Patents

Literature

700results about How to "Reduce hydrophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making polysiloxane emulsions

A method for making oil free polysiloxane standard, fine and microemulsions using emulsion polymerization is disclosed. The method comprises reacting a cyclicsiloxane in the presence of a catalyst, ionic surfactant and nonionic surfactant within a certain operating window. Emulsions containing silicone copolymers can also be produced using the method of the instant invention.

Owner:DOW SILICONES CORP

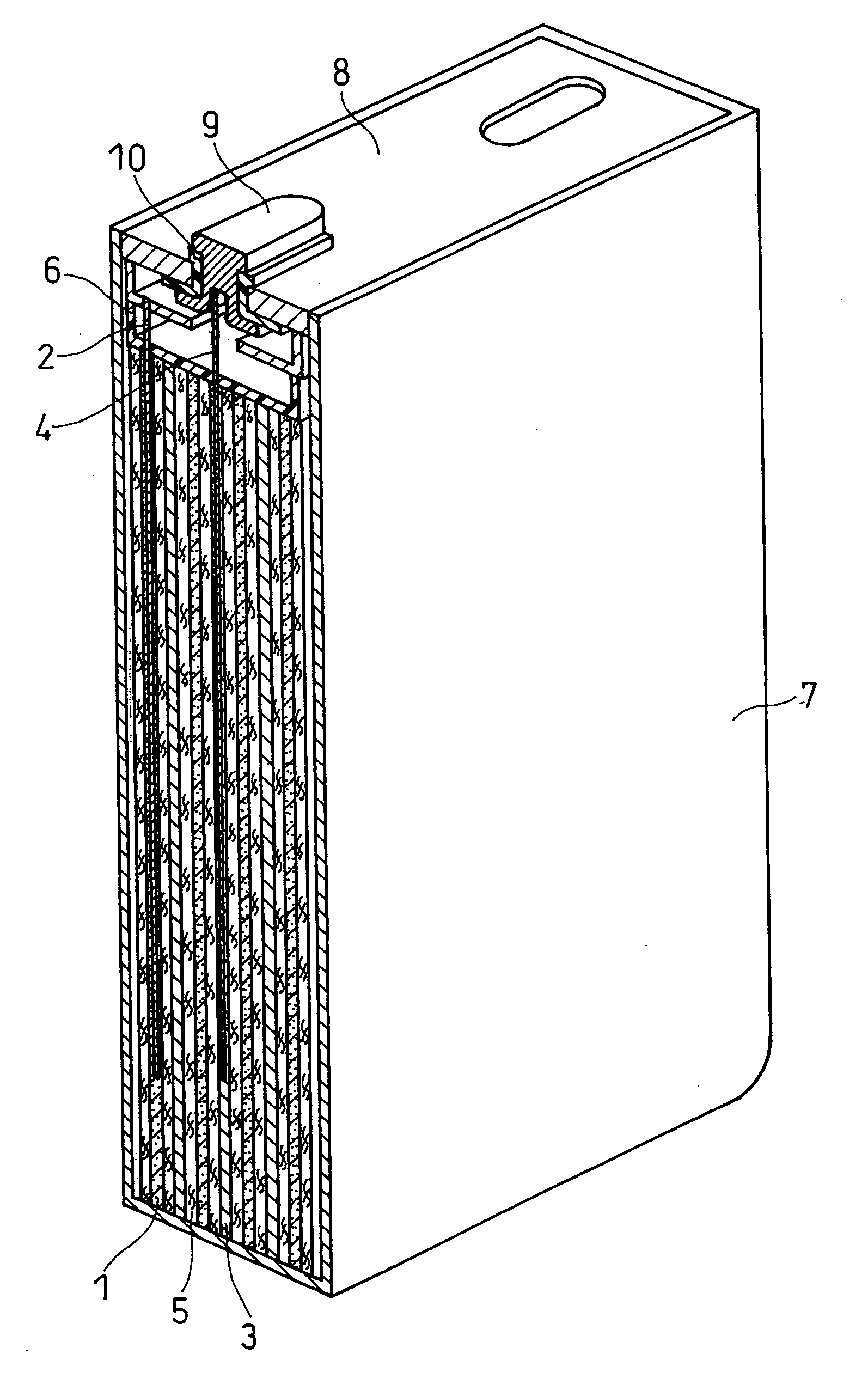

Negative electrode for lithium ion secondary battery and lithium ion secondary battery prepared by using the same

InactiveUS20070065720A1Good adhesive propertySuppress adsorptionSmall-sized cells cases/jacketsSecondary cellsLithiumPolymethacrylic Acids

A negative electrode for a lithium ion secondary battery includes a negative electrode active material layer. The negative electrode active material layer contains a negative electrode active material capable of reversibly absorbing and desorbing lithium, and a binder. The binder comprises at least one polymer selected from the group consisting of polyacrylic acid and polymethacrylic acid, and the polymer comprises an acid anhydride group.

Owner:PANASONIC CORP

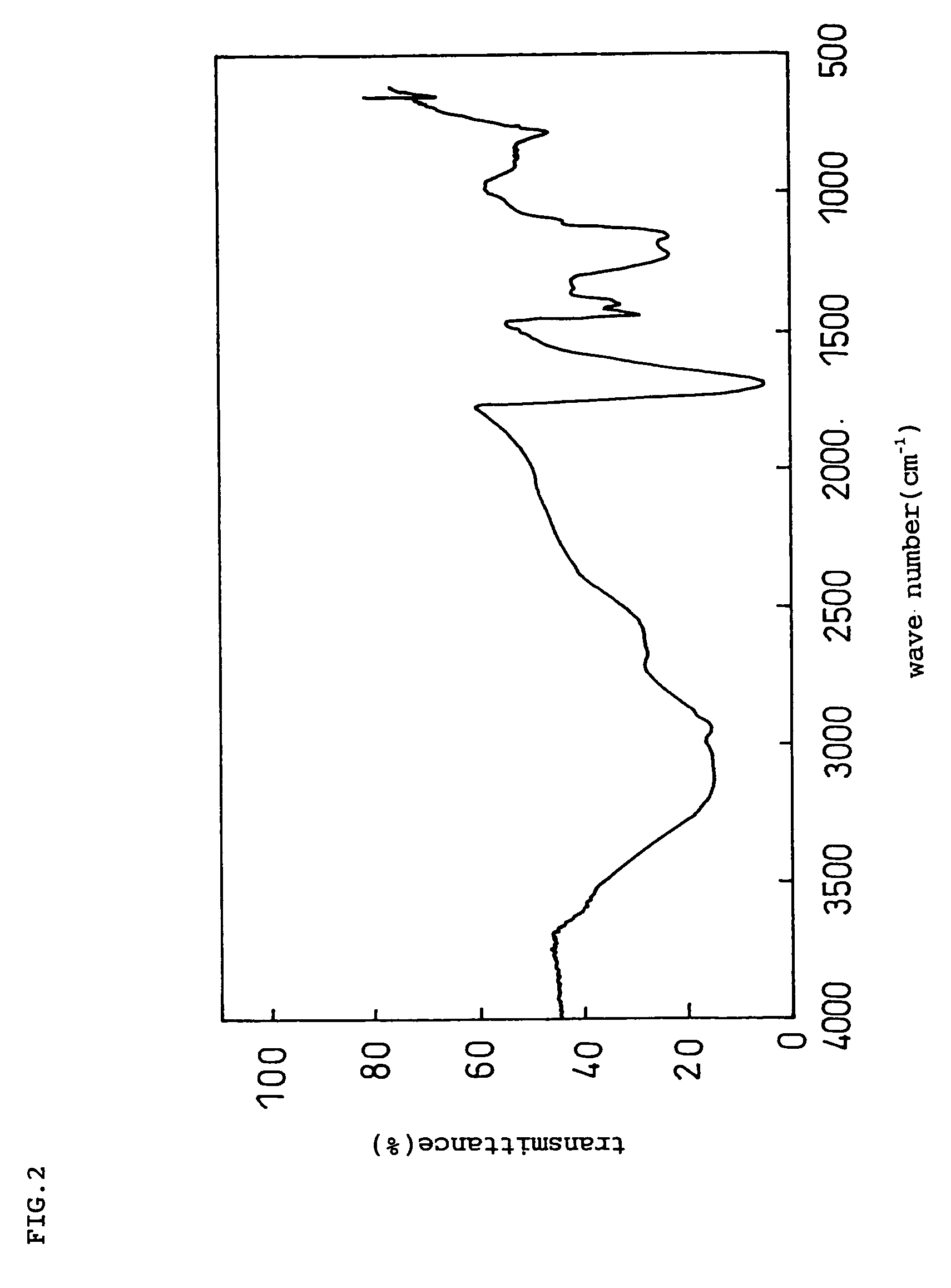

Polypeptide-polysiloxane copolymers

InactiveUS6358501B1Simple processWithout usingCosmetic preparationsHair cosmeticsOrganic chemistryCopolymer

The present invention relates to polypeptide-polysiloxane copolymers, to their preparation by thermal copolymerization of amino acids with organofunctional polysiloxanes, and to their use as interface-active substances. The polypeptide-polysiloxane copolymers consist of at least one polysiloxane unitand of at least one polypeptide unit

