Patents

Literature

96results about How to "Stable positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

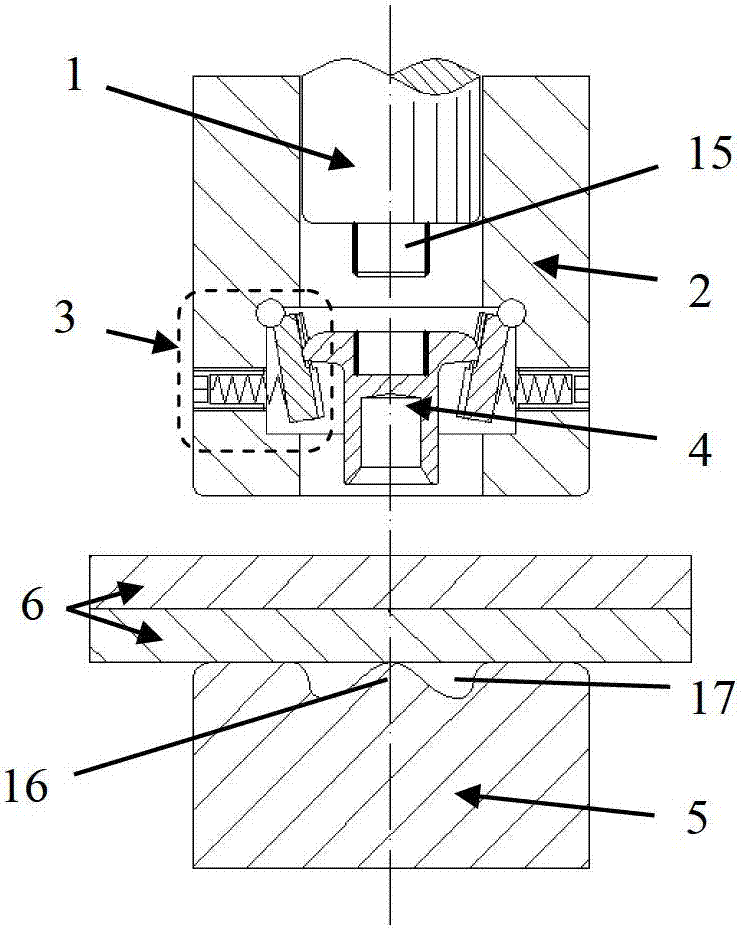

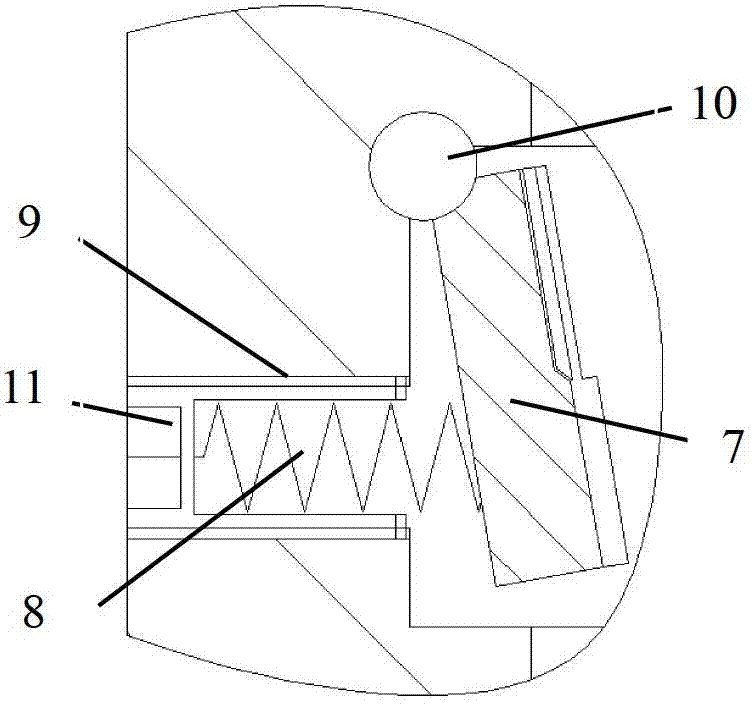

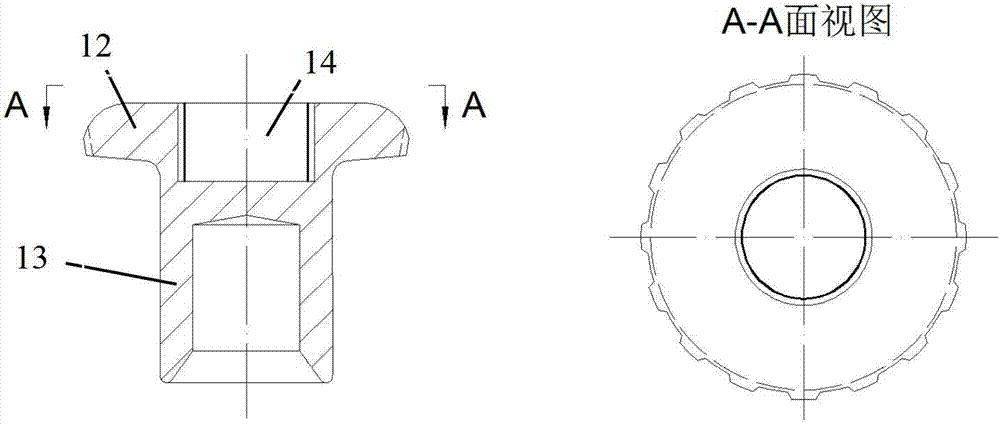

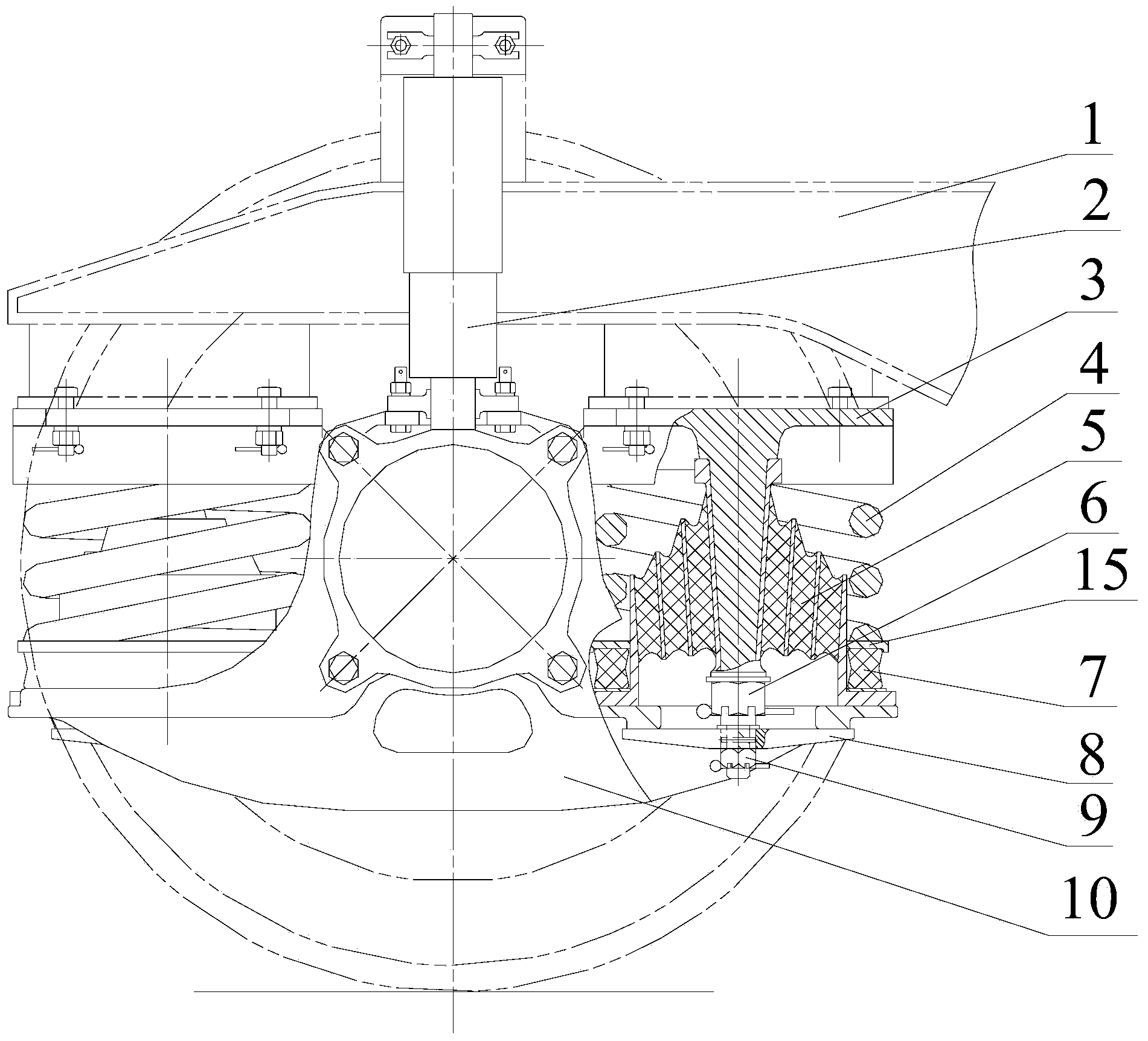

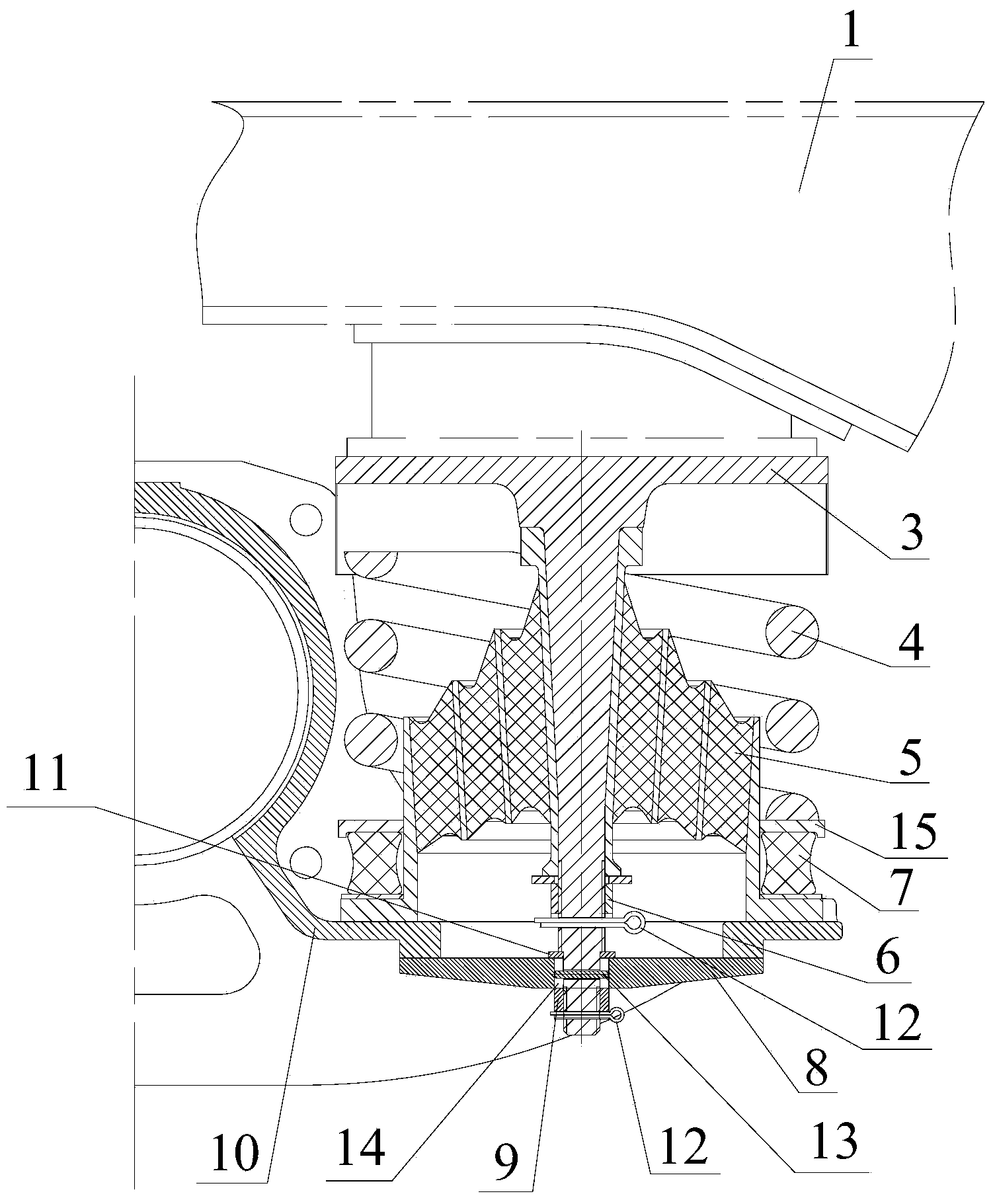

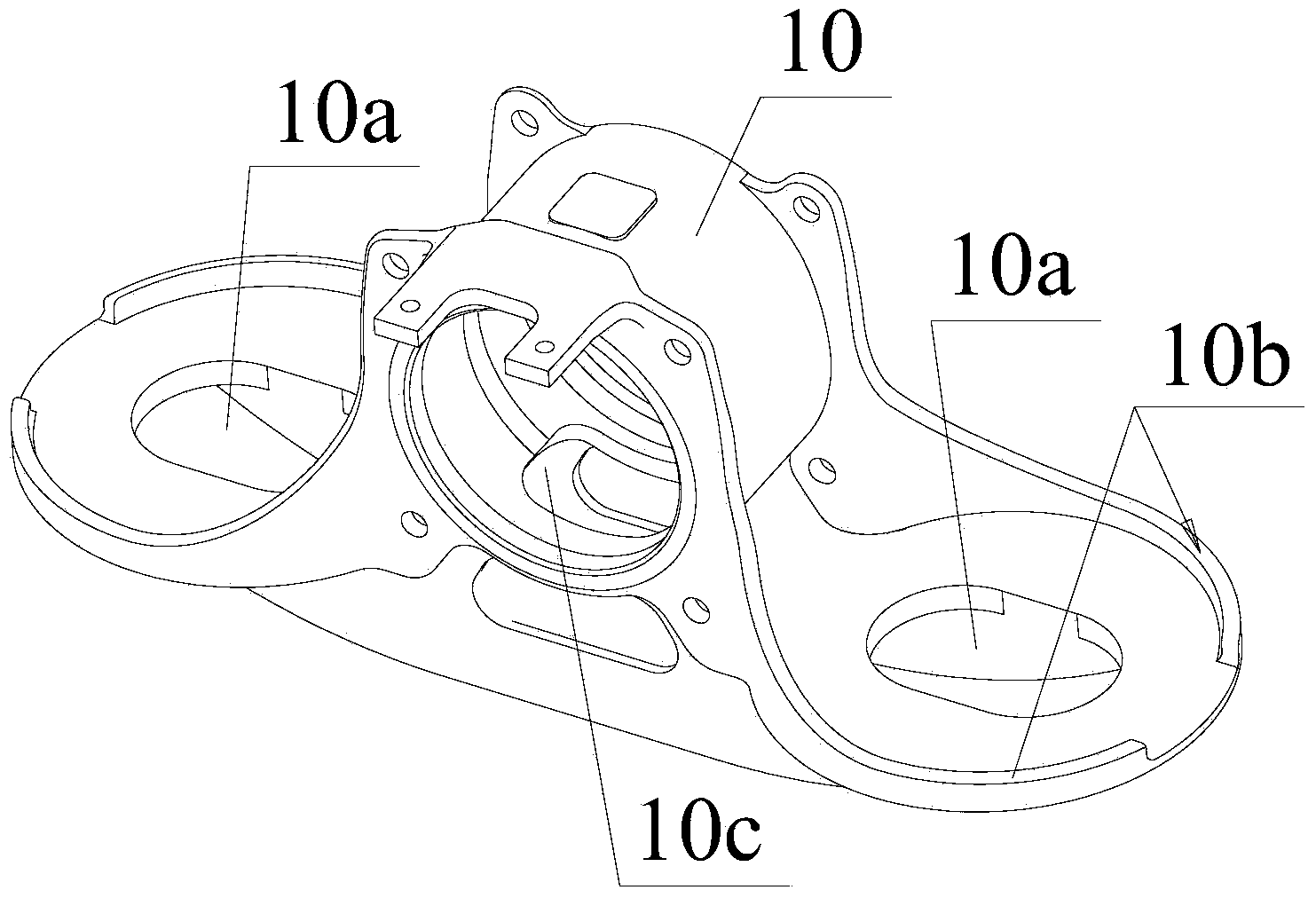

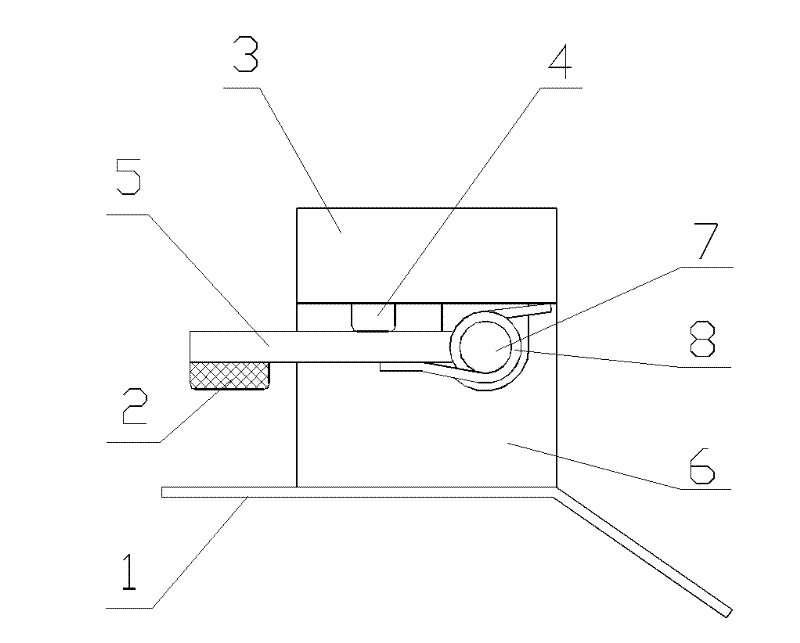

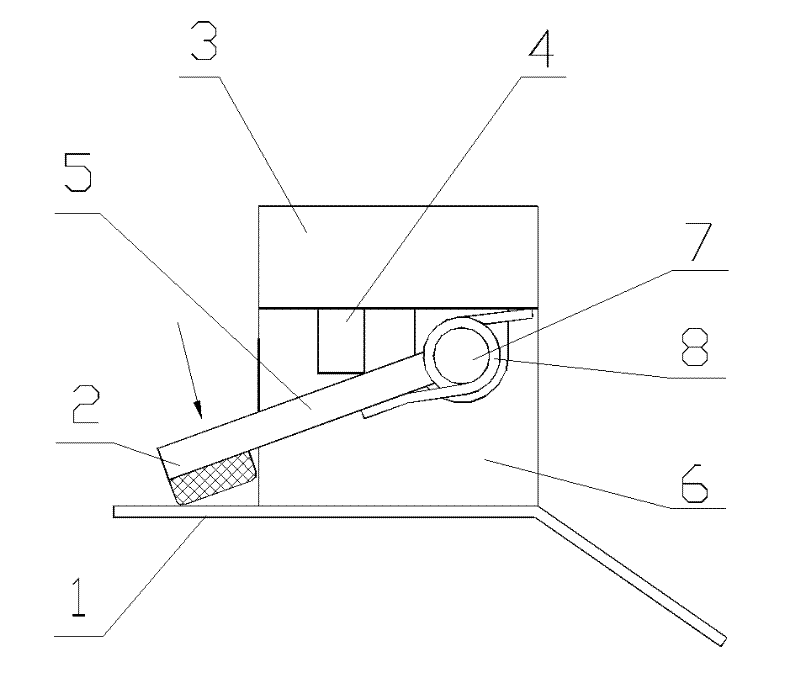

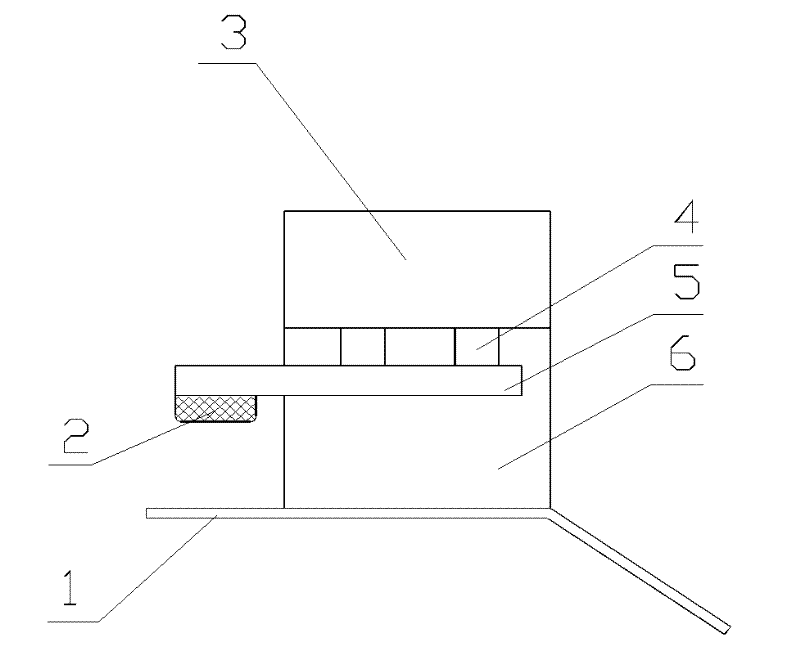

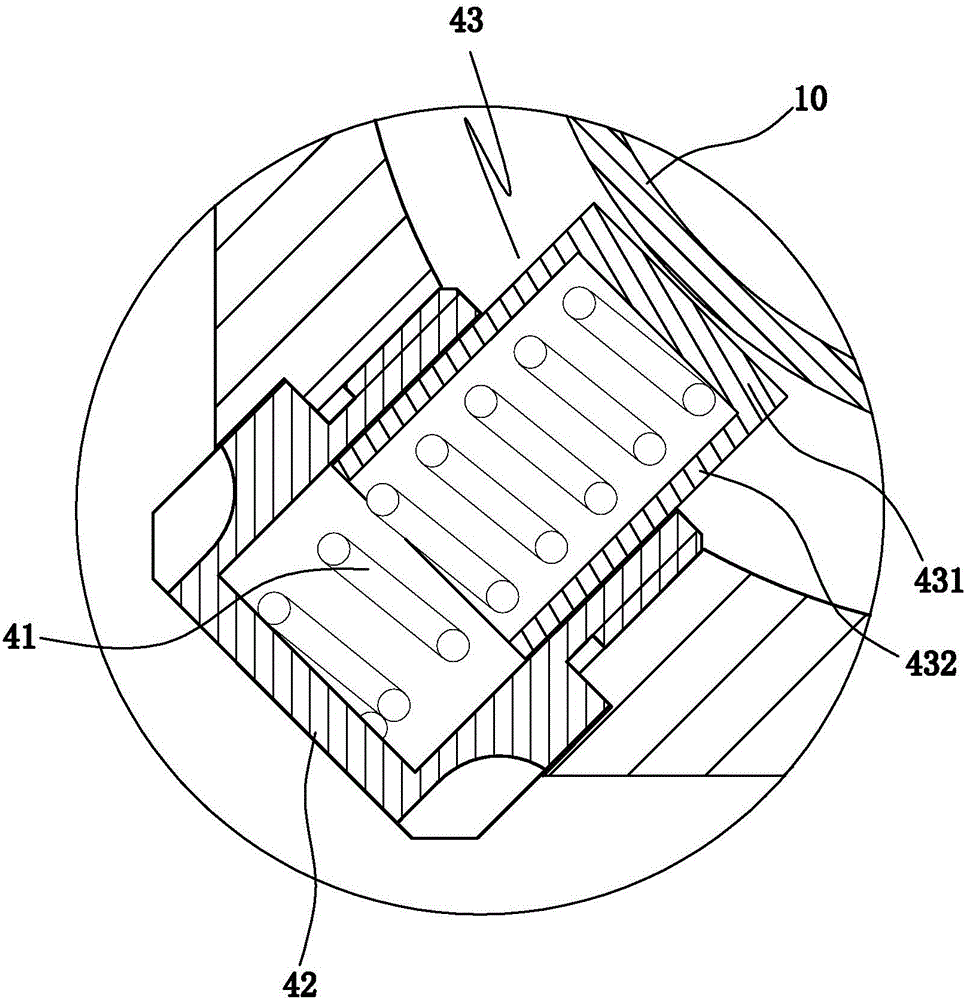

Machinery-solid phase composite connecting device and machinery-solid phase composite connecting method

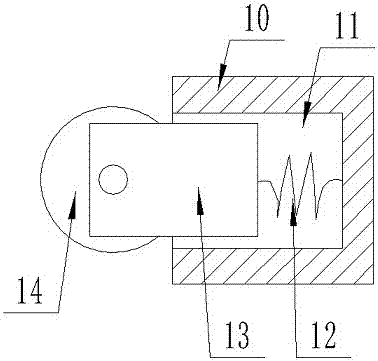

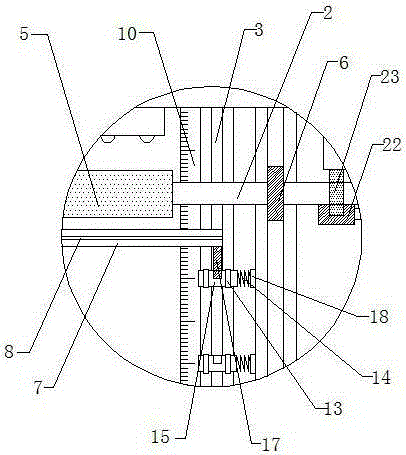

The invention discloses a machinery-solid phase composite connecting device. A blank holder and a female die are arranged from top to bottom, a plate is arranged between the blank holder and the female die, a drive needle is sleeved inside the blank holder, a plurality of spring wafer positioning mechanisms are radially and horizontally distributed in the blank holder, semitubular rivets are vertically arranged in the blank holder and is contacted with the spring wafer positioning mechanisms, and the drive needle, the blank holder, the semitubular rivets and the female die are coaxially arranged. The invention further discloses a machinery-solid phase composite connecting method, accurate positioning and stable driving of the semitubular rivets can be realized through utilizing the spring wafer positioning mechanisms, and process stability and reliability are improved; and solid mixing needles are replaced by the semitubular rivets, rivet force is reduced, joint efficiency is improved, process shrinkage holes through friction stir spot welding are eliminated and machinery-solid phase double connection can be realized at the same time, and static and dynamic mechanics performance of joints are improved. The machinery-solid phase composite connecting method can not only be used for connecting light alloy such as aluminum, magnesium and the like, but also be used for connecting non-metal materials such as composite materials, plastics and the like.

