Patents

Literature

135 results about "Jacquard loom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Jacquard machine (French: [ʒakaʁ]) is a device fitted to a power loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. It was invented by Joseph Marie Jacquard in 1804, based on earlier inventions by the Frenchmen Basile Bouchon (1725), Jean Baptiste Falcon (1728), and Jacques Vaucanson (1740). The machine was controlled by a "chain of cards"; a number of punched cards laced together into a continuous sequence. Multiple rows of holes were punched on each card, with one complete card corresponding to one row of the design. Several such paper cards, generally white in color, can be seen in the images below. Chains, like Bouchon's earlier use of paper tape, allowed sequences of any length to be constructed, not limited by the size of a card.

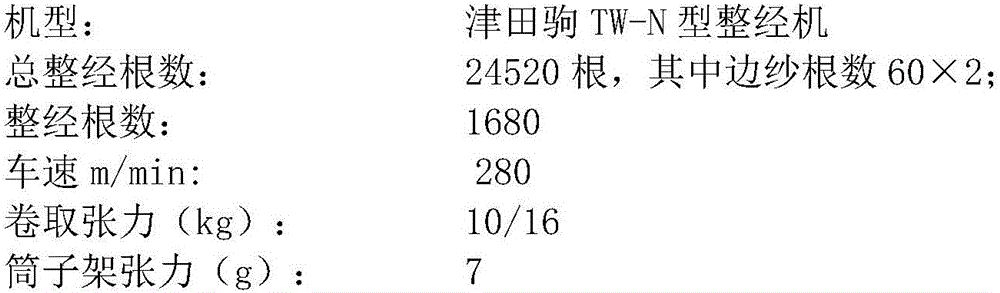

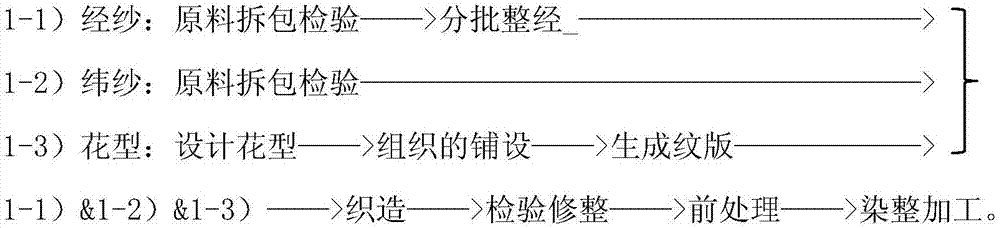

Method for manufacturing jacquard fabric with different material quality and style

InactiveCN101109121AExpress the verve of pen and inkImprove weaving methodJacquardsCard-punching apparatusGraphicsJacquard loom

The invention relates to a preparing way for a jacquard fabric, in particular to a preparing way for a jacquard fabric of different materials and styles, which comprises the treating of several graphic images of different styles, designing texture boards for fabrics, combining the texture boards, creating a complete texture-board document, sending the texture boards for an electronic jacquard loom to weave; also placing a warp of one or more materials and a weft of at least 2 materials on the loom; and turning on the loom to make the fabric. The invention uses different materials to express the artistic effect of color jacquard fabric of different styles of the same picture. The textures in the fabric run smoothly, the joining sites are smooth and natural; the color and brightness of the whole fabric are harmonic, and the topic is clear, which expresses better the romantic charm in original artistic works.

Owner:韩容

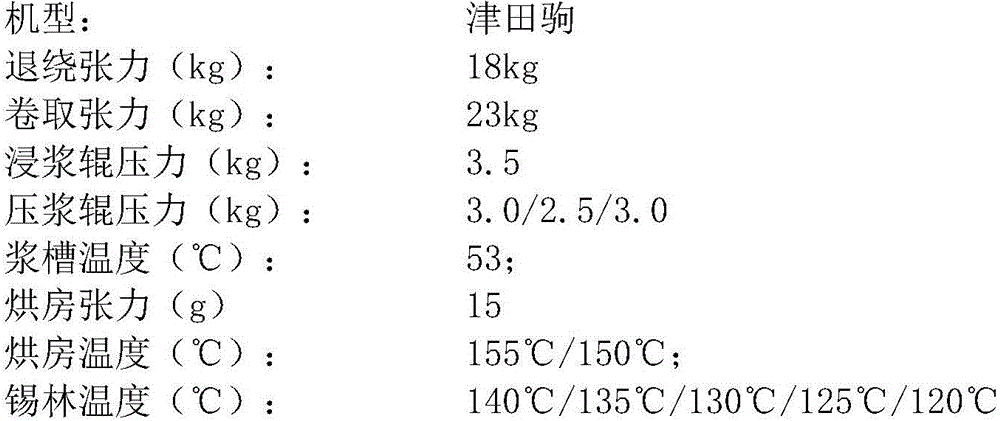

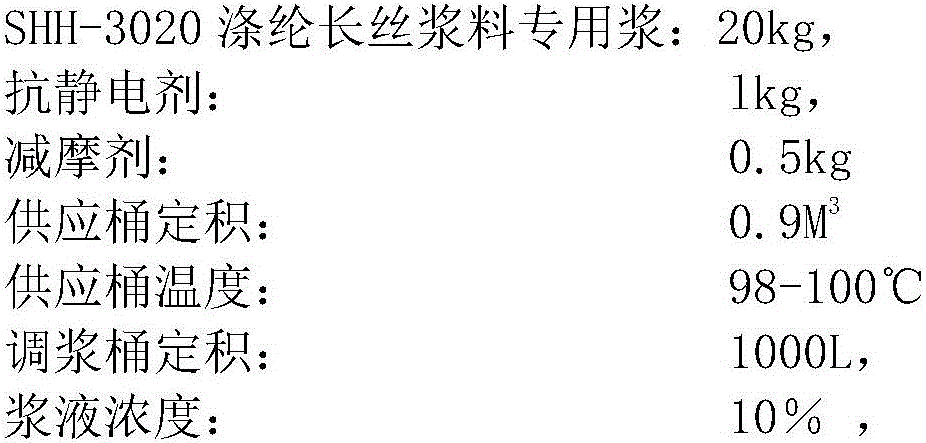

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

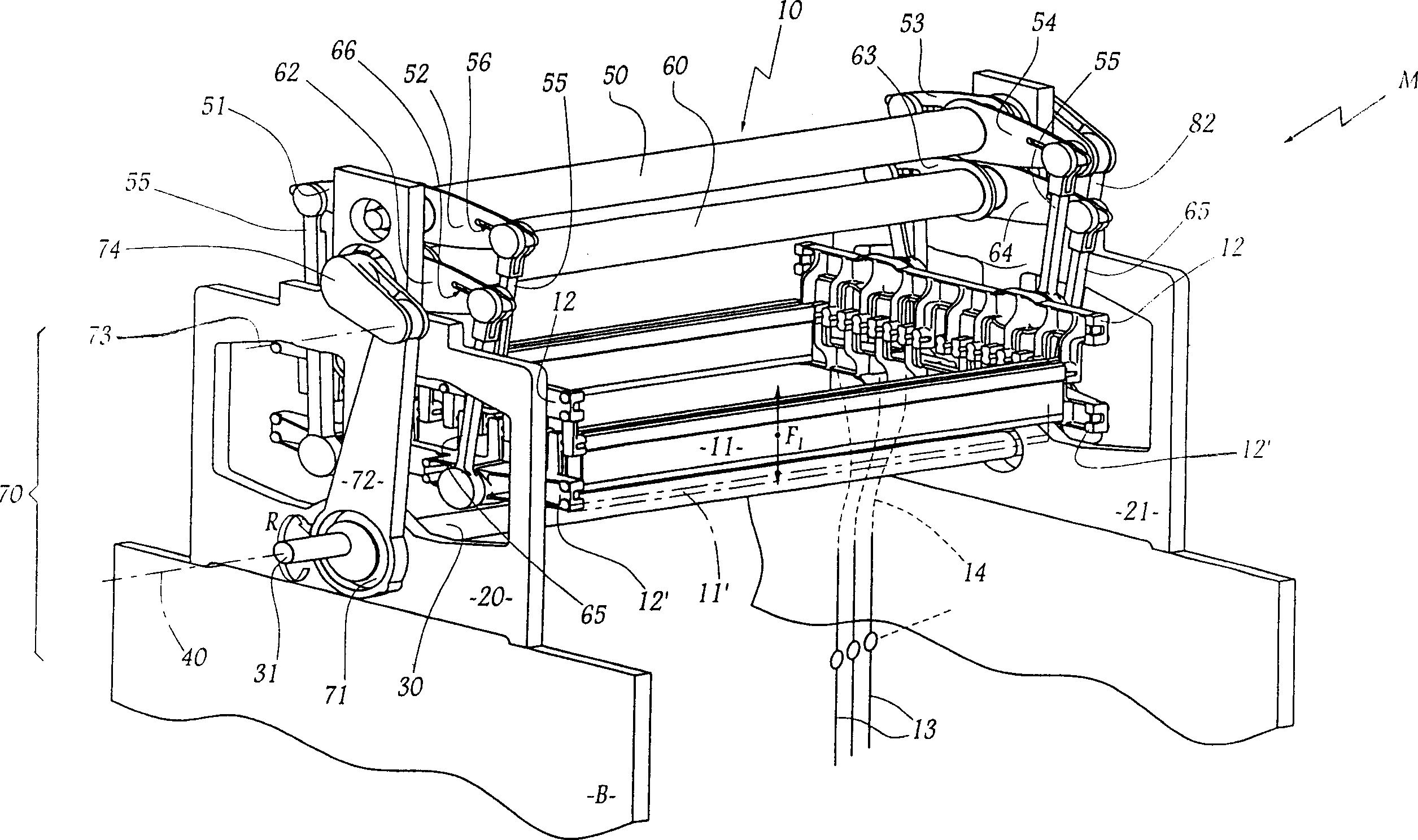

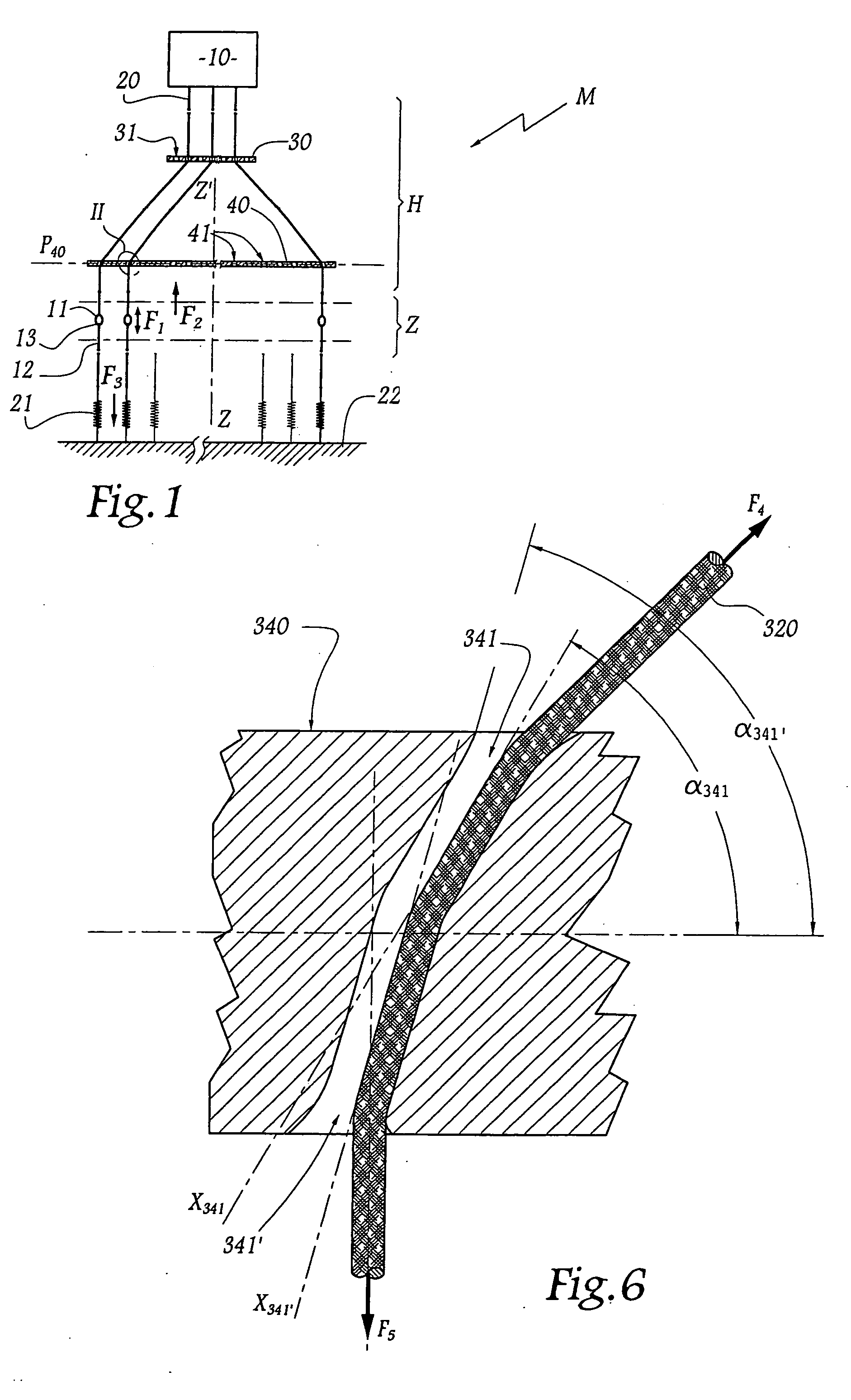

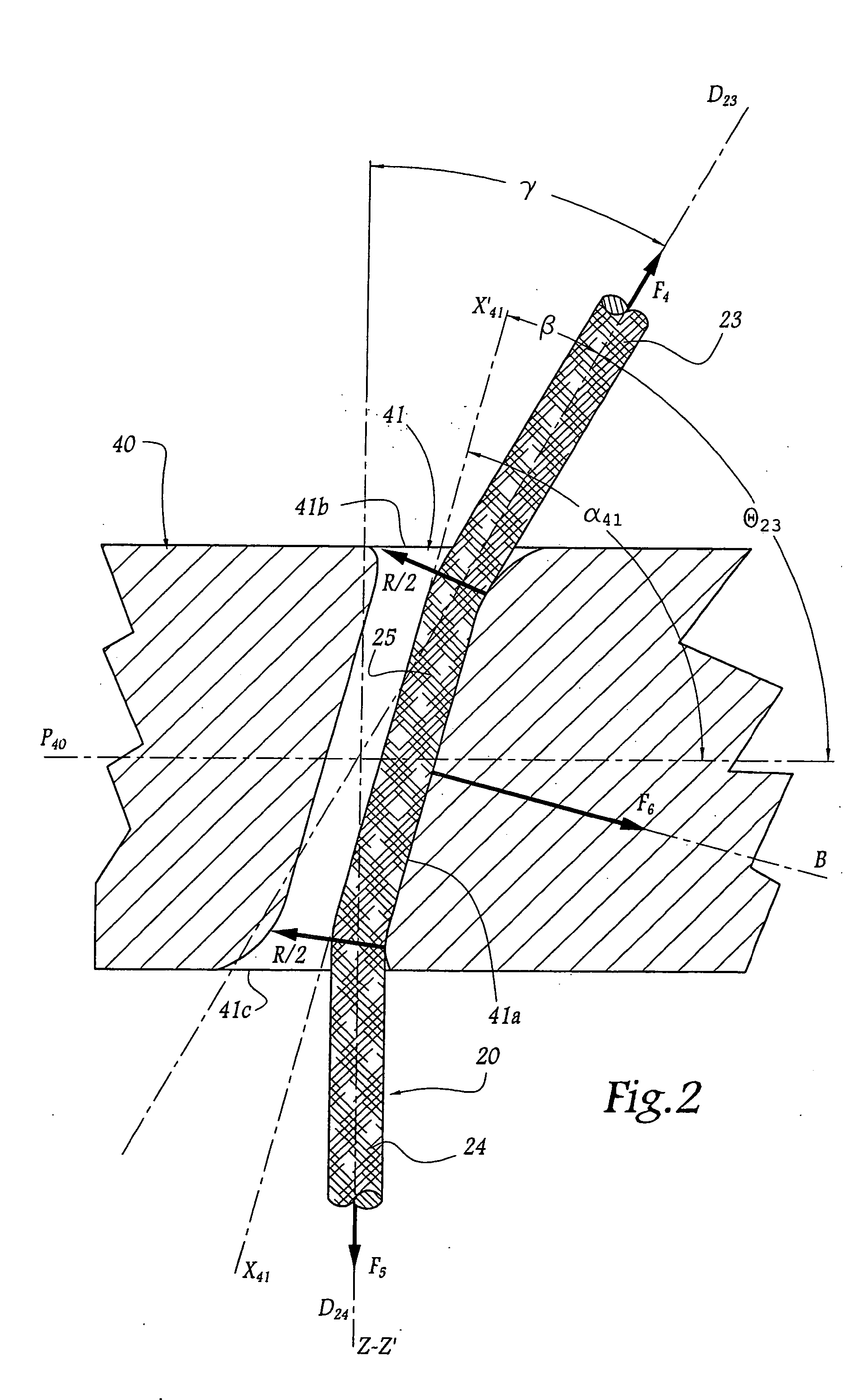

Shed forming device and weaving loom of the jacquard type equipped with such a device

ActiveCN1550592ARealize one-way controlEfficient driveJacquardsCam shedding mechanismJacquard loomStructural engineering

Owner:施托布利里昂公司

Method for preparing polyester heddle twine for jacquard loom

The present invention relates to a production method of jacquard polyester heddle twine. Said invention utilizes selection of industrial polyester multifilament and uses it as new material for makingheddle twine on the lay-over arrangement of jacquard loom, and adopts the processes of improved cabling, sizing and infrared drying so as to obtain the invented product jacquard polyester heddle twine. As compared with existent jacquard polyester heddle twine its tensile breaking strength is raised by once, under the identical test condition its expand and contract amount of reduced by 20-95% andits cost also is reduced by 30%.

Owner:SHANGHAI UNIV OF ENG SCI +1

Jacquard vinylon polyester oil mounting thread and its manufacturing method

The invention relates to a method of jacquard loom, through choosing polyester multifilament with high strength and low expansion for industry and comeandgo for producing the material of thread of the jacquard loom shedding motion, and by using the advanced processing techniques like cabling, filling and then wax oil, making the tensile break strength of jacquard loom / be increased 40-50N / one than the present one and the distortion value is decreased by 95-115%, meanwhile, its abrasive resistance is one time higher than the vinylon.

