Patents

Literature

36results about How to "Not to be wasted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

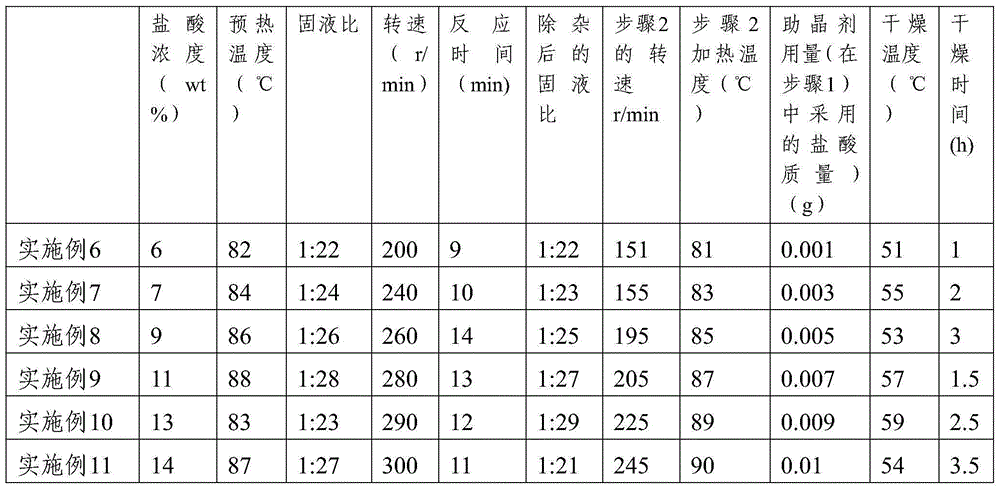

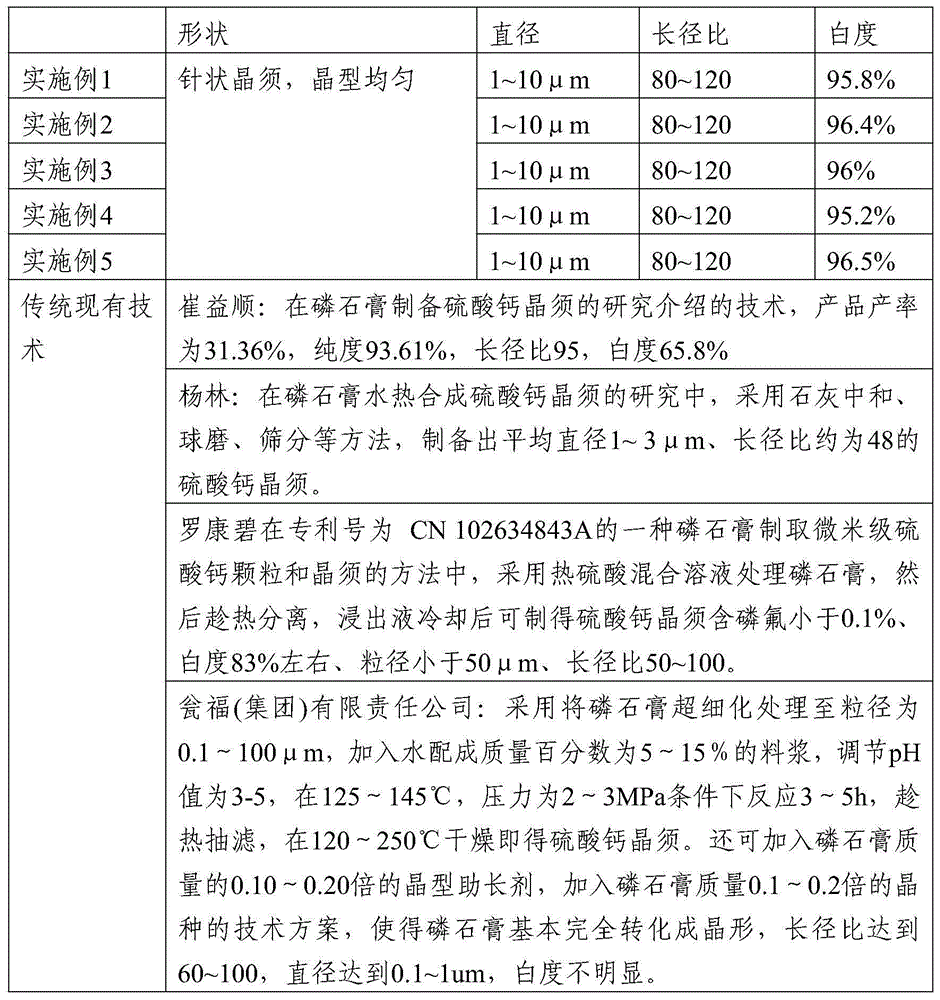

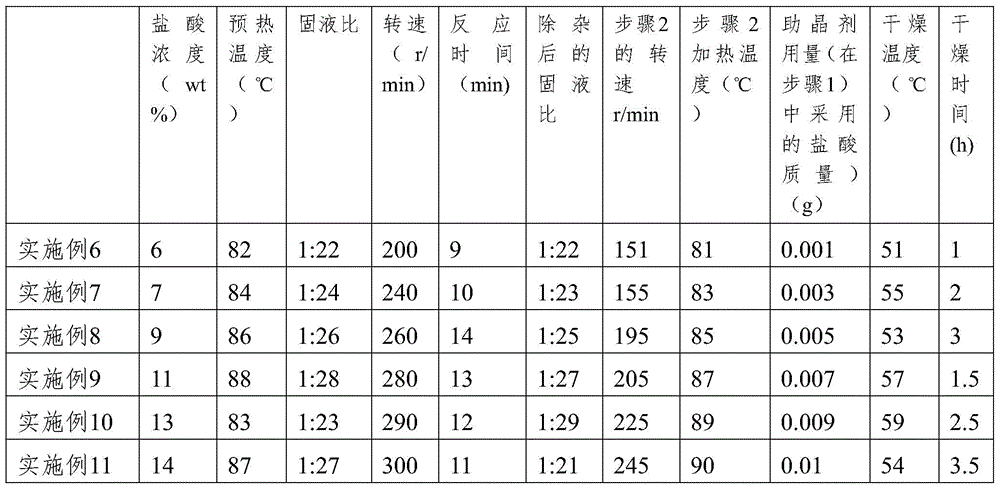

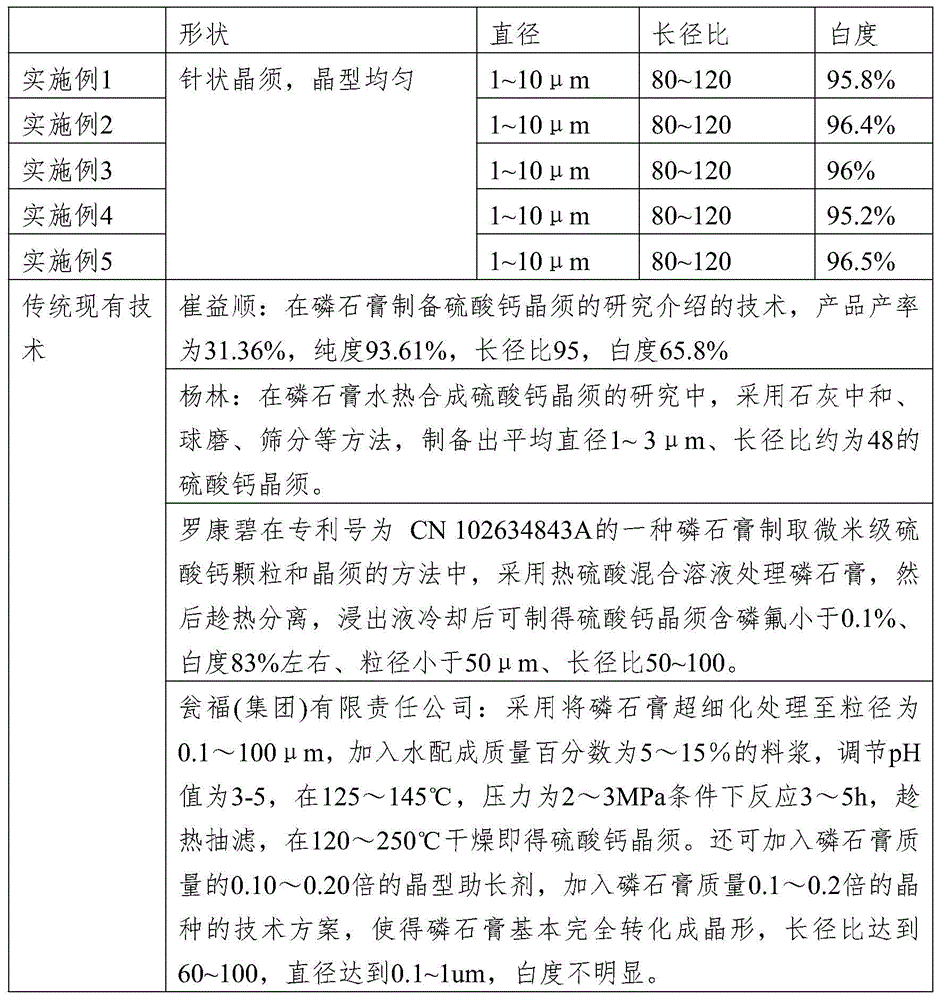

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

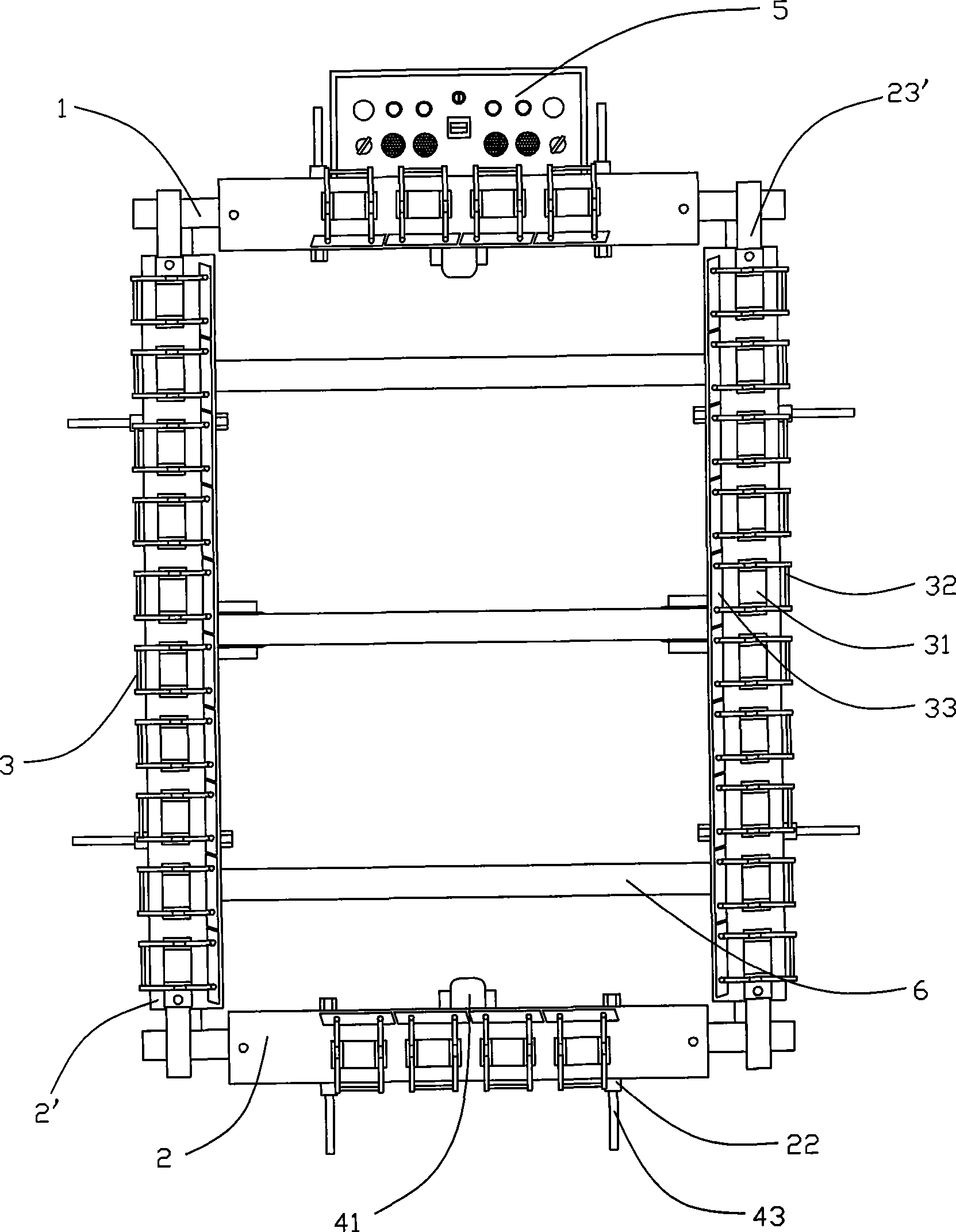

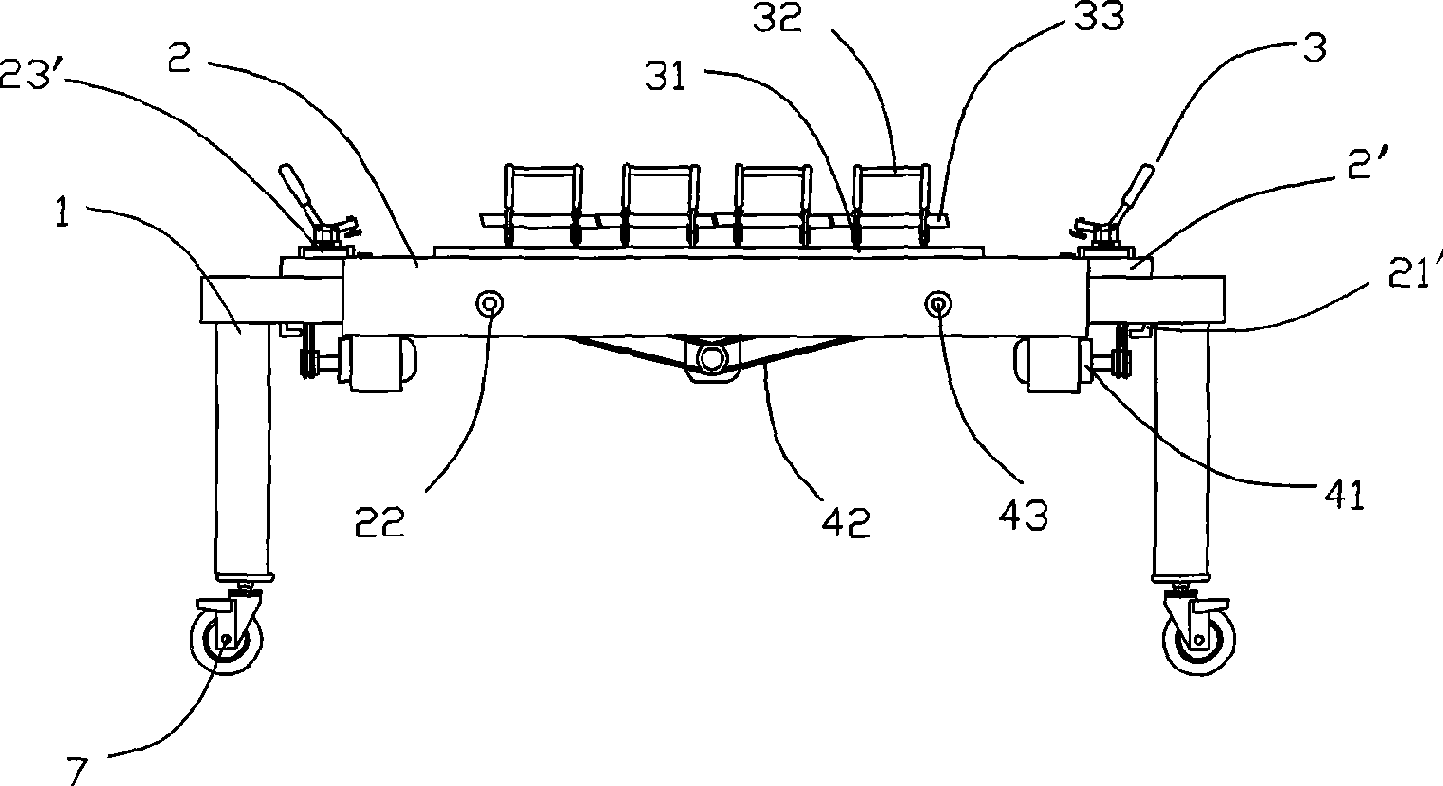

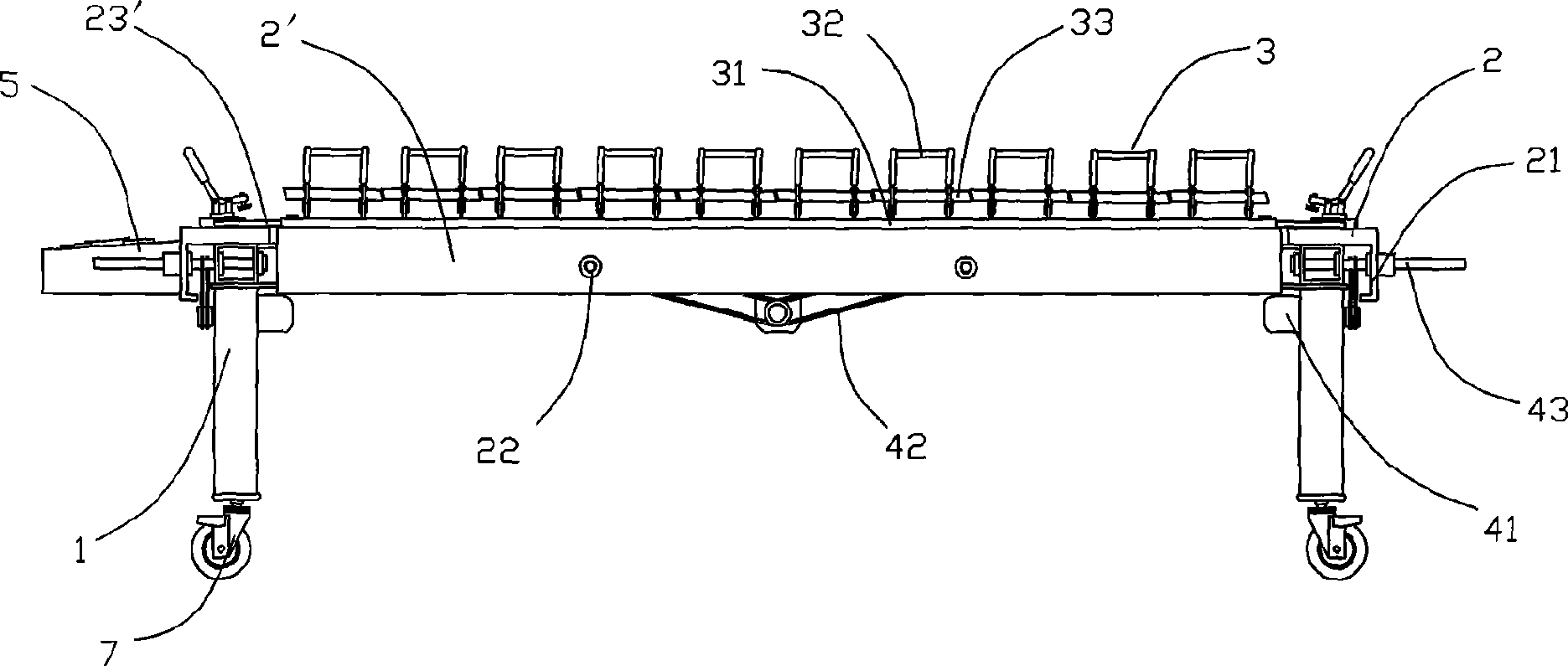

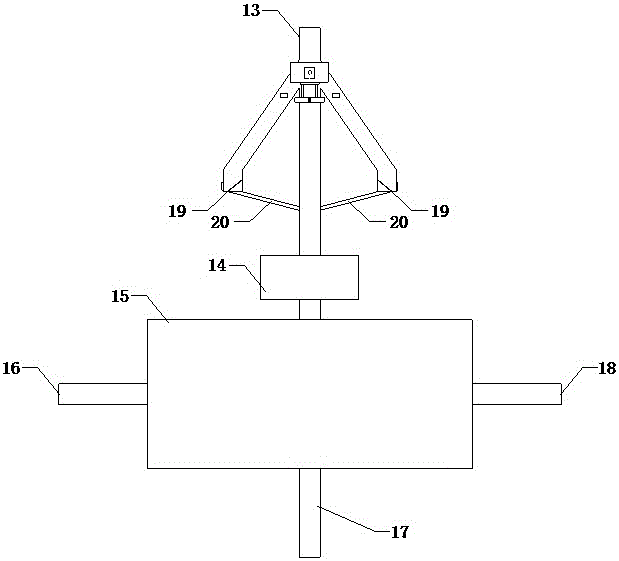

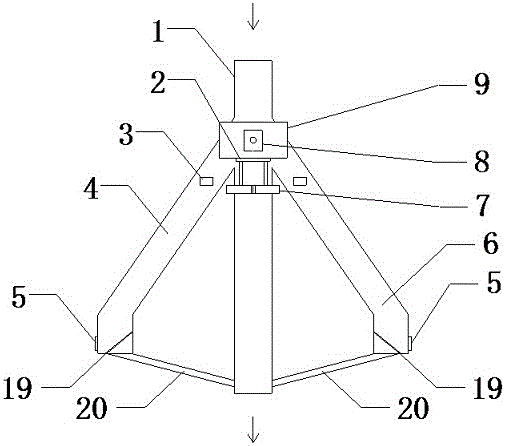

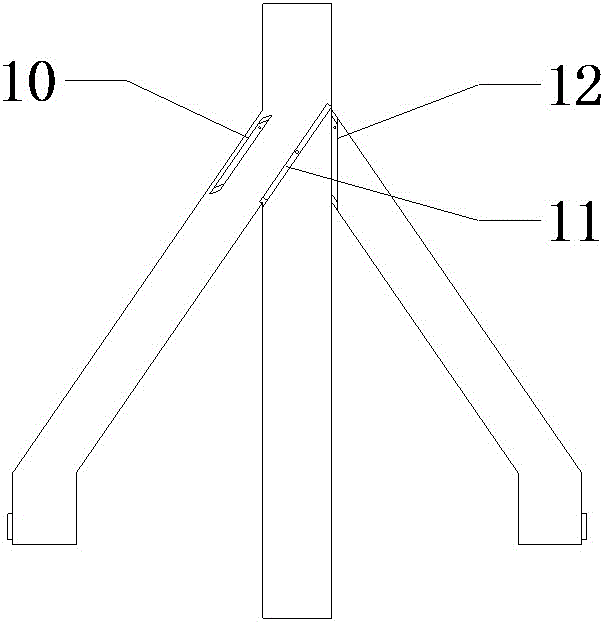

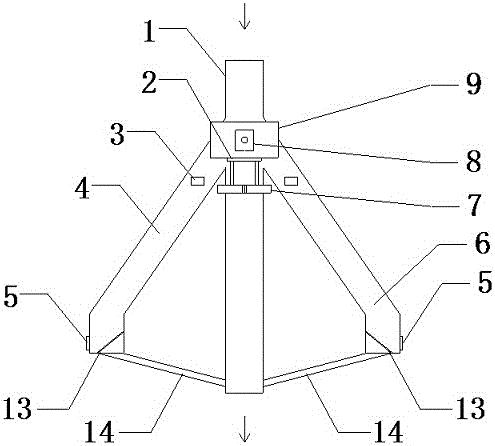

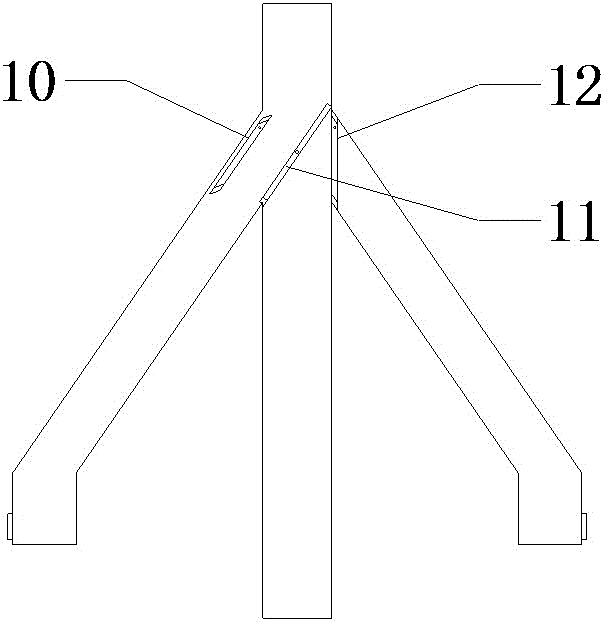

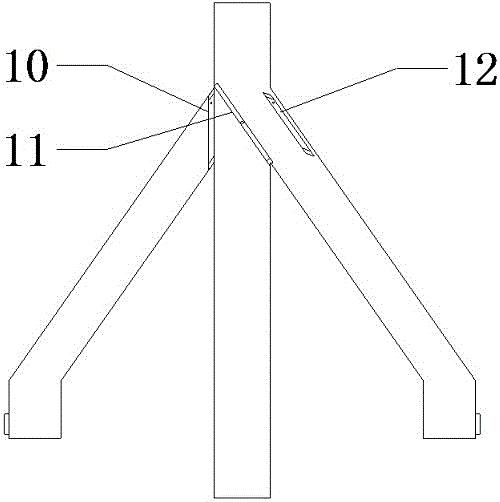

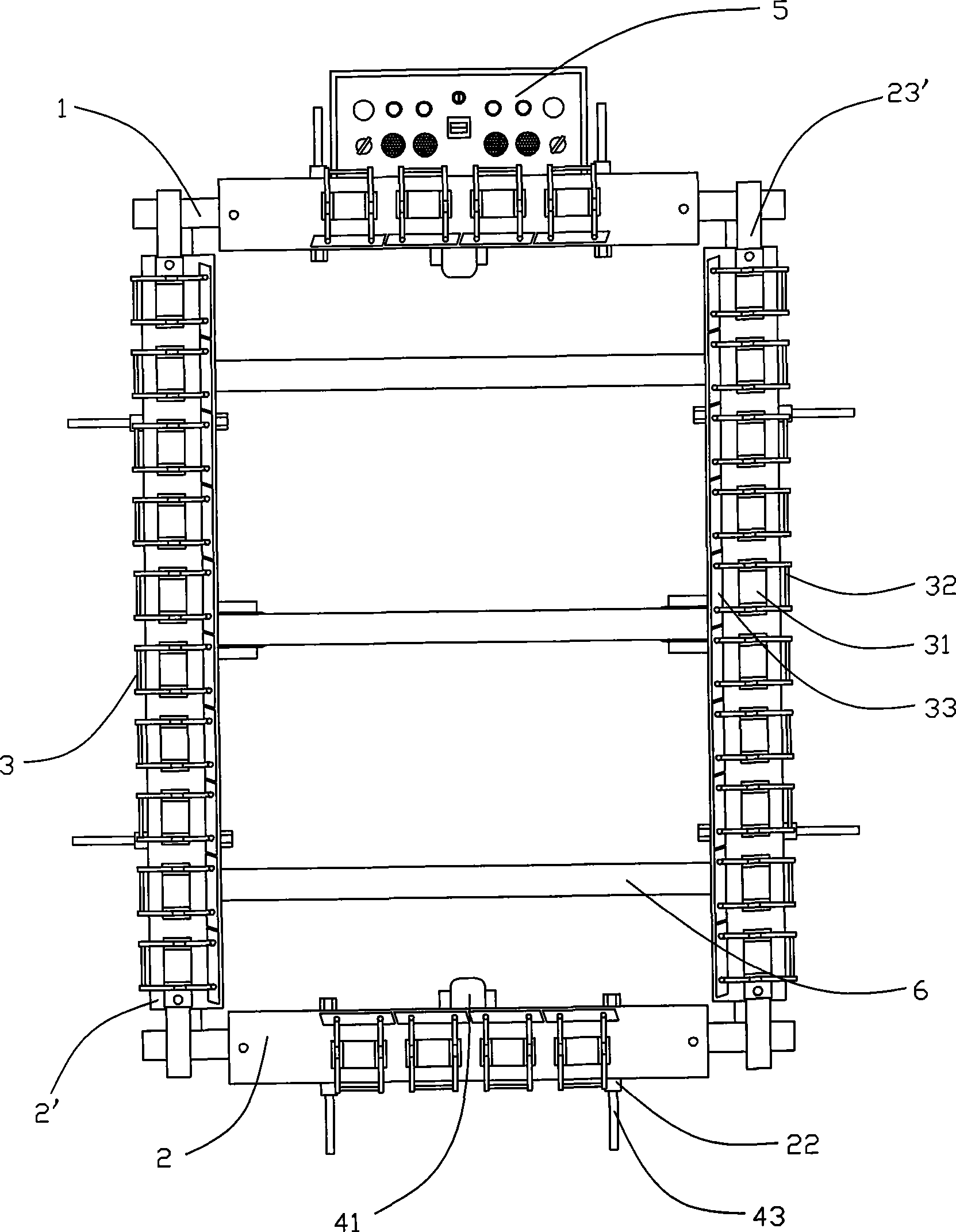

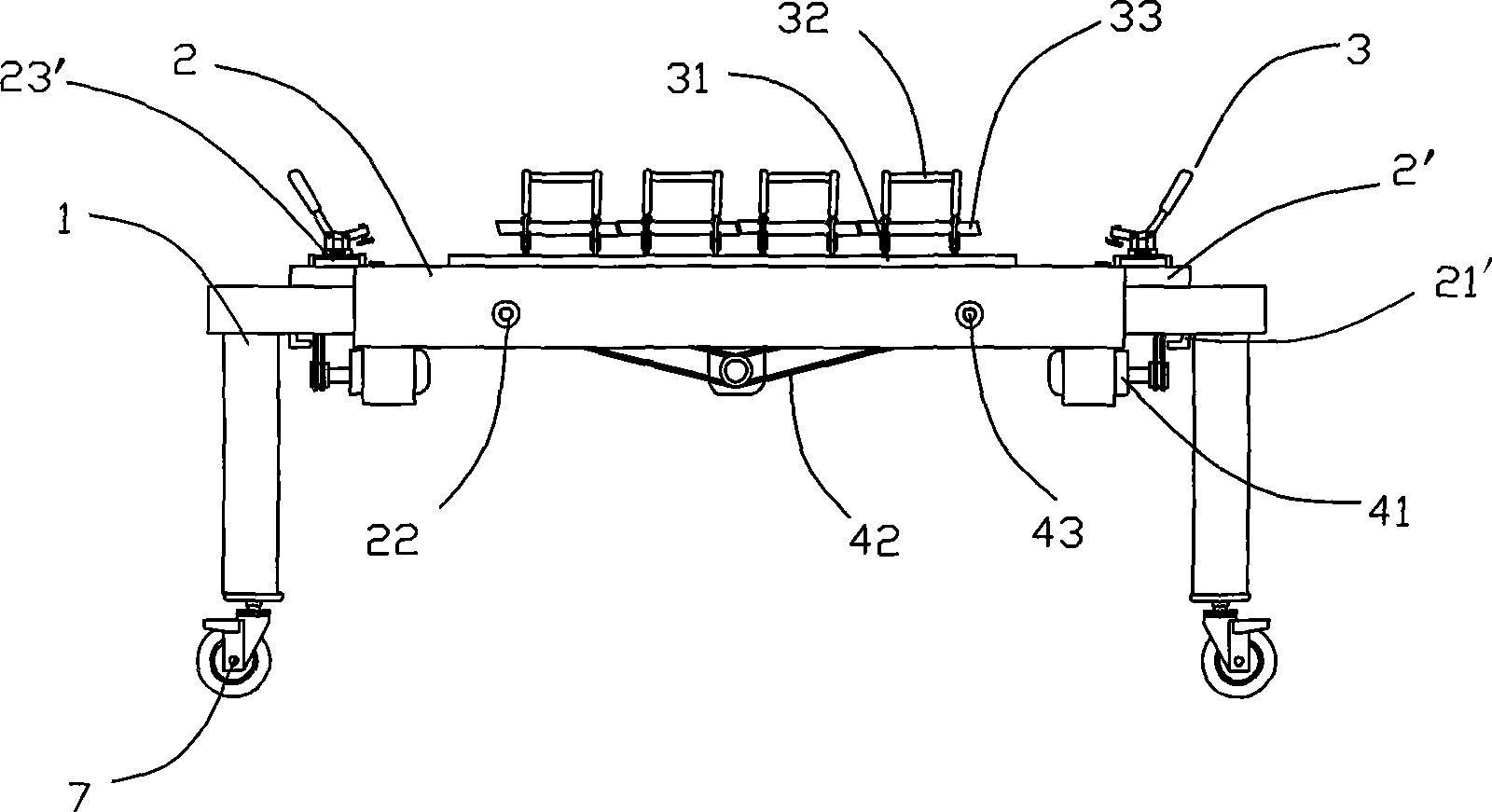

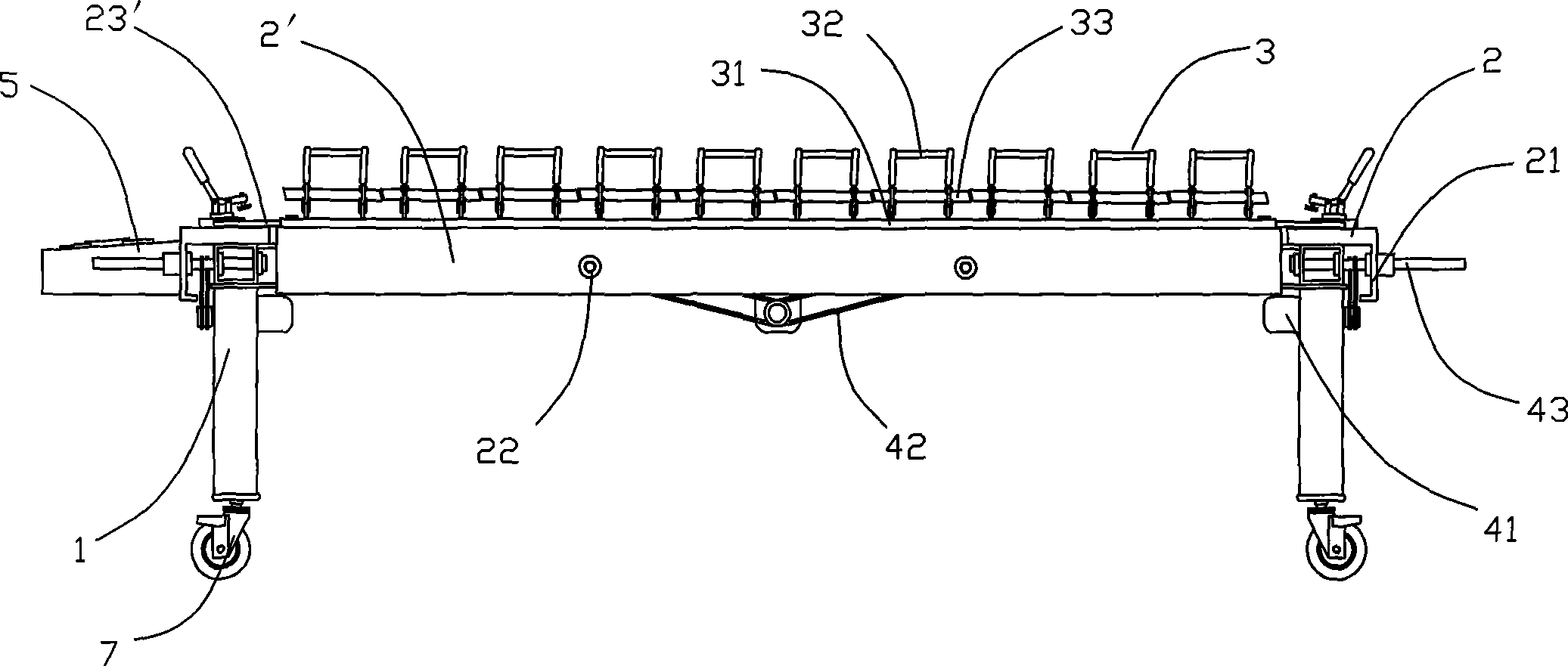

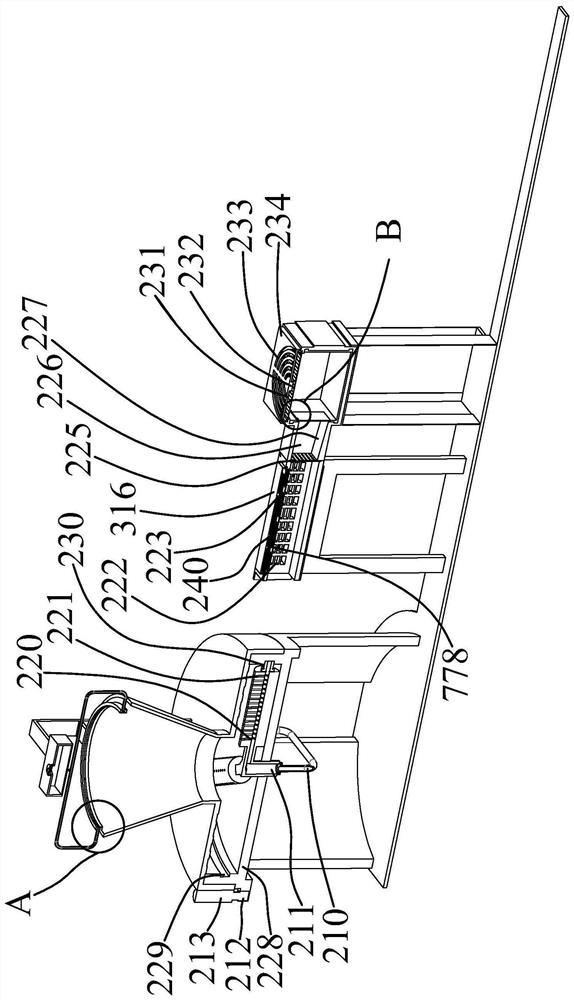

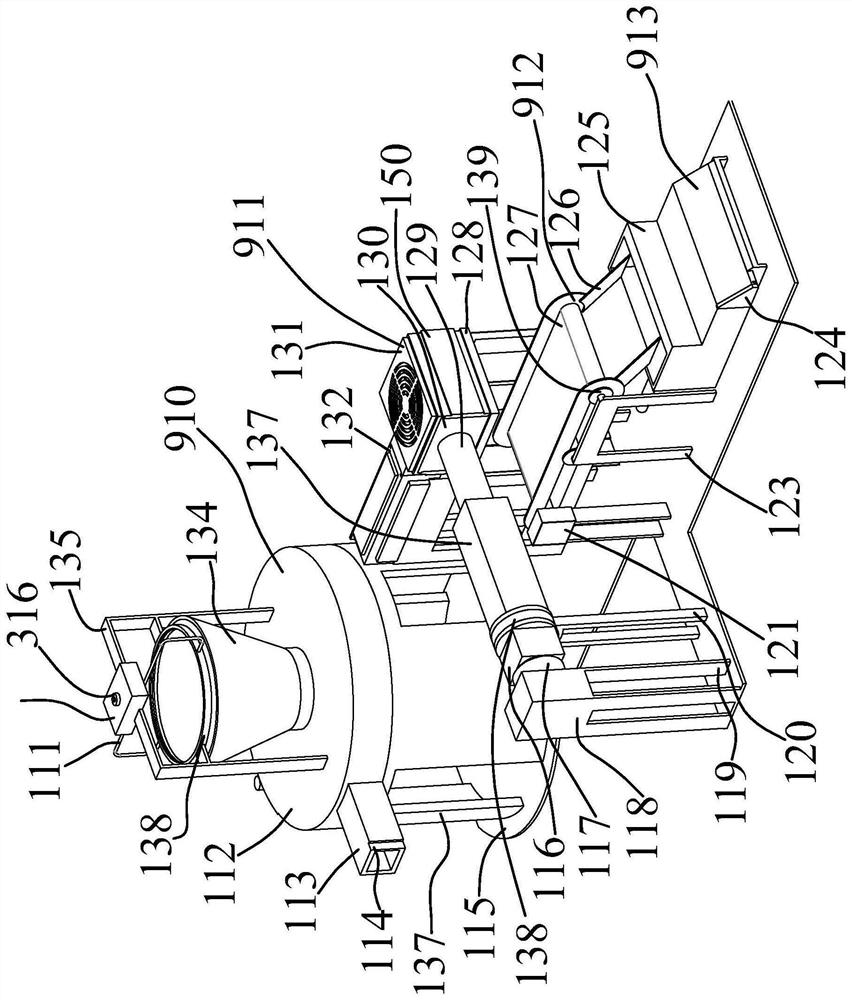

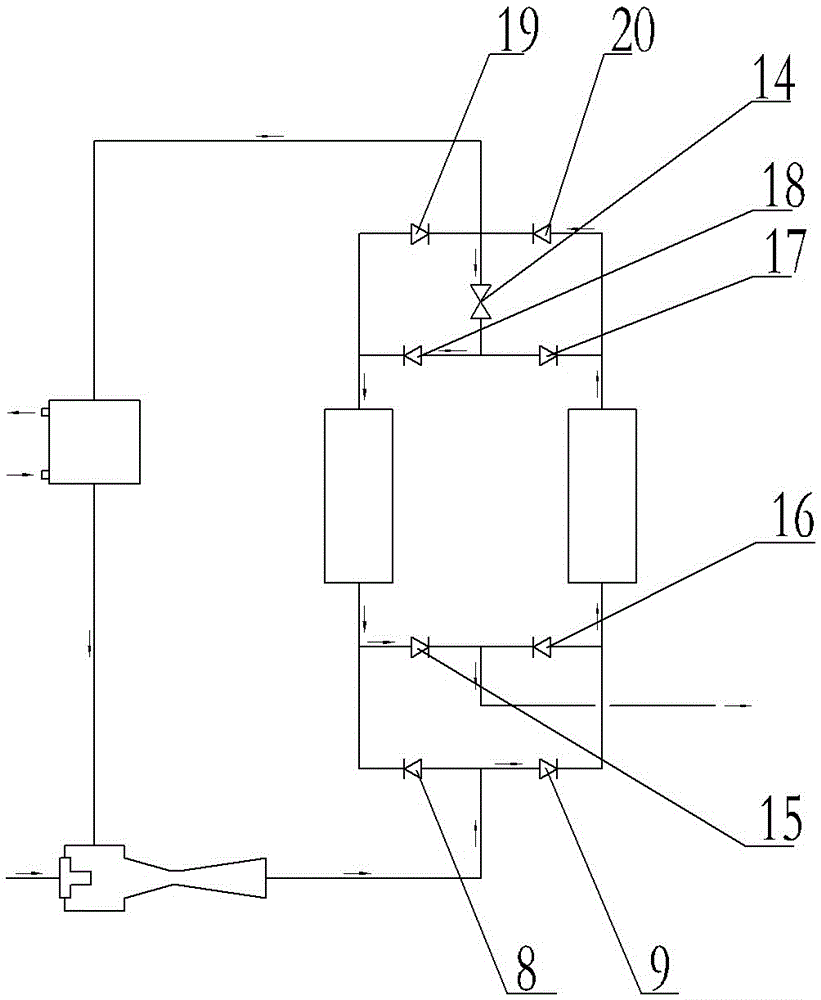

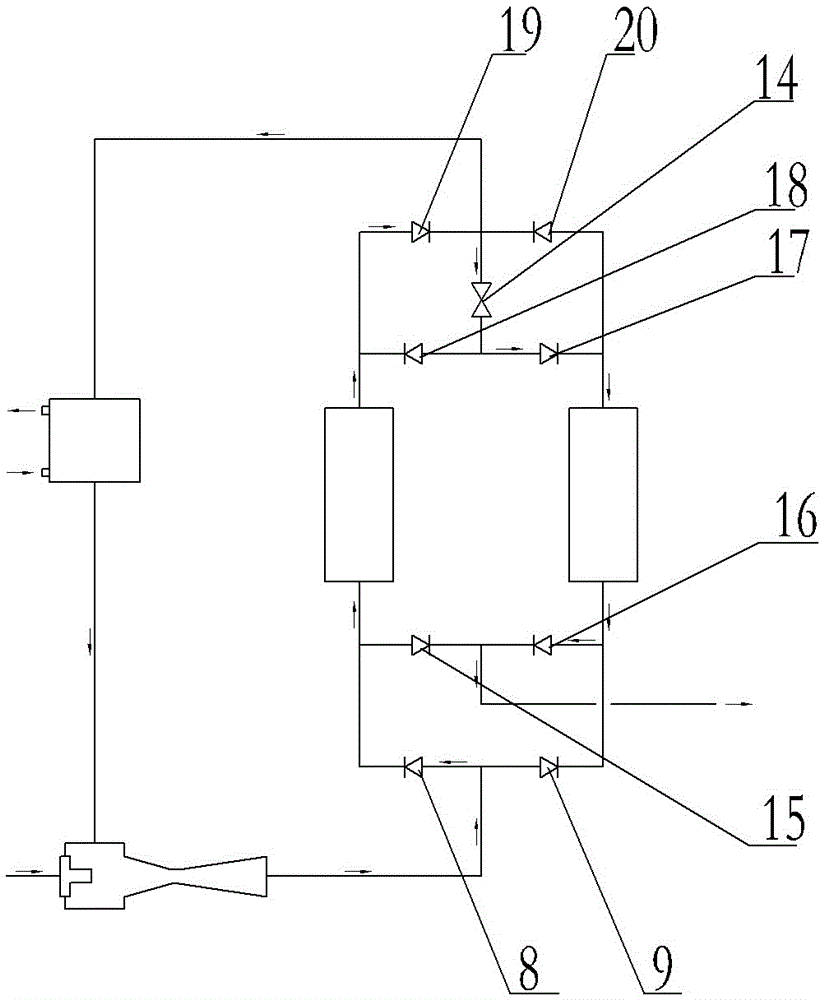

Automatic synchronization net puller and net pulling method

InactiveCN101380840AGuaranteed force balanceHigh precisionScreen printersSynchronous motorEngineering

The invention discloses a self-synchronizing net stretching machine and a stretching method thereof. The net stretching machine comprises a frame, horizontal and vertical line screw mandrel shifting devices arranged around the frame and net stretching collets arranged on the horizontal and vertical line screw mandrel shifting devices, wherein, the frame is provided with a synchronous motor group which controls the synchronous relative inward or outward shift of the horizontal and vertical opposite line screw mandrel shifting devices. While stretching the net, screw mandrel shifting devices at symmetrical sides of the horizontal line or the vertical line are controlled by the synchronous motor group to shift synchronously in succession for pre-stretching, then the mesh cloth is vertically fixed and firmly clamped, and synchronous net stretching from both symmetrical sides is carried out. The method has the advantages that net stretching can be carried out synchronously from symmetrical sides, thus ensuring that the force the mesh bears is balanced; besides, the horizontal lines and vertical lines are ensured to be vertical to each other during the process of synchronous net stretching, thereby largely improving the accuracy of net stretching; moreover, four sides of the mesh cloth can be ensured not to be wasted while stretching, thus improving the utility ratio of the mesh cloth.

