Patents

Literature

99results about How to "Precise cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of embossing laminating release paper

ActiveCN101597874AWon't happenUnity of depthPaper coatingLaminationLow-density polyethylenePulp and paper industry

The invention discloses a production technology of embossing laminating release paper, the production technology is characterized by comprising the following steps: 1) preparing laminating paint, adding the high-density polyethylene and the low-density polyethylene into a stirring vessel to mix and stir for 5-10 minutes to mix evenly, the weight ratio of the high-density polyethylene and the low-density polyethylene is 1:1.5-2, and then heating, bridging, heating and melting, pressing and extruding the mixture. 2) preparing the embossing laminating release paper, laminating the extruded polyethylene mixture to the surface of the paper by a composite wheel, pressing and compositing the mixture by the composite wheel, and cooling the temperature at 30-40 DGE C after compositing, continually moving the paper after laminating driven by a roller and cooling the paper at the temperature of 12-20 DGE C, and side cutting, rolling, packaging for the paper, finally, coating silicon oil on the surface of the laminating paper to prepare the finished product of the embossing laminating release paper. The invention has convenient production technology; the embossing laminating release paper prepared by the production technology has the advantages of beautiful shape and good use effect, can be widely used in the technology of manufacturing the embossing laminating release paper.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

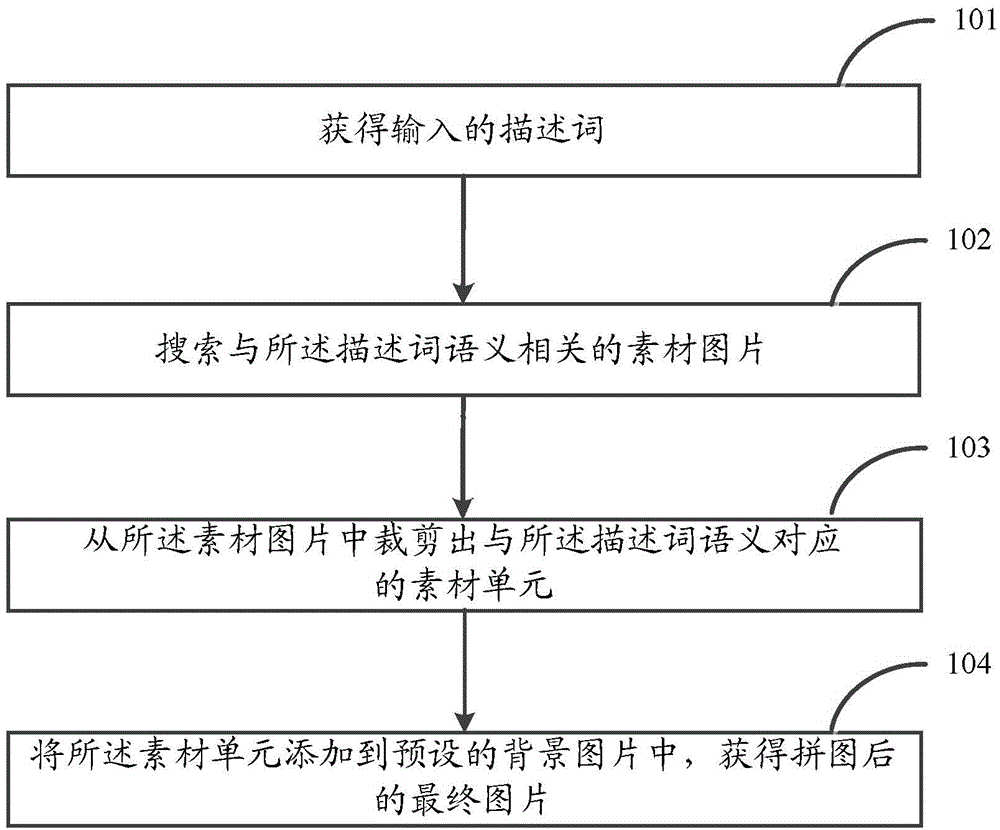

Method and device for processing pictures

ActiveCN104133956AStrong personalizationFlexible combinationSpecial data processing applicationsPersonalizationComputer graphics (images)

The invention discloses a method and a device for processing pictures, and relates to the field of computers and images. The method and the device are used for realizing the manufacturing of personalized pictures. The method comprises the following steps that: an input descriptor is obtained; a material picture relevant to the semantics of the descriptor is searched; a material unit corresponding to the semantics of the descriptor is cut from the material picture; and the material unit is added into a preset background picture to obtain a final picture after the picture splicing. According to the embodiment of the invention, the materials required by a user are obtained through semantic searching and image cutting; the materials are combined in a picture splicing mode; and the personalized pictures with the eminent design feeling are obtained.