Owner:倪轮官

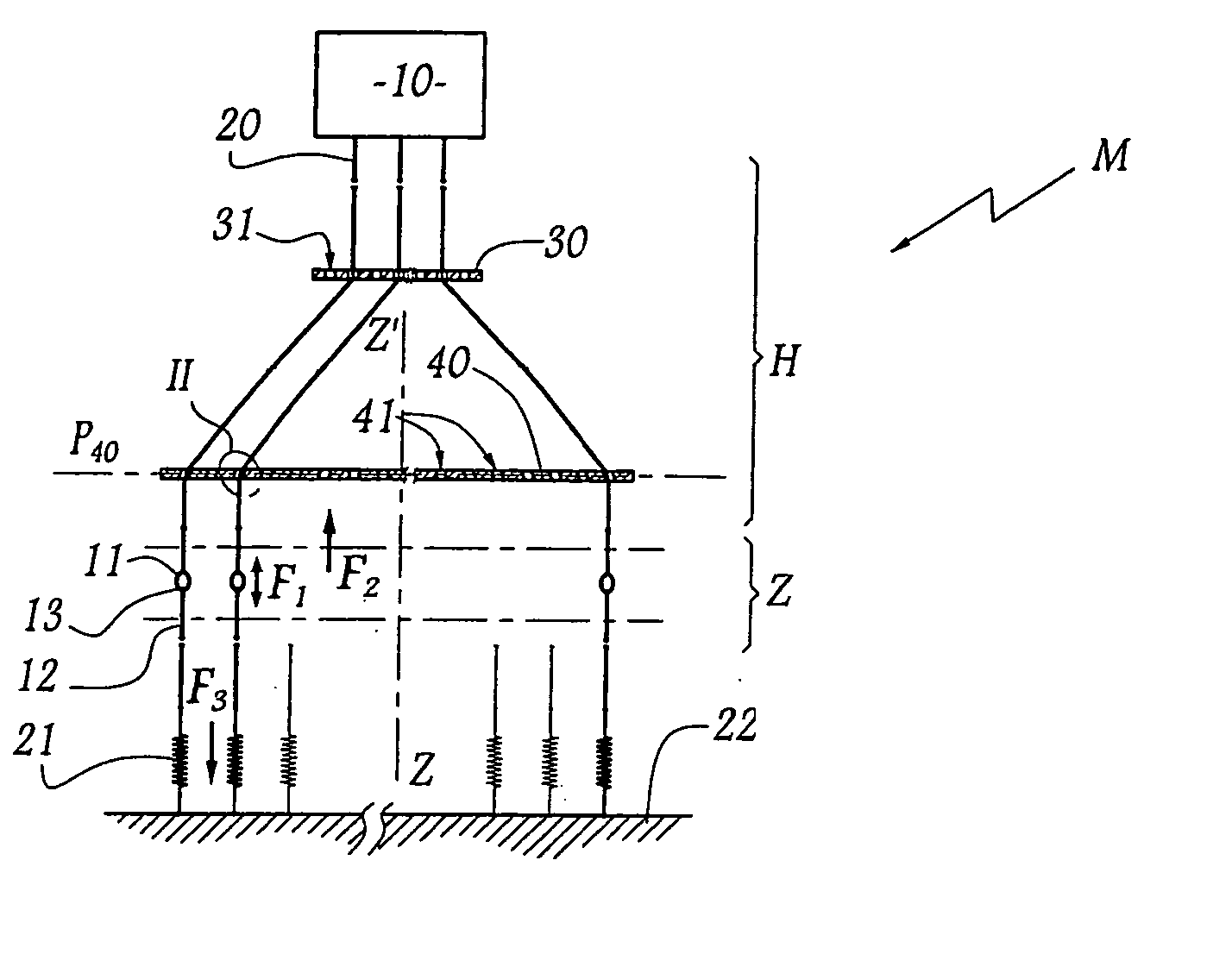

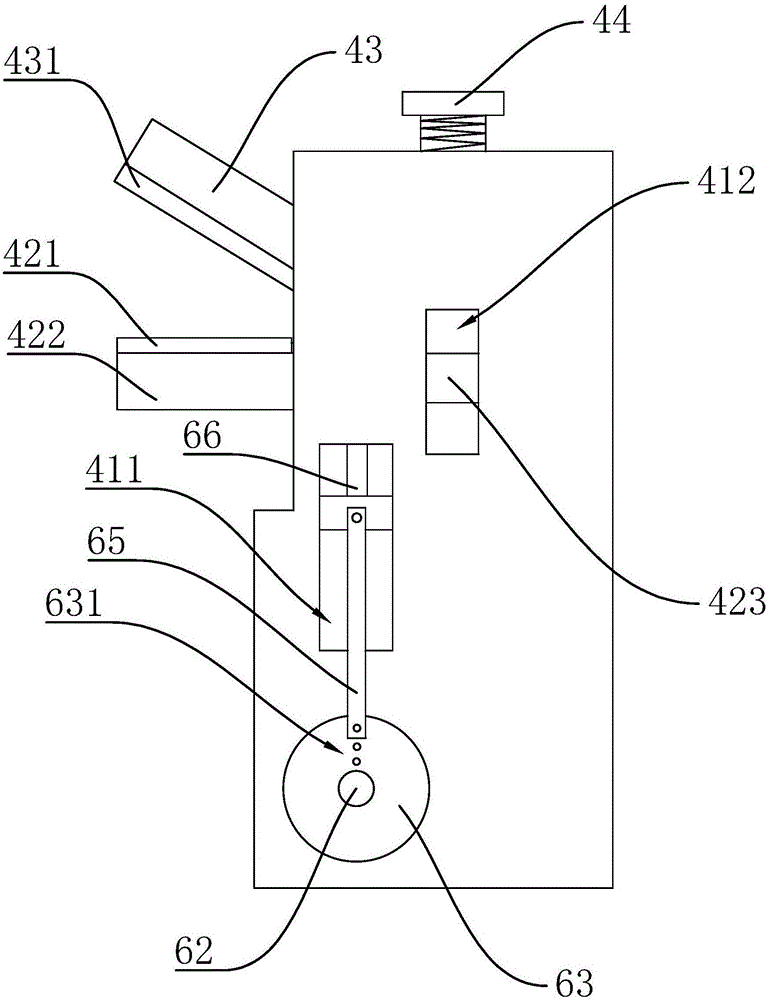

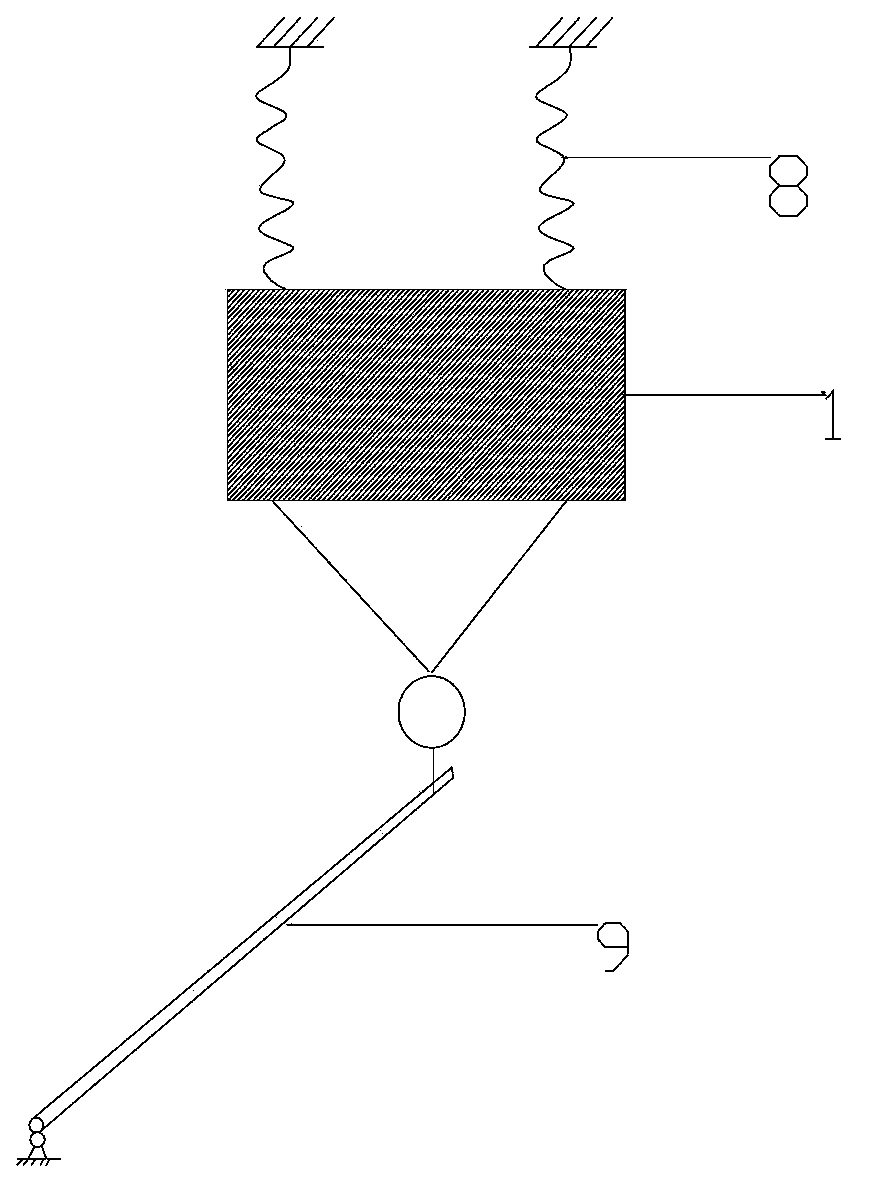

Spring dampened shedding device

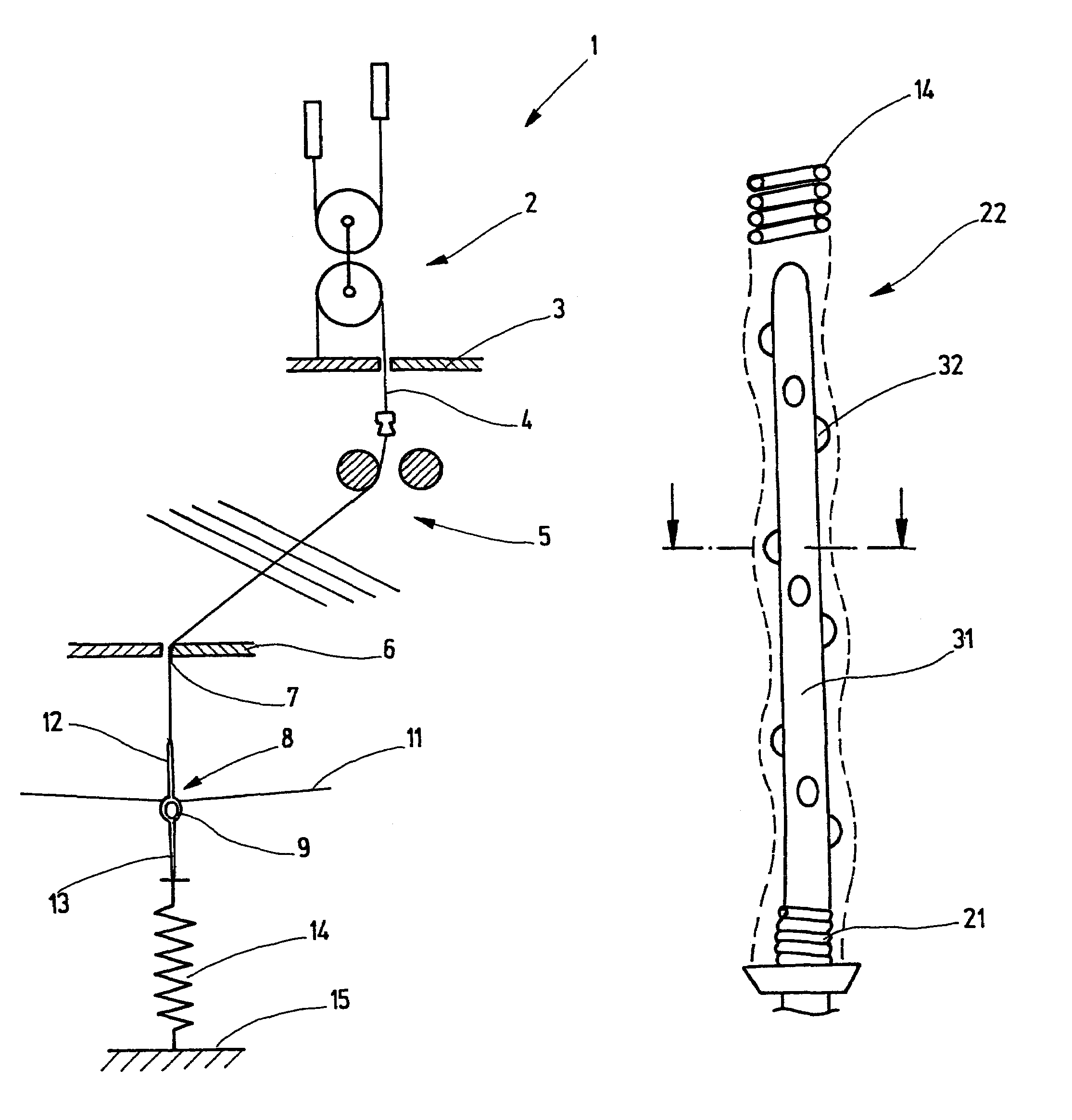

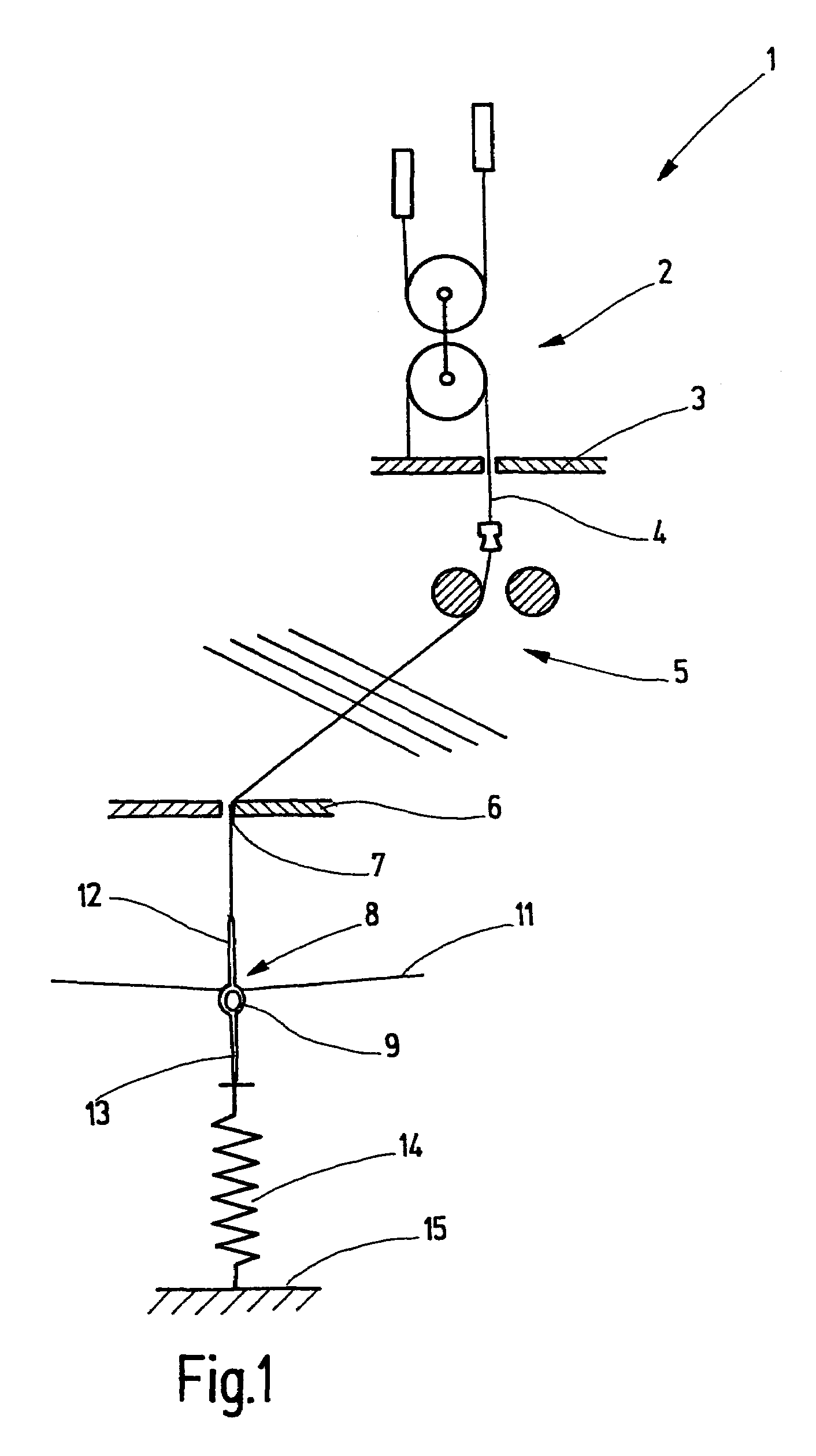

InactiveUS7036532B2Effectively dampens undesirable resonating propagationAccurate pressureJacquardsLeno shedding mechanismJacquard loomResonance

A shedding device in a jacquard loom, having a heddle with a retracting spring rigidly anchored in the loom or to the floor for urging the heddle to a lower shed forming position. To suppress the development of resonance in the spring, a core element is provided, which contacts the inside of the spring at points spaced apart from one another and forces the spring to take a course which deviates from the rectilinear. As a result, friction forces that contribute to damping the spring motion are created between the spring and the core element.

Owner:DEUTE INST FUR TEXTIL & FASERFORSCHUNG STUTTGART

Method for producing multi-pile high-jacquard carpet and jacquard Loom thereof

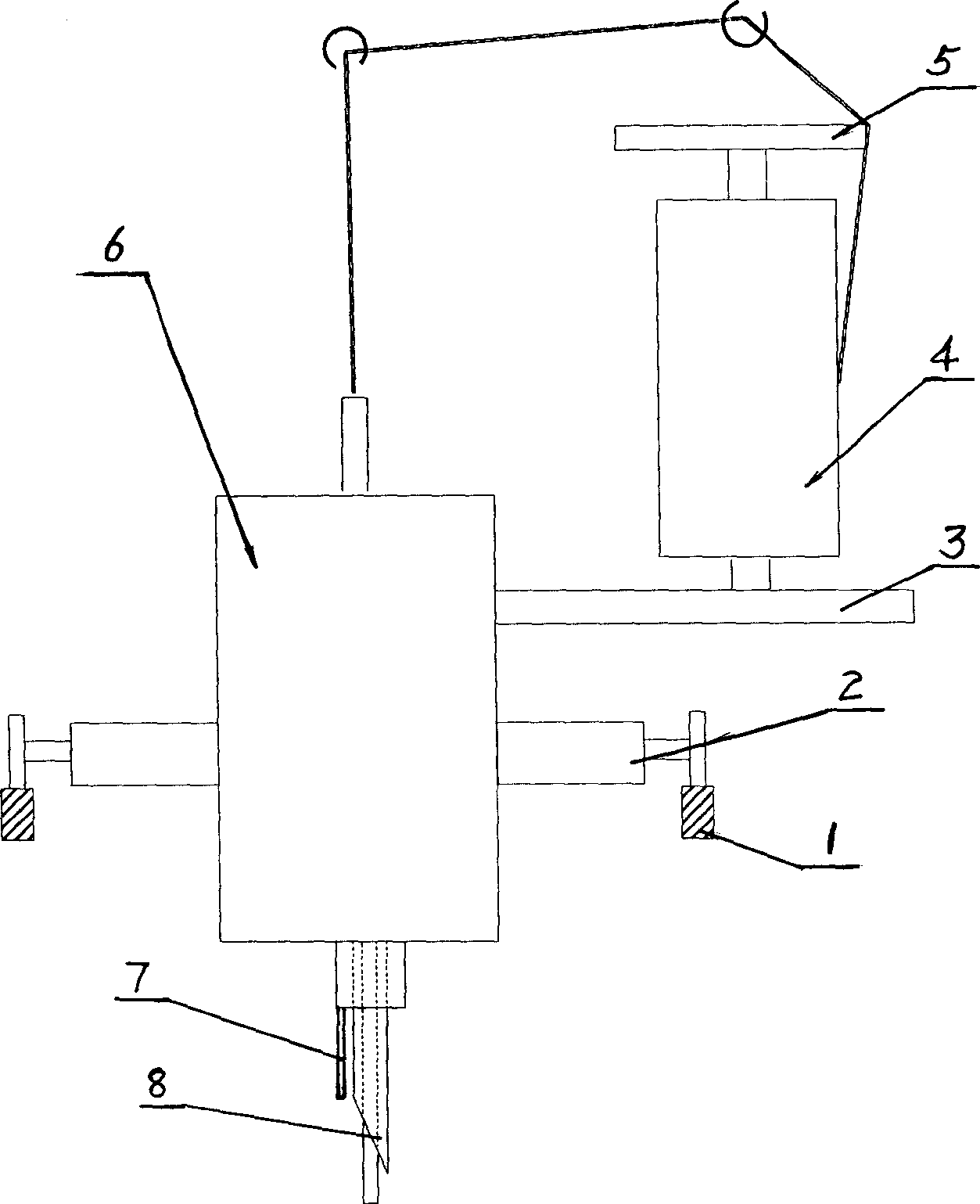

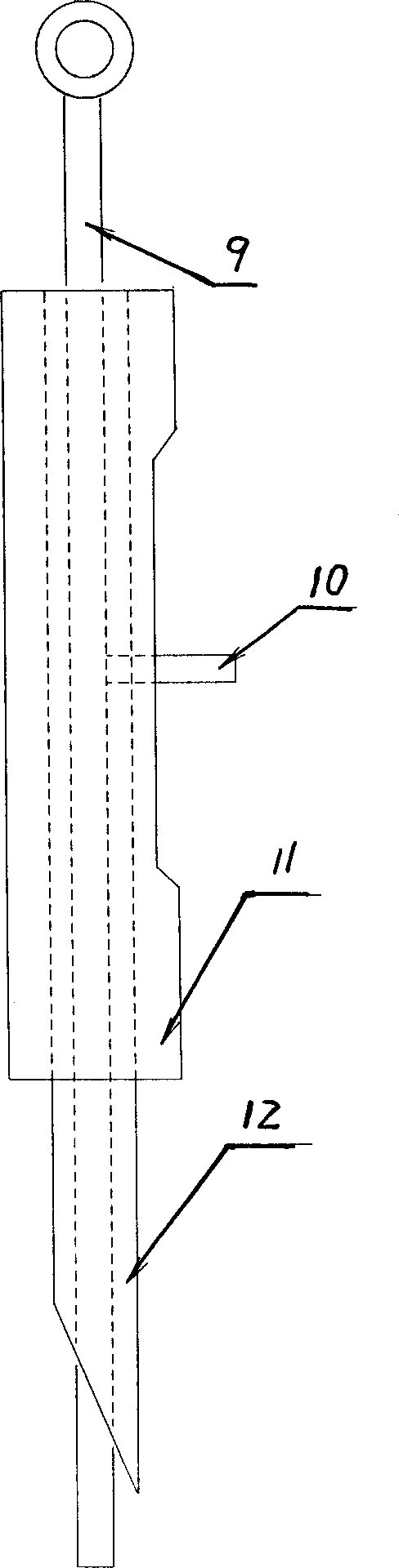

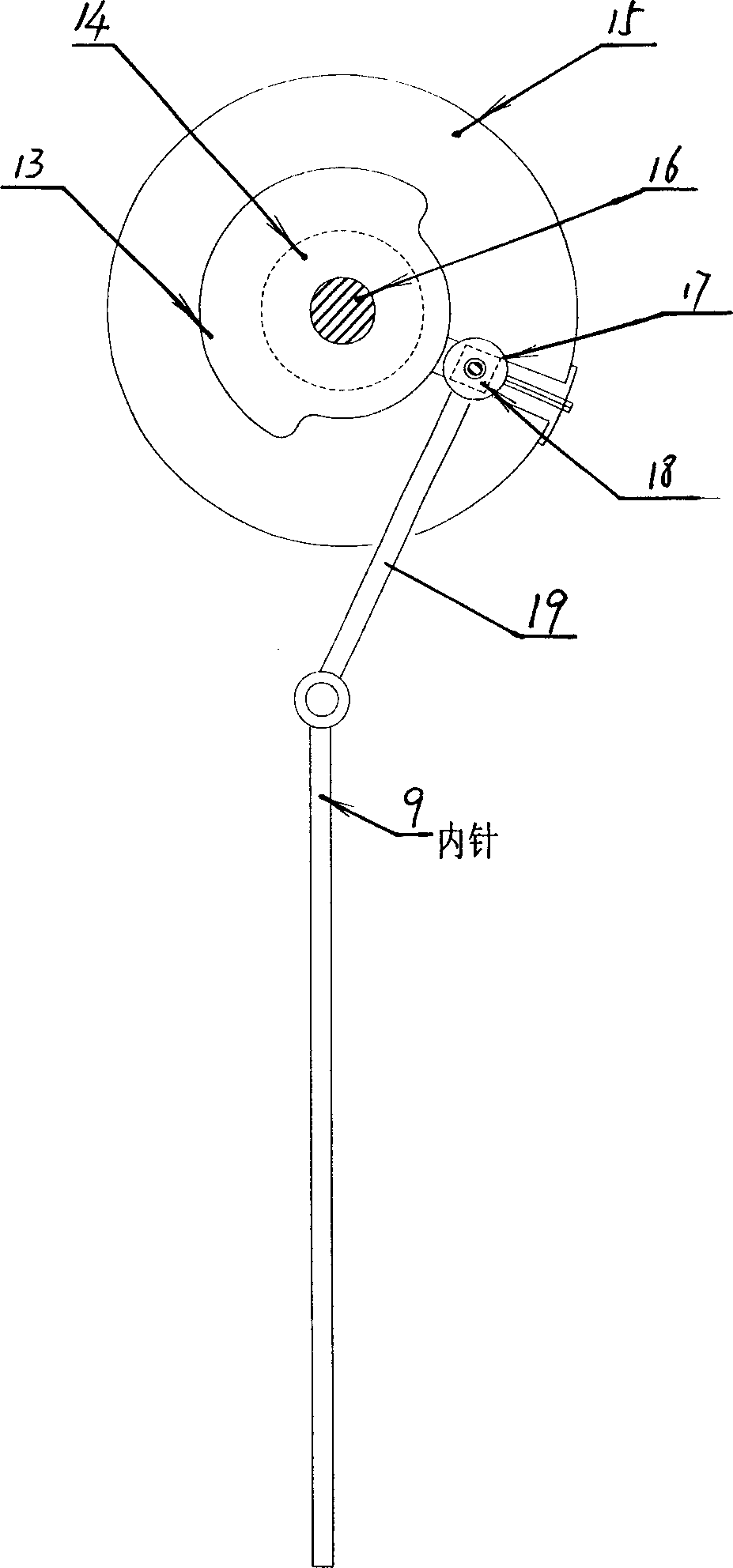

The present invention relates to a method for producing jacquard carpet with several pile-heights by adopting non-vector quantification pattern method. The technical scheme adopted by said invention includes the following steps: creating mathematical function relationship of carpet surface pile position and height and its non-vector quantification pattern pixel point correspondent position and gray level; utilizing carpet loom to make line-by-line or column-by-column scanning according to the pattern pixel arrangement created by using the above-mentioned mathematical function formula and weave the invented jacquard carpet. Said carpet loom includes guideway, crossbeam, machine frame, yarn bobbin, compound needle mechanism, inner needle variable-stroke reciprocating mechanism, outer needle reciprocating mechanism, revolving mechanism and antislip needle.

