Preparation method for metal organic framework structure wrapped ammonium polyphosphate fire retardant and application

A metal-organic framework and ammonium polyphosphate technology, which is applied in the field of material preparation, can solve the problems of reducing the flame retardancy of materials, migration and exudation, and easy moisture absorption, so as to improve compatibility and dispersion, reduce polarity and affinity Water-based, simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

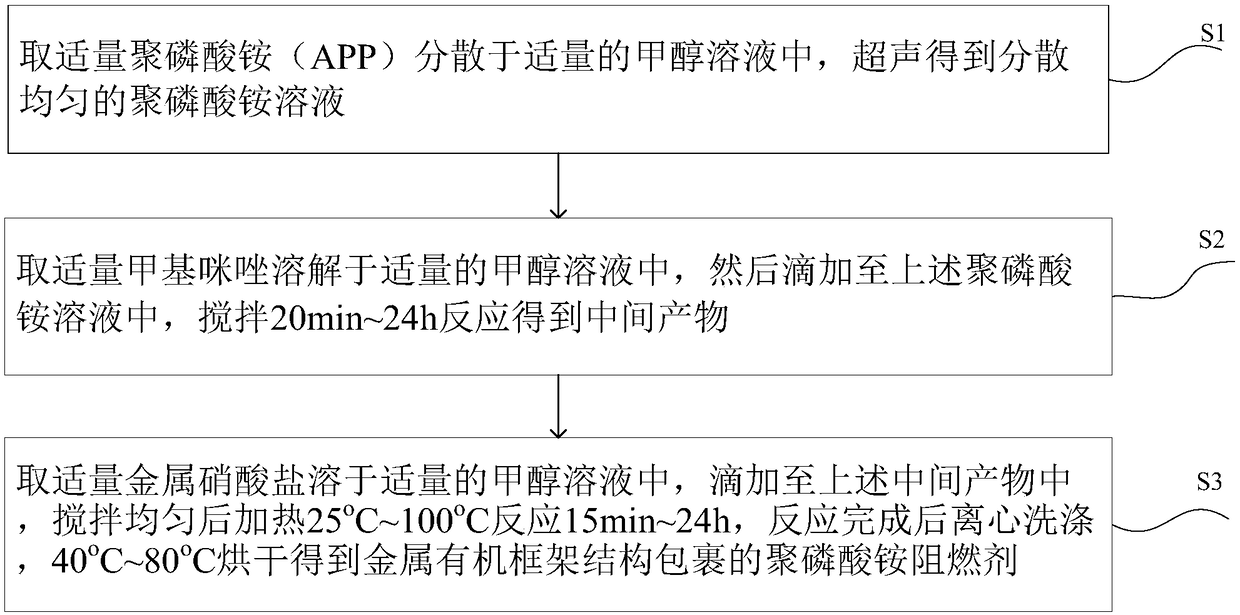

[0028] The embodiment of the present invention provides a method for preparing a metal-organic framework-wrapped ammonium polyphosphate flame retardant. Ammonium polyphosphate is dispersed in methanol, a methanol solution containing dimethylimidazole is added thereto, and the mixture containing The methanol solution of metal nitrate is stirred evenly and then heated to reflux for reaction. After the reaction is completed, it is centrifuged, washed, and dried to obtain an ammonium polyphosphate flame retardant wrapped by a metal-organic framework structure.

[0029] Metal-organic frameworks (MOF) is a new type of organic-inorganic hybrid porous crystal structure formed by self-assembly of metal ions / metal clusters and organic link units through coordination forces; it has high porosity, low density , ultra-high specific surface area, pore rules, adjustable pore size, topological structure diversity and tailorability, etc.; the use of metal-organic frameworks to wrap ammonium pol...

Embodiment 2

[0042] According to the method of Example 1 of the present invention, the ammonium polyphosphate flame retardant wrapped by the metal organic framework structure was prepared, 1.0g APP was added into 25mL methanol solution, ultrasonically dispersed for 20min, and 2.46g methylimidazole was dissolved in 25mL methanol solution Add dropwise into the dispersed APP solution, stir for 20min, dissolve 1.485g of zinc nitrate hexahydrate in 50mL of methanol, add dropwise into the above solution, stir for 20min, put it in an oil bath at 60°C for 4h, centrifuge and wash for 60 °C drying to obtain APP@Zn-MOF flame retardant. All the other are the same as embodiment one.

[0043] A metal-organic framework structure Zn-MOF is prepared according to the method of the embodiment of the present invention.