Owner:XIAOMI INC

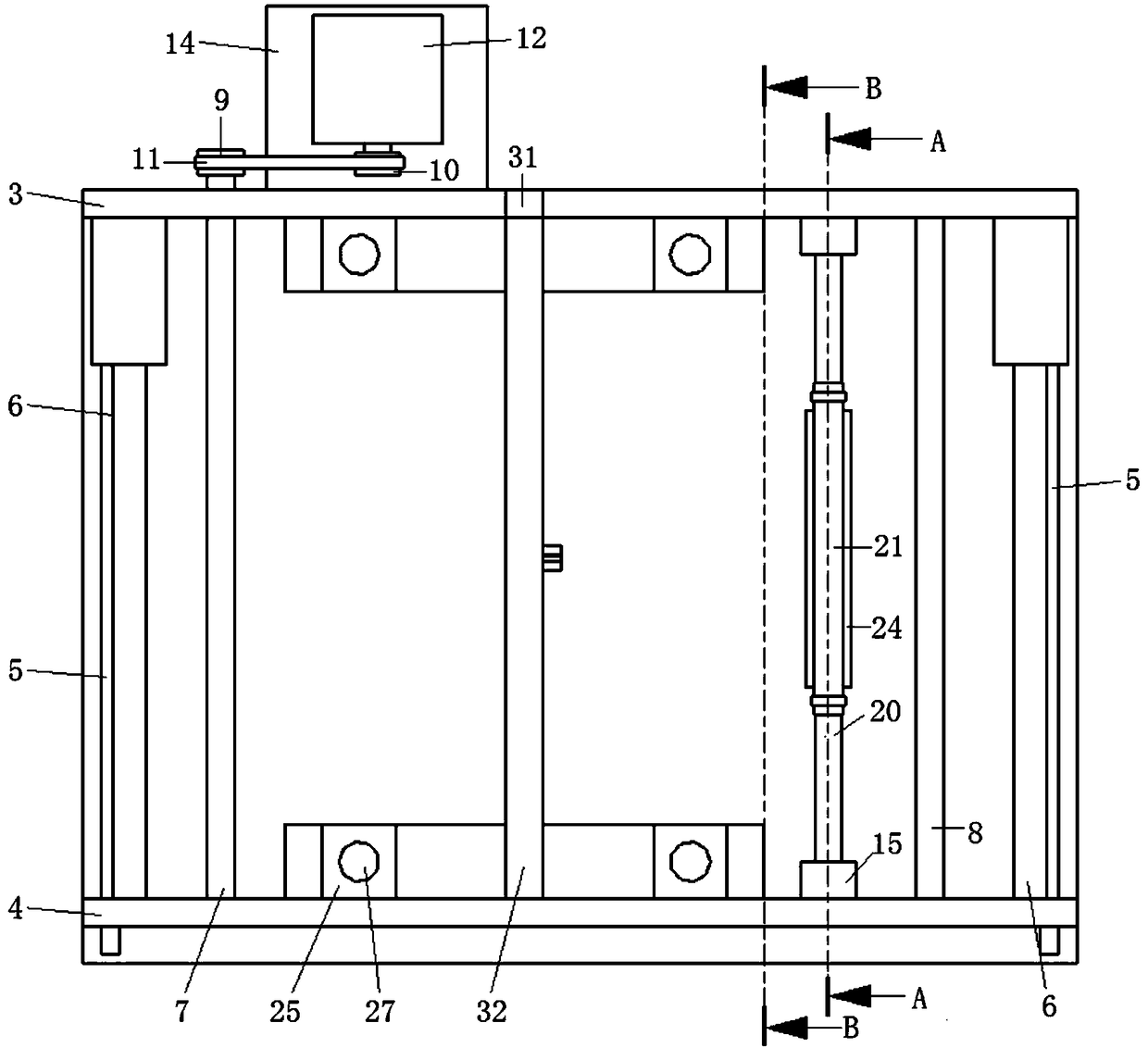

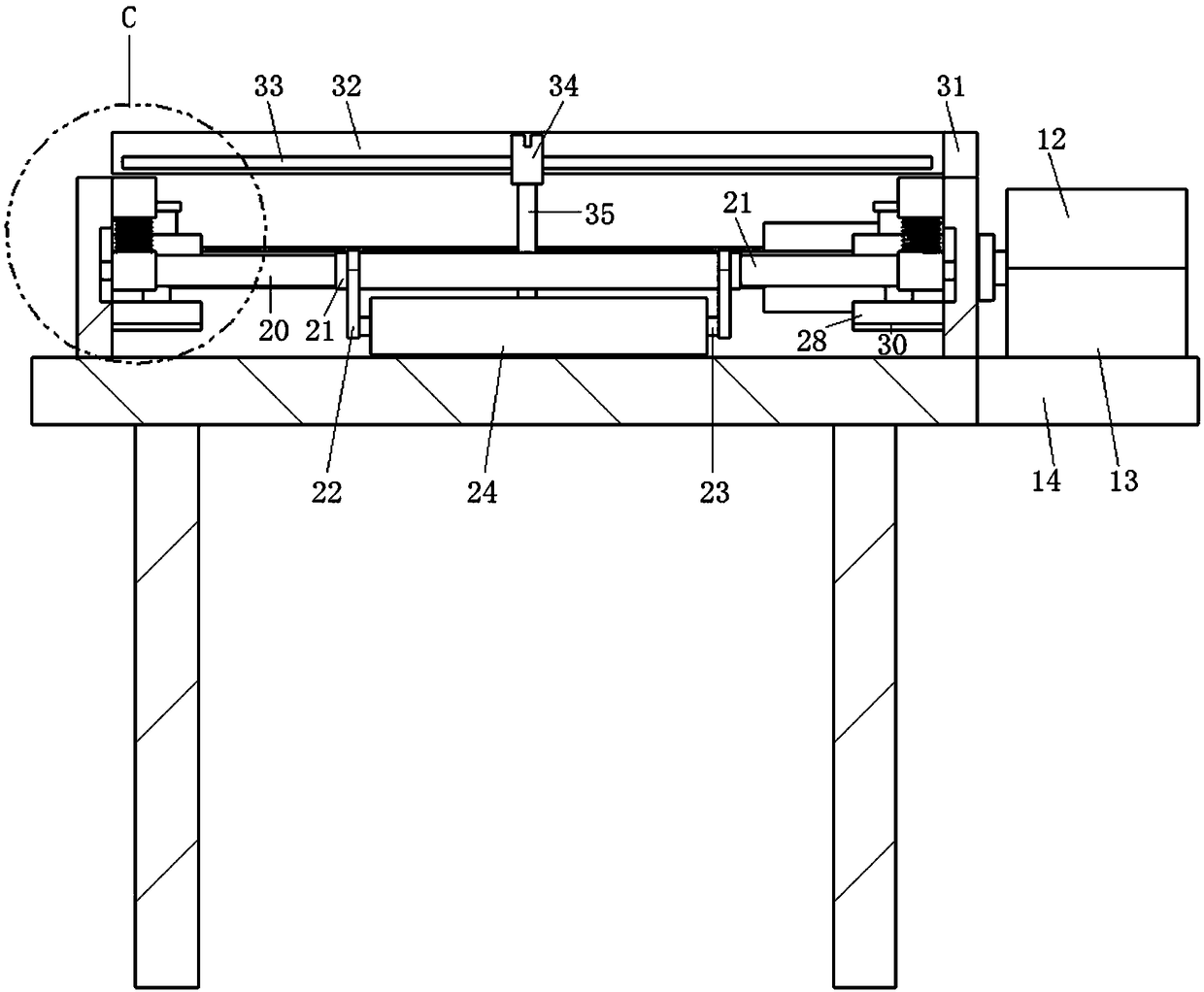

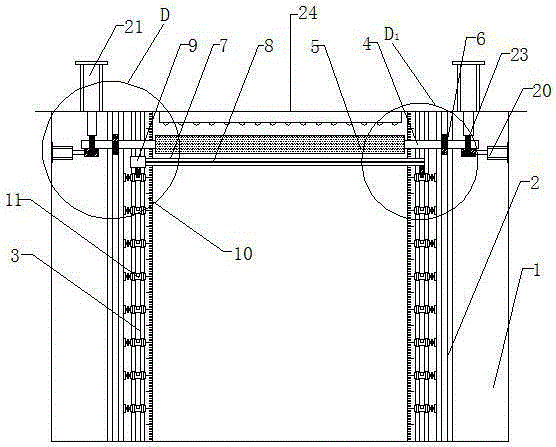

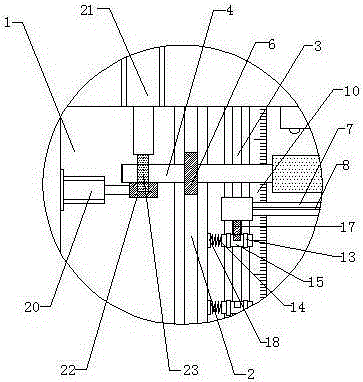

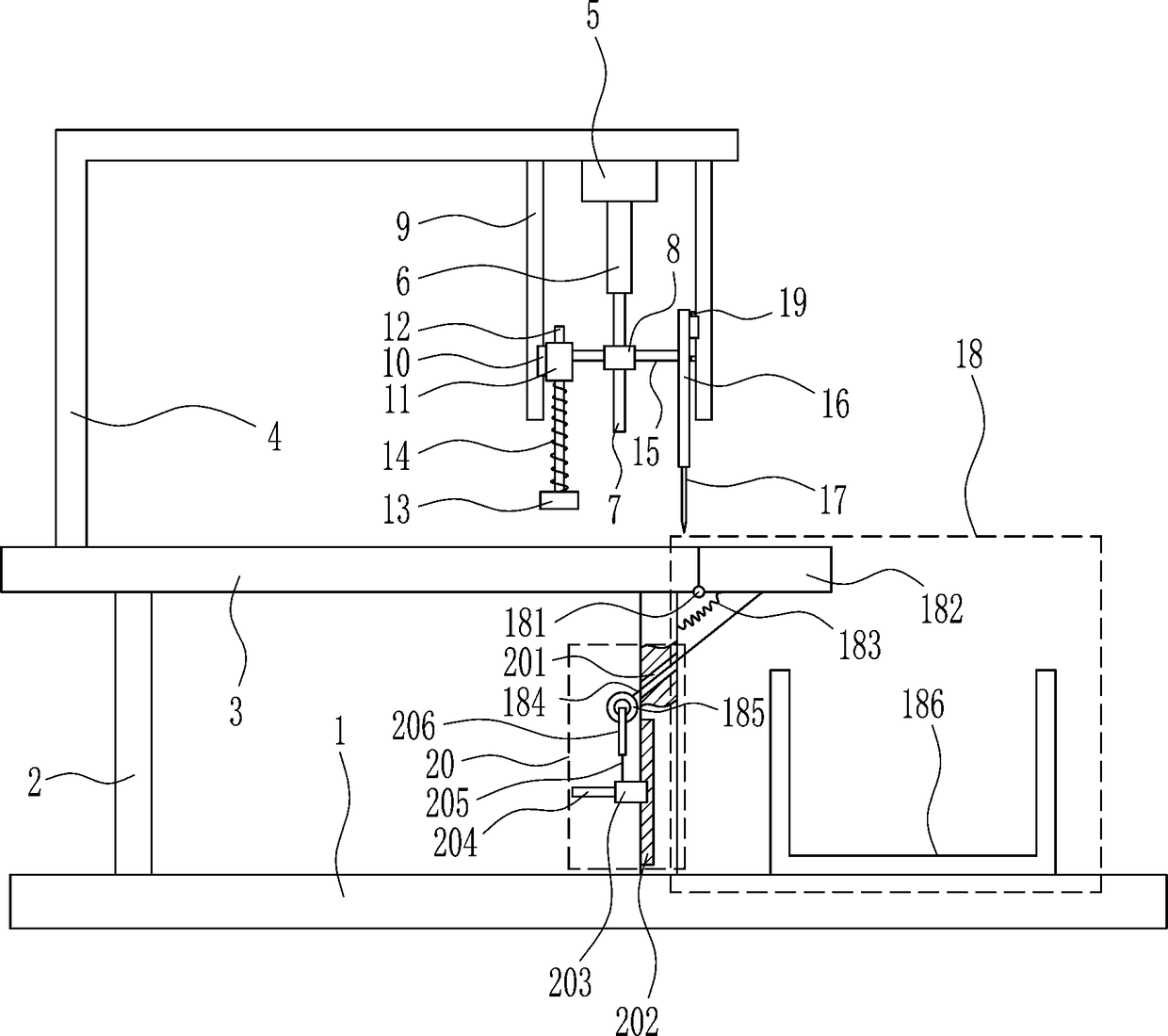

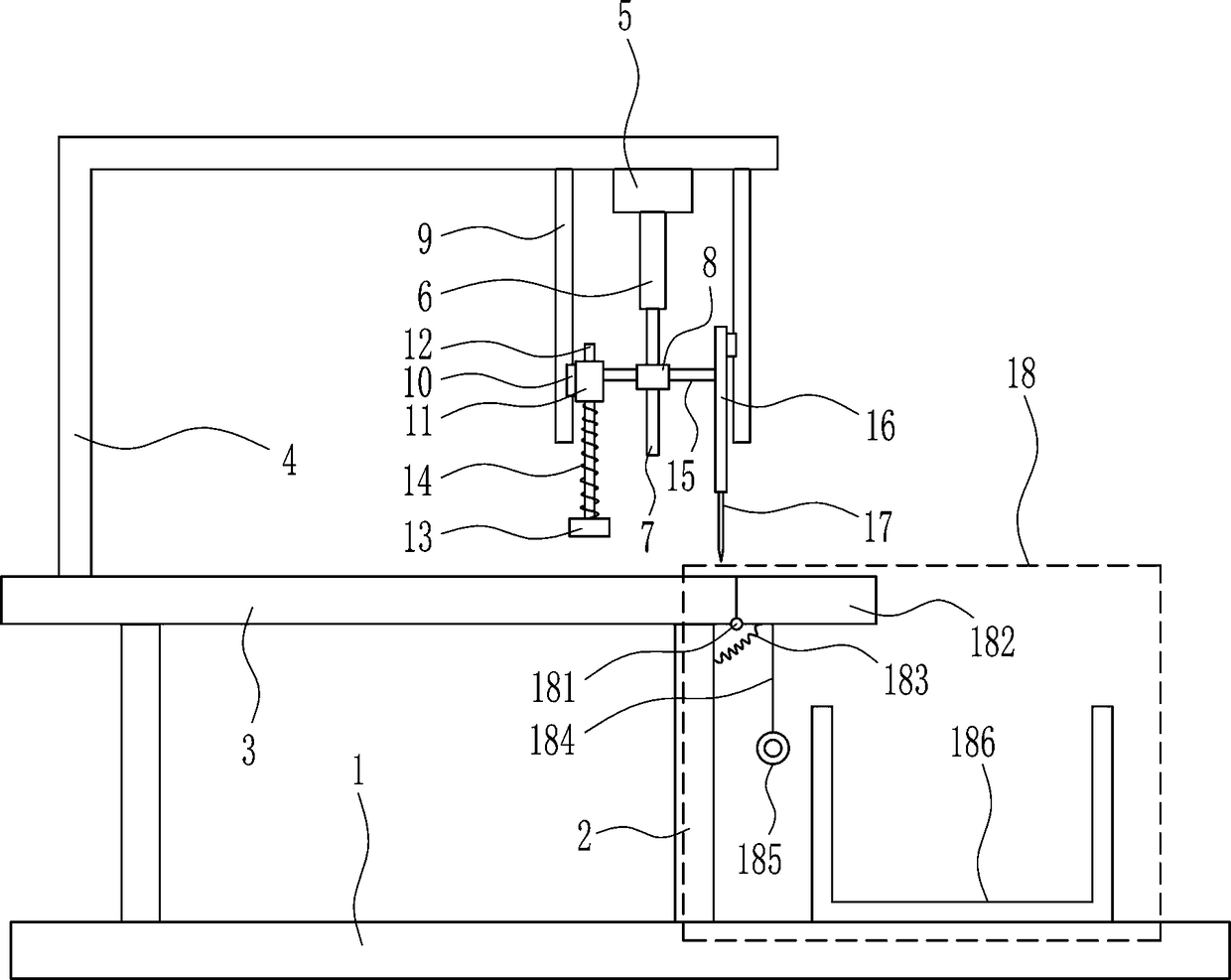

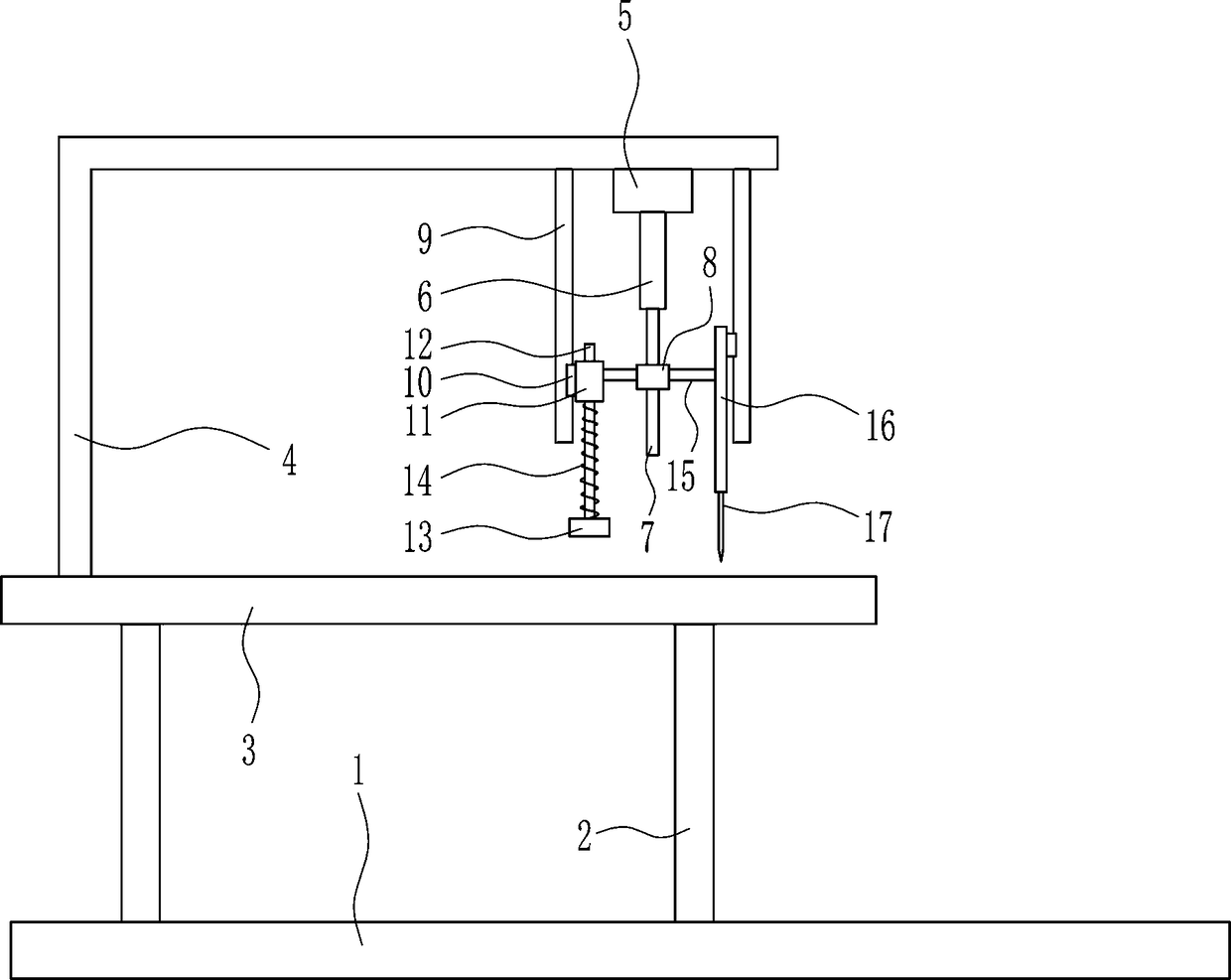

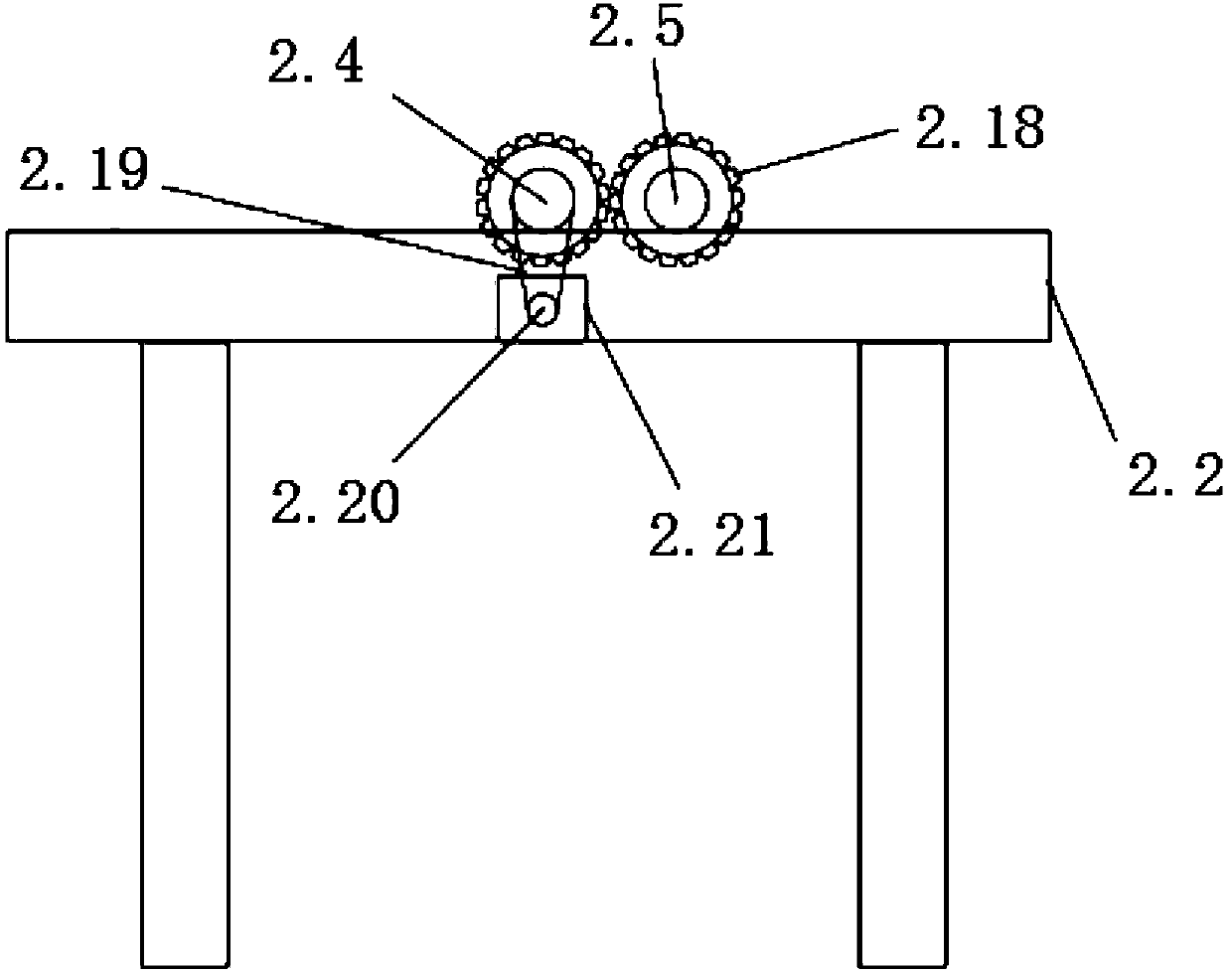

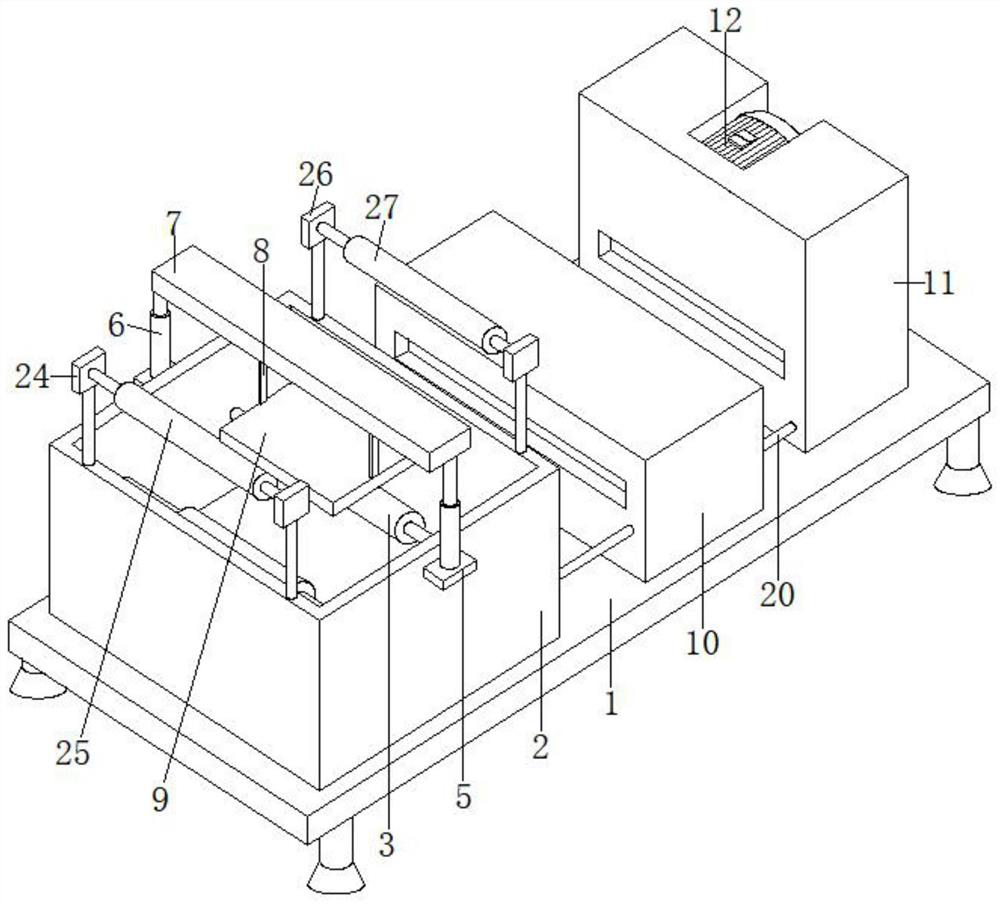

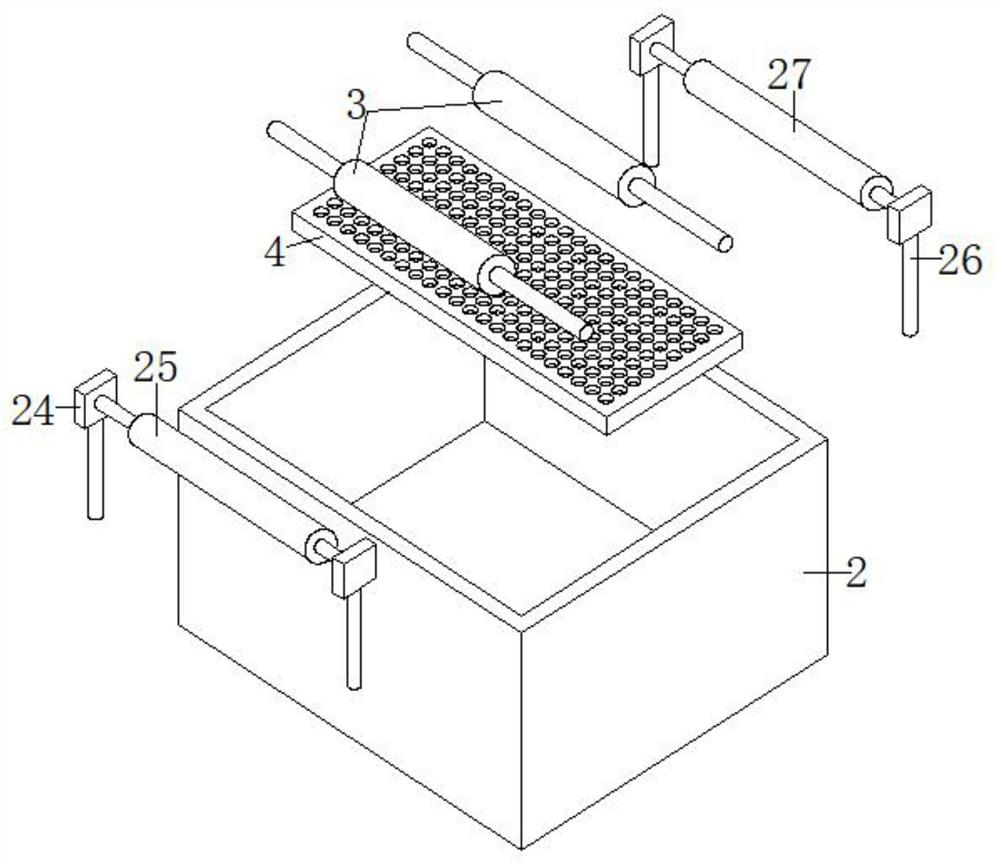

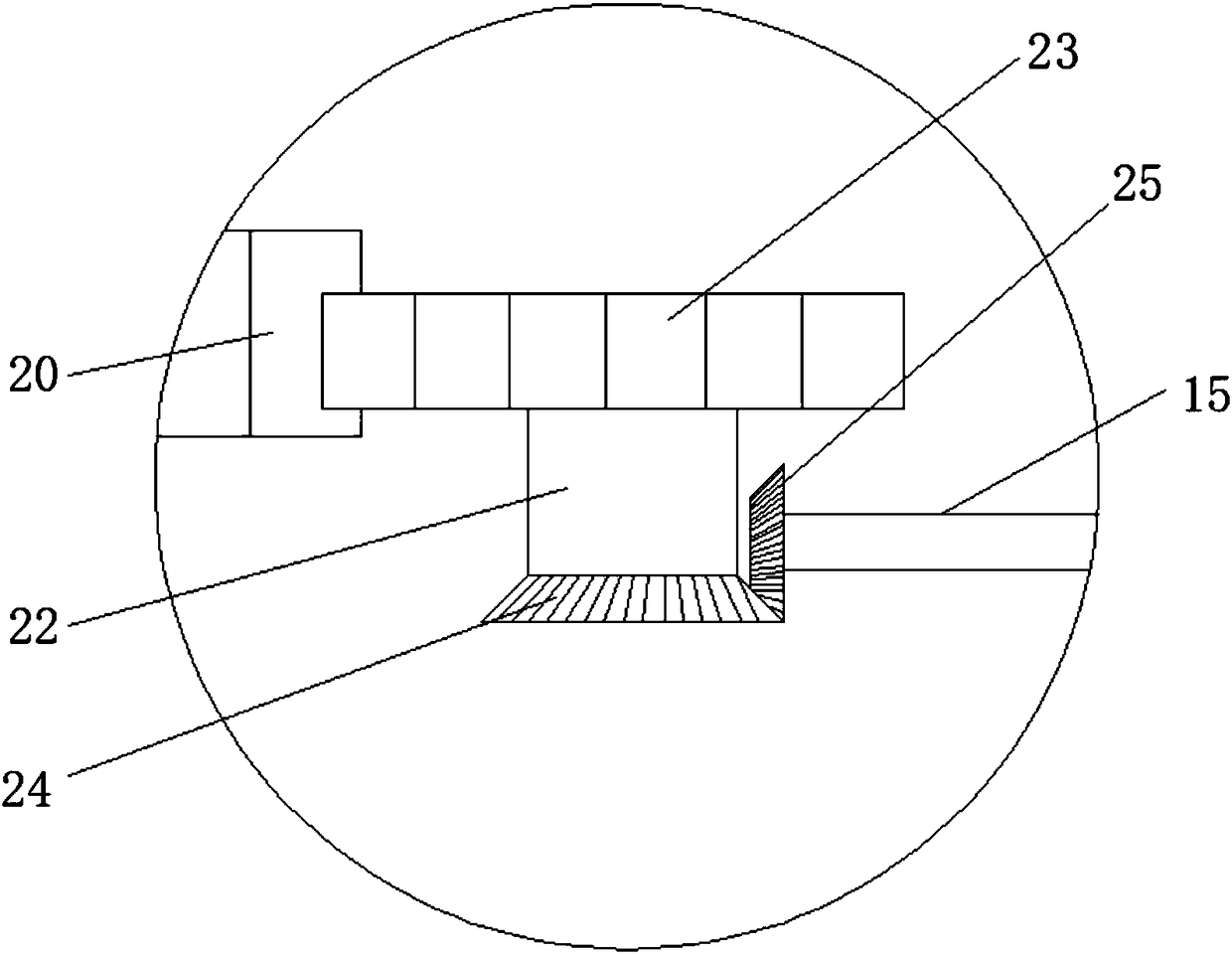

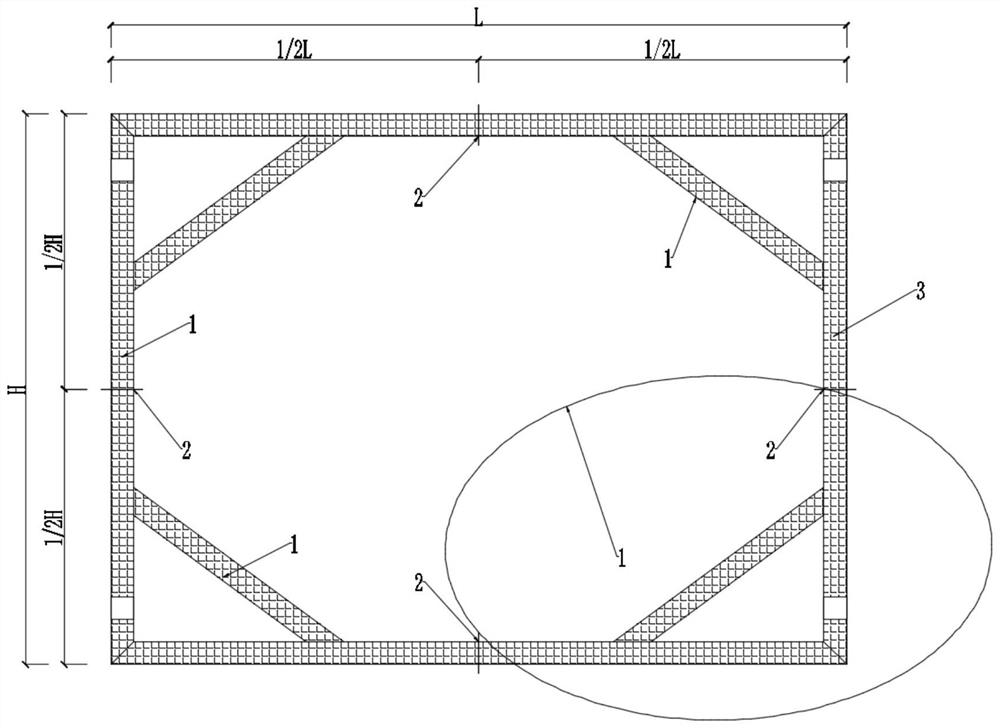

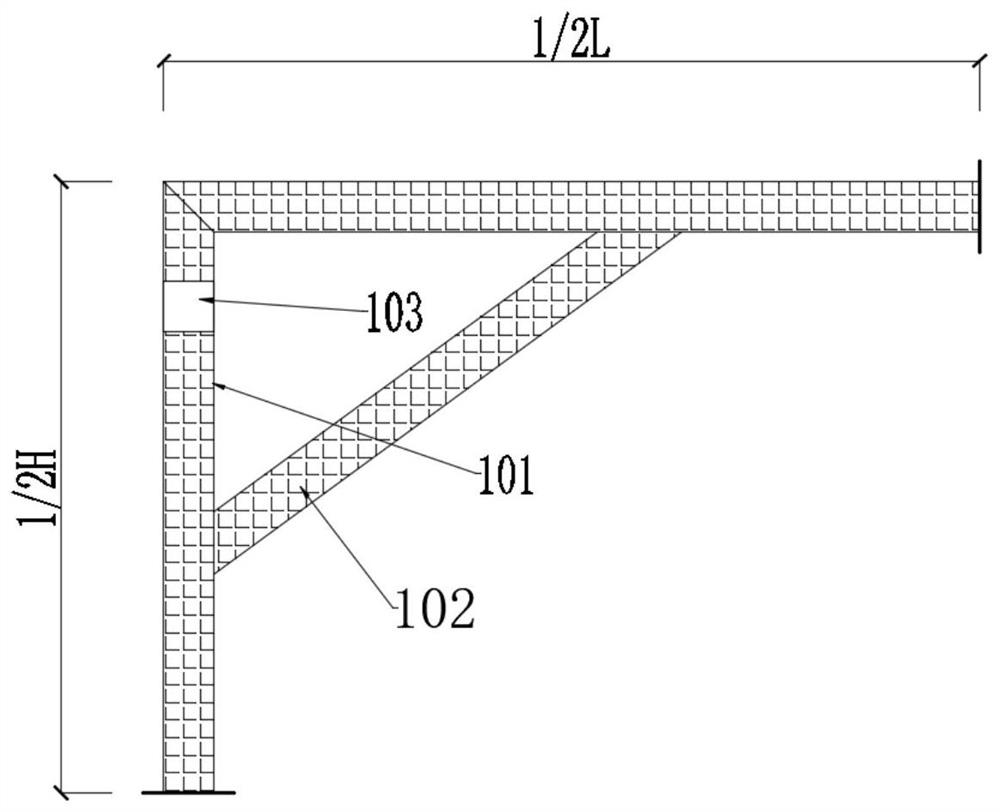

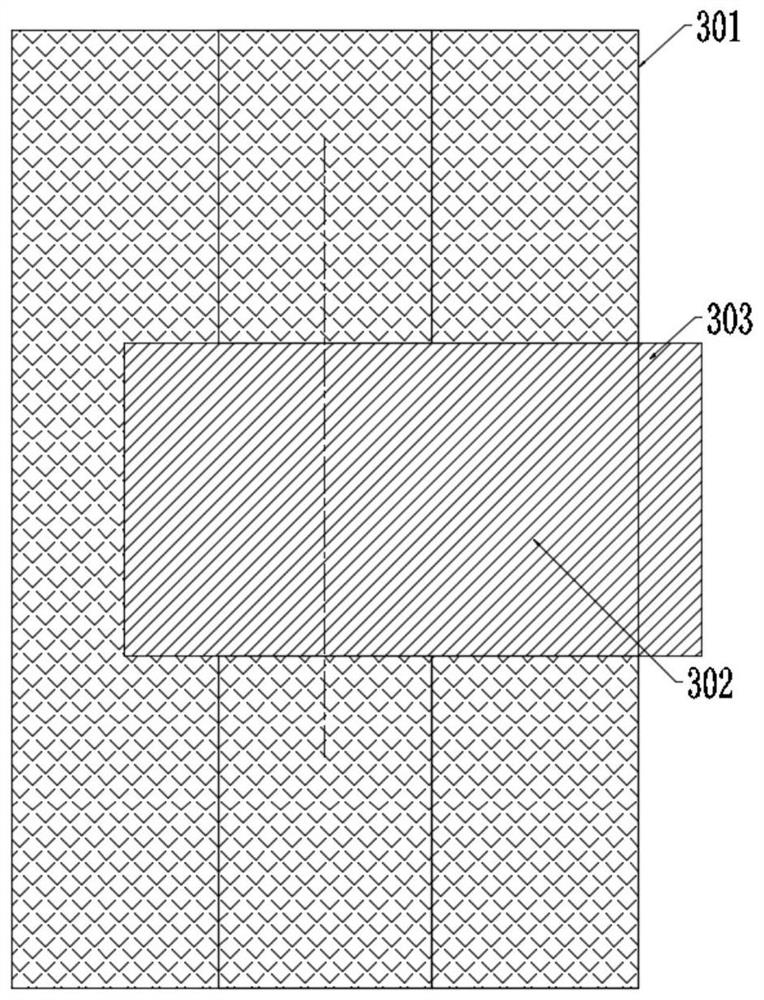

Cloth cutting device for garment processing

ActiveCN108842434AReduce lossesPrecise positioningMarking textilesSevering textilesDrive wheelEngineering

The invention discloses a cloth cutting device for garment processing. The device comprises a workbench, a fixing plate is arranged at one end of the workbench, a moving plate is arranged at the end,away from the fixing plate, of the workbench, the other two ends of the workbench are provided with first sliding grooves respectively, the bottoms of the two ends of the moving plate are slidably connected in the first sliding grooves through first sliding blocks respectively, the two ends of the fixing plate are connected with the moving plate through telescopic rods respectively, the sides, close to each other, of the two telescopic rods are provided with a driving roller and a driven roller respectively, one end of the driving roller penetrates through the fixing plate to the side, away from the moving plate, of the fixing plate and is fixedly provided with a driven wheel, one side of the driven wheel is provided with a driving wheel, the driving wheel is in transmission connection with the driven wheel through a transmission belt, the end, away from the fixing plate, of the driving wheel is connected with an output shaft of a motor, the side, close to the driving roller, of the driven roller is further provided with a leveling mechanism, a press mounting mechanism is further arranged between the leveling mechanism and the driving roller, and a cutting mechanism is arranged above the press mounting mechanism. The cloth cutting device for garment processing can greatly improve the precision of cutting, reduce cloth loss and reduce cost.

Owner:JIXI YUANDAO AGRI IND TECH

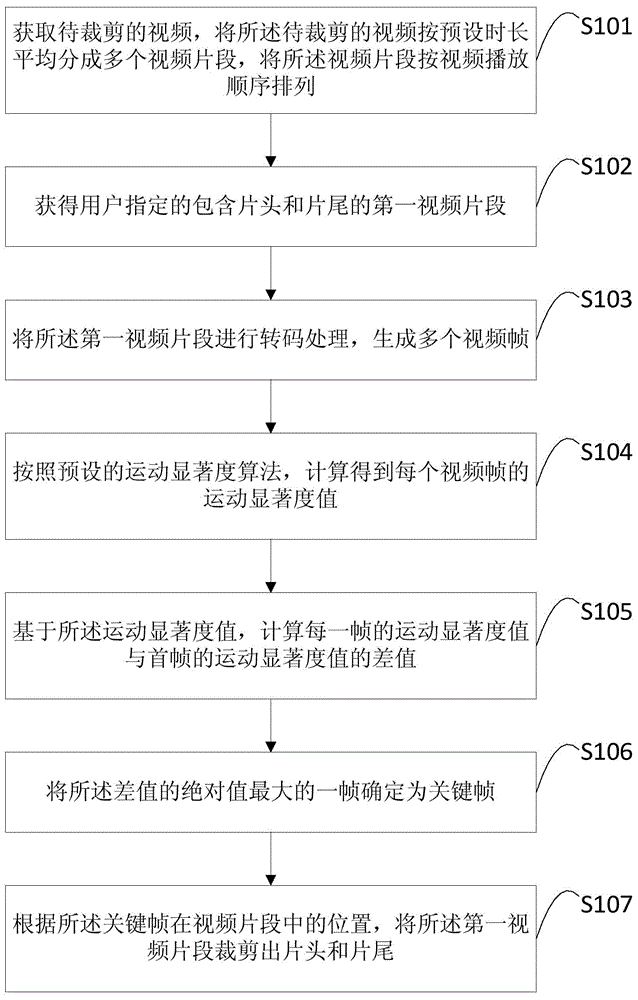

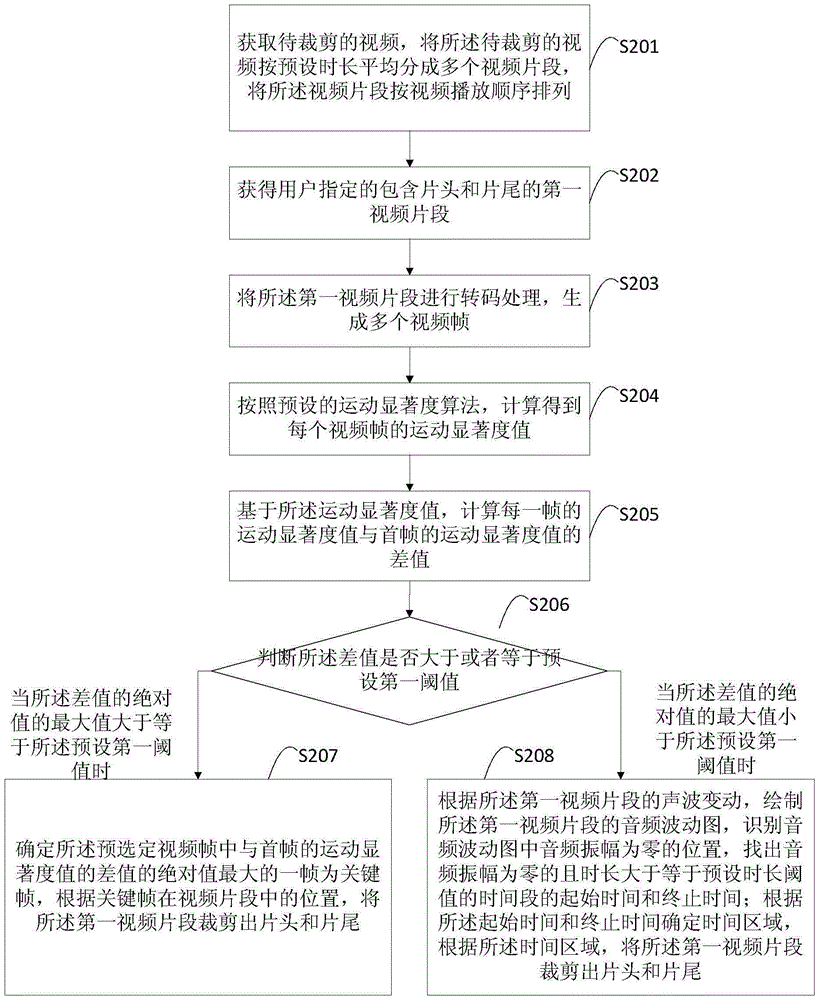

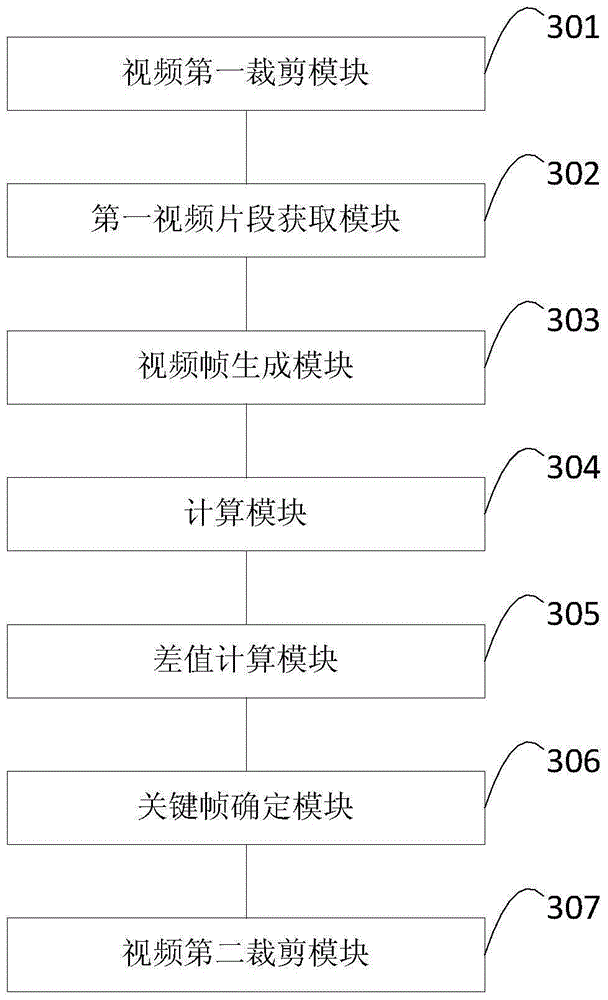

Method and device for cutting video

ActiveCN105227999APrecise croppingImprove experienceSelective content distributionComputer graphics (images)Significance values

The embodiment of the invention discloses a method and a device for cutting a video. The method comprises the following steps: obtaining a to-be-cut video, equally dividing the to-be-cut video into a plurality of video clips according to the preset duration, and arranging the video clips according to a video play order; obtaining a first video clip, which comprises a film title and a tail leader and is appointed by a user; carrying out a transcoding treatment on the first video clip and generating a plurality of video frames; calculating a motion significance value of each video frame according to a preset motion significance algorithm; calculating the difference value between the motion significance value of each frame and the motion significance value of the first frame on the basis of the motion significance value; determining the frame with the maximum absolute value of the difference value as a key frame; and cutting out the film title and the tail leader from the first video clip according to the position of the key frame in the video clip. Through the application of the method and the device for cutting the video, the video can be accurately cut; and the user experience is improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