Owner:刘峰

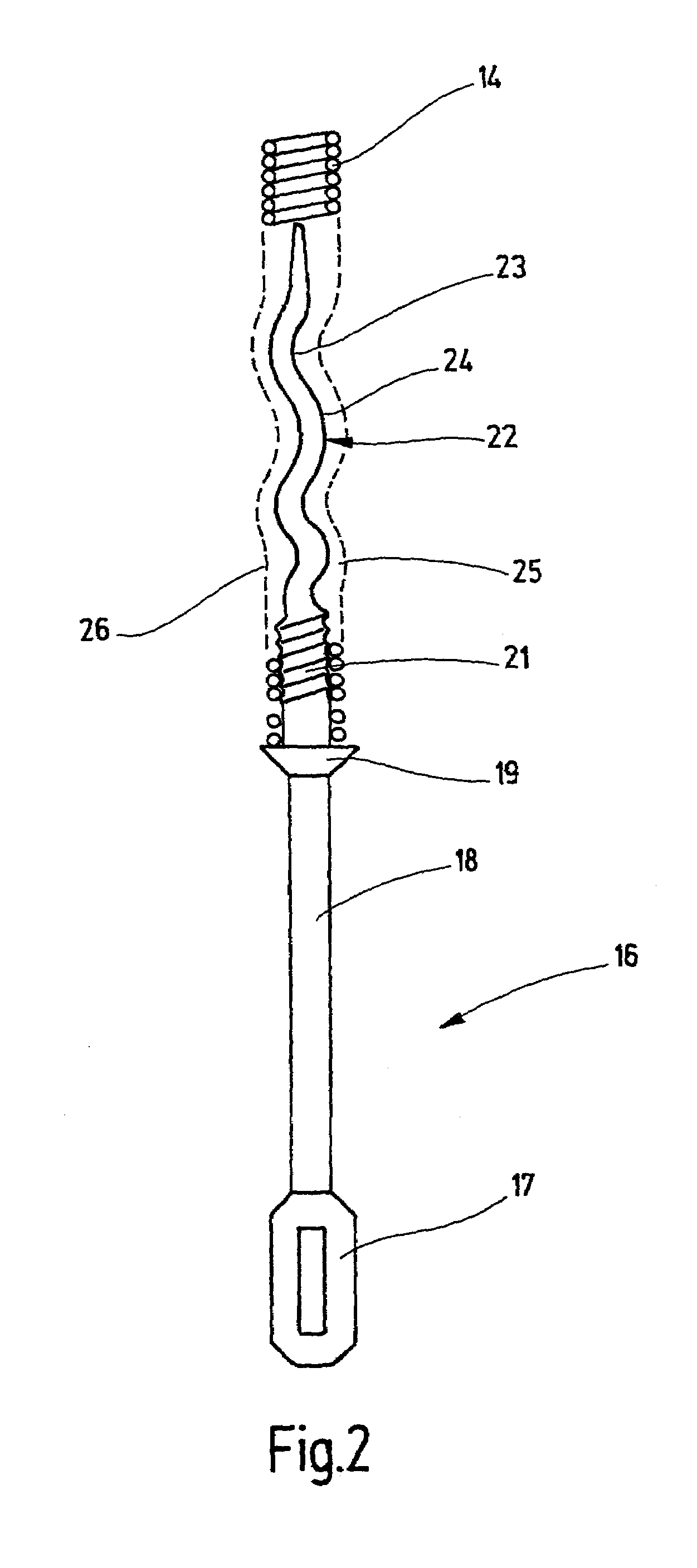

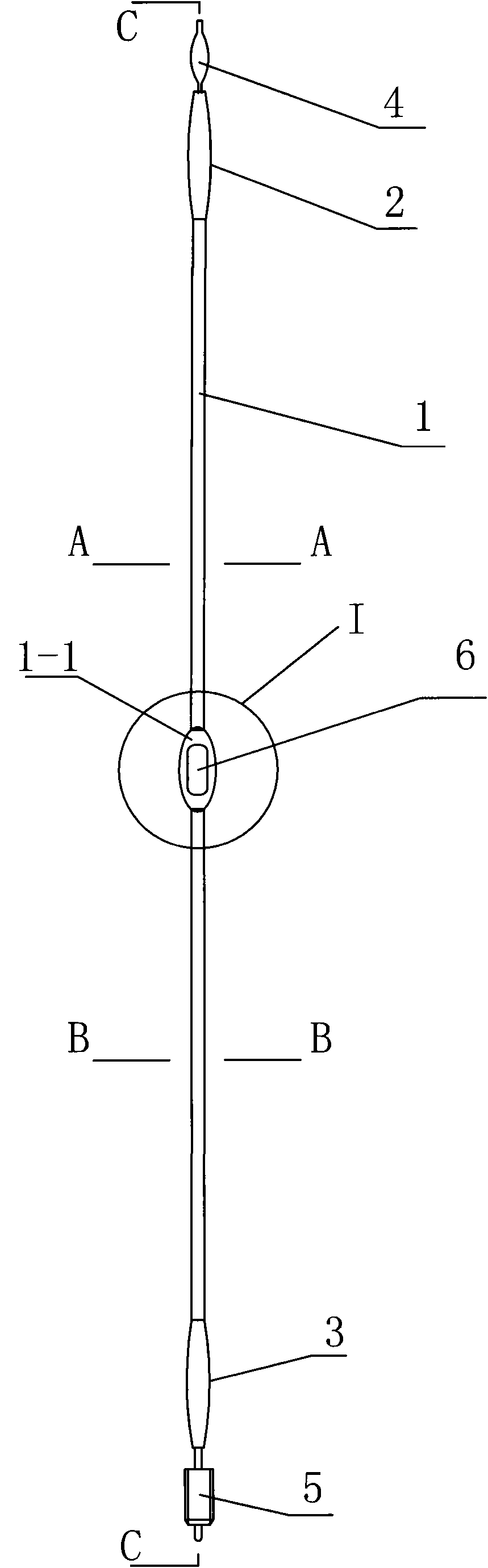

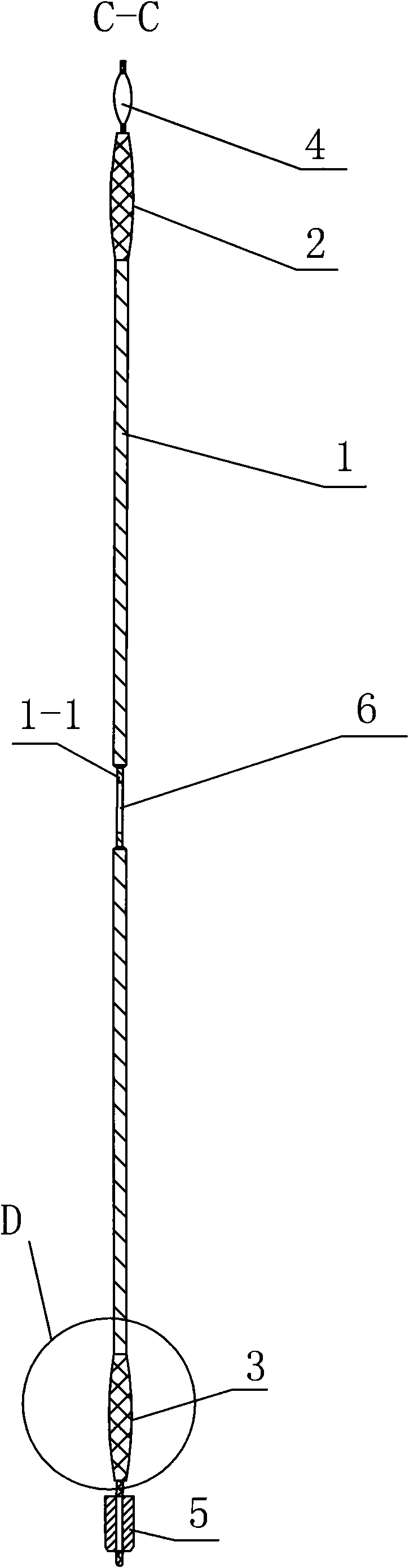

Integral heald wire for jacquard loom and its making process

The integral heald wire for jacquard loom as yarn guide has members in two ends for connection with other parts and one mail eye in the middle part. One of the connecting member has small hole and the other has thread. Warp is threaded via the mail eye to form one opening with the elevated heald wire, so that the weft introduced into the opening perpendicularly to the warp can be interwoven with the warp. The section with mail eye of the heald wire is turned by one 0-55 deg angle to the other sections. The making process of the integral heald wire includes the steps of rolling, punching, polishing and injection molding. The integral heald wire has no rust, no contamination to the fabric, long service life and other advantages.

Owner:DANYANG CITY XINLONG TEXTILE +1

Novel technology for weaving song brocade

InactiveCN103668704ABeautiful flower shapeFashionableFibre treatmentSwivel-woven fabricsFiberJacquard loom

The invention discloses a novel technology for weaving song brocade. The novel technology comprises the following steps that firstly, first warp raw materials, second warp raw materials and weft raw materials are selected; secondly, the first warp raw materials and the second warp raw materials are steeped; thirdly, the first warp raw materials and the second warp raw materials are naturally aired; fourthly, reeling is conducted on first warp and second warp; fifthly, twisting, sizing, combination, secondary twisting, sizing, skein forming, silk dyeing and winding are conducted on the first warp in sequence; sixthly, warping is conducted on the first warp and the second warp; seventhly, raw material selection, color absorption testing, dyeing and detection are conducted on weft in sequence; eighthly, the first warp, the second warp and the weft are woven on a rapier jacquard loom. The song brocade fabric is woven from real silk and viscose through the novel rapier jacquard loom according to the technology and classic traditional graphic pattern and color in history, waterproof, antifouling and oil-proof treatment adopted by a chemical fiber industry is utilized, so that the song brocade is fine and smooth in weave grain, attractive in pattern, sufficiently practical. According to the technology, the traditional technology and the modern fashion are perfectly combined.

Owner:DING SHENG SILK

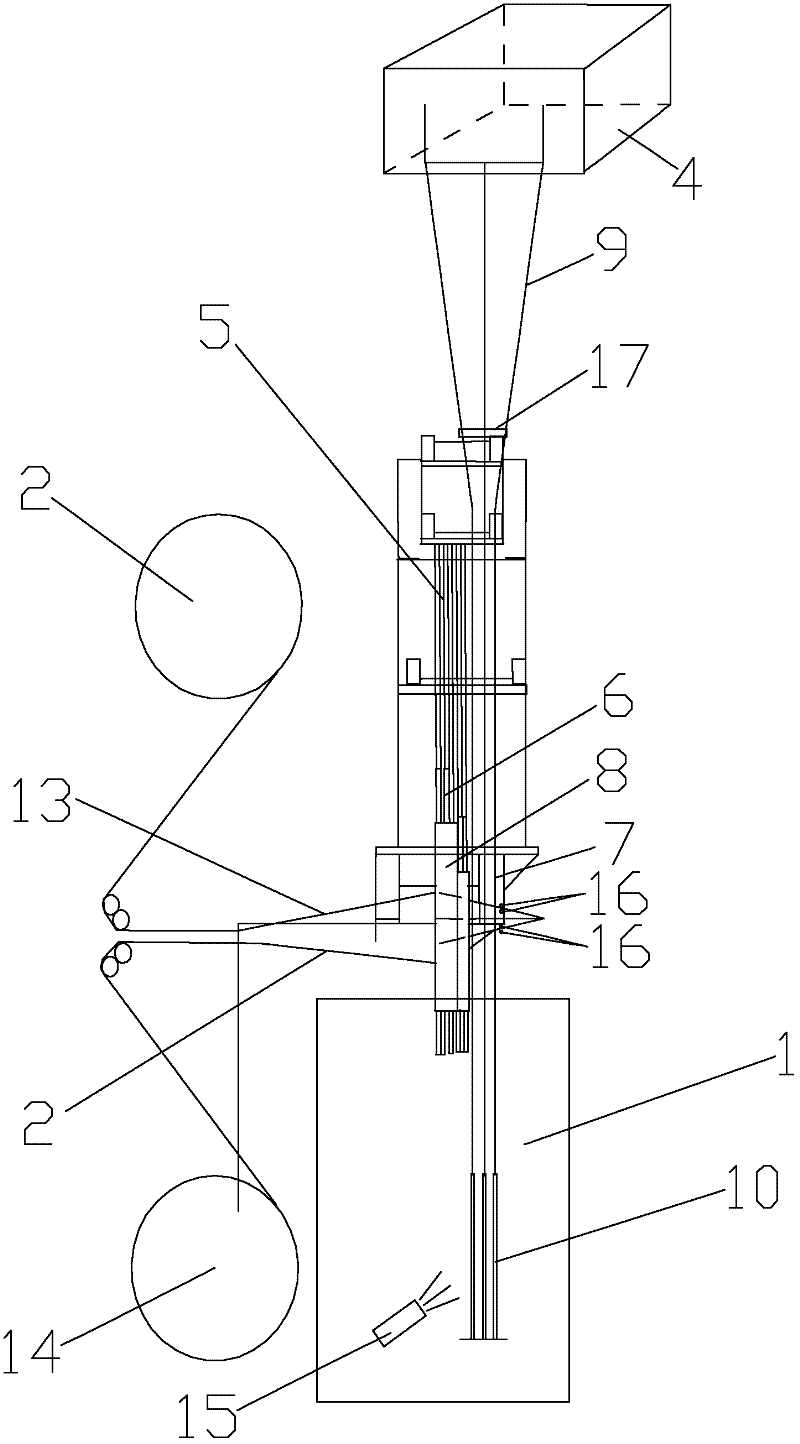

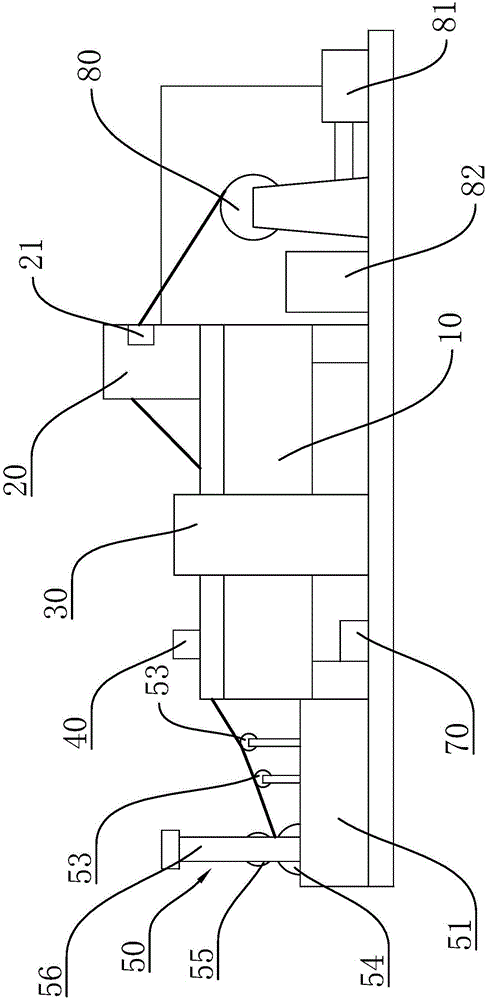

Winding device for jacquard loom

InactiveCN108505195AExpand the scope of activitiesIncrease flexibilityMechanical cleaningPressure cleaningJacquard loomElectric machinery

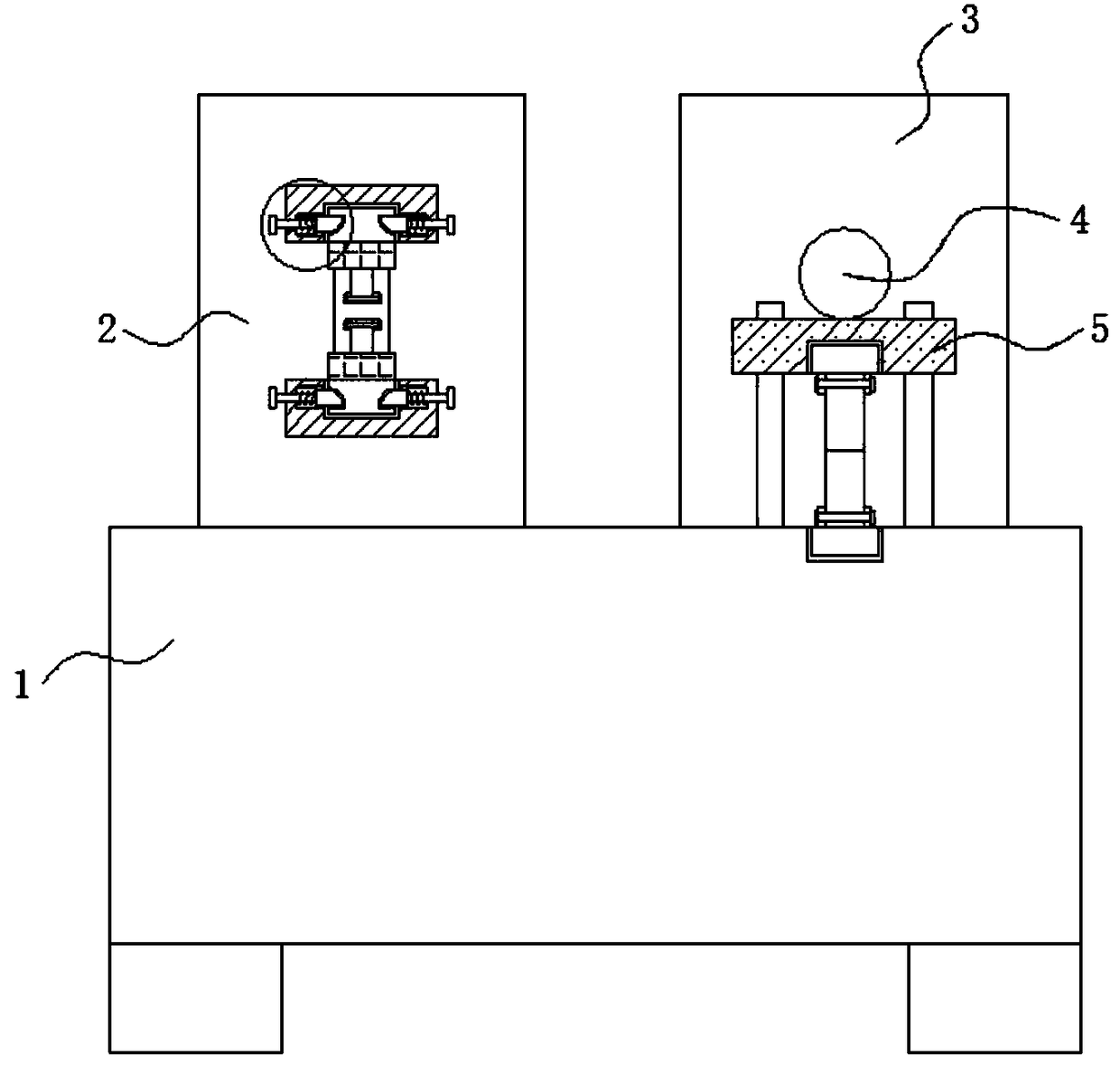

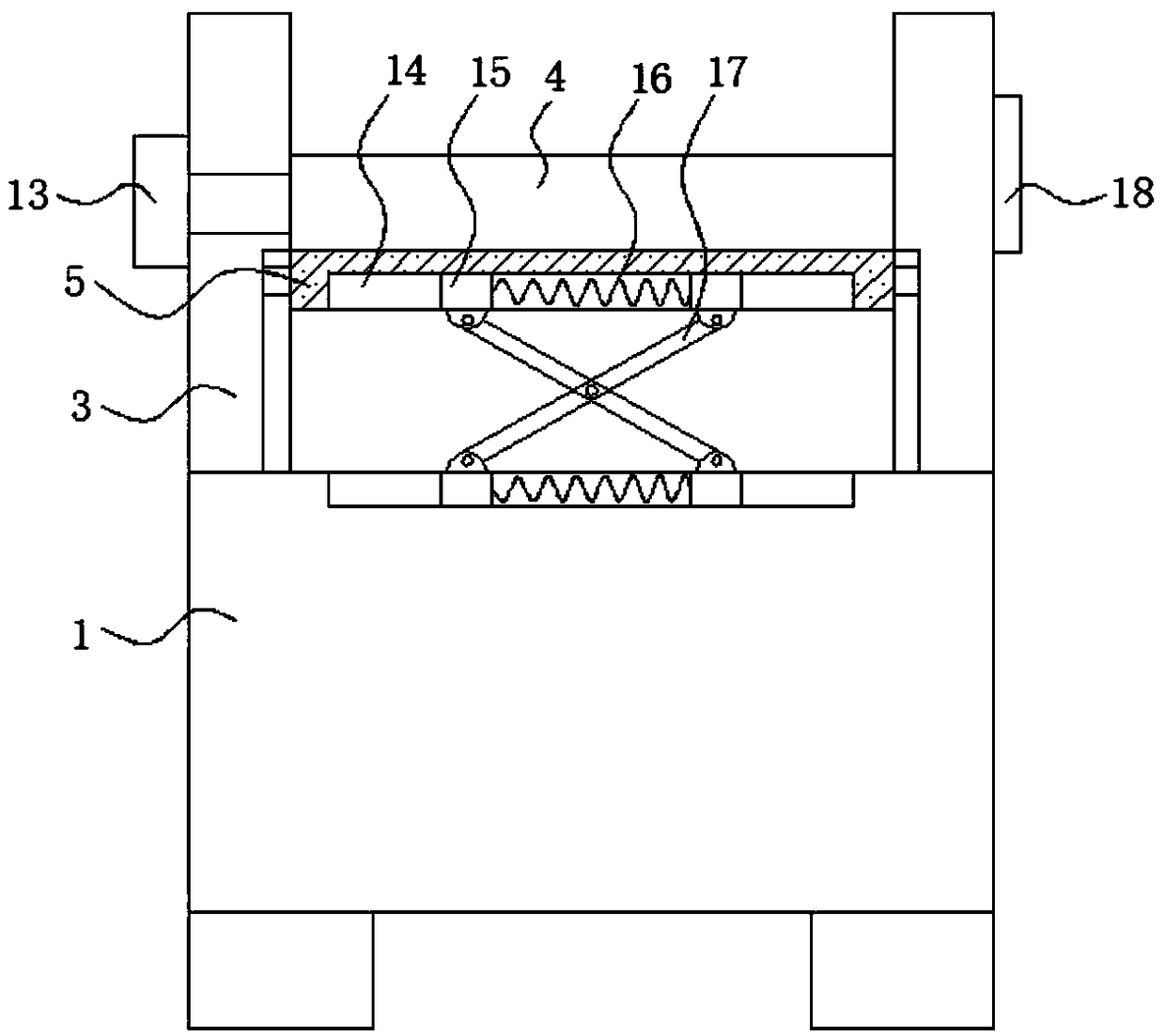

The invention discloses a winding device for a jacquard loom. The winding device comprises a working table. A dust removal mechanism and a winding mechanism are arranged on the two sides of the top end of the working table respectively. The dust removal mechanism comprises two separated side plates. Two horizontal connecting plates are arranged between the two side plates. Brushes are arranged onthe sides, close to each other, of the two connecting plates respectively. The winding mechanism comprises two separated supporting plates. The bottom ends of the supporting plates and the bottom endsof the side plates are all fixed to the working table. A driving motor is fixed to the side wall of one side of each supporting plate. By means of the winding device, cloth can be directly clamped through the mechanical transmission mode and prevented from falling, the movement range of a pressing plate is large, flexibility is high, smoothening or fluff removing can be conducted on the producedcloth before winding, it is avoided that the attractive appearance and use effect of the cloth are influenced by the too much disorder fluff on the surface of the cloth, the brushes can be conveniently installed and detached through clamping, and it is avoided that the normal use is influenced after the brushes are used for a long time.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

Method for weaving polyester high-shrinkage filament single-layer concave-convex bedding fabric

ActiveCN107338557AHigh strengthImprove wear resistanceHeating/cooling textile fabricsDry-cleaning apparatus for textilesYarnPolyester

The invention discloses a method for weaving polyester high-shrinkage filament single-layer concave-convex bedding fabric. The fabric is that warp yarn is combed cotton tight spun yarn, the specification is 9.7 tex, and the warp density is 681 threads / 10 cm; weft yarn is carded cotton yarn, and the specifications include 9.7 tex, polyester FDY high-shrinkage filaments, 150 D / 72F, the proportion of 2:1 and weft density being 283 threads / 10 cm; texture is large jacquard fabric; the fabric width of the finished product is 300 cm. The method for weaving the fabric includes the steps that warping is performed in batches through a warping machine, sizing is performed through a sizing machine, double drafting is performed through a drawing-in machine, weaving is performed through a rapier large jacquard loom, and dressing is performed.