Owner:SHANGHAI JIAO TONG UNIV

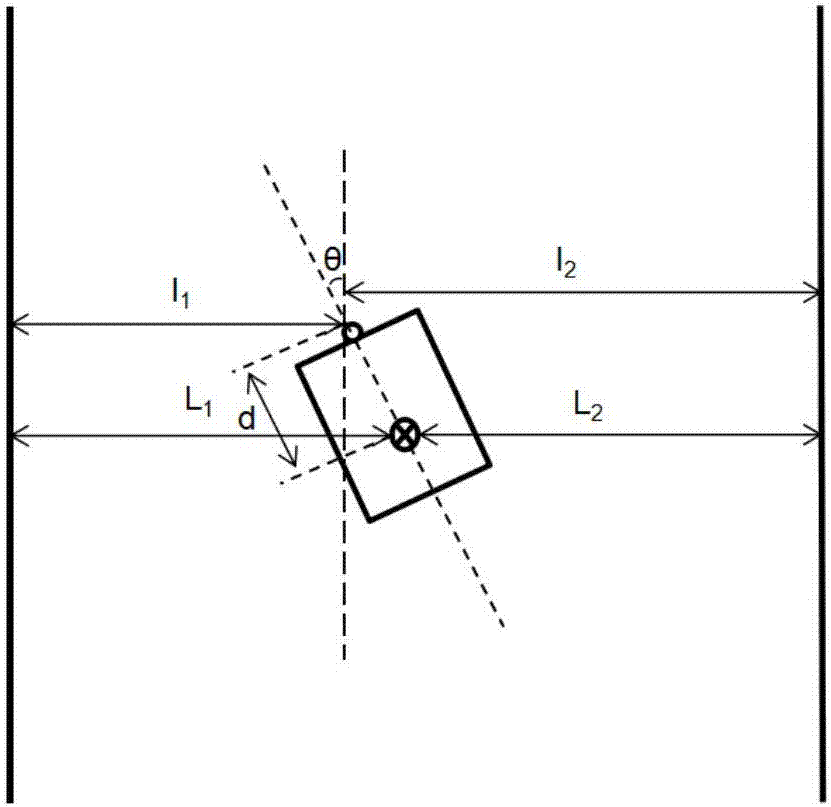

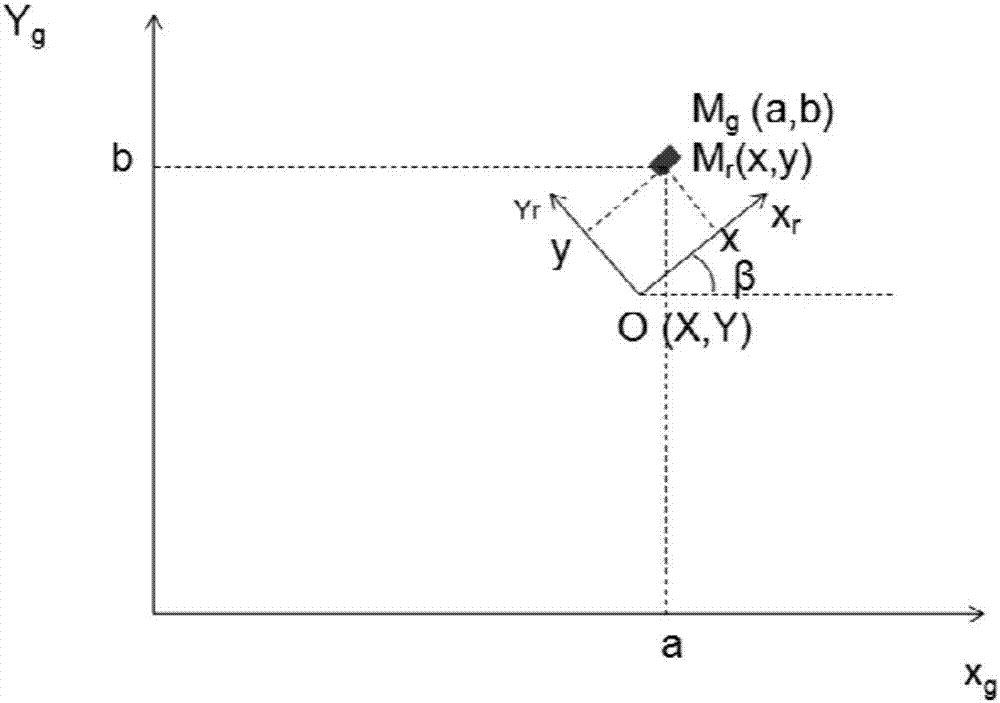

Vision-based AGV patrolling navigation and positioning method

InactiveCN107121981ALow retrofit costReduce maintenance costsPicture interpretationPosition/course control in two dimensionsVision basedOdometer

The invention discloses a vision-based AGV patrolling navigation and positioning method. The method comprises steps: an image in front of the current heading is acquired; according to first preset features of a navigation reticule, a navigation reticule object meeting the first preset features is recognized in an image; the relative position relationship between the AGV and the navigation reticule is acquired, and the relative position relationship is used for correcting the position and the heading of the AGV. An image acquisition device is adopted to replace a magnetic guidance sensor, a color adhesive tape is adopted to lay an auxiliary path, and the navigation path modification and maintenance cost is greatly reduced. In view of the shortcoming of a small viewing field of the image acquisition device, through fusing visual features and odometer information, the real-time pose of the AGV is tracked accurately. Besides, in view of accumulated errors of the odometer caused by reasons such as side slipping of a movable device and slipping of a caster, the odometer information of the AGV is corrected through setting a position correction mark with known global coordinates, and high-precision and stable AGV positioning and navigation can be realized.

Owner:NANJIANG ROBOT

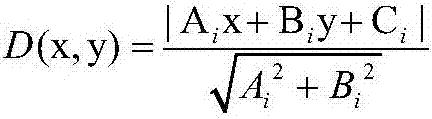

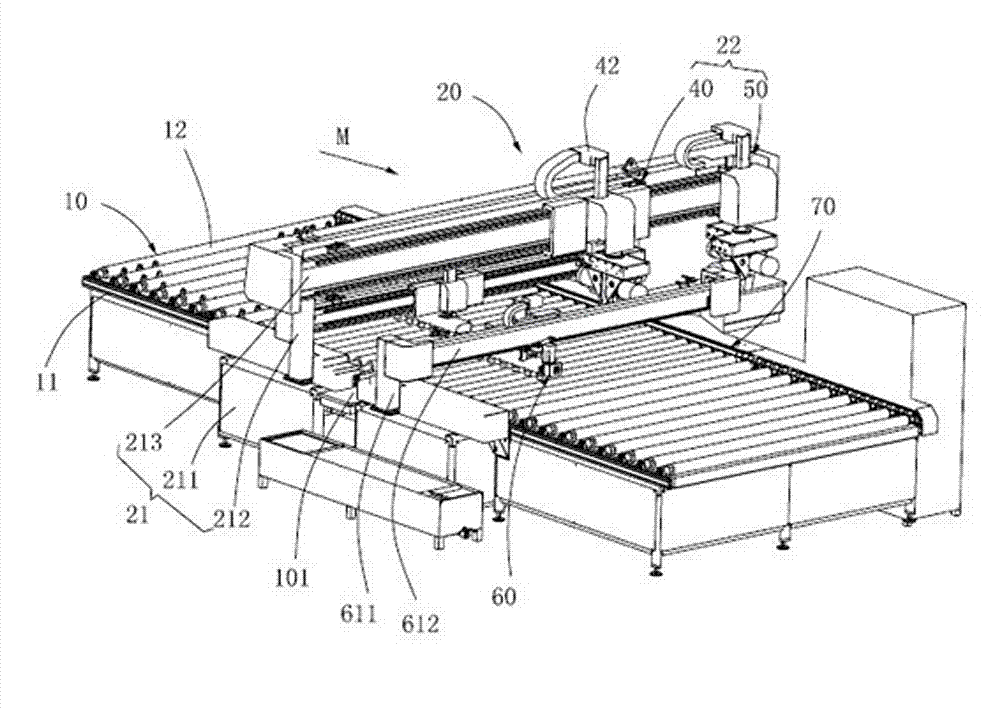

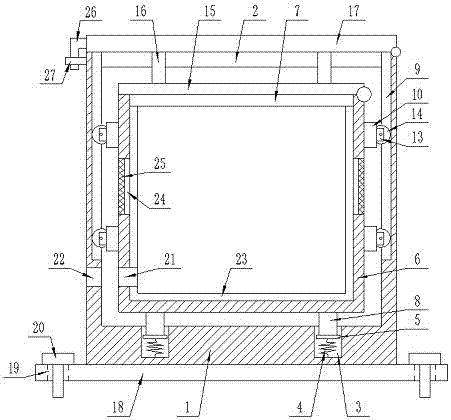

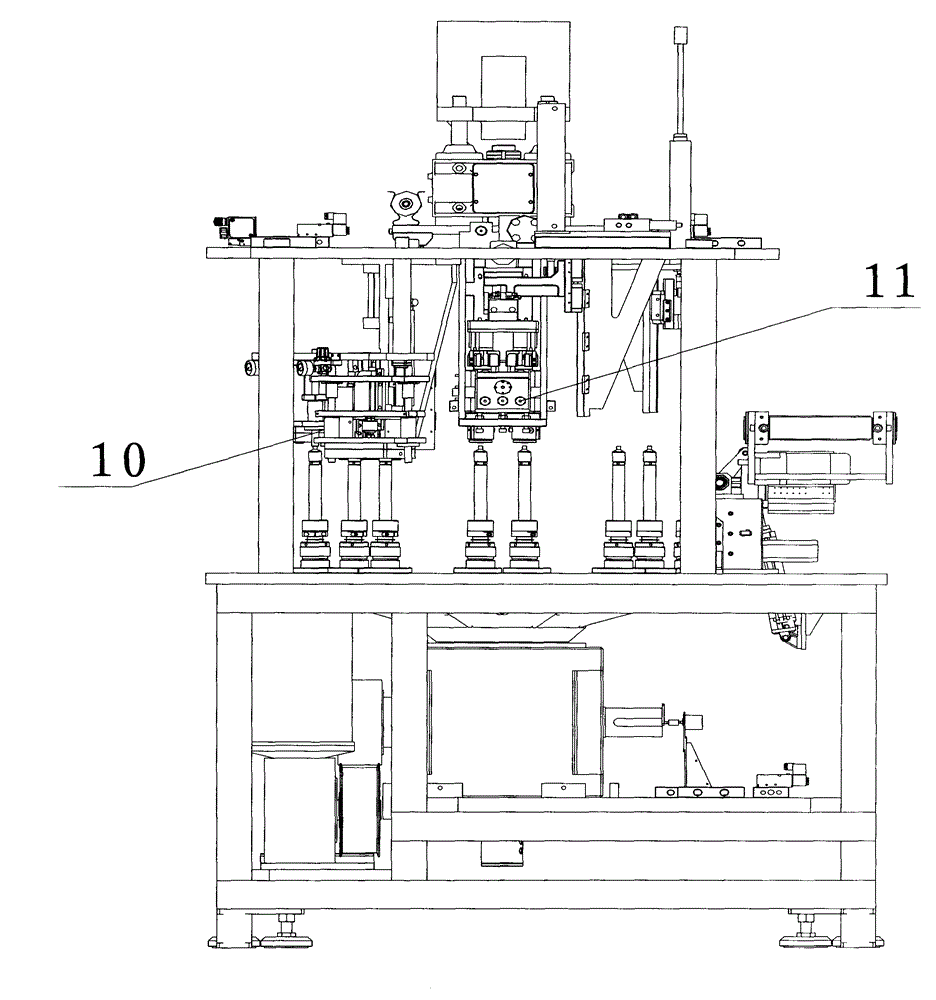

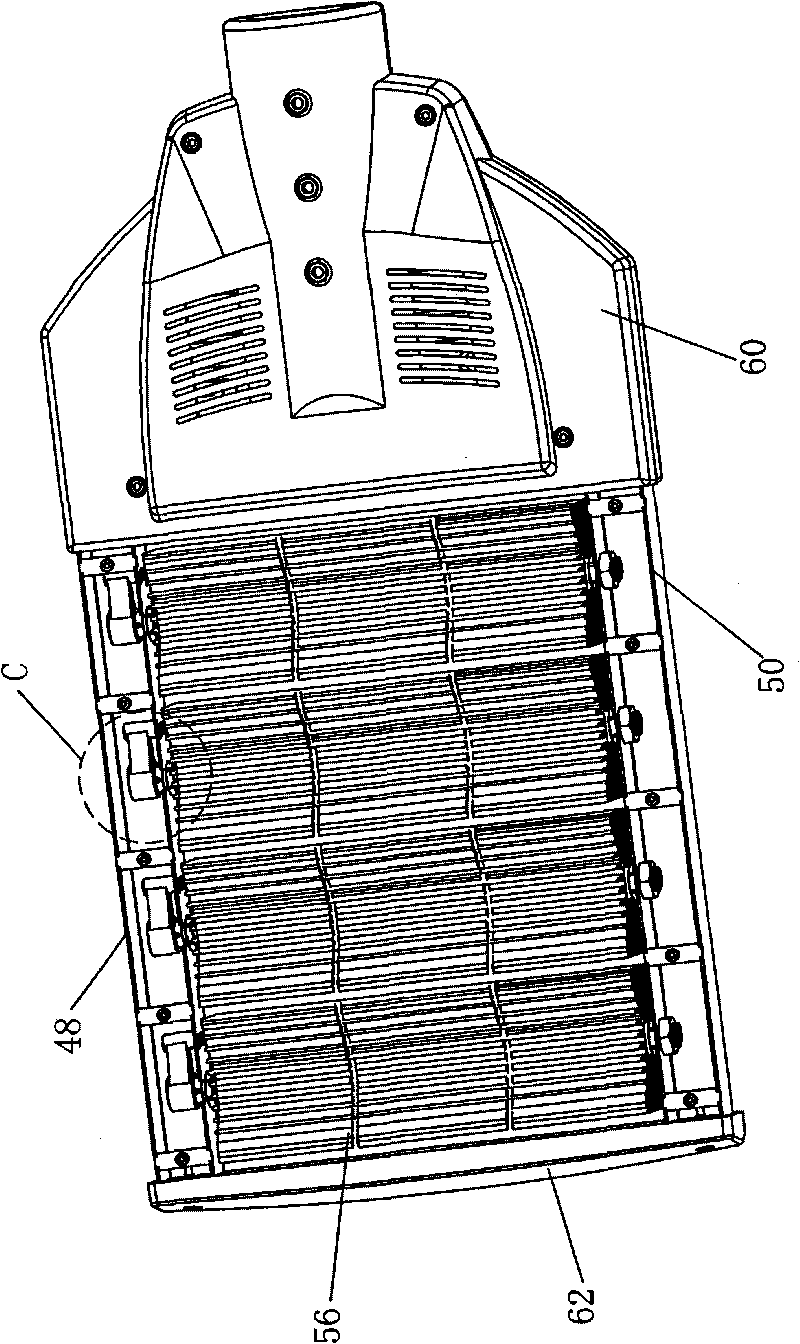

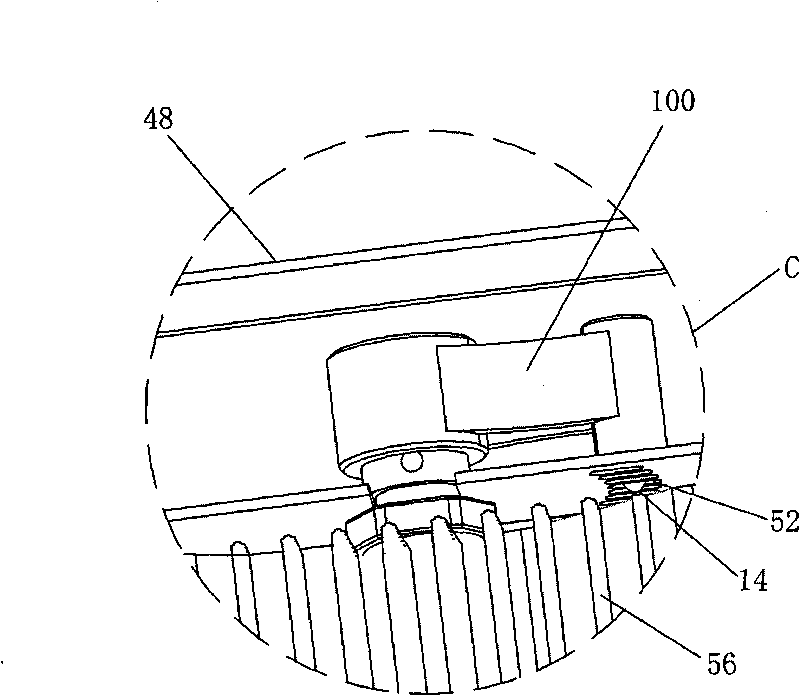

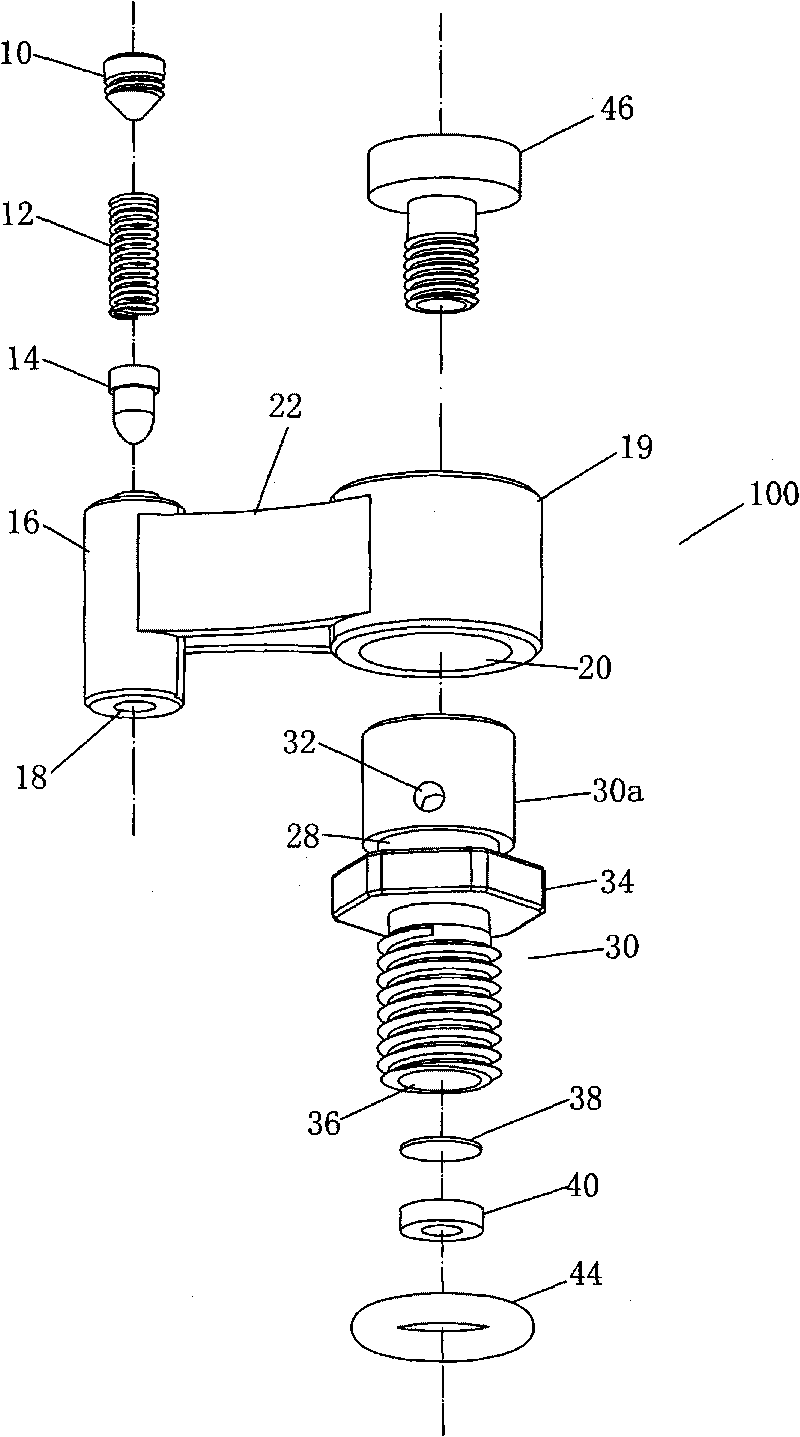

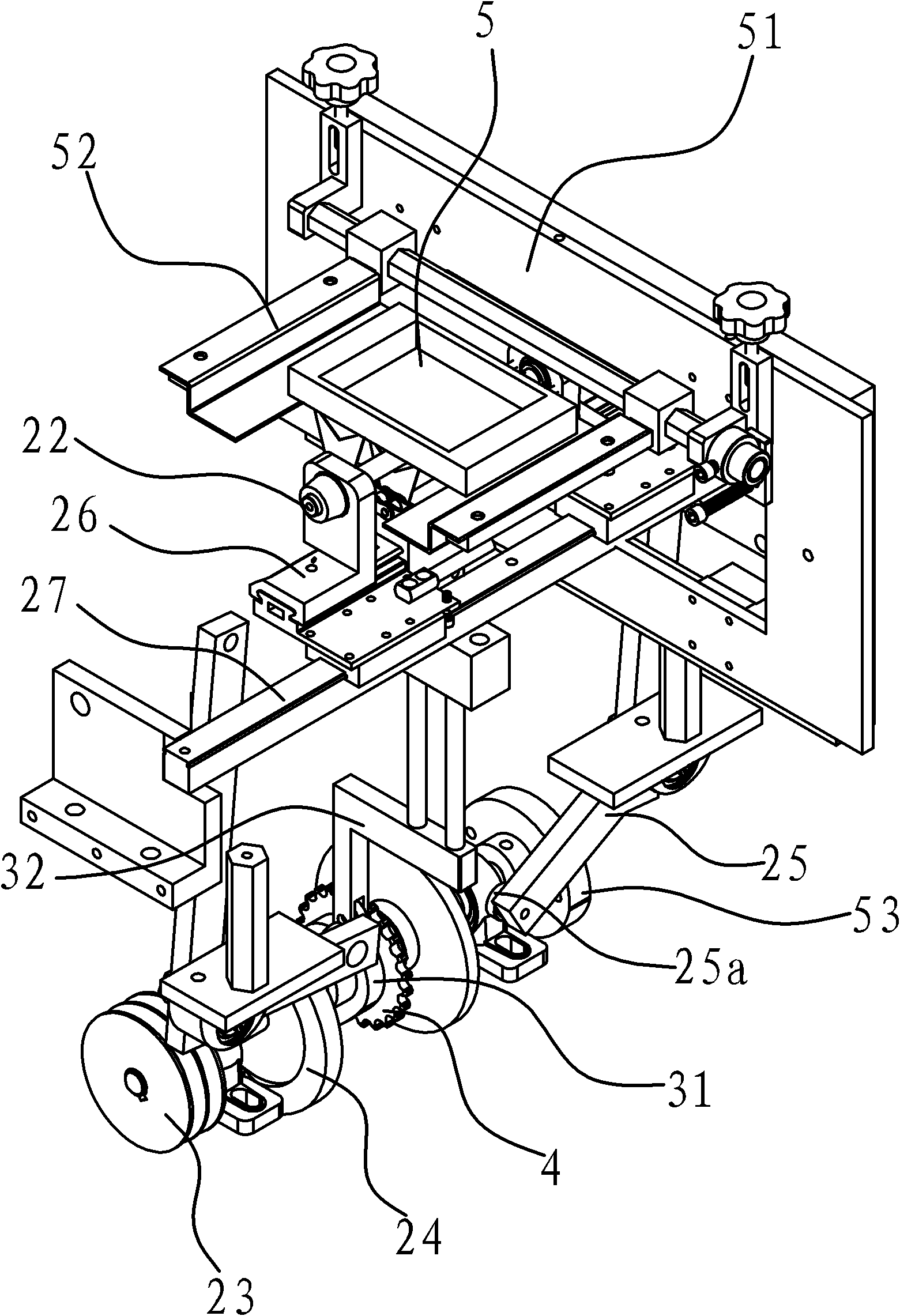

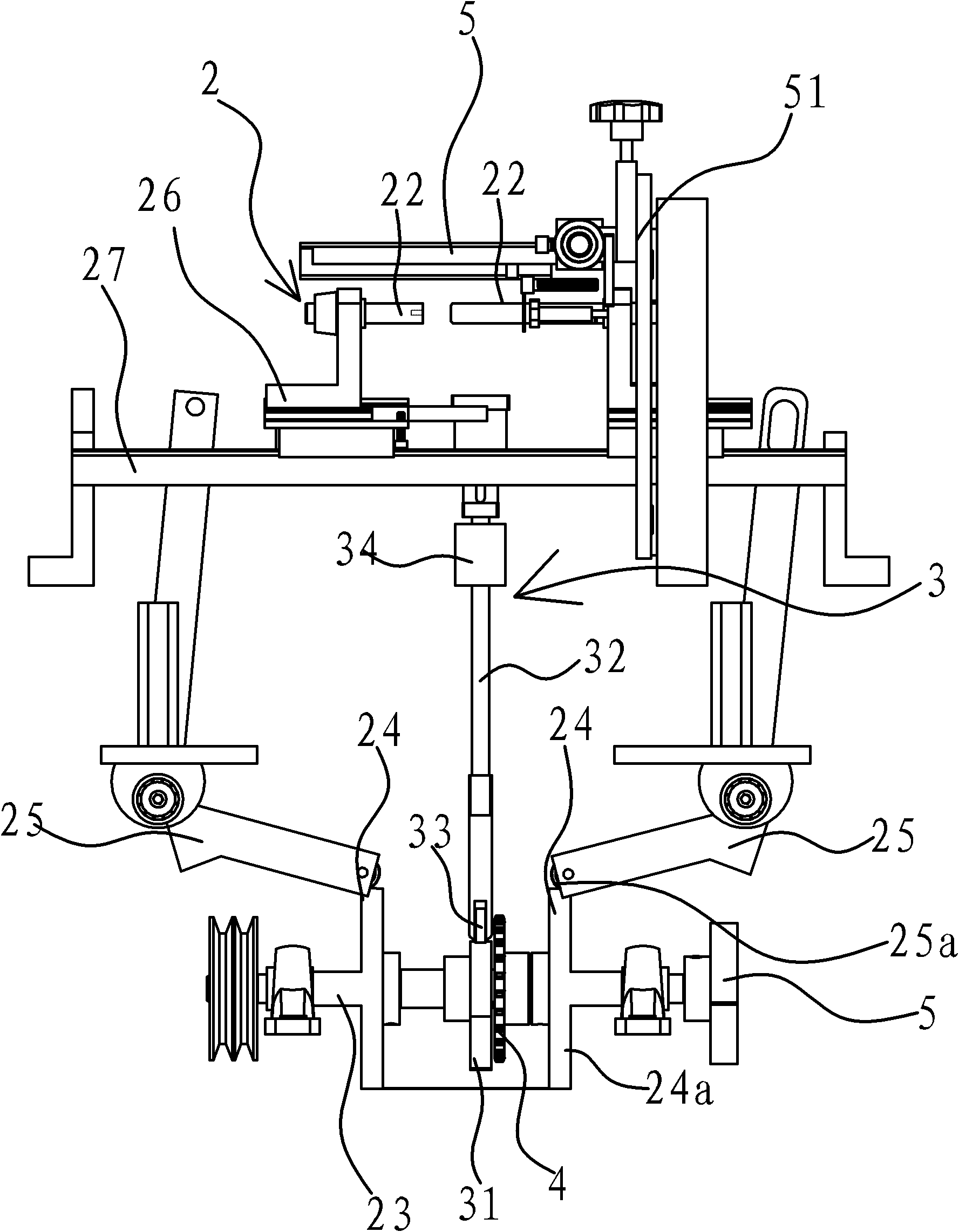

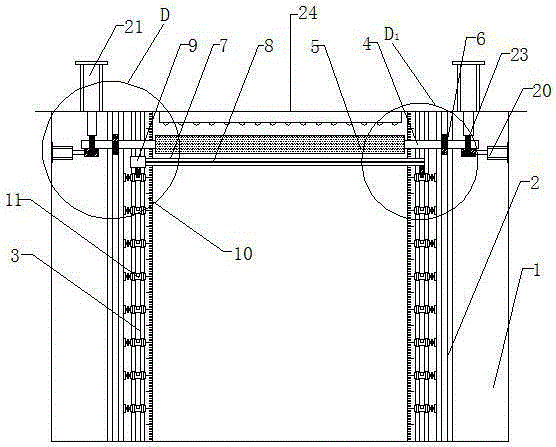

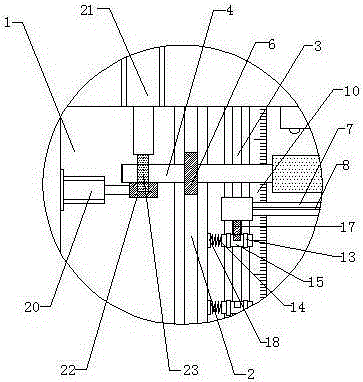

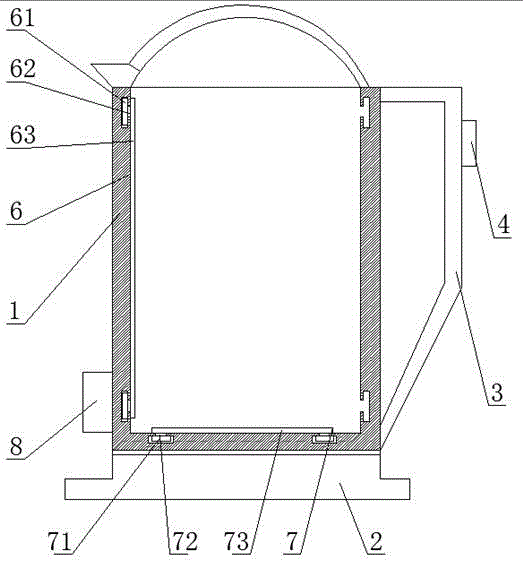

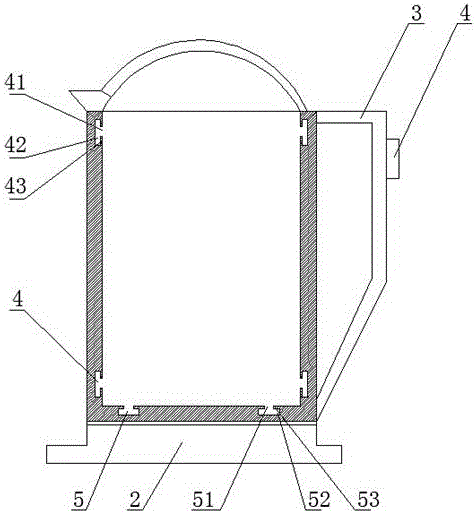

Fully-automatic horizontal glass linear four-edge edge grinding machine and edge grinding processing method thereof

ActiveCN103692311AStable positioningEasy to operateEdge grinding machinesGrinding feedersGrindingStructural engineering

The invention relates to the field of glass processing equipment, and discloses a fully-automatic horizontal glass linear four-edge edge grinding machine and an edge grinding processing method thereof. The edge grinding machine comprises a conveying system, an edge grinding system and a lateral pressure system, wherein the edge grinding system comprises an edge grinding frame and an edge grinding mechanism arranged on the edge grinding frame; the edge grinding mechanism comprises a fixed grinding head group and a movable grinding head group, wherein the fixed grinding head group is fixedly arranged on one side of the conveying system; the movable grinding head group is arranged opposite to the fixed grinding head group and can slide along the edge grinding frame; the lateral pressure system comprises a lateral positioning mechanism and a lateral compression mechanism, wherein the lateral positioning mechanism is fixedly arranged on one side of the conveying system; the lateral compression mechanism is opposite to the lateral positioning mechanism and can slide. According to the fully-automatic horizontal glass linear four-edge edge grinding machine, glass can be more stably positioned, four edges of the glass can be automatically and continuously grinded and processed, chamfering and side surface processing are simultaneously carried out, and the processing efficiency is higher.