Owner:冯兆坚

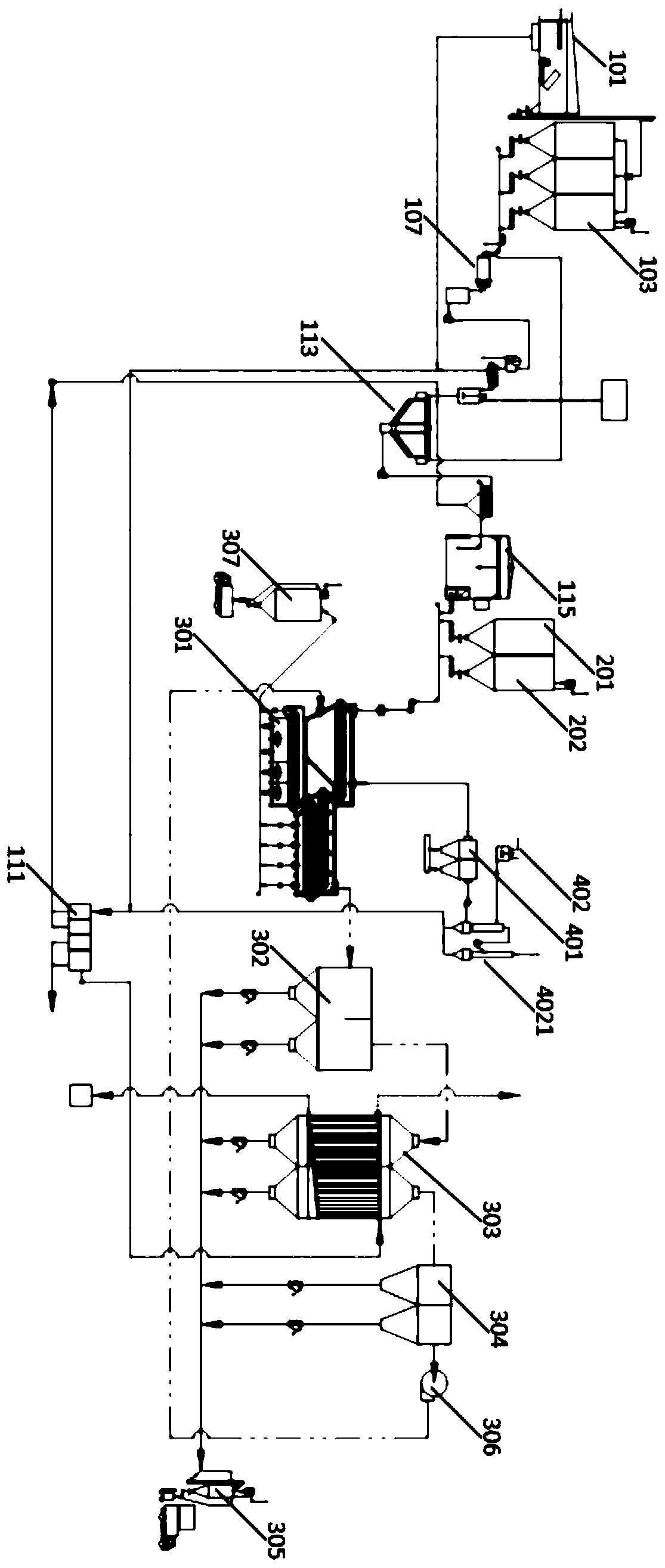

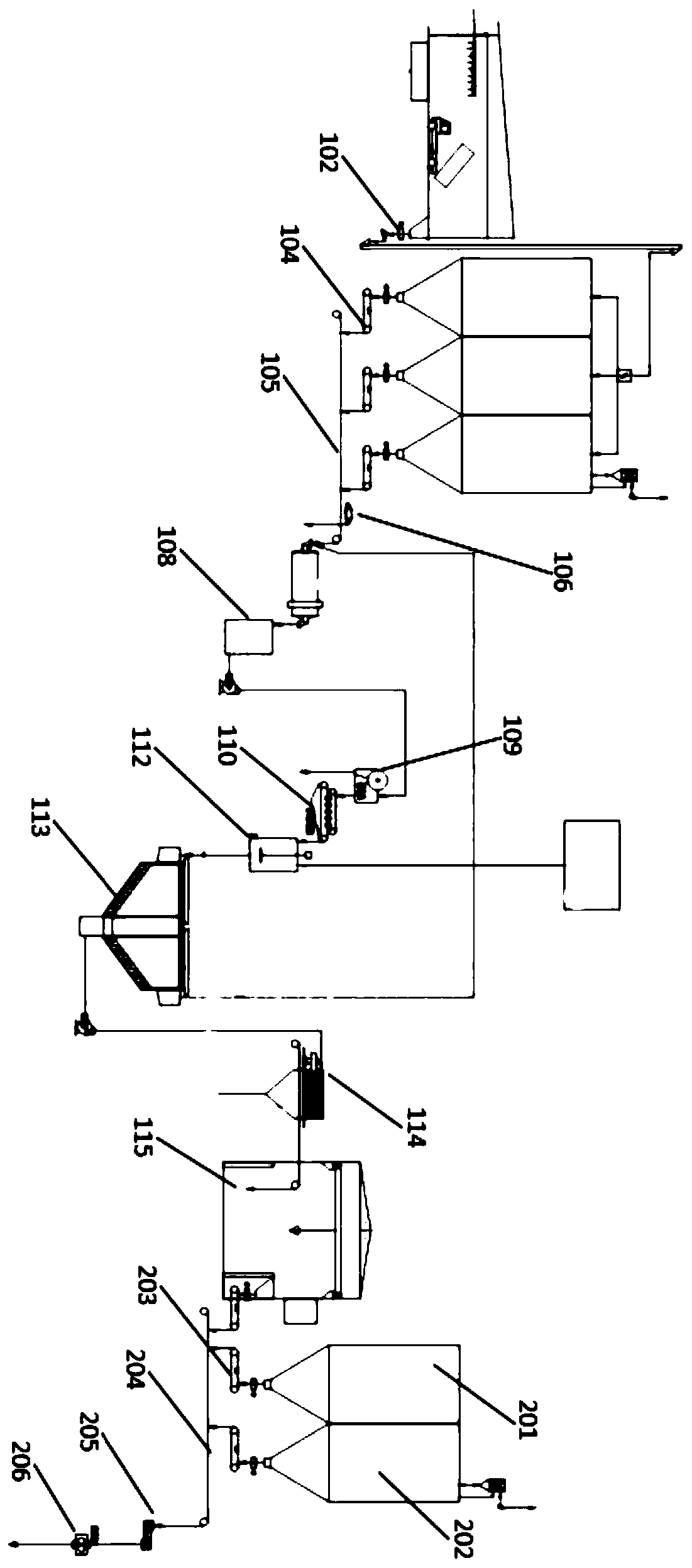

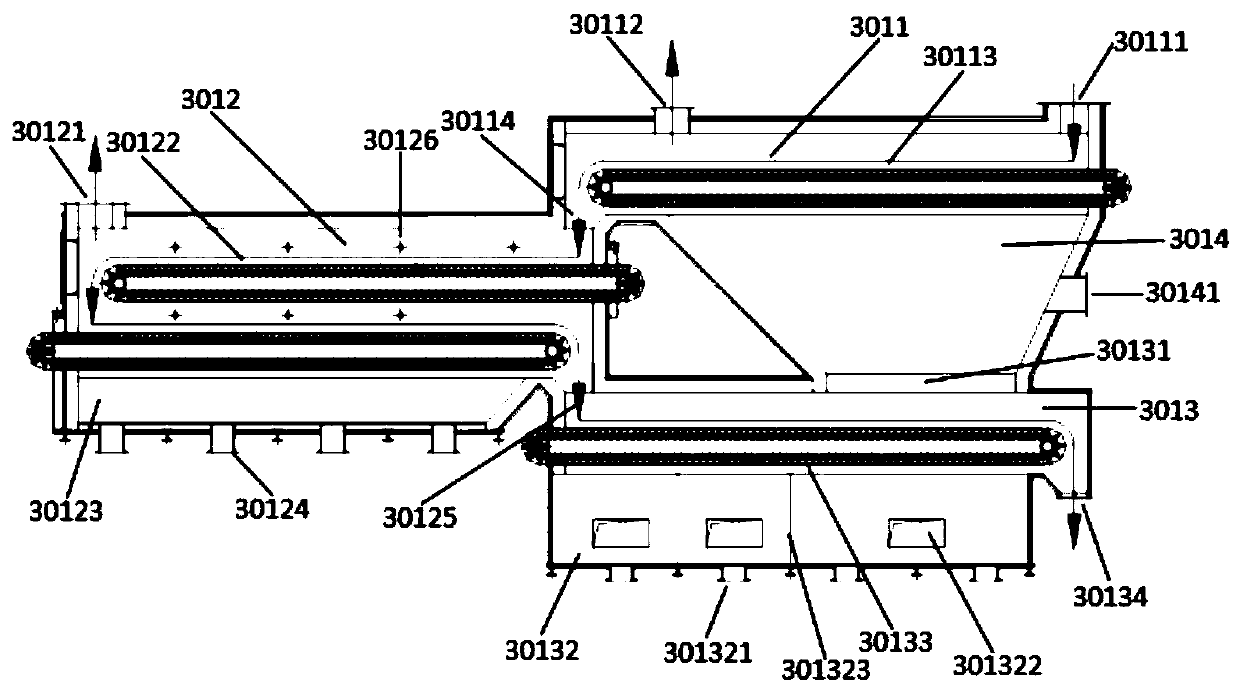

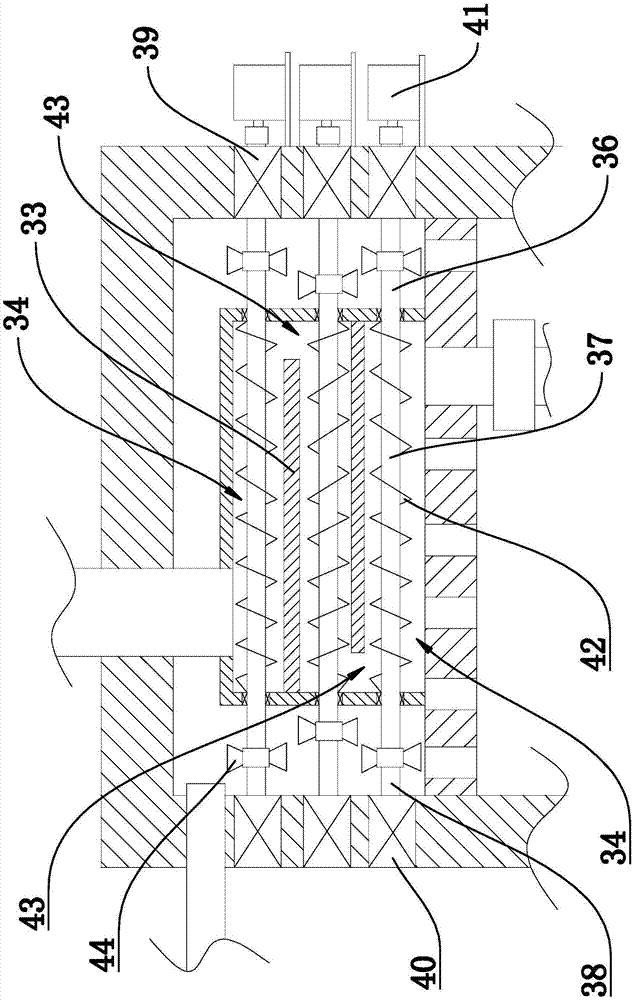

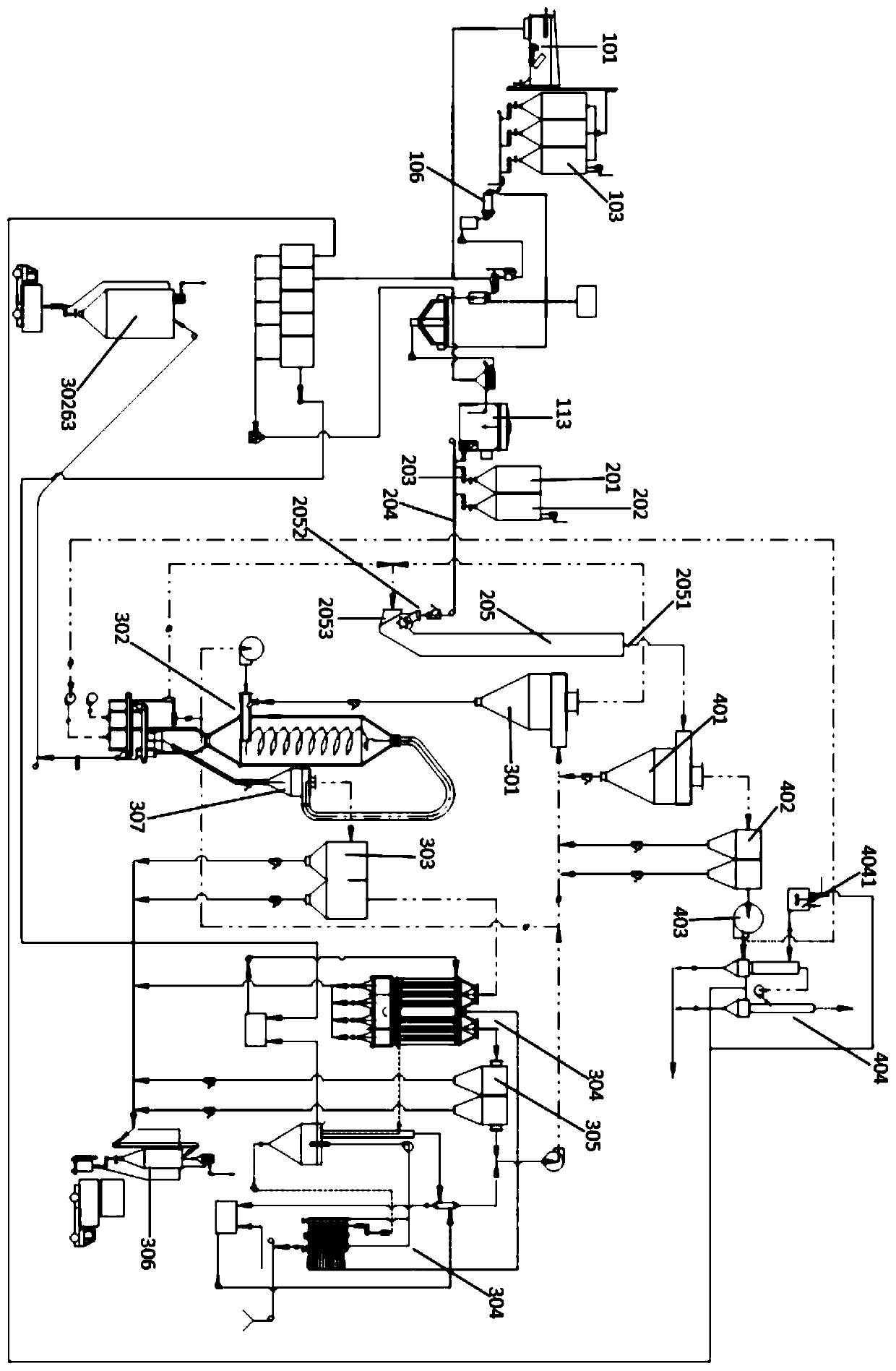

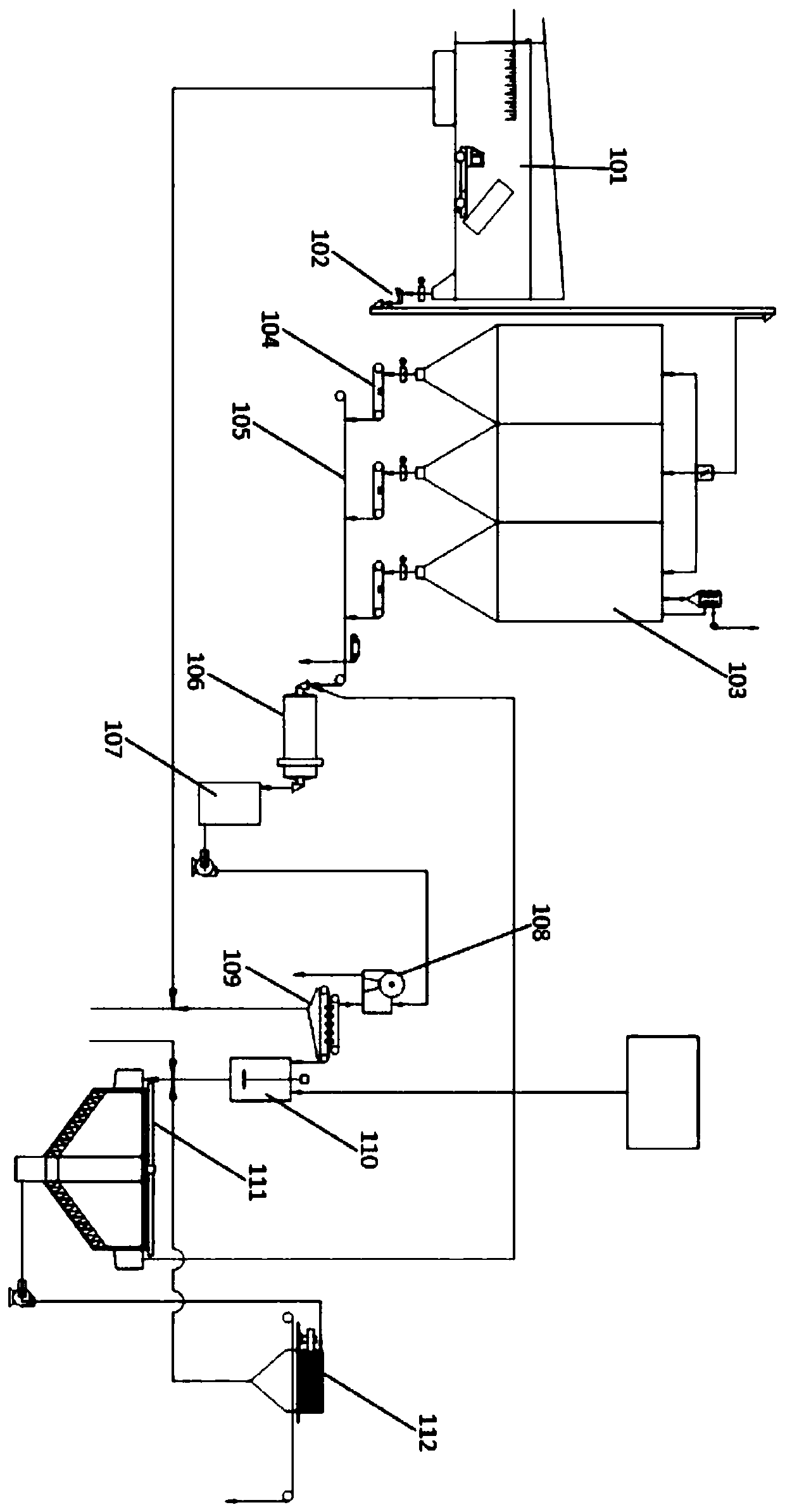

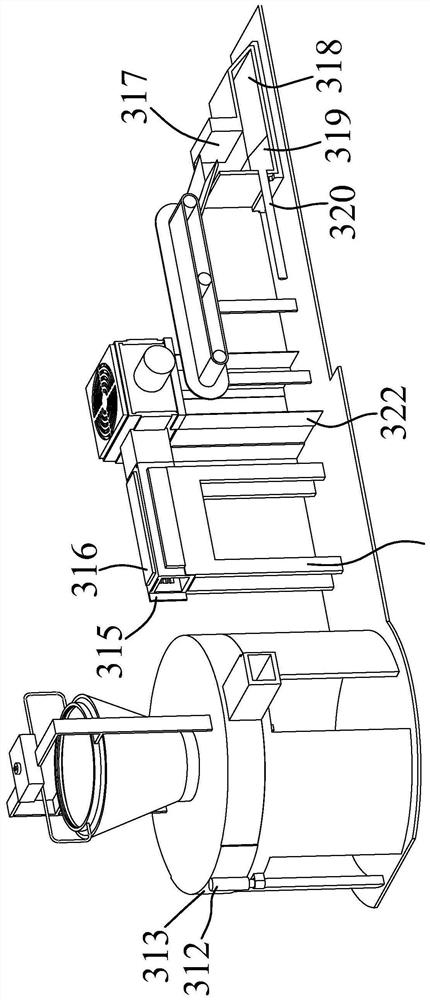

System and method for disposing steel plant collected dust through chain plate type high-temperature reduction furnace

PendingCN111270077AFast responseImprove reduction efficiencyCombination devicesWater/sewage treatmentPelletizingProcess engineering

The invention discloses a system and method for disposing steel plant collected dust through a chain plate type high-temperature reduction furnace. The system comprises a washing dechlorination system, a pelletizing granulation system, a volatile zinc extraction system and a flue gas treatment system; and the volatile zinc extraction system comprises the chain plate type high-temperature reductionfurnace, an oxidizing chamber, a brine evaporation and flue gas settling machine, a high-temperature static dust collector and a solid storage which are connected in sequence, the high-temperature static dust collector is connected with the chain plate type high-temperature reduction furnace through an exhaust fan, the chain plate type high-temperature reduction furnace comprises a furnace body and a cavity wrapped with the furnace body, and the cavity is composed of an evaporation preheating part, a high-temperature reduction part and a cooling part. The chain plate type high-temperature reduction furnace is utilized as main incineration refining equipment, and the equipment is simple and unique in structure, convenient to operate and low in cost.

Owner:长沙中硅环保科技有限公司

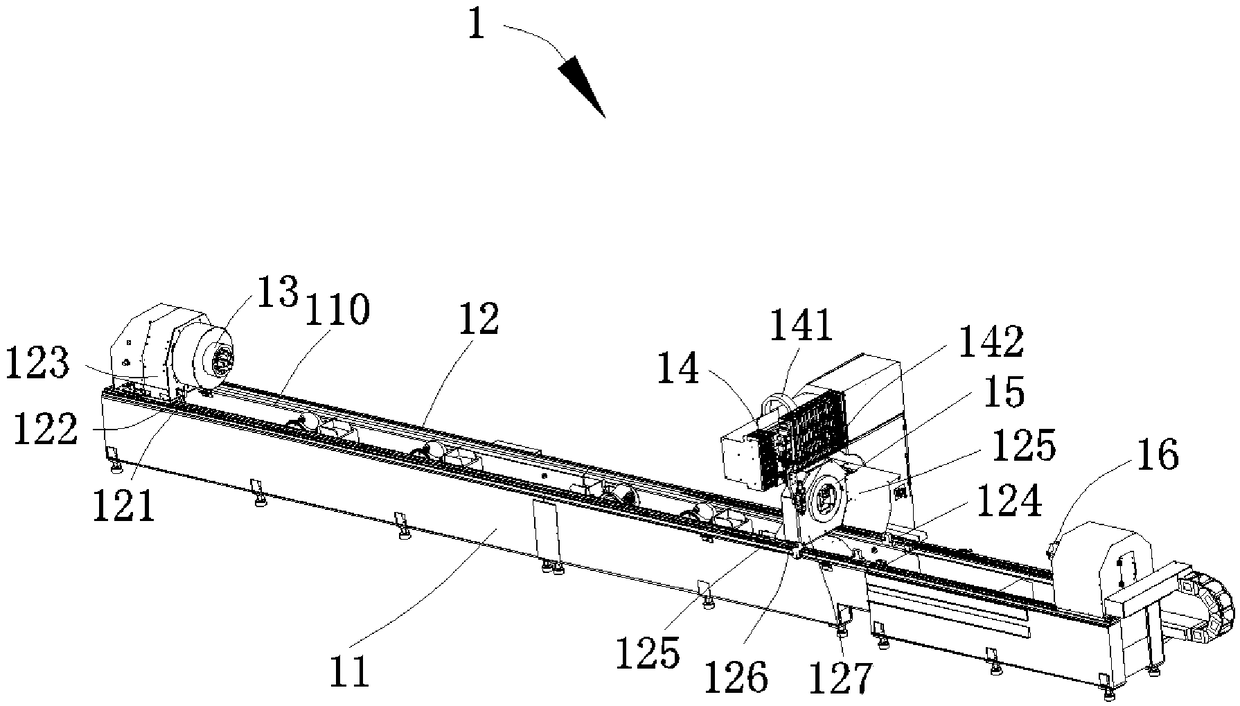

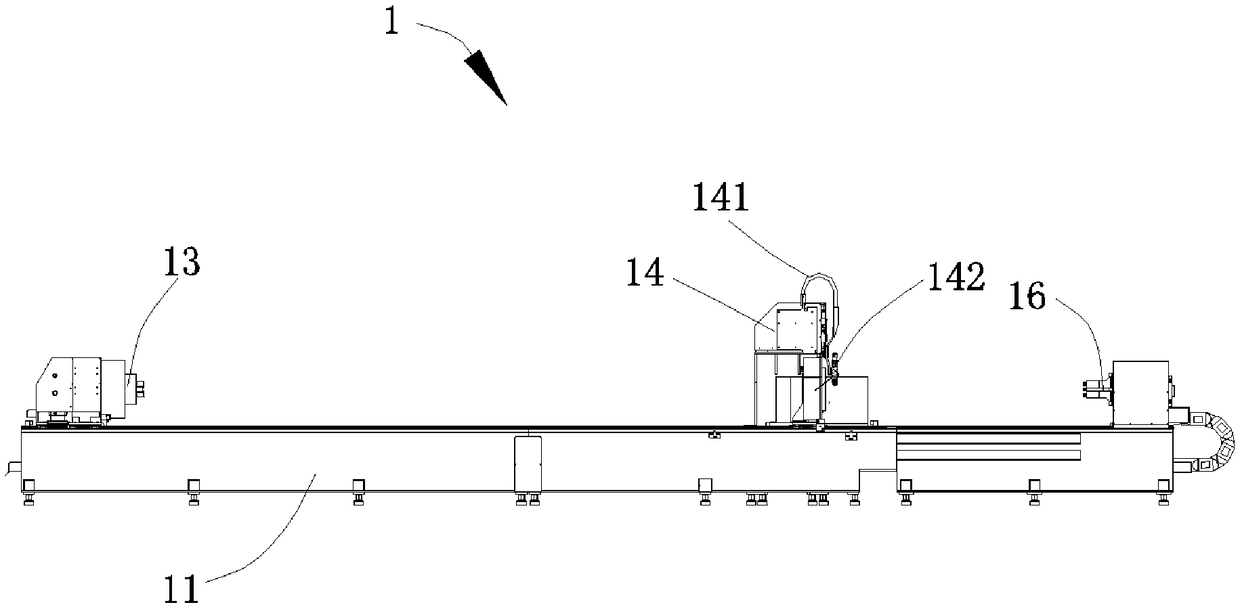

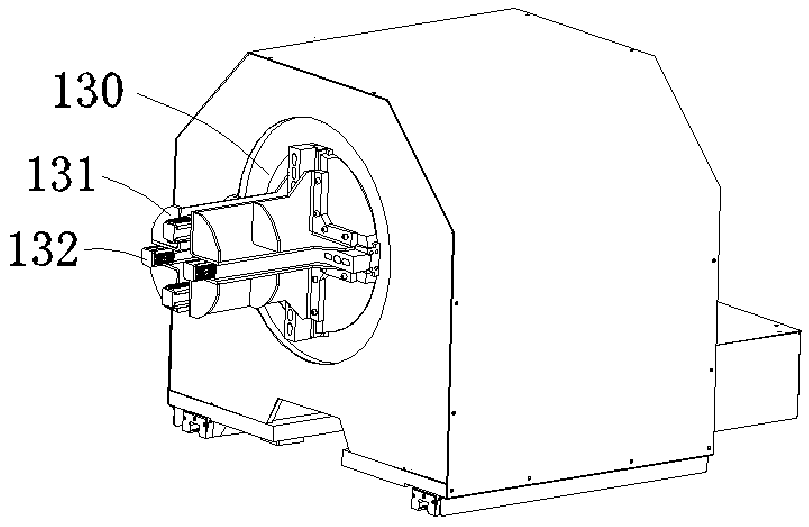

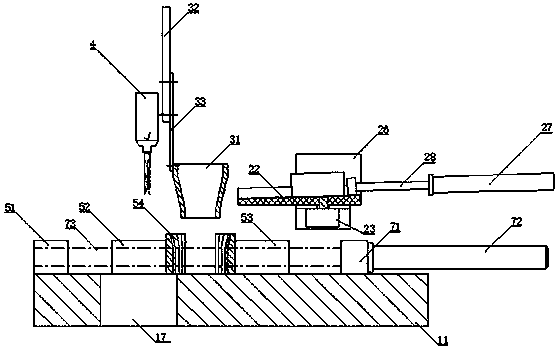

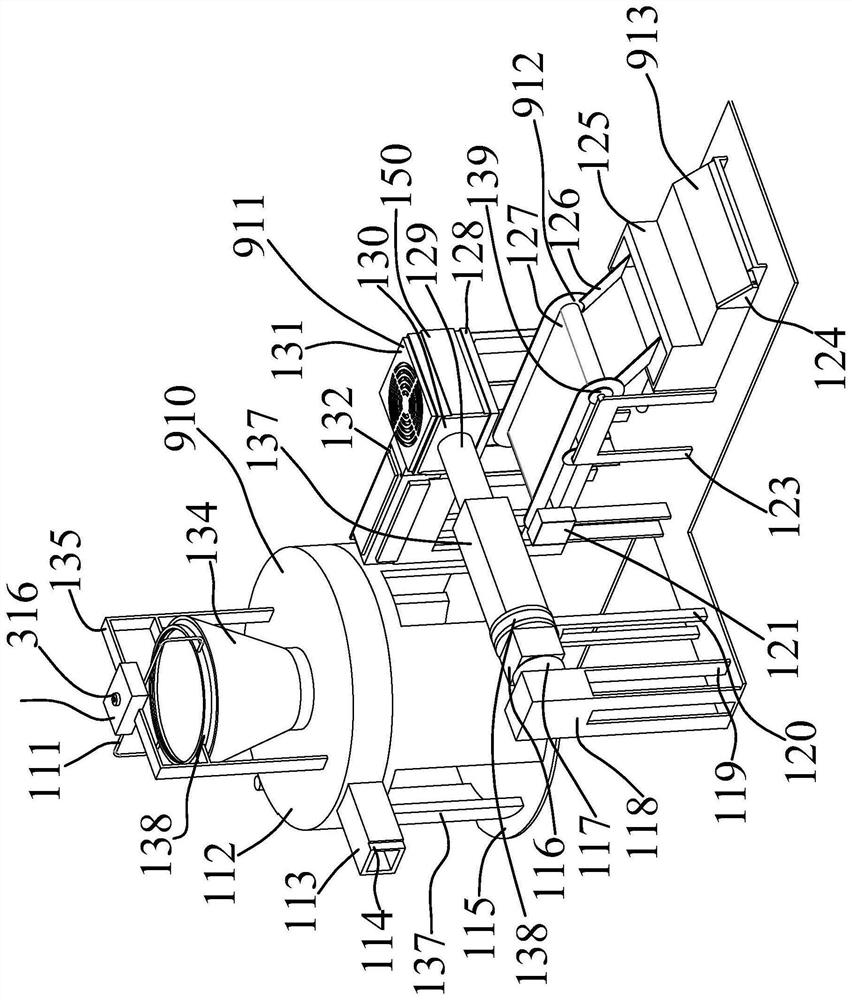

Profile laser cutting machine and using method thereof

A profile laser cutting machine comprises a frame assembly, a profile conveying mechanism for conveying a profile to be cut, a first clamping device for clamping a profile to be cut, a rotating mechanism for driving rotation of the profile to be cut, a laser cutting mechanism, a second clamping device, adjacent to the laser cutting mechanism, for clamping the profile to be cut, and a third clamping device for clamping the profile. The first clamping device, the second clamping device and third clamping device are movable. If the profile is too long, the profile is removed after first processing is completed, and the clamping and processing are performed in another direction.

Owner:苏州领创先进智能装备有限公司

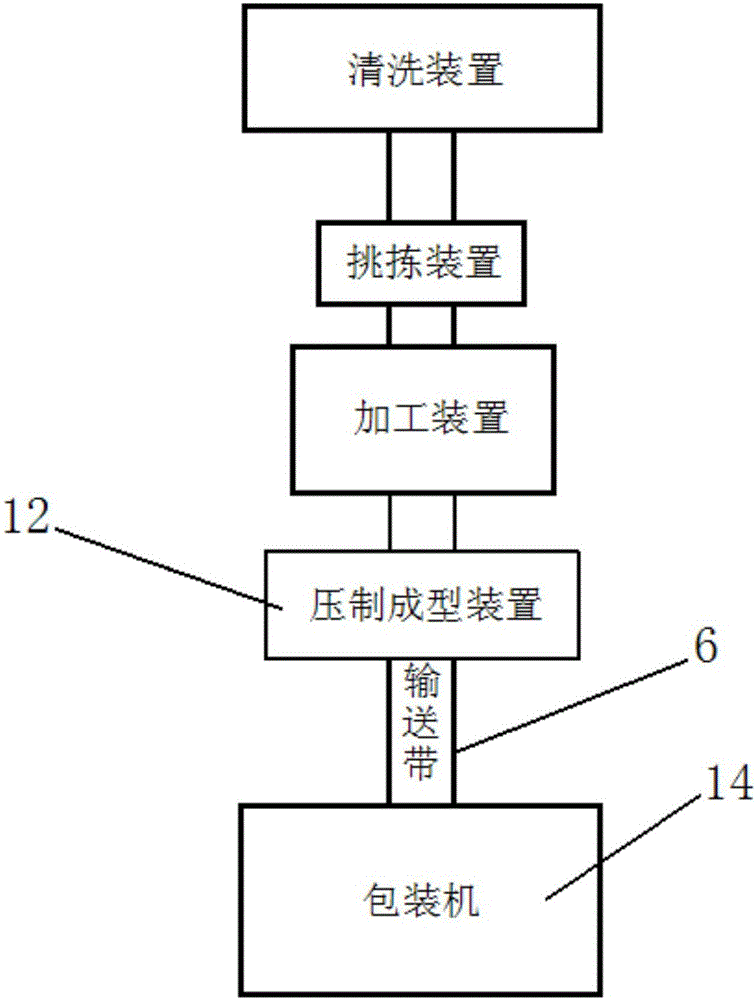

Sweet potato processing apparatus

The invention discloses a sweet potato processing apparatus. The sweet potato processing apparatus comprises a washing apparatus, a picking and choosing apparatus, a processing apparatus and a press molding apparatus, which are successively connected in series by virtue of a conveying apparatus, wherein the washing apparatus comprises a roller-type washing passage, a peeling apparatus and a slicing apparatus; the roller-type washing passage is serially connected with the peeling apparatus and the slicing apparatus by virtue of a conveying apparatus; the picking and choosing apparatus comprises a screening passage, a swinging rod and an unqualified product storage cabin; the processing apparatus comprises a boiling passage, a paste making apparatus, an extruding apparatus, a press molding apparatus and a curing apparatus; and the boiling apparatus, the paste making apparatus, the extruding apparatus, the press molding apparatus and the curing apparatus are successively connected in series by virtue of the conveying apparatus. By adopting the sweet potato processing apparatus, the unqualified potato can be sliced, the qualified sweet potato slices are reserved to be processed for eating next time; and the apparatus can reprocess the unqualified sweet potato, can prevent the waste of the sweet potato and can automatically wash and process the sweet potato.

