Patents

Literature

64results about How to "Improve external quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

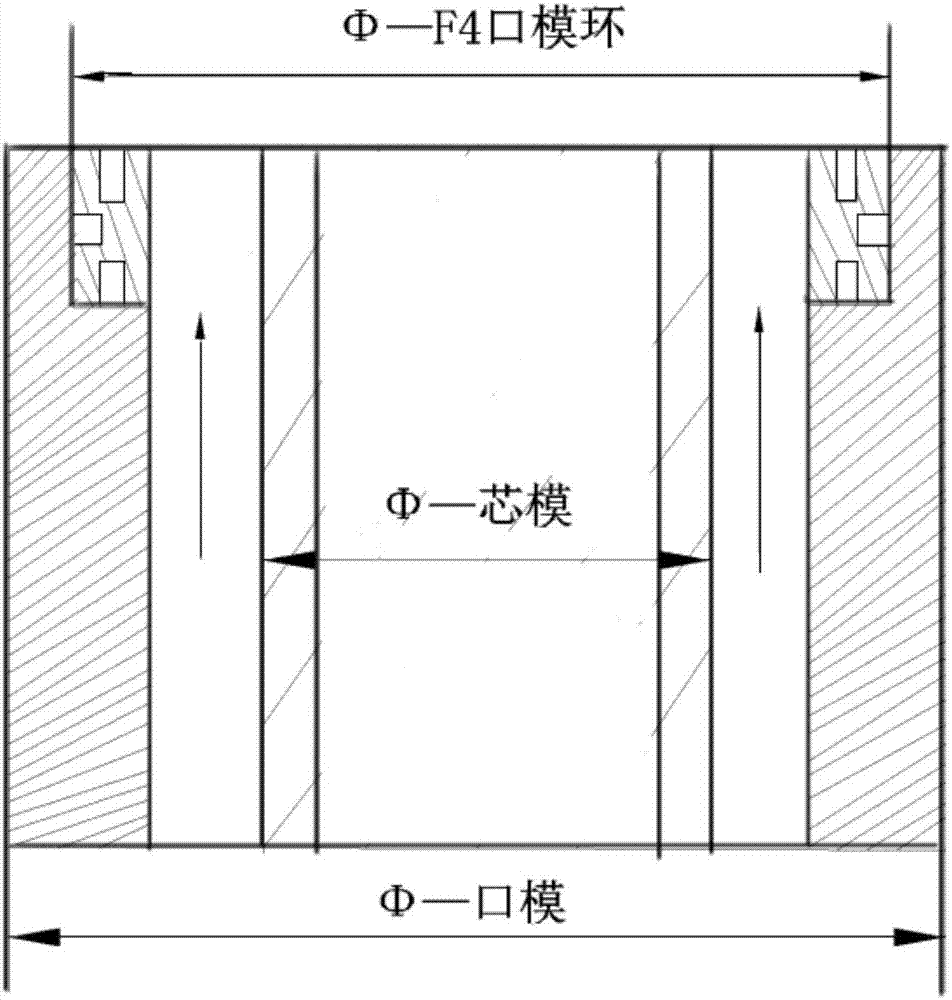

High-alkalinity mould flux used for niobium/vanadium/titanium-containing low alloy wide and heavy plate blank and manufacturing method thereof

The invention discloses a high-alkalinity mould flux used for niobium / vanadium / titanium-containing low alloy wide and heavy plate blanks and a manufacturing method thereof. The high-alkalinity mould flux is made from the following raw materials in percentage by weight: 35 to 45 percent of pre-melting materials, 11 to 14 percent of fluorite, 28 to 30 percent of wollastonite, 3 to 6 percent of flint clay, 3 to 6 percent of limestone, 2 to 4 percent of sodium carbonate, 1 to 3 percent of lithium carbonate, 1 to 3 percent of manganese carbonate, 2 to 4 percent of magnesium oxide, 2 to 4 percent of carbon black, 4 to 7 percent of graphite and 1 to 3 percent of binders. The mould flux has a good capability of absorbing Al (s), V, Ti, Nb and other metals and metal oxides or carbides thereof and nitride inclusions in molten steel, and remains unchanged after molten steel purification. Therefore, not only are the performances of the mould flux stable, but also the internal quality of casting blanks is improved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

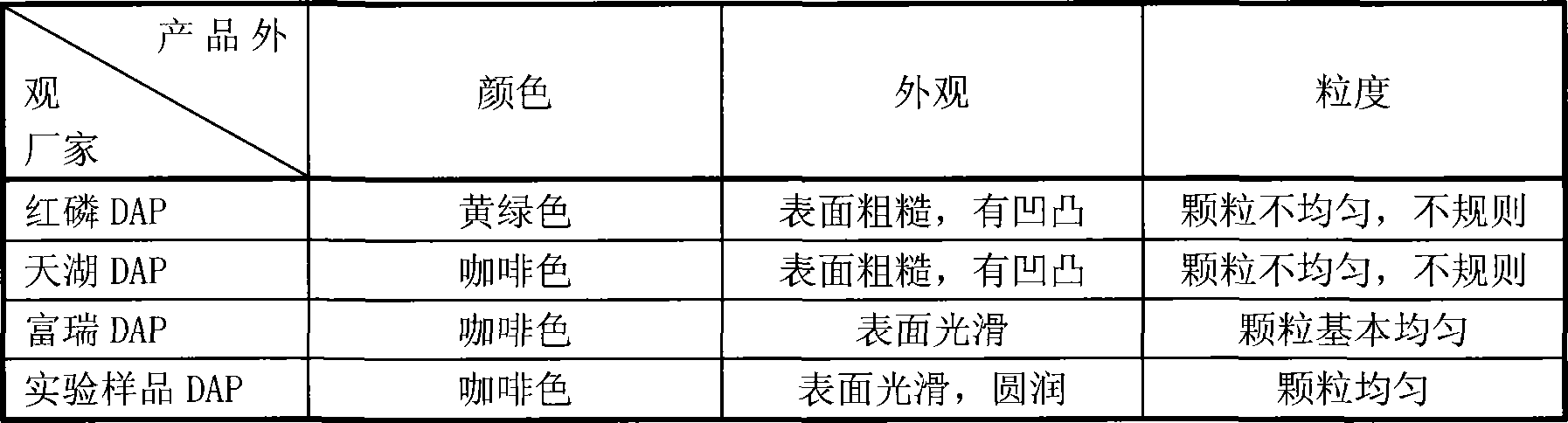

Method for dyeing phosphorus complex fertilizer

InactiveCN101234926AComponents that do not changeUniform colorFertiliser formsFertilizer mixturesDiammonium phosphatePhosphoric acid

The invention relates to a method for processing chemical fertilizer, in particular to a method for dyeing chemical fertilizer. The invention includes the preparation, addition, dyeing, and granulation of colorant, and comprises the following steps: A. adding weighted colorant into a phosphoric acid tank, an acid pump outlet or a pre-neutralization slot for producing phosphate compound fertilizer; B. mixing water solution with phosphate compound fertilizer for dyeing; C. spraying the slurry for granulation after dyeing. The method for dyeing chemical fertilizer is mainly used for appearance dyeing of various nitrogen and phosphate fertilizers and products, and can dye coffee on products evenly and effectively. The dyed products with high-quality appearance color do not have discoloration and color change so as to hit the target of unifying product color. Compared with that imported from America, diammonium phosphate dyed through the method for dyeing chemical fertilizer has the equal and even better color. As coffee color products sell well in the market, the invention can reduce sales cost.

Owner:云南云天化国际化工有限公司

Method for fermenting cigar filling leaves

The invention discloses a method for fermenting cigar filling leaves. The method is characterized by comprising the following steps: controlling the water content of the cigar filling leaves which are subjected to impurity removal and modulation to be 30+ / -2%, and tidying the cigar filling leaves into cigar leaf bundles of which the leaf tips are towards the same direction; stacking the cigar leaf bundles to form a rectangular cigar leaf stack; covering a layer of hessian cloth on the surface of the cigar leaf stack to be used as an air permeable heat-insulating layer; inserting temperature measuring probes into the cigar leaf stack; overturning the stack when the stack filling temperature measured by any temperature measuring probe reaches the alarm upper limit temperature or is in the trend of reducing; after the fermentation is finished, airing the cigar leaves, reducing the moisture of the cigar filling leaves to be 20+ / -2%, and packaging for storage. According to the method, the appearance, the absorbed smell and the quality consistency of the cigar filling leaves can be obviously improved, the content of a harmful ingredient NNK in raw materials can be reduced, and the industrial availability of the cigar leaves can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

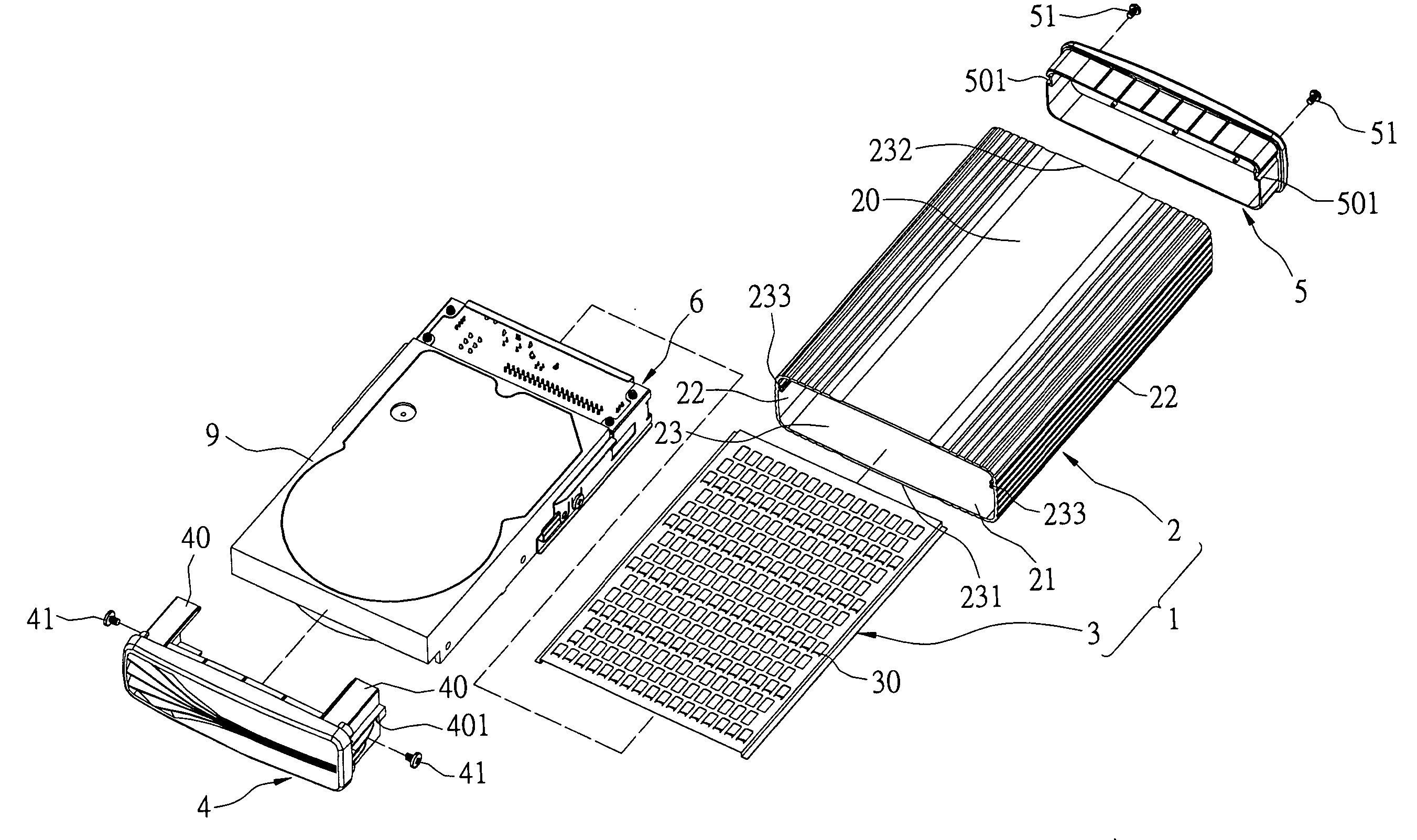

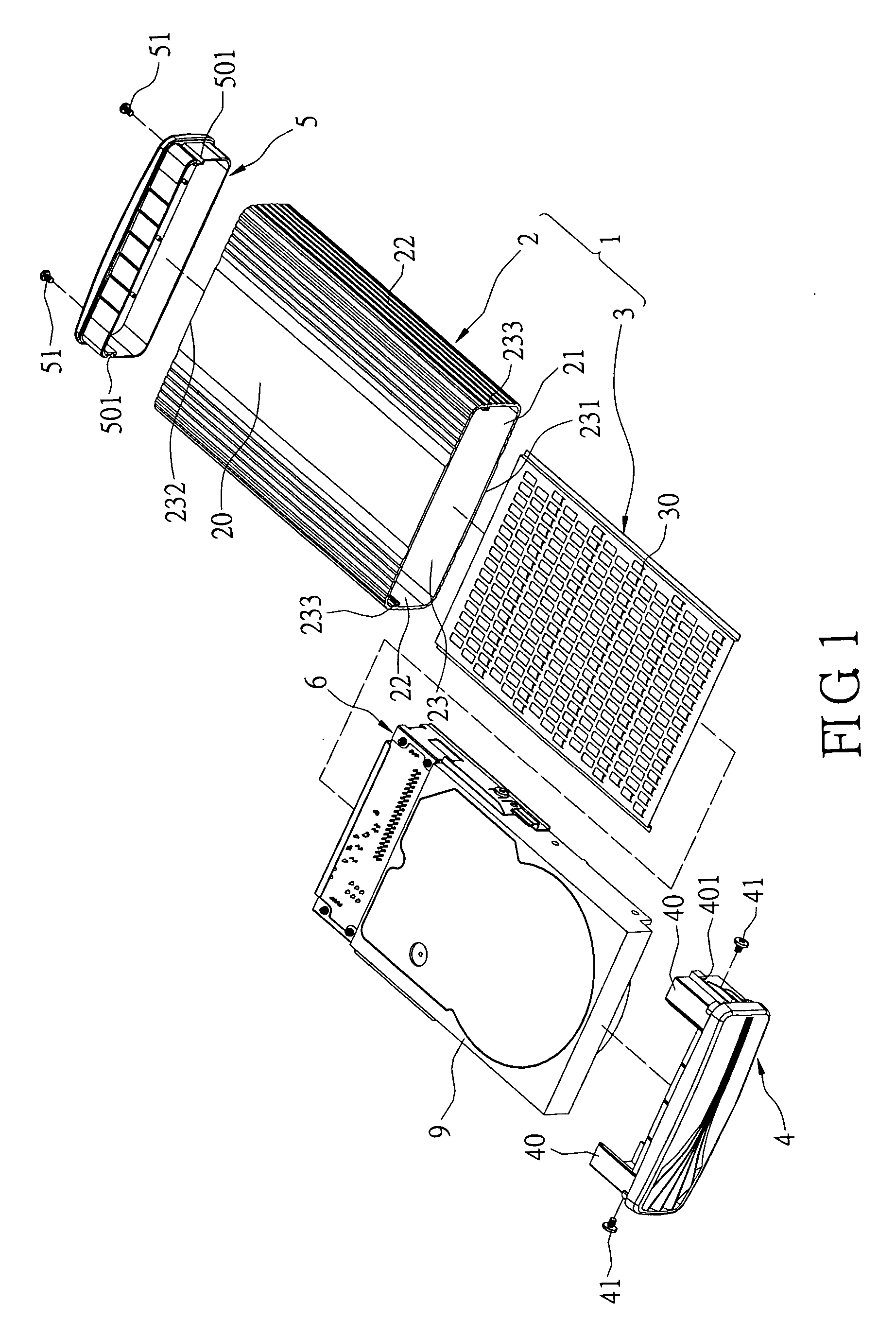

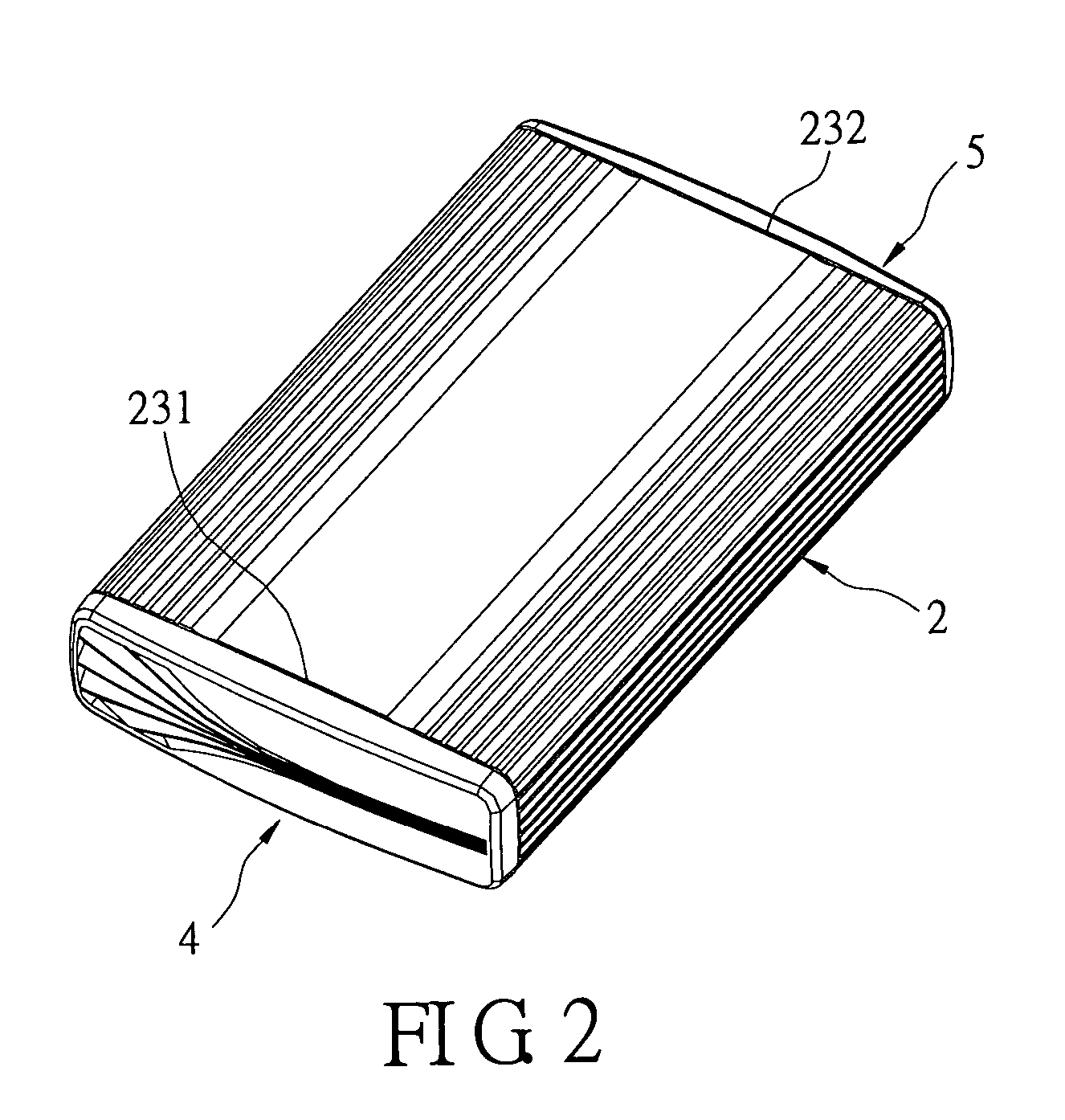

External connection box and a case body thereof for a storage device

InactiveUS20070030646A1Improve efficiencyImprove stabilityDigital data processing detailsUndesired vibrations/sounds insulation/absorptionCushioningEngineering

An external connection box and a case body thereof are for receiving a storage device therein. The external connection box for a storage device has a case body, a front cover, and a rear cover. The case body has an outer casing and at least one metal inner plate. The outer casing forms a receiving space therein. The at least one metal inner plate is disposed at an inner surface of the outer casing. The at least one metal inner plate has a plurality of resilient fins, and the resilient fins extend into the receiving space. As such, the case body of the external connection box for a storage device of the present invention has a heat dissipating function, an EMI shielding function, a reinforcing function, and a cushioning function.