Owner:江苏悦达家纺制品有限公司

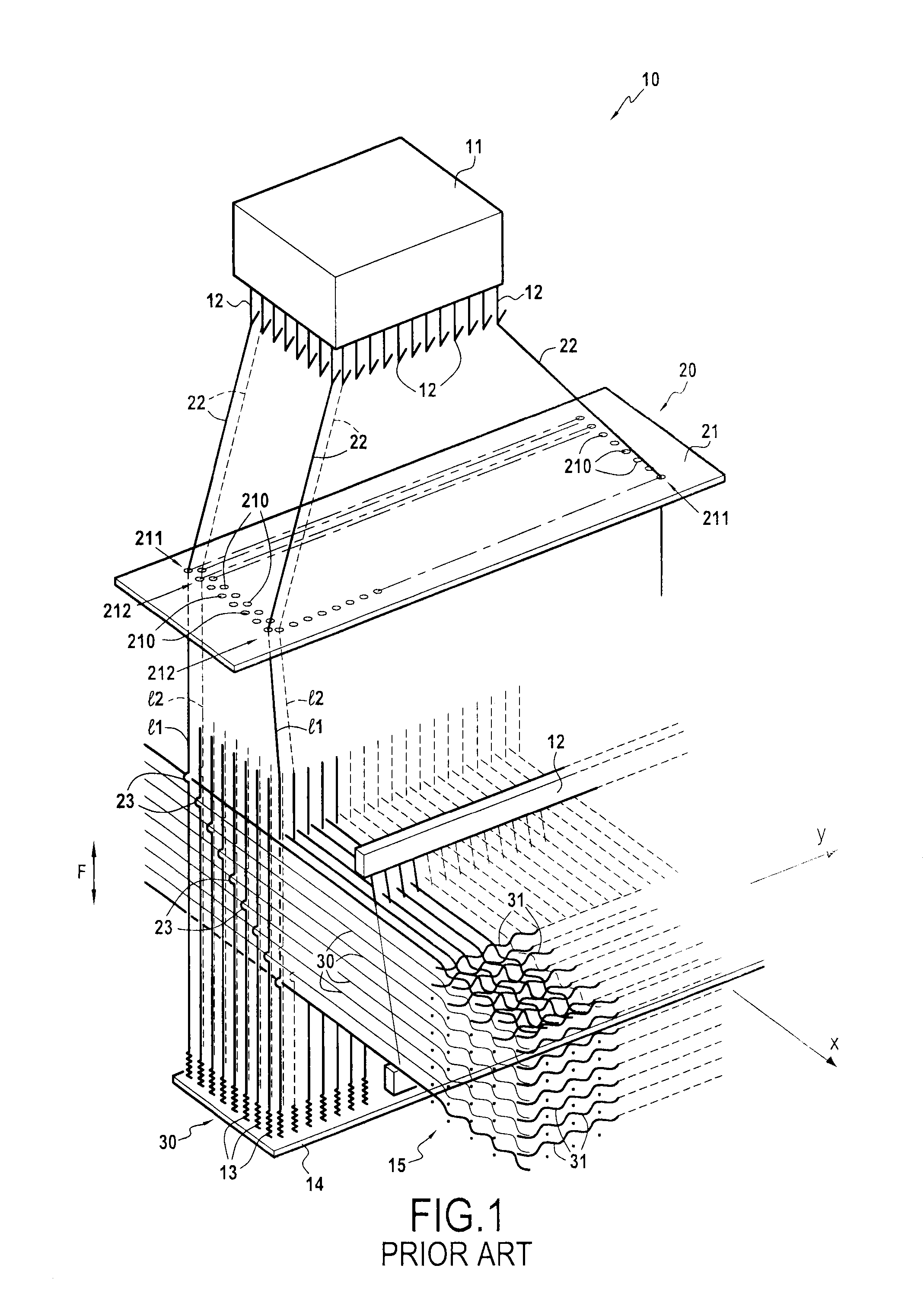

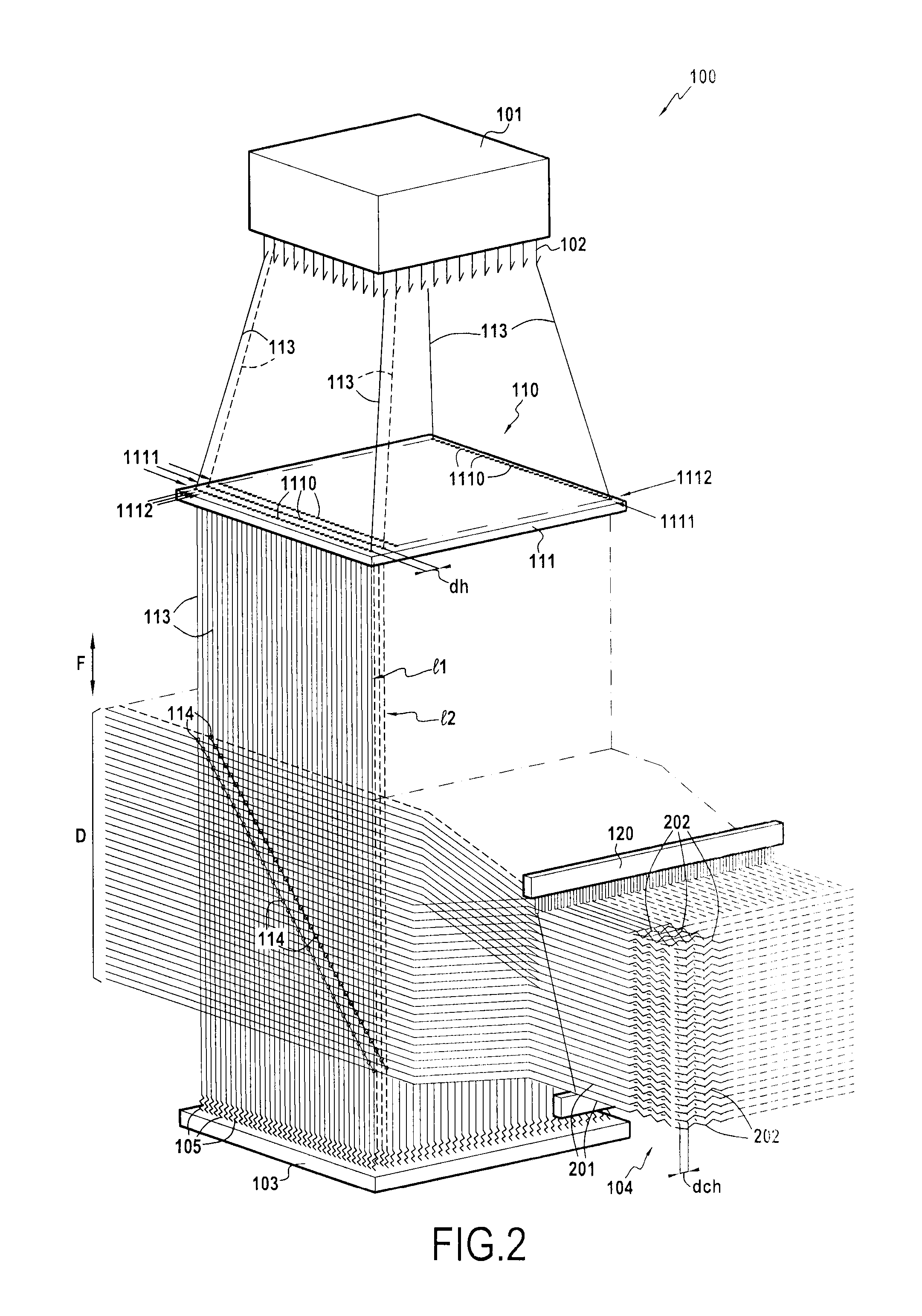

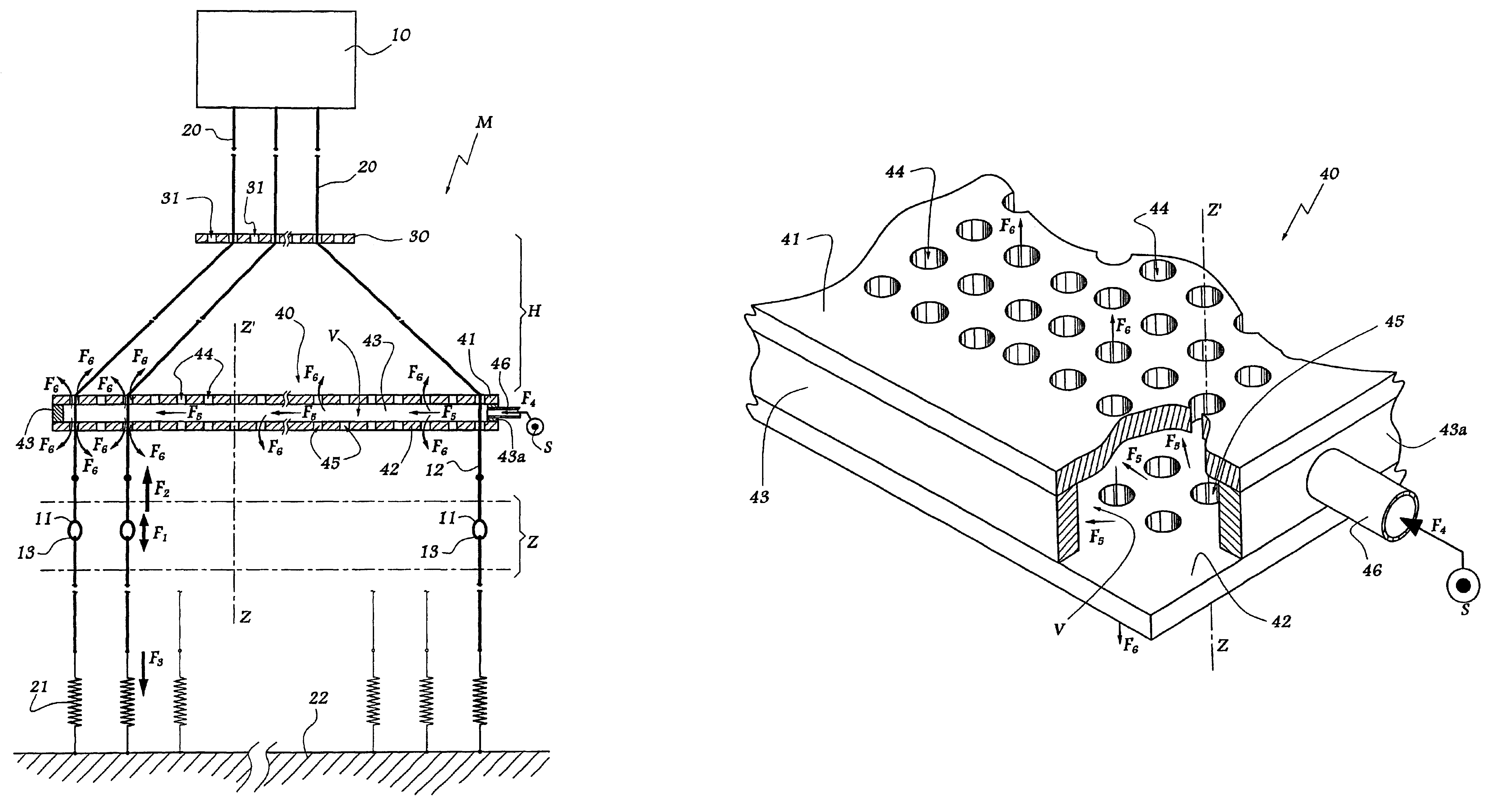

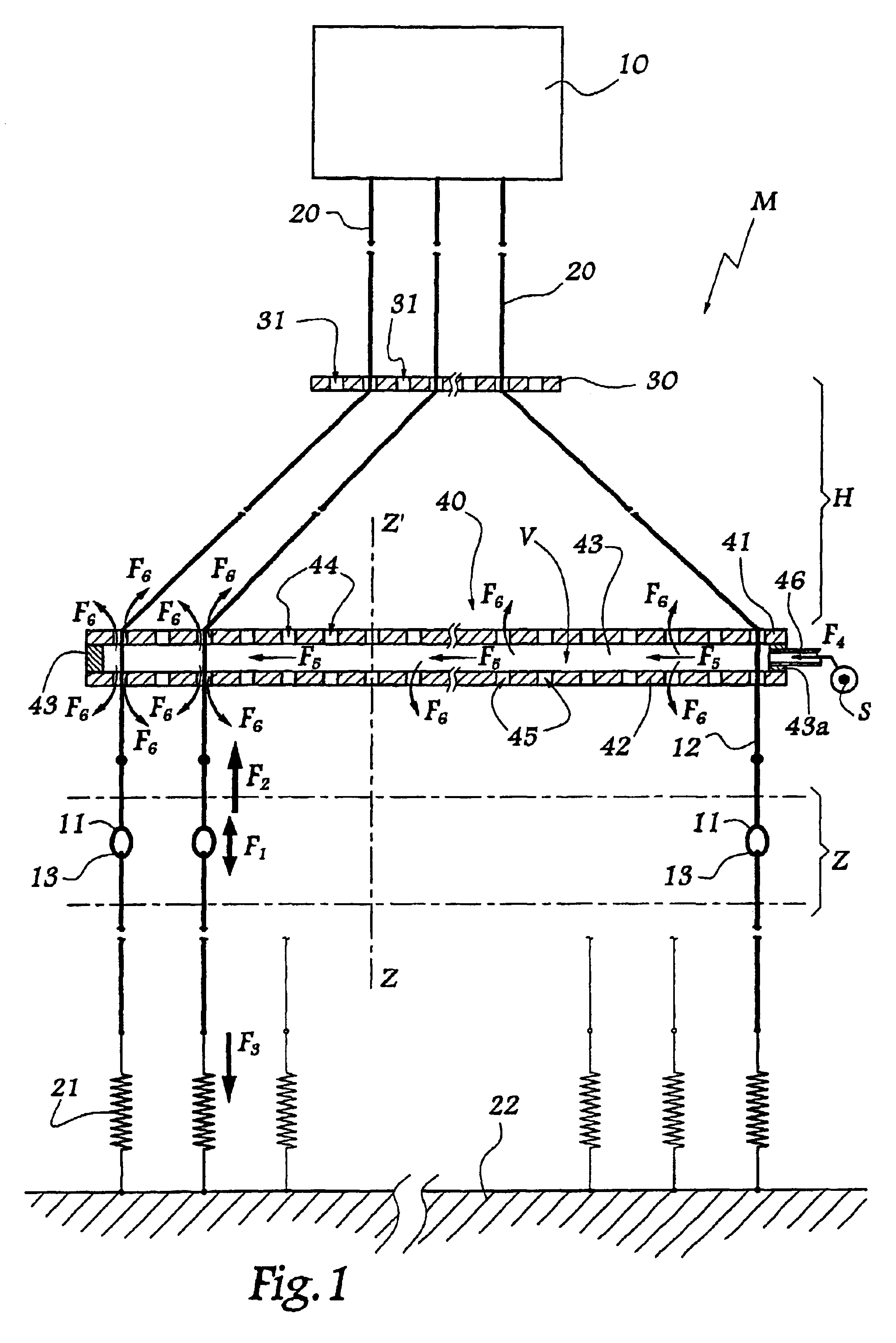

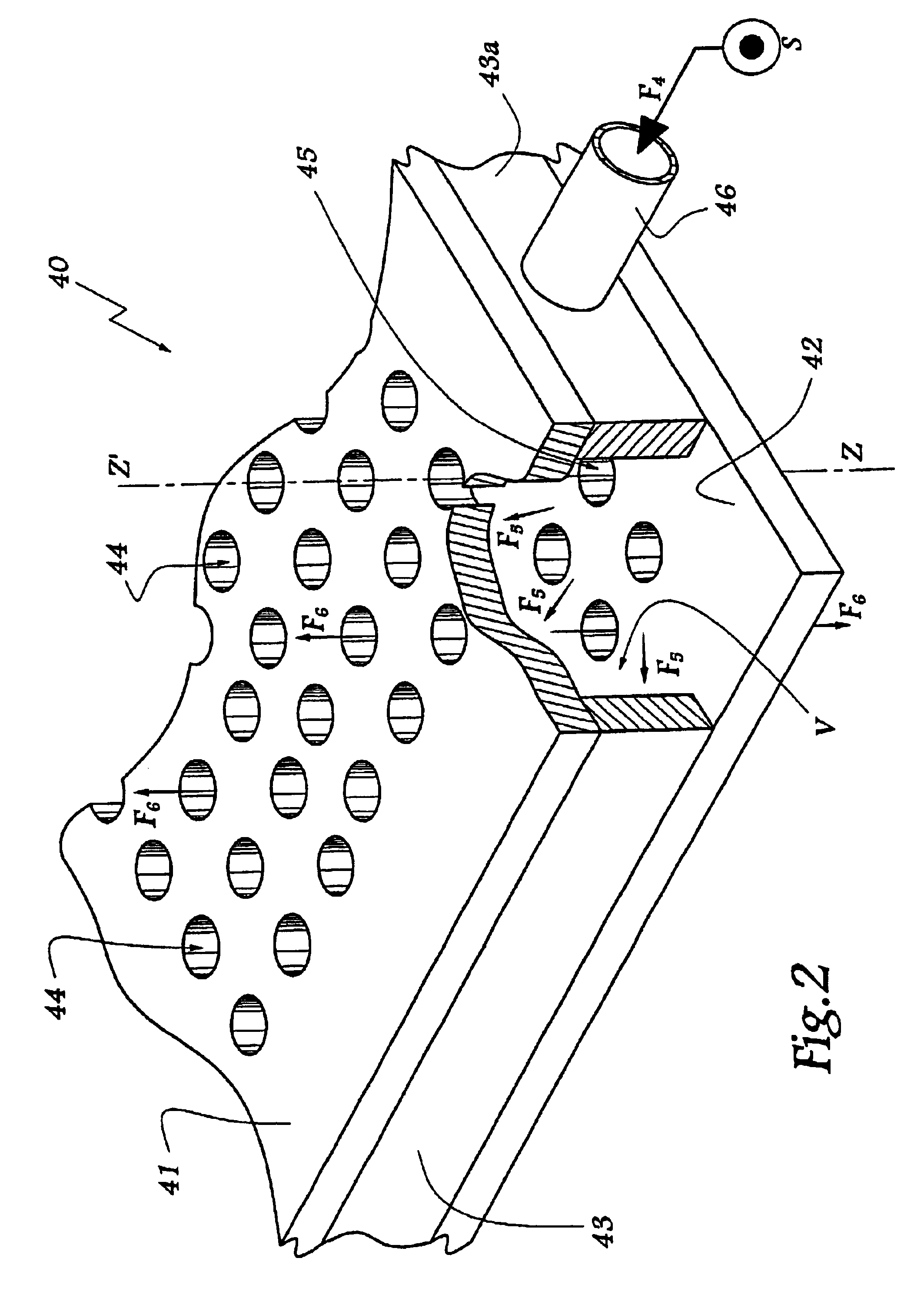

Jacquard loom having optimized warp yarn density

A jacquard type loom for making a fabric by weaving plural warp yarns with plural weft yarns, the fabric including a determined number of columns of warp yarns per unit length and a determined number of layers of weft yarns. The loom includes a comber board including plural holes passing a corresponding number of control cords, each control cord including an heddle eye through which a warp yarn passes. The holes are distributed in a determined number of columns extending parallel to the warp yarn direction and a determined number of rows per column extending in a direction perpendicular to the warp yarn direction. The comber board includes a number of columns of holes per unit length smaller than the number of warp columns in the same unit length in the fabric, and a number of rows of holes greater than the number of warp layers in the fabric.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

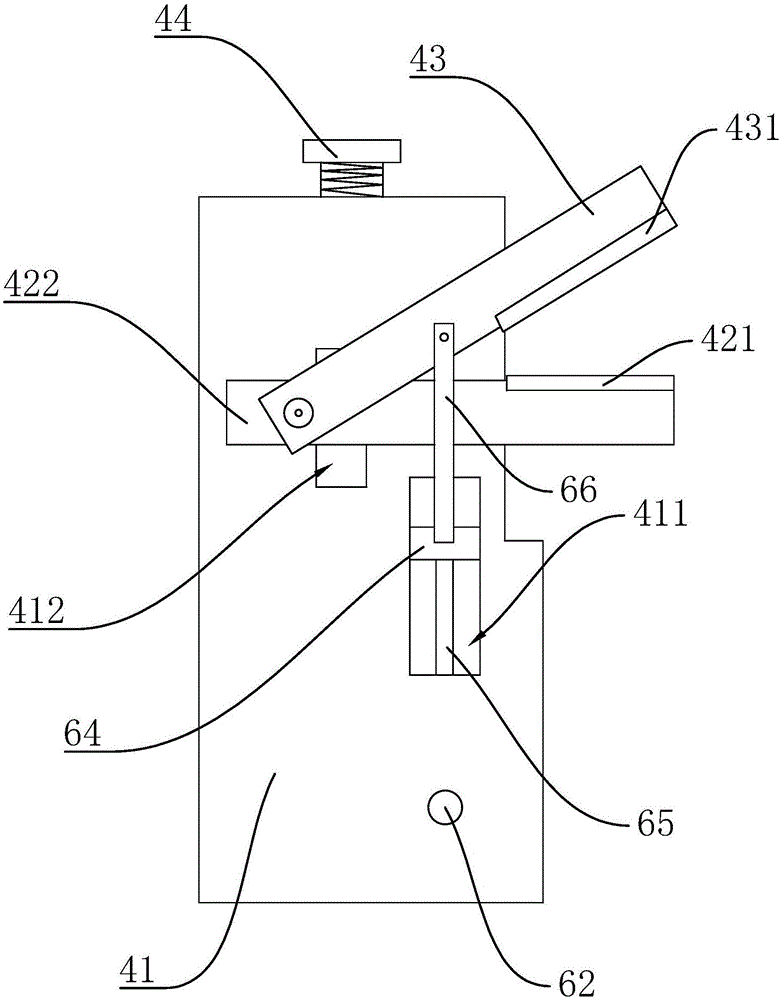

Electronic shedding device of jacquard loom

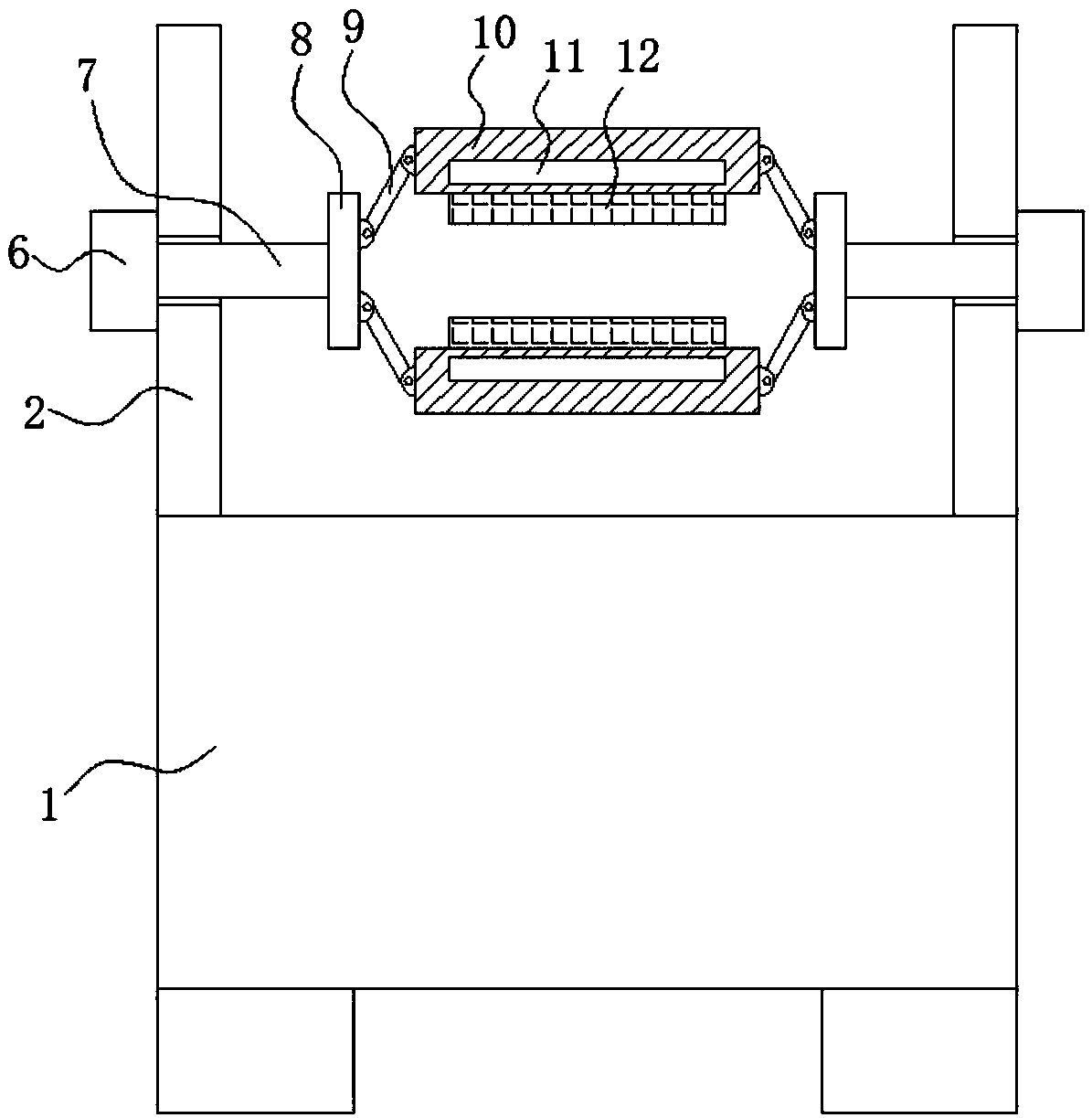

The present invention relates to an electronic shedding device of a jacquard machine. Said device comprises at least two groups of synchronous jointing tool mechanism performing a up and down reciprocating motion with each group comprising jointing tool beams set at both ends, a plurality of jointing tools connected between two jointing tool beams; a plurality of motors transforming input electric signals into angular displacement output and running synchronously to a weaving machine; a plurality of transmission mechanisms connected to output terminals of motors and used for transforming the angular displacement of motor output into linearity displacement, and connected to two jointing tool beam locating at the same side for driving two groups of jointing tool mechanisms to perform synchronous up and down reciprocating motion. Furthermore, the present invention is also capable of adopting a linear motor to drive the jointing tool mechanisms to perform up and down reciprocating motion, meaning that the present invention replaces a mechanical shedding device in a conventional jacquard machine with an electronic shedding device. Therefore, by removing a complicated cam connecting rod mechanism, said device having a simple mechanical structure is capable of running stably with reduced vibrations, which shedding height is capable of being not mechanically but electrically adjusted.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

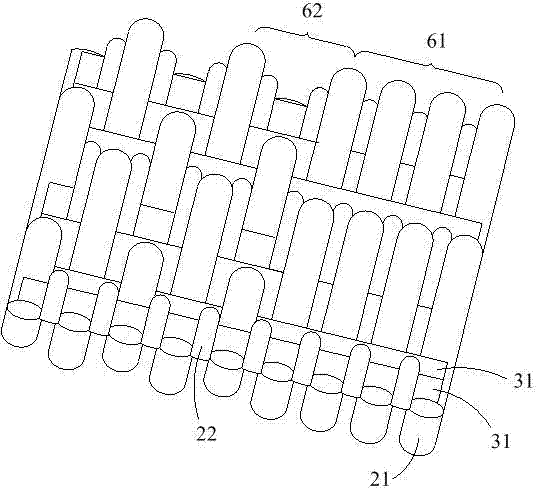

Functional woven vamp cloth

InactiveCN104294447AWith thickness differenceImprove wear resistanceWoven fabricsJacquard loomPulp and paper industry

The invention discloses a piece of functional woven vamp cloth, which is woven by a double-pan-head jacquard loom according to weave composition. The double-pan-head jacquard loom comprises two warp beam yarn feeding wheels, a jacquard, and multiple weft yarn feeding mechanisms. The loom is characterized in that a warp yarn system comprises multiple first warp yarn units and multiple second weft yarn units; the two warp beam yarn feeding wheels are respectively used for conveying the multiple first warp yarn units and the multiple second weft yarn units; a weft yarn system comprises multiple weft yarn units; the multiple weft yarn feeding mechanisms are used for conveying the corresponding weft yarn units respectively; and the jacquard performs weaving of the wrap yarn system and the weft yarn system in an interwoven manner according to the weave composition. By employing the difference of yarn textures and diameters of the multiple first warp yarn units and the multiple second weft yarn units, the functional woven vamp cloth is produced by a single weaving process.