Owner:泉州市联控自动化科技有限公司

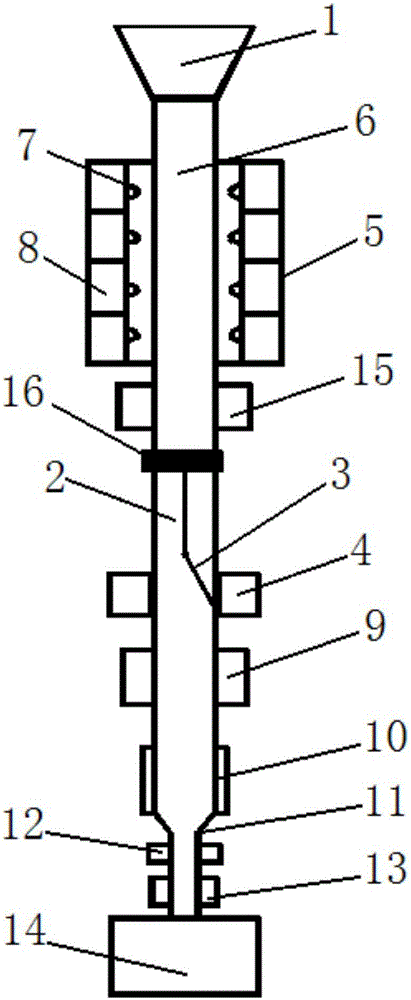

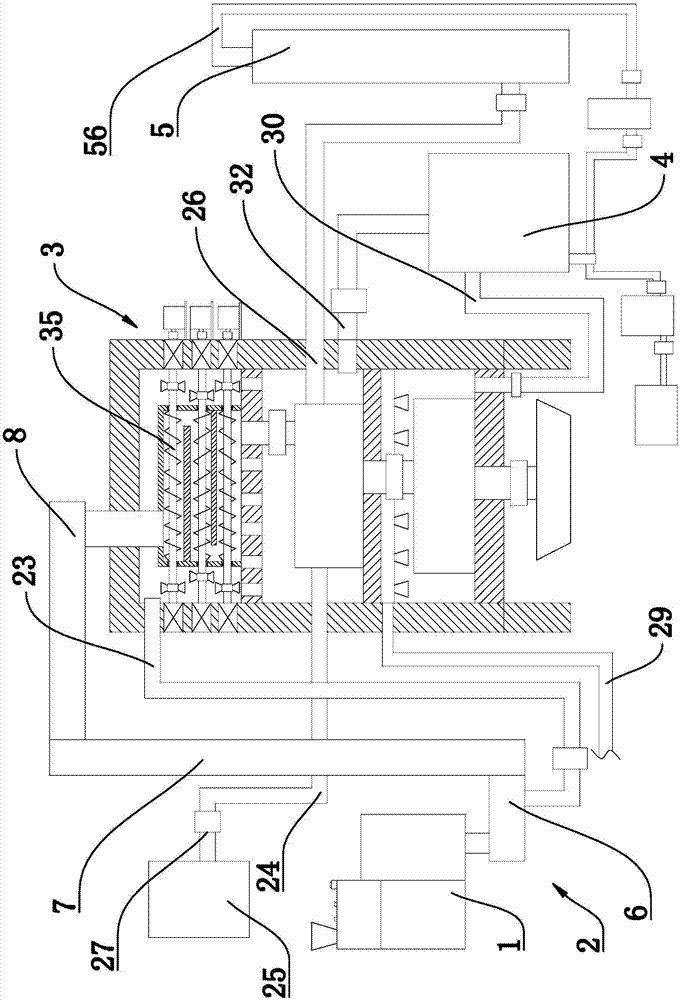

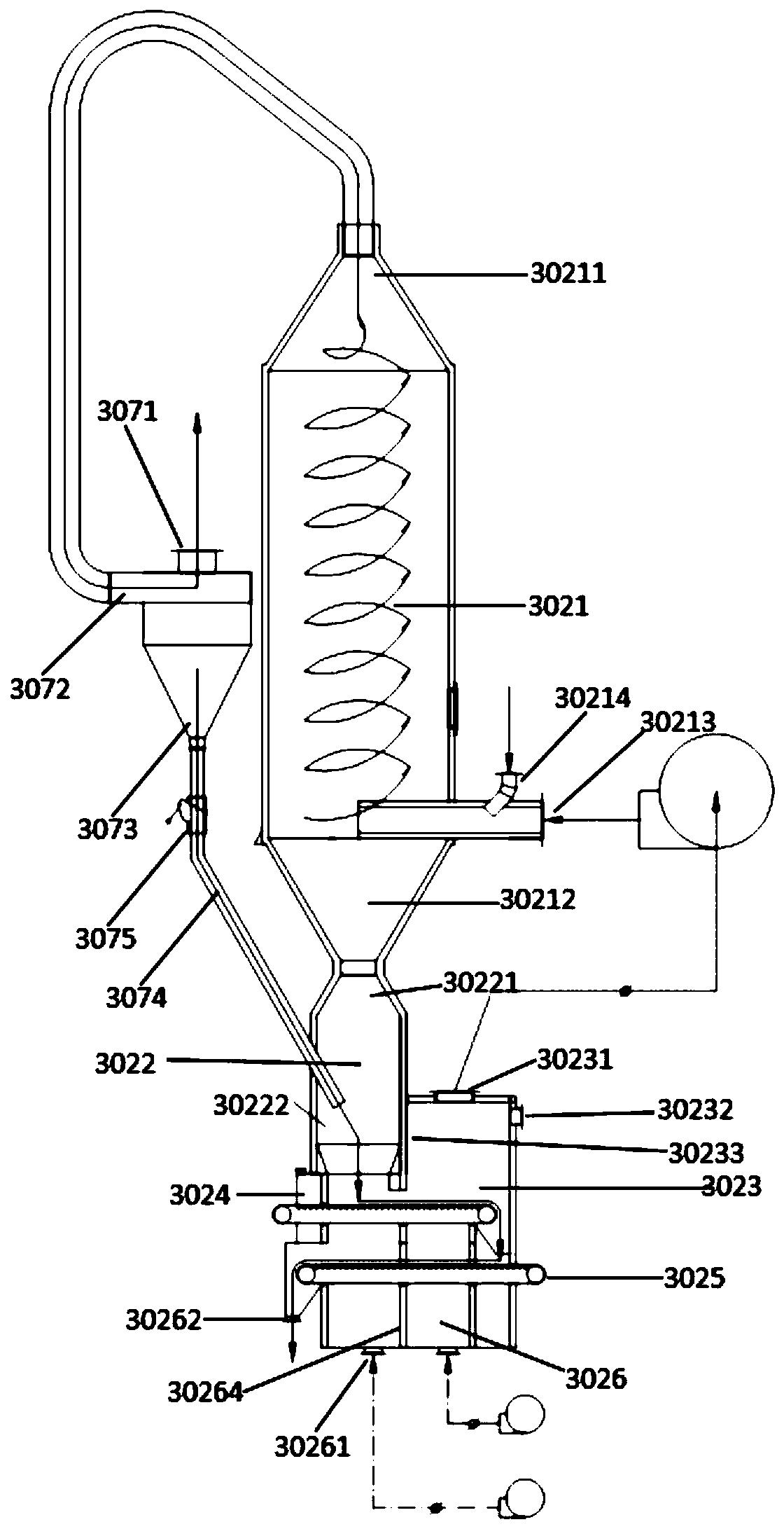

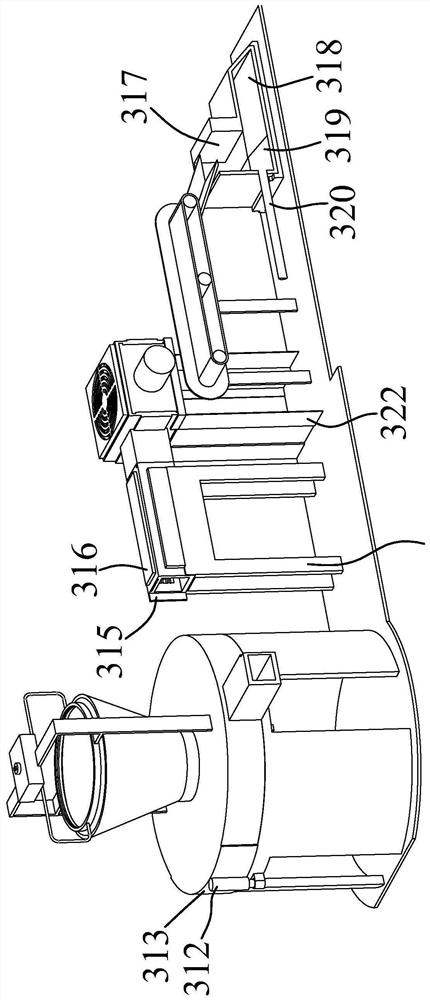

Crop straw carbonizing equipment

ActiveCN107513393ARelieve stressTake advantage ofBiofuelsIndirect heating destructive distillationFlue gasCooling chamber

Crop straw carbonizing equipment comprises a straw grinding machine, a feeding mechanism, a carbonizing furnace, a heating furnace, and a flue gas processing tower. The carbonizing furnace comprises an outer furnace body, a pyrolysis chamber, a carbonizing chamber, and a cooling chamber. The outer furnace body comprises a heat cavity A, a heat cavity B, and a cooling cavity. The pyrolysis chamber is arranged in the heat cavity A. The carbonizing chamber is arranged in the heat cavity B. The cooling chamber is arranged in the cooling cavity. The heat cavity A and the heat cavity B are communicated. The heat cavity B is connected to the heating furnace. The straw grinding machine is connected to the pyrolysis chamber through the feeding mechanism. The output end of the feeding mechanism is connected to the inlet end of the carbonizing chamber. The output end of the carbonizing chamber is connected to the inlet end of the cooling chamber. The output end of the cooling chamber is connected to a receiving hopper under the carbonizing furnace. The heat cavity A is communicated with the feeding mechanism through an exhaust pipe A. The carbonizing chamber is connected to a nitrogen tank through an air inlet pipe. The carbonizing chamber is connected to the flue gas processing tower through an exhaust pipe B. A spraying pipe is arranged in the cooling cavity and faces the cooling chamber. The spraying pipe is connected to a tap water main. The cooling cavity is provided with a liquid outlet. The liquid outlet is connected to the heating furnace through a liquid inlet pipe.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

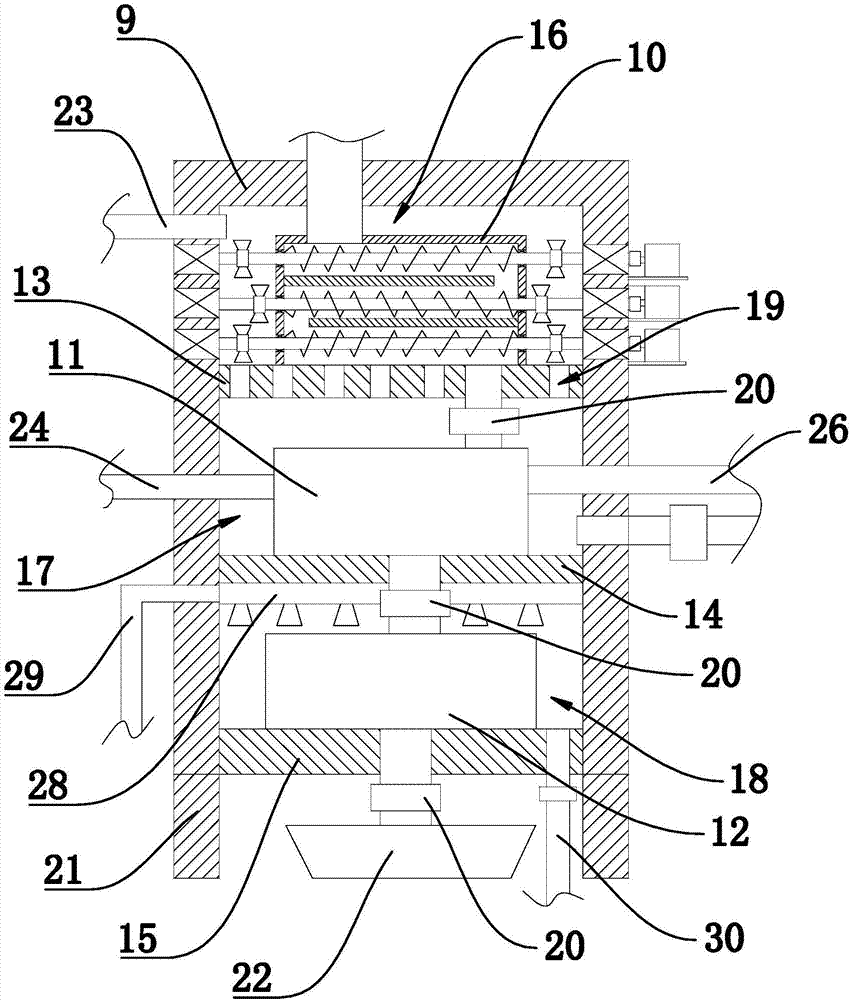

System and method for disposing dust collection ash of iron and steel plant through mesh belt type suspension combined reduction furnace

PendingCN111282961AEnsure complete combustionExtended burn timeCombination devicesTransportation and packagingThermodynamicsFlue gas

The invention discloses a system for disposing dust collection ash of an iron and steel plant through a mesh belt type suspension combined reduction furnace. The system comprises a washing dechlorination system, a drying dehydration system, a volatilization zinc extraction system and a flue gas treatment system, wherein the volatilization zinc extraction system comprises a cyclone preheater, the mesh belt type suspension combined reduction furnace, an oxidation chamber, a saline water evaporation and flue gas sedimentation system, a high-temperature electrostatic dust collector and an exhaustfan which are sequentially connected; the mesh belt type suspension combined reduction furnace is composed of a furnace body and a cyclone separator; and the furnace body comprises a rotational flow part, a boiling part, a cooling chamber, a sealing chamber, a high-temperature mesh belt machine and an inflation chamber from top to bottom. The mesh belt type suspension combined reduction furnace isused as main cremation refining equipment, and the equipment is simple and unique in structure, convenient to operate and low in manufacturing cost.

Owner:长沙中硅环保科技有限公司

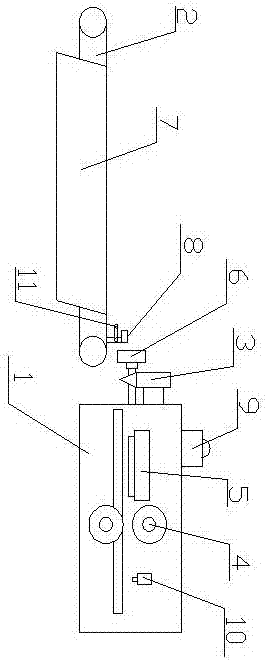

Electric wire cut-off machine with detection device

InactiveCN107442698ANot to be wastedAvoid affecting sales qualityMetal working apparatusEngineeringAlarm device

The invention provides a wire cutting machine with a detection device, which includes a feeding machine and an unloading conveyor belt. The unloading conveyor belt is arranged at the left end of the feeding machine. There is a feed roller on the machine, and a length confirmer is set beside the feed roller. The length confirmer is associated with the wire cutter. The length of the passing wire is confirmed by the length confirmer, and the wire cutter is controlled to cut the wire. The wire cutter There is a wire detection ring next to it. When the wire detection ring detects that there is a wire joint on the wire, the wire cutter will cut the wire, and the length confirmer will re-measure the length, so as to ensure that the material is not wasted as much as possible, reduce production costs, and pass The alarm device reminds the operator to sort out the wires containing the wire joints, so as to avoid being mixed into the product and affecting the sales quality.

Owner:WUHU SHUNCHENG ELECTRONICS

Novel plate heat exchanger

ActiveCN106767046AGuaranteed continuous supplyAchieve uninterrupted supplyRecuperative heat exchangersCorrosion preventionNew energySlag

The invention relates to a novel plate heat exchanger and belongs to the technical field related to new energy. The novel plate heat exchanger mainly comprises a heat exchanger body and a slag filter communicating with the heat exchanger body. The slag filter is provided with a vertically arranged slag washing water inlet pipe. The left side of the slag washing water inlet pipe communicates with a first slag storage bin. The right side of the slag washing water inlet pipe communicates with a second slag storage bin. A supporting frame is installed on the slag washing water inlet pipe. A gearbox is arranged on the supporting frame and provided with a first output shaft, a second output shaft and a third output shaft. The first output shaft is connected with a first sealing plate. The second output shaft is connected with a filter screen frame. The third output shaft is connected with a second sealing plate. The first sealing plate, the filter screen frame and the second sealing plate are all located inside the slag washing water inlet pipe. The bottom of the first slag storage bin and the bottom of the second slag storage bin are both provided with slag discharging ports. By the adoption of the novel plate heat exchanger, slag in slag washing water can be filtered out, and meanwhile, the shutdown time caused by slag removal is greatly shortened.

Owner:南京普兰特换热设备有限公司

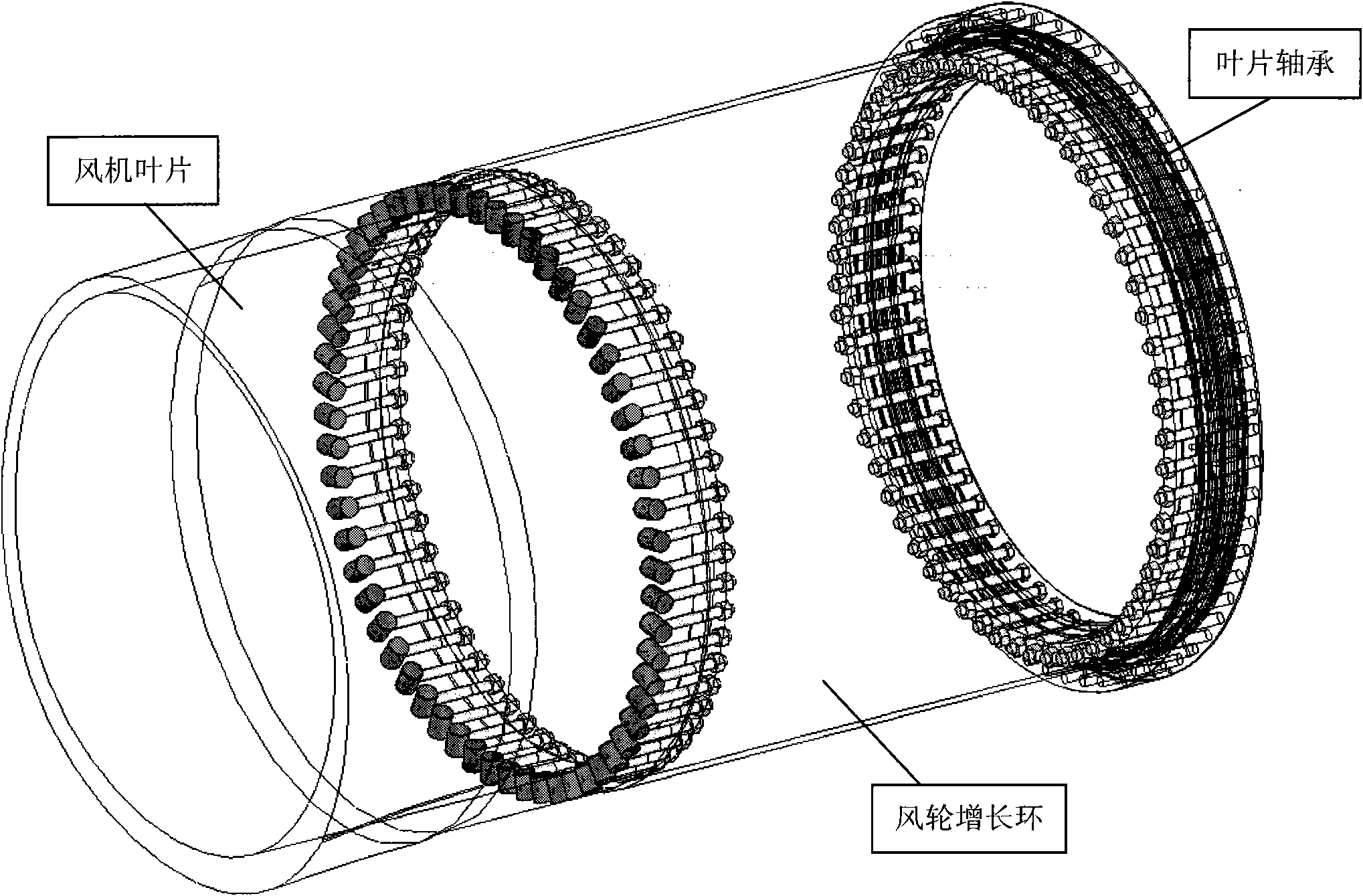

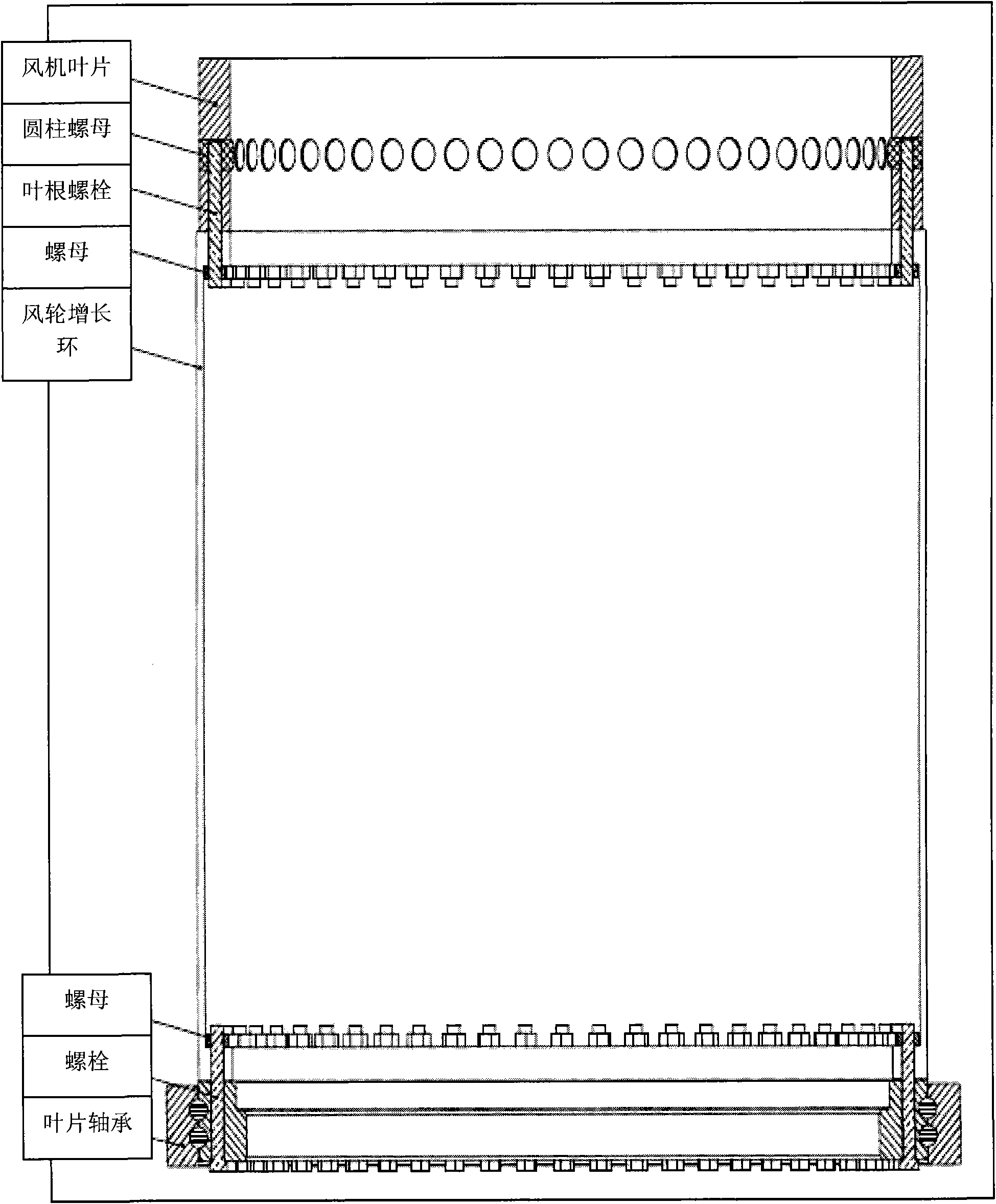

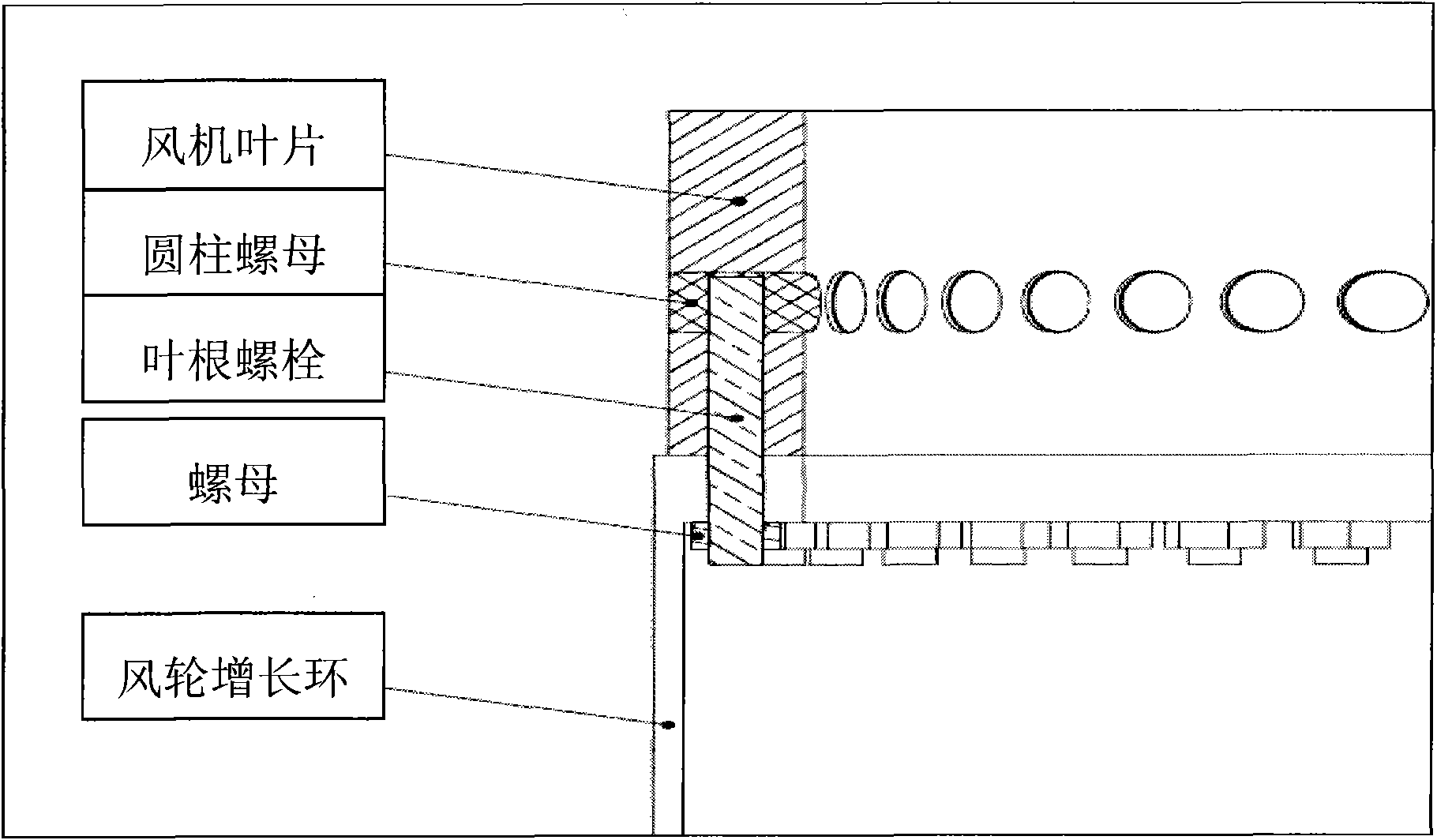

Wind wheel lengthening ring

InactiveCN102338045AIncrease the swept areaReduce development costsFinal product manufactureMachines/enginesElectricityEngineering

The invention discloses a wind wheel lengthening ring for a blade of a wind generating set. Along with the continuous enlargement of a wind wheel of the generating set, the length of the blade is necessary to lengthen; the traditional method is as follows: the blade is designed again; but the development period of the bade is shortened because of the rapid development of wind power industry, therefore, a lot of blade moulds and support equipment are wasted; furthermore, the transportation difficulty and the transportation cost of the fan blade which is ultra-long originally are also further increased. According to the wind wheel lengthening ring disclosed by the invention, a columnar cylinder is used as a main body; the blade and a blade bearing are respectively connected to the two ends of the columnar cylinder; on the basis of using the original blade, the blade is lengthened; the wind sweeping area of the wind wheel is increased; by means of the application of the wind wheel lengthening ring, the blade development cost is saved, therefore, a lot of blade moulds and the support equipment are not wasted; the manufacture cost and the transportation cost resulted from the lengthening of the blade are reduced; meanwhile, the standardization degree and the batch production of the blades are also facilitated.

