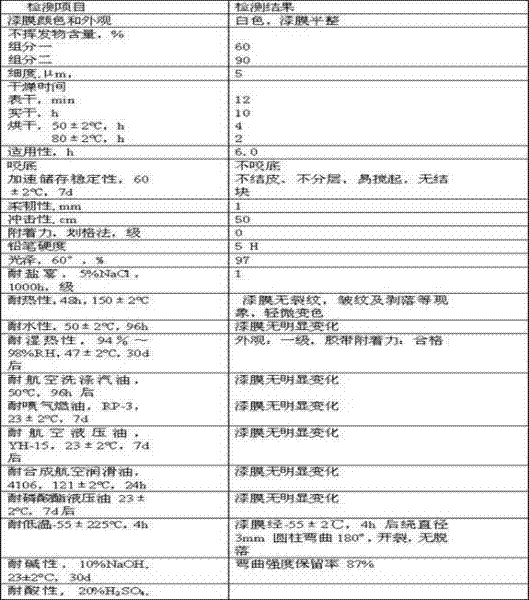

Patents

Literature

317 results about "Isobornyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Touch panel

ActiveUS20140134433A1Enhancing performance of inhibiting changeImprove cohesive strengthFilm/foil adhesivesMacromolecular adhesive additivesElectrical conductorMeth-