Owner:DEERTEX

Production and processing method for fine-polyester high-warp-density bicolor large-jacquard-pattern home textile fabrics

ActiveCN104404684AMeet needsEasy to operateSwivel-woven fabricsLappet-woven fabricsPolyesterPolymer science

The invention relates to a production and processing method for fine-polyester high-warp-density bicolor large-jacquard-pattern home textile fabrics. The production and processing method comprises the following steps of: (1) preparing raw materials: the warp adopts FDY fine-polyester bright twisted filament of 50D / 36F to 50D / 144F, the weft adopts 14.6 tex cotton / modal 50 / 50 siro compact yarn; (2) beam-warping: performing beam-warping in batches, wherein the overall warp number is 35000 to 40000; (3) drafting; (4) adopting a rapier jacquard - 340 weaving machine for weaving, with the speed of 220-250rpm, the opening mode of jacquard head, the opening time of 315 degrees to 325 degrees, the of 65 degrees to 75 degrees, the time of 180 degrees, the preset tension of 340-350kg, thus ensuring the production efficiency of the weaving machine and the quality of the gray fabric when leaving the machine; (5) after treatment and printing and dyeing: performing after treatment to ensure the top quality rate of the products when leaving the machine, wherein the dying temperature in the printing and dyeing process needs to be strictly controlled to be not more than 130 DEG C, polyester and cotton can be dyed with different colors according to requirements, and the dyes which can dye the polyester but not the cotton or dye the cotton but not the polyester to perform overdying.

Owner:JIANGSU YUEDA HOME TEXTILE

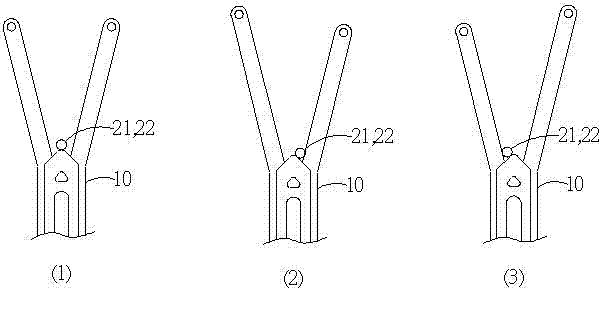

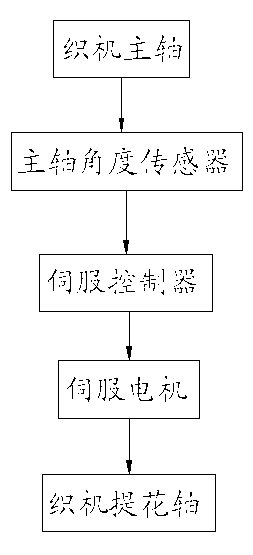

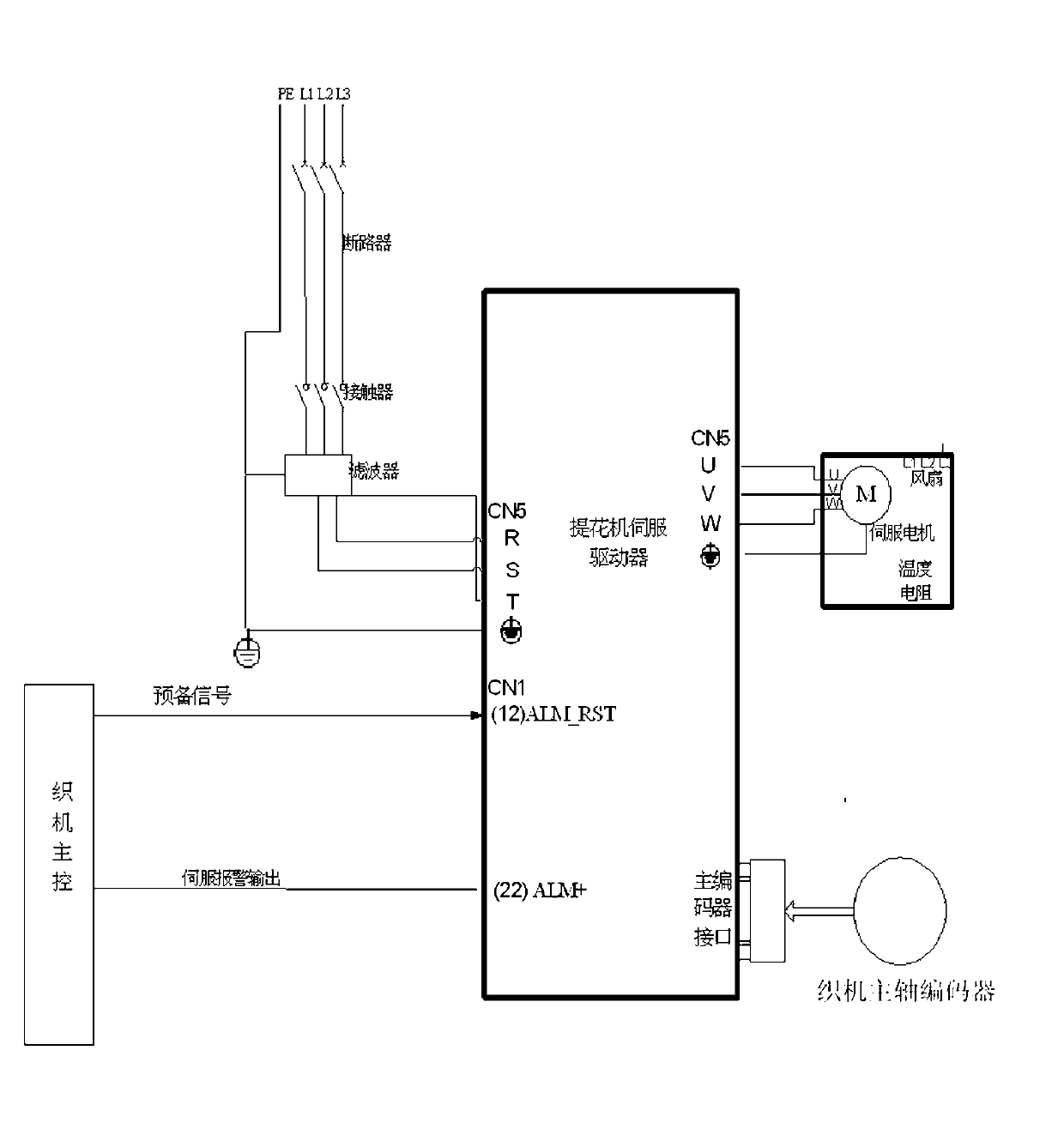

Servo control device and operation and control method for jacquard loom

InactiveCN103306000ASimple structureImprove efficiencyJacquardsNumerical controlJacquard loomWeak current

The invention discloses a servo control device and an operation and control method for a jacquard loom. According to the operation and control method for the jacquard loom, the operation state of a loom spindle is monitored in real time by utilizing a spindle angle sensor, a rotation weak current detection signal of the loom spindle is timely transferred to a controller, and the weak current detection signal is amplified and driven by utilizing the controller and is output to a serve motor so as to control the serve motor to drive a loom jacquard shaft to work so as to realize tracking operation of the loom jacquard shaft and the loop spindle. According to the servo control device, the conventional mechanical connection and driving manner is changed; the structure is simple, the efficiency is high, the mounting and the maintaining are convenient, and the reliability is high; the damage of cone teeth during a use process is avoided, the production and use costs are saved, and the safety of the production is guaranteed.

Owner:苏州御能动力科技有限公司

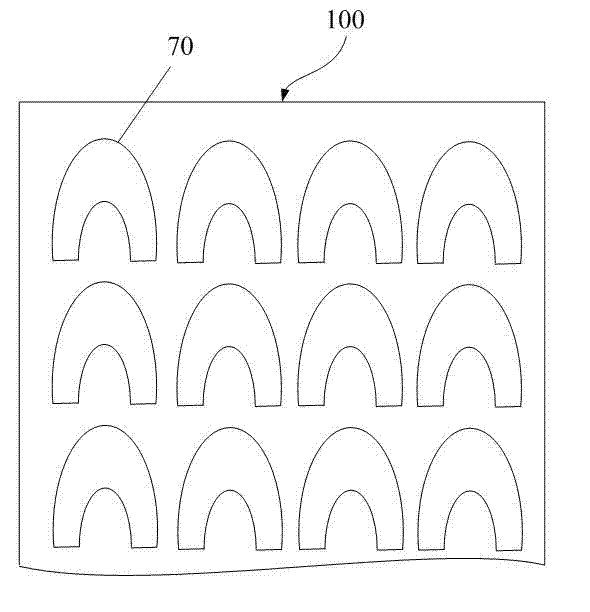

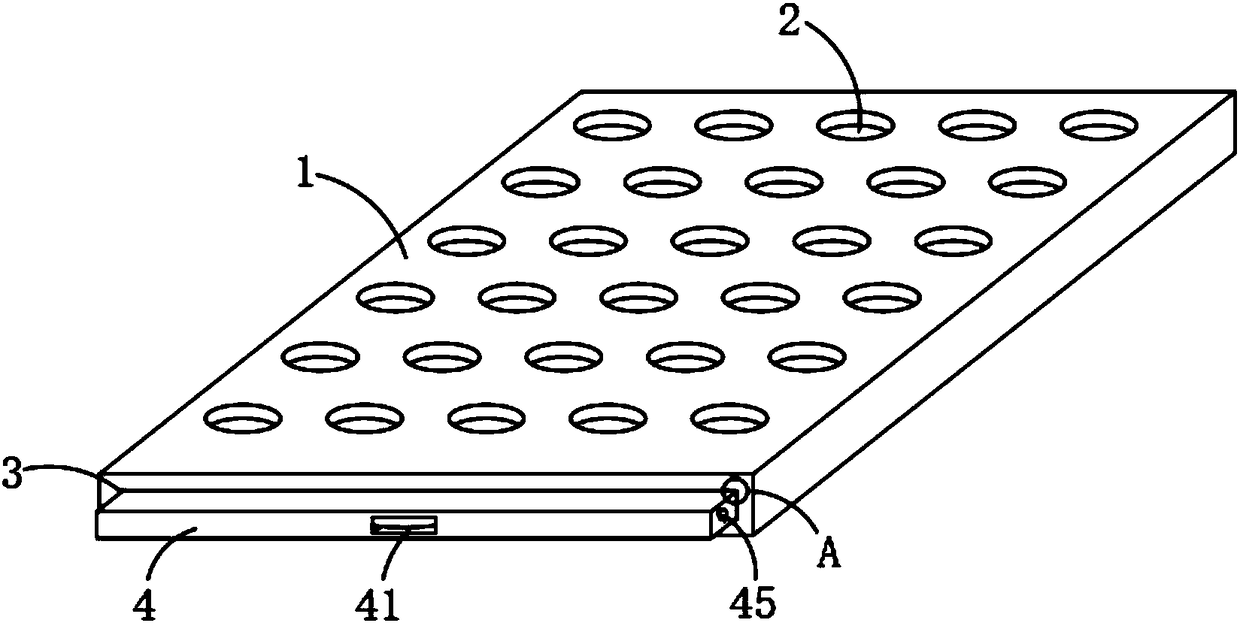

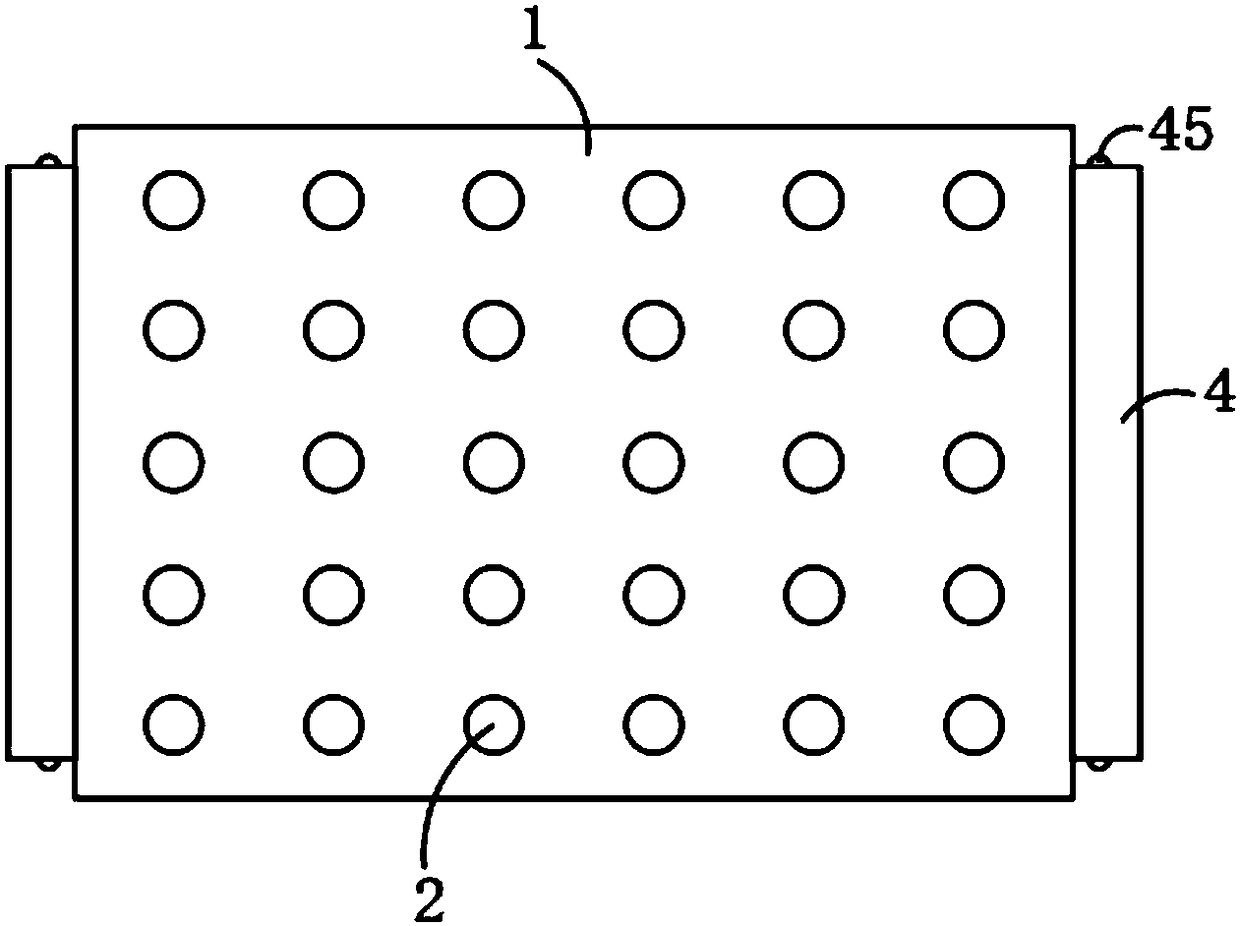

Harness cord anti-breakage mesh plate for jacquard loom

The invention discloses a harness cord anti-breakage mesh plate for a jacquard loom. The mesh plate comprises a mesh plate body. A plurality of harness cord holes are formed in the upper surface of the mesh plate body in a rectangular array. Installation grooves are formed in the two ends of the mesh plate body respectively and each internally provided with a fixed slider. A harness cord inlet isformed in one side of each harness cord hole. The end, opposite to the harness cord inlet, of the harness cord hole is provided with a harness cord outlet. The upper inner wall and the lower inner wall of each harness cord hole are each provided with a rubber soft cushion. The upper inner wall and the lower inner wall of each harness cord hole are fixedly provided with three upper pressing rollersand a lower pressing roller at equal intervals through supports in the horizontal direction respectively. By arranging the upper pressing rollers, clamping grooves, the lower pressing roller and limiting clamping blocks, the tension of harness cords can be ensured, and the rapid conveying of the harness cords is facilitated; by arranging the fixed sliders, slide rails, extension springs and clamping balls, the mesh plate is rapidly installed, the telescopic movement of the fixed sliders is facilitated, the space occupied by the mesh plate is reduced, and the conveying of the mesh plate body is facilitated.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

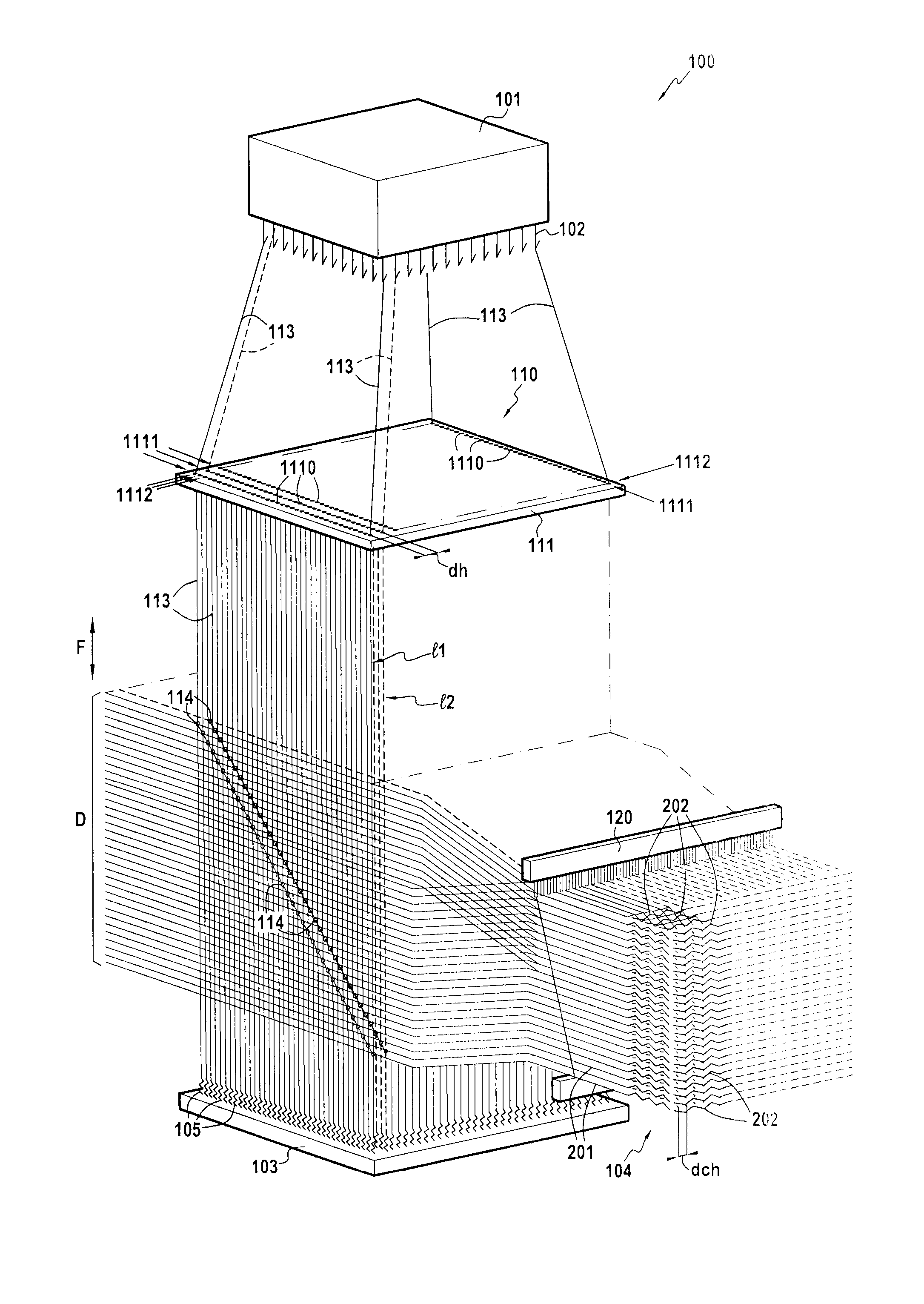

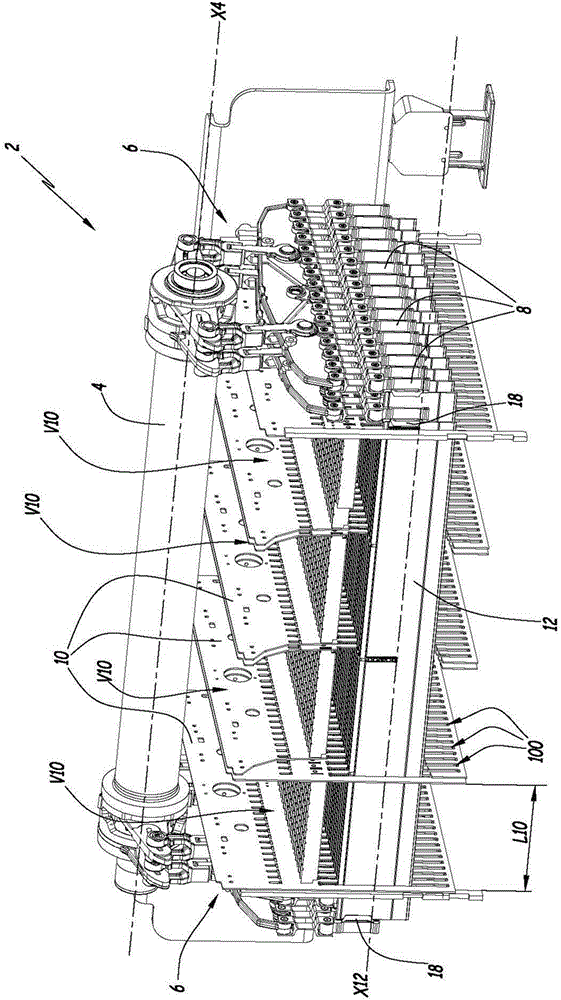

Method and apparatus for guiding the harness cords of a Jacquard loom

InactiveUS6769458B2Eliminate and limit abrasionLimit loss of their technical characteristicJacquardsWeft knittingJacquard loomEngineering