Owner:GOLDSCHMIDT GMBH

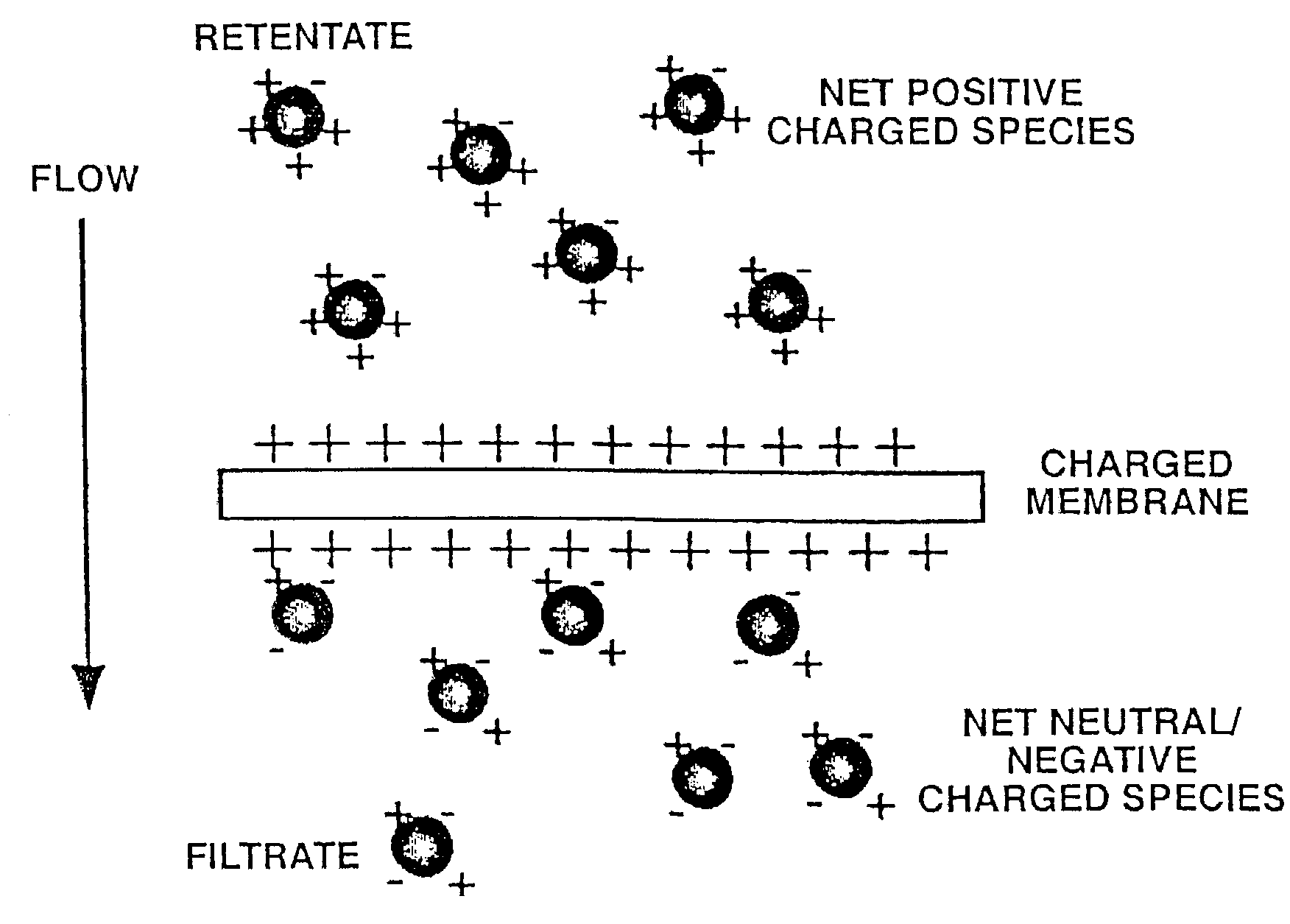

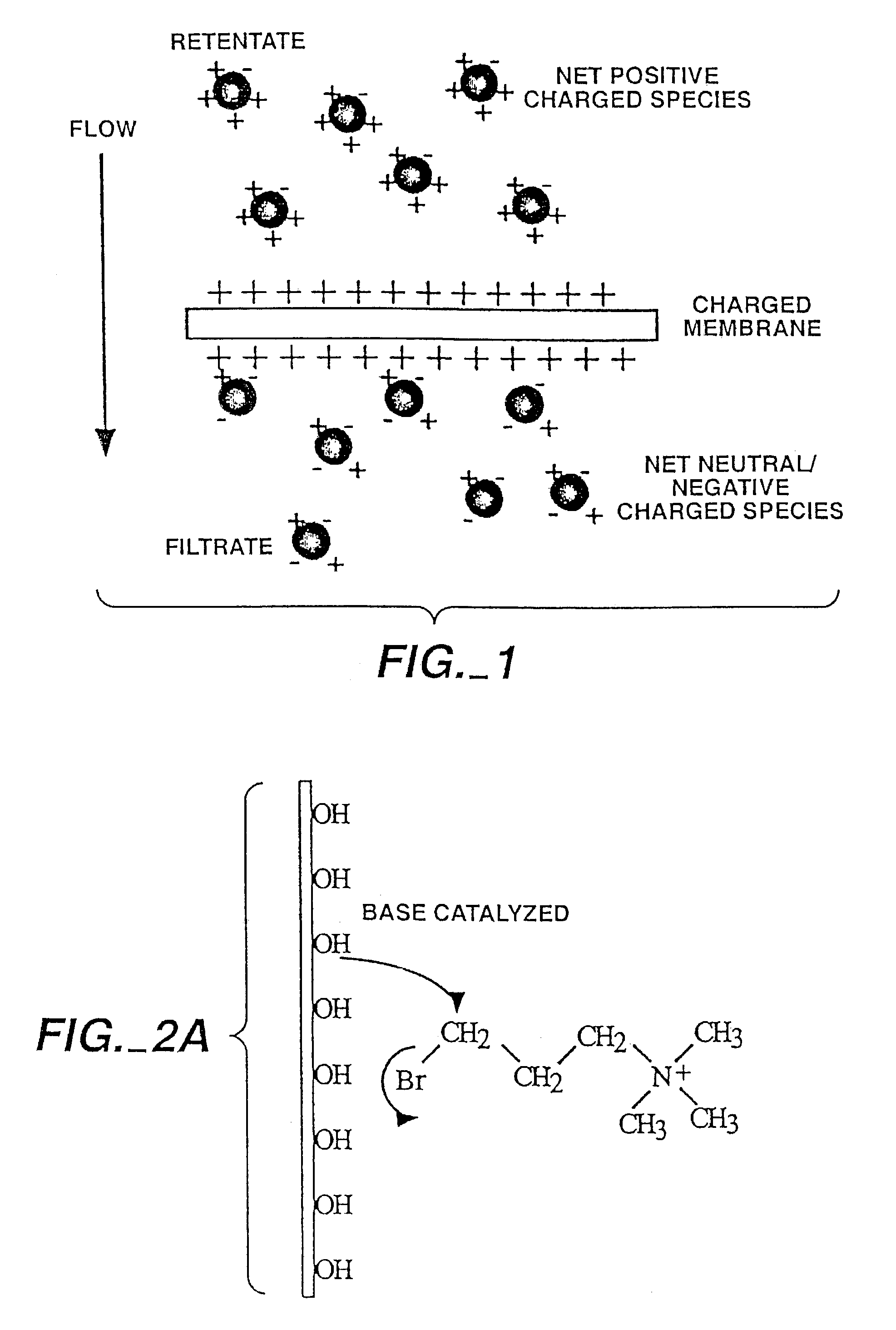

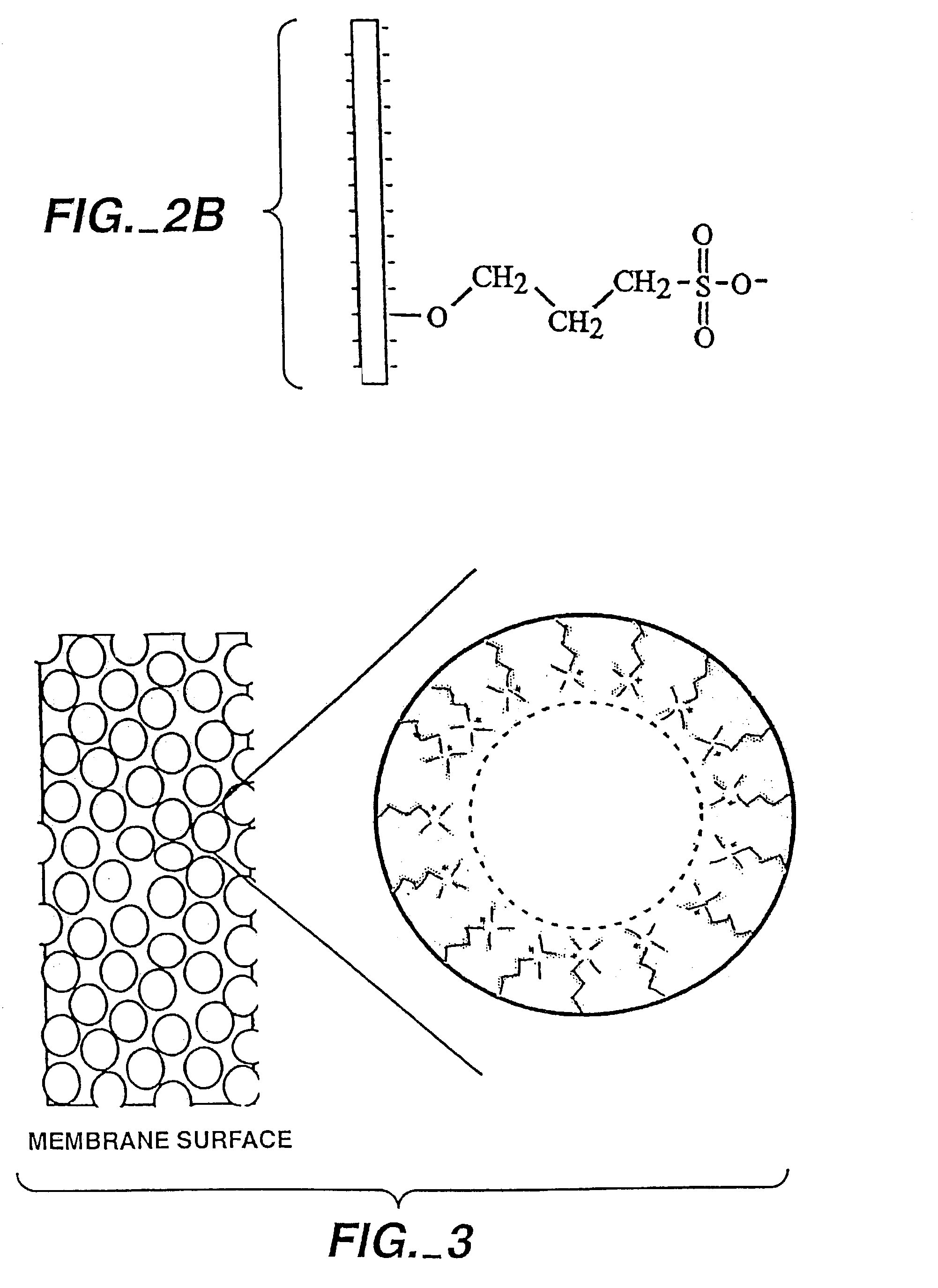

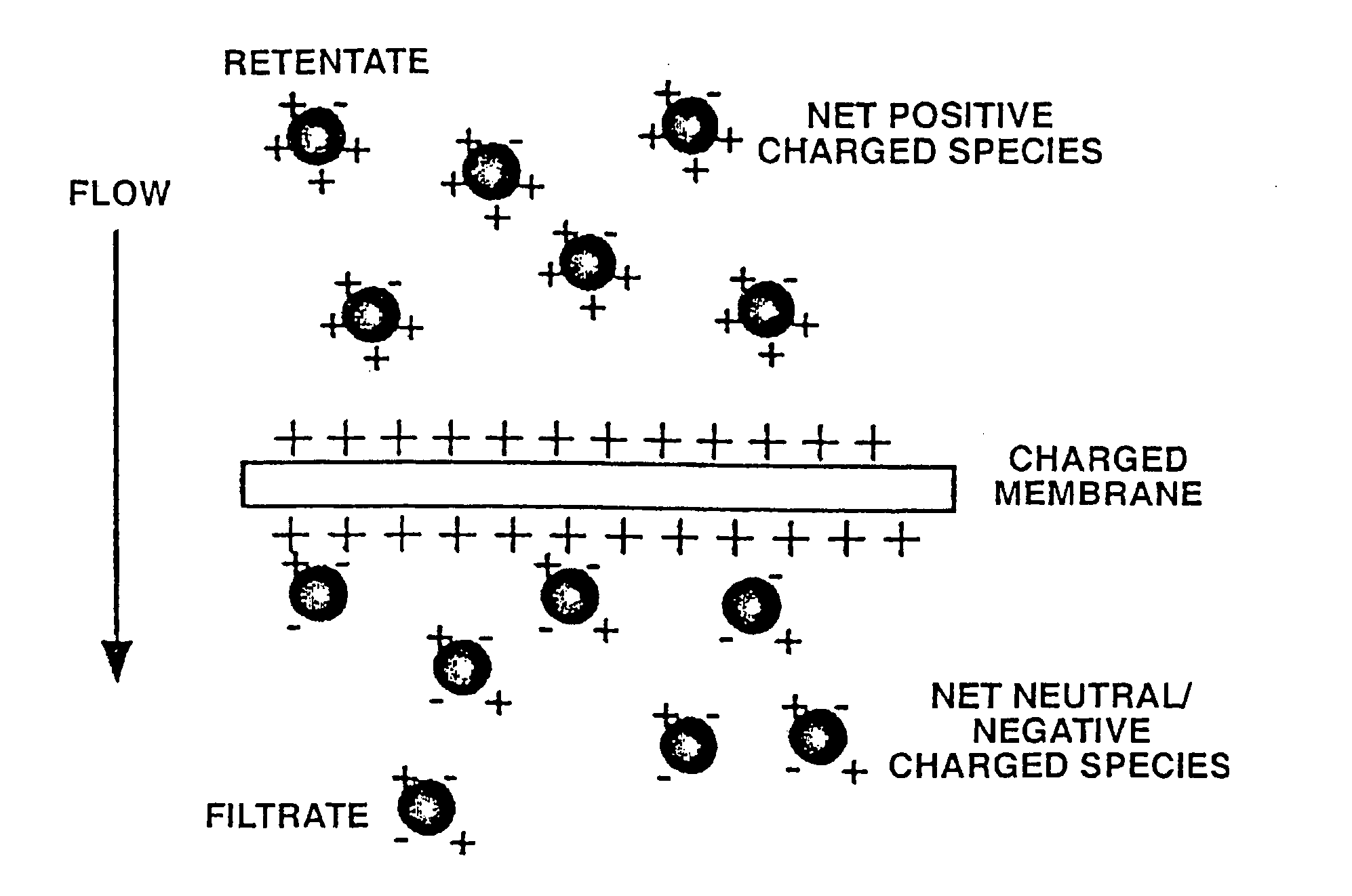

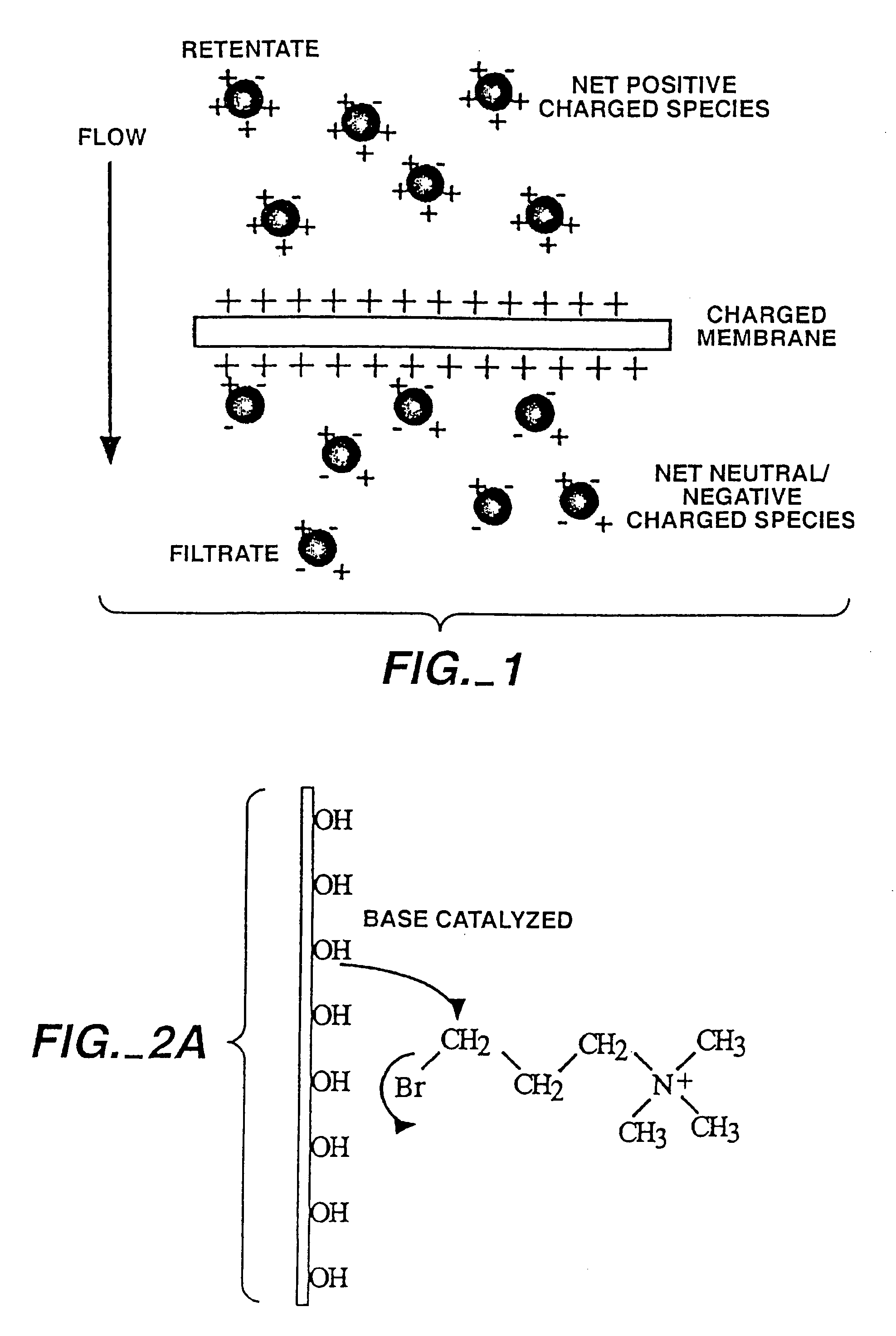

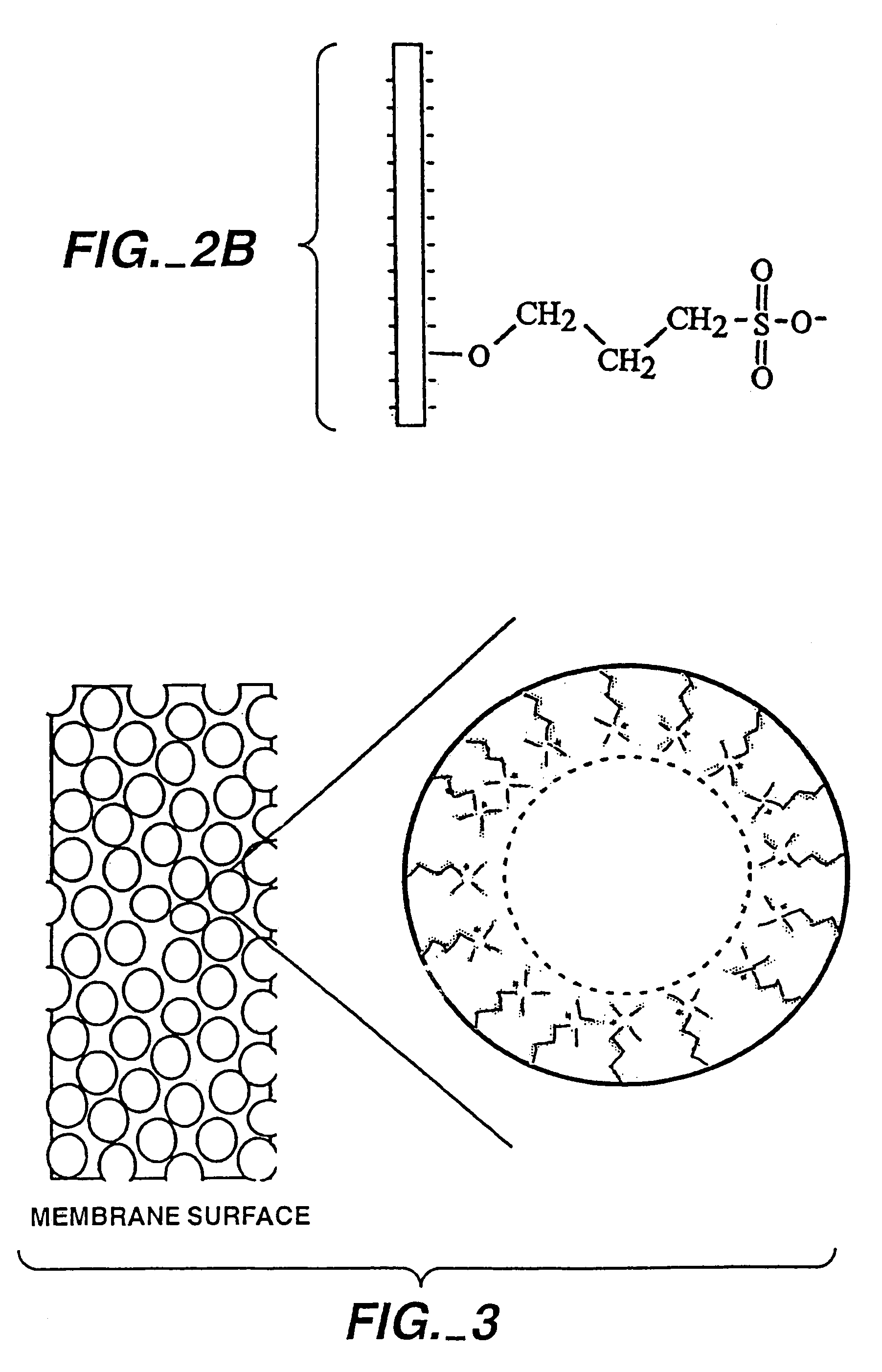

Charged filtration membranes and uses therefor

InactiveUS7001550B2Limiting separation speedLimiting protein recoverySolvent extractionUltrafiltrationFiltration membraneSolvent

The invention relates to charged filtration membranes and their use for separation of a protein from solvent, low molecular weight solutes or a mixture of proteins. Modification of the membranes to generate charge includes modification of membrane pores to alter charge within a pore and alter the size of a pore. Consequently, the protein is separated from other solutes in a mixture based on size as well as net protein charge and membrane charge.