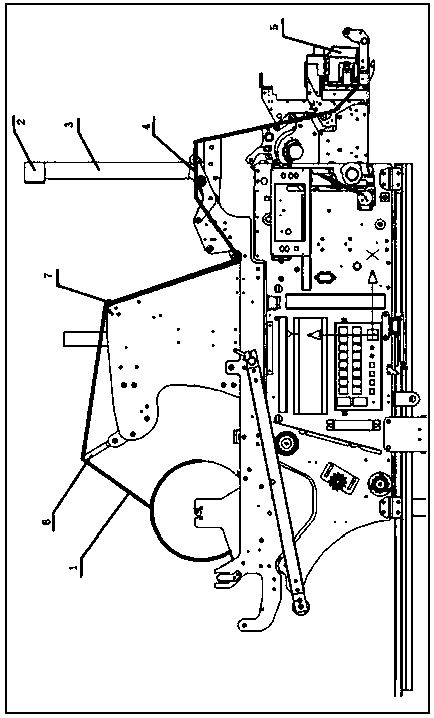

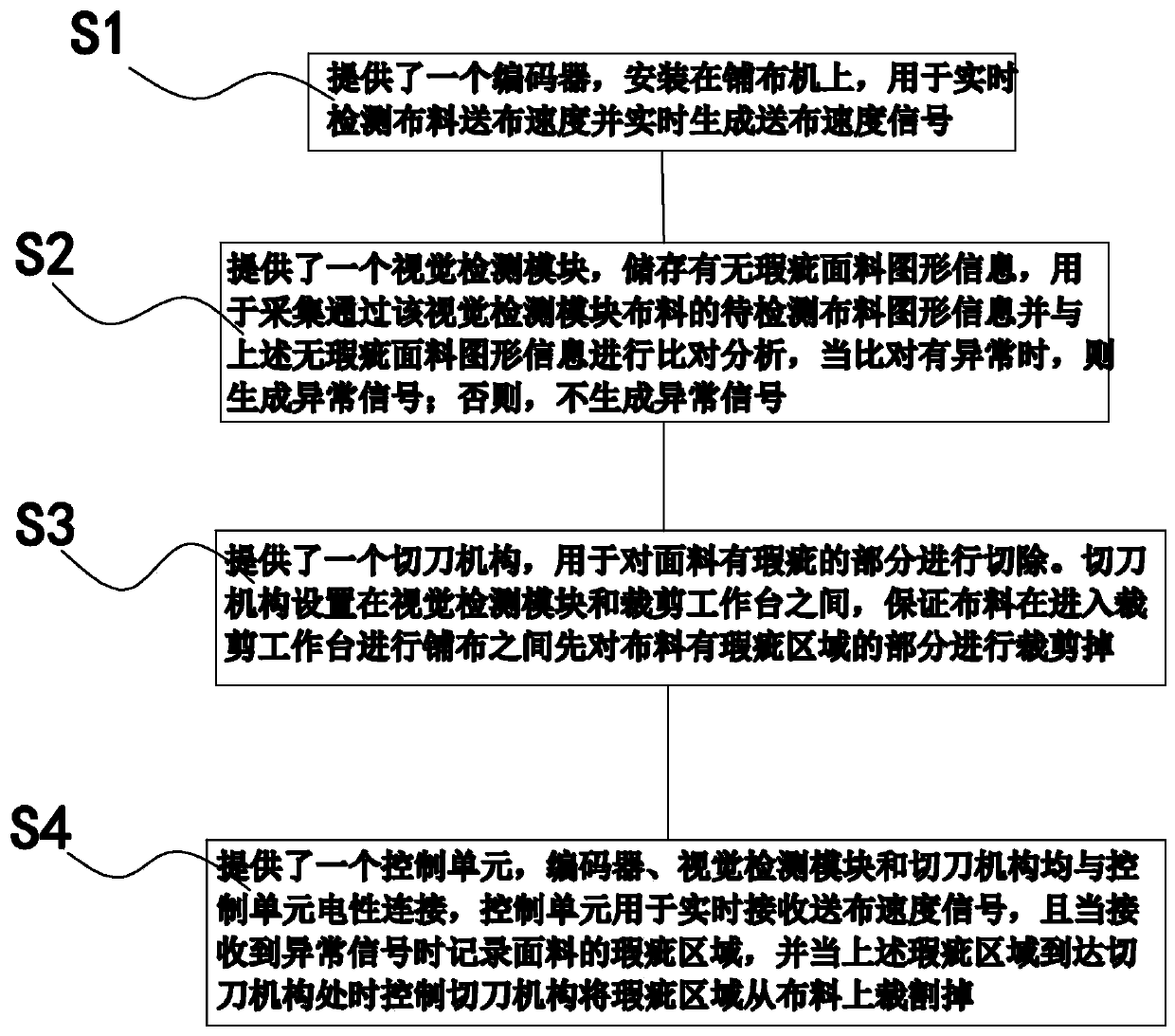

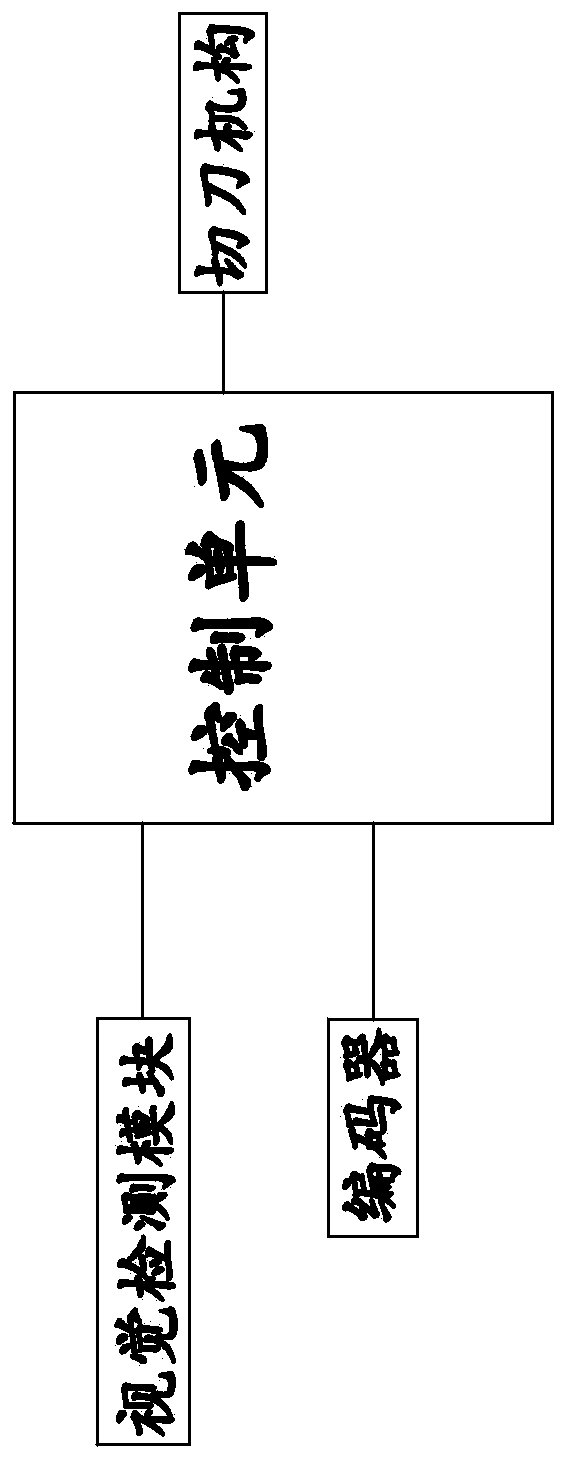

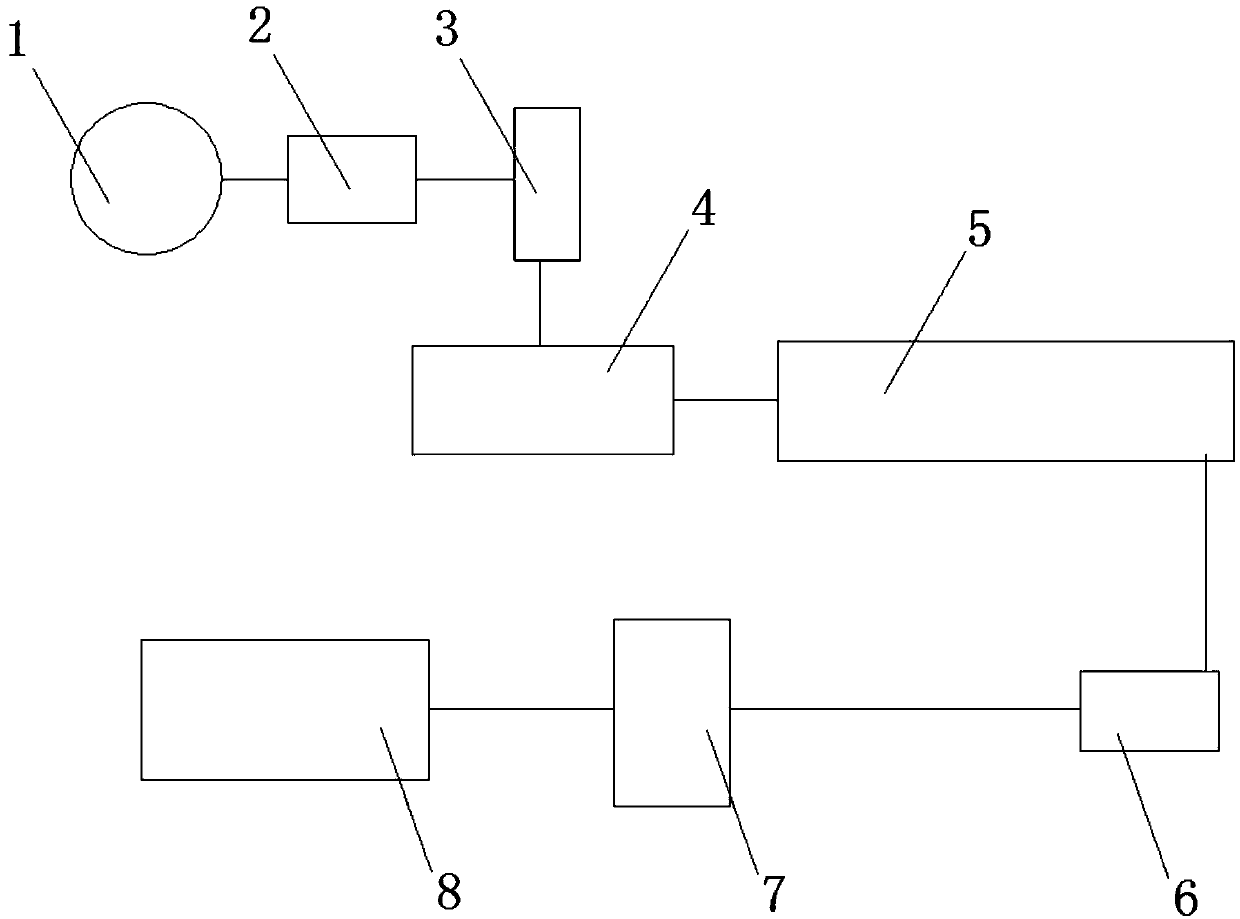

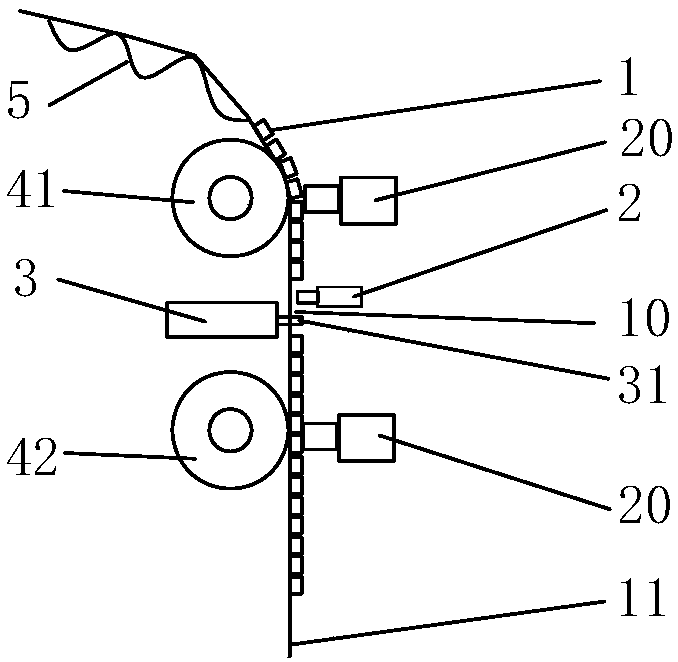

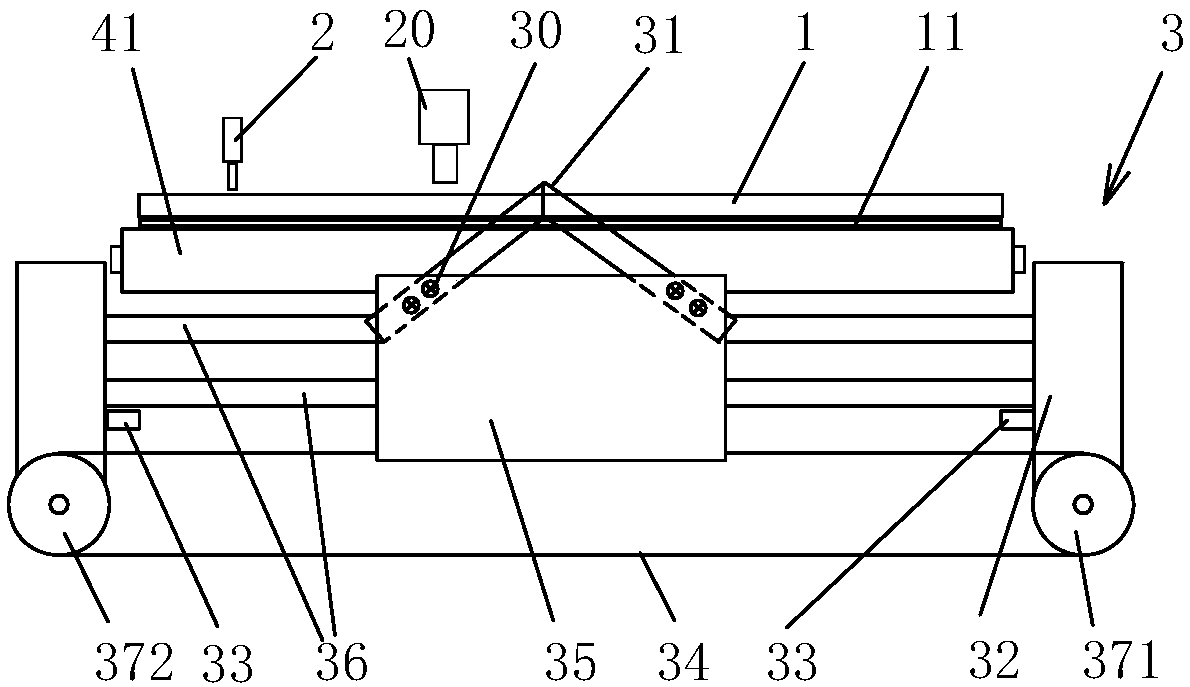

Cloth flaw detection control system on cloth spreading machine

InactiveCN110057832AAccurate cuttingImprove spreading efficiencyMaterial analysis by optical meansUnfolding thin materialsMachine controlControl system

The invention provides a cloth flaw detection control system on a cloth spreading machine and belongs to the field of cloth spreading machine control technologies. Through the system, the problems that in the prior art, cloth flaw detection efficiency is low, and accuracy is not high are solved. A cloth flaw detection control method comprises the steps that S1, an encoder is provided; S2, a visiondetection module is provided, wherein the vision detection module is used for collecting graphic information of to-be-detected cloth, performing comparative analysis and generating an anomaly signalwhen an anomaly is found through comparison; S3, a cutter mechanism is provided, wherein the cutter mechanism is used for cutting off a flawed part of the cloth; and S4, a control unit is provided, wherein the control unit is used for receiving a cloth-conveying velocity signal in real time, recording a flawed area of the cloth when receiving the anomaly signal and controlling the cutter mechanismto cut the flawed area off the cloth when the flawed area reaches the cutter mechanism. The cloth flaw detection control method has the advantages of high detection efficiency and high accuracy.