Owner:STAUBLI LYON

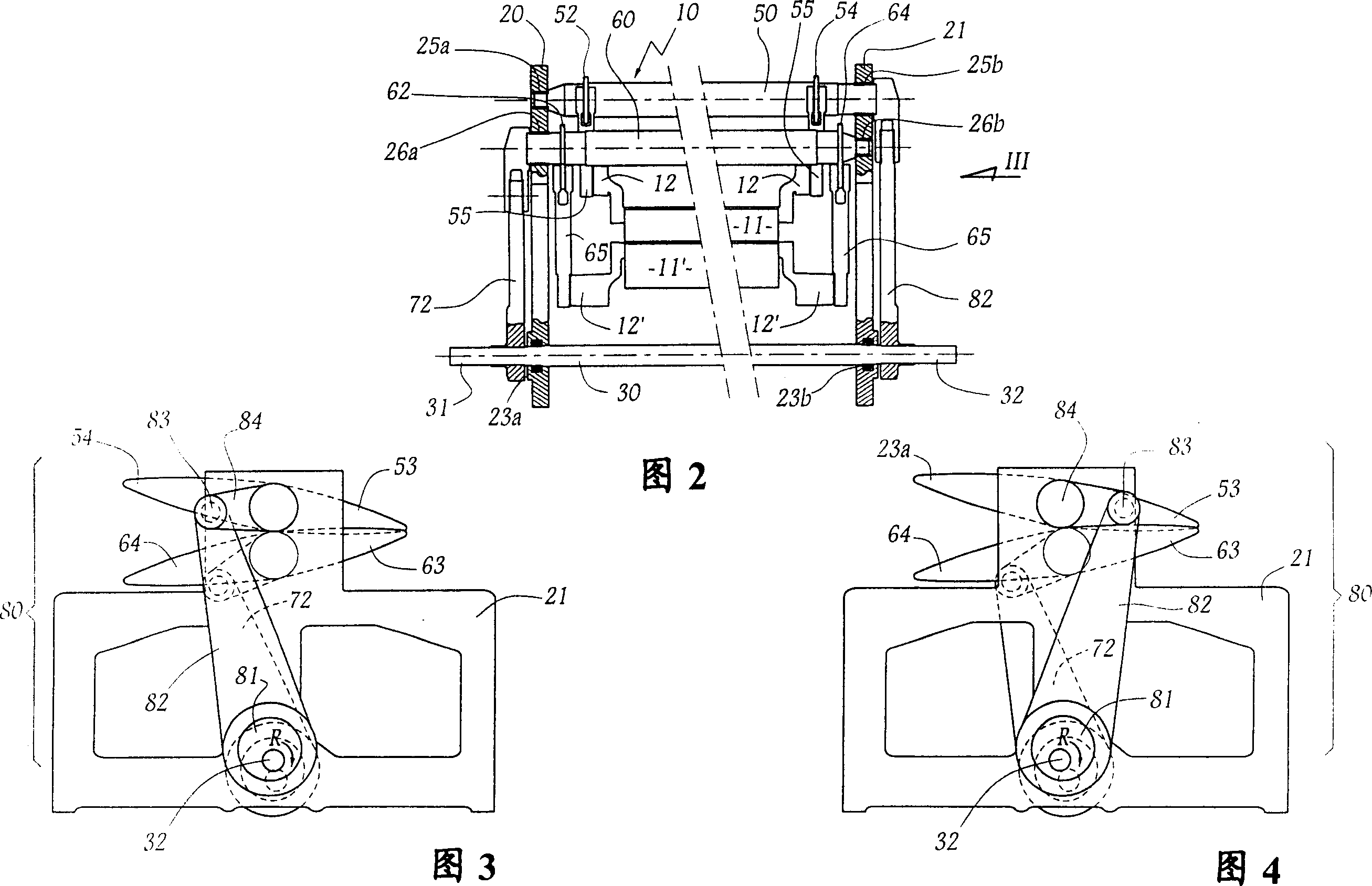

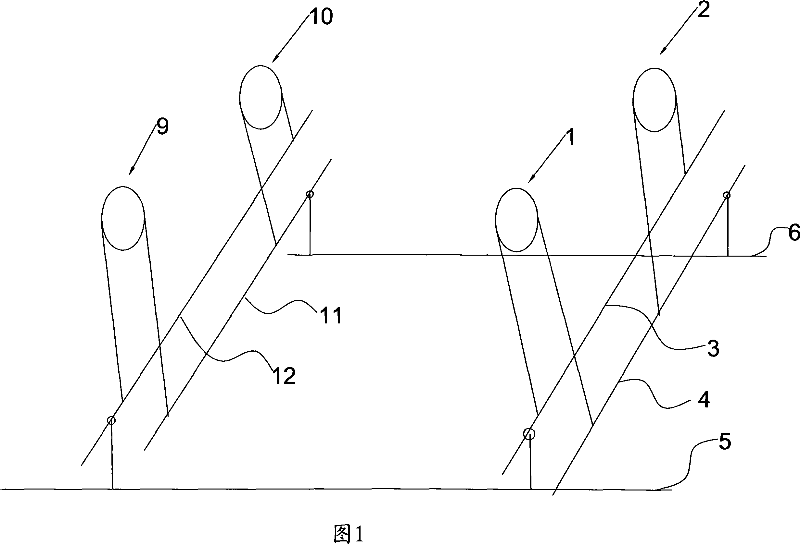

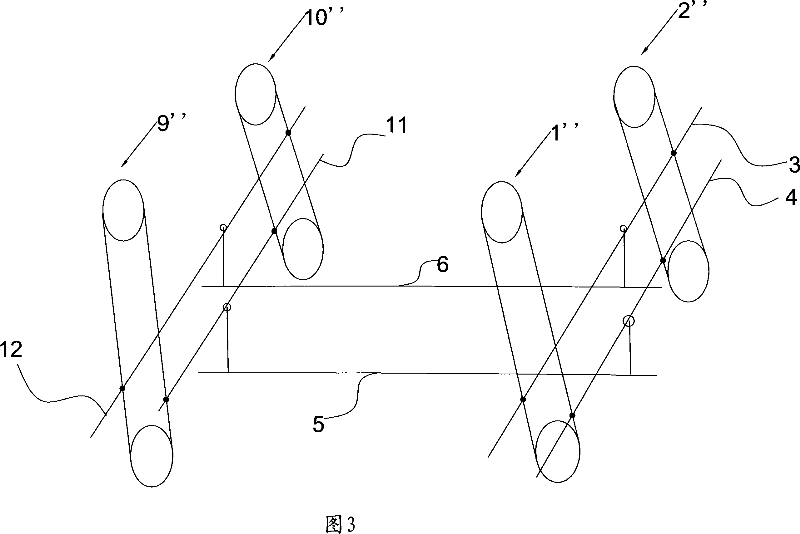

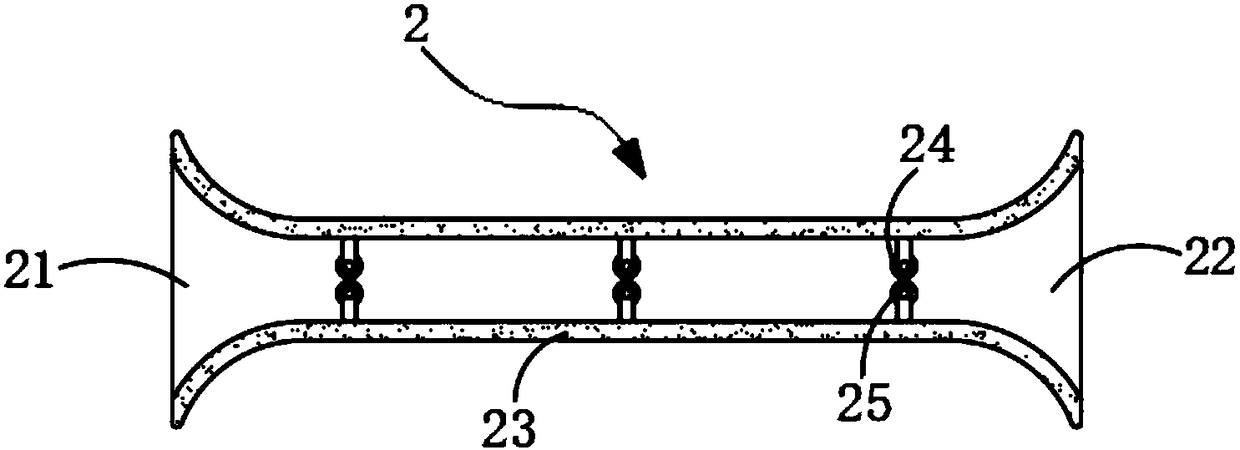

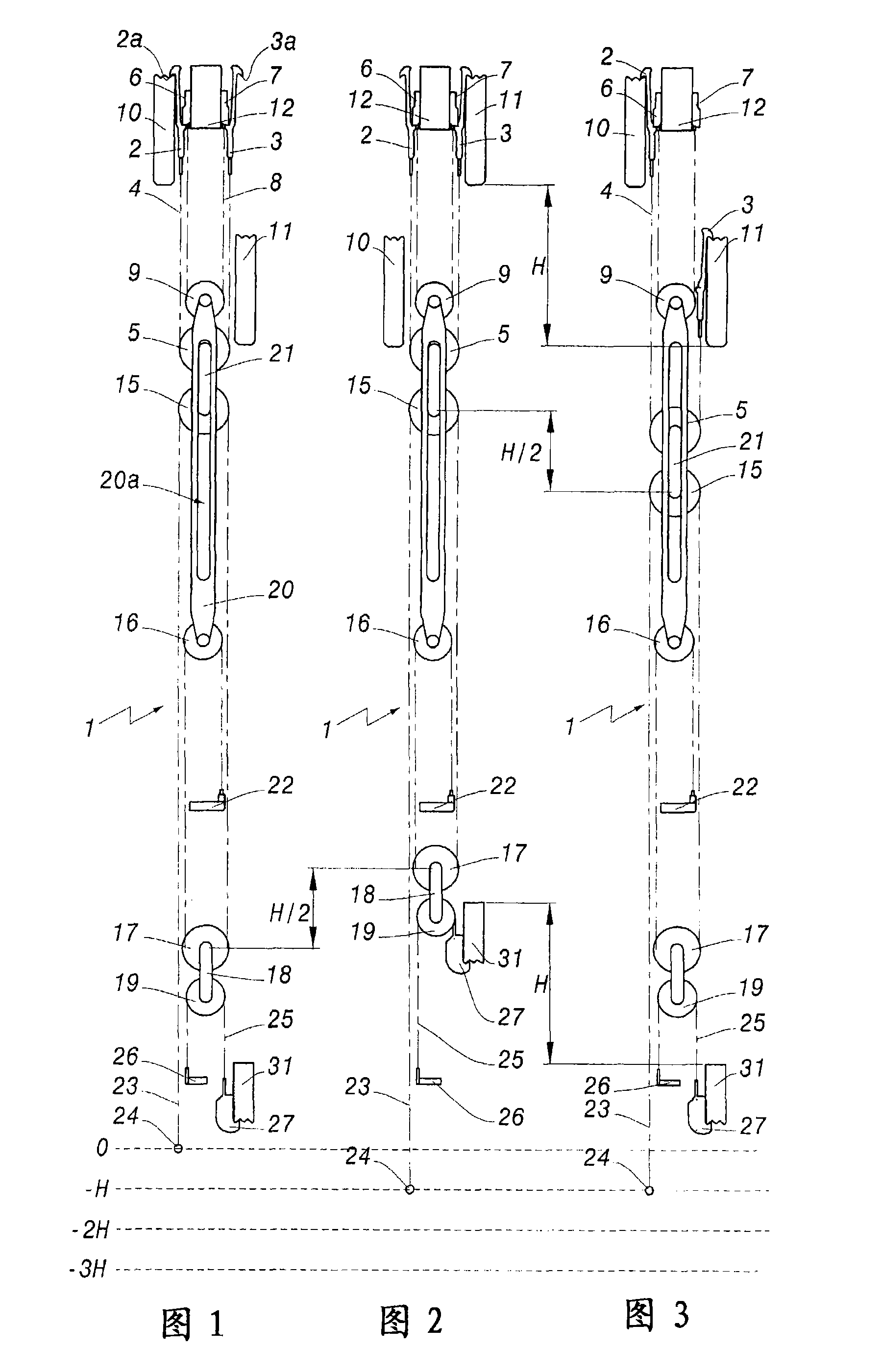

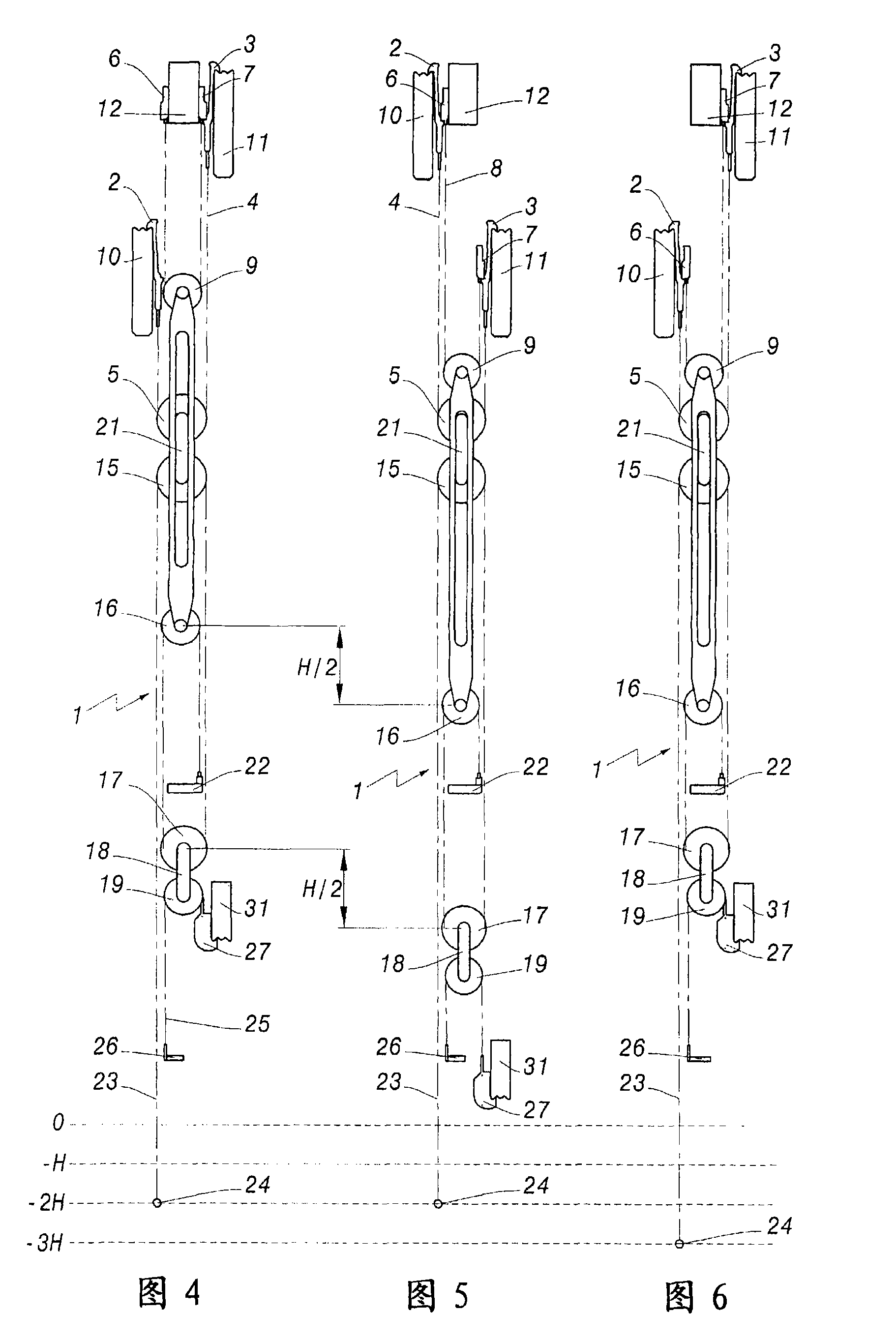

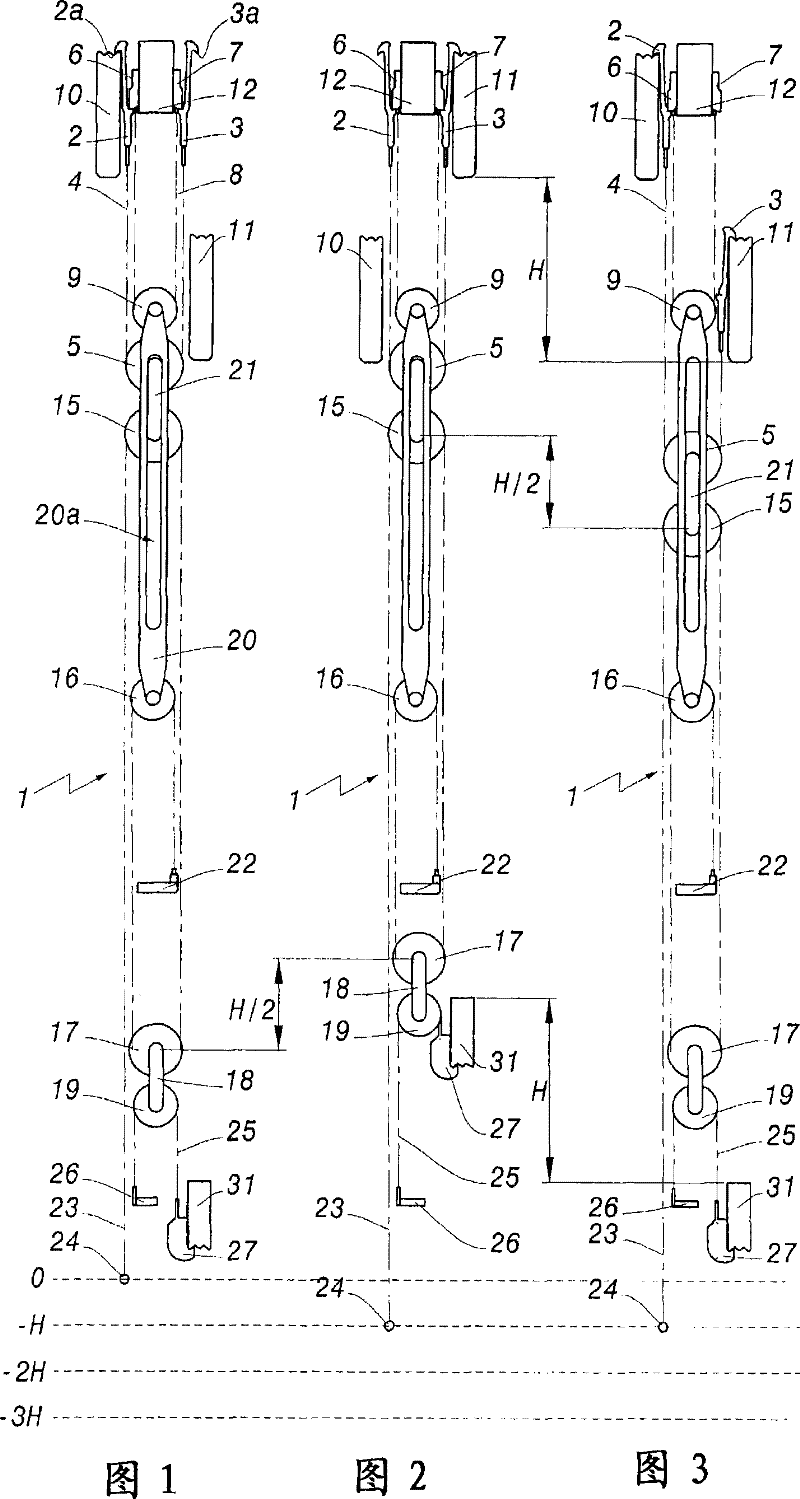

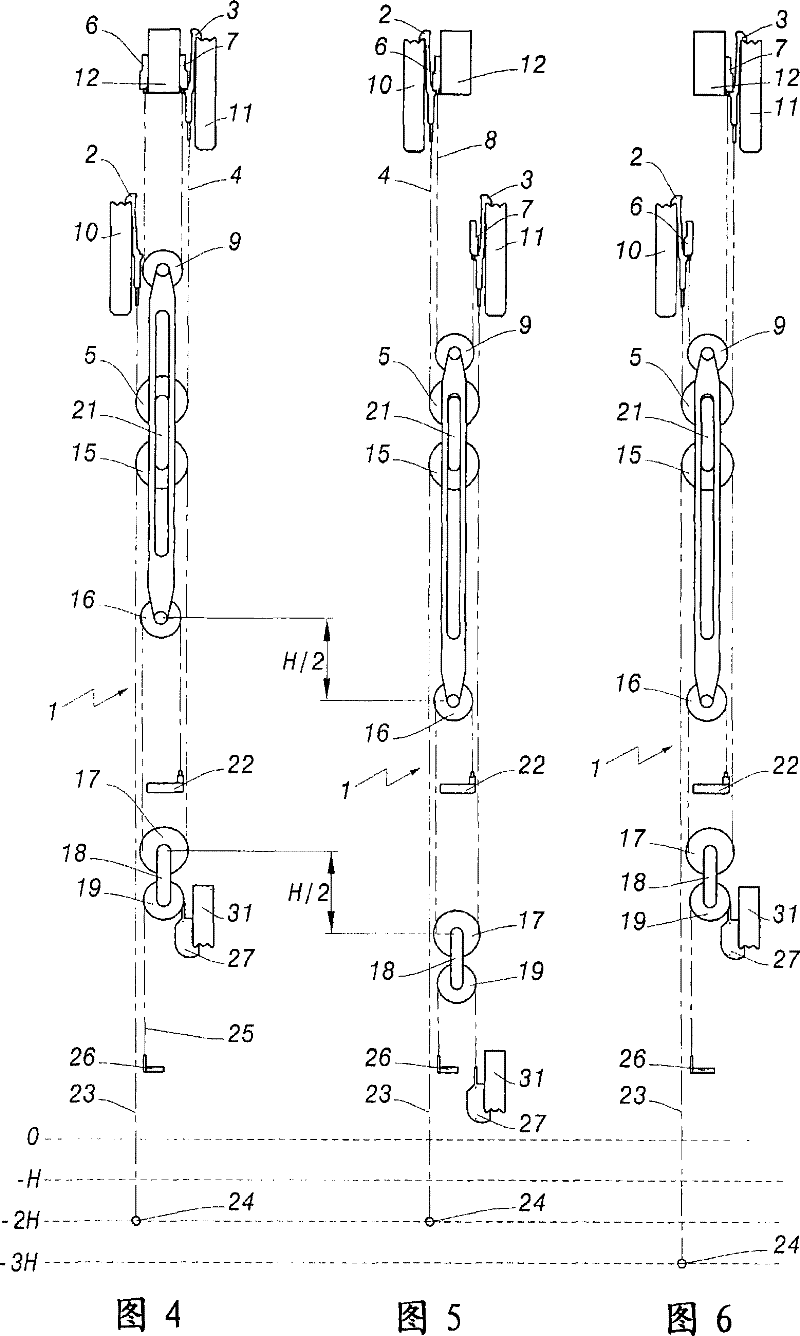

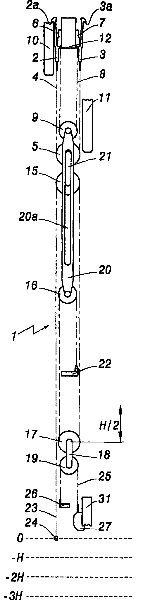

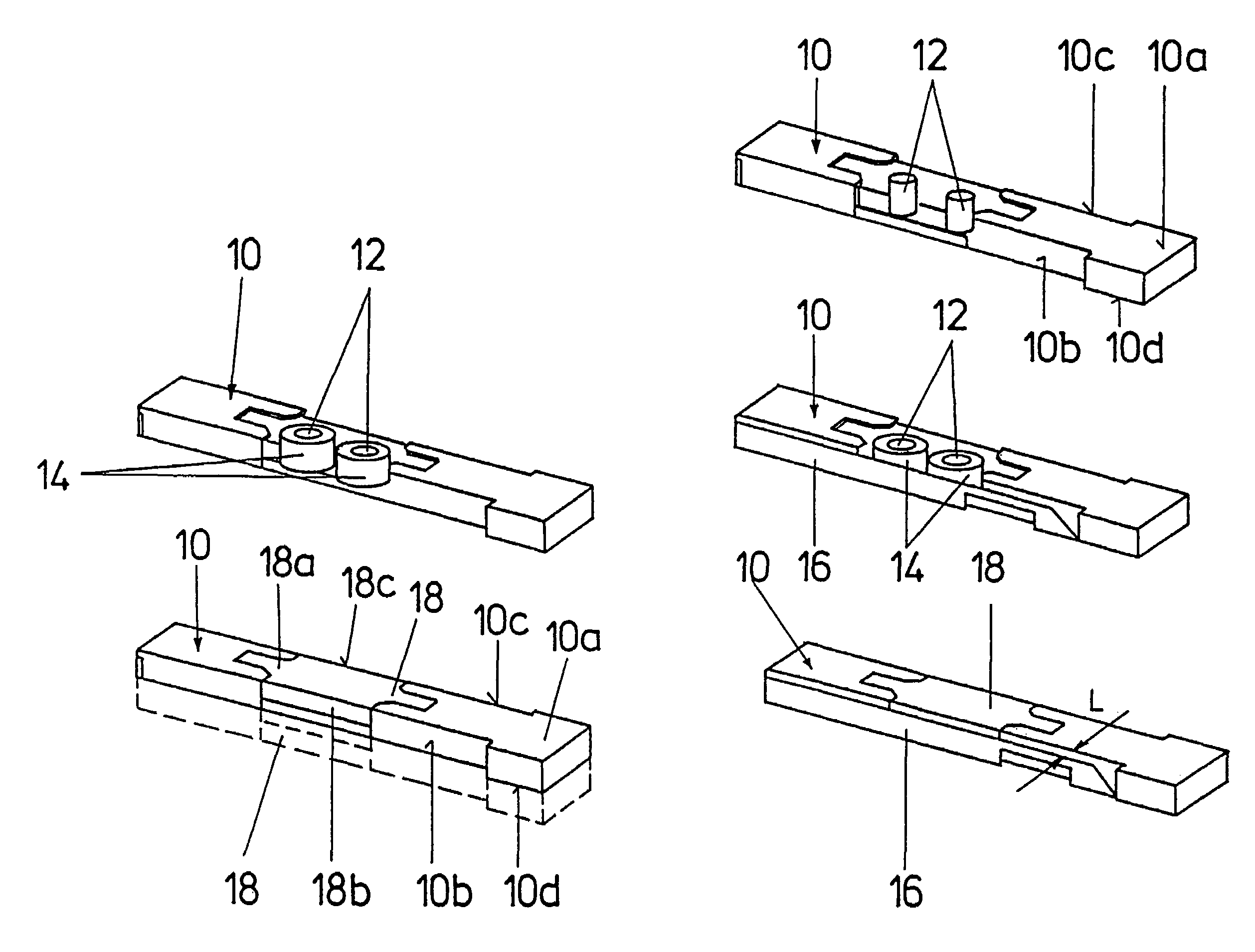

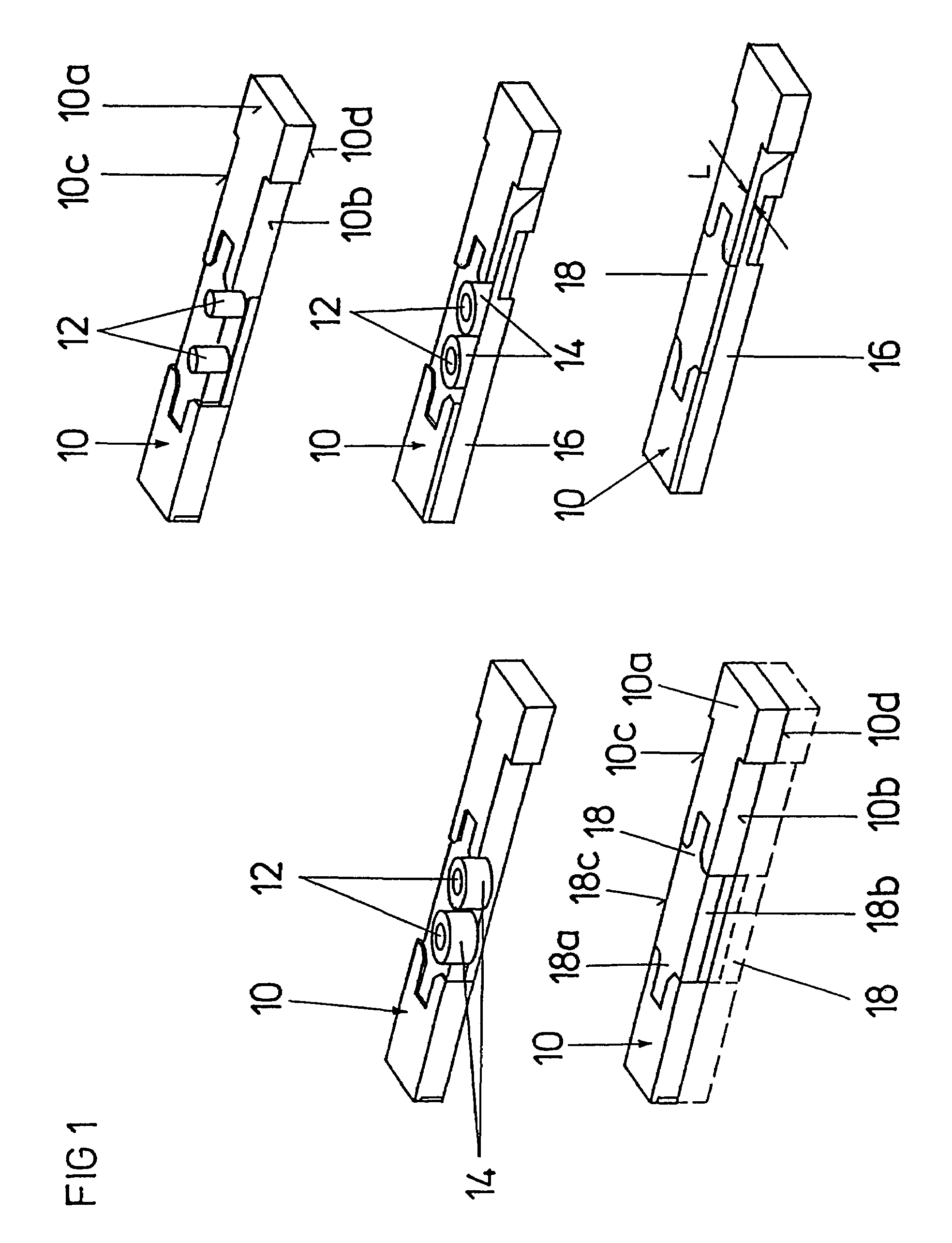

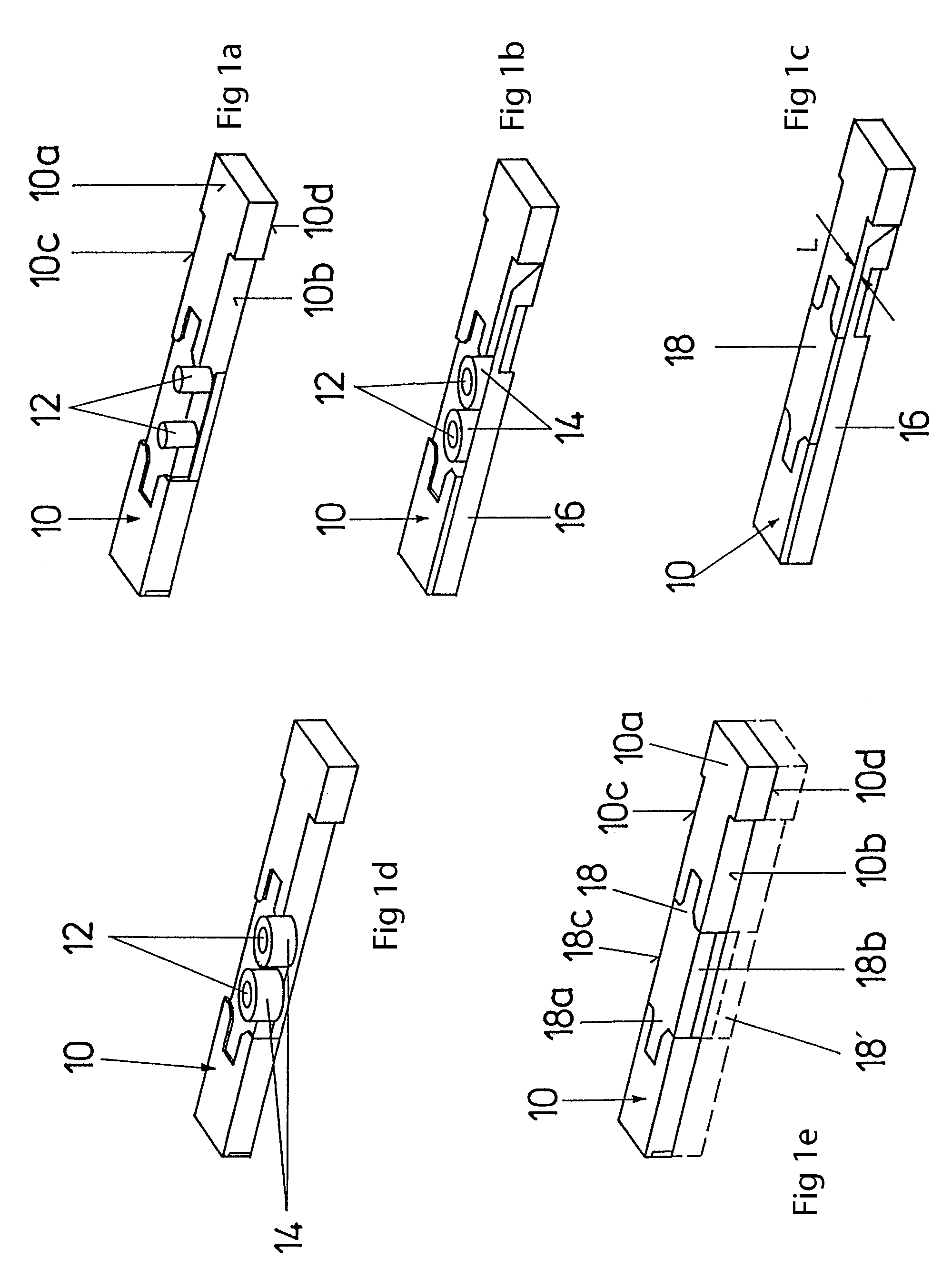

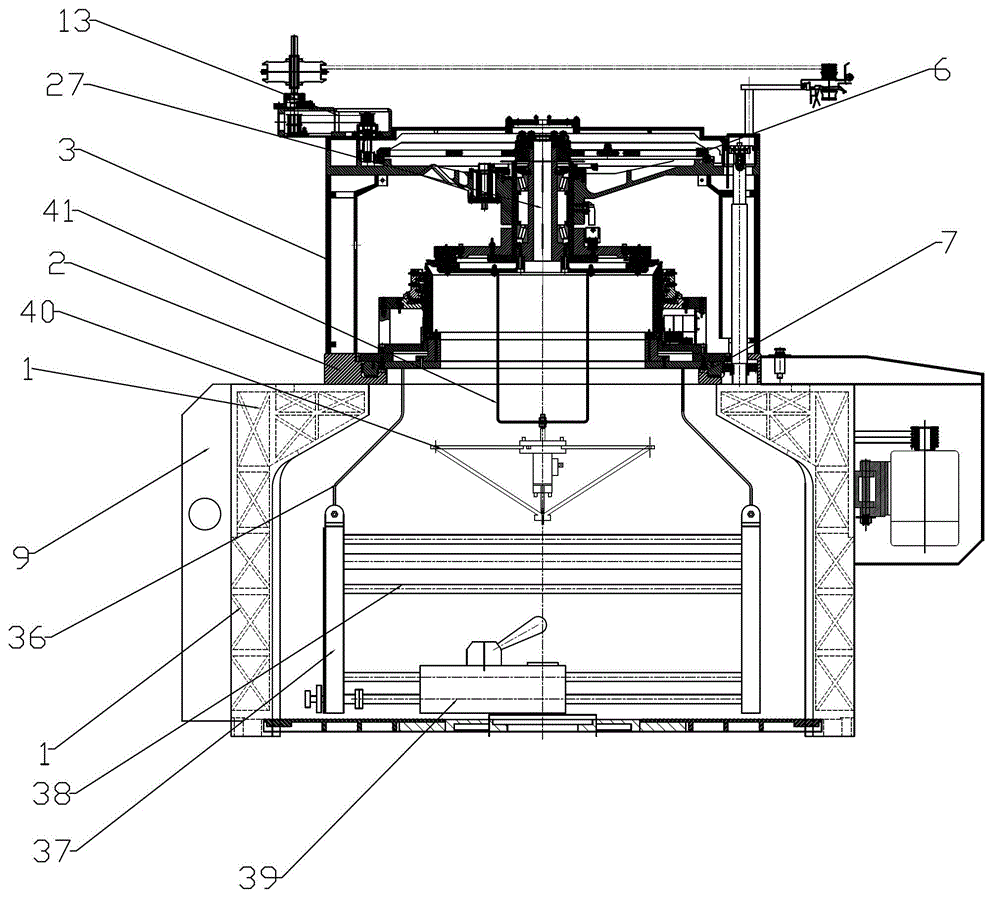

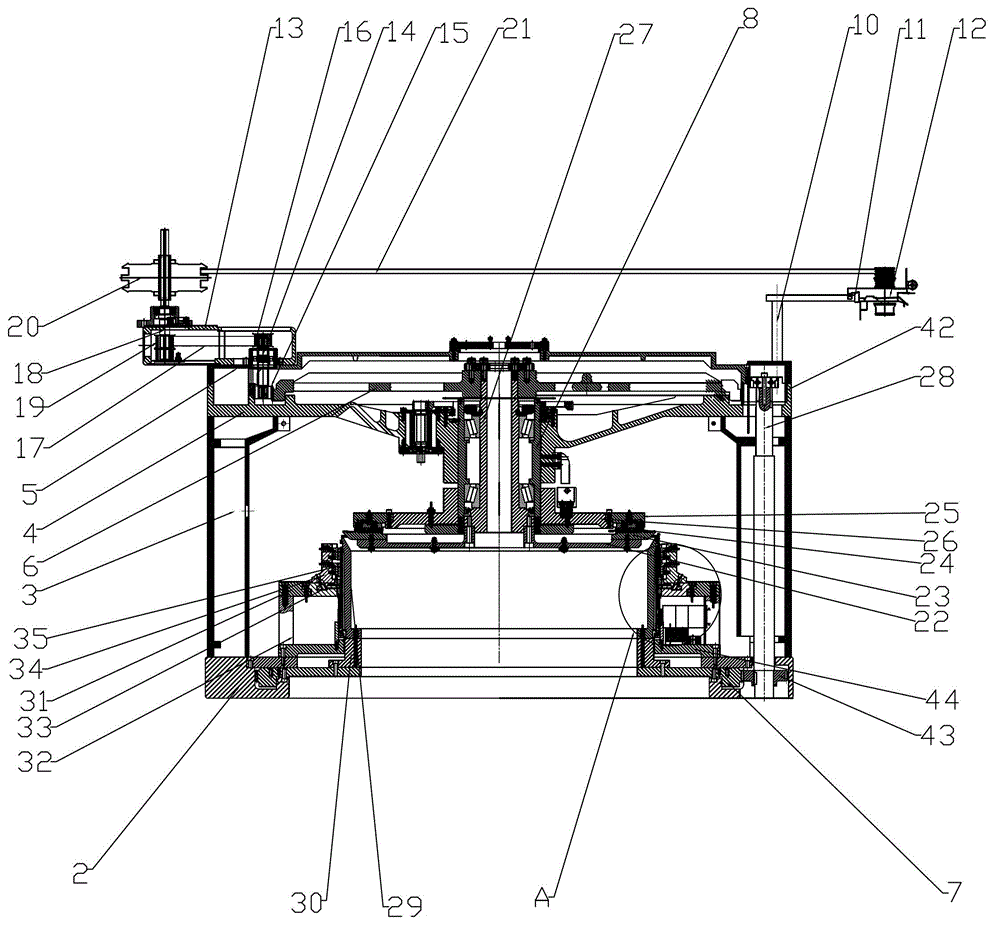

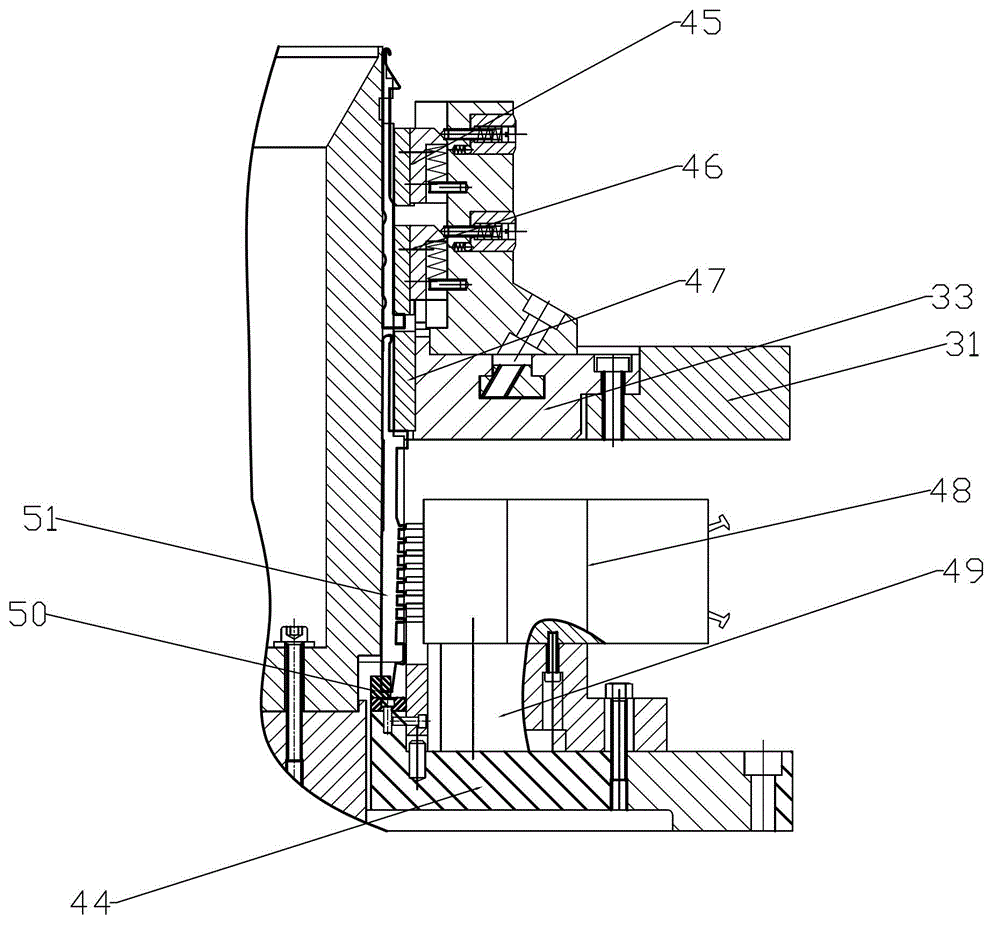

Shed forming device in a jacquard loom, and jacquard loom equipped with such a device

The invention discloses a weaving mechanism comprising shed forming devices (1) each comprising an upper movable carabiner (2, 3, 6, 7) movable by two lifting knives (10, 11) . Each device (1) comprises a set of pulleys (5, 9, 15, 16, 17) comprising pulleys (15, 16, 17) partly wound with a rope (23) whose One end is provided with elastic hooks (24) adapted to be fastened on the heddles. The pulley (17) wound with a rope (23) can be moved vertically by a linkage comprising a rope (25) wound on an additional pulley (19) relative to the Pulley (17) is fixed. One end of rope (25) is fixed on the frame, and the other end can be moved by lifting knife (31).