Owner:GENENTECH INC

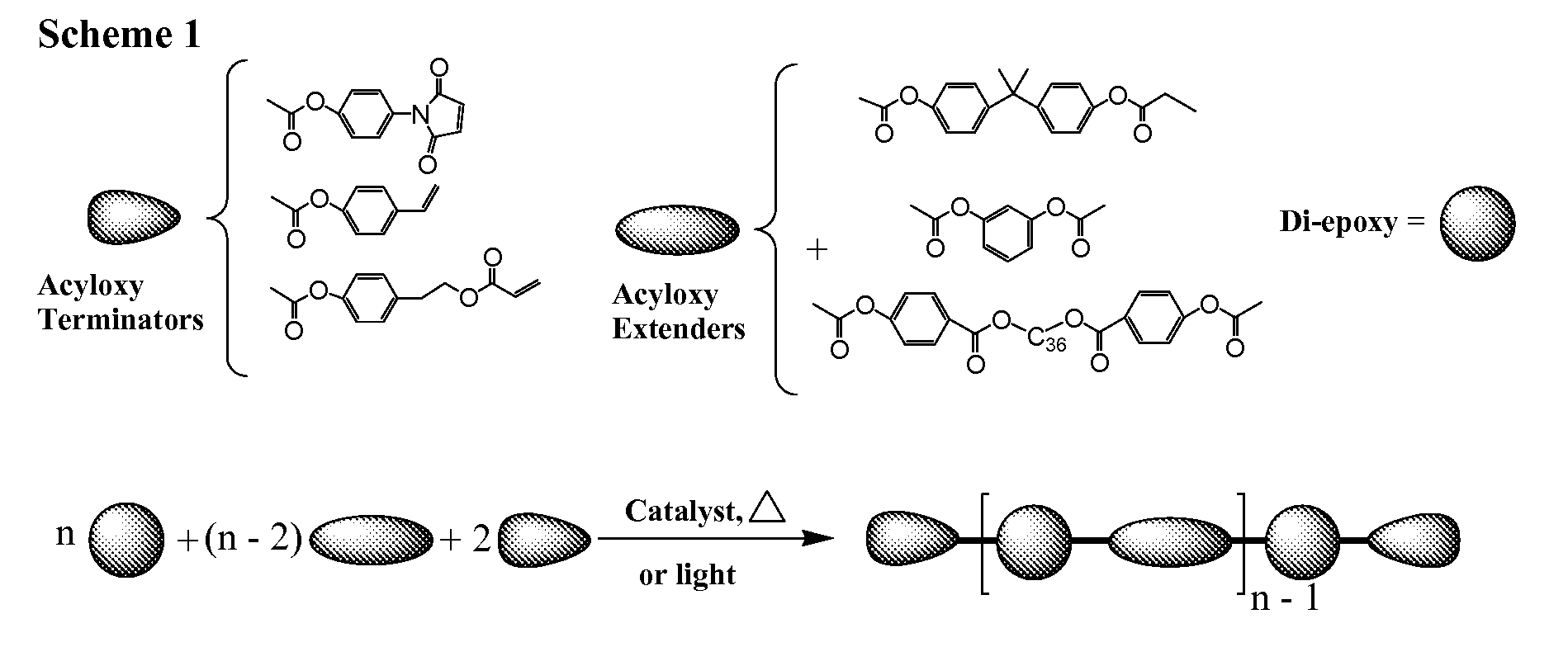

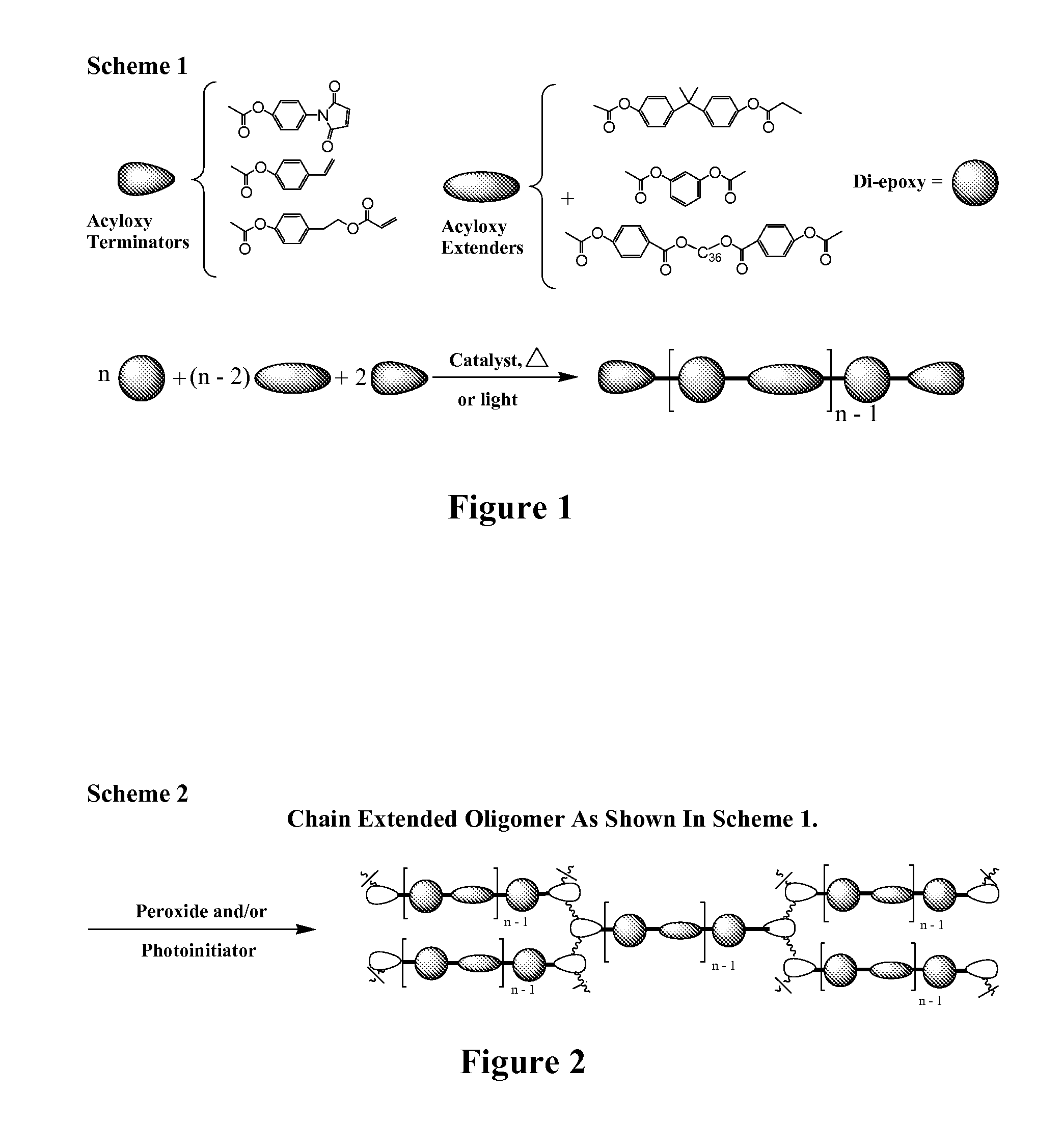

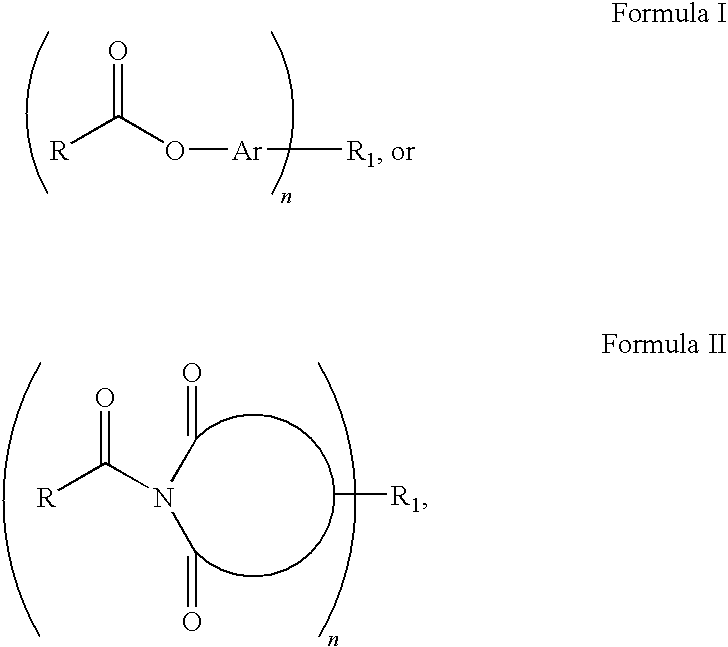

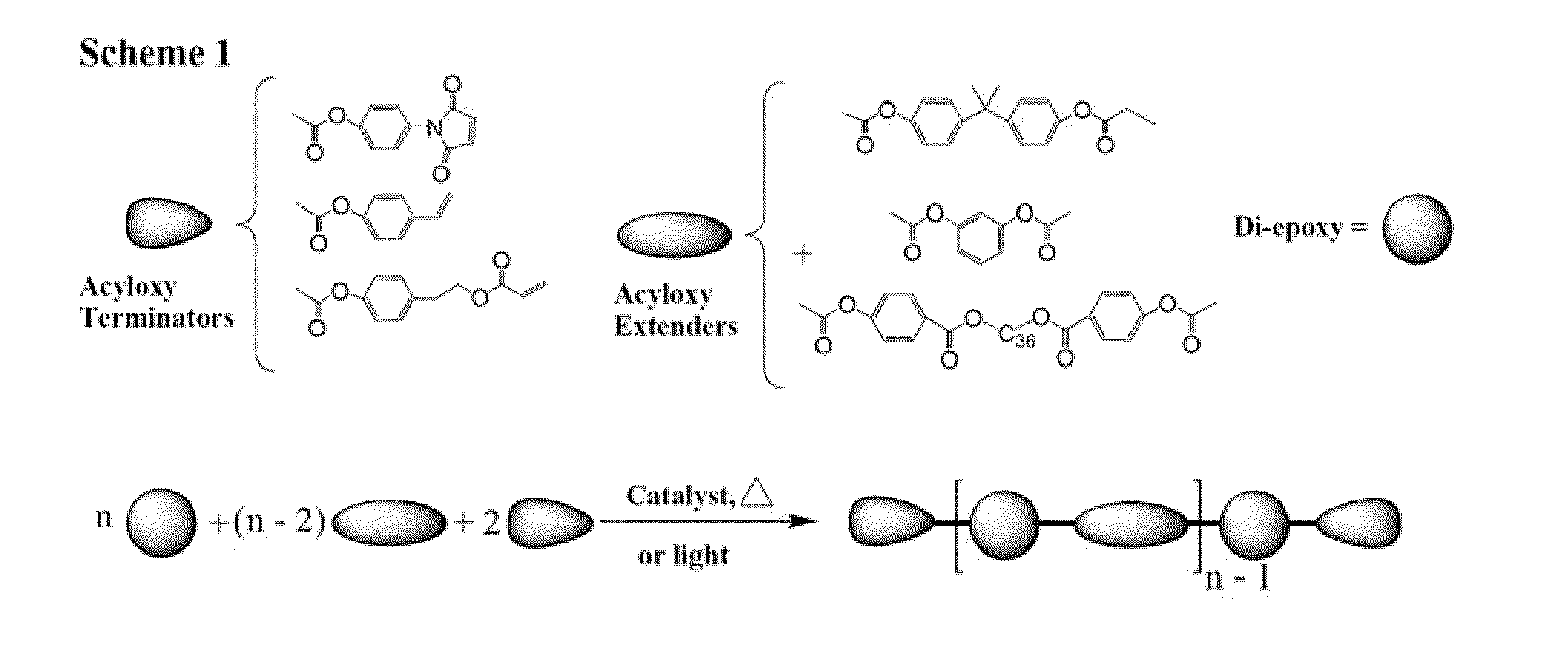

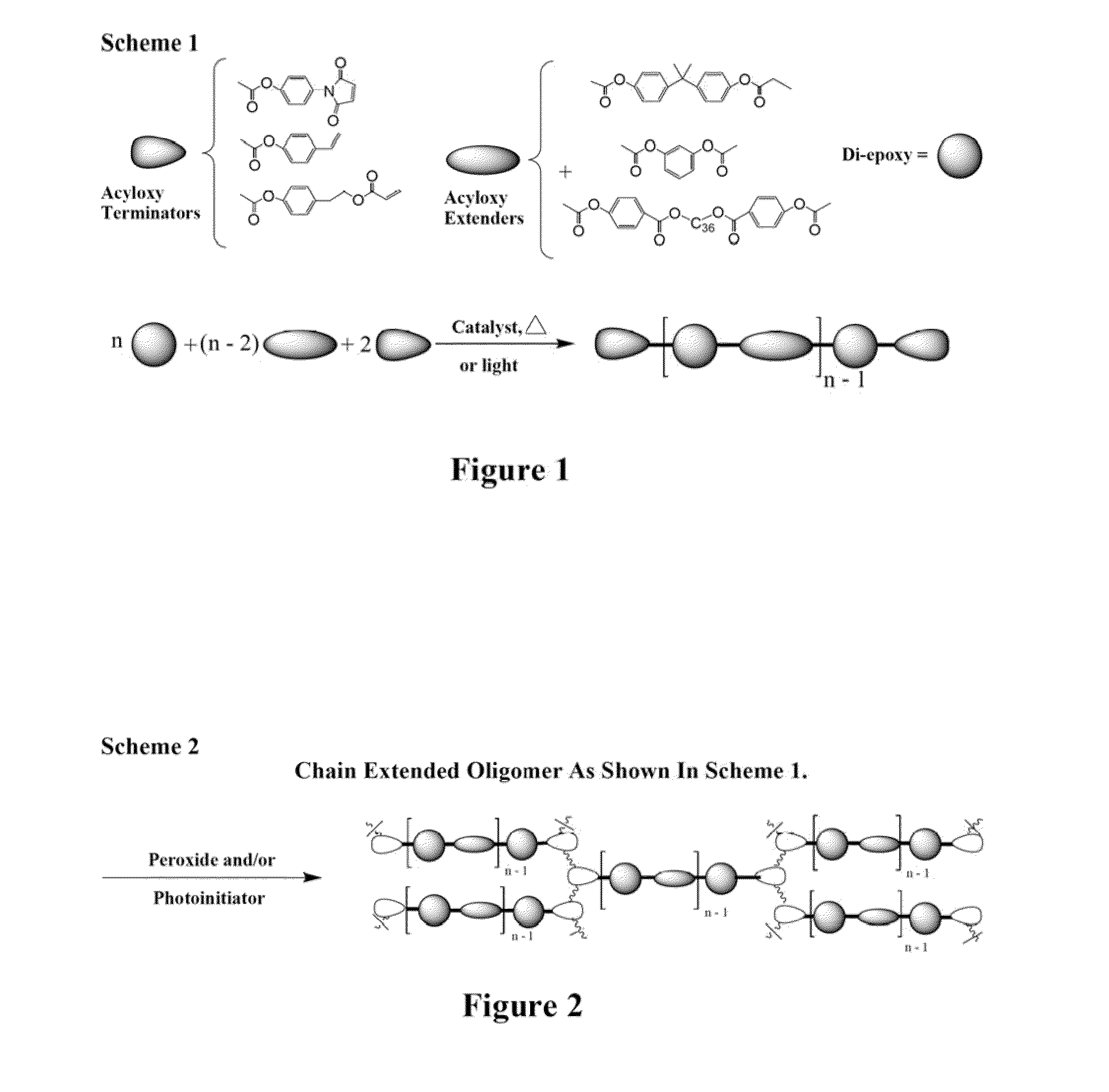

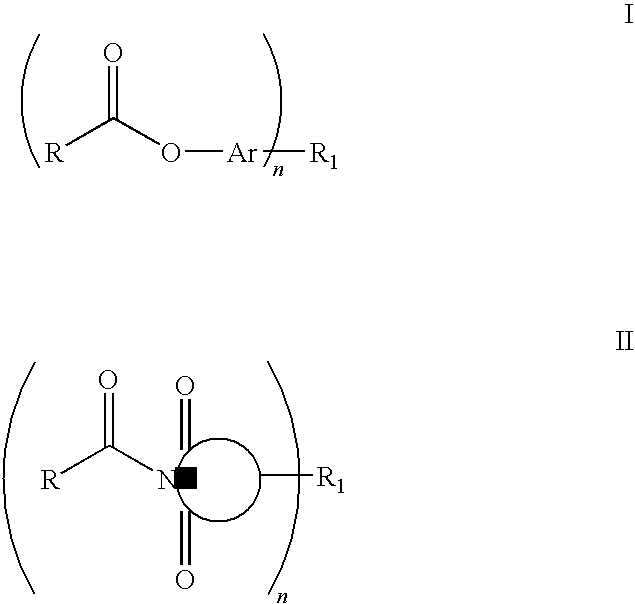

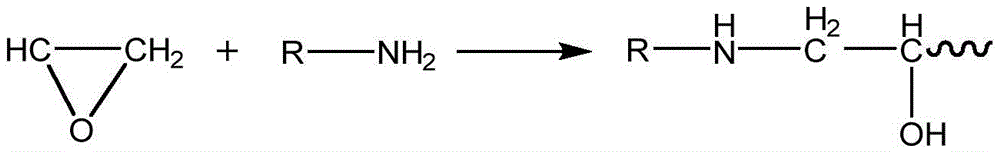

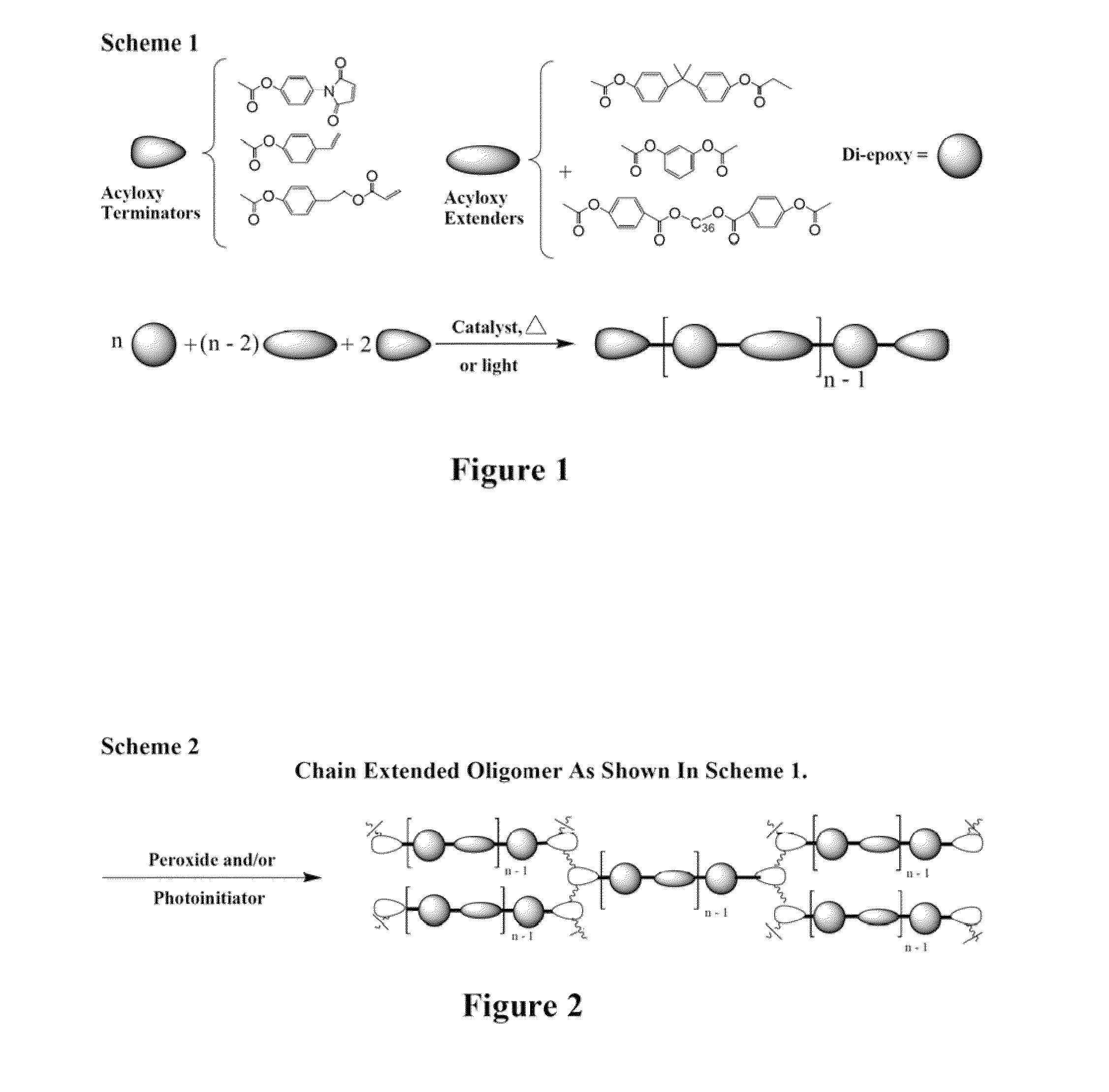

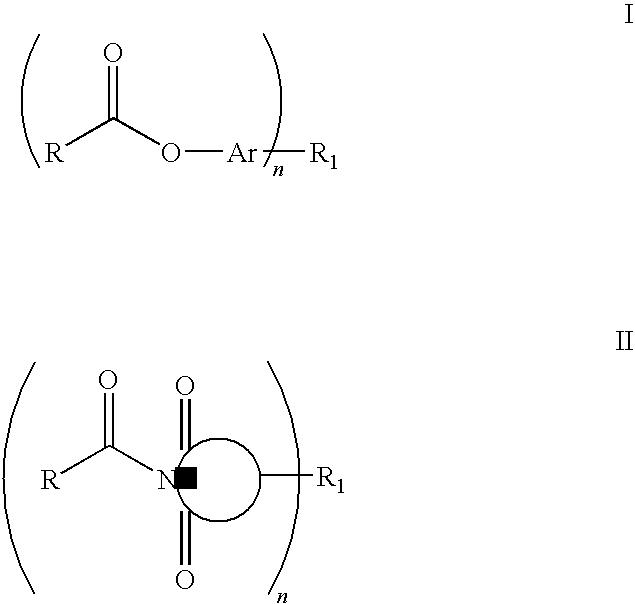

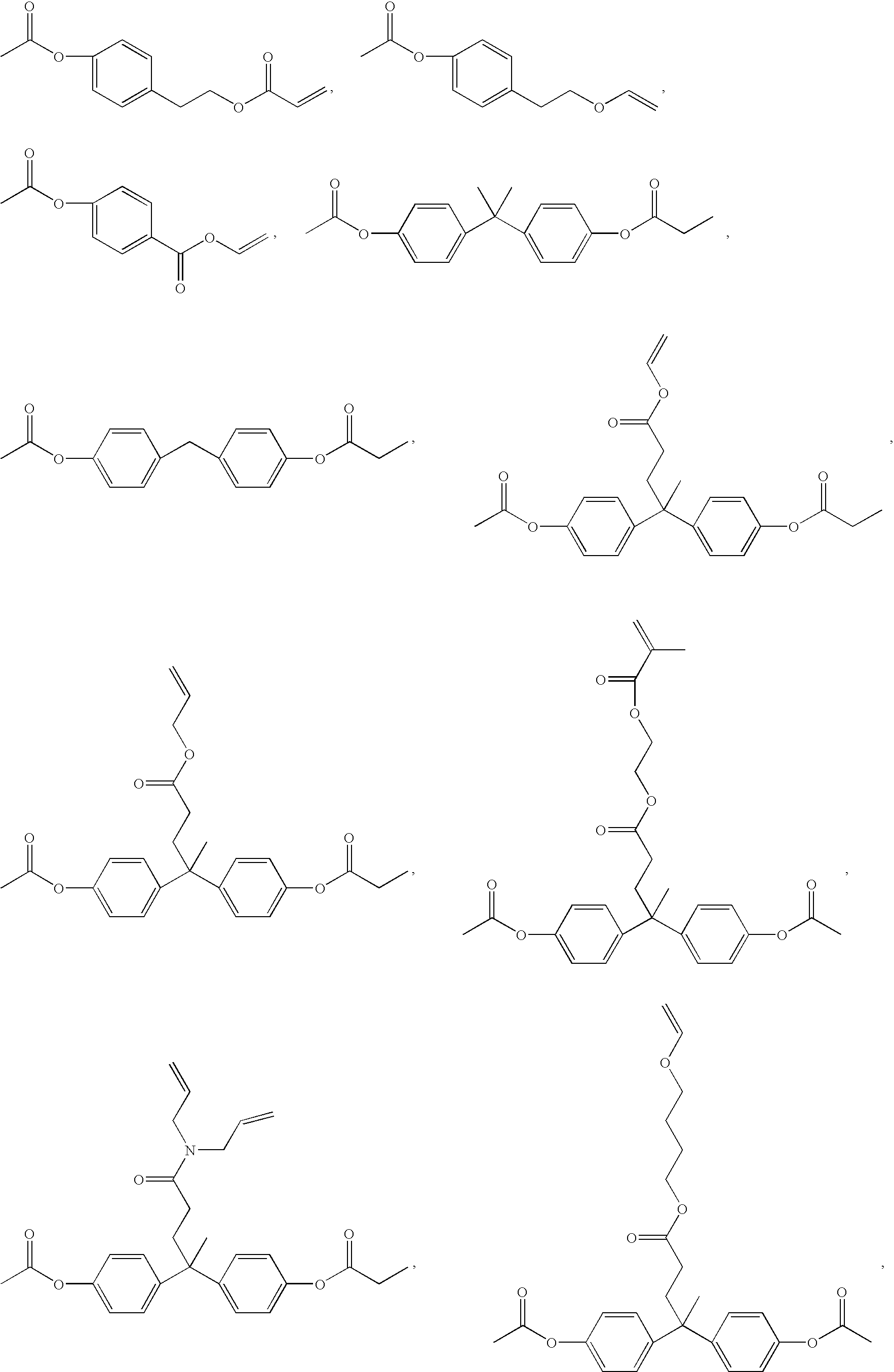

Curatives for epoxy adhesive compositions

InactiveUS20100113643A1Increase opportunitiesReduce hydrophilicitySilicon organic compoundsCosmetic preparationsFirming agentEpoxy adhesive

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

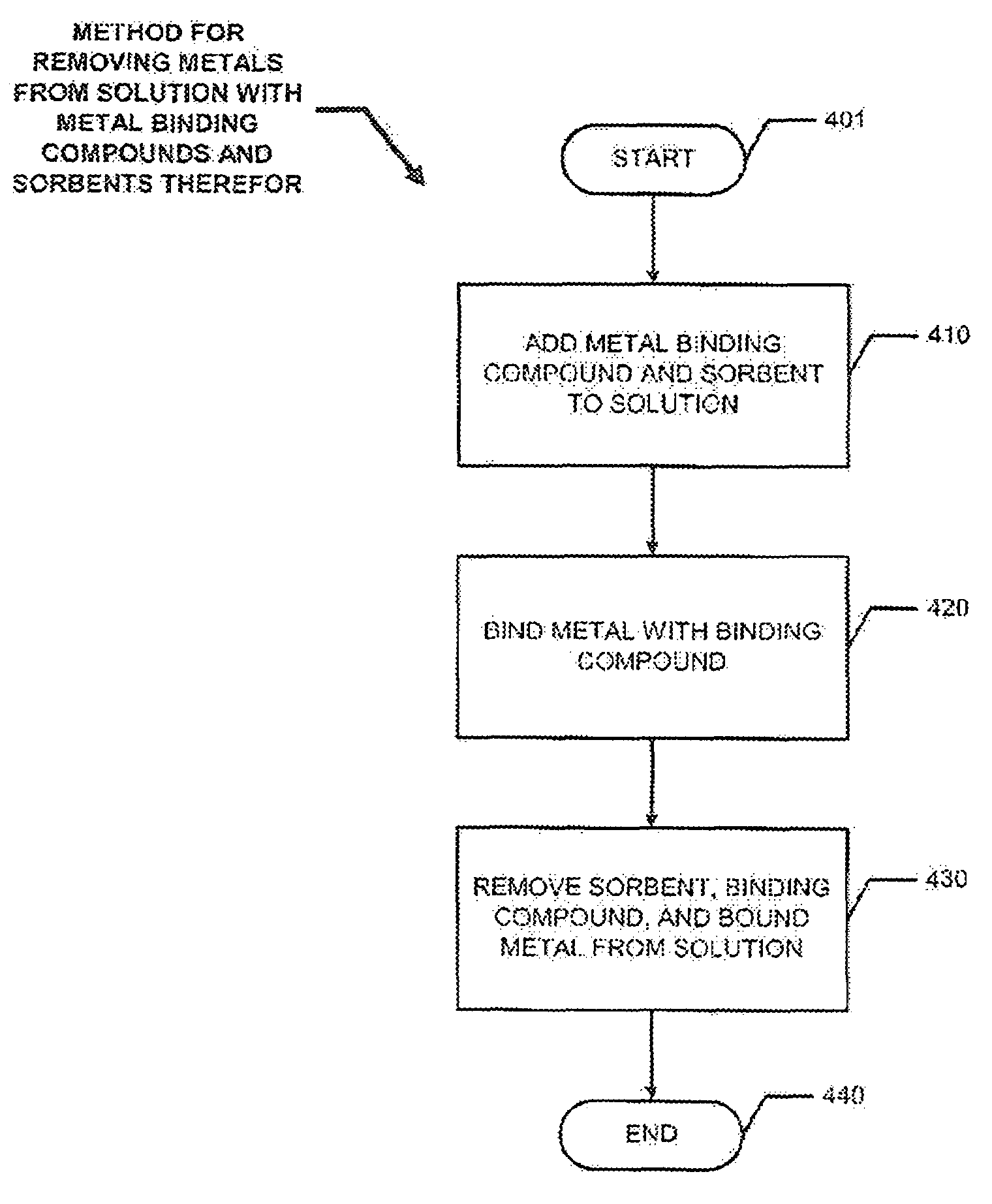

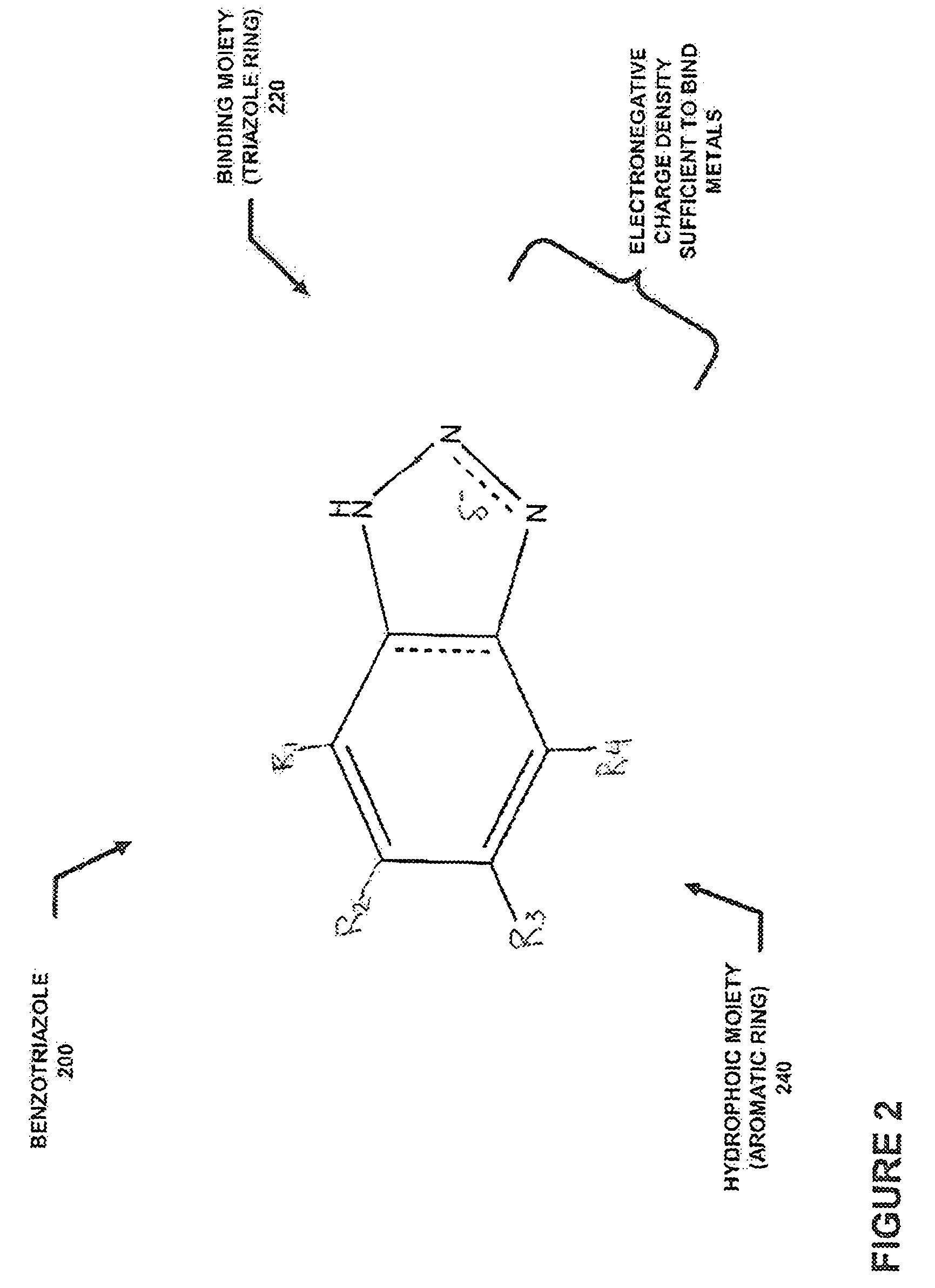

Removing metals from solution using metal binding compounds and sorbents therefor

ActiveUS7361279B2Reduce hydrophilicityWaste water treatment from quariesWater treatment parameter controlSorbentWastewater

Removing metals from metal containing acidic solutions, such as contaminated waters and industrial wastewaters, is described. An amphipathic, heterocyclic, metal-coordinating compound (an extraordinaiy ligand) and a sorbent are added to a solution, such that the addition, at a specific acidic pH of the solution, causes at least some of the metal-coordinating compound to bind with some of the metal cations and at least some of the metal-coordinating compound sorbs to the sorbent, along with any metal cations bound therewith. The compound and the sorbent may be added to the solution, either together or independently, so that the compound may bind the metal. The metal binding compound may be a benzotriazole, a benzothiazole, or another compound to bind a metal. The sorbent is selected to interact with the metal-coordinating compound in sequestering the metal from solution as part of a complexation. Thereafter, the ligand-metal complex may be removed from the solution.

