Automatic tea cake packaging machine and automatic tea cake packaging method

An automatic packaging machine and tea block technology, applied in transportation and packaging, wrapping paper bending devices, packaging, etc., can solve the problems of large packaging materials, low production efficiency, troublesome operation, etc., and achieve easy packaging operation and low packaging cost The effect of reducing and avoiding packaging waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

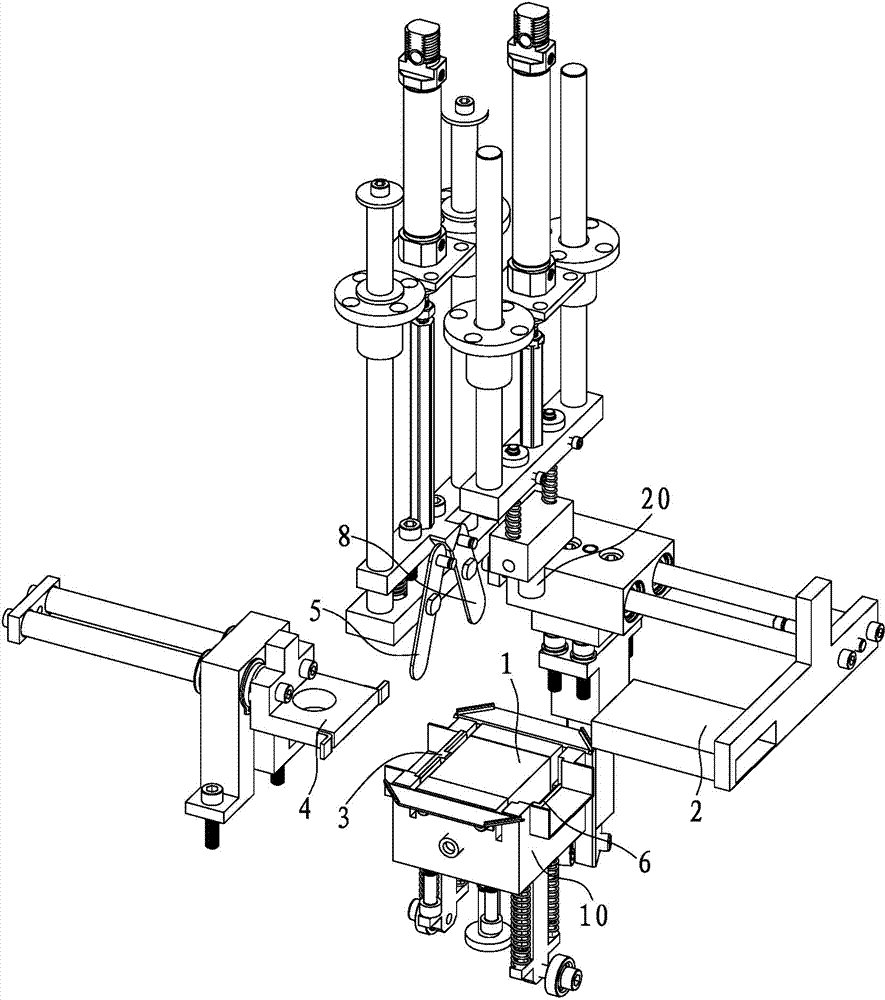

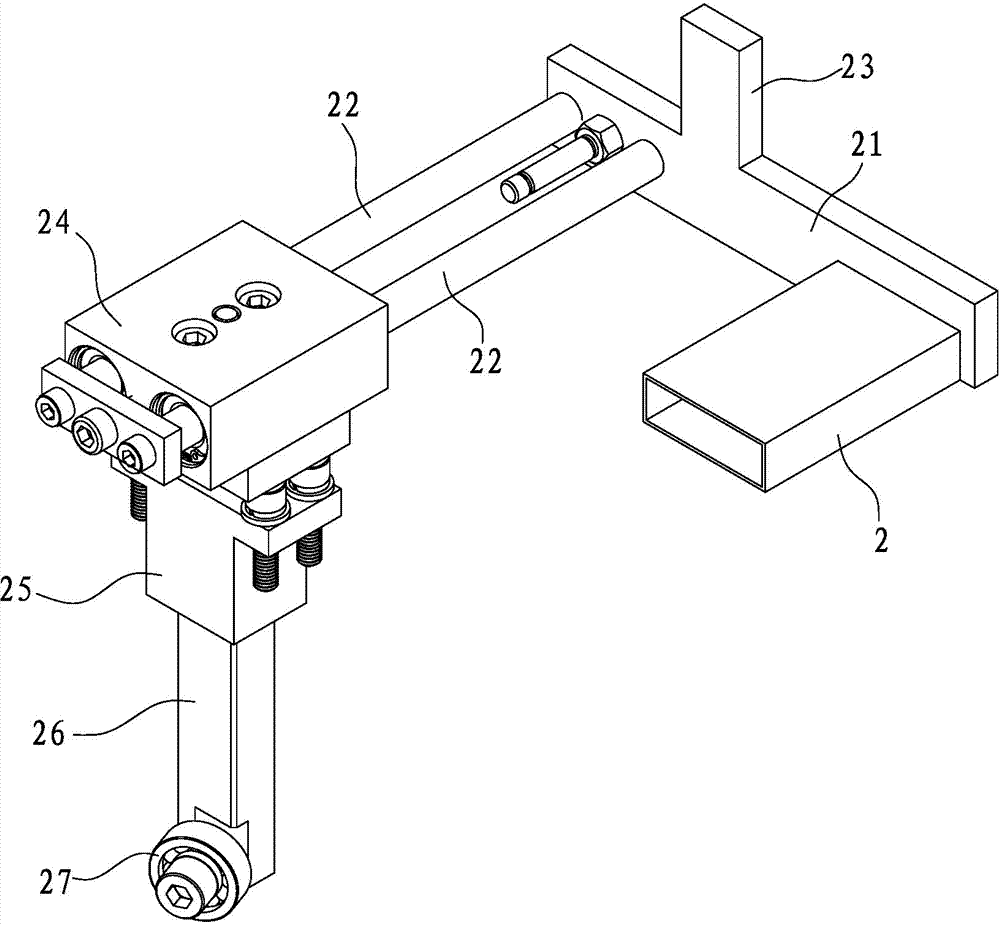

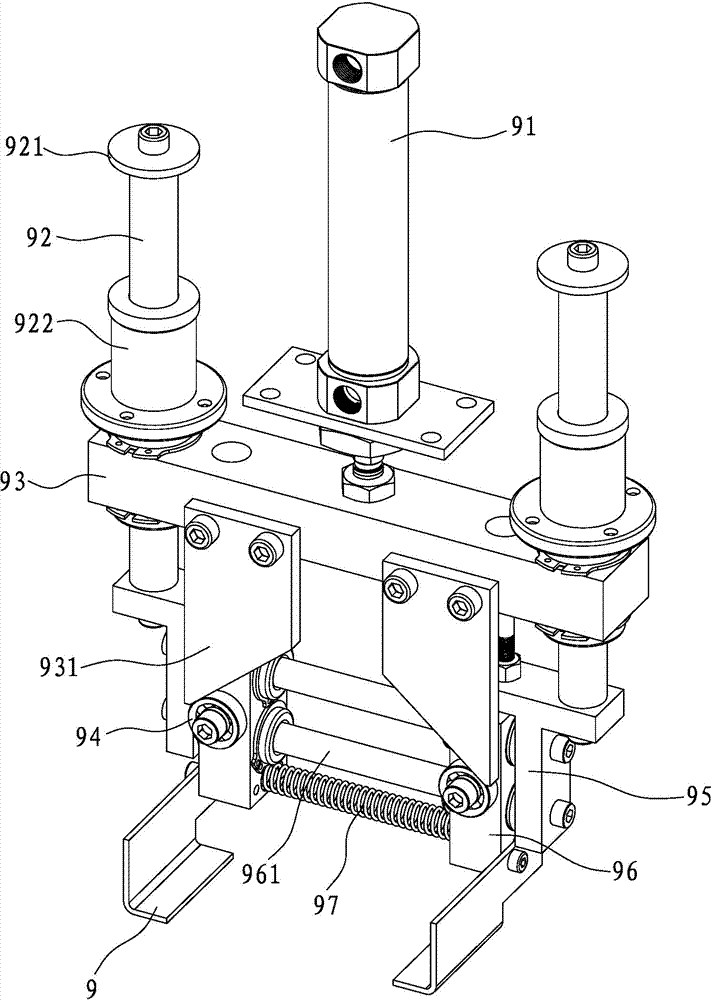

[0057] Such as figure 1 As shown, an automatic tea block packaging machine disclosed by the present invention includes a U-shaped tooling base 10, a paper support block 1, a tea bag mold 2, an inner side pushing cardboard 3, an inner side pressing cardboard 4, and an inner side pressing cardboard marking board 5. Outer cardboard pusher 6, outer presser plate (same structure as inner presser 4 and opposite to each other, limited by the drawing, not shown in the figure), outer presser plate 8 (and inner presser 4) Plates 5 have the same structure and relative positions, limited by the drawing, not shown in the figure), folding paper plates 9 on both sides (limited by the drawing, not shown in the figure), heat sealing head 20 and transmission mechanism, wherein , the transmission mechanism is divided into several parts corresponding to each component, which are used to control the movement of each component and realize the relative control function to complete the mechanized prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com