Microstructured surface film assembly for liquid acquisition and transprot

A microstructuring, assembly technology, used in nanotechnology for materials and surface science, fixed conduit components, floors, etc., to solve problems such as ineffective removal of liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

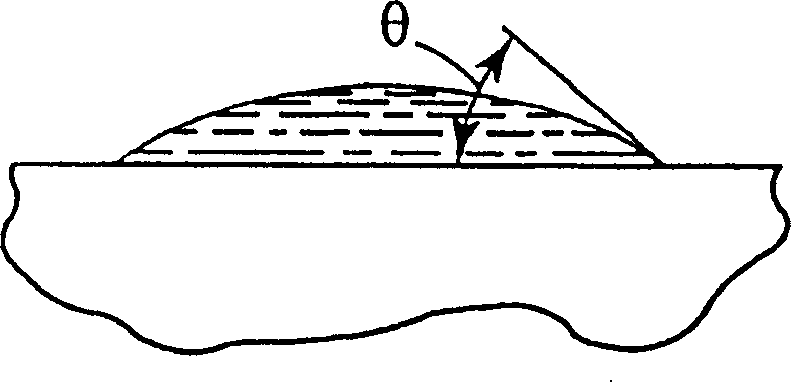

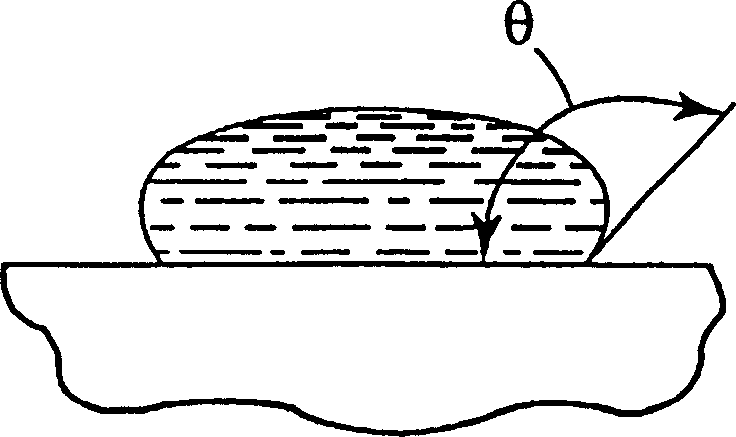

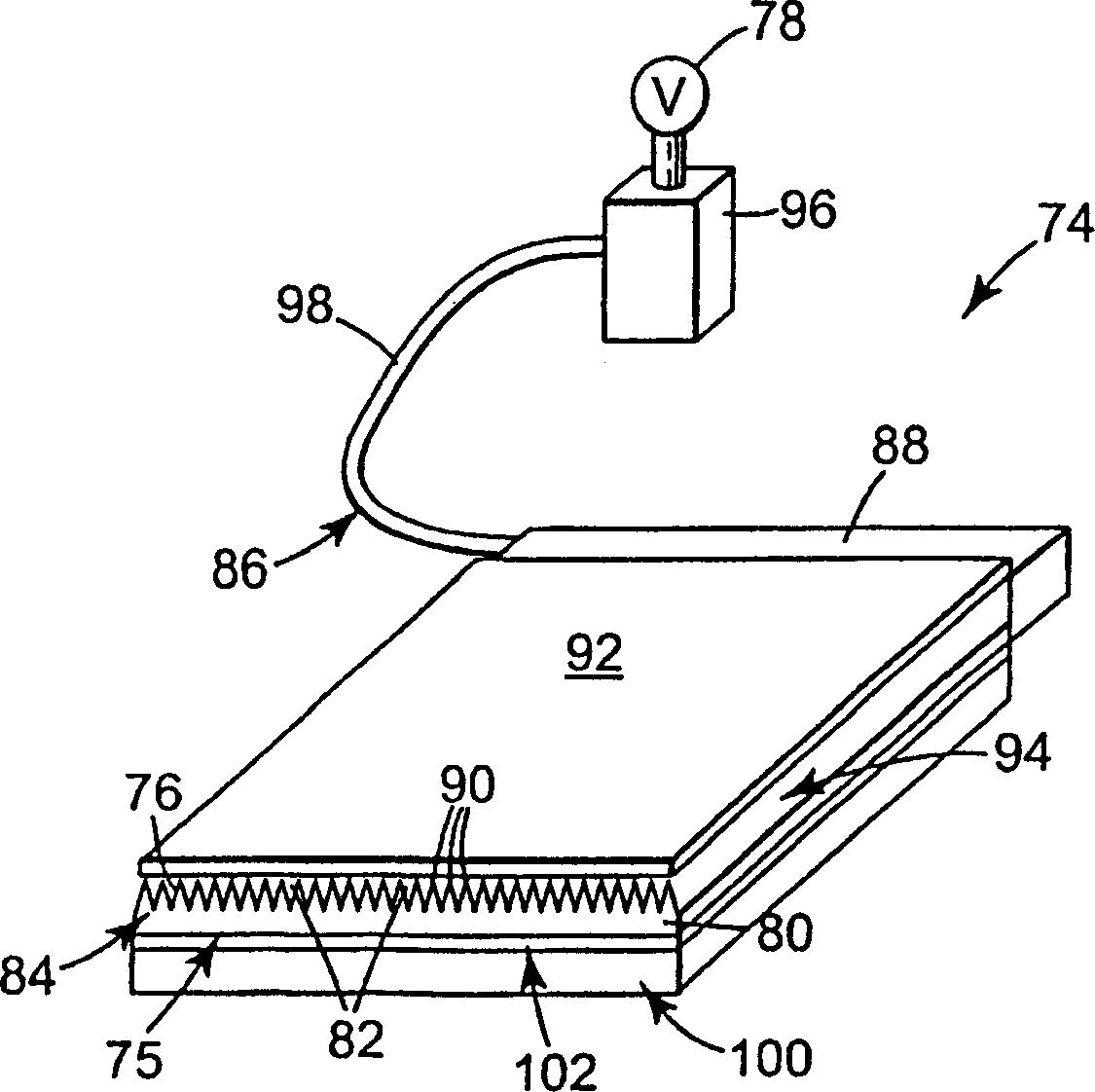

[0133] Example 1 - A liquid removal system for collecting, delivering and removing liquid formed from an unstructured flat film attached to a substrate. Potential energy is applied to enhance the flow of liquid across the membrane, and the flat membrane material is covered with a capping layer. Such as Figure 7a and 7b As shown, the flat unstructured film is formed from a flat polyethylene film 150 attached to a substrate 152 with a double-sided pressure sensitive adhesive and covered with a linoleum cover layer 154 (this cover layer 154 is not attached to On the film 150, just cover on the film 150). Potential energy is provided by means of a vacuum (6 inches of Hg) drawn by vacuum system 156 comprising bore 158 , conduit 160 , collection sump 162 , and vacuum pump 164 . The vacuum promotes continuous dehydration of the area below the membrane 150, which facilitates the collection of overflowing liquid from this area. The test area was approximately 18 inches by 36 inche...

Embodiment 2

[0135] Example 2 - A liquid removal system for collecting, delivering and removing liquid formed from a liquid conveyor belt attached to a substrate. This system is evaluated on the aircraft, especially for the purposes (such as subfloor) of being contained in the galley and washroom in the