Patents

Literature

202results about How to "Does not fade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

Digital reactive dye printing process for mulberry silk fabric

InactiveCN103451970AHigh color yieldIncrease color depthHeating/cooling textile fabricsDyeing processDigital printingUrea

The invention provides a digital reactive dye printing process for a mulberry silk fabric. The process comprises the following steps: carrying out textile sizing, drying, carrying out jet printing, steaming, washing by cold water, washing by hot water, washing by soap, washing by hot water, washing by cold water, and drying, wherein a sizing agent used in the textile sizing step comprises the following components in percentage by weight: 1%-3% of sodium sulfate powder, 0.5%-1% of sodium alginate, 3%-5% of urea, 0.5%-1.5% of sodium hydrogen carbonate, 1%-2% of modified starch, 5%-7% of electrolyte and the balance being water. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the inkjet printing color depth on a textile is increased, the color difference between a pattern on the textile and an electronic pattern is reduced, and the hand feel of the fabric is good.

Owner:SHIJIAZHUANG HEXI APPL TRADING

High gloss and high abrasion resistant water-based overprinting varnish and preparation method thereof

InactiveCN101974269AEnsure safety and environmental protectionGood effectPaper coatingCoatingsSolventVolatile organic compound

The invention discloses a high gloss and high abrasion resistant water-based overprinting varnish and a preparation method thereof. The overprinting varnish comprises the following components: deionized water, water-soluble solid acrylic resin, non film-forming material, film material, ammonia water, water-soluble emulsion wax, wetting and leveling agent, defoaming agent and thickener. The overprinting varnish of the invention uses water as solvent; when the overprinting varnish is used, only water is volatilized, thus the overprinting varnish is environmentally friendly; and the overprinting varnish does not contain heavy metals and can pass through the volatile organic compound (VOC) detection, thus being a safe and green product. The product of the invention uses water-soluble acrylic emulsion as the main matrix which combines with water-soluble solid acrylic resin, thus the safety and environmental friend of the product can be further ensured; and by adopting the special raw material combination, the product has good printing and glazing effects, high transparency and lustrousness and excellent wear resistance and is color-fast and scratch resistant; and after printed and glazed, the product has good water resistance and is not easy to scratch.

Owner:苏州凯康化工科技有限公司

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Personal characterized color steel sheet and making method and special use thereof

InactiveCN1358630AScratch resistantCorrosion resistanceCovering/liningsDomestic cooling apparatusGas phaseEngineering

The production method of personality colour steel plate includes the following steps: cutting colour shell plate into required size, stripping outermost layer protecting film of front face, designing and processing personality pattern, photo, characters and symbolic information in computer, outputting and printing the above-mentioned personality informatino on the transfer printing paper or film, sticking one side on which the ink is printed to the outermost layer structure of front face of the steel plate, heating and pressurizing to make the above-mentioned personality information transfer on the colour steel plate, then sticking strippable protecting film on its surface.

Owner:HAIER GRP CORP +1

Ink-absorbing quick-drying painting canvas

ActiveCN103741481AImprove antioxidant capacityNot easy to fadeFibre treatmentChemistryEconomic shortage

The invention discloses an ink-absorbing quick-drying painting canvas. The preparation method of the canvas comprises the following steps: (1) painting gel resin on the surface of fabric, drying in an oven with a temperature of 100 to 120 DEG C so as to obtain a gel resin layer; (2) painting prime paint on the gel resin layer, drying in an oven with a temperature of 90 to 100 DEG C so as to obtain a prime paint layer; (3) painting surface paint on the prime paint layer, drying in an oven with a temperature of 70 to 85 DEG C so as to obtain a surface paint layer, wherein during this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute; (4) painting ink-absorbing quick-drying paint on the surface paint layer, drying in an oven with a temperature of 70 to 85 DEG C, wherein in this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute. The ink-absorbing quick-drying painting canvas preserves the unique wash-painting effect of raw Xuan paper, overcomes the inherent shortages of raw Xuan paper, thus enlarges the application range and increases the collection value of wash paintings.

Owner:沭阳凤凰画材有限公司

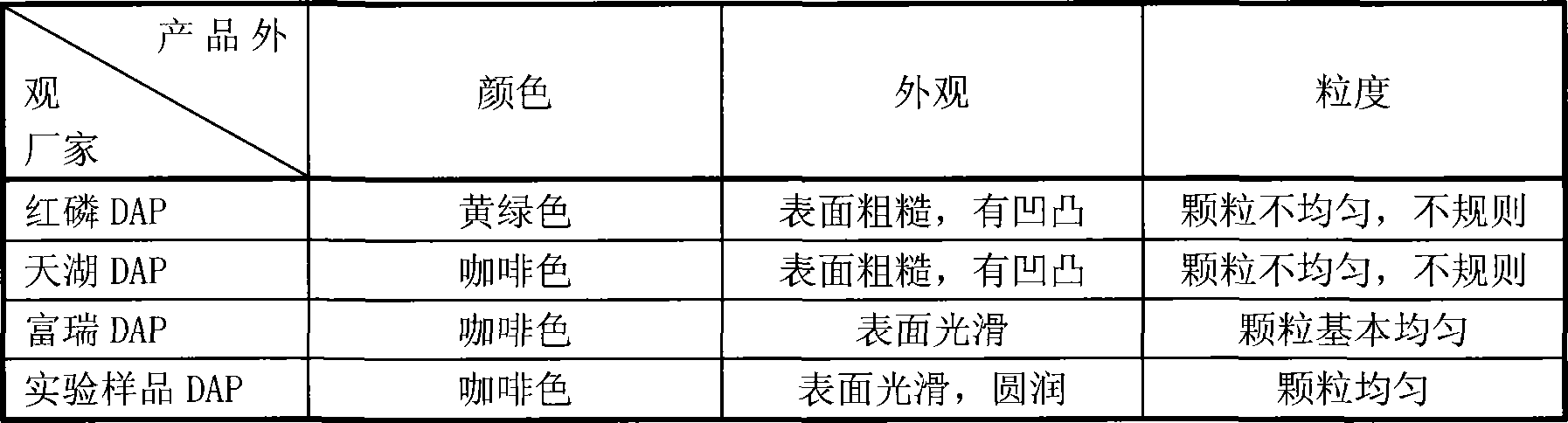

Method for dyeing phosphorus complex fertilizer

InactiveCN101234926AComponents that do not changeUniform colorFertiliser formsFertilizer mixturesDiammonium phosphatePhosphoric acid

The invention relates to a method for processing chemical fertilizer, in particular to a method for dyeing chemical fertilizer. The invention includes the preparation, addition, dyeing, and granulation of colorant, and comprises the following steps: A. adding weighted colorant into a phosphoric acid tank, an acid pump outlet or a pre-neutralization slot for producing phosphate compound fertilizer; B. mixing water solution with phosphate compound fertilizer for dyeing; C. spraying the slurry for granulation after dyeing. The method for dyeing chemical fertilizer is mainly used for appearance dyeing of various nitrogen and phosphate fertilizers and products, and can dye coffee on products evenly and effectively. The dyed products with high-quality appearance color do not have discoloration and color change so as to hit the target of unifying product color. Compared with that imported from America, diammonium phosphate dyed through the method for dyeing chemical fertilizer has the equal and even better color. As coffee color products sell well in the market, the invention can reduce sales cost.

Owner:云南云天化国际化工有限公司

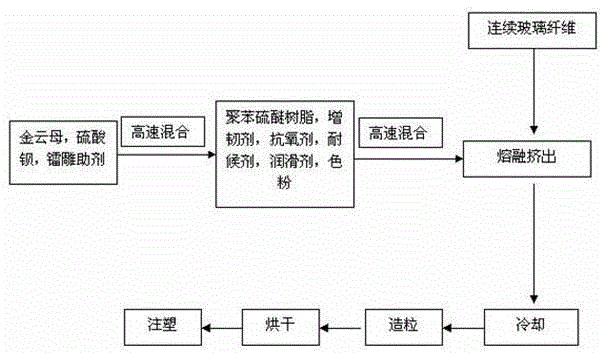

Glass fiber reinforced polyphenylene sulfide composite material with laser engraving function and preparation method of composite material

InactiveCN104448827AImprove mechanical propertiesExcellent Laser Marking PerformanceColored whiteLubrication Agents

The invention relates to the technical field of high polymer materials and in particular relates to a glass fiber reinforced polyphenylene sulfide composite material with a laser engraving function and a preparation method of the composite material. The glass fiber reinforced polyphenylene sulfide composite material with the laser engraving function comprises the following raw materials in parts by weight: 49.4-82.5 parts of polyphenylene sulfide resin, 0-40 parts of continuous glass fibers, 5-8 parts of a flexibilizer, 0.5-1.0 part of a weather-resistant agent, 0.3-0.5 part of an antioxidant, 0.3-0.5 part of a lubricating agent, 3-5 parts of flogopite, 1-2 parts of barium sulfate, 0.1-0.3 part of laser etching aids and 0-1 part of carbon black. The composite material disclosed by the invention has excellent mechanical property, mechanical strength and weather fastness and also has an excellent laser engraving function, and black, white or gray distinctive laser markers of which the strokes are clear and smooth and the colors are obvious and long-lasting and do not fade can be etched in substrates of different colors with laser; and moreover, the preparation method is simple and can be favorably popularized and used.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

