Water-soluble silk-screen printing ink and preparation method thereof

A screen printing ink, water-soluble technology, applied in the field of chemical coatings, can solve the problems of poor water resistance and wear resistance, poor adhesion, low colorability, etc., to achieve the effect of good colorability, enhanced adhesion, transparent and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

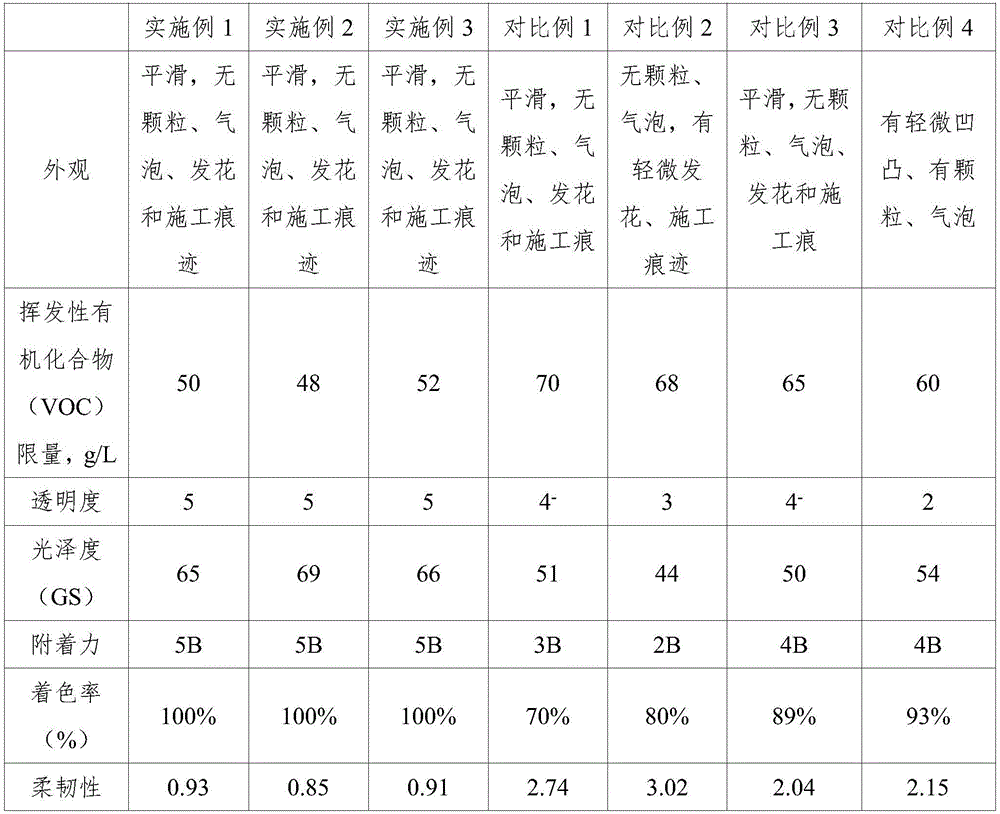

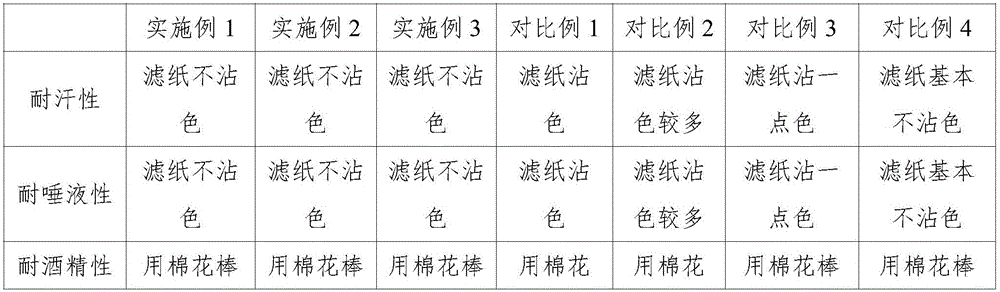

Examples

Embodiment 1

[0037] Embodiment 1, a kind of water-soluble screen printing ink

[0038] Described water-soluble screen printing ink is made up of following components and parts by weight thereof:

[0039] 45 parts of water-based polyurethane resin, 14.1 parts of water-based propionic acid resin, 12 parts of white paste, 0.5 part of crosslinking agent, 0.3 part of polydimethylsiloxane, 1 part of tripropylene glycol ether and 10.2 parts of Coapur XS7; The crosslinking agent is composed of carbodiimide and trimethylolpropane triacrylate in a weight ratio of 6:1;

[0040] Described white pulp is made up of following components and parts by weight thereof:

[0041]70 parts of titanium dioxide, 1 part of acrylic acid-maleic acid copolymer, 0.2 part of the etherified product of polyethylene glycol monomethyl ether, 1 part of polyethylene glycol stearyl ether and 15 parts of deionized water, the particle diameter of the white pulp It is 3um.

[0042] Preparation:

[0043] Preparation of S1 whit...

Embodiment 2

[0046] Embodiment 2, a kind of water-soluble screen printing ink

[0047] Described water-soluble screen printing ink is made up of following components and parts by weight thereof:

[0048] 50 parts of water-based polyurethane resin, 30.3 parts of water-based propionic acid resin, 15 parts of white paste, 0.8 part of crosslinking agent, 0.4 part of polydimethylsiloxane, 3 parts of tripropylene glycol ether and 10.5 parts of Coapur XS7; The crosslinking agent is composed of carbodiimide and trimethylolpropane triacrylate in a weight ratio of 5:2;

[0049] Described white pulp is made up of following components and parts by weight thereof:

[0050] 77.4 parts of titanium dioxide, 2 parts of acrylic acid maleic acid copolymer, 0.6 part of etherified product of polyethylene glycol monomethyl ether, 2 parts of polyethylene glycol stearyl ether and 18 parts of deionized water, the particle diameter of the white paste It is 4um.

[0051] The preparation method is similar to Examp...

Embodiment 3

[0052] Embodiment 3, a kind of water-soluble screen printing ink

[0053] Described water-soluble screen printing ink is made up of following components and parts by weight thereof:

[0054] 65 parts of water-based polyurethane resin, 30 parts of water-based propionic acid resin, 18 parts of white pulp, 2 parts of crosslinking agent, 0.6 part of polydimethylsiloxane, 3 parts of tripropylene glycol ether and 10.8 parts of Coapur XS7; The crosslinking agent is composed of carbodiimide and trimethylolpropane triacrylate in a weight ratio of 4:3

[0055] Described white pulp is made up of following components and parts by weight thereof:

[0056] 80 parts of titanium dioxide, 4 parts of acrylic acid maleic acid copolymer, 0.8 part of etherified product of polyethylene glycol monomethyl ether, 4 parts of polyethylene glycol stearyl ether and 20 parts of deionized water, the particle diameter of the white paste It is 3um.

[0057] The preparation method is similar to Example 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com