Patents

Literature

848results about "Leather clicking/perforating/clicking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

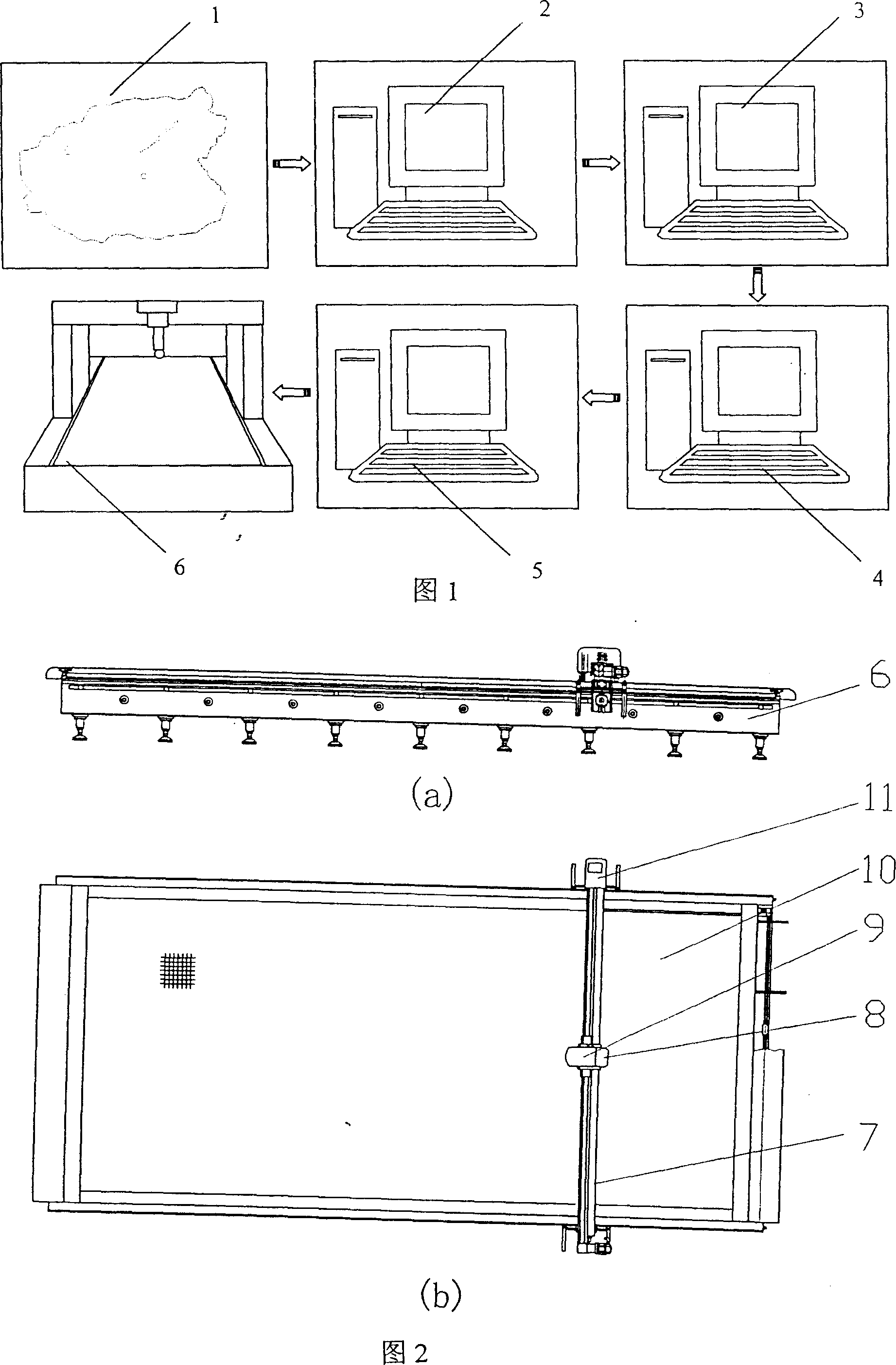

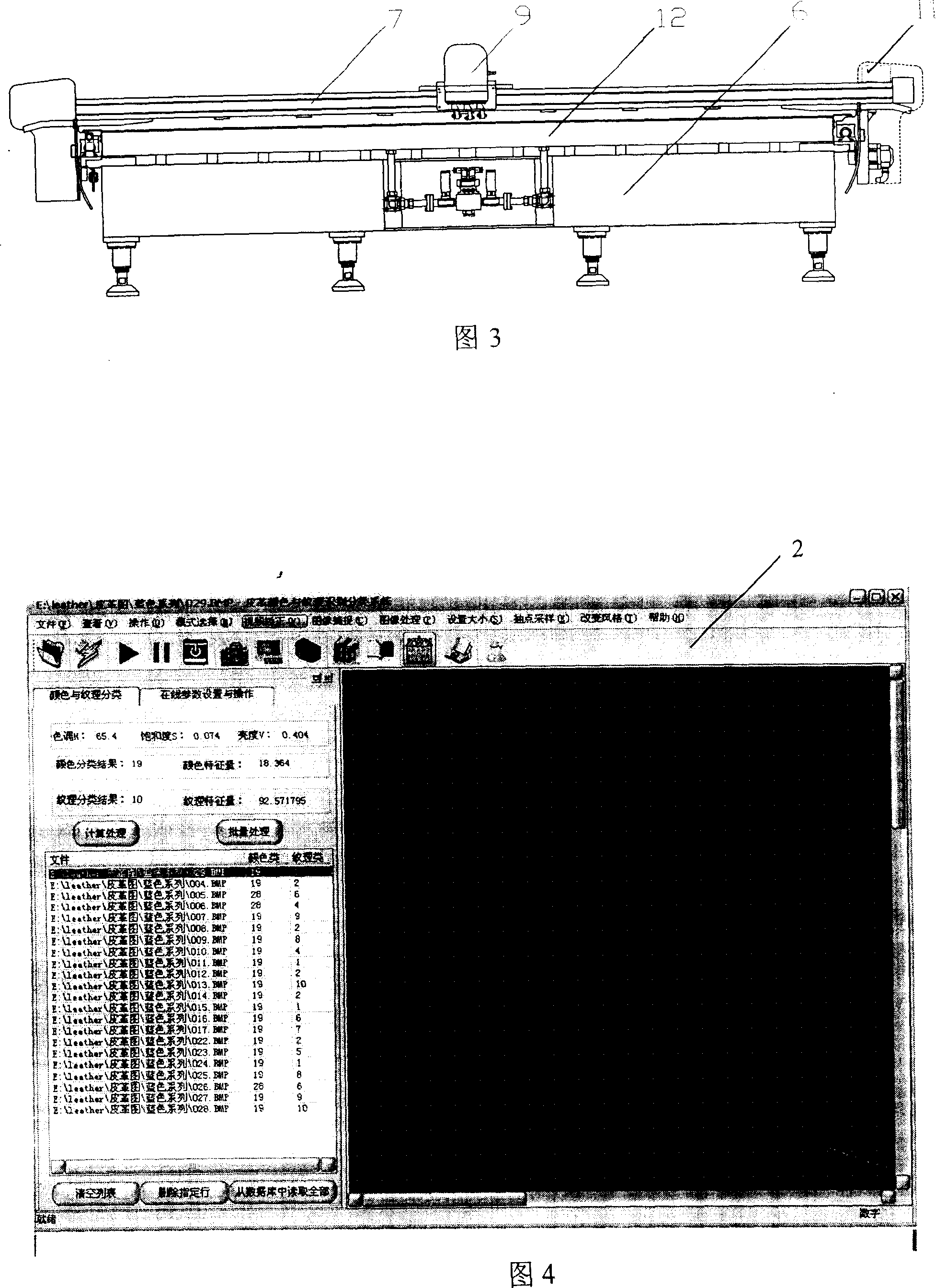

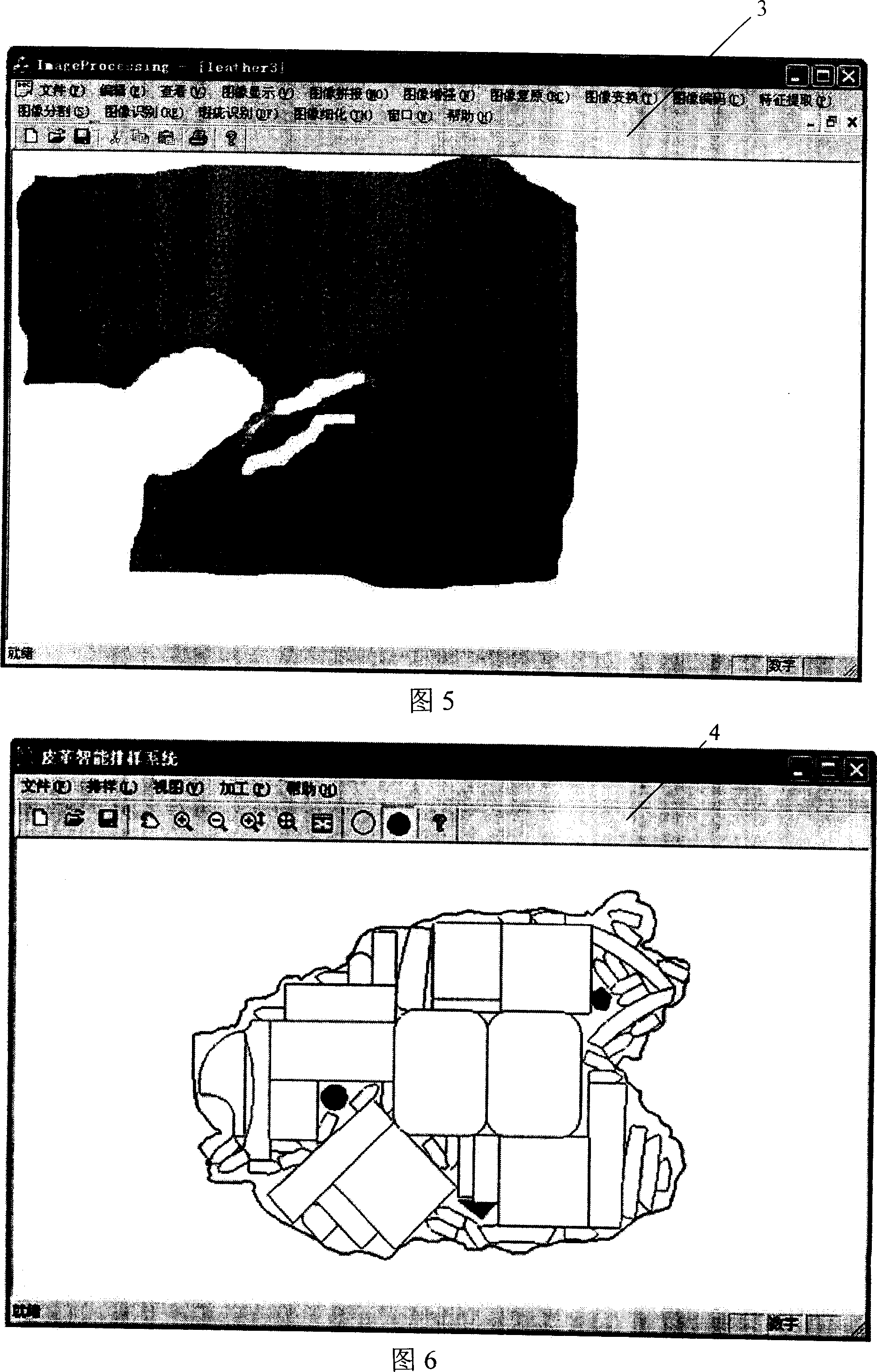

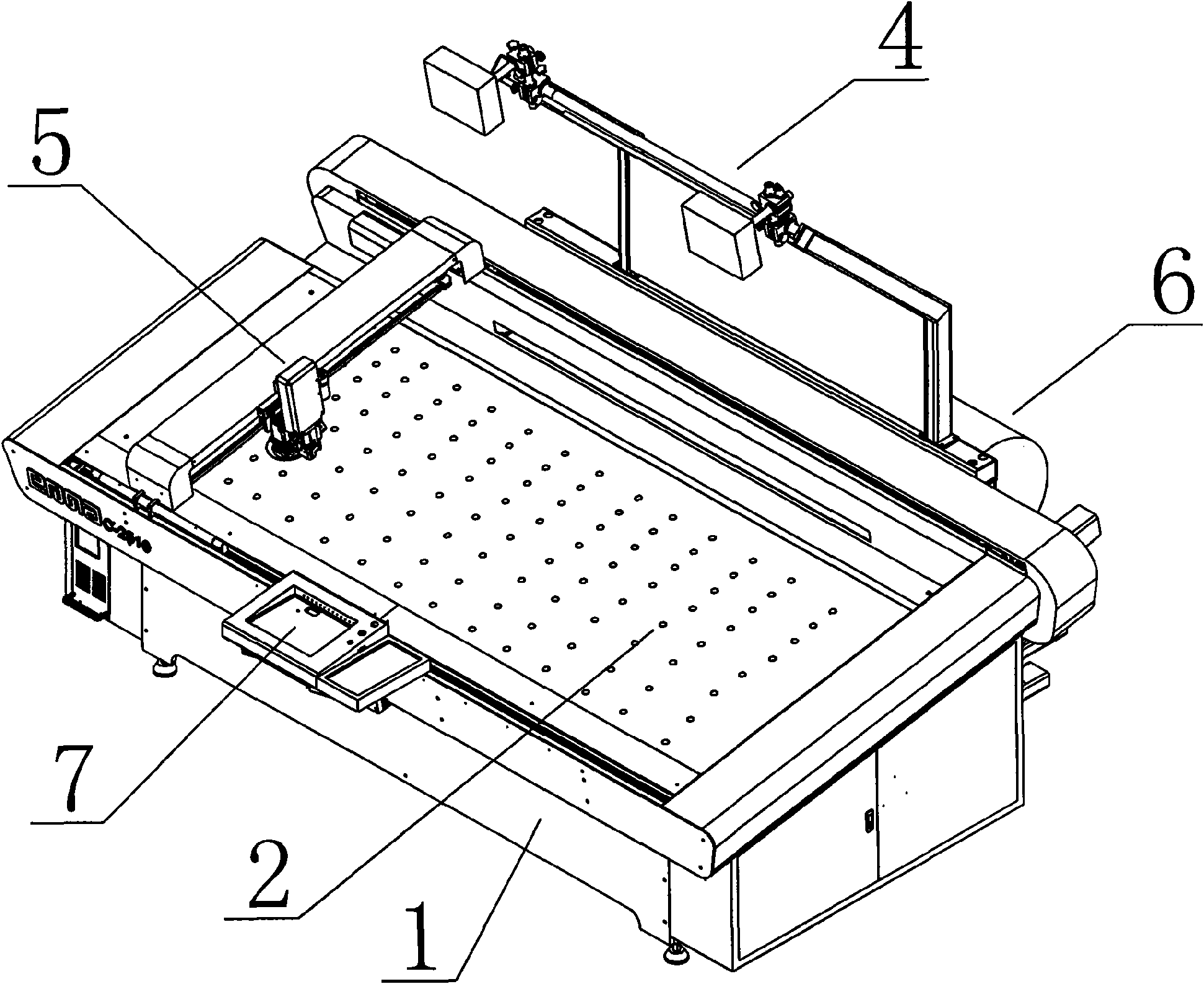

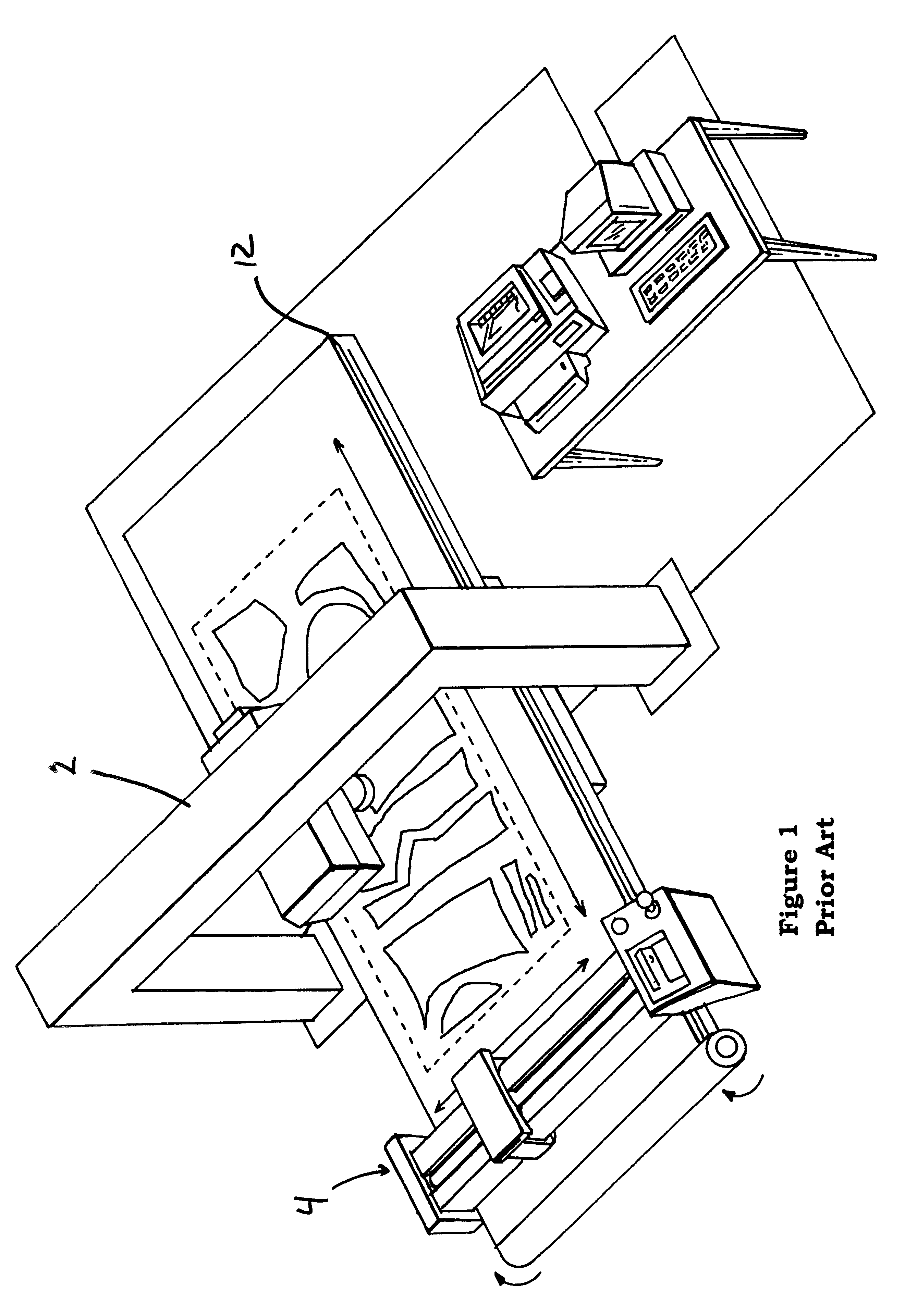

Function integrated numerically controlled automatic leather cutting method

InactiveCN1986835AQuick responseChange typeLeather clicking/perforating/clickingNumerical controlPattern recognitionSystem identification

The function integrated numerically controlled automatic leather cutting method includes four parts, automatic leather color and grain identification and classification, automatic leather flaw detection and boundary recognition, automatic optimized template layout and numerically controlled cutting. The automatic leather color and grain identification subsystem completes the leather color and grain matching, the automatic leather flaw detection and boundary recognition subsystem provides the available region information of the leather, the automatic optimized template layout subsystem arranges the optimized cutting template on the available region of the leather to reach maximum leather material utilization rate, and the numerically controlled cutting subsystem completes leather cutting automatically.

Owner:ZHEJIANG UNIV

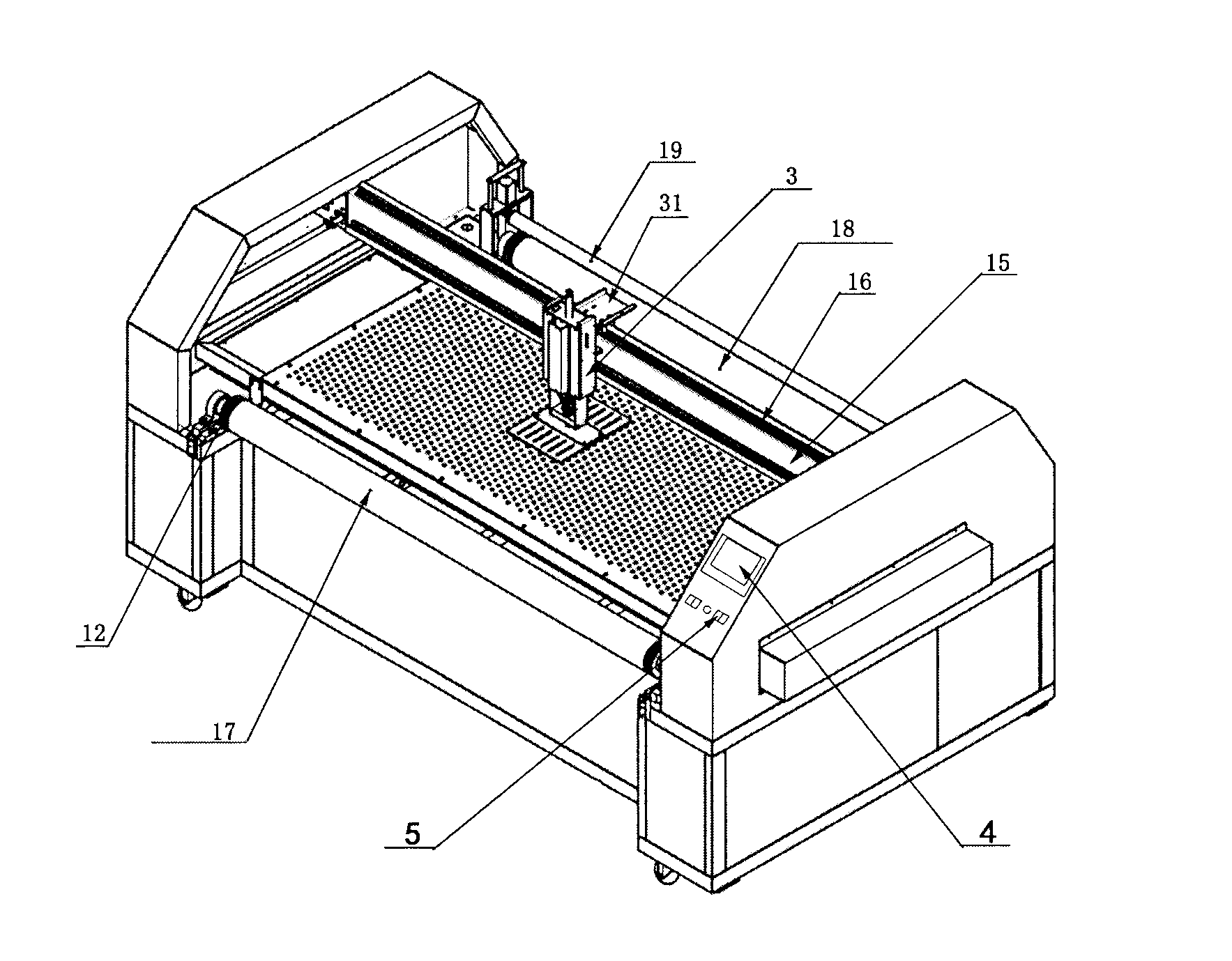

Cutting method of leather materials and skiving machine for implementing same

ActiveCN101660009ARealize automatic cycle feedingSimple structureLeather clicking/perforating/clickingControl systemPulp and paper industry

The invention discloses a cutting method of leather materials, comprising a rack and a work bench which is arranged on the rack. The method comprises the following steps: 1. arranging an adsorption device; 2. arranging a projecting device; 3. arranging a cutting device; 4. arranging a feeding device; and 5. arranging a cutting controlling system, wherein, the cutting controlling system is respectively connected with the adsorption device, the projecting device, the cutting device and the feeding device and controls the working conditions thereof to realize the actions of cutting materials or uncutting materials. The invention also discloses a skiving machine to realize the method. The method provided in the invention can finish the cutting action of the leather materials full-automatically and rapidly with high accuracy; the skiving machine provided in the invention has high degree of automization, novel structure and strong practicability, can finish the cutting of various complex graphs, and can save materials to the greatest extent, thus improving production efficiency greatly, ensuring product quality and strengthening the competitive power of enterprises while reducing labor intensity simultaneously.

Owner:DONGGUAN EMMA CNC TECH CO LTD

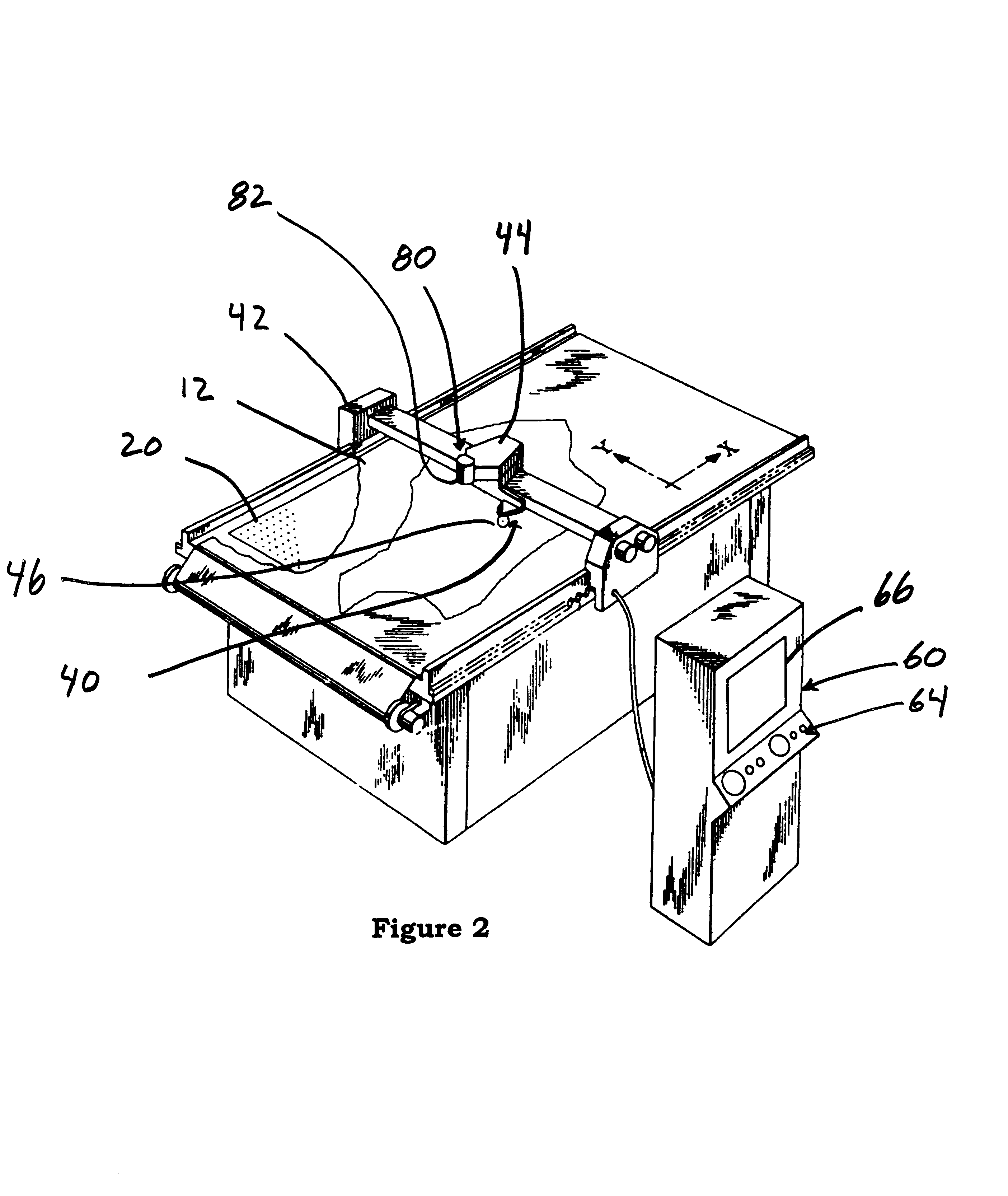

Method and apparatus for displaying an image of a sheet material and cutting parts from the sheet material

InactiveUS6856843B1Easy to tryLeather clicking/perforating/clickingMetal working apparatusComputer graphics (images)Distortion

A method and apparatus for acquiring image data of a plurality of portions of a sheet material calibrating the acquired image data of each portion to address any pincushioning distortions, aligning the calibrated images to form a composite and displaying the composite image to an operator. The system employs a camera that is translated with a cutting assembly and a program for calibrating acquired image data to provide for tiling of captured images.