Owner:JESS-LINK PRODUCTS

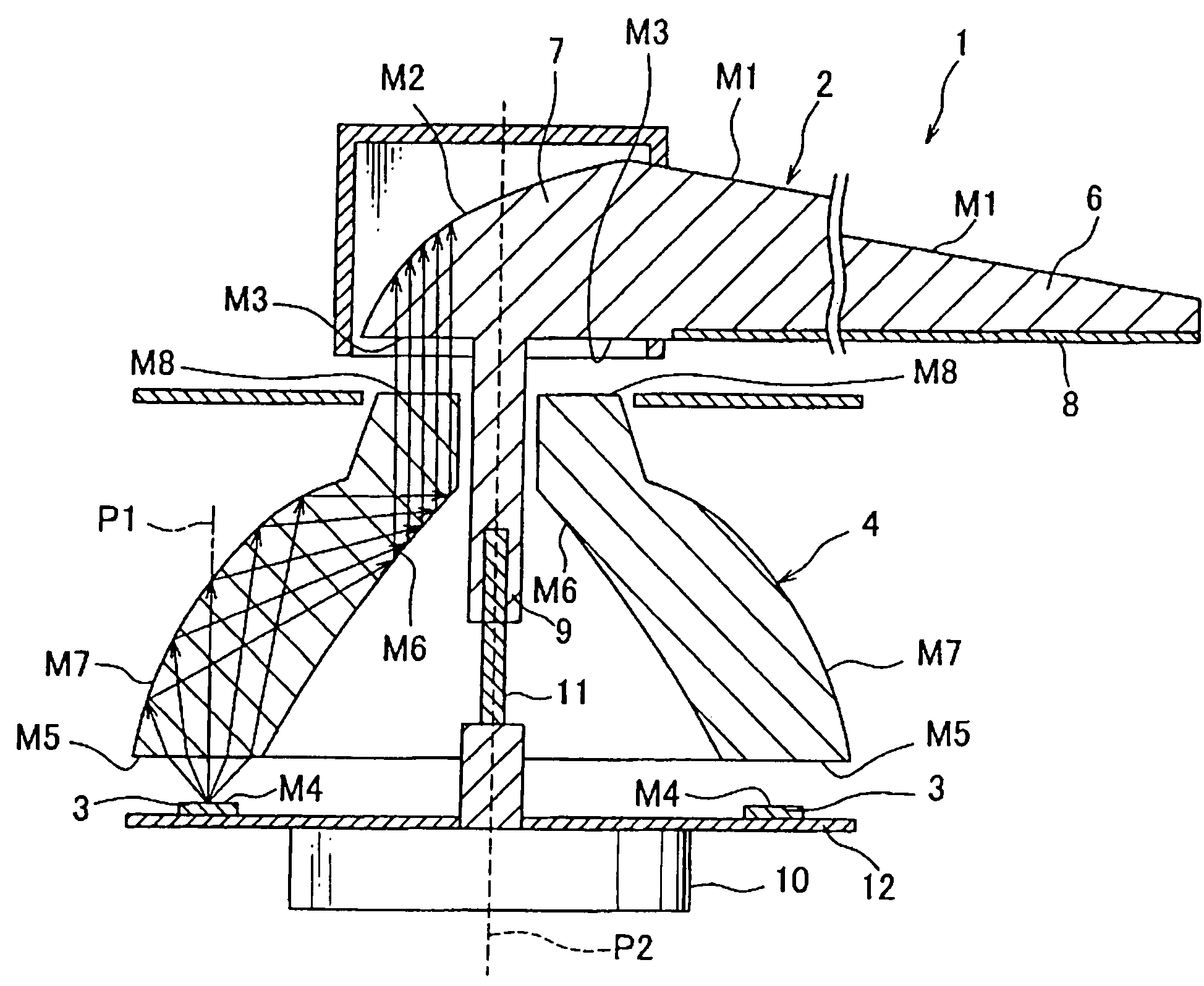

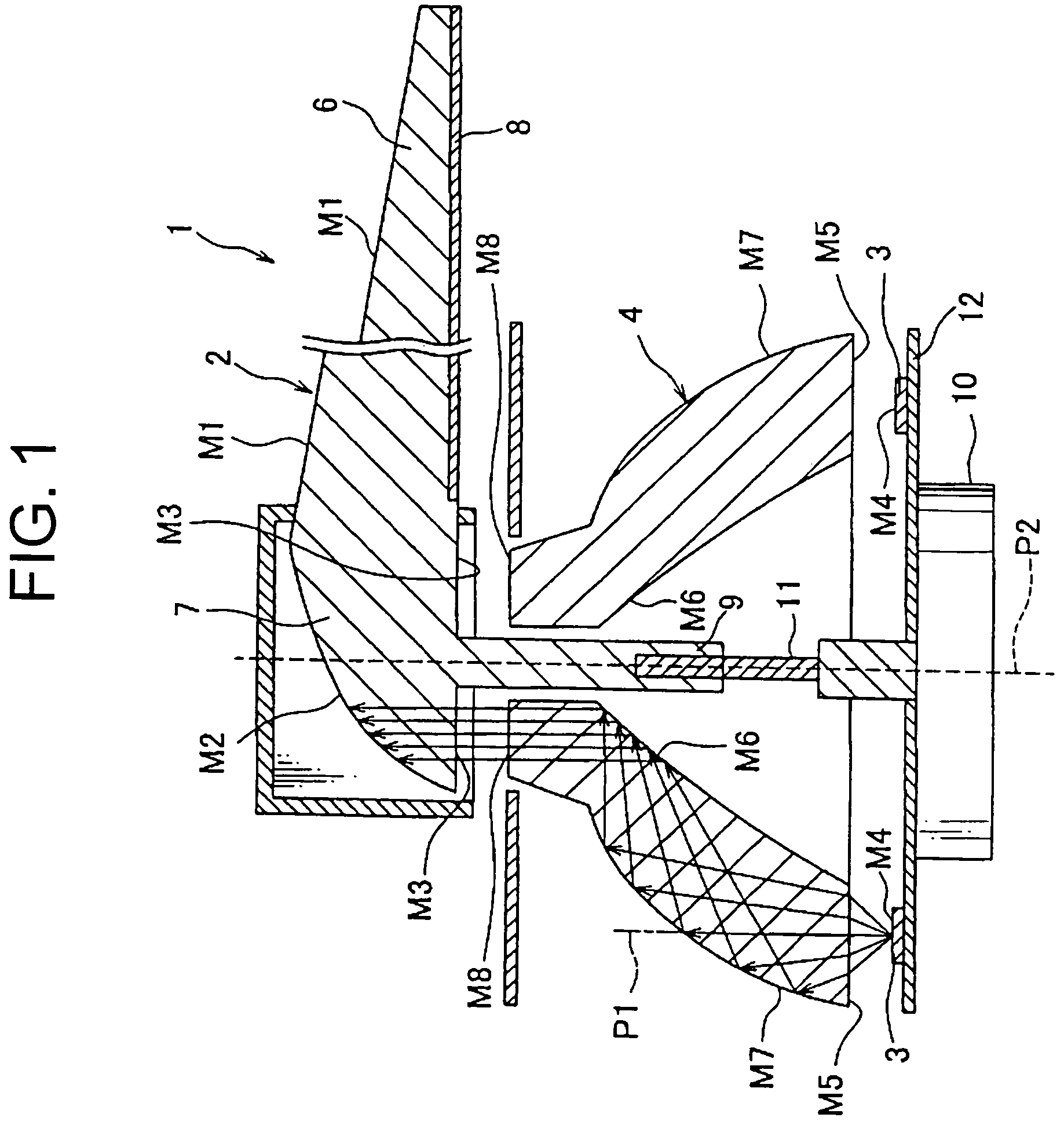

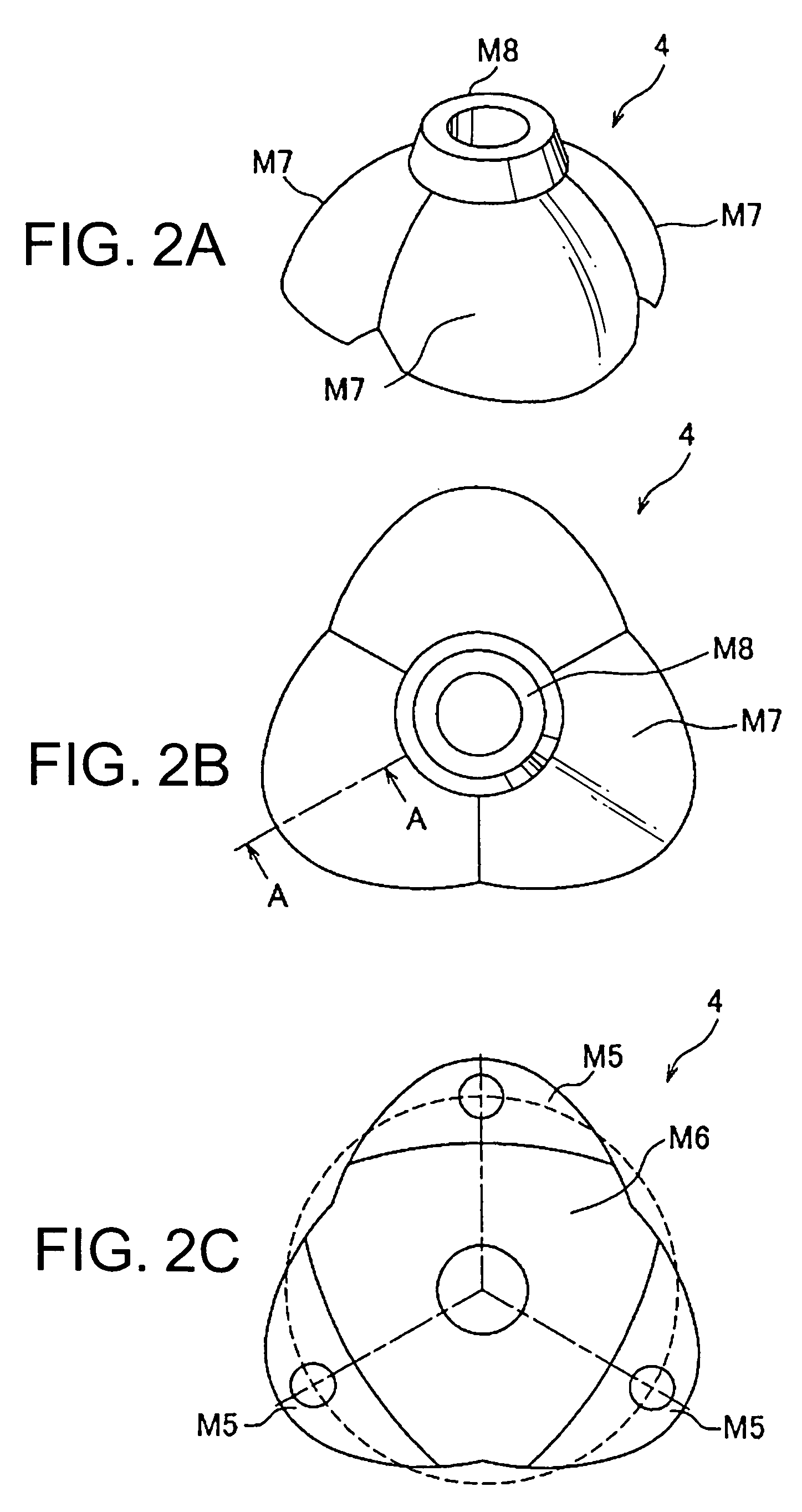

Illumination device for an indicating needle

InactiveUS7665857B2Reduce variation brightnessIncrease awarenessMeasurement apparatus componentsIndication apparatusControl unitLight source

An illumination device for an indicating needle includes a plurality of light sources, an indicating needle, a guiding member, and a luminance control unit. The indicating needle includes a needle body and a needle base. The base has an entrance surface and a reflection surface. A luminance control unit controls luminance of the light sources in response to turning of the indicating needle such that the luminance is lowest when a light emitted perpendicularly from a center of an emitting surface of the light source is reflected off a reflection surface's region which a longitudinal central line of the needle body intersects with, and that the luminance gradually increases as the light emitted by the light source from the center of the emitting surface thereof is reflected off a region that is more distant from the region which the longitudinal central line of the needle body intersects with.