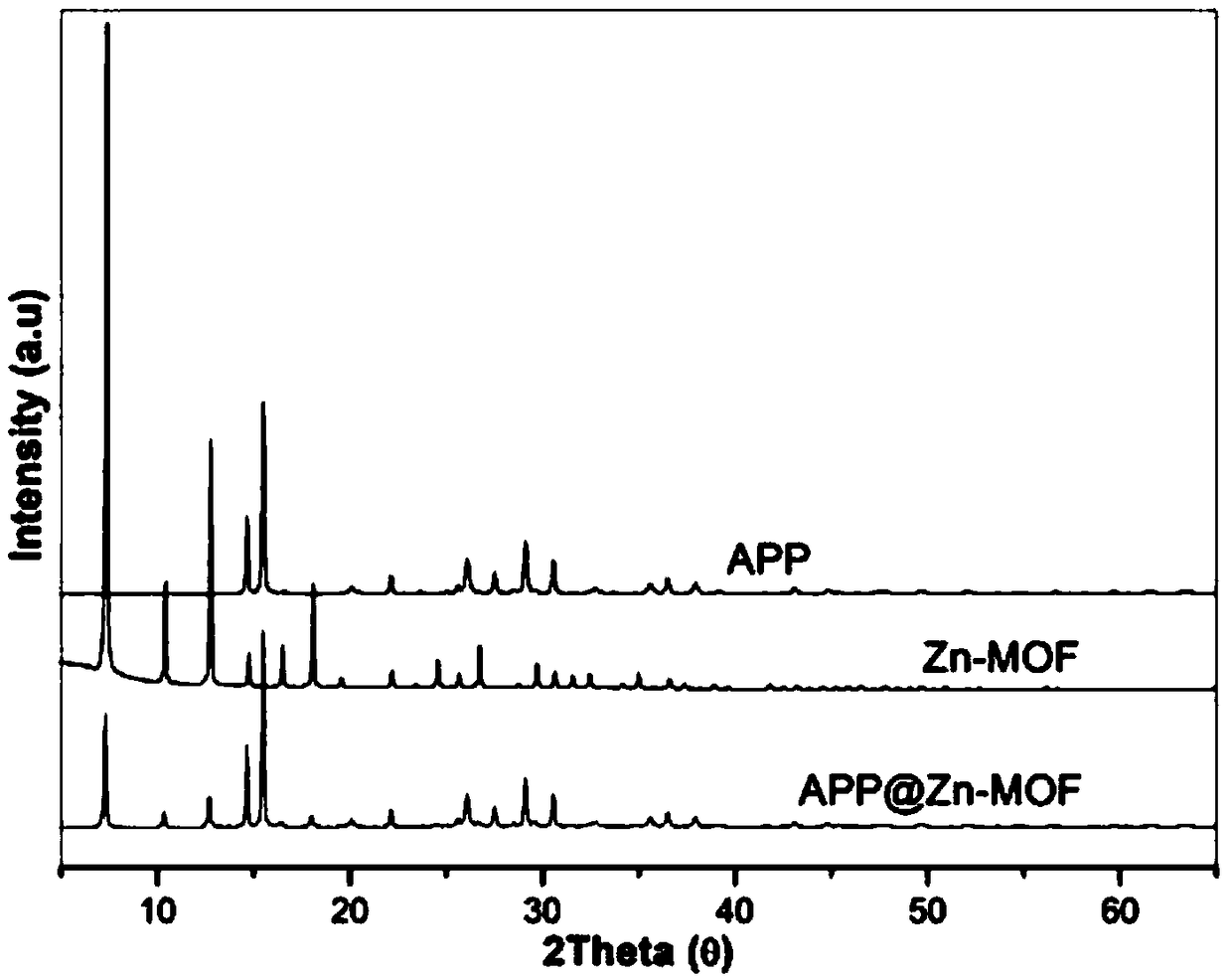

[0044] Refer to attached figure 2 , the XRD diffraction peaks of APP and the synthesized Zn-MOF structure are consistent with the standard card, while the APP samples wrapped with Zn-MOF h...

Embodiment 3

[0047]According to the method of Example 1 of the present invention, the ammonium polyphosphate flame retardant wrapped by the metal-organic framework structure was prepared, 1.0g APP was added to 25mL methanol solution, and ultrasonically dispersed for 20min to obtain a uniformly dispersed APP solution; 2.46g methylimidazole was taken Dissolve in 25mL of methanol solution and add dropwise to the APP solution, stir for 20min; take 1.485g of cobalt nitrate hexahydrate and dissolve in 50mL of methanol, add dropwise to the above solution, stir for 20min, put in an oil bath at 60°C Reacted for 4 hours, washed by centrifugation, and dried at 60°C to obtain APP@Co-MOF flame retardant. All the other are the same as embodiment one.

[0048] Co-MOF with metal organic framework structure was prepared according to the method of the embodiment of the present invention.

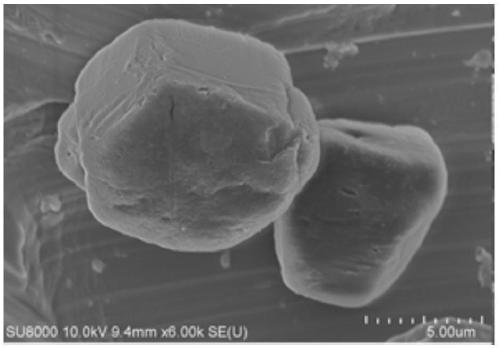

[0049] Refer to attached image 3 , 5 , the surface of unwrapped APP is smooth, but after wrapped with Co-MOF, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com