Owner:施托布利里昂公司

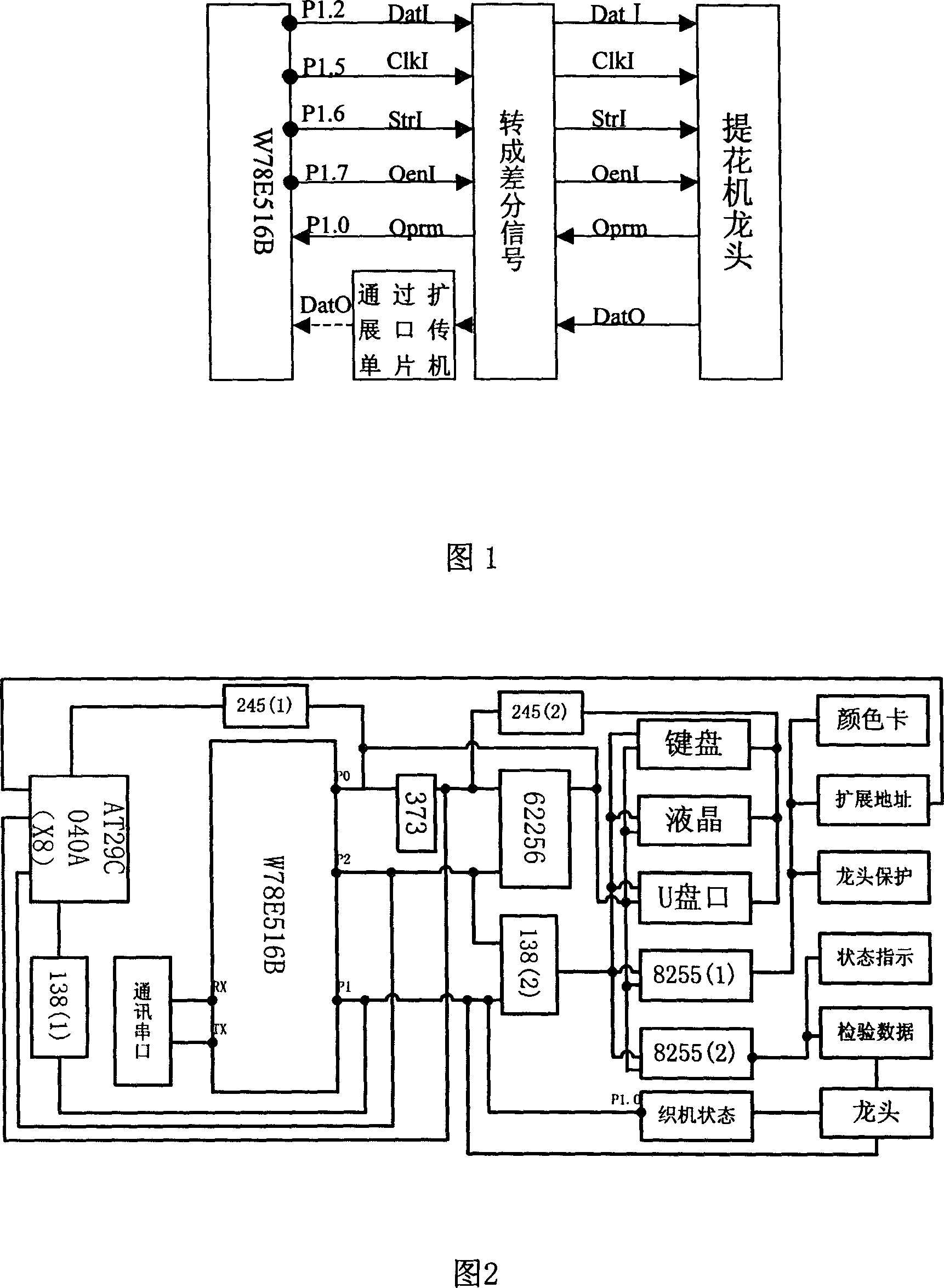

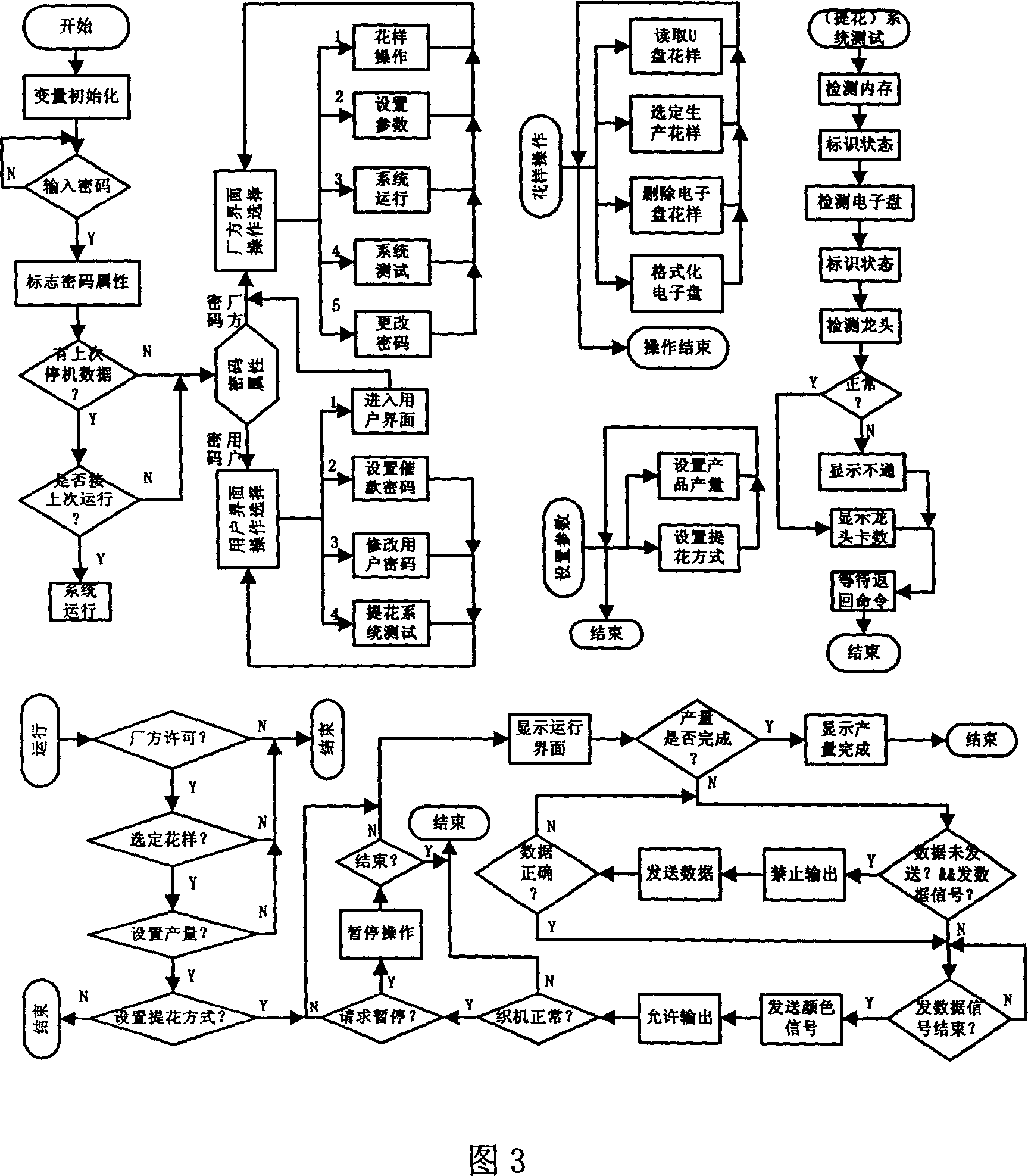

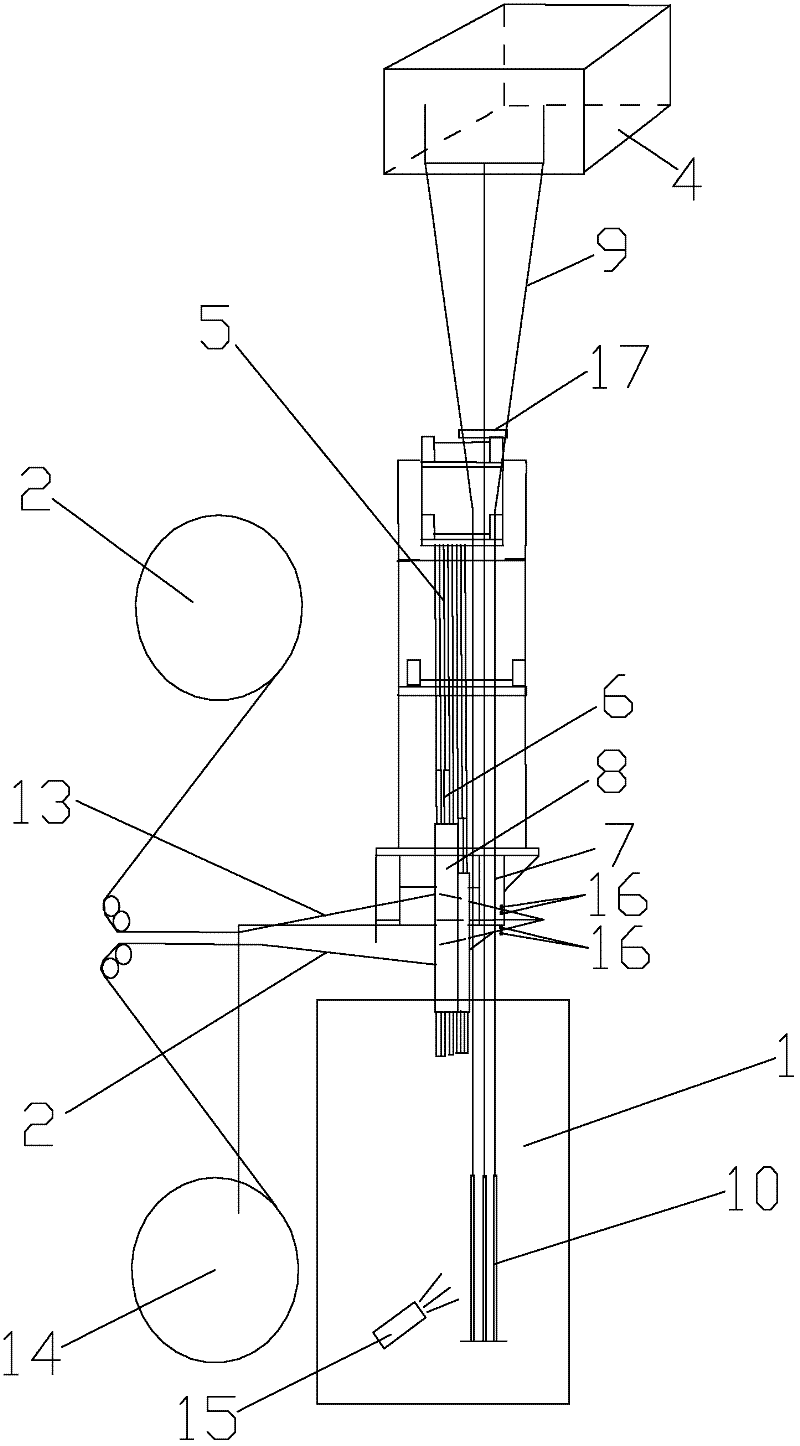

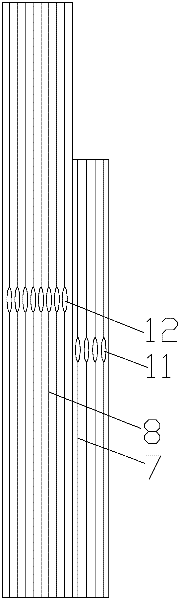

Electronic jacquard loom controller

InactiveCN101021024ASolve restricted problemsNot easy to loseProgramme controlJacquardsMicrocontrollerJacquard loom

The electronic jacquard loom controller consists of a main control board based on monochip computer, an expanding interface and a USB electronic disk interface circuit mainly. The USB electronic disk interface circuit is used for reading the pattern data into the monochip computer so as to control the cock in the electronic jacquard loom by means of the monochip computer and the expanding interface. The present invention uses USB disk, rather than floppy disk, for pattern inputting, and thus has short input time and no limitation on weft number. The controller has USB port for communication with PC and makes it possible to realize on-line control of the jacquard loom. The present invention adopts Flash disk for pattern memory, and has less data loss and easy expansion.