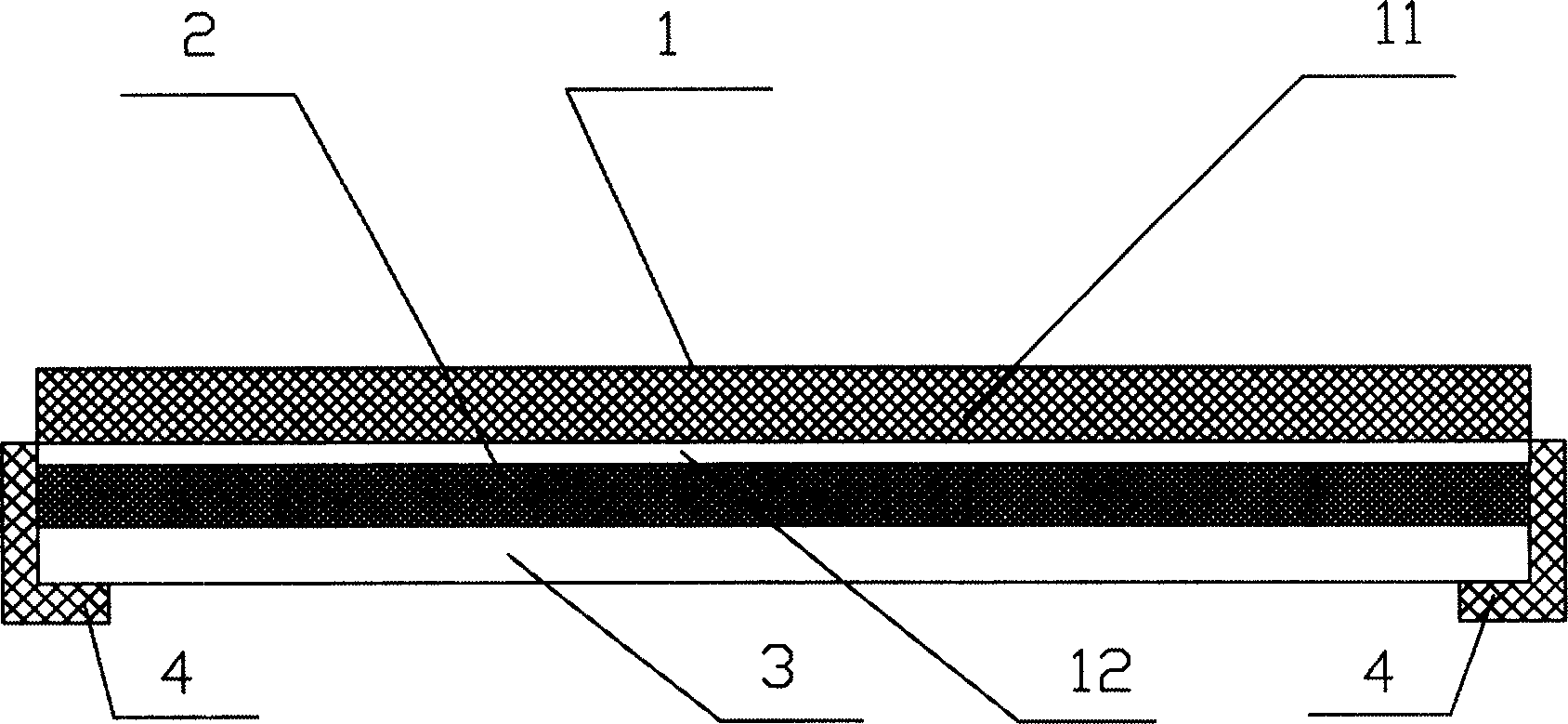

A woven back-cloth plastering carpet and method for manufacturing the same

InactiveCN1729899AFlat surfaceRealistic patternTufting apparatusLayered productsEngineeringBack-stripping

The invention relates to a woven back stripping carpet and its manufacturing method, comprising following steps: combing the spinning; beating the spinning and combining into section; weaving; printing decoration; filtering; fixing color; water washing; drying; scalding and cutting; and gluing the back stripping. In addition, the invention also relates to a carpet produced by said method, which has the advantages of flat surface of carpet, reality of pattern, non-fading, burliness, stability of fluff, and the neatness of the border while the bottom of carpet is antiskid and permeable to air.

Owner:刘福利 +1

Method for fabricating wheat stalk picture

InactiveCN101049791AHigh cutting accuracyUniform mass productionDecorative surface effectsOrnamental structuresLacquerEngineering

A method for making a wheat straw picture includes such steps as choosing wheat straws, rinsing, fumigating, splitting, scraping, chemical antiseptic treating, baking, splicing, ironing for smoothing, painting or printing, cutting by needed sizes, ironing, charring, coloring, sticking, and mounting. Its apparatus is also disclosed.

