Patents

Literature

1863 results about "Surface film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

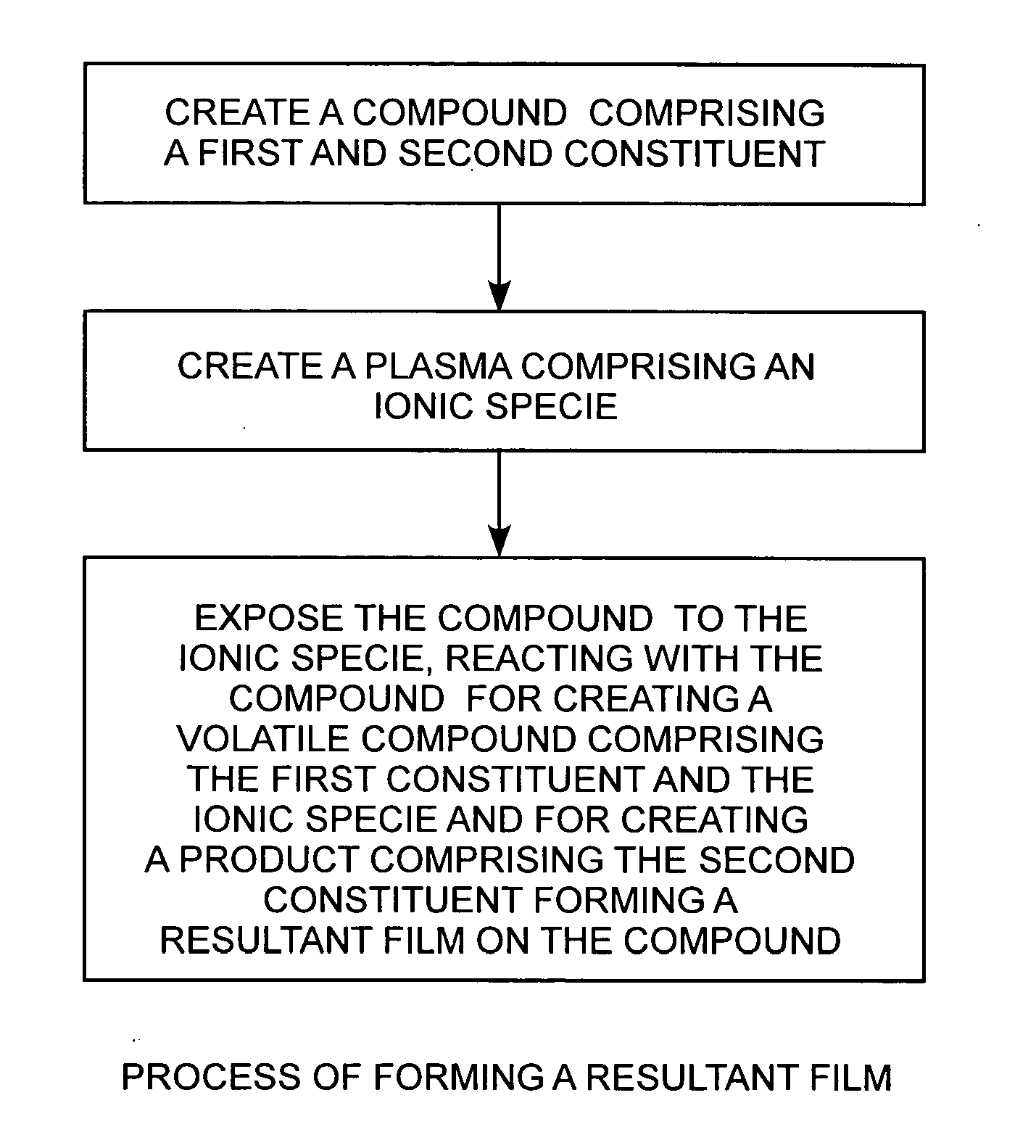

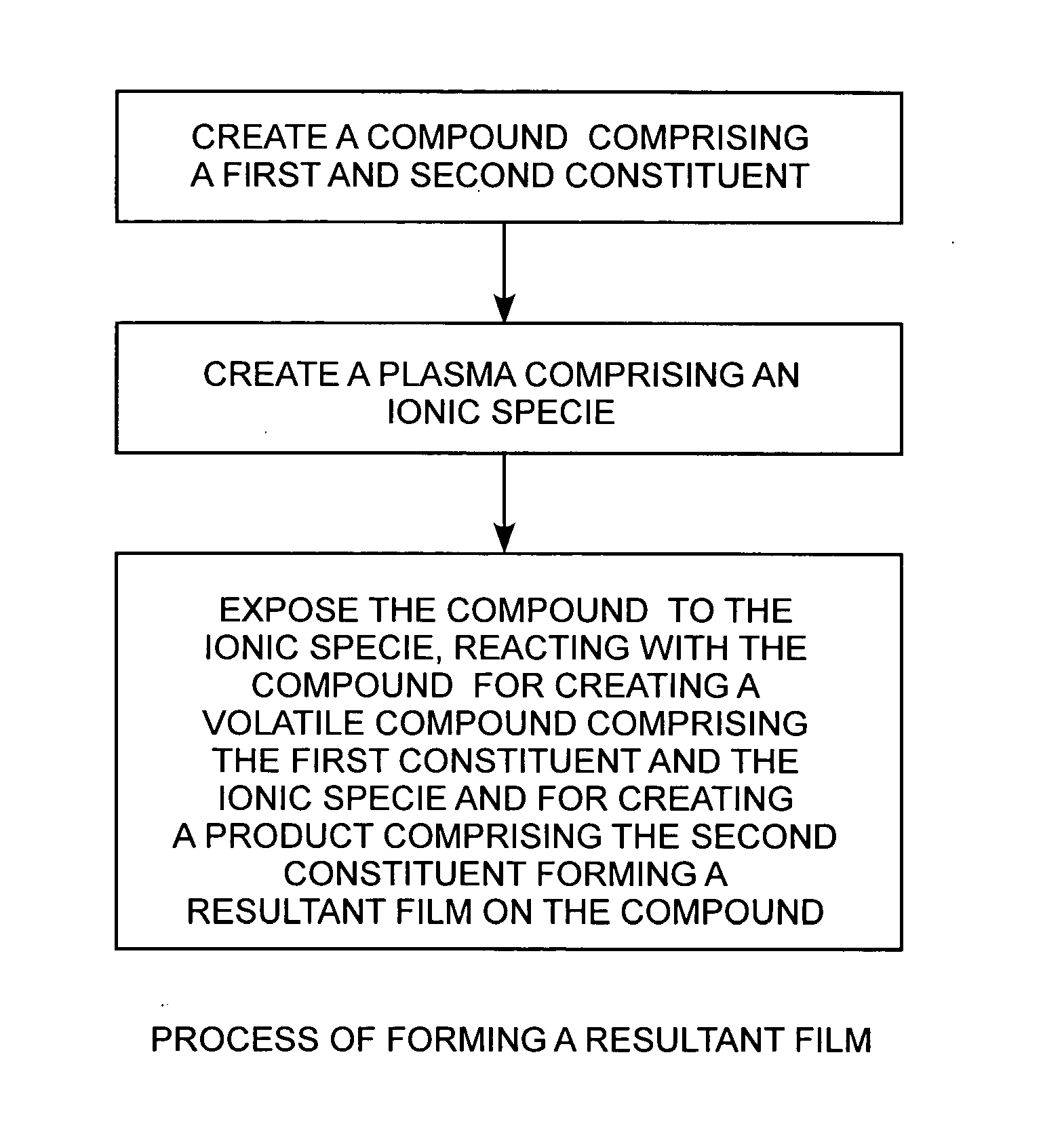

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS20060068125A1Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon filmCarbon coating

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

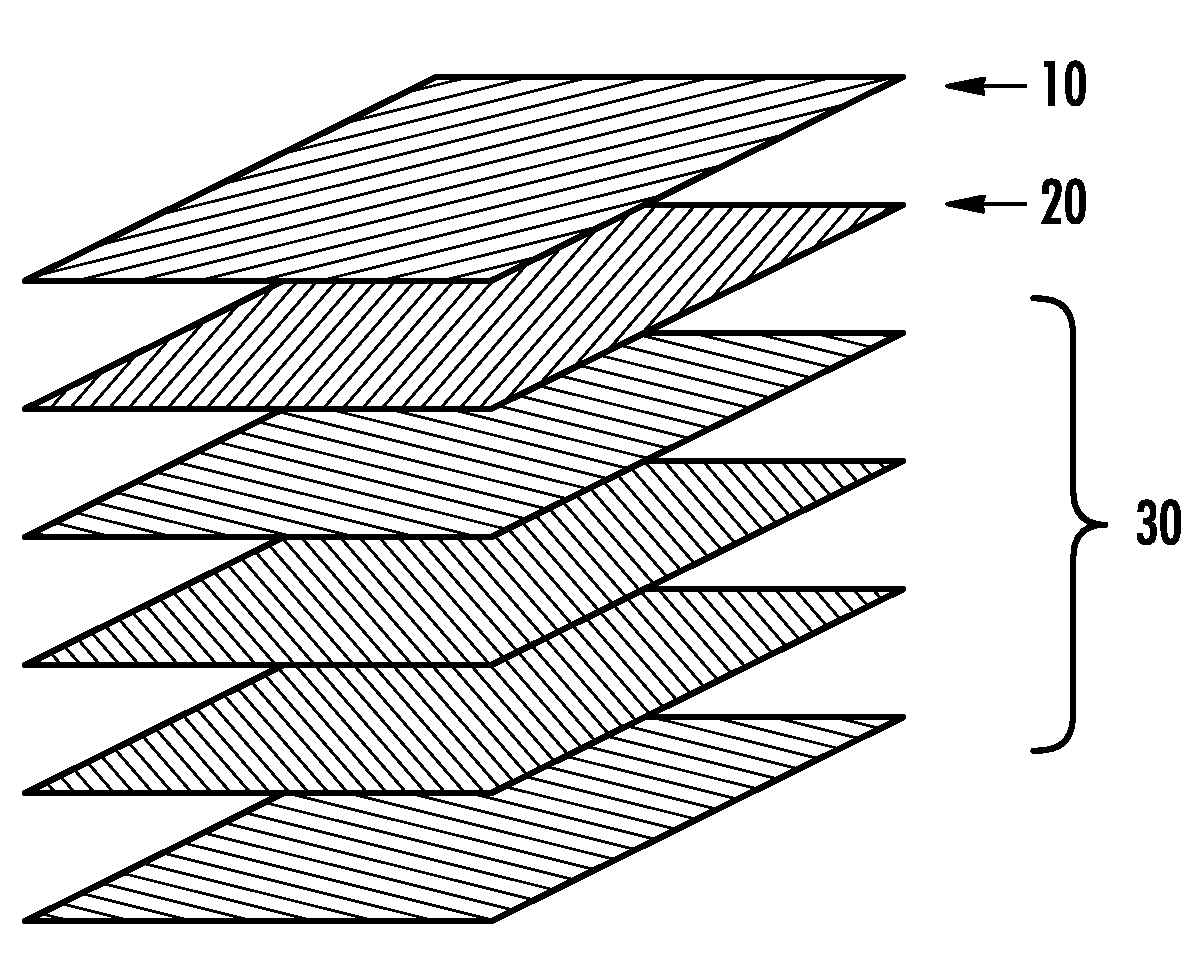

Low density lightning strike protection for use in airplanes

ActiveUS20090227162A1Minimize micro-crackingWeight optimizationConductive materialWarp knittingFiberEpoxy

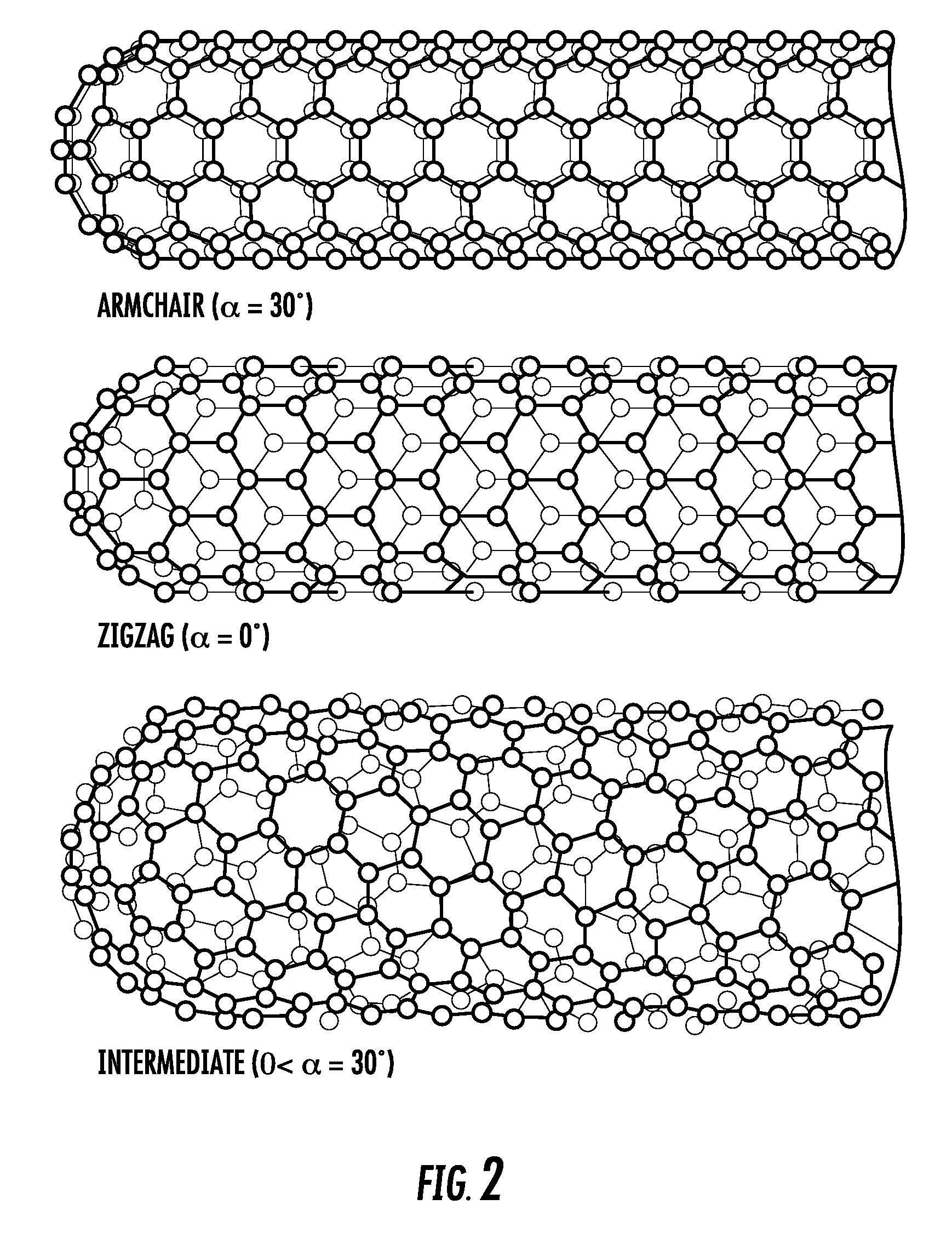

Surface films, paints, or primers can be used in preparing aircraft structural composites that may be exposed to lightning strikes. Methods for making and using these films, paints or primers are also disclosed. The surface film can include a thermoset resin or polymer, e.g., an epoxy resin and / or a thermoplastic polymer, which can be cured, bonded, or painted on the composite structure. Low-density electrically conductive materials are disclosed, such as carbon nanofiber, copper powder, metal coated microspheres, metal-coated carbon nanotubes, single wall carbon nanotubes, graphite nanoplatelets and the like, that can be uniformly dispersed throughout or on the film. Low density conductive materials can include metal screens, optionally in combination with carbon nanofibers.

Owner:ROHR INC +1

Negative electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery using the same

InactiveUS20050191550A1Reduce battery capacityBig ratioOrganic electrolyte cellsSecondary cellsMaterials scienceElectrolyte

An object of the invention is to provide a negative electrode for a nonaqueous electrolyte secondary battery having a small surface film resistance and a high negative electrode strength. The present invention relates to a negative electrode for a nonaqueous electrolyte secondary battery, wherein an active material layer containing an active material and a binder is formed on a collector, the active material being a material in which metal oxide fine particles having an average particle diameter of 250 nm or less are attached to the surface and the binder being a binder having an olefinic unsaturated bond.

Owner:MITSUBISHI CHEM CORP

Surface film for polarizing sheet and polarizing sheet using same

ActiveUS20090279170A1Not prevent visibilityPrevent visibilityRadiation pyrometryOther printing matterDisplay devicePolarizer

Provided is a surface film for a polarizing plate in which transparent patterns having a non-visible light reflective regularity are printed on a surface of a substrate and in which a reflection preventive layer or an antiglare layer is formed thereon or on a back side thereof, wherein an ink constituting the above transparent patterns contains a material reflecting a non-visible light. Capable of being provided is a surface film which can suitably be used for providing additional informations to an image display medium in such a manner that data are input by handwriting directly on a display device and in which the function described above is built-in from the beginning without making it necessary for the user to stick later a sheet having the above function.

Owner:DAI NIPPON PRINTING CO LTD

High temperature resistant P.T.F.E. coated filter material

ActiveCN1768912AAvoid cloggingExcellent "surface filter" characteristicsSemi-permeable membranesSynthetic resin layered productsTetrafluoroethyleneGlass fiber

The invention relates to a high temperature-resistant polytetrafluoroethylene tectorial filter material, belonging to the improvement on present polytetrafluoroethylene composite filter material, which comprises a glass fiber base cloth and a polytetrafluoroethylene surface film. It is characterized in that: first using after-treatment agent to process the dipping process on the glass fiber base cloth, then processing the high-temperature heat compression on the polytetrafluoroethylene surface film. The invention uses film forming emulsifier, fluorine silane coupling agent and fluoroplymer emulsion to form a film on the glass fiber base cloth, which can improve the effects of anti-soil, oil-proof and preservation, and it can have fusion combination with expanded micro-pore polytetrafluoroethylene film in the condition of high-temperature heat compression, to effectively solve the problem of hard fusion combination between inorganic material of glass fiber and organic inertia material of polytetrafluoroethylene to significantly improve the fastness between them.

Owner:中材科技膜材料(山东)有限公司

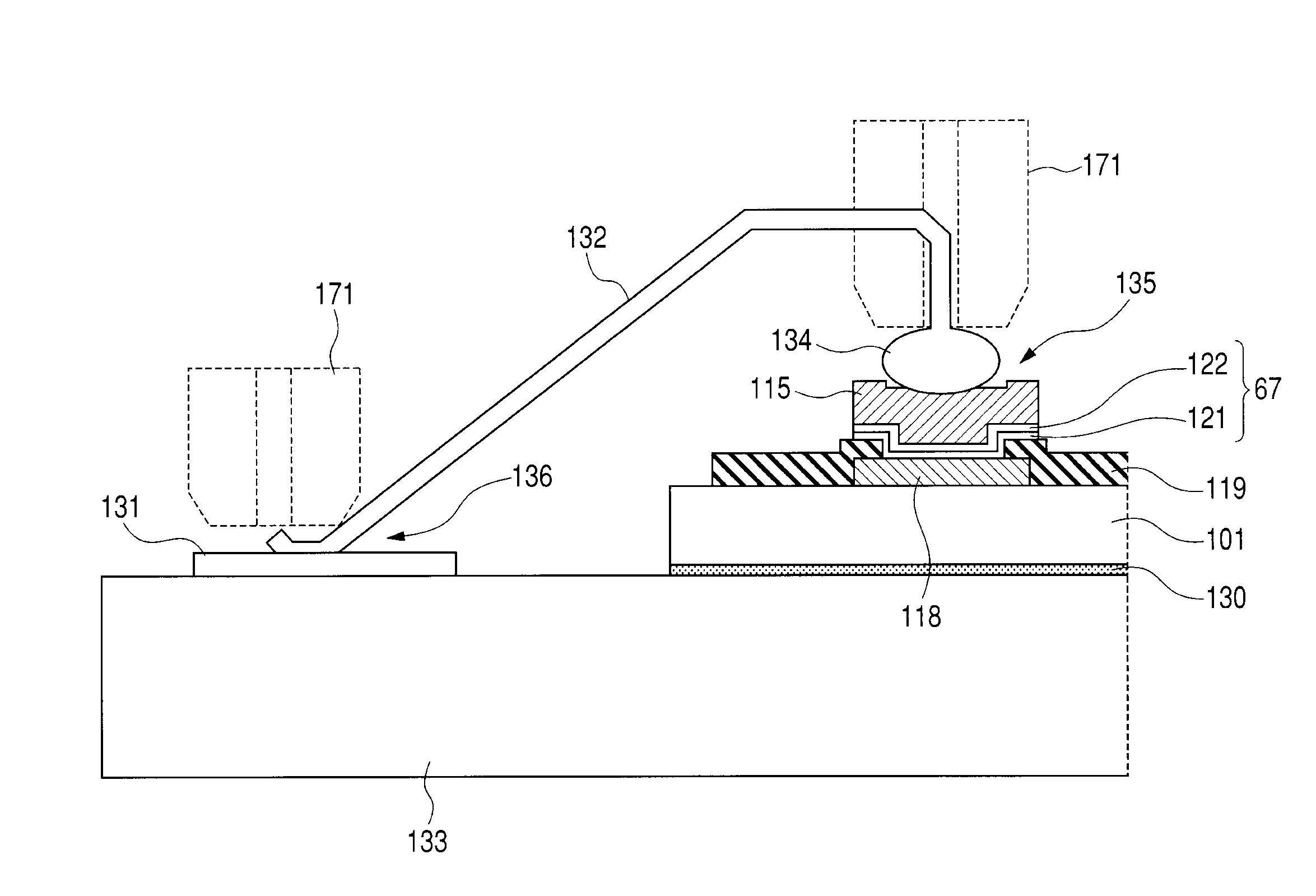

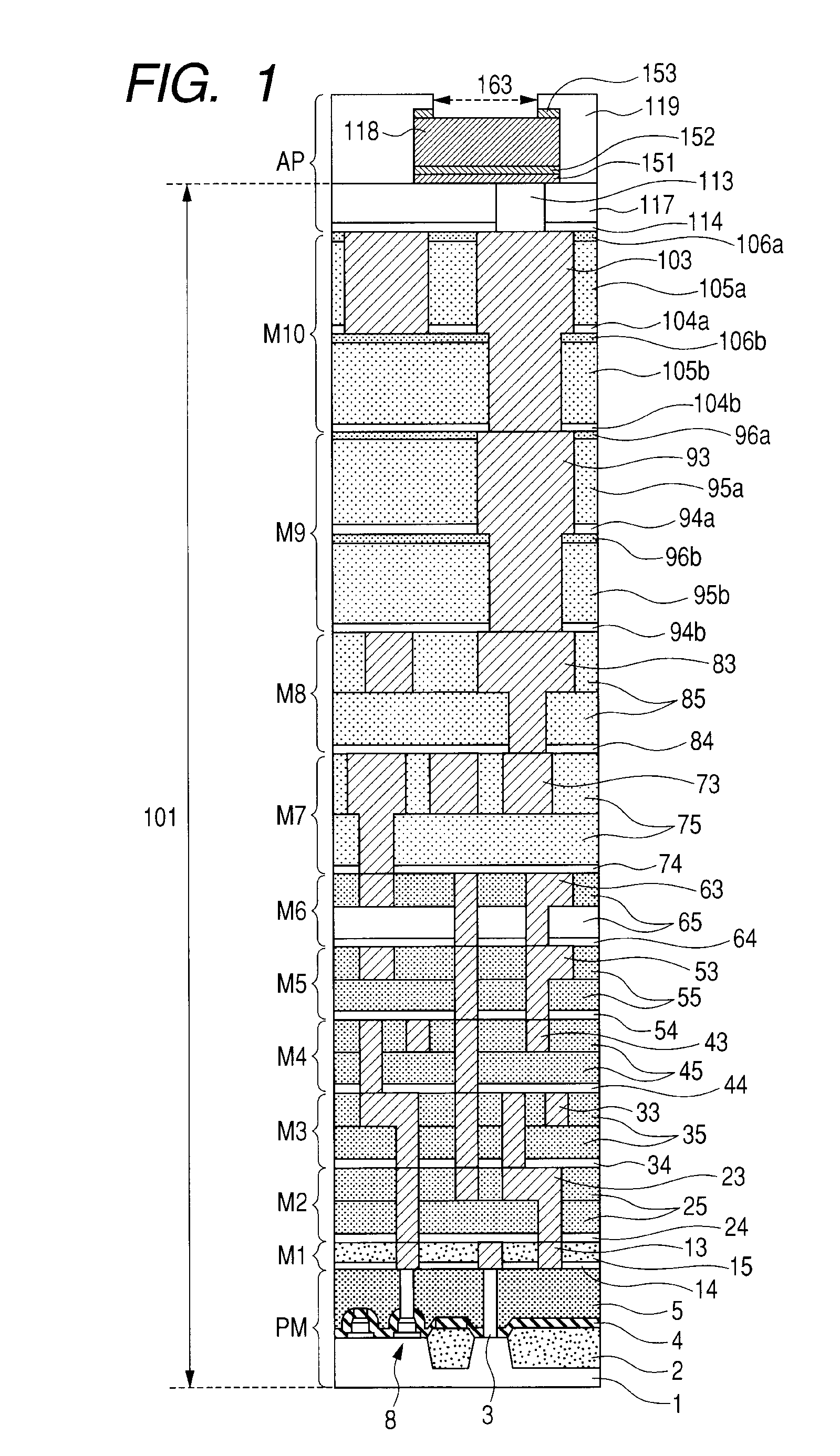

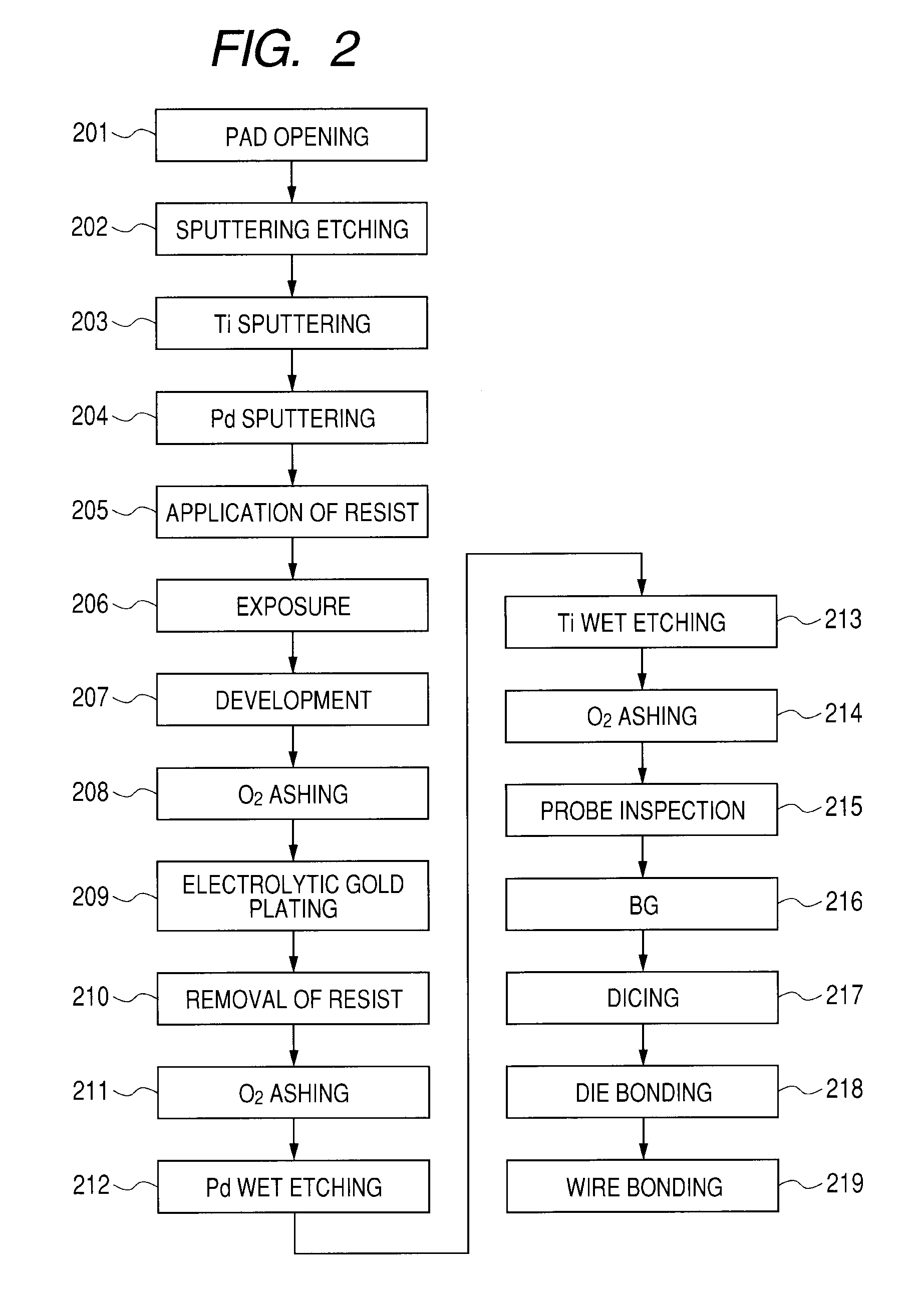

Semiconductor integrated circuit device

ActiveUS20100133688A1Improve reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipInterconnection

In semiconductor integrated circuit devices for vehicle use or the like, in general, an aluminum pad on a semiconductor chip and an external device are coupled to each other by wire bonding or the like using a gold wire and the like for the convenience of mounting. Such a semiconductor integrated circuit device, however, causes a connection failure due to the interaction between aluminum and gold in use for a long time at a relatively high temperature (about 150 degrees C.). The invention of the present application provides a semiconductor integrated circuit device (semiconductor device or electron circuit device) which includes a semiconductor chip as a part of the device, an electrolytic gold plated surface film (gold-based metal plated film) provided over an aluminum-based bonding pad on a semiconductor chip via a barrier metal film, and a gold bonding wire (gold-based bonding wire) for interconnection between the plated surface film and an external lead provided over a wiring board or the like (wiring substrate).