Owner:YAZAKI CORP

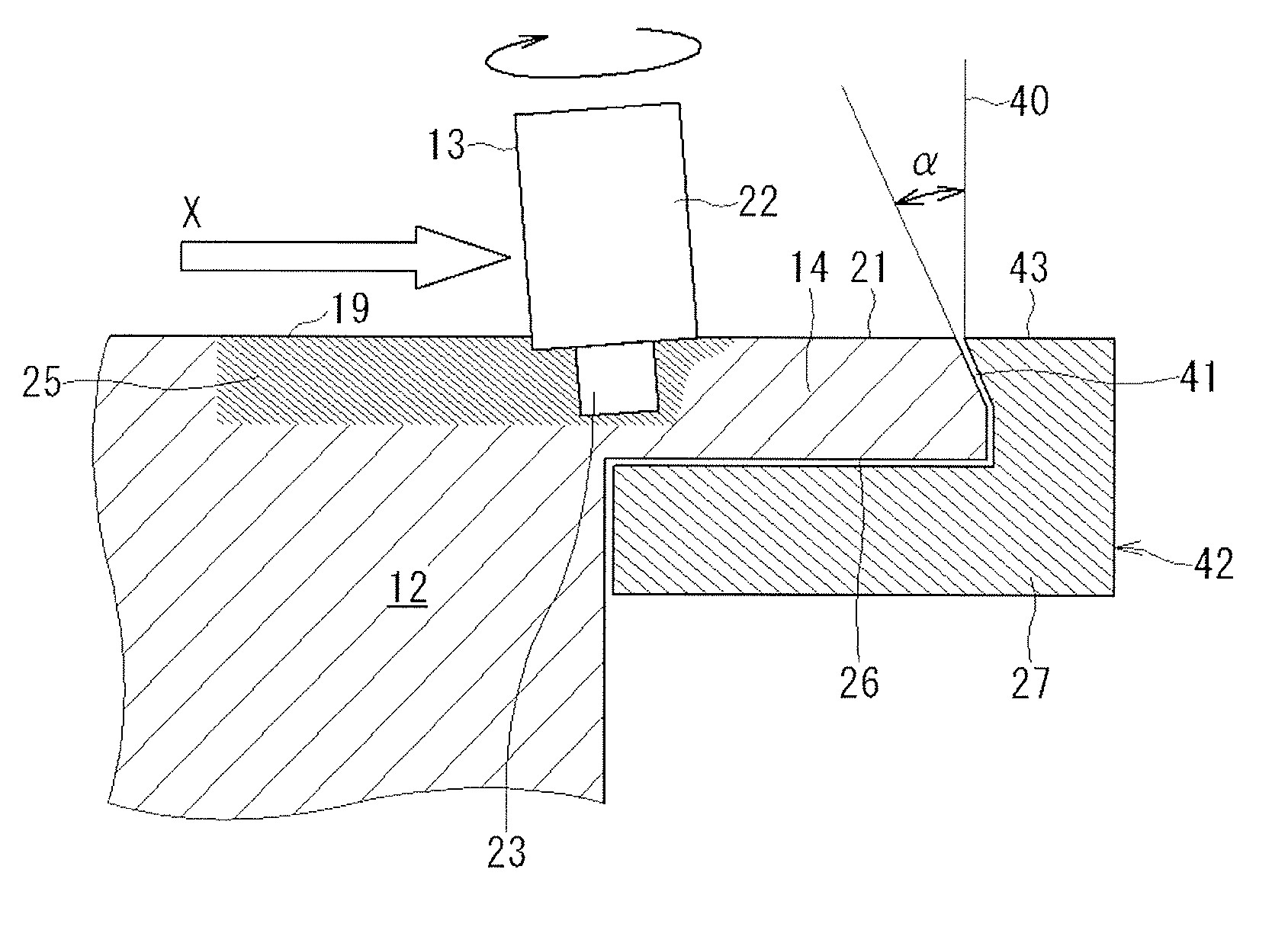

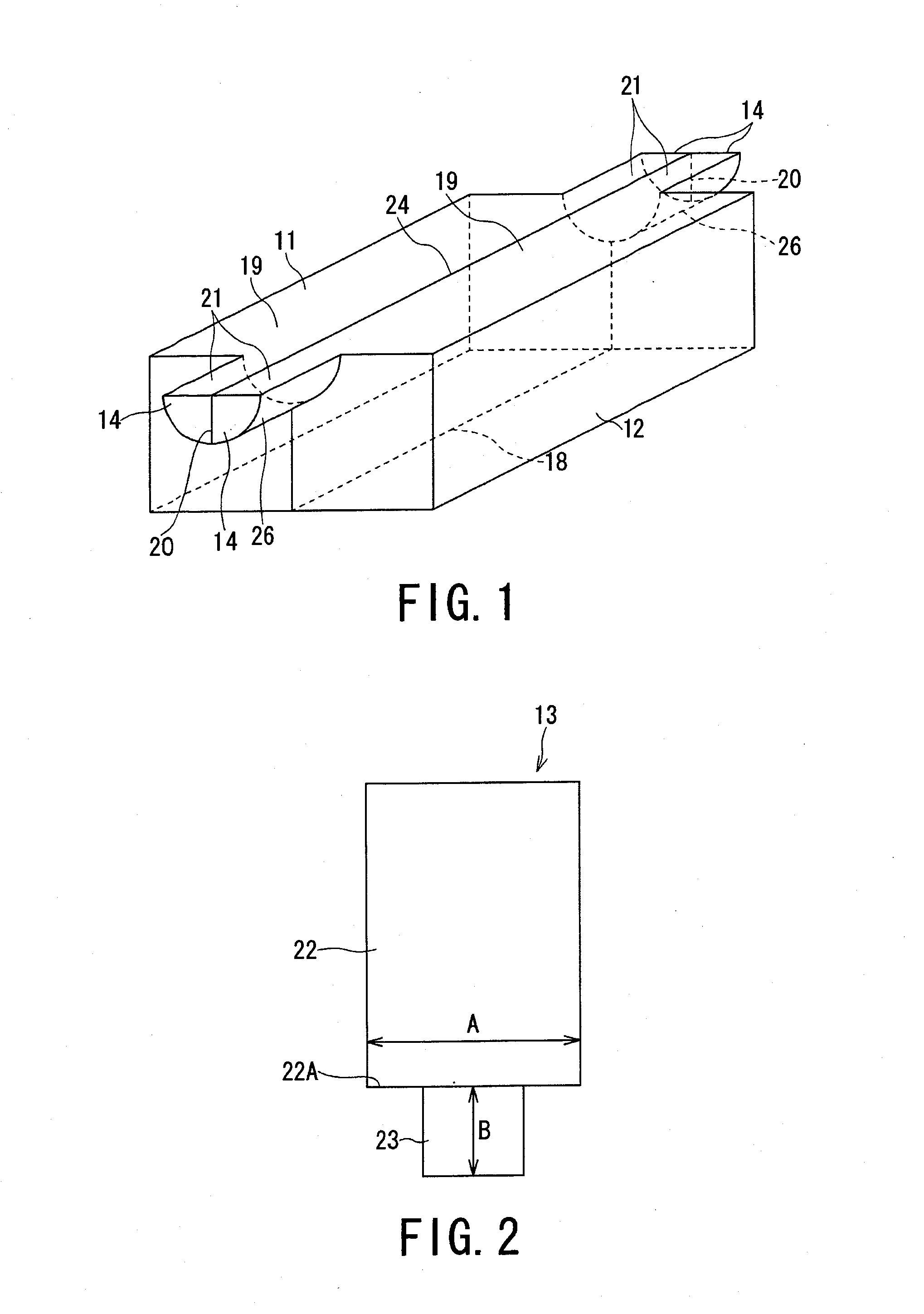

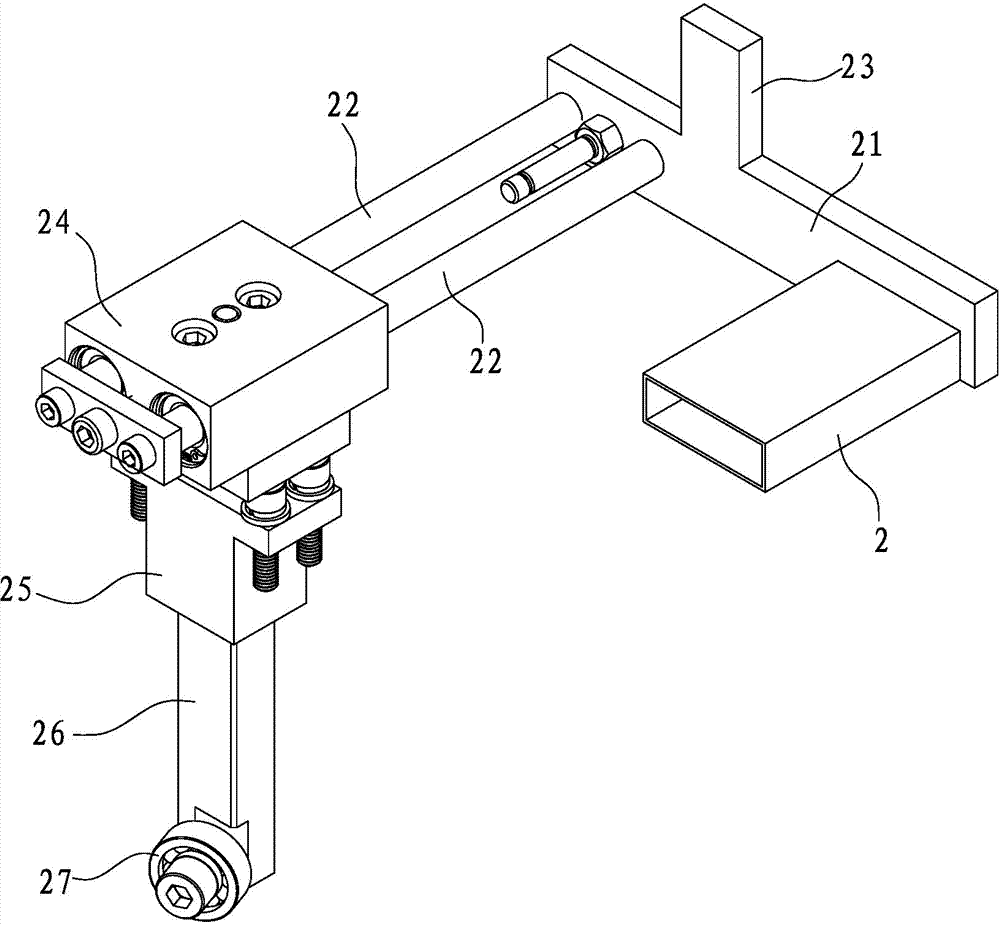

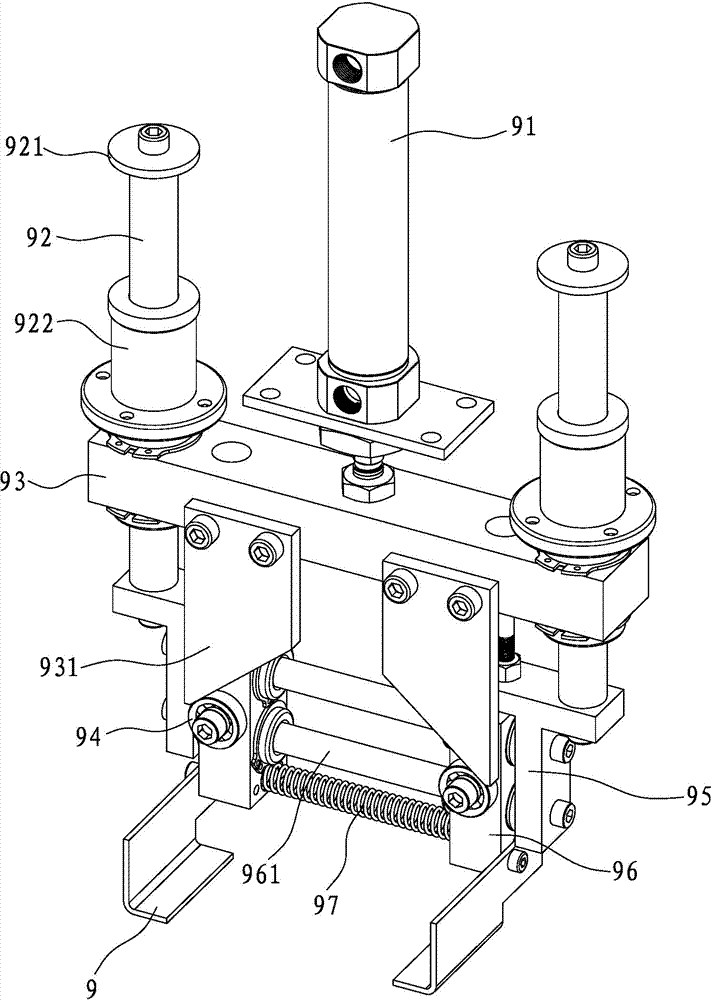

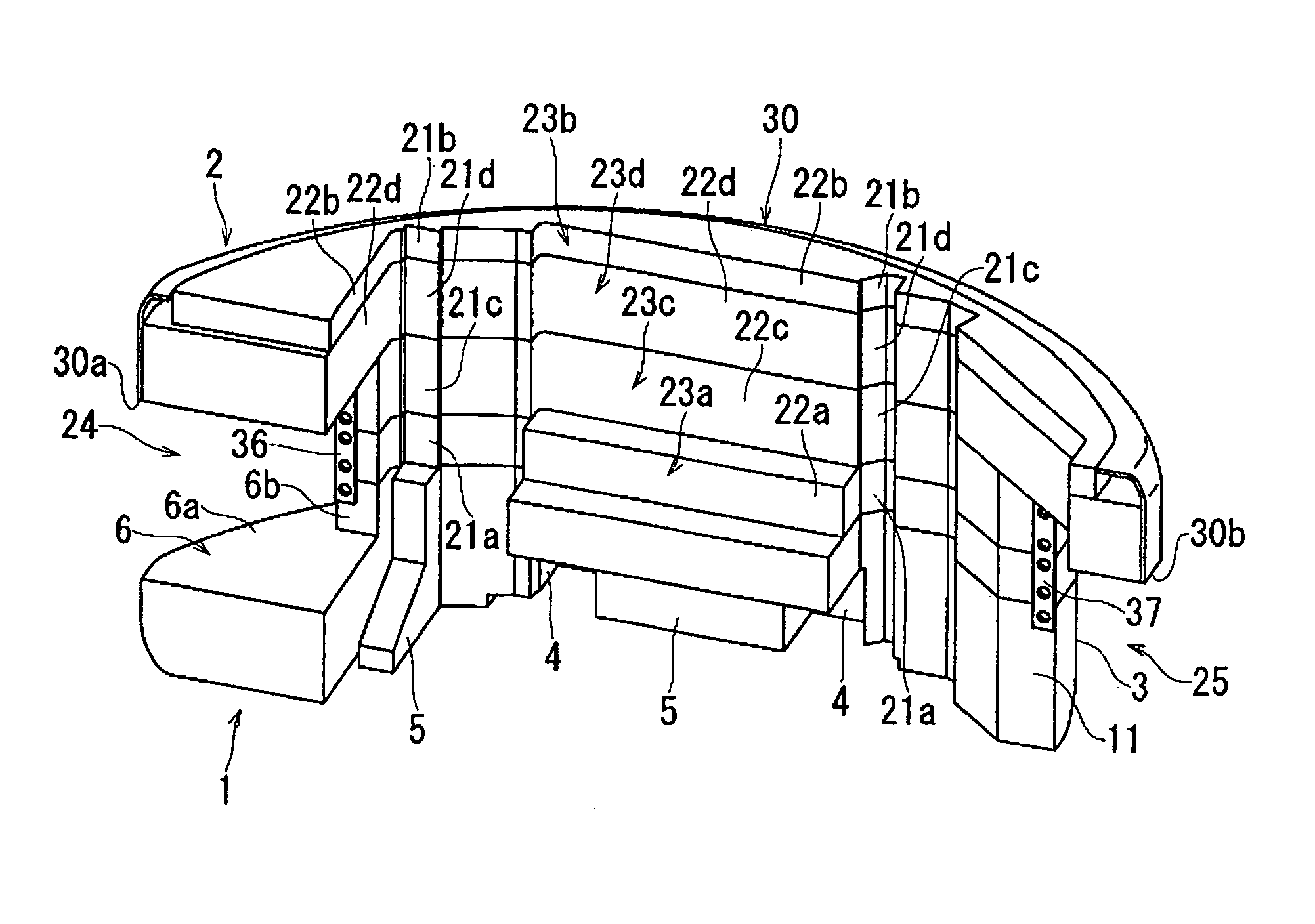

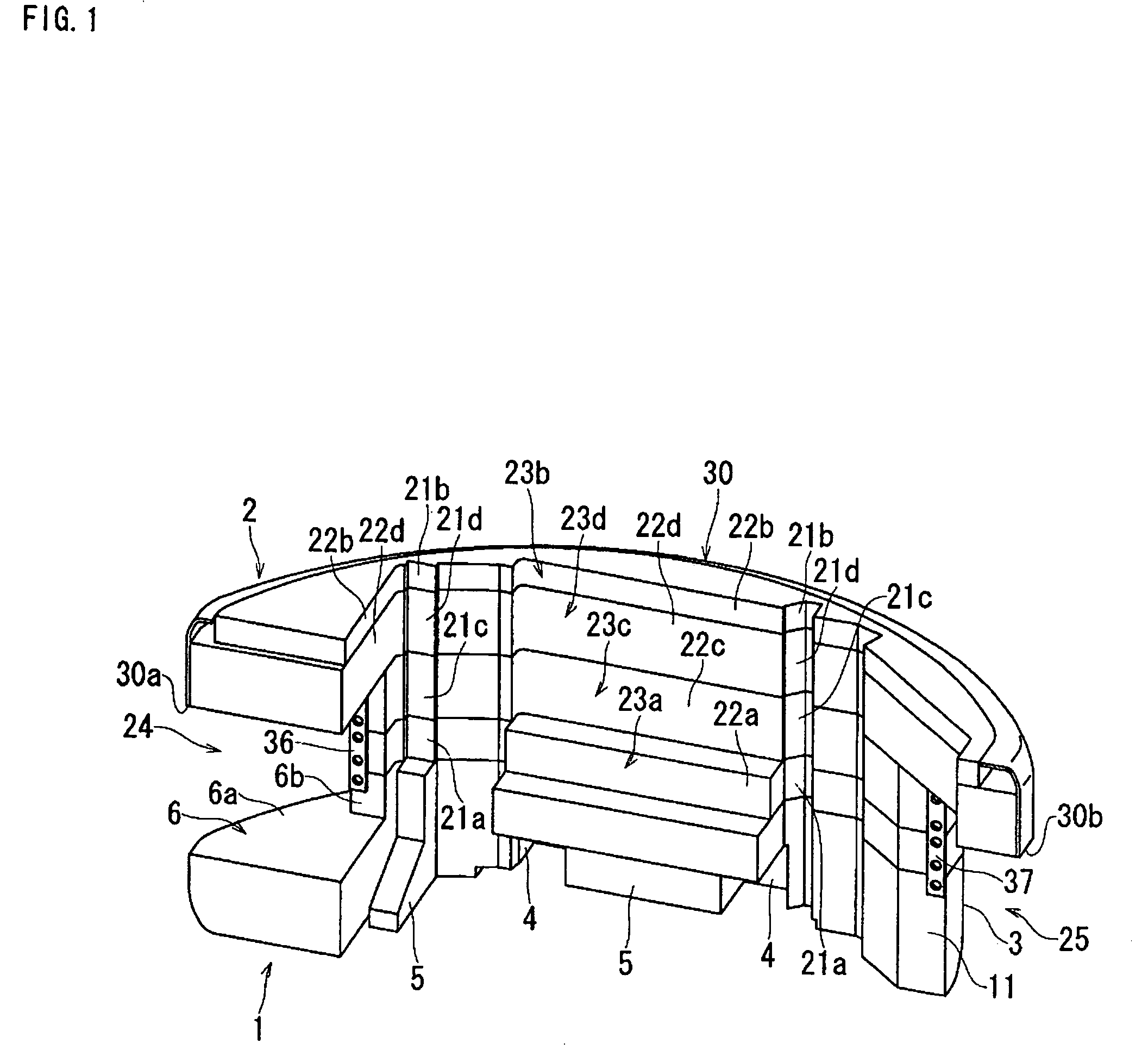

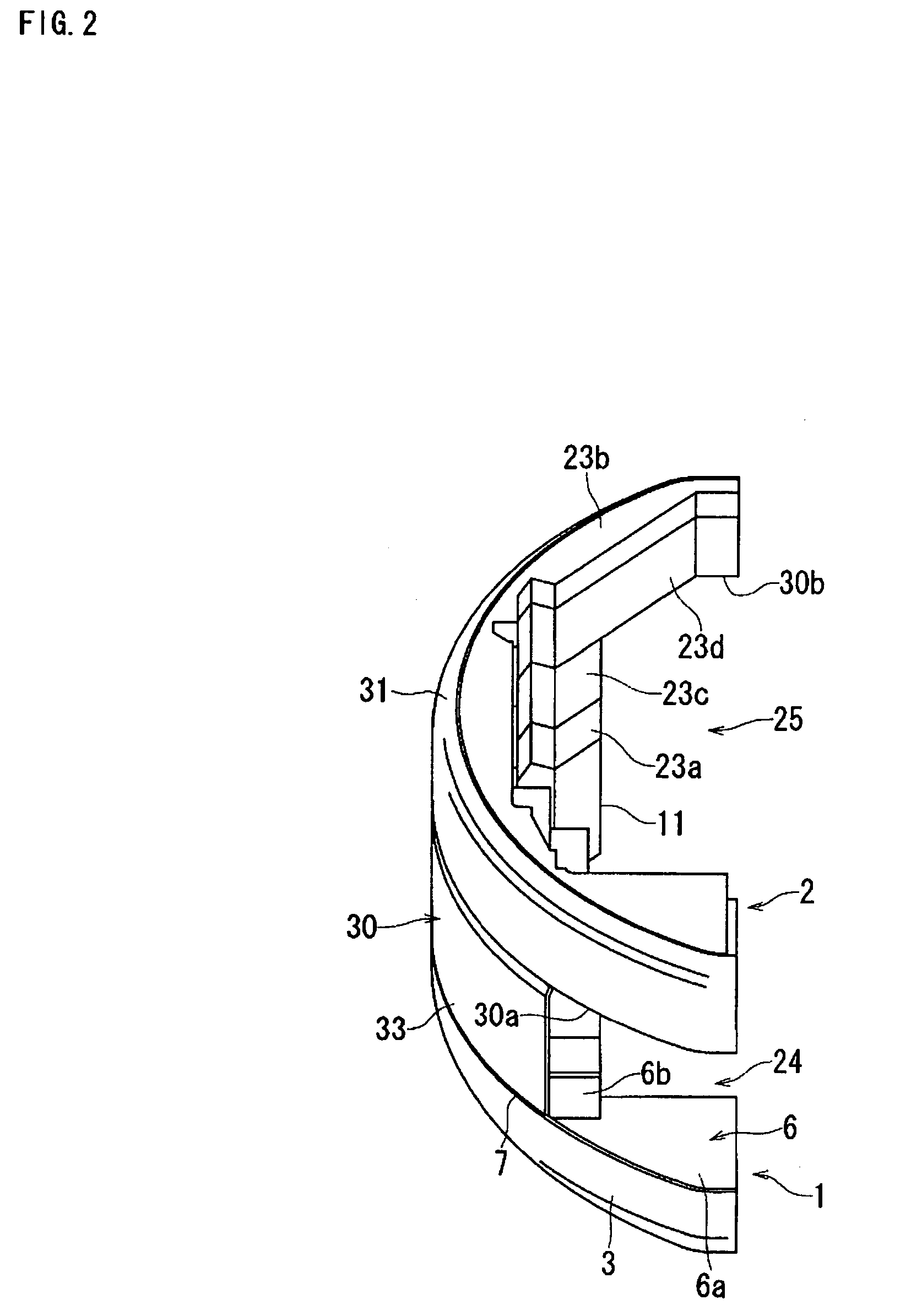

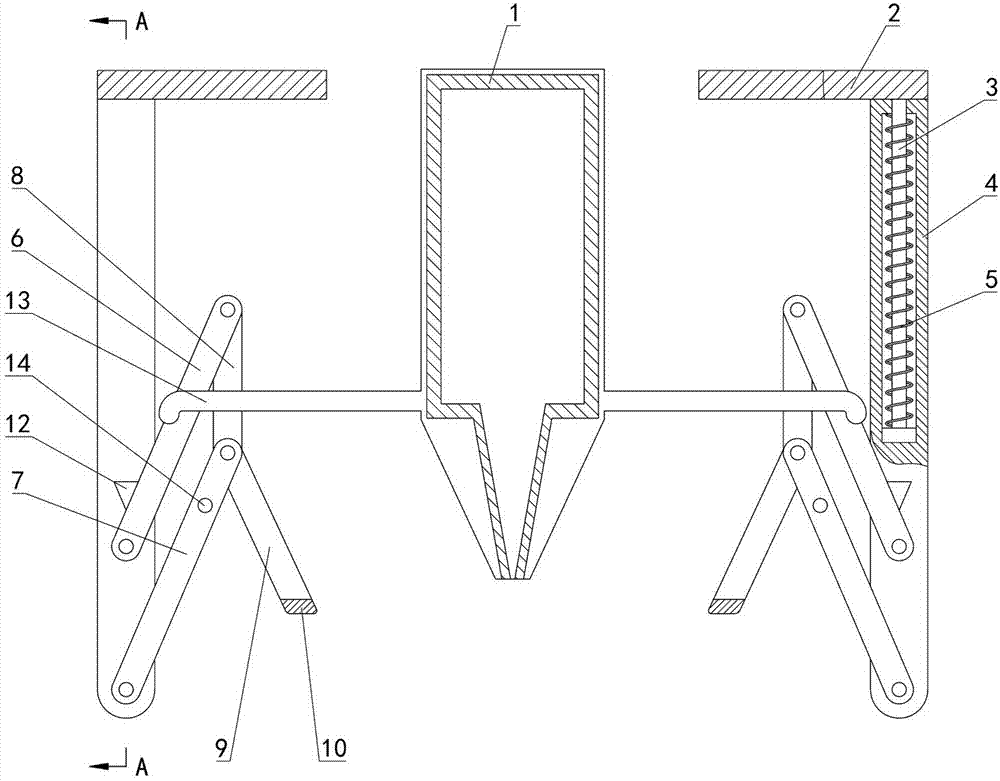

Friction stir welding method and welding jig used therefor

InactiveUS20120227890A1Improve appearance qualityReliable preventionWelding/cutting auxillary devicesLaminationEngineeringFriction stir welding

A friction stir welding performed by preparing a pair of members to be welded, each including an abutment surface and a margin portion provided in an extended manner, the margin portion including a welding surface that is continuous to the abutment surface by using a welding tool for performing friction stir welding. The welding tool integrally includes a columnar shoulder portion and a probe portion formed on a leading end surface of the shoulder portion, the probe portion having a diameter smaller than a diameter of the shoulder portion. The abutment surfaces and the welding surfaces are brought into contact with each other so as to form a continuous welding line therebetween.

Owner:SUZUKI MOTOR CORP

Low-alkalinity crystallizer covering slag prepared from building waste clay

The invention discloses low-alkalinity crystallizer covering slag prepared from building waste clay. The low-alkalinity crystallizer covering slag comprises the following raw material components in percentage by mass: 30 to 55 percent of clay, 8 to 15 percent of fluorite, 15 to 30 percent of lime stone, 8 to 15 percent of sodium carbonate, 1 to 3 percent of magnesium oxide, 2 to 4 percent of carbon black, 5 to 15 percent of graphite and 1 to 3 percent of binder. The covering slag prepared from the clay serving as a main material can maintain the complete granules of the hollow covering slag, has good heat-preserving effect in the using process and is melted uniformly without caking so as to guarantee to introduce molten slag uniformly and smoothly, effectively control the heat transfer ofa crystallizer, avoid the caking of the crystallizer and a blank shell and improve the external quality of cast blanks.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

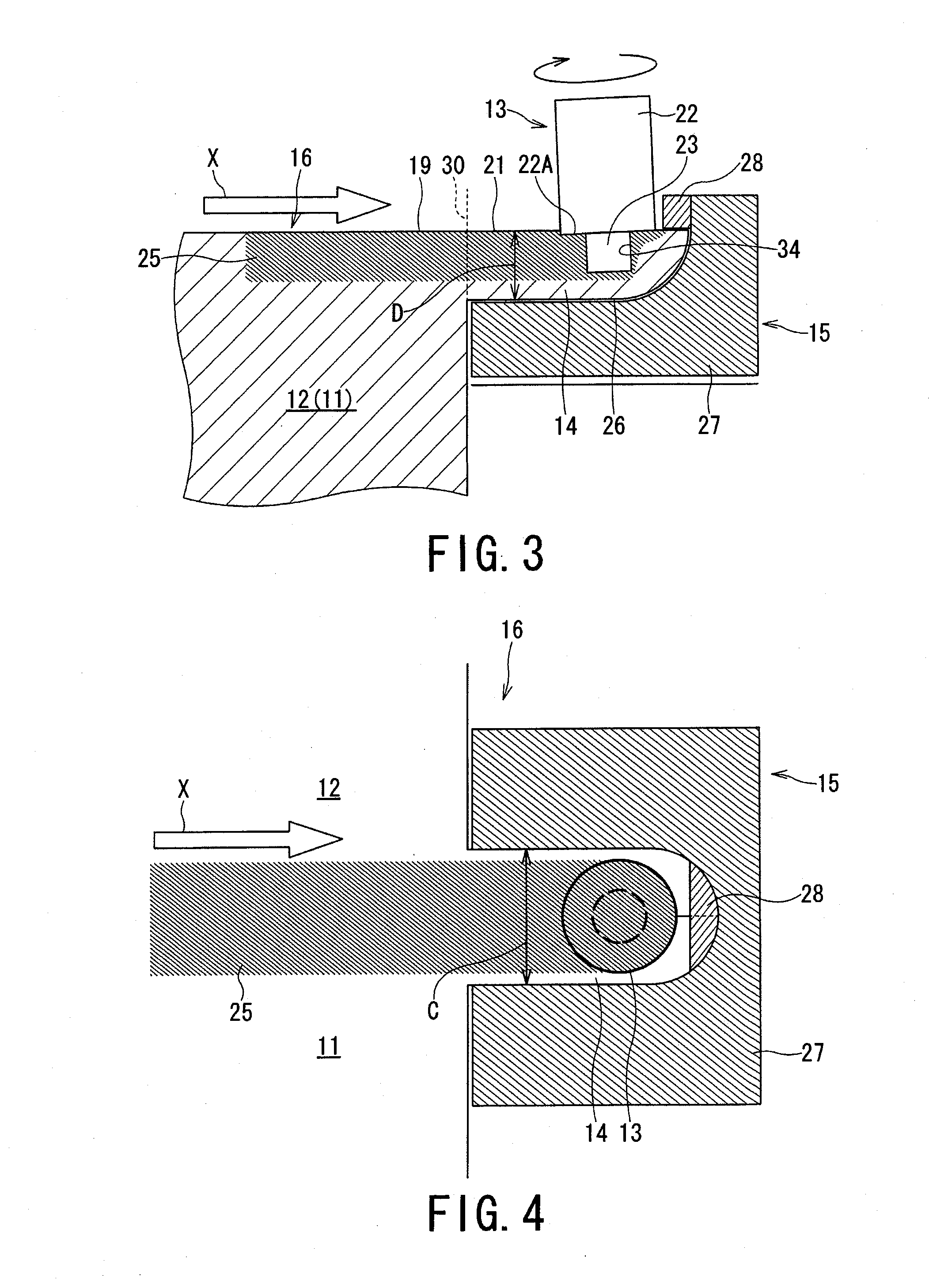

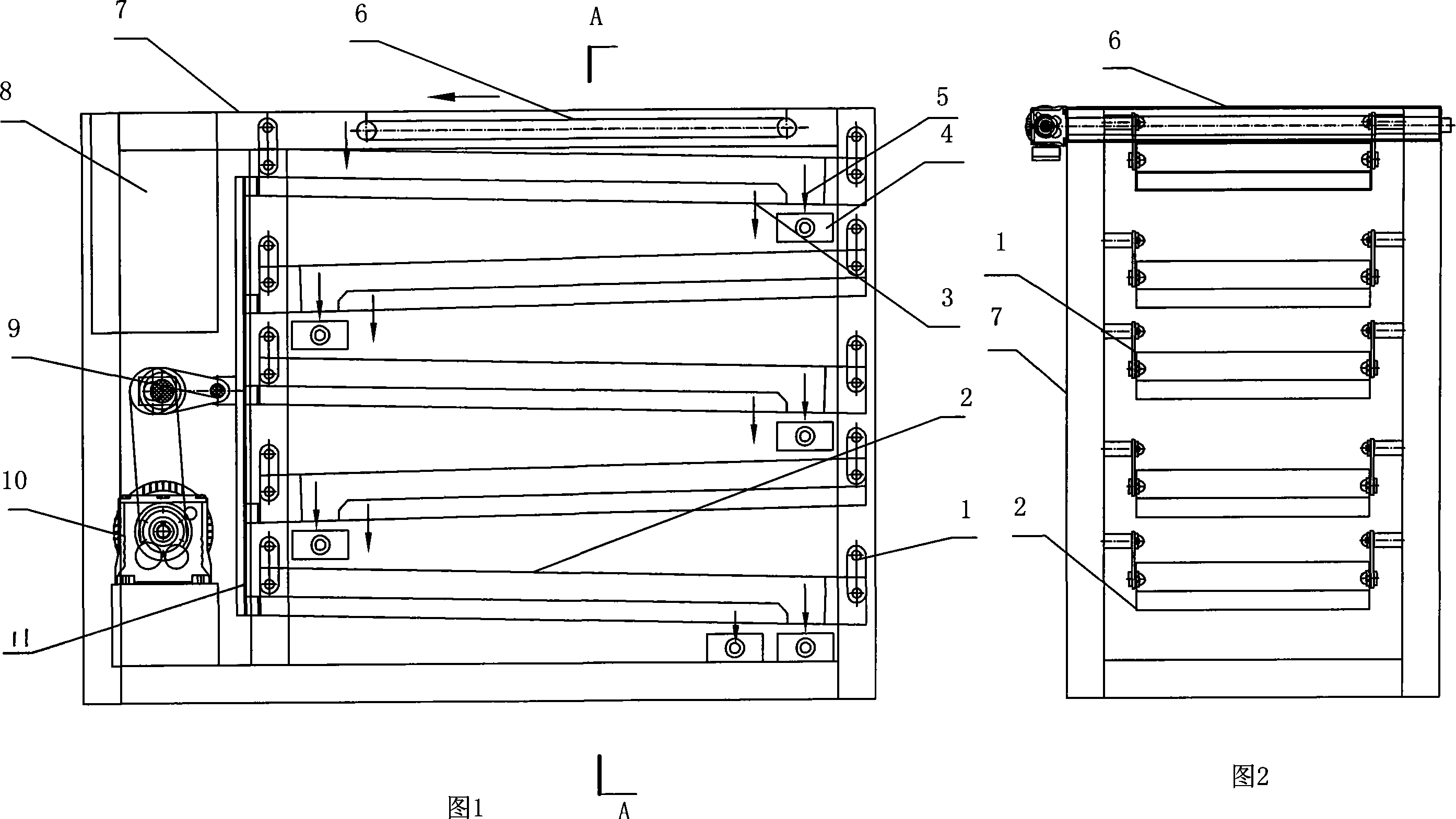

Cut tobacco structure measuring method and its vibrating screen

InactiveCN101109683AAvoid mistakesThe preventer is interceptedCigarette manufactureMaterial weighingEngineeringSieve

The invention relates to a method for determining the structure of cut tobacco and a testing vibration sieve for that, which is characterized in that, certain amount of cut tobacco sample to be tested is placed on a sieve mesh at the top layer of a testing sieve comprising a plurality layers of sieves that are placed layer by layer according to the sieve mesh sizes; all sieves moves horizontally in set frequency, so that all cut tobacco in size less than the mesh at the top layer will fall on the second layer of sieve, all cut tobacco in size less than the mesh at the second layer will fall on the third layer of sieve, and so on; in this way, the cut tobacco of different structural sizes can be separated; finally, by weighing, the masses of different cut tobaccos can be obtained; and the proportions of different cut tobaccos can be obtained through dividing the masses of different cut tobaccos by the total mass of the sample. The invention provides an integral and feasible way for rapidly determining the structure of cut tobaccos.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

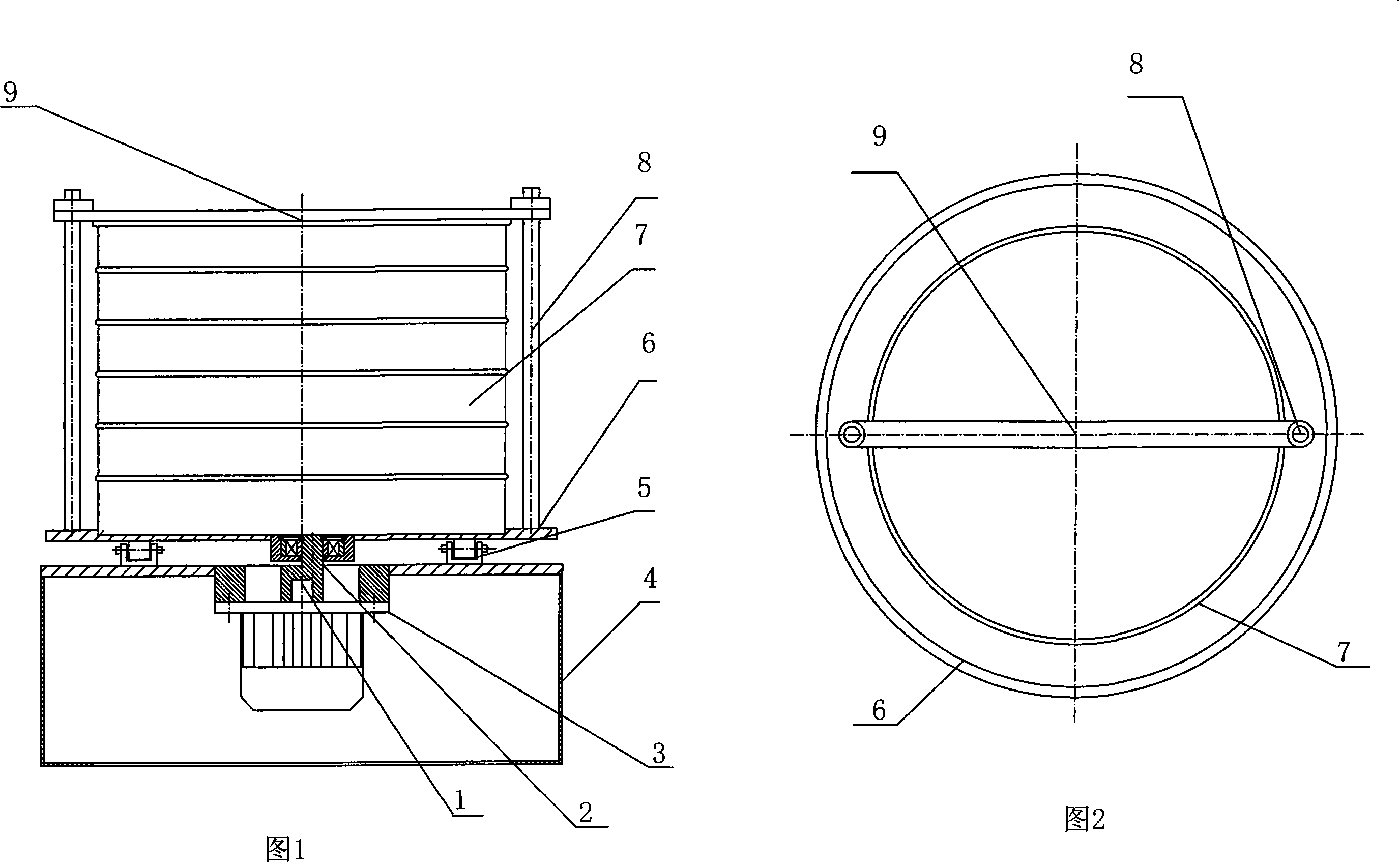

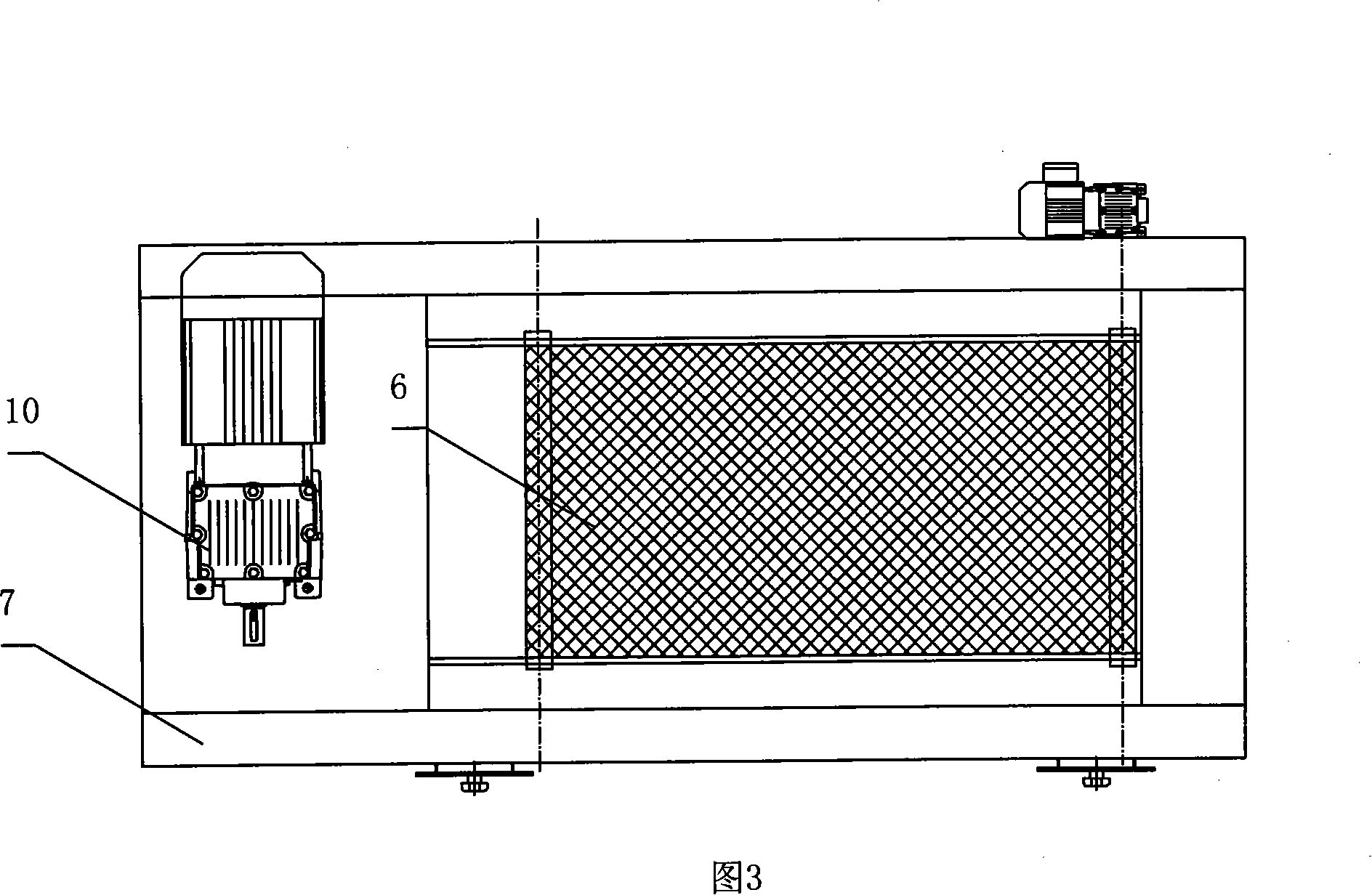

Automatic tea cake packaging machine and automatic tea cake packaging method

ActiveCN102951315AEasy to operateIncrease productivityWrapper folding/bending apparatusCardboardPulp and paper industry

The invention discloses an automatic tea cake packaging machine. A through hole is formed on a U-shaped tooling base, a paper supporter is mounted in the through hole, and a packaging die is arranged on the top surface of the paper supporter. Two paper folding plates are mounted on the top surface of the U-shaped tooling base and on the left side and the right side of the through hole respectively. An inner paper pushing plate and an outer paper pushing plate are inserted in the through hole and disposed inside and outside the paper supporter. An inner creasing plate and an outer creasing plate are positioned above the U-shaped tooling base and correspond to the inner side and the outer side of the paper supporter. An inner paper pressing plate and an outer paper pressing plate are respectively mounted on the top surface of the U-shaped tooling base and positioned on the inner side and the outer side of the through hole. A heat seal head is positioned above the paper supporter. A transmission mechanism controls movements of the paper supporter, the packing die, the inner paper pushing plate, the outer paper pushing plate, the inner paper pressing plate, the outer paper pressing plate, the inner creasing plate, the outer creasing plate, the inner paper folding plate, the outer paper folding plate and the heat seal head. The invention further discloses an automatic tea cake packaging method. By the automatic tea cake packaging machine and the automatic tea cake packaging method, mechanical packaging of tea cakes is realized, production efficiency is improved, appearance quality of tea cakes is improved, packaging material usage is low, and packaging cost is lowered.