Owner:SHANGHAI ELECTRIC WIND ENERGY CO LTD

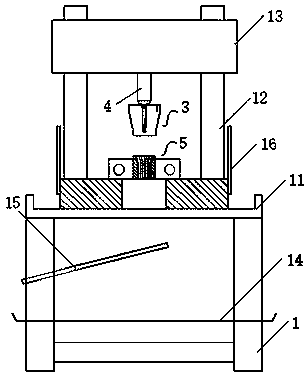

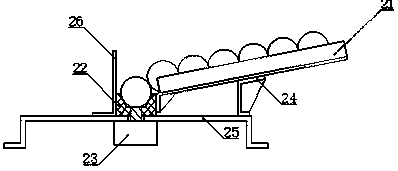

Production device for pipe pile die assembly accessories

PendingCN111054984AAvoid wastingGuaranteed stabilityThread cutting feeding devicesThread cutting machinesStructural engineeringMechanical engineering

The invention relates to a production device for pipe pile die assembly accessories. The device comprises a rack, a feeding assembly, a blanking device, a tapping device, a clamping mechanism, a differential assembly and a horizontal driving mechanism, the feeding assembly comprises a feeding groove, a workpiece feeding and discharging guide seat, an electromagnet and a feeding mechanism, the clamping mechanism comprises a limiting block, a left clamping block and a right clamping block, a left clamping die and a right clamping die which are used for clamping workpieces are symmetrically arranged in the middle of the left clamping block and the middle of the right clamping block, the left clamping die and the right clamping die are driven in a differential structure mode, the left clampingdie and the right clamping die are respectively provided with a cavity, the upper portion of each cavity is of an inverted circular truncated cone structure, the lower portion of each cavity is of acylindrical structure, and the inverted circular truncated cone structure cavities can be attached to the upper portions of blanking guide sections of the blanking hoppers. The feeding device has theadvantages that the whole structure is compact, the occupied space is small, the workpiece feeding can be guaranteed orderly, the discharging is stable, and the production efficiency is high.

Owner:RUGAO ZHONGZHENG MACHINERY

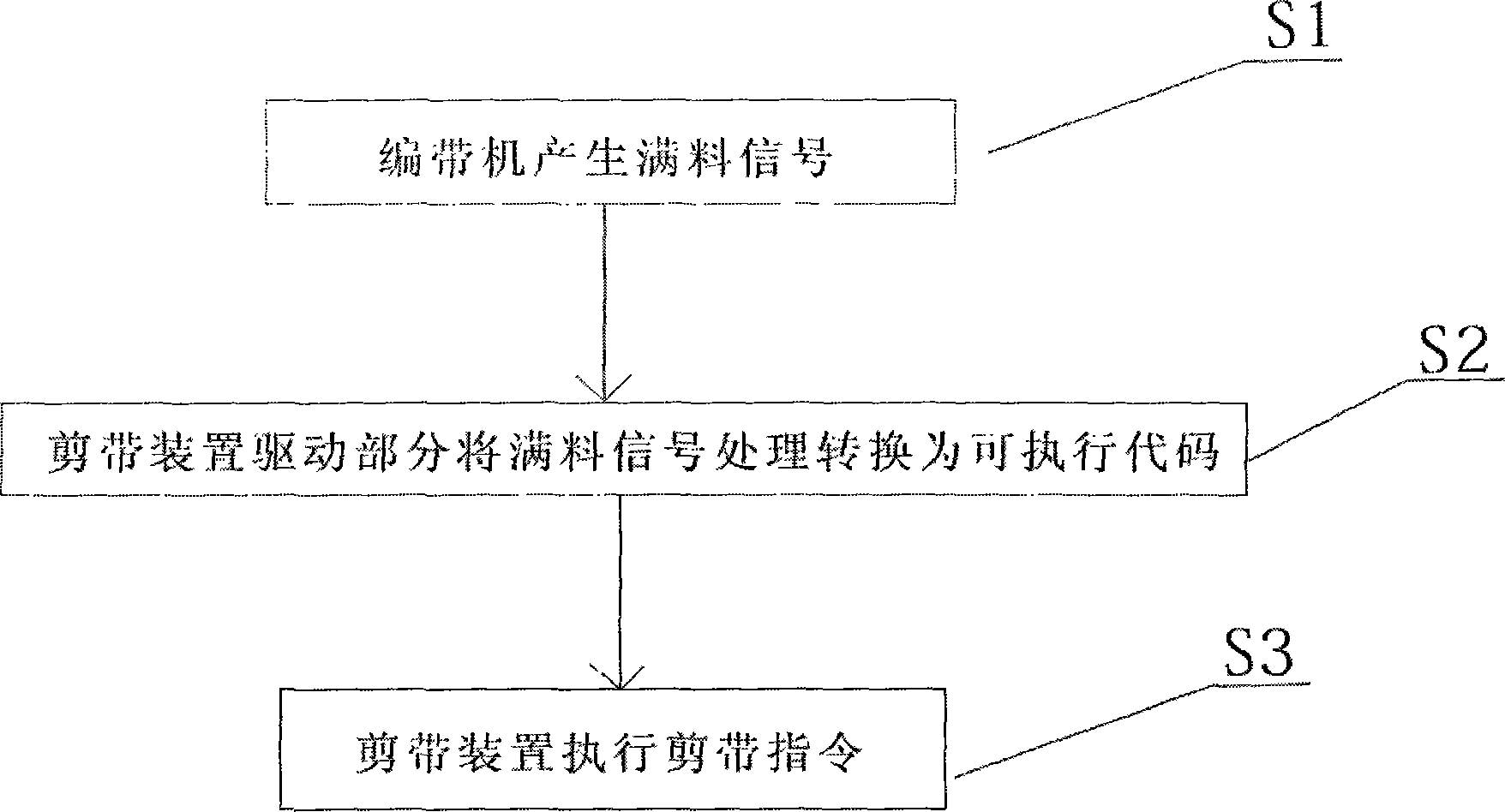

Automatic braid shearing achieving method for automatic braiding machine full of materials

InactiveCN103863620AEliminates manual tape cuttingHigh degree of automationPackaging automatic controlEngineeringBraid

The invention discloses an automatic braid shearing achieving method for an automatic braiding machine full of materials. The method comprises the following steps of S1, when the number of elements in a finished take-up reel of the automatic braiding machine reaches the set limiting value, generating a fill-up material signal and sending the fill-up material signal to a braid shearing device drive part; S2, after the braid shearing device drive part receives the fill-up material signal, processing the signal, converting the signal into executable codes capable of being identified by the braid shearing machine, and sending the executable codes to a braid shearing device; S3, executing the braid shearing instruction by the braid shearing device according to the codes. According to the method, the operation work procedure of manual braid shearing is removed, the automation degree of the automatic braiding machine is obviously improved, material braids shorn by the braid shearing device can precisely jump aside the packaging part of the elements, the elements are not damaged, and wasted, and the percent of pass of the products is improved.

Owner:SHENZHEN JINGTAI

A kind of method for preparing calcium sulfate dihydrate whisker from phosphogypsum

InactiveCN104005086BNot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

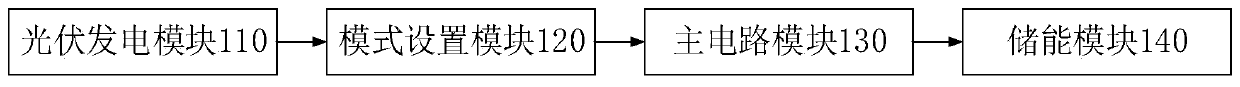

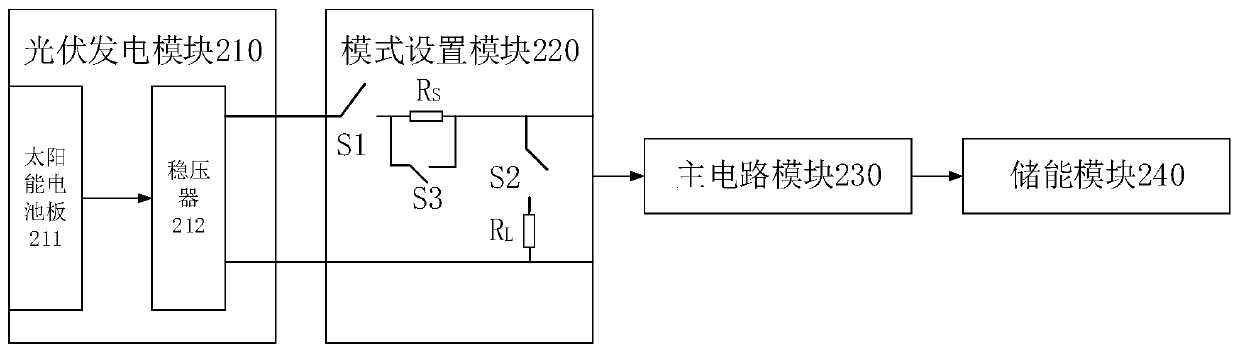

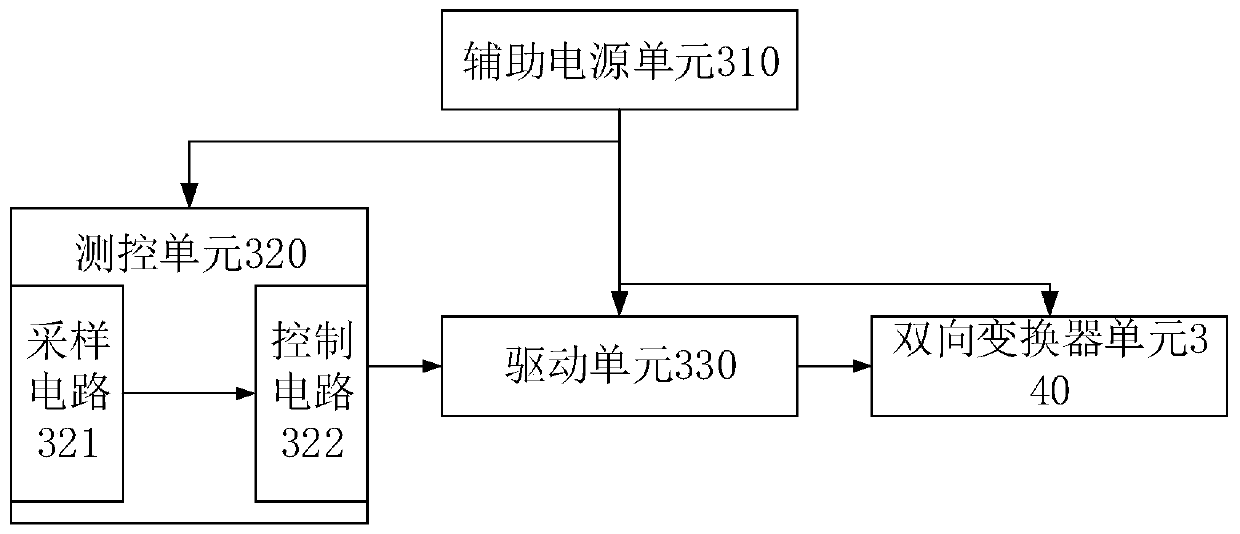

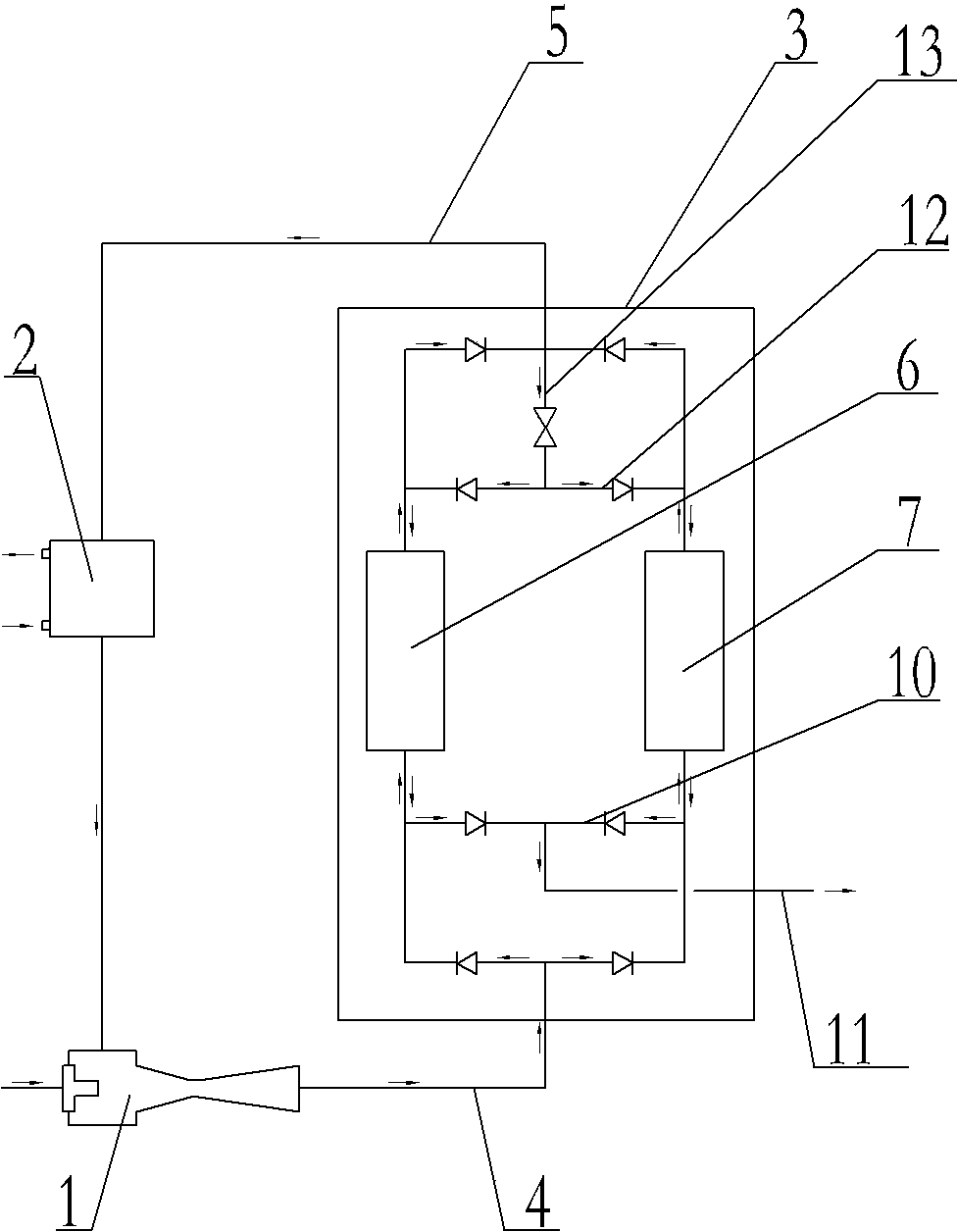

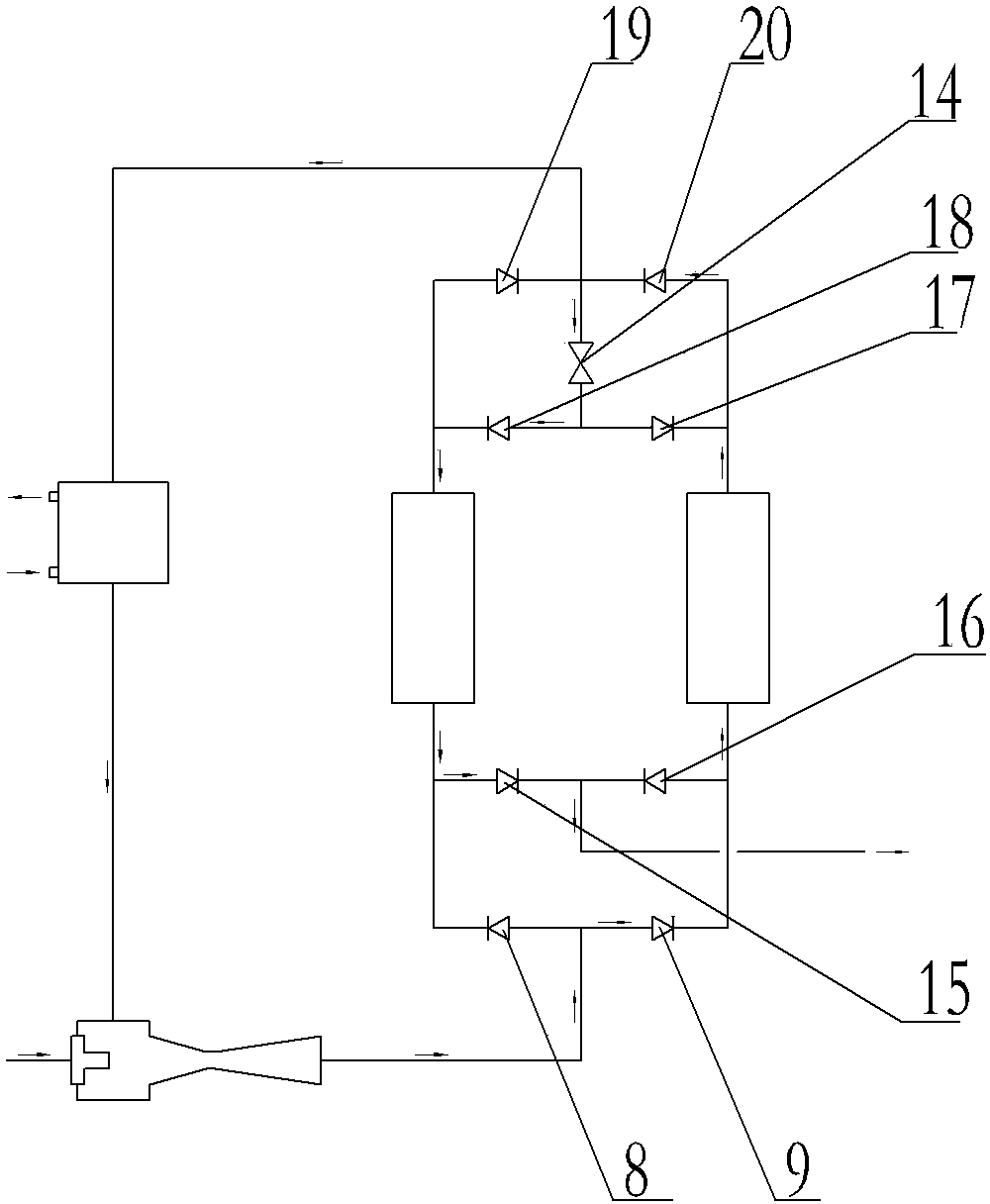

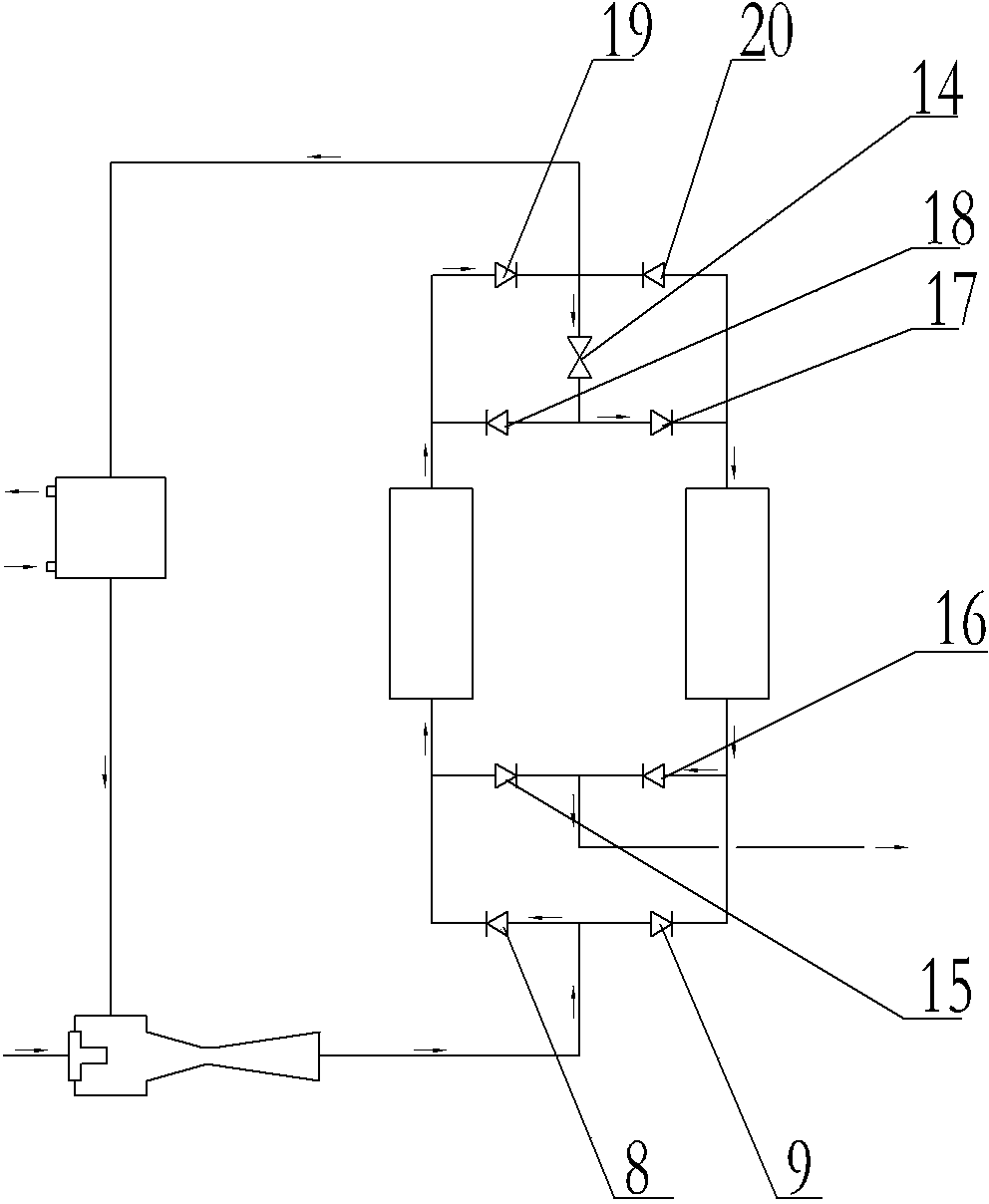

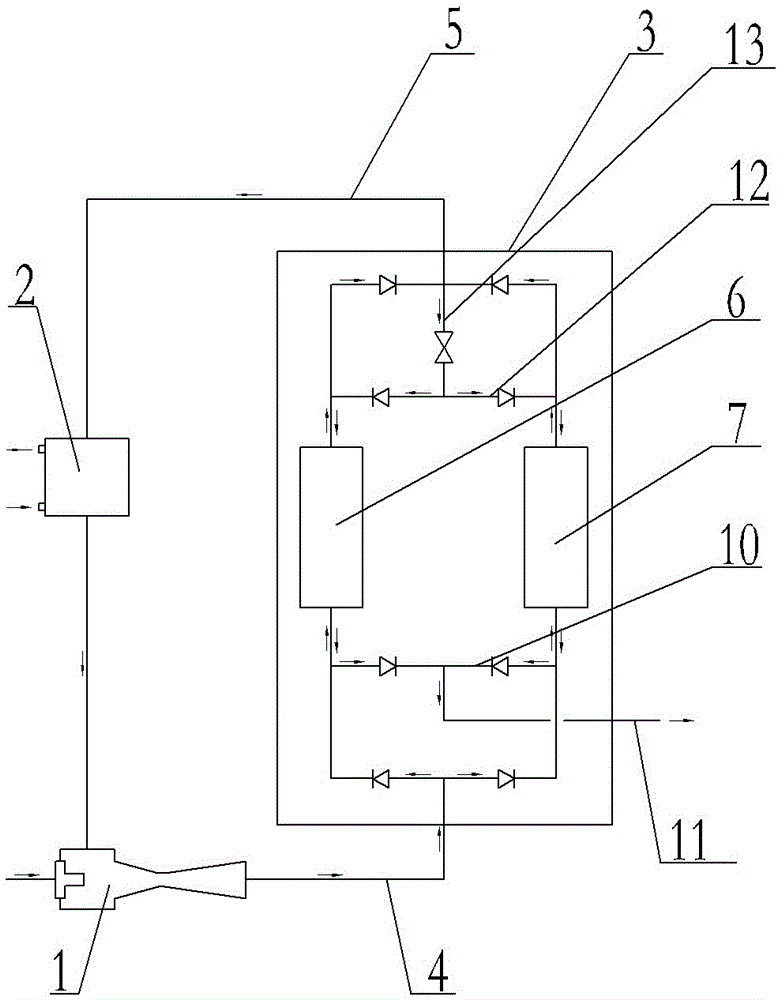

Photovoltaic power generation interface system and control method thereof

InactiveCN110707992ASufficient powerNot to be wastedPV power plantsDc-dc conversionControl signalHemt circuits

The invention discloses a photovoltaic power generation interface system which comprises a photovoltaic power generation module, a mode setting module, a main circuit module and an energy storage module. The main circuit module uses a bidirectional half-bridge converter, the transmission power is small, the efficiency is high, and the conversion of charging and discharging modes of the photovoltaic power generation interface system is conveniently realized. Meanwhile, according to the control method of the photovoltaic power generation interface system, a single-chip microcomputer is adopted to directly generate the PWM signal, and the output of the photovoltaic power generation interface system can be adjusted by sampling the output of the main circuit module and then changing the duty ratio of the PWM signal; whether the photovoltaic power generation interface system works normally or not can be judged according to the selected working mode and the actual working state, and protection is provided for the photovoltaic power generation interface system. According to the control scheme that digital control generates PWM control signals, the problems of temperature drift, interference and the like of an analog circuit are solved, high precision can be achieved through software control, and meanwhile upgrading and reconstruction of the system are simple and convenient to expand.

Owner:XIANGTAN UNIV

Slag washing water filter

InactiveCN106362463AGuaranteed continuous supplyAchieve uninterrupted supplyStationary filtering element filtersWater filterNew energy

The invention relates to a slag washing water filter, and belongs to the related technical field of new energy. The slag washing water filter mainly comprises a vertically arranged water inlet pipe; the left side of the water inlet pipe is communicated with a first slag storage bin, and the right side of the water inlet pipe is communicated with a second slag storage bin; a support frame is installed on the upper portion of the water inlet pipe, and a gearbox is arranged on the support frame; the gearbox is provided with a first output shaft, a second output shaft and a third output shaft; the first output shaft is connected with a first sealing plate, the second output shaft is connected with a filter screen frame, and the third output shaft is connected with a second sealing plate; the first sealing plate, the filter screen frame and the second sealing plate are all located inside the water inlet pipe; filter screens are arranged on the lower portion of the first slag storage bin and the lower portion of the second slag storage bin respectively, and the bottom of the first slag storage bin and the bottom of the second slag storage bin are communicated with the lower portion of the water inlet pipe through transition pipes respectively and provided with skimming holes respectively. According to the slag washing water filter, slag in slag washing water is filtered out, and meanwhile the downtime caused by slag removal is greatly shortened.