Owner:RENESAS ELECTRONICS CORP

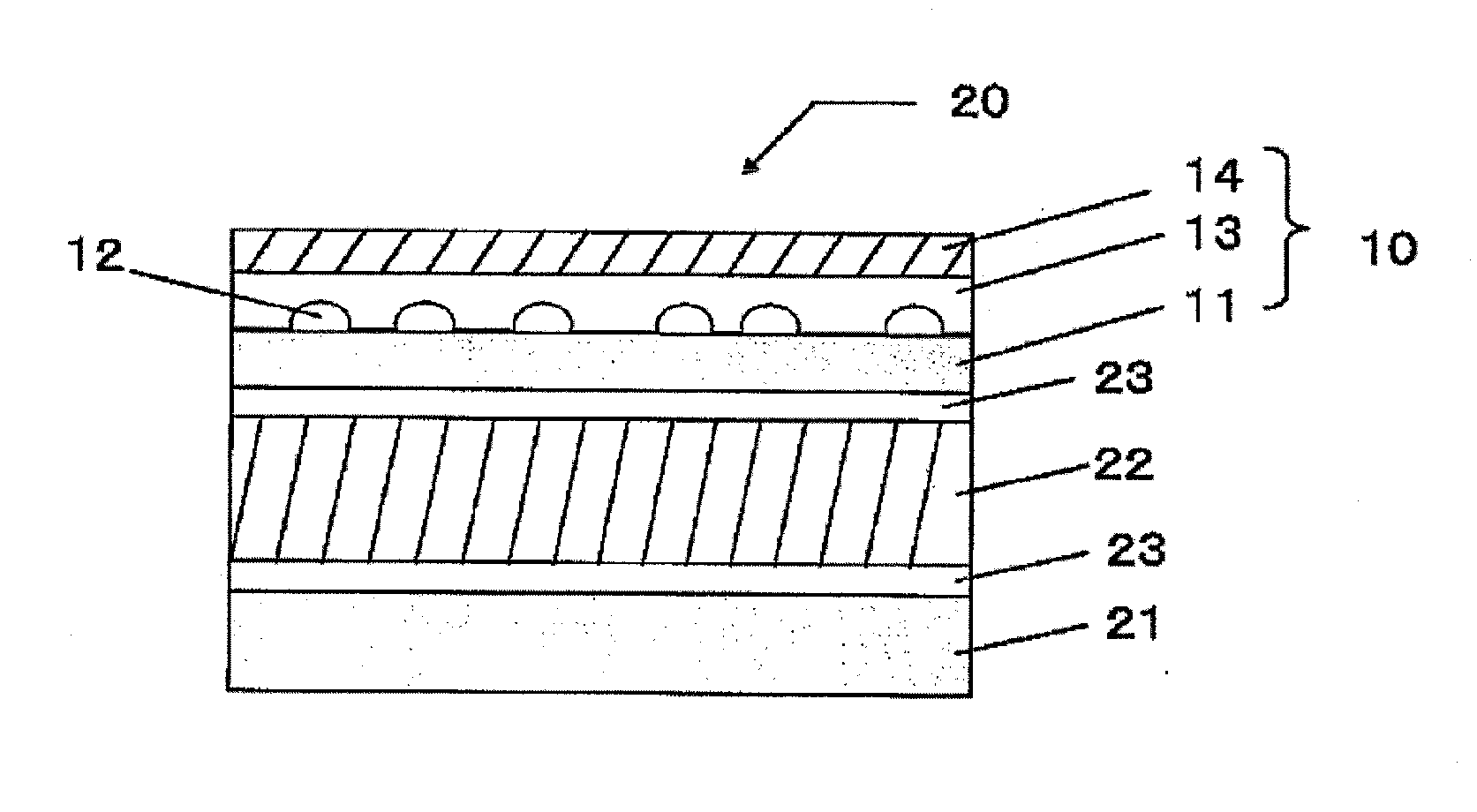

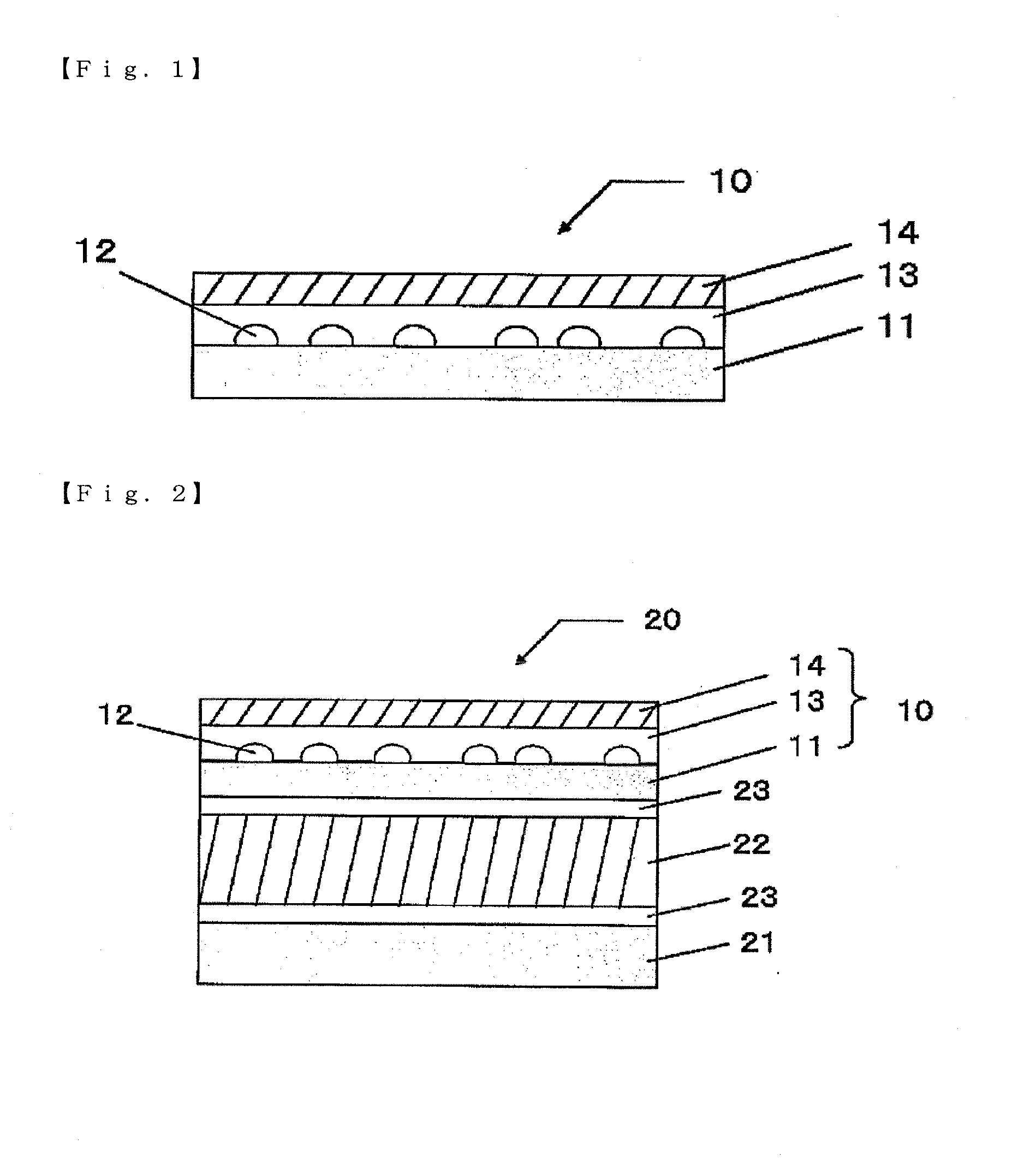

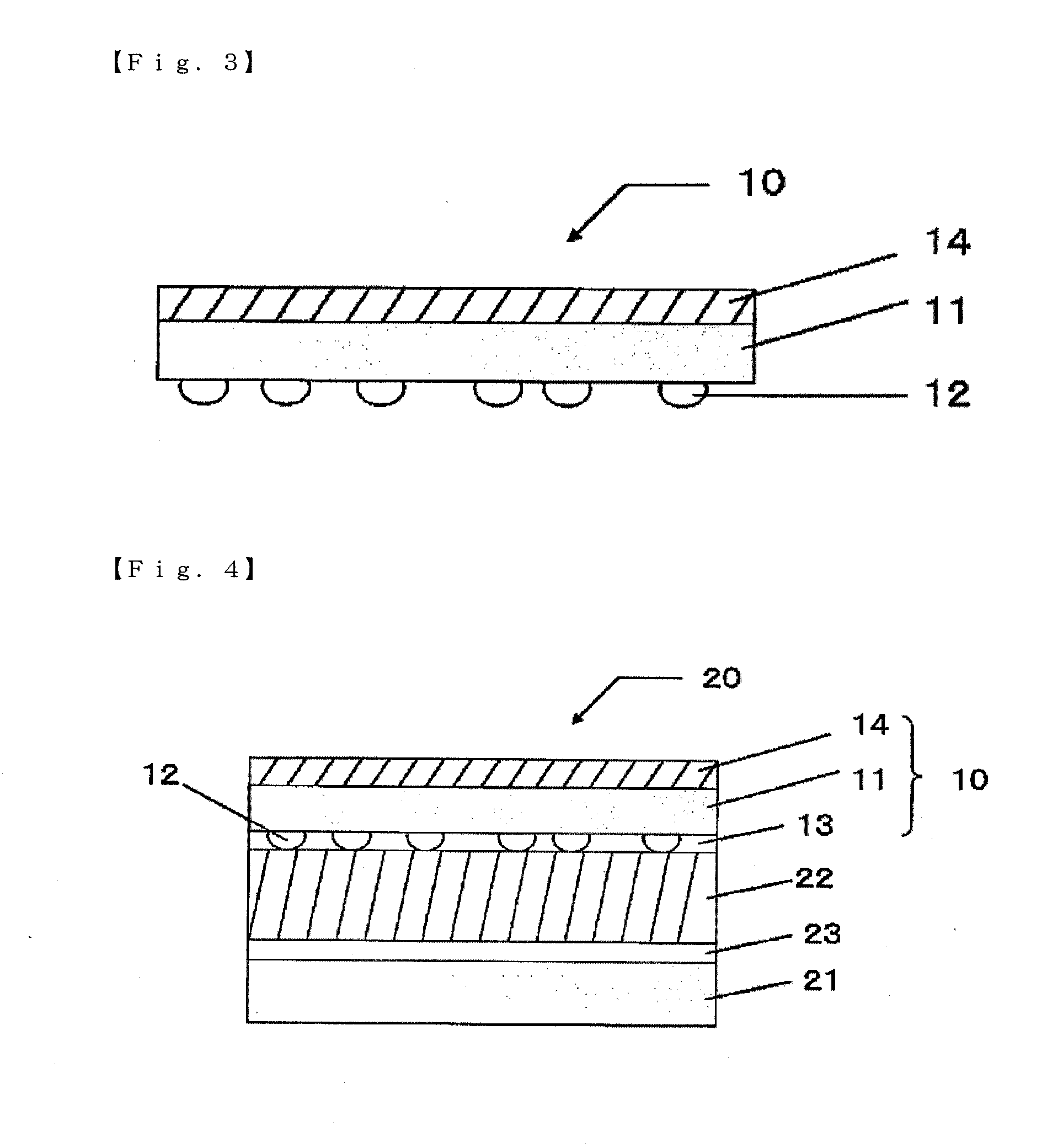

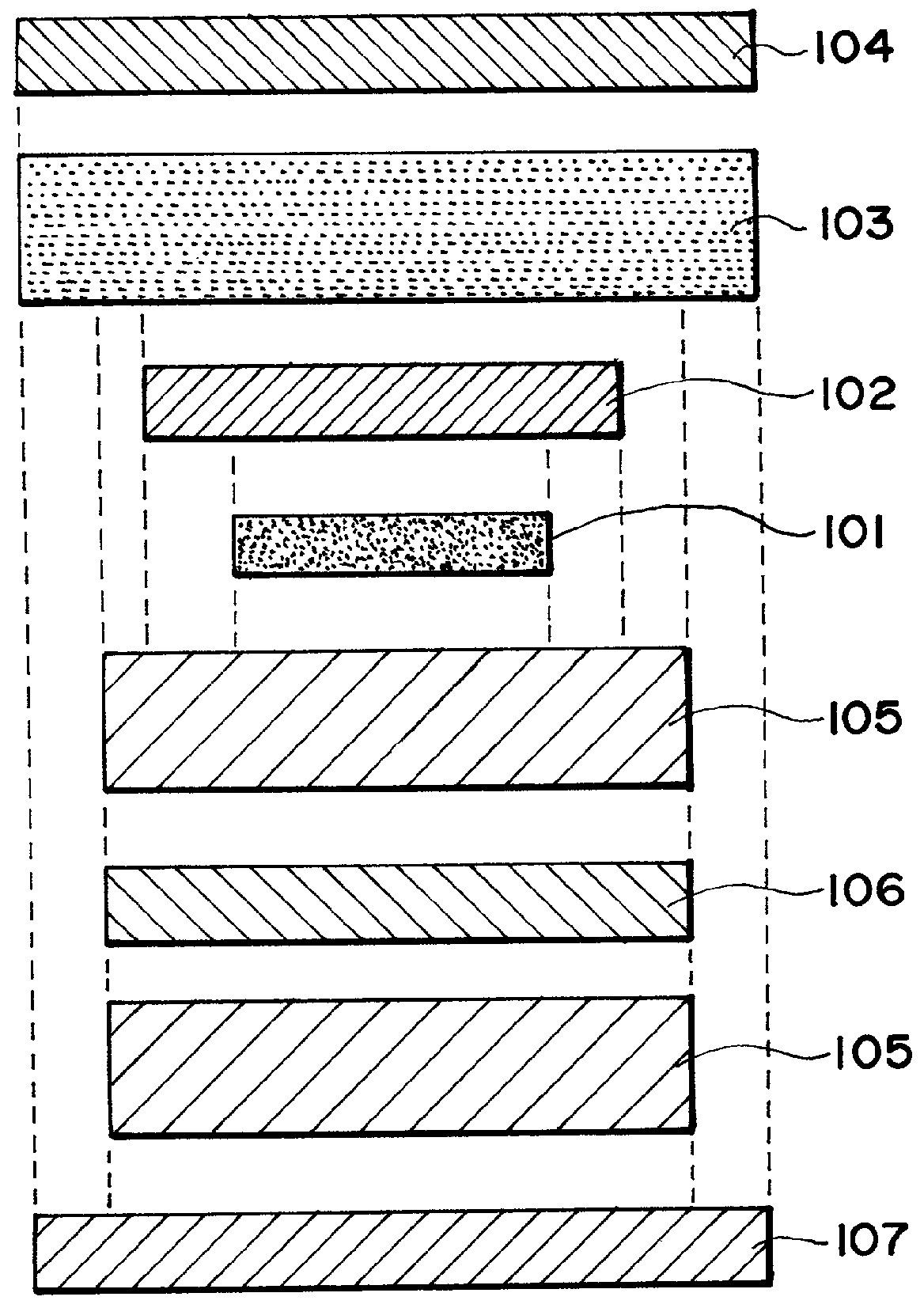

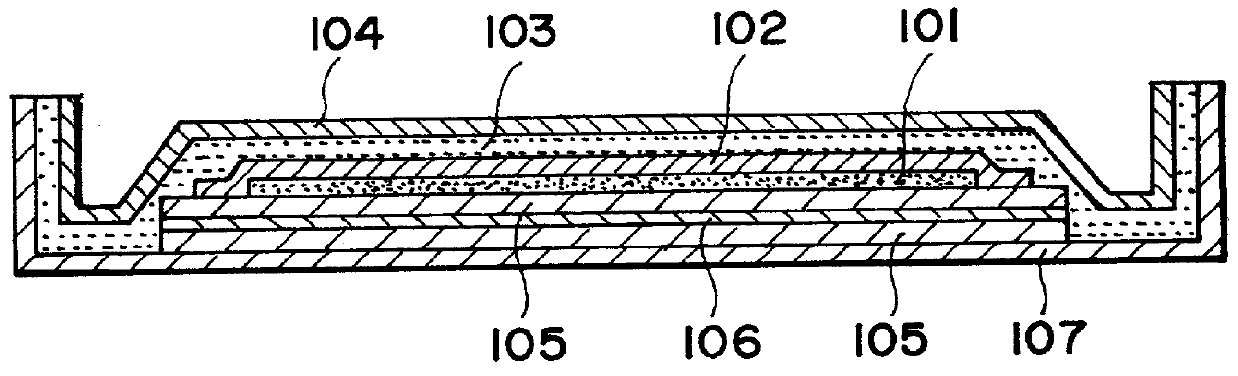

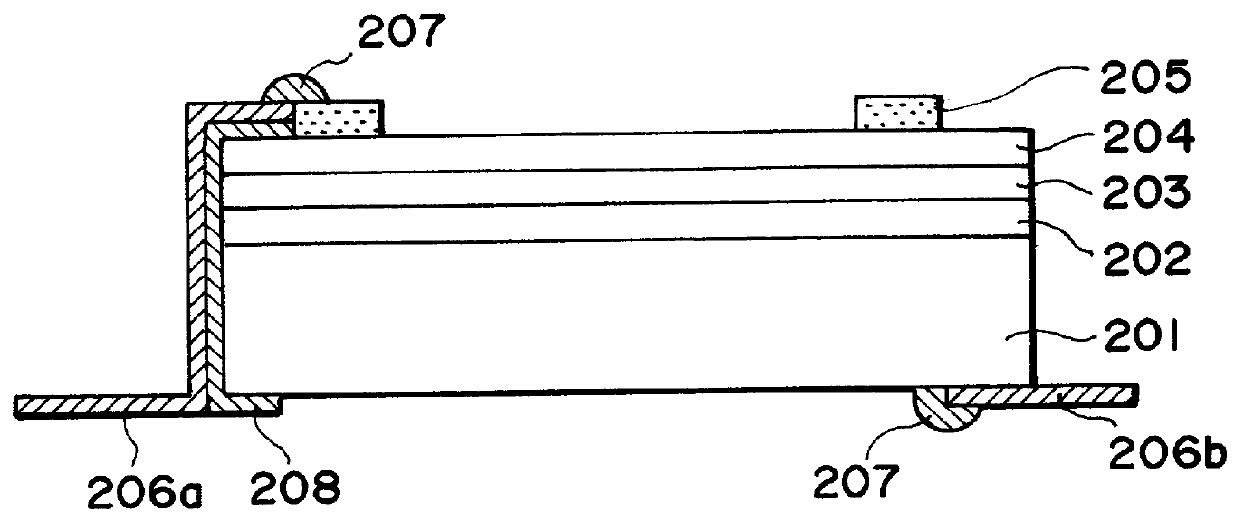

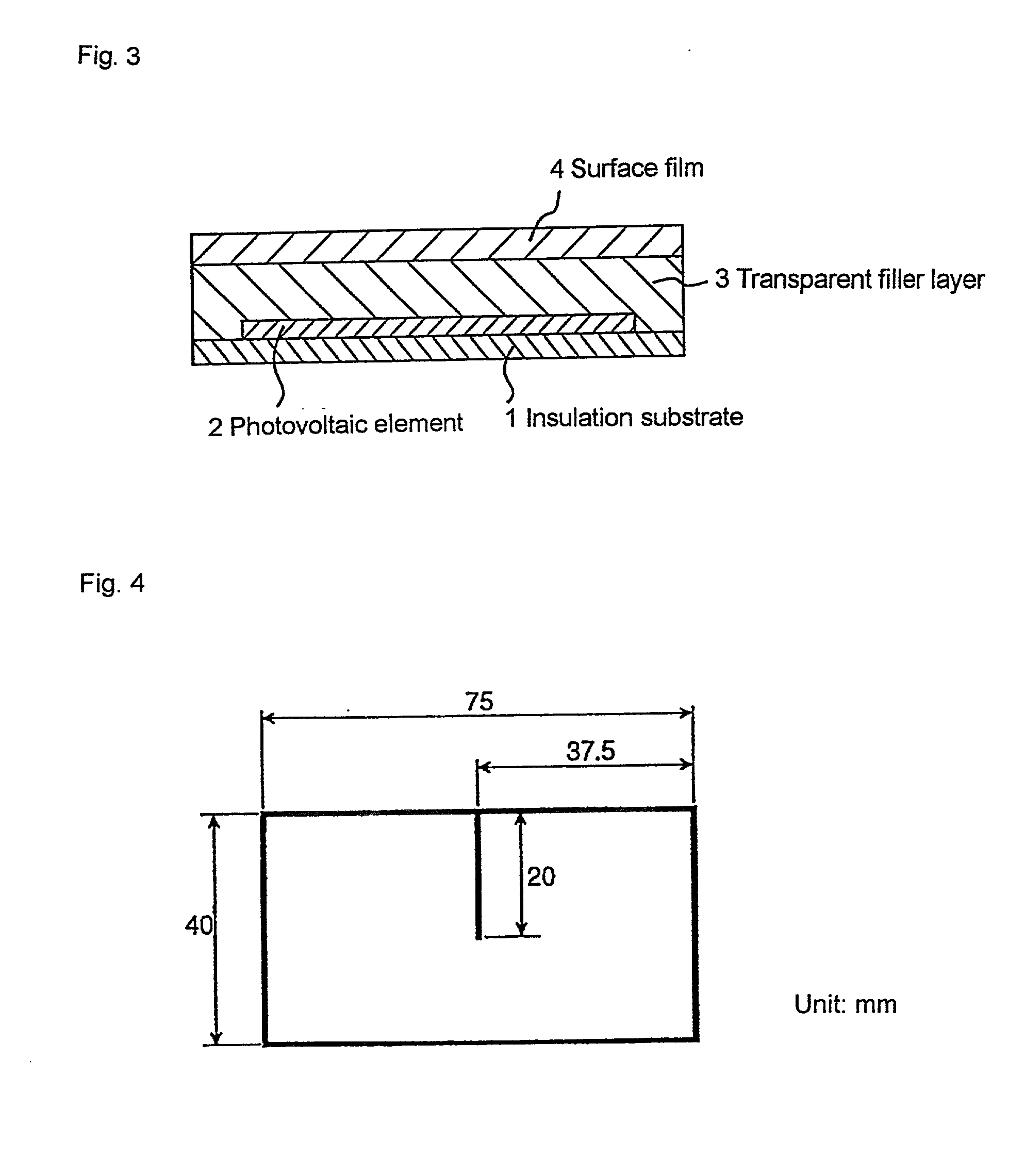

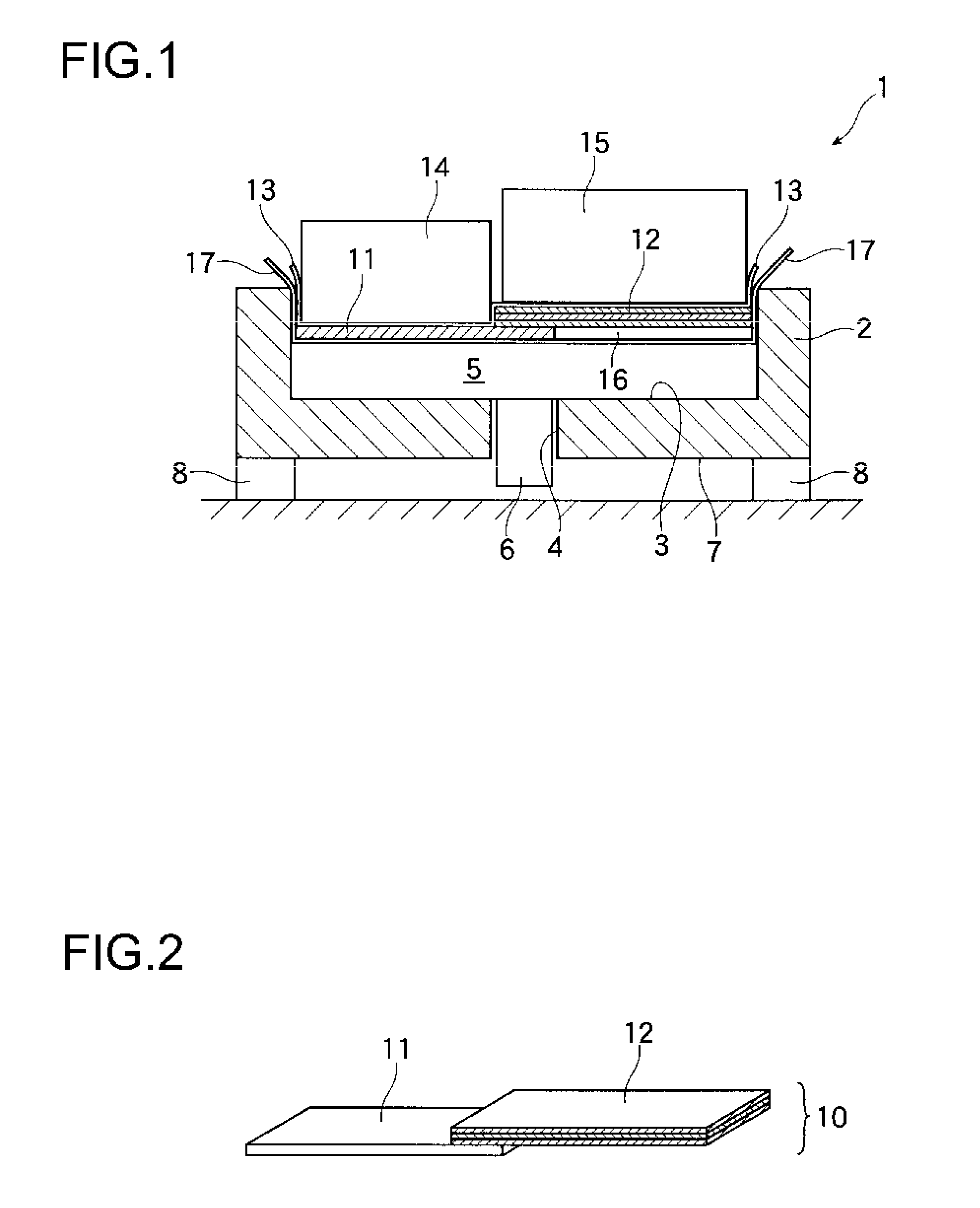

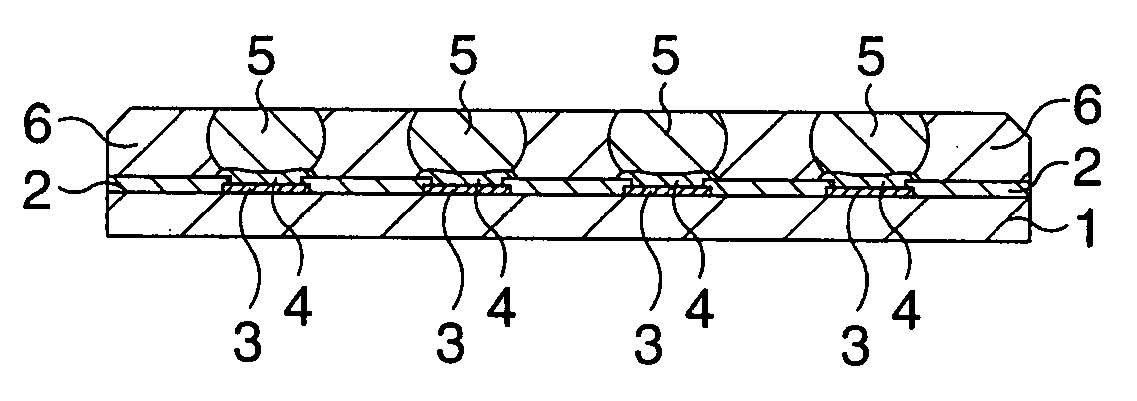

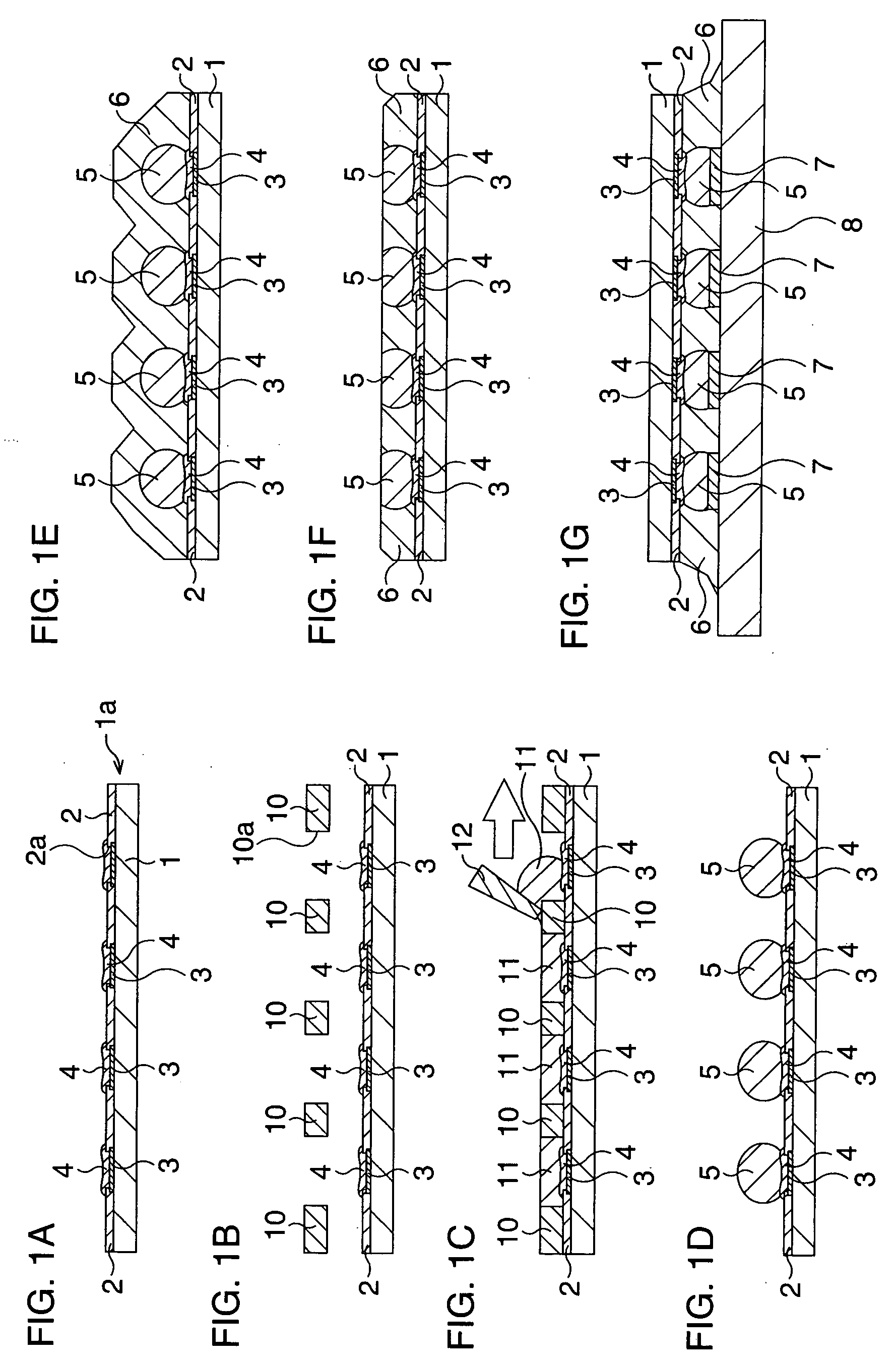

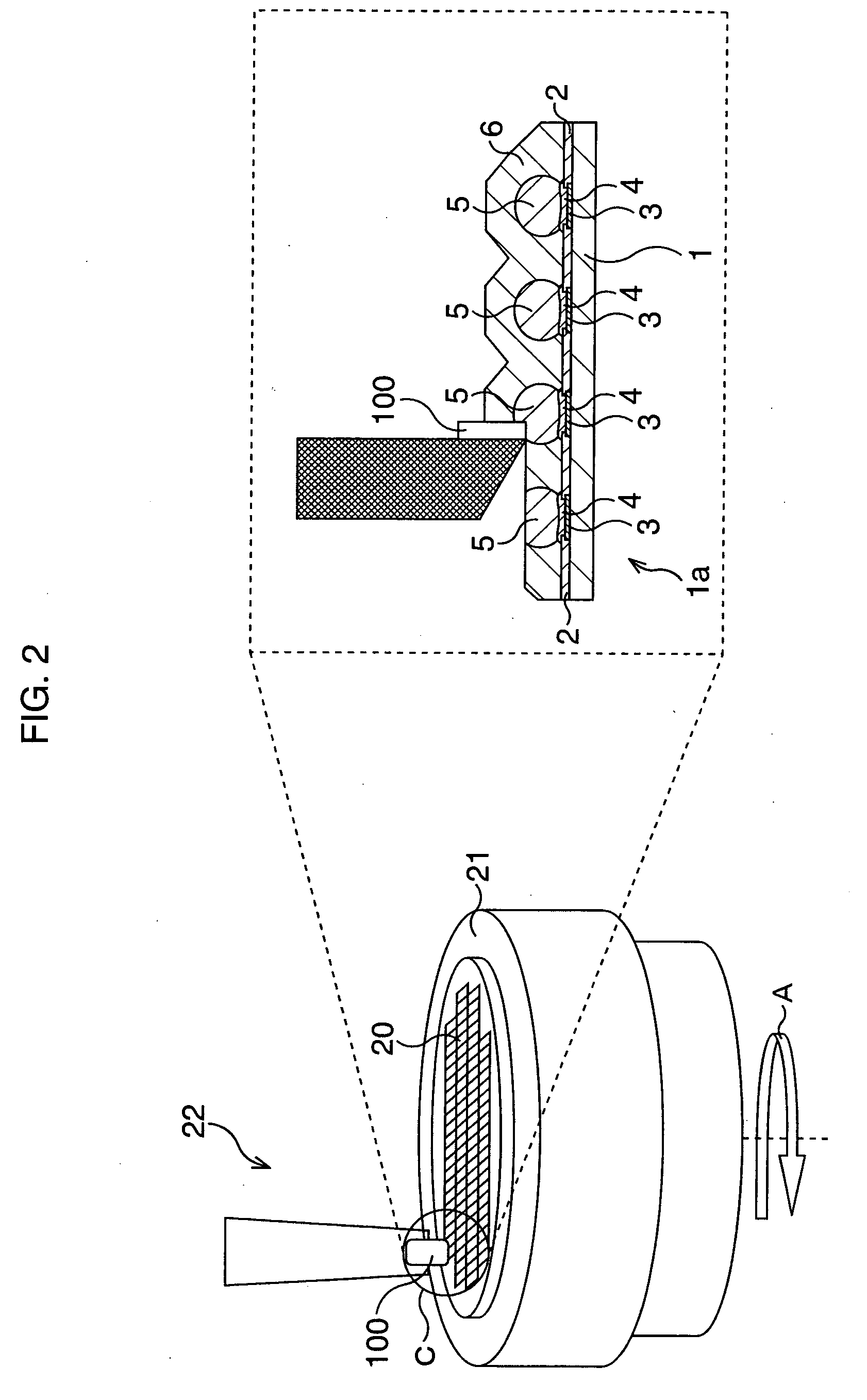

Solar cell module

A solar cell module includes a substrate, a photo-electricity generating device (i.e., a solar cell or a block of solar cells), a filler resin sealing the photo-electricity generating device on the substrate, and a surface film covering the filler resin. An insulating film is inserted between the photo-electricity generating device and the substrate so as to be inside the substrate, and an inorganic fibrous sheet is inserted between the photo-electricity generating device and the surface film so as to be disposed inside the insulating film. The substrate is bent at a portion thereof free from the insulating film. The solar cell member thus provided can exhibit a long-term reliability for outdoor use because of effective suppression of intrusion of moisture thereinto.

Owner:CANON KK

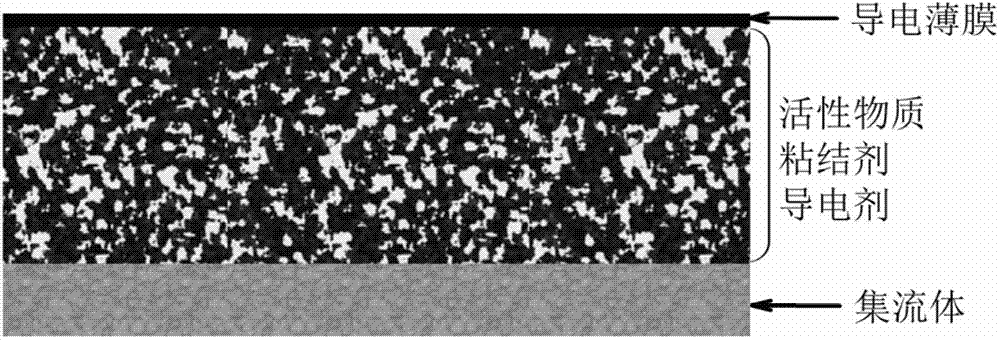

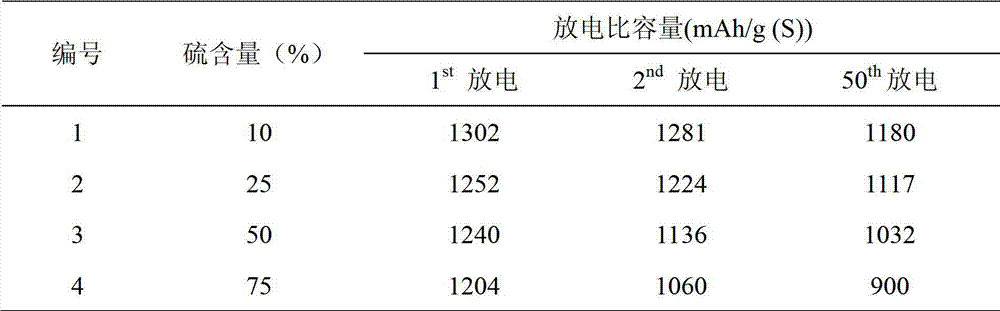

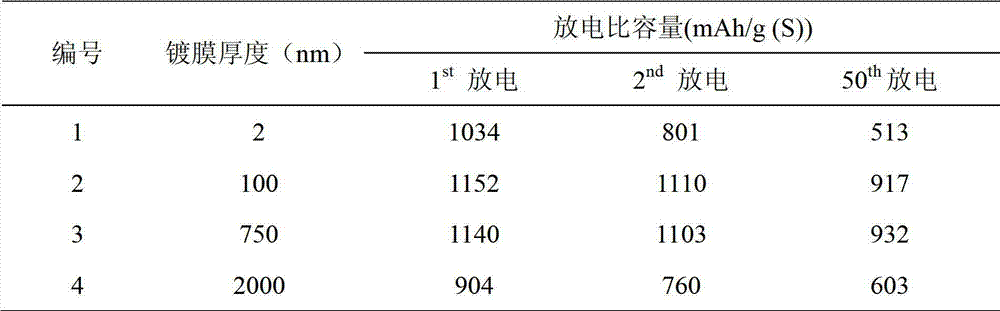

Composite anode of multi-layer structure for lithium-sulfur rechargeable battery and preparation method

InactiveCN103050667AImprove conductivityThickness is easy to controlElectrode manufacturing processesCyclic processSulfur