Owner:郝保学

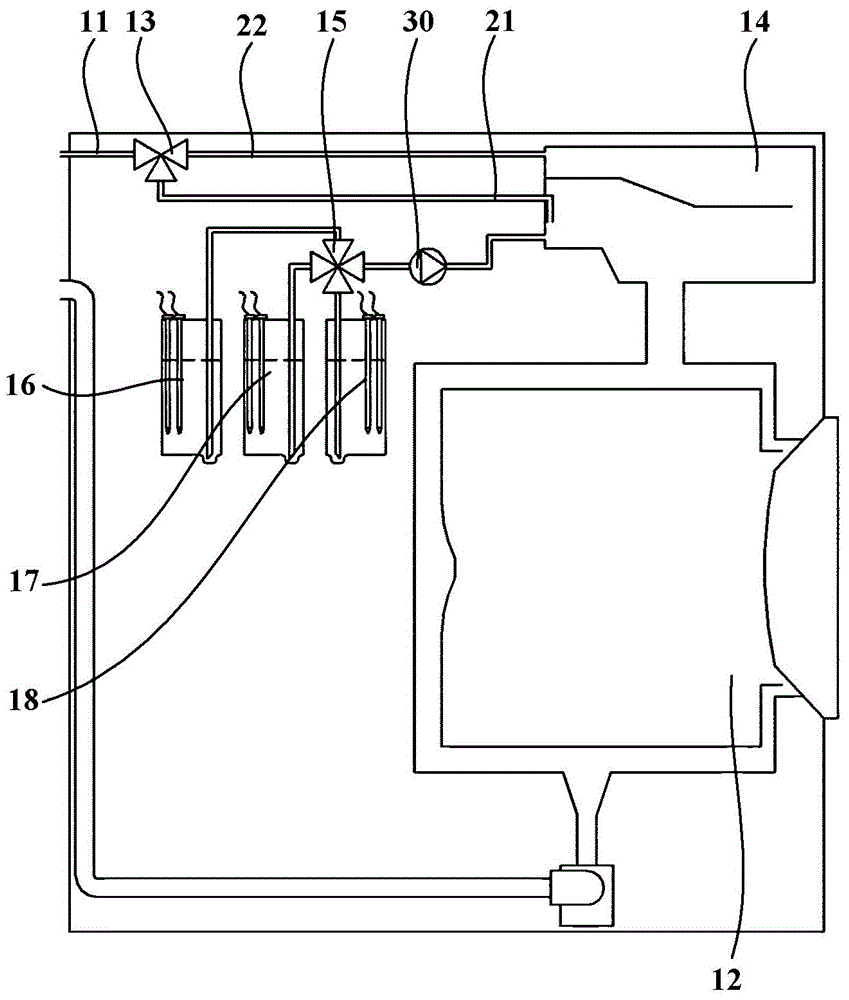

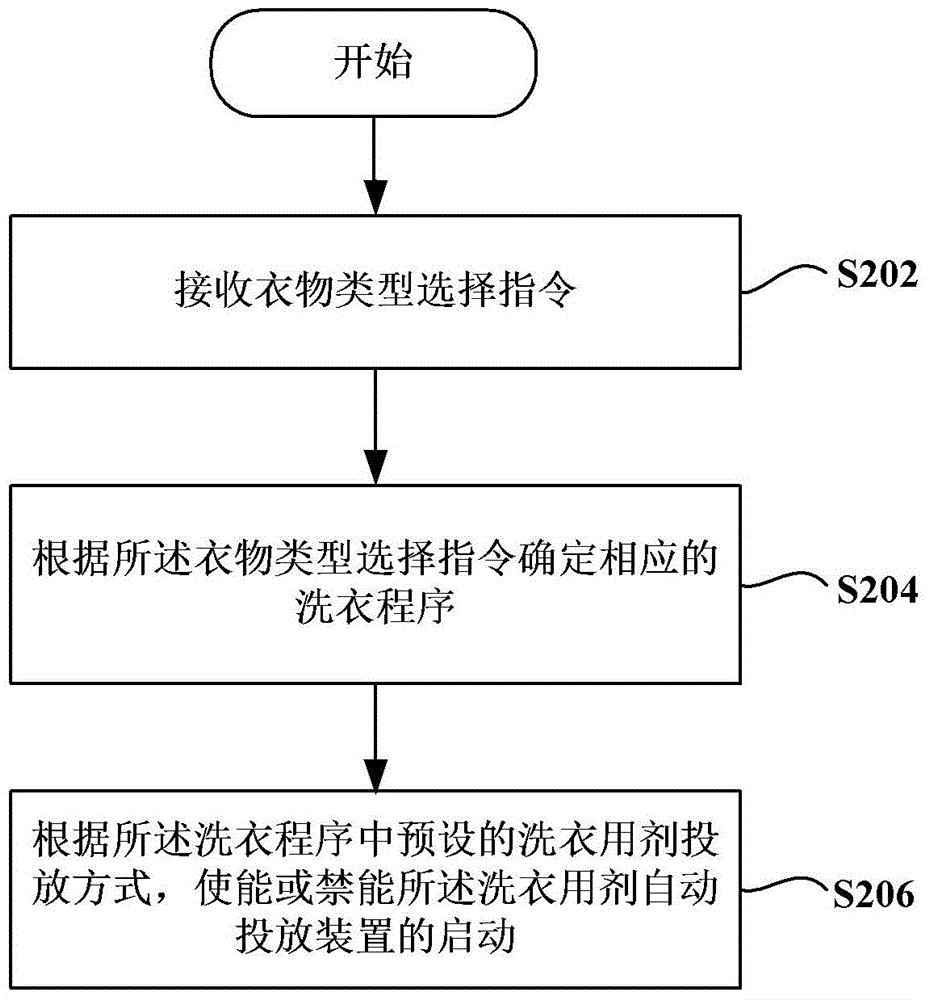

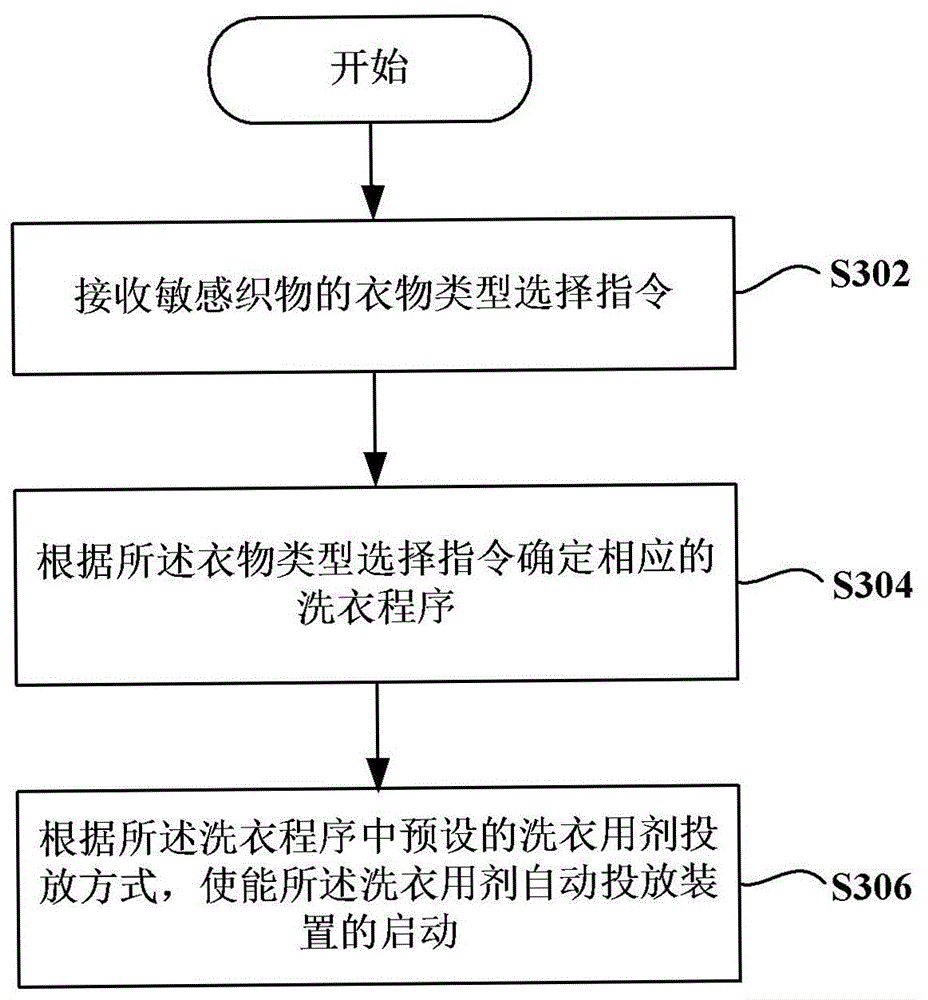

Washing machine and control method thereof

ActiveCN105624982AImprove experienceNot shrinkOther washing machinesControl devices for washing apparatusProcess engineeringLaundry detergent

The invention provides a washing machine and a control method thereof. The control method comprises that a clothing type selection instruction is received; a corresponding washing program is determined according to the clothing type selection instruction, and a laundry detergent feeding manner is preset in the washing program; according to the laundry detergent feeding manner preset in the washing program, the starting of a laundry detergent automatic feeding device is allowed or forbidden. According to the invention, a corresponding washing program can be selected according to the clothing type, according to the laundry detergent feeding manner preset in the washing program, the user can allow or forbid the starting of the laundry detergent automatic feeding device. and therefore the user can operate the washing machine more conveniently.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Aging method of cattail

InactiveCN105965646AImprove smoothnessGood flexibilityRadiation/waves wood treatmentWood treatment detailsAge methodMicrowave

The invention discloses an aging method of cattail. The aging method particularly comprises the steps of arrangement, fermentation, aging and drying. The aging method of cattail is simple, and is low in cost; the cost is saved by 13.4%; cattail is subjected to yeast fermentation treatment, so that a fiber structure is softened, a smoothness sense of cattail is improved, the soaking of an aging treatment agent is accelerated, and the weaving speed is increased; the aging treatment agent is extracted from all natural raw material, two times of extraction are conducted after lactobacillus fermentation, and the aging treatment agent is safe and nontoxic, so that the mildewproof and mothproof effects are improved significantly, the color and luster of the aged cattail are pure and natural, and an extraction yield is increased by 8.4%; the aging treatment is conducted through microwave ultrasound, so that the painting is quick and uniform, the flexibility of cattail is improved, the grade of a woven product is raised, the drying is facilitated, and the working efficiency is improved.