Owner:GERBER SCI INT

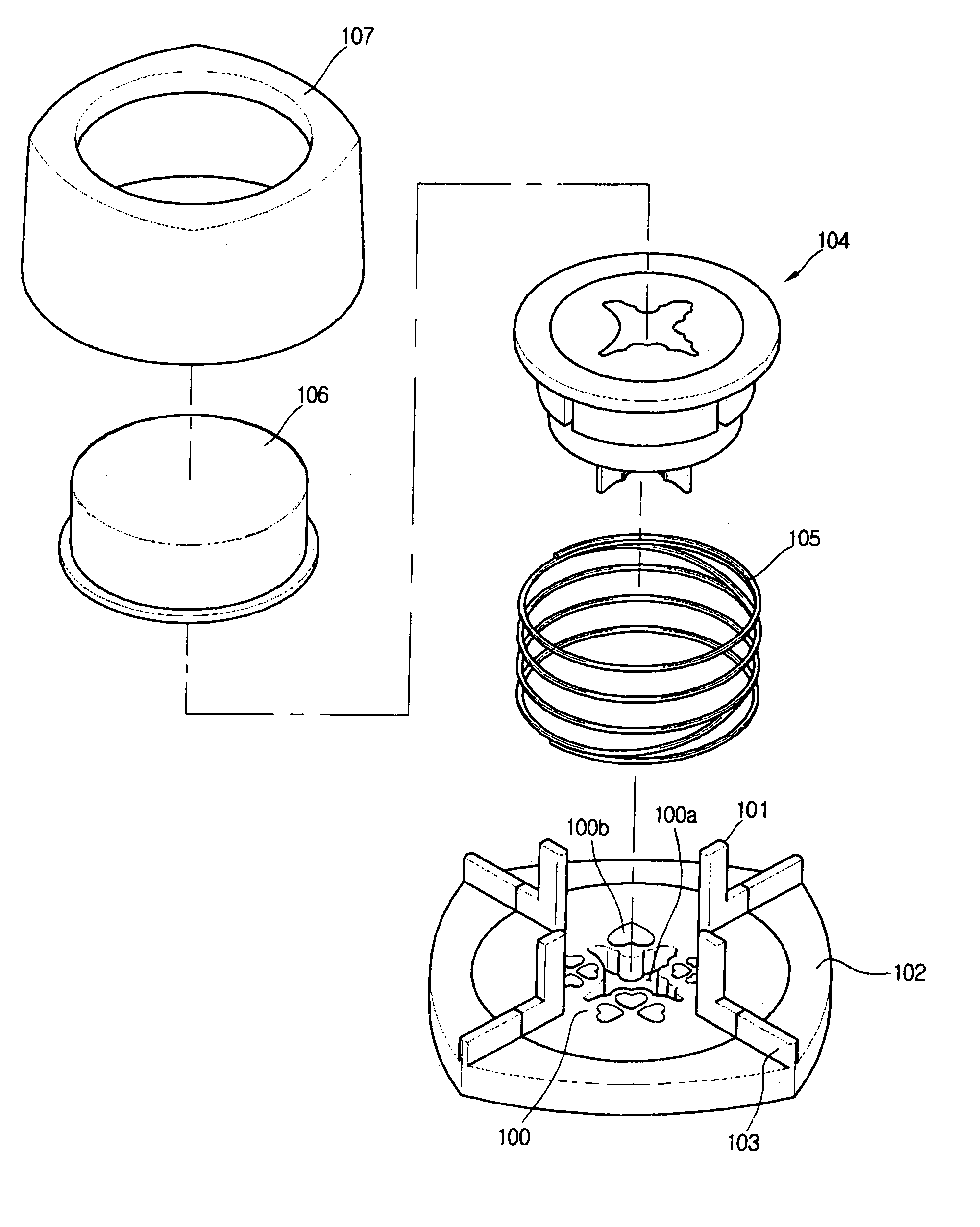

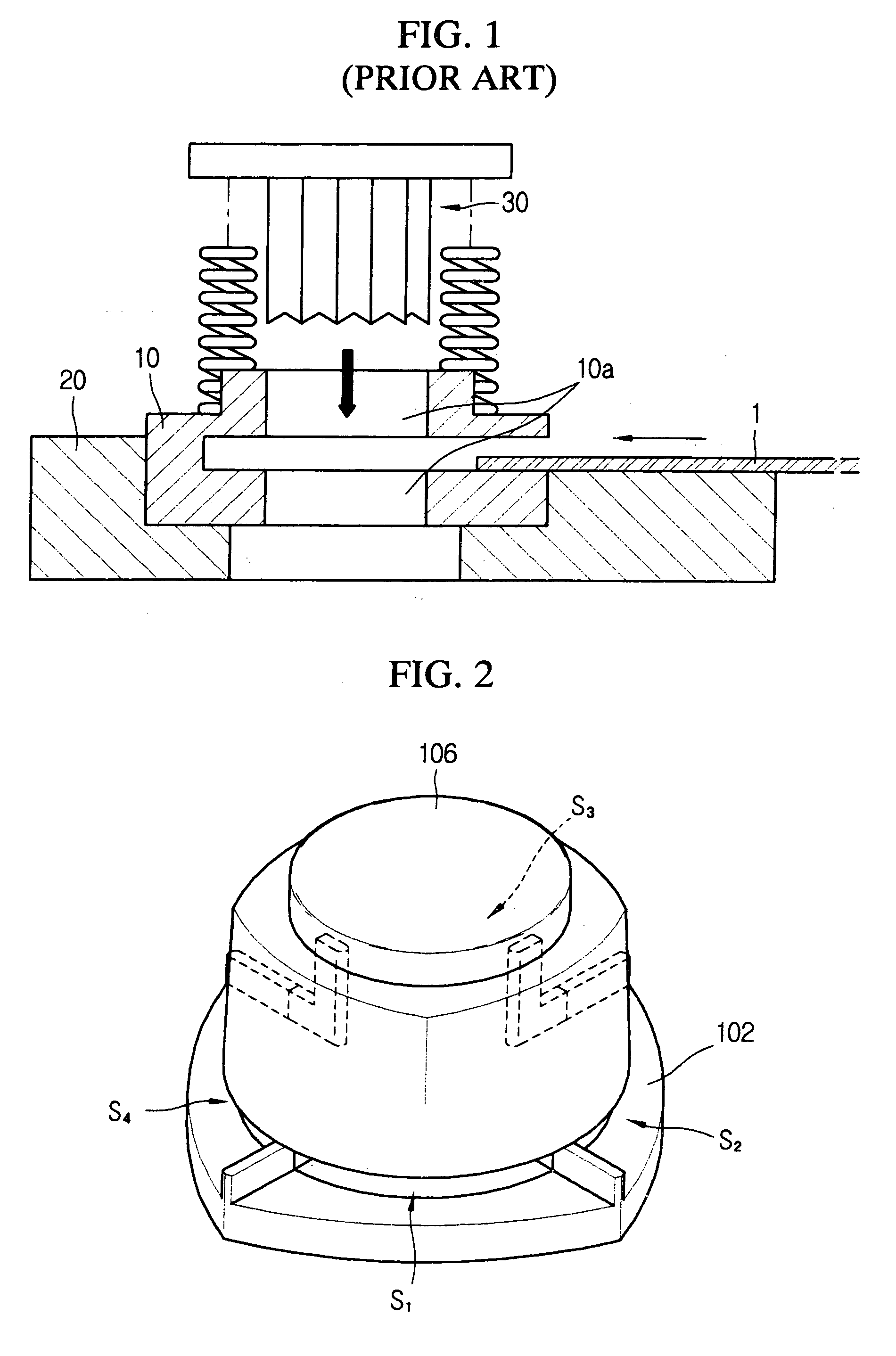

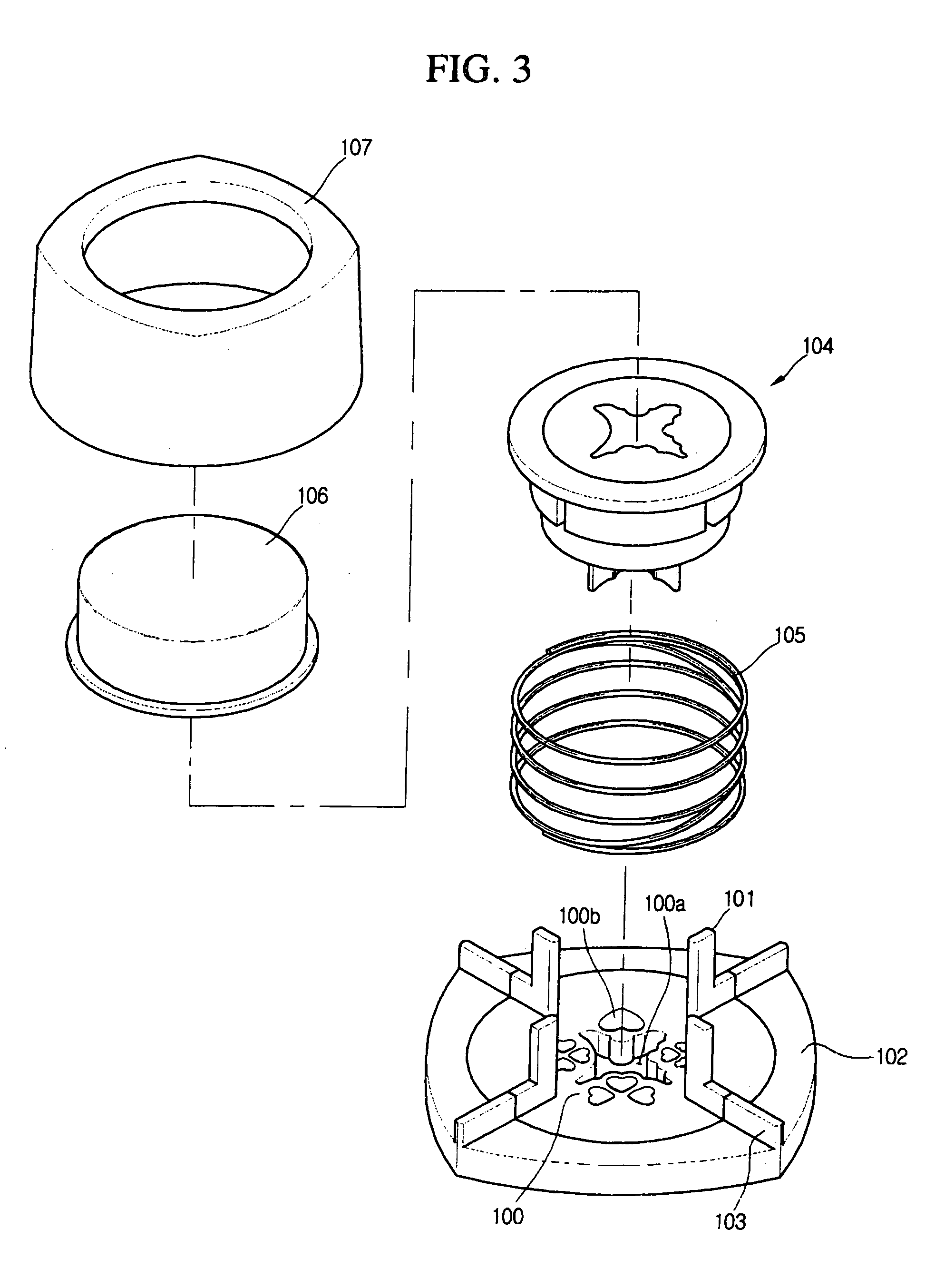

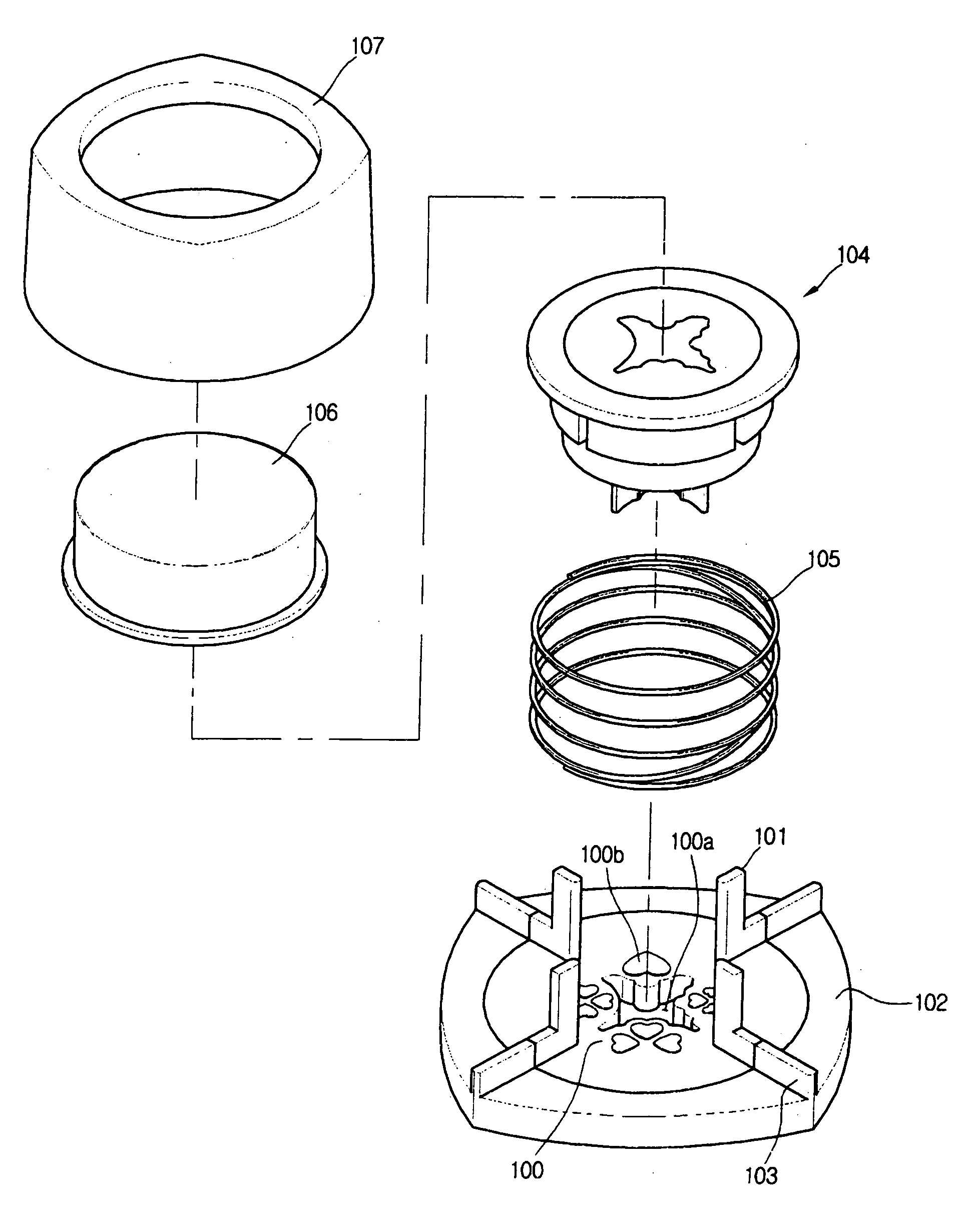

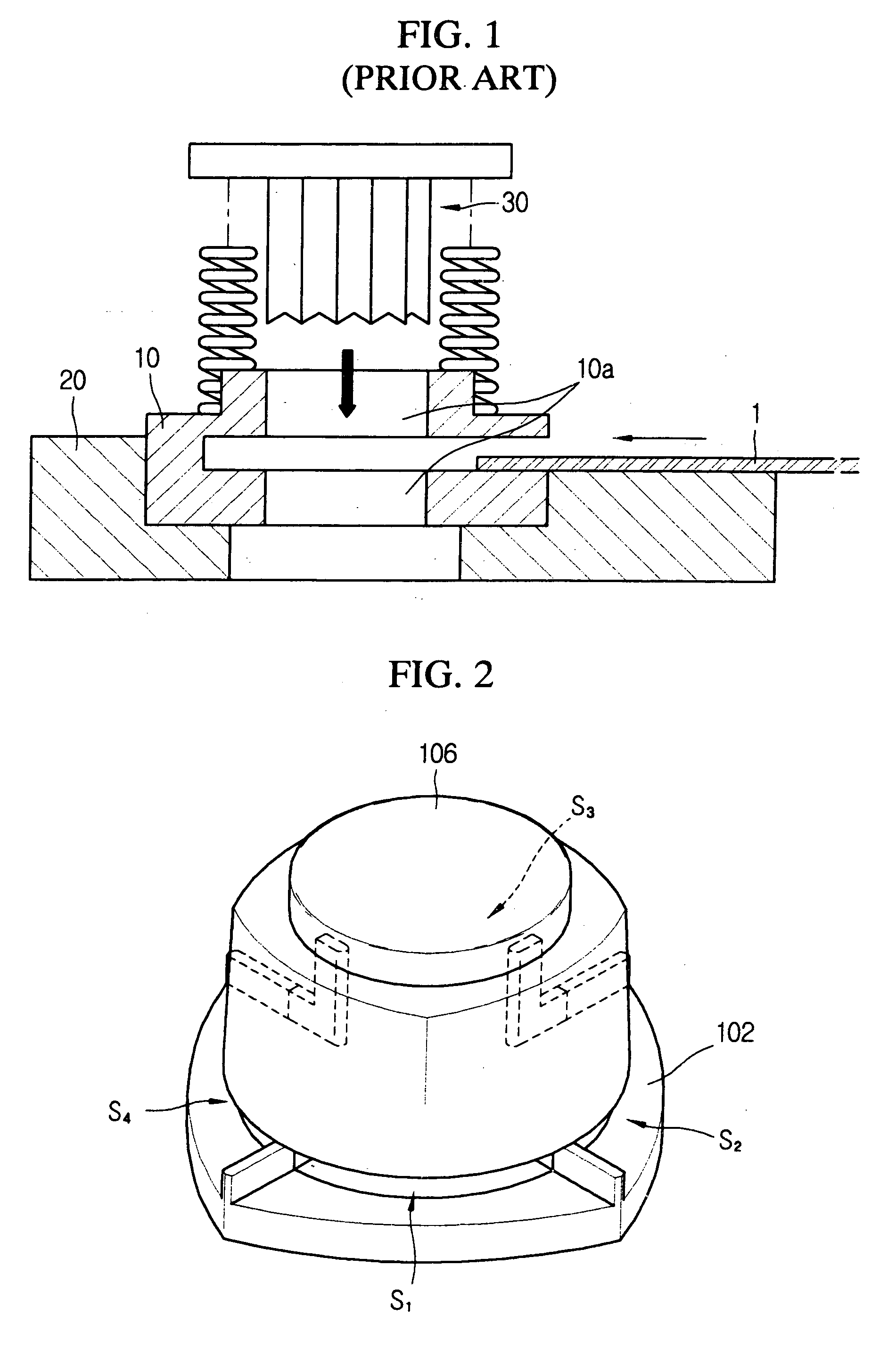

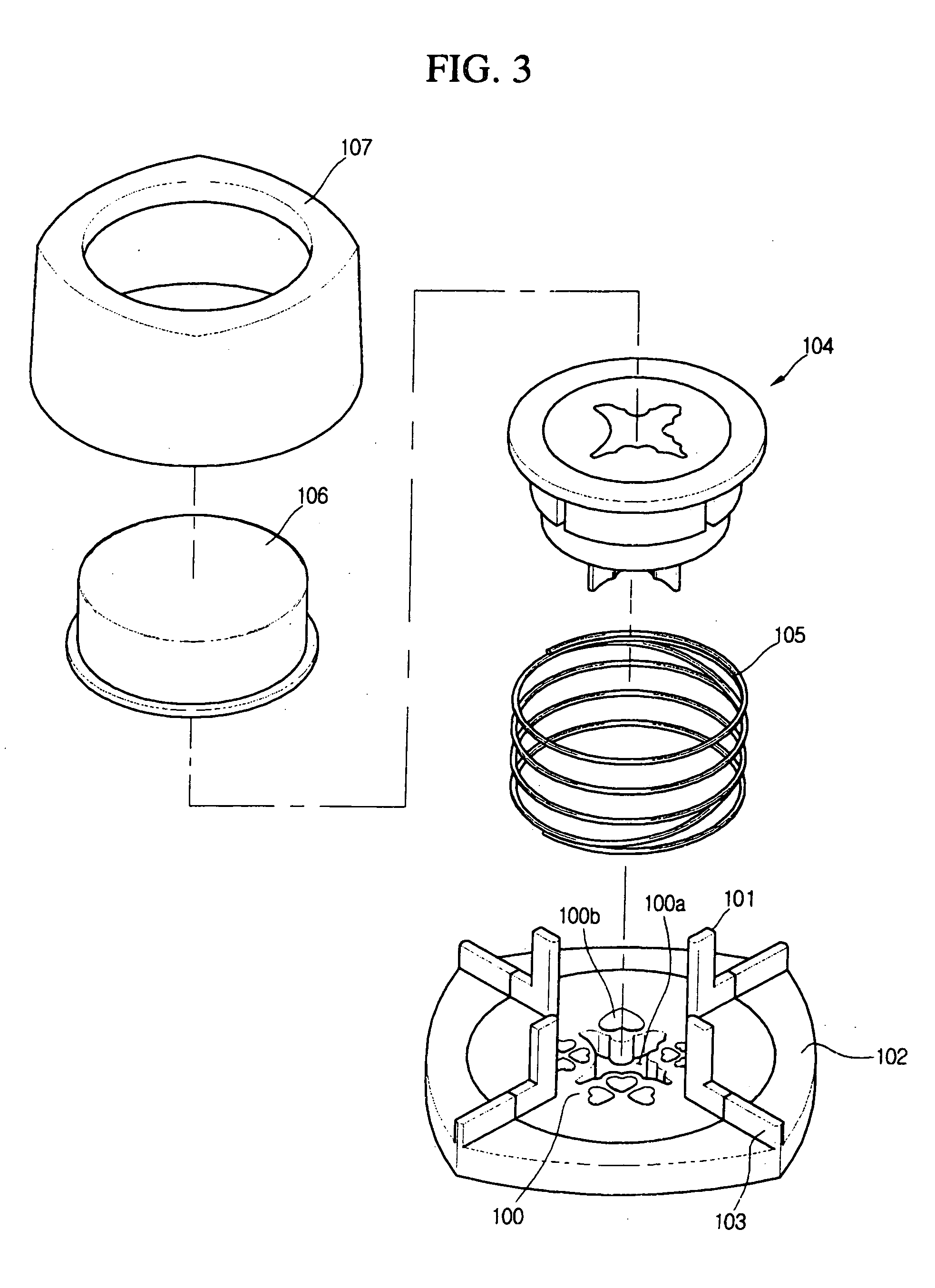

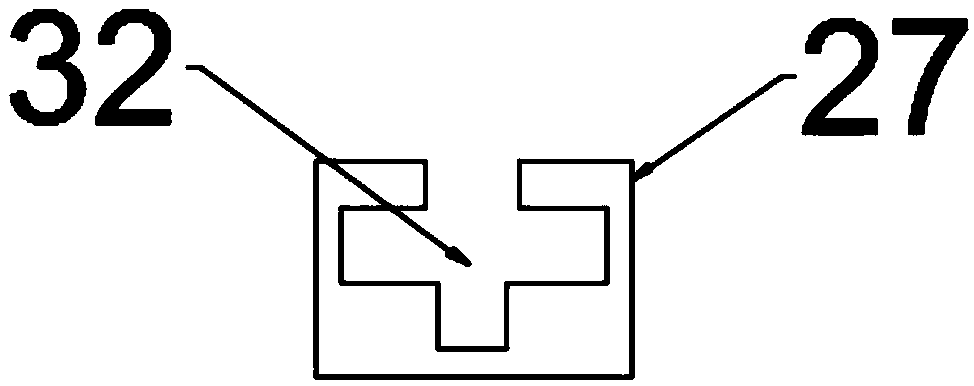

Punch capable of punching an object at four directions

InactiveUS7201101B2Simple structureEasy to useMechanical working/deformationLeather manufacturingPunch pressEngineering

A punch includes a jig having four punching regions, each punching region having a pattern hole and a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig; a punching member punching and embossing the rectangular corner of a sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body to elastically bias the punching member upward.

Owner:DN CRAFT

Intelligent electricity-scalding cutting device

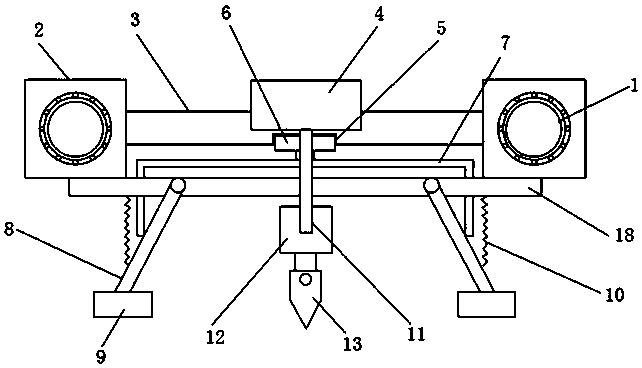

InactiveCN103161063AImprove operational safetyImprove cutting efficiencyLeather clicking/perforating/clickingSevering textilesElectricityDrive shaft

The invention discloses an intelligent electricity-scalding cutting device and belongs to the filed of electric cutting devices. The main structure of the intelligent electricity-scalding cutting device comprises a transmission mechanism, a tool mechanism, a pneumatic mechanism, a control mechanism, trundles, a main framework and a power source. A motor, the power source, a control unit, an operation panel and a control switch are arranged on a box on one side of the main framework. The trundles are arranged at the lower end of the main framework. The tool mechanism is movably arranged on a sliding rail of a cross beam between a left support and a right support. A motor output shaft is connected with the transmission mechanism through a transmission shaft. Multi-shaft motor control is adopted in the intelligent electricity-scalding cutting device, an operator can set cutting process and monitor cutting states through terminal software arranged on a machine tool, and therefore full-automatic feeding and cutting can be achieved. In the process of actual production, the intelligent electricity-scalding cutting device can improve cutting efficiency, save labor cost and cutting materials and greatly increase operation safety coefficients of operation workers.

Owner:上海谦羽智能科技有限公司

Punch capable of punching an object at four directions

InactiveUS20050211036A1Simple structureEasy to useDrawing diesLeather manufacturingPunch pressEngineering

A punch capable of punching an object at four directions is disclosed. The punch includes a jig having four punching regions radially symmetrical to each other on the basis of a punching center, each punching region having a pattern hole and / or a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig and giving a supply surface so that a rectangular corner of a sheet member to be punched is supplied between the adjacent guide columns; a punching member having a punch pin and / or a convex embossment corresponding to the pattern hole and / or the concave embossment, and punching and / or embossing the rectangular corner of the sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body interposed between the punching member and the jig to elastically bias the punching member upward.