Owner:BULLMER ELECTROMECHANICAL TECH

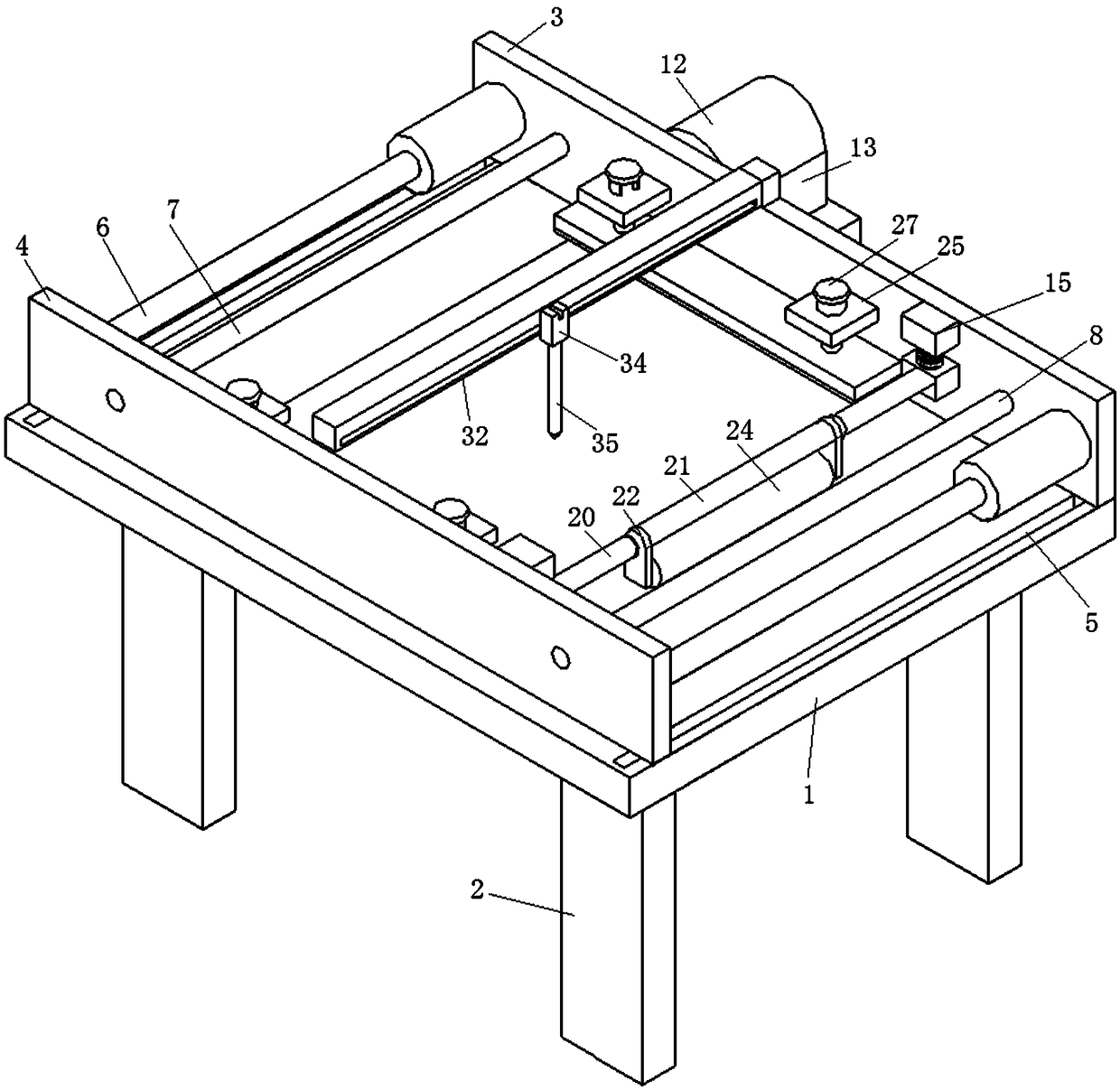

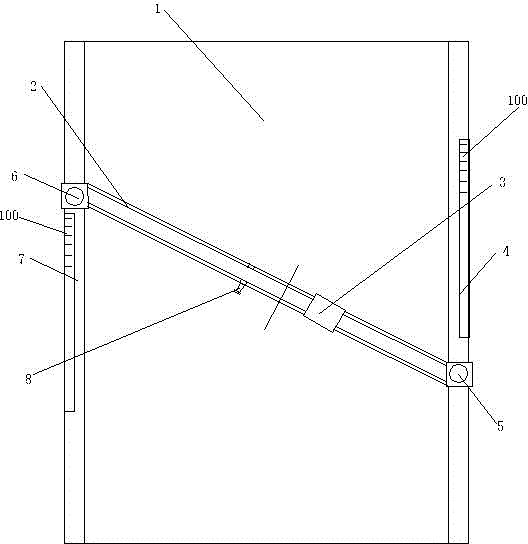

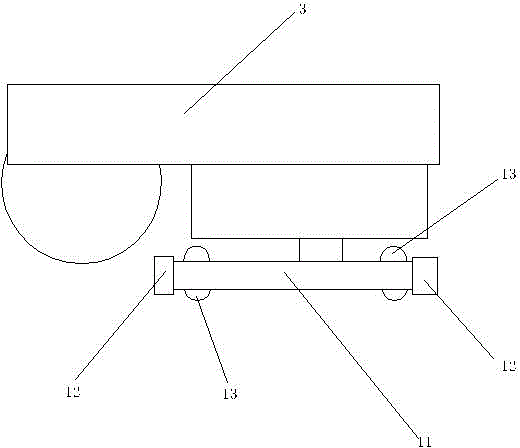

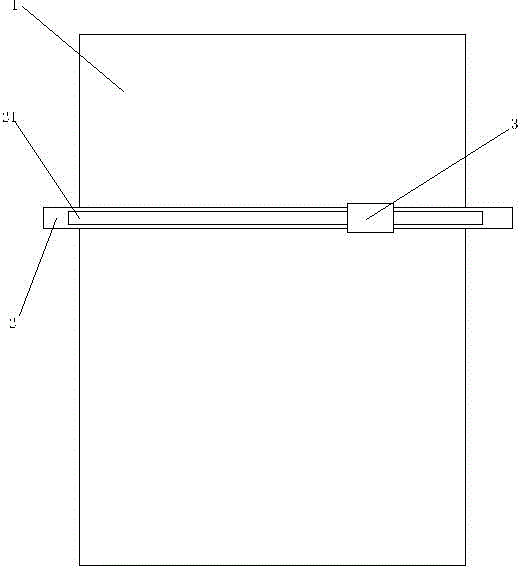

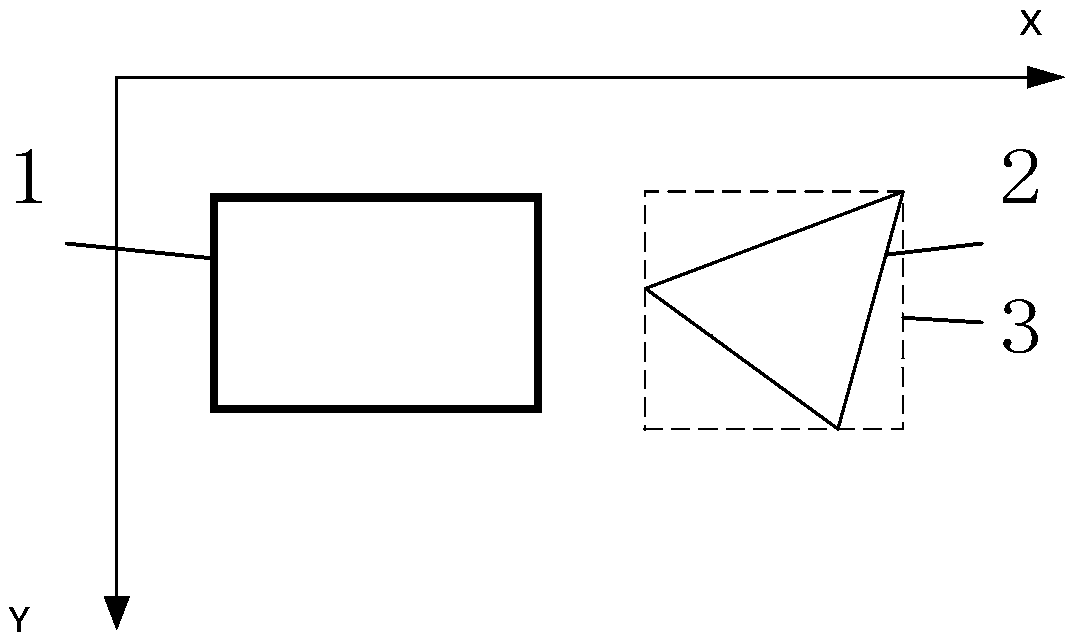

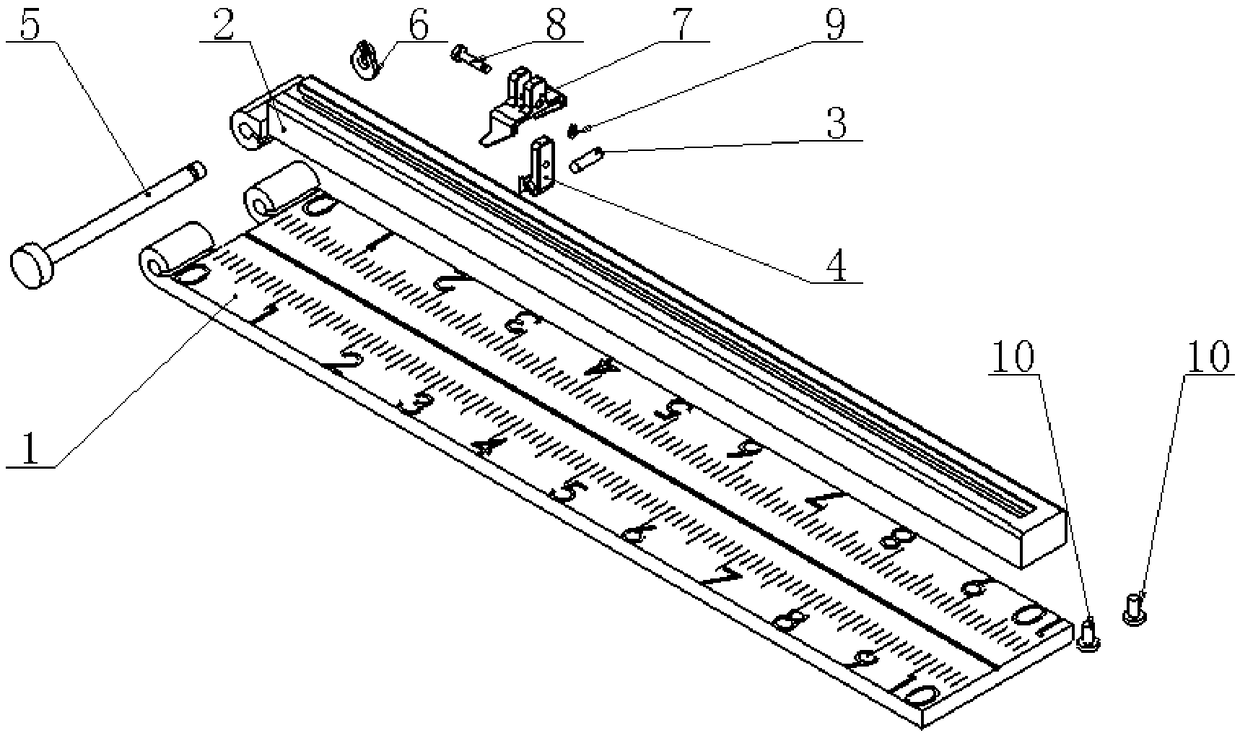

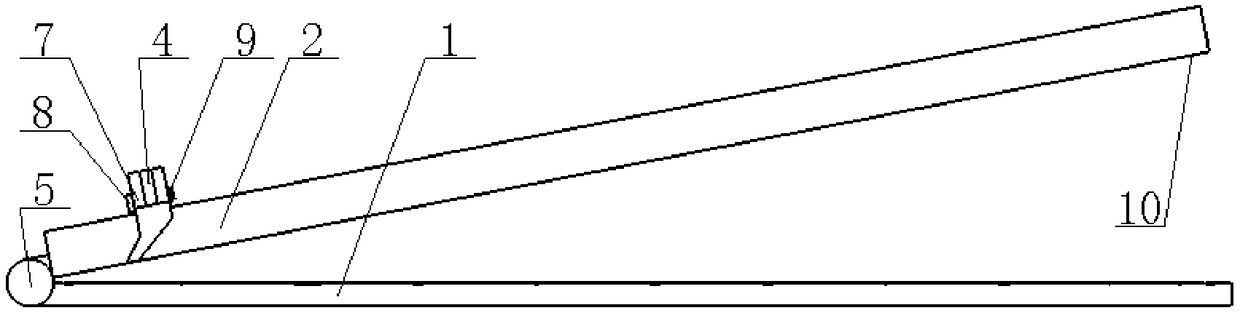

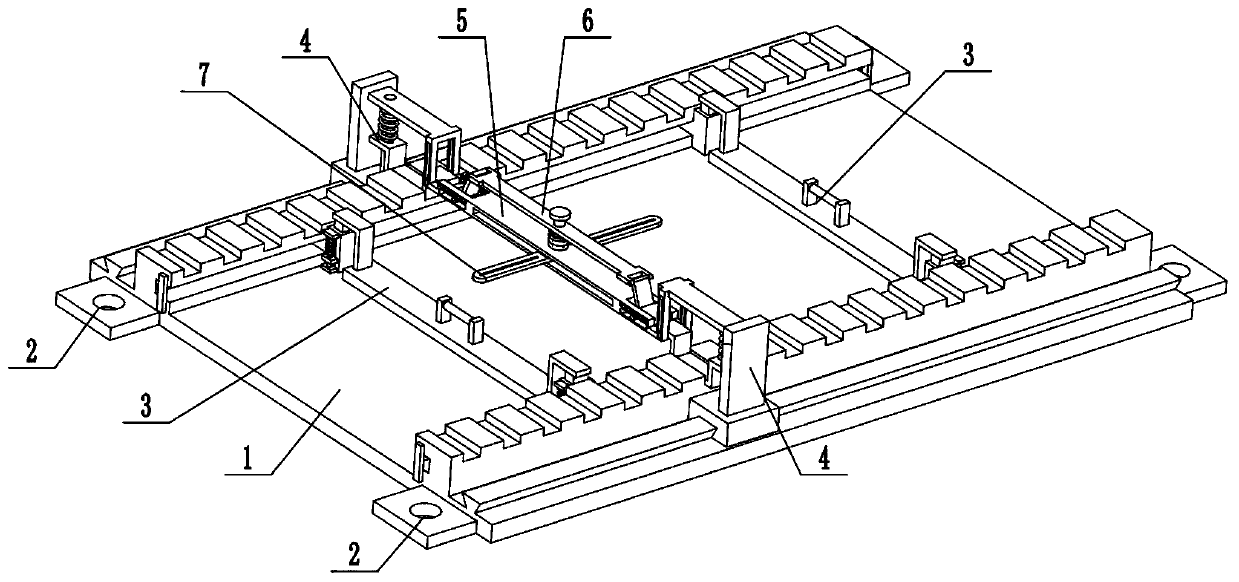

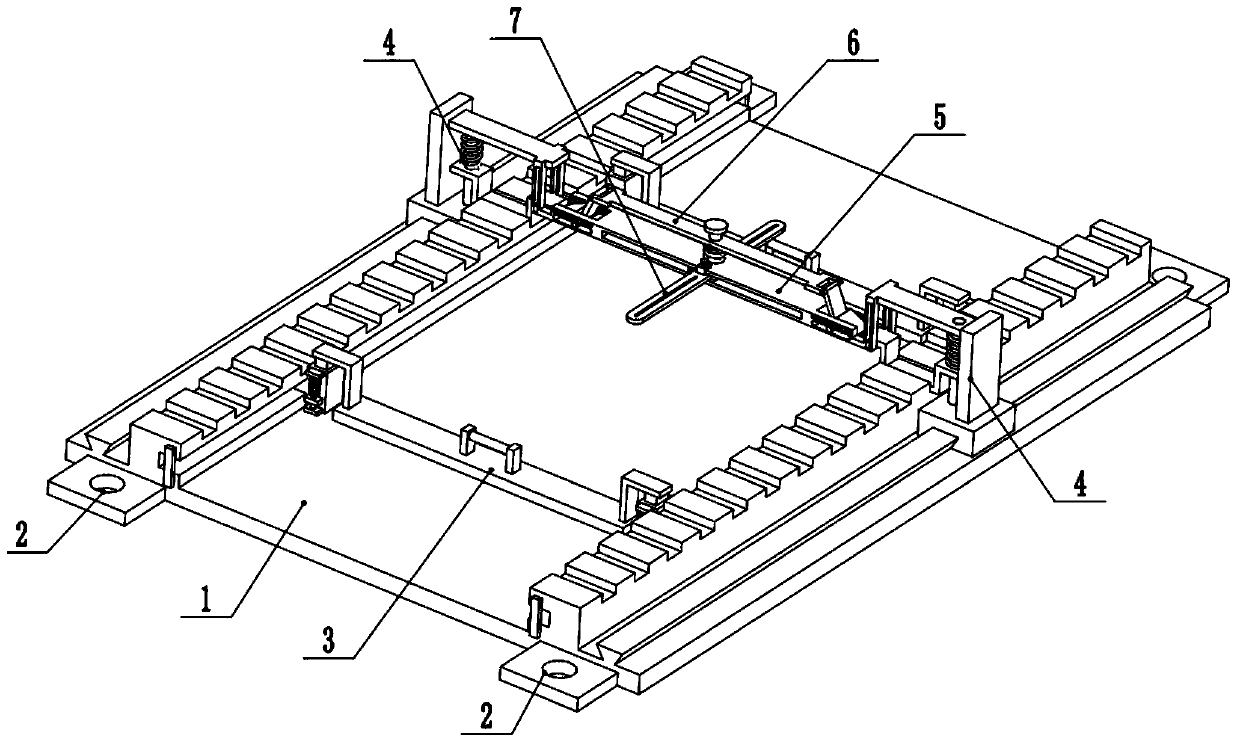

Table-type cloth cutting machine with sliding guide rail

InactiveCN103184682APrecise croppingSolve the shortcomings of inaccurate cropping angleSevering textilesEngineeringMechanical engineering

A table-type cloth cutting machine with a sliding guide rail belongs to the field of textile machinery. The cloth cutting machine comprises a lathe bed and a guild rail, wherein a first slideway and a second slideway are arranged on the two sides of the lathe bed; the guide rail is arranged between the first slideway and the second slideway in a sliding manner; the guide rail comprises a first guide rail and a second guide rail; the second guide rail which can slide relatively is arranged on the first guide rail; a first fixing piece used for fixing the first guide rail on the second guide rail is arranged on the first guide rail; a second fixing piece used for fixing the first guide rail on the first slideway is arranged on the first guide rail; the first guide rail can rotate relative to the second fixing piece; a third fixing piece used for fixing the first guide rail on the second slideway is arranged on the second guide rail; and the second guide rail can rotate relative to the third fixing piece. Compared with the prior art, the cutting machine can cut out cloth of different inclination angles accurately according to different requirements, and primarily solves the problem that a previous cutting machine is poor in accuracy when cutting an inclination cloth material.

Owner:NINGBO EASTSUN TEXTILES

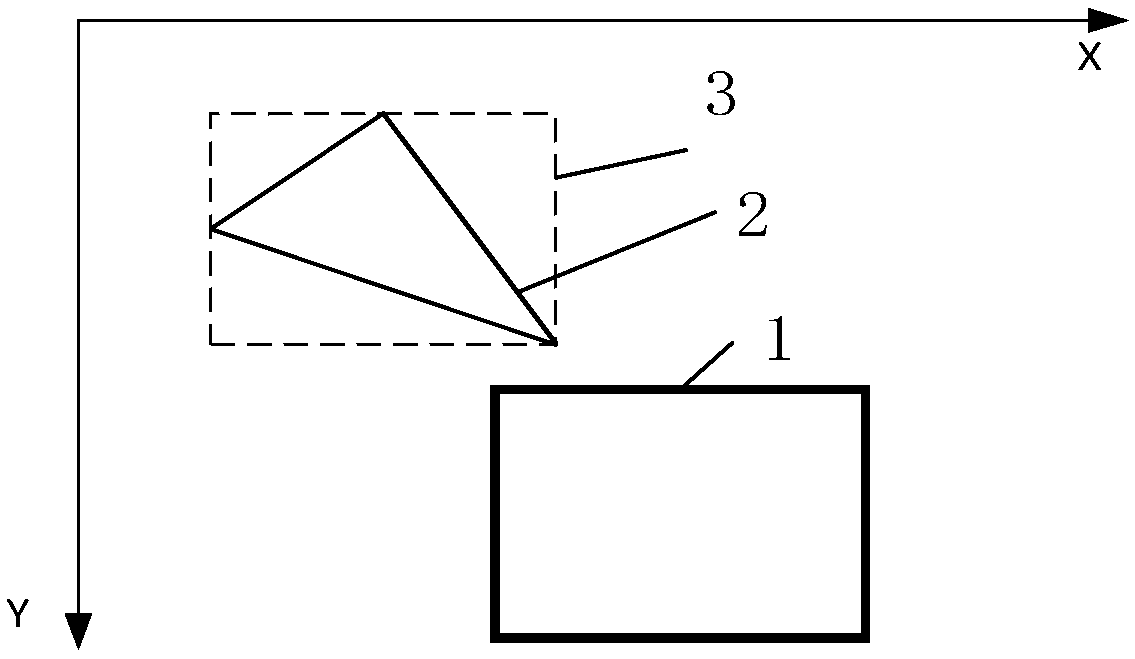

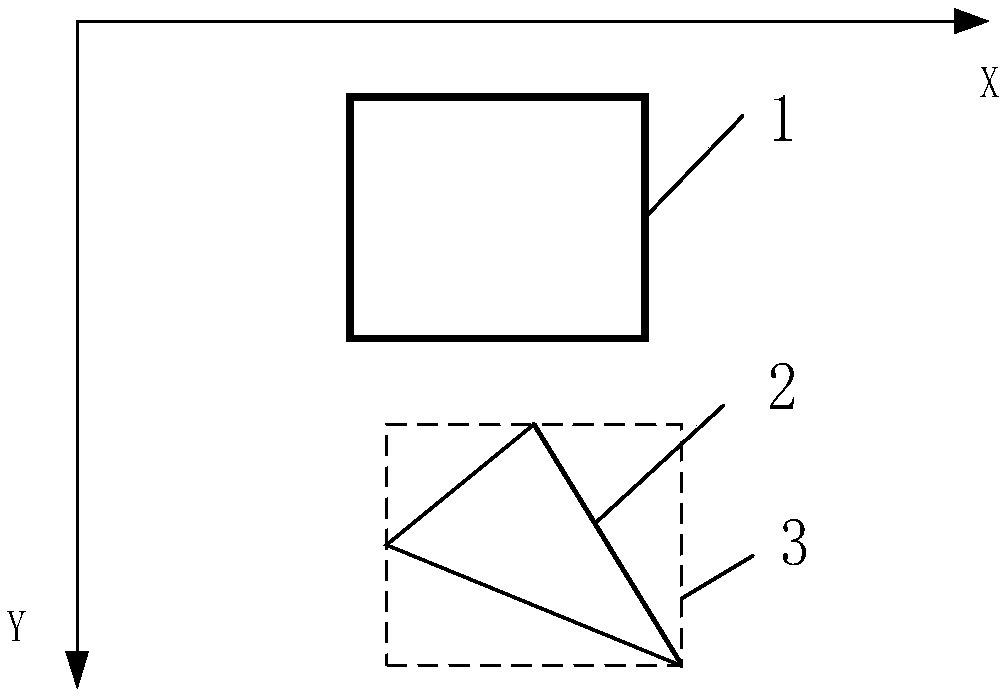

Polygon graphic element cutting method based on a bounding box, computer-readable storage medium, electronic device

InactiveCN109410213AReduce workloadReduce complexityImage enhancementImage analysisComputer graphics (images)High complexity

The invention relates to a polygon graphic element cutting method based on a bounding box, a computer-readable storage medium and an electronic device, which solve the problems of high complexity of the prior cutting algorithm and large hardware consumption. The method comprises the following steps: 1) obtaining a smallest rectangular region containing a polygon primitive in a polygon primitive coordinate system, wherein the smallest rectangular region is a bounding box; 2) convert a polygonal graph element coordinate system into a clipping coordinate system, and comparing that coordinate of the bounding box and the coordinate of the clipping window in the clipping coordinate system; 3) determining a clipping region; 4) clipping the polygonal graph element; retaining the polygonal graph elements in the clipping region, removing the graph elements outside the clipping region, and clipping the polygonal graph elements.

Owner:XIAN UNIV OF POSTS & TELECOMM

Full-automatic cutting platform used for home textile fabric

The invention discloses a full-automatic cutting platform used for home textile fabric. The full-automatic cutting platform comprises a vertical platform, on which two outer guide rails and two inner guide rails are vertically arranged. A pressing plate is slidably arranged between the two inner guide rails in a transverse direction and provided with a cutting hole. One end of the pressing plate is provided with a pair of electric clippers. A rolling shaft is slidably connected between the two outer guide rails and provided with a roll for accommodating home textile fabric. The front side surface at two ends of the pressing plate is provided with a first positioning column. Two end portions of the rolling shaft are provided with positioning holes. Multiple locking mechanisms are arranged on the two inner guide rails. Two sides at the upper end of the vertical platform are provided with double-cylinder synchronous-positioning mechanisms. The full-automatic cutting platform used for home textile fabric has following advantages: by means of the vertical cutting platform, home textile fabric can be well and conveniently flattened; automated cutting is achieved so that precise cutting accuracy is ultimately realized; the double-cylinder synchronous-positioning mechanisms are utilized for automatically, precisely and stably positioning the rolling shaft; and cutting efficiency is increased and labor intensity of workers is decreased.

Owner:JIANGSU AUDIANO HOME TEXTILES

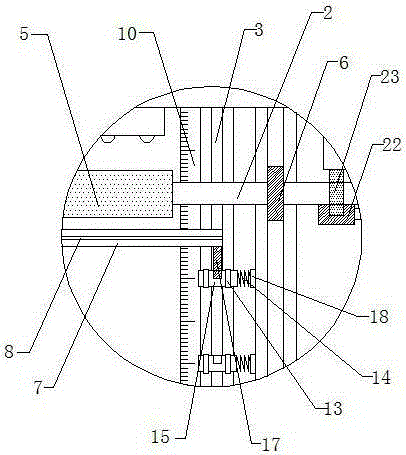

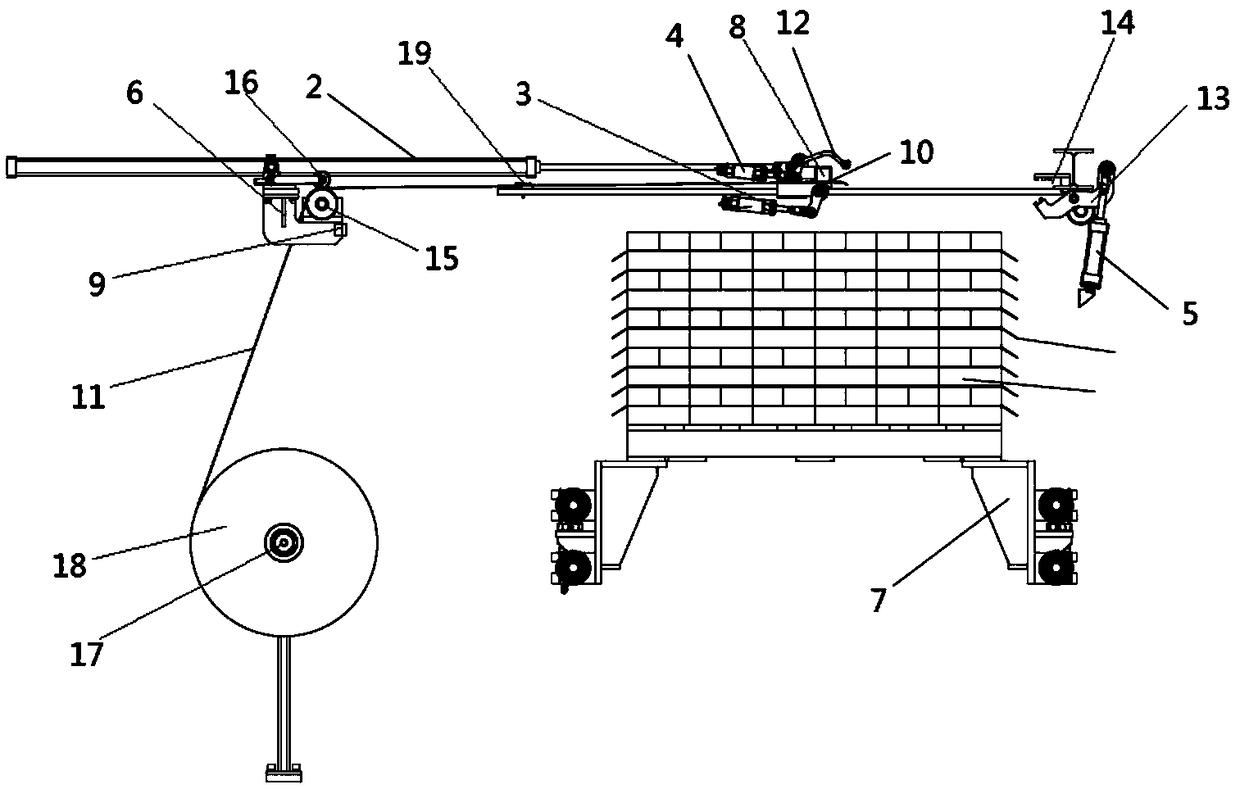

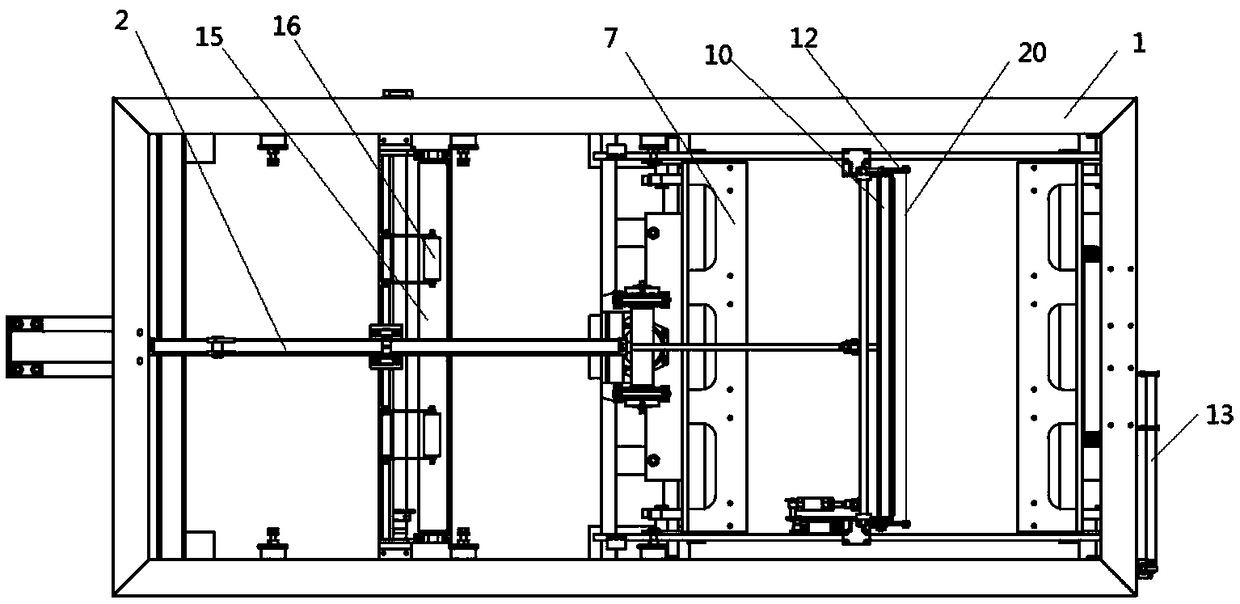

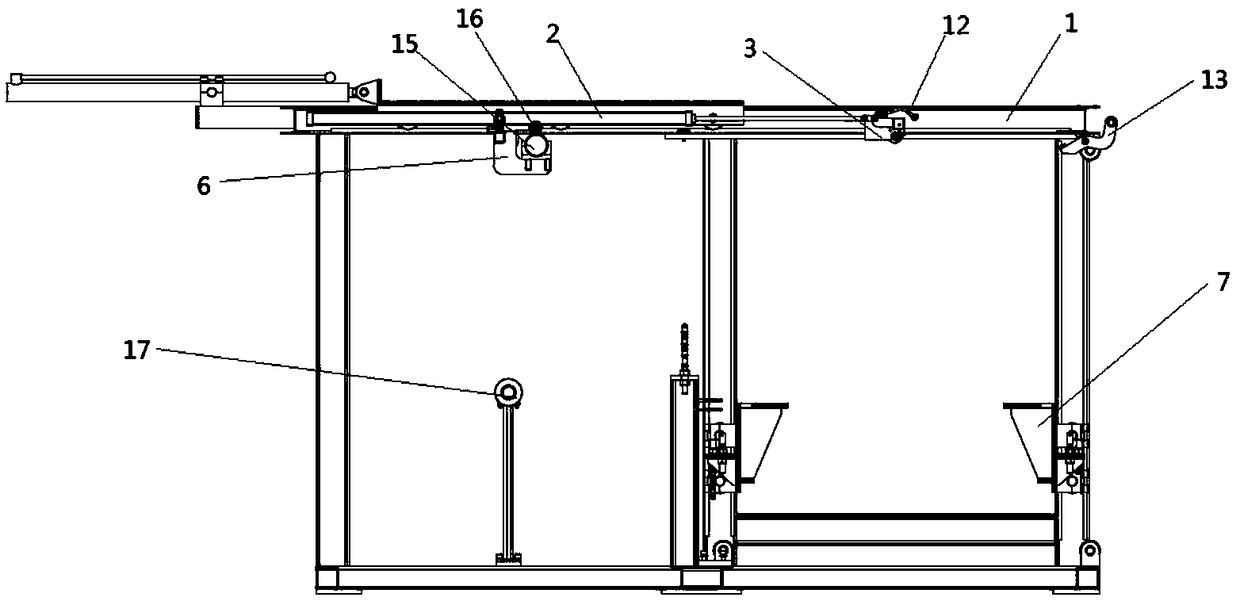

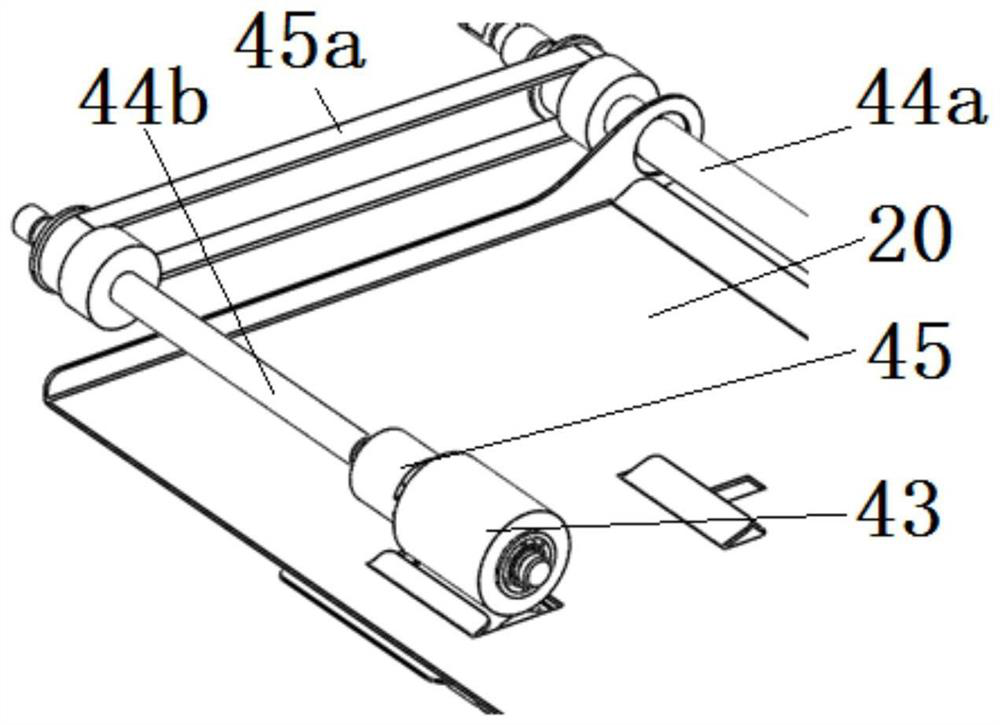

Rapid and precise coating mechanism

ActiveCN109178494APrevent fallingPrecise croppingWrapping material feeding apparatusPackaging automatic controlHydraulic cylinderBrick

The invention discloses a rapid and precise coating mechanism, which comprises a machine frame, a film conveying assembly, a film sending and clamping assembly, a film cutting assembly, a film clamping assembly, a film guiding assembly, a brick lifting assembly, a film conveying sensor and a brick lifting sensor. The film conveying assembly is an air cylinder or hydraulic cylinder. The film sending and clamping assembly comprises a transmission device and a clamping device. The film cutting assembly comprises a transmission device and a cutting device, and a high-temperature cutting wire is arranged on the cutting device. The film clamping assembly comprises a transmission device and a film clamping unit. The film conveying assembly is located in the middle of the upper portion of the machine frame. The film sending and clamping assembly and the film cutting assembly are mounted at the head end of the film conveying assembly. The film clamping assembly is located at the right end of the machine frame, the film guiding assembly is located at the left end of the machine frame, and the brick lifting assembly is located at the bottom of the machine frame. The rapid and precise coatingmechanism can rapidly and precisely coat a brick and has the advantages of being simple and stable in structure, and rapid, precise and efficient in coating.