Owner:广东高力威机械科技有限公司

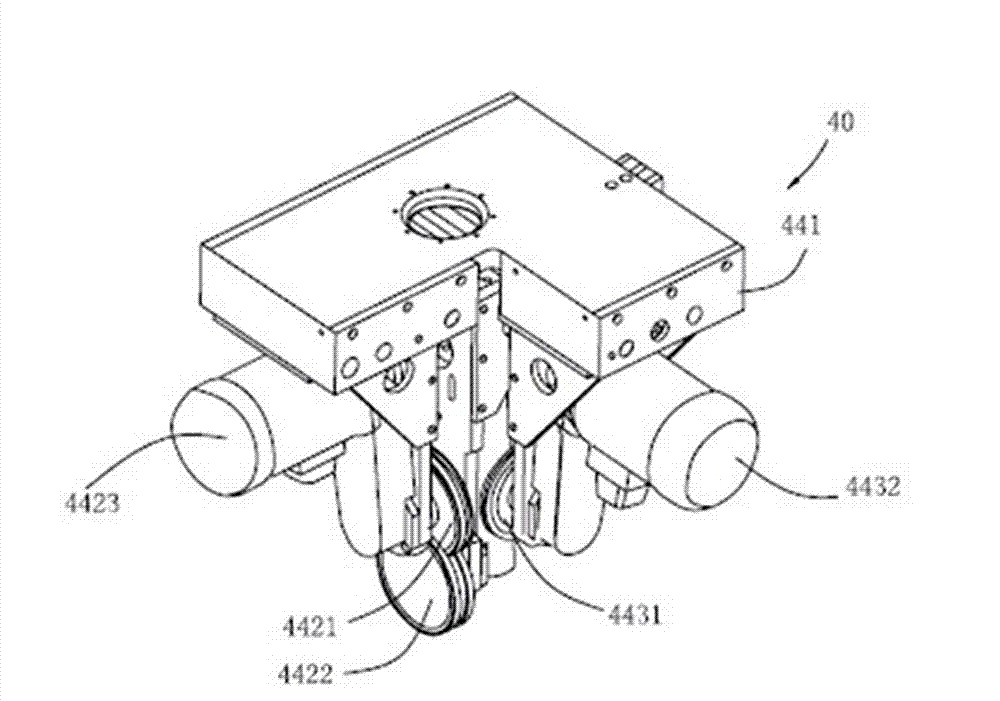

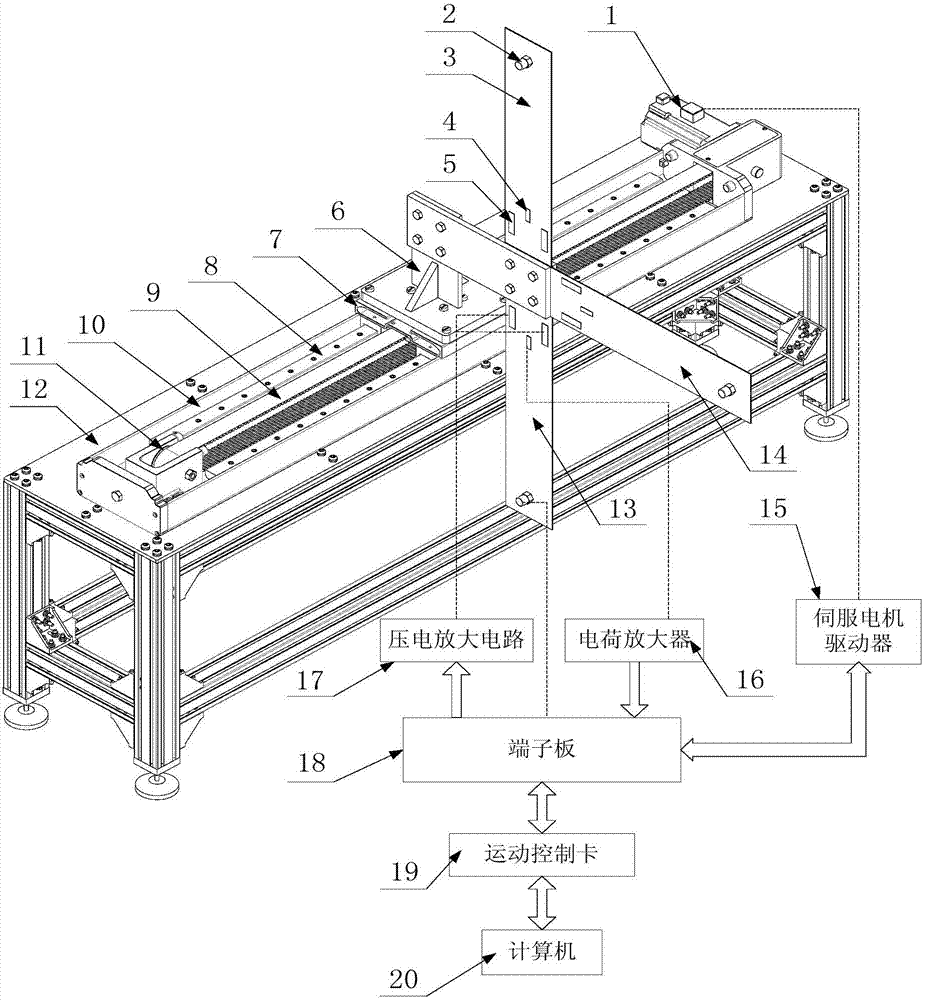

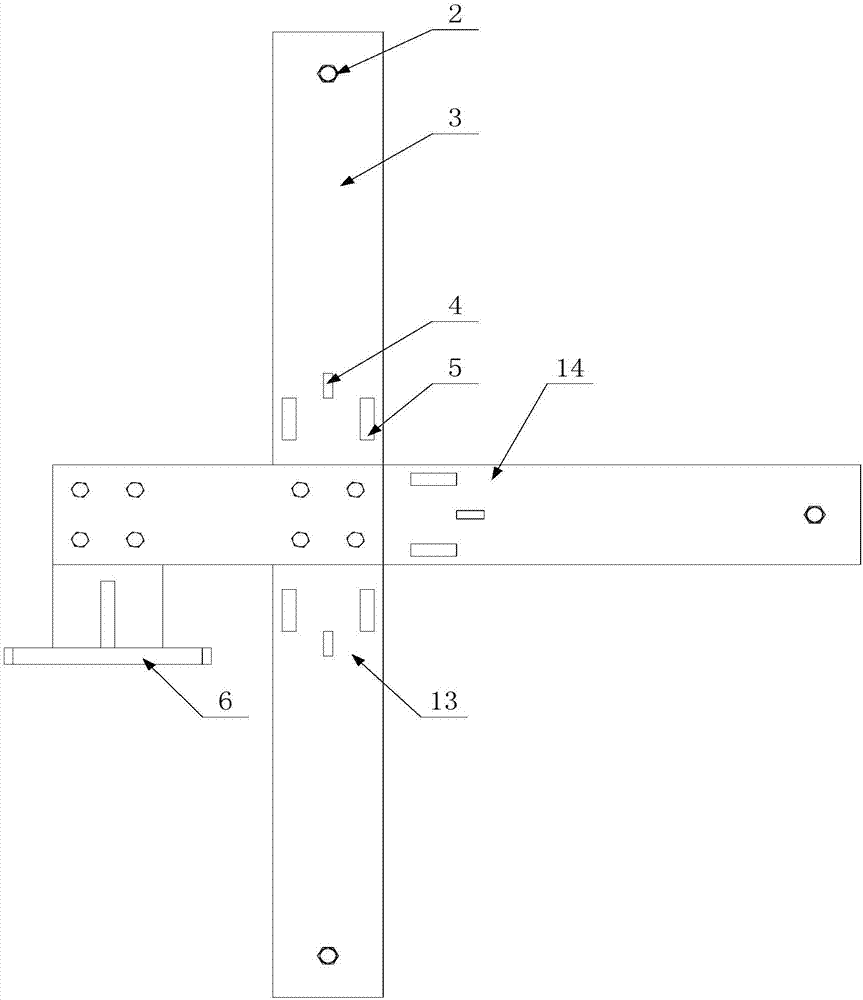

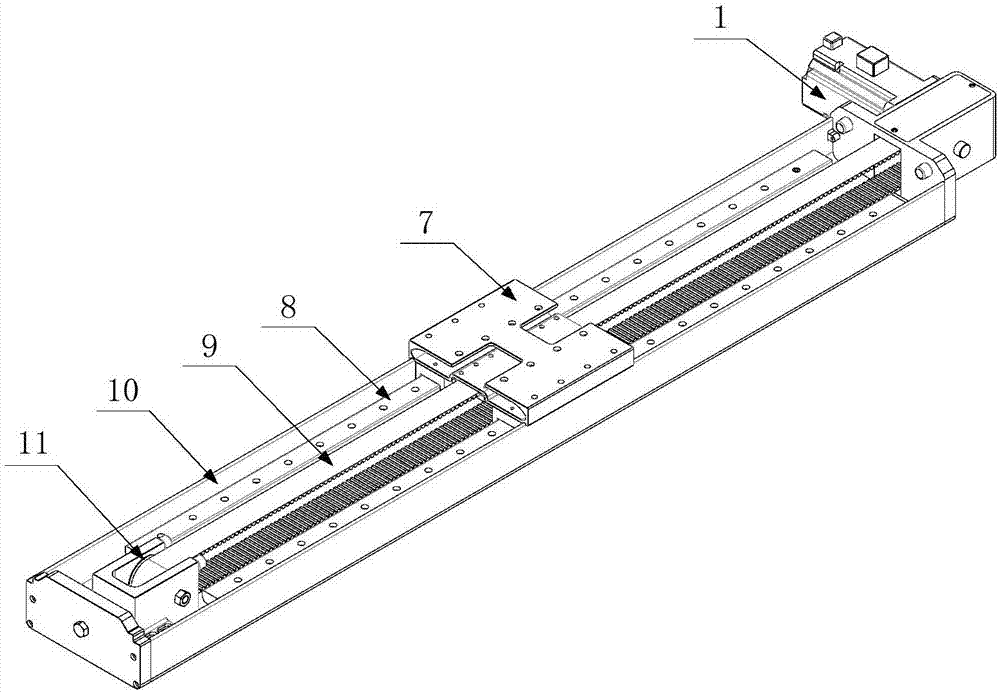

Multi-flexible beam vibration control device and method based on synchronous belt drive

InactiveCN106933266AEliminates the effects of vibration control effectsStable positioningMechanical oscillations controlVibration controlControl system

The invention discloses a multi-flexible beam vibration control device and method based on synchronous belt drive. The device comprises a flexible beam body, a detection part and a control part. The flexible beam body comprises three flexible beams of the same size. The detection part comprises a piezoelectric sensor and an acceleration sensor, wherein the piezoelectric sensor and the acceleration sensor are respectively arranged on the flexible beams. The control part comprises a synchronous belt drive control system and a piezoelectric drive control system. The vibration signal of the flexible beam structure is detected by the piezoelectric sensor and the acceleration sensor. A synchronous belt driven by a servo motor and a piezoelectric drive are used as an actuator for suppressing vibration. The device can be used to study the influence and vibration control of gravity, synchronous belt gap characteristics, synchronous belt elasticity and other factors on the vibration of the flexible beam structure.

Owner:SOUTH CHINA UNIV OF TECH

Rail wagon bogie single-stage shaft housing hanging and positioning device

ActiveCN104163180AReduce effortReduce wearBogie-underframe connectionsAxle-boxes mountingBogieSingle stage

The invention discloses a rail wagon bogie single-stage shaft housing hanging and positioning device. The rail wagon bogie single-stage shaft housing hanging and positioning device comprises a shaft housing, a vertical hydraulic buffer, spring guide pillars, steel circular springs, rubber-metal pad locators and hoisting check blocks, wherein the vertical hydraulic buffer is arranged between the top of the shaft housing and a side frame of a framework assembly; the spring guide pillars, the steel circular springs and the rubber-metal pad locators are arranged between the upper surfaces of spring bearing platforms on the two sides of the shaft housing and the bottom of the framework assembly; the hoisting check blocks are arranged below the spring bearing platforms on the two sides of the shaft housing. The two-stage threaded connection method of the spring guide pillars is of an integrated design, so that the structure is simple and compact, the performance is reliable, stable positioning performance is guaranteed, the requirements for different positioning stiffness in the vertical direction, longitudinal direction and the transverse direction are met, the unsprung mass can be reduced, wheeltrack dynamic force is lowered, and wheeltrack abrasion is reduced; an infrared shaft temperature detection hole is formed in the bottom of a saddle surface of the shaft housing, so that the shortcoming that an infrared thermometry technology cannot be adopted for an existing rail wagon bogie single-stage shaft housing in the line operation process is overcome, the bearing temperature of a rail wagon in an operating state can be detected in real time, a hot box fault caused by detection omission can be avoided, and rail transportation safety is guaranteed.

Owner:CRRC YANGTZE CO LTD

Battery protection box convenient to assemble and disassemble

InactiveCN107195819AConvenient for frequent loading and unloadingStable positioningCell component detailsRoad surfaceElectrical and Electronics engineering

Owner:江苏泰霸电源系统有限公司

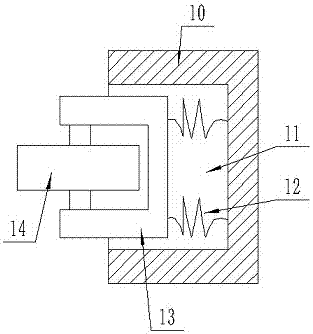

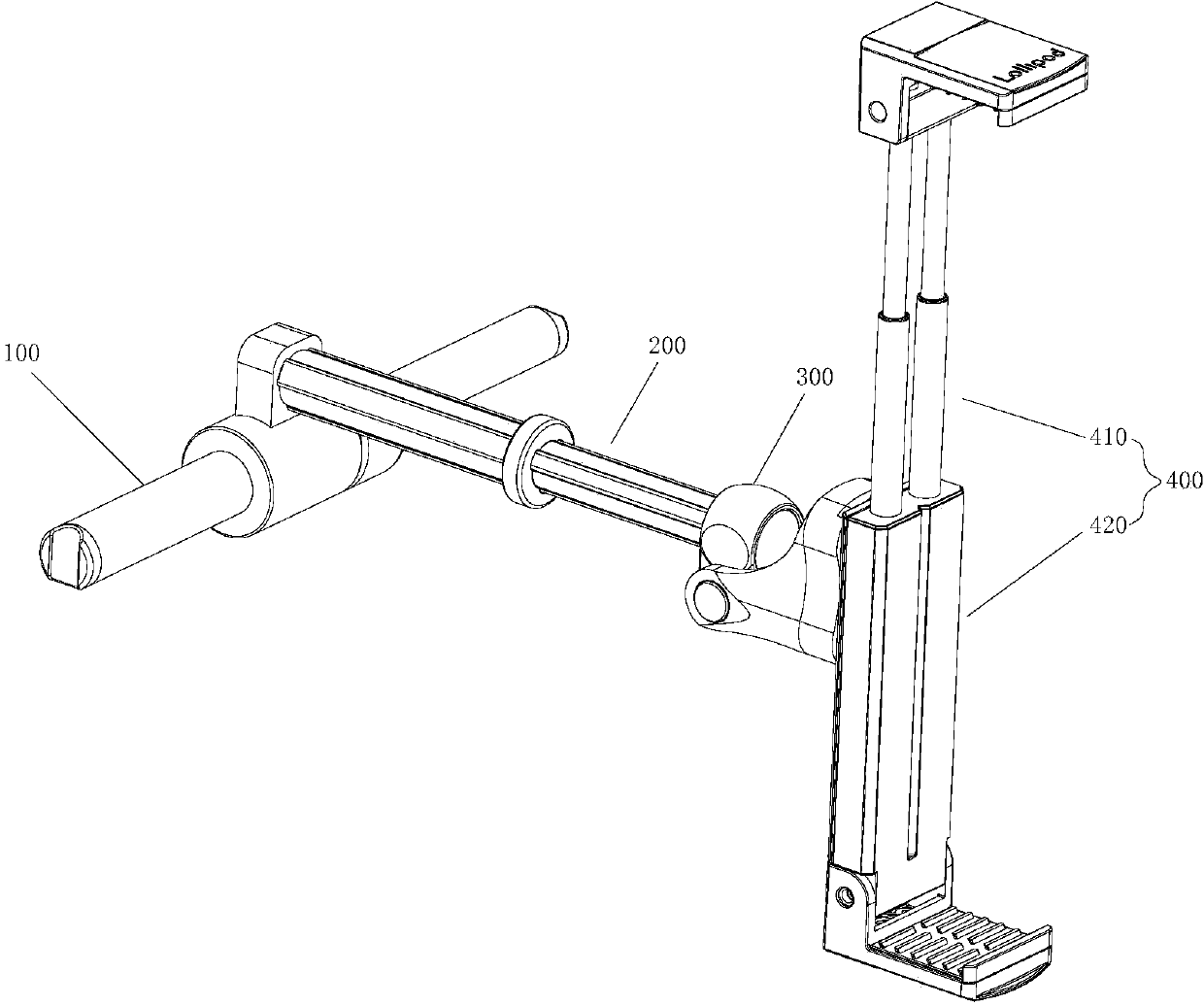

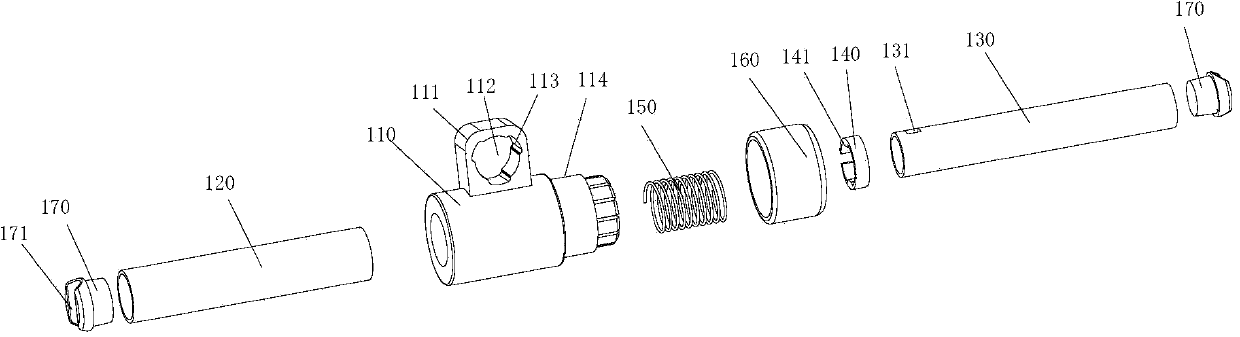

Automotive mobile terminal clamping device

InactiveCN104197153AStable positioningPrecise positioningStands/trestlesEngineeringMechanical engineering

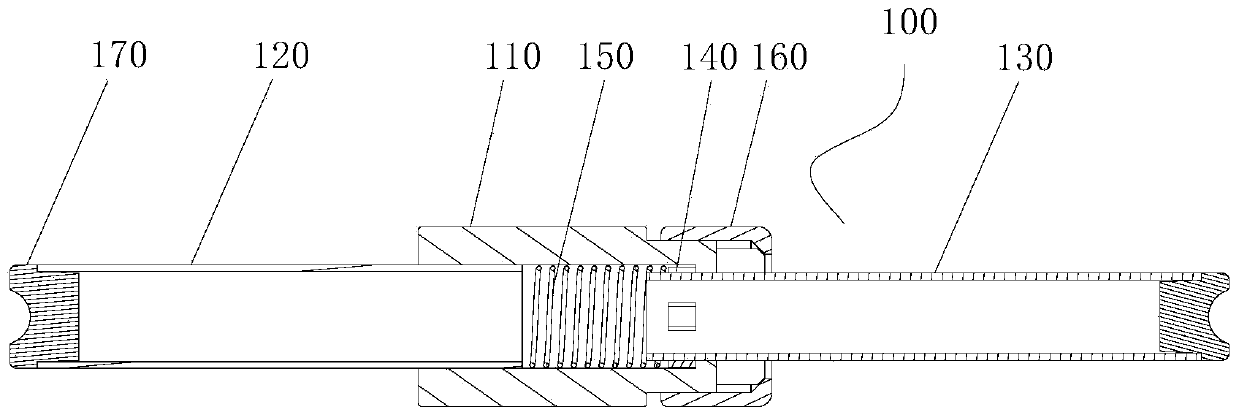

The invention discloses an automotive mobile terminal clamping device which comprises a clamping assembly, a fixing assembly and a branch pipe assembly for connecting the clamping assembly with the fixing assembly. The clamping assembly comprises a main body and a moving mechanism arranged on the main body, wherein a lower fixing end is arranged at the lower end of the main body, the moving mechanism comprises a plurality of connecting rods and elastic parts for resetting the connecting rods, and an upper fixing end corresponding to the lower fixing end is arranged at the upper end of each connecting rod. The fixing assembly comprises a connecting screw, a fixing rod arranged on the connecting screw and a movable rod, wherein a reset spring is arranged in the connecting screw, and an installing seat for the branch pipe assembly to be fixed is arranged on the connecting screw. The automotive mobile terminal clamping device is fixed on a supporting rod behind the position between a seat body and a pillow of an automobile seat, and the reset spring enables the movable rod to be always clamped on the supporting rod. By means of a structure on the seat, firm positioning is achieved, and people sitting on backseats can also easily use a mobile terminal on the road.

Owner:REAPER PHOTO SUPPLY +1

Management system and management method for intelligent warehouse AGV (Automatic Guided Vehicle)

InactiveCN107194442ALow costImprove efficiencyCo-operative working arrangementsLogisticsEngineeringRadio frequency

The invention relates to a management system for an AGV (Automatic Guided Vehicle), in particular to a management system and a management method for an intelligent warehouse AGV (Automatic Guided Vehicle). The management system comprises a vehicle radio frequency card, a radio frequency sensing node and a vehicle management system, wherein the radio frequency sensing node scans the vehicle radio frequency card and is connected with the vehicle management system through a wireless network; the vehicle radio frequency card is installed on one end of the vehicle; the radio frequency sensing node is installed above a goods shelf path; the radio frequency sensing node scans the vehicle radio frequency card and is provided with a wireless module, and scanning data is transmitted to the vehicle management system through the wireless network by the wireless module; and the vehicle management system calculates the position of the vehicle to realize the real-time positioning of the vehicle, plan the path of the vehicle and control the movement and the stopping of the vehicle. By use of the management system and a management method for the intelligent warehouse AGV, the vehicle can be subjected to real-time positioning and control, optimal path planning is carried out according to requirements, and the whole system has the advantages of low cost, high efficiency and stability in positioning and navigation.

