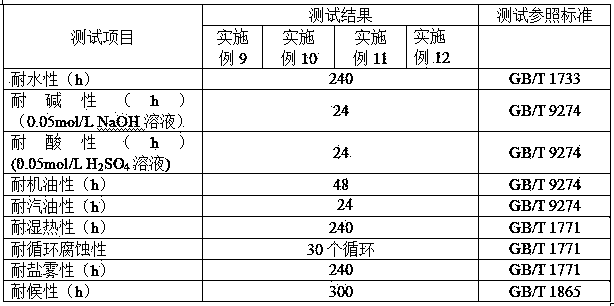

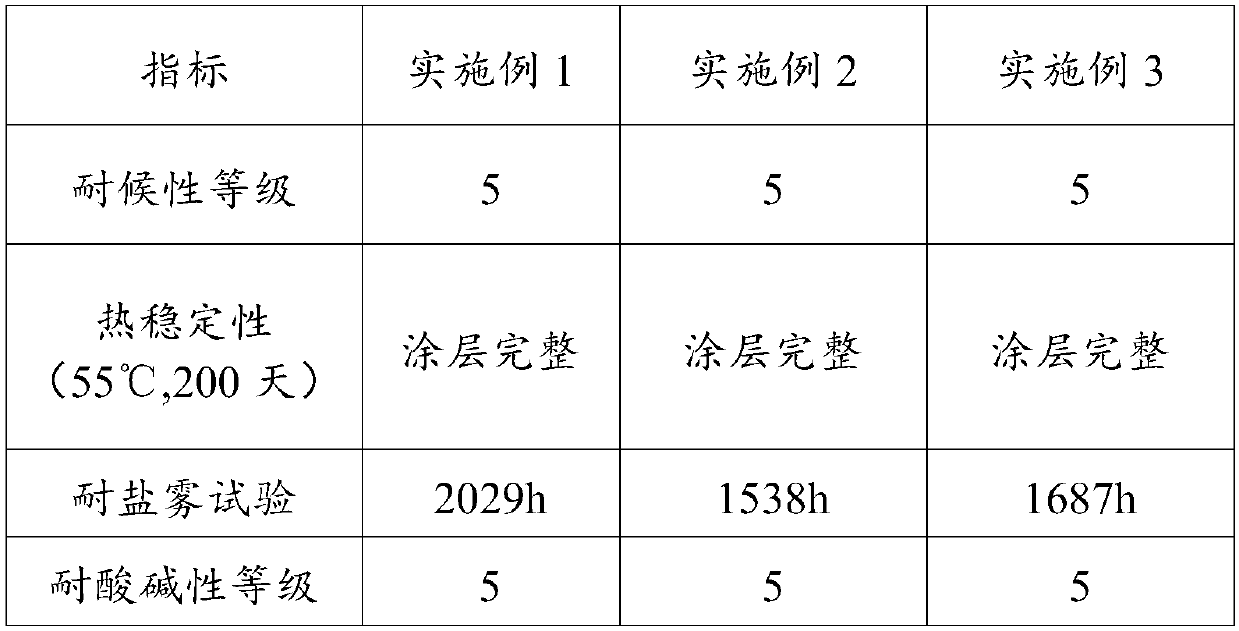

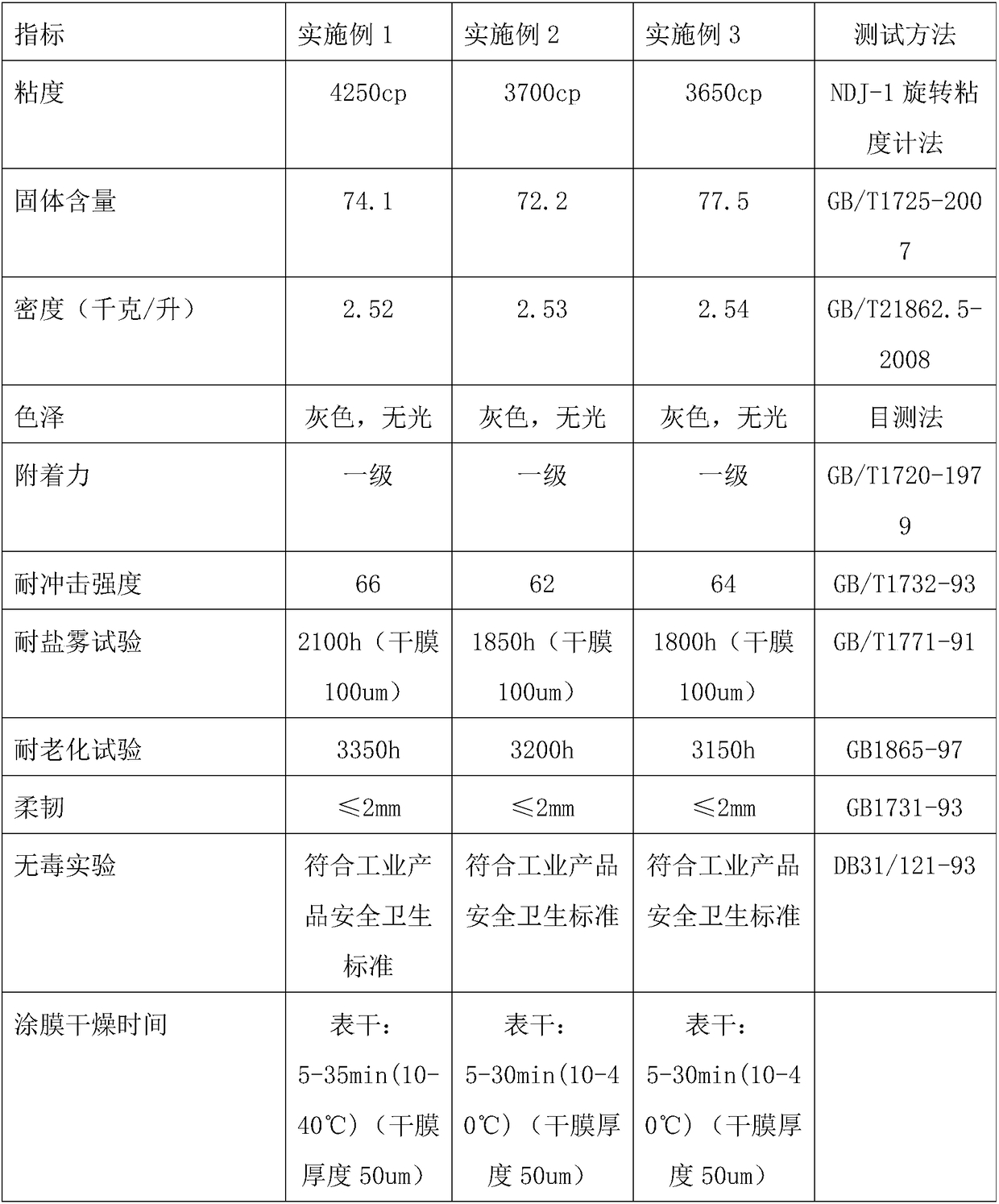

Rare-earth colorful anticorrosive water-based paint and preparation method thereof

ActiveCN109575774AImprove water resistanceImprove aging resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedHigh resistance

The invention relates to rare-earth colorful anticorrosive water-based paint and a preparation method thereof. The rare-earth colorful anticorrosive water-based paint, made from polystyrene-acrylic resin, water-based polyurethane, silane coupling agents, surfactants, water, a rare earth colorant solution system, wetting agents, fillers, defoamers, dispersants, antioxidants and UV absorbers in an appropriate weight ratio, are non-toxic and harmless; no organic solvent is volatilized during storage and use, and environmental protection is achieved; the rare-earth colorful anticorrosive water-based paint has high resistance to acid, alkali, corrosion, water and aging, strong color fastness and high adhesion; paint layers formed after coating have high toughness, gloss and adhesion and do notcontain residual toxic and harmful small molecular substances and toxic heavy metals to achieve high safety; the coating speed of the paint and the production efficiency are high, the coating amount per unit area is small, the energy consumption is low, and the cost can be greatly reduced.

Owner:BAOTOU RARE EARTH RES & DEV CENT CHINESE ACADEMY OF SCI

Process for producing color chitin viscose fibre spinning dope

InactiveCN1944721AIncrease productivityStrong color fastnessMonocomponent cellulose artificial filamentChitinEnvironmental chemistry

The process of producing color chitin viscose fiber spinning dope includes the following steps: 1. alkalizing the chitin material through soaking it in water solution of sodium hydroxide in the concentration of 10-60 % at the temperature from -15 deg.c to 40 deg.c for 20-600 min in the bath ratio of 2-30; 2. xanthating reaction to obtain viscous solution of chitin xanthate; and 3. mixing the viscous solution of chitin xanthate, viscose fiber spinning dope and coloring agent in certain weight proportion to react to obtain the color chitin viscose fiber spinning dope. Colorizing the spinning dope has greatly raised production efficiency, raised product color homogeneity and color fastness and lowered pollution and waste.