Owner:阜南县大喜柳编工艺品有限公司

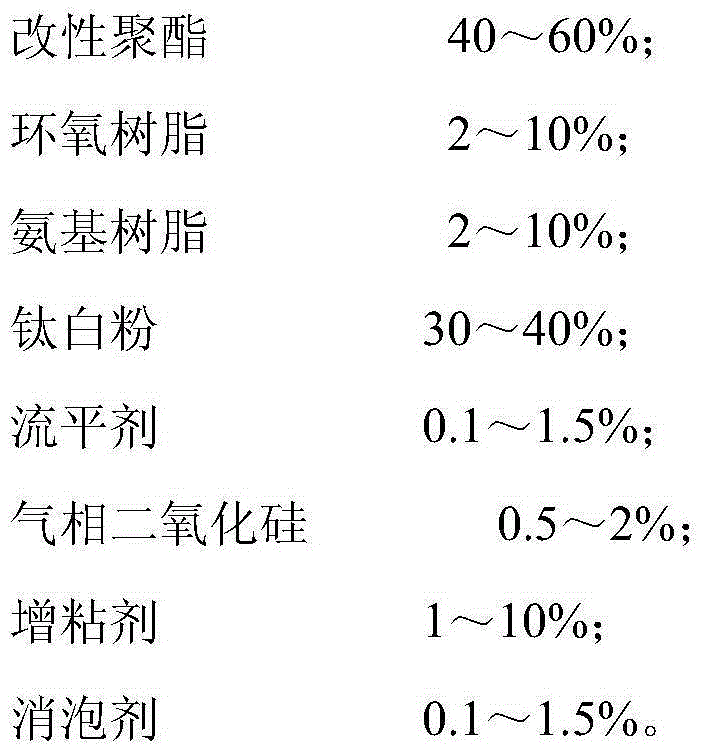

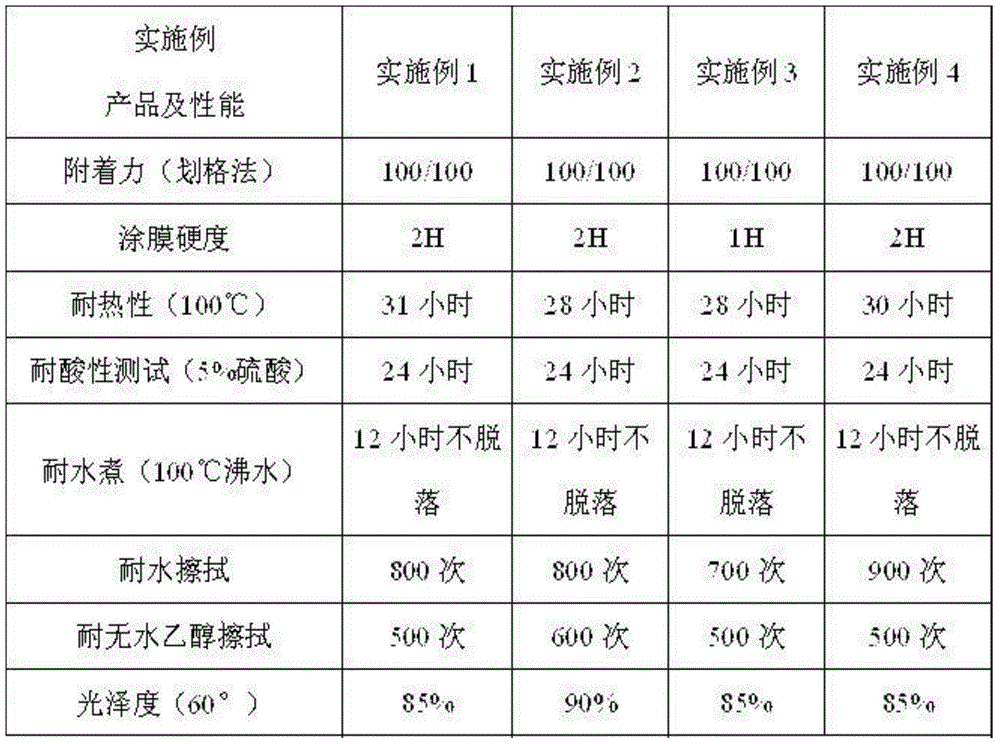

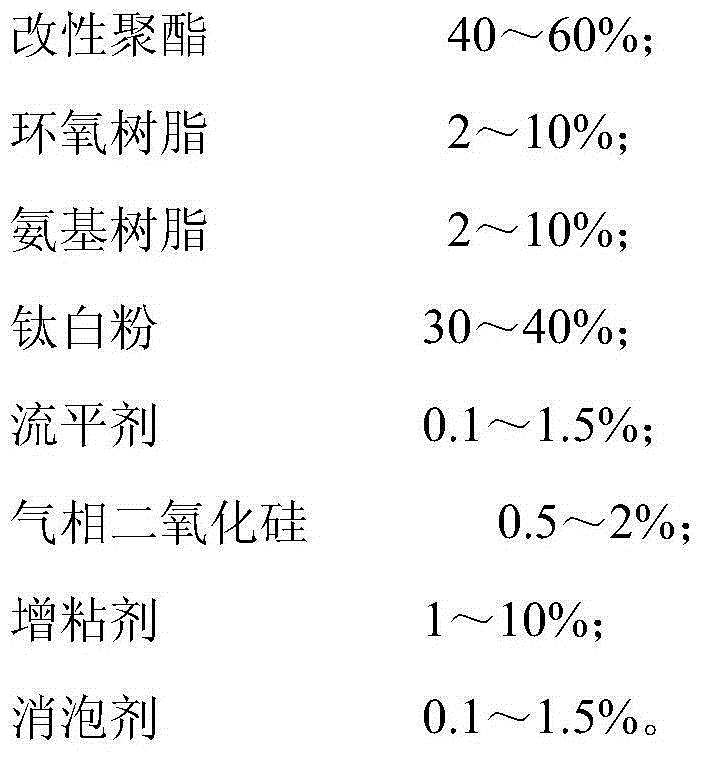

Waterproof single-component glass printing ink and preparation method thereof

The invention provides waterproof single-component glass printing ink. A raw material formula of the waterproof single-component glass printing ink comprises, by weight percentage, 40-60% of modified polyester, 2-10% of epoxy resin, 2-10% of amino resin, 30-40% of titanium dioxide, 0.1-1.5% of flatting agent, 0.5-2% of fumed silica, 1-10% of tackifier and 0.1-1.5% of antifoaming agent, wherein the modified polyester is organic silicone modified polyester. The epoxy resin is heat-resistant epoxy resin, and the heat-resistance temperature is 185-205 DEG C. The amino resin is etherified amino resin with a solid content of 45%. The grain size of the titanium dioxide is 100 nanometers or below. Correspondingly, the invention further provides a method for preparing the waterproof single-component glass printing ink. The prepared glass printing ink has the advantages of being good in water resistance, high in gloss and weather resistance, good in interlayer adhesion and resistant to friction.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

Method for dyeing bamboo chip by walnut skin plant dye

InactiveCN102172937ASimple processRaw materials are easy to getWood treatment detailsChemistryColour fastness

The invention discloses a method for dyeing a bamboo chip by a walnut skin plant dye, successively comprising the following steps: (1) piling collected outer walnut skins, naturally fermenting after the walnut skins are heated, and drying to obtain a puce massive plant dye raw material; (2) smashing the above plant dye raw material to obtain dye powder, adding the dye powder into a container filled with bath lotion, meanwhile adding a penetrating agent, adjusting the pH value of dye liquor to 9-11, adding the bamboo chip, sealing the container, heating to 120-140DEG C, and dipping; and (3) cooling to room temperature after dipping, taking out the bamboo chip, cleaning with clear water, and drying to obtain the rufous bamboo chip. The invention also discloses a method for dyeing brown green bamboo chips. Compared with the prior art, the method has the advantages of simple technology because of dying the bamboo chips by the walnut skins, abundant raw materials and good dry and wet friction colour fastness after dyeing, is safe, reliable and free from pollution and can ensure that the bamboo chips do not fade for a long time.

Owner:董超萍

Color printing ink for printing heat shrink film labels and preparation method of color printing ink

ActiveCN103265843ADoes not fadeDoes not fall offInksPolymer sciencePolyethylene terephthalate glycol

The invention discloses color printing ink for printing heat shrink film labels and relates to environmental-friendly ink. The color printing ink comprises the following components: acrylic resin, nitrocotton, VINISOL OH, CAB (Cellulose Acetate Butyrate) resin, EVA (Ethylene Vinyl Acetate) resin, a color pigment, additives and a diluent, wherein the additives are polyethylene wax and fumed silica. Compared with the prior art, the color printing ink for printing the heat shrink film labels, disclosed by the invention, has the advantages that the color printing ink is free of benzene and ketone, resists tetrahydrofuran and can be applied to PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), OPS (Oriented Polystyrene) heat shrink film base materials, and after the color printing ink is matched with heat shrink films for printing, the shrink films do not curl and are free of tinting. The products printed by adopting the color printing ink are in line with environment-friendly requirements, are safe and non-toxic and can be recycled; and after printing, the shrink films have very strong capability of resisting alcohol and tetrahydrofuran, thus the problem of the compatibility between the thin films and glue occurring when the thin films are subjected to skin packaging and are glued is solved very well.

Owner:CHENGDU PRESSTER NEW MATERIALS

Two-dimensional code waterborne stereoscopic anti-counterfeit color-changing ink

The invention belongs to the technical field of two-dimensional codes, and particularly relates to a two-dimensional code waterborne stereoscopic anti-counterfeit color-changing ink. The ink is prepared from the following components in mass by percentage: 30% to 50% of aqueous acrylic resin solution; 15% to 25% of acrylic emulsion; 5% to 10% of waterborne polyurethane resin solution; 15% to 25% ofthermochromic powder; 10% to 20% of foaming agent; and 1.0% to 3.0% of auxiliaries. The thermochromic powder is a reversible thermochromic powder capable of changing from colorless to colored at 55 DEG C to 75 DEG C, and the foaming agent is a heat-expandable microcapsule. An anti-counterfeiting mark of the two-dimensional code using the ink (the anti-counterfeiting mark can be letters, numbers,graphics and the like, and can be connected with a database of a production company) is not visible at a normal temperature, and presents a three-dimensional shape at a high temperature, and the colorchanges from colorless to colored, the ink is strong in three-dimension, has clear edges and good friction resistance, is not easy to fall off, and is green and environmentally friendly. The color isreversible while a bulge is irreversible, and use of two-dimensional code is avoided being stolen while maintaining fun.

Owner:永发印务(东莞)有限公司

Digital printing process for real silk fabric

InactiveCN106758384AHigh color yieldIncrease color depthUltrasonic/sonic fibre treatmentDyeing processWarm waterEngineering

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following procedures: real silk fabric preparation; low-temperature plasma processing; pretreatment liquid padding; drying; inkjet printing; drying; dry heat fixation; cold water flushing; warm temperature washing; soaping; warm water cleaning; and drying, wherein pretreatment liquid in the pretreatment liquid padding contains the following components by contents: 5g / L-10g / L of sodium alginate, 30g / L-50g / L of baking soda, 30g / L-50g / L of urea and 5g / L-15g / L of a defoaming agent. By virtue of the digital printing process, the tinctorial yield of the digital printing of a silkworm silk fabric is increased, the color depth of the digital printing on a textile is increased, and the chromatic aberration with an electronic pattern is reduced; and furthermore, the color fastness is high, and multiple experiments prove that the fabric does not fade or lose color even at relatively hostile experimental environments.

Owner:顾朝晖

Copper antioxidant and preparation method thereof

The invention discloses a copper antioxidant and a preparation method thereof and belongs to the technical field of metal anti-oxidation. According to the copper antioxidant and the preparation method thereof, the copper antioxidant is good in protective property and does not corrode for a long time and does not fade. The copper antioxidant is characterized in that the copper antioxidant per liter contains the following ingredients by weight: 50-100g of hydroxy ethylidene diphosphonic acid, 50-100g of ethanol, 80-150g of hydrogen peroxide, 20-40g of a corrosion inhibitor, 10-20g of isothiocyanate, 8-15g of alkyl sulfate, 10-20g of sodium molybdate, 8-12g of sodium tripolyphosphate and the balance of water. The preparation method of the copper antioxidant comprises the steps: (1) weighing all the ingredients; (2) putting the ingredients weighed in the step (1) in a reaction vessel, adding water until the volume is 1L, and then, stirring for 20-60 minutes at the temperature of 40-50 DEG C, thereby obtaining the copper antioxidant.

Owner:BOLINDA SCI TECH SHENZHEN

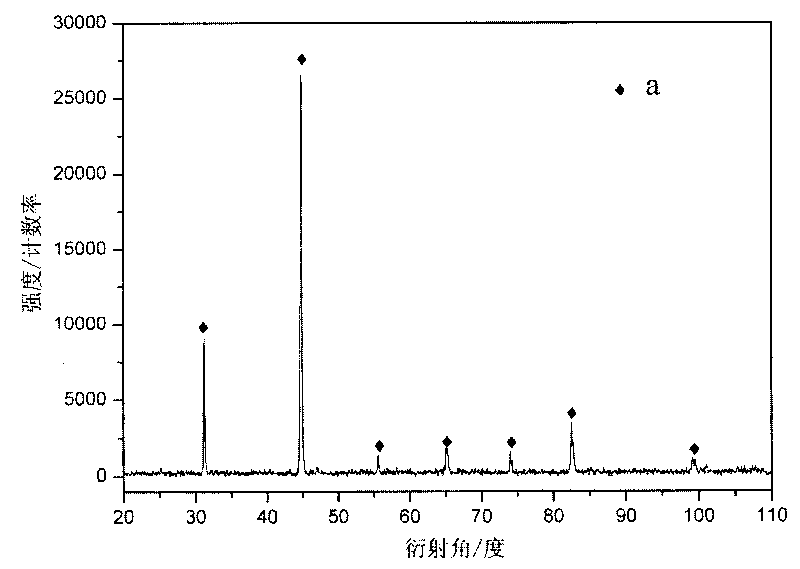

Al-Co grain refiner of Mg-Al-based alloy, preparation method and using method thereof