Owner:DN CRAFT

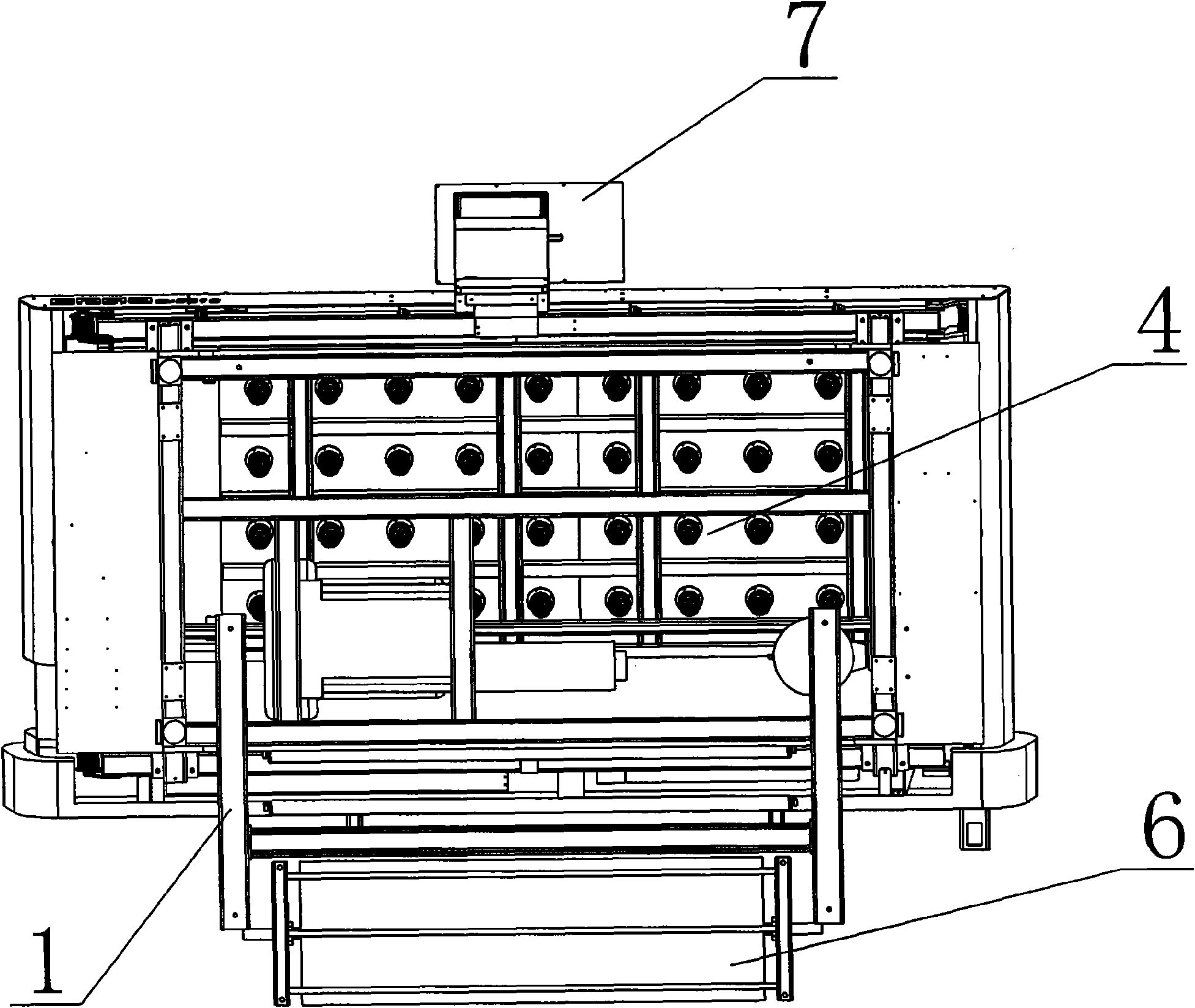

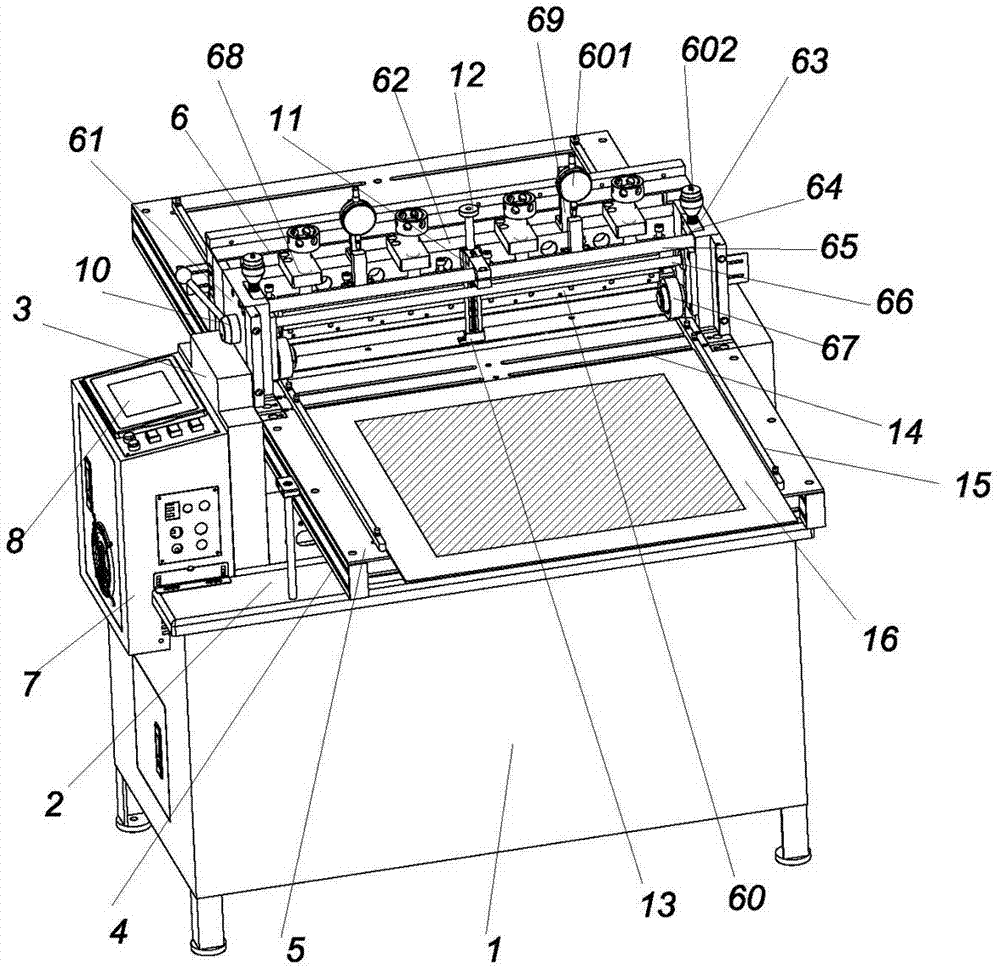

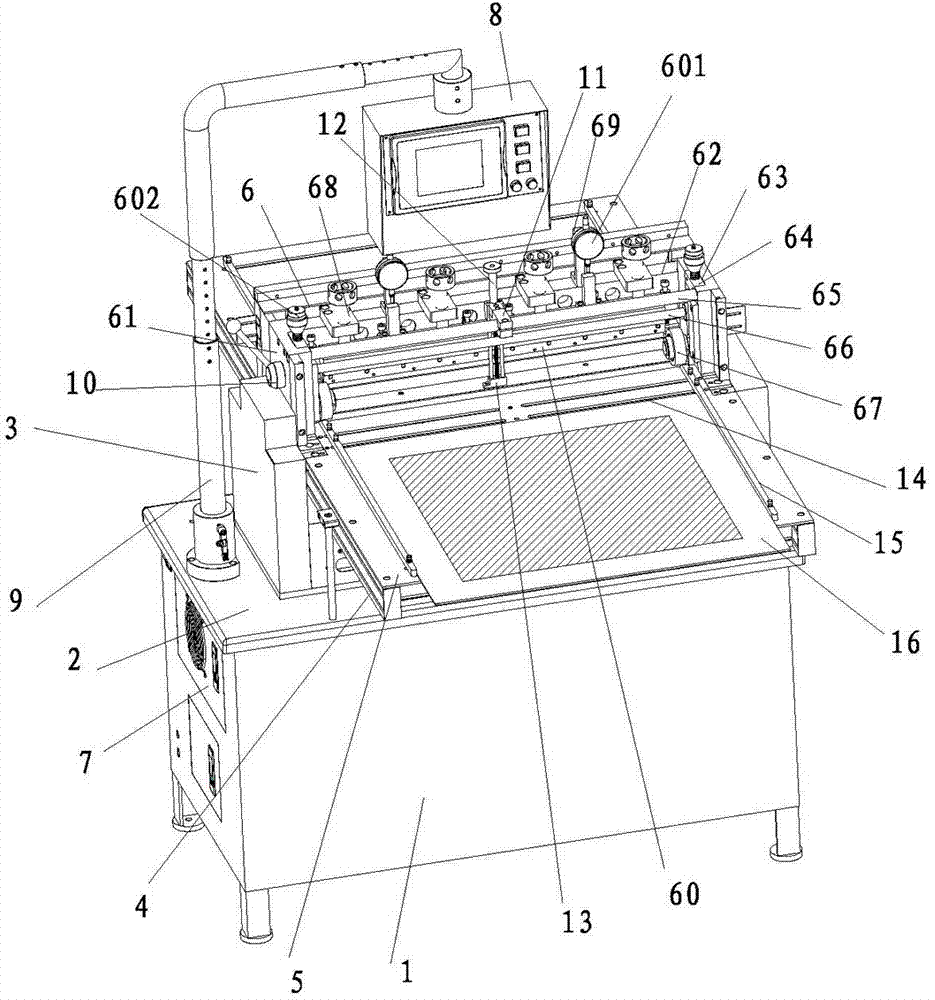

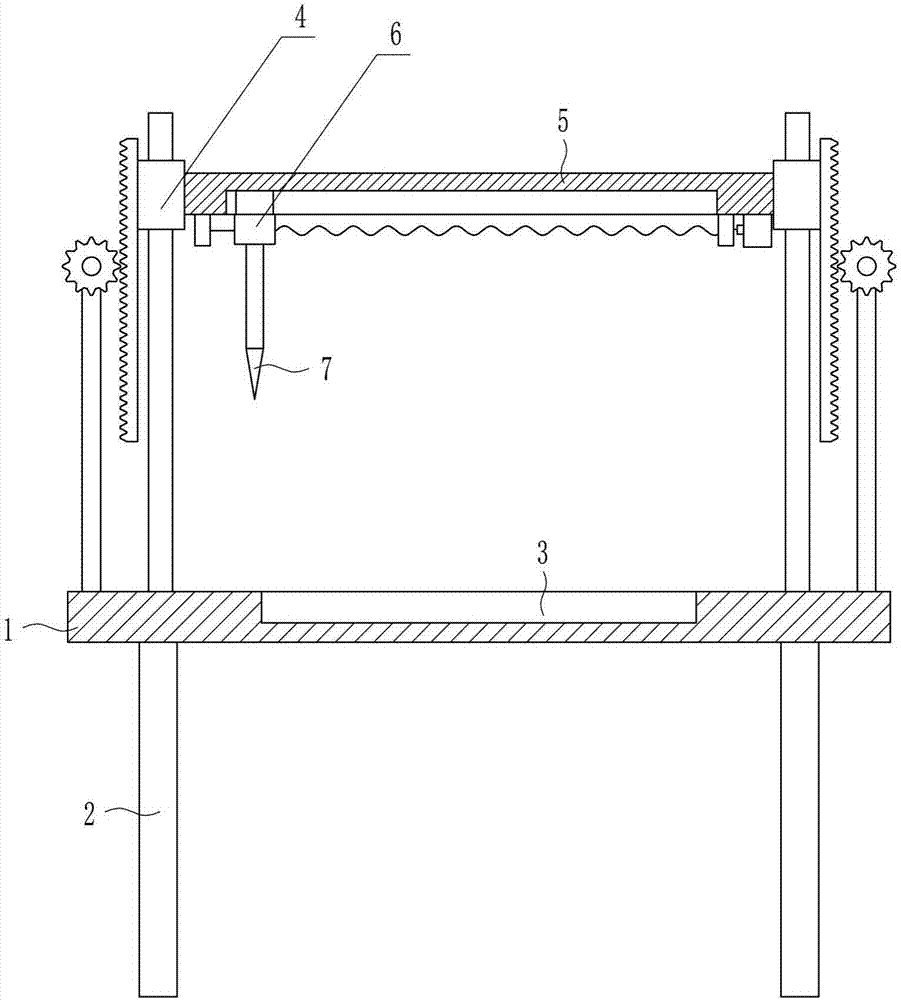

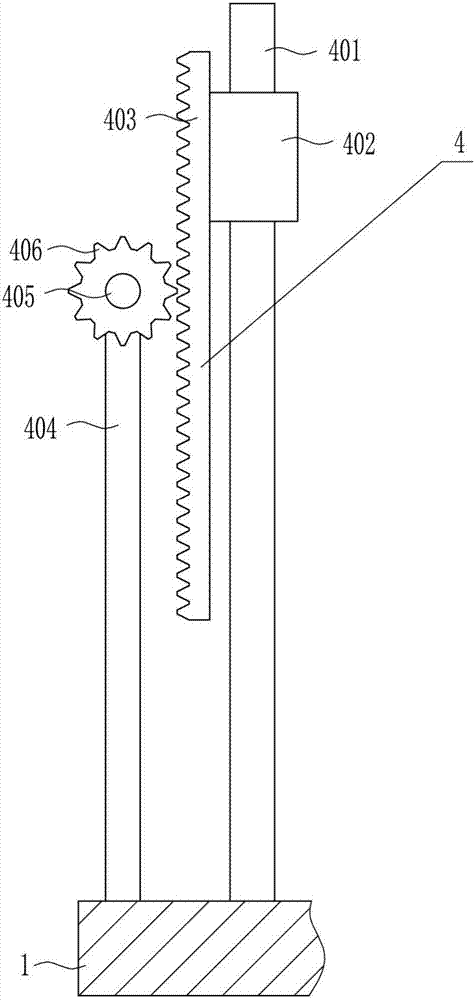

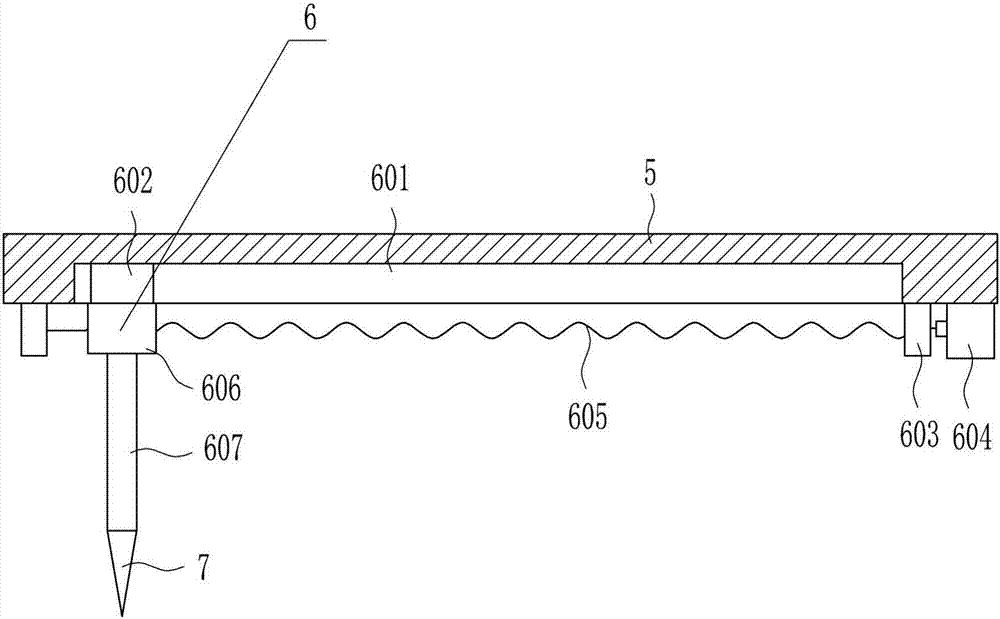

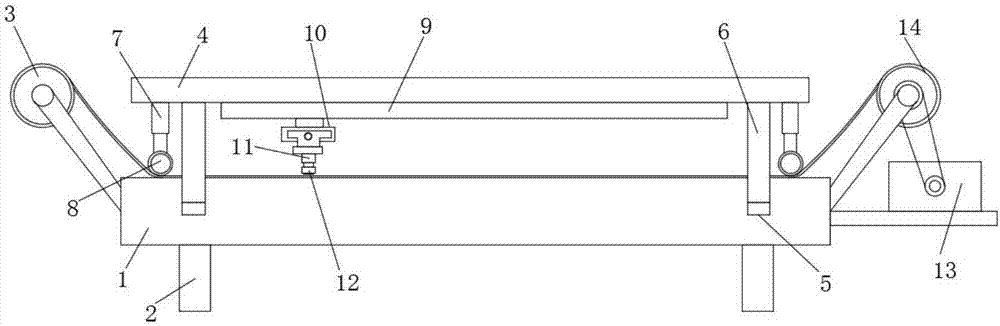

Automatic cutting machine

ActiveCN103934840AEasy to operateLeather clicking/perforating/clickingSevering textilesNumerical controlIdler-wheel

The invention discloses an automatic cutting machine which comprises a work machine table. The upper end of the work machine table is provided with a work table top. The work table top is provided with two supports corresponding to each other. A work-piece conveying table bracket is arranged between the two supports and provided with two corresponding work-piece conveying tables. A cutting device is arranged between the two work-piece conveying tables. One side of the work machine table is provided with an electrical appliance power distribution cabinet. One end of the work table top is provided with a touch type operation panel. Flaky materials are placed on an acrylic plate, a start key is pressed, and feeding idler wheels can advance in a running-down mode; when a photoelectric sensor senses coming of the materials, the edges can be automatically cut and trimmed neatly according to the length set by the photoelectric cardinal number, fixed length cutting is carried out and the cutting number is controlled according to the cut length set by a numerical control device; after the number of cutting is finished, the feeding idler wheels enable the acrylic plate to retreat to the original start position according to the length set by the reversing length.

Owner:东莞市塘厦肇颖机械五金厂

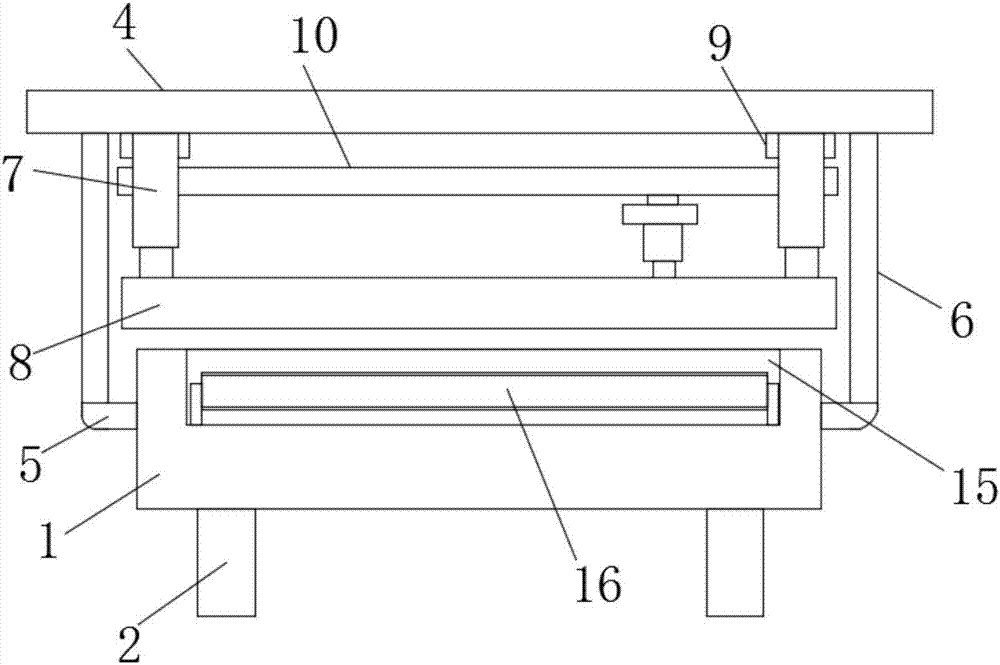

Cutting device for leather bag manufacturing

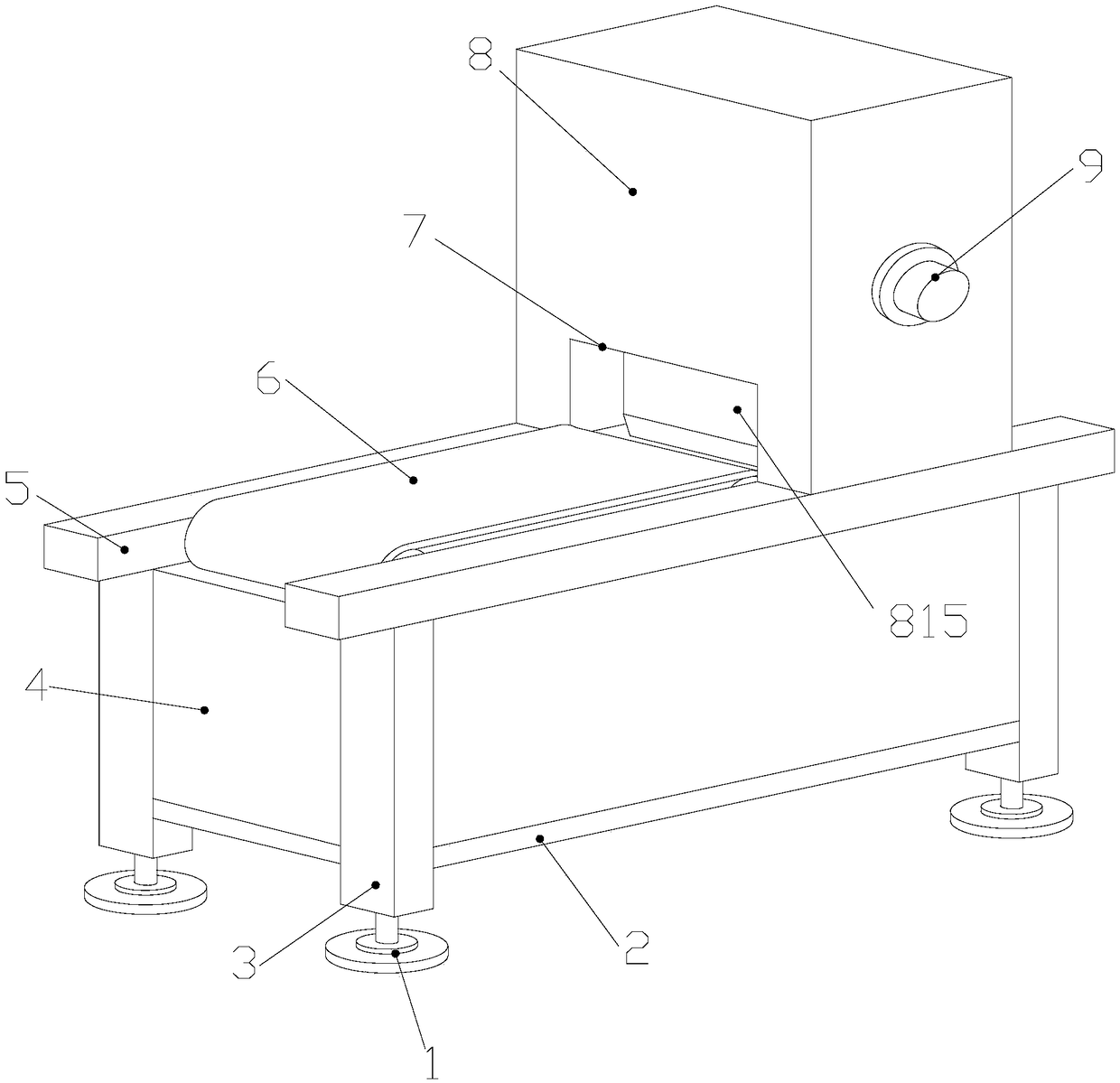

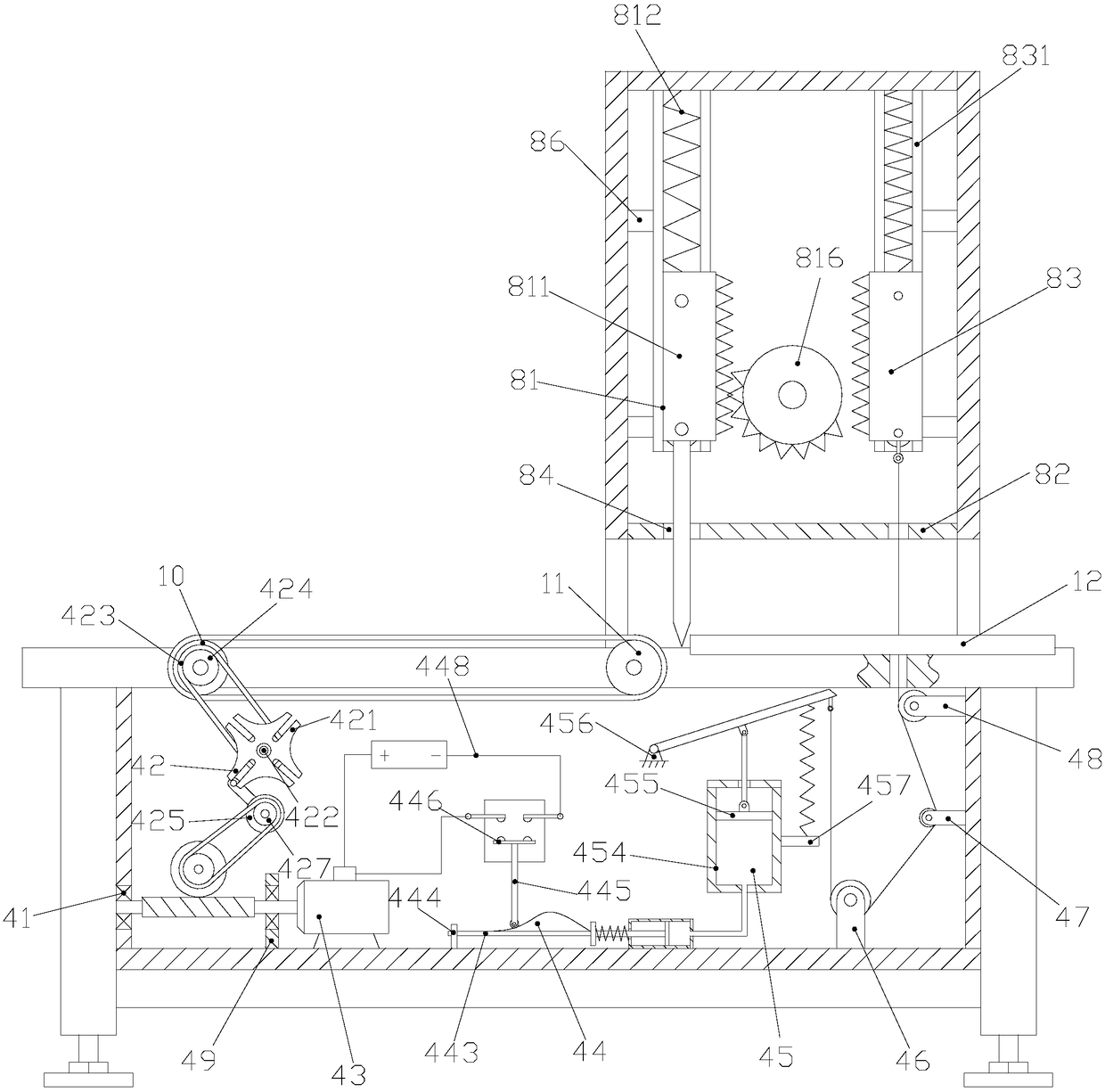

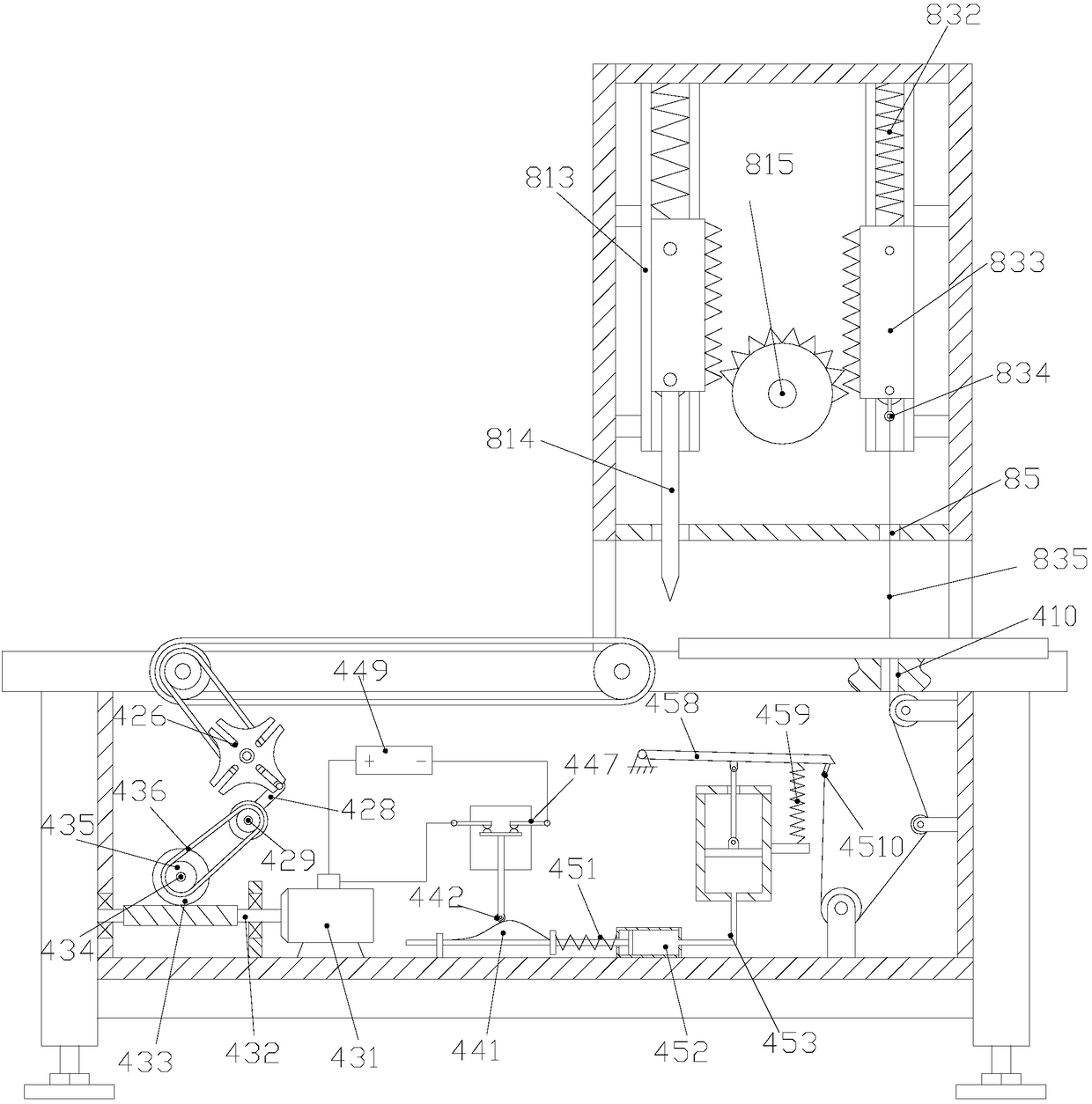

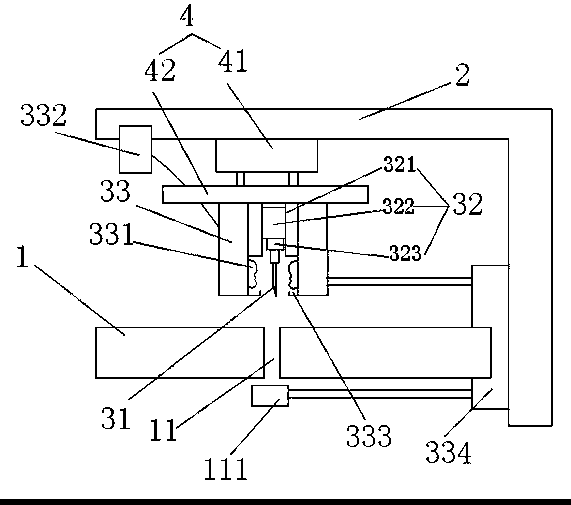

InactiveCN108277303AImprove work efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusStopped workEngineering

The invention discloses a cutting device for leather bag manufacturing. The cutting device structurally comprises foot cups, a supporting frame, supporting legs, a transmission box, a workbench, a conveying belt, a feed port, a cutting box, a first motor, a power drum, an unpowered drum and a supporting plate; the foot cups are vertically arranged at the bottoms of the supporting legs in a boltedconnection manner; and the tops of the supporting legs are vertically arranged at the four corners of the bottom of the workbench by welding. The conveying belt on the workbench is matched with a cutting device body in the transmission box in an intermittent feeding manner, when the cutting device body works, the conveying belt stops feeding, and when the cutting device body stops working, the conveying belt continues to feed, so that leather is continuously machined by adopting an intermittent cutting and feeding mode, a manual cutting mode is replaced, and the working efficiency is improved.

Owner:南安富诚阁工业设计有限公司

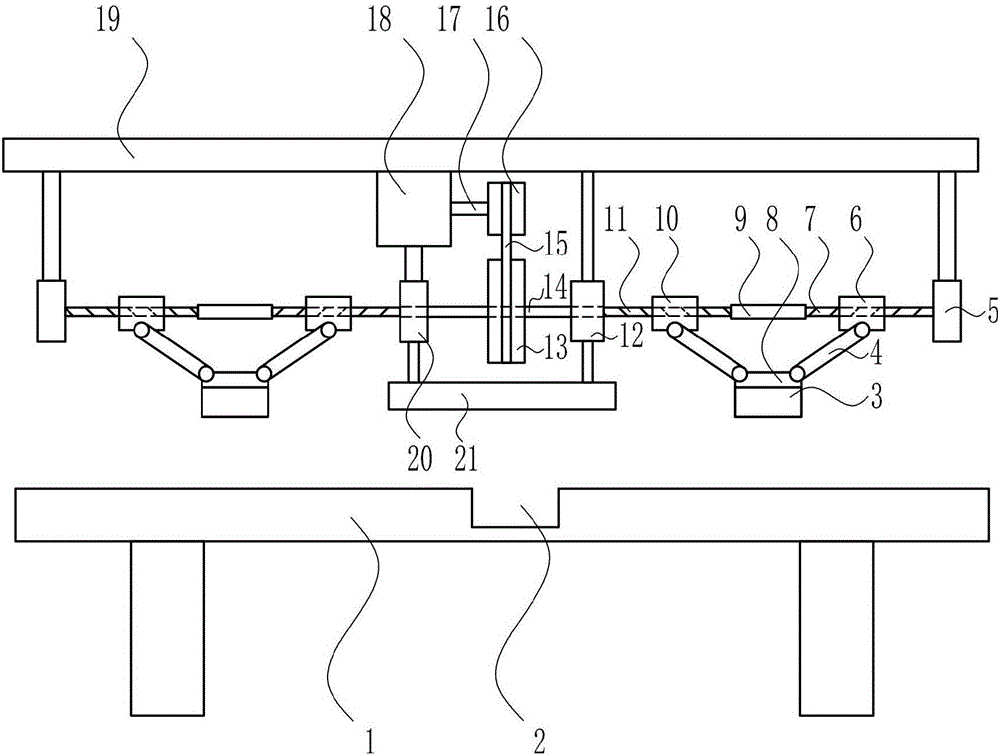

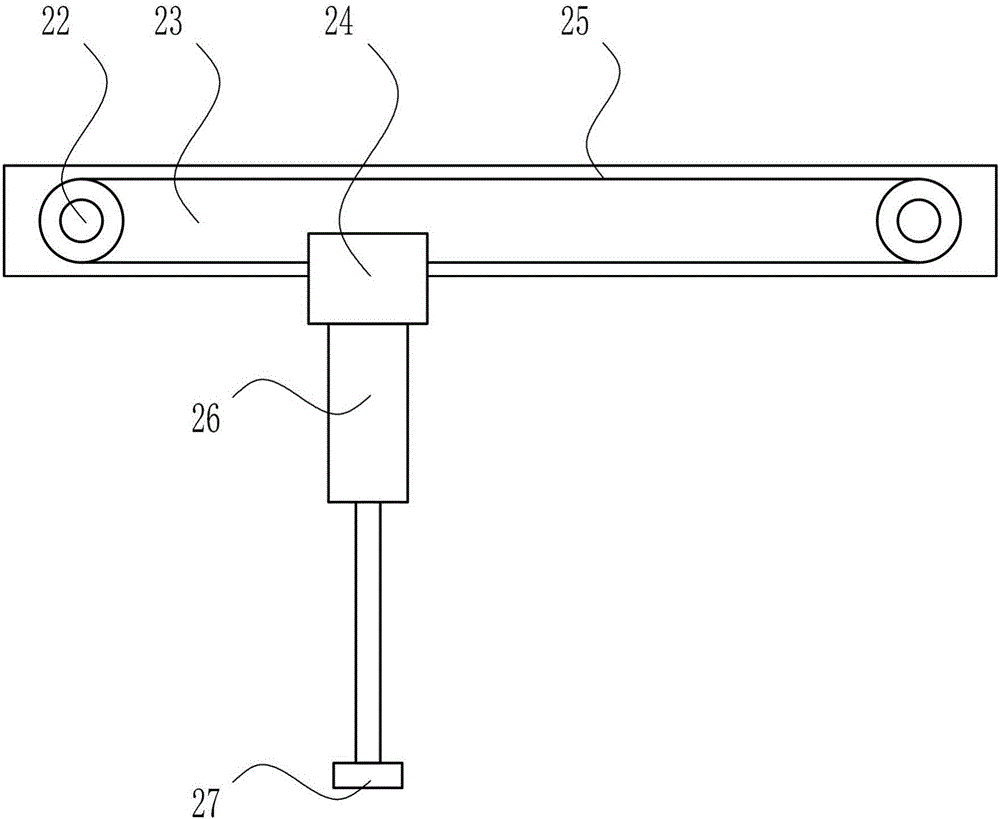

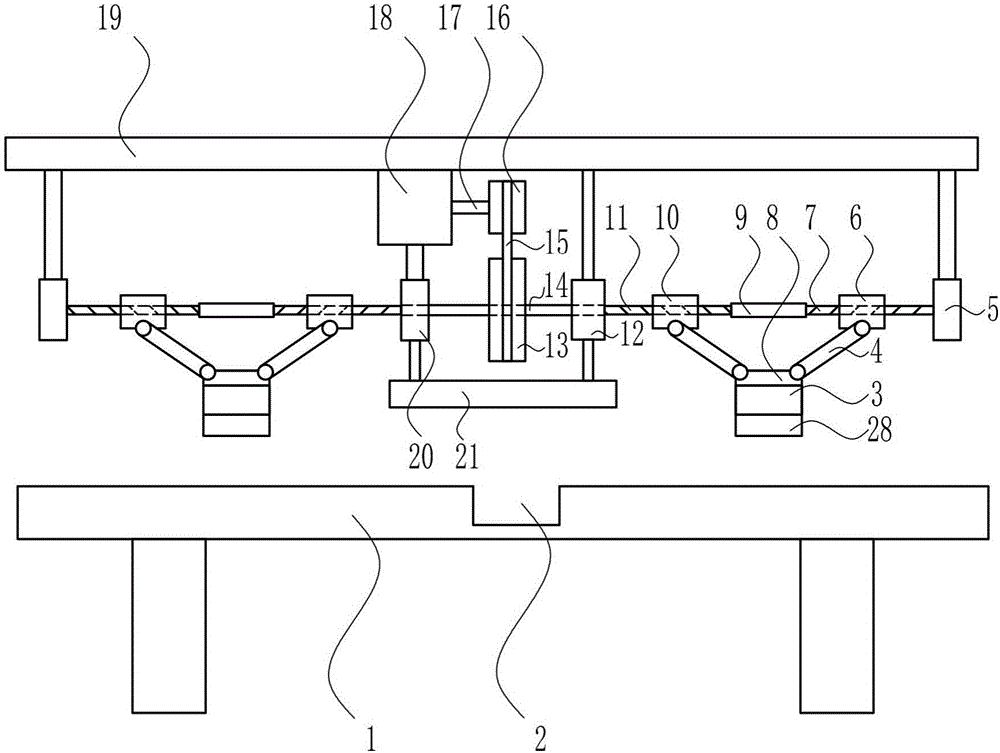

Efficient cutting device for sofa leather

ActiveCN104263860AAbsorb in timeTimely processingLeather clicking/perforating/clickingMetal working apparatusMechanical engineeringStructure control

The invention belongs to the field of sofa processing and relates to an efficient cutting device for sofa leather. The cutting device comprises a cutting table, a cutting structure arranged above the cutting table, and a mounting frame used for mounting the cutting structure, wherein a cutting joint strip is arranged on the cutting table; the cutting structure comprises a cutting knife arranged over the cutting joint strip, a control structure used for controlling the cutting knife to move up and down, and pressure heads which are arranged on the two sides of the cutting knife and used for stabilizing the leather; the cutting structure is mounted on the mounting frame through a drive structure; the drive structure is used for controlling the cutting structure to move up and down. The cutting device is simple in structure, easy to operate, high in cutting efficiency, small in cutting error, little in environmental pollution and relatively environment-friendly; generated dust can be absorbed and processed in time.