Owner:AOYANG SCI & TECH JIANGSU

Inorganic special historic building wall coating adopting flyash and preparation method thereof

ActiveCN103496932AGood natural colorFade resistantSolid waste managementEnvironmental resistanceBrick

The invention relates to an inorganic special historic building wall coating adopting flyash and a preparation method thereof. The inorganic special historic building wall coating adopting flyash is prepared by utilizing industrial waste residues including levigated flyash and levigated quicklime powder or levigated slaked lime powder as cementing materials and edible cane sugar as an additive. The coating is an inorganic chemical component composition comprising the following components in parts by weight: 50-60 parts of flyash, 20-30 parts of lime, 5-10 parts of edible cane sugar and 20-30 parts of water. The coating has the advantages that by utilizing the characteristic that the flyash is grey and coincides with the colors of the historic grey bricks of historic building walls, the coating has good natural color and is resistant to fading, without adding color matching pigments; meanwhile, the coating has better caking property and durability and has the function of maintaining the natural colors of historic buildings; the coating is waterproof, fireproof, antibacterial, anti-aging, nontoxic, harmless and environment-friendly and insulates heat and sound; environmental pollution is avoided in the preparation process and the using process; the flyash is recycled, so that the coating has good social and economic benefits.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

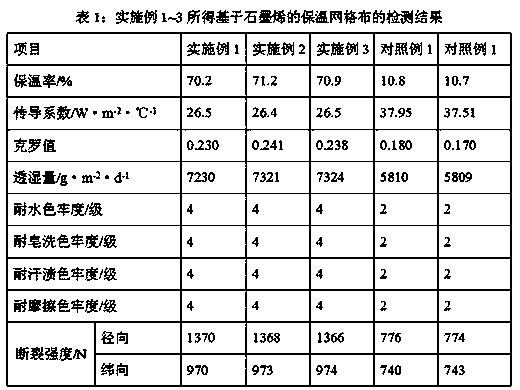

Thermal insulation mesh cloth based on graphene and preparation method thereof

ActiveCN108677325AImprove polyester strengthImprove thermal stabilityMelt spinning methodsWoven fabricsThermal insulationPolyester

The invention discloses a thermal insulation mesh cloth based on graphene and a preparation method thereof, and belongs to the technical field of grid cloth. The thermal insulation mesh cloth preparation method based on graphene comprises the following steps of: preparation of a first treatment agent, preparation of a second treatment agent, preparation of a grid material, preparation of polyestermonofilaments and preparation of a grid cloth. The thermal insulation mesh cloth based on graphene prepared by the method has the advantages of good hand feeling, strong air permeability, high colorfastness, long service life and strong thermal insulation effect.

Owner:FUJIAN FENGYUANSHENG TEXTILE TECH CO LTD

Methods for the manufacture of colorfast masonry

ActiveUS10717674B2High color intensitySecure adhesionLiquid surface applicatorsBacteriaMicroorganismBrick

The invention is directed to compositions and methods for the manufacture of pigmented solids structures for which can be used for construction and / or decoration. Manufacturing comprises fixing one or more pigments to an aggregate material such as crushed rock, stone or sand. The pigmented aggregate is incubated with urease or urease producing microorganisms, an amount of a nitrogen source such as urea, and an amount of calcium source such as calcium chloride forming calcite bridges between particles of aggregate. The resulting solid has a hardness and colorfastness for most any construction material. Using selected aggregate and pigment, the process also provides for the manufacture of simulated-stone materials such as clay or granite bricks or blocks, marble counter-tops, and more. The invention is also directed to composition containing microorganisms and pigment as kits that can be added to most any aggregate materials.

Owner:BIOMASON

Indoor wide seamless glass bead composite decorative material and preparation technology thereof

The invention discloses an indoor wide seamless glass bead composite decorative material, sequentially comprising a base material, an ink absorption resin coating, an adhesive layer, a glass bead particle film formation layer and a protective layer, wherein the base material is a polyvinyl chloride (PVC) foamed base material; the ink absorption resin coating covers the base material, the adhesive layer is then added onto the absorption resin coating, the glass bead particle film formation layer formed by glass bead particles is placed on the adhesive layer, and the protective layer covers the glass bead particle film formation layer to serve as an outer layer. The invention also discloses a preparation technology of the indoor wide seamless glass bead composite decorative material. The indoor wide seamless glass bead composite decorative material fills in a gap of a material between a hard decorative material and a soft decorative material, and the wide and seamless material is in accordance with the requirement of a market for perfectness of new material products, so that the indoor wide seamless glass bead composite decorative material is wide in application scope and can be applied in the industries such as home decoration, industrial decoration, wall surfaces, furniture veneers, decorative pictures, tourism products and artware; after the technology is adopted, the width of 3.2m can be reached, so that the problems that terminal consumer groups depend on the craftsmanship of a construction master worker, are afraid of seams and are worried about the defects of products can be thoroughly solved; the indoor wide seamless glass bead composite decorative material is perfect in visual effect and hand touch.