The invention provides a composite anode of a multi-layer structure for a lithium-sulfur rechargeable battery and a preparation method, which is characterized in that: an anode active substance, a conductive agent, and a binder are uniformly mixed, and then are coated on a current collector, and after coat is dried, a layer of conductive film is sprayed on the surface. The anode surface film is used for conducting and cutting off the sulfur in a cyclic process, thereby effectively raising a first capacity conservation rate of the battery and the cyclic stability.

Owner:CENT SOUTH UNIV

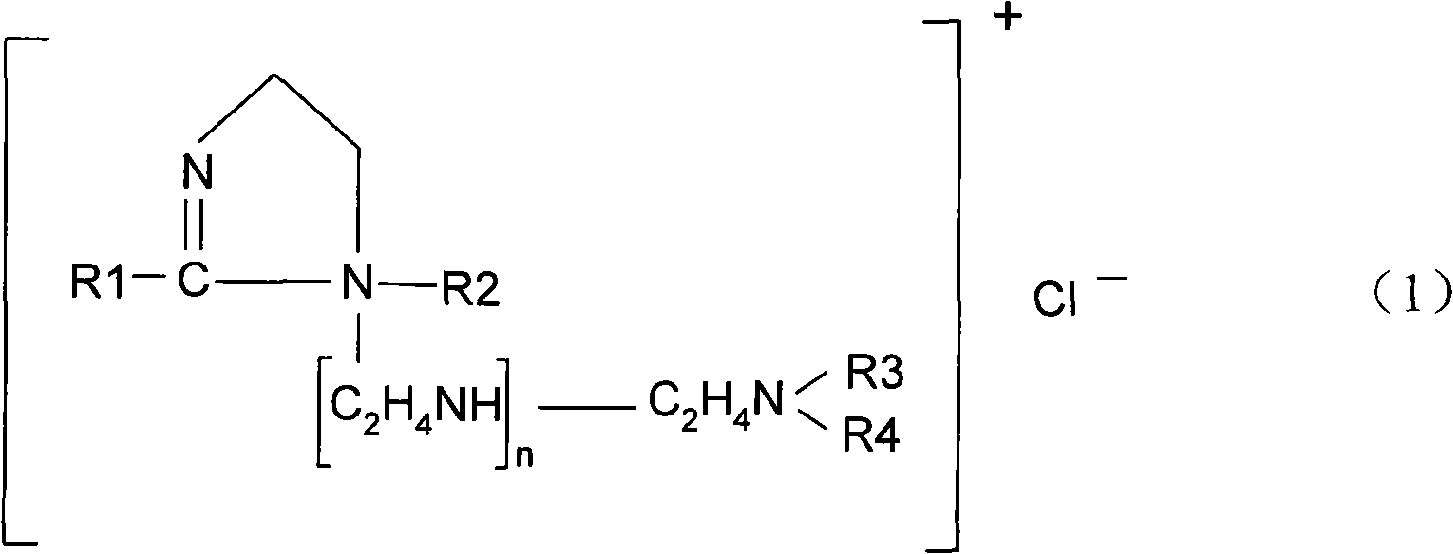

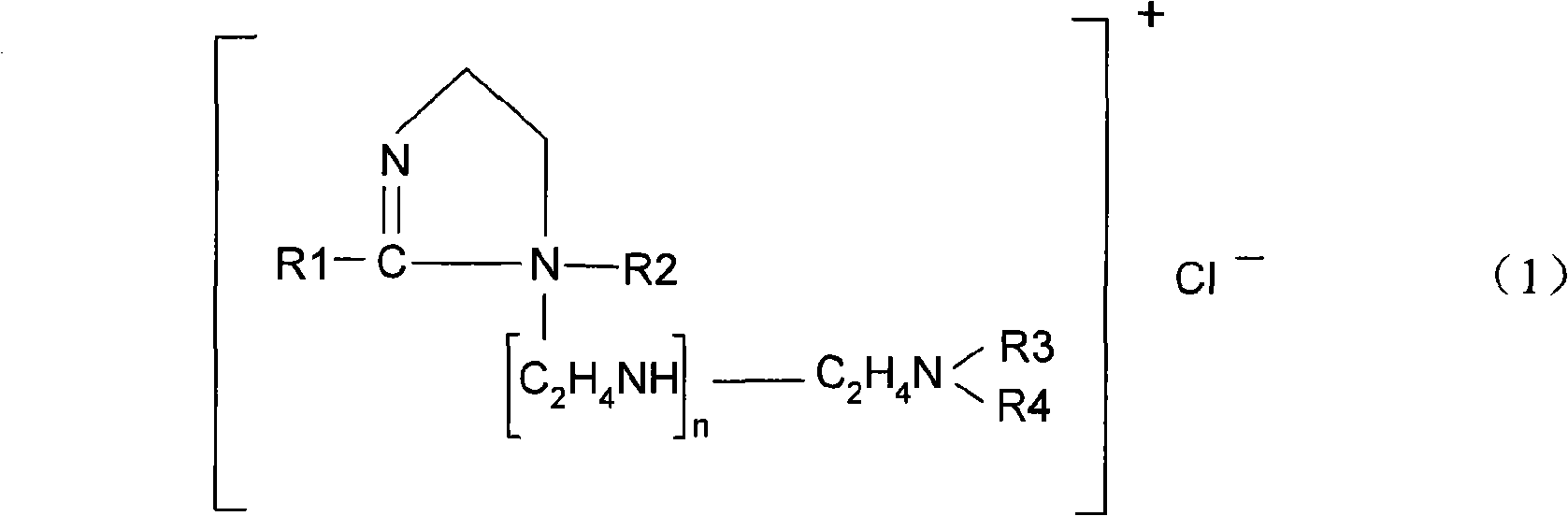

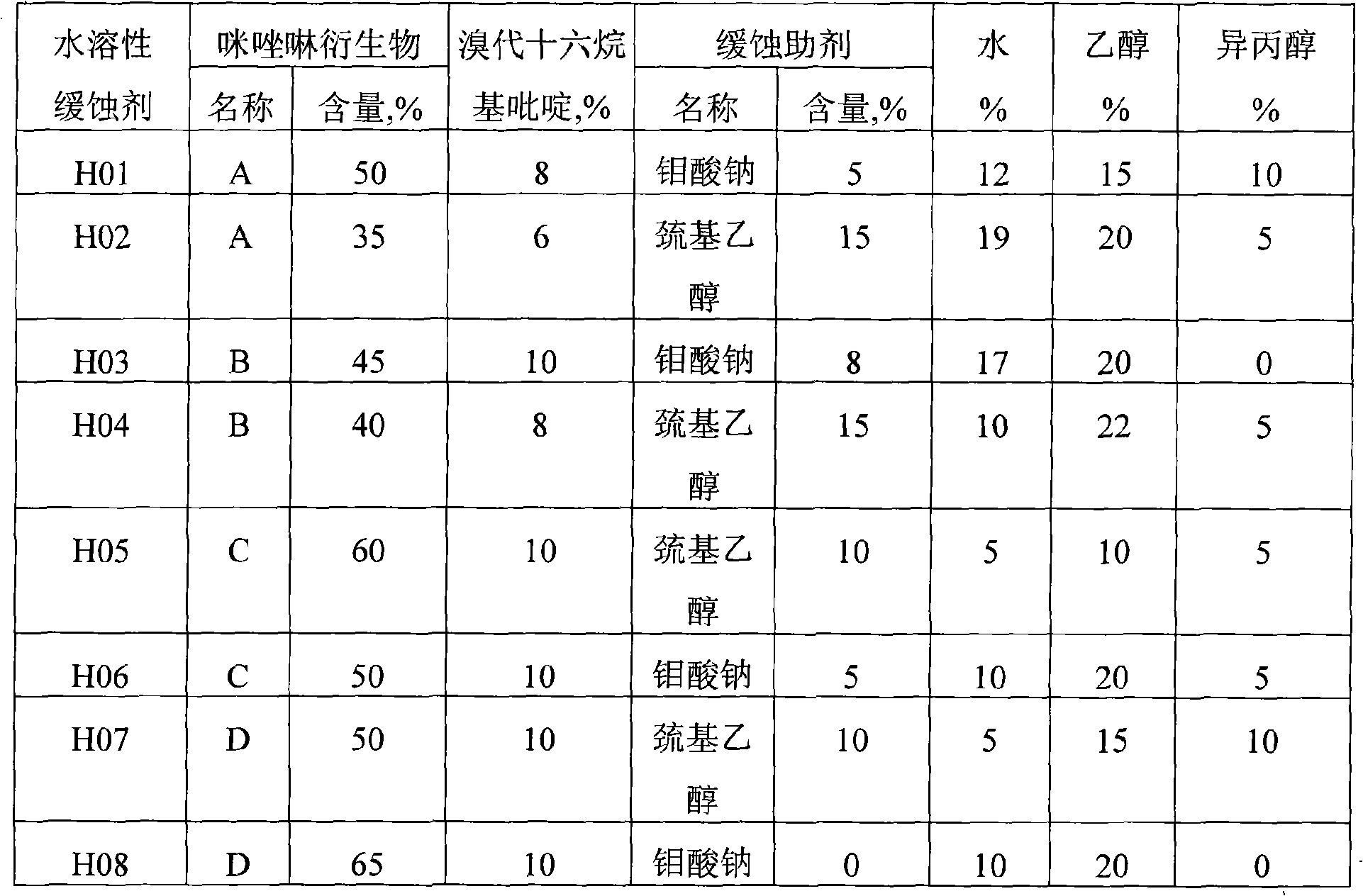

Water-soluble corrosion inhibitor, preparation and application thereof

InactiveCN101280222AHigh corrosion inhibition efficiencyGood chemical stabilityTreatment apparatus corrosion/fouling inhibitionWater solubleImidazoline derivatives

The invention discloses a water soluble corrosion inhibitor, the preparation method and the application of the corrosion inhibitor, solving the defect of narrow application range of the corrosion inhibitor pH in the prior art; the water soluble corrosion inhibitor is composed of 20-70 weight proportion of imidazolines derivates, 1-10 weight proportion of pyridine derivates, 1-20 weight proportion of corrosion inhibition auxiliary agent and 10-50 weight proportion of solvent, based on the total weight of the corrosion inhibitor as the reference. The water soluble corrosion inhibitor in the invention has corrosion inhibition effect on the metal material in the medium with wide PH variation range (pH equals to 1-10) and good metal surface film formation property.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