Owner:XIAMEN GUANG WANG IND

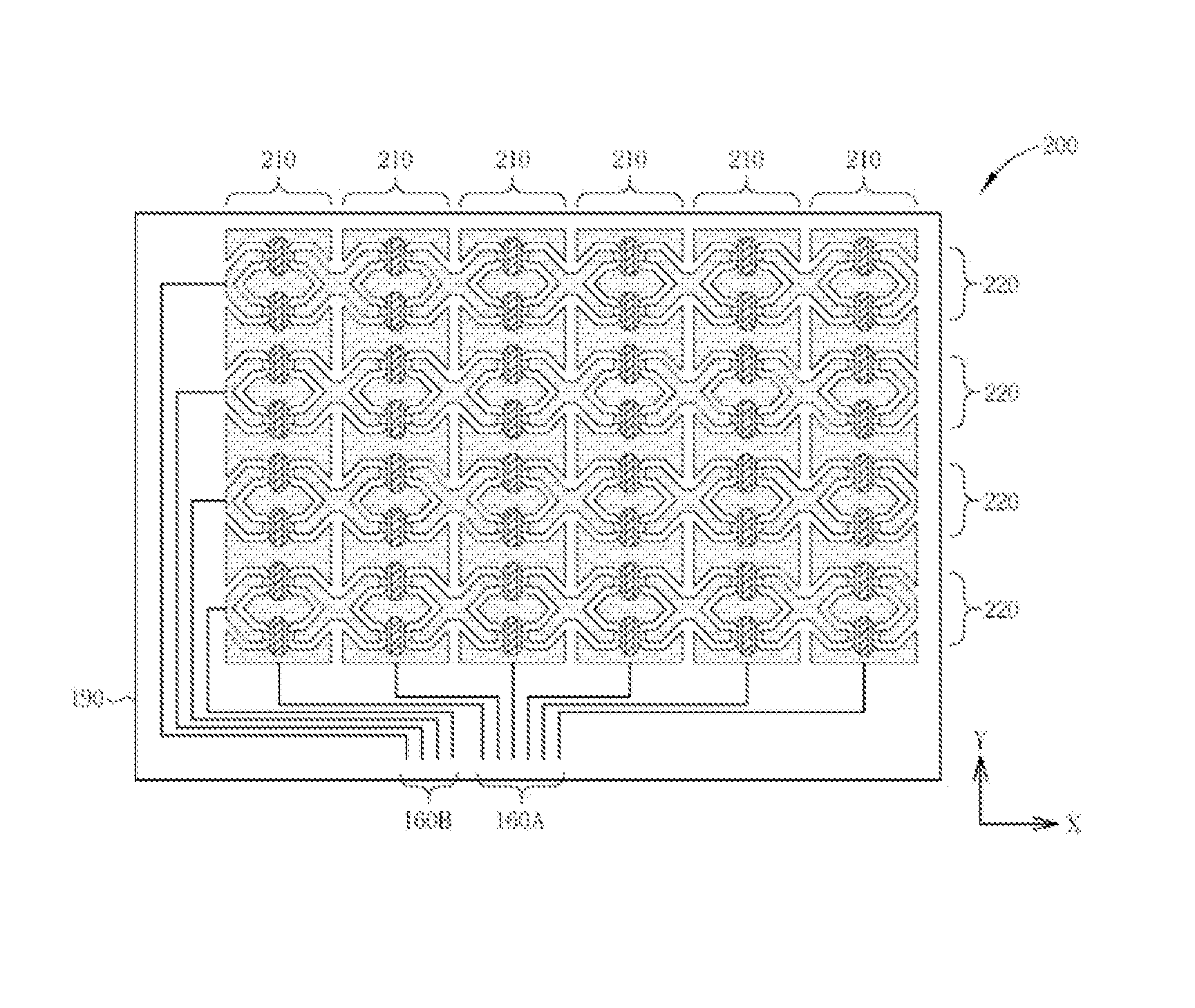

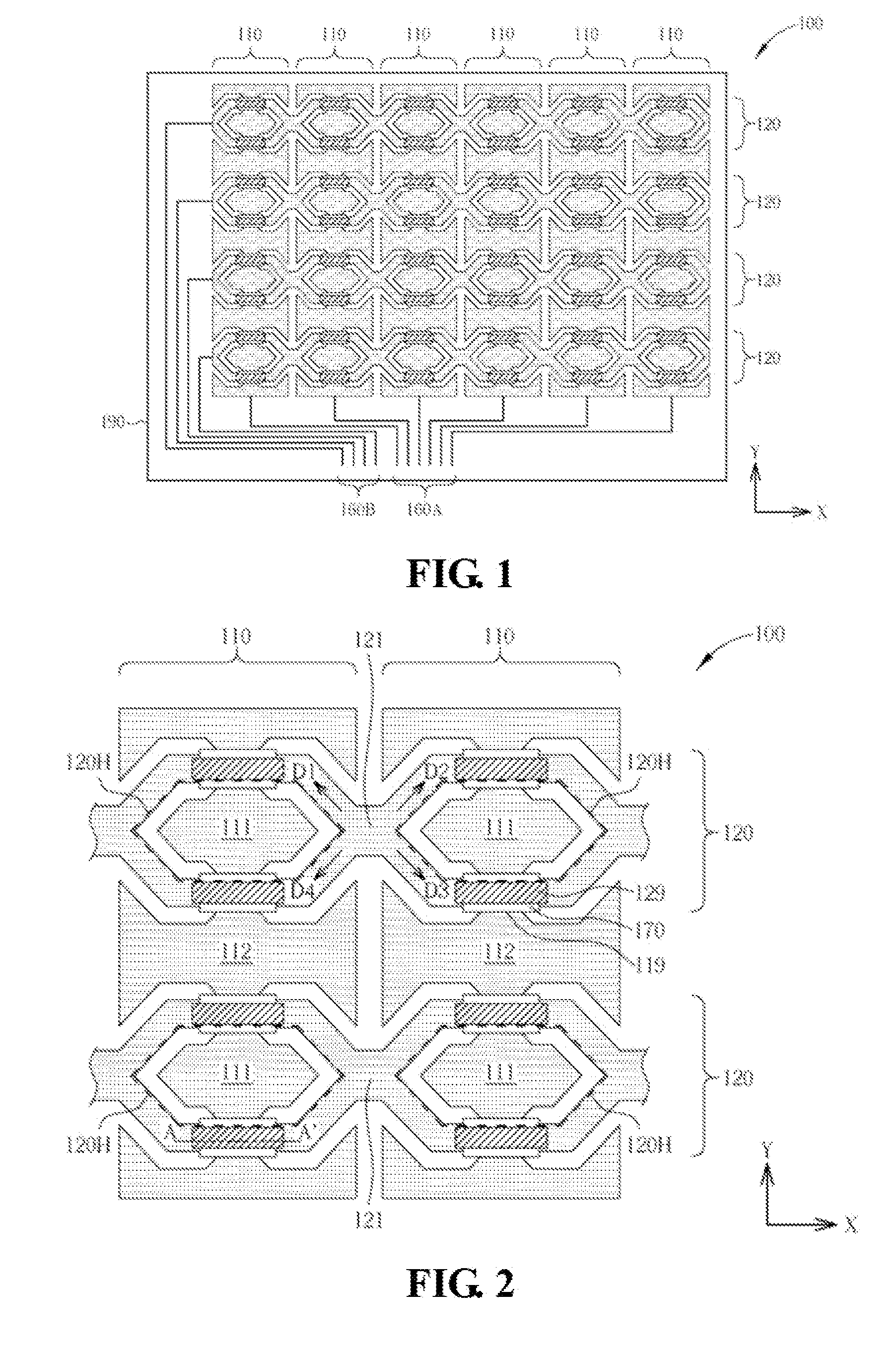

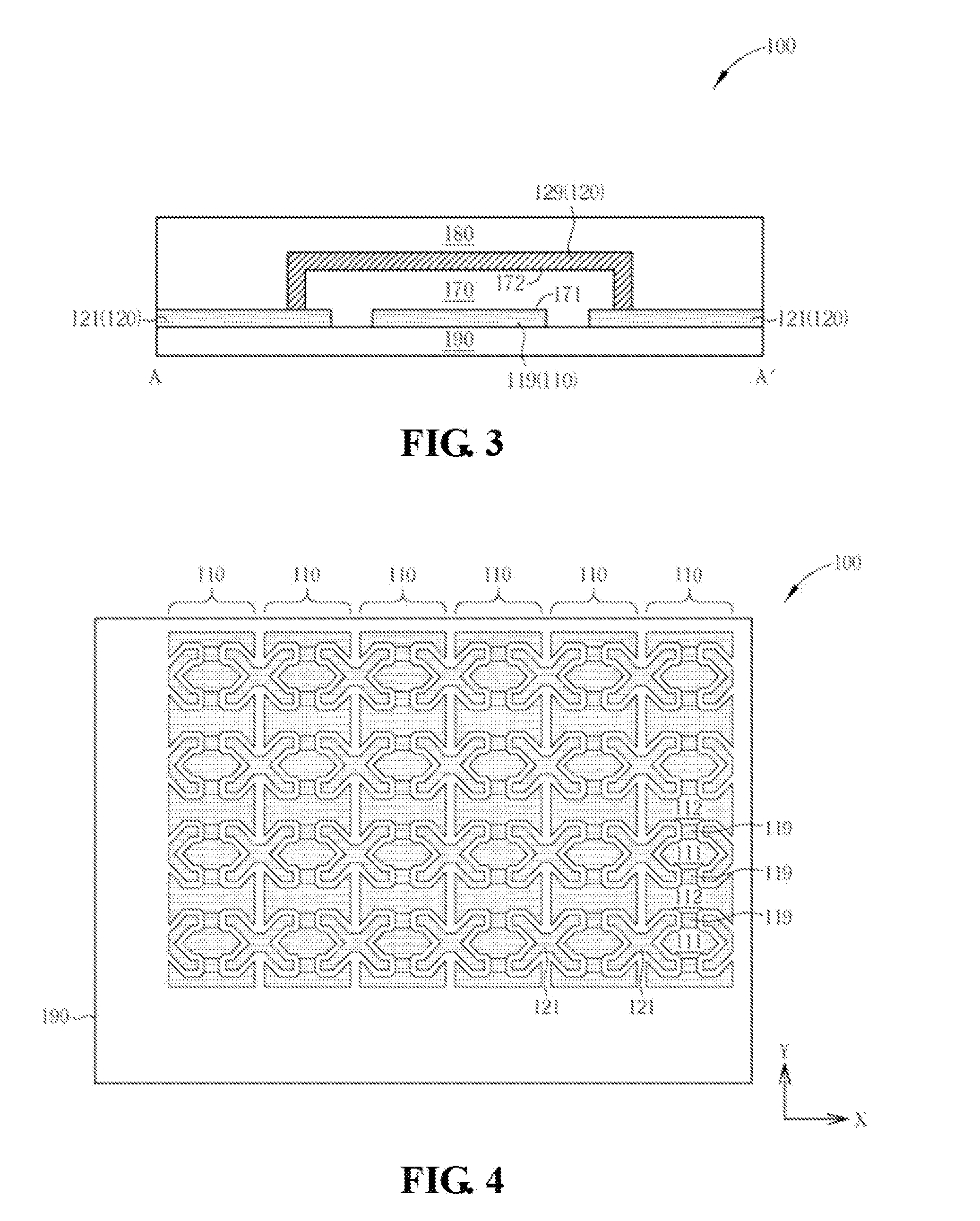

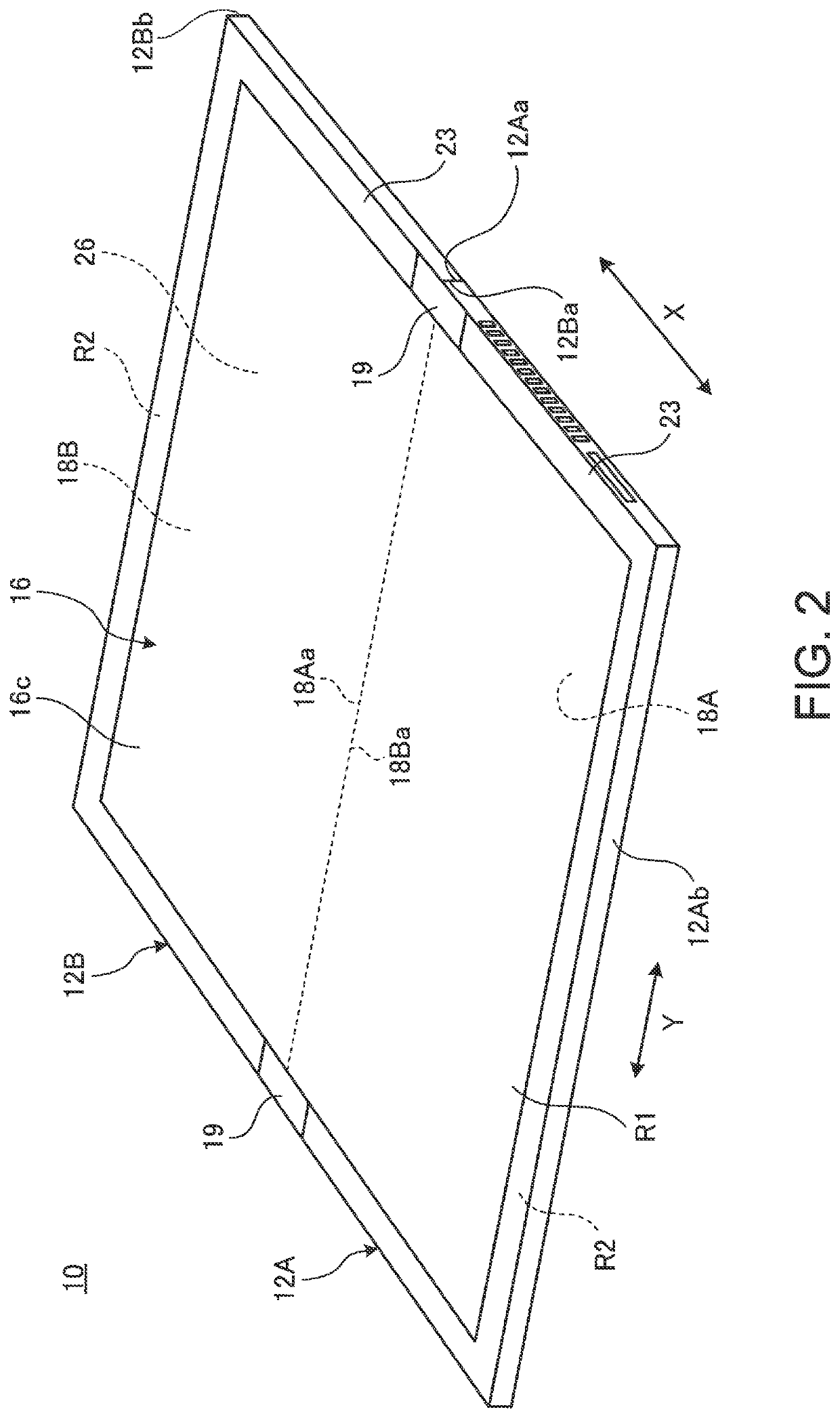

Touch panel

ActiveUS8866775B2Improve external qualityReduce impactInput/output processes for data processingInductanceTouch panel

The present disclosure relates to an input interface and particularly to a novel touch panel which includes a plurality of first axial electrodes and a plurality of second axial electrodes. Each of the first axial electrodes is extended in a first direction. Each of the first axial electrodes includes a plurality of first inductive electrodes, a plurality of second inductive electrodes, and a plurality of first connecting lines. The first inductive electrodes and the second inductive electrodes are disposed alternatively along a first direction. Each of the first connecting lines is disposed between the first inductive electrodes and the second inductive electrodes. Each of the second axial electrodes is extended in a second direction. Each of the second axial electrodes has a plurality of hollow areas arranged along the second direction, and each of the first inductive electrodes is disposed within said hollow areas.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

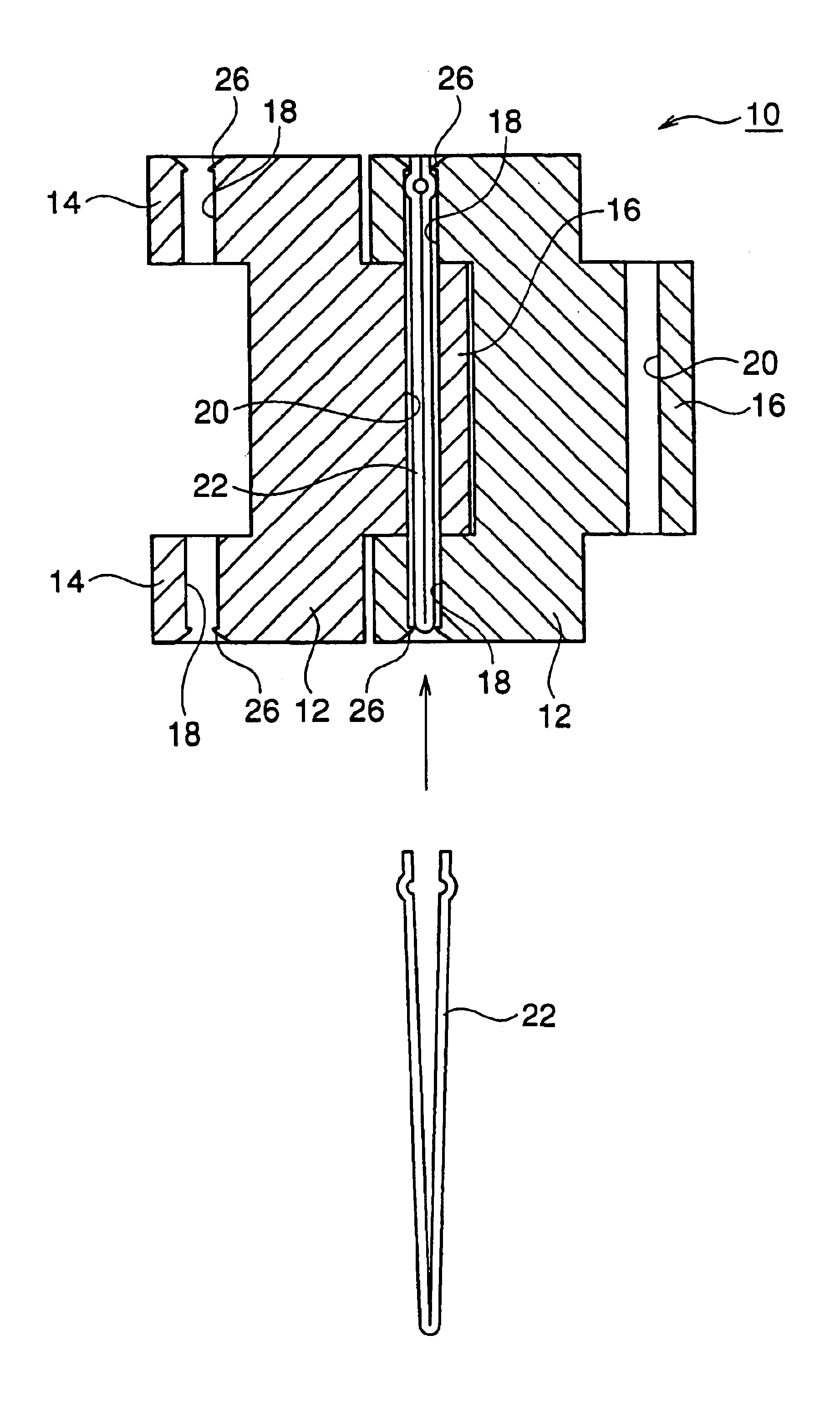

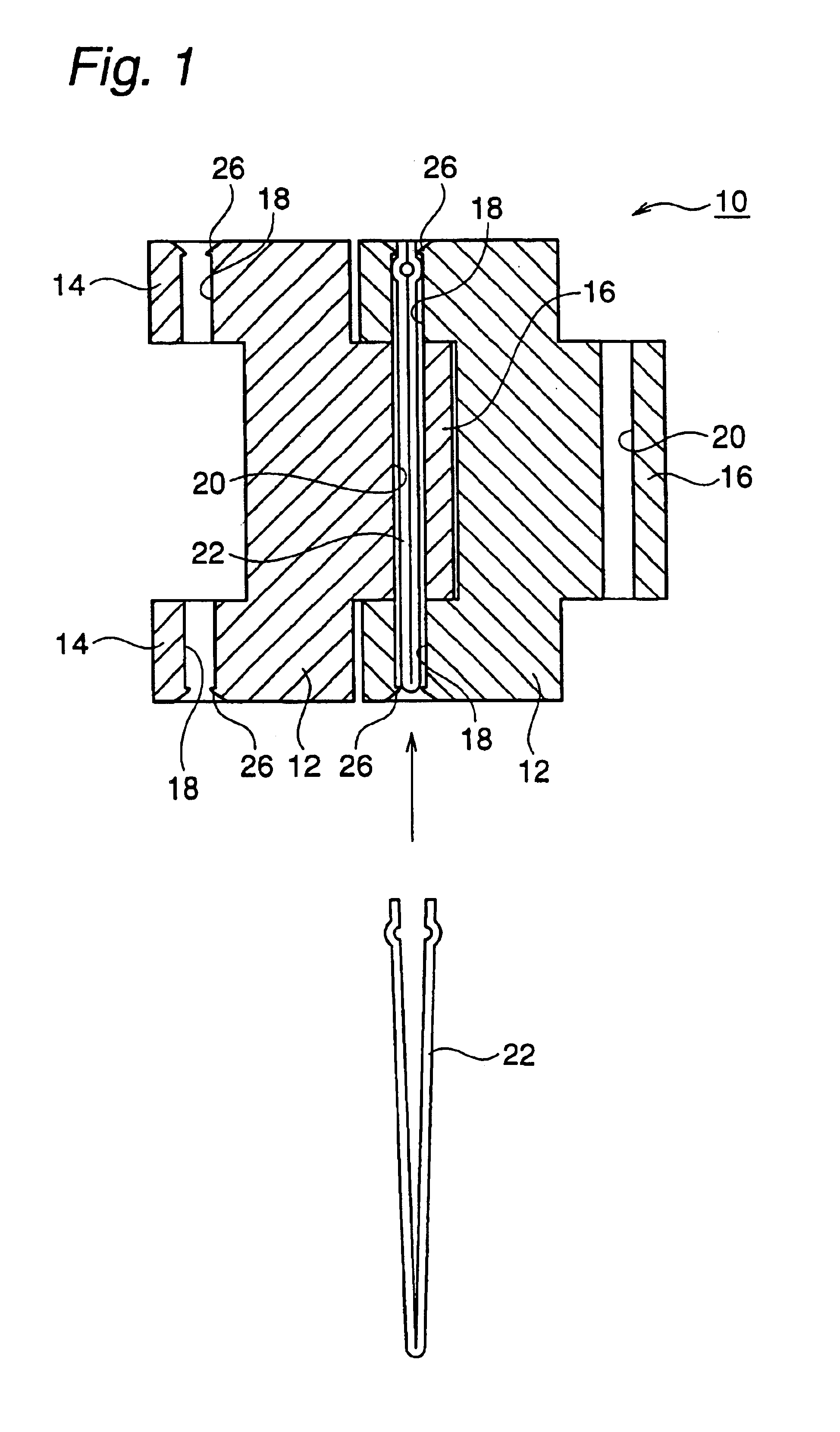

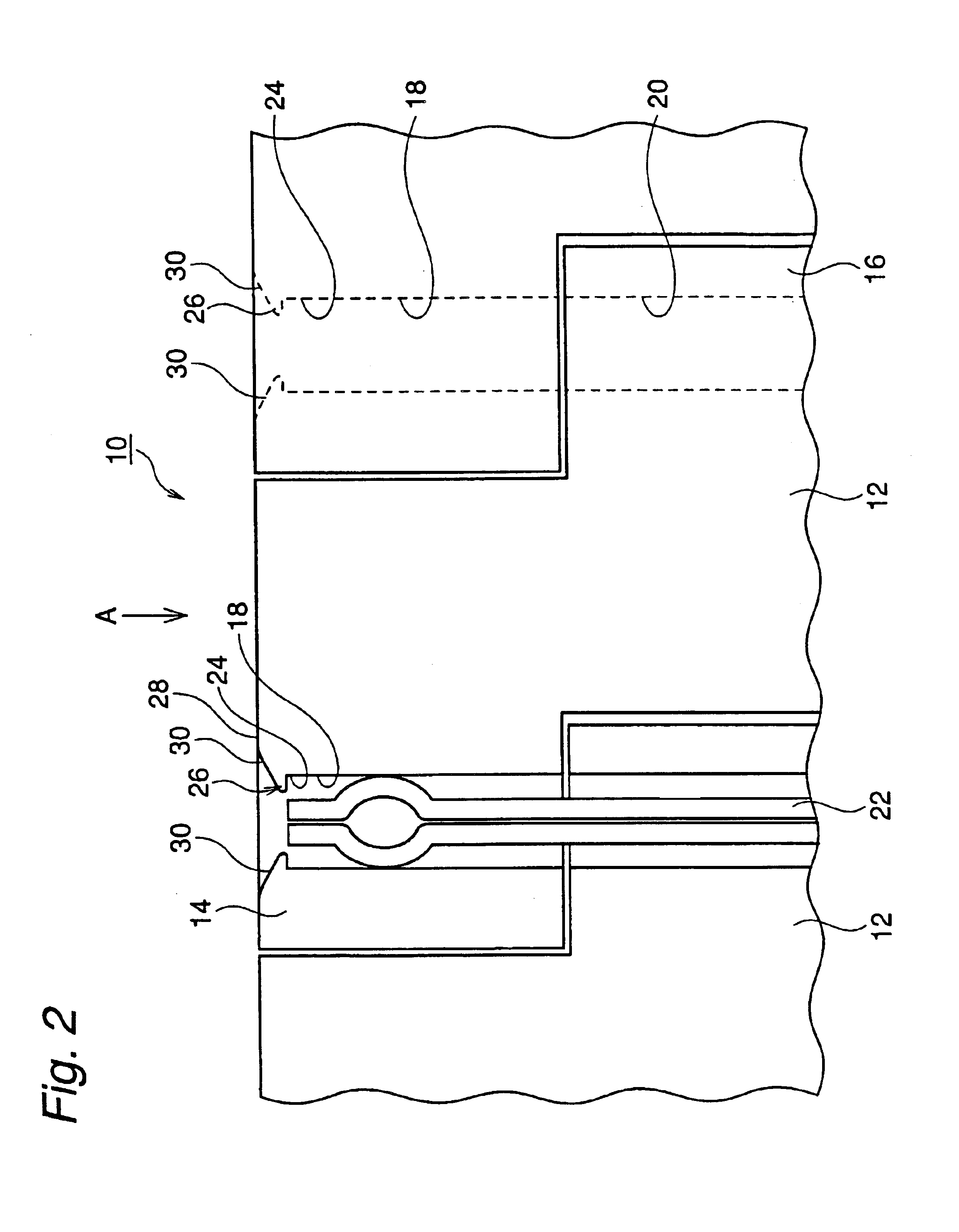

Band coupling structure and method of manufacturing piece member therefor

InactiveUS6913411B2Sufficient resistance forceAvoid reliabilityPlungersTrunk pistonsCouplingEngineering

A coupling structure of a watch band in which a coupling member such as a coupling pin or a hair pin does not sup from a coupling hole even if a user practices strenuous sports or a rotation and a twist are always applied to the coupling portion due to use for years, and a method of manufacturing a piece member for the band coupling structure. In a coupling structure of a band comprising a plurality of piece members, a projection protruded in a central direction of a coupling hole from an internal wall of the coupling hole is formed on an outer end of the coupling hole in the piece member positioned on an outside in a transverse direction, and a coupling member is inserted in the coupling hole provided in the transverse direction of the piece member and is engaged with the projection, thereby coupling the piece members to each other.