Owner:SHENZHEN ZHEYEHONG IND CO LTD

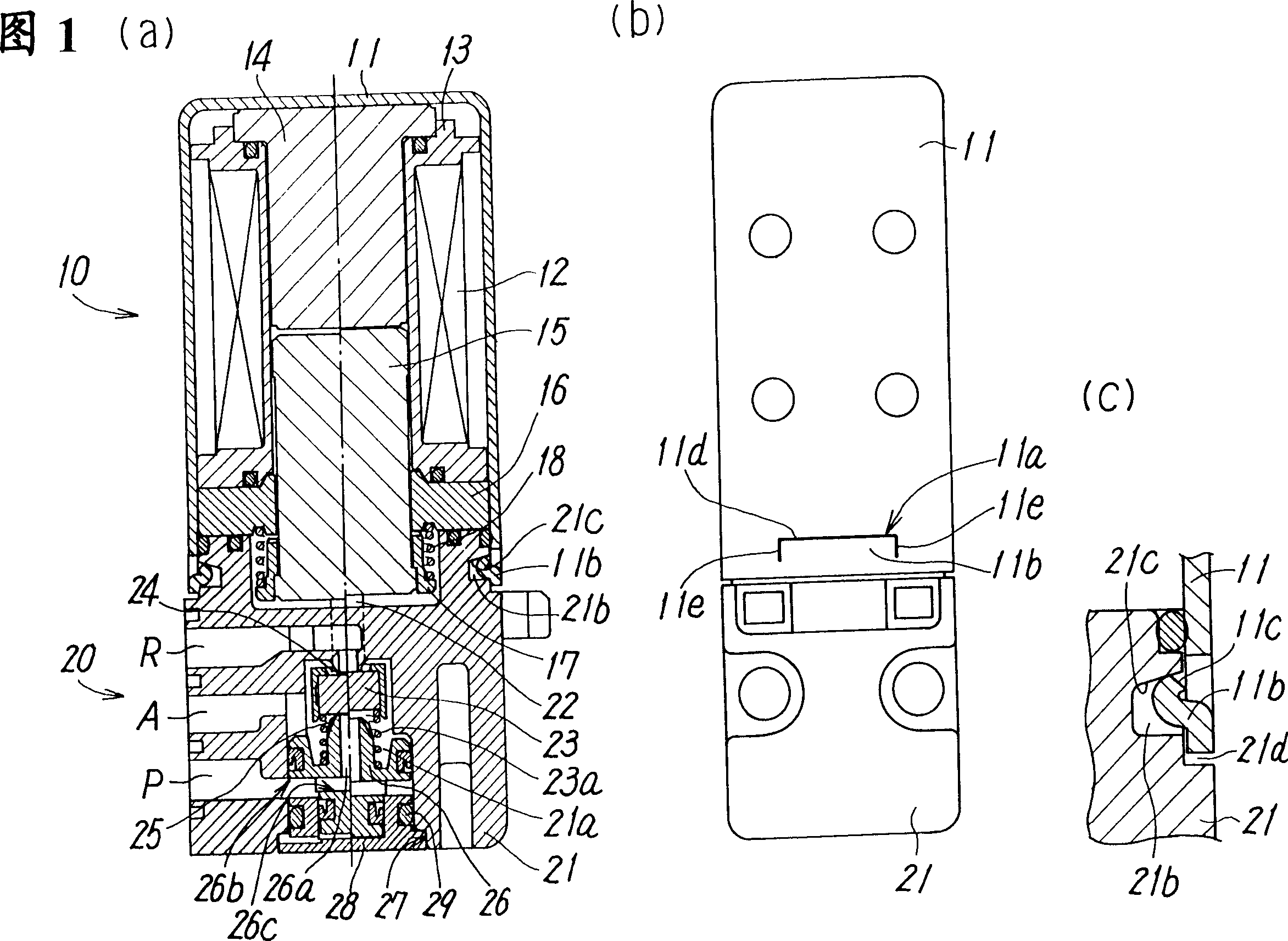

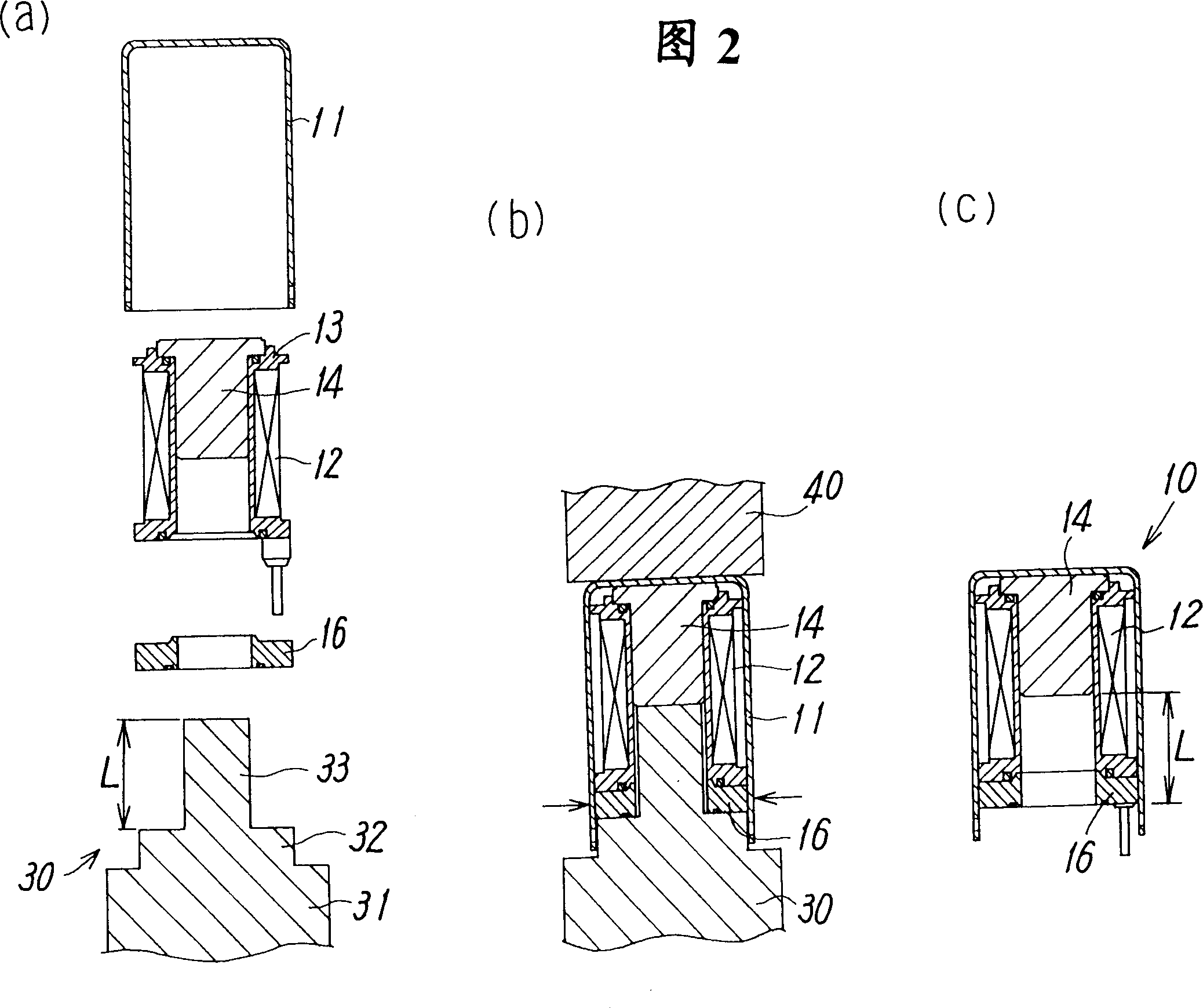

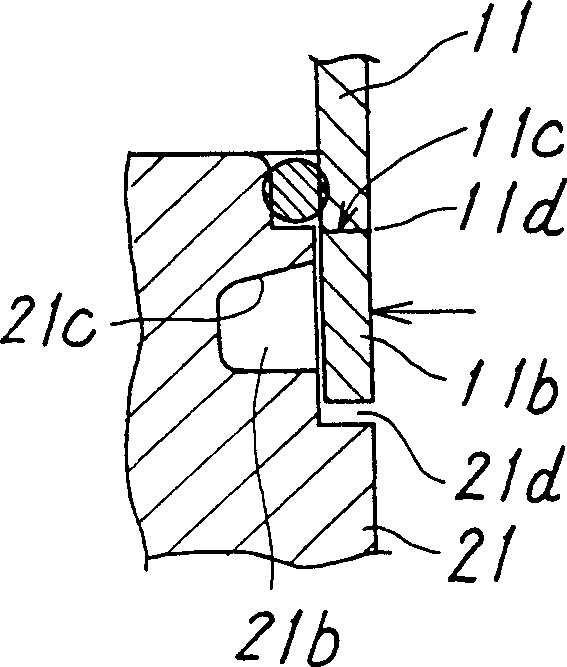

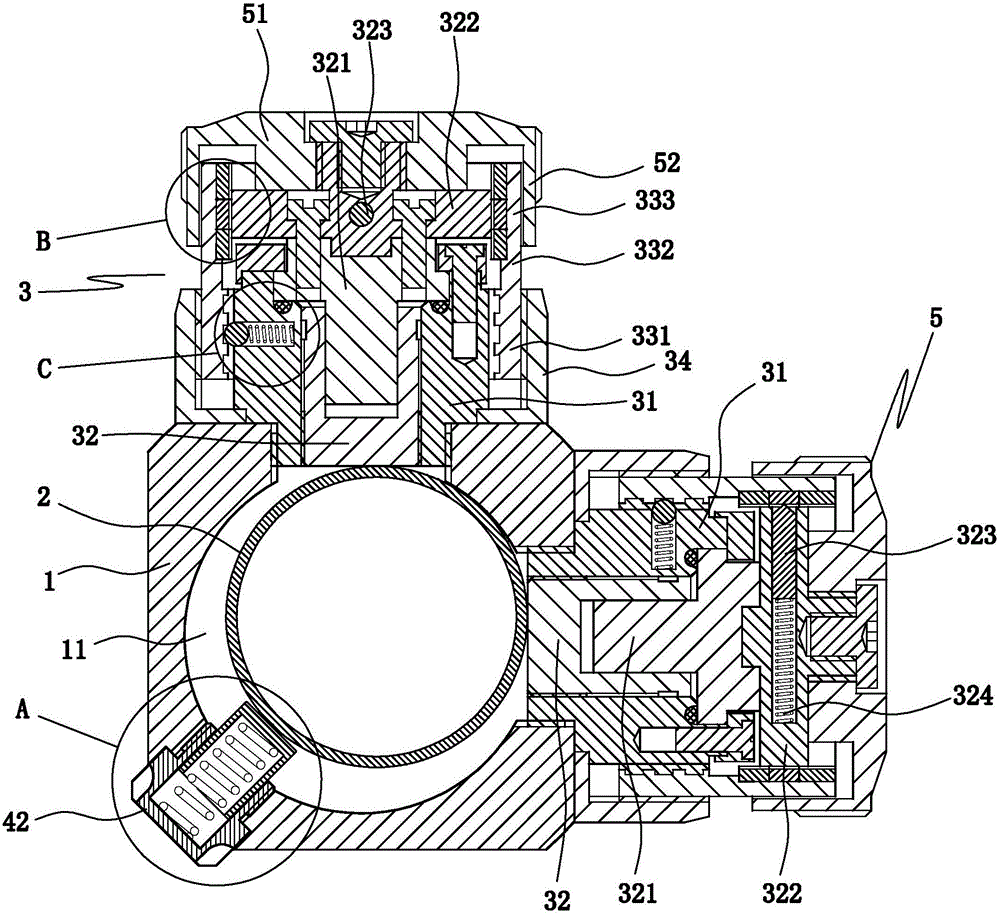

Electromagnetic valve

InactiveCN1407265AStable positioningCorrect positioningOperating means/releasing devices for valvesThin material handlingSizingEngineering

The invention provides an electromagnetic valve where a high coupling strength between a valve portion and a solenoid portion can be secured simply at a low cost without large-sizing the solenoid portion. Recessed portions 21b which are positioned on one end side of a valve body 21 and whose inner wall faces formed by inclining faces 21c which incline from the one end side of the valve body 21 to the other end side towards its depth are provided on a valve body 21 side face positioned on one end side of the valve body 21 so as to be opposed to each other, while cuttings 11a for forming caulking pieces 11b are provided at positions corresponding to the recessed portions 21b on the side wall positioned on an opening side of a magnetic case 11, and the valve portion 20 and the solenoid portion 10 are coupled to each other in the state where they have been biased in directions in which they are fitted to each other by causing the caulking pieces 11b to abut on the inclining faces 21c of the recessed portions to caulk them in the recessed portions.

Owner:SMC CORP

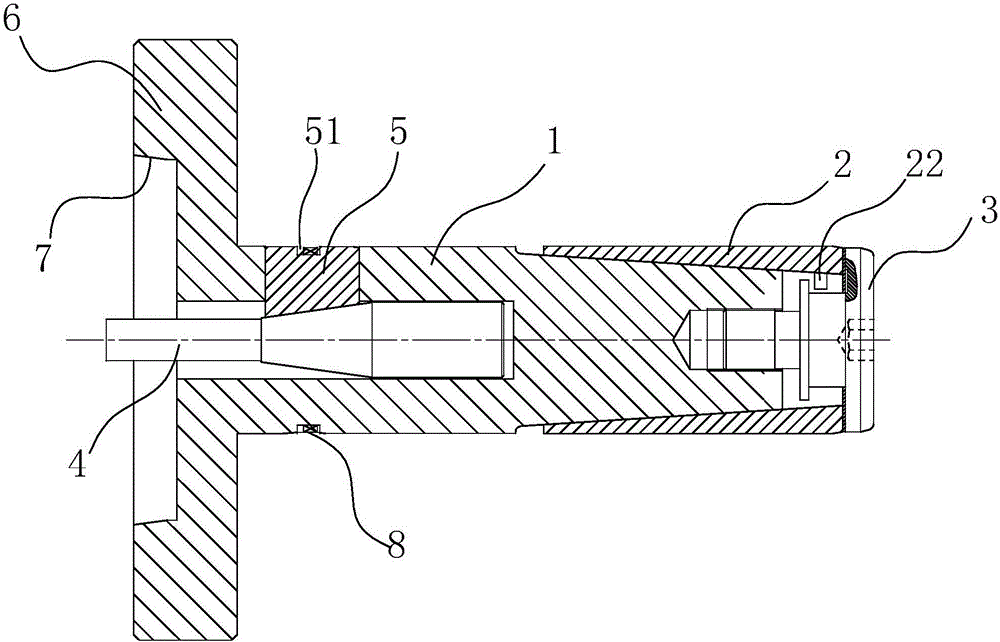

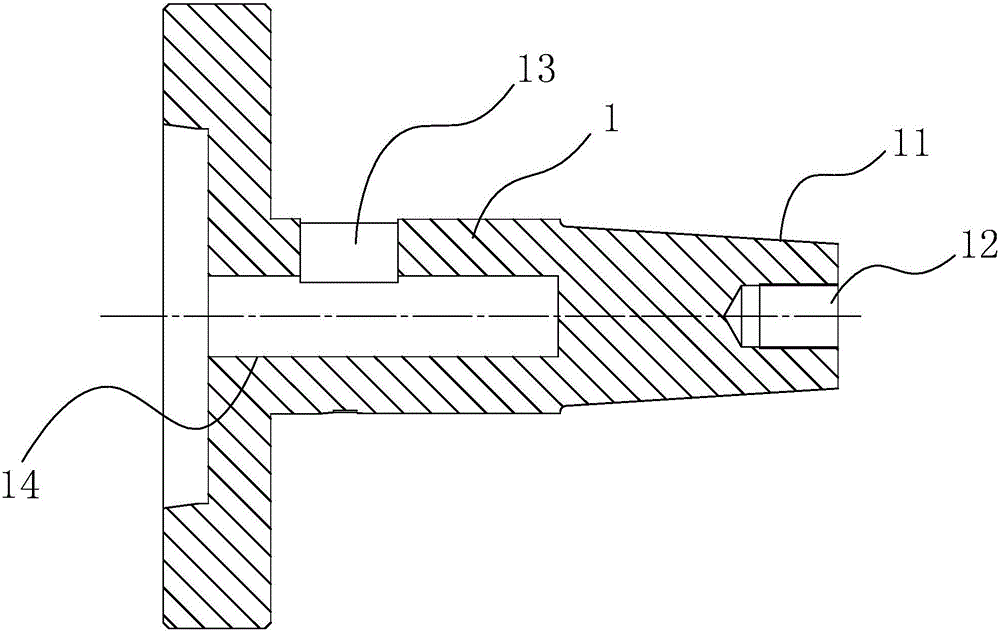

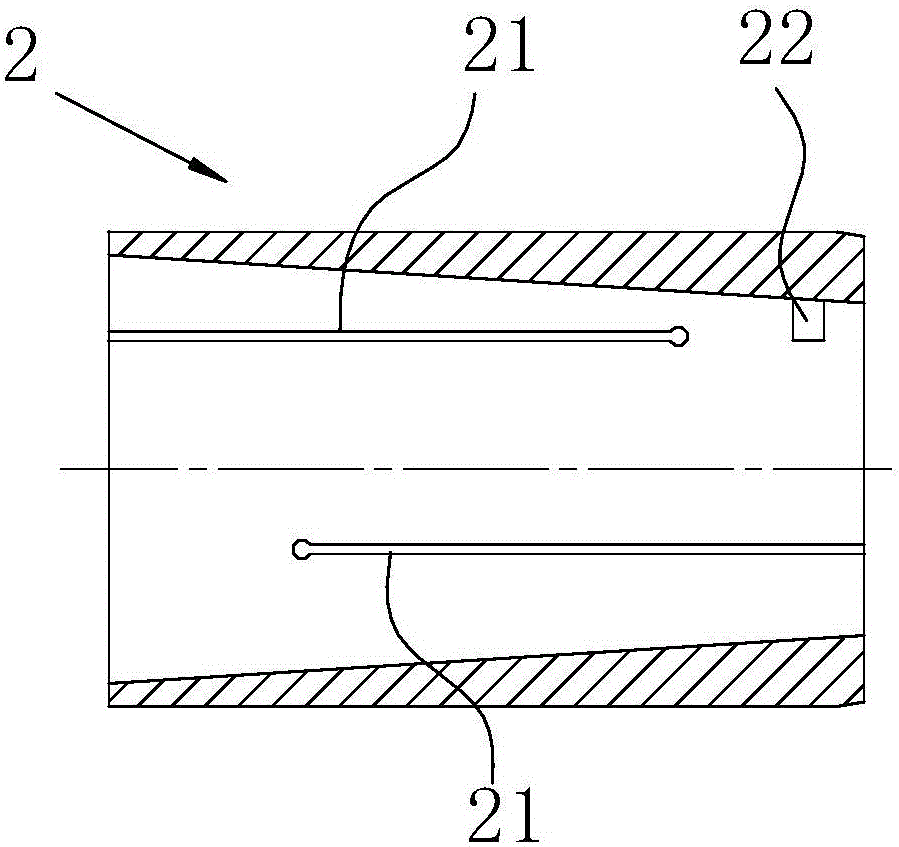

Outward expansion mandrel with multiple support parts

Owner:TENGXUAN TECH

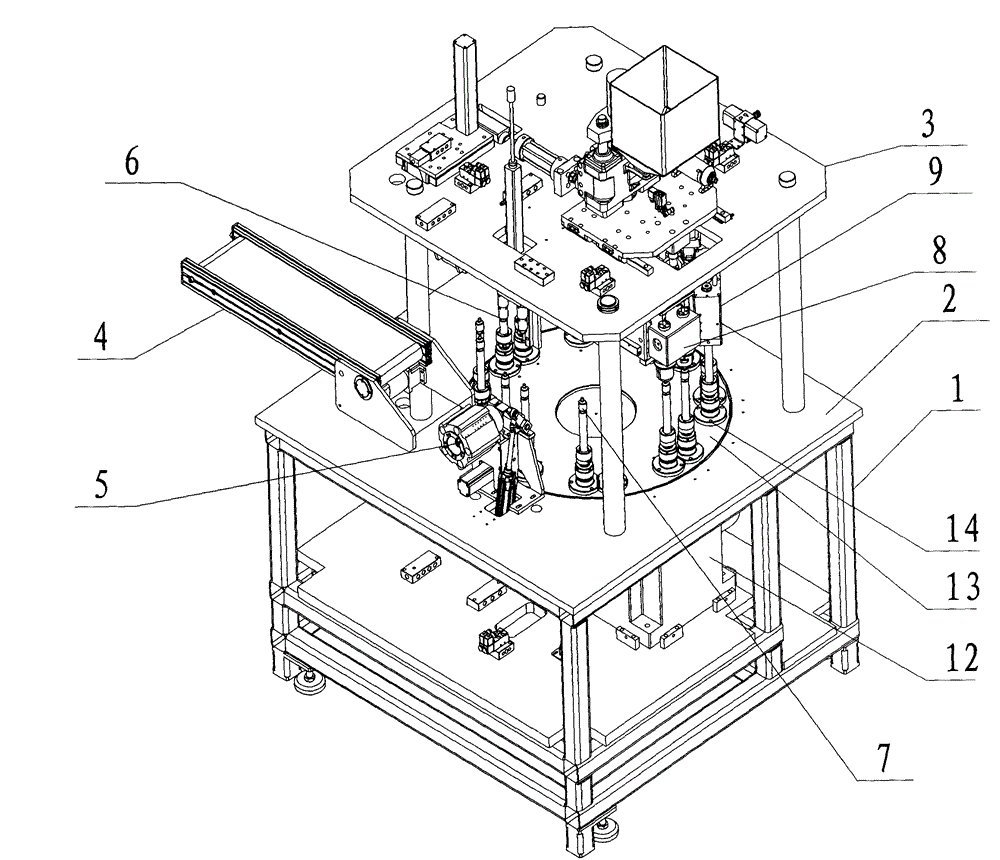

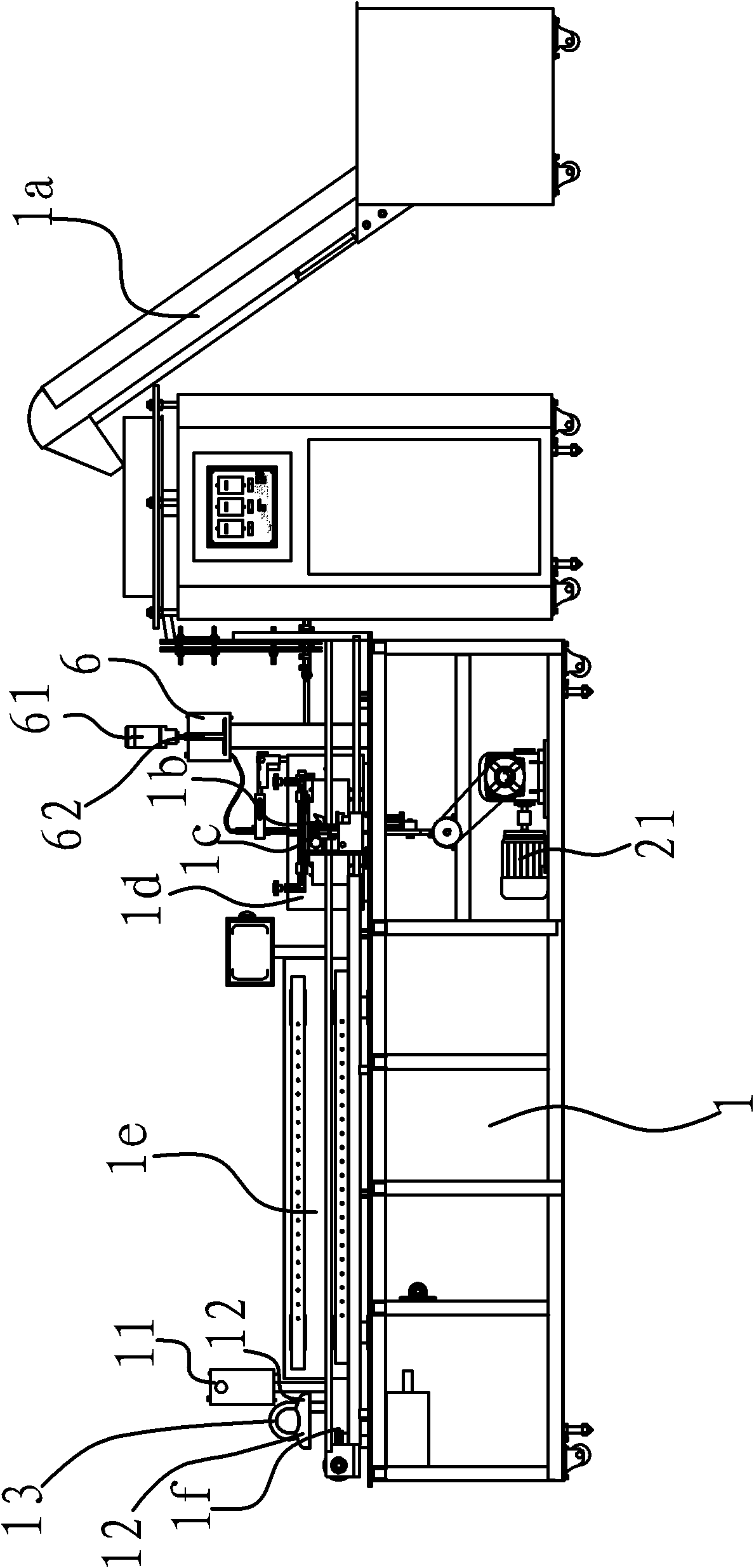

Automatic high speed flexible pipe shoulder forming machine

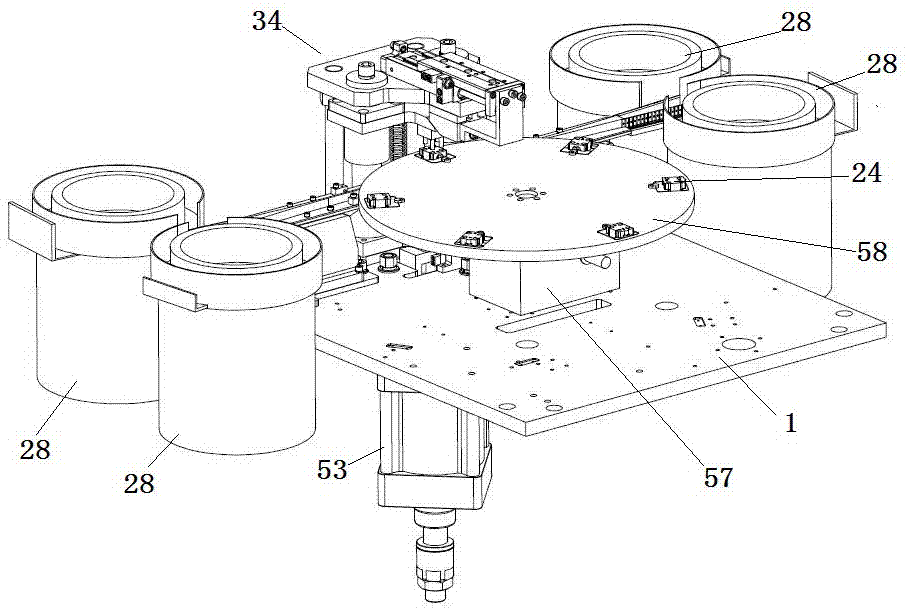

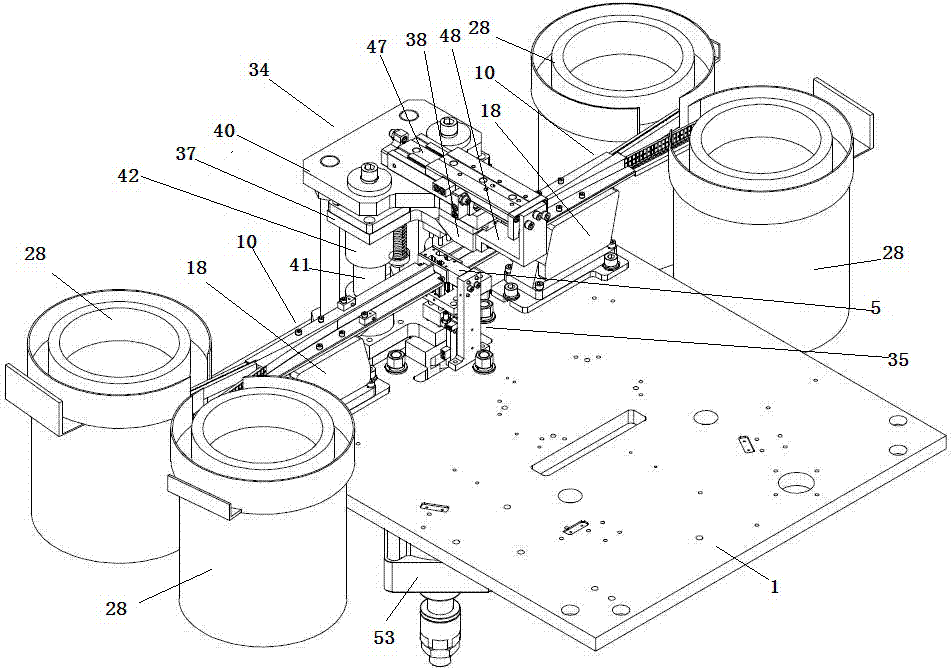

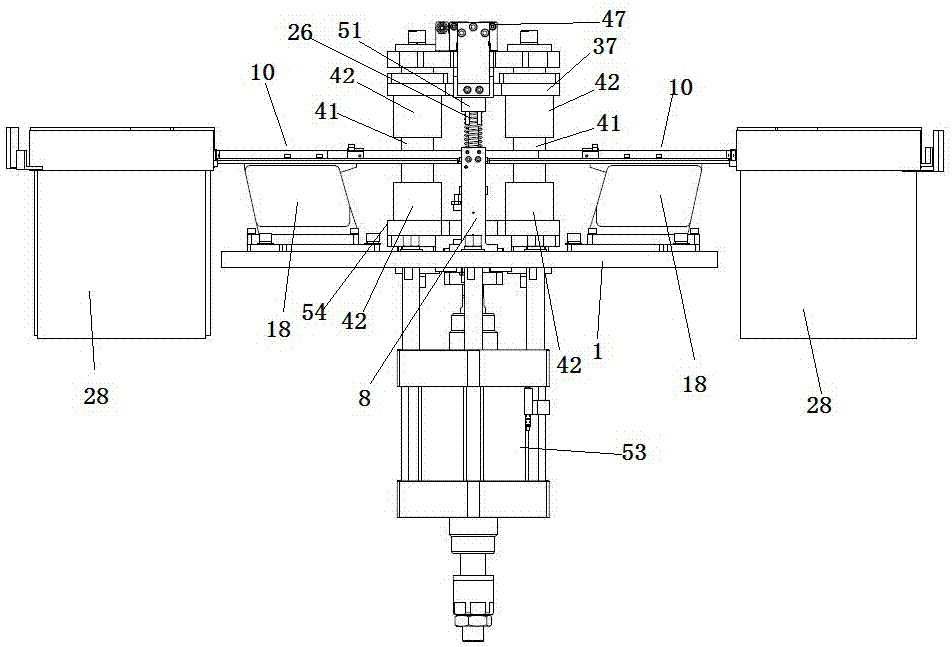

ActiveCN102744831AImprove molding processing efficiencyReduce labor intensityTubular articlesControl systemForm processing

The invention discloses an automatic high speed flexible pipe shoulder forming machine which comprises a frame and a working platform arranged on the frame, wherein a circular turntable mechanism driven by a main driving motor is mounted on the working platform. The forming machine is characterized in that the circular turntable mechanism is provided with a plurality of pairs of material cups, an automatic pipe feeding device, a detection device, an automatic plastic spitting device, an automatic forming device, a cooling device and an automatic pipe discharging device are correspondingly arranged around each pair of the material cups in order, and all the devices are controlled by PLC. According to the invention, the automation degree of the forming machine provided in the invention is high; an industrial PLC control system is used for automatic pipe feeding, automatic plastic spitting and automatic pipe discharging, and therefore, automatic forming processing operation of flexible pipes is realized, forming processing efficiency of the flexible pipes is improved, labor intensity is mitigated, and precise positioning and smooth and steady motion in processing of the flexible pipes are guaranteed; through utilization of the automatic pipe feeding device and simultaneous running of double pipes, high speed running is realized and production efficiency is enhanced.

