Suspension type suction filtration forming method and suction filtration forming device for plant fiber molding forming

A technology of suction filtration molding and molding molding, which is applied in the direction of textiles and papermaking, etc. It can solve problems such as wet billet tearing, production troubles, and large mold clamping errors, achieve stable up and down movement or positioning, reduce servo motor load, and fast The effect of entering or exiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

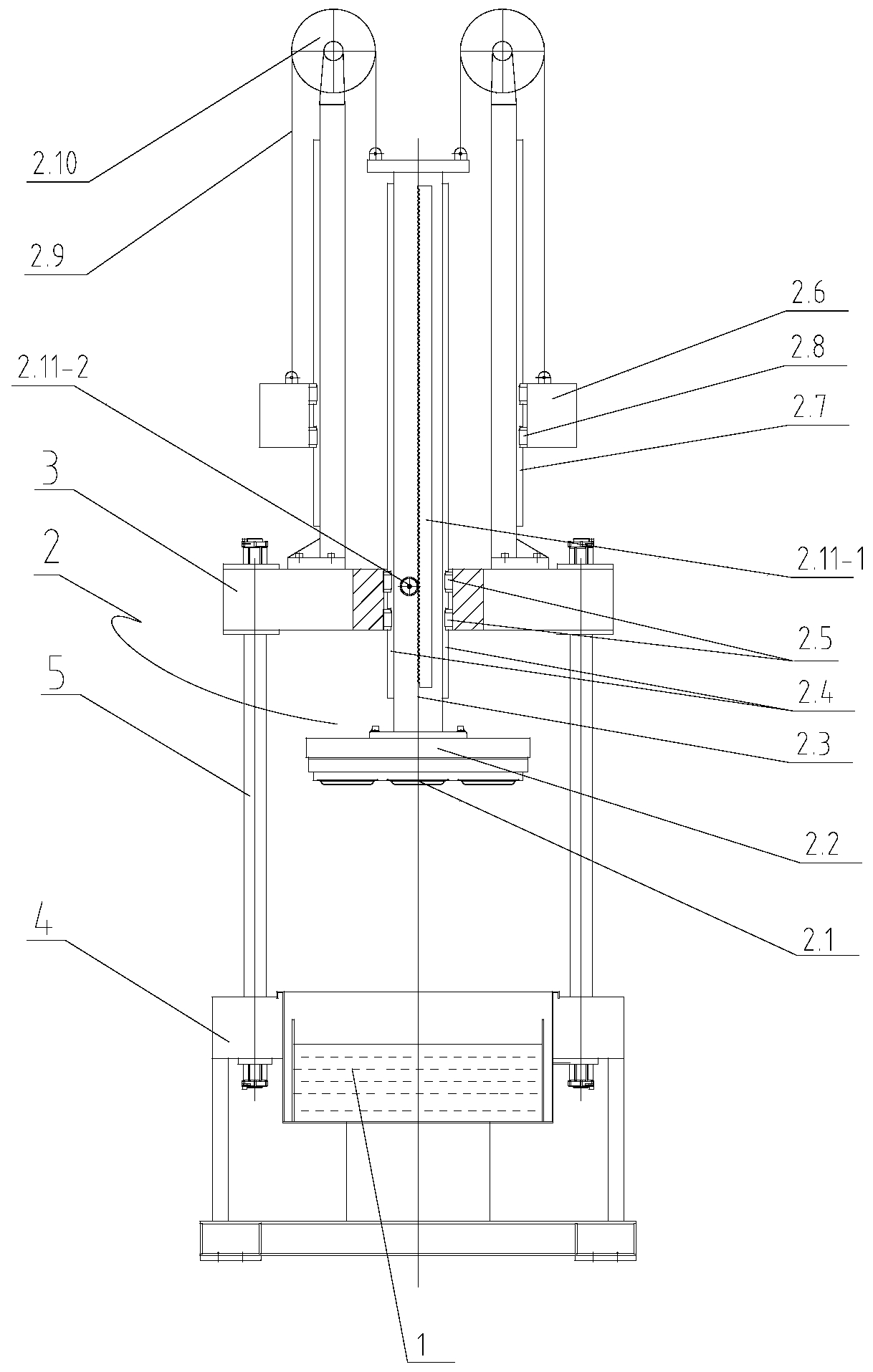