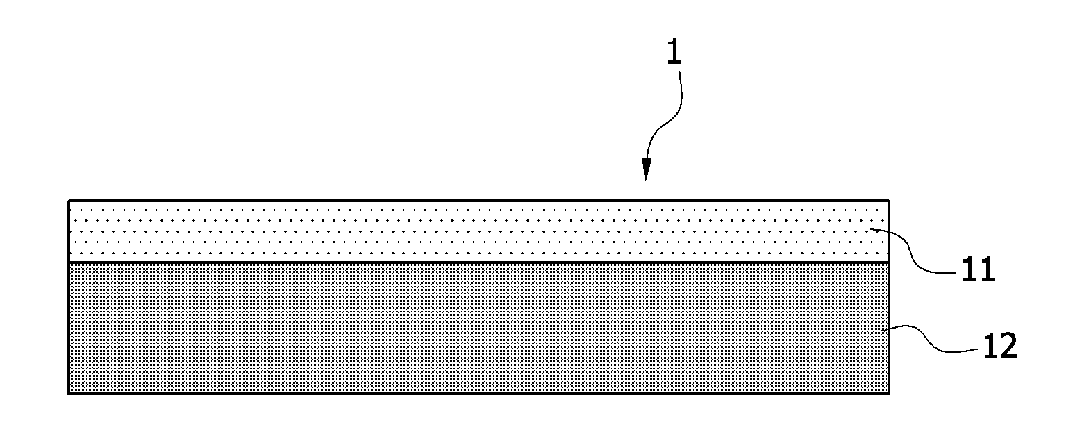

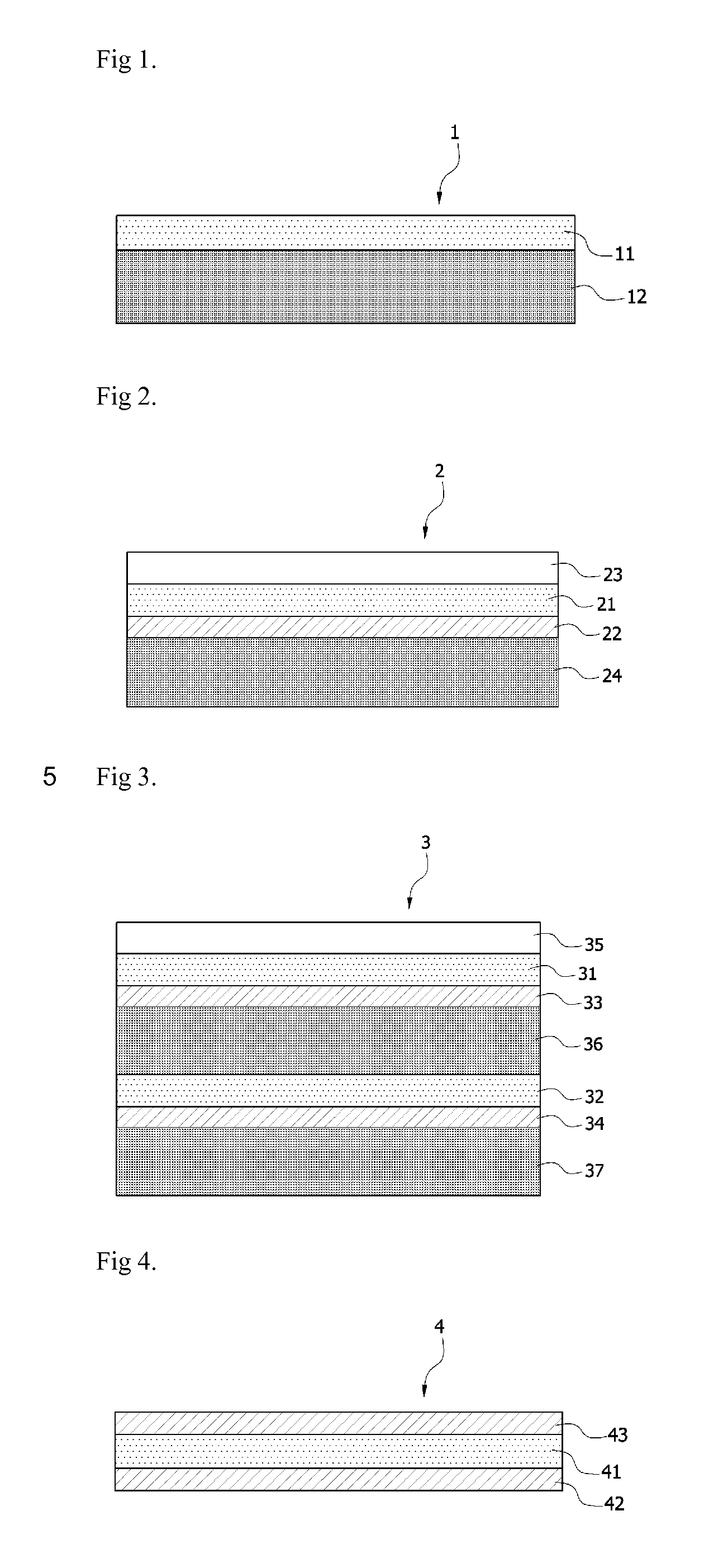

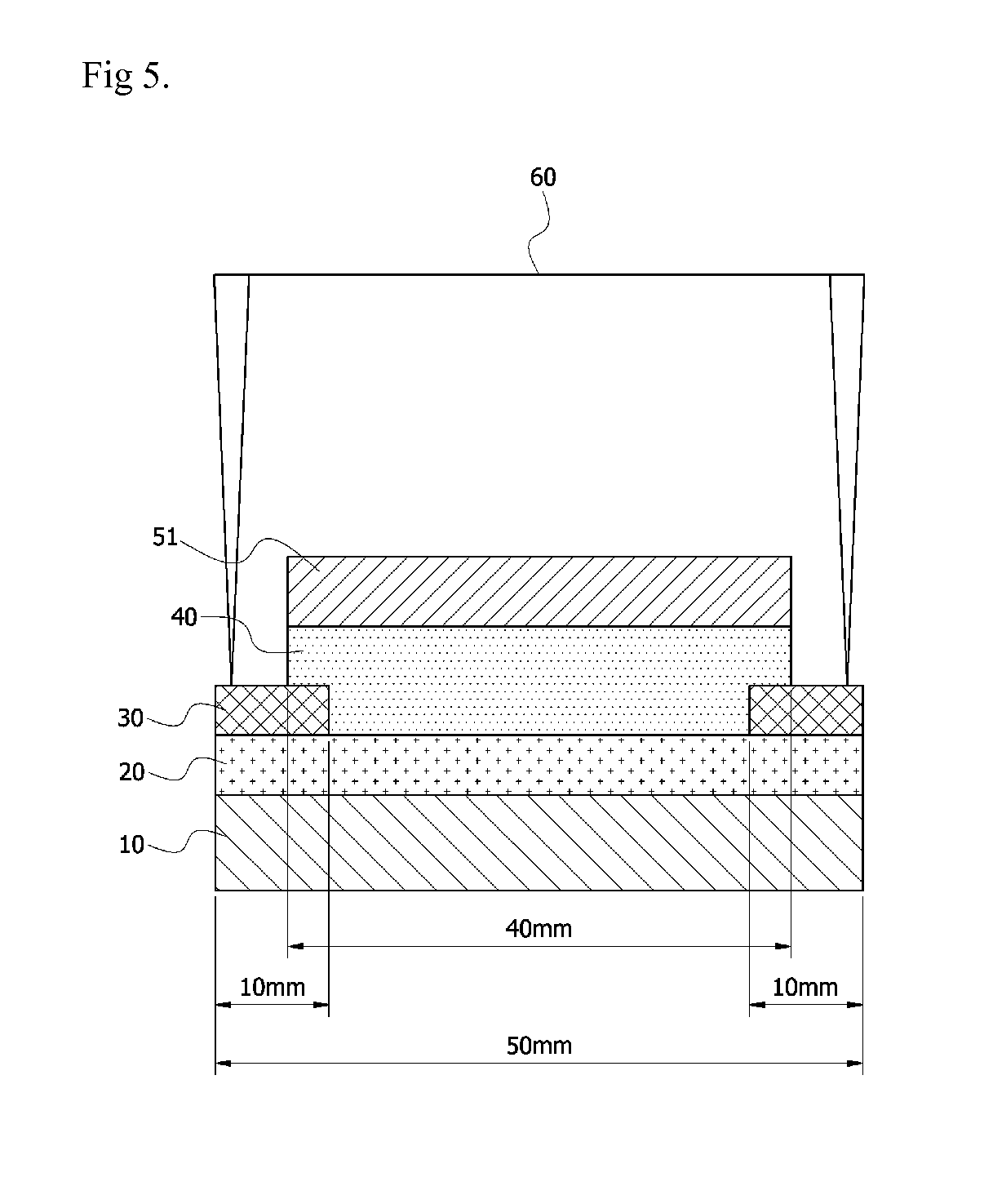

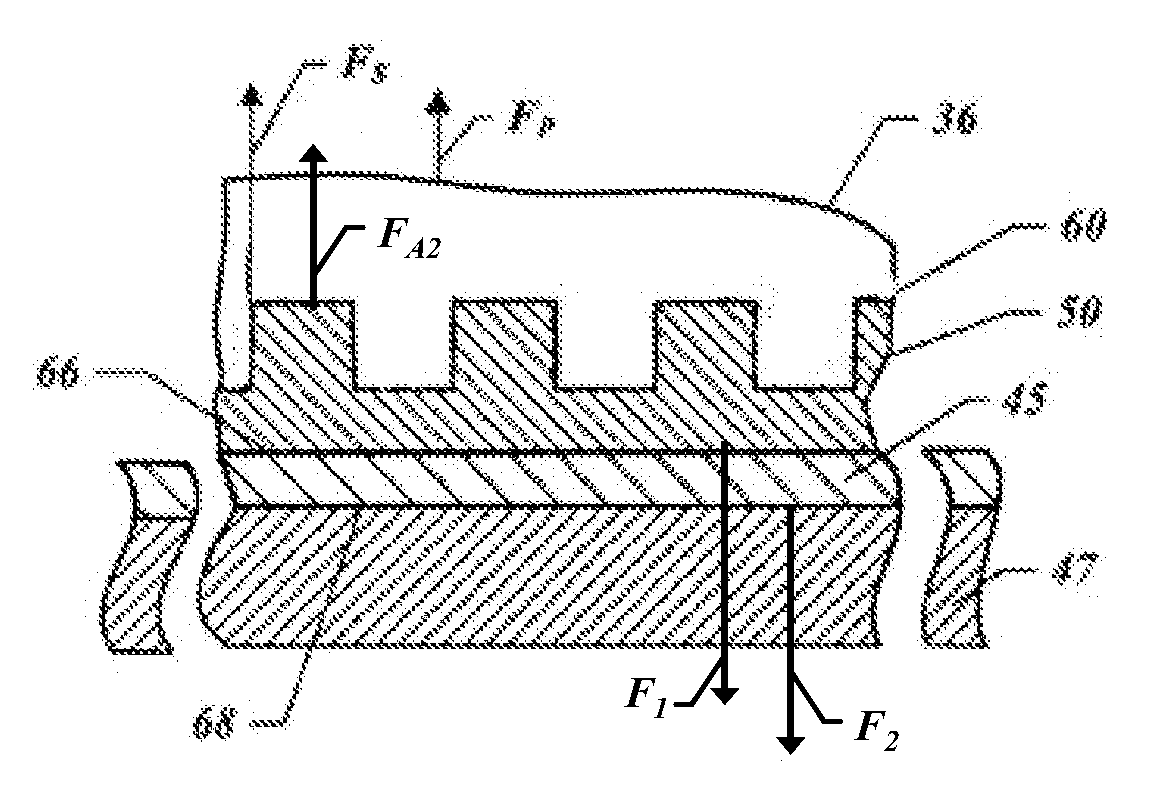

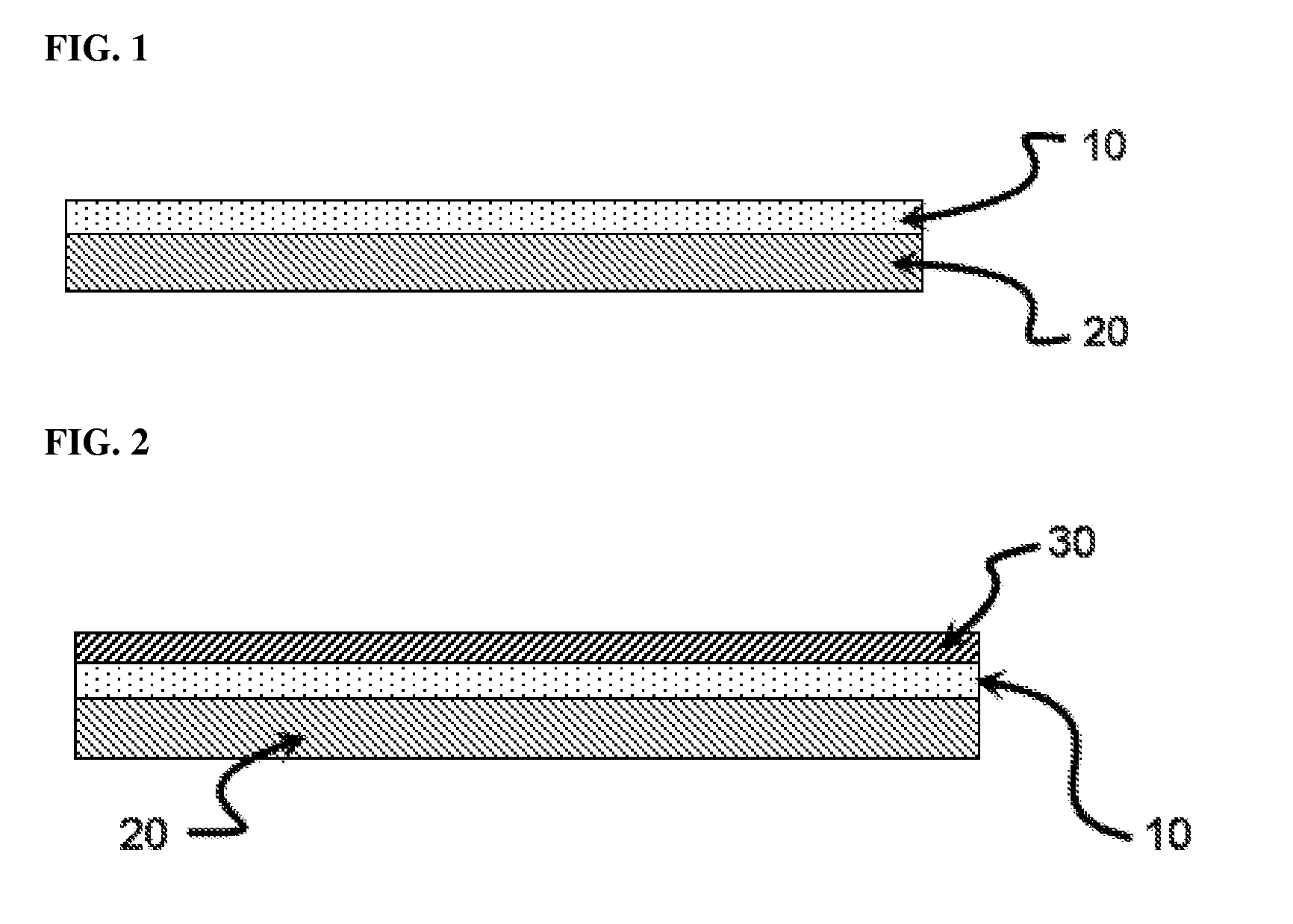

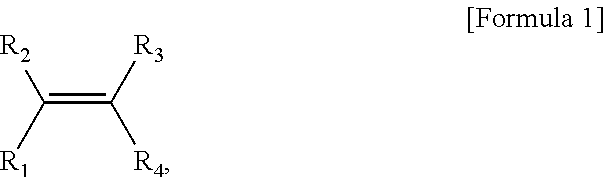

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and including an acryl-based polymer containing an acryl polymer containing 5 to 30 parts by weight of isobornyl (meth)acrylate, and 5 to 40 parts by weight of methyl (meth)acrylate in a polymerized form. Accordingly, it can effectively inhibit penetration of oxygen, moisture or other impurities at an interface between the base and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and the pressure-sensitive adhesive layer, and prevent degradation in optical properties such as visibility, etc. due to bubbles generated at the pressure-sensitive adhesive interface. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, a change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel can be stably driven for a long time.

Owner:LG CHEM LTD

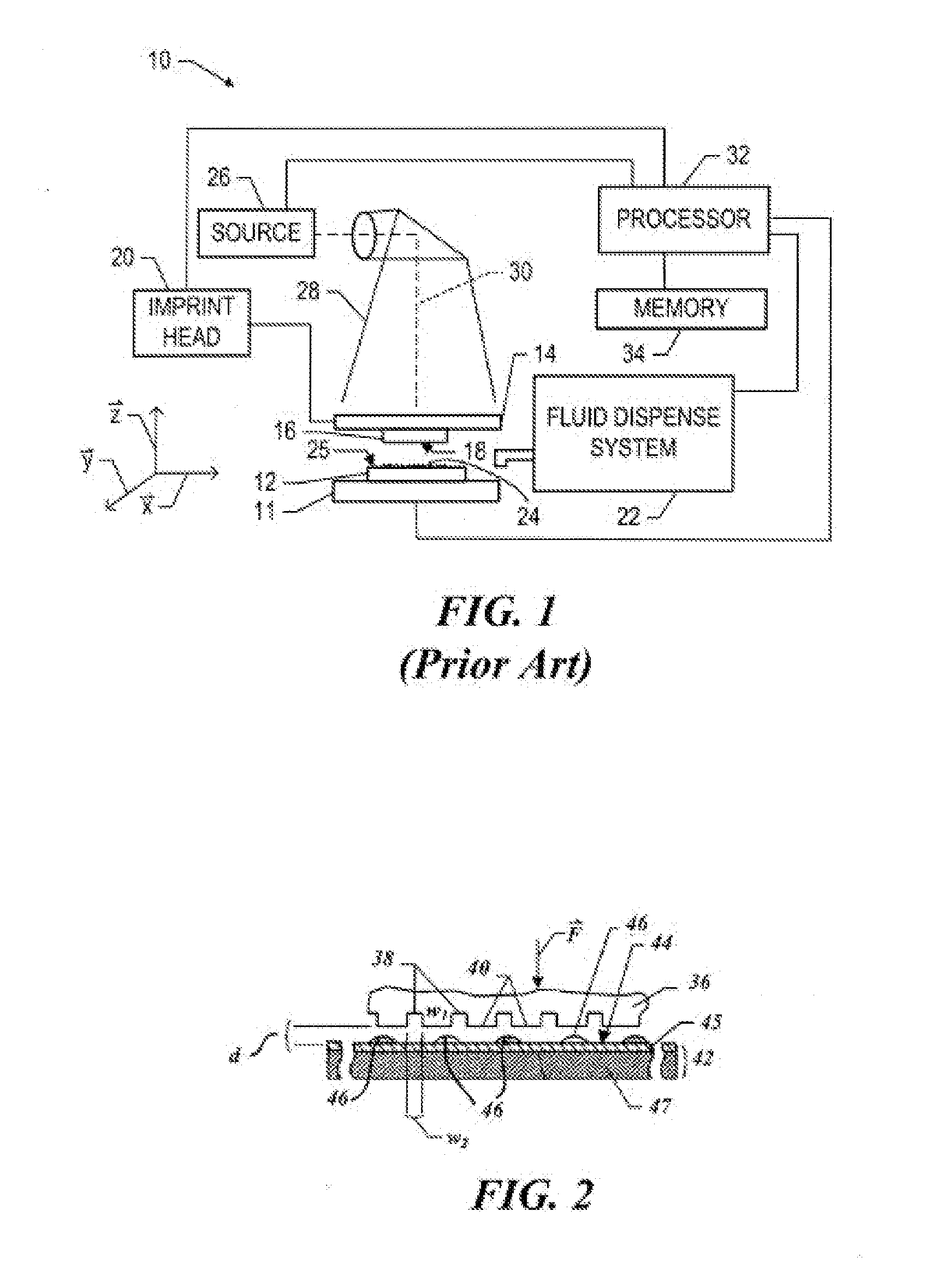

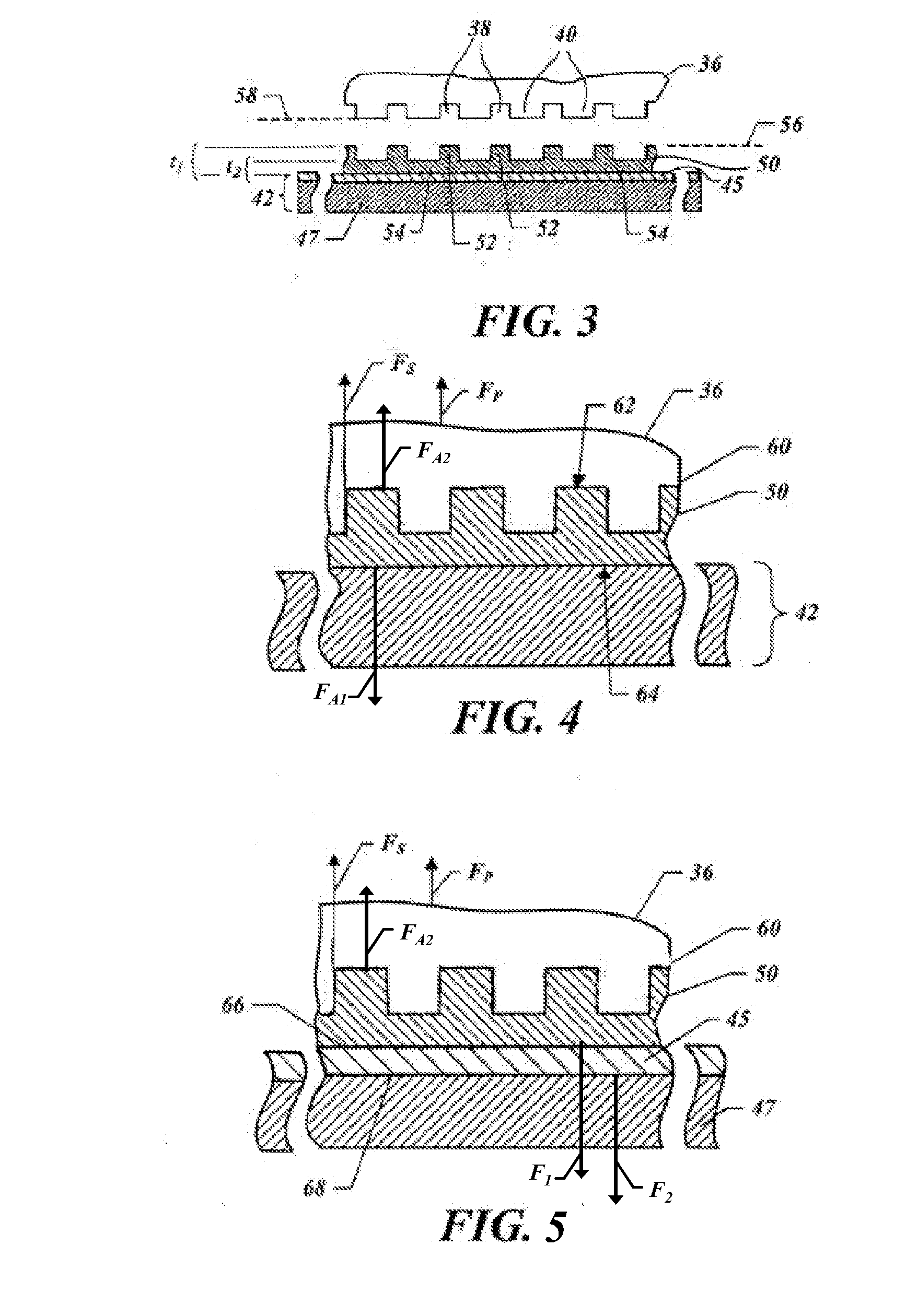

Methods and Compositions for Providing Preferential Adhesion and Release of Adjacent Surfaces

The present invention provides a method and composition for providing preferential adhesion and release of adjacent surfaces, that features solidifying a composition to form a solidified layer having first and second opposed sides, with the first side facing a first surface and being adhered thereto with a first adhesive forces and the second side facing the second surface and being adhered thereto with a second adhesive force, with the first and second adhesive forces establishing a predetermined preferential adhesion ratio. Generally, the first surface is covalently bonded to the first side and adhesion between the second side and the second surface occurs through Van der Waal forces. It has been found that the use of a fluorine group for enhancing the release properties (as a priori fluorinated release layer or a fluorinated release agent) is no longer needed for such method and composition. In one embodiment, the composition can be formed from an isobornyl acrylate component; an aliphatic urethane acrylate component; a 1,6-hexanediol diacrylate component; and a 2-hydroxy-2-methyl-1-phenyl-propan-1-one component. The first surface can be formed by polymerizing a compound formed from a multi-functional component that contains functional groups facilitating the formation of covalent bonds with the above mentioned polymerizable composition during an imprinting process, a cross-linking agent component, a catalyst component, and a solvent component. The second surface is usually a patterned or smoothed portion of a quartz mold.