Owner:NANTONG BAOTIAN PACKING MACHINERY

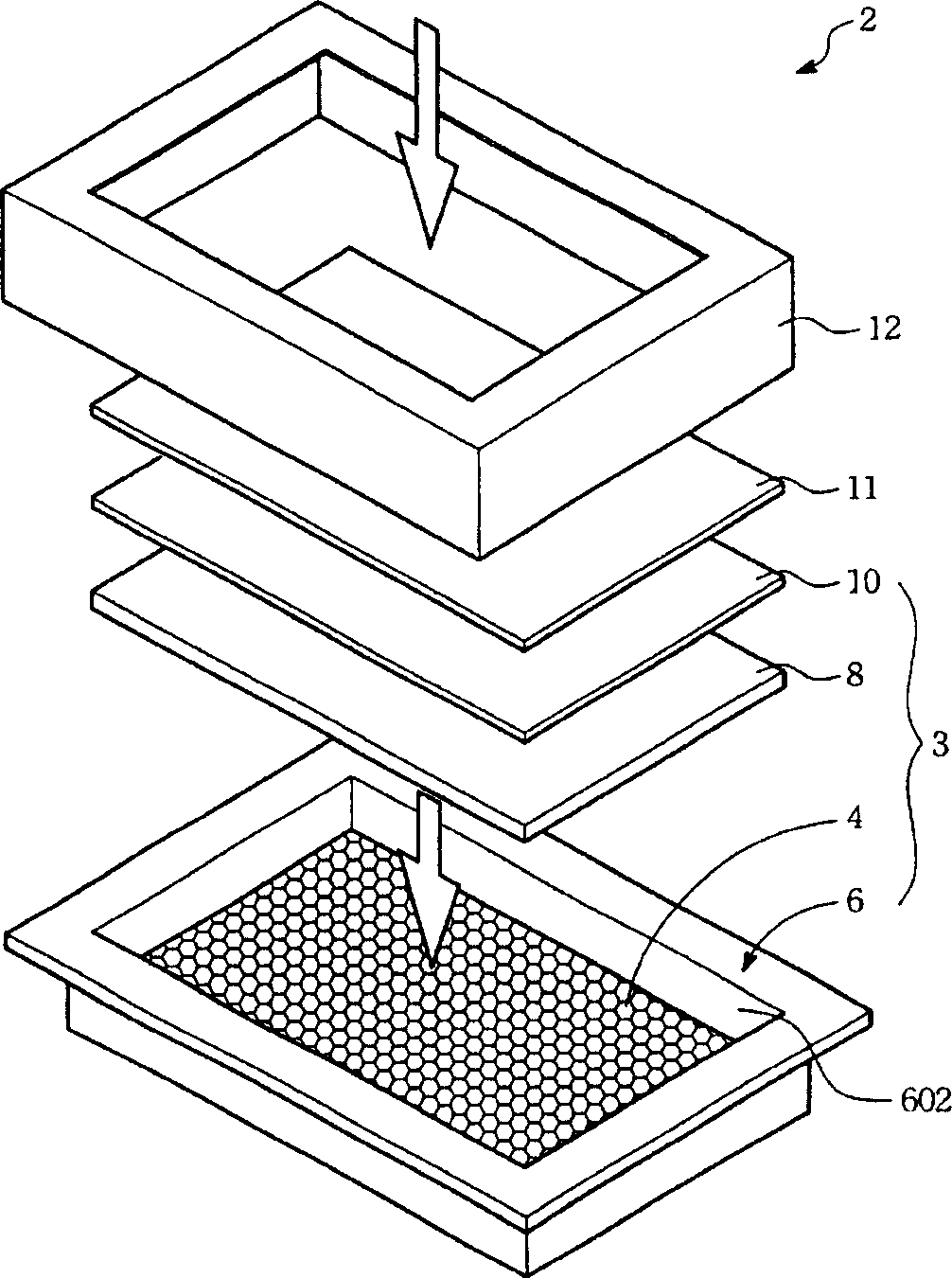

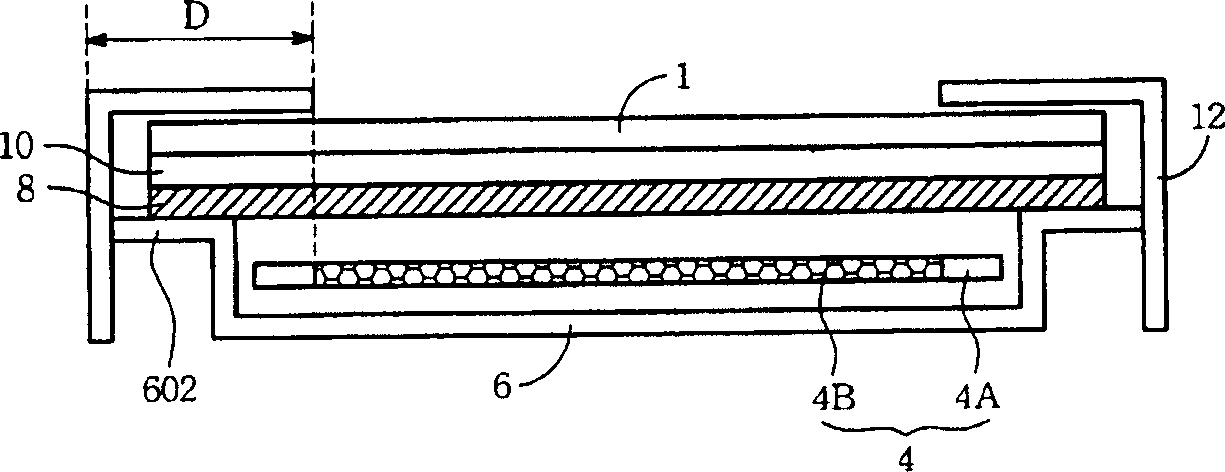

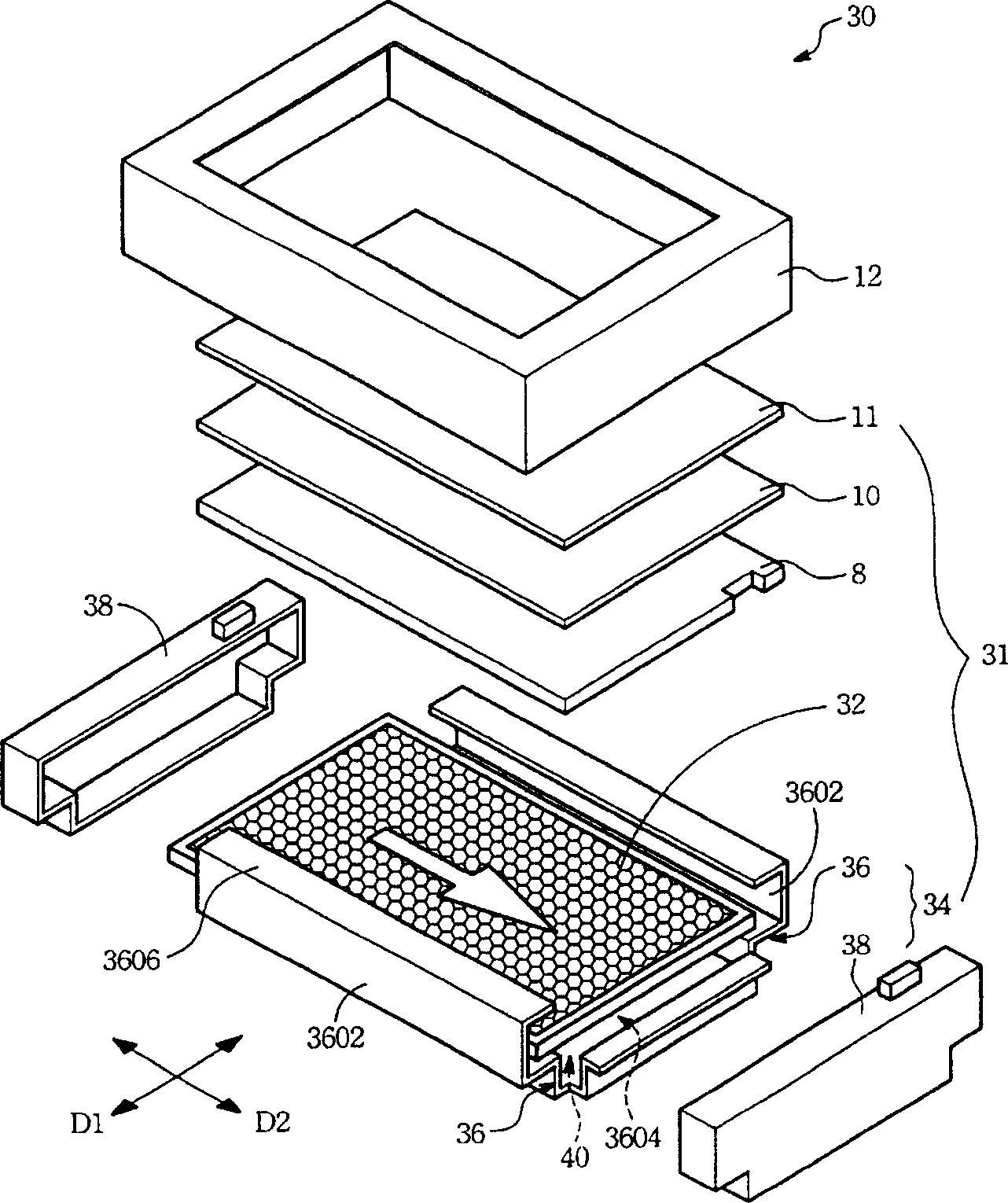

Backlight source assembly

InactiveCN1766705AEasy to disassembleStable positioningStatic indicating devicesNon-linear opticsEngineeringLight source

Owner:CORETRONIC

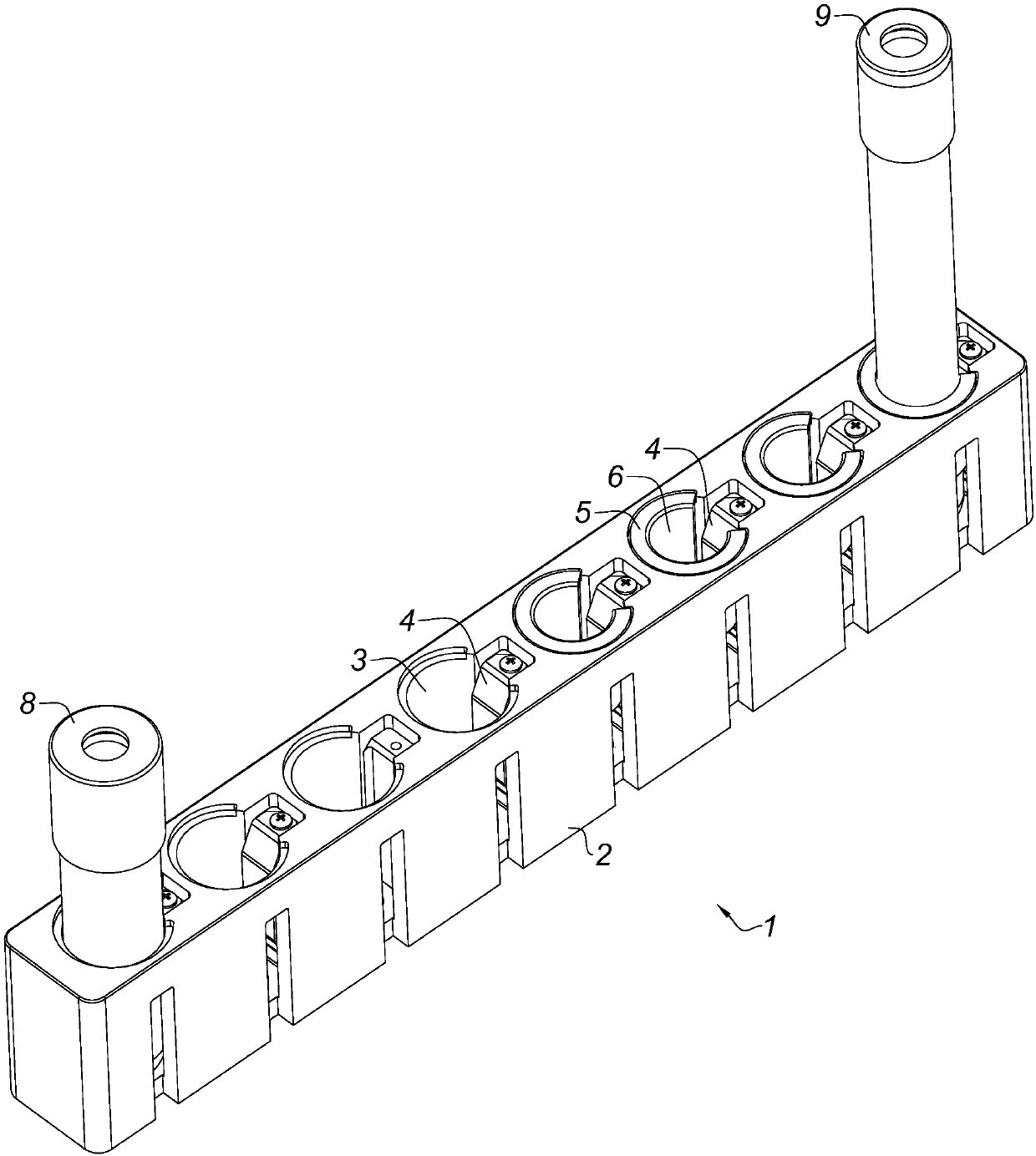

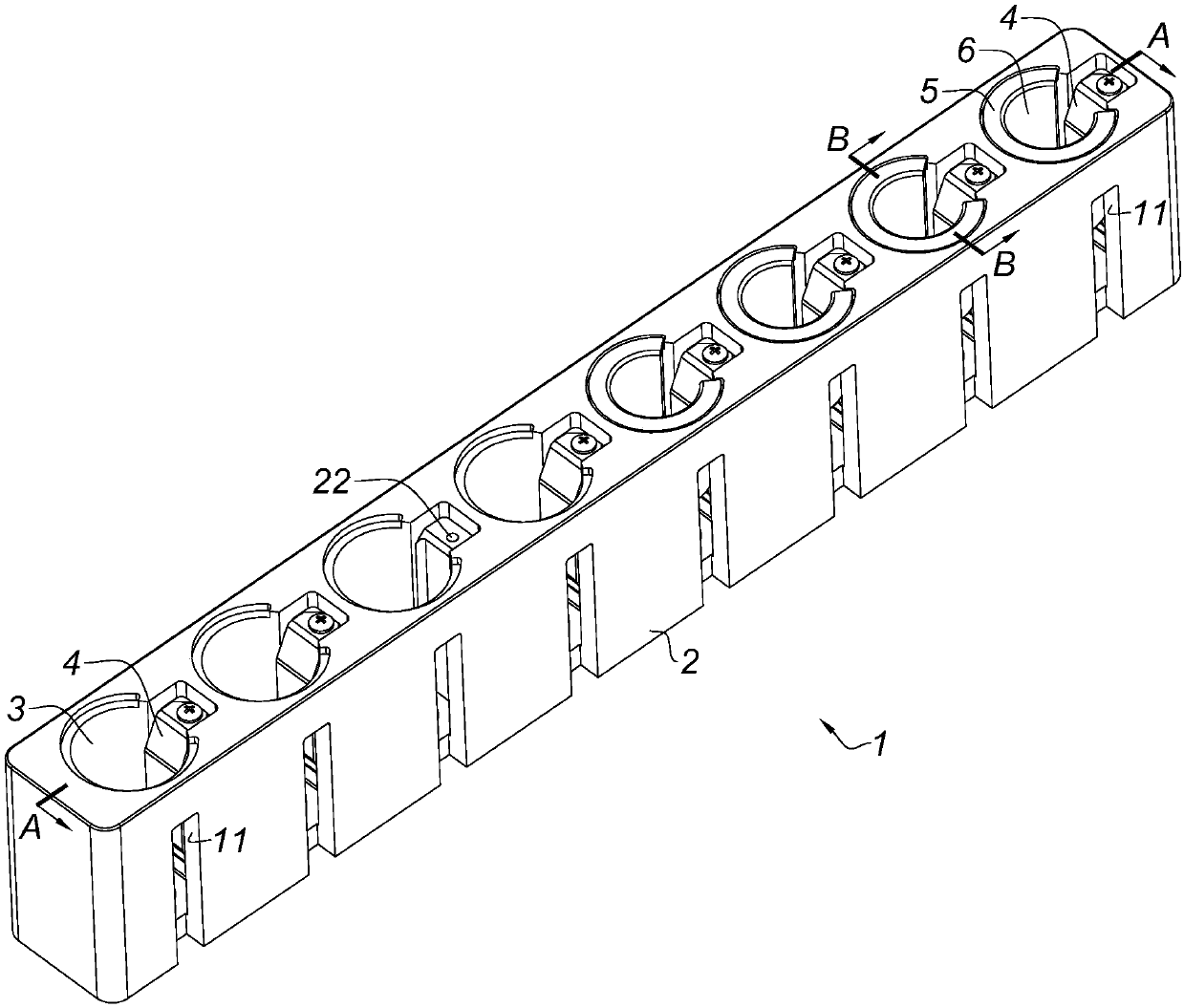

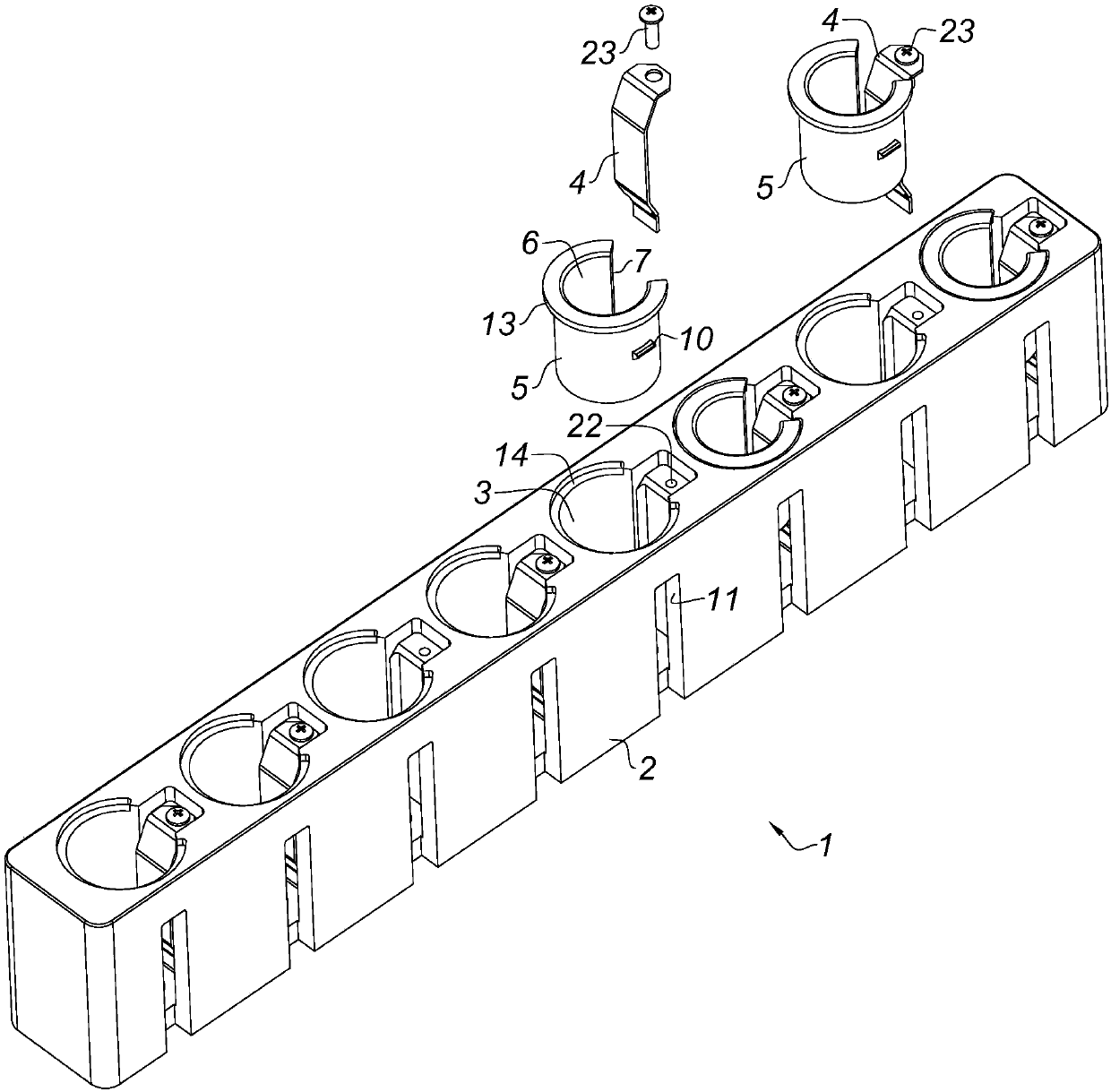

Test-tube rack

InactiveCN107913752APrecise positioningWide range of compatibilityTest tube stands/holdersEngineeringTest tube

The invention belongs to the technical field of biochemical experiment auxiliary appliances and provides a test-tube rack in order to solve the problems that an existing test-tube rack is small in compatible range and complicated in structure, cannot position test tubes accurately and cannot clamp the test tubes stably and the like. The test-tube rack comprises a main body, wherein inserting holesallowing insertion of the test tubes are formed in the main body; the test-tube rack further comprises elastic pieces and adapters, the elastic pieces are arranged in the inserting holes and can supply elastic pressure to the test tubes, the adapters are inserted in the inserting holes and provided with through holes allowing insertion of the test tubes, each adapter is further provided with a notch yielding to the corresponding elastic piece, and the elastic piece can penetrate through the notch to supply elastic pressure to the corresponding test tube. With combination of the adapters and the elastic pieces, the test-tube rack can load and position the test tubes stably and accurately; besides, the test-tube rack requires a few parts and is simple in structure, the adapters can be processed into various sizes, various test tubes can be compatible by selecting the adapters with proper sizes, the operation is easy, flexibility is quite high, and the manufacturing cost of the test-tuberack is low.

Owner:MGI TECH CO LTD

High-heat dissipation LED module street lamp cap with adjustable angle

InactiveCN101761831AEasy to operateStable positioningPoint-like light sourceElectric circuit arrangementsEngineeringLight head

The invention discloses a high-heat dissipation LED module street lamp cap with an adjustable angle, which comprises a fixed seat, a first support and a second support which are fixedly connected with the fixed seat, a positioning bracket used for fixing the first support and the second support and an LED module arranged between the first support and the second support. Positioning screws and positioning devices are arranged at both ends of the LED module; U-shaped bayonets are arranged on the first support; tap position clamping holes are arranged on one side of the U-shaped bayonets; the distance from each tap position clamping hole to each U-shaped bayonet is the same as the axial distance from each positioning contact to each connecting screw; the second support is correspondingly provided with the U-shaped bayonets of which the positions and the number are the same as those of the first support; the positioning screws of the positioning devices are clamped in the U-shaped bayonets of the second support; the connecting screws are clamped in the U-shaped bayonets of the first support; and the positioning contacts are clamped in the tap position clamping holes. The LED module street lamp cap has the advantages of simple operation, stable positioning, convenient assembly, environmental protection and energy conservation.

Owner:中山市盈点光电科技有限公司 +1

Screen printing device in automatic round-surface screen printing machine

InactiveCN102126335AStable positioningGood printing qualityScreen printersEngineeringElectrical and Electronics engineering

The invention provides a screen printing device in an automatic round-surface screen printing machine, belonging to the field of mechanical technology and solving the problems of complex structure and low production efficiency of the traditional screen printing device. The screen printing device in the automatic round-surface screen printing machine is arranged on a stand and comprises a transmission chain for transmitting a workpiece, wherein the transmission chain is fixedly connected with a support for holding the workpiece, a screen printing ink box for printing the workpiece is arranged above the transmission chain, the stand is provided with a translation mechanism for controlling the screen printing ink box to reciprocate along a horizontal plane, the stand is provided with a jacking mechanism capable of jacking the workpiece on the support onto the screen printing ink box, two sides of the stand are further provided with a clamping mechanism with two supporting members, the supporting members can rotate by taking the respective axis as a center, and when the workpiece is jacked up by the jacking mechanism, the two supporting members can jack and press the two ends of the workpiece respectively. The screen printing device in the automatic round-surface screen printing machine has the advantages of good printing quality, high efficiency, high printing speed, low fault rate and the like.