Owner:ZHEJIANG ANJI HUIYE FURNITURE

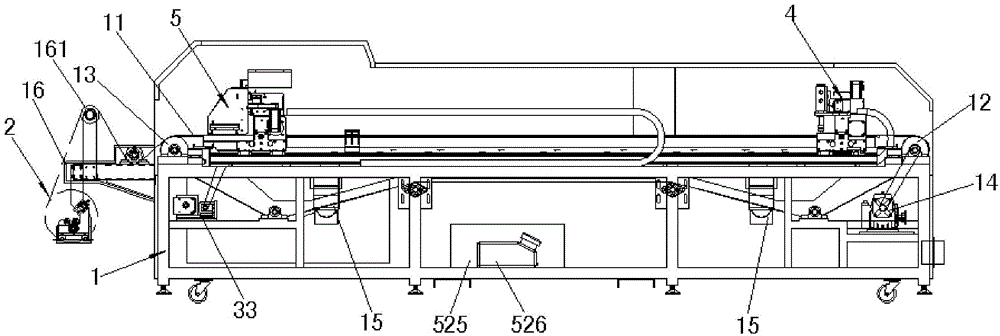

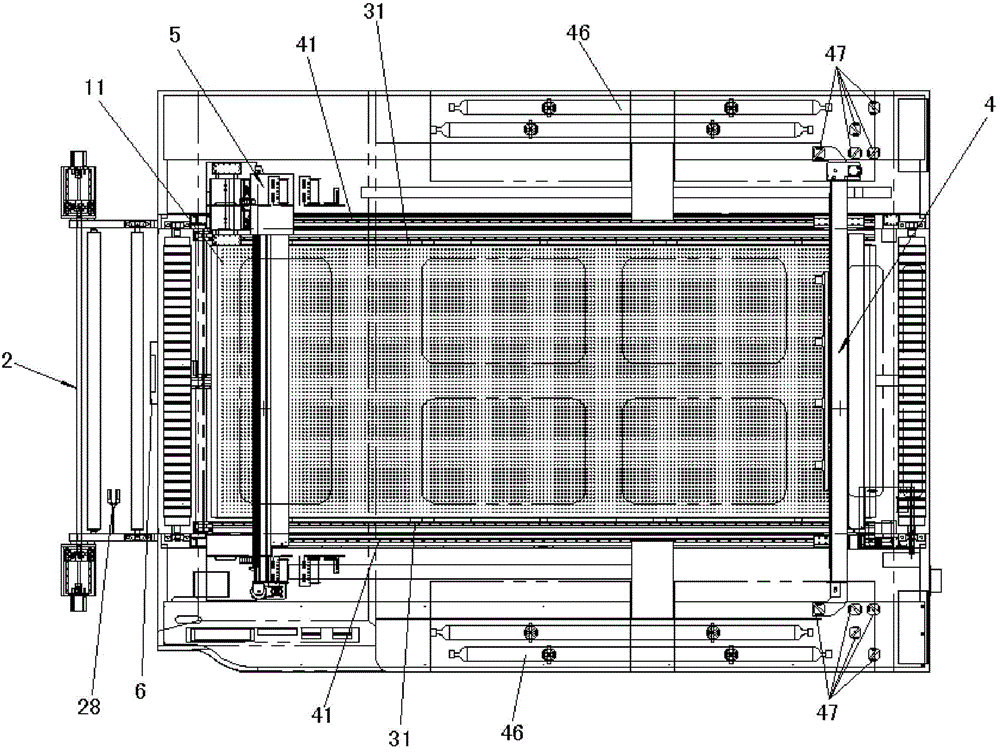

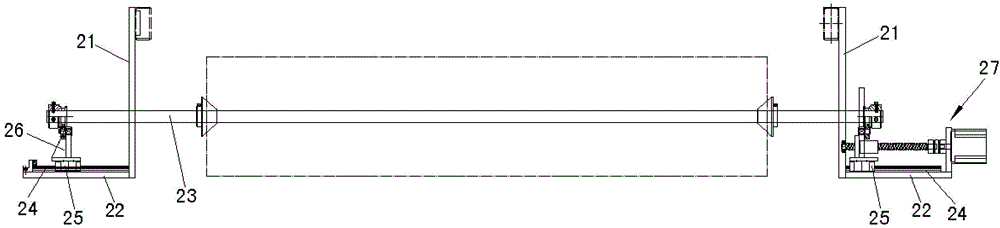

Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

InactiveCN104818350ASolve processabilitySolve the large number of laborLeather clicking/perforating/clickingTypewritersComputer control systemGraphics

The invention discloses a full-automatic leather printing and cutting machine which comprises a framework, an automatic rectifying mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism and a control system. A frame and a frame shaft are arranged at the front end of the framework, the frame shaft is arranged on the frame, the automatic rectifying mechanism is arranged at the front end of the framework, the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism are arranged on the framework, and the control system is arranged in the framework and is connected with the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism. The full-automatic leather printing and cutting machine has the advantages that manual production can be truly replaced by machines, accordingly, the leather processing efficiency and processing precision can be greatly improved, and the processing cost can be reduced; optional patterns can be accurately printed by the printing mechanism by the aid of the computer control system, and the problem of asymmetric pattern printing in existing leather processing procedures can be effectively solved.

Owner:DONGGUAN DEL LASER TECH

Novel leather high speed cutting machine and cutting method

InactiveCN102517405AIncrease productivityQuality assuranceLeather clicking/perforating/clickingComputer moduleEngineering

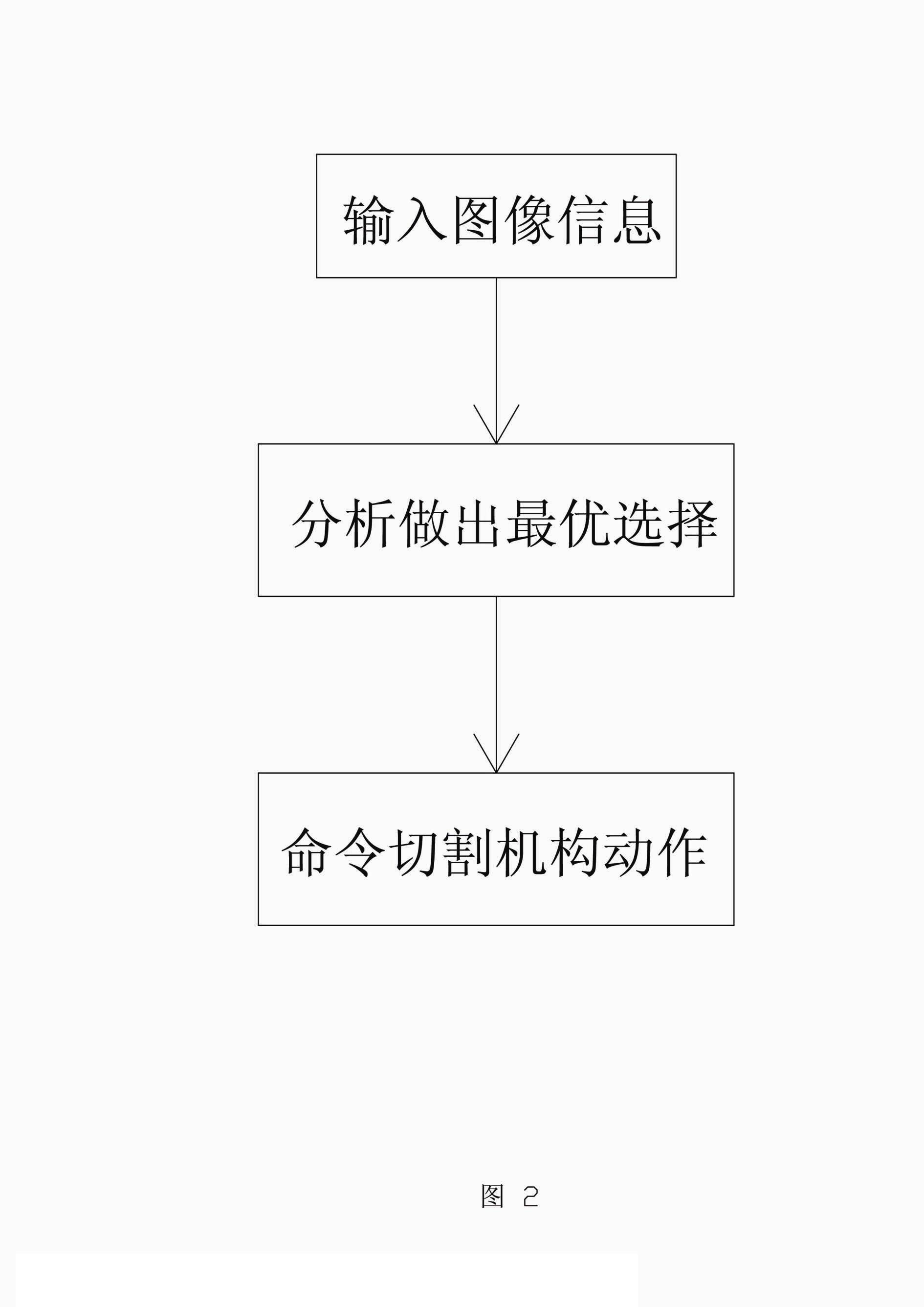

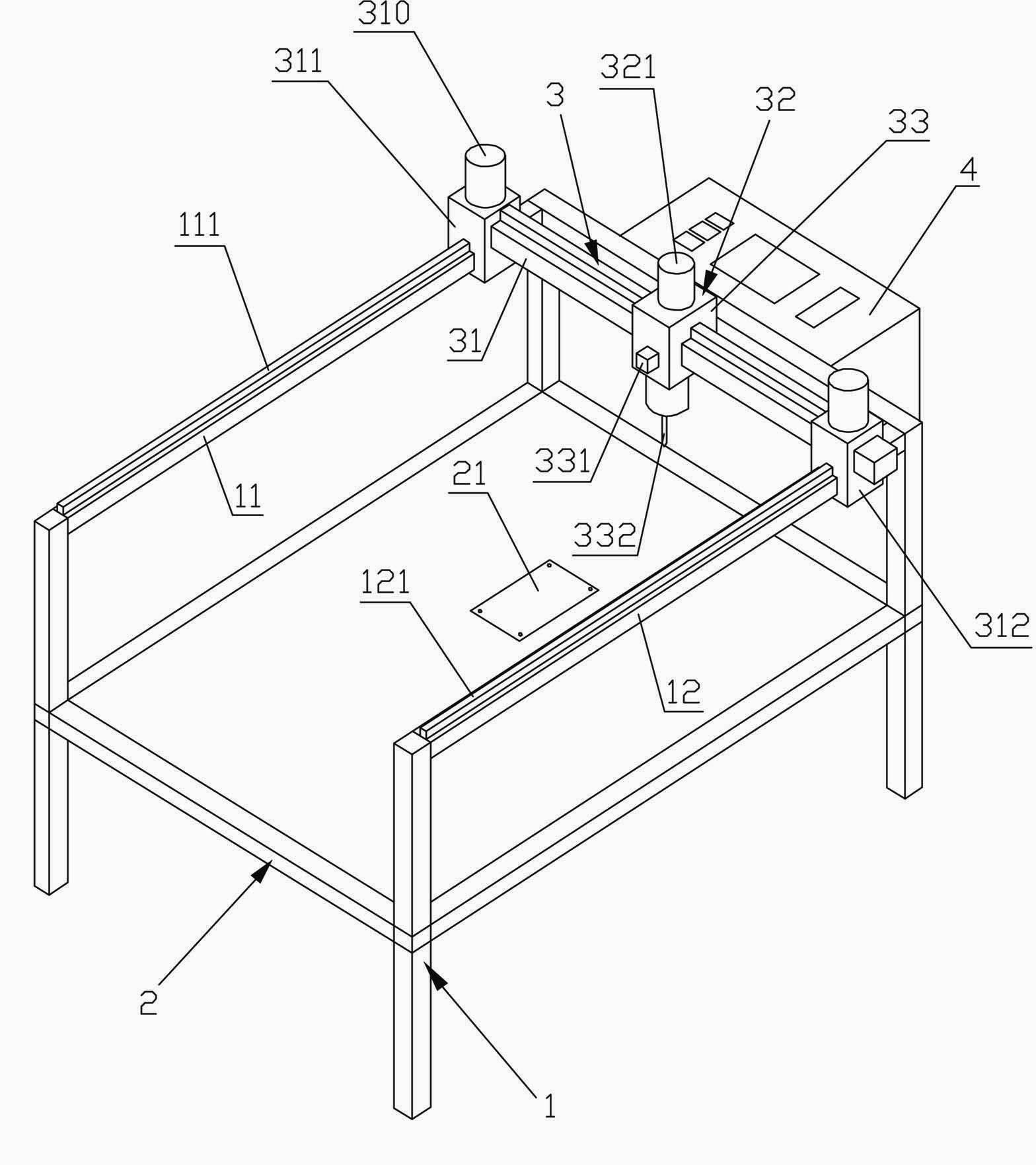

The invention relates to a novel leather high speed cutting machine. The machine comprises a frame, a workbench and a cutting mechanism, wherein the cutting mechanism comprises a knife rest beam and a longitudinal driving mechanism; a cutting knife device and a transverse driving mechanism which can slide on the knife rest beam are arranged on the knife rest beam; the cutting knife device comprises a knife rest which is connected with a laser head and a knife head capable of extending and retracting in the vertical direction; and a numerical control system connected with the cutting mechanism is arranged in the rear of the frame. A cutting method by using the novel leather high speed cutting machine comprises the following steps of: inputting graphical information of a sample which is needed to be cut into the numerical control system; analyzing the graphical information to select the optimal cutting mode by using an automatic analysis module; and driving the knife head and the laser head to act to cut leather by using the numerical control system. The machine can perform graphical analysis automatically to select the optimal cutting mode, and is multifunctional, the leather is not required to be accurately aligned for the second time, the quality of a product is ensured, machining steps are saved, the cost of the machine is greatly reduced, automatic production can be realized, and production efficiency is high.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

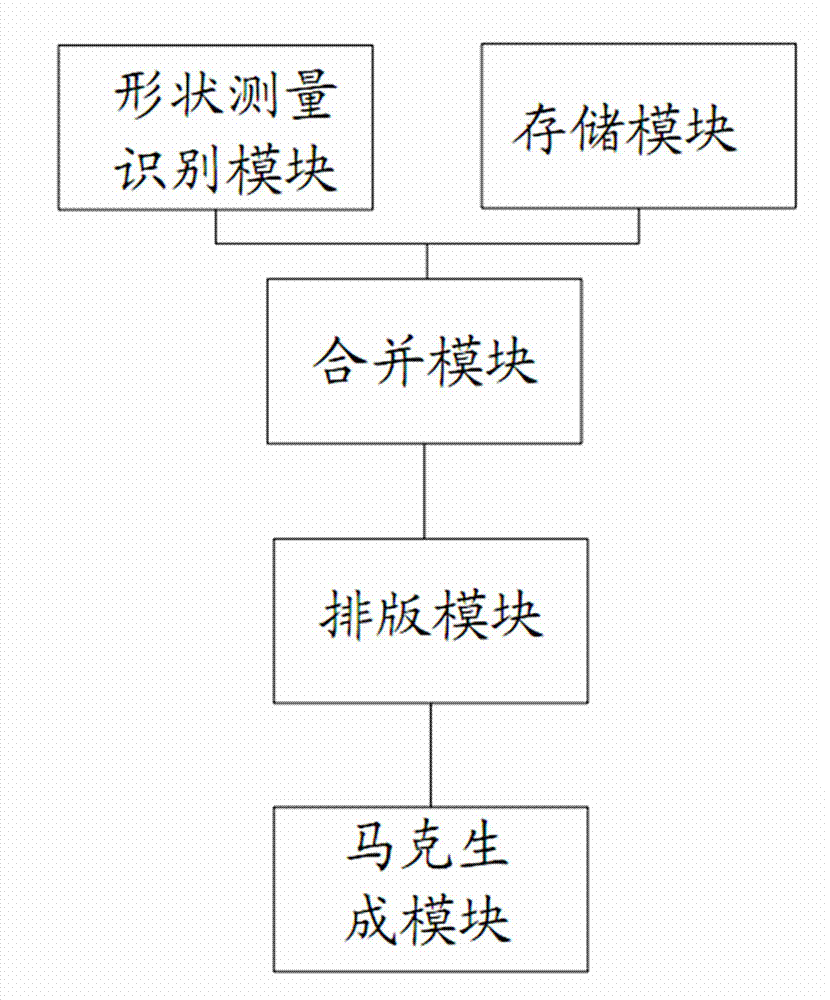

Type setting method and type setting system of leather and cloth

InactiveCN103114429ATake advantage ofIncrease profitLeather clicking/perforating/clickingSevering textilesComputer moduleRaw material

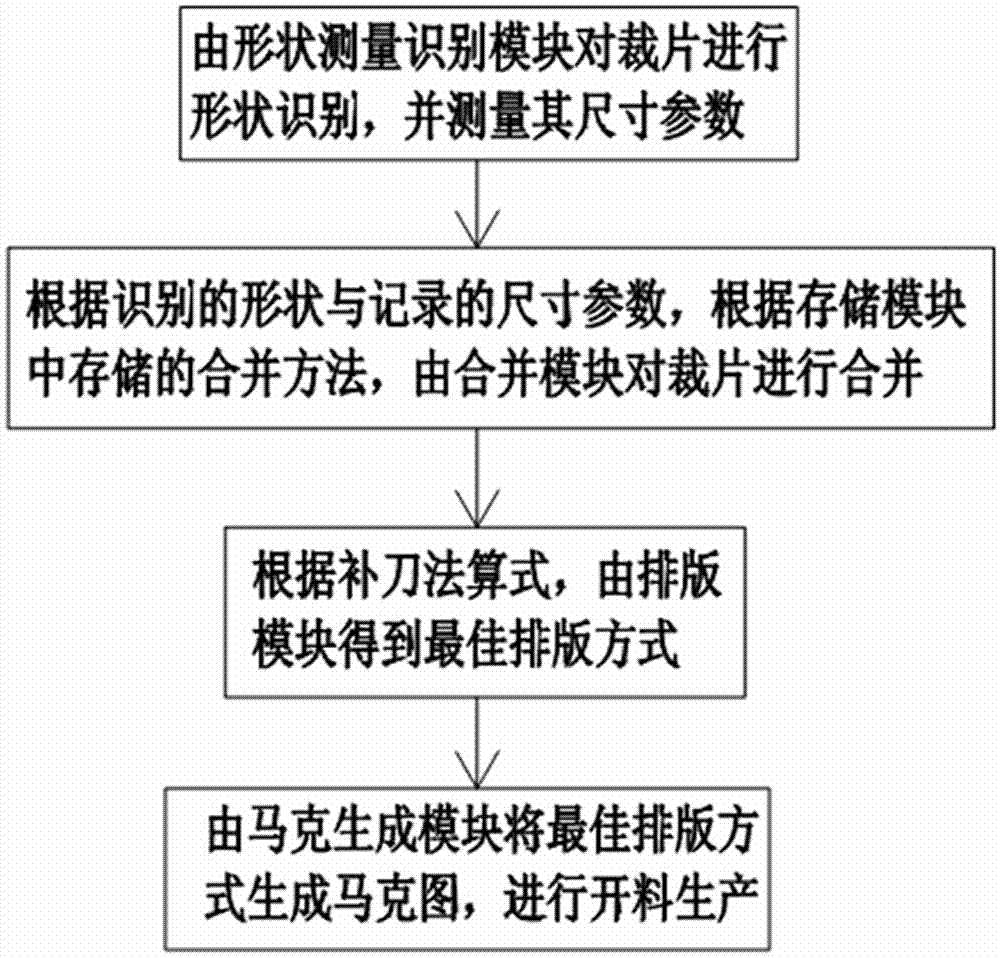

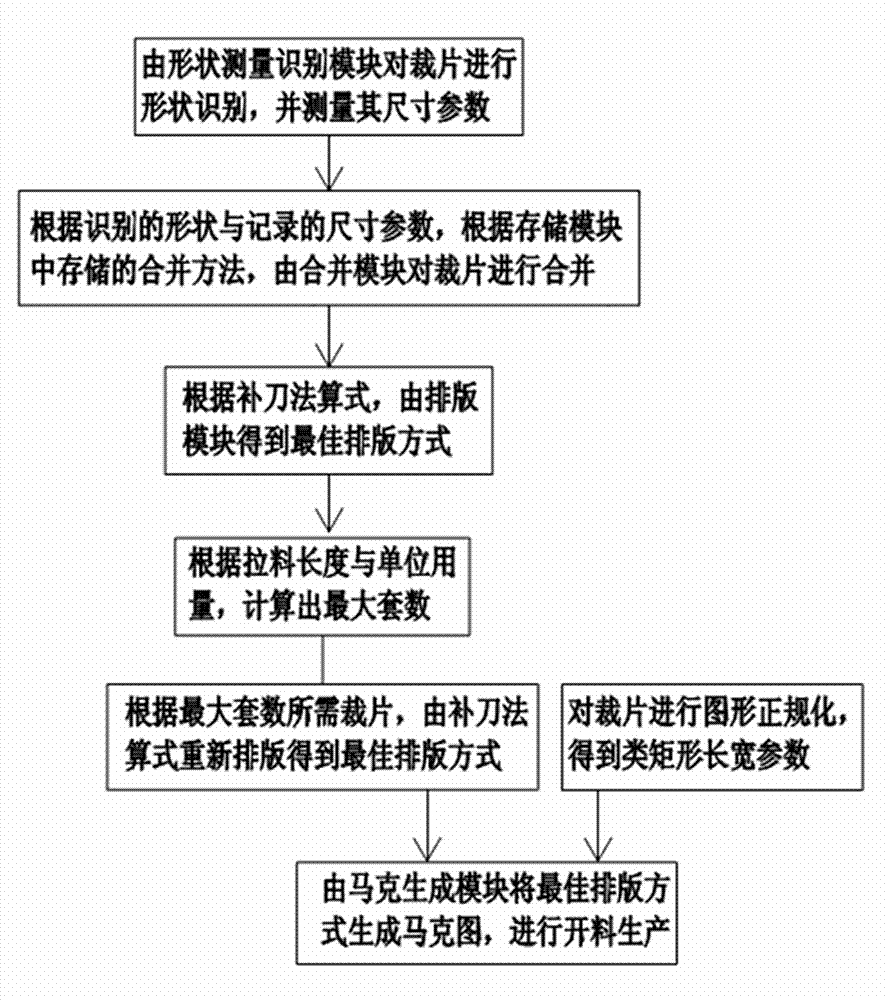

The invention discloses a type setting method of leather and cloth. Cutting piece shapes of a product is firstly identified by a shape measuring identifying module. A parameter is recorded. The cutting pieces are combined and operated by a combining module according to data of identifying record. Filling knife method equation is combined. The type setting is carried out by a type setting module. The best way is selected and a mosaic picture is produced. Cutting production is carried out. The whole type setting is automatically completed by the system. Compared with other types of setting ways in the prior art, the type setting speed is improved greatly. Type setting is carried out according to the filling knife method equation, times of changing cutting mould is reduced to the lowest, thus cutting efficiency is high. Besides, the cutting pieces are combined and operated before the cutting pieces are type set. The leather and the cloth can be fully used reasonably. Use rate of raw materials is improved. Product cost is reduced intangibly. Competitiveness of a factory is improved.