Owner:UNIV OF COLORADO THE REGENTS OF

Curatives for epoxy compositions

ActiveUS20100249276A1Improve adhesionLow viscositySilicon organic compoundsOrganic compound preparationEpoxyChemistry

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

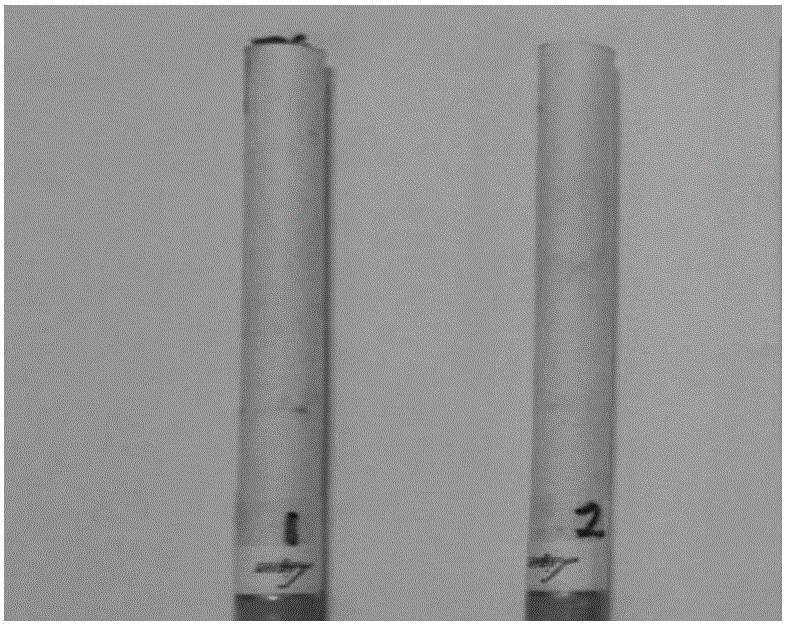

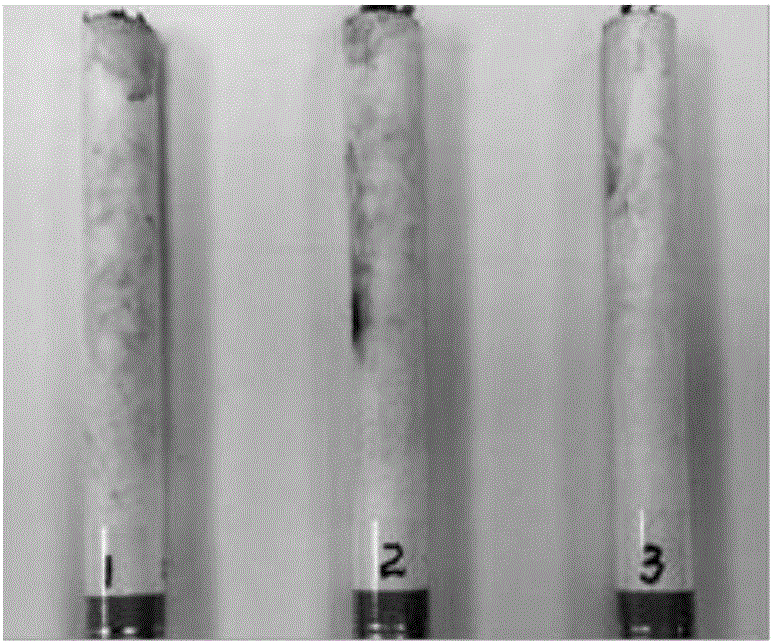

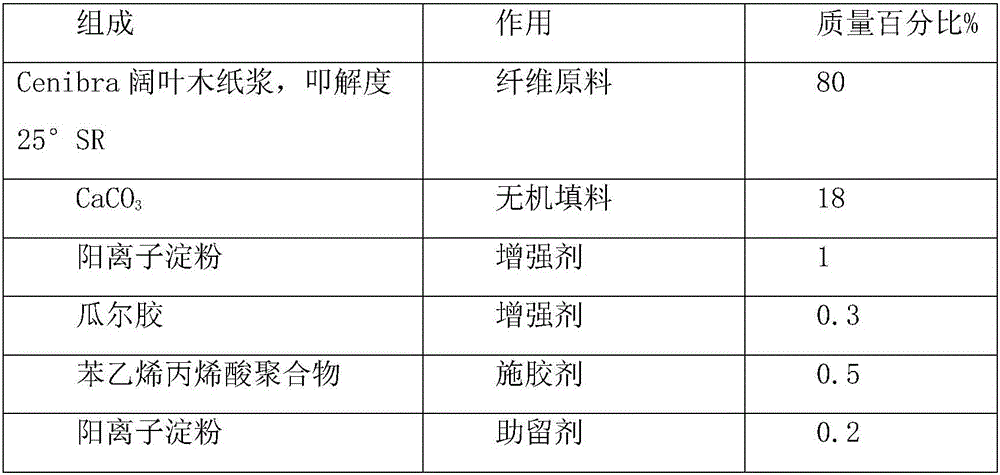

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

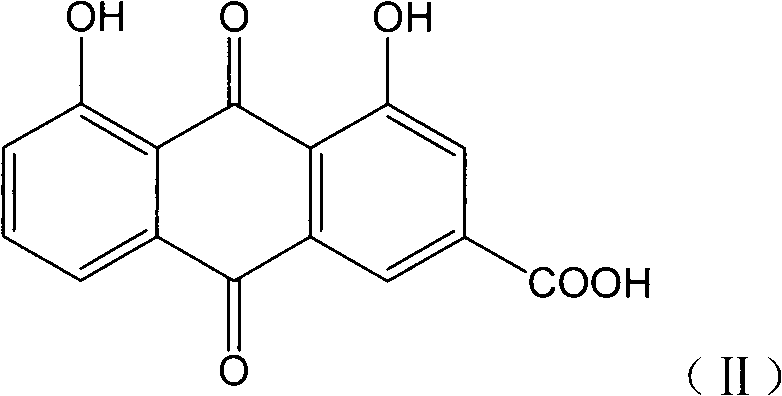

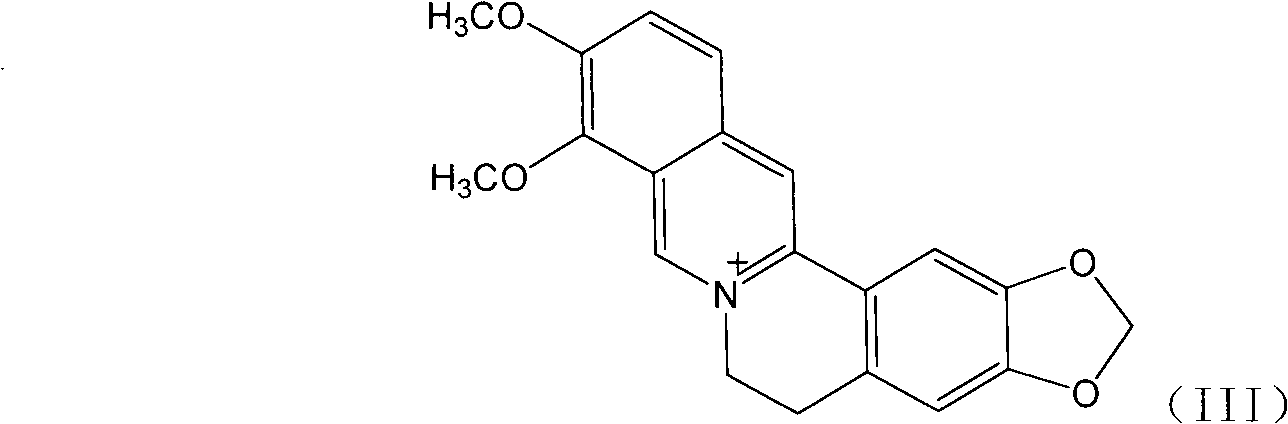

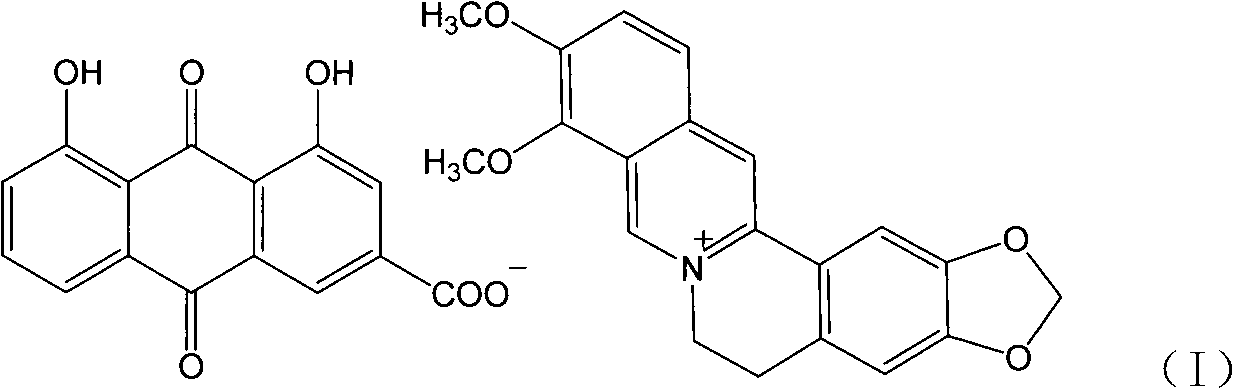

Rheinic acid berberine ion pair compound, preparation method and applications

InactiveCN103319479AReduce hydrophilicityEnhance lipophilicityAntibacterial agentsOrganic active ingredientsIonSolubility

The invention relates to a rheinic acid berberine ion pair compound with a formula (I) structure and a preparation method thereof, comprising the following steps of: (1) preparing a berberine hydrochloride solution, (2) adding rheinic acid or an alkali metal salt of rheinic acid into the solution obtained in the step (1), heating, stirring and fully reacting; and (3) filtering, washing, refining and drying the reaction products to obtain the rheinic acid berberine ion pair compound. The invention further relates to pharmaceutical compositions containing the ion pair compound, wherein the weight of the ion pair compound is 0.1-99.9% that of the compositions. The invention also relates to applications of the ion pair compound and the compositions thereof for preparing medicines for treating bacterial infection, peptic ulcer, diabetes, hyperlipemia, obesity, arthritis, heart failure, arrhythmia, platelet aggregation, hypertension, intestinal adhesion, etc. The rheinic acid berberine ion pair compound can increases lipid solubility of rheinic acid and berberine, and substantially raises a biological utilization degree.

Owner:王从品 +1

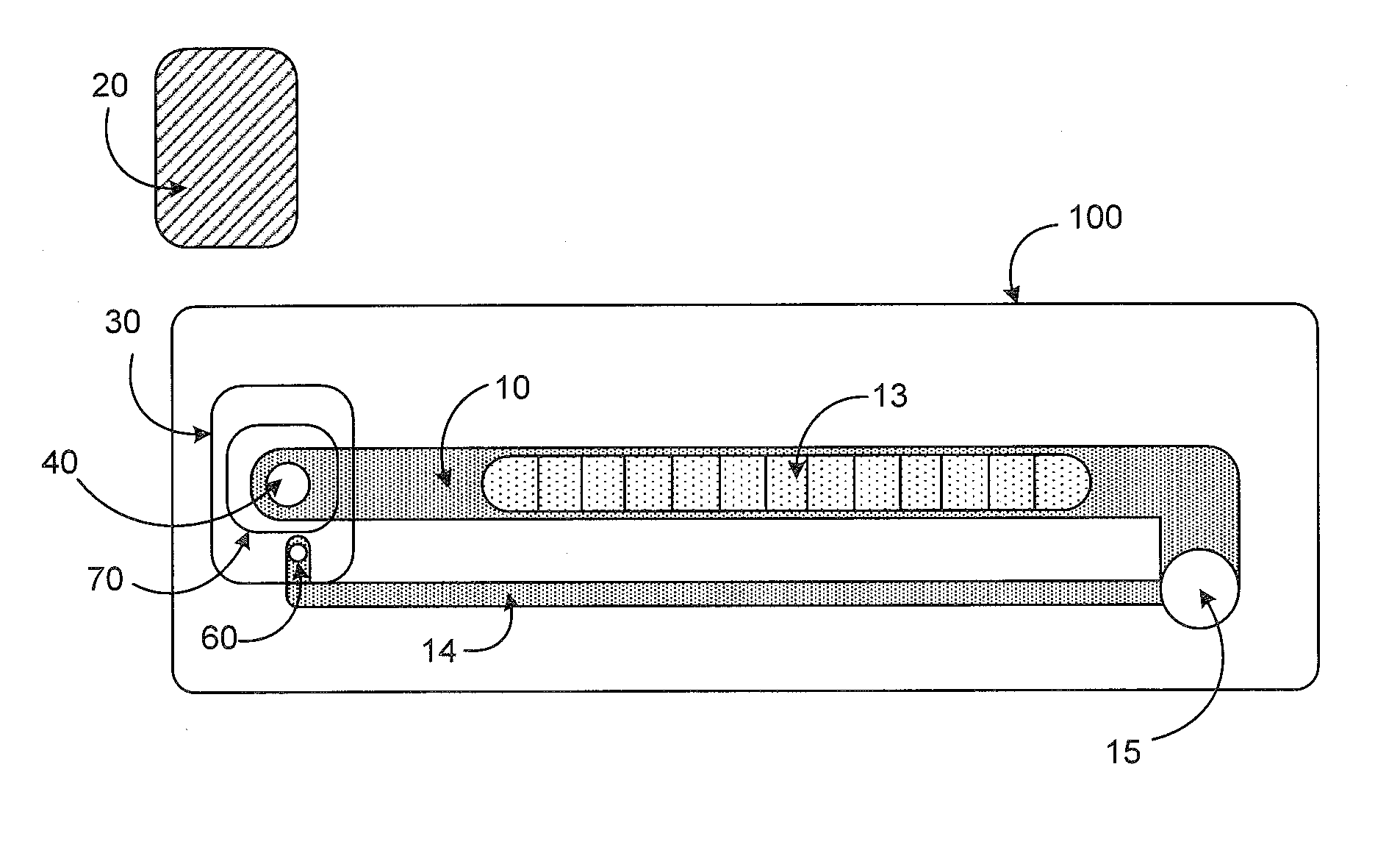

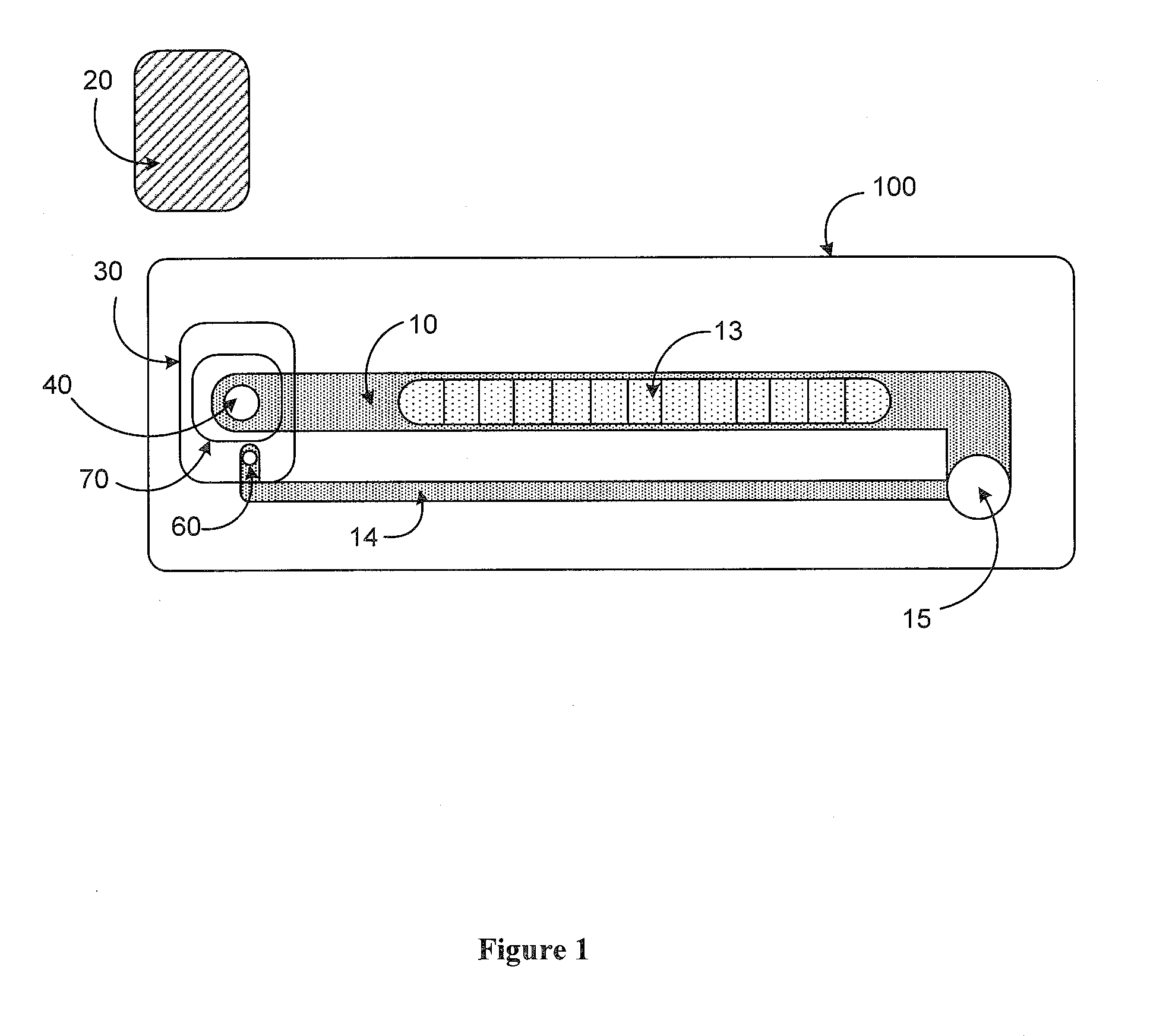

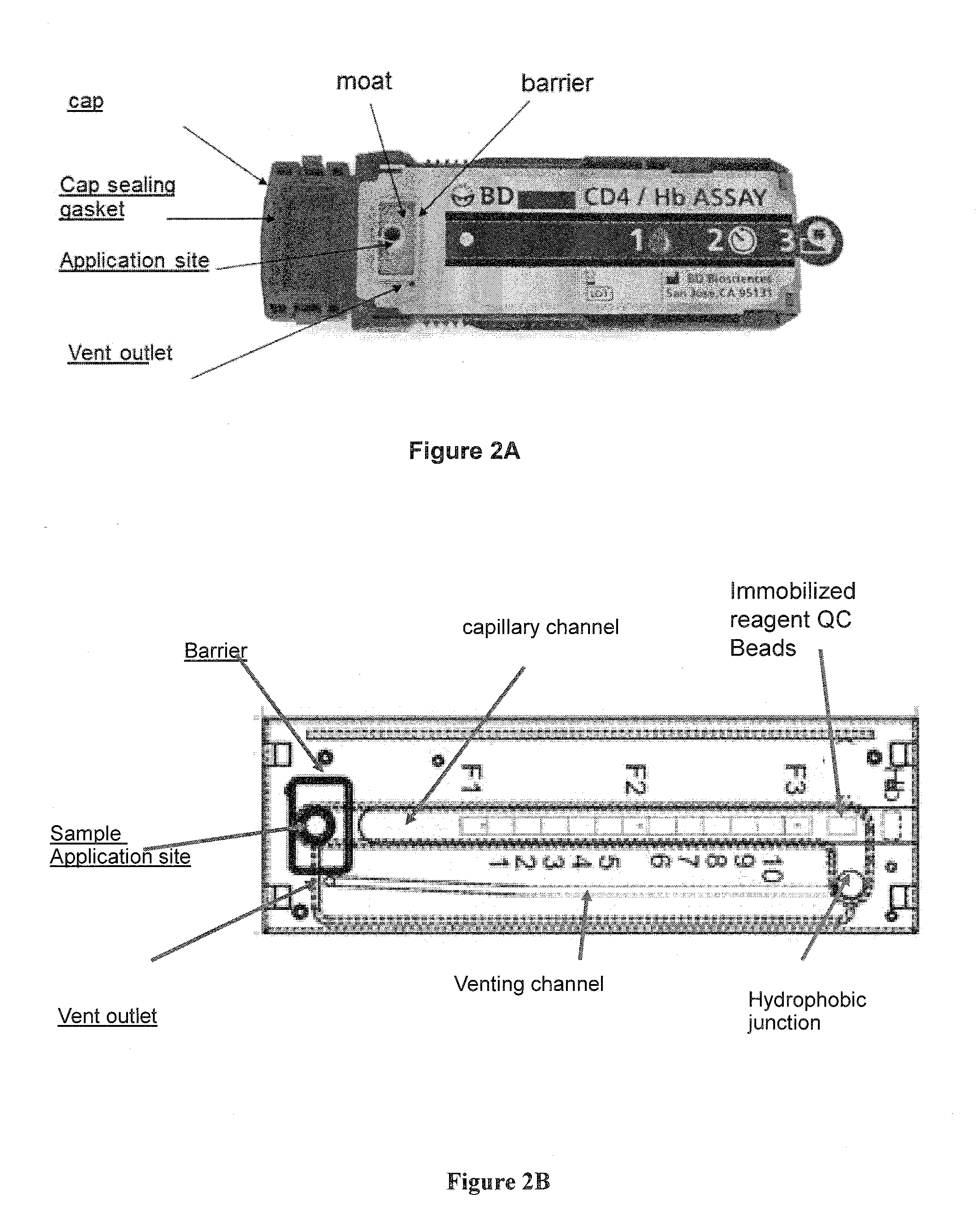

Low-cost point-of-care assay device

ActiveUS20140200154A1Improve hydrophilicityReduce hydrophilicityComponent separationLibrary screeningAssayMedicine

The present disclosure provides methods and systems for analyzing a liquid sample. A micro-fluidic device to perform an assay of a liquid sample is described that includes a sample application site and a vent outlet in fluid communication with the capillary channel. A cap is provided that is configured to seal both the vent outlet and the sample application site in a shared volume and separate from an outside environment.