Owner:GUANGXI HONGFA HEAVY IND MACHINE

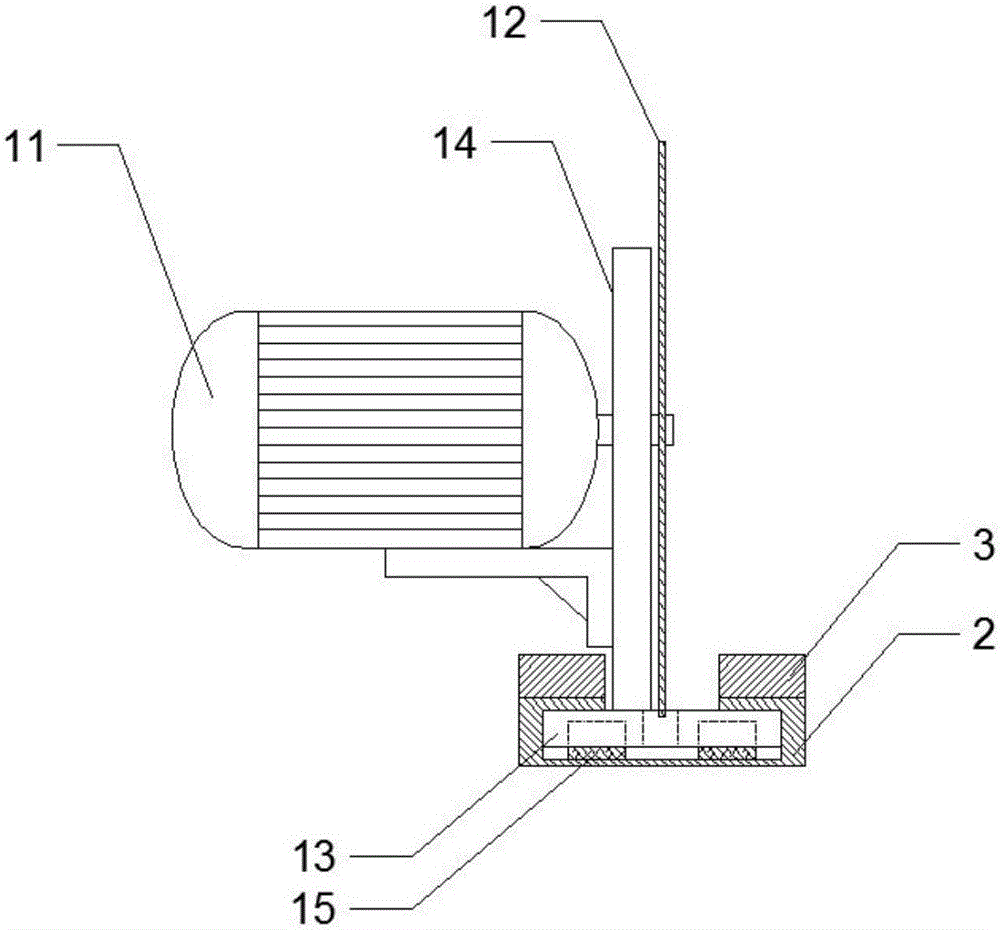

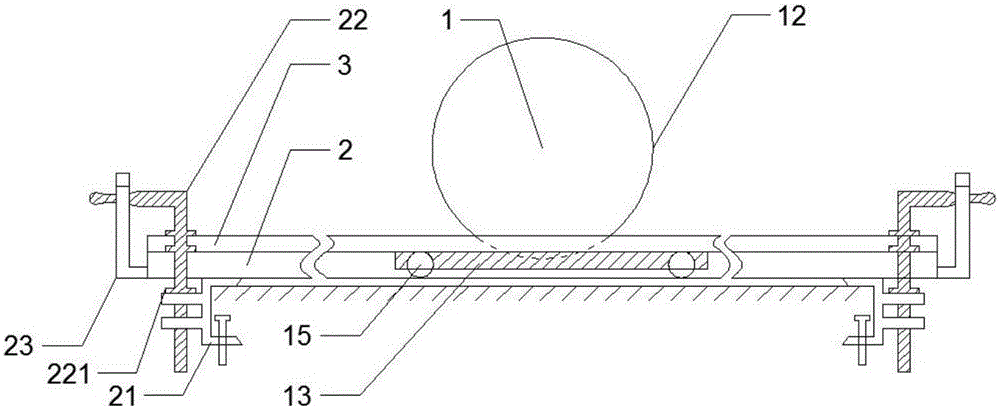

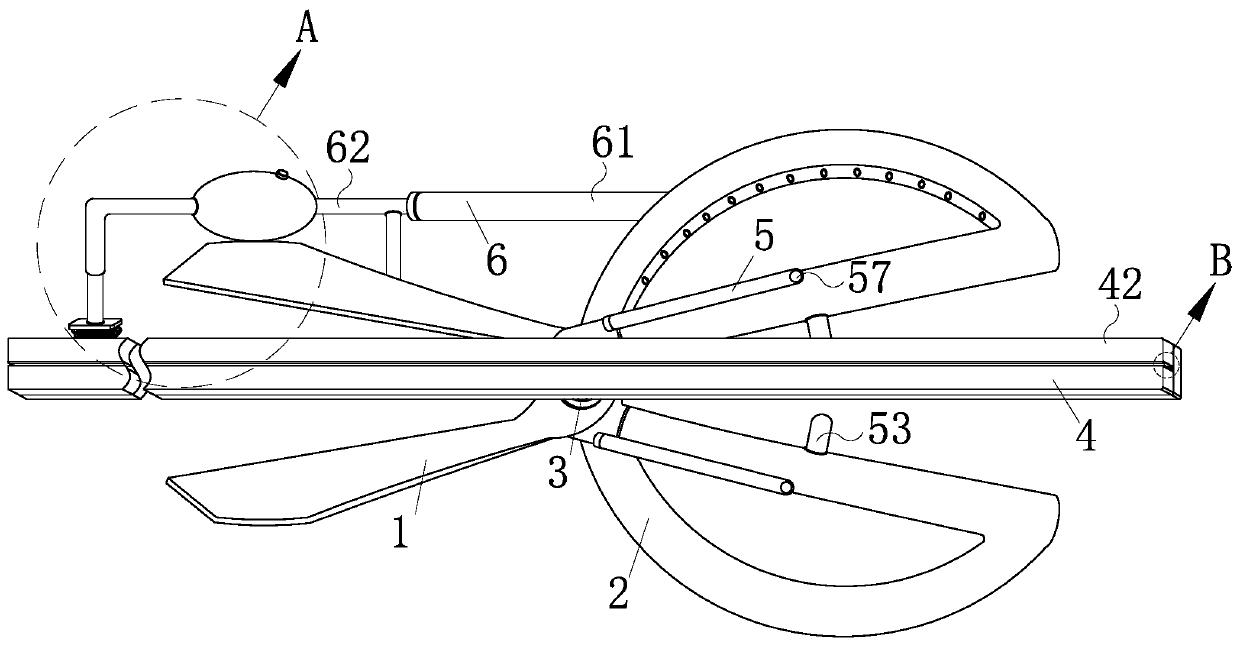

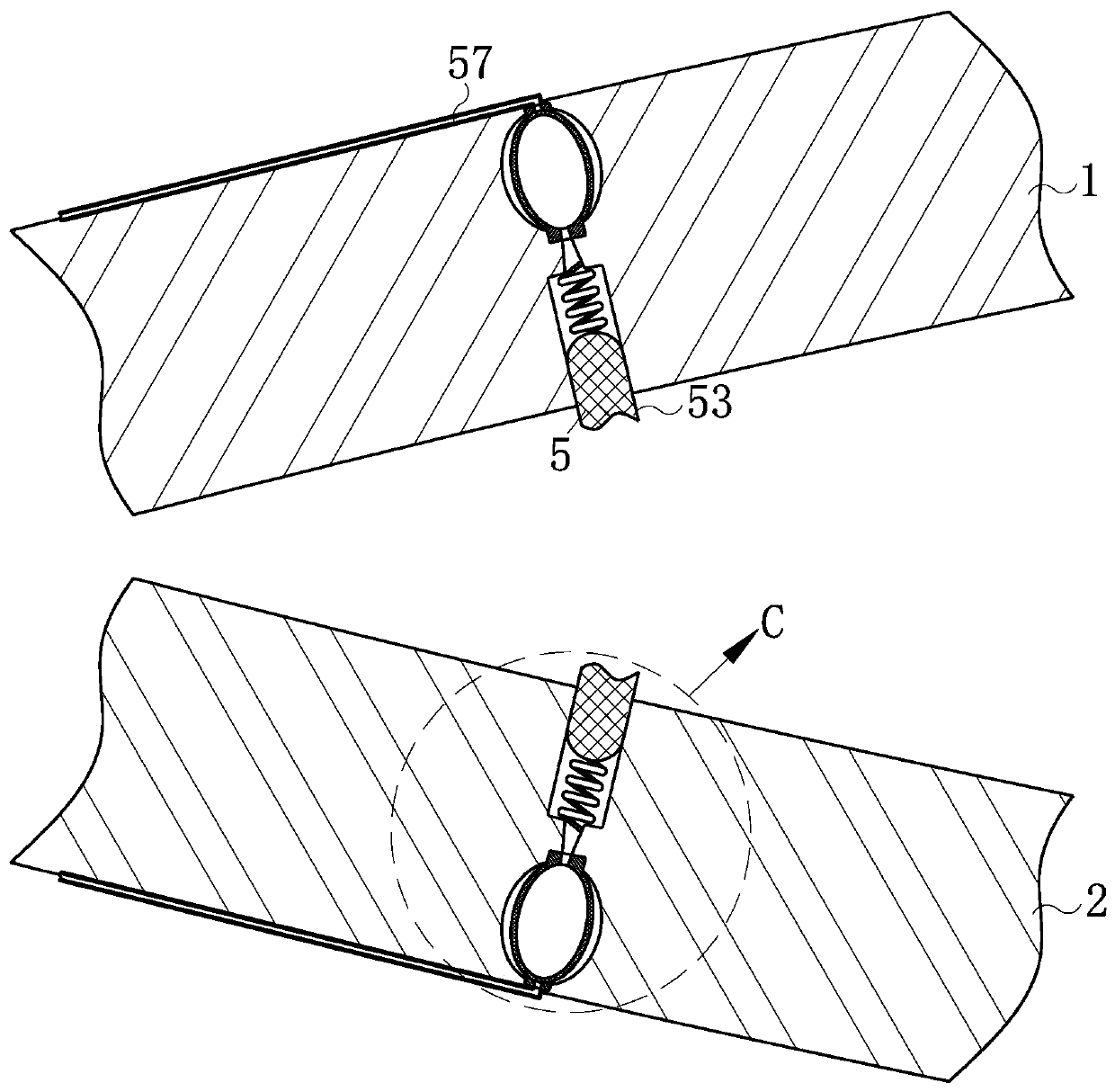

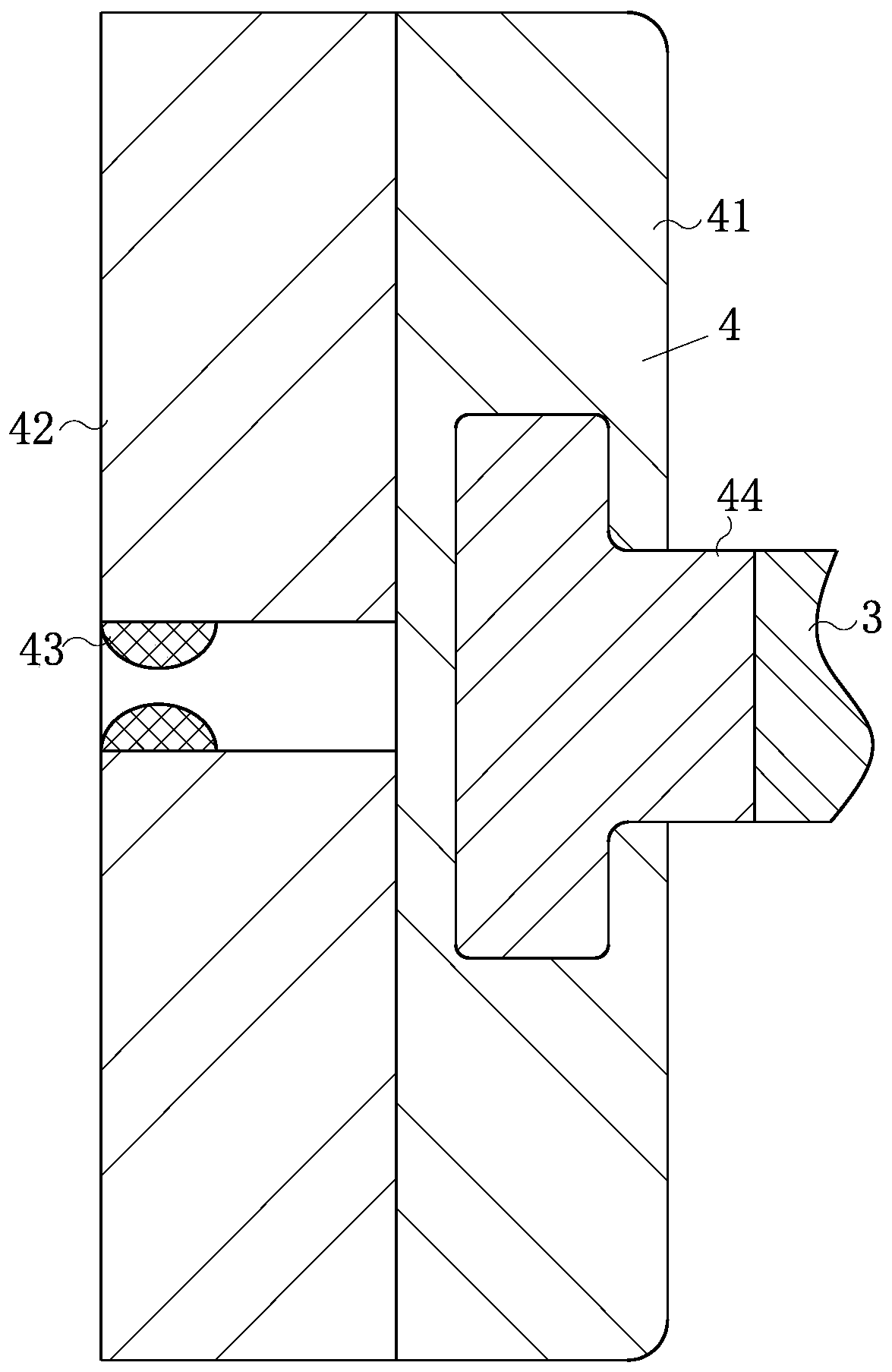

Cloth cutting machine

The invention belongs to the field of clothing sewing equipment, and in particular relates to a cloth cutting machine; aiming at the problem that the existing cloth cutting machine cannot cut high-strength cloth and thick cloth due to the movement of electric scissors, the invention provides a Cloth cutting machine, including electric scissors (1), sliding rails (2), pressing rods (3), electric scissors (1) can slide on sliding rails (2) and pressing rods (3), and pressing rods (3) press On the slide rail (2), the pressure rod (3) is used to compress and fix the cloth, making it easier for the electric scissors to cut the cloth, thereby solving the problems of the existing cloth cutting machine; at the same time, the present invention has a simple structure and low upgrade costs Low, easy to promote.

Owner:青阳县乐辰工艺品有限责任公司

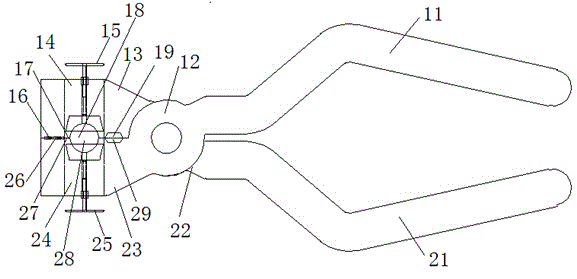

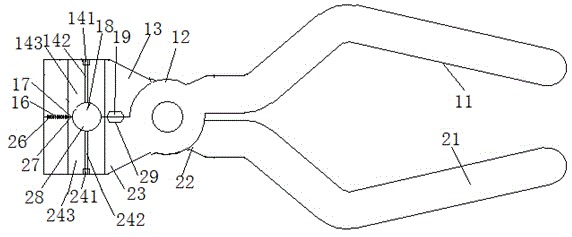

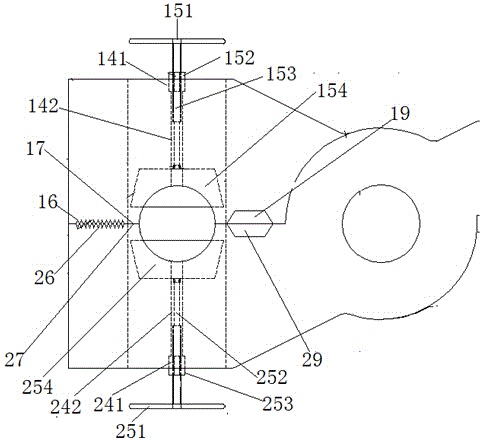

Cutting nippers

The invention relates to cutting nippers. The cutting nippers comprise a first nipper body and a second nipper body, the two of which are connected in a pivoting manner. Each of the first nipper body and the second nipper body comprises a jaw section, a pivoting section and a nipper handle section, all of which are orderly connected with each other. An open groove for mounting a cutting device is formed in the middle inside the jaw section and a first cutting device is arranged in the open groove. An anti-skidding tooth, a semi-cylindrical through hole and a cutting opening are orderly formed in the inner wall of the jaw section from front to back. The cutting device comprises a rotating handle, a threaded rod, a rotating table and a cutting blade. The rotating handle is turned, and then the threaded rod drives the cutting blade to move in a straight line in the open groove. According to technical scheme, the cutting nippers are capable of overcoming the defects of the prior art; the cutting nippers are capable of accurately cutting pipelines, wiring harnesses or metal plates in the production and manufacturing process of passenger cars, and also have the fastening function of the nippers.

Owner:ANHUI ANKAI AUTOMOBILE

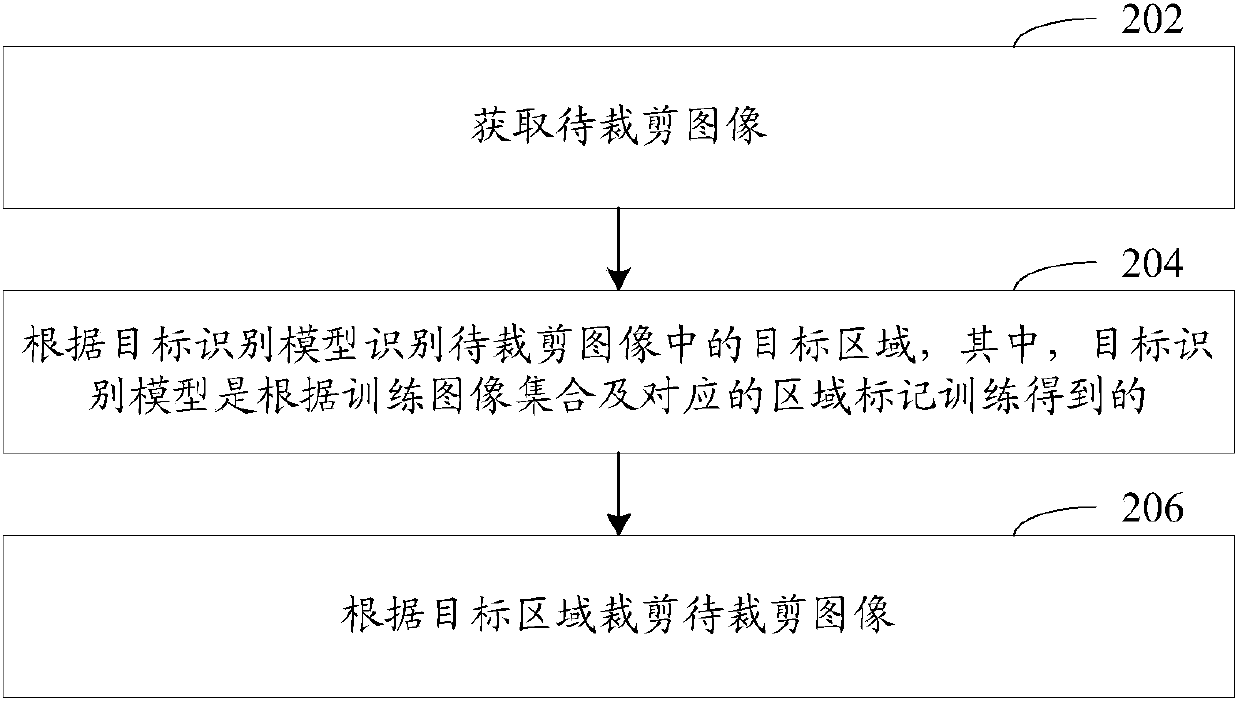

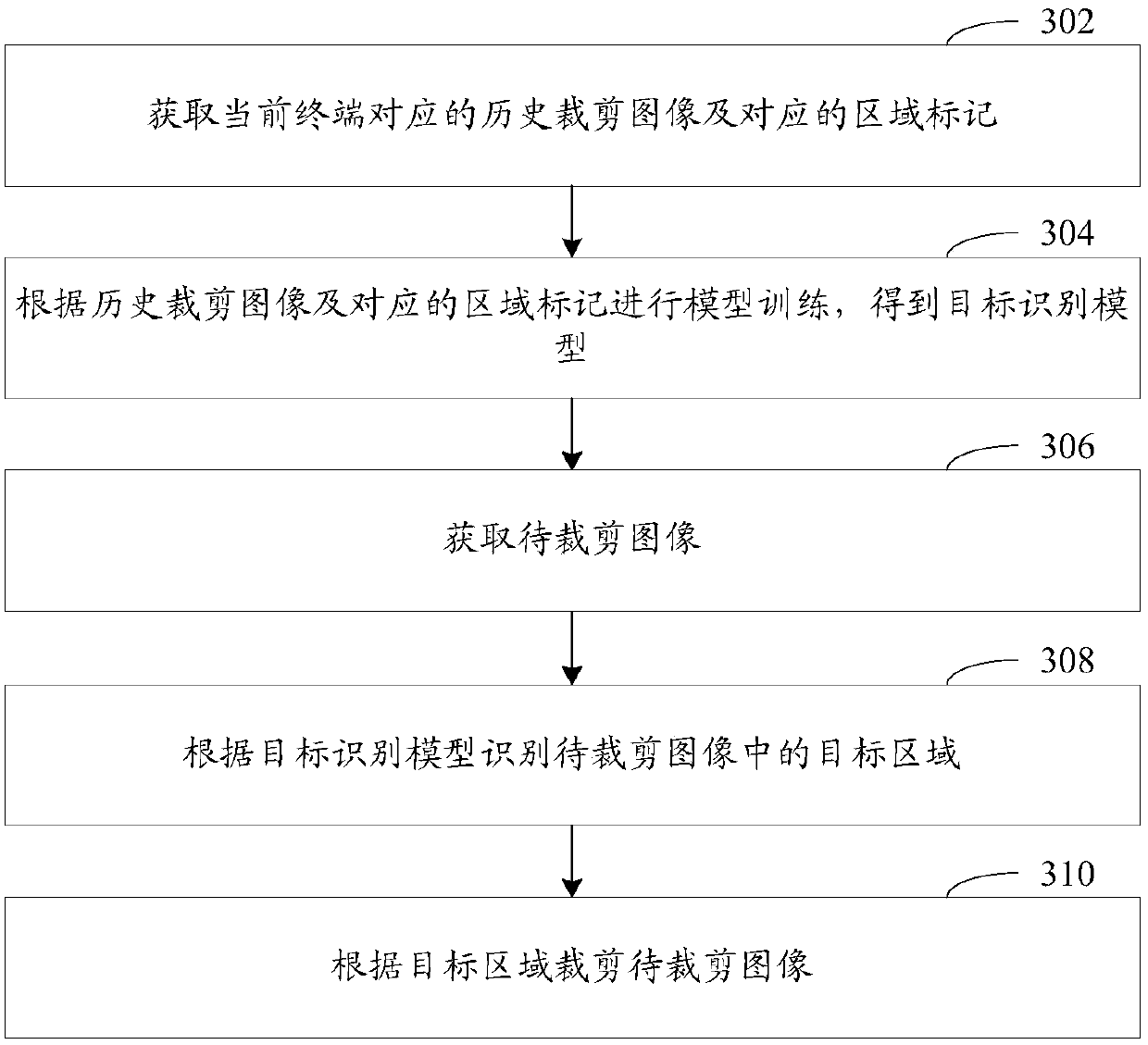

Image cutting method and device, computer readable storage medium, and computer equipment

ActiveCN107622497APrecise croppingImprove accuracyImage analysisCharacter and pattern recognitionComputer engineeringComputer equipment

The invention relates to an image cutting method and device, a computer readable storage medium, and computer equipment. The method comprises the following steps: acquiring an image to be cut; recognizing a target area in the image to be cut according to a target recognition model, wherein the target recognition model is obtained according to a training image set and a corresponding area marker bytraining; and cutting the image to be cut according to the target area. The image cutting method and the device, the computer readable storage medium, and the computer equipment provided by the invention can improve the accuracy of image cutting.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Garment tailoring device suitable for families

The invention relates to a tailoring device, in particular to a garment tailoring device suitable for families. The technical aims that in the garment tailoring device suitable for families, fabrics cannot be tailored to be damaged, and tailoring is accurate are achieved. The garment tailoring device suitable for families comprises a bottom plate, supporting rods, a containing plate, an installingframe, a motor, a rotating shaft, a threaded rod, a nut, first sliding rails, a first sliding block, a guiding sleeve, a guiding rod, a pressing block, a first spring and the like; the supporting rods are symmetrically arranged on the left side on the bottom plate left and right, the containing plate is connected to the top ends of the supporting rods, the installing frame is arranged on the leftside of the top of the containing plate, the motor is installed on the right side of the top in the installing frame, and the rotating shaft is connected on an output shaft of the bottom of the motor. According to the a garment tailoring device suitable for families, the effects that tailor fabrics cannot be tailored to be damaged, and tailoring is accurate are achieved; the fabrics are pressed through the pressing block and tailored through a tailoring cutter, the tailoring accuracy is increased, and the fabrics cannot be tailored to be damaged.

Owner:晋江诺研机械设计有限公司

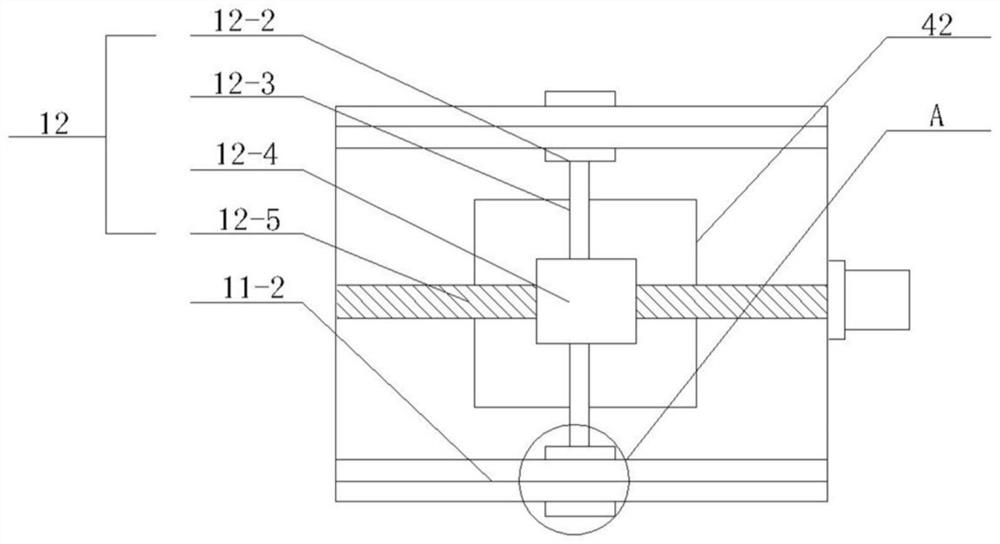

Film clipping device with compression positioning and guide clipping functions and application method of film clipping device

The invention provides a film clipping device with compression positioning and guide clipping functions and an application method of the film clipping device. The film clipping device comprises an upper plate, a lower plate and a clipper, axle wires of the upper plate and the lower plate are coincident, a hinge shaft is arranged at the joint of the upper plate and the lower plate, the upper plateand the lower plate are rotationally connected through the hinge shaft, a strip-shaped guide rail groove is formed in the plate face of the upper plate in the film clipping direction, the clipper is arranged in the guide rail groove and slide along the guide rail groove, a strip-shaped cutting groove is formed in the plate face of the lower plate in the film clipping direction, and the guide groove is matched with the cutting groove. By means of the film clipping device, accurate film clipping can be achieved, the accuracy and the regularity are improved, operation difficulty is reduced, operation of the clipping film becomes easy to implement for a green hand, interference of human factors in clipping accuracy is reduced, influences of inaccurate operation caused by insufficient shear clipping experience traditionally are avoided, and therefore the equipment is worthy of wide application and popularization, and the working efficiency is improved.