Owner:田芳

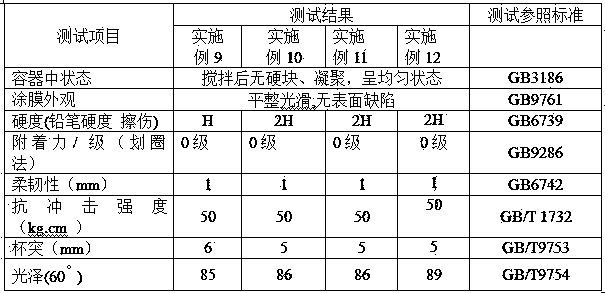

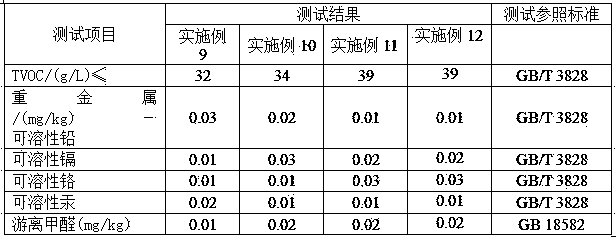

Highly-anticorrosive water-based coating for containers, and preparation method thereof

InactiveCN108300235AStrong color fastnessImprove adhesionFireproof paintsAnti-corrosive paintsWater basedBoron carbide

The invention provides a highly-anticorrosive water-based coating for containers, and a preparation method thereof, and relates to the technical field of coatings. The highly-anticorrosive water-basedcoating for containers comprises, by weight, a mixture of polyurethane resin and a polystyrene-acrylate emulsion, a silicon-acrylic emulsion, heavy calcium carbonate, talcum powder, titanium dioxide,kaolin, boron carbide, aluminum silicate, graphite powder, an iron pigment, borax, a film forming aid, a thickener, an anti-aging agent, an antioxidant 3010, an antifoaming agent HT6520, a dispersant, a heat stabilizer, a surfactant, ammonia water, polytetrafluoroethylene and water. The preparation method includes the following steps: weighing above raw materials, and mixing and stirring the weighed raw materials. The highly-anticorrosive coating for containers has the advantages of strong color fastness, good adhesion, good flame resistance and good corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Thermal transfer printing process of moisture-absorption quick-dry fabric based on regenerated polyester fibers

InactiveCN105714583ALightfast washableStrong color fastnessTransfer printing processDyeing processPolyesterFiber

The invention discloses a thermal transfer printing process for moisture-absorbing and quick-drying fabrics based on regenerated polyester fibers, which comprises the following steps: firstly, a blended fabric of raw materials in the following weight percentages is used: 85% regenerated polyester fibers, 15% tencel; After the alkali reduction process, it has dilution and quick-drying properties, and then uses a digital inkjet cutting machine and a manual flat heat transfer machine for fabric heat transfer printing. The thermal transfer printing fabric of the present invention has the characteristics of fastness to light and washing, strong color fastness, and rich and bright colors, and because the pattern is printed on the paper in advance, it eliminates the shortcomings of inaccurate alignment and defects, so the thermal transfer There are basically no defective products in printing.