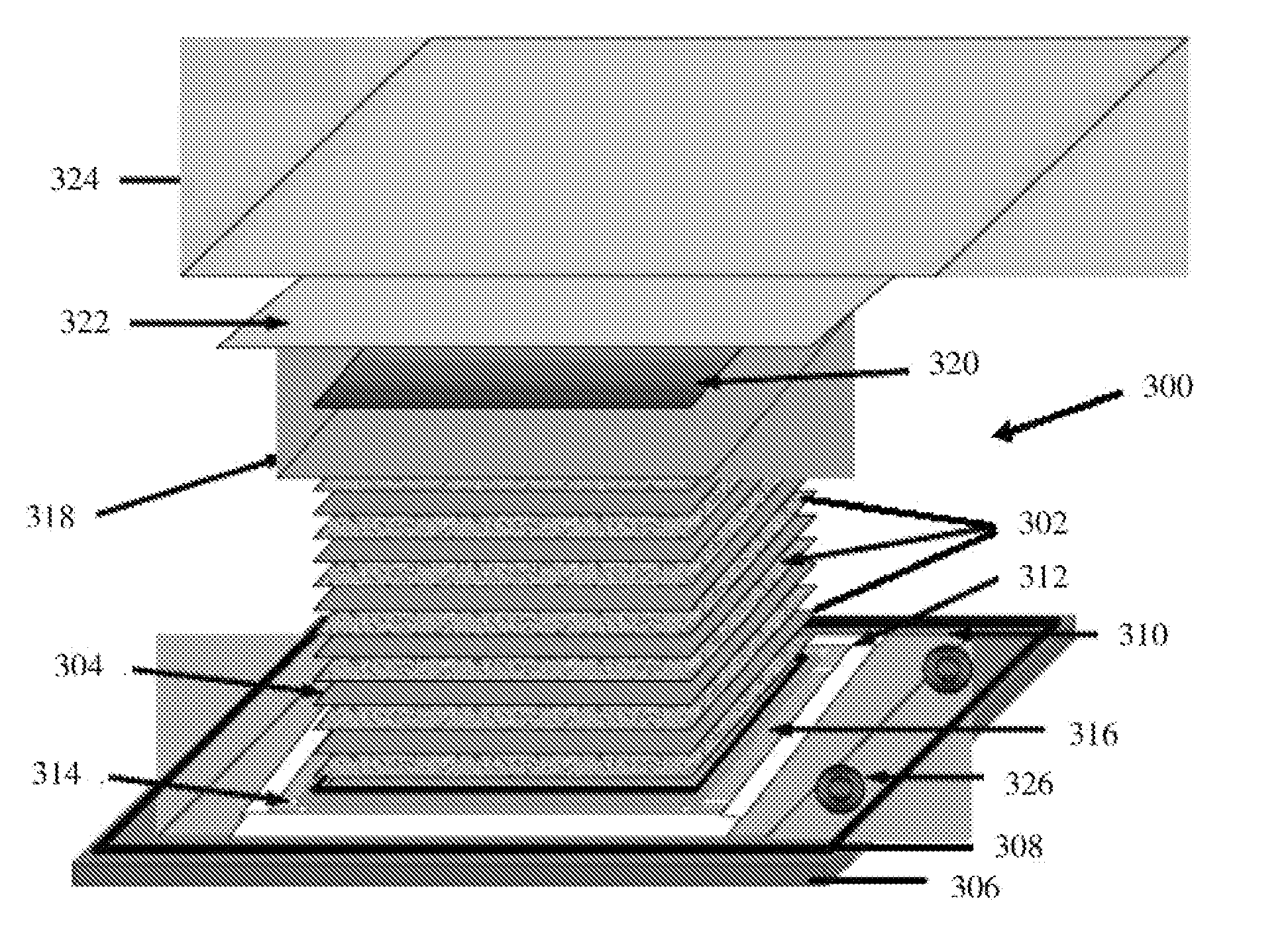

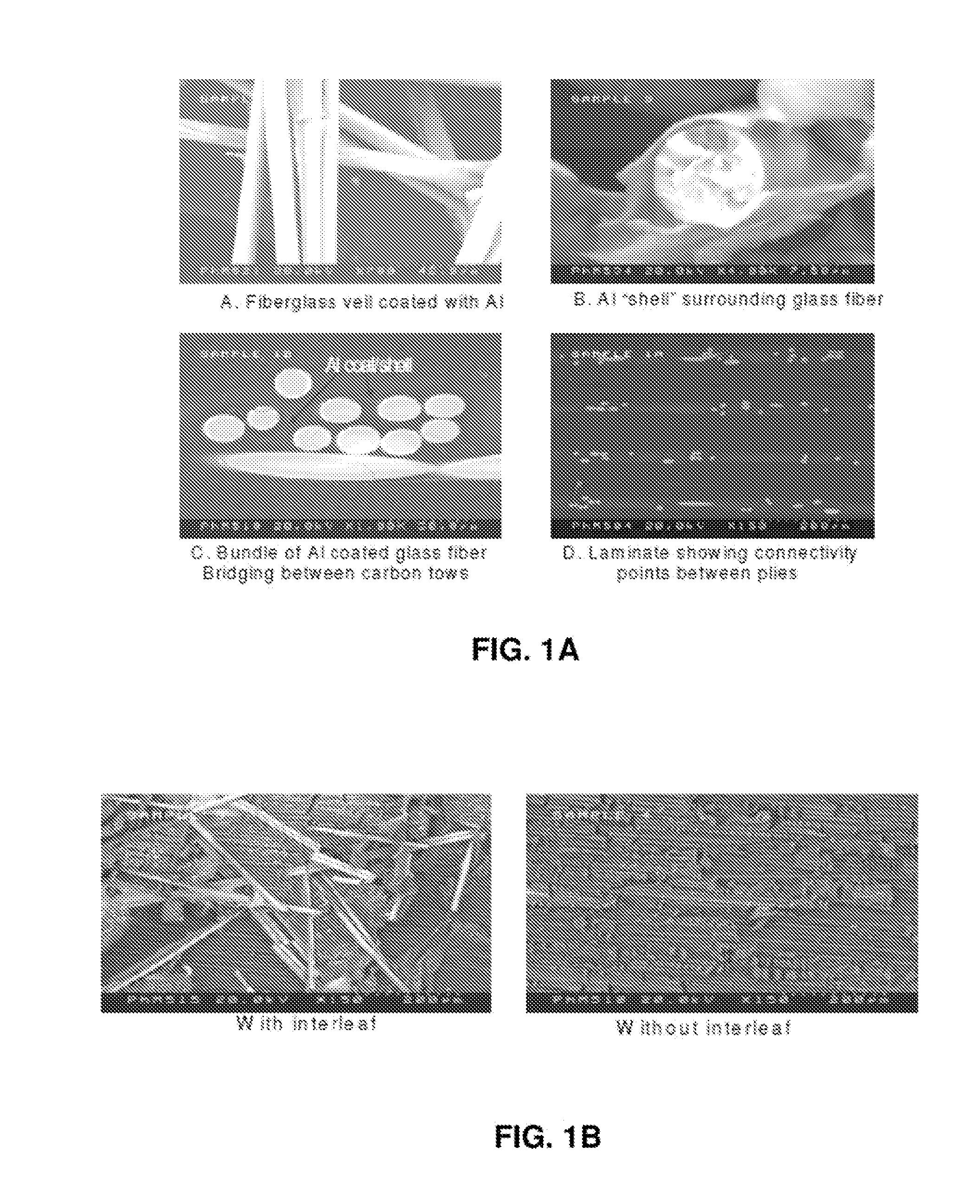

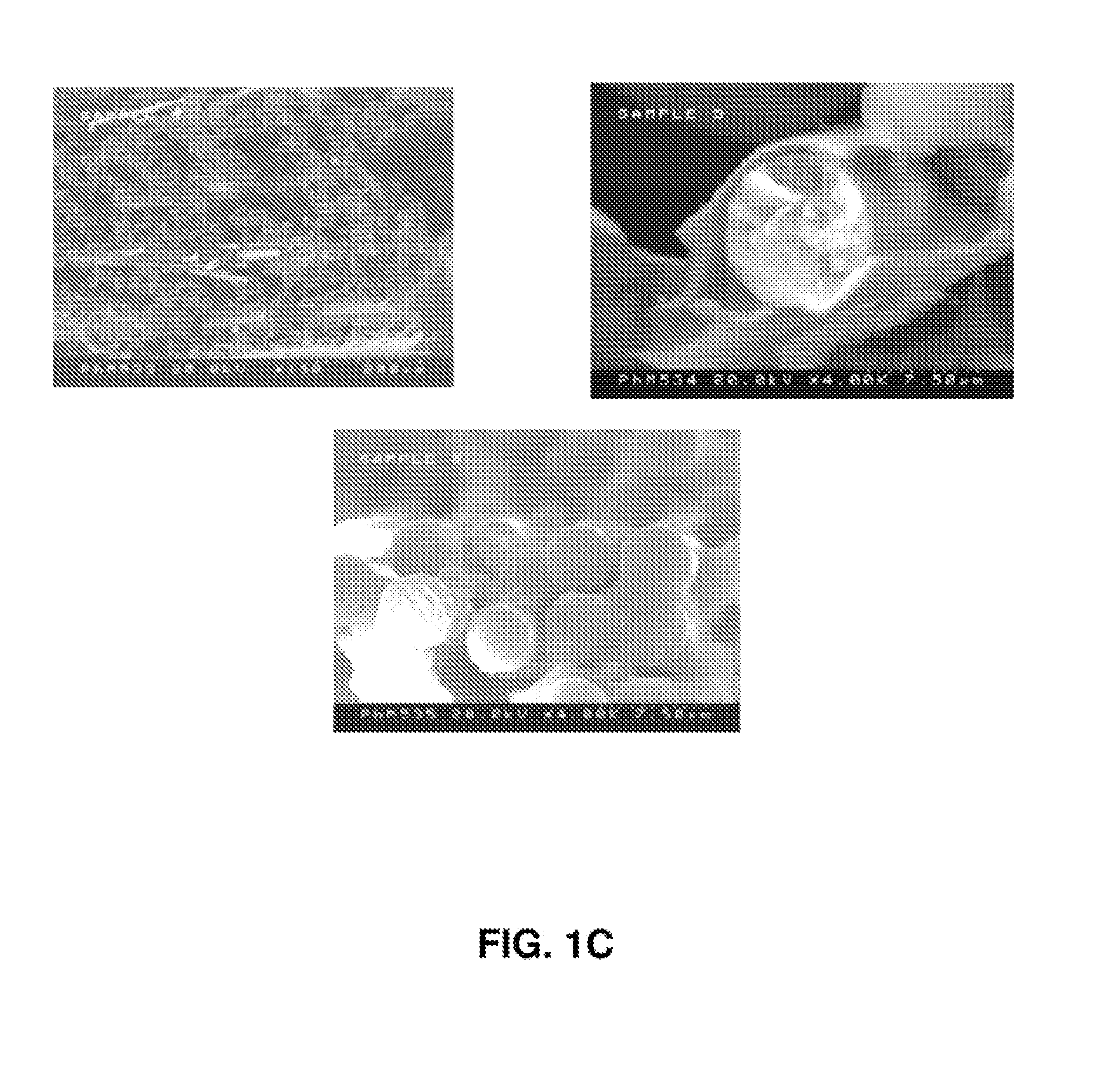

Methods of imparting conductivity to materials used in composite article fabrication & materials thereof

ActiveUS20110159764A1Increased impact valueReduce harmAircraft lighting protectorsLaminationLightning strikeGas phase

Embodiments of the invention are directed to metal- or metal alloy-coated sheet materials (hereinafter, “metal-coated sheet material”) including, but not limited to, fabrics and veils which have a metal content of between one (1) and fifty (50) grams per square meter (gsm). The metal-coated sheet materials may be used as-is or in conjunction with prepregs, adhesives or surfacing films to provide lightning strike protection (LSP) and / or bulk conductivity, among other benefits, to the resultant composite article. In one embodiment, the metal-coated sheet material is impregnated with a resin. According to embodiments of the invention, a metal is applied to one or two sides of the fabric or veil by a physical vapor deposition coating process. The resultant metal-coated fabric or veil may be used as a carrier in surfacing films to impart surface conductivity; may be used as a carrier in adhesives to form conductive adhesive-bonded joints; may be interleaved (one or more metal-coated veils) between layers of prepreg to impart surface and / or bulk conductivity as well as toughness; or may be used to fabricate composite articles.

Owner:CYTEC TECH CORP

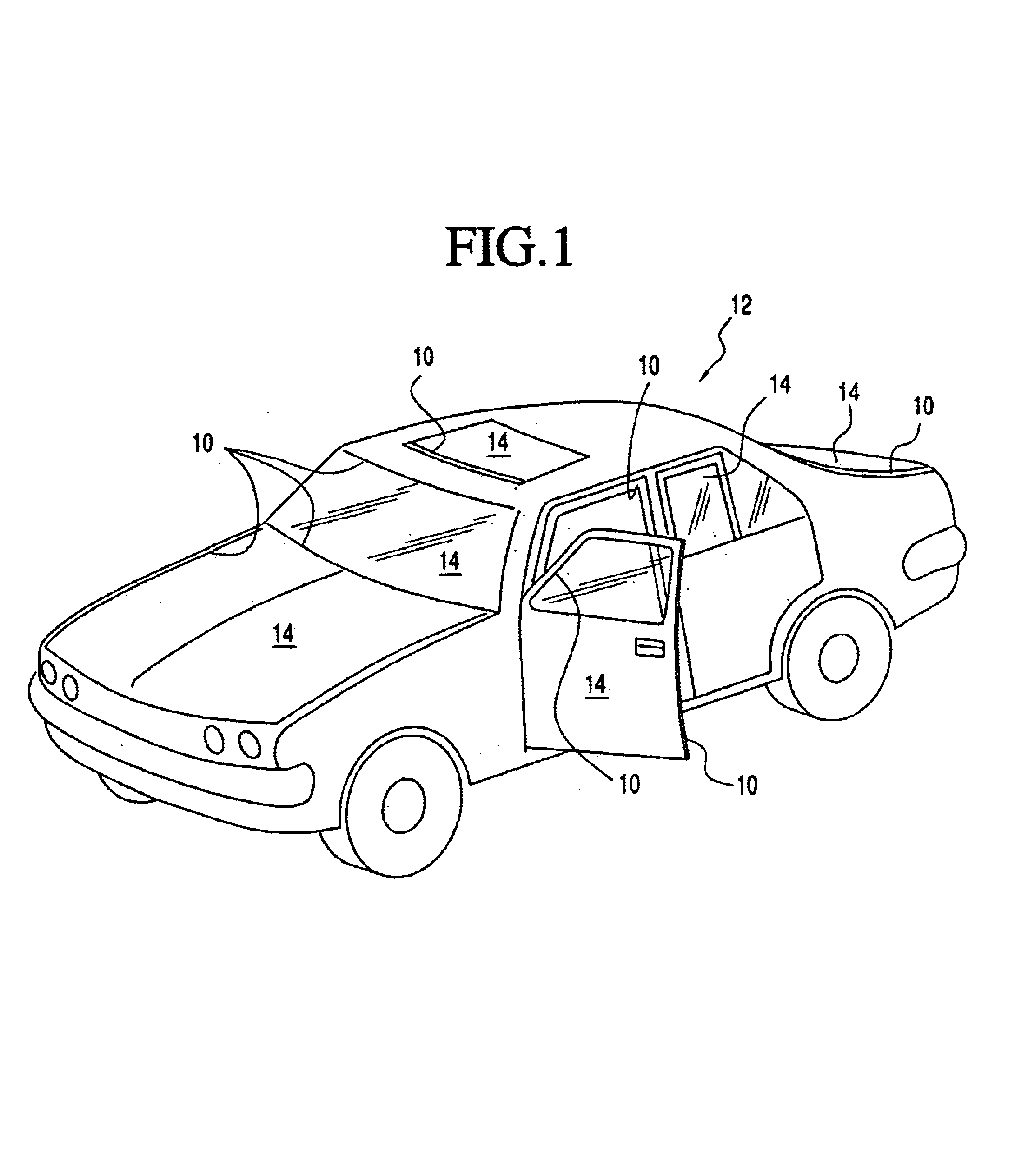

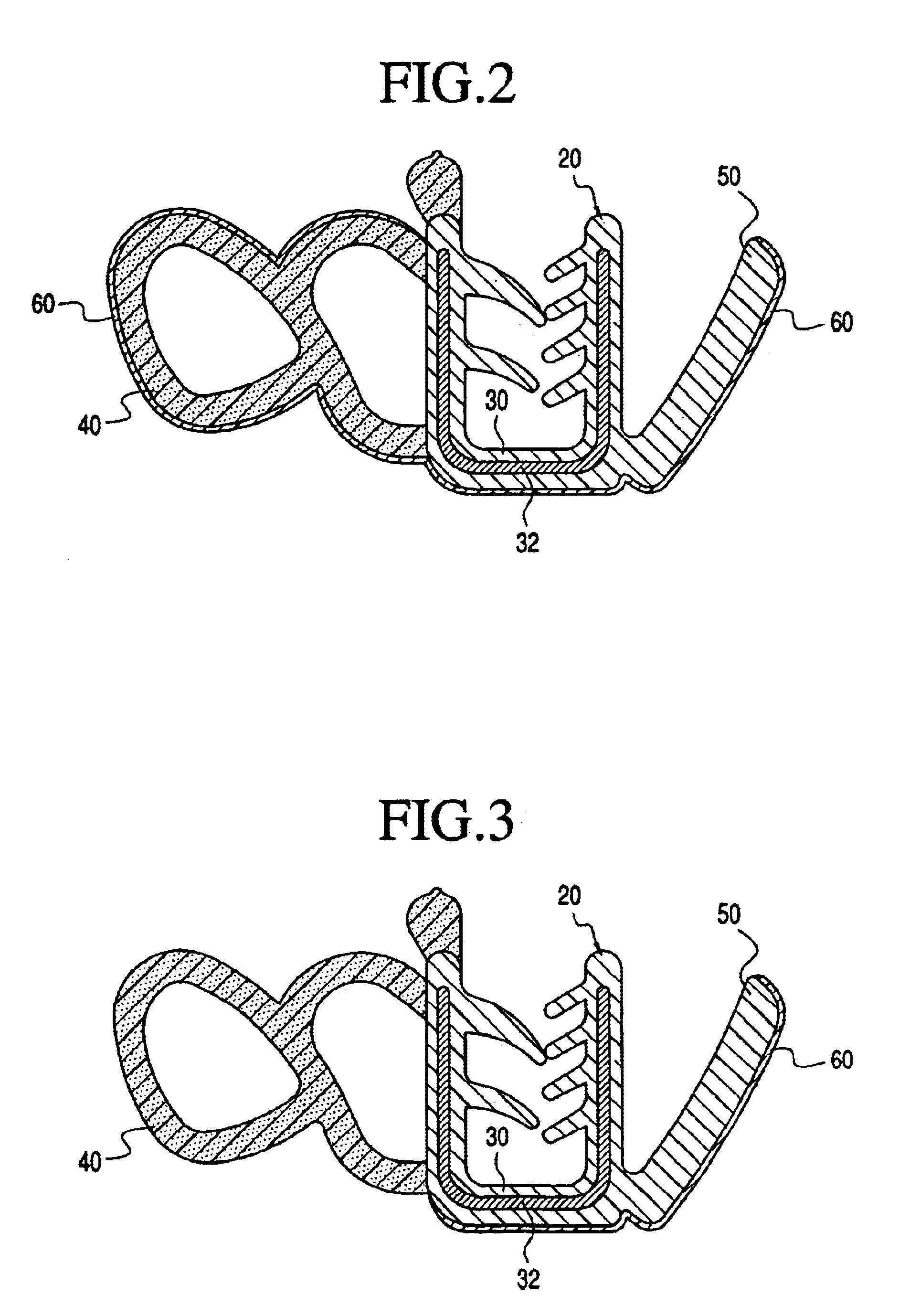

Contiguous colliquefaction forming a surface film for a composite strip

InactiveUS6849310B2Reduce coefficient of frictionLiquid surface applicatorsRecord information storageMaterials sciencePowder coating

A contiguous surface film for a composite strip, such as a weatherseal is disclosed, wherein the surface film is formed of a colliquefied powder coating. The surface film can be located on a carrier, sealing or trim portion of the weatherseal, wherein the surface film can be colored, and selected to provide a desired surface characteristic such as reduced coefficient of friction.

Owner:SCHLEGEL

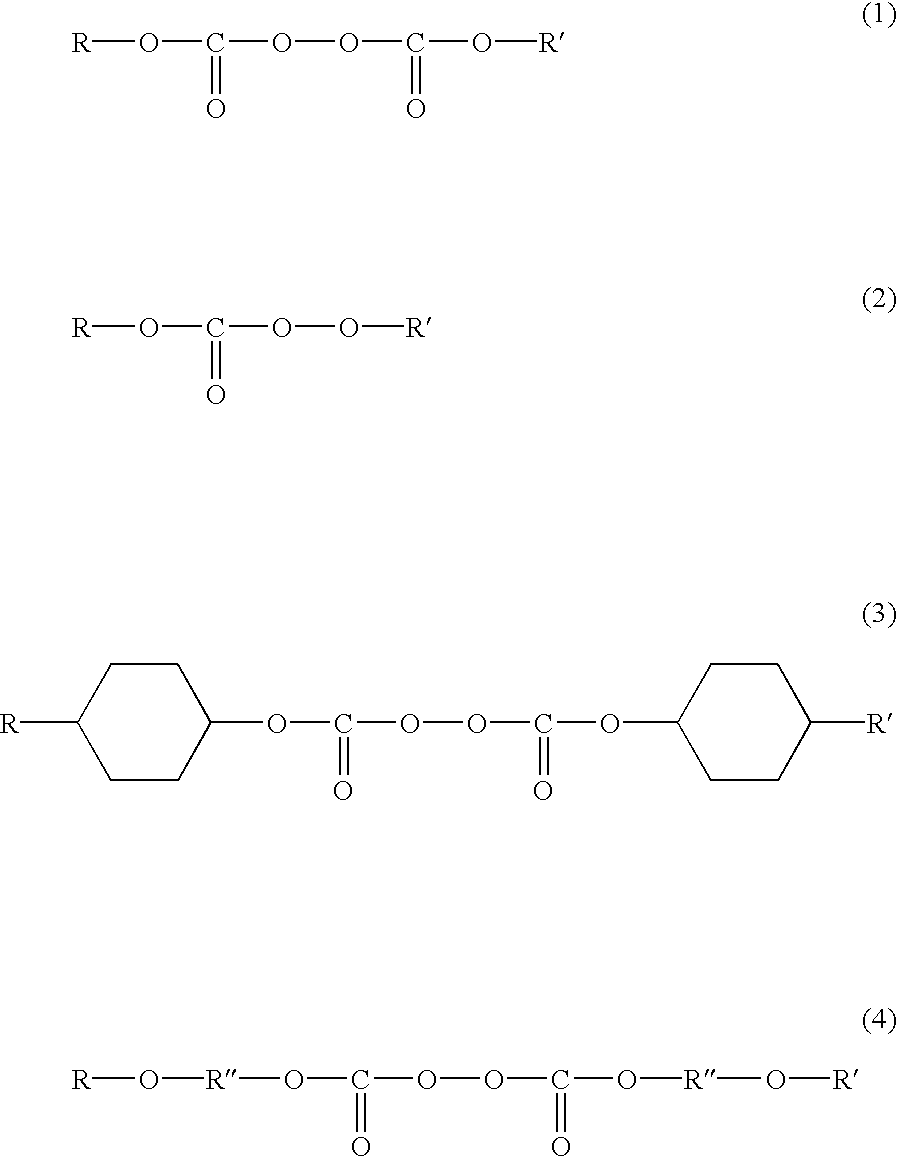

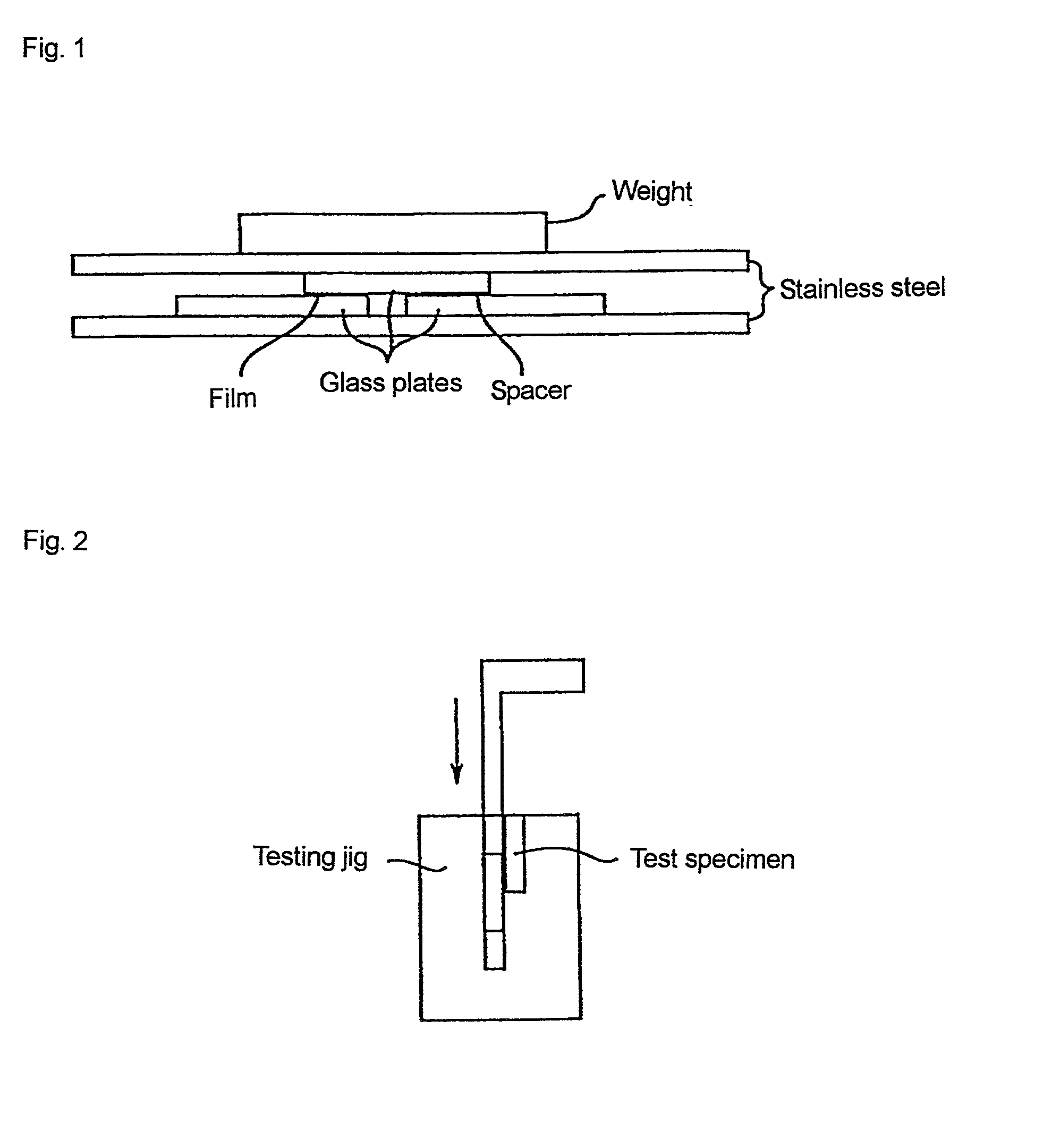

Tetrafluoroethylene copolymer and use thereof

InactiveUS20020128412A1Maintain good propertiesLow heat resistanceSynthetic resin layered productsThin material handlingSolventPolymer chemistry

A tetrafluoroethylene copolymer comprising 30 to 81 mole % of tetrafluoroethylene and a 70 to 19 mole % of at least one other monomer, and having terminal carbonate groups at polymer chain ends, which has a melt flow rate of 0.1 to 100 g / 10 min. at 200.degree. C. under a load of 5 kg, and a melting point of 90 to 200.degree. C., a laminate comprising a layer of the above tetrafluoroethylene copolymer, and a layer of other material, and a surface film or a transparent filler material for a solar cell, which comprises the above tetrafluoroethylene copolymer is disclosed. The fluororesin can be firmly adhered directly to other materials such as resins, metals, glass, crystalline silicon, polycrystalline silicon and amorphous silicon, while maintaining characteristics such as chemical resistance, solvent resistance, non-tackiness, electrical insulation properties, stain-proofing properties and flame retardance. The fluororesin can also be molded at a lower temperature than conventional fluororesins, and thus can be heat bonded or co-extruded with general purpose resins having low heat resistance.

