Patents

Literature

77results about How to "Import uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-alkalinity mould flux used for niobium/vanadium/titanium-containing low alloy wide and heavy plate blank and manufacturing method thereof

The invention discloses a high-alkalinity mould flux used for niobium / vanadium / titanium-containing low alloy wide and heavy plate blanks and a manufacturing method thereof. The high-alkalinity mould flux is made from the following raw materials in percentage by weight: 35 to 45 percent of pre-melting materials, 11 to 14 percent of fluorite, 28 to 30 percent of wollastonite, 3 to 6 percent of flint clay, 3 to 6 percent of limestone, 2 to 4 percent of sodium carbonate, 1 to 3 percent of lithium carbonate, 1 to 3 percent of manganese carbonate, 2 to 4 percent of magnesium oxide, 2 to 4 percent of carbon black, 4 to 7 percent of graphite and 1 to 3 percent of binders. The mould flux has a good capability of absorbing Al (s), V, Ti, Nb and other metals and metal oxides or carbides thereof and nitride inclusions in molten steel, and remains unchanged after molten steel purification. Therefore, not only are the performances of the mould flux stable, but also the internal quality of casting blanks is improved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Low-alkalinity crystallizer covering slag prepared from building waste clay

The invention discloses low-alkalinity crystallizer covering slag prepared from building waste clay. The low-alkalinity crystallizer covering slag comprises the following raw material components in percentage by mass: 30 to 55 percent of clay, 8 to 15 percent of fluorite, 15 to 30 percent of lime stone, 8 to 15 percent of sodium carbonate, 1 to 3 percent of magnesium oxide, 2 to 4 percent of carbon black, 5 to 15 percent of graphite and 1 to 3 percent of binder. The covering slag prepared from the clay serving as a main material can maintain the complete granules of the hollow covering slag, has good heat-preserving effect in the using process and is melted uniformly without caking so as to guarantee to introduce molten slag uniformly and smoothly, effectively control the heat transfer ofa crystallizer, avoid the caking of the crystallizer and a blank shell and improve the external quality of cast blanks.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

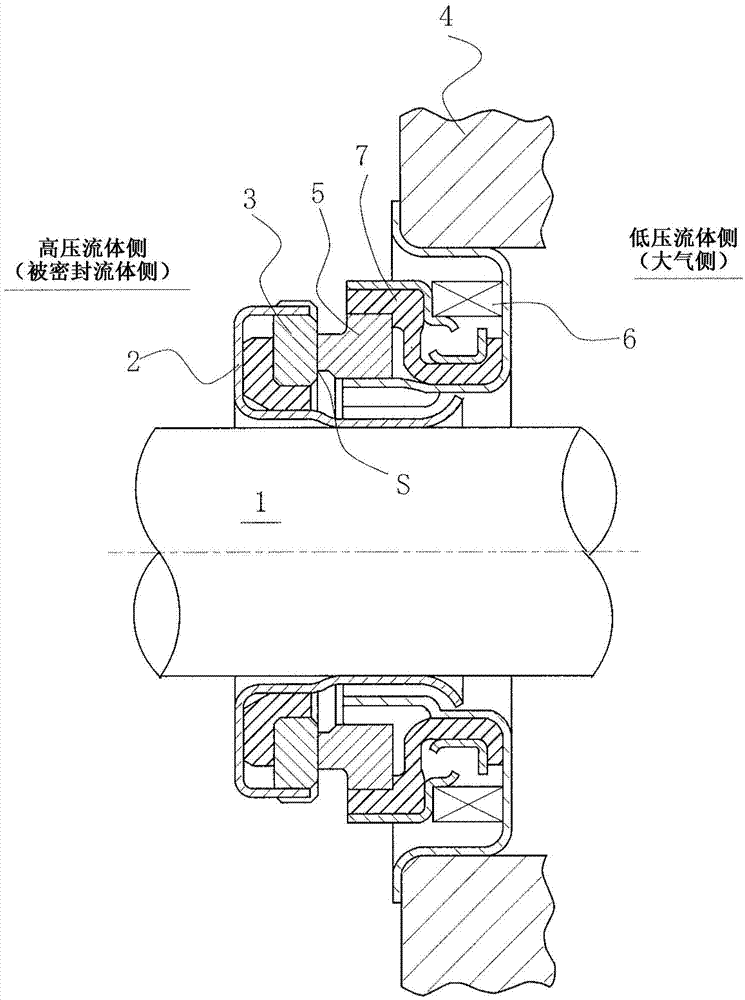

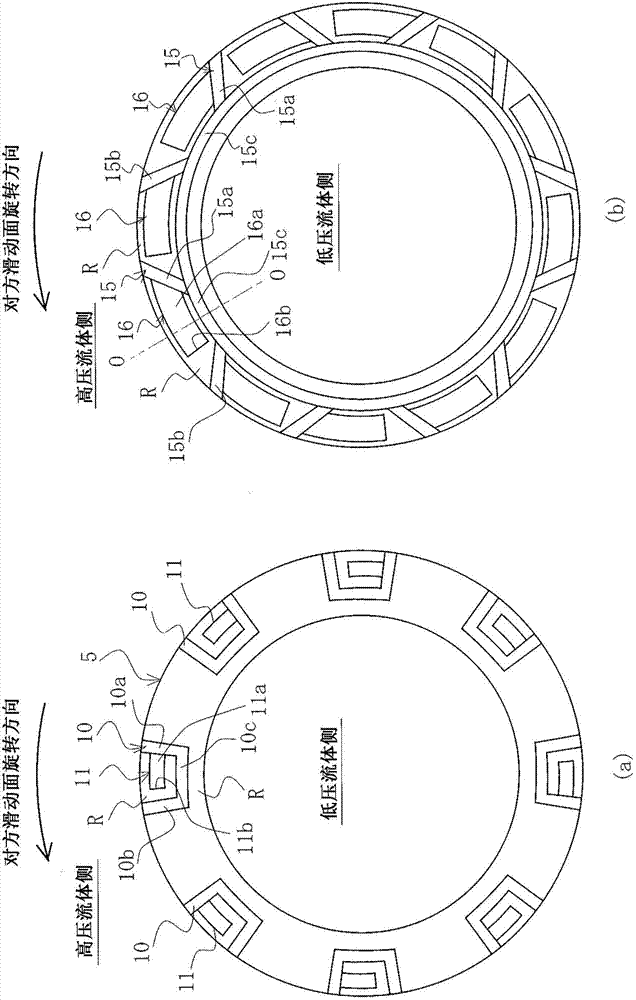

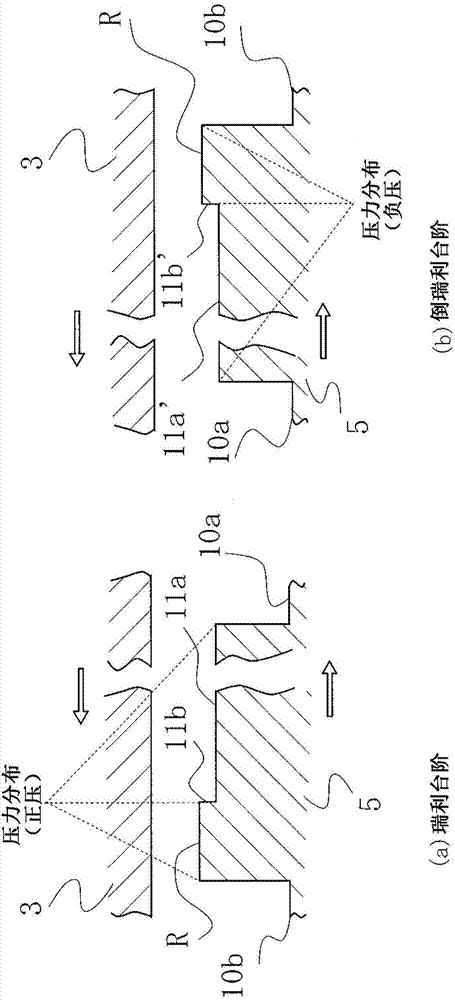

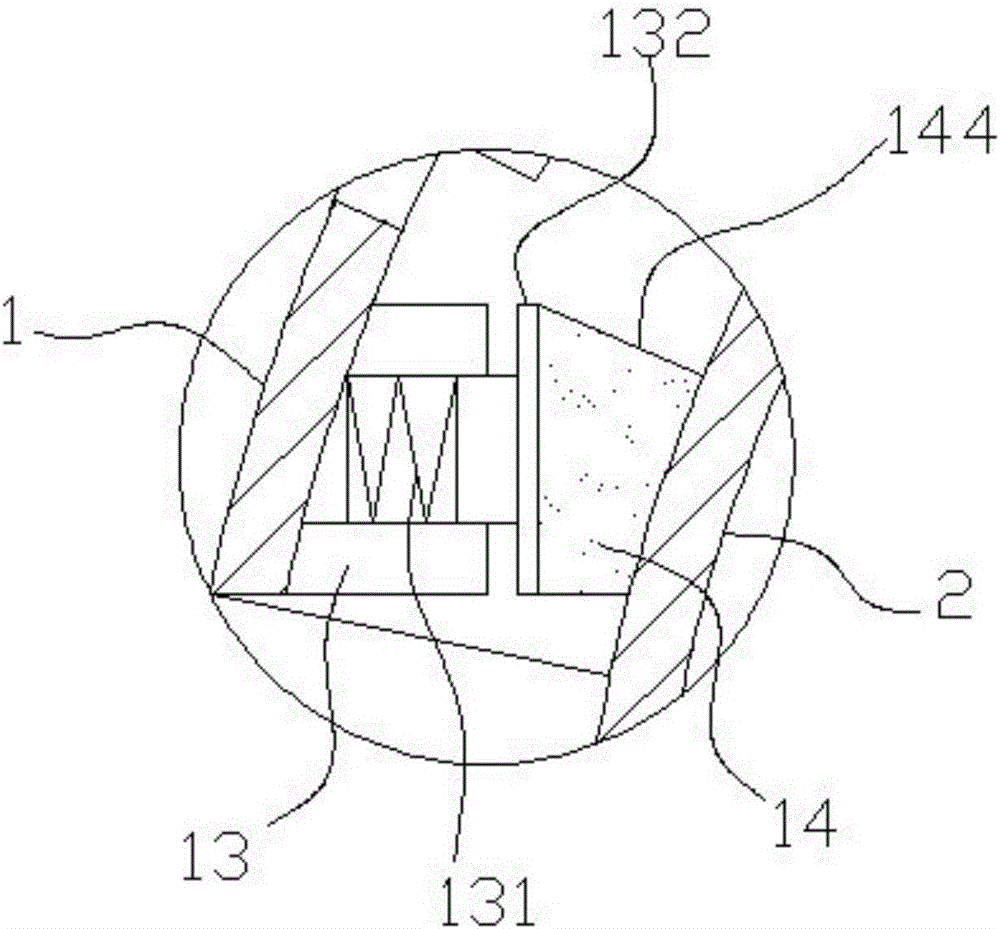

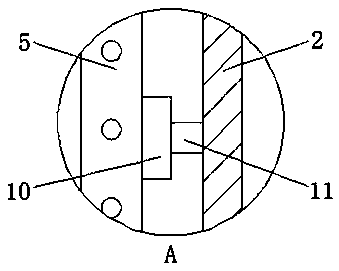

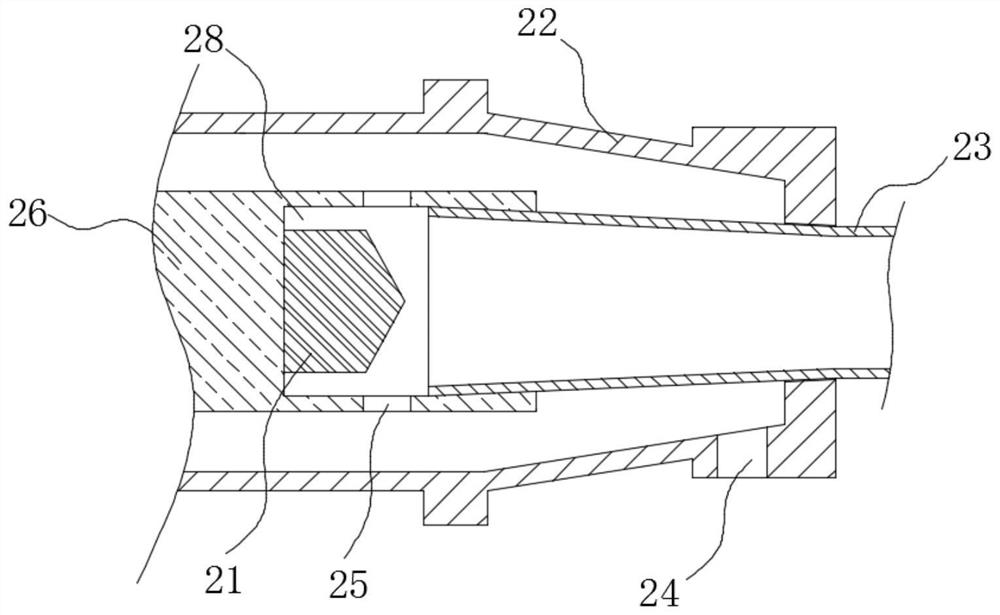

Sliding component

Provided is a sliding component that, while achieving both the opposing conditions of sealing and lubricating, by means of actively taking in, discharging, and recycling a fluid at the sliding surface, prevents the occurrence of deposits at the sliding surface and is able to maintain the sealing functionality of the sliding surface over the long term. The present invention is characterized in that a fluid recycling groove (10) that is configured from an entrance section (10a), which enters from a high-pressure-fluid side, an exit section (10b), which leads to the high-pressure-fluid side, and an interconnection section (10c), that interconnects the entrance section and exit section, is provided to one of the sliding surfaces at which a pair of sliding components slide relative to each other, the fluid recycling groove (10) is isolated from a low-pressure-fluid side by a land section, a positive pressure generation mechanism (11) is provided to a section encircled by the fluid recycling groove (10) and the high-pressure-fluid side, the positive pressure generation mechanism (11) interconnects with the entrance section (10a), and the exit section and high-pressure-fluid side are isolated by a land section (R).

Owner:EAGLE INDS

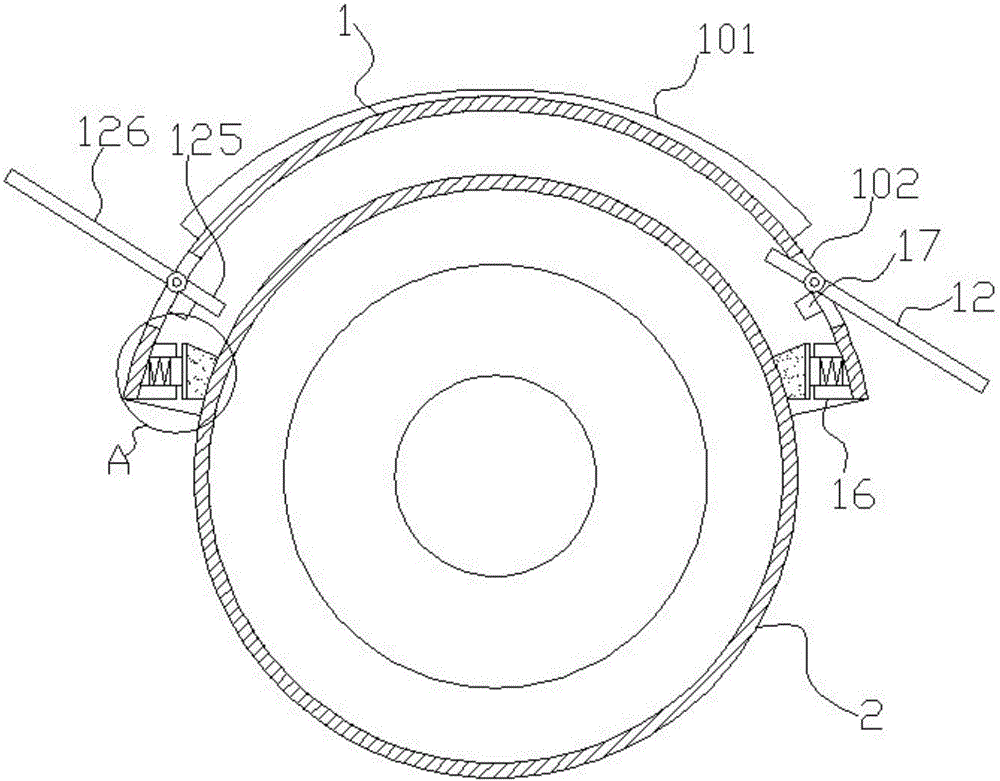

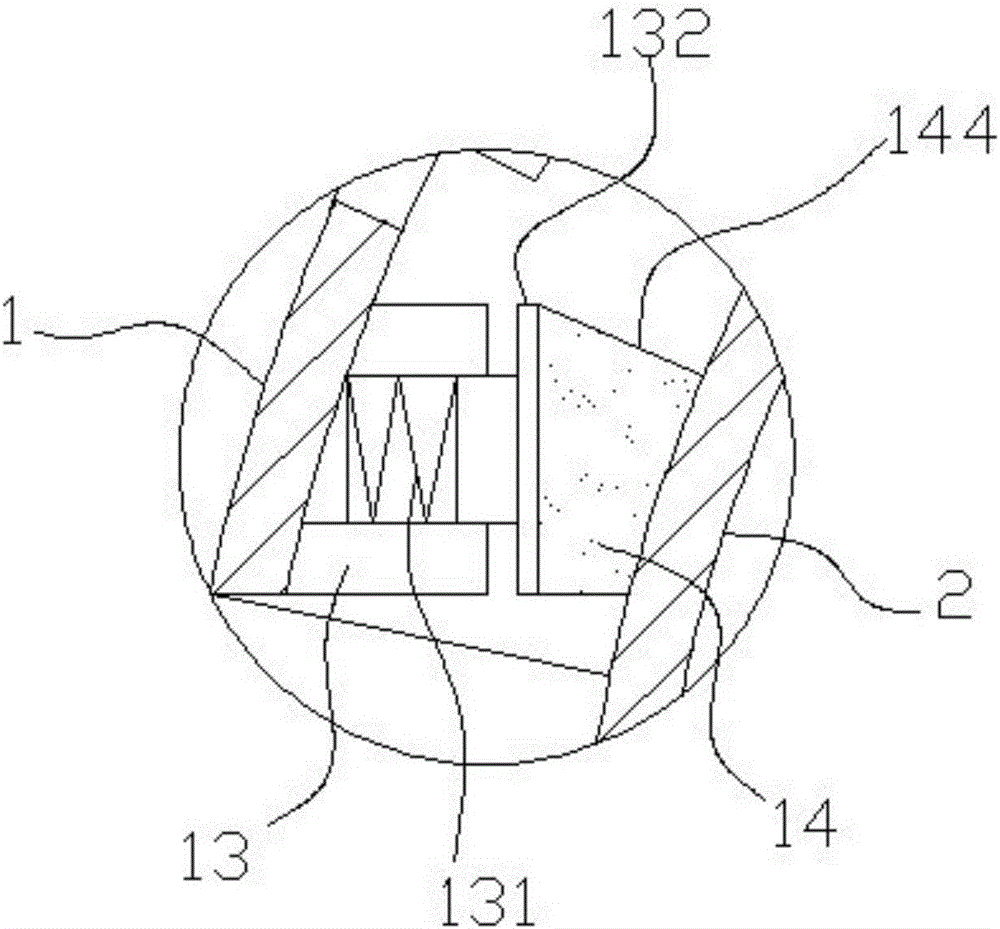

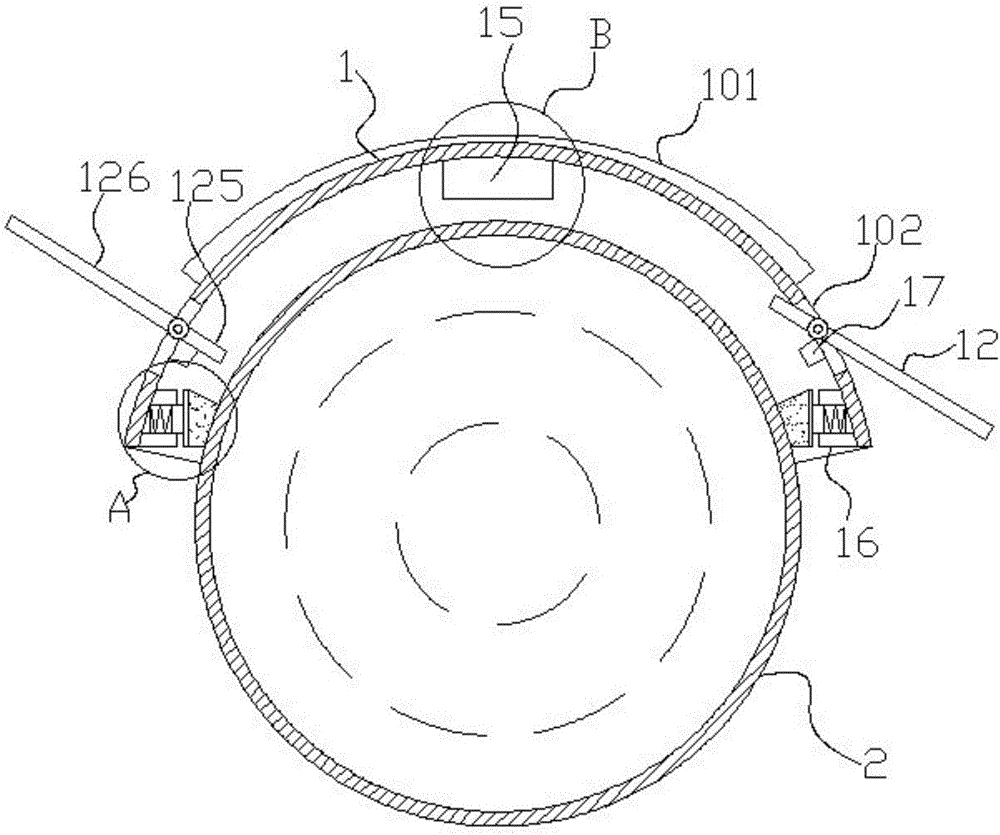

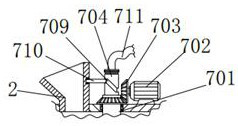

System for cleaning streetlamp through raindrops

InactiveCN106016101APlay a protective effectPrevent fallingLighting elementsLighting heating/cooling arrangementsAgricultural engineeringLamp shell

This invention discloses a system for cleaning a streetlamp through raindrops. The system comprises a lamp shell plate fixed to an installing frame; a rotating lampshade is arranged below the lamp shell plate; a lamp body is arranged in the rotating lampshade; a sleeve shaft is arranged at one end of the rotating lampshade and connected with a motor; the motor is arranged in the installing frame; wipers are arranged on the two sides of the inner wall of the lamp shell plate; rain guiding holes are formed in the portions, above the wipers, of the two sides of the lamp shell plate; rain guiding plates are hinged in the rain guiding holes through torsion springs; each rain guiding plate comprises a lower short plate and an upper long plate; limiting lugs are arranged at the two ends of each lower short plate and provided with iron blocks; electromagnets are arranged on the lamp shell plate and located below the rain guiding holes; each lower short plate is located on the inner side of the lamp shell plate, and each upper long plate is located on the outer side of the lamp shell plate; each wiper comprises an elastic base fixed to the lamp shell plate, a telescopic base is arranged on each elastic base, and a compression spring is arranged at the bottom of each elastic base; the telescopic bases are connected with fixing strips; and sponge brushes are arranged on the fixing strips. The system can improve the protecting strength of the streetlamp body, the streetlamp can be cleaned in real time through rainwater, the cleaning effect is good, and energy consumption is low.