Owner:DONGGUAN LEANERP SOFTWARE

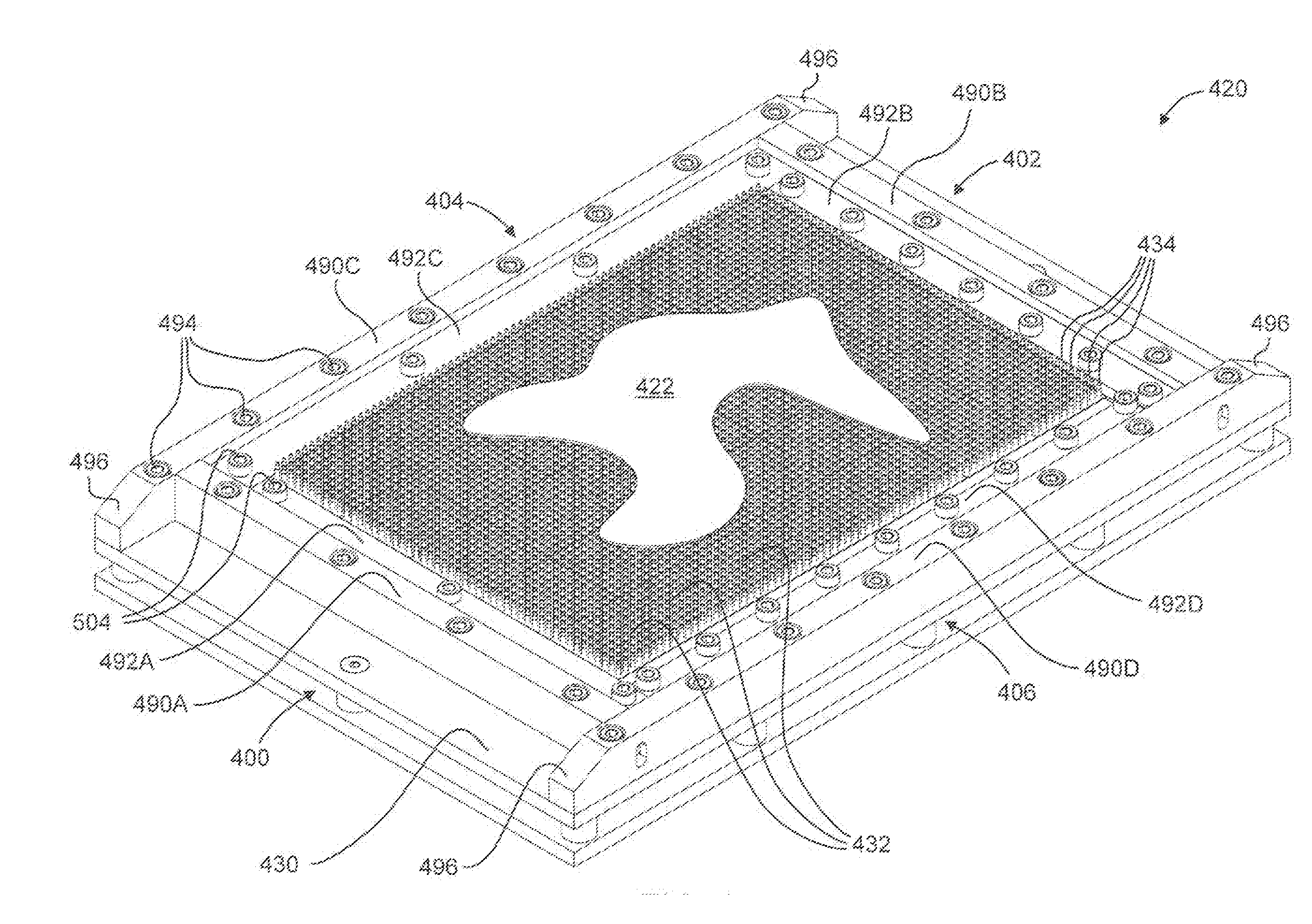

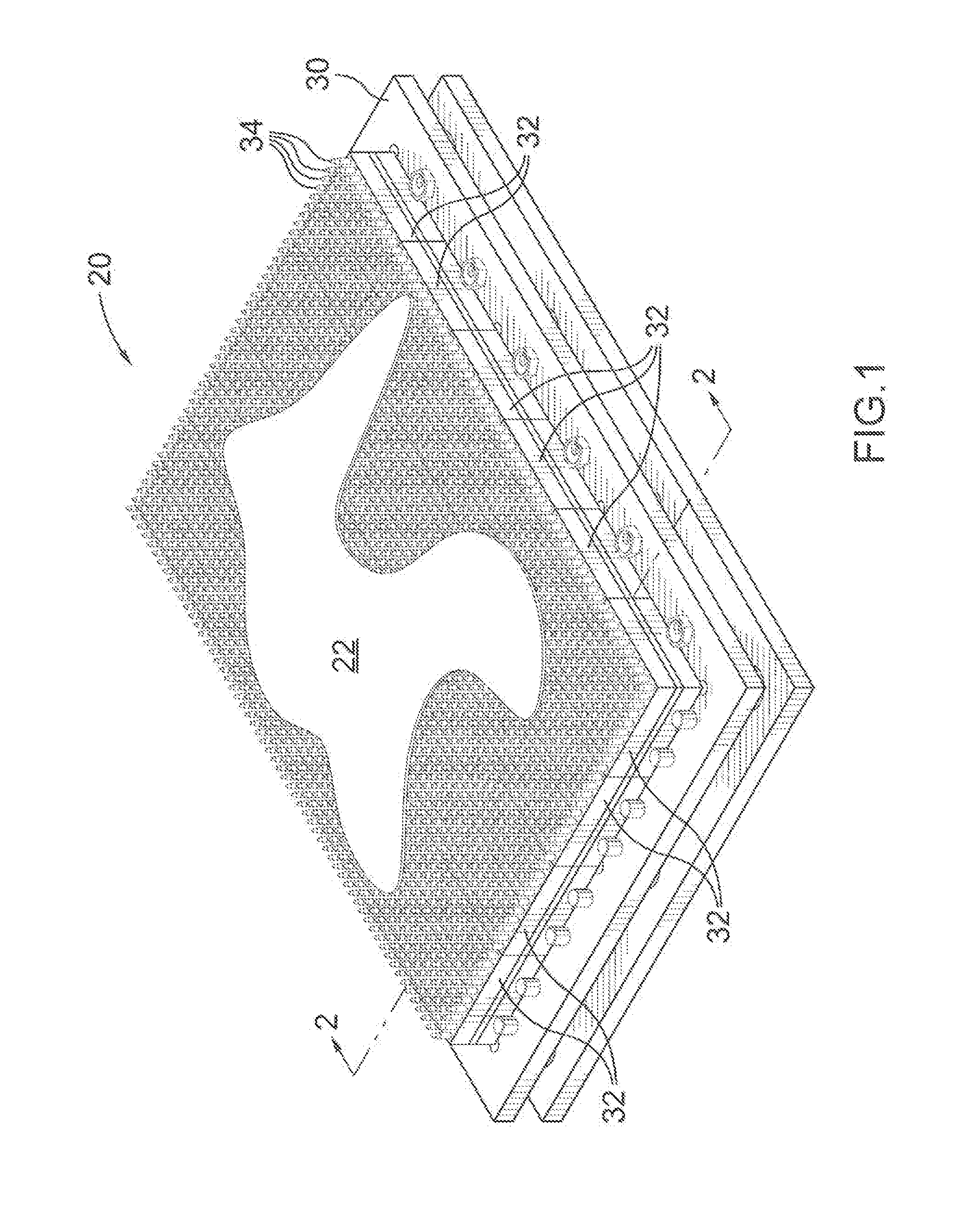

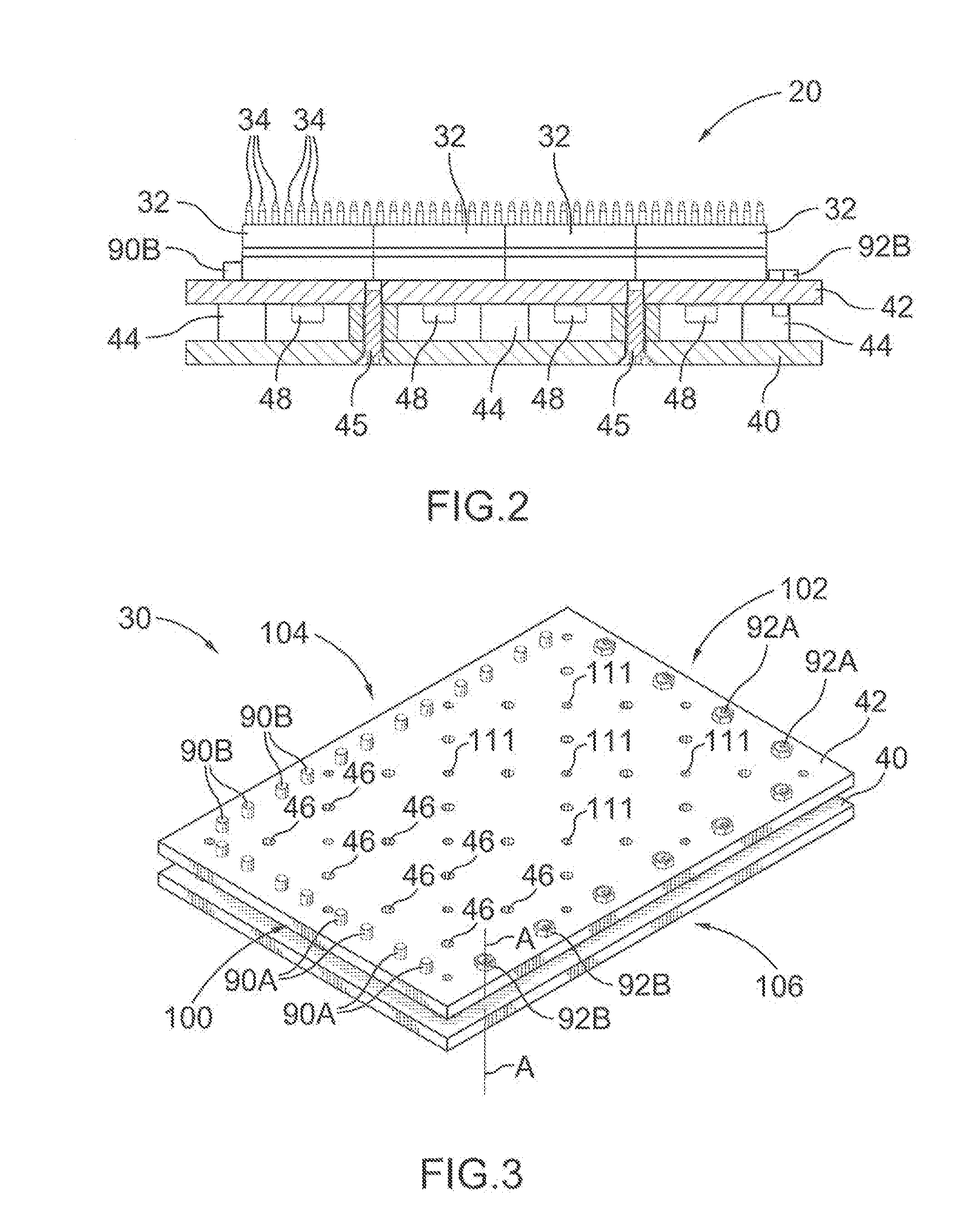

Apparatus and Methods for Perforating Leather Using Perforation Tiles

InactiveUS20150000485A1Leather clicking/perforating/clickingSevering textilesMaterial PerforationFastener

According to some aspects disclosed herein, there is an apparatus for perforating a sheet of material. The apparatus includes a tile holder and a plurality of perforation tiles removably mountable to the tile holder. Each perforation tile includes a fastener plate for removably mounting the perforation tile to the tile holder; a punch plate supported by the fastener plate opposite the tile holder, the punch plate having at least one aperture therein; and at least one punch received in the at least one aperture and extending outwardly beyond the punch plate away from the fastener plate for perforating the sheet of material.

Owner:ONTARIO DIE INT

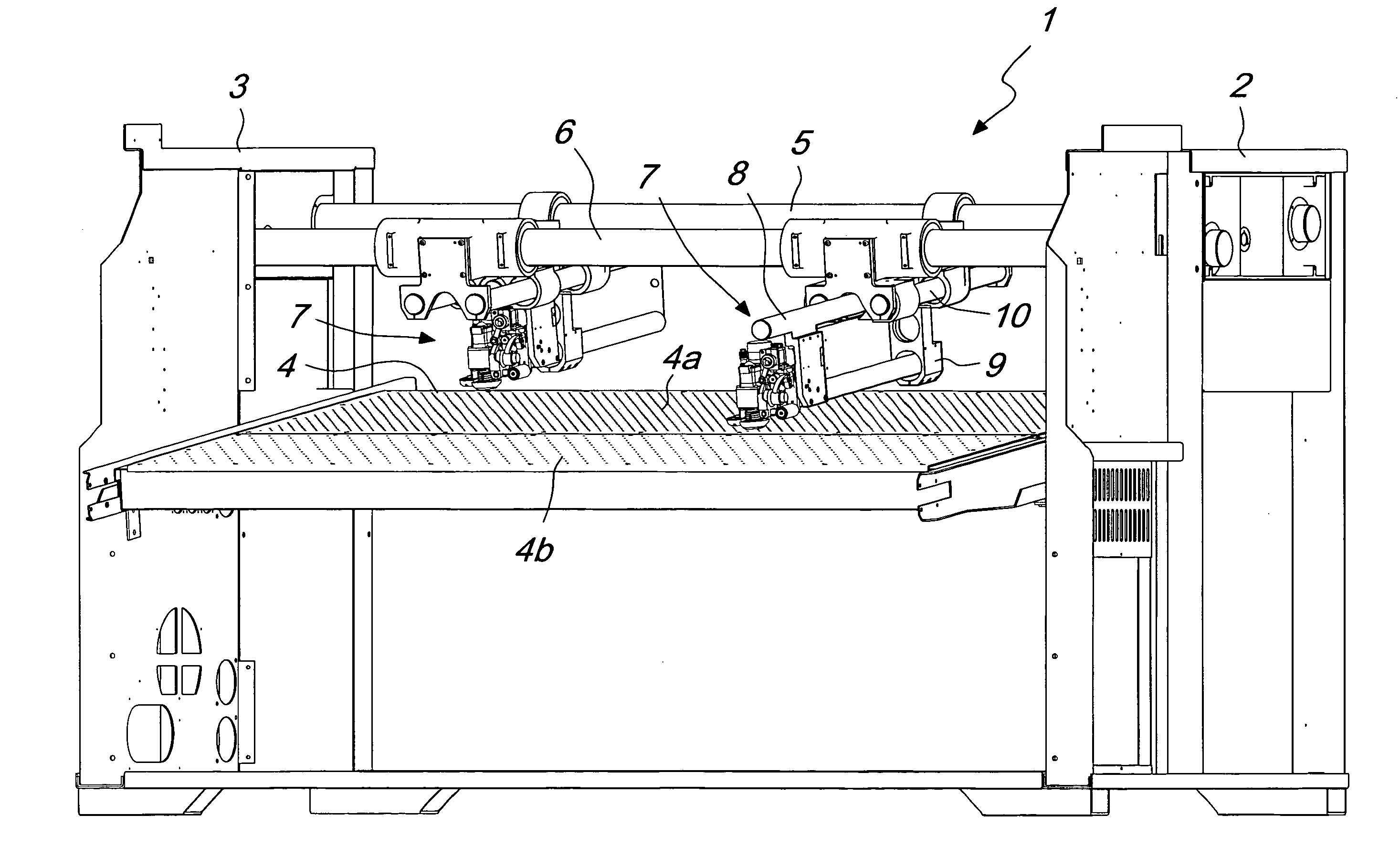

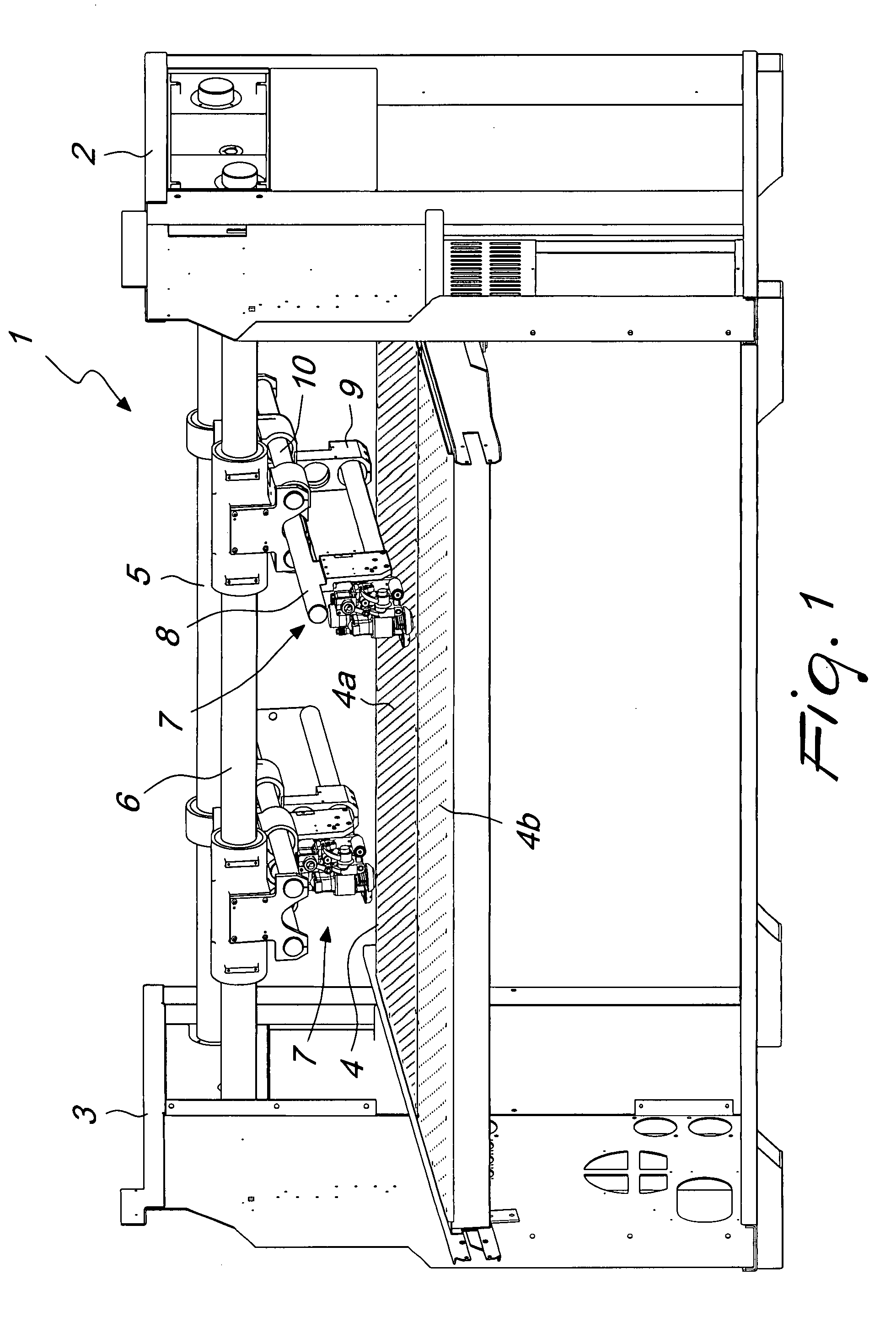

Cutting machine, particularly for leather and similar materials

ActiveUS20100043501A1Rigid enoughAdd depthLeather manufacturingLeather clicking/perforating/clickingEngineeringConveyor belt

A cutting machine, particularly for leather and similar materials, comprising a pair of shoulders which are connected by a system of guides arranged so as to lie above a conveyor belt, at least one cutting head being movable along the guide system, the movement of the cutting head in the same advancement direction as the conveyor belt and at right angles to the guide system being distributed on two or more elements, at least one of which is cantilevered.

Owner:COMELZ SPA

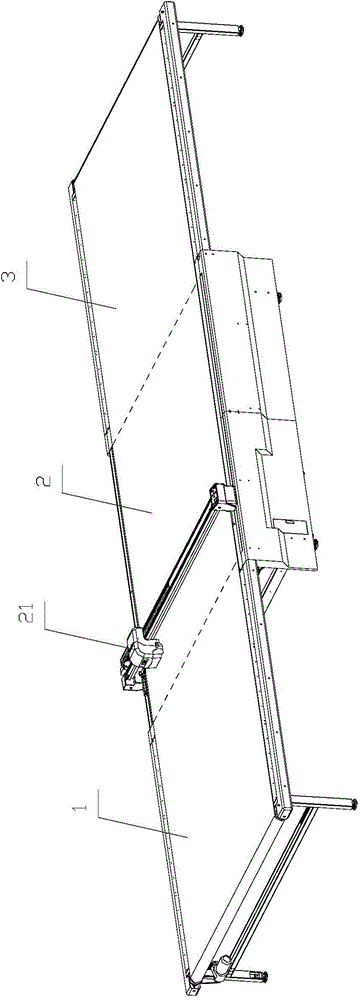

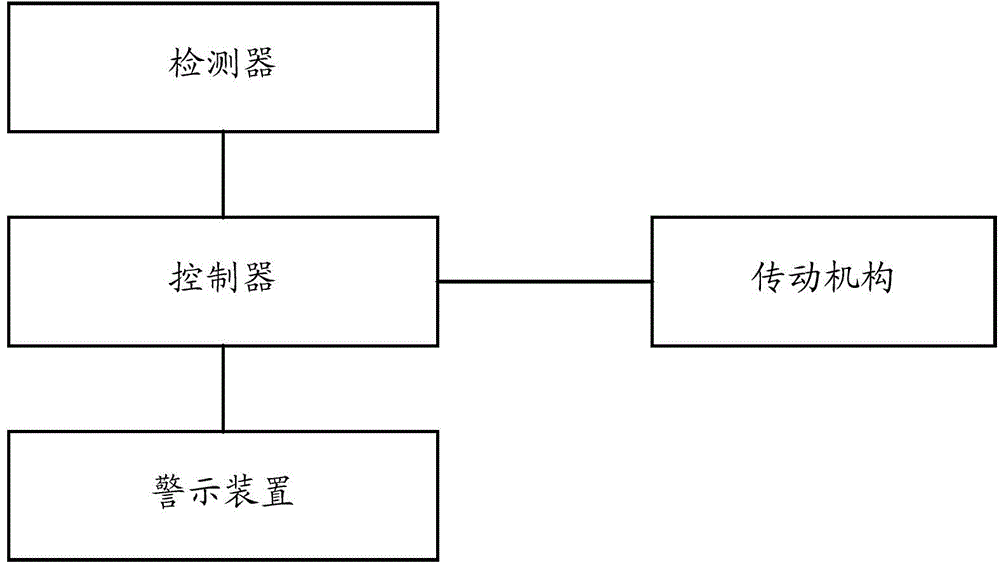

Automatic cutting machine and automatic cutting method thereof

ActiveCN104532536AHigh degree of automationAvoid harmLeather clicking/perforating/clickingSevering textilesControl signalEngineering

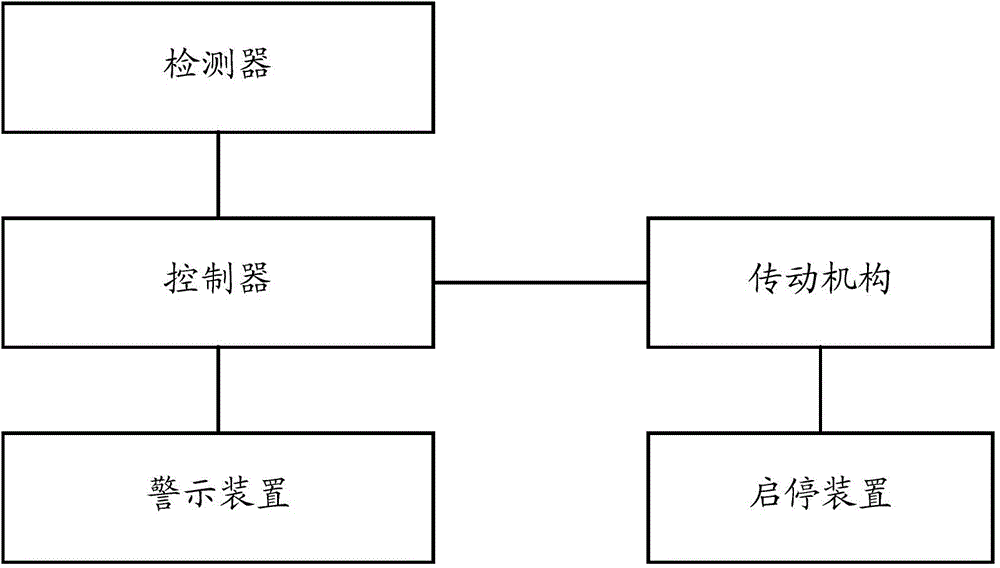

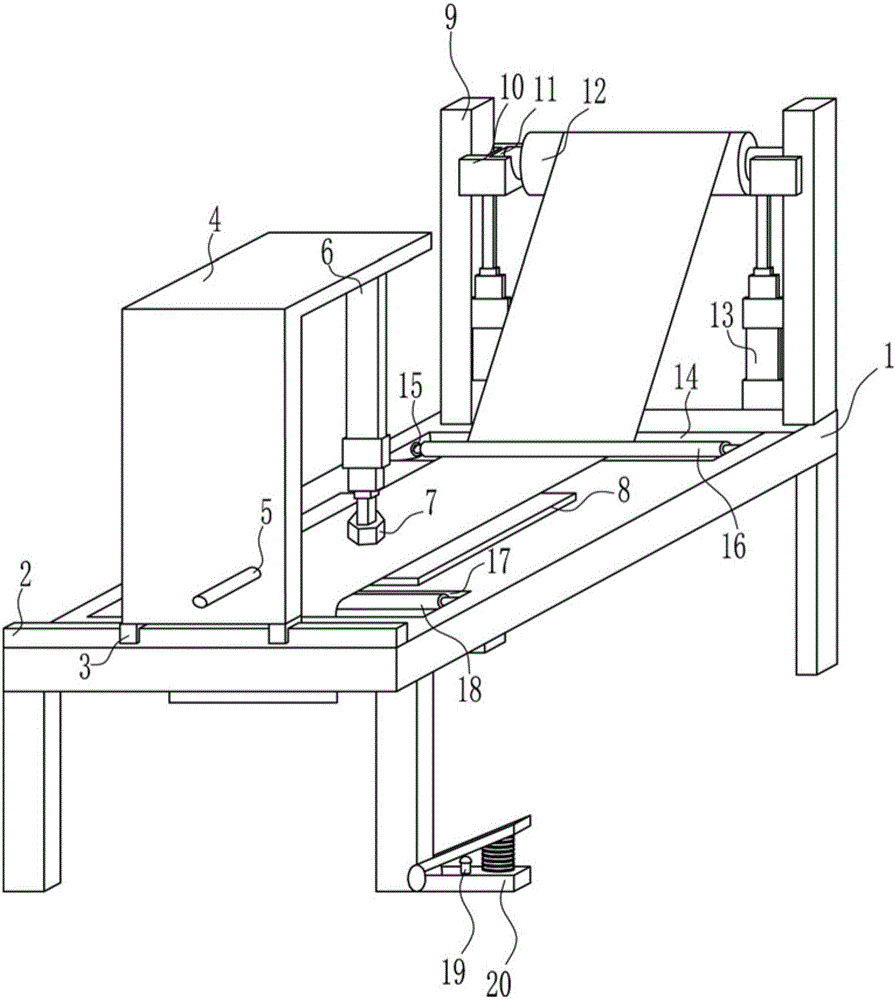

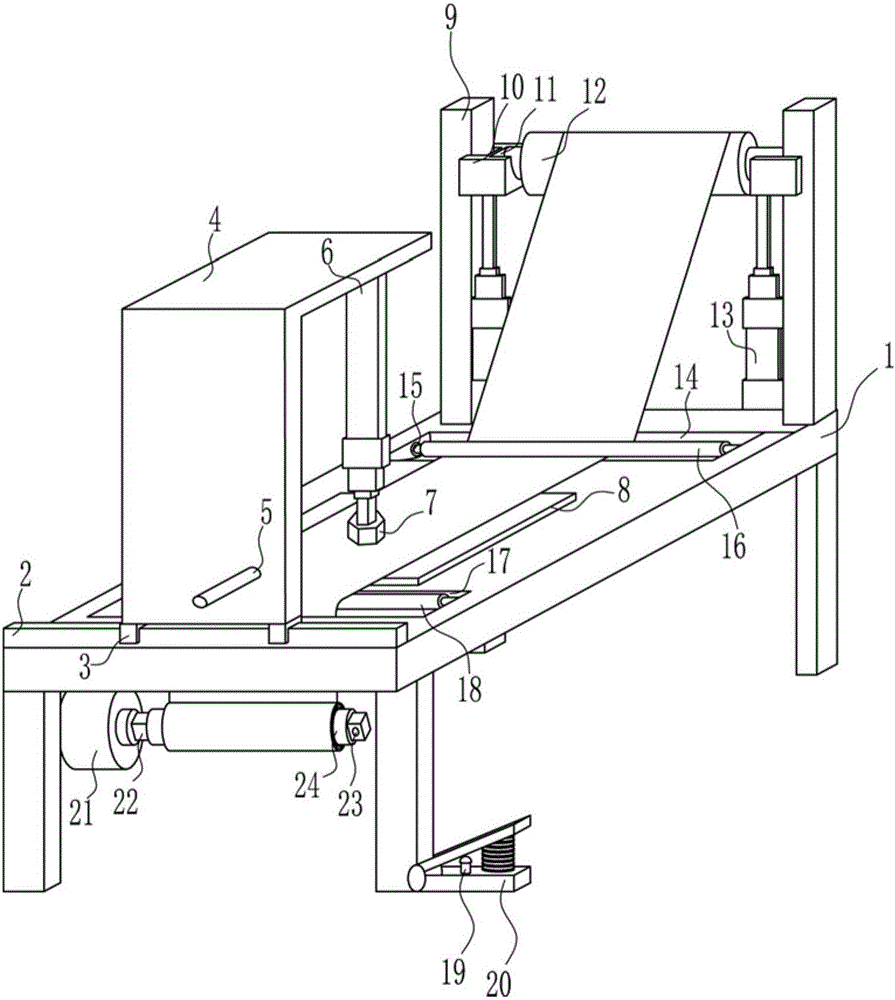

The invention relates to the field of material cutting and discloses an automatic cutting machine and an automatic cutting method thereof. The automatic cutting machine includes a cutting table, a laying table, a pickup table and a transmission mechanism. The transmission mechanism is used for conveying materials to be cut to the cutting table and then conveying the materials to the pickup table after cutting. The automatic cutting machine further includes a detector, a controller and a warning device. The controller is connected with the detector, the warning device and the transmission mechanism respectively. The detector is used for detecting whether men are located on the table surface of the laying table or the cutting table. The controller is used for sending control signals when the detector detects men on the table surfaces. Control signals are used for triggering the warning device to send warning messages and / or controlling the transmission mechanism to stop turning. The automatic cutting machine can protect personal safety of operators during operation, improves the production automatic degree and avoids personnel injury occurred in the production process of the machine.

Owner:长园和鹰科技(河南)有限公司

Leather cutting operation table for football production

InactiveCN106399595ASave human effortAvoid damageLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMechanical engineering

The invention relates to a leather cutting operation table, in particular to a leather cutting operation table for football production. The leather cutting operation table for football production has the beneficial effects that time and labor are saved, the cutting efficiency is high, the cutting speed is high, cutting is smooth, partial leather cannot be easily worn in the manual pulling-out process of leather, and the leather quality can be improved. For realizing the beneficial effects, the leather cutting operation table for football production comprises an operation table body, first sliding rails, first sliding blocks, a 7-shaped plate, a push rod, a first air cylinder, a hexagonal blade, a cutting plate, second sliding rails, second sliding blocks, a second air cylinder and the like, wherein the front of the top of the operation table body is connected to the first sliding rails through bolts. According to the leather cutting operation table for football production, workers push the push rod and step on a pedal to drive the hexagonal blade to cut large-batch leather.