Owner:MOLECULAR IMPRINTS

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Pressure-sensitive adhesive composition for optical use

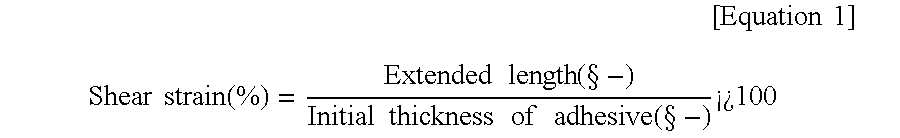

InactiveUS20120270038A1Increased durabilityGood strainPolyureas/polyurethane adhesivesRecord information storageMeth-Oligomer

A pressure-sensitive adhesive composition for optical use is disclosed. The adhesive composition includes 40 to 80 wt. % of a mono-functional urethane acrylate oligomer; 5 to 55 wt. % of isobornyl (meth)acrylate as a first mono-functional diluted monomer; 5 to 55 wt. % of a second mono-functional diluted monomer having a glass transition temperature of not less than 1° C. and an unsaturated ethylene group; and 0.1 to 5 wt. % of a free radical photo-initiator, so as to attain excellent adhesiveness to inorganic materials as well as plastic materials, durability such as heat resistance and moist heat resistance, and shear strain, wherein it does not contain any alternative solvent, to thereby render a thick film type adhesive film to be fabricated.

Owner:DONGWOO FINE CHEM CO LTD

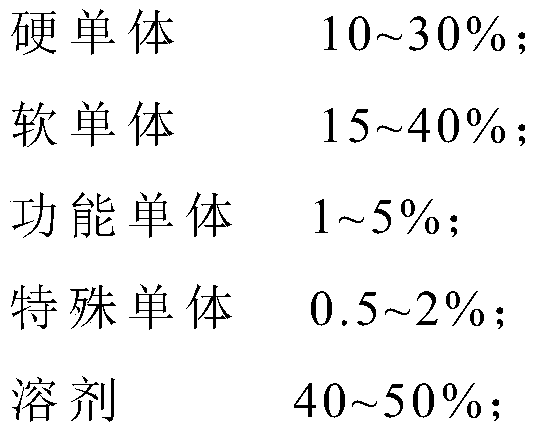

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

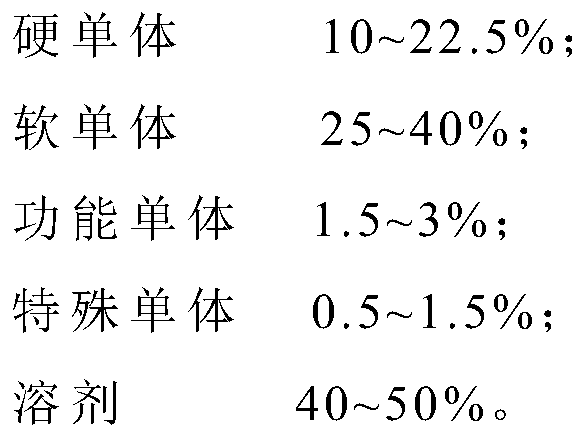

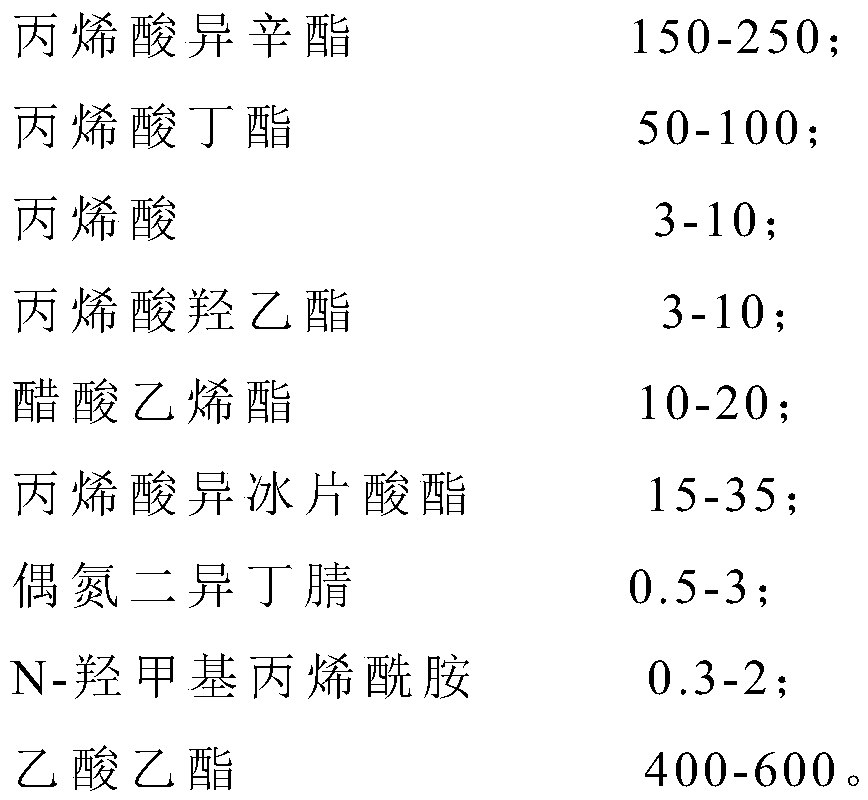

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

Digital printing inks

Owner:SUN CHEM CORP

Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

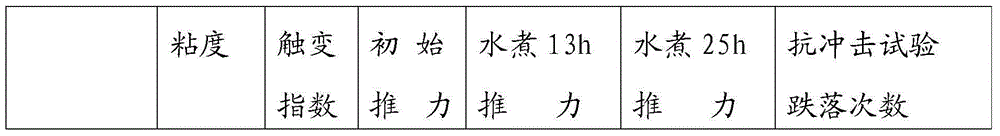

ActiveCN104531041AGood flexibilityExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveShock resistance

The invention belongs to the technical field of adhesives and relates to a polyether-type urethane acrylate UV-cured adhesive and a preparation method thereof. The polyether-type urethane acrylate UV-cured adhesive comprises, by weight, 20-70 parts of polyether-type urethane acrylate, 10-40 parts of auxiliary resin, 5-20 parts of ethylene-acrylate rubber, 5-40 parts of an acrylate monomer, 5-35 parts of isobornyl acrylate, 1-7 parts of a photoinitiator, 1-5 parts of fumed silica and 0.5-2 parts of a silane coupling agent. Through use of the polyether-type urethane acrylate, auxiliary resin, ethylene-acrylate rubber and acrylate monomer, the polyether-type urethane acrylate UV-cured adhesive has excellent long-term high temperature resistance, low temperature resistance, high temperature and high humidity resistance, excellent shock resistance and a low cost and can be prepared by simple processes.

Owner:信泰永合(烟台)新材料有限公司

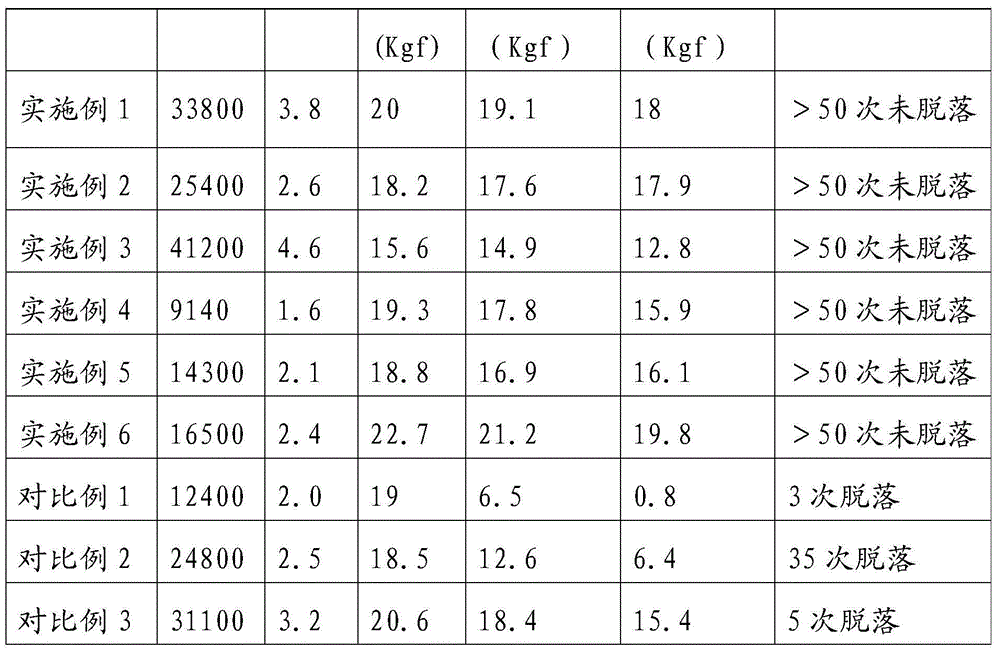

UV glue and preparation method thereof

ActiveCN106833497AImprove adhesionImprove thixotropyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer science(Hydroxyethyl)methacrylate

The invention provides UV glue and a preparation method thereof. The UV glue is prepared from the following ingredients of 35 to 60 weight parts of prepolymer, 35 to 50 weight parts of monomer and 1 to 6 weight parts of photoinitiator, wherein the prepolymer is epoxy acrylate and / or modified polyurethane acrylate, and the monomer is chosen from one or several of (methyl) isobornyl acrylate, tetrahydrofuran acrylate and hydroxyethyl methylacrylate. The UV glue can be applied to the surface of a silver-coated material, has the characteristics of high bonding strength, small viscosity, high fluidity, good wear resistance and the like and overcomes the defects of existing photochemical solidification adhesive.

Owner:东莞市亚聚光固新材料有限公司

Ultraviolet curing urethane acrylate adhesive and preparation method thereof

InactiveCN101649175AWon't happenNo pollution in the processPolyureas/polyurethane adhesivesAdhesiveHazardous substance

The invention relates to an ultraviolet curing urethane acrylate adhesive and a preparation method thereof, disclosing an approach for obtaining an environment-friendly adhesive. The adhesive is mainly used as a bonding agent for electric products and can be applied to the bonding of PDP displays, LED displays, OLED displays and FPD displays. The adhesive is prepared by using isobornyl acrylate which is an active diluent as a solvent for replacing methylbenzene and benzene, adding toluene diisocynate into polyether, using a chain extender in the reaction, and finishing the reaction within three hours. The adhesive cannot generate poisonous and harmful substances in the processes of production or use and has no pollution to the environment. Meanwhile, the invention has short reaction time and low reaction temperature and can achieve the purpose of energy saving.

Owner:成都航天明江科技实业有限公司 +1

Ink composition and hardened material using thereof

ActiveUS20100233448A1Improve adhesionSatisfactory ejection stabilityDecorative surface effectsLayered productsCaprolactamMonomer

An active energy ray-curable ink composition having excellent adhesiveness to various base materials and satisfactory ejection stability is provided. An active energy ray-curable inkjet ink composition comprising polymerizable monomers, the polymerizable monomers comprising 60 to 98% by weight of monofunctional monomers, the monofunctional monomers comprising 25 to 65% by weight of isobornyl acrylate and 12.5 to 69% by weight of N-vinyl caprolactam based on the total amount of the polymerizable monomers.