Owner:SHANGHAI CHANGHAI HOSPITAL

Efficient production line for clothes

InactiveCN109527685AEasy to storeReduce work proceduresClothes making applicancesYarnProduction line

The invention discloses an efficient production line for clothes, which sequentially comprises a knitting machine, a cloth inspecting device, a loosening machine, a fabric placing frame, a cutting machine, a sewing machine, an ironing device and a finishing system from front to back, wherein yarns are knitted into a fabric by the knitting machine, after being rolled into a cloth roll, the fabric is sent to the cloth inspecting device for cloth inspecting operation; after the fabric passes through the cloth inspecting device, the fabric is directly sent to the cloth loosening machine for clothloosening; after the cloth loosening is finished, the fabric is placed on the fabric placing frame; after the fabric is stored on the fabric placing frame, when the fabric needs to be cut, the fabricis pushed to the front of the cutting machine, and after the fabric is cut, the fabric is sent to a sewing machine to be sewed to form clothes, then is sent to an ironing device to be ironed, and thenis sent to a finishing system to be finished to finally form the finished clothes. The efficient production line for the clothes can avoid cloth wrinkles and improve the smoothness of the cloth, thefabric placing frame has a larger capacity of, and the cloth is smoothly distributed and conveyed on the cutting machine, the cutting speed is high.

Owner:江阴嘉美针织制衣有限公司

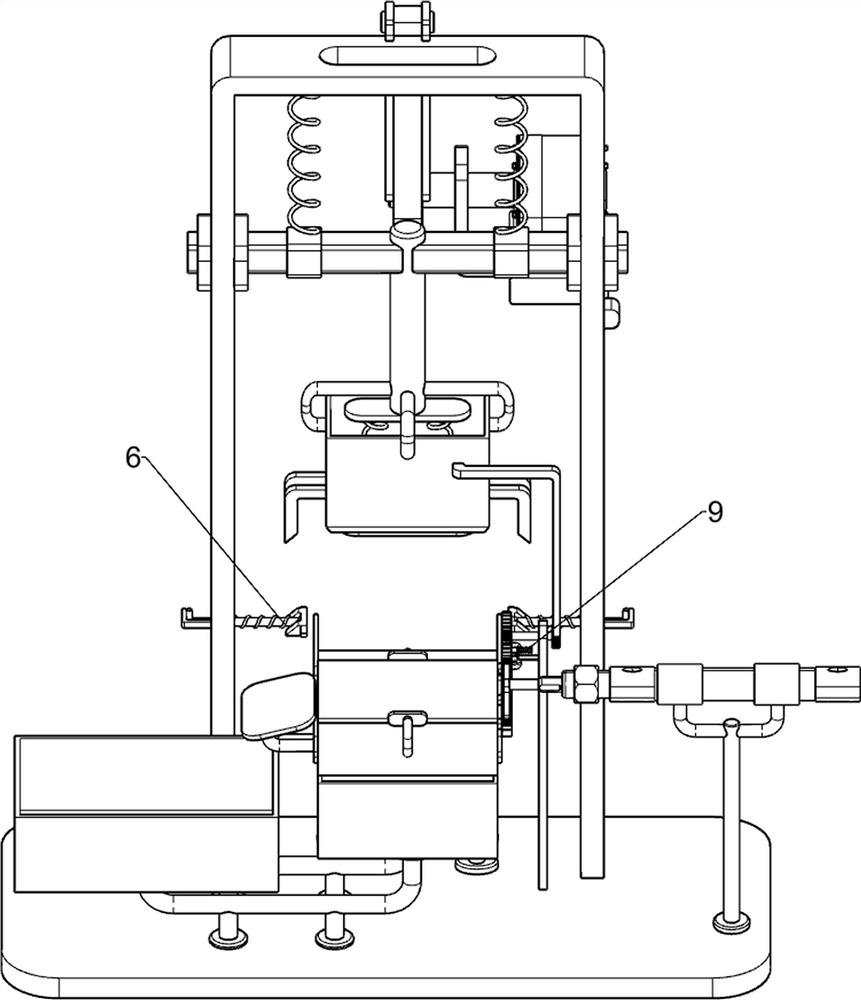

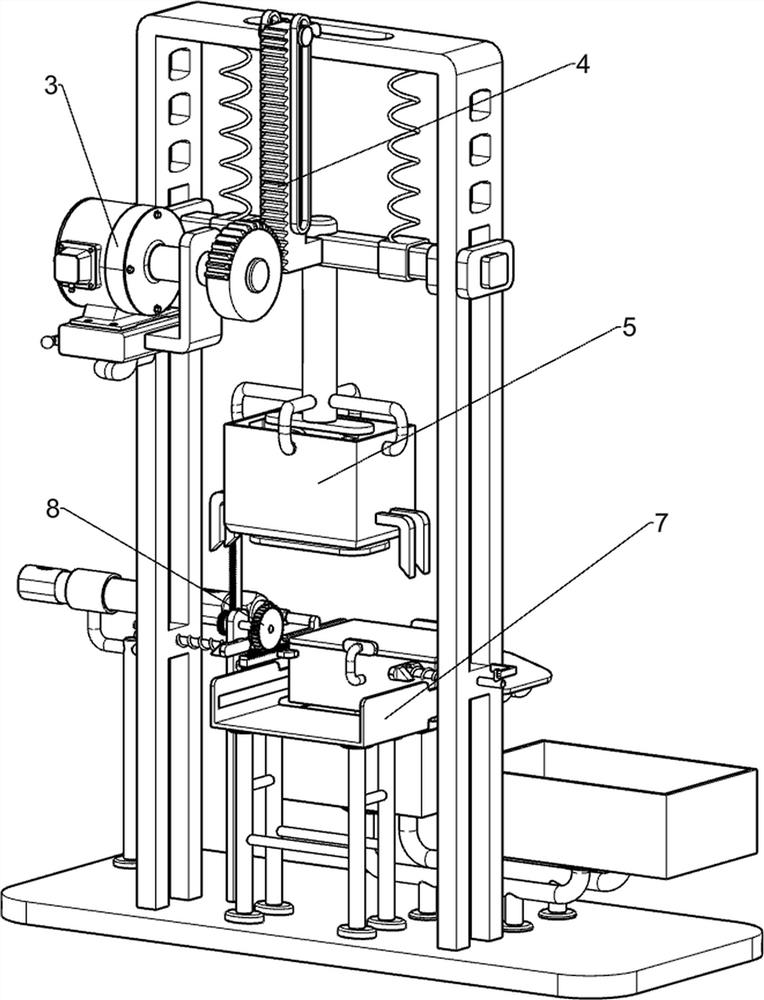

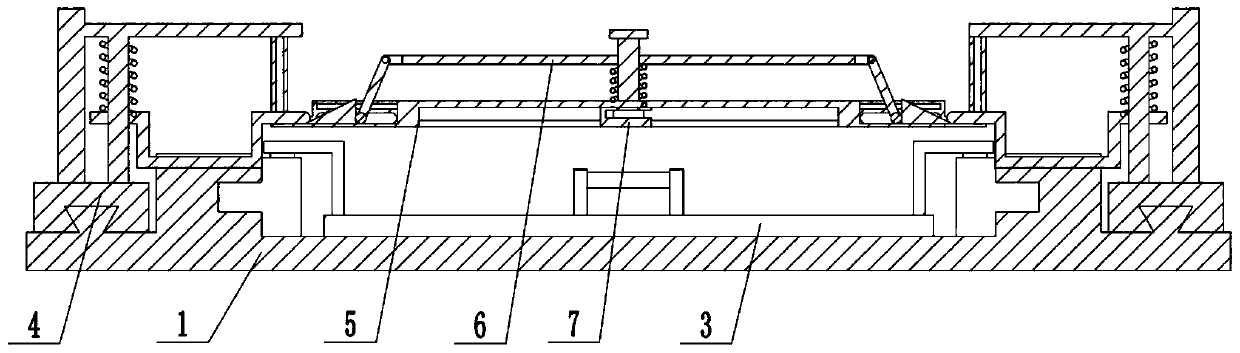

Batch stamping and cutting device for metal plates

ActiveCN112719419APrecise croppingImprove cutting efficiencyFeeding apparatusNibbling shearing machinesStampingStructural engineering

The invention relates to a stamping and cutting device, and particularly relates to a batch stamping and cutting device for metal plates. According to the batch stamping and cutting device for the metal plates, the cutting precision and the cutting efficiency of the metal plates are high, and manual operation is safe. The batch stamping and cutting device for the metal plates comprises a mounting frame connected to one side of a base plate; a driving mechanism connected to one side of the mounting frame; a lifting mechanism connected to the other side of the mounting frame; a blanking mechanism connected to the lifting mechanism; a jacking mechanism connected between the mounting frame and the blanking mechanism; a discharging mechanism connected to the other side of the base plate; and a conveying mechanism connected between the base plate and the discharging mechanism. The beneficial effects of the device are that under the effect of the driving mechanism, the lifting mechanism, the blanking mechanism, the jacking mechanism, the discharging mechanism and the conveying mechanism, people can continuously and accurately cut the metal plates.

Owner:合肥亿昌兴智能科技有限公司

Gauze edge cutting device with positioning function

ActiveCN110842986AAchieve positioningQuality assuranceCleaning using toolsCleaning using gasesEngineeringMechanical engineering

The invention relates to the technical field of gauze screen edge cutting, in particular to a gauze edge cutting device with a positioning function. The device comprises a first cutting piece, a second cutting piece, a fixing bolt, a positioning mechanism, a first pneumatic mechanism, a second pneumatic mechanism and a cleaning mechanism; the user distracts two pressing blocks to the proper gap, the gauze needing to be cut enters the gap of the two pressing blocks, then the user releases the hand, the two pressing blocks compress the gauze under the action of the elastic force of the first spring, so that the gauze can be cut more accurately when the gauze is used, the worker can cut more accurately when the gauze is cut, the situation that the cropping deviation occurs is avoided, and thequality of the cut gauze is guaranteed; and in the cutting process, a connecting rod drives an air rod to move along with the continuous movement of a first cutting knife, the air rod drives a sleeveand a sleeve rod to move, the sleeve rod drives a dust cleaning brush to clean larger debris on the gauze, so that the influence on the cutting process can be further avoided, and the working efficiency is improved.

Owner:LIXIN FUYA GAUZE CO LTD

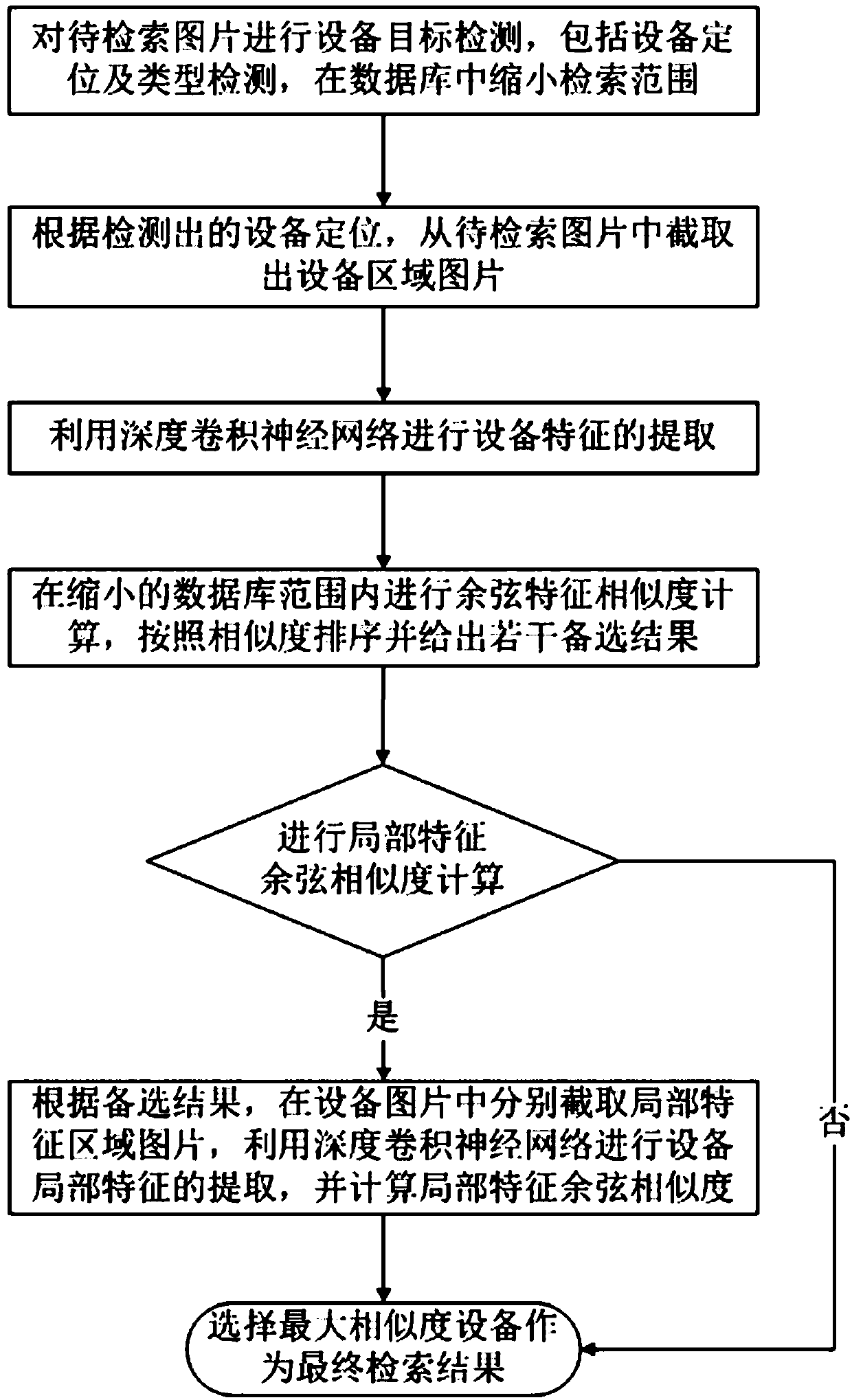

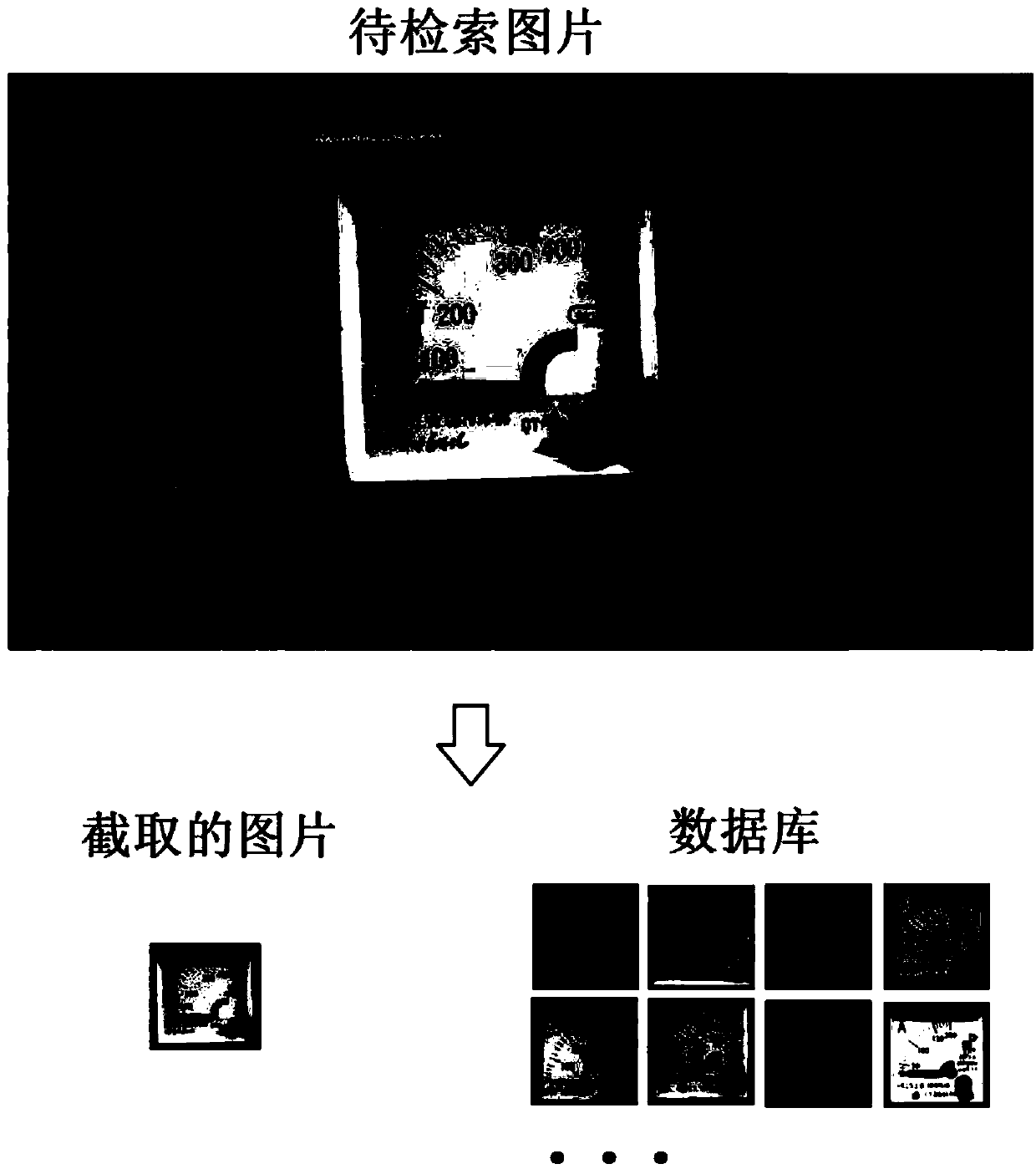

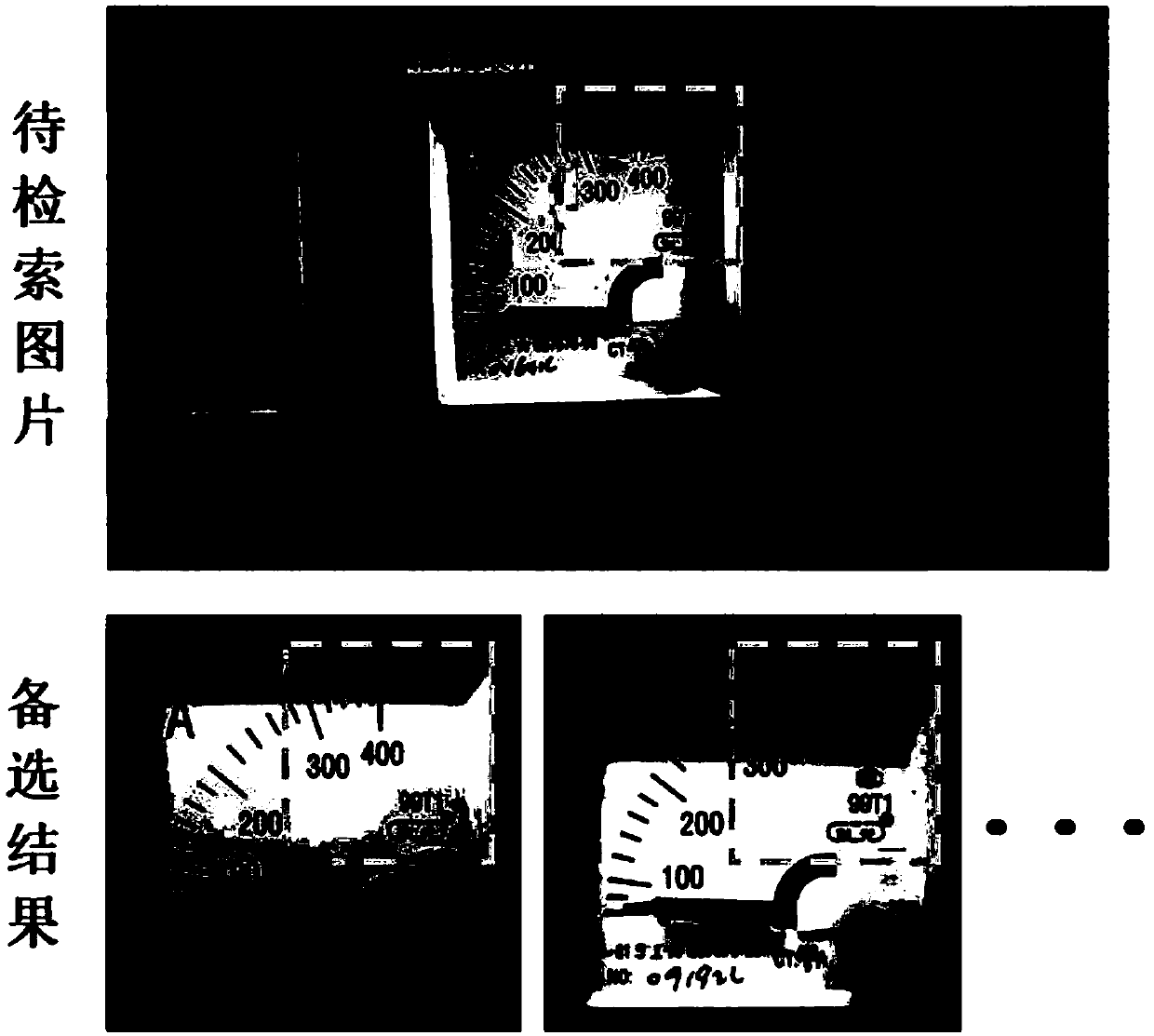

Power equipment retrieval method based on deep learning

ActiveCN109614512AReduce noise interferenceImprove accuracyMetadata still image retrievalSpecial data processing applicationsDevice typeFeature extraction

The invention provides a power equipment retrieval method based on deep learning, and relates to the technical field of image processing. The invention provides a power equipment retrieval method based on deep learning. The power equipment retrieval method comprises the steps of detecting target equipment, intercepting an equipment area picture, extracting equipment characteristics, calculating cosine characteristic similarity and determining a final retrieval result. According to the invention, a target detection method in deep learning is combined; according to the method, the device positioning in the device picture and the accurate cutting of the device area are realized, the noise interference of the background picture is reduced, the feature extraction is carried out by adopting thedeep convolutional neural network, the retrieval precision is improved, the retrieval range in the database is reduced through the target detection result, and the retrieval efficiency is improved. Inaddition, the calculation of the local cosine feature similarity of the equipment can more accurately distinguish the equipment type with extremely high similarity, so that the retrieval precision isfurther improved.

Owner:YIJIAHE TECH CO LTD

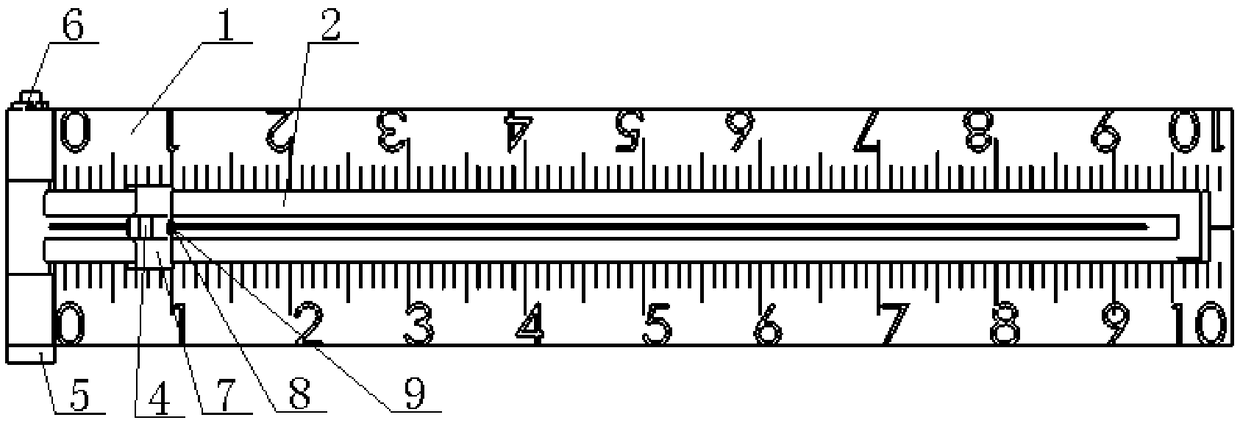

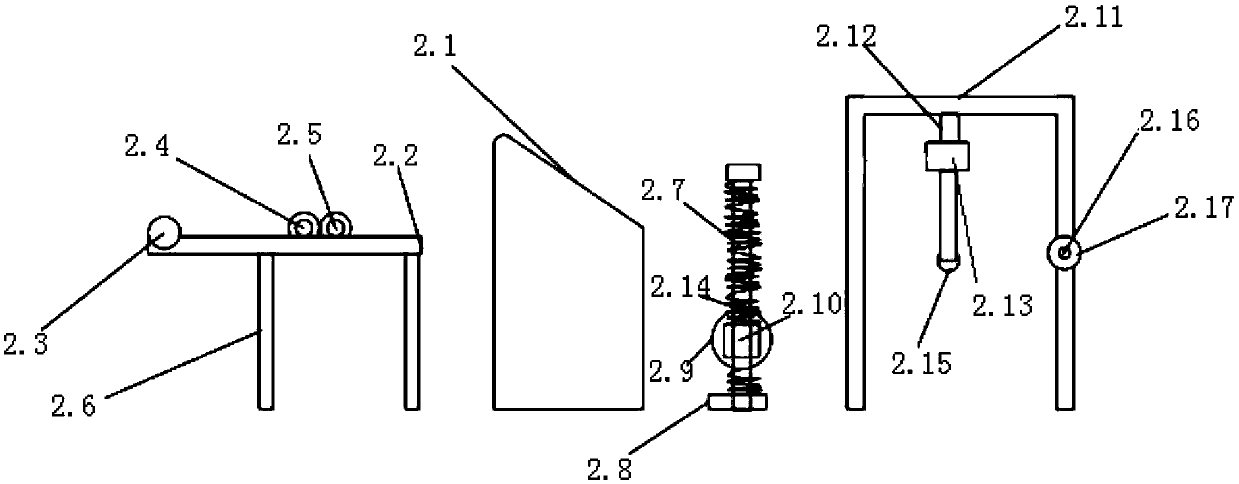

Workbench for garment processing

ActiveCN109875167AImprove processing qualityAccurate measurementClothes making applicancesEngineeringWorkbench

The invention provides a workbench for garment processing, and relates to the field of garment processing. The workbench comprises a processing platform assembly, a fixing seat, cloth flattening and pressing assemblies, positioning sliding seat assemblies, a vertical scale assembly, a vertical measurement adjustment assembly and a horizontal scale assembly. The workbench for garment processing hasthe advantages that cloth can be measured and subjected to size marking, and the cloth can be flattened and fixed; the number of the cloth flattening and pressing assemblies is two, the two cloth flattening and pressing assemblies are symmetrically, slidably and cooperatively connected at the left and right ends of the processing platform assembly, the number of the positioning sliding seat assemblies is two, the two positioning sliding seat assemblies are symmetrically, slidably and cooperatively connected at the front and rear ends of the processing platform assembly, the vertical scale assembly is fixedly connected between the the two positioning sliding seat assemblies, the two ends of the vertical scale assembly abut against the inner sides of the two positioning sliding seat assemblies, the vertical measurement adjustment assembly is slidably and cooperatively connected on the vertical scale assembly, and the two ends of the vertical measurement adjustment assembly abut againstthe two ends of the vertical scale assembly.