Owner:BECTON DICKINSON & CO

Preparation method of wear-resistant super-hydrophobic nanometer titania coating

InactiveCN105602412AExtended service lifeImprove protectionEpoxy resin coatingsPigment treatment with organosilicon compoundsEpoxyWear resistant

The invention discloses a preparation method of a wear-resistant super-hydrophobic nanometer titania coating. The preparation method includes firstly, dissolving silane coupling agent in ethyl alcohol and then heating and stirring to react to obtain a solution; secondly, adding nanometer titania into the solution and then stirring and drying to obtain hydrophobic nanometer titania powder; thirdly, mixing a certain quantity of epoxy resin with hardener while adding in diluting agent to dilute the resin completely to obtain a diluted liquid, adding the hydrophobic nanometer titania powder into the diluted liquid, then subjecting the mixture to ultrasonic dispersion with complete stirring to allow the nanometer titania to contact with the resin completely so as to obtain a suspension liquid; and finally, coating the suspension liquid on a base material and drying completely so as to obtain the wear-resistant super-hydrophobic nanometer titania coating. Compared with the pure hydrophobic nanometer coating, the wear-resistant super-hydrophobic nanometer titania coating prepared by the method has the advantages that coating hardness is improved greatly, and super-hydrophobic property of the coating is guaranteed while interlayer adhesion and inner binding force of the nanometer coating are improved greatly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

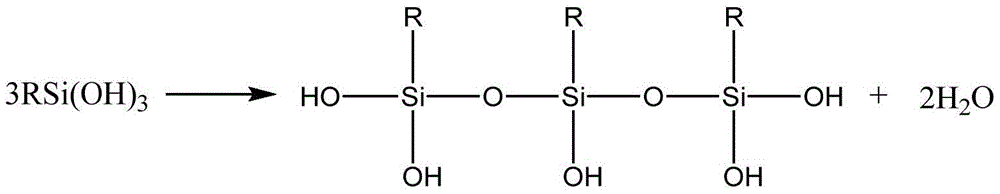

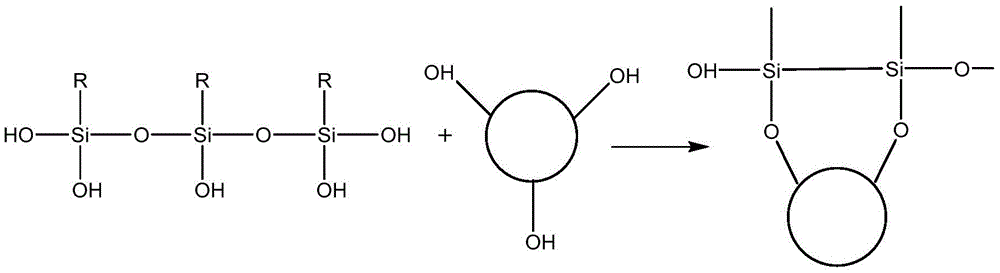

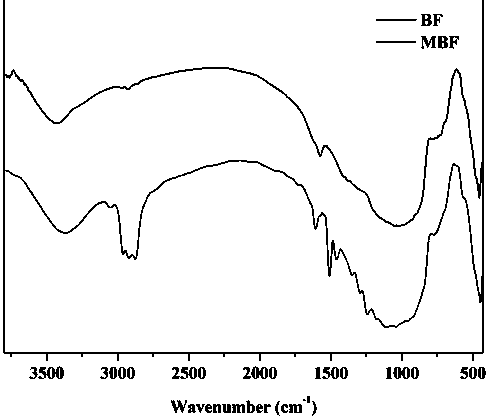

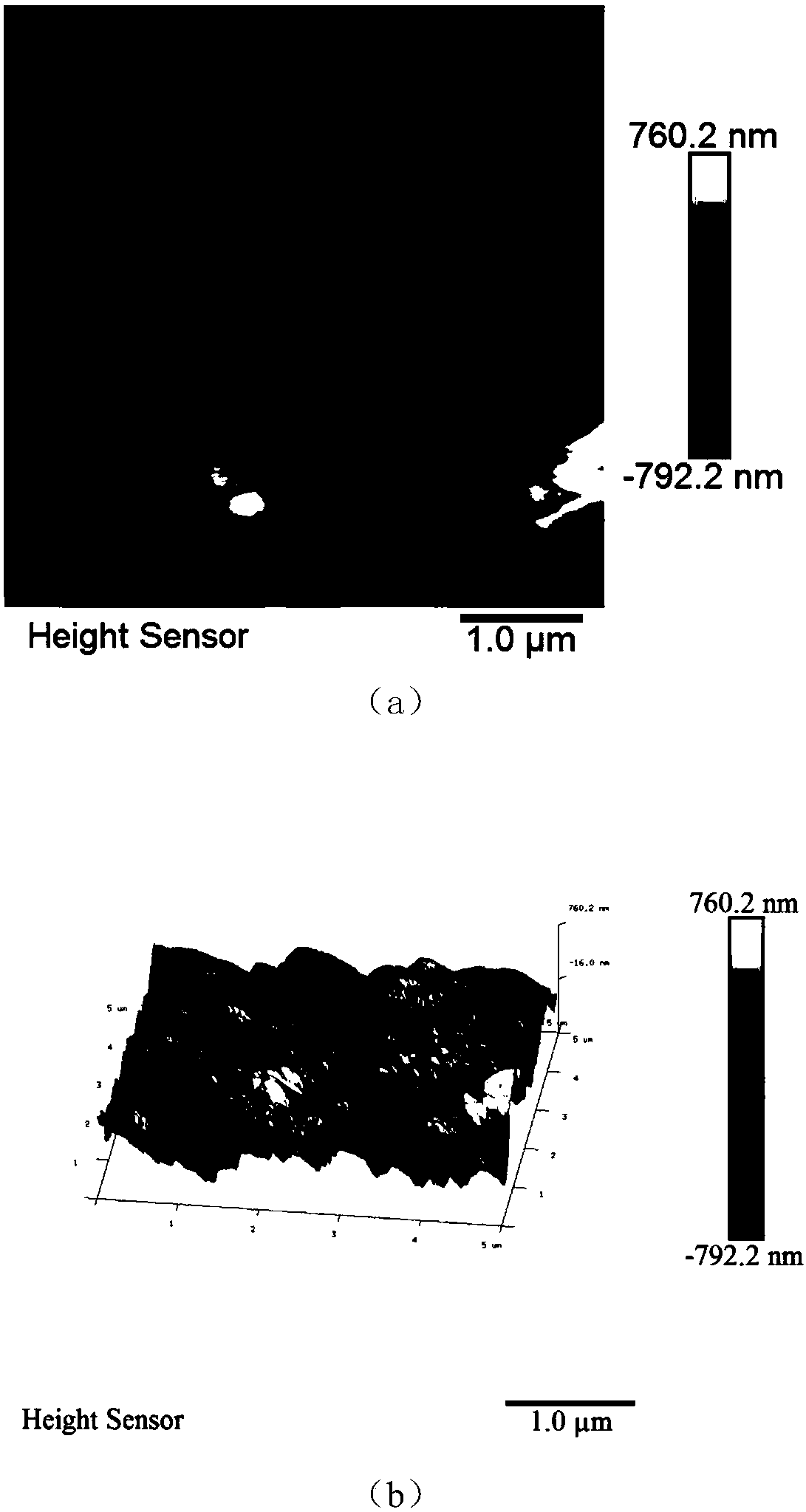

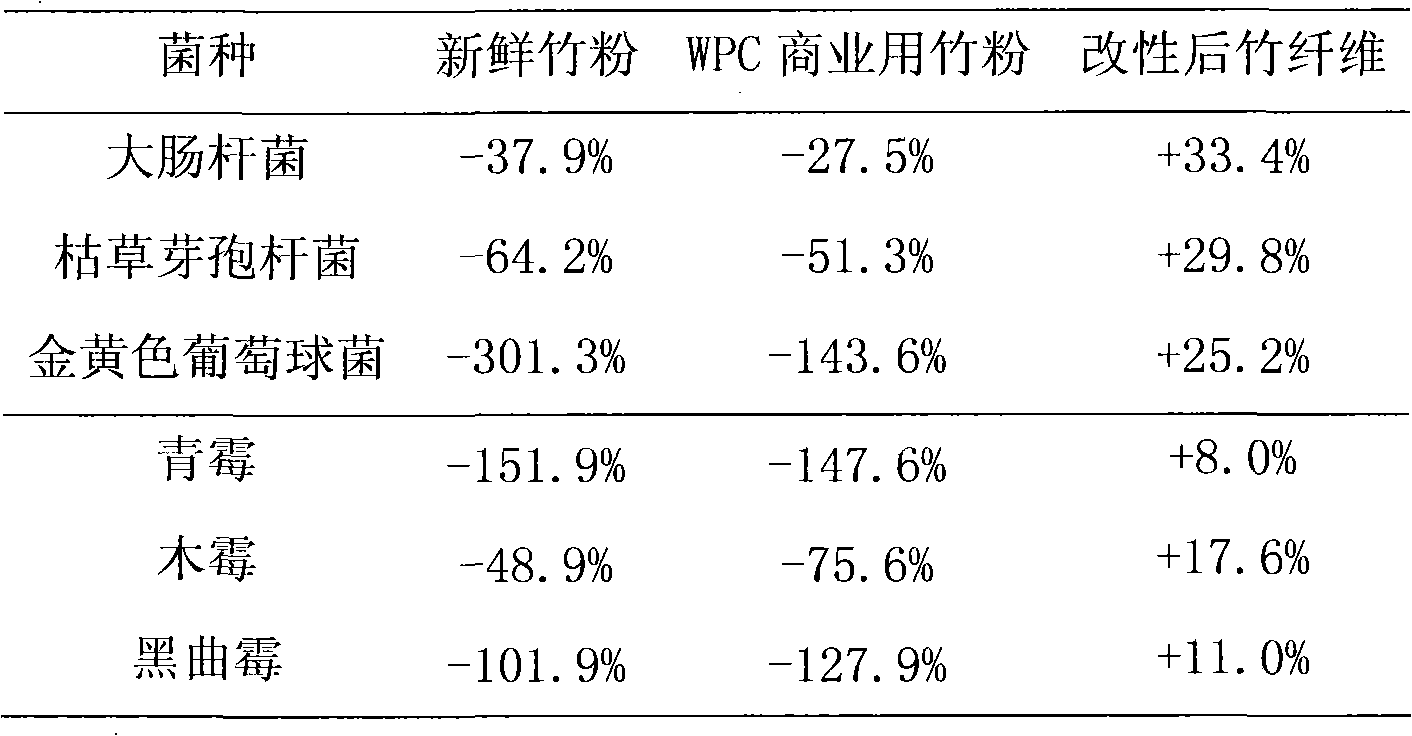

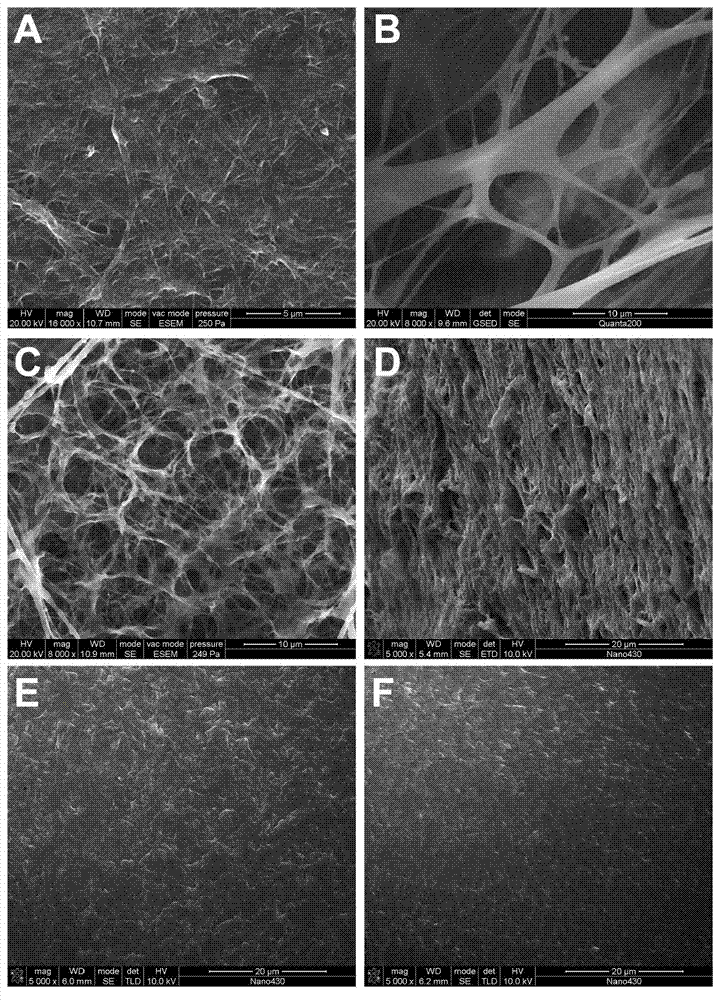

Preparation method and application of basalt fiber surface modified coating

ActiveCN107640913AEasy to operateReduce hydrophilicityTreatment with anaerobic digestion processesSustainable biological treatmentEmulsionSurface-active agents

The invention belongs to the technical field of inorganic fiber modification, and relates to basalt fiber surface modification, in particular to a preparation method of a basalt fiber surface modifiedcoating. The method includes the steps: firstly, adding silane coupling agents, surface active agent solution, polyacrylamide solution and 1 / 3 water-borne epoxy resins into an appropriate amount of nano-silicon dioxide dispersion liquid, and performing reflux reaction; secondly, dropping residual water-borne epoxy resins and initiating agent solution when heating, and performing continuous reaction of an alkaline system to obtain the basalt fiber surface modified coating. The invention further discloses an application of the prepared basalt fiber surface modified coating. Basalt fiber surfacegroups are activated by strong H2SO4 / H2O2 mixed solution, etched by hydrochloric acid, soaked into the coating to graft and dried to constant weight. Prepared coating emulsion does not contain any organic solvents and is green, environmentally friendly, convenient and simple in operation technique, high in applicability and stable in performance and can be applied to the field of microbial film carrier materials, basalt fibers can be rapidly and effectively modified, and the surface roughness of the basalt fibers is obviously increased.

Owner:JIANGSU UNIV

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Cement admixture and cement composition

InactiveUS6919388B2Stable maintenanceImprove the level ofOrganic chemistryInksMaterials scienceUltimate tensile strength

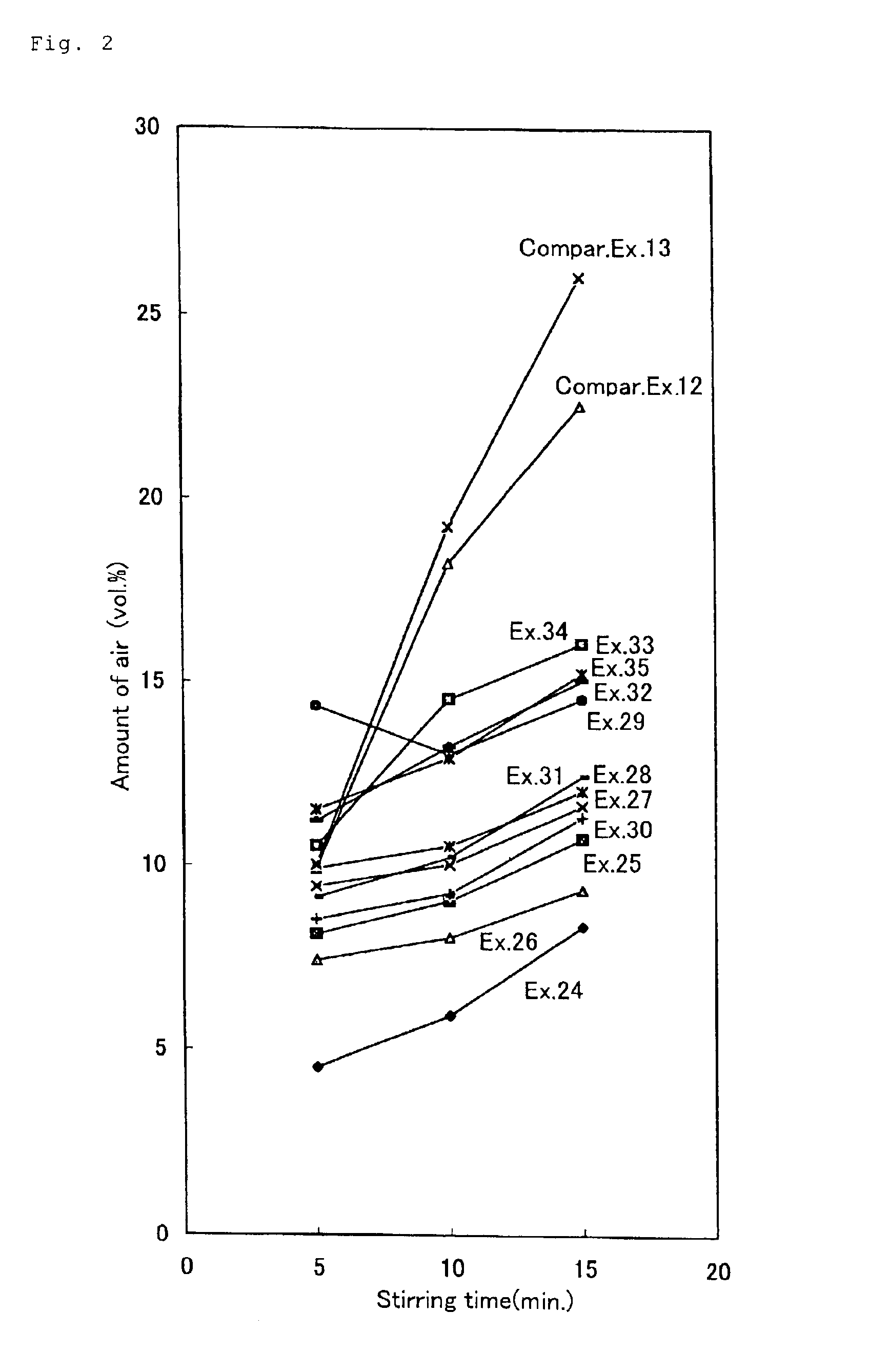

The admixtures for a cementitious composition of the invention, which have the above-mentioned constitutions, can suitably be used in cement pastes, mortar, concrete and like cement compositions and can stabilize the amount of air entrained with the lapse of time and thus facilitate the quality control of cement compositions and, further, can improve the workability of cement compositions owing to their excellent dispersing capacities. The cement compositions of the invention which comprise such admixture for a cementitious composition are excellent in water-reducing ability and workability and can give hardened products excellent in strength and durability and, further, can stably maintain the amount of air entrained without allowing increases in the amount of air even when the time of kneading is prolonged in the production.