Owner:嘉兴尚云自动化设备有限公司

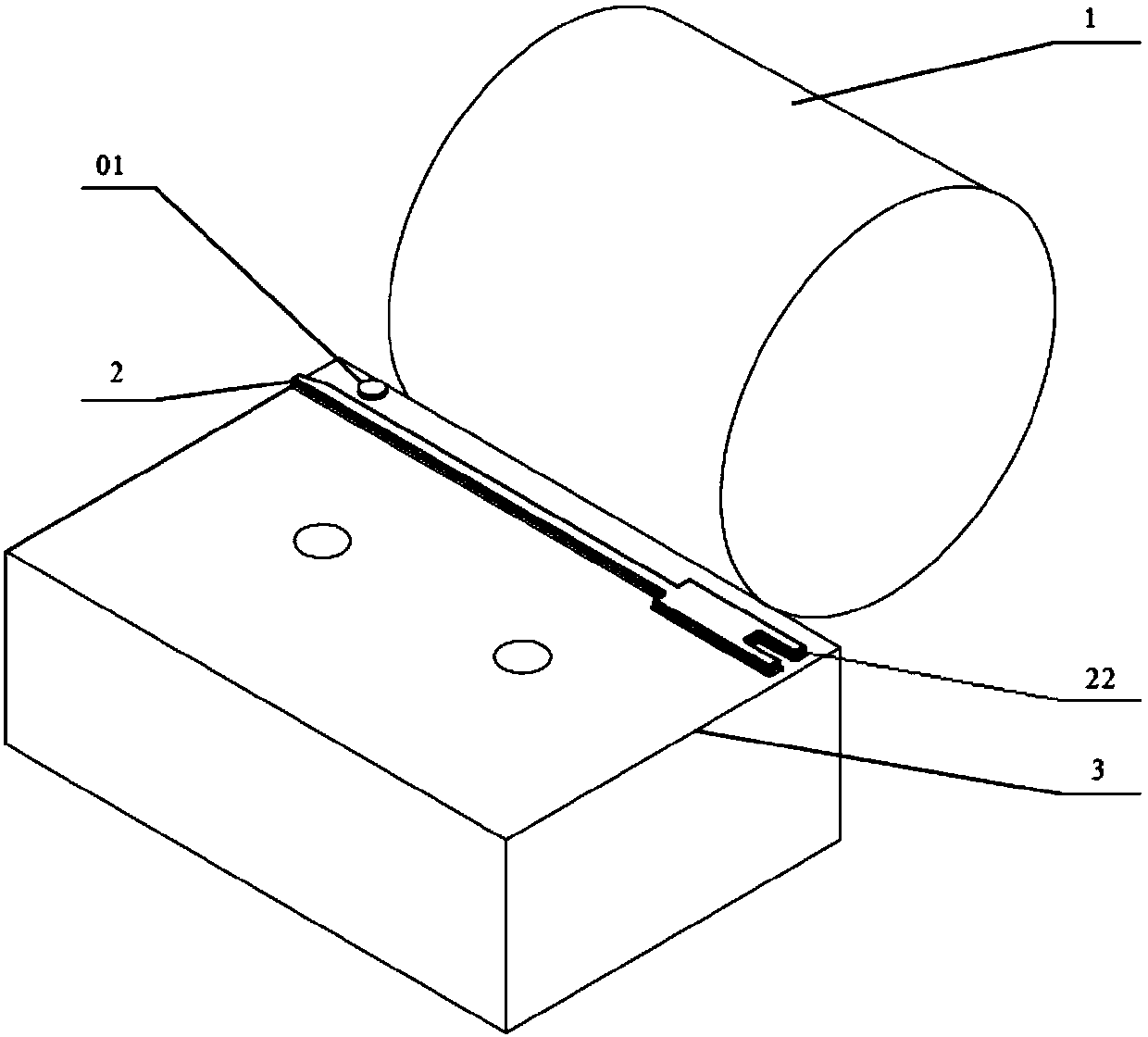

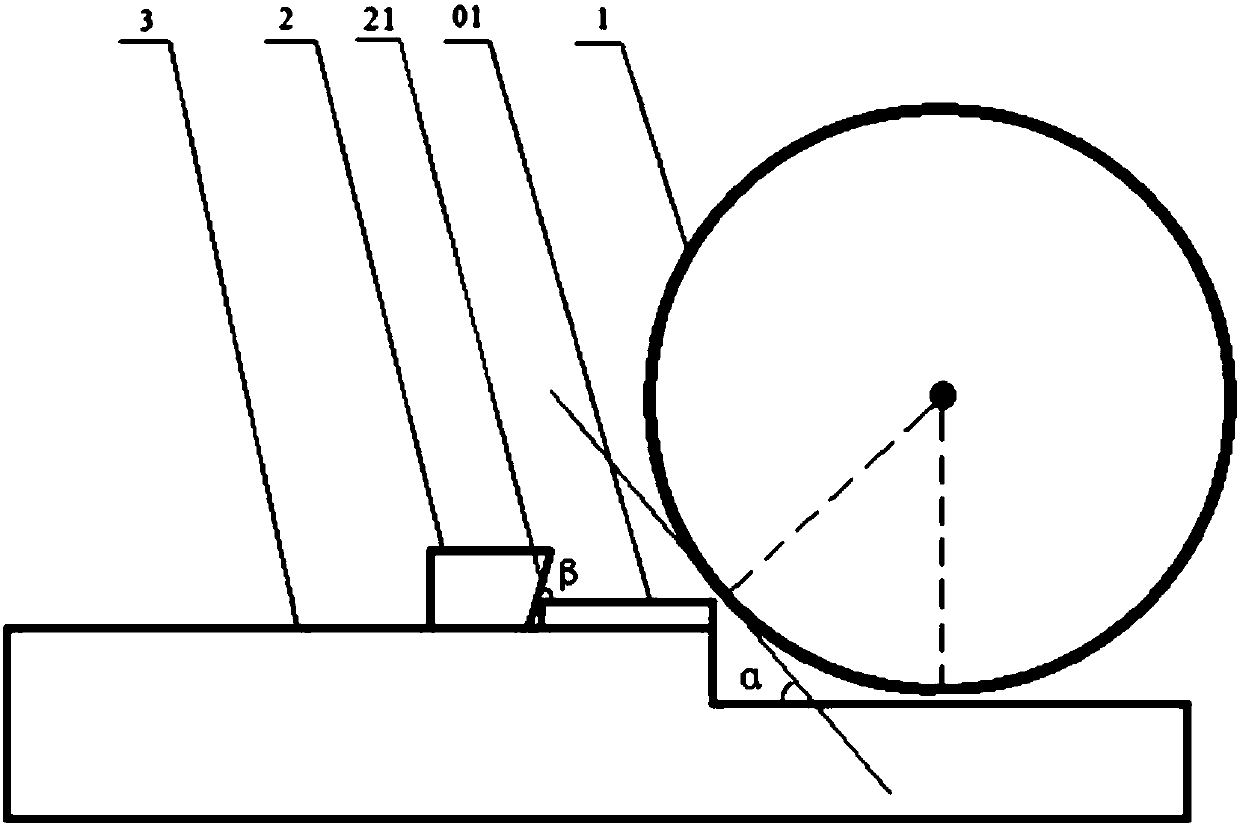

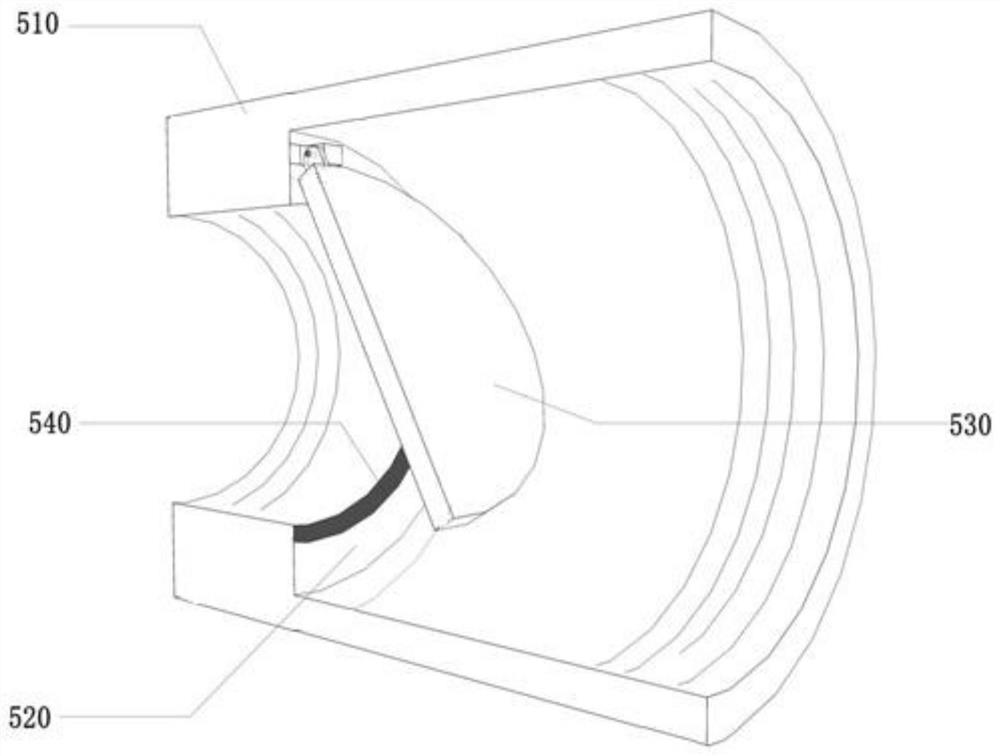

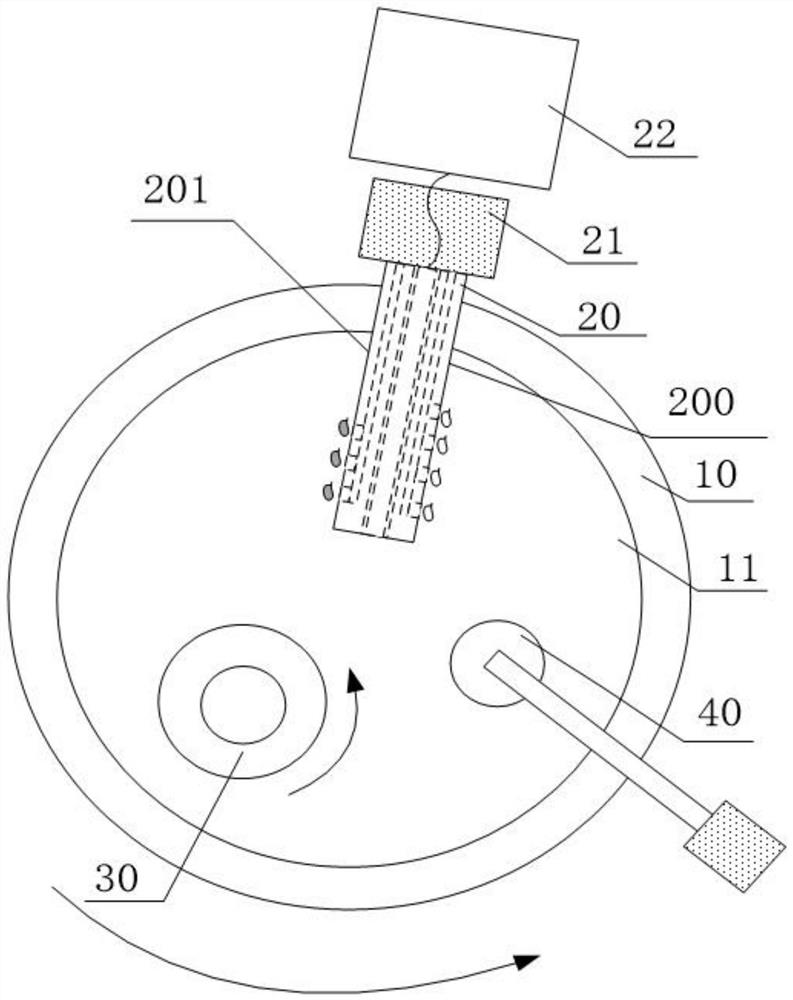

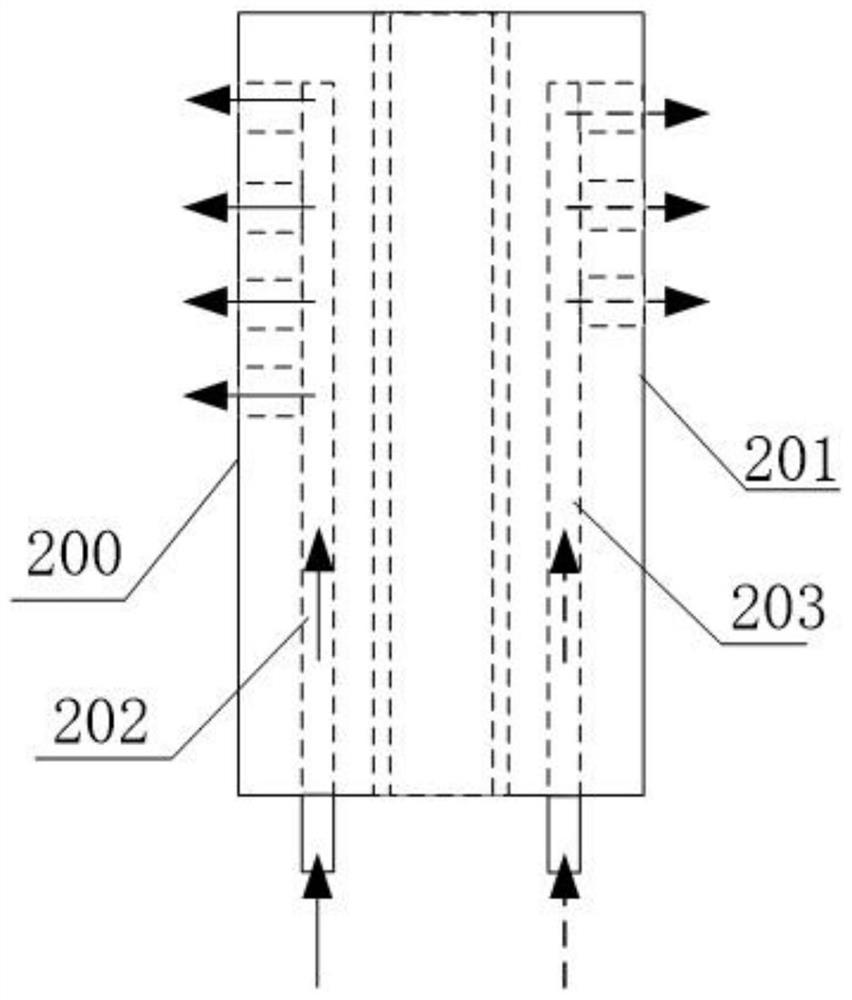

Processing method for beveling of disc lens, and beveling processing device

PendingCN109551332ANot to be wastedImprove qualityEdge grinding machinesEngineeringCylindrical grinding

The invention provides a processing method for beveling of disc lens. The method comprises: using a beveling processing device including a transverse cylindrical grinding wheel, a tensioning piece anda support table, wherein an outer circular surface of the grinding wheel is provided with sand grains for grinding a lens to form a beveling, and length of the cylindrical grinding wheel is more thanone time of perimeter of a disc lens, laying the disc lens which is to be processed with the beveling on the support table, height of the tensioning piece being larger than or equal to thickness of the disc lens. On one hand, the tensioning piece is used to press the lens to the outer circular surface of the grinding wheel on a horizontal direction, and on the other hand, when the tensioning piece is pulled horizontally along the length direction of the grinding wheel, the tensioning piece is used to make the lens rotate for more than a circle in a horizontal plane in a translation process along the length direction of the grinding wheel with autorotation of the grinding wheel, to grinding and process to obtain a circular beveling of the lens. The processing method can make a lens productnot wasted by falling, and beveling uniformity quality is good, and the method is simple in process and high in efficiency.

Owner:LENS TECH CHANGSHA

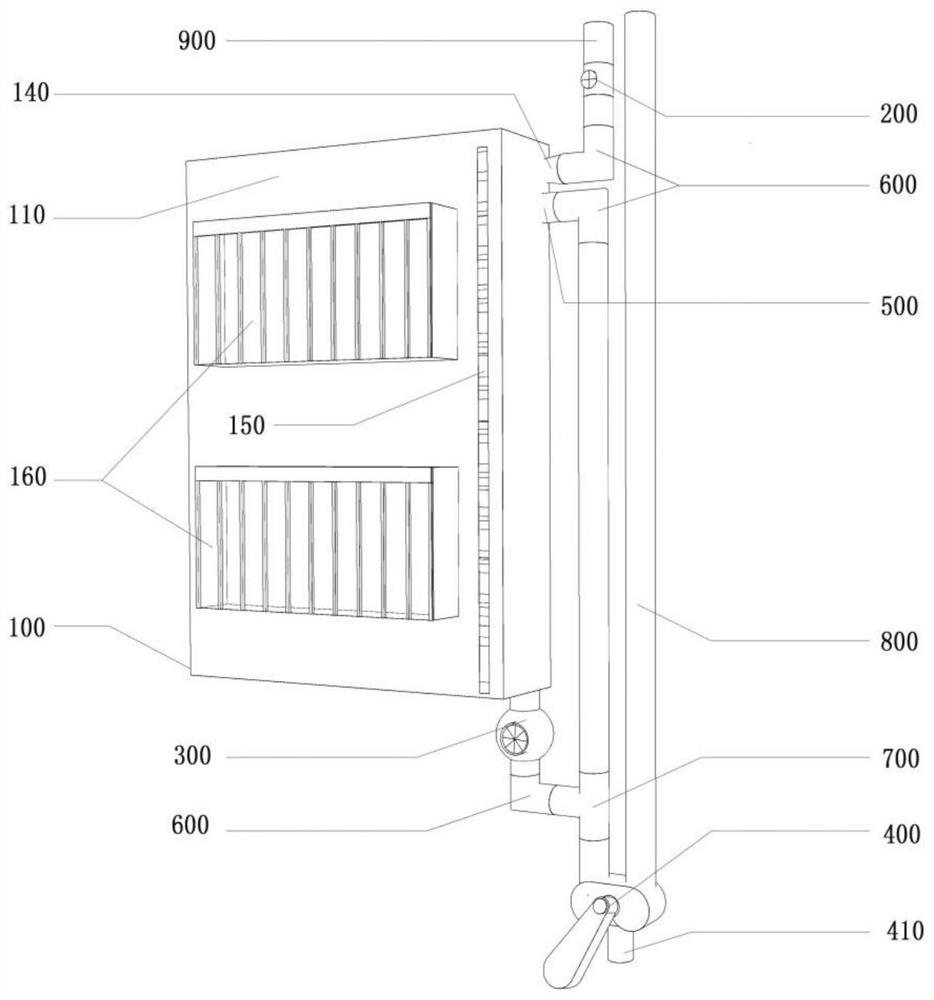

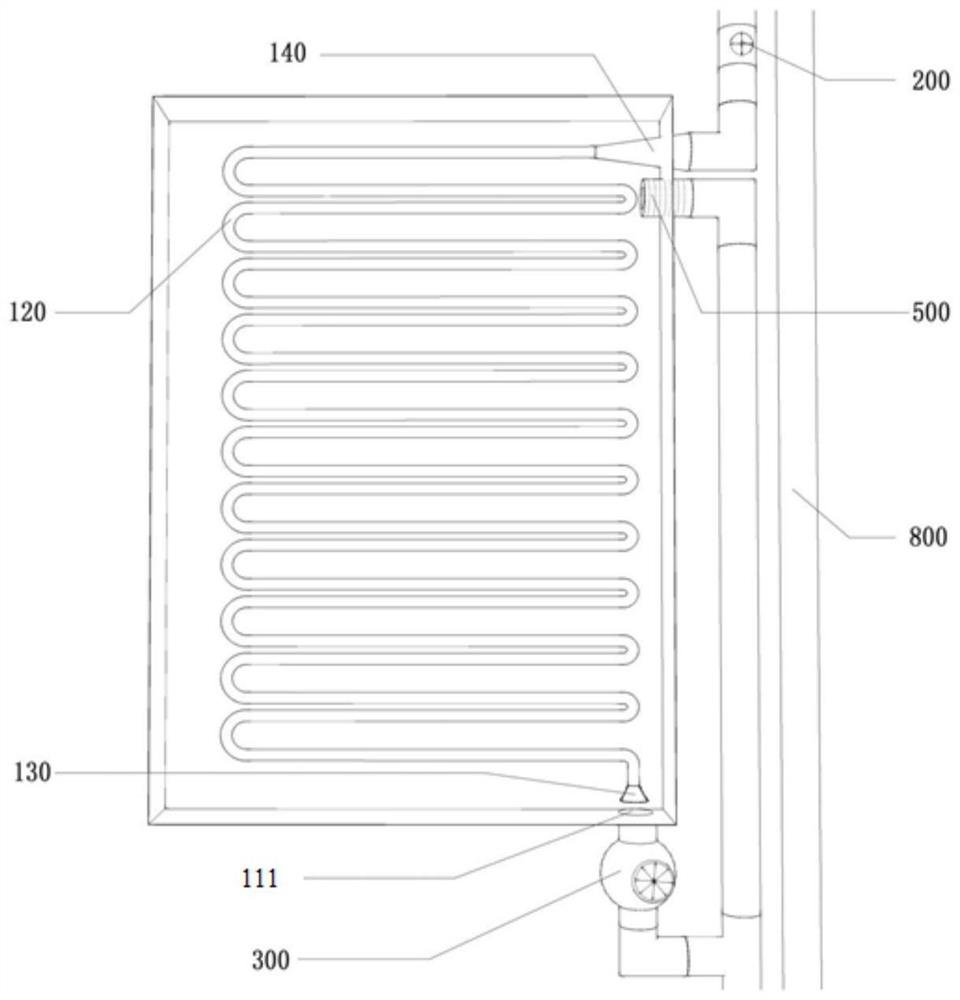

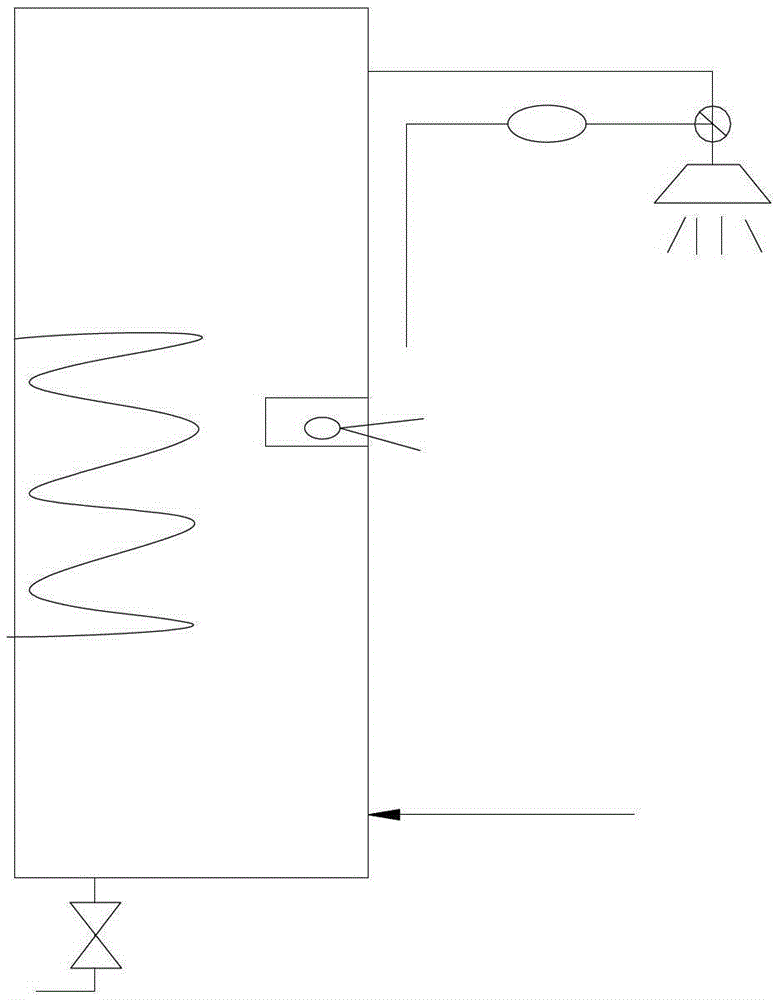

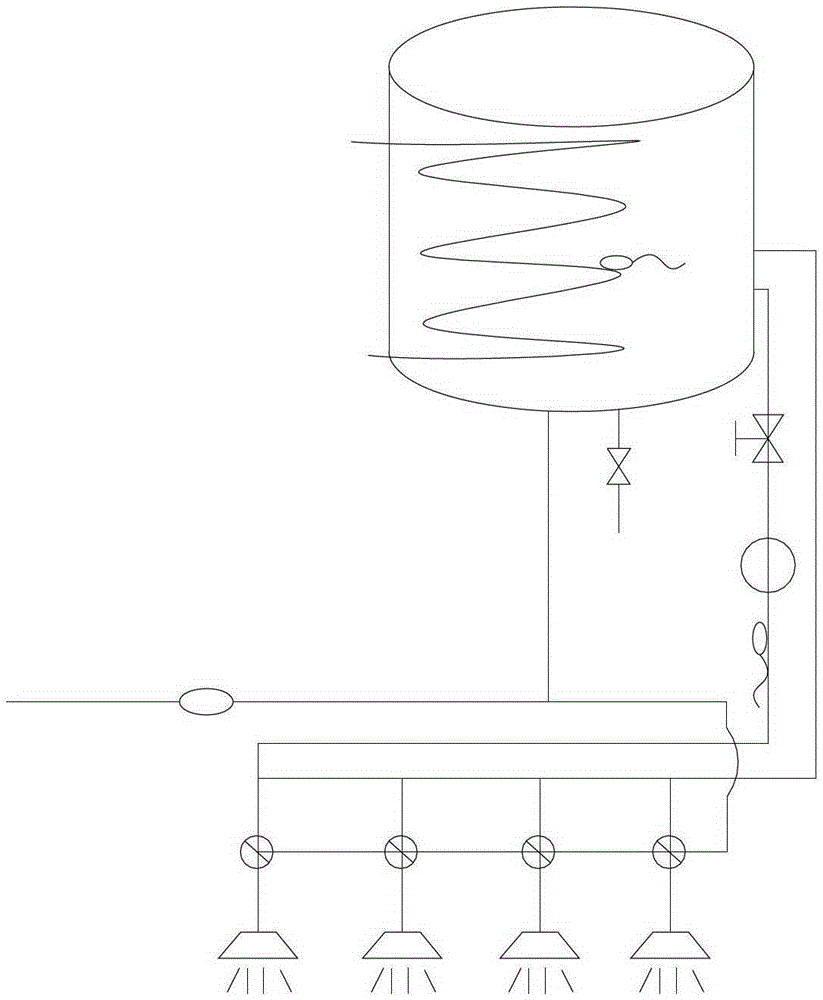

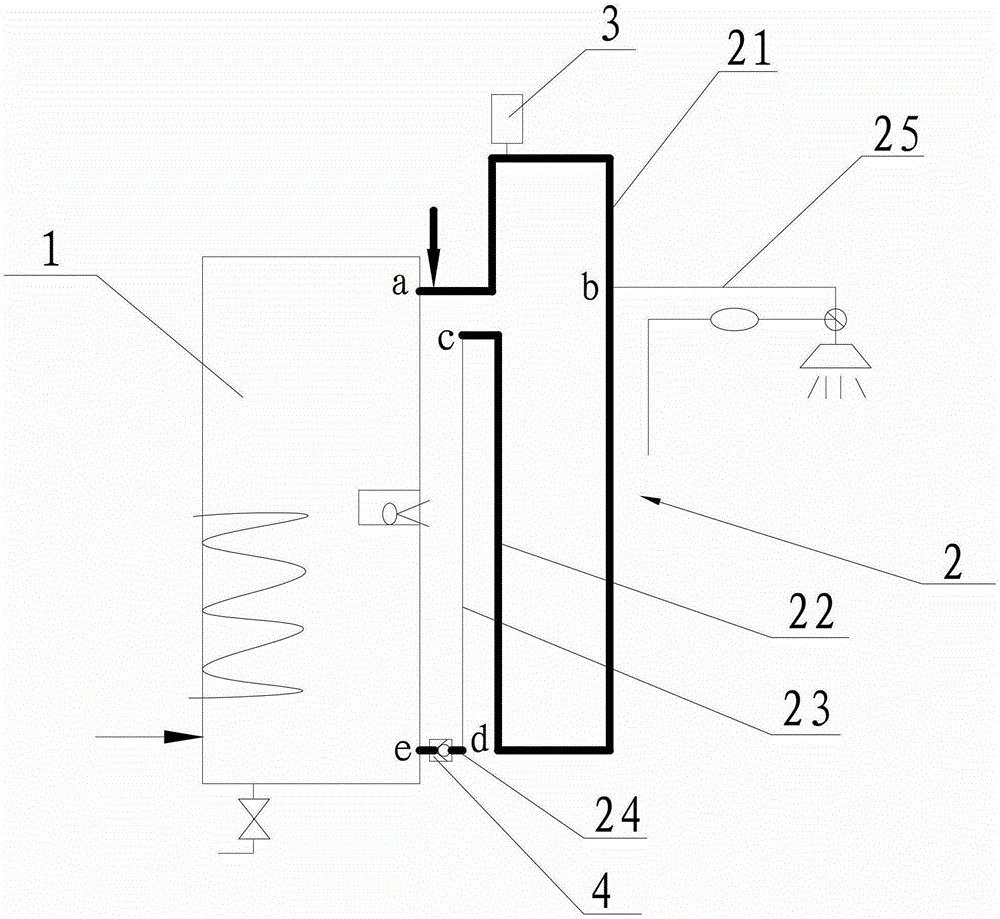

Self-operated domestic water-saving device capable of recycling cold and hot water

PendingCN113883928ANot to be wastedFluid heatersStationary tubular conduit assembliesWater savingThermal water

The invention discloses a self-operated domestic water-saving device capable of recycling cold and hot water. The self-operated domestic water-saving device comprises a water storage container, wherein the water storage container comprises a container shell and a heat exchange pipe, the container shell is provided with a water outlet, the heat exchange pipe is arranged in the container shell, and a reserved gap is reserved between the output end of the heat exchange pipe and the water outlet; a pipeline valve arranged between a hot water pipeline and the heat exchange pipe; a self-operated temperature control valve, wherein an inlet of the self-operated temperature control valve communicates with the water outlet; and a faucet, wherein the faucet comprises a hot water inlet and a cold water inlet, the hot water inlet of the faucet is connected with an outlet of the self-operated temperature control valve, and the cold water inlet of the faucet communicates with a cold water pipeline.