Owner:沧州明珠服装服饰科技有限公司

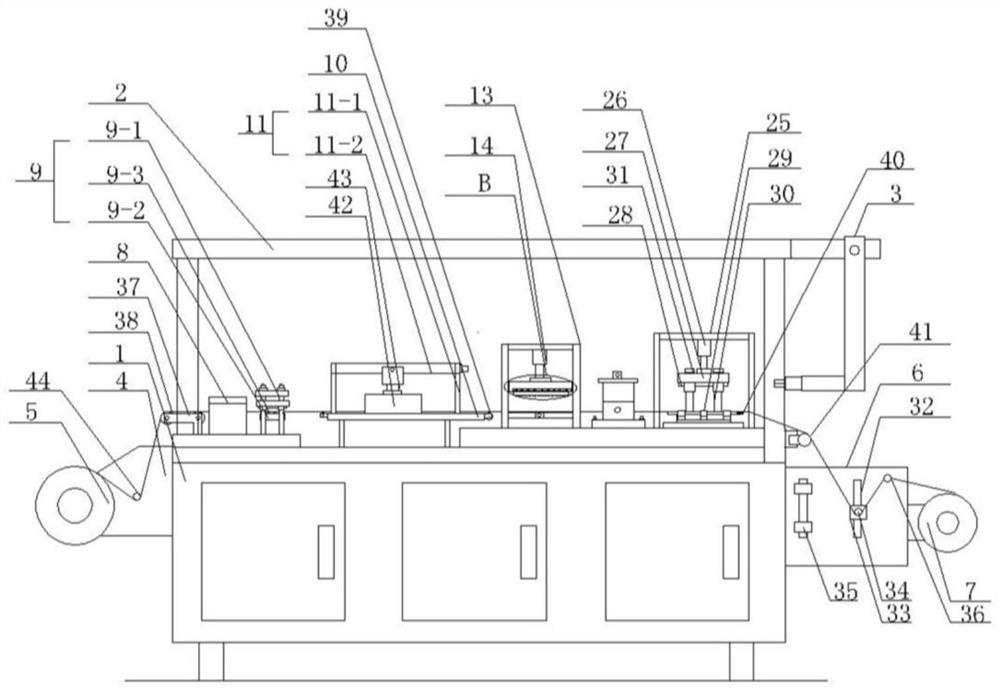

Garment production cloth cleaning and cutting device

PendingCN112647271AReduce usageReduce manufacturing costMechanical cleaningPressure cleaningProcess engineeringWaste material

The invention relates to the technical field of garment processing and production, and discloses a garment production cloth cleaning and cutting device. The garment production cloth cleaning and cutting device comprises a supporting platform, a conveying device and a waste collecting device are correspondingly arranged on the left side and the right side of the supporting platform, and a cloth cleaning device, an ironing device, an imprinting device, a traction device and a cutting device are sequentially arranged at the top end of the supporting platform from left to right. A sealing support is arranged at the top end of the supporting platform, and a mechanical gripper is hinged to the right end of the sealing support. According to the garment production cloth cleaning and cutting device, cloth can be cut in batches, so that the cloth cutting efficiency is improved, and it is ensured that the standard of cloth cutting in the same batch is unified; and by integrating all procedures of cloth processing, the use amount of labor force is reduced, the cost expenditure is reduced, and meanwhile, the overall operation efficiency is ensured.

Owner:浙江天驰服饰有限公司

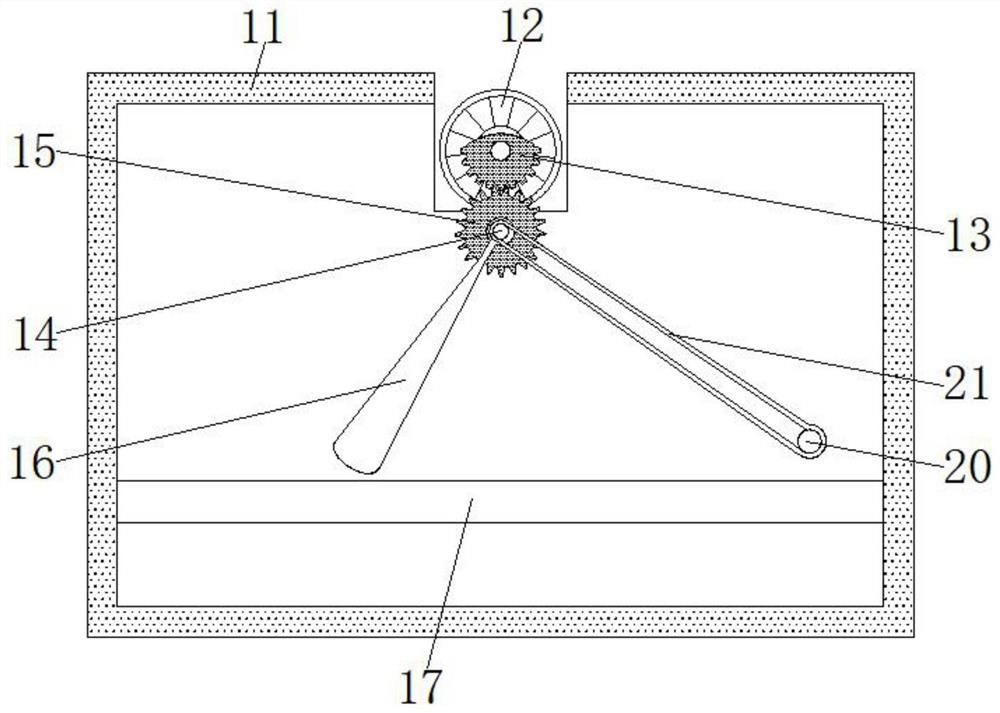

Energy-saving cloth dyeing machine with good cloth dyeing effect

ActiveCN113355824AKeep expandedSmooth transmissionLiquid/gas/vapor treatment machines driving mechanismsSevering textilesPolymer scienceEngineering

The invention discloses an energy-saving cloth dyeing machine with the good cloth dyeing effect. The machine comprises a machine base and an open cloth dyeing vessel; the open cloth dyeing vessel is fixedly installed on the left side of the top of the machine base; the interior of the open cloth dyeing vessel is fixedly connected with a middle carrier plate smaller than the open cloth dyeing vessel; two parallel cloth guide rollers are further rotationally installed on the inner wall of the open cloth dyeing vessel and located above the middle carrier plate; and a magnetic field mechanism is arranged in the open cloth dyeing vessel. According to the energy-saving cloth dyeing machine with the good cloth dyeing effect, the distance between a stamping magnetic plate and a magnetic layer is gradually reduced, then a magnetic field is increased, a power magnetic block gradually moves upwards under the action of the magnetic field, the power magnetic block drives a reaming ejector pin plug to move upwards and abut against cloth, and line holes of the cloth are expanded, so that the dyeing area of the cloth and cloth dyeing liquid is increased, and the cloth dyeing effect is improved; and through driving of an electric telescopic rod, magnetic force of the magnetic field mechanism is controllable, so that cloth with different elasticity is dyed.

Owner:苏州市博睿云霞信息科技有限公司

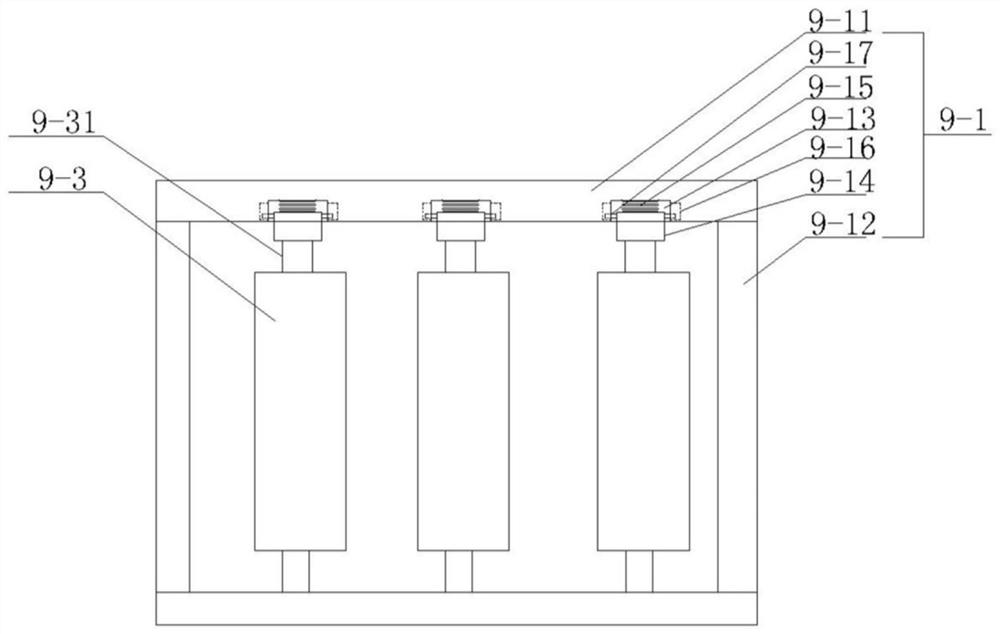

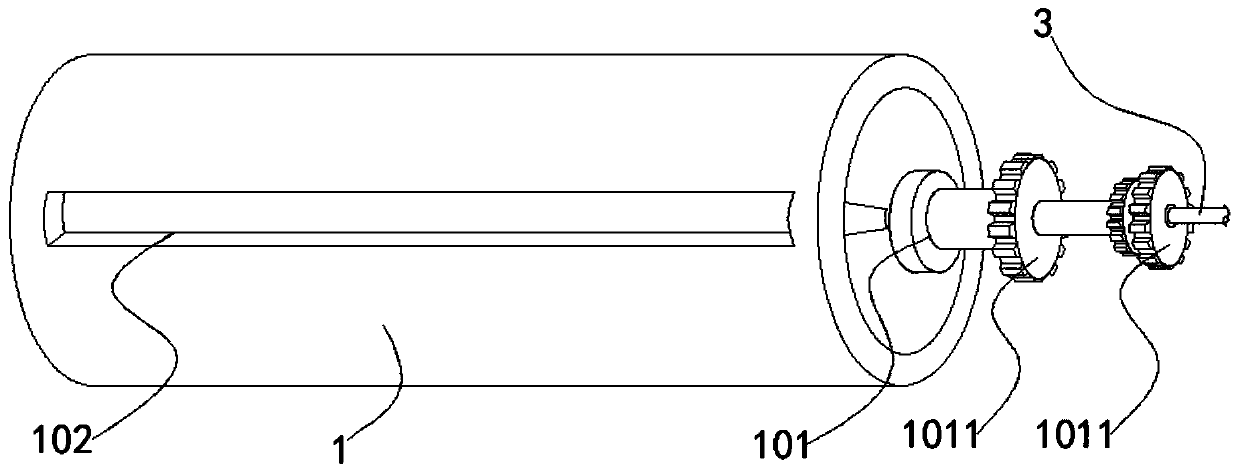

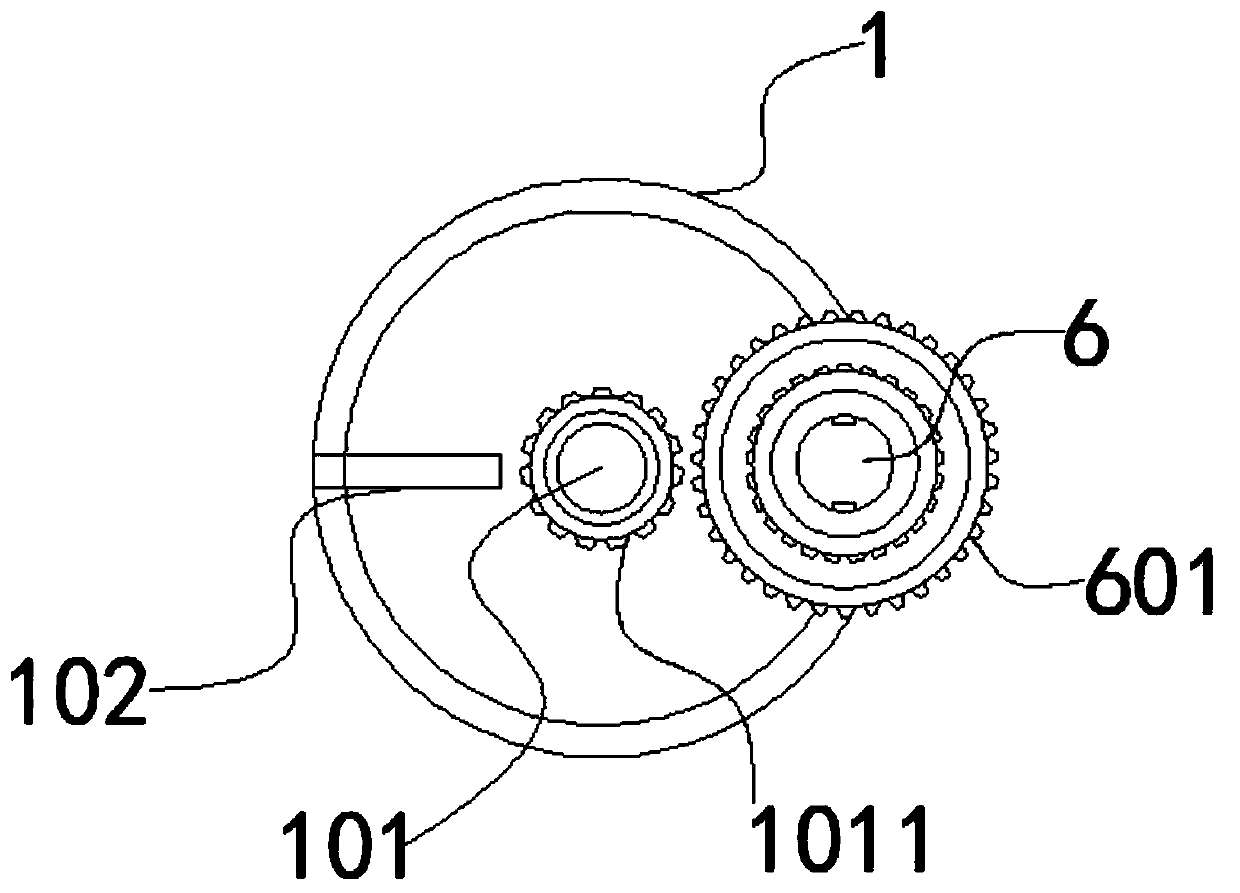

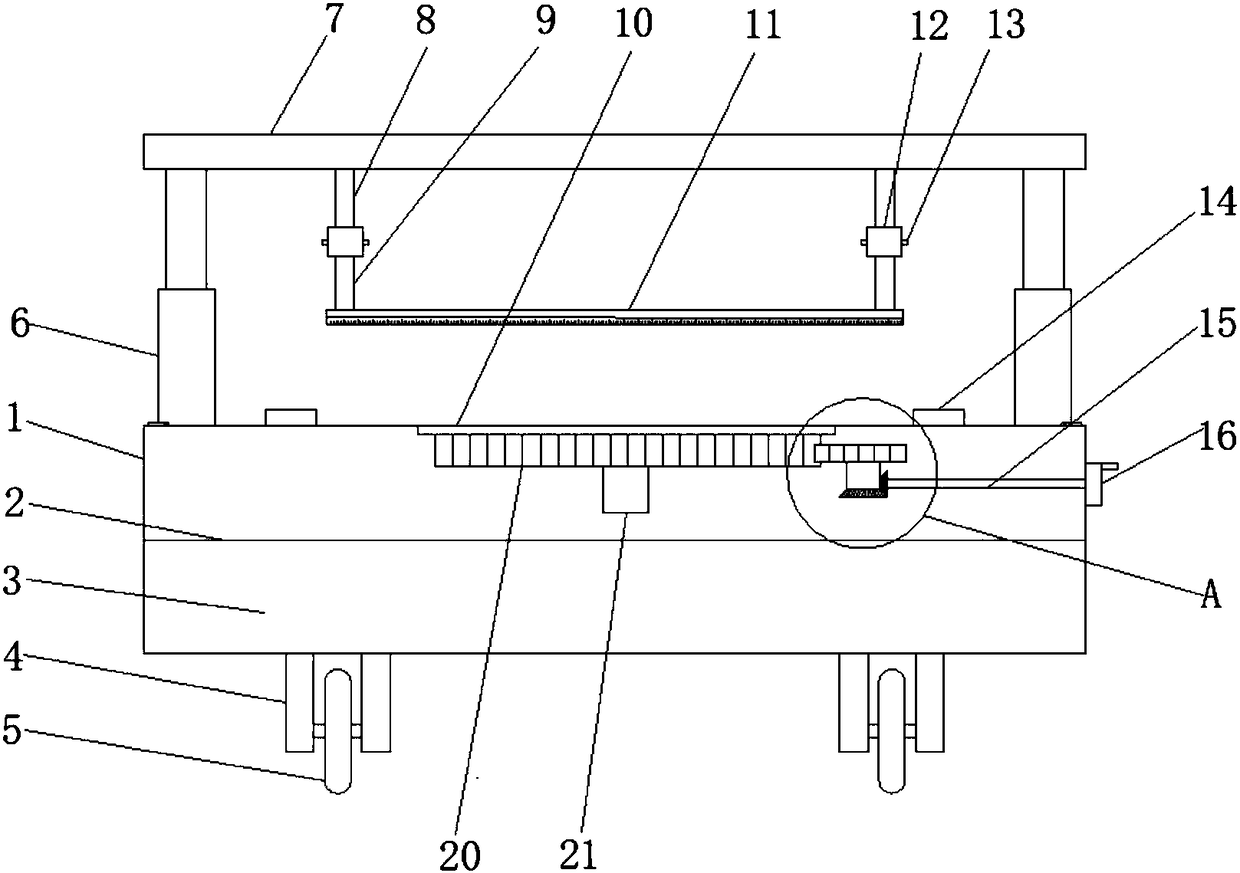

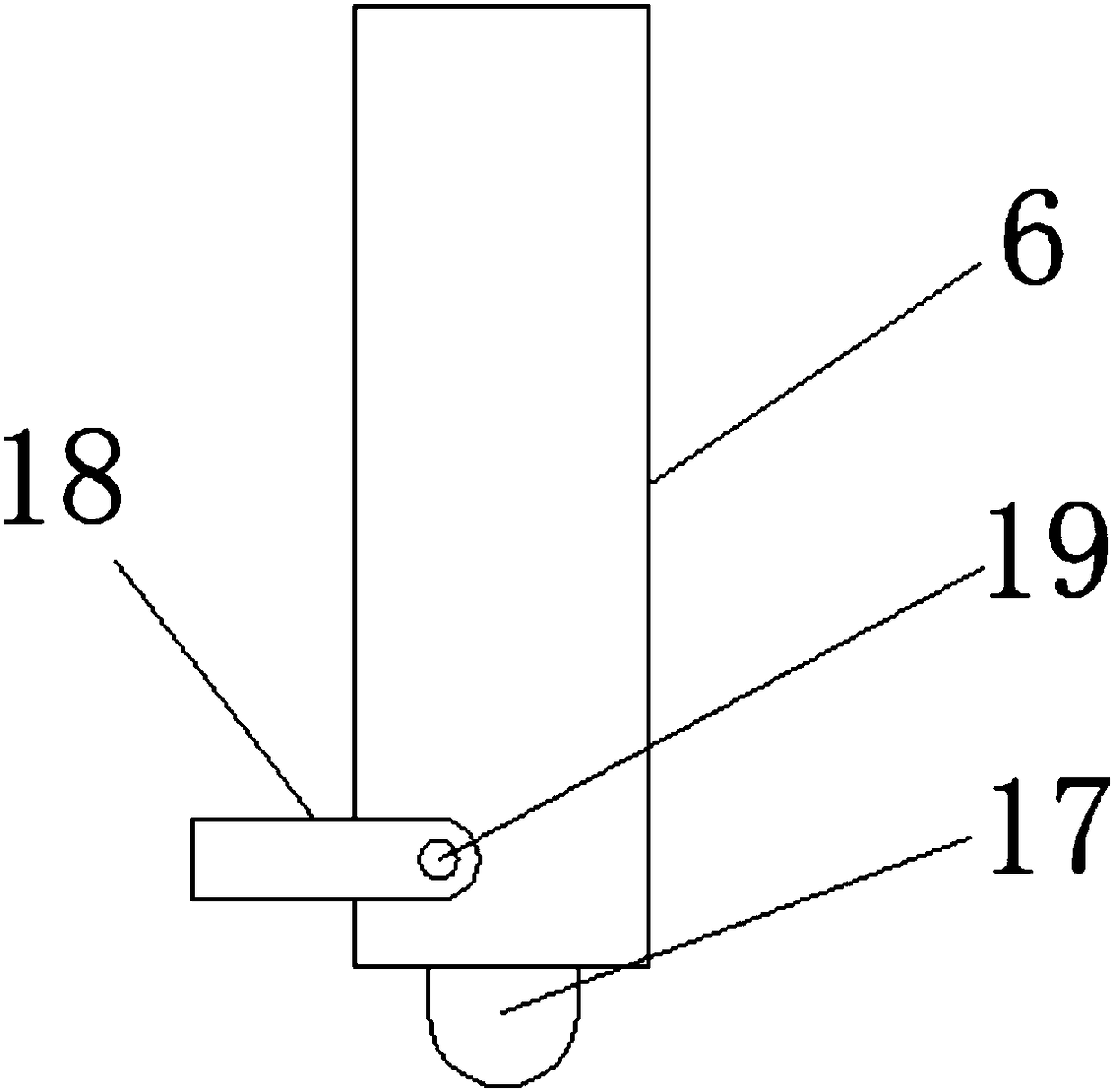

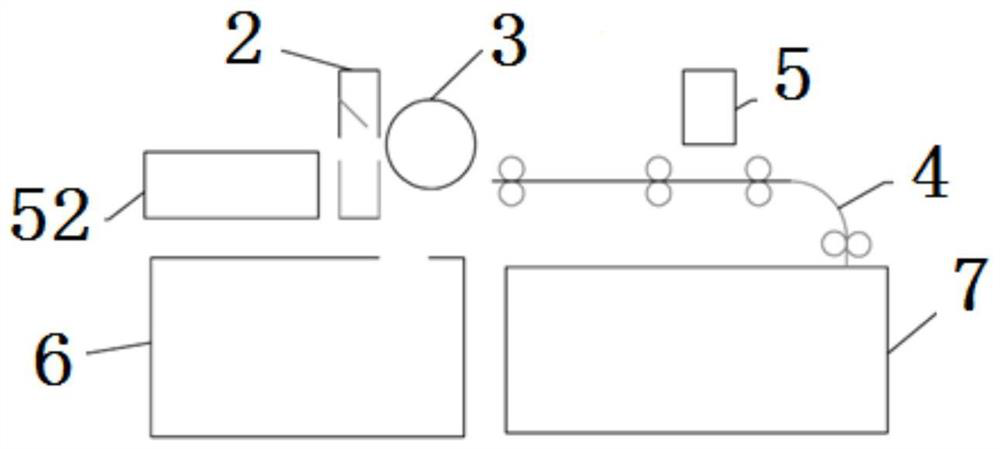

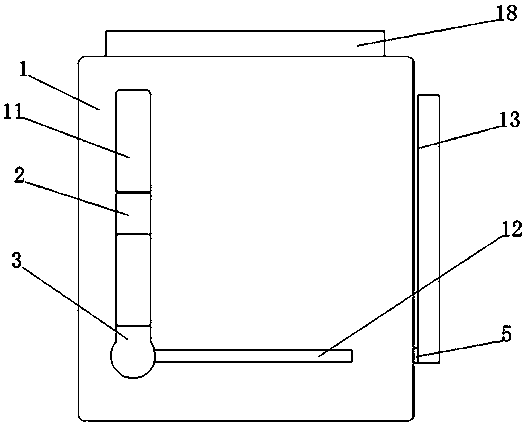

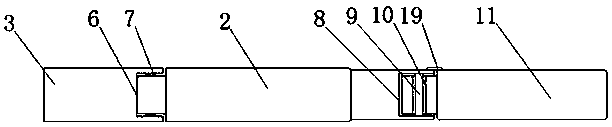

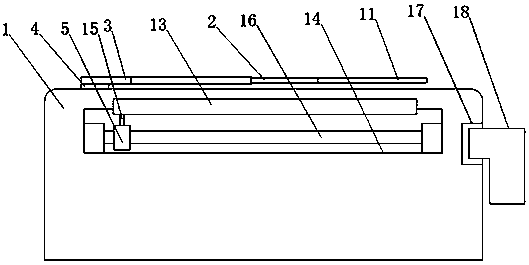

Speed-variable cutting integrated paper feed roll for paper machine

ActiveCN110239998ADoes not affect crop timingPrecise croppingArticle deliveryWebs handlingPiston rodFault rate

The invention provides a speed-variable cutting integrated paper feed roll for a paper machine. The speed-variable cutting integrated paper feed roll comprises the paper feed roll, a belt pulley, a linking rod, limiting guide slots, a cutter, a variable speed loop bar, a limiting extension sleeve, a first right-angled transmission gear, a second right-angled transmission gear, a third right-angled transmission gear, an output end rod, a cutting port, fixed gears, touch surfaces, piston rods, passive plates, a change gear, linkage limiting teeth and a linkage limit groove, wherein the surface of the paper feed roll is provided with the cutting port in an open manner; the belt pulley is integrally arranged on one side of the paper feed roll. The first right-angled transmission gear is linked with the second right-angled transmission gear and the third right-angled transmission gear, and further the linking rod changes the rotating speed by using the rotating speed of the paper feed roll, and the device cuts more accurately; the cutting time of the cutter is prevented from being affected whether the rotating speed of the paper feed roll is increased or reduced, so that the device is simpler in control and lower in fault rate.

Owner:博兴战新产业发展有限公司

Cutting device for clothes

The invention discloses a cutting device for clothes. The cutting device for clothes comprises a workbench, electric telescopic rods, a turnplate, a first scale plate and a second scale plate; the workbench comprises a storage chamber and a control chamber; a partition plate is inserted between the storage chamber and the control chamber; the storage chamber is arranged below the control chamber;the four corners of the bottom end of the workbench are vertically connected with supporting feet; universal wheels are arranged at the bottom ends of the supporting feet; the electric telescopic rodsare arranged on the two sides of the upper end face of the workbench; the top ends of the two groups of electric telescopic rods are fixedly connected with cross rods; the internal part of the control chamber is rotatably connected with a rotating plate through a rotating shaft; the rotating shaft is fixedly and vertically inserted in the middle of the control chamber; the upper end of the rotating shaft is rotatably connected with the rotating plate; and a driving gear is arranged at the lower end of the rotating plate in a sleeving way. The cutting device for clothes can be used for rotating clothes manually, can adjust and control the rotating angle conveniently, reduces the measuring time and improves the cutting efficiency.

Owner:南安市专利创新协会

Cutting device and method for nailed geomembrane

The invention discloses a cutting device and method for a nailed geomembrane. The cutting device comprises a cutting tool and a sliding cutter, wherein the cutting tool is of a rectangular structure and is used for pressing the flattened nailed geomembrane on a cutting platform; and the sliding cutter is installed on at least one side edge of the cutting tool and used for cutting the nailed geomembrane. According to the cutting device and method, the nailed geomembrane can be accurately cut, and multiple times of measurement and trimming are not needed; and tool positioning is adopted, one-step cutting can be achieved, and the labor cost and the time cost are saved.