Owner:DAIKIN IND LTD

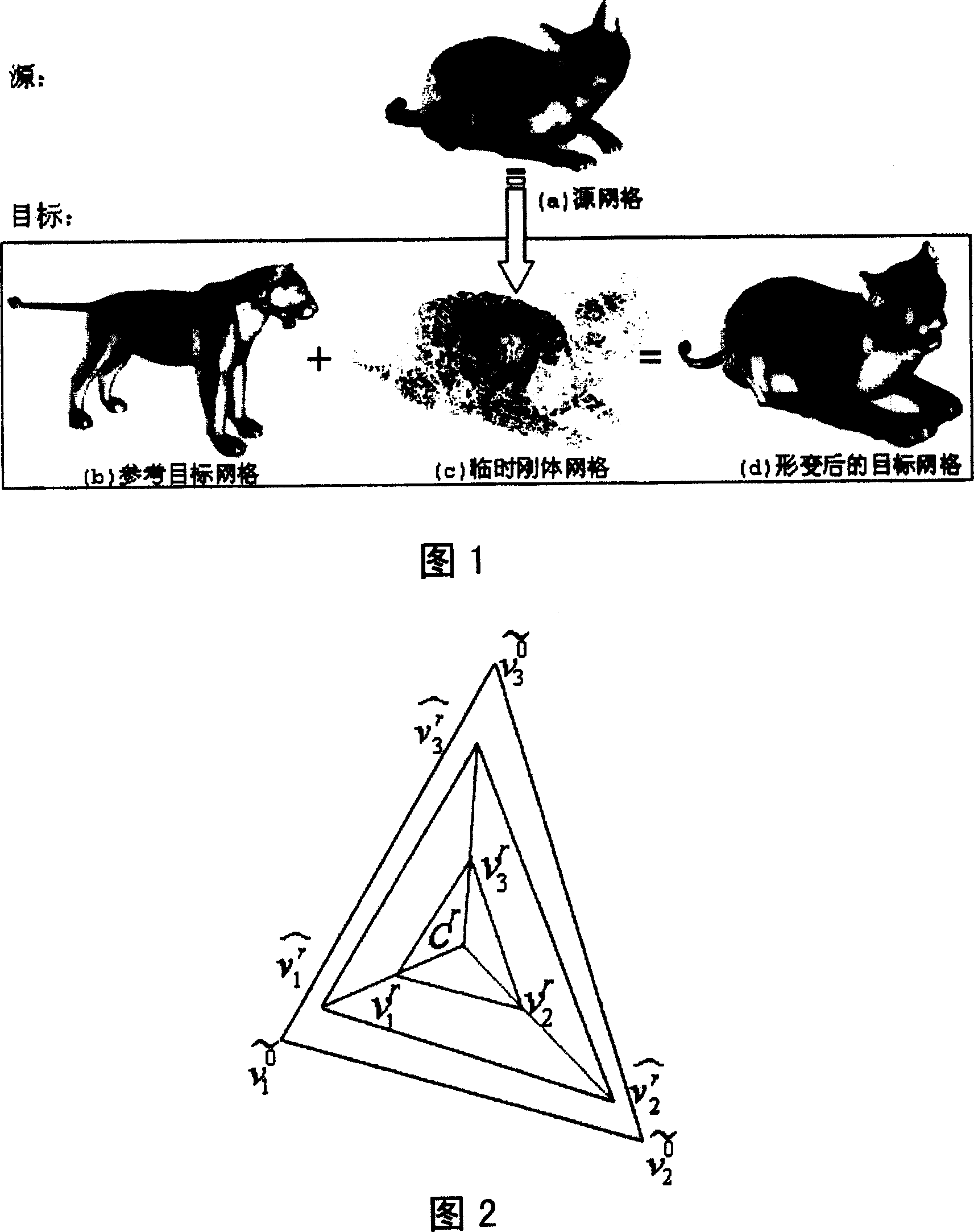

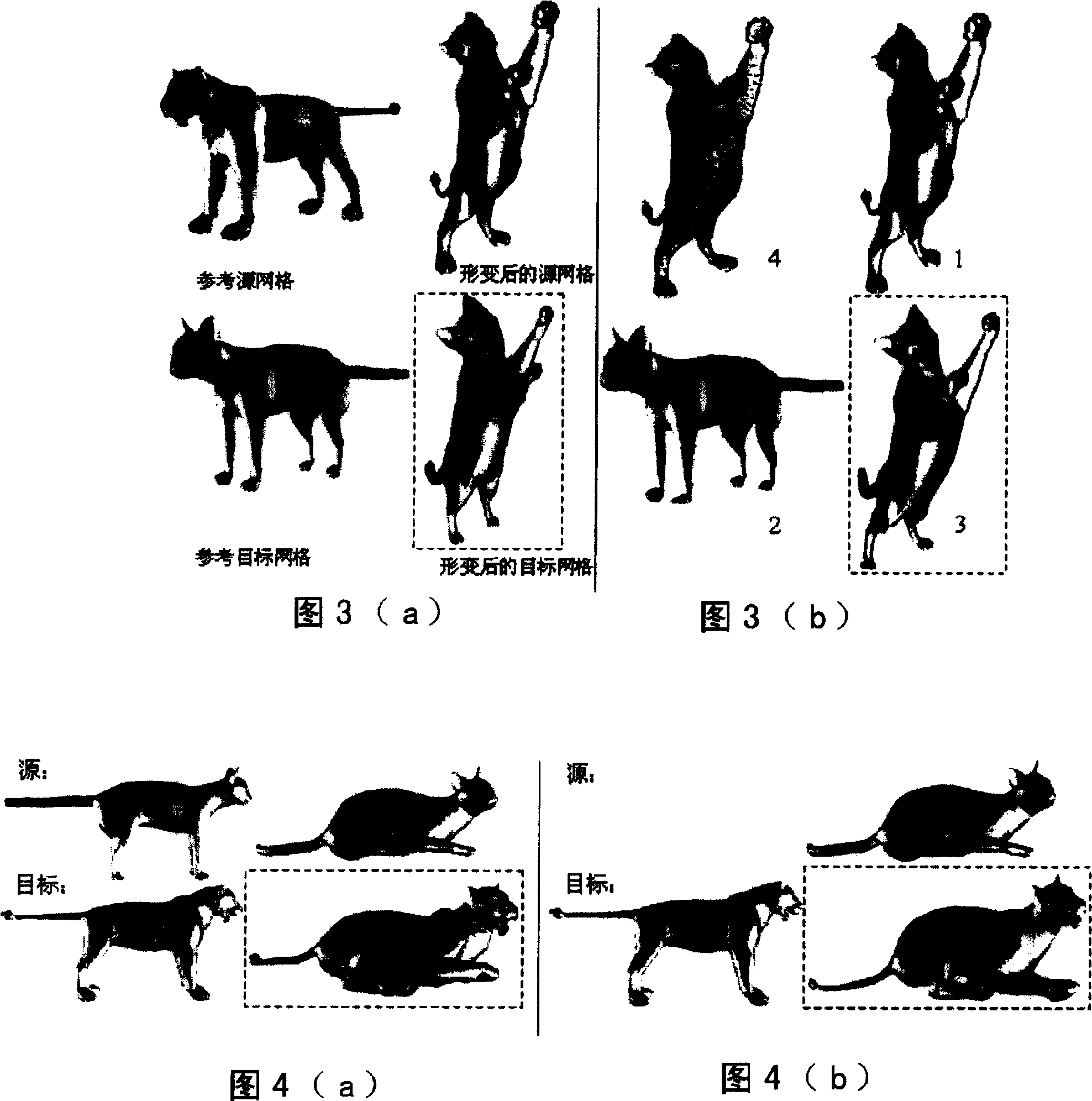

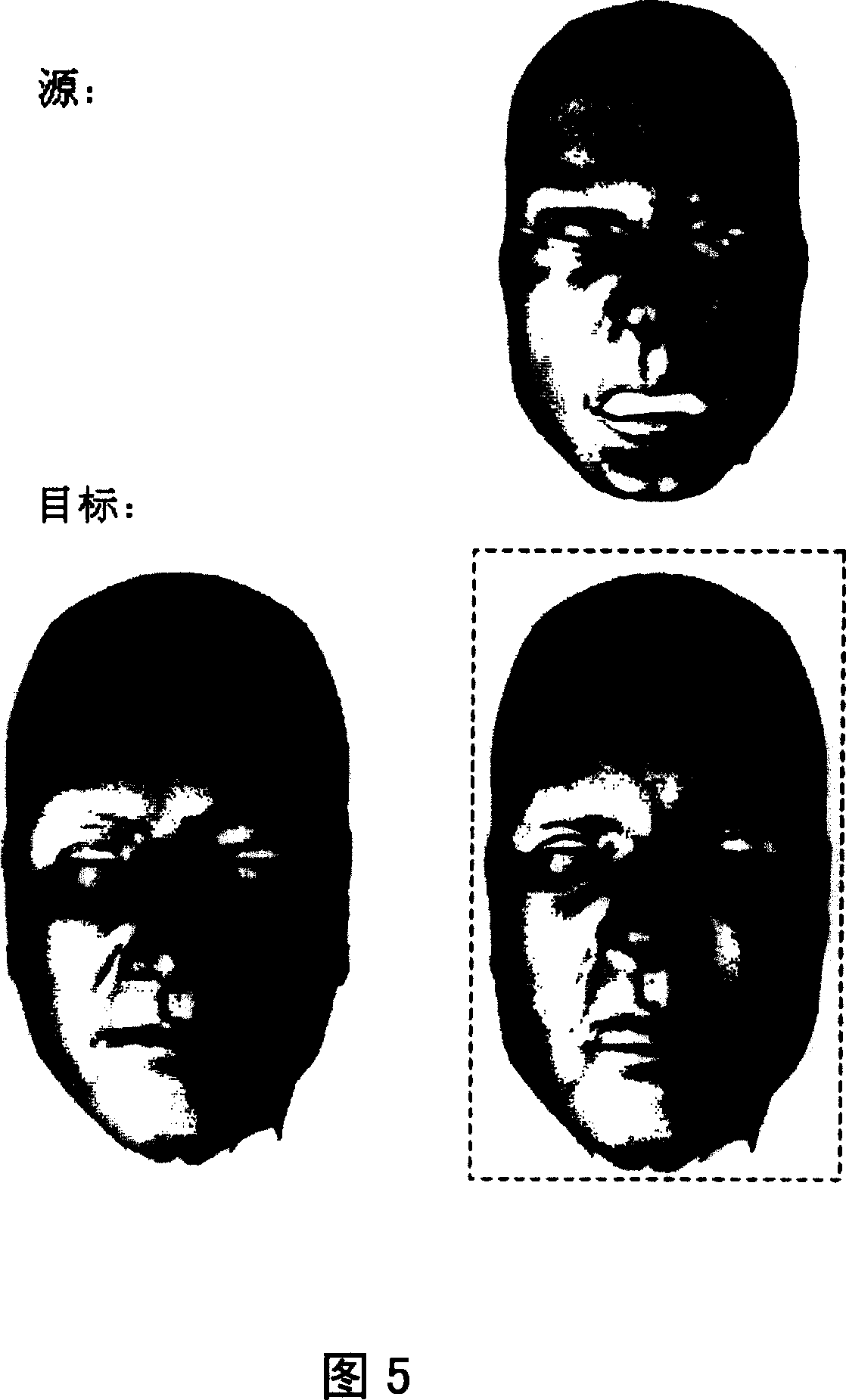

Method for directly transferring three-dimensional model attitude

This invention is a three-dimensional model of direct transfer method gesture involving computer graphics technology, the 3D model directly to the source posture passed to target three-dimensional model. First, the user specified source / target model features corresponding anchor, and then the corresponding algorithm automatically establish the source and destination of the triangular relationship; Then, the triangular surface film formation rotation and translation to a temporary mesh, the network from a reference targets Gatti Grid rigid elements, while retaining a possible source grid posture information; then the provisional grid in the face of the film in accordance with the predefined Laplace differential binding re-arranged, splicing generate meaningful three-dimensional model . This invention solution to a single three-dimensional model of transmission between posture, both the overall structure of the skeleton or fine skin deformation; help efficient 3D animation division has been rapid use of 3D model library to produce complex three-dimensional model of posture, and no need to start from scratch or repeated time-consuming manual adjustment.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

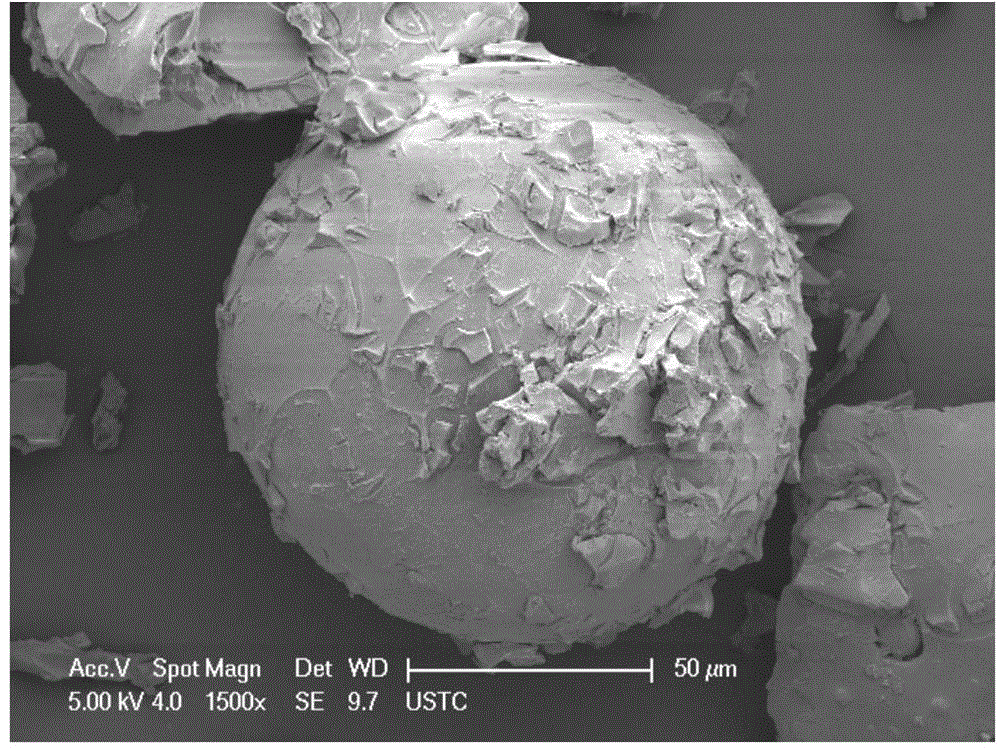

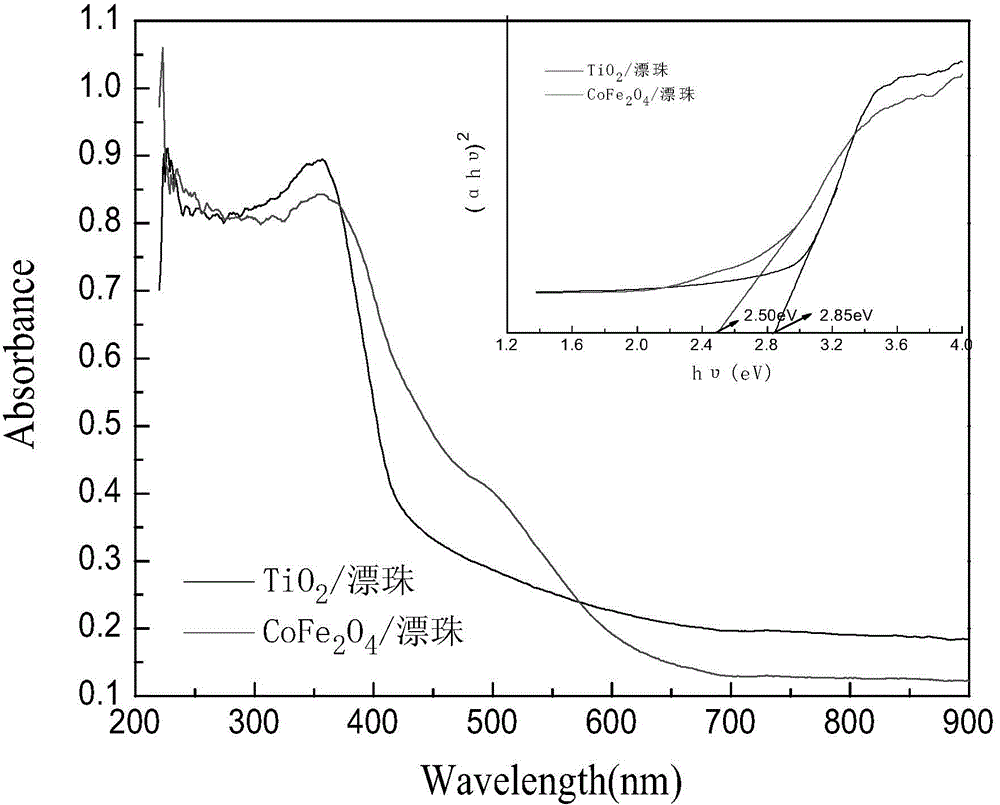

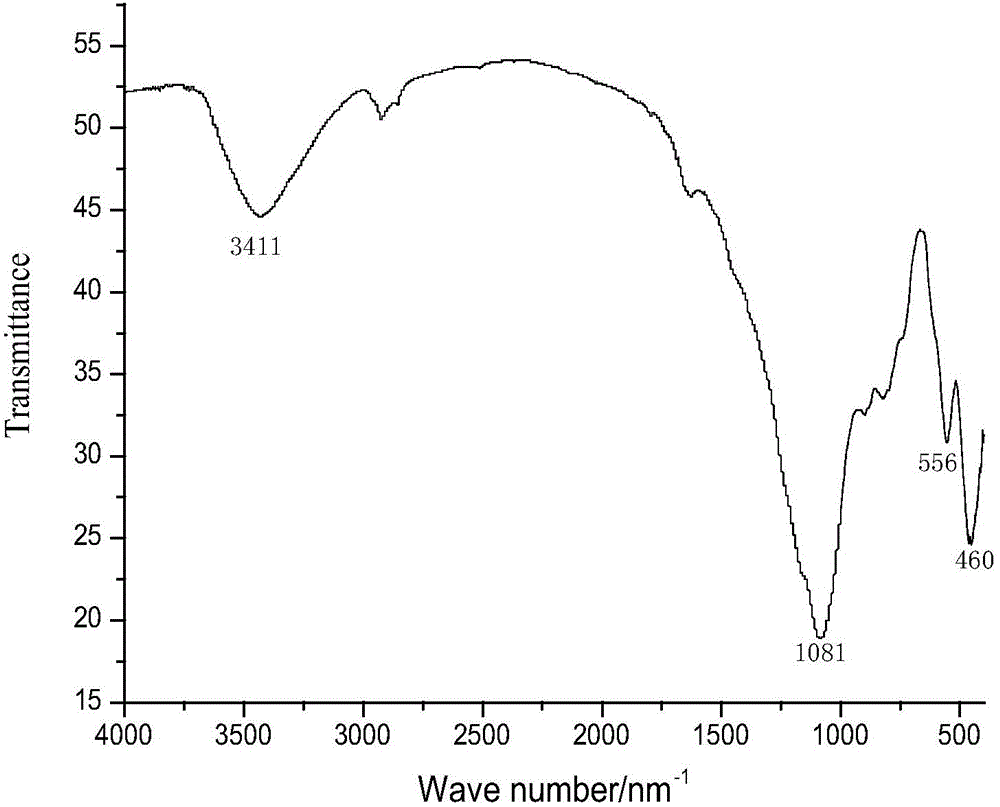

Floating type CoFe2O4/TiO2/floating bead composite photocatalyst and preparation method thereof

ActiveCN104128184AIncrease profitExtended service lifeCatalyst carriersWater/sewage treatment by irradiationActive componentWastewater

The invention discloses a floating type CoFe2O4 / TiO2 / floating bead composite photocatalyst and a preparation method thereof, and specifically relates to a CoFe2O4 / TiO2 / floating bead composite photocatalyst for treating organic wastewater, and a preparation method thereof. The CoFe2O4 / TiO2 / floating bead composite photocatalyst comprises catalyst active components and a catalyst carrier. The catalyst active components comprise, by weight, 0.5-1 wt% of Co, 1-2 wt% of Fe, 12-18 wt% of Ti, and the balance being a fly ash floating bead catalyst carrier. In the obtained CoFe2O4 / TiO2 / floating bead composite photocatalyst, CoFe2O4 is loaded on TiO2 film on the surface of the floating bead, thereby increasing specific surface area and increasing absorption performance.

Owner:淮南市德瑞环保科技有限公司

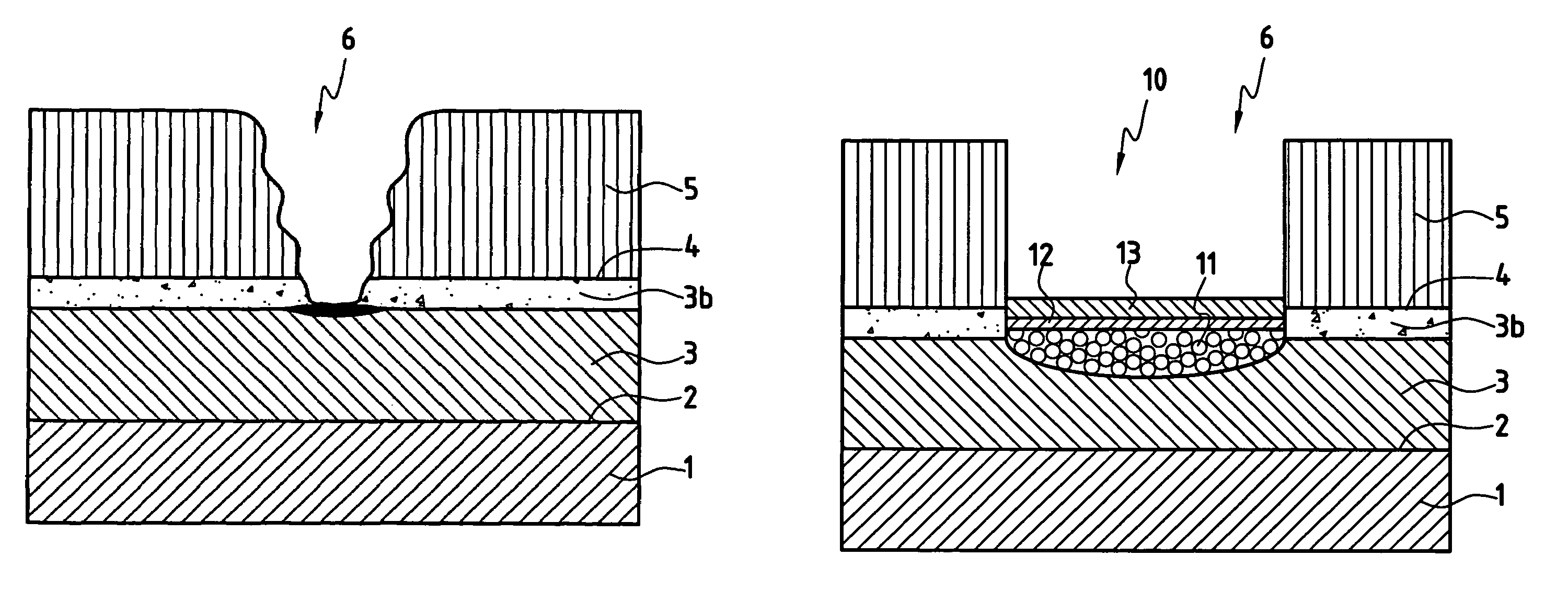

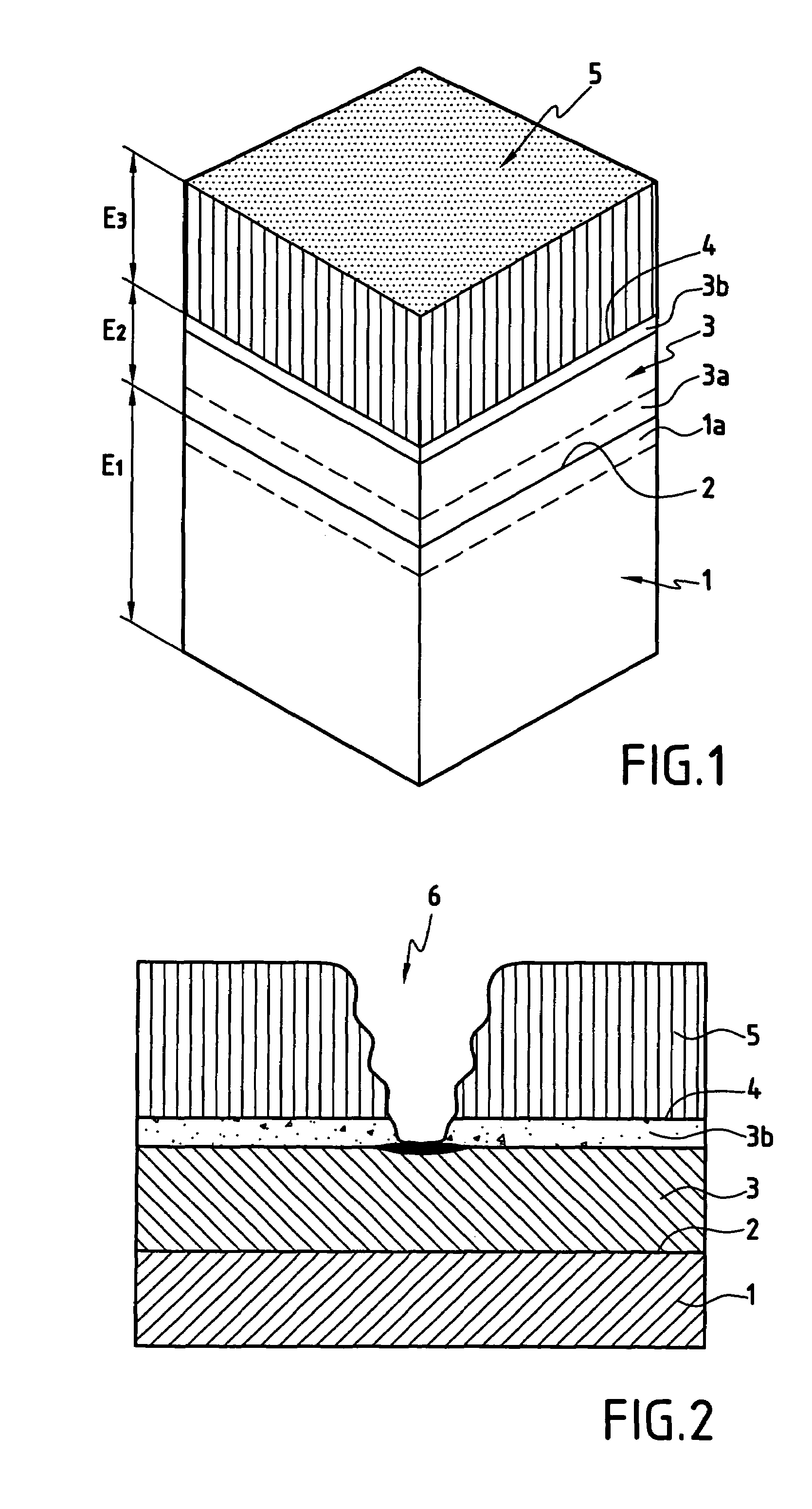

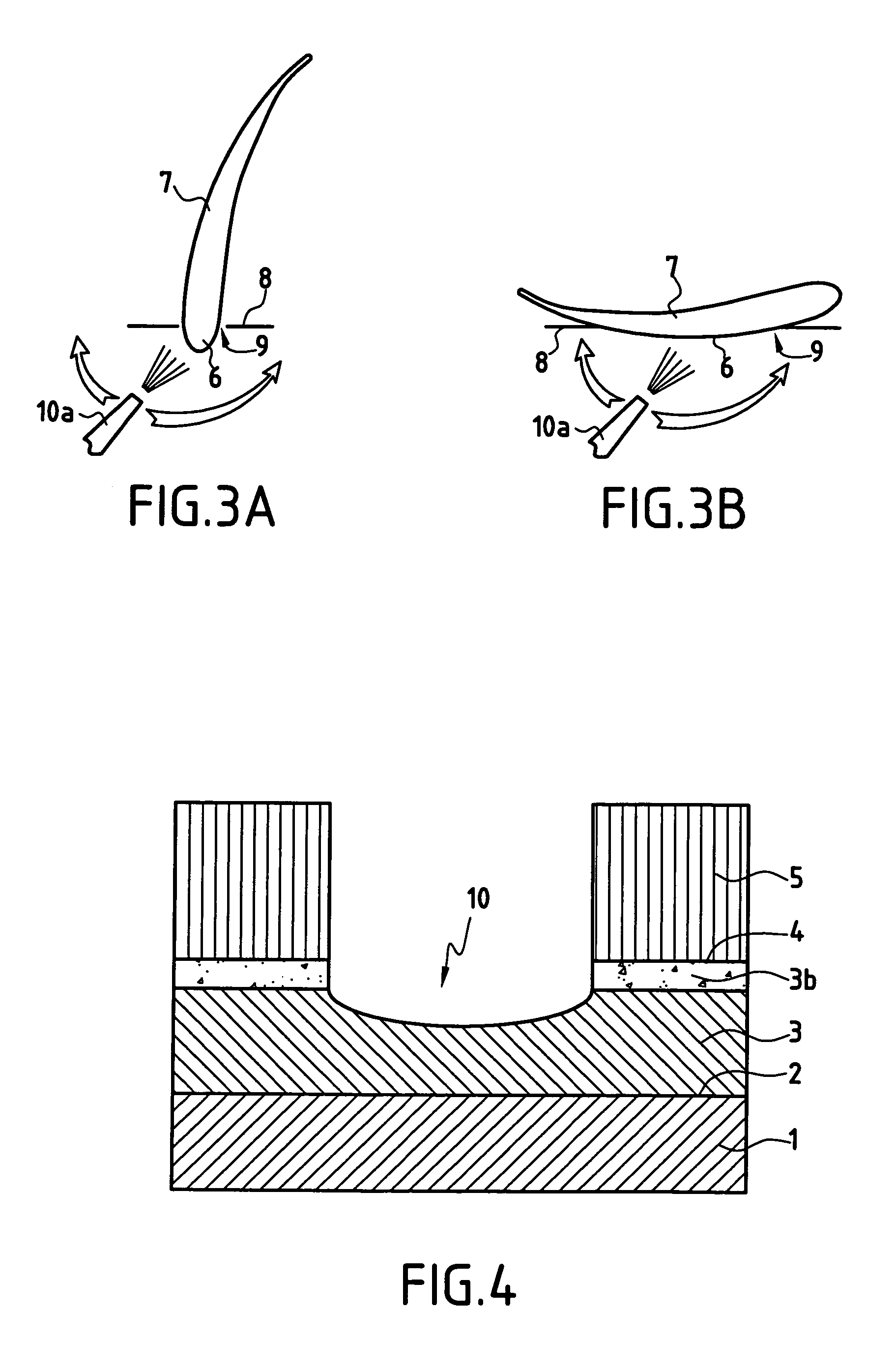

Method of locally repairing parts covered with a thermal barrier

A method of locally repairing parts coated with a thermal barrier including a ceramic outer layer and a metal underlayer of alumina-forming alloy for protecting the substrate against oxidation and for bonding with the ceramic outer layer, includes: defining the zone for repair with a mechanical mask adapted to the shape of the part and the zone for repair; scouring the zone for repair so as to remove the ceramic, the alumina layer, and the damaged portions of the underlayer; supplying materials for repairing the underlayer to the repair zone by subjecting the partially-scoured part to metal deposition by use of an electrical current; and subjecting the part to a heat treatment in order to enable the added metals to diffuse into the remaining underlayer in the repair zone for repair and to enable a surface film of alumina to form. After the underlayer has been reconstituted, the zone for repair is again defined by a mechanical mask and a new ceramic layer is deposited thereon.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

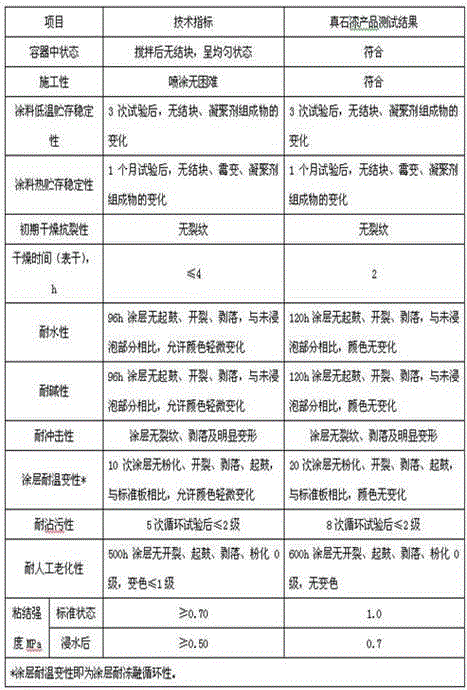

Real stone paint and preparation method thereof

The invention discloses a real stone paint and a preparation method thereof. The real stone paint is prepared from the following raw materials in parts by weight: 80.0-120.0 parts of water, 3.0-17.0 parts of ethylene glycol, 1.0-10.0 parts of a dispersant, 0.2-1.0 part of a wetting agent, 0.2-4.0 parts of cellulose, 0.2-4.0 parts of a PH modifier, 10.0-40.0 parts of silica sol, 30.0-50.0 parts of elastic emulsion, 20.0-90.0 parts of styrene-acrylic emulsion, 40.0-60.0 parts of 20-40mesh natural colored fine sand, 160.0-240.0 parts of 40-80mesh natural colored medium sand, 400.0-480.0 parts of 80-120mesh natural colored coarse sand, 50.0-70.0 parts of color sheets of the real stone paint, 1.0-10.0 parts of coalescing agent, 0.2-4.0 parts of defoamer and 0.2-4.0 parts of a corrosion remover. By adopting the preparation method of the real stone paint, the elastic emulsion and the styrene-acrylic emulsion are matched; the film has the hardness of a surface film and the advantage of interior flexibility of a coating, can resist external damage, can cope with flaws caused by similar wall cracking and substrate construction defects, and is especially applicable to an area with a large temperature difference between day and night.