Owner:TOYO INK SC HOLD CO LTD

Hydrolyzable UV (ultraviolet) protection ink

The invention provides a hydrolyzable UV (ultraviolet) protection ink, which is prepared by mixing the following components in parts by weight: 30-48 parts of modified organosilicon acrylic resin, 6-15 parts of modified epoxy acrylic resin, 5-12 parts of isobornyl acrylate, 10-15 parts of trimethylolpropane triacrylate, 5-12 parts of chlorinated rubber, 7-15 parts of grass green pigment, 2-5 parts of silane coupling agent, 0.1-0.5 part of defoaming agent, 0.5-1.0 part of leveling agent, 0.02-0.04 part of polymerization inhibitor, 5-15 parts of calcium carbonate and 2-8 parts of 369 photoinitiator. The UV protection ink provided by the invention is a hydrolyzable UV curing protection ink of which the curing time can be obviously shortened. In addition, after finishing processing touch screen cover plate glass or ITO glass, the protective film can be removed by soaking in alkaline water. The UV protection ink has the advantage of no residue, can be peeled easily, and thus, has wide application prospects.

Owner:XIAMEN HOWER MATERIAL

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

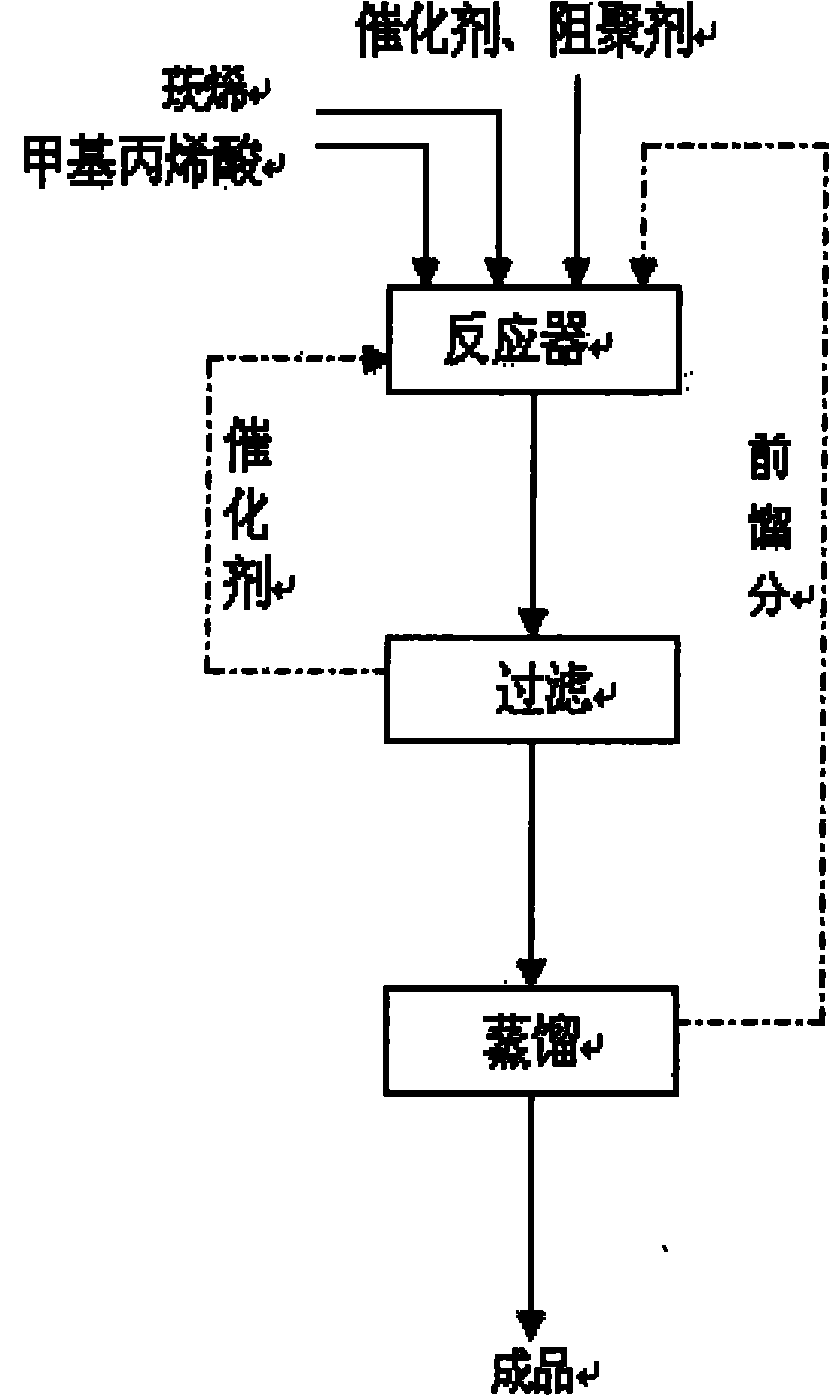

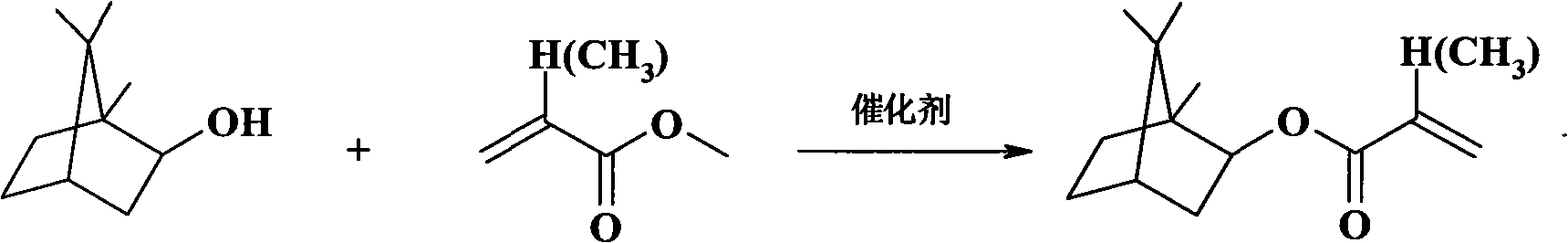

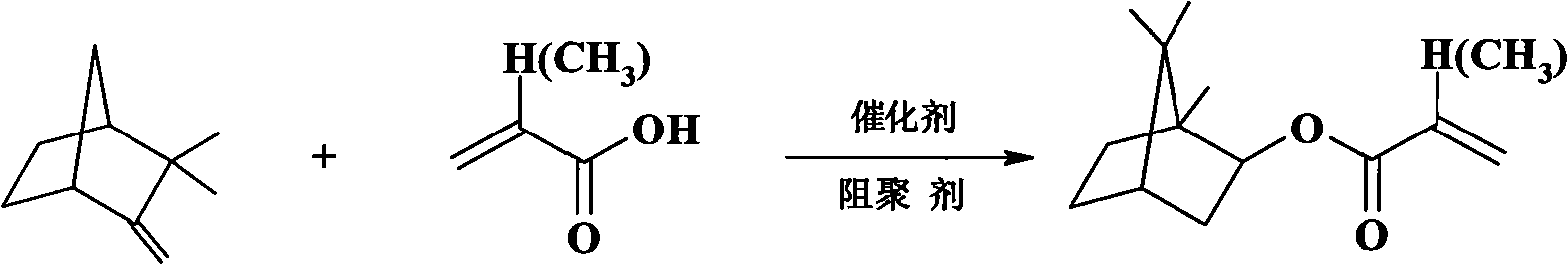

Method for catalytically synthesizing isobornyl methacrylate by activated carbon supported stannic chloride

InactiveCN101863763AEasy to makeLow costPhysical/chemical process catalystsOrganic compound preparationIsomerizationSolvent

The invention provides a method for catalytically synthesizing isobornyl methacrylate by activated carbon supported stannic chloride, which is characterized by using isomerized solution obtained by isomerizing alpha-pinene by metatitanic acid as the raw material and using the activated carbon supported stannic chloride as a catalyst, directly esterifying the isomerize solution, the activated carbon supported stannic chloride and (methyl) acrylic acid without additional solvents, filtering the esterified solution to remove the catalyst and then directly distilling the esterified solution without washing to obtain isobornyl acrylate (methyl). The method has the following advantages: the isomerized solution can be directly esterified without being purified and the esterified solution is directly distilled without being washed to obtain isobornyl acrylate (methyl). The synthetic method has the advantages of low energy consumption, low environmental pollution, good isomerization and esterification reaction selectivity, high yield and the like.

Owner:NANJING FORESTRY UNIV +1

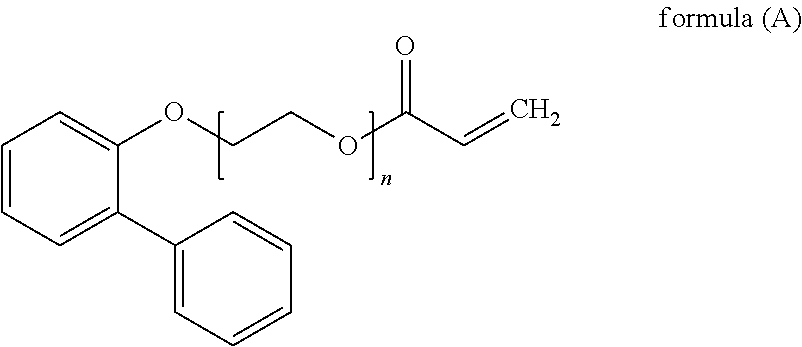

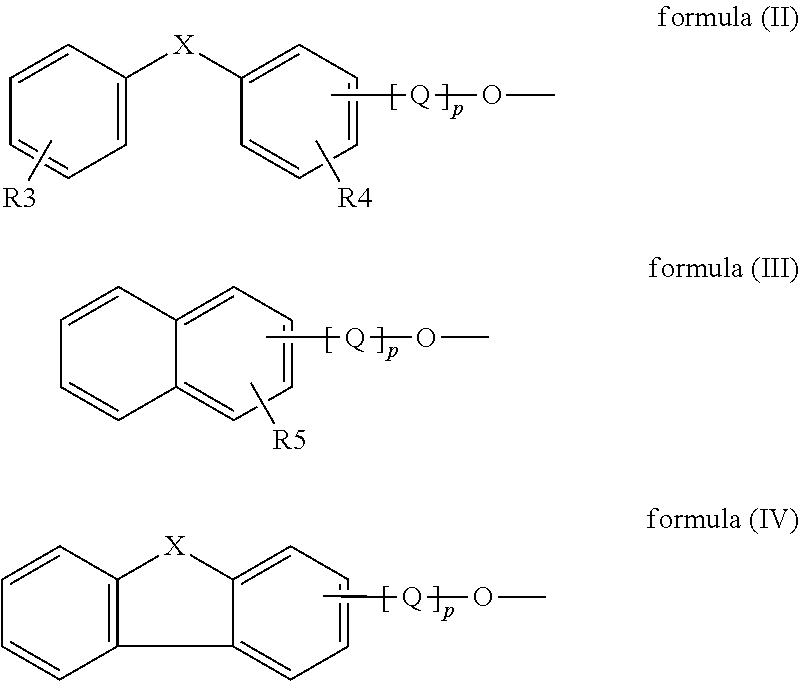

Digital printing inks

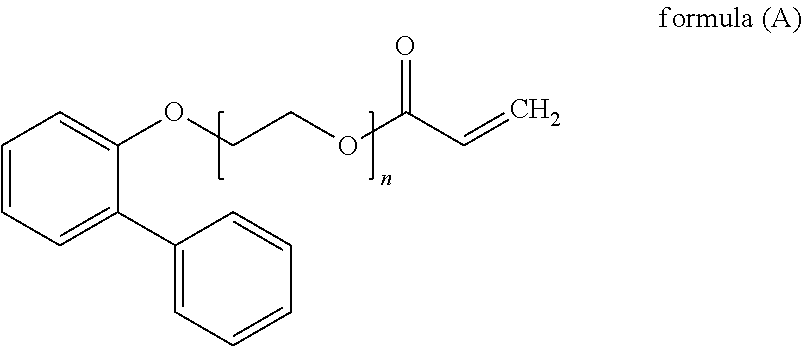

The acrylate monomers of the present invention, particularly o-phenyl phenoxyethyl acrylate, provide very fast curing, hard and solvent resistant digital printing inks, and yet are also still surprisingly flexible. These properties make for a technically superior alternative to the widely accepted very hard monomer isobornyl acrylate. O-phenyl phenoxyethylacrylate also has the additional benefit of being free from the strong odor associated with isobornyl acrylate.