Owner:玉环东美塑机有限公司

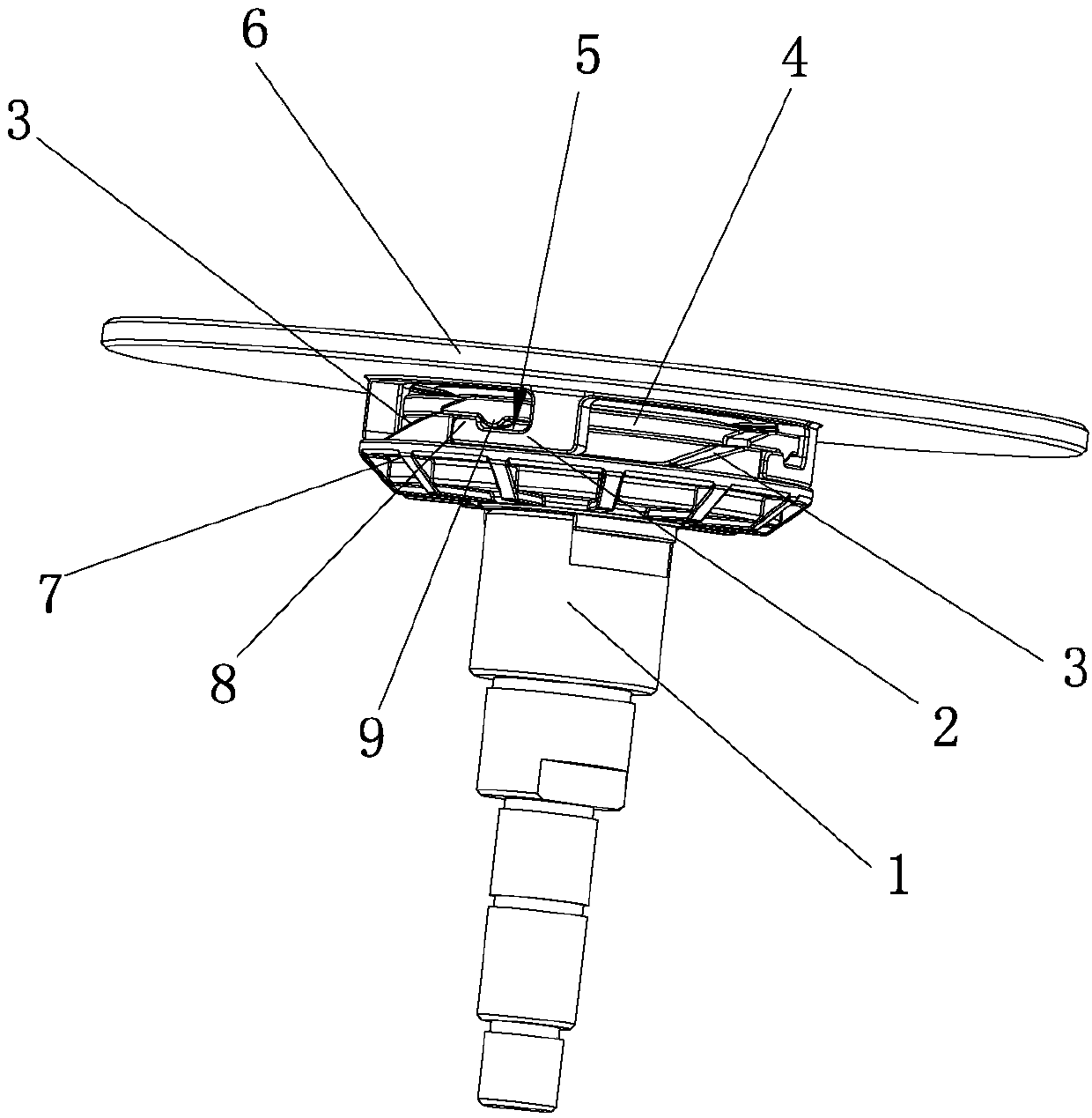

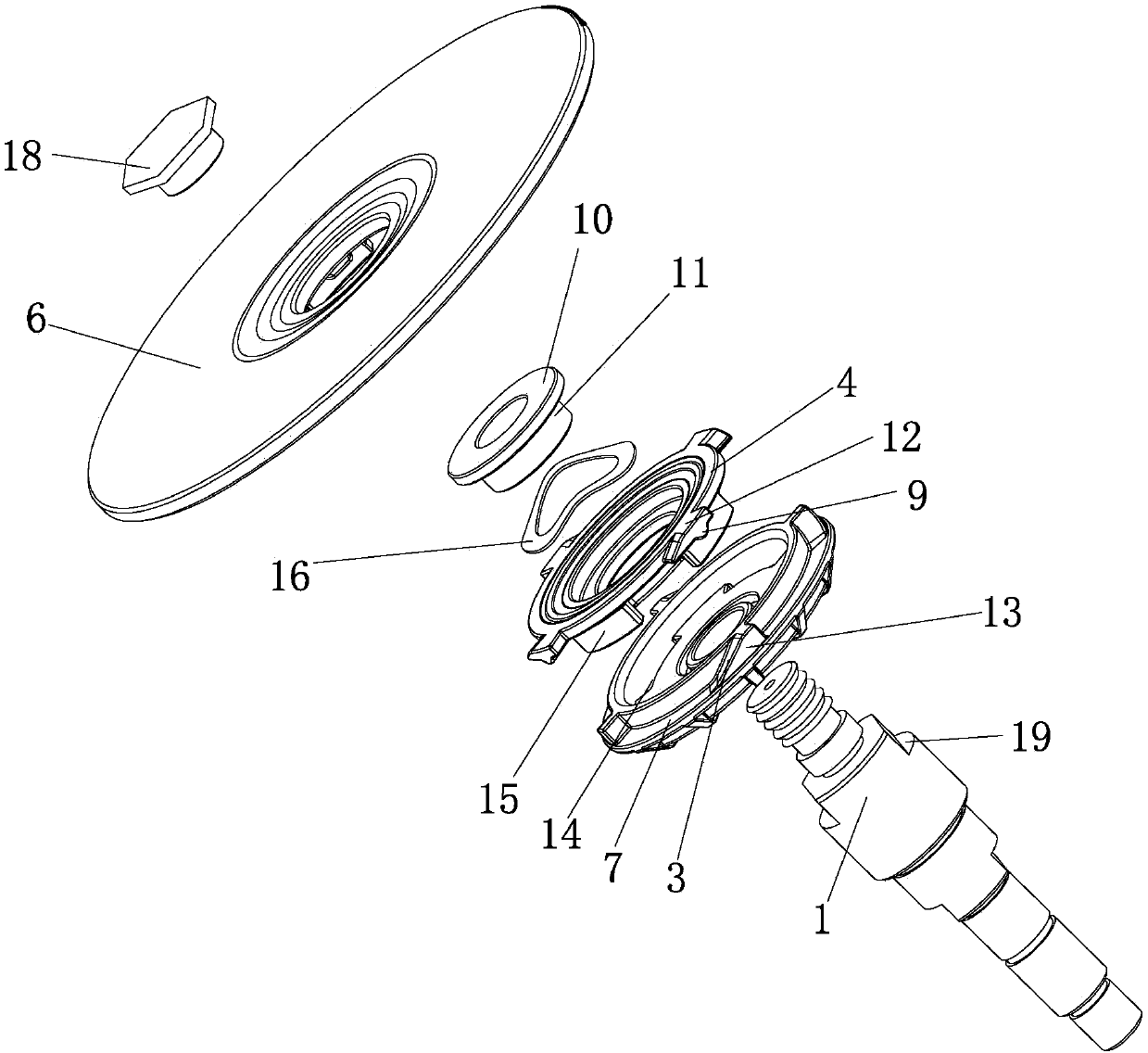

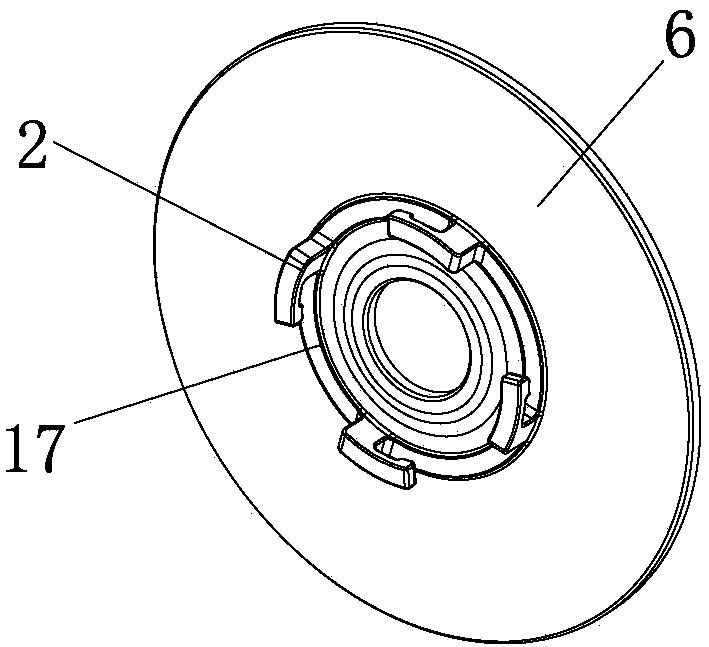

Quick clamp assembling mechanism for grinding wheel

ActiveCN105945726AQuick Change Grinding WheelsStable positioningGrinding wheel securing apparatusEngineeringAnnular array

The invention provides a quick clamp assembling mechanism for a grinding wheel and belongs to the technical field of electric tools. The quick clamp assembling mechanism comprises a discoidal mounting base and a connecting plate, wherein the mounting base is inserted into an output shaft of the electric tool and is limited; a plurality of clamping grooves forming an annular array are formed in the mounting base; the connecting plate is fixed on one surface of the grinding wheel; clamping claws which correspond to the clamping grooves and form an annular array are arranged on the connecting plate; and when the clamping claws are connected with the corresponding clamping grooves, a trip preventing device is also arranged for fastening the clamping grooves and the clamping claws. According to the device, the aim of quickly replacing and clamping the grinding wheel is achieved; in addition, the quick clamp assembling mechanism is suitable for all electric tools using the grinding wheels; and during replacement and clamping, the clamping claws are twisted into the corresponding clamping grooves to realize the positioning, and the stability in positioning is realized.

Owner:武义史夫克工具股份有限公司

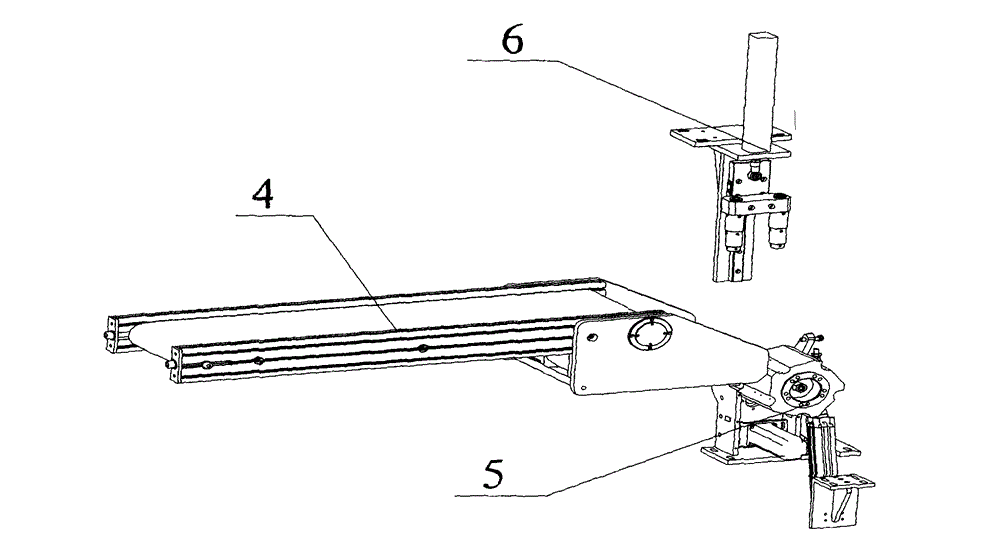

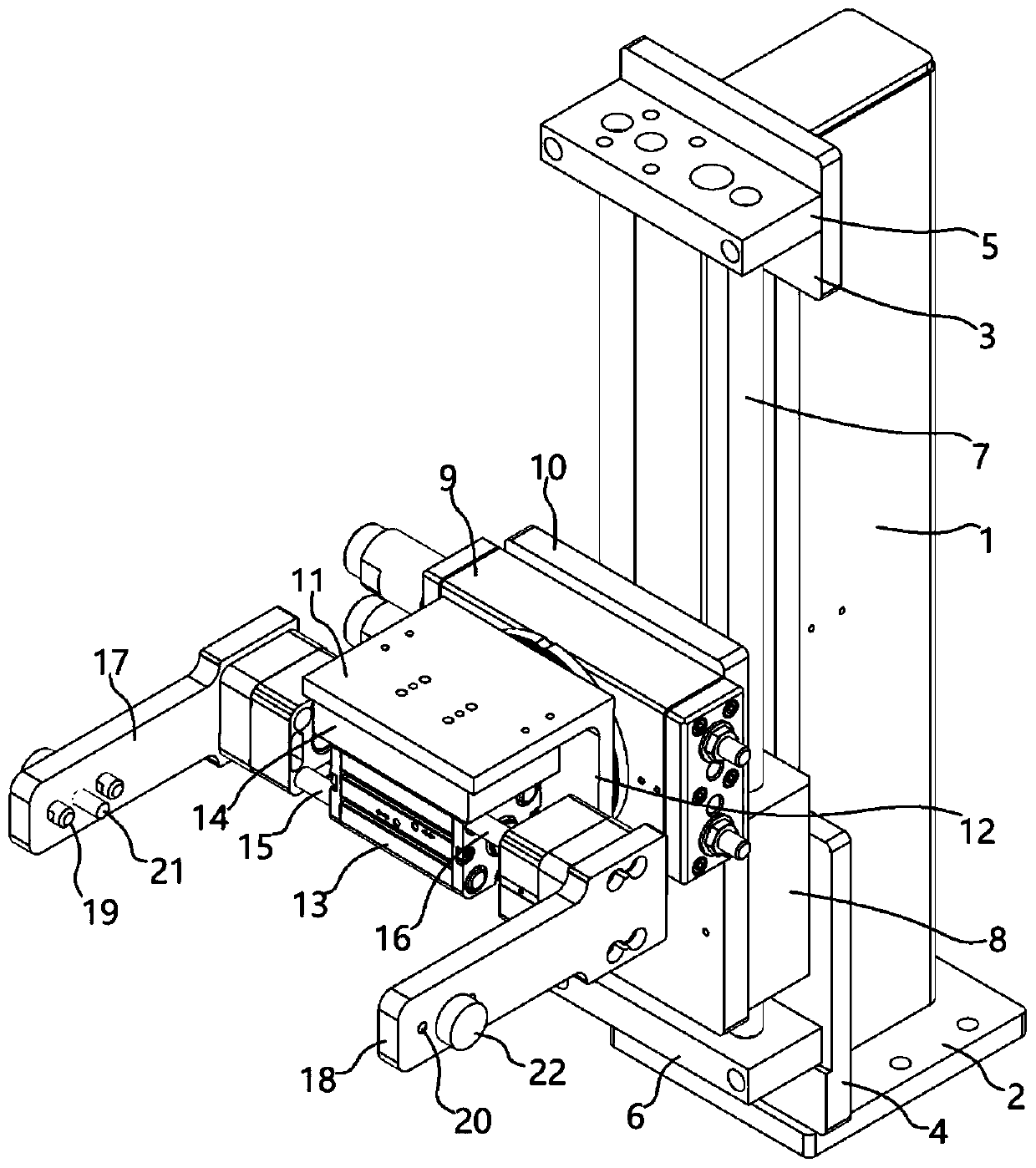

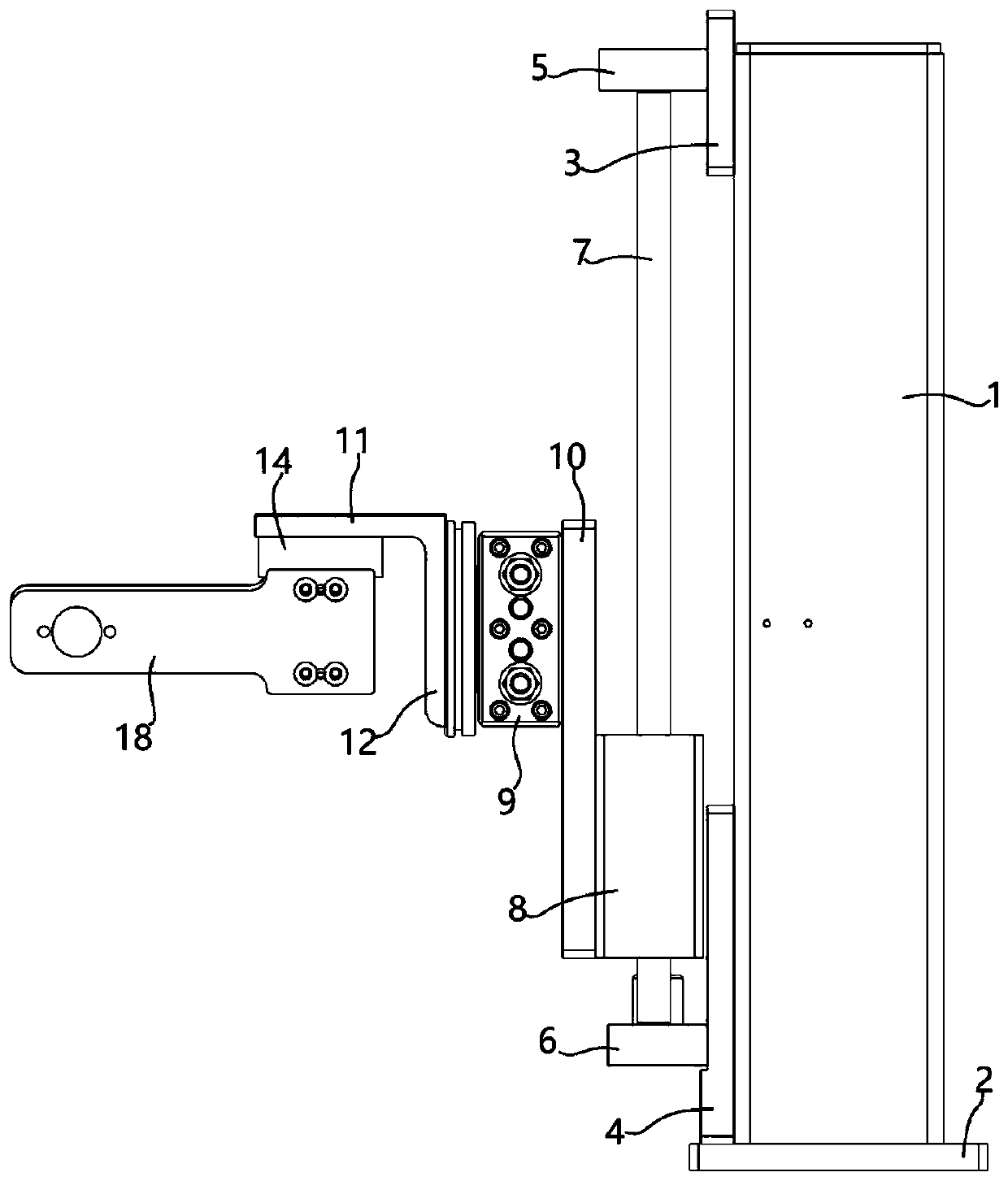

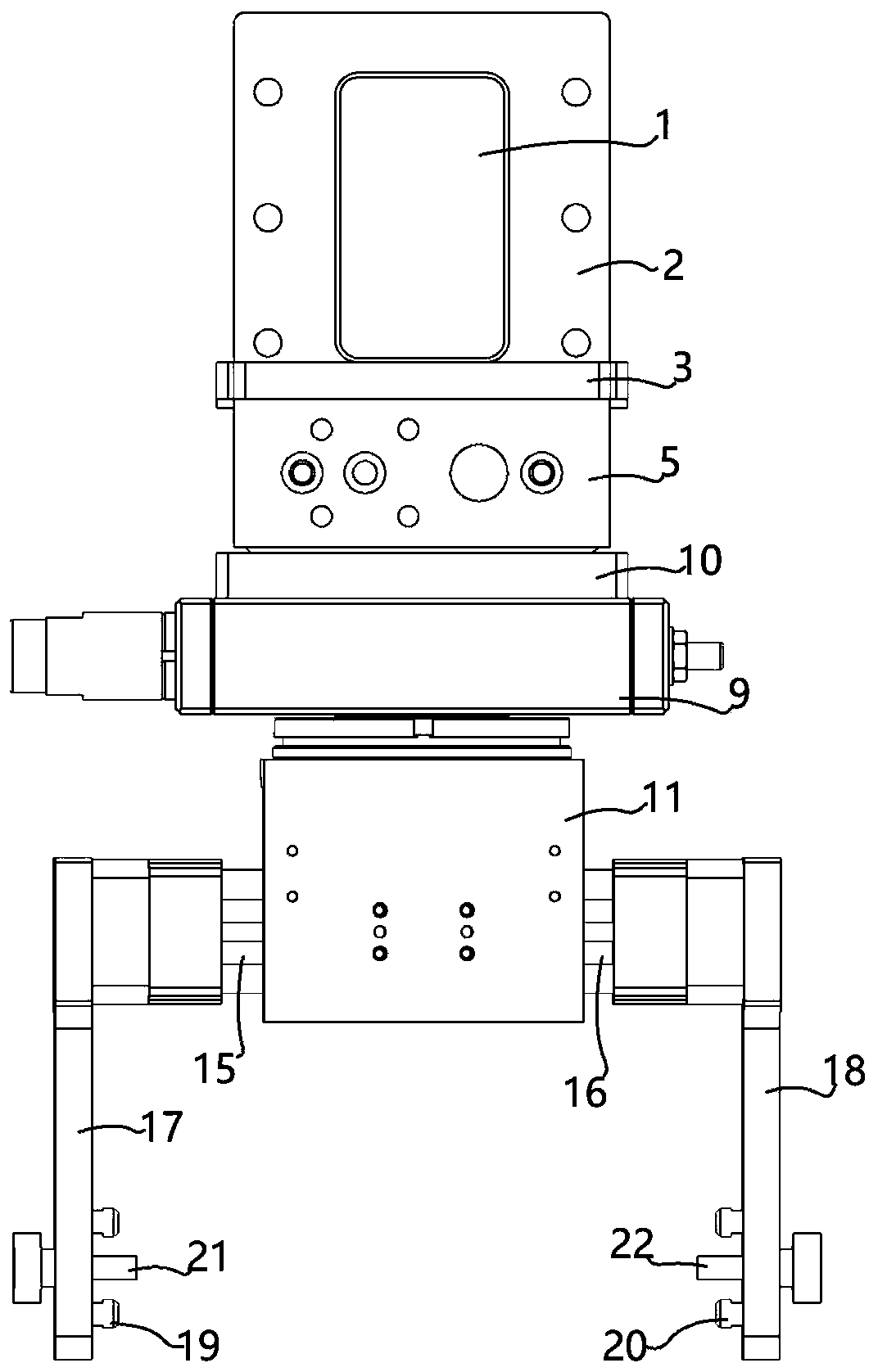

Furniture plate turnover device

InactiveCN110482190AStable positioningPrevent looseningConveyor partsEngineeringMechanical engineering

The invention provides a furniture plate turnover device. The furniture plate turnover device comprises a supporting mechanism, a lifting mechanism, a rotating mechanism and a clamping mechanism, wherein the supporting mechanism is fixed in a frame; the lifting mechanism is arranged on the supporting mechanism; the rotating mechanism is arranged on the lifting mechanism; the clamping mechanism isarranged on the rotating mechanism; and the clamping mechanism is provided with a positioning mechanism for fixing a furniture plate. The lifting mechanism drives the rotating mechanism, the clampingmechanism and the furniture plate carried by the clamping mechanism to rise and fall, and the rotating mechanism drives the clamping mechanism and the furniture plate carried by the clamping mechanismto rotate. According to the turnover device, the rotating mechanism is arranged on the lifting mechanism, and the rotating mechanism can move to a proper height through the lifting mechanism before overturning, so that the rotating mechanism is conveniently matched with processing equipment, the collision between the rotating mechanism and surrounding parts is avoided, and therefore, the turnoverdevice is suitable for various working conditions.

Owner:上海天彧家具有限公司

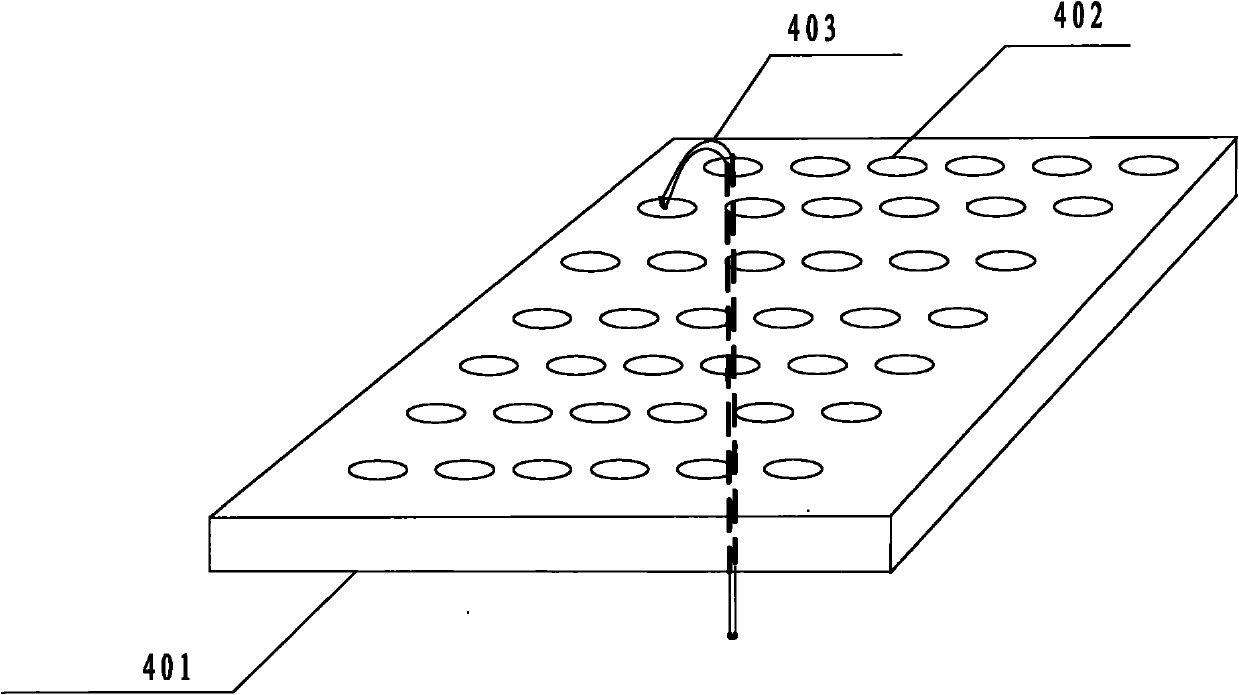

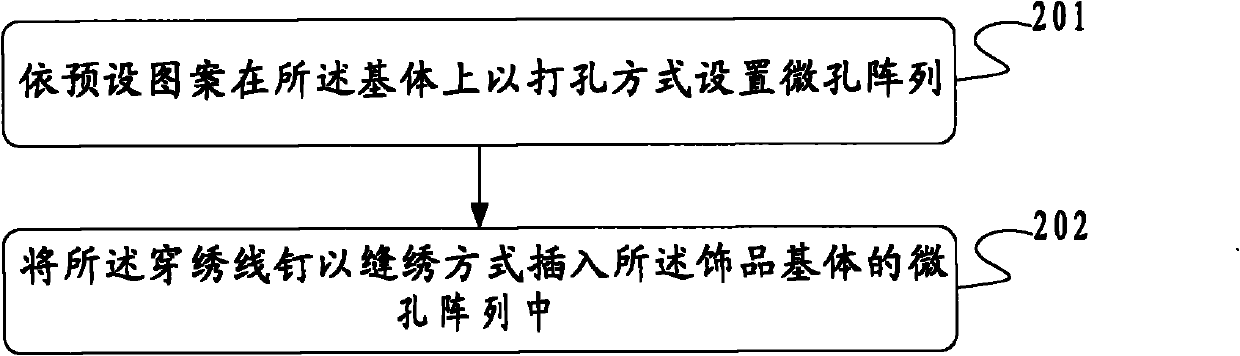

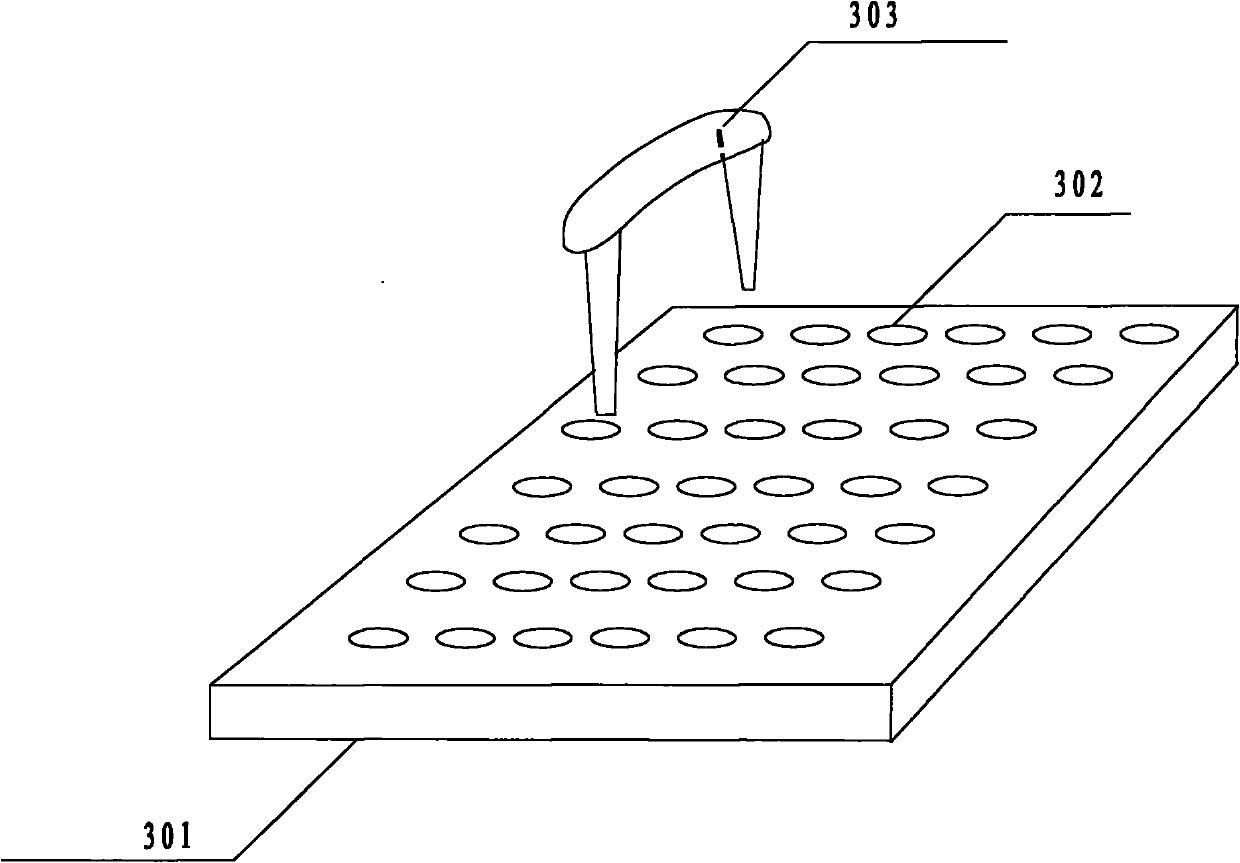

Method for manufacturing ornamental article and ornamental article

The embodiment of the invention discloses a method for manufacturing an ornamental article and the ornamental article. In the embodiment of the invention, an embroider line nail is fixed on an ornamental article of which an array is formed by punching according to a preset pattern so as to form an ornamental pattern, so that an attractive appearance of the pattern of the ornamental article is realized; and more importantly, because the ornamental article is fixed in a micropore through the embroider line nail, firmly positioned and protected from artificial damage, the storage durability of the pattern of the ornamental article is realized. The method overcomes the defects of wearing caused by human, difficult storage of a durable clear pattern and unfavorable storage in the prior art; meanwhile, the embodiment of the invention also discloses the ornamental article corresponding to the method for manufacturing the ornamental article. The ornamental article fixes the embroider line nail on the punched ornamental article, firmly positions the nail, has long storage time and meets the requirement of long-term storage of the ornamental article.