aircraft cabin, the test device of embodiment 2 is identical with embodiment 1, difference is The flat polyethylene film 150 is replaced with a liquid control film. Liquid conveyor belts have a structured surface made of Figure 2i The materials and structures of the film 138 are shown. Apply energy to the liquid conveyor belt to enhance the flow of the liquid, with a suitable cover layer placed on the microstructured surface. The liquid conveyor belt is attached to the horizontal ground base of the airliner with a pressure sensitive adhesive. The adhesive was a 65:35 ratio of 2-ethylhexyl acrylate (EHA) and isobornyl acrylate (IBOA), applied in a layer thickness of about 2 mils. A suit...

Embodiment 3

[0138] Example 3 - By placing absorbing bands on top of the microstructured film and perpendicular to the channels therein, the Figure 8a and Figure 8b The liquid removal system shown is modified. The system before improvement is shown in Figure 8a , after improvement is shown in Figure 9 Absorbent strip 185 is placed on top of microstructured film 170 (beneath cover layer 174 ) and is perpendicular to channel 175 . Absorbent strips 185 connect the holes 178 and allow fluid to flow from adjacent channels 175 to the holes. The size of each absorbent tape is approximately 0.5 inches x 16 inches. The absorbent tape material used for hole-to-hole attachment in this embodiment is a paper fabric, such as commercially available WYPALL® (supplier is Kimberly- Clark Corporation, Irving, TX,). However, the absorbent tape can be made of other paper products, fabrics, porous filter paper, sponges, spunbond fabrics, nonwoven fabrics, or other similar materials (i.e., any material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com