Owner:BEIJING GEOENVIRON ENG & TECH

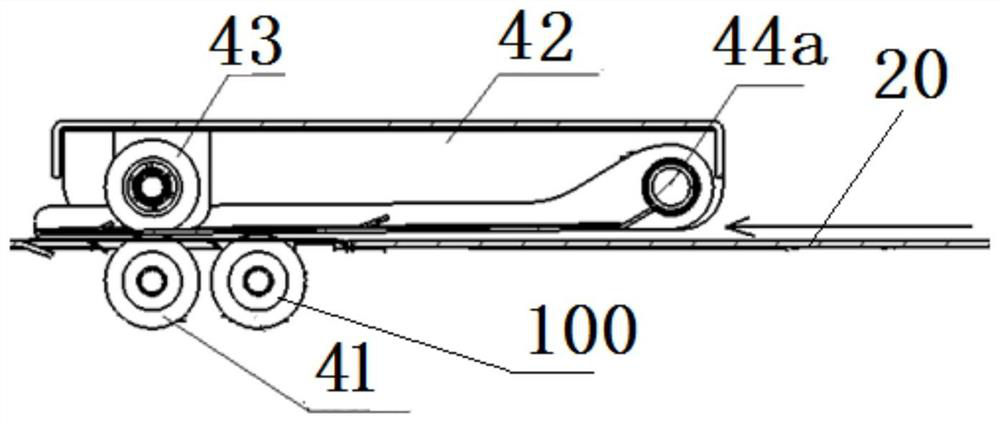

Automatic bamboo mat substrate cutting equipment

The invention discloses automatic bamboo mat substrate cutting equipment which comprises a rack, an upper roll wheel mounted on the rack, a lower roll wheel mounted on the rack and below the upper roll wheel, a position sensor fixed on the rack, between the upper roll wheel and the lower roll wheel and used for collecting the connecting gap information of the substrate of a bamboo mat, a travelling mechanism mounted on the rack, a blade, two electromagnet coils and a controller, wherein the blade is fixed on the travelling mechanism and cuts off the substrate of the bamboo mat along with moving of the travelling mechanism; the shells of the electromagnet coils are fixed on the rack; when the iron cores of the electromagnet coils stretch out, the iron cores compress bamboo mats on the upperroll wheel and the lower roll wheel and the bamboo mats are not moved; and the controller is connected with electric appliance parts in the position sensor, the electromagnet coils and the travellingmechanism. The automatic bamboo mat substrate cutting equipment has the beneficial effects of being simple in structure, low in cost, precise in cutting and high in working efficiency.

Owner:应鸿

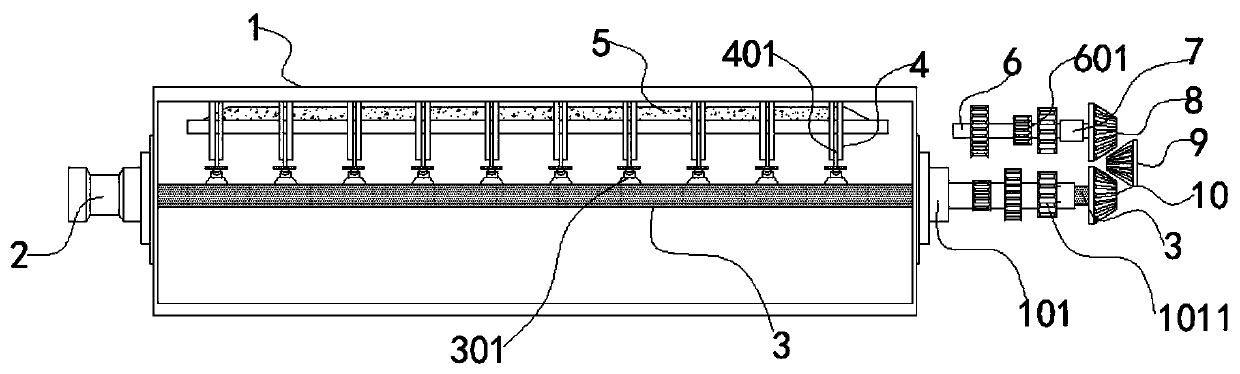

Multi-plicate chain type paper processing mechanism

PendingCN111792434AProcessing speedImprove work efficiencyStampingArticle deliveryStampingComputer printing

The invention discloses a multi-plicate chain type paper processing mechanism. The mechanism comprises a rack, a paper conveying component suitable for conveying multi-plicate paper forwards, a papercutting component, a paper separating component suitable for carrying out separating processing on the cut multi-plicate paper and a stamping component suitable for carrying out stamping on at least part of the separate paper, wherein the paper cutting component comprises a transverse cutting assembly and a vertical cutting assembly, the transverse cutting assembly is suitable for cutting the multi-plicate paper conveyed to the transverse cutting position in the transverse direction, and the vertical cutting assembly is suitable for cutting the multi-plicate paper in the conveying process in the vertical direction. The mechanism can be used without a printer, continuous separating, stamping and storage procedures are realized, so that the paper processing speed is greatly improved, the mechanism is not affected by the printing speed and complex structure, meanwhile, the cost can be reduced, and the working efficiency can be improved.

Owner:CHANGZHOU HANS & WILSON ELECTRONICS TECH

Cloth cutting device capable of realizing cutting tidiness

The invention discloses a cloth cutting device capable of realizing cutting tidiness and belongs to the field of cloth cutting. The cloth cutting device capable of realizing cutting tidiness comprisesa cutting device body, wherein an L-shaped groove is formed in the upper end of the cutting device body, a first slider is glidingly connected with the inner end of the L-shaped groove, a connectingplate is rotationally connected with the upper end of the first slider, a groove is formed in the right end of the connecting plate, an extension scale is inserted in the inner side of the groove, theleft end of the extension scale is matched with the groove, semicircular bulges are fixedly connected with the inner wall of the groove and the surface of one end, close to the groove, of the extension scale, a square groove is formed in the right end of the extension scale, a rotating shaft is fixedly connected with the inner wall of the square groove, an angle ruler is inserted in the inner side of the square groove, a through hole is formed in one side, close to the square groove, of the rotating shaft, and the through hole is matched with the rotating shaft. The effect of accurately cutting out cloth with required sizes can be realized, and the effect of moving the ruler upwards, downwards, leftwards and rightwards can be realized.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

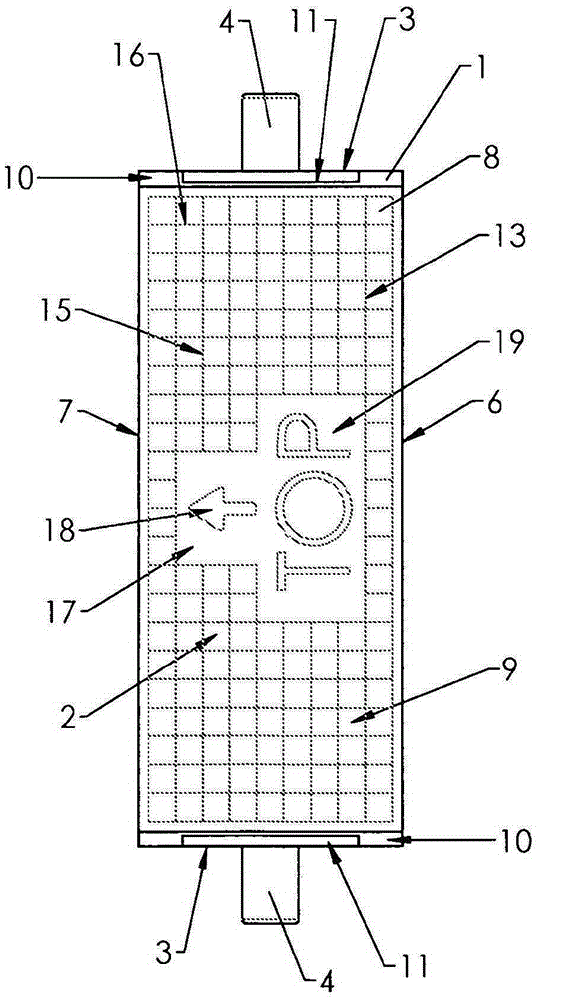

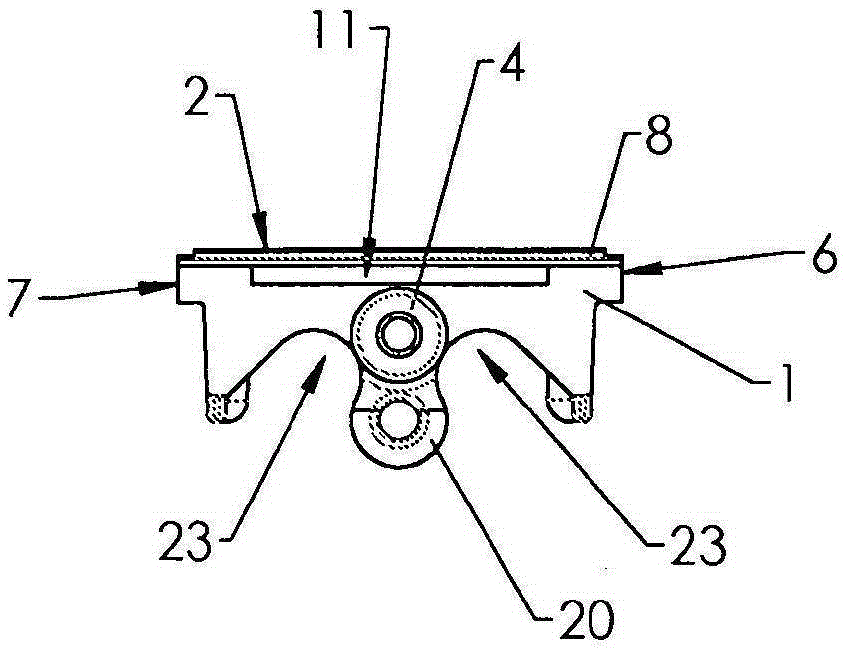

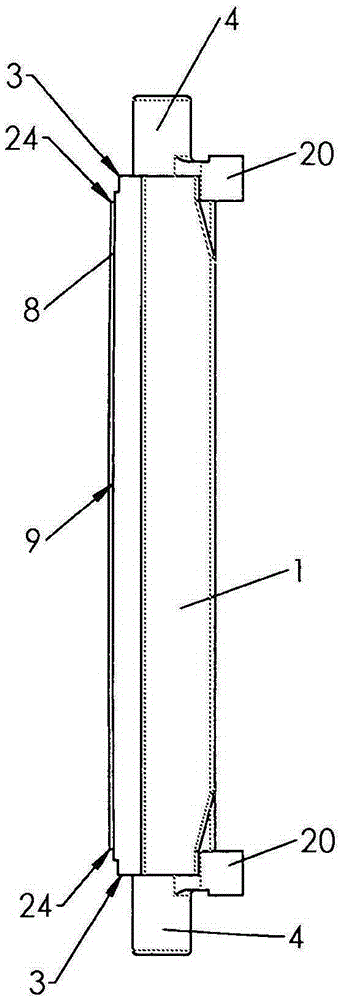

Plate carrier having a grid pattern for a self-inking stamp and production method

A plate carrier (1) for a self-inking stamp (5) and a method for producing a plate carrier (1) having an adhesive surface (9) for attaching a text plate (14) to a printing side (2) of the plate carrier (1), said plate carrier (1) having, on the printing side (2), a grid pattern (13) oriented in relation to the edges (3, 6, 7) of the plate carrier (1) for aligning the text plate (14) when attaching it to the plate carrier (1).

Owner:刻乐圃印章制造斯高贝有限两合公司

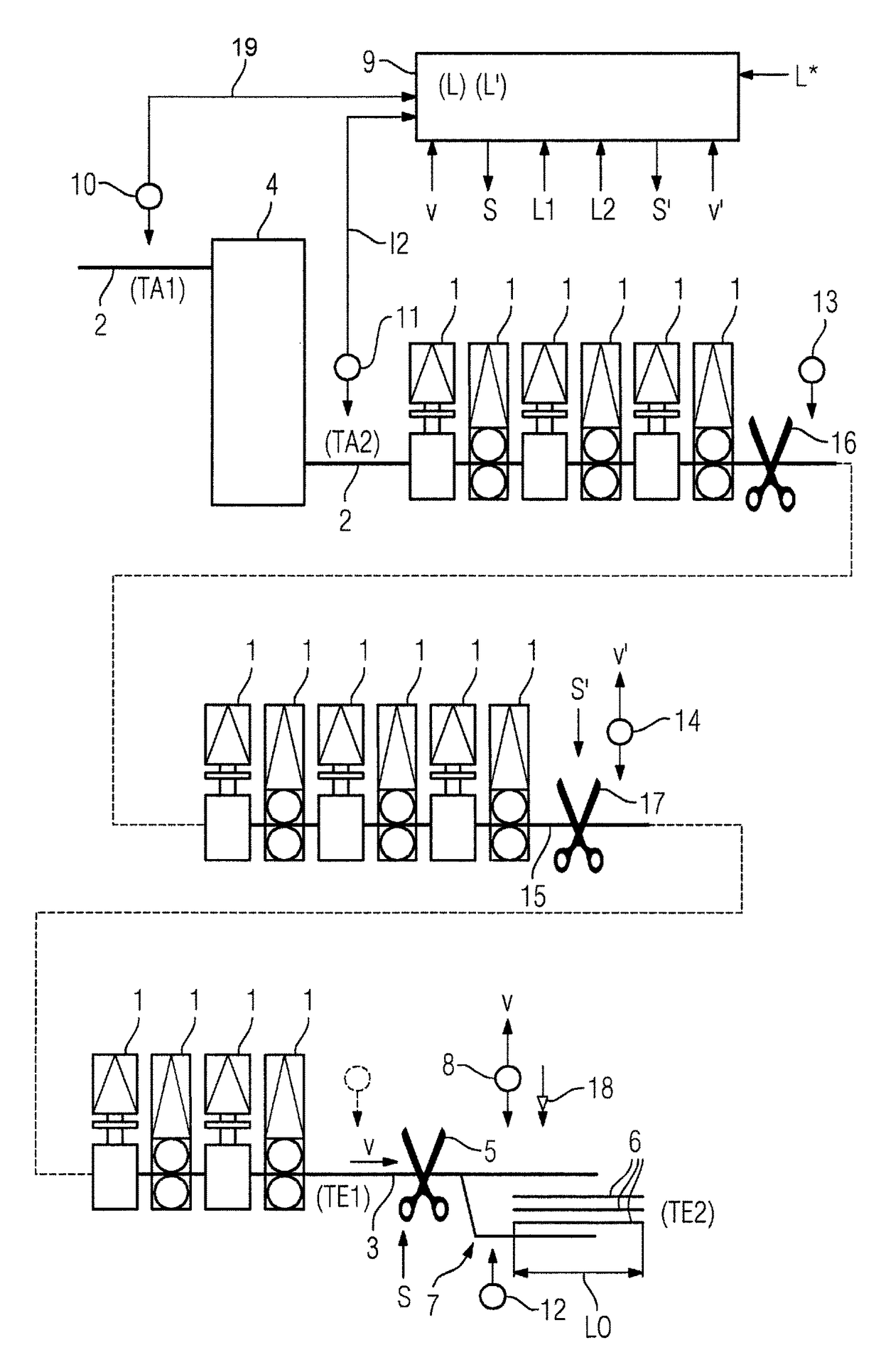

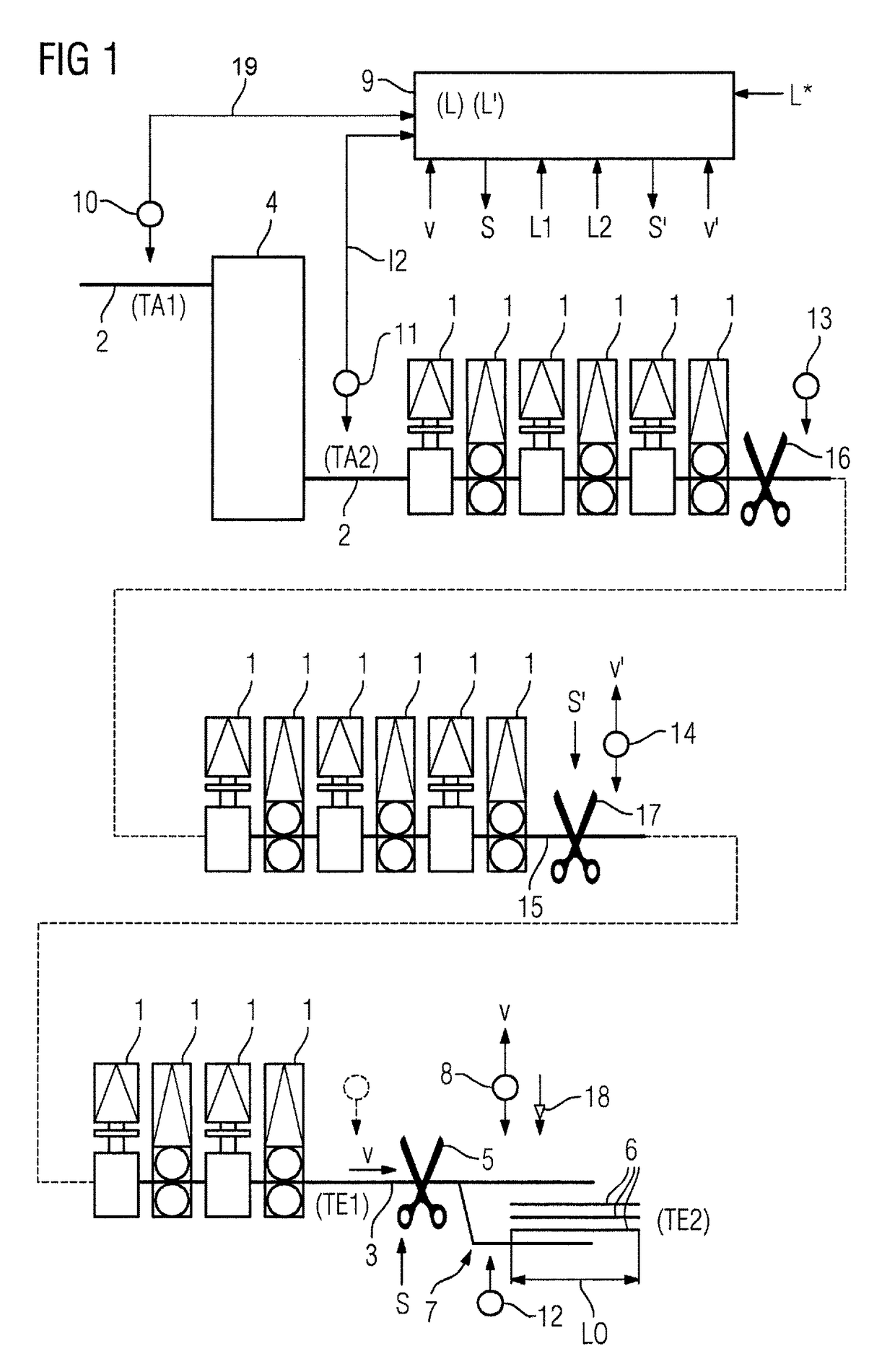

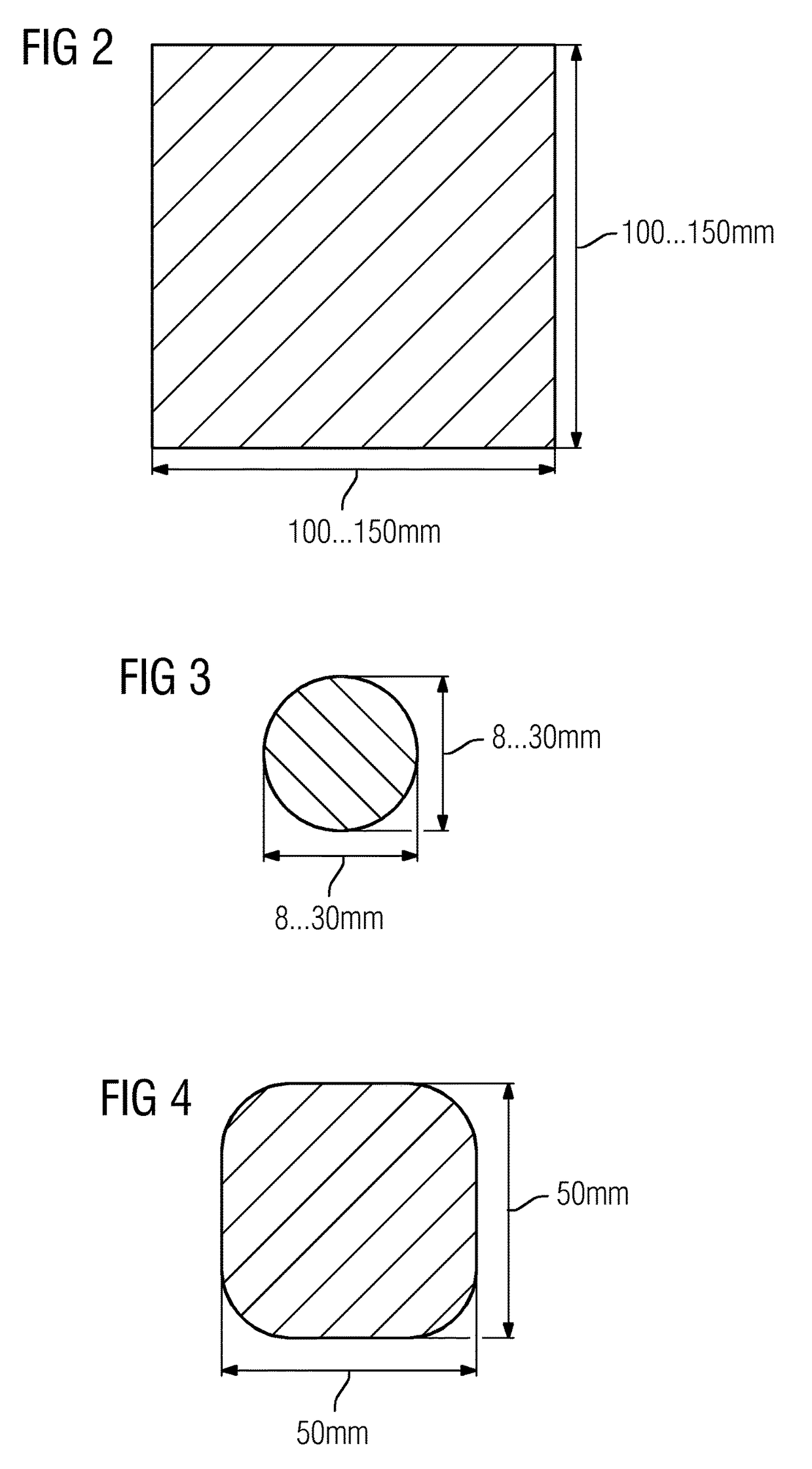

Rolling mill with optimized determination of cutting points

ActiveUS9776230B2Length minimizationImprove accuracyRare end control deviceMeasuring devicesMeasurement deviceEngineering

A billet (2) is rolled to a rod (3) in a rolling mill. The rod (3) exits the rolling mill with a finishing temperature (TE1). A rear laser measurement device (8) arranged downstream of the rolling mill detects the head end and the speed (v) of the rod (3). The detected speed (v) of the rod (3) is integrated to its length and an instantaneous length (L) of the rod (3) is determined. Dependent on the determined instantaneous length (L) of the rod (3), cutting commands (S) to a rear shears (5) arranged downstream of the rolling mill are provided for cutting the rod (3) in sections (6) of predetermined length (L0). The sections (6) of the rod (3) are cooled down in a cooling bed (7).

Owner:PRIMETALS TECH GERMANY

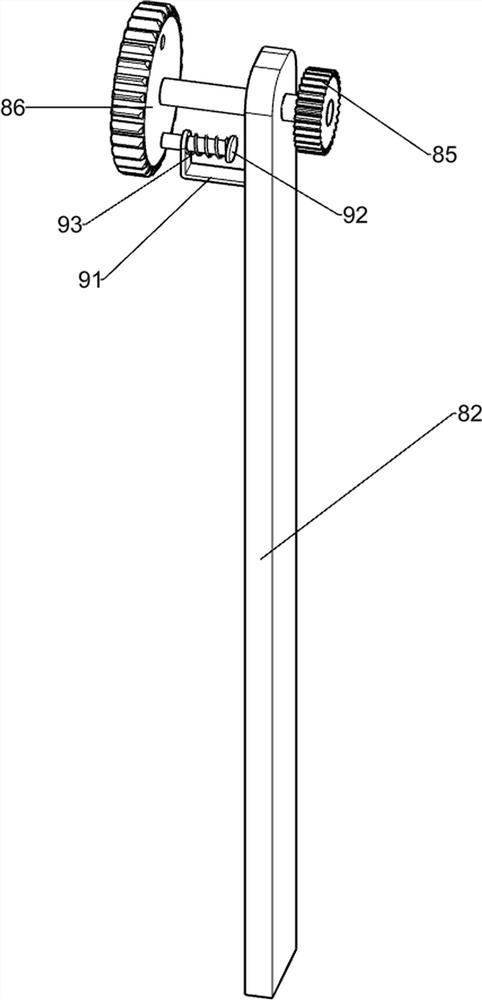

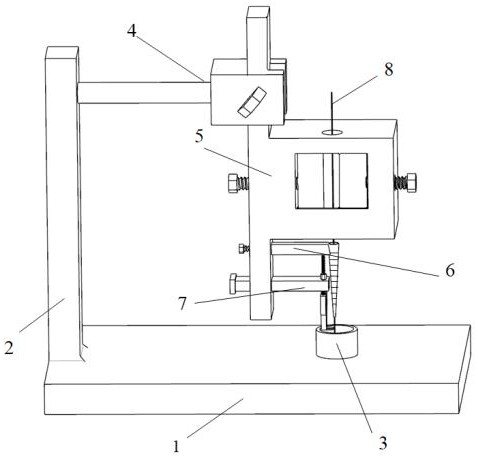

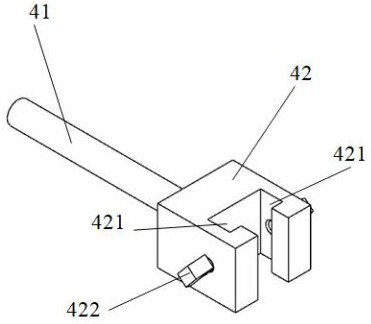

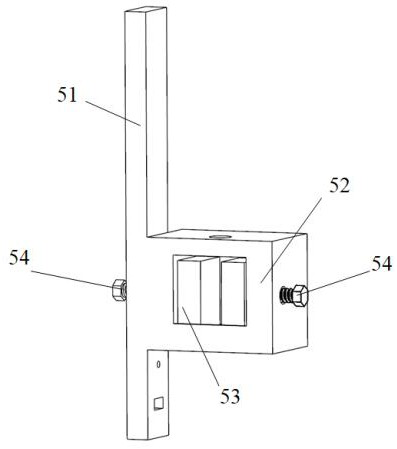

A vertical cold inlay device and inlay method for small ceramic matrix composite materials

ActiveCN111089775BEasy to fixSolve vertical fixation issuesPreparing sample for investigationFixed frameEngineering

The invention discloses a ceramic-based small composite material vertical cold embedding device and an embedding method. The device comprises a base, a vertical upright, an embedding die, a horizontalfixing device, a vertical moving device, a vertical fixing device and a cutting device; the embedding die is of a barrel-shaped structure with a closed lower end; the horizontal fixing device comprises a beam and a chuck; the vertical moving device comprises a clamping plate, a fixed frame, two sliding blocks and a threaded screw; the fixed frame is a mouth-shaped frame with an observation clamping slot in the middle, and is provided with a transverse threaded hole; vertical through holes are symmetrically arranged at an upper side frame center and a lower side frame center of the fixed frame; a testing sample manufactured by the ceramic-based small composite material can vertically penetrate through the two vertical through holes and the observation clamping slot; the cutting device comprises a movable push-pull rod, a vertical screw and a vertical scissor. The testing sample can be kept to be vertical when the testing sample is firmly fixed, and the vertical fixing problem of the ceramic-based small composite material during cold embedding is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com