Owner:CITIZEN WATCH CO LTD

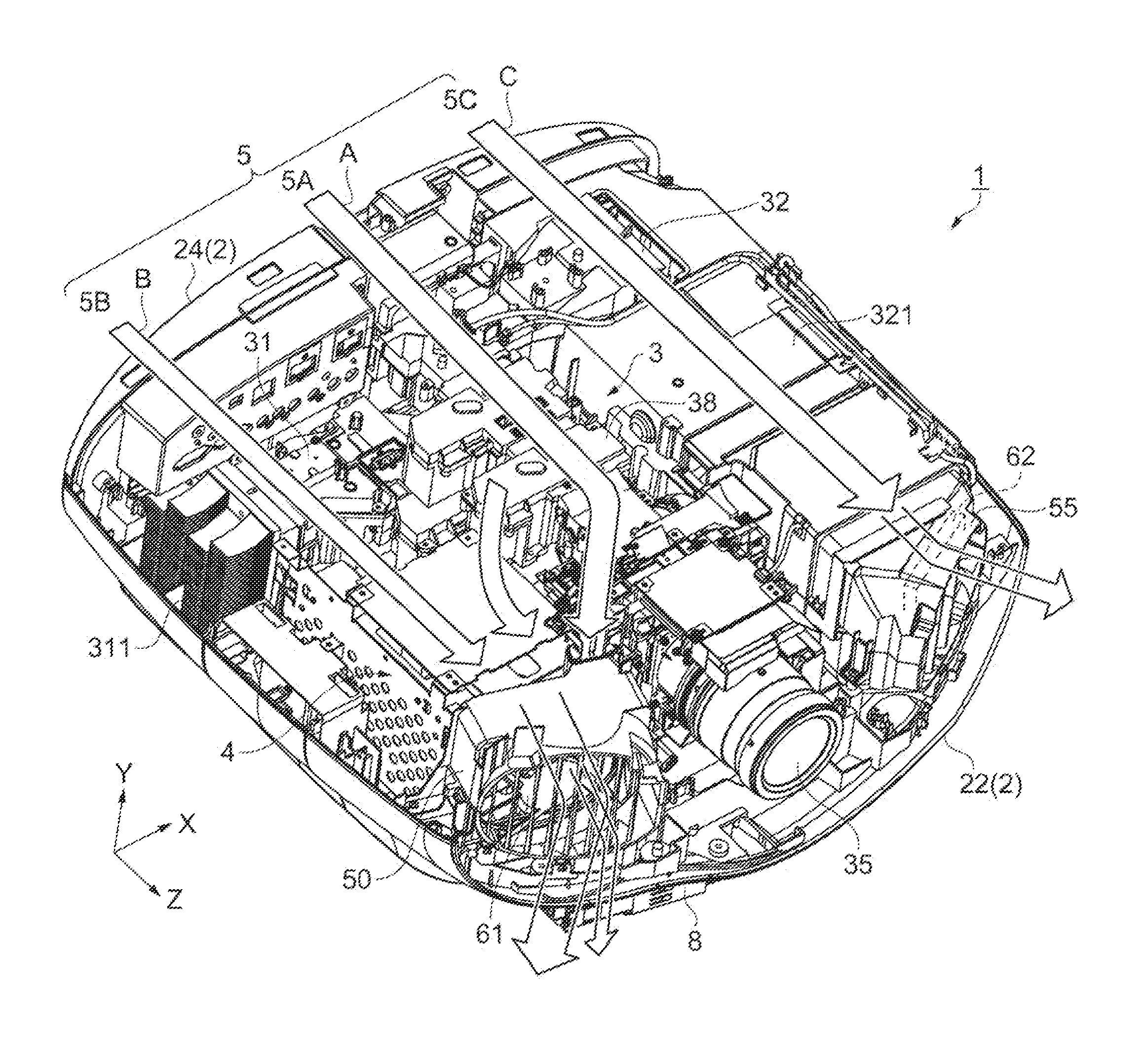

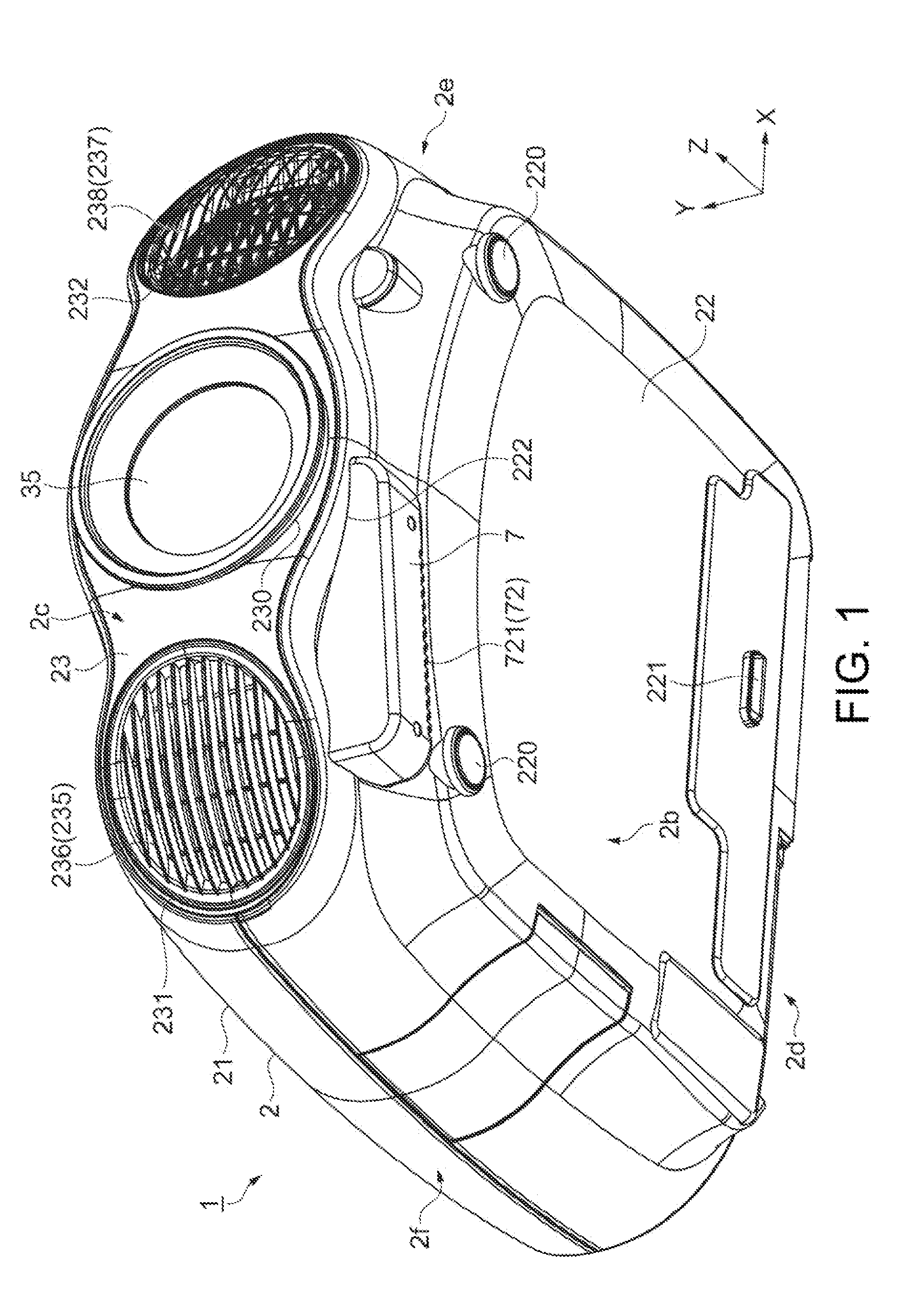

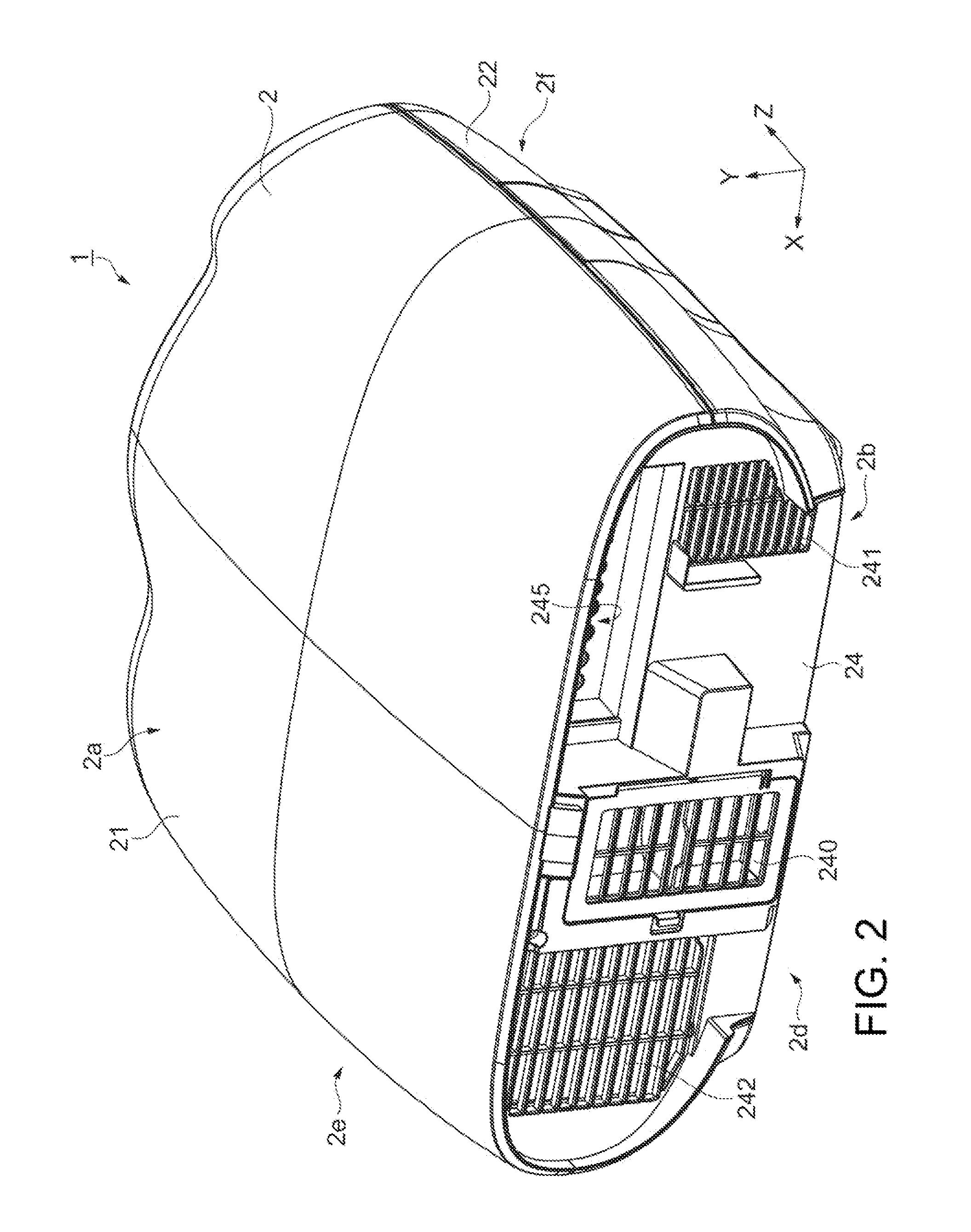

projector

A projector includes a light source apparatus, a light modulator that modulates a light flux outputted from the light source apparatus in accordance with image information, a projection lens that projects the light flux modulated by the light modulator, an exterior enclosure that accommodates the light source apparatus, the light modulator, and the projection lens, an exhaust fan (first exhaust fan) that exhausts air inside the exterior enclosure out thereof through an exhaust port (first light source exhaust port) provided in the exterior enclosure, and a functional device (wireless device) that provides a predetermined function and is heated to a temperature higher than the temperature of the exhaust air from the first exhaust fan. The wireless device is disposed in a position downstream of the first exhaust fan, and part of the exhaust air discharged from the first exhaust fan flows to the wireless device.

Owner:SEIKO EPSON CORP

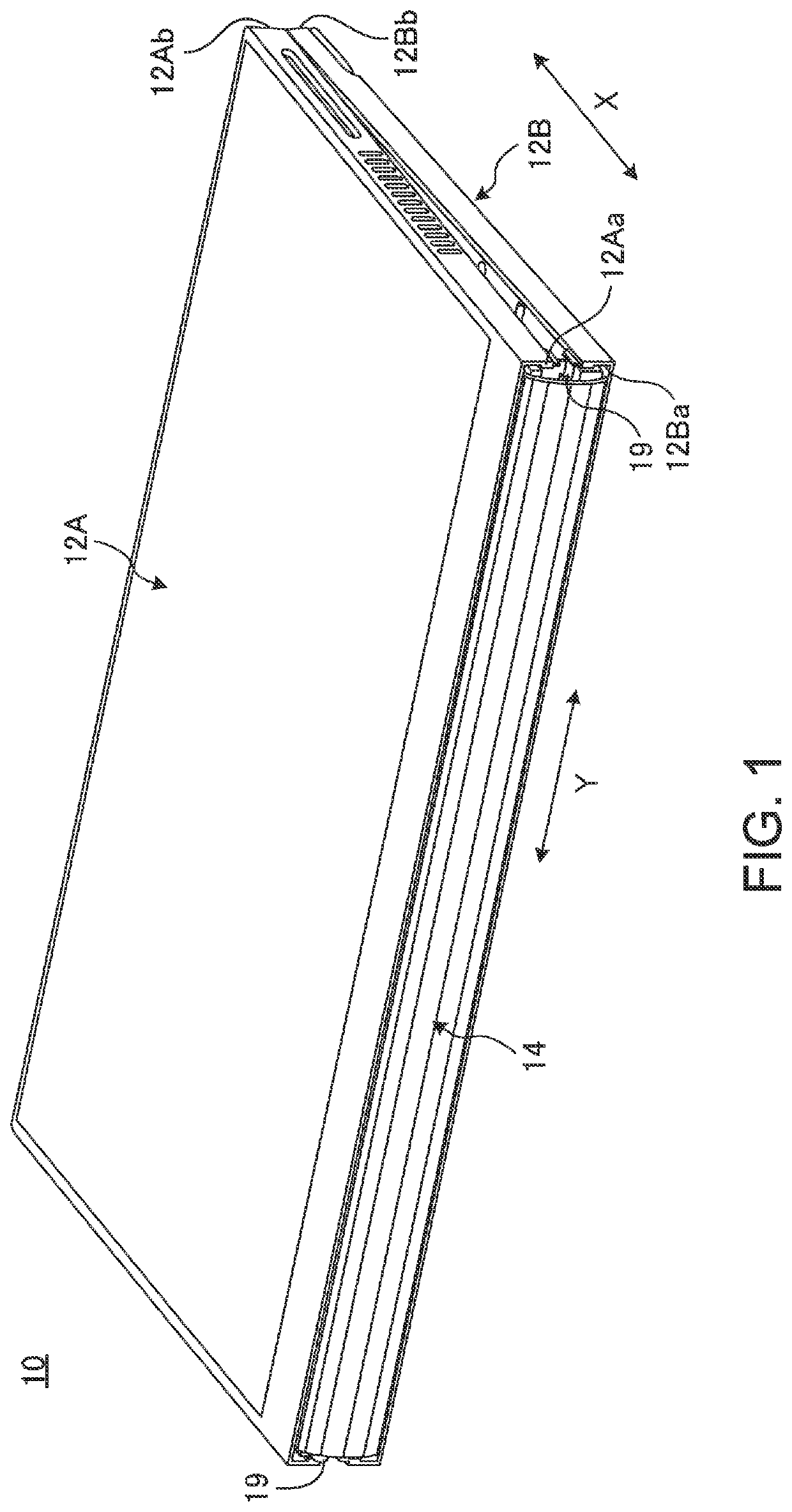

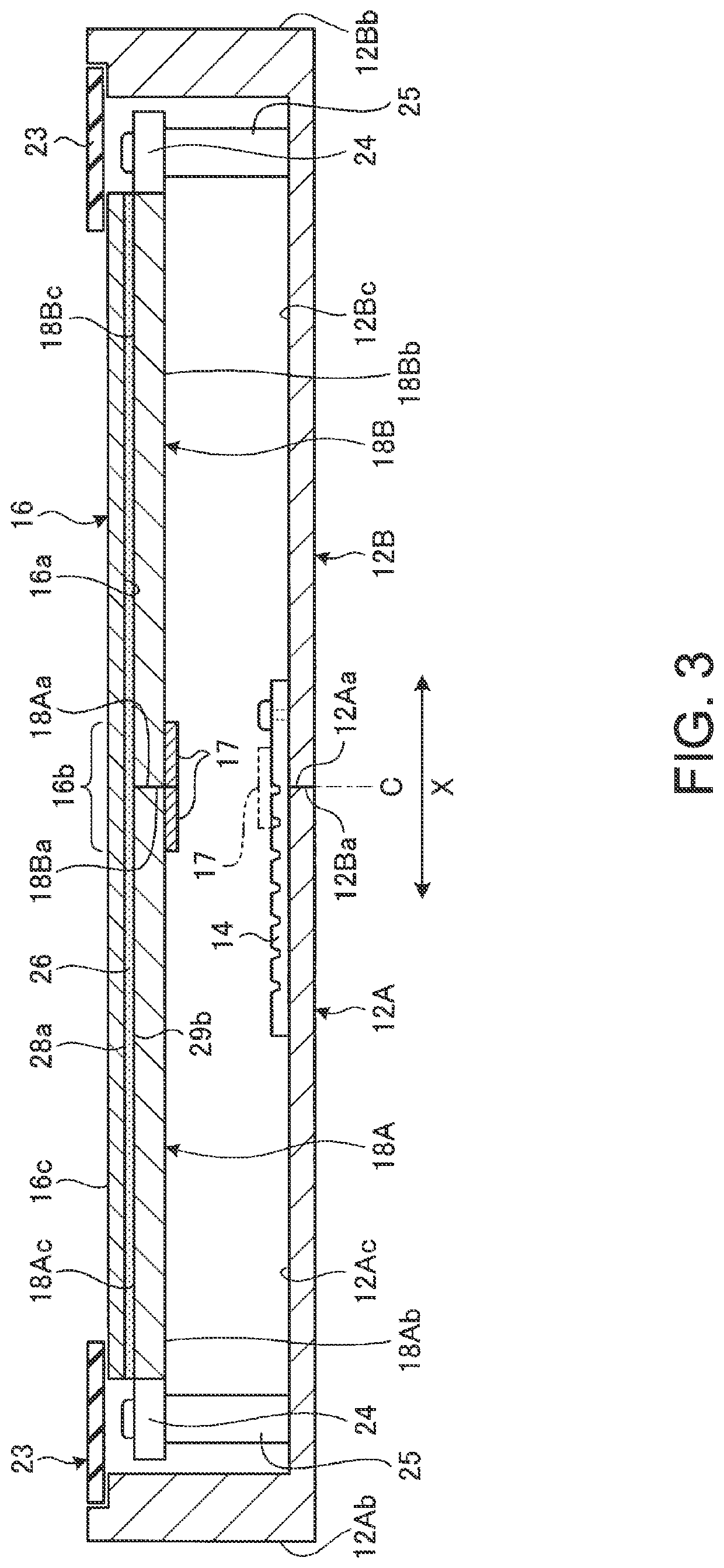

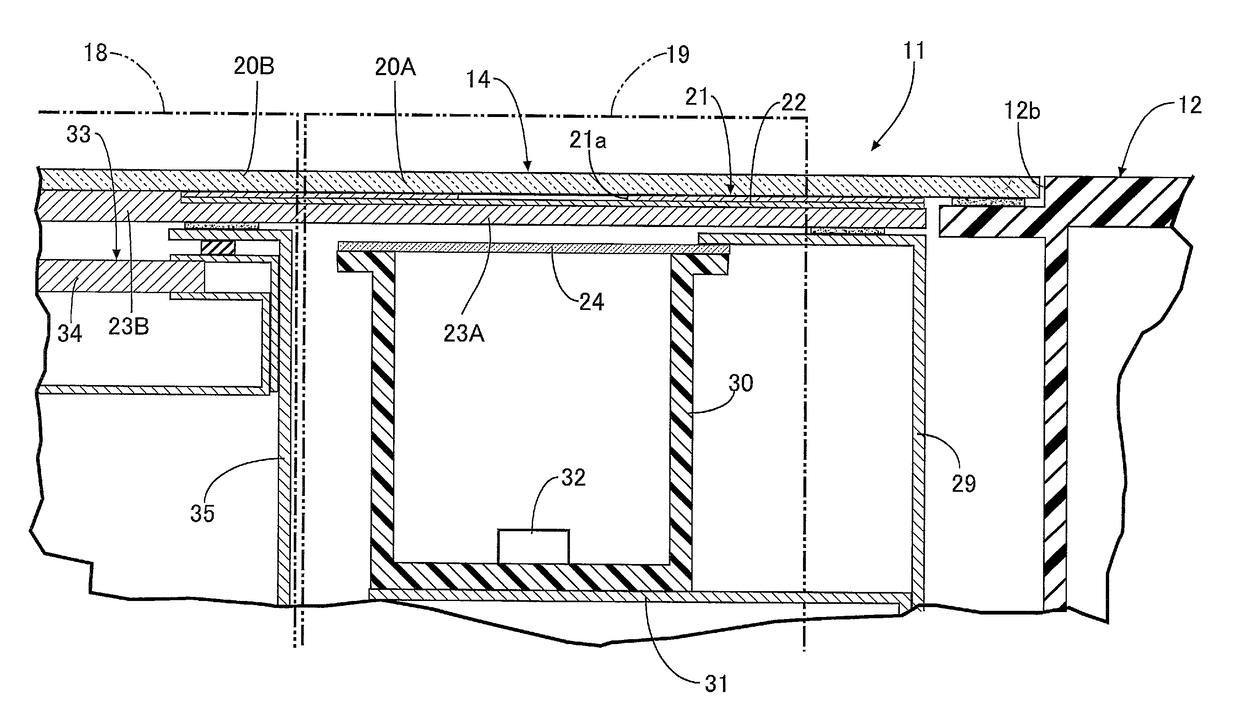

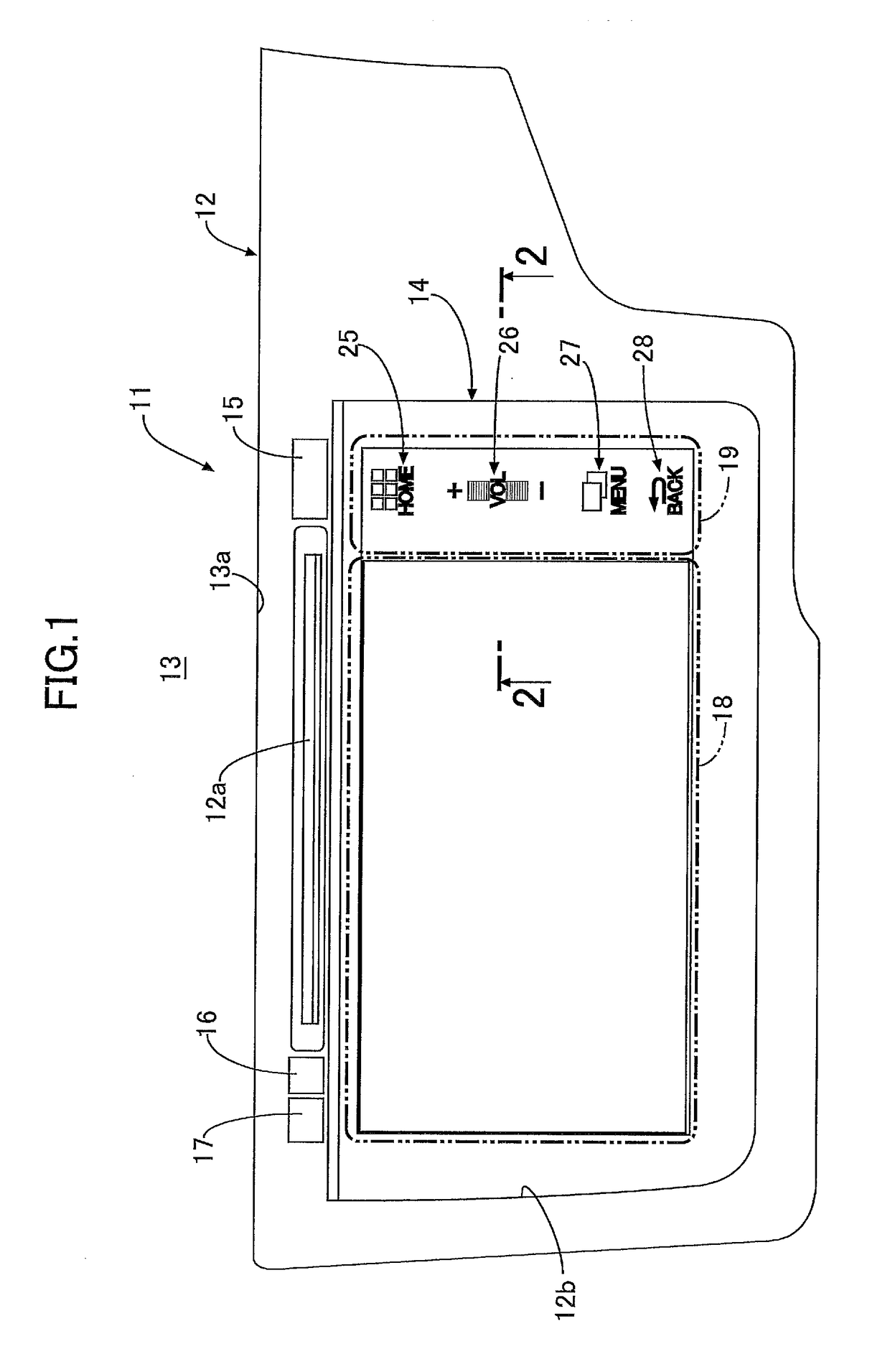

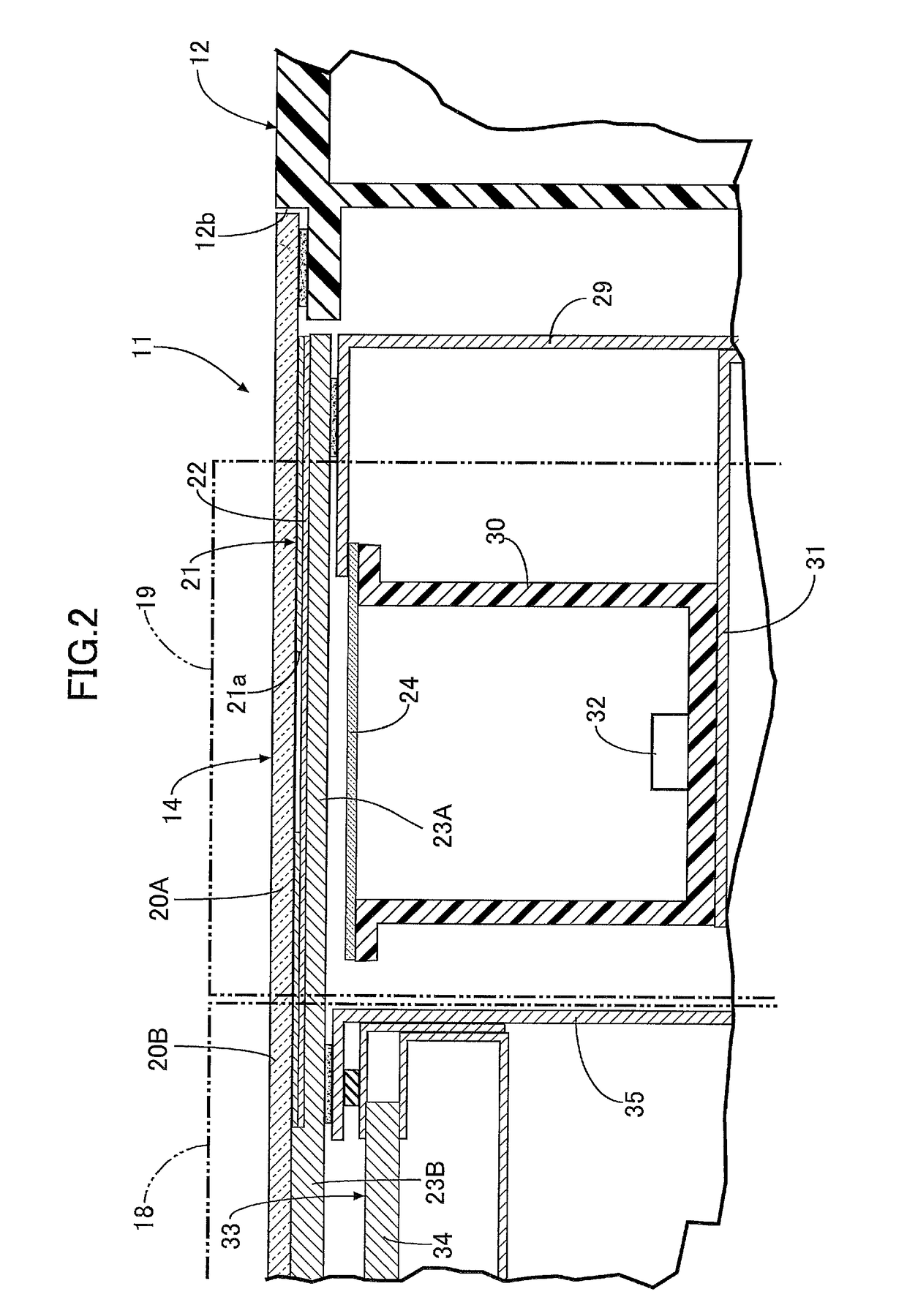

Portable information device

ActiveUS10831234B1Improve of visibility of displayImprove external qualityCasings with display/control unitsCasings/cabinets/drawers detailsSoftware engineeringDisplay device

The portable information device includes: a display whose back surface is supported on respective front surfaces of first and second support plates; and an adhesive member that adheres to the front surfaces of the first and second support plates and the back surface of the display and fastens them together. In the portable information device, an area that overlaps with at least a folding area includes a weak adhesive section in which an adhesive force of the adhesive member between the first and second support plates and the display is reduced to be lower than the other section or a non-adhesive section that does not adhere to at least either the first and second support plates or the display. The portable information device further includes a magnet provided below the back surface of the display and in a position that overlaps with the folding area. The magnet can attract a magnetic body.