Owner:ZHEJIANG INST OF HYDRAULICS & ESTUARY

Automatic synchronization net puller and net pulling method

InactiveCN101380840BGuaranteed force balanceHigh precisionScreen printersSynchronous motorEngineering

The invention discloses a self-synchronizing net stretching machine and a stretching method thereof. The net stretching machine comprises a frame, horizontal and vertical line screw mandrel shifting devices arranged around the frame and net stretching collets arranged on the horizontal and vertical line screw mandrel shifting devices, wherein, the frame is provided with a synchronous motor group which controls the synchronous relative inward or outward shift of the horizontal and vertical opposite line screw mandrel shifting devices. While stretching the net, screw mandrel shifting devices atsymmetrical sides of the horizontal line or the vertical line are controlled by the synchronous motor group to shift synchronously in succession for pre-stretching, then the mesh cloth is vertically fixed and firmly clamped, and synchronous net stretching from both symmetrical sides is carried out. The method has the advantages that net stretching can be carried out synchronously from symmetricalsides, thus ensuring that the force the mesh bears is balanced; besides, the horizontal lines and vertical lines are ensured to be vertical to each other during the process of synchronous net stretching, thereby largely improving the accuracy of net stretching; moreover, four sides of the mesh cloth can be ensured not to be wasted while stretching, thus improving the utility ratio of the mesh cloth.

Owner:冯兆坚

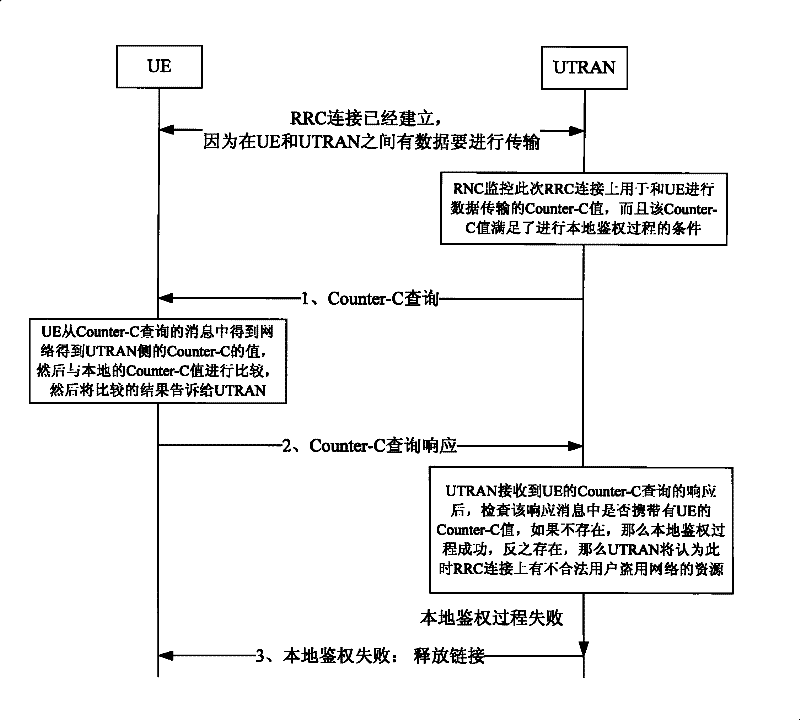

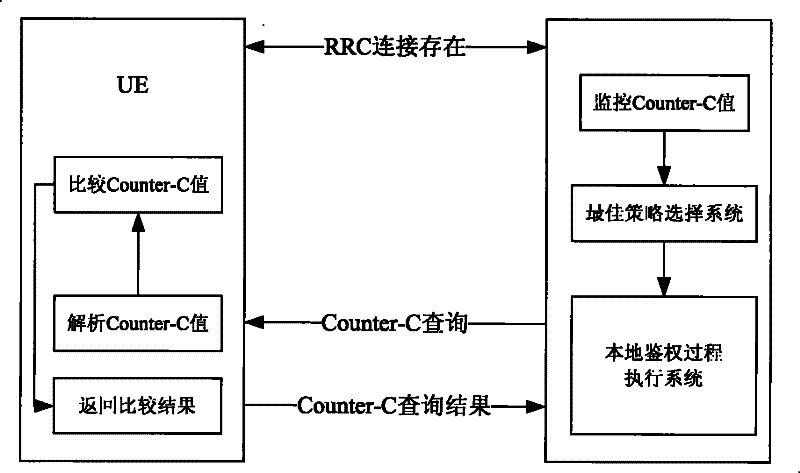

Method for performing mobile equipment local authentication in third-generation mobile communication system

ActiveCN101631308BImprove securityNumber of times to avoid local authenticationConnection managementSecurity arrangementCumulative costTerra firma

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

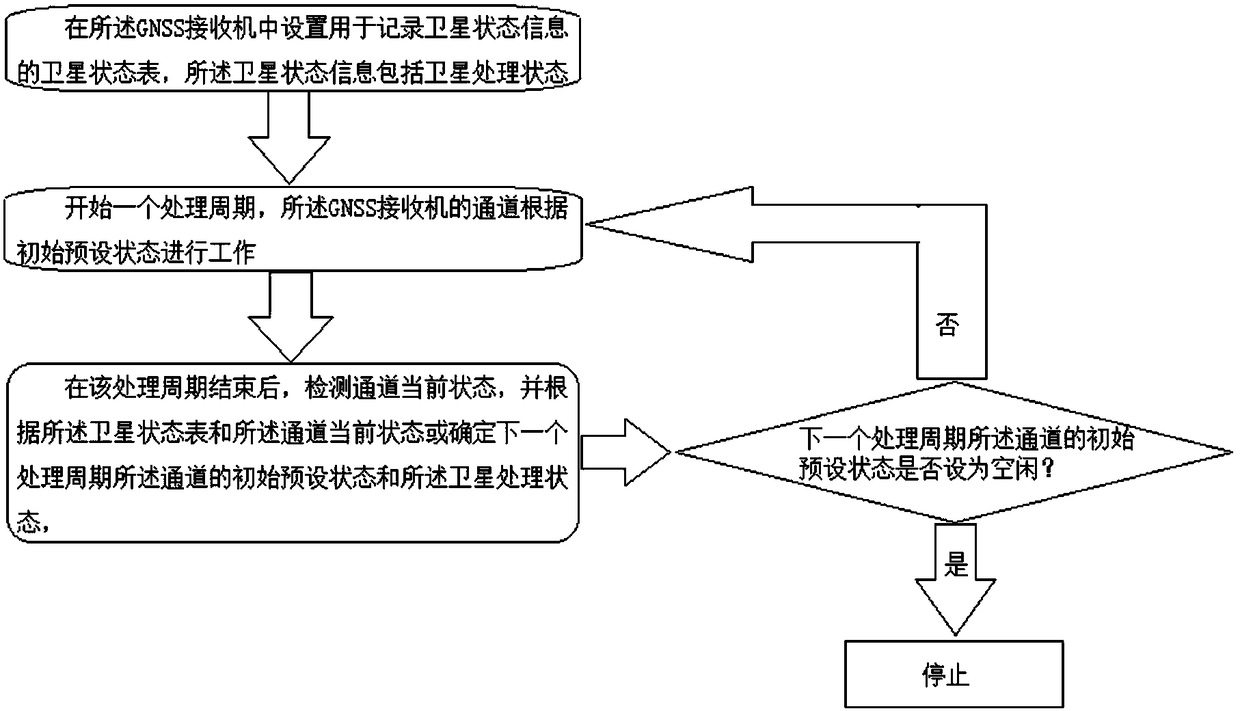

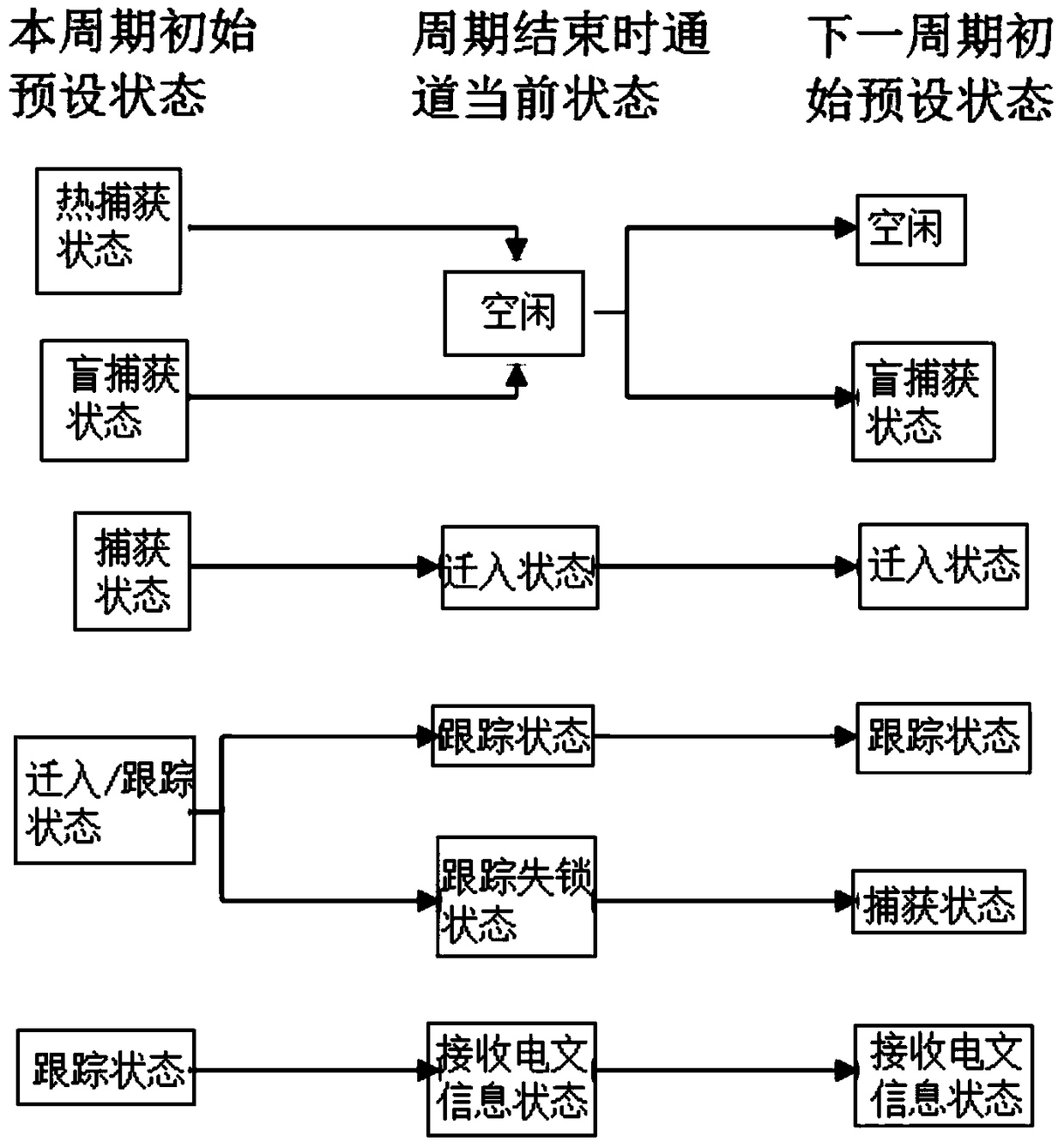

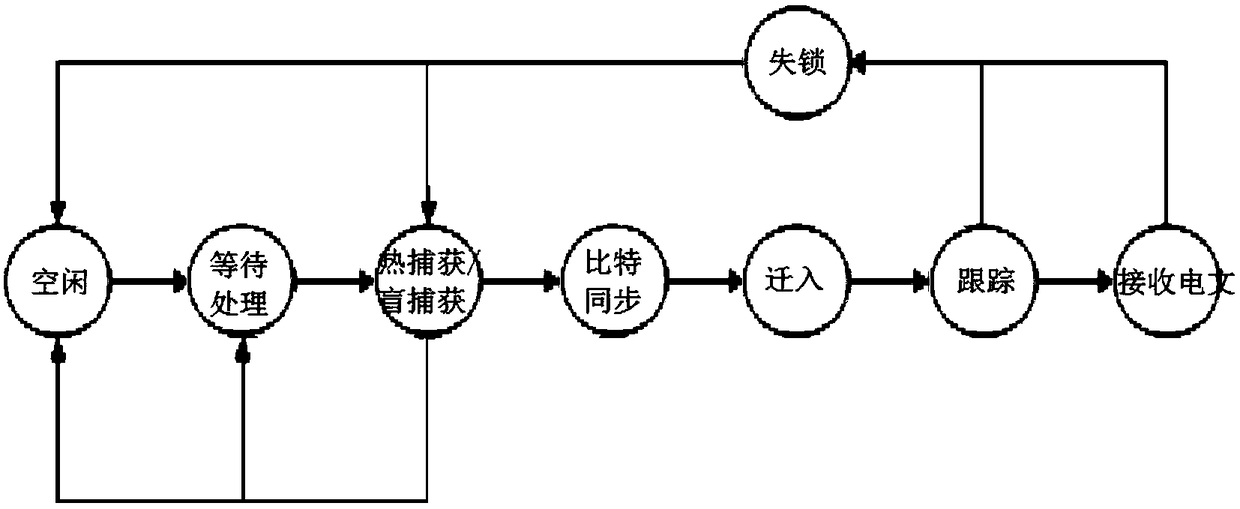

A kind of GNSS receiver state scheduling method and GNSS receiver

ActiveCN105929410BNot to be wastedEasy to handleSatellite radio beaconingSatelliteReal-time computing

The invention provides a GNSS receiver and a state scheduling method thereof. The method comprises the steps that 1) a satellite state table for recording satellite state information which comprises a satellite processing state is set in the GNSS receiver; 2) one processing period is started, and a channel of the GNSS receiver works according to an initial preset state; and 3) after that the processing period is completed, the present state of the channel is detected, the initial preset state of the channel in the next processing period and the satellite processing state are determined according to the satellite state table and the present state of the channel, and the step 2) is returned to till the initial preset state of the channel in the next processing period is idle.

Owner:SHANGHAI JIAOTONG UNIV

Self-exhausting type safe injector

InactiveCN112206153ADoes not affect pumpingNot to be wastedInfusion syringesPharmaceutical containersEngineeringStructural engineering

The invention discloses a self-exhausting type safe injector. The self-exhausting type safe injector comprises a needle cylinder and a needle tube fixedly connected with the needle cylinder, wherein apush rod is placed in the needle cylinder, a fixing block is arranged at the lower end of the push rod, a rubber plug is bonded to the joint of the fixing block and the inner wall of the needle cylinder, and a plurality of vertical grooves are formed in the fixing block in a penetrating manner; a sliding block is mounted in each vertical groove in a sliding manner, a plurality of first through holes are symmetrically formed in the middle of each sliding block, a plurality of soft plugs are symmetrically connected to the top of each sliding block in a glued manner, each soft plug does not coincide with the corresponding first through hole, and a blocking ring and a limiting ring are fixedly arranged in each vertical groove; and each blocking ring and the corresponding limiting ring which are located in the same vertical groove are located above and below the corresponding sliding block, and a plurality of second through holes are symmetrically formed in each blocking ring. Before liquid medicine injection, a manual defoaming operation is not needed, the injection efficiency and the injection effect are not affected, and besides, liquid medicine waste cannot be caused.

Owner:陆明京

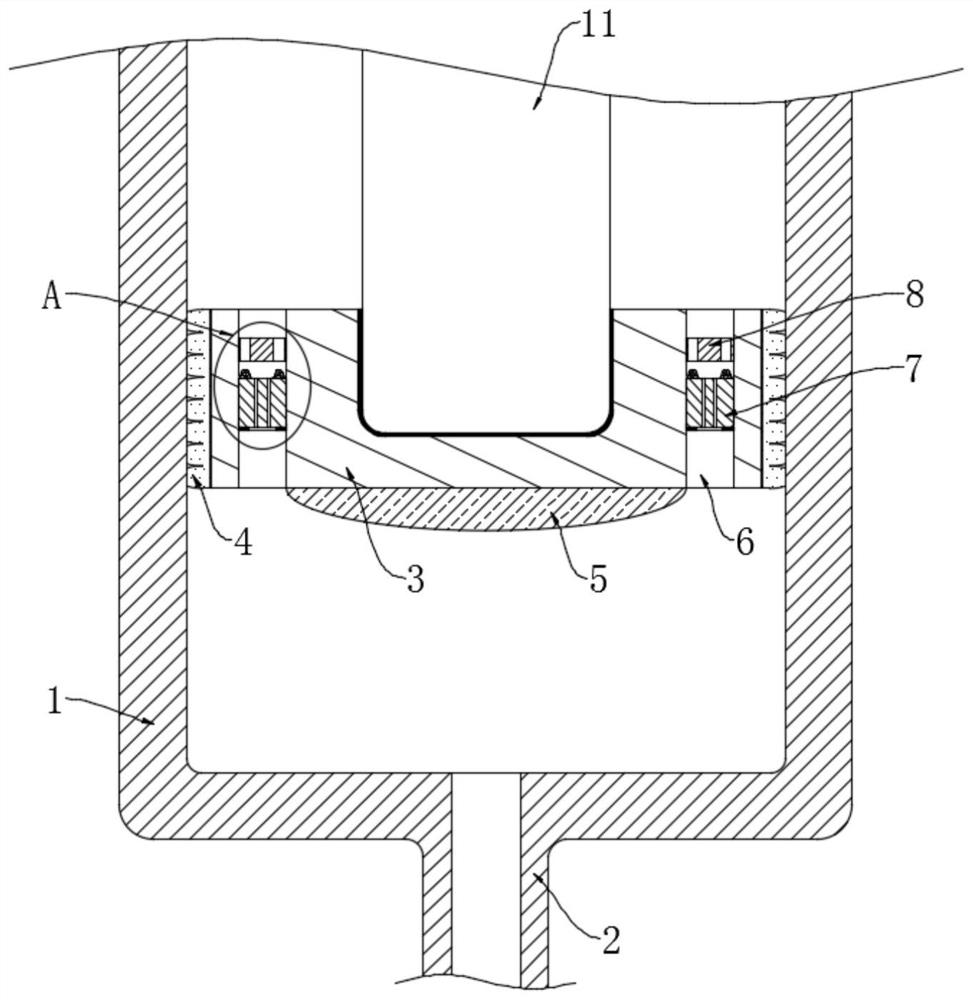

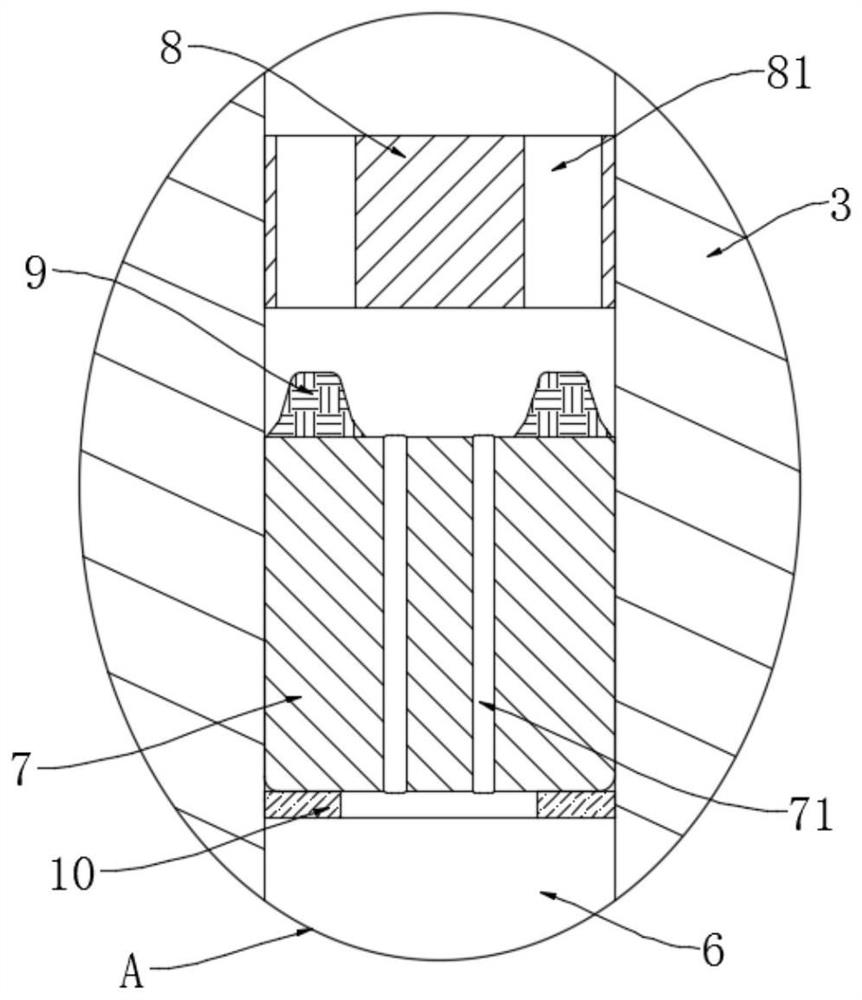

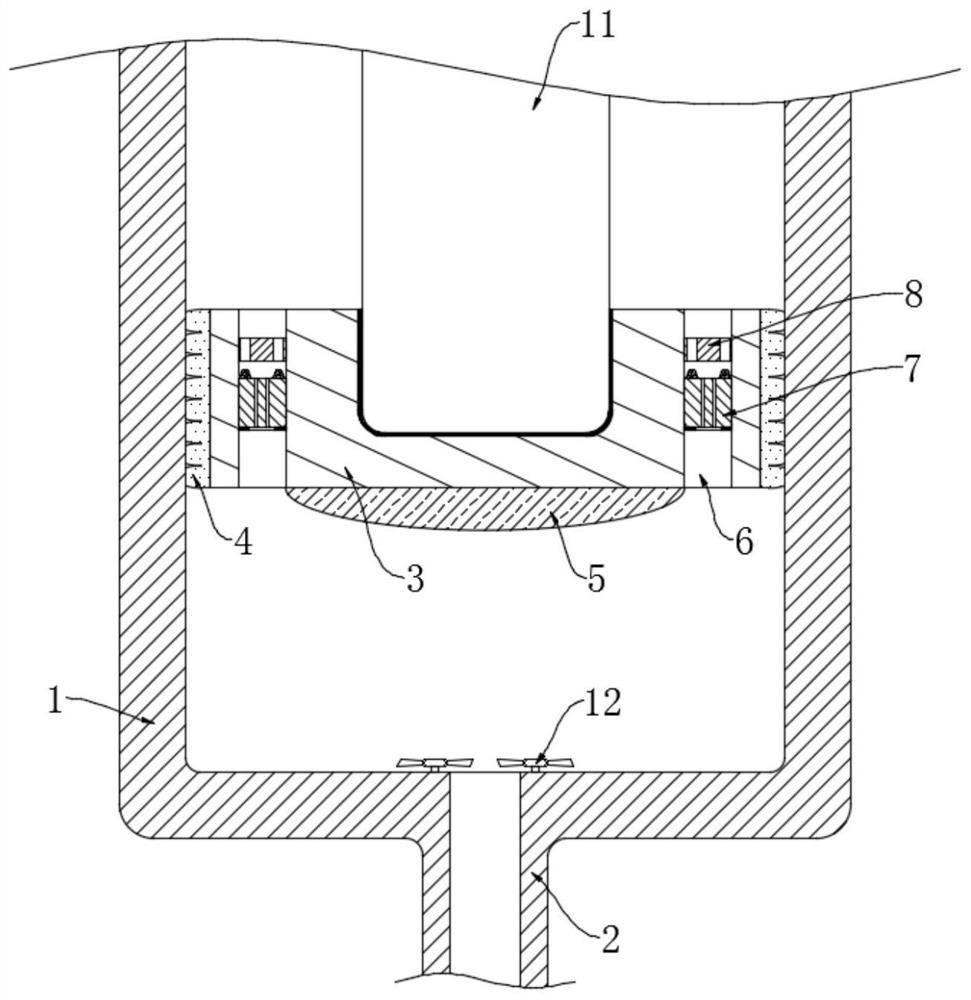

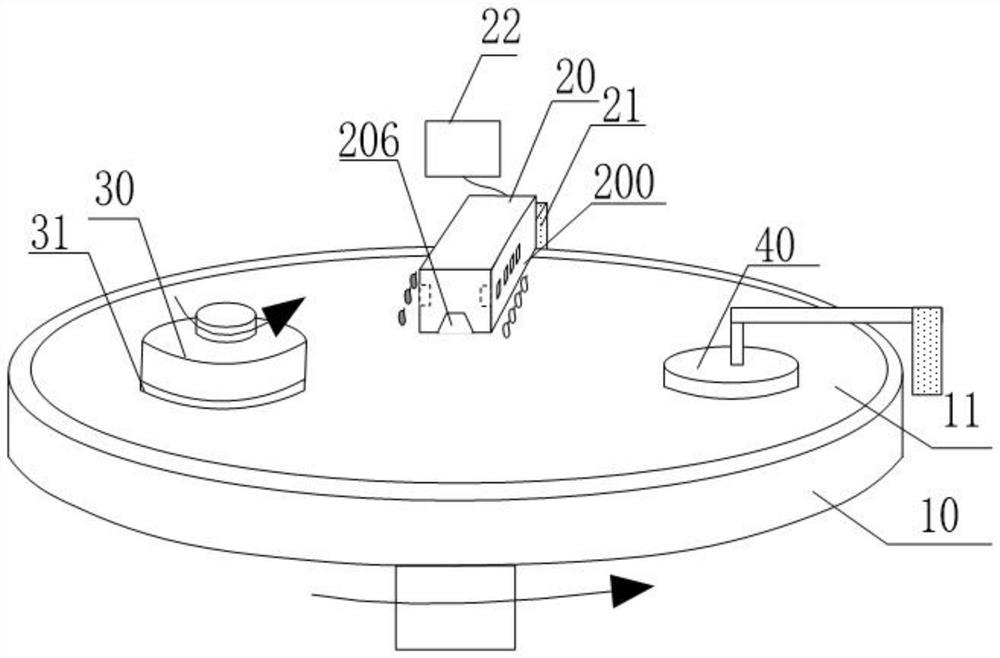

A chemical mechanical planarization device and its application

ActiveCN112720247BWon't wasteNot to be wastedLapping machinesAbrasive surface conditioning devicesMechanical engineeringMaterials science

The invention discloses a chemical mechanical planarization device and its application. The chemical mechanical planarization device includes a wafer carrier, a polishing pad arranged on the wafer carrier, and a wafer installed on the polishing pad. The bearing base, the first base installed on the outside of the wafer carrier, and the release arm, one end of the release arm is connected to the first base, the other end extends to the center of the polishing pad, and the inside of the release arm It includes a first delivery tube and a second delivery tube, through which a first type of liquid is provided to clean the surface of the polishing pad, and at the same time, the release arm is used to press the polishing pad to remove the first type of liquid, through The second conveying pipe provides the second type of liquid to flow to the surface of the polishing pad to form a layer of polishing liquid to grind the wafer. The chemical mechanical planarization equipment provided by the invention and its application can reduce the waste of grinding liquid, reduce wafer damage, and prevent mixing of different liquids.