Owner:ZHEJIANG DUNNU UNITED IND

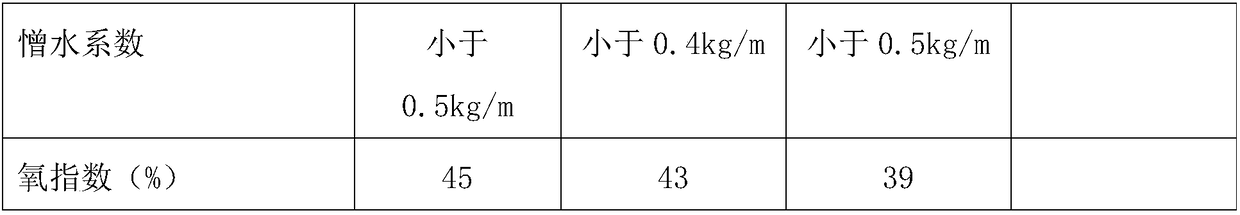

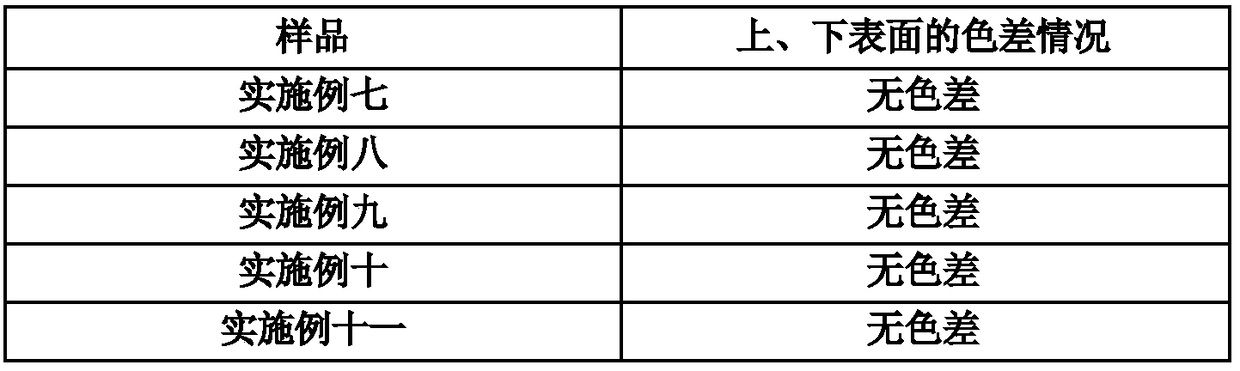

Saponification dyeing method of polyamide acetate fiber composite yarns

The invention provides a saponification dyeing method of polyamide acetate fiber composite yarns. The method includes the steps: (1) carrying out saponification modification treatment of the polyamideacetate fiber composite yarns which needs dyeing; (2) dyeing the polyamide acetate fiber composite yarns after saponification modification treatment with a reactive dye; (3) dyeing with a dispersed acidic dye; and (4) washing with water after dyeing. Firstly, an acetic acid fiber component contained in the polyamide acetate fiber filament composite yarns is subjected to partial saponification modification, after the modification of the acetic acid fiber, the reactive dye is adopted, dyeing is performed by a dispersed and acidic dye two-bath dyeing process, and the polyamide acetate fiber filament composite yarns are dyed by the creative dyeing method and have the advantages of bright color and luster, elegant luster, bright dyeing, strong dyeing fastness, and soft and smooth hand feeling.The soaping fastness of a dark color system can reach 4 level or more.

Owner:恒天宝丽丝生物基纤维股份有限公司

Etched-out velvet fabric

InactiveCN103057184AImprove the three-dimensional effect of printingGood flexibilityPattern makingLayered productsEngineeringCoating

The invention discloses etched-out velvet fabric. The etched-out velvet fabric comprises a horizontally arranged grey fabric layer, wherein a fluff layer formed by fleecing and fluffing one surface of the grey fabric is fixed at the top surface of the grey fabric layer; a first coating layer is also fixed at the top surface of the grey fabric layer; each fluff of the fluff layer runs through the first coating layer; each fluff is covered with a second coating layer; the second coating layer is connected to the first coating layer; the second coating layer is thinner than the first coating layer; the fluff layer is provided with at least a recess formed by roller printing; a third coating layer is also fixed at the bottom surface of the grey fabric layer; each recess has a petal-shaped section at the top surface of the fluff layer; more than two recesses are provided; and the depth of each recess decreases or increases progressively along the extension direction of the grey fabric layer. The etched-out velvet fabric not only has strong stereoscopic sensation of the printed patterns, but also keeps softness and hand feeling comfortableness of the etched-out velvet fabric efficiently, has strong color fastness, is not easy to fade, and has rational design and a simple structure.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

Two-sided etched-out velvet fabric

InactiveCN103042745AImprove the three-dimensional effect of printingGood flexibilityPattern makingLayered productsEngineeringCoating

The invention discloses two-sided etched-out velvet fabric, including a flat gray fabric layer. The top surface of the gray fabric layer is fixed with a first fluff layer formed by single-sided fleecing and fluffing. Each piece of fluff of the first fluff layer is covered with a first coating layer. The first fluff layer is provided with at least a first recess formed by roller printing. The bottom side of the gray fabric layer is fixed with a second fluff layer formed by single-sided fleecing and fluffing. Each piece of fluff of the second fluff layer is covered with a second coating layer. The second fluff layer is provided with at least a second recess formed by roller printing. The two-sided etched-out velvet fabric is strong in design three-dimensional character of printing, effectively maintains softness and comfort feeling of the velvet, and is strong in color fastness, not easy to fade, reasonable in design, and simple in structure.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