Owner:浙江傲博体育用品有限公司

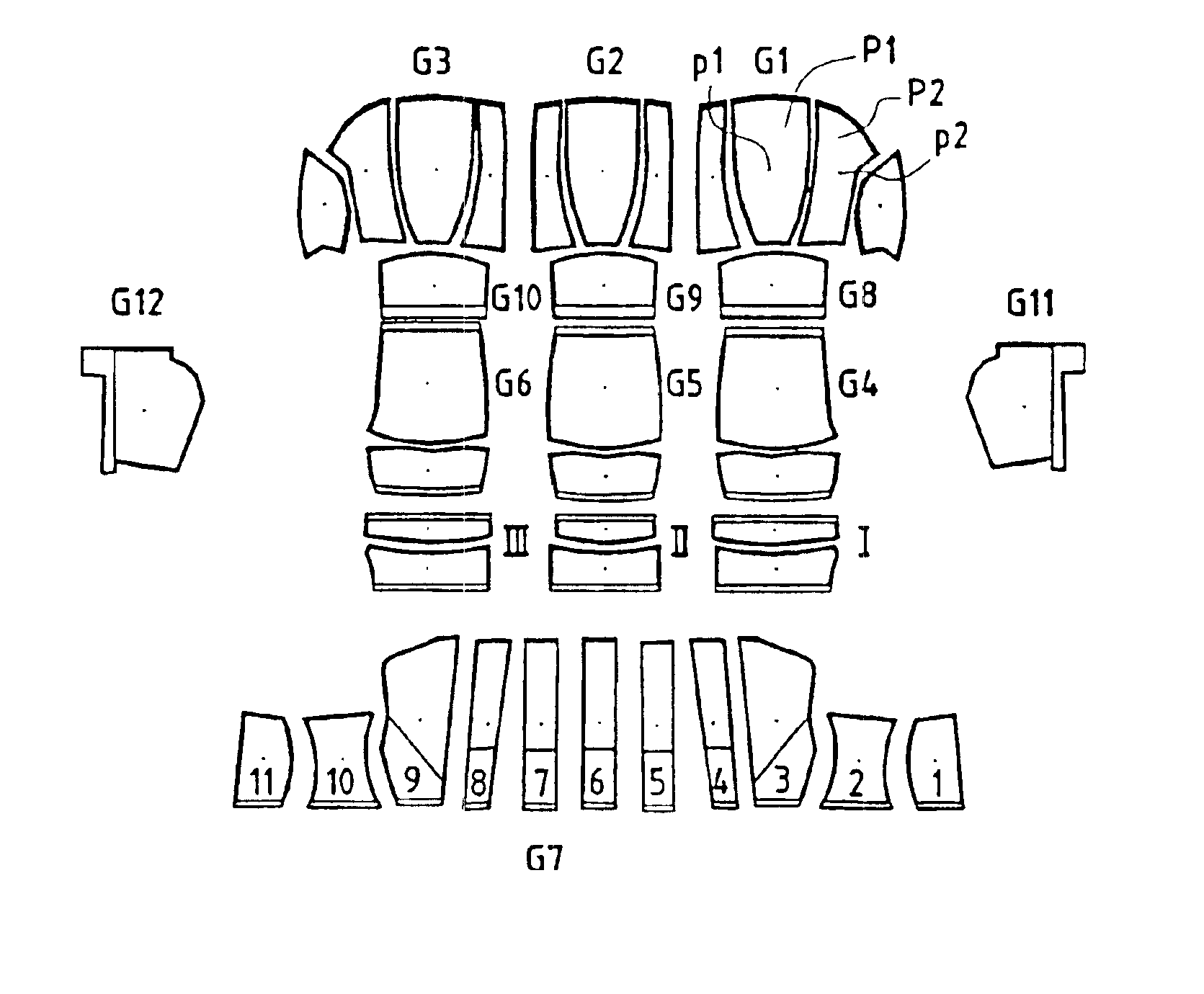

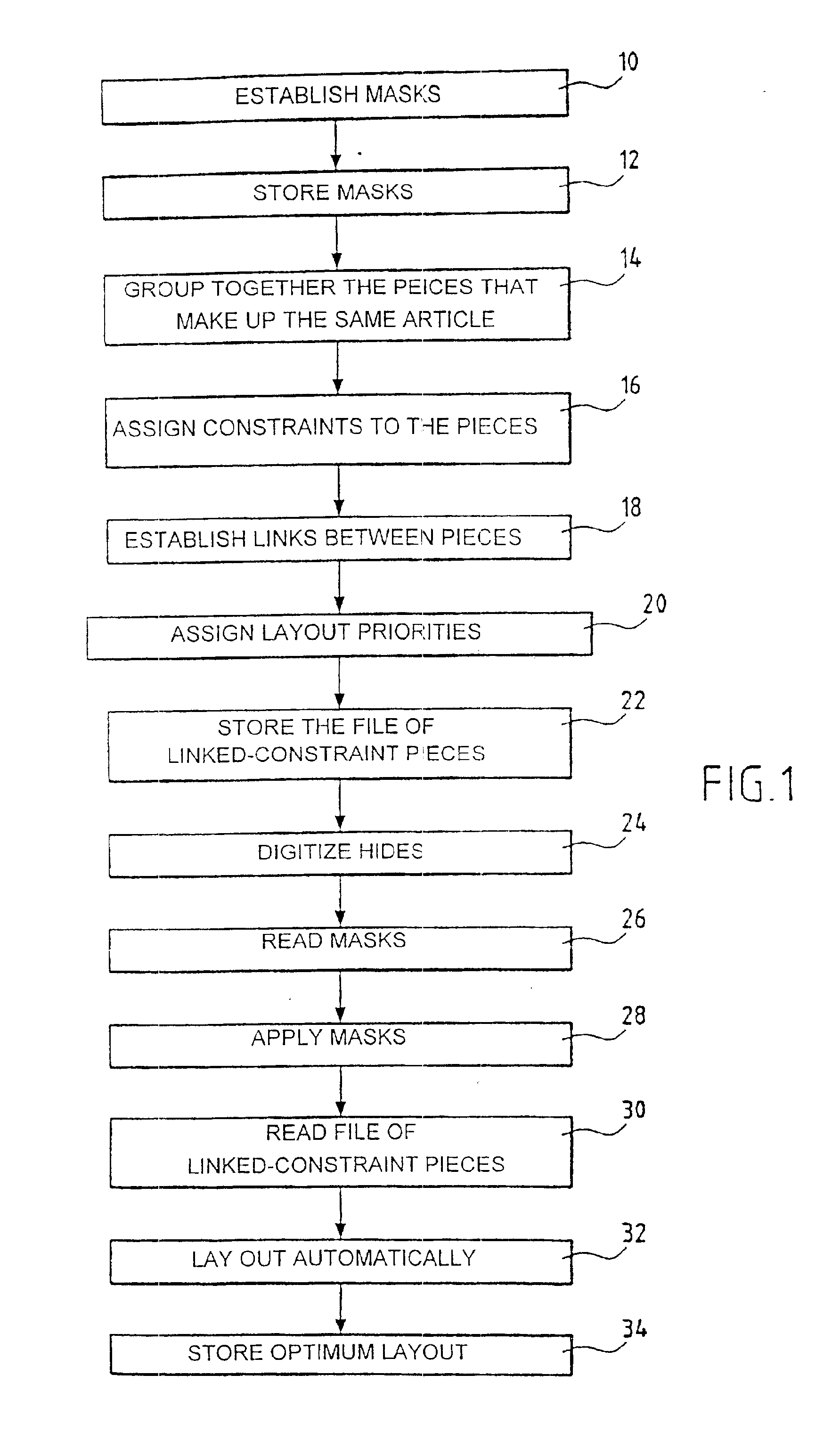

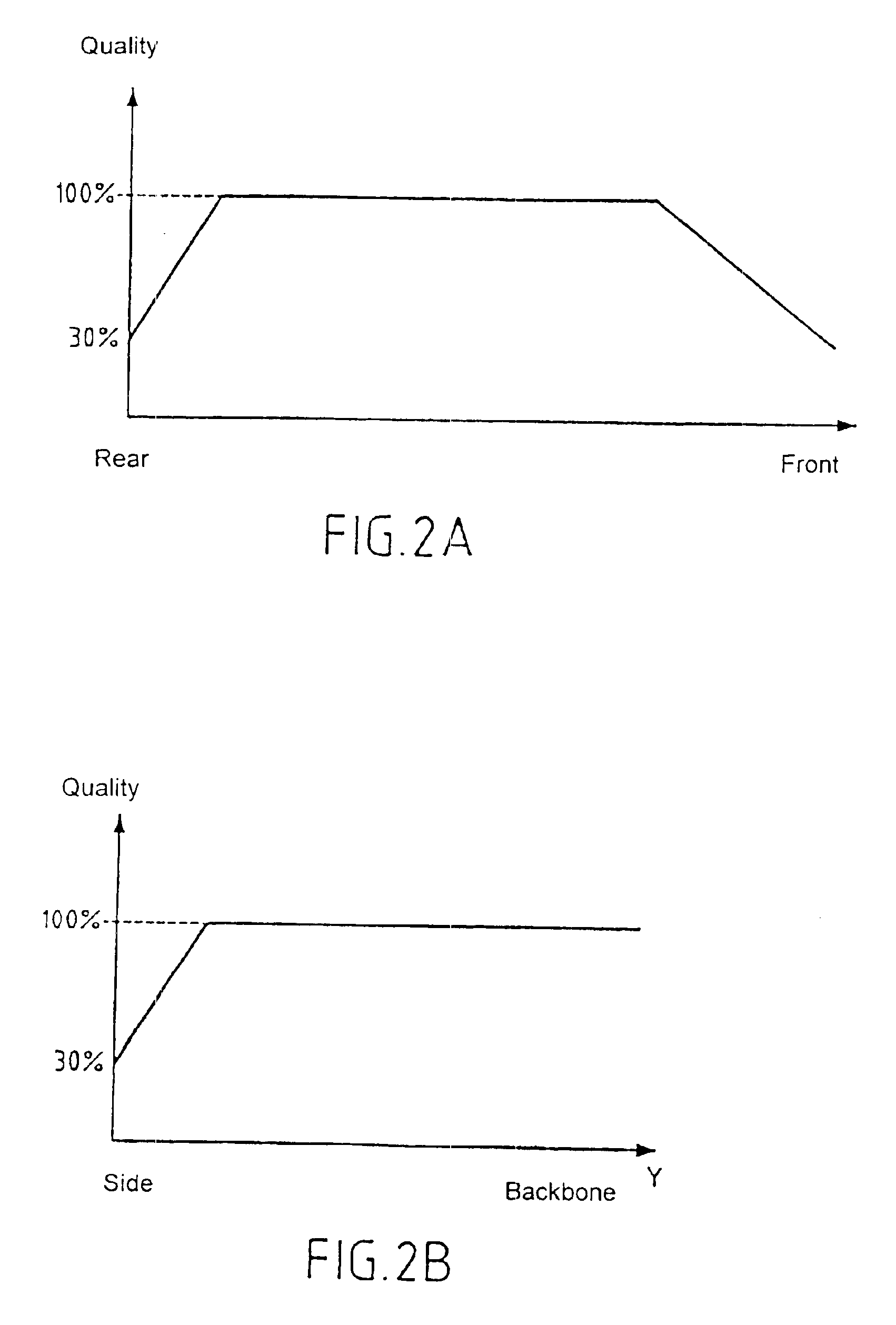

Method for automatically placing parts on leather pieces with non-homogeneous characteristics

InactiveUS6868303B1Leather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineering

A method for laying out pieces to be cut out from a remnant of flexible material, the cut out pieces being used to manufacture an article. A mask generic to remnants of a given type is generated. The at least one generic mask is subdivided into zones which correspond to different gradations of a characteristic of the remnant, e.g. leather color or leather grain. At least some of the pieces to be cut out are assigned a set of constraints including at least one value constraint for a characteristic of the remnant. At least some of the pieces to be cut out are linked to each other, for example, as a function of the constraints assigned to the respective pieces. The at least one generic mask is applied to a particular remnant of the given type to subdivide the particular remnant into zones having uniform characteristics. The pieces to be cut out are automatically laid out on the particular remnant as a function of any constraints assigned to the pieces, and in compliance with the links defined between the pieces.

Owner:LECTRA SA (FR)

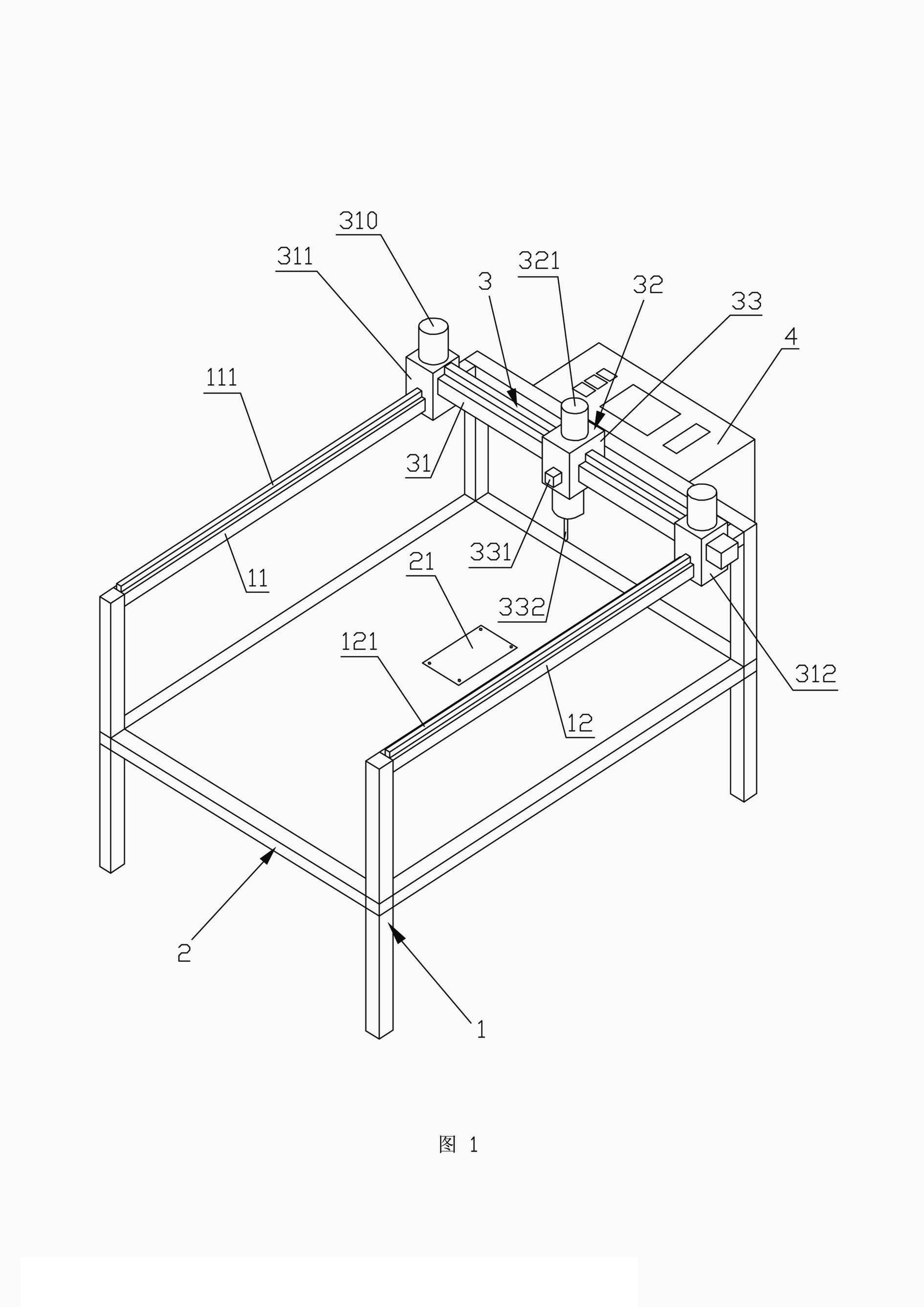

Cutting device for leather

InactiveCN106987661APrevent movementEasy to useLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineering

The invention belongs to the technical field of leather production, and particularly relates to a cutting device for leather. The cutting device for leather aims to achieve the technical effects that the labor intensity of workers can be reduced, the cutting efficiency can be improved, operation is easy and use is convenient. In order to achieve the technical effects, the cutting device for leather comprises a table top and the like, the bottom of the table top is connected with supporting legs through bolts, the middle of the table top is transversely provided with a groove, the top of the table top is provided with an up-down movement mechanism, a movement component of the up-down movement mechanism is connected with a transverse plate, the bottom of the transverse plate is provided with a left-right movement mechanism, and a movement component of the left-right movement mechanism is connected with a cutter. By means of the left-tight movement mechanism, the cutter moves rightwards to cut the leather, and the leather is fixed through a fixing device.

Owner:湖州东方皮革有限公司

Adjustable leather cutting machine

InactiveCN109321691ANo wastePrecise croppingLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention discloses an adjustable leather cutting machine. The adjustable leather cutting machine comprises a device main body. The adjustable leather cutting machine is characterized in that a displacement operation cavity which penetrates left and right is formed inside the device main body; a transporting device is arranged inside the displacement operation cavity; pressing rollers are rotatably arranged inside the transporting device; and when leather is moved below the pressing rollers, the leather can be pressed flat through the pressing rollers, subsequent tailoring accuracy is guaranteed, and waste of the leather is not generated. The adjustable leather cutting machine aims to achieve the technical effects that automatic tailoring of the leather can be achieved; the leather canbe pressed and smoothed automatically before being tailored; smoothness of the leather tailored is guaranteed; tailoring of rough leather is prevented from happening; waste of the leather is avoidedto the maximum extent; and meanwhile, automatic adjustment can be conducted on the tailoring position of the leather, and the intelligentized degree is higher.

Owner:东阳市明汇服装有限公司

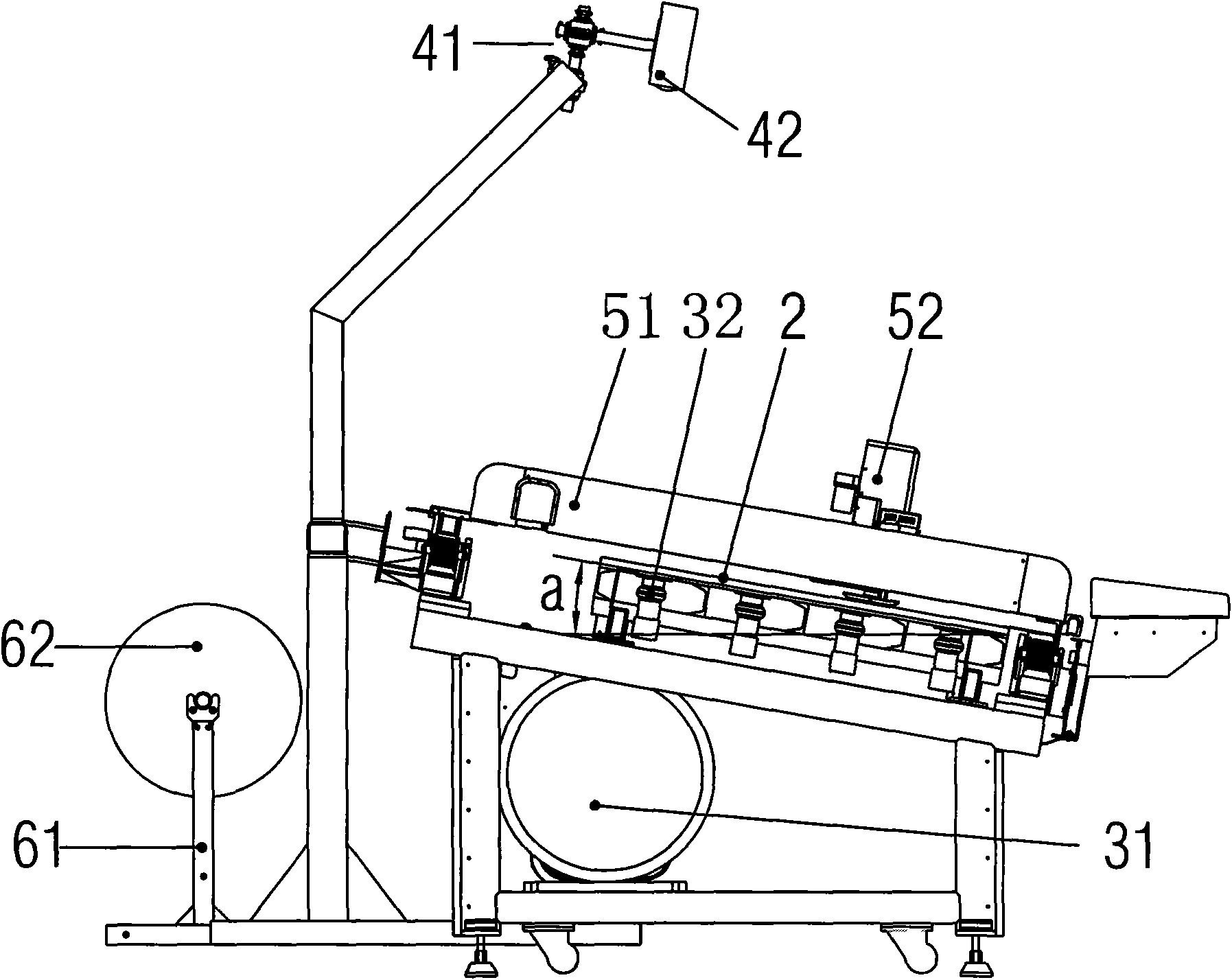

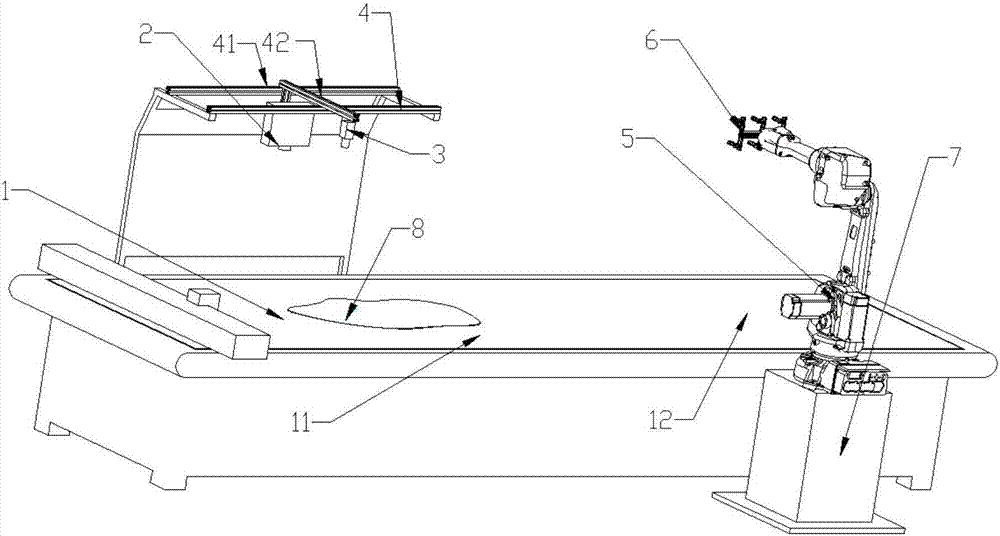

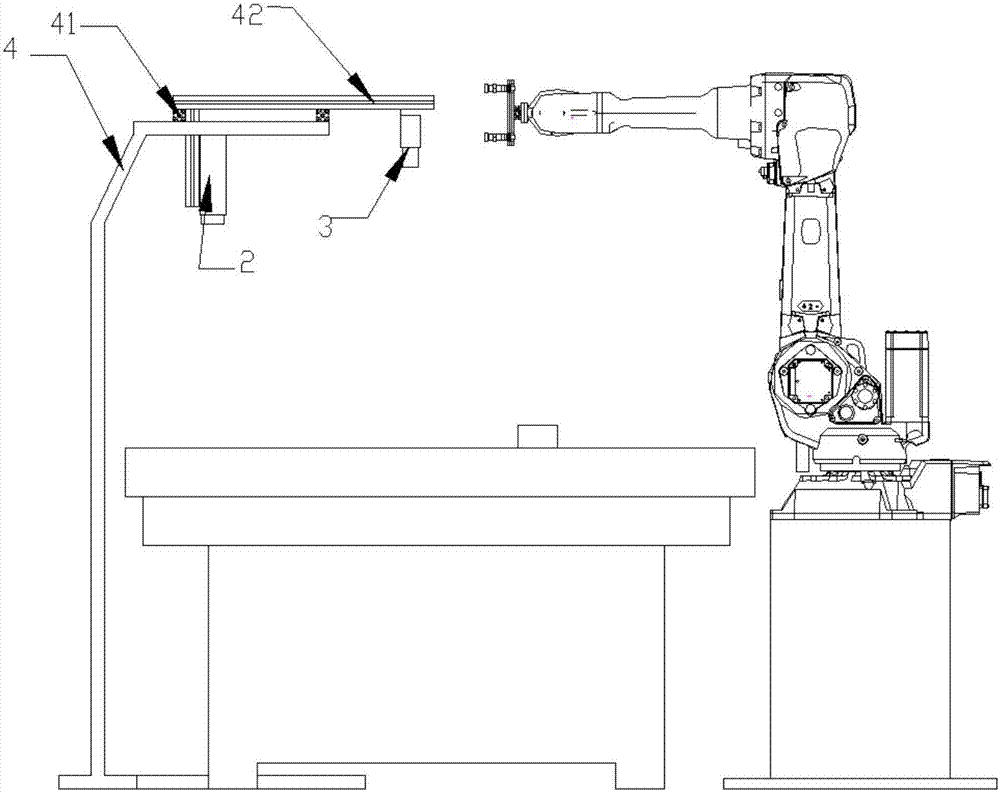

Flexible leather piece cutting device and realizing method thereof

InactiveCN107058642AReduce labor costsImprove efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringManipulator

The invention discloses a flexible leather piece cutting device and a realizing method thereof. The device comprises a working table top, a projector, an industrial camera, a mounting bracket, a manipulator, a matrix sucker clamp and a base, wherein the mounting bracket is arranged above the working table top and is located in a corresponding range of a rear cutting region of a numerically controlled leather cutting machine; the projector and the industrial camera are separately arranged on the mounting bracket; the manipulator is mounted on the base; and the matrix sucker clamp is located above the manipulator and connected with the manipulator through a mounting rack of the matrix sucker clamp. The cutting device provided by the invention is low in labor cost and high in efficiency, and can realize the classified collection of leather pieces, save labor and increase the production efficiency.