Owner:西北永新涂料有限公司

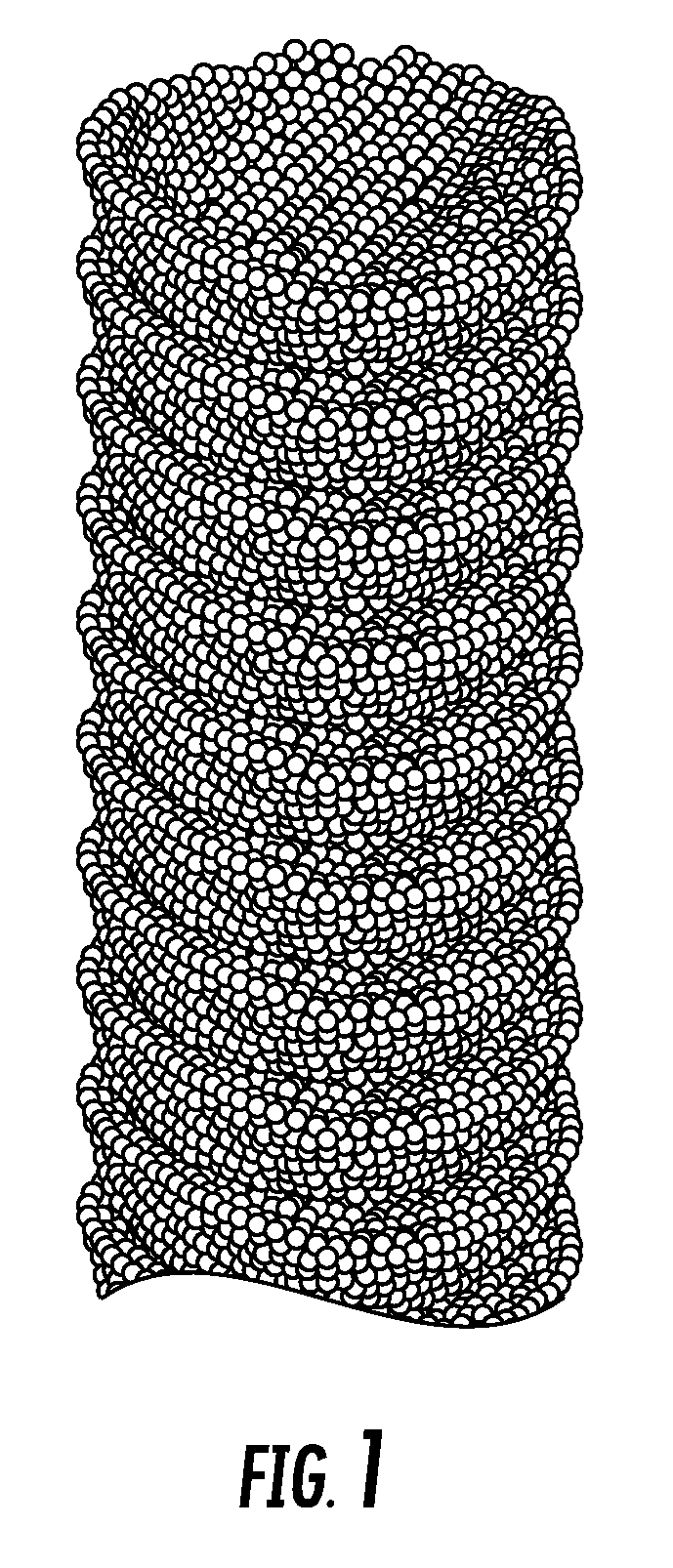

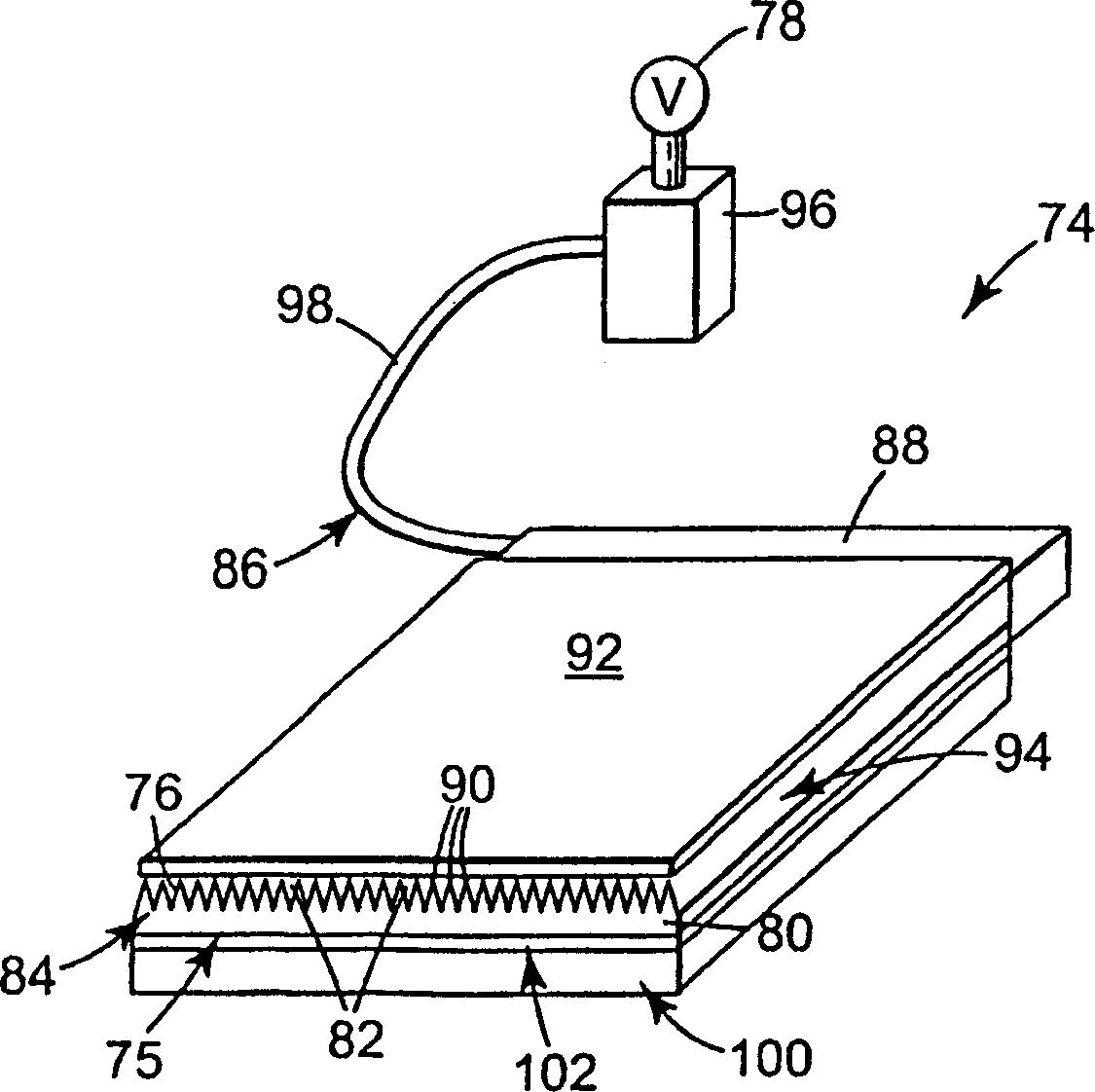

Lightning strike protection

ActiveUS20110049292A1Carbon fibresWarp knittingElectrical resistance and conductanceLightning strike

An aircraft component having an external surface includes an improved lightning strike protection surface film disposed on or proximate to the external surface. The surface film includes a preform that includes a substrate having a first areal weight density and a plurality of spaced carbon nanotubes grown on the substrate, the nanotubes having a second areal weight density. The sum of the first areal weight density and the second areal weight density is less than about 500 grams per square meter, and the preform has a surface resistance less than about 1 ohm / square.

Owner:ROHR INC +1

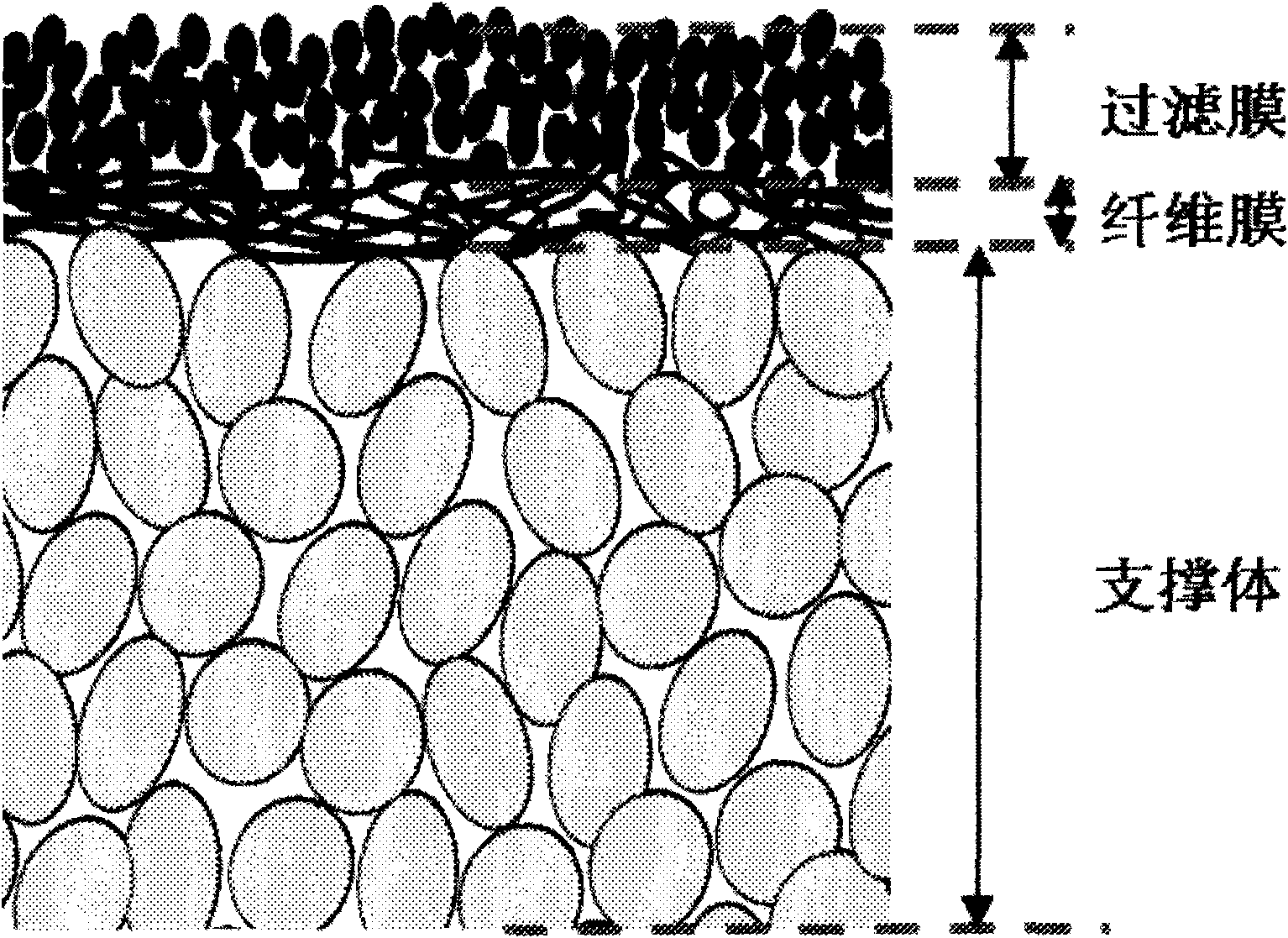

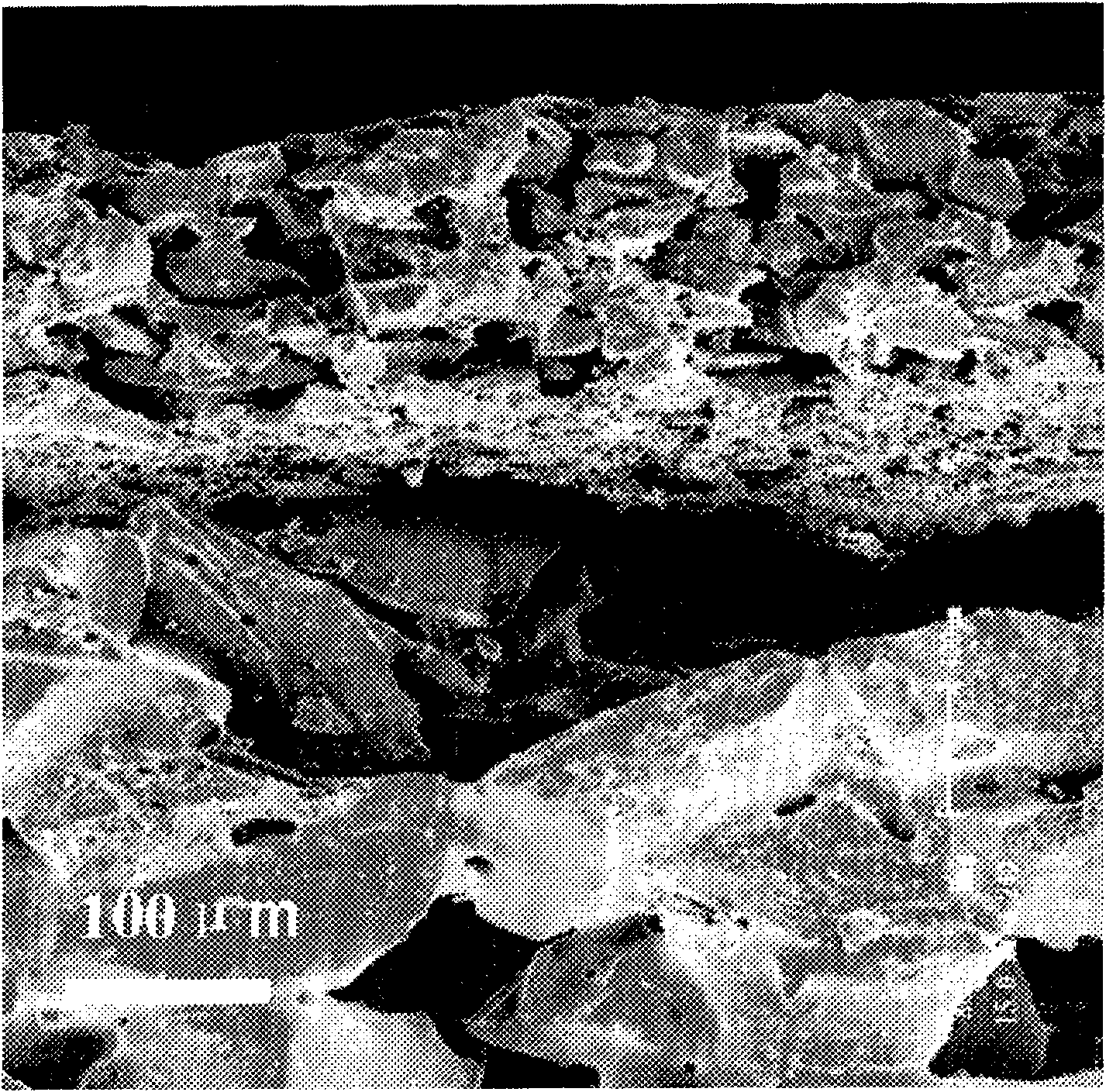

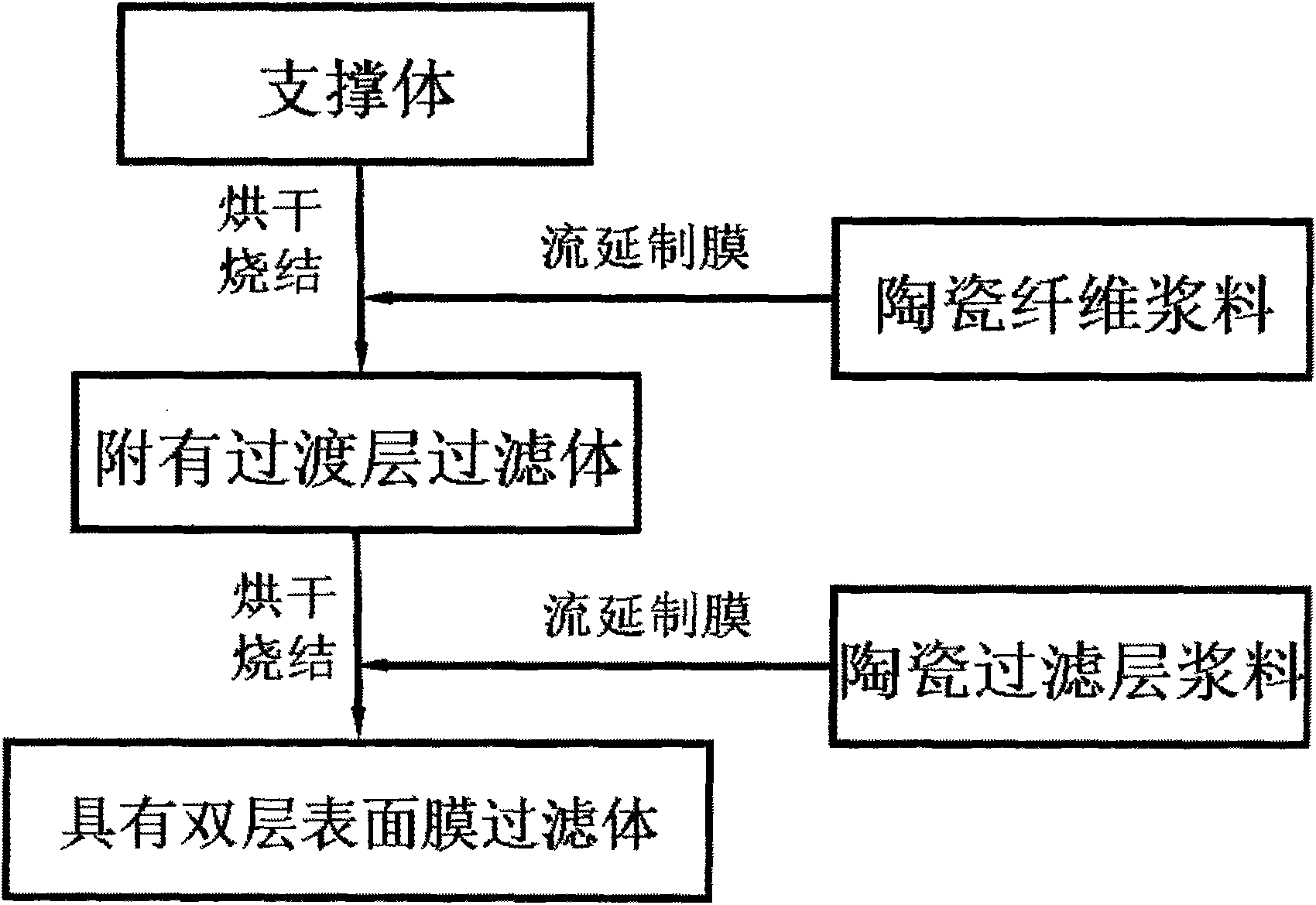

Double-layer asymmetrical surface film of porous ceramic filter tube for dust filter and preparation method thereof

ActiveCN101954246AGood ability to absorb slurryPromote formationSemi-permeable membranesFiberManufacturing technology

The invention relates to a double-layer asymmetrical surface film of a porous ceramic filter tube for a dust filter and a preparation method thereof, belonging to the field of a porous ceramic filter tube manufacture technology. The double-layer asymmetrical surface film is characterized in that ceramic fibers are prepared into fiber film slurry; a ceramic fiber filter film of the set thickness is prepared on the surface of a support of the aperture larger than the particle size of surface film powder; and a filter film having the action of filtering is prepared on the surface of the ceramic fiber film after dried and sintered at high temperature. The prepared double-layer asymmetrical surface film has the advantages of more effective filter pressure drop reduction of the filter tube and longer service life prolongation compared with the traditional single-layer particle surface film.

Owner:TSINGHUA UNIV

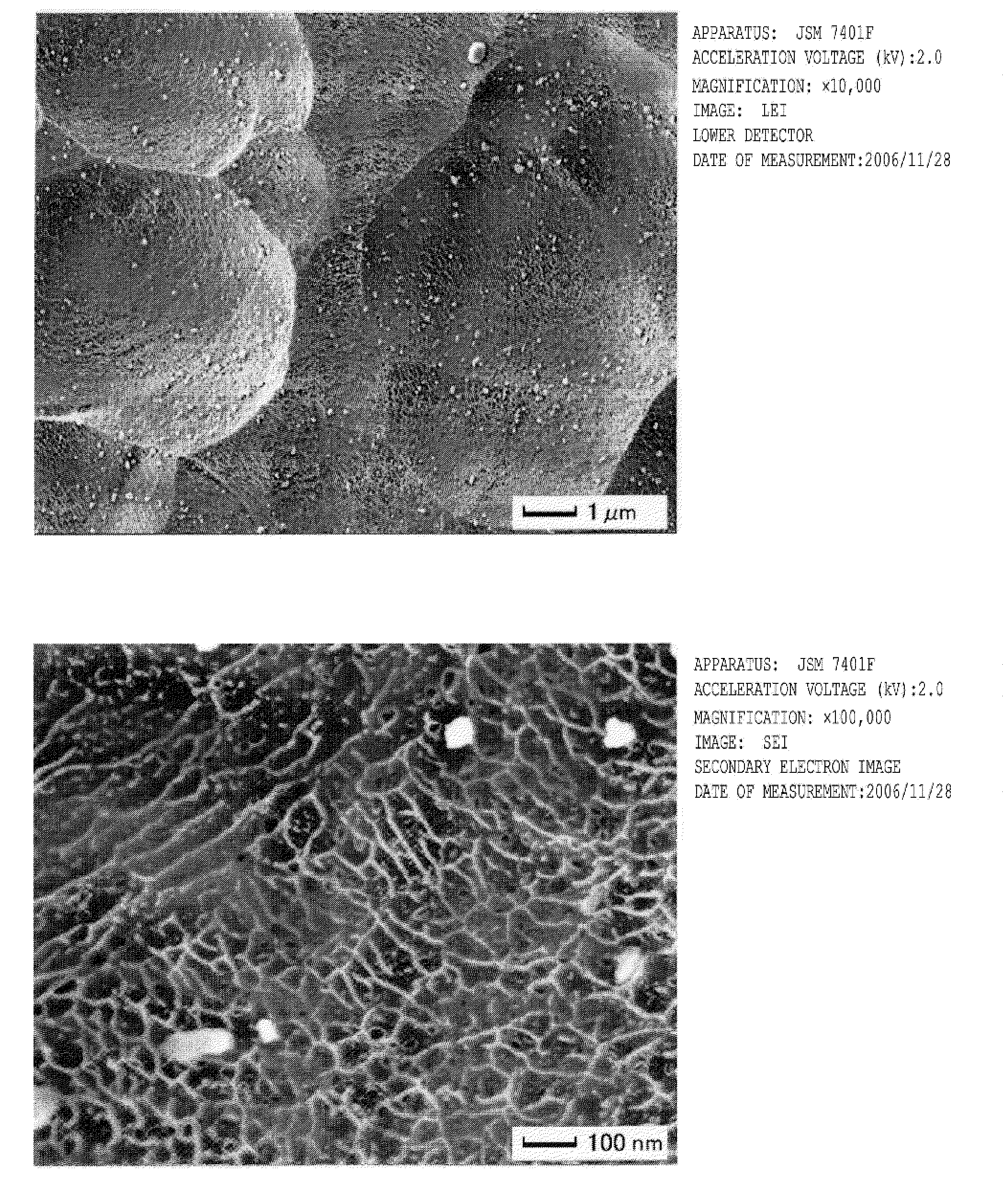

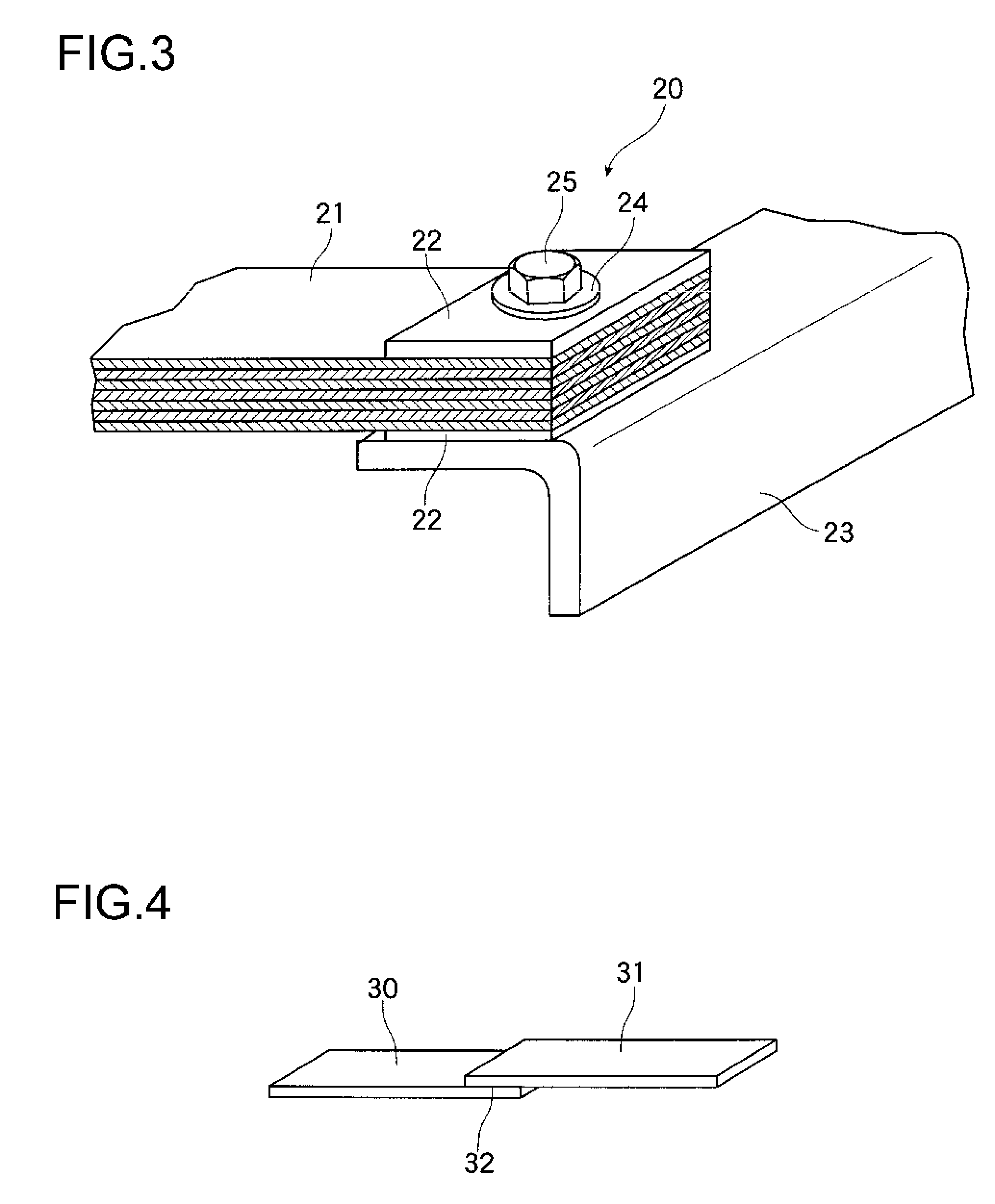

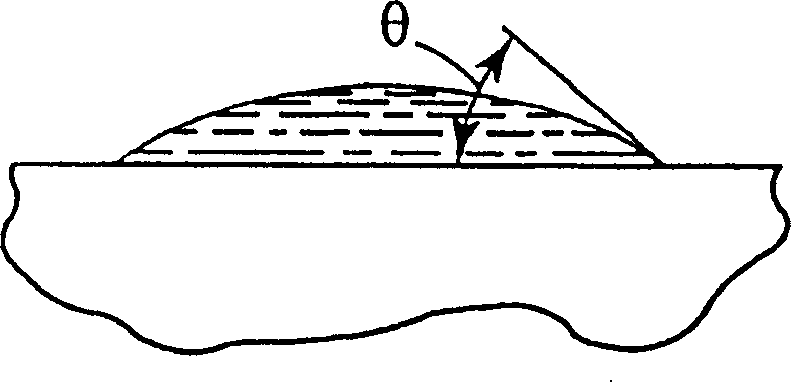

Aluminum alloy composite and method for joining thereof

The object of the present invention is to strongly join an aluminum alloy part with an FRP prepreg. An object obtained by subjecting an aluminum alloy to a suitable liquid treatment so as to form a surface having large, micron-order irregularities and also fine irregularities with a period of several tens of nanometers, eliminating the presence of sodium ions from the surface and additionally forming a surface film of aluminum oxide, which is thicker than a natural oxide layer, has been found to have a powerful adhesive strength with epoxy-based adhesives. By simultaneously curing an FRP prepreg which uses the same epoxy-based adhesive in the matrix, an integral composite or structure in which FRP and aluminum alloy have been united at a joining strength of unprecedented magnitude is produced.