Owner:HUNAN CITY UNIV

Street lamp capable of maintaining illumination intensity

InactiveCN106090726APlay a protective effectPrevent fallingMechanical apparatusFouling preventionAgricultural engineeringLamp shell

The invention discloses a street lamp capable of maintaining the illumination intensity. The street lamp comprises a lamp shell plate and rotary lampshade. The rotary lampshade is connected with a motor. Wipers are arranged in the lamp shell plate. Rain guide holes are formed in the two sides of the lamp shell plate. Rain guide plates are hinged to the rain guide holes. Electromagnets are arranged on the lamp shell plate. A mounting frame is provided with a rainfall induction box. A sealed flexible film plate is arranged at the bottom of the rainfall induction box. A pressure sensor is arranged under the center of the flexible film plate. An arc-shaped mesh opening plate is arranged at a box opening of the rainfall induction box. Water outlet holes are evenly formed in the two sides of the bottom of the rainfall induction box. Each wiper comprises a sponge brush. Oblique water guide grooves are evenly formed in each sponge brush symmetrically. A pollution clearing box is arranged at the top ends of the inner walls of the rain guide plates. A detergent is contained in the pollution clearing box. A discharge seam is formed in the center of the bottom of the pollution clearing box. A mixing plate is arranged in the middle of the discharge seam. A compressed spring is arranged at the rear end of the mixing plate. An electromagnet is arranged at the rear end of the compressed spring. According to the street lamp maintaining the illumination intensity, intelligent automatic cleaning can be achieved, the cleaning effect is good, power consumption is low, and the illumination intensity of the street lamp can be guaranteed for a long time.

Owner:HUNAN CITY UNIV

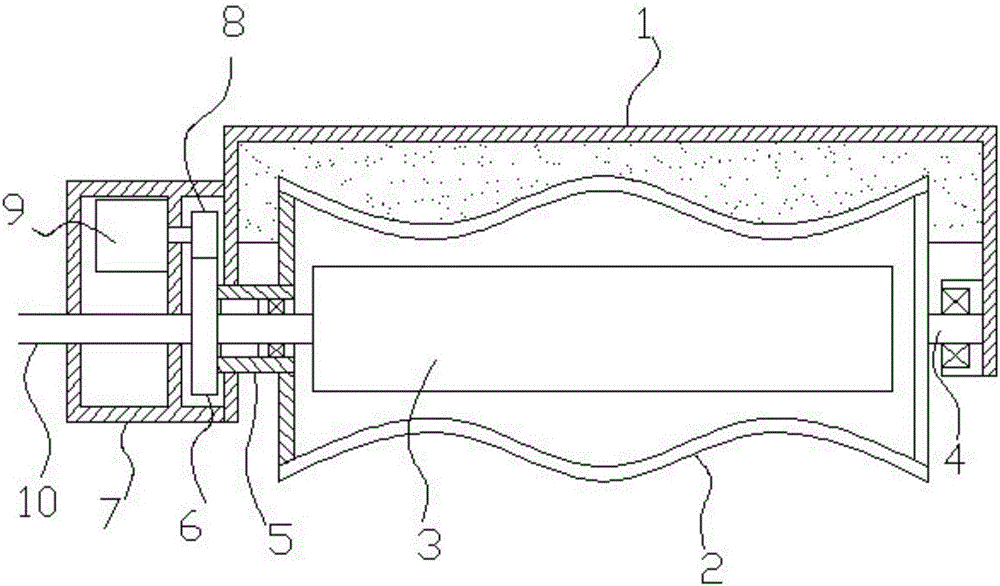

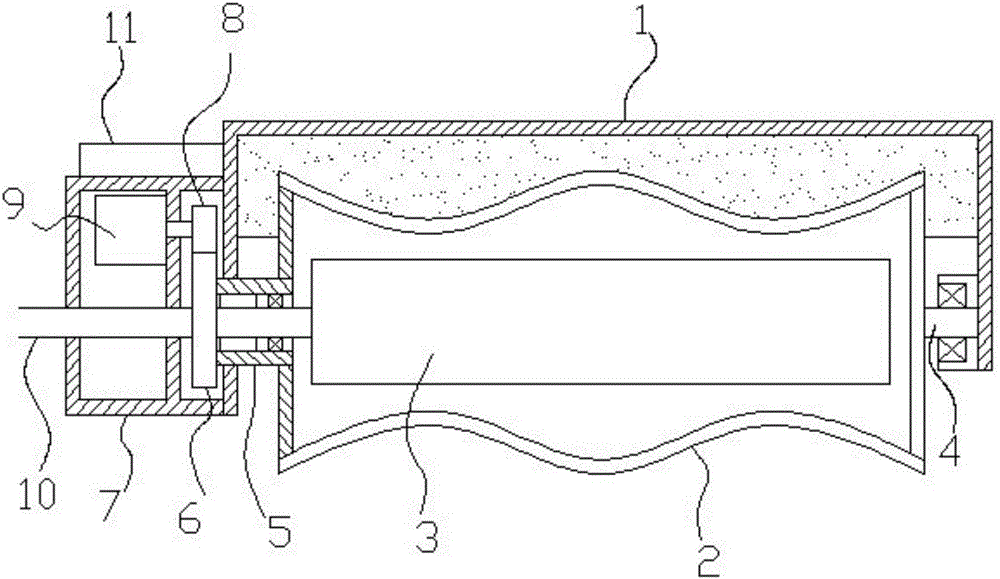

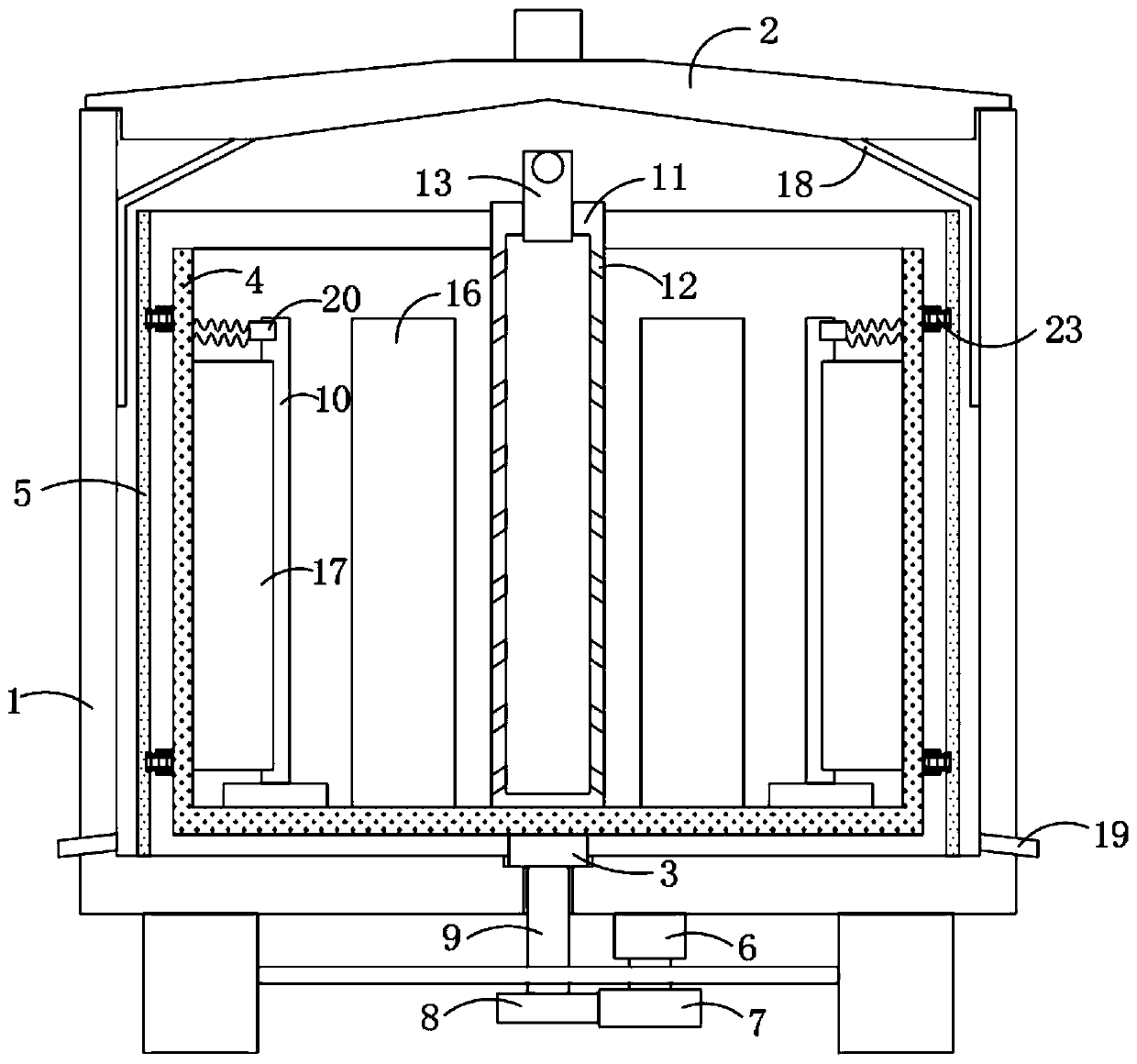

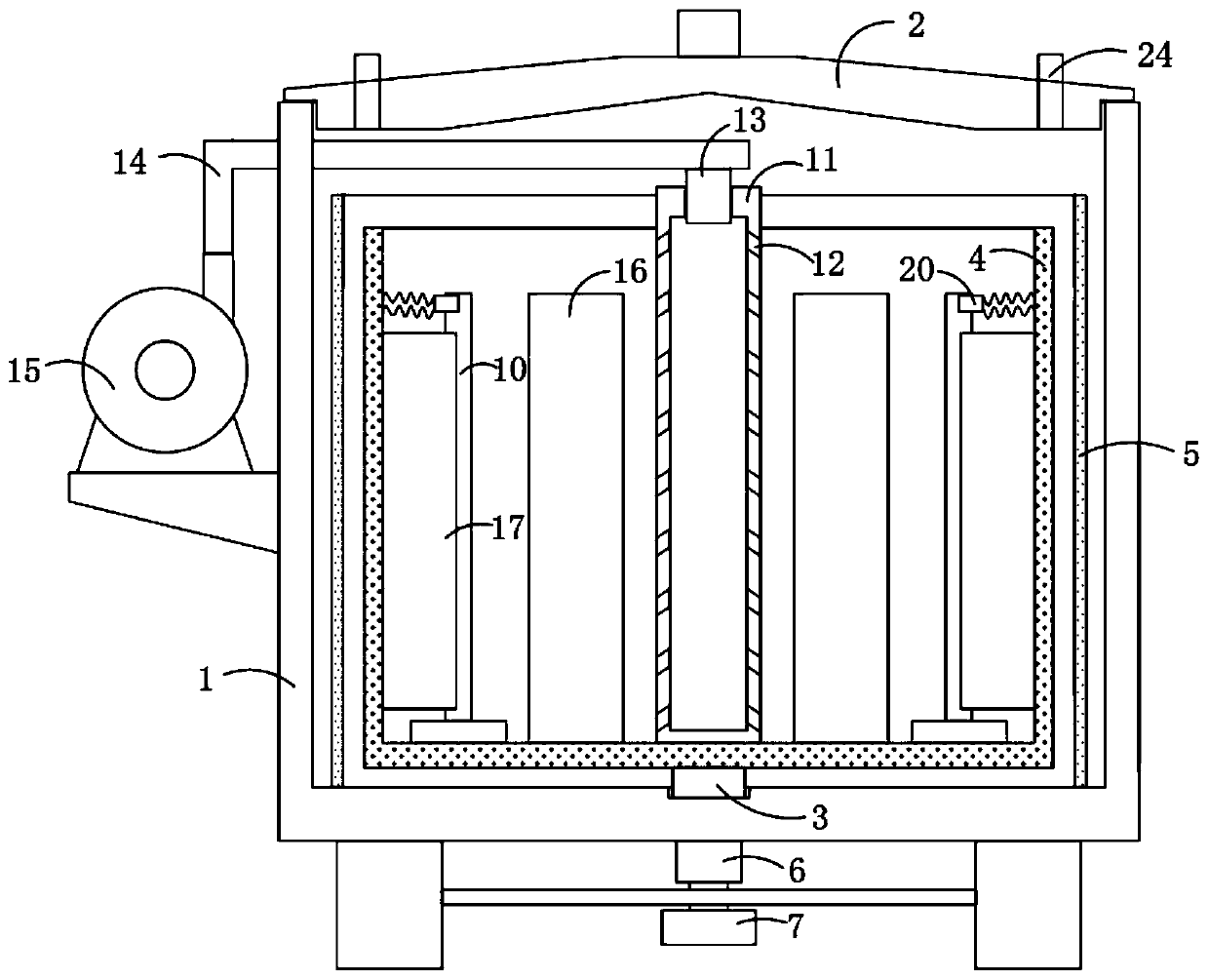

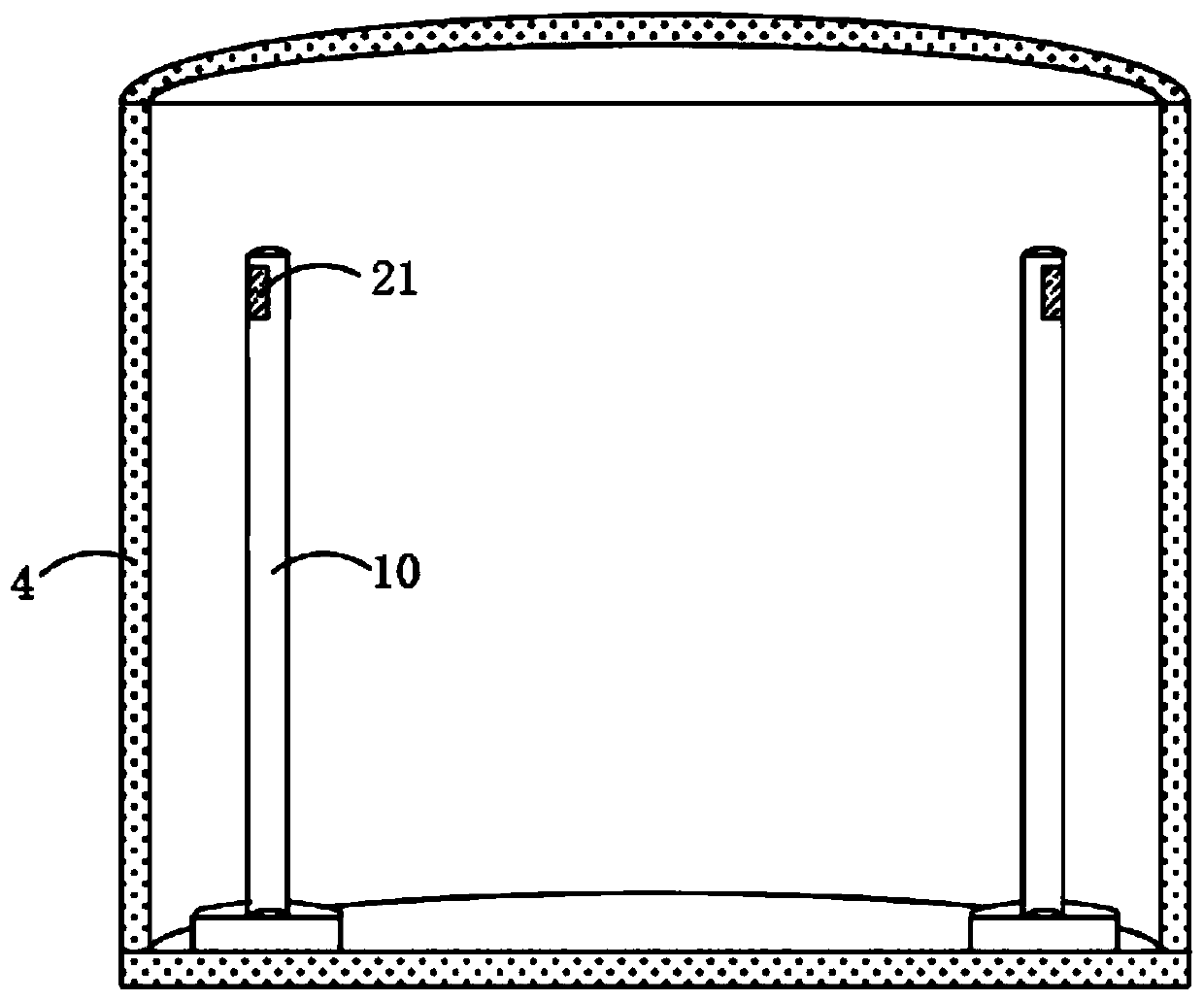

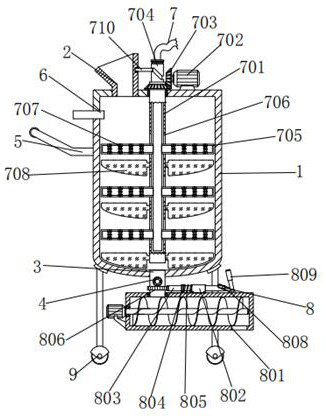

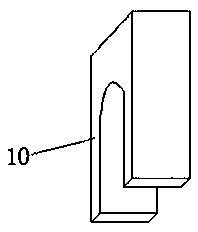

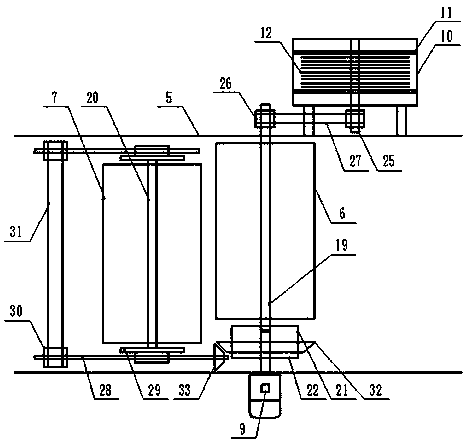

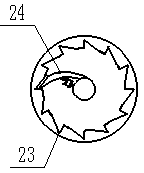

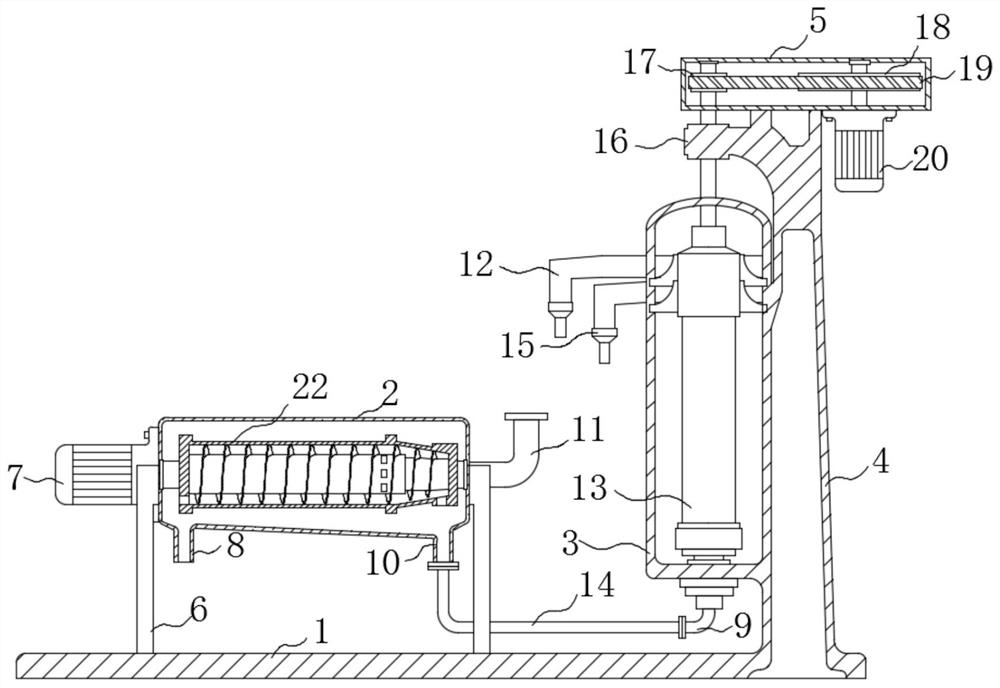

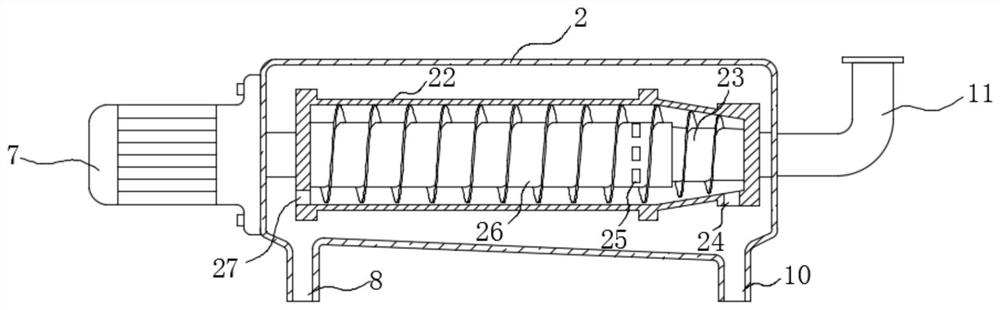

Special spinning and drying device for cotton yarns

ActiveCN110207473AImport uniformImprove heating uniformityDrying gas arrangementsDrying chambers/containersYarnWater vapor