Owner:FOSHAN SHIKE INTELLIGENT TECH CO LTD

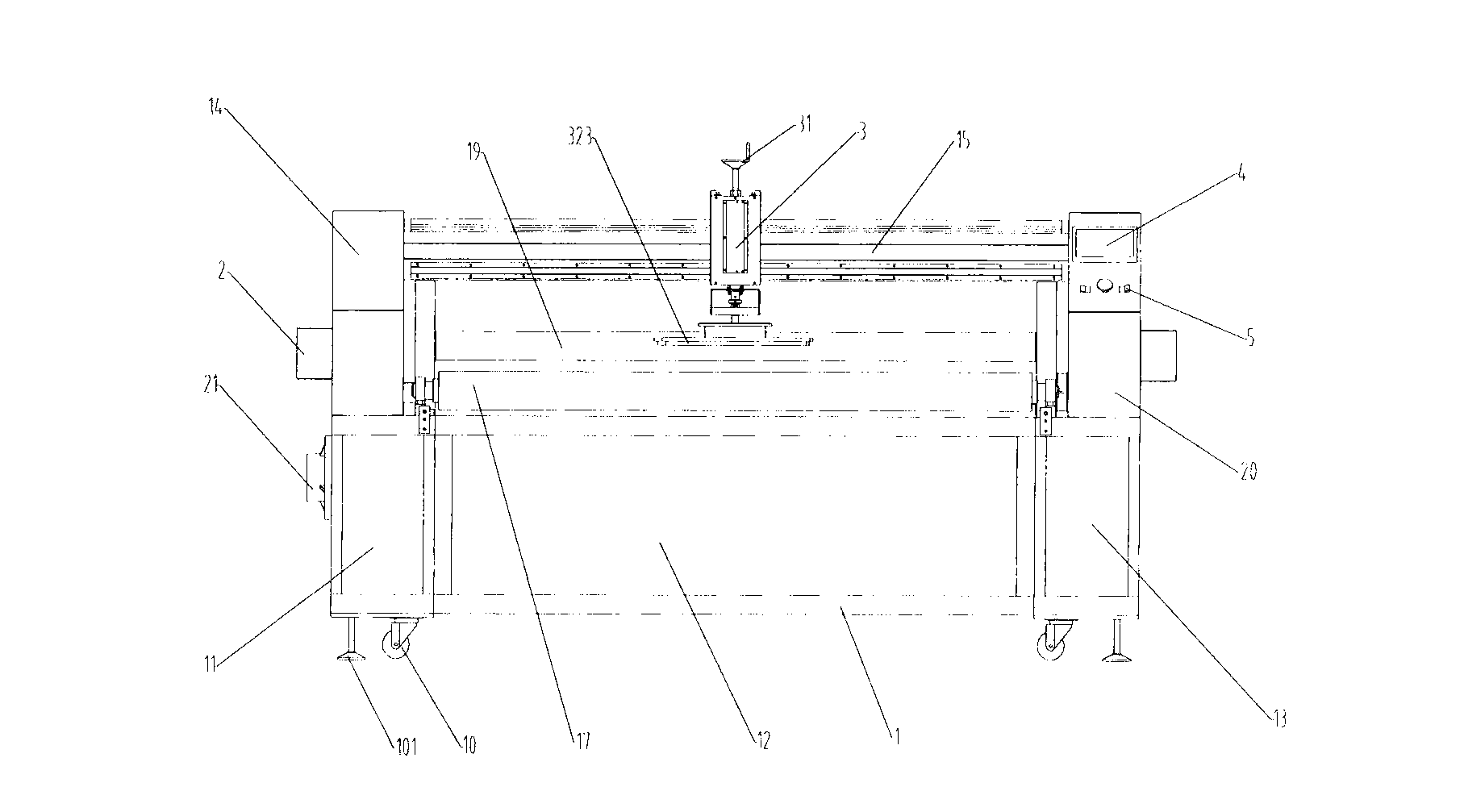

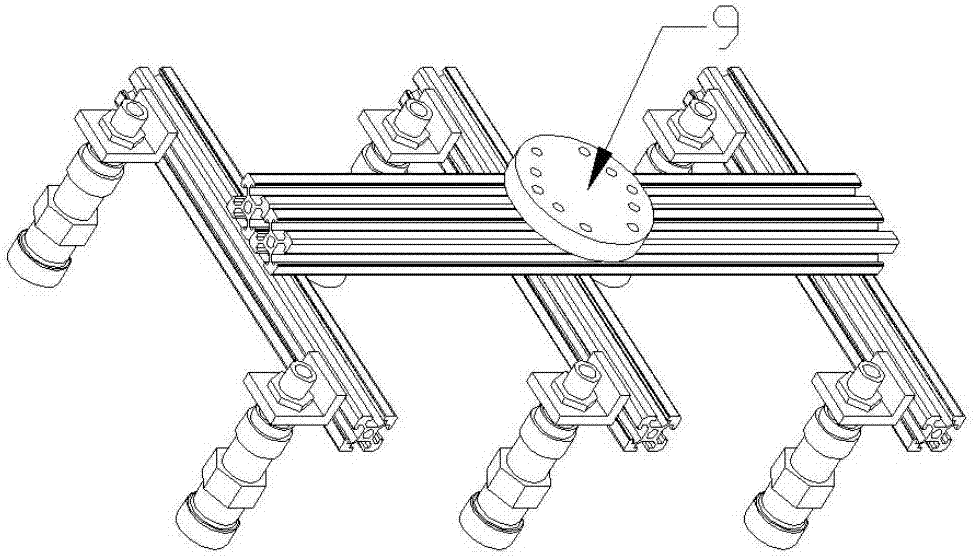

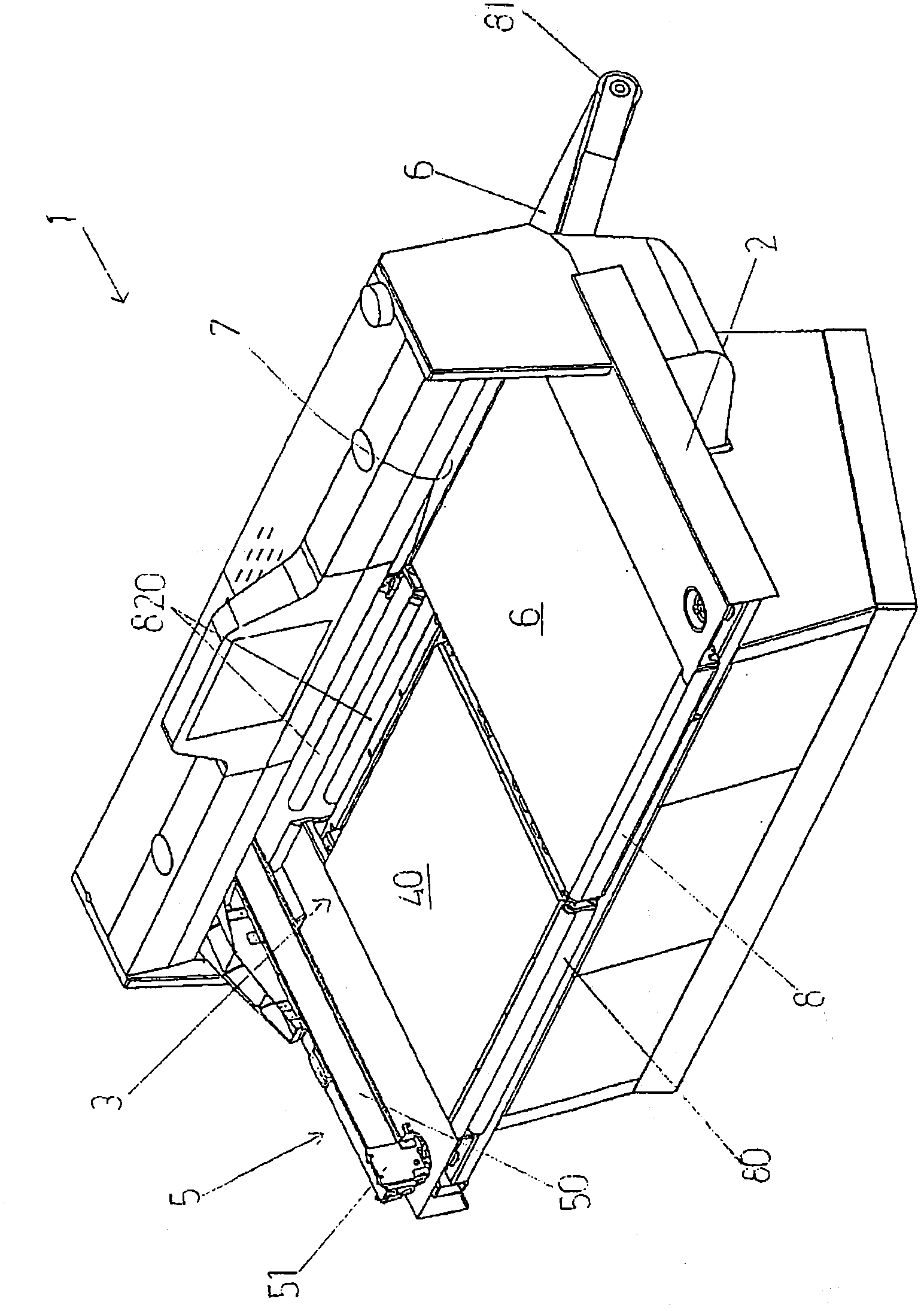

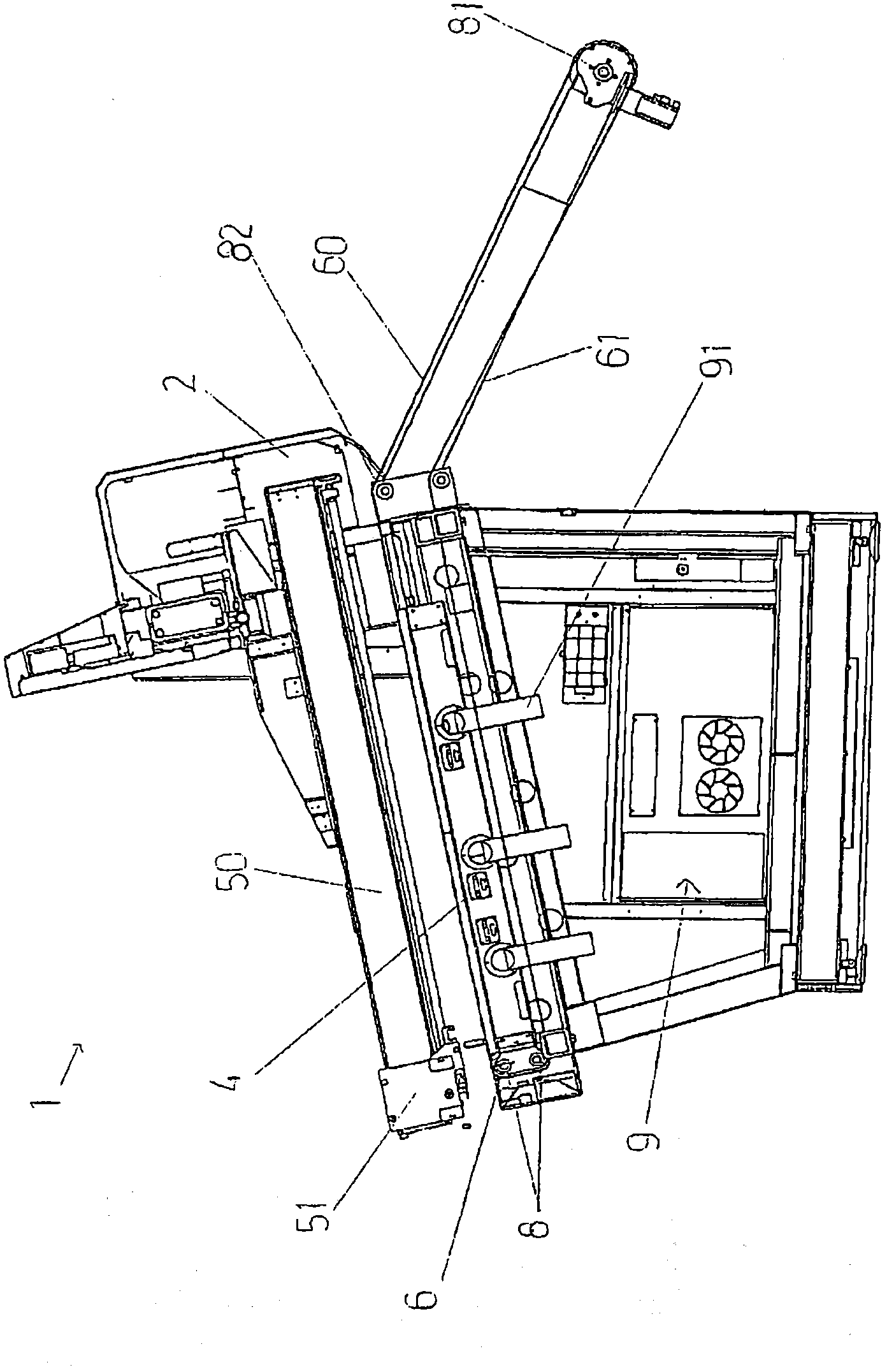

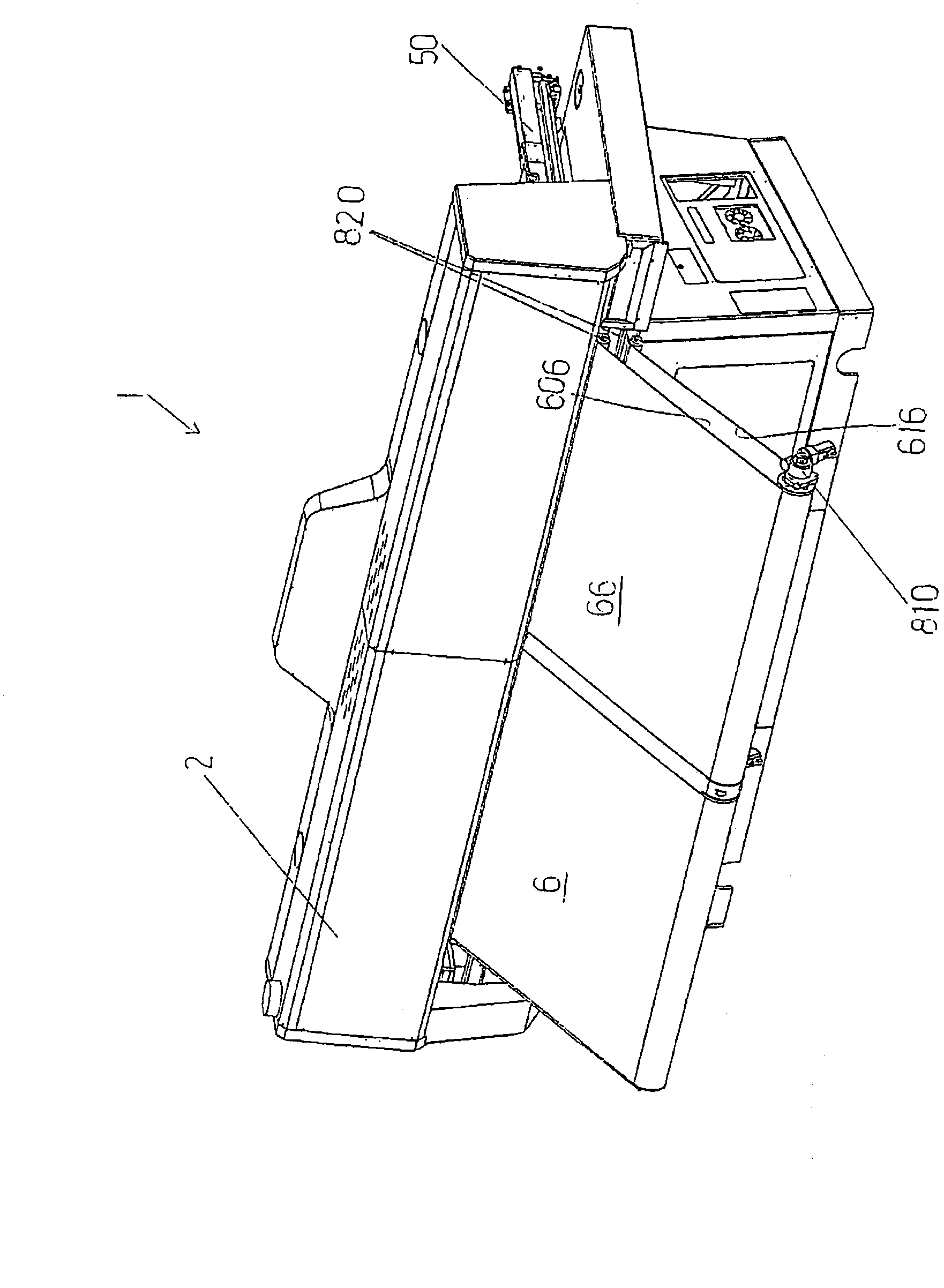

A machine for cutting leathers

ActiveCN103534361AShorten the timeImprove productivityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusClosed loopEngineering

A machine for cutting leathers (1), comprising: a structure (2) which circumscribes an operating area (3) where the leathers are to be laid, maintained stretched and still such as to allow cutting operations; at least an aspirating plane (4, 40) arranged at the operating area (3) and connected to a depression source (9) such as to maintain the leather stretched and still following activation of the depression source (9); a cutting unit (5), borne by the structure (2), arranged above the operating area (3) and movable with respect thereto, such as to realise the cut In the leathers in the operating area (3); the machine (1) comprising at least two closed-loop belts (6, 66) made of a permeable material and flanked to one another, each comprising an upper branch (60, 606) and a lower branch (61, 616), each of the belts (6, 68) being arranged such that the upper branch (60, 606) thereof remains above and in proximity of the aspirating plane (4, 40), in order to restingly receive the leathers to be cut and in order to enable laying of the leathers thereon; the belts (6, 66) being attracted by the aspirating plane (4, 40) following activation of the depression source (9), such that the leathers thereon remain stretched and still; the structure (2) comprising an outlet passage (7) of the leathers, arranged facing the upper branch (60, 606) of each of the belts (6, 66); each belt (6, 66) being activatable, following the completion of the cutting operations thereon, such that the relative upper branch (60, 606) is movable towards the outlet passage (7) in order for the cut leathers to be transferred out of the operating area (3), externally of the structure (2), independently of the other belt (6, 66).

Owner:TESEO SPA

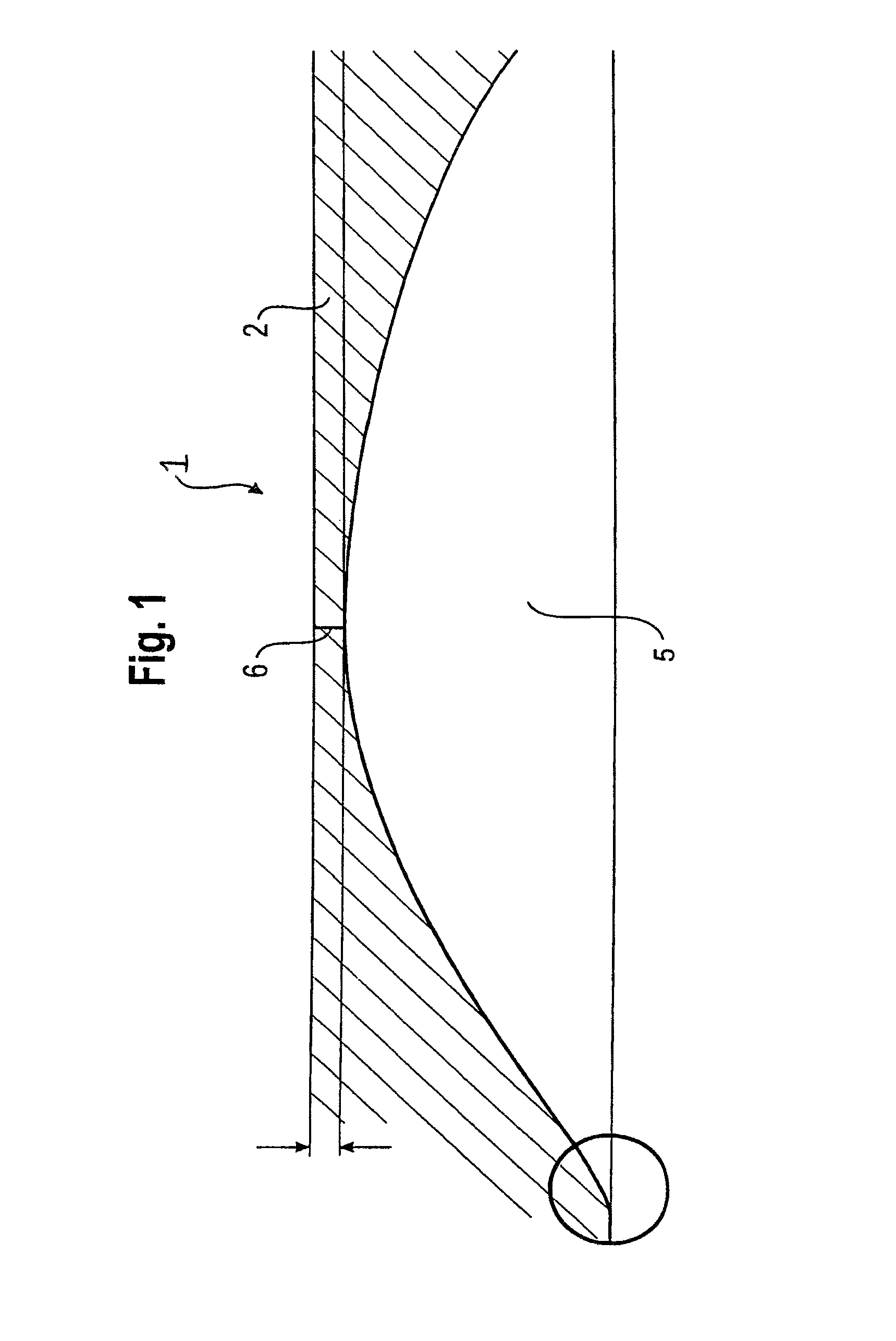

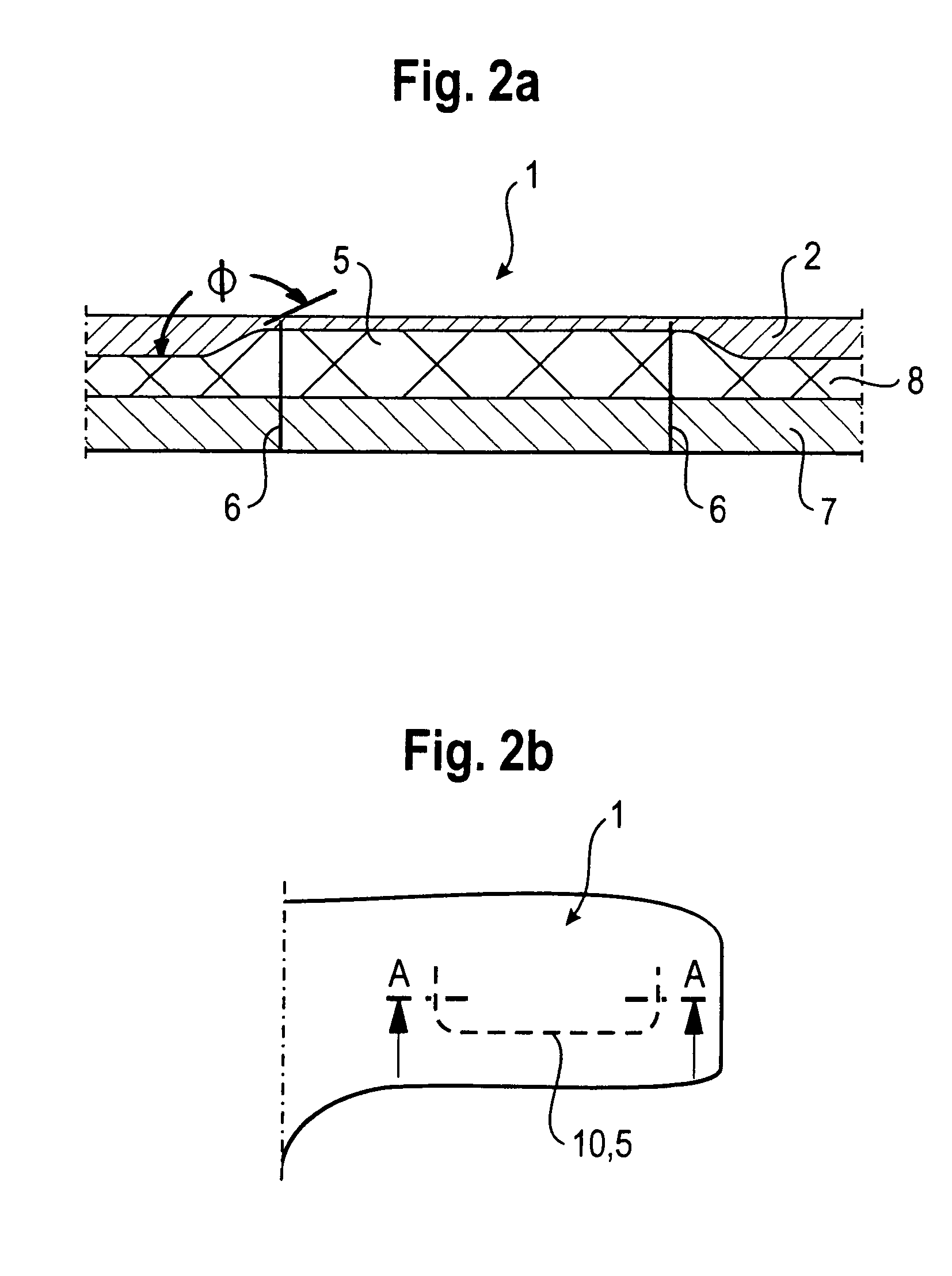

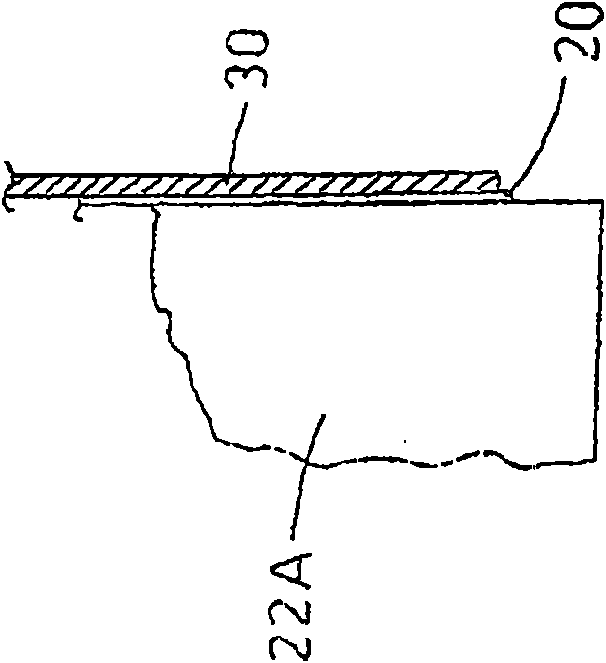

Airbag covering having a weakened leather layer

A process for producing an airbag covering having a leather layer, particularly for use in a motor vehicle, with a partial weakening for the initiation of a tear and / or the propagation thereof along a previously defined path is disclosed. In one embodiment, a skived region is introduced into the leather layer and at least one incision is introduced into the previously created skived region.

Owner:LISA DRAXLMAIER GMBH

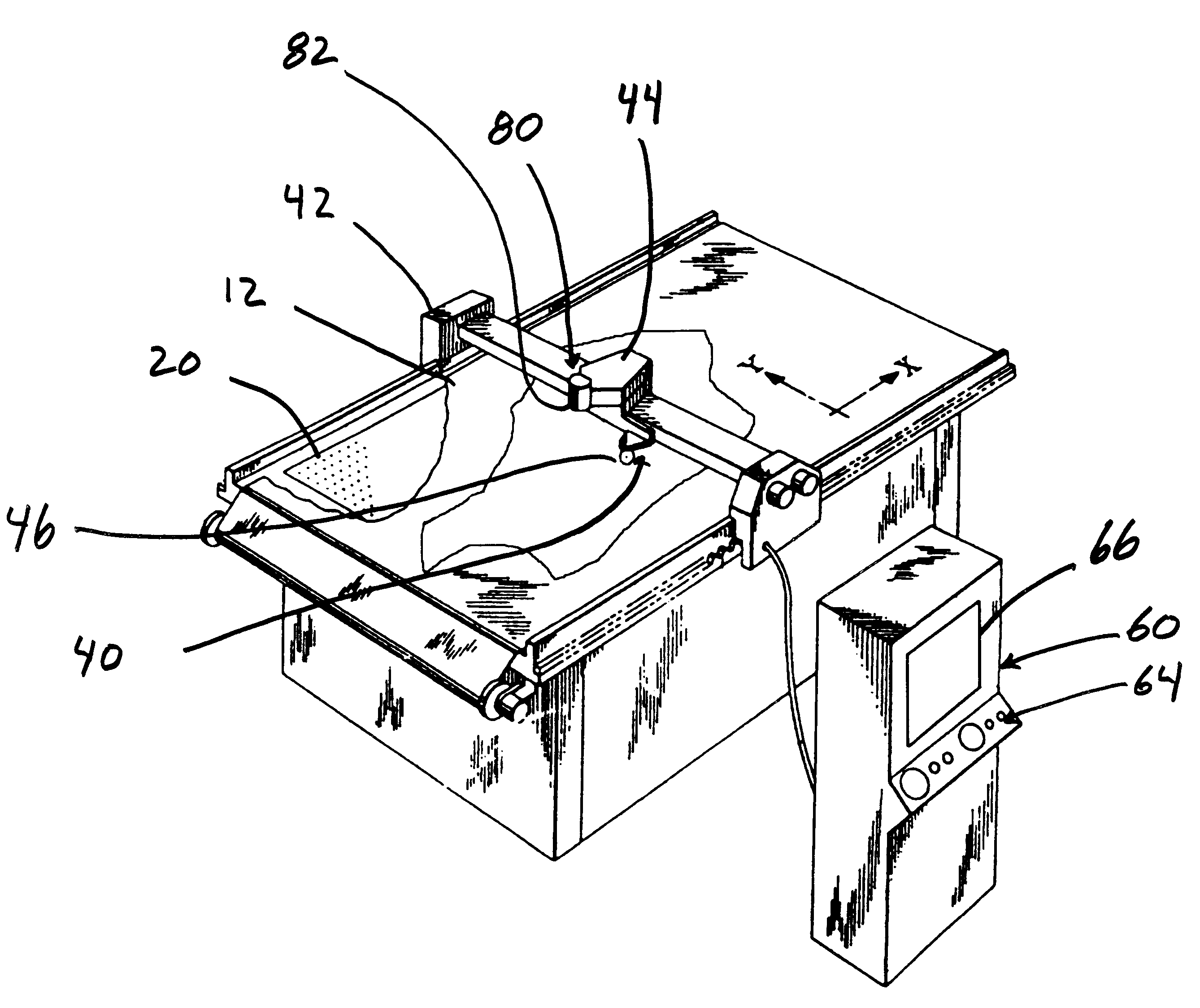

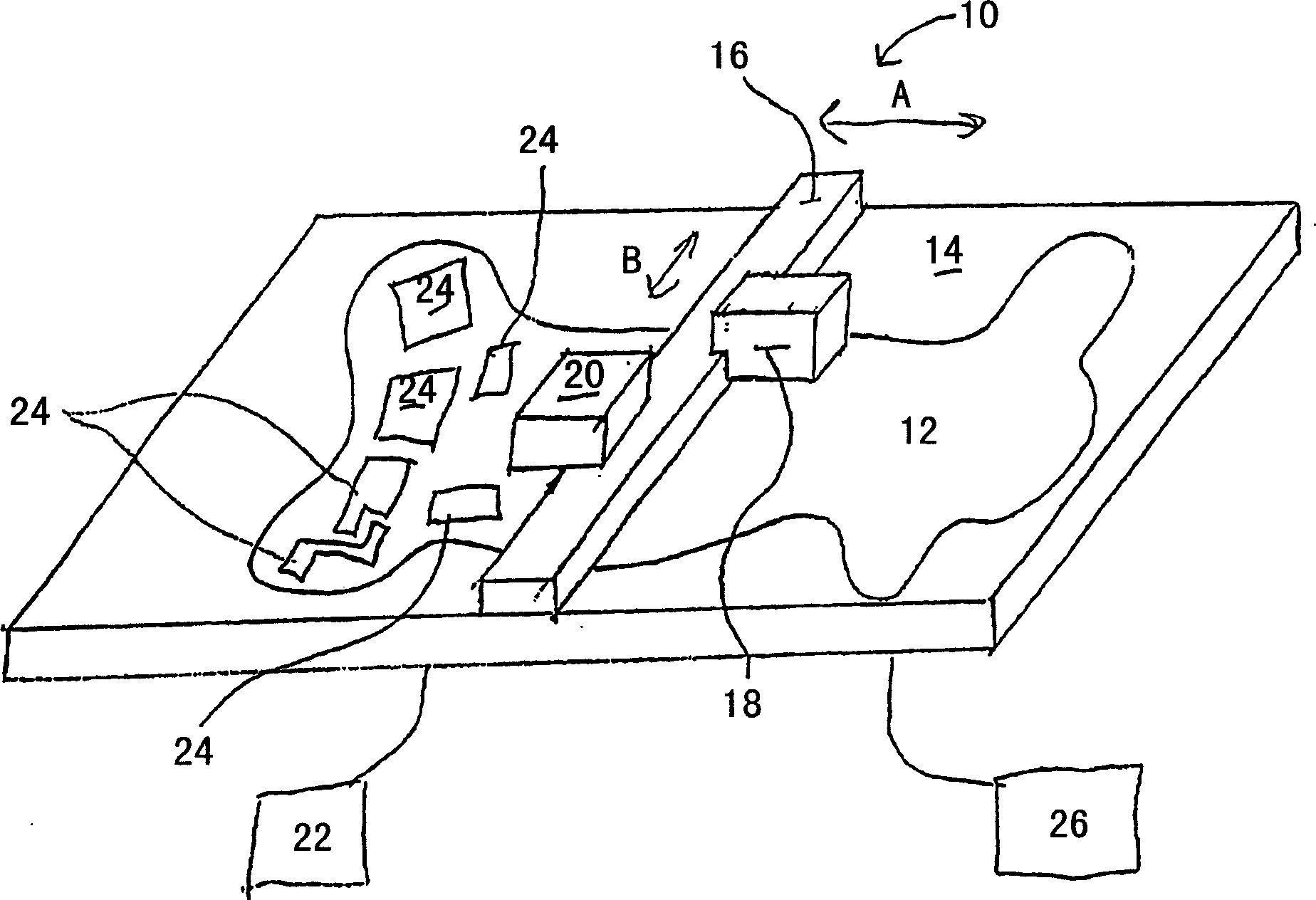

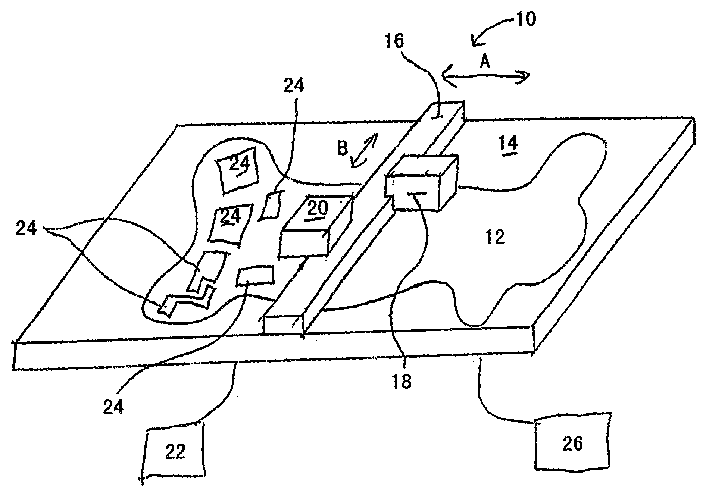

Method for scanning sheet-type work material and cutting pattern pieces therefrom

InactiveCN1671587AShorten the timeMinimize the amount of spaceLeather clicking/perforating/clickingMetal working apparatusEngineeringSupport surface

In a method for scanning and cutting sheet-type work material carried on a support surface, the work material is automatically scanned to determine a periphery thereof and to allow for the detection of any flaws within the periphery of the work material. The layout of a marker is then established on the work material and a nesting process for pattern pieces is begun. A first pattern piece is nested onto the work material and a subsequent pattern piece is also nested onto the work material while the first pattern piece is simultaneously cut therefrom. These steps are repeated until all of the pattern pieces are cut from the work material.

Owner:GERBER GARMENT TECH

Efficient cutting device for leather production

InactiveCN108411047AAvoid displacementImprove cut qualityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringProper length

The invention discloses an efficient cutting device for leather production. The device comprises two parallel screws, the outer walls of the two screws are sleeved with ball nuts, the outer walls of the ball nuts are sleeved with moving blocks, a linear guide rail is jointly connected between the side walls of opposite sides of the two moving blocks, and comprises a guide rail body and a sliding block arranged on the outer wall of the guide rail body in a sleeving manner, a mounting opening is formed in the lower side wall of the guide rail body, a first air cylinder is arranged in the mounting opening, the drive end of the first air cylinder is connected with a U-shaped plate, the lower side walls of the two moving blocks are jointly connected with a connecting plate, and two rotating rods are rotatably connected with the lower side wall of the connecting plate. Leather can be clamped and then tailored through a pressing block, leather displacing during tailoring can be avoided, cutting quality is improved, meanwhile, through moving of the moving blocks and the sliding blocks, the leather with the proper length and width can be tailored, the adaptation is wider, the structure issimple, and the device is convenient and practical.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