Owner:NIPPON SHOKUBAI CO LTD

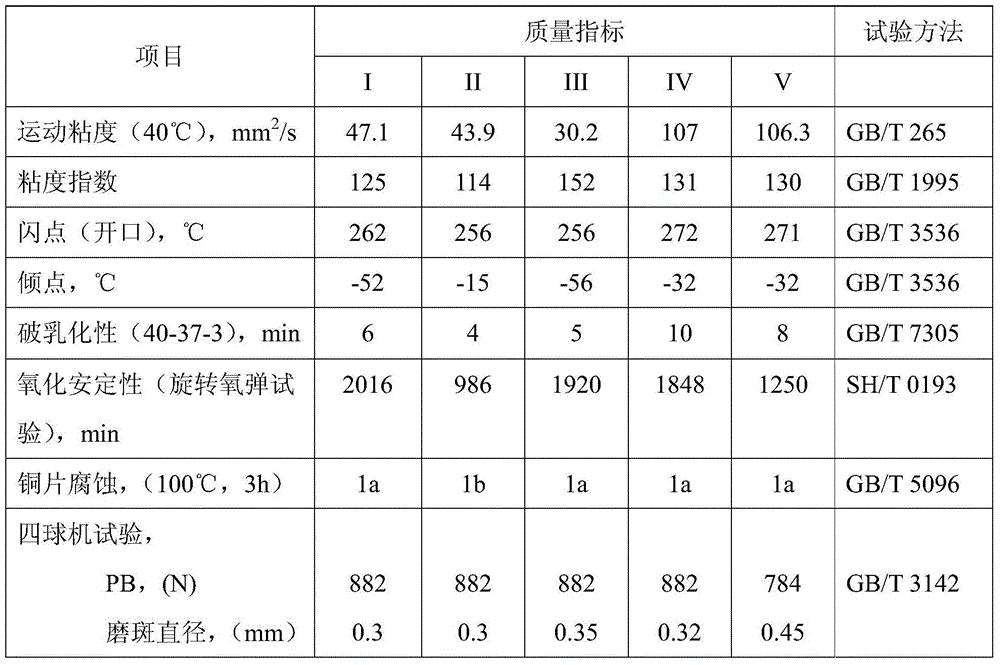

Air compressor oil composition and preparing method thereof

ActiveCN103820192AImprove lubricity and wear resistanceImprove solubilityLubricant compositionEmulsionAir compressor

The invention relates to an air compressor oil composition and a preparing method thereof. The air compressor oil composition comprises the following ingredients: A, base oil consisting of ester oil and PAO (Polyalphaolefin) oil; B, antioxidant consisting of an amine antioxidant and dialkyl dithiocarbamate ester; C, at least one oiliness additive; D, at least one high-viscosity complex ester compound; E, at least one metal passivator; F, at least one emulsion breaker; G, at least one antifoamer. The air compressor oil composition has the advantages of environment-friendliness, capability of saving energy and reducing consumption and excellent oxidation resistance. The invention further relates to the preparing method of the air compressor oil composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

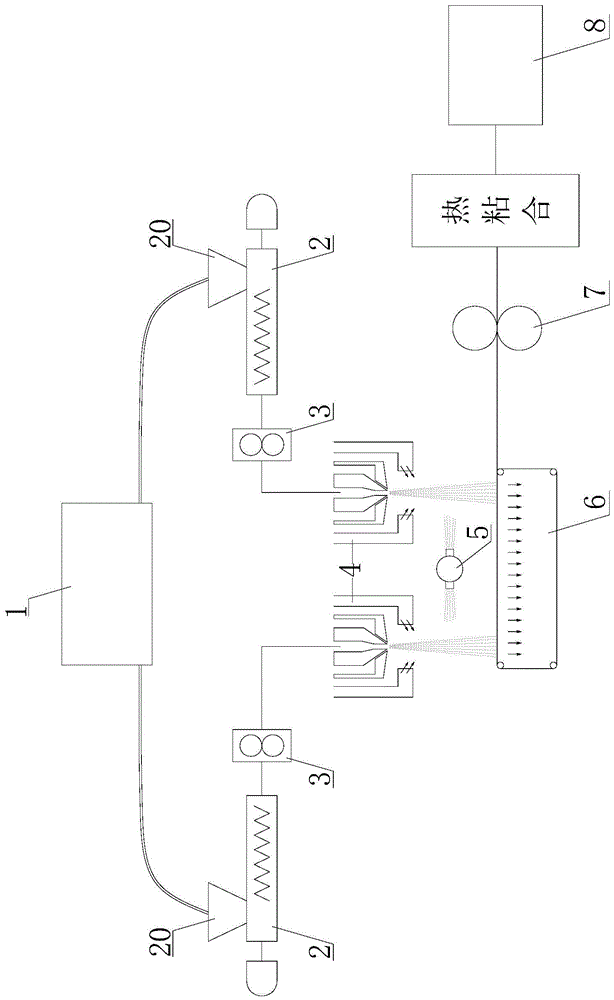

Super-soft skin-close mask specific non-woven fabric and manufacturing method for same

ActiveCN105463699ANon-toxic, tasteless and odorlessLow densityCosmetic preparationsToilet preparationsElastomerFiber

The invention discloses a super-soft skin-close mask specific non-woven fabric comprising the following components by parts: 35 to 105 parts of propylene based elastomer, 12 to 36 parts of polypropylene resin, 2.5 to 7.5 parts of hydrophilic master batches and 0.5 to 1.5 parts of soft master batches. The invention further provides a manufacturing method for the super-soft skin-close mask specific non-woven fabric. The manufacturing method comprises the following steps of preparing raw material, mixing and stirring raw material, conveying raw material, fusing and extruding, extruding spinning filaments, forming a net via air flows, conducting a heat bonding technology and cutting and packing. The manufacturing method for the super-soft skin-close mask specific non-woven fabric has simple steps; Vistamaxx 7050 type propylene based elastomer and S2040 type polypropylene resin are raw material for the non-woven fabric fibers and have great softness, small density and great skin-close property; a technical problem of decreased skin-close property of mask base cloth due to low density of the mask base cloth in the prior art can be solved; and mask base cloth quality and practicality can be enhanced.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

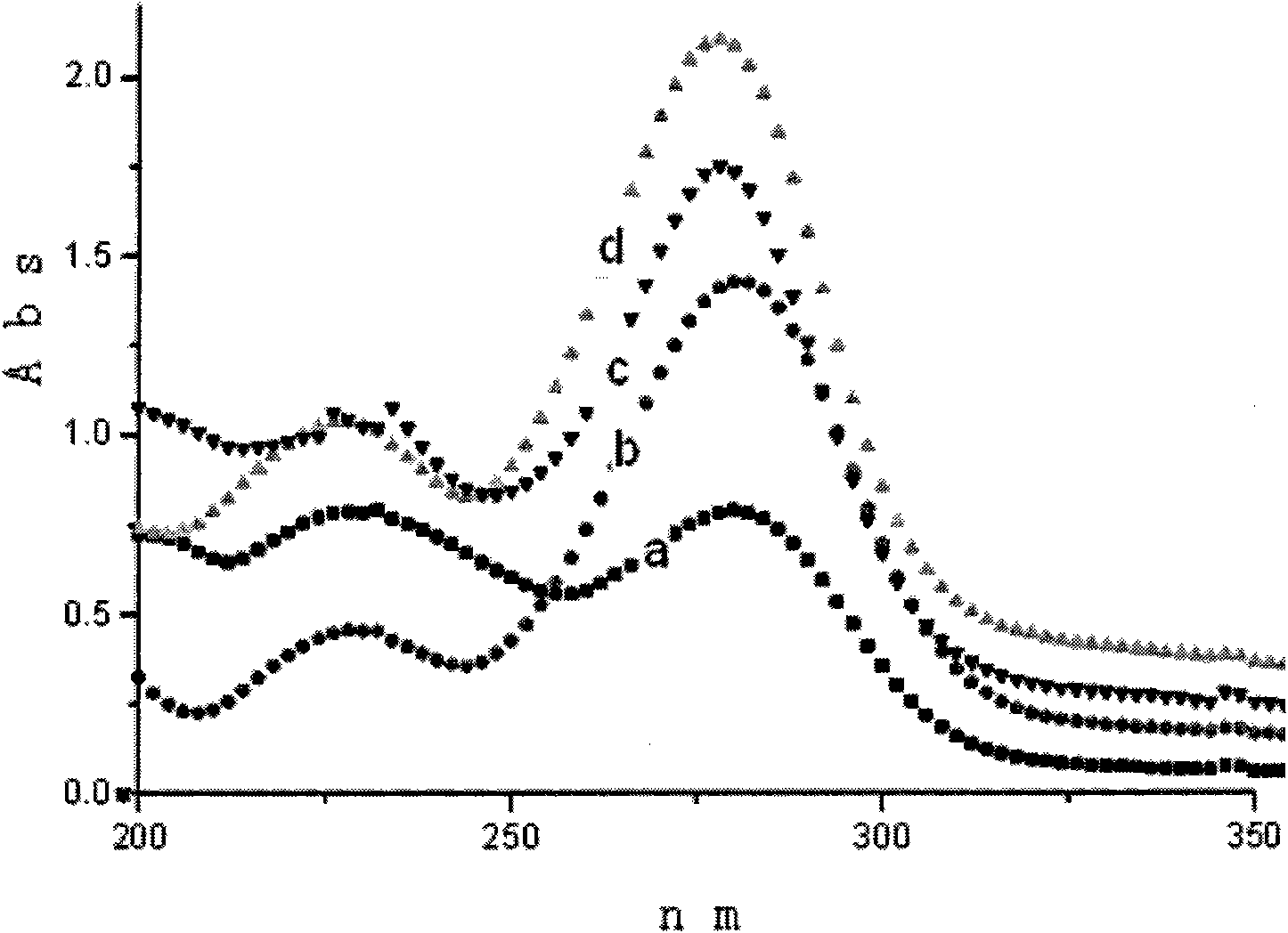

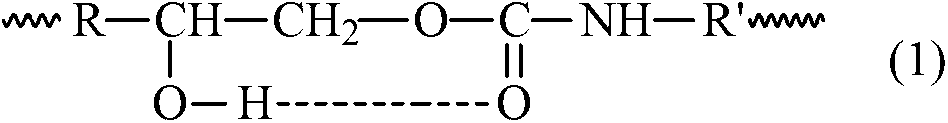

Durable cellulose fiber and application thereof

InactiveCN101831801AReduce hydrophilicityReduce polarityVegetal fibresPolymer scienceCellulose fiber

The invention relates to the technical field of macromolecular composite materials, in particular to durable cellulose fiber and application thereof. A preparation method for the durable cellulose fiber comprises the following steps of: dispersing cellulose fiber in solvent in an amount which is 1 to 10 times the total amount of the cellulose fiber; adding diisocyanate monomer which accounts for 10 to 60 percent of the total weight of the cellulose fiber, and metal catalyst or amine catalyst, which accounts for 0 to 5 percent of the total weight of the cellulose fiber, for polyurethane synthesis into the dispersed solution to perform reaction, and then adding siloxane monomer or siloxane polymer which accounts for 5 to 50 percent of total weight of the cellulose fiber into the reaction solution to perform reaction; and finally, cooling the obtained reaction product to room temperature, washing and separating filtrate, and drying the filtrate to obtain the durable cellulose fiber of the invention. The obtained durable cellulose fiber has the advantages of obviously improved hydrophobic property, good thermal stability, ultraviolet ageing resistance and antibacterial performance, and meanwhile has good durability when the durable cellulose fiber is applied in a wood-plastic composite material.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

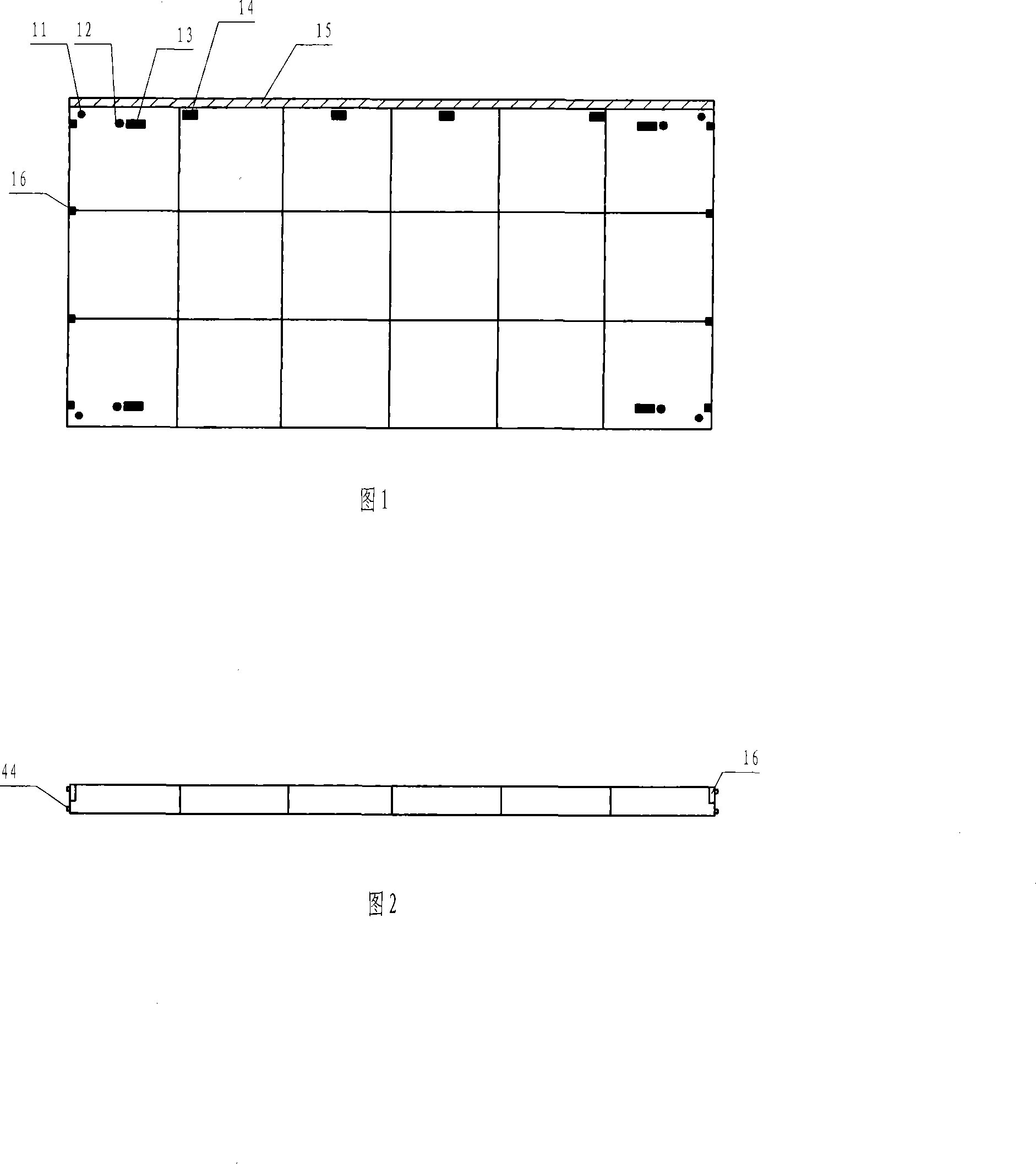

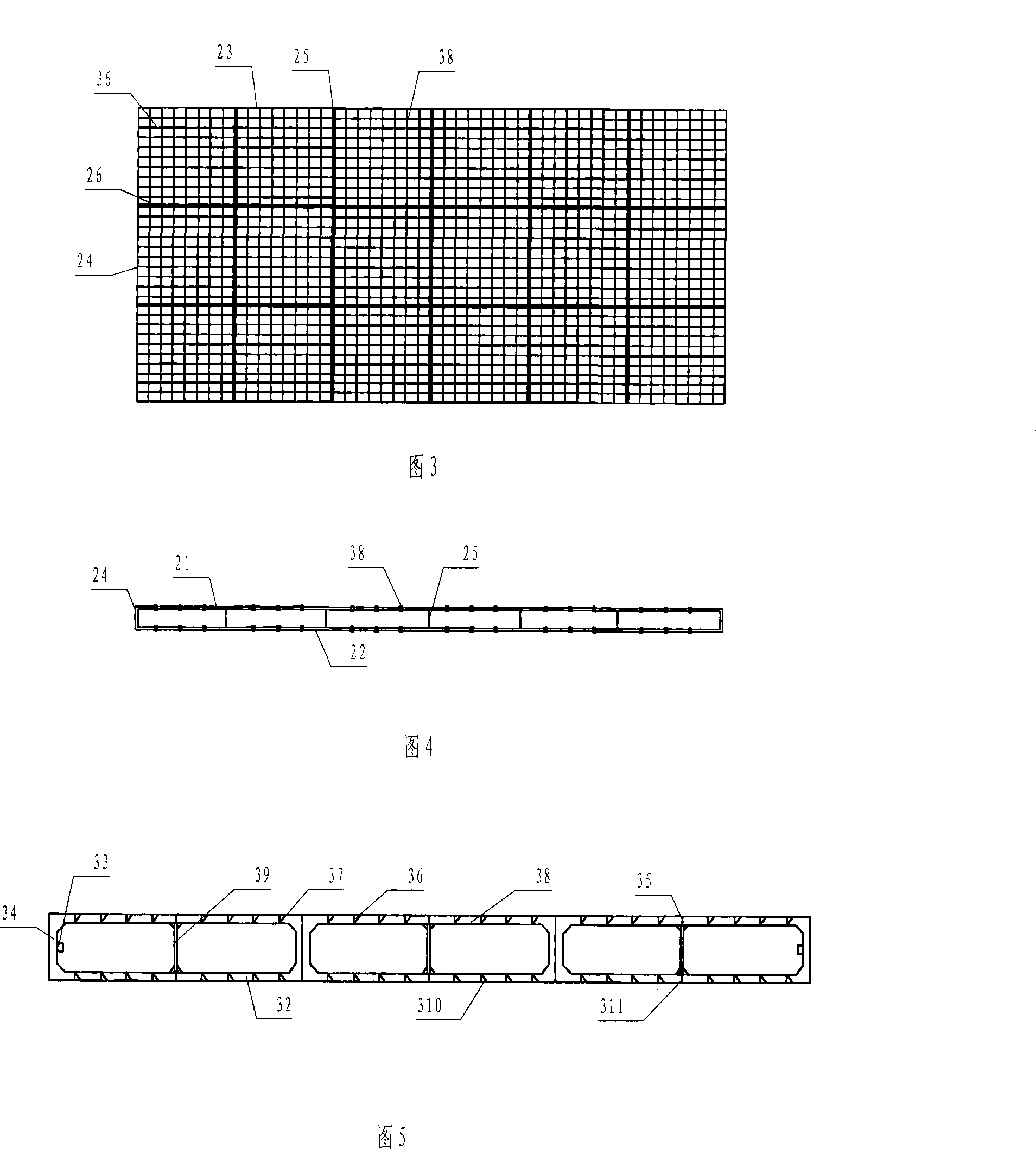

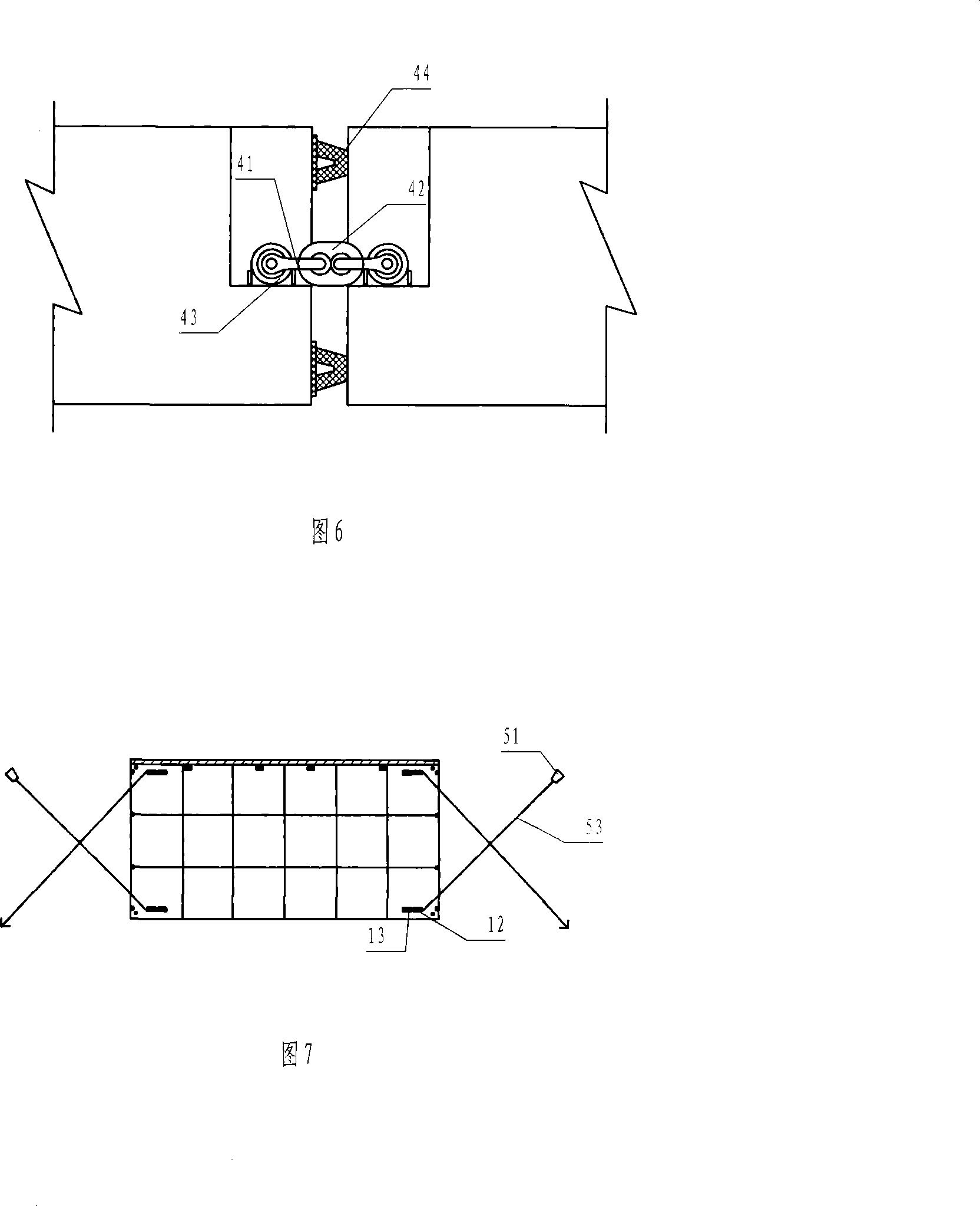

Ecological landscape float island

InactiveCN101219706AReduce construction costsSave structural materialSolar heating energyGeneral water supply conservationFresh water organismEngineering

The invention discloses an ecological landscape floating island, comprising one or a plurality of floating modules and floating link channels; each floating module is connected with each other, and the floating module and other objects are connected through the floating link channels; a plurality of platforms with different functions are arranged on the floating module; an anchoring positioning device is arranged under the floating module. The invention has the advantages of that the invention has low elevation and strong hydrophilicity, arbitrariness of establishing platforms, multifunction (uniqueness) of utilization, freeness from conditionality of fixed natural geography, movability (self-propulsion); the invention can carry out a series of wind power, hydropower, solar power and moon power generation, seawater desalination, freshwater purification, sewage purification, environmental protection, construction of the ecological landscape on the floating island, pseudo-classic architecture and modern architecture, as well as scientific experiment place of a marine science field; the invention has the advantages of huge scale, novel technology, good integrity, strong impermeability, light deadweight, high strength, large bearing capacity and good durability.

