Shed forming device and weaving loom of the jacquard type equipped with such a device

A jacquard loom, equipped with technology, applied in the direction of jacquard loom, cam opening mechanism, textile, etc., can solve the problems of difficult adjustment, large number of joints, high cost, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

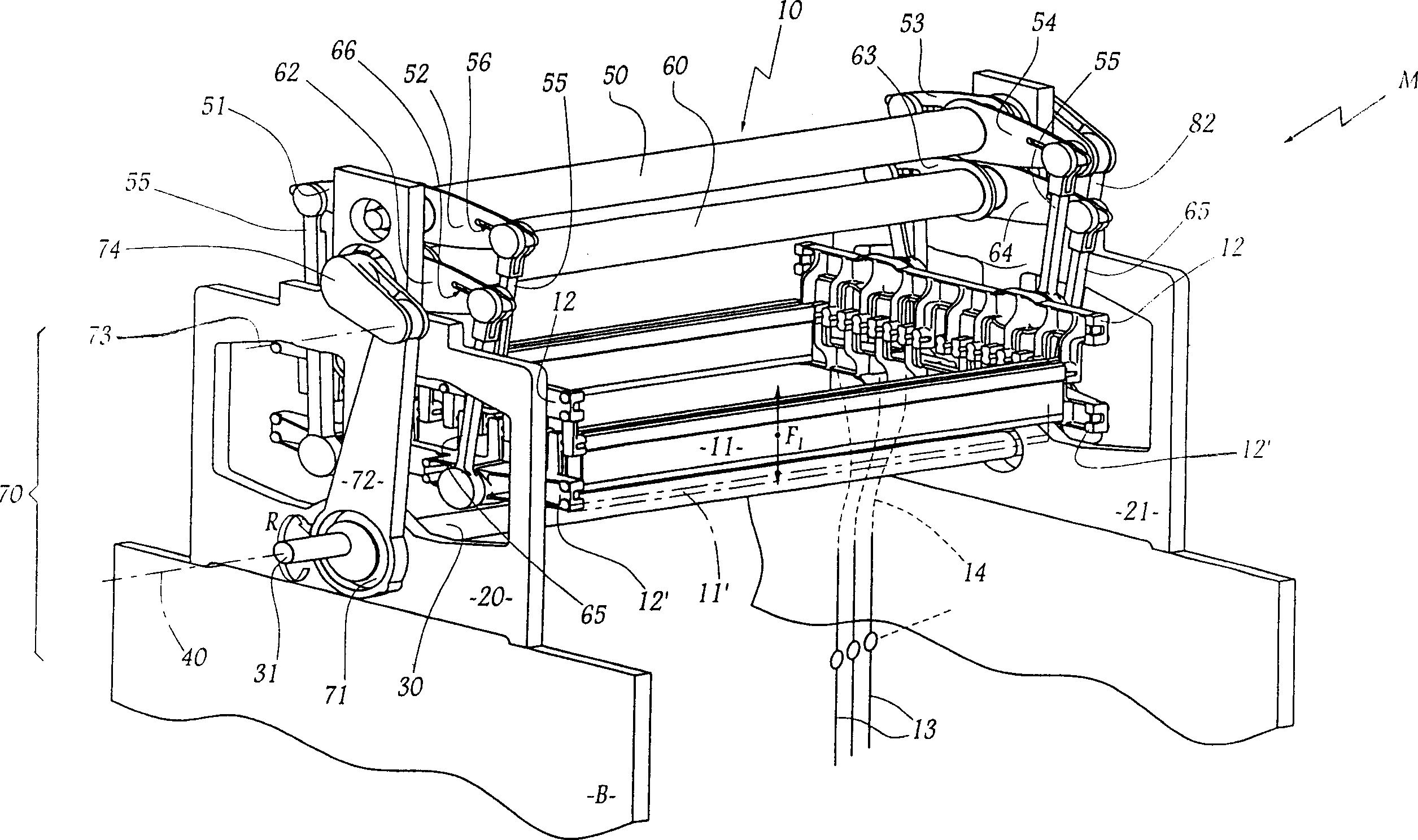

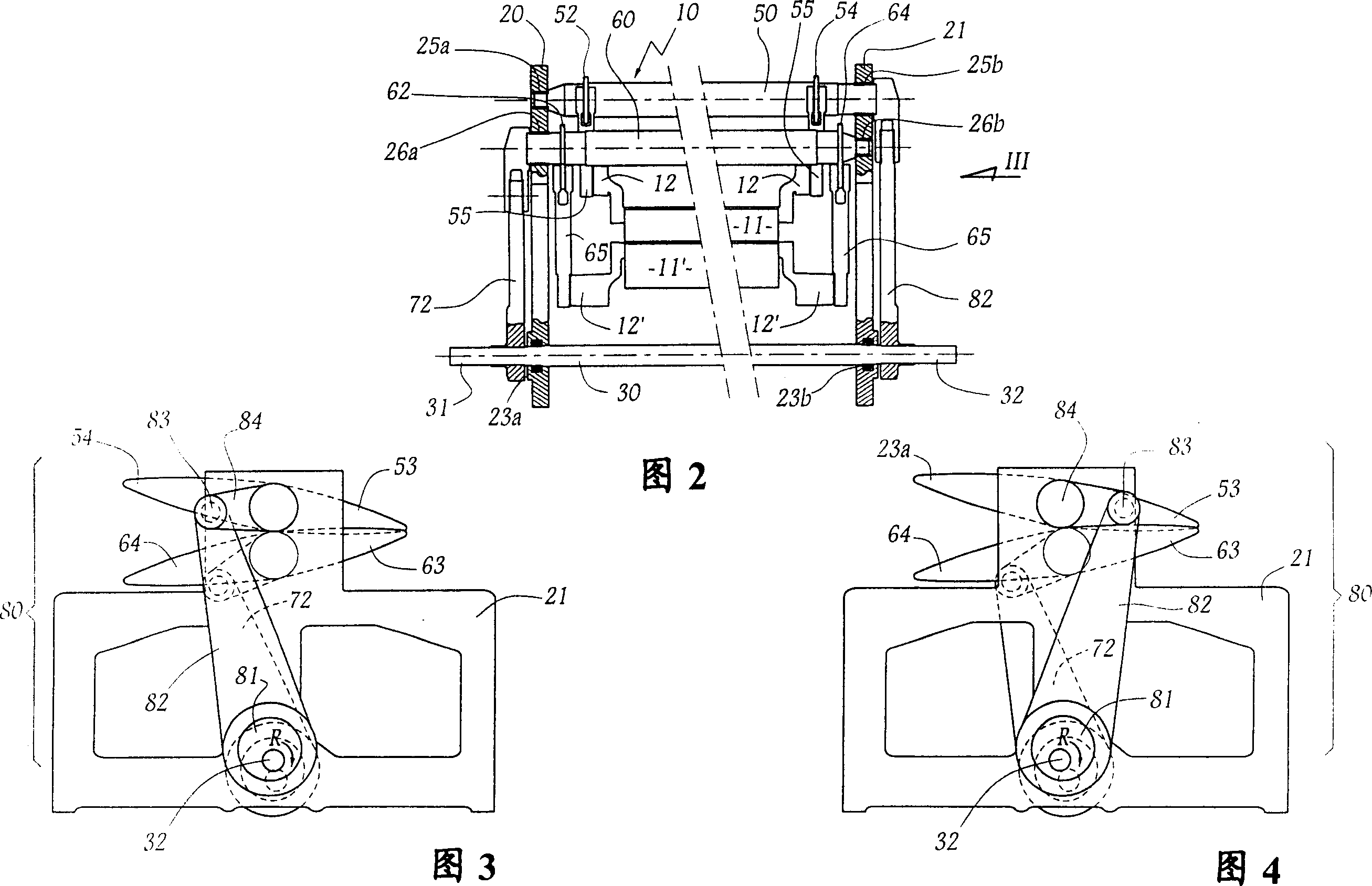

[0019] figure 1 The weaving machine M shown schematically in , is equipped with a shedding device 10 comprising two sets of blades or broaches.

[0020] The first set of blades 11 is supported by two crossbars / cross members 12 forming a first bracket, while the second set of blades 11' is supported by the other two crossbars 12' forming a second bracket.

[0021] The blades 11 and 11' are adapted to move in a vertical oscillating motion indicated by the double arrow F1, which enables the hooks (not shown) to move between their respective top dead center and bottom dead center positions for controlled passage The movement of the heddle 13 with the harness 14 connected to a hook is well known in the technical field of jacquard looms.

[0022] The bars or brackets 12 and 12' and the blades 11 and 11' interacting therewith are arranged between two plates 20 and 21 to be connected to a frame B.

[0023] There is an input shaft 30 extending between the plates 20 and 21 and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com