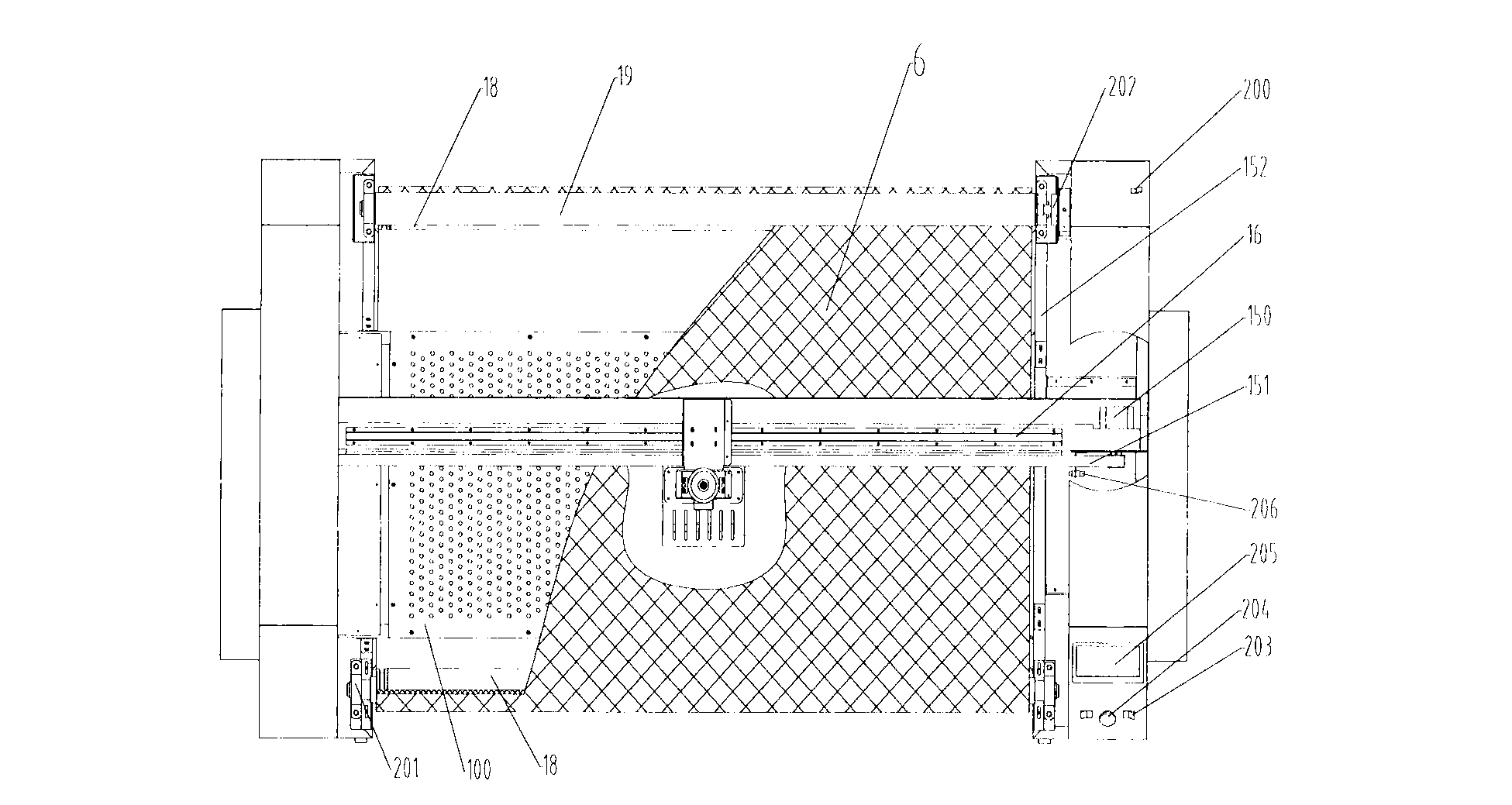

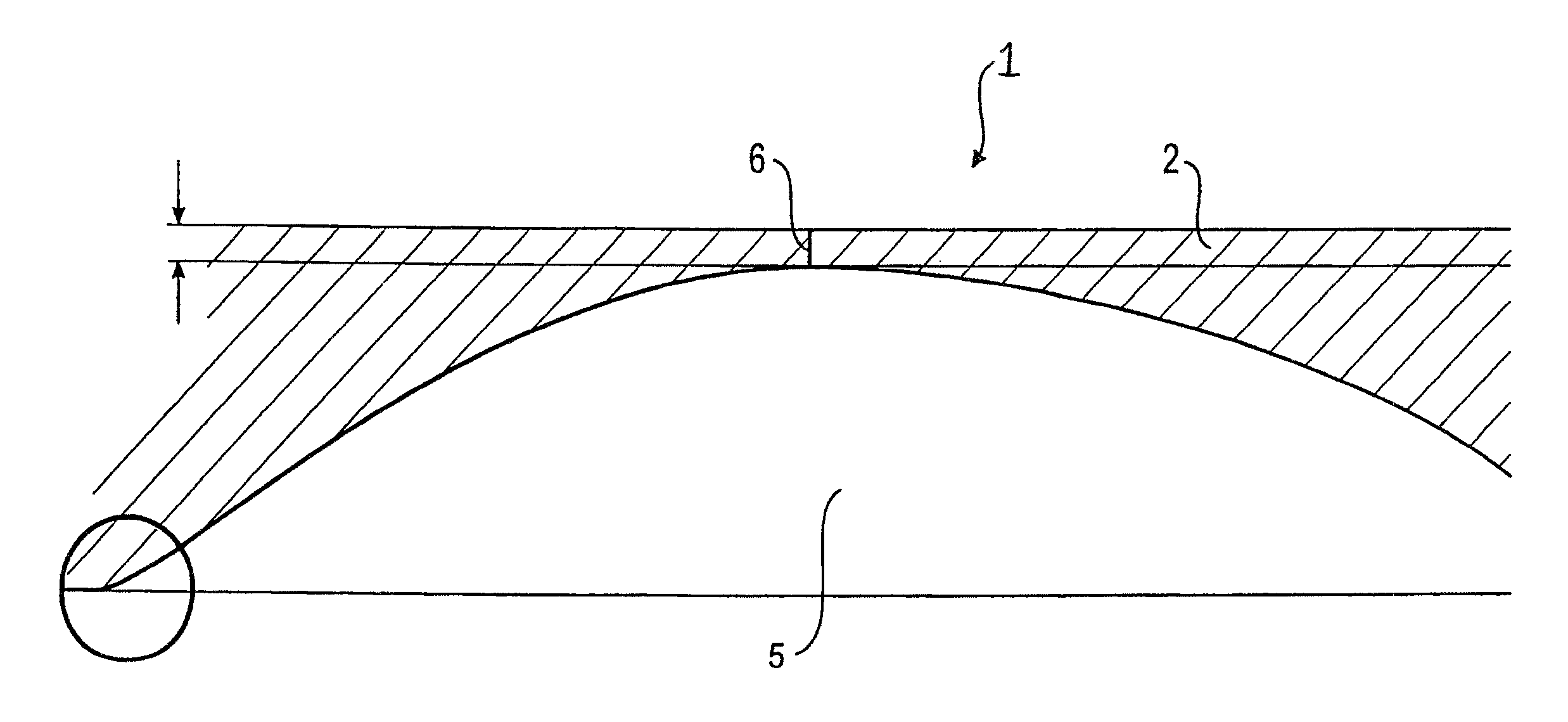

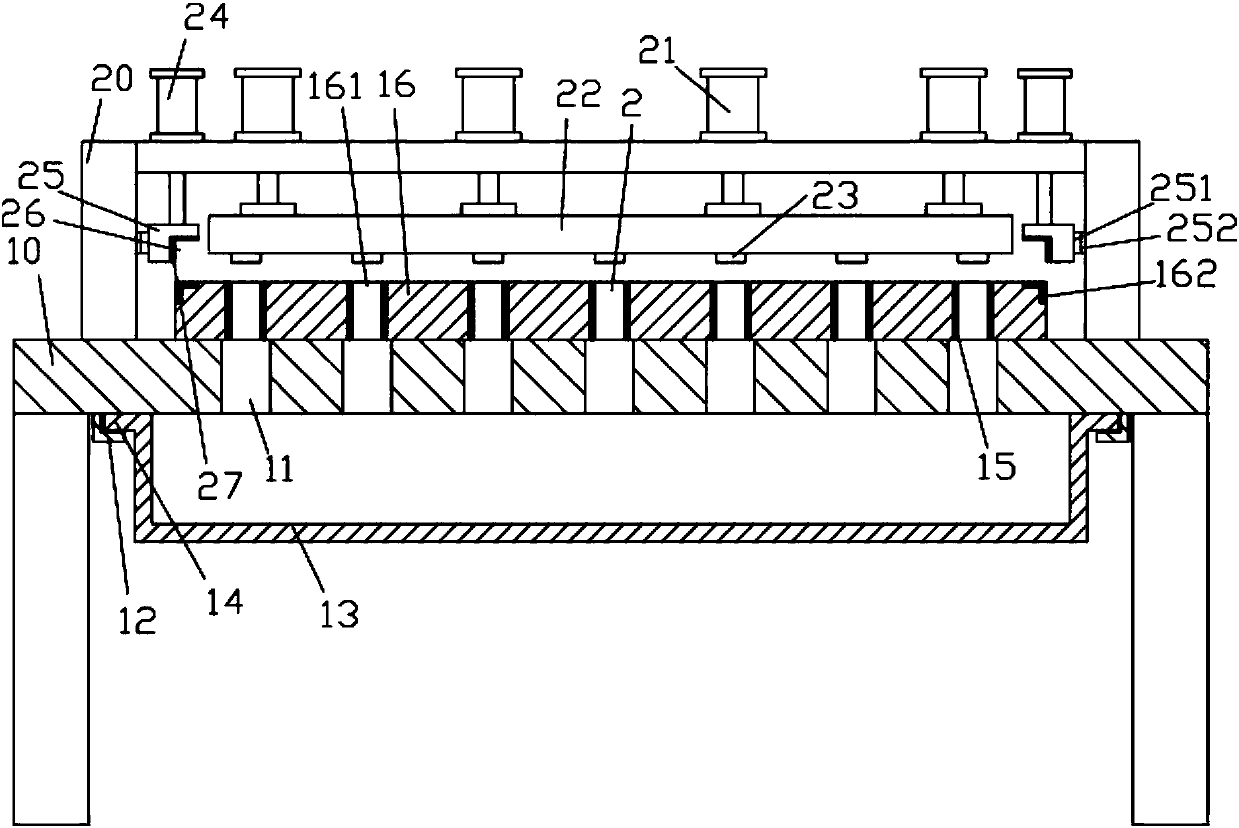

A machine for moving and cutting hides and the like

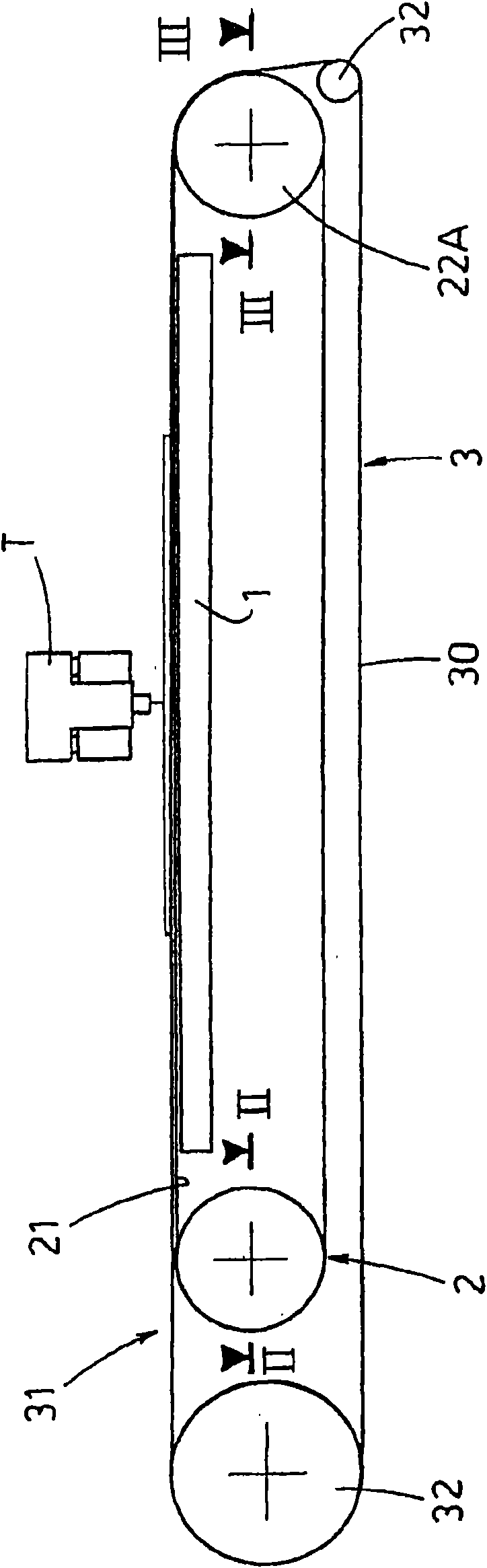

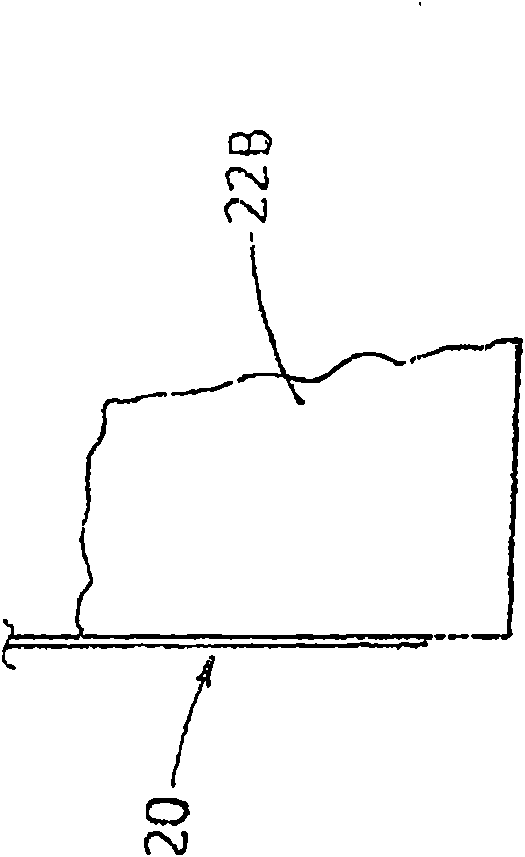

InactiveCN101573455ALow costLeather clicking/perforating/clickingMetal working apparatusEngineeringMechanical engineering

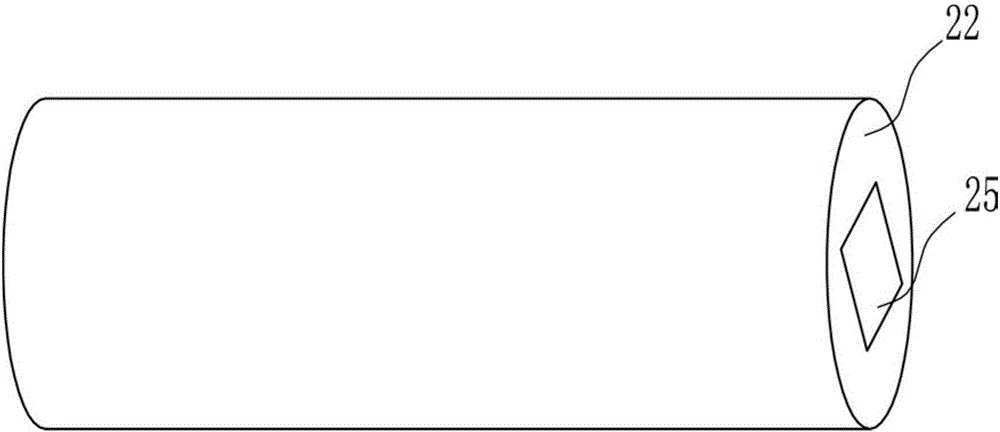

The present invention discloses a machine for moving and automatically cutting hides and the like, comprising: an aspirating plane (1); an overlying cutting unit (T); a first ring-wound conveyor (2) comprising a belt (20) made of a permeable material wound on relative rollers (22A, 22B), comprising a drive roller (22A) and a driven roller (22B), having an upper branch (21) which is superposed on the aspirating plane (1), and interested at edges thereof by broadenings (25, 26); the belt (20) being attracted during transit by the aspirating plane (1), dragging without constraint above the aspirating plane; a second conveyor (3), made of permeable material, an upper branch (31) of which restingly receives the hides P and is interposed between the cutting unit (T) and the upper branch (21) ofthe first conveyor (2).

Owner:TESEO SPA

Basketball leather cutting device

InactiveCN107283072AAvoid displacementEasy to moveLeather clicking/perforating/clickingWelding/cutting auxillary devicesArchitectural engineeringReceipt

The invention discloses a basketball leather cutting device, which comprises a workbench, a first support rod is fixed on both sides of the top of the workbench, a second support rod is fixed at the end of the first support rod, and the second support rod is connected with the The first support rods are perpendicular to each other, the bottom of the two first sliding blocks is installed with the second electric slide table, and the first electric slide table and the second electric slide table are perpendicular to each other, and the bottom of the second sliding block is installed with the first push rod motor, the bottom of the first push rod motor is equipped with a cutting machine, the top of the workbench is provided with an installation groove, a conveyor belt is installed in the installation groove, a raw material reel is installed at one end of the workbench, and the workbench A reel is installed at the other end of the top plate, pressure rollers are provided on both sides of the bottom of the top plate, and a second push rod motor is installed on both sides of the top of the pressure roller, and the upper end of the second push rod motor is fixed on the top plate. bottom. The invention has novel structure, ingenious design, reasonable structure and is suitable for popularization.

Owner:浙江傲博体育用品有限公司

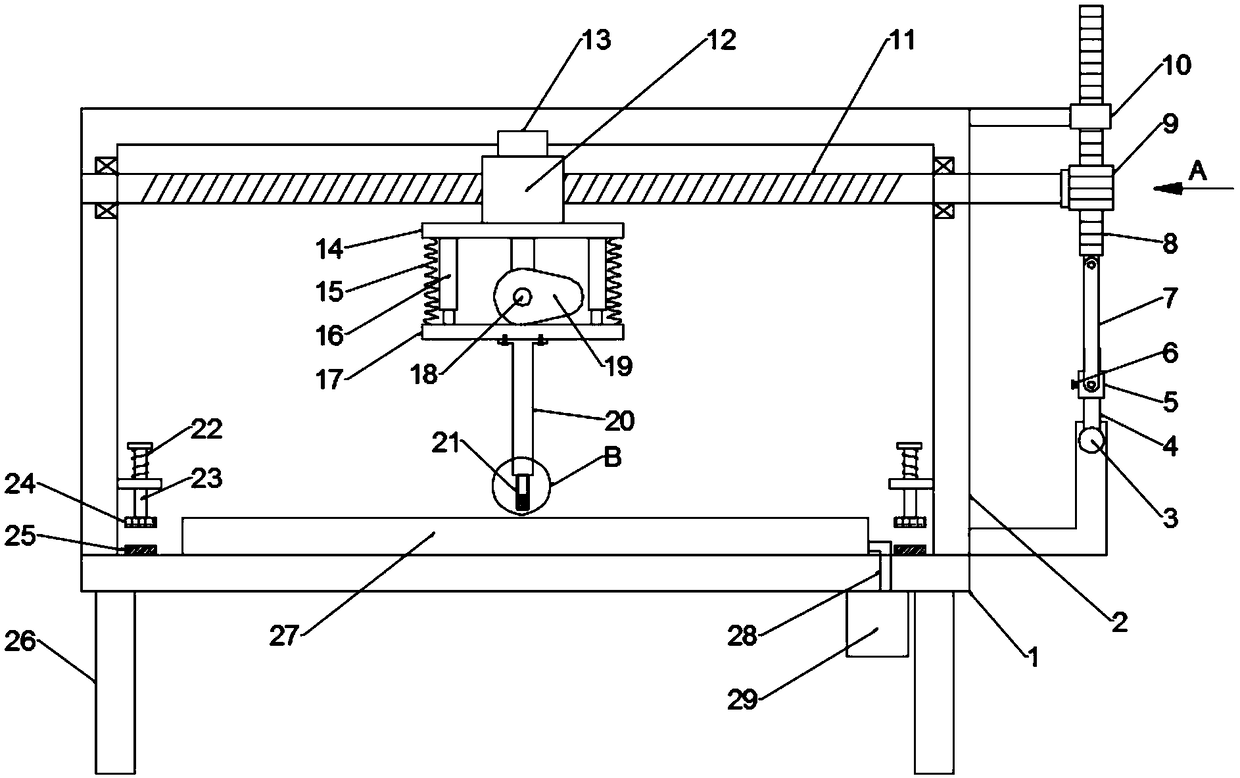

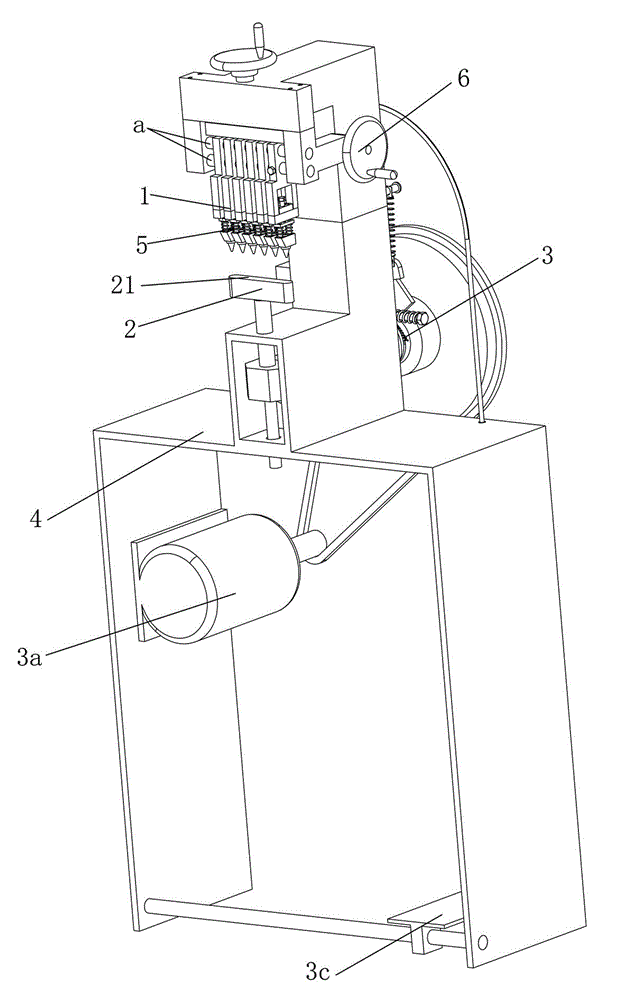

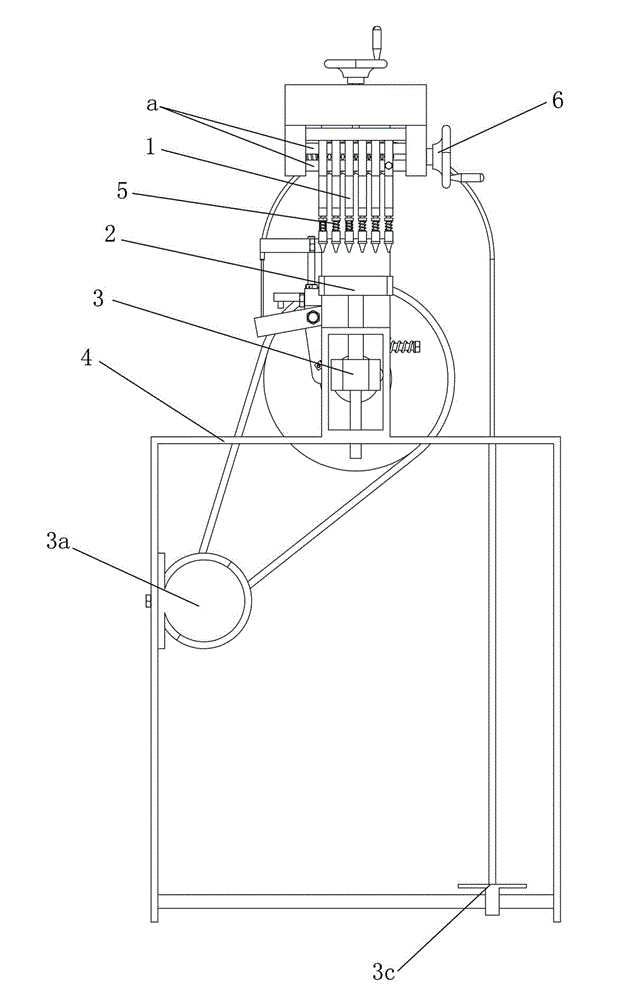

Punching device for belt machining

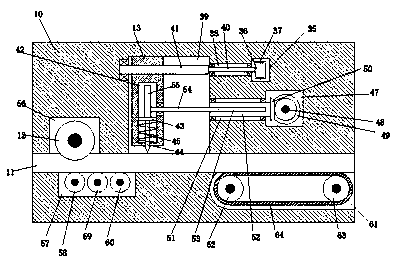

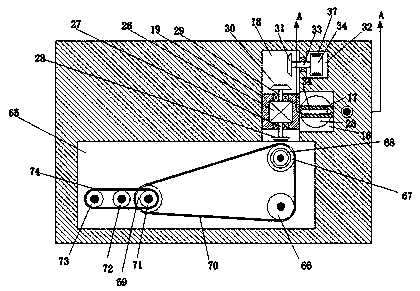

InactiveCN108624725AEasy to operateContinuous equidistant punchingLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusPunchingAnnular cutter

The invention discloses a punching device for belt machining. The punching device comprises a base plate, a support, a workbench, a cross groove, a compressing device, a threaded rod, a movable block,a first installing plate, a telescopic rod, a second installing plate, a second spring, a first motor, a cam, an installing rod, an annular blade, a second motor, an adjusting rod, a sleeve, a connecting rod, a rack, a gear, an inner ratchet, a pawl and a fourth spring. The compressing device comprises a hinge pin, a first spring, a magnet and an iron plate. The punching device is provided with the workbench, the compressing device, a gas pipe and a dust collector, a belt is fixed, operation is simple, and convenience and quickness are achieved. The movable block, the threaded rod, the firstmotor, the cam, the annular cutter, the second motor, the adjusting rod, the sleeve, the connecting rod, the rack, the gear, an inner gear and the pawl are arranged and matched, continuous punching can be conducted at equal intervals, work efficiency is high, in addition, the hole space can be adjusted by adjusting the relative position of the sleeve and the adjusting rod, so that different needsare met, and applicability is high.

Owner:郭想

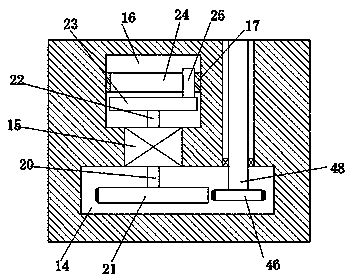

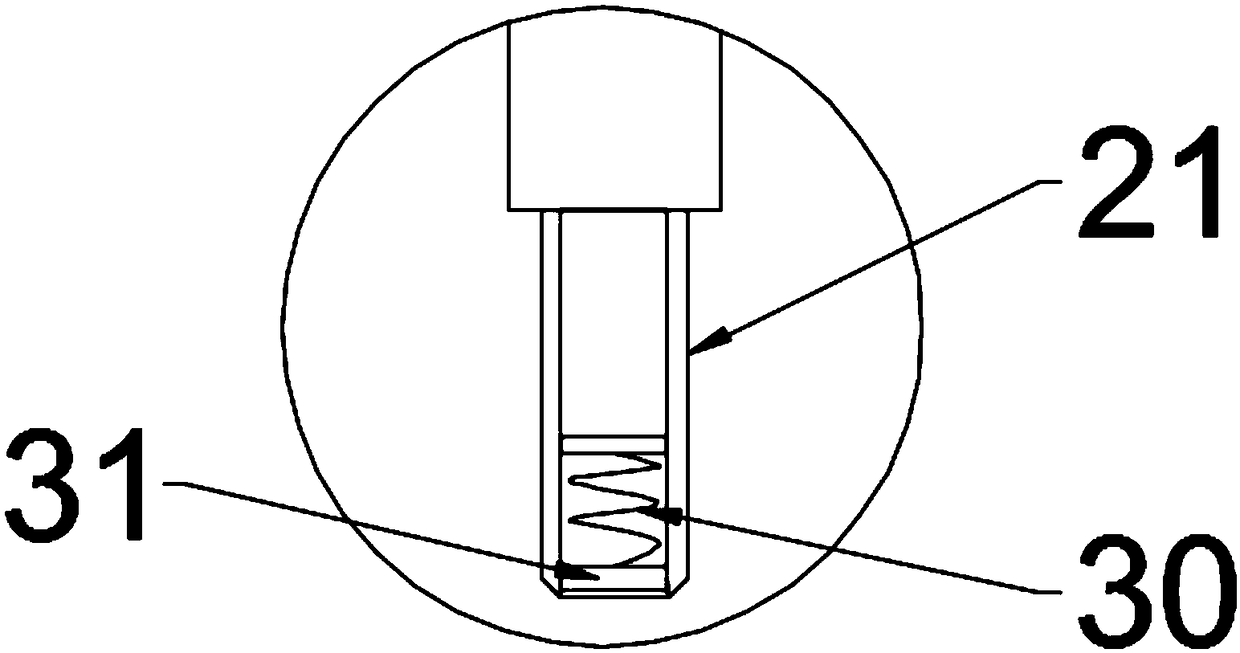

Punching machine suitable for cloth, leather and artificial leather

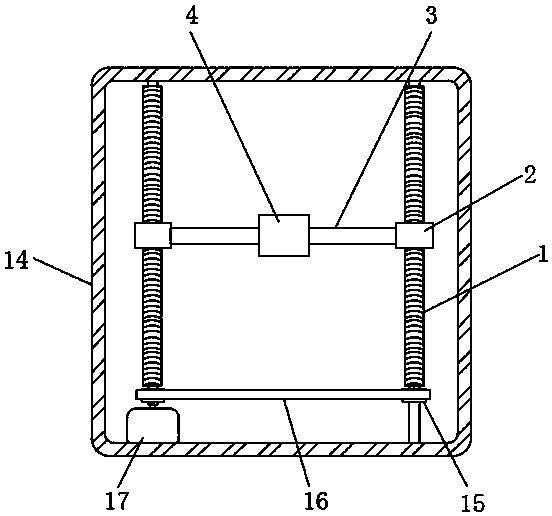

InactiveCN103144139AMake up for flatness errorAvoid incomplete cuttingLeather clicking/perforating/clickingSevering textilesPunchingElastic component

The invention provides a punching machine which is uniform in impact and excellent in punching precision and punching effect, and suitable for cloth, leather and artificial leather, and is especially capable of improving the punching precision and the punching effect aiming at multiple holes. The punching machine provided by the invention comprises a rack, wherein a punching cutter, a punching plate and a drive mechanism are arranged in the rack; the punching plate is movably arranged in the rack up and down and impacts the punching cutter; the punching plate is driven to move up and down by the drive mechanism; the tail end of the punching cutter is in a plane shape of which the area is equal to the area of a punching hole to be processed; the punching plate comprises a surface in a plane shape; the surface of the punching plate is parallel to the plane of the tail end of the punching cutter; the surface area of the punching plate is larger than the area of the plane formed at the tail end of the punching cutter; the rack comprises an elastic component acting on the punching cutter; and the punching cutter comprises a static station under the action of the elastic component only, and comprises an up and down microstroke under the combined action of the punching plate and the elastic component.

Owner:广州市集盛服饰皮具有限公司

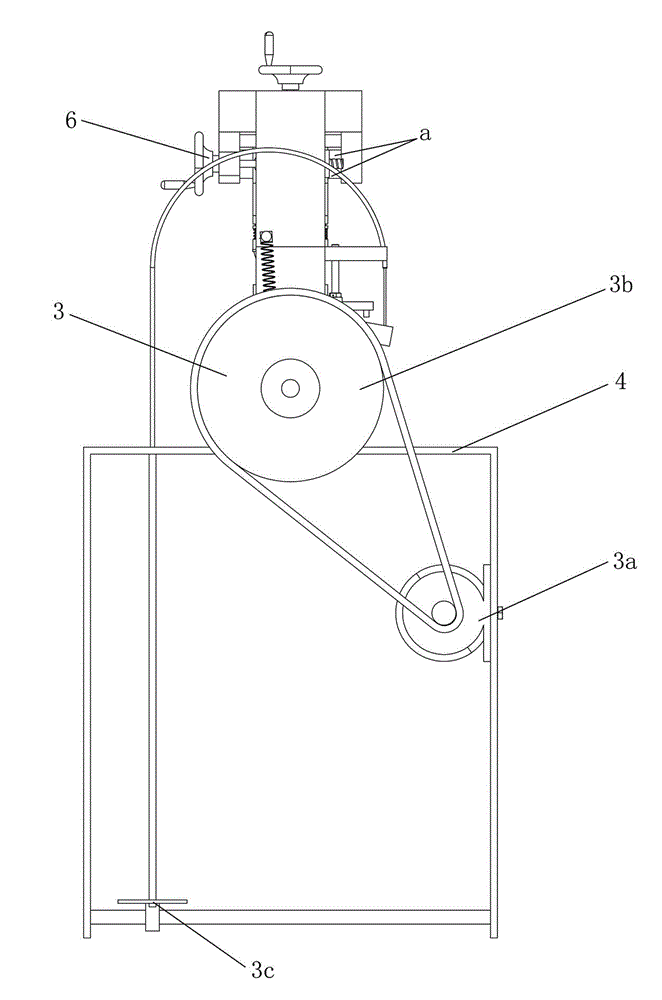

Leather rapid cutting device for shoemaking

InactiveCN106119436AFast cutting speedImprove cutting effectLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusPulleyLeather belt

The invention provides a cutting device and in particular to a leather rapid cutting device for shoemaking. Aiming at solving the technical problems, the invention provides the leather rapid cutting device for shoemaking, which is rapid in cutting speed, good in cutting effect and high in working efficiency. In order to solve the problems above, the invention provides the leather rapid cutting device for shoemaking. The leather rapid cutting device for shoemaking comprises an object placement platform, pressing blocks, connecting rods, third bearing seats, second nuts, second screw rods, connecting blocks, connecting rods, first nuts, a first screw rod, a first bearing seat, a large belt wheel, a second rotary shaft, a flat belt, a small belt wheel, a first rotary shaft, a first motor, a top plate, a second bearing seat and a cutting-off device; and a positioning groove is opened in the top of the object placement platform. The leather rapid cutting device for shoemaking has the effects of rapid cutting speed, good cutting effect and high working efficiency; and meanwhile, the device can be used for separately placing leather with different quality, and the leather is not easy to confuse and is convenient to distinguish, so that working errors are reduced.

Owner:WENZHOU YIMAIDA SHOES CO LTD

Hardware perforating mechanism provided with material receiving tank

InactiveCN107599049AImprove punching effectImprove efficiencyLeather clicking/perforating/clickingMetal working apparatusMechanical engineeringEngineering

The invention discloses a hardware perforating mechanism provided with a material receiving tank. The mechanism comprises a rack. An upper supporting frame is fixed to the top surface of a top plate of the rack. A lower die block is fixed to the top surface of the middle of the top plate of the rack. A plurality of positioning and stamping through holes are formed in the top surface of the lower die block. A plurality of stamping oil cylinders are fixed to the top surface of a top plate of the upper supporting frame. Push rods of the stamping oil cylinders penetrate through the top plate of the upper supporting frame to be fixed to the top surface of an upper pressing block. The bottom surface of the upper pressing block is provided with a plurality of puncher pins corresponding to the positioning and stamping through holes. The top plate of the rack is provided with discharging through holes corresponding to the positioning and stamping through holes. Side guide bent blocks are fixedto the two sides of the bottom surface of the top plate of the rack. Bent extension sides are arranged on the two sides of the material receiving tank and are inserted into and sleeved with positioning inserting grooves formed between the side guide bent blocks and the bottom surface of the top plate of the rack. The discharging through holes face the material receiving tank. The hardware perforating mechanism provided by the invention can be used for perforating a plurality of holes at a time, and is good in perforating effect and high in efficiency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com