Owner:TAISEI PLAS CO LTD

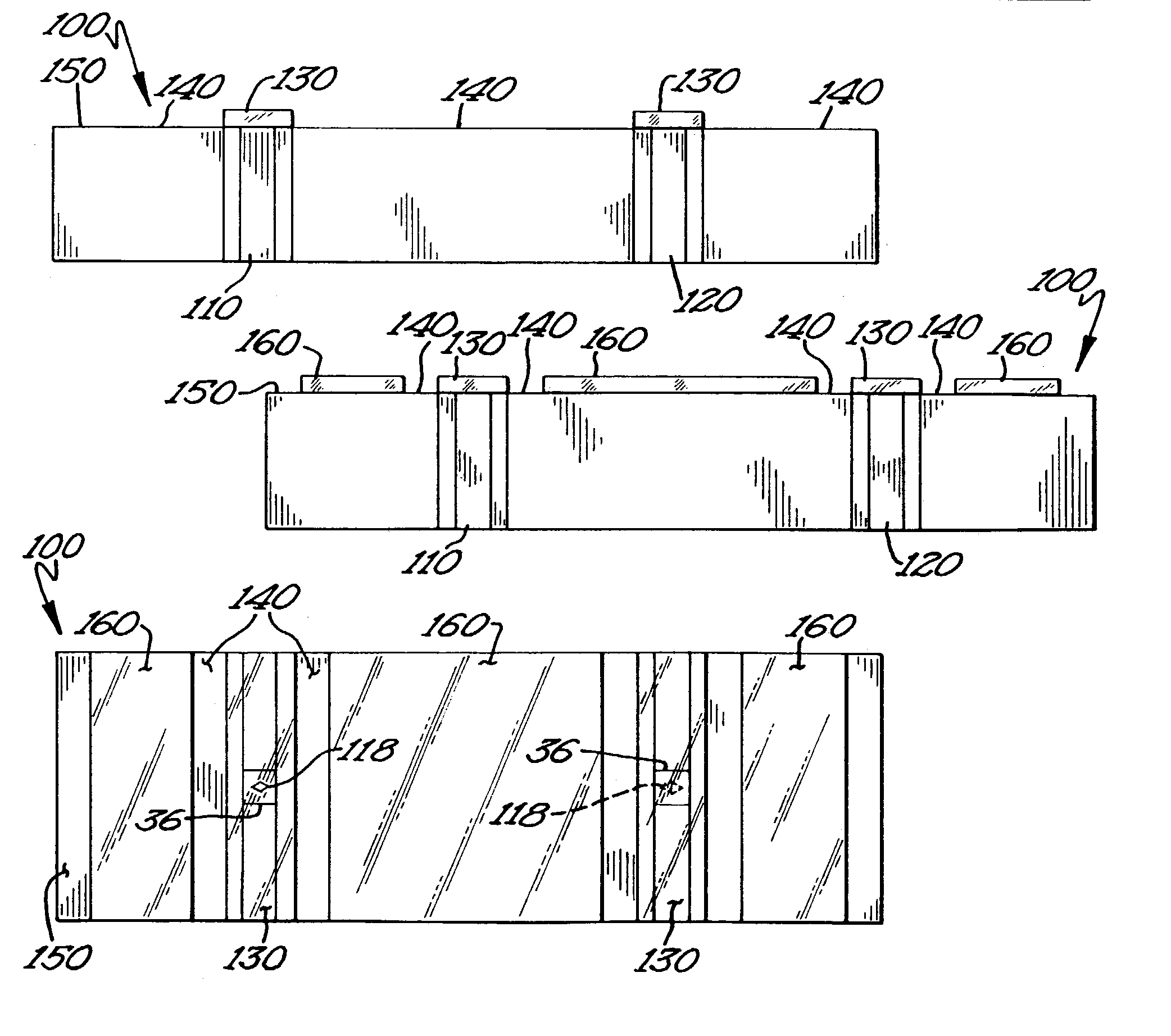

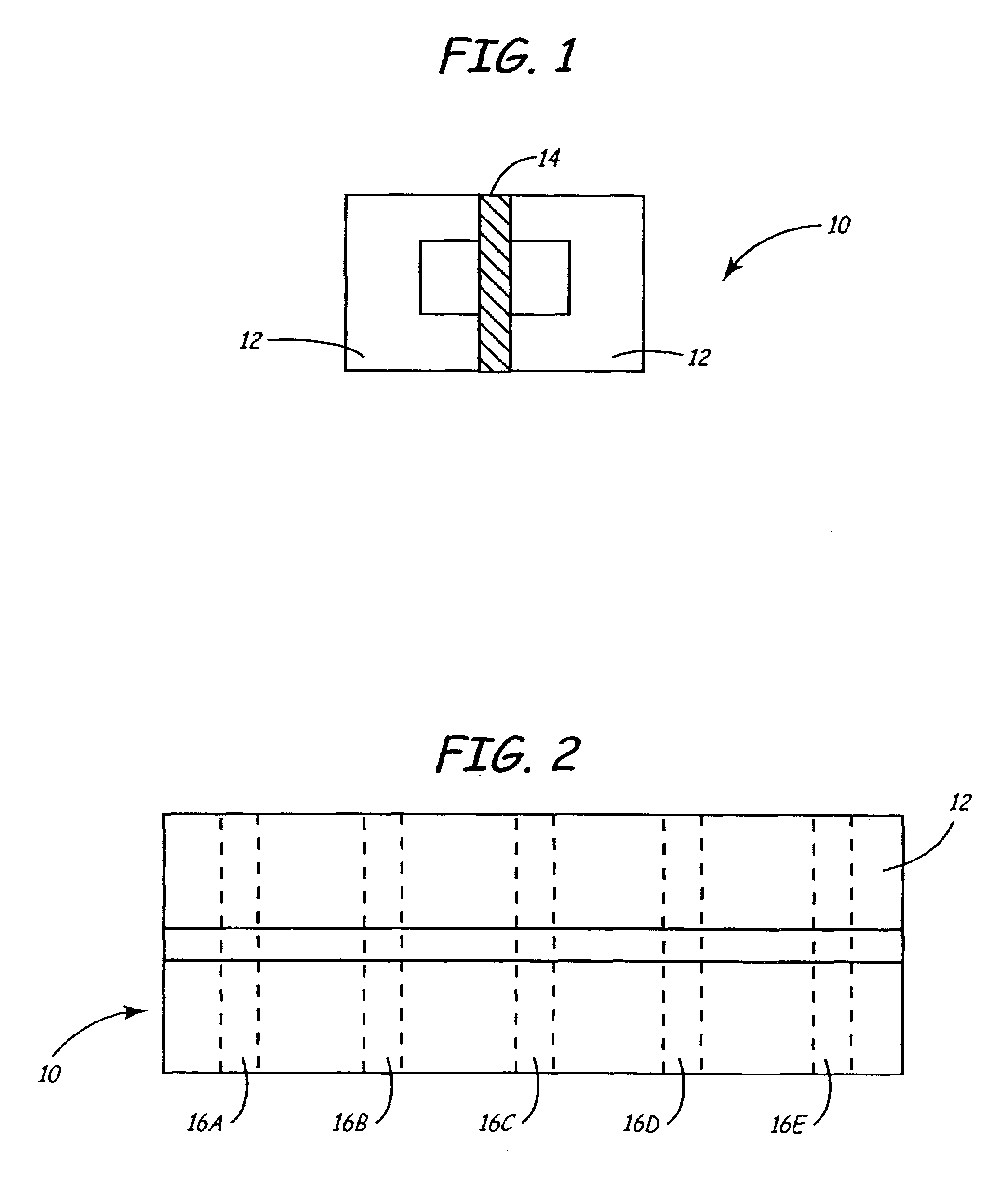

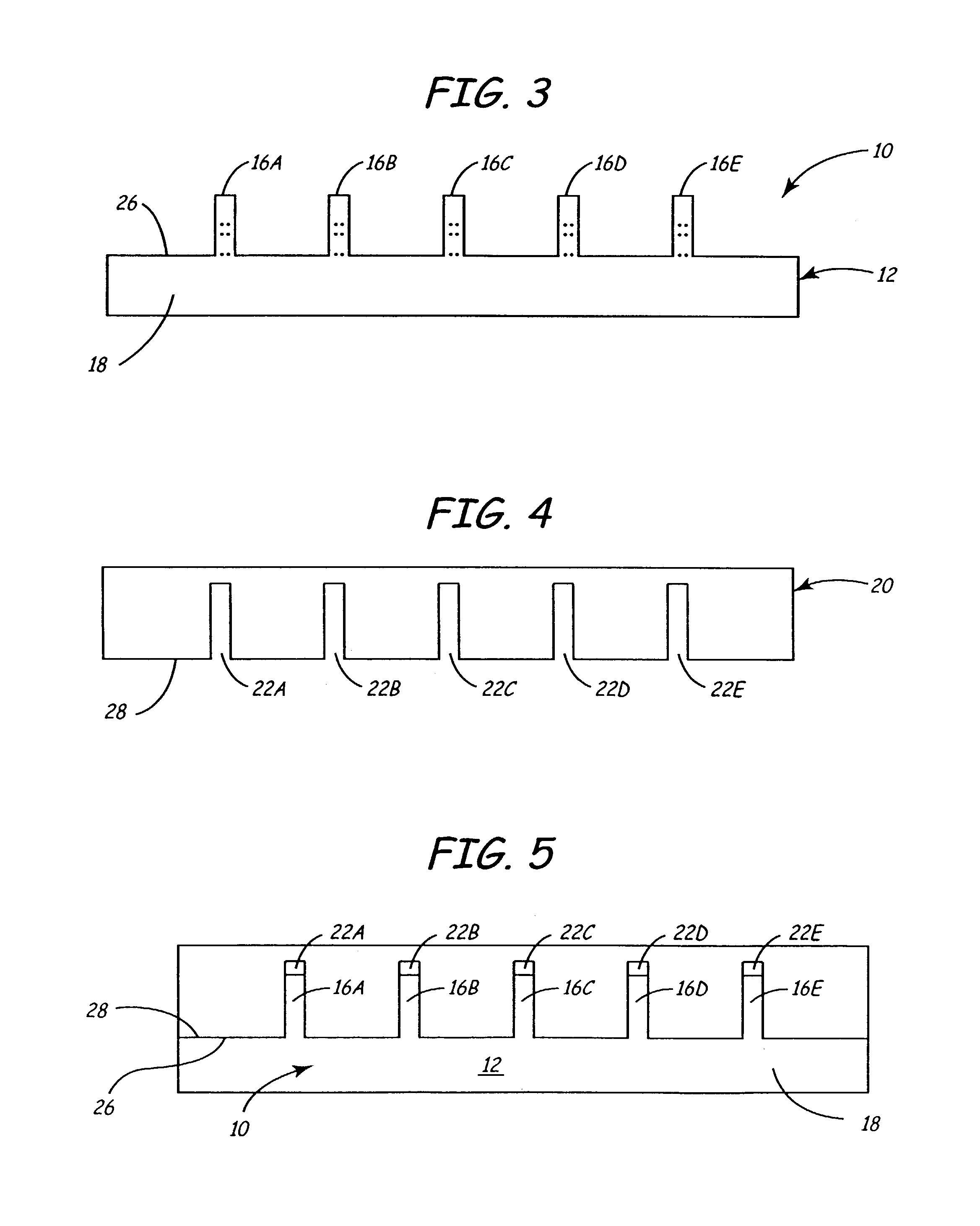

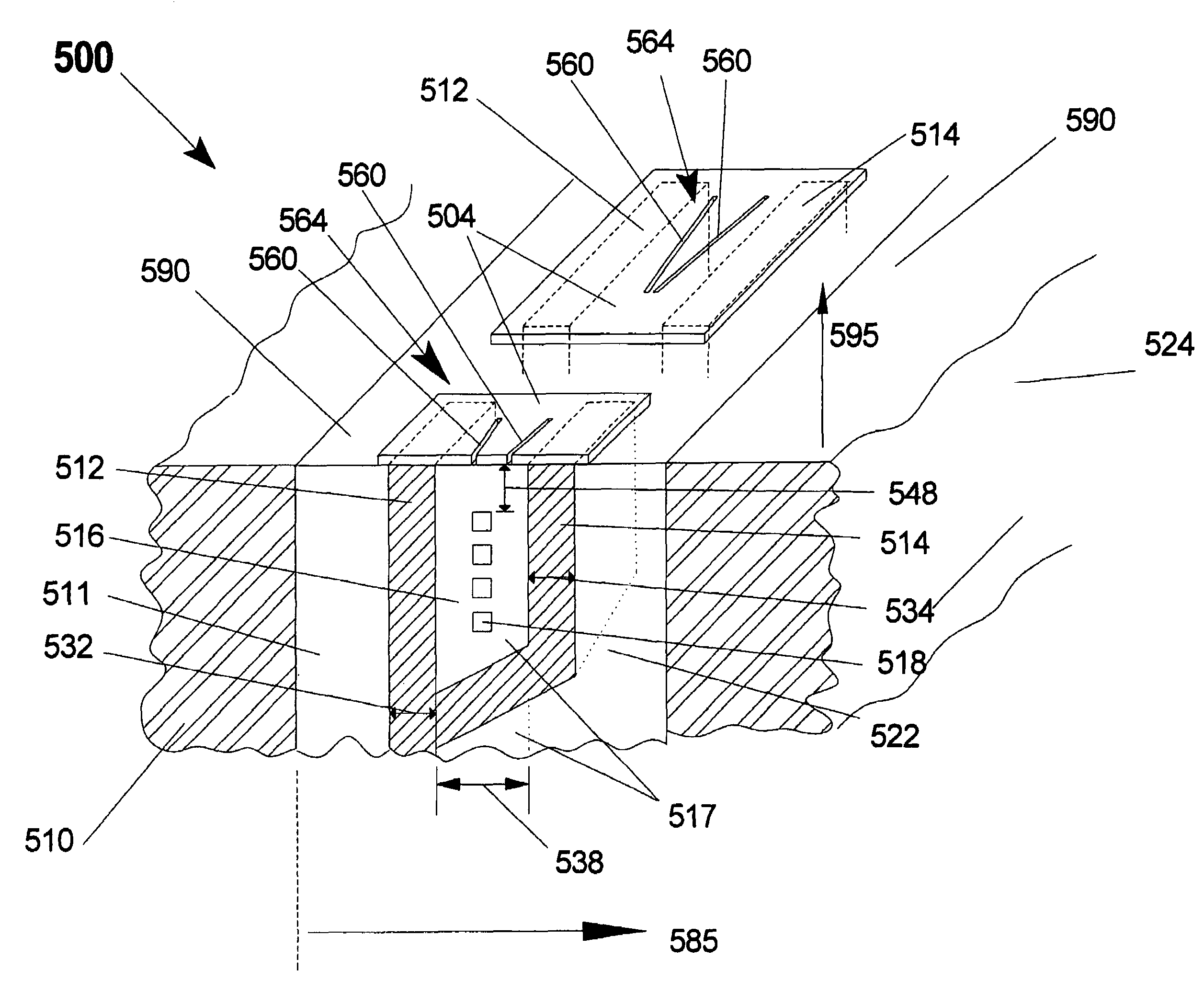

Wear pads for timing-based surface film servo heads

InactiveUS6989960B2Avoid negative effectsQuick wearElectrical transducersManufacture head surfaceEngineeringBearing surface

A thin film magnetic recording head is provided with a tape bearing surface that has magnetically isolated channels while still providing a maximum continuous surface area with which to engage the media. This can be accomplished by providing spaces in the magnetically permeable thin film that are large enough to prevent cross-talk between the channels, but small enough to prevent significant interference with the moving media. Alternatively, magnetically impermeable thin film spacers can be provided to magnetically isolate each of the channels. The spacers are generally even with the magnetically permeable thin film so as to provide a continuous media-bearing surface.

Owner:ADVANCED RES

Method for processing base

InactiveUS20060027936A1Low costImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesRoom temperatureDiamond

Electrodes and an insulating film are both formed of materials which have characteristics that they are solid and do not exhibit adhesiveness at a room temperature, exhibit adhesiveness at and above a first temperature higher than this, and are cured at and above a second temperature higher than this. Planarication processing is carried out by performing cutting with a hard cutting tool made of diamond and the like so that surfaces film the electrodes and a surface of the insulating film become continuously planar.

Owner:FUJITSU LTD

Membrane-laminated fiberglass filter medium capable of denitration and dust removal

ActiveCN103463871ADoes not affect inherent performanceAchieve emissionsNitrous oxide captureDispersed particle separationGlass fiberFilter media

The invention discloses a membrane-laminated fiberglass filter medium capable of denitration and dust removal. The membrane-laminated fiberglass filter medium capable of denitration and dust removal comprises a fiberglass filter base material, a NOX catalyst removing dip coating layer and an expanding micropore polytetrafluoroethylene filtering film; the membrane-laminated fiberglass filter medium capable of denitration and dust removal is characterized in that firstly, soakage drying post treatment is carried out on the fiberglass filter base material by using a NOX catalyst removing batch mixture, the NOX catalyst removing dip coating layer is formed on the surface of fiberglass, high-temperature hot pressing is carried out on the NOX catalyst removing dip coating layer and a polytetrafluoroethylene surface film, and the functional membrane-laminated filter medium which has a NOX catalyst removing function and can prevent the PM2.5 is prepared. The membrane-laminated fiberglass filter medium capable of denitration and dust removal provided by the invention can not only avoid the detrimental effect on a catalyst caused by flying ash particles, but also effectively reduce tiny dust such as PM2.5, and the discharge of the smoke dust which is below 5mg / Nm<3> is realized; the combination of catalyst powder and the filter medium are firm, the inherent properties of the filter medium are not affected, and the filter medium is particularly suitable for industrialized production.

Owner:ANHUI JINHON GREENISM TECH

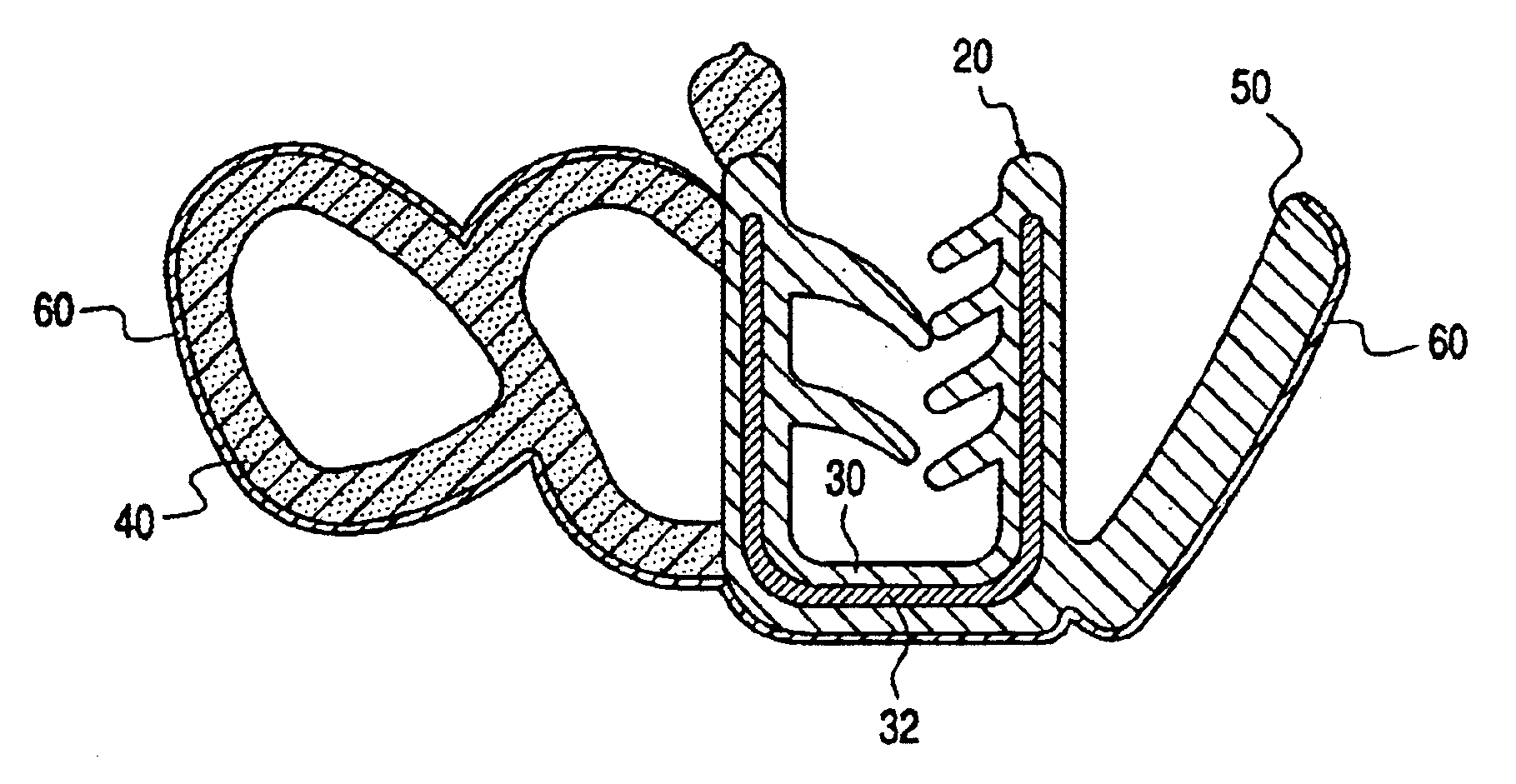

Microstructured surface film assembly for liquid acquisition and transprot

InactiveCN1489521AIncrease surface areaEasy to handleMaterial nanotechnologyLayered productsEngineeringAdjacent channel

A film or tape has one of its major surfaces defined by microstructured features including a plurality of channels defined by spaced apart protrusions. The microstructured film is able to acquire liquids and to control the directional transport of such liquids for subsequent removal therefrom. The transport can be passive or active (i.e., caused or enhanced by an applied potential). The inventive microstructured films and tapes have applications in laminate floor assemblies (for spill removal) and industrial articles such as computer keyboards and other devices and assemblies that benefit from fluid removal. The invention also has application in evaporative and condensation applications. In one embodiment, at least one cross-channel is formed on the microstructured surface to join adjacent channels for liquid flow therebetween.

Owner:3M INNOVATIVE PROPERTIES CO

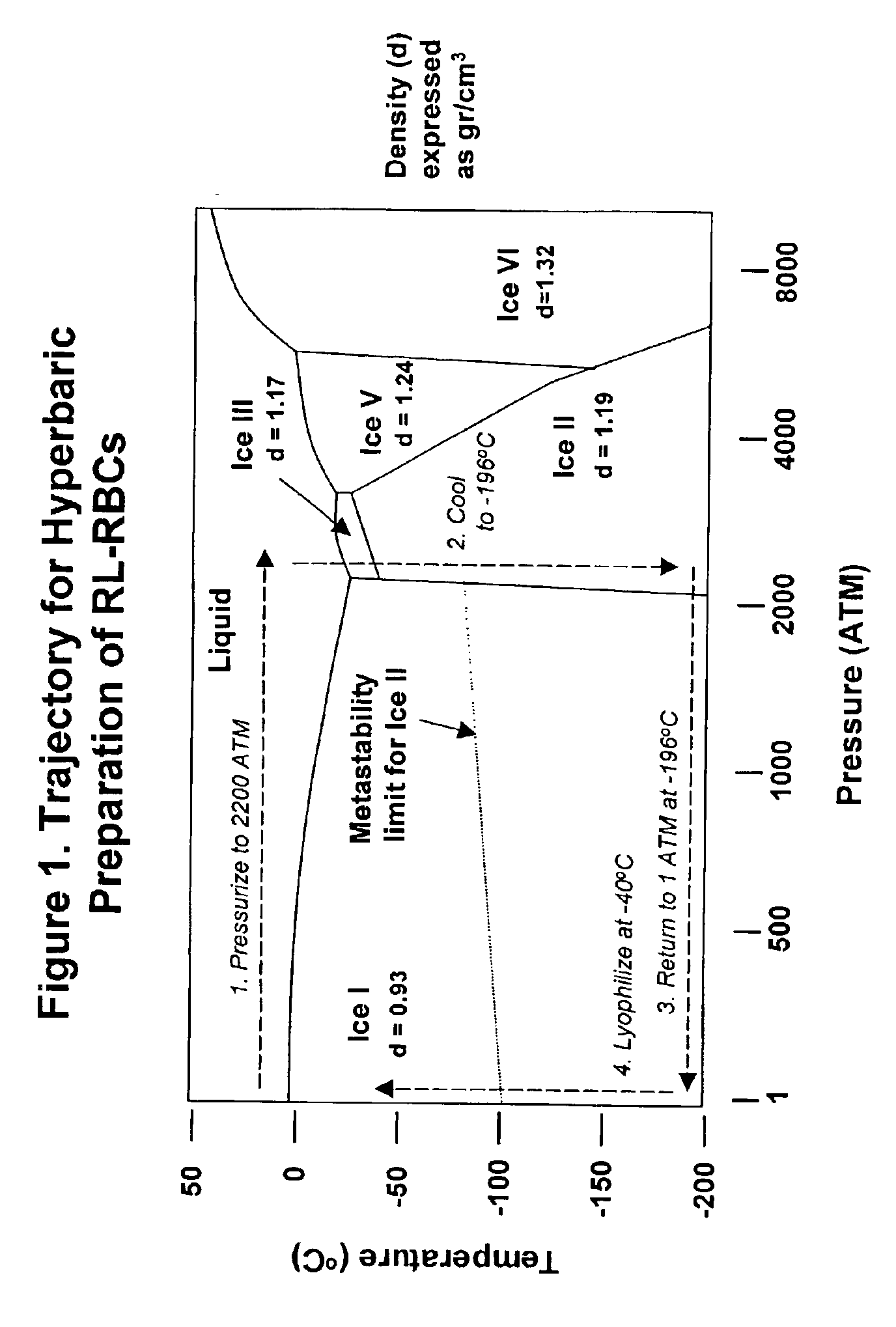

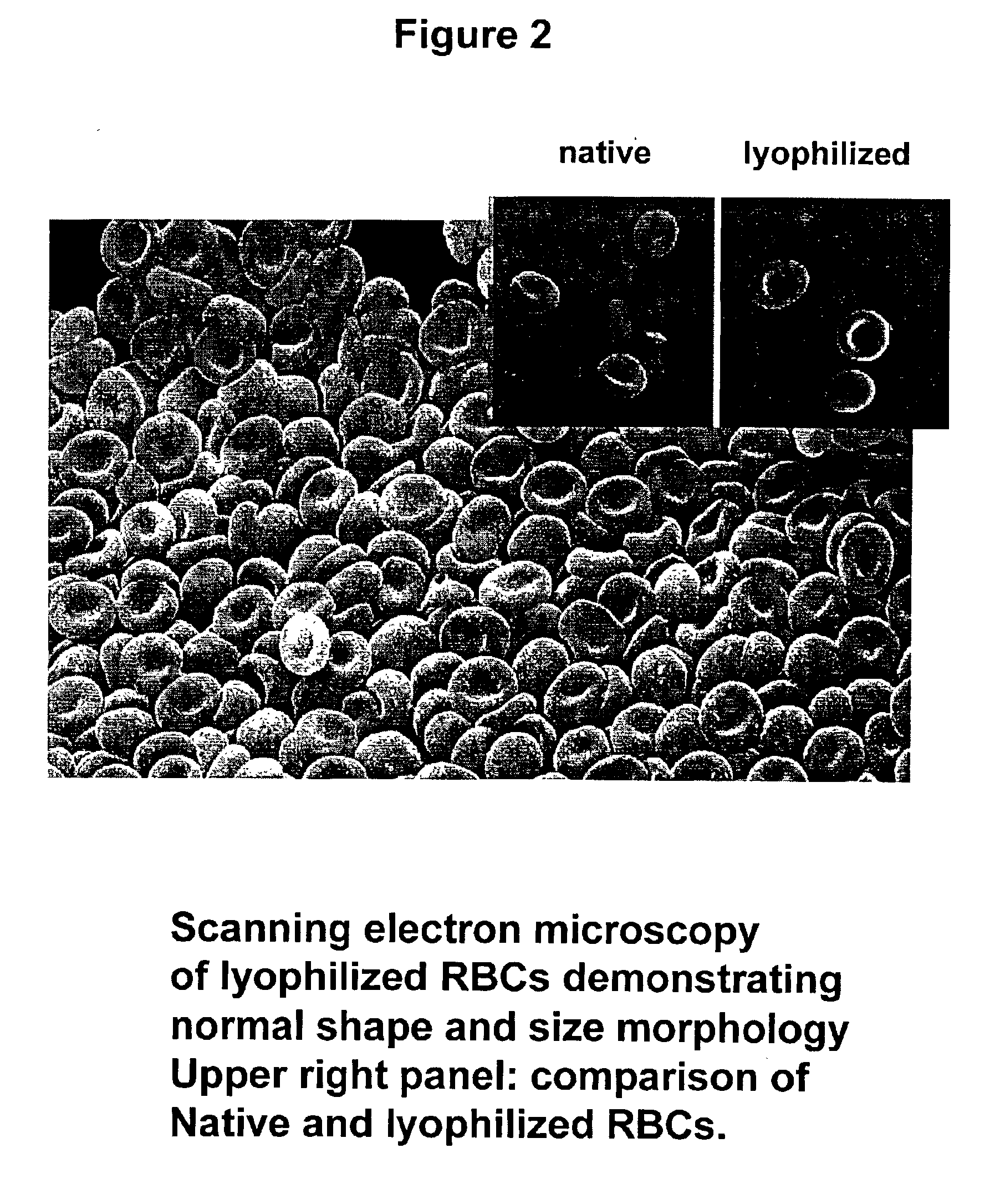

Fixed dried red blood cells and method of use

Fixed-dried red blood cells (RBCs), and processes for preparing the same are disclosed. The red blood cells, upon reconstitution with distilled water or appropriate buffer: bind oxygen with native affinities, have partial deformability, present minimal thrombogenicity to platelets, and have oblated blood group antigens. The RBCs are preferably fixed by means of cross-linkers with aldehyde functions such as paraformaldehyde or glutaraldehyde either alone or in combination. Native oxygen kinetics are achieved by preparing the red blood cells with 1,6-diphosphofructose. Blood group antigens and chemical functions that render the lyophilized RBCs thrombogenic are occluded by chemically attaching polyoxyethylene glycol polymers to the surface membrane of the red blood cells. The cross-linked red blood cells are preferably died by lyophilization.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