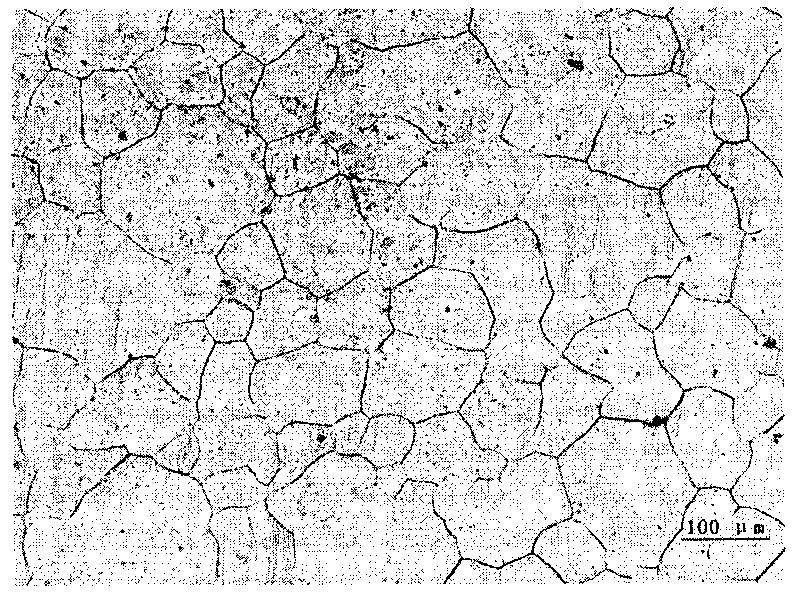

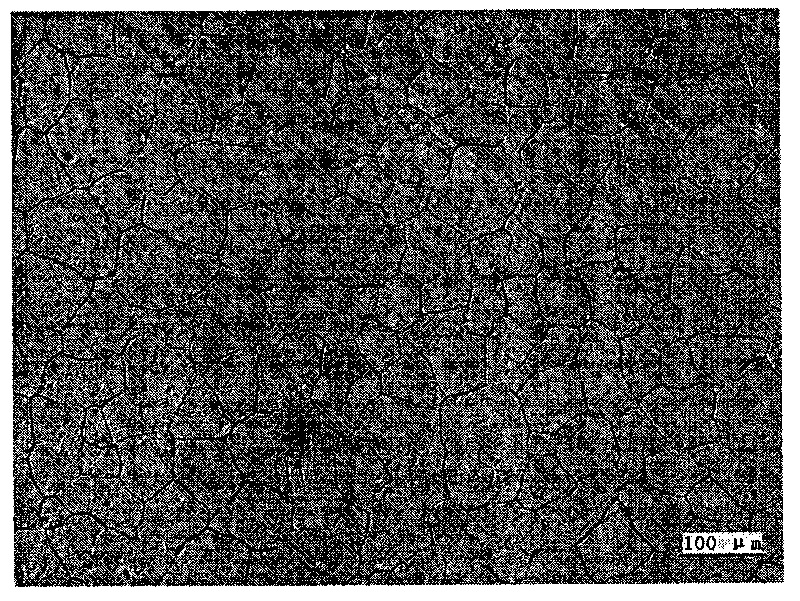

The invention relates to an Al-Co grain refiner of Mg-Al-based alloy, a preparation method and a using method thereof. The refiner comprises the components by weight percent: 20-34% of Al and 66-80% of Co which have the grain diameter of 25-35mu m. The preparation method comprises the following steps: (1) blending according to the weight percent of the components of the Al-Co grain refiner: 20-34% of Al and 66-80% of Co, and obtaining mixed metal; (2) washing the mixed metal; and (3) putting the washed mixed metal into an electric arc furnace, vacuumizing and filling argon gas into the electric arc furnace for smelting for four times, and finally crushing into grains with the grain diameter of 25-35mu m by a physical method. The preparation method and the using method of the Al-Co grain refiner of the Mg-Al-based alloy are simple, and the volume of addition and the refining effect of the Al-Co grain refiner are easily controlled, so that the aim of very good refining can be achieved by adding trace of the Al-Co grain refiner, and the refining effect does not fade within 1h.

Owner:NORTHEASTERN UNIV

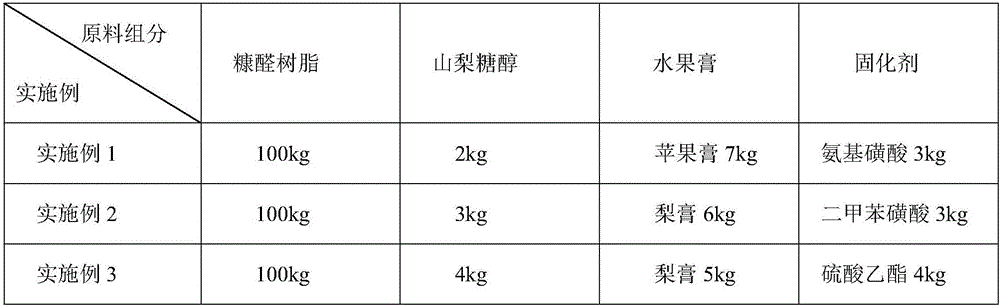

Method for preparing graphene foam material from furfural acetone formaldehyde resin, graphene foam material and application of graphene foam material

The invention discloses a method for preparing a graphene foam material from furfural acetone formaldehyde resin. The method includes the steps that curing molding is conducted on furfural acetone formaldehyde resin by adding non-carbon-atom matter which can be easily removed at a high temperature, then high-temperature carbonization and graphitization are conducted in an inert gas environment, and thus the novel super-power graphene foam material with a hexagonal or pentagonal two-dimensional or three-dimensional polyhedral crystal net structure is formed. The obtained material is a carbon foam material with excellent performance, has the prominent properties of low thermal expansivity, high porosity and pore uniformity, good stability, high temperature resistance, corrosion resistance, good oxidation resistance, small density, light weight, processibility and the like, and the advantages of high thermal conductivity, high melting point, large specific heat, good electric conductivity and excellent shielding performance, and is wide in application range and long in service life. Besides, low-cost and large-batch production of the material can be achieved through the preparation method, no pollution is generated in the preparation or use process, and batch application of the graphene foam material is achieved.

Owner:杨佳伟

Non-toxic color superlight clay and manufacturing method thereof

The invention discloses non-toxic color superlight clay and a manufacturing method thereof and belongs to the field of production, processing and manufacturing of superlight clay. The non-toxic colorsuperlight clay is prepared from the following raw material components: 8 to 10 parts of superlight physical microsphere, 18 to 20 parts of polyvinyl alcohol, 3 to 5 parts of water-soluble color paste, 0.5 to 1.5 parts of wetting agent, 0.5 to 1.5 parts of anti-freezing agent, 2 to 2.5 parts of Vaseline and 60 to 70 parts of water. The product has the following beneficial effects: the non-toxic color superlight clay is safe and non-toxic, has superhigh tensile property, is not greasy in the use process and can maintain hands to be wet; the formula is reasonable, the components are stable and the production process is simple; and the product is high in formability, easy to model and easy to adhere, is not cracked, can be reused when being not dried and can be stored for a long time after being dried.

Owner:山东博士爱文具有限公司

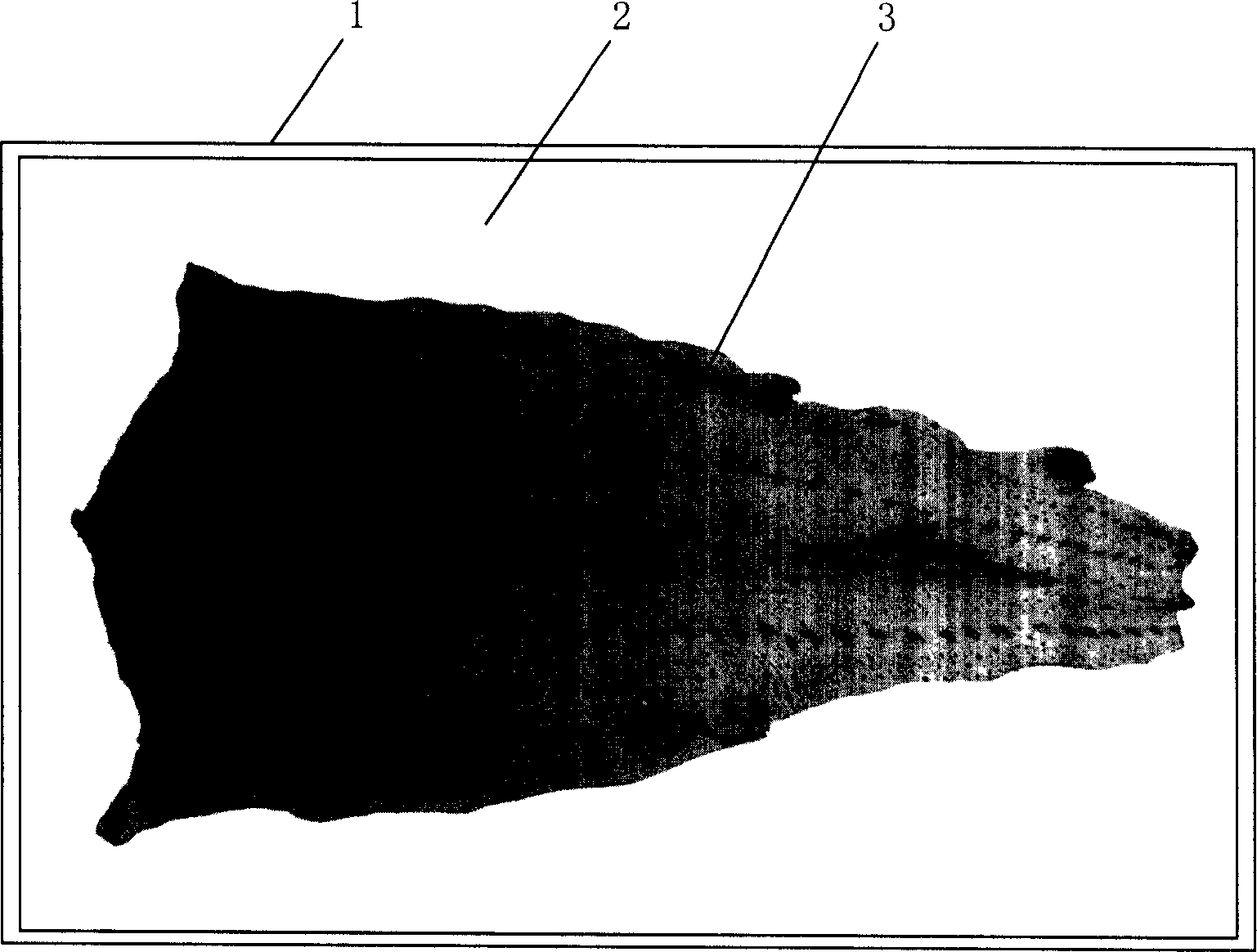

Sturgeon leather painting and making method therefor

InactiveCN1836920AStrong three-dimensional imageFor long-term storageTanning treatmentPre-tanning chemical treatmentNatural resourceCuticle

The present invention belongs to the field of culture and tourist product, and is especially the making process of sturgeon skin paint on leather of artificially cultivated sturgeon. The present invention features that the sturgeon skin is treated to make sturgeon leather with outward bone plate. The sturgeon skin paint has the features of saving in natural resource, high stereo feeling, primitively simple and elegant style, bright color, no deformation, etc.