Owner:SUN CHEM CORP

Aqueous acrylic resin, and preparation method and application thereof

ActiveCN102516446AGood molding performanceGood physical propertiesThermographyHot stampingInformation layer

The invention discloses an aqueous acrylic resin, and a preparation method and an application thereof. An efficient emulsifier and an improved emulsion polymerization method are used for realizing the preparation of an aqueous emulsion; a novel polymerized monomer, namely, isobornyl methacrylate is added for overcoming the defect of brittleness of high Tg point resin; and a curing agent with certain components is added before the coating operation is performed, so that the temperature tolerance of the resin is obviously increased and the problem of mold-pressing at higher temperature of the resin is solved. The harm to environment and human health caused by an organic solvent during a use process is avoided and certain cost is saved, by using the aqueous acrylic resin. The novel polymerized monomer, namely, isobornyl methacrylate is added for solving the problem of applying acrylic resins to a laser hot-stamping foil information layer, an excellent toughening function is achieved and the mold-pressing implementation of the resin is increased. Under the action of the applied efficient emulsifier and the improved emulsion polymerization method, the prepared resin has excellent physical and chemical properties as well as storage and use stability both reaching the production standard.

Owner:佛山市南海高拓包装材料有限公司

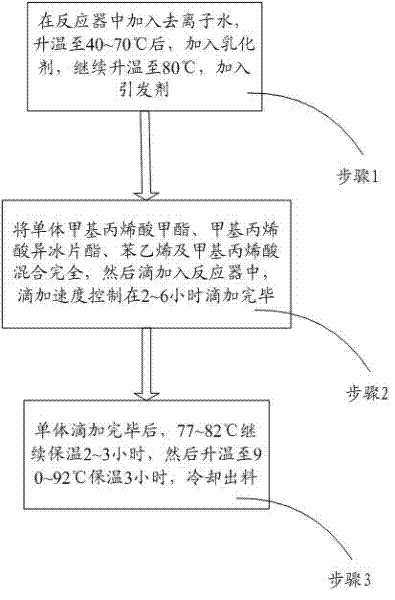

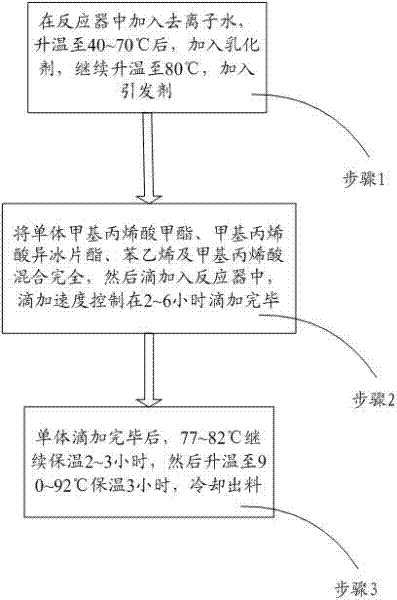

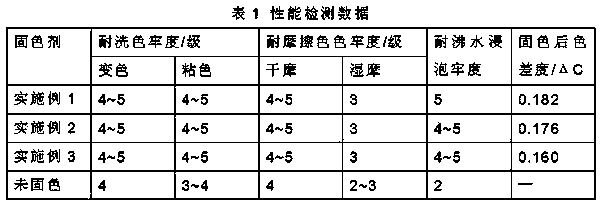

Fabric formaldehyde-free fixing agent and preparation method thereof

ActiveCN103669041AImprove washing fastnessSimple preparation processDyeing processPolymer scienceMeth-

The invention relates to a fabric formaldehyde-free fixing agent, and a preparation method thereof, and belongs to the technical field of textile auxiliary agents. The fixing agent comprises the following components in parts by weight: 15-25 parts of crylic acid butyl ester, 5-9 parts of chitosan hyamine, 6-10 parts of isobornyl acrylate, 7-14 parts of acrylyl oxyethyl acrylate trimethyl ammonium chloride, 8-10 parts of triallylamine, 2-5 parts of organo-siloxane, 3-5 parts of glacial acetic acid, 0.1-1 part of azodiisobutyronitrile and 100-120 parts of deionized water. The fabric formaldehyde-free fixing agent is simple in preparation process, the prepared fixing agent is free of formaldehyde and APEO (Alkylphenol Ethoxylates), static combination of cation groups in fixing agent molecules with anion groups in dye can be achieved, insoluble lake can be formed on the surface of a fabric, and hydrosolvent groups of the dye are sealed up, so that the washing fastness of the colored fabric can be improved.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

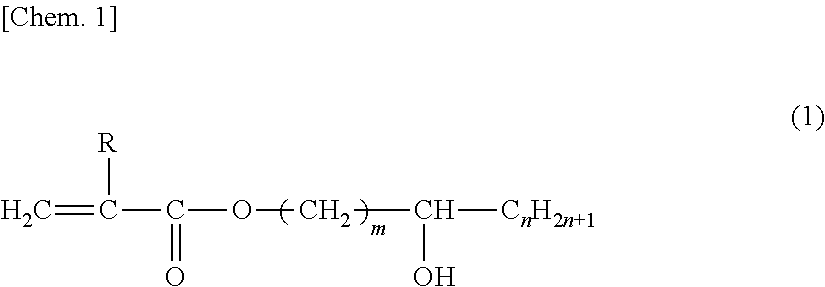

Polyester modified fluoro acrylic resin, and preparation method and coating thereof

The invention discloses polyester modified fluorine-containing acrylic resin, and a preparation method and a coating thereof. The polyester modified fluorine-containing acrylic resin is prepared by carrying out a polymerization reaction on a polyester precursor, a mixed monomer and an initiator in a mixed solvent, wherein the amount of the mixed monomer for reaction accounts for 56.7 percent of the total feeding amount; the mixed monomer comprises the following components by mass percentage of the mixed monomer: 4-8 percent of styrene, 18-22 percent of isobornyl thiocyanoacetate methacrylic acid, 13-17 percent of butyl methacrylate, 13-17 percent of hydroxyethyl methacrylate, 18-22 percent of butyl acrylate, 4-6 percent of methacrylic acid, 4-6 percent of versatic acid ethylene oxidic ester and 13-17 percent of fluorine-containing monomer. In the invention, the polyester precursor and an acrylic acid monomer solution are polymerized to obtain the polyester modified fluorine-containing acrylic resin with high solid components and the polyester modified fluorine-containing acrylic resin is prepared into a skin material which is specially tested to coat by using the coating; the result shows that the resin has excellent performance and is remarkably superior to fluorine-containing acrylic resin for preparing a skin material of a helicopter in the strong reflective characteristics, hardness, acid and alkali resistance, and the like.

Owner:ZHEJIANG YUTONG NEW MATERIAL

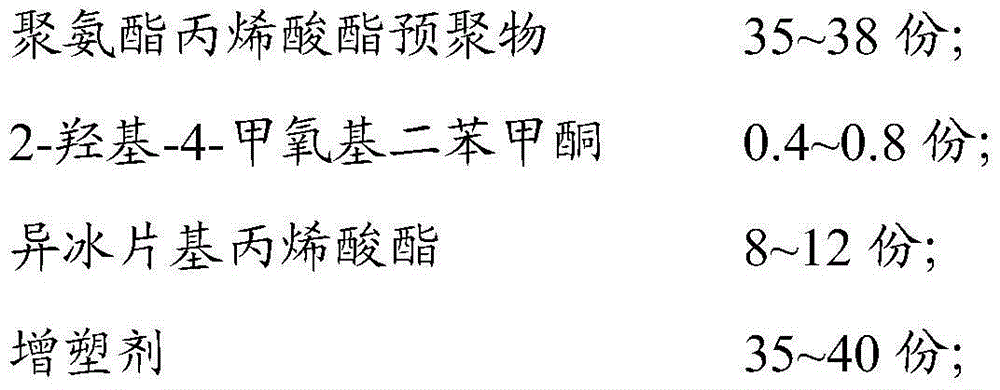

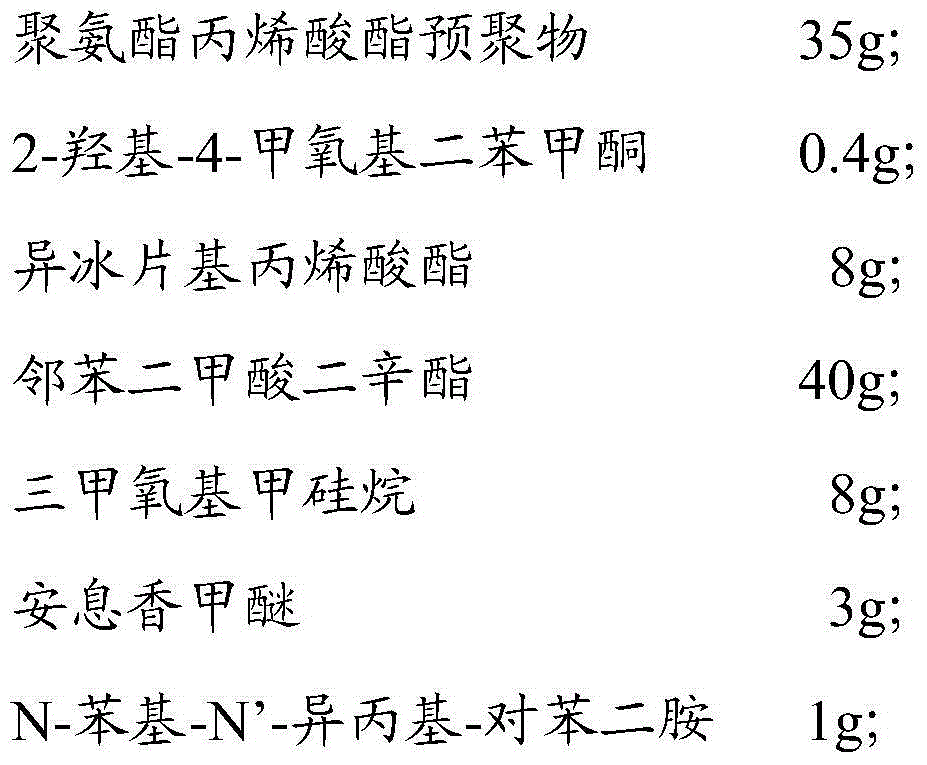

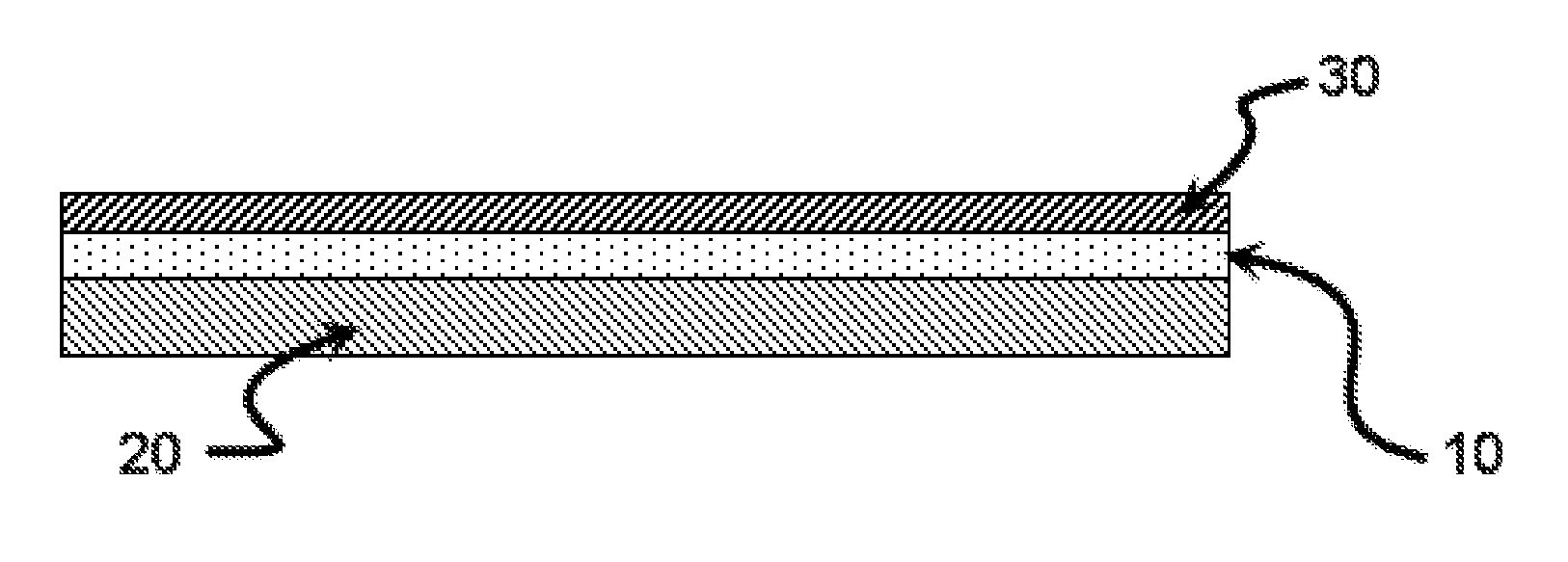

Optical adhesive and preparation method thereof

InactiveCN104099056AMeet the viscosityFulfil requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesVacuum pumpingAntioxidant

