Starch-filled PLA/PBAT full-biodegradable composite material and preparation method thereof

A composite material and all-biological technology, which is applied in the field of starch-filled PLA/PBAT fully biodegradable composite materials and its preparation, can solve the problems of poor toughness of polylactic acid, poor resin compatibility, difficult starch processing, etc., and achieve short production cycle, The effect of reducing white pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

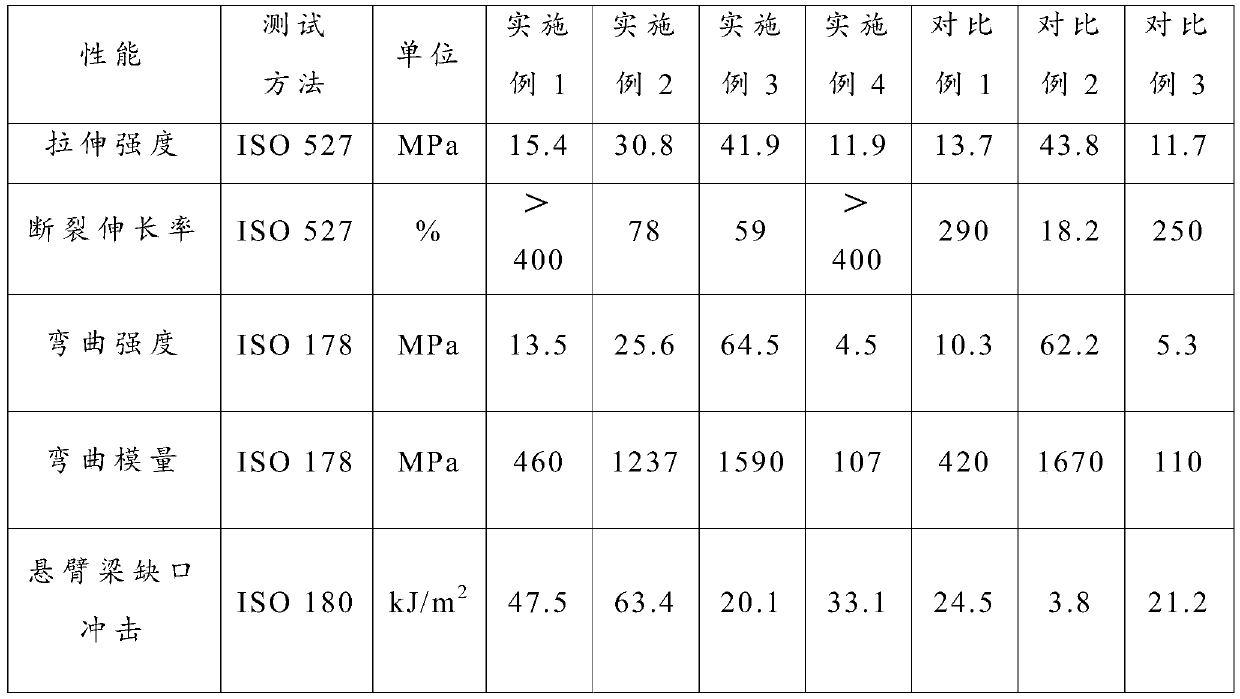

Examples

Embodiment 1

[0023] Formula: 5 parts of PLA (4060D), 75 parts of PBAT (TH801T), 20 parts of corn starch, 5 parts of plasticizer (PEG400), 1 part of coupling agent (KH560), 0.5 parts of dispersant (calcium stearate), 0.5 part of compatibilizer (MDI), 0.1 part of antioxidant 1010 and 0.1 part of antioxidant 168.

[0024] Preparation method: Dry PLA, PBAT and starch at 80°C for 4 hours in advance, then weigh the materials according to the above weight ratio, and mix them in a high-speed mixer at 60°C for 25 minutes. Then use a twin-screw extruder to blend and extrude to pelletize. The temperature of the extruder area (from the feed port to the die head) is set to 130°C, 160°C, 160°C, 160°C, 160°C, 160°C, 160°C, 165°C, 165°C, 165°C, 160°C , the feed rate is 30kg / h, and the rotation speed of the extrusion screw is 300rpm. The selected twin-screw extruder is φ35mm×2, L / D=44.

Embodiment 2

[0026] Formula: 40 parts of PLA (4060D), 20 parts of PBAT (TH801T), 40 parts of corn starch, 10 parts of plasticizer (glycerin), 3 parts of coupling agent (phenylboronic acid), 0.5 parts of dispersant (calcium stearate) , 0.5 parts of compatibilizer (HDI), 0.1 parts of antioxidant 1010 and 0.1 parts of antioxidant 168.

[0027]Preparation method: Dry PLA, PBAT and starch at 80°C for 4 hours in advance, then weigh the materials according to the above weight ratio, and mix them in a high-speed mixer at 60°C for 25 minutes. Then use a twin-screw extruder to blend and extrude to pelletize. The temperature of the extruder area (from the feed port to the die head) is set to 130°C, 160°C, 160°C, 160°C, 160°C, 160°C, 160°C, 165°C, 165°C, 165°C, 160°C , the feed rate is 30kg / h, and the rotation speed of the extrusion screw is 300rpm. The selected twin-screw extruder is φ35mm×2, L / D=44.

Embodiment 3

[0029] Recipe: 70 parts of PLA (4060D), 20 parts of PBAT (TH801T), 10 parts of corn starch, 3 parts of plasticizer (acetyl triethyl citrate), 1 part of coupling agent (phenylboronic acid), 0.2 parts of dispersant (calcium stearate), 0.2 parts of compatibilizer (TDI), 0.1 part of antioxidant 1010 and 0.1 part of antioxidant 168.

[0030] Preparation method: Dry PLA, PBAT and starch at 80°C for 4 hours in advance, then weigh the materials according to the above weight ratio, and mix them in a high-speed mixer at 60°C for 25 minutes. Then use a twin-screw extruder to blend and extrude to pelletize. The temperature of the extruder area (from the feed port to the die head) is set to 130°C, 160°C, 160°C, 160°C, 160°C, 160°C, 160°C, 165°C, 165°C, 165°C, 160°C , the feed rate is 30kg / h, and the rotation speed of the extrusion screw is 300rpm. The selected twin-screw extruder is φ35mm×2, L / D=44.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com