Owner:LENOVO PC INT

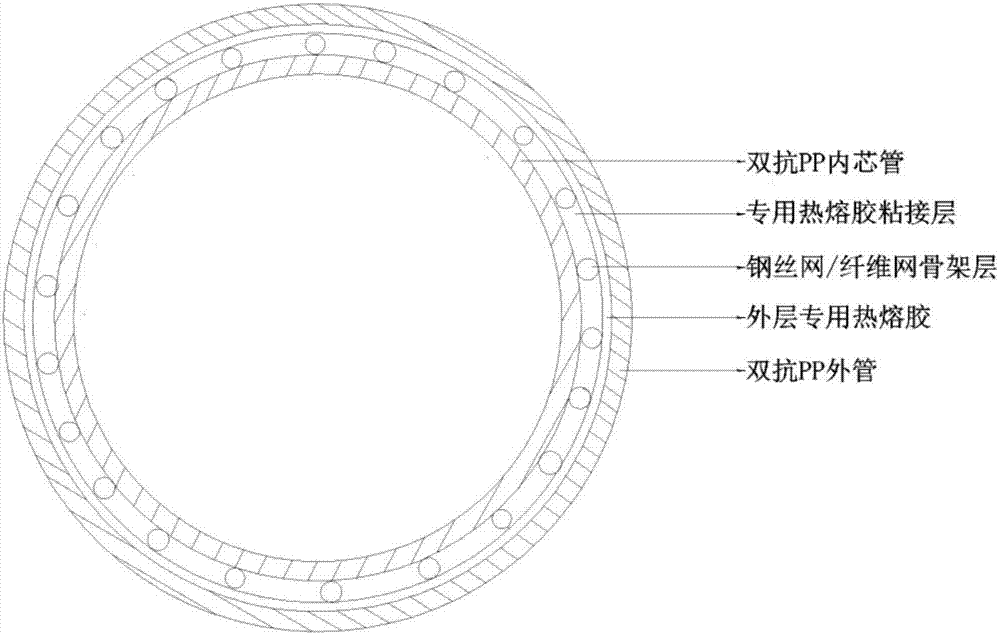

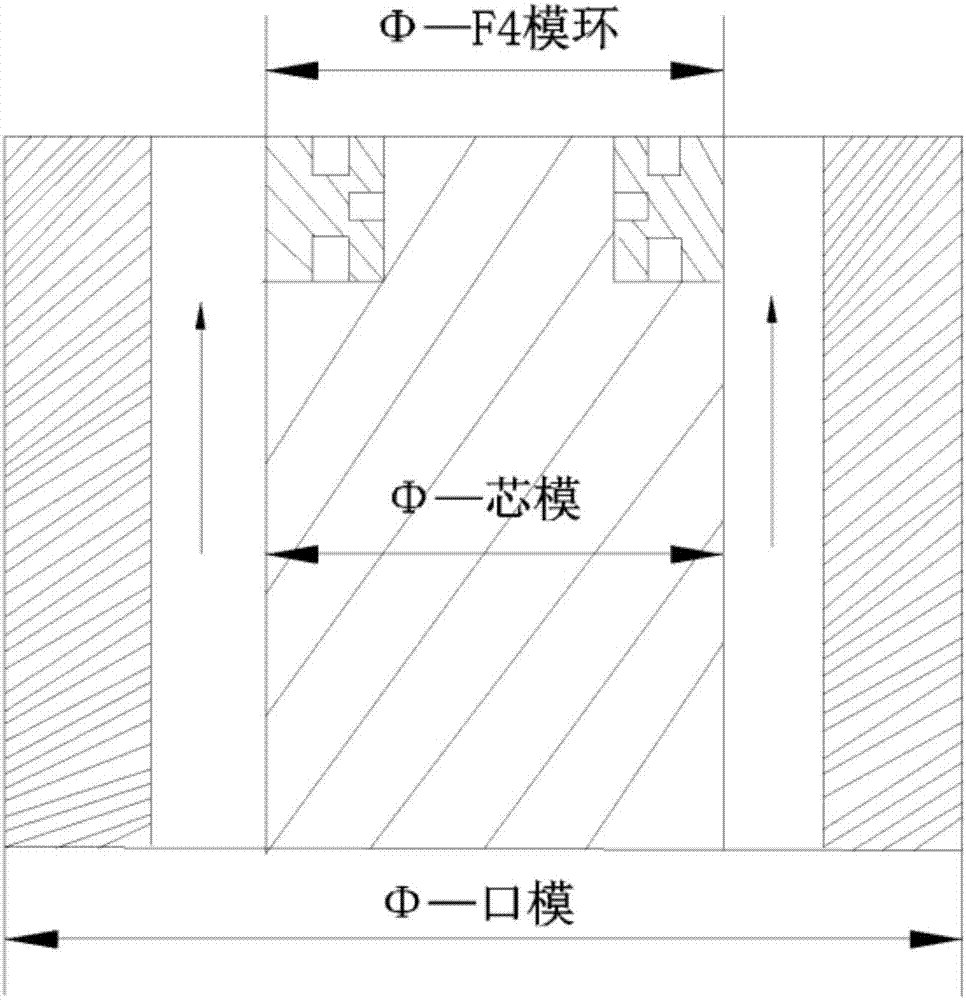

Production molding technique of steel wire mesh/fiber mesh framework dual-resistance PP composite pipe used underground coal mine

The invention provides a production molding technique for a steel wire mesh / fiber mesh framework dual-resistance PP composite pipe used underground a coal mine, and belongs to the technical field of production of PP composite pipes. The molding technique specifically comprises the steps of surface coating of steel wires / fibers, extrusion of a dual-resistance PP modified inner core pipe, formation of a steel wire mesh / fiber mesh formwork through winding of the steel wires / fibers, formation of a steel wire mesh / fiber mesh framework reinforcing layer (injecting extrusion of hot melt adhesives on the inner layer and coating extrusion of hot melt adhesives on the outer layer), extrusion molding of a dual-resistance PP modified composite pipe outer layer, and the like. By adoption of the production molding technique for the steel wire mesh / fiber mesh framework dual-resistance PP composite pipe used underground the coal mine, the surface of the obtained composite pipe is compact, smooth and clear and has a good anti-static effect.

Owner:北京新红原聚合科技有限公司

Method for determining tobacco shred structure in cigarette

InactiveCN1885002AImprove splicing qualityReduce weightMaterial weighingVibration amplitudeEngineering

The invention relates to a method for testing the structure of thread tobacco of cigarette, which is characterized in that: a, arranging cigarette into the condition as temperature at 20+-2 Deg. C and humidity is 65+-5%, then taking out the cigarette, to be uniformly divided into two parts, and taking out the thread tobacco from the cigarette; b, inputting two sample thread tobaccos into seven-layer screener to be screened for two times, while the vibration amplitude is 55-70 and the time is 10-20 minutes; c, using laminated weighting, recording the weight of thread tobacco of each layer after each screening, to calculate out the total weight; d, comparing the weight of each layer with the total weight, to obtain the ratio of each layer; e, adding the ratios of same layer of two times of screening, to obtain the average value, to test the ratio of different thread tobacco in the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Cut tobacco structure measuring method and its vibrating screen

InactiveCN101109684AAvoid mistakesThe preventer is interceptedCigarette manufactureMaterial weighingEngineeringMechanical engineering

The invention relates to a method for determining the structure of cut tobacco and a testing vibration sieve for that, which is characterized in that, certain amount of cut tobacco sample to be tested is placed evenly on a conveying belt, and a sieve mesh at the top layer of a testing sieve comprising a plurality layers of sieves that are placed layer by layer according to the sieve mesh sizes is supplied with cut tobacco by the conveying belt at set speed; the cut tobacco in size bigger than the mesh at the top layer will go into a first cut-tobacco collecting and weighing container, the rest will go to the second layer; the cut tobacco in size bigger than the mesh at the second layer will go into a second cut-tobacco collecting and weighing container, the rest will go to the third layer, and so on; in this way, the cut tobacco of different structural sizes can be separated; finally, by weighing, the masses of different cut tobaccos can be obtained; and the proportions of different cut tobaccos can be obtained through dividing the masses of different cut tobaccos collected in each cut-tobacco collecting and weighing container by the total mass of the sample.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

Counter weight

InactiveUS7147250B2Improve accuracyEasy to attachMetal-working feeding devicesPedestrian/occupant safety arrangementVehicle framePrecession

To provide a counter weight capable of forming an attaching part to a vehicle frame with high precision, capable of improving attaching precision to this vehicle frame, and further, capable of decreasing a manufacture cost thereof. The counter weight includes a base made of cast iron having an attaching part, whereby the counter weight is attached to a vehicle frame; and a weight part made of a slab material having a block body made of a slab material; wherein the weight part made of the slab material is attached on the above-described base made of cast iron. The outer surface of the above-described weight part made of the slab material is coated with the cover. In addition, the connection plate is attached to the above-described base made of cast iron, the lower end edge of the above-described cover is joined to the base made of cast iron through the above-described connection plate, and the upper end edge of the above-described cover is joined to the upper part of the above-described weight part made of the slab material. Since the base made of cast iron is attached to the vehicle frame, it is possible to form the attaching part to the vehicle frame at a low cost, simply, and with high precession.

Owner:KOMATSU LTD

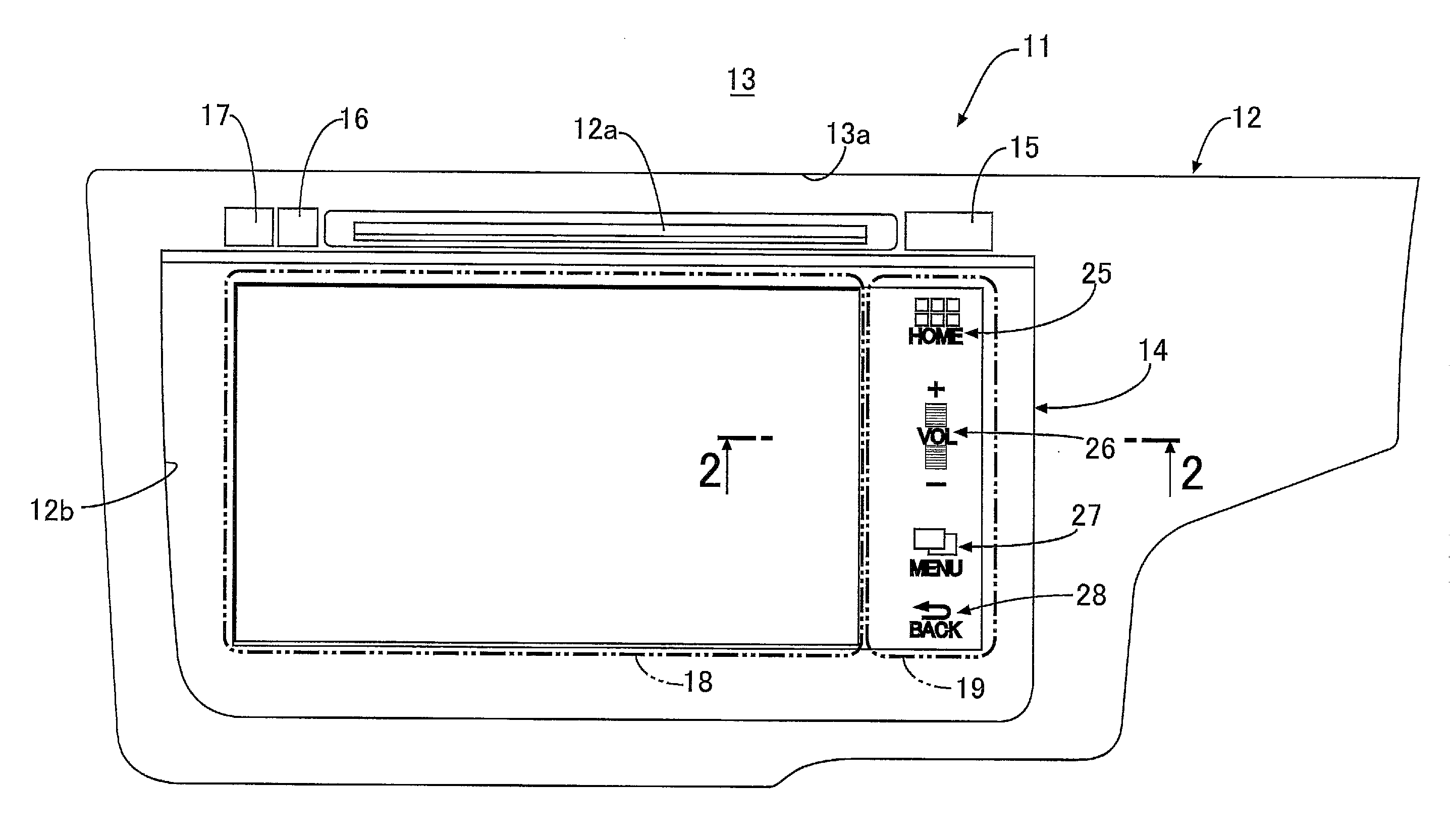

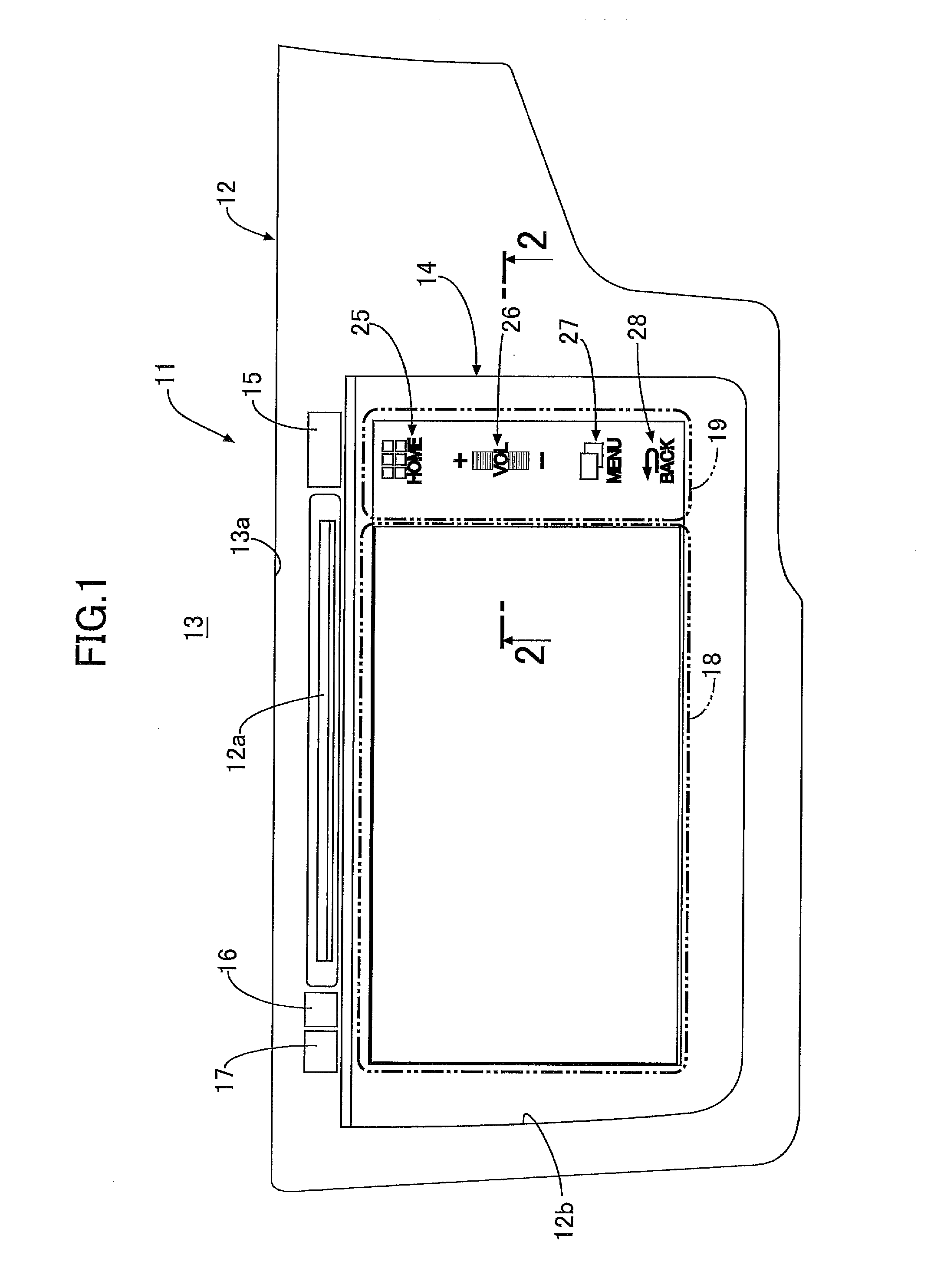

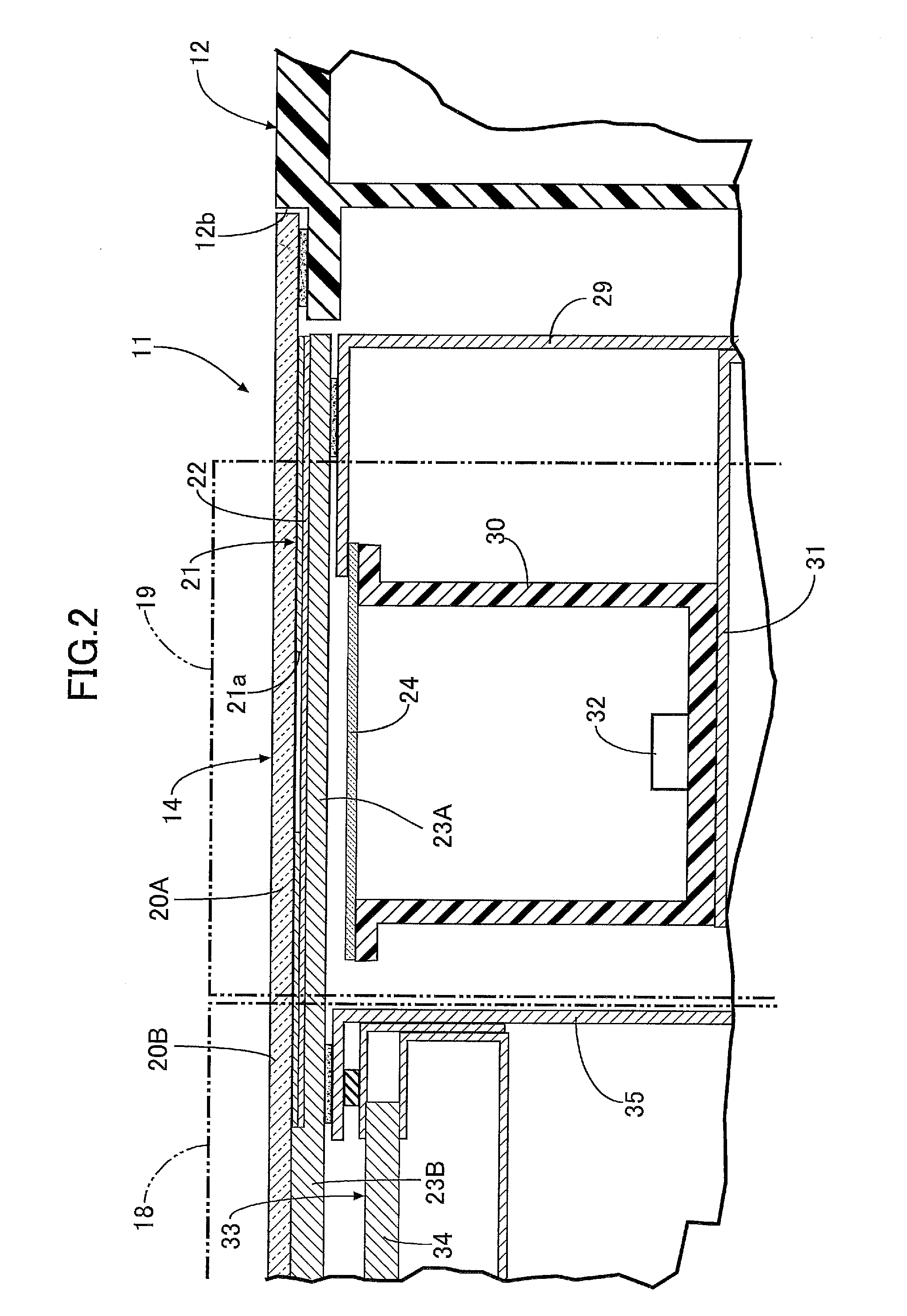

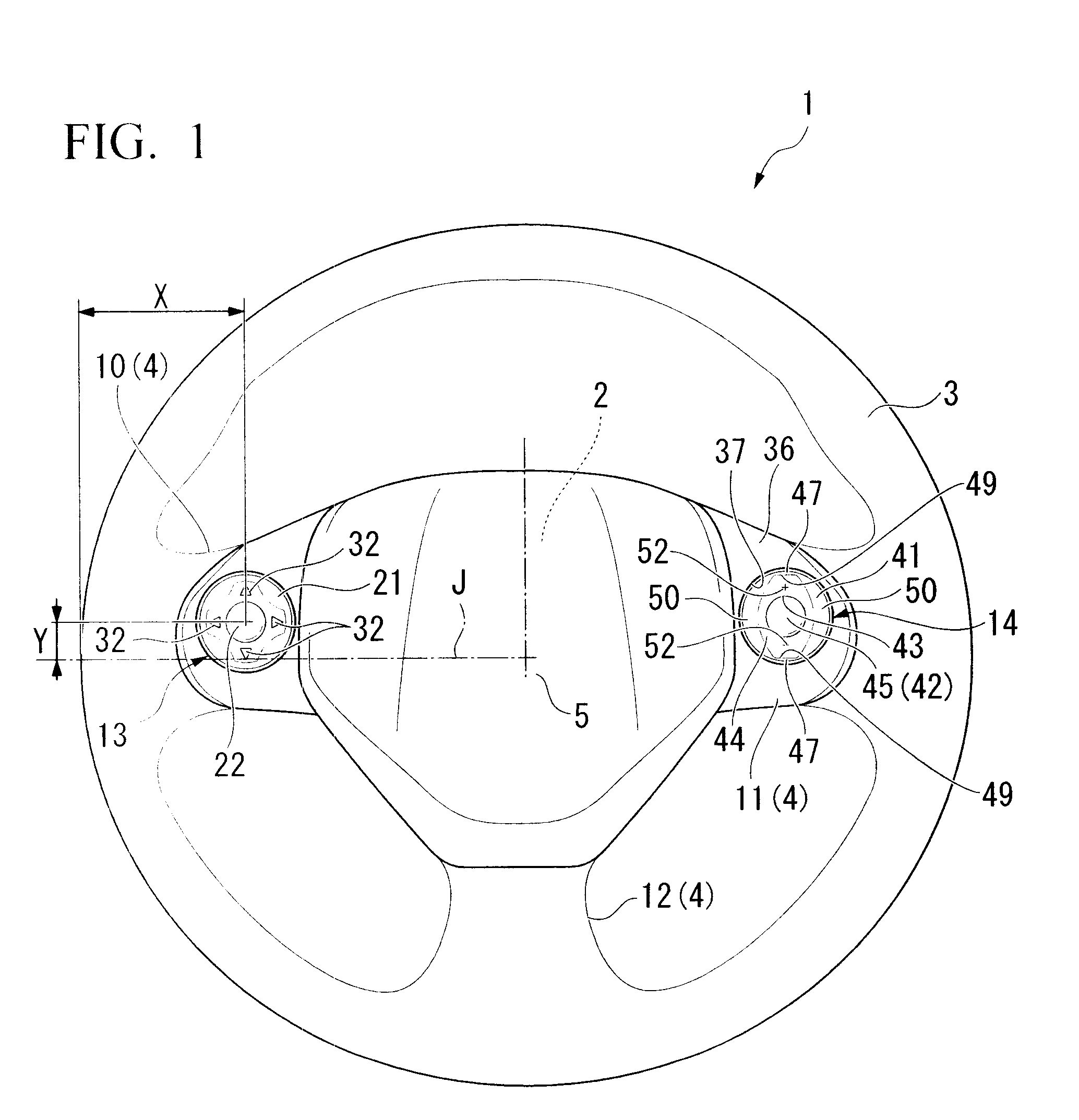

Vehicle-mounted display device

ActiveUS20160059701A1Increase brightnessEnsure visibilityDashboard fitting arrangementsInstrument arrangements/adaptationsVisibilityDisplay device

A vehicle-mounted display device includes a software switch region in which a first transparent resin layer, a symbol and design printed layer, a smoke printed layer, a first touch sensor sheet, and a diffusion sheet are layered in order from the front side toward the back side, and a liquid crystal touch panel region in which a second transparent resin layer, a second touch sensor sheet, and a liquid crystal sheet are layered in order from the front side toward the back side. Since the software switch region includes the diffusion sheet, not only is it possible to ensure the visibility when sunlight shines, but it is also possible to prevent the internal structure from being seen when the light source is turned off, thus enhancing the quality of the external appearance

Owner:HONDA MOTOR CO LTD

Vehicle-mounted display device

ActiveUS9855845B2Increase brightnessEnsure visibilityDashboard fitting arrangementsInstrument arrangements/adaptationsVisibilityDisplay device

A vehicle-mounted display device includes a software switch region in which a first transparent resin layer, a symbol and design printed layer, a smoke printed layer, a first touch sensor sheet, and a diffusion sheet are layered in order from the front side toward the back side, and a liquid crystal touch panel region in which a second transparent resin layer, a second touch sensor sheet, and a liquid crystal sheet are layered in order from the front side toward the back side. Since the software switch region includes the diffusion sheet, not only is it possible to ensure the visibility when sunlight shines, but it is also possible to prevent the internal structure from being seen when the light source is turned off, thus enhancing the quality of the external appearance.