Owner:蓝泽桥

Water-soluble silk-screen printing ink and preparation method thereof

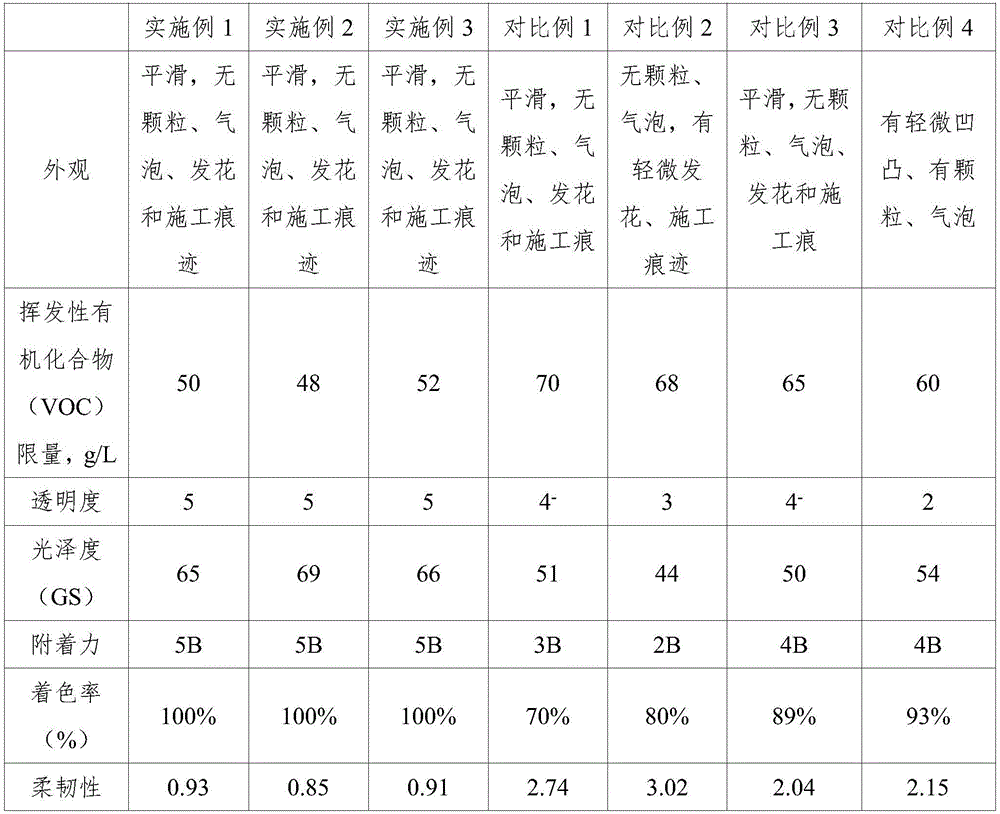

The invention belongs to the field of chemical coatings and particularly relates to water-soluble silk-screen printing ink and a preparation method thereof. The water-soluble silk-screen printing ink is mainly prepared from waterborne polyurethane resin, waterborne acrylic resin, white paste, a crosslinking agent, a leveling agent, tripropylene glycol ether and a thickener, wherein the white paste is mainly prepared from titanium dioxide, a dispersant, a wetting agent, an antifoaming agent and deionized water, and the particle size of the white paste is 3-4 mu m. A formula of the water-soluble silk-screen printing ink is reasonably and scientifically matched, all components cooperate to enhance adhesion, coloring rate, flexibility, sweat resistance and corrosion resistance of a water-soluble silk-screen printing ink coating, a printed product painted with the coating has the effects that the printed product has transparent and bright surface, is glossy and do not fade or peel off after long-term usage, and the water-soluble silk-screen printing ink has low content of VOCs (volatile organic compounds) and heavy metals, is healthy and environment-friendly and meets the requirements of modern people.

Owner:ZHONGSHAN YONGHUI CHEM

A kind of environment-friendly water-based aluminum foil ink and preparation method thereof