The invention discloses a special spinning and drying device for cotton yarns. The special spinning and drying device for the cotton yarns comprises an outer barrel and an inner barrel rotatably connected into the outer barrel through a rotary shaft, wherein a cover plate is arranged at the upper end of the outer barrel in a sealing way; the rotary shaft is rotatably connected to the inner bottompart of the outer barrel; a drive mechanism for driving the rotary shaft is arranged at the lower end of the outer barrel; an annular heat-insulation plate is fixedly arranged on the inner bottom partof the outer barrel in a sleeving way and is arranged on the outer side of the inner barrel in a sleeving way; an air guiding cylinder is fixedly connected to the middle of the inner bottom part of the inner barrel; and the upper end of the air guiding cylinder extends to the outer side of the annular heat-insulation plate. The special spinning and drying device for the cotton yarns provided by the invention is compact in structure; the cotton yarn can be conveniently arranged on a sleeve rod in a sleeving way; through the cooperative use of the air guiding cylinder, a first flow guiding plate and a second flow guiding plate, the drying efficiency and the quality of the cotton yarns are improved; and meanwhile, in the drying process, water vapor can be favorably collected, guided to flowand discharged, so that the occurrence of the phenomenon that the drying quality is influenced due to excessive moisture remained in the drying device is avoided.

Owner:江西荣盛棉纺有限公司

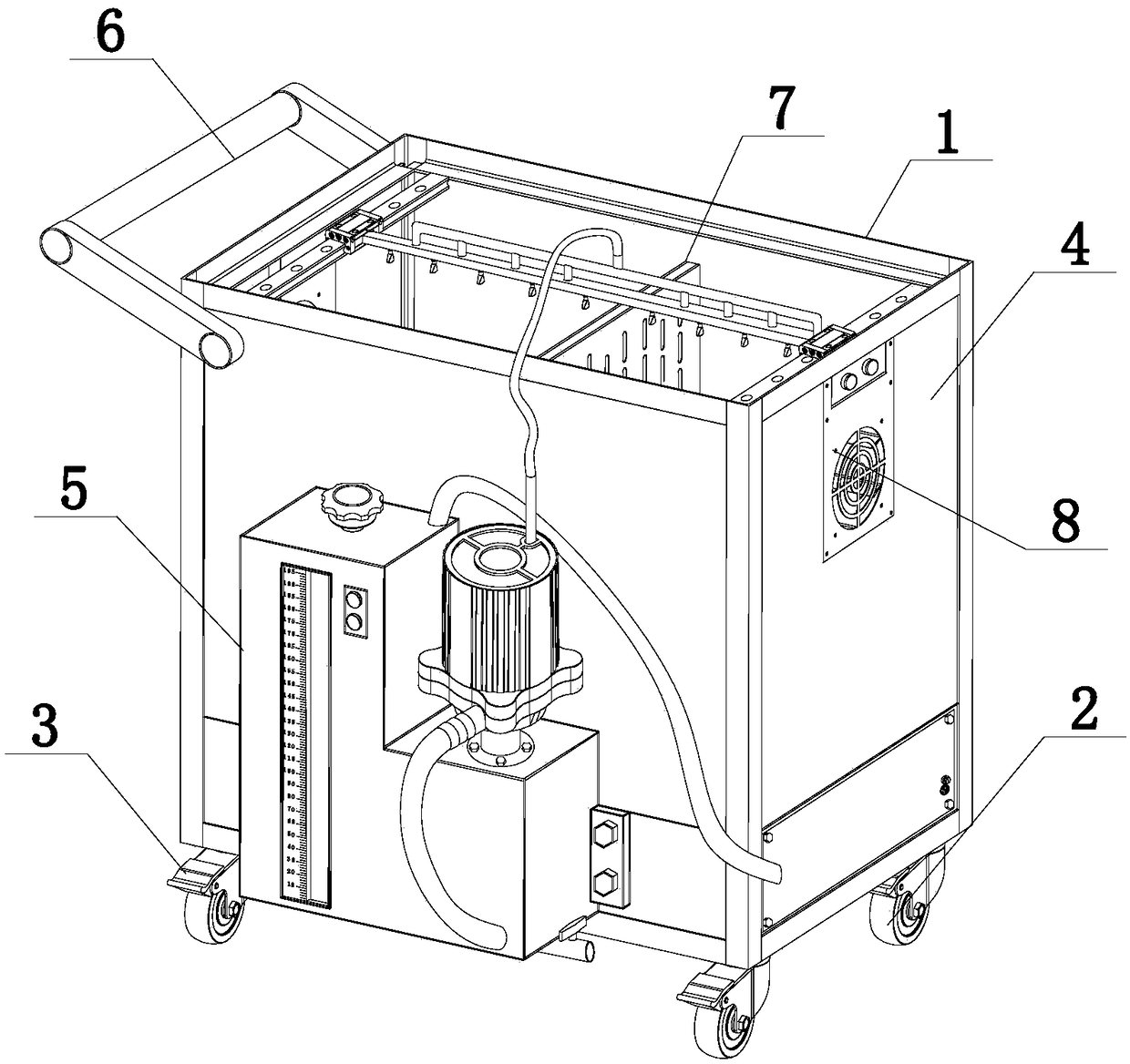

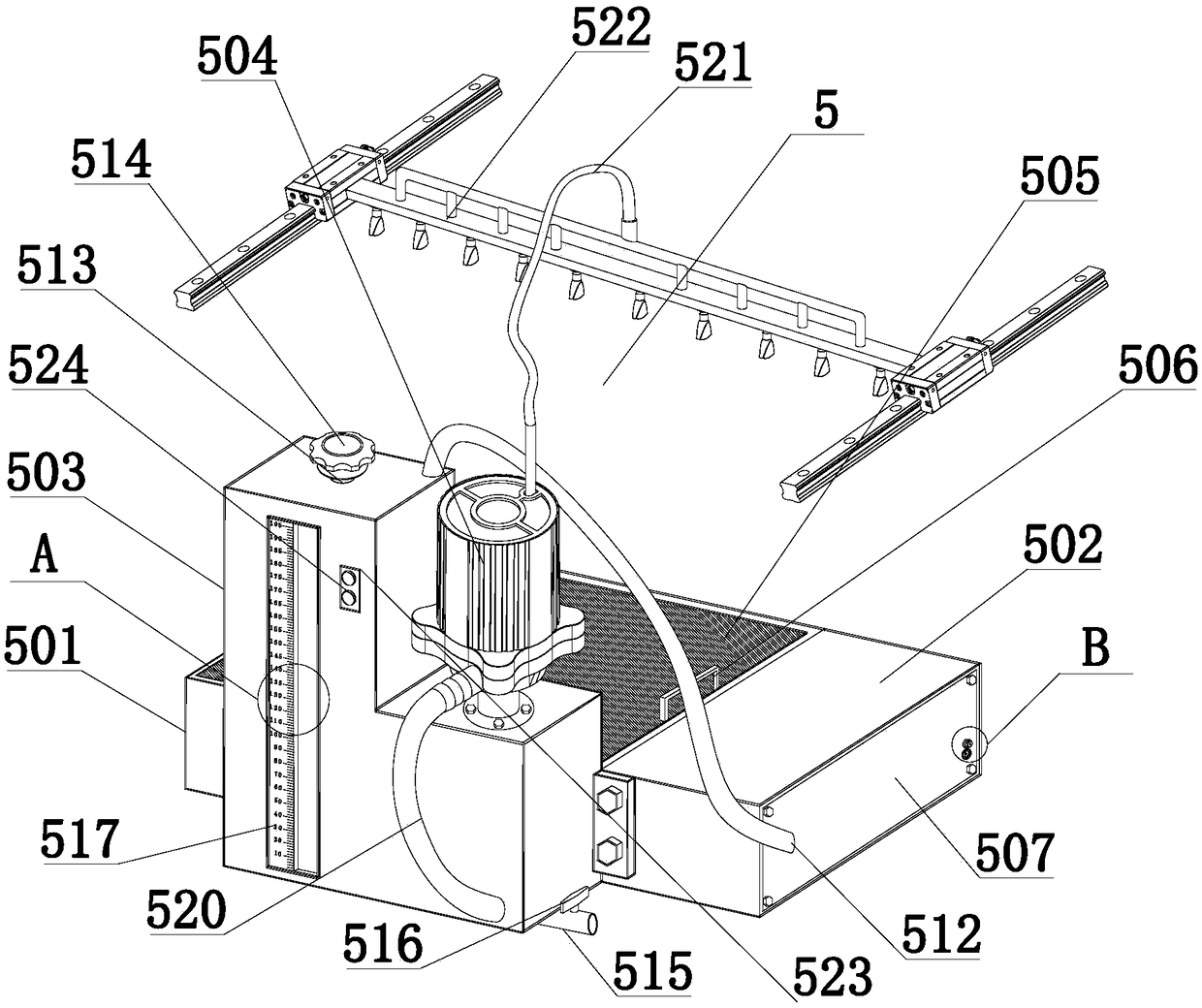

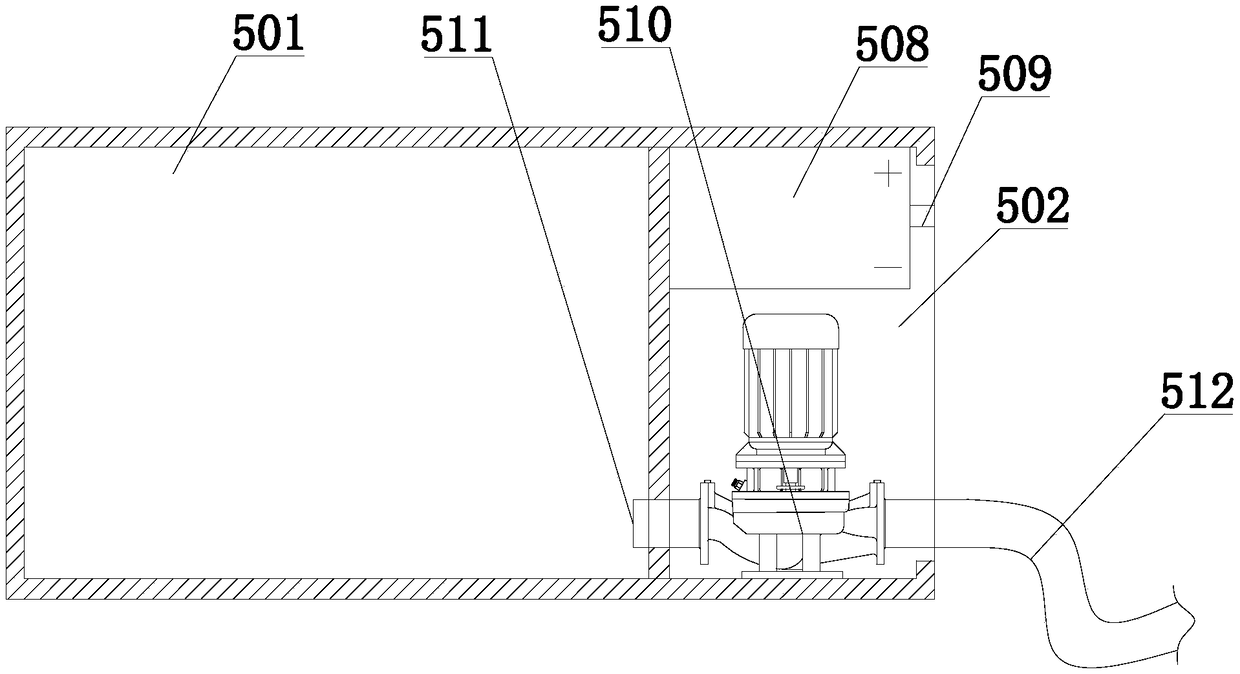

Sports goods moving vehicle

InactiveCN109349832AEasy to cleanAir dryDrying gas arrangementsBall sportsMobile vehicleVehicle frame

The invention discloses a sports goods moving vehicle. A vehicle frame is arranged on an outer frame of the moving vehicle; four corners at the bottom end of the vehicle frame are vertically connectedwith universal wheels in a bolted manner; and the top ends of the universal wheels are connected with brakes in a rotary manner. The vehicle has the following advantages: when in use, water in a water tank can be pumped into a water disc through a first water pump, the sports goods can be sprayed and cleaned by the water through a 6-point flat-mouth sprinkler head, the water can be recycled intoa water collecting tank after being filtered through a filter screen plate, and can be pumped back into the water tank through a second water pump; and meanwhile, an electric motor in an air-drying device can drive a fan to rotate to generate air flow, and thus the sporting goods in a placing frame are subjected to air-drying treatment, so that the problem that the physical and mental health of users is damaged caused by the fact that bacteria are easily generated on the surfaces of the ball sports goods and unpleasant smell is generated due to the fact that the existing sports goods moving vehicle cannot better clean and air-dry the used ball sports goods during use is solved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

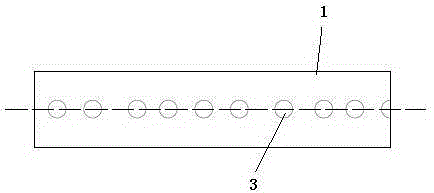

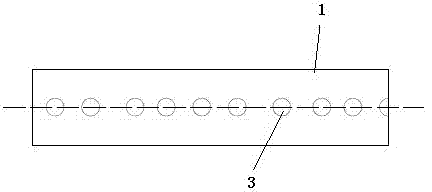

Flow guide pipe for vacuum filling and preparation method thereof

The invention relates to a flow guide pipe for vacuum filling and a preparation method thereof. The flow guide pipe comprises a flow guide pipe main body, wherein a bottom plate is arranged at the bottom of the flow guide pipe main body, and the flow guide pipe main body and the bottom plate are integrally molded to form a whole body with a hollow inner part; a plurality of flow guide holes are formed in the bottom plate at equal distances along the extending direction of the flow guide pipe main body; and the flow guide pipe is obtained by putting a mixed material of polypropylene resin and polyethylene resin into an extruder, then extruding the mixed material into a corresponding mold after fusing, and cooling and molding. Compared with the prior art, the flow guide pipe for the vacuum filling, provided by the invention, has the advantages of printing mark prevention, capability of guiding resin at a high speed and the like.

Owner:JIANGSU YUEKE NEW MATERIAL

Rhizoma atractylodis processing device capable of achieving pulverizing and drying

InactiveCN110756267AReduce heat lossEasy disassembly and cleaningSievingScreeningHot blastElectric machinery

The invention discloses a rhizoma atractylodis processing device capable of achieving pulverizing and drying. A first drive motor, a temperature sensor, a body and a bearing frame are included. Through installation of a silencing cover, a PLC, a heating wire, a temperature sensor, an air guiding main pipe, a body, an air guiding branch pipe and filter cloth, the device can heat gas through the heating wire, the temperature sensor is used for monitoring the gas temperature situation in a hot air cavity constantly, the monitored data are sent to the PLC, once the temperature reaches the preset value, the PLC can control the heating wire to power off and stop heating, and a good temperature control heating function is achieved. By utilization of the functions of the air guiding main pipe andthe air guiding branch pipe, hot airflow can be evenly guided into the body, and uniformity during drying is improved; and through the arrangement of the filter cloth, the situation that dust scraps in the body enter the air guiding main pipe and the air guiding branch pipe, and blockage is caused can be avoided, and accordingly the practicability of the device is enhanced.