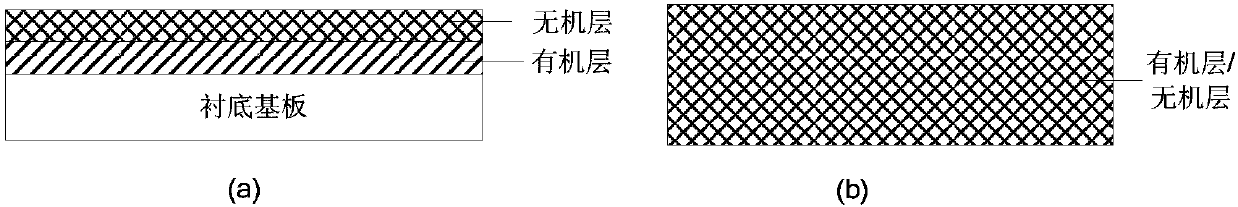

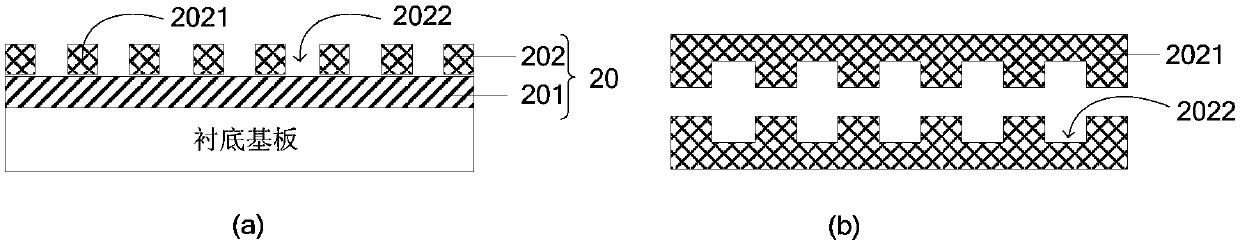

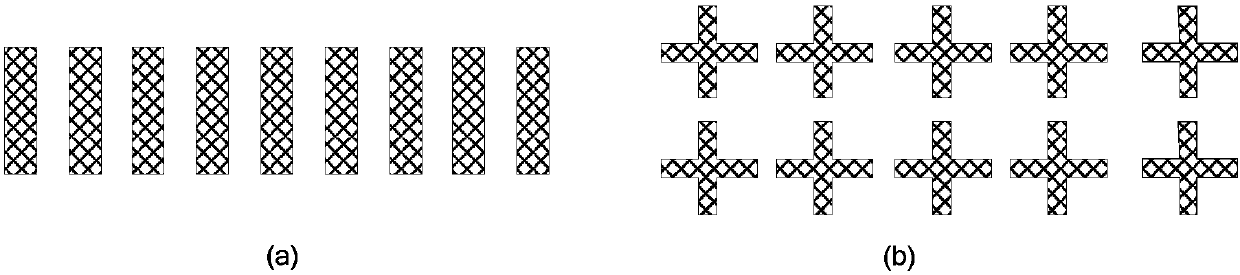

OLED flexible substrate, OLED display panel and production method

InactiveCN107689420AImprove bendabilityExtended service lifeFinal product manufactureSolid-state devicesOptoelectronicsInorganic layer

The invention discloses an OLED flexible substrate. The flexible substrate comprises a substrate layer, wherein the substrate layer comprises a first organic layer and an inorganic layer which are successively superimposed; and the first organic layer is a whole-surface film layer, and the inorganic layer is a patterned structure. By adopting the OLED flexible substrate, the OLED display panel andthe production method, the bendability of the flexible substrate can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Negative electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery using the same

InactiveUS7491467B2Reduce surface resistanceOrganic electrolyte cellsSecondary cellsMetalMaterials science

A negative electrode for a nonaqueous electrolyte secondary battery having a small surface film resistance and a high negative electrode strength, wherein the negative electrode includes a collector and an active material layer formed thereon, wherein the active material layer contains an active material and a binder composition, wherein the active material is a material in which metal oxide fine particles having an average particle diameter of 250 nm or less are attached to the surface thereof, and wherein the binder composition contains a binder having an olefinic unsaturated bond.

Owner:MITSUBISHI CHEM CORP

Semiconductor wafer film thickness detecting device on basis of infrared optical interference method

ActiveCN101660896APerfect polishing processImprove product qualitySemiconductor/solid-state device testing/measurementUsing optical meansEngineeringControl circuit

The invention provides a semiconductor wafer film thickness detecting device on the basis of an infrared optical interference method and relates to the technical field of chemical-mechanical polishing devices for a semiconductor wafer. The device comprises a wafer bearing and moving mechanism, a laser assembly and a data detecting and controlling circuit and is characterized in that the laser assembly is a movable laser assembly and the wafer bearing and moving mechanism is a wafer bearing and rotating mechanism. By adopting the device, multi-point detection on the surface of the wafer can becarried out, thus knowing the thickness and distribution condition of a wafer surface film layer so as to ensure the process parameters of a next polishing process, thus perfecting the polishing process and increasing the product quality. The device is especially suitable for the chemical-mechanical polishing device for the semiconductor wafer.

Owner:THE 45TH RES INST OF CETC

High-flame-retardancy polyester-fiber-reinforced PVC (polyvinyl chloride) composite material

ActiveCN103317802AImprove flame retardant performanceObvious cost advantageSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention discloses a high-flame-retardancy polyester-fiber-reinforced PVC (polyvinyl chloride) composite material. From top to bottom, the composite material sequentially comprises a flame-retardant PVC surface film layer, a flame-retardant PVC paste surface layer, a polyester fiber mesh cloth substrate, a flame-retardant PVC paste bottom surface layer and a flame-retardant PVC bottom film layer. The high-flame-retardancy polyester-fiber-reinforced PVC composite material has the advantages of excellent flame retardancy, soft feeling and favorable bending resistance, and can not easily produce creases by repeated use and folding. Compared with the polyester fiber base cloth subjected to flame-retardant treatment, the PVC composite material disclosed by the invention has obvious cost advantage.

Owner:FUZHOU UNIV

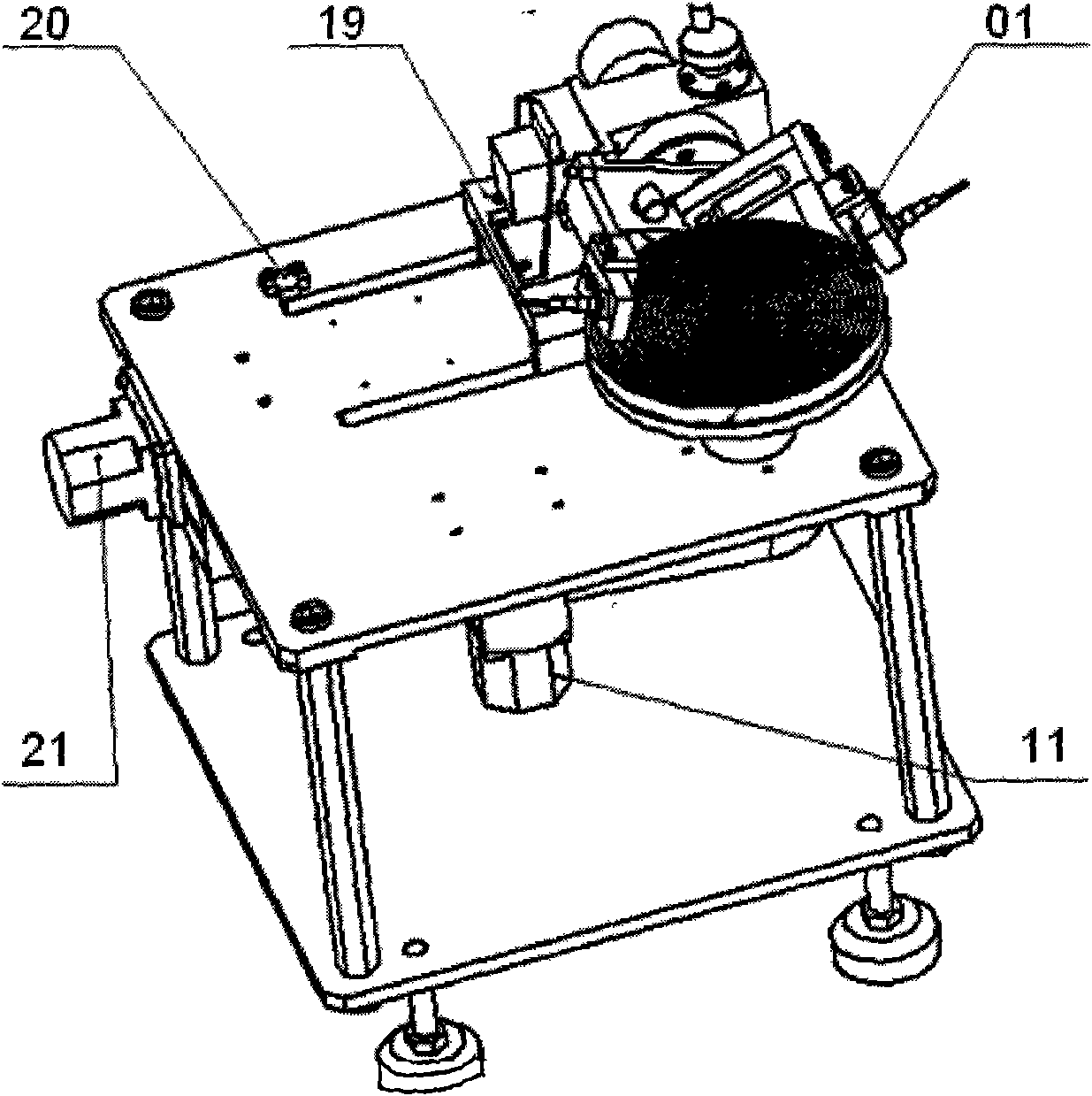

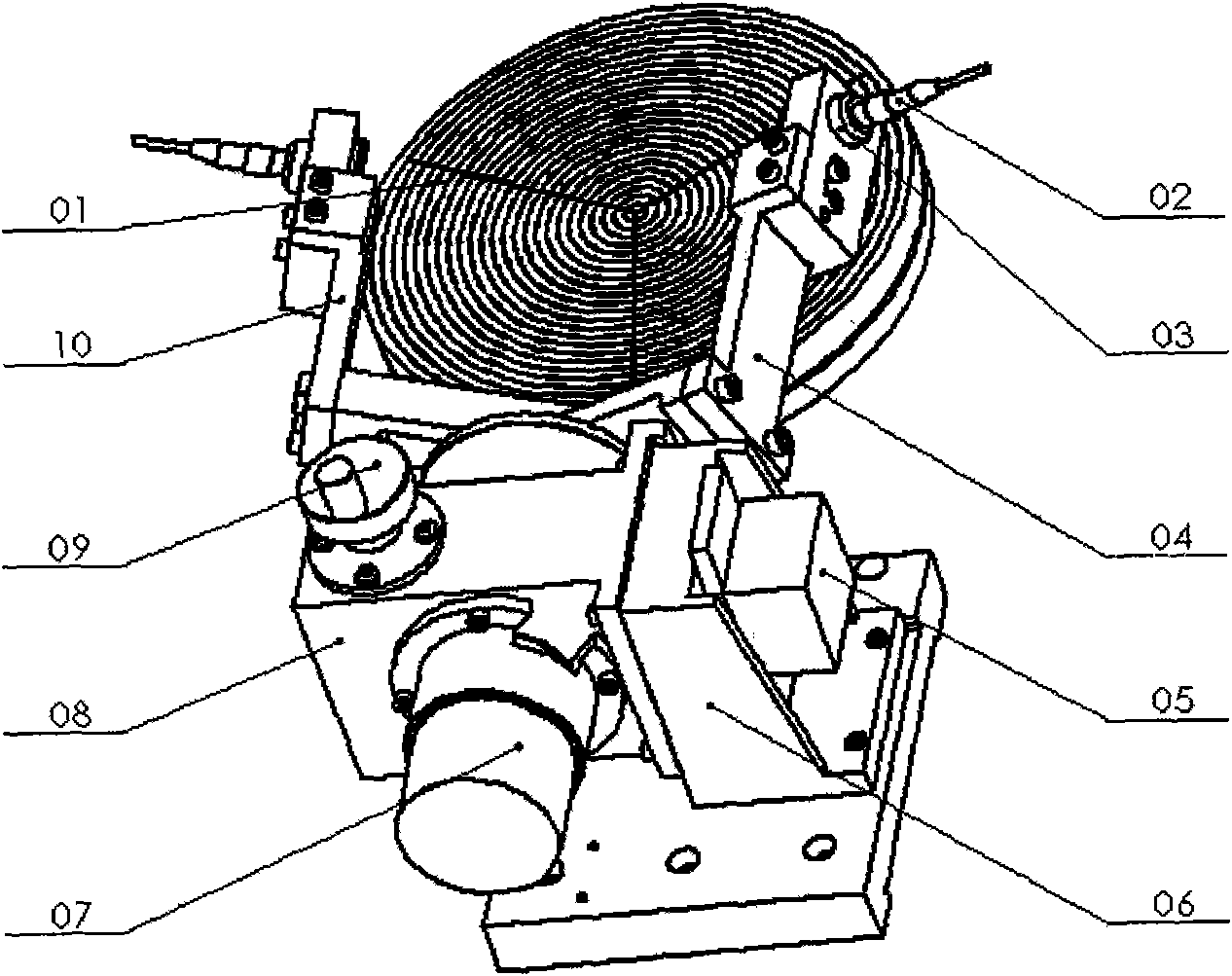

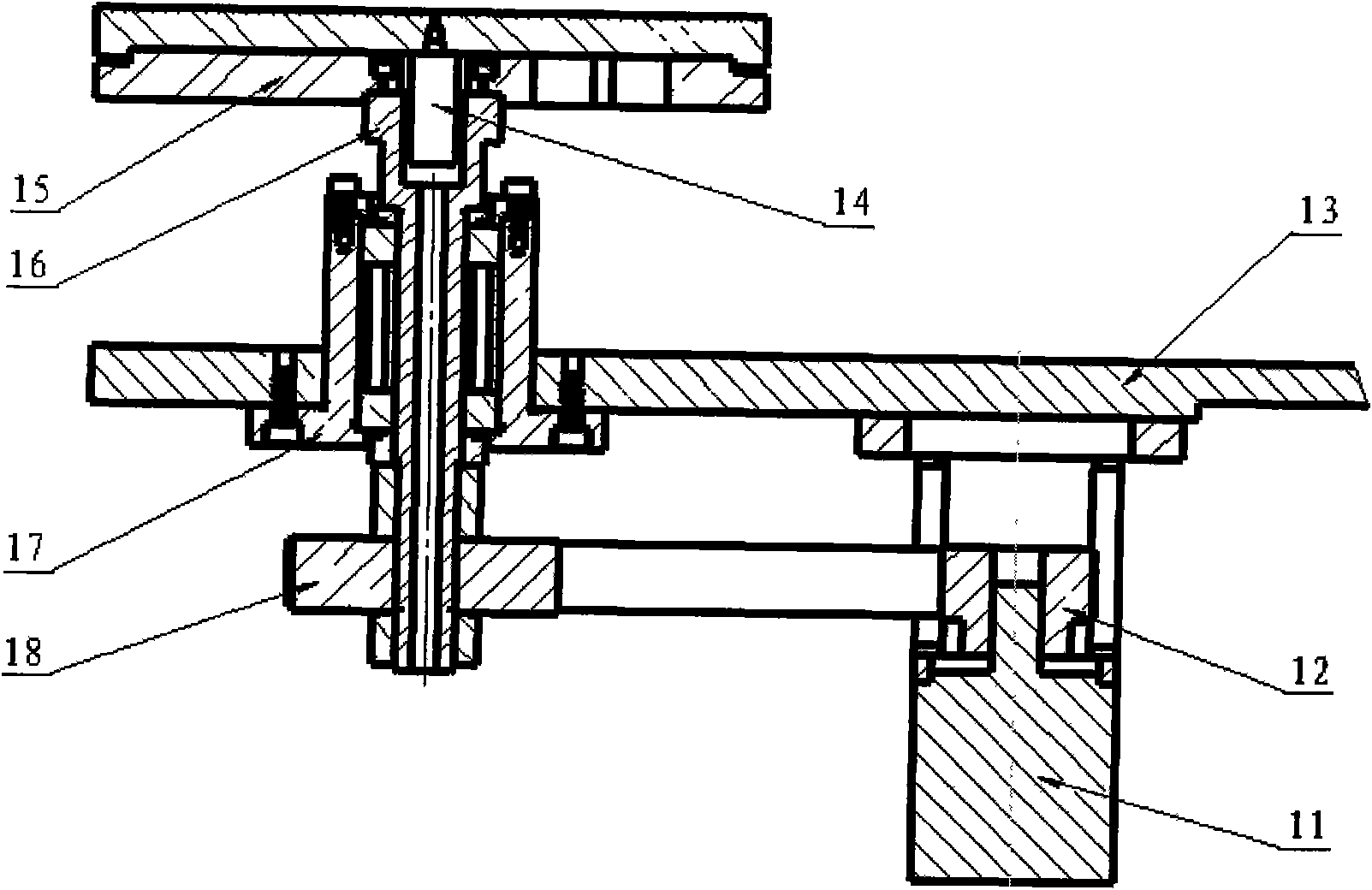

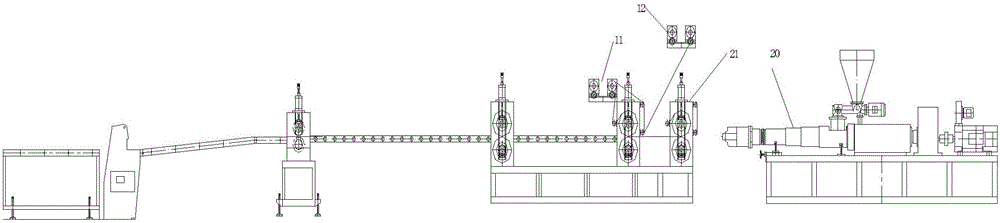

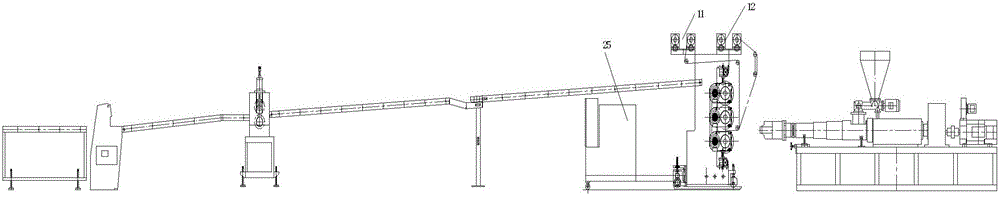

Four-roll calendering and draping production device for PVC plastic floor surface film attachment

ActiveCN105711226AImprove bindingEasy to produceLamination ancillary operationsLaminationEngineeringCalendering

The invention discloses a four-roll calendering and draping production device for PVC plastic floor surface film attachment. The four-roll calendering and draping production device comprises a four-roll calender, a wear-proof film unwinding mechanism, a printing film unwinding mechanism, a wear-proof film attaching mechanism, a printing film attaching mechanism and a guide-out mechanism. The printing film unwinding mechanism and the wear-proof film unwinding mechanism are installed on the two sides of the top end of the four-roll calender respectively. The wear-proof film attaching mechanism, the printing film attaching mechanism and the guide-out mechanism are sequentially arranged on the right side of a shading roll from top to bottom. The wear-proof film attaching mechanism is obliquely arranged on the right side of the shading roll. The printing film attaching mechanism and the guide-out mechanism are parallelly arranged on the right side of the shading roll. According to the four-roll calendering and draping production device, a vertical design is adopted, and a lower mirror roll and an upper mirror roll are used for determination of thickness; air is evenly extruded and exhausted by means of false attachment of a first guide-out roll in the printing film attaching mechanism, a PVC bottom board, a printing film and a wear-proof film can be more easily bound firmly, and production becomes convenient, simple and stable.

Owner:WUXI BOYU PLASTIC MACHINERY

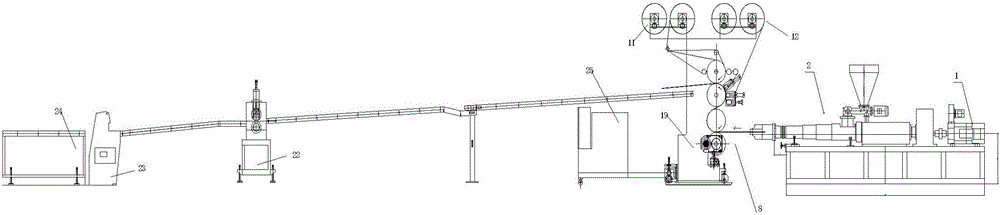

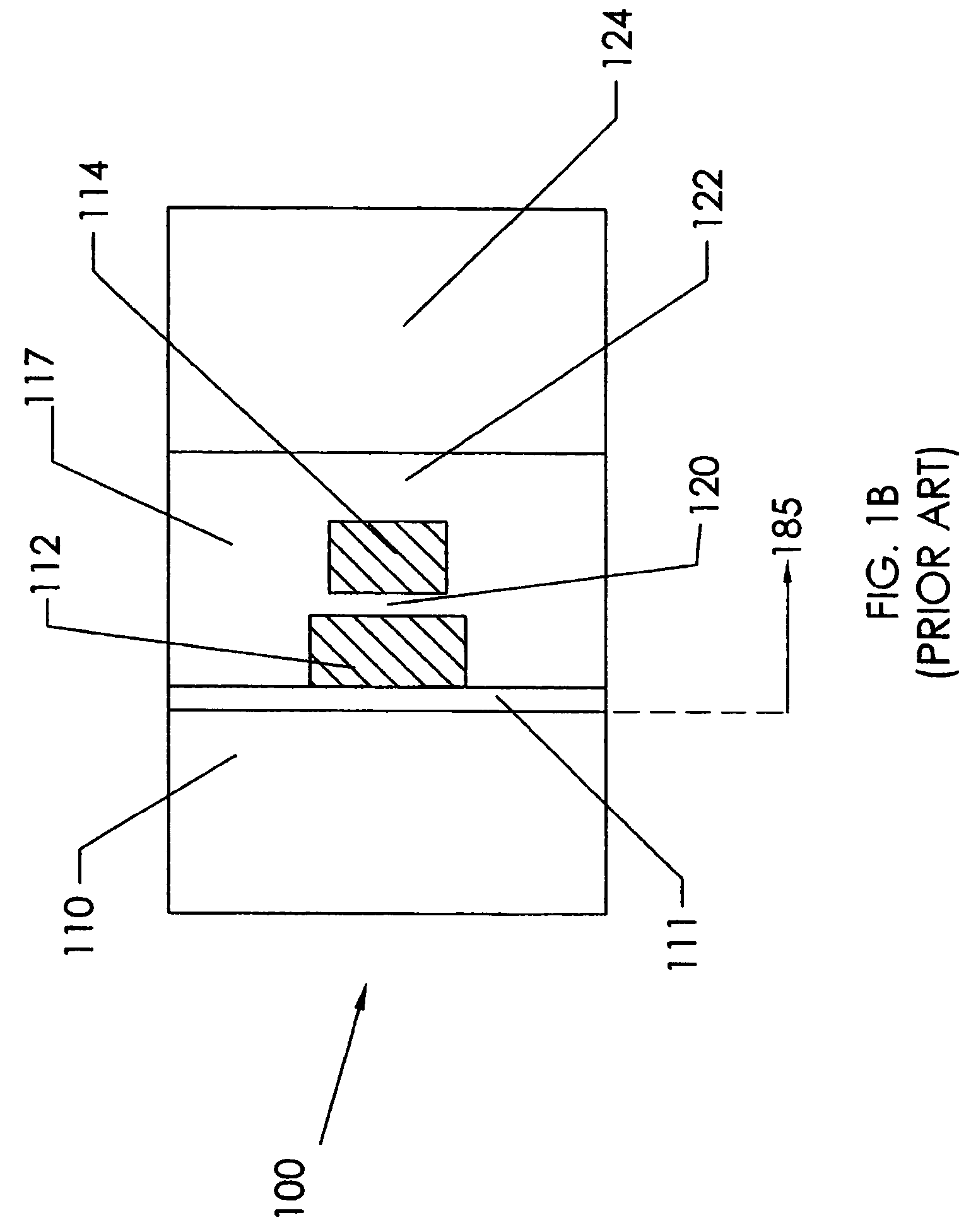

Intergrated thin film subgap subpole structure for arbitrary gap pattern magnetic recording heads and method of making the same

InactiveUS7450341B2Improve linearity and efficiencyManufacture head surfaceDriving/moving recording headsBearing surfaceSurface film

An arbitrary gap thin film magnetic recording head is fabricated by forming a substrate based on traditional vertical planar thin film head wafer technology which is designed to produce an integrated subgap and subpole substrate structure. The recording head includes a pair of magnetically permeable thin film subpoles, separated by a low permeability subgap structure. An electrically conductive coil may be embedded, in part, within the subgap structure. Thus, the subpoles and subgap structure form part of a magnetic circuit. A highly permeable magnetic surface film spans from one subpole to the other having one or more arbitrary gap patterns. That is, a surface thin film is deposited and patterned on the tape bearing surface of the head to optimize various element configurations, gap patterns and head-to-tape medium contact.

Owner:ADVANCED RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com