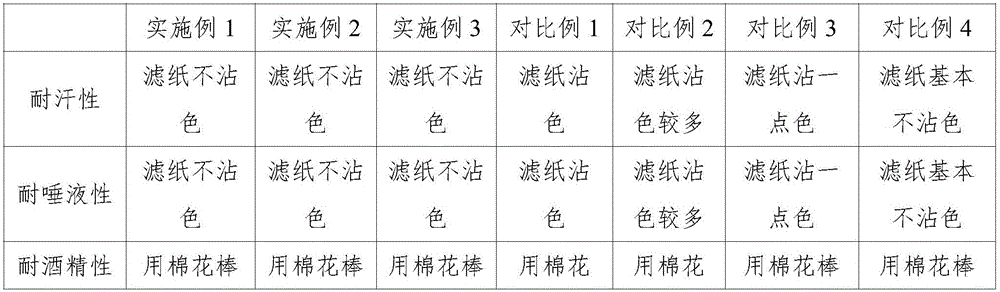

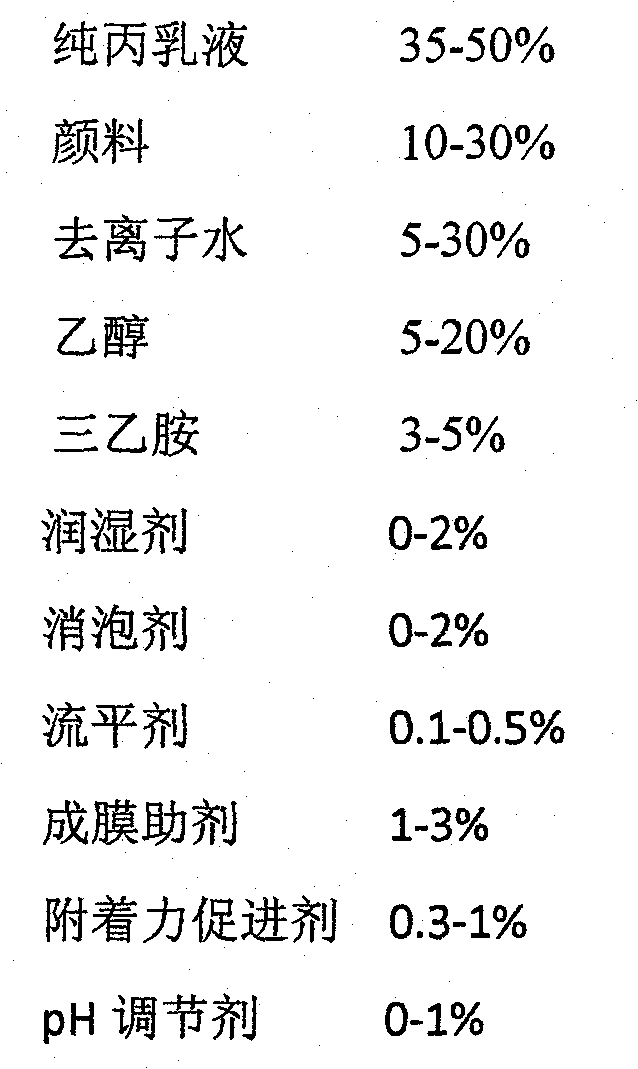

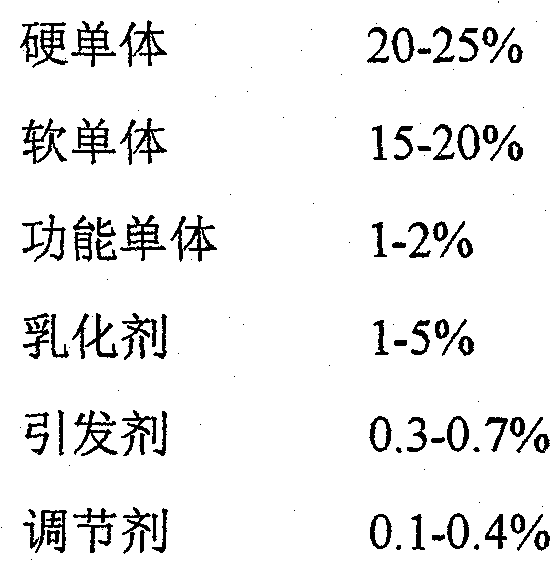

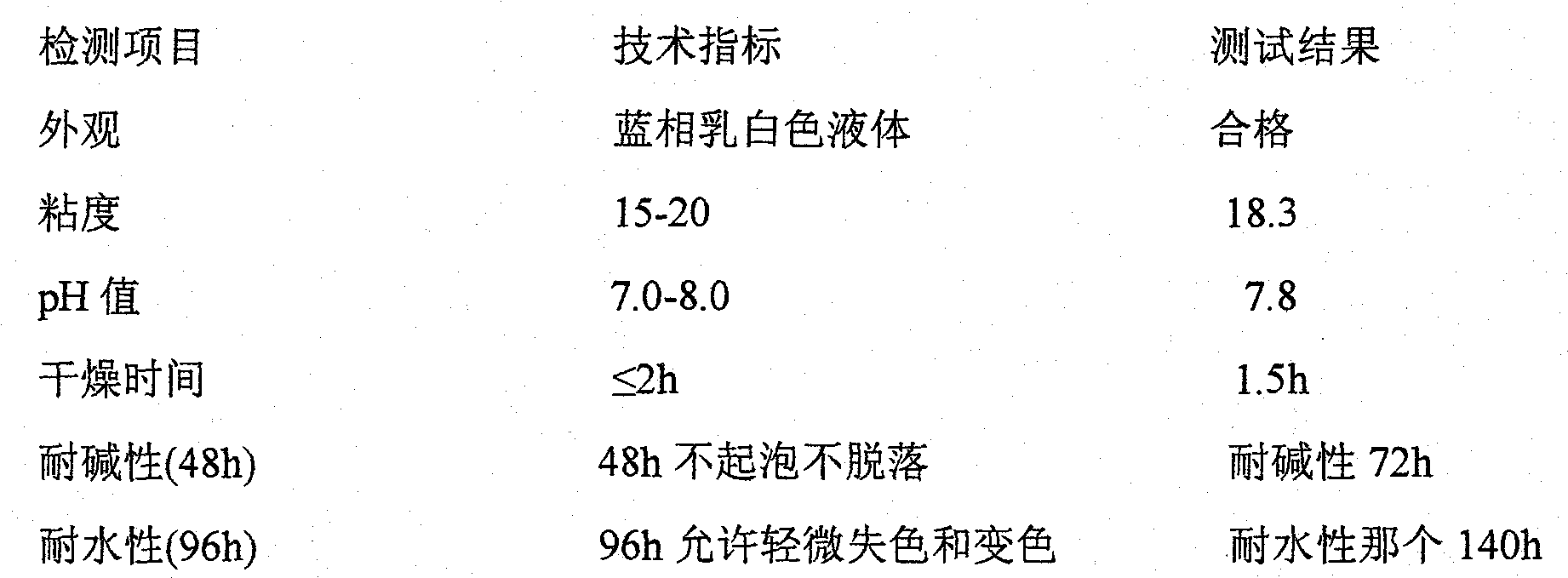

The invention discloses aqueous aluminum foil ink with pure acrylic emulsion as a base material and a making method thereof. The ink is composed of the following raw materials in mass ratio: 35-50% of pure acrylic emulsion, 10-30% of pigment, 5-30% of deionized water, 5-20% of ethanol, 3-5% triethylamine, 0-2% of wetting agent, 0-2% of defoamer, 0.1-0.5% of levelling agent, 1-3% of film-forming aid and 0.3-1% of adhesion promoter. The making method comprises adding the raw materials into a reaction kettle according to the mass ratio, stirring at room temperature, milling with a sand mill, and adjusting the pH value to 7.0-8.5 with 0-1% of pH regulator to obtain the aqueous aluminum foil ink. Compared with the prior art, the product has the characteristics of clear printed patterns, water resistance, alcohol resistance and base resistance after being dried, and no decolorizing and fading; the production process is simple and the reaction processes are carried out at normal temperature and normal pressure; the added raw materials are completely converted into a product; the product has extremely low contents of volatile organic compounds (VOC) and has no residue of solvents harmful to human bodies; and the production cost is lowered.

Owner:哈尔滨大东方新材料科技股份有限公司

Printed non-woven fabric and manufacturing device

InactiveCN102704191AChange appearanceIncrease color varietyRotary intaglio printing pressNon-woven fabricsEngineeringDesign methods

The invention discloses printed air-thermal-bonded non-woven fabric which is mainly used for the surface or the second-layer material of a personal sanitary nursing article. According to the printed air-thermal-bonded non-woven fabric, printing is carried out by adopting an ink transferring technology on the basis of air-thermal-bonded non-woven fabric, which has the advantages that the problems that the existing air-thermal-bonded non-woven fabric is single in design and color and difficult to print are solved, the appearance attractiveness of the sanitary article is enhanced, and the aesthetic fatigue of a consumer during use is reduced. The design method is novel and available for effectively improving the appearance of the air-thermal-bonded non-woven fabric.

Owner:北京大源非织造股份有限公司

Water-based white ink for PVC shrink film bottle labels and preparation method thereof

The invention discloses a water-based white ink for PVC shrink film bottle labels and a preparation method thereof. The water-based white ink is composed of a waterborne binder, a color paste, assistants, a diluent and a defoaming agent. The ink preparation method includes the three steps of: 1. preparation of the waterborne binder, 2. preparation of white color paste, and 3. blending of a water-based shrink film white ink. Compared with the existing invention, the shrink film water-based white ink protected by the invention has the characteristics of low VOC, no environmental pollution, and high shrinkage, can be used for a PVC heat shrinkage film substrate, and after mating printing with a PVC heat shrinkage film, the printing film does not curl and is free of scumming, and the printed product meets the requirements, is safe and non-toxic, and recoverable. And after printing, the shrink film has very strong resistance to chloroform and cyclohexanone, thus well solving the environmental pollution problem generated by printing of the film with solvent ink.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