Owner:ZHEJIANG UNIV

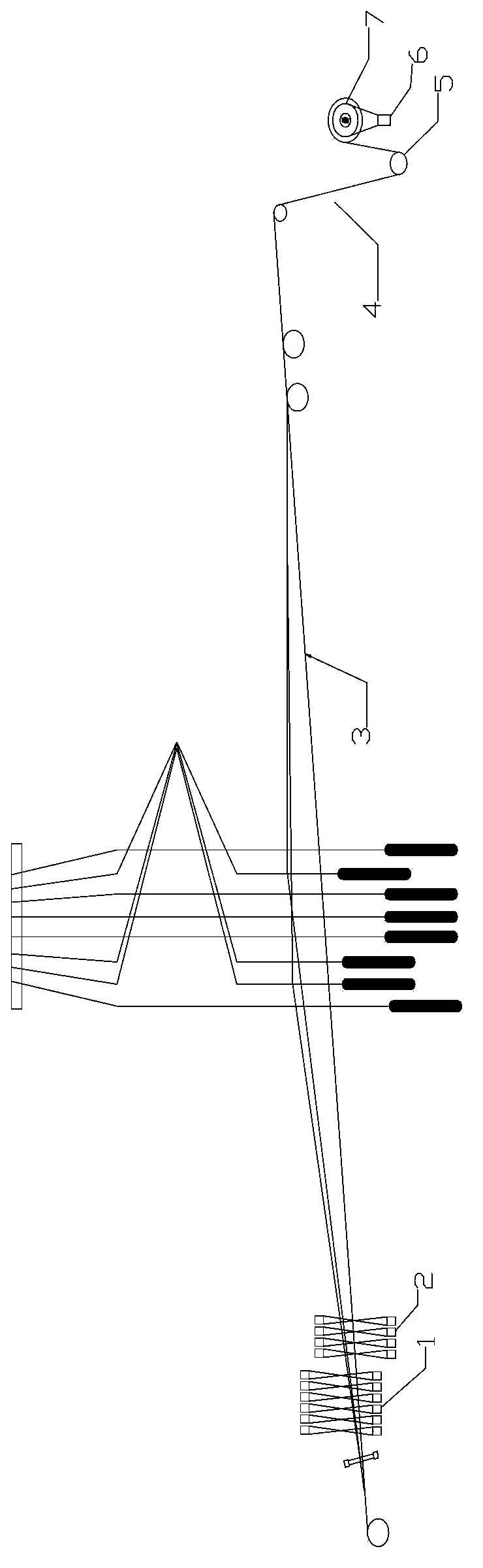

Weaving method and weaving device for multiple-weft high-density water spraying jacquards

The invention discloses a weaving method and a weaving device for multiple-weft high-density water spraying jacquards. The weaving device comprises a weaving machine body, a first warp beam, a second warp beam, a jacquard loom, a multiple-arm loom, a heald frame, a plurality of first harness wires, a plurality of second harness wires, a plurality of harness cords, a plurality of harness wire returning springs and at least one weft storing device. The jacquard loom and the multiple-arm loom are installed on the weaving machine body, the plurality of harness cords are arranged on the jacquard loom, the lower ends of the harness cords are connected with the first harness wires, the lower ends of the first harness wires are connected with the harness wire returning springs, and the lower endsof the harness wire returning springs are fixed on the weaving machine body. The first harness wire are provided with first mail eyes, the lower portion of the multiple-arm loom is connected with theheald frame, the second harness wires are arranged in the heald frame, and second mail eyes are arranged on the second harness wires. First warps and second warps are respectively wound on the first warp beam and the second warp beam, the first warps penetrate through the first mail eyes, second warps penetrate through the second mail eyes, the first warps and the second warps form a shed along with movement of the first harness wires and the second harness wires, and wefts on the weft storing device penetrate through the shed. The weaving method and the weaving device for the multiple-weft high-density water spraying jacquards improves definition of a weaving hole (the shed) and achieves good weaving of high-density jacquard fabrics.

Owner:ZHEJIANG SANZHI TEXTILES +2

Special columella thread for jacquard loom and production method thereof

InactiveCN101275323ABeware of getting drenchedIncrease productivityJacquardsYarnMolten stateJacquard loom

A pillar wire is an easy consume article in operation of hook loom. In the past, people using general cotton wax wire, or simply dips and coats the cotton wax wire in the bleached bees wax to be used as the pillar wire, which has short service life. The invention provides a hook loom special pillar wire and producing method thereof. The novel pillar wire is formed by dipping the cotton wax wire or Vinylon harness in wax liquid, which is a liquid state wax of beeswax and white wax according to the mass ratio formula of 1:0.3-0.6 and heated to a molten state, the mass ratio formula of beeswax and white wax is preferably 1:0.35-0.55, more preferably 1:0.4-0.5, and 1:0.45 at best. The hook loom special pillar wire producing method includes steps of cutting, wax matching, heating, impregnation and even steaming. The invention has concise technique, convenient operations, uniform products waxiness, largely increased firm degree and prolonged service life; for users, the consumption can be reduced and the productivity effect of the hook loom can be greatly improved.

Owner:徐新明

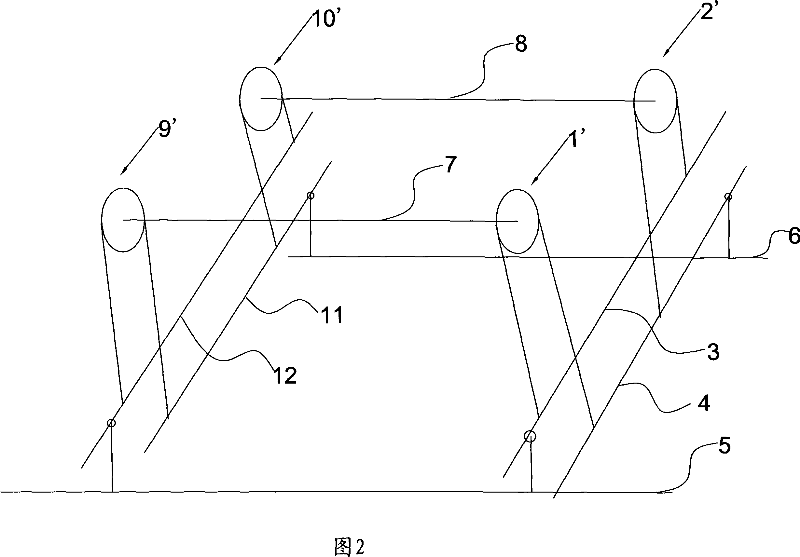

Weaving device, and jacquard loom equipped with such a device

The mechanism has a shed forming device (1) comprising pulleys (5, 9, 15, 16, 17) vertically aligned in middle part of the device. The pulley assembly of a cord (23) is vertically arranged by a hitch comprising a fillet (25) that surrounds a lower pulley (19) integrated in translation from the pulley assembly. One end of the fillet is fixed to a frame of the mechanism, while another end of the fillet is arranged with a lower cutter (31) displacing the lower pulley and cord.

Owner:施托布利里昂公司

Integral harness wire of jacquard loom and manufacturing method thereof

The invention discloses an integral harness wire of a jacquard loom and a manufacturing method thereof. A finished product of the invention has a stainless steel body, wherein both ends of the body are provided with a first connecting component and a second connecting component which are related to relevant parts and respectively connected with both ends of the body; the first connecting componentis provided with a through hole; the second connecting component is provided with an outer thread section; a middle flattening section of the body is provided with a heald eye; and the body is mainlycharacterized by the circular or quadrangular or elliptic cross section. The manufacturing method comprises the following working procedures of rolling, die cutting, injection molding and polishing.The integral harness wire of the jacquard loom and the manufacturing method thereof have the advantages of difficult bending and deformation, high strength, strong antirust capacity, high wearing resistance, long service cycle, wide economic application range, simplicity and high working efficiency.

Owner:潘伟健

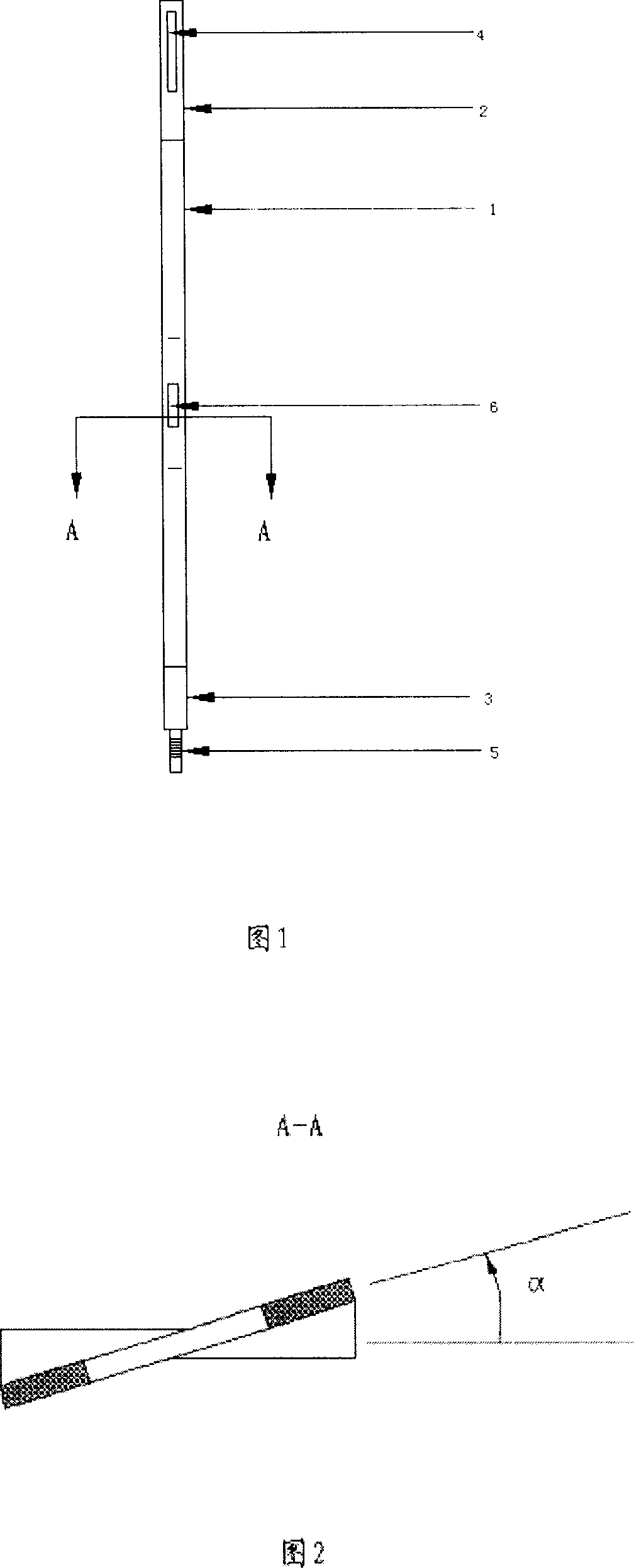

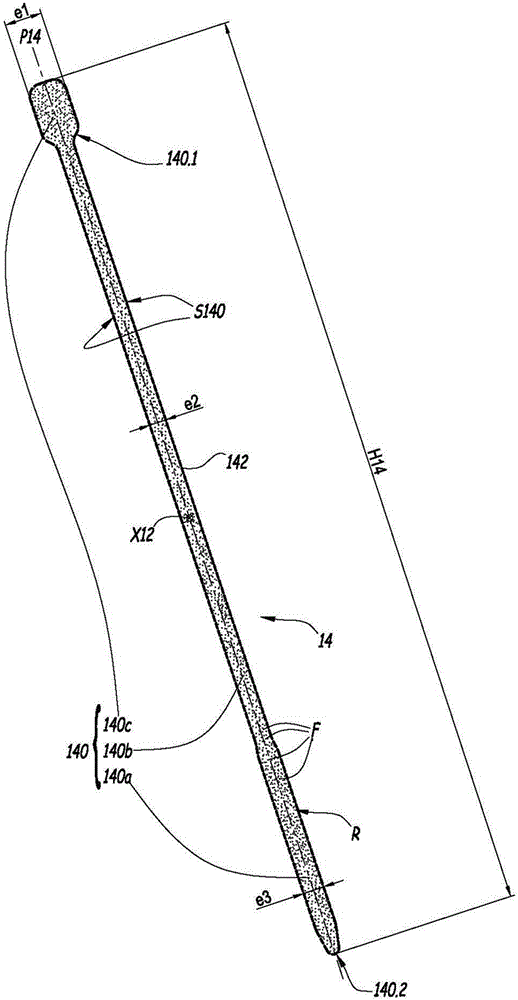

Guiding member, jacquard harness incorporating such a member, process for manufacturing such a member and weaving loom comprising such a member

This member for guiding the harness cords of a Jacquard loom harness is substantially planar and provided with holes for passage of the cords. At least one of these holes extends in a direction which is oblique with respect to the principal plane of this member. This arrangement makes it possible to limit the efforts of friction undergone by the harness cords, particularly at the level of the edges of the holes.

Owner:STAUBLI LYON

Manufacturing method of curtain fabric with anti-flaming and anti-ultraviolet combined functions

ActiveCN106283355ARealize the comprehensive effect of multifunctional integrationAchieve effectCurtain accessoriesLoomsJacquard loomComposite function

Owner:ZHEJIANG HEXIN TEXTILE

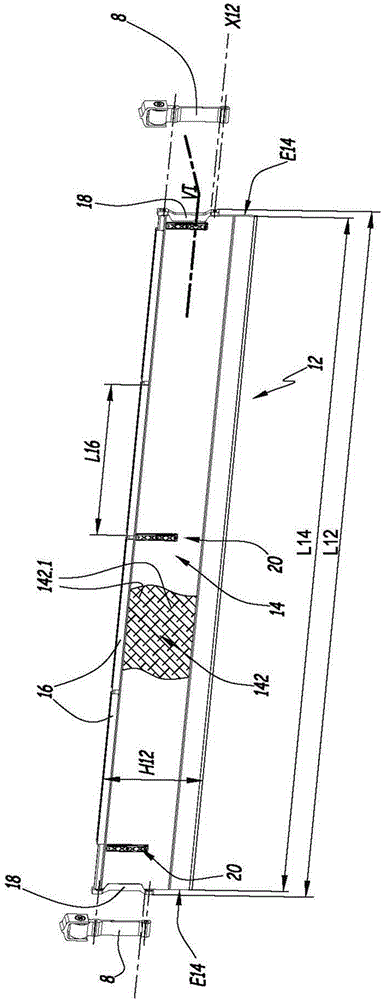

Blade for moving hooks of a jacquard mechanism and jacquard mechanism comprising such a blade

The invention relates to a blade (12) for moving hooks of a Jacquard mechanism for forming a shed on a Jacquard loom. This blade comprises at least one profile (14) made from a composite material, having a body made up of unidirectional fibers that extend in the longitudinal direction (X12) of the profile and are embedded in a resin.

Owner:施托布利里昂公司

Guide rods for a Jacquard loom

A guide rod assembly for a Jacquard loom is described which is narrower (10 mm or less), instead of 13 mm of conventional guide rods. This reduction in width is attained reducing the overall height of the magnet system integrated in the guide rod. The magnet system has a support member in the form of an iron core with an elongated or oval cross-section, with an excitation coil wound around the iron core. Pole strips are in contact with both front faces of the iron core. The respective top surfaces of the pole strips are spaced apart by less than 13 mm.

Owner:N V MICHEL VAN DE WIELE

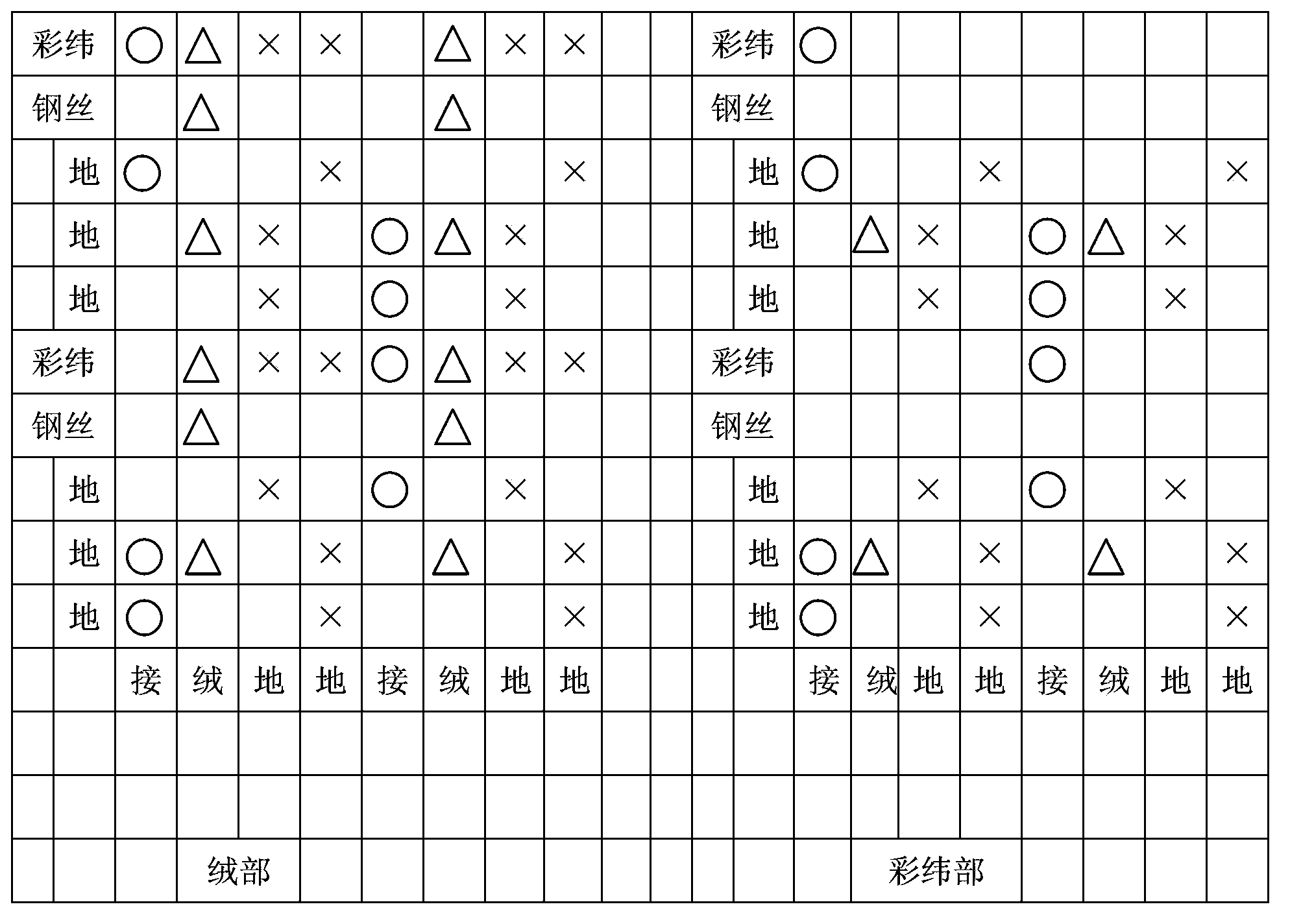

Weaving process for Zhuanghua woolen product and weaving equipment thereof

The invention relates to a weaving process for a Zhuanghua woolen product and weaving equipment thereof. A method for weaving the Zhuanghua woolen product by a Dahualou jacquard loom comprises the following steps of picking up stripe pick patterns according to pattern sample information with an anti-weaving method; lifting and dragging a bundle heald; weaving a ground pick when a model frame is opened; when the bundle heald and an obstacle frame are subjected to hybrid opening, weaving a stripe pick; when only the bundle heald is opened, weaving a steel wire; forming a Zhuanghua woolen semi-finished product by the processes of battening, coiling and warp pacing; after the Zhuanghua woolen semi-finished product is taken out of the machine, pile warps coated on the steel wire are cut off to form the Zhuanghua woolen finished product. According to the weaving equipment disclosed by the invention, the pile warp pacing part of a common Dahualou loom is provided with a constant force independent warp pacing device; pile warps in the device are respectively coiled on a tension heavy punch and a pipe on which velvet lines are coiled; a friction heavy punch is hung on the fixed pipe on which velvet lines are coiled. According to the invention, the Zhuanghua woolen variety with the highest technical content in brushed fabric can be weaved, and meanwhile, the Zhuanghua woolen weaving technology and equipment failing to be handed down from past generations for more than a centenary can be copied.

Owner:南京锦绣盛世云锦织造有限公司

Computer jacquard and cut loop velvet machine

ActiveCN102912579ACompact structureReasonable structureDouble pile fabrics splittingPile loops cuttingJacquard loomEngineering

The invention relates to a computer jacquard and cut loop velvet machine, which belongs to the technical field of jacquard looms. The computer jacquard and cut loop velvet machine comprises a low velvet needle pressing triangle, a high velvet needle pressing triangle, a middle shell needle pressing triangle, a needle selector, a needle selector seat, a pulling triangle, a pattern bit, a low plate knife needle, a high plate knife needle, a low plate loop reversing needle, a high plate loop reversing needle, a cut velvet plain-knitting triangle, a cut velvet needle-raising triangle, a safety triangle and a jacquard needle-raising triangle, wherein the low velvet needle pressing triangle and the high velvet needle pressing triangle are connected above and below the internal side of a second Hough in sequence; and the internal side of a middle shell is connected with the middle shell needle pressing triangle. The velvet shearing flat needle triangle is connected to the low velvet needle pressing triangle; and the velvet shearing needle raising triangle is connected with the high velvet needle pressing triangle. The computer jacquard and cut loop velvet machine provided by the invention has the advantages as follows: compact and reasonable structure is obtained; any pattern with one to four colors, such as high and low cut velvet patterns, a high cut low loop pattern, a high and low loop pattern, a flat cut pattern, a flat loop pattern and a hollow-out pattern, can be woven; the product quality is improved; and the production cost is reduced.

Owner:WUXI JIALONG TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com