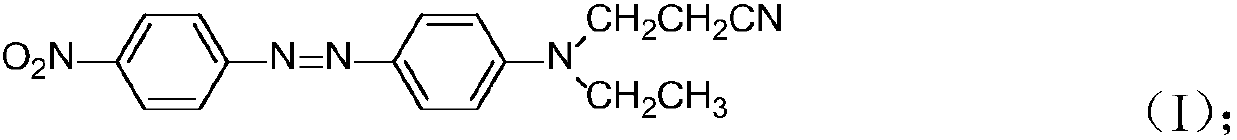

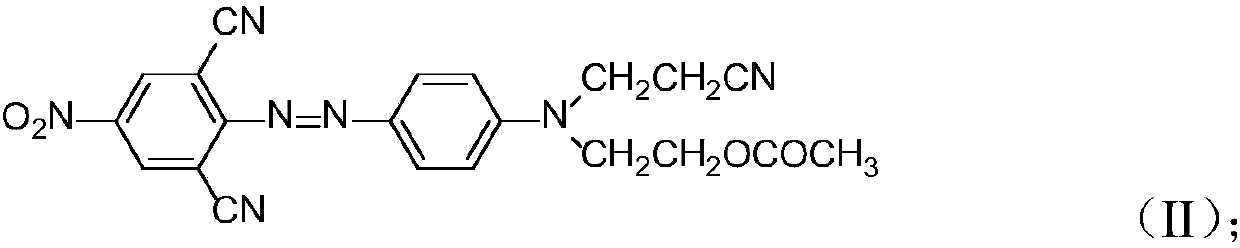

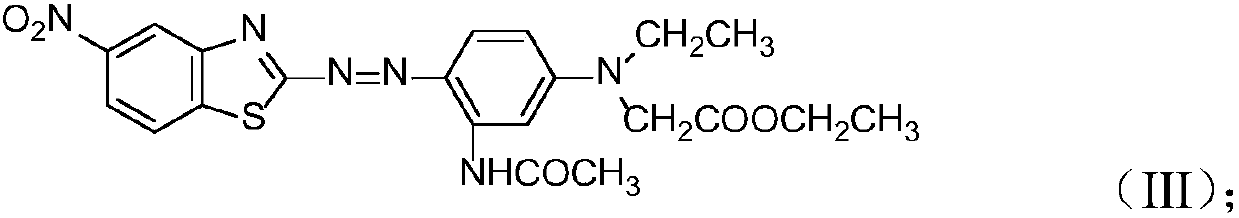

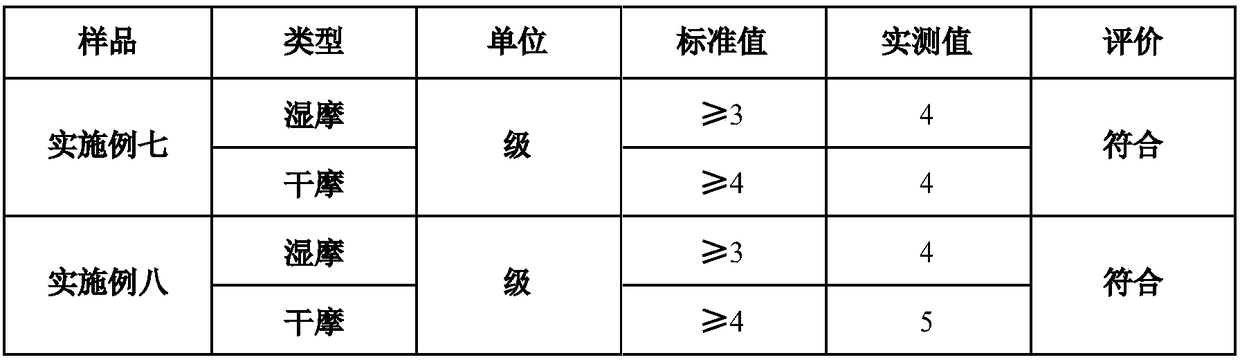

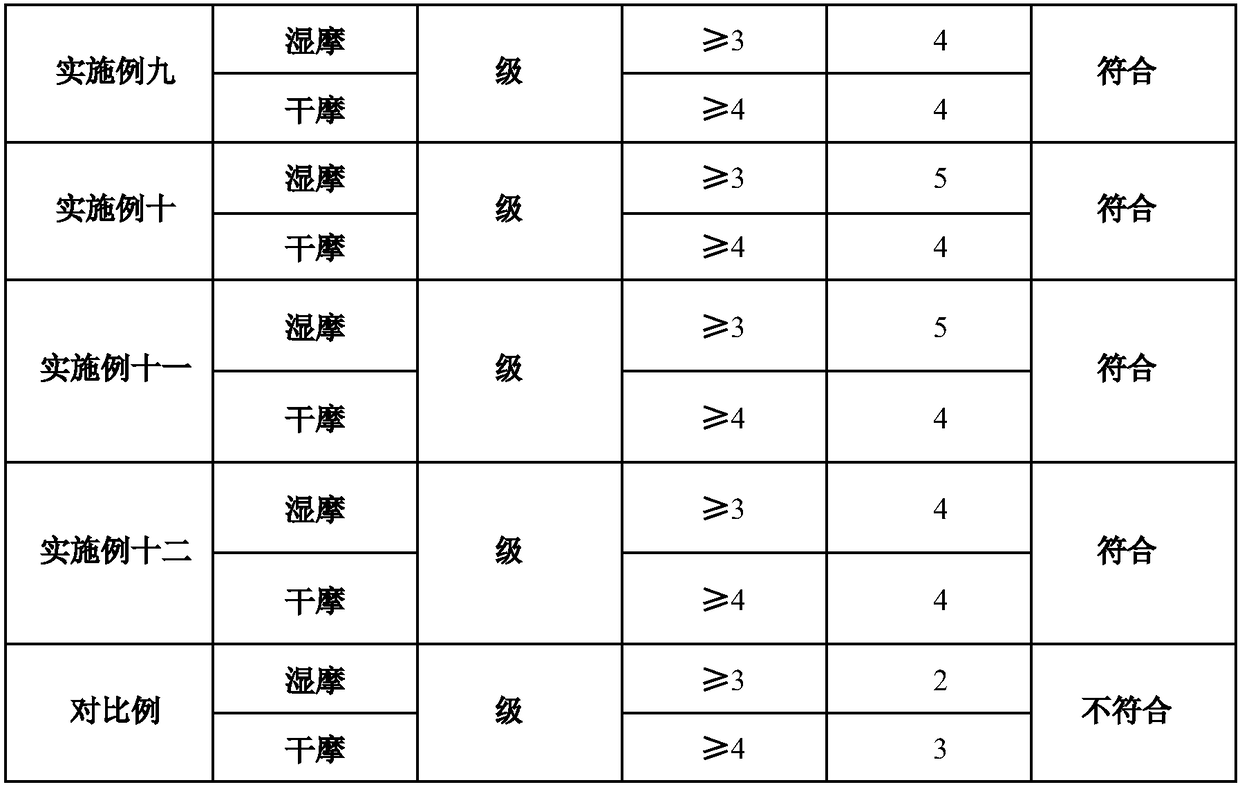

Black dye composition and application of black dye composition in wool dyeing

InactiveCN107936615AGood dyeing rateHigh color fastnessOrganic dyesDyeing processDisperse dyeWool fiber

The invention discloses a black dye composition and application of the black dye composition in wool dyeing. The black dye composition comprises 30-50% of a component A which is shown in a formula (I), 30-50% of a component B which is shown in a formula (II), 1-15% of a component C which is shown in a formula (III), 1-15% of a component D which is shown in a formula (IV) and 1-10% of a component Ewhich is shown in a formula (IV). According to the black dye composition and application of the black dye composition in wool dyeing, the reactive dye (the component E) is mixed with a disperse dye so as to obtain the dye composition which takes the disperse dye as the main component and the reactive dye as the assistant component; and not only can the dye composition have good wet fastness and strong color fastness, but also the binding ability of the dye composition and wool fiber can be enhanced greatly since the component E has a modifying effect on other disperse dye monomers, so that the dye composition has high dye-uptake to the wool fiber.

Owner:卢梅雅

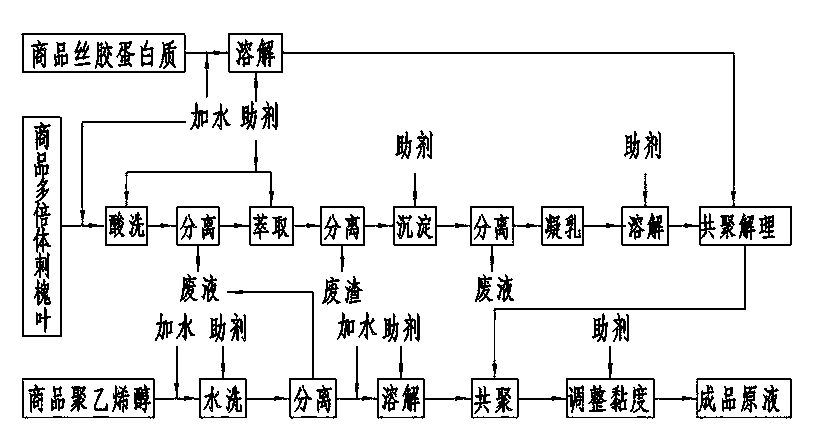

Protein regeneration composite fiber spinning solution and production method thereof

InactiveCN103388194AStrong color fastnessLow priceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyvinyl alcoholPotassium bisulfite

The invention relates to a regeneration animal-plant double-protein composite fiber spinning solution and a production method thereof. The protein regeneration composite fiber spinning solution includes an animal protein and / or a plant protein, the animal protein is sericin protein obtained by processing of reeling silk leftovers, and the plant protein is a protein obtained by extraction of multiploid locust leaves. The protein regeneration composite fiber spinning solution also includes the following components by weight: 0-40 parts of the animal sericin protein, 0-40 parts of the plant polyploid locust leaf protein, 58.6-74.4 parts of polyvinyl alcohol, 0.3-0.8 part of potassium sulfite or potassium bisulfite and 0.3-0.8 part of hydrogen peroxide, performic acid or peracetic acid; and then the composite spinning solution with the viscosity of 800-1200 centipoises is obtained by adding water and sodium hydroxide for copolymerization. According to the regeneration animal-plant double-protein composite fiber spinning solution and the production method thereof, the cost of fiber is reduced, the quality of products is improved, and the problems of chromaticity, color fastness, resistance to hot water and boiling water shrinkage of the fiber are solved.