The invention discloses an optical adhesive, which is prepared from the following ingredients in parts by weight through mixing: 35-38 parts of polyurethane-acrylate prepolymer, 0.4-0.8 part of 2-hydroxy-4-methoxybenzophenone, 8-12 parts of isobornyl acrylate, 35-40 parts of a plasticizer, 6-8 parts of a coupling agent, 2-3 parts of a photoinitiator and 1-2 parts of an antioxidant. The invention further discloses a preparation method for the optical adhesive, which comprises the following steps: uniformly mixing the polyurethane-acrylate prepolymer, the 2-hydroxy-4-methoxybenzophenone, isobornyl acrylate, the plasticizer, the coupling agent, the photoinitiator and the antioxidant, heating the mixture to 50-80 DEG C, stirring for reaction for 1.5-1.8 h, performing vacuum-pumping for removing bubbles, and cooling, so that the optical adhesive is prepared. The optical adhesive provided by the invention has the advantages as follows: yellowing and ageing speed of the optical adhesive is lowered in the use process greatly, the service life of the optical adhesive is prolonged, and the refractive index of the optical adhesive is increased.

Owner:TAICANG ZHANXIN ADHESIVE MATERIAL

Active-energy-ray-curable inkjet recording ink composition and method for forming image

ActiveUS20140160215A1Easy curingMaintain good propertiesDuplicating/marking methodsInksVinyl etherCaprolactam

An active-energy-ray-curable inkjet recording ink composition is provided, in which a polymerizable compound having an active-energy-ray-polymerizable group and a polymerizable compound having at least two active-energy-ray-polymerizable groups are used in amounts of 60 to 95 mass % and 5 to 40 mass % relative to the total amount of the active-energy-ray-polymerizable compound, respectively; the polymerizable compound having an active-energy-ray-polymerizable group includes N-vinyl-2-caprolactam and isobornyl acrylate in amounts of 1 to 15 mass % and 1 to 25 mass % relative to the total amount of the active-energy-ray-polymerizable compound, respectively; and the polymerizable compound having at least two active-energy-ray-polymerizable groups includes a polymerizable compound having a vinyl ether group. Furthermore, a method for forming an image is provided.

Owner:DAINIPPON INK & CHEM INC

Adhesive composition, adhesive sheet, and back grinding method for semiconductor wafer

InactiveUS20110139347A1Reduce hydrophilicityExcellent wafer-proofing propertyLamination ancillary operationsSynthetic resin layered productsWafer backgrindingSemiconductor

The present invention relates to a pressure-sensitive adhesive composition including a polymer of a monomer mixture containing isobonyl (meth)acrylate, a pressure-sensitive adhesive sheet, and a semiconductor wafer backgrinding method. In the present invention, by using isobonyl (meth)acrylate which is a hard-type monomer and has a low hydrophilic property, a pressure-sensitive adhesive composition having superior releasing and re-releasing properties and wettability with respect to the wafer, and having an excellent wafer-proofing property; a pressure-sensitive adhesive sheet prepared by using the pressure-sensitive adhesive composition; and a backgrinding method using the pressure-sensitive adhesive sheet can be provided.

Owner:LG CHEM LTD

Thermoplastic acrylic resin and preparation method for same

The invention discloses a thermoplastic acrylic resin. The thermoplastic acrylic resin is characterized by comprising the raw materials in parts by weight: 25-40 parts of methyl methacrylate, 20-30 parts of butyl acrylate, 15-30 parts of alkyl-containing acrylic monomer, 2-5 parts of hydroxyethyl acrylate, 1-2 parts of acrylic acid, and 1-2 parts of initiator, wherein the alkyl-containing acrylic monomer is one of isobornyl methacrylate, isobornyl acrylate, cyclohexyl methacrylate, tert-butyl cyclohexyl methacrylate and 3,3,5-trimethyl cyclohexyl methacrylate, or the compound thereof. The invention further provides a preparation method for the thermoplastic acrylic resin. The thermoplastic acrylic resin disclosed by the invention is high in Tg value, low in viscosity, good in application property, levelling property and dryness, full and bright in appearance, not easy to generate indentations, low in VOC (volatile organic compounds) discharge, and environment-friendly.

Owner:CHONGQING BODUO PAINT

High temperature-resistant acid-resistant anti-corrosion priming paint

InactiveCN103694858AHigh mechanical strengthBright colorAnti-corrosive paintsEpoxy resin coatingsEpoxy(Hydroxyethyl)methacrylate

The invention relates to paint, and particularly relates to high temperature-resistant acid-resistant anti-corrosion priming paint. The high temperature-resistant acid-resistant anti-corrosion priming paint is prepared from the following raw materials in parts by weight: 12-14 parts of E-12 epoxide resin, 20-24 parts of organic silicon resin, 10-12 parts of amine resin, 3-5 parts of mica powder, 1-2 parts of polyhexamethylene guanidine hydrochloride, 25-30 parts of epoxy acrylate, 2-3 parts of hydroxyethyl methacrylate phosphate, 5-8 parts of isobornyl acrylate, 1-2 parts of triethanolamine, 3-4 parts of p-tert-pentylphenol, 3-4 parts of methyl acrylate, 1-2 parts of cross-linking agents TAIC (Triallyl Isocyanurate), 8-10 parts of isoamyl butyrate, 24-28 parts of nanometer diatomite powder, 7-9 parts of linseed alkyd resin, 1-2 parts of anti-aging agents NBC, 2-3 parts of isocyanate, 2-3 parts of zinc naphthenate, 5-6 parts of auxiliary agents, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The high temperature-resistant acid-resistant anti-corrosion priming paint disclosed by the invention has the advantages of high paint adhesive force, brightness in paint film colour and lustre, fast drying, high-temperature damage endurance, acid resistance, anti-corrosion and long service life and is priming paint with excellent comprehensive property.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Method for preparing microgel resin and UV-cured contamination resistant coating prepared from microgel resin

InactiveCN101870760AParticle size controllableGood anti-fingerprintAntifouling/underwater paintsPaints with biocidesCross-linkMicro nano

The invention discloses a method for preparing microgel resin and a UV-cured contamination resistant coating prepared from the microgel resin. The method comprises the following steps of: initiating room temperature reversible addition fragmentation chain transfer (RAFT) radical polymerization on an iso-bornyl acryl monomer, alkyl methacrylate, a cross-linking agent, a chain transfer agent, a photo initiator and a solvent by using UV-visible light or visible light to synthesize branched polyacrylate; continuously adding fluorine(methyl)-containing acrylate monomers for RAFT block copolymerization to prepare microgel resin taking a fluorine-containing acrylate hydrophobic and oleophobic chain as a shell and the branched polyacrylate as a core; and preparing the UV-cured contamination resistant coating by mixing the microgel resin, other light-cured resin, monomers, the photo initiator and the like. The branched-block fluorine-containing acrylate microgel resin designed and synthesized can migrate to the surface in the process of leveling the coating, and can be cross-linked with matrix components in the UV curing process to form a permanent hydrophobic and oleophobic low-surface contamination resistant coating with a micro-nano structure, and the fingerprint resistance and skin grease contamination resistance of the coating are good.

Owner:湖南宏泰新材料有限公司

Coating composition and method for forming coating film

InactiveUS20110052822A1Excellent finished appearanceModerate curabilityLiquid surface applicatorsPolyurea/polyurethane coatingsMeth-Acrylic resin

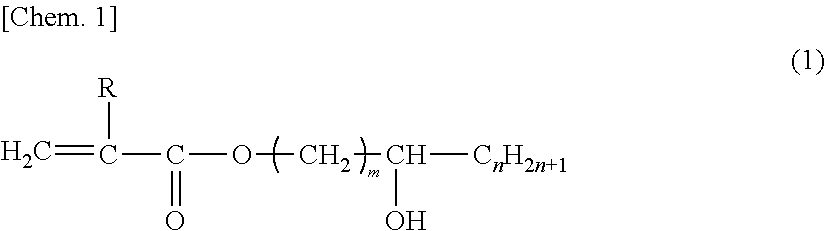

The present invention provides a coating composition that is excellent in application workability, and that can form a cured coating film excellent in coating film performances such as scratch resistance, acid resistance, stain resistance, finished appearance, sagging resistance, etc. Specifically, the present invention provides a coating composition comprising an acrylic resin (A), a polyisocyanate compound (B) and a specific non-aqueous dispersion-type acrylic resin (C), wherein: the acrylic resin (A) is obtainable by copolymerization of a specific secondary hydroxyl group-containing monomer (a-1), a secondary hydroxyl group-containing polyoxyalkylene mono(meth)acrylate monomer (a-2), an isobornyl (meth)acrylate monomer (a-3) and at least one other copolymerizable unsaturated monomer (a-4), the unsaturated monomer (a-1) being used in an amount (mass) greater than that of the monomer (a-2).

Owner:KANSAI PAINT CO LTD

Coloring layer coating suitable for silver alumite hot stamping foils and preparation method thereof

ActiveCN108059858AHigh hardnessStructural solutionFilm/foil adhesive primer layersCoatingsHot stampingSolvent

The invention discloses coloring layer coating suitable for silver alumite hot stamping foils and a preparation method thereof. Paint films of silver alumite hot stamping foils in the prior art are prone to efflorescence; in gold stamping, the defects of gold flying, powder falling and the like are prone to happening; thus, hot stamping quality and a production efficiency are affected. The coloring layer coating disclosed by the invention is prepared from the following raw materials in parts by weight: 15 to 25 parts of thermoplastic methacrylic resin, 1 to 5 parts of chloride-acetate resin, 1to 8 parts of styrene-maleic anhydride copolymer, 1 to 10 parts of cellulose acetate butyrate, 1 to 10 parts of methyl isobornyl acrylate, 1 to 5 parts of impact modifier and 50 to 70 parts of solvent. According to the coloring layer coating disclosed by the invention, the impact modifier is added into the formula ingredients, so that paint film toughness is effectively improved; meanwhile, the coloring layer coating has the characteristics of moderate viscosity, good adhesion with aluminum layers, simple production technology easy to control, stable quality, convenience in long-time storageand the like; a coloring layer paint film of alumite containing the coloring layer coating has the characteristics of high glossiness, large hardness, toughness, wear resistance and the like.

Owner:云南玉溪东魅包装材料有限公司

Water-based acrylic emulsion resin, water-based coating emulsion and preparation method

ActiveCN105949378AStable storageStable coating performanceCoatingsWater basedPolyethylene terephthalate glycol

The invention discloses water-based acrylic emulsion resin, a water-based coating emulsion and a preparation method. The water-based acrylic emulsion resin is prepared from a reactive emulsifier SR-10, has stable storage and film performance and can improve the water resistance and solution resistance of a coating. Besides, isobornyl acrylate with a relatively large non-polar side group is taken as a functional monomer and can improve infiltration and adhesion performance of a BOPET(biaxially-oriented polyethylene terephthalate) film and improve the alcohol resistance of a resin system. According to the water-based coating emulsion, water-based melamine resin replaces conventional isocyanate or aziridine to serve as a crosslinking agent, the toughness, the adhesive force and the solution resistance of the coating are improved, and the printing and dyeing property of the resin system can be improved through introduction of amino resin.