Owner:湖北宏图中药材科技有限公司

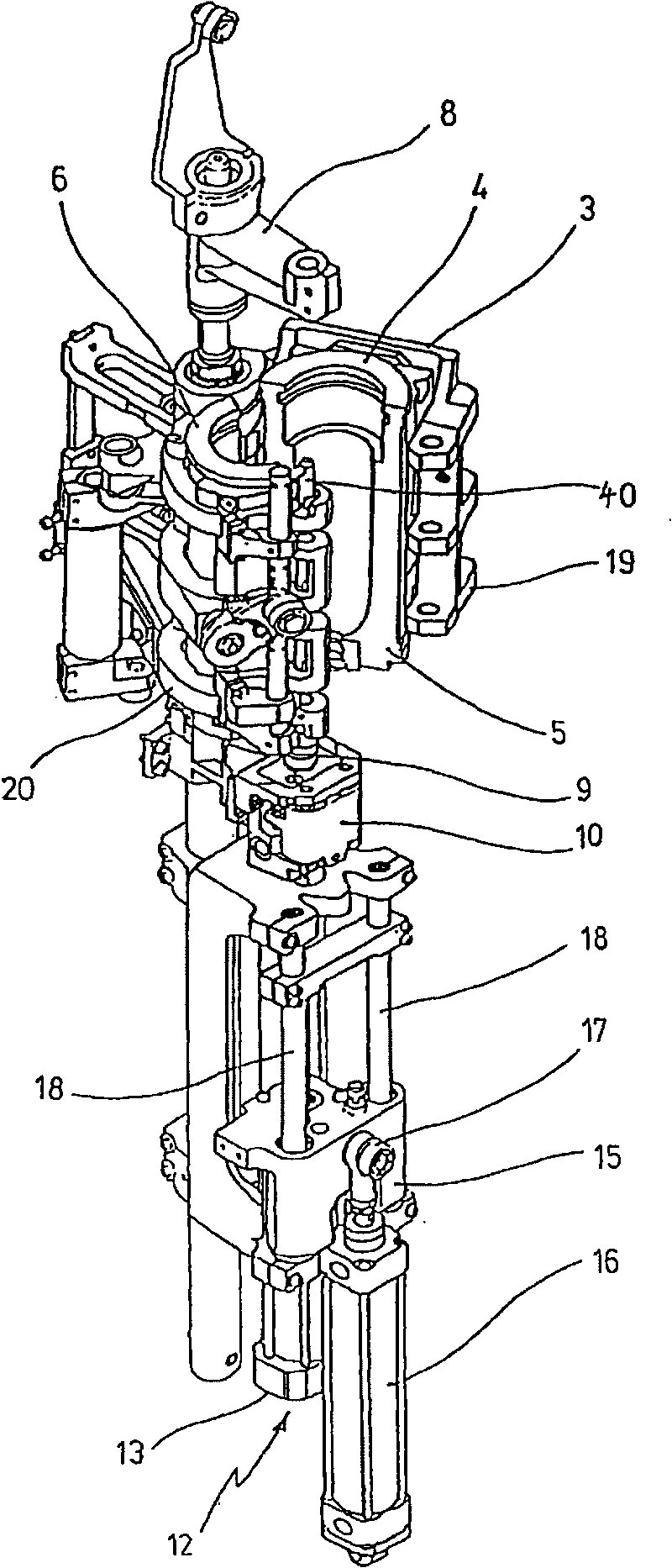

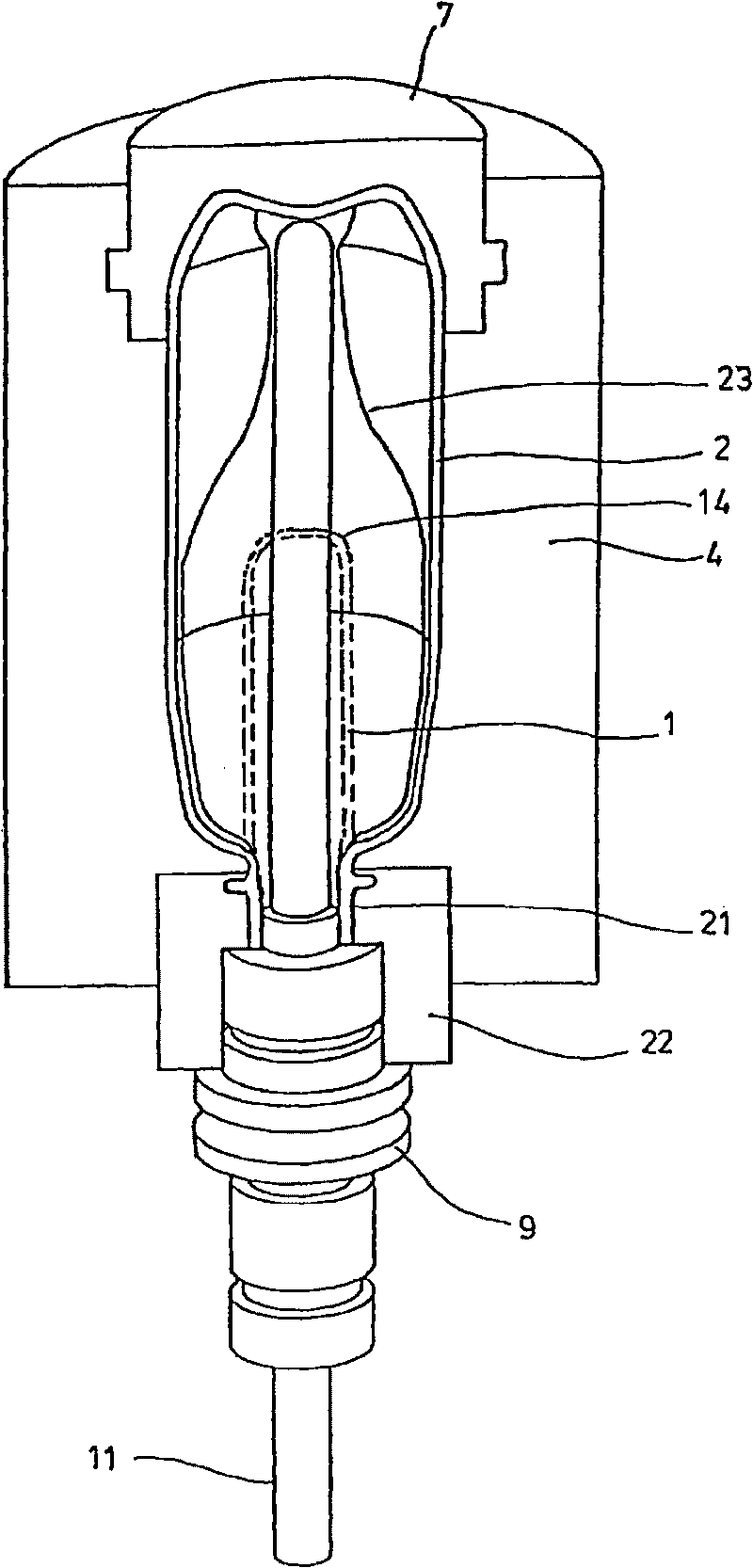

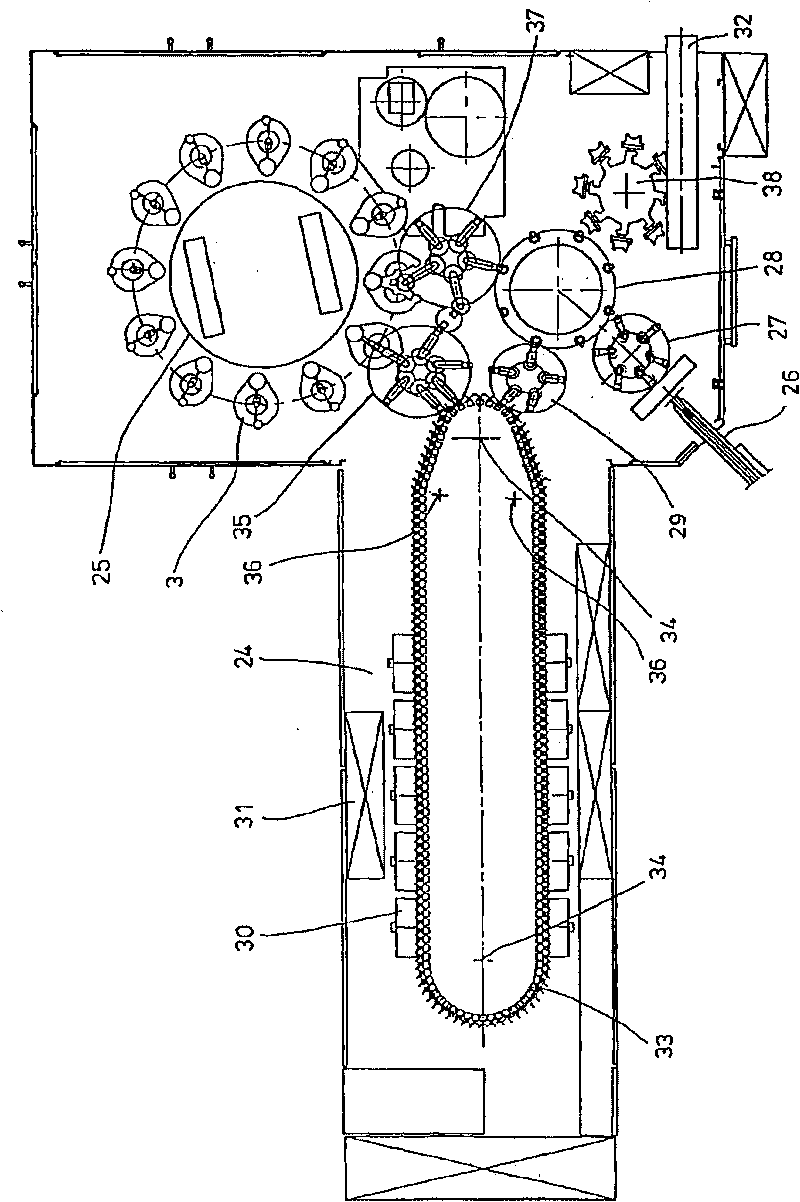

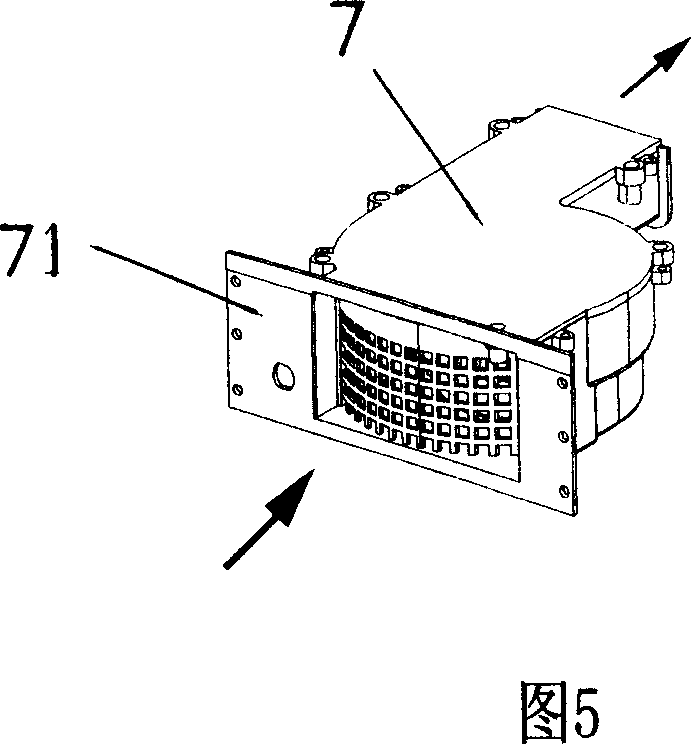

Device for blow-molding containers

ActiveCN101707950AImport uniformReduce structural weightOperating means/releasing devices for valvesValve housingsBlow moldingMain channel

The invention relates to a device for blow-molding containers, comprising at least one blow-molding station having a blow mold. A flow path for a blow gas for blow-molding the containers extends through a connecting element. Said connecting element has a valve support supporting at least one valve. Said valve encircles a main channel of the valve support.

Owner:KHS GMBH +1

Inorganic foam concrete preparation device

InactiveCN111993593AImprove stirring efficiencySave time at workDischarging apparatusCement mixing apparatusStructural engineeringPipe

The invention discloses an inorganic foam concrete preparation device. The device comprises a box body, a feeding hopper is fixedly connected to the left side of the top of the box body, rolling supporting legs are fixedly connected to the bottom of the box body, and a mixing assembly is arranged above the box body. According to the inorganic foam concrete preparation device, through meshing connection of the gears and rotation of the transverse pipe and the stirring paddle, the material stirring efficiency is higher, the working time is saved, meanwhile, the material quality is guaranteed, bubbles can be evenly guided into a mixed material through annular equidistant arrangement of the through holes, and through up-down movement of the transverse pipe, the material quality is improved, the contact area of the bubbles and the materials is further increased, the mixing sufficiency of the bubbles and the materials is further improved, the material quality is improved, the auger conveyorcan be rotated and fixed under the action of an extension spring through clamping connection of a second gear and a clamping rod, and then the discharging position of the auger conveyor can be adjusted; and the method is suitable for different use conditions.

Owner:范文芳

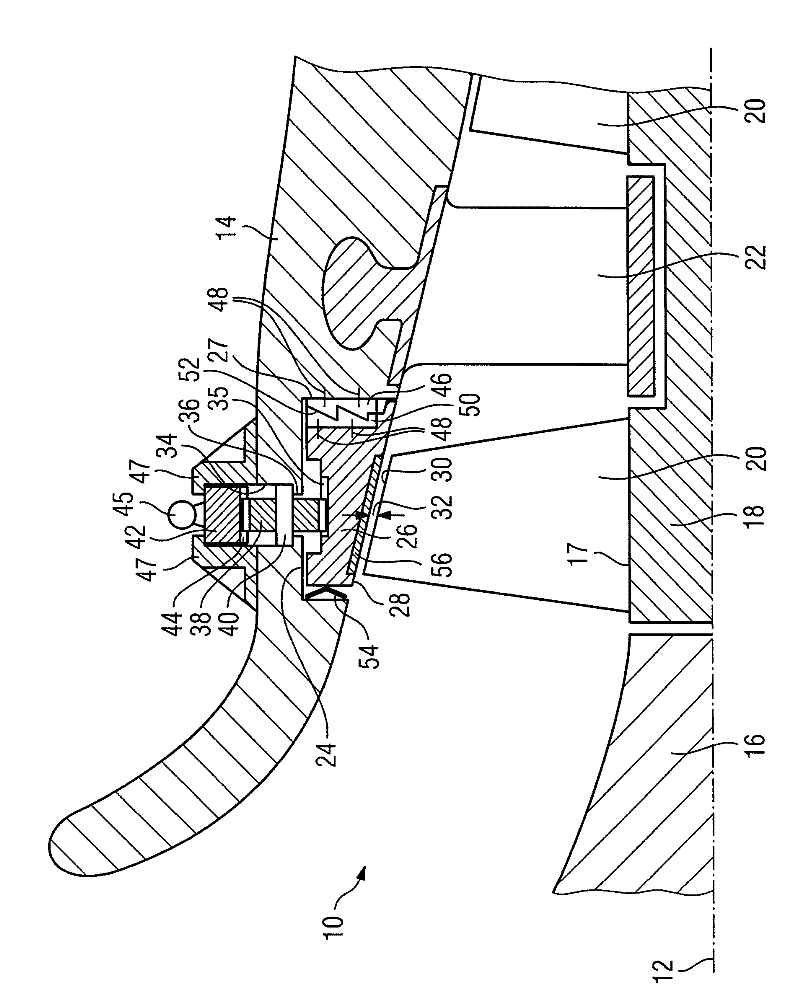

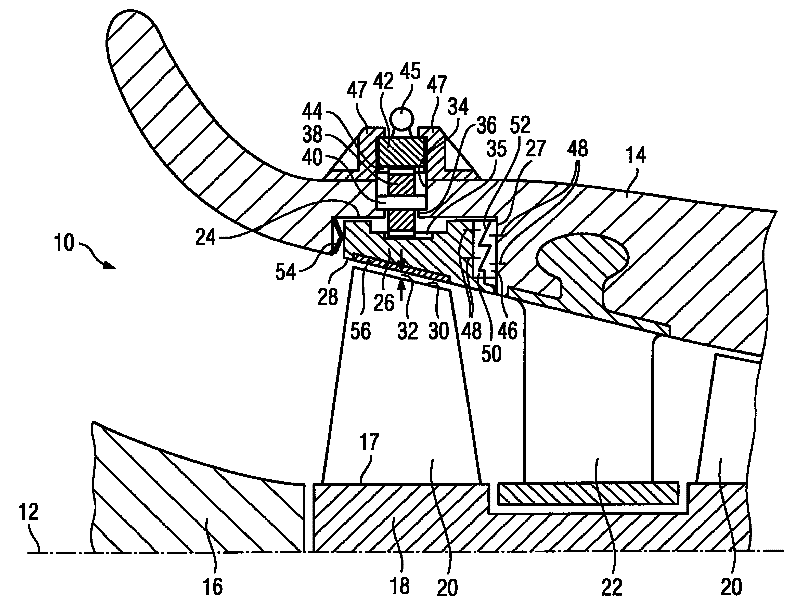

Passage wall section for an annular flow passage of an axial turbomachine with radial gap adjustment

InactiveCN102242644ASimple determination of axial positionAvoid warpingGas turbine plantsLeakage preventionAxial displacementMechanics

The invention provides a passage wall section (14) of an annular flow passage (10) of an axial turbomachine with which a simple and reliable adjustment of a radial gap between the inner wall surface (28) of a guide ring (26) and a rotor blade tip (30) oppositely arranged on the wall surface (28) is possible. The guide ring (26) has a first toothing arrangement (20) which is in contact with a second toothing arrangement (46) arranged on a sidewall (27) of a circumferential groove (24) which accommodates the guide ring (26), wherein for axial displacement of the displaceable guide ring (26), the guide ring is rotatable in a circumferential direction.

Owner:SIEMENS AG

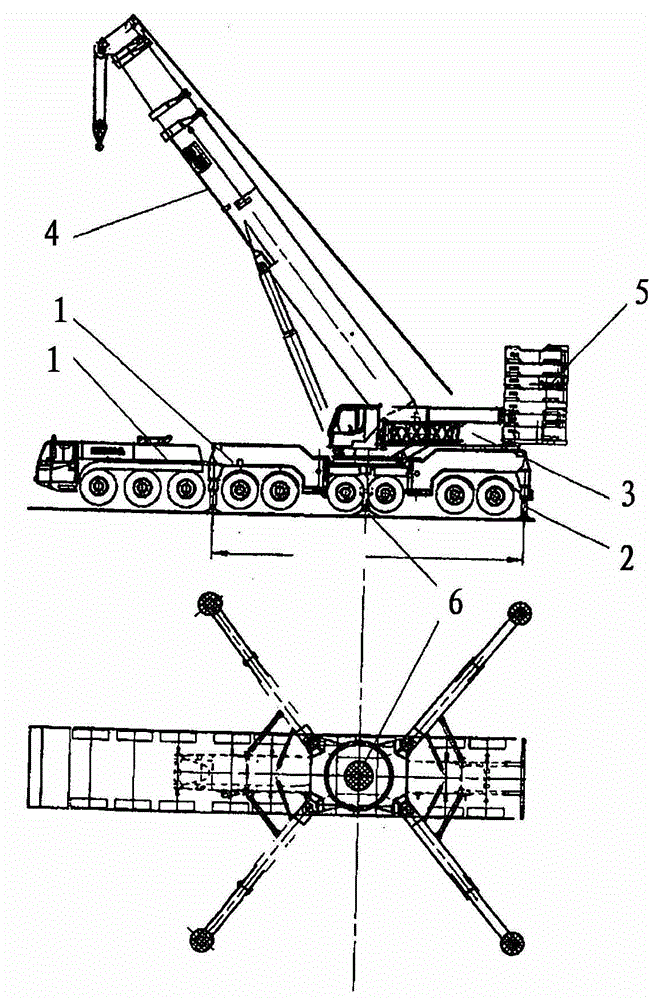

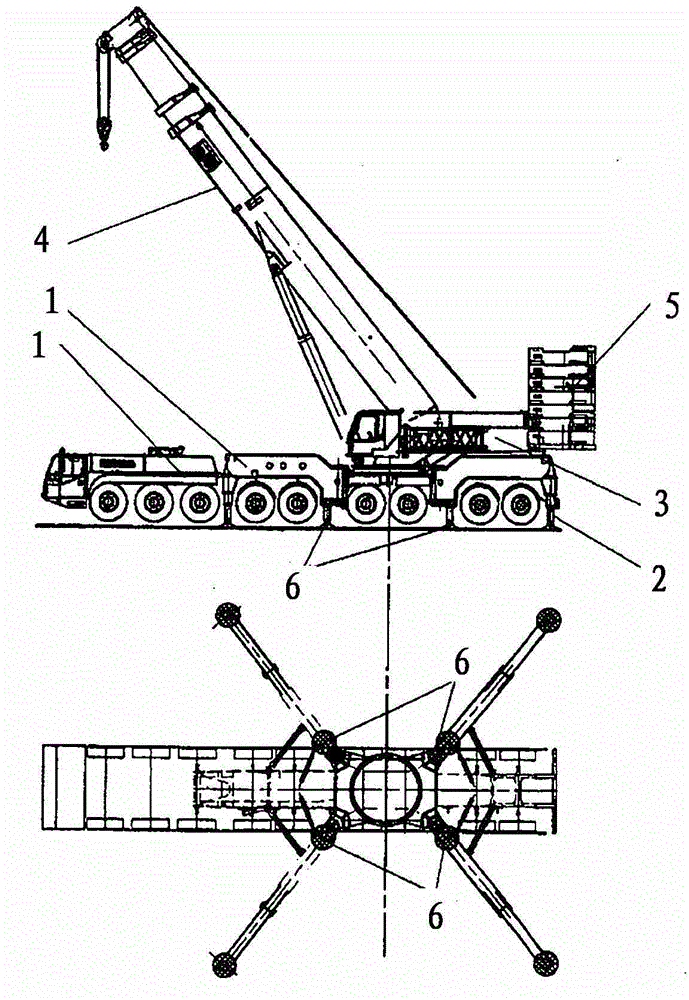

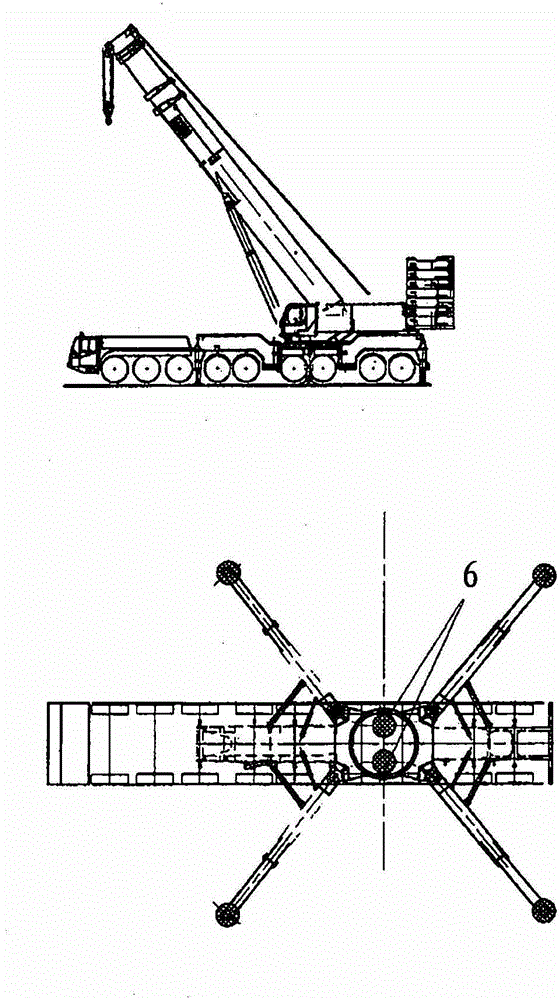

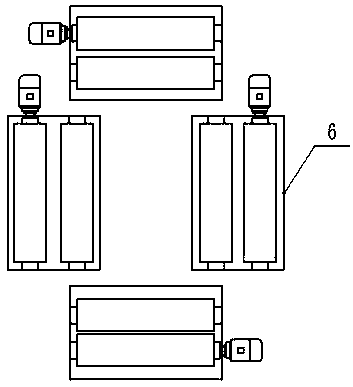

Movable working device, in particular mobile crane

InactiveCN103910293AEasy to stuffEven local loadLoad-engaging elementsCranesMechanical engineeringMobile work

The present invention relates to a mobile working machine, especially a mobile crane, having an undercarriage (1) and a support device with support cylinders (2) to create the support base required for operation, a top carriage (3) mounted pivotably on the undercarriage (1), as well as an apparatus compatible with the type of the working machine, in particular outriggers (4) and a counterweight arrangement (5). One or more additional hydraulic supports (6) are arranged on the undercarriage (1) underneath or in the proximity of the pivot bearing of the top carriage (3), as well as a control unit (7, 8, 9), which monitors the loads of the support device (2) and controls and monitors the additional supports (6).

