A kind of indium tin oxide film hand-held probe testing device and method thereof

An indium tin oxide film and testing device technology, applied in the direction of measuring device, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of slow operation, lower yield, poor consistency, etc., and achieve low processing accuracy, Reduced stress, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

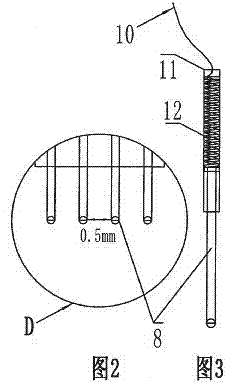

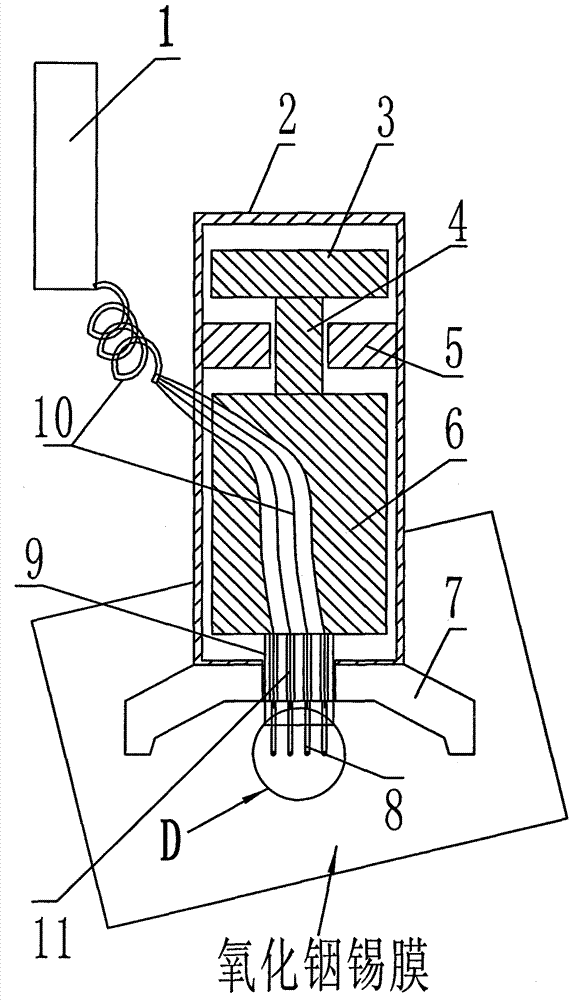

[0042] As shown in the figure, an indium tin oxide film hand-held probe test device is composed of: resistance tester device 1, hand-held probe test device shell 2, self-weight counterweight 3, upper sliding rod 4, shell inner baffle 5, Test inner core device 6, base support anti-skid device 7, smooth probe needle 8, sliding rod device 9, wire 10, test probe sleeve 11, S-shaped cantilever spring 12; base support anti-skid is set above the indium tin oxide film Device 7, a hand-held probe testing device shell 2 is arranged above the base support anti-slip device 7; a hole is reserved in the middle between the base support anti-slip device 7 and the hand-held probe test device shell 2, and a sliding rod device 9 is set in the hole;

[0043] At least four test probe casings 11 are arranged in the lower rod device 9, and an S-shaped cantilever spring 12 is arranged in the test probe casing 11; , the round probe needle 8 is set in the lower part of the test probe casing 11;

[004...

Embodiment 2

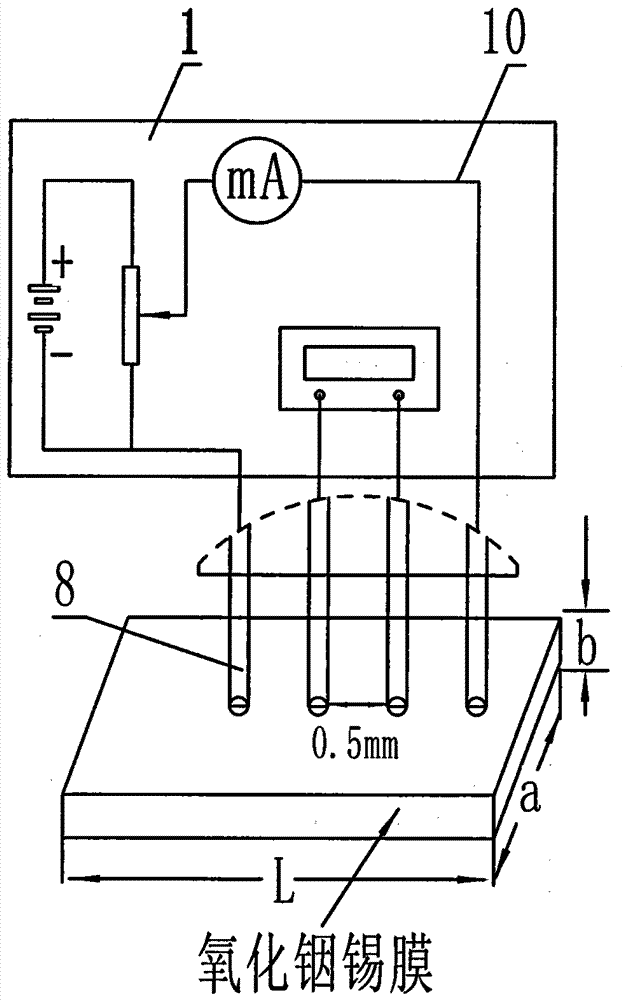

[0050] As shown in the figure, a method for testing an indium tin oxide film with a hand-held probe, the specific method steps are as follows: first, turn on the resistance tester device 1, prepare a test square sample of the indium tin oxide film, and place an oxide The base support anti-slip device 7 of the indium tin film hand-held probe testing device is placed on the prepared tested square sample of the indium tin oxide film;

[0051] At the same time, the self-weight counterweight 3 in the shell 2 of the hand-held probe testing device acts on the upper sliding rod 4 by its own gravity, so that the upper sliding rod 4 slides downward through the inner baffle plate 5 of the outer shell to test the inner core device 6, and then The test inner core device 6 pushes the lower rod device 9 to slide downward, and the smooth probe needle 8 in the lower rod device 9 moves downward synchronously with the test probe casing 11; when the smooth probe needle 8 and the indium tin oxide f...

Embodiment 3

[0056] As shown in the figure, a method for testing an indium tin oxide film with a hand-held probe, the specific method steps are as follows: first, turn on the resistance tester device 1, prepare a test square sample of the indium tin oxide film, and place an oxide The base support anti-slip device 7 of the indium tin film hand-held probe testing device is placed on the prepared tested square sample of the indium tin oxide film;

[0057] At the same time, the self-weight counterweight 3 in the shell 2 of the hand-held probe testing device acts on the upper sliding rod 4 by its own gravity, so that the upper sliding rod 4 slides downward through the inner baffle plate 5 of the outer shell to test the inner core device 6, and then The test inner core device 6 pushes the lower rod device 9 to slide downward, and the smooth probe needle 8 in the lower rod device 9 moves downward synchronously with the test probe casing 11; when the smooth probe needle 8 and the indium tin oxide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com