Owner:FOSHAN JIAEN NEW MATERIALS CO LTD

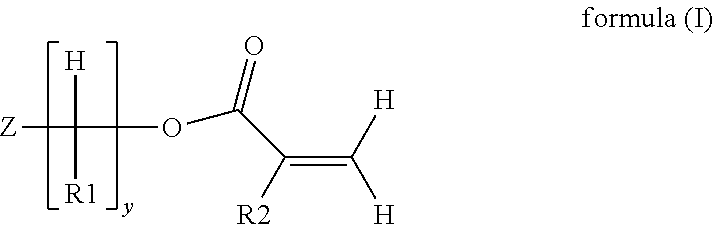

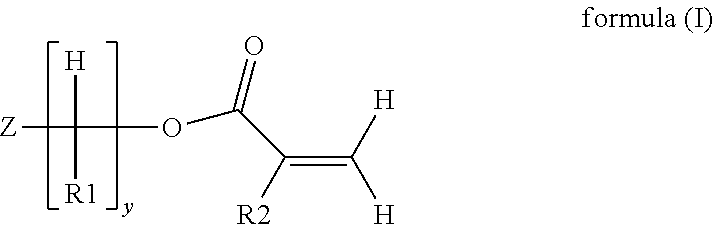

Anticorrosive, terminal-attached covered electric wire, and wiring harness

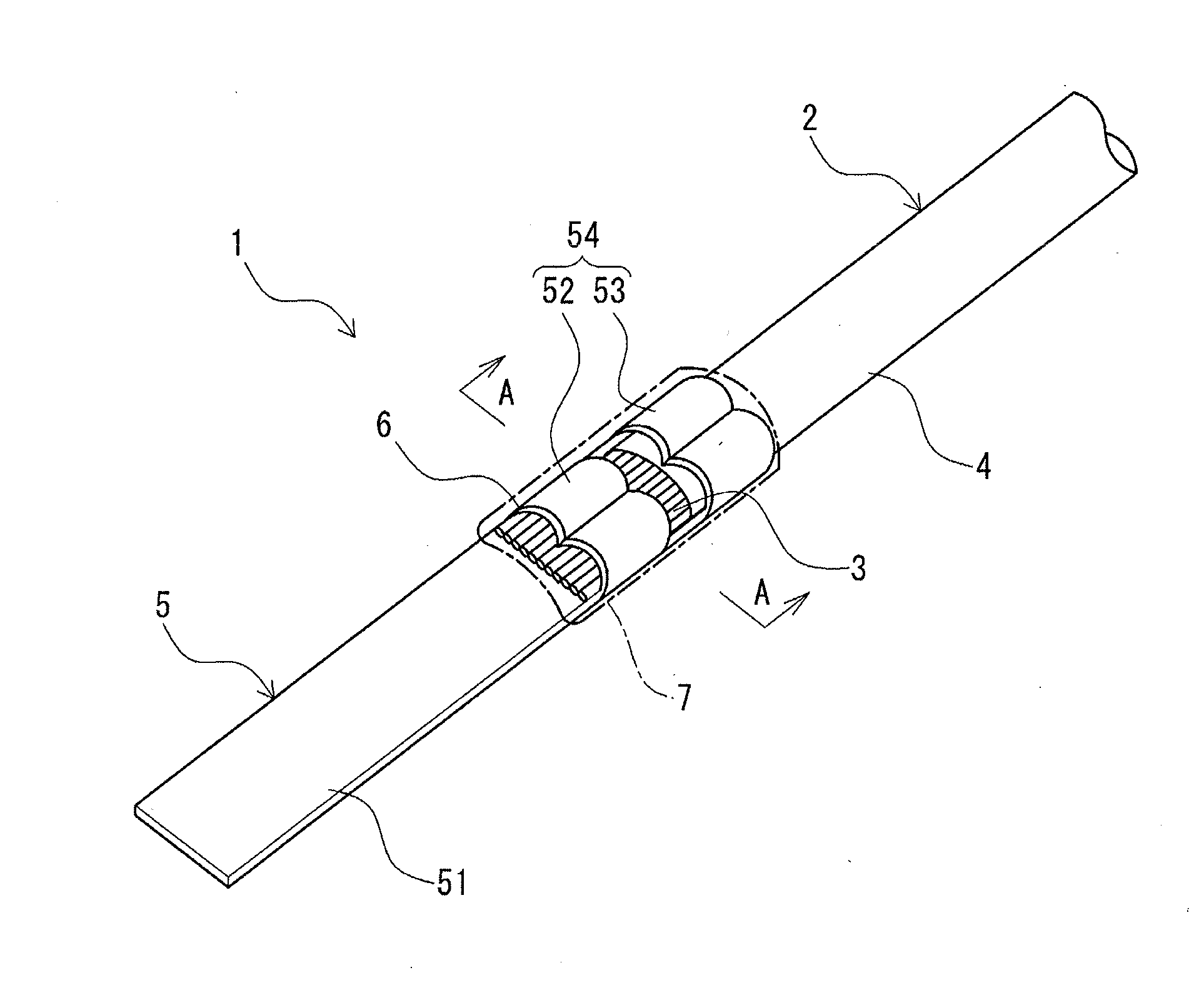

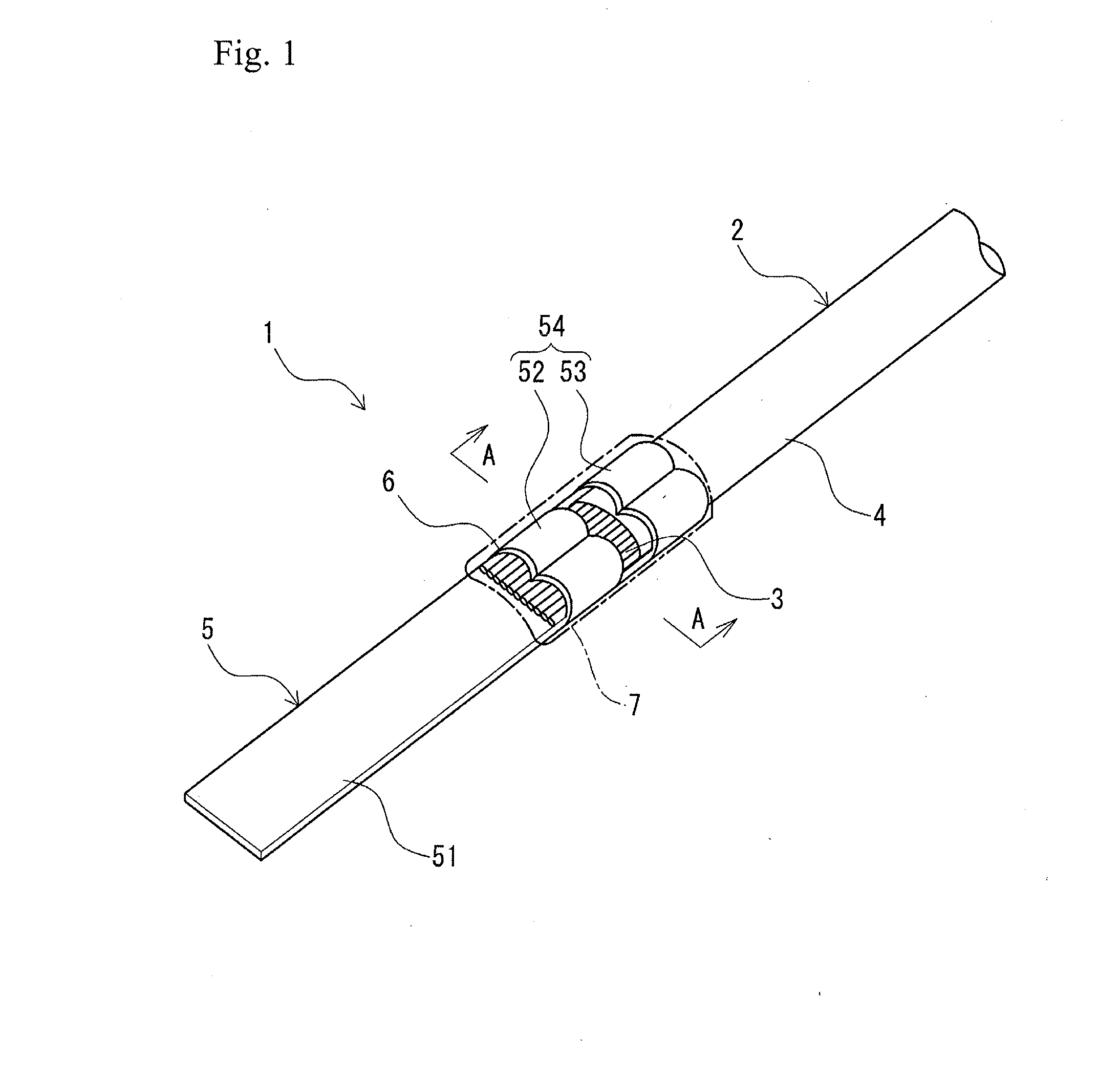

ActiveUS20150368389A1Improve anti-corrosion performanceImprove adhesionCoupling device detailsSoldered/welded conductive connectionsCarbon numberElectrical conductor