Owner:郭洁清 +1

Special color fixing agent for dyneema rope and dyneema rope dyeing method

The invention provides a special color fixing agent for a dyneema rope. The special color fixing agent comprises the following components in parts by weight of 30-50 parts of polyacrylate emulsion, 30-50 parts of vinyl acetate-ethylene co-emulsion, 30-50 parts of veova / acrylic emulsion, 30-50 parts of pure acrylic emulsion, 30-50 parts of aqueous epoxy phosphate emulsion, 30-50 parts of polyisocyanate solution, 1-20 parts of leveling agent, 1-20 parts of brightener, 30-50 parts of acrylic acid adhesive and 1-20 parts of titanium dioxide. The special color fixing agent for the dyneema rope is used for coloring the dyneema rope in the production process, and the rope can be dried, dried in the sun or dried through blowing instantly, so that the production efficiency is improved; the rope isbright in color after being dried, is consistent in the colors inside and outside, and is strong in color firmness; the produced rope has strong bonding force, is soft, and has a relatively long bending life, and the hardness can be adjusted according to needs. The special dyeing method for the dyneema rope is simple in process, the force retention rate of the obtained colored ultrahigh molecularweight polyethylene fiber after being dyed reaches 94%, the washing fastness reaches grade 3 to 5, and the fastness of soaping reaches grade 4.

Owner:叶杰锋

Dioscorea cirrhosa natural dye and application thereof

InactiveCN108997780AImprove adsorption capacityStrong color fastnessBiocideFungicidesEcological environmentDioscorea cirrhosa

The invention provides a Dioscorea cirrhosa natural dye and an application thereof. A method for preparing the natural dye comprises the following steps: weighing 10 to 30 parts of a dioscorea cirrhosa extract and 0.5 to 5 parts of an acidic solution, uniformly mixing the materials and performing standing for 3-6 h to obtain a red mud-like object, drying and solidifying the red mud-like object, and pulverizing the red mud-like object to obtain the dioscorea cirrhosa natural dye. The natural dye has the advantages of high pigment adsorption power, strong color fastness, uniform dyeing, simple extraction process, high extraction efficiency, low cost, wide market prospect, sterilization effect, and good compatibility with the ecological environment, and is biodegradable, and can be applied tothe prevention and control of pests and diseases.

Owner:苏州典传创意科技有限公司

Pigment additive for sewage-free nano printing and dyeing, its preparation method and application

ActiveCN108004696BWon't happenSolve processing problemsDyeing processLiquid/gas/vapor textile treatmentAgricultural engineeringWastewater

The invention discloses a waste water-free nano printing and dyeing technology. The waste water-free nano printing and dyeing technology includes the following steps: (1) leading color paste to an evenness padder; (2) importing a gray fabric; (3) performing coloring; (4) importing an additive; and (5) performing shape forming, importing the color paste to the evenness padder, soaking the gray fabric in the color paste, and performing coloring at the temperature of 100-120 DEG C, wherein the color paste can quickly attach to and permeate into the gray fabric, and the dyed fabric has excellent color firmness. The shaping forming machine can perform shaping forming on the gray fabric, and the additive can improve the tenacity and the stiffness of the gray fabric; after the color paste permeates into the gray fabric and the dyeing is completed, there is no waste water in the evenness padder, and waste water can be avoided after dyeing.

Owner:常州安达环保科技有限公司

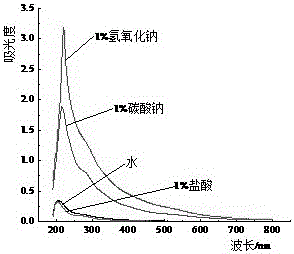

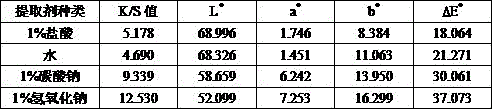

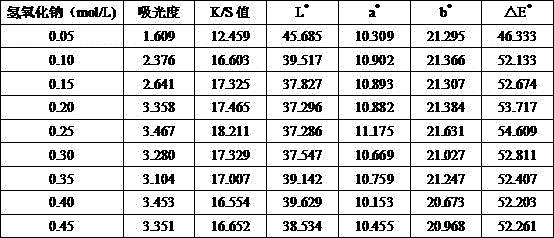

Extracting method and application of pyrola calliantha dye

The invention discloses an extracting method and application of pyrola calliantha dye. The method comprises the steps that pyrola calliantha is smashed into powder with a pulverizer, and the extraction conditions are that the sodium hydroxide molar concentration ranges from 0.05 mol / L to 0.45 mol / L, the extraction temperature ranges from 50 DEG C to 100 DEG C, the extraction time ranges from 5 min to 90 min, the solid-to-liquid ratio, namely, the mass ratio of the pyrola calliantha to a sodium hydroxide solution ranges from 1:10 to 1:80, and after extraction is completed, cooling and filtration are conducted; the dye is used for conducting direct dyeing and mordant dyeing on wool. The extracting method and application of the pyrola calliantha dye have the advantages of being green, environmentally friendly and free of pollution, having important health-care value and being high in dyefastness and resistant to abrasion, soaping and light.

Owner:南通虹纬纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com