Owner:TEREX CRANES GERMANY

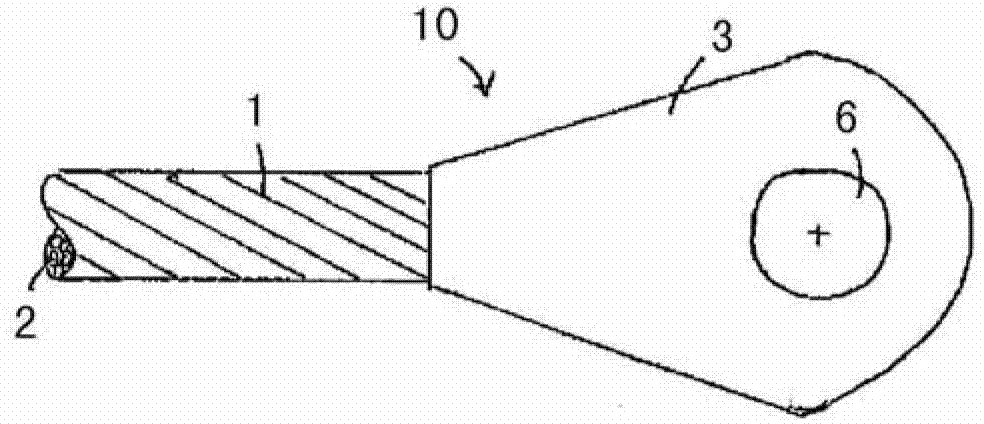

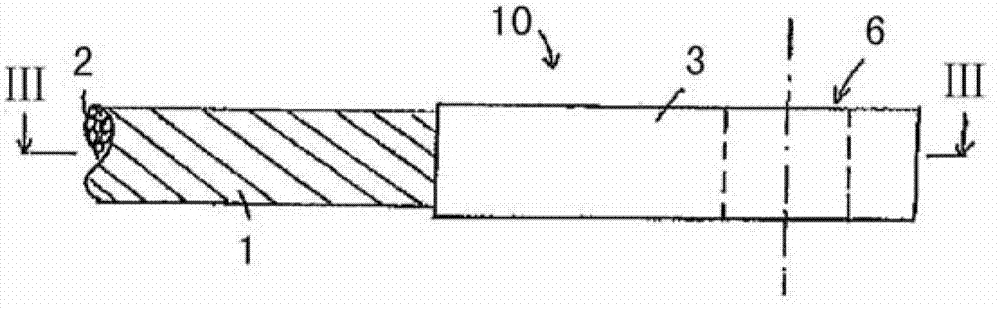

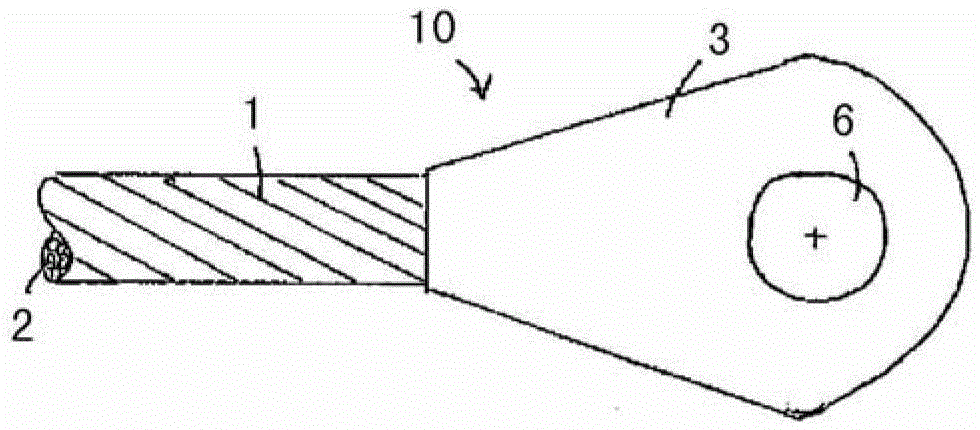

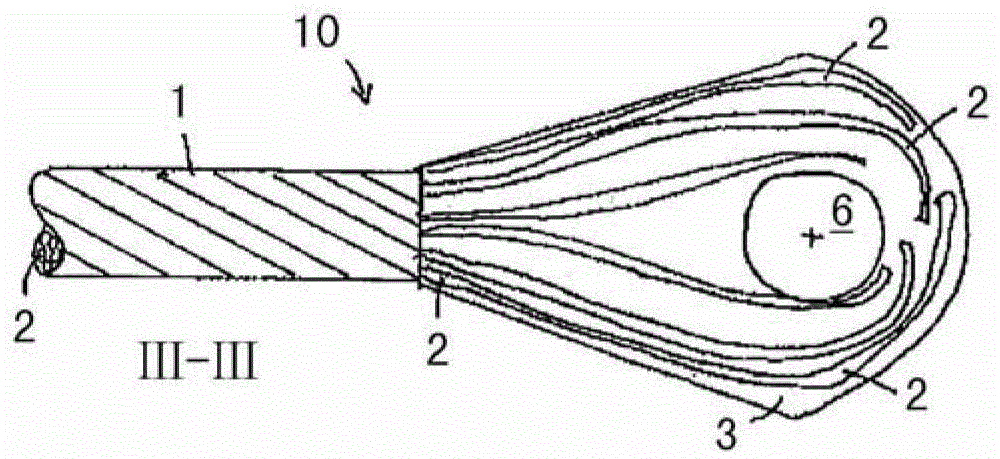

Cable end connection

ActiveCN102893056AHigh strengthIncreased durabilityRopes and cables for vehicles/pulleyHaberdasheryEngineeringInjection moulding

A cable end connection (10) for a cable (1) which is constructed from a plurality of intertwined filaments (2), wherein an end part (3) is provided for installing or supporting the cable (1), said end part being fastened to one end of the cable, wherein the cable end connection is characterized in that the end part (3) is a part which is fitted without a sleeve and is made from a castable, curable material, and in that the end part (3) is connected without additional mechanical connecting elements in a form-fitting manner to the filaments (2) solely by being cast therearound or moulded thereon. The filaments (2) are advantageously fanned out in the material of the end part (3) and are in particular substantially completely embedded therein. The filaments (2) are released from the original stranding assembly in the region of the end part (3) and distributed substantially uniformly. The end part (3) is produced in a casting mould by the injection moulding of synthetic resin, and the filaments (2) are embedded in and cast in a form-fitting manner around the material of the end part (3) under prestress.

Owner:UNIV STUTTGART

Ultralow-alkalinity high-vitrification covering slag for bloom medium-high carbon steel and preparation method thereof

The invention discloses ultralow-alkalinity high-vitrification covering slag for bloom medium-high carbon steel and a preparation method thereof, and belongs to the technical field of steelmaking metallurgy auxiliary materials. The ultralow-alkalinity high-vitrification covering slag for the bloom medium-high carbon steel is prepared from the following raw materials of, by weight, 15-35 parts of wollastonite, 15-30 parts of power plant molten coal cinder waste, 2-13 parts of quartz, 6-13 parts of albite, 2-8 parts of sodium fluoride, 1-5 parts of sodium carbonate, 6-10 parts of fluorite, 2-5 parts of magnesia powder, 1-6 parts of 390 medium-carbon graphite, 2-6 parts of high-carbon amorphous graphite, 1.5-3 parts of semi-reinforcing natural gas carbon black and 5-8 parts of sodium silicate. The ultra-low alkalinity is adopted, the vitrification rate in the slag solidification process is controlled to be high, and then the blank shell thickness and the lubricating effect in the medium-high carbon continuous casting process are guaranteed; the high viscosity is adopted, under the condition that a casting blank has certain shrinkage, molten slag is evenly guided in, solid slag film is uniform, and it is guaranteed that the surface of the casting blank is smooth; slightly high melting point and viscosity are adopted, so that the use amount of flux is reduced, the slag surface tension is improved, and the slag entrapment probability is reduced; and compound carbon blending is adopted, and then the problem of accidental carbon pickup of the casting blank is relieved by adjusting the carbon blending.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