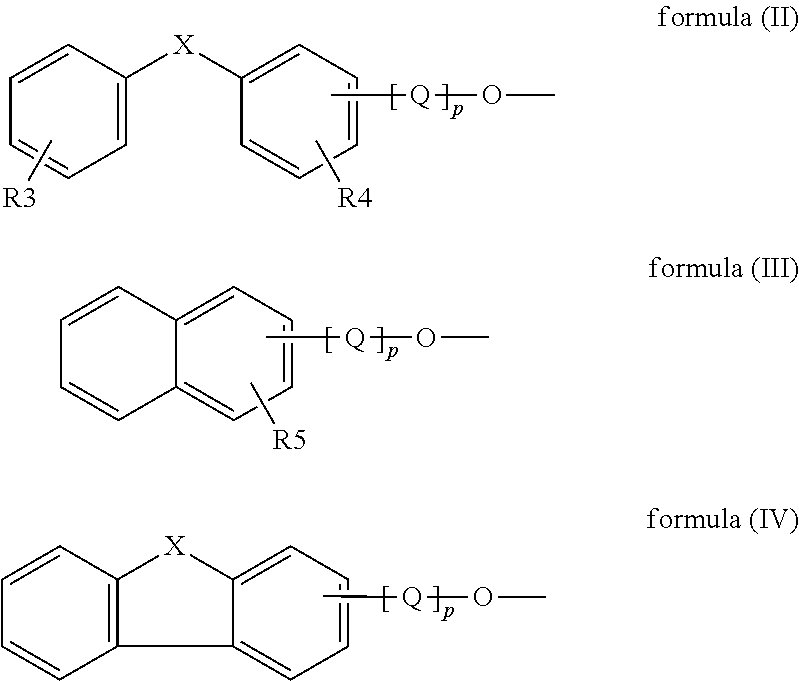

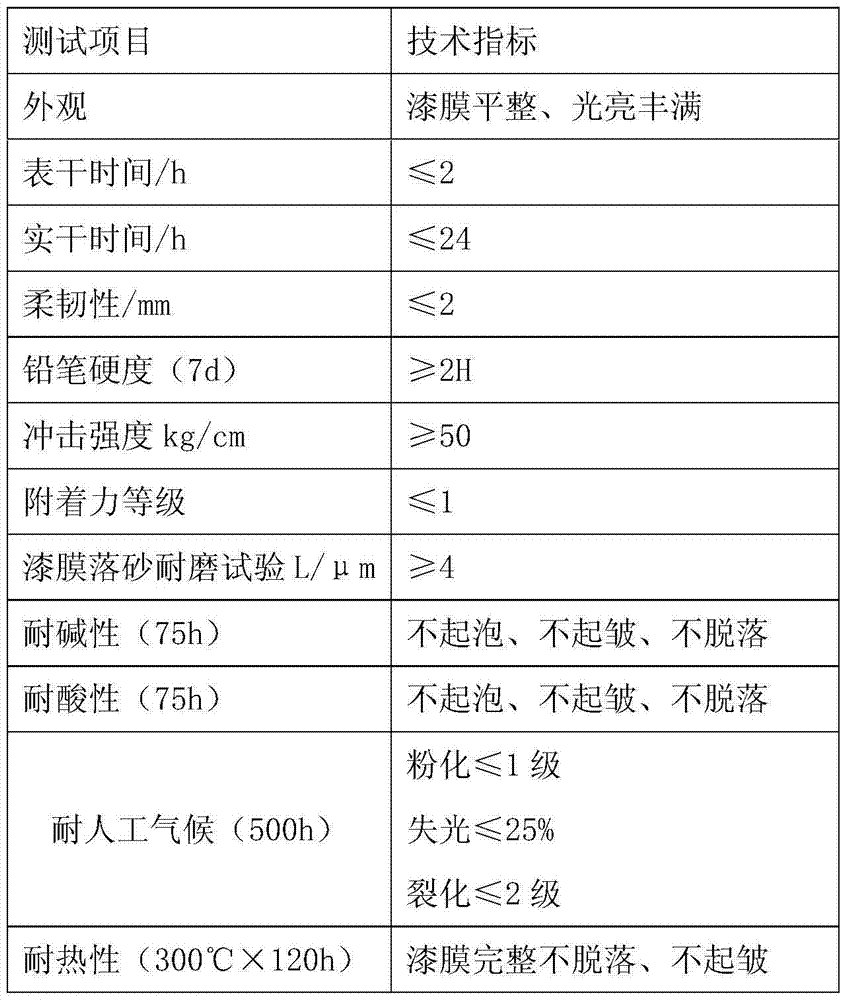

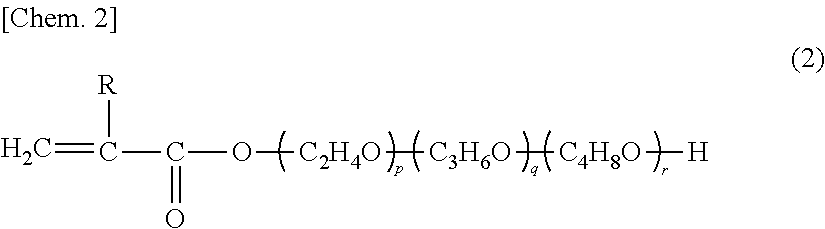

Provided is an anticorrosive containing a curable resin composition and that has a high anticorrosive capability and a good adhesion to an oily surface, and a terminal-attached covered electric wire and a wiring harness using the anticorrosive. The terminal-attached covered electric wire has a contact portion where a wire conductor of a covered electric wire and a connection terminal contact each other. The contact portion is covered with the anticorrosive. The wiring harness contains the terminal-attached covered electric wire. The curable resin composition contains 100 parts by mass of a polymer of a (meth)acrylate monomer, the polymer having two or more (meth)acrylate groups, 40 to 90 parts by mass of isobornyl (meth)acrylate, and 1 to 15 part by mass of an alkyl (meth)acrylate represented by formula 1, where R1 is either H or CH3, and R2 is an alkyl group having a carbon number of 8 to 13,

Owner:AUTONETWORKS TECH LTD +2

Water-soluble acrylic resin and preparing method thereof

InactiveCN105859951AGood resistance to salt sprayImprove aging resistanceAcrylic resinDibenzoyl Peroxide

The invention relates to water-soluble acrylic resin and a preparing method thereof, and relates to the technical field of chemical raw materials. The water-soluble acrylic resin is prepared from methyl methacrylate, n-butyl methacrylate, acrylic acid, n-butyl acrylate, 2-ethylhexyl acrylate, methyl isobornyl acrylate, hydroxy-propyl acrylate, dibenzoyl peroxide, water, a neutralizing agent and isobutyl alcohol. The water-soluble acrylic resin is formed by (methyl) methacrylate monomers as a main raw material through chemical polymerization. According to the water-soluble acrylic resin and the preparing method thereof, the water-soluble acrylic resin can be matched with curing agents such as fully etherificated amino resin and closed isocyanate to prepare outdoor environment-friendly paint, and a paint film has excellent salt mist resistance, ageing resistance, self-cleaning performance and weather resistance.

Owner:GUANGZHOU NUOBAO TECH DEV CO LTD

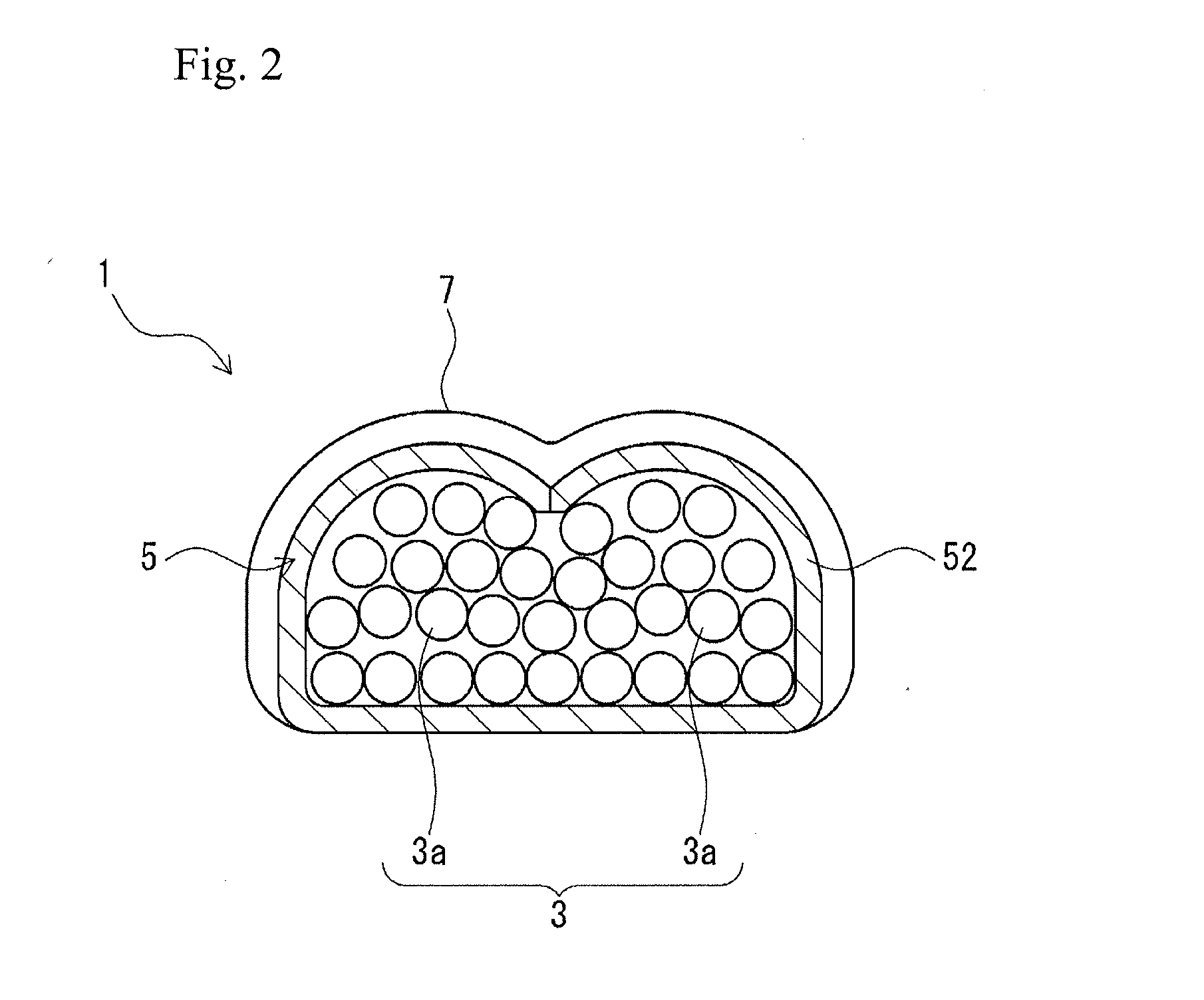

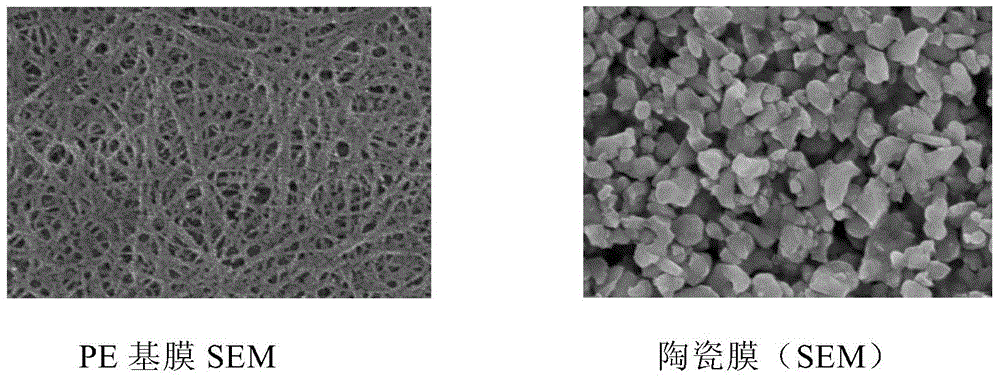

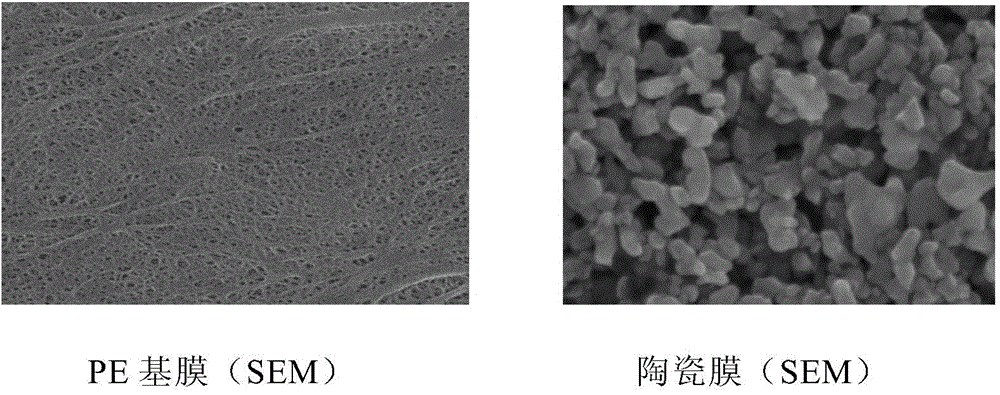

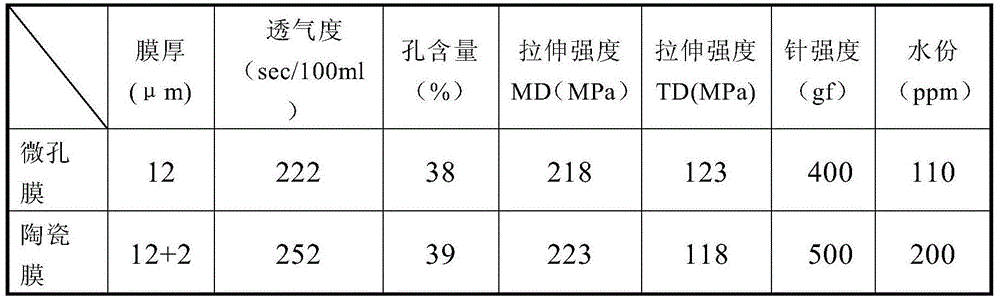

Manufacture method and applications of high temperature resistant and deformation resistant composite microporous membrane

InactiveCN105713228AImprove high temperature stabilityImprove mechanical propertiesCell component detailsCarbamatePolymer science

The invention discloses a manufacture method and applications of a high temperature resistant and deformation resistant composite microporous membrane. The manufacture method comprises the following steps: (a) providing a polymer microporous membrane; (b) dispersing ceramic nano particles into an aqueous adhesive to form aqueous slurry; (c) painting the aqueous slurry on the surface of the polymer microporous membrane to form a composite microporous membrane; wherein the aqueous adhesive comprises a main adhesive and an interlayer adhesive, the main adhesive is prepared from cellulose ether, natural polymer and derivatives thereof, or a mixture of cellulose ether and natural polymer and derivatives thereof; the interlayer adhesive is prepared from polyacrylamide, poly(vinyl amide), polyvinylpyrrolidone, polymethyl methacrylate, polycarboxylic acid, modified paraffin resin, carbomer, polyacrylic acid, urethane acrylate, polyacrylate copolymer emulsion, cis-polybutadiene, butadiene styrene rubber, polyurethane, carbamate, and liquid glue made of part of acrylic epoxy resin, isobornyl acrylate, starch, modified polyurea, and low molecular polyvinyl wax, and the weight ratio of the main adhesive to the interlayer adhesive is 20:55-65:5.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Waterproof UV glue

ActiveCN105505287AAvoid layeringPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveEpoxyDiphenylphosphine oxide

The invention discloses a waterproof UV glue which mainly comprises the following components in percentage by weight: 20%-40% of bifunctional modified polyurethane resin, 15%-35% of acrylic acid-grafted epoxy resin, 10%-25% of hydroxypropyl methacrylate, 10%-25% of isobornyl acrylate, 1%-5% of 1-hydroxy-cyclohexyl phenyl ketone, 0.1%-5% of 2,4,6-trimethybenzoyl- diphenylphosphine oxide and 0.05%-2% of a fluorescent agent. Meanwhile, in order to further improve the application performance of the waterproof UV glue, the waterproof UV glue also comprises 0.05%-5% of microcrystalline cellulose.

Owner:重庆索梦得新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com