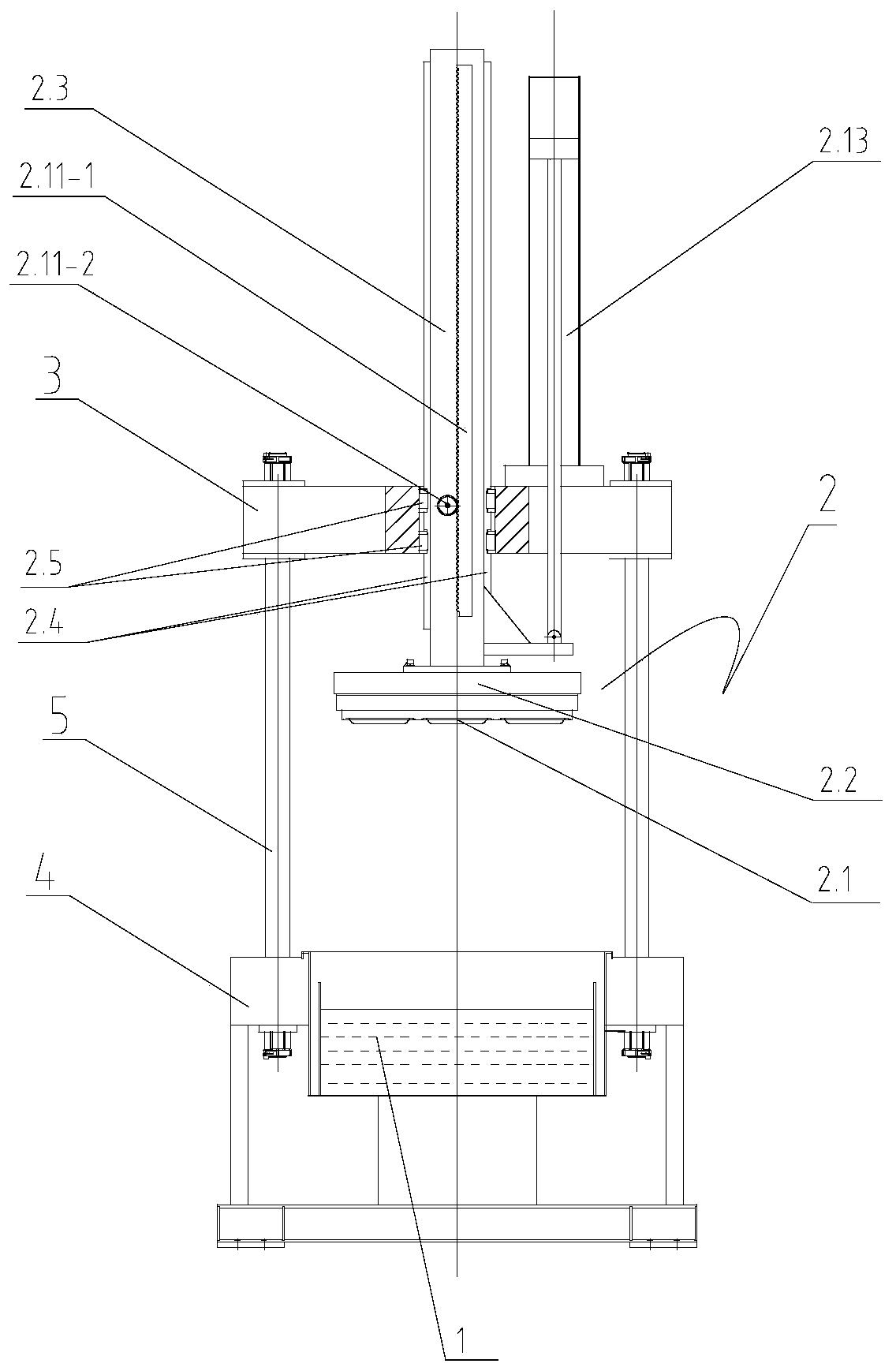

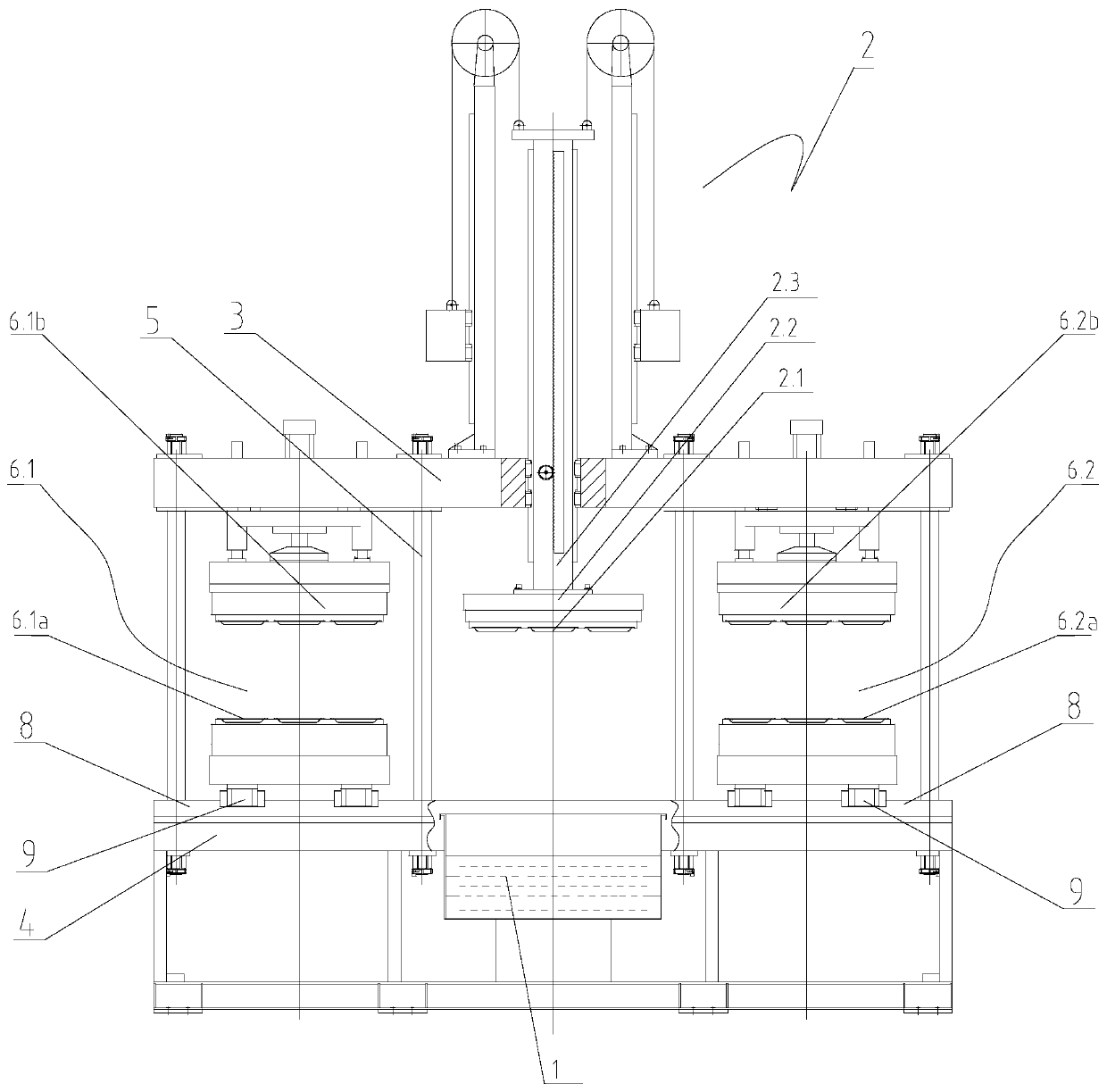

[0044] Such as figure 1 As shown, the plant fiber molding machine includes a slurry tank 1, a suction filter forming device 2, and a frame. Slurry is housed in the slurry tank 1, and frame is made up of pull bar 5, lower frame 4 and upper frame 3, and pull bar 5 fixes upper frame 3 on lower frame 4, makes upper frame 3 and lower frame 4 Keep a certain distance; the slurry tank 1 is arranged in the lower frame 4, the suction filter forming device 2 is above the slurry tank 1, and the suction filter forming mold 2.1 of the suction filter forming device 2 can move up and down vertically, when the suction filter forming device 2 The suction filter forming mold 2.1 moves down vertically to the slurry in the slurry tank 1, the suction filter forming mold 2.1 vacuums the slurry in the slurry tank 1, and the suction filter forming mold sucks the wet billet in the slurry for a certain period of time in the suction filter forming mold Formed on the top, the suction filter forming mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com