Owner:NEXCHIP SEMICON CO LTD

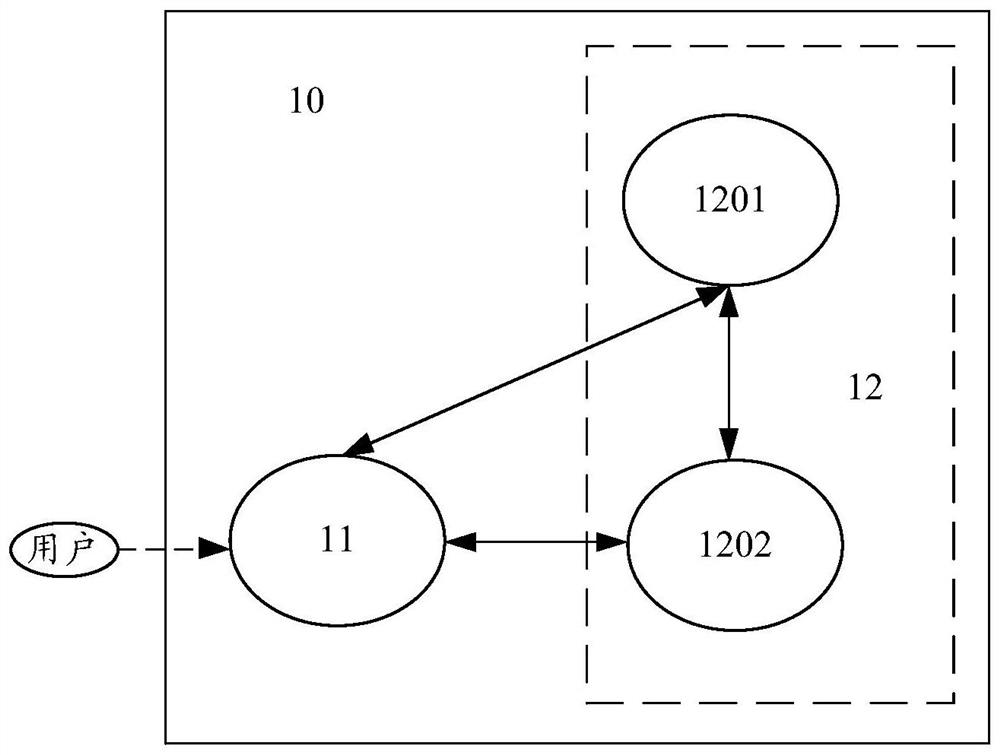

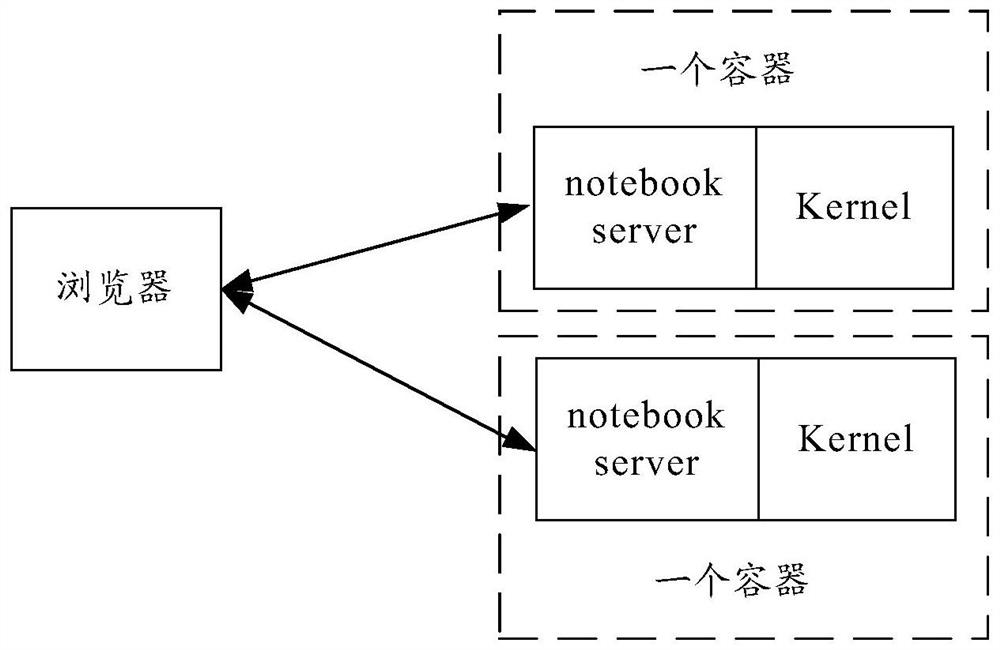

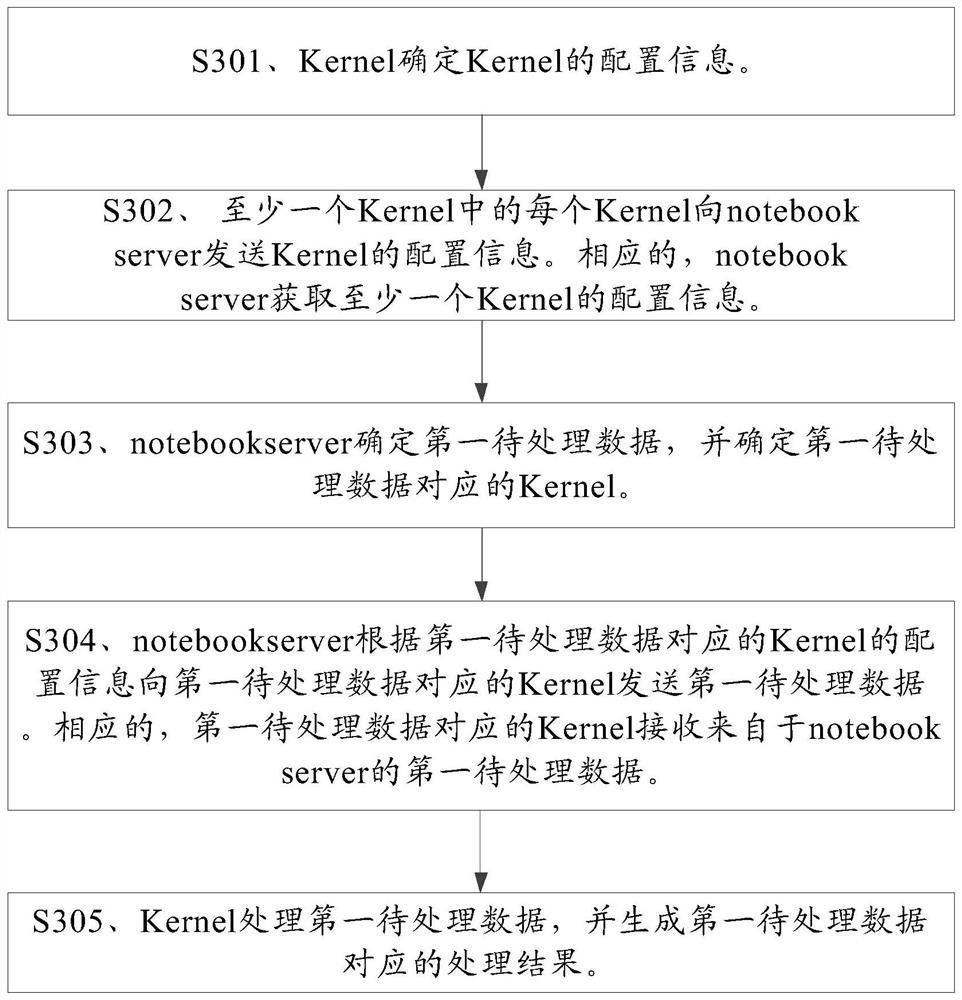

Application program deployment method and device and computer readable storage medium

PendingCN114281475AImprove resource utilizationNot to be wastedResource allocationSoftware simulation/interpretation/emulationSoftware engineeringApplication procedure

The invention provides an application program deployment method and device and a computer readable storage medium, relates to the technical field of computers, and can separately deploy a notebook server and a Kernel, thereby avoiding the waste of computing resources and improving the resource utilization rate of the computing resources. The method comprises the following steps of: acquiring configuration information of at least one Kernel by a notebook server; the notebook server determines first data to be processed, and determines a Kernel corresponding to the first data to be processed; and the notebook server sends the first to-be-processed data to the Kernel corresponding to the first to-be-processed data according to the configuration information of the Kernel corresponding to the first to-be-processed data. According to the embodiment of the invention, the method and the device are used in the Juser notebook in which the notebook server and the Kernel are separately deployed.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

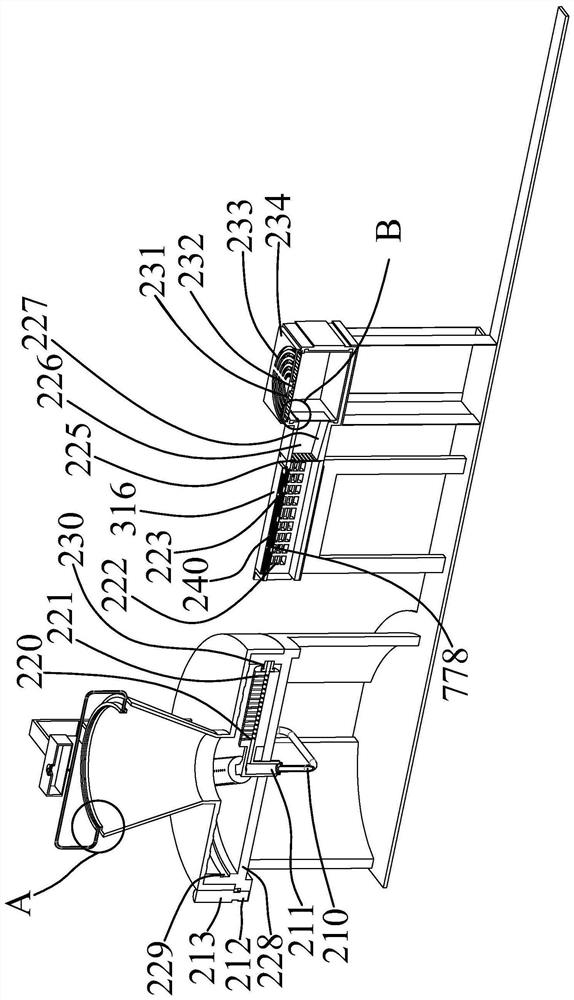

Musk processing and packaging equipment

ActiveCN112009733AImprove textureIncrease productivitySolid materialCleaning using liquidsProcess engineeringIndustrial engineering

The invention discloses musk processing and packaging equipment which comprises a base. The base is formed by welding and connecting sheet metal, a cleaning and diluting module for primarily cleaningmusk and taking out pungent smells is mounted at the leftmost end of the base, a heating filter screen module for heating and distilling the cleaned musk is mounted at the right end of the cleaning and diluting module, a conveying module for conveying the musk to a next procedure is mounted at the right end of the heating filter screen module; and the rightmost end of the base is provided with a press-fitting module for packaging the processed musk. According to the equipment, through the cleaning and diluting module, the heating filter screen module, the conveying module and the press-fittingmodule, automatic dilution of the musk is achieved, the smell is taken out, impurities are filtered out, the texture of the musk is finer through distillation volatilization, musk blocks produced bythe equipment are uniform through automatic press-fitting, and the production efficiency and the weight accuracy of the musk blocks are improved.

Owner:江西天元药业有限公司

Steam pressure lifting adsorption method and heat pump utilizing same

ActiveCN103615831AEfficient use ofIncrease usageEnergy efficient heating/coolingClimate change adaptationSteam pressureEngineering

The invention provides a steam pressure lifting adsorption method. Currently, mature heat pumps mainly have two types including an electric-driven mechanical compressing system and a liquid-gas absorption system; both the two systems have defects, the mechanical compressing system is power-energy consuming, high in equipment investment, high operation cost and restricted in large-scale application, and the liquid-gas absorption system affected by low efficiency is large in equipment size and poor in economic efficiency; due to characteristics of refrigerant, absorber, mechanical equipment and system techniques, low heat-pump output temperature is the common problem of existing heat pumps. The steam pressure lifting adsorption method by which substantial waste heat can be fully utilized is provided to overcome the defects. The invention further provides a steam pressure lifting adsorption pump. By the steam pressure lifting adsorption pump which transmits heat and directly introduces waste-heat steam as circulatory media according to the steam pressure lifting adsorption method, heat transmission steps and system equipment composition are simplified, and the problems of low-grade waste-heat steam utilization and about energy conservation are solved.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Water circulation system for water heater

The invention discloses A water circulation system for a water heater, wherein a circulating water inlet is provided at the lower end of the water heater, and a circulating water pipe is provided between the water outlet of the water heater and the circulating water inlet, and the circulating water pipe is divided into successively connected outlet pipe sections, circulation pipe sections, pressure The pipe section and the water inlet pipe section, in which the insulation layer is set on the outer circumference of the water outlet pipe section, the circulation pipe section and the water inlet pipe section, and there is a height difference between the two ends of the pressure pipe section. When hot water is not used, the water outlet pipe section Under the action of gravity, the water flows back to the water tank of the water heater along the circulation pipe section, the pressure pipe section and the water inlet pipe section, so that it can be heated together with the water in the water heater tank and then output, so as to ensure that the water in the water circulation pipe will not be wasted. , save water resources, and can ensure that the output is always hot water. In the process of water circulation, the heat loss of water is small, which saves a lot of energy. The water circulation system of the water heater has a simple structure and is convenient to use.

Owner:苏州爱科意智能科技有限公司

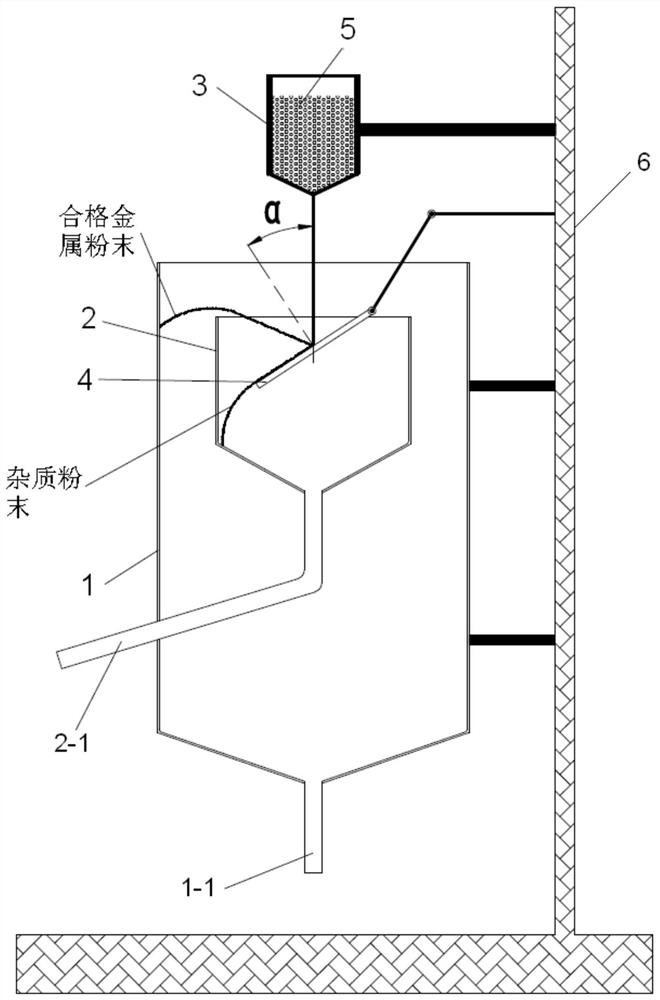

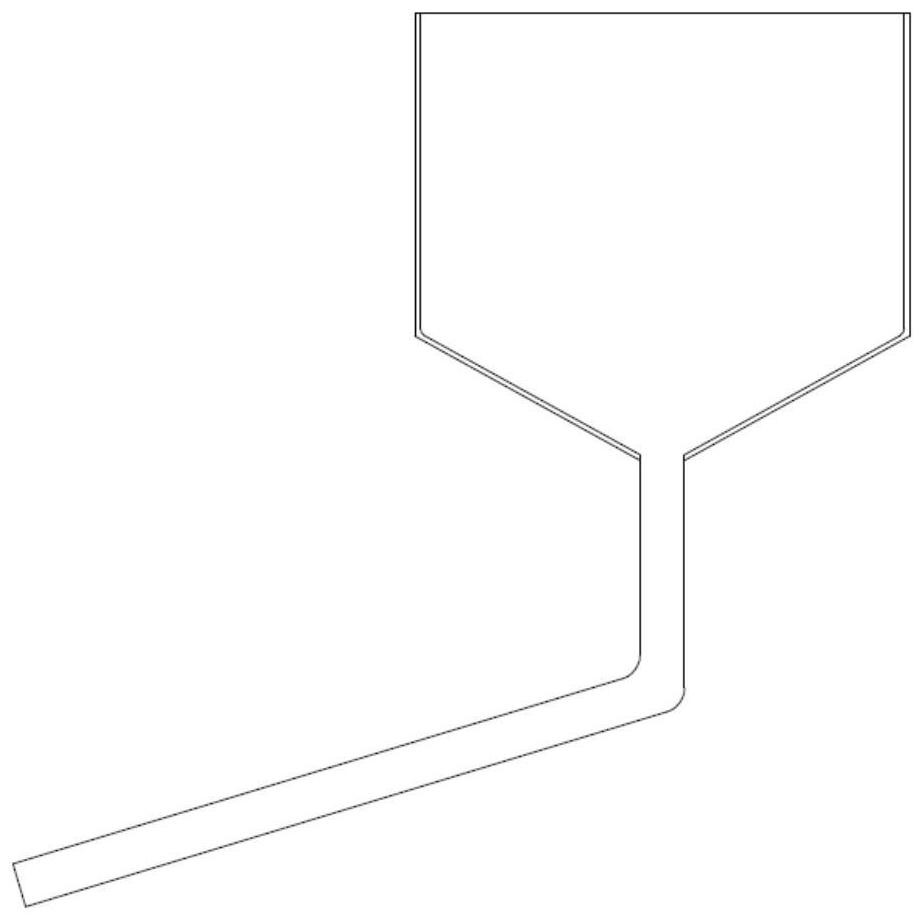

A metal spherical powder impurity removal device and impurity removal method

The present invention relates to a metal spherical powder impurity removal device and impurity removal method. The device comprises a first collection container, a second collection container, a funnel and a separation plate, wherein the second collection container is arranged inside the first collection container, and the second collection container is arranged inside the first collection container. The end face of the collection container is lower than the end face of the first collection container, the separation plate is arranged inside the second collection container, and the end face of the second collection container is inclined at an angle, and does not contact the second collection container, and the funnel is arranged in the two collection containers. Above, and keep a distance between the outlet end of the funnel and the separation plate, the funnel is filled with metal spherical powder to be removed, when the metal spherical powder to be removed falls to the separation plate, the metal spherical powder enters the first collection container, and the impurities enter the second Two collection containers, the present invention realizes the removal of impurities from the metal spherical powder, without the need for power supply, transmission and other power devices, low price, simple structure, no size, shape and position accuracy requirements for processing and assembly, and can achieve high-efficiency and low-cost removal of metal spherical powder. miscellaneous.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

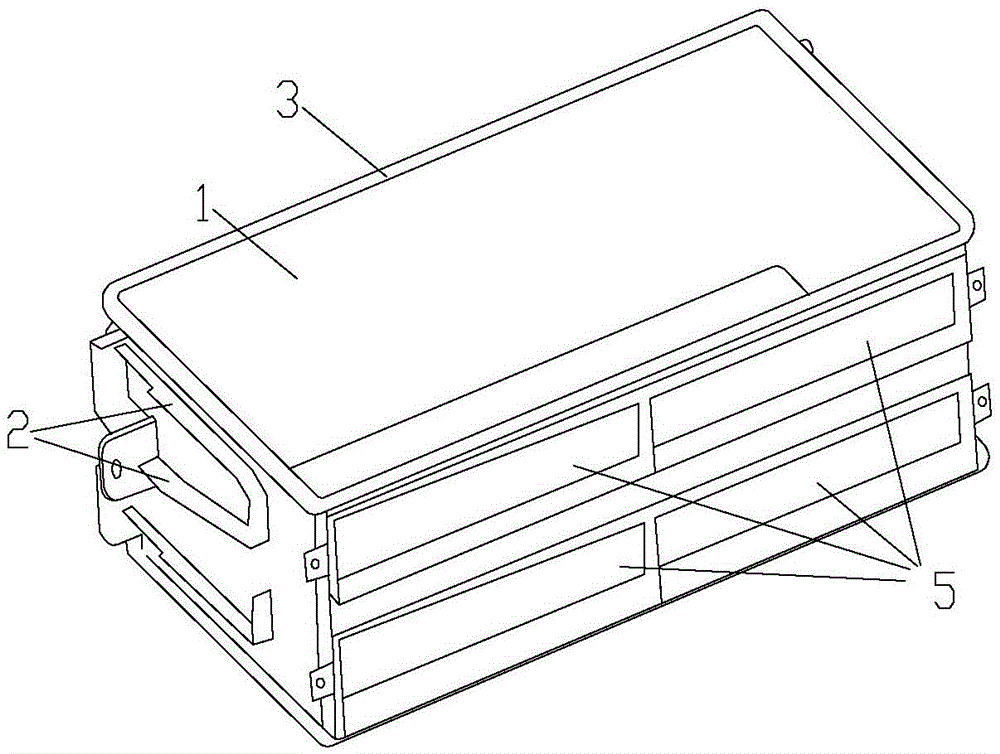

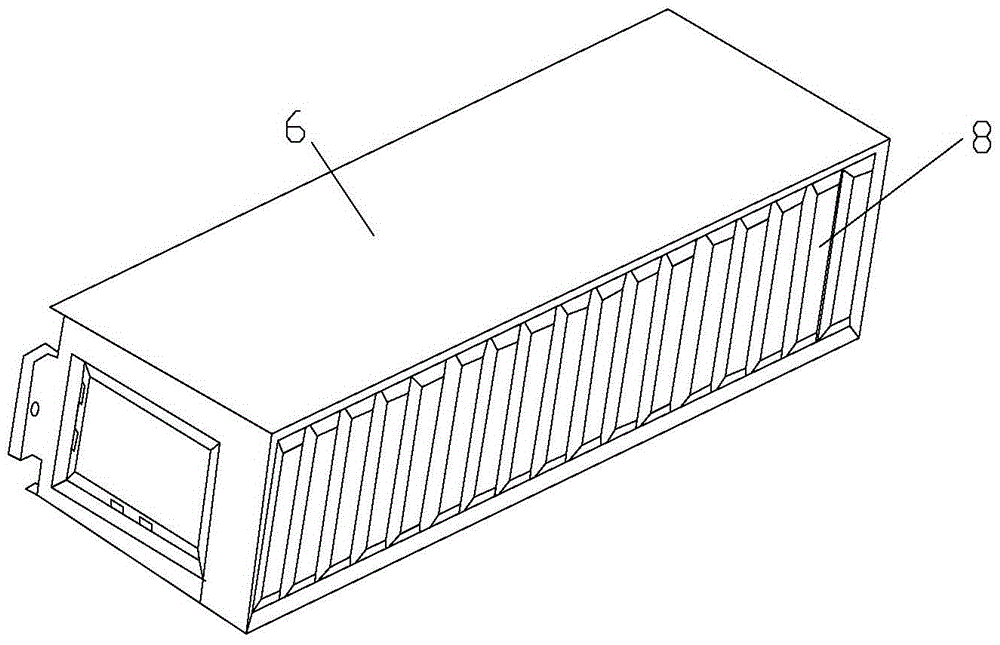

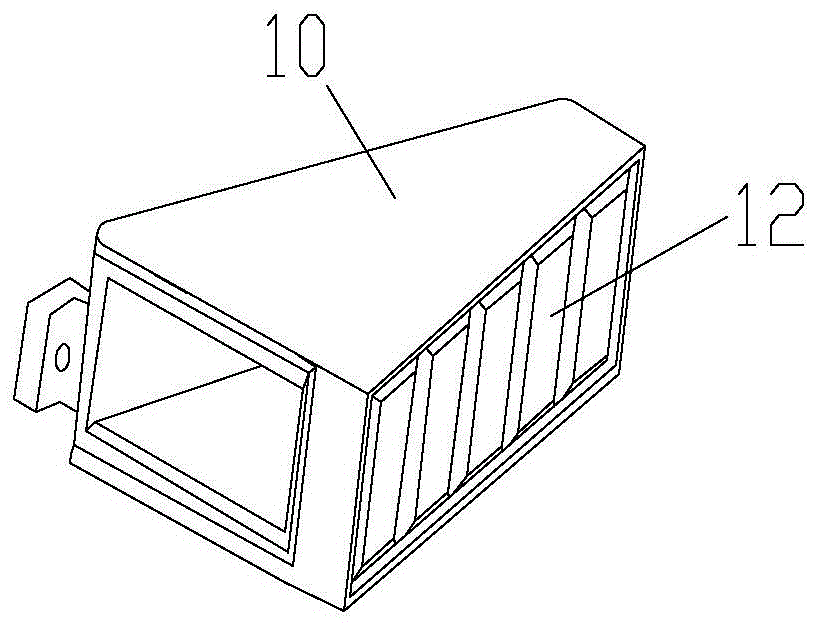

An air duct for accurately supplying air to the side of communication equipment

ActiveCN103974606BNot to be wastedImprove cooling effectCooling/ventilation/heating modificationsCold airEngineering

Owner:赵威

A kind of musk processing and packaging equipment

ActiveCN112009733BImprove textureIncrease productivitySolid materialCleaning using liquidsProcess engineeringIndustrial engineering

Owner:江西天元药业有限公司

A vapor pressure up-and-down adsorption method and a heat pump using the method

ActiveCN103615831BEfficient use ofIncrease usageClimate change adaptationEnergy efficient heating/coolingSteam pressureEngineering

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com