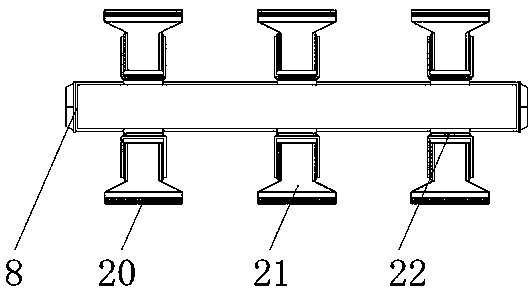

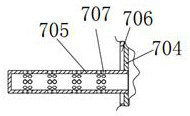

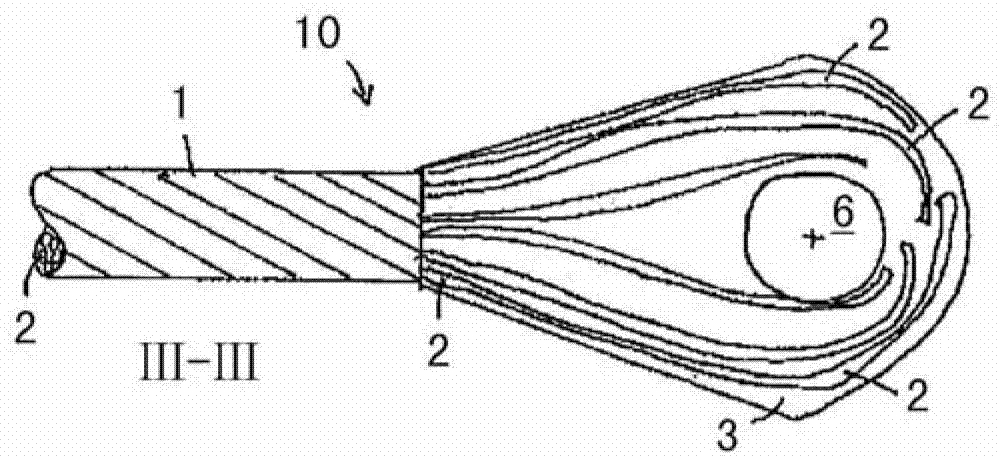

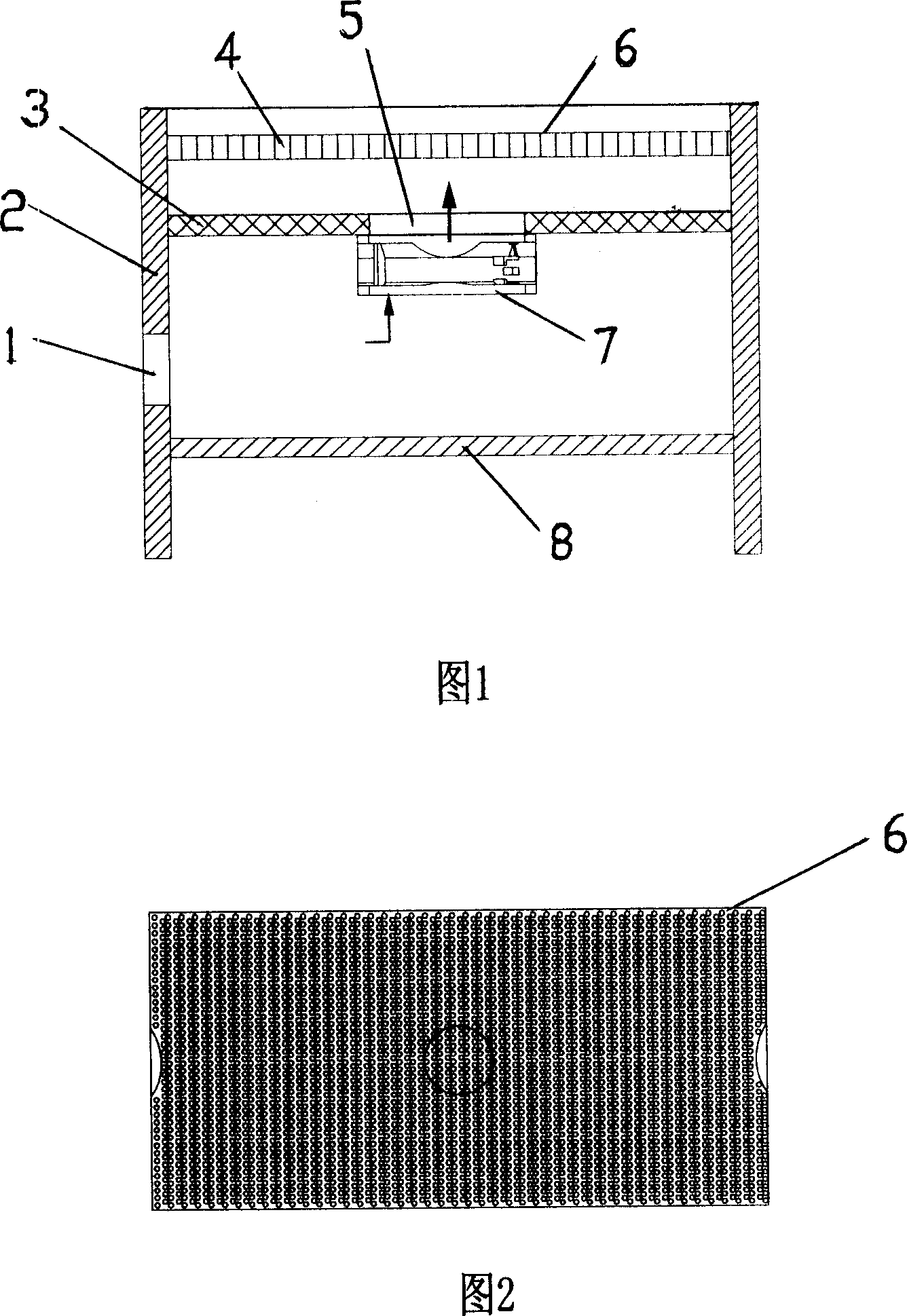

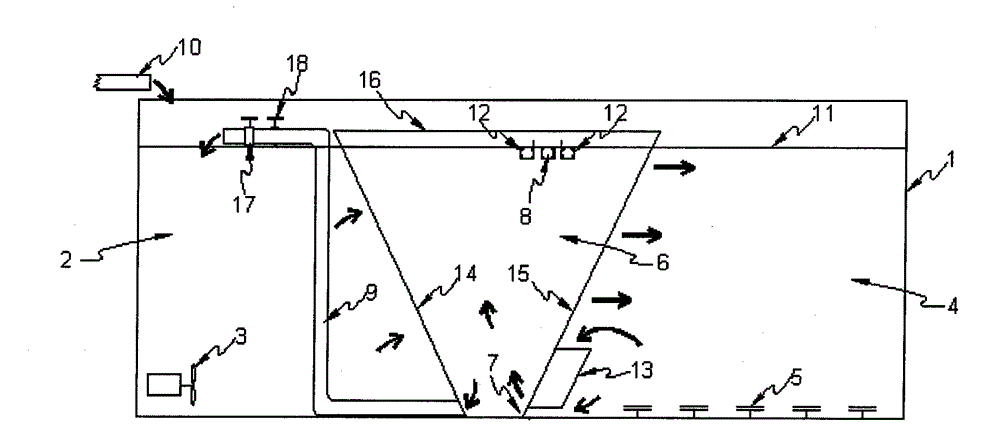

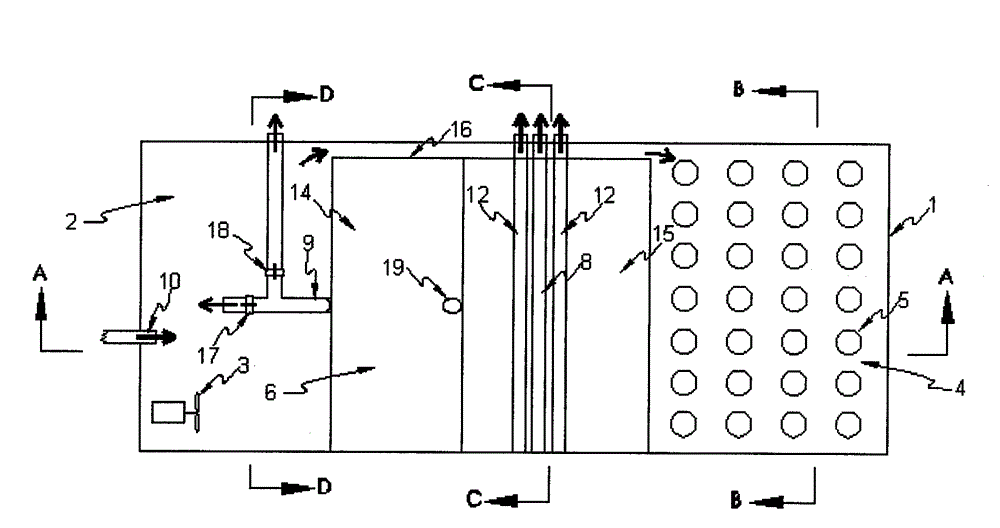

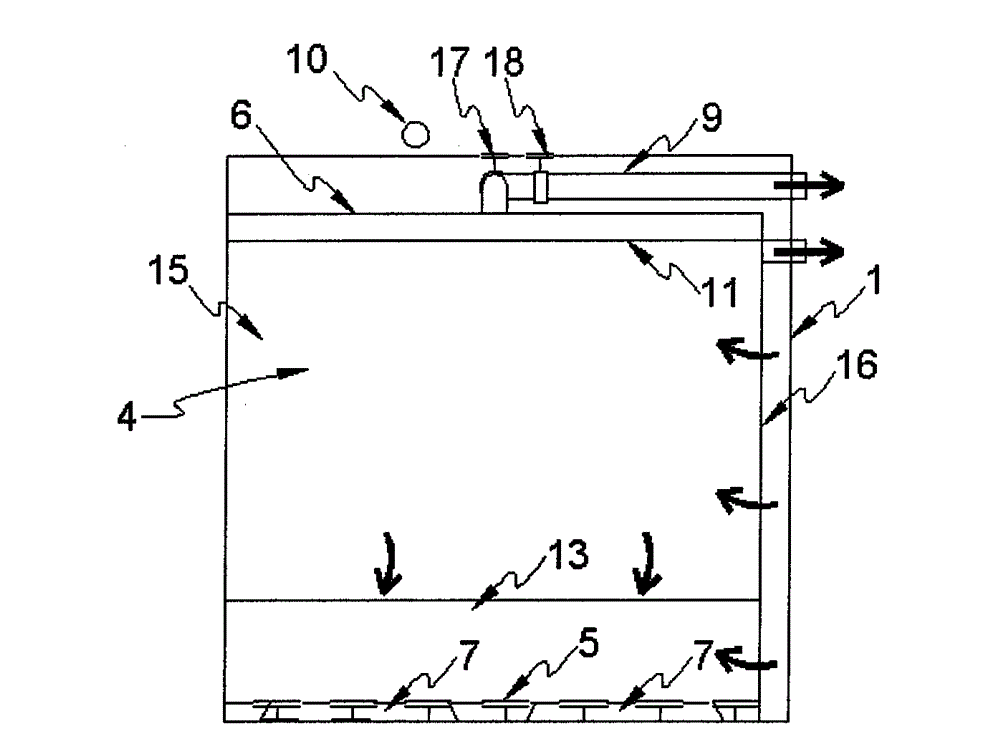

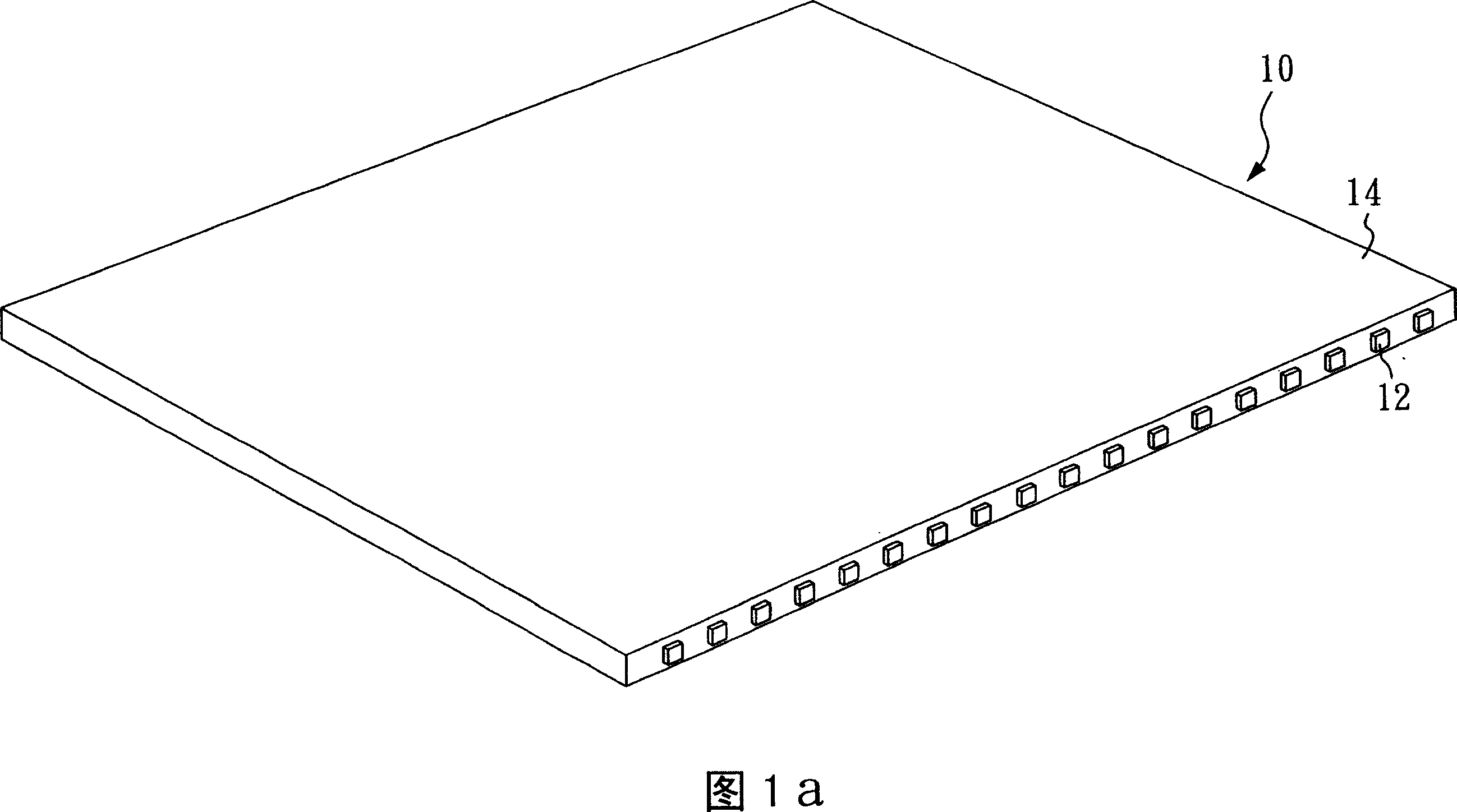

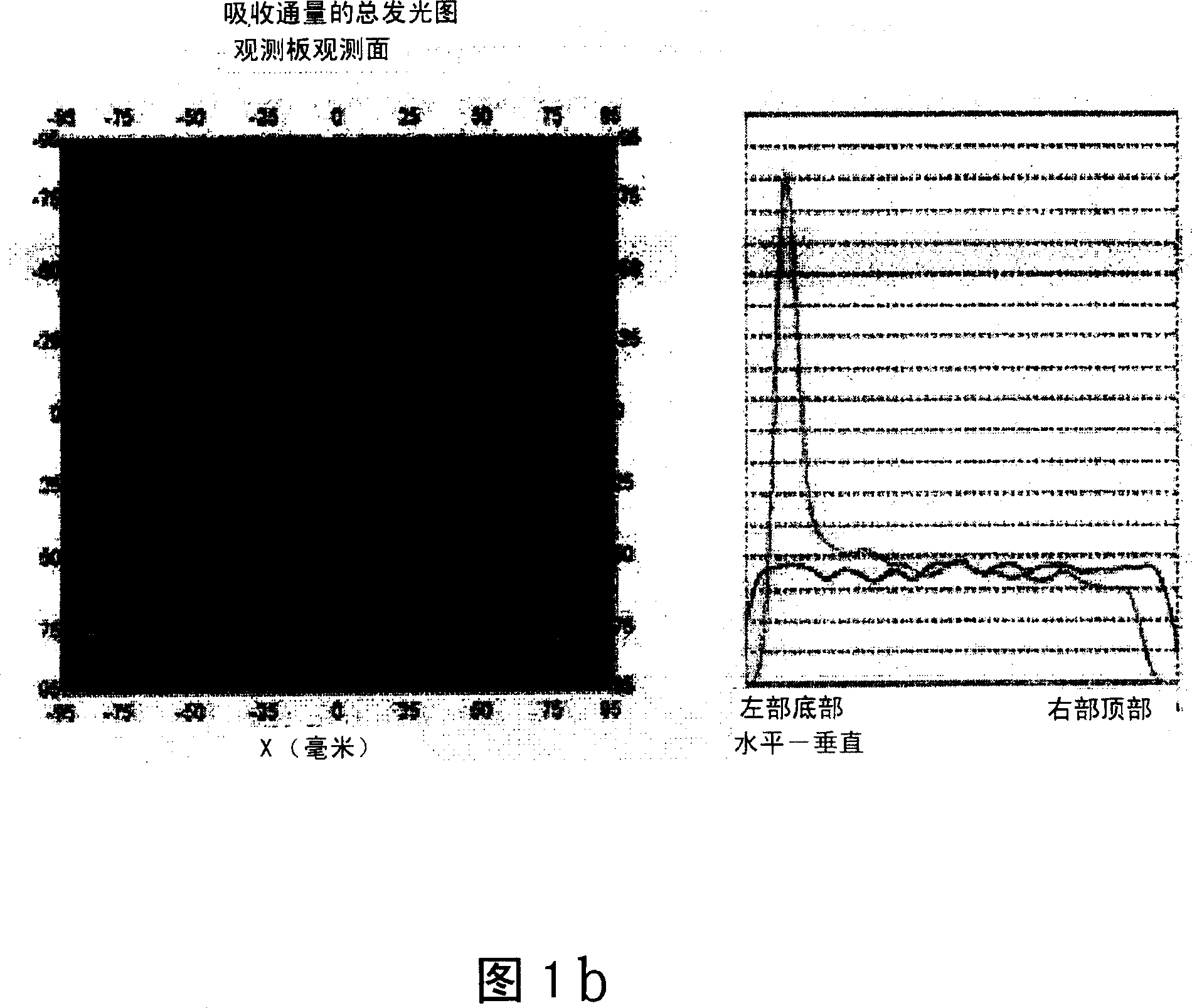

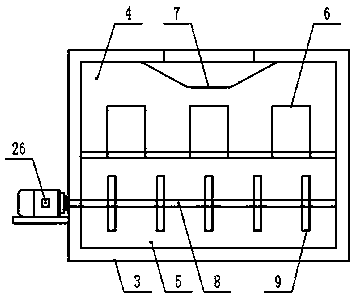

Table air hokey aide air-feeding method and table air hokey

The invention relates to a method for feeding wind beside air ball table, and relative air ball table, wherein it comprises that: it uses beside feeding method; the table is formed by table panel, middle plate, low panel and side panel, to form sealed space; the wind only is discharged at the porous of table panel; the side panel has wind inlet; the middle plate has ventilating outlets; the fan is mounted on the wind inlet; the airflow is guided via the ventilating outlet uniformly into the space between table panel and middle plate to be discharged via porous.

Owner:SHENZHEN S&T MOTOR CO LTD

Sewage treatment facility and process

ActiveCN102249479BReduce civil areaReduce sizeMultistage water/sewage treatmentChemistryDecomposition

The invention discloses an active sludge sewage treatment facility, which consists of an anoxic reaction chamber, an aerobic reaction chamber and a filtering and clarifying chamber communicated in sequence. Sewage is mixed with a large amount of active sludge reflowing from the filtering and clarifying chamber and flows into the aerobic reaction chamber after entering the anoxic reaction chamber.In the aerobic reaction chamber, a large quantity of bacteria, epiphytes and microorganisms are metabolized into suspended objects under the actions of aeration, oxidation and decomposition. The sludge inlet of the filtering and clarifying chamber is used for controlling the sludge current flowing in from the aerobic reaction chamber. The bottom of the filtering and clarifying chamber is providedwith a sludge outlet which is used for making the sludge reflow into the anoxic reaction chamber and be mixed with sewage entering the anoxic reaction chamber for starting a new cycle of treatment procedure which is the same as the process. Purified water flows out of a purified water overflowing weir on the top of the filtering and clarifying chamber. The active sludge sewage treatment facility has a compact structure, a small occupied area and good energy saving and emission reduction effects, and can be widely applied to various sewage treatment industries, in particular to a large quantity of middle-small cities, development areas, dispersive towns, tourist attractions and the like.

Owner:北京森普杨环境工程有限公司

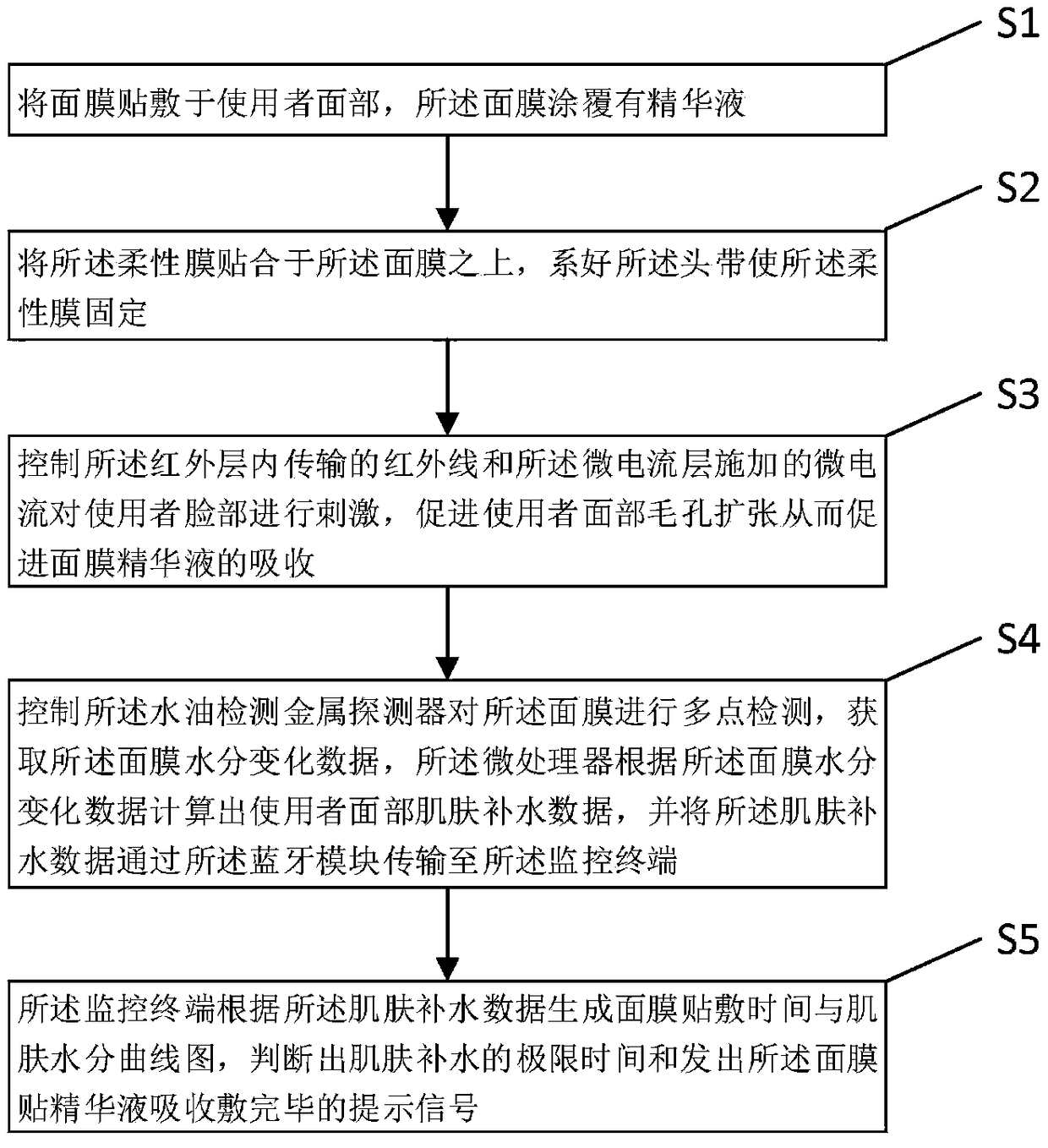

Full-face beauty treatment instrument based on liquid metal printing technology and method thereof

InactiveCN109432592AImprove efficiencySolve the damageElectrotherapyMedical devicesEngineeringLiquid metal

The invention provides a full-face beauty treatment instrument based on a liquid metal printing technology, which is used for promoting the absorption of facial mask essence. The beauty treatment instrument comprises an instrument body and a headband, the headband is connected to an instrument body, the instrument body comprises a flexible film, an infrared layer and a water-oil detecting metal detector disposed on the flexible film, and a micro-current layer for printing liquid metal on the flexible film, the infrared layer is used to transmit infrared light, the micro-current layer is used to apply the micro current to the user's face, a water-oil detection metal detector is used to detect the moisture change of a mask at multiple points, the headband is provided with a microprocessor and a Bluetooth module, the microprocessor is respectively connected with a water-oil detection metal detector and a Bluetooth module, and the microprocessor calculates the skin hydration data accordingto the moisture change data of the mask, and transmits the skin hydration data to a monitor terminal through the Bluetooth module. The full-face beauty treatment instrument has the beneficial effectsof promoting the uniform introduction of the mask essence into the user's face, intuitively understanding the use condition of the mask, and improving the use efficiency and time efficiency of the mask.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A catheter for vacuum perfusion and its preparation method