Owner:许是勇

Activation energy beam curable coating composition

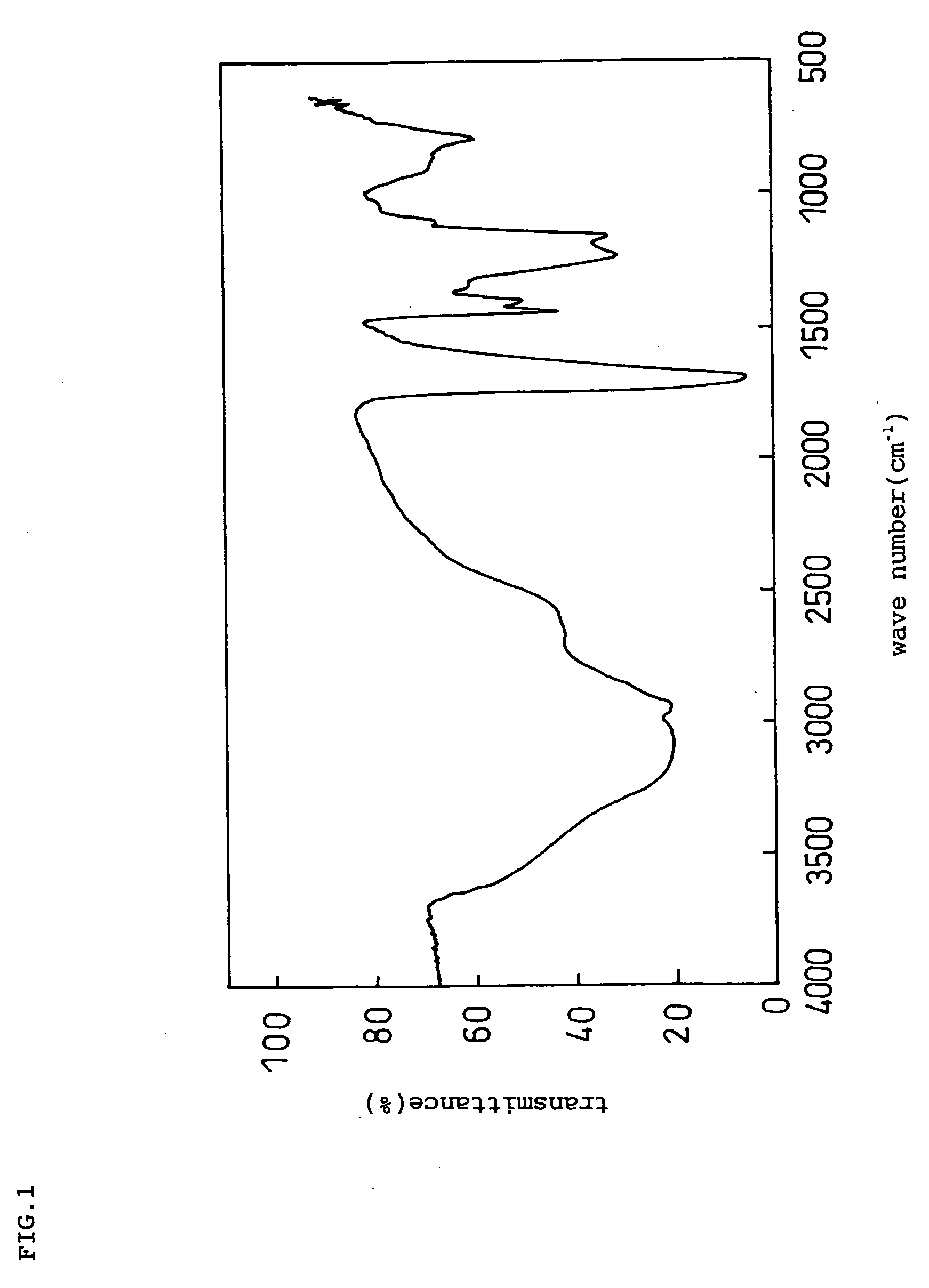

InactiveUS6017974AExcellent antistatic property and abrasion resistanceExcellent in antistatic property and transparency and abrasion resistanceMixing methodsCoatingsCoated surfacePolymer science

An activation energy beam curable coating composition containing (A) a polymer having an organopolysiloxane unit and a quaternary ammonium salt unit and (B) a polyfunctional acrylate having 3 or more acryloyl groups in the molecule is disclosed. A film excellent in abrasion resistance, antistatic properties and transparency can be formed by applying the activation energy beam curable coating composition of the present invention to the surface of a material, and irradiating the coated surface with an activation energy beam.

Owner:MITSUBISHI CHEM CORP

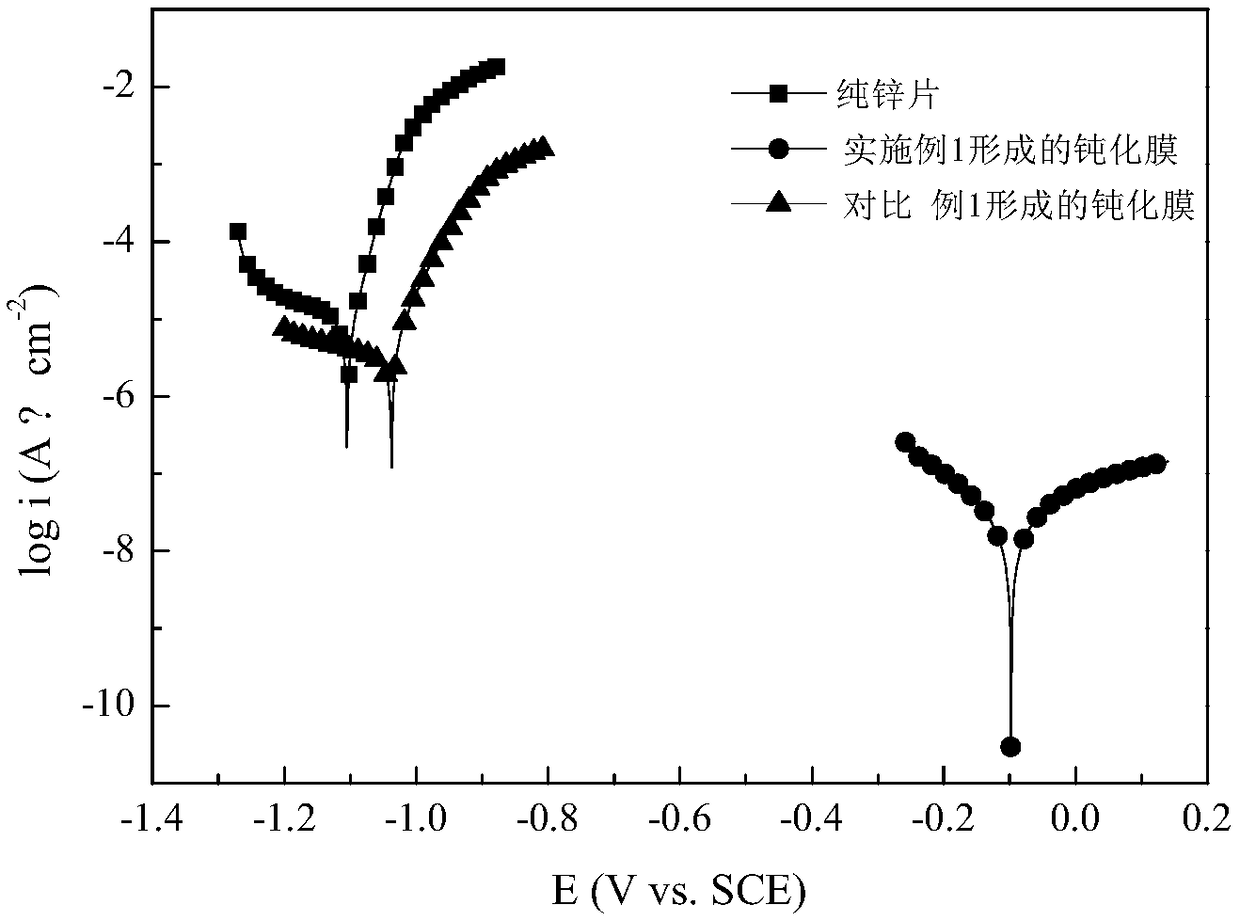

Silane/graphene oxide composite passivation liquid and preparing method and application thereof

ActiveCN108642484AAchieve silane functionalizationImprove anti-corrosion performanceMetallic material coating processesWater basedSilanes

The invention relates to silane / graphene oxide composite passivation liquid and a preparing method and application thereof. The preparing method comprises the following steps that a water-based silanecoupling agent, water and alcohol are mixed according to the volume ratio being 1:(7-9):(0.8-1.2) to obtain mixing liquid; graphene oxide is added into the mixing liquid, and ultrasonic treatment iscarried out to obtain dispersion liquid; the pH value of the dispersion liquid is adjusted to be 2-4, and hydrolysis is carried out to obtain the silane / graphene oxide composite passivation liquid. The silane / graphene oxide composite passivation liquid and the preparing method of the silane / graphene oxide composite passivation liquid combine advantages of the graphene oxide and silane, the graphene oxide and the water-based silane coupling agent are used for joint hydrolysis, and the silane functionalization of the graphene oxide is achieved; and the silane coupling agent and a metal substrateform covalent bonds, the bonding force between a film layer and the metal substrate is improved, and the lamellar graphene oxide can strengthen the physic shielding property of the film layer on a corrosion medium.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Amino/mercapto silane modified silica and preparation method thereof

ActiveCN102964881AEvenly dispersedImprove silanol reactionPigment treatment with organosilicon compoundsRubber materialAutocatalysis

The invention belongs to the field of silica materials for the rubber industry, and particularly relates to an amino / mercapto silane modified silica and a preparation method thereof. According to the invention, an in-situ synthesis method is adopted, so that aminosilane and mercapto silane coordinately modify the surface of silica; and in the process of modification, by using the autocatalysis action of aminosilane, the hydroxyl radical reaction of mercapto silane and the surface of silica is accelerated, so that the aminosilane and the mercapto silane are effectively wrapped on the surface of the silica, thereby improving the dispersion of the silica in rubber materials; and meanwhile, the reaction between silane coupling agents can be inhibited, thereby improving the processing performance of rubber materials.

Owner:BEIJING RED AVENUE INNOVA

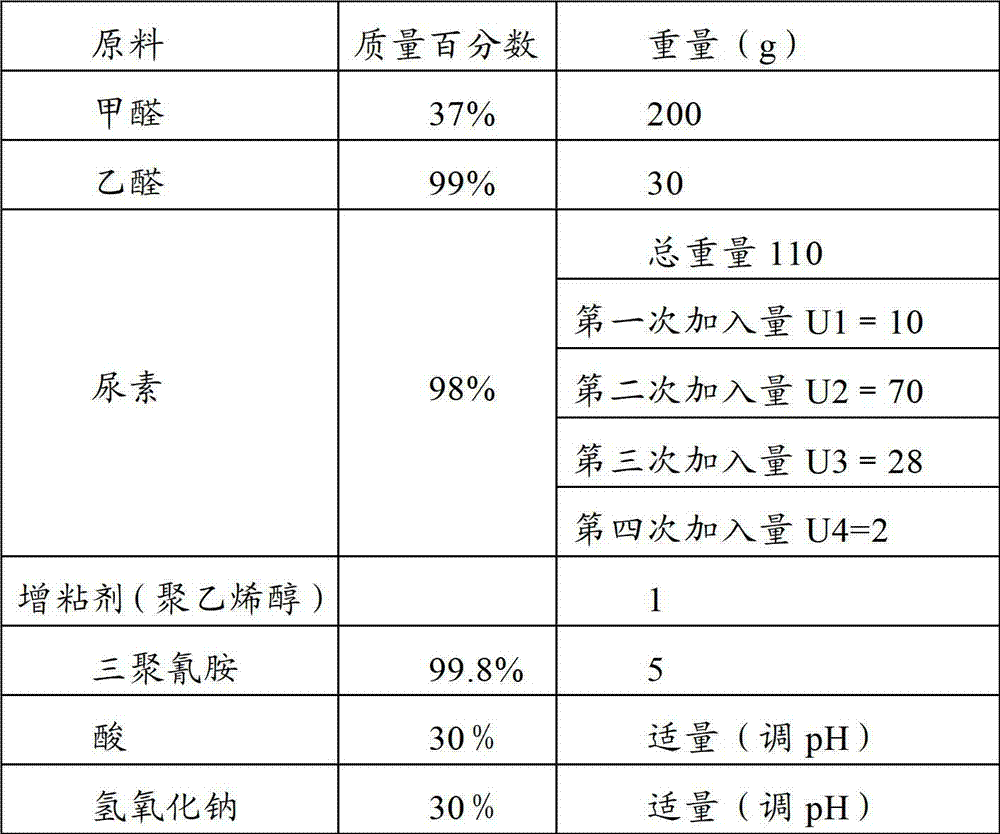

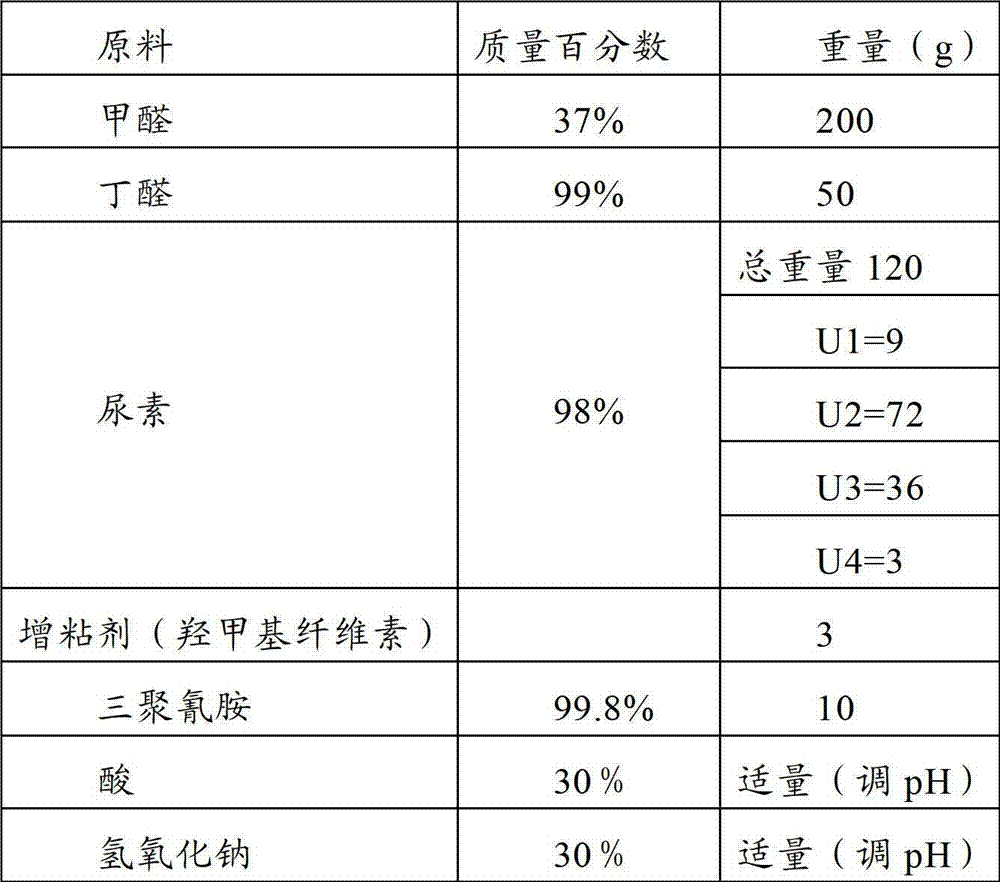

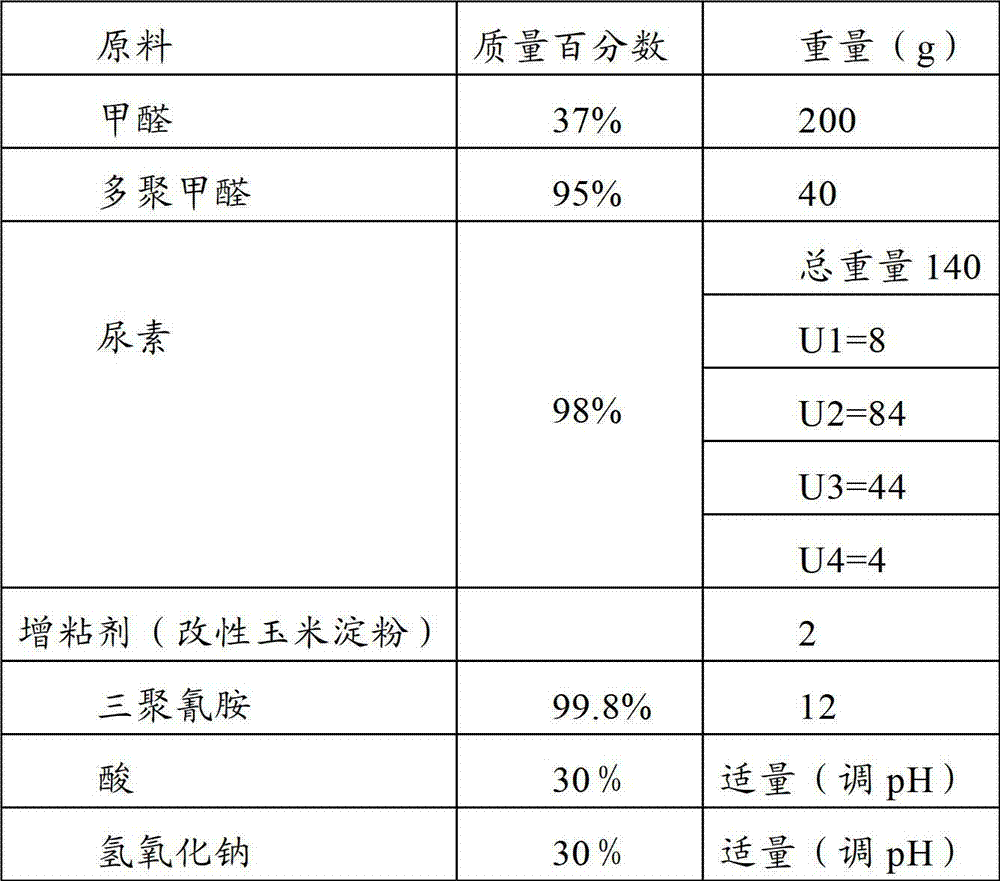

Adhesive for veneering of artificial board and preparation method of adhesive

InactiveCN103031095AReduce penetrationReduce generationMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolubilityAdhesive

The invention relates to an adhesive for a veneering of an artificial board and a preparation method of the adhesive. The adhesive comprises the components in parts by weight: 200 parts of formaldehyde, 20-50 parts of a modifier, 110-140 parts of urea, 5-15 parts of tripolycyanamide, and 1-10 parts of a tackifier. By addition of appropriate parts of modifier, on the one hand, the high solid content adhesive can be prepared without dehydration, moisture brought to a base material during coating is reduced, permeation of the adhesive is reduced, and glue penetration is reduced. In addition, through addition of the modifier, the molar ratio of formaldehyde and urea in the polycondensation phase in the urea resin synthetic process can be greatly reduced, so that hydrophilic radicals in the resin structure are greatly decreased. Meanwhile, tripolycyanamide in appropriate parts is added to modify, so that the water-solubility of the adhesive is reduced, the hydrophobicity of the adhesive is enhanced, and glue penetration is beneficially reduced. The tackifier in appropriate parts is added to improve the initial adhesion of the adhesive and reduce malposition of a veneer on the base material, so that the product quality is improved.