Owner:宋硕昌

Improved upward and downward compression mechanism of keyhole machine tool

InactiveCN102358997AStable positioningReduce assembly requirements and debugging difficultiesPressersKeyholeMechanical construction

The invention discloses an improved upward and downward compression mechanism of a keyhole machine tool. An upward and downward compression structure of the keyhole machine tool comprises a retainer plate of which the lower part is fixed horizontally and a compression plate of which the upper side can be opened / closed; and the compression plate is horizontal, and moves vertically up and down in horizontal state under the driving action of a cylinder. When the upward and downward compression structure is pressed down vertically, the problem of displacement of cloth caused by shearing force of a rotary extrusion upward and downward compression structure in the conventional product is solved, the linearity of a shirt top fly keyhole is increased greatly, and the attractiveness of a shirt top fly is ensured; compared with the conventional rotary extrusion upward and downward compression structure, the vertically-pressed upward and downward compression structure has the advantages: the mechanical structure is simplified greatly, the assembling difficulty and debugging difficulty are lowered greatly, the mechanical assembling efficiency is increased, and the maintenance cost of a customer is lowered; and due to the adoption of the vertically-pressed upward and downward compression structure, a sufficient stress surface is ensured during compression of cloth is ensured, the stress is more uniform, and the compression effect is better.

Owner:SHANGHAI WEISHI MACHINERY

Full-automatic cutting platform used for home textile fabric

The invention discloses a full-automatic cutting platform used for home textile fabric. The full-automatic cutting platform comprises a vertical platform, on which two outer guide rails and two inner guide rails are vertically arranged. A pressing plate is slidably arranged between the two inner guide rails in a transverse direction and provided with a cutting hole. One end of the pressing plate is provided with a pair of electric clippers. A rolling shaft is slidably connected between the two outer guide rails and provided with a roll for accommodating home textile fabric. The front side surface at two ends of the pressing plate is provided with a first positioning column. Two end portions of the rolling shaft are provided with positioning holes. Multiple locking mechanisms are arranged on the two inner guide rails. Two sides at the upper end of the vertical platform are provided with double-cylinder synchronous-positioning mechanisms. The full-automatic cutting platform used for home textile fabric has following advantages: by means of the vertical cutting platform, home textile fabric can be well and conveniently flattened; automated cutting is achieved so that precise cutting accuracy is ultimately realized; the double-cylinder synchronous-positioning mechanisms are utilized for automatically, precisely and stably positioning the rolling shaft; and cutting efficiency is increased and labor intensity of workers is decreased.

Owner:JIANGSU AUDIANO HOME TEXTILES

Riveting device for L-shaped leaf springs of travel switch cores

The invention relates to a riveting device for L-shaped leaf springs of travel switch cores. The riveting device comprises a working table top. A positioning block is fixedly connected to the upper side of the working table top, a rotary disc driven by a motor and a cam indexer to rotate is arranged above the positioning block, a plurality of carrying bases for carrying travel switches to be riveted are uniformly distributed on the surface of the rotary disc in the circumferential direction, vertical clearance grooves used for being communicated with rivets in the travel switches are formed in the carrying bases, vertical guide grooves communicated with the vertical clearance grooves are formed in the positioning block, a pressing mechanism used for pressing the upper end heads of the rivets is arranged above the positioning block, and an ejecting mechanism used for being inserted in the vertical guide grooves and ejecting leaf springs to the lower end tails of the rivets from bottom to top is arranged below the positioning block. The ejecting mechanism comprises leaf spring ejecting rods located in the vertical guide grooves, and clearance through holes are formed in the leaf spring ejecting rods in the axial direction. A riveting mechanism used for being inserted in the clearance through holes and riveting the leaf springs to the rivets from bottom to top is arranged below the ejecting mechanism. The structure is simple.

Owner:FUZHOU UNIVERSITY

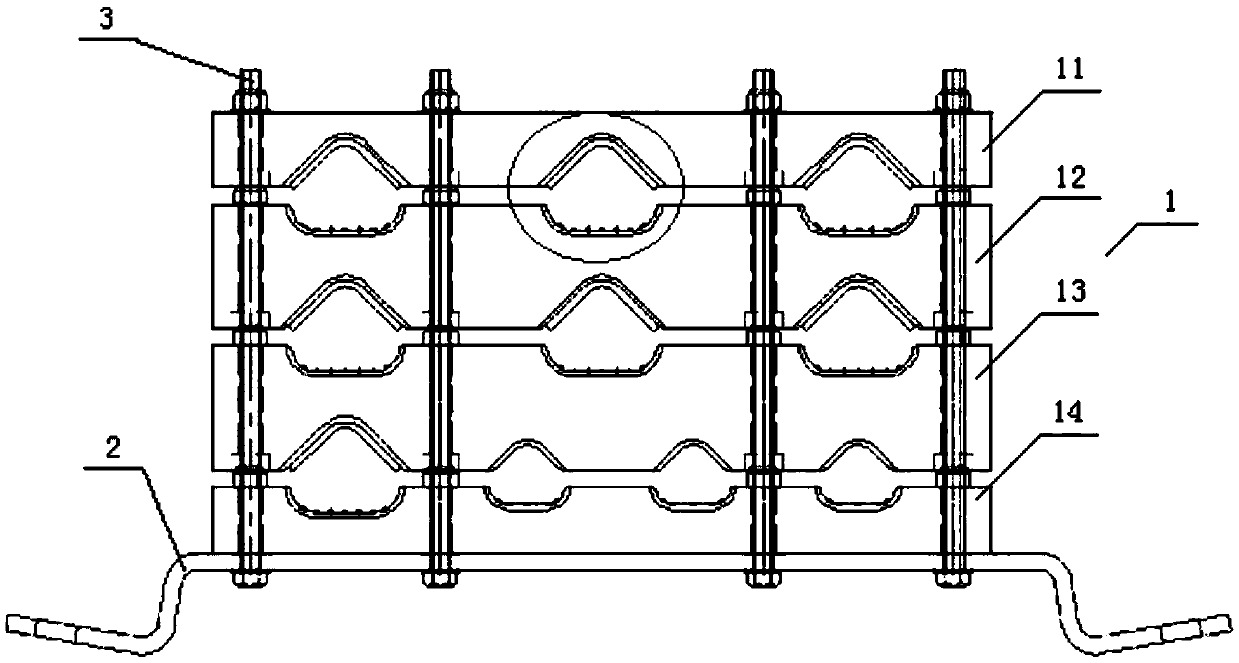

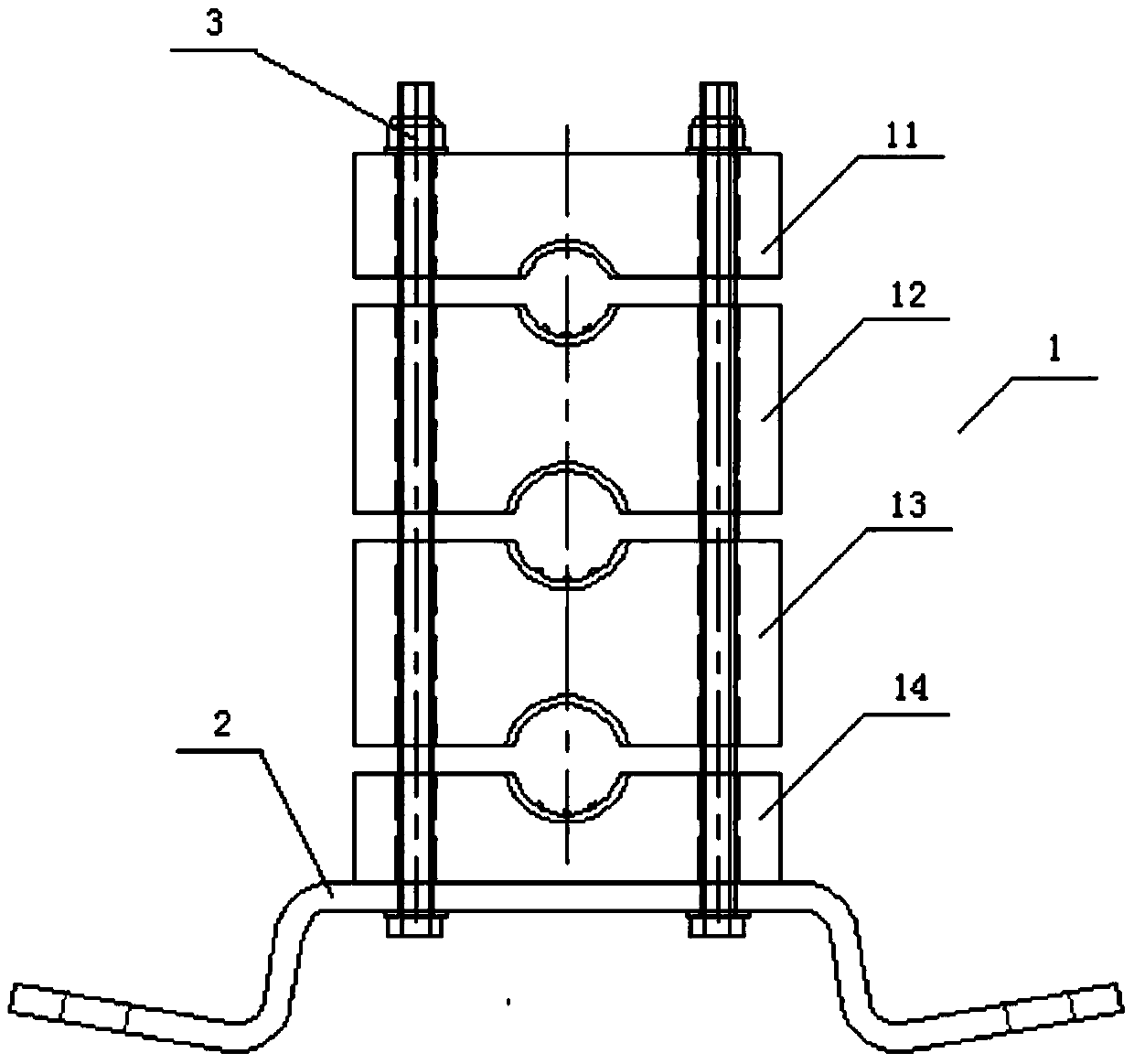

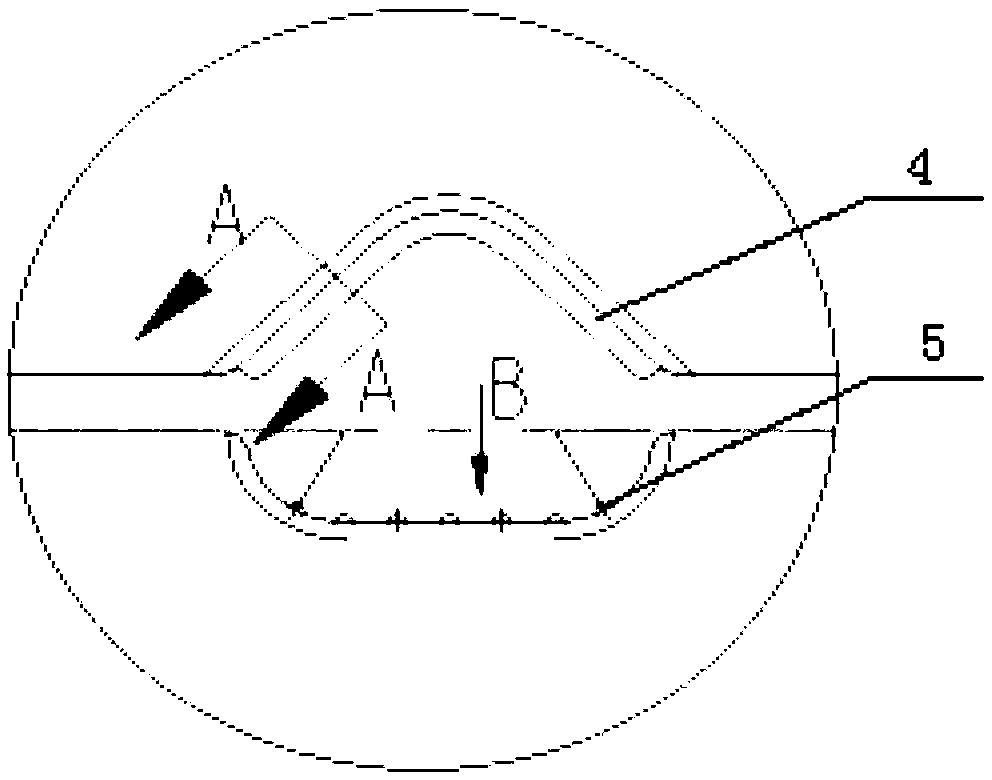

Composite cable clamping plate special for wind power generation tower barrel

InactiveCN105508151AHigh mechanical strengthStable mechanical strengthEngine fuctionsMachines/enginesFiberAlkali free

A composite cable clamping plate special for a wind power generation tower barrel comprises a clamping plate body (1), a clamping plate support (2) and tightening bolts (3). The clamping plate body is fixed to the clamping plate support through the tightening bolts, and the clamping plate body is made of resin, a low-shrinkage additive, an initiator, pigment paste, zinc stearate, magnesium oxide, styrene, alkali-free glass fibers and aluminum hydroxide. The composite cable clamping plate special for the wind power generation tower barrel has the advantages of being high in mechanical strength and bend resistance performance, free of distortion and brittle failures, resistant to acid-base, good in corrosion resistance, aging resistance, insulation performance and frame retardant property and the like. According to the composite, the high-strength alkali-free glass fibers serve as a reinforcing material, and the high-performance unsaturated polyester resin serves as a base material, so that the product has excellent physical and chemical performance, and the cable clamping plate is novel, can replace existing cable clamping plates made of various other materials, and has good application and popularization value.

Owner:宁夏顺和电工有限公司

Aiming and focusing mechanism

Owner:宁波舜成智能科技有限公司

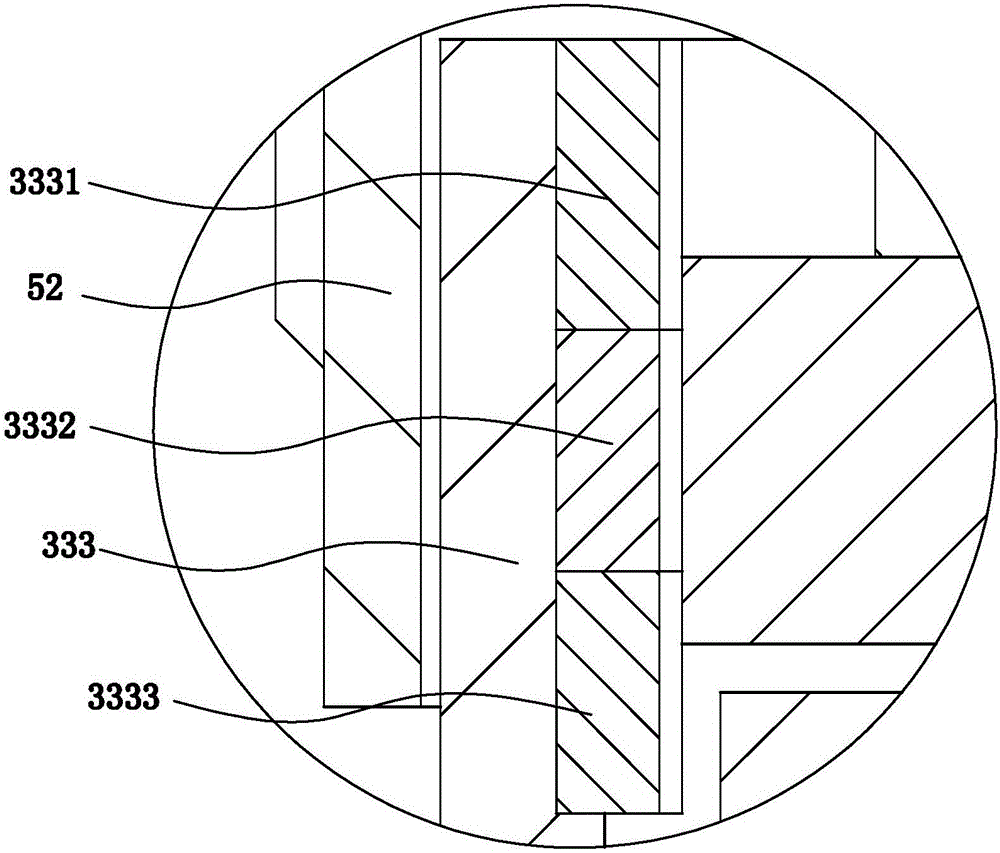

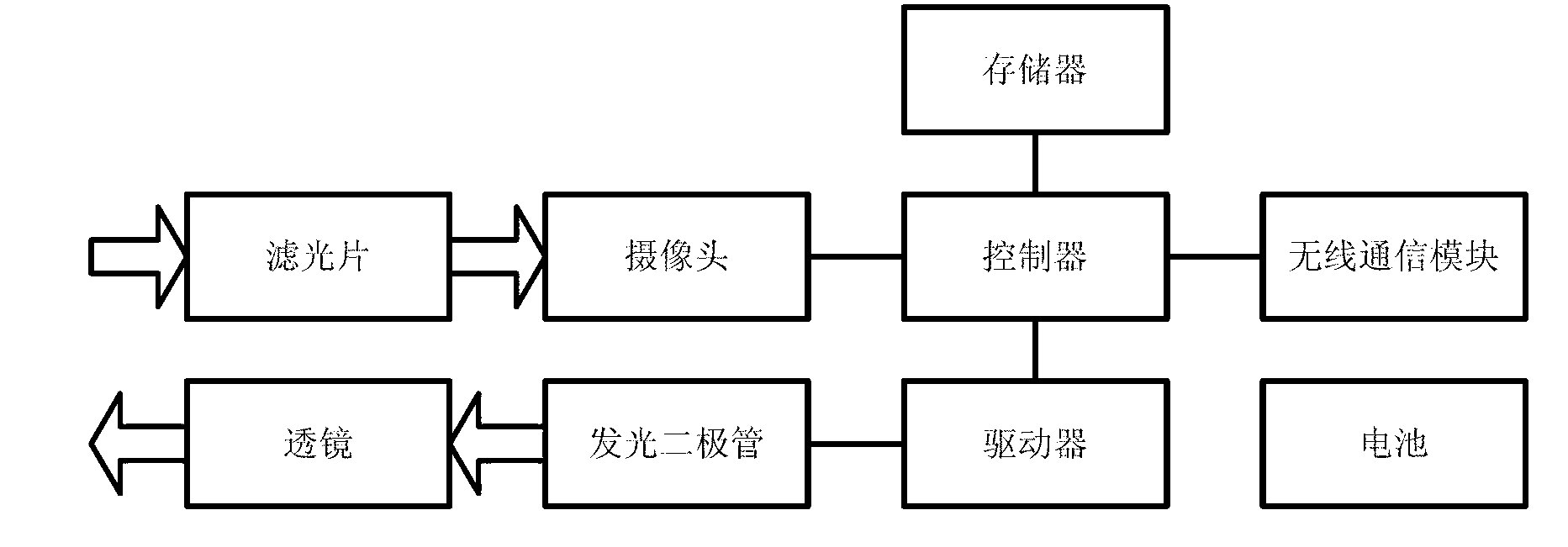

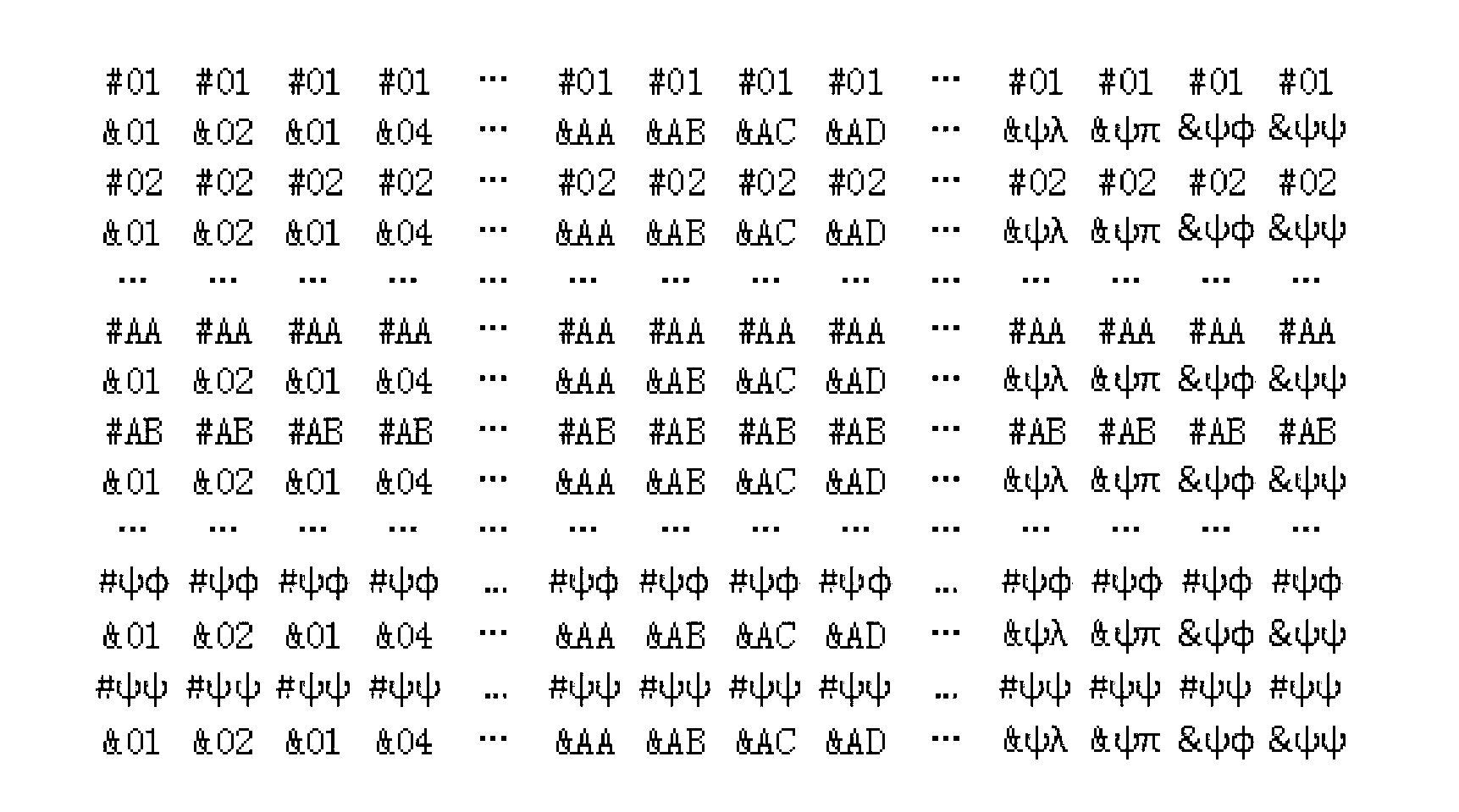

Positioning device and method of electronic whiteboard system

ActiveCN103235669AThere will be no occlusionThere will be no problem of interruption of positioning signalsInput/output processes for data processingWhiteboardFluorescence

The invention provides a positioning device of an electronic whiteboard system. The positioning deivce is characterized in that a controller, a storage, a camera, a driver, a light emitting diode, a wireless communication module, a battery, an optical filter and a lens are arranged in a pen body of an electronic whiteboard pen. The controller controls the light emitting diode to emit light through the driver, images are obtained through the camera, image identification is performed to obtain positioning information which is sent by the wireless communication module, the light emitting diode working in an ultraviolet band is adopted to transmit ultraviolet lights, and a projection screen is characterized in that short-wave ultraviolet lights are adopted to excite fluorescent ink to print coordinate information. The invention further provides a positioning method of the positioning device of the electronic whiteboard system. The positioning device and method of the electronic whiteboard system have the advantages that shielding of the electronic whiteboard pen and the projection screen is avoided, the electronic whiteboard pen is in wireless connection with a control device of the electronic whiteboard system, the positioning performance is stable, and positioning signal interruption is avoided.

