Quick clamp assembling mechanism for grinding wheel

A technology of assembling mechanism and grinding wheel, which is applied to the device for fixing grinding wheel, parts of grinding machine, metal processing equipment, etc. It can solve the problem of cumbersome replacement and achieve the effect of stable positioning and quick replacement of grinding wheel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

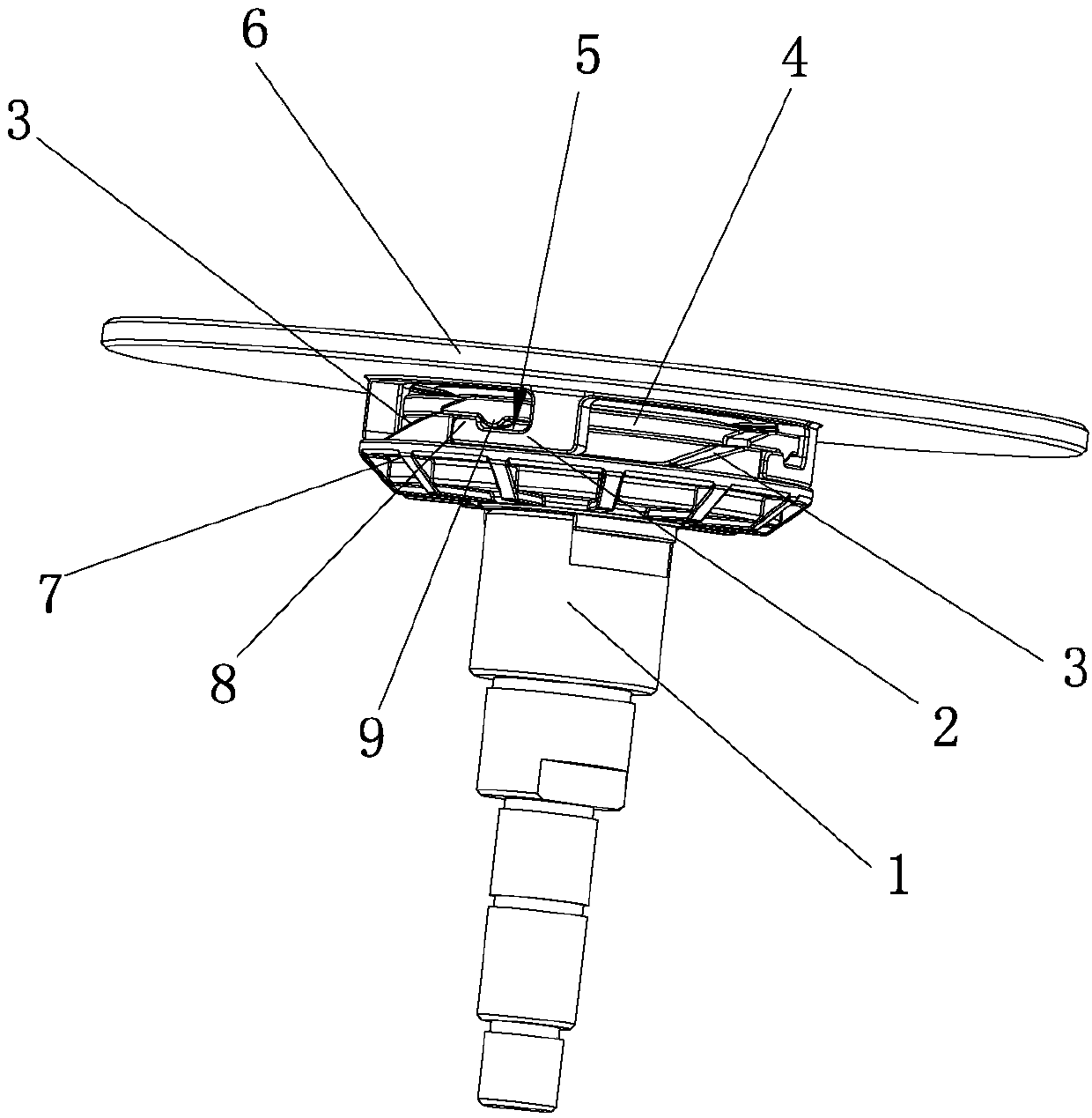

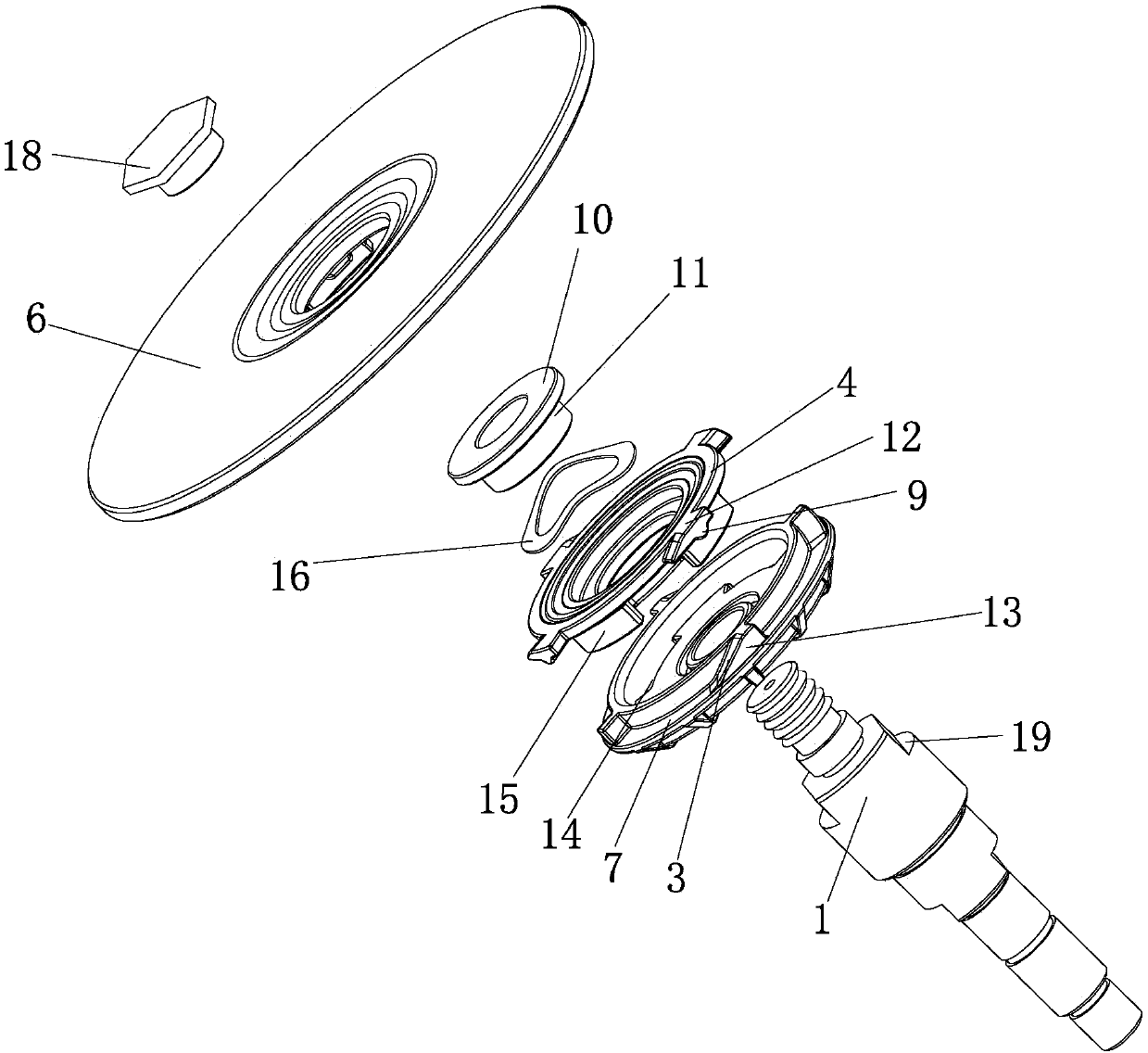

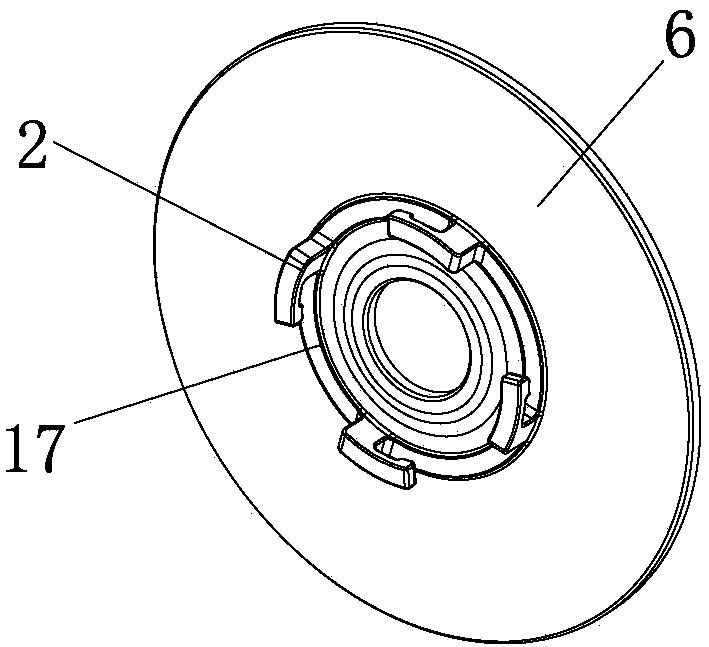

[0019] figure 1 As shown, the present invention includes a mounting base and a connection plate 17. The mounting base is inserted into the output shaft 1 of the electric tool. The output shaft 1 has its own side groove 19, and the mounting base is blocked by the side groove 19 and cannot rotate. , The end of the output shaft 1 is provided with a nut 18, the nut 18 fastens the mounting seat on the output shaft 1, and the connecting disc 17 is fixed on one side of the grinding wheel 6.

[0020] figure 1 , 2 As shown, the mounting seat includes a circular chassis 7, a positioning disc 4, a central fastener 11 and a wave disc spring 16. The edge of the chassis 7 is provided with a plurality of limit blocks 13 in an annular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com