Owner:EVERFIRST WISEFUND TECH BEIJING

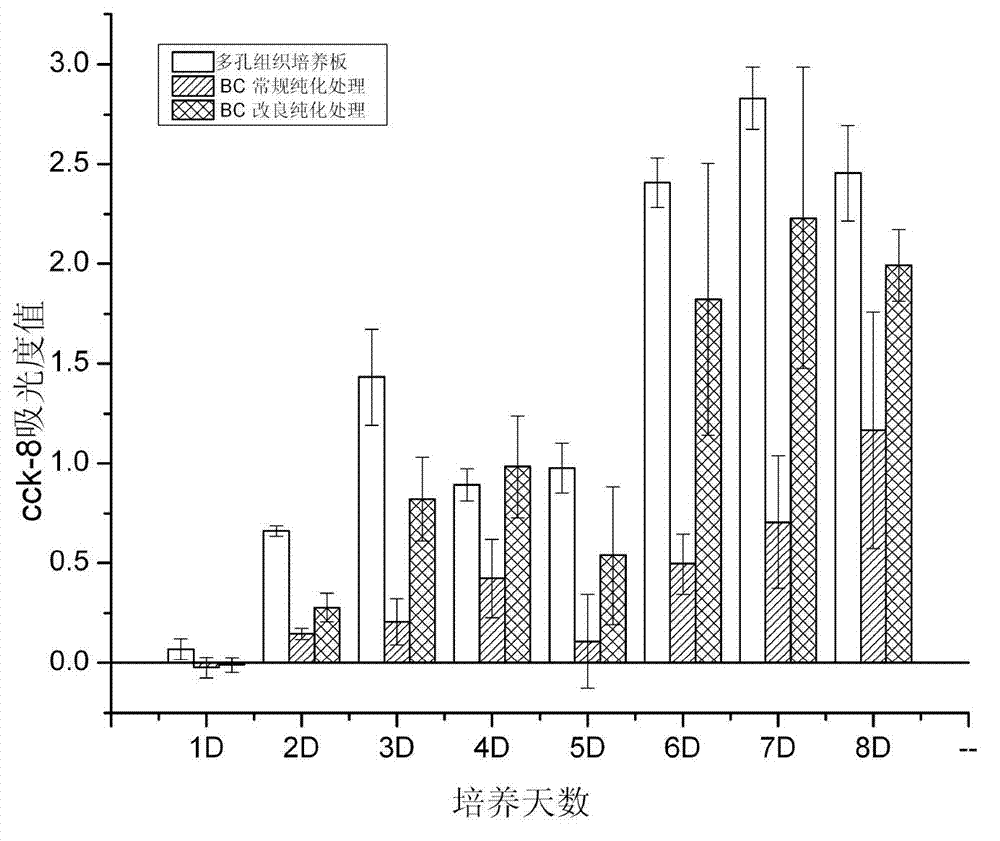

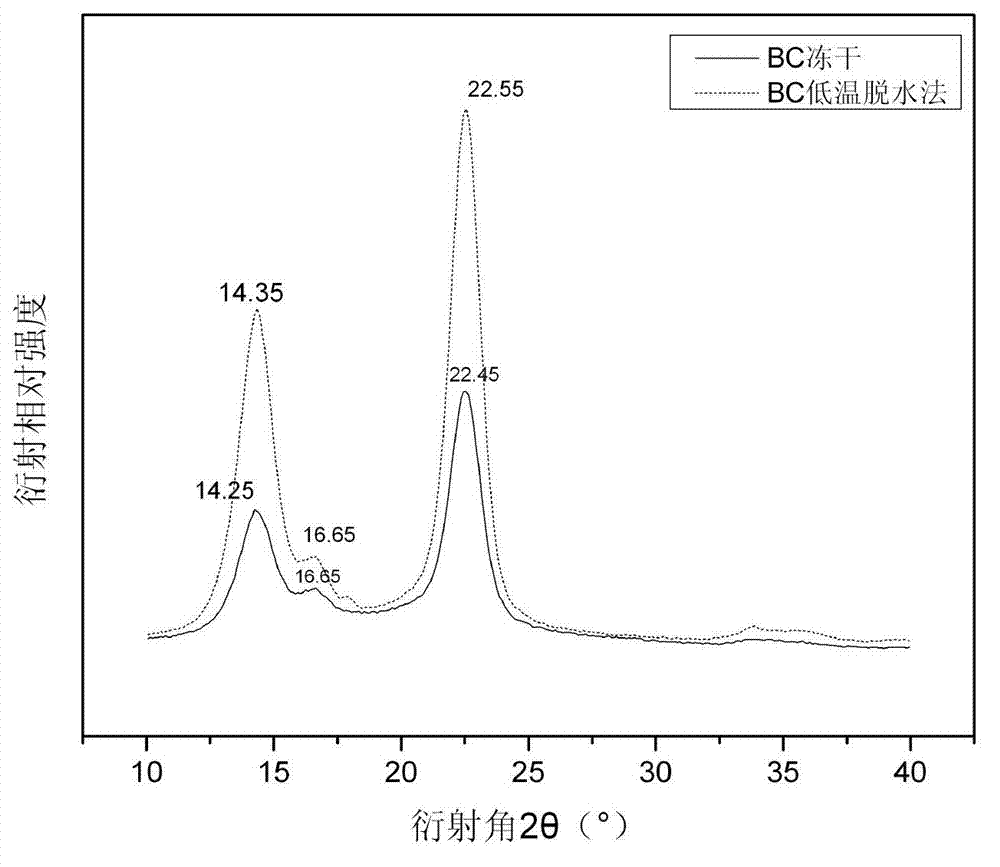

BC (Bacterial Cellulose)/PVA (Polyvinyl Alcohol) composite material, as well as preparation method and application thereof

ActiveCN102961784AOptimizing purification stepsGood compatibilityProsthesisFreeze thawingPolyvinyl alcohol

The invention discloses a BC (Bacterial Cellulose) / PVA (Polyvinyl Alcohol) composite material, as well as preparation method and application thereof. The preparation method comprises the following steps of: (1) preparing a medical BC wet film block; (2) preparing a polymer solution preparation, namely, under the conditions of high temperature of 95-130 DEG C and high pressure of 0.05-0.15 MPa, preparing a 20-40wt% PVA water solution, namely the polymer solution; (3) soaking the BC wet film block in the polymer solution; and (4) carrying out freeze thawing crosslinking to form the composite material. According to the PVA / BC composite series material prepared by the preparation method, when the PVA concentration reaches 20%, the modulus of compression reaches more than 30 MPa, especially, when the PVA concentration reaches 28%, the modulus of compression reaches more than 50 MPa, the composite material can be used for preparing a replacement for meniscus or cartilage tissue, or preparing replication products of meniscus or cartilage tissue, and the composite material can meet the mechanical strength requirement of bearing tissues, such as the foot cartilage and the meniscus.

Owner:SOUTH CHINA UNIV OF TECH

Charged filtration membranes and uses therefor

InactiveUS7153426B2High yieldImprove permeabilitySolvent extractionUltrafiltrationFiltration membraneSolvent

The invention relates to charged filtration membranes and their use for separation of a protein from solvent, low molecular weight solutes or a mixture of proteins. Modification of the membranes to generate charge includes modification of membrane pores to alter charge within a pore and alter the size of a pore. Consequently, the protein is separated from other solutes in a mixture based on size as well as net protein charge and membrane charge.

Owner:GENENTECH INC

Curatives for epoxy compositions

ActiveUS8431655B2Reduce hydrophilicityLow viscosityGroup 4/14 element organic compoundsPolyether coatingsEpoxyChemistry

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

Preparation method of hydrophobic modified cationic polyacrylamide flocculant

ActiveCN103319652AReduce hydrophilicitySettling fastWater/sewage treatment by flocculation/precipitationSuspended particlesColloidal particle

A preparation method of hydrophobic modified cationic polyacrylamide flocculant comprises the following steps: weighing and mixing acrylamide, acryloyloxyethyl trimethyl ammonium chloride, butyl acrylate, perfluorinated octyl ethyl acrylate and a surfactant, obtaining polymer monomer aqueous solution by adding deionized water and mixing well by stirring, and then adding a plurality of additives; adding a compound initiator for polymerization and then adding a photoinitiator for polymerization; after the polymerization reaction, taking out colloidal particles for prilling, drying, crushing, and sifting, so that the hydrophobic modified cationic polyacrylamide flocculant is obtained. The flocculant provided by the present invention is able to improve the adsorption capacity of polymers to suspended particles, especially organic matters in water, by introducing lyophobic group into the macromolecule of the flocculant. Meanwhile, the flocculant possesses the properties of hydrophobic associating polymer, which is beneficial to the interaction between macromolecules, reducing the hydrophilic performance of the floc body, increasing the settling velocity of the floc body, and improving intensity of the flocs and water separation capability of the filter cake.

Owner:格润化学(东营)有限公司

Halogen-free flame-retardant master batch

The invention discloses a halogen-free flame-retardant master batch. The halogen-free flame-retardant master batch is composed of the following raw materials in parts by mass: 30-80 parts of halogen-free flame retardant, 15-69.7 parts of polyolefin carrier, 0.2-2 parts of silicone oil, and 0.1-3 parts of coupling agent. During preparation, the raw materials aforementioned are weighed according to a ratio at first, and then the polyolefin carrier, the silicone oil and the coupling agent are added in a high-speed stirring machine and stirred for 3 minutes with a medium-low speed, and finally, the halogen-free flame retardant is added and stirred for 5 minutes with a high speed; and the stirred raw materials are transferred into a two-stage vacuum double-screw extruder, and granulated via extrusion, wherein the temperature of the extruder is set to be 100-130 DEG C. The halogen-free flame-retardant master batch disclosed by the invention is excellent in mechanical property, good in water resistance, excellent in physical and mechanical properties, and easy to process and store.

Owner:宁波一彬电子科技股份有限公司

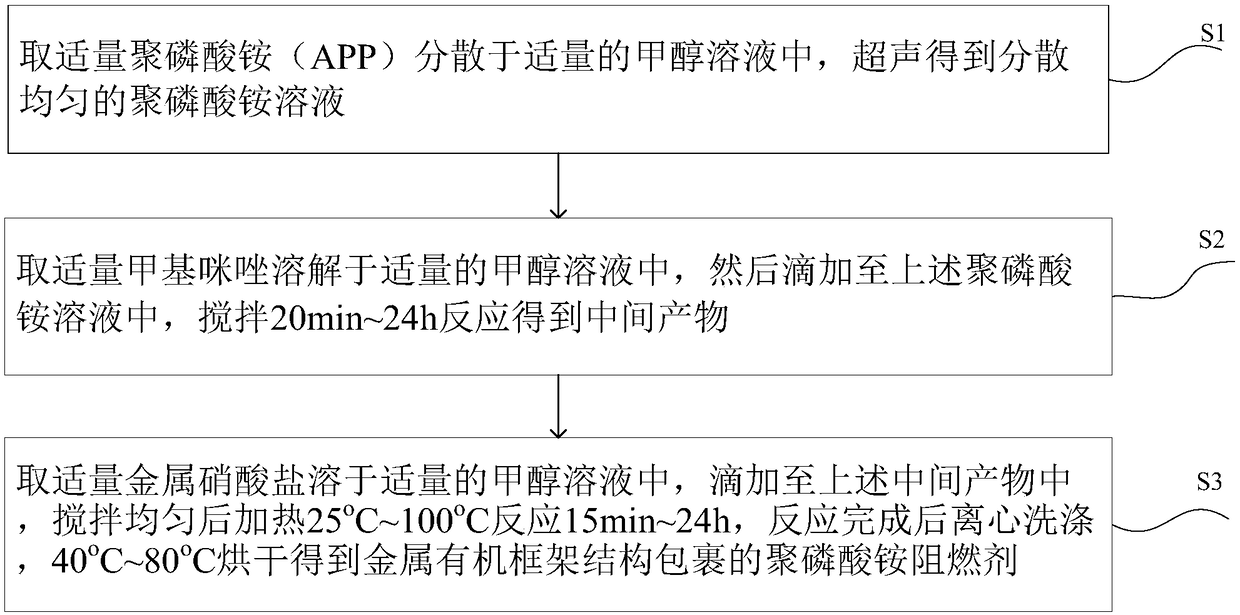

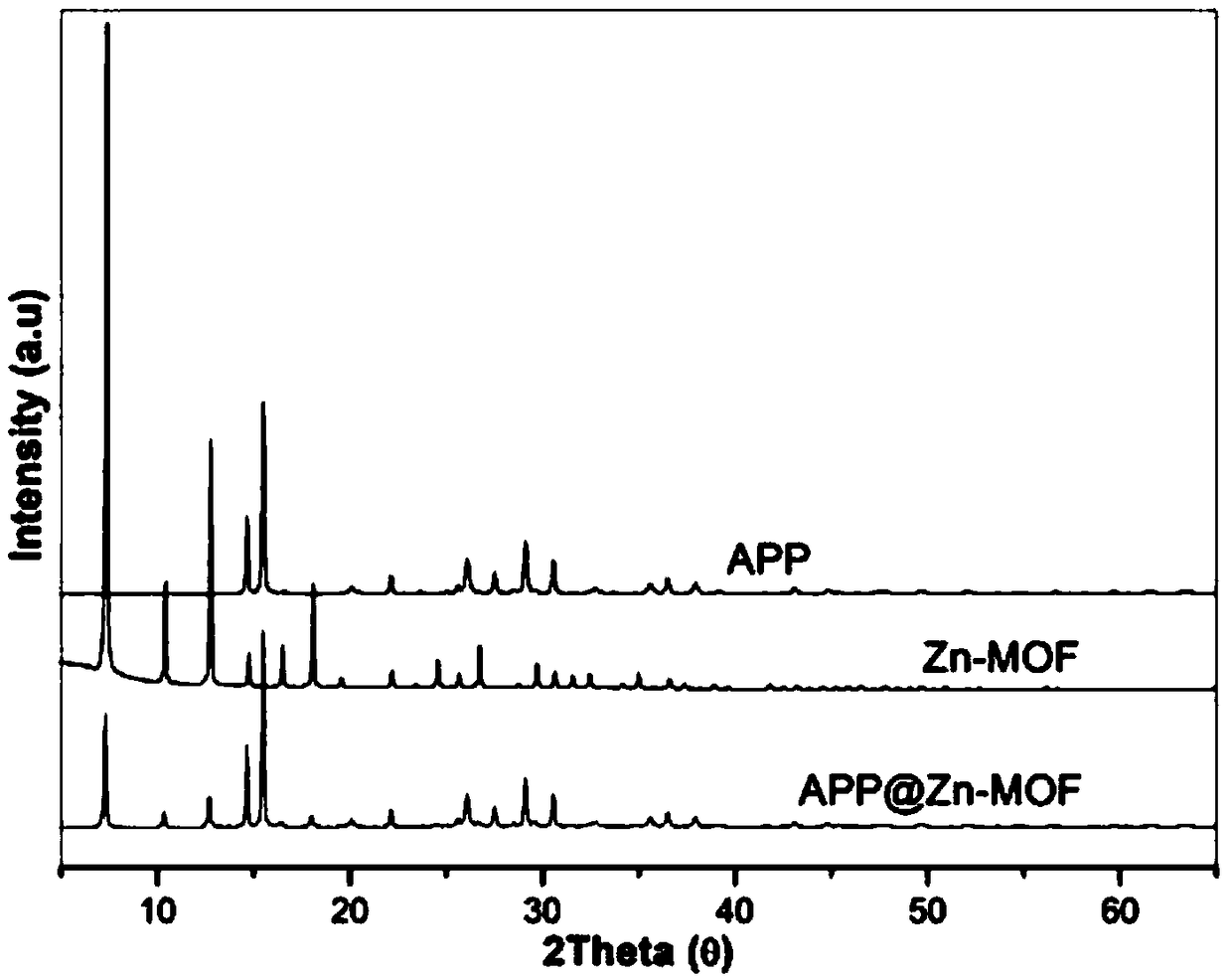

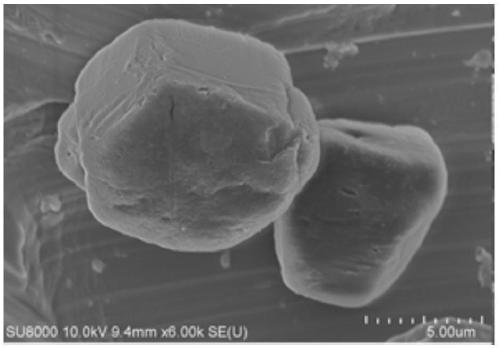

Preparation method for metal organic framework structure wrapped ammonium polyphosphate fire retardant and application

ActiveCN109320910AThe process steps are simpleStrong maneuverabilityAmmonium polyphosphateMetal-organic framework

The invention discloses a preparation method for a metal organic framework structure wrapped ammonium polyphosphate fire retardant and application. The preparation method comprises the following steps: dispersing ammonium polyphosphate in a methanol solution, adding the methanol solution containing dimethylimidazole in the mixed solution, uniformly stirring and mixing, dropwise adding the methanolsolution containing metal nitrate, uniformly stirring, performing a heating reflux reaction, centrifuging, washing and drying after completing the reaction, thereby obtaining the fire retardant. Thepreparation method has the advantages of simple processing step, high operability and low preparation cost; the active site of ammonium polyphosphate is sealed by adopting a metal organic framework structure to form an organic isolation layer with certain thickness to block the invasion of water, so that the polarity and the hydrophily of the material can be effectively reduced, the compatibilityand the dispersibility of the material and an organic high-molecular polymer are improved, and meanwhile, the catalytic charing effect is achieved, and the flame retardant efficiency of ammonium polyphosphate is improved; and the preparation method can be widely applied to fields of flame retardant materials such as epoxy resin, polyurethane, polystyrene, polylactic acid or polyolefin.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

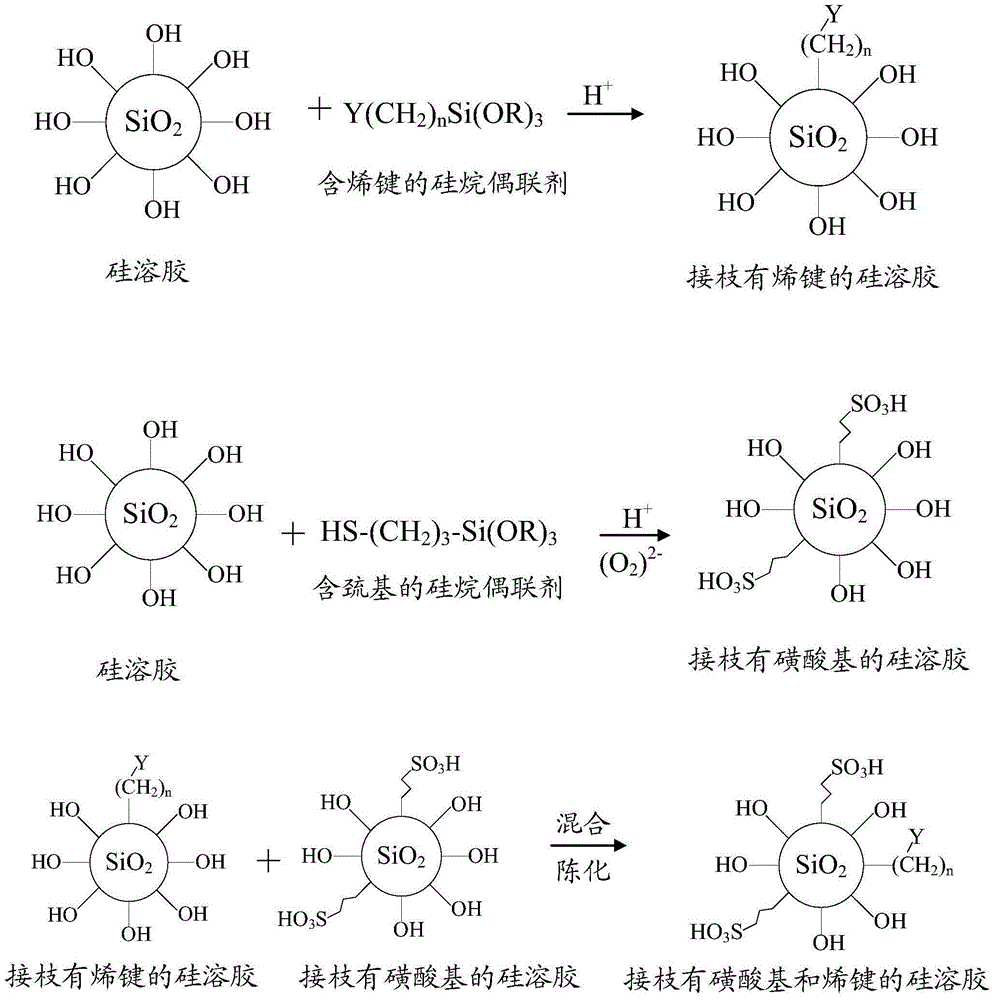

Modified silica sol, and preparation method and application thereof

ActiveCN105176179AHigh reactivityImprove hydrophilicityCoatingsPigment treatment with organosilicon compoundsSilica gelOrganic polymer

The invention discloses modified silica sol, and a preparation method and application thereof. The preparation method for the modified silica sol comprises the following steps: preparing olefinic-bond-grafted silica sol; preparing sulfonic-group-grafted silica sol; and subjecting the olefinic-bond-grafted silica sol and the sulfonic-group-grafted silica sol to mixing, stirring and aging so as to obtain silica sol simultaneously grafted with an olefinic bond and a sulfonic group, wherein a mass ratio of the olefinic-bond-grafted silica sol to the sulfonic-group-grafted silica sol is 0.2-1: 1. The modified silica sol prepared by using the method in the invention has excellent hydrophilic property and good compatibility with an organic polymer monomer, and can be used as an important raw material of a super hydrophilic and antifogging coating.

Owner:福建富兰光学股份有限公司

Preparation method of epoxy non-isocyanate polyurethane heavy anti-corrosion coating

ActiveCN103013322AReduce hydrophilicityImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyRoom temperature

The invention discloses a preparation method of an epoxy non-isocyanate polyurethane heavy anti-corrosion coating comprising a component A and a component B. The component A is a mixture of a cyclic-carbonate-terminated compound and an epoxy-terminated compound; the component B is amine-terminated polyether which is one or a mixture of amine-terminated polyether D-230, D-400 and T-403; and the mass ratio of the component A to the component B is (2.1-1):1. The components A and B of the epoxy non-isocyanate polyurethane heavy anti-corrosion coating are stored independently, and the shelf life of the components A and B is longer than half a year at a room temperature; the usage period of the mixture of the components A and B is longer than 1 hour; and after the coating is solidified for half a hour at 100 DEG C, the peeling strength of the coating can reach a maximum value of 40%, or after the coating is solidified for 7 days at a room temperature, the peeling strength of the coating can reach the maximum value.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com