Owner:HONDA MOTOR CO LTD

Granular feed for carps

The invention provides a granular feed for carps. The granular feed comprises the following components in parts by weight: 10-15 parts of middling, 10-15 parts of fish meal, 5-10 parts of wheat starch, 10-15 parts of soybean meal, 10-15 parts of colza cakes, 20-30 parts of barley bran, 5-10 parts of corn protein powder, 2-5 parts of pine needle meal, 3-5 parts of humic acid, 0.3-0.8 part of a fat emulsion, and 0.5-1 part of premix. The feed is strict and reasonable in sorting, the raw materials of the feed are allocated newly, so that the food-calling capacity and the digestion utilization rate of the feed are increased, the reduction rate and the powder content of the feed are reduced, the losses of nutrient substances are reduced, the quality of the feed is improved, and the cost of the raw materials is reduced.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

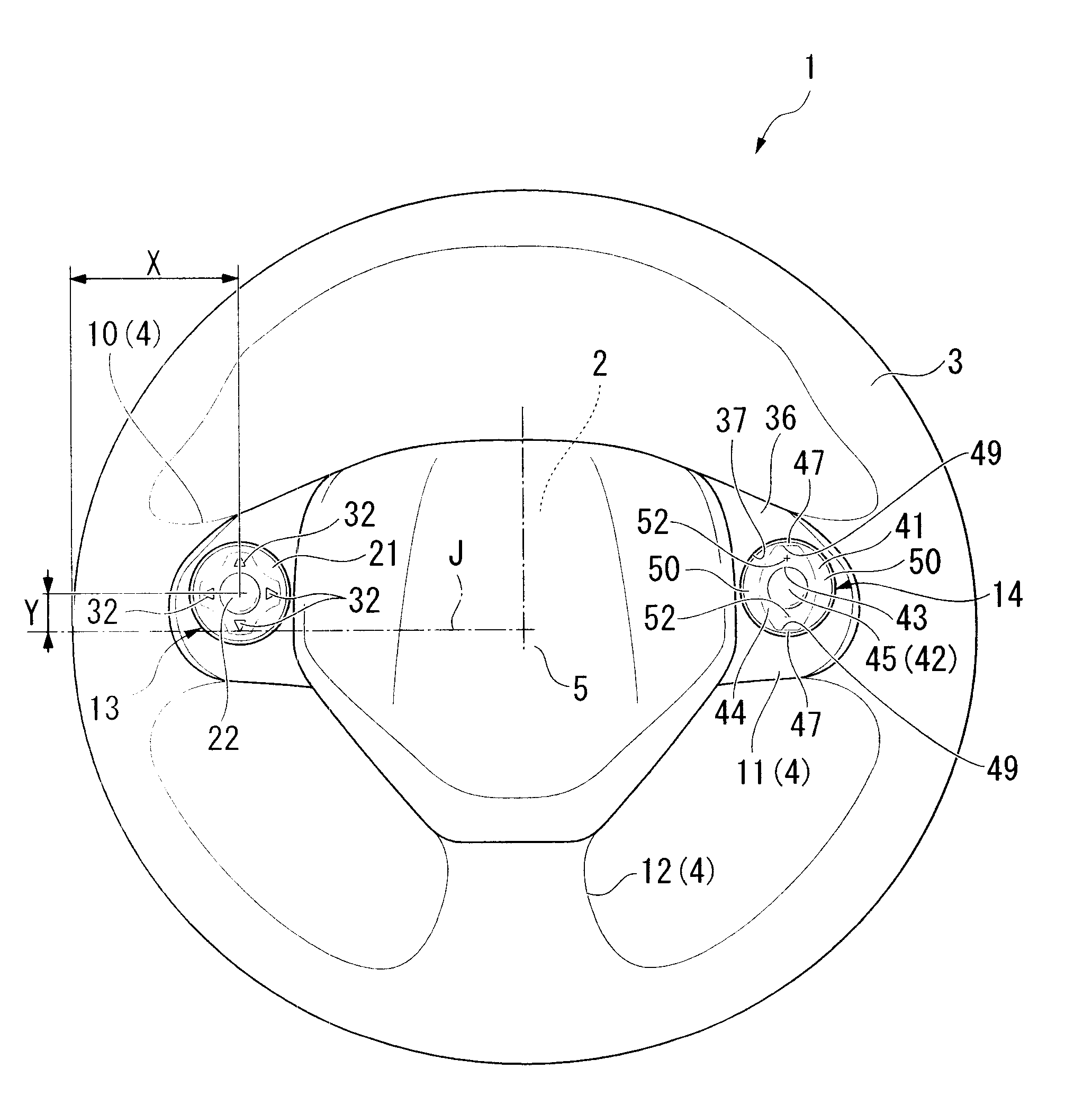

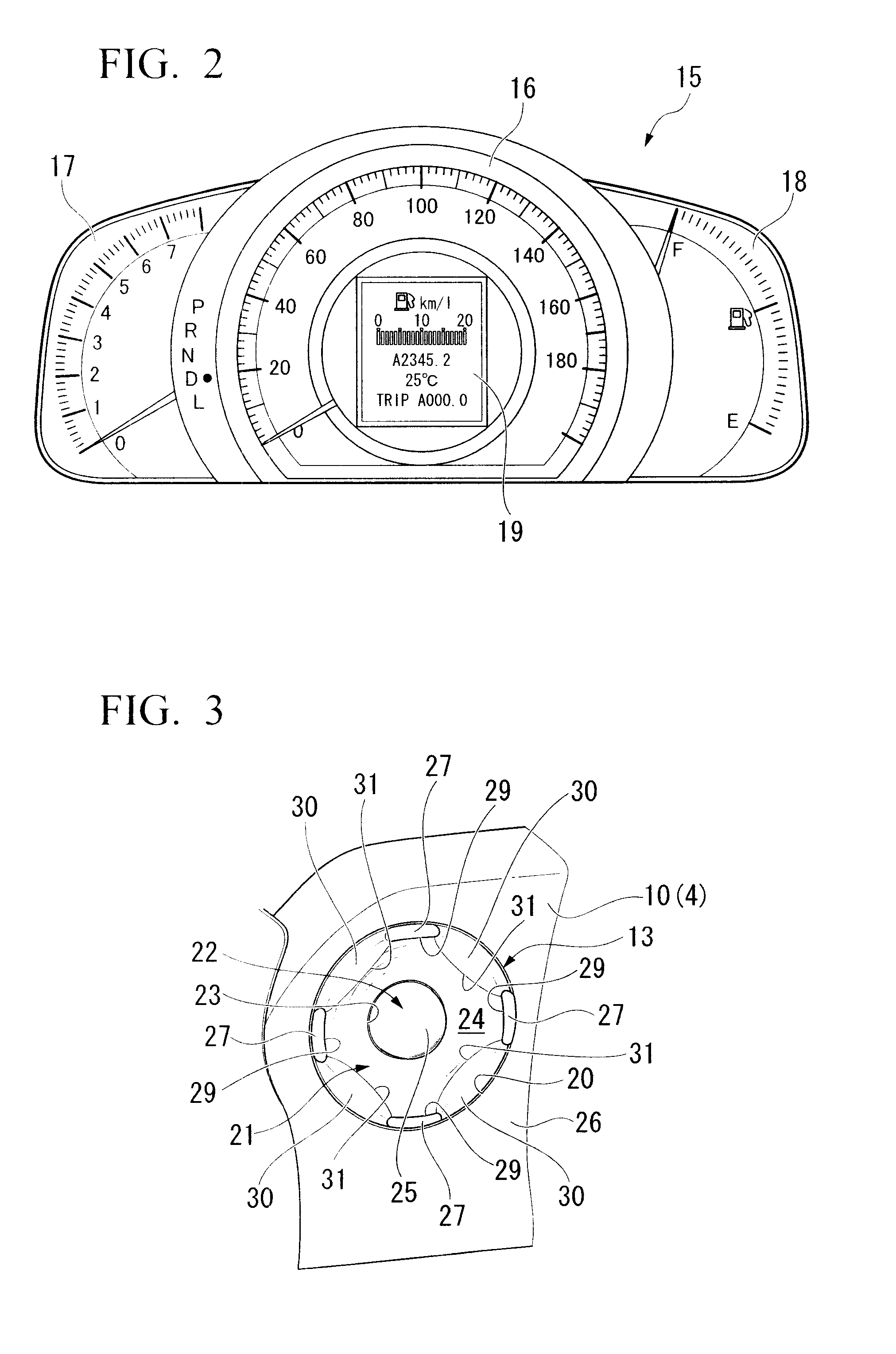

Switch for vehicle

ActiveUS20110232412A1Reduce the possibilityEasy to operateControlling membersMechanical apparatusEngineeringElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

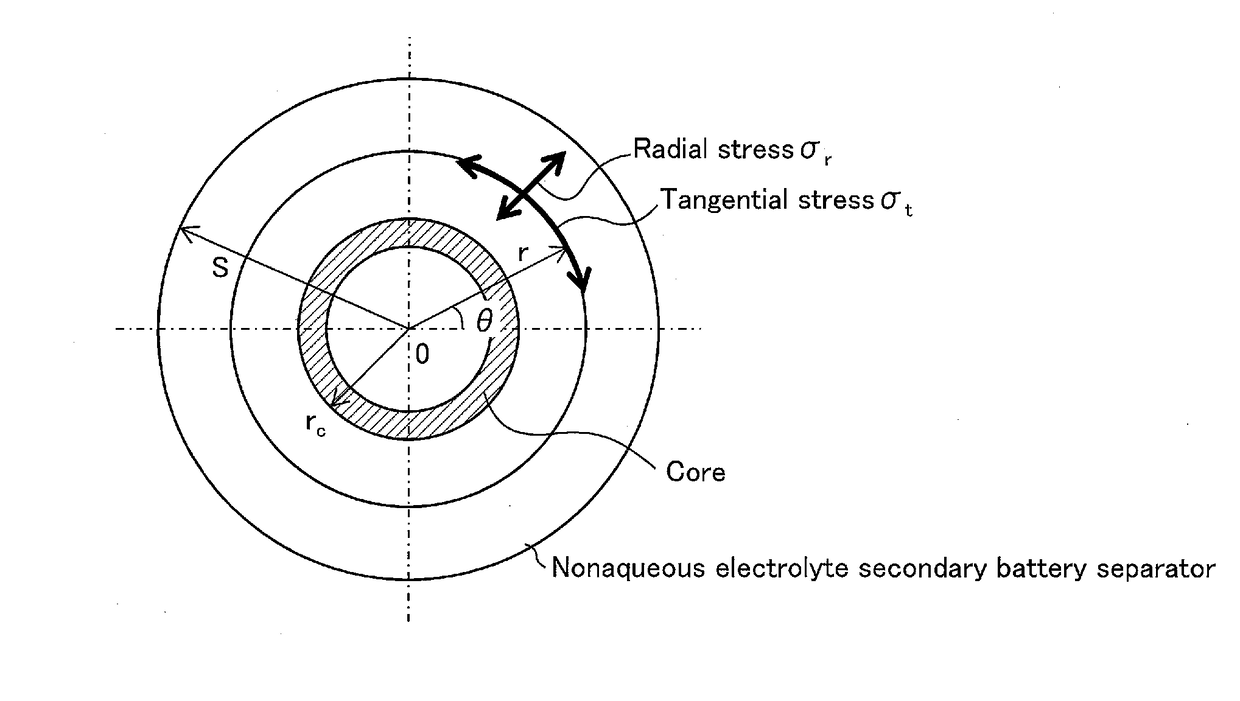

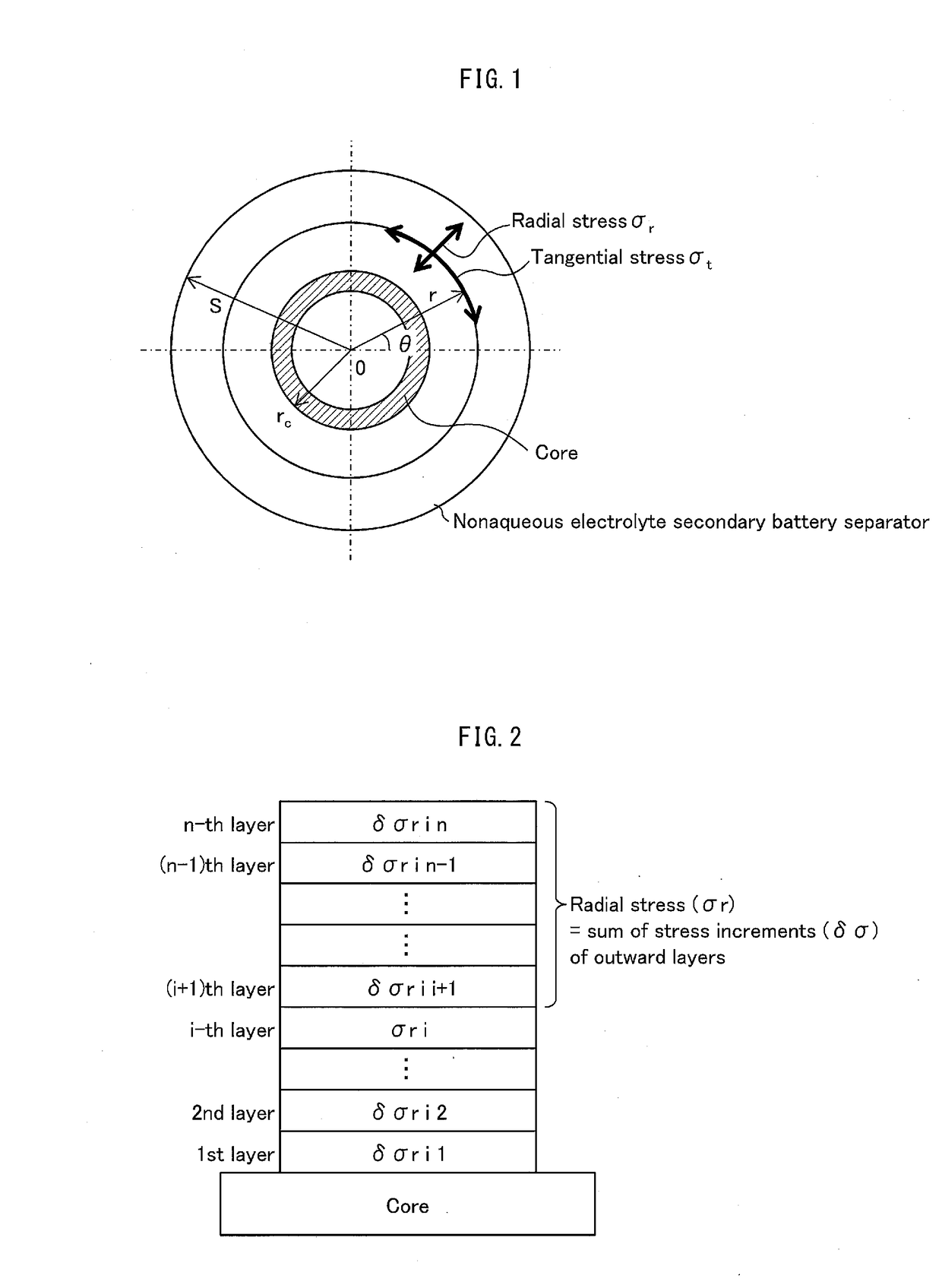

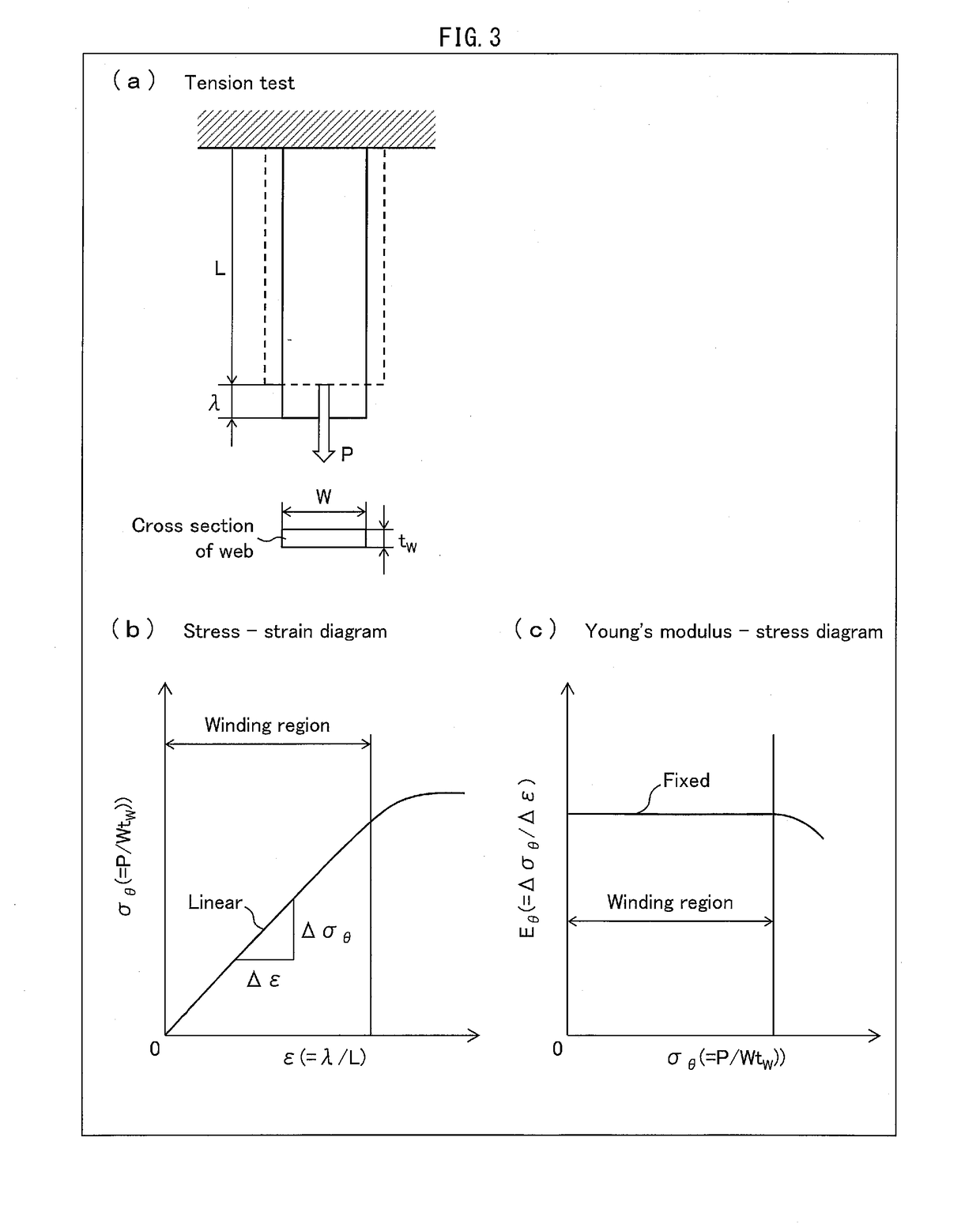

Separator roll and method for manufacturing same

InactiveUS20170271640A1Reduce distortionImprove external qualityCell seperators/membranes/diaphragms/spacersFinal product manufactureRadial stressEngineering

Provided is a separator roll in which deformation is reduced and an external quality is improved. In the separator roll, a separator is wound around a core, and an absolute value of radial stress σr applied to the core is not more than a critical stress σcr. The critical stress σcr is a value obtained by multiplying A by B, where: A is an absolute value, of radial stress σr applied to the core, as observed in a case where a maximum value of Von Mises stress σm in the core is equal to a yield stress σy of a material of the core; and B is a safety factor of 0.5.

Owner:SUMITOMO CHEM CO LTD

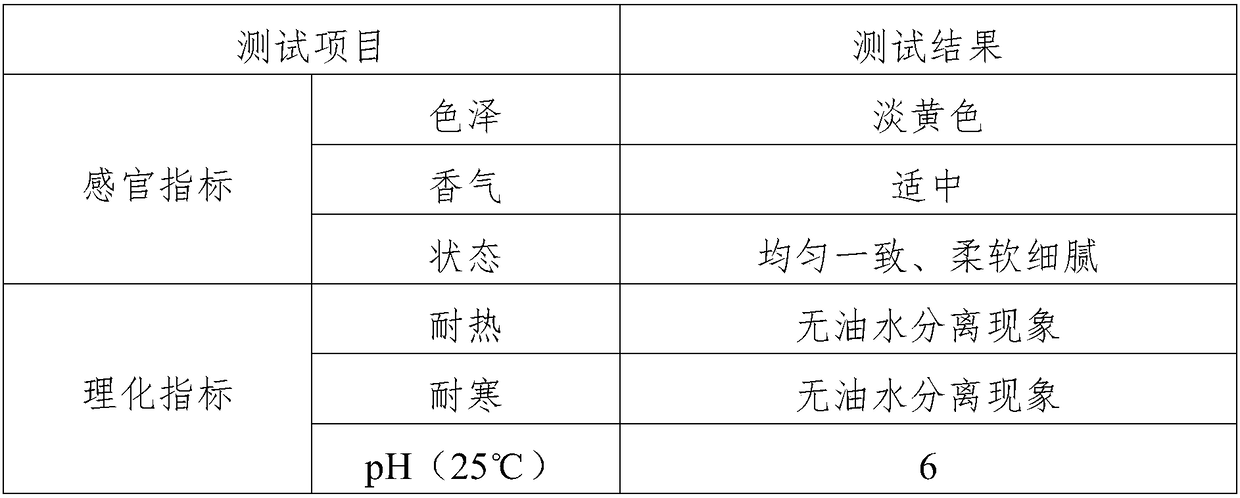

Reliving cream and preparation method thereof

ActiveCN108354891AGood affinityPrevent moisture lossCosmetic preparationsToilet preparationsTriethanolamineSensitization

The invention discloses reliving cream which comprises the following components in percentage by weight: 3.1-16% of effective components, 1.6-5% of an emulsifier, 9-20% of grease, 3-10% of a silk extract, 0.5-3% of Carbomer, 0.5-3% of triethanolamine, 1-5% of propylene glycol, 3-5% of 1,2-pentanediol and the balance of deionized water, wherein the effective components comprise a centella asiaticaextract, lactoferrin, a saccharomyces lysate extract and ceramide-3. The invention further discloses a preparation method of the reliving cream. The reliving cream is prepared from the silk extract which is compounded with the centella asiatica extract, the lactoferrin, the saccharomyces lysate extract and the ceramide-3, under coactions of the emulsifier, a moistening agent, a thickening agent, the grease, a pH value adjusting agent and a preservative, synergetic effects of the raw materials are taken into play, high external quality of the made cream can be maintained, remarkable relieving and itching quenching functions can be achieved, the sensitization rate can be reduced, and the relieving cream has the advantages of being gentle and non-irritant, high in moistening degree, good in skin feeling, easy to absorb, safe and free of toxic or side effect, and the like.

Owner:SOUTHWEST UNIVERSITY

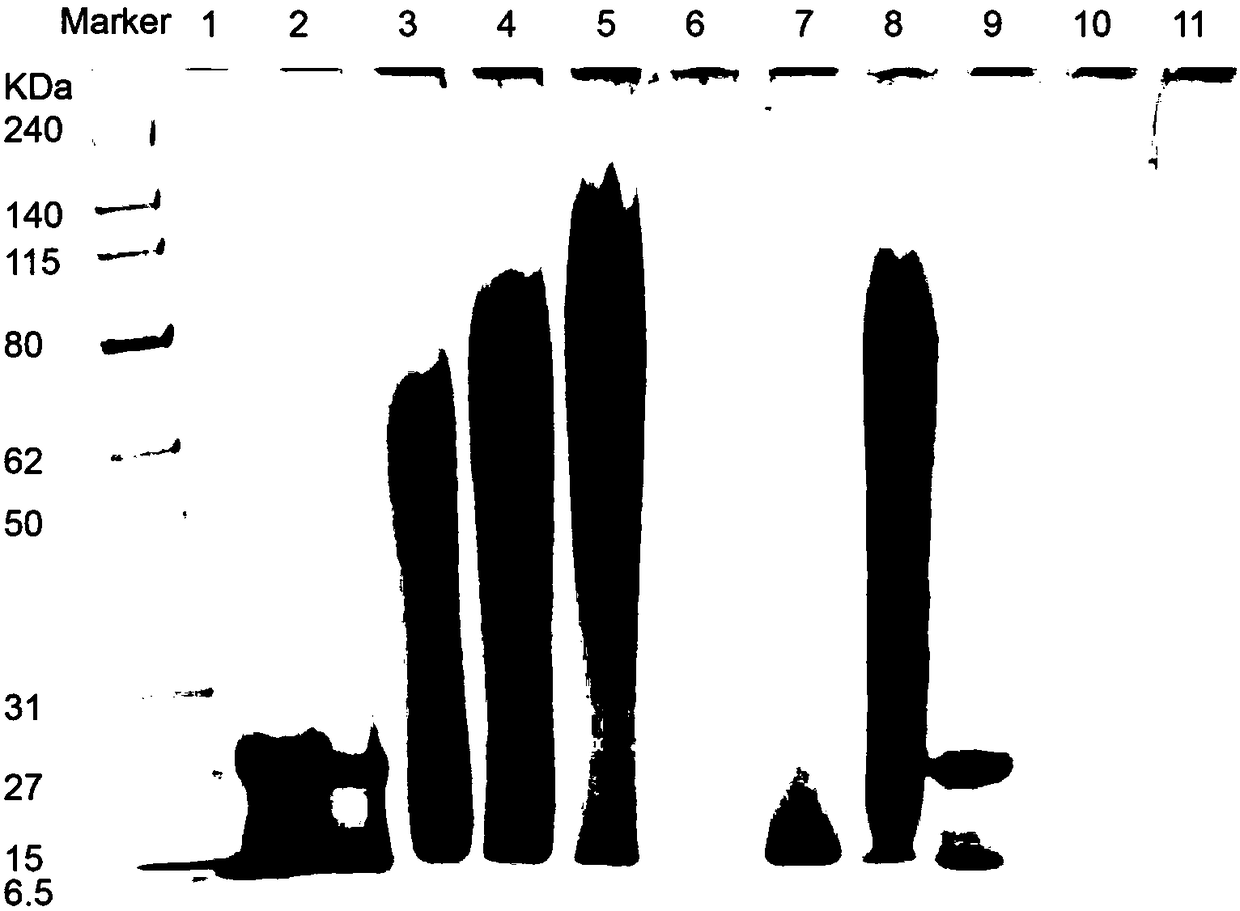

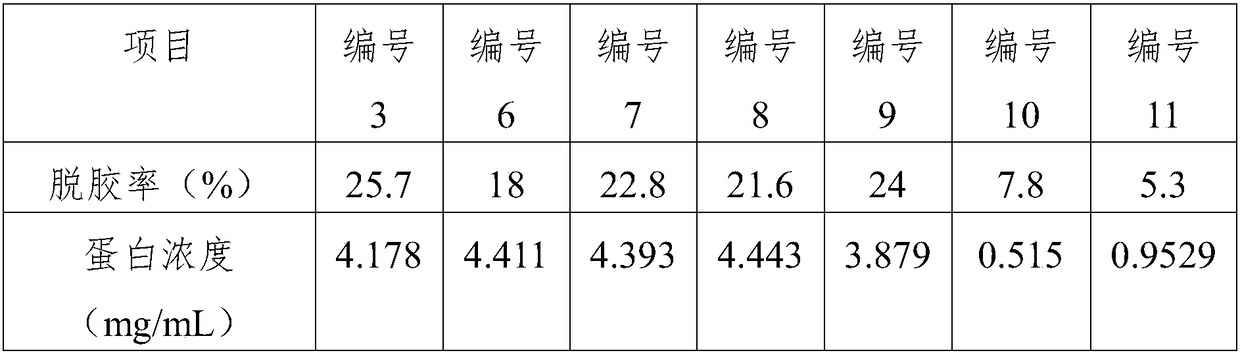

Leech extract and preparation method and application thereof

InactiveCN108079022AImproved activity and quality controllabilityIncrease profitNervous disorderBlood disorderUltrafiltrationAnticoagulant effect

The invention discloses a leech extract preparation method. The method is characterized in that water is added in leech and the materials are homogenized, and steps of controllable enzymatic hydrolysis, deposition with an organic solvent, ultrafiltration, and anion exchange chromatography are carried out to prepare the leech extract. The leech extract can be used for preparing the medicines havingthe anticoagulant effect, thrombolysis effect, platelet aggregation inhibition effect and nerve protection effect. From technical requirements of modernization of traditional Chinese medicines, a controllable enzymatic hydrolysis technology is employed for extracting a peptide component in leech, combining with a biopharmaceutical technology, an ultrafiltration technology and a gel chromatographyseparating technology can be employed for further purifying, and the extract having higher purity and stronger activity than that of the traditional leech extract can be obtained. The method breakthroughs the bottleneck of the traditional animal drugs on extraction and separating aspects, and solves the problems of large amount and fishy smell of used raw powder.