Owner:JIANGSU YUEKE NEW MATERIAL

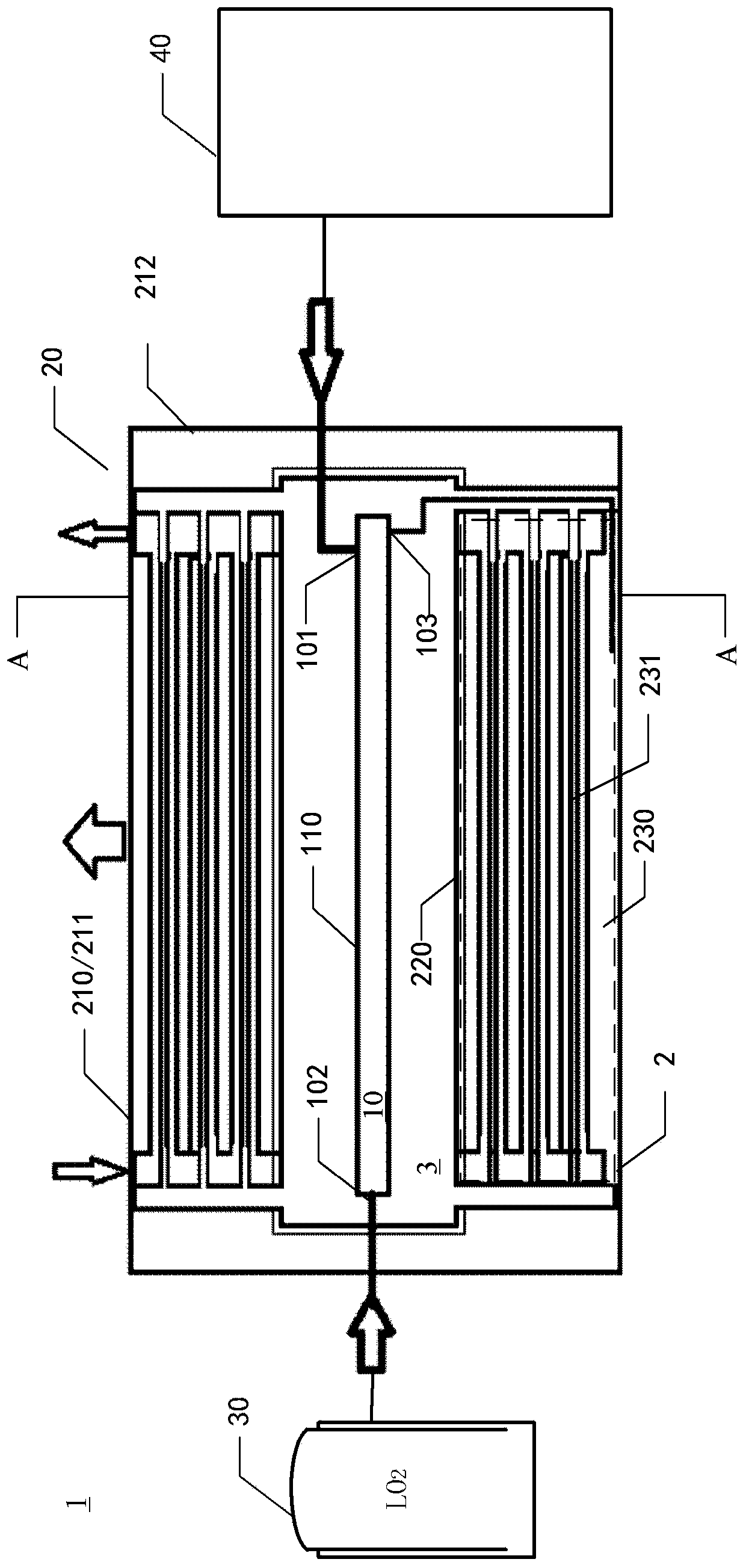

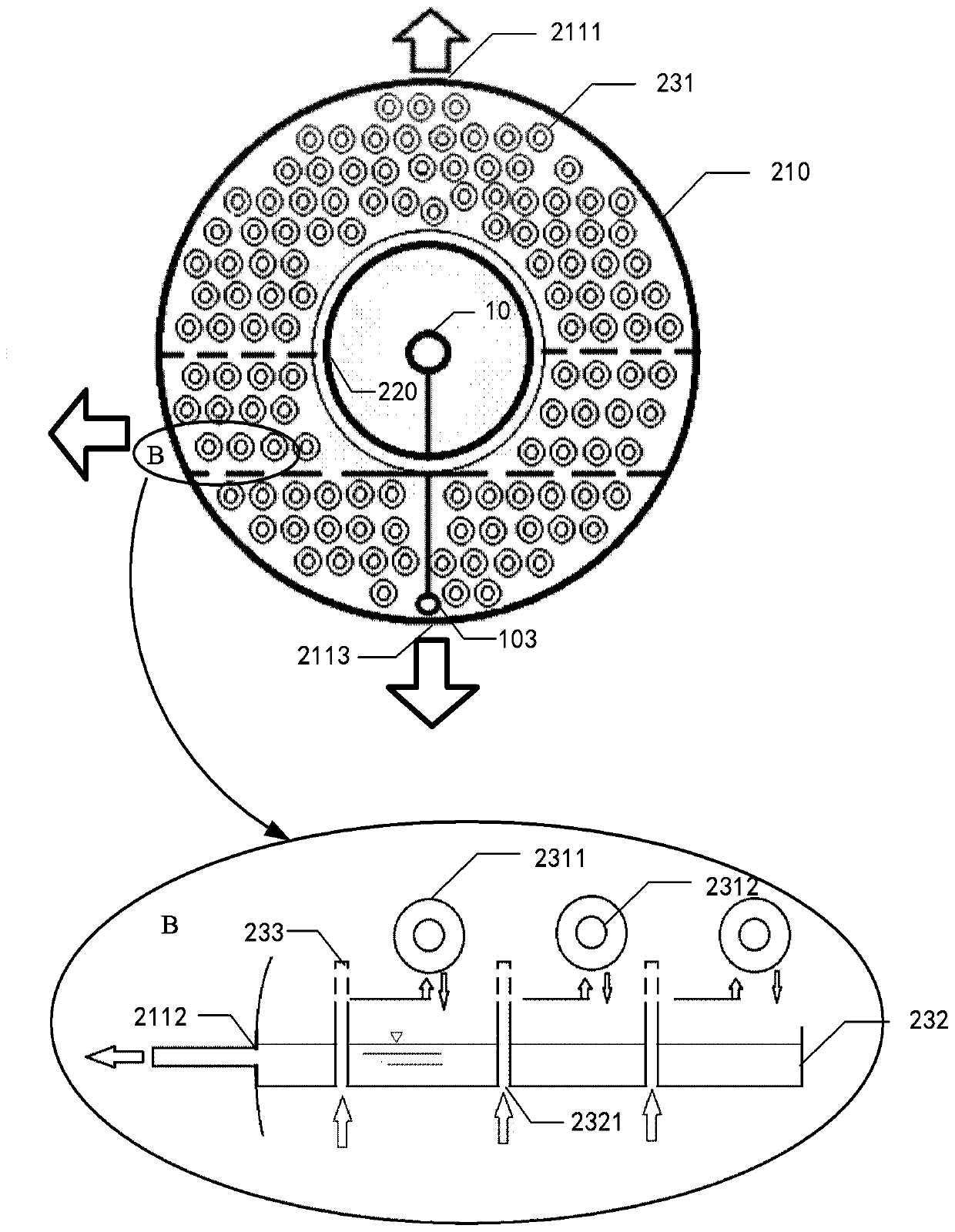

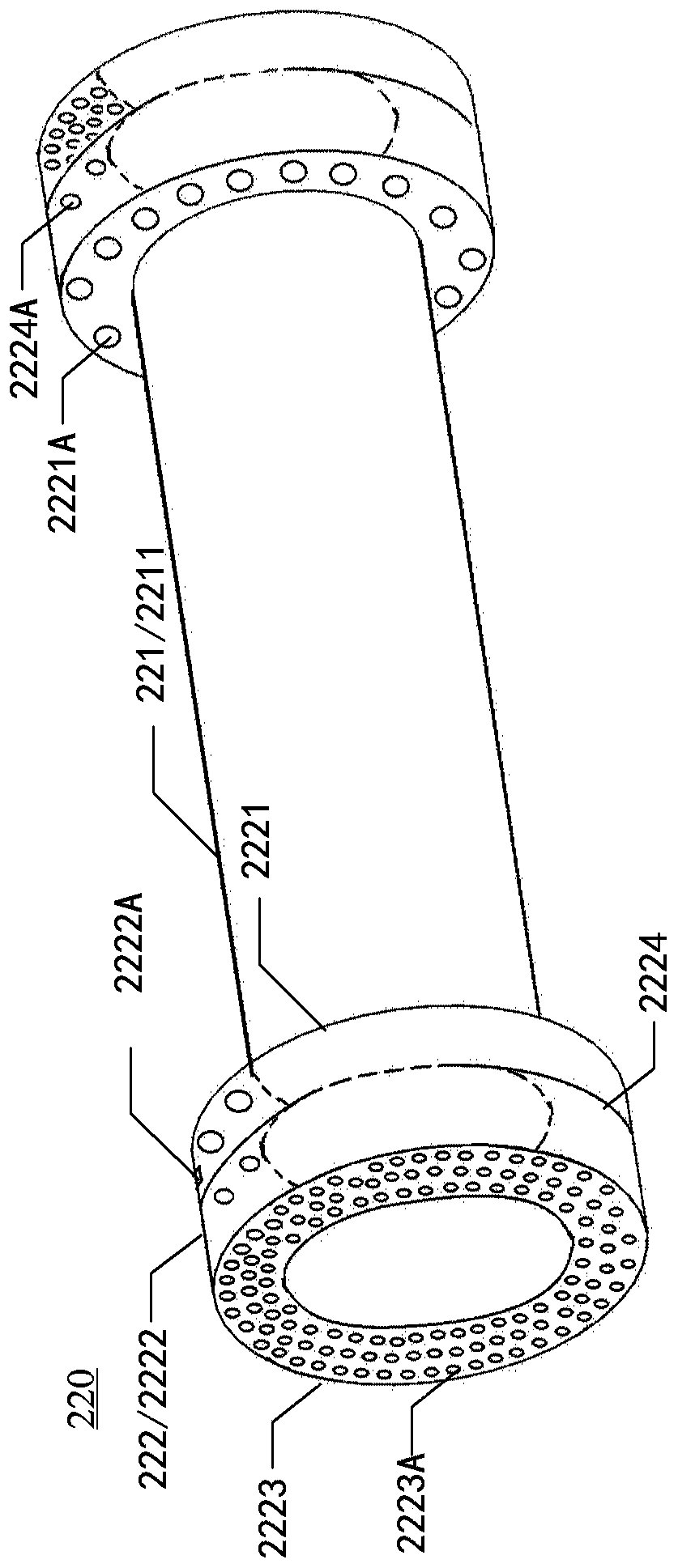

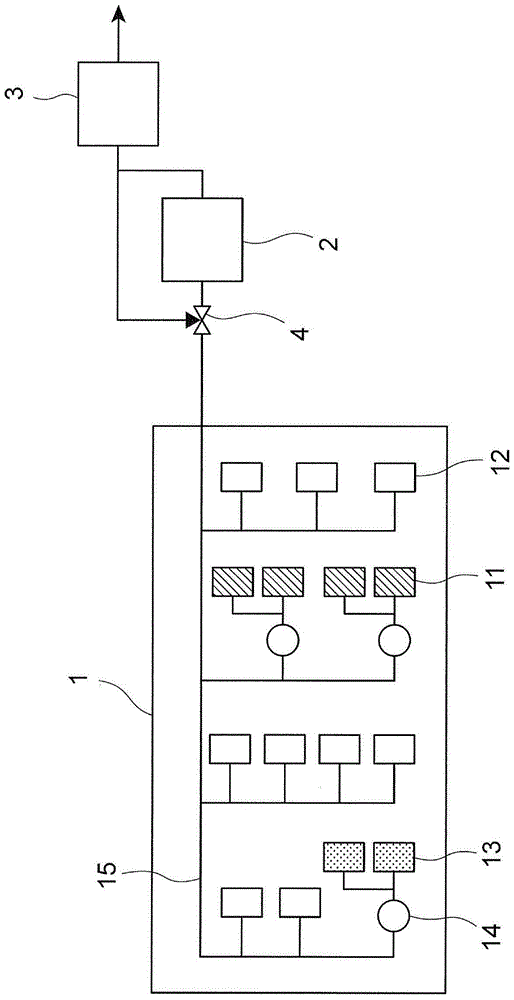

Supercritical water oxidation system

ActiveCN109851029AEffective coolingAvoid damageWater contaminantsWater/sewage treatment by oxidationLiquid lineNuclear engineering

A supercritical water oxidation system is provided. The system comprises a reactor, a protective device, an oxidant supply device and an organic material supply device. The reactor comprises a reactorshell, wherein an oxidant feeding port, an organic matter feeding port and a discharge port are arranged on the reactor shell, and the reactor releases reaction products through the discharge port. The protective device comprises an outer protective layer, a cooling layer and an inner protective layer, wherein the inner protective layer and the outer protective layer are surrounded by a first space and a second space. The cooling layer includes a liquid conduit capable of storing liquid, the liquid conduit being disposed in the first space. The reactor is disposed in the second space, and a discharge port of the reactor extends to an area in the first space other than the area where the liquid line is located, so that the reaction product discharged from the discharge port can be cooled through the liquid stored in the liquid line. The oxidant supply device is communicated with the oxidant feed port, and the organic material supply device is communicated with the organic material feedport.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

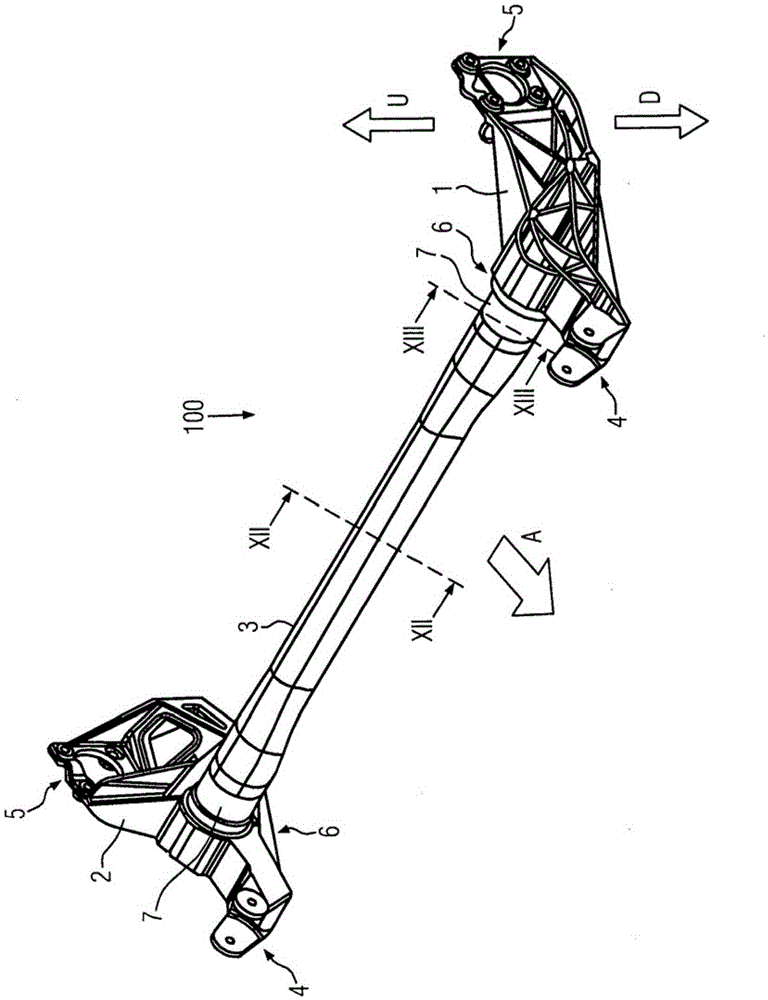

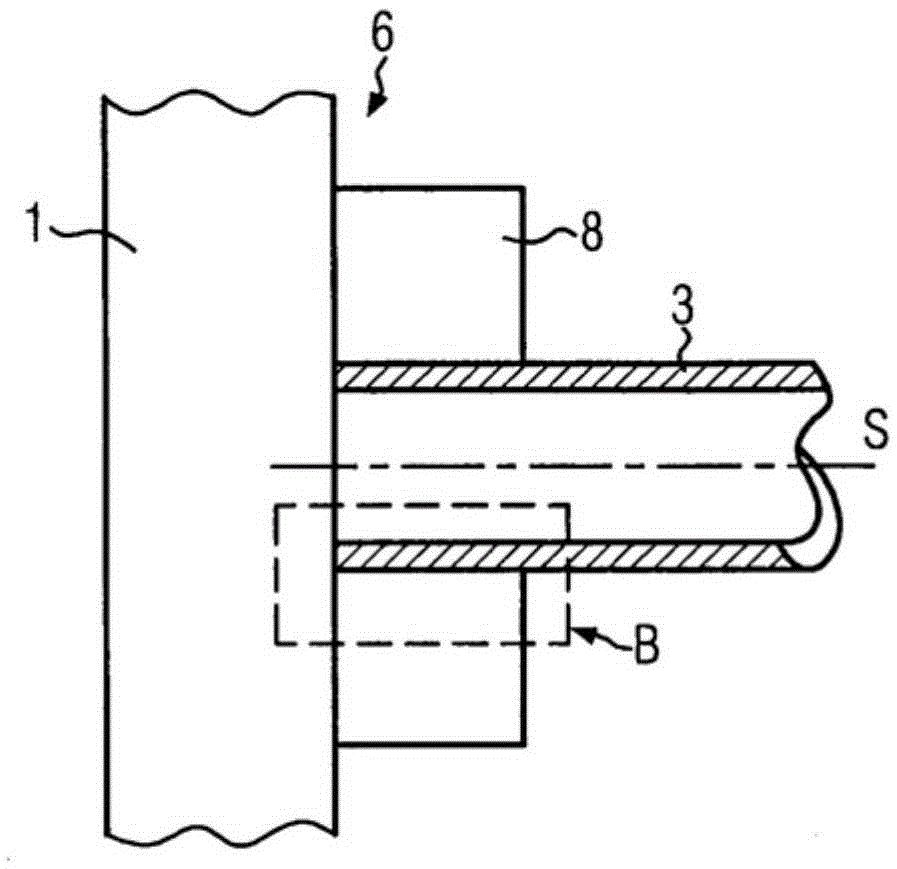

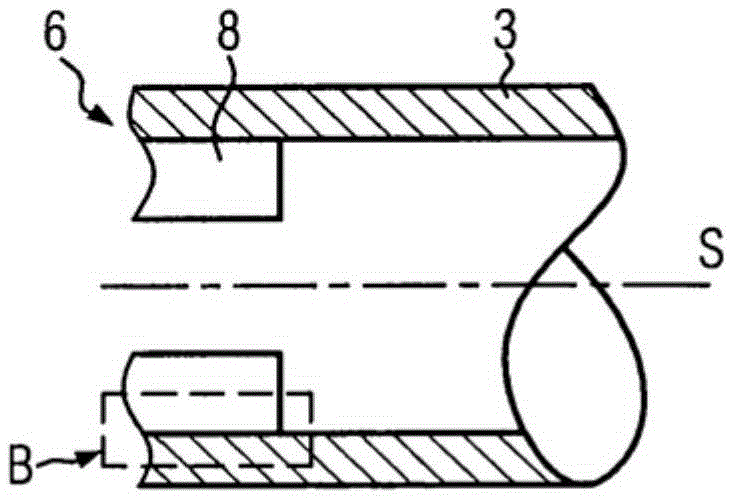

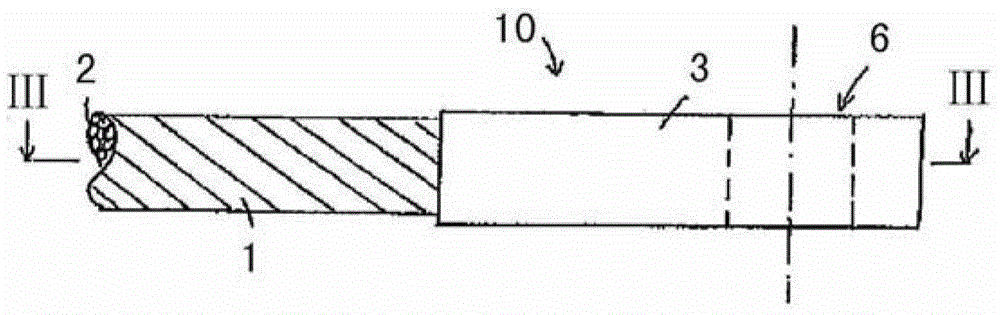

Twist beam axle

ActiveCN105408139AImprove stabilityEasy to receiveSpringsInterconnection systemsMetallic materialsEngineering

The invention relates to an assembly (100) for a vehicle, comprising two longitudinal members (1, 2) and a crossmember (3) arranged therebetween, which crossmember extends approximately perpendicularly to the longitudinal members (1, 2), wherein the crossmember (3) is an elastically twistable torsion member, and the crossmember (3) is made predominantly of fibre composite material and the longitudinal members (1, 2) are made predominantly of a metal material, and the crossmember (3) is connected to the longitudinal members (1, 2), wherein the crossmember (3) is clamped or supported on one of the two longitudinal members (1, 2), at a connection point (6) of the crossmember to the longitudinal members (1, 2), by means of respective ends (7) of the crossmember, and torsional forces are transmitted to the crossmember (3) at said connection point (6). In order to improve the assembly to the effect that the crossmember can be easily connected to the longitudinal member and the forces and torques occurring at the connection point nevertheless can be transmitted to the crossmember well at the connection point and the connection point has high stability at the same time, the connection point (6) between the crossmember (3) and the longitudinal member (1, 2) comprises an overlapping region (B), in which a connection segment (8) of the longitudinal member (1, 2), which is predominantly composed of metal material, overlaps at least in some segments with a part of the crossmember (3), which is predominantly composed of fibre composite material.

Owner:COSMA ENG EURO AG

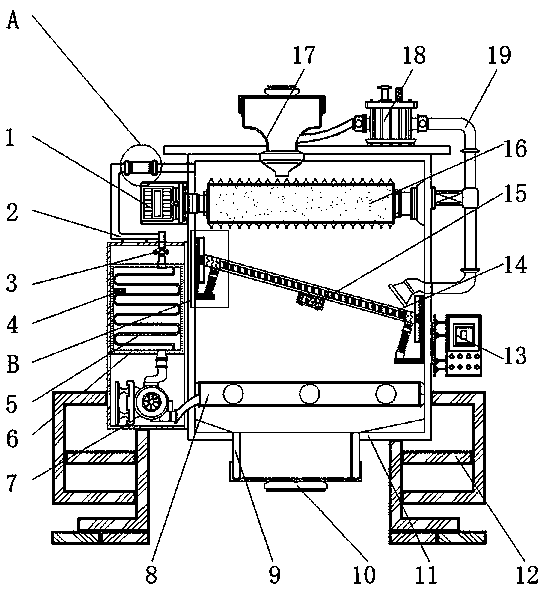

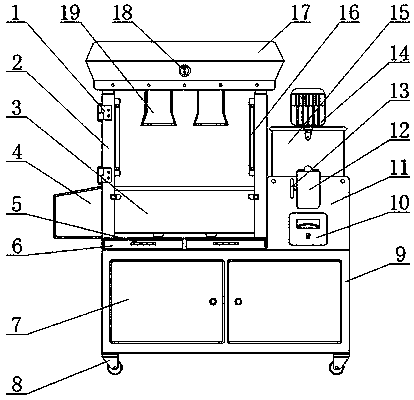

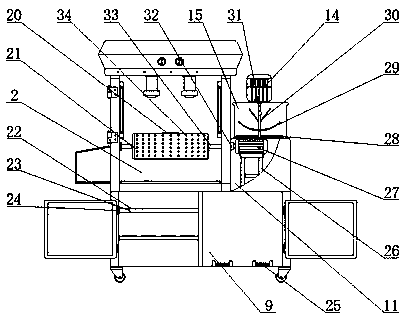

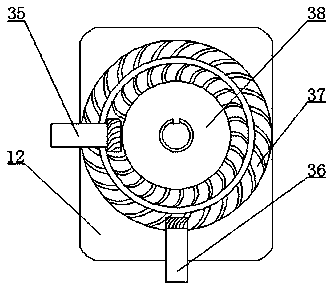

Commercial popcorn machine with high expansion rate

InactiveCN107625057AScientific and reasonable structureSafe to useFood shapingEngineeringExpansion rate

The invention discloses a commercial popcorn machine with high expansion rate. The commercial popcorn machine with high expansion rate comprises a placing box and an auxiliary motor; road wheels are arranged under a left side of the placing box; a cabinet door is arranged at a left side of a front surface of the placing box; a popcorn box is arranged above an left end of the placing box; oil collecting boxes are arranged under a left side of the front surface of the popcorn box; a baffle is arranged on the oil collecting boxes; a residue discharge groove is arranged at a lower left side of thepopcorn box; and an anti-sticking blade is arranged on the popcorn machine so that grains at a bottom of a popcorn fryer are stirred by the anti-sticking blade arranged on a stirring shaft when the grains are stirred in the popcorn fryer, and thus, uniform heating of the grains at the bottom of the popcorn fryer is ensured so as to effectively reduce the condition of sticking of the grains to thefryer; moreover, washing difficulty of the popcorn fryer is also reduced. In addition, an auxiliary transmission box is arranged on the popcorn fryer so that the popcorn fryer can be slowly tilted through operation of a turntable after production of the popcorns.

Owner:王晓雷

A raw material pretreatment device for petroleum processing

ActiveCN111359491BImprove mixing efficiencyEasy to disassembleRotary stirring mixersTransportation and packagingWeb structureProcess engineering

The invention discloses a raw material pretreatment device for petroleum processing, which comprises a raw material storage tank body, the upper end of the raw material storage tank body is provided with a tank cover, and the outer wall of the raw material storage tank body is provided with a first feeding pipe and supporting legs , and the lower end of the raw material storage tank is provided with a discharge pipe, the inner wall of the raw material storage tank is provided with several support rods, and the inside of the raw material storage tank is provided with a guide tube, and the outer wall of the guide tube is provided with a guide tube As for the fixing block, the outer wall of the material guide tube is provided with a through hole, the lower end of the material guide tube fixing block is provided with a groove, and one end of the support rod is stuck in the groove at the lower end of the material guide tube fixing block. The raw material pretreatment device for petroleum processing is provided with a feeding structure, which can uniformly introduce the pretreatment agent directly into the raw material, and improve the mixing efficiency of the raw material.

Owner:东营岳泰光耀信息科技有限公司 +1

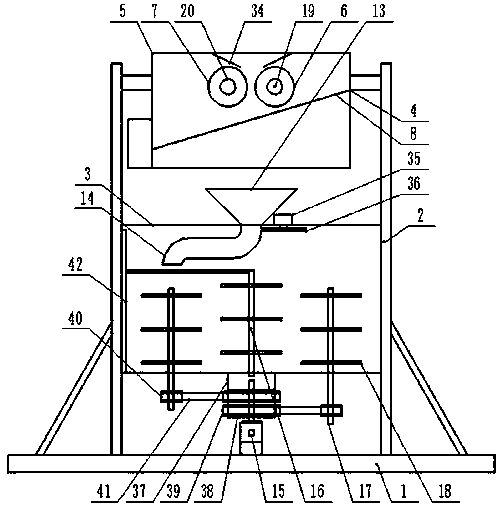

Polyurethane composite material mixing machine for producing automobile roofs

The invention discloses a polyurethane composite material mixing machine for producing automobile roofs, and the machine comprises a base and a vertical fixing frame, a mixing box body is fixedly arranged between the lower end of the vertical fixing frame, a material preparing mechanism is arranged between the upper end of the vertical fixing frame, the material preparing mechanism comprises a material preparing box body, a driving grinding roller, a driven grinding roller, an inclined vibrating mesh screen, a first motor, a gas filtering shell, an extrusion plate and a filtering layer, the upper end of the mixing box body is provided with a round table-shaped material collecting bin, the inner top end of the mixing box body is movably connected with a curved material dispersing pipe corresponding to the position of a material inlet, a second motor is arranged at the middle side below the position of the mixing box body, a first stirring shaft is vertically arranged at the middle sideof the inner end of the mixing box body, the inner end edge of the mixing box body is uniformly and vertically provided with a second stirring shaft in equal radian, and the first stirring shaft and the second stirring shaft are respectively and uniformly provided with stirring rods at equal intervals.