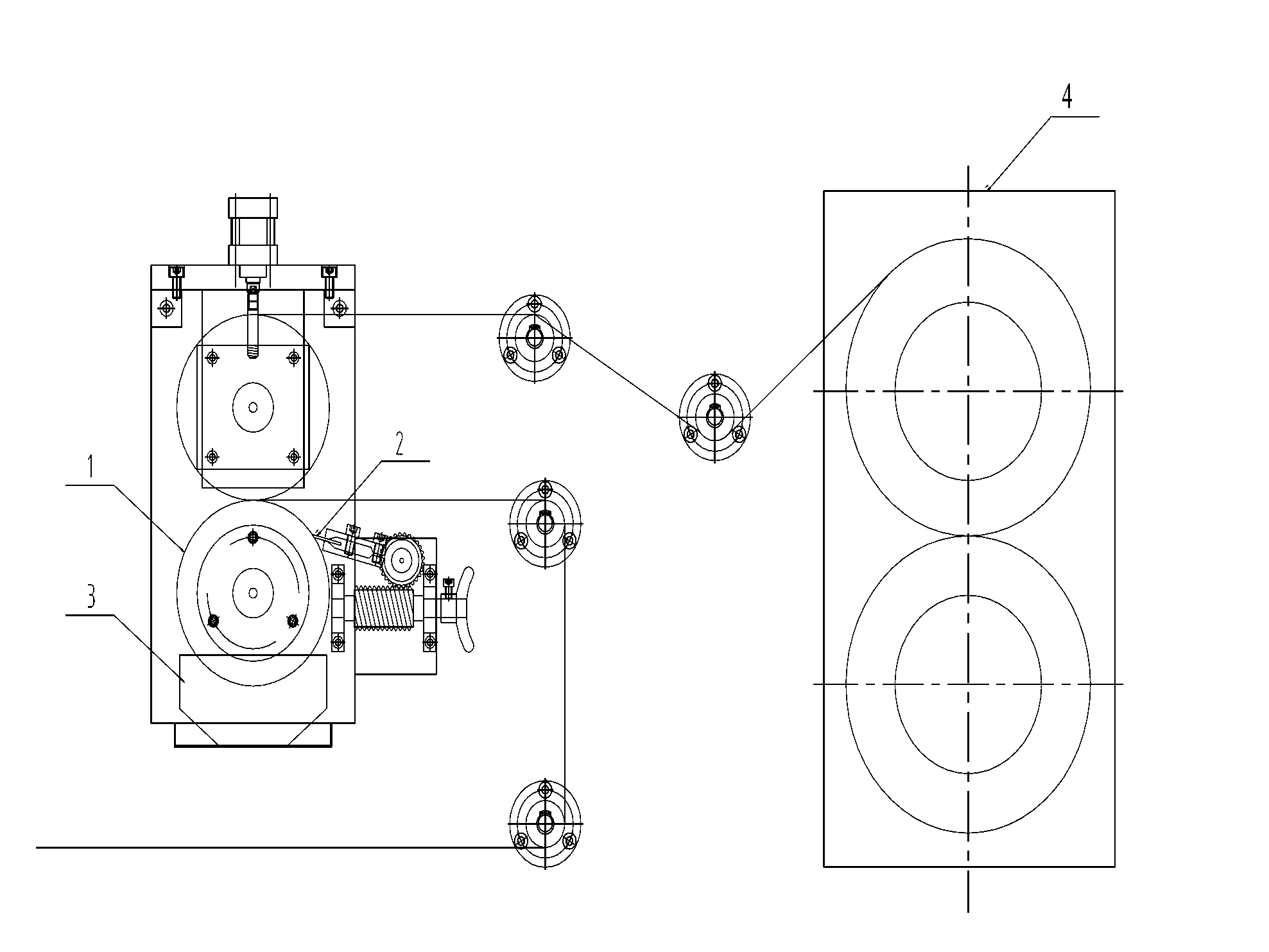

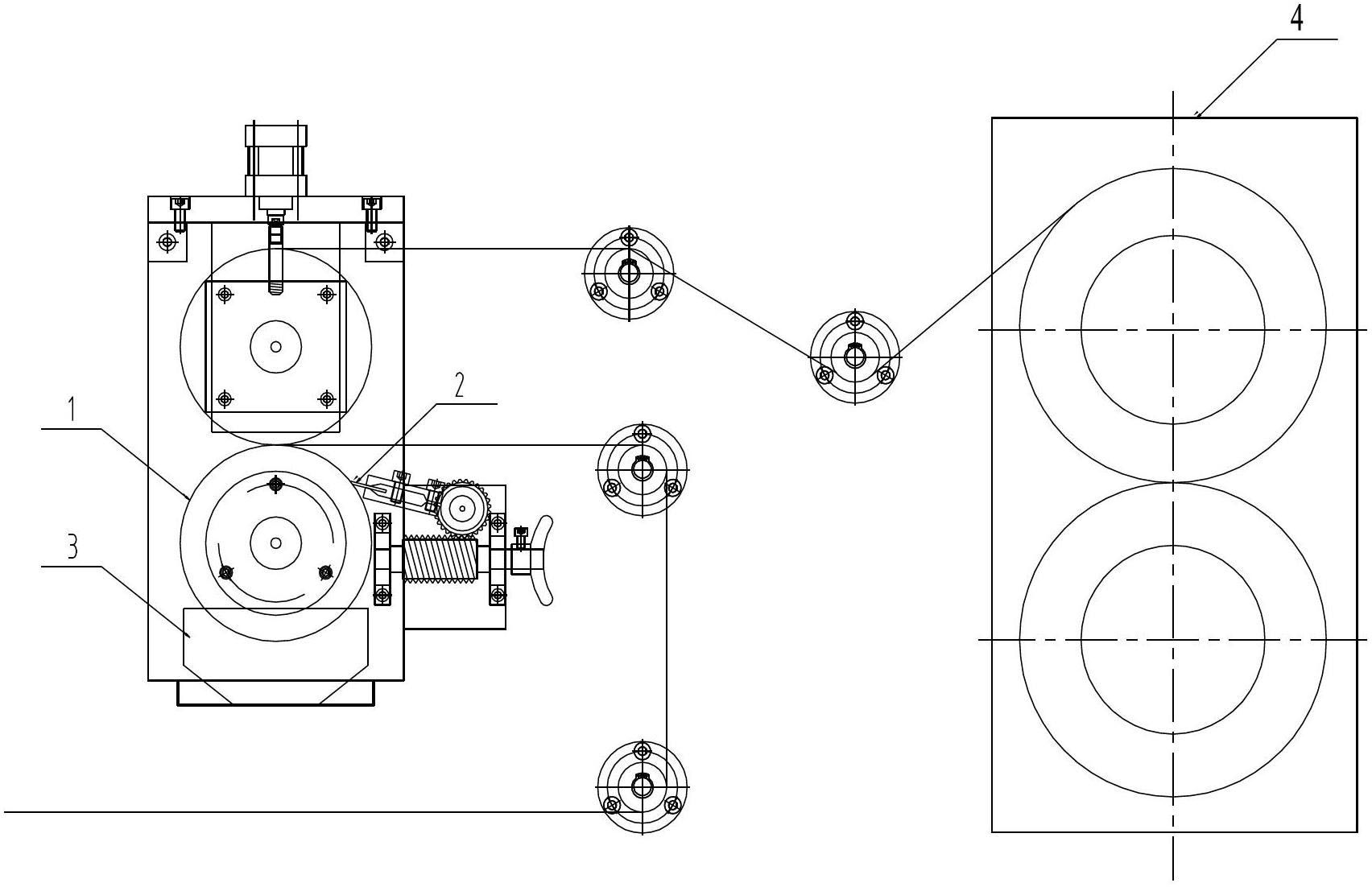

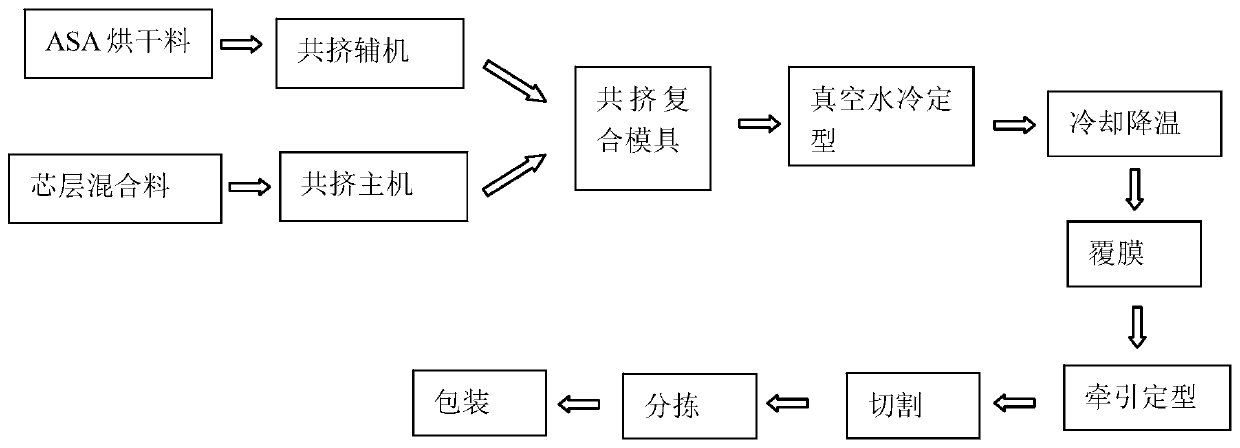

PVC and ASA co-extrusion profile and preparation method thereof

InactiveCN111038051AGood weather resistanceImprove mechanical propertiesSynthetic resin layered productsPolymer scienceWeather resistance

The invention belongs to the technical field of PVC material preparation, and particularly relates to a PVC and ASA co-extrusion profile and a preparation method thereof. The PVC and ASA co-extrusionprofile comprises a core layer and a skin layer, and is prepared from the core layer raw materials: 75 parts by mass of PVC resin, 20-60 parts by mass of a filling material, 3-5 parts by mass of a heat stabilizer, 1-3 parts by mass of a light stabilizer, 0.2-0.5 part by mass of an ultraviolet light absorber, 0.5-1 part by mass of an antioxidant, 2-5 parts of an anti-ultraviolet modifier, 0.3-1 part by mass of a lubricant, 0.5-2 parts by mass of a processing aid and 0-3 parts by mass of a pigment, and skin layer raw materials: 10-20 parts by mass of ASA resin granules. The prepared co-extrusionprofile has high weather resistance and mechanical property, does not fade and is good in electrical insulating property; meanwhile, the invention further provides the preparation method of the co-extrusion profile, a skin layer structure and a core layer structure can be obtained by the preparation method, the thickness of the co-extrusion layer can be smaller, and the product is more attractive.

Owner:SHANDONG BODO PLASTICS CO LTD

Preparation method of high strength antibacterial environmental protection fabric

InactiveCN108070941AImprove antibacterial propertiesNovel functional designBiochemical fibre treatmentDyeing processEnvironmental resistanceMoisture absorption

The invention discloses a preparation method of a high strength antibacterial environmental protection fabric. The fabric is prepare from that, by weight, 45% super fine denier polypropylene fiber, 35% cotton fiber, 10% chitosan fiber, 5% silver fiber and 5% soybean protein fiber are blended to obtain warp; by weight, 55% galamina fiber, 35% bamboo fiber and 10% milk protein fiber are blended to obtain weft. The high strength antibacterial environmental protection fabric not only makes a product have a good antibacterial property, protect the skin, but also has strong moisture absorption and permeability, an antibacterial finishing liquid is adopted, the antibacterial effect of the fabric is further increased, in dyeing process, all natural plant stains are adopted, after fixation, the dyeing is uniform, color cannot fade, the process is simple and the color is firm; the fabric adopts natural materials throughout the whole process, is environmental friendly and low in cost, the designof the fabric is novel and the grade of the fabric is high, and the product has good comfort degree and high added value.

Owner:TIANJIN SAIYUAN HEALTH PROD

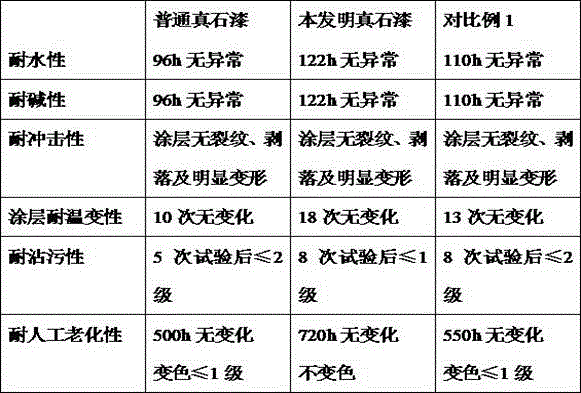

Environment-friendly high-service life anti-fouling lacquer

ActiveCN106243880AColorful appearanceBeautiful appearance and colorAntifouling/underwater paintsPaints with biocidesFiberLacquer

The invention discloses an environment-friendly high-service life anti-fouling lacquer, which is prepared from the following components: pure acrylic emulsion, ethyl silicate, modified gum arabic, castor oil, active silica fume powder, a dispersant, sodium dodecyl sulfonate, manihot esculenta starch, a polyurethane thickener, a film forming auxiliary agent, hollow glass micro-bead, an antifoaming agent, lotus leaf slurry water, natural coloring sand and modified lignin fibers. Compared with the lacquer in the prior art, the lacquer of the present invention has advantages of bright appearance color, beautiful outlook, environmental protection, strong adhesion, excellent waterproof performance, effective protection of the building from harsh environment erosion, and service life prolonging; and the use age of the lacquer prepared through the formula of the present invention is prolonged by 2-2.5 times compared with the ordinary lacquer, the lacquer has the rich color with the color sand, and the color can be lasting and no fading is generated. According to the present invention, the prepared lacquer has the stone imitation effect and further has a certain heat insulation property, is the wide-use novel building energy-saving material, and has the broad market prospect.

Owner:ANHUI FURUIXUE CHEM SCI & TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com