Owner:石佳媛

Granulated grass carp fodder

The invention provides a granulated grass carp fodder comprising the following components: 10-15 parts by weight of wheat middling, 10-15 parts by weight of fish meal, 5-10 parts by weight of wheat starch, 10-15 parts by weight of bean pulp, 10-15 parts by weight of rape seed cake, 15-25 parts by weight of barley bran, 15-25 parts by weight of wheat bran, 2-5 parts by weight of pine needle powder, 3-5 parts by weight of humic acid, 0.3-0.6 part by weight of cellulase, 0.3-0.8 part by weight of fat emulsifier, and 0.5-1 part by weight of premix compound. The materials of the fodder are strictly and reasonably selected; the feeding attraction and the digestive utilization ratio of the fodder are increased by re-proportioning the raw materials of the fodder, meanwhile, the breakage rate and the powder content of the fodder are reduced, the loss of nutriment is reduced, the quality of the fodder is increased, and the cost on the raw materials is reduced.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

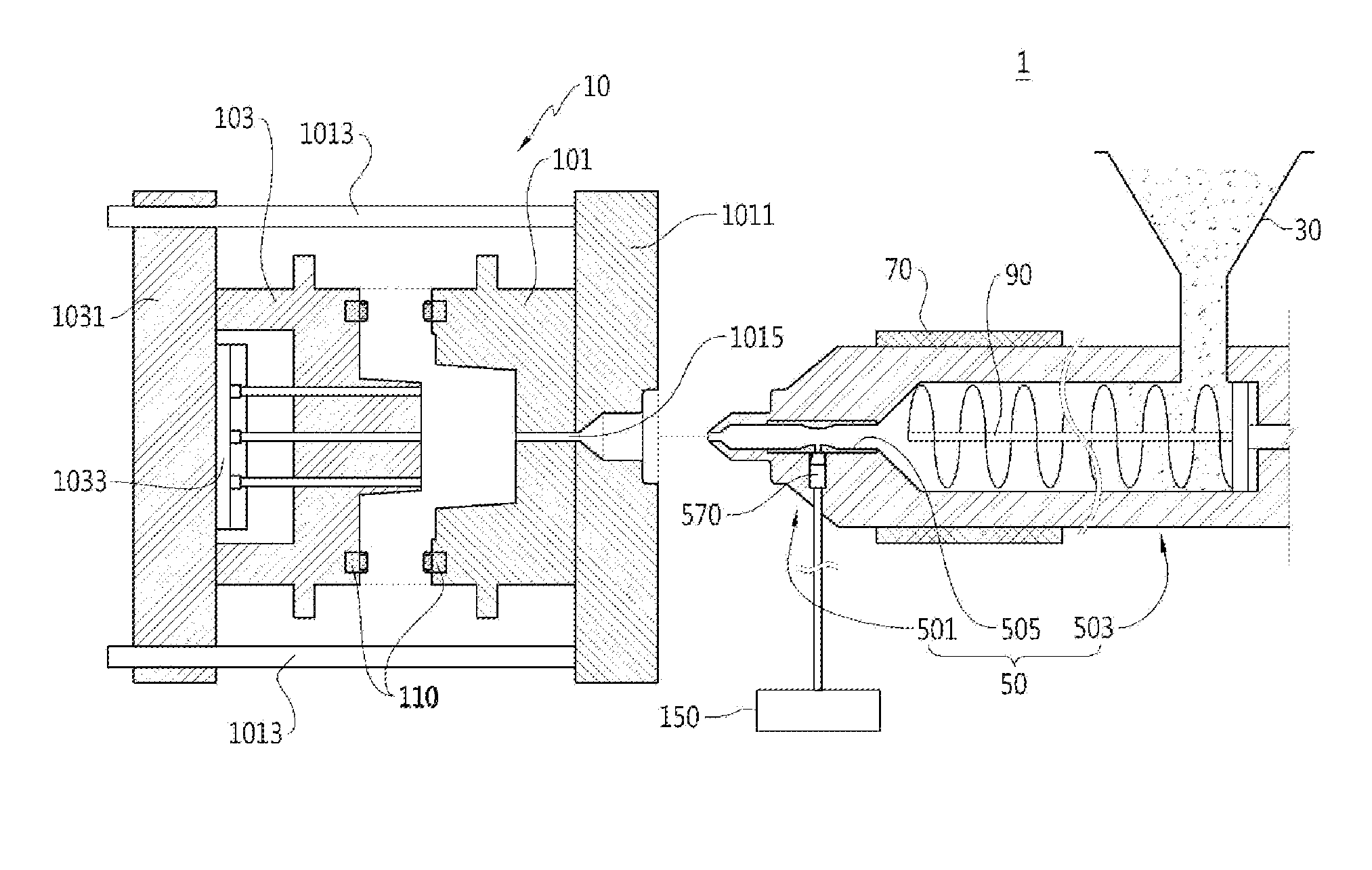

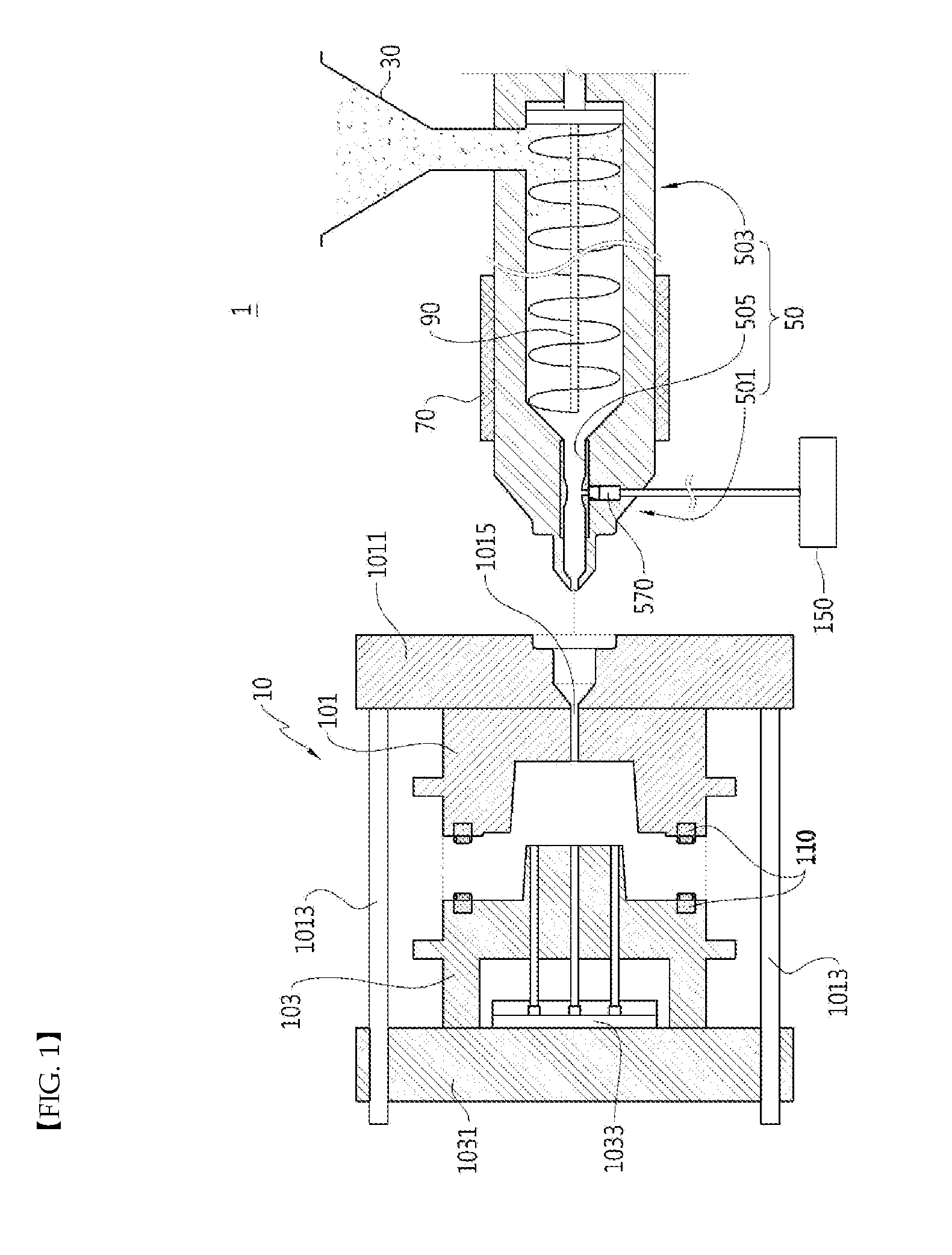

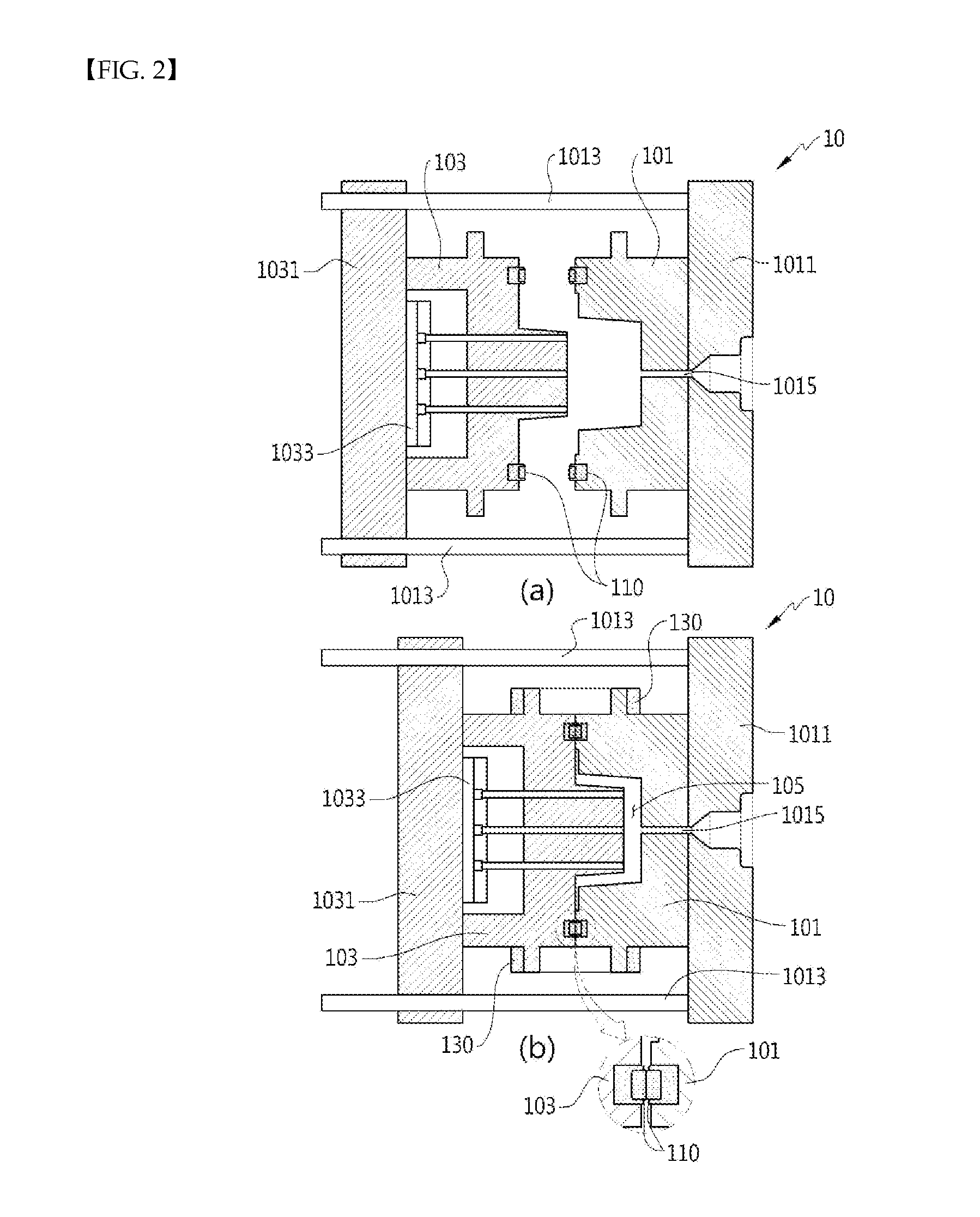

Vacuum injection molding device and injection molding method using same

InactiveUS20150336313A1Extended maintenance periodReduce maintenance costsFood shapingFistEngineering

A vacuum injection molding device according to an embodiment of the present invention includes: a first mold which is connected to an injection nozzle and is supplied with resin; a second mold which is coupled with the first mold so as to form an injection cavity; a fist seal member and a second seal member which surrounds an outer side of a contacting surface of the first mold and the second mold and faces one another to contact one another; and a vacuum pump which exhausts gas in the injection cavity so as to form a vacuum state in the injection cavity. A gas exhausting passage is provided to communicate with the injection cavity via one or more of the first seal member and the second seal member, and the vacuum pump exhausts the gas in the injection cavity via the gas exhausting passage.

Owner:MPA TECH

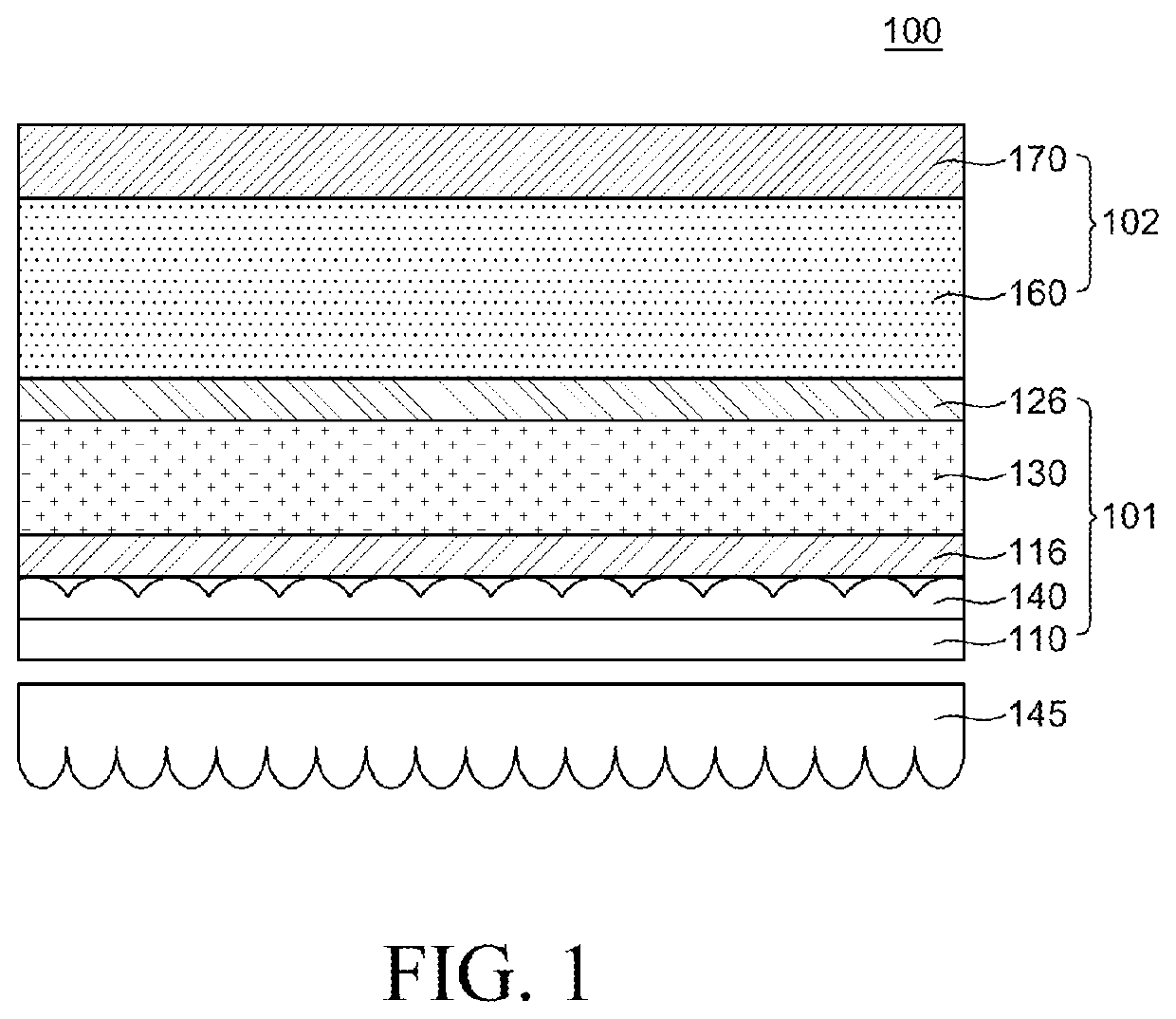

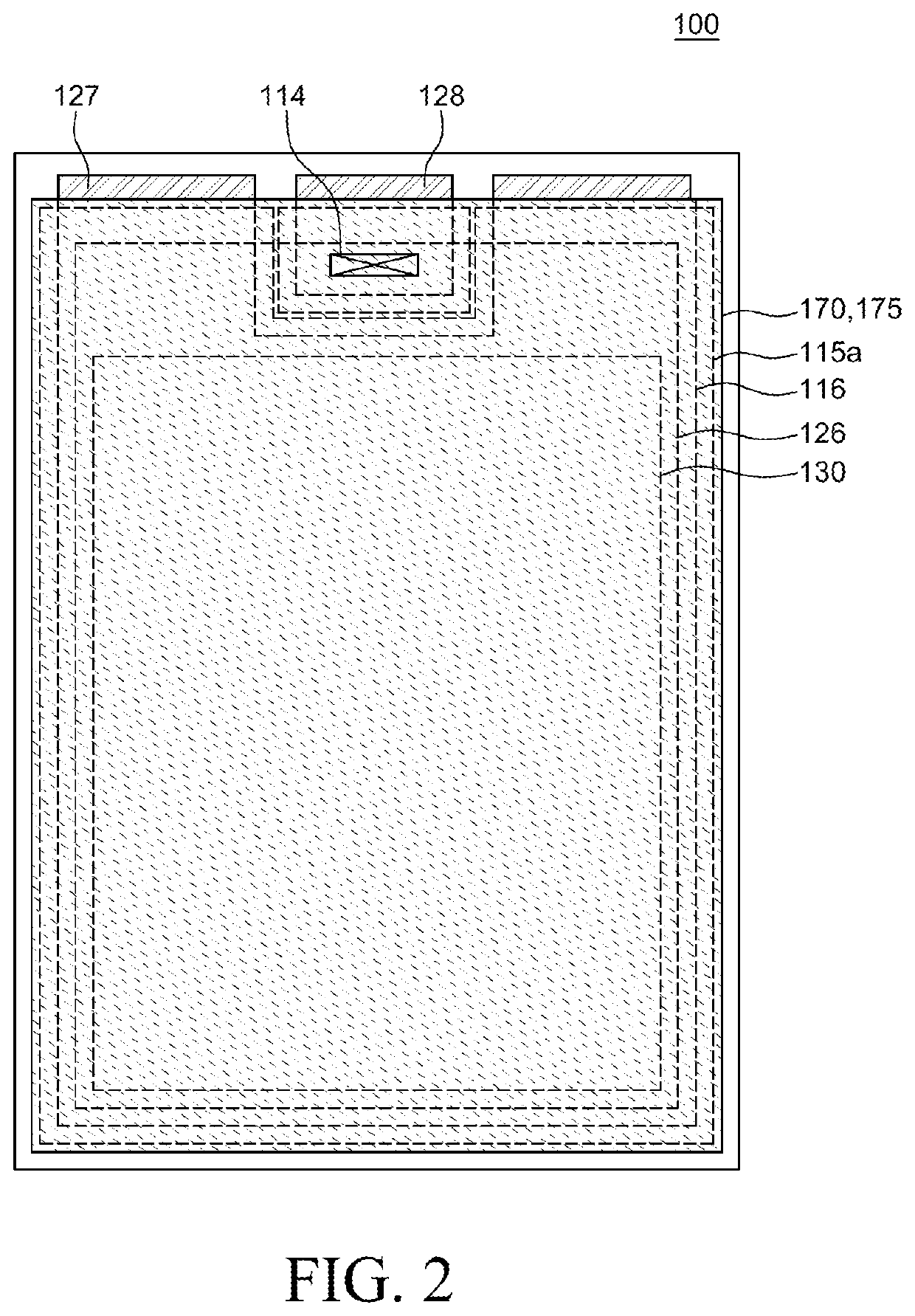

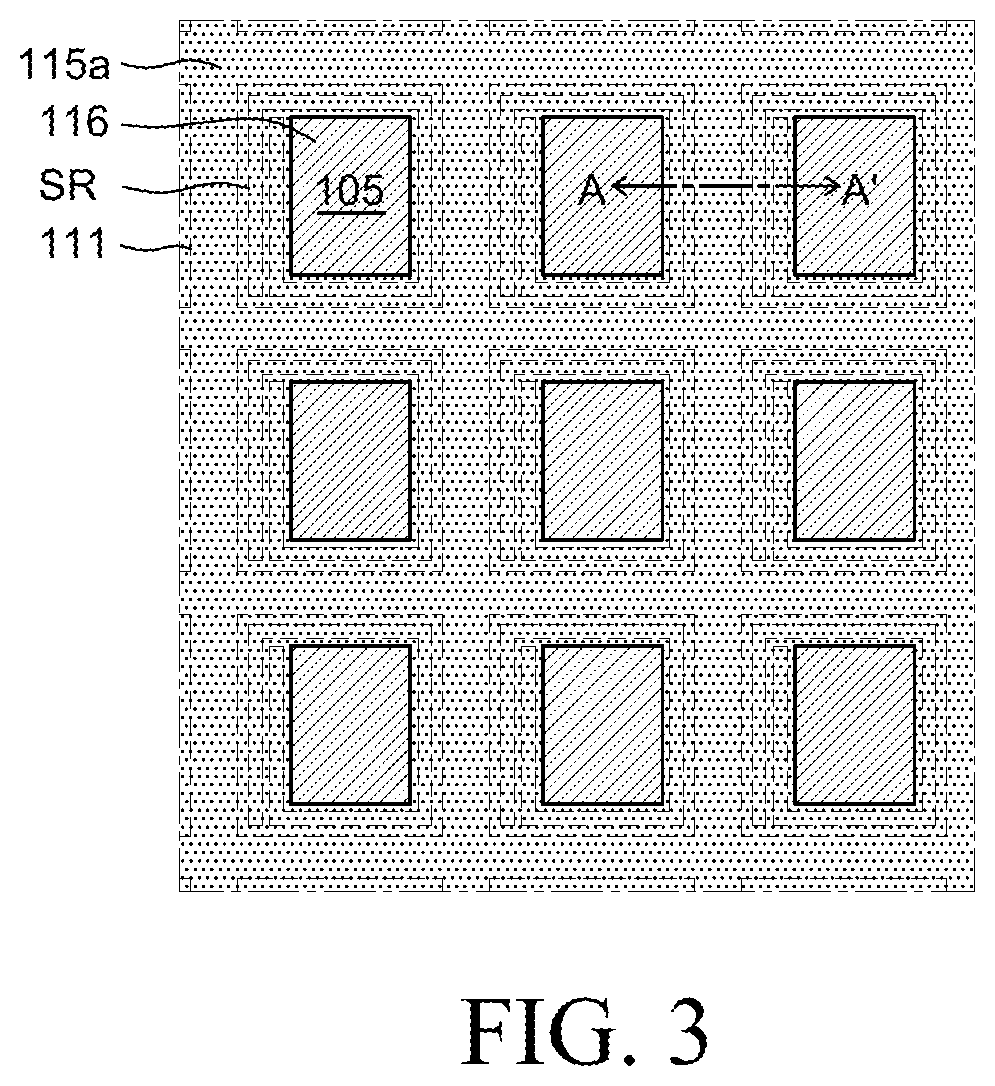

Lighting apparatus using organic light emitting diode

ActiveUS20200028111A1Decrease in luminanceUniform maintenanceSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeOLED

A lighting apparatus including organic light-emitting diodes comprises an anode disposed in an emission area of a substrate; first and second pad electrodes disposed on an outer side of the emission area of the substrate; a short-circuit reduction pattern surrounding an emission zone of each of pixels and formed by removing a part of the anode; a passivation layer comprising the short-circuit reduction pattern and disposed on the anode; an organic layer and a cathode disposed on the passivation layer in the emission area of the substrate; and a metal film disposed in the emission area of the substrate, wherein the short-circuit reduction pattern has a gradually-reducing resistance with an increased distance between the pixels and the first and second pad electrodes.

Owner:LG DISPLAY CO LTD

A clean production process of natural organic green tea

ActiveCN103988921BImprove inner qualityAchieve refinementPre-extraction tea treatmentBiotechnologyNutrition

The invention relates to a natural organic green tea clean-production technology. The natural organic green tea clean-production technology utilizes green tea leaves as making raw materials and the used green tea leaves grow in an organic tea garden and are picked in the spring and summer. The natural organic green tea clean-production technology comprises fresh green tea selection, fresh tea grading tedding, de-enzyming, spreading cooling, winnowing, rolling, deblocking sieving, primary baking, tea strip tidying and shaping, re-baking, autoclaving fragrance-improvement, inspection classification and packaging. The natural organic green tea obtained by the technology has the characteristics of light and elegant tea soup color, sweet tea taste, fresh and lasting fragrance, abundant nutrition and good health care effects, can continuously adjust human body functions, adjust blood pressure, reduce blood fat, prevent cardiovascular diseases, protect heart and cerebral vessels, eliminate fatigue and improve immunity by being drunk by drinkers and is a good health beverage suitable for people of all ages.

Owner:柞水福青山茶文化有限公司

Preparation method of pig feed

InactiveCN106387394AAvoid the problem of being easily oxidized and deterioratedImprove external qualityAccessory food factorsCrusherFodder

The present invention provides a preparation method of a pig feed. The preparation method comprises the following steps: (1) raw material weighing; (2) raw material crushing: the weighed materials in the step (1) are added into a crushing chamber of a crusher, then 50-80 parts of water is added, and the materials are crushed for 15-30 minutes; (3) material homogenizing: the crushed materials in the step (2) are transported into a homogenizer to be homogenized for 20-30 minutes; and (4) material drying: the homogenized materials in the step (3) are transported into a freeze dryer to be freeze-dried to obtain the pig feed. The method is strict in material selection and reasonable in matching. Each of the raw materials consisting the feed are crushed, the crushed materials are homogenized, and the homogenized materials are subjected to the freeze-drying treatment, so that the feed is reduced in broken rate and powder containing rate, good in rehydration, less in nutrient loss, improved in quality, and reduced in the raw material costs.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

Thermoplastic film cutting device for adhesive tape packaging

ActiveCN107487496ANo thermal deformationImprove aestheticsWrapping material feeding apparatusAdhesive beltTorsion spring

The invention relates to a thermoplastic film cutting device for adhesive tape packaging. The thermoplastic film cutting device comprises a hot air cutter. Fixing plates are arranged on the two sides of the hot air cutter correspondingly and provided with a plurality of stand columns arranged below the fixing plates. The stand columns are provided with sliding blocks capable of sliding. A spring is arranged between each stand column and the corresponding sliding block. Each sliding block is provided with a first connecting rod and a second connecting rod which are parallel to each other, wherein one end of the first connecting rod and one end of the second connecting rod are hinged to the sliding block, the first connecting rod is provided with a vertical rod located between the hot air cutter and the sliding block, the two ends of the vertical rod are hinged to the other end of the first connecting rod and the other end of the second connecting rod, and the vertical rod is provided with an oblique rod arranged below the vertical rod. The multiple oblique rods arranged on the same side of the hot air cutter are connected through a pressing plate located below the oblique rods. Torsion springs are arranged at the hinged parts of the first connecting rods and the sliding blocks, and the sliding blocks are provided with limiting blocks. The hot air cutter is provided with a plurality of stirring rods corresponding to the sliding blocks. The second connecting rods are provided with stop rods arranged below the stirring rods. The thermoplastic film cutting device is ingenious in structure, the cutting process is stable and continuous, and cut thermoplastic film notches are tidy.

Owner:PUYANG TAIPU ADHESIVE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com