Owner:南京汇科高分子材料有限公司

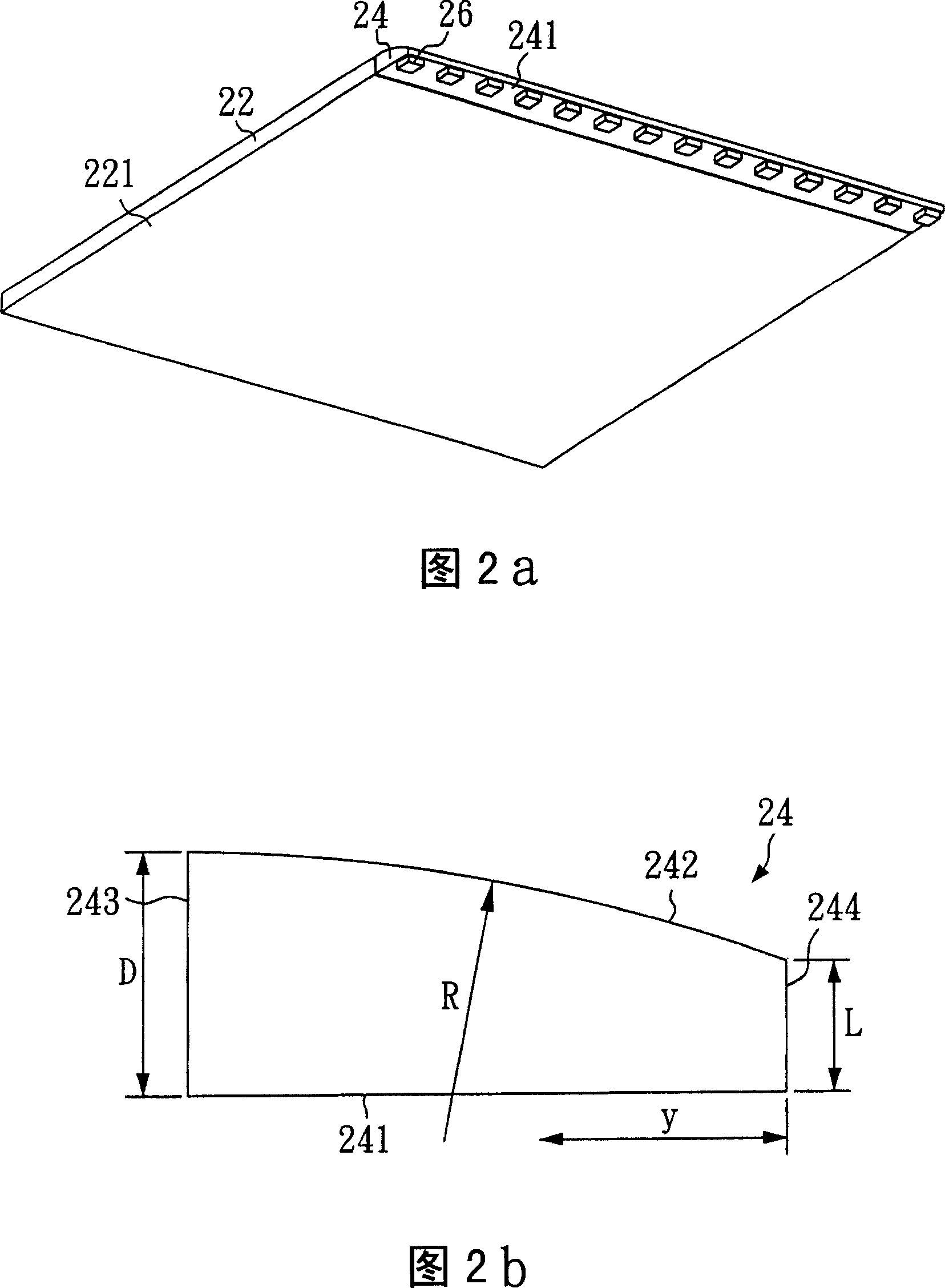

Backlight module for flat display device

A backlight module used on flat display device is prepared as arranging a groove on light guide plate, setting a cylindrical optical element with a full reflection surface and a base surface as well as the first side surface in said groove, and setting multiple light source at base surface of said cylindrical optical element for obtaining optimum light-outgoing effect.

Owner:合肥福映光电有限公司

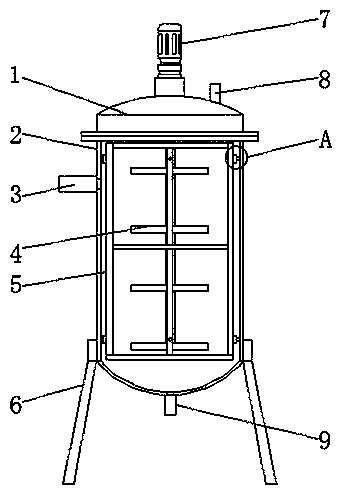

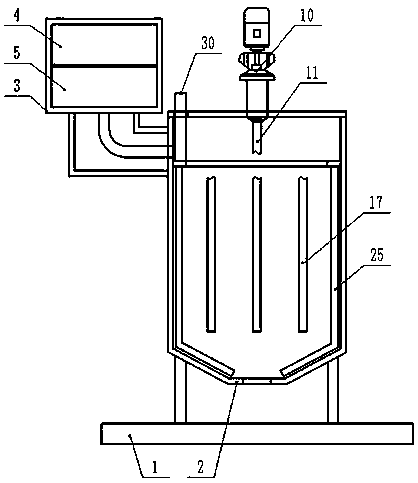

Reaction kettle device for high-performance polyphenylene sulfide composite material

PendingCN110270287AReduce wasteImport uniformHollow article cleaningChemical/physical/physico-chemical stationary reactorsMaterials preparationDrive shaft

The invention discloses a reaction kettle device for a high-performance polyphenylene sulfide composite material. The reaction kettle device comprises a basic base and a reaction kettle body, wherein a material preparation box body is arranged beside the outer side of the top end of the reaction kettle body; the inner chamber of the material preparation box body is divided into an upper material guiding and grinding chamber and a lower stirring and drying chamber through a barrier layer; a material guiding cylinder and a material collection bin are arranged in the upper material guiding and grinding chamber; a rotating shaft is arranged in the lower stirring and drying chamber; stirring rods are uniformly arranged on the rotating shaft; a driving assembly is arranged at the central part of the top end of the exterior of the reaction kettle body; a transmission shaft is vertically arranged at the central side of the top end of the interior of the reaction kettle body; a cross-shaped rotating frame is connected with and arranged at the bottom end of the transmission shaft; the lower end of the cross-shaped rotating frame is provided with a manual stirring paddle adjusting and control mechanism; an annular rotating frame is movably arranged on the end wall of the inner side of the top part of the reaction kettle body; the inner side of the annular rotating frame is provided with an annular feeding frame; feeding openings are uniformly arranged on the annular feeding frame in an equal radian; and scraping plates are uniformly and vertically arranged at the lower end of the annular feeding frame in an equal radian.

Owner:南京清研新材料研究院有限公司

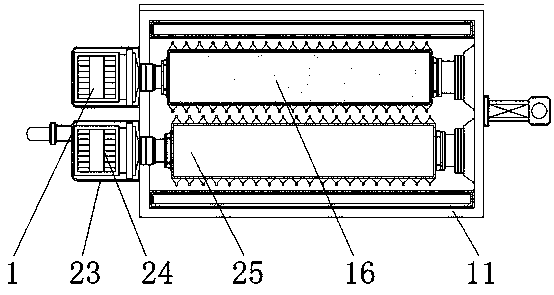

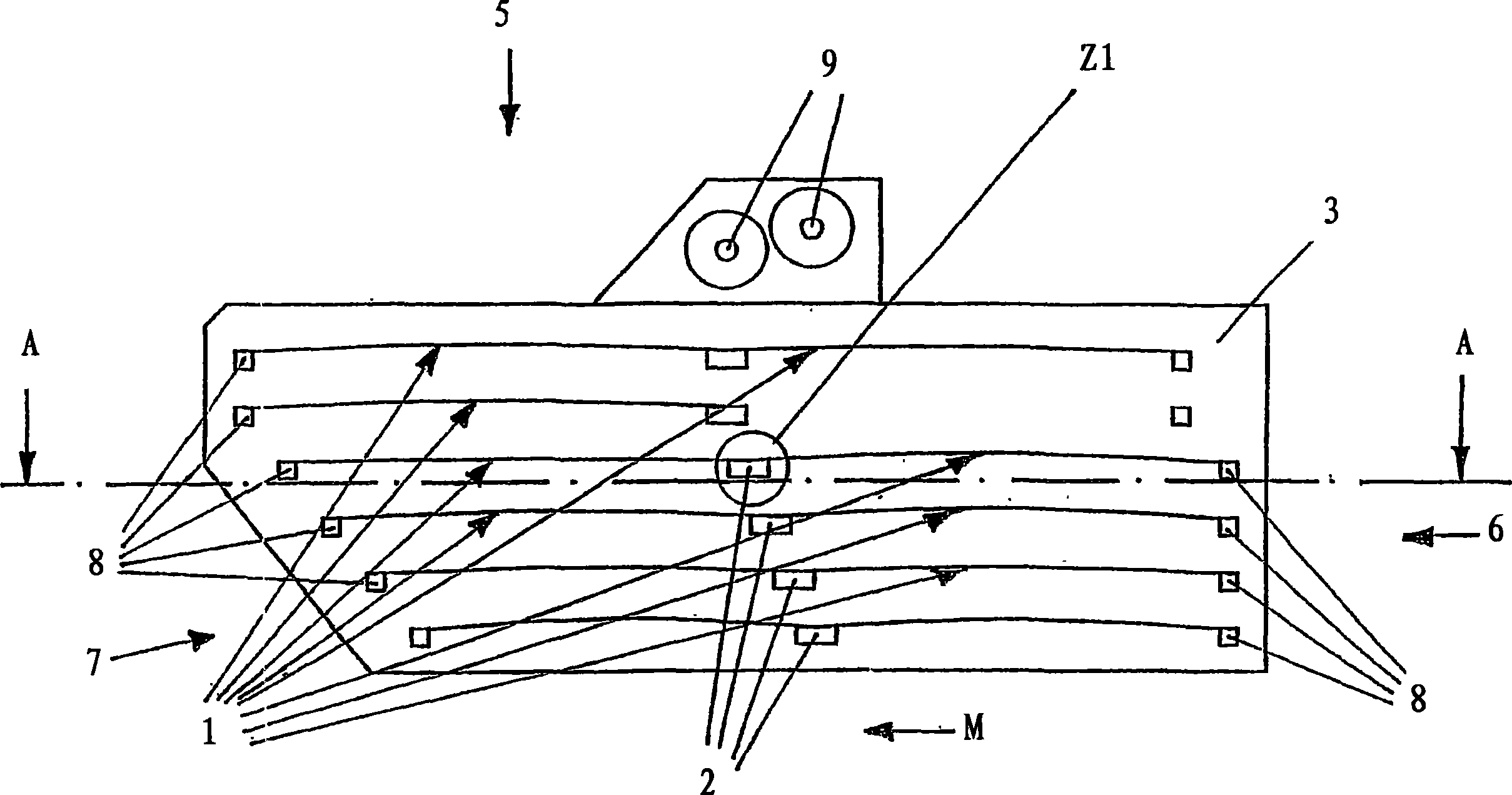

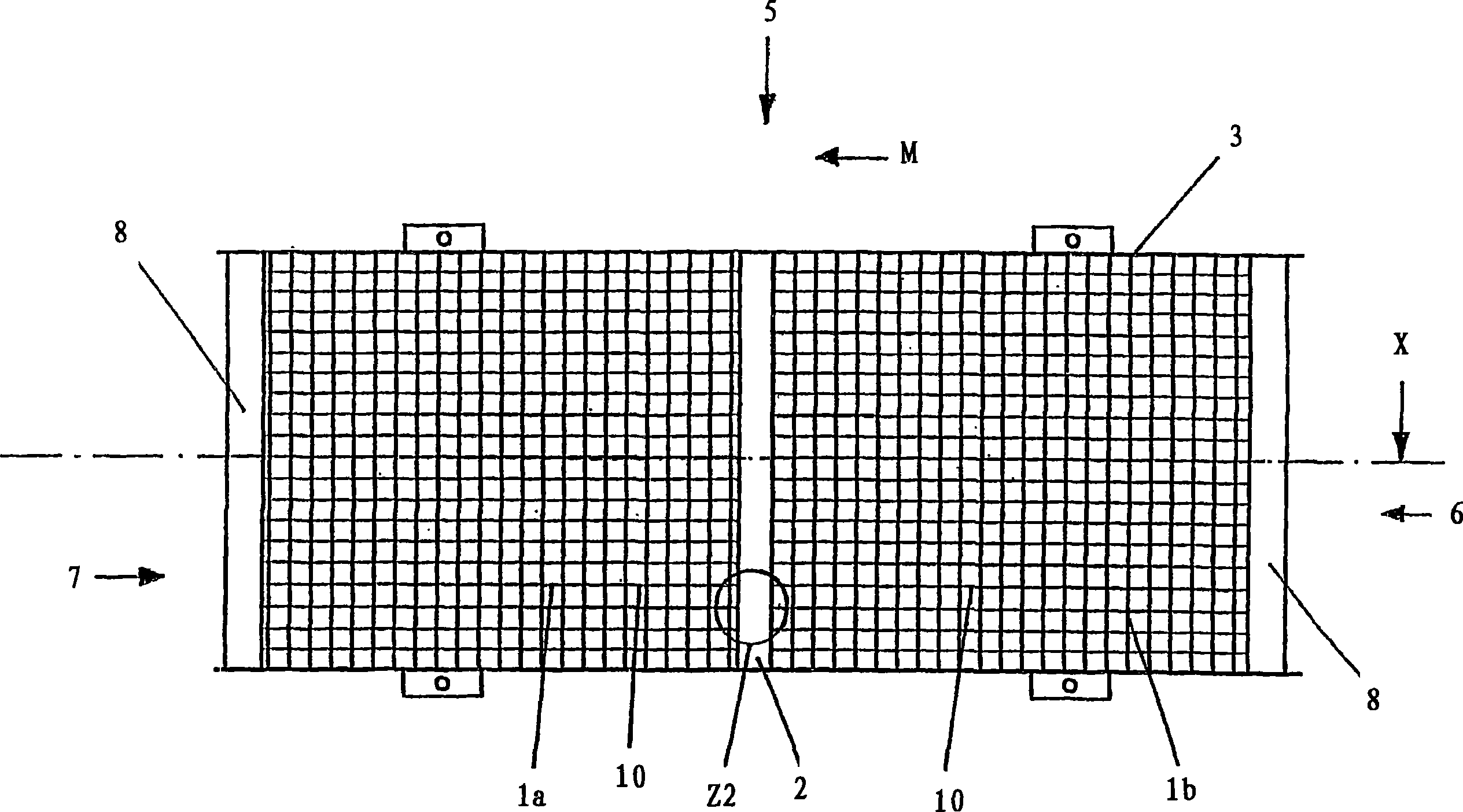

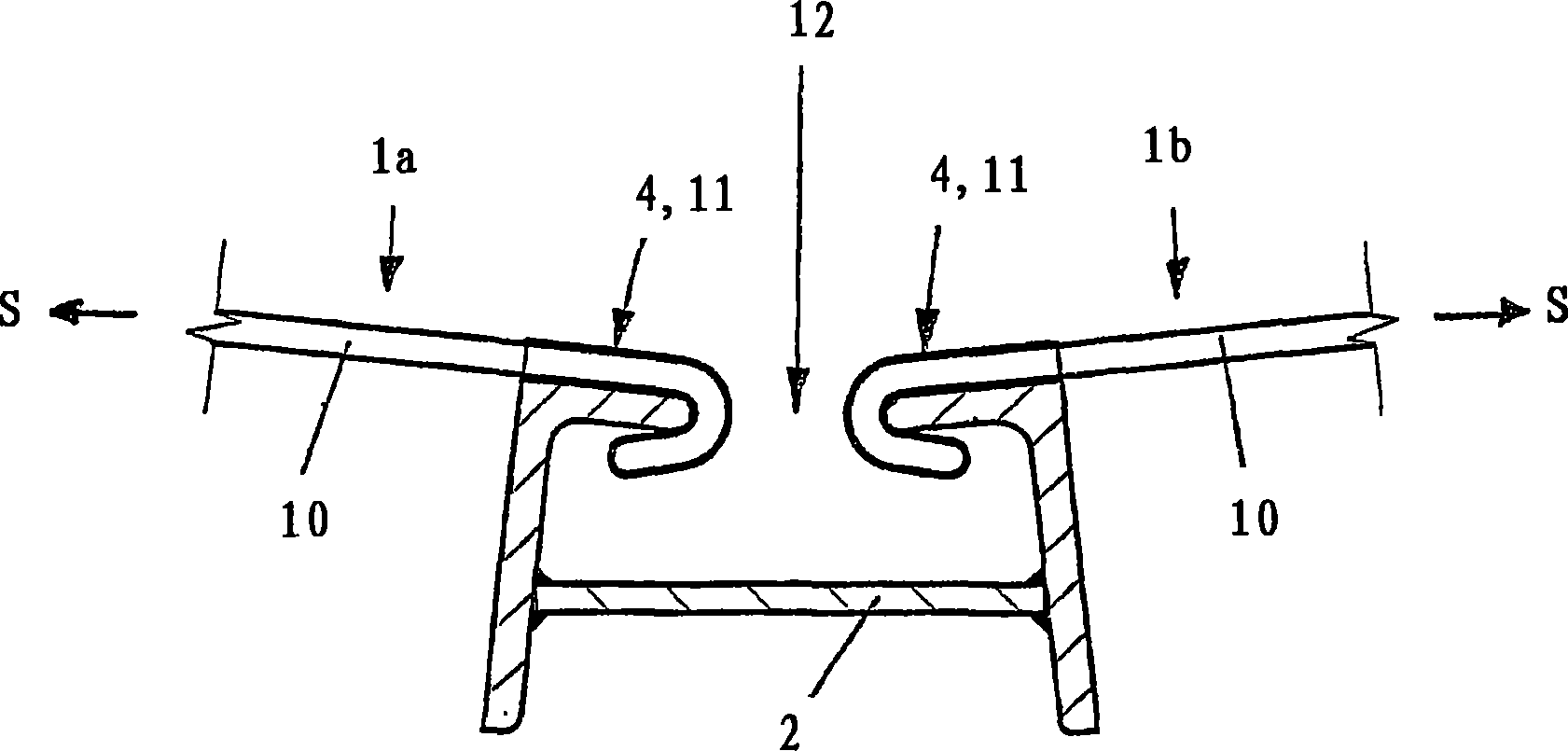

Fixing method for filter screen plug-in component in oscillation sieving machine and oscillation sieving machine of asphalt mixing apparatus

The invention relates to a vibrating screen machine (5) for asphalt mixing installations, comprising mesh inserts (1a, 1b) that are fixed to tension bars (2) in the centre of the machine. In order to fix the respective mesh insert (1a, 1b), both the mesh insert (1a, 1b) and the respective tension bars (2) have tubular sections (14, 16) that are successively alternately arranged along a common axis (Y), and are penetrated by a coupling rod (17) in such a way that the mesh insert (1a, 1b) and the tension bar (2) are interconnected in a positively locking manner in the mesh tensioning direction (S) and in both directions perpendicular thereto. If the positively locked connection is broken, the coupling rod (17) can be axially removed from the tubular sections (14, 16). In this way, the invention enables mesh inserts (1a, 1b) to be replaced in a simple and rapid manner compared to those of prior art.

Owner:安曼瑞士股份公司

A kind of oxidized polyethylene separation tower and separation method thereof

ActiveCN109999538BAchieve separationImport uniformLiquid separationFiltration circuitsEngineeringMaterial transfer

The invention discloses an oxidized polyethylene separation tower. The oxidized polyethylene separation tower comprises a base, wherein a solid-liquid separation mechanism and a liquid-liquid separation mechanism are mounted on the upper end surface of the base and are communicated through a connecting pipe; a feeding pipe is communicated with the solid-liquid separation mechanism; a light liquiddischarging pipe and a heavy liquid discharging pipe are communicated with the liquid-liquid separation mechanism; a drive mechanism and a transmission mechanism are mounted at the upper end of the liquid-liquid separation mechanism. The invention further discloses an oxidized polyethylene separation method. The method comprises following steps: S1, filtering; S2, screening; S3, solid-liquid separation; S4, liquid-liquid separation; S5, repeating of operation. The structure is ingenious, the solid-liquid separation mechanism and the liquid-liquid separation are combined, separation of smaller-particle waxy semi-solids and waxy solids and separation of white viscous oxidized polyethylene with different molecular weights are realized, separation speed of oxidized polyethylene is increased, and loss in a material transfer process is reduced.

Owner:NANJING YANGZI FINE CHEM

Rope end connection

ActiveCN102893056BHigh strengthIncreased durabilityRopes and cables for vehicles/pulleyHaberdasheryClassical mechanicsStructural engineering

The invention relates to a rope end connection device (10) for a rope (1) consisting of a plurality of wires (2) wound around one another, wherein a means for assembling or holding the rope (1) is provided. ) of an end piece (3) fixed to the end of a rope, the rope end connection device is characterized in that the end piece (3) is made of a castable and hardenable material , a component that is assembled without a sleeve and the end piece (3) is connected in a form-locking manner to the wire (2) only by casting or molding without additional mechanical connecting elements. The threads (2) advantageously fan out from the material of the end piece (3) and are in particular substantially completely embedded in said material. The wires (2) are released from the original twist assembly in the area of the end pieces (3) and are arranged substantially evenly distributed. The end piece (3) is produced by injection molding of synthetic resin in a mold and the wire (2) is embedded under prestress and cast-fitted in the material of the end piece (3).

Owner:UNIV STUTTGART

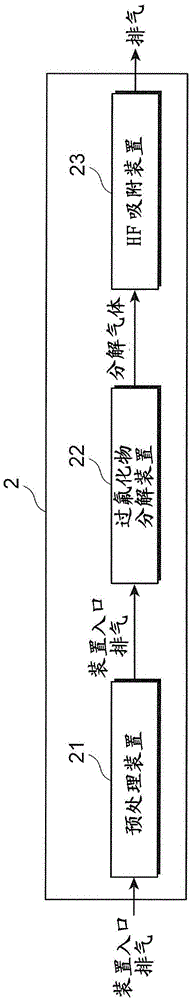

Perfluoride Treatment Unit

ActiveCN104107623BImport uniformEasy to controlDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureReplacement agentDecomposition

The present invention provides a perfluoride treatment device and the like capable of more reliably removing acid components from decomposed gas and more smoothly replacing chemical agents for dry removal of acid components. A perfluoride treatment device, characterized in that it includes: a heating unit, which heats gas and water containing perfluoride, and uses a catalyst to hydrolyze the perfluoride to generate decomposition gas; it is arranged at the front and rear of the heating unit The heat exchange unit of the section; and the acid component removal unit for dry removal of the acid component in the decomposition gas. The acid component removal unit is equipped with a gate at the bottom of the device that can be opened and closed, and takes out the reacted chemical when it is opened. (251a-251e) (gate (251)); and the slit portion (252), which is arranged between the gates (251), has slopes (S1, S2) facing the gate (251) from above, and on the slope ( S1 , S2 ) have slits ( 252 a ) of a size that allow decomposition gas to pass through but not medicine to pass through.

Owner:株式会社力森诺科

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com