Owner:BEIJING SHUNYUAN KAIHUA TECH LTD

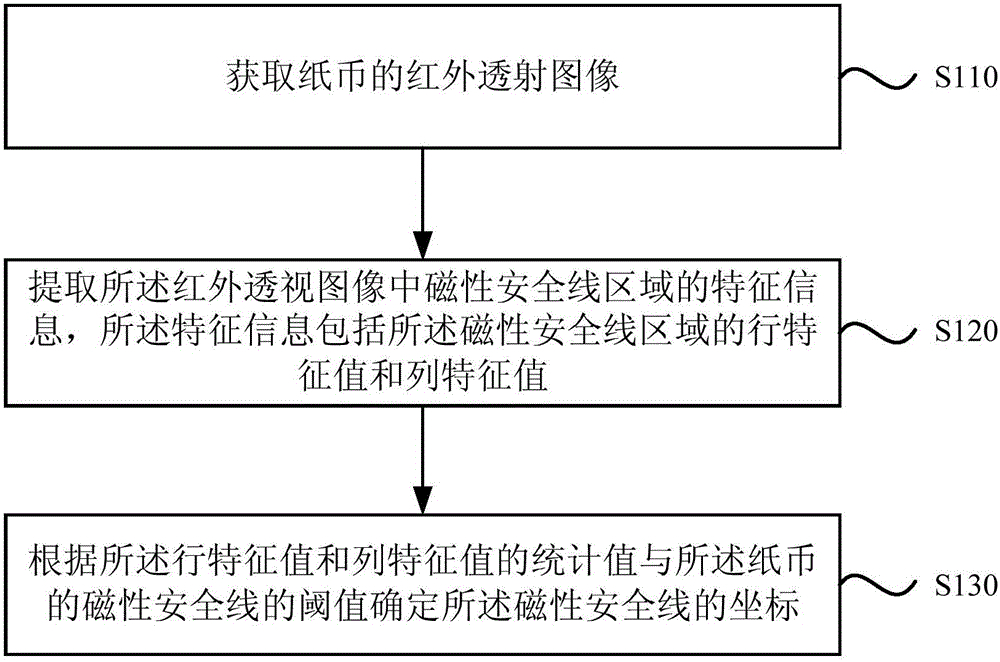

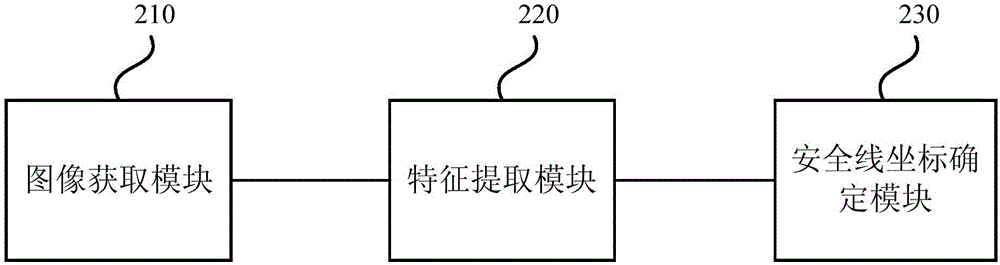

Method and device for detecting magnetic security thread of banknote

ActiveCN106504409AEasy to identifyStable positioningPaper-money testing devicesCharacter and pattern recognitionComputer scienceInfrared transmission

The invention discloses a method and a device for detecting a magnetic security thread of a banknote. The method comprises the steps of: acquiring an infrared transmission image of the banknote; extracting characteristic information of a magnetic security thread region in the infrared transmission image, wherein the characteristic information includes a row characteristic value and a column characteristic value of the magnetic security thread region; and determining coordinates of the magnetic security thread according to a statistical value of the row characteristic value and the column characteristic value as well as a threshold value of the magnetic security thread of the banknote. The method and the device have the advantages of being capable of ensuring that the identification and positioning effect is stable, having small error and being short in time consumption.

Owner:SHENZHEN YIHUA COMP +2

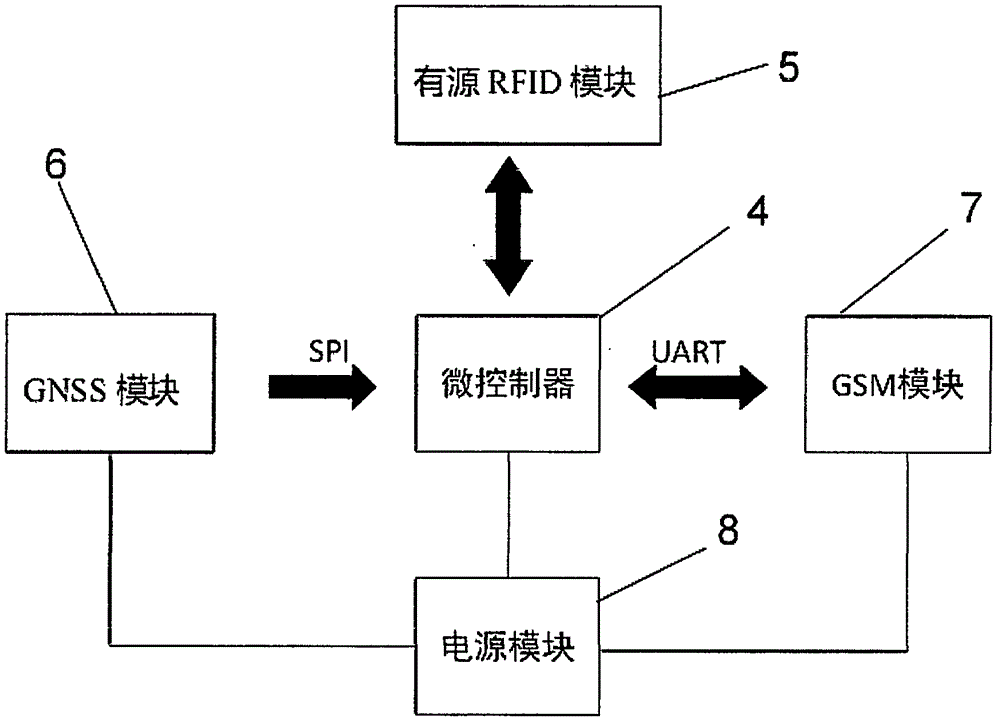

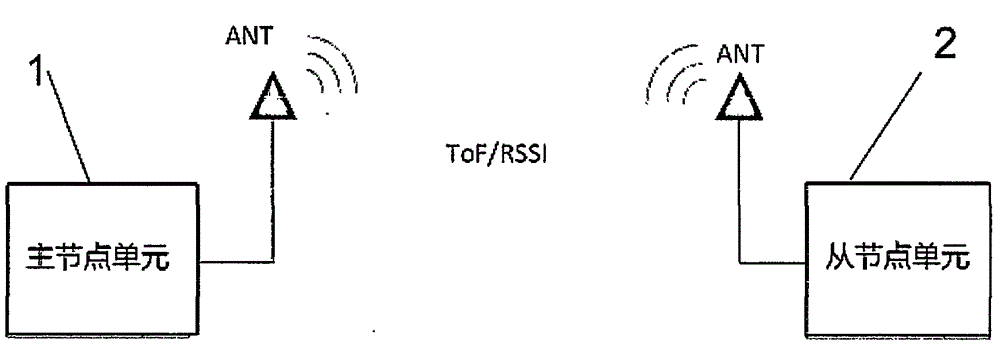

Composite precise positioning system and positioning method thereof

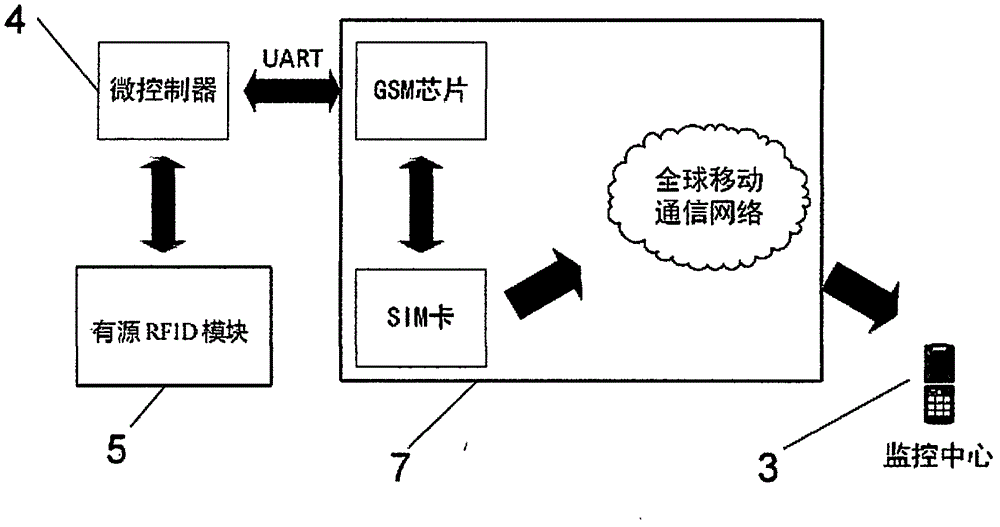

InactiveCN104570034ARealize all-round trackingAchieve positioningSatellite radio beaconingMicrocontrollerComputer module

The embodiment of the invention discloses a composite precise positioning system which comprises a main node unit, a slave node unit serving as a positioned object, and a monitoring center, wherein the slave node unit is connected with the main node unit and the monitoring center in a wireless communication manner respectively; the main node unit comprises an active RFID (radio frequency identification) module; the slave node unit comprises a microcontroller, an active RFID module, a GNSS (global navigation satellite system) module, a GSM (global system for mobile communications) module and a power supply module; the microcontroller, the active RFID module, the GNSS module and the GSM module are electrically connected with the power supply module respectively; both the GNSS module and the GSM module are connected with the microcontroller through serial ports. The embodiment of the invention further discloses a positioning method of the composite precise positioning system. With the adoption of the positioning system and the positioning method, high-precision positioning can be realized.

Owner:SHANGHAI CRIMINAL SCI TECH RES INST +1

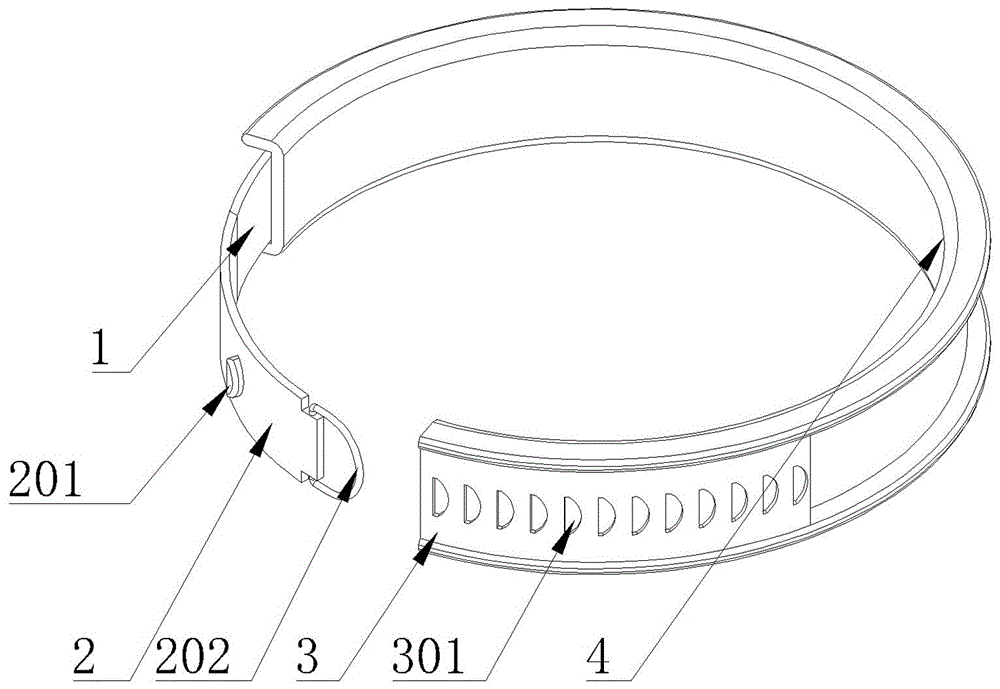

Holding hoop for pipeline

InactiveCN106439350AStable positioningHold firmlyPipe connection arrangementsMechanical engineeringEngineering

The invention discloses a holding hoop for a pipeline. The holding hoop for the pipeline comprises an unclosed annular holding hoop body, a clamping tongue and a clamping part; the clamping tongue is positioned at one end of the unclosed annular holding hoop body; the clamping part is positioned at the other end of the unclosed annular holding hoop body; a cavity for the clamping tongue to pass is formed in the centre in the length direction of the clamping part; a groove is formed in the clamping tongue; an elastic bump is formed in the groove, is cylindrical and is connected with the groove through a spring; a plurality of positioning holes which adjust the inside diameter of the annular holding hoop body are formed in the clamping part. Compared with the holding hoop which is connected by a bolt in the prior art, the holding hoop is easy and quick to operate; the work of fastening and detaching can be finished within 1 to 2 seconds; time and labour are saved; meanwhile, through the arrangement of the cylindrical elastic bump, the holding hoop is positioned and clamped more stably; two pipelines are connected more compactly, and do not fall off easily.

Owner:贵州省遵义市永力机电安装有限公司

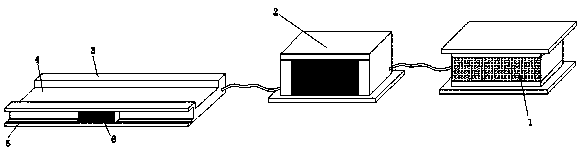

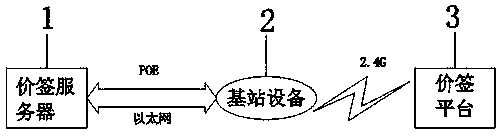

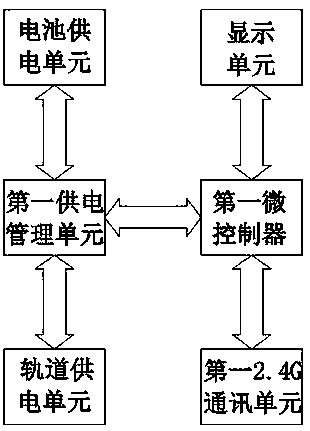

Electronic price tag positioning system

PendingCN110334793AStable positioningHigh utility valueCo-operative working arrangementsTransmissionSystems designCommunication unit

The invention relates to an electronic price tag positioning system. The system belongs to the technical field of electronic price tag positioning. The system comprises a price tag server, base station equipment and a price tag platform. The price tag server carries an MQTT server. The base station equipment is powered by a POE switch. The base station equipment communicates with the price tag server through the Ethernet and the MQTT server. The price tag platform is connected with the base station equipment through 2.4 G. A server system is arranged in the price tag server. A gateway system is arranged in the base station equipment. An article placing groove is formed in the price tag platform. A guide rail is arranged on one side of the price tag platform. An electronic price tag is slidably mounted on the guide rail. The electronic price tag takes a liquid crystal screen or an ink screen as a display module. The guide rail is an electricity taking guide rail. The server system is composed of a first microcontroller, a display unit, a first 2.4 G communication unit and a first power supply management unit. The system is reasonable in design, high in stability, stable in positioning, capable of meeting actual requirements and high in practical value.

Owner:昆山市华显光电科技有限公司

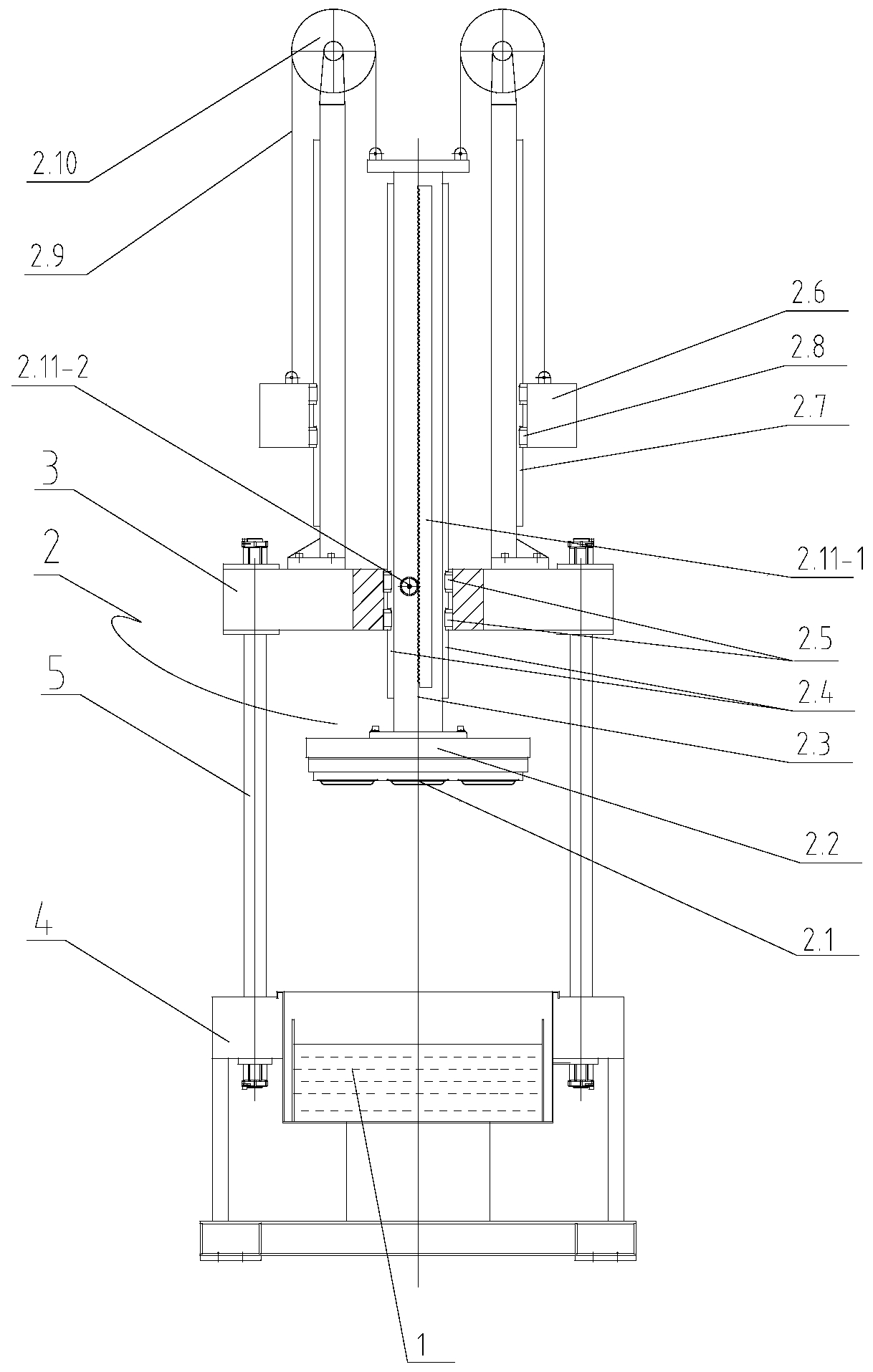

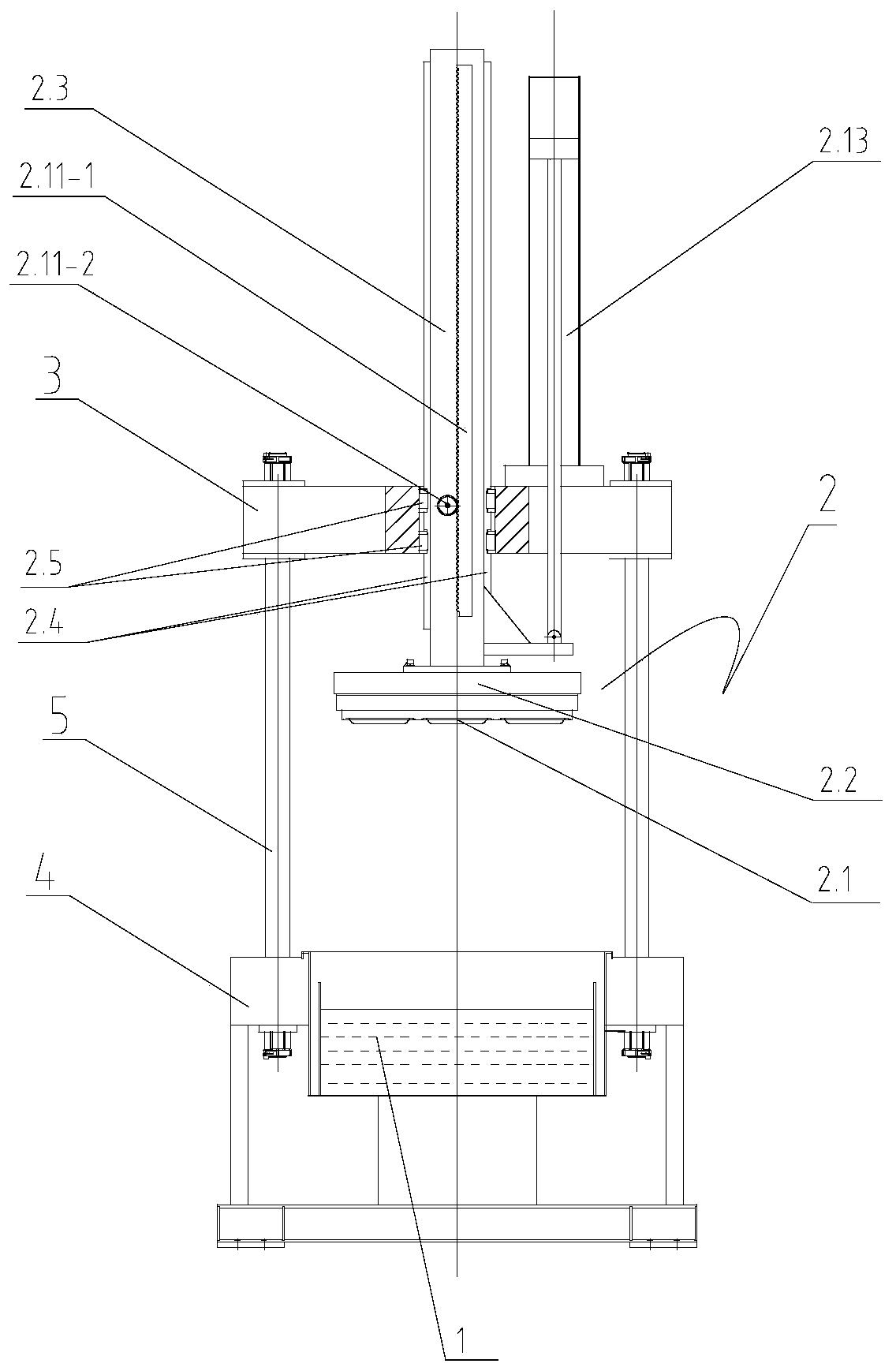

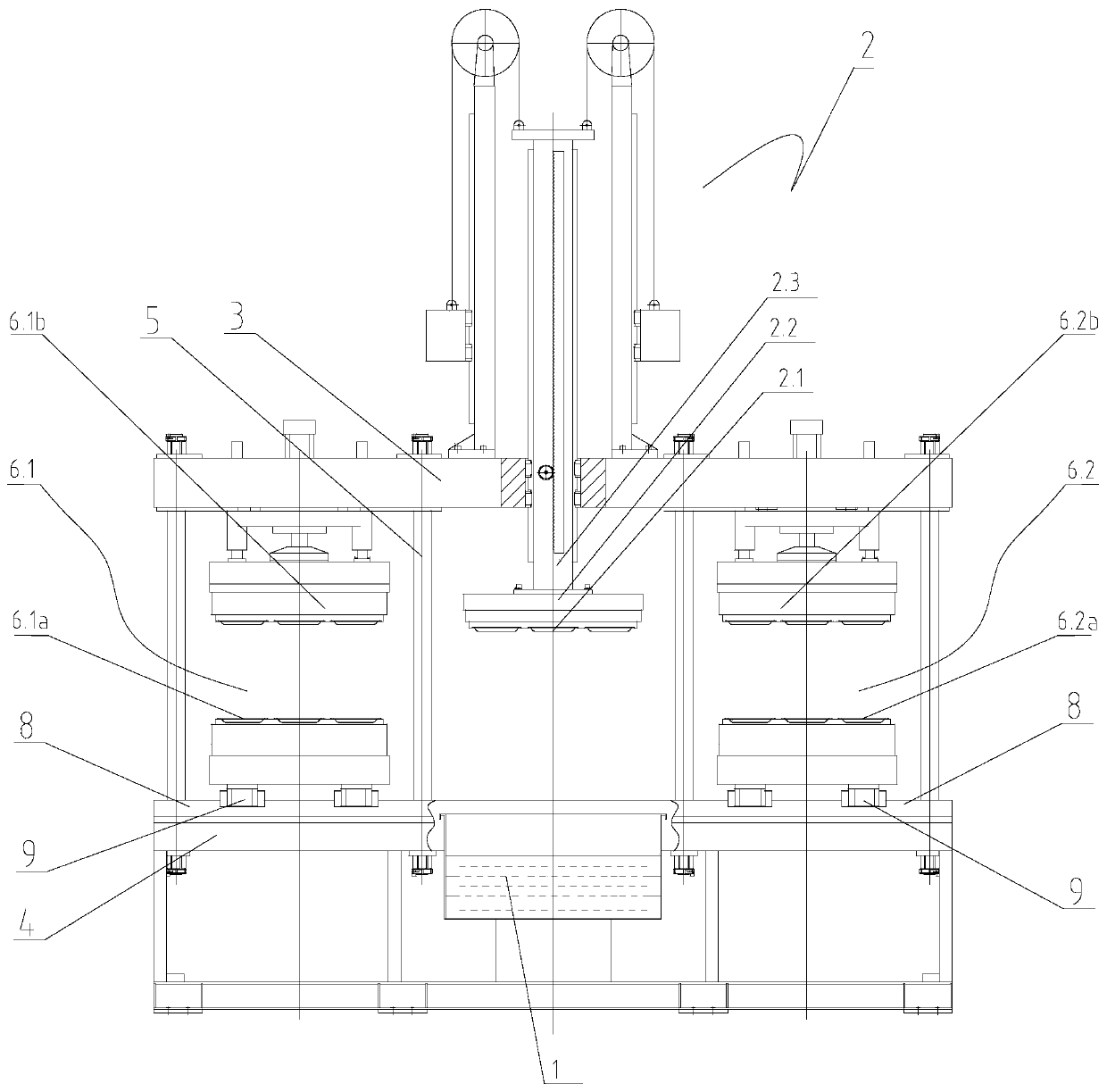

Suspension type suction filtration forming method and suction filtration forming device for plant fiber molding forming

The invention relates to a method and device for manufacturing a plant fiber product comprising paper pulp in a molding mode. According to the technical scheme, the suspension type suction filtrationforming method for plant fiber molding forming comprises the following steps of: 1) a suction filtration forming die vertically move downwards from a set height, and suction filtration forming is carried out in slurry in a slurry tank; 2) the suction filtration forming mold drives the wet blank to vertically move upwards to leave the liquid level of the slurry tank, and stops moving after rising to a certain height; (3) the wet blank in the suction filtration forming mold is sent out and delivered to the next procedure to be dried; and (4) the step (1) and the step (3) are repeated, so that plant fiber molding forming is continuously carried out. In the suction filtration forming process, slurry can be more evenly distributed on the surface of the suction filtration forming mold, and the suction filtration forming mold can accurately, stably and rapidly enter or move out of the slurry.

Owner:EURASIA LIGHT IND EQUIP MFR +1

Electronic water boiler convenient for cleaning

The invention discloses an electronic water boiler convenient for cleaning. A kettle body (1) is cylindrical; a round slide I (4) is arranged at each of an upper end and a lower end of the inner wall of the kettle body (1); the round slide II (5) is arranged at the bottom of the kettle body (1); a side annular scraper (6) and a bottom horizontal scraper (7) are further arranged on the kettle body (1); the electronic water boiler further comprises an external magnet arranged at the outside of the kettle body (1). The external magnet at the external of the kettle body, the magnet block I at the side and the magnet block II at the bottom are used for driving the scrapers to perform the descaling operation at the side and the bottom; each scraper is firm in locating on the kettle body due to the existence of a clamping part, and the use is extremely convenient.